Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1874results about "Cosmonautic propulsion system apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

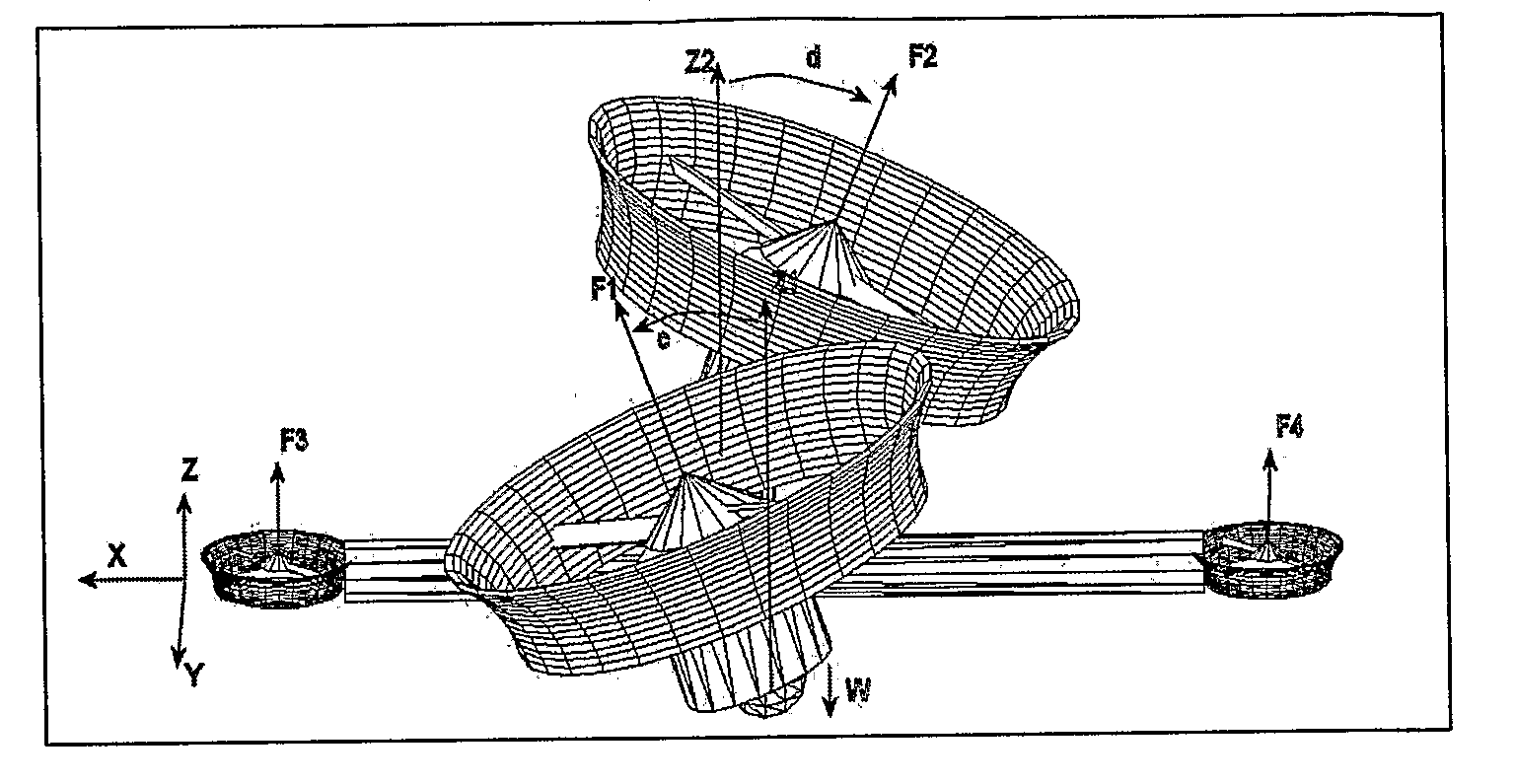

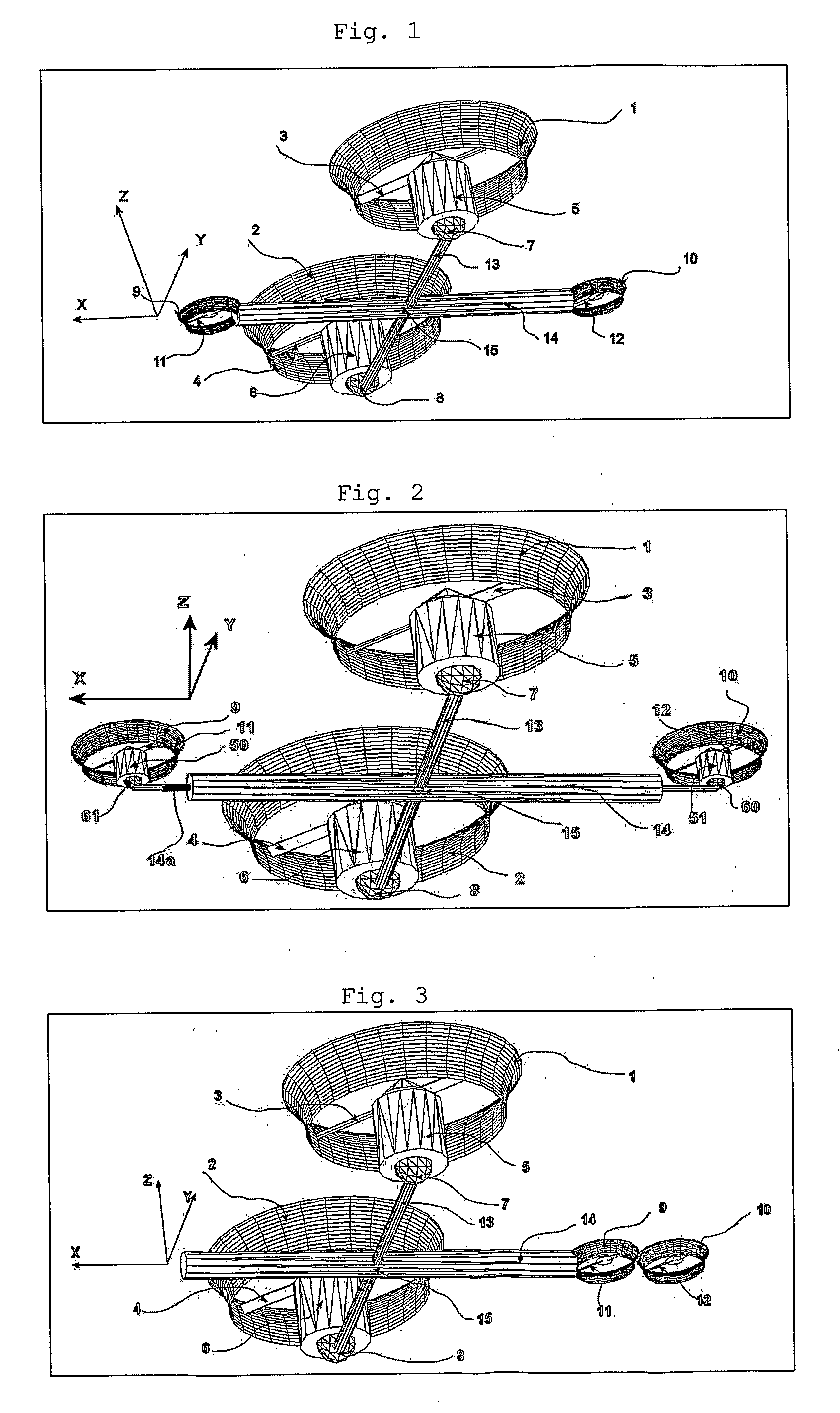

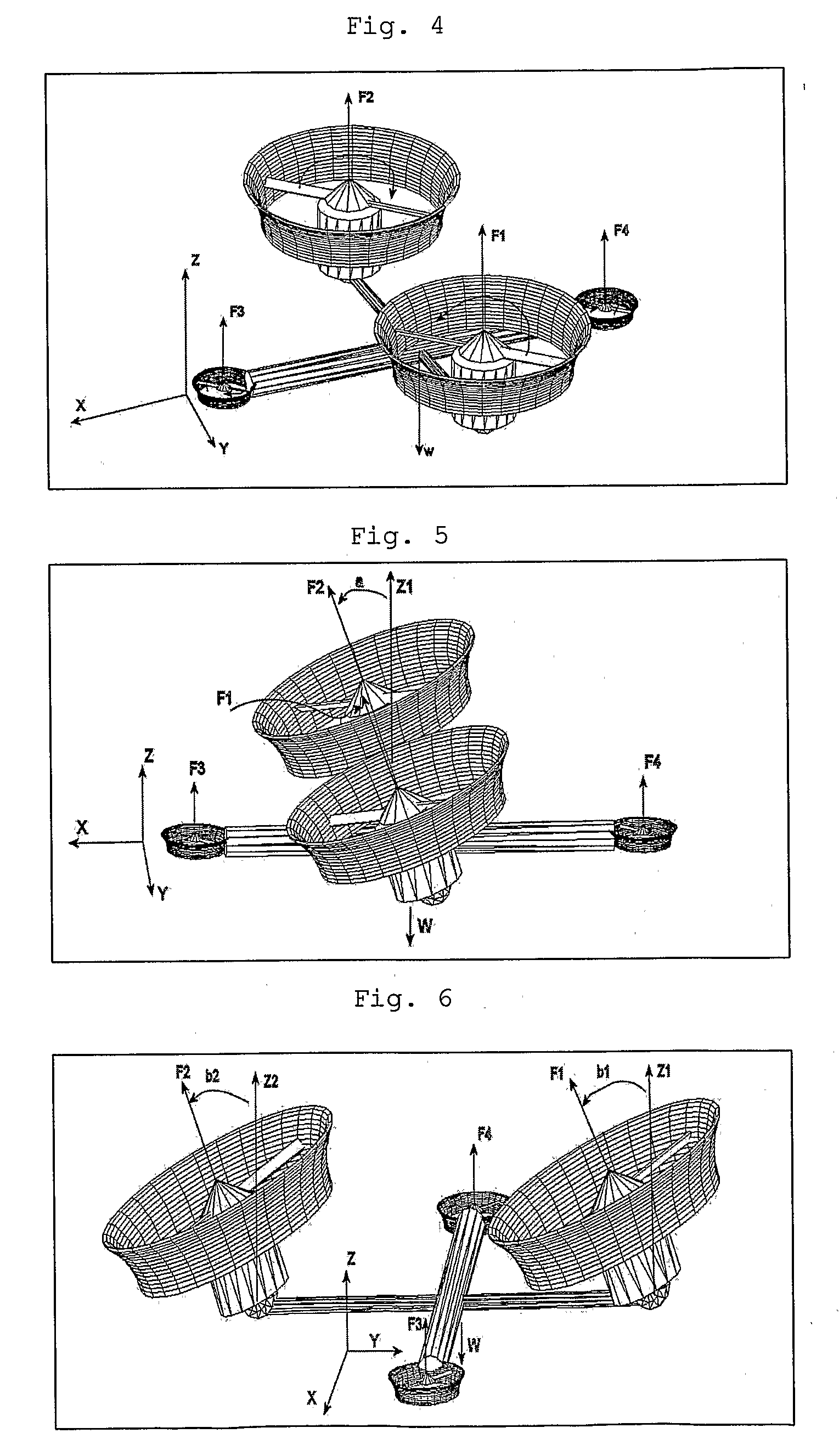

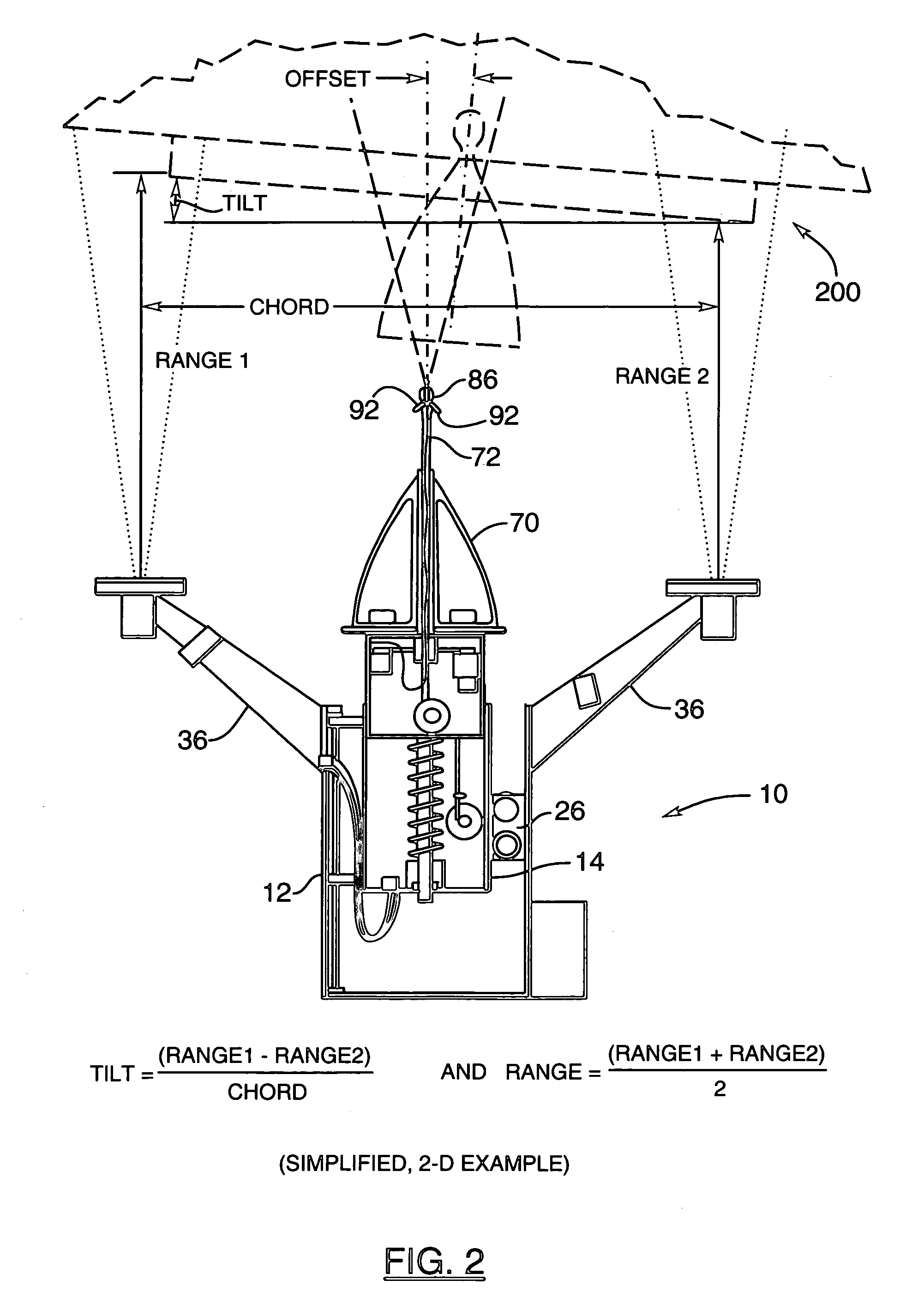

System and Process of Vector Propulsion with Independent Control of Three Translation and Three Rotation Axis

ActiveUS20100301168A1Reduces the passenger's discomfortEasy to controlCosmonautic vehiclesDigital data processing detailsControl systemVector control system

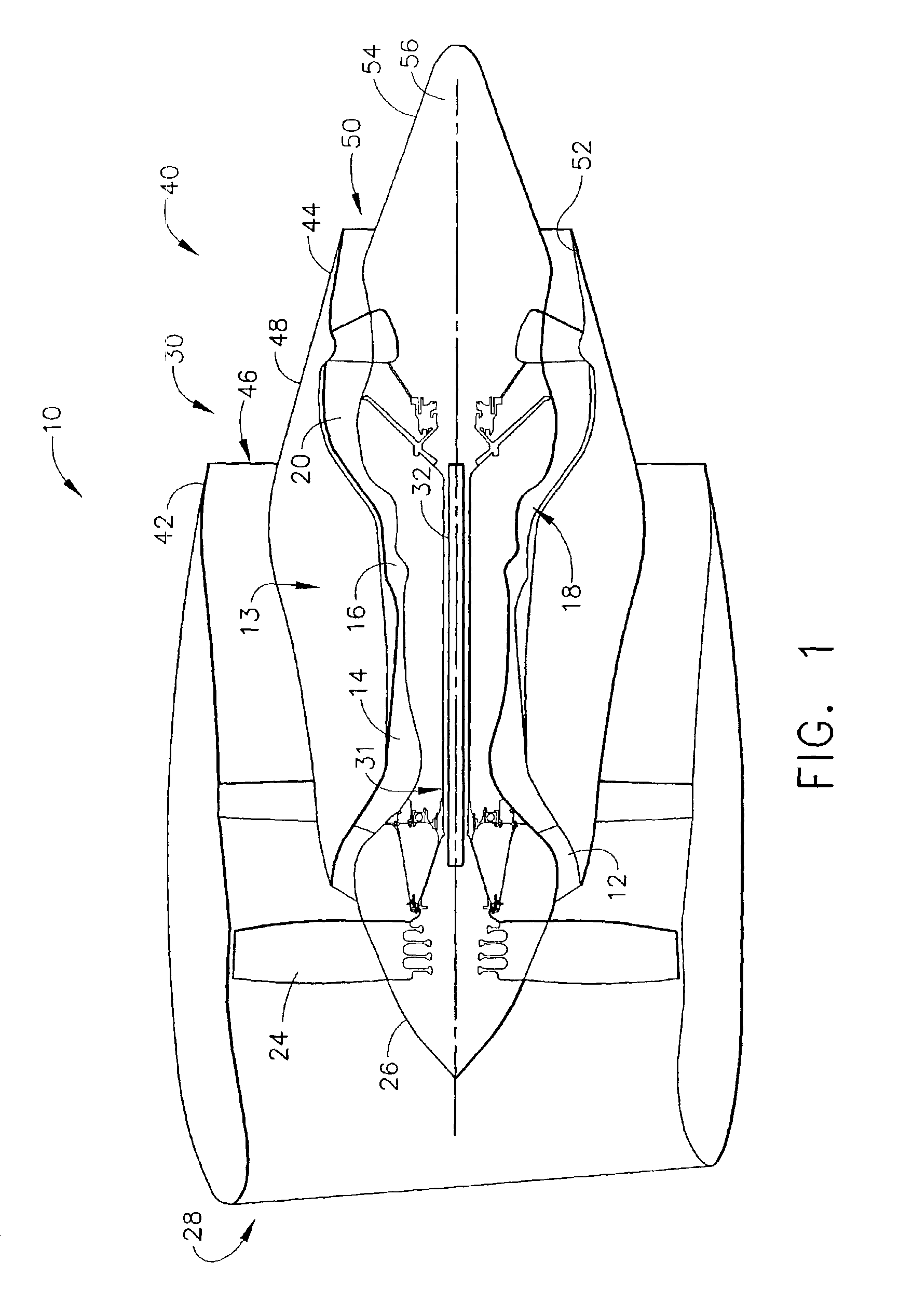

The present invention relates to a propulsion system of a vertical takeoff and landing aircraft or vehicle moving in any fluid or vacuum and more particularly to a vector control system of the vehicle propulsion thrust allowing an independent displacement with six degrees of freedom, three degrees of translation in relation to its centre of mass and three degrees of rotation in relation to its centre of mass. The aircraft displacement ability using the propulsion system of the present invention depends on two main thrusters or propellers and which can be tilted around pitch is (I) by means of tilting mechanisms and, used to perform a forward or backward movement, can be tilted around roll axis (X) by means of tilting mechanisms and, used to perform lateral movements to the right or to the left and to perform upward or downward movements (Z), the main thrusters being further used to perform rotations around the vehicle yaw axis (Z) and around the roll is (X). The locomotion function also uses one or two auxiliary thrusters or propellers and mainly used to control the rotation around the pitch axis, these thrusters or propellers and being fixed at or near the longitudinal is of the vehicle, with there thrust perpendicular or nearly perpendicular to the roll and pitch axis of the vehicle.

