Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Reduce the gas flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

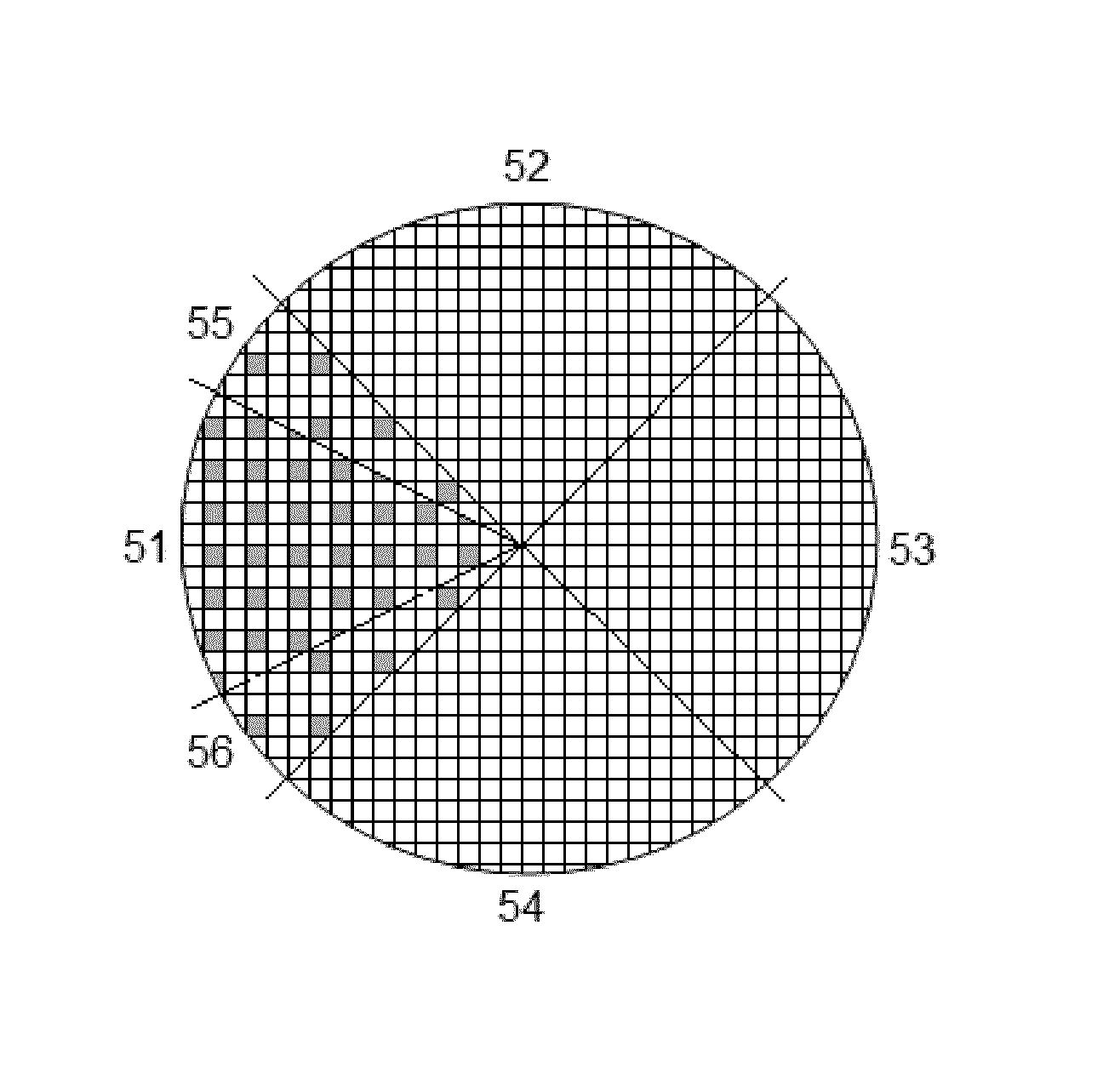

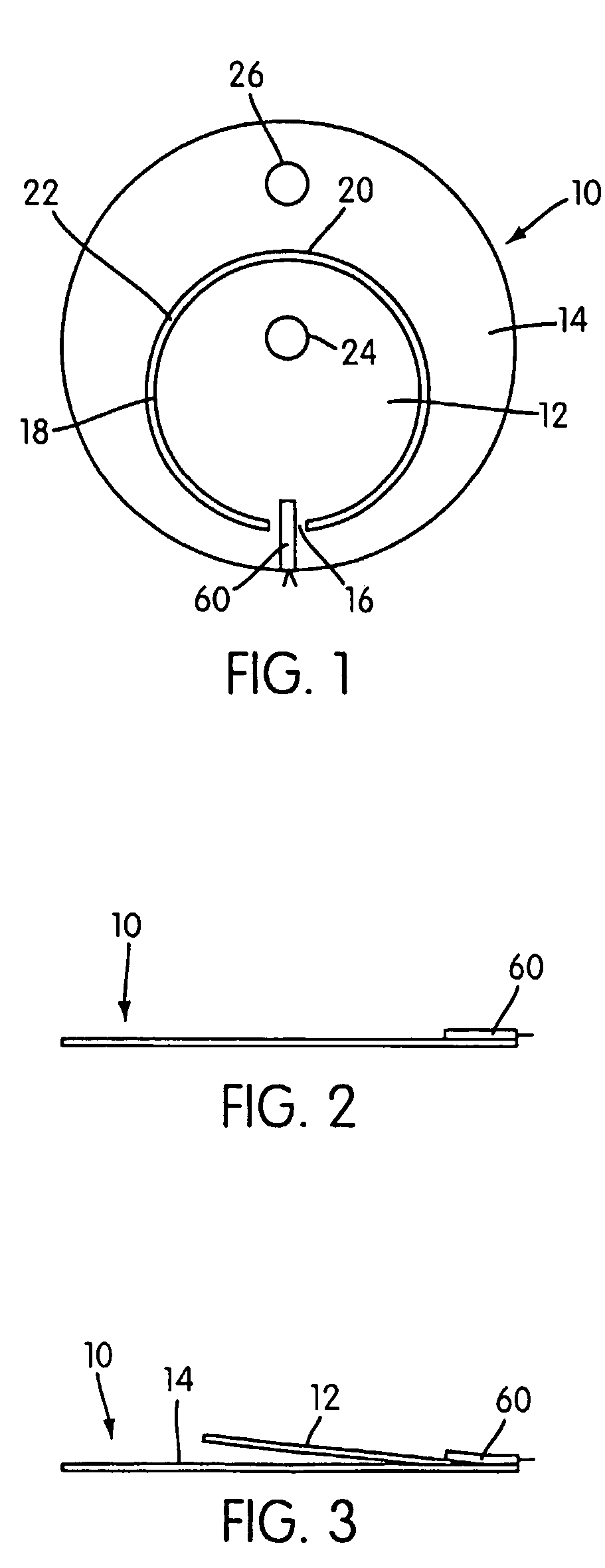

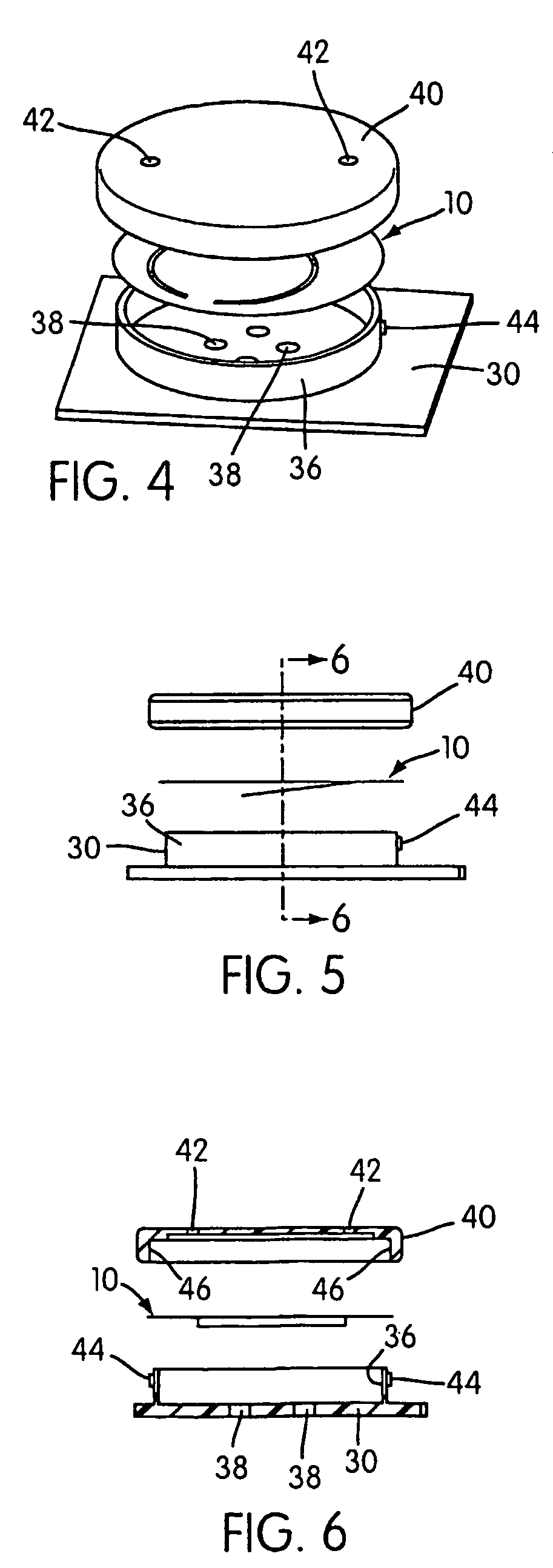

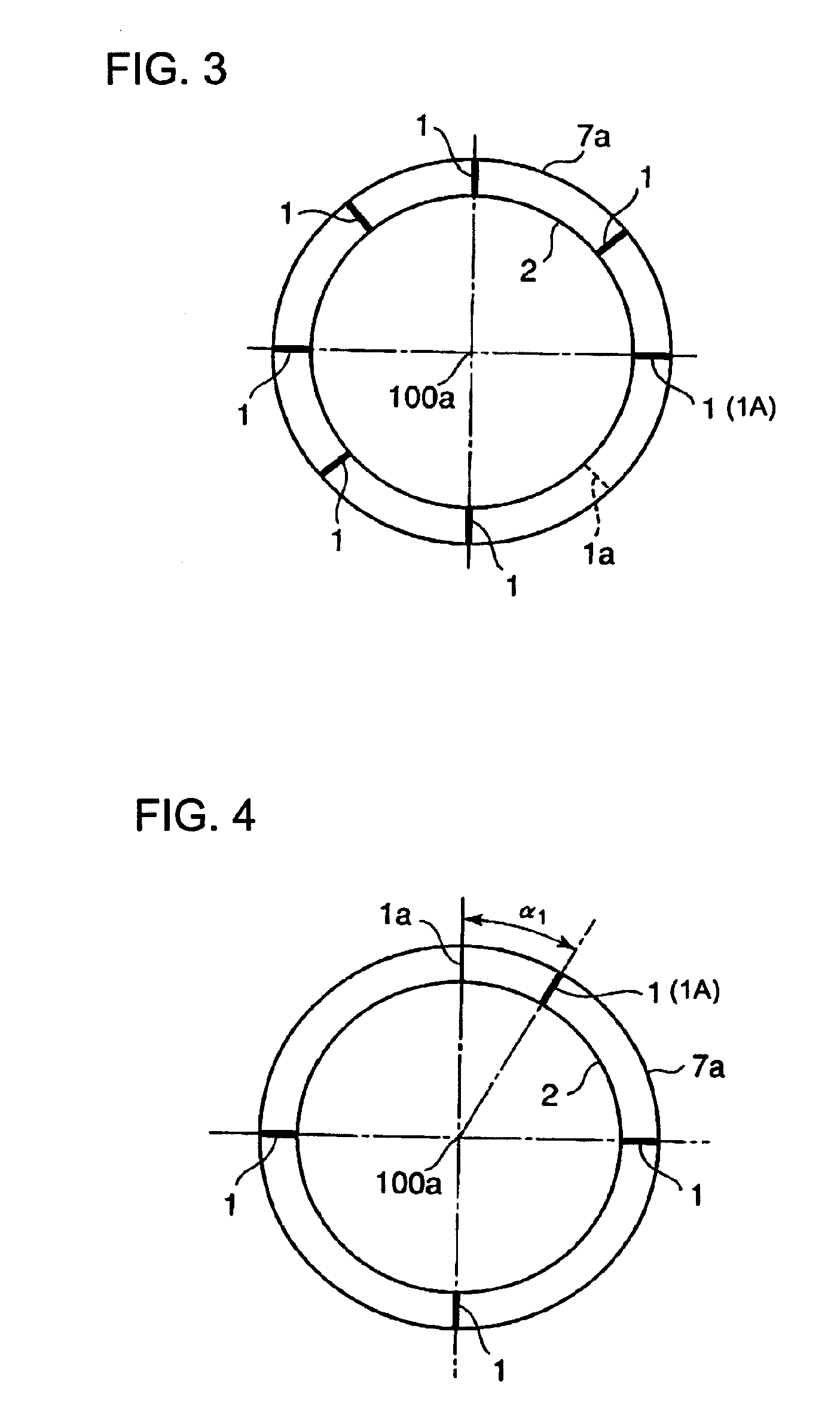

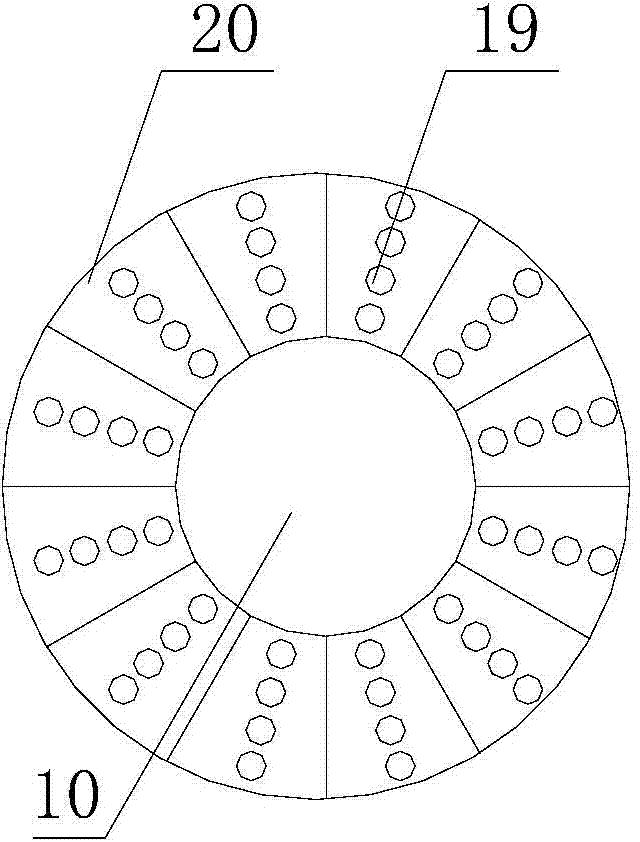

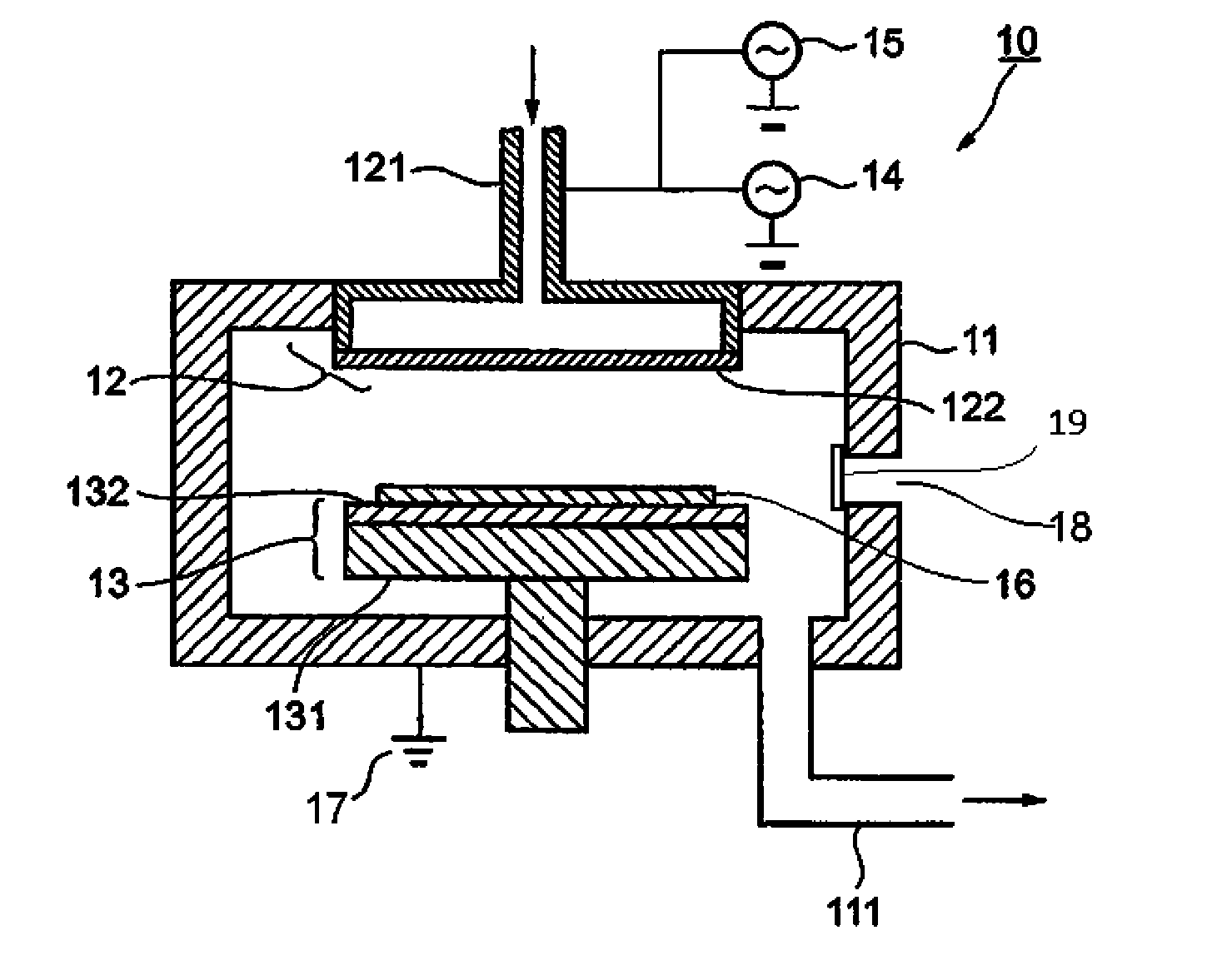

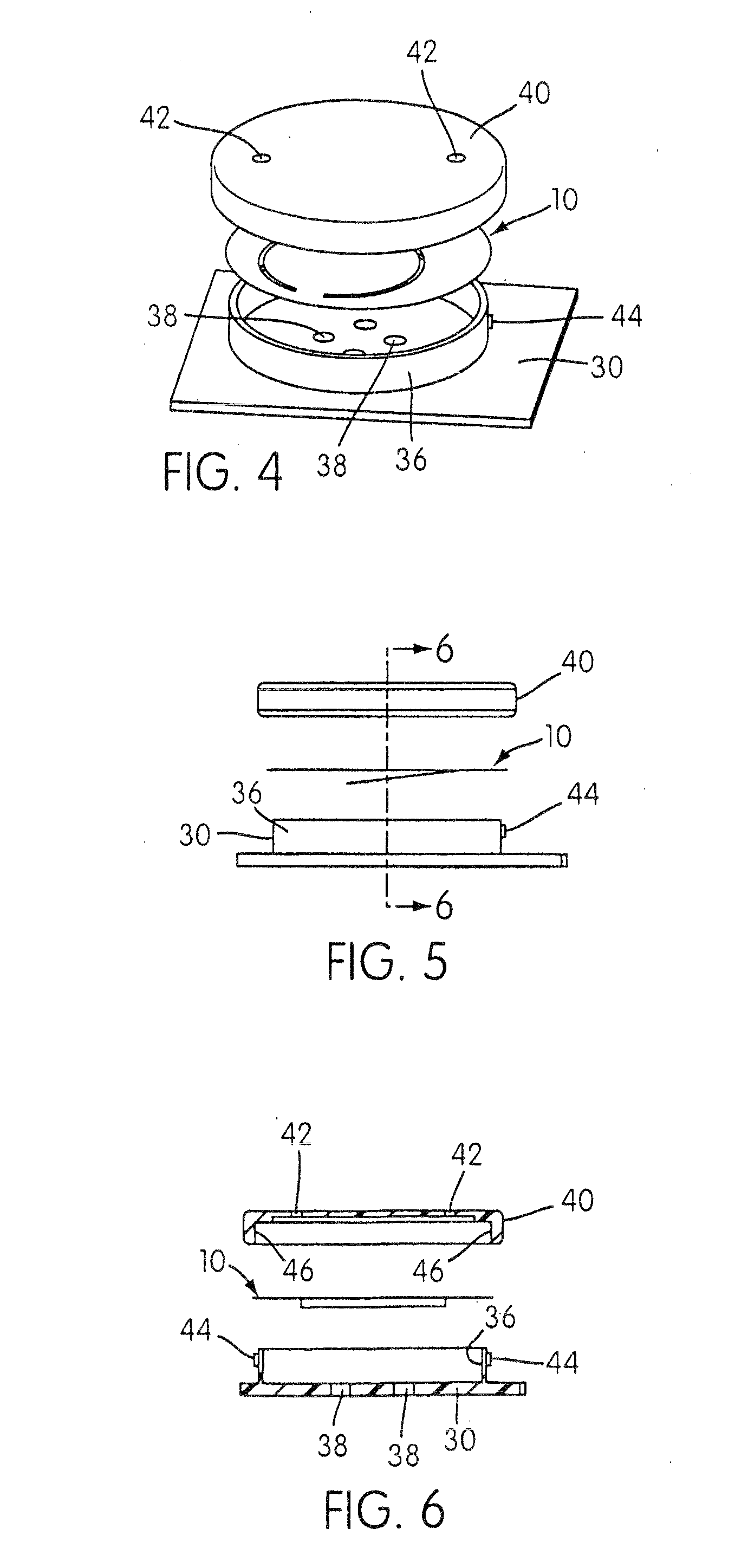

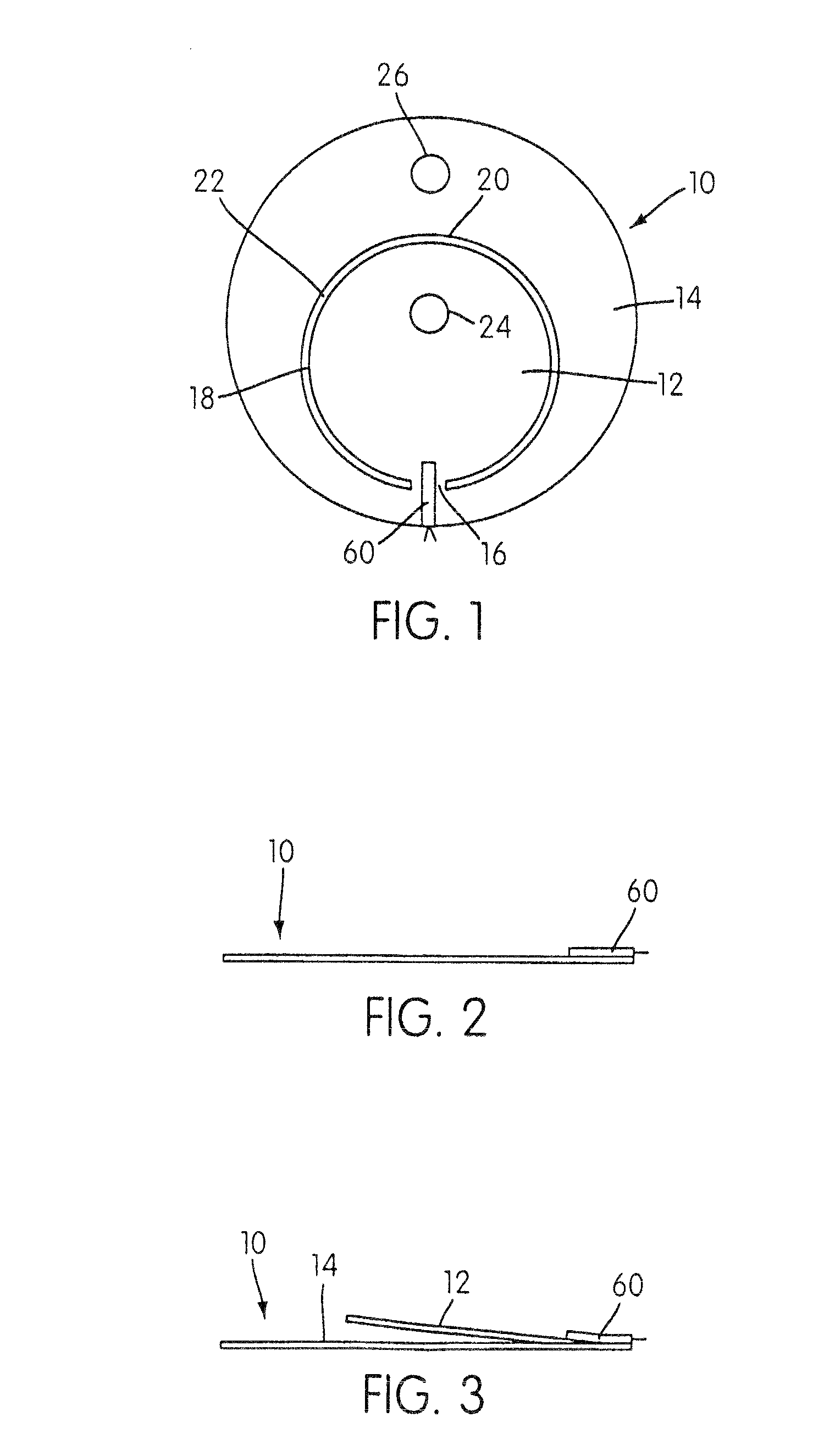

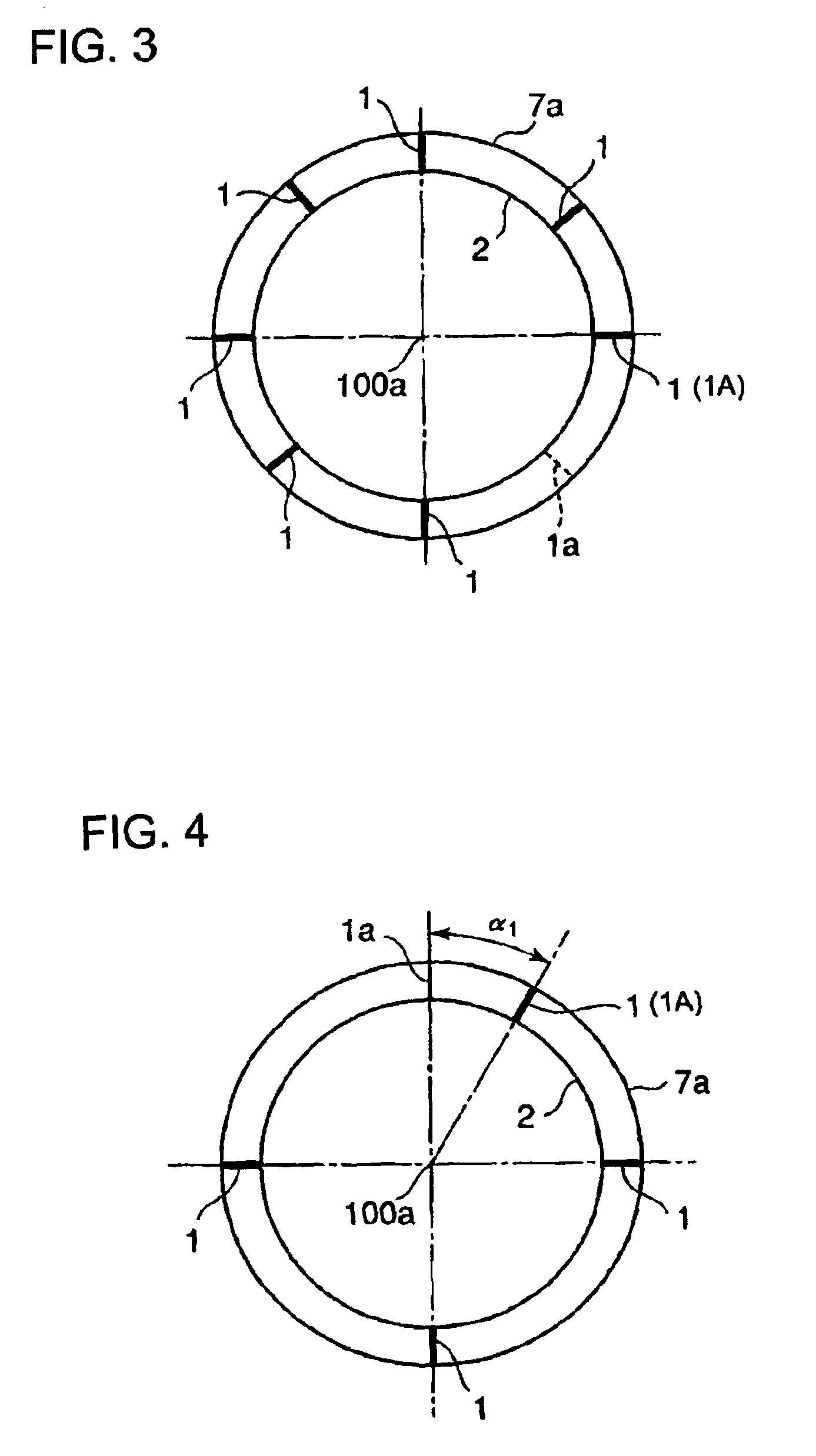

Shower plate having different aperture dimensions and/or distributions

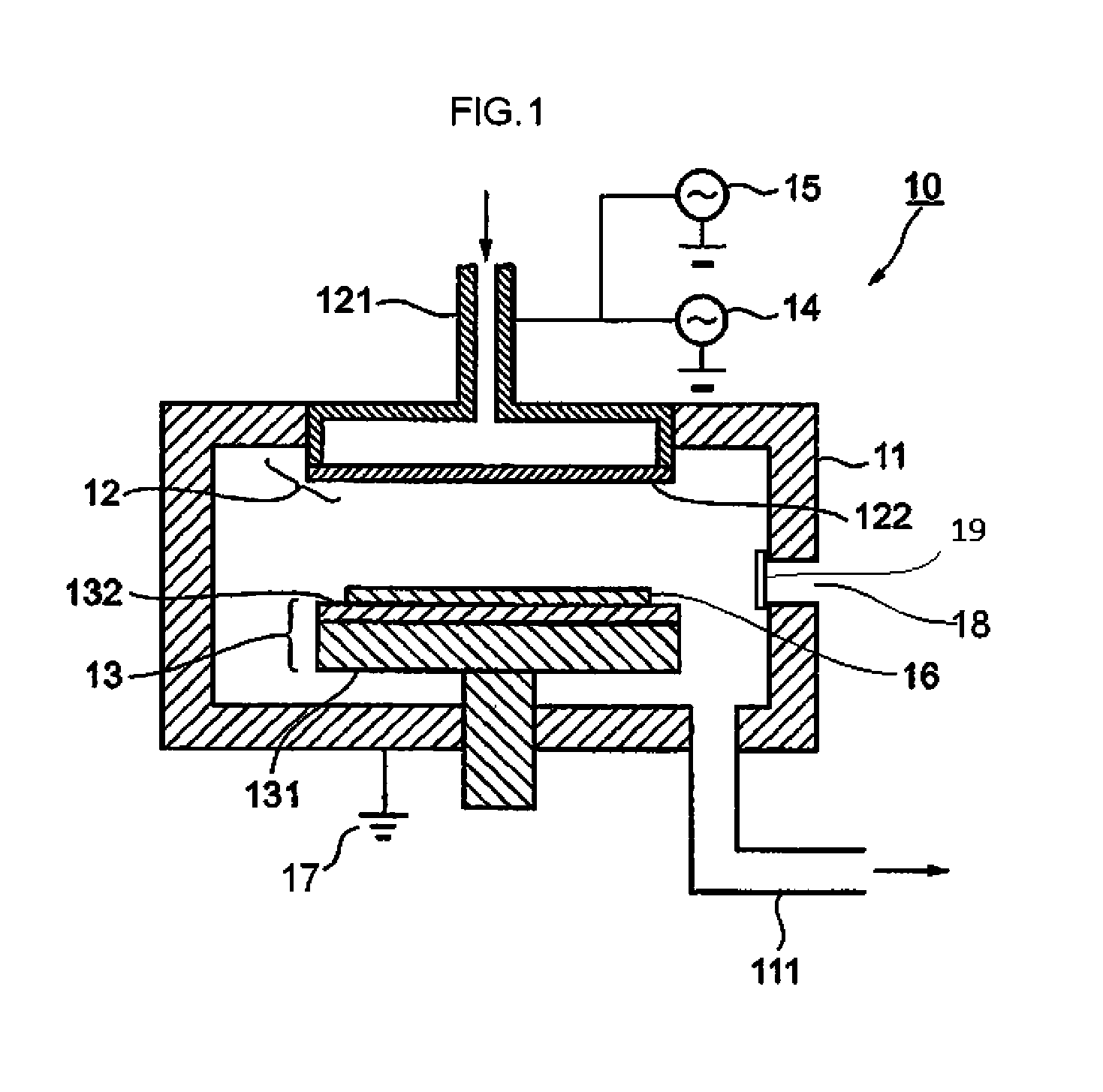

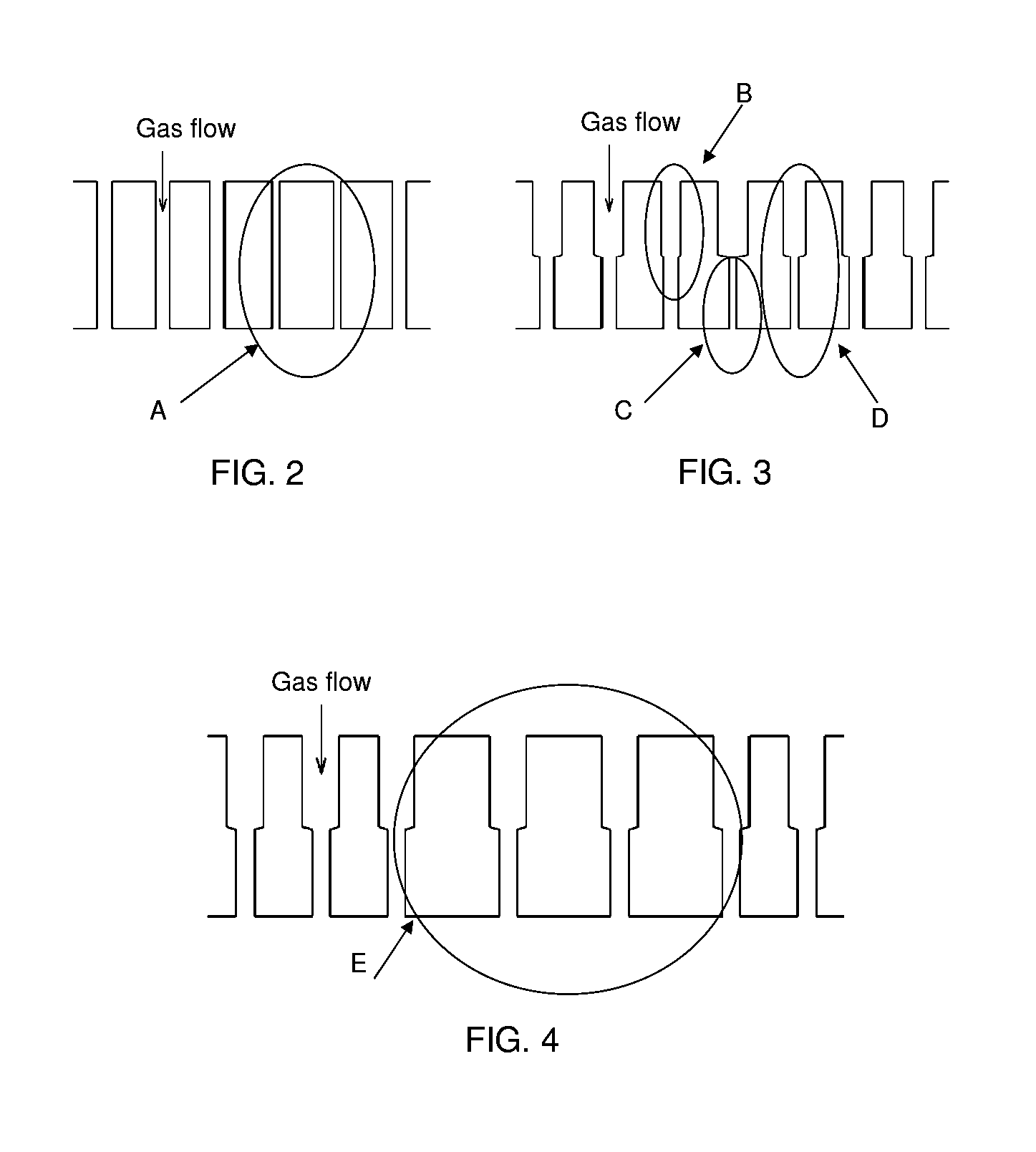

ActiveUS8845806B2Improve uniformityUniform propertyElectric discharge tubesSemiconductor/solid-state device manufacturingSusceptorMechanical engineering

A shower plate is adapted to be attached to the showerhead and includes a front surface adapted to face the susceptor; and a rear surface opposite to the front surface. The shower plate has multiple apertures each extending from the rear surface to the front surface for passing gas therethrough in this direction, and the shower plate has at least one quadrant section defined by radii, wherein the one quadrant section has an opening ratio of a total volume of openings of all the apertures distributed in the section to a total volume of the one quadrant section, which opening ratio is substantially smaller than an opening ratio of another quadrant section of the shower plate.

