Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

573results about How to "Increase the circulation area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

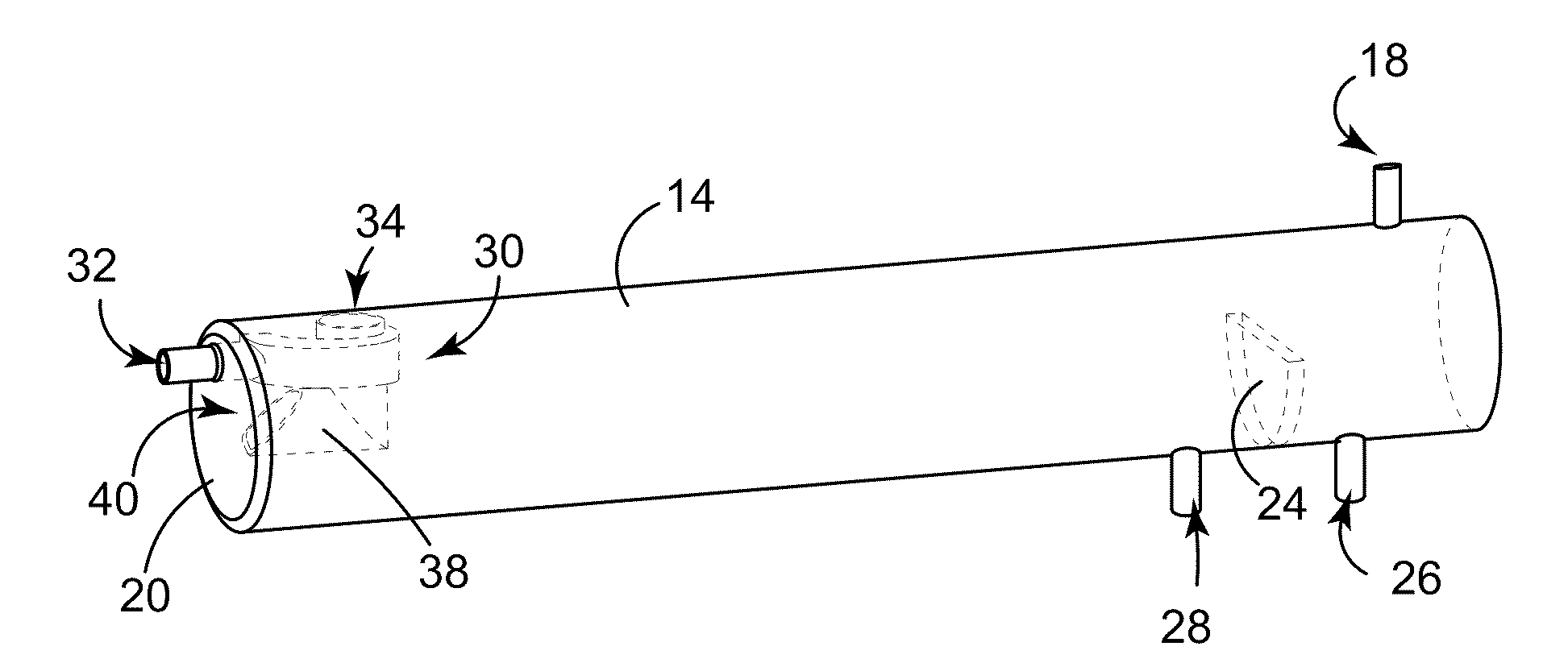

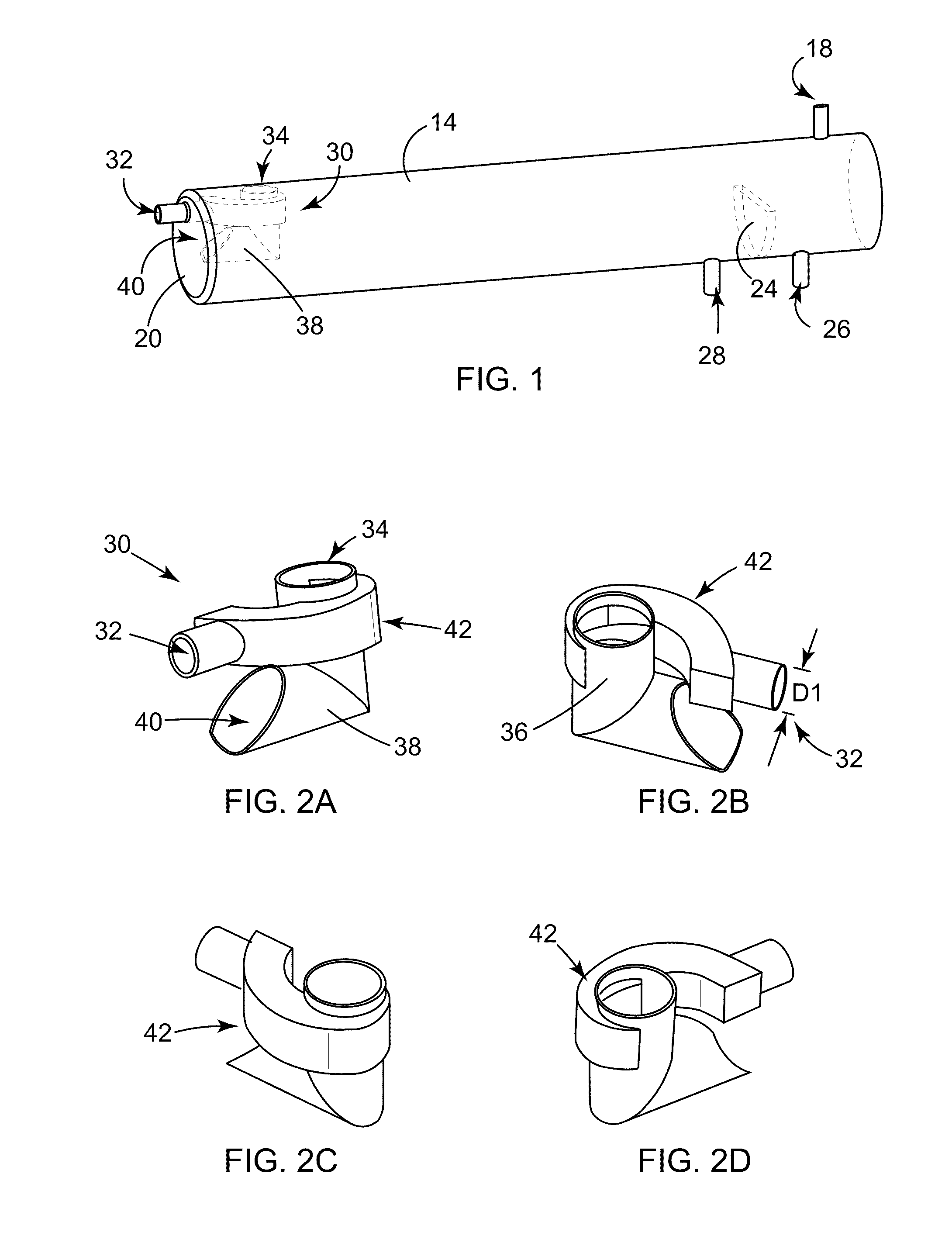

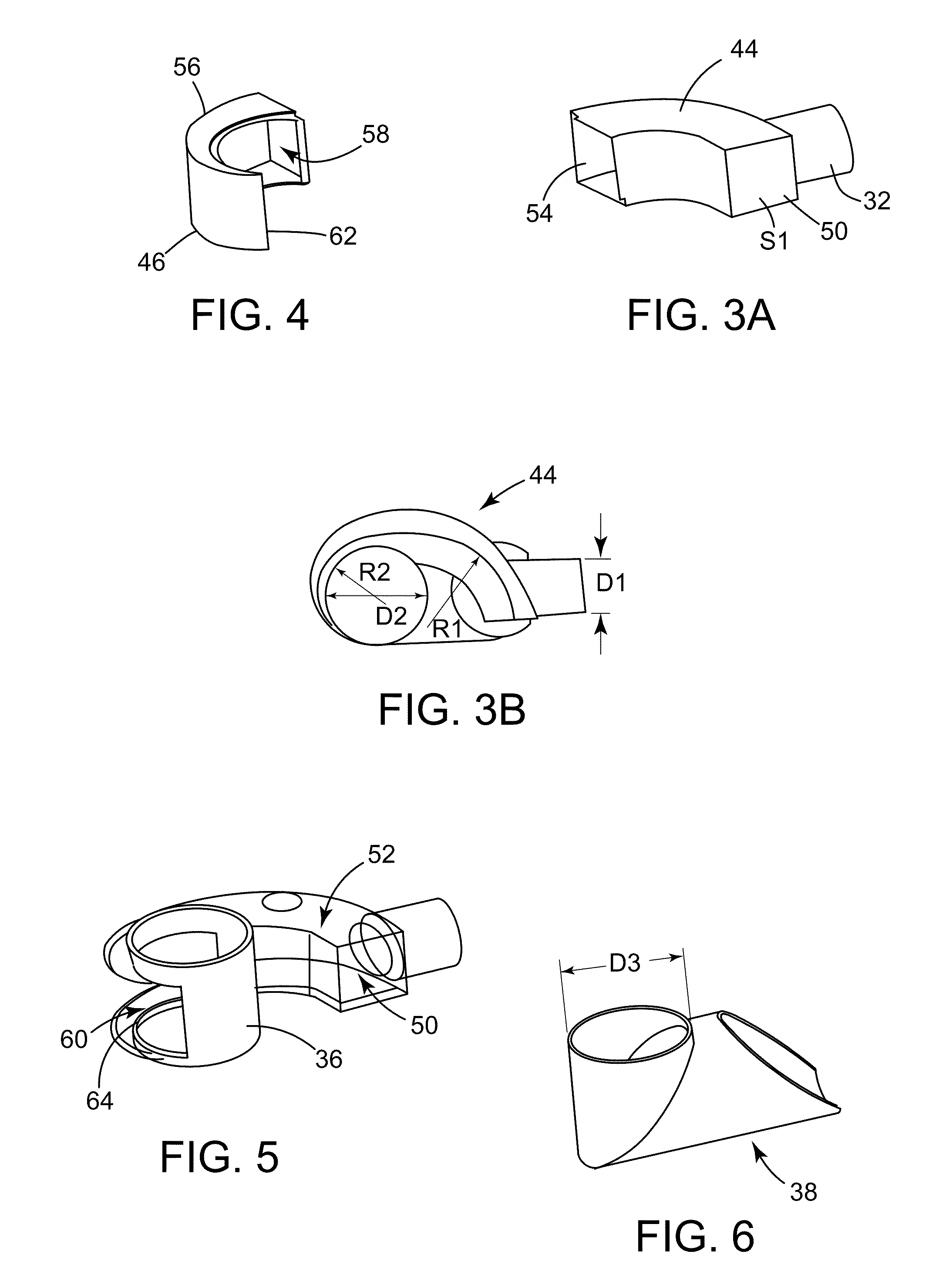

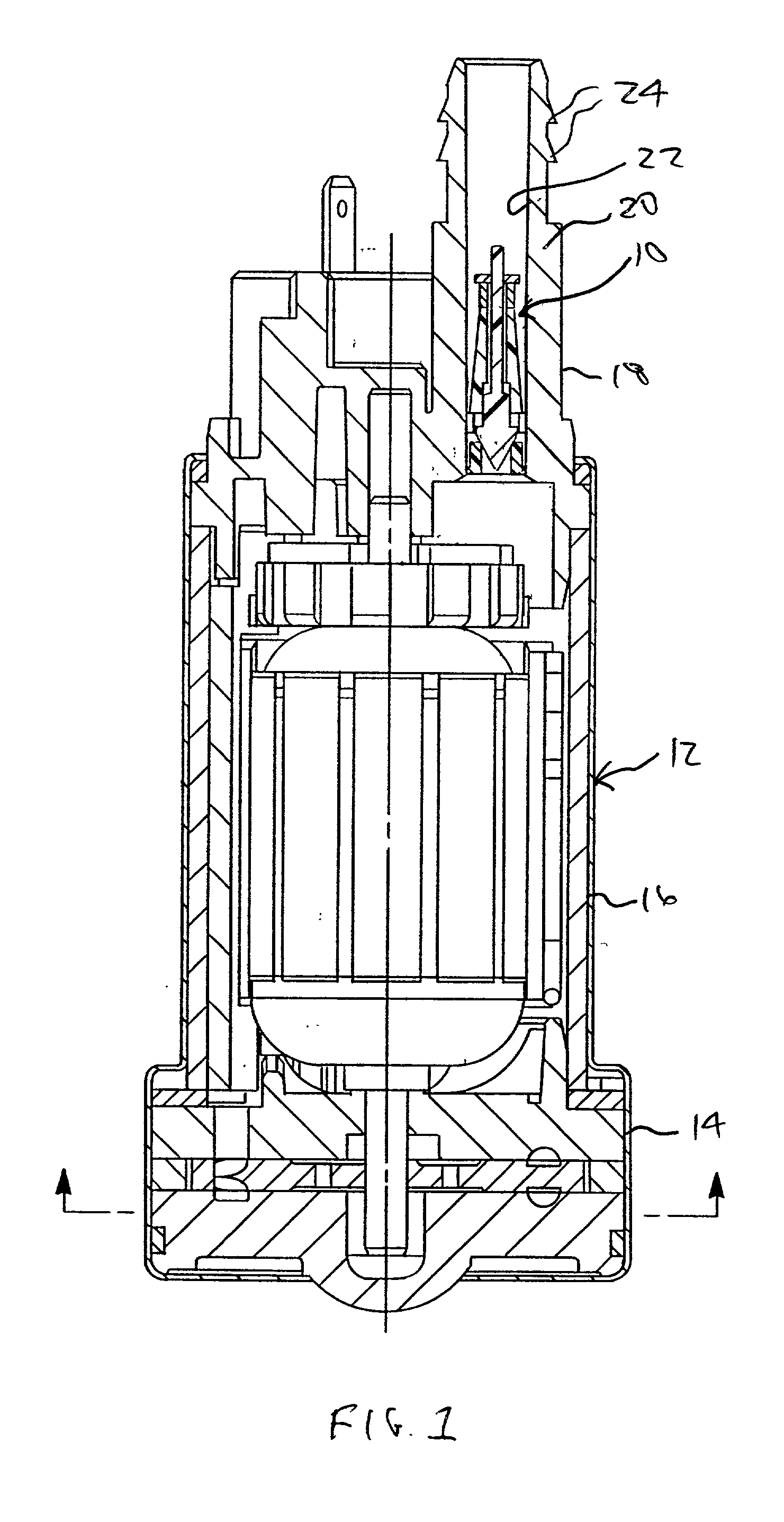

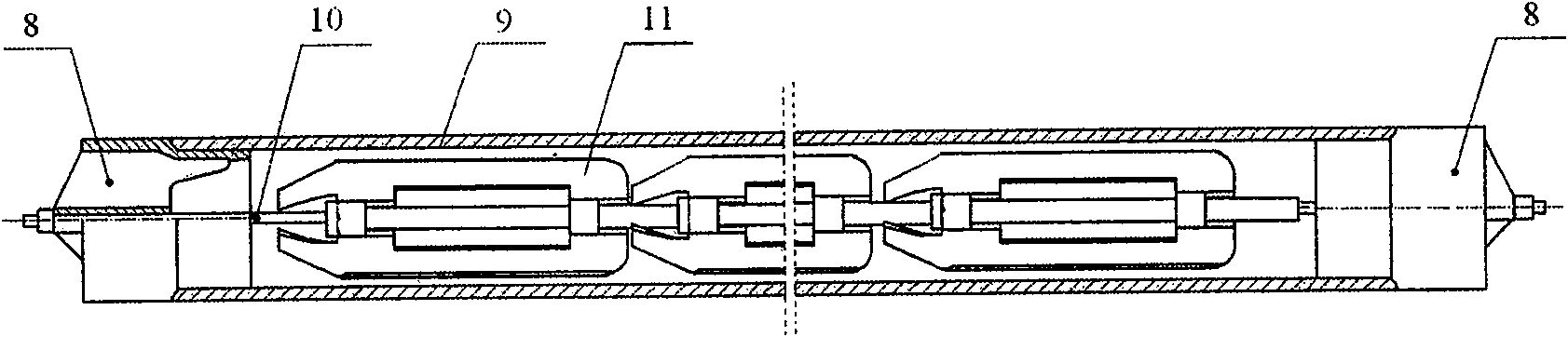

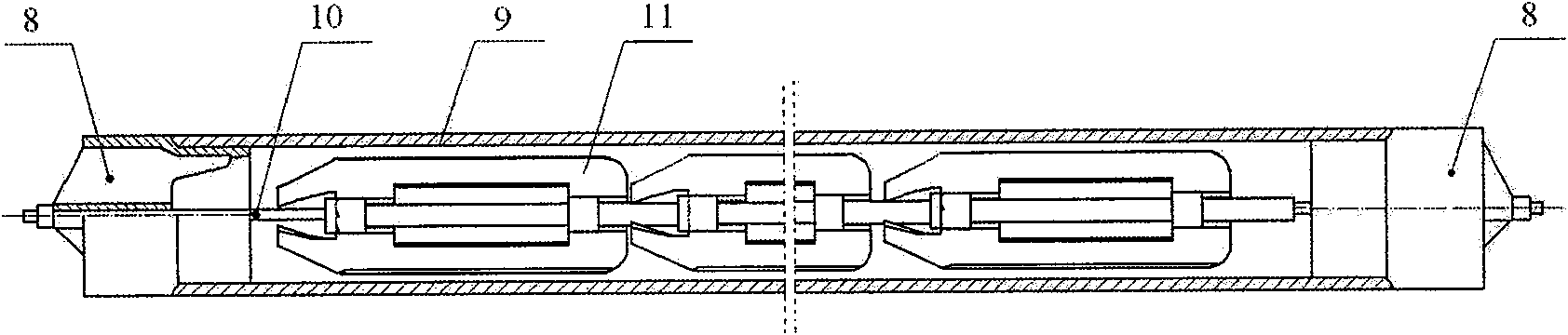

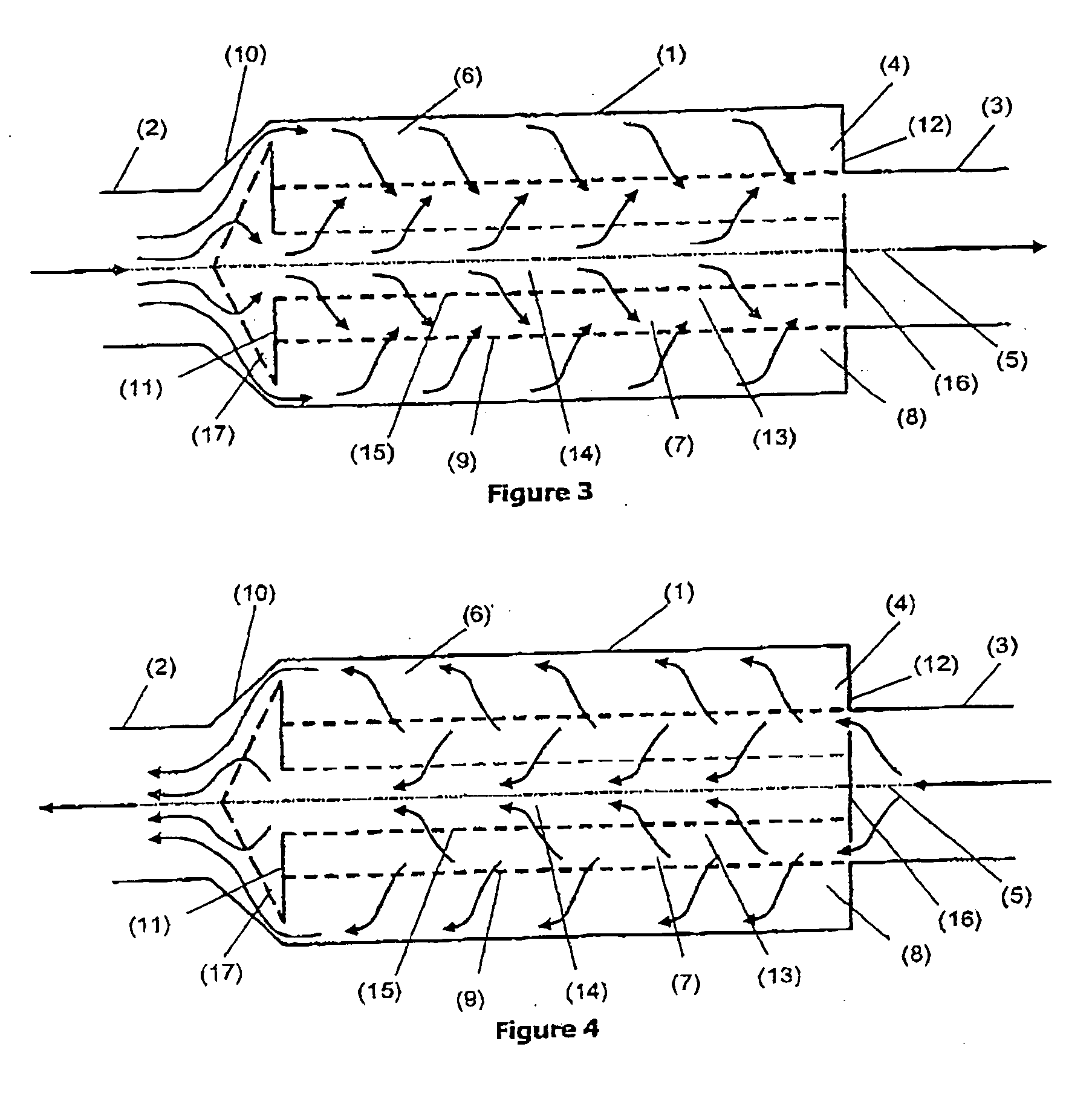

Apparatus for separation of gas-liquid mixtures and promoting coalescence of liquids

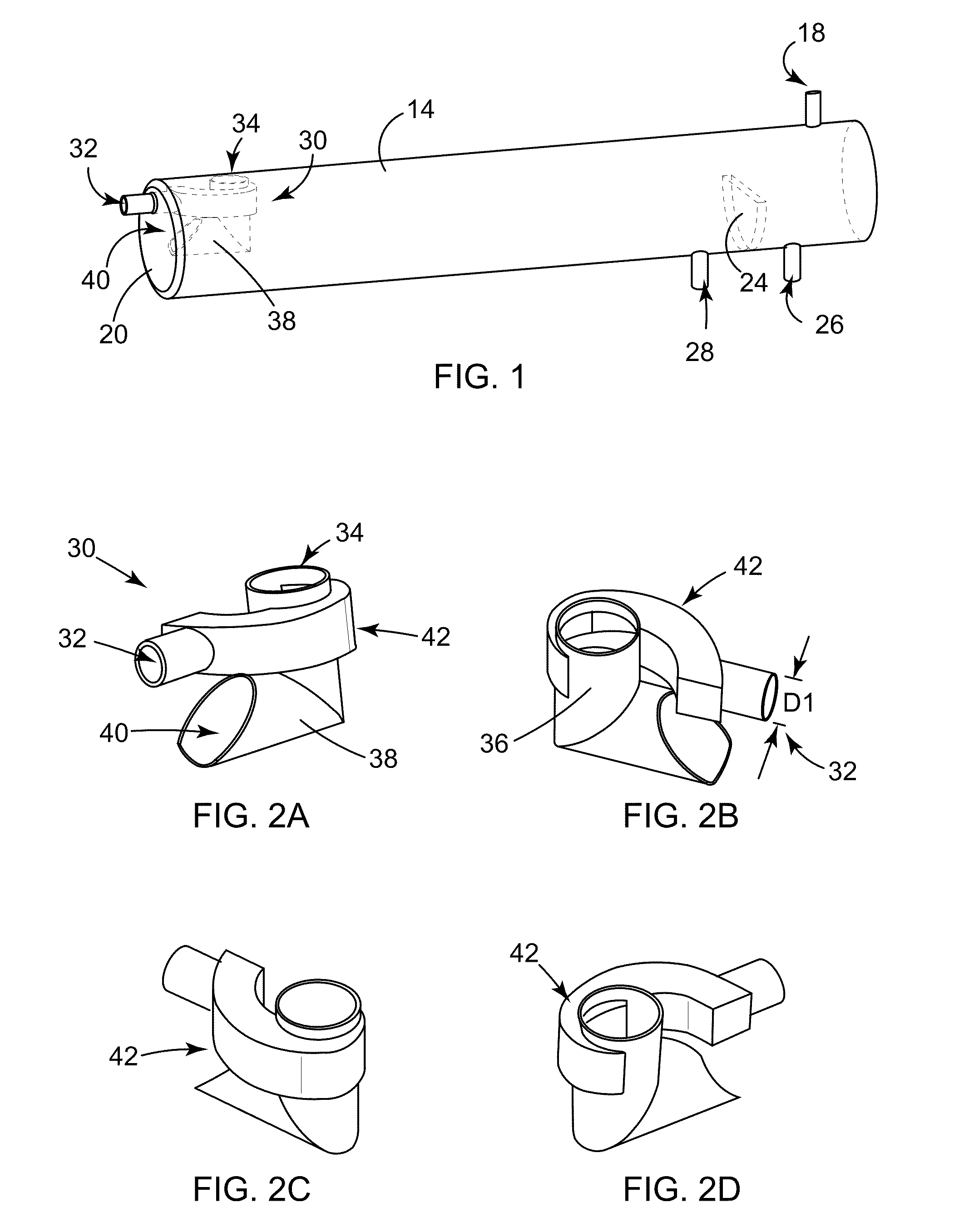

ActiveUS20110247500A1Reduce momentumPromote droplet coalescenceLiquid degasificationReversed direction vortexChemical physicsOil separation

Provided herein is a conditioning apparatus that includes a geometrical configuration having an inlet flow deceleration conduit and a cyclonic tube to effectuate both liquid-gas separation and droplet coalescence. The apparatus is typically positioned at the inlet of a separator vessel used for removing water and gas from extracted crude oil containing entrained water and gas. The apparatus promotes droplet coalescence and gas separation for mixed fluids flowing into an existing water and oil separation device.

Owner:SAUDI ARABIAN OIL CO

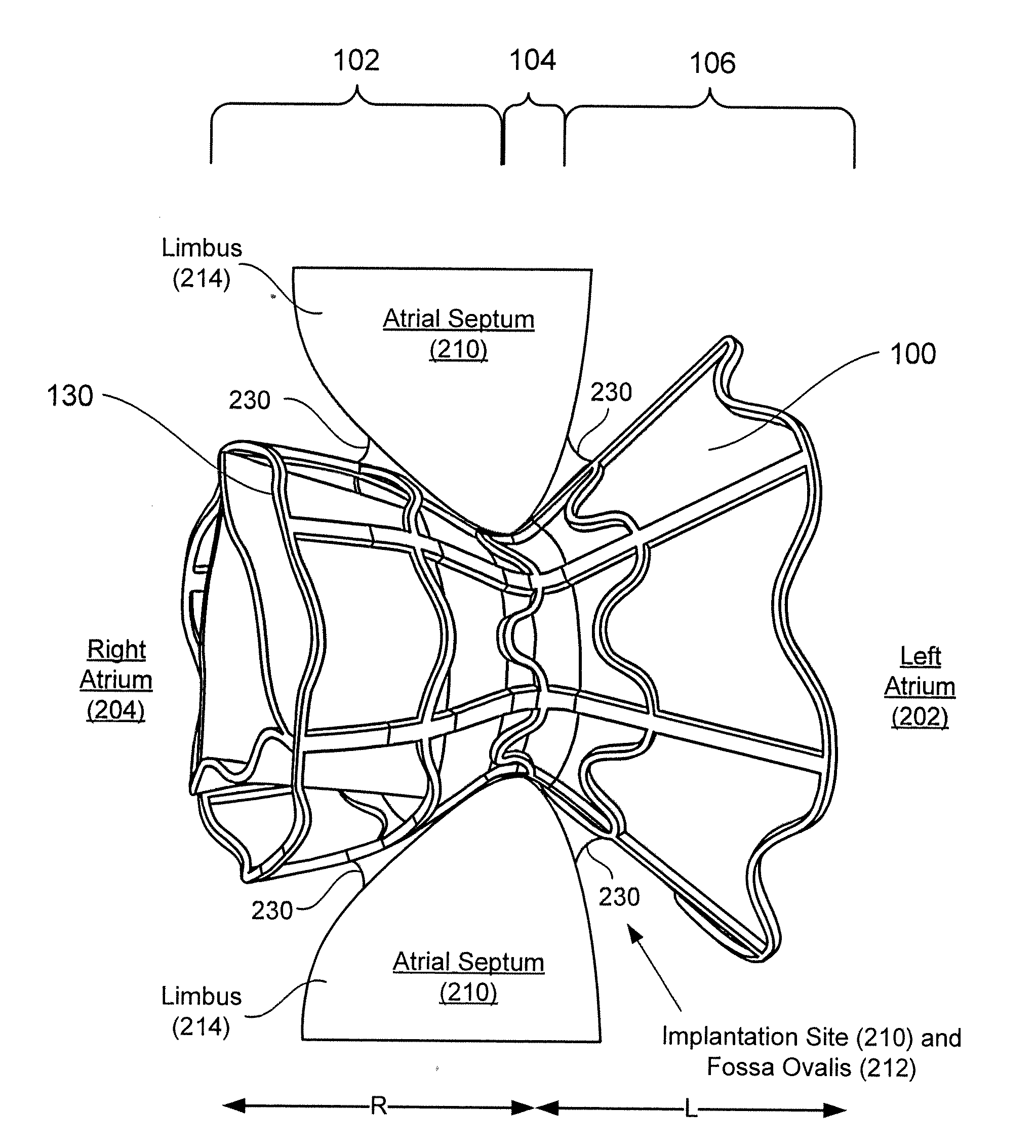

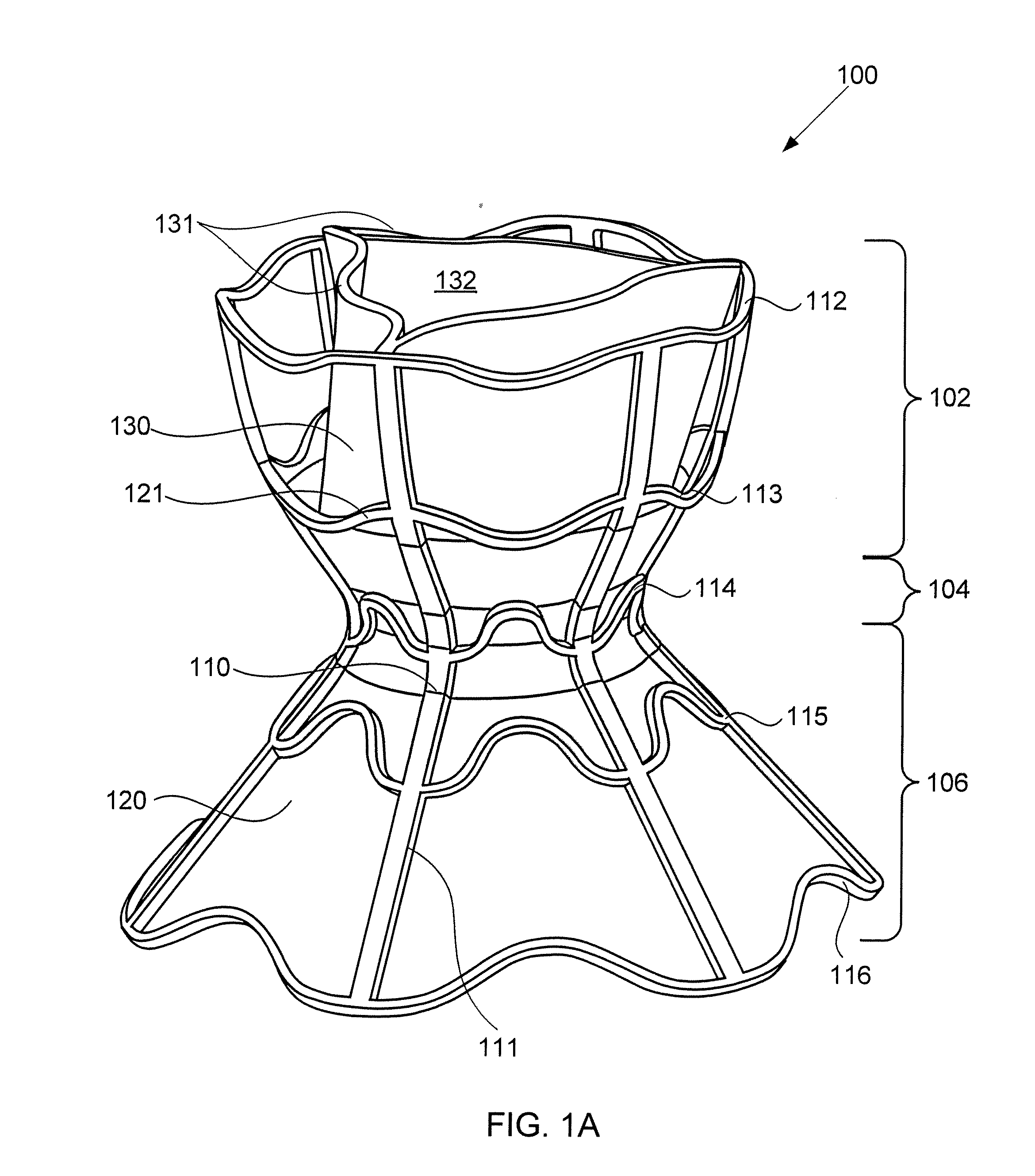

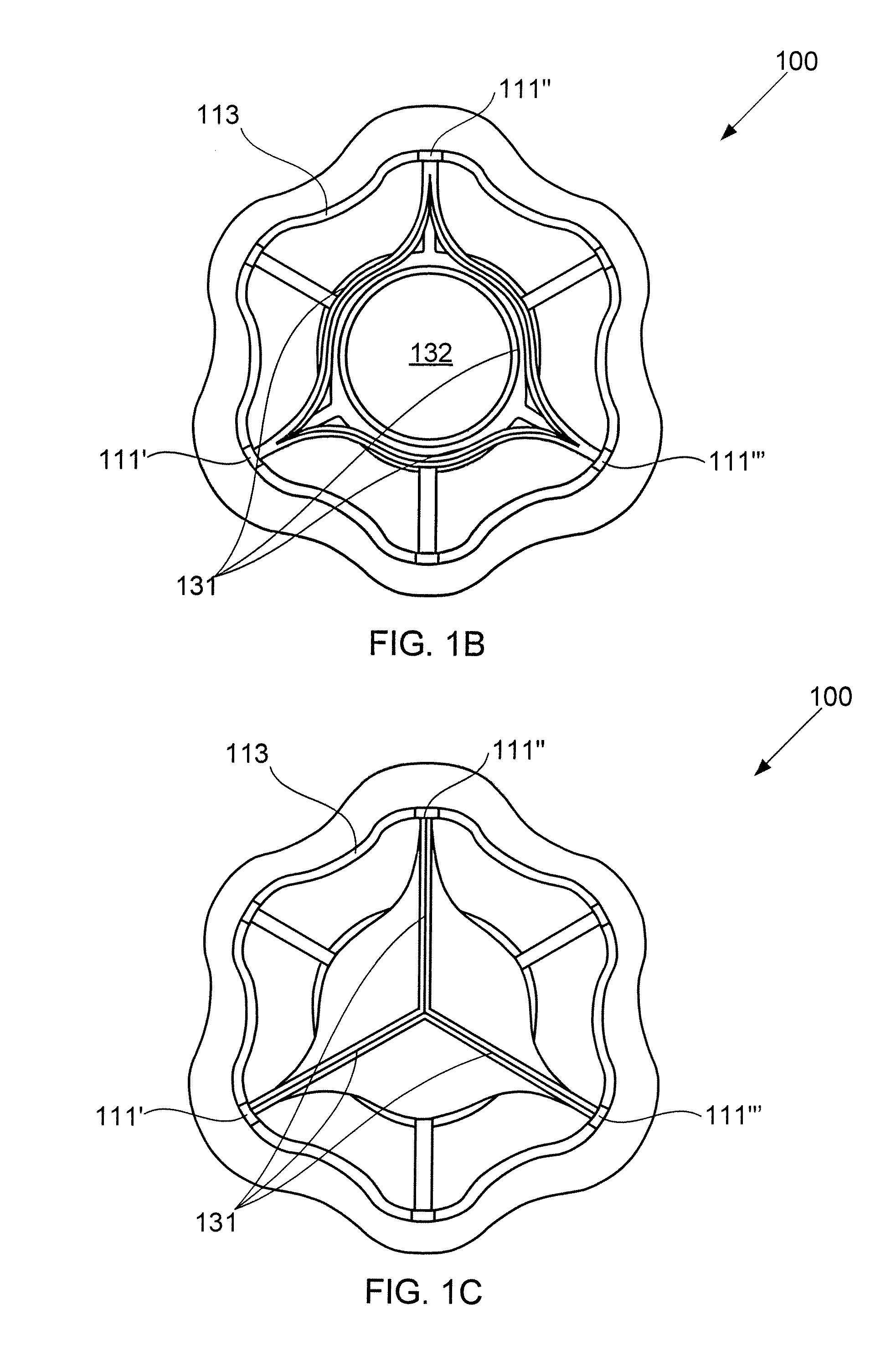

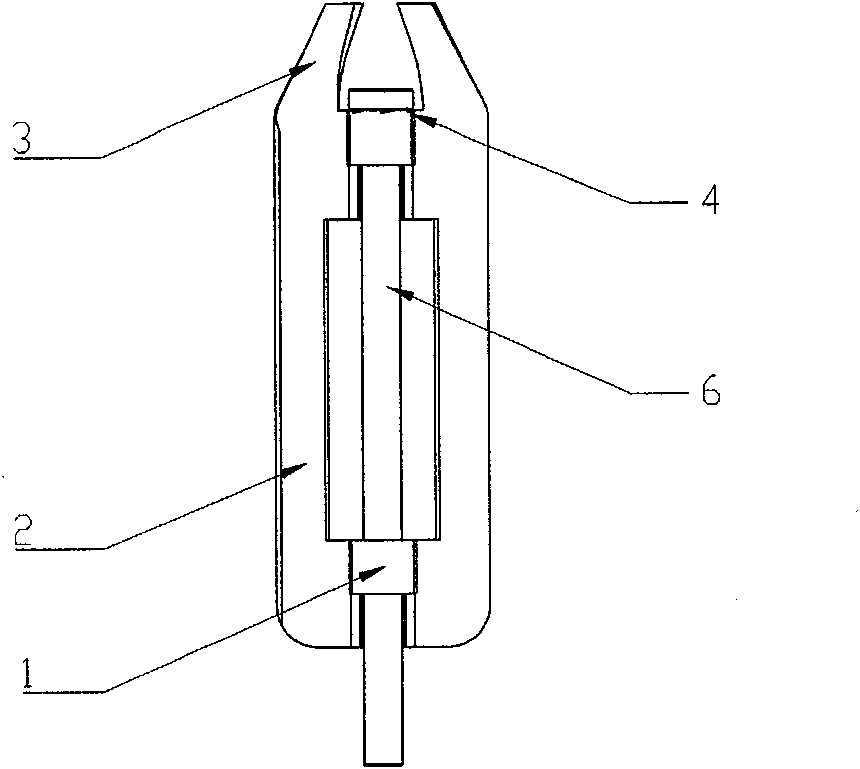

Devices for reducing left atrial pressure having biodegradable constriction, and methods of making and using same

ActiveUS20130030521A1Reducing left atrial pressureIncrease cardiac outputHeart valvesSurgeryLeft ventricular sizeLeft atrial pressure

A device for regulating blood pressure between a patient's left atrium and right atrium comprises an hourglass-shaped stent comprising a neck region and first and second flared end regions, the neck region disposed between the first and second end regions and configured to engage the fossa ovalis of the patient's atrial septum; and a one-way tissue valve coupled to the first flared end region and configured to shunt blood from the left atrium to the right atrium when blood pressure in the left atrium exceeds blood pressure in the right atrium. The inventive device may include a biodegradable material that biodegrades to offset flow changes caused by tissue ingrowth. The inventive device may reduce left atrial pressure and left ventricular end diastolic pressure, and may increase cardiac output, increase ejection fraction, relieve pulmonary congestion, and lower pulmonary artery pressure, among other benefits.