Owner:RAPOSO SEVERINO

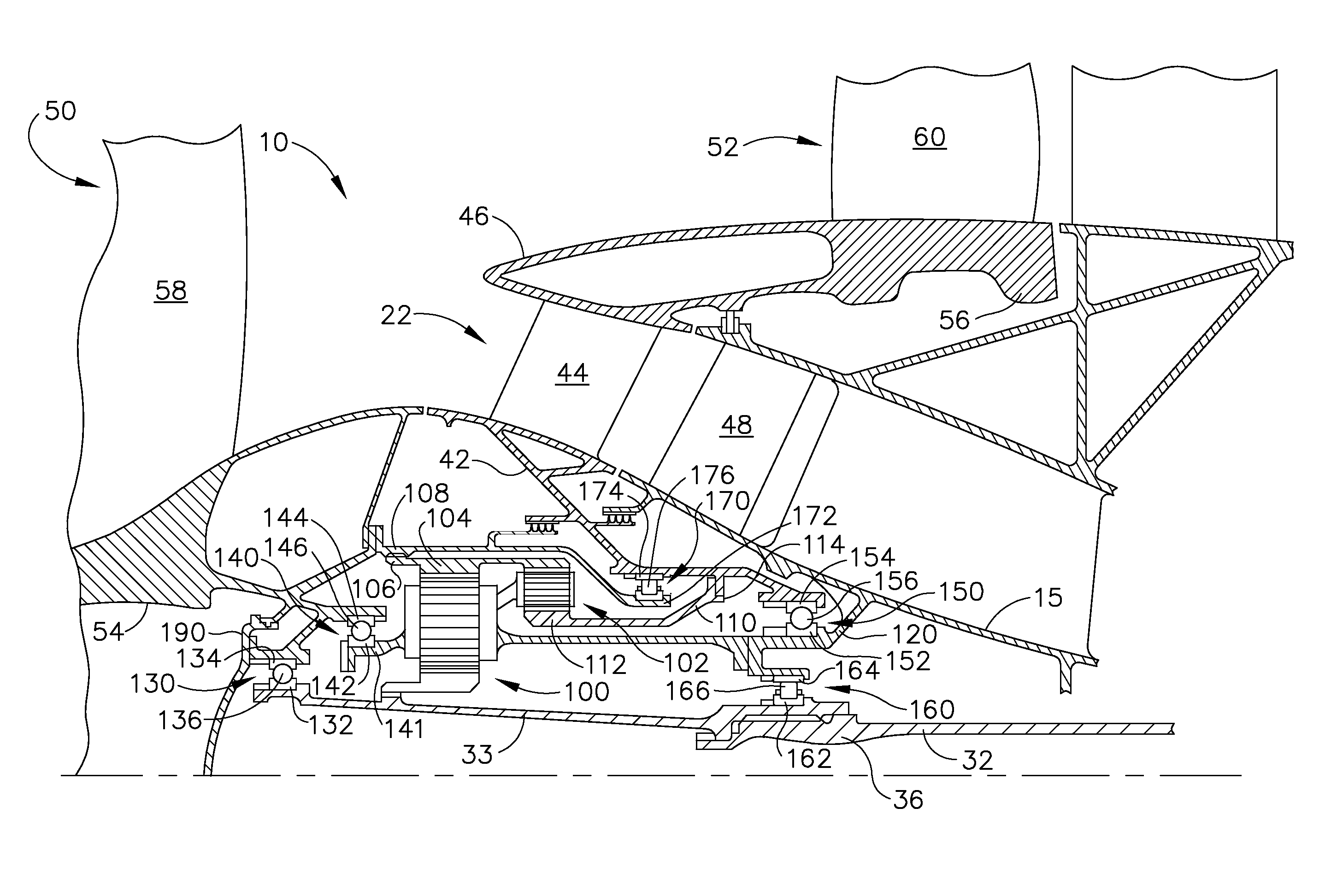

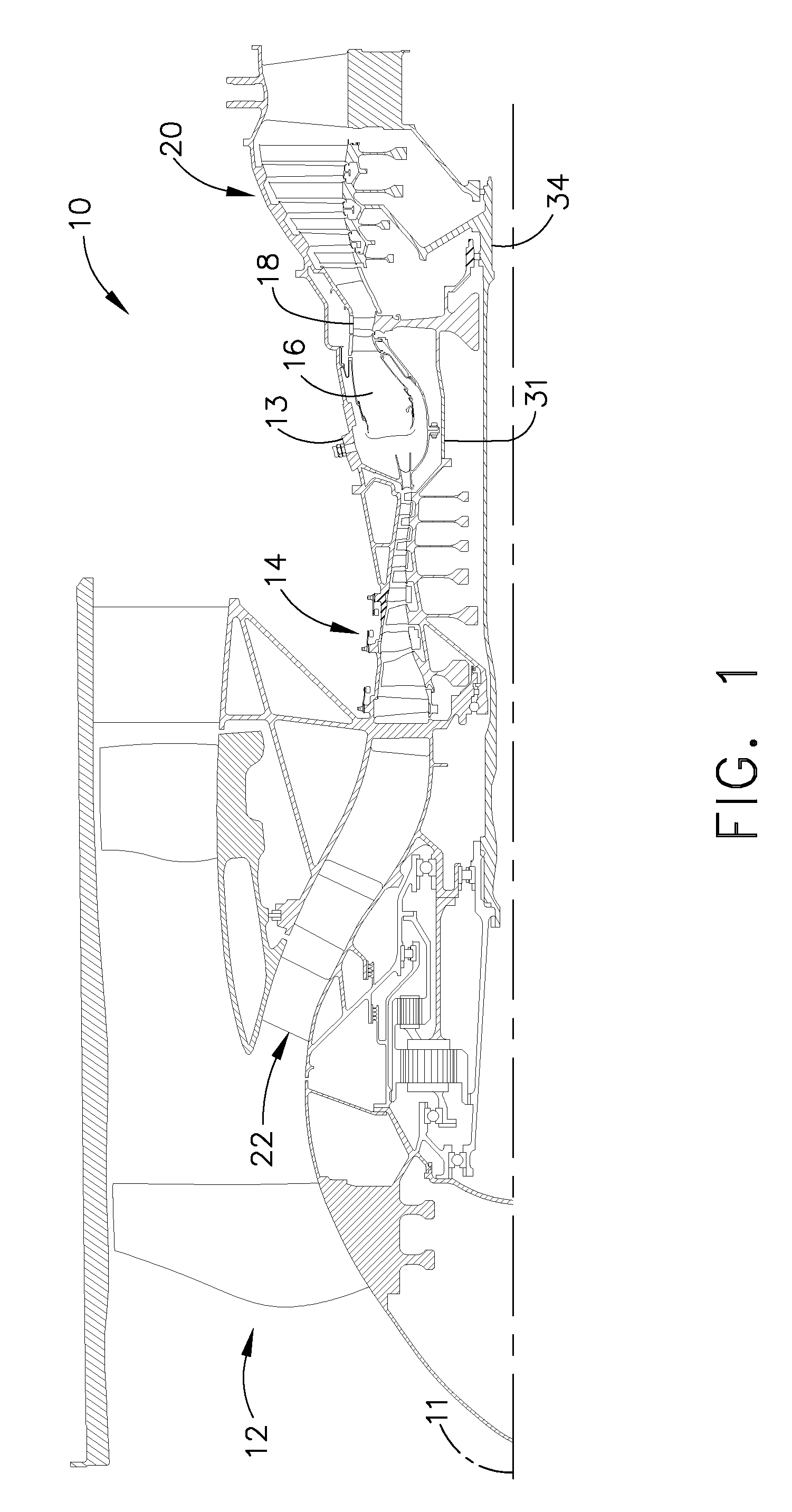

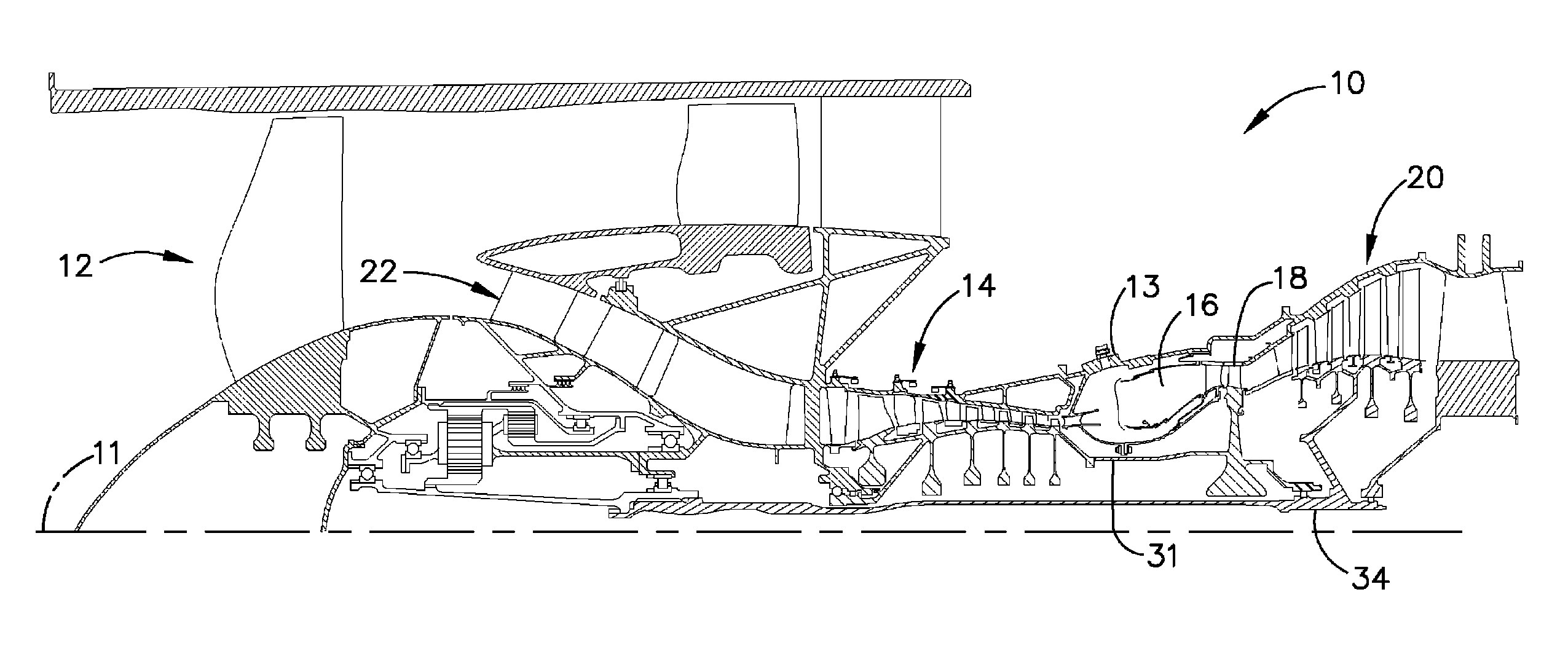

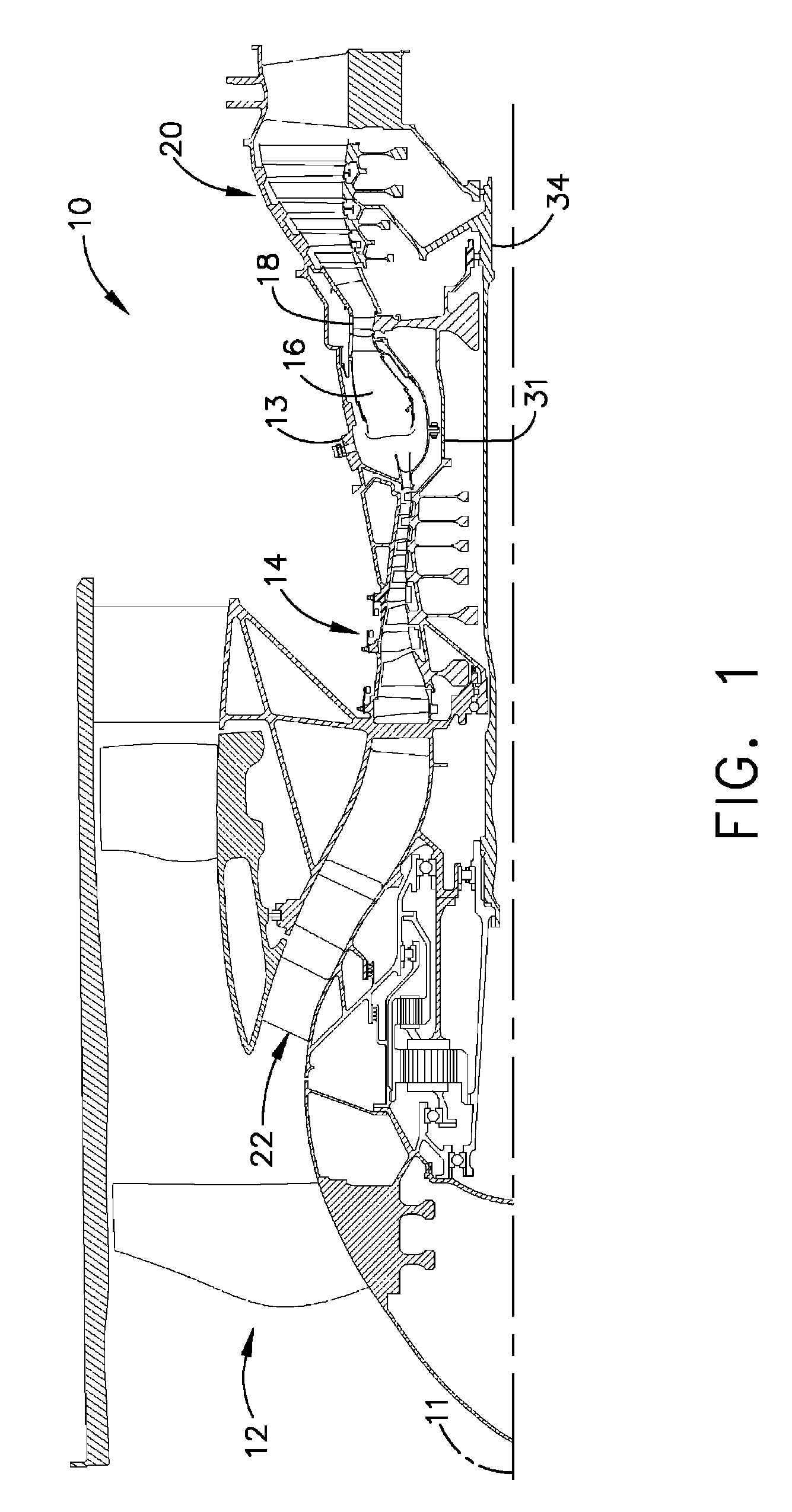

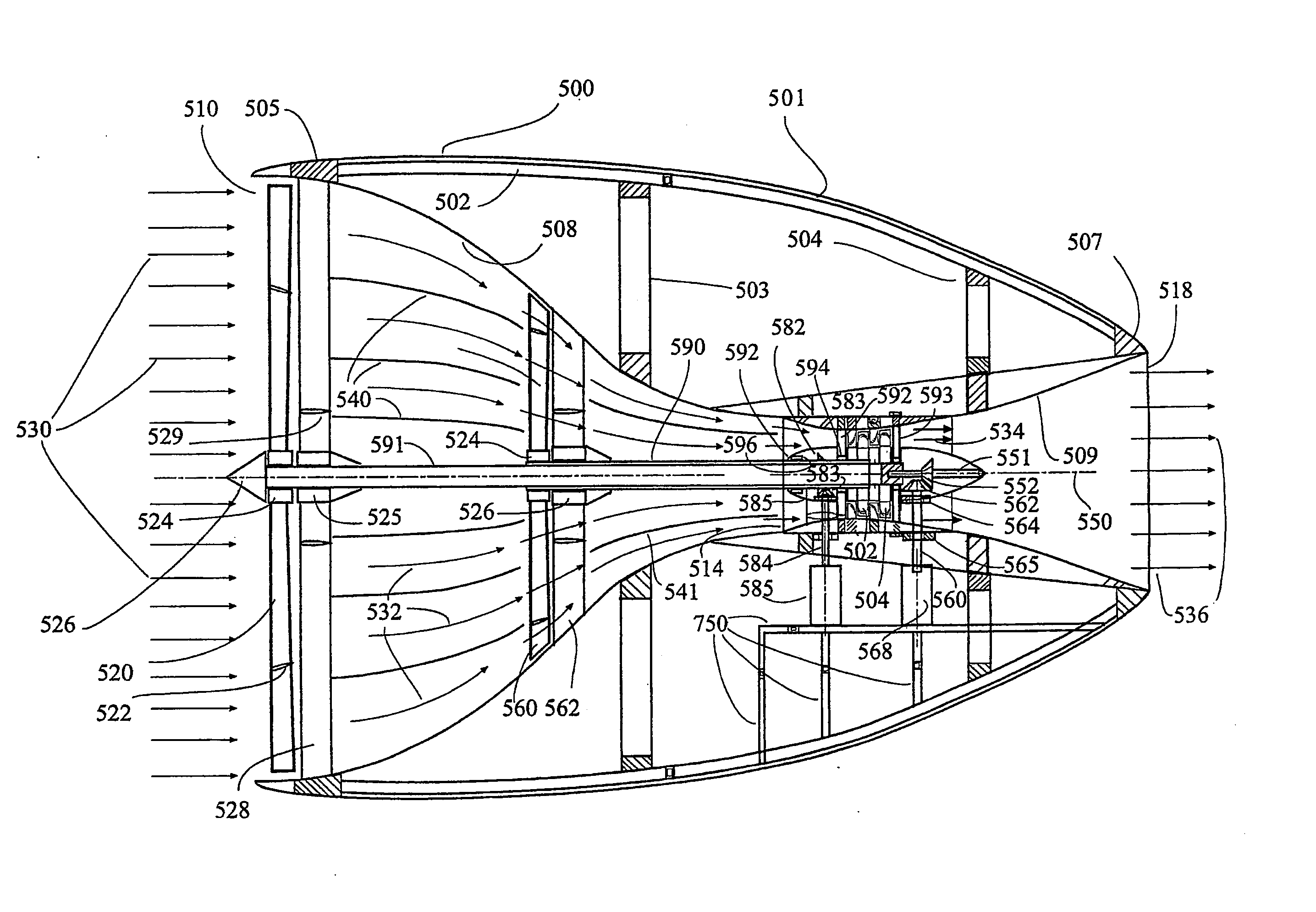

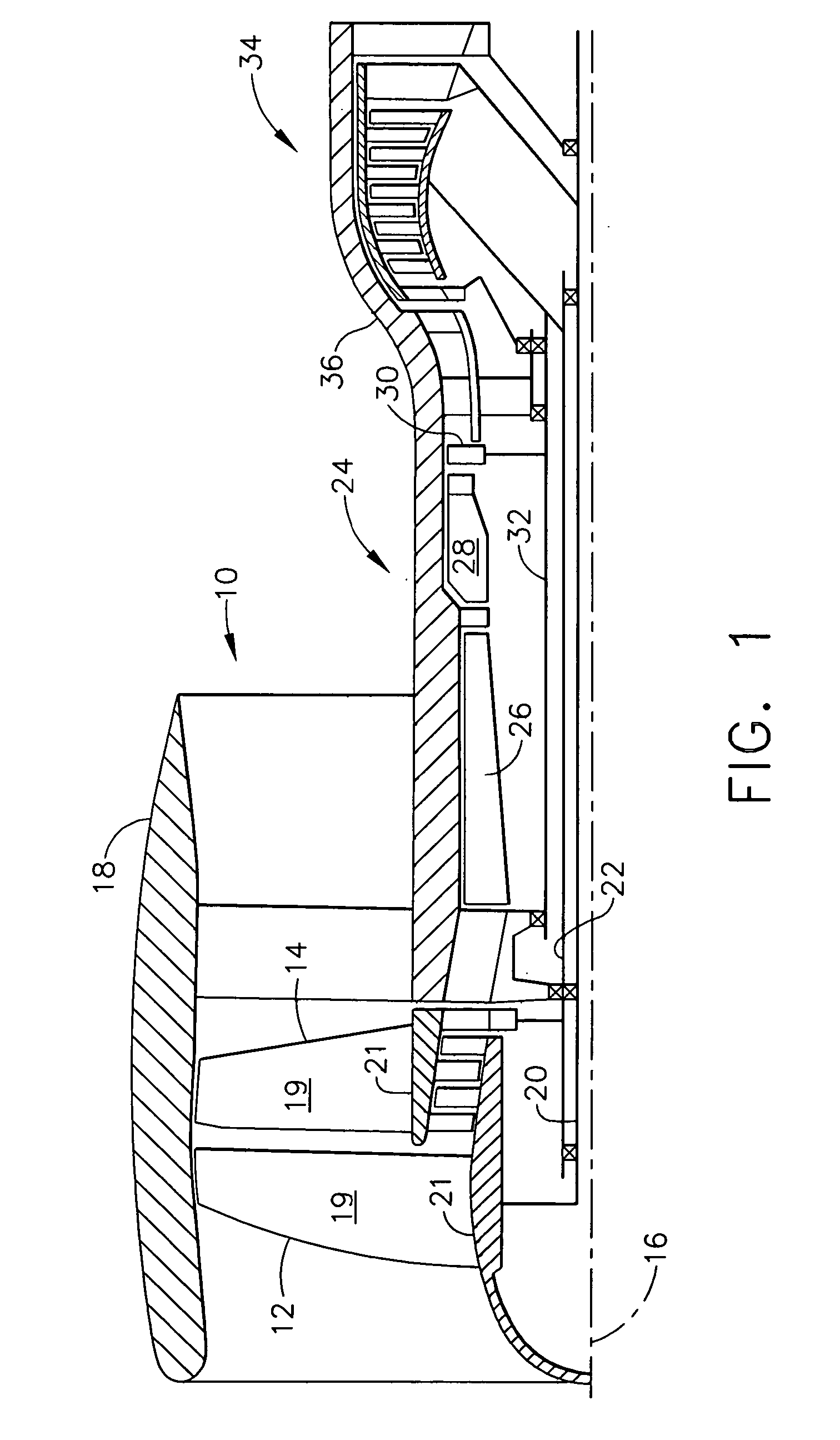

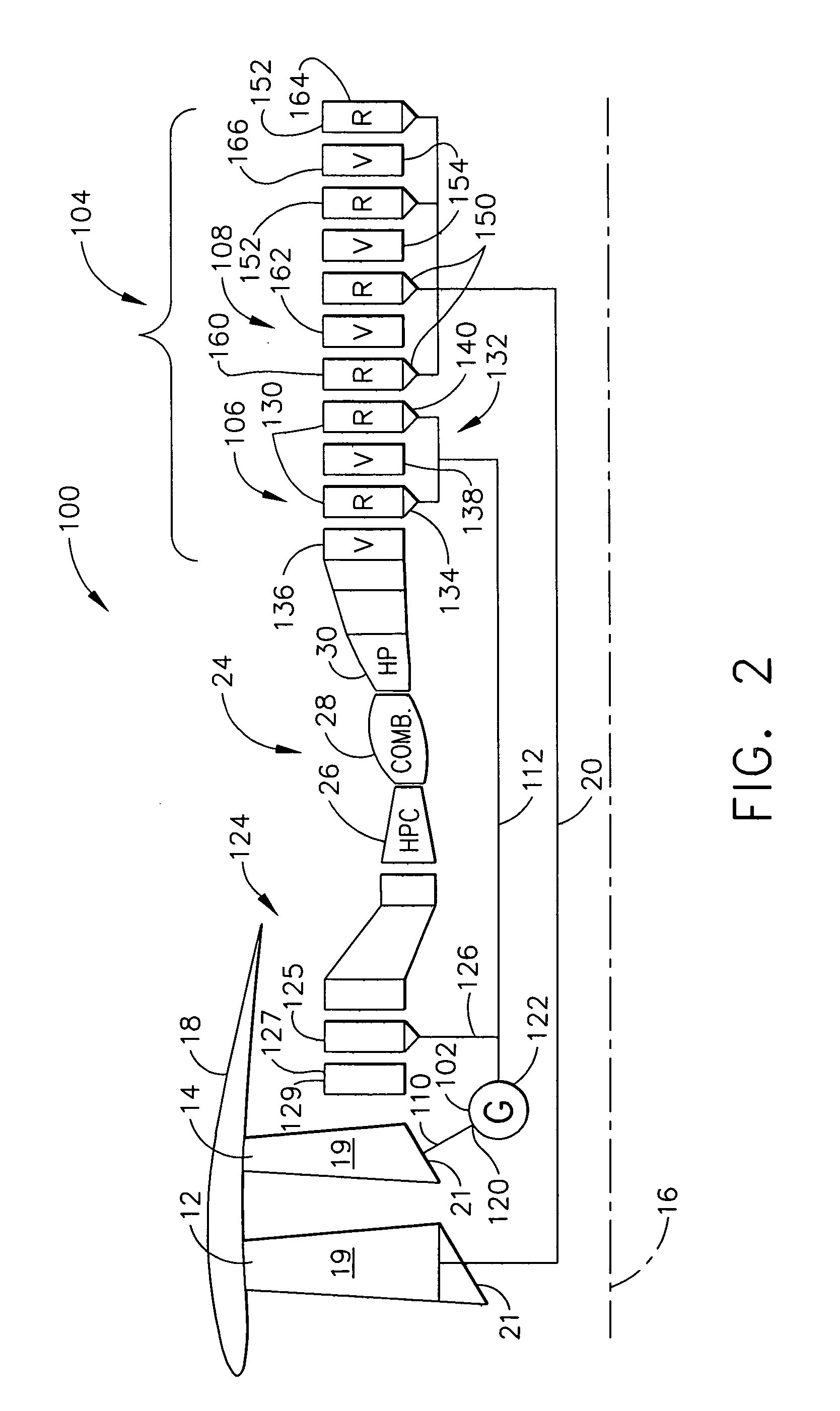

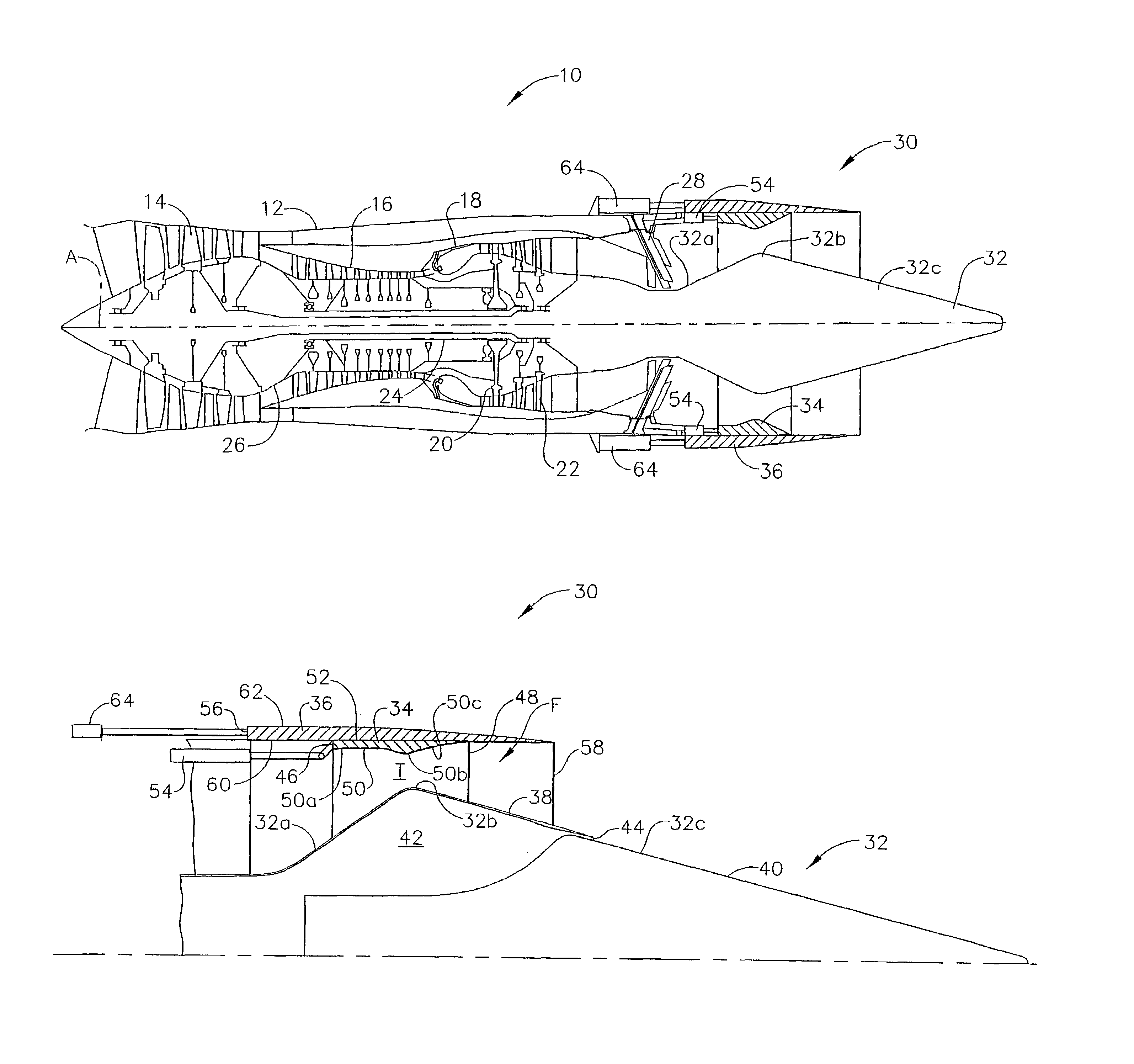

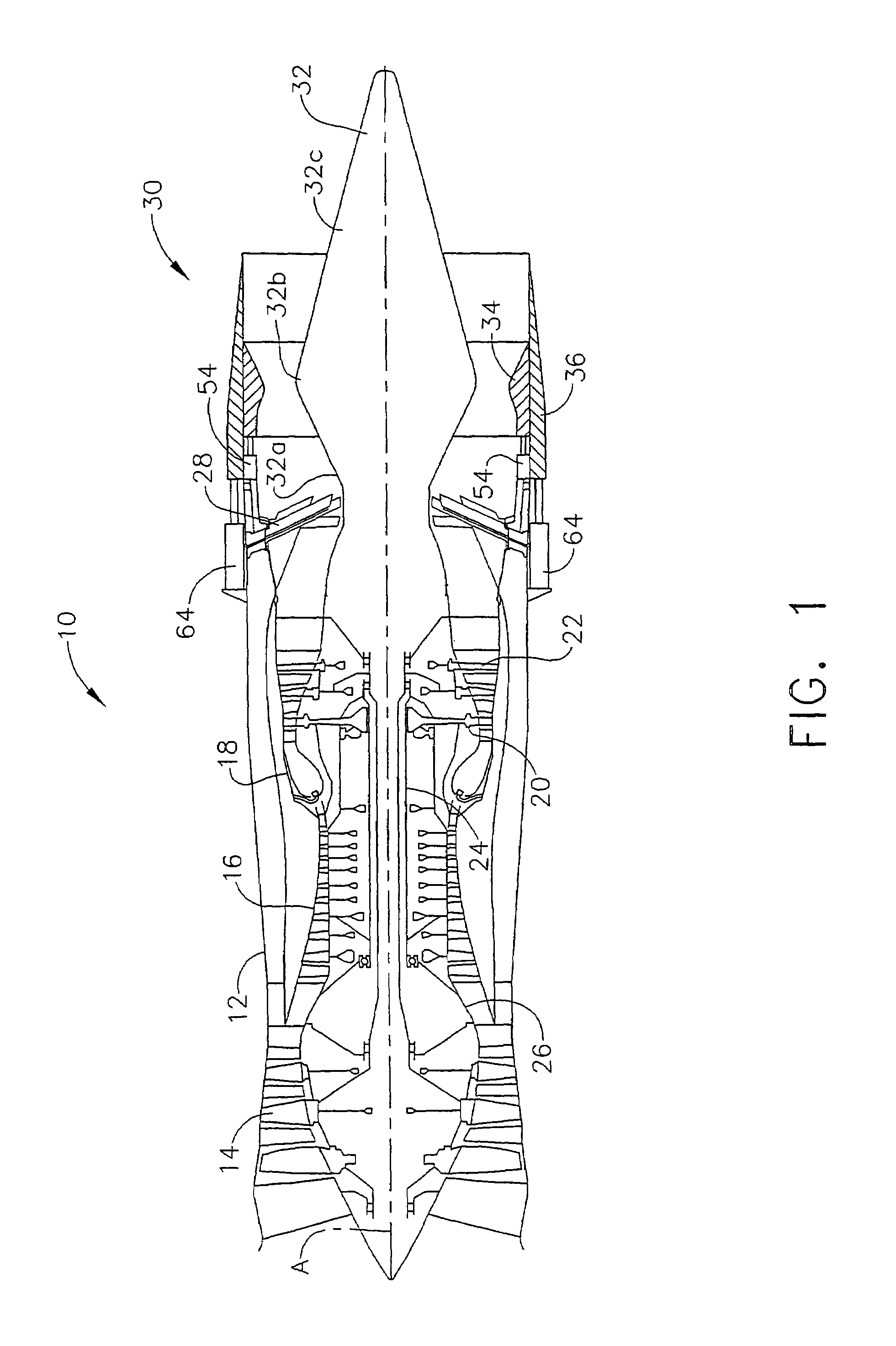

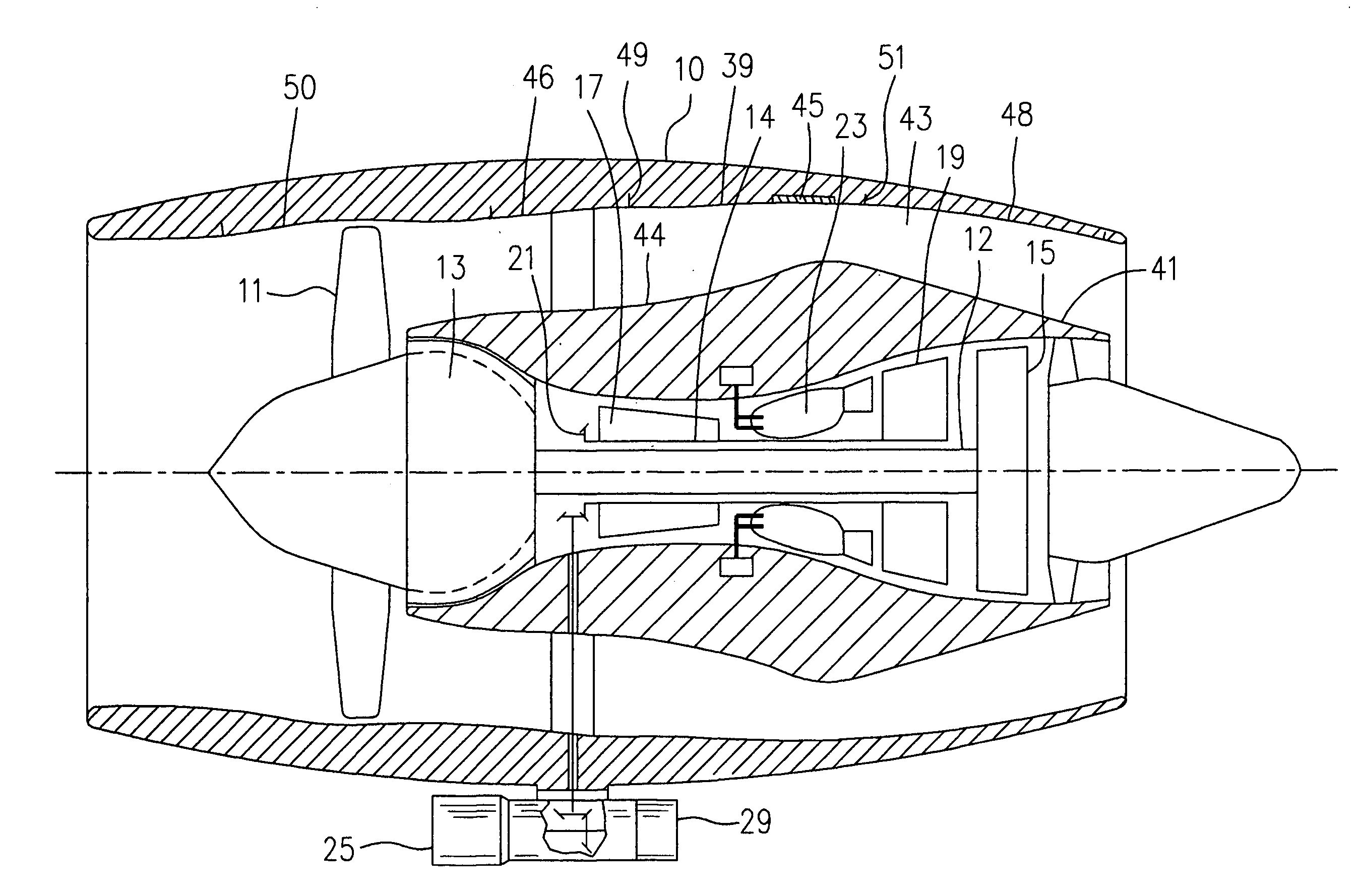

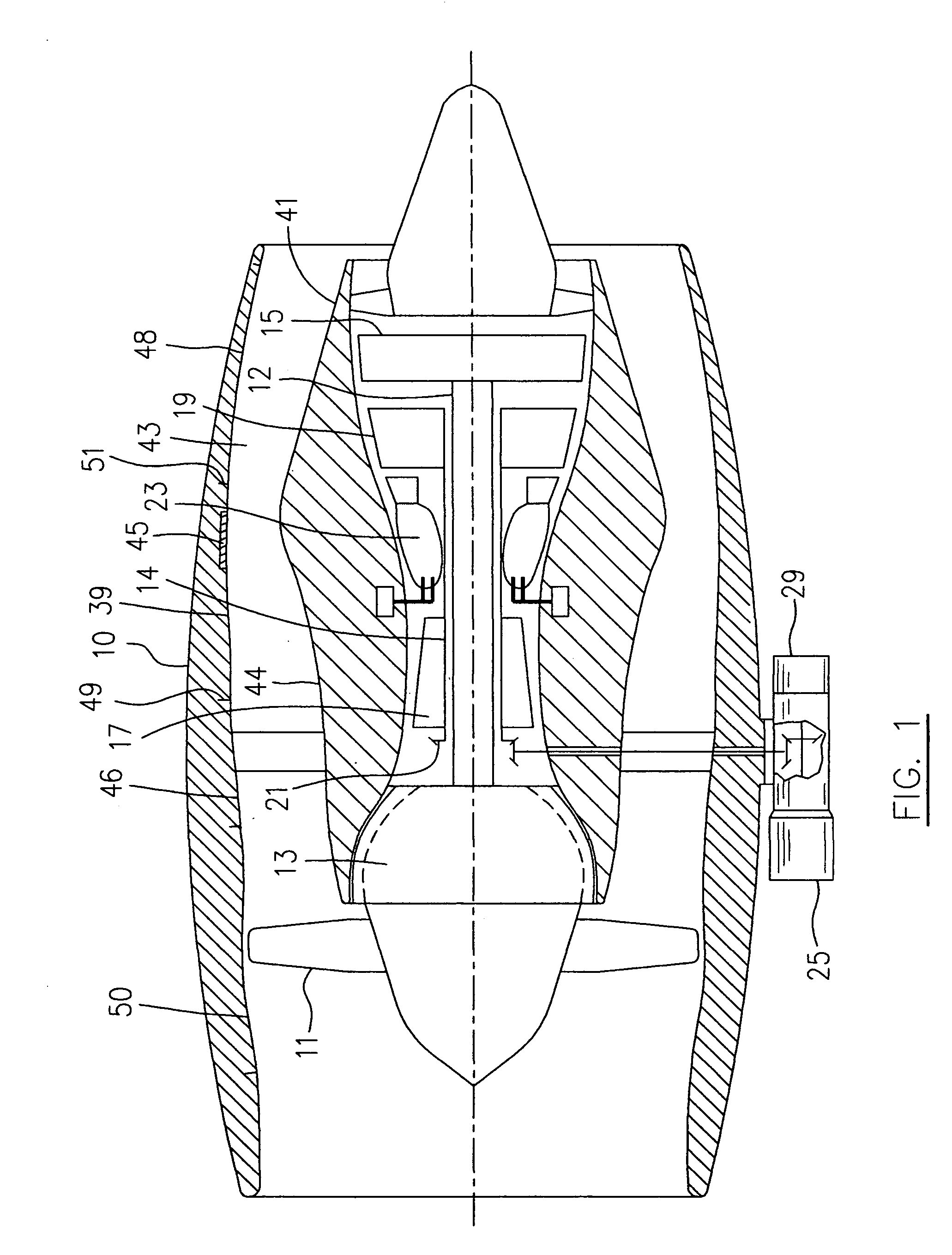

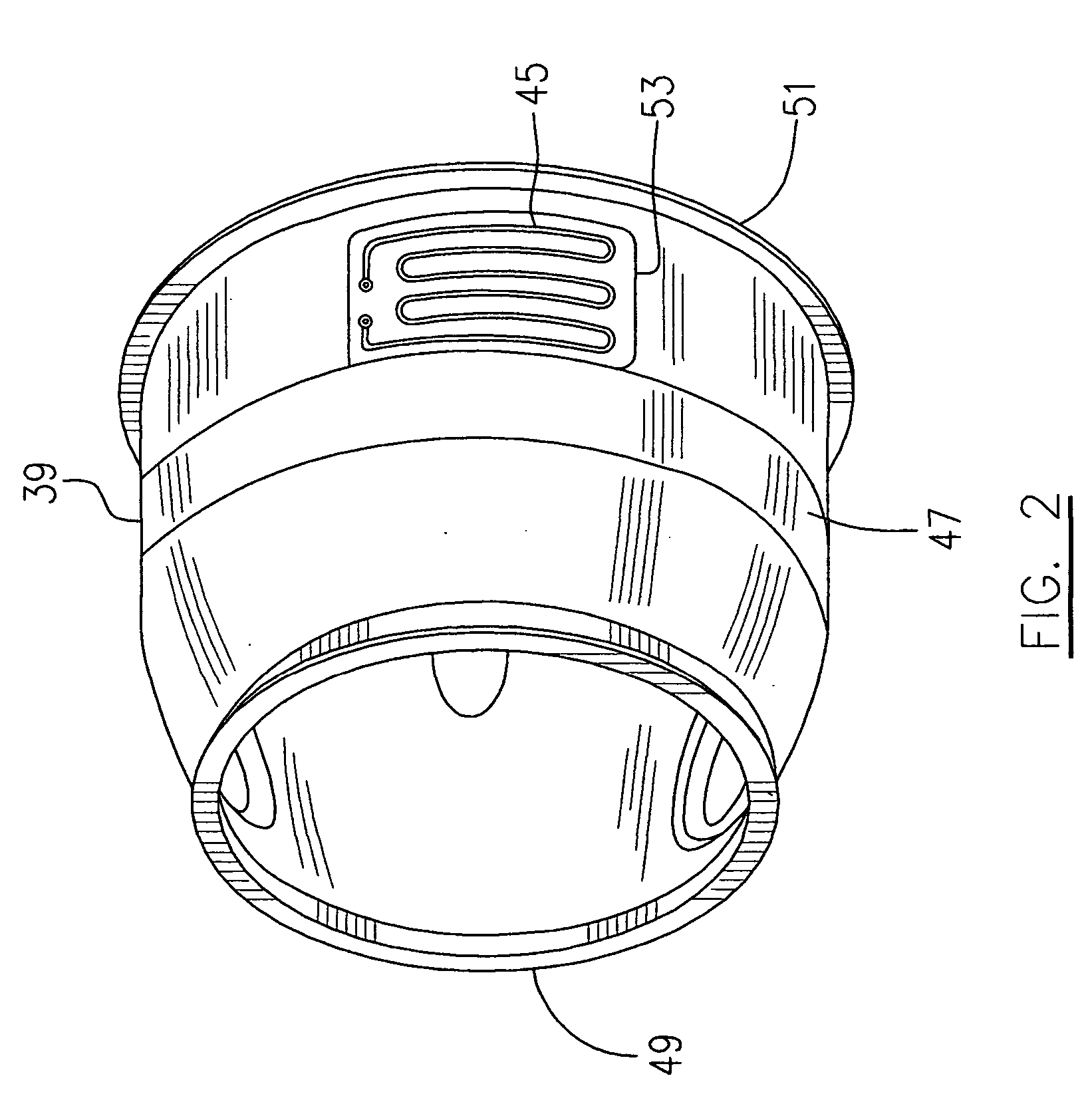

Turbofan engine assembly and method of assembling same

InactiveUS20080120839A1Cosmonautic vehiclesCosmonautic propulsion system apparatusCombustorHigh pressure