Owner:ASM JAPAN

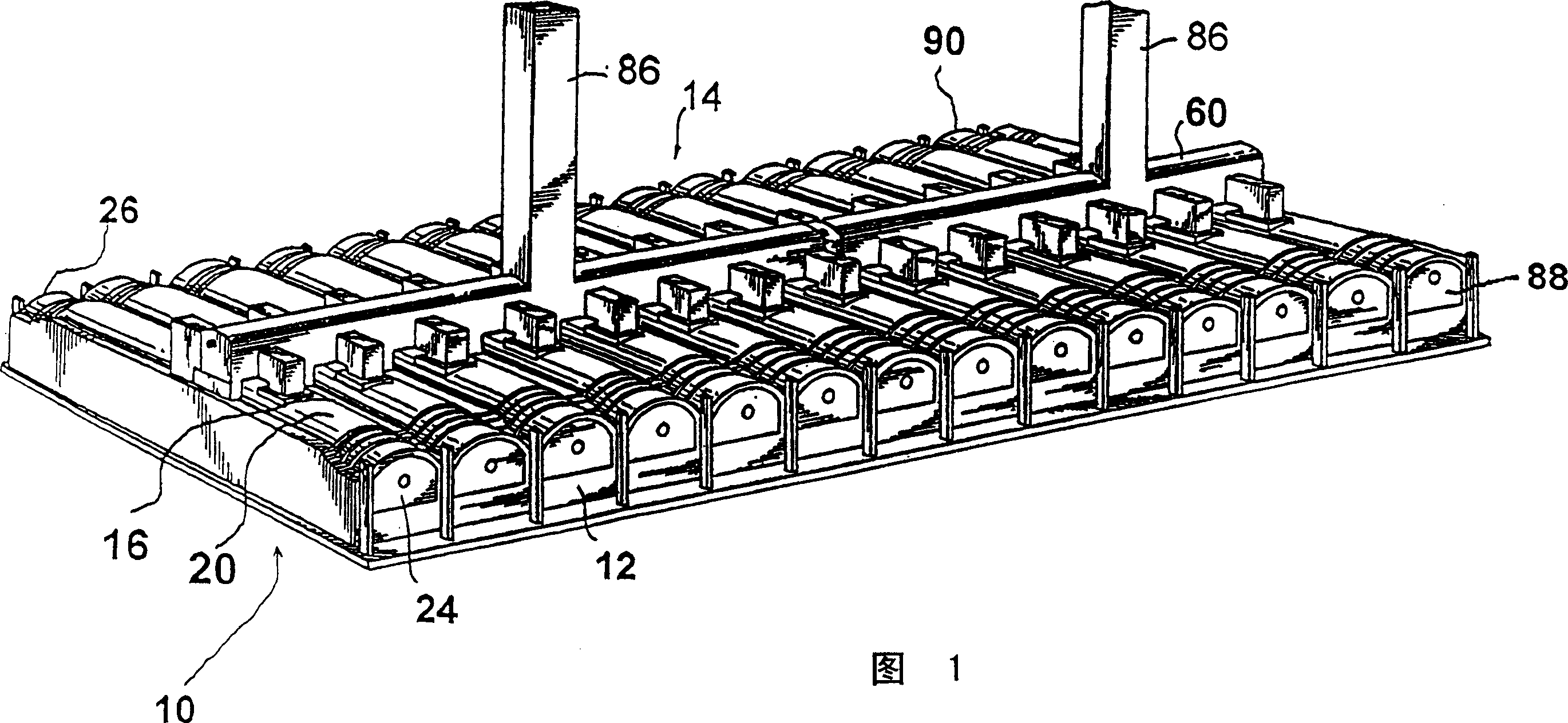

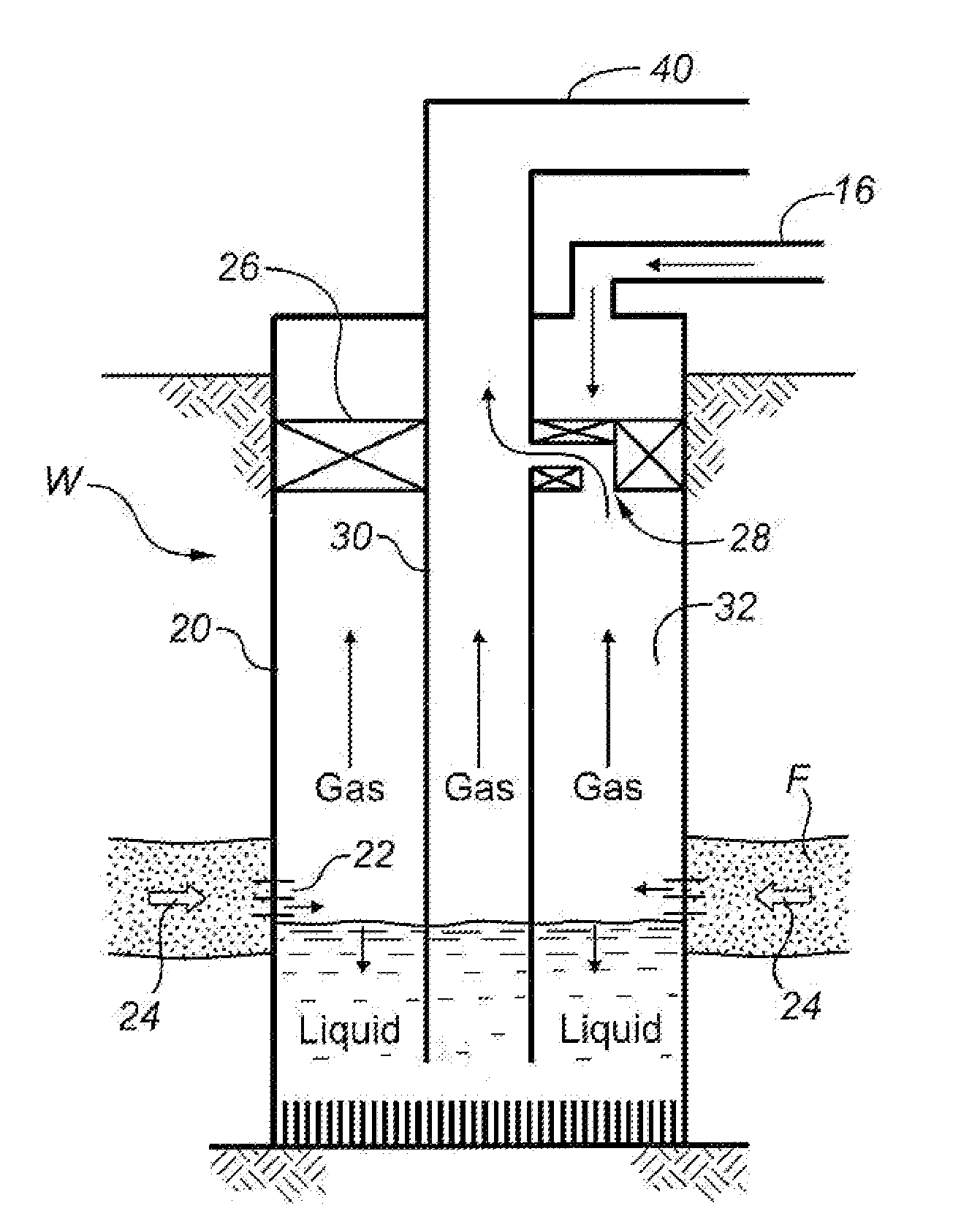

Coke oven flue gas sharing

InactiveCN1527872AExtend your lifeReduce the gas flow rateCombustible gas coke oven heatingBeehive ovensFlue gasProduct gas

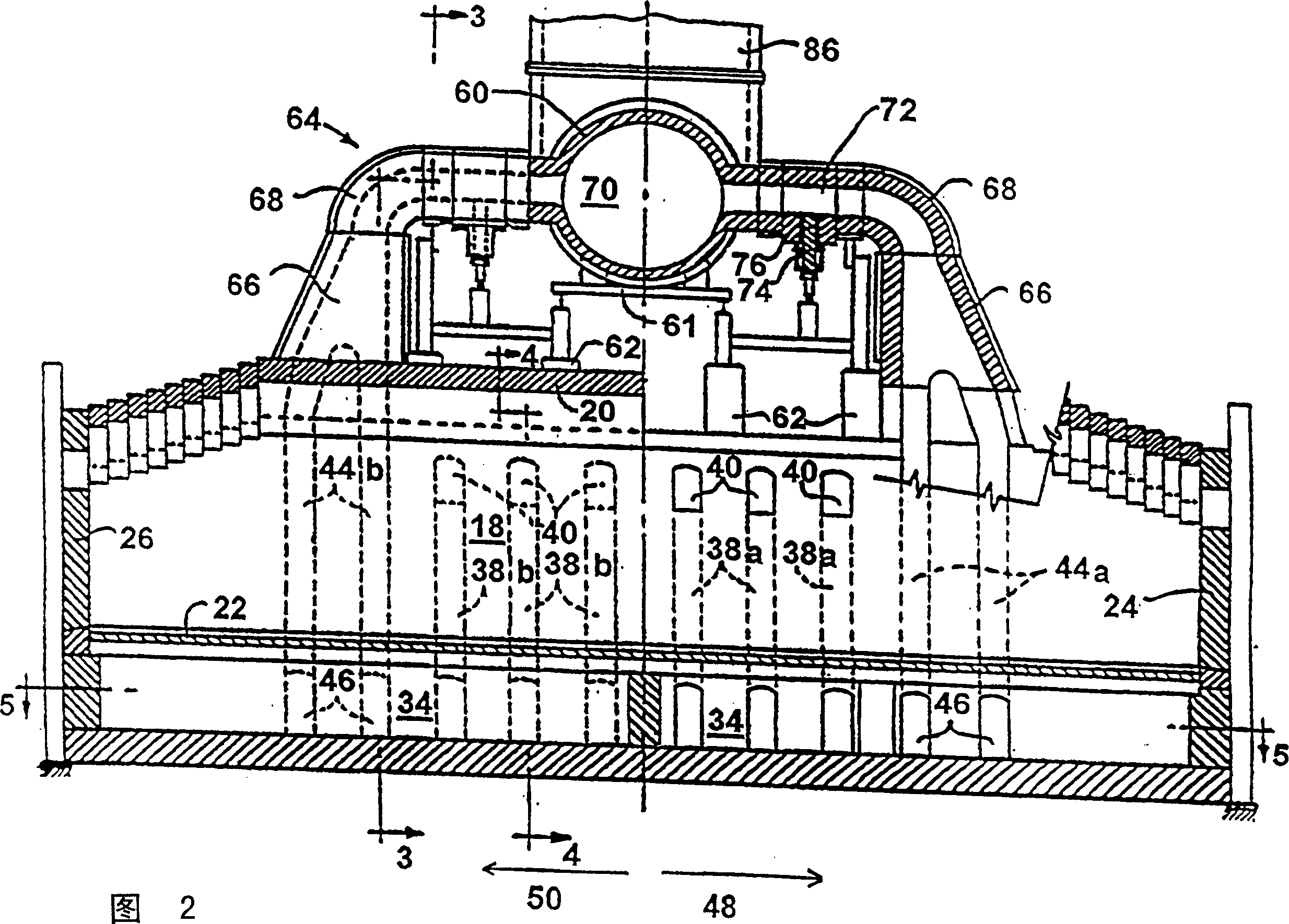

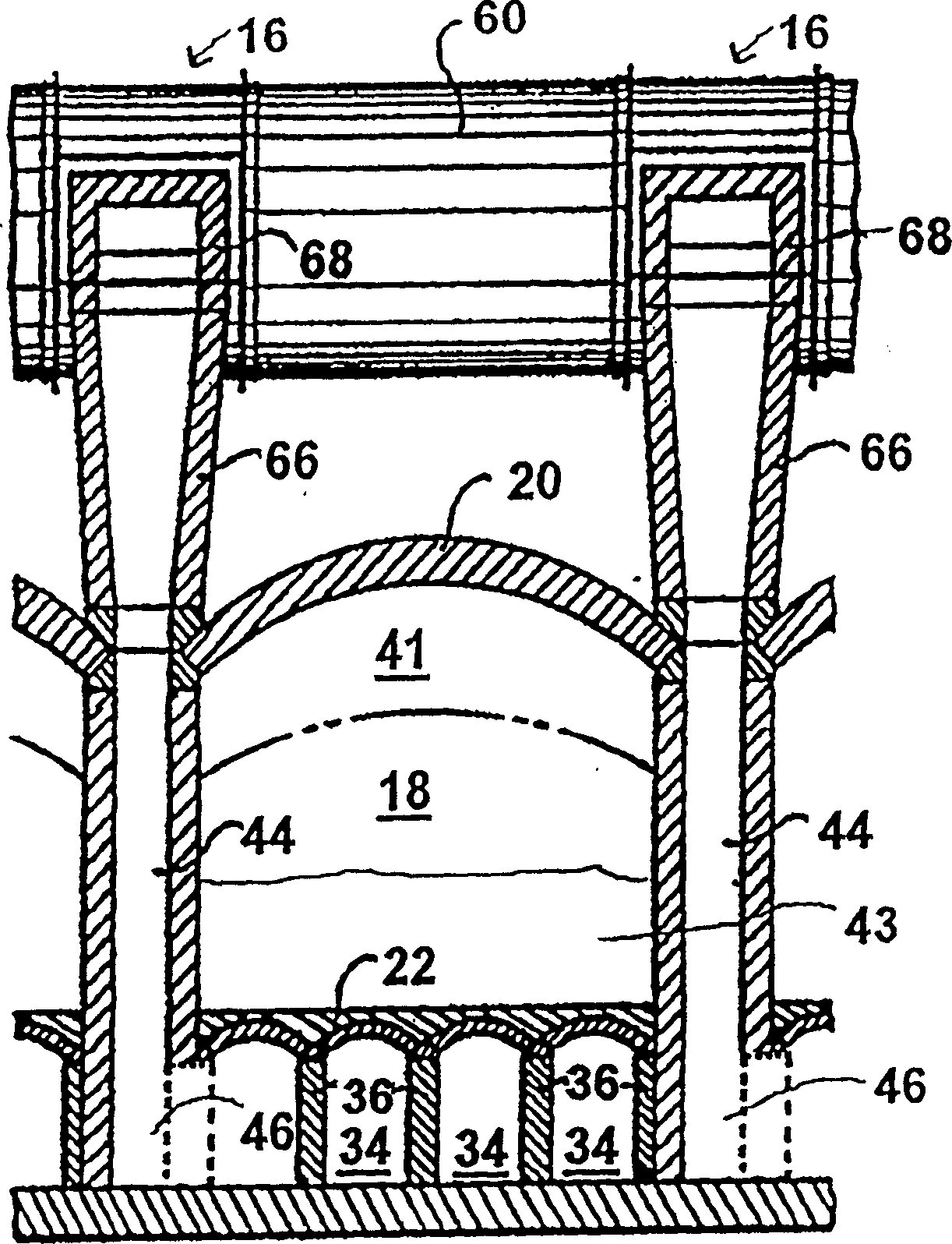

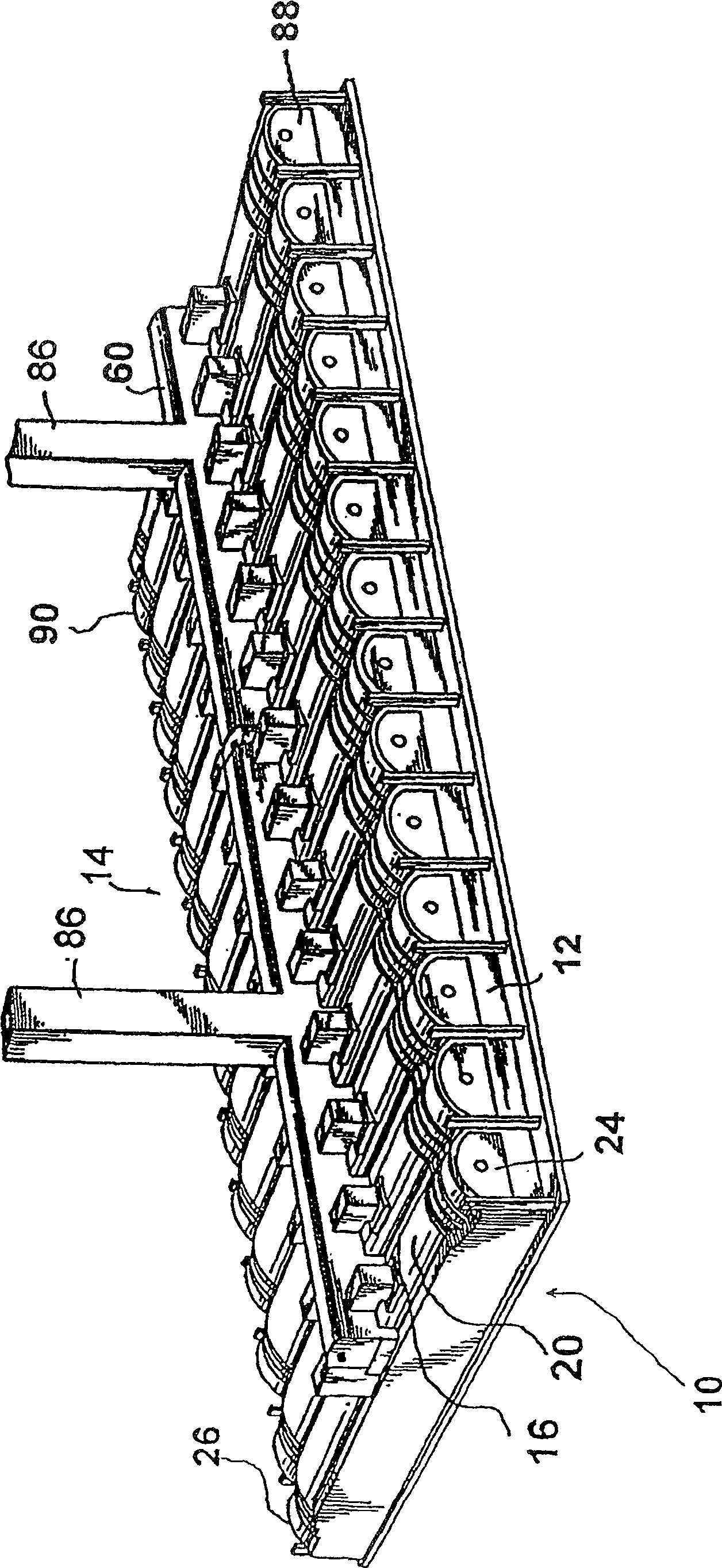

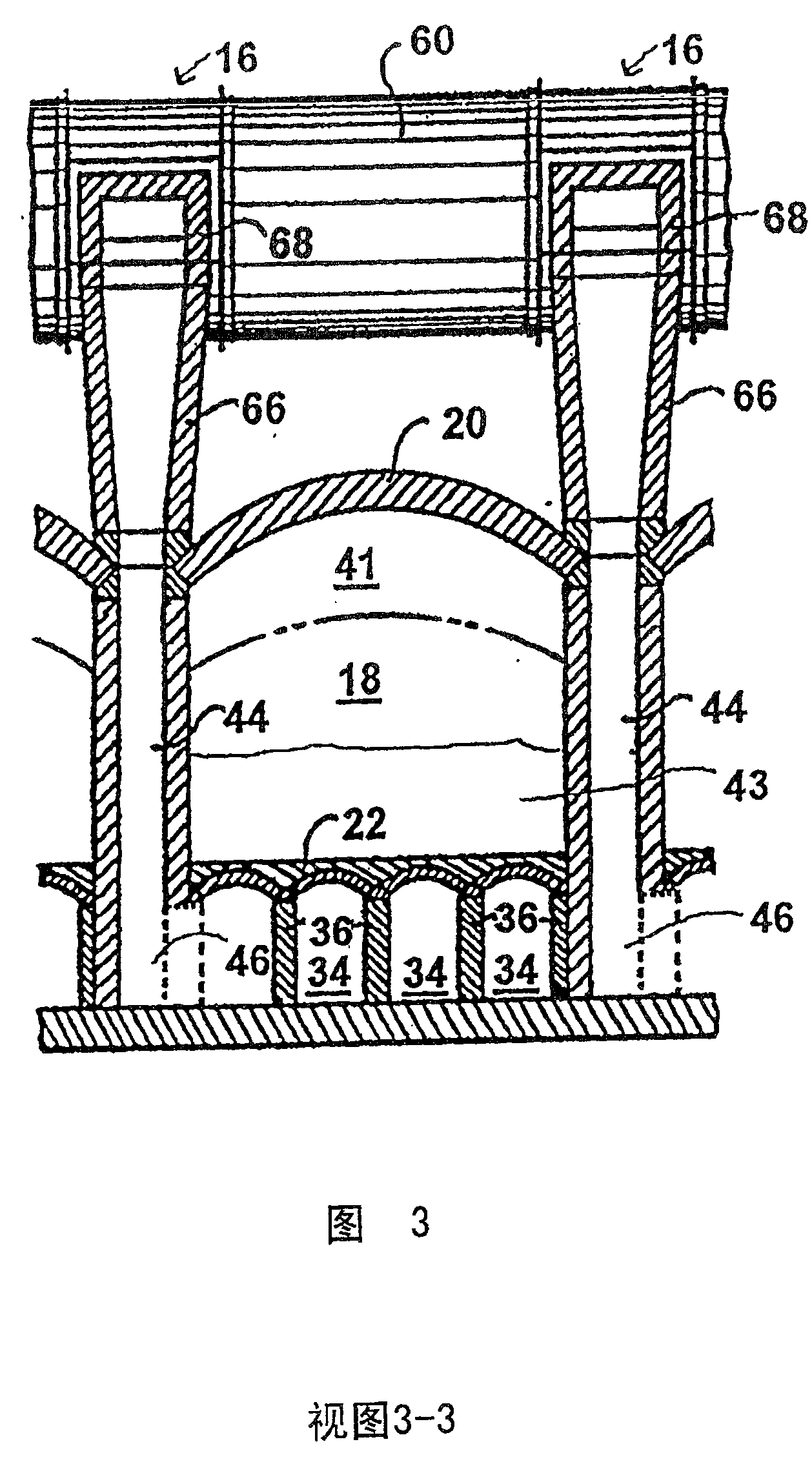

The invention provide a method and apparatus for decreasing gas flow rates in a sole flue gas system for a coke oven during at least an initial coking operation after charging a coking oven with coal (43). The method includes providing a duct system (96, 98) between a first coke oven having a first coking chamber (18) and a second coke oven having a second coking chamber (18) to direct at least a portion of gas from a gas space (41) in first coking chamber (18) to the second coke oven thereby reducing a gas flow rate in the first sole flue gas system of the first coke oven. Reduction in sole flue gas flow rates has a beneficial effect on product throughput, the life of the coke oven and environmental control of volatile emissions from coke ovens.

Owner:SUNCOKE TECH & DEV LLC

Coke oven flue gas sharing

InactiveCN100510004CExtend your lifeReduce the gas flow rateCombustible gas coke oven heatingBeehive ovensCoke Oven EmissionFlue gas

The invention provides a method and apparatus for reducing the gas flow velocity in the bottom flue gas system of a coke oven during at least one initial coking operation after the coke oven has been charged with coal (43). The method includes providing a ductwork (96, 98) between a first coke oven having a first coking chamber (18) and a second coke oven having a second coking chamber (18) for transferring at least a portion of the gas from The gas space (41) in the first coking chamber (18) is led into the second coking oven, thereby reducing the gas flow velocity in the first bottom flue gas system of the first coking oven. Reducing the gas flow velocity in the bottom flue has beneficial effects on product yield, coke oven life and environmental control of coke oven volatile emissions.

