Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Reduce fluid velocity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

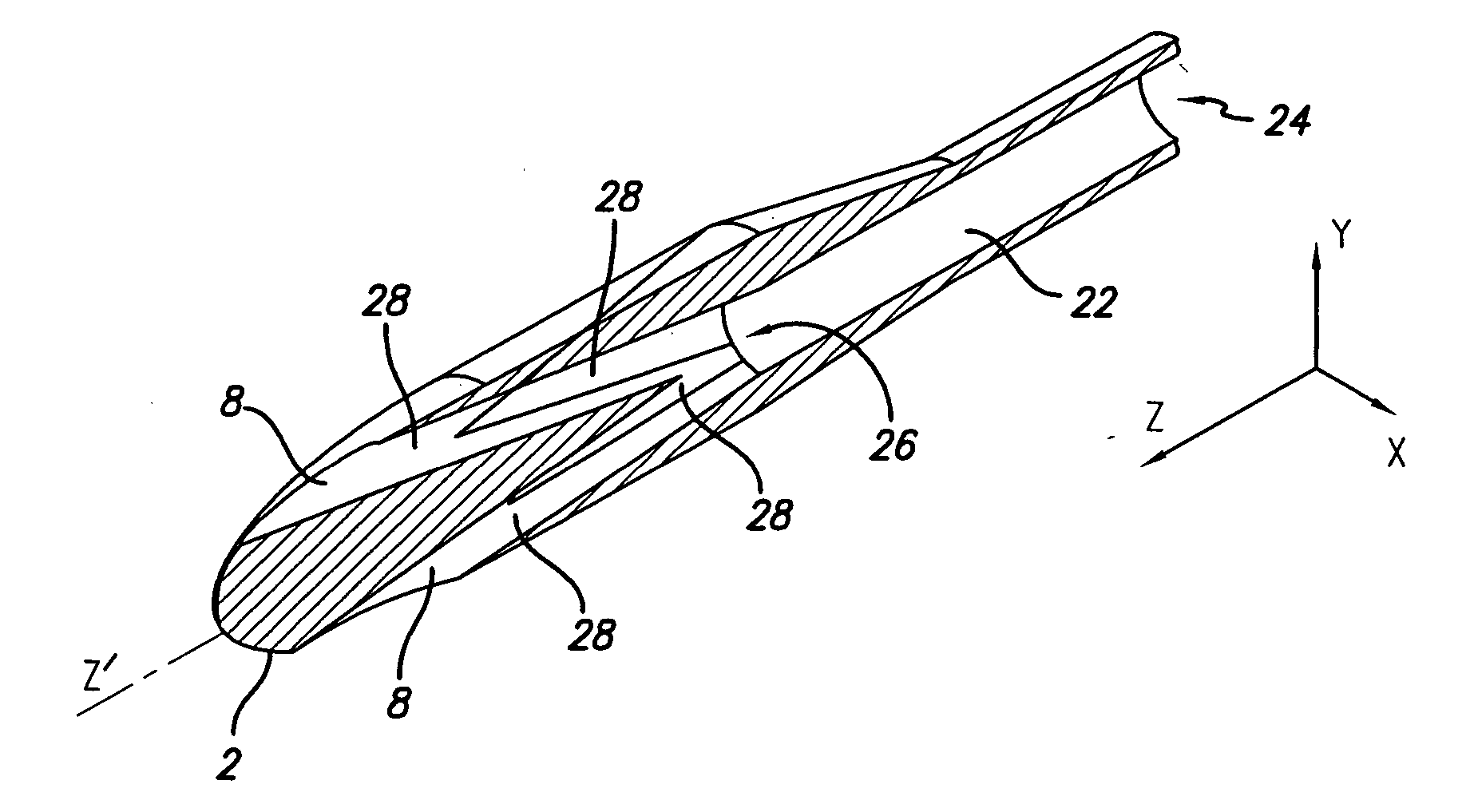

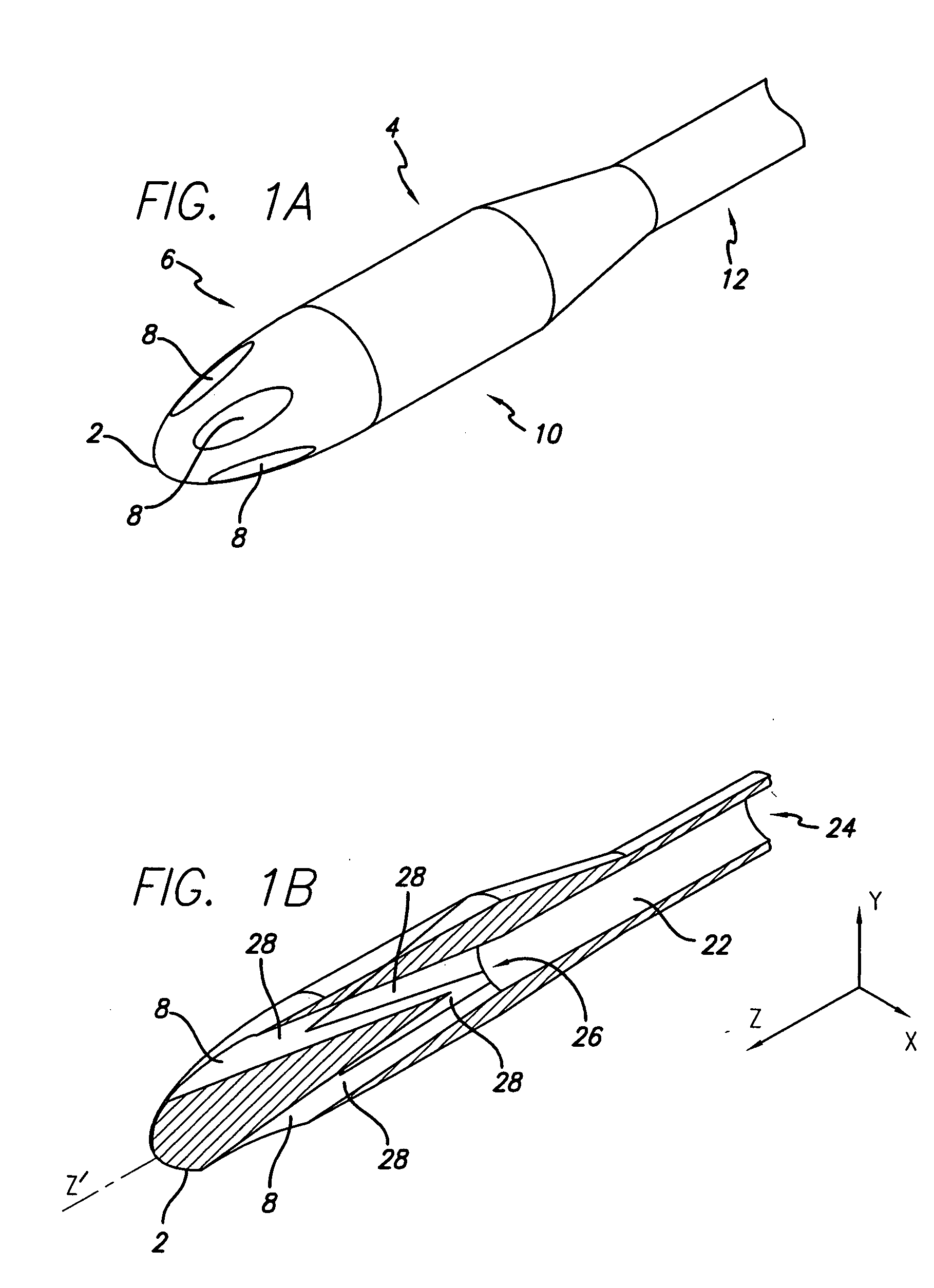

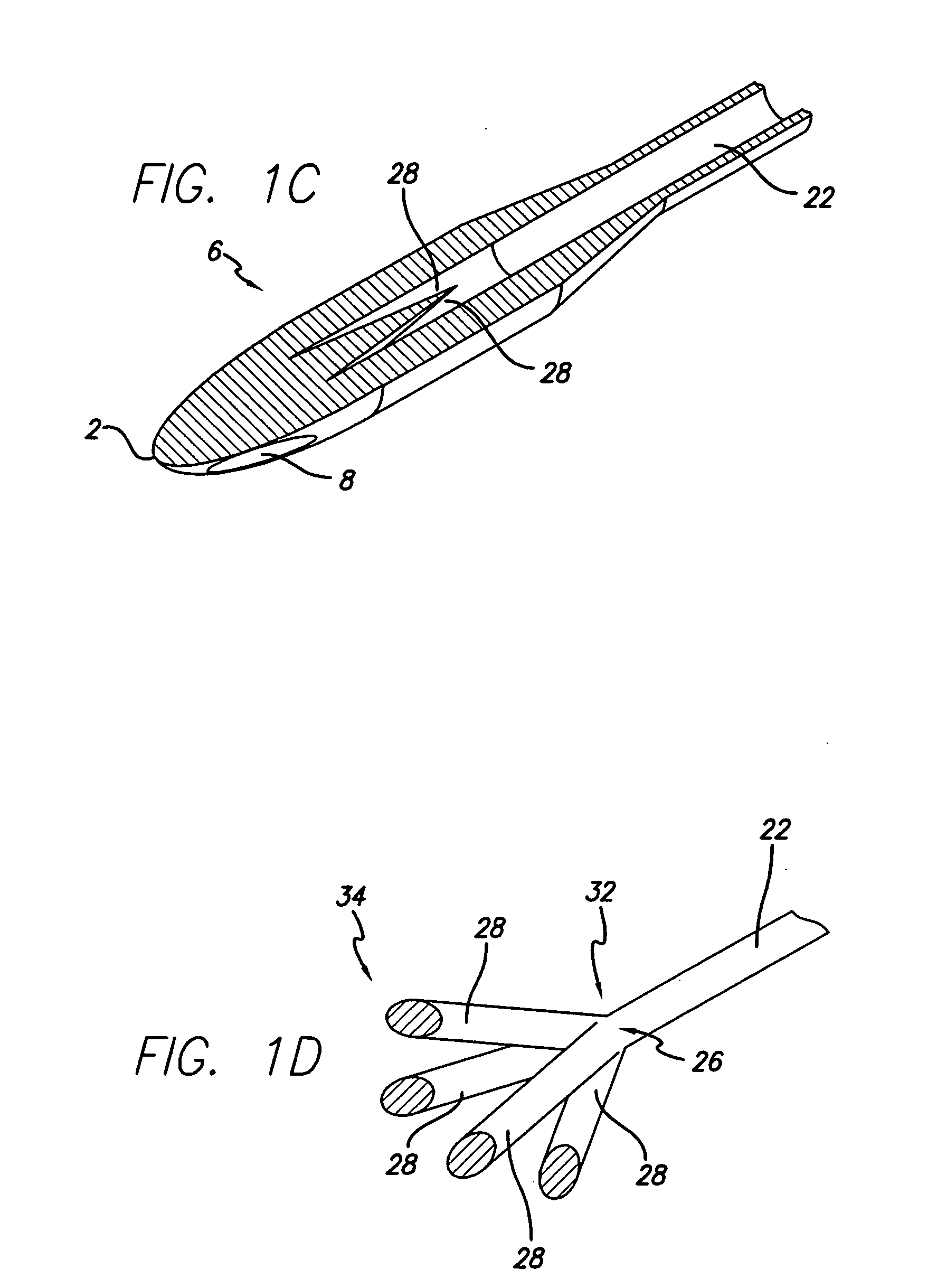

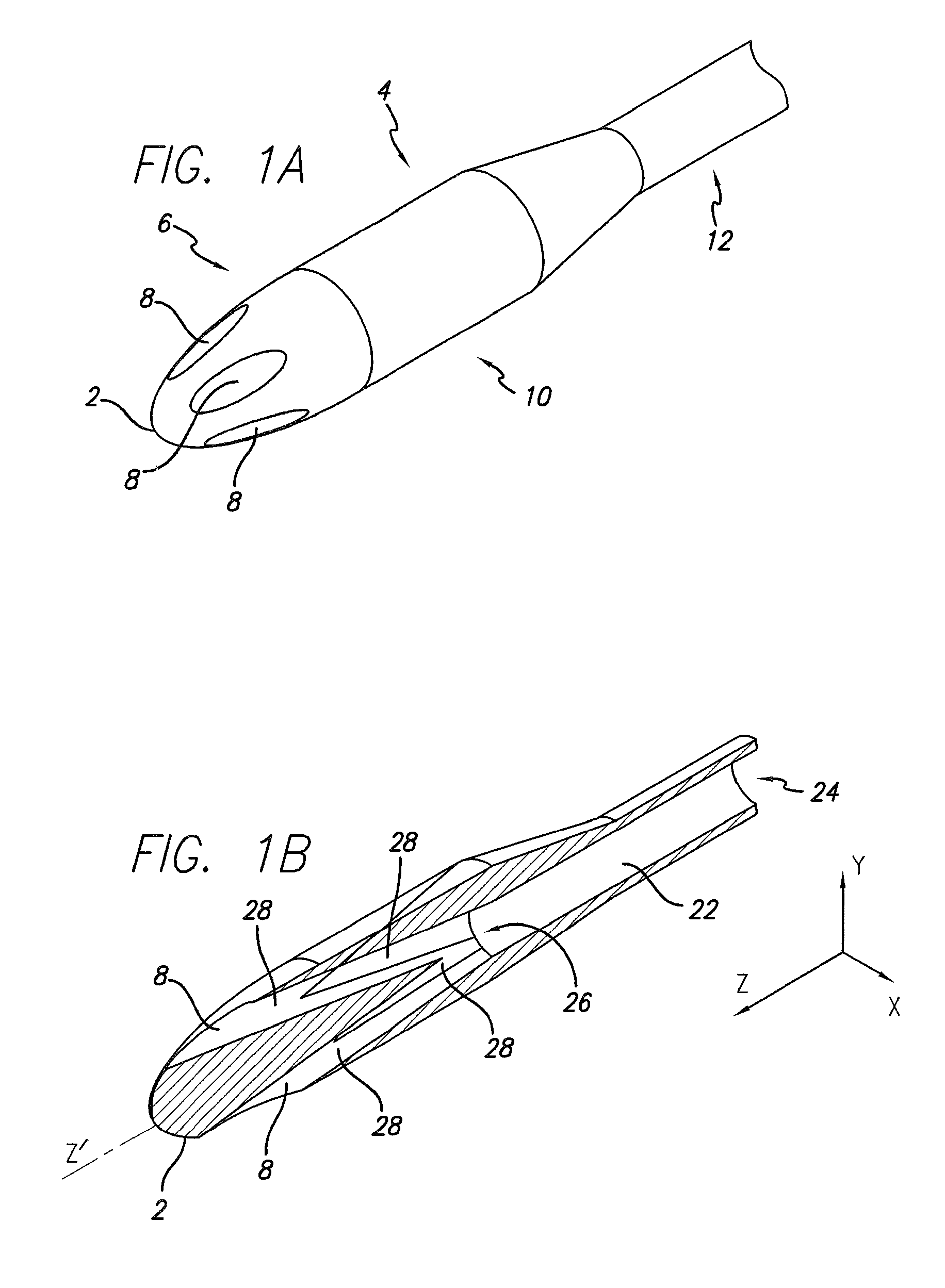

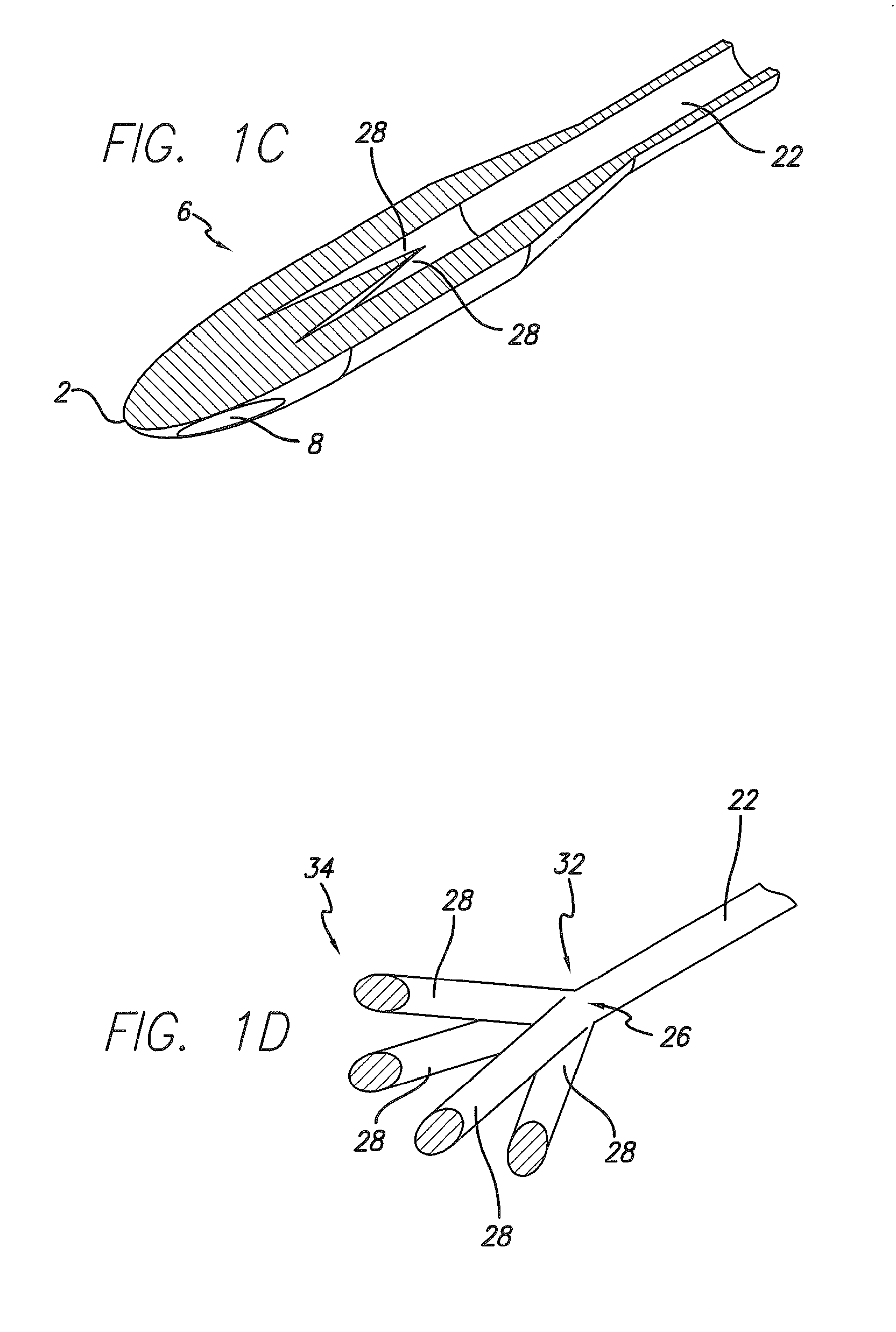

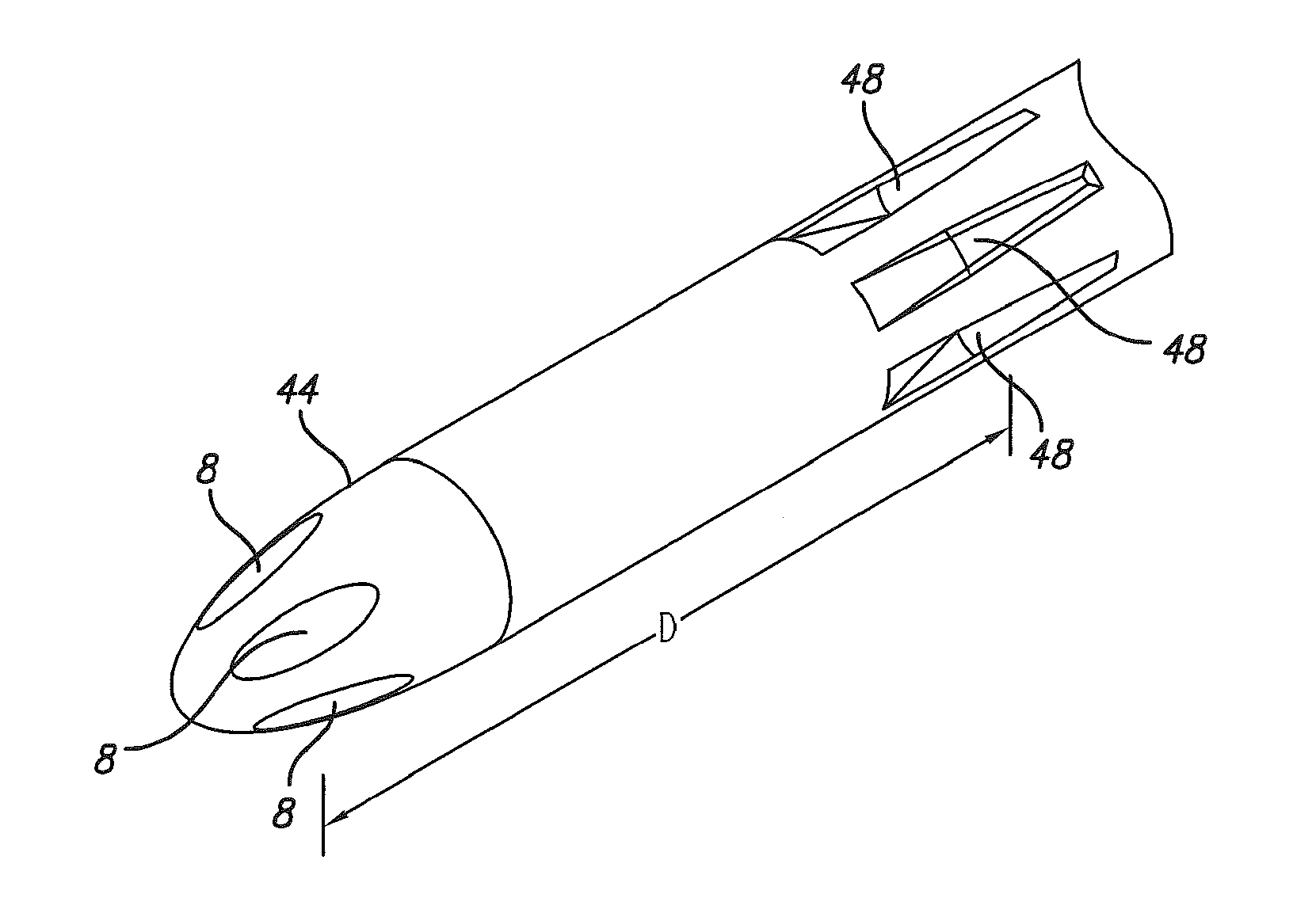

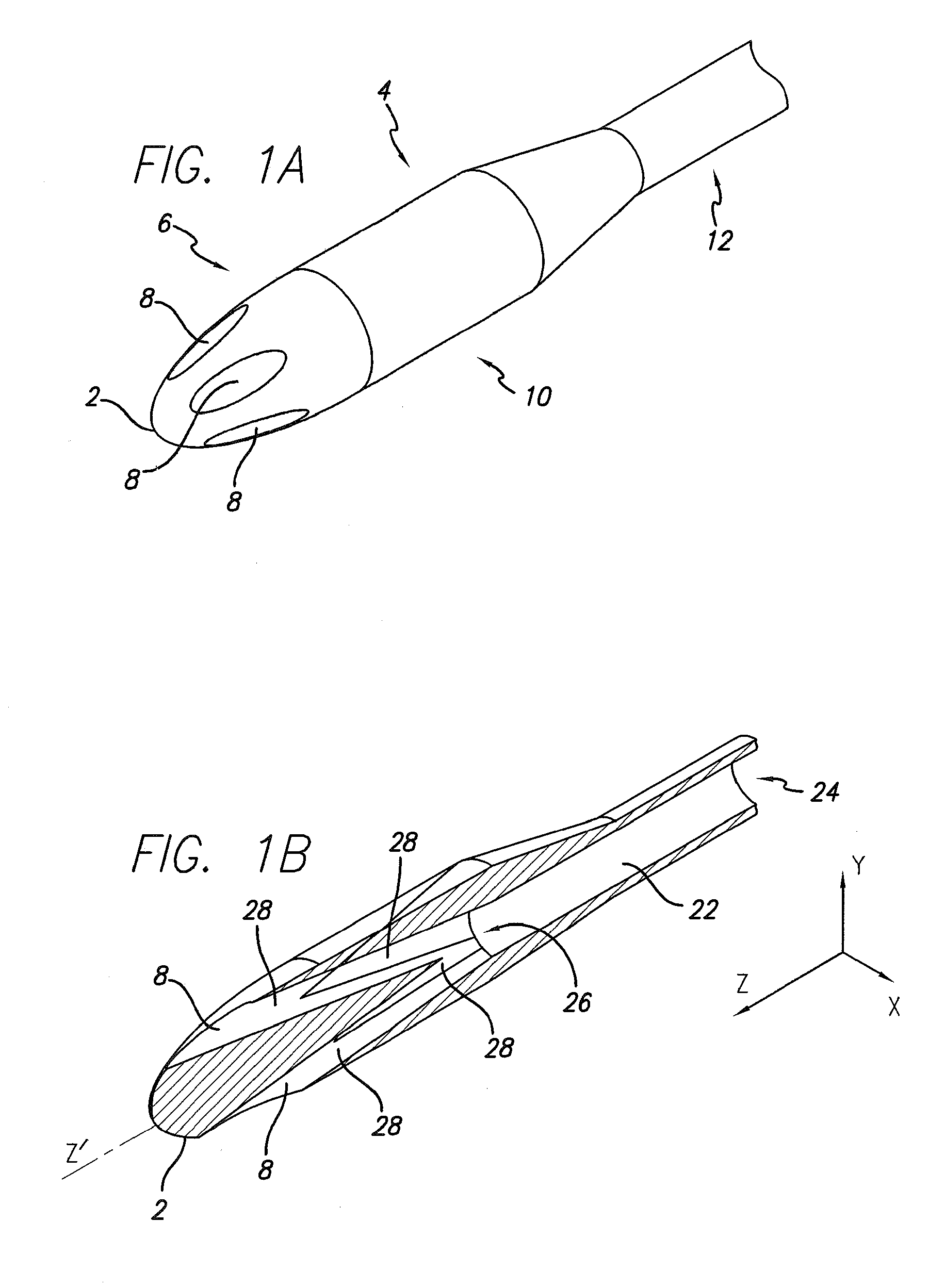

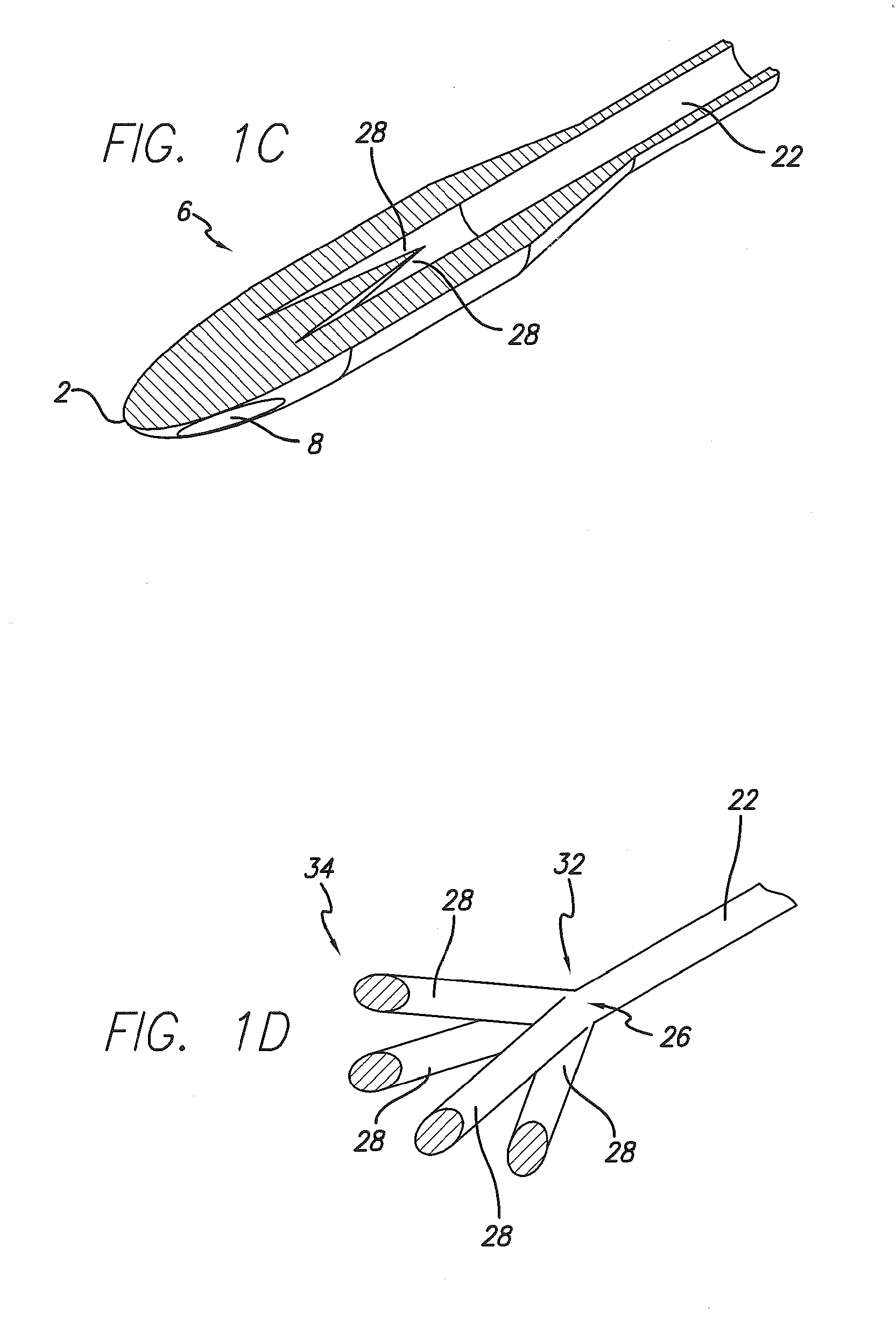

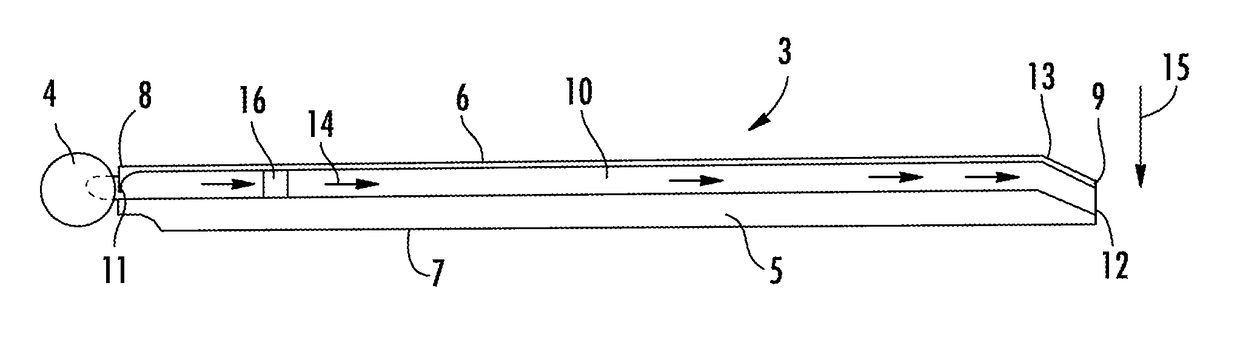

Reduction of recirculation in catheters

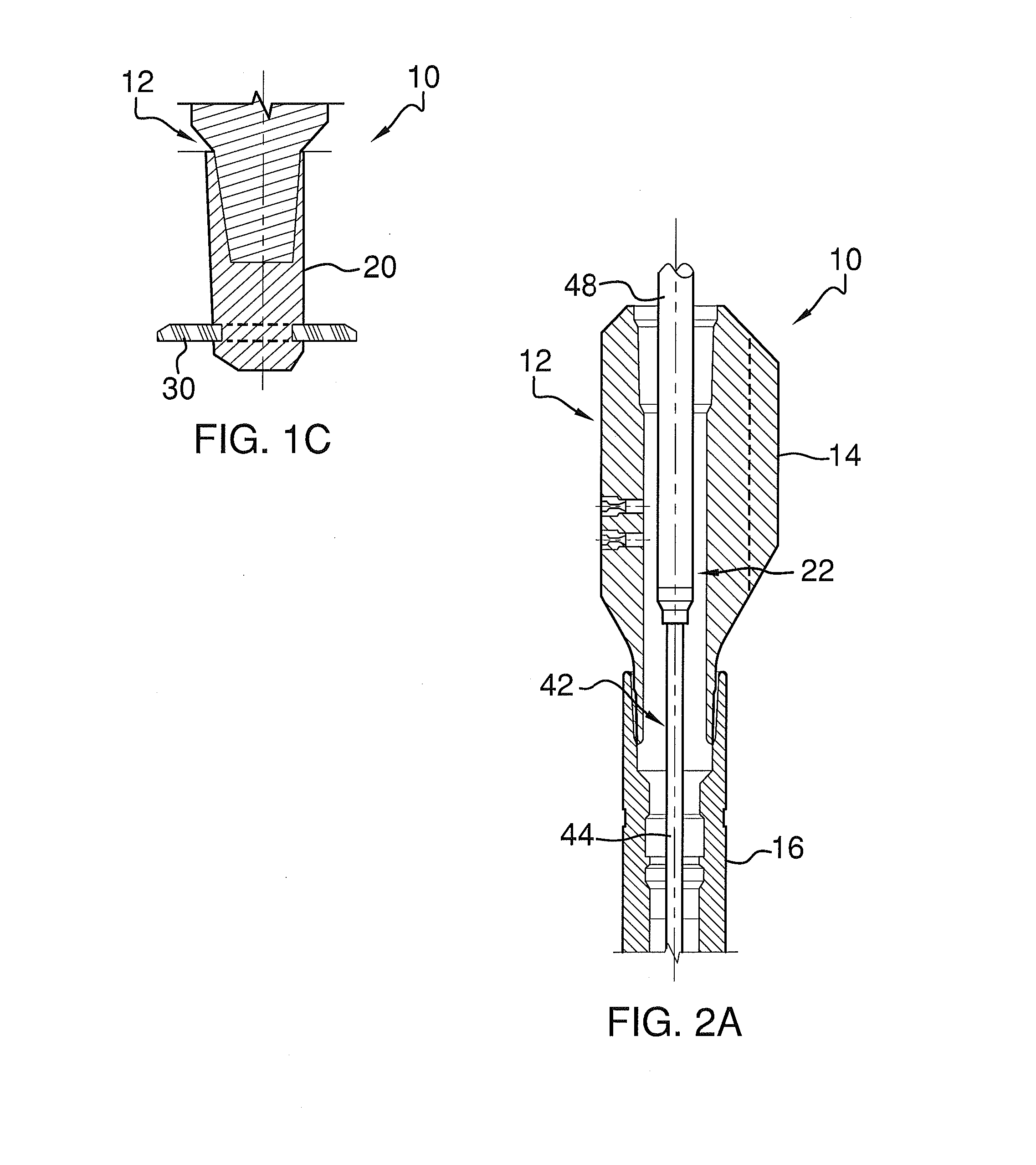

InactiveUS20060004316A1Decrease outflow velocity of fluidPrevent sprayingMedical devicesCatheterDistal portionNose

A catheter tip designed to reduce the outflow velocity and / or directional momentum of fluid being infused by a catheter having such a tip. In one variation, a plurality of channels is provided at the distal portion of the catheter to increase the outflow cross-sectional area. In another variation, the diameter of the catheter at its distal portion where the fluid exits is increased. In yet another variation, a bullet-shaped nose is implemented which may decrease turbulence at the distal end of catheter tip. The low velocity outflow catheter tip may also be implemented on a dual lumen catheter, such as a hemodialysis catheter, to reduce recirculation rate. Various device configurations and methods for such implementations are also disclosed.