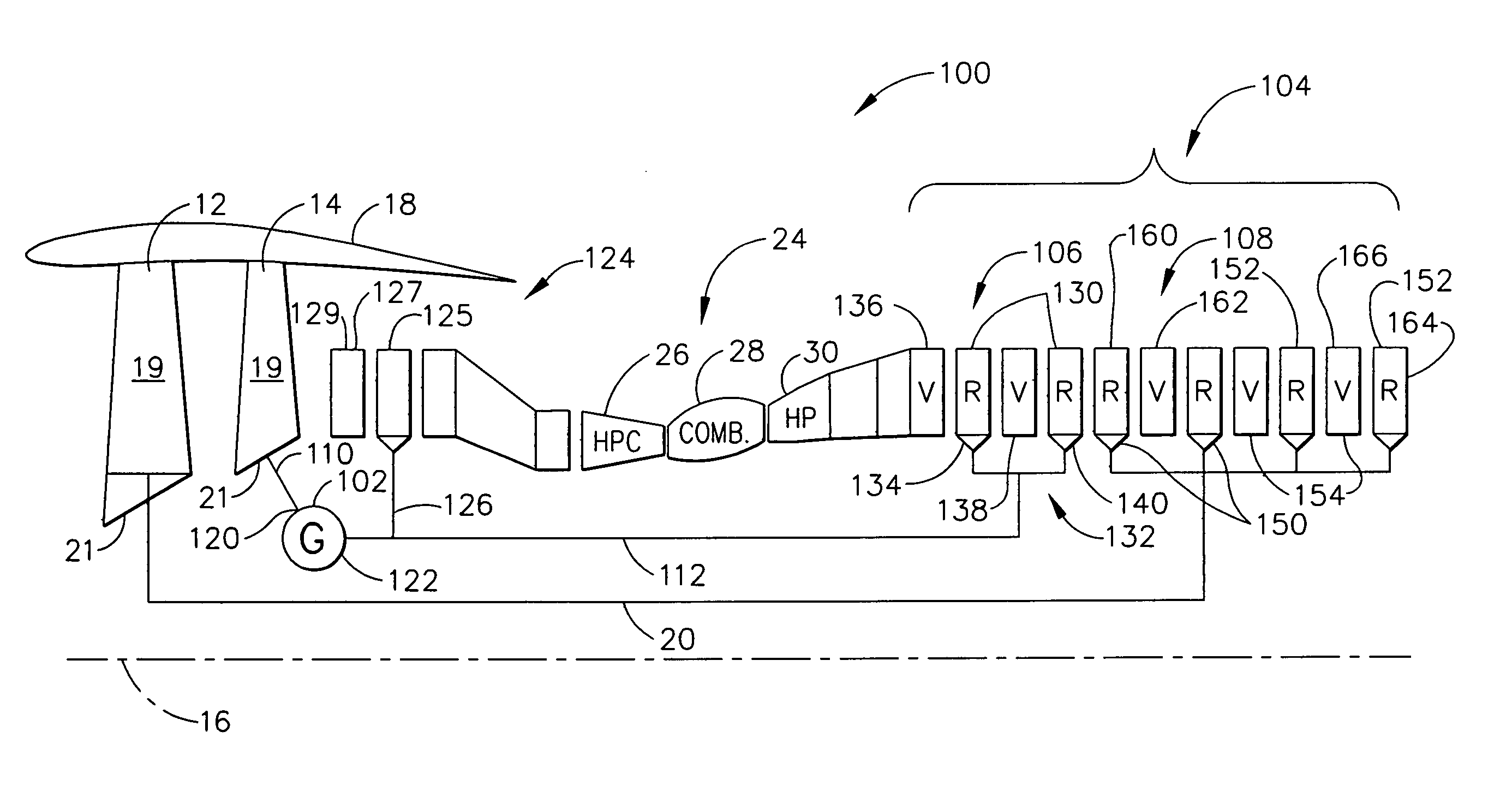

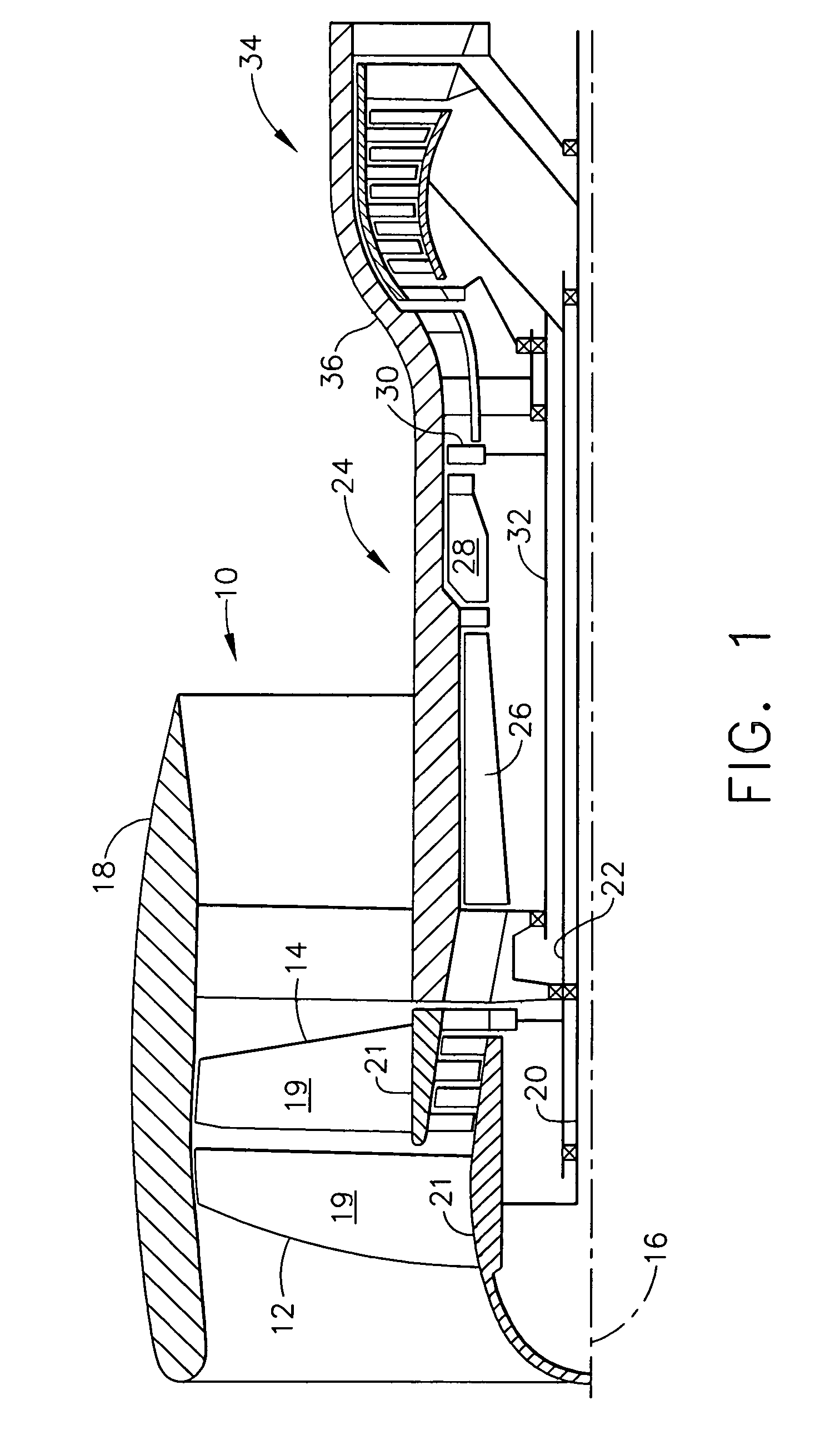

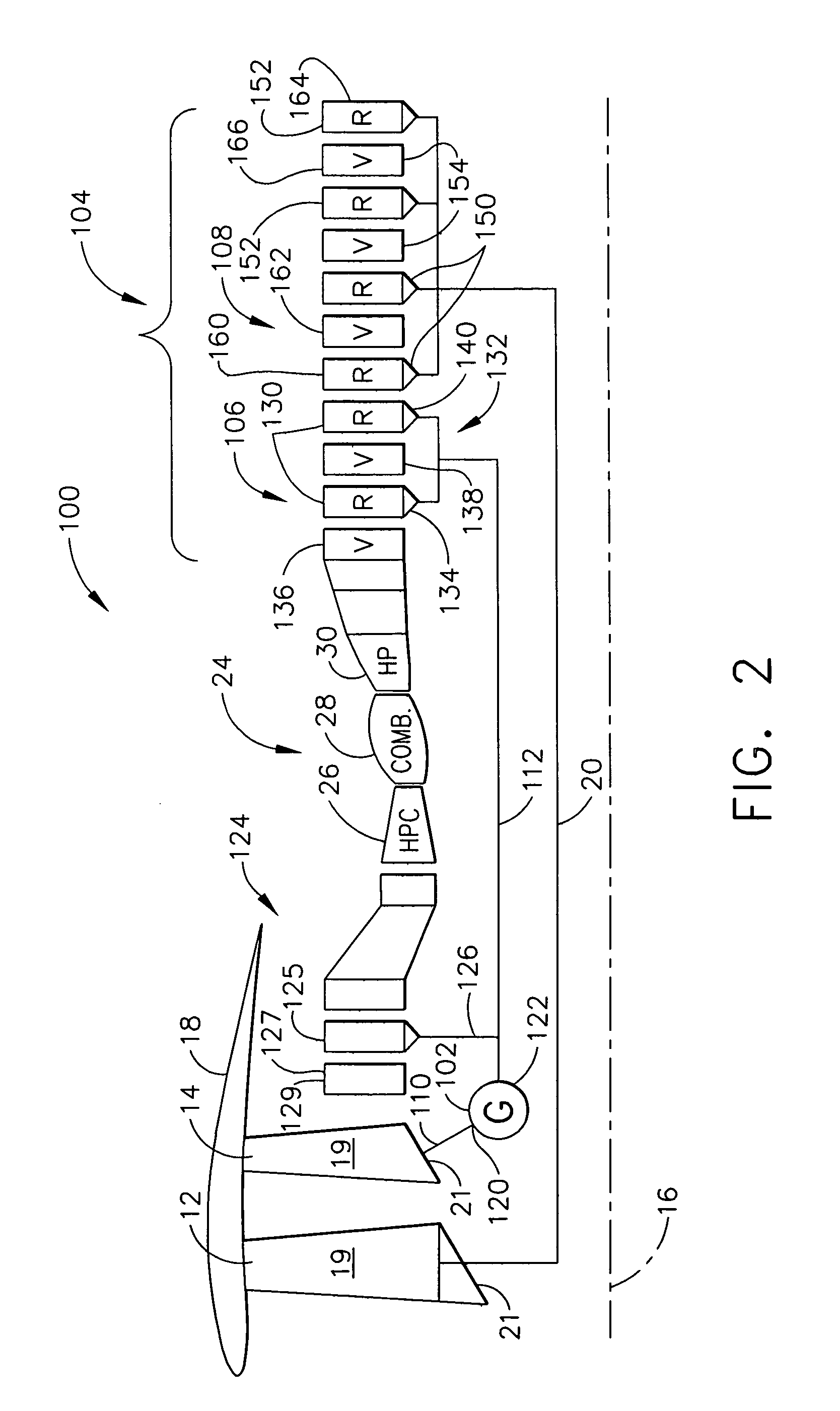

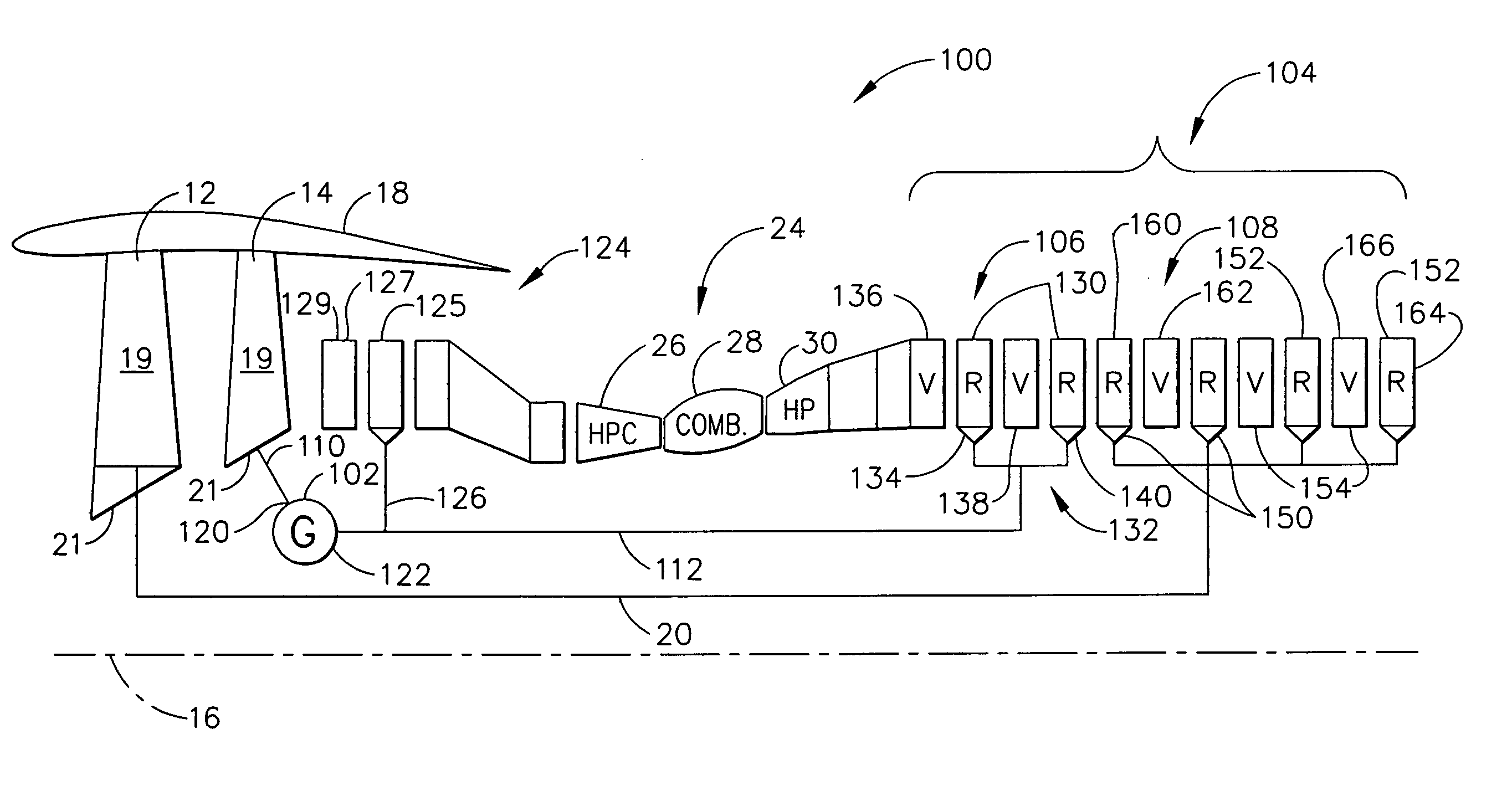

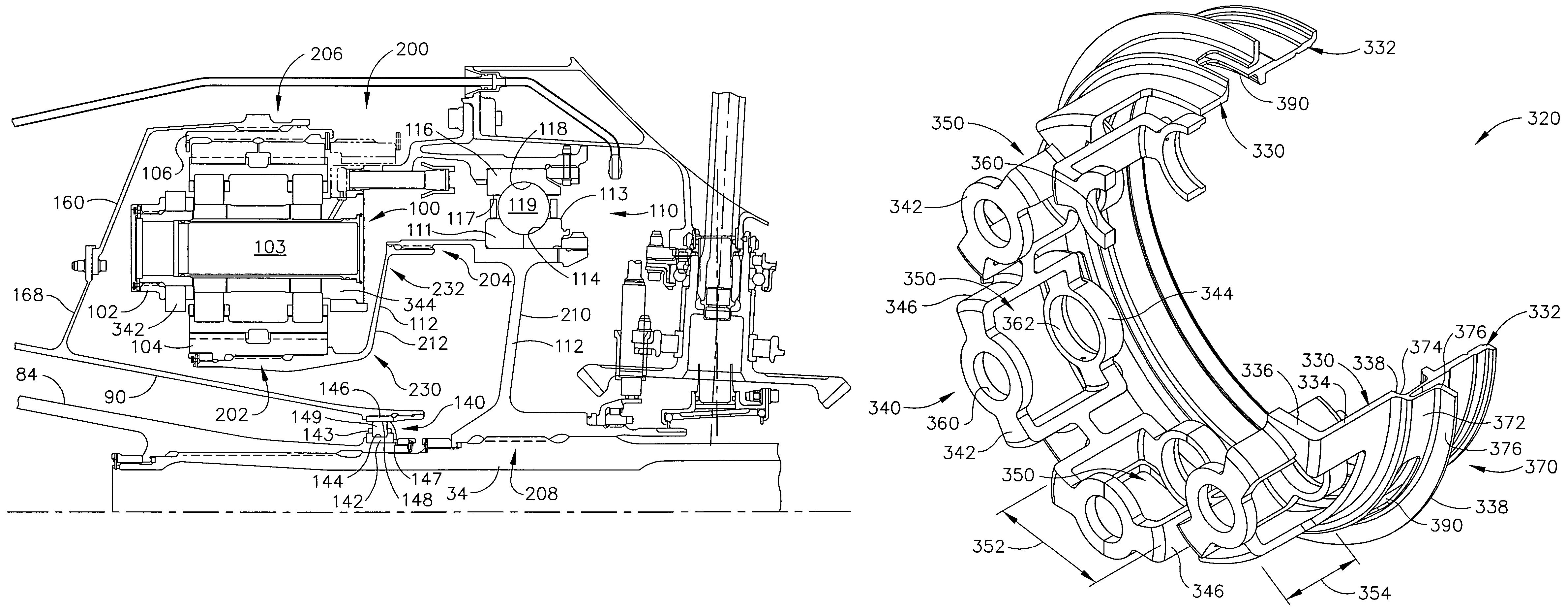

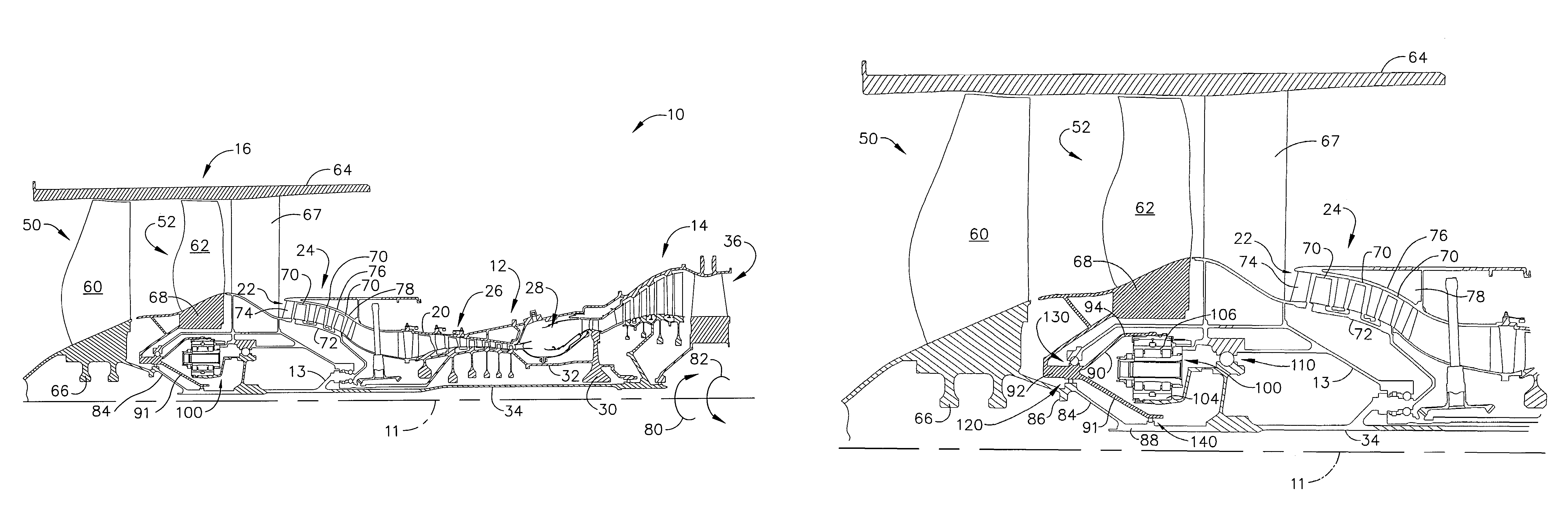

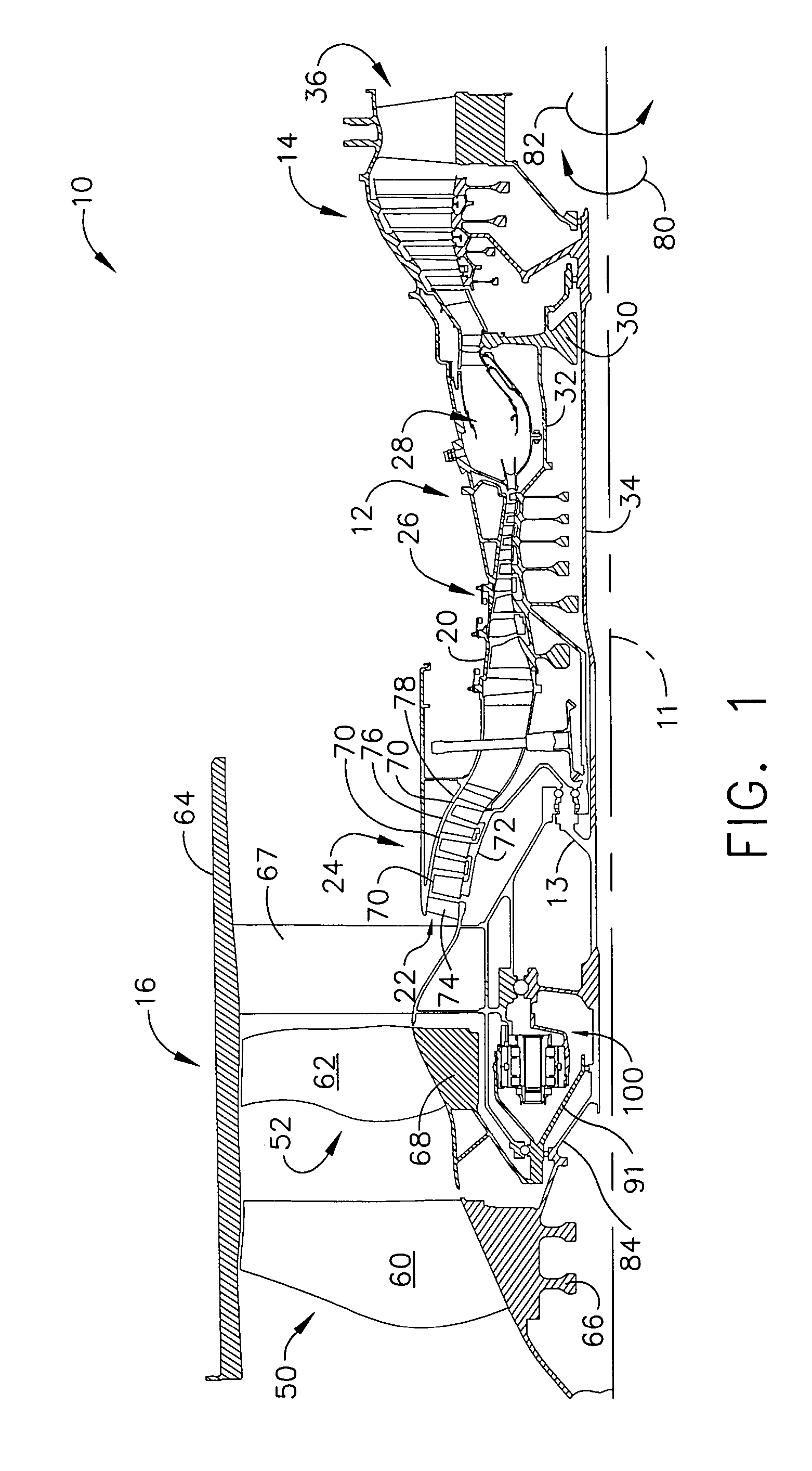

A turbofan engine assembly includes a core gas turbine engine including a high-pressure compressor, a combustor, and a high-pressure turbine, a first fan assembly disposed upstream from the core gas turbine engine, a first gearbox coupled to the first fan assembly, and a second gearbox coupled to a booster compressor such that the booster compressor rotates in a rotational direction that is opposite to the rotational direction of the first fan assembly. A method of assembling the above turbofan engine assembly is also described herein.

Owner:GENERAL ELECTRIC CO

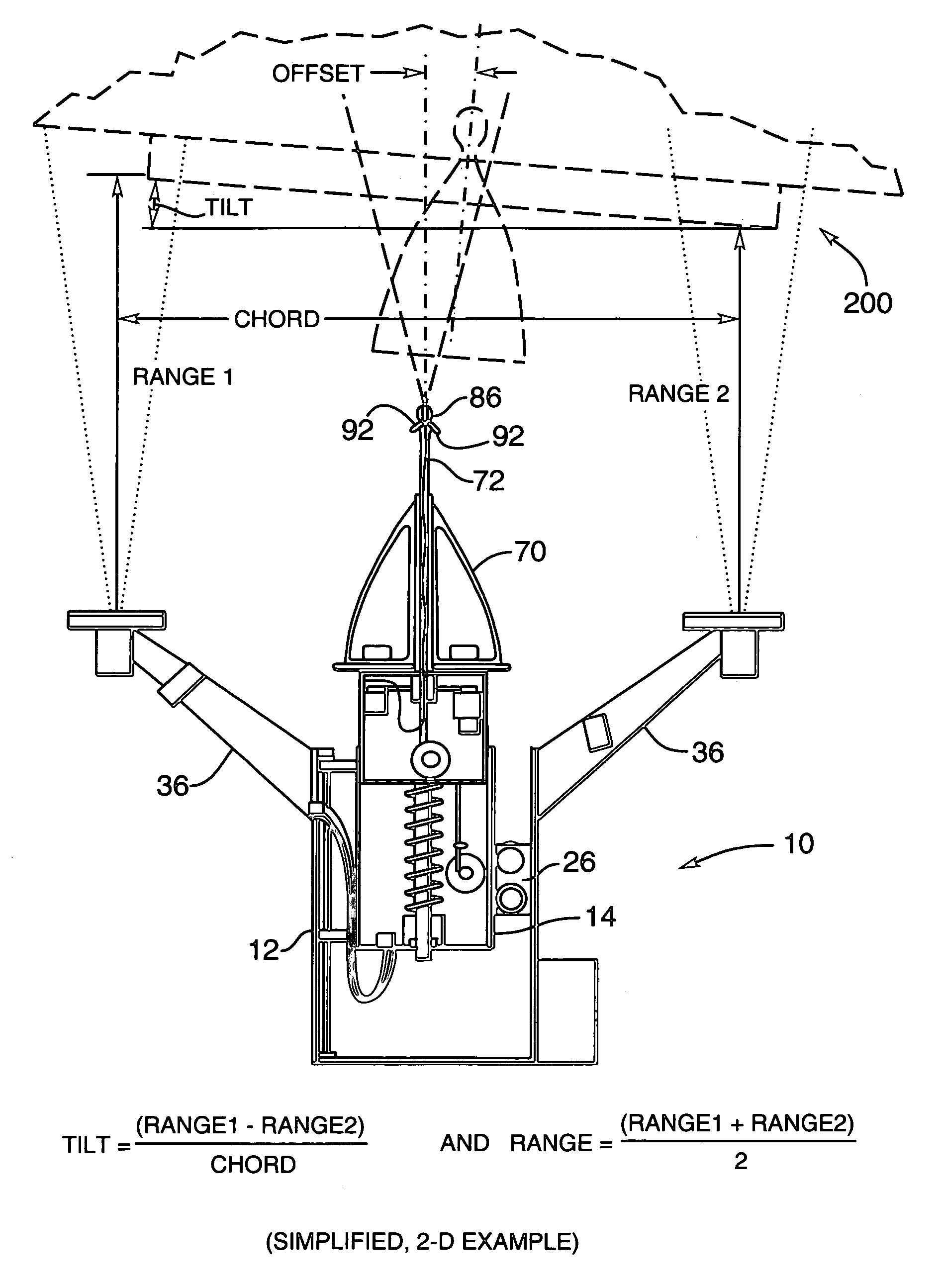

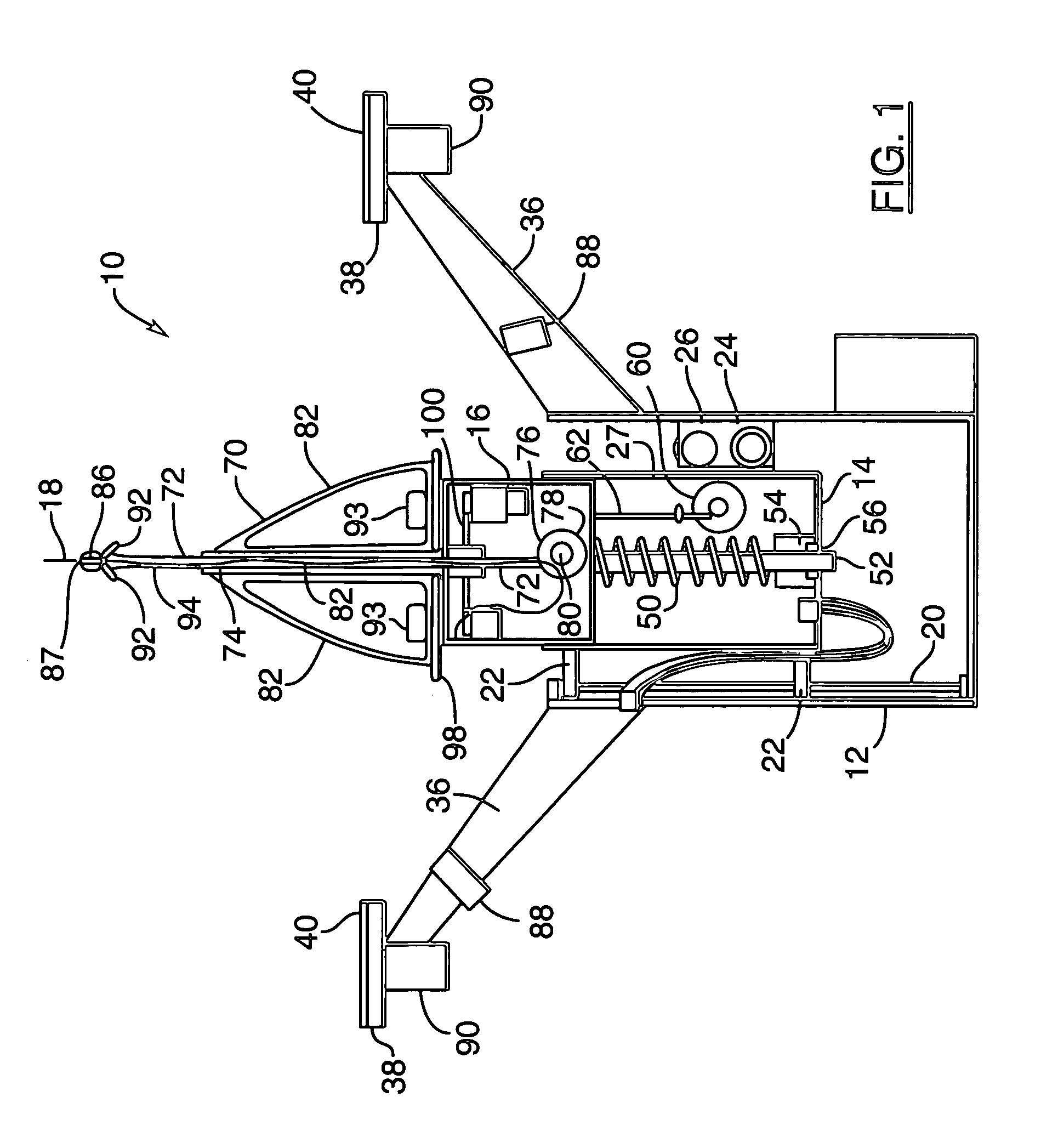

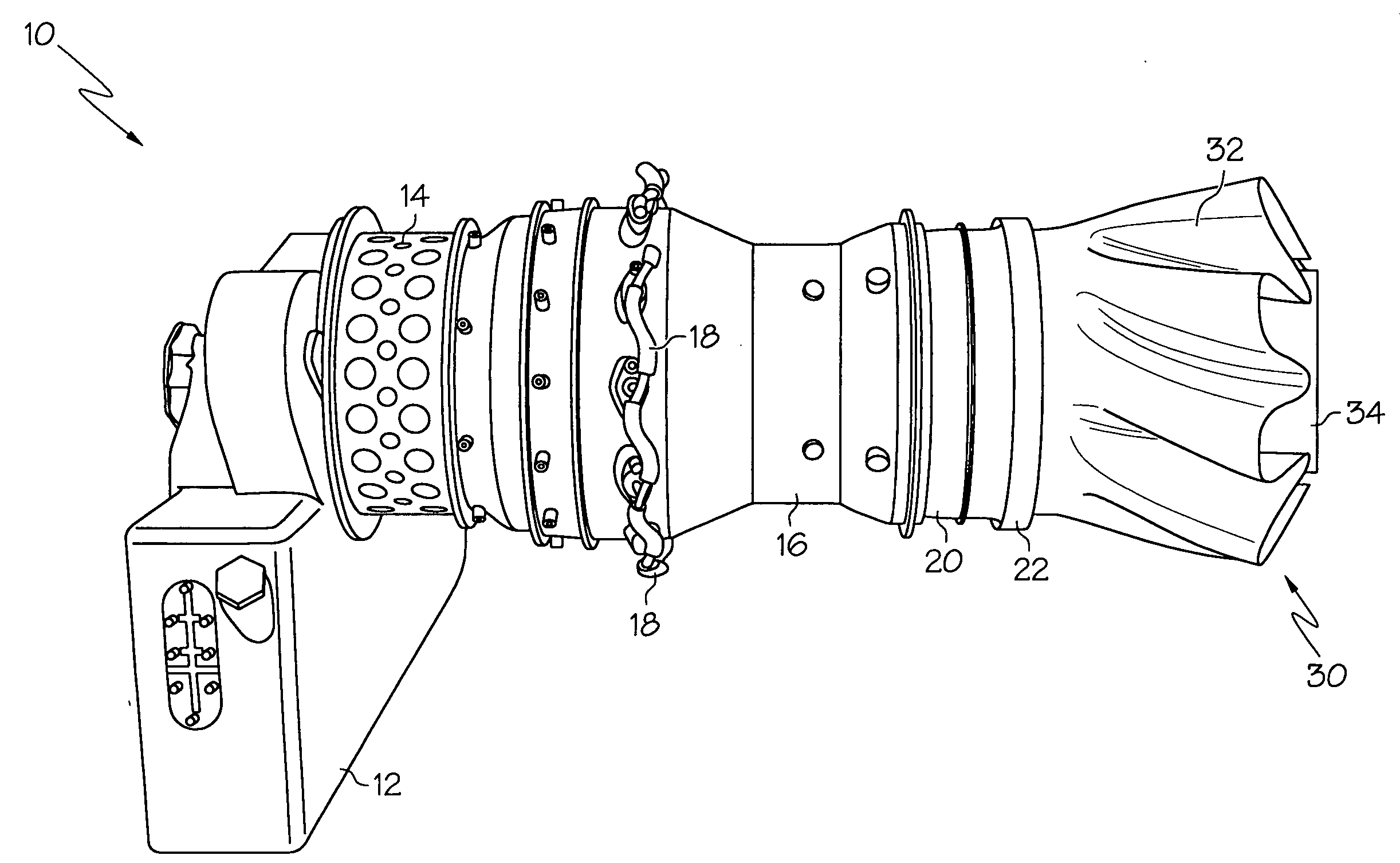

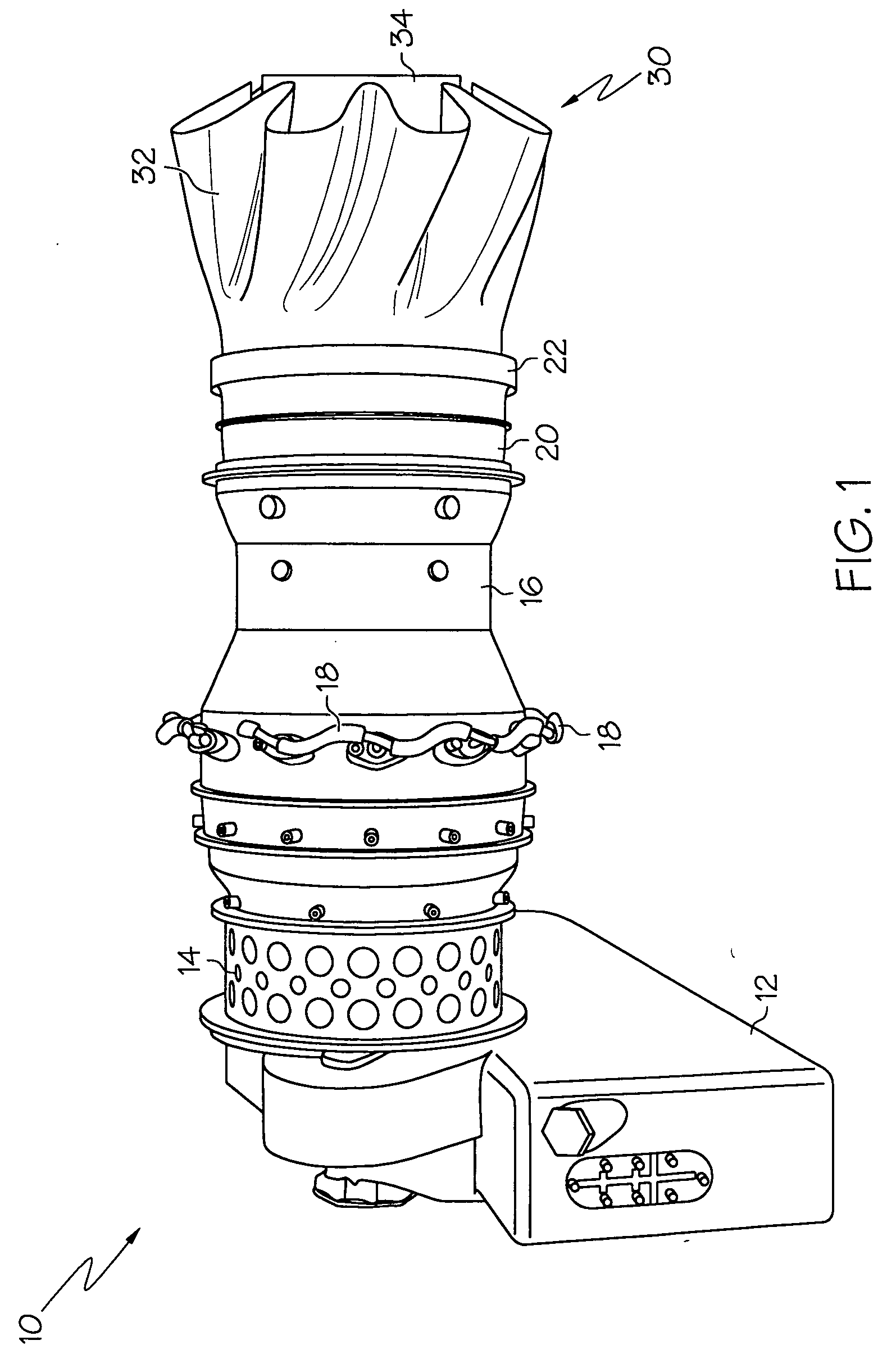

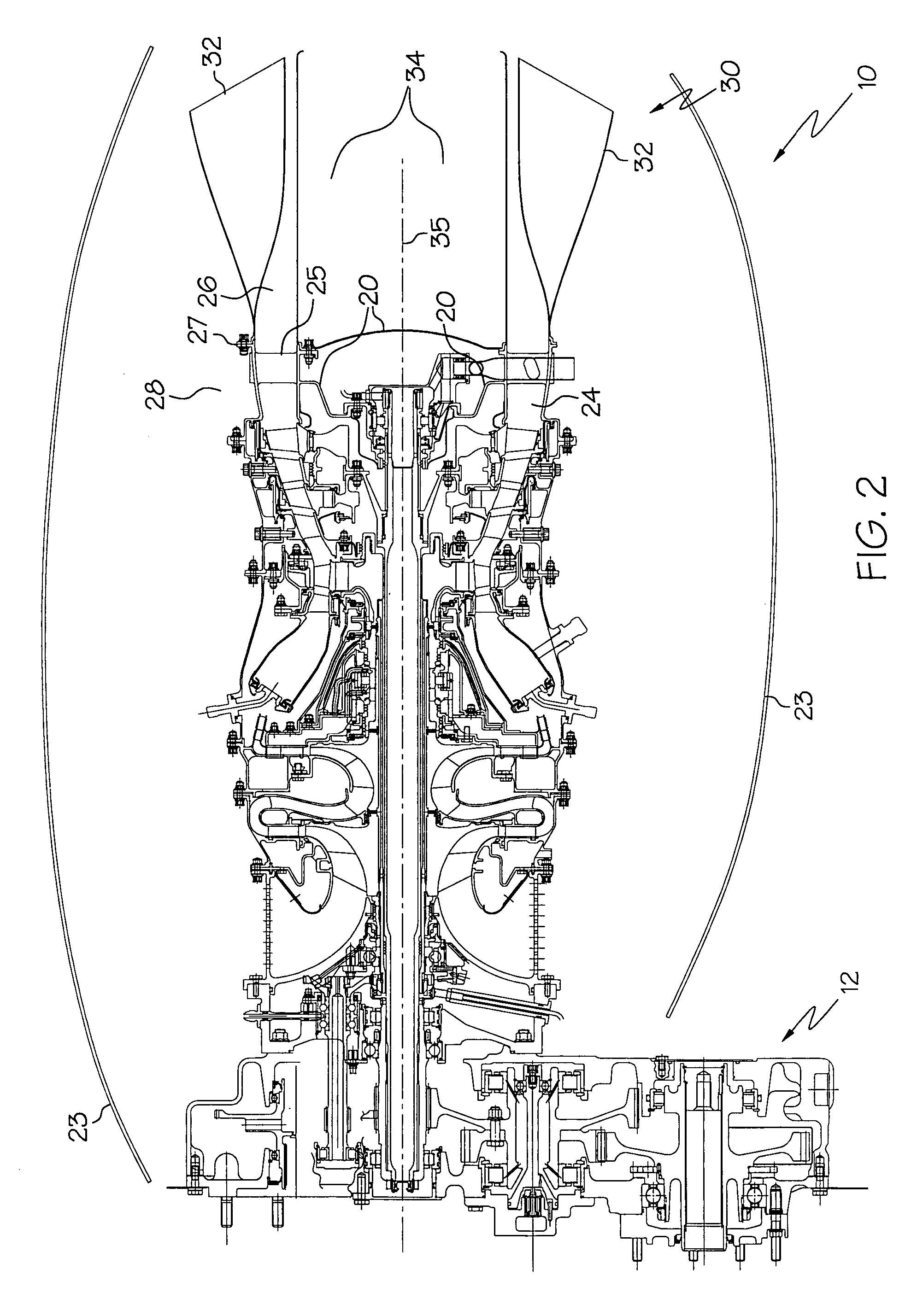

Spacecraft docking mechanism

The present invention provides a docking mechanism that is capable of interfacing with Apogee Boost Motors (ABM) including Liquid Apogee Motors (LAM) of the satellite being captured to allow a servicing spacecraft to dock with a satellite that has no special docking features. The docking mechanism includes a compliant probe with spring-loaded fingers at its tip which is inserted into the LAM by the approach motion of the servicer spacecraft. When the probe tip has passed beyond the throat of the LAM the finger extend to trap the LAM on the probe thus achieving capture. The rigidization stage of docking is achieved by retracting the probe to pull the two spacecraft together. The docking mechanism includes abutment pads which interface with the launcher interface ring of the client spacecraft. With the preload applied by the probe retraction mechanism reacted through these pads, the docking mechanism can maintain a rigid docked interface under loads induced by thrusting maneuvers of the combined spacecraft or loads induced by on-orbit servicing operations.

Owner:MACDONALD DETTWILER & ASSOC INC

Turbofan engine assembly and method of assembling same

InactiveUS7882693B2Cosmonautic vehiclesCosmonautic propulsion system apparatusCombustorHigh pressure

A turbofan engine assembly includes a core gas turbine engine including a high-pressure compressor, a combustor, and a high-pressure turbine, a first fan assembly disposed upstream from the core gas turbine engine, a first gearbox coupled to the first fan assembly, and a second gearbox coupled to a booster compressor such that the booster compressor rotates in a rotational direction that is opposite to the rotational direction of the first fan assembly. A method of assembling the above turbofan engine assembly is also described herein.

Owner:GENERAL ELECTRIC CO

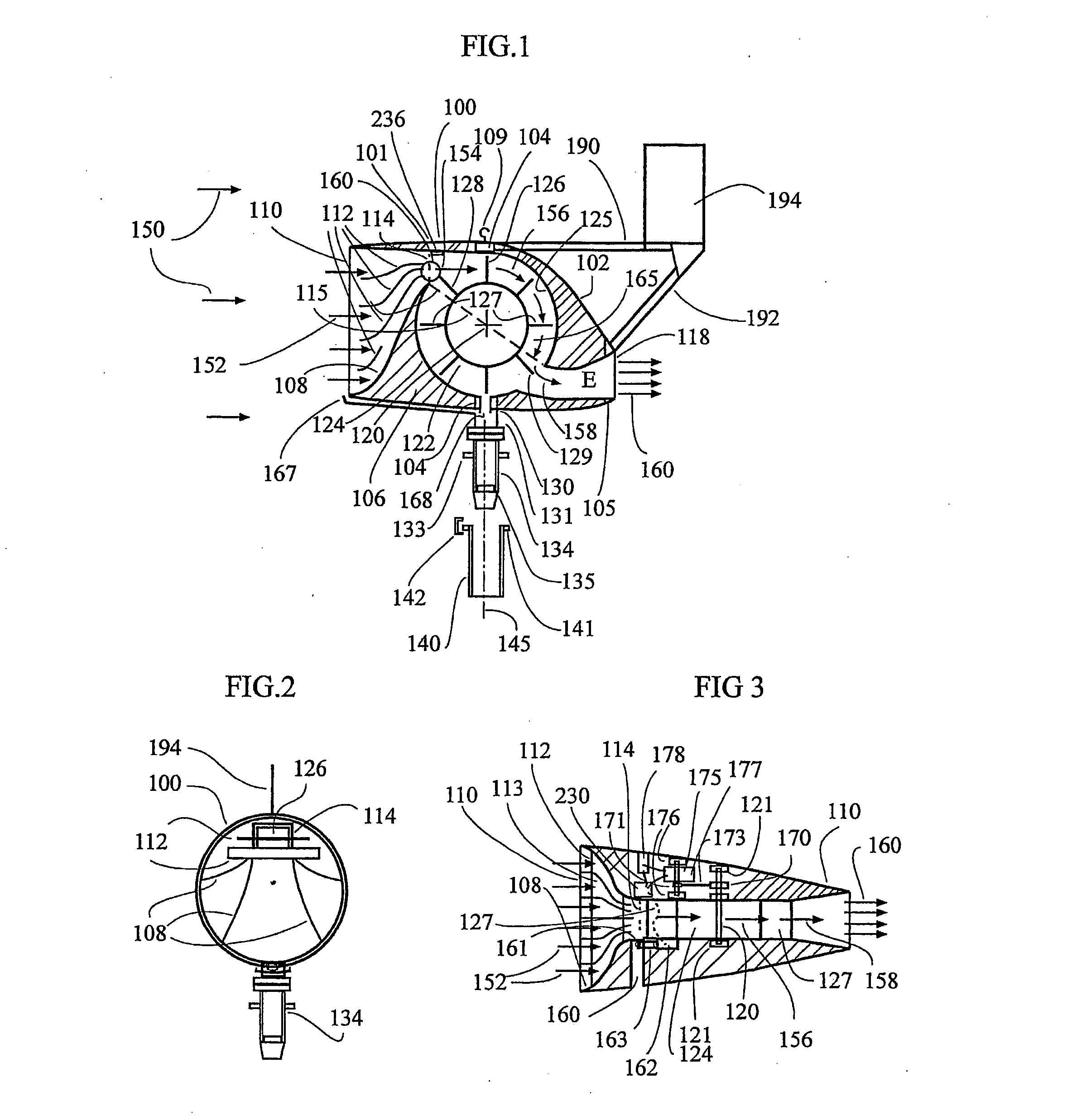

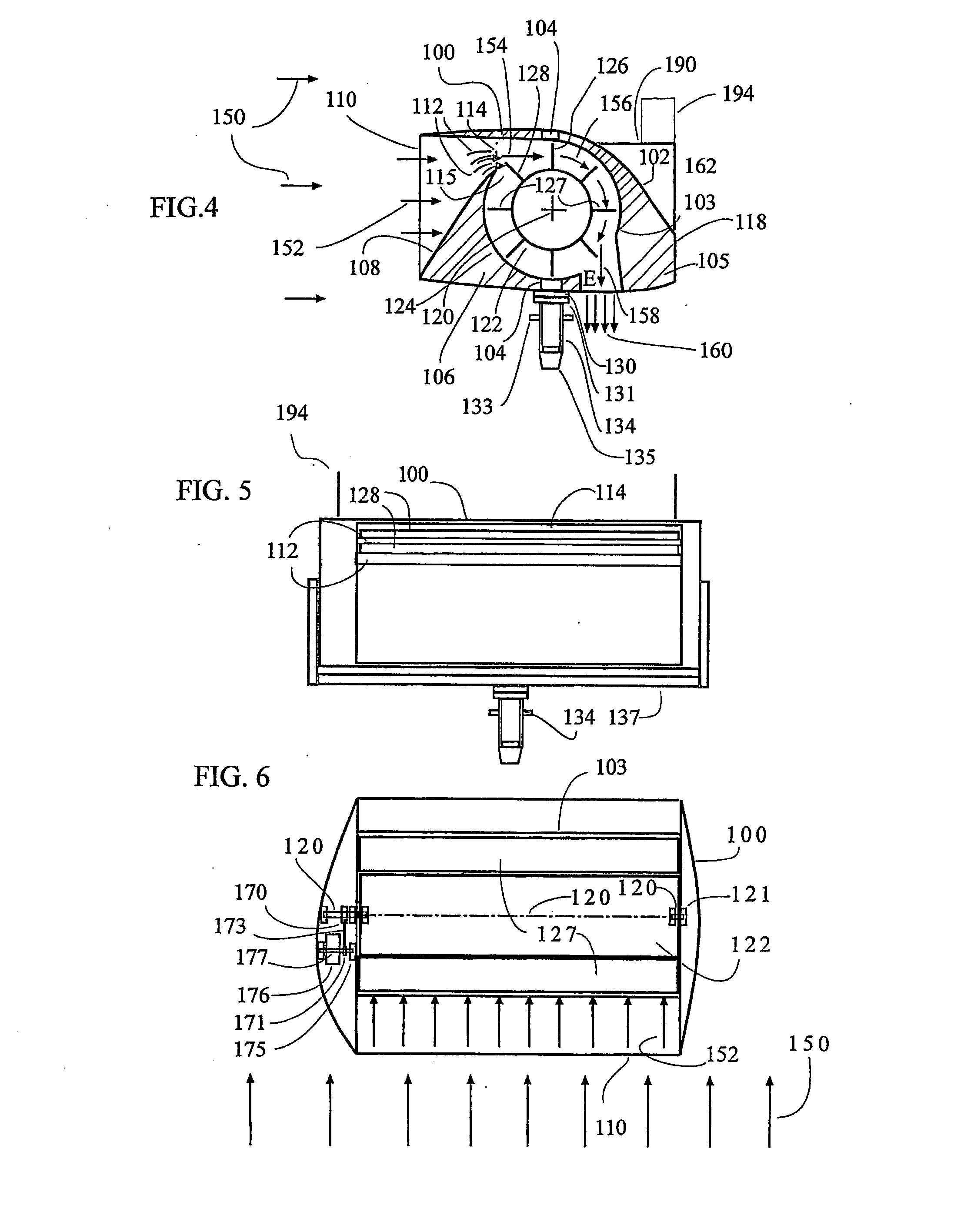

Use of Air Internal Energy and Devices

InactiveUS20080061559A1Increase static pressureAvoid accumulationCosmonautic vehiclesReaction enginesMoisture condensationLiquid water

A method of converting air internal energy into useful kinetic energy is based on air flowing through substantially convergent nozzle, which accelerates the air as the cross section of the nozzle decreases thus increasing the air kinetic energy. The increment of the kinetic energy equals to the decrement of air internal energy, i.e., air temperature. Within said nozzle a turbine is placed to convert airflow kinetic energy into mechanical energy that transformed into electrical energy or transferred into a gearbox to provide driving moment. Devices uses this method could use natural wind as airflow source or artificial airflow means. Devices, which incorporate means to create airflow artificially, can be used as engines for land, sea and flying vehicle. Since air temperature drops within the nozzle, moisture condensation exists and liquid water can be accumulated for further use.