Owner:SUNCOKE TECH & DEV LLC

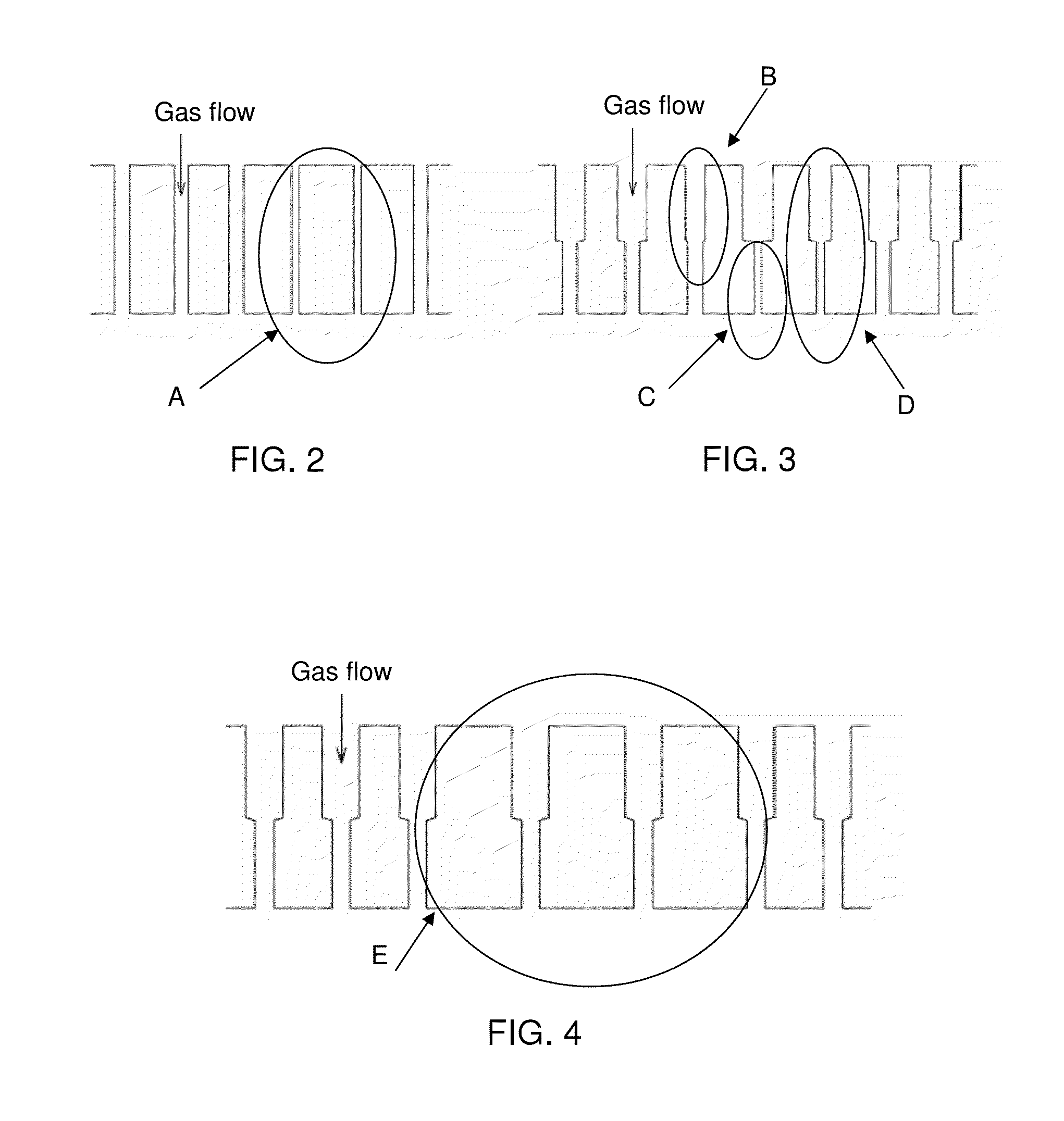

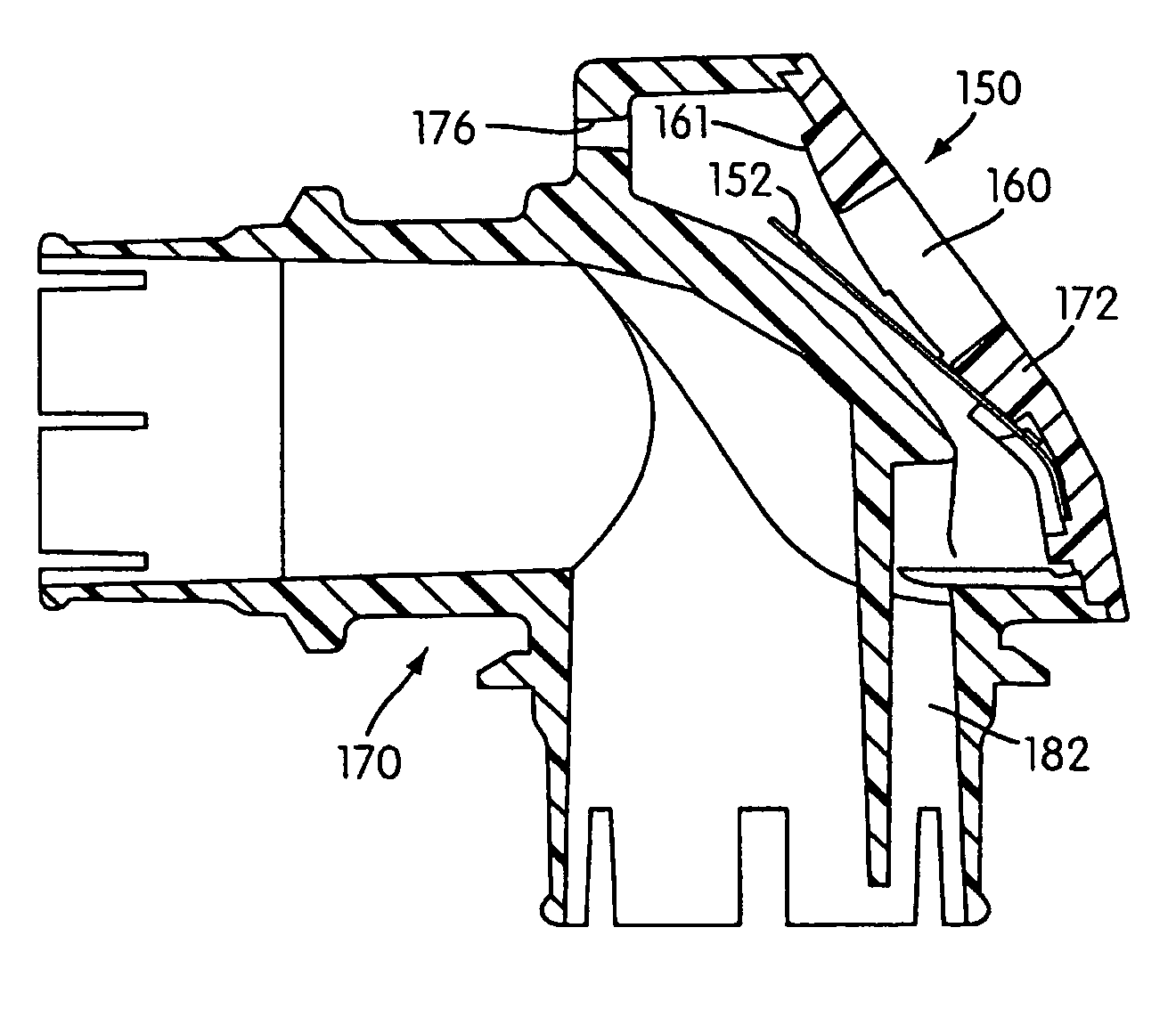

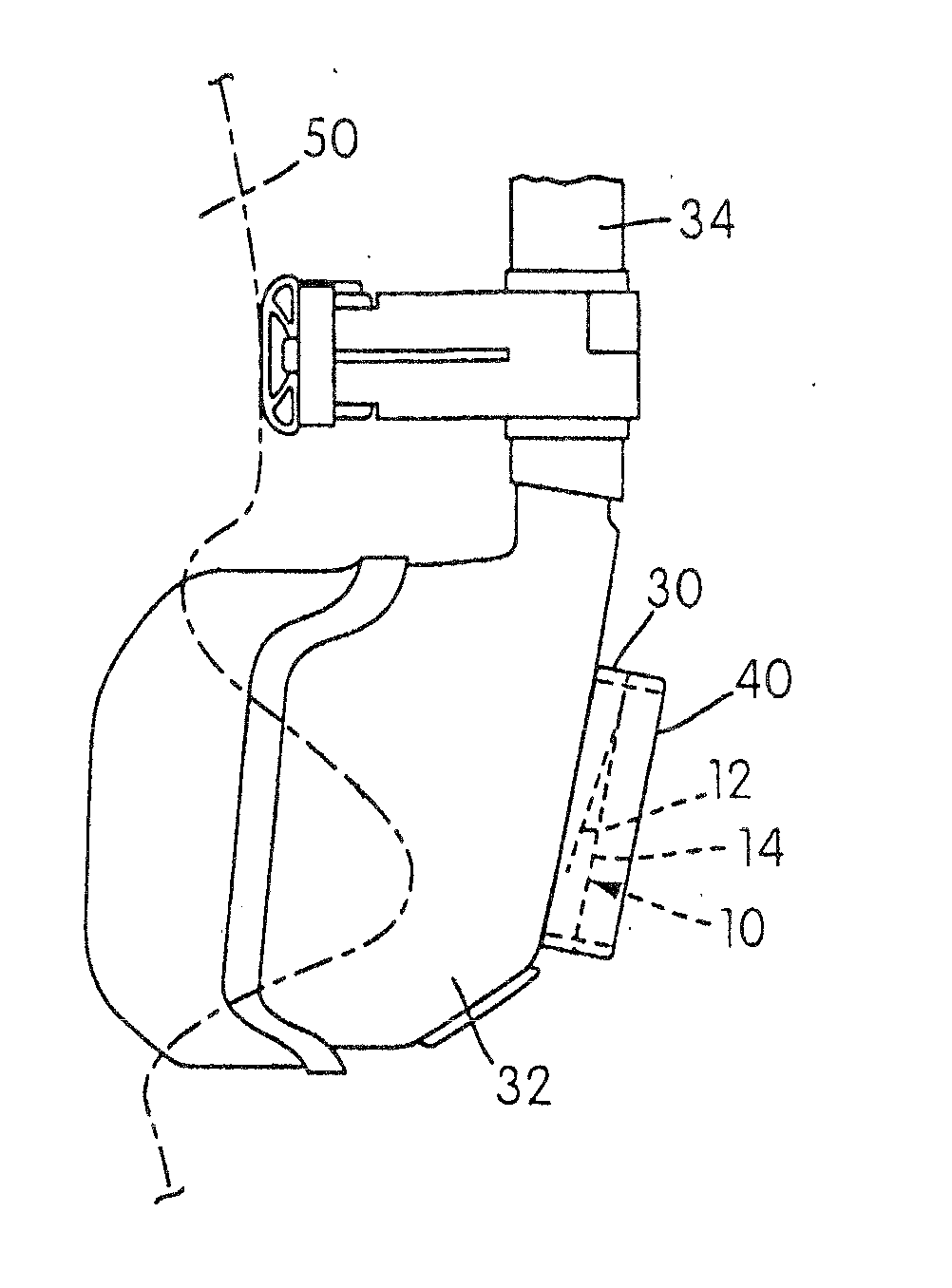

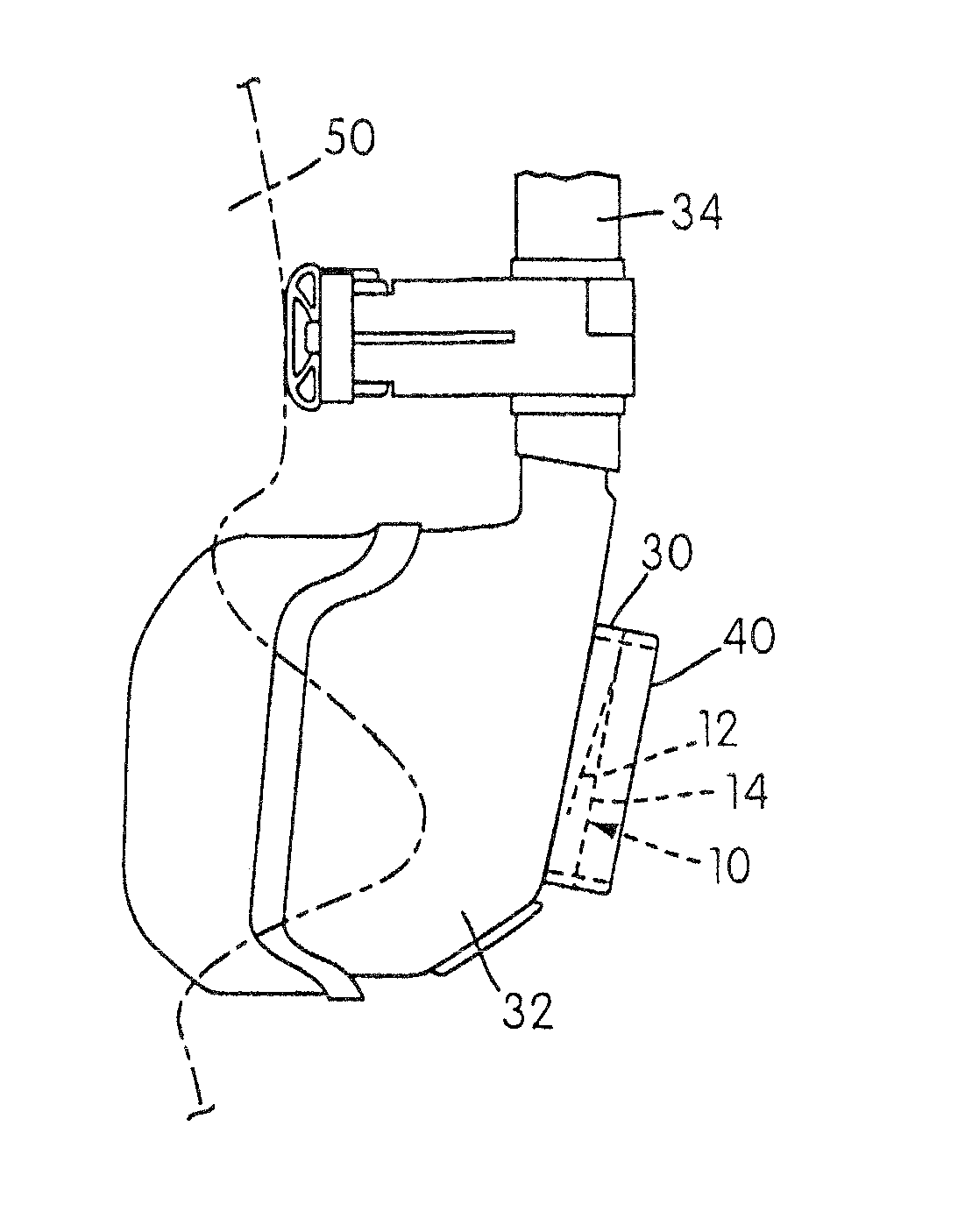

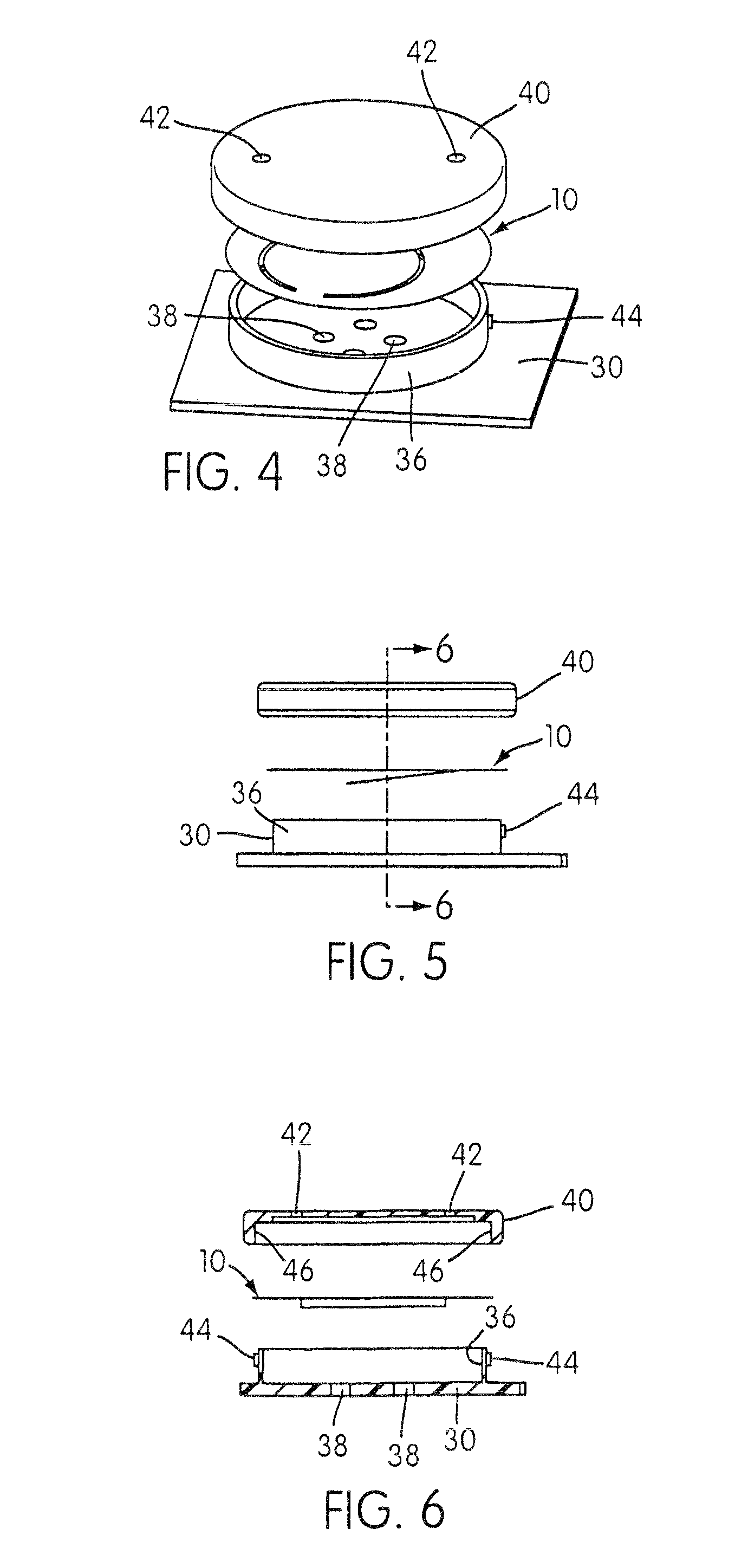

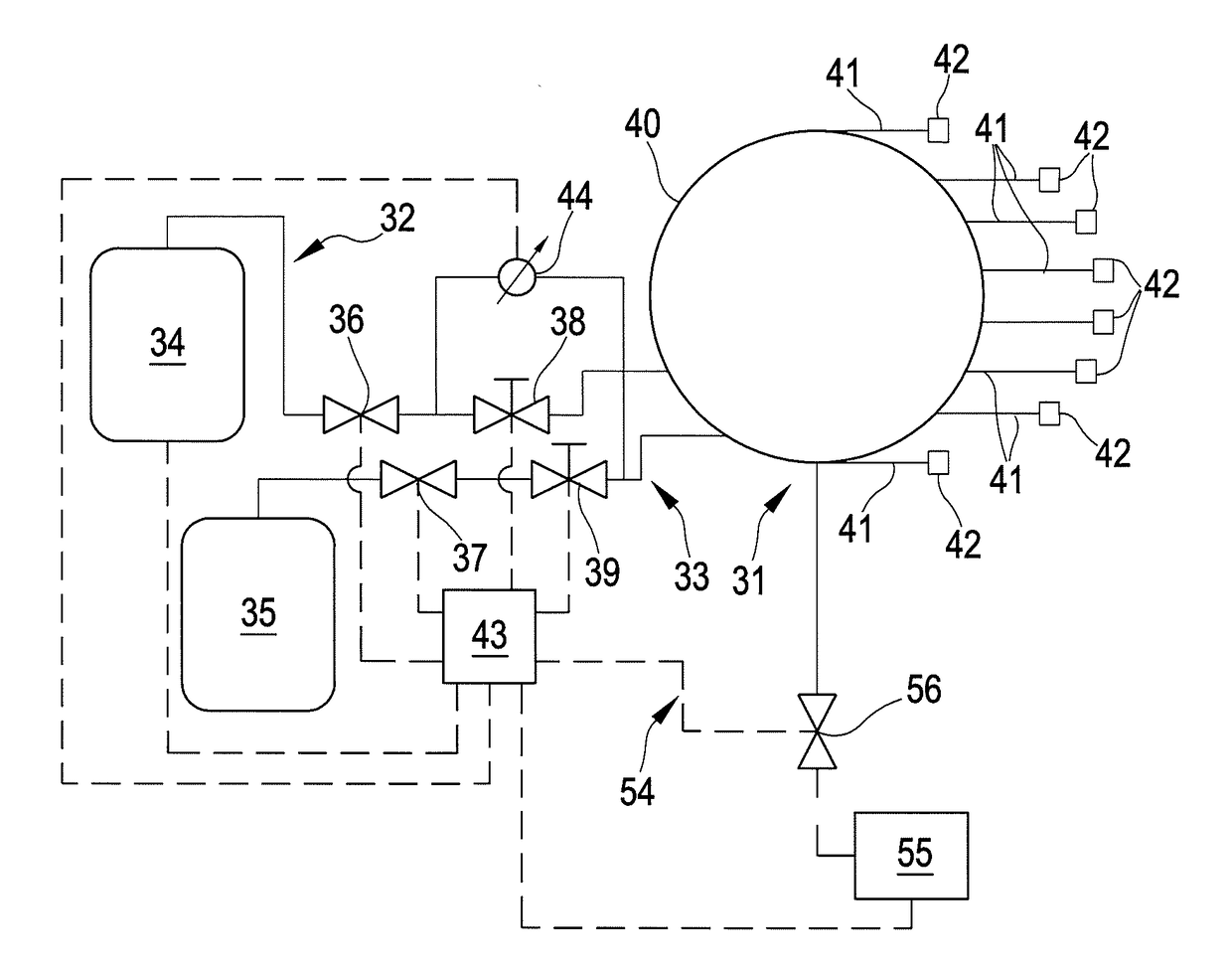

Flow regulation vent

ActiveUS8439035B2Decreasing gas flow areaReduce gas flow rateOperating means/releasing devices for valvesRespiratory masksAirflowHinge angle

A flow regulation vent includes a fixed portion adapted to engage a gas supply conduit and a spring force biased movable portion connected by a hinge to the fixed portion and flowingly connected to the pressurized gas supply. The fixed portion includes a gas flow orifice. The movable portion is pivotally movable between 1) a relaxed position, whereby at a specified minimum operating pressure, the movable portion is pivoted by the spring force away from the fixed portion to a position to establish a first gas washout flow area between the movable portion and the gas flow orifice; and 2) a fully pressurized position, whereby at a specified maximum operating pressure, the pressurized gas offsets the spring force to pivot the movable portion to a position adjacent the fixed portion to establish a minimum gas washout flow area between the movable portion and the gas flow orifice.