Owner:WAVE LTD V

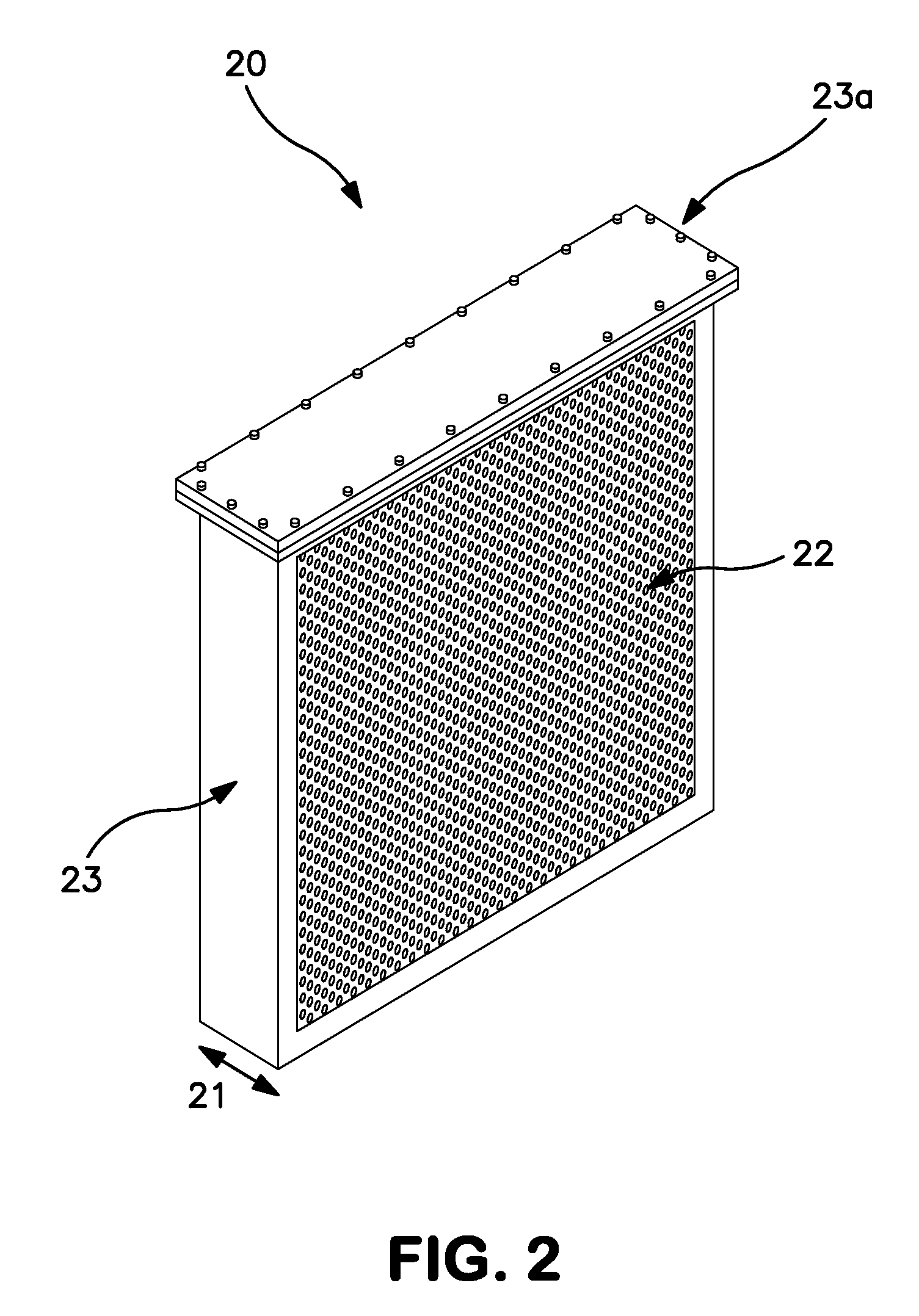

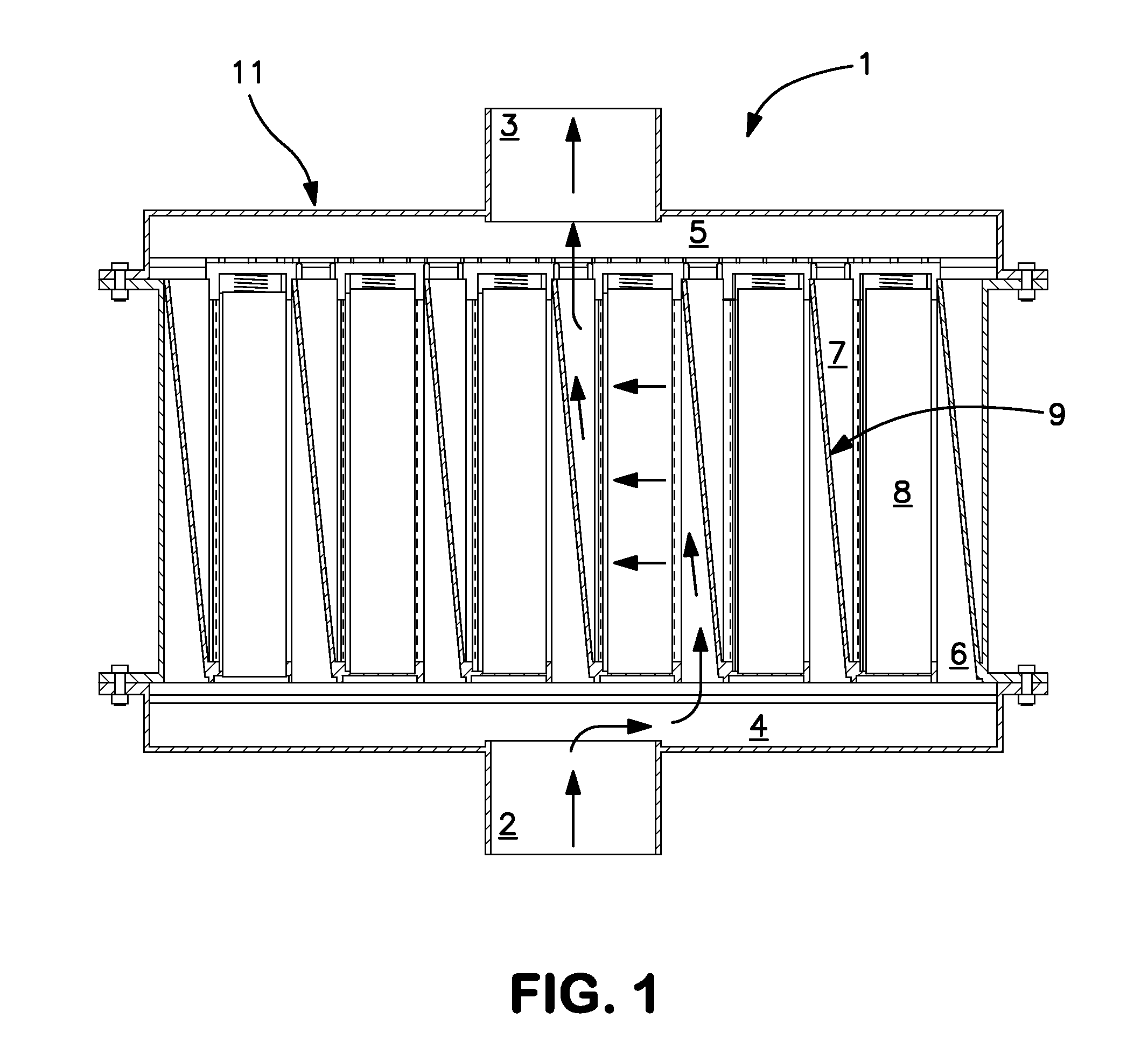

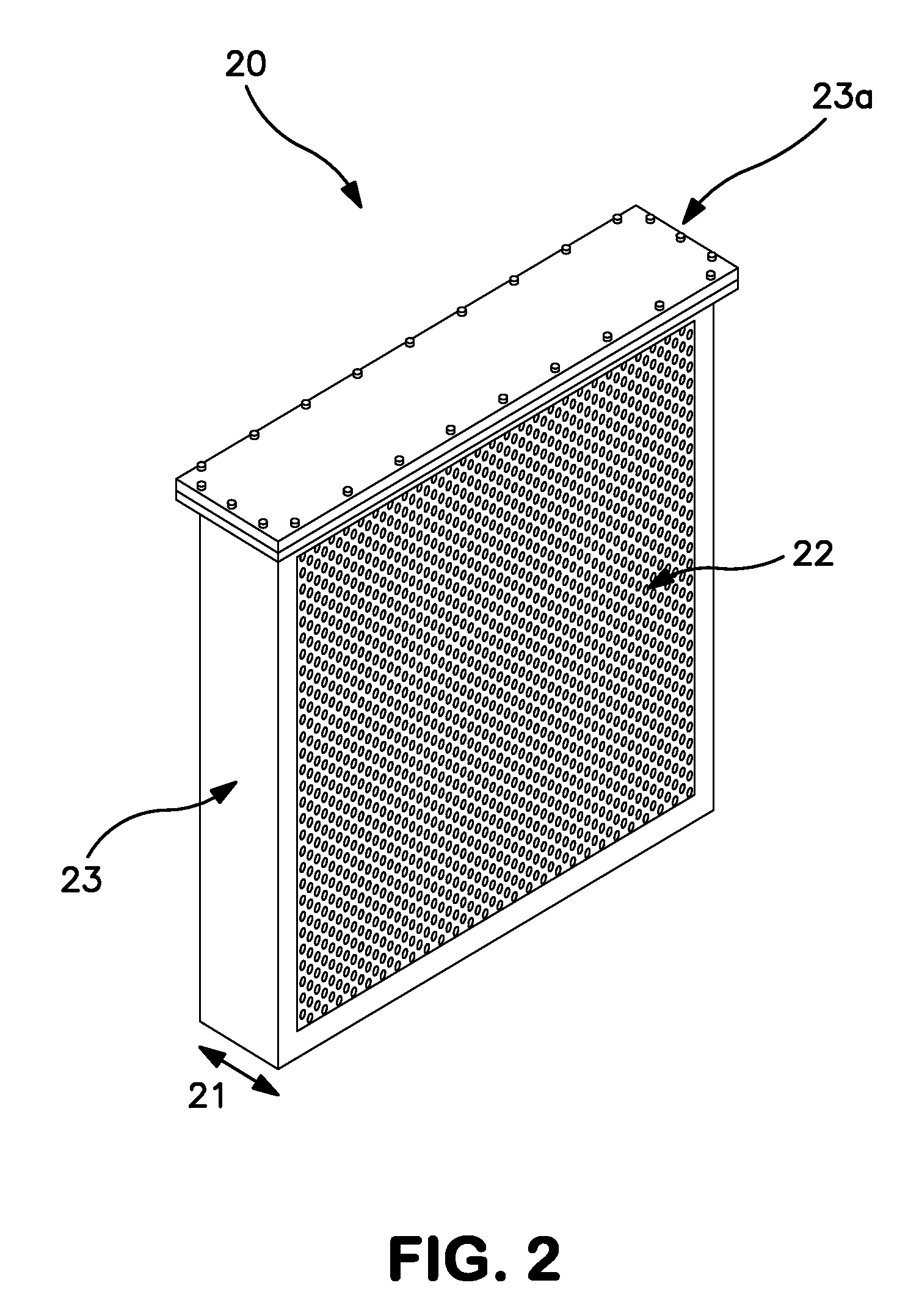

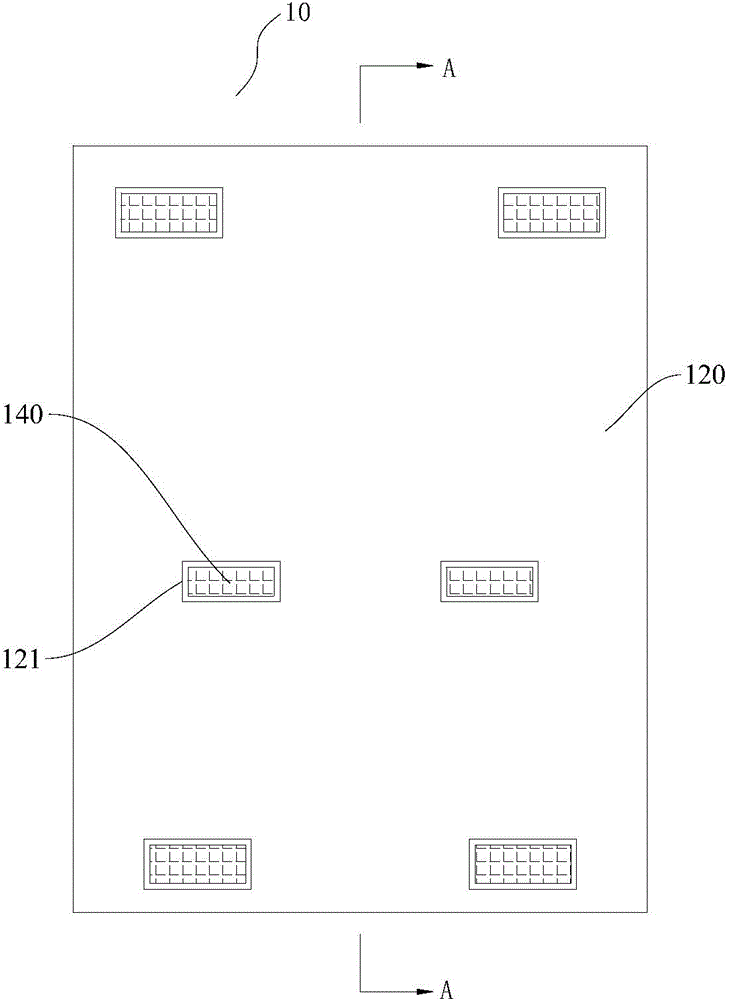

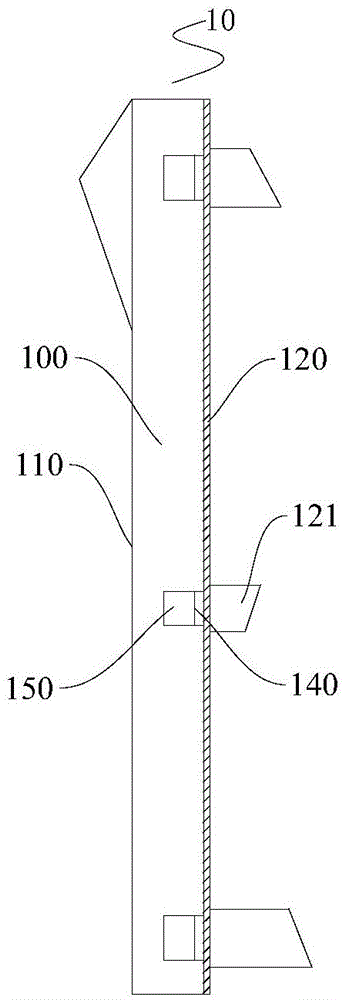

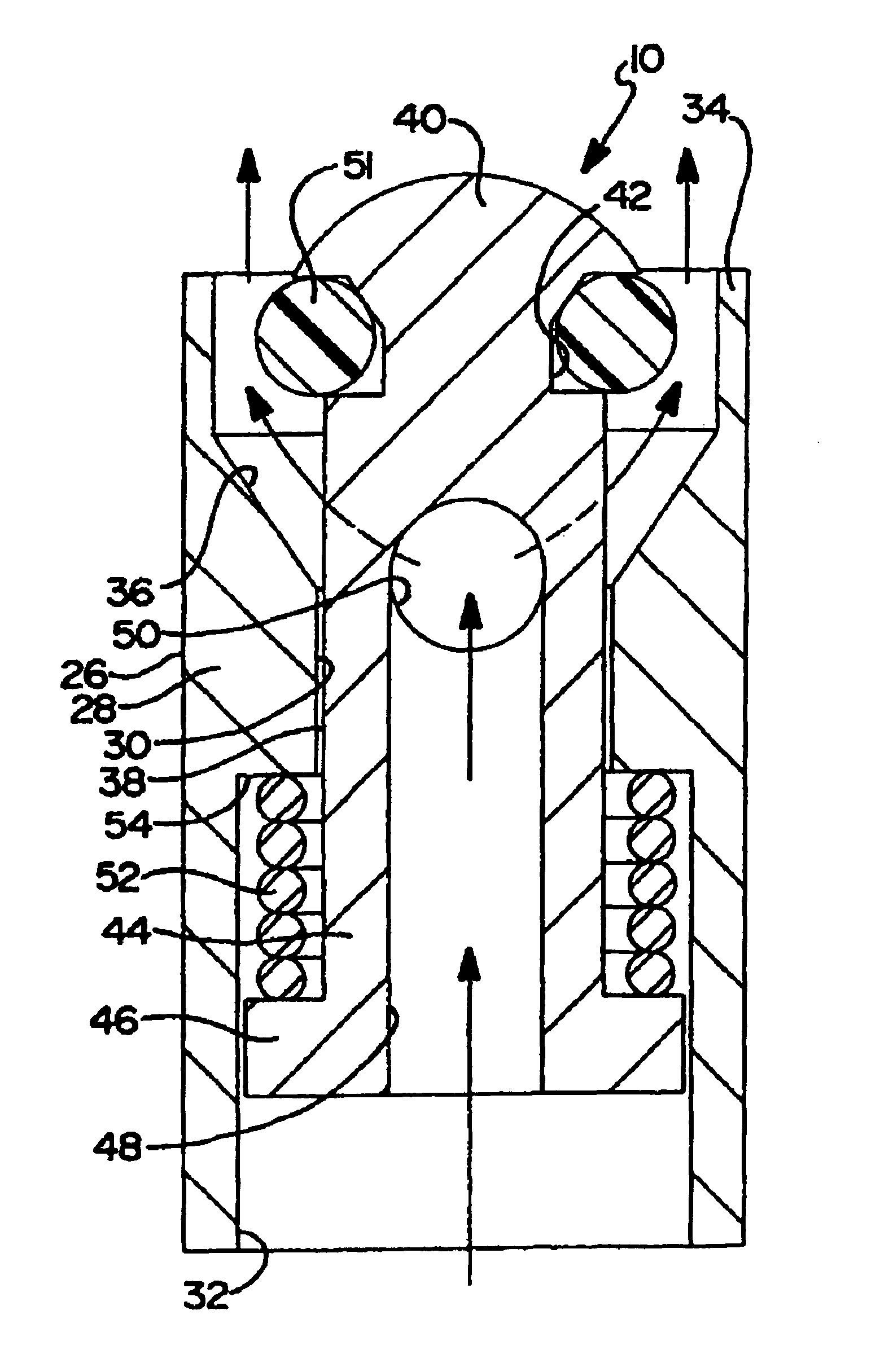

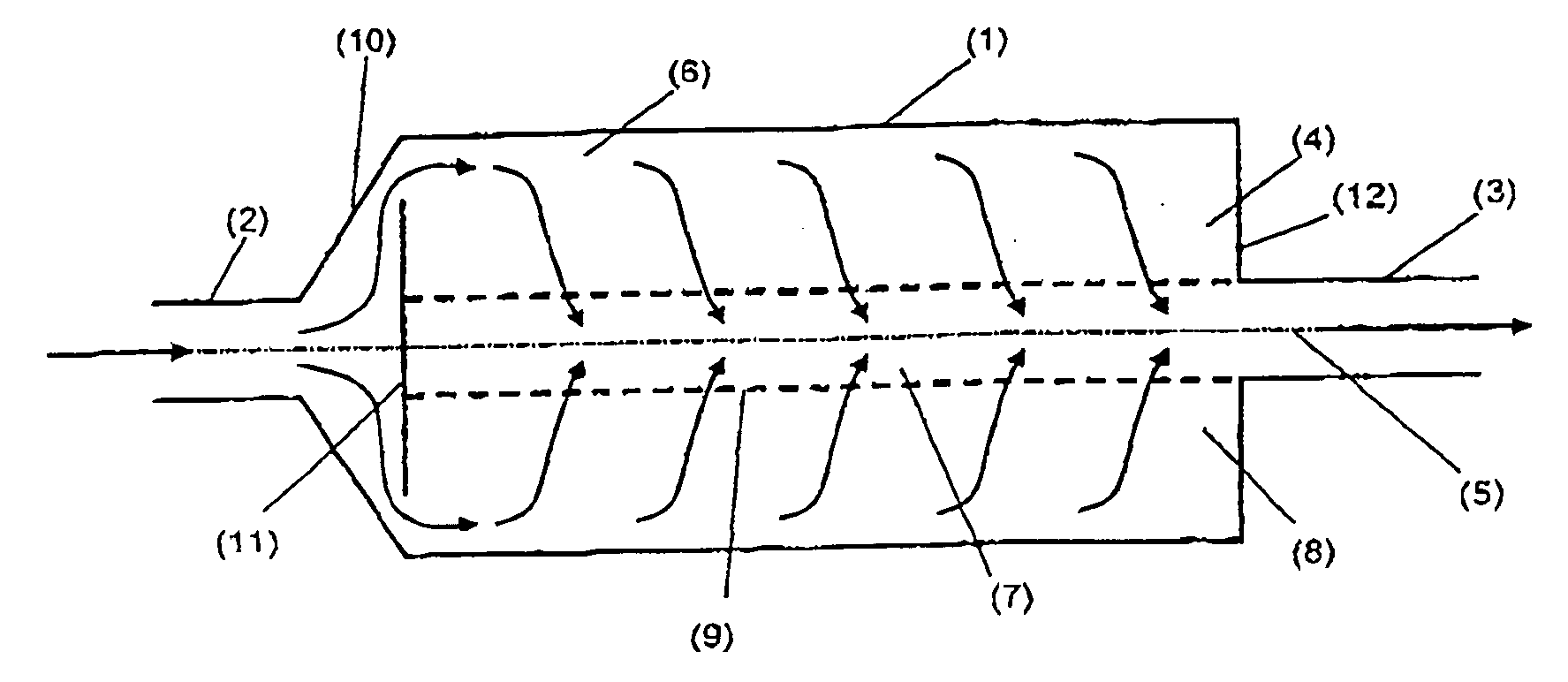

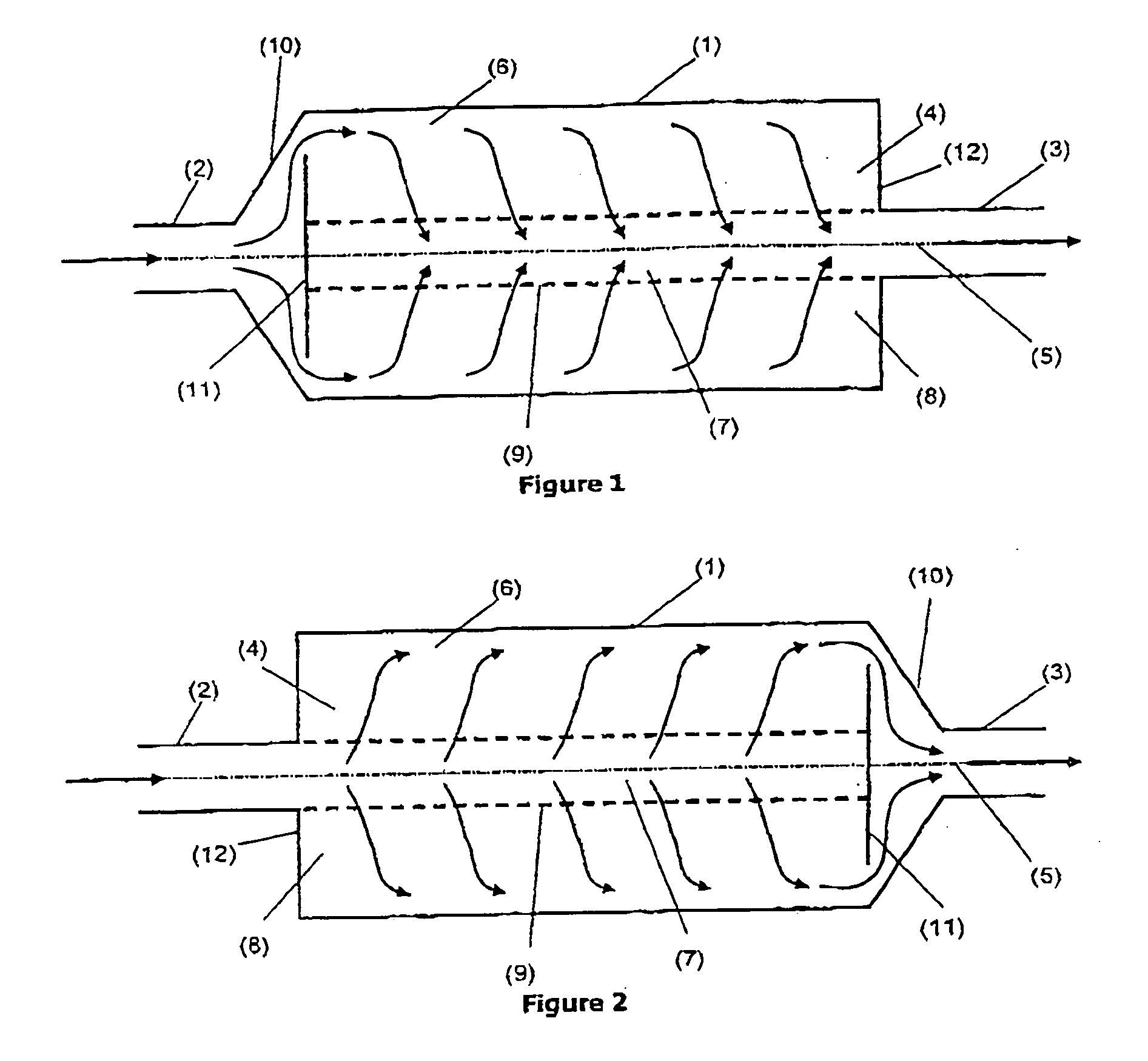

Modular compact adsorption bed

A modular and compact adsorbent bed structure is disclosed for use in an adsorption-based gas separation plant. The conventional adsorbent bed in a gas separation plant is replaced with a plurality of modular adsorbent bed units connected to make the adsorbent bed structure. Modular adsorbent bed units of this invention provide higher capacity of product per unit volume of adsorbent material (i.e., increased adsorbent utilization) as compared to that obtained from conventional adsorbent beds. The modular design requires lower fabrication costs; is easier to transport; has less maintenance and repair requirements; and is easier to load with adsorbent material.