Owner:CR BARD INC

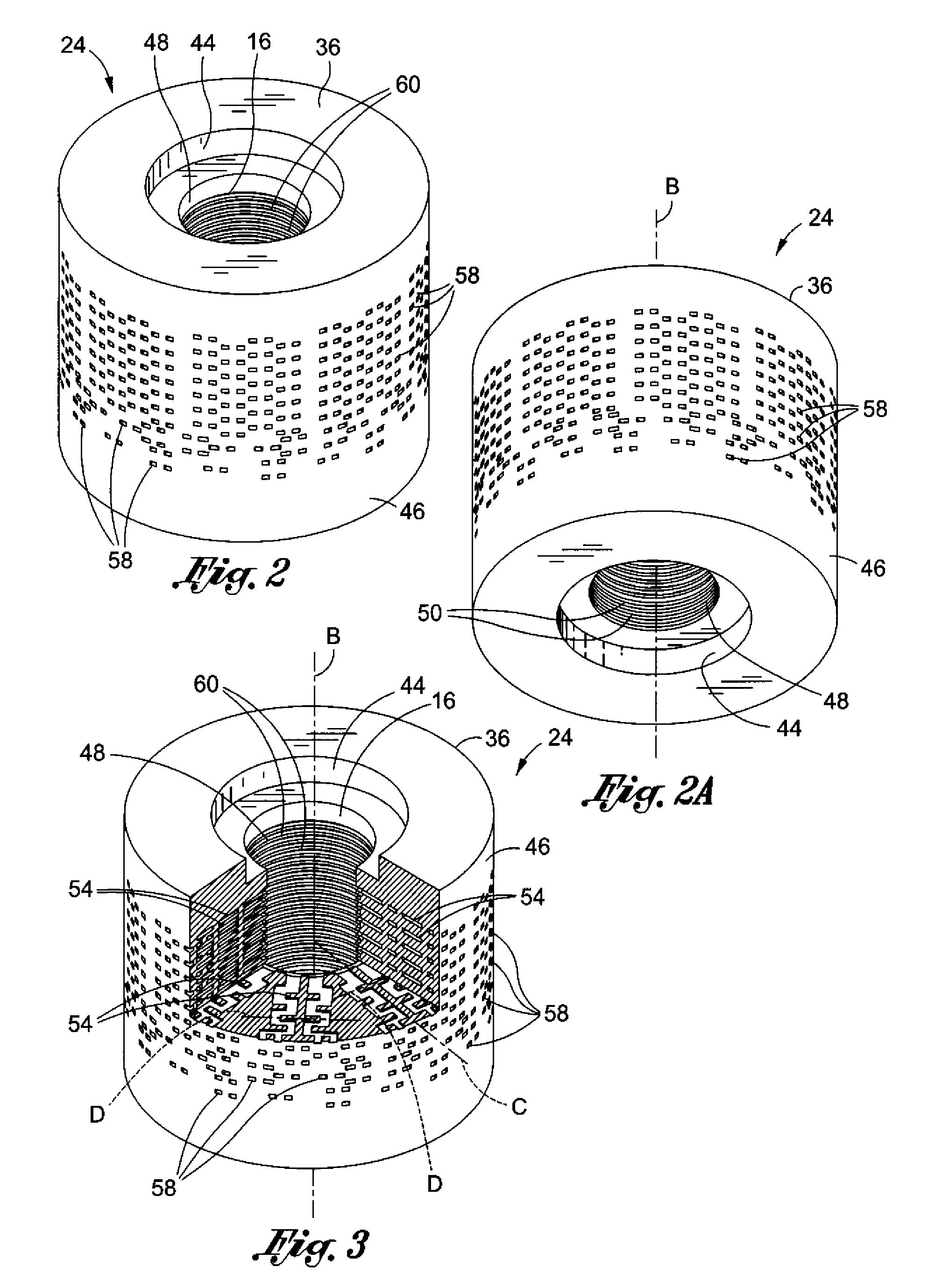

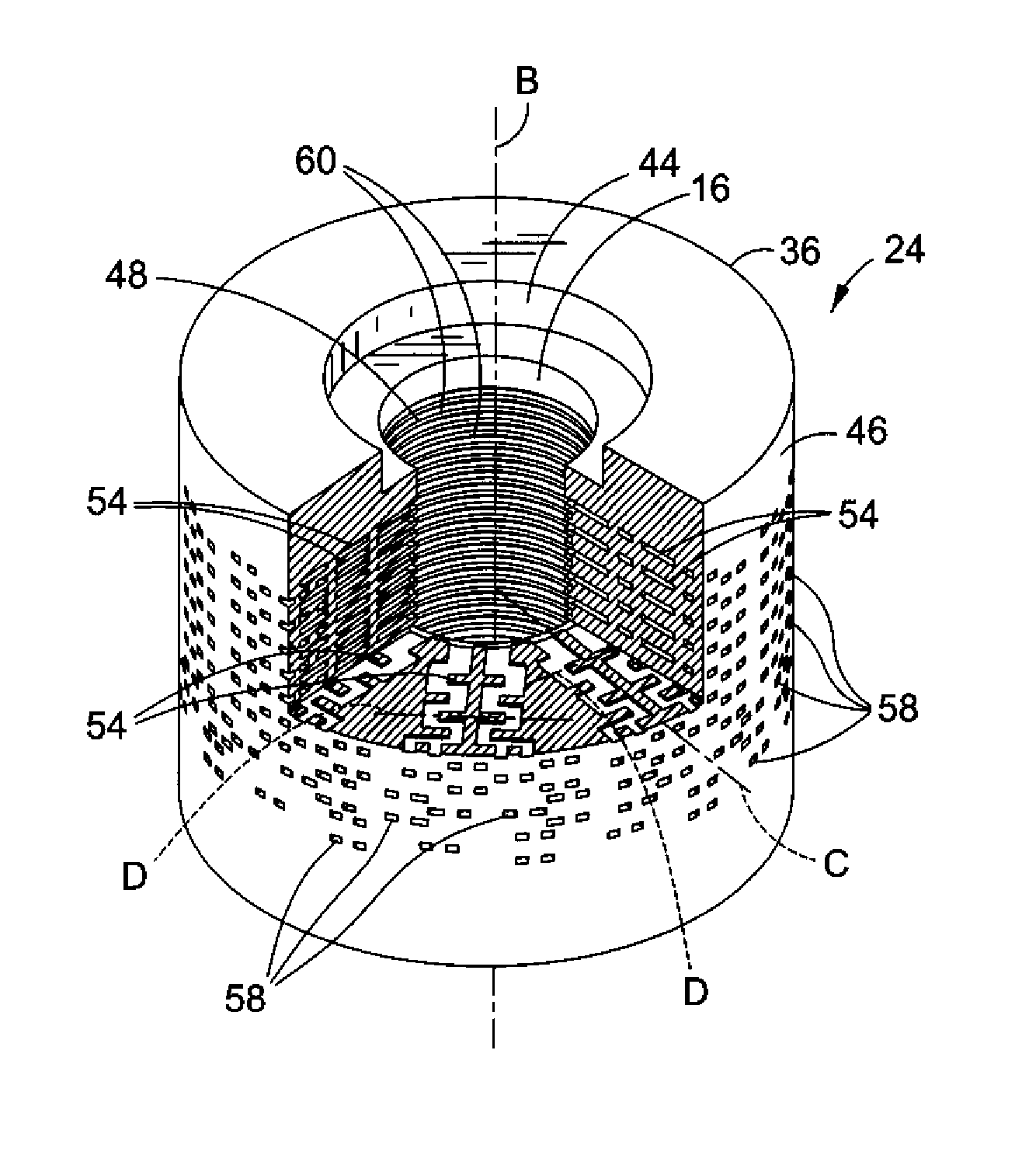

Direct metal laser sintered flow control element

ActiveUS20090183790A1Reduce velocity of fluidHigh degree of accuracyAdditive manufacturingValve members for absorbing fluid energyEngineeringMetallic materials

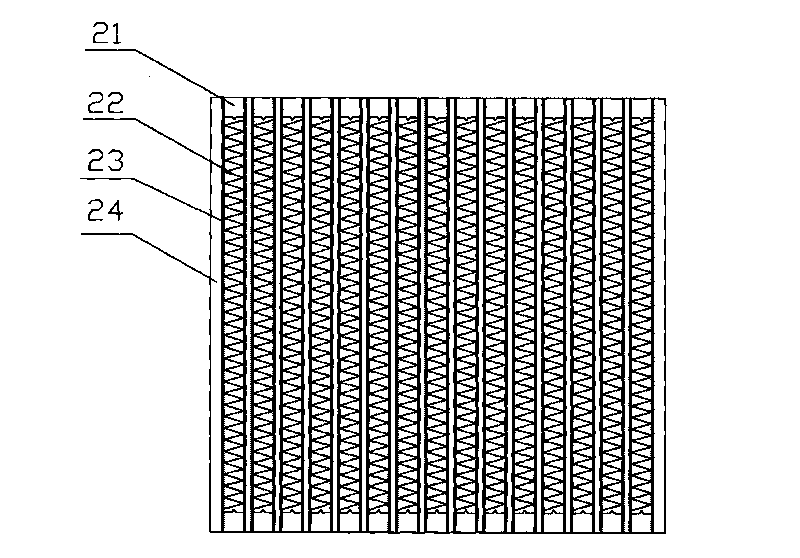

A flow control element comprises a cylindrical element body having a bore formed therethrough. The cylindrical element body may include inner and outer peripheral surfaces and define a plurality of tortuous flow passages which extend between the inner and outer peripheral surfaces. The flow control element is formed as a unitary structure wherein the flow passages are oriented along at least two axes. The flow control may be formed by direct to metal laser sintering wherein successive layers of powdered metallic material are solidified by applying laser energy to the selected portions until the flow element is formed as a unitary structure with a plurality of flow passages extending therethrough. The laser energy is selectively applied to the powdered metallic material according to a computer model of the flow control element.

Owner:CONTROL COMPONENTS INC

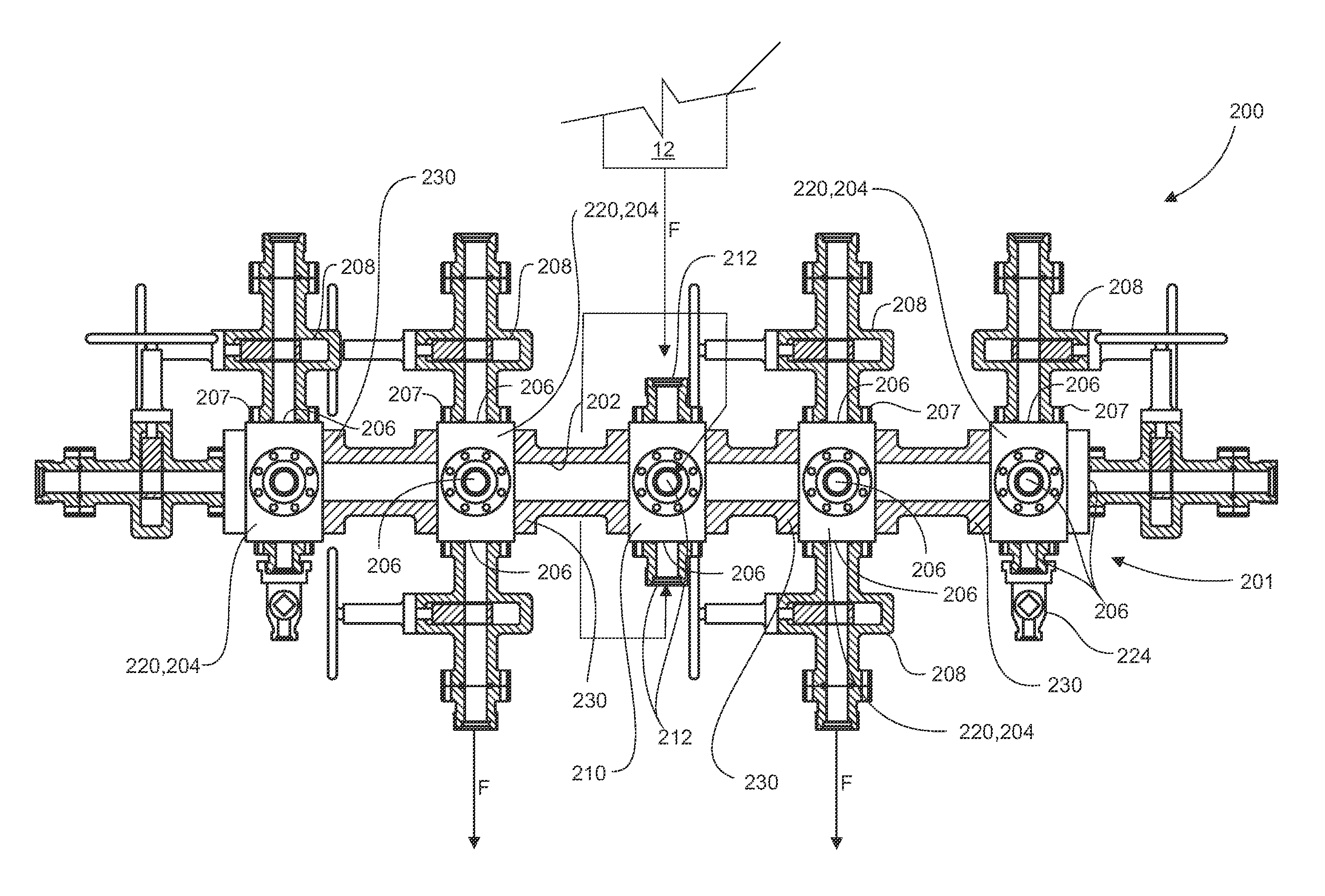

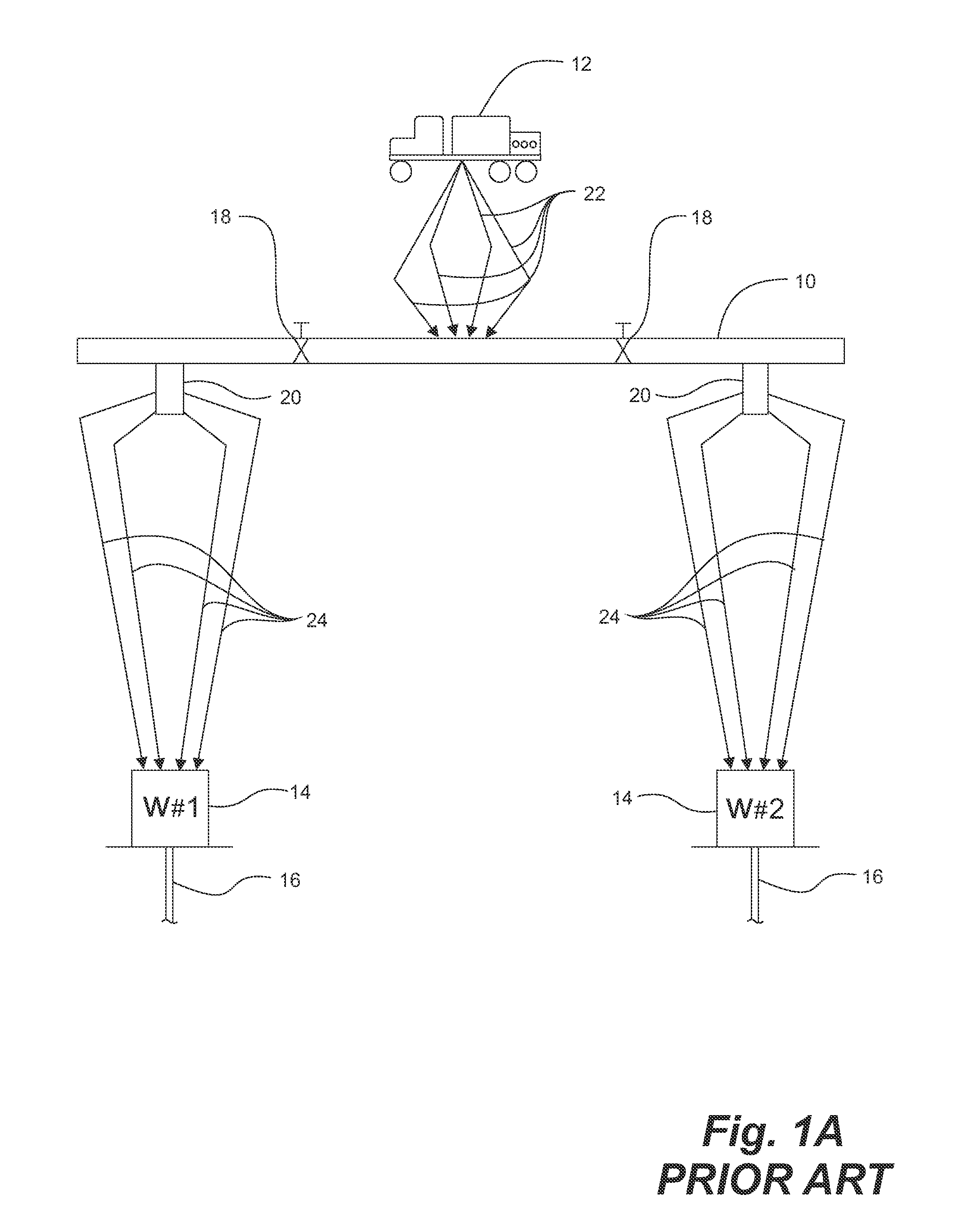

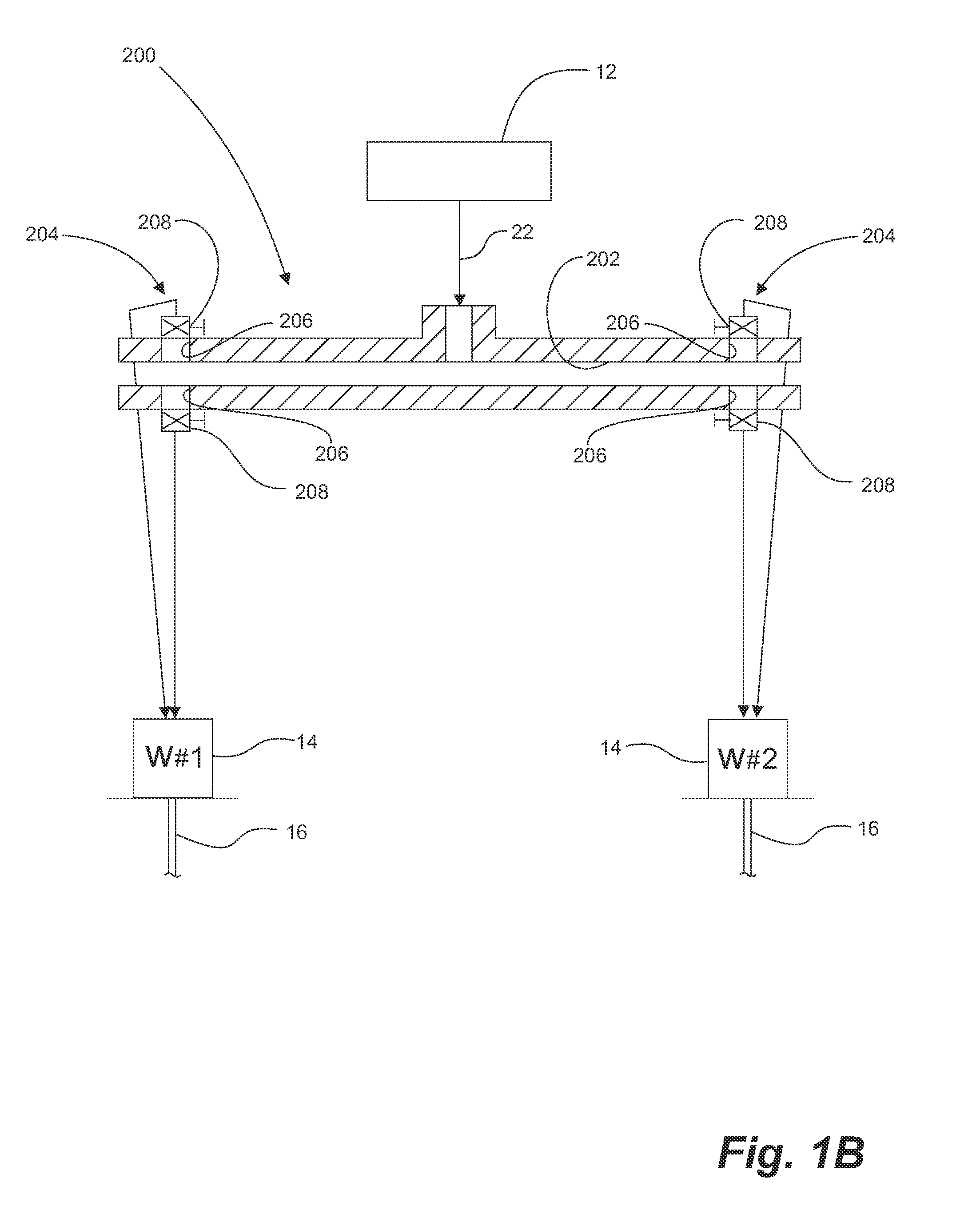

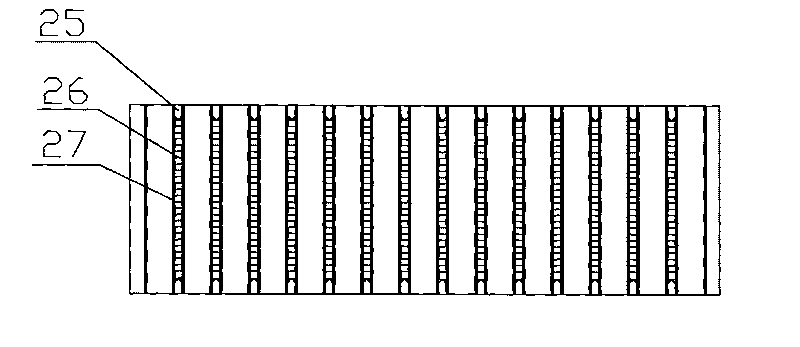

Manifold and system for servicing multiple wells

InactiveUS20110048695A1Reduce velocity of fluidProlong operational lifeDrilling rodsFluid removalWellheadVelocity reduction

A manifold for distribution of well servicing fluids, such as fracturing fluids, to a plurality of wells. The manifold has a single bore through which the fluid flows and a plurality of outlets which are connected to the bore. Two or more of the outlets deliver the fluid to each wellhead. Valves are positioned in each of the outlets so that each of the wellheads can be independently isolated from the fluids for selecting which of the wells will be serviced at any given time. A total cross-sectional area of the outlets feeding each of the wells is greater than the cross-sectional area of the bore which results in a velocity reduction in the outlets which reduces erosion in the manifold and the downstream components Systems are described using prior art manifolds or manifolds according to embodiments of the invention for use specifically with fracturing fluids containing proppant. Proppant can be delivered to the fracturing fluid through the manifold, directly to the wellhead or both, to reduce erosion. Use of a manifold according to embodiments of the invention, in combination with the systems described, are particularly useful for reducing erosion with proppant-laden fracturing fluids.