Owner:RESMED LTD

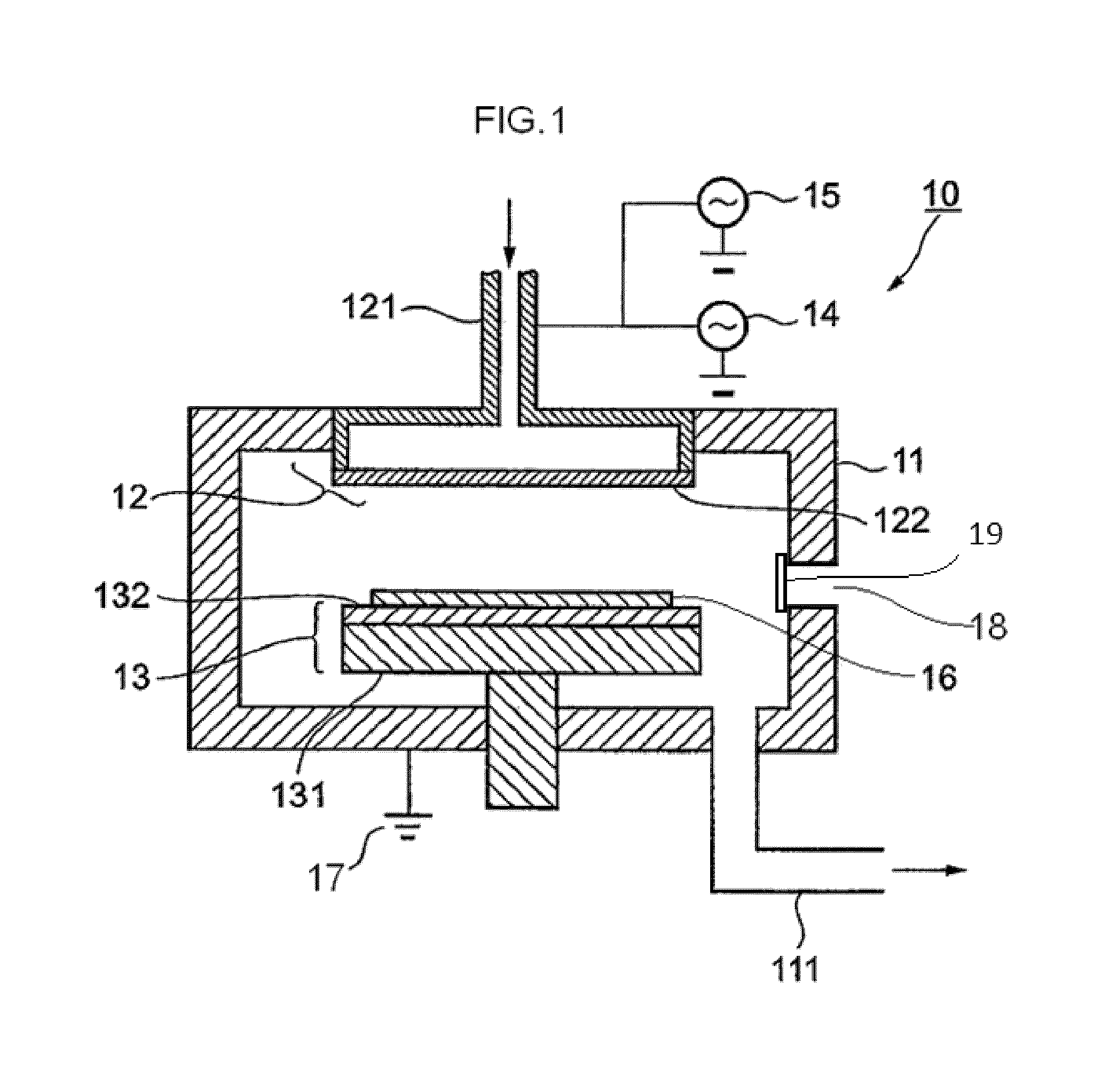

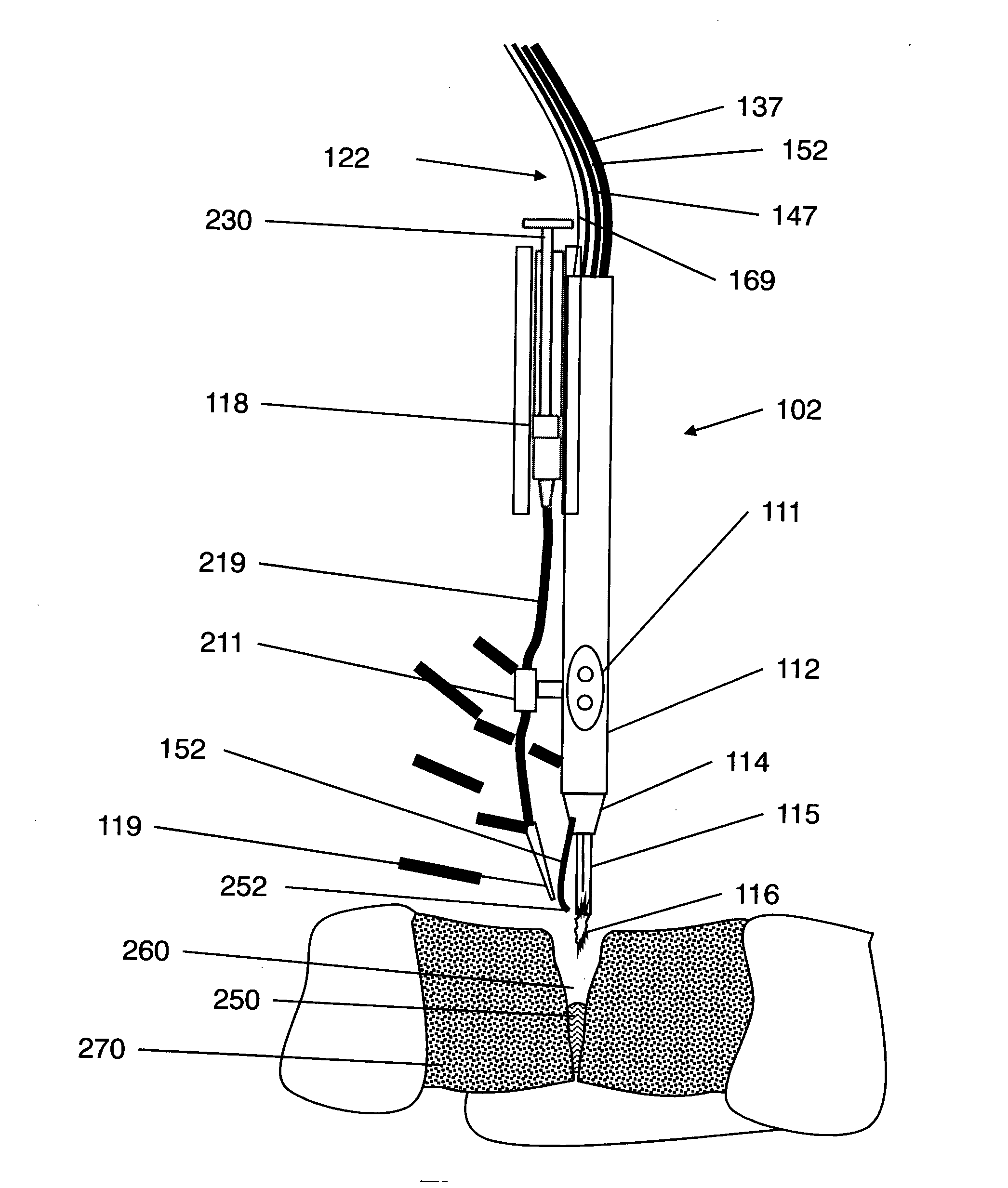

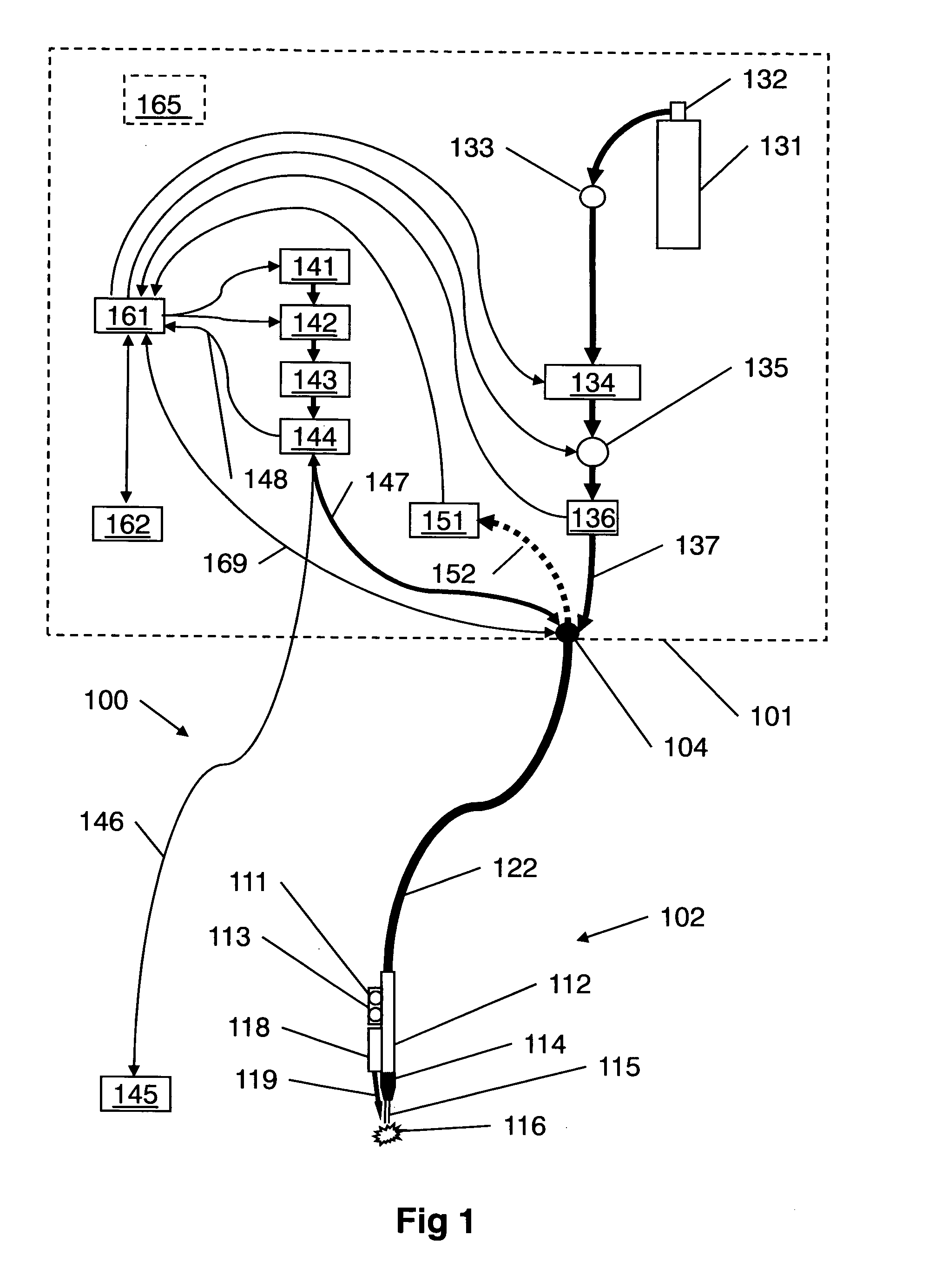

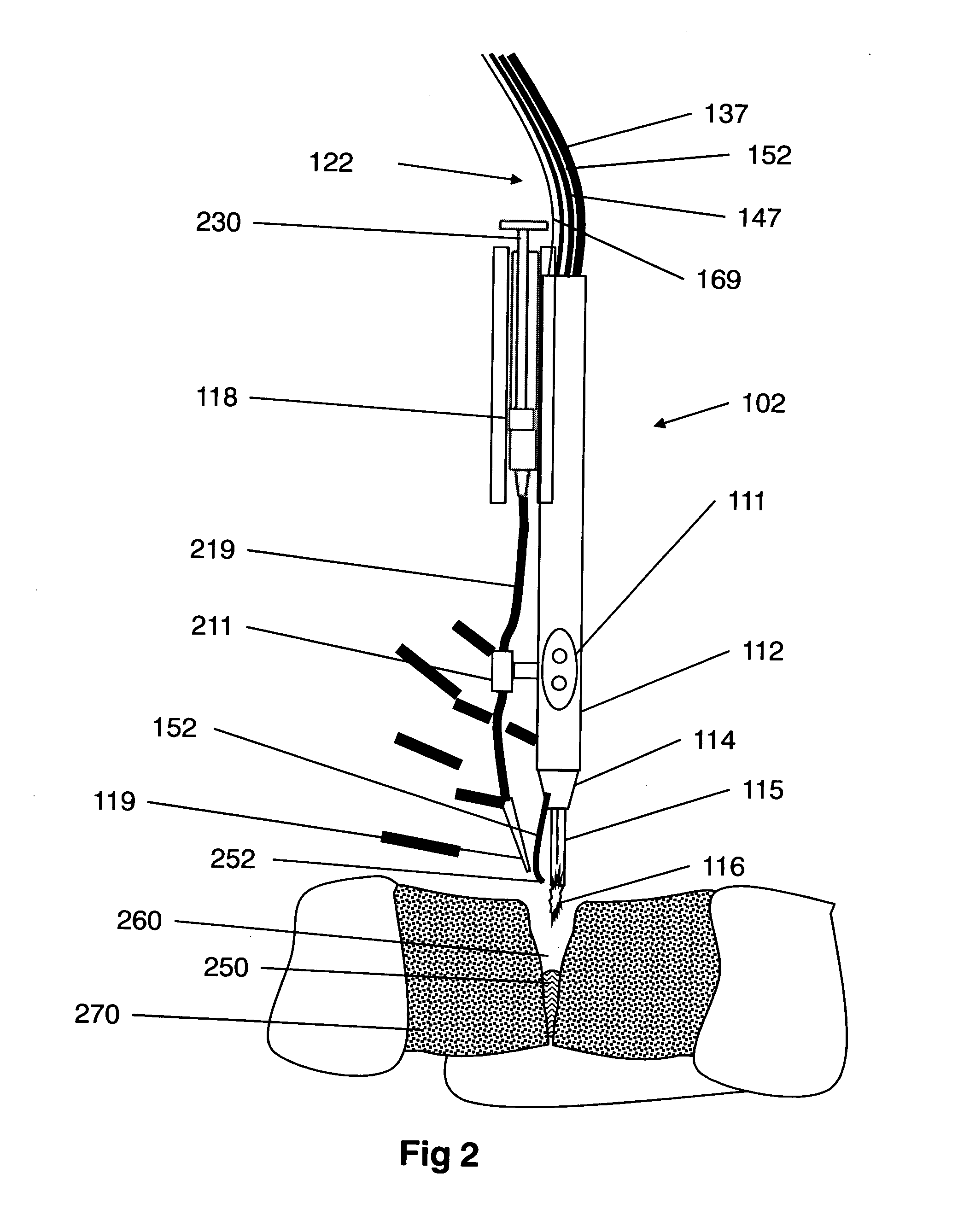

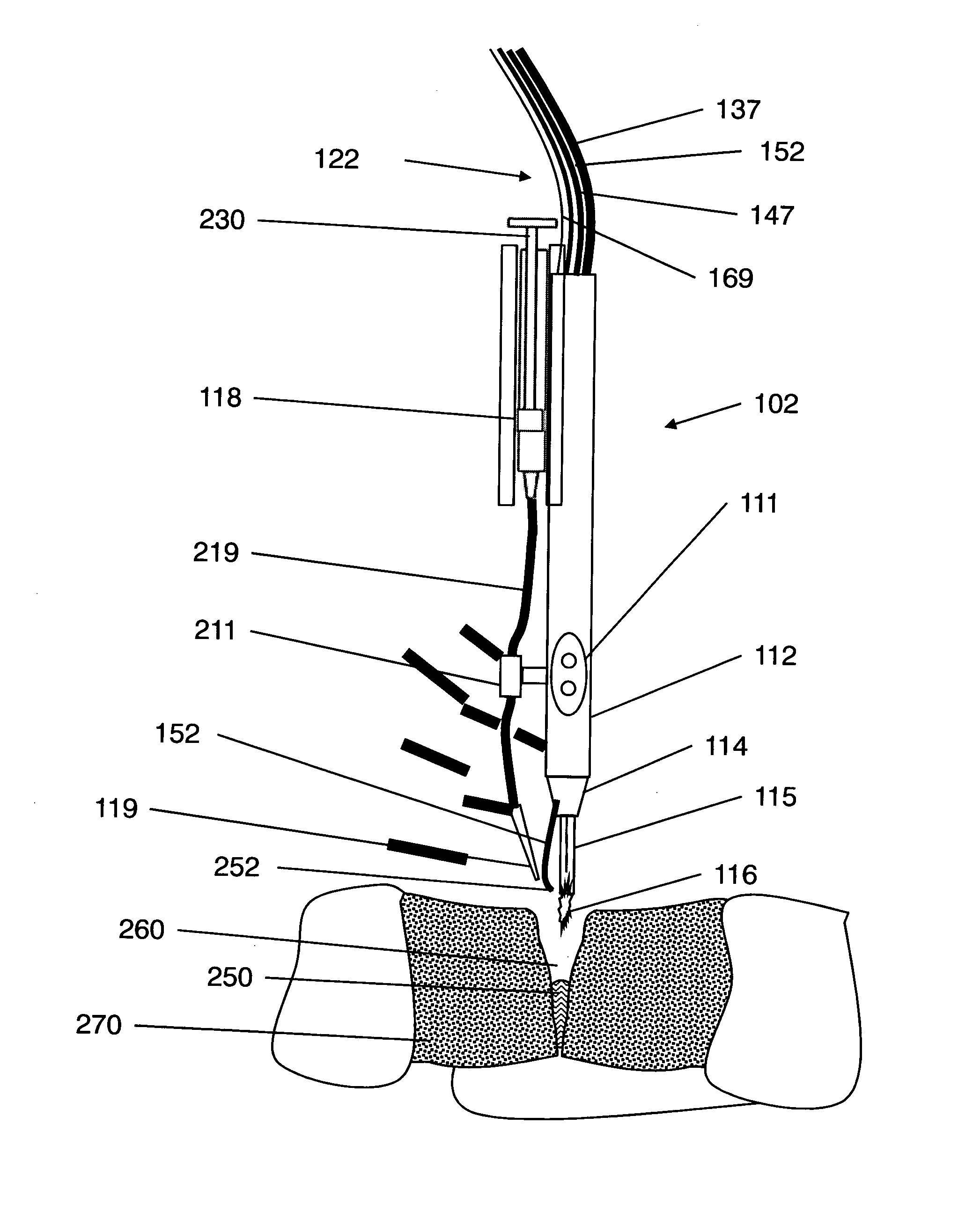

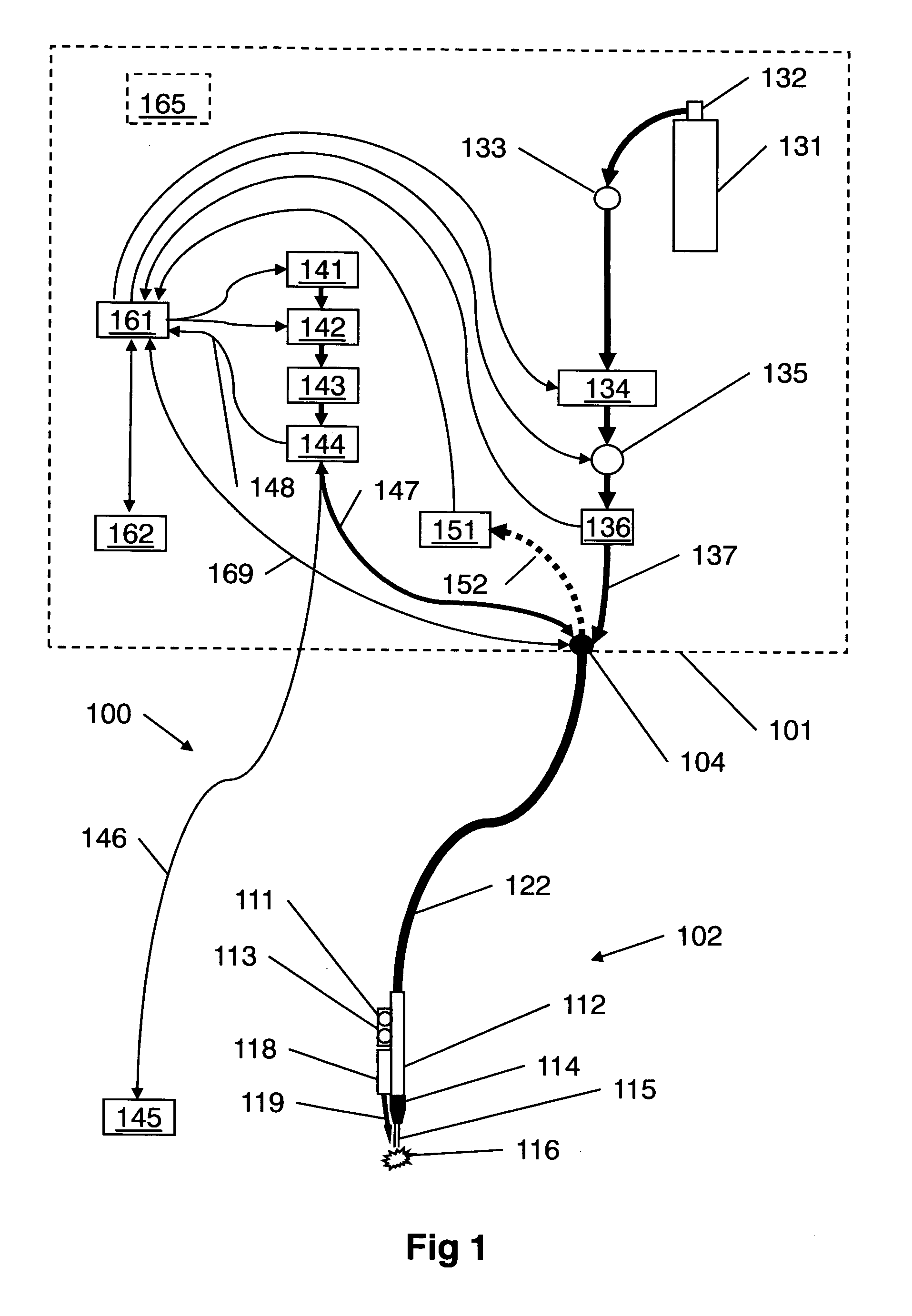

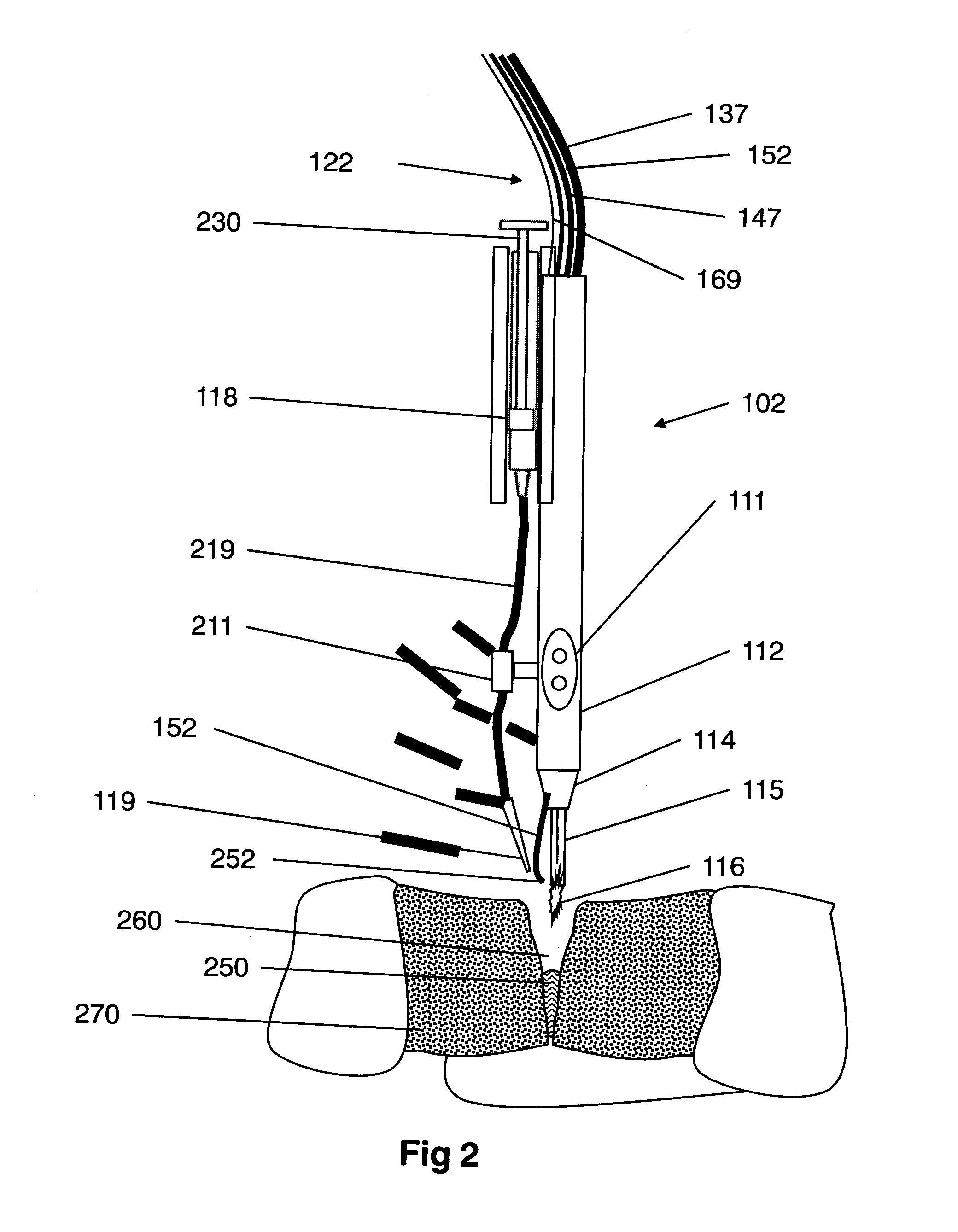

Plasma head for tissue welding

InactiveUS20120283732A1Decrease mortality and morbidityDecrease operative timeDiagnosticsSurgical instruments for heatingBlood plasmaBiomedical engineering

A compact medical device for tissue welding is provided. The hand-held plasma heads are configured for deep cuts and long cuts. A bio-compatible liquid capable of solidifying in response to application of plasma, such as an albumin solution, is applied to the wound. Plasma created from a gas such as helium is then applied to said bio-compatible liquid to solidify it and seal the wound. An additional polymerizing gas may also be applied. A feedback mechanism may maintain the temperature of said plasma. A wiper fort removal of excess liquid may also be provided.

Owner:IONMED

Plasma head for tissue welding

InactiveUS9060750B2Easy to adjustIncreasing RF power/frequencyDiagnosticsSurgical instruments for heatingAlbumin solutionHand held

A compact medical device for tissue welding is provided. The hand-held plasma heads are configured for deep cuts and long cuts. A bio-compatible liquid capable of solidifying in response to application of plasma, such as an albumin solution, is applied to the wound. Plasma created from a gas such as helium is then applied to said bio-compatible liquid to solidify it and seal the wound. An additional polymerizing gas may also be applied. A feedback mechanism may maintain the temperature of said plasma. A wiper fort removal of excess liquid may also be provided.

Owner:IONMED

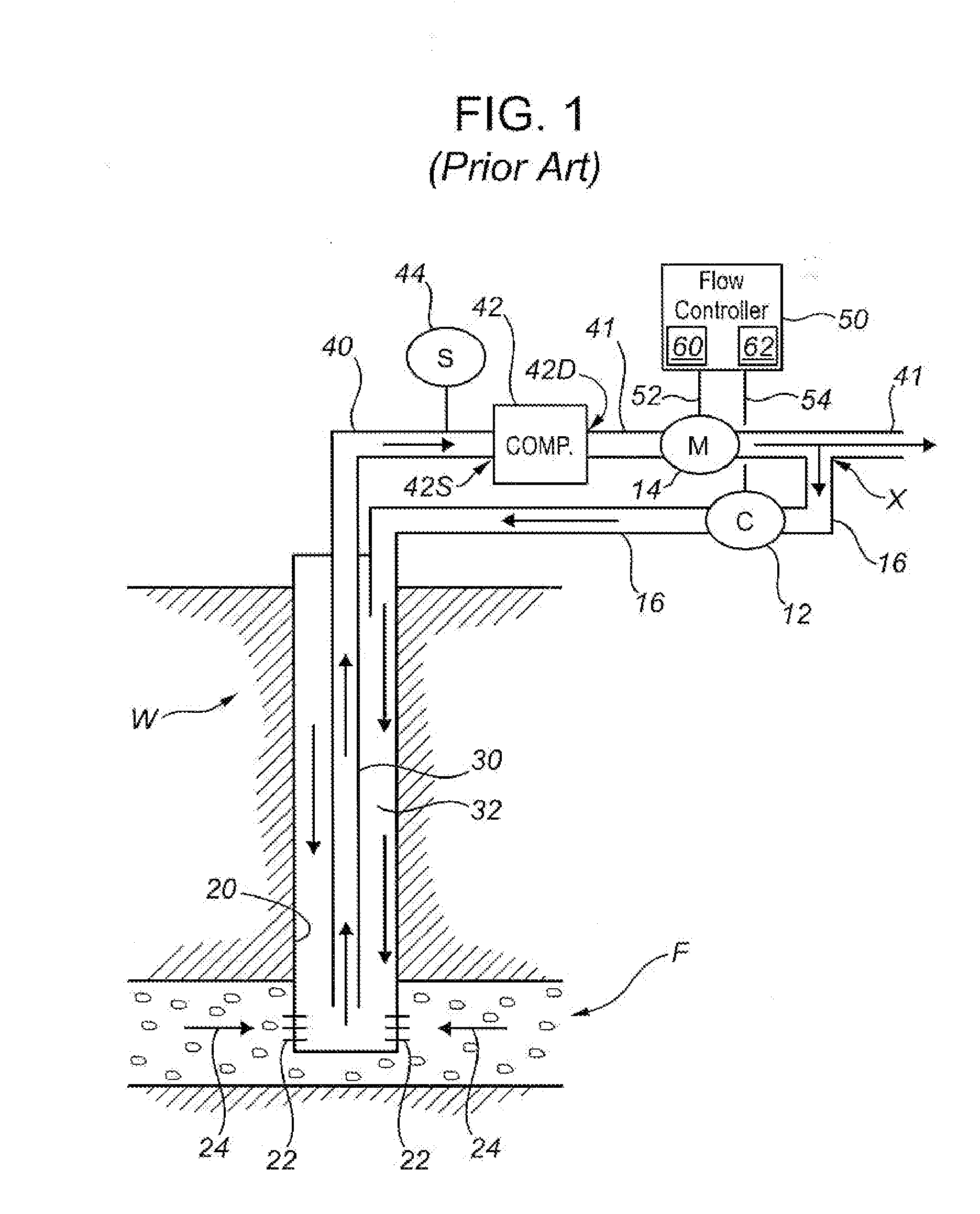

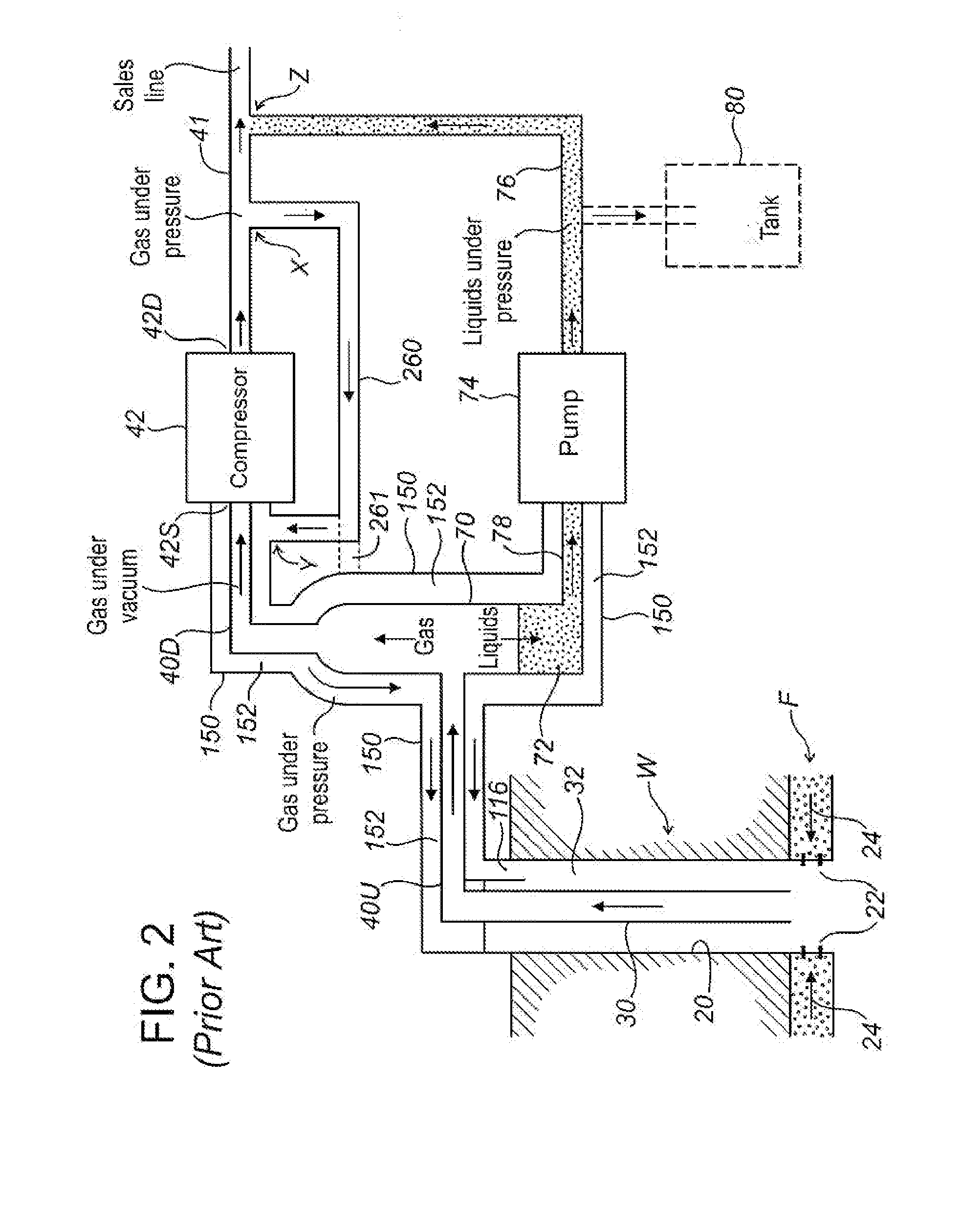

Control logic method and system for optimizing natural gas production

InactiveUS20110004352A1Reduce fluid velocityReduce the gas flow rateDiaphragm valvesOperating means/releasing devices for valvesSet pointNatural gas

In a system for optimizing natural gas production in response to real-time variations in wellbore parameters, a PLC or other wellsite intelligence technology is used to monitor liquid and gas production from the wellbore under friction-loaded conditions. Using baseline production data obtained during production tests, the PLC determines and initiates the appropriate operating mode for the wellbore to optimize a selected production criterion to suit measured wellbore parameters. The operating mode either a continuous clean-out mode, in which gas is continuously injected into the wellbore to control liquid loading, or an intermittent clean-out, in which liquid loading is regulated by intermittent gas injection. In preferred embodiments, the system uses bladder-type control valves having upstream and downstream solenoids, to control production tubing flow rate within a range between upper and lower set points.