Owner:PRAXAIR TECH INC

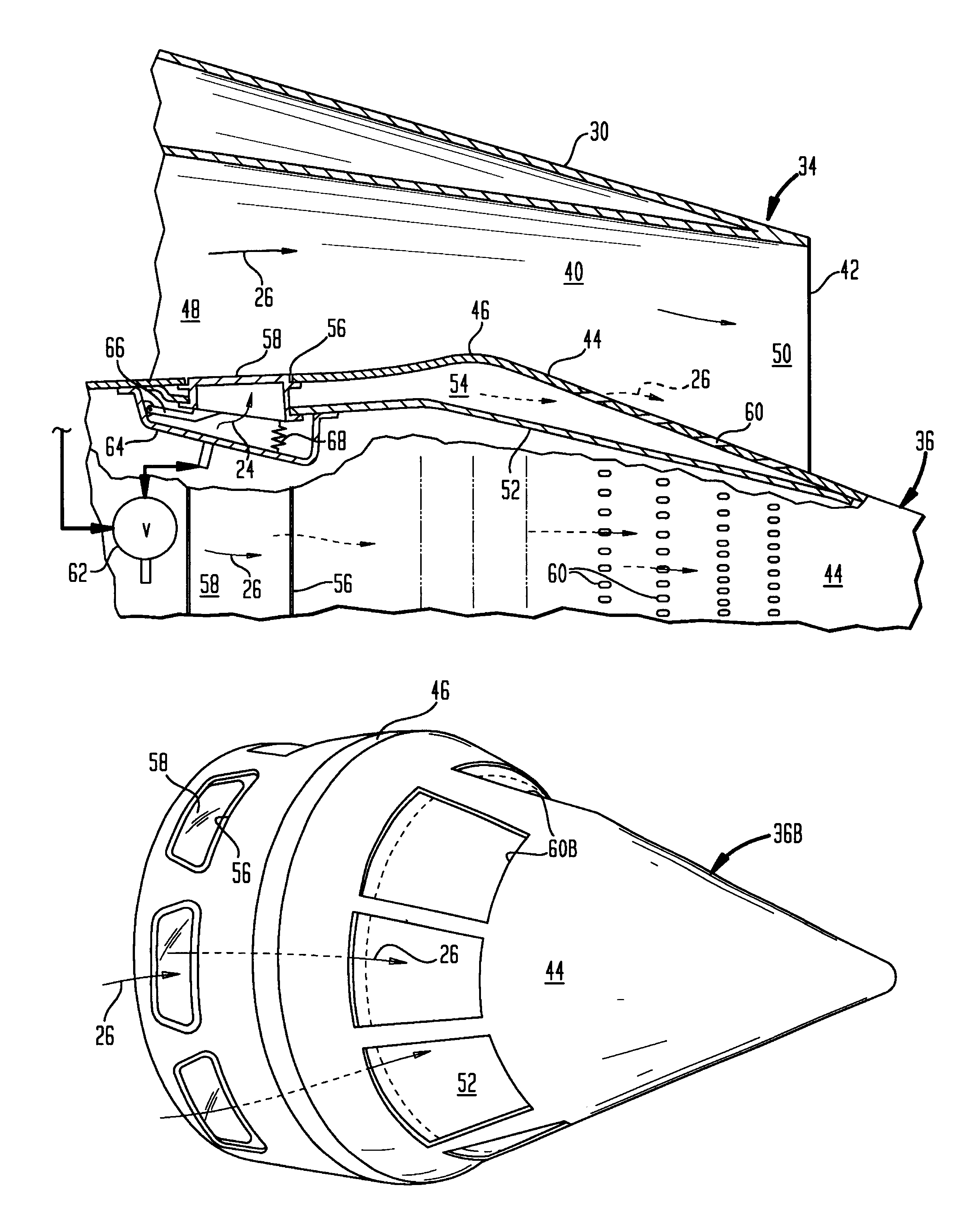

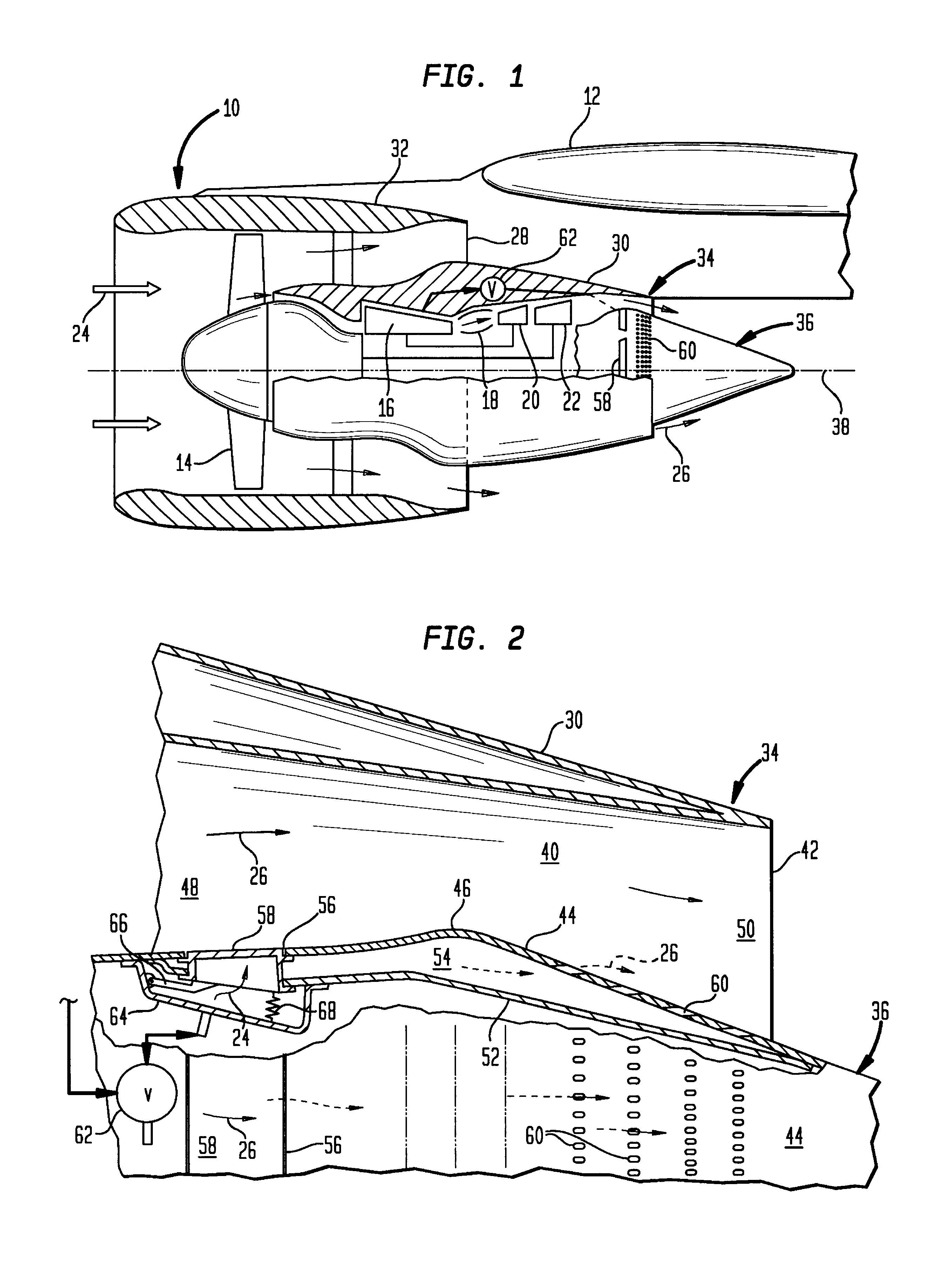

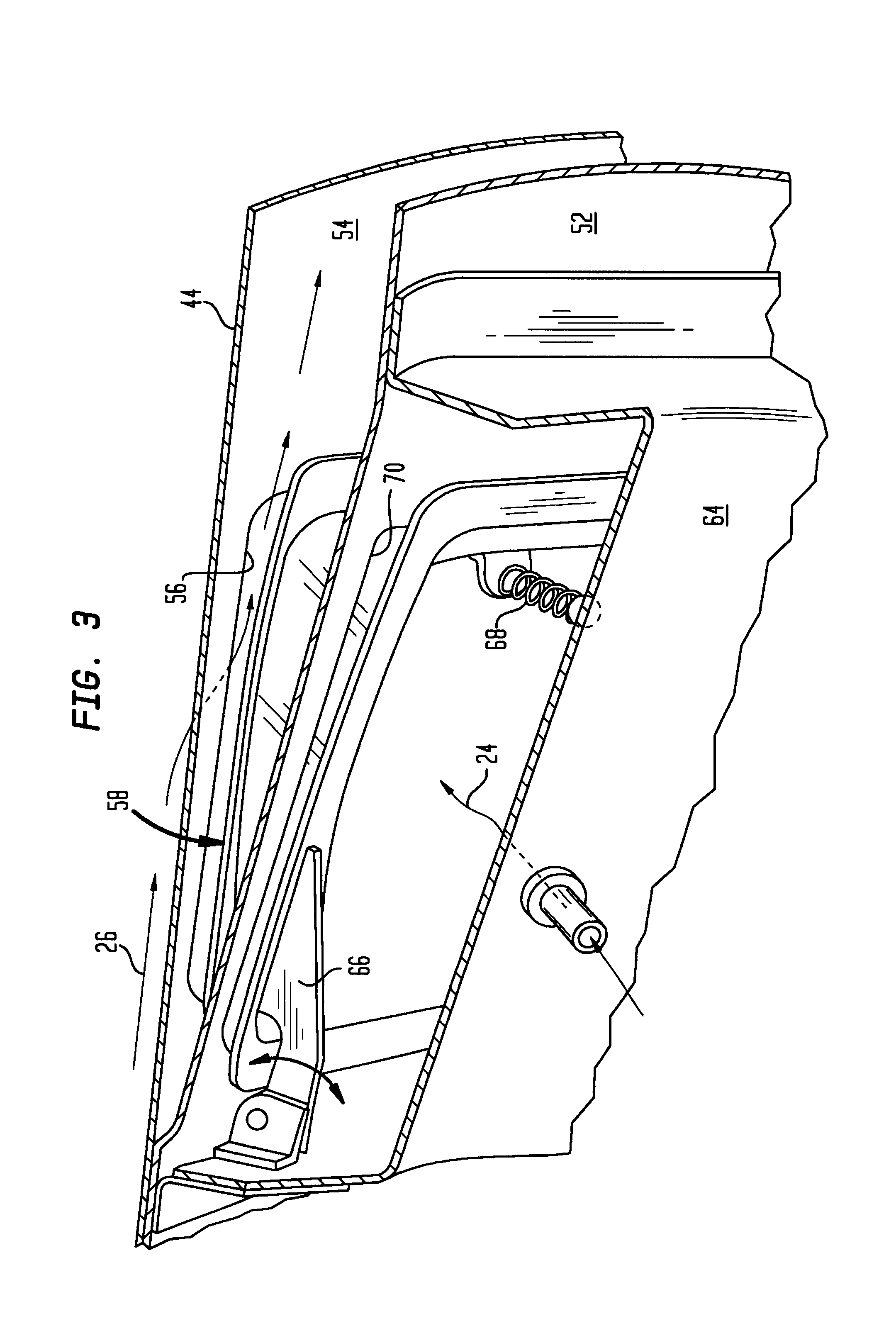

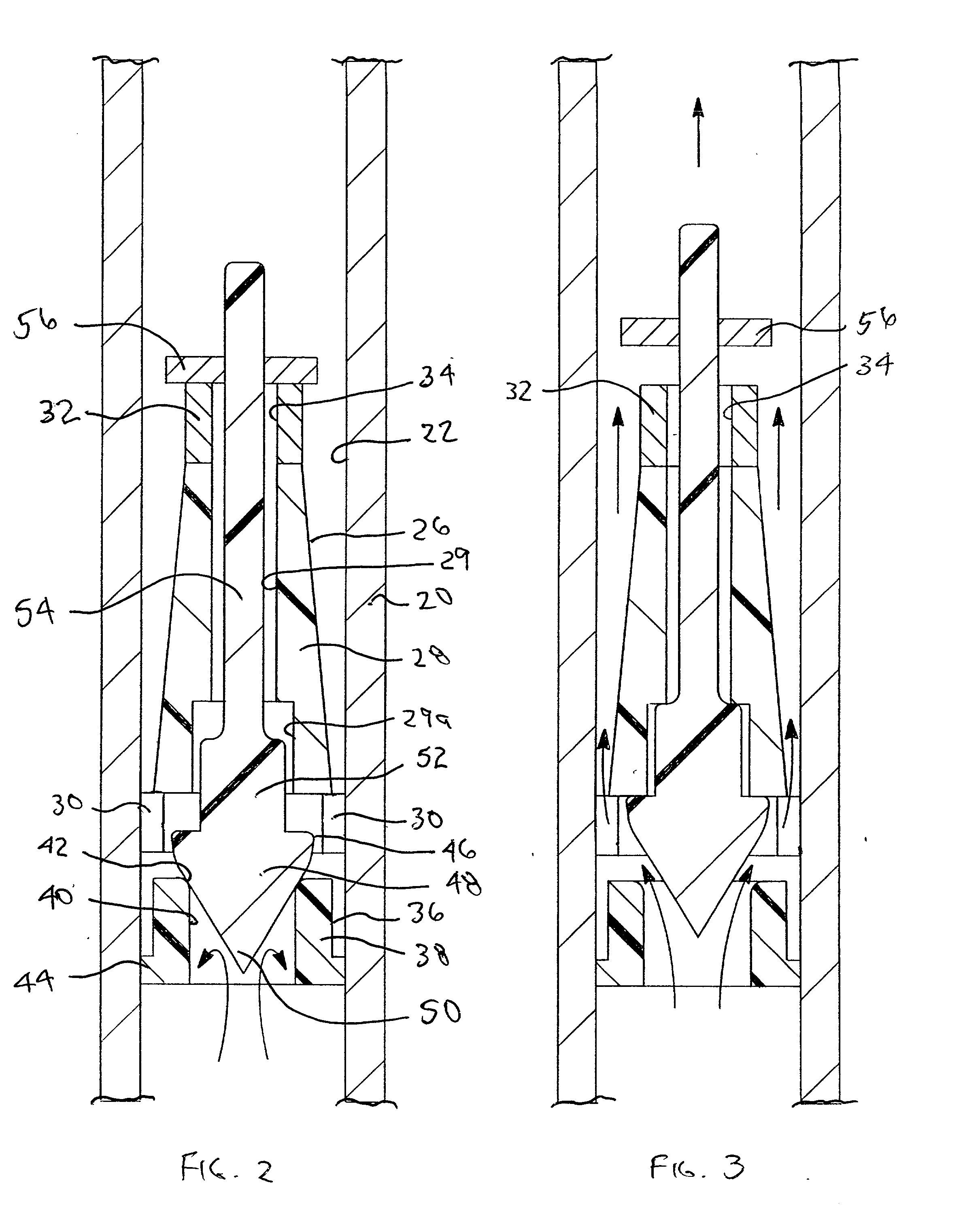

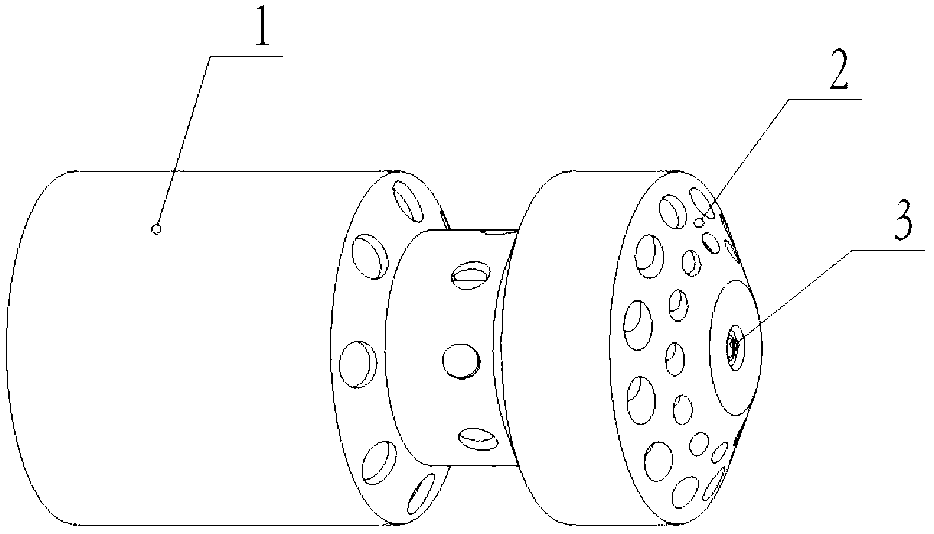

Variable area plug nozzle

InactiveUS6845607B2Increase the circulation areaShorten speedCosmonautic vehiclesCosmonautic propulsion system apparatusAirplaneTakeoff

A center plug is configured for variable area use in an exhaust nozzle. A forward portion of the plug includes an inlet having a closing flap therein, and an aft portion of the plug includes an outlet. The flap is selectively open during aircraft takeoff operation and up to a preset climb altitude for bypassing a portion of core exhaust flow through the plug, with the flap being closed from preset altitude and cruise operation. Opening the flap correspondingly increases the available flow area for discharging the exhaust flow for reducing velocity thereof, and attenuating noise.

Owner:AERONAUTICAL CONCEPT OF EXHAUST +1

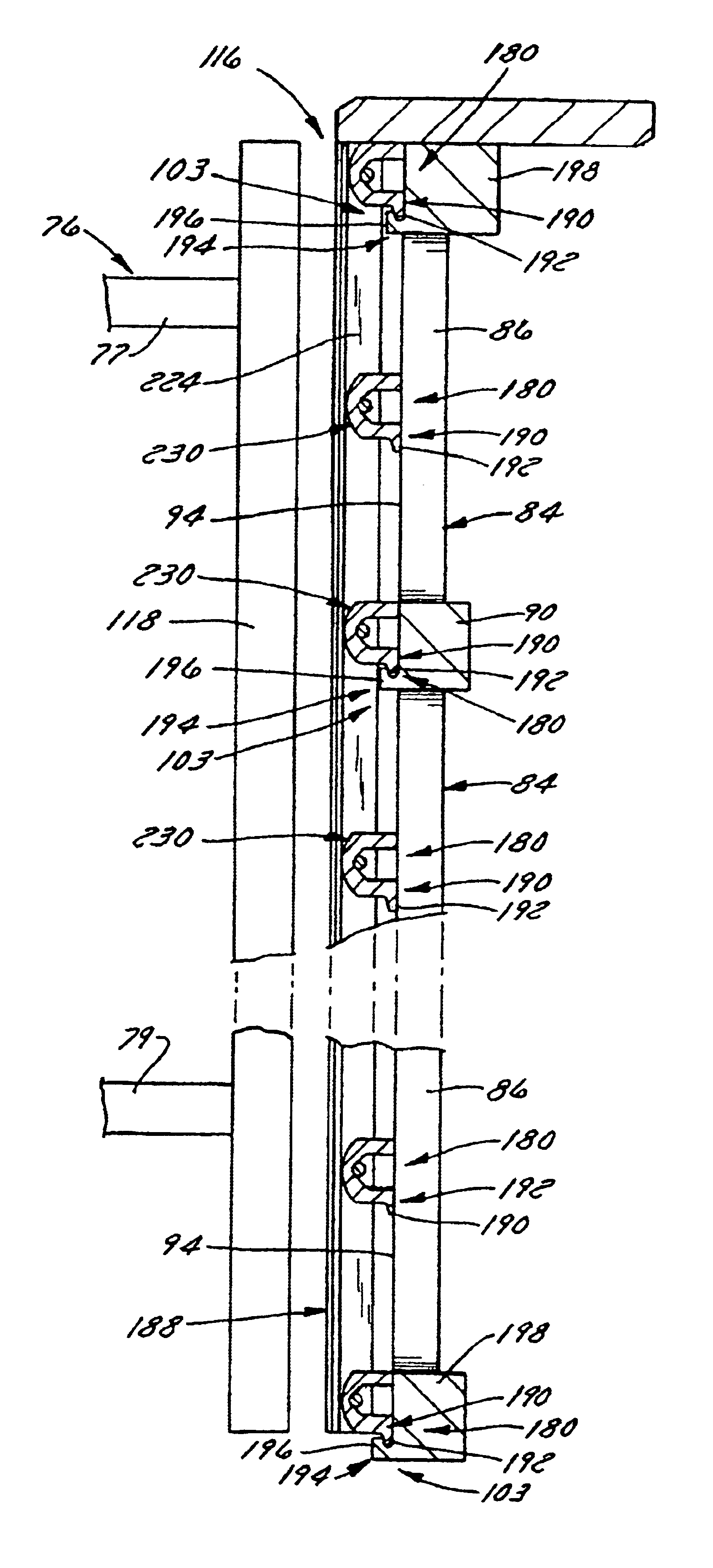

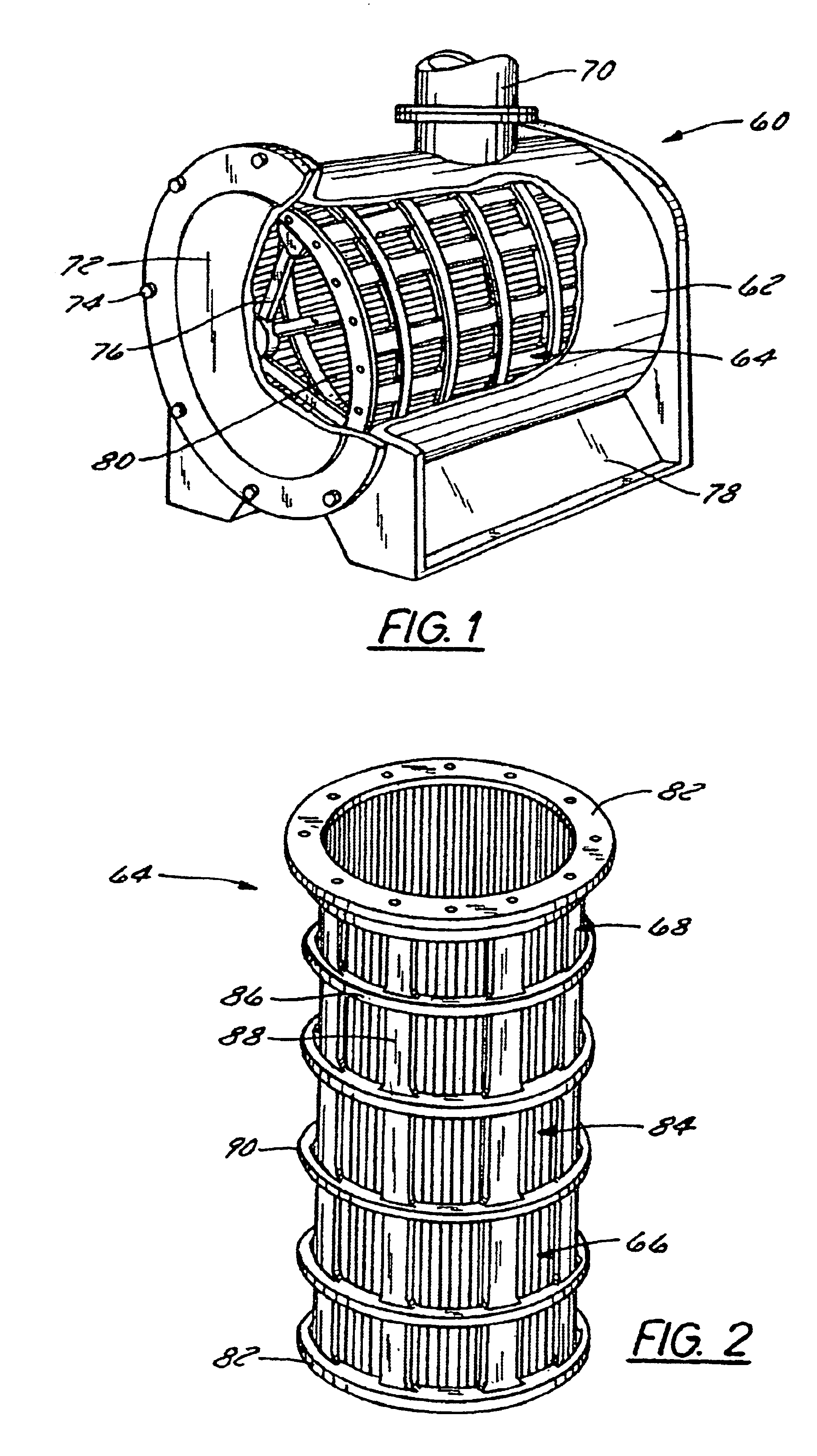

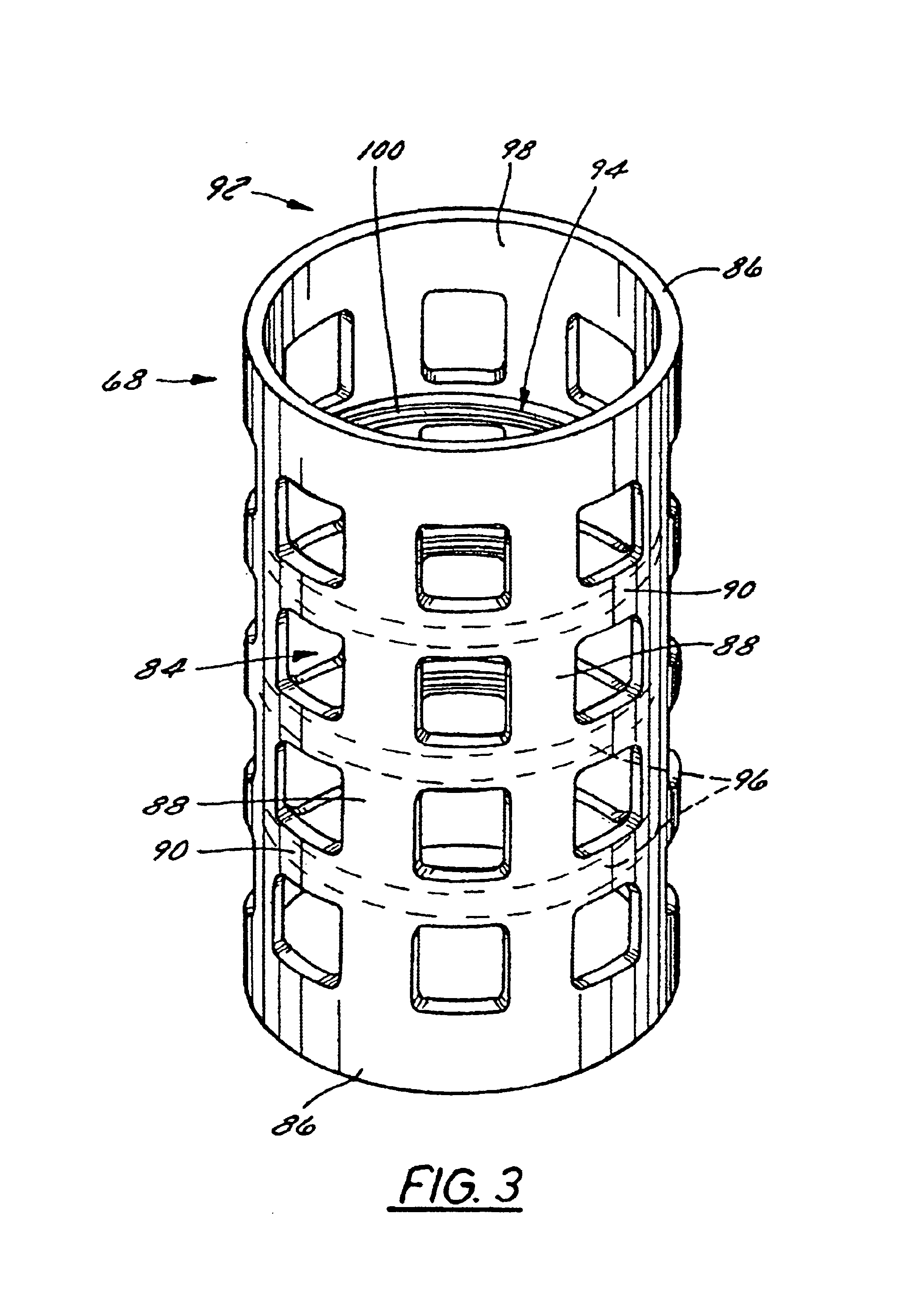

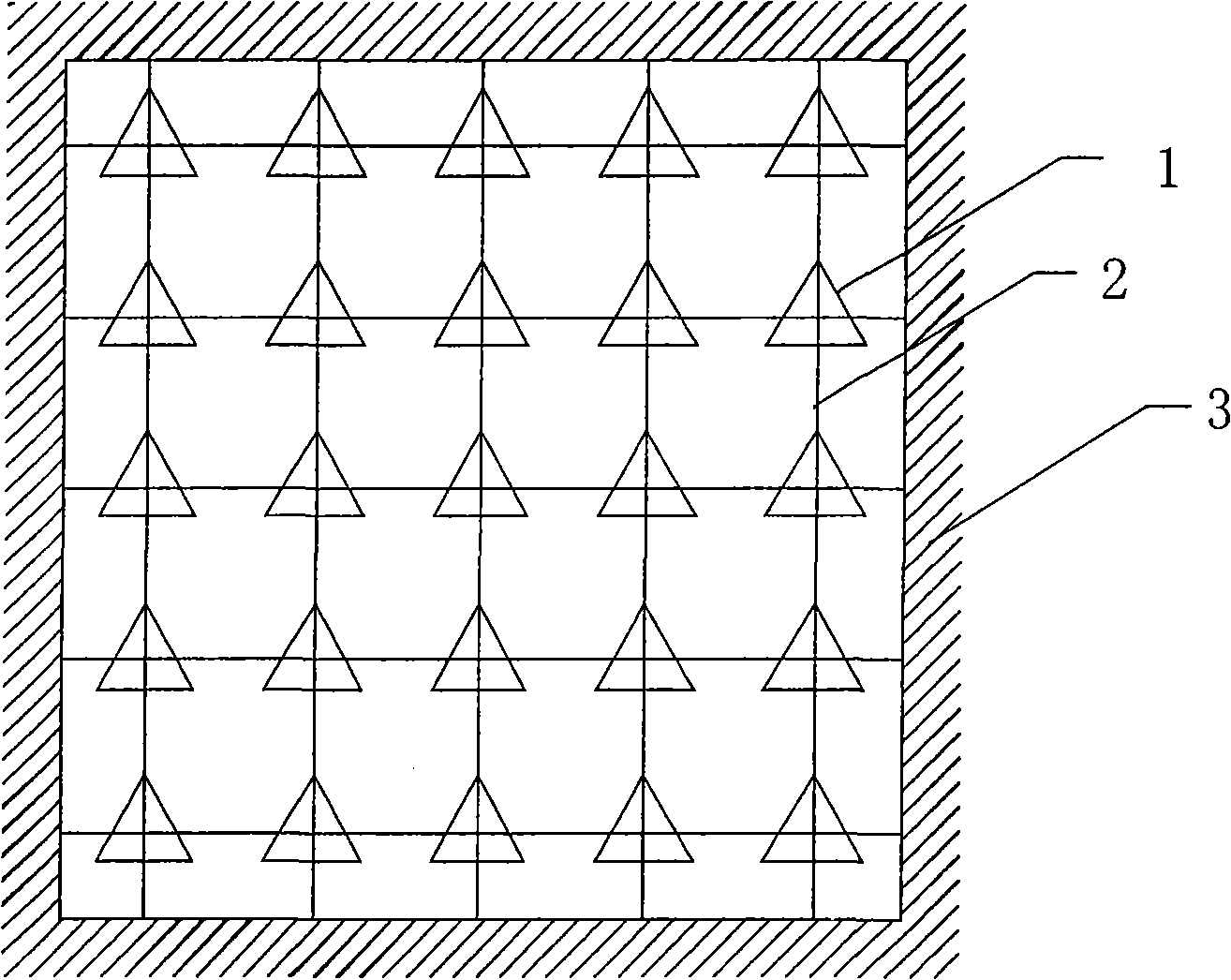

Screen cylinder and method

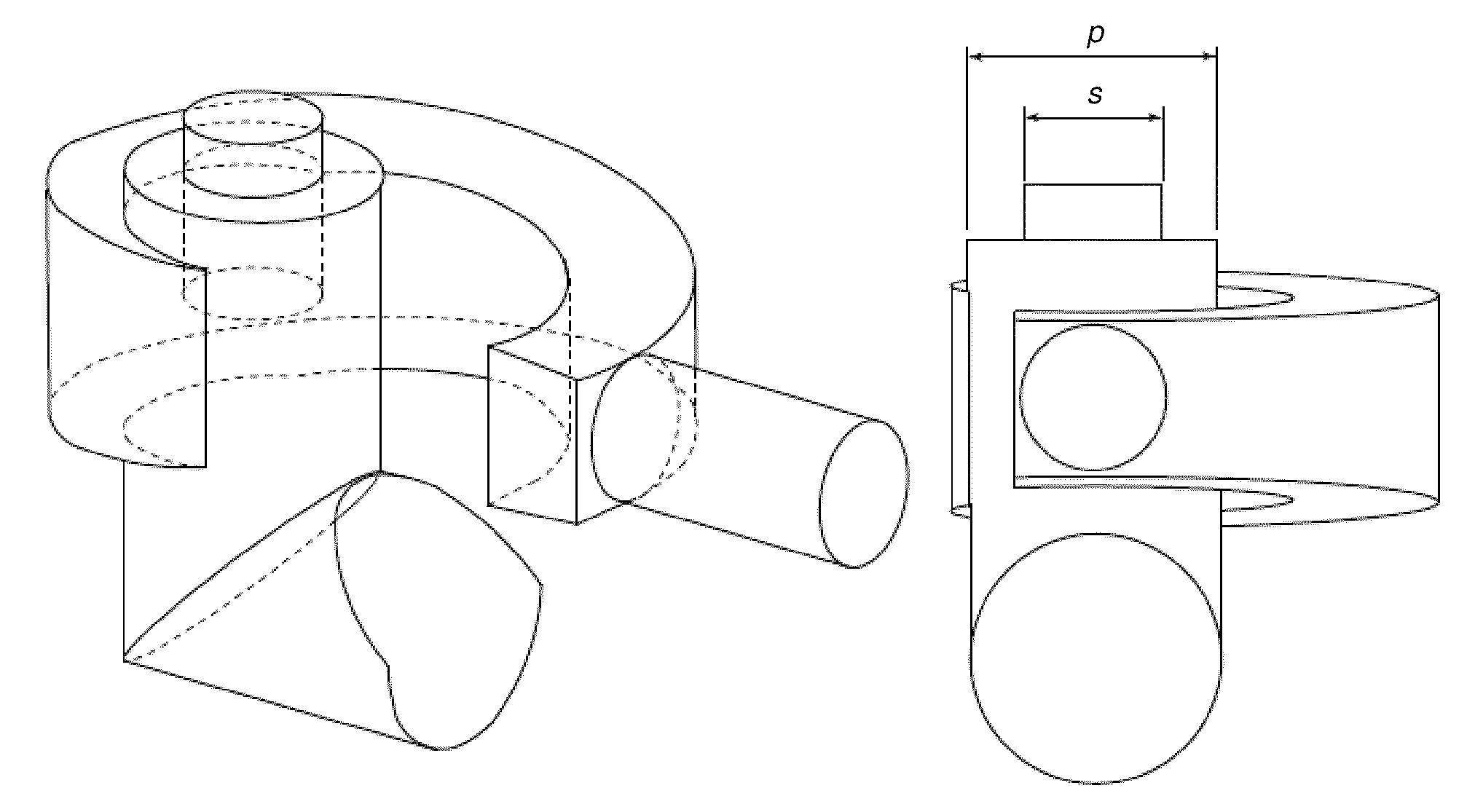

InactiveUS6915910B2Increase the circulation areaStrong stressSievingScreeningPreferred frameMechanical engineering

A pulp screen cylinder that includes screen media releasably engaged with a frame at spaced locations opposing movement of the media away from the frame during screening. A preferred frame includes a plurality of spaced engaging structures that releasably engage screen media. A preferred frame includes an arrangement of flow windows that are triangular or rhomboid. A preferred method includes producing a frame cylinder by centrifugal casting and machining flow windows using a jet cutting process. A preferred screen media has a plurality of spaced apart engaging structures that each releasably engages the frame at spaced apart locations. A preferred screen media is of wedgewire construction having engaging structure carried by a plurality of spaced wire retaining clips. A preferred clip has vee-shaped rounded slots and an arm thicker than an end wall. A preferred engaging structure includes a projection that has a lip or hook for releasable interlocking engagement.