Owner:ISOLATION EQUIP SERVICES

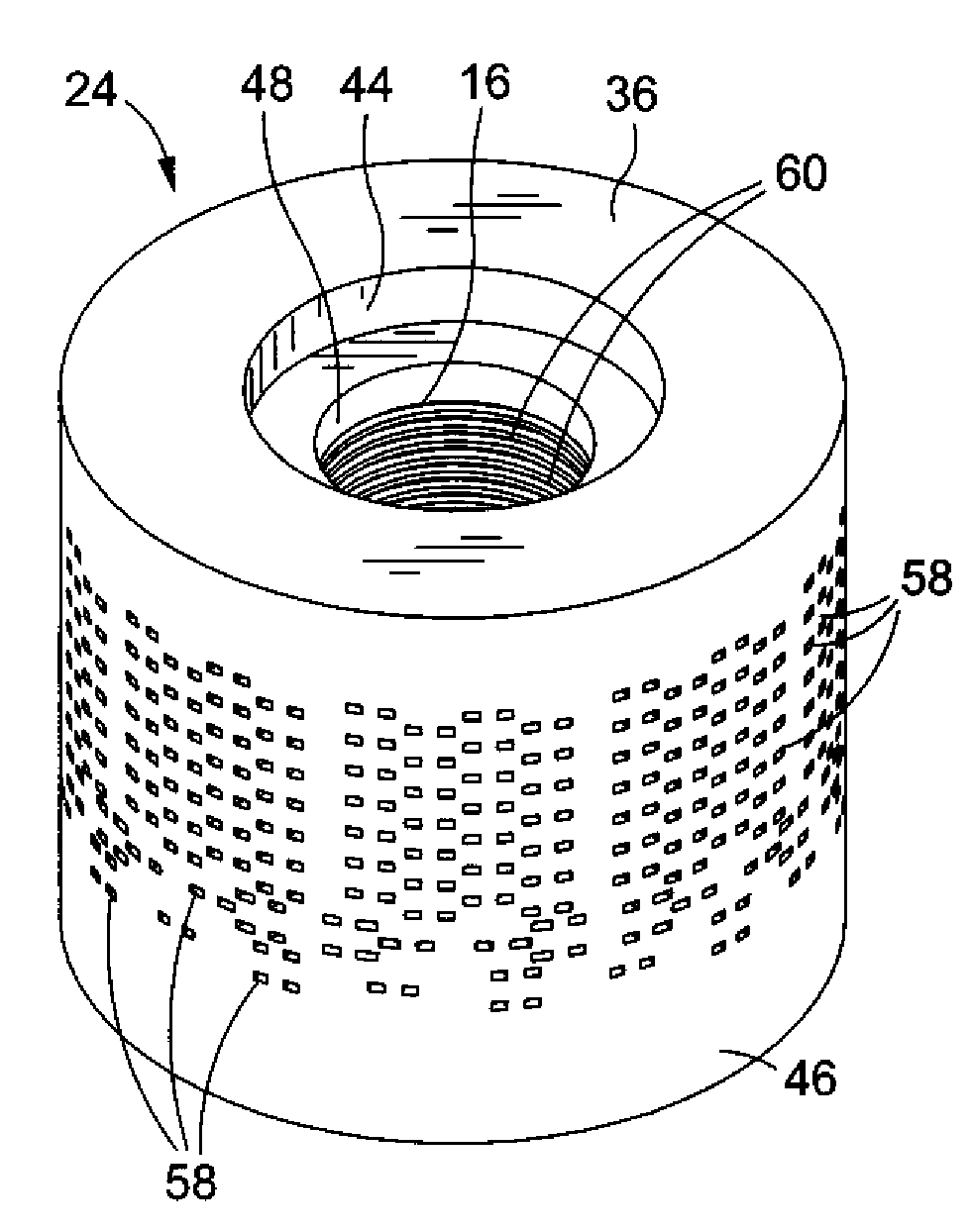

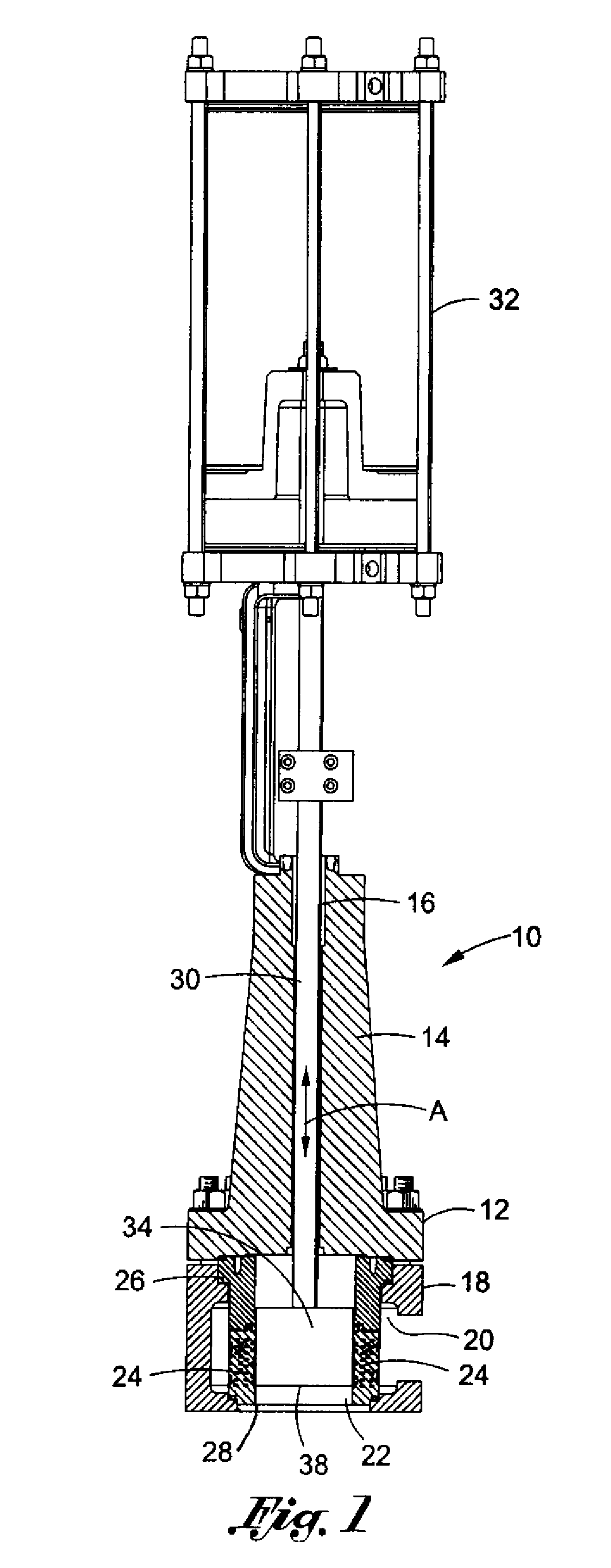

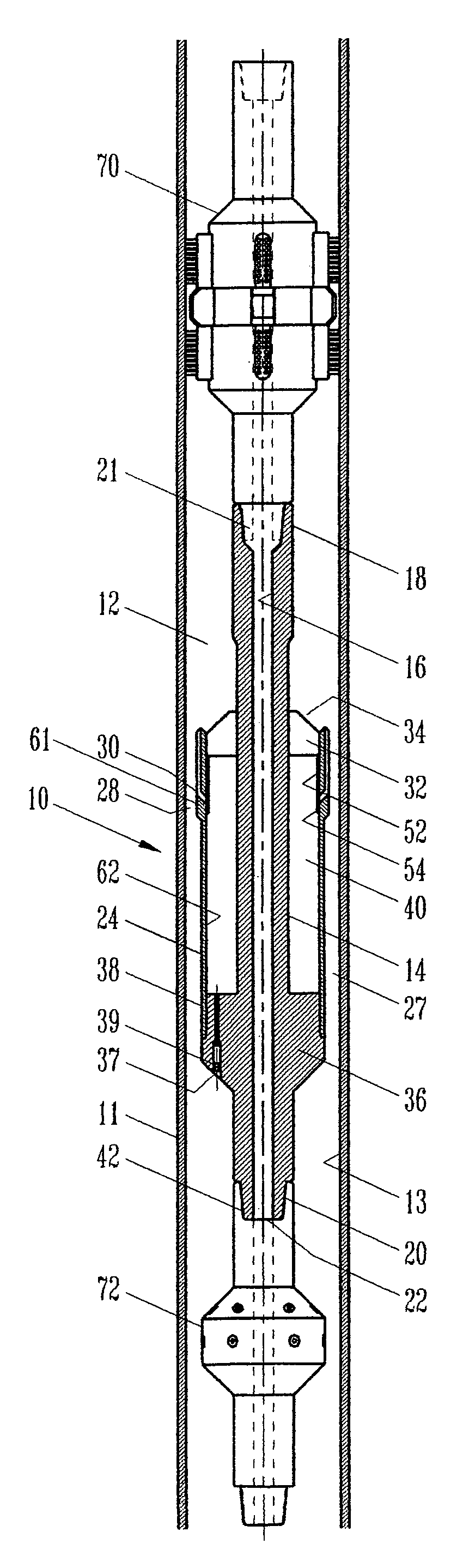

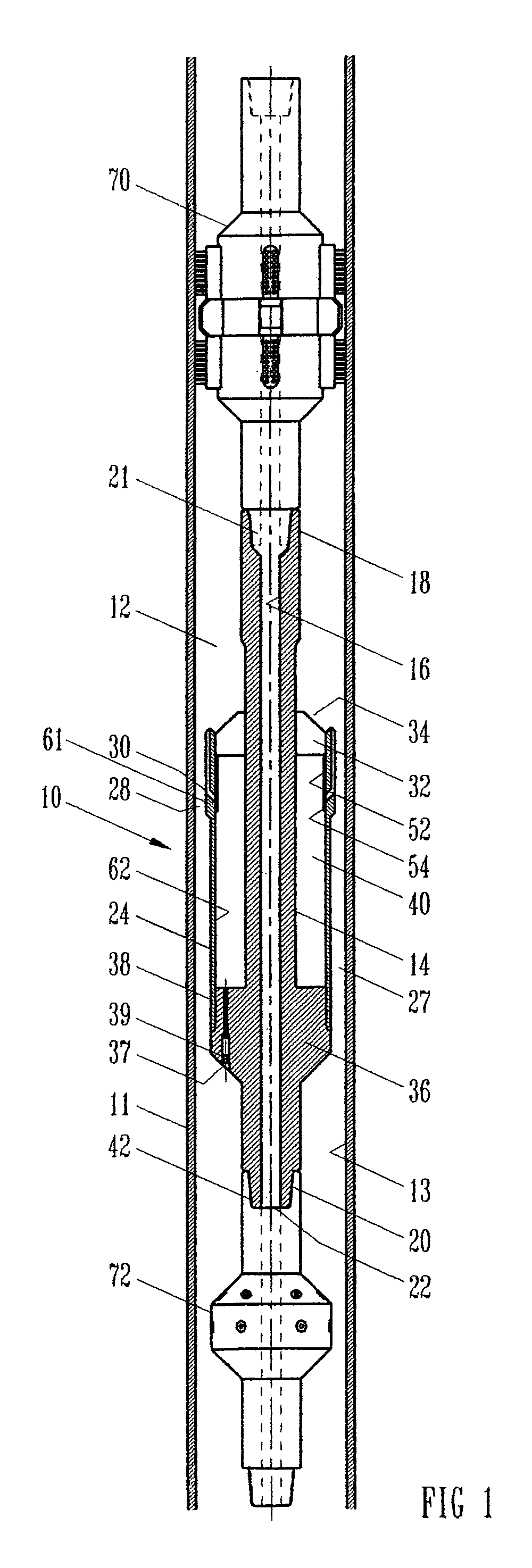

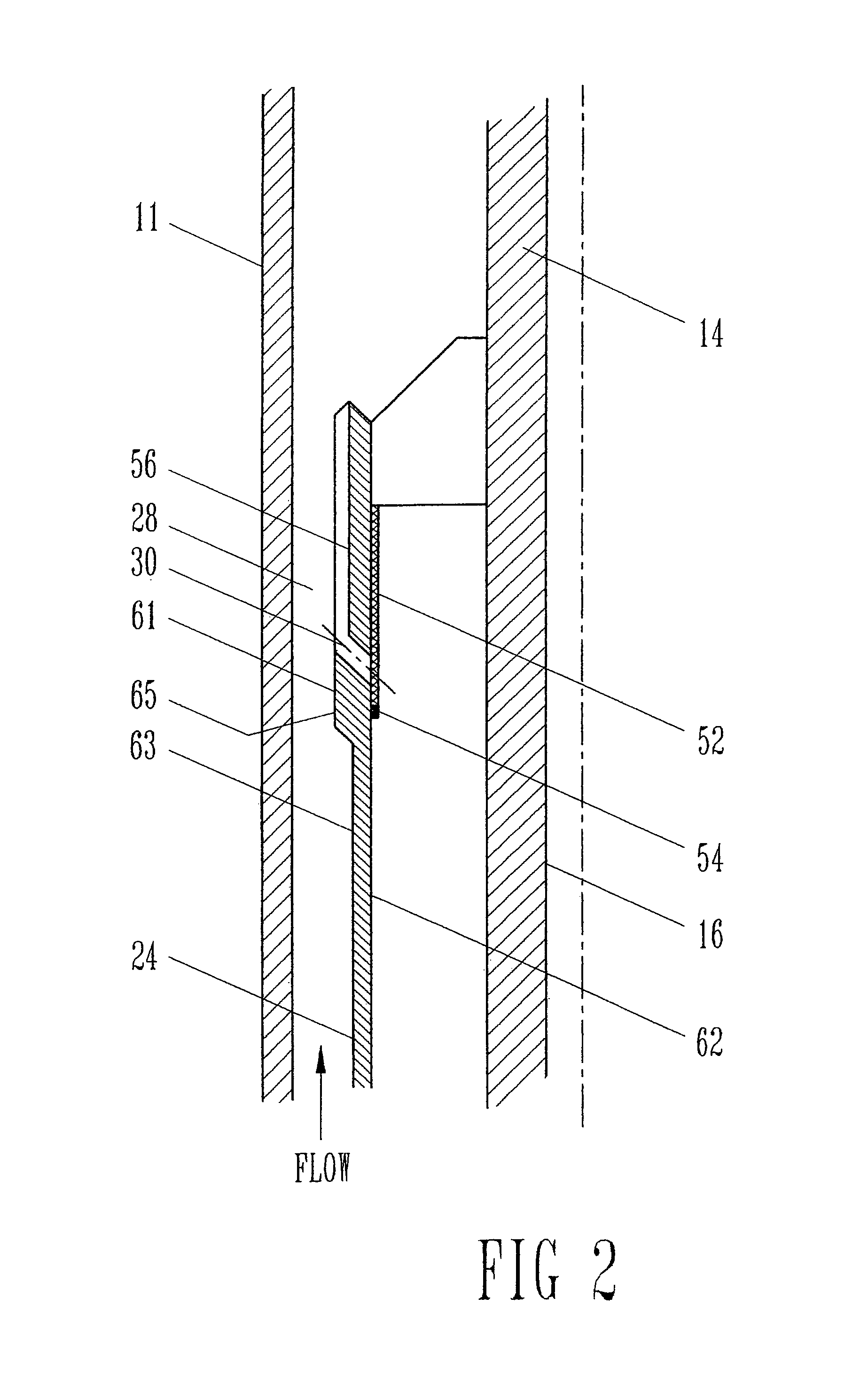

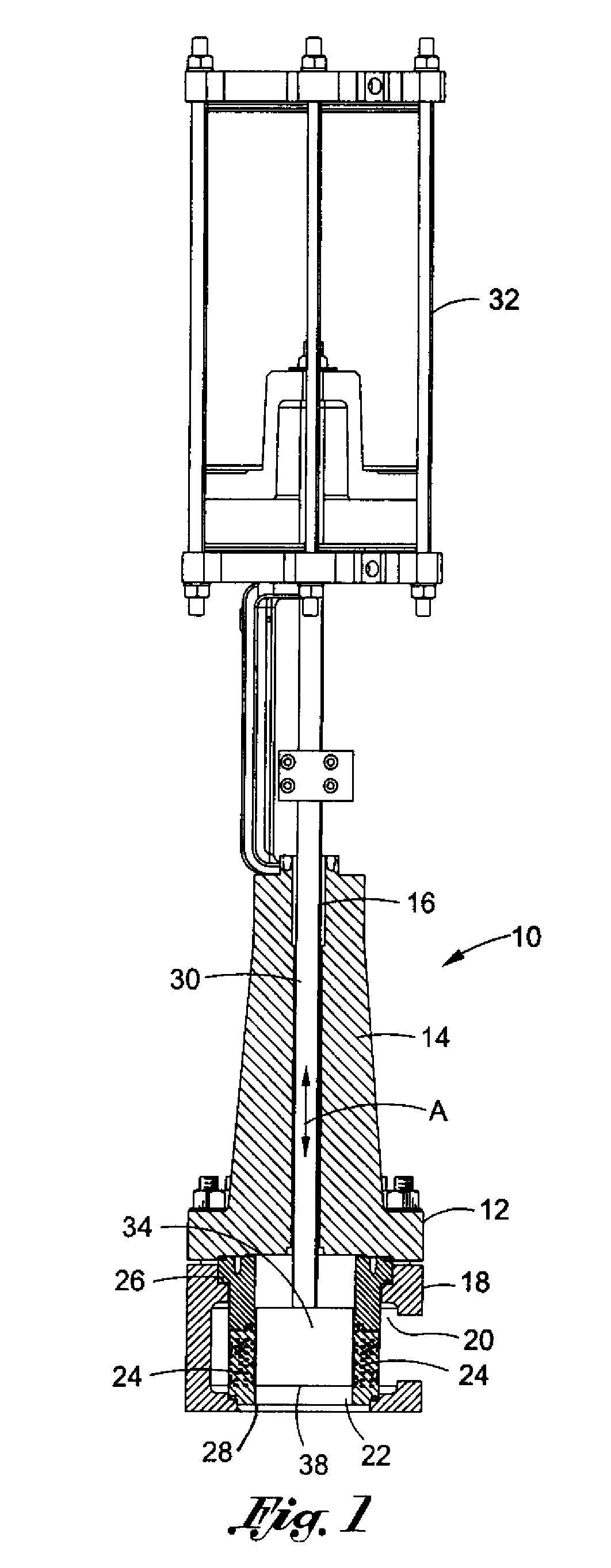

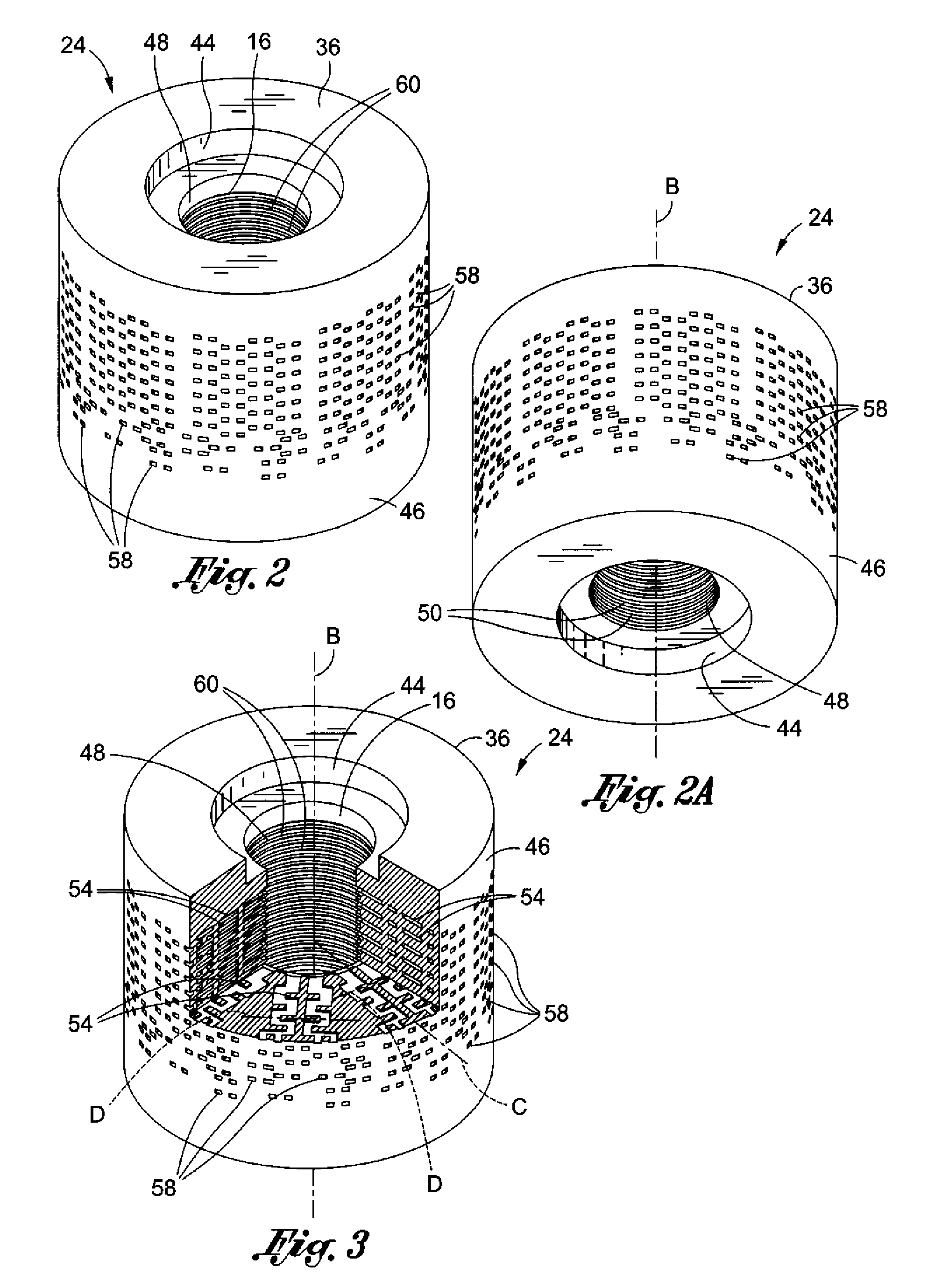

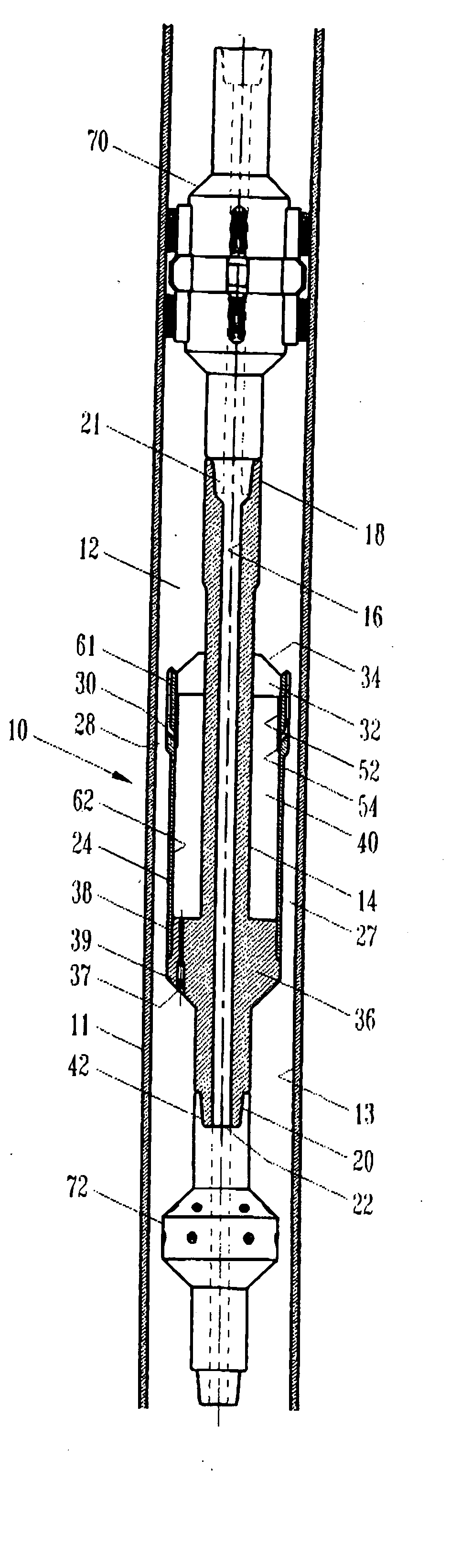

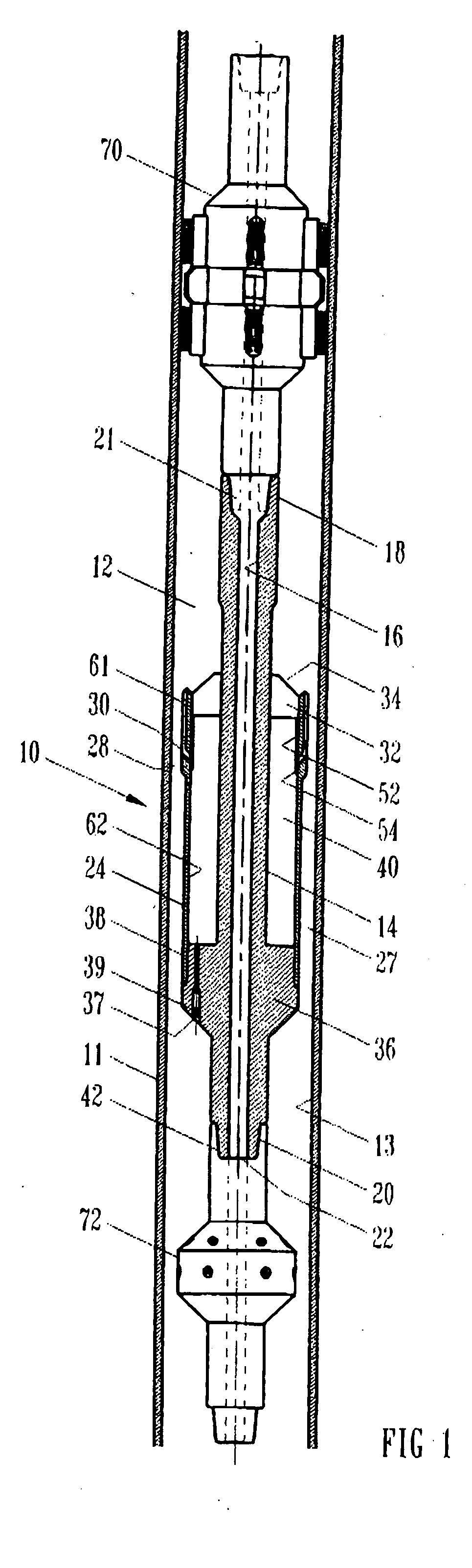

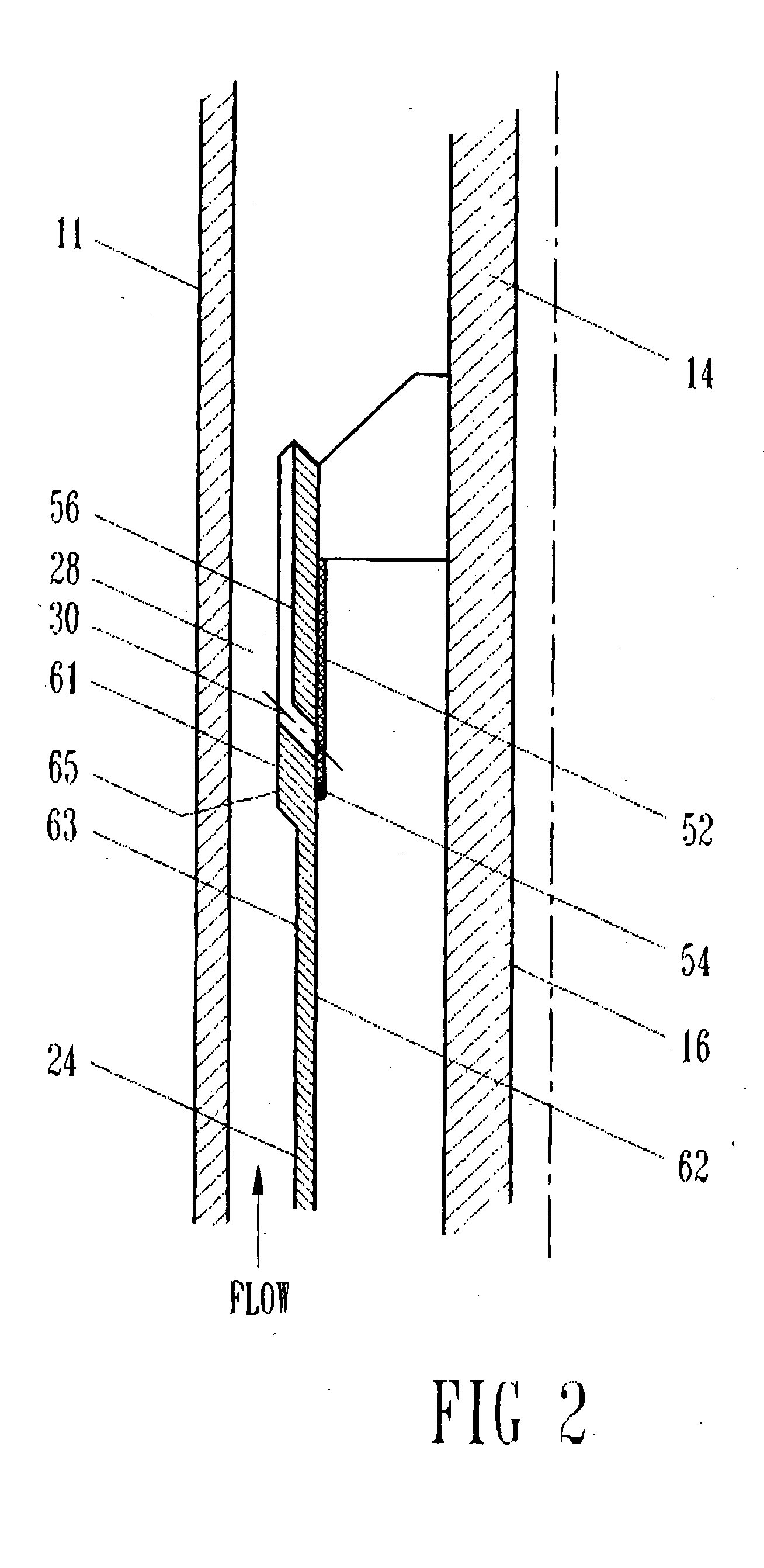

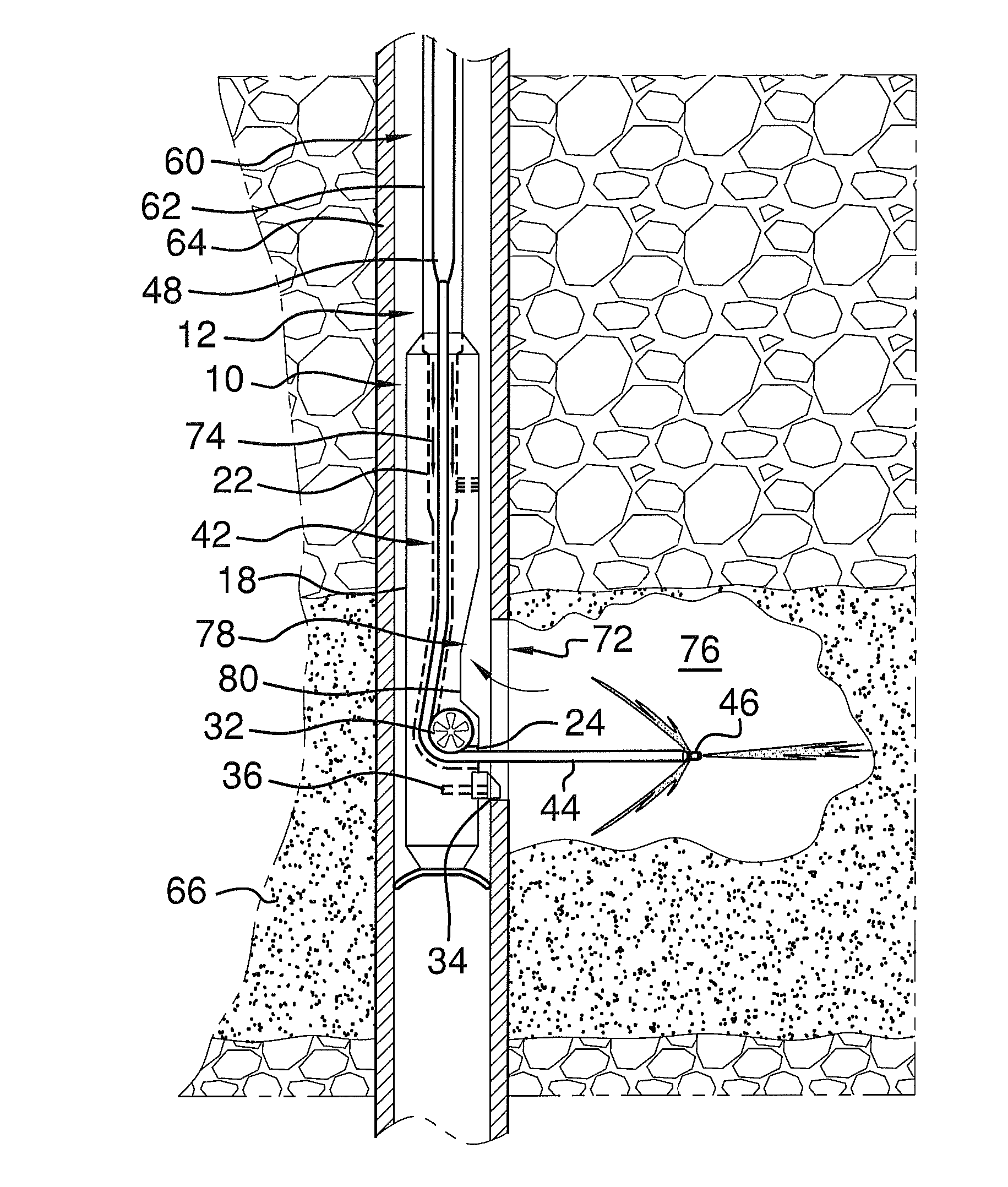

Junk basket and method

ActiveUS6951251B2Reduce fluid velocityFluid drag lossesCleaning apparatusFluid removalEngineeringWellbore

Junk basket 10 is provided for collecting debris from a wellbore cleaning operation, and includes a central mandrel 14 having a throughbore 16 and an outer shell 24 defining a generally annular junk space 40. The outer shell 24 may be configured such that the annulus 27 includes a reduced portion 28. Flow holes 30 in the outer shell are preferably angled substantially upward, and are positioned to discharge fluid to the annulus 27. According to a method of the invention, fluid is passed from an upper tubing string, through the central mandrel, into the wellbore and upward through the annulus and past the flow holes, thereby reducing pressure of flow past the well holes to pass fluid from the junk space through the flow holes.

Owner:BILCO TOOLS

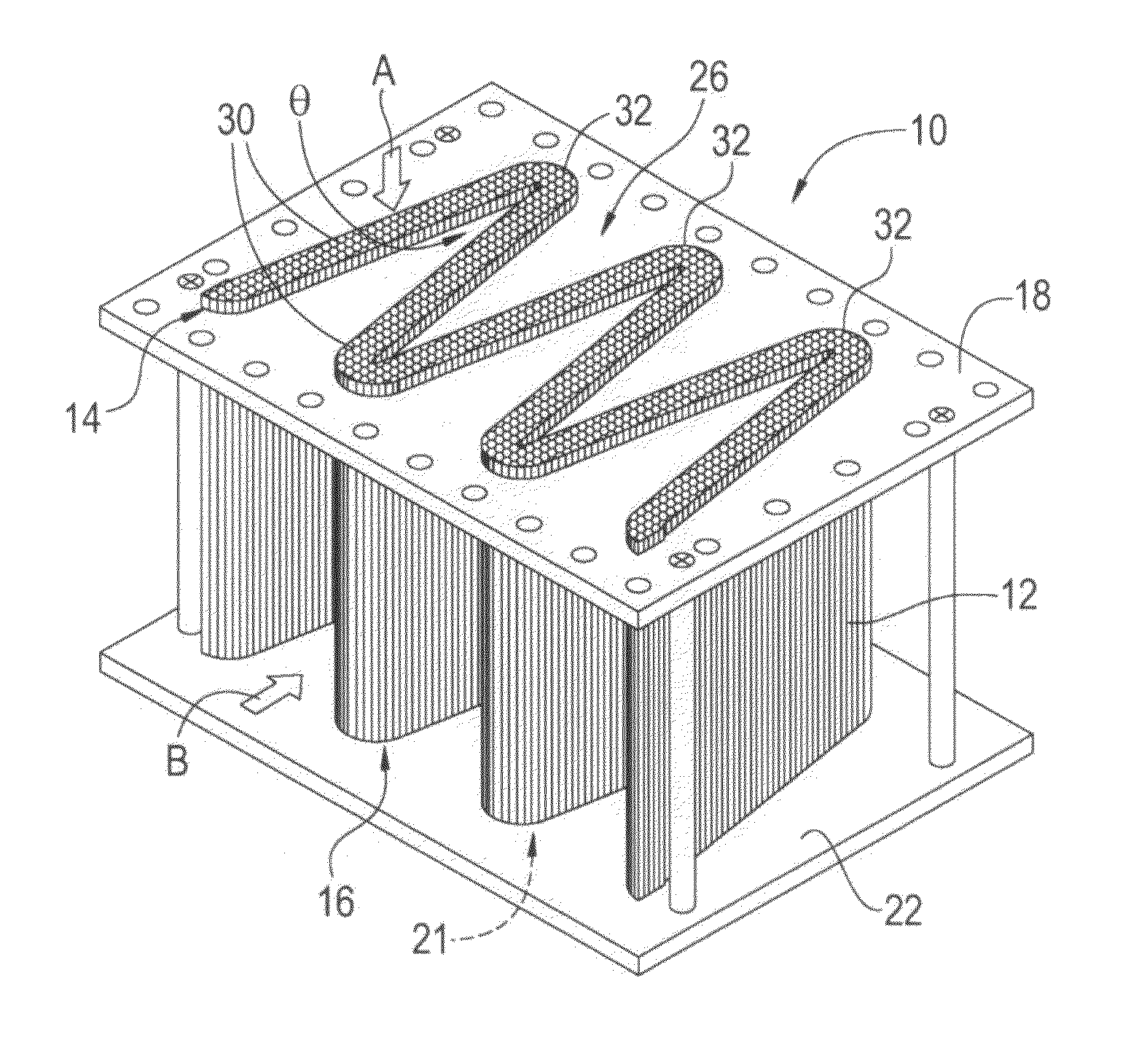

Direct metal laser sintered flow control element

ActiveUS8826938B2High precisionReduce fluid velocityAdditive manufacturingValve members for absorbing fluid energyDirect metal laser sinteringMetallic materials

A flow control element comprises a cylindrical element body having a bore formed therethrough. The cylindrical element body may include inner and outer peripheral surfaces and define a plurality of tortuous flow passages which extend between the inner and outer peripheral surfaces. The flow control element is formed as a unitary structure wherein the flow passages are oriented along at least two axes. The flow control may be formed by direct to metal laser sintering wherein successive layers of powdered metallic material are solidified by applying laser energy to the selected portions until the flow element is formed as a unitary structure with a plurality of flow passages extending therethrough. The laser energy is selectively applied to the powdered metallic material according to a computer model of the flow control element.

Owner:CONTROL COMPONENTS INC

Reduction of recirculation in catheters

ActiveUS8920404B2Reduce the average velocityPrevent sprayingMedical devicesCatheterDistal portionNose

A catheter tip designed to reduce the outflow velocity and / or directional momentum of fluid being infused by a catheter having such a tip. In one variation, a plurality of channels is provided at the distal portion of the catheter to increase the outflow cross-sectional area. In another variation, the diameter of the catheter at its distal portion where the fluid exits is increased. In yet another variation, a bullet-shaped nose is implemented which may decrease turbulence at the distal end of catheter tip. The low velocity outflow catheter tip may also be implemented on a dual lumen catheter, such as a hemodialysis catheter, to reduce recirculation rate. Various device configurations and methods for such implementations are also disclosed.

Owner:CR BARD INC

Junk basket and method

ActiveUS20050072571A1Reduce fluid velocityFluid drag lossesCleaning apparatusFluid removalEngineering

Junk basket 10 is provided for collecting debris from a wellbore cleaning operation, and includes a central mandrel 14 having a throughbore 16 and an outer shell 24 defining a generally annular junk space 40. The outer shell 24 may be configured such that the annulus 27 includes a reduced portion 28. Flow holes 30 in the outer shell are preferably angled substantially upward, and are positioned to discharge fluid to the annulus 27. According to a method of the invention, fluid is passed from an upper tubing string, through the central mandrel, into the wellbore and upward through the annulus and past the flow holes, thereby reducing pressure of flow past the well holes to pass fluid from the junk space through the flow holes.

Owner:BILCO TOOLS

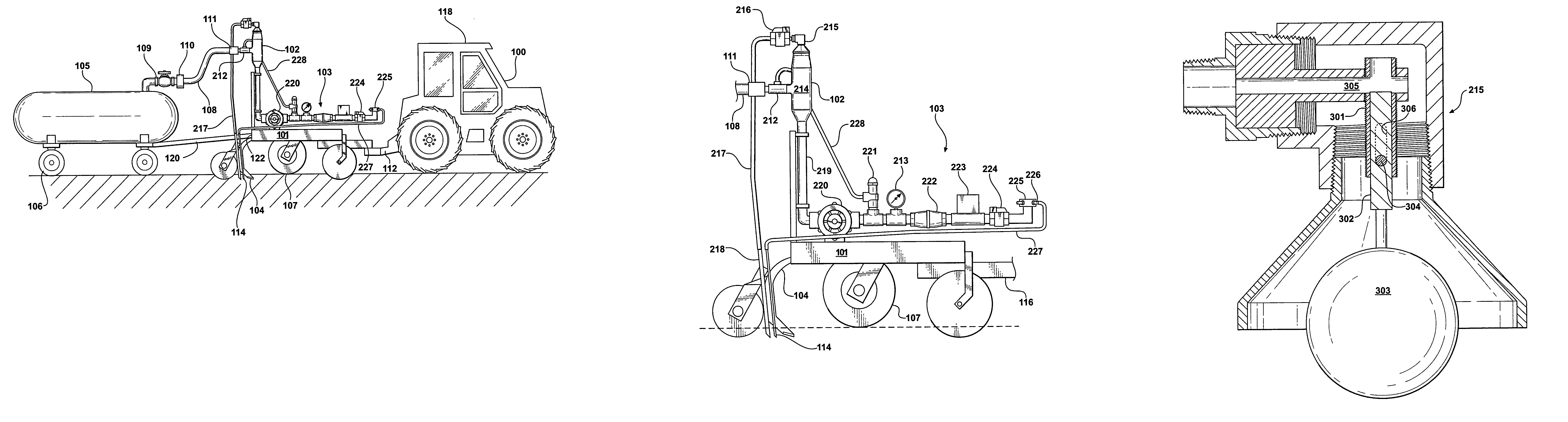

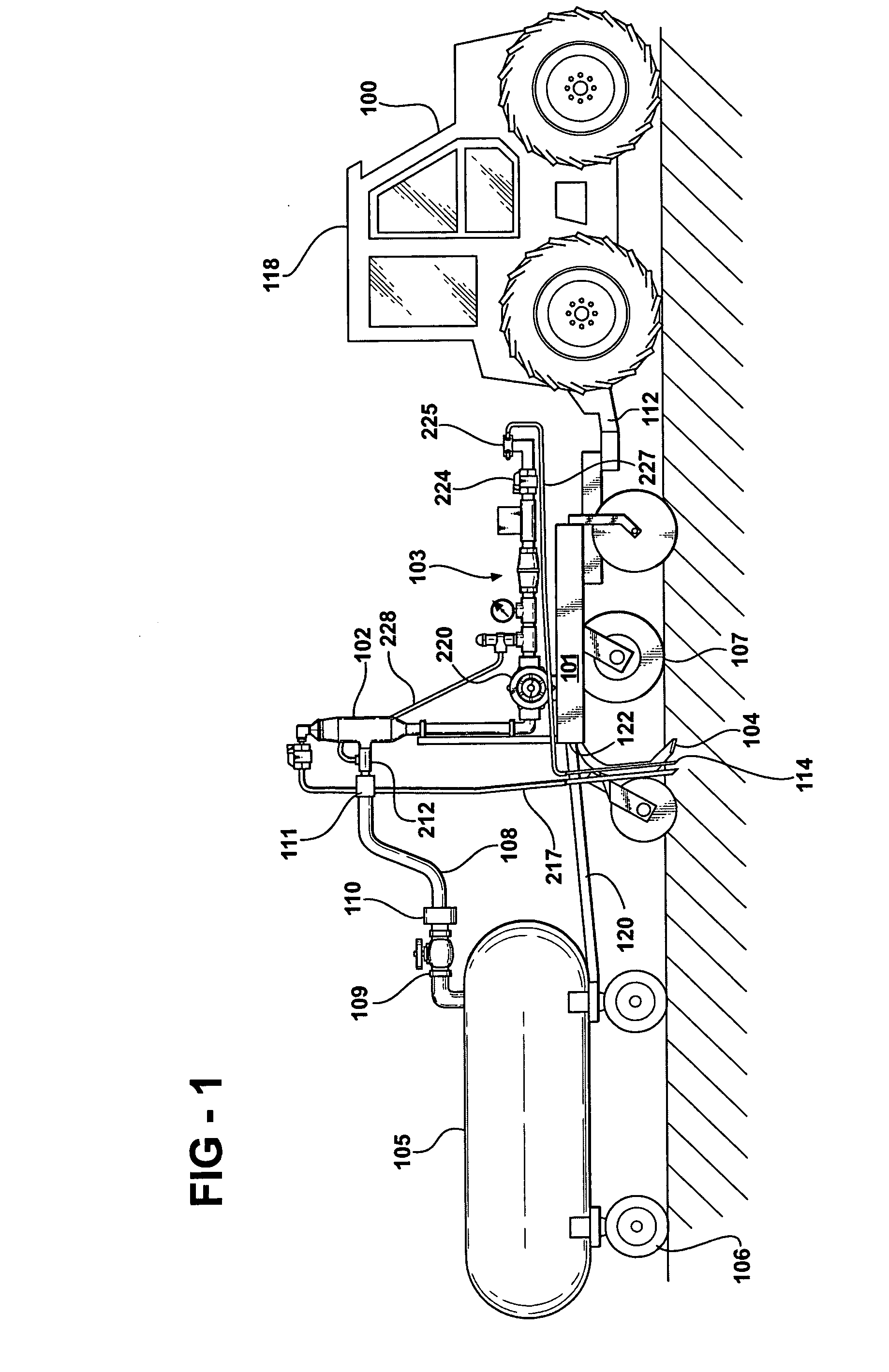

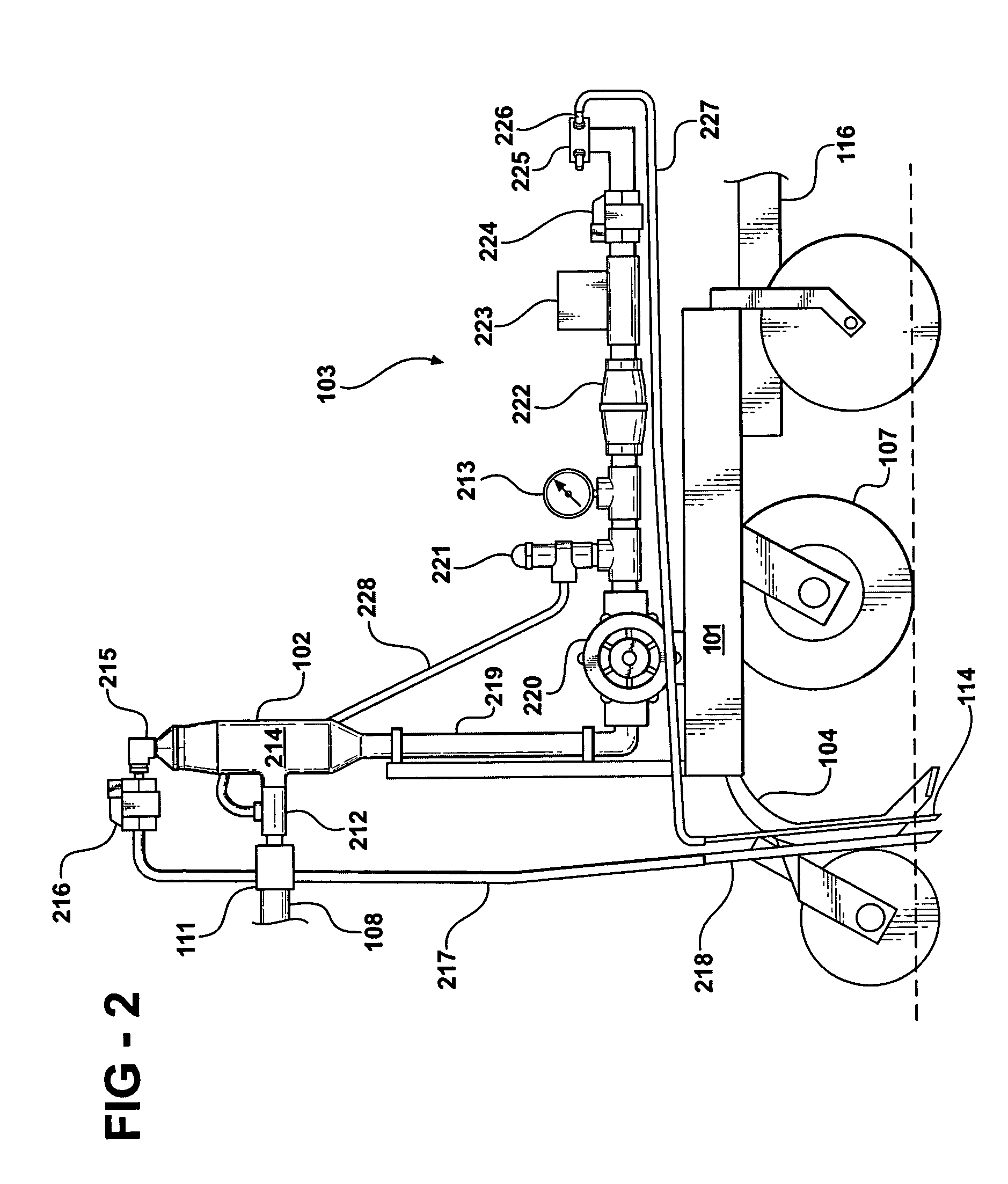

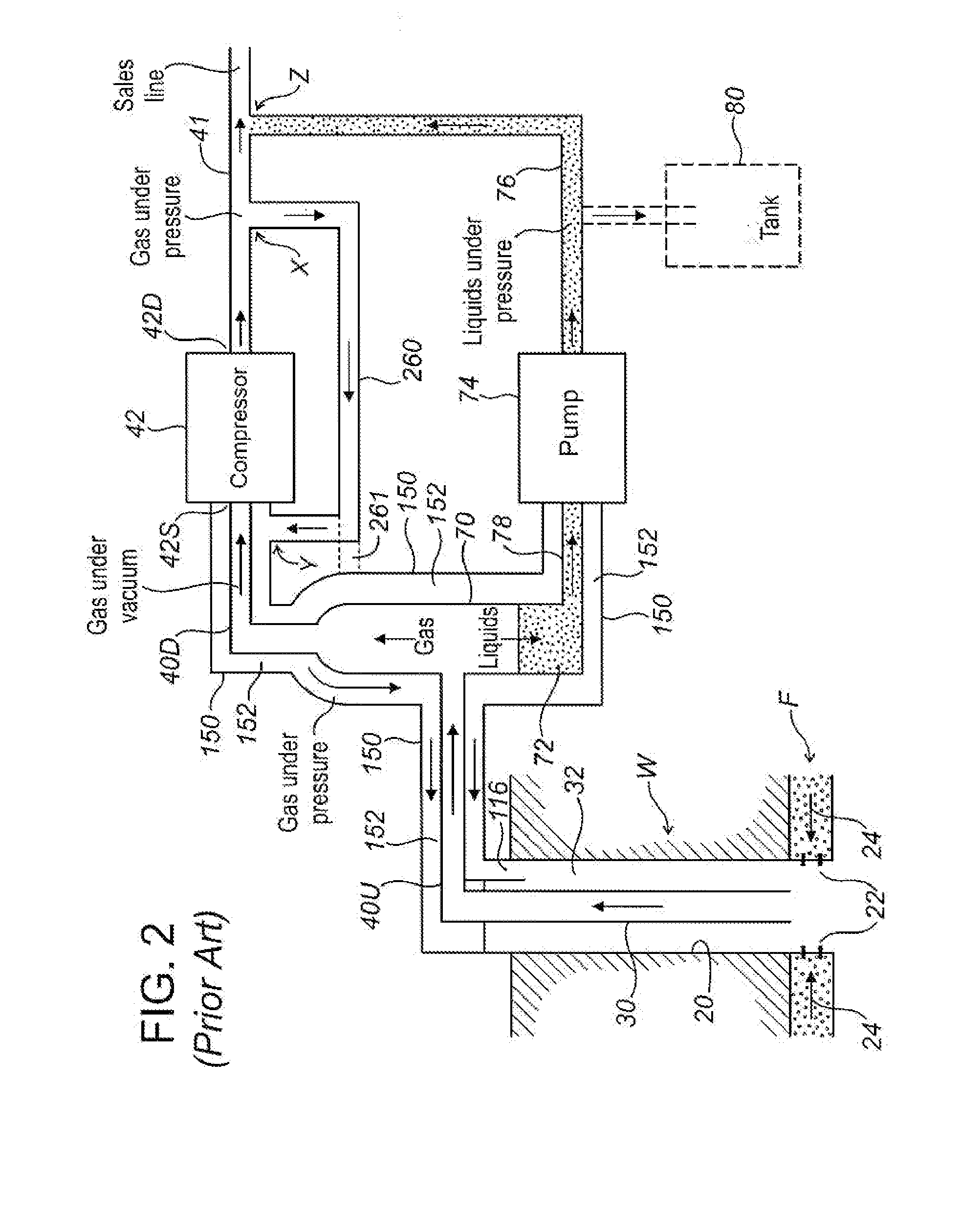

Anhydrous ammonia fertilizer flow control apparatus and method

ActiveUS7096802B1Reduce the amount requiredIncrease volumePlantingLiquid fertiliser distributionControl systemEngineering

A method and apparatus for supplying liquid anhydrous ammonia to a pump or other flow control system whereby a separation chamber removes vapor generated by friction in the flow path from a storage tank containing saturated anhydrous ammonia. Additionally, liquid ammonia in the separation chamber creates a static head pressure. The difference in height between the inlet near the top of the separation chamber and the outlet at the bottom causes the static head pressure. The static head assures pure liquid at the bottom since absolute pressure exceeds saturation pressure. As a result, the feed stream to the pump or other flow control system is free of ammonia vapor.

Owner:360 YIELD CENT

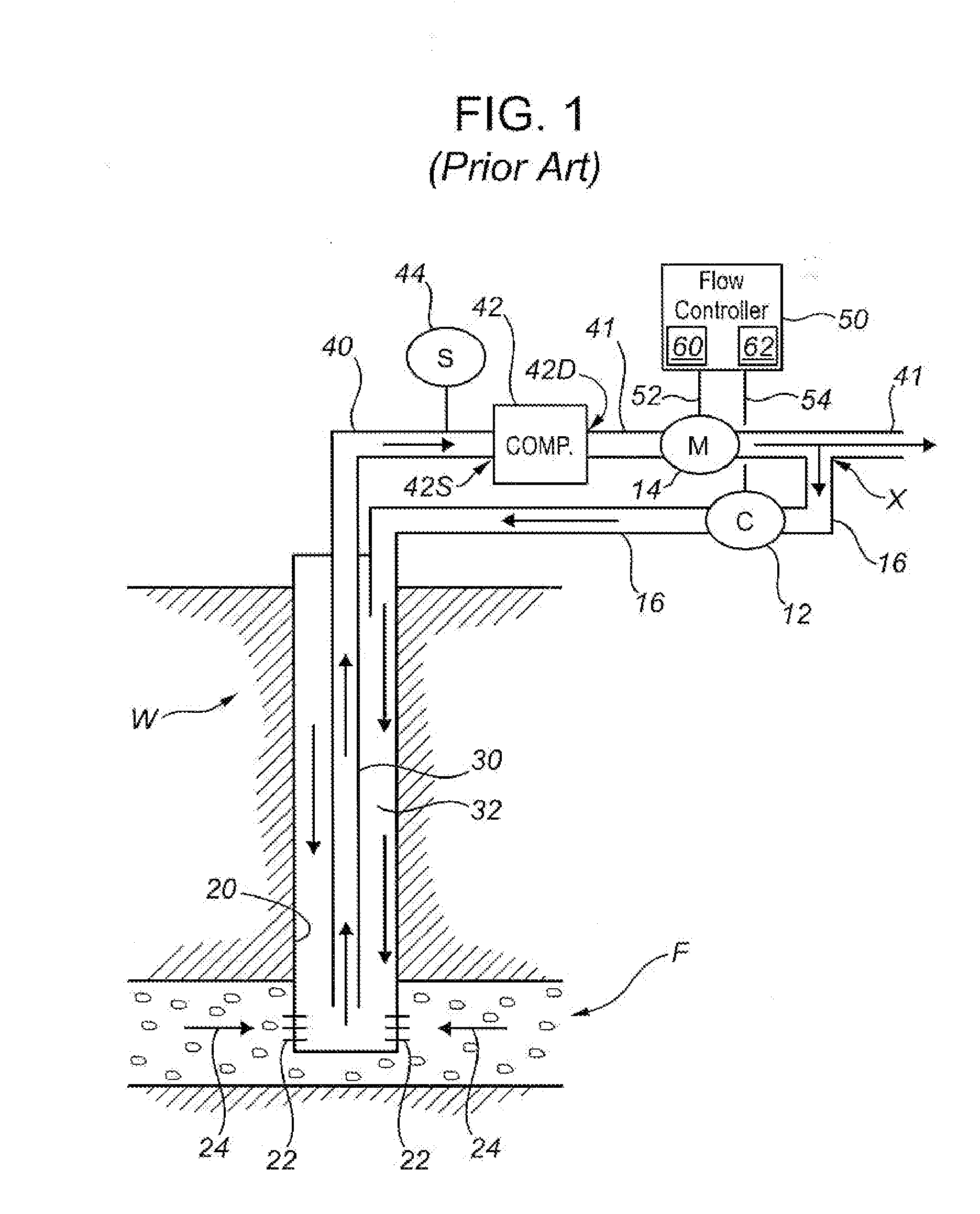

Control logic method and system for optimizing natural gas production

InactiveUS20110004352A1Reduce fluid velocityReduce the gas flow rateDiaphragm valvesOperating means/releasing devices for valvesSet pointNatural gas

In a system for optimizing natural gas production in response to real-time variations in wellbore parameters, a PLC or other wellsite intelligence technology is used to monitor liquid and gas production from the wellbore under friction-loaded conditions. Using baseline production data obtained during production tests, the PLC determines and initiates the appropriate operating mode for the wellbore to optimize a selected production criterion to suit measured wellbore parameters. The operating mode either a continuous clean-out mode, in which gas is continuously injected into the wellbore to control liquid loading, or an intermittent clean-out, in which liquid loading is regulated by intermittent gas injection. In preferred embodiments, the system uses bladder-type control valves having upstream and downstream solenoids, to control production tubing flow rate within a range between upper and lower set points.