Owner:HIRSHBERG ISRAEL

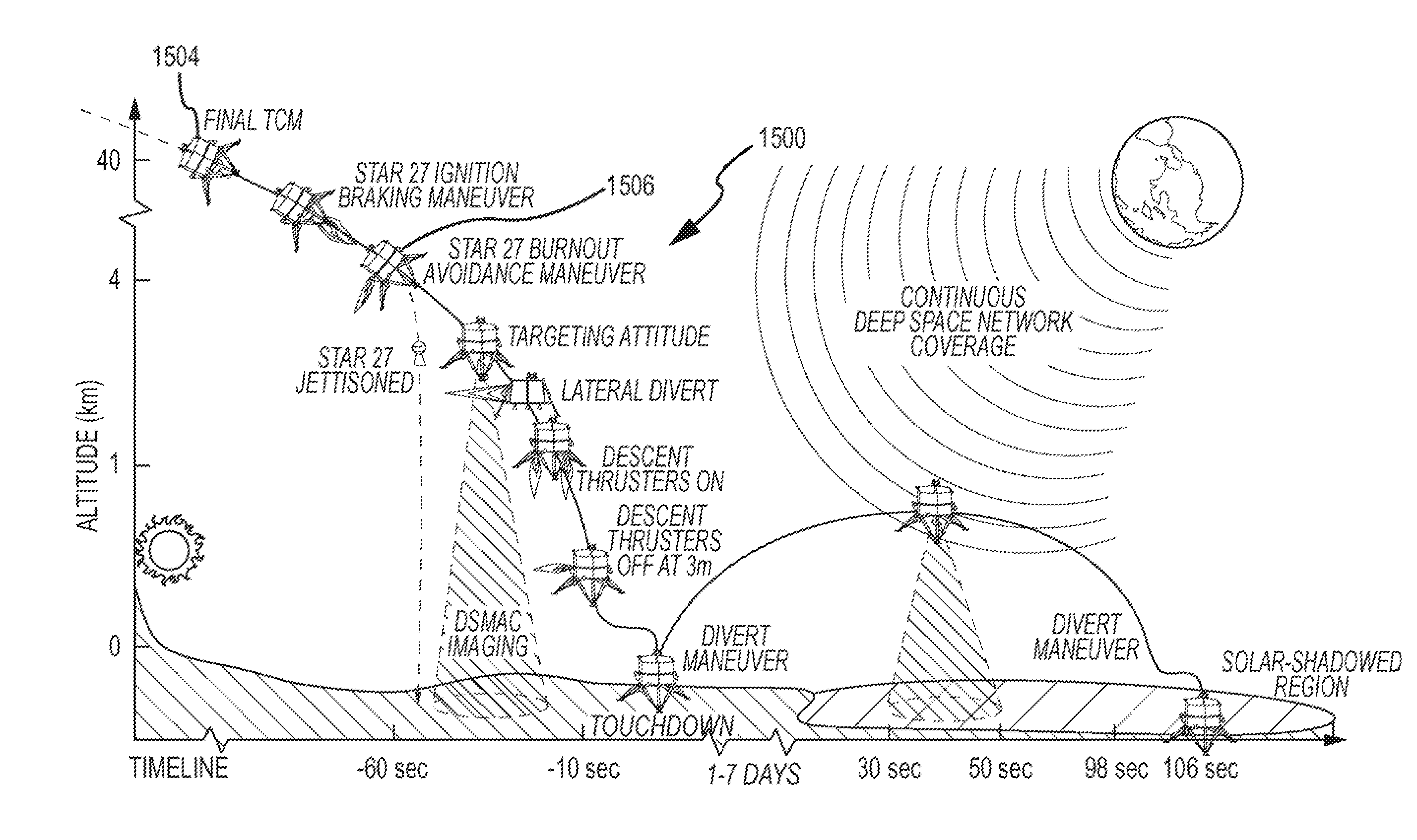

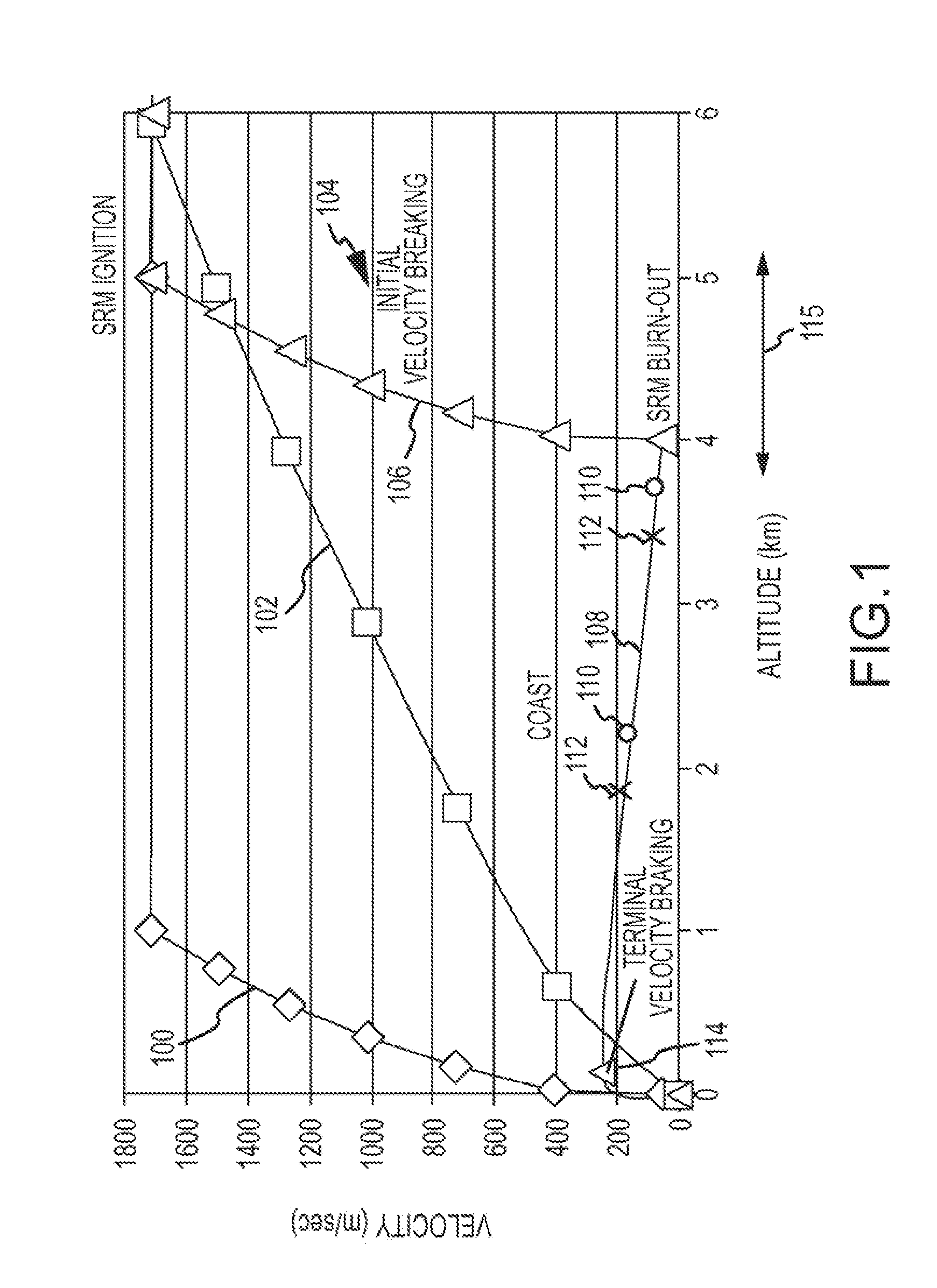

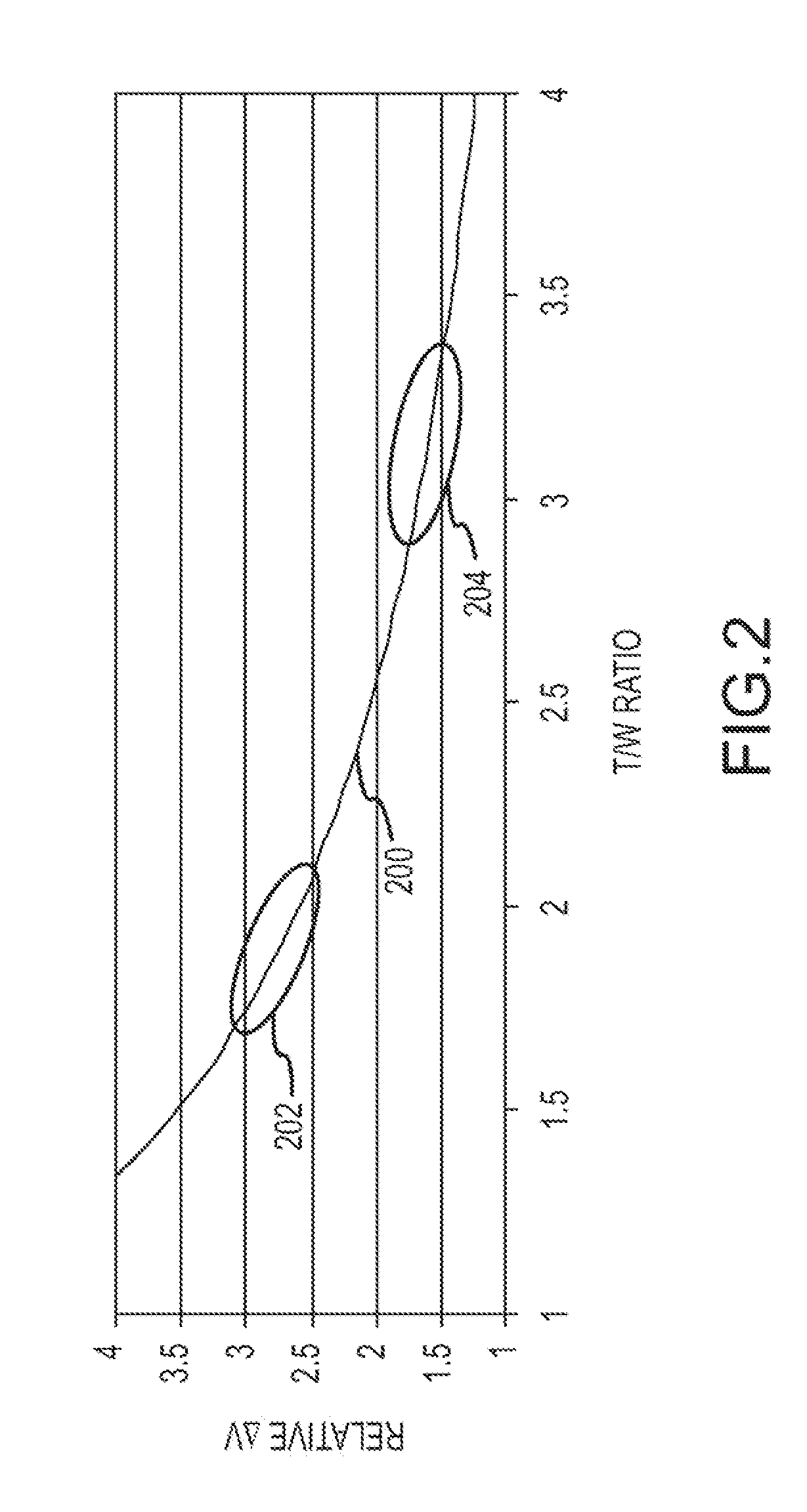

Autonomous Space Flight System and Planetary Lander for Executing a Discrete Landing Sequence to Remove Unknown Navigation Error, Perform Hazard Avoidance and Relocate the Lander and Method

ActiveUS20080023587A1Detect and avoid hazardIncreased payload capacityCosmonautic propulsion system apparatusInstruments for comonautical navigationReference mapImage resolution

An autonomous unmanned space flight system and planetary lander executes a discrete landing sequence including performing an initial velocity braking maneuver to remove velocity at altitude, coasting during which the planet surface is imaged and correlated to reference maps to estimate cross-track and along-track navigation errors and one or more lateral braking maneuvers are performed to reduce cross-track navigation error, and performing a terminal velocity braking maneuver(s) to reduce the along-track braking maneuver and remove the remainder of the velocity just prior to landing. A bi-propellant propulsion system provides a very high T / M ratio, at least 15:1 per nozzle. Short, high T / M divert maneuvers provide the capability to remove cross-track navigation error efficiently up to the maximum resolution of the reference maps. Short, high T / M terminal velocity braking maneuver(s) provide the capability to remove along-track navigation error to a similar resolution and remove the remaining velocity in a very short time window, approximately 3-15 seconds prior to touchdown. The propulsive efficiency frees up mass which can be allocated to a fuel to remove the unknown navigation errors, perform hazard avoidance and / or relocate the lander by flying it to another site or be allocated to additional payload.

Owner:RAYTHEON CO

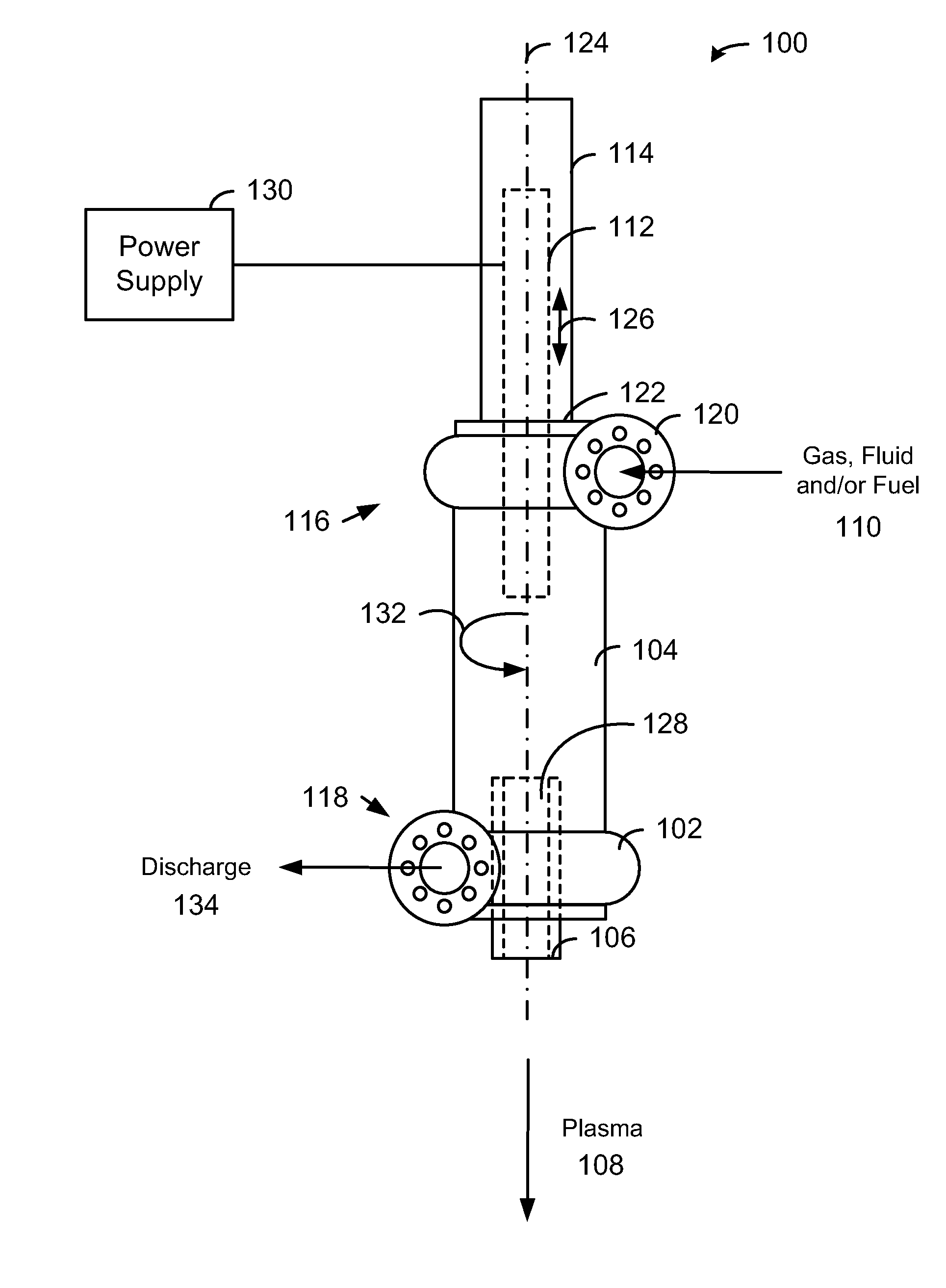

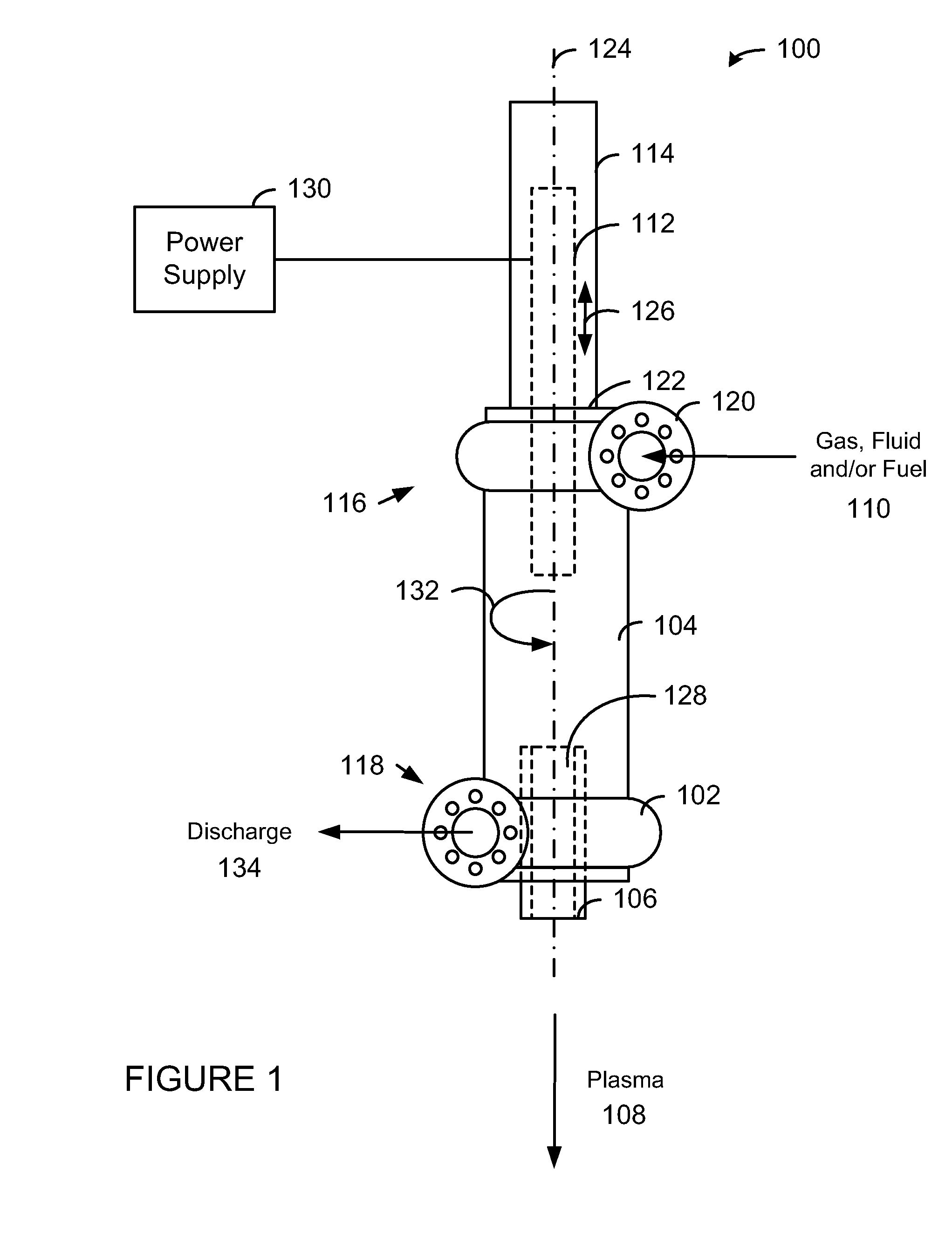

System, method and apparatus for lean combustion with plasma from an electrical arc

The present invention provides a plasma arc torch that can be used for lean combustion. The plasma arc torch includes a cylindrical vessel, an electrode housing connected to the first end of the cylindrical vessel such that a first electrode is (a) aligned with a longitudinal axis of the cylindrical vessel, (b) extends into the cylindrical vessel, and (c) can be moved along the longitudinal axis, a linear actuator connected to the first electrode to adjust a position of the first electrode, a hollow electrode nozzle connected to the second end of the cylindrical vessel such that the center line of the hollow electrode nozzle is aligned with the longitudinal axis of the cylindrical vessel, and wherein the tangential inlet and the tangential outlet create a vortex within the cylindrical vessel, and the first electrode and the hollow electrode nozzle crate a plasma the discharges through the hollow electrode nozzle.

Owner:FORET PLASMA LABS

Twisted mixer with open center body

An exhaust mixer assembly having a twisted mixer and an open centerbody is provided. The open centerbody is centrally disposed within the twisted mixer and helps to provide efficient cooling of exhaust air from gas turbine engines. A method for cooling exhaust air from a gas turbine engine using the exhaust mixer assembly of the invention is also provided.

Owner:HONEYWELL INT INC

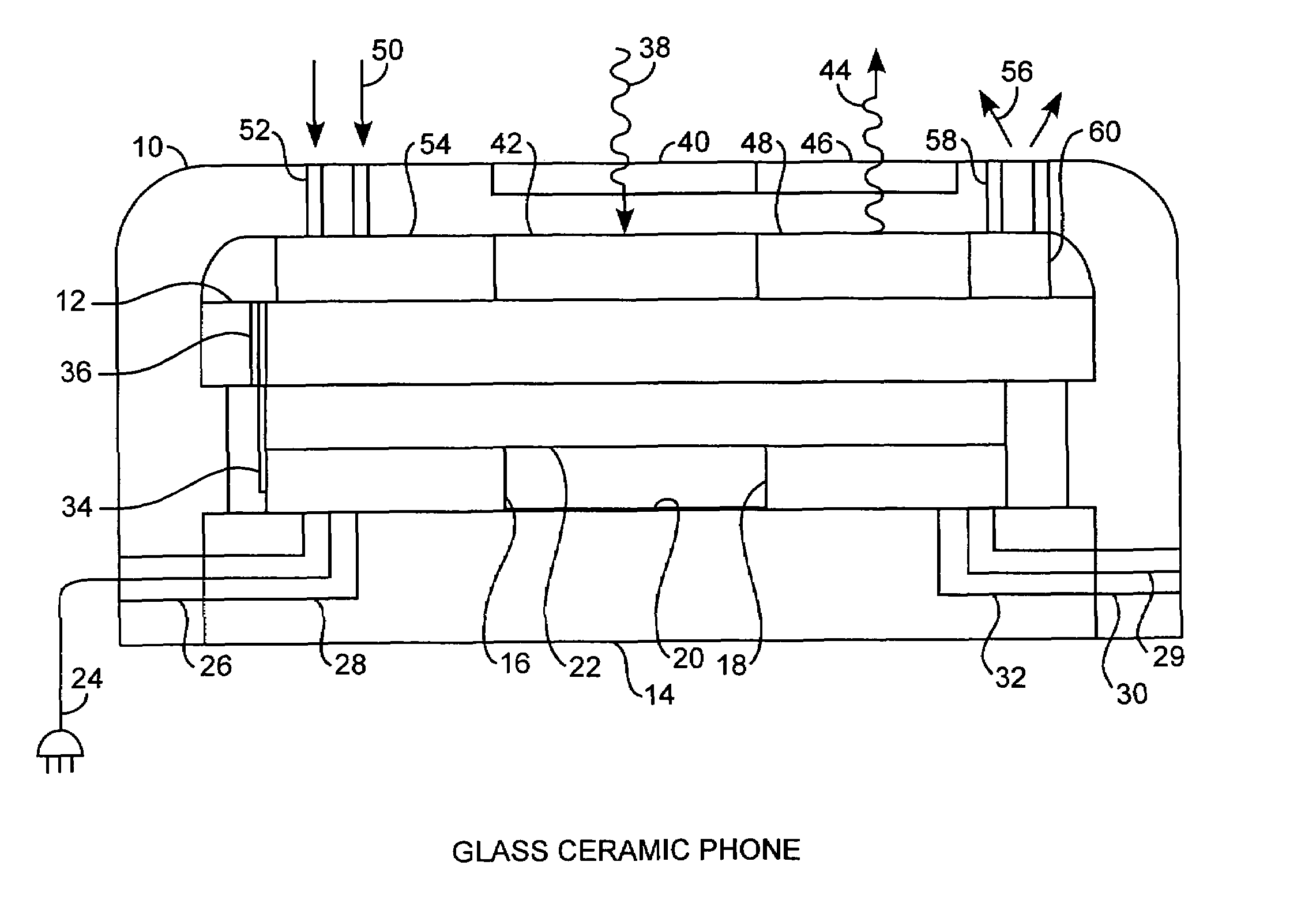

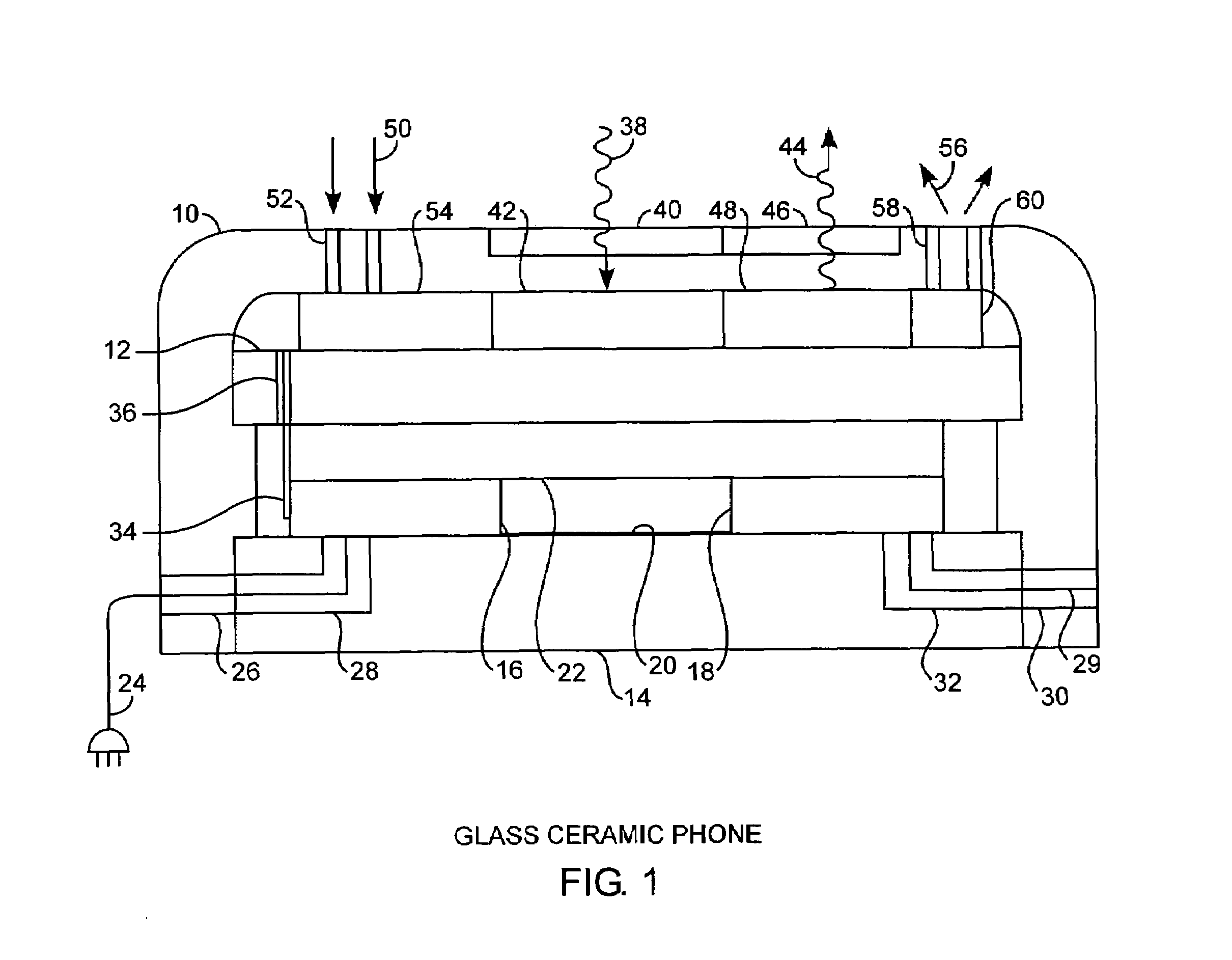

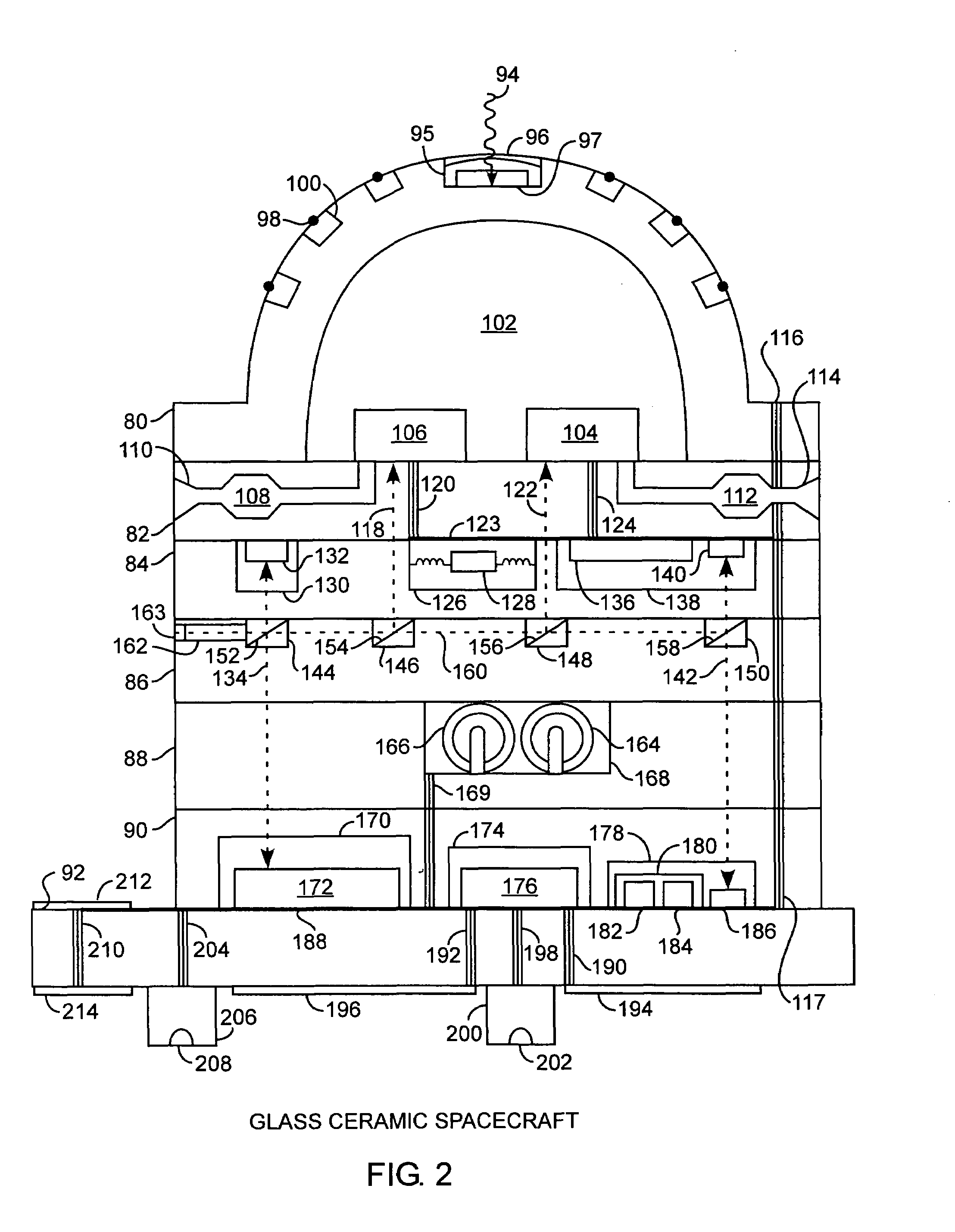

Integrated glass ceramic systems

ActiveUS6952530B2Improve structural strengthLow thermal conductivityCosmonautic propulsion system apparatusCosmonautic power supply systemsElectricityOptical communication

Integrated glass ceramic spacecraft include a plurality of glass ceramic components including molded, tempered, annealed, and patterned glass ceramic components coupled together for forming a support structure or frame or housing through which is communicated optical signals through an optical communications grid and electrical signals through an electrical communications grid, with the optical communications grid and electrical communication grid forming a composite electrooptical communications grid for spacecraft wide intercommunications. The support structure multifunctions as a frame, a housing, a support, a thermal control system, and as part of an electrooptical communications grid while encapsulating a plurality of optical, electronic, electrical, and MEMS devices between which is communicated the electrical and optical signals over the electrooptical communication grid.