Owner:OPTIMUM PROD TECH INC

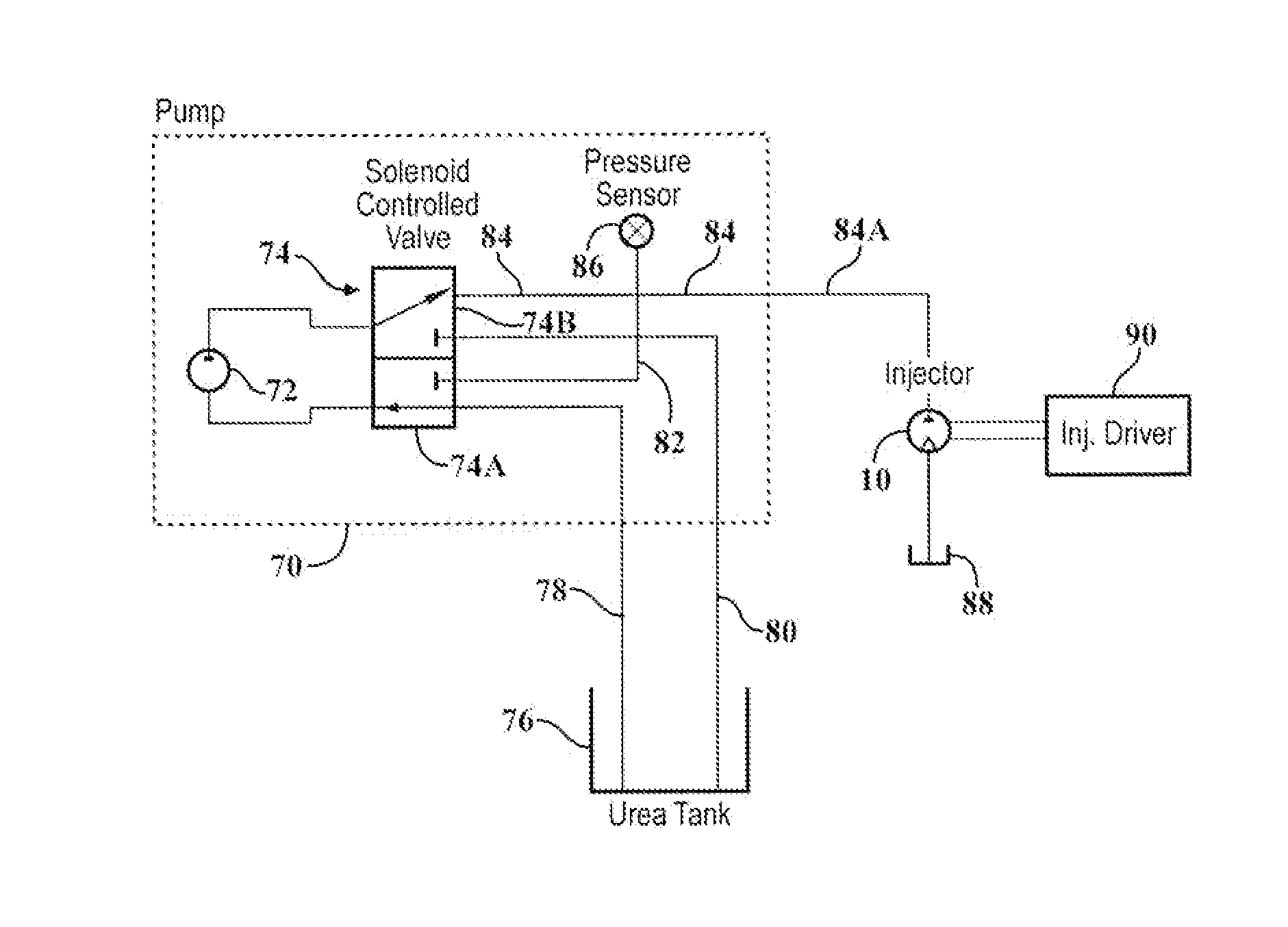

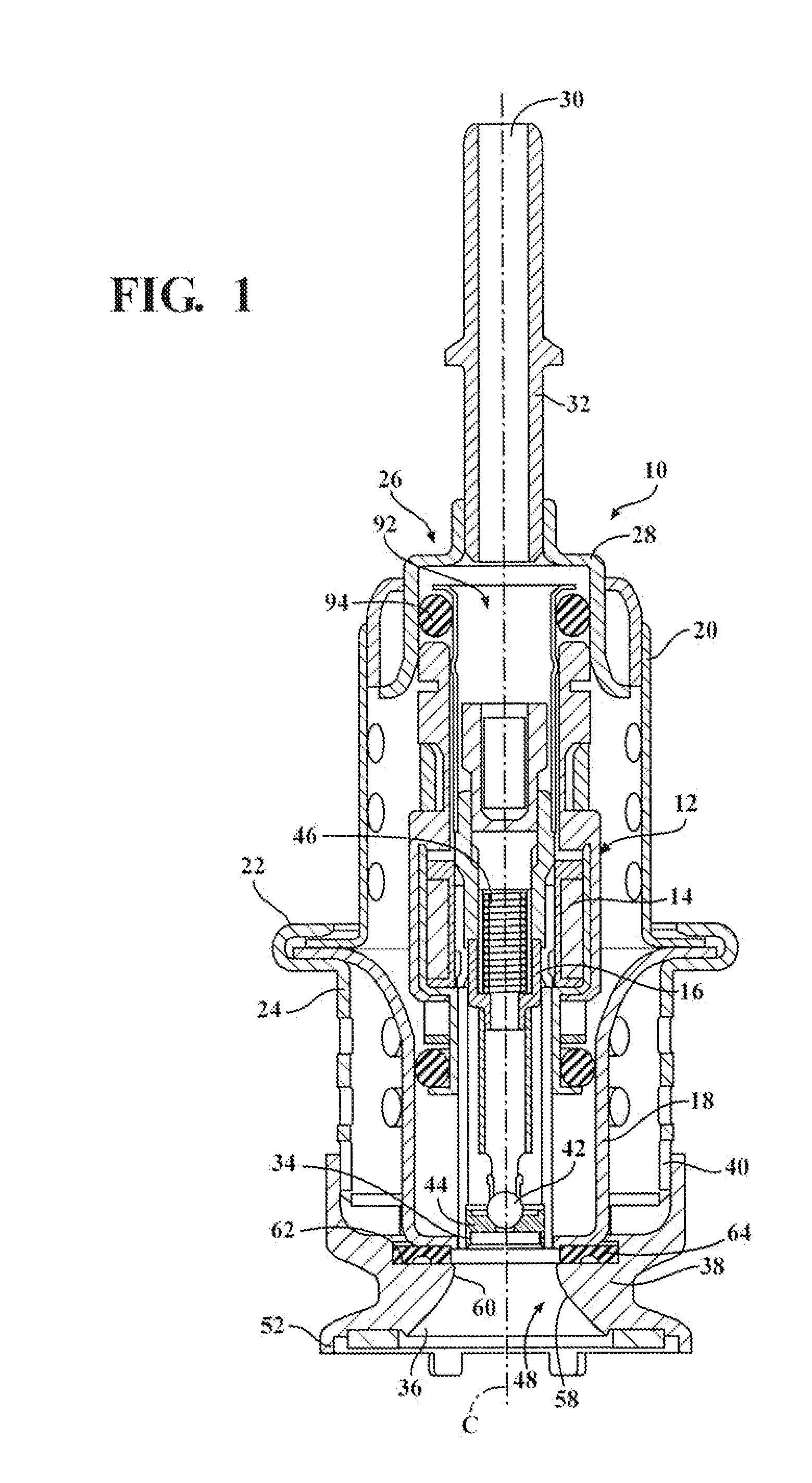

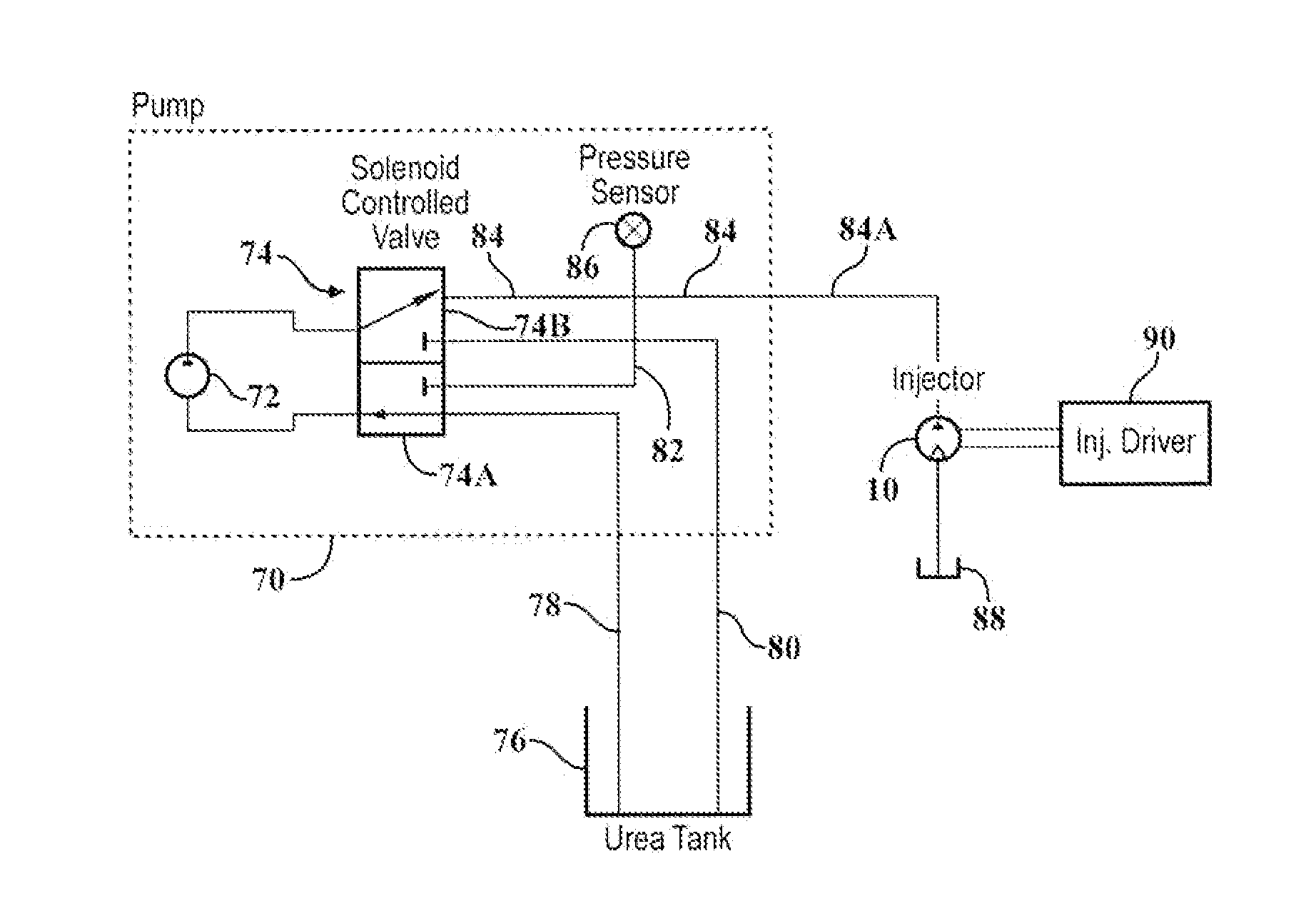

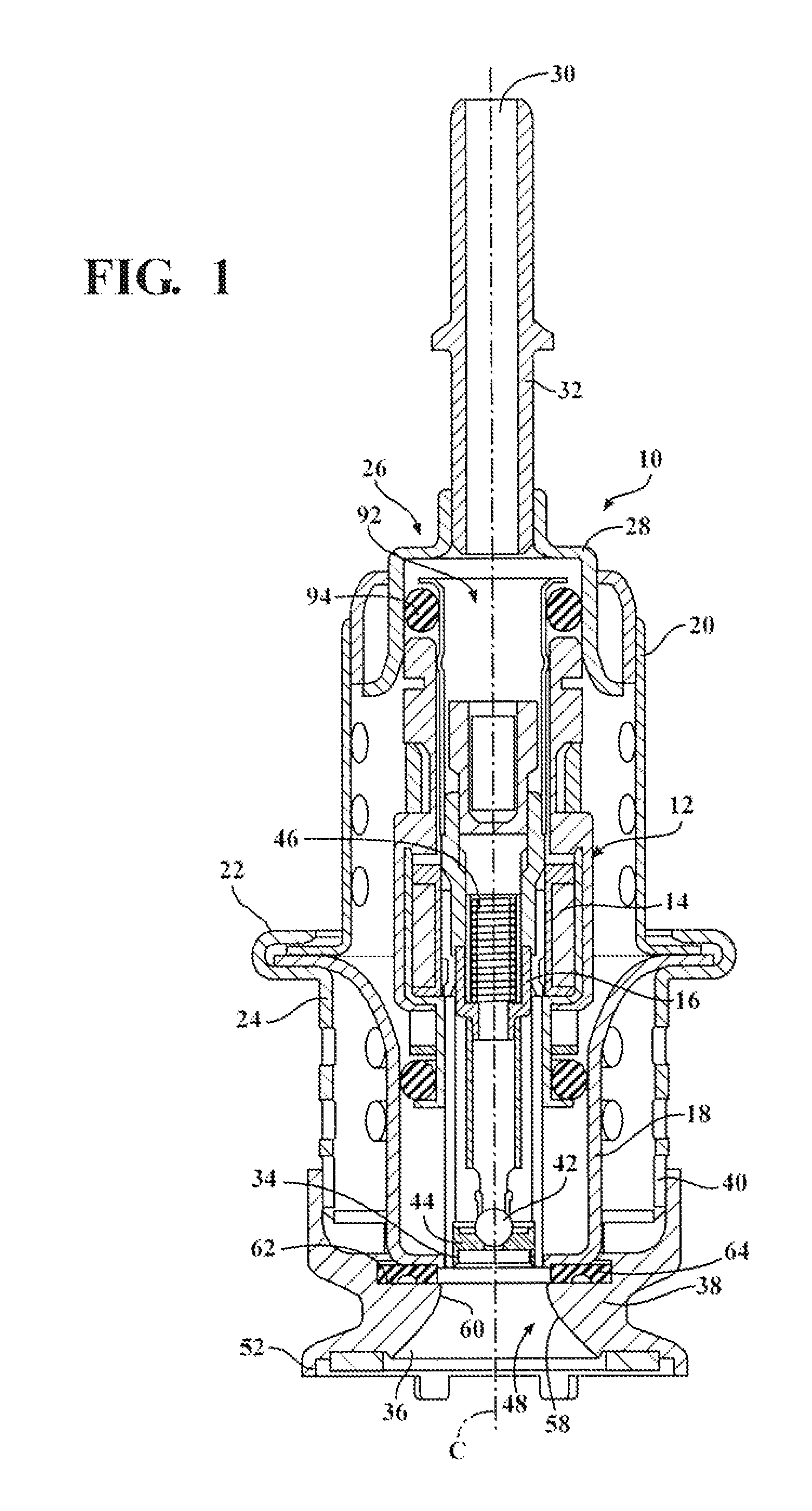

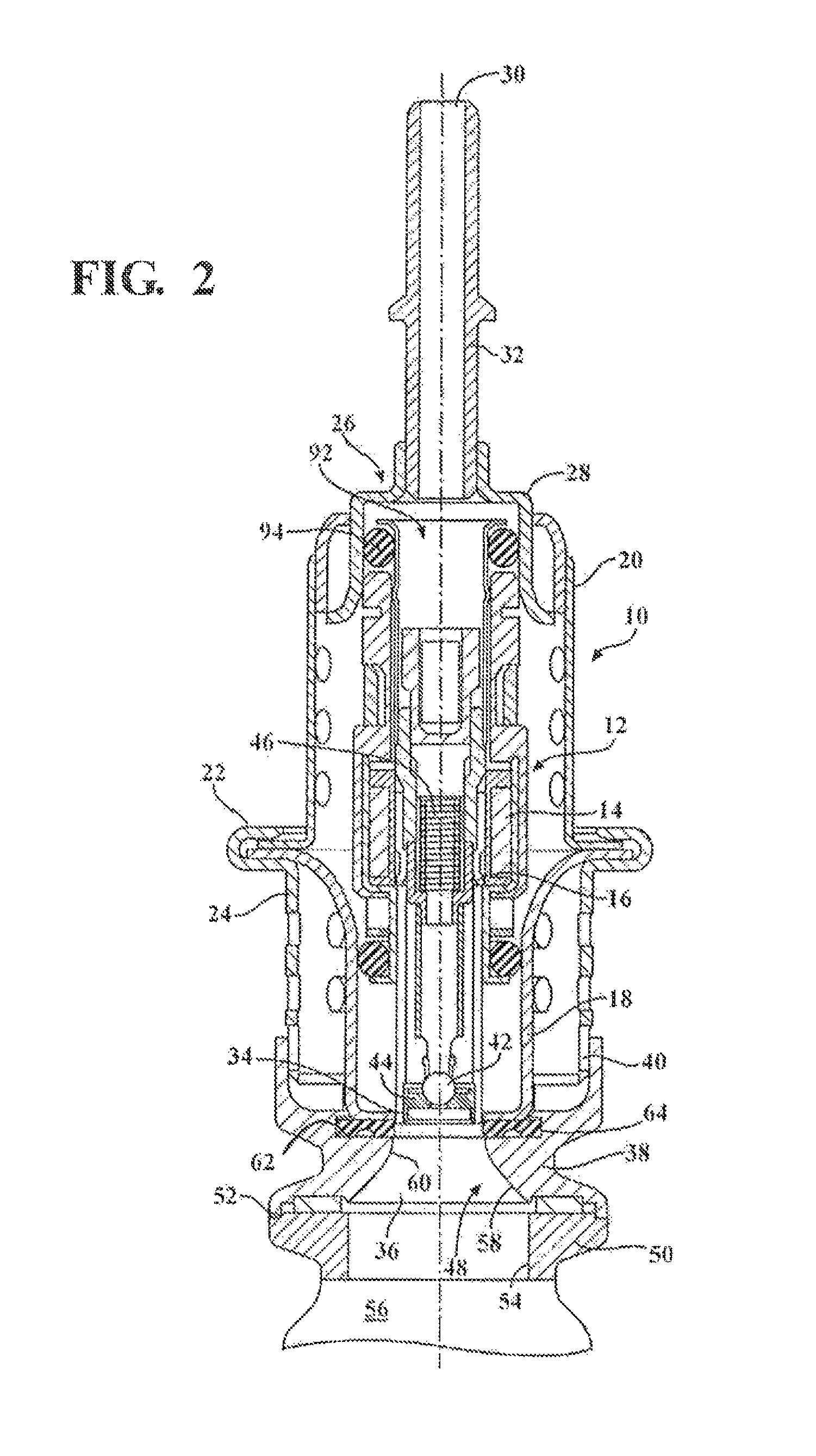

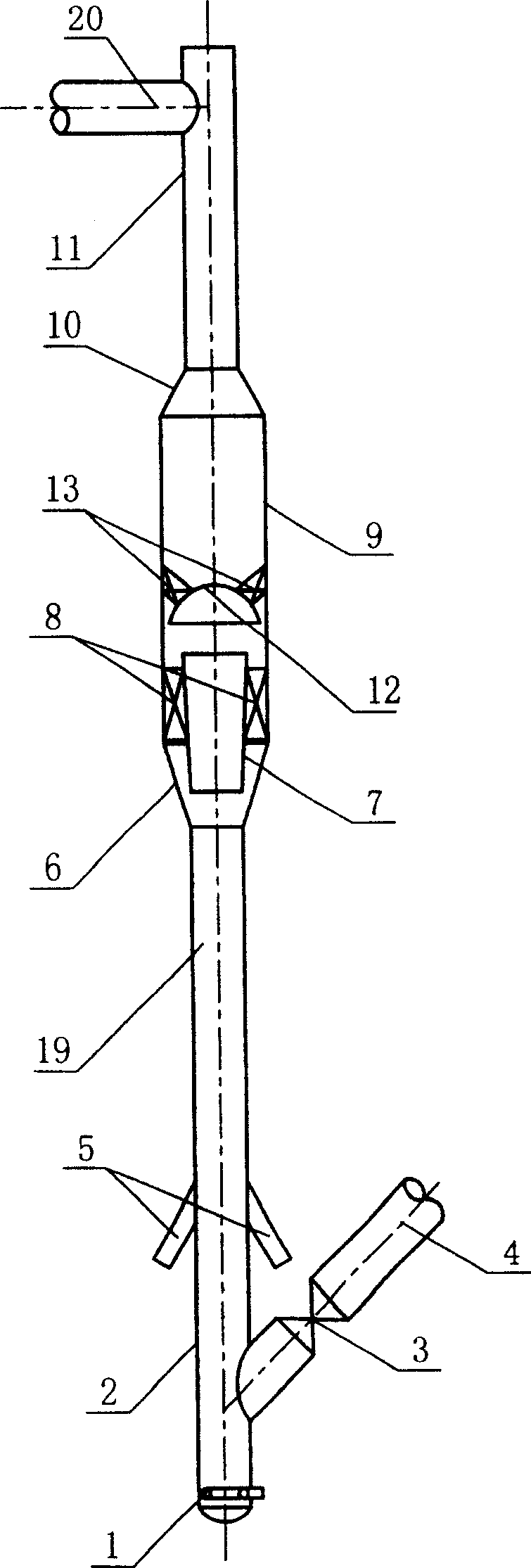

Purge system for reductant delivery unit for a selective catalytic reduction system

ActiveUS20150115051A1Maximize fluid volumeReduce sealing load of sealingInternal combustion piston enginesExhaust apparatusExhaust fumesAmbient pressure

A purge procedure which is part of an injector, that may be used as part of a reductant delivery unit (RDU), where the RDU is part of a selective catalytic reduction system for injecting diesel exhaust fluid into an exhaust system, to control exhaust emissions. The RDU delivers a reductant carrier to the engine exhaust system. The purge process includes a control strategy to improve the quality of the purge cycle (i.e., increase the amount of fluid evacuated). The sequence of the purge event is adjusted in order to generate a strong vacuum in the fluid supply line and the injector—this enhances the efficiency of the purge by increasing the initial flow rates through the injector. However, upon opening the injector, the pressure inside the fluid path increases to a level just below the ambient pressure outside the injector, therefore the gas flow rate is substantially reduced.

Owner:VITESCO TECH USA LLC

PCVD method for making large-diameter fibre-optical mandrel

ActiveCN101182113AImprove uniformityQuality improvementGlass making apparatusHigh frequency powerEngineering

The invention relates to a PCVD manufacturing method for an optical fiber mandrel with large diameter. The external diameter of a quartz liner is determined to be 36-46mm, the inner diameter to be 32-40mm and the length of the liner to be 1.45-1.85m for the process of PCVD. Parameters of a processing technology are that the high frequency power of a microwave resonator is controlled to be 6KW-15KW and the deposition temperature is 1080-1130 degree Celsius. The variety of mixed air flowing through the liner includes silicon tetrachloride vapor, germanium tetrachloride vapor, high-purity oxygenand Freon. The inside pressure of the liner is 10-15millibar. The air flow rate inside the liner is 30-80m / s. the air volumetric flow rate is 4400-8800SCCM. The invention solves a technical problem of unstable plasma caused by the fast air flow rate. The uniformity of the liner deposition is improved. The effective length of the liner deposition mandrel is increased, which increases the wire drawing length of a single mandrel. The working efficiency and the equipment utilization ratio are improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

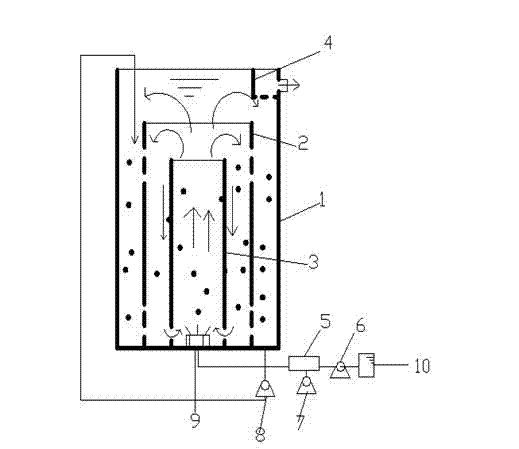

Biological membrane fluidized bed wastewater treatment method

ActiveCN103043783AReduce power consumptionPromote growthSustainable biological treatmentWaste water treatment from plant processingFluidized bedBiochemical engineering

The invention relates to a biological membrane fluidized bed wastewater treatment method and belongs to the field of environmental engineering. The method comprises the following steps: adopting natural paper pulp fibers with good biocompatibility as fluidized bed carrier fillers and adopting a three-chamber composite biological membrane fluidized bed as a fluidized bed reactor. The method has the beneficial effects that the power consumption can be greatly reduced; meanwhile, as a plurality of fine fibers and micro pores are formed in the cellulose fibers, the growth and the adhesion of microorganisms are facilitated; and under the bridging and collecting action of the fine fibers, the problem existing in a conventional filler that microorganisms are easy to fall off is solved to a great degree. The method has good application prospect.

Owner:朱勇强

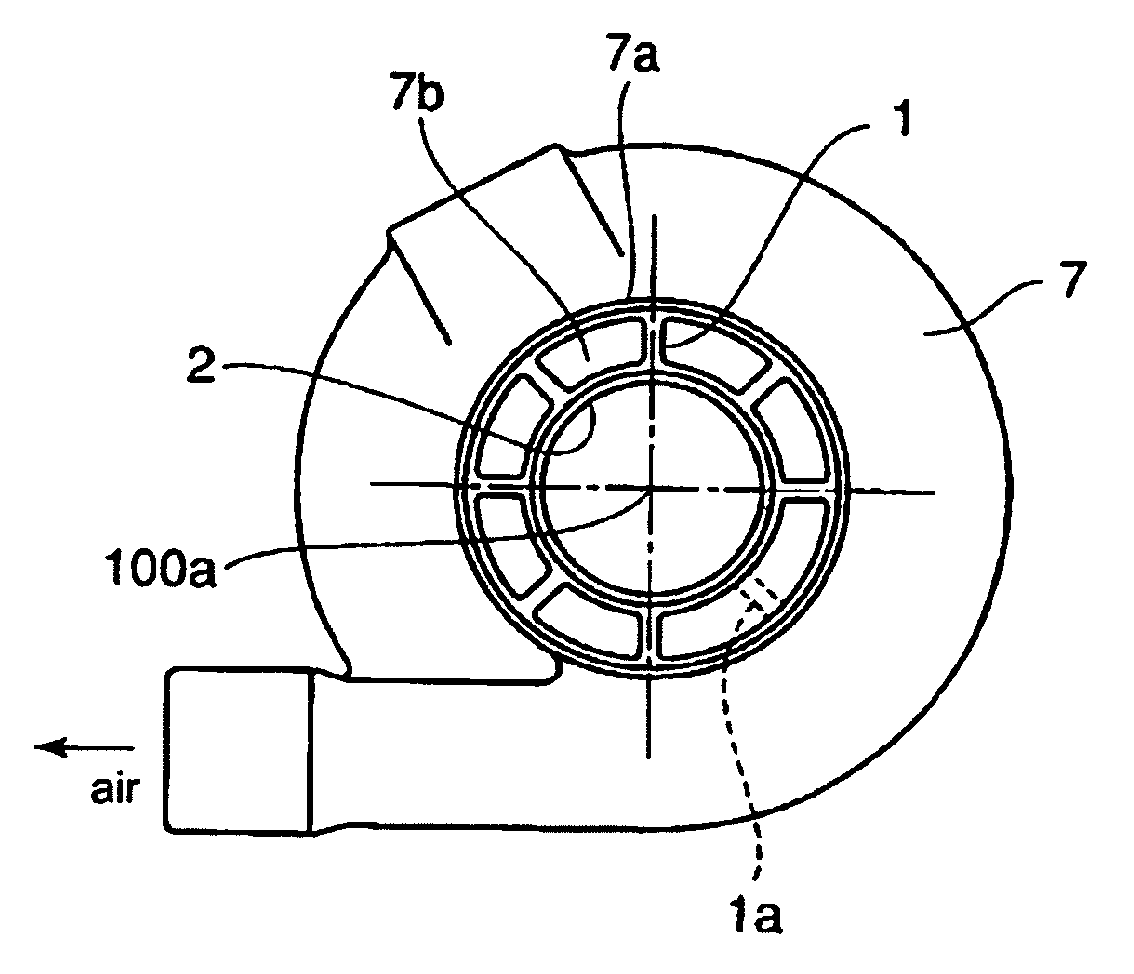

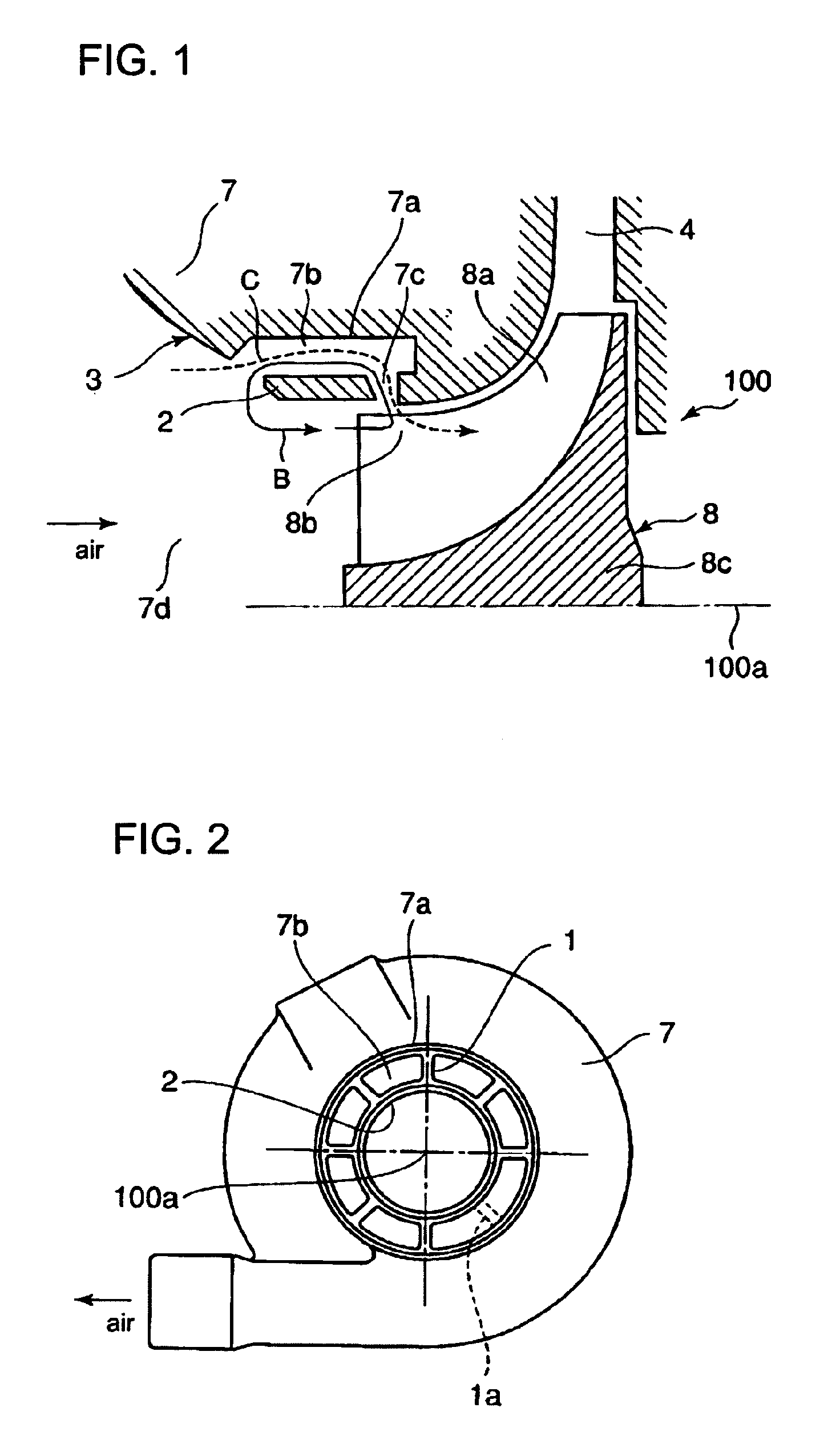

Centrifugal compressor

ActiveUS20090214334A1Speed up the gas flowBroaden the stable operating rangePump componentsBlade accessoriesCentrifugal compressorElectrical and Electronics engineering

A centrifugal compressor can be provided with which frequency of noise produced by rotation of the impeller having a plurality of blades does not resonate with natural frequency of vibration of gas in a plurality of axial slots which serve to increase gas flow rate in an operation range of increased gas flow rate and broaden stable operation range in an operation range of decreased gas flow rate resulting in reduction of noise caused by rotation of the impeller. The axial slots are formed between the peripheral part of the inlet passage of the compressor housing by the peripheral surface of the inlet passage and an annular ring part of the housing supported by a plurality of struts extending from the peripheral surface, four or more struts are provided to support the annular ring part, and all but one of them are located at positions which will be determined when all the struts are located at circumferentially equal spacing and one of the struts is shifted circumferentially from one of said positions by a certain central angle.

Owner:MITSUBISHI HEAVY IND LTD

Water sealing fire retardance explosion venting device

The invention discloses a water sealing fire retardance explosion venting device which comprises a fire retardance device and an explosion venting machine. The fire retardance device comprises a fire retardance barrel body, an air inlet pipe, an air outlet pipe and a water filtering metal ring net. One end of the air inlet pipe is placed out of the fire retardance barrel body, the other end of the air inlet pipe extends into the fire retardance barrel body and is inserted to the position below a sealing water liquid level, and the water filtering metal ring net is arranged above the sealing water liquid level and is arranged outside the air inlet pipe in a sleeving mode. The explosion venting machine comprises an explosion venting barrel body, an exhaust pipe and an explosion venting pipe. The exhaust pipe and the explosion venting pipe are communicated with the explosion venting barrel body. The fire retardance barrel body is communicated with the explosion venting barrel body through the air outlet pipe and a communication pipe arranged at the bottom. An explosion piece is arranged in the explosion venting pipe. An air outlet end pipe opening of the air inlet pipe is sealed. An exhaust hole is formed in the side wall, placed below the sealing water liquid level, of the air inlet pipe. The exhaust hole is connected with an air guiding pipe. Air guiding holes for air discharging are distributed in the air guiding pipe. The instability and the acute fluctuation of the liquid level caused when air is discharged from the device exhaust pipe can be avoided, water level control is convenient, and the safety and the reliability of the device are improved.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Purge system for reductant delivery unit for a selective catalytic reduction system

ActiveUS9273581B2Improve purge efficiencyPrevent component damage during freezing conditionsInternal combustion piston enginesExhaust apparatusExhaust fumesAmbient pressure

A purge procedure which is part of an injector, that may be used as part of a reductant delivery unit (RDU), where the RDU is part of a selective catalytic reduction system for injecting diesel exhaust fluid into an exhaust system, to control exhaust emissions. The RDU delivers a reductant carrier to the engine exhaust system. The purge process includes a control strategy to improve the quality of the purge cycle (i.e., increase the amount of fluid evacuated). The sequence of the purge event is adjusted in order to generate a strong vacuum in the fluid supply line and the injector—this enhances the efficiency of the purge by increasing the initial flow rates through the injector. However, upon opening the injector, the pressure inside the fluid path increases to a level just below the ambient pressure outside the injector, therefore the gas flow rate is substantially reduced.

Owner:VITESCO TECH USA LLC

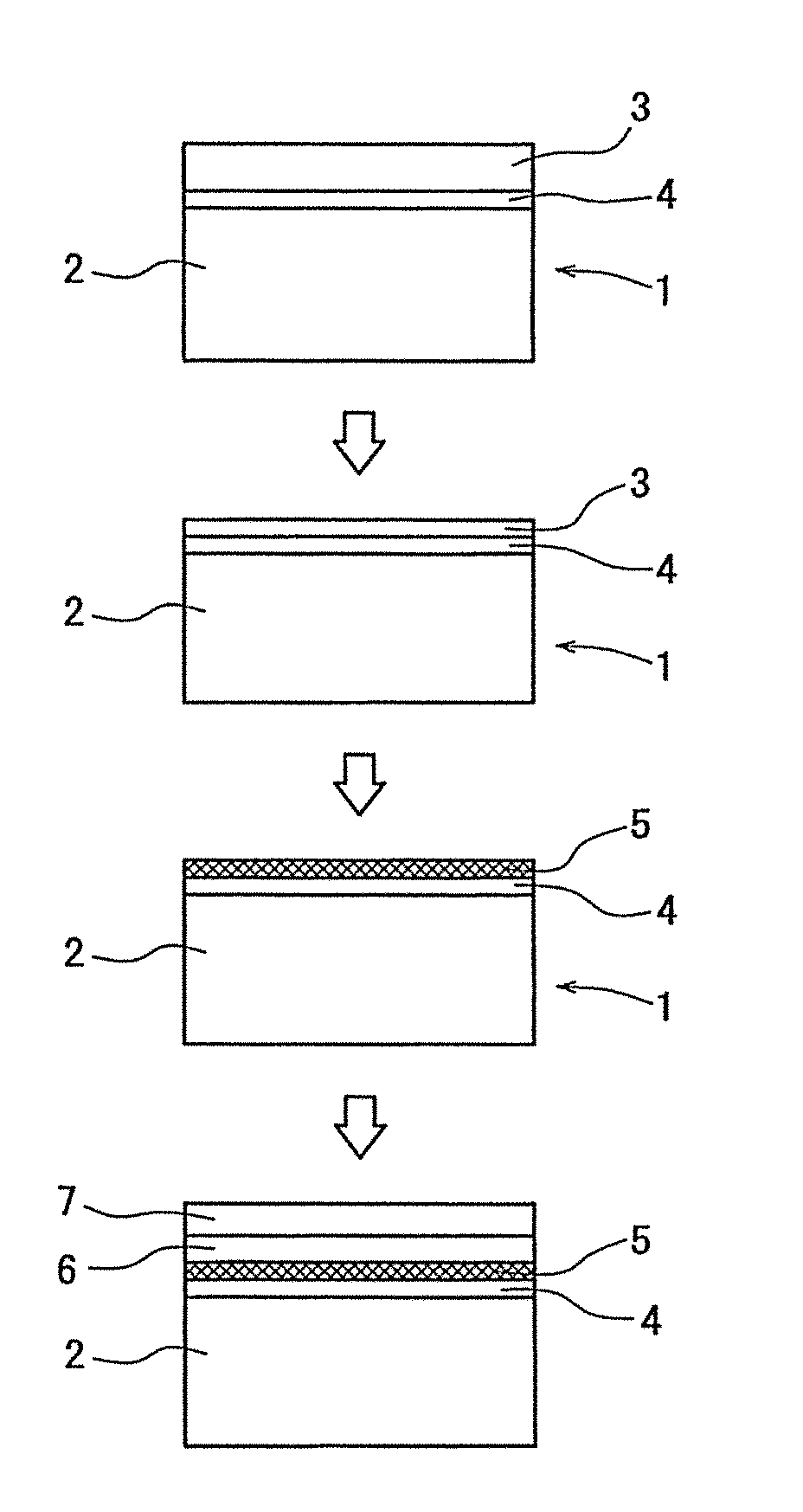

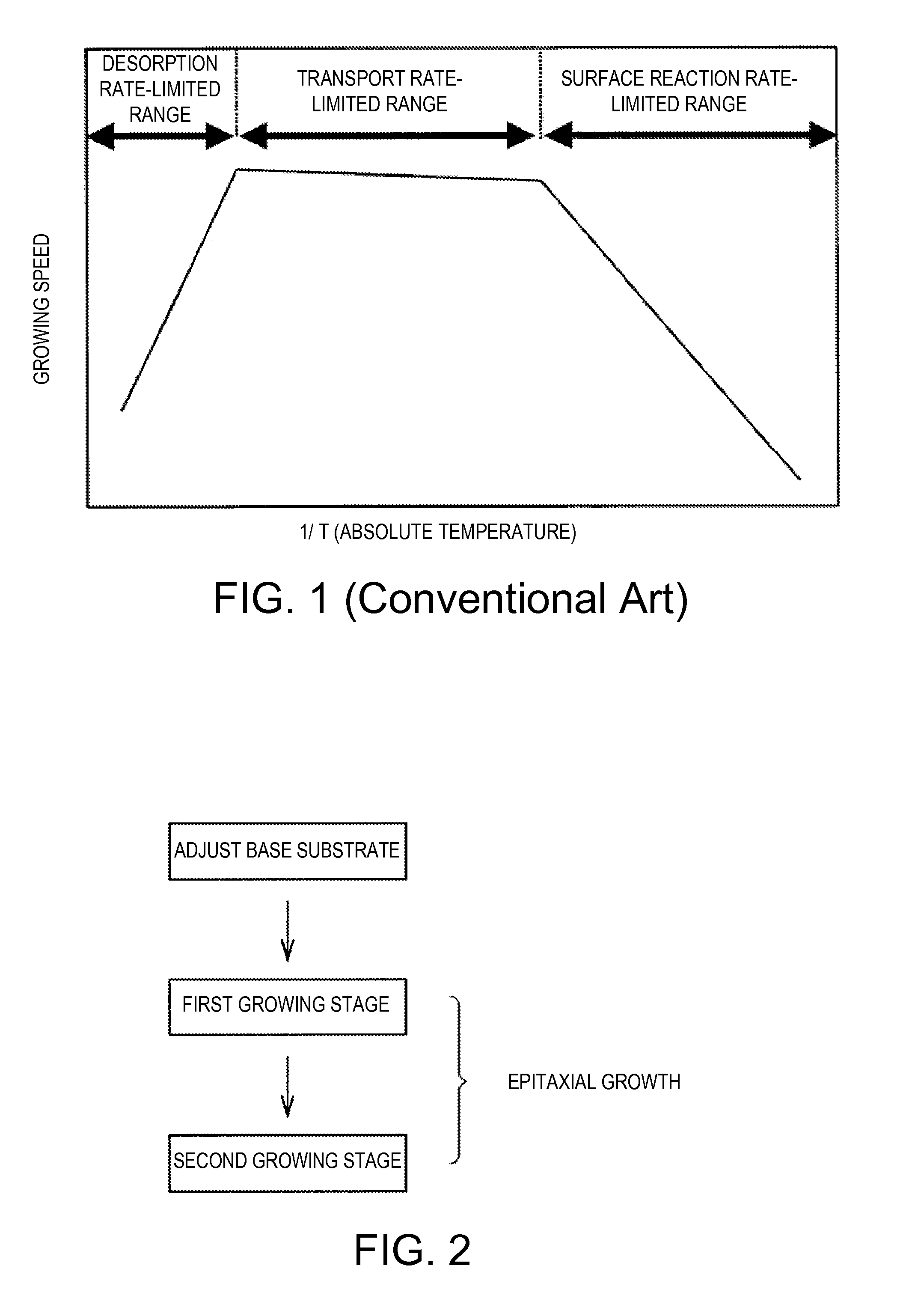

Method of manufacturing single crystal 3c-sic substrate and single crystal 3c-sic substrate obtained from the manufacturing method

ActiveUS20130040103A1Improve flatnessReduce surface pittingPolycrystalline material growthSemiconductor/solid-state device manufacturingDevice materialSingle crystal

To provide a method of manufacturing a single crystal 3C-SiC substrate that can dramatically reduce surface defects generated in a processing of epitaxial growth and can secure a quality as a semiconductor device while simplifying a post process. The method of manufacturing a single crystal 3C-SiC substrate where a single crystal 3C-SiC layer is formed on a base substrate by epitaxial growth is provided. A first growing stage of forming the single crystal 3C-SiC layer to have a surface state configured with a surface with high flatness and surface pits scattering in the surface is performed. A second growing stage of further epitaxially growing the single crystal 3C-SiC layer obtained in the first growing stage so as to fill the surface pits is performed.

Owner:AIR WATER INC

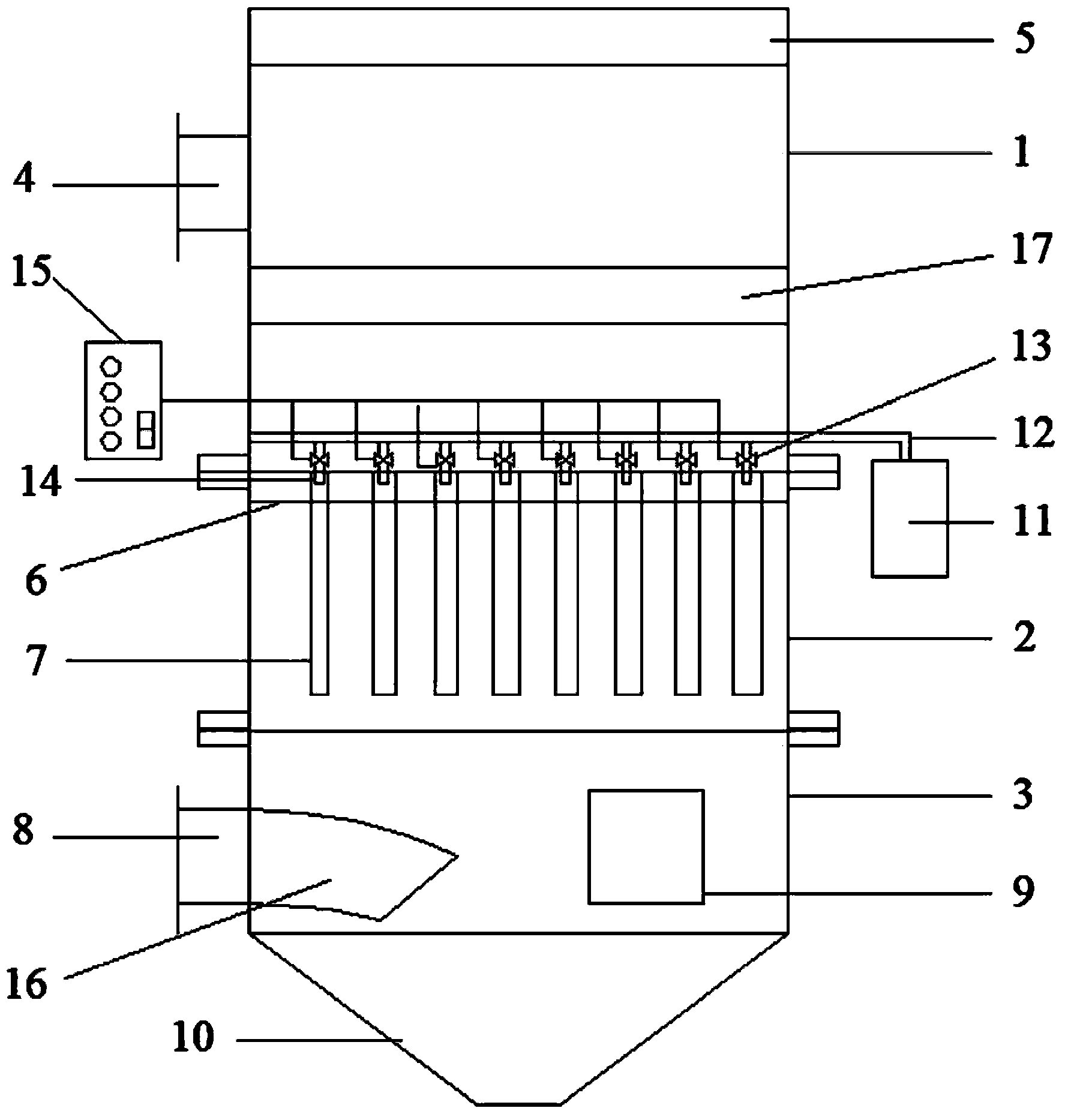

Single pulse bag type dust collector

InactiveCN103372361ASolution to short lifeEasy to separateCombination devicesPulse controlEngineering

The invention discloses a single pulse bag type dust collector, which is characterized by including an upper box body, a middle box body and a lower box body. An air outlet and a flip top cover are arranged on the upper box body; and a dust cleaning system is arranged in the upper box body. The middle box body is provided with a tubesheet and filter bags. The lower box body is provided with an air inlet and an overhaul door, and the hopper is arranged below the lower box body. The dust cleaning system comprises a gas tank, an outlet pipe, a plurality of pulse valves and blowing tubes, which are connected sequentially, and a pulse control instrument in signal connection with the pulse valves; and the air inlet is provided with an airflow homogenizing device. The invention has the beneficial effects that: the pulse blowing mode for cleaning dust has the advantages of good cleaning effect, high purification efficiency, long service life of the filter bags, small workload for repair, and safe and reliable operation; and the airflow homogenizing device is arranged at the air inlet to slow down the airflow entering the hopper, so as to isolate large particles conveniently as well as effectively reduce pressure loss of the dust collector.