Owner:OPTIMUM PROD TECH INC

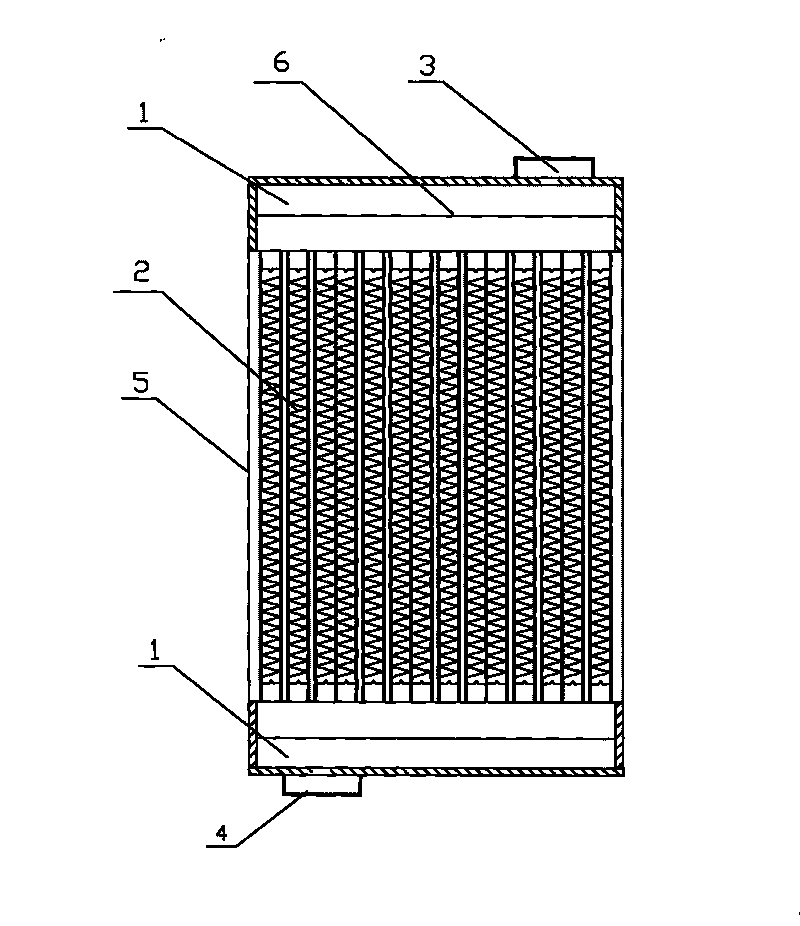

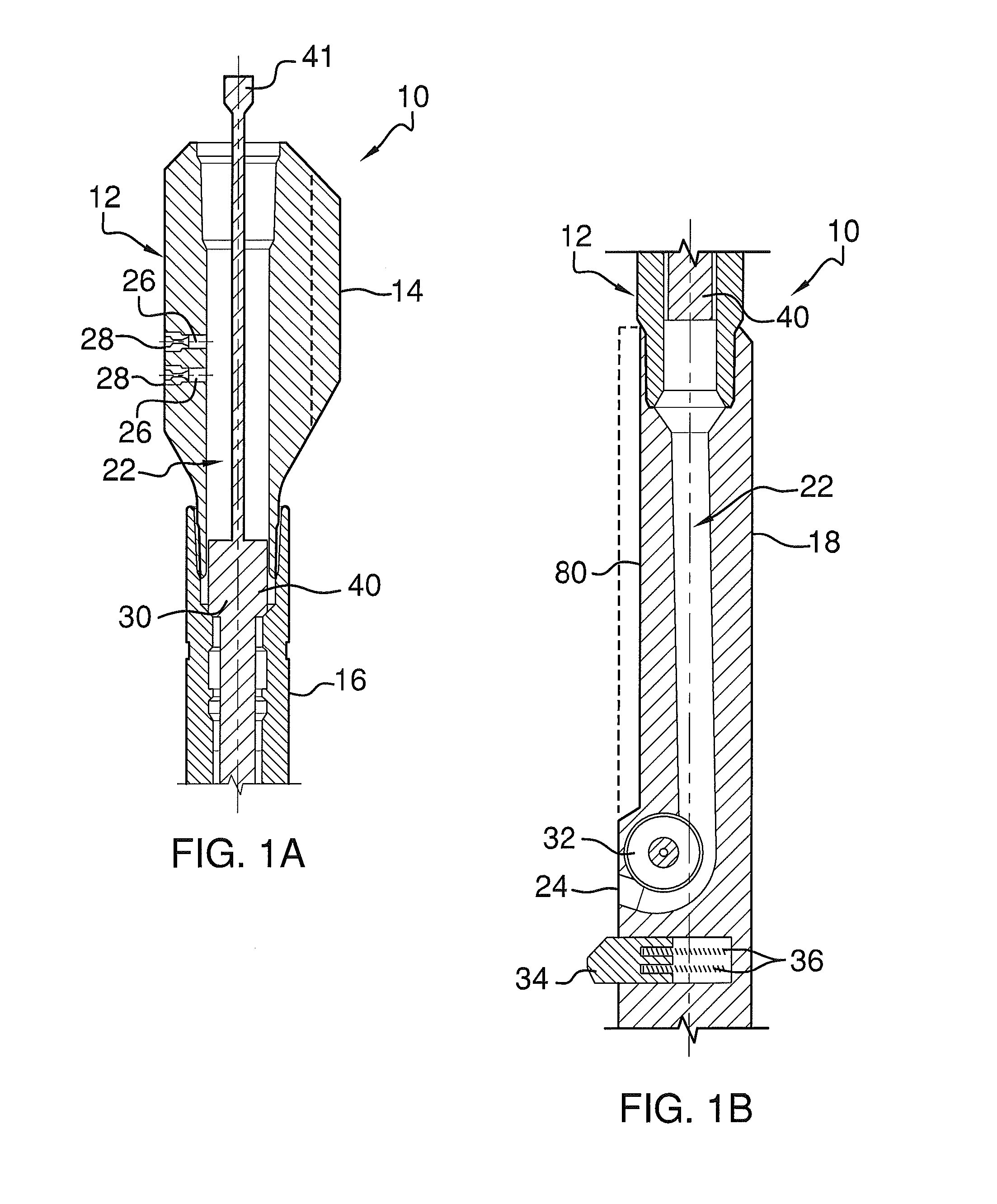

Plate-fin heat exchanger

InactiveCN101696857AImprove heat transfer effectPass smoothlyStationary conduit assembliesHeat exchanger casingsPunchingEngineering

The invention relates to heat exchange equipment and discloses a plate-fin heat exchanger. The plate-fin heat exchanger comprises a shell, a fixing part arranged on the shell and used for fixing the plate-fin heat exchanger, a heat exchange core and an end socket cavity welded at two ends of the heat exchange core, wherein the end socket cavity is welded with an inlet pipe and an outlet pipe; the heat exchange core comprises outside clapboards, inside clapboards, an inside fin, an inside seal, an outside fin, an outside seal and bilateral side plates; the outside fin and the outside seal arranged between the outside clapboards forms a cold passageway ; the inside fin and the inside seal arranged between the inside clapboards forms a hot passageway; the end socket cavity is communicated with the hot passageway; the cold passageway and the hot passageway are arranged in a layered crossing way; the inside of the end socket cavity is provided with a punching baffle, and holes with diameters from small to large are distributed along a central axis of the punching baffle from inside to outside. The structure improves the uniformity of flow velocity distribution of outlet cross-section of the whole plate and improves the heat exchange performance of the heat exchanger.

Owner:WUXI JIALONG HEAT EXCHANGER

Method and Apparatus for Completion of Heavy Oil Unconsolidated Sand Reservoirs

InactiveUS20140096966A1Reduce the impactLess attentionArtificial islandsLiquid/gas jet drillingEngineering

Owner:FREITAG MR GARY

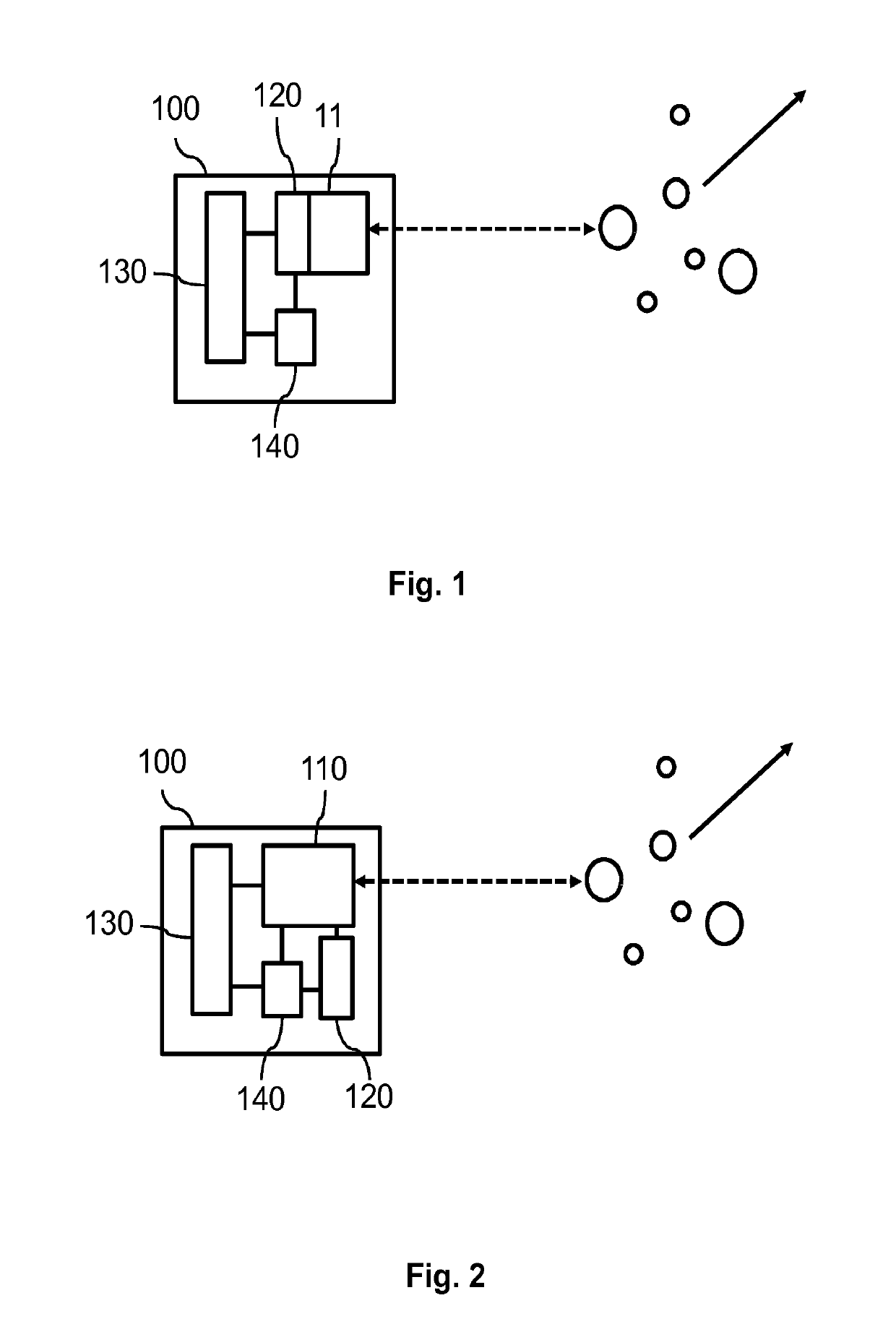

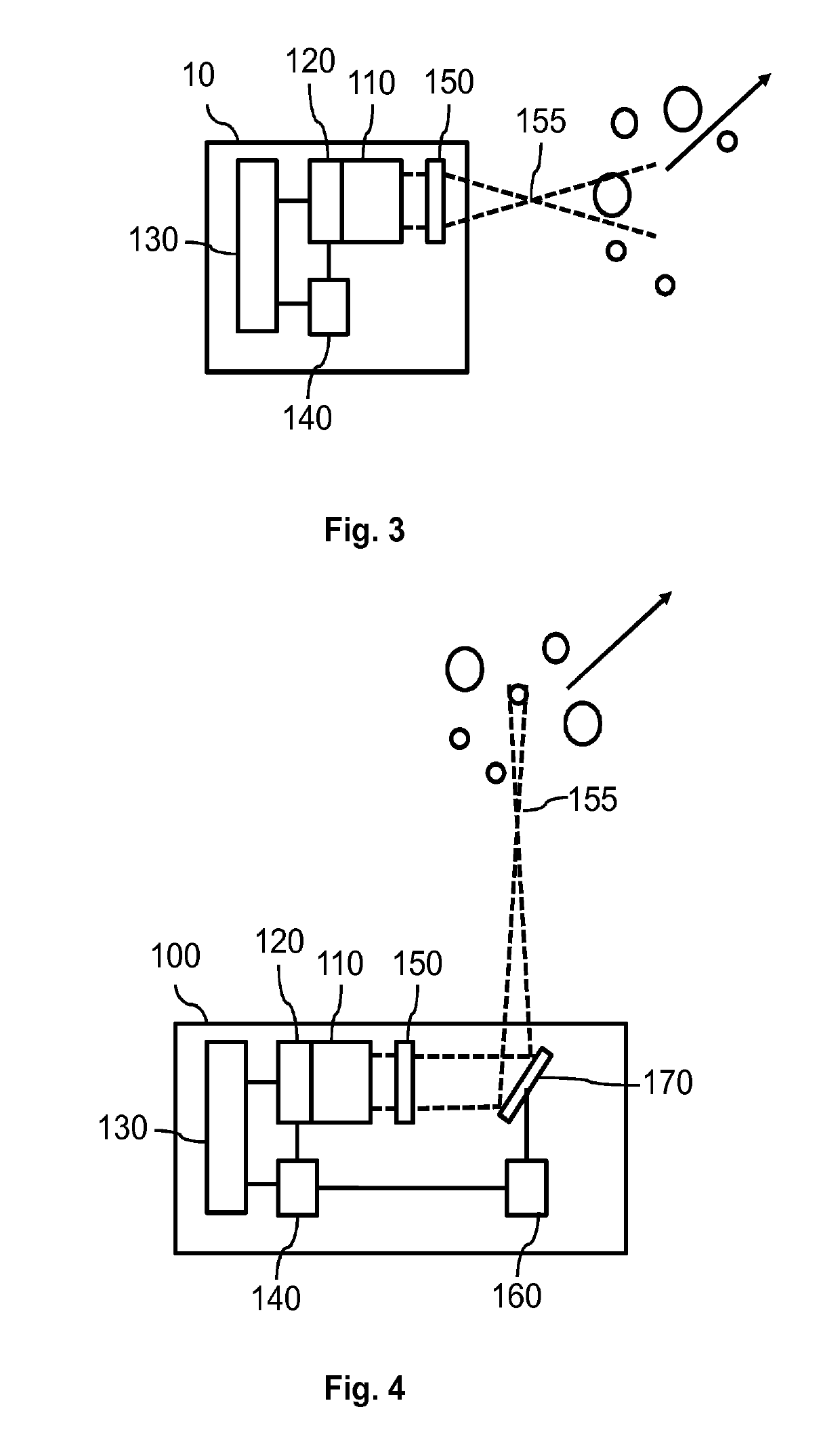

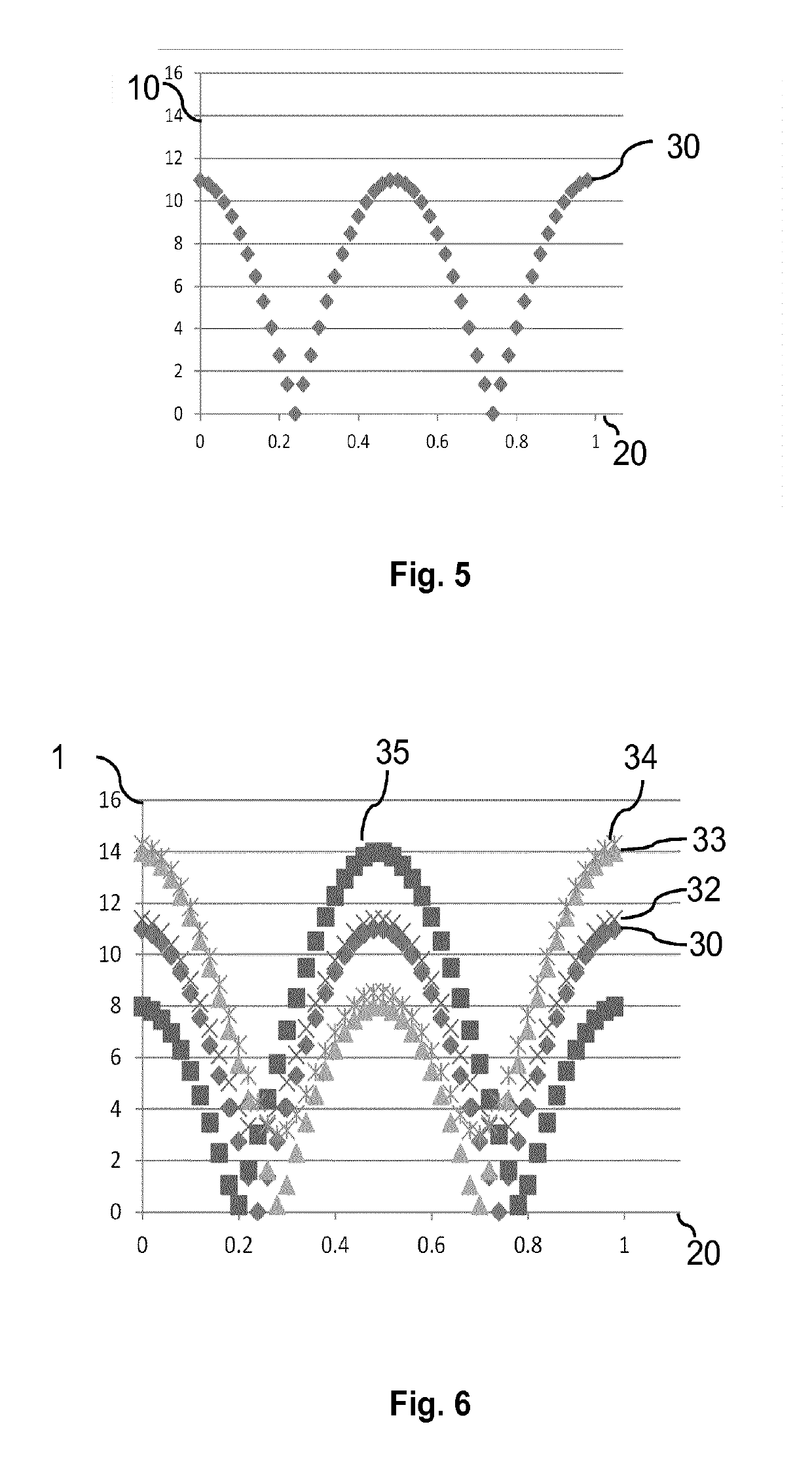

Laser sensor for particle detection

ActiveUS20190285753A1Increase flow resistanceReduce fluid velocityParticle size analysisParticle suspension analysisFluid transportParticle density

The invention describes a laser sensor or laser sensor module (100) using self-mixing interference for particle density detection, a related method of particle density detection and a corresponding computer program product. The invention further relates to devices comprising such a laser sensor or laser sensor module. It is a basic idea of the present invention to detect particles by means of self-mixing interference signals and determine a corresponding particle density. In addition at least a first parameter related to at least one velocity component of a velocity vector of the particles is determined in order to correct the particle density if there is the relative movement between a detection volume and the particles. Such a relative movement may for example be related to a velocity of a fluid transporting the particles (e.g. wind speed). Furthermore, it is possible to determine at least one velocity component of the velocity of the particles based on the self-mixing interference signals.

Owner:PHILIPS PHOTONICS GMBH +1

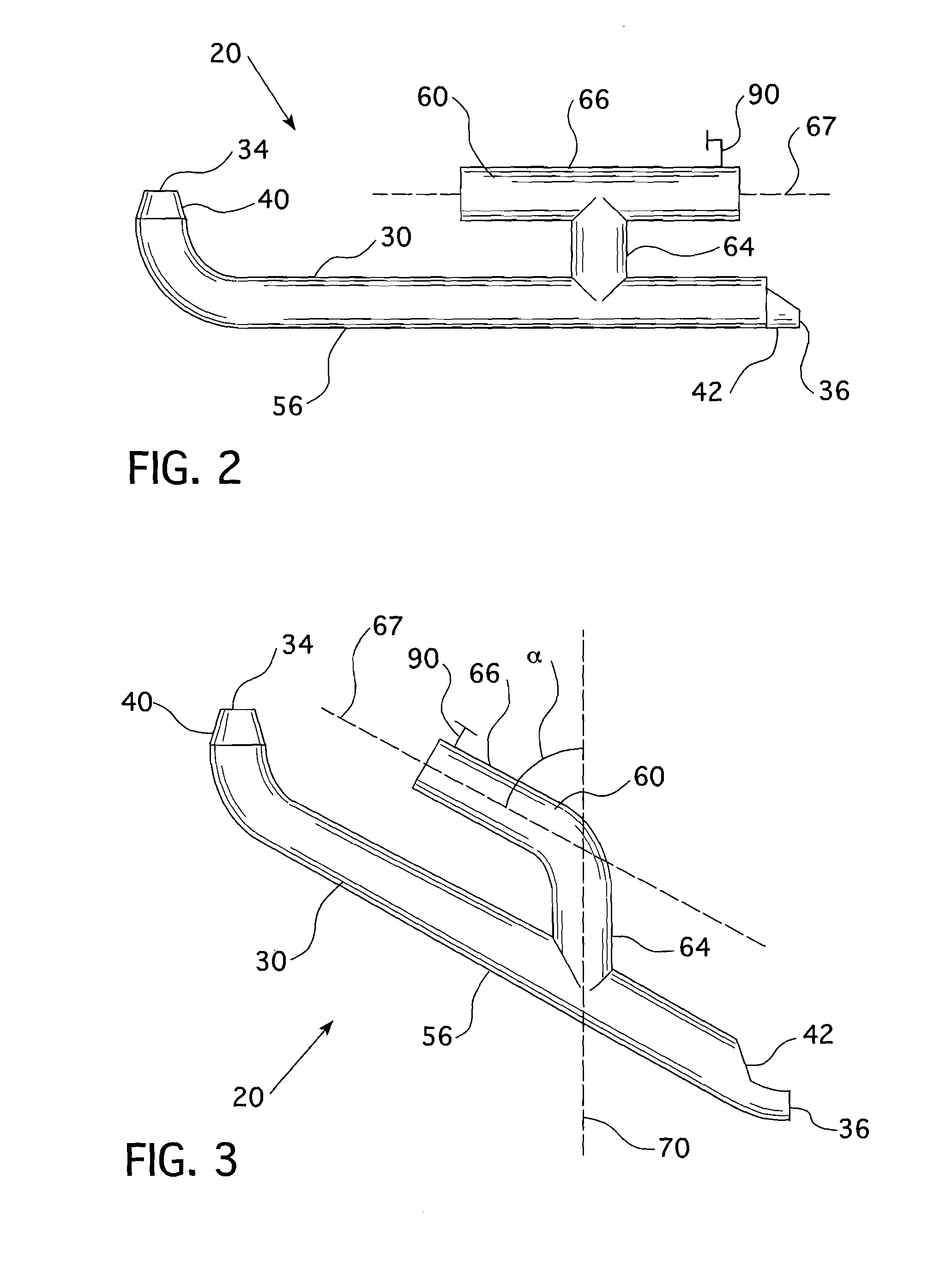

Pump suction gas separator

InactiveUS20110174159A1Increase the diameterReduce gas volumeLiquid degasificationMetal working apparatusEngineeringSlow rate

A gas separator on pipe structured to transport a liquid is provided. The gas separator includes a section of piping, located upstream of a pump, having an increased diameter which is in fluid communication with an overhead pocket. Fluid flow in the portion of the pipe having an increased diameter is at a slower rate than other portions of the pipe. The slower fluid speed allows entrained gasses to stratify and float to the top of the pipe whereupon the gas will flow into the pocket. Thus, the fluid downstream from the gas separator has a reduced amount of gas in the liquid flow.

Owner:WESTINGHOUSE ELECTRIC CORP

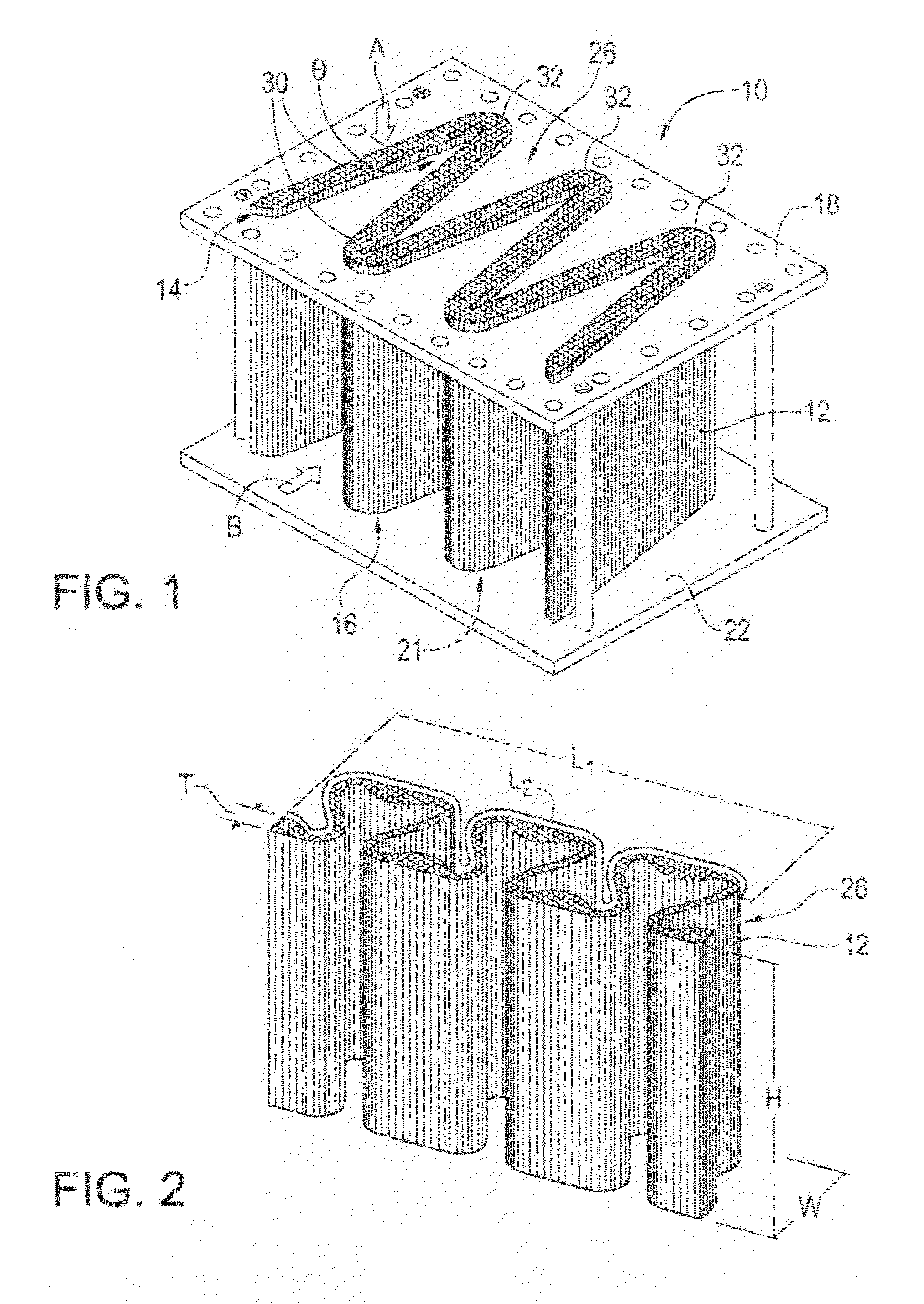

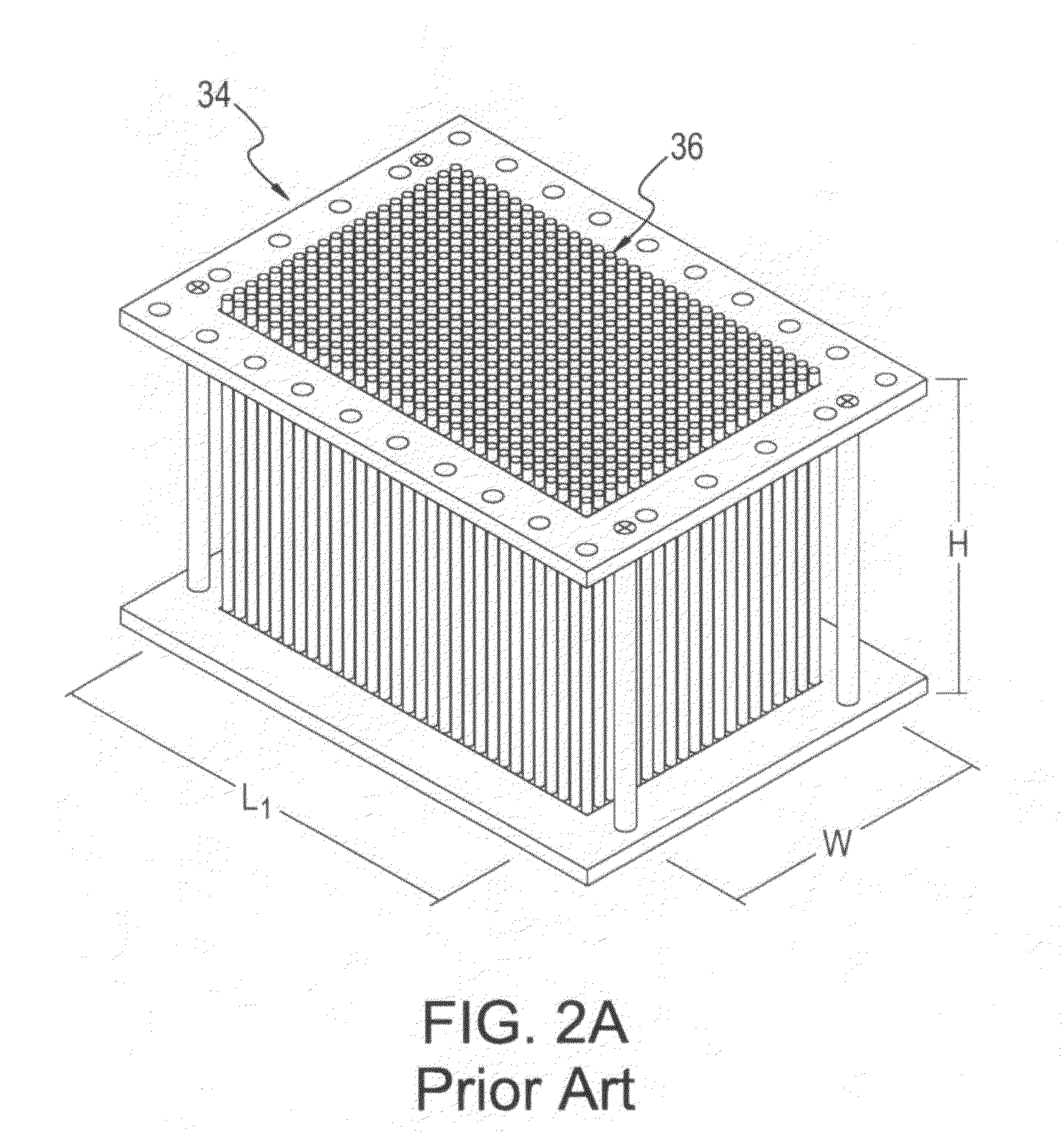

Corrugated Micro Tube Heat Exchanger

InactiveUS20100230081A1Efficient and simple and cost-effectiveRatio deterioratesStationary conduit assembliesHeat exchanger casingsEngineeringMechanical engineering

A heat exchanger device having a plurality of substantially parallel tubes. Each tube has an outer diameter which is less than or equal to one millimeter and further includes a first end portion and a second end portion. A first manifold forms an inlet for the first fluid and further forms a plurality of first openings, whereby each of the first end portions of the parallel tubes is attached in a sealed manner to the first manifold so that each tube is in fluid communication with a respective one of the first openings. A second manifold spaced from and opposing the first manifold forms an outlet for the first fluid and further forms a plurality of second openings, whereby each of the second end portions of the parallel tubes is attached in a sealed manner to the second manifold so that each tube is in fluid communication with a respective one of the second openings. The plurality of substantially parallel tubes are laterally disposed relative to one another so that they form at least one corrugated pattern when viewed in an imaginary plane which intersects and is perpendicular to the longitudinal axes of the tubes.