Owner:KADANT BLACK CLAWSON LLC

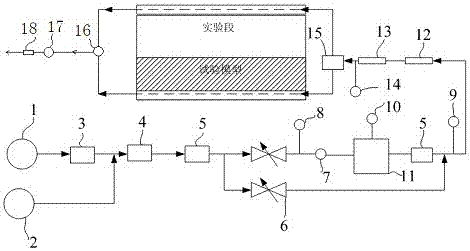

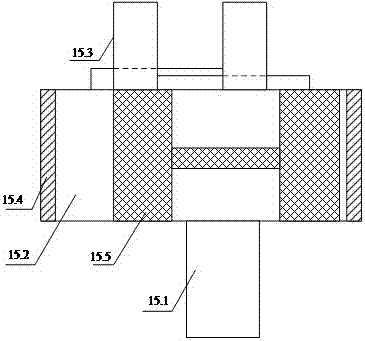

Icing wind tunnel hot gas anti-icing test high-precision simulation method and device

ActiveCN107271134AAvoid low temperature freezing and other problemsReduce high pressure heatAerodynamic testingWind energy generationThermodynamicsTemperature conditioning

The present invention discloses an icing wind tunnel hot gas anti-icing test high-precision simulation method and device. The device comprises a gas source, a pressure reduction device, a filter, an air heater, a multistage electric heating device and a test section in order from a gas input direction to a gas output direction. The gas path behind the pressure reduction device is divided into two paths, one path is heated and then is subjected to flow mixing with the other unheated path, a pneumatic switching valve in an icing wind tunnel plenum chamber is configured to divide the gas path into two paths, gas of one path enters a test section and flows out after passing through a test model to perform flow measurement, gas of the other path is flown through from the external portion of the test section and performs flow measurement, and gas of a model main path and gas of a simulation bypass path are combined into one path after passing through the wind tunnel test section and are exhausted through a flowmeter and a silencer; a cold and hot gas mixing mode is employed to rapidly reduce the high-pressure hot gas behind the air heater so as to reach the effect of rapid temperature adjustment; and the multistage electric heating device is employed to perform high-precision temperature regulation and control so as to perform high-precision temperature adjustment of high-pressure hot gas prior to the high-pressure hot gas entering a test model step by step.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

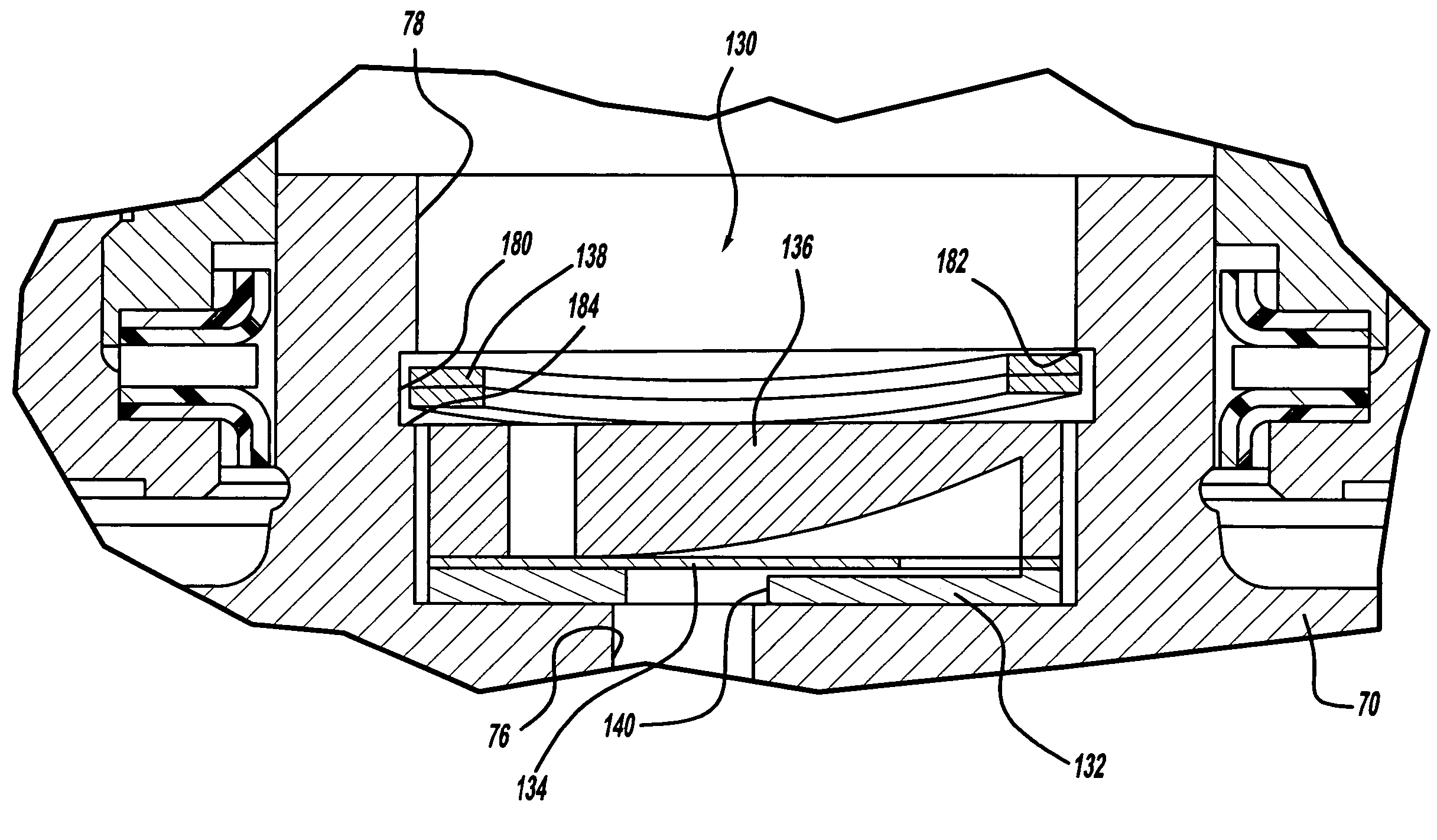

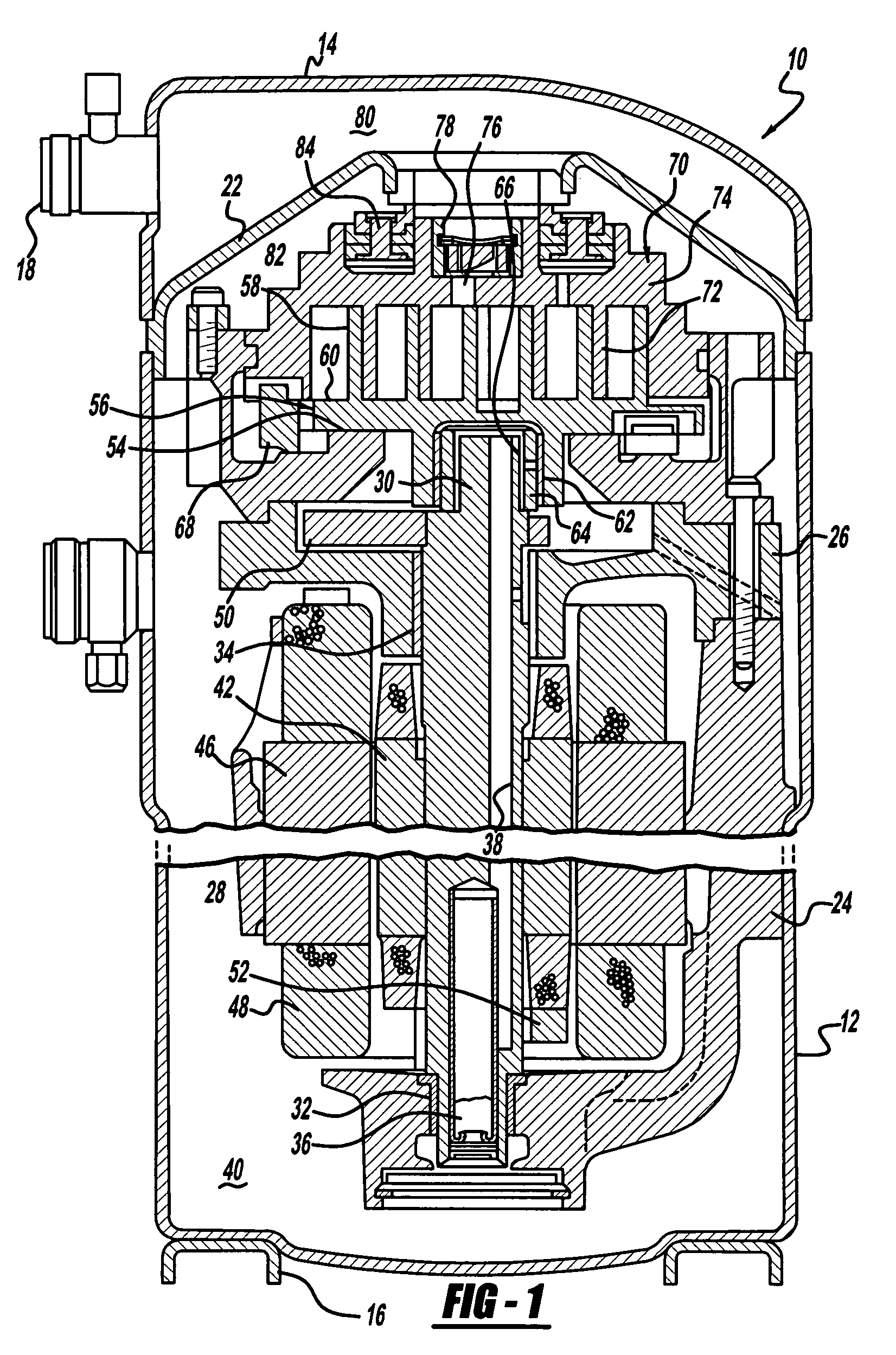

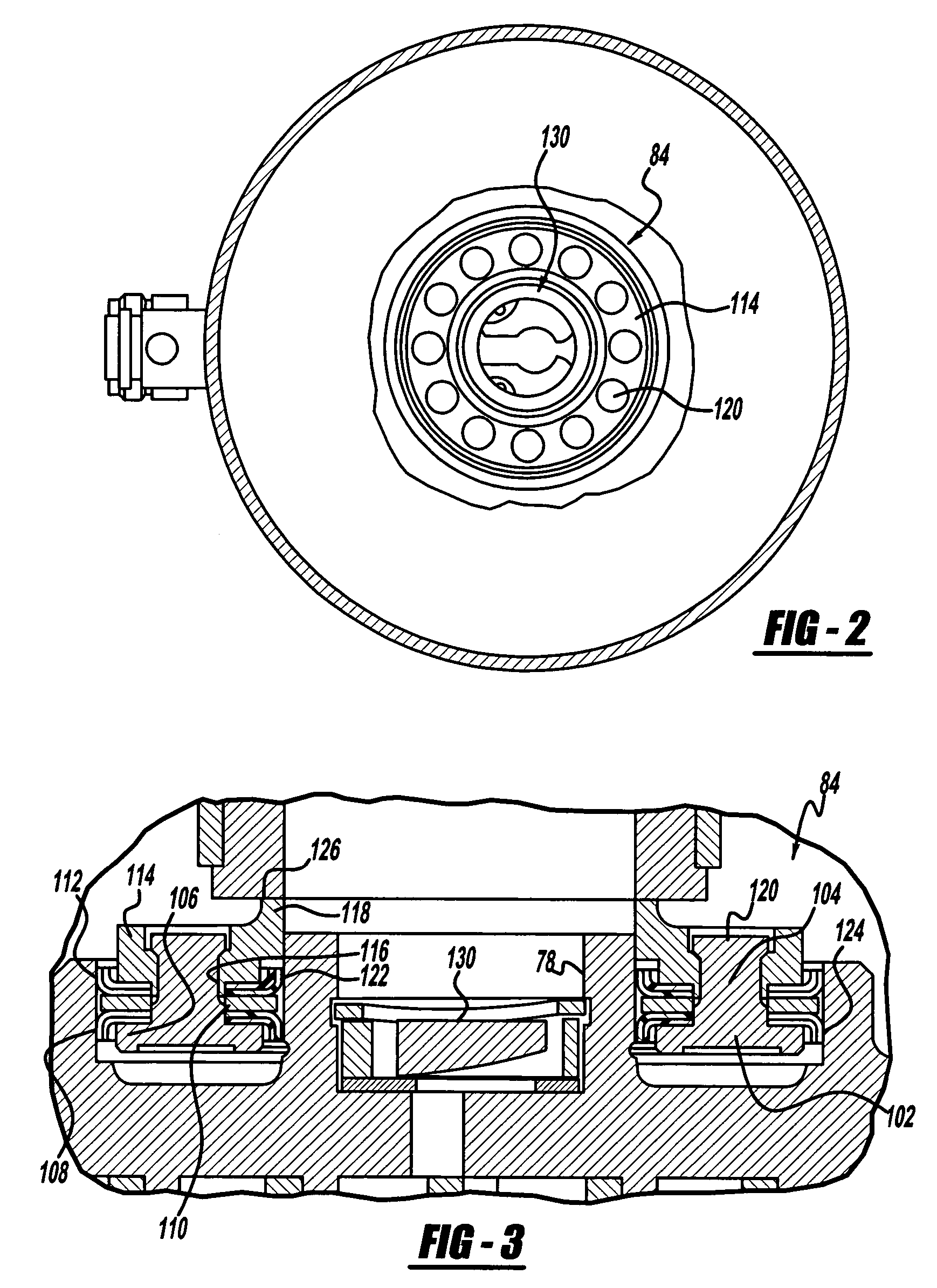

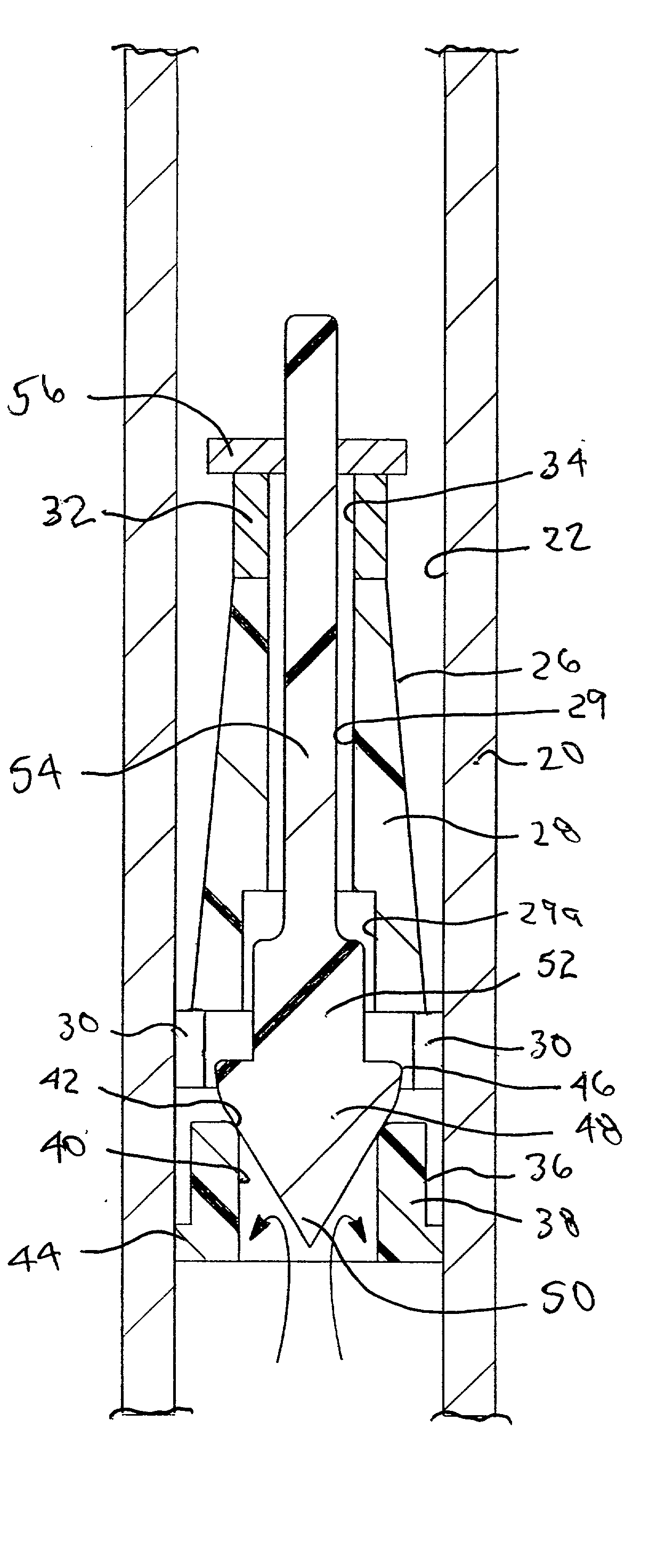

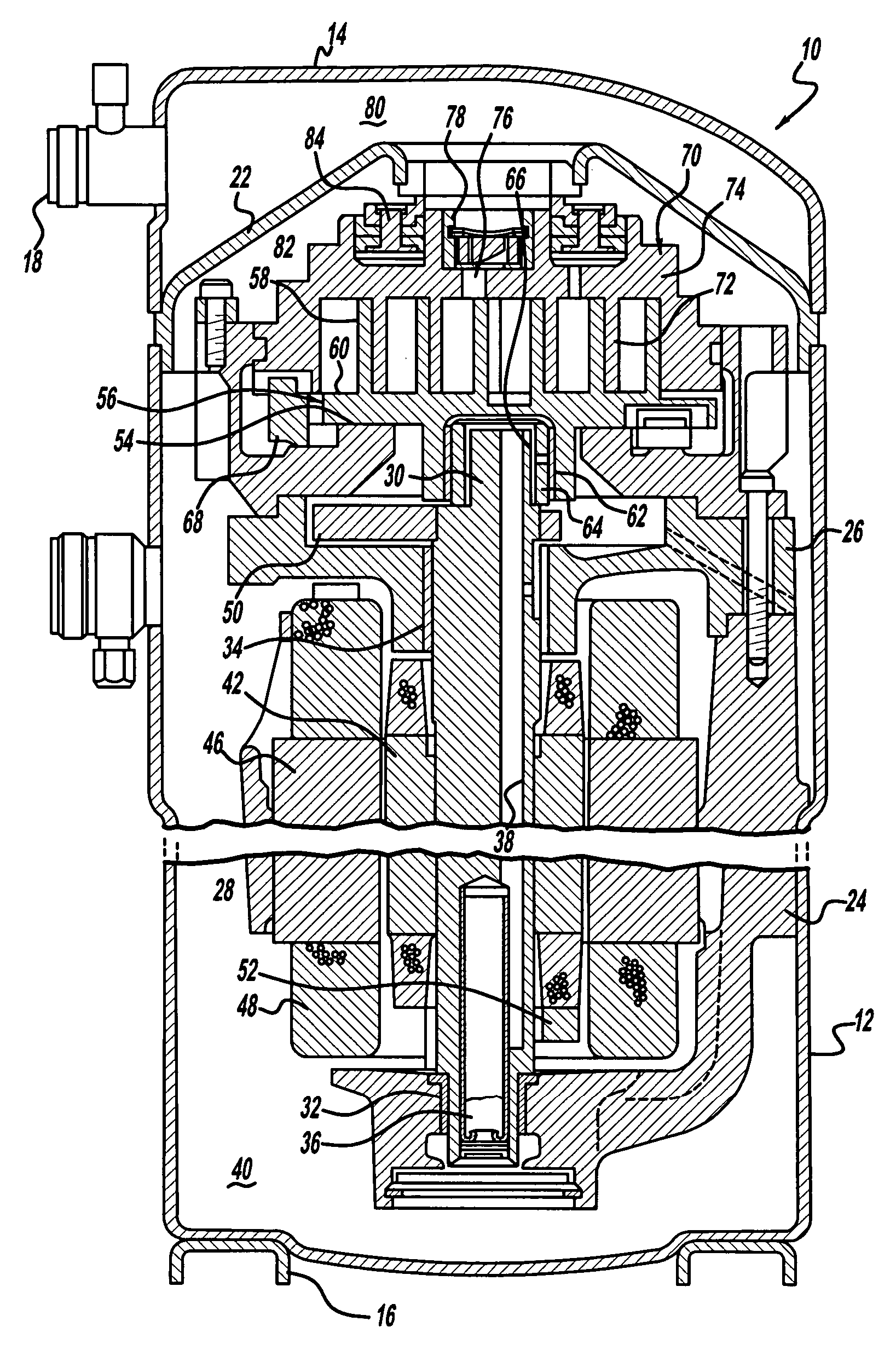

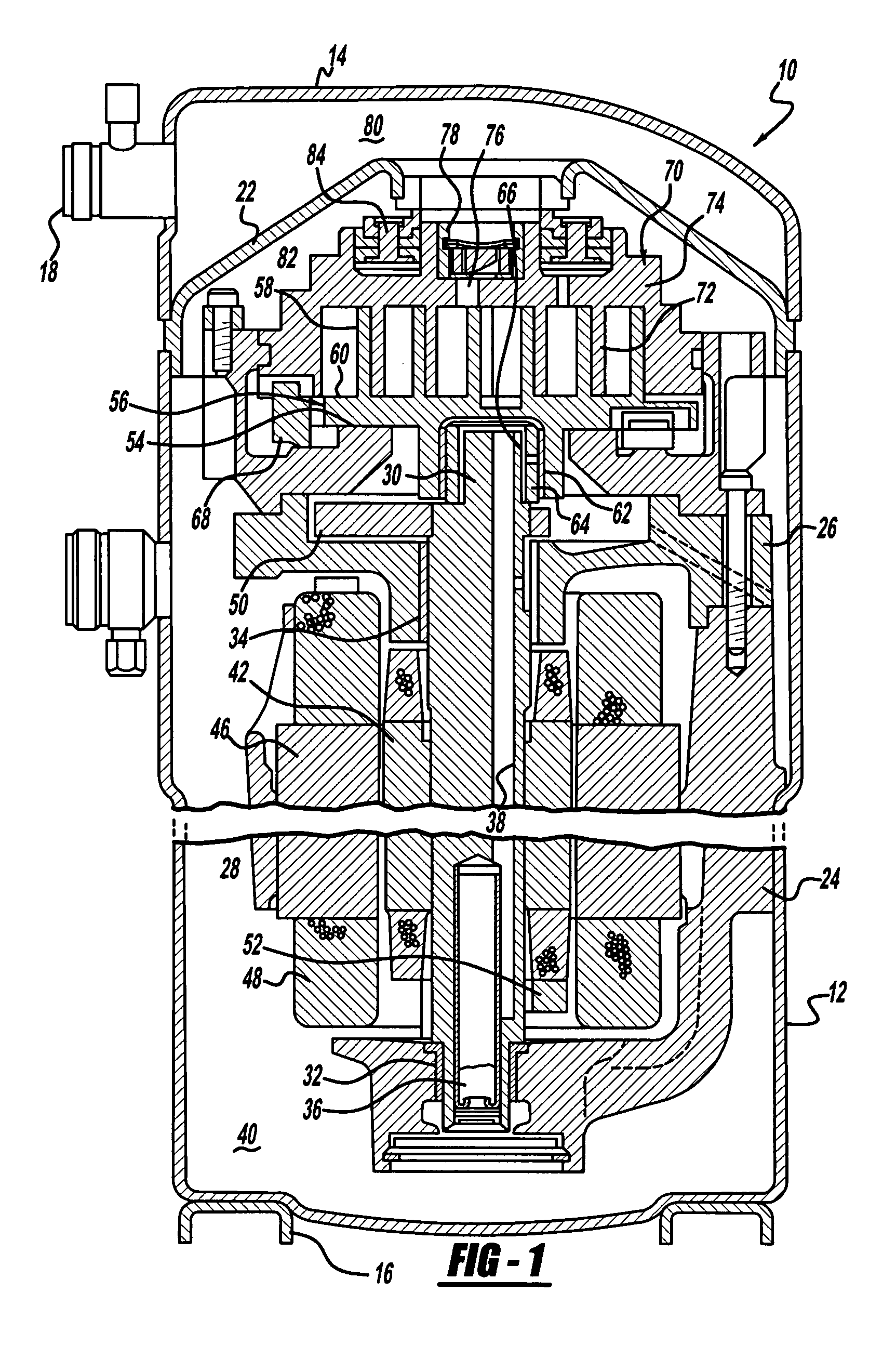

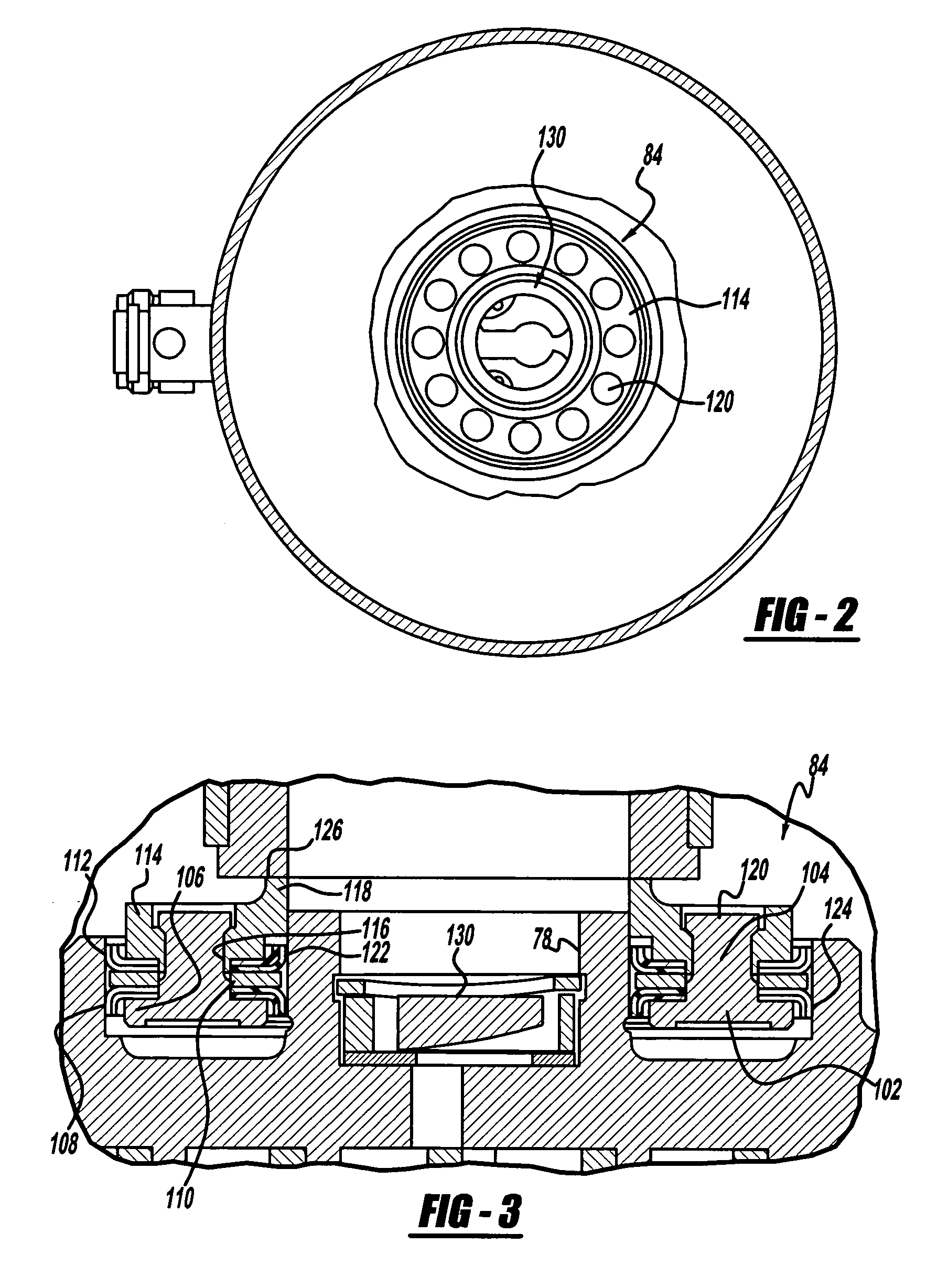

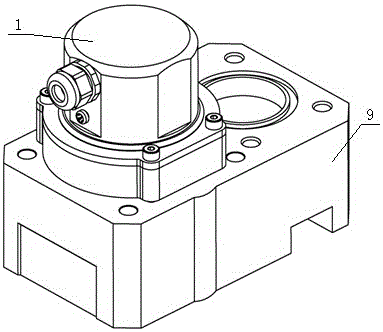

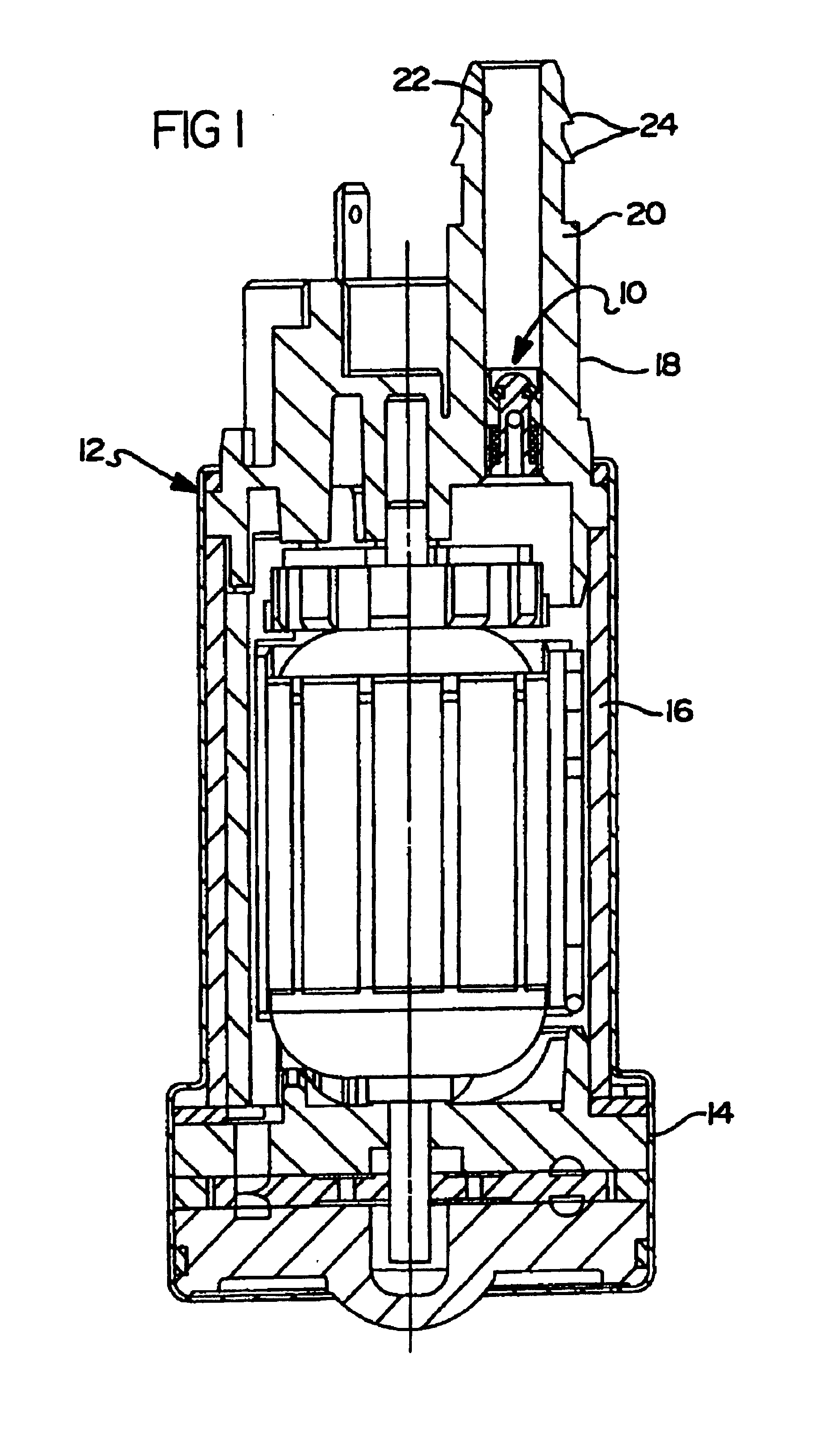

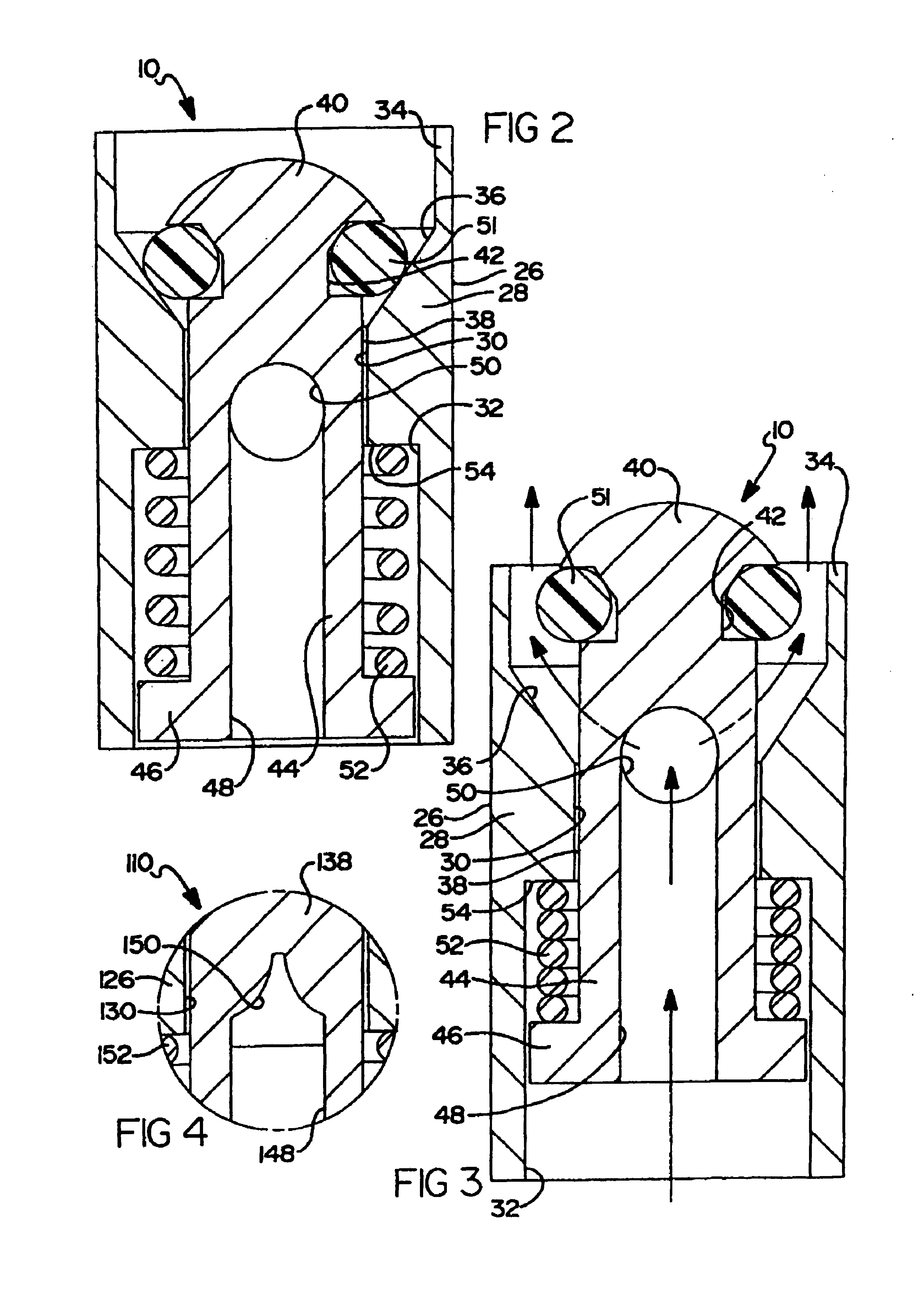

Scroll machine

ActiveUS7160088B2Performance maximizationImprove compressor performanceRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringRefrigerant

A compressor includes a normally open discharge valve assembly for controlling compressed refrigerant flow from the discharge chamber through the compression members. This controlling of flow results in an increased performance for the compressor by reducing recompression volume and the elimination of reverse rotation at shut down. The discharge valve assembly includes a valve seat, a valve plate and a valve stop secured within a recess formed within the compressor with a wave ring retainer. The valve stop and the valve seat include a contoured surface that is engaged by the valve plate when it opens and closes. The contoured surface controls the movement of the valve plate.

Owner:EMERSON CLIMATE TECH INC

Apparatus for separation of gas-liquid mixtures and promoting coalescence of liquids

ActiveUS8337603B2Promotes coalescenceEasy to separateLiquid degasificationReversed direction vortexChemical physicsOil separation

Provided herein is a conditioning apparatus that includes a geometrical configuration having an inlet flow deceleration conduit and a cyclonic tube to effectuate both liquid-gas separation and droplet coalescence. The apparatus is typically positioned at the inlet of a separator vessel used for removing water and gas from extracted crude oil containing entrained water and gas. The apparatus promotes droplet coalescence and gas separation for mixed fluids flowing into an existing water and oil separation device.