Owner:张家港市盛港绿色防火建材有限公司

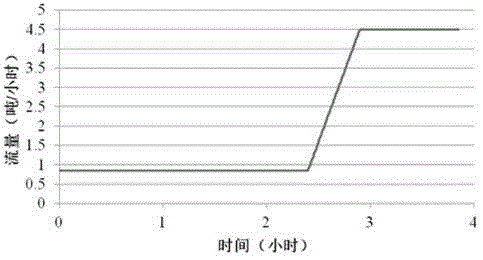

Starting emission reduction method for ethene device

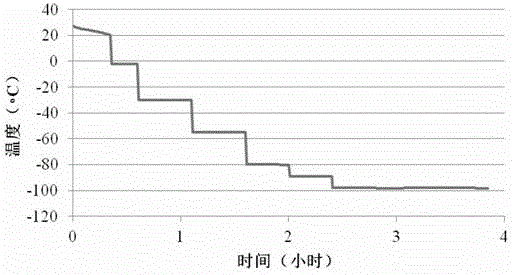

ActiveCN104152173AShorten cooling timeEmission reductionThermal non-catalytic crackingEthylene productionRefluxGas compressor

The invention relates to a starting emission reduction method for an ethene device. The method comprises the following steps: first, an ethene and propylene refrigeration system is started and a refrigerating capacity is supplemented for cold box precooling; second, the cold box precooling is started; third, total reflux of an ethene rectifying tower, a propylene rectifying tower and an ethane removing tower is established; fourth, a cracking furnace is started; fifth, a cracked gas compressor is started; sixth, a subsequent device is started and starting of the ethene device is finished. Because the cold box is subjected to cooling before formal feeding, the product qualified time of the cold box is shortened greatly, the cooling process of the cold box is controllable, and leakage dangers are avoided. Through establishment of total reflux of a low-temperature depropanization tower, the total qualified time of a high-low-pressure depropanization tower is shortened. Because natural gases are introduced to supplement the feed of the compressor, the number of starting feeding cracking furnaces is decreased, and therefore the whole discharge capacity of torches is reduced.

Owner:PETROCHINA CO LTD +2

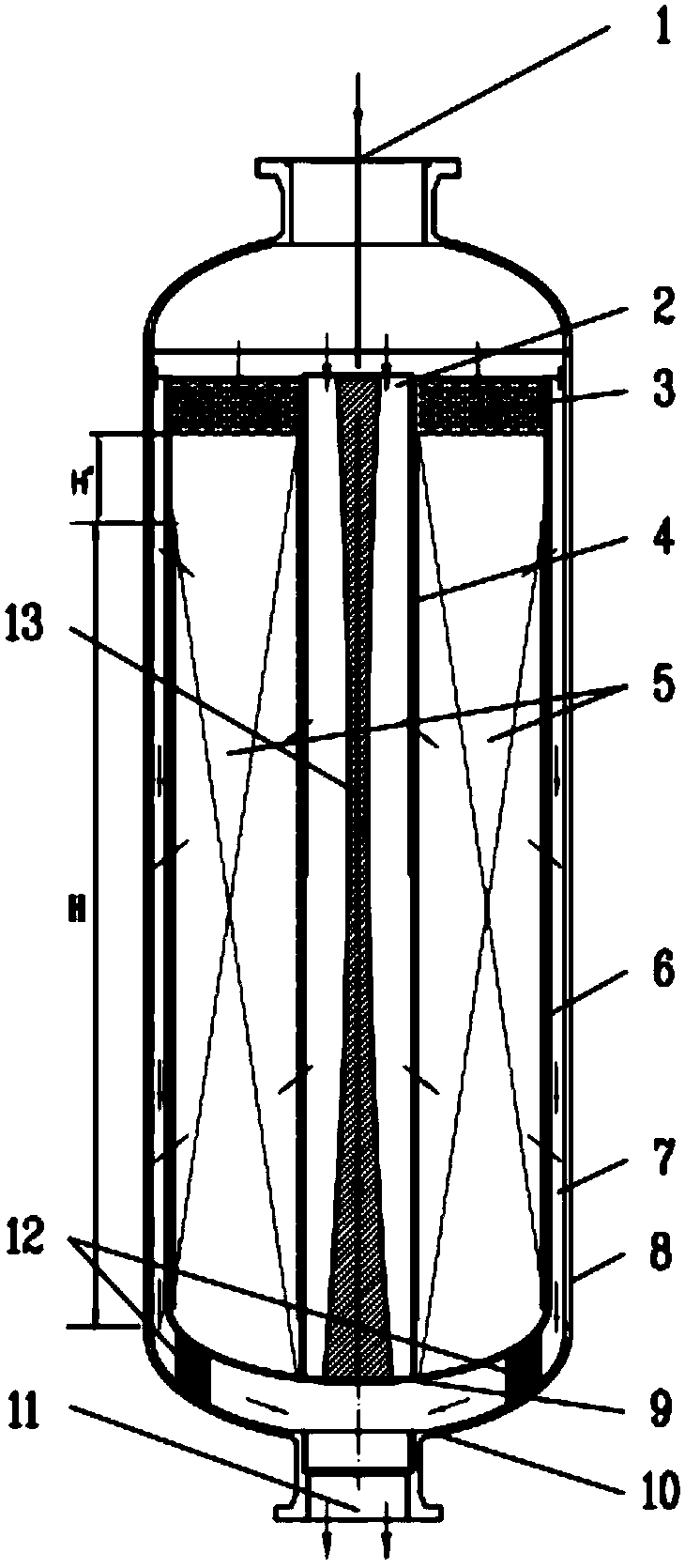

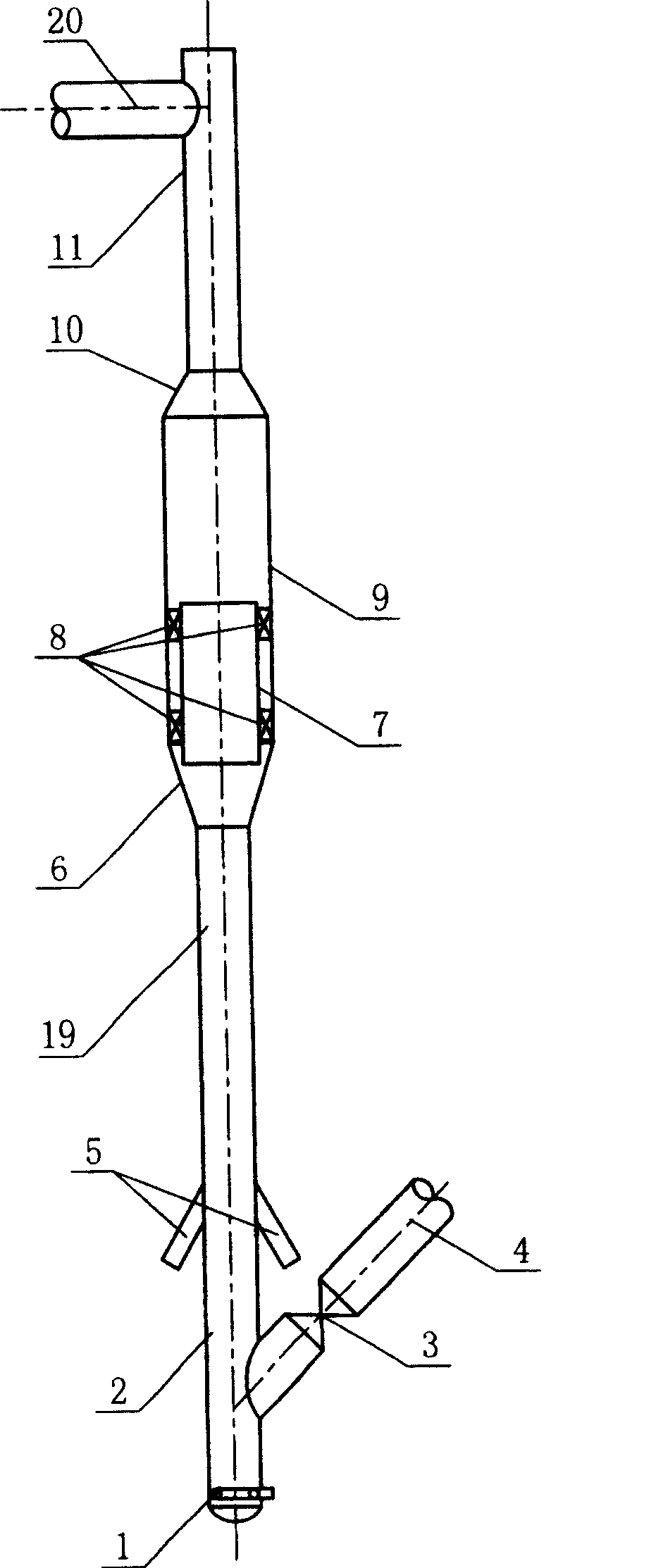

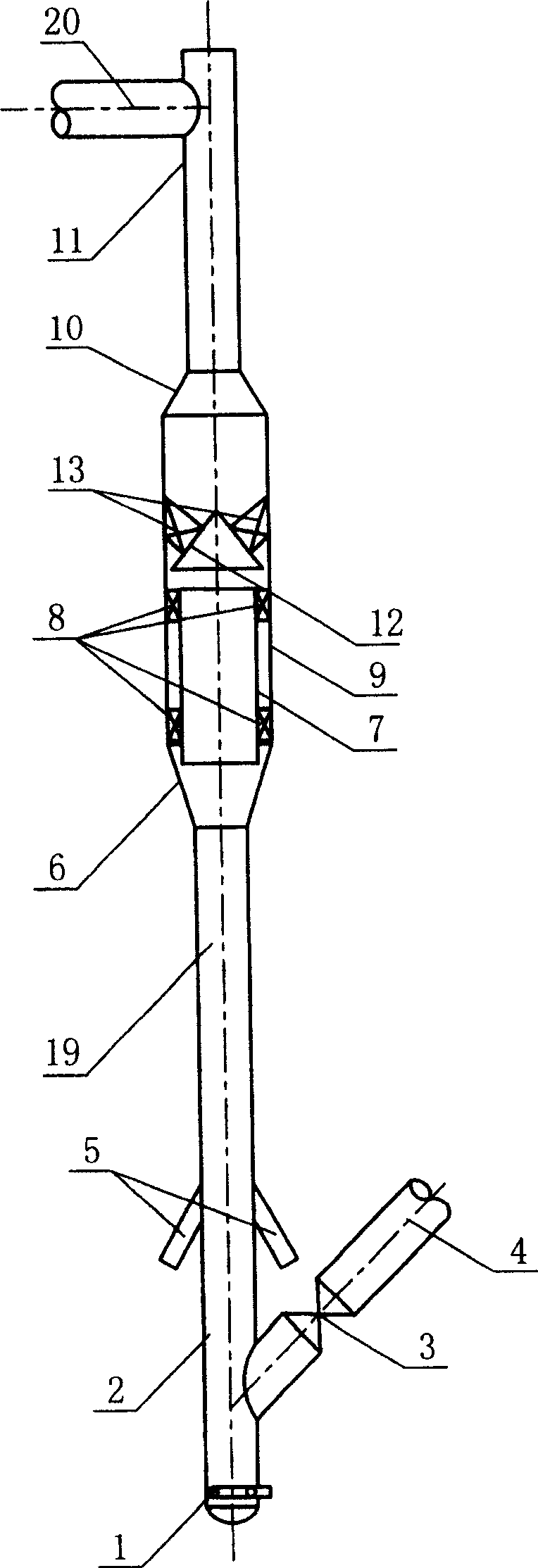

Lift-pipe reactor

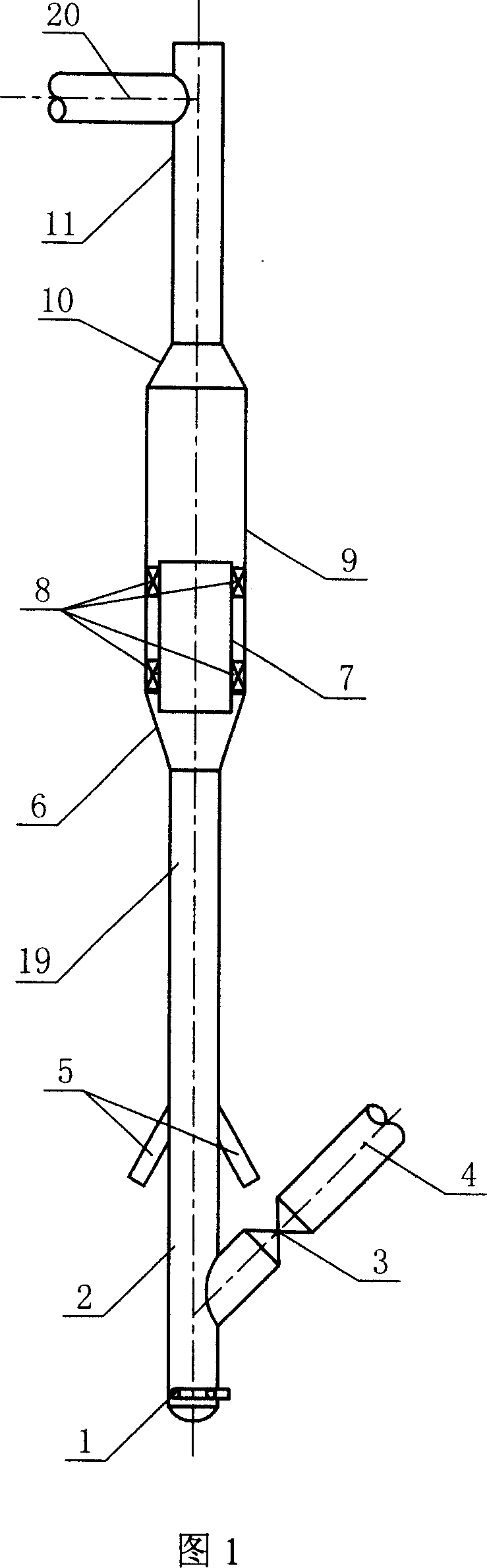

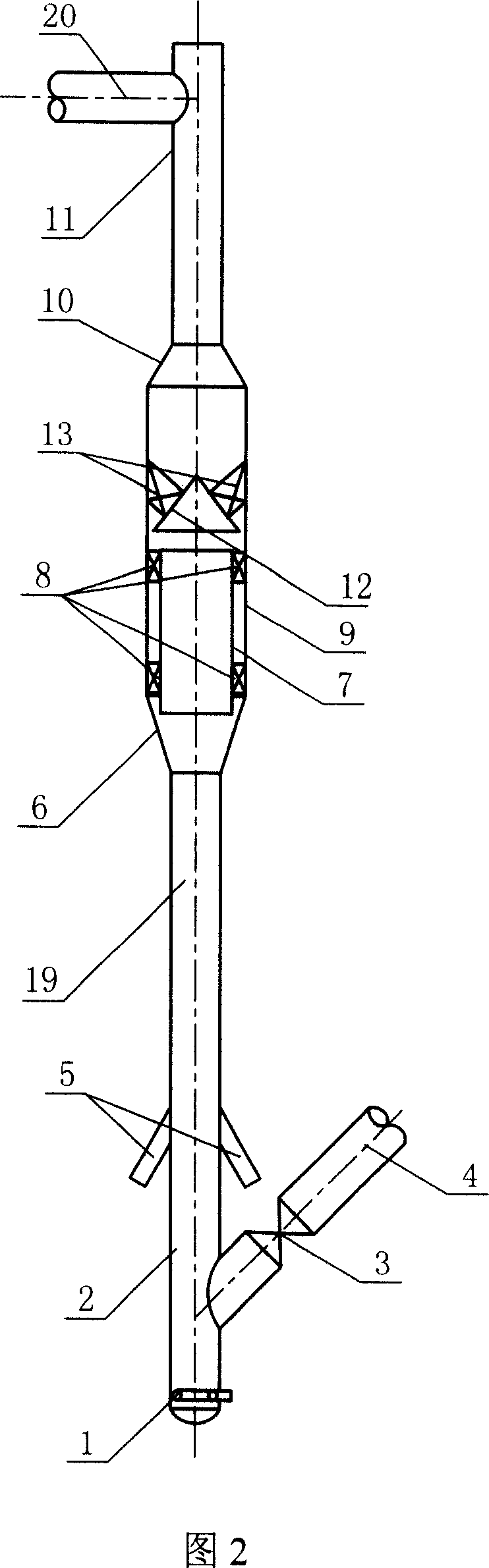

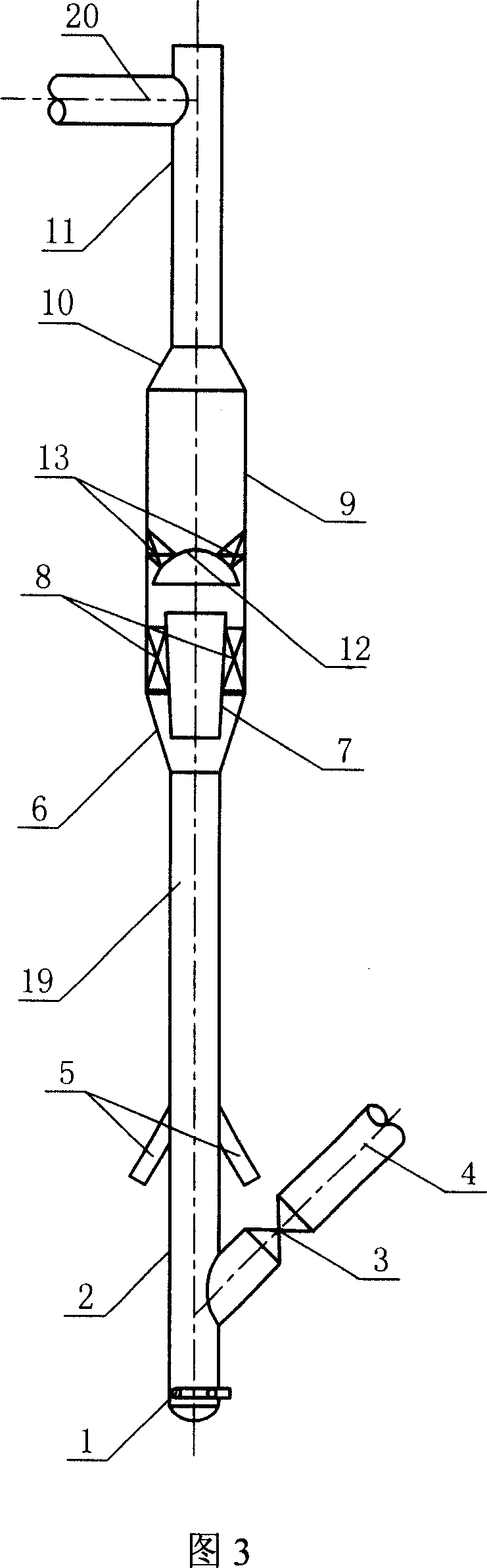

ActiveCN101028588AReduce the gas flow rateIncrease cycle strengthCatalytic crackingChemical/physical processesEngineering

A lift-pipe reactor is composed of such units from bottom to top as pre-lifting segment, the first reaction segment, the second reaction segment, and optional discharging segment. It features that a flow guiding pipe is arranged at lower part of the second reaction segment to decrease the gas flow speed in its wall region for generating a dense phase region of catalyst, so increasing the concentration of catalyst in second reaction segment.

Owner:CHINA PETROLEUM & CHEM CORP +1

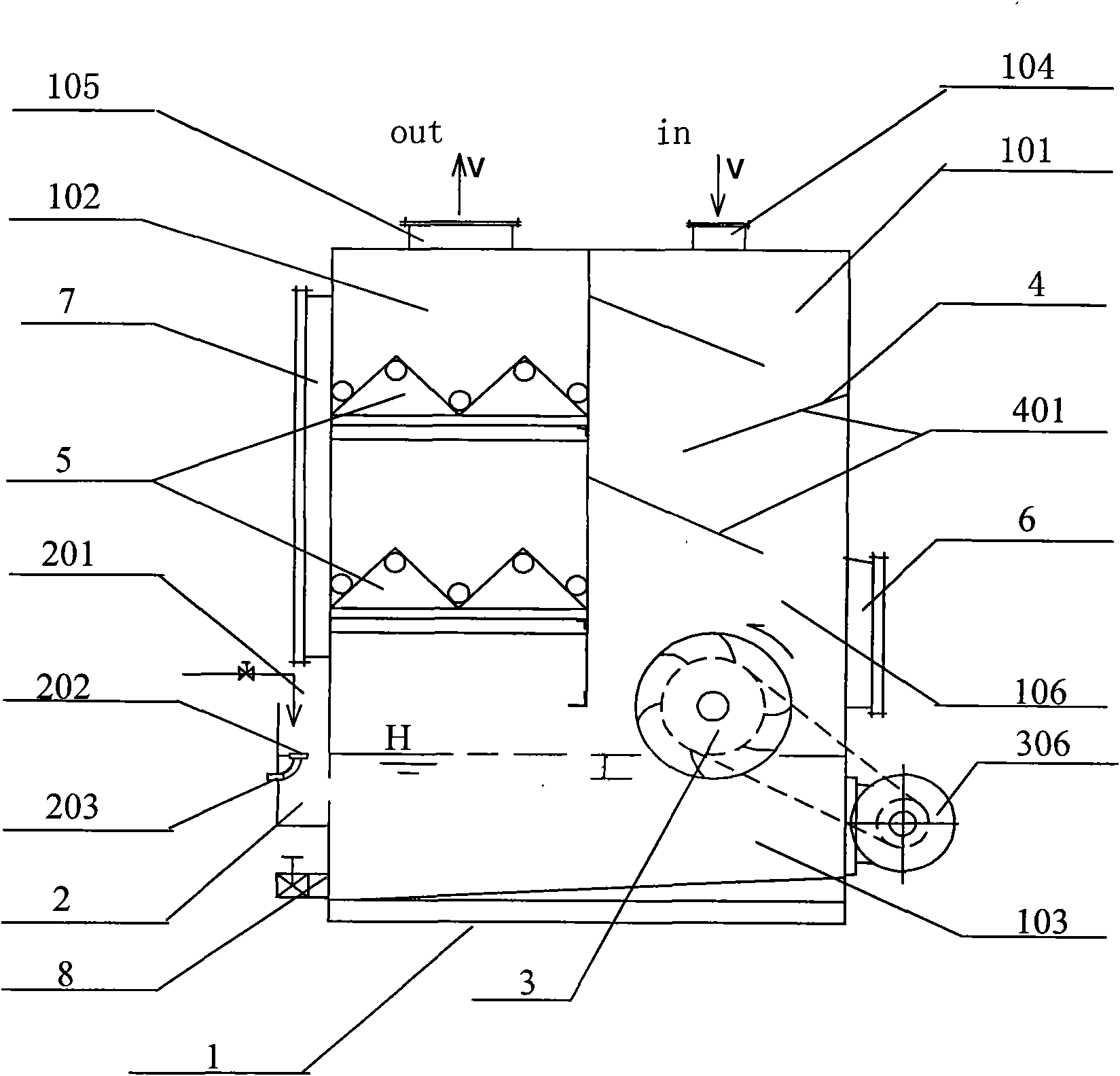

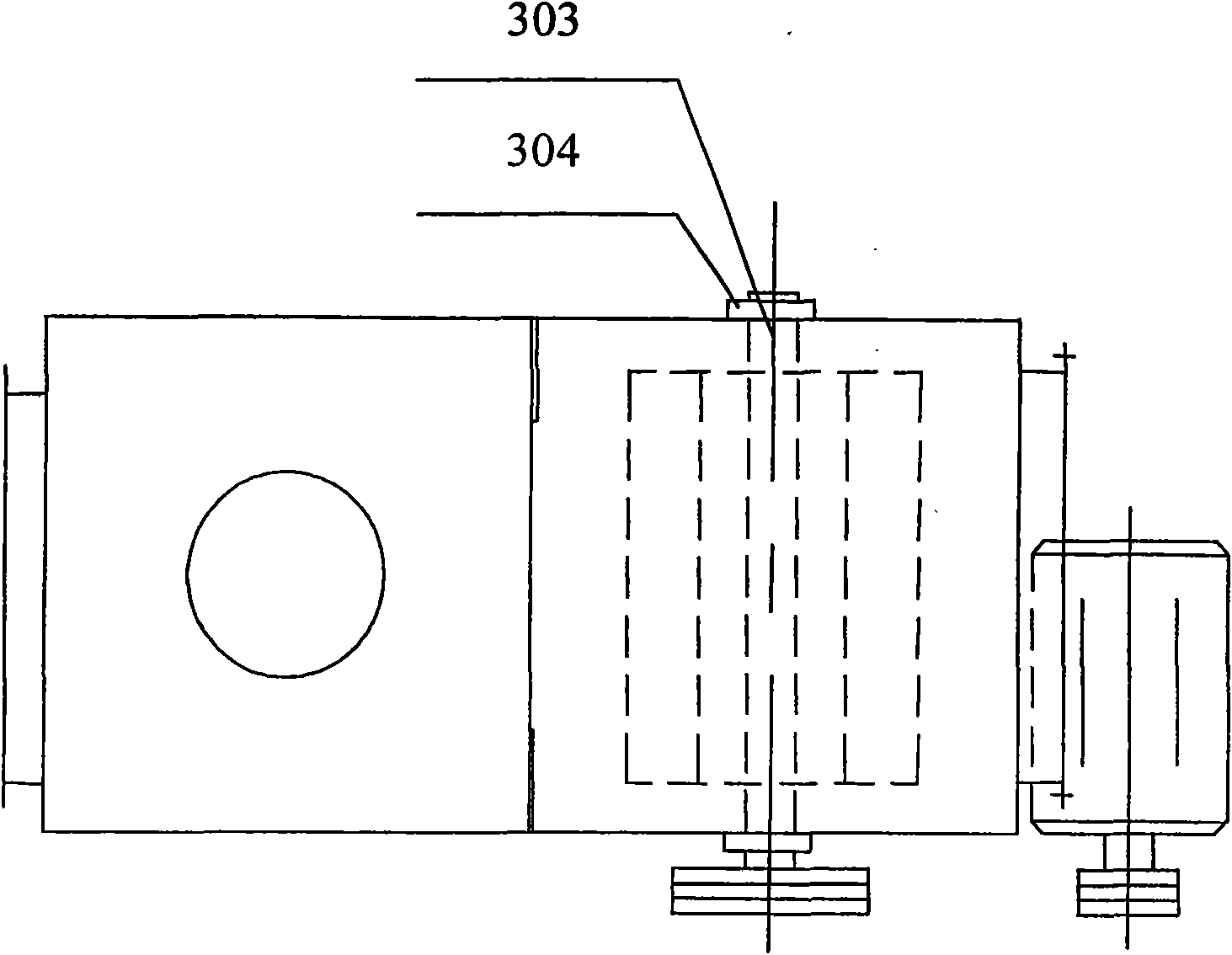

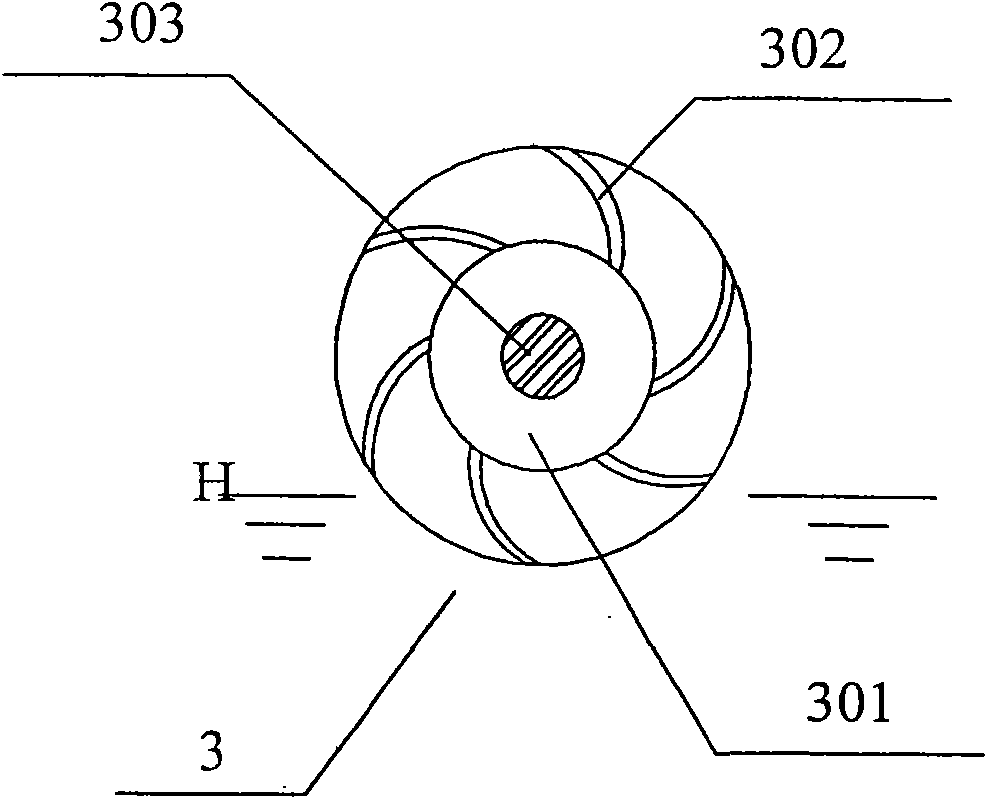

High-speed rotary atomization and absorption device for desulfurizing and removing smoke dust

The invention provides a high-speed rotary atomization and absorption device for desulfurizing and removing smoke dust. The device comprises a cavity, wherein the bottom of the cavity is provided with a solvent trough, and the cavity above the solvent trough is divided into two chambers of which the bottoms are communicated; the two chambers are respectively provided with an air inlet and an air exhaust port which are respectively used for inputting smoke (waste gas) to be treated and outputting treated tail gas, the bottom of the chamber with the air inlet is provided with a rotary aerating device, and a part of a rotating wheel blade of the rotary aerating device is soaked into a solution in the solvent trough; the chamber with the air exhaust port is internally provided with at least one stage of microfiltration device; the liquid level of the solvent trough can be regulated and controlled; and if necessary, a flow guide device and a plurality of stages of rotary aerating devices can be arranged in the cavity. The device can be widely applied to the fields of exhaust smoke purification for diesel generator rooms and power plants, the desulfurization and dust removal of smoke for industrial waste gas and oily fume in restaurants and institution kitchens, and the like.