Owner:THE AEROSPACE CORPORATION

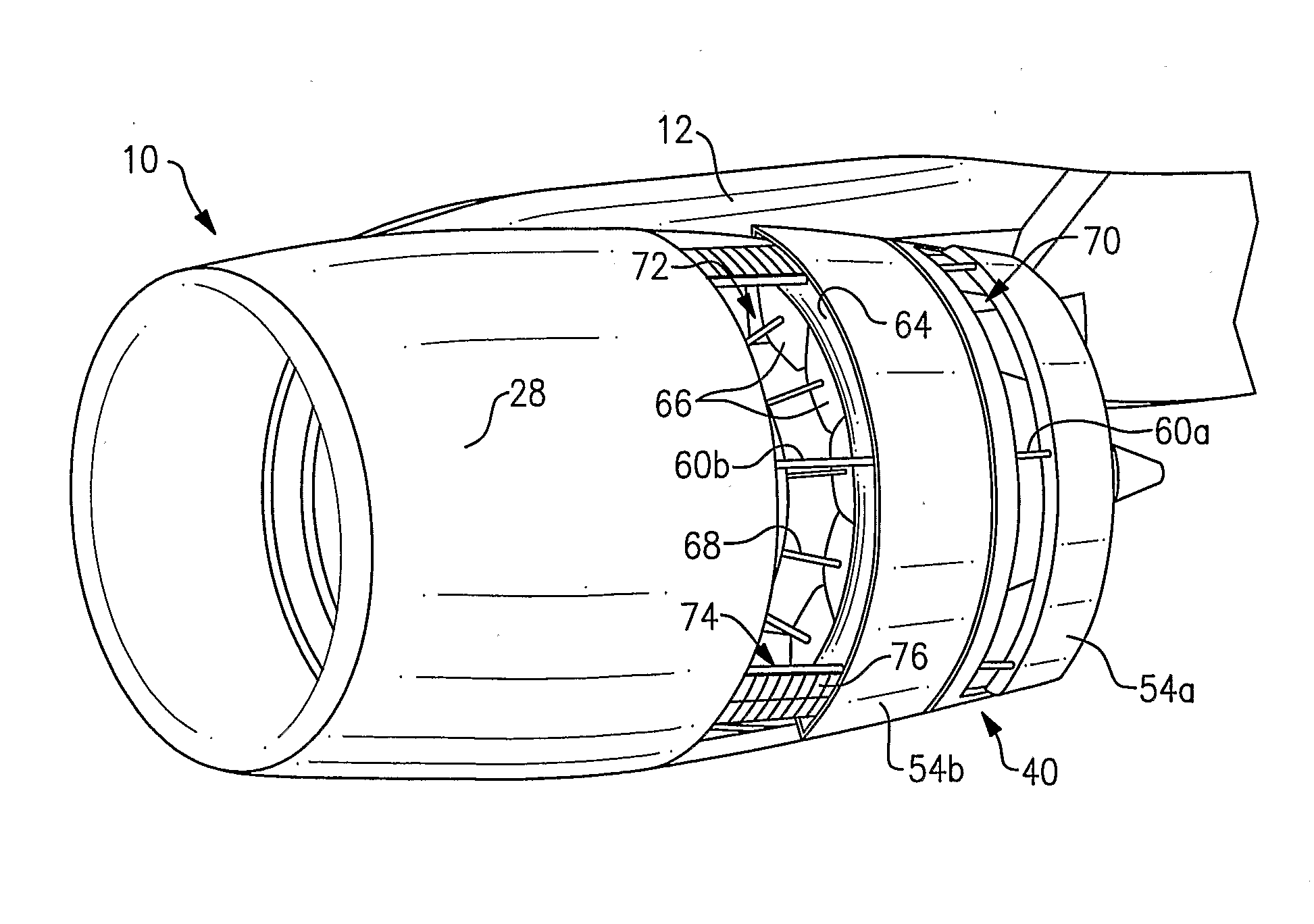

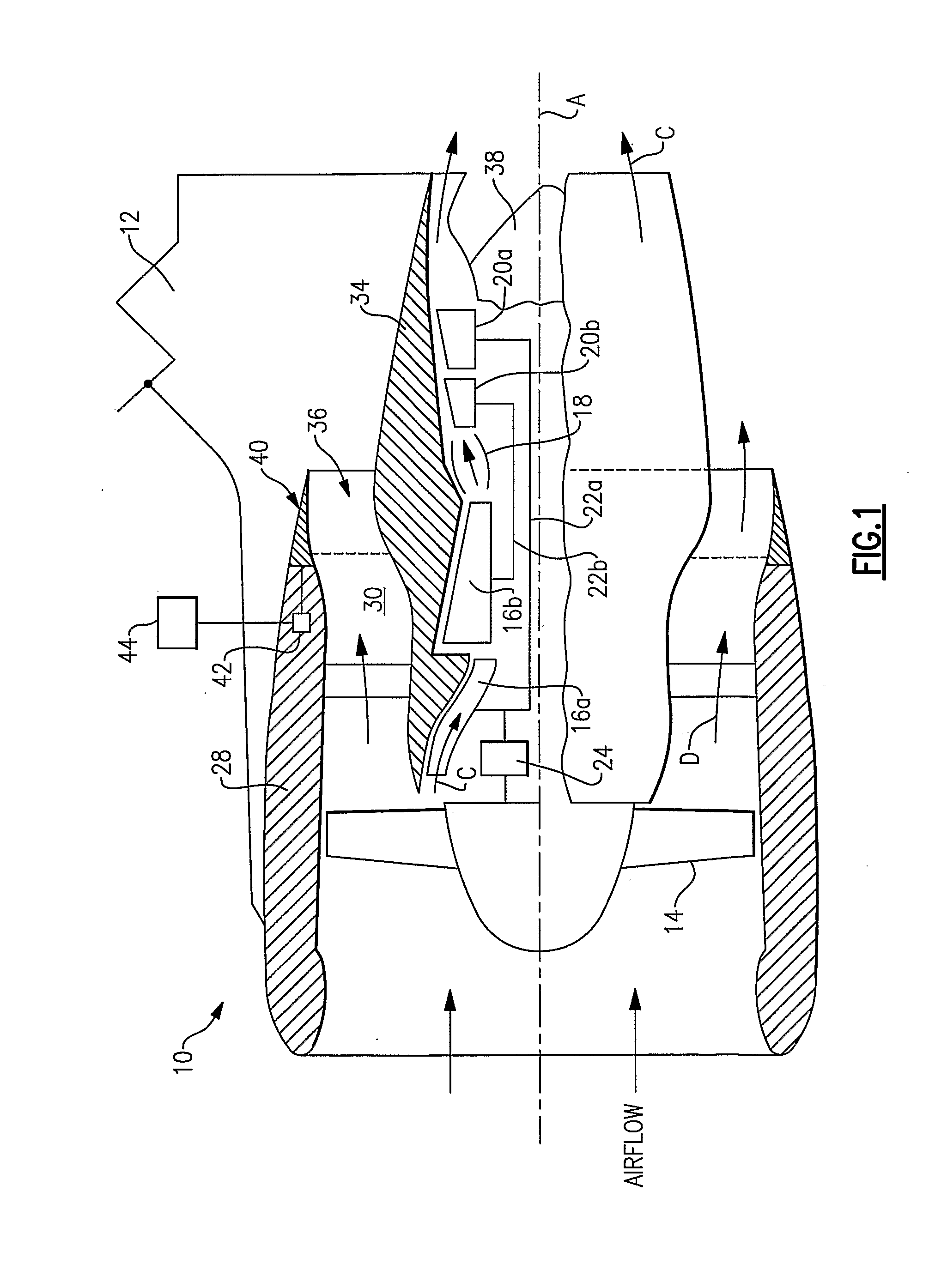

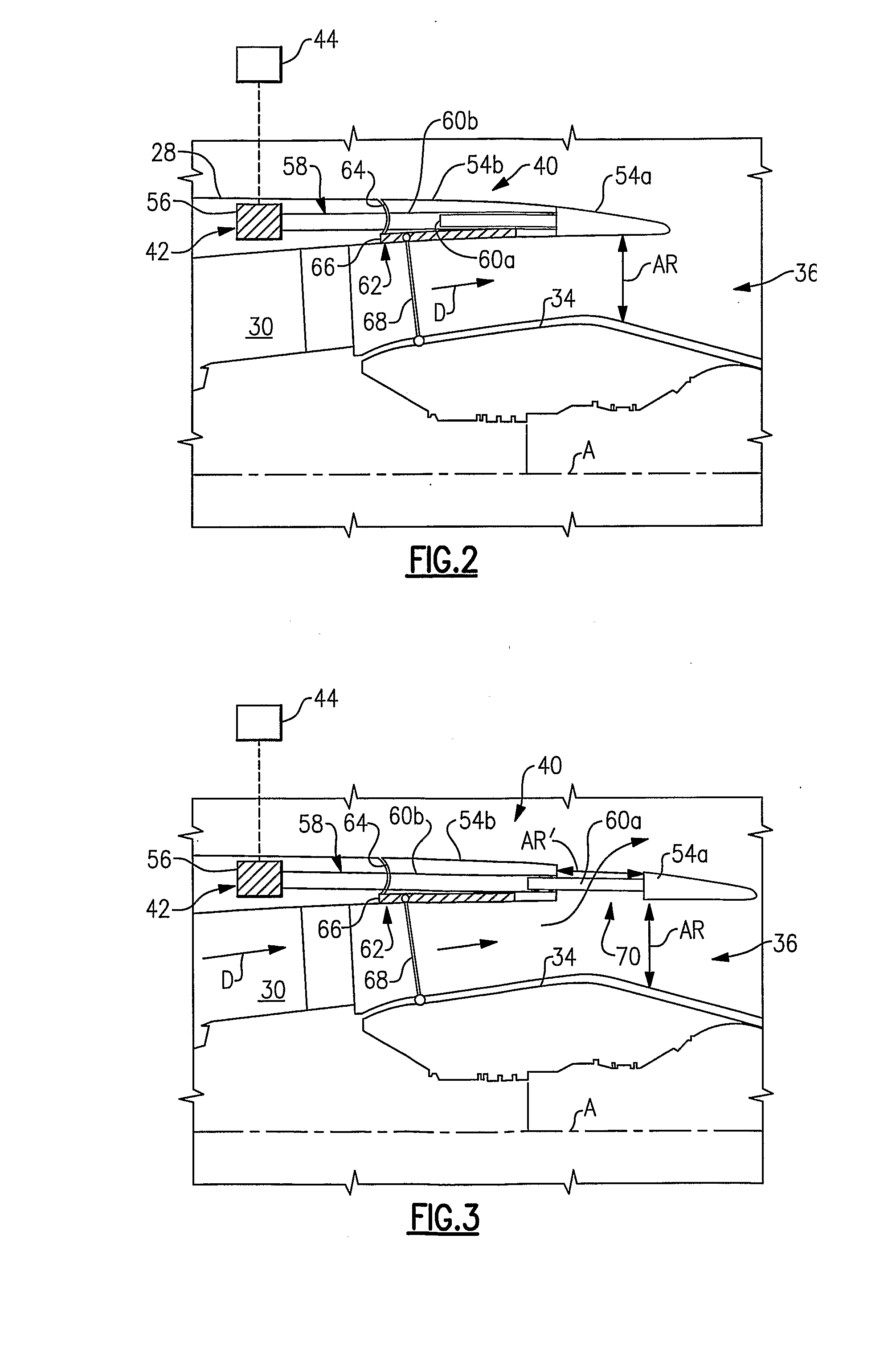

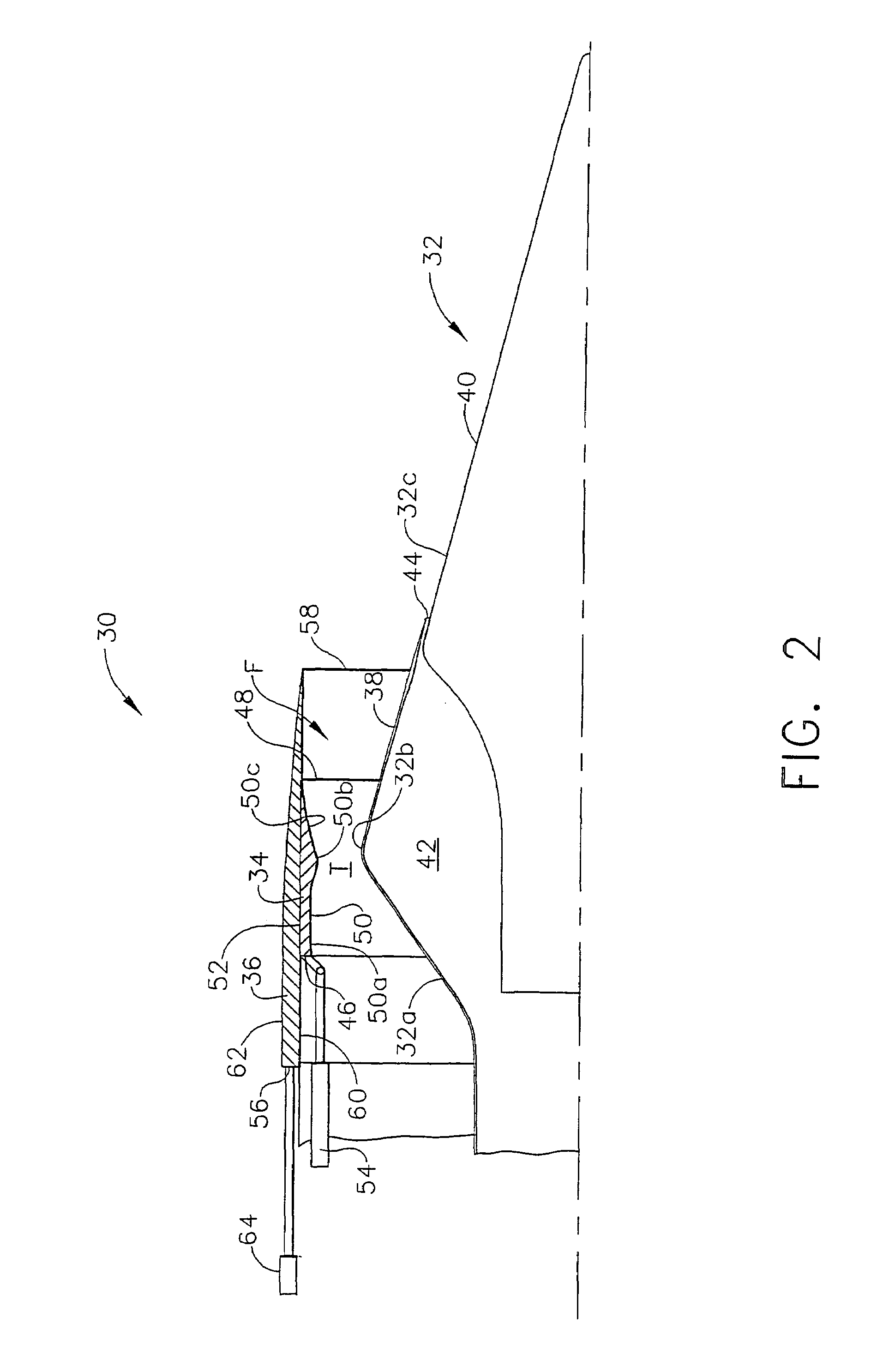

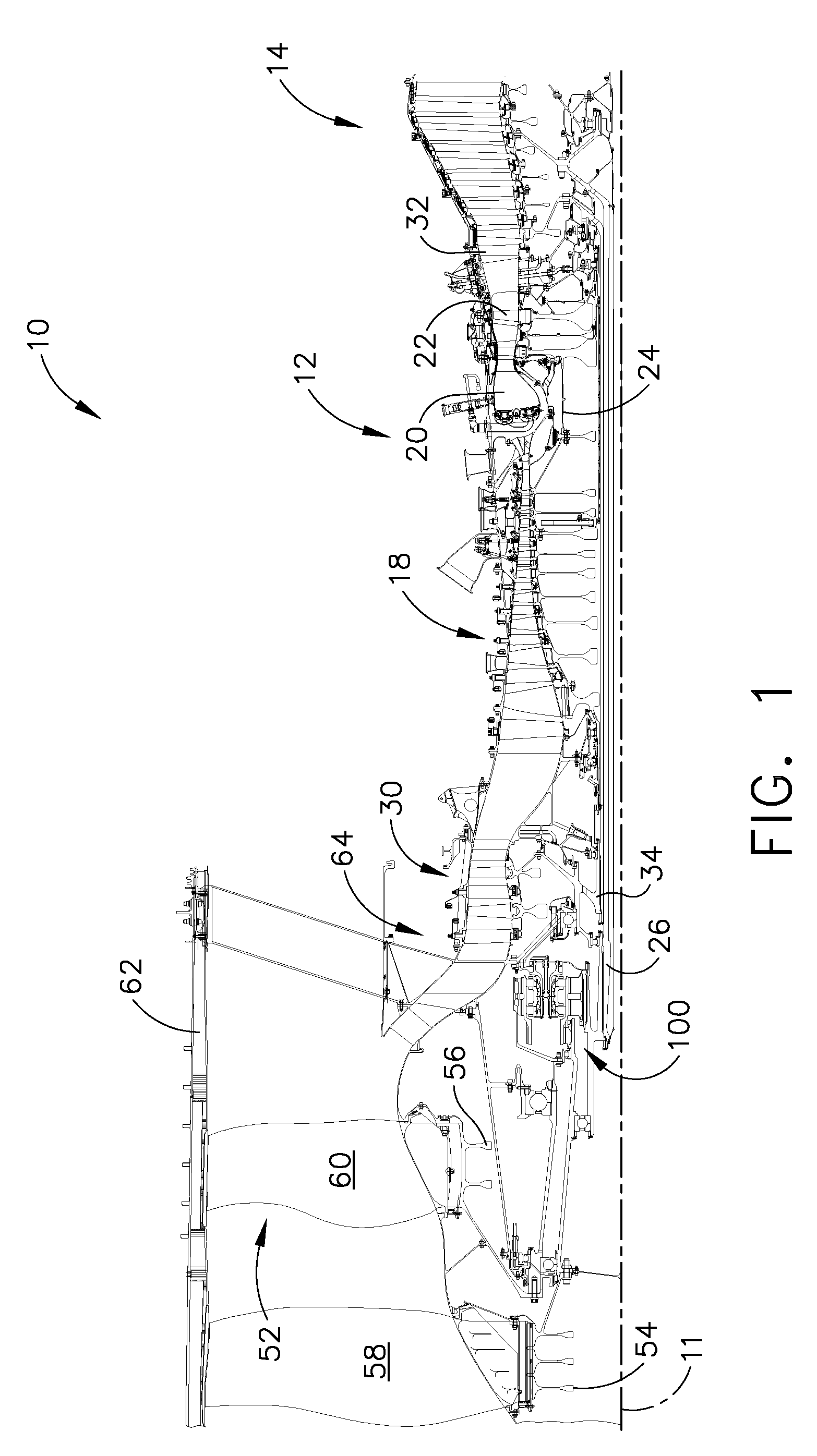

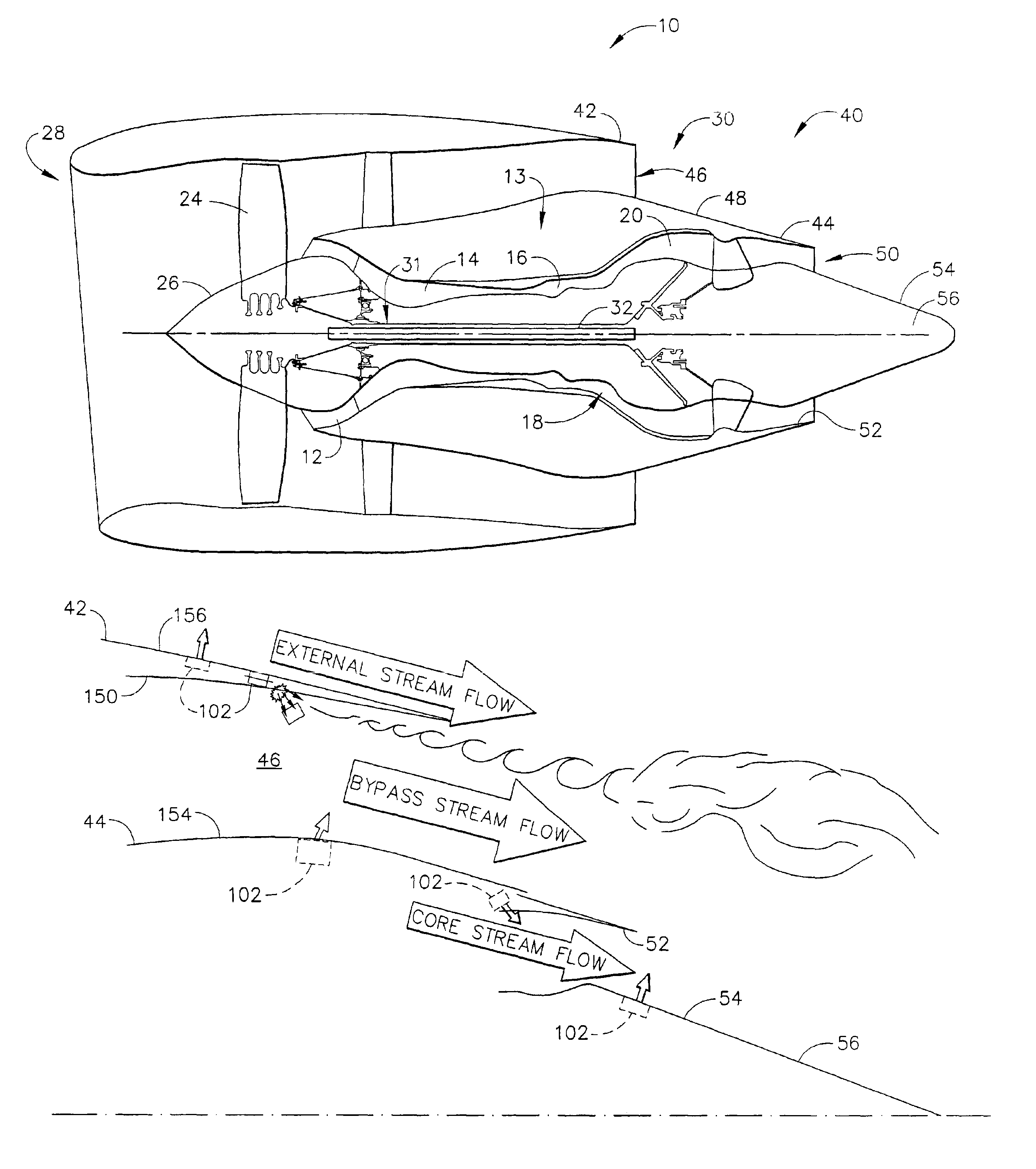

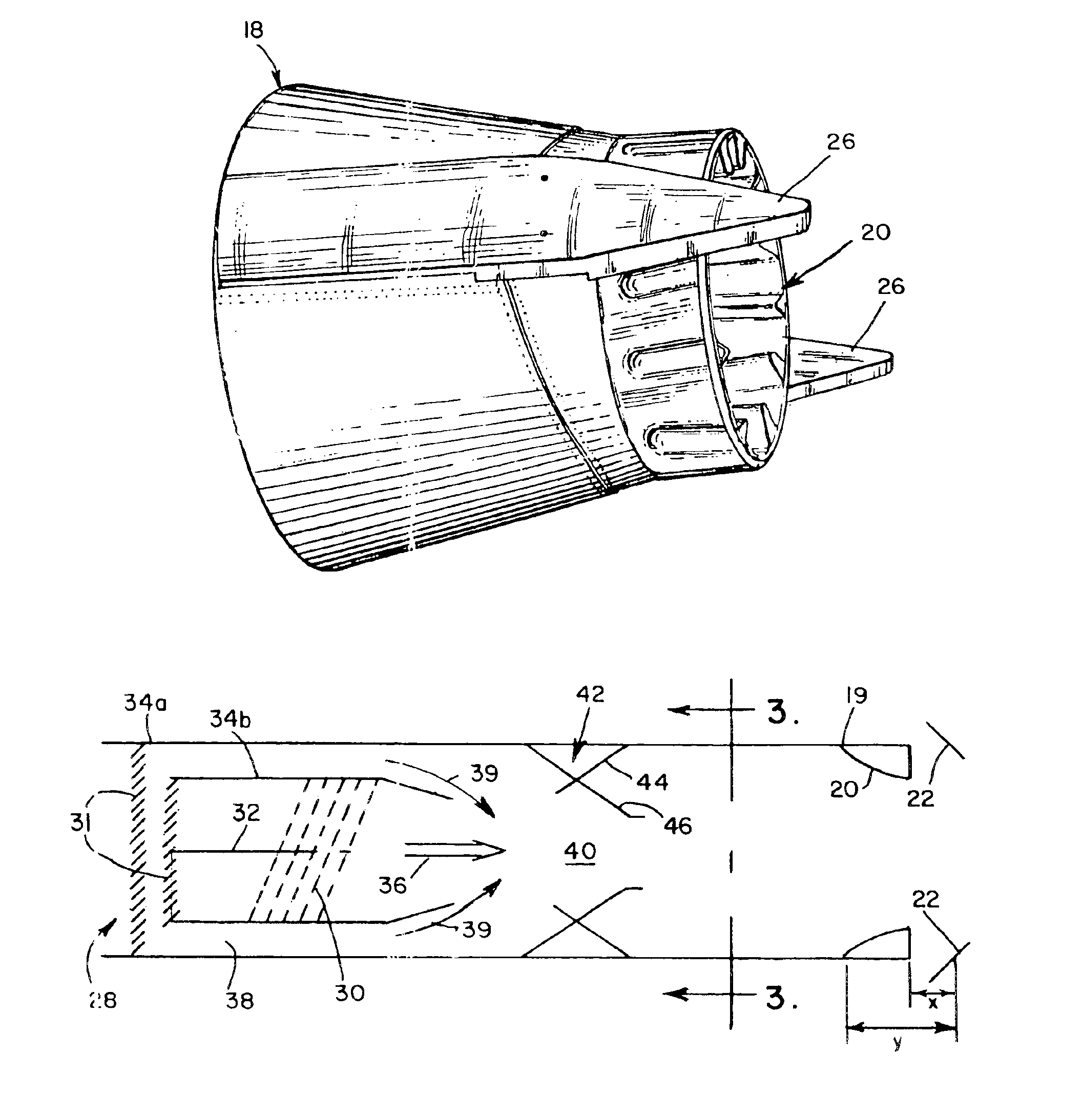

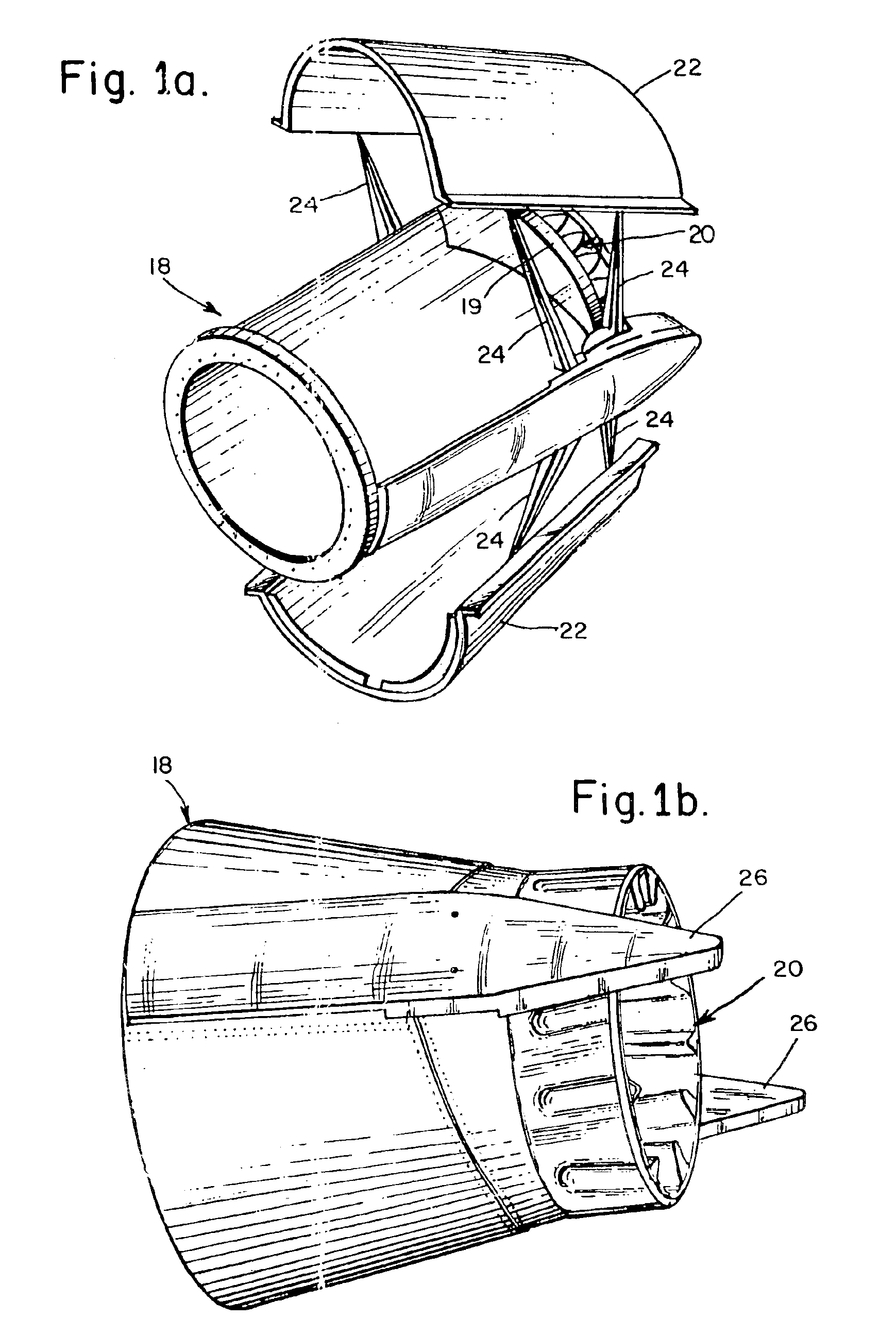

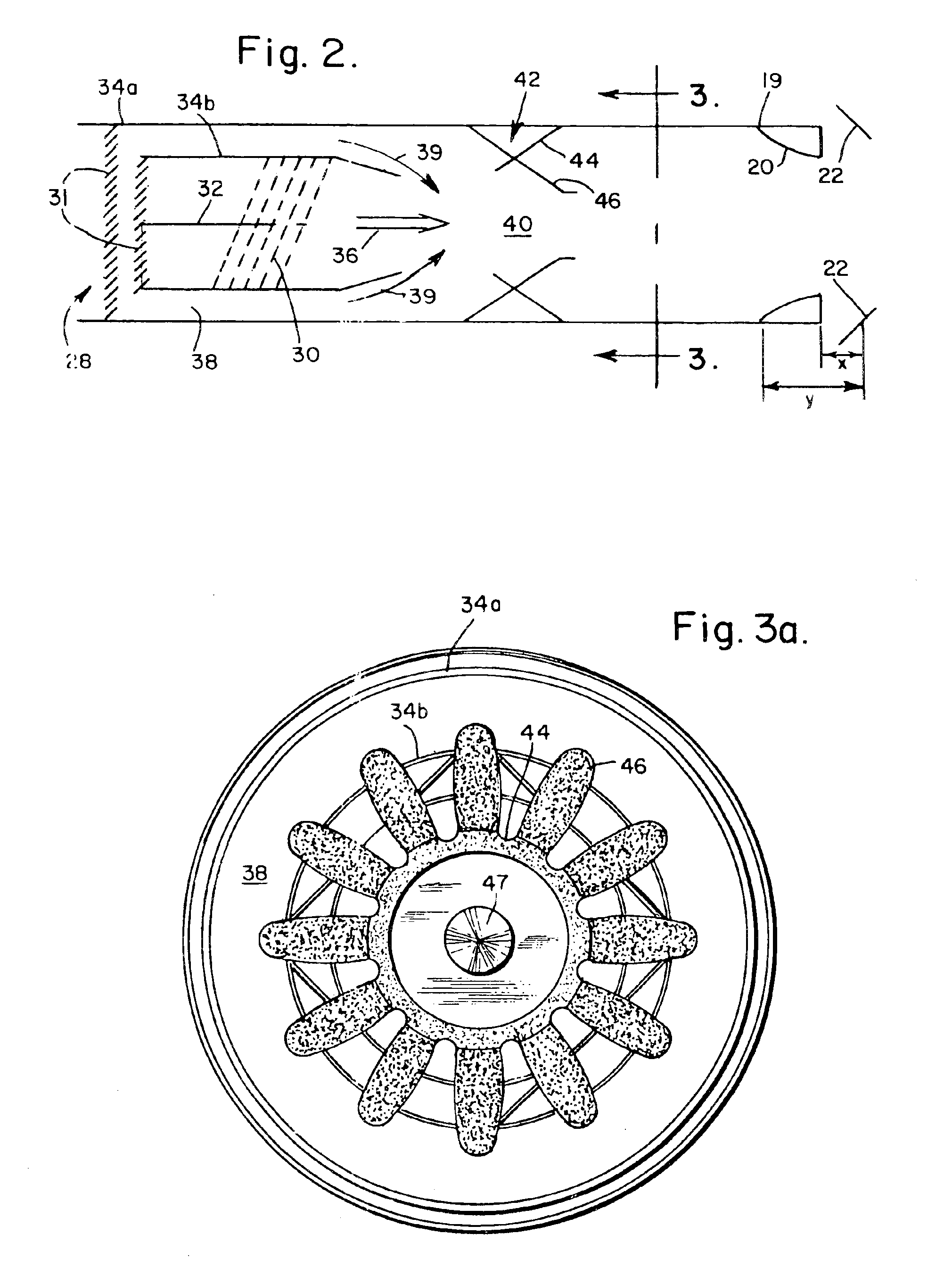

Tri-body variable area fan nozzle and thrust reverser

A gas turbine engine system includes a fan (14), a housing (28) arranged about the fan, a gas turbine engine core having a compressor (16) at least partially within the housing, and a fan bypass passage (30) downstream of the fan for conveying a bypass airflow (D) between the housing and the gas turbine engine core. A nozzle (40) associated with the fan bypass passage includes a first nozzle section (54a) that is operative to move in a generally axial direction to influence the bypass airflow, and a second nozzle section that is operative to also move in a generally axial direction between a stowed position and a thrust reverse position that diverts the bypass airflow in a thrust reversing direction. An actuator (42) selectively moves the first nozzle section and the second nozzle section to influence the bypass airflow and provide thrust reversal.