Owner:SAUDI ARABIAN OIL CO

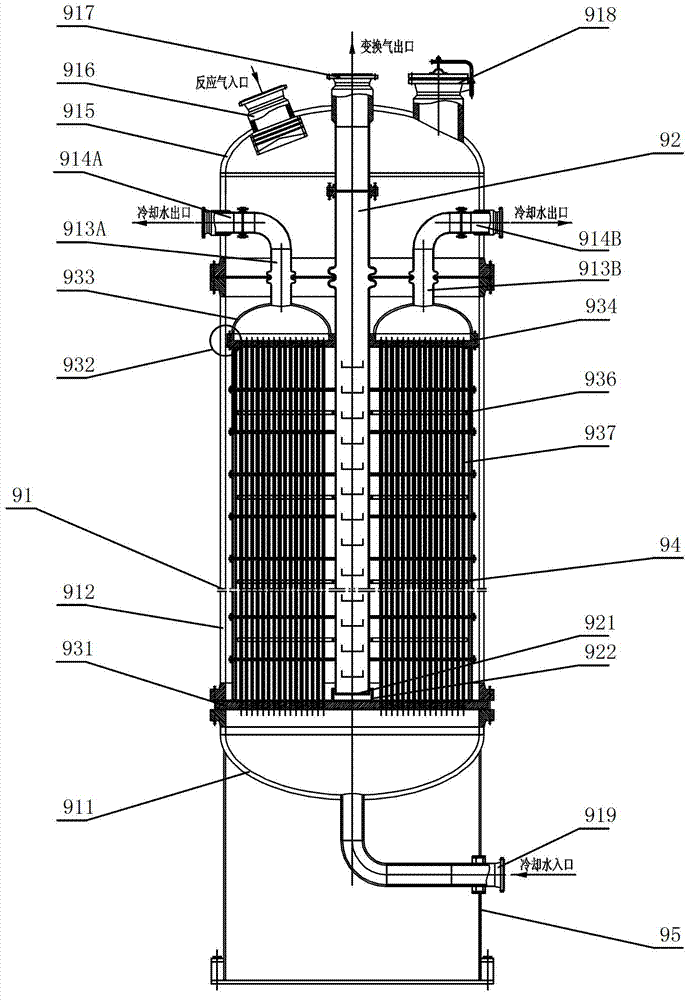

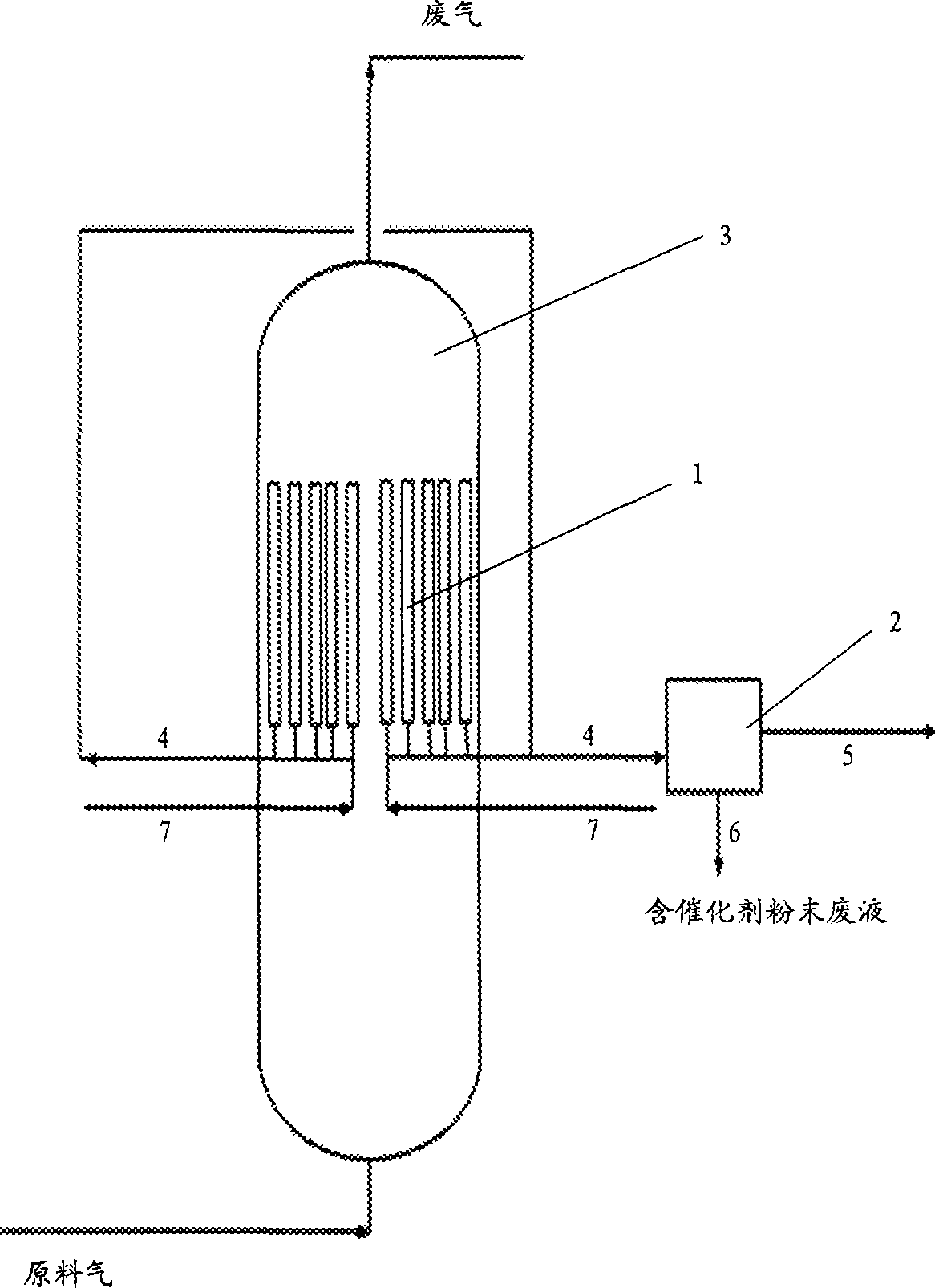

Low-moisture low-variable serial saturation tower thermal CO transformation technology

ActiveCN102888253AShort transformation processReduce resistanceHydrogenCombustible gas catalytic treatmentDry gasMoisture

Owner:CHINA PETROCHEMICAL CORP +2

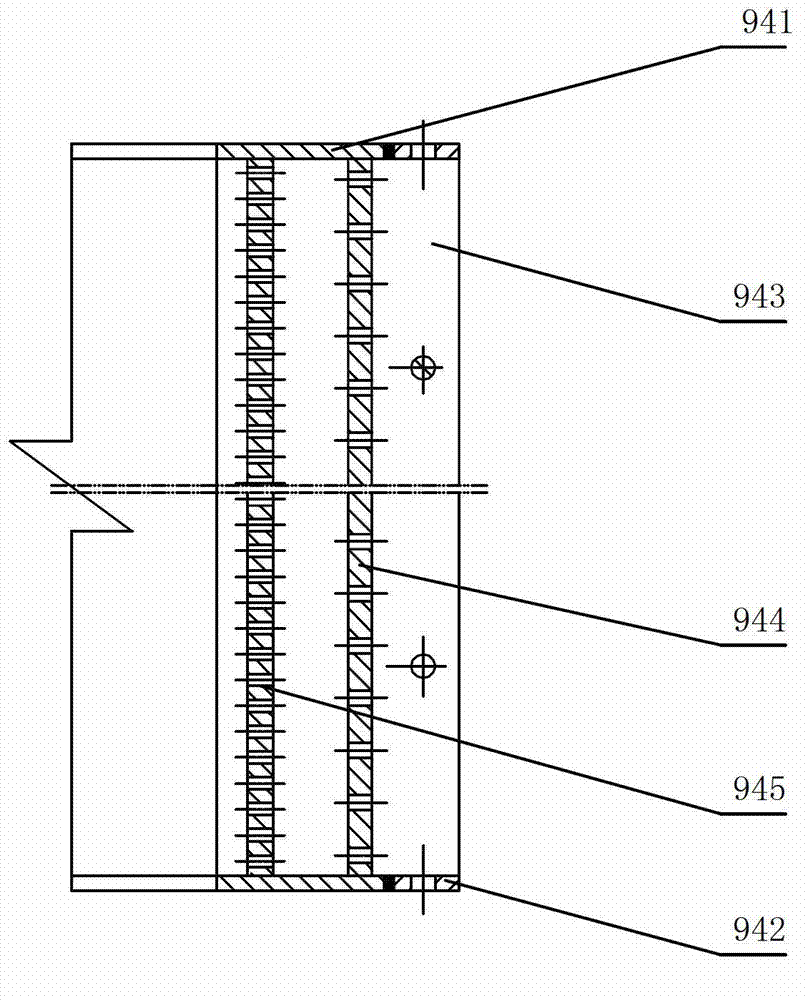

Check valve for fuel pump

InactiveUS20030037822A1Increase the circulation areaImproves fuel pump performanceCheck valvesEqualizing valvesContact forceCheck valve

A check valve for a fuel pump of a vehicle includes a retainer adapted to be disposed in an outlet member of the fuel pump. The check valve also includes a valve seat adapted to be disposed in the outlet member and spaced from the retainer. The check valve includes a valve member disposed in the outlet member between the retainer and the valve seat. The valve member has a closed position to engage the valve seat to prevent fuel from flowing through the outlet member and an open position to allow fuel to flow through the outlet member. The check valve further includes a magnet cooperating with the valve member for generating a magnetic force on the valve member to maintain a contact force between the valve member and the valve seat when the valve member is in the closed position.

Owner:DELPHI TECH INC

Scroll machine

ActiveUS20050069444A1Maximizing of performance of compressorIncrease discharge pressureRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringCompression member

A compressor includes a normally open discharge valve assembly for controlling compressed refrigerant flow from the discharge chamber through the compression members. This controlling of flow results in an increased performance for the compressor by reducing recompression volume and the elimination of reverse rotation at shut down. The discharge valve assembly includes a valve seat, a valve plate and a valve stop secured within a recess formed within the compressor with a wave ring retainer. The valve stop and the valve seat include a contoured surface that is engaged by the valve plate when it opens and closes. The contoured surface controls the movement of the valve plate.

Owner:EMERSON CLIMATE TECH INC

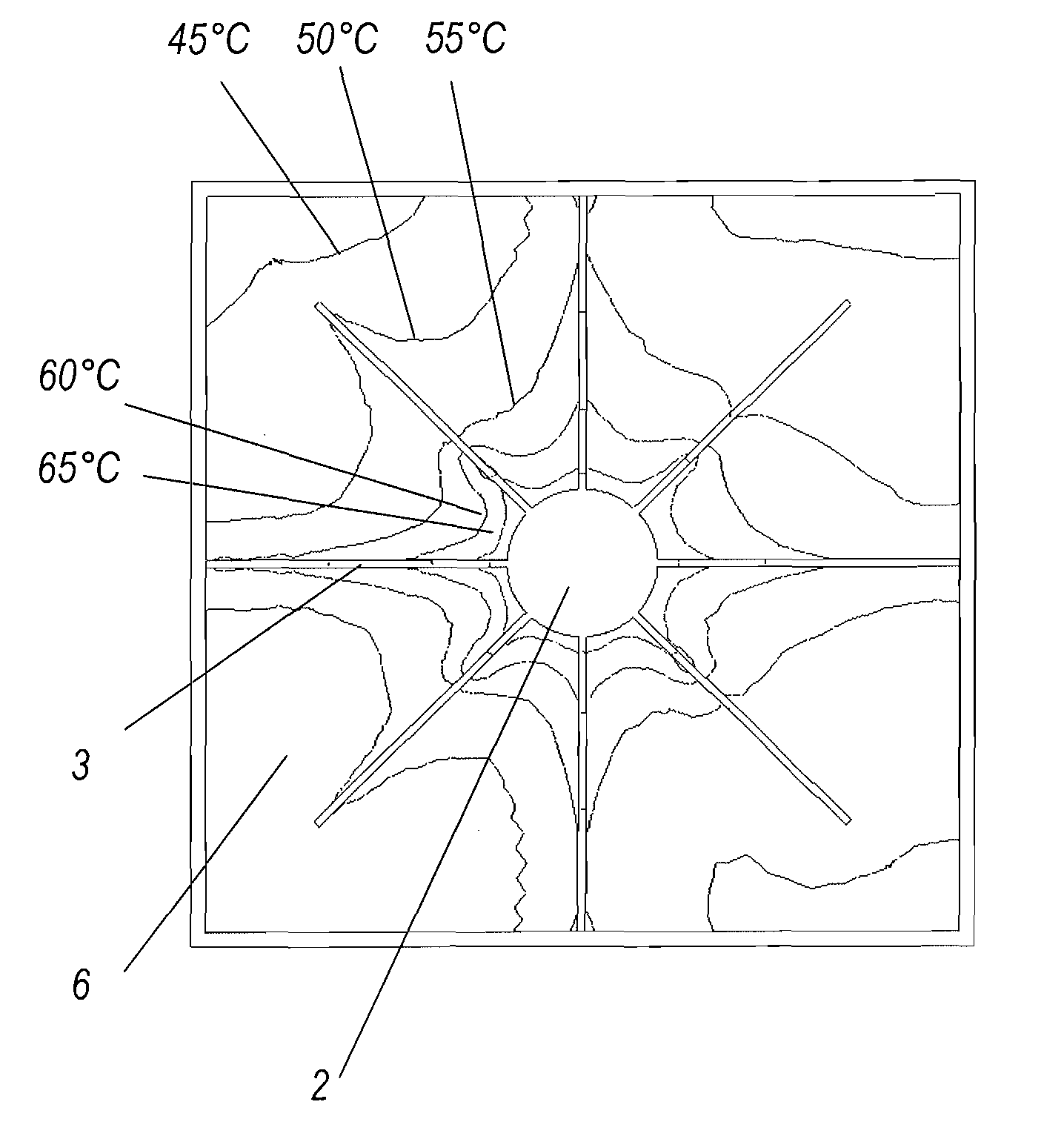

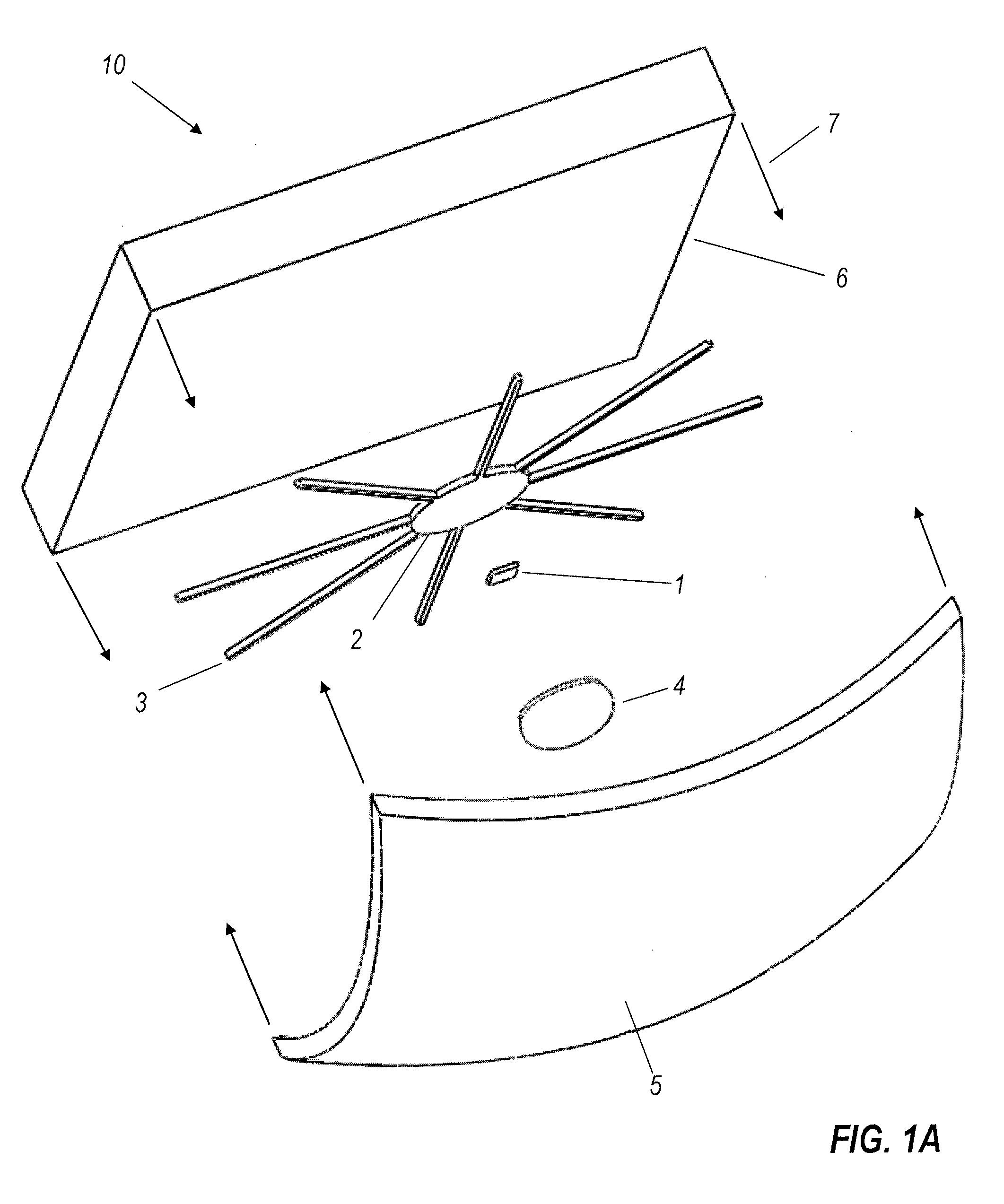

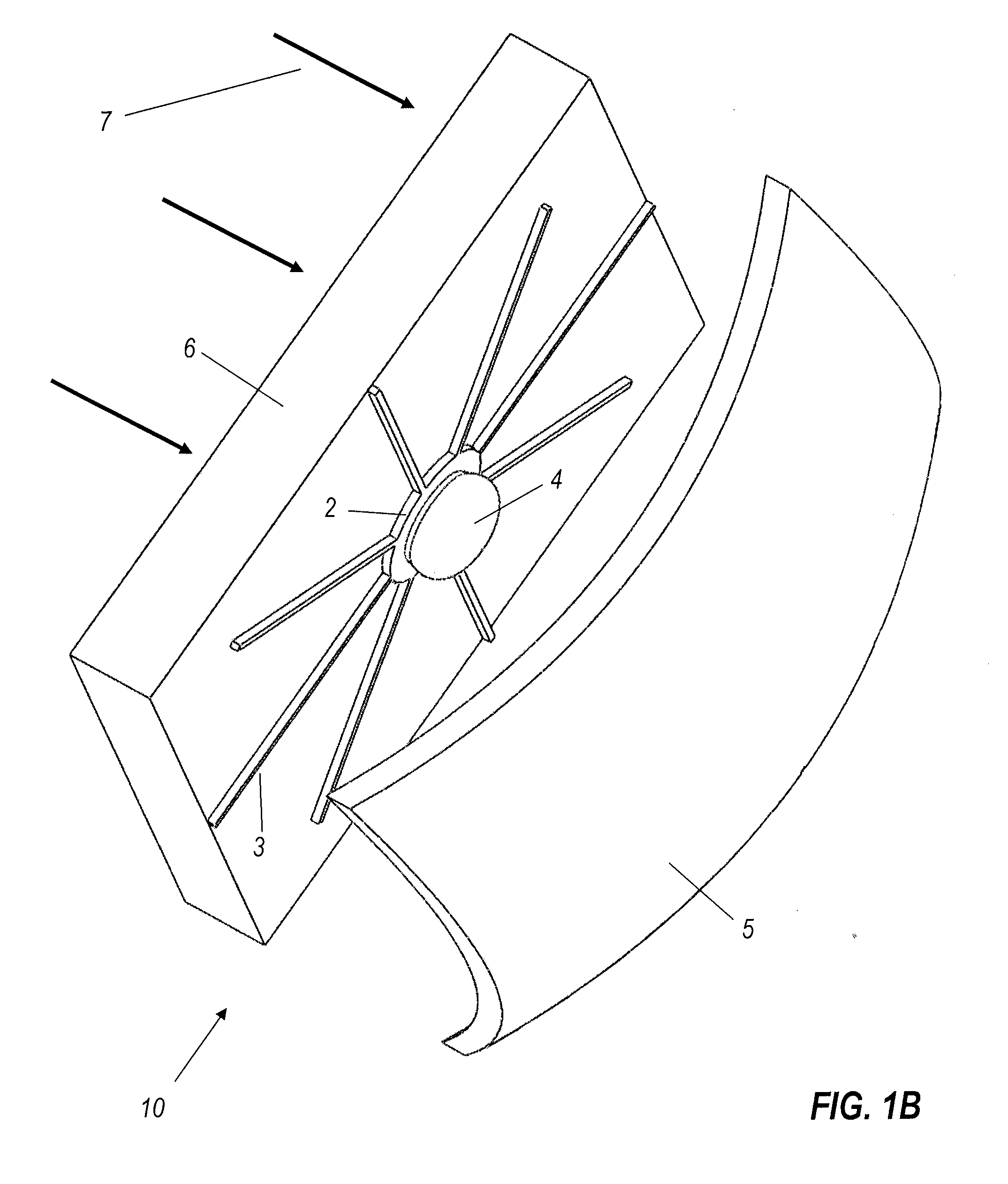

On-window solar-cell heat-spreader

InactiveUS20110120539A1Easy to cleanImprove isolationMaterial analysis by optical meansPhotoelectric discharge tubesElectrical conductorTransducer

An optoelectrical device, which may be a luminaire or a photovoltaic concentrator, has a transparent cover plate. A target with an optoelectrical transducer that produces waste heat in operation is mounted at an inside face of the transparent cover plate. A primary mirror reflects light between being concentrated on the target and passing generally collimated through the cover plate. A heat spreader is in thermal contact with the target. The heat spreader has heat conductors that thermally connect the target with the inside surface of the cover plate. The heat conductors may be arms extending radially outwards, and may be straight, zigzag, or branching. An array of targets may be mounted on a common cover plate, and their heat spreaders may be continuous from target to target.

Owner:LIGHT PRESCRIPTIONS INNOVATORS

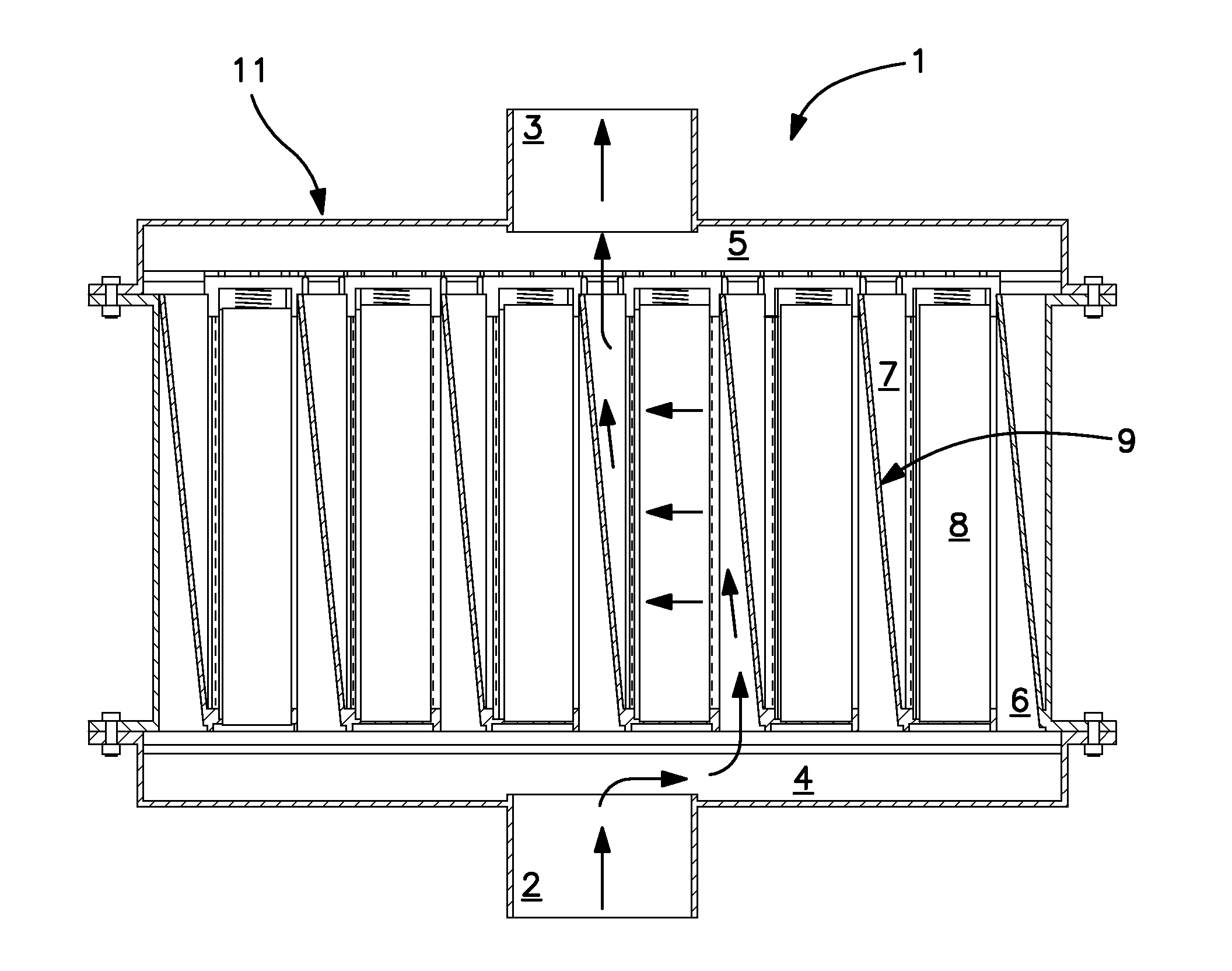

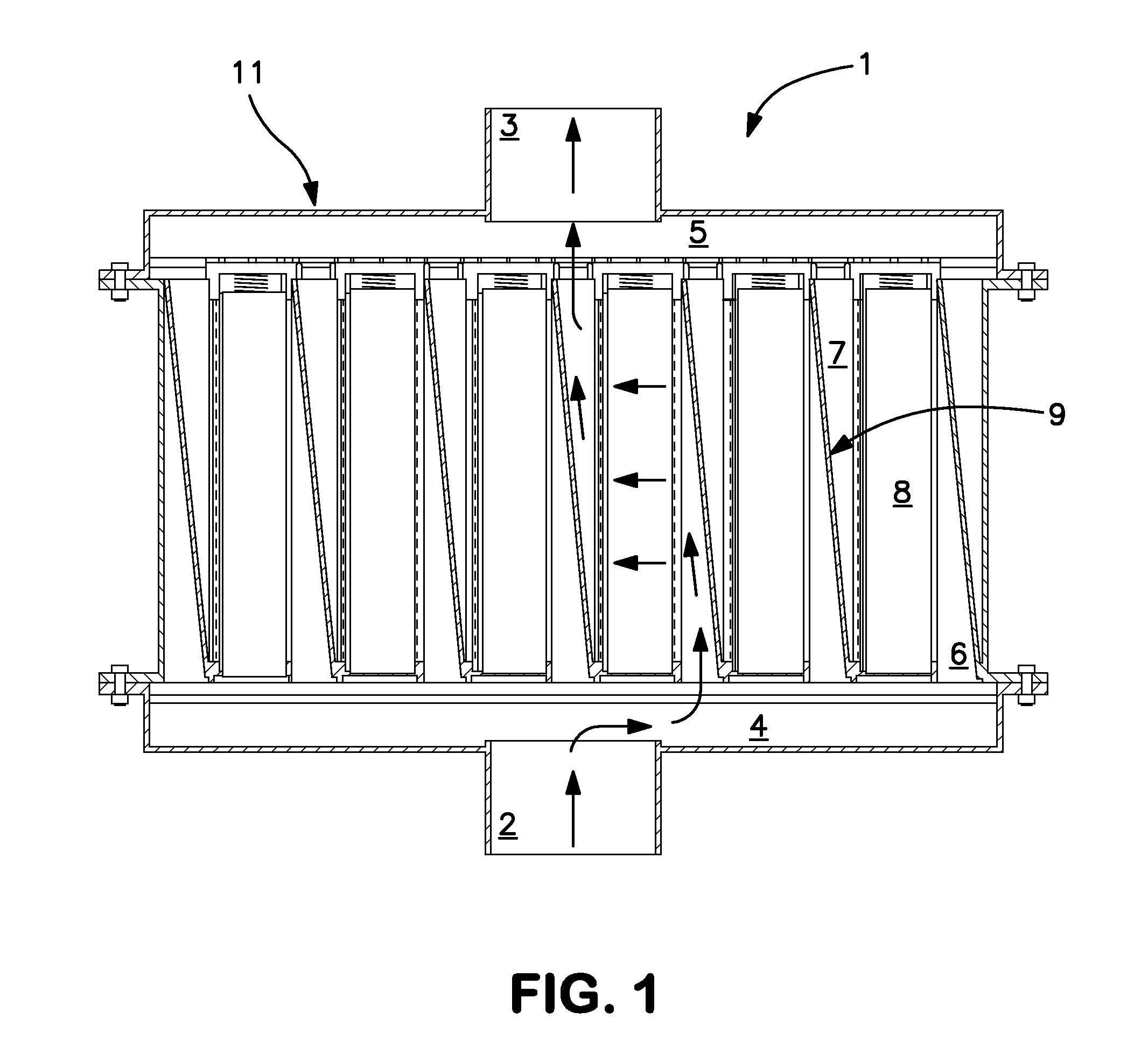

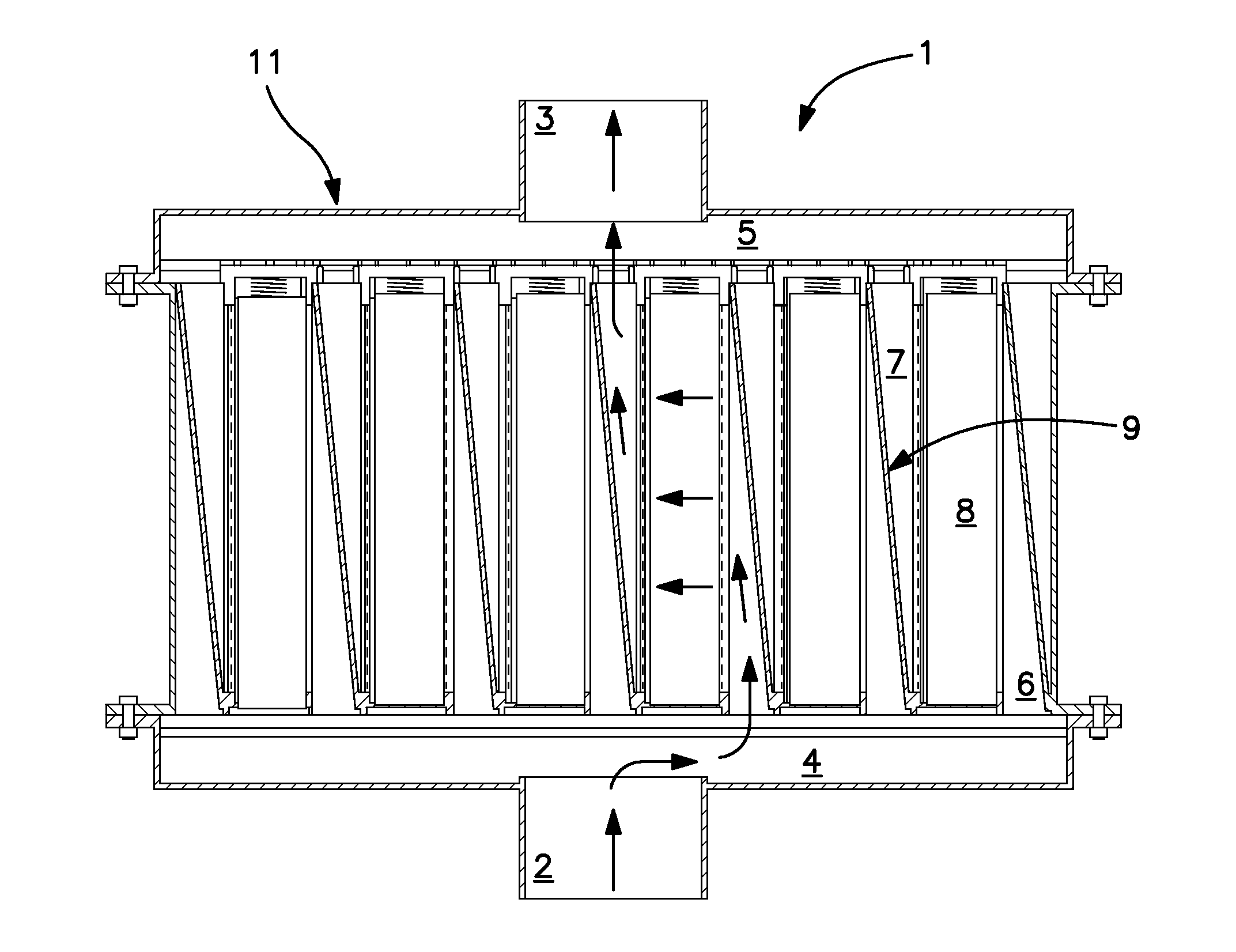

Modular compact adsorption bed

ActiveUS20110146487A1Easier adsorbent material loadingFacilitates increased bed frontal areaIsotope separationSorbentModular design

A modular and compact adsorbent bed structure is disclosed for use in an adsorption-based gas separation plant. The conventional adsorbent bed in a gas separation plant is replaced with a plurality of modular adsorbent bed units connected to make the adsorbent bed structure. Modular adsorbent bed units of this invention provide higher capacity of product per unit volume of adsorbent material (i.e., increased adsorbent utilization) as compared to that obtained from conventional adsorbent beds. The modular design requires lower fabrication costs; is easier to transport; has less maintenance and repair requirements; and is easier to load with adsorbent material.

Owner:PRAXAIR TECH INC

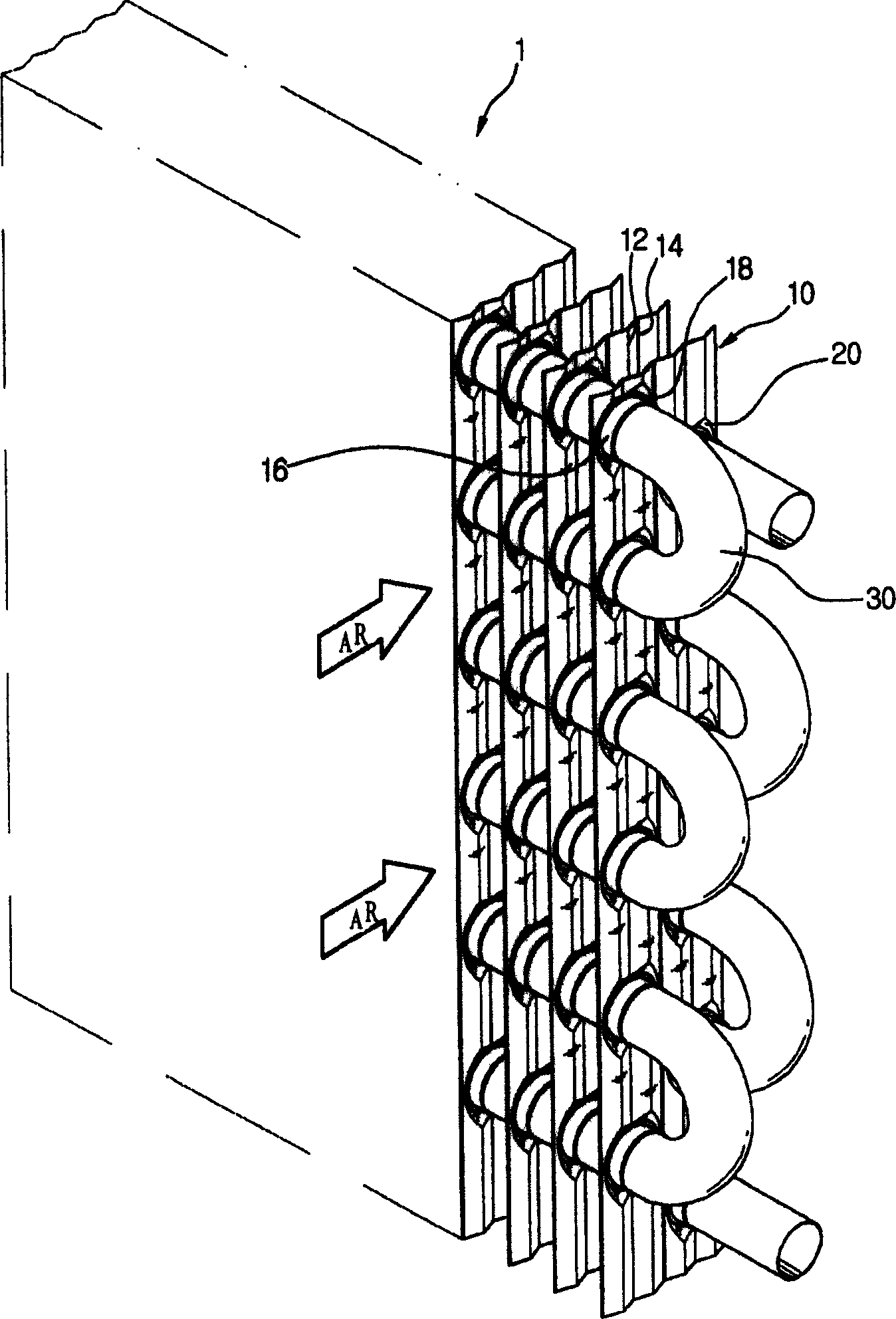

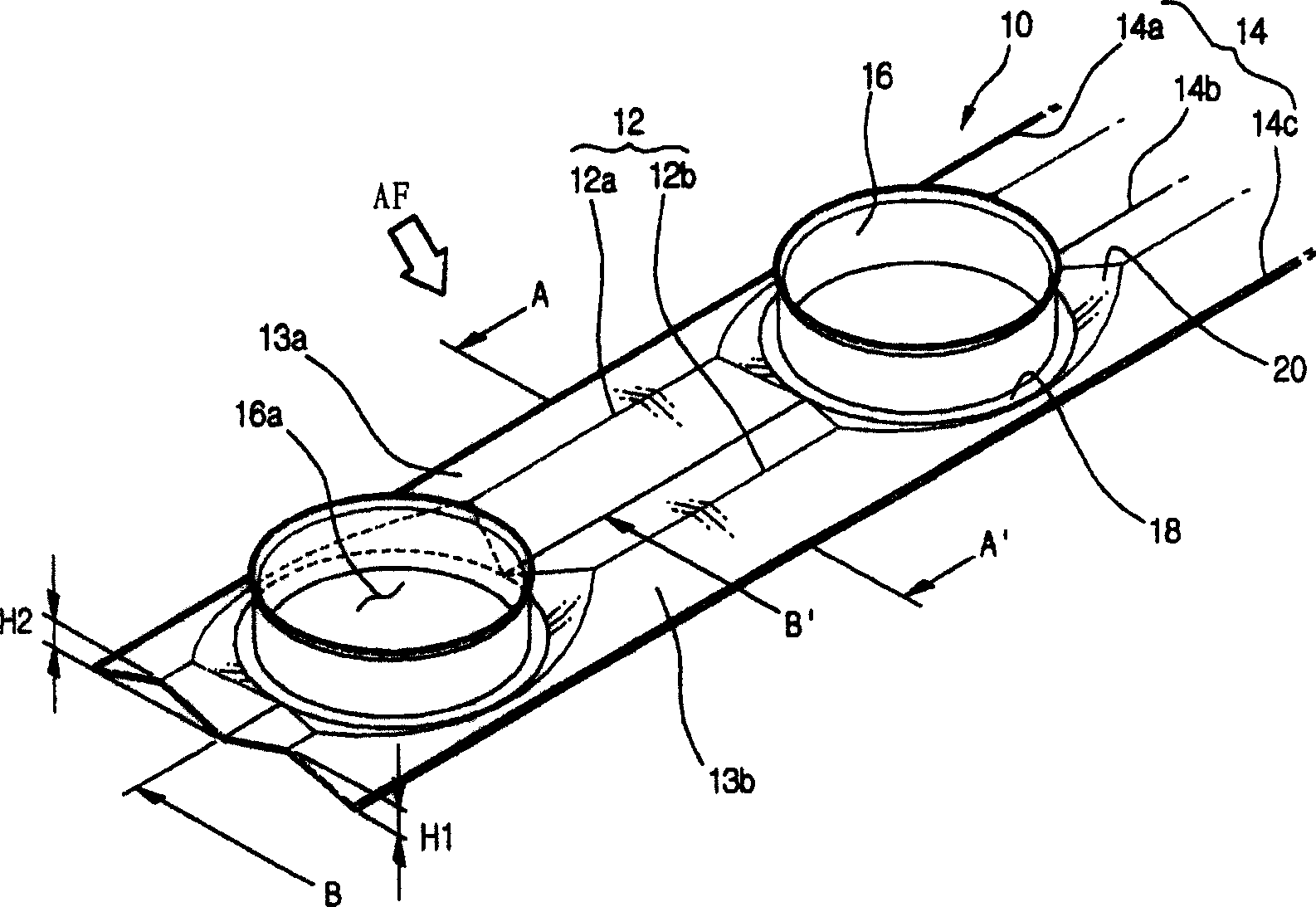

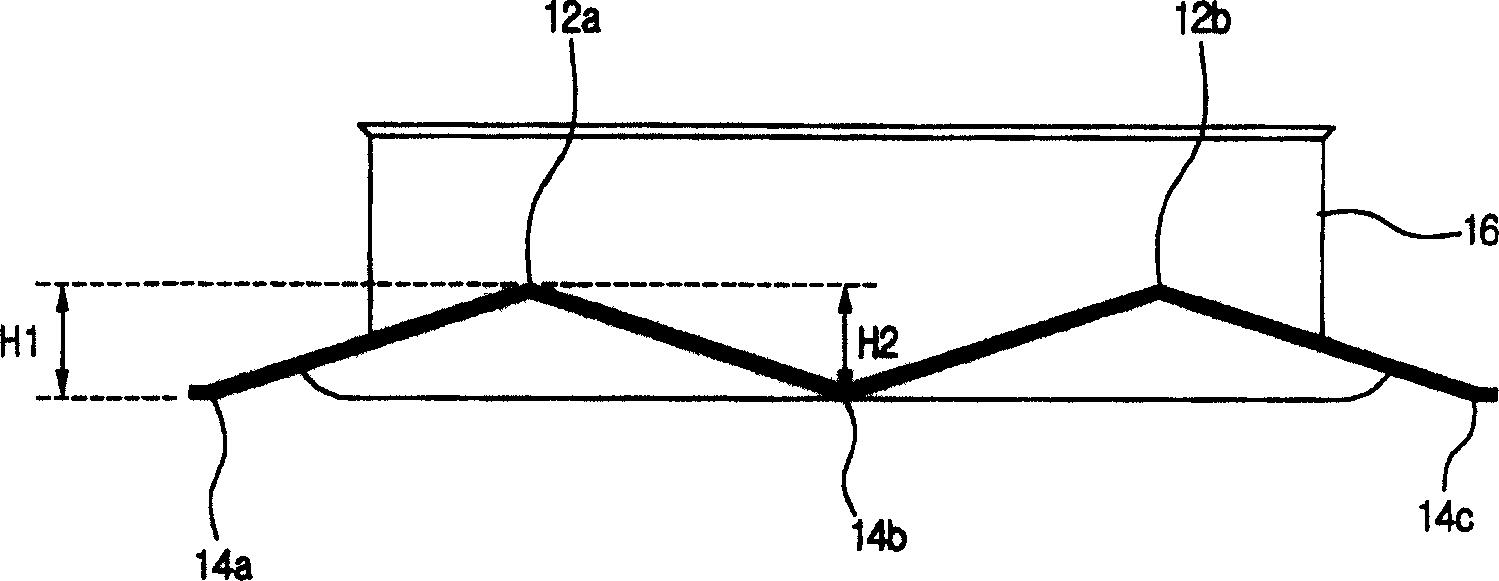

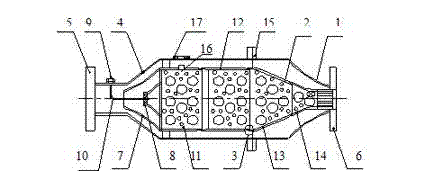

Heat exchanger

InactiveCN1573271AImprove heat exchange efficiencyIncrease the circulation areaEvaporators/condensersSpace heating and ventilation detailsRefrigerantMechanical engineering

Disclosed is a heat exchanger including a plurality of tubes through which refrigerants flow, the tubes being spaced away from each other, and a plurality of fins through which the tubes are perpendicularly inserted, the fins being spaced away from each other at a predetermined distance, each of the fin having more than four peak portions and more than four valley portions that are alternately disposed. Heights or depths of at least two peak portions or at least two valley portions being different from each other.