Owner:易敏华

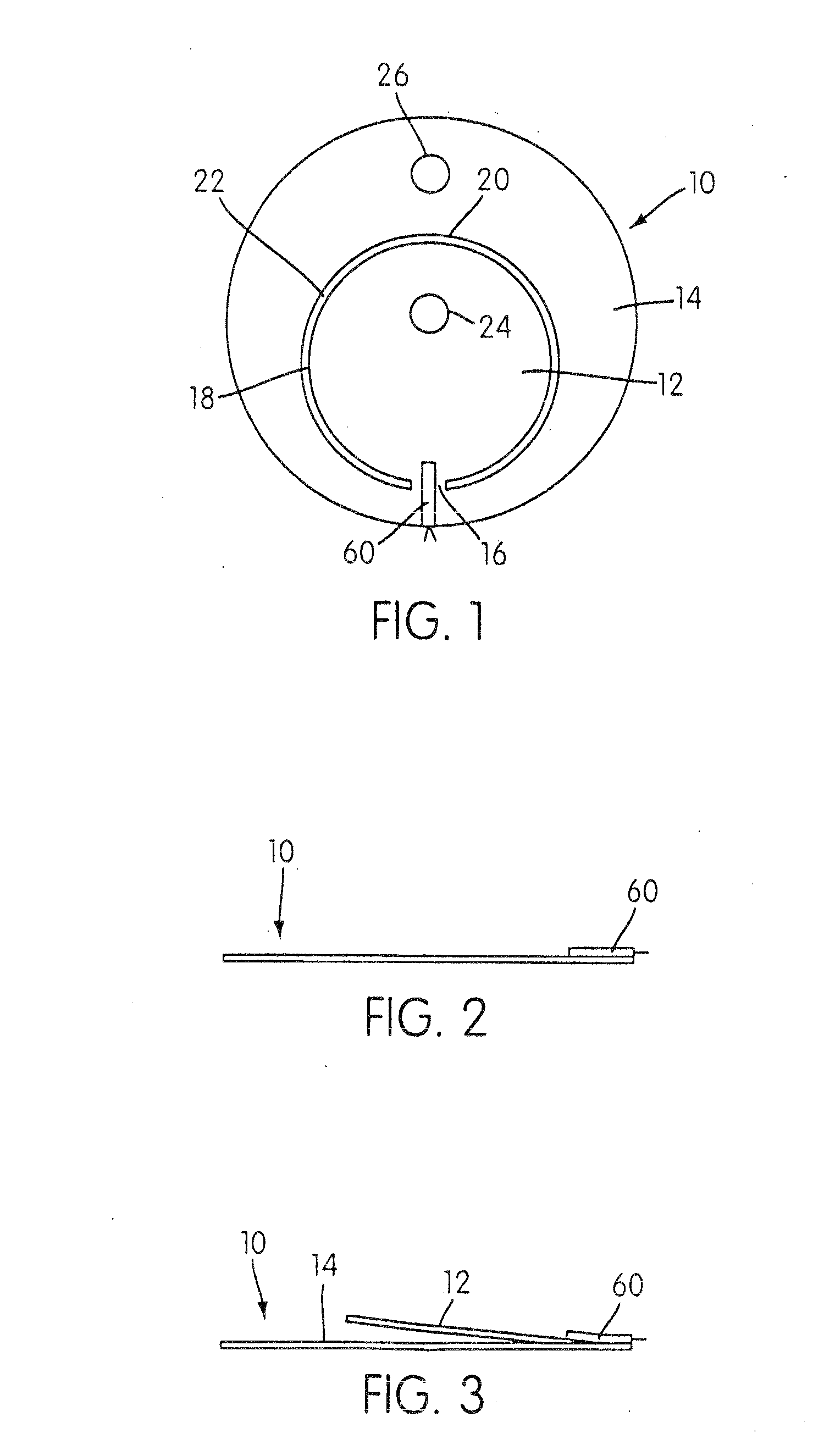

Shower Plate Having Different Aperture Dimensions and/or Distributions

ActiveUS20120100307A1High in-plane uniformityUniform propertyElectric discharge tubesFire rescueEngineeringMechanical engineering

A shower plate is adapted to be attached to the showerhead and includes a front surface adapted to face the susceptor; and a rear surface opposite to the front surface. The shower plate has multiple apertures each extending from the rear surface to the front surface for passing gas therethrough in this direction, and the shower plate has at least one quadrant section defined by radii, wherein the one quadrant section has an opening ratio of a total volume of openings of all the apertures distributed in the section to a total volume of the one quadrant section, which opening ratio is substantially smaller than an opening ratio of another quadrant section of the shower plate.

Owner:ASM JAPAN

Flow regulation vent

A flow regulation vent includes a fixed portion adapted to engage a gas supply conduit and a spring force biased movable portion connected by a hinge to the fixed portion and flowingly connected to the pressurized gas supply. The fixed portion includes a gas flow orifice. The movable portion is pivotably movable between 1) a relaxed position, wherein at a specified minimum operating pressure, the movable portion is pivoted by the spring force away from the fixed portion to a position to establish a first gas washout flow area between the movable portion and the gas flow orifice; and 2) a fully pressurized position, wherein at a specified maximum operating pressure, the pressurized gas offsets the spring force to pivot the movable portion to a position adjacent the fixed portion to establish a minimum gas washout flow area between the movable portion and the gas flow orifice.

Owner:RESMED LTD

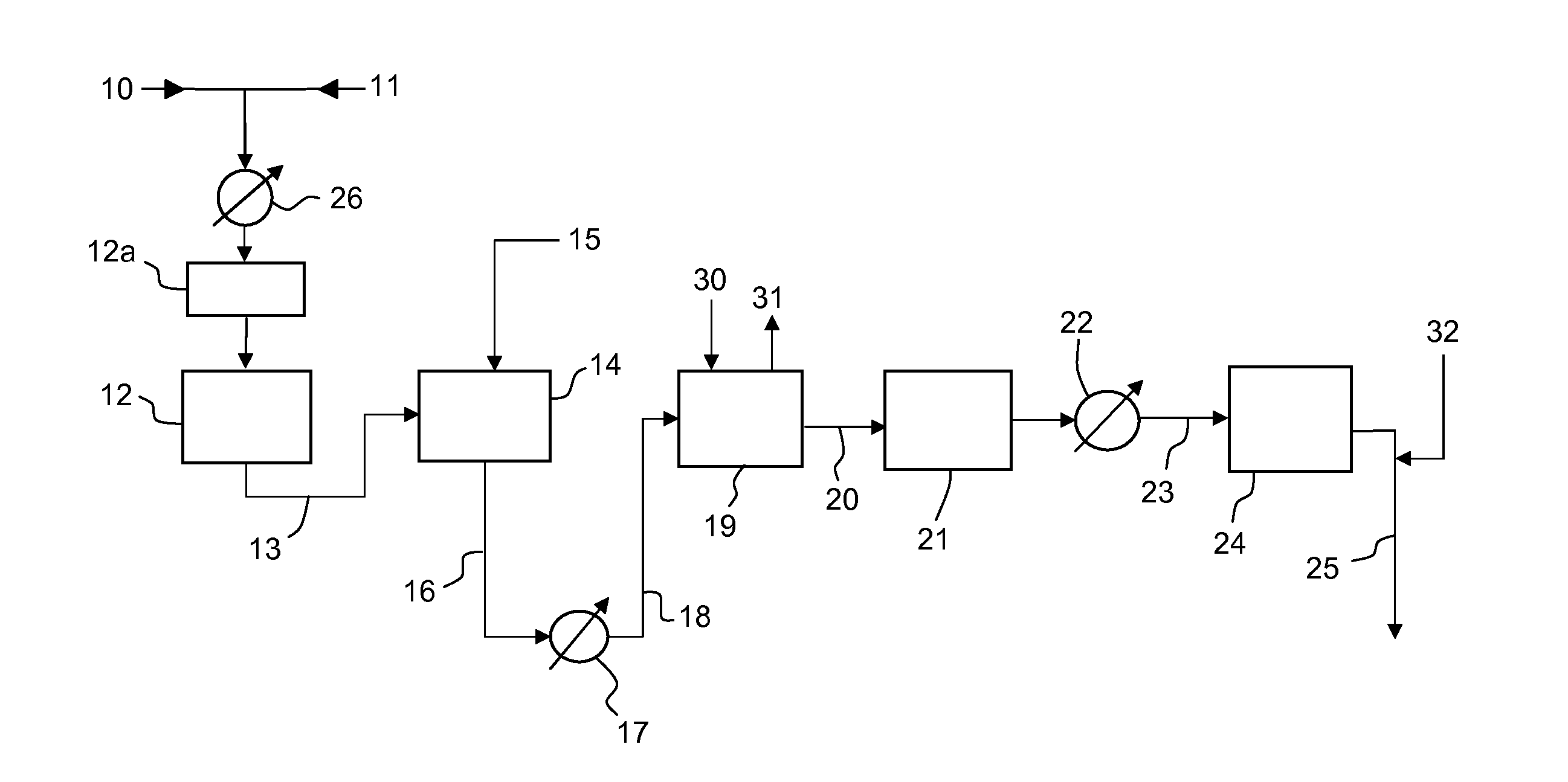

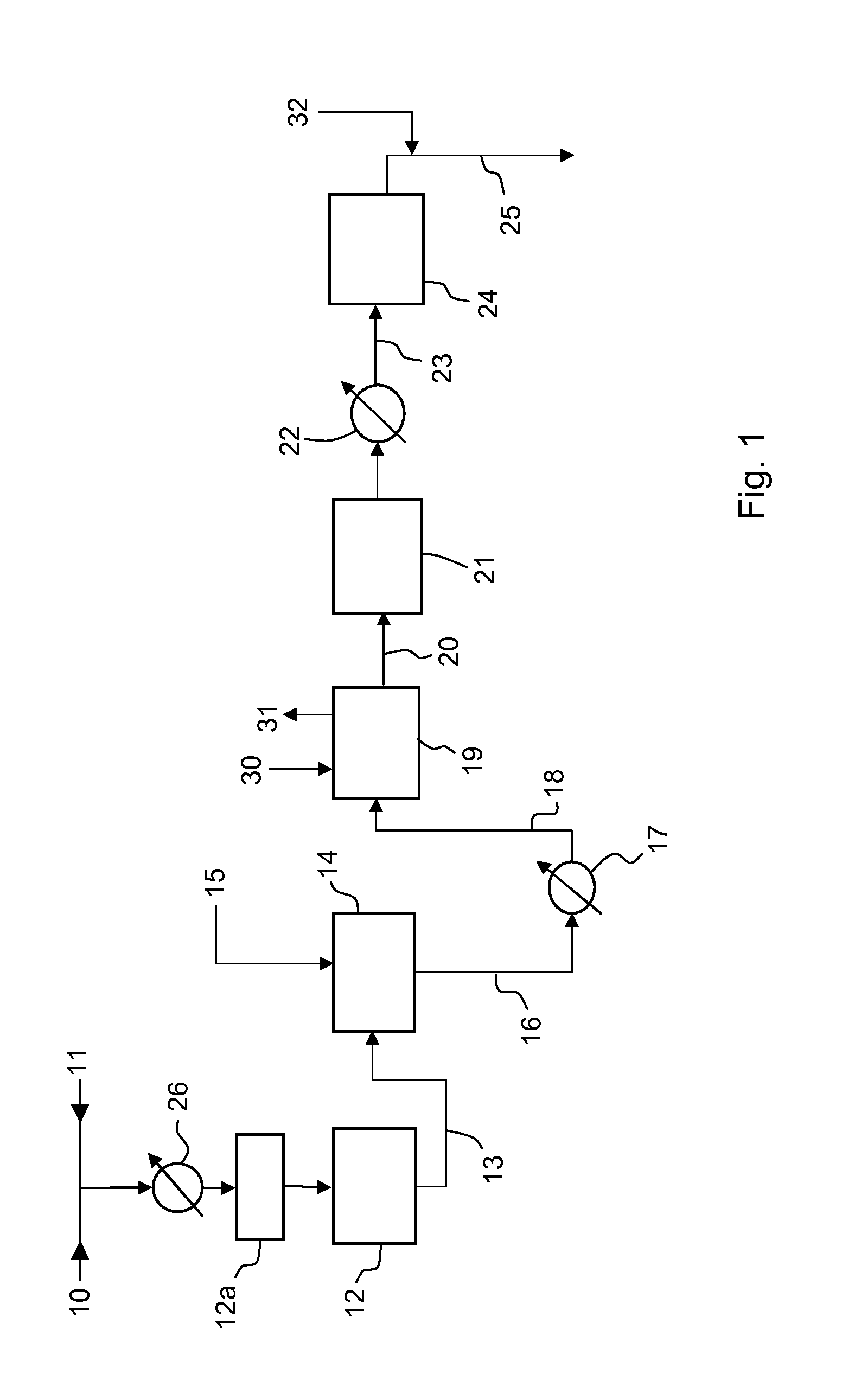

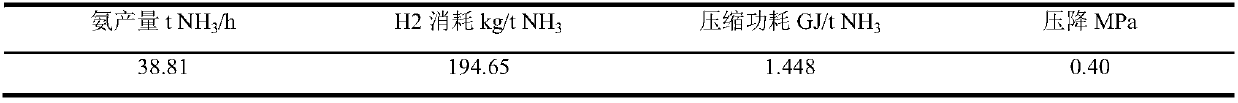

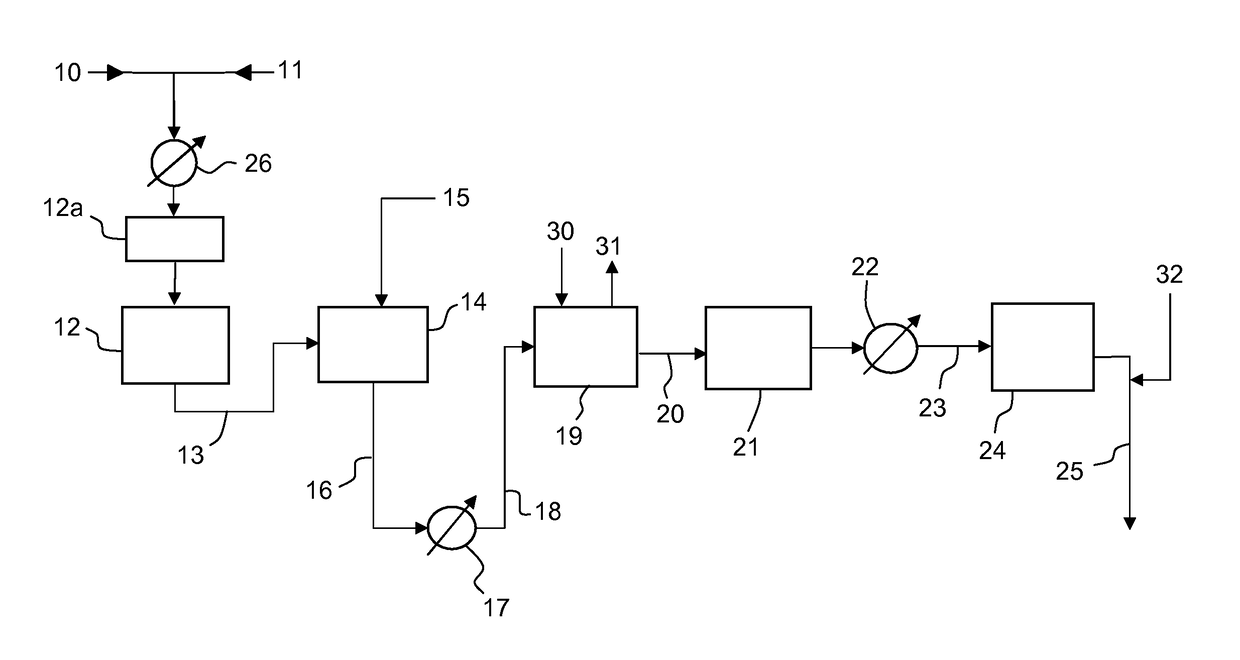

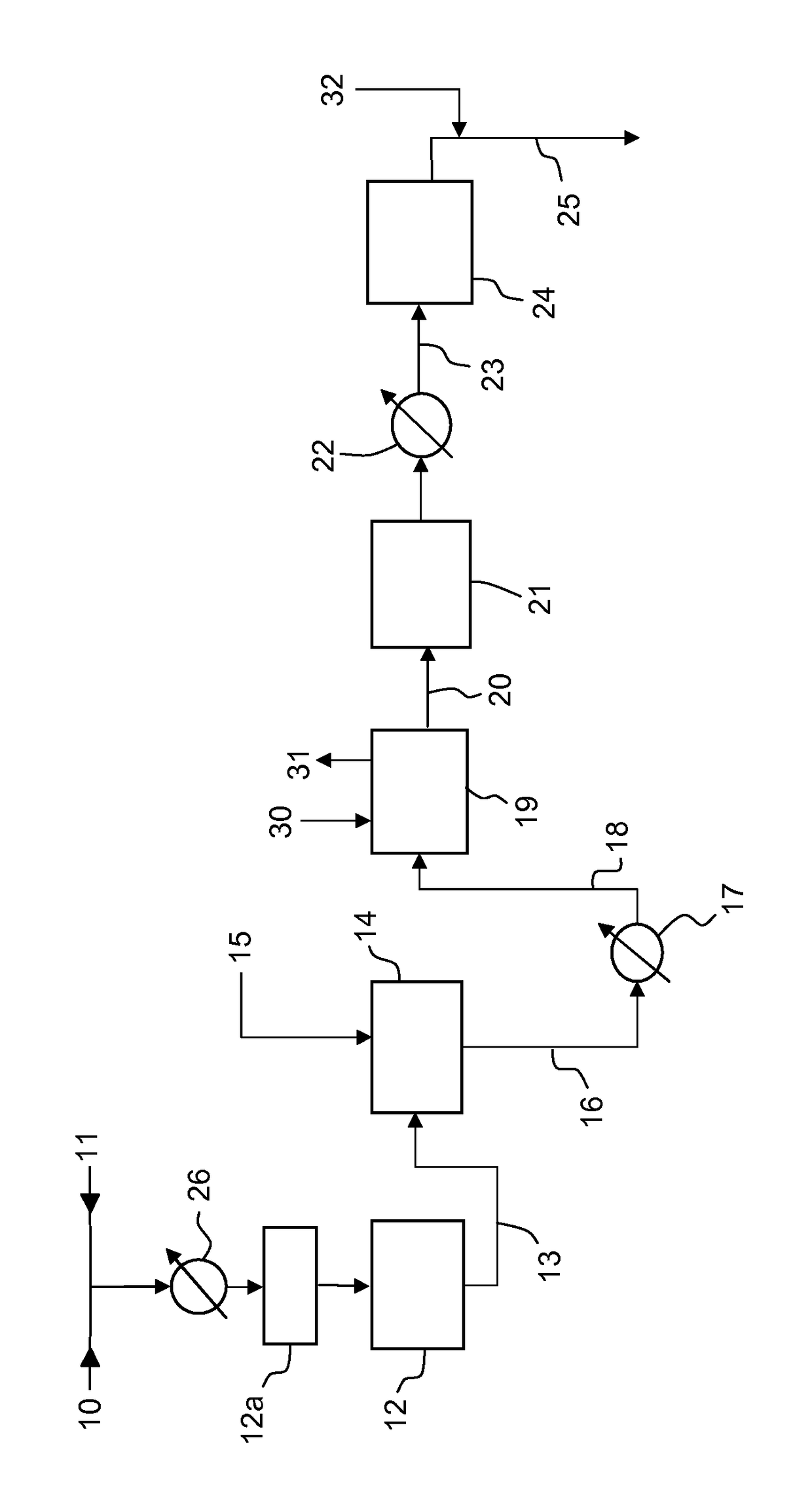

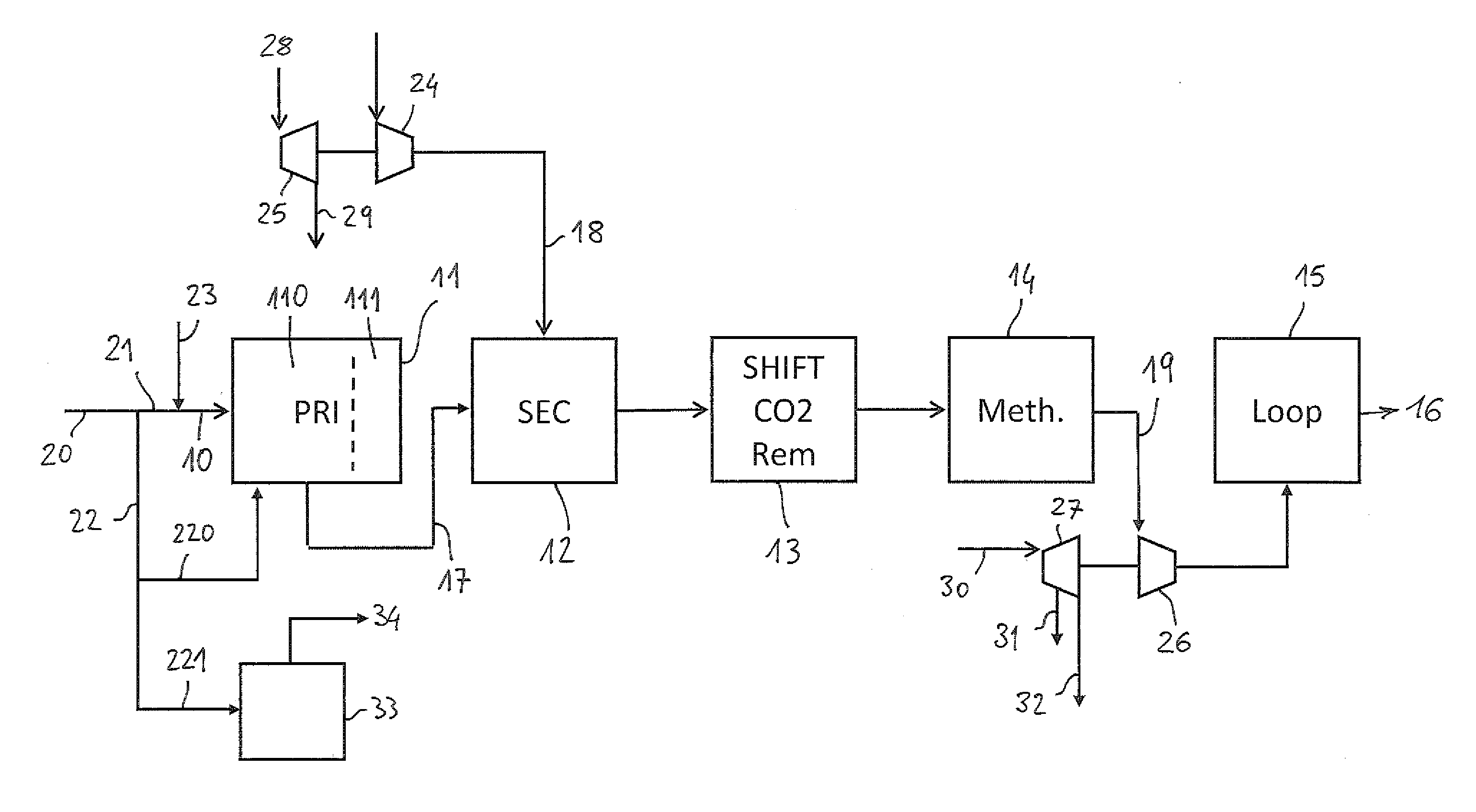

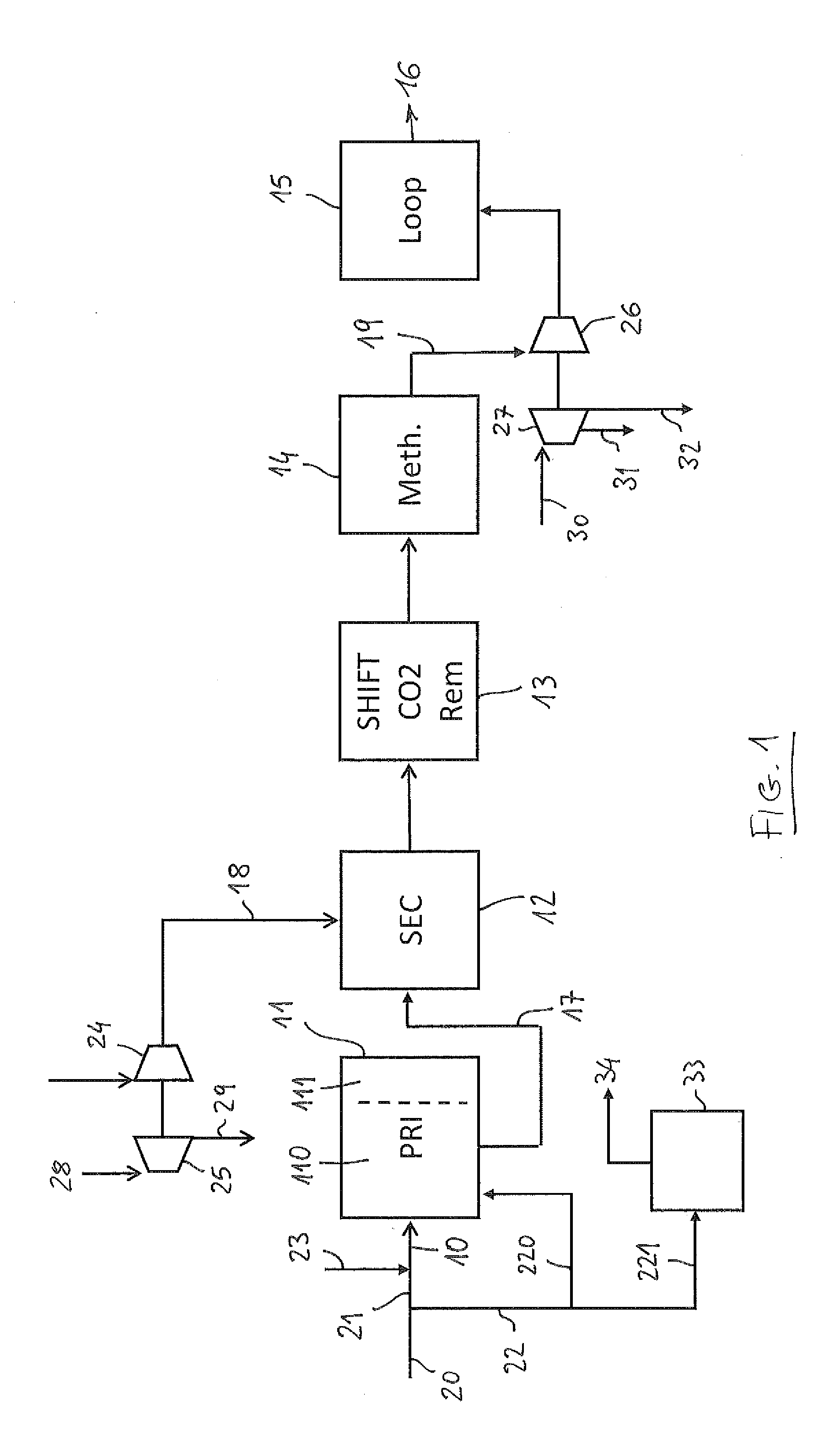

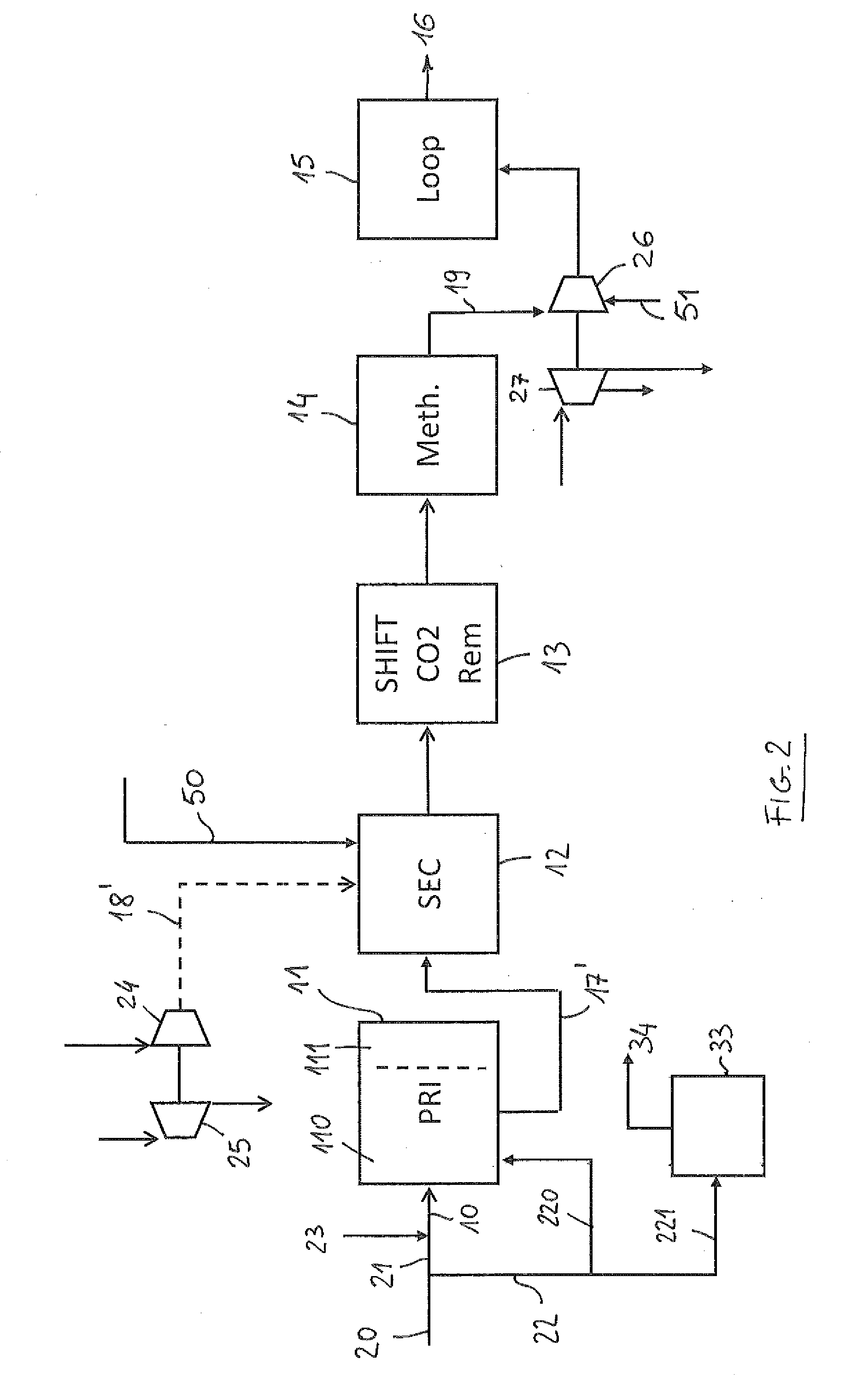

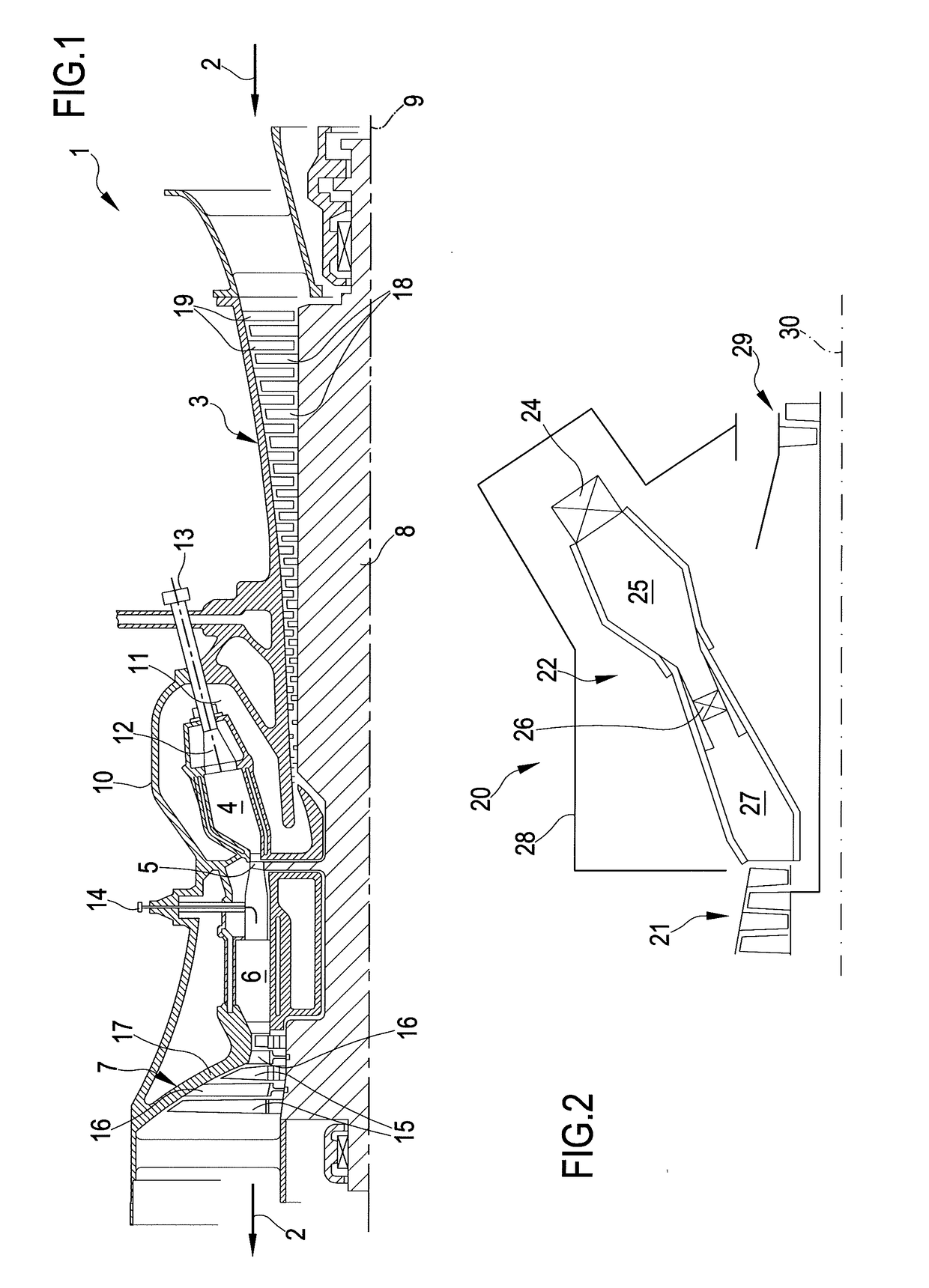

Process for Producing Ammonia Synthesis Gas

ActiveUS20130101490A1Increase flow rateReduce flow rateHydrogen separation at low temperatureHydrogen separation using solid contactSyngasMethanation

A process for producing ammonia synthesis gas from a hydrocarbon-containing feedstock, with steps of primary reforming, secondary reforming with an oxidant stream, and further treatment of the synthesis gas including shift, removal of carbon dioxide and methanation, wherein the synthesis gas delivered by secondary reforming is subject to a medium-temperature shift (MTS) at a temperature between 200 and 350° C., and primary reforming is operated with a steam-to-carbon ratio lower than 2. A corresponding method for revamping an ammonia plant is disclosed, where an existing HTS reactor is modified to operate at medium temperature, or replaced with a new MTS reactor, and the steam-to-carbon ratio in the primary reformer is lowered to a value in the range 1-5-2, thus reducing inert steam in the flow rate trough the equipments of the front-end.