Owner:RTX CORP

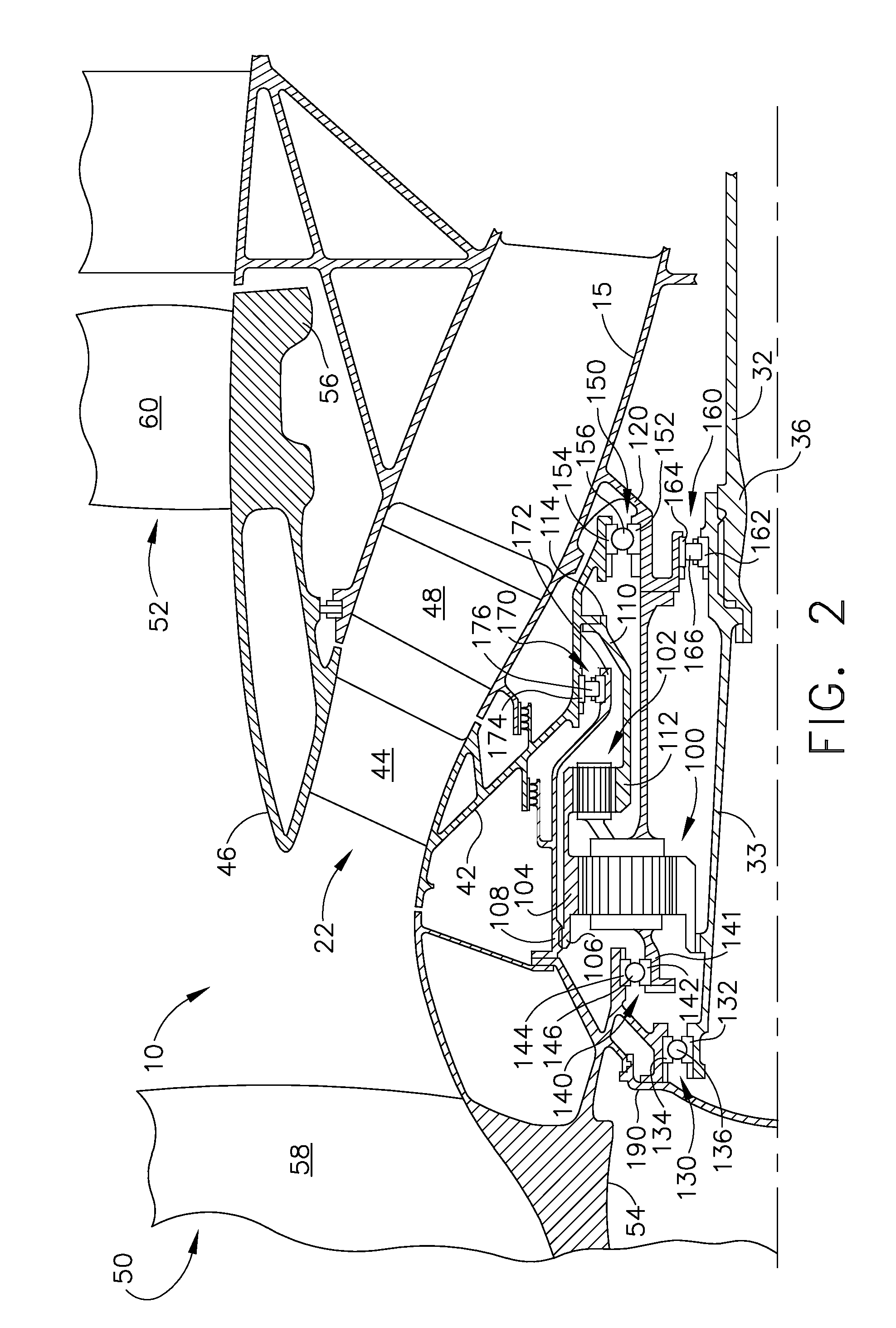

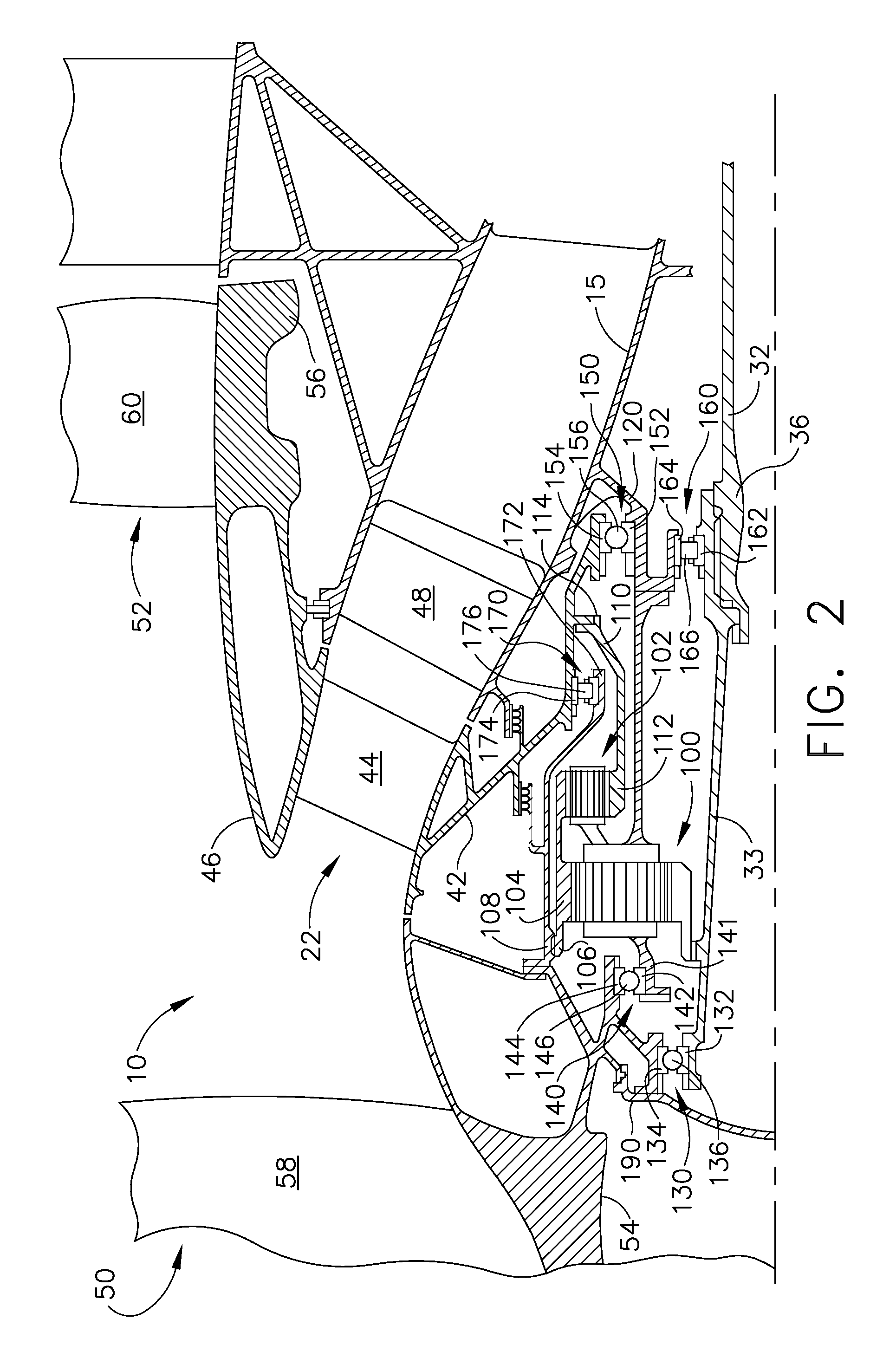

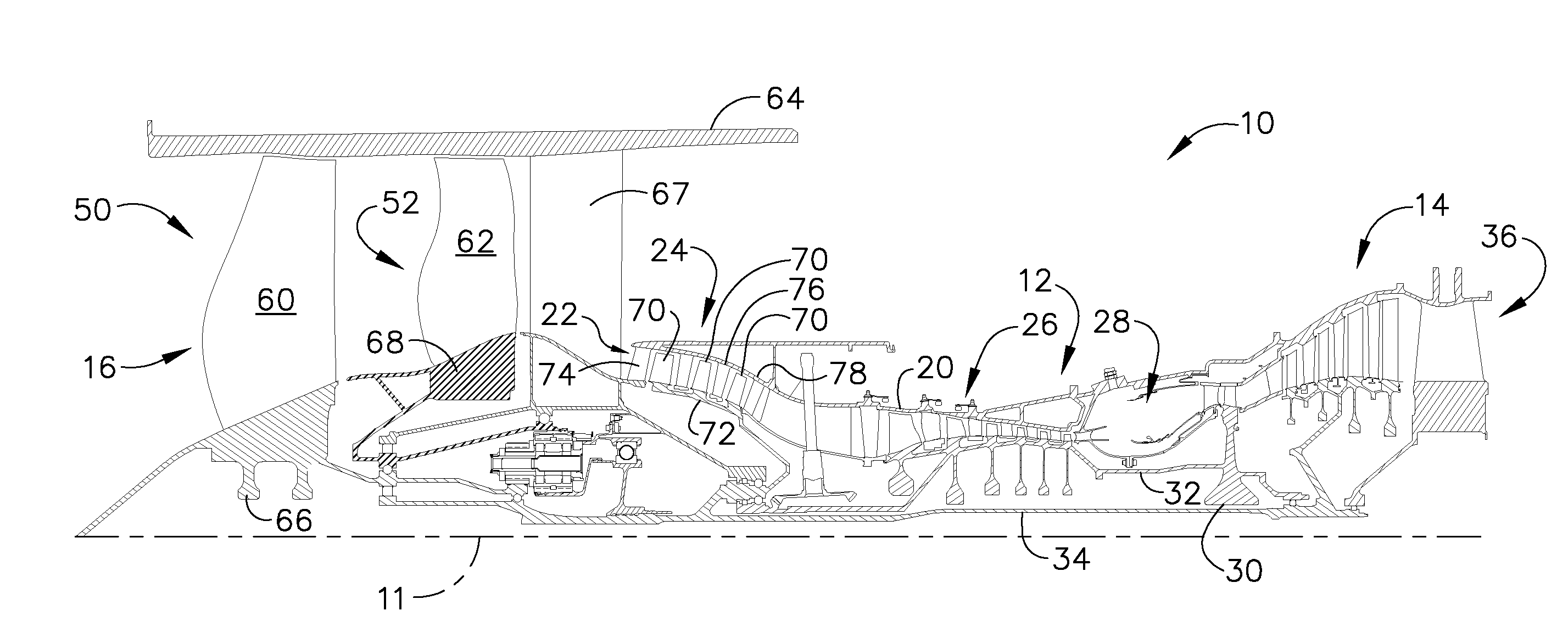

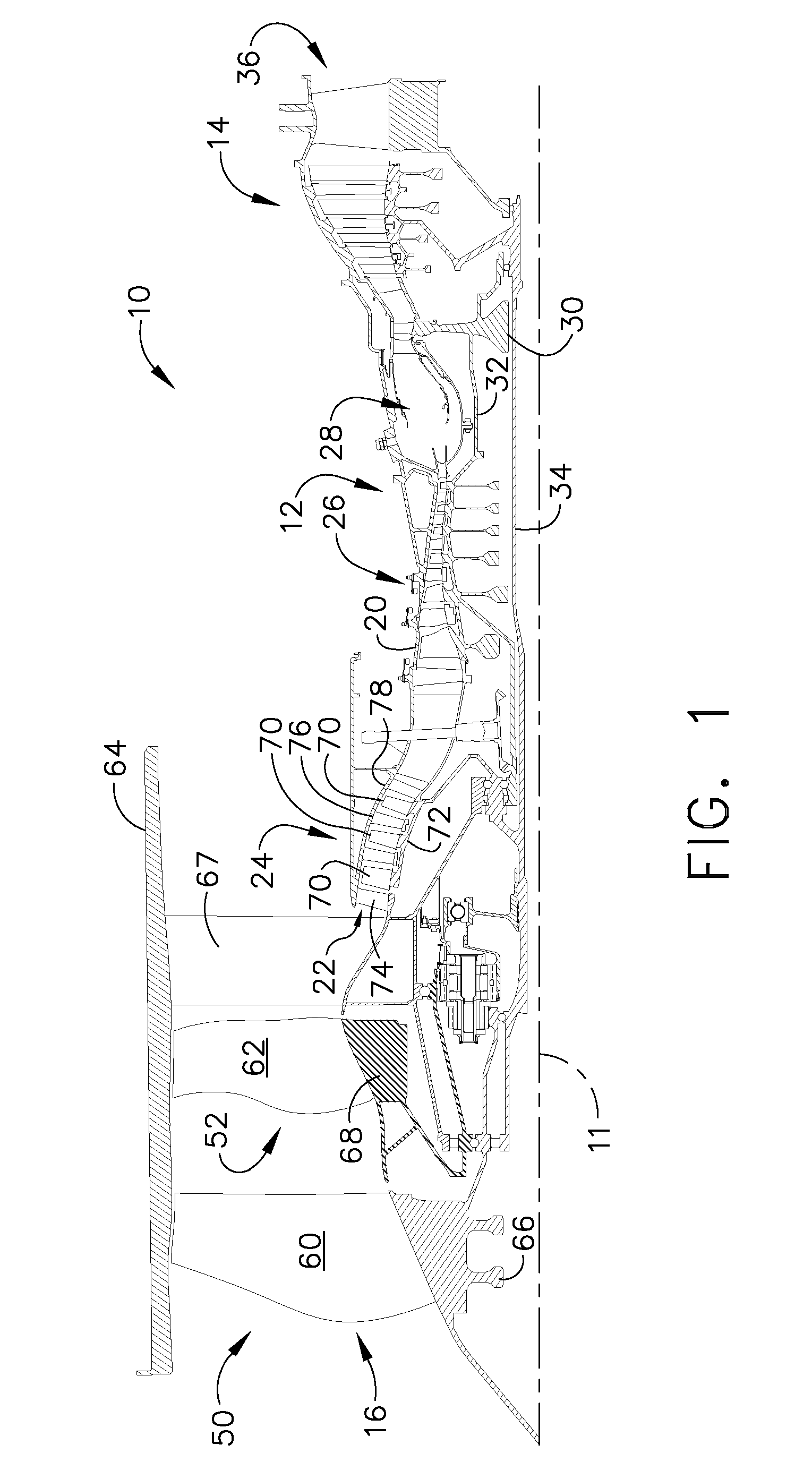

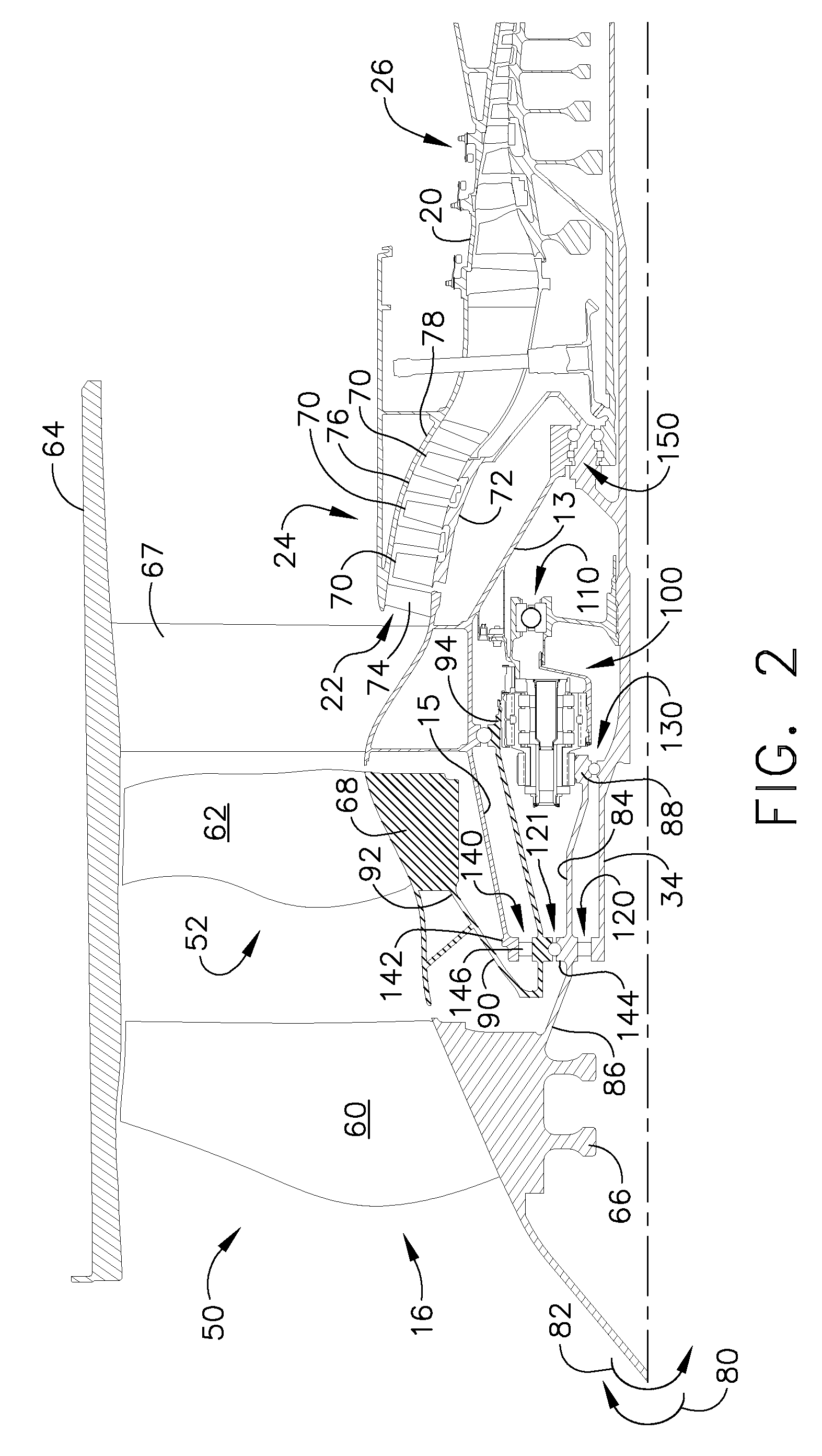

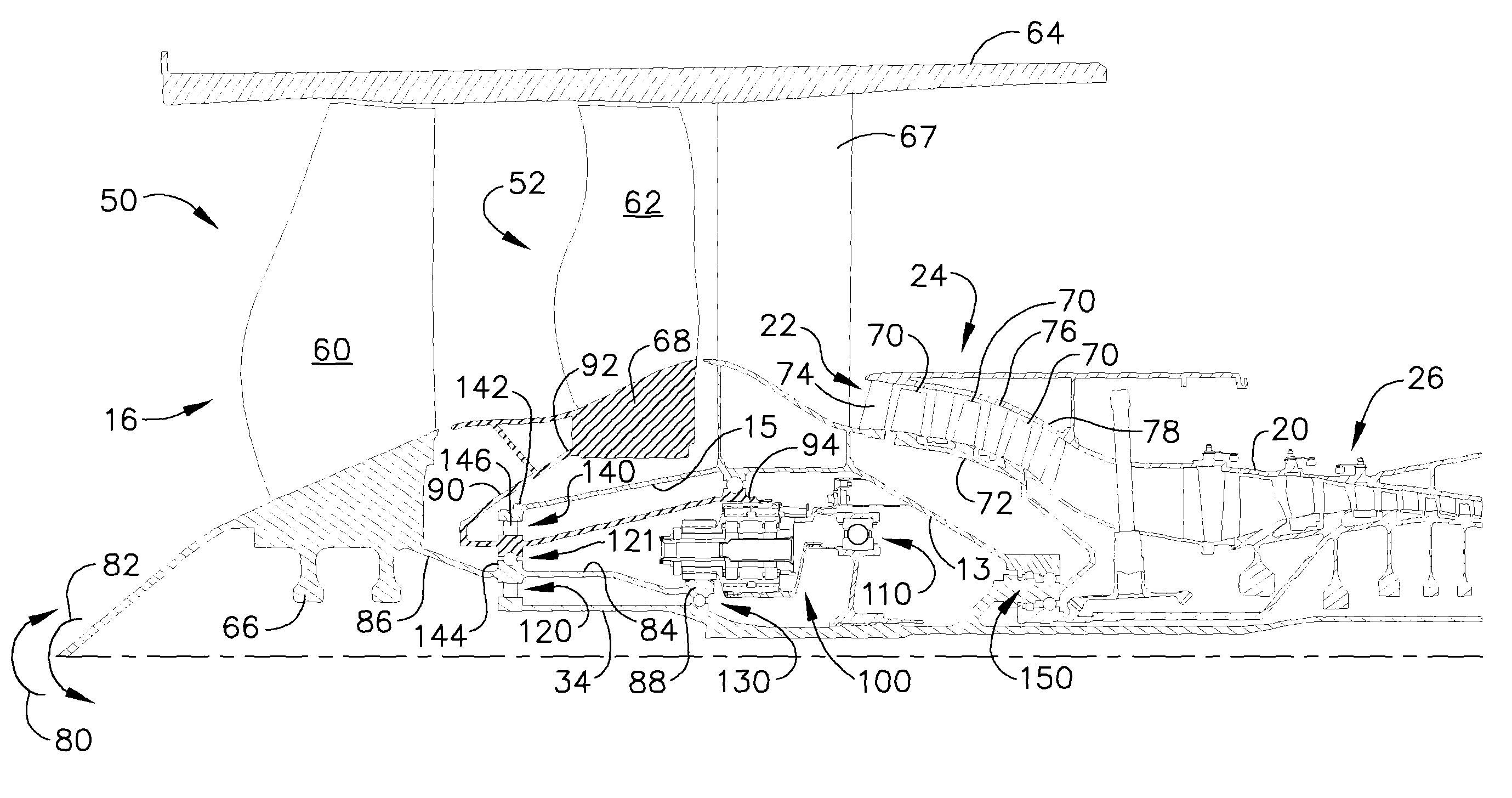

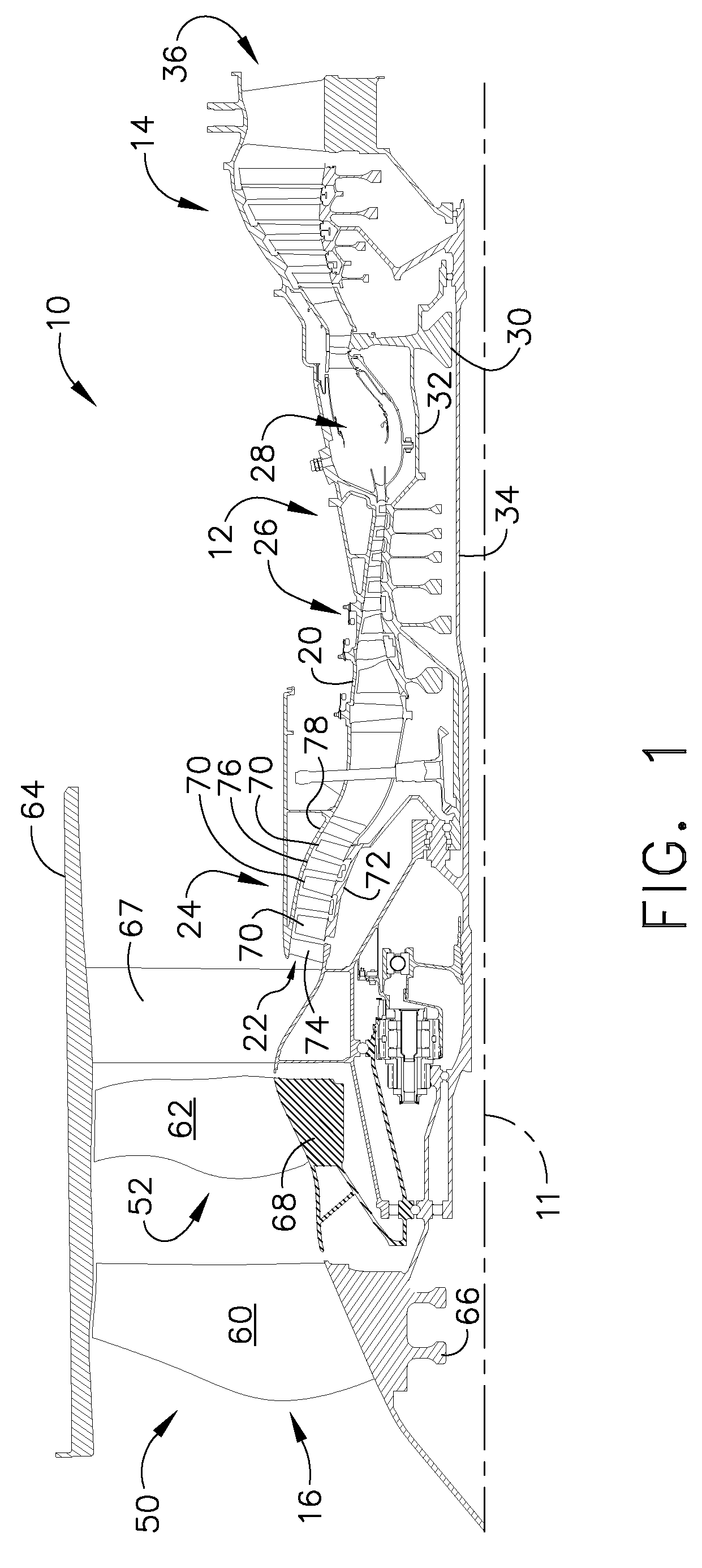

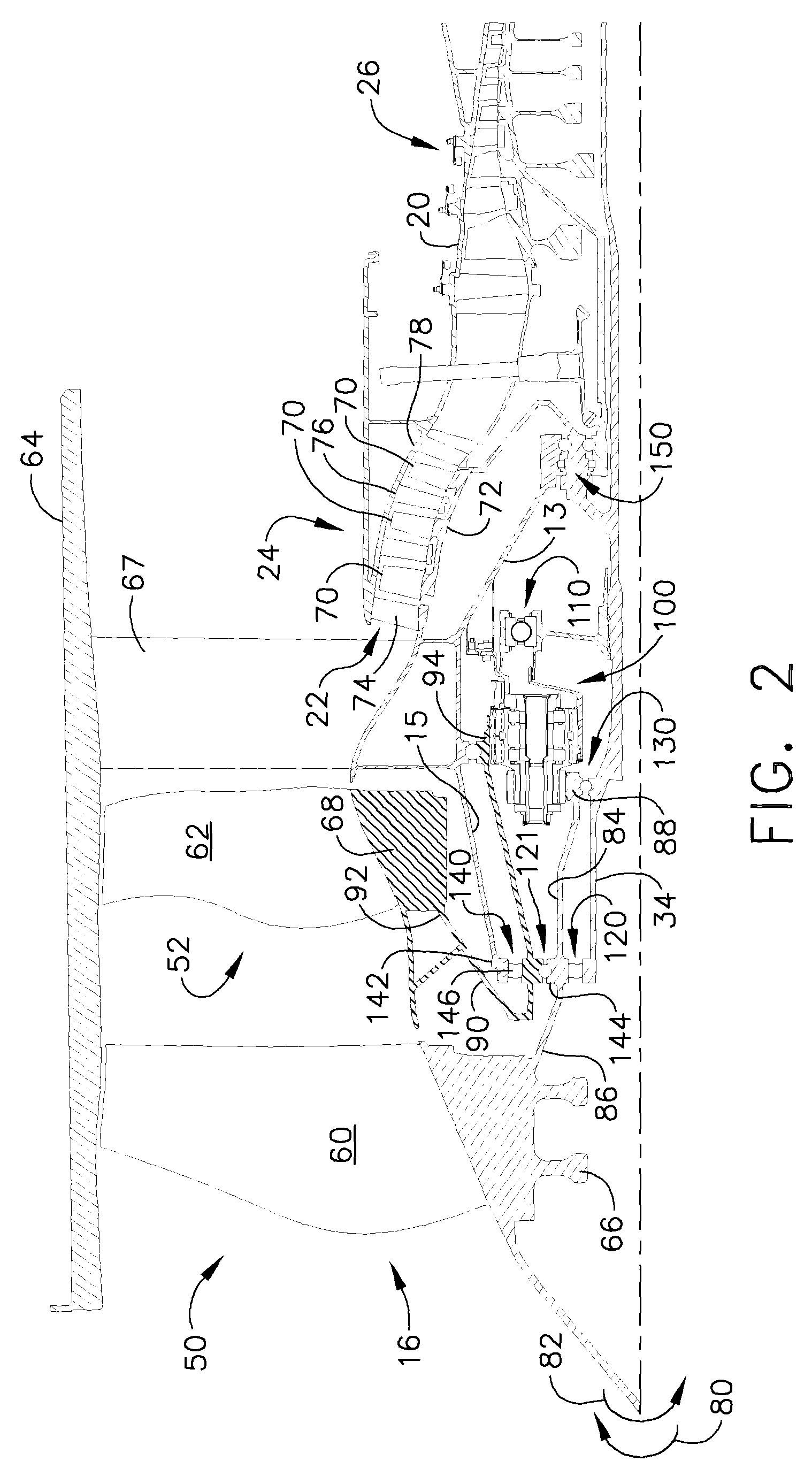

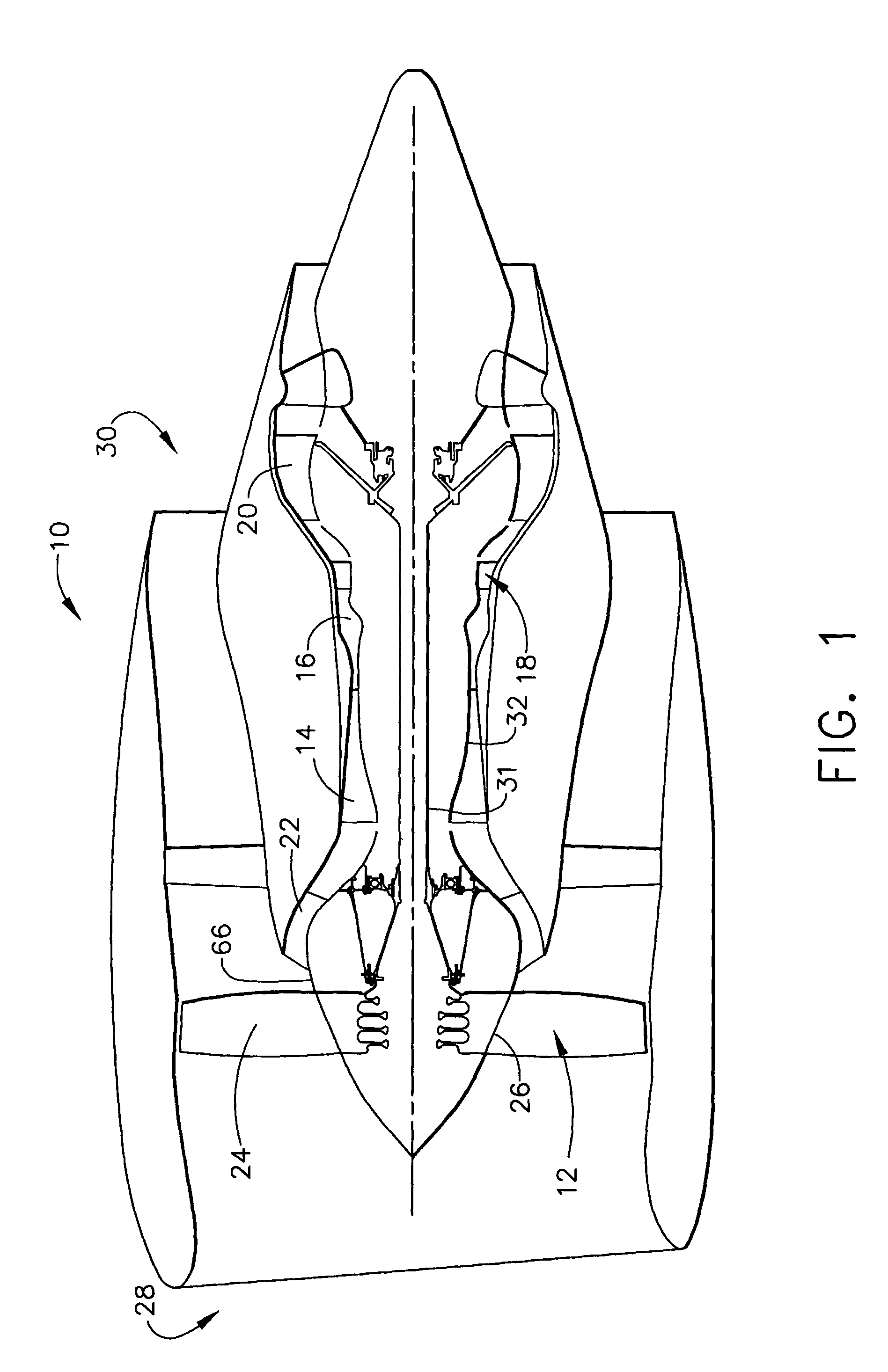

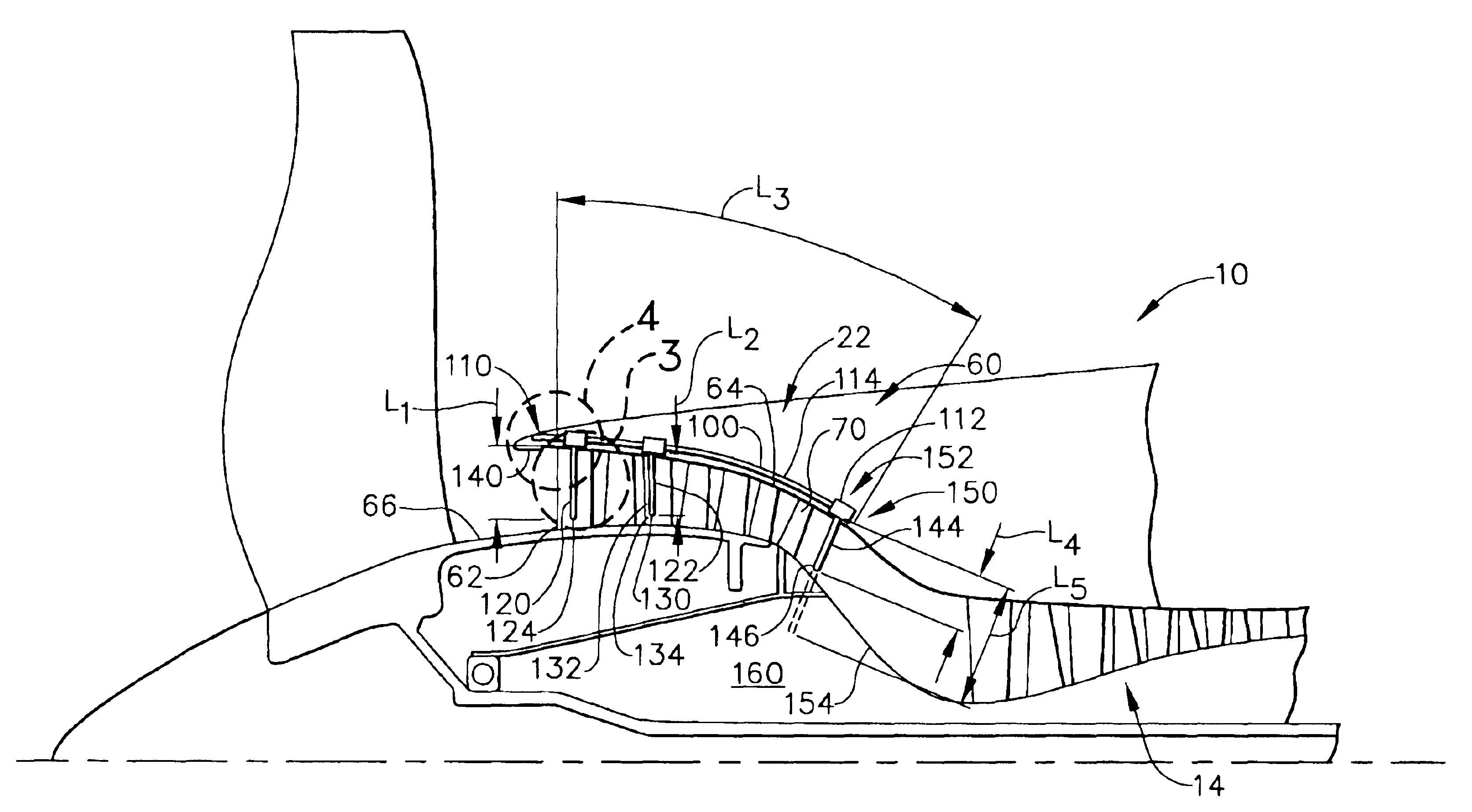

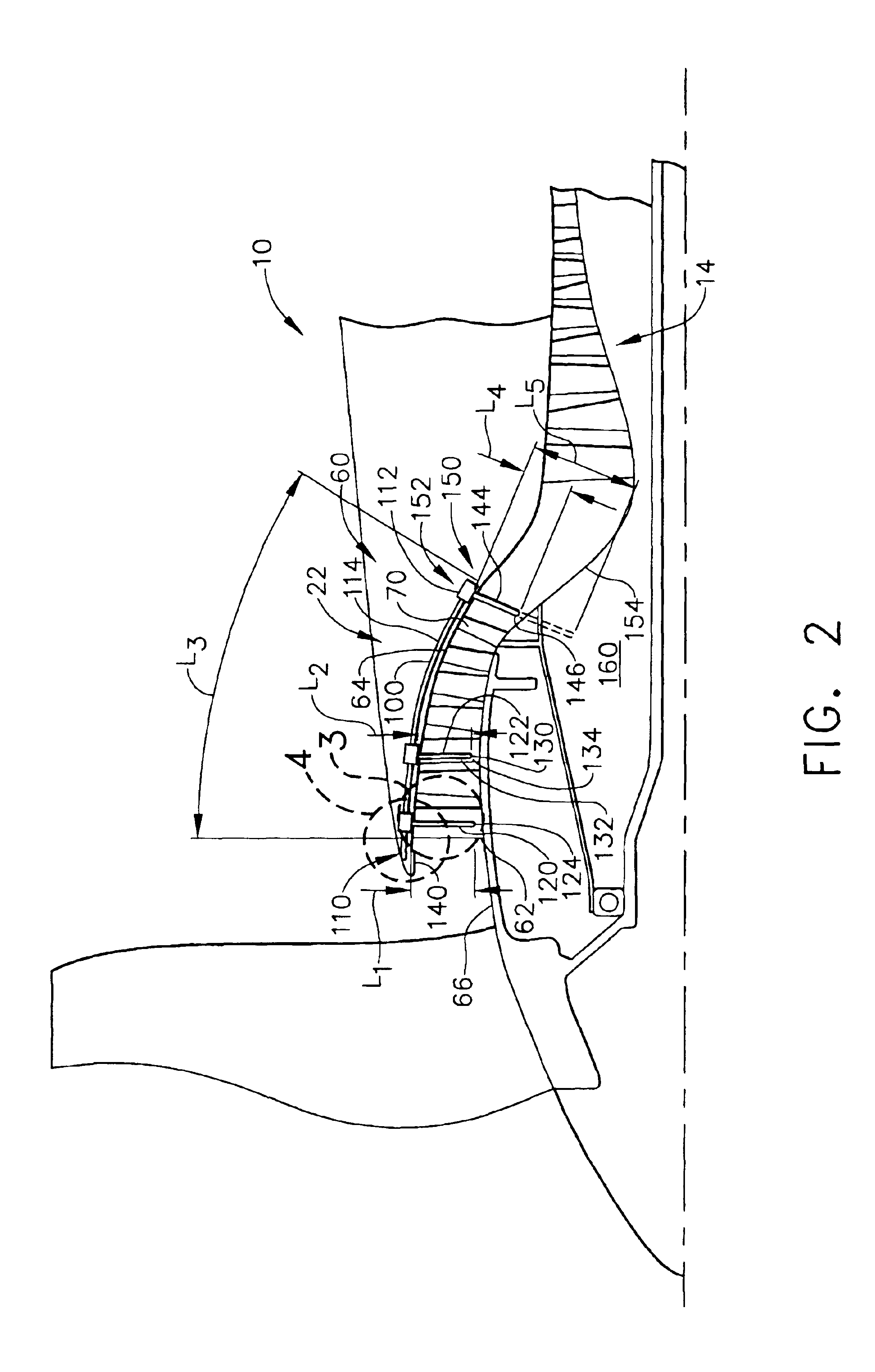

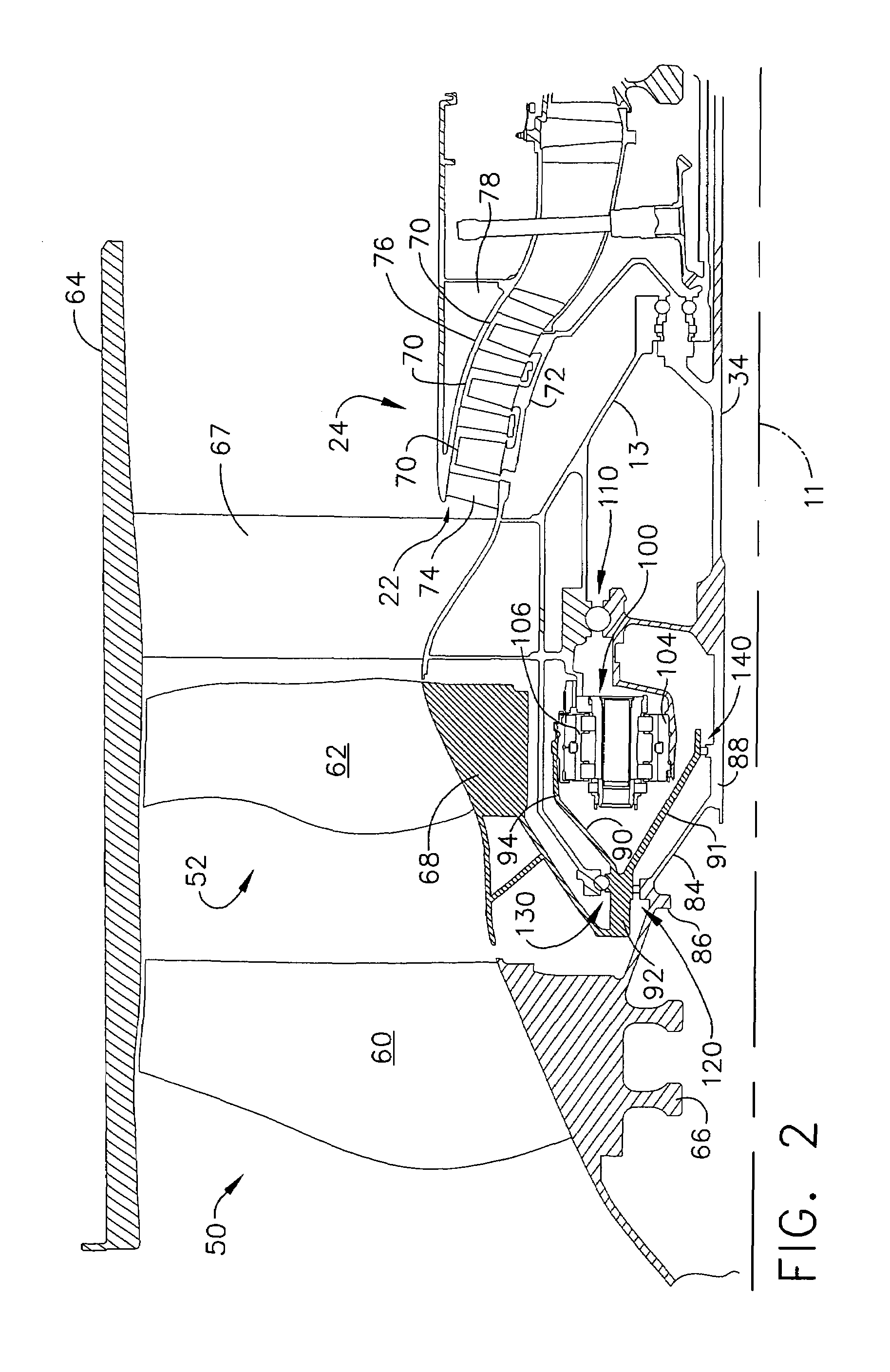

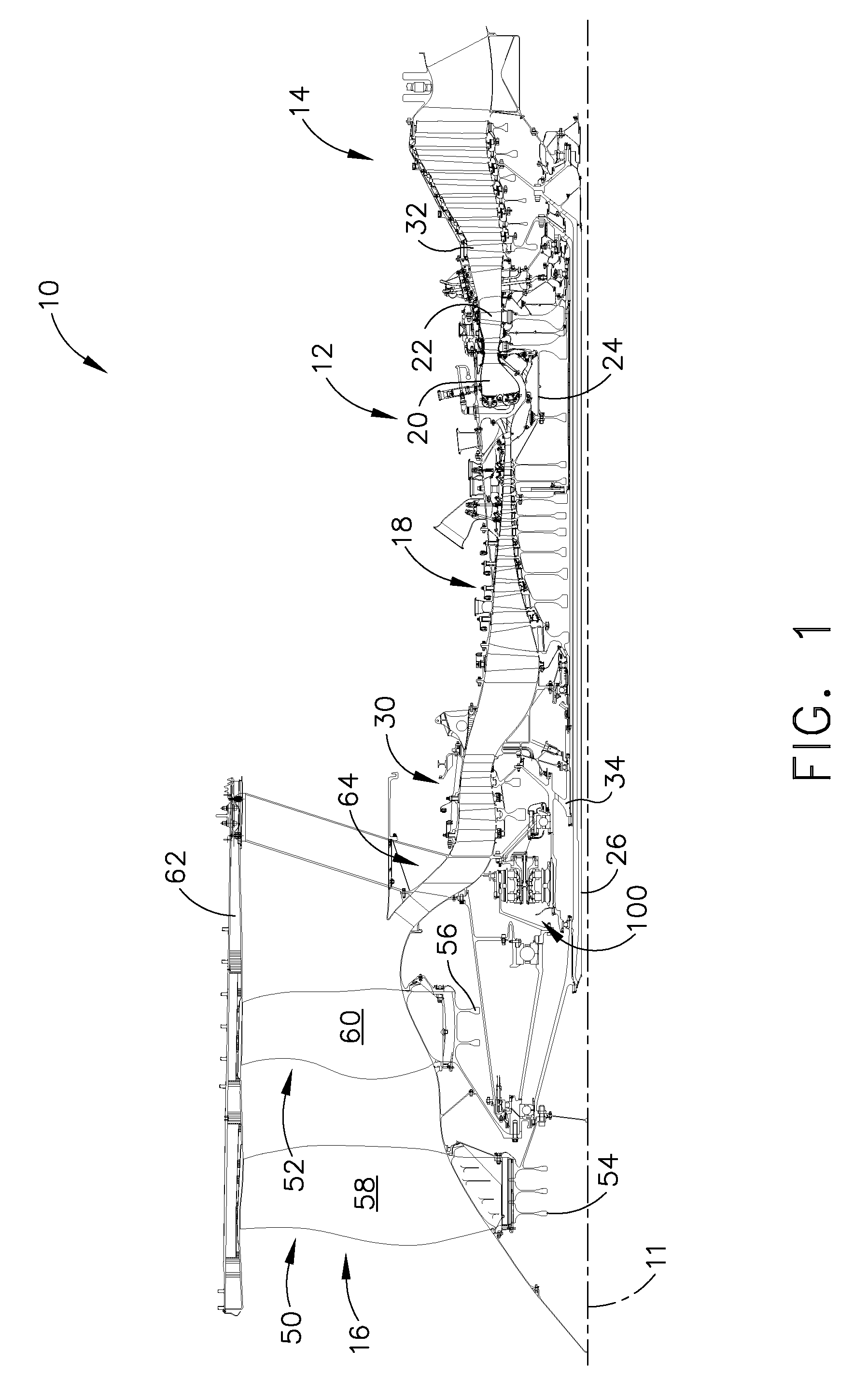

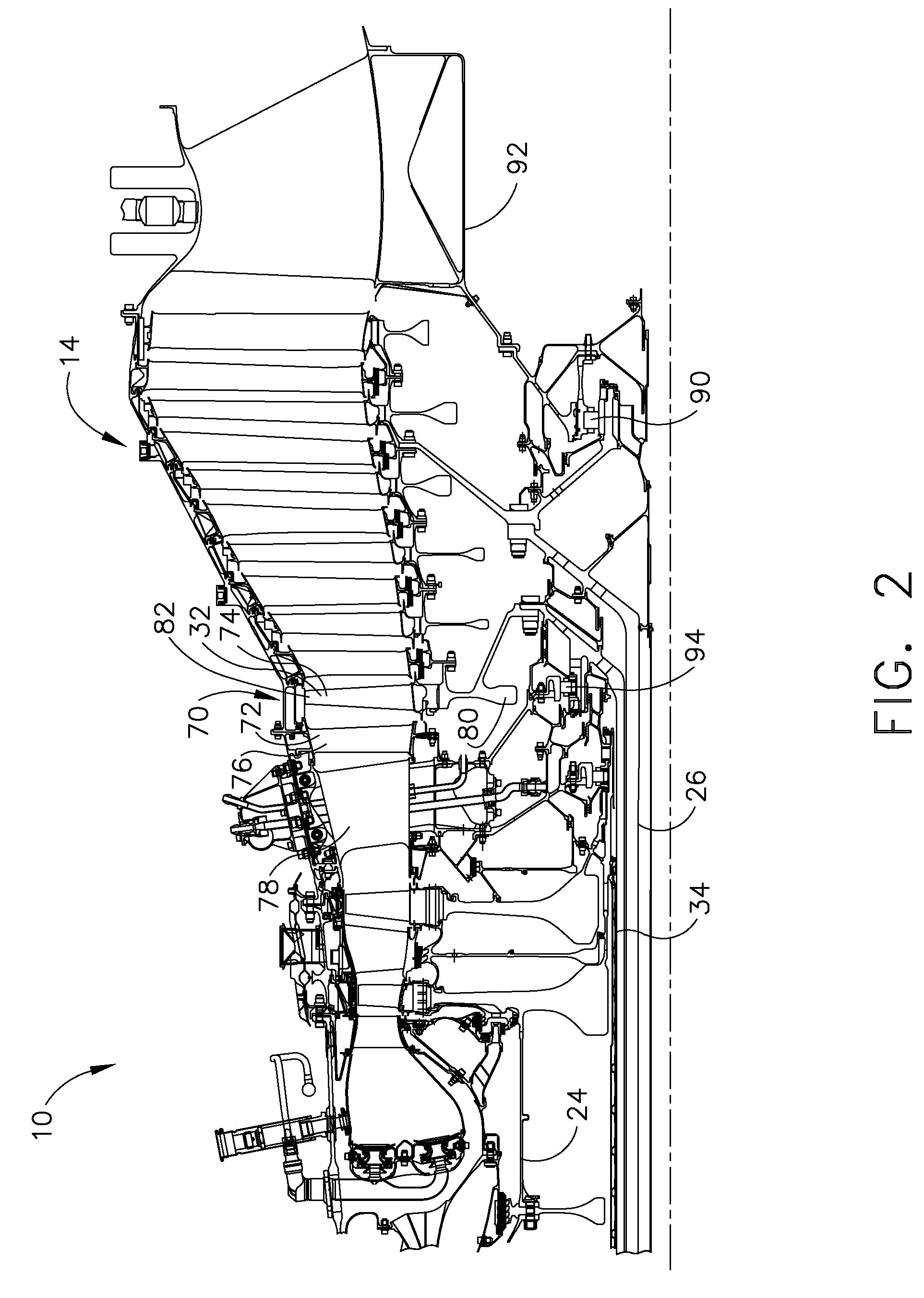

Gas turbine engine assembly and methods of assembling same

InactiveUS20080098716A1Cosmonautic vehiclesCosmonautic propulsion system apparatusTurbineGas turbines