Owner:LG ELECTRONICS INC

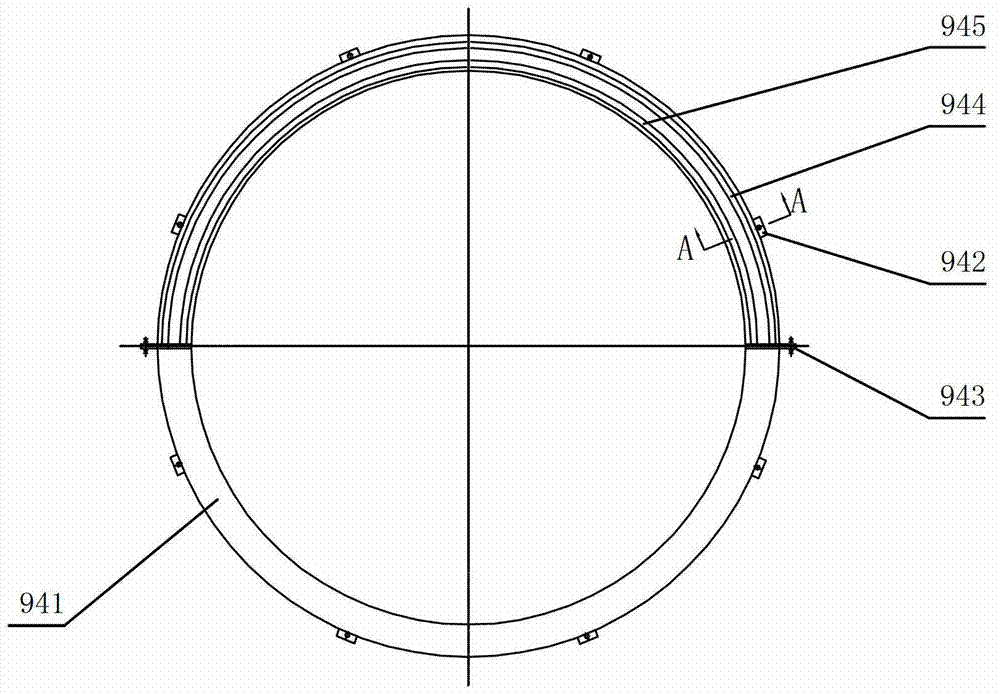

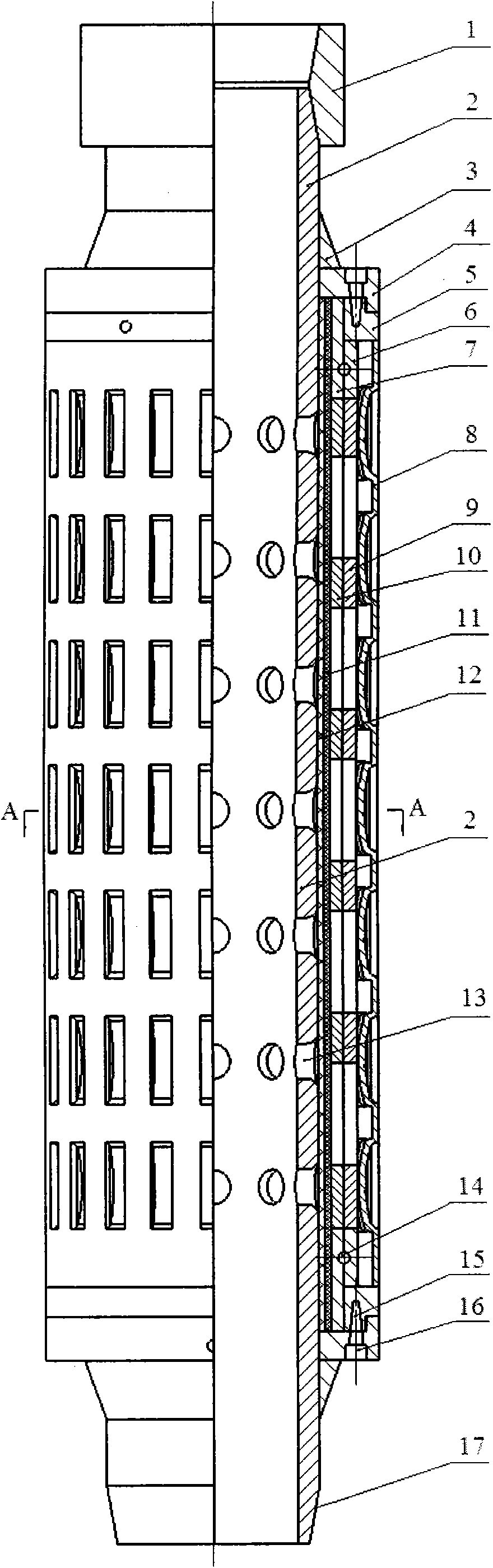

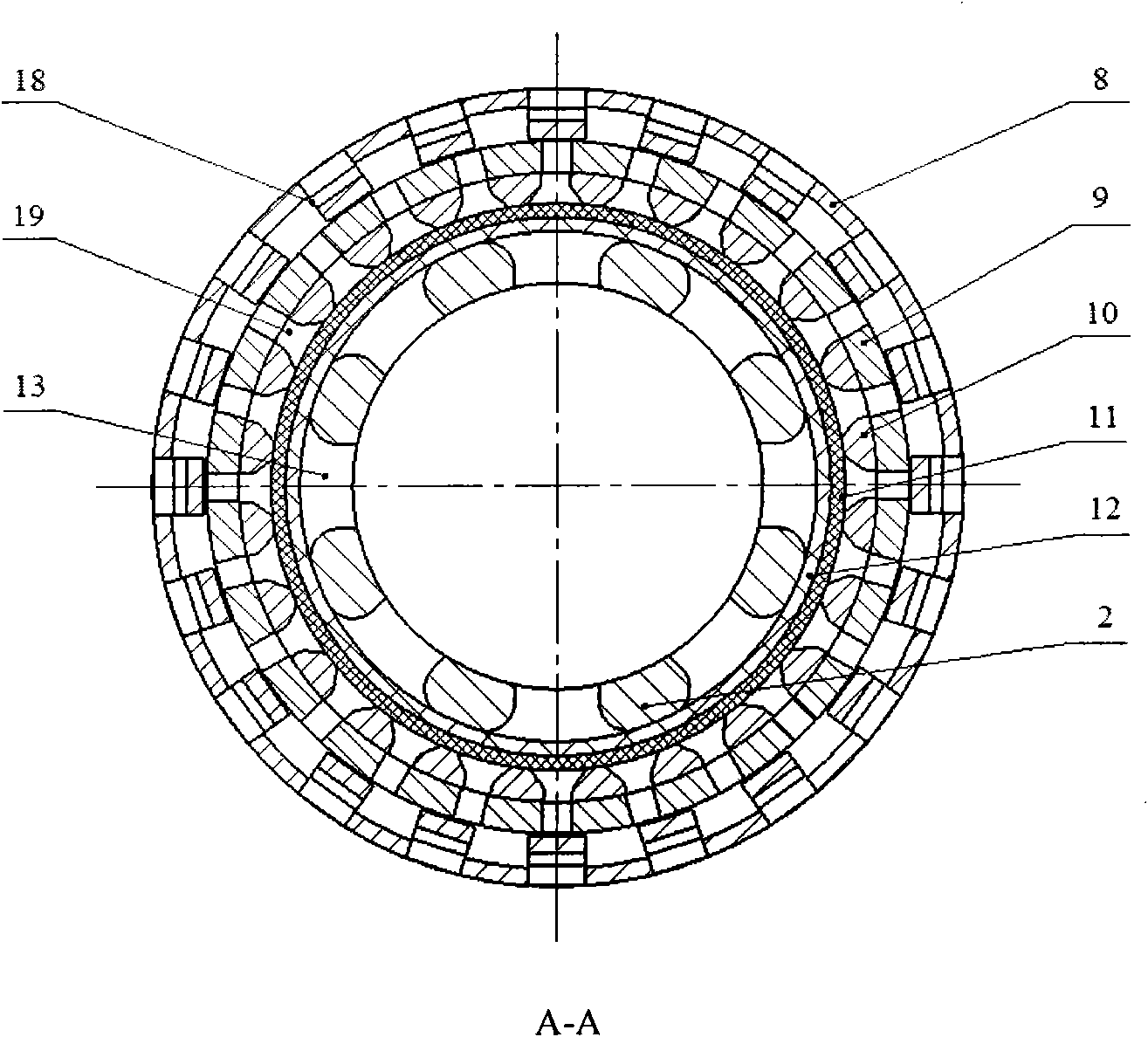

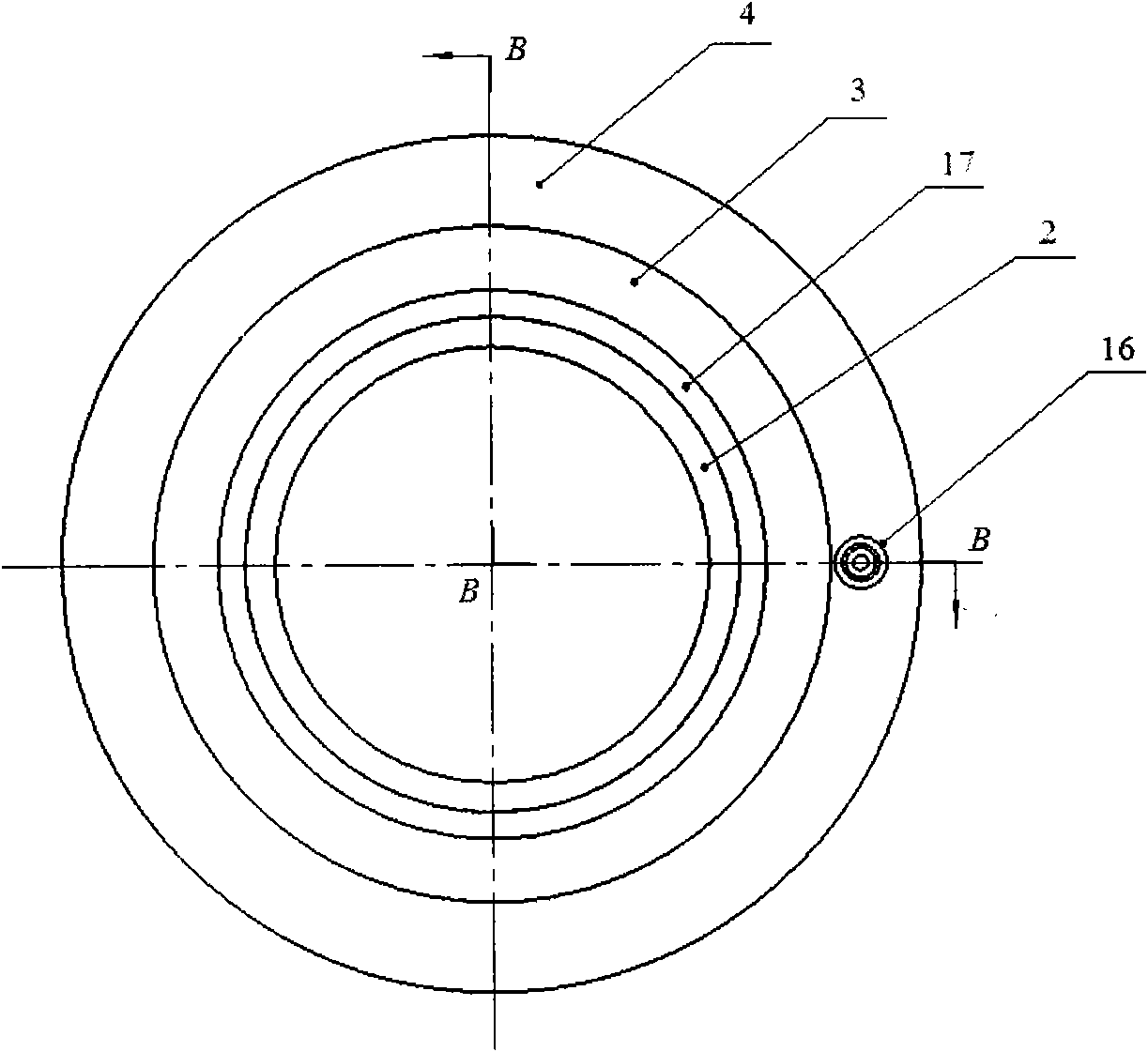

Novel sand control screen pipe with adjustable on-site sand stop precision

ActiveCN102071914AFunction increaseGood sand blocking effectFluid removalHigh volume manufacturingReal time design

The invention discloses a novel sand control screen pipe with adjustable on-site sand stop precision, and belongs to the field of oil well completion sand control. The novel sand control screen pipe mainly comprises five parts, namely a central pipe, a fixed-precision sand stop layer, an adjustable-precision sand stop layer, an outer protective sleeve and a sand stop precision precise adjusting mechanism, wherein the central pipe is provided with spirally distributed through holes and is mainly used for supporting the entire screen pipe and allowing oil to pass through; the fixed-precision sand stop layer is mainly used for controlling sand; the adjustable-precision sand stop layer can change the sand stop precision under the adjustment of the precise adjusting mechanism to play a major role in sand control; the outer protective sleeve is mainly used for protecting the internal structure of the screen pipe and reducing erosion effect of internal fluid and sand; and the sand stop precision precise adjusting mechanism is mainly used for adjusting sand stop precision of the adjustable-precision sand stop layer. Compared with the conventional sand control screen pipe with fixed sand stop precision, the adjustable-precision sand control screen pipe can realize on-site real-time design and sand stop precision adjustment aiming at the characteristics of a single well to improve the sand control effect; the novel sand control screen pipe is convenient for mass production of the screen pipe manufacturers and can precisely control the sand control precision; and the novel sand control screen pipe is convenient for screen pipe development, is convenient for suppliers to provide a sand control design, integrated service of the sand control screen pipe, and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Unit-combination type heat transfer enhancement device

ActiveCN101813437ASmall footprintReduce blocking rateHeat transfer modificationRotary device cleaningEngineeringUnit type

A unit-combination type heat transfer enhancement device of the invention relates to the field of the unit type heat transfer enhancement device which utilizes the fluid of a heat transfer pipe as the power, comprising rotors, a support frame, sleeve shafts and a connecting axis, wherein the support frame is fixed at the two ends of the heat transfer pipe; the two ends of the connecting axis are respectively fixed on the support frame; the centers of the sleeve shafts are through holes; a plurality of the sleeve shafts are arranged on the connecting axis in a penetrating manner; the rotors are arranged on the sleeve shafts in a penetrating manner; and one or more rotors is / are matched with one sleeve shaft. The rotor consists of flow-disturbing rotary vanes, a hinge structure and tail end spiral drive blades. The fluid in the pipe in the technical scheme drives the rotors to rotate at a proper speed by the tail end spiral drive blades, thus having the inhibiting and cleaning effects on the fouling deposit; the proportion of the length of the flat and straight part of the flow-disturbing rotary vane and that of the tail end spiral drive blades can be changed flexibly; and according to the practical needs, bulges are also arranged on the thin sheet of the edge to further disturb the fluid to flow, thus further improving the effects of the heat transferring and self cleaning.

Owner:山西英蓝科技有限公司

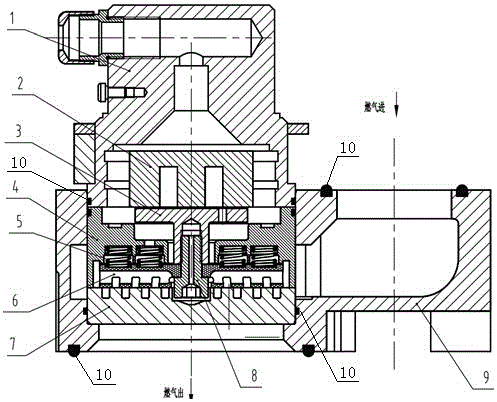

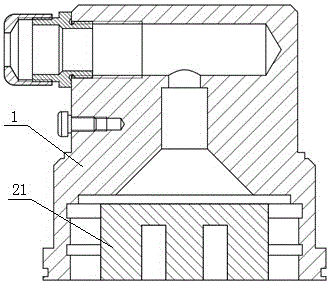

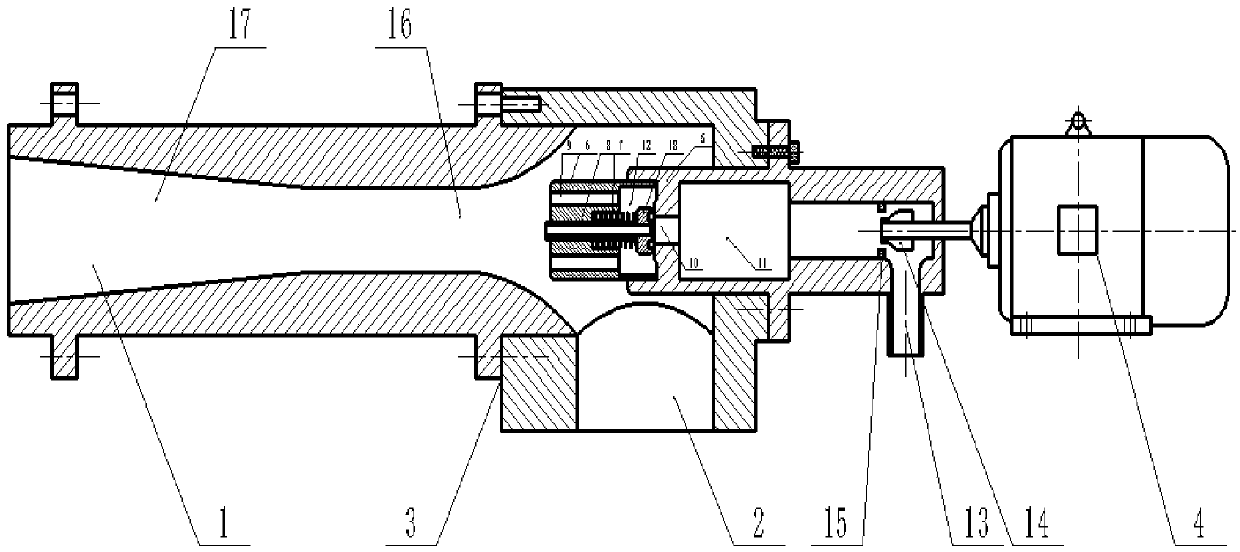

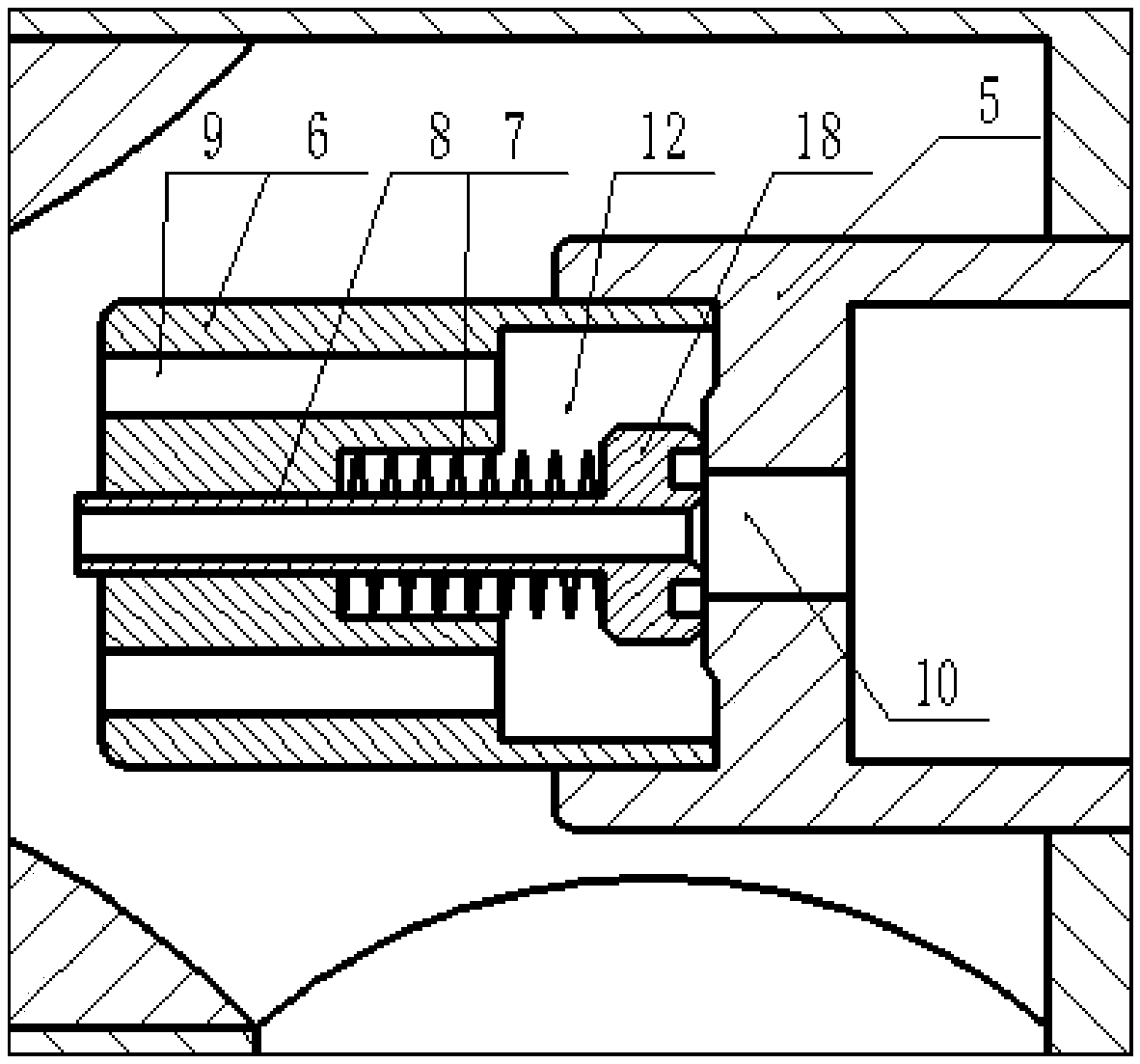

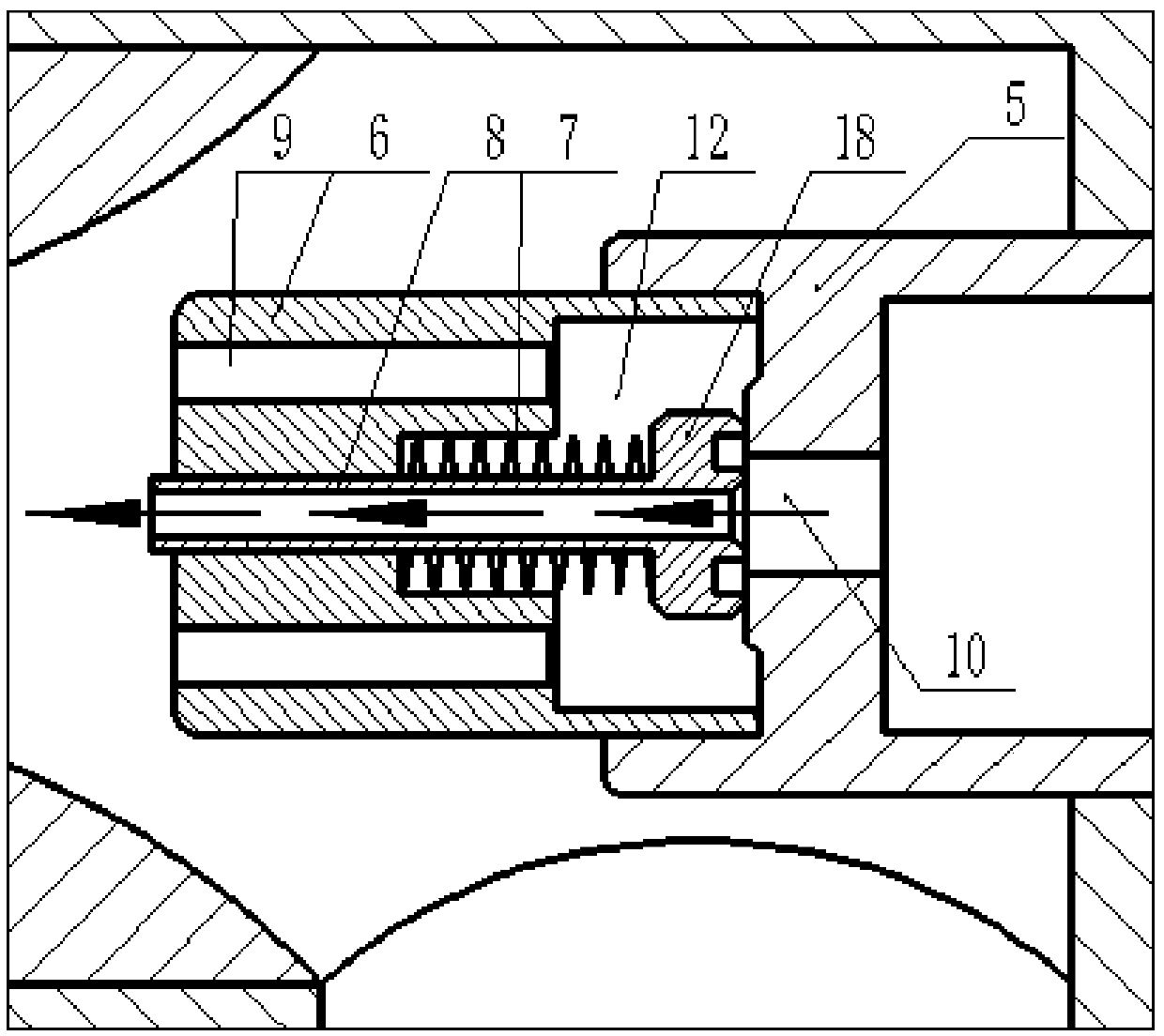

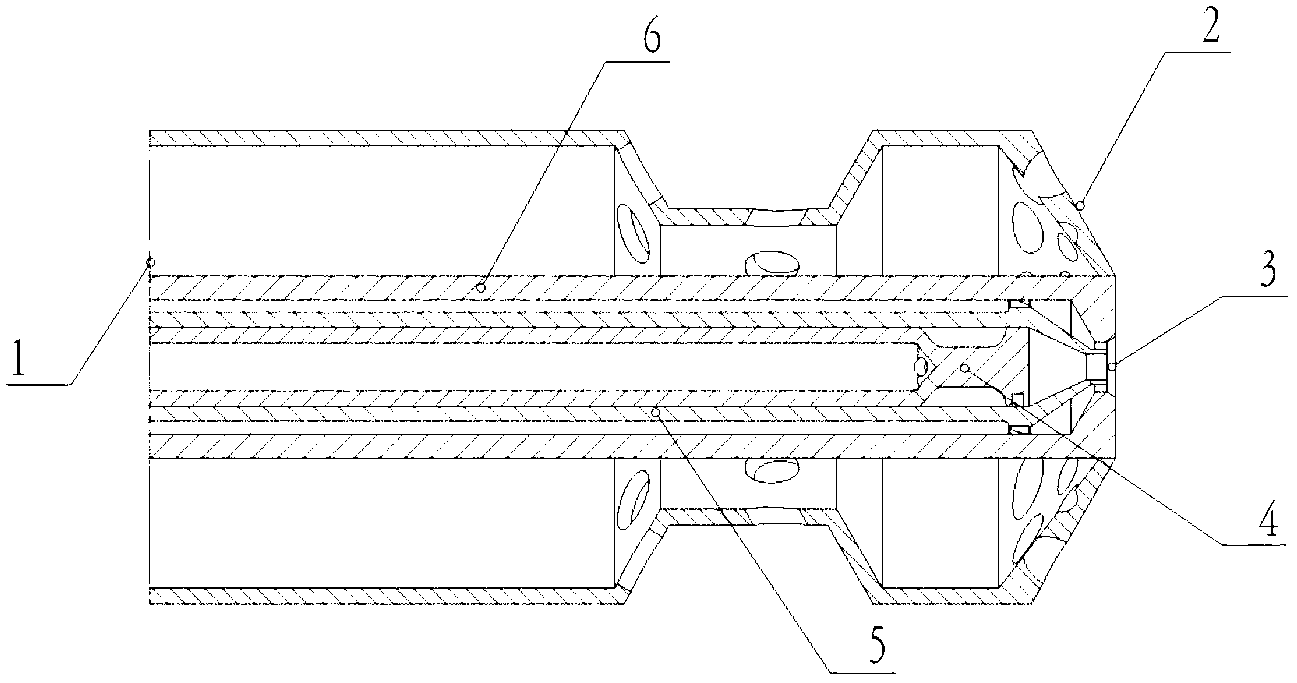

Fuel gas electronic injection valve used for gas fuel engine

ActiveCN106121867AReduce wearGood self-sealing effectInternal combustion piston enginesFuel supply apparatusEngineeringElectromagnetic valve

The invention discloses a fuel gas electronic injection valve used for a gas fuel engine. The fuel gas electronic injection valve comprises a shell, an electromagnetic valve component and a valve element component. The valve element component comprises a valve element, a valve block, a valve seat and an armature, wherein the valve block is installed in the valve element and fixedly connected with the lower end of the armature; when the electromagnetic valve component is powered on, under the effect of electromagnetic force, the armature pulls the valve block to upwards move so as to form a fuel gas channel between the lower surface of the valve block and the upper surface of the valve seat; and when the electromagnetic valve component is powered off, the lower surface of the valve block and the upper surface of the valve seat are attached to form a sealing face, and the fuel gas channel is blocked. The fuel gas electronic injection valve can be suitable for high-speed gas machines and dual-fuel engines, and the requirements of high response speed, accurate fuel gas metering, wide single cylinder power covering scope and the like are met.