Owner:CASALE SA

Flow regulation vent

A flow regulation vent includes a fixed portion adapted to engage a gas supply conduit and a spring force biased movable portion connected by a hinge to the fixed portion and flowingly connected to the pressurized gas supply. The fixed portion includes a gas flow orifice. The movable portion is pivotably movable between 1) a relaxed position, wherein at a specified minimum operating pressure, the movable portion is pivoted by the spring force away from the fixed portion to a position to establish a first gas washout flow area between the movable portion and the gas flow orifice; and 2) a fully pressurized position, wherein at a specified maximum operating pressure, the pressurized gas offsets the spring force to pivot the movable portion to a position adjacent the fixed portion to establish a minimum gas washout flow area between the movable portion and the gas flow orifice.

Owner:RESMED LTD

Centrifugal compressor

ActiveUS8172525B2Speed up the gas flowIncrease rangePump componentsBlade accessoriesEngineeringCentrifugal compressor

Owner:MITSUBISHI HEAVY IND LTD

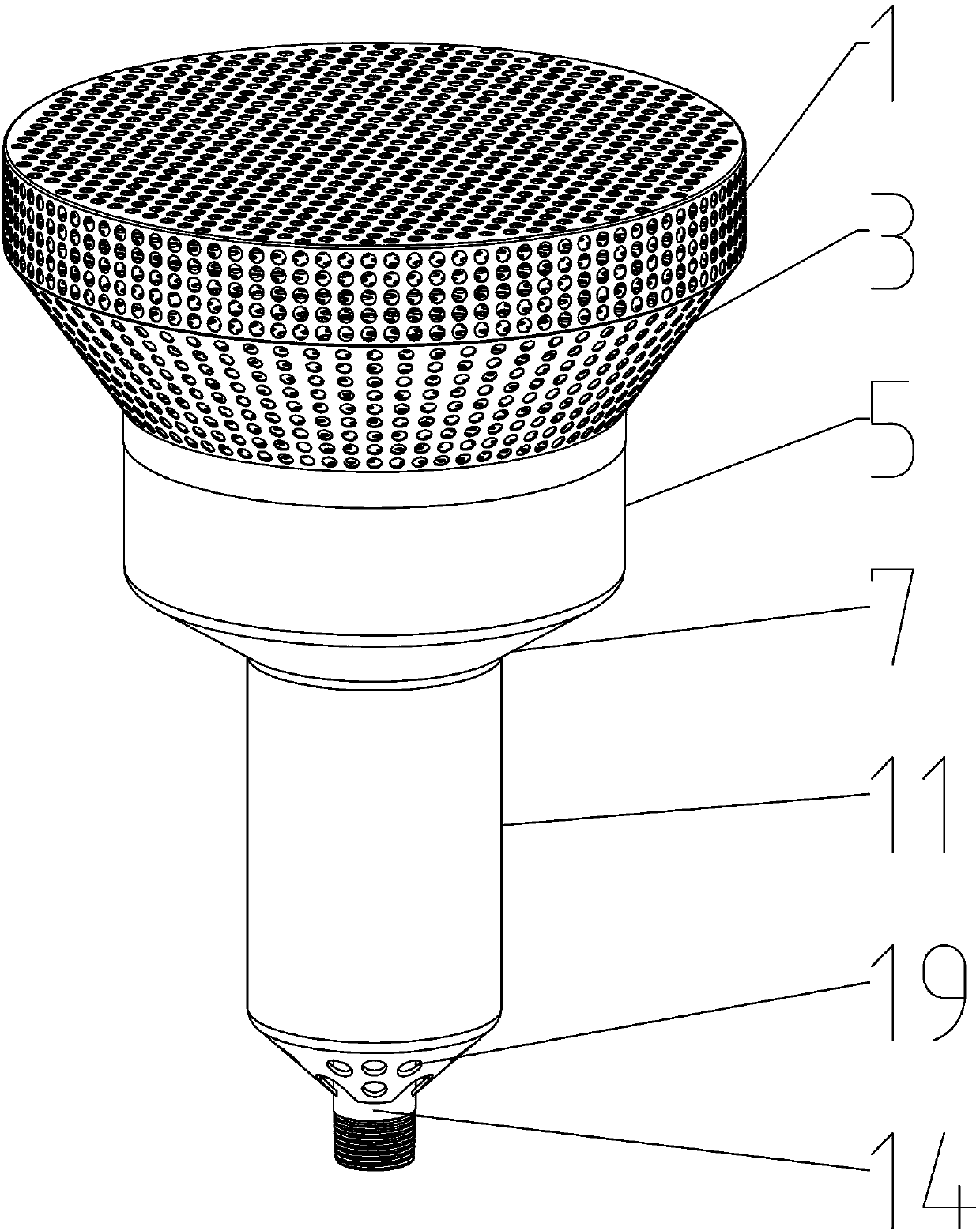

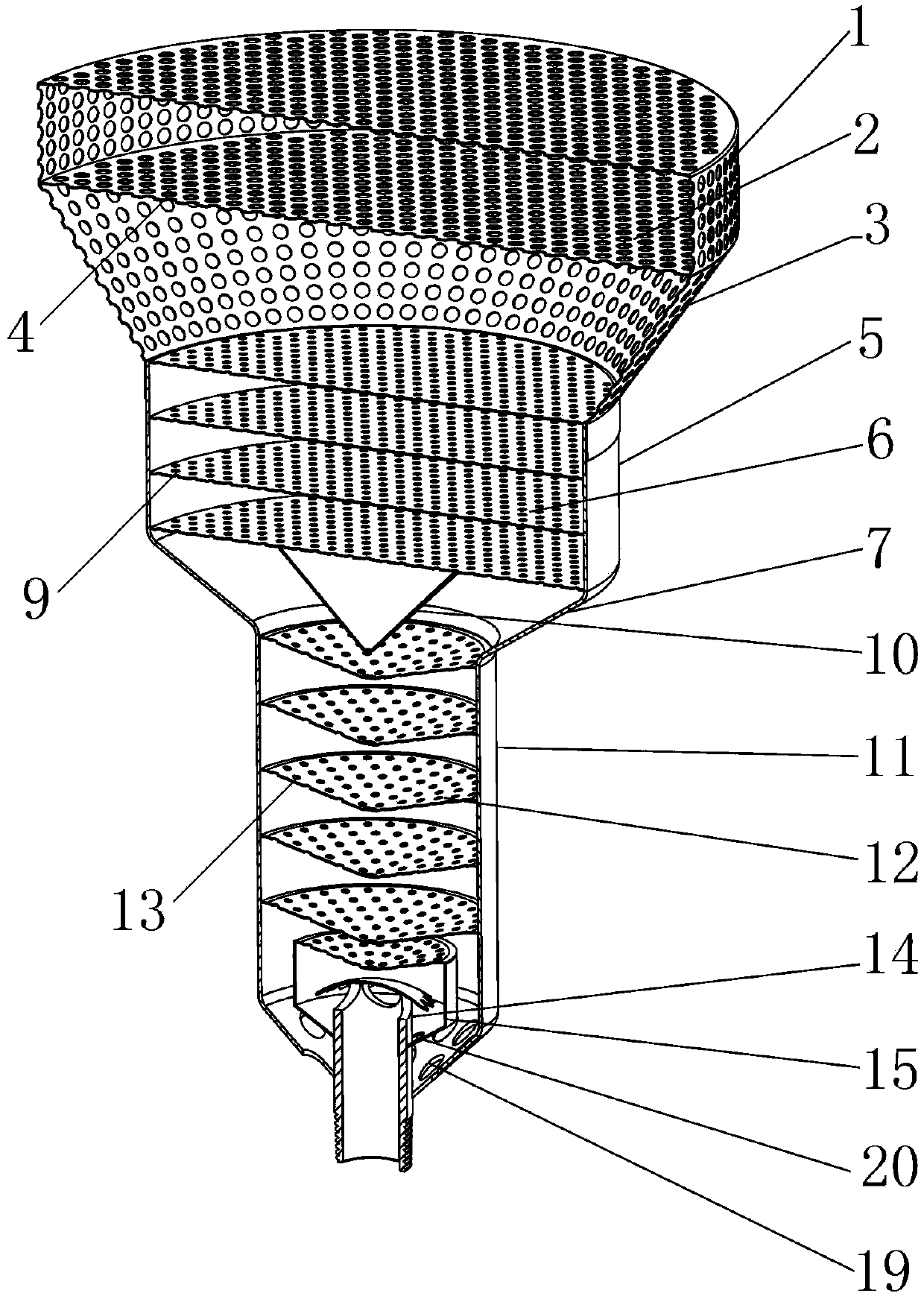

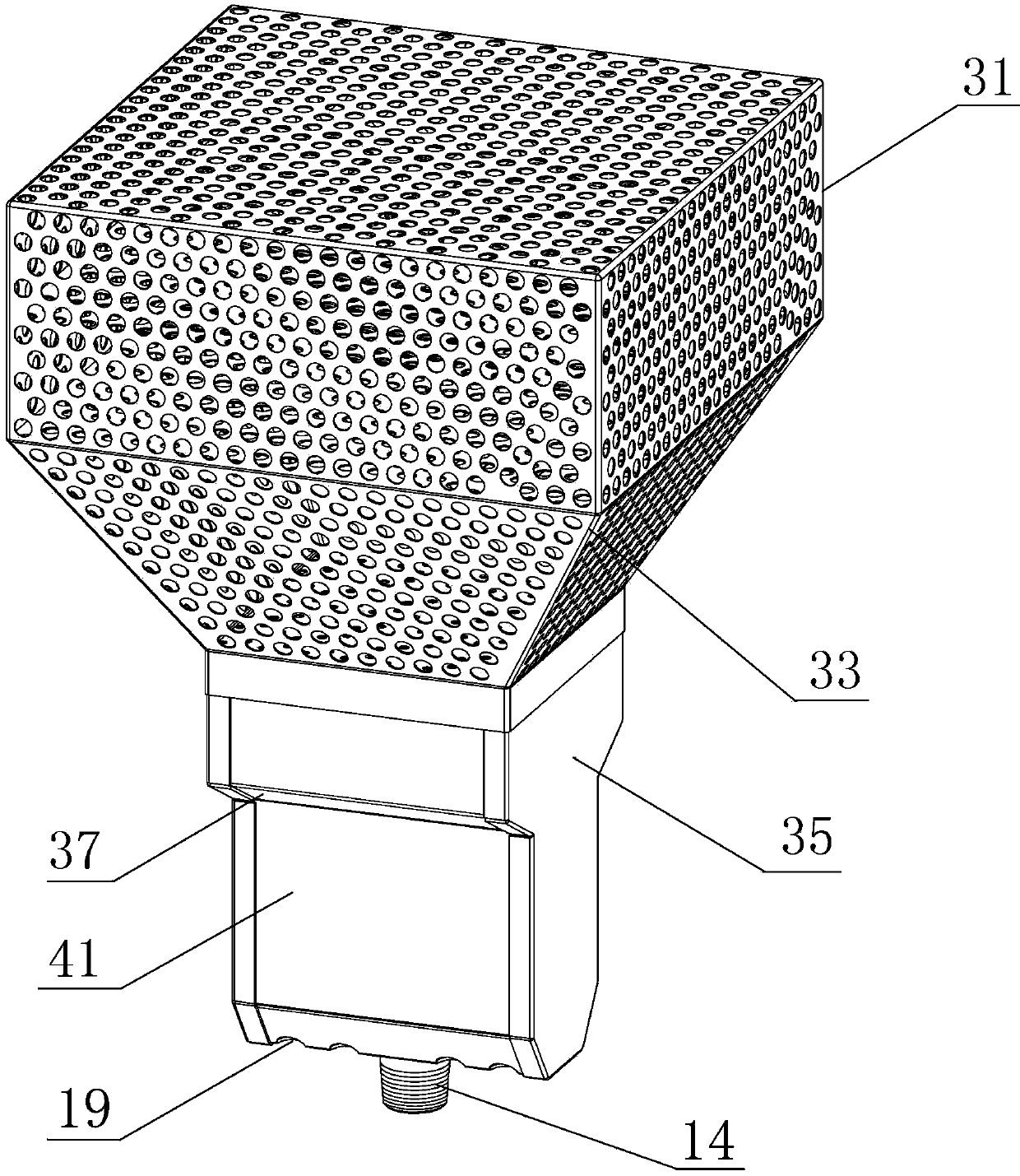

Anti-clogging aerator

ActiveCN103435120AReduce the gas flow rateLarge service areaTreatment using aerobic processesSustainable biological treatmentGas bubbleMechanics

The invention relates to an anti-clogging aerator which comprises an upper bubble rectifying device, a middle bubble cutting device, a lower bubble cutting device and an air intake component, wherein the upper bubble rectifying device comprises a cowling, a rectifying plate and a funneled cowling transitional connection casing; the middle bubble cutting device comprises a middle casing, a middle cutting plate and a middle funneled transitional connection casing; the lower bubble cutting device comprises a lower casing and a lower cutting plate; the air intake component comprises an air inlet pipe, a cover body and a baffle plate. According to the invention, gas is smashed into bubbles through cutting holes in the gas and liquid mixing process, after being cut at each stage, the bubbles become smaller in size and are increased in number, meanwhile, the gas flow rate is lowered so as to enlarge the service area of the bubbles. Blowdown holes are formed in the lower casing and the lower part of the cover body, the cutting holes are formed in the cutting plates and are not blocked easily or required to be cleaned, and the use is not influenced even the cutting plates scale slightly. The anti-clogging aerator is simple in structure and convenient to operate; procedures for cleaning the aerator frequently are reduced, and the production efficiency is improved.

Owner:石家庄金钛净化设备有限公司

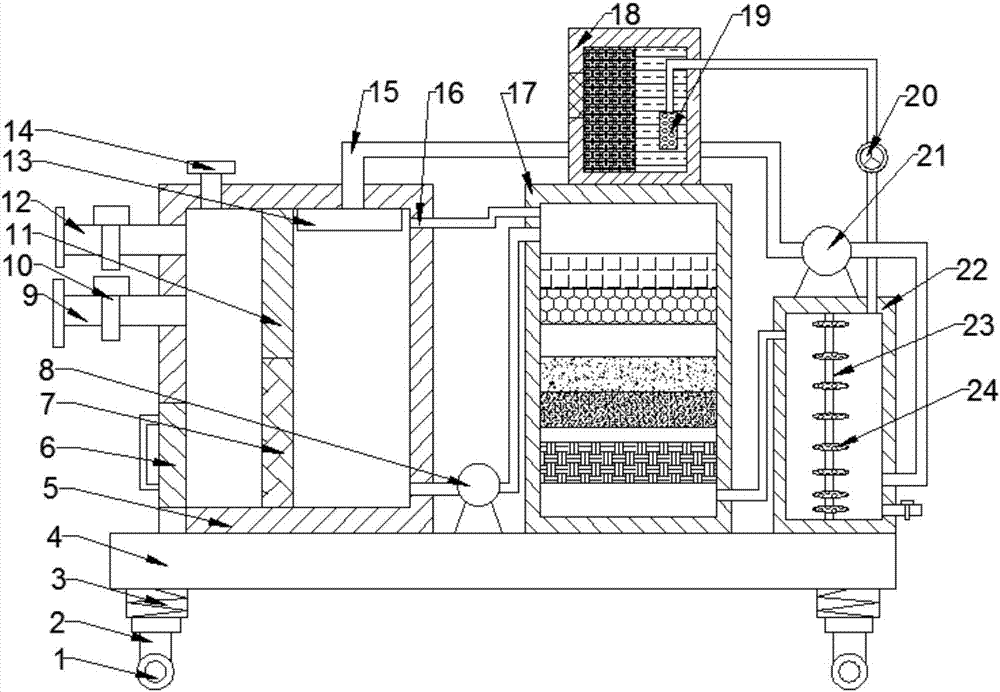

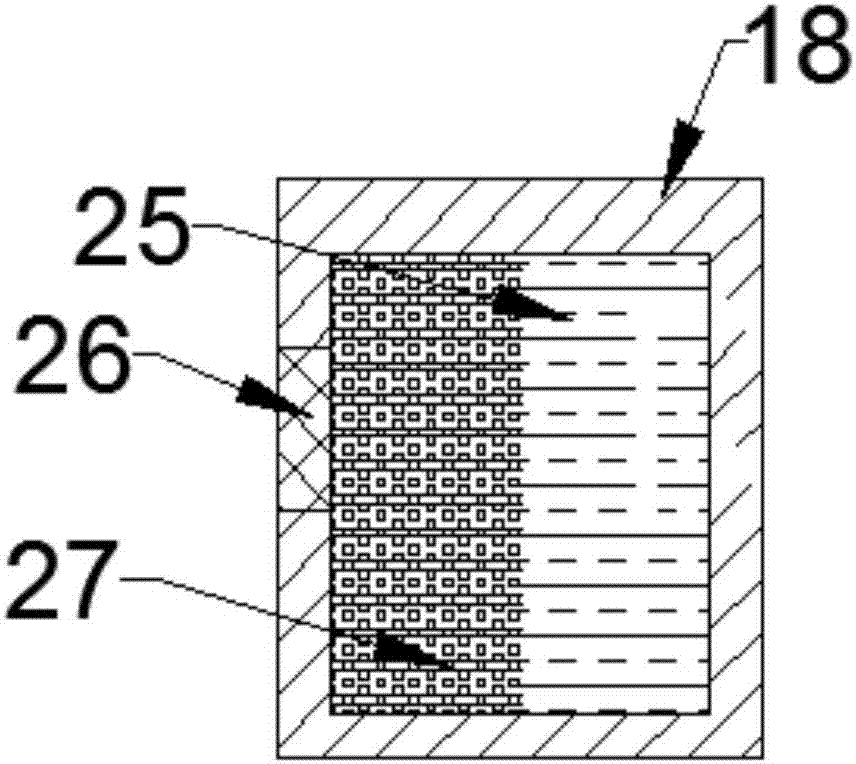

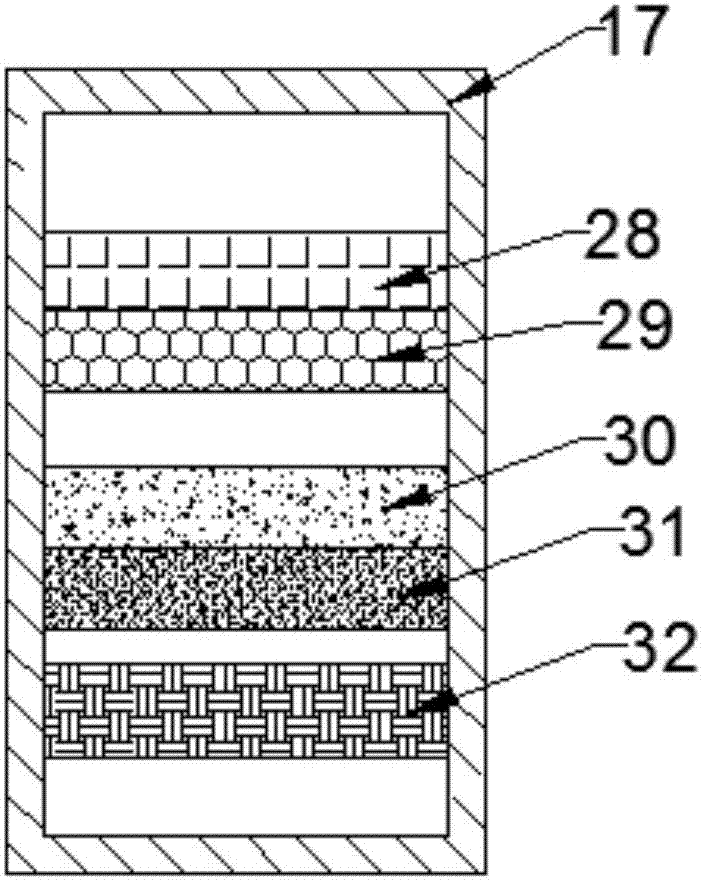

Environment-friendly type waste water and waste gas purifying and recycling device

InactiveCN107381957AReduce the gas flow rateSimple structureCombination devicesGas treatmentWater pipeTreatment effect

The invention provides an environment-friendly type waste water and waste gas purifying and recycling device, belonging to the field of environment-friendly purification. A waste water inlet pipe is arranged on the upper end of the left side of a primary treatment tank; a waste gas inlet pipe is arranged on the left side of the primary treatment tank and below the waste water inlet pipe; a purification and filtering tank is arranged on a bottom plate and on the right side of a water suction pump, the right end of the purification and filtering tank is connected with a disinfection tank through a water pipe, and the disinfection tank is arranged on the right end on the bottom plate; a deodorization tank is fixedly arranged on the upper end of the purification and filtering tank. A filtering plate is arranged on the lower end of a partition plate fixedly, thus achieving the functions of removing impurities from waste water and filtering waste water; a biological deodorizing filler is arranged on the right side of an inner cavity of the deodorization tank, and a biological filling adsorption layer is arranged on the left side of the biological deodorizing filler, so that the function of deodorizing waste gas can be achieved by adopting biological and physical methods; and the device has the characteristics of simple structure, strong practicability and good waste water and waste gas treatment effects.

Owner:郑州莉迪亚医药科技有限公司

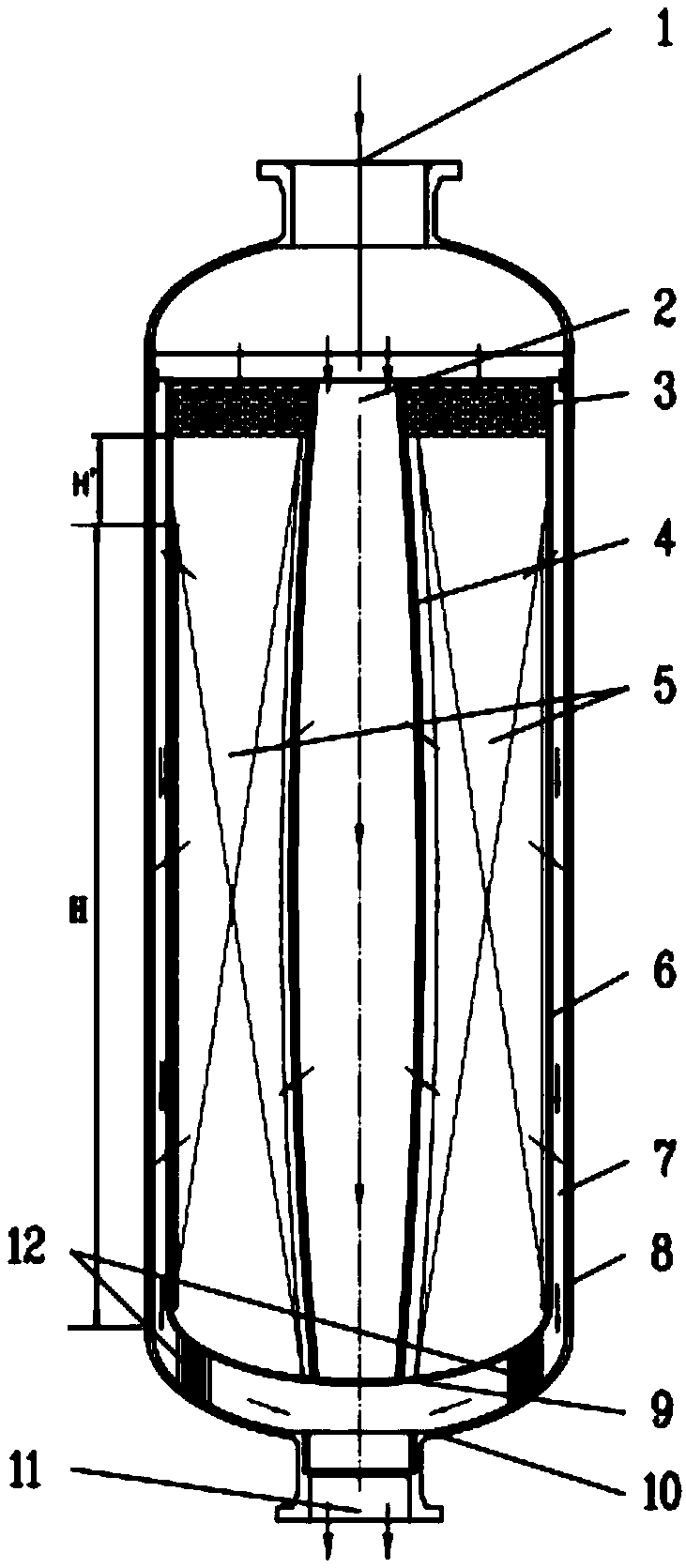

Low-pressure-drop Z-type radial centrifugal flow fixed bed reactor

ActiveCN110871046AOvercoming the Effects of Pressure ChangesSmall pressure dropChemical/physical processesFixed bedEngineering

The invention provides a low-pressure-drop Z-type radial centrifugal flow fixed bed reactor which includes: a cylindrical pressure container, an inner cylinder, an outer cylinder, and a catalyst bed,wherein the inner cylinder, the outer cylinder and the cylindrical pressure container are arranged coaxially. An interlayer is formed between the outer wall surface of the inner cylinder and inner wall surface of the outer cylinder. The catalyst bed is formed by enclosing a lower support seal, the inner cylinder and the outer cylinder; the lower support seal is arranged in the cylindrical pressurecontainer and located on the bottom of same. The inner cylinder is communicated with a gas inlet to form a bypass path of reaction gas. A reaction gas collection flow path is formed between the outerwall surface of the outer cylinder and the inner wall surface of the cylindrical pressure container and is connected to the gas outlet. The bypass path is a diameter-variable flow path. The whole inner cylinder is provided with pores while a part of the outer cylinder is provided with pores. The reaction gas flows from the inner cylinder to the exterior radially via the bypass path and passes through the catalyst bed, then flows into the collection flow path and flows out of the fixed bed reactor through the outer cylinder. In the reactor, the flowing path of the reaction gas is Z-like in shape.

Owner:PETROCHINA CO LTD

Process for producing ammonia synthesis gas

ActiveUS10087074B2Lower ratioReduce flow rateHydrogen separation at low temperatureHydrogen separation using solid contactSyngasMethanation

A process for producing ammonia synthesis gas from a hydrocarbon-containing feedstock, with steps of primary reforming, secondary reforming with an oxidant stream, and further treatment of the synthesis gas including shift, removal of carbon dioxide and methanation, wherein the synthesis gas delivered by secondary reforming is subject to a medium-temperature shift (MTS) at a temperature between 200 and 350° C., and primary reforming is operated with a steam-to-carbon ratio lower than 2. A corresponding method for revamping an ammonia plant is disclosed, where an existing HTS reactor is modified to operate at medium temperature, or replaced with a new MTS reactor, and the steam-to-carbon ratio in the primary reformer is lowered to a value in the range 1-5−2, thus reducing inert steam in the flow rate trough the equipments of the front-end.

Owner:CASALE SA

Method of revamping of an ammonia plant fed with natural gas

ActiveUS20150151272A1Increase capacityLower outlet temperatureHydrogen productionChemical/physical/physico-chemical stationary reactorsNitrogenProcess engineering

A method of revamping of an ammonia plant fed with natural gas comprising a primary reformer (11) and a secondary reformer (12), the method comprising at least the following interventions: reducing the outlet temperature of the gas (17) flowing out from said primary reformer; adding a feeding line of substantially pure oxygen (30) directed to said secondary reformer (12) to at least partially replace the comburent process air; adding a nitrogen injection line (31) in an amount necessary to obtain a make-up gas suitable for ammonia synthesis.

Owner:CASALE SA

Lift-pipe reactor

ActiveCN100469432CReduce the gas flow rateIncrease cycle strengthCatalytic crackingChemical/physical processesEngineering

A lift-pipe reactor is composed of such units from bottom to top as pre-lifting segment, the first reaction segment, the second reaction segment, and optional discharging segment. It features that a flow guiding pipe is arranged at lower part of the second reaction segment to decrease the gas flow speed in its wall region for generating a dense phase region of catalyst, so increasing the concentration of catalyst in second reaction segment.

Owner:CHINA PETROLEUM & CHEM CORP +1

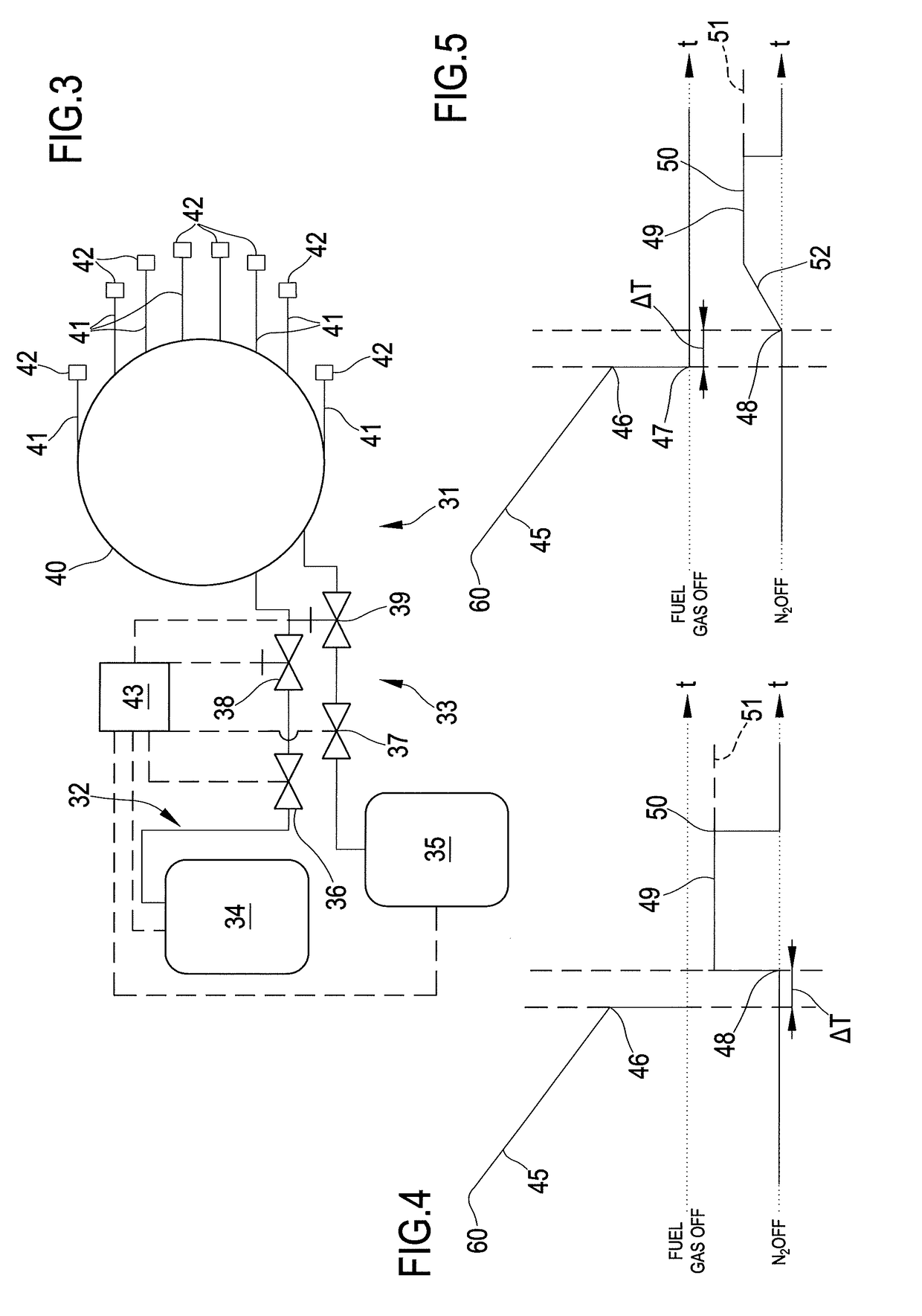

Method for operating a supply assembly for supplying fuel gas and inert media to a gas turbine combustor, such supply assembly and a gas turbine comprising such supply assembly

ActiveUS20180187609A1Reduce flow rateReduce the gas flow rateContinuous combustion chamberTurbine/propulsion fuel flow conduitsCombustorFuel distribution

A method for operating a supply assembly configured for supplying fuel gas and an inert purge media to a gas turbine combustor, the method including supplying fuel gas in a fuel gas circuit with an upper flow rate; reducing the fuel gas flow rate in the fuel gas circuit from the upper flow rate to a lower flow rate; stopping the supply of the fuel gas in the fuel gas circuit; and starting the supply of the inert purge media in the inert purge media circuit, wherein the starting is performed before the stopping to have a temporary parallel supply of fuel gas and of inert purge media to a fuel distribution system.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com