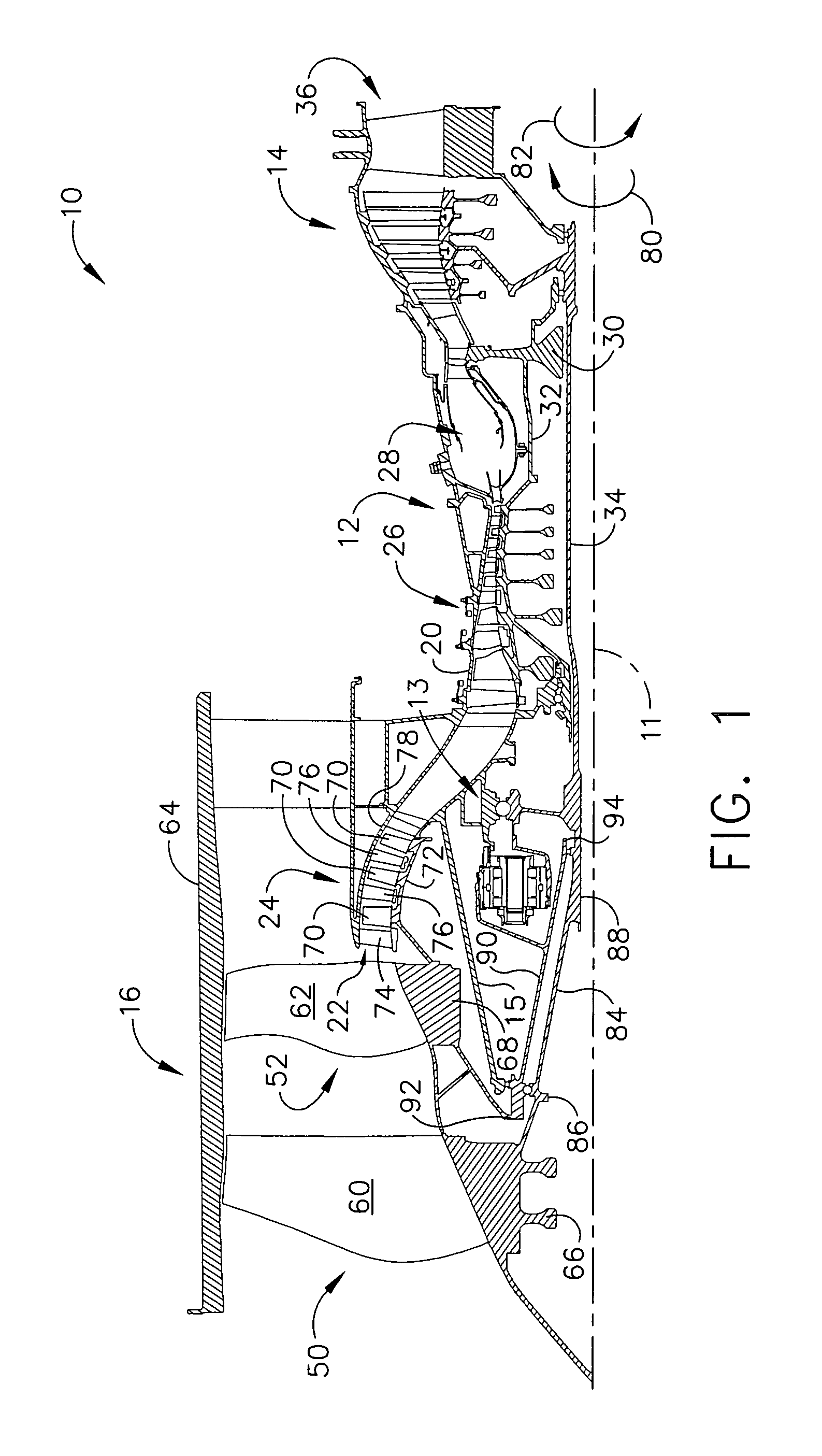

A method for assembling a gas turbine engine includes coupling a low-pressure turbine to a core turbine engine, coupling a counter-rotating fan assembly including a forward fan assembly and an axially aft fan assembly to the low-pressure turbine such that the forward fan assembly rotates in a first direction and the aft fan assembly rotates in an opposite second direction, and coupling a booster compressor directly to the low-pressure turbine such that the booster compressor rotates in the first direction.

Owner:GENERAL ELECTRIC CO

Gas turbine engine assembly and methods of assembling same

A method for assembling a gas turbine engine includes coupling a low-pressure turbine to a core turbine engine, coupling a counter-rotating fan assembly including a forward fan assembly and an axially aft fan assembly to the low-pressure turbine such that the forward fan assembly rotates in a first direction and the aft fan assembly rotates in an opposite second direction, and coupling a booster compressor directly to the low-pressure turbine such that the booster compressor rotates in the first direction.

Owner:GENERAL ELECTRIC CO

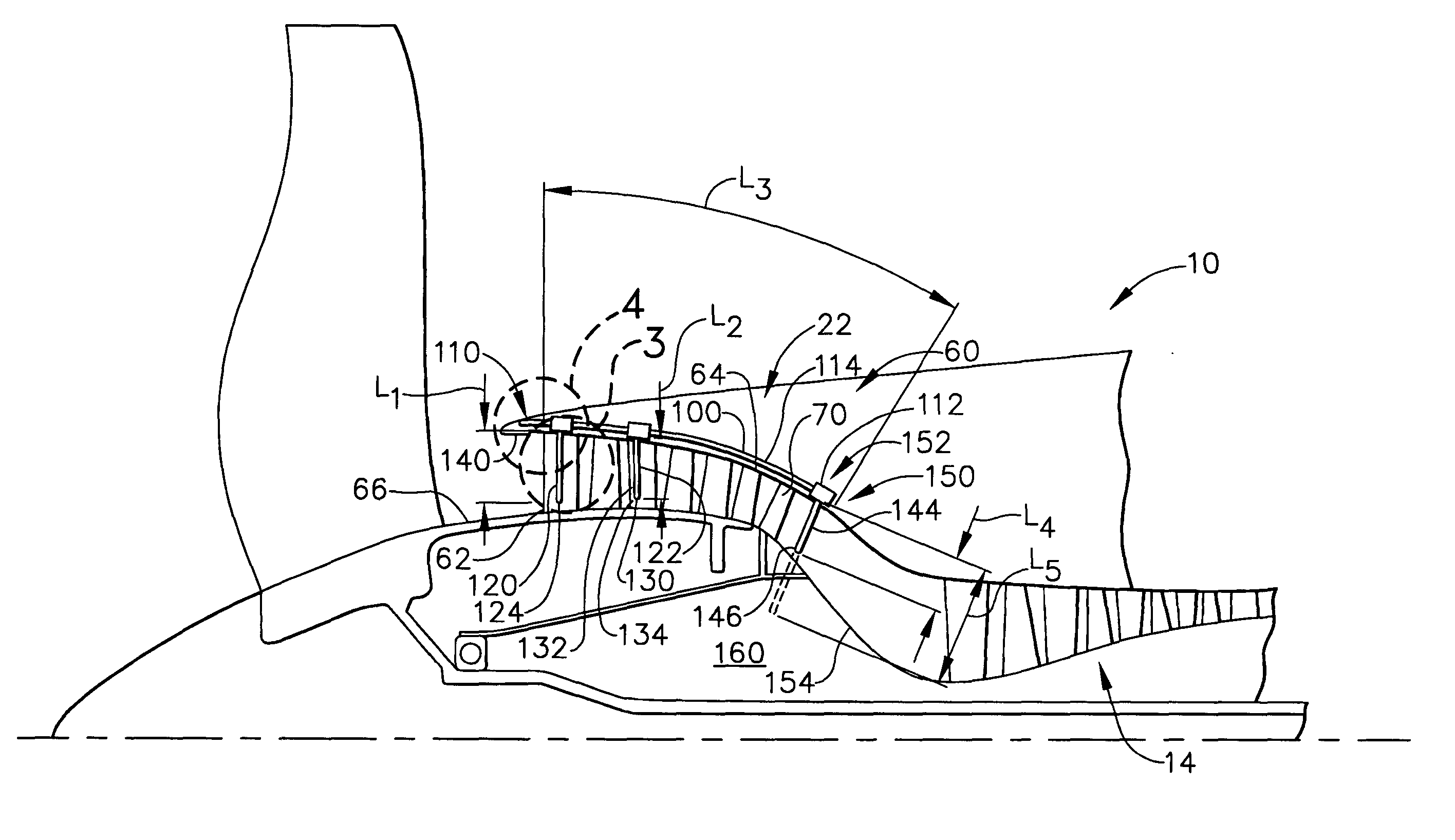

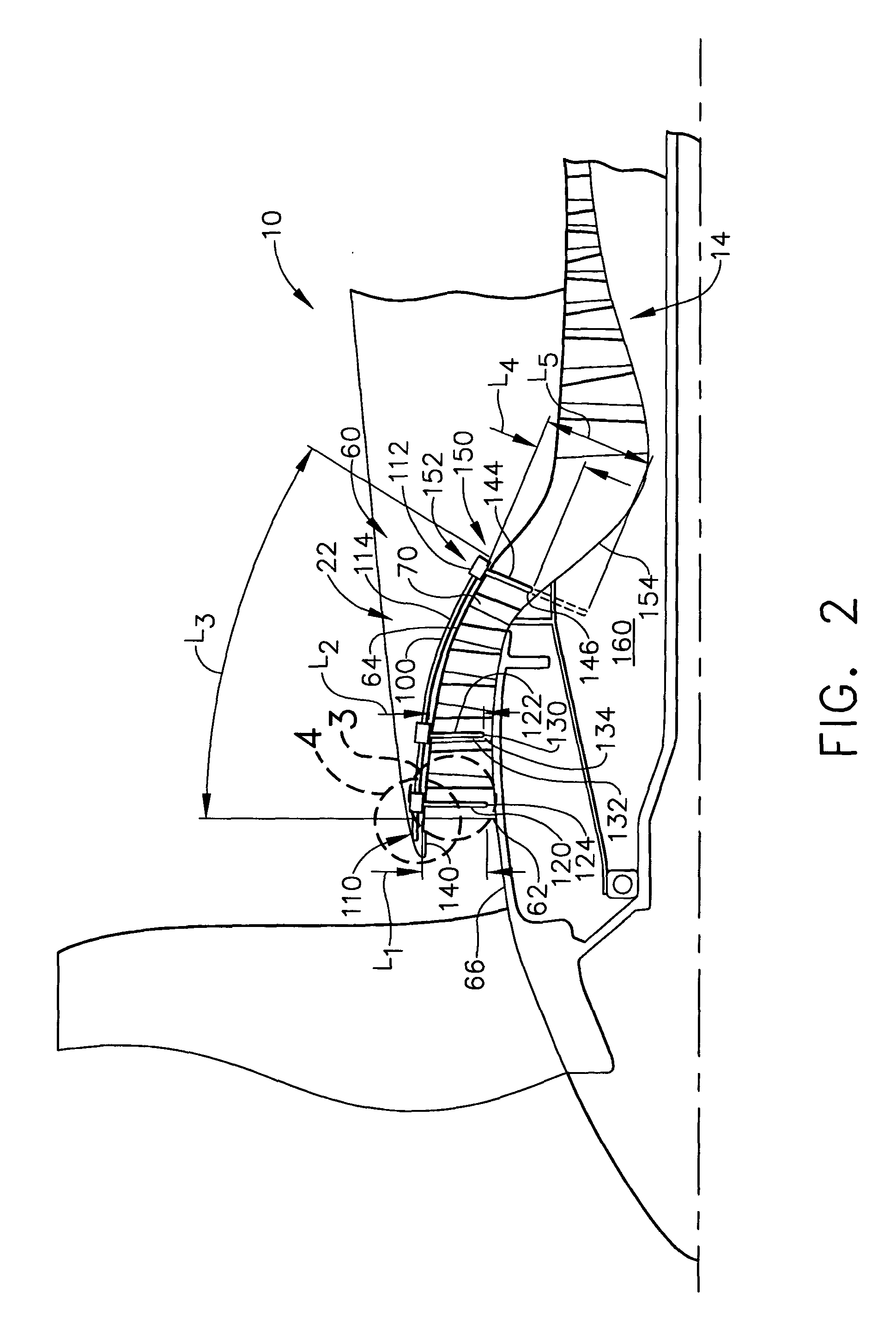

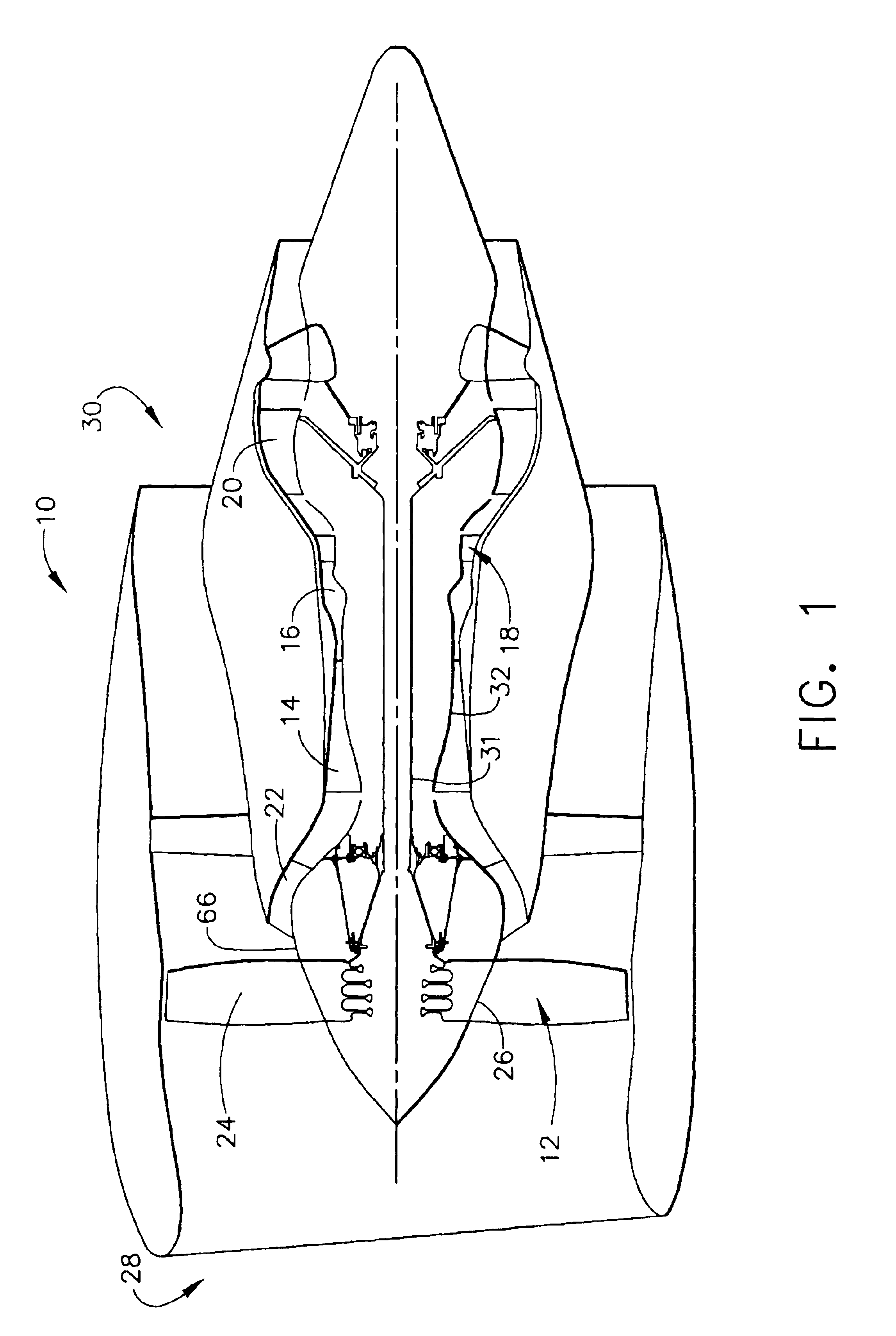

Counter-rotating gas turbine engine and method of assembling same

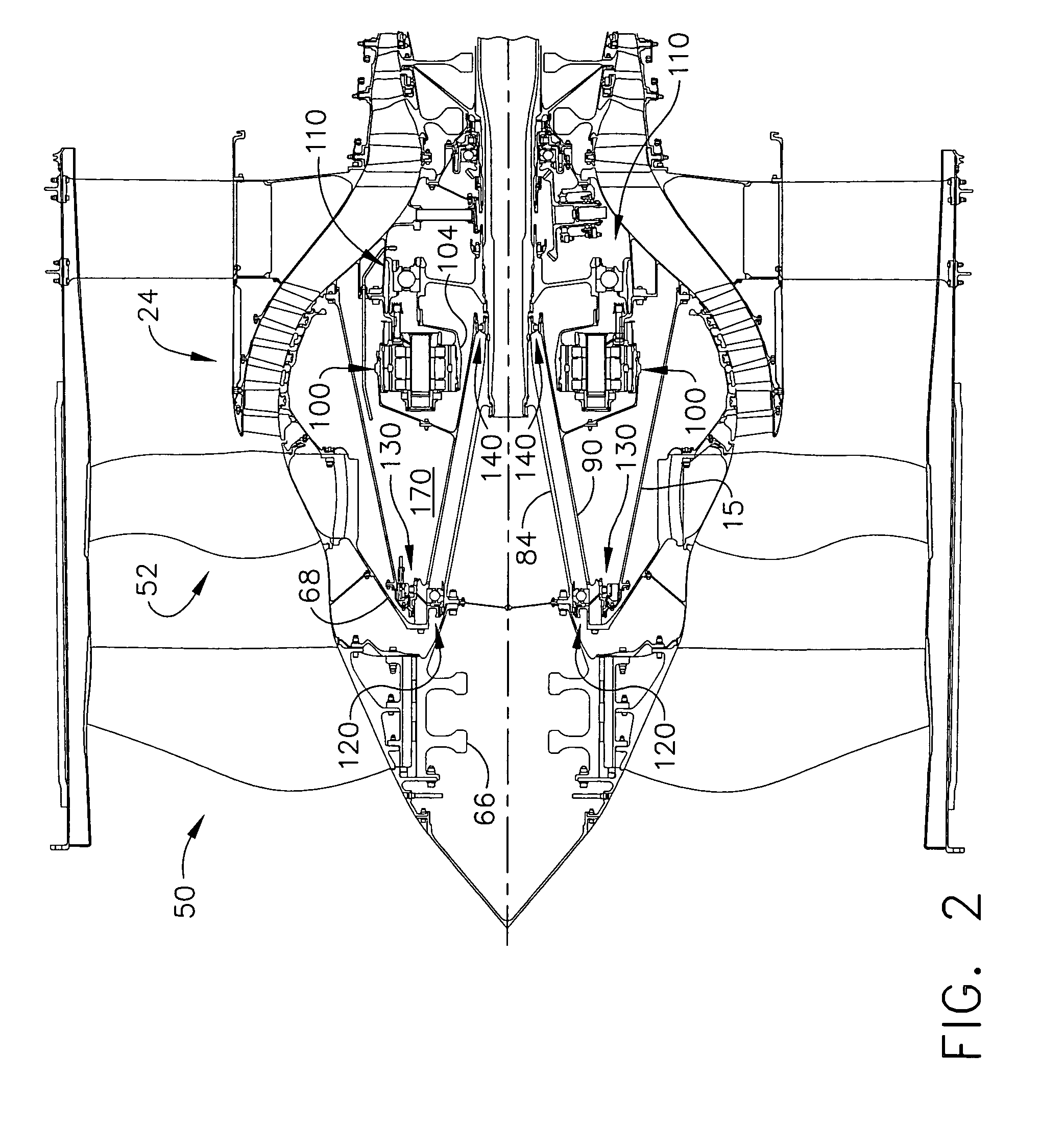

A method for assembling a gas turbine engine includes providing a first fan assembly including a plurality of rotor blades that are configured to rotate in a first rotational direction at a first rotational speed, rotatably coupling a second fan assembly axially aft of the first fan assembly, wherein the second fan assembly includes a plurality of rotor blades that are configured to rotate in a second rotational direction, and coupling a gearbox to the second fan assembly that is configured to rotate the second fan assembly at a second rotational speed that is different than the first rotational speed.

Owner:GENERAL ELECTRIC CO

Counter-rotating gas turbine engine and method of assembling same

InactiveUS20060090451A1Cosmonautic vehiclesCosmonautic propulsion system apparatusTurbineGas turbines

A method for assembling a gas turbine engine includes providing a first fan assembly including a plurality of rotor blades that are configured to rotate in a first rotational direction at a first rotational speed, rotatably coupling a second fan assembly axially aft of the first fan assembly, wherein the second fan assembly includes a plurality of rotor blades that are configured to rotate in a second rotational direction, and coupling a gearbox to the second fan assembly that is configured to rotate the second fan assembly at a second rotational speed that is different than the first rotational speed.

Owner:GENERAL ELECTRIC CO

Methods and apparatus for operating gas turbine engines

ActiveUS20050050877A1Facilitate preventing ice accumulationCosmonautic vehiclesPump componentsTurbineGas turbines

Owner:GENERAL ELECTRIC CO

Split shroud exhaust nozzle

A variable geometry convergent-divergent nozzle for a gas turbine engine includes a centerbody extending rearward along a longitudinal axis of the engine which has a throat section of increased diameter. An inner shroud surrounds the centerbody and cooperates with the centerbody to define the throat of the nozzle. An outer shroud surrounds the inner shroud and cooperates with the centerbody to define the exit area of the nozzle. Both shrouds are independently translatable to provide independent control of the nozzle throat area and the nozzle expansion ratio.

Owner:GENERAL ELECTRIC CO

Methods and apparatus for operating gas turbine engines

A method facilitates assembling a turbine engine to facilitate preventing ice accumulation on the turbine engine during engine operation. The method comprises coupling at least one heat pipe to the engine such that a first end of the at least one heat pipe is coupled in thermal communication with a heat source, and coupling a second end of the at least one heat pipe in thermal communication with an outer surface of an engine component that is upstream from the heat source.

Owner:GENERAL ELECTRIC CO

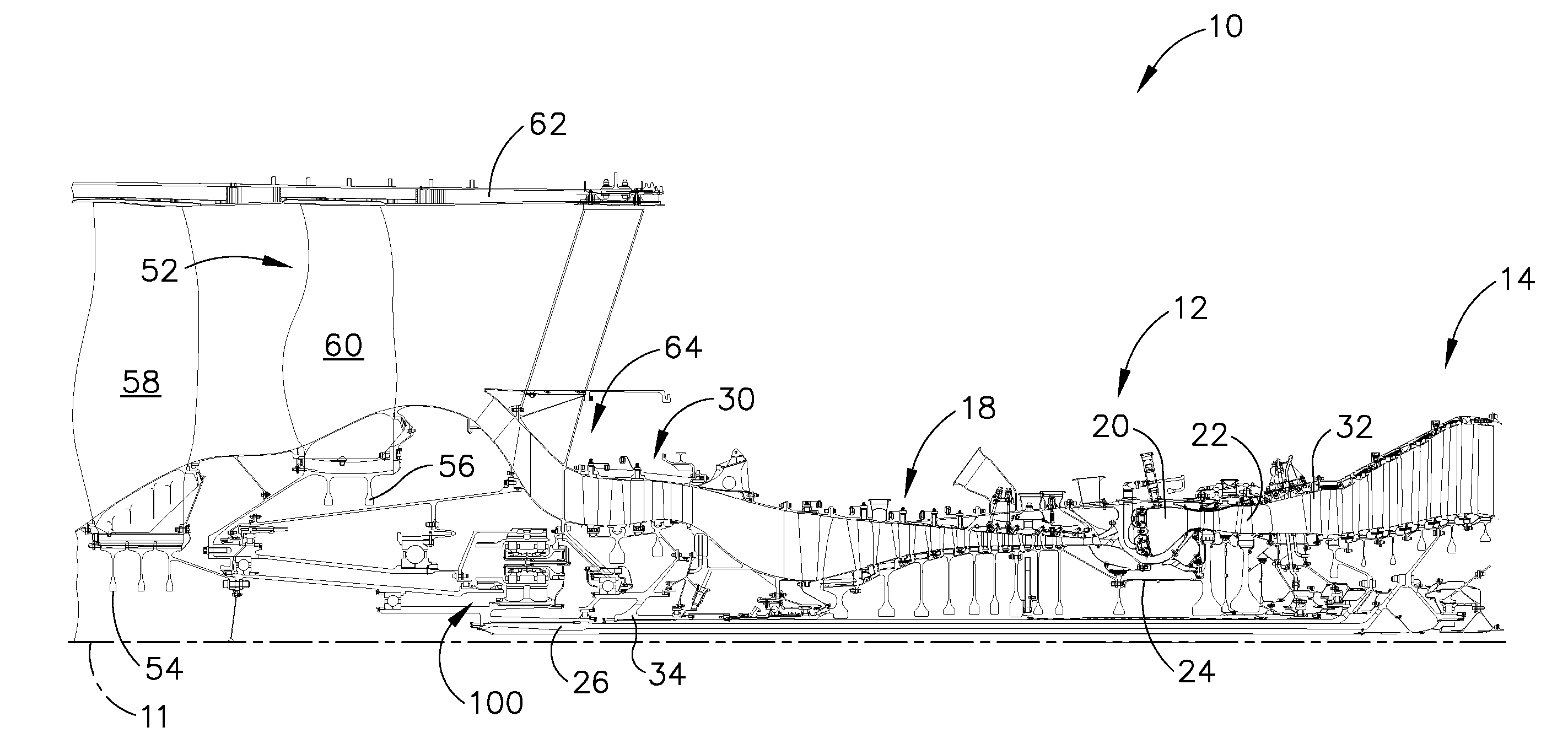

Turbofan engine assembly and method of assembling same

A turbofan engine assembly includes a core gas turbine engine including a high-pressure compressor, a combustor, and a high-pressure turbine, a booster compressor coupled upstream from the core gas turbine engine, an intermediate-pressure turbine coupled to the booster compressor, the intermediate-pressure turbine disposed downstream from the core gas turbine engine, a counter-rotating fan assembly disposed upstream from the booster compressor, the counter-rotating fan assembly comprising a first fan configured to rotate in a first direction and a second fan configured to rotate in an opposite second direction, and a low-pressure turbine disposed downstream from the intermediate-pressure turbine, the low-pressure turbine configured to drive the counter-rotating fan assembly. A method of assembling the above turbofan engine assembly is also described herein.