Owner:CHONGQING HONGJIANG MACHINERY

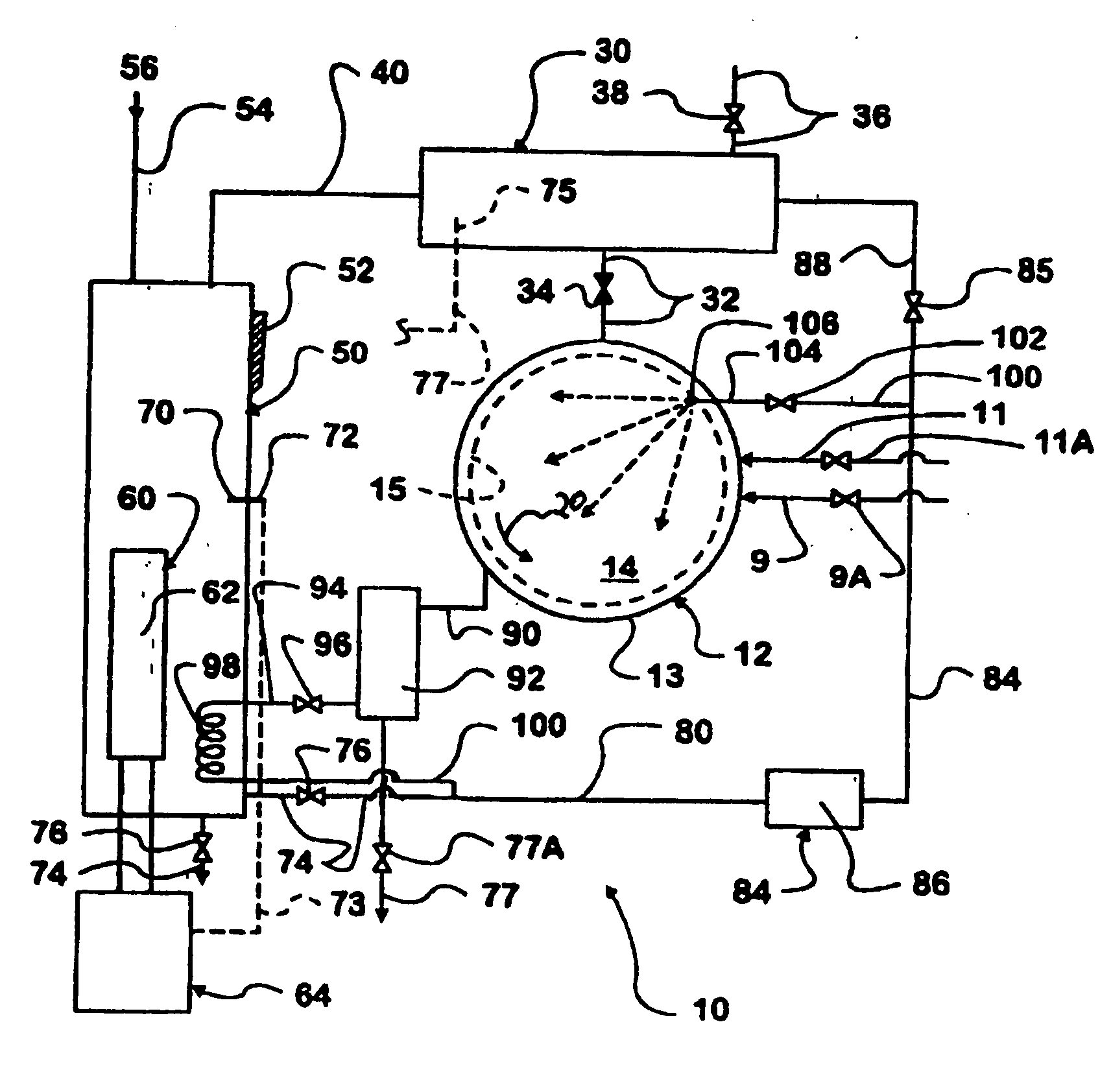

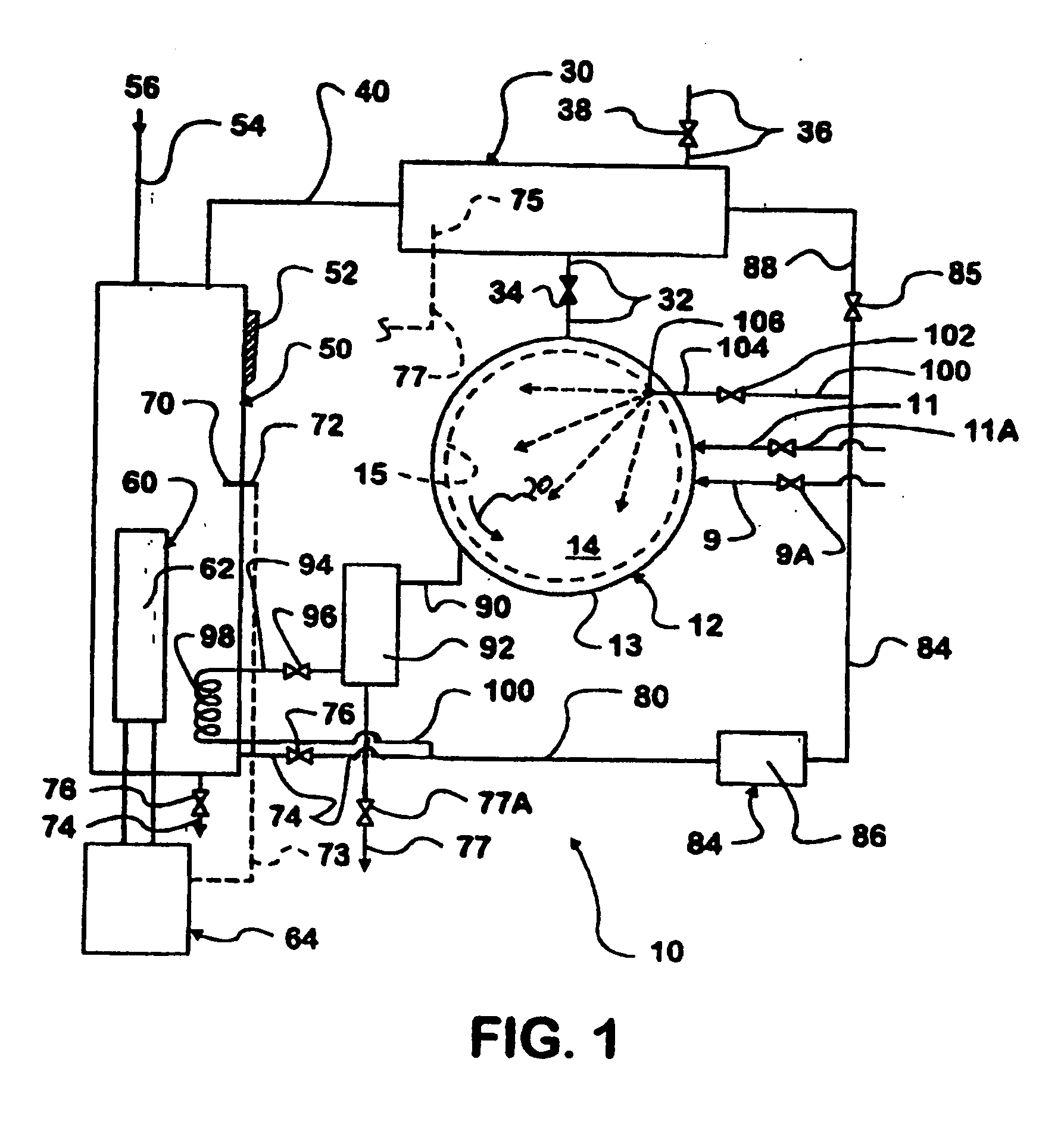

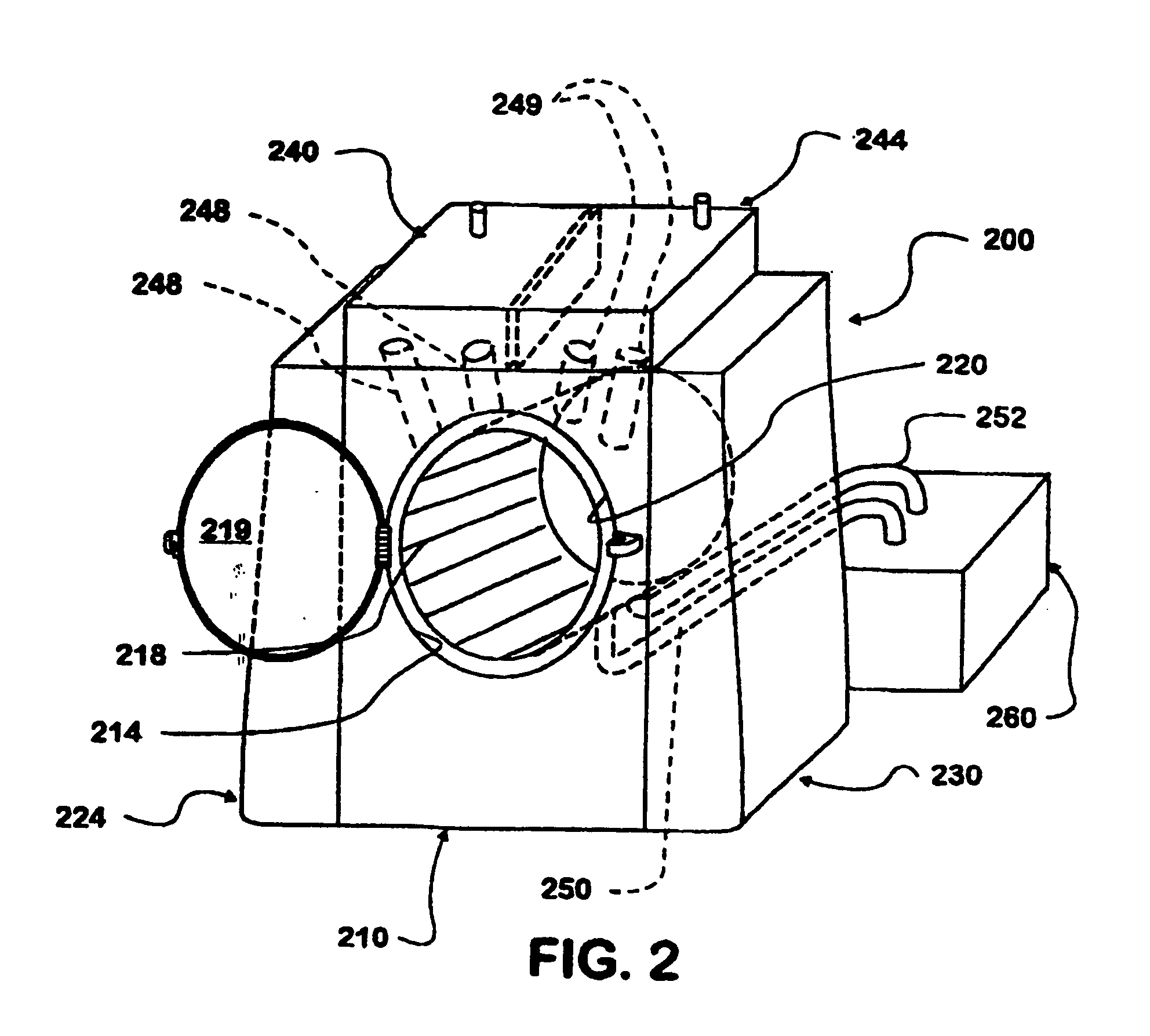

Washer method and apparatus

InactiveUS20070130698A1Improve washing effectIncrease water flow areaOther washing machinesTextiles and paperEngineeringRefrigeration

An improved washer (10, 210, 710) having a quick fill (32, 34) and a quick drain (36, 38) with reduced overall wash time is provided. Means are provided for doing a very cold wash to permit machine washing of fine clothing that heretofore was hand washed or dry cleaned. The washer (10, 210, 710) can be provided with one (30), two (224, 230) or three tanks (750A, B & C, 950A, B & C) for water at three temperatures, very cold (refrigerated), tap or city water supply temperature, or hot water. The very cold can be made by a refrigeration or chilling means (62, 64, 98), located in or adjacent the very cold water tank. The hot water can be provided from or have a heater (230, 320, 750C, 950C) therein one of the tanks. The washer also includes an improved embossed basket (600) with increased surface area. The features can be built into a new washer or retrofitted into an existing washer. Very cold water wash and rinse can be provided so that cloths, and particularly clothes such as made of wool, rayon, acetate or other clothes, such as leathers or furs, usually dry cleaned or hand washed, can be machine washed with the present invention without use of hazardous chemicals or shrinkage.

Owner:KIM SU HEON

Nozzle, ejector based on nozzle and having adjustable flow characteristic, and application of ejector

InactiveCN109630479AImprove performanceReduce outlet pressureJet pumpsMachines/enginesAutomatic controlHydrogen

The invention discloses a nozzle, an ejector based on the nozzle and having an adjustable flow characteristic, and application of the ejector. The nozzle comprises a nozzle body, a small nozzle, a large nozzle and an elastic part; a thin and long hollow pipe with a valve is adopted as the small nozzle, and the elastic part is arranged between the set of large nozzle and the set of small nozzle; one end of the elastic part jacks the valve part of the small nozzle, and the other end of the elastic part jacks the large nozzle; and the elastic part can change the position of the valve of the smallnozzle under the effect of to-be-ejected gas, and then a flowing path of the to-be-ejected gas is controlled. The supply quantities of hydrogen and recycled hydrogen are automatically controlled by the nozzle according to system loads; when the low load exists, the small nozzle acts, the pressure of a nozzle outlet is small, the recovery rate of the recycled hydrogen is high, and the hydrogen utilization rate is increased; when the medium-high loads exist, the two sets of nozzles act simultaneously, and the large nozzle is used for enlarging the circulating area to provide the larger fuel flow; and the small nozzle is used for increasing the ejecting speed to improve properties of the ejector.

Owner:SHANDONG UNIV

Air duct assembly and refrigerator

InactiveCN104534780AIncrease the circulation areaReduce flow rateLighting and heating apparatusCooling fluid circulationRefrigerated temperatureAerospace engineering

The invention provides an air duct assembly and a refrigerator with the air duct assembly. The air duct assembly comprises an air duct body, an air duct cover plate, a fan and an air outlet baffle, wherein the air duct cover plate and the air duct body are connected to define an air duct, an air outlet is formed in the air duct cover plate, the fan is arranged in the air duct, the air outlet baffle is connected with the air duct cover plate and can rotate between a first position where the air outlet is opened and a second position where the air outlet is closed, and the opening degree of the air outlet is in positive correlation with the rotating speed of the fan. According to the air duct assembly, the opening degree of the air outlet is in positive correlation with the rotating speed of the fan, when the fan operates at a low speed, the opening degree of the air outlet baffle is small on the premise of meeting the air supply requirement, and when the fan operates at a high speed, the opening degree of the air outlet baffle is large so as to enlarge the flow area of the air outlet and reduce the flow speed at the air outlet, and therefore noise under high rotating speed of the fan is lowered.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

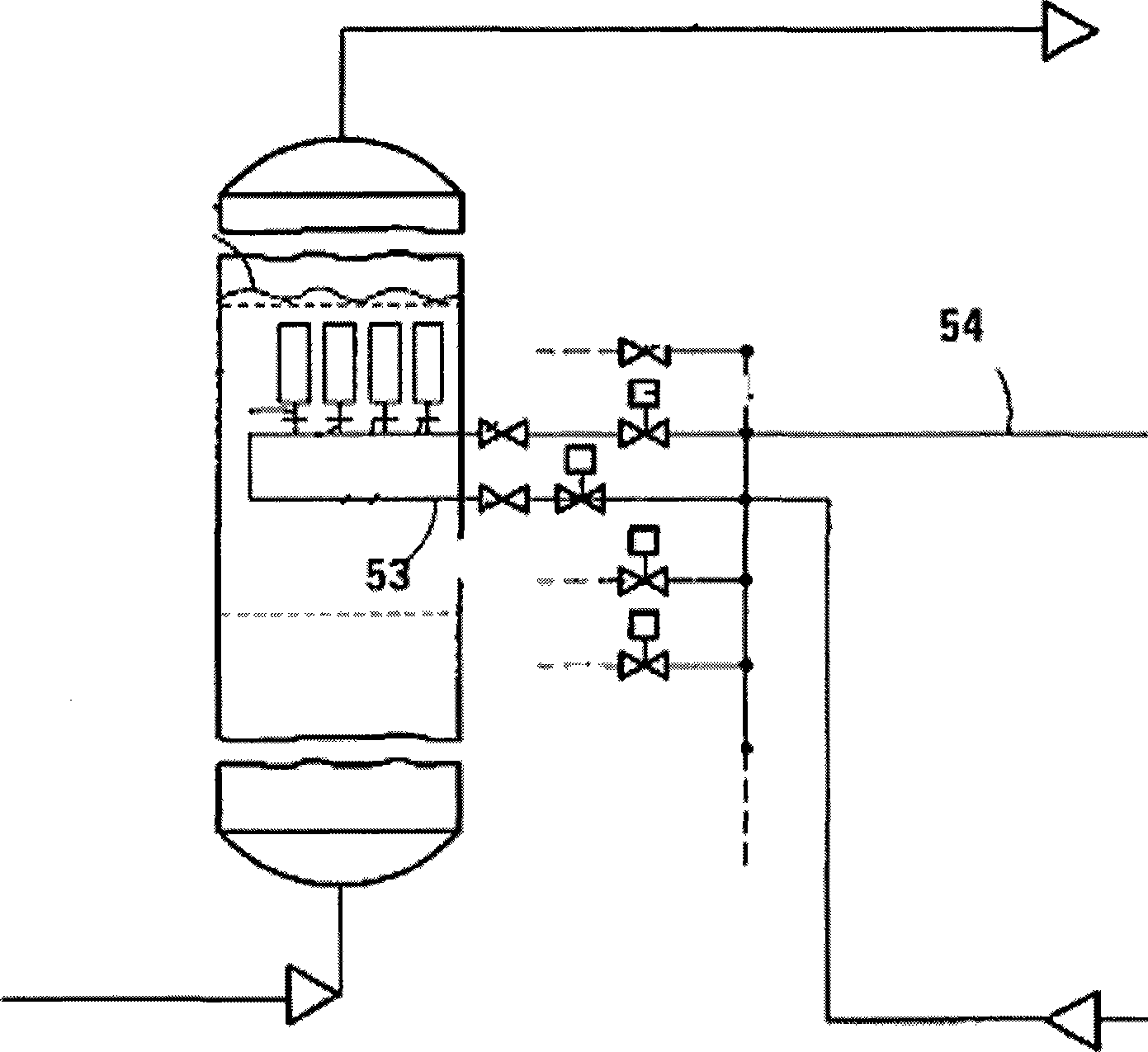

Extraction method of heavy fraction of ft synthetic product from slurry bed reactor

ActiveCN101391196AAvoid bringing outImprove operational stabilityHydrocarbon from carbon oxidesChemical/physical processesDownstream processingGas phase

The invention provides a method for extracting Fischer-Tropsch synthesis product heavy distillate from a slurry bed reactor, concretely comprising the following steps: in the slurry bed reactor, when a Fischer-Tropsch reaction gas phase stream and a slurry phase stream flow through a metal sintering filter stick arranged in a liquid phase of the slurry bed reactor, the Fischer-Tropsch synthesis heavy distillate and part of catalyst powder can be separated out from the slurry phase of the slurry bed reactor; and the Fischer-Tropsch synthesis heavy distillate and part of catalyst powder are fed into a subsequent solid-liquid separation device for further separating the Fischer-Tropsch synthesis heavy distillate and the catalyst powder, so as to make the obtained Fischer-Tropsch synthesis heavy distillate meet the demand of downstream processing. The method avoids the catalyst particles from being brought out from the top part of the reactor by the gas phase stream and depositing on equipment such as a heat exchanger after being further crushed, and also improves the operational stability of the slurry bed reactor and extends the operation cycle of the apparatus, and can also provide qualified Fischer-Tropsch synthesis product heavy distillate to downstream units.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

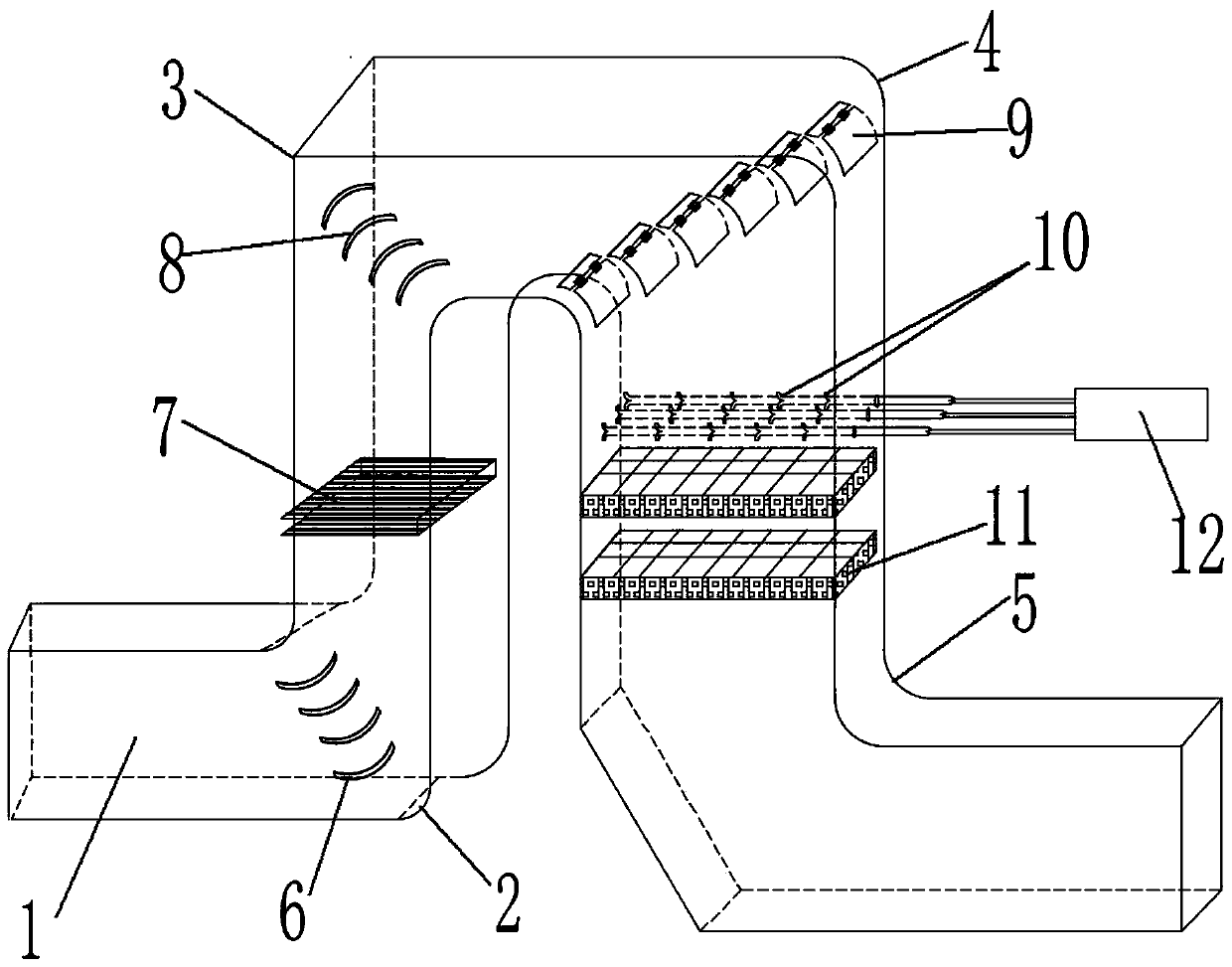

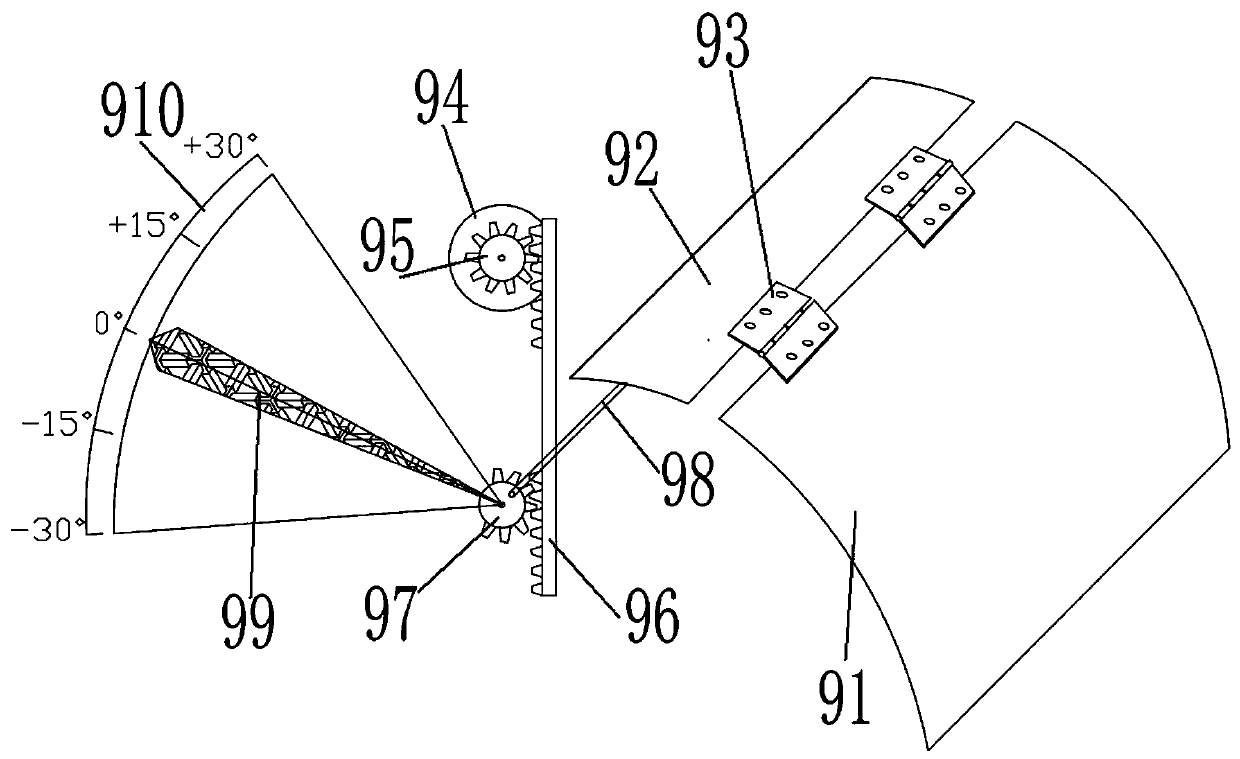

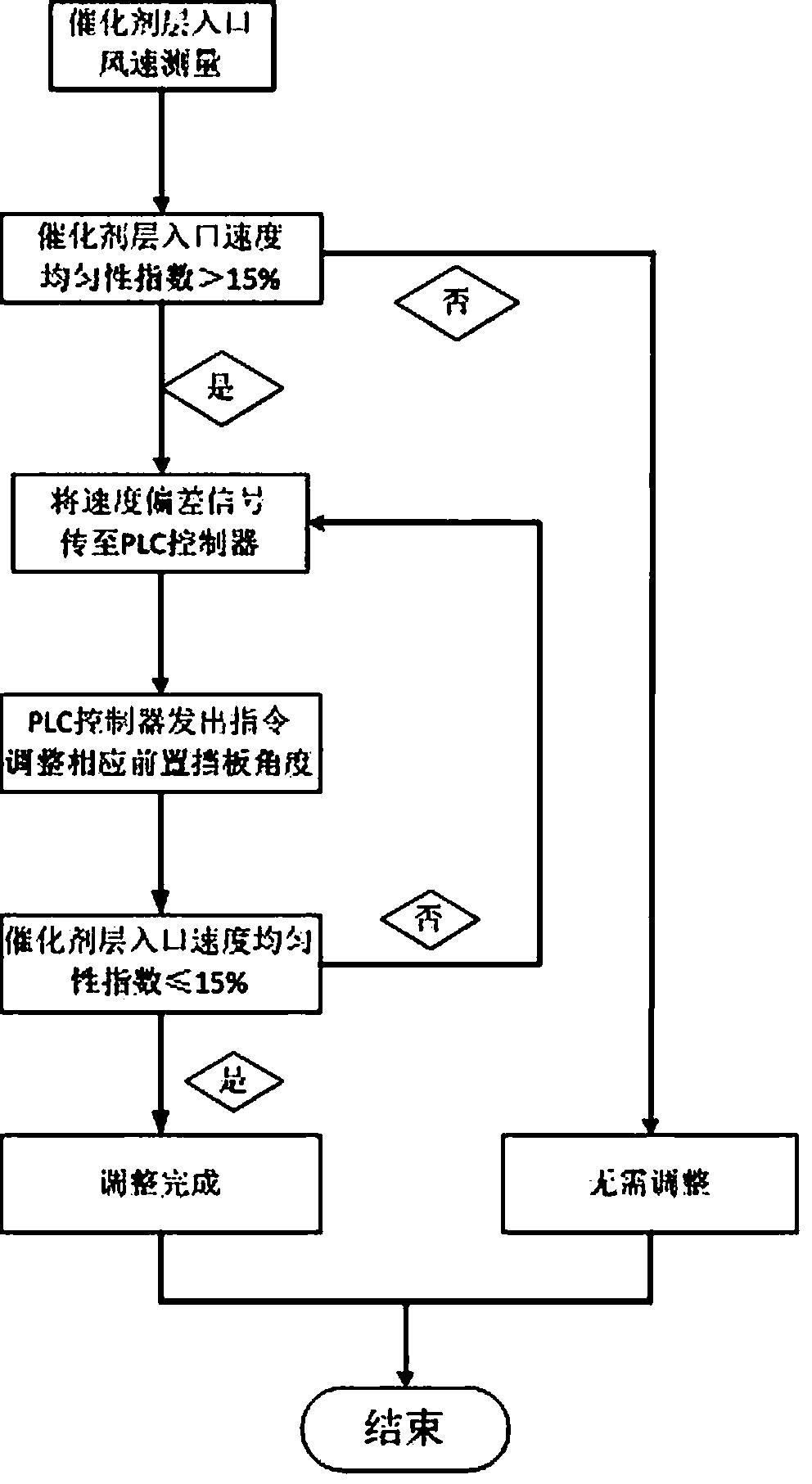

System and method for improving uniformity of selective catalytic reduction (SCR) flow field

ActiveCN107198964AIncrease the circulation areaReduce cloggingGas treatmentDispersed particle separationFlue gasDifferential pressure

The invention relates to a system and a method for improving the uniformity of a selective catalytic reduction (SCR) flow field. The system comprises a flue, a plurality of circular arc-shaped primary guide plates, a plurality of circular arc-shaped secondary guide plates, an ammonia injection grid, N tertiary guide plates, a plurality of catalyst layers, and M sets of differential pressure measurement components which are horizontally arranged along the width direction of the flue and are positioned between the catalyst layers and the tertiary guide plates, wherein each set of differential pressure measurement component is evenly provided with N differential pressure detection devices arranged at intervals along the depth direction of the flue. The system and the method can improve the flue gas flow field in front of the catalyst layers, guarantees the speed uniformity of an SCR system, and effectively reduces the phenomenon that the catalyst layers are blocked or worn.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

Check valve for fuel pump

InactiveUS6877525B2Low cost designIncrease the circulation areaCheck valvesEqualizing valvesEngineeringCheck valve

A check valve for a fuel pump of a vehicle includes a valve housing adapted to be disposed in an outlet member of the fuel pump and a valve seat formed on the valve housing. The check valve also includes a valve member disposed in the valve housing and having a closed position to engage the valve seat to prevent fuel from flowing through the outlet member and an open position to allow fuel to flow through the outlet member. The valve member has at least one outlet port a predetermined dwell distance from the valve seat when the valve member is in the closed position and allows fluid flow past the valve seat when the valve member is in the open position.

Owner:DELPHI TECH IP LTD

Filtering device for diesel engine exhaust gas

ActiveUS20080209872A1Easy to shapeLarge filter areaCombination devicesDispersed particle filtrationExhaust gasPollutant

A filtering device for diesel engines is based on metal foams. In order to achieve high filtration efficiency with low pressure drop using deep bed filtration metal foams, a radial flow concept is used based on a “porosity gradient”. The foams can also be coated with catalytically active material to enhance soot oxidation (regeneration), as well as reduction of other exhaust gas pollutants (CO, hydrocarbons, nitrogen oxides). This may be accomplished by using non-uniform amounts of catalytic materials within the filter depending on the targeted application. An additional secondary filter segment may be placed within the metal support of the main filter segment. The metallic diaphragms at the entrance and exit of the external shell are designed in such a way as to allow the flow to be divided between the main and the secondary filter segments according to the respective flow resistances.

Owner:ARISTOTLE UNIV THESSALONIKI RES COMMITTEE +1

Flame tube structure of thrust combustion chamber used for supercharger test

InactiveCN102788699AImprove structural strengthHigh temperature resistanceContinuous combustion chamberEngine testingCombustion chamberEngineering

The invention discloses a flame tube structure of a thrust combustion chamber used for a supercharger test. The flame tube structure includes two parts, namely a flame tube outer casing (1) and a flame tube inner casing (2), and further includes functional structures such as an air film cooling tank structure (3), a nozzle swirler and a second-stage diffuser, wherein a main combustion zone (11), a mixture zone (12), a cooling transition zone I (13) and a cooling transition zone II (14) all of the flame tube inner casing (2) are connected with one another through the novel air film cooling tank structure (3) which is a curve rectangular hole provided with diversion trenches, and the proportion of the air inlet passage sectional area in the sectional area of the film cooling tank structure is larger; the proportion of the air circulation sectional areas of the four zones in the sectional areas of corresponding positions of the flame tube outer casing (1) is larger; and the thickness of both the flame tube outer casing (1) and the flame tube inner casing (2) is 4.5 mm. According to the invention, the structural strength of the flame tube is increased, the formation of carbon deposition is reduced, the economic efficiency of the fuel is improved, the heat dissipation effect of the wall of the flame tube is improved, and the tolerance temperature of the combustion chamber and the flame tube as a whole is improved.