Owner:INT MEZZO TECH

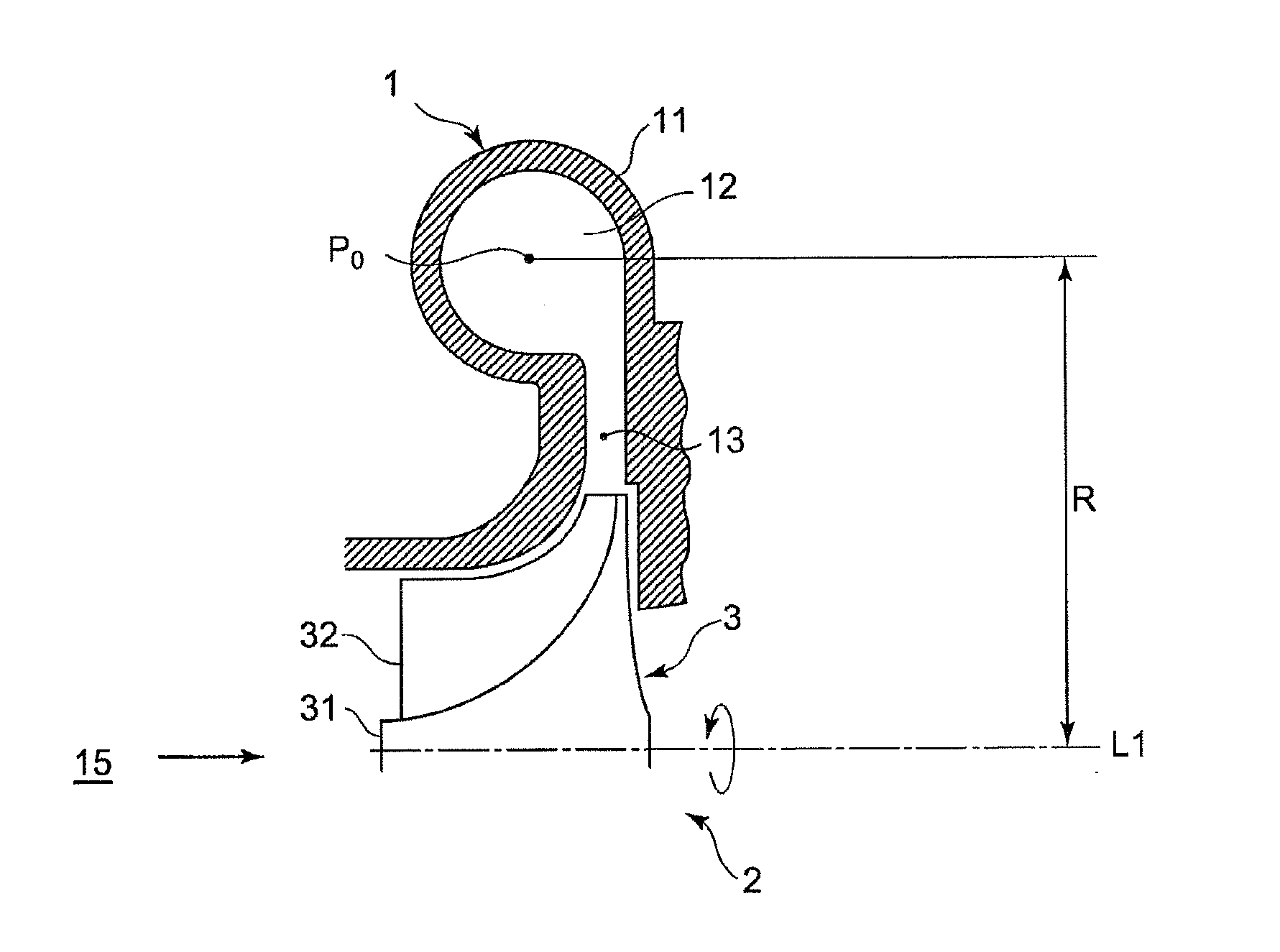

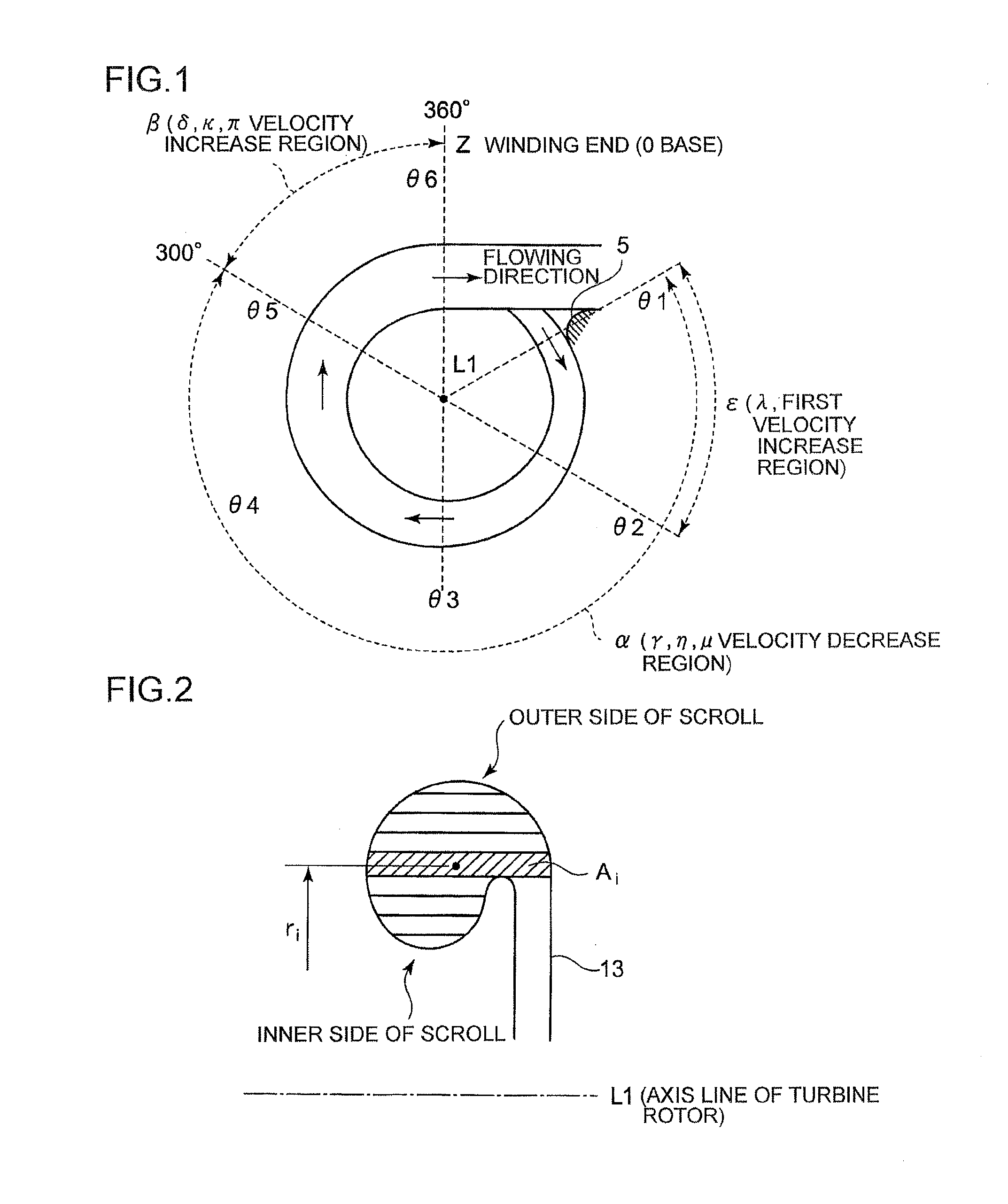

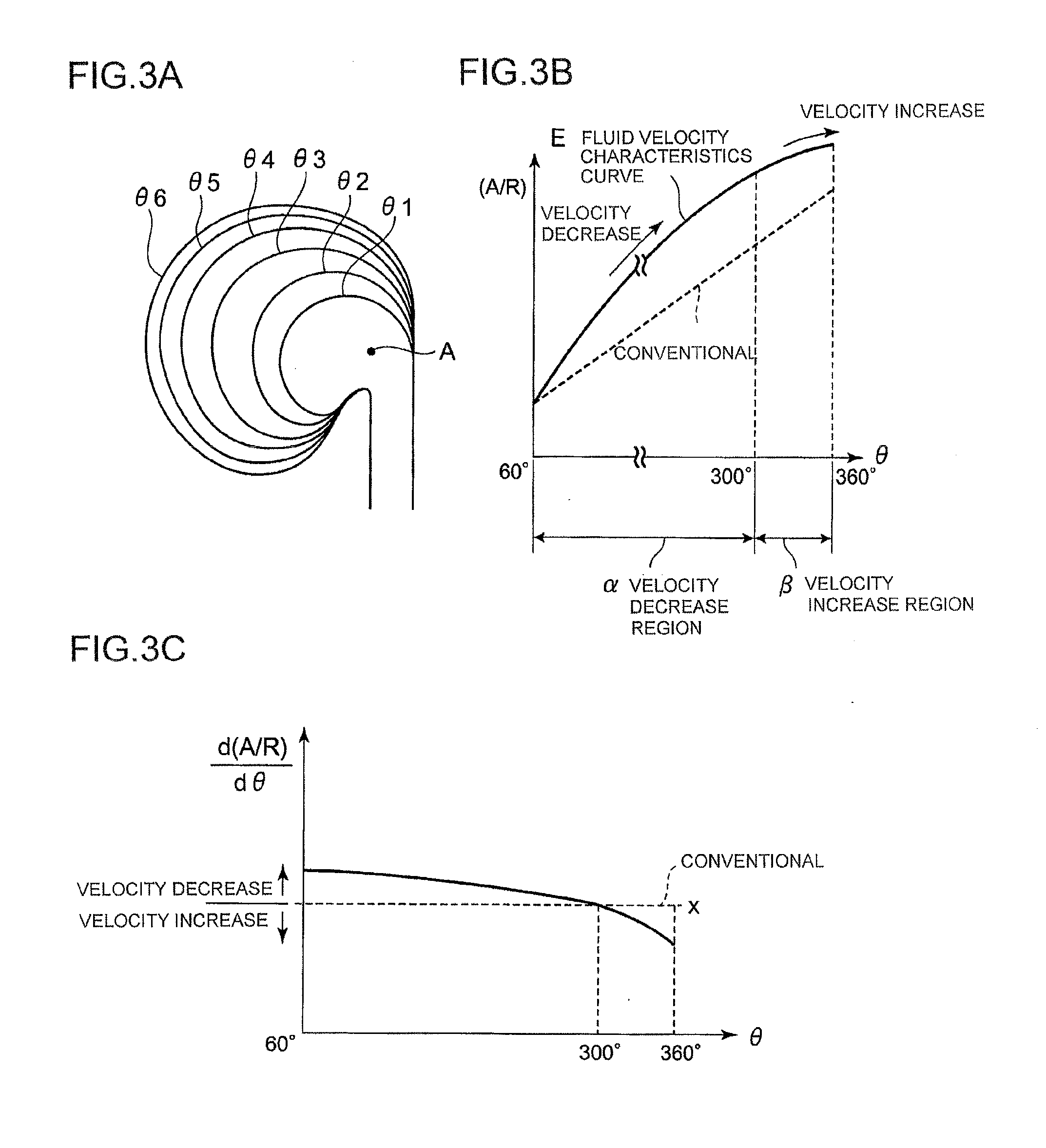

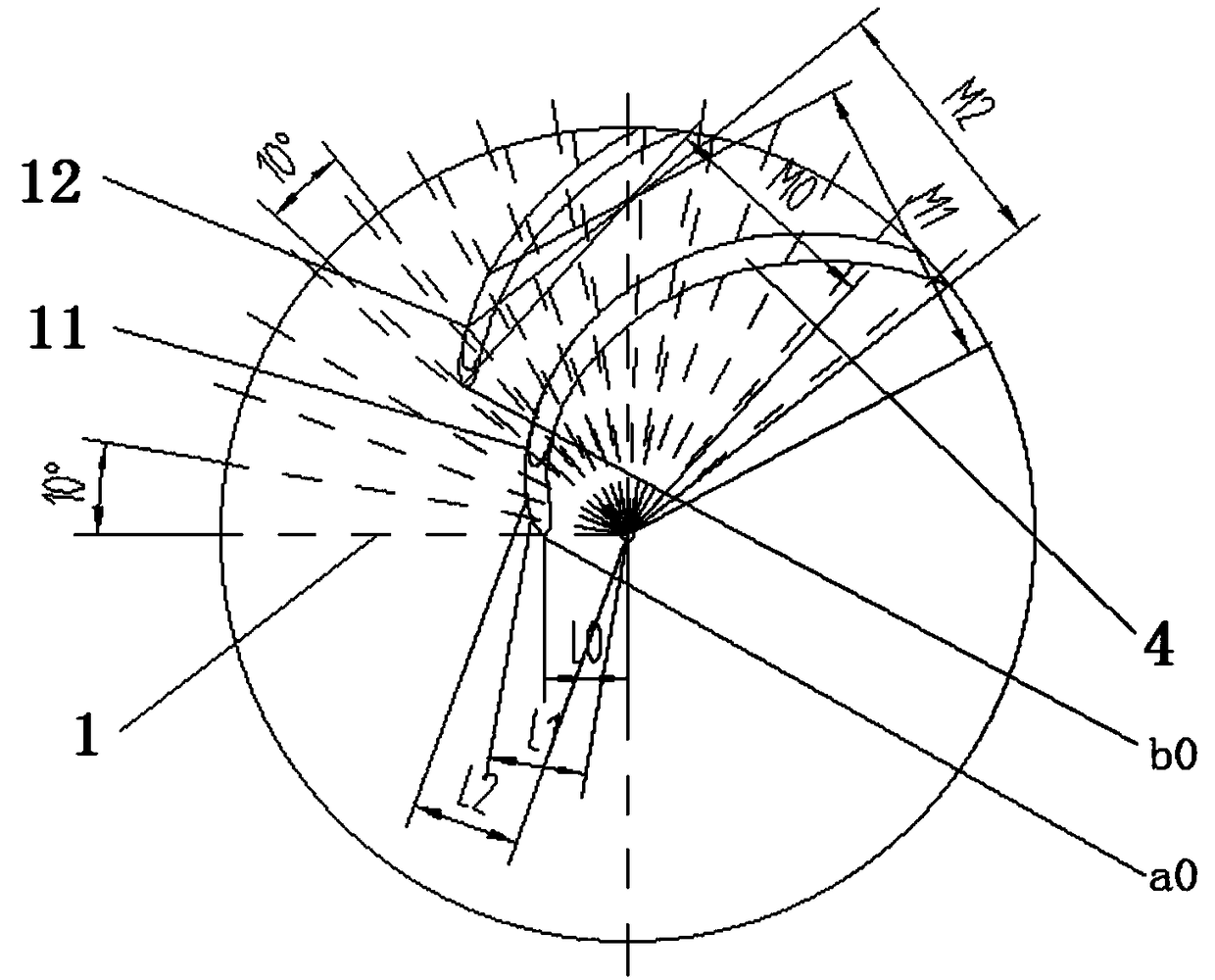

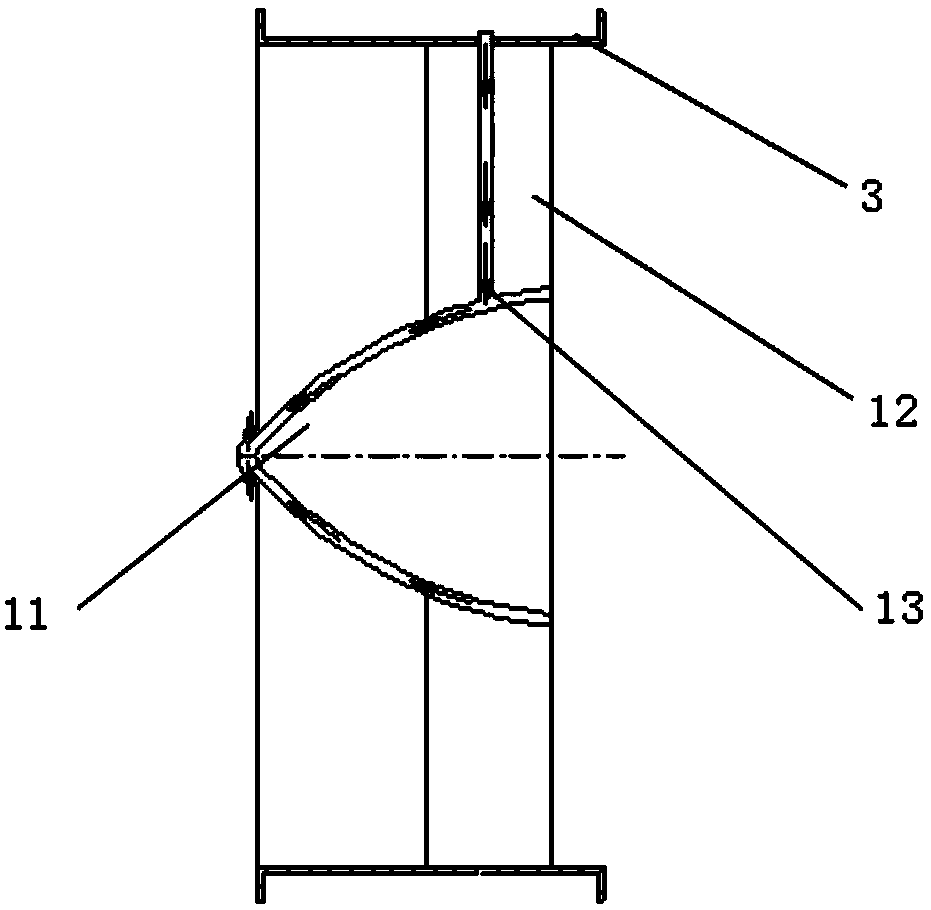

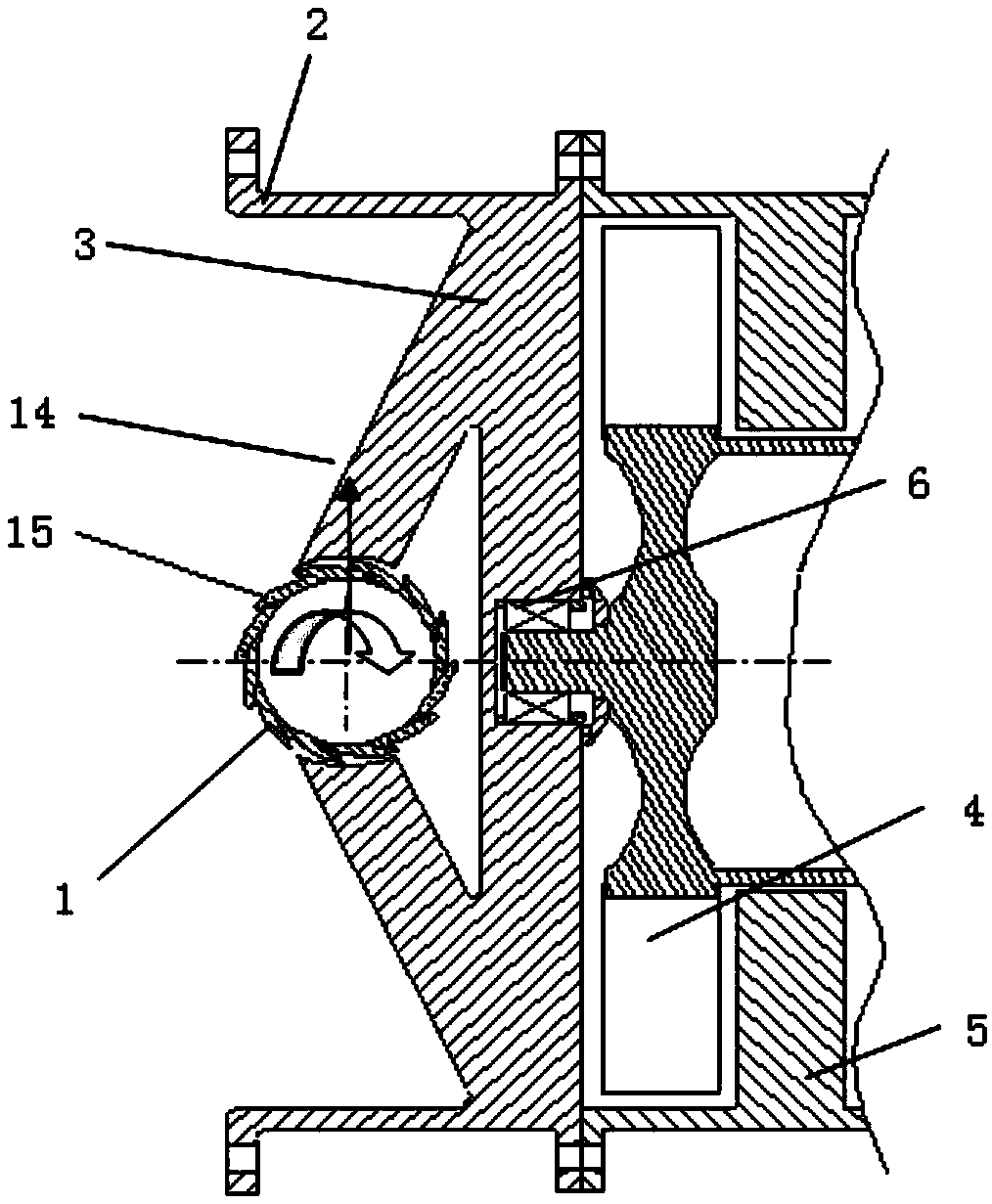

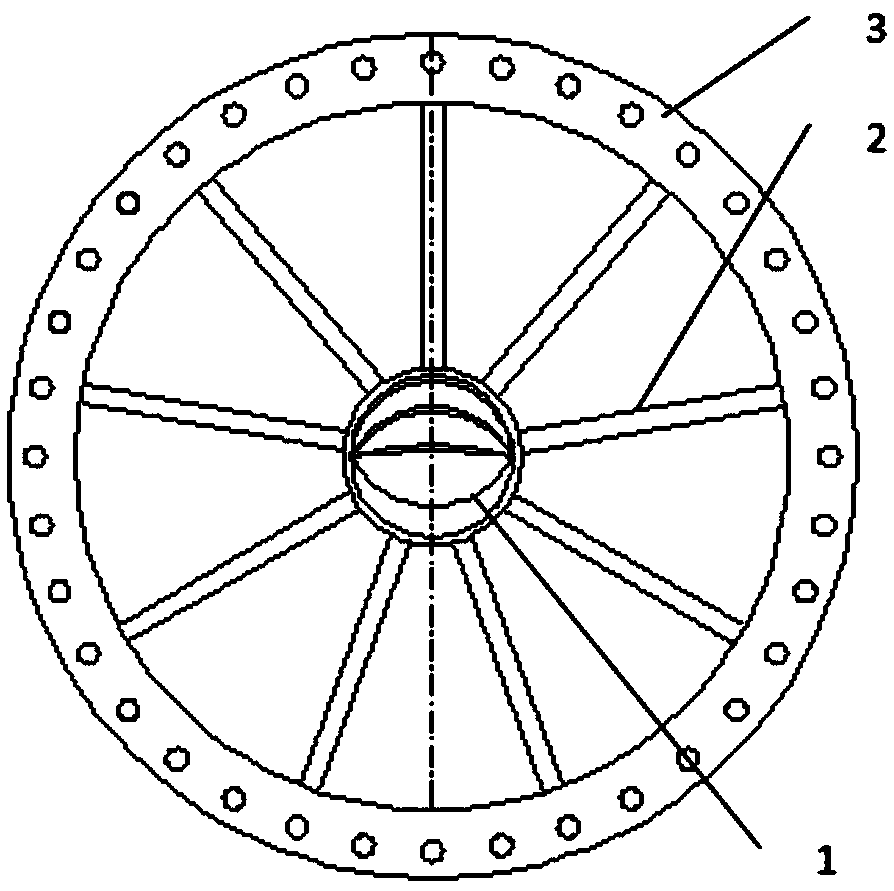

Scroll shape of centrifugal compressor

ActiveUS20130294903A1Area maximizationImprove performanceEngine manufacturePump componentsEngineeringCentrifugal compressor

In a scroll shape of a centrifugal compressor, an enlargement rate of a ratio A / R of a cross-sectional area A of a scroll portion 12 to a radius R from an axis L1 of a compressor impeller 3 to a centroid P0 of a cross section of the scroll portion is reduced from a winding start to a winding end of the scroll portion.

Owner:MITSUBISHI HEAVY IND LTD

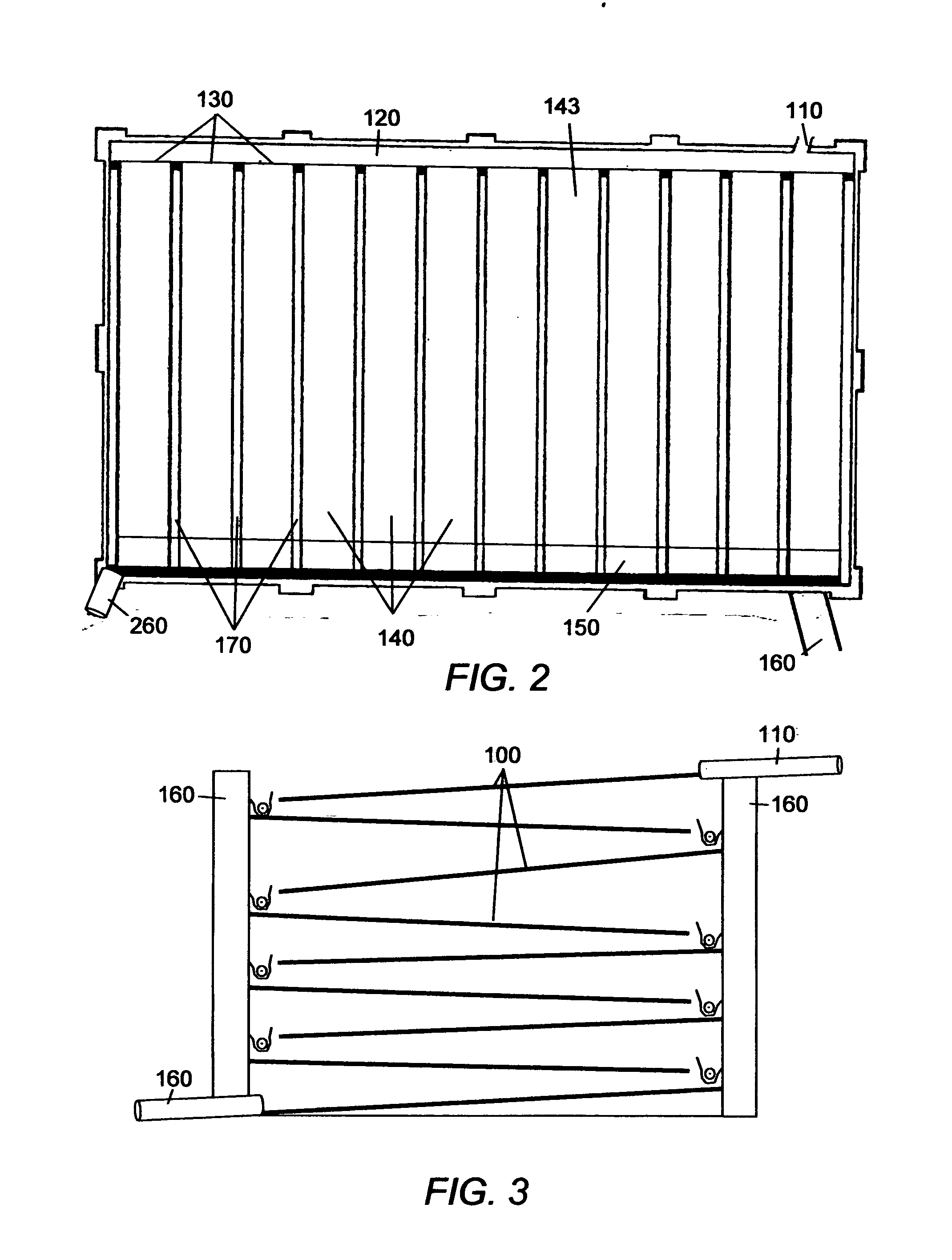

Reduction of Recirculation in Catheters

ActiveUS20120089115A1Reduce the average velocityPrevent sprayingMedical devicesCatheterDistal portionHemodialysis Catheter

A catheter tip designed to reduce the outflow velocity and / or directional momentum of fluid being infused by a catheter having such a tip. In one variation, a plurality of channels is provided at the distal portion of the catheter to increase the outflow cross-sectional area. In another variation, the diameter of the catheter at its distal portion where the fluid exits is increased. In yet another variation, a bullet-shaped nose is implemented which may decrease turbulence at the distal end of catheter tip. The low velocity outflow catheter tip may also be implemented on a dual lumen catheter, such as a hemodialysis catheter, to reduce recirculation rate. Various device configurations and methods for such implementations are also disclosed.

Owner:CR BARD INC

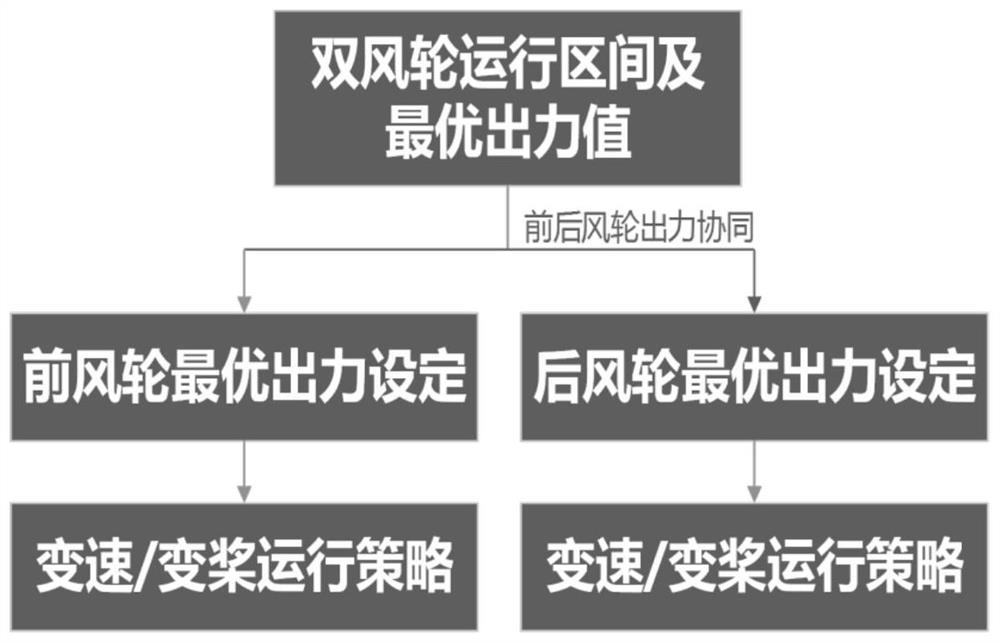

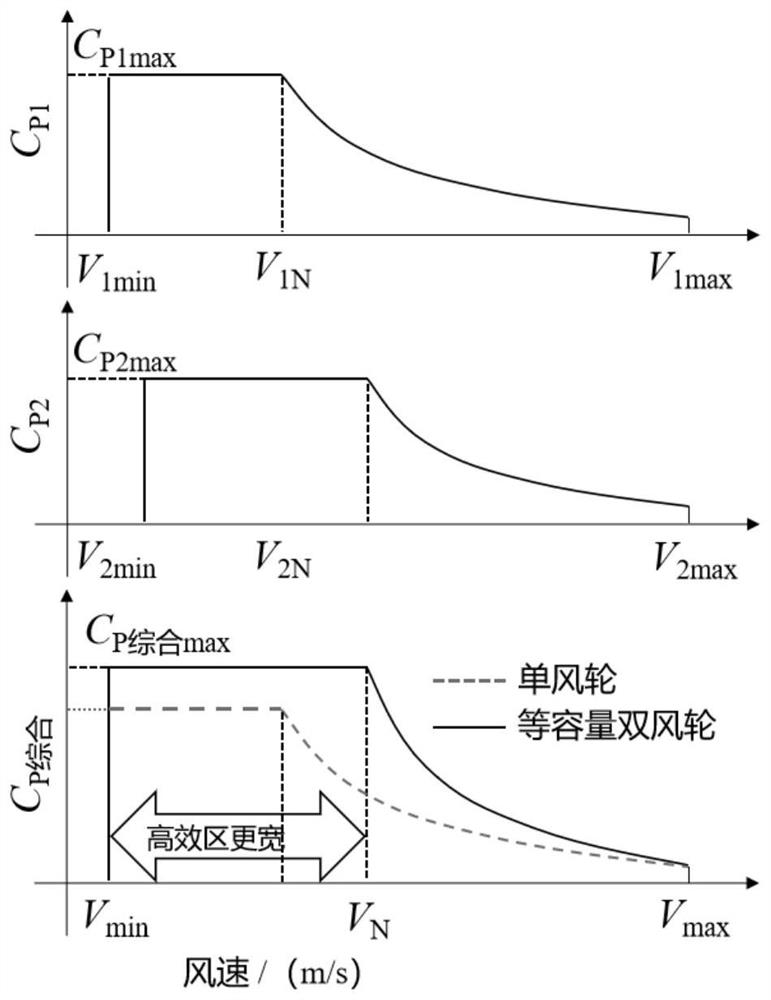

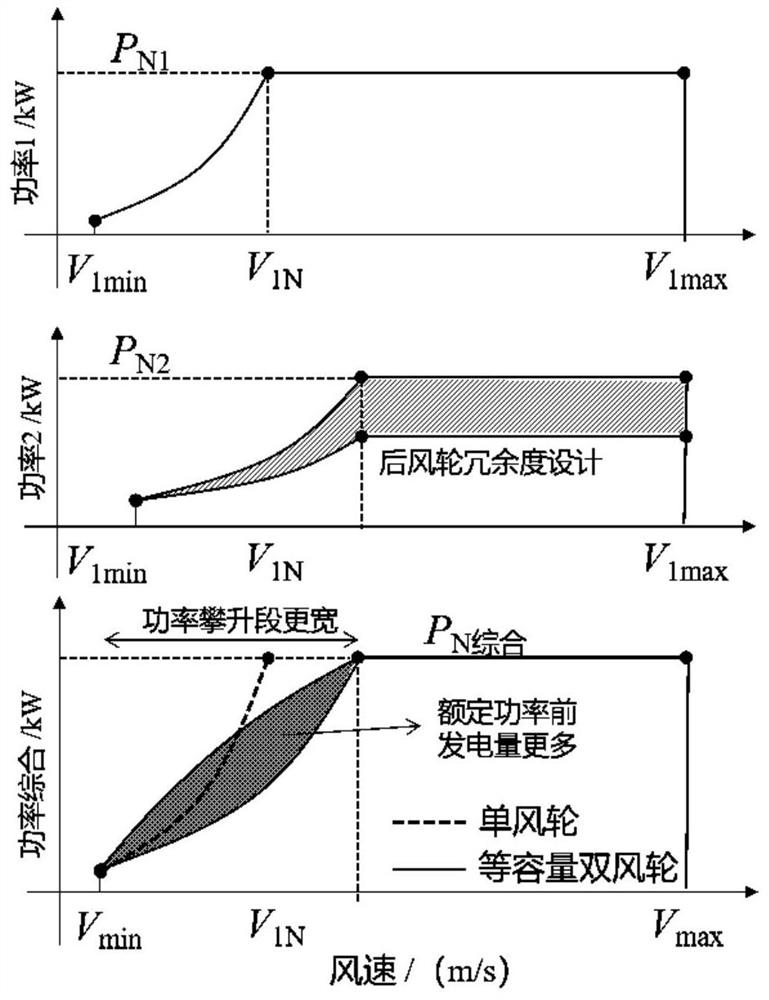

Cooperative control method for tandem double-wind-wheel wind turbine generator set

ActiveCN112648141AImprove machine efficiencyReduce electricity costsWind motor controlMachines/enginesControl engineeringGrid connection

The invention discloses a cooperative control method for a tandem double-wind-wheel wind turbine generator set, and belongs to the technical field of wind power control. The problems that an existing tandem double-wind-wheel wind turbine generator set is not decoupled in operation and low in operation efficiency are solved. The tandem double-wind-wheel wind turbine generator set front and back wind wheel cooperative control strategy with transmission decoupling is provided, firstly, after operation intervals of front and back wind wheels are divided and the optimal output value is determined, the maximum overall output of the wind turbine generator set serves as the target, and output cooperative control over the front wind wheel and the rear wind wheel is carried out by adjusting the rotating speeds and pitch angles of the front wind wheel and the rear wind wheel. According to the cooperative control method for the tandem double-wind-wheel wind turbine generator set, the highest overall efficiency and the lowest load of the unit are taken as control targets, the front and rear wind wheels cooperate with each other, so that the unit is higher in efficiency, wider in high-efficiency area and more friendly in grid connection, the kilowatt-hour cost of the wind turbine generator set can be greatly reduced, and the grid connection characteristic of the unit is improved.

Owner:HUANENG CLEAN ENERGY RES INST +1

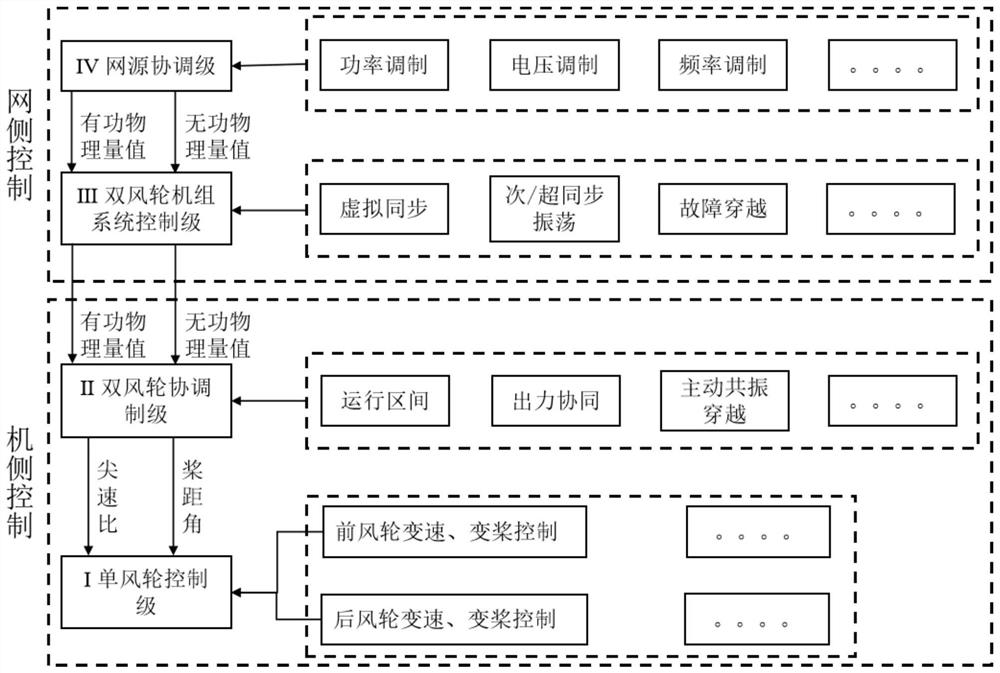

Four-stage hierarchical control method for tandem double-wind-wheel wind turbine generator

ActiveCN112664390AReduce electricity costsImprove grid connection characteristicsWind motor controlMachines/enginesControl engineeringUnit system

The invention discloses a four-stage hierarchical control method for a tandem double-wind-wheel wind turbine generator, and belongs to the technical field of wind power control. Four-stage hierarchical control logic is adopted, and through a four-stage control framework of a single-wind-wheel control stage, a two-wind-wheel coordination control stage, a double-wind-wheel unit system control stage and a network source coordination stage, complete protection control logic is formed from a double-wind-wheel unit network source side to a unit side, a cooperative control side and a single-wind-wheel side in a layer-by-layer progressive mode. The four-stage hierarchical control aims at optimal unit output and lowest load and cooperatively controls double-wind-wheel output, so that the unit efficiency is higher, grid connection is more friendly, the wind energy utilization rate is increased, the kilowatt-hour cost of the wind turbine generator is greatly reduced, and the grid connection characteristic of the unit is improved.