Owner:GENERAL ELECTRIC CO

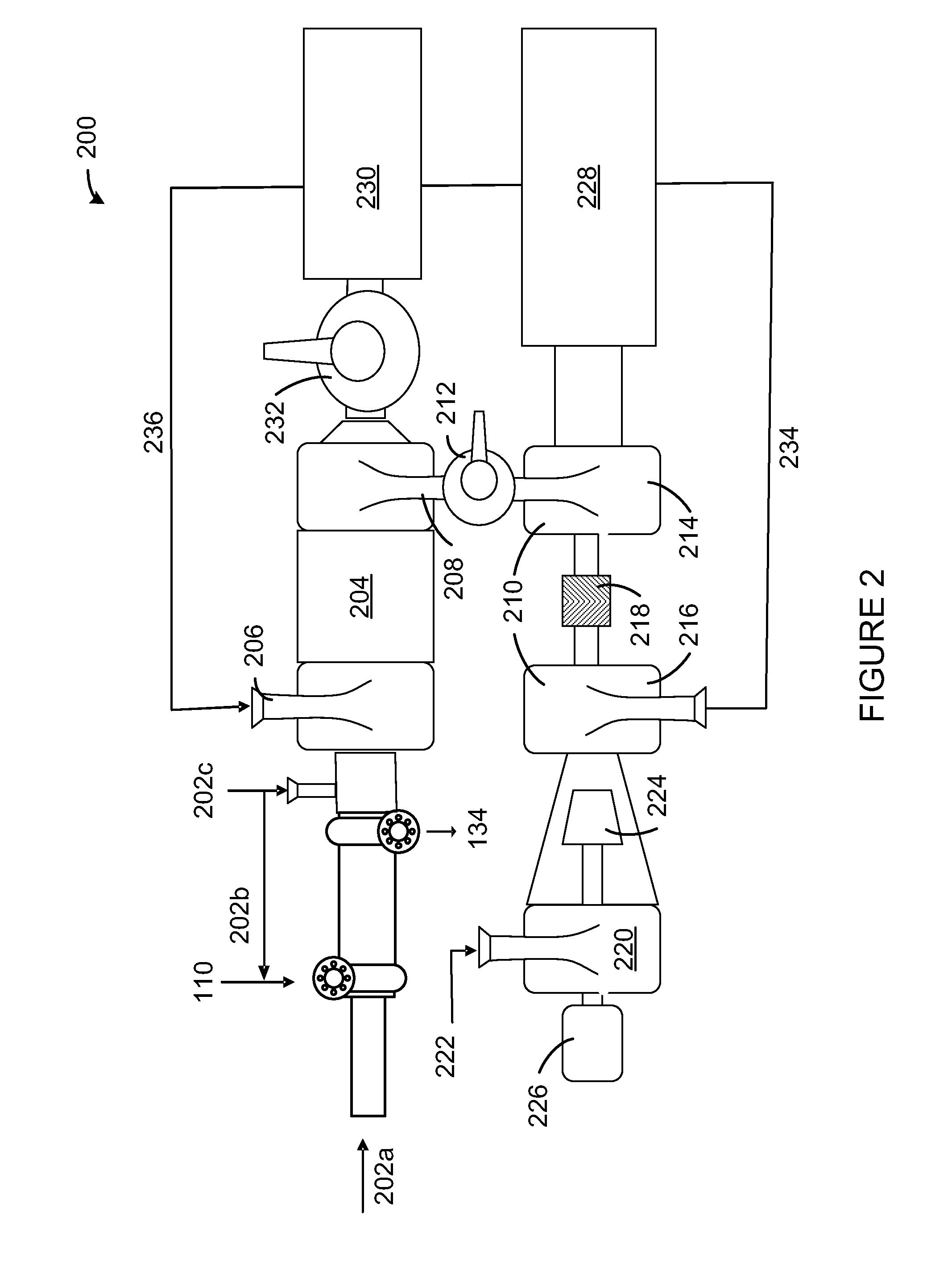

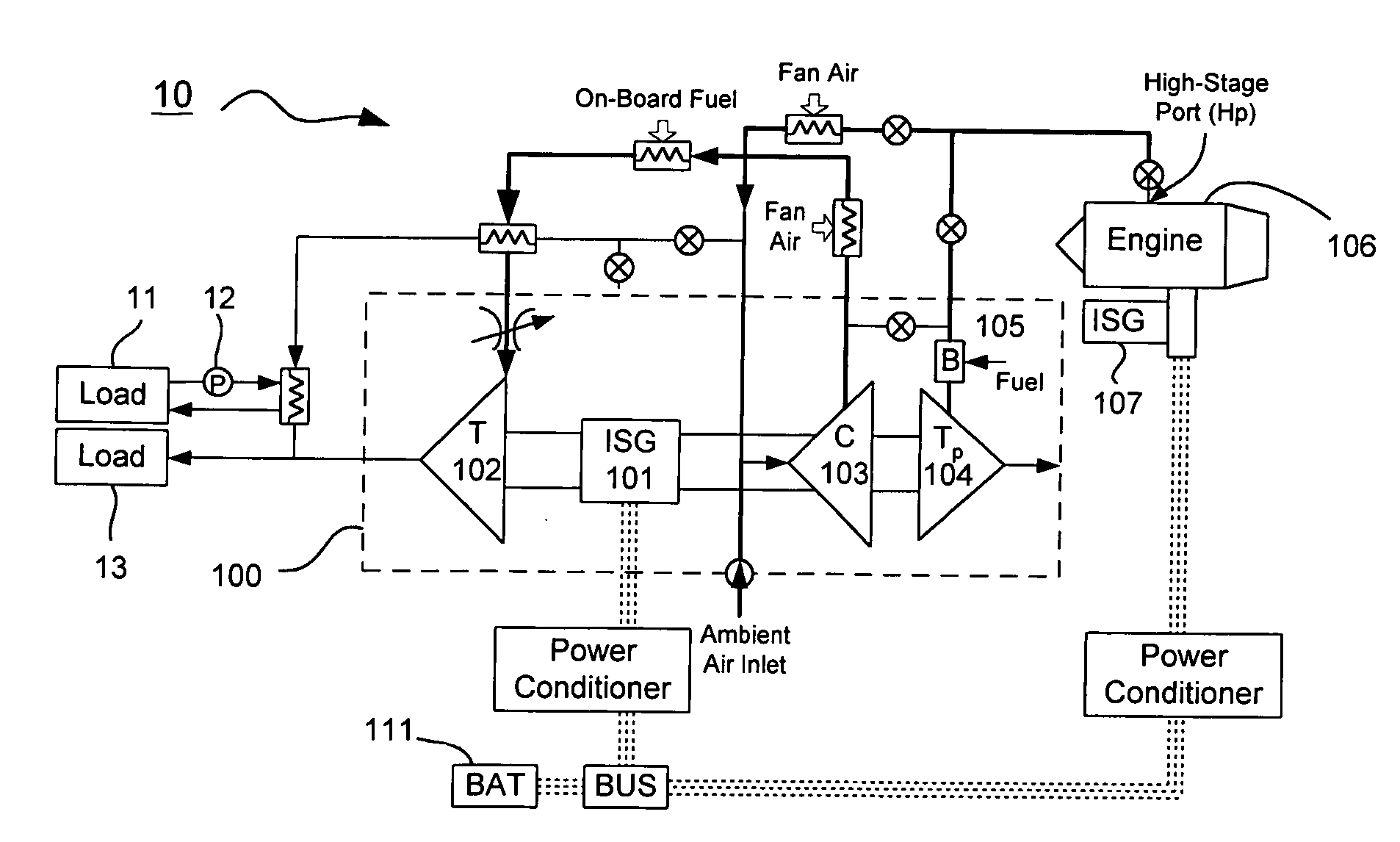

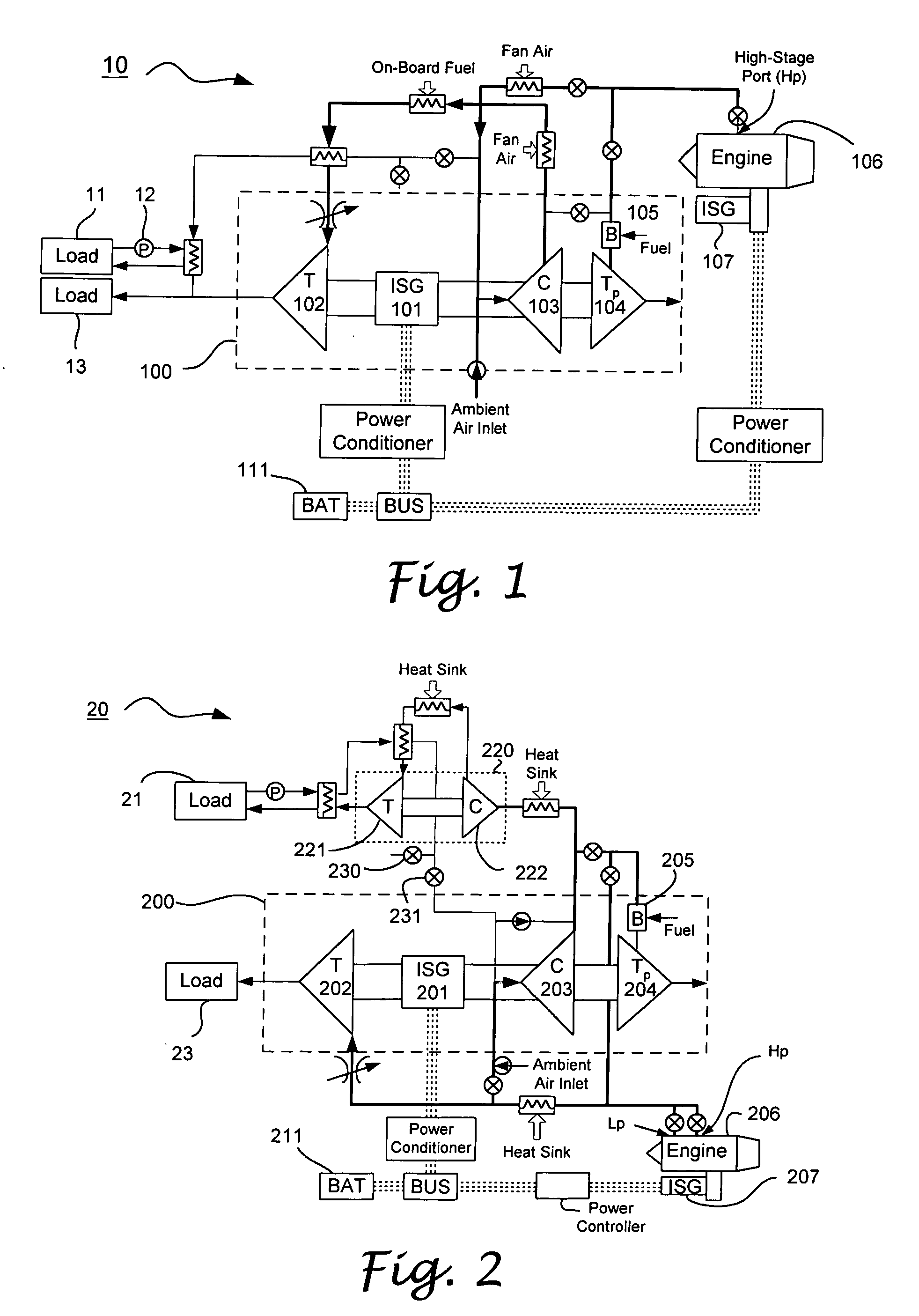

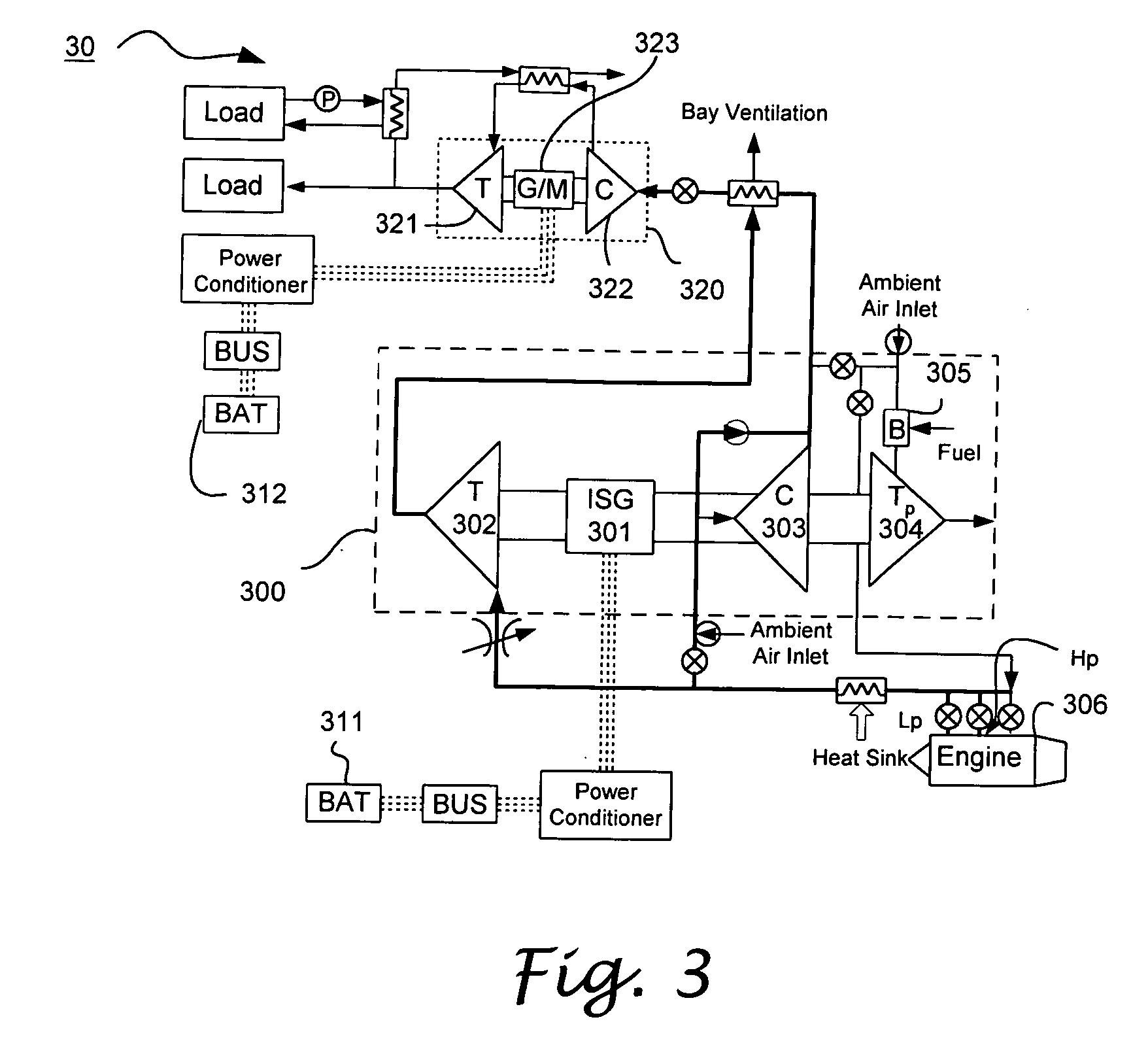

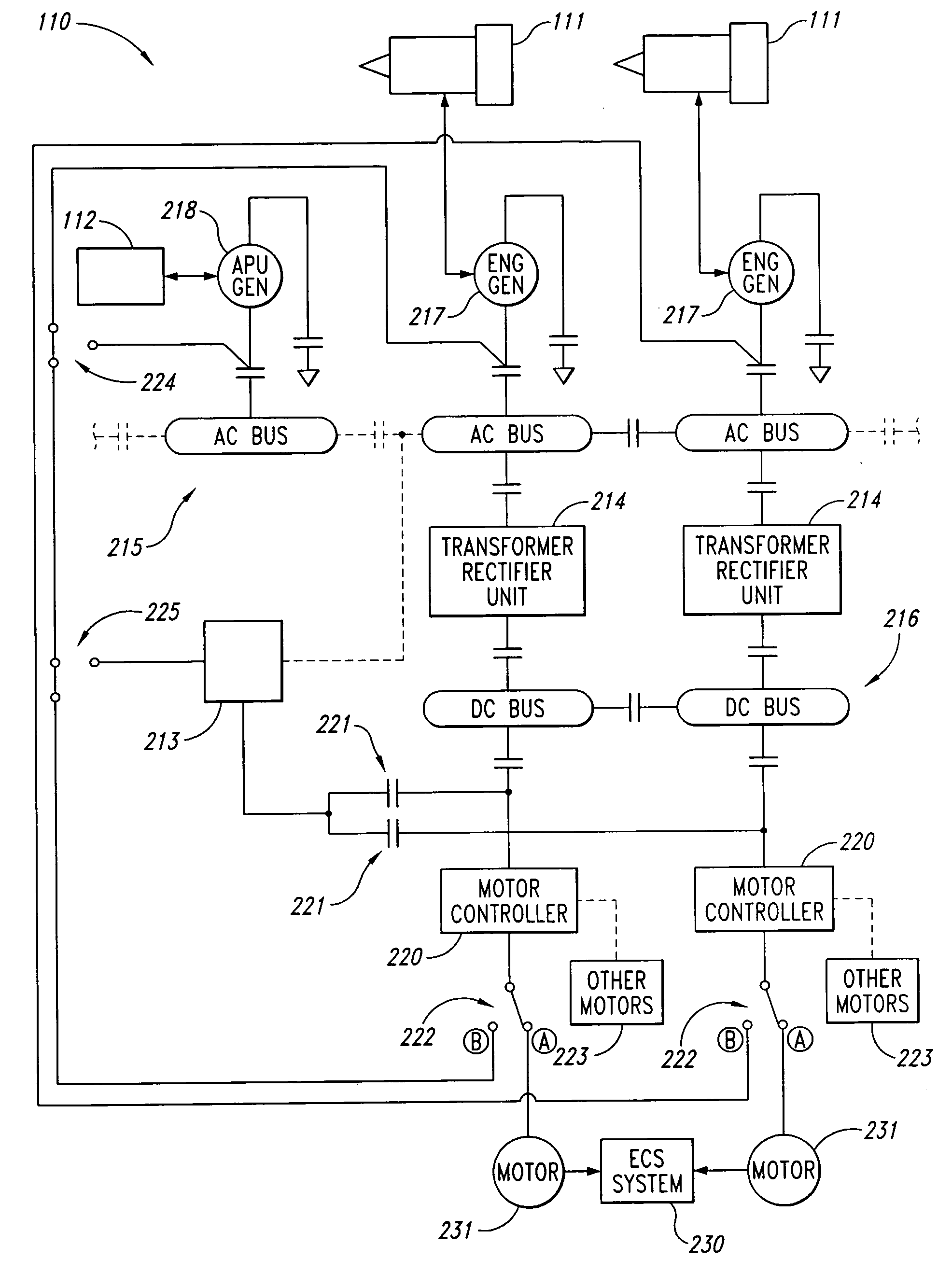

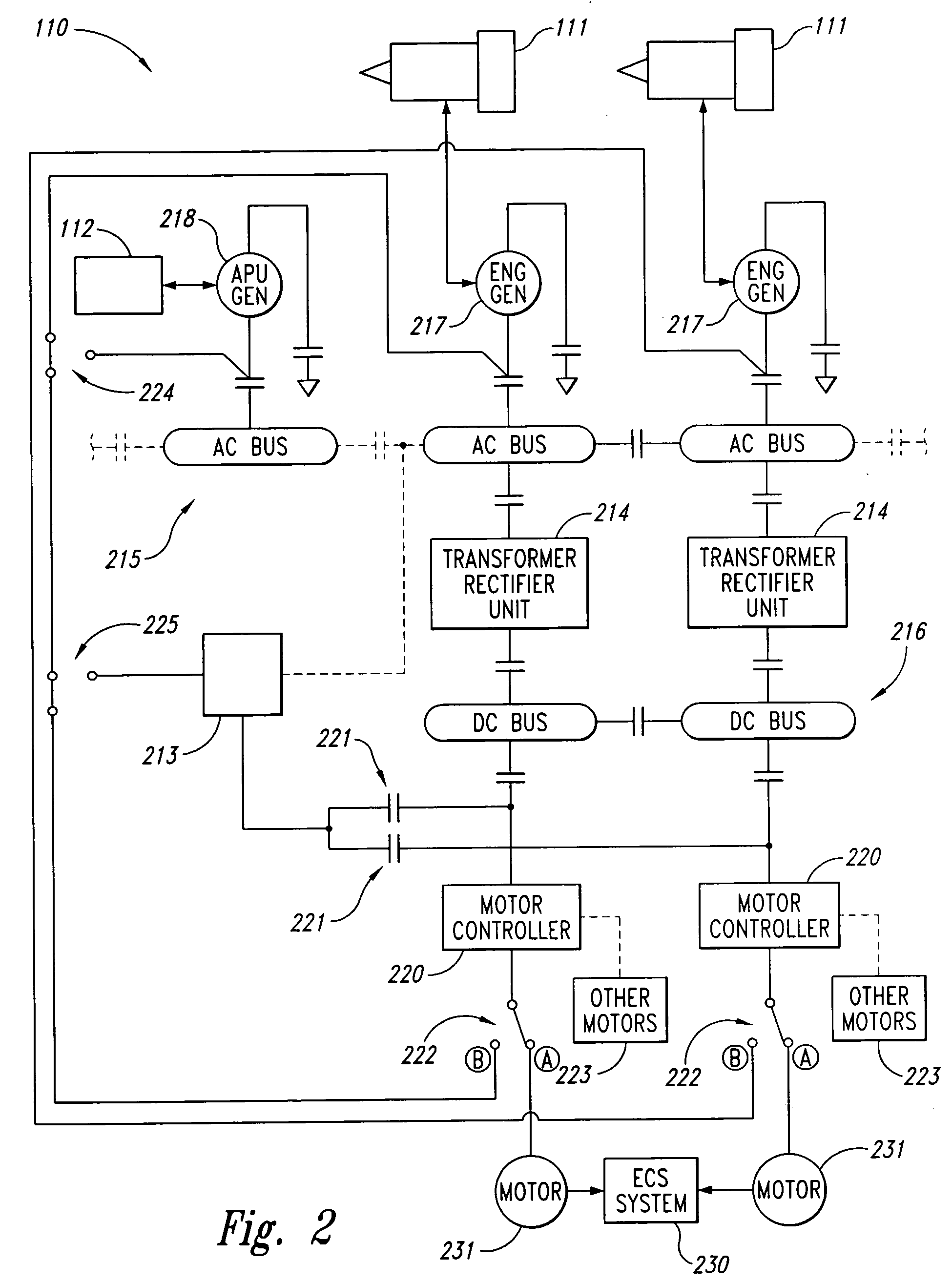

Flexible power and thermal architectures using a common machine

ActiveUS20070266695A1Reduce riskImprove cooling effectCosmonautic vehiclesDomestic cooling apparatusStarter generatorElectricity

A power and cooling management system configured to flexibly couple various adaptive modules to an integrated power and cooling unit to suit any aircraft platform is provided. The integrated power and cooling unit has a compressor, a power turbine, a cooling turbine and an integral starter generator mounted to the shaft of the power and cooling turbine. The integrated power and cooling unit may be pneumatically and / or pneumatically coupled to an adaptive module that comprises an additional compressor and an additional turbine or electrically coupled to a fuel cell which provides the main power after entering the full operation mode. When the engine includes an integral starter generator mounted thereto, the integral starter generator of the integrated power and cooling unit is operative to receive electric power from the engine mounted generator. Alternatively, a motor / generator may be mounted to the shaft of the additional turbine of the adaptive module.

Owner:NORTHROP GRUMMAN SYST CORP

Gas turbine engine assembly and methods of assembling same

InactiveUS7490460B2Cosmonautic vehiclesCosmonautic propulsion system apparatusEngineeringGas turbines

Owner:GENERAL ELECTRIC CO

Method and apparatus for noise attenuation for gas turbine engines using at least one synthetic jet actuator for injecting air

ActiveUS7055329B2Facilitate attenuating jet noiseEasy to operatePower plant exhaust arrangementsCosmonautic vehiclesActuatorNoise suppression

A method enables a gas turbine engine to be operated. The method comprises channeling exhaust gases from a core engine through an exhaust assembly and past at least one flow boundary surface, and selectively operating a noise suppression system extending from the at least one flow boundary surface to facilitate attenuating noise generated during engine operation.

Owner:GENERAL ELECTRIC CO

Gas turbine engine assembly and methods of assembling same

A method for assembling a gas turbine engine includes coupling a low-pressure turbine to a core turbine engine, coupling a counter-rotating fan assembly including a forward fan assembly and an axially aft fan assembly to the low-pressure turbine such that the forward fan assembly rotates in a first direction and the aft fan assembly rotates in an opposite second direction, and coupling a booster compressor to the low-pressure turbine such that the booster compressor rotates in the first direction.

Owner:GENERAL ELECTRIC CO

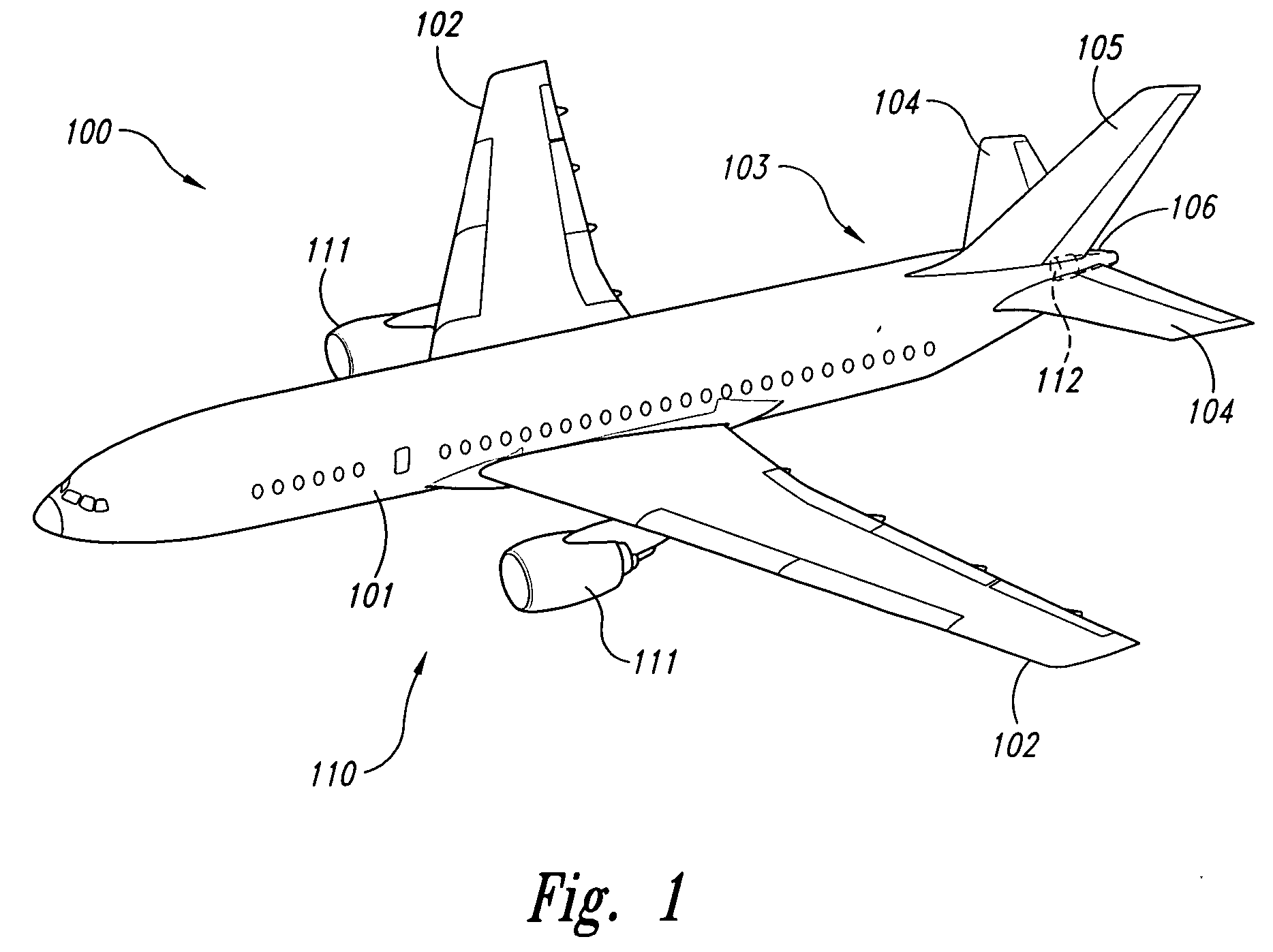

Systems and methods for starting aircraft engines

Methods and systems for starting aircraft turbofan engines are disclosed. A system in accordance with one embodiment includes an electrically-powered starter motor coupled to a turbofan engine to provide power to the turbofan engine during an engine start procedure. The system can further include an on-board, deployable, ram air driven turbine coupled to an electrical generator, which is in turn coupled to the starter motor to provide electrical power to the starter motor. In other embodiments, the ram air driven turbine can be replaced with a fuel cell or a battery. In still further embodiments, a single controller can control operation of both the engine starter and other motors of the aircraft.

Owner:THE BOEING CO

Jet nozzle mixer

InactiveUS6854260B2Reduce noiseAvoid problemsAircraft navigation controlCosmonautic vehiclesJet engineThrust efficiency

An external jet nozzle mixer (20) includes identically formed lobes (48), equal in number those of the internal mixer (42). External mixer (20) works with internal mixer (42), further to mix the engine internal bypass flow with the internal jet engine core flow, to level the disparate exhaust flow velocities, to reduce the peak velocities from the jet engine core and increase the lower bypass velocities of the engine internal bypass flow, and thereby to reduce noise. The internal lobe contours act as lifting flutes, causing mixing of the primary hot and cold flows before exiting the nozzle. The external lobe contours act as venturi chutes, accelerating the cooler ambient air secondary flow. The lobes thus act collectively as an injector to force the cooler ambient secondary flow into the previously mixed primary flow as it exits the nozzle. Also obtained is an increased thrust efficiency and a consequently decreased fuel consumption and engine emissions.

Owner:COMTRAN LTD

Turbofan engine assembly and method of assembling same

A turbofan engine assembly includes a core gas turbine engine including a high-pressure compressor, a combustor, and a high-pressure turbine, a booster compressor coupled upstream from the core gas turbine engine, an intermediate-pressure turbine coupled to the booster compressor, the intermediate-pressure turbine disposed downstream from the core gas turbine engine, a counter-rotating fan assembly disposed upstream from the booster compressor, the counter-rotating fan assembly comprising a first fan configured to rotate in a first direction and a second fan configured to rotate in an opposite second direction, and an intermediate-pressure turbine disposed downstream from the core gas turbine engine, wherein the intermediate-pressure turbine drives the booster compressor and the second fan assembly. A method of assembling the above turbofan engine assembly is also described herein.

Owner:GENERAL ELECTRIC CO

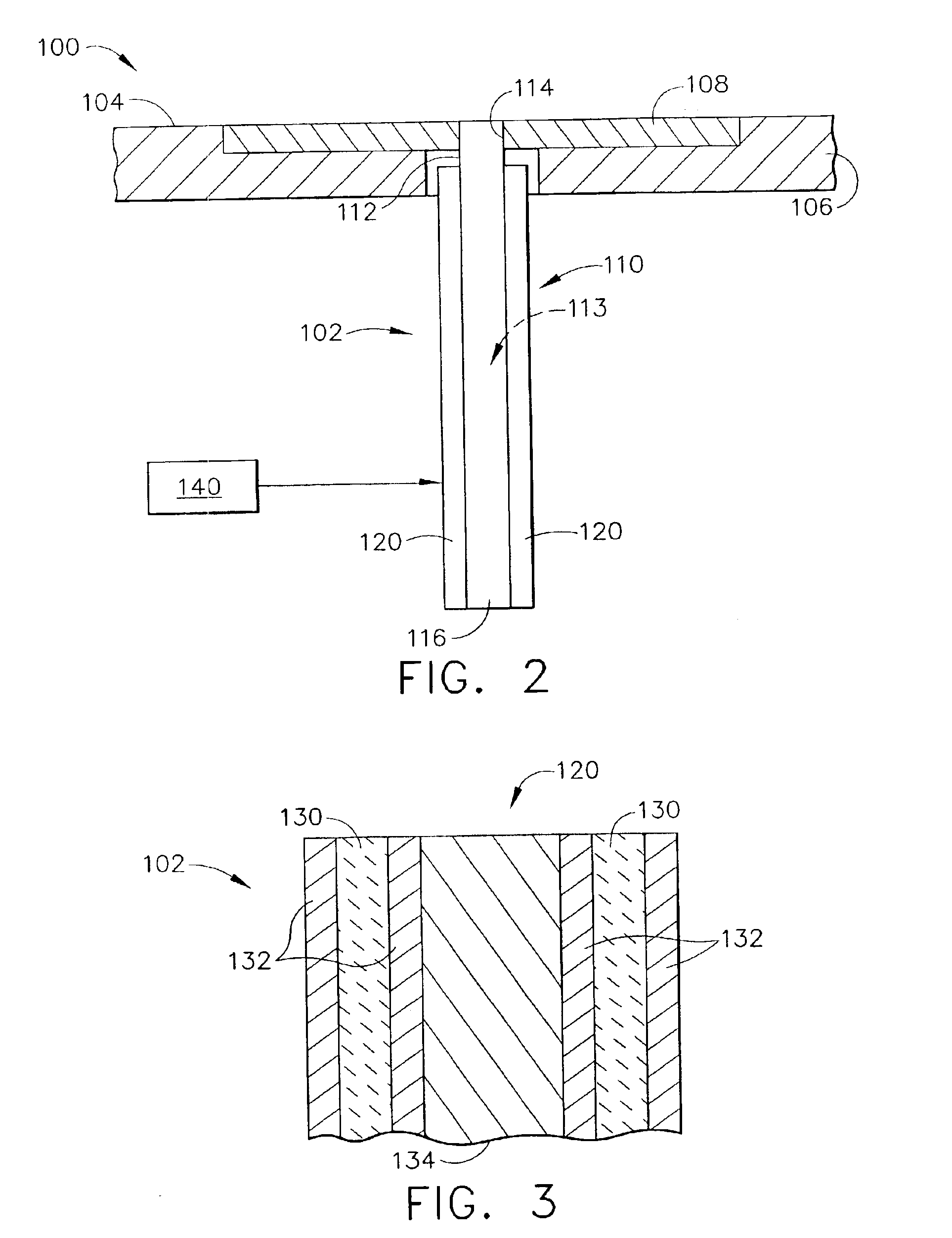

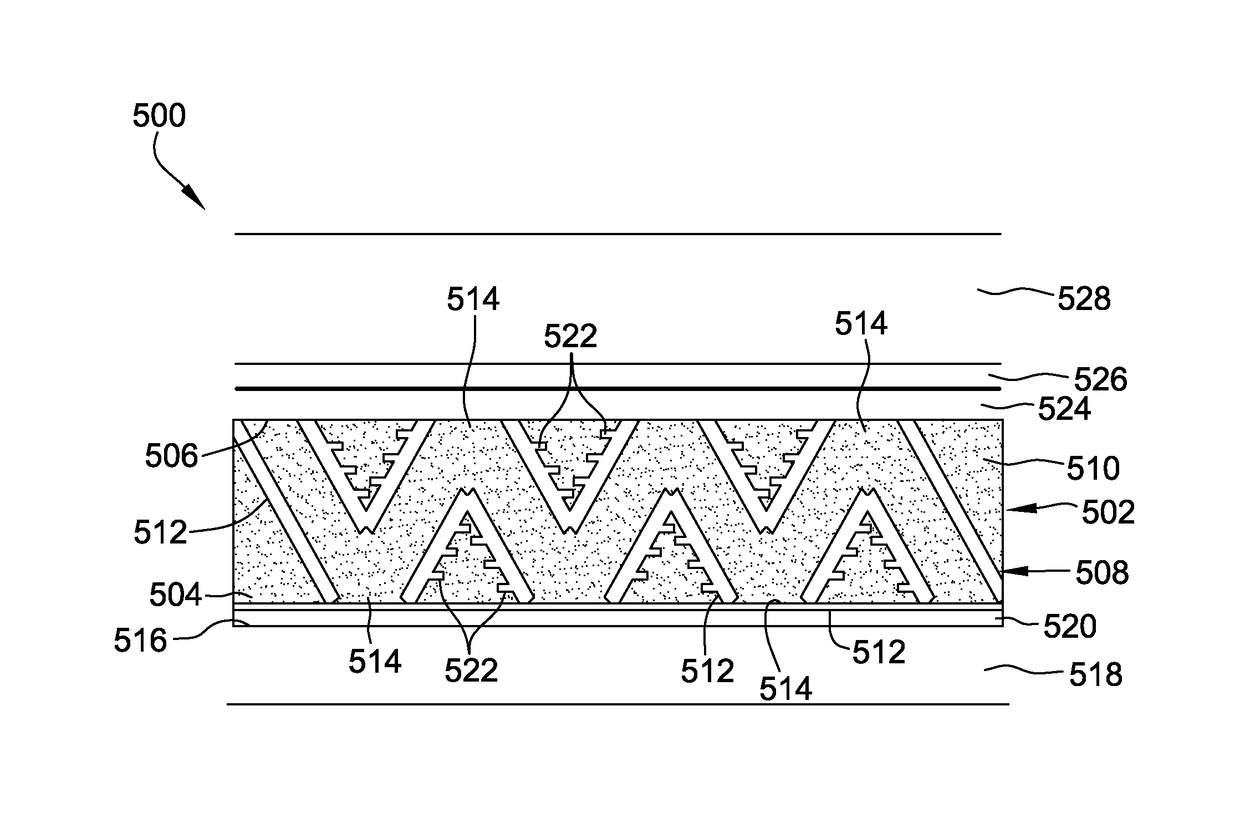

Vessel insulation assembly

A vessel includes a vessel wall and an insulation assembly coupled to the vessel wall. The insulation assembly includes a stochastic foam material and a microtruss structure encased within the foam material. The microtruss structure includes a plurality of truss members interconnected at a plurality of nodes. Each truss member is in contact with the foam material such that the microtruss structure provides a structural core for the foam material.

Owner:THE BOEING CO

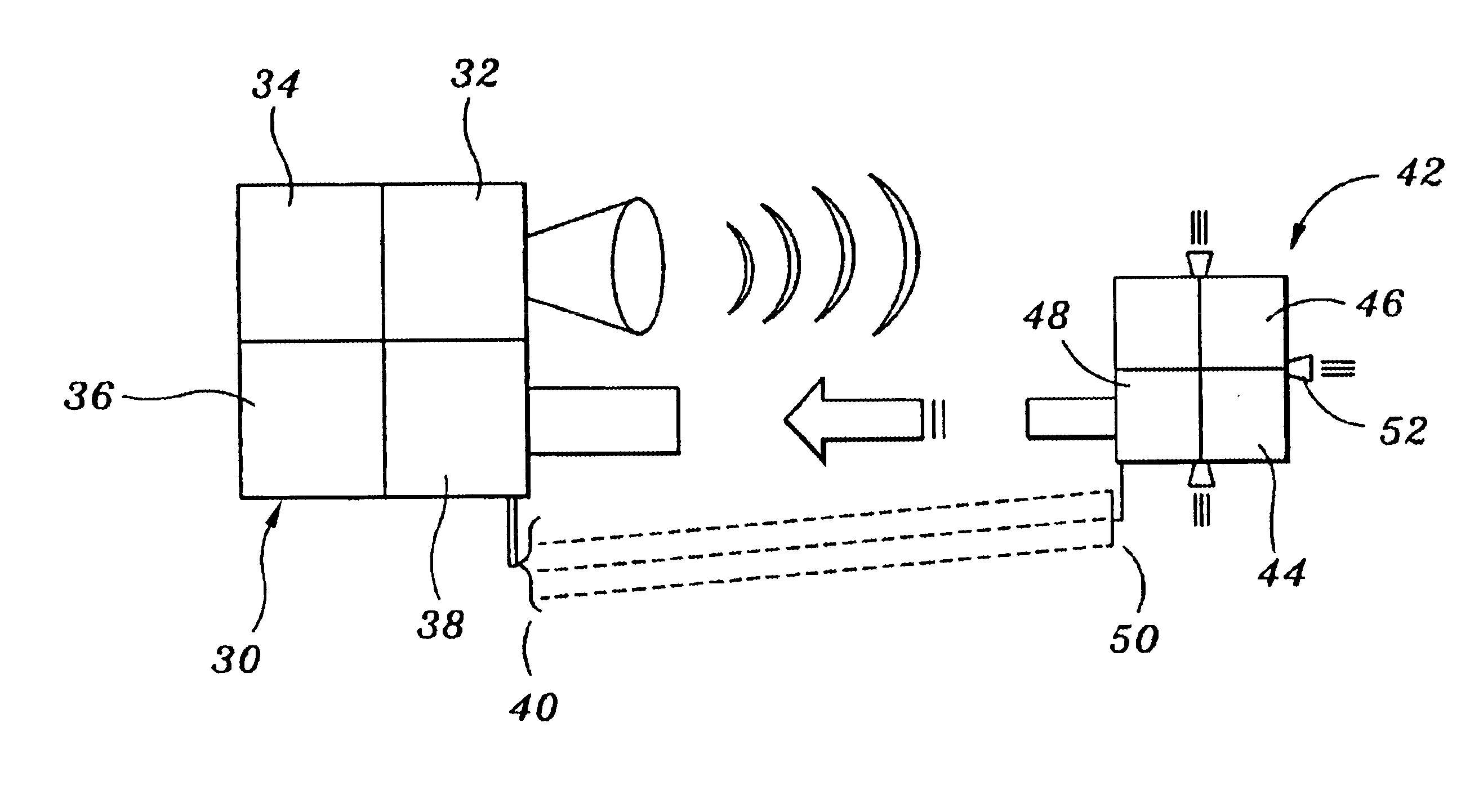

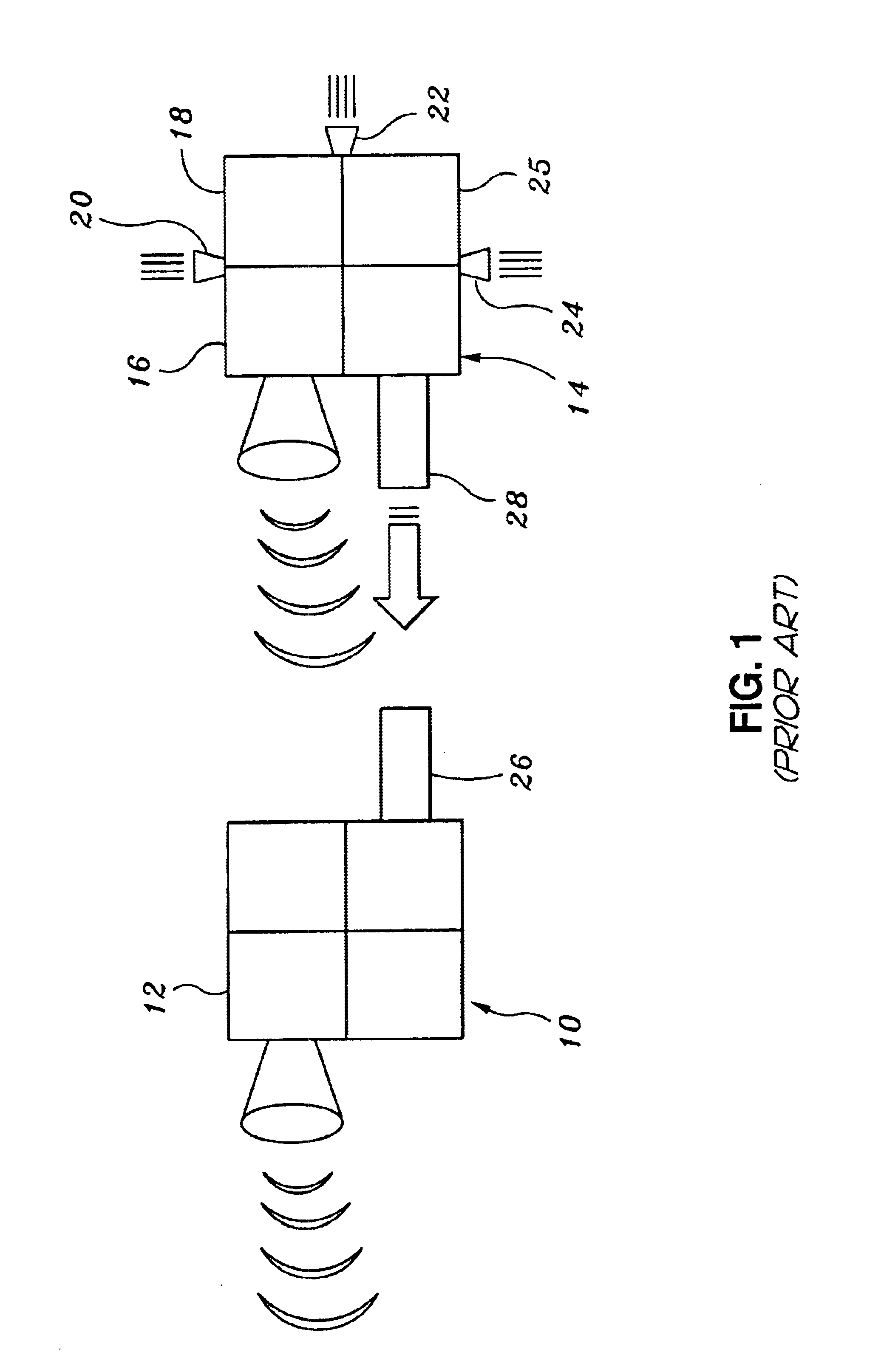