Owner:NO 70 INST OF CHINA NORTH IND GRP

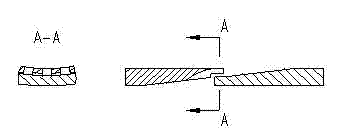

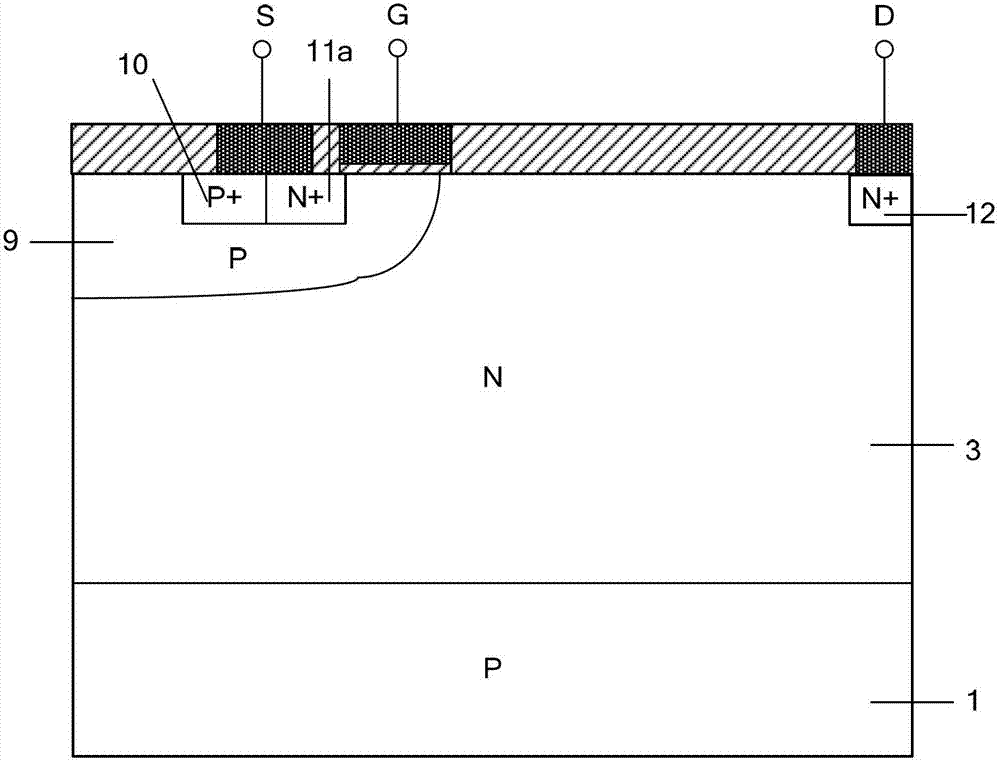

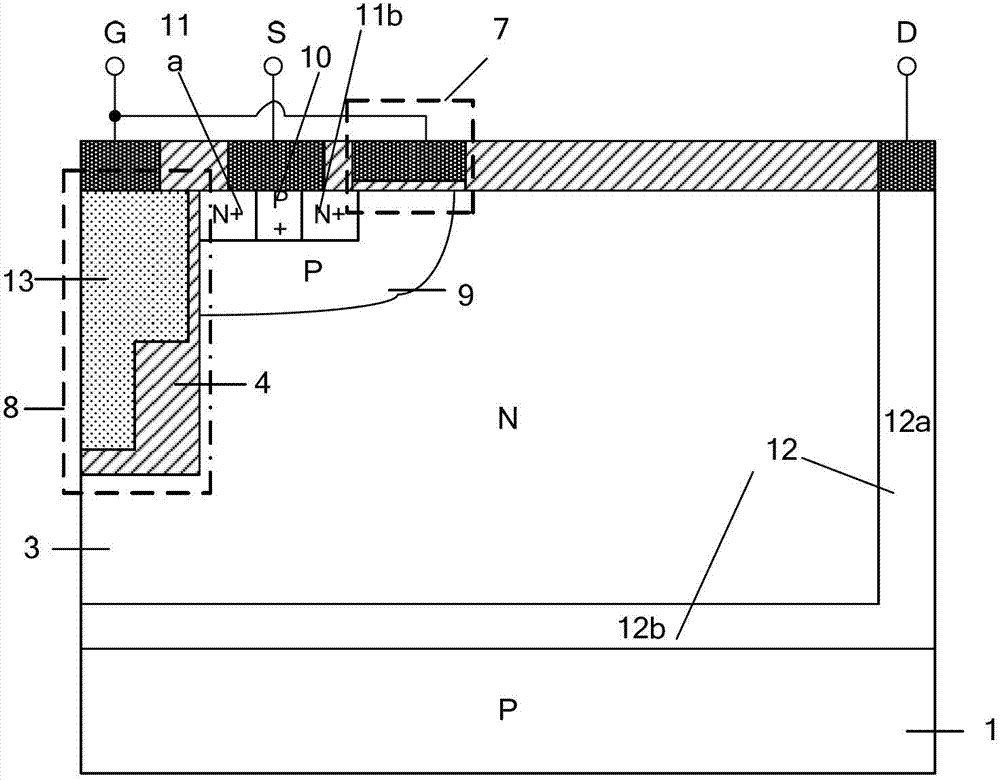

Bigrid power MOSFET (Metal-Oxide-Semiconductor Field Effect Transistor) device

InactiveCN102738240AReduce withstand voltageShorten the conduction pathSemiconductor devicesField-effect transistorElectrode Contact

The invention discloses a bigrid power MOSFET (Metal-Oxide-Semiconductor Field Effect Transistor) device, belonging to the technical field of semiconductor power devices. According to the invention, on the basis of a common bigrid LDMOS (Laterally Diffused Metal Oxide Semiconductor) device, by means of extending a drain-electrode contact area connected with drain-electrode metal to a place below an active layer to form a longitudinal drain-electrode contact area (12a) and introducing a layer of heavily-doped buried layer namely a transverse drain-electrode contact area (12b) connected with the lower end of the longitudinal drain-electrode contact area (12a) between the active layer and the substrate, a current conduction path is shortened; meanwhile, a bigrid structure is adopted to form a double-current channel, so that the current flow area is enlarged, and on-resistance and power consumption are reduced greatly; and compared with the devices with the same transverse dimensions, the device disclosed by the invention is slightly reduced in withstand voltage.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

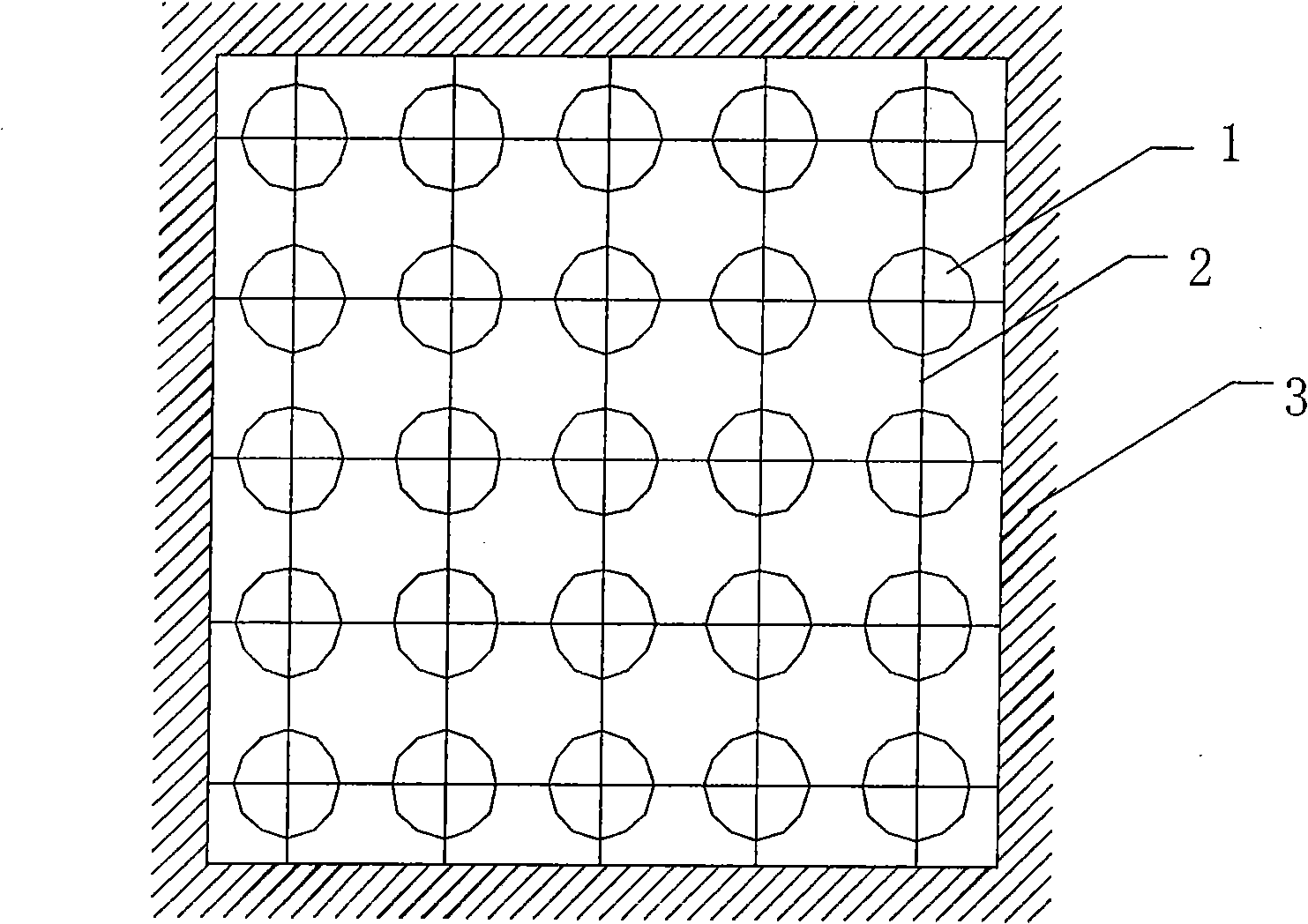

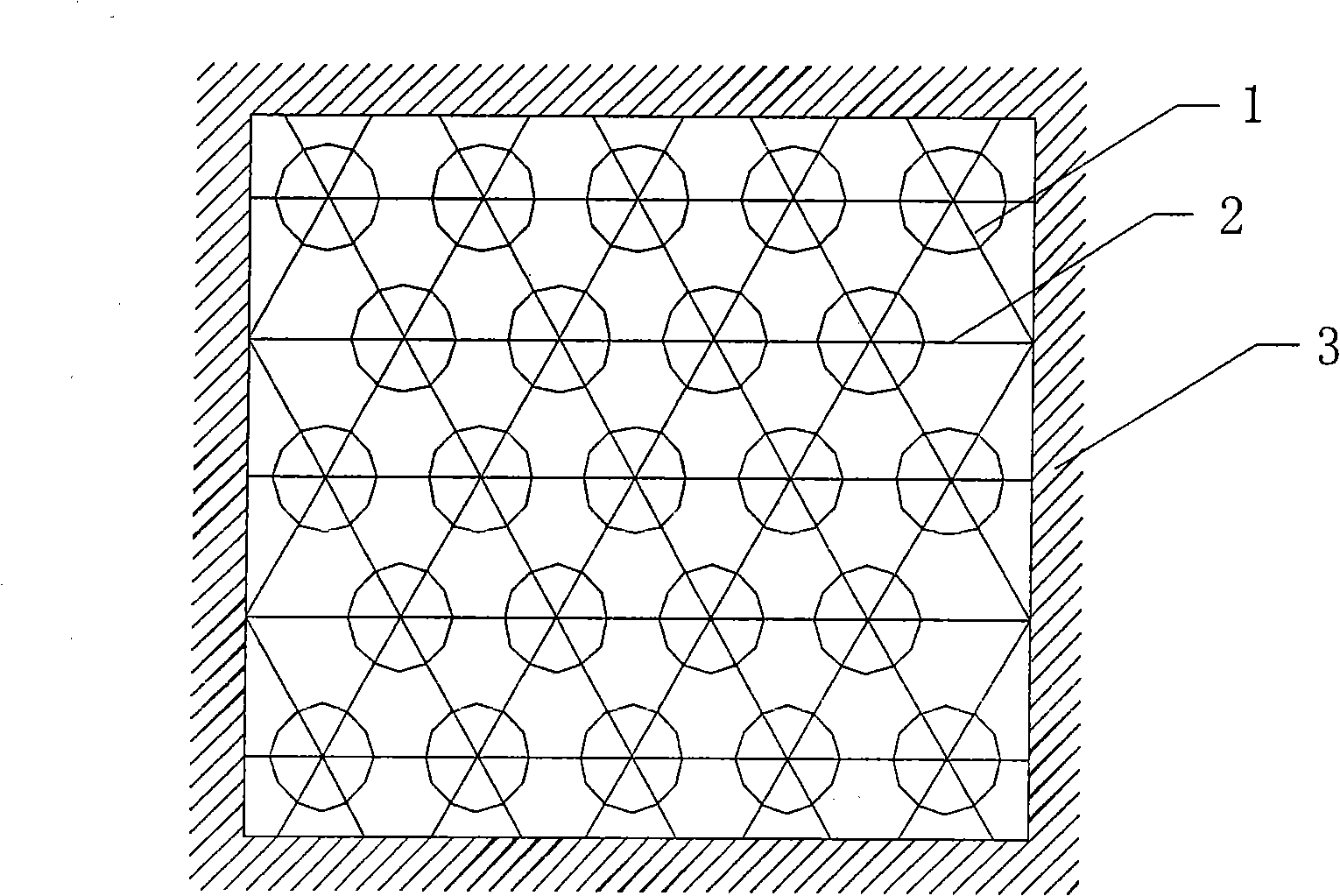

Array type silencer

InactiveCN101275700AIncrease the circulation areaShorten the lengthPipe elementsRigid pipesEngineeringNoise reduction

The invention discloses an array type muffer, the technical problems to be solved are to advance the silencing ability. The array type muffer is provided with an absorbing body in the tube, wherein the absorbing body is a tube provided with sound absorption material inside, the axis of the tube is arranged along the airflow direction in parallel, and the tube is fixedly arranged in the air pipe through the bracket. Compared with the existing technology, in the same length of the muffer, the absorption surface of the unit cross area is increased, the absorption property is advanced, the noise reduction effect is good, which ensures that in the same noise reduction effect, the length and the volume of the muffer are reduced, the air flow area of the unit cross area is increased, the flow velocity of the absorbing body is reduced, the air noise is reduced, the pressure loss is small, thereby reducing the pressure of the system fan, reducing the cost of the air system. The whole muffer is decomposed into each small absorbing body and the parts for installing the bracket, which is convenient for the transportation and installment.

Owner:方庆川 +1

Gas circuit axial grading type dual-fuel nozzle

InactiveCN103175223AIncrease the circulation areaReduce radial sizeContinuous combustion chamberWater vaporEngineering

The invention aims to provide a gas circuit axial grading type dual-fuel nozzle which comprises a gas circuit outer wall and a main oil circuit wall arranged inside the gas circuit outer wall. An auxiliary oil circuit wall is arranged inside the main oil circuit wall. A main oil circuit channel is formed between the main oil circuit wall and the auxiliary oil circuit wall. An auxiliary oil circuit channel is formed inside the auxiliary oil circuit wall. A gas circuit is formed between the gas circuit outer wall and the main oil circuit wall. The gas circuit comprises a gas circuit front cavity, a gas circuit laryngeal and a gas circuit rear cavity in sequential communication. A first level gas circuit gas ejection hole is formed in a position, arranged on the gas circuit front cavity, of the gas circuit outer wall. A laryngeal gas ejection hole is formed in the gas circuit laryngeal. A second level gas circuit gas ejection hole is formed in the gas circuit rear cavity. Due to the fact that a gas circuit axial grading type structure is adopted, the gas circuit axial grading type dual-fuel nozzle has the advantages of reducing the radial size of the nozzle, simultaneously increasing gas circuit flow area, enhancing mixing of fuel and air, strengthening burning, shortening flame, and simultaneously not burning the wall surface of a flame tube. When liquid fuel is burned, water vapor reinjection is conducted by the gas circuit.

Owner:HARBIN ENG UNIV

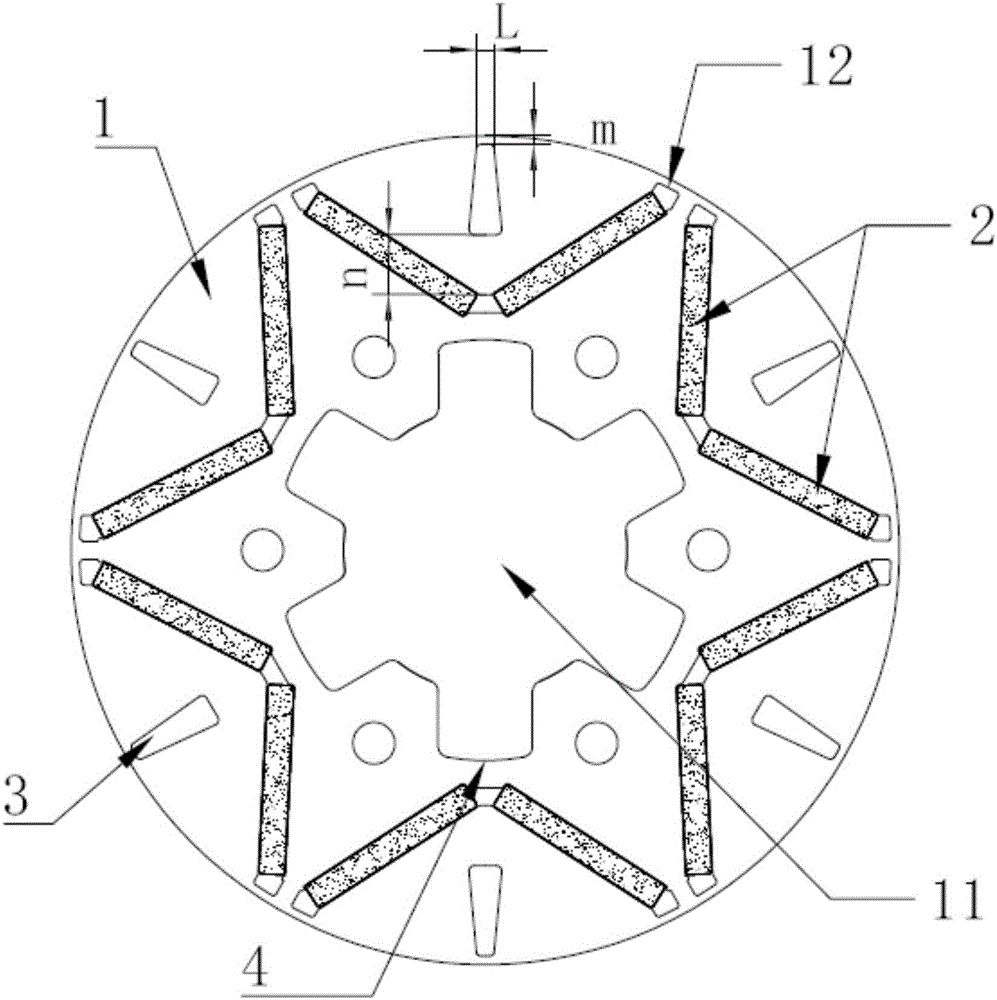

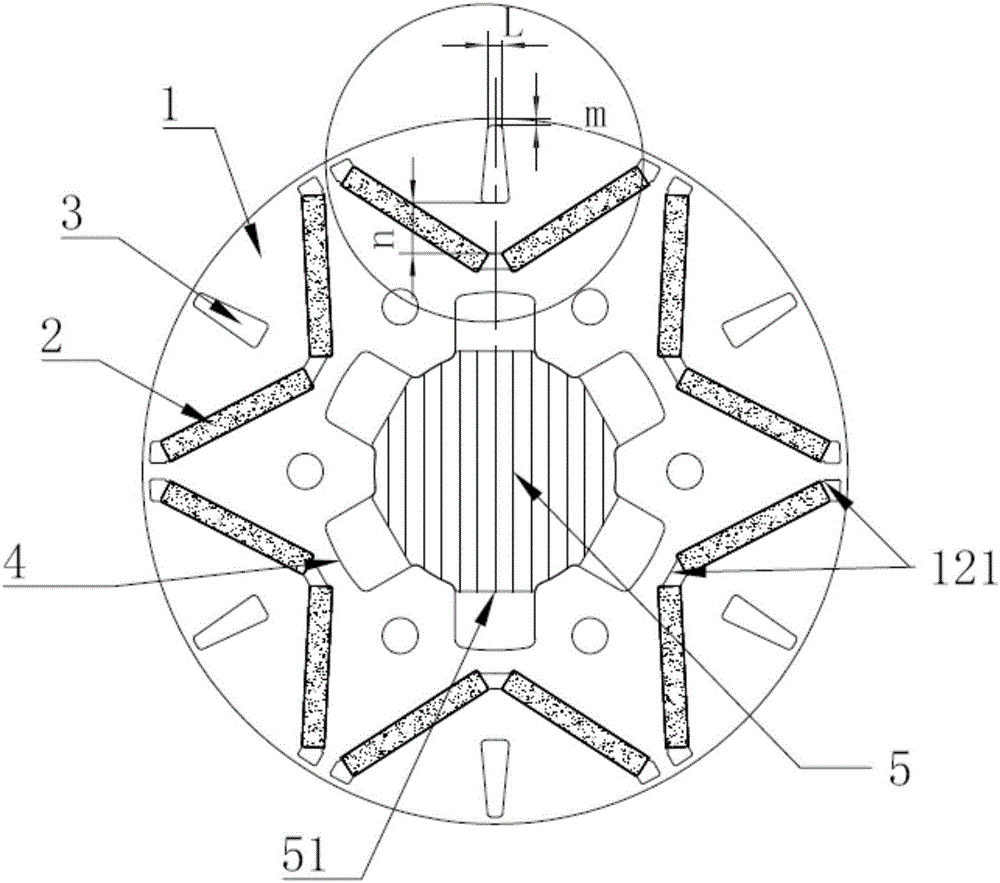

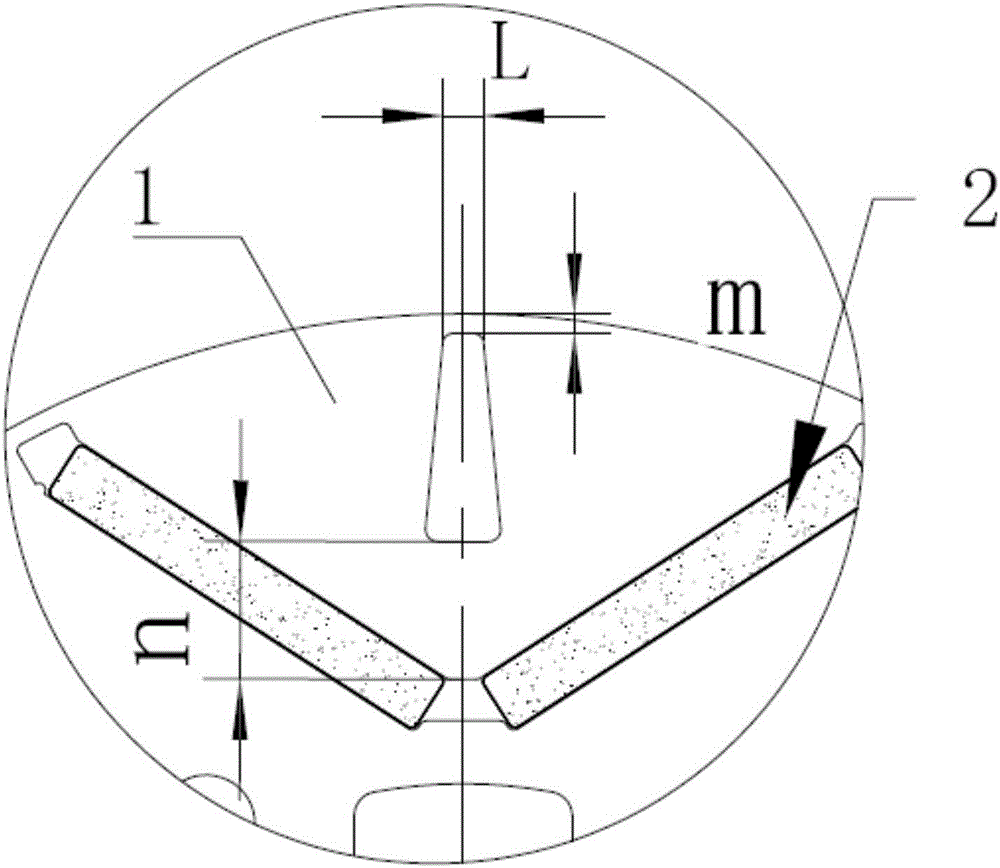

Rotor structure, motor and compressor

ActiveCN106451849AIncrease the circulation areaImprove cycle efficiencyMagnetic circuit rotating partsEngineeringCycle efficiency

The invention discloses a rotor structure, a motor and a compressor. The rotor structure comprises a rotor iron core and magnetic steel. A shaft hole fixed connected with a revolving shaft and an even number of magnetic steel tanks are formed in the rotor iron core in a rotation axis of the rotor iron core, and magnetic steel tanks are symmetrically formed in the rotor iron core and around the outer periphery of the shaft hole; magnetic steel is installed in the magnetic steel tanks in a one-to-one correspondence mode; first through grooves are symmetrically formed in the rotor iron core and around the inner wall face of the shaft hole, extending in the axial direction and concaved in the radial direction; first through holes are formed between the first through grooves and the outer wall face of the revolving shaft. The motor includes a stator and the rotor structure arranged in the inner hole of the stator. The compressor includes the motor. The first through holes are directly formed in the shaft hole of the rotor iron core to serve as one part of the shaft hole, can increase the circulation areas of the rotor, accelerate the overall cycle efficiency of refrigerant and oil, and are beneficial to heat dissipation of the motor and the revolving shaft. At the same time, the revolving shaft is fixedly matched with the first through holes, and thus the torque between the rotor and the revolving shaft is ensured.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

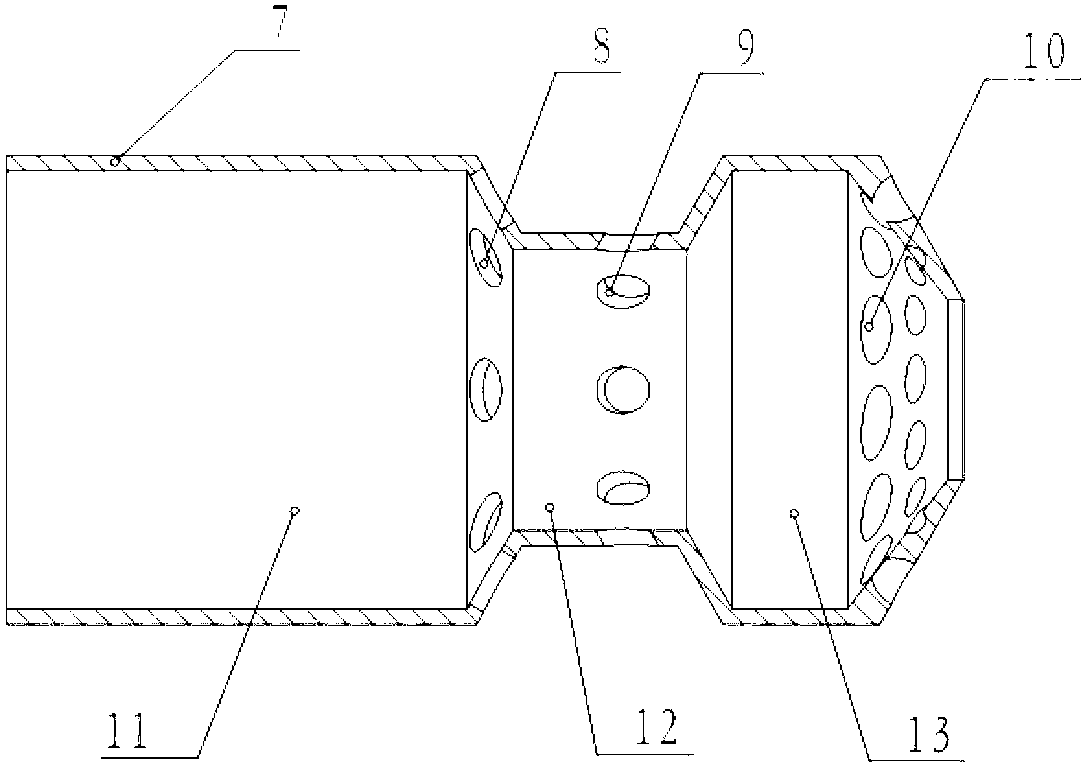

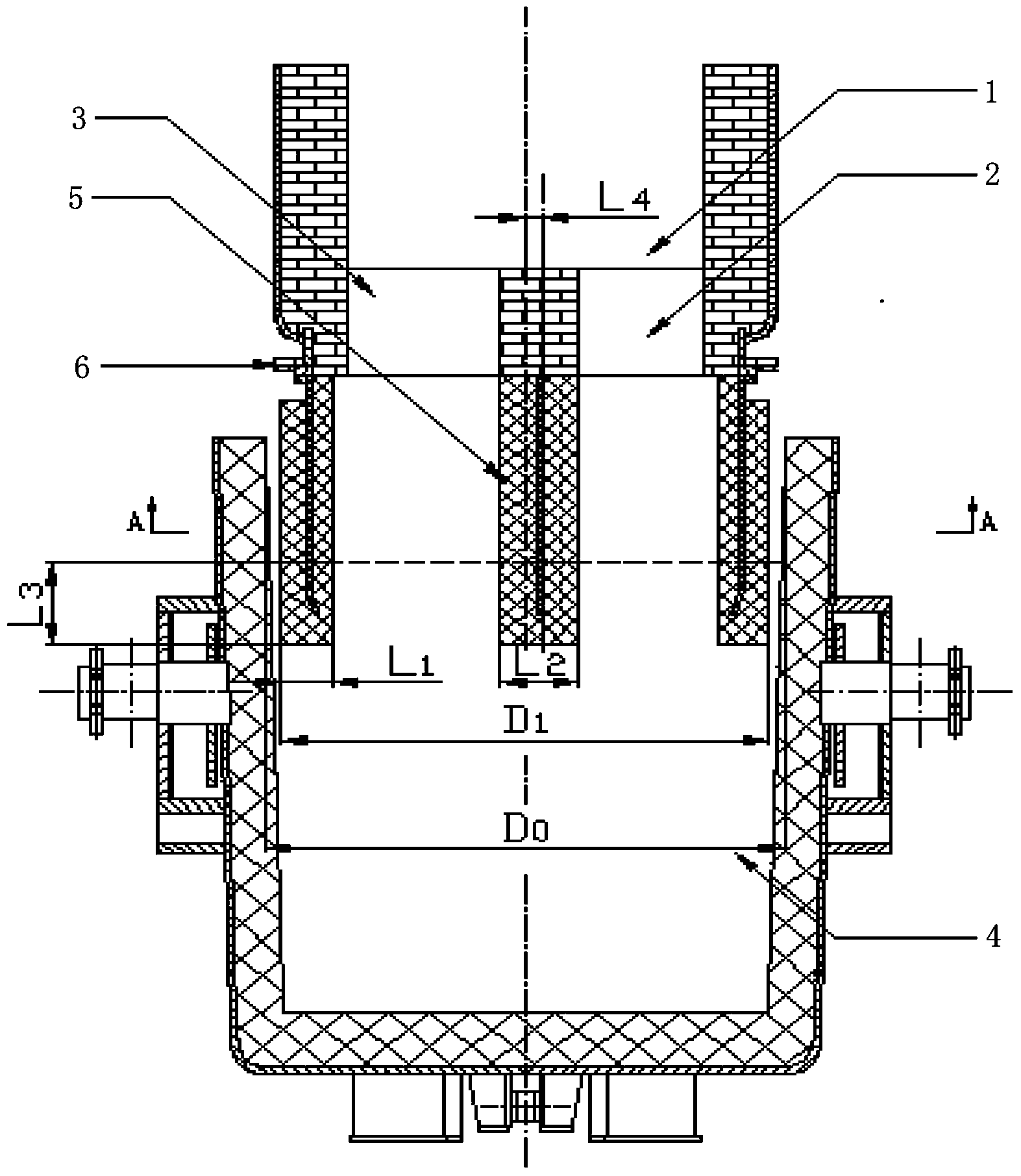

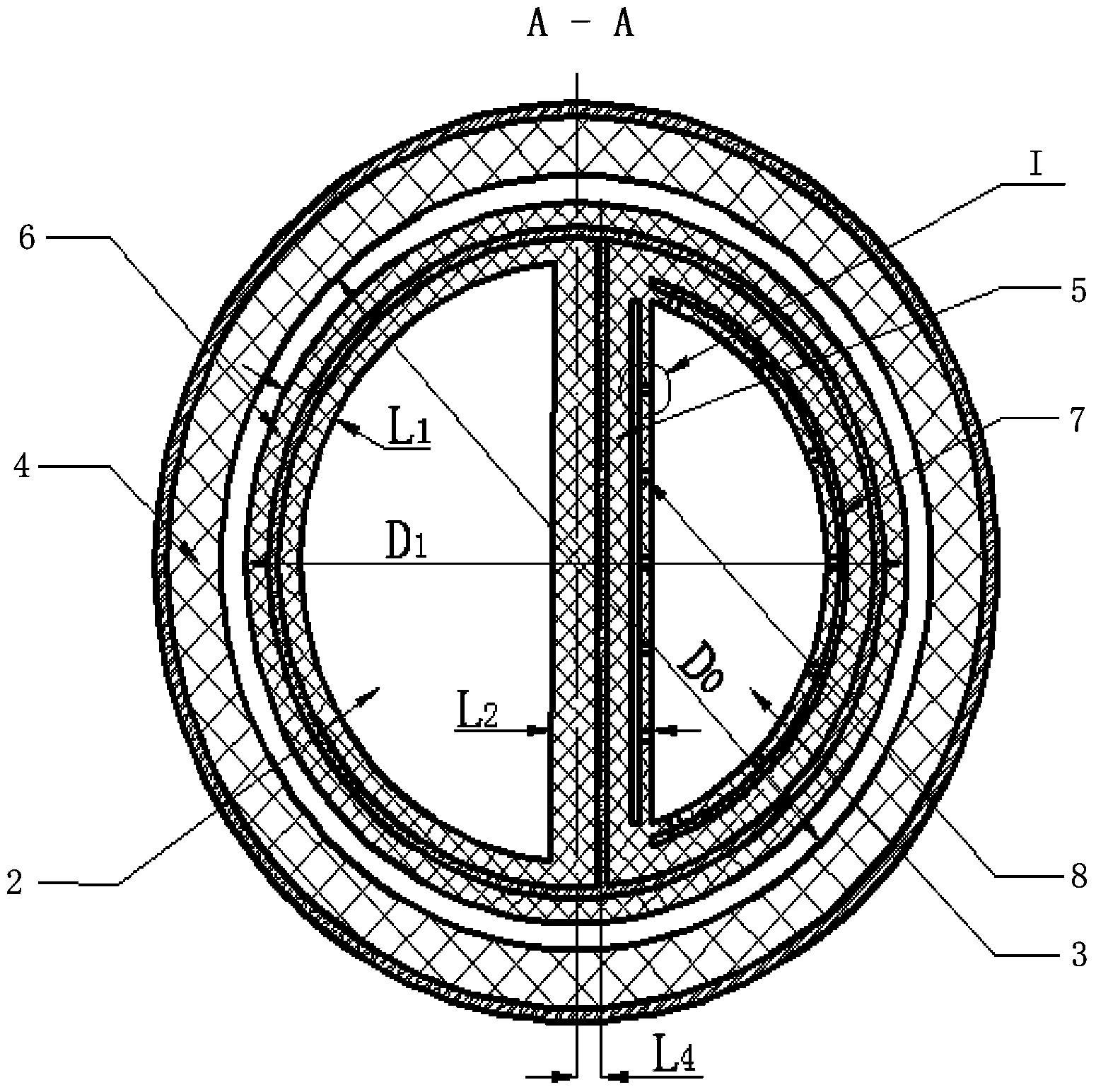

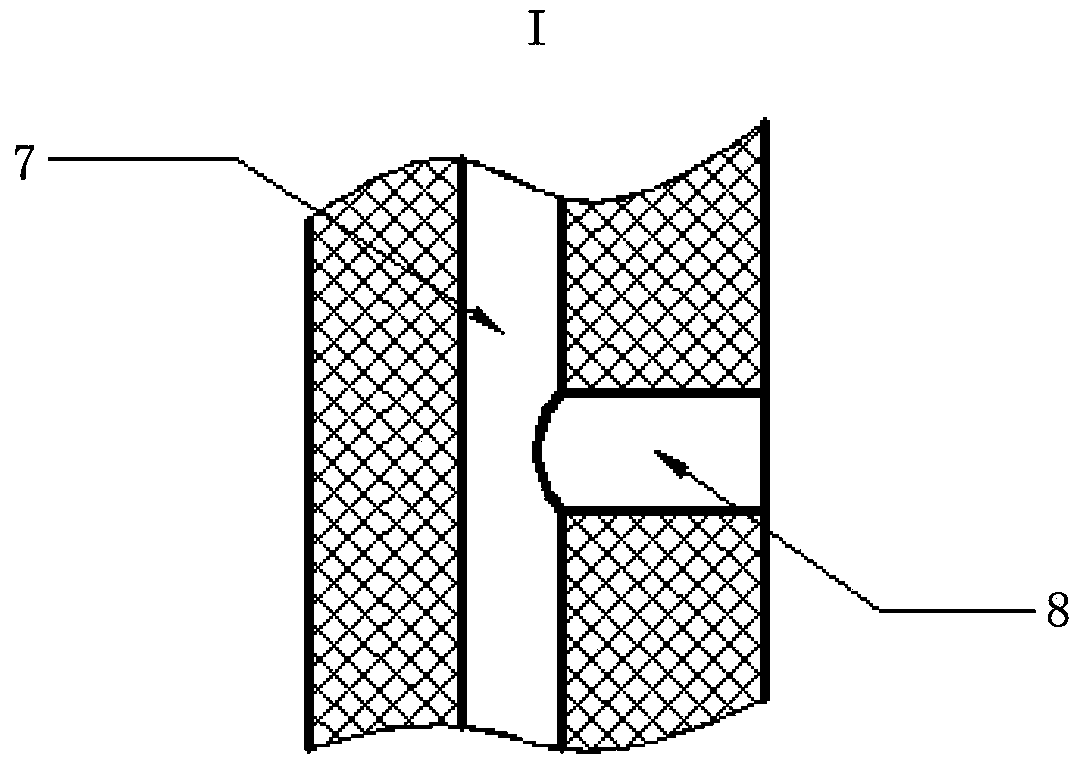

Dip pipe for RH vacuum refining device

ActiveCN103834766AIncreased area equivalent diameterIncrease the circulation areaLifting gasEngineering

The invention discloses a dip pipe for an RH vacuum refining device. The dip pipe comprises an ascension pipe and a descending pipe and is divided into the arc-shaped ascension pipe and the arc-shaped descending pipe by a middle partition wall, wherein a lifting gas blowing-in guide pipe is arranged at the lower part of the ascension pipe, a lifting gas outlet is formed in the lifting gas blowing-in guide pipe, and the dip pipe formed by the ascension pipe and the descending pipe is fixed at the lower end of a vacuum chamber through a flange welded on the dip pipe. As the dip pipe with the structure fully utilizes the space of the bottom of the vacuum chamber, a gap between the ascension pipe and the descending pipe of a conventional dip pipe, which is generated due to a refractory material, is omitted, the flow area of dip pipe molten steel is enlarged, and therefore, the circular flow of a vacuum circulating gas stripping unit RH can be obviously increased.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com