Owner:HUANENG CLEAN ENERGY RES INST +1

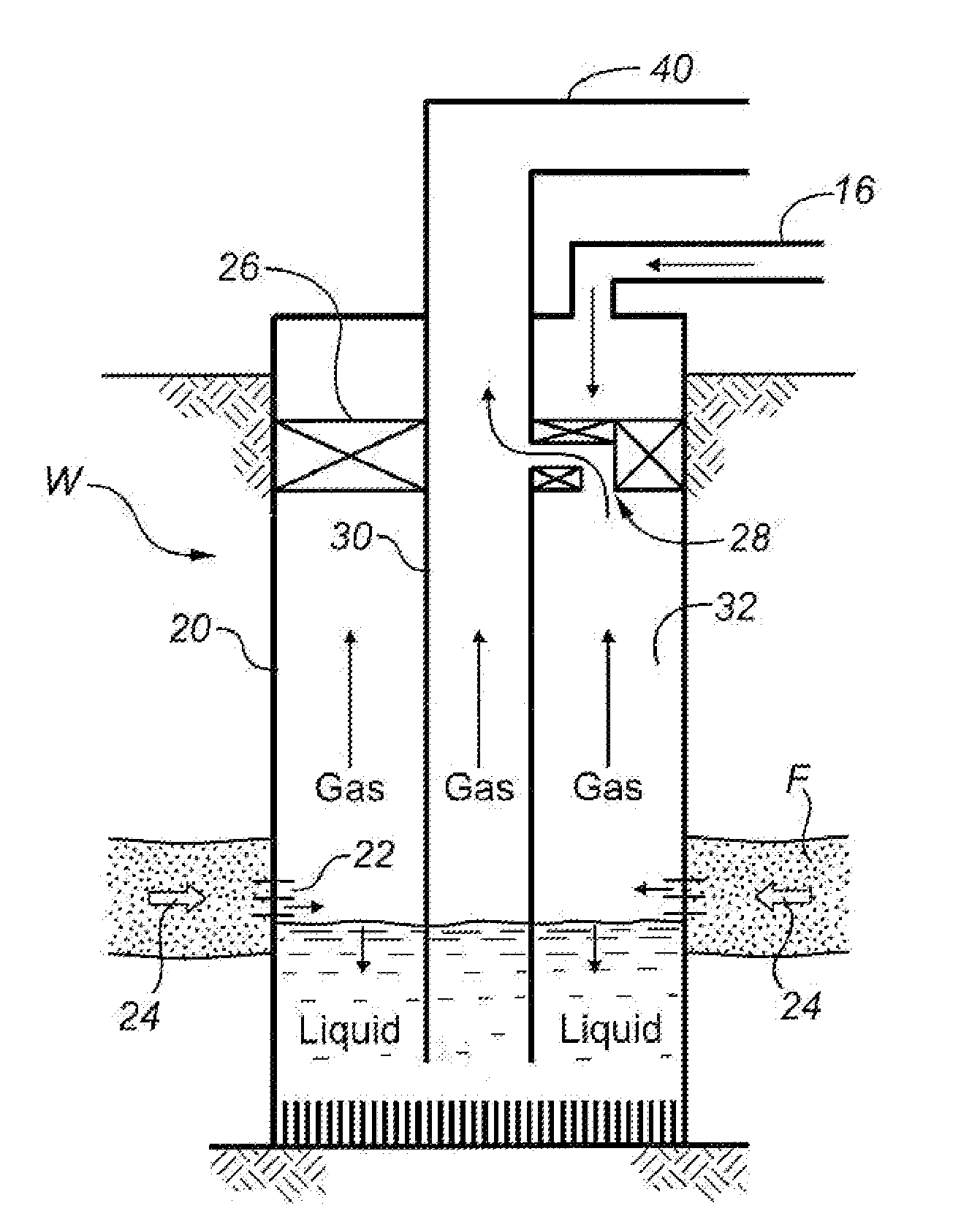

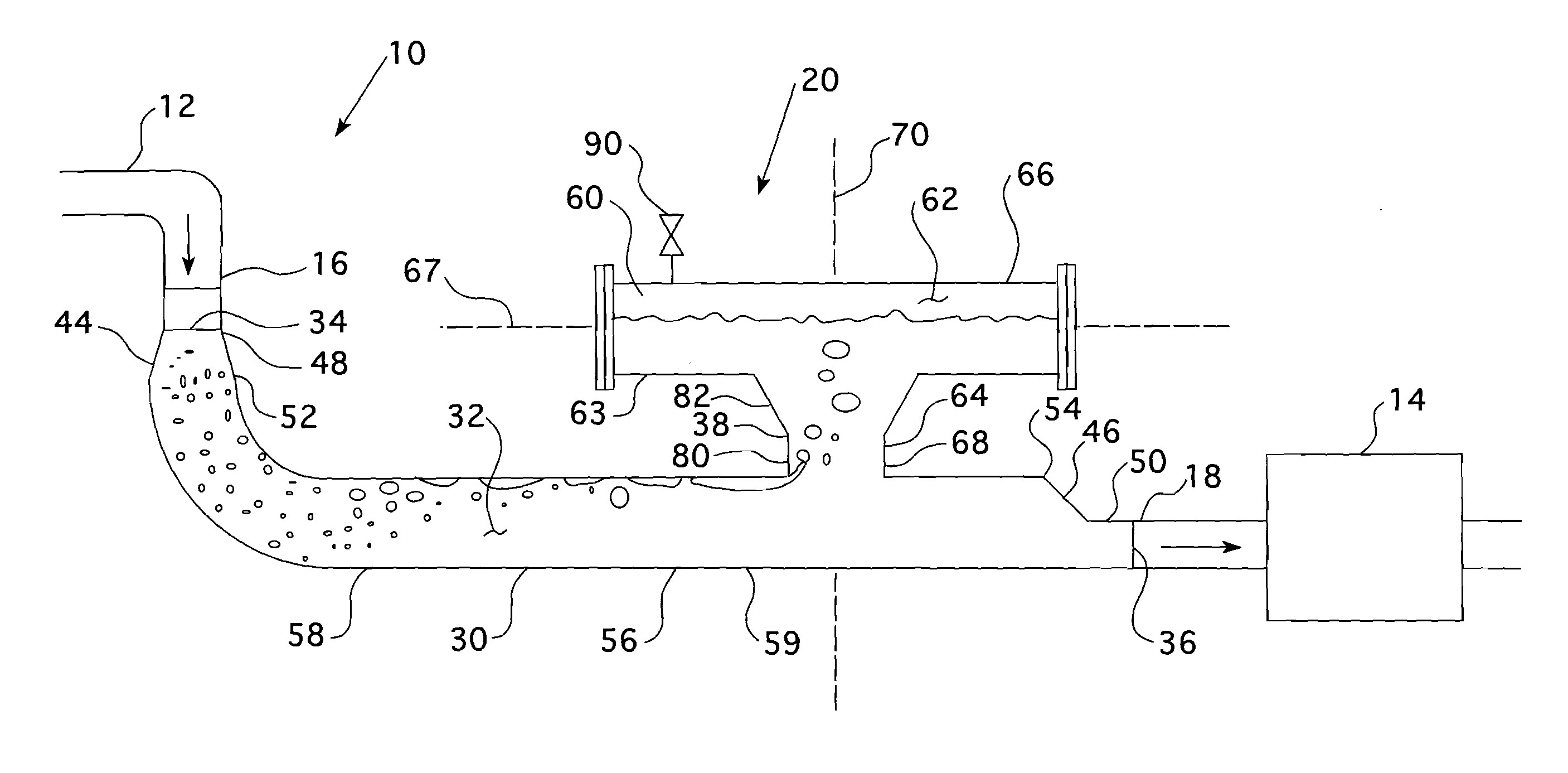

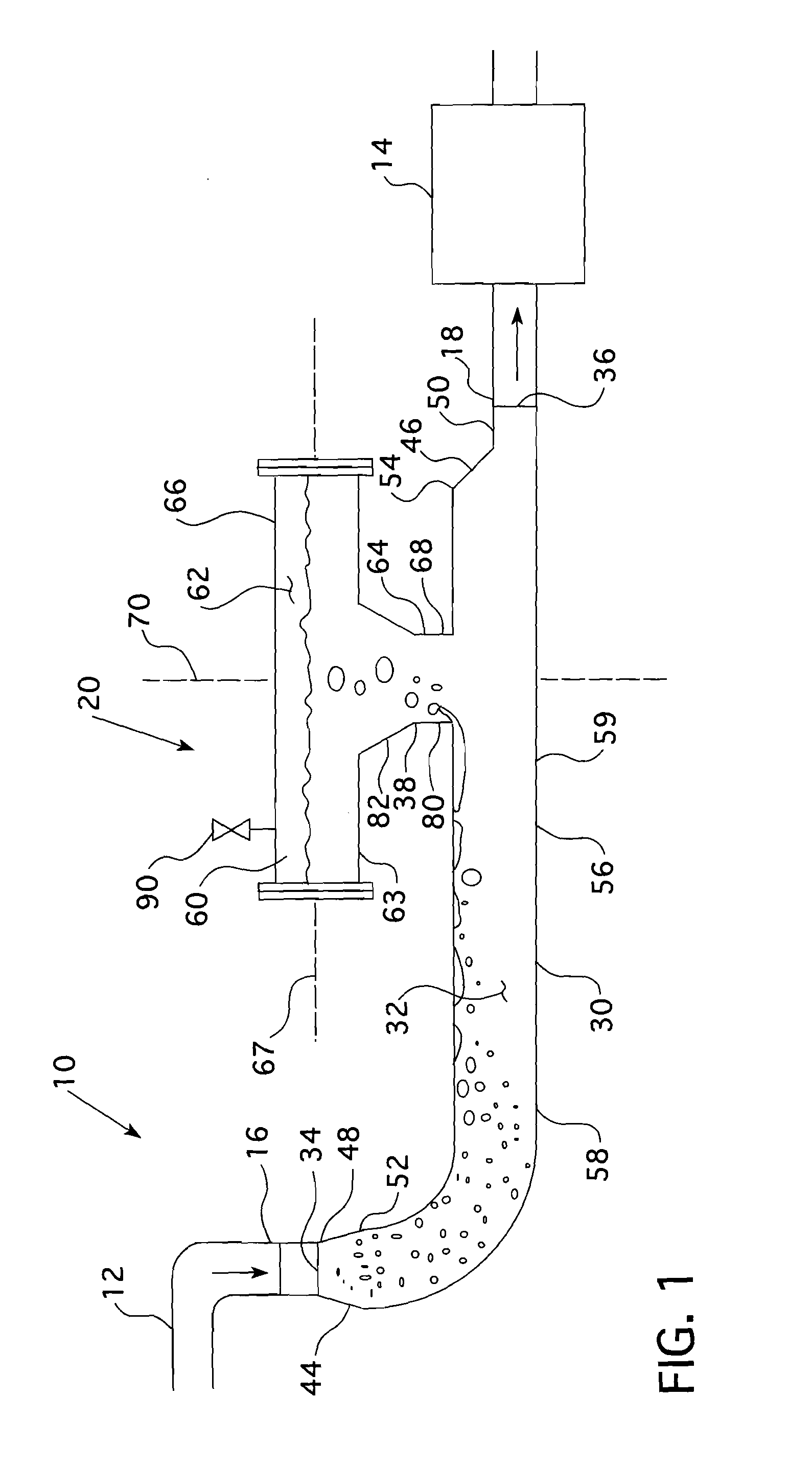

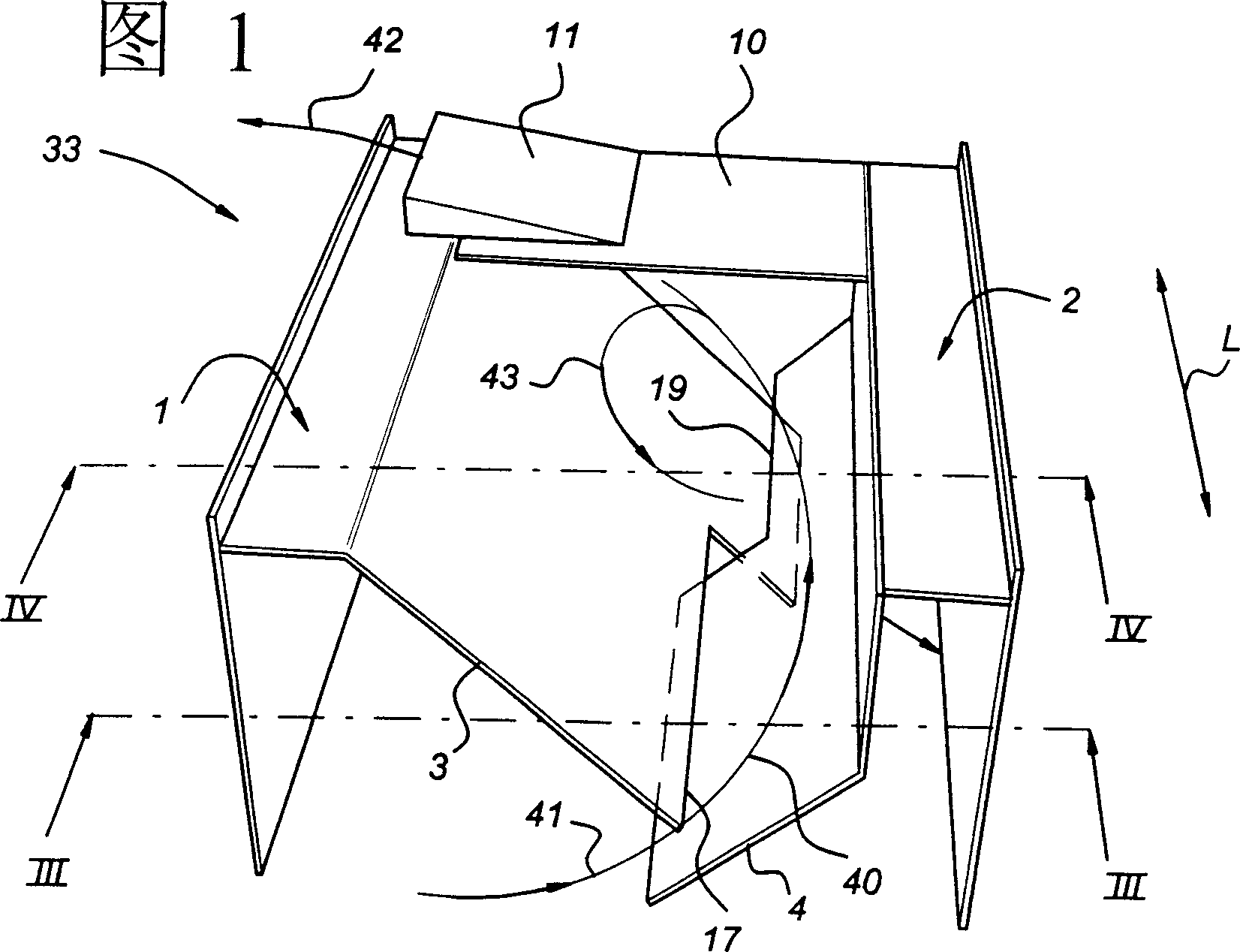

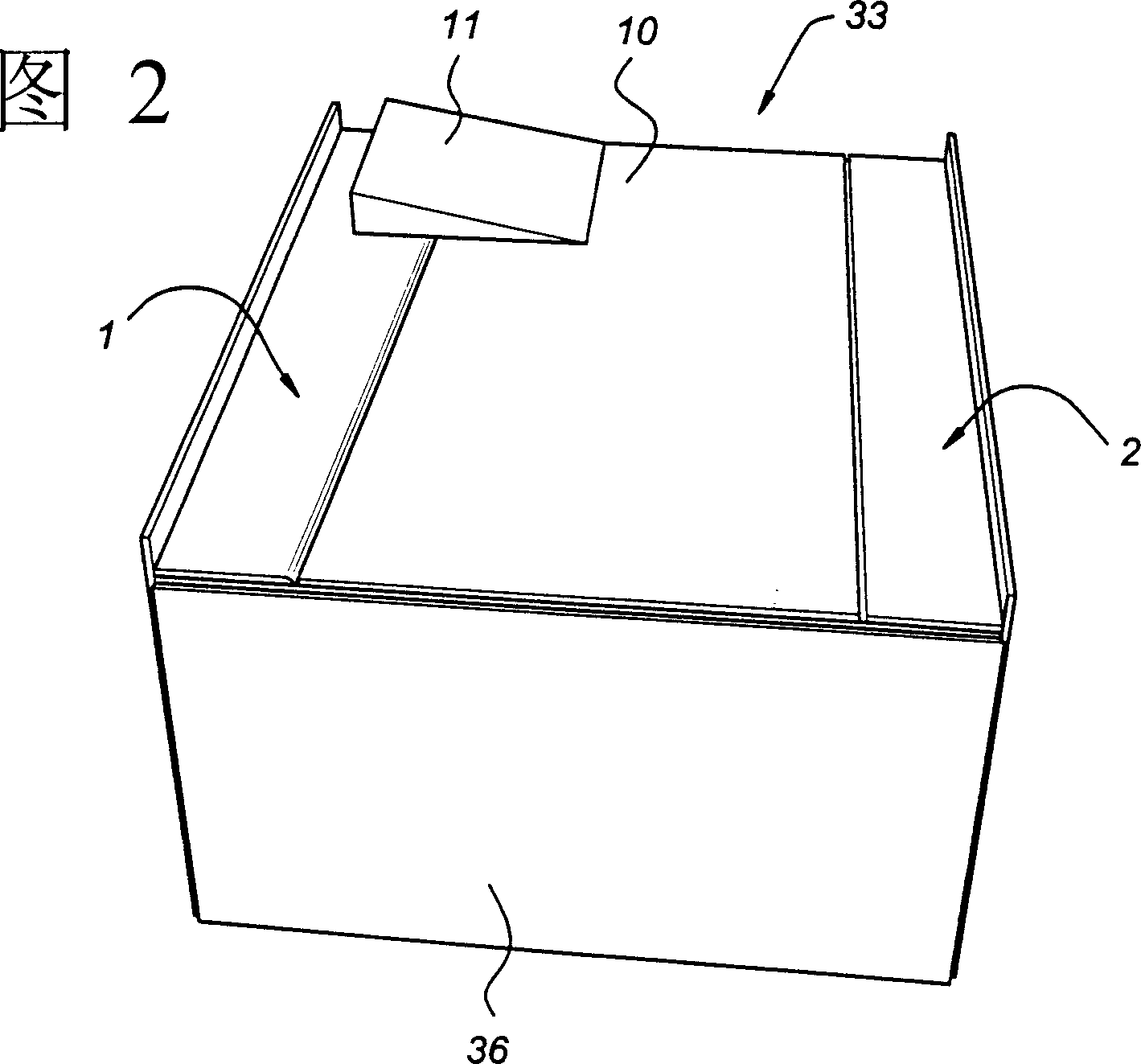

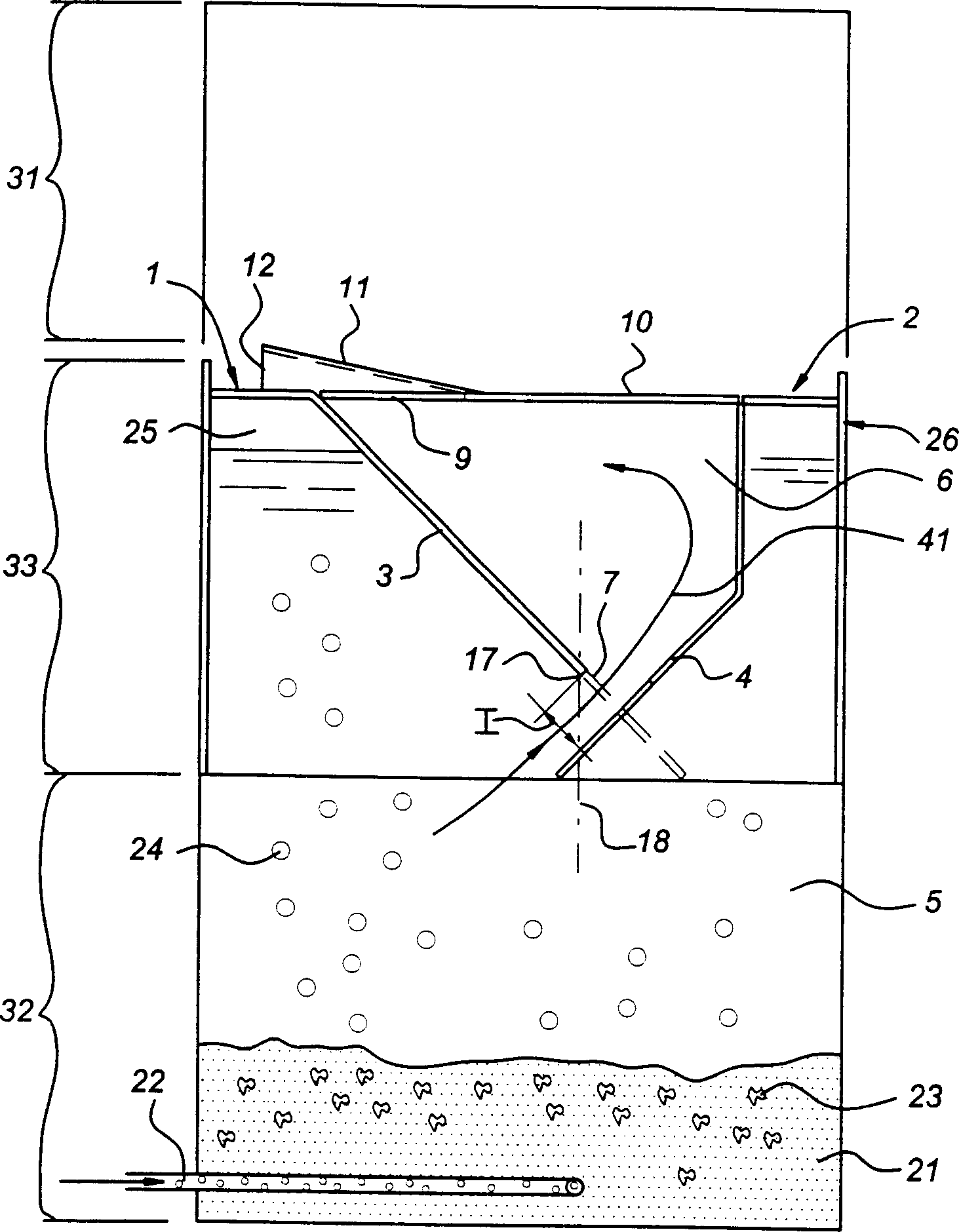

Three-phase separator and device for biological sewage purification

InactiveCN1406879AReduce fluid velocityTreatment using aerobic processesGas production bioreactorsInlet channelSewage

The present invention relates to a three-phase separator (33) for separating off from a fluid gas and particles contained therein, comprising at least one pair of two gas collection caps (1, 2) extending in a horizontal longitudinal direction (L) and each having a plate section (3, 4). The plate sections converge in the downward direction. At the bottom ends the plate sections leave an inlet passage (7), elongated in the longitudinal direction, for the fluid containing particles and an outlet passage (8), elongated in the longitudinal direction, for settled particles. A discharge opening (9) for fluid, opening into the settling chamber, is provided at a level higher than the inlet and outlet passages. The inlet passage (7) and the outlet passage (8) are located in the extension of one another, viewed in the longitudinal direction. The surface area of the inlet passage is preferably greater than the surface area of the outlet passage. The discharge opening is provided level with or beyond the outlet passage.

Owner:PAQUES I P

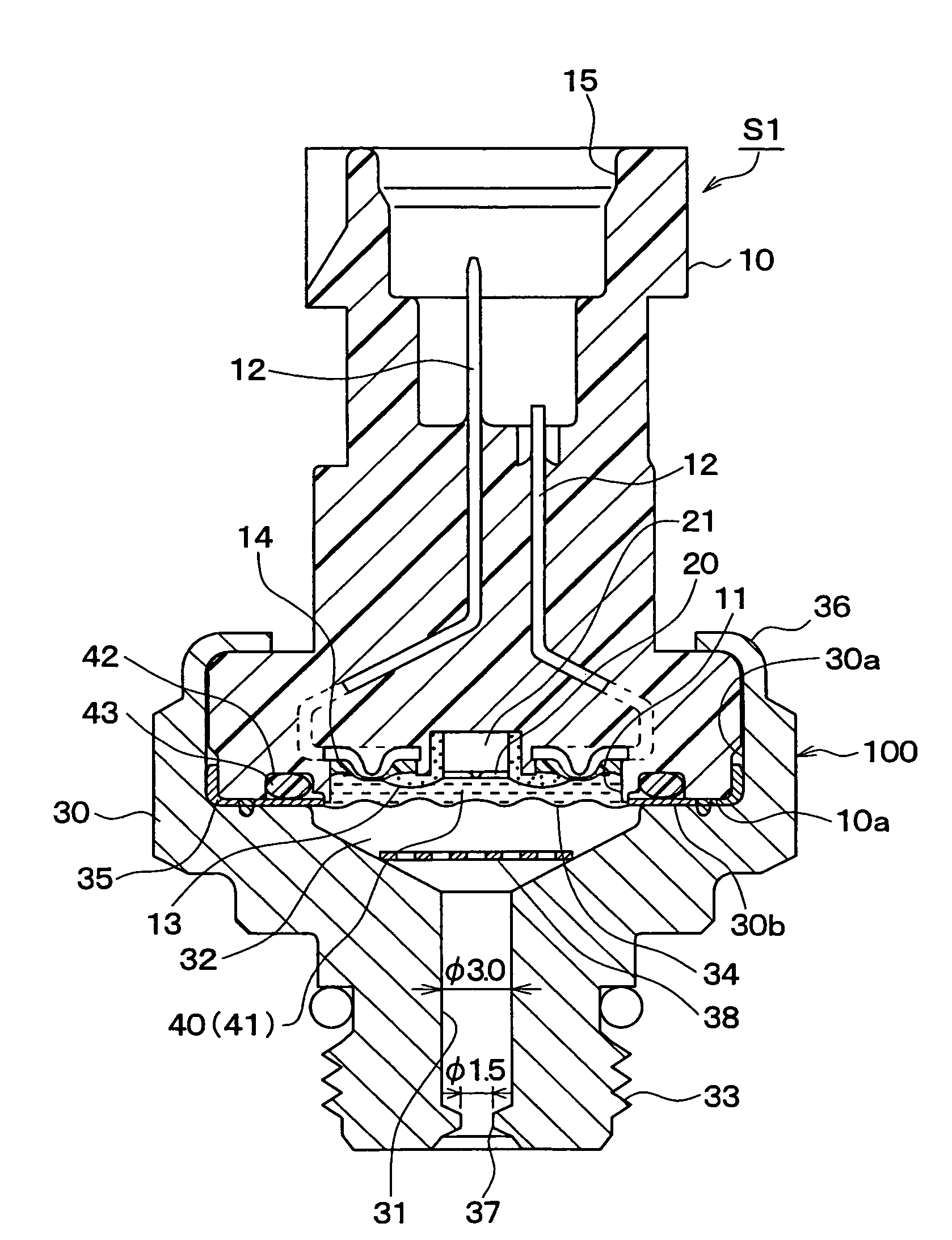

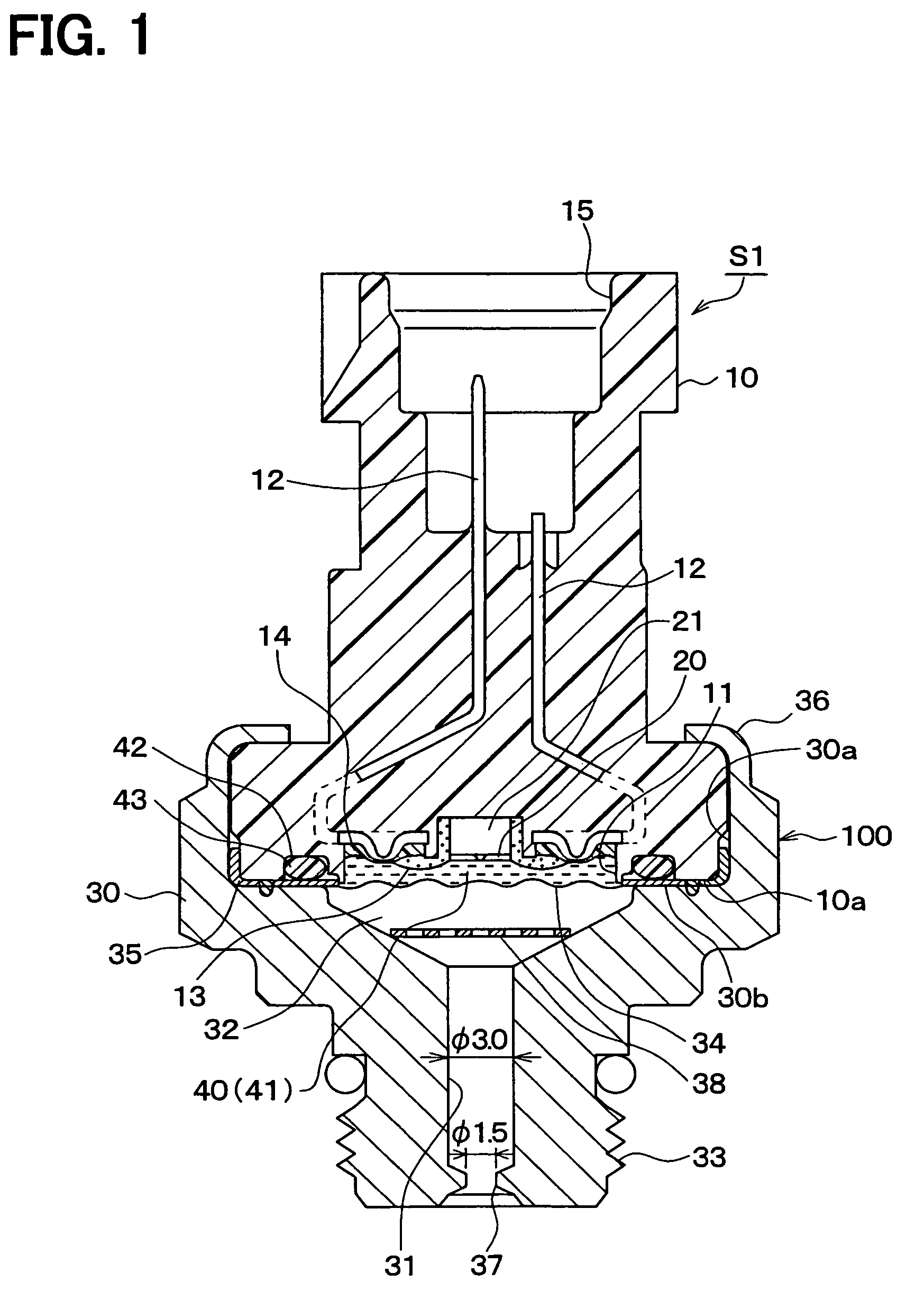

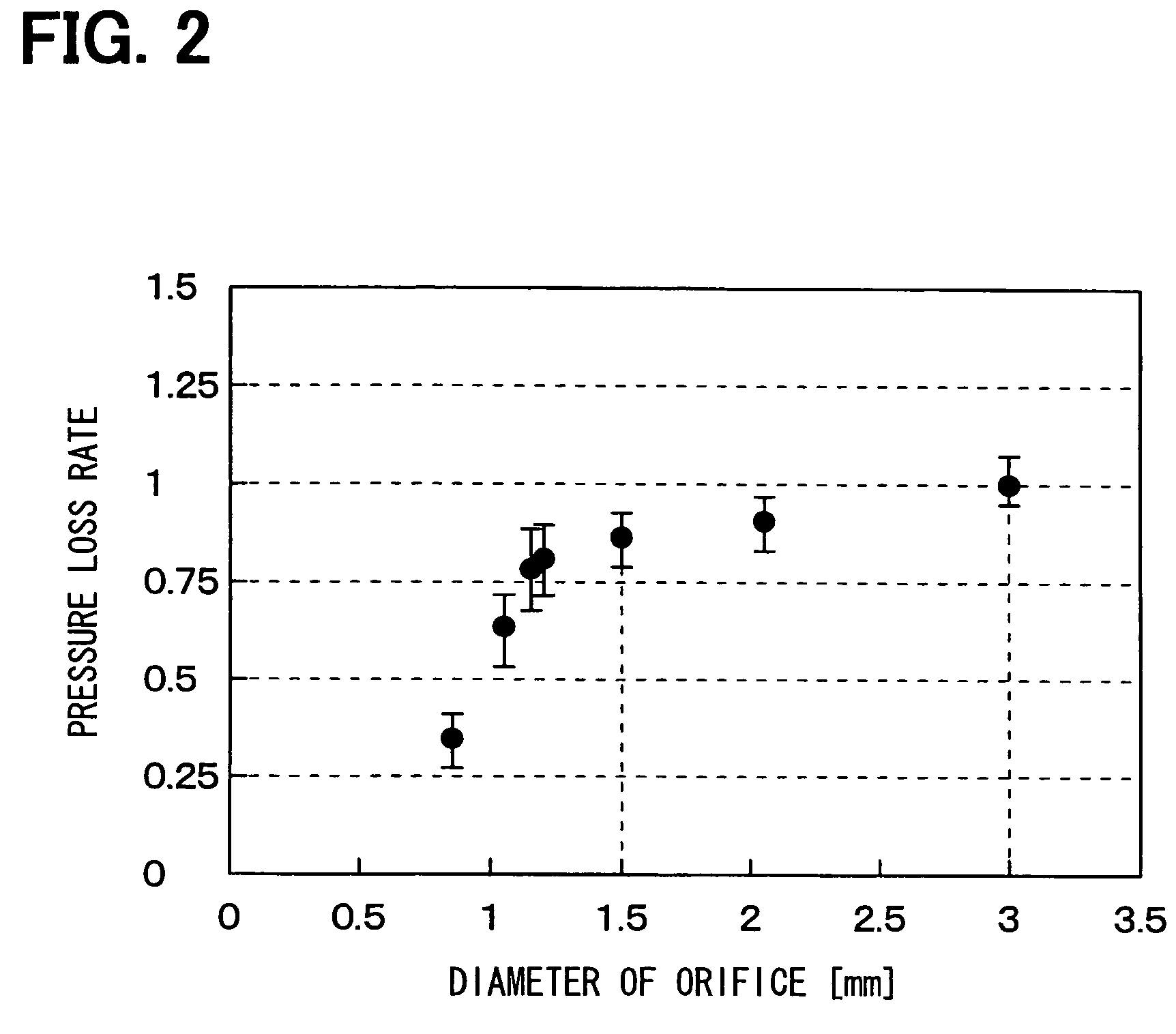

Pressure sensor

InactiveUS7340959B2Prevents unevenness of applied pressureReduce the cross-sectional areaFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsPressure senseBiomedical engineering

A pressure sensor includes a casing formed with a first case and a second case that has a pressure introduction hole for introducing a measurement object, a pressure sensing portion in the casing and a metal diaphragm disposed between an end face of the first case and a reception face of the second case. The measurement object is introduced into a subspace that is formed as an expanded end of the pressure introduction hole in the second case for measurement of pressure by transmitting the pressure through the diaphragm to the pressure sensing portion, and the pressure sensing hole has an orifice that reduces a cross-sectional area of the pressure sensing hole.

Owner:DENSO CORP

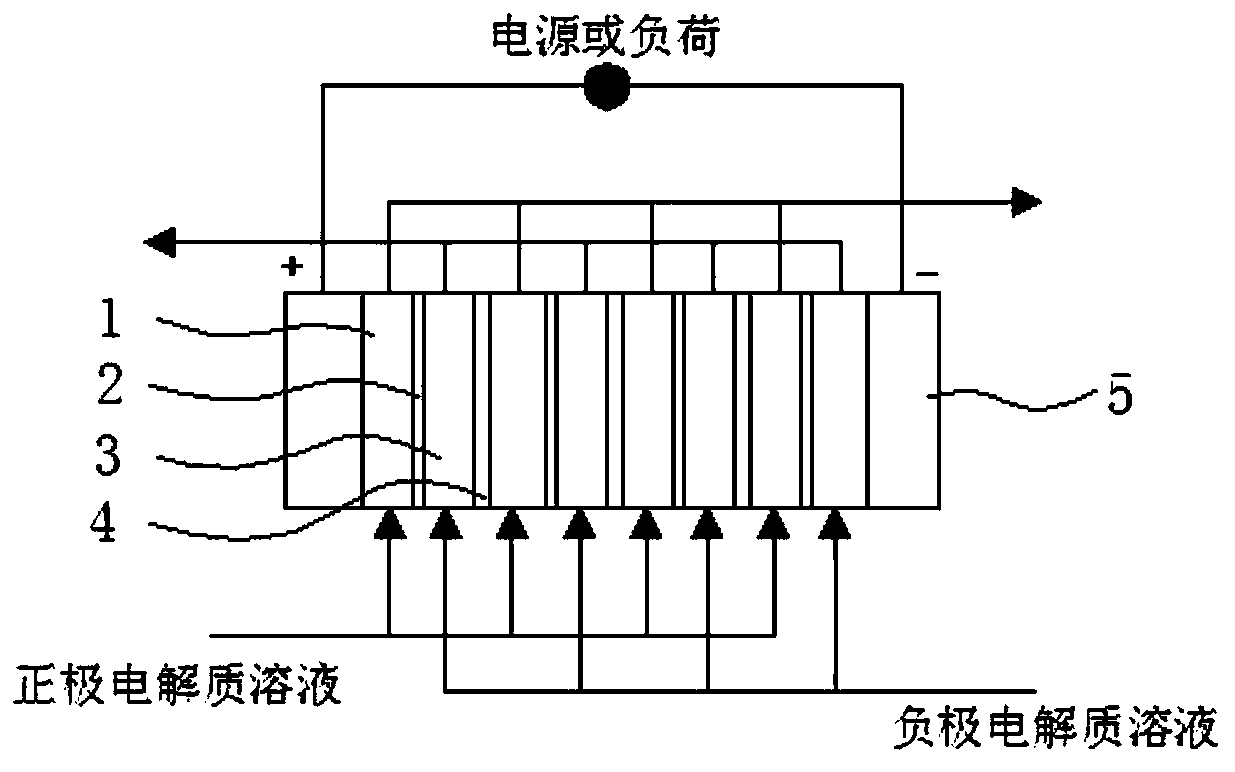

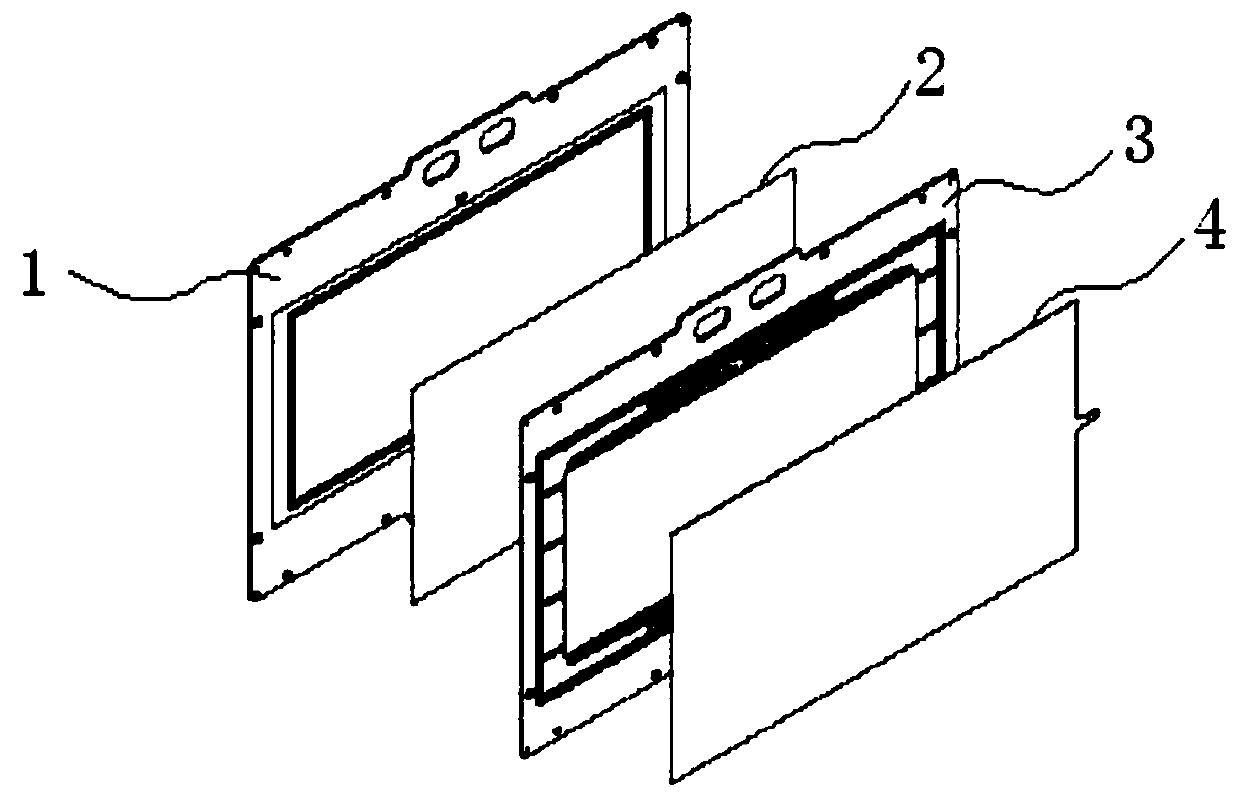

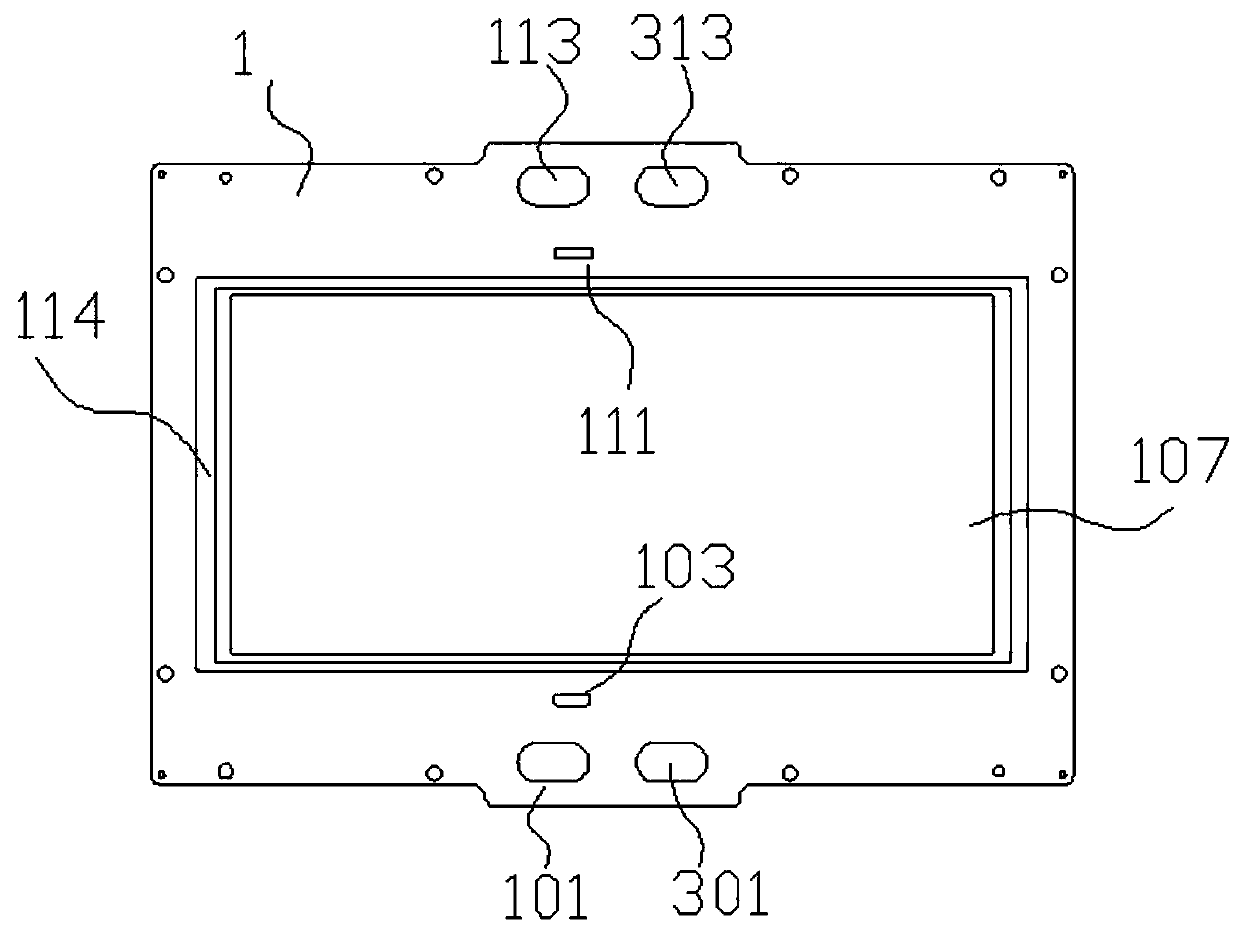

Redox flow battery electrode plate frame runner and redox flow battery runner

PendingCN110048141AIncrease capacityReasonable distributionRegenerative fuel cellsSurface reactionRedox

The invention discloses a redox flow battery electrode plate frame runner. The redox flow battery electrode plate frame runner comprises an electrode plate frame body, a lower-part electrolyte flowingsharing passage and a flowing limiting runner and also comprises at least one flowing dispersing runner and a flow sharing flowing runner, wherein the lower-part electrolyte flowing sharing passage is arranged at the electrode plate frame body in a penetrating way, the flowing limiting runner communicates with the lower-part electrolyte flowing sharing passage, the sharing flowing runner is connected with a plurality of flowing allocation runners, one end of each of the plurality of flowing allocation runners is connected with the flowing dispersing runner, and the other ends of the pluralityof flowing allocation runners communicate with an electrode cavity. In the redox flow battery electrode plate frame runner proposed by the invention, gradual dispersing flowing to the electrode cavity is employed, an electrolyte simultaneously enters the electrode cavity from the plurality of flowing allocation runners and acts with a porous electrode material, the redox flow speed is reduced, the uniformity of redox flow in the electrode material is improved, full contact of the electrolyte and the electrode material is improved, the surface utilization ratio of the electrode material is improved, the surface reaction polarization of the electrode is reduced, the internal current loss of the battery is reduced, the average power of a battery unit comprising the redox flow battery electrode plate frame runner can reach 300W or above, and the corresponding battery stack power can exceed 30kW.

Owner:SHANGHAI LONGVAULT ENERGY TECH CO LTD

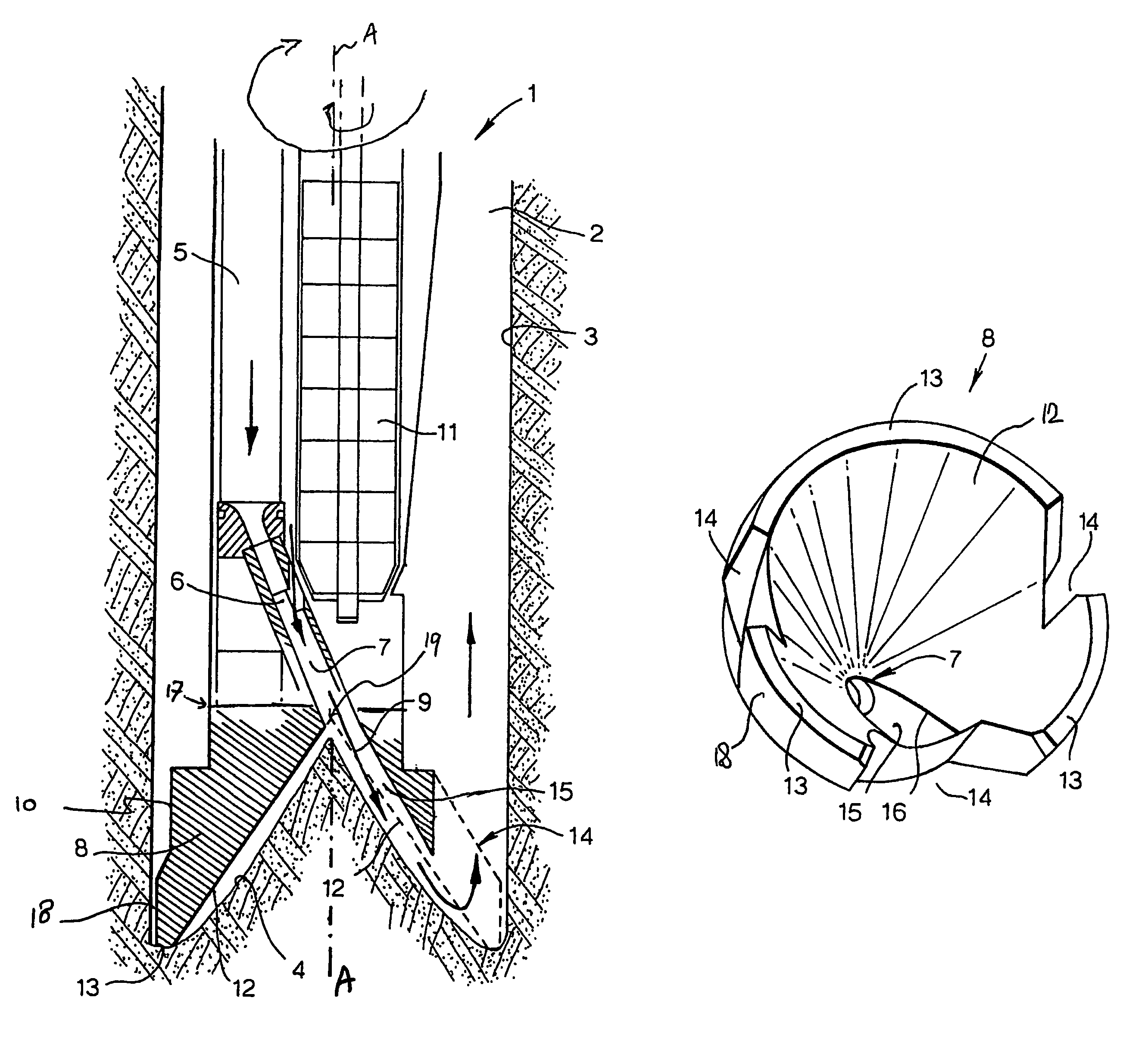

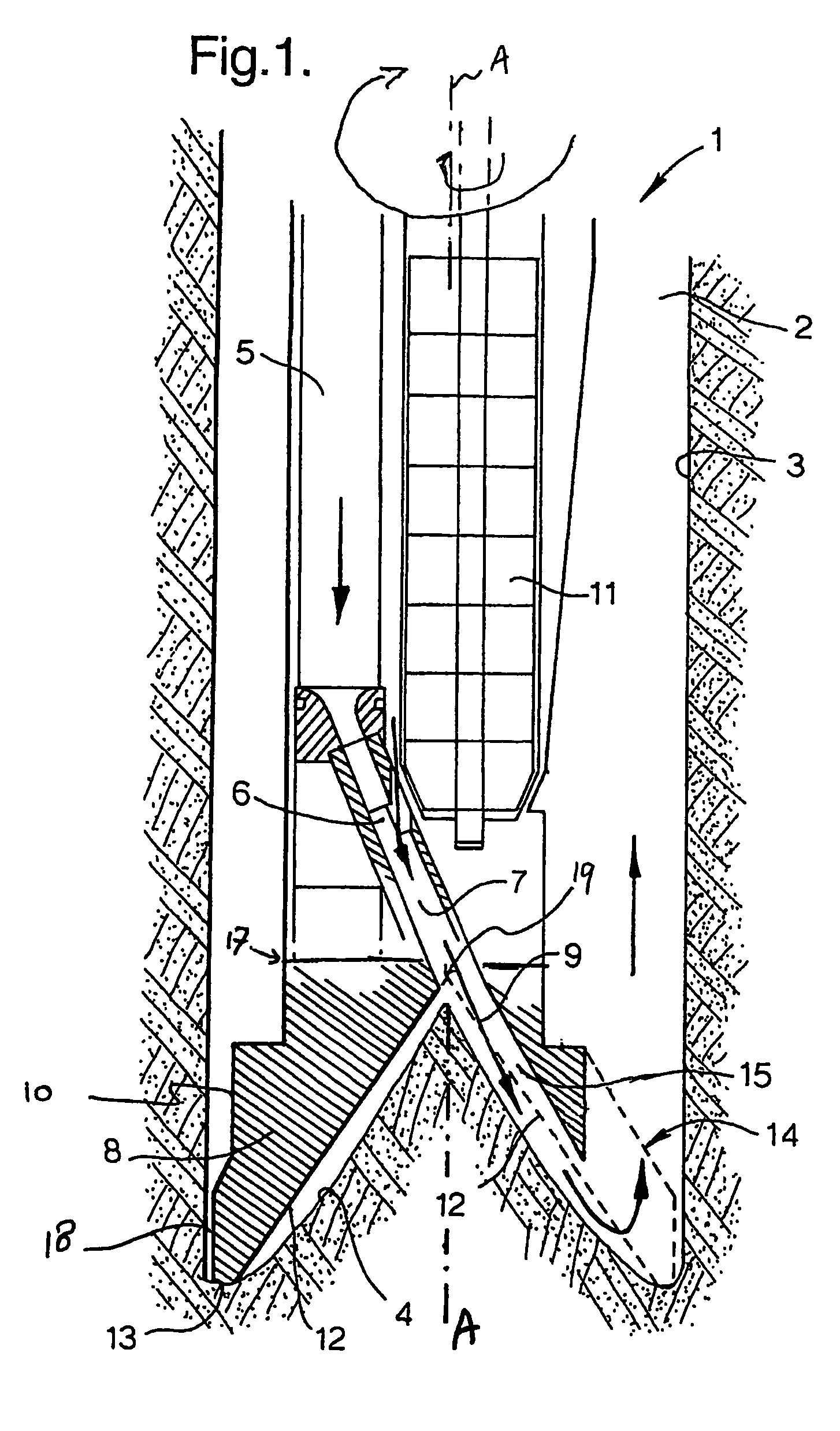

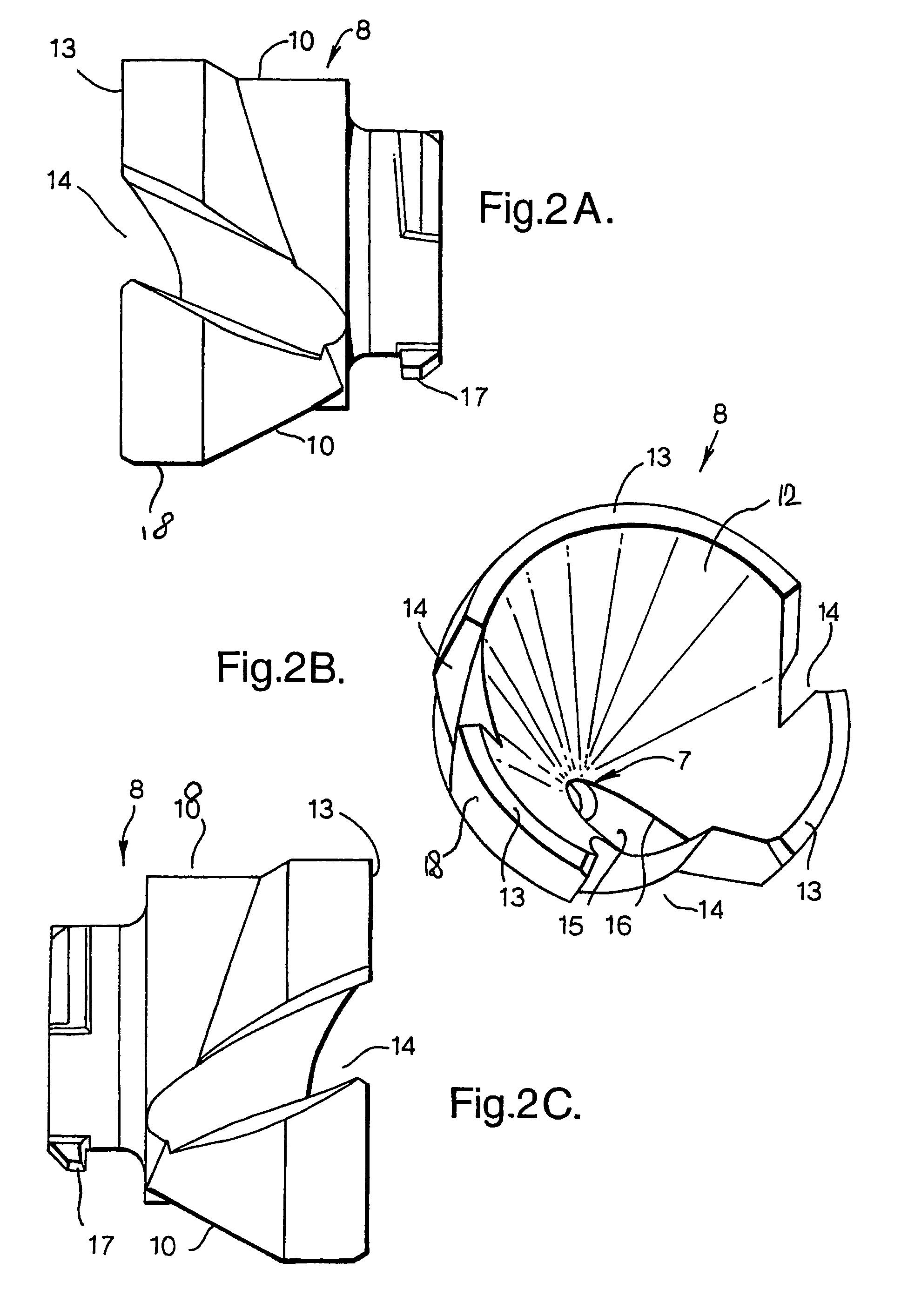

Fluid jet drilling tool

InactiveUS7419014B2Improve efficiencyReduce fluid velocityLiquid/gas jet drillingFluid removalEngineeringGeological structure

The invention features an excavating device for excavating a hole in a geological formation, which excavating device includes:a body rotatable inside the hole along a rotation axis;a nozzle arranged on the body to jet a stream of an abrasive fluid onto a surface in the geological formation in order to generate the hole, wherein the stream has at least an radial velocity component and one parallel to the rotation axis. The excavating device further hasa distance holder arranged on the body to ensure a predefined distance between the nozzle outlet and the surface; whereinthe distance holder has a trumpet shaped inner surface section facing the geological formation, which trumpet shaped inner surface section is provided with an opening for allowing the stream to pass through.The opening in the trumpet shaped inner surface section is defined by a recess that is formed in the inner surface of the wall of the distance holder, whereby the nozzle is arranged to discharge in the recess. The invention also features a distance holder such as described above.

Owner:SHELL OIL CO

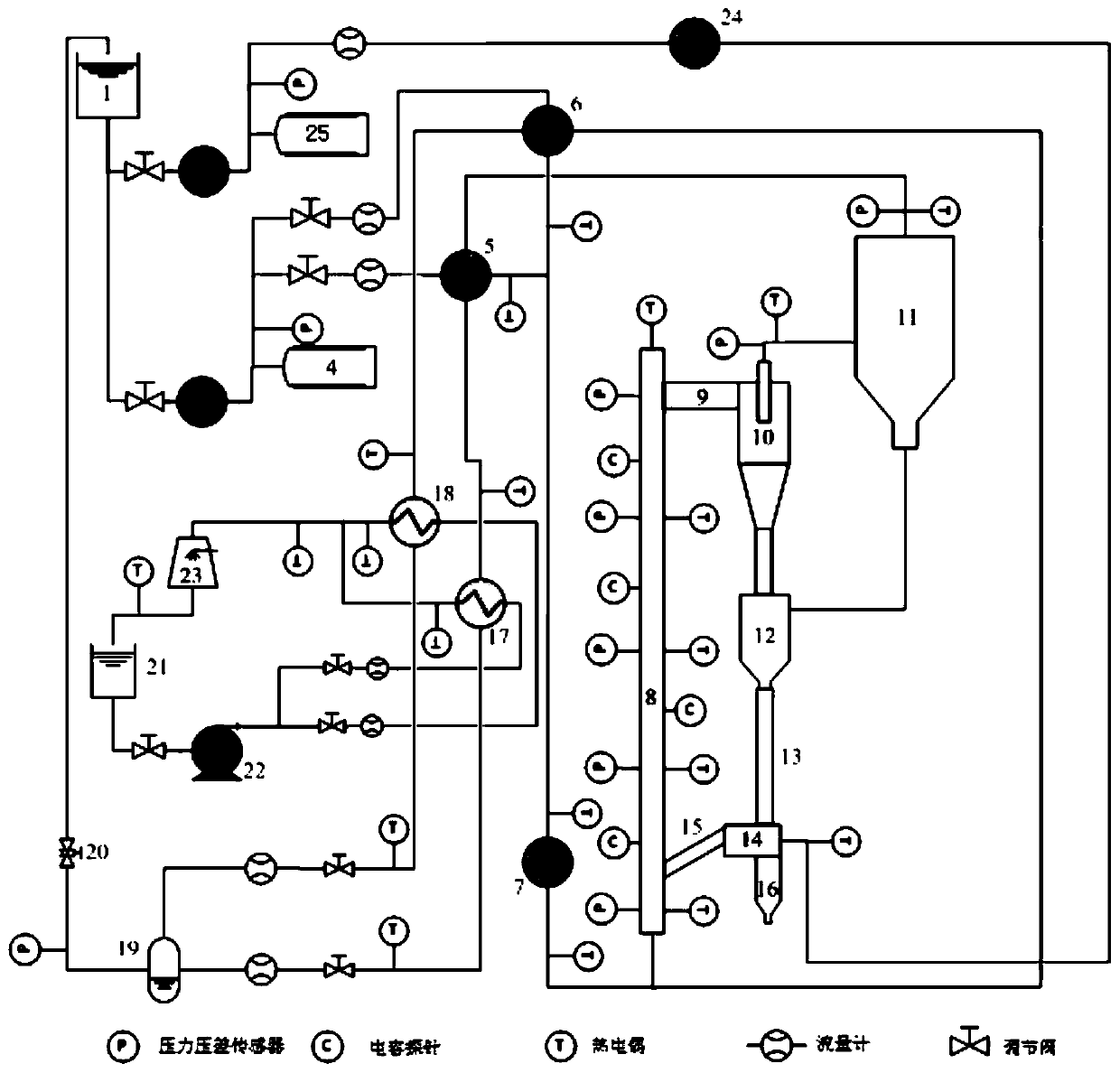

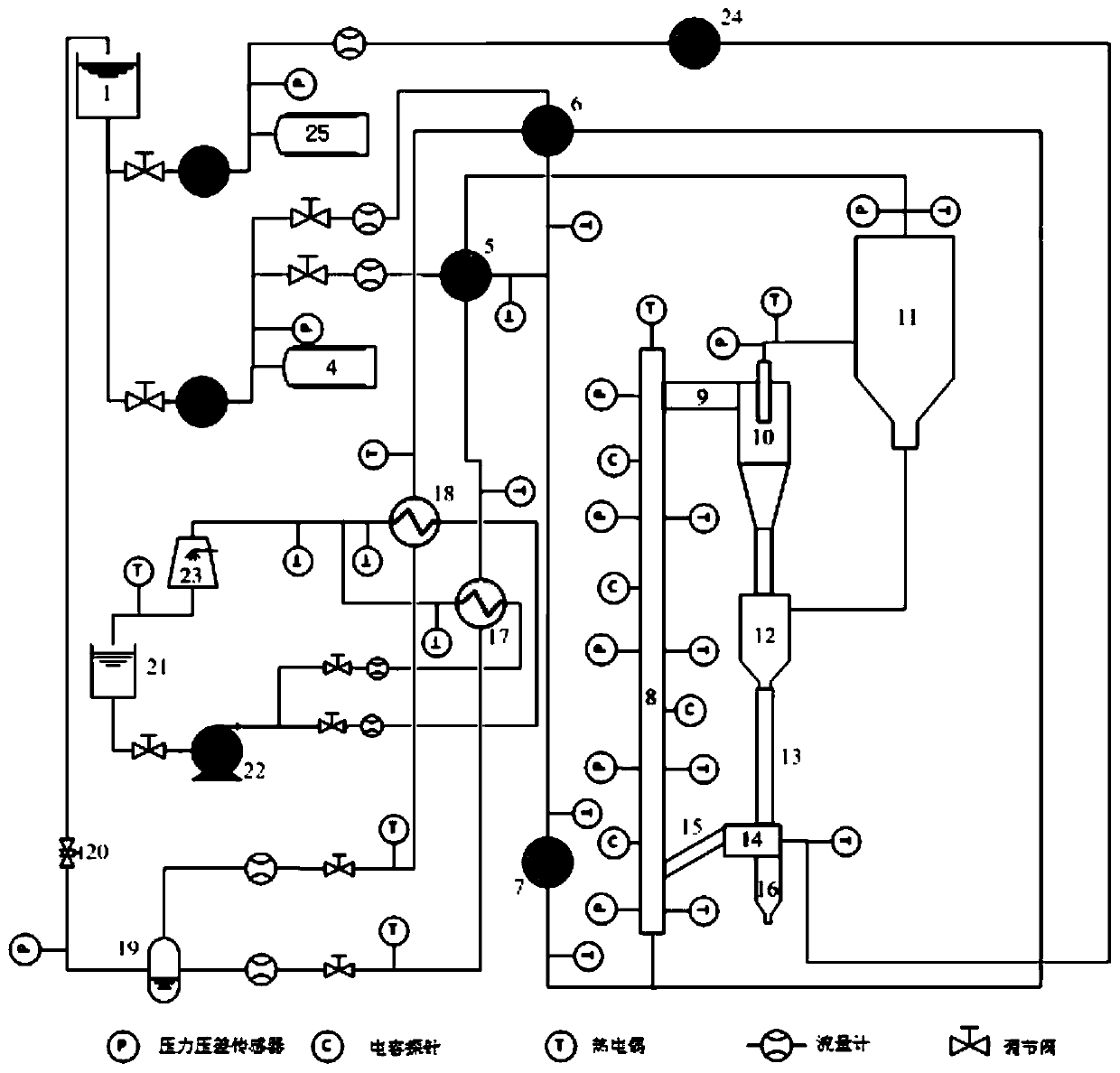

Device for testing multi-phase flow and heat transfer characteristics of supercritical water circulating fluidized bed

PendingCN109990973AStructural solutionSolve measurement difficultiesHydrodynamic testingMaterial heat developmentCapacitanceCooling tower

The invention discloses a device for testing multi-phase flow and heat transfer characteristics of a supercritical water circulating fluidized bed, which consists of an experimental section, a circulating system and a testing system, and comprises a lifting pipe, a cyclone separator, a filter, a feeding bin, a vertical pipe, an L-shaped material return valve, a circulating water tank, a first plunger pump, a second plunger pump, a damping buffer, a flowmeter, a first heat regenerator, a second heat regenerator, a first heater, a second heater, a back pressure valve, a cooling water tank, a cooling water pump, a first cooler, a second cooler, an open cooling tower, a plurality of regulating valves and other parts, and a plurality of K-type thermocouples, pressure difference sensors, capacitance probes and other testing devices. The device for testing multi-phase flow and heat transfer characteristics of the supercritical water circulating fluidized bed lays a foundation for research onthe multi-phase flow and heat transfer characteristics of the supercritical water circulating fluidized bed reactor, establishment of design theory, optimization of operation conditions and popularization of application.

Owner:XI AN JIAOTONG UNIV

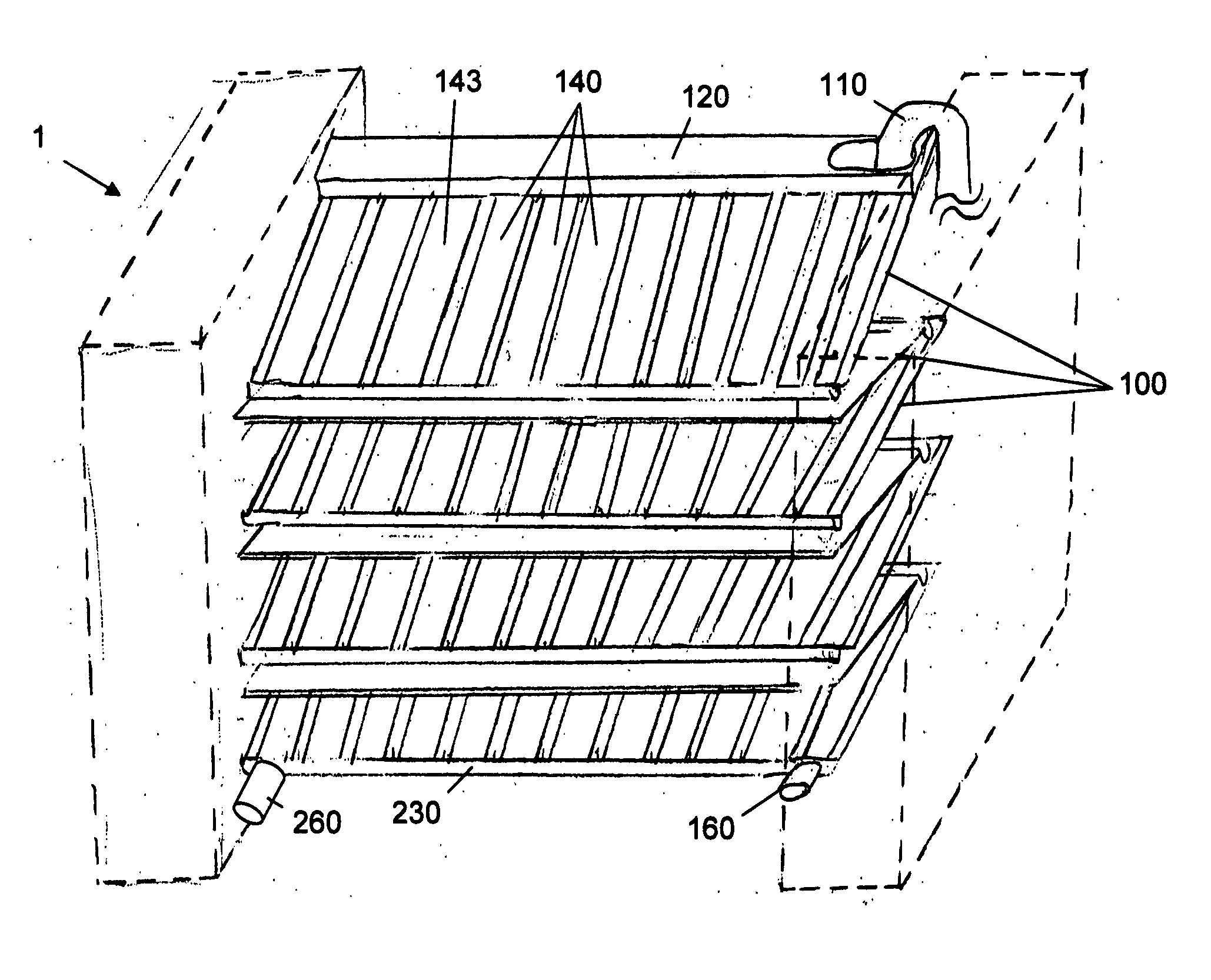

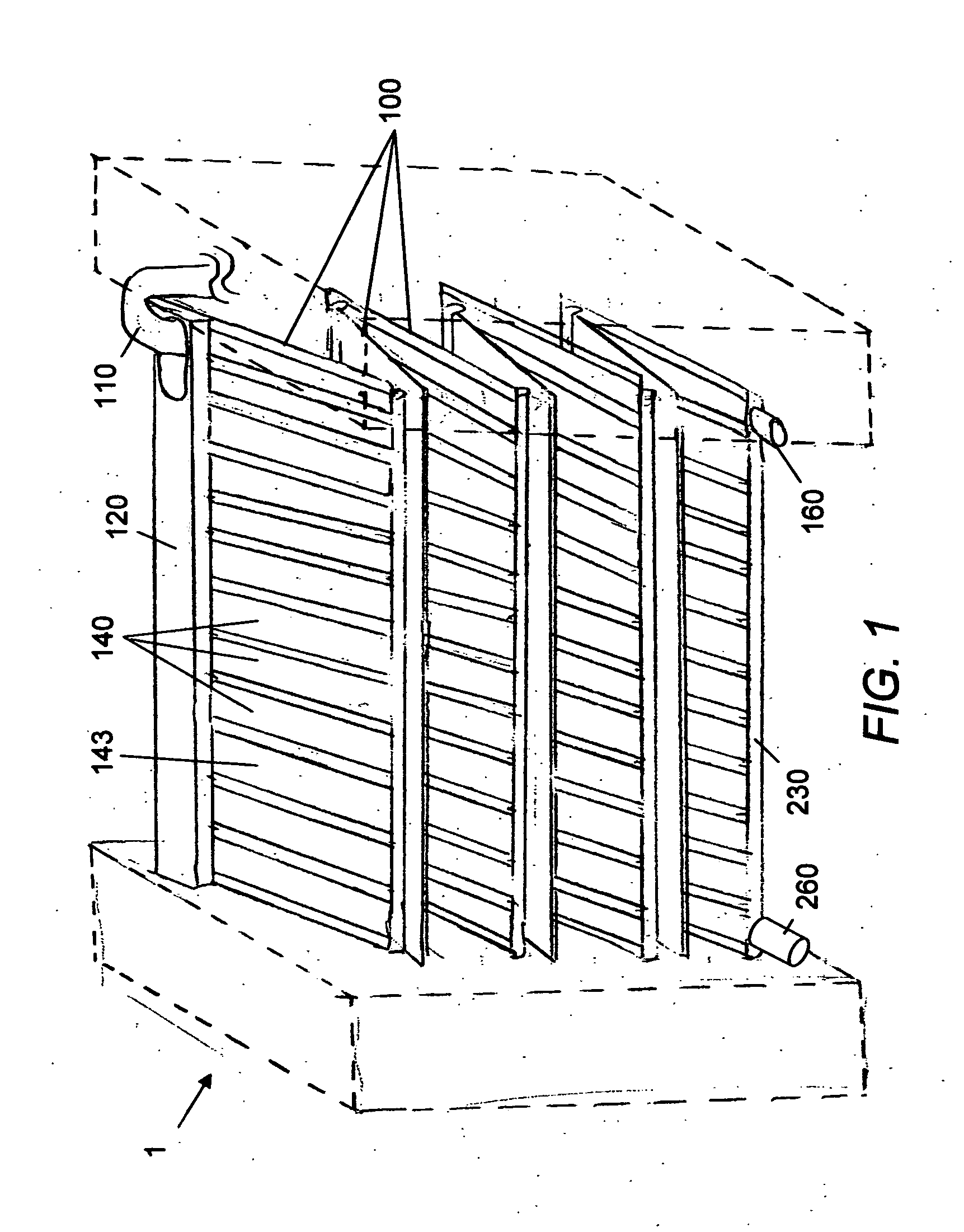

Fluid remediation system

InactiveUS20070241038A1Reduce temperature pollutionShorten speedWater treatment parameter controlIon-exchanger regenerationSludgeEngineering

A system for separating suspended and dissolved materials in a fluid having a pH offset from neutral is disclosed. It employs a plurality of stacked, generally flat treatment beds each having a surface angled downward for receiving the fluid. Since the fluid is spread over a large surface, its velocity slows causing suspended materials to drop out of the fluid as a sludge. A pH correction device adds an agent to the flowing fluid which will bring the pH closer to neutral thereby causing said dissolved materials to precipitate out and into the sludge. Portions of the beds may be isolated and the sludge collected resulting in a fluid having substantially less suspended and dissolved materials at a pH and temperature closer to normal. This invention is especially useful for remediating acid mine drainage.

Owner:GILLIS CHRISTOPHER

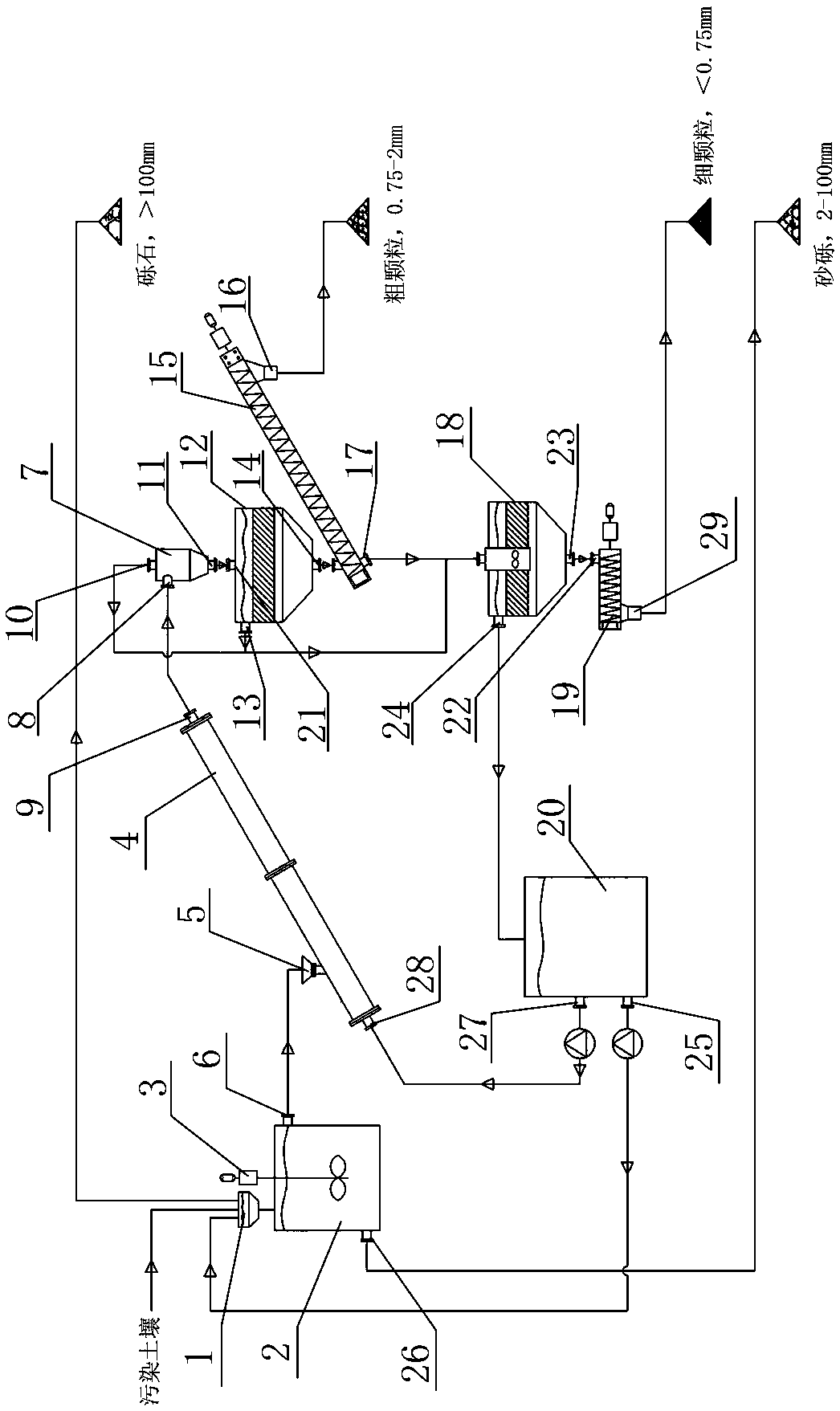

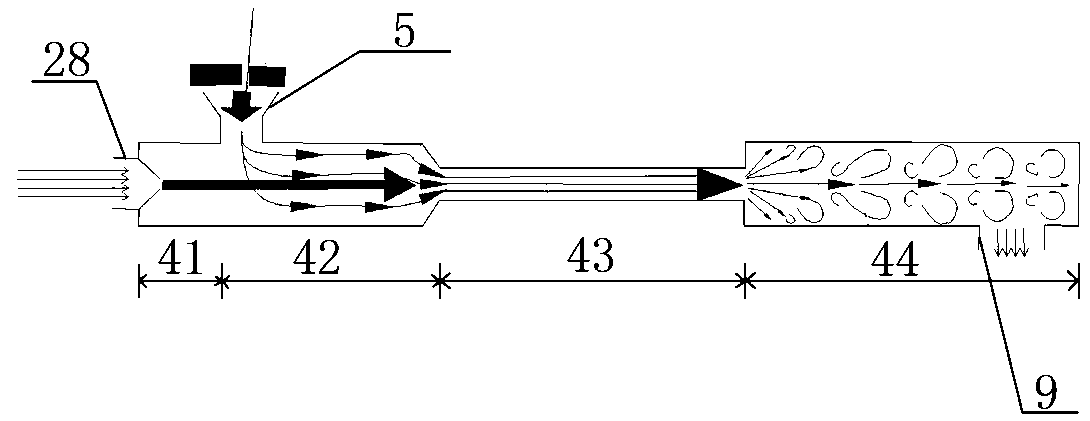

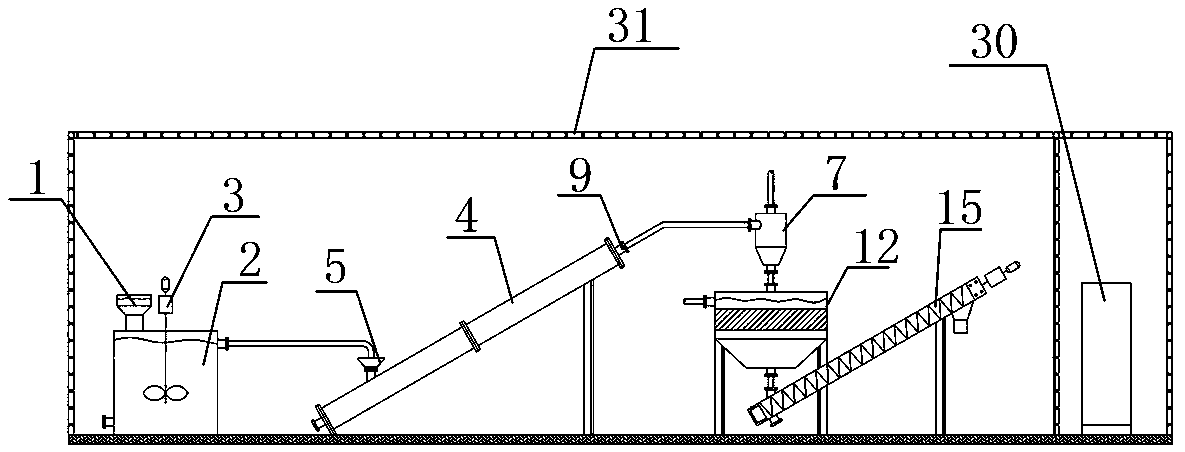

Soil leaching remediation reduction system and construction method thereof

ActiveCN111167846AReduce fluid velocityIncrease the Reynolds numberContaminated soil reclamationFiltration circuitsSoil treatmentSoil remediation

The invention discloses a soil leaching remediation reduction system and a construction method thereof, and belongs to the technical field of soil remediation. The soil leaching remediation reductionsystem comprises a feeding primary grading unit, a high-pressure jet separation unit, a secondary grading unit, a slurry settling concentration unit, a filter pressing unit, a sewage treatment unit, adust tail gas treatment unit and an instrument electrical control unit which are connected in sequence. According to the system, the grading quantity and the equipment quantity are greatly reduced, and for soil treatment of small-sized polluted sites, the whole system can adopt modularized container equipment or skid-mounted equipment which is convenient to move, so that the on-site constructioncost can be greatly reduced, the construction period can be greatly shortened, and the remediation efficiency is improved. The system is simple and ingenious in structure, easy and convenient to operate, low in equipment investment cost, small in occupied area, particularly suitable for remediation projects of small contaminated sites, capable of achieving multi-equipment parallel operation, suitable for treatment of medium and large sites, wide in application range, good in effect and wider in application prospect.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

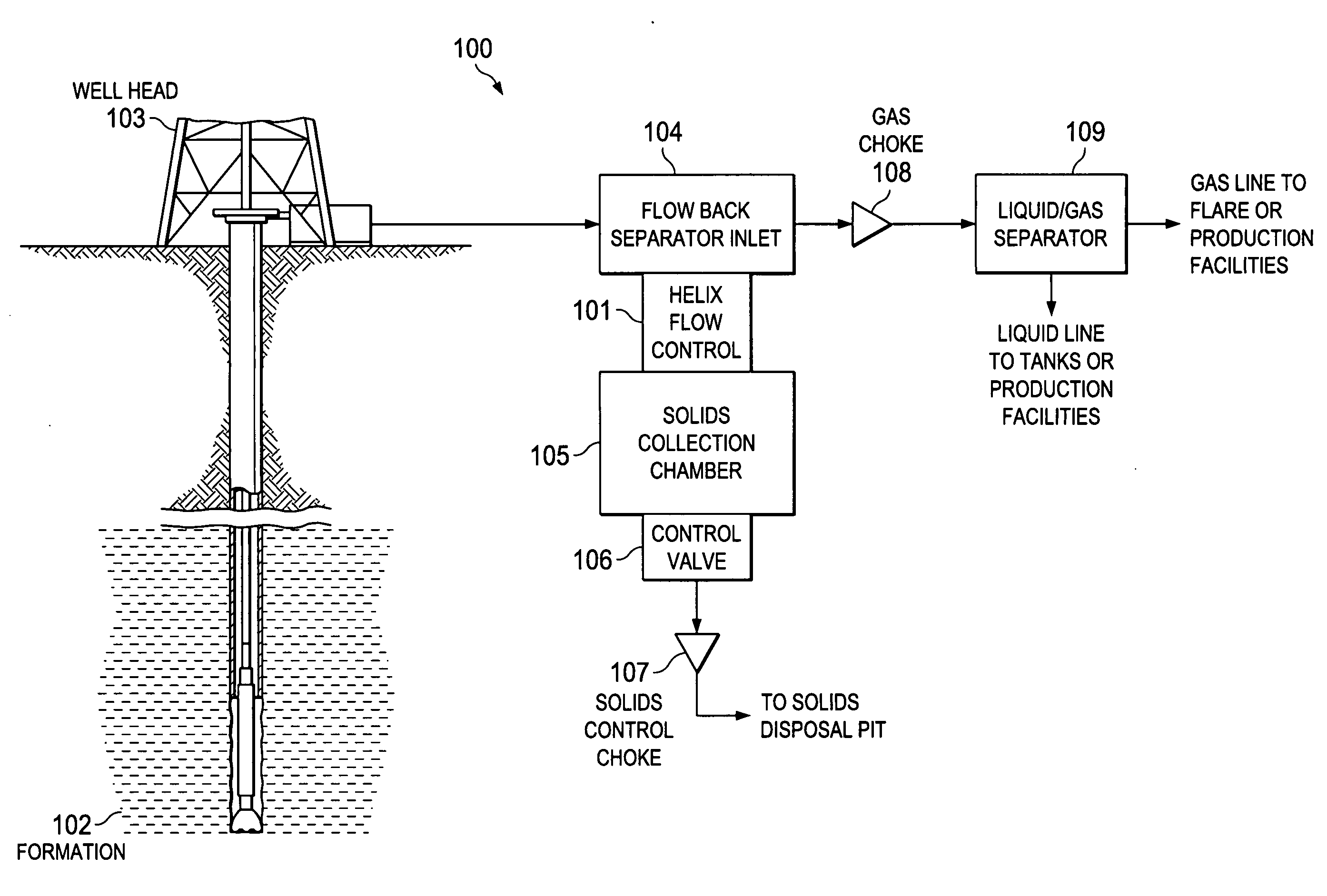

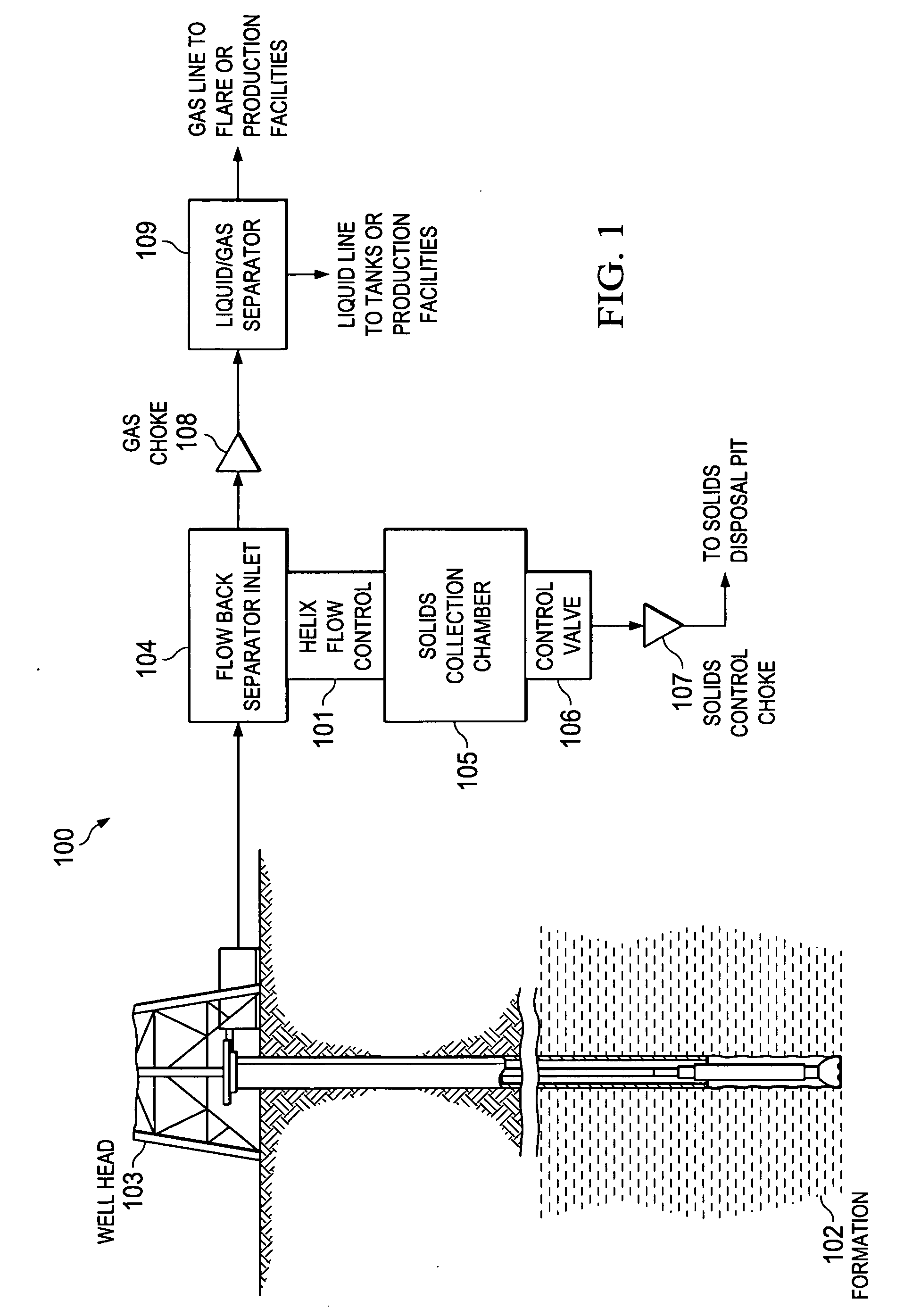

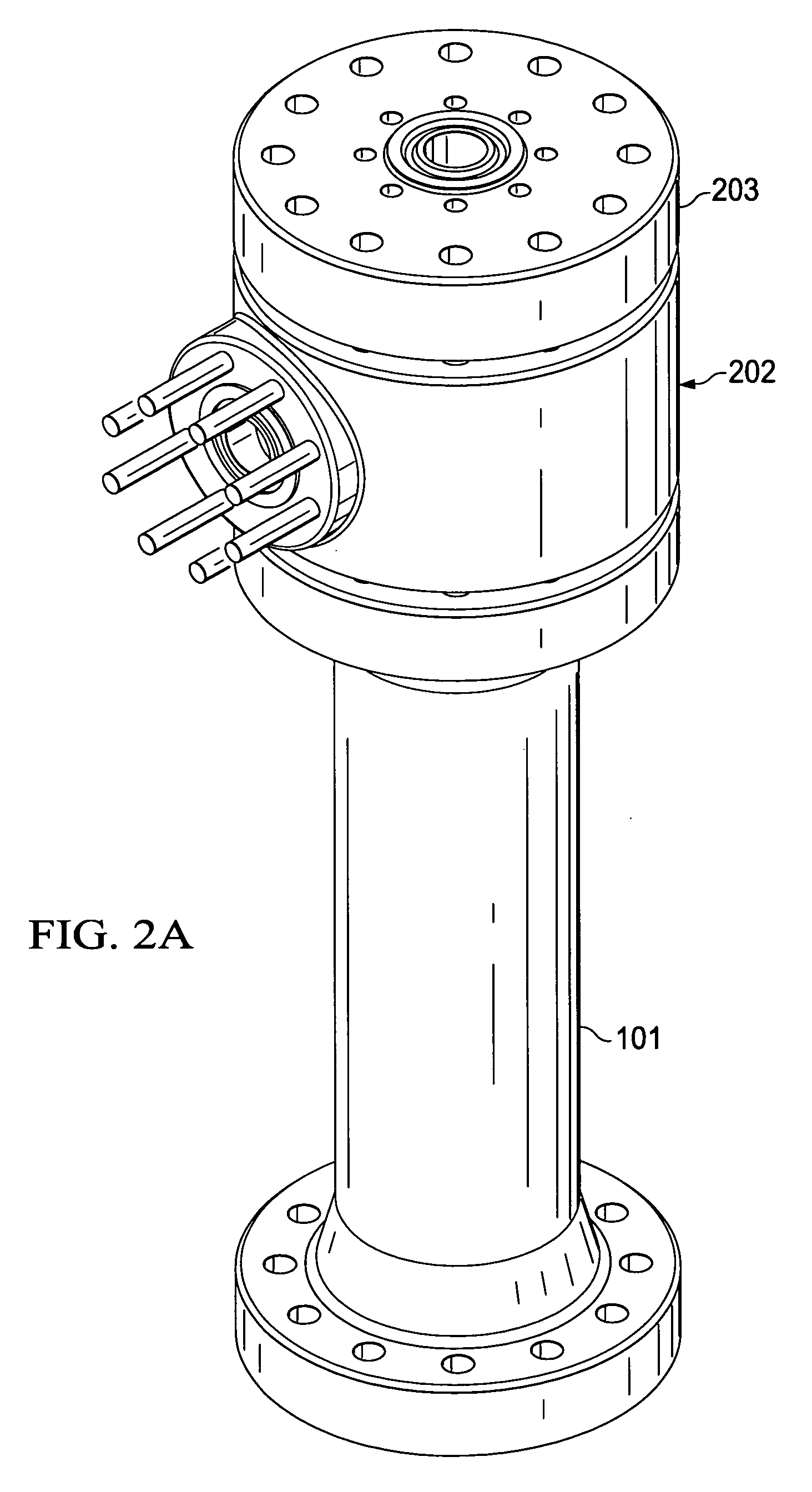

Flow back separators

InactiveUS20090133872A1More energyReduce the amount requiredWater/sewage treatment by centrifugal separationReversed direction vortexFormation fluidCentrifugal force

A flow back separator including a housing including a bore housing for communicating with a solid collection chamber, an inlet port for receiving formation fluid flow, and a helical member disposed within the housing bore for directing formation fluid flow received through the inlet port along a helical path wherein solids within the formation fluid flow are forced towards a wall of the housing bore under centrifugal force.

Owner:BOOTS & COOTS SERVICES

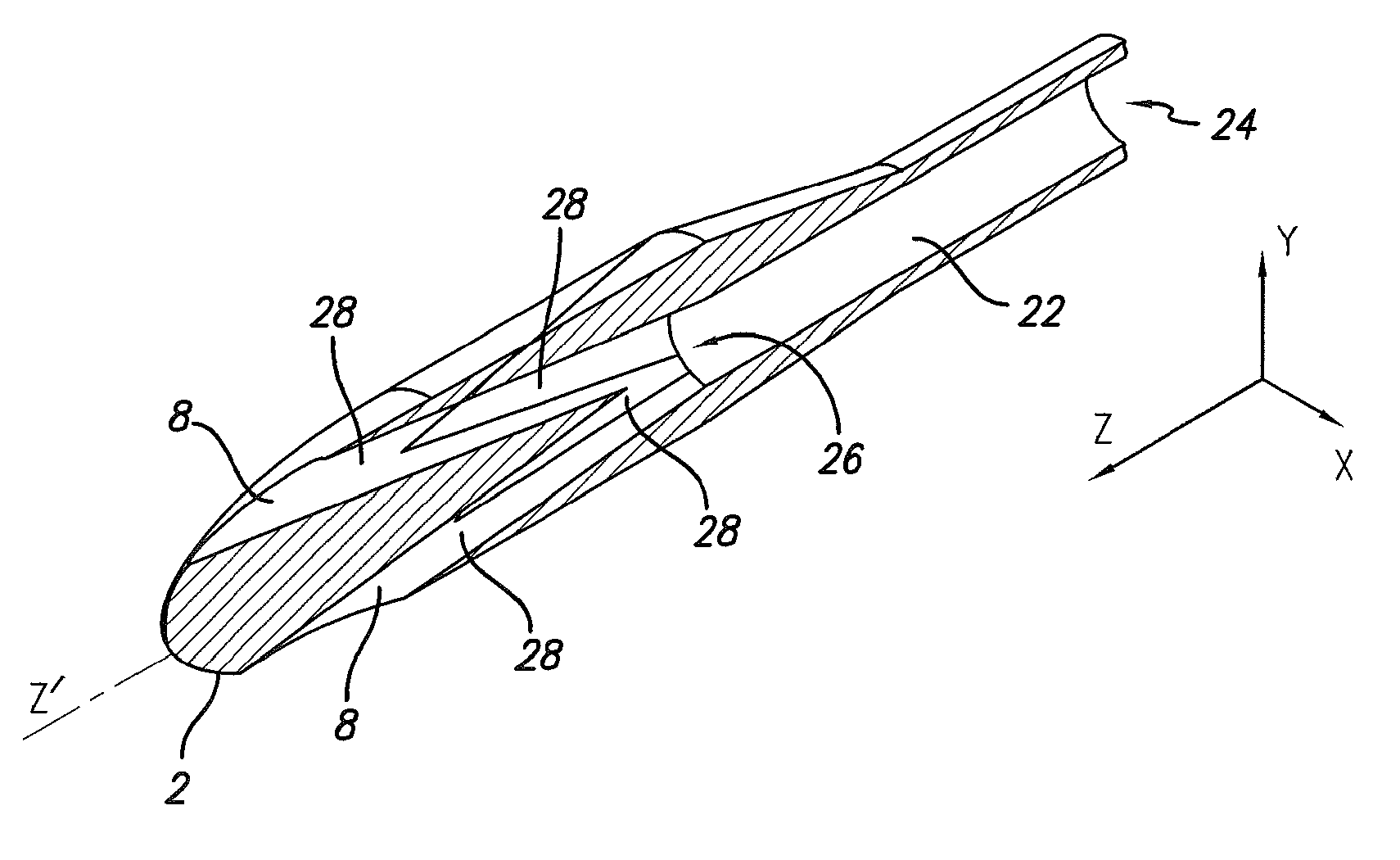

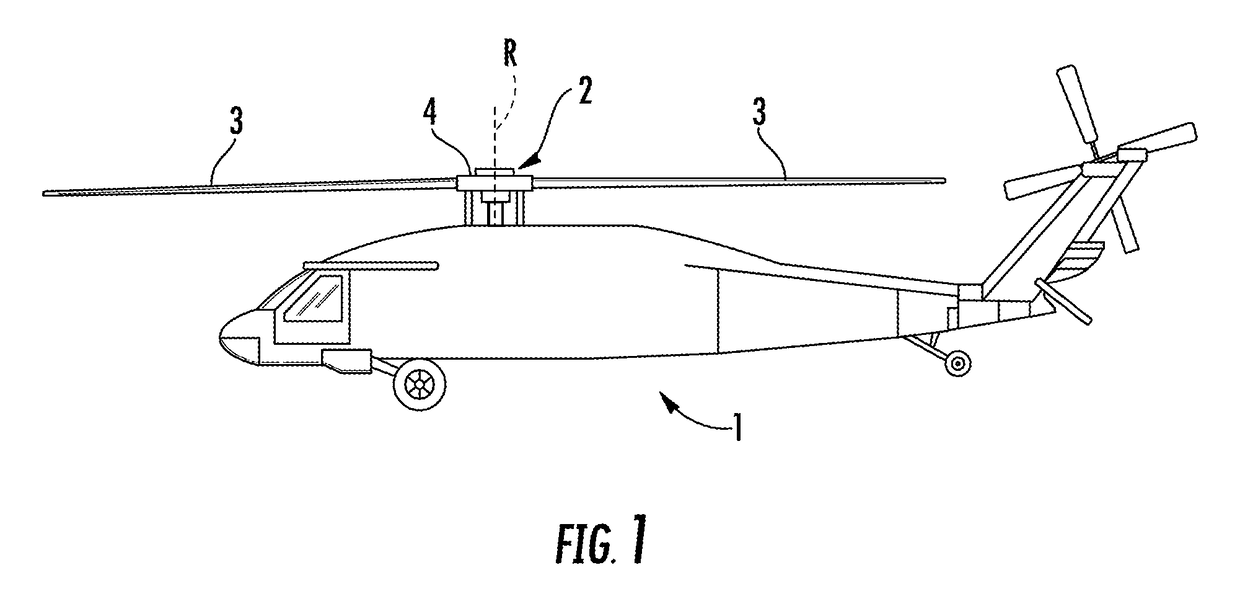

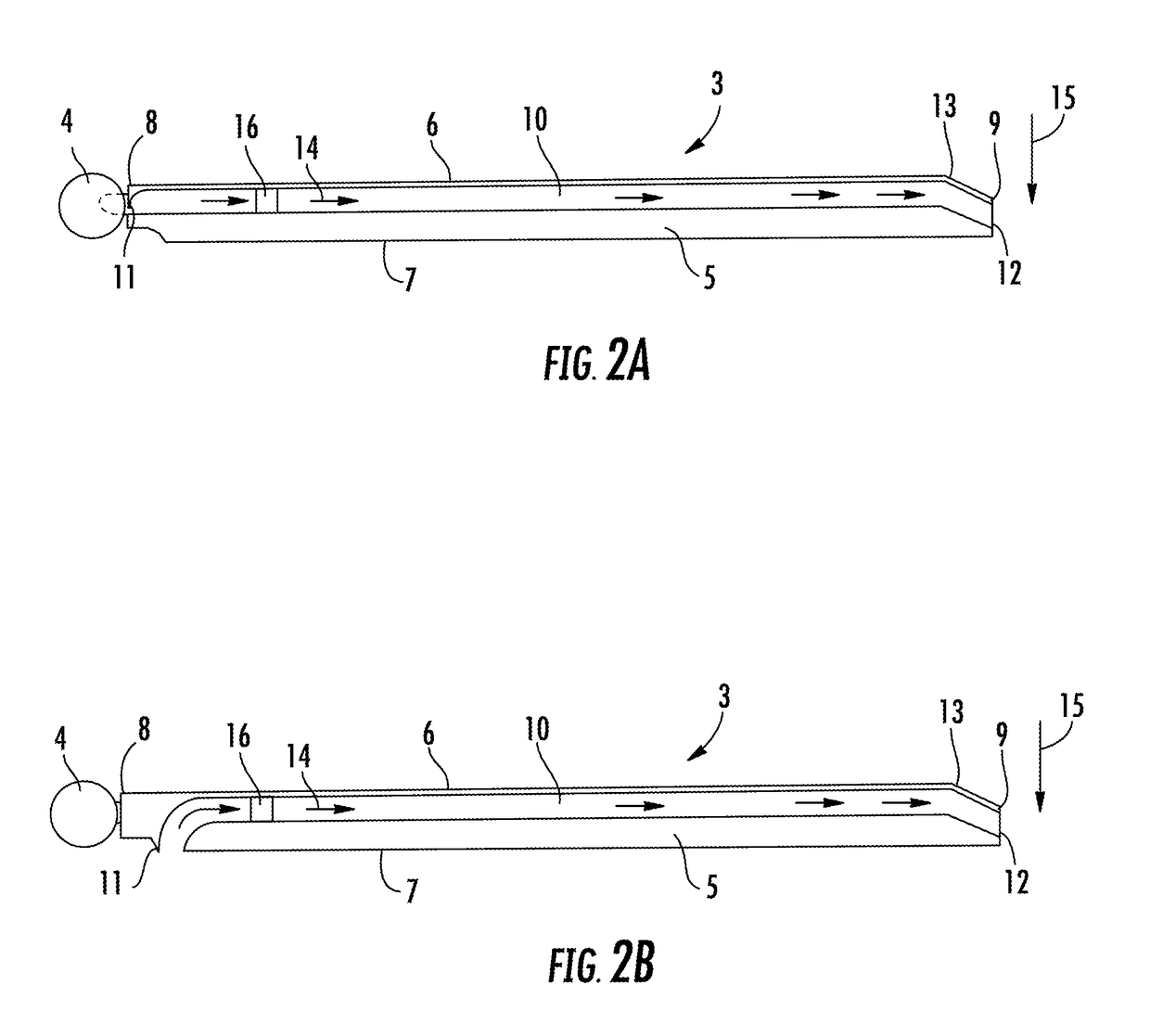

Low noise rotor blade design

A rotor blade includes an elongated body having a leading edge, a trailing edge, a proximal end, and a distal end; a fluid inlet; a fluid outlet arranged near the distal end of the elongated body; and a fluid duct contained within the elongated body, the fluid duct being substantially open between the fluid inlet and the fluid outlet, the fluid duct having a shape to reduce fluid velocities C generated by the interaction of fluid exiting the fluid duct and external fluid at the distal end.

Owner:SIKORSKY AIRCRAFT CORP

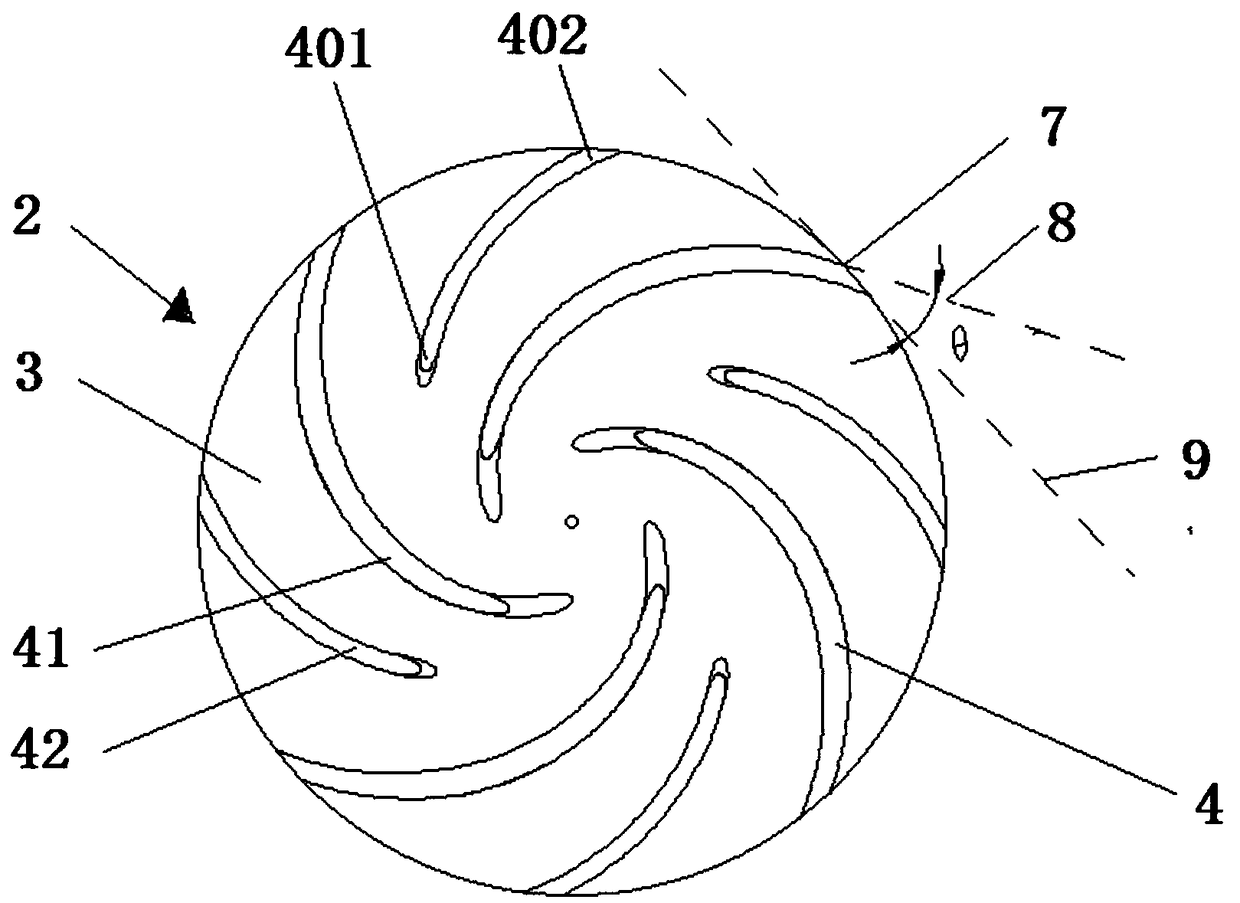

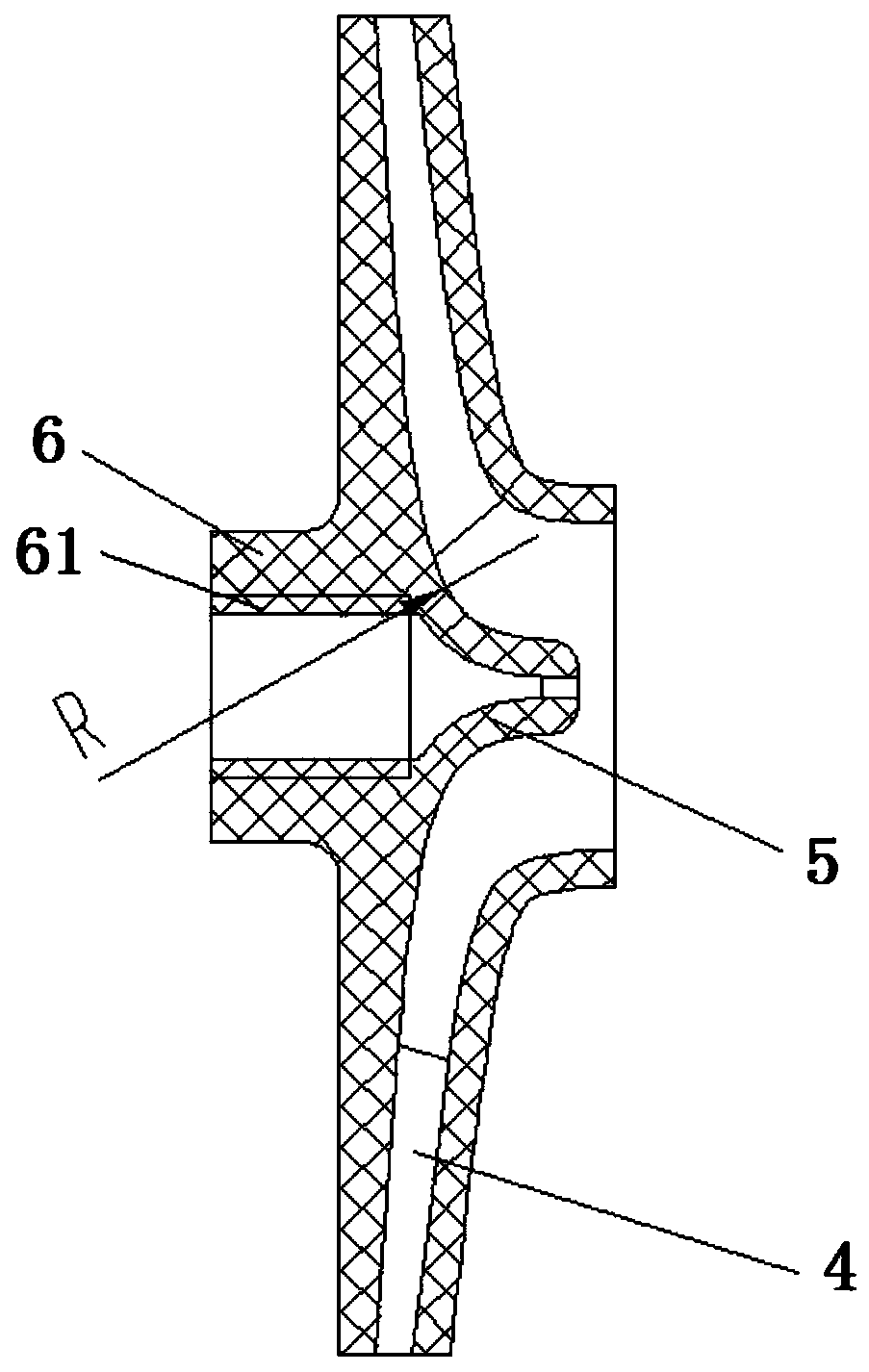

High-lift pump impeller for electric automobile

The invention relates to the field of impellers and discloses a high-lift pump impeller for an electric automobile. The high-lift pump impeller for the electric automobile comprises an impeller body (2) installed in a pump body, the impeller body (2) comprises a panel (3) and blades (4) installed on the panel (3), the blades (4) comprise main blade bodies (41) and auxiliary blade bodies (42), themain blade bodies (41) and the auxiliary blade bodies (42) are circumferentially arranged round the central axis of the panel (3), and the length of the main blade bodies (41) is larger than that of the auxiliary blade bodies (42). According to the high-lift pump impeller for the electric automobile, the two kinds of blade bodies are arranged, so that the flow area between the blades is increased;since bending of the blades is reduced and jamming of the blades is also reduced, the circulation area of the blades is increased; and the inlet flow speed is reduced, so that the anti-cavitation performance of the impeller is improved.

Owner:ZHEJIANG KELI VEHICLE CONTROL SYST

Aero-engine rectifier cover based on Magnus effect

ActiveCN109630273AIncrease fluid velocityReduce fluid velocityGas turbine plantsTurbine/propulsion air intakesAviationAgricultural engineering

The invention discloses an aero-enginerectifier cover based on the Magnus effect. The autogyration rectifier cover is in a sphere shape. Prostrate crescent protrusions are arranged on the sphere anticlockwise. A mounting edge is arranged on the outer ring of the front end of an air inlet machine. A special-shaped rectifier supporting plate is welded to the front end of the air inlet machine. Holeswith stairs are formed in horizontal two ends of the autogyration rectifier cover. The holes are self-lubricating bearing outer ring mounting seats. Stair shafts are arranged on the left and right sides of the air inlet machine in the horizontal direction of the autogyration rectifier cover. The shafts are self-lubricating bearing inner ring mounting seats. The autogyration rectifier cover is mounted on the air inlet machine through a self-lubricating bearing. A groove bearing mounting seat is arranged at the middle of the air inlet machine. A front fulcrum bearing is arranged in the bearingmounting seat and is locked by nuts. A sealing component is arranged at the front end of a low-pressure rotor in a sleeving mode. The low-pressure rotor is connected to the front fulcrum bearing. A low-pressure stator is arranged at the rear end of the air inlet machine. The structure is rational, and ice resisting and ice removing systems of the aero-engine can be omitted.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

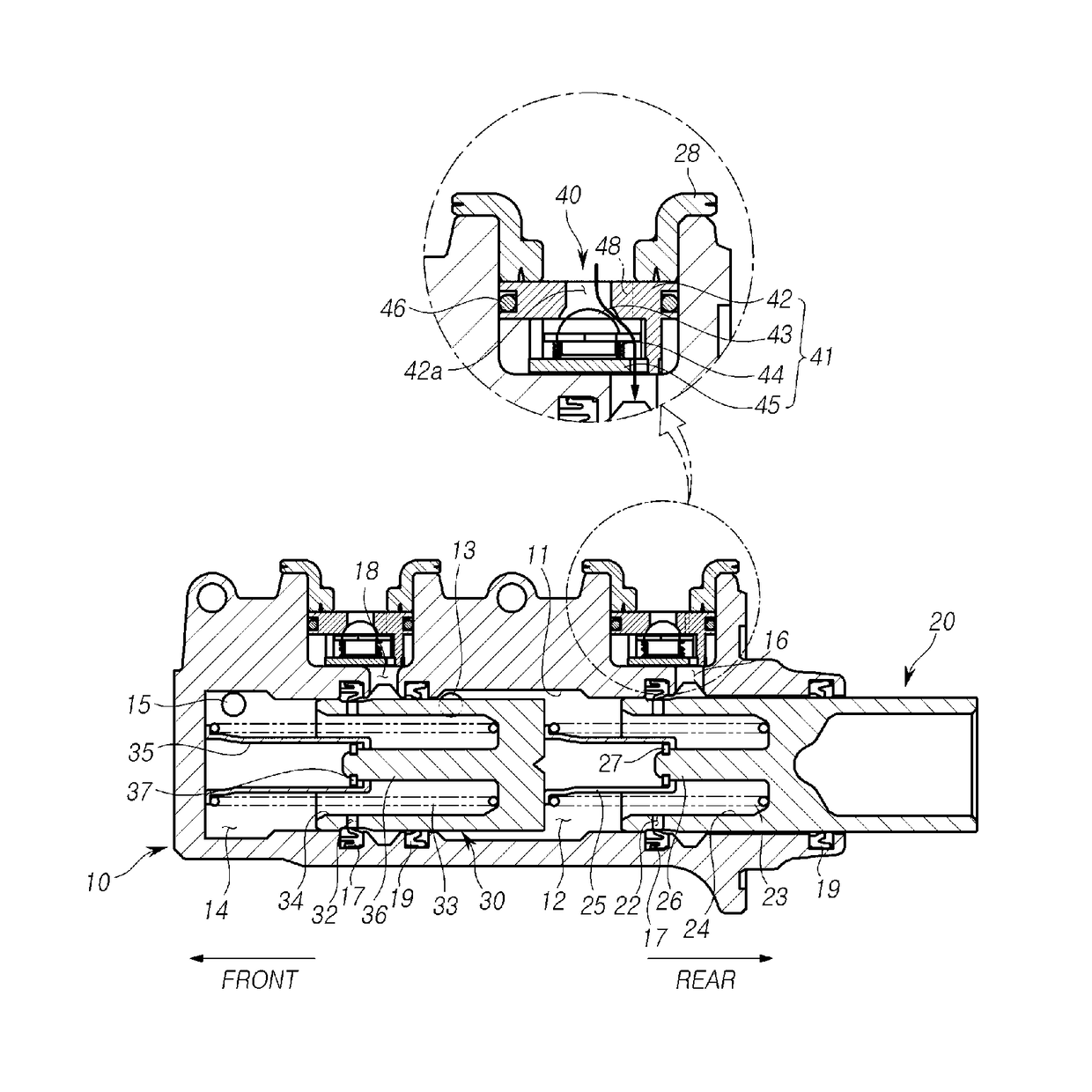

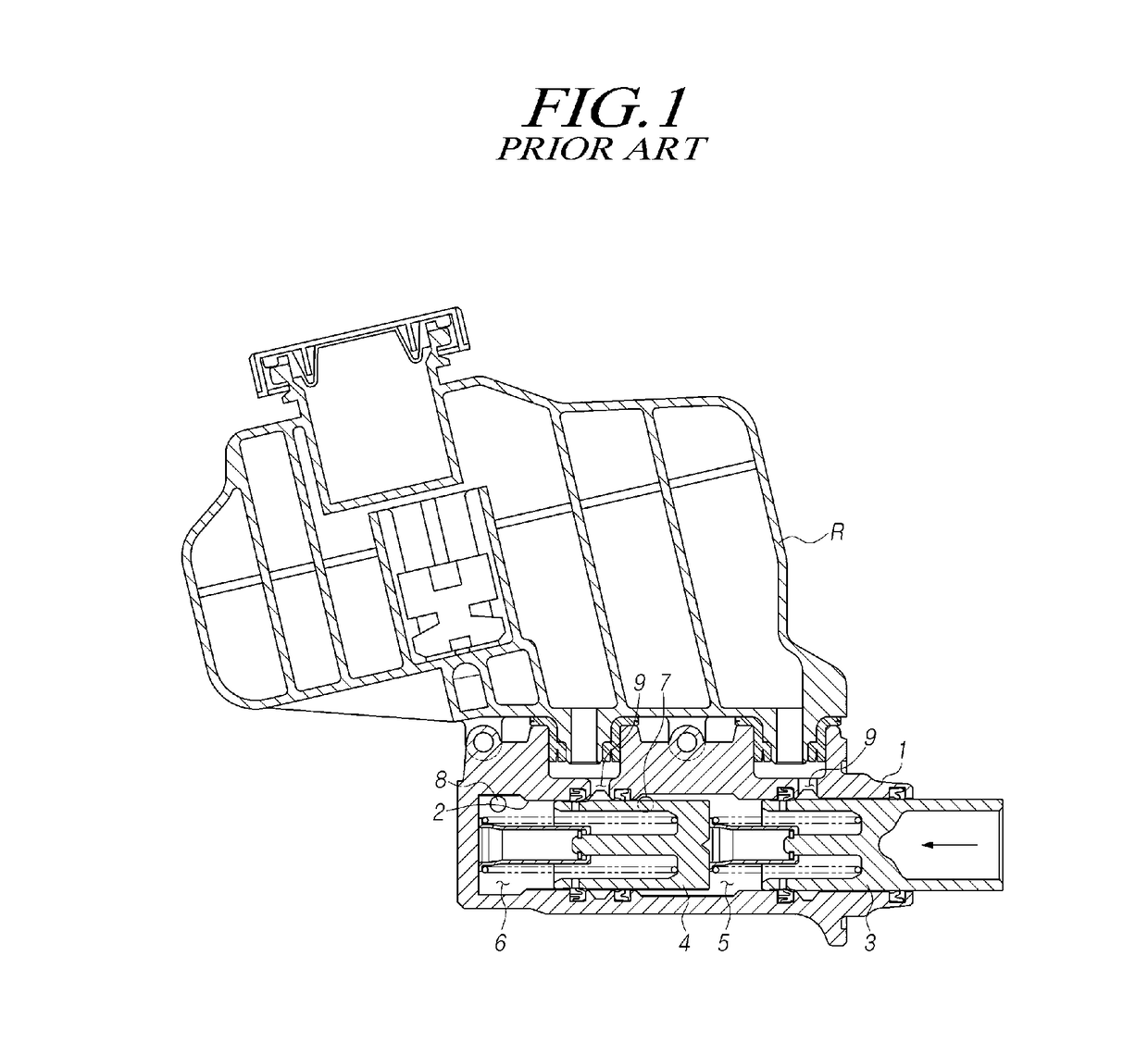

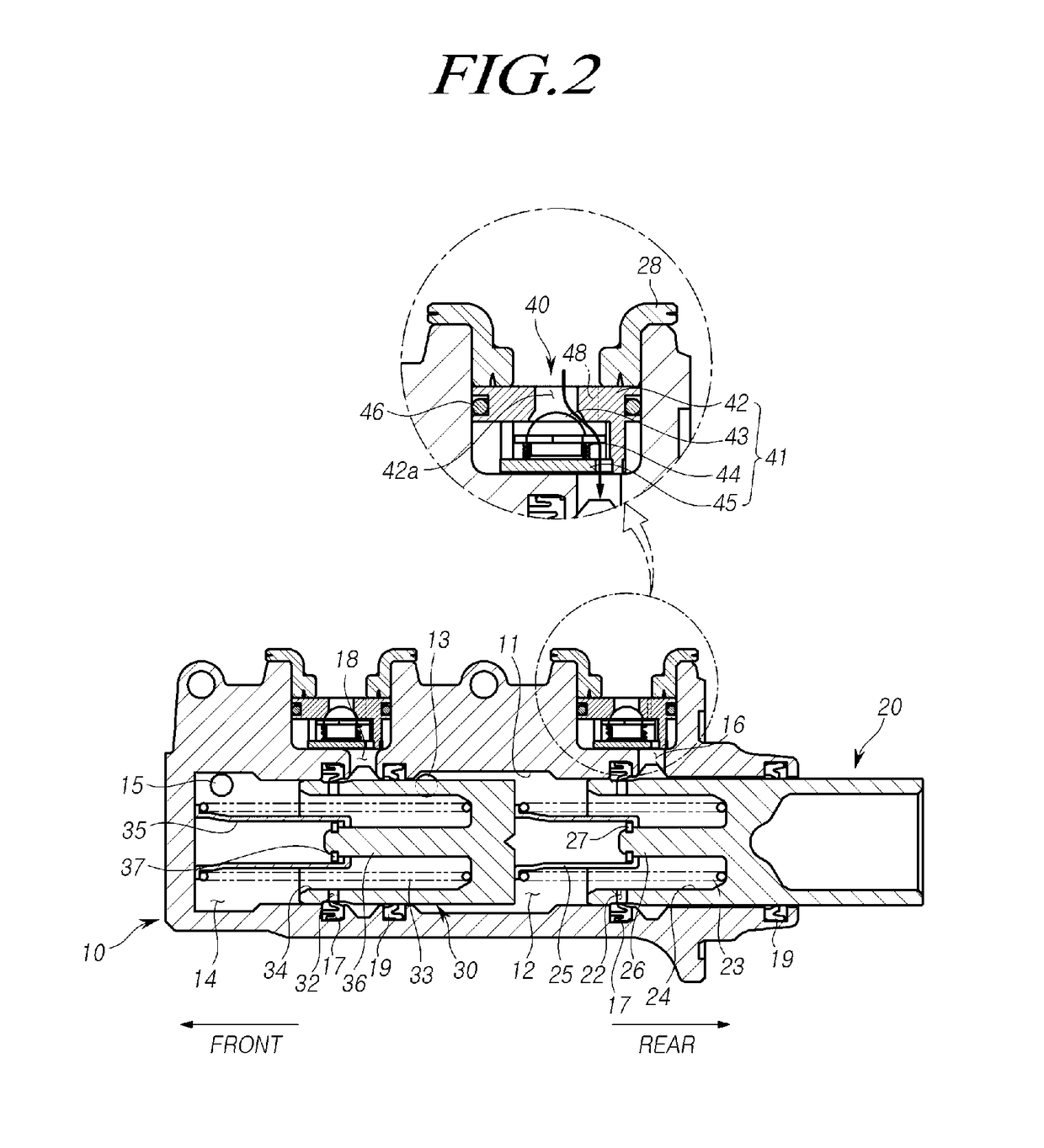

Master cylinder for brake system

ActiveUS9862367B2Reduce travel requirementsPrevent pressureFluid braking transmissionMaster cylinderEngineering

Owner:HL MANDO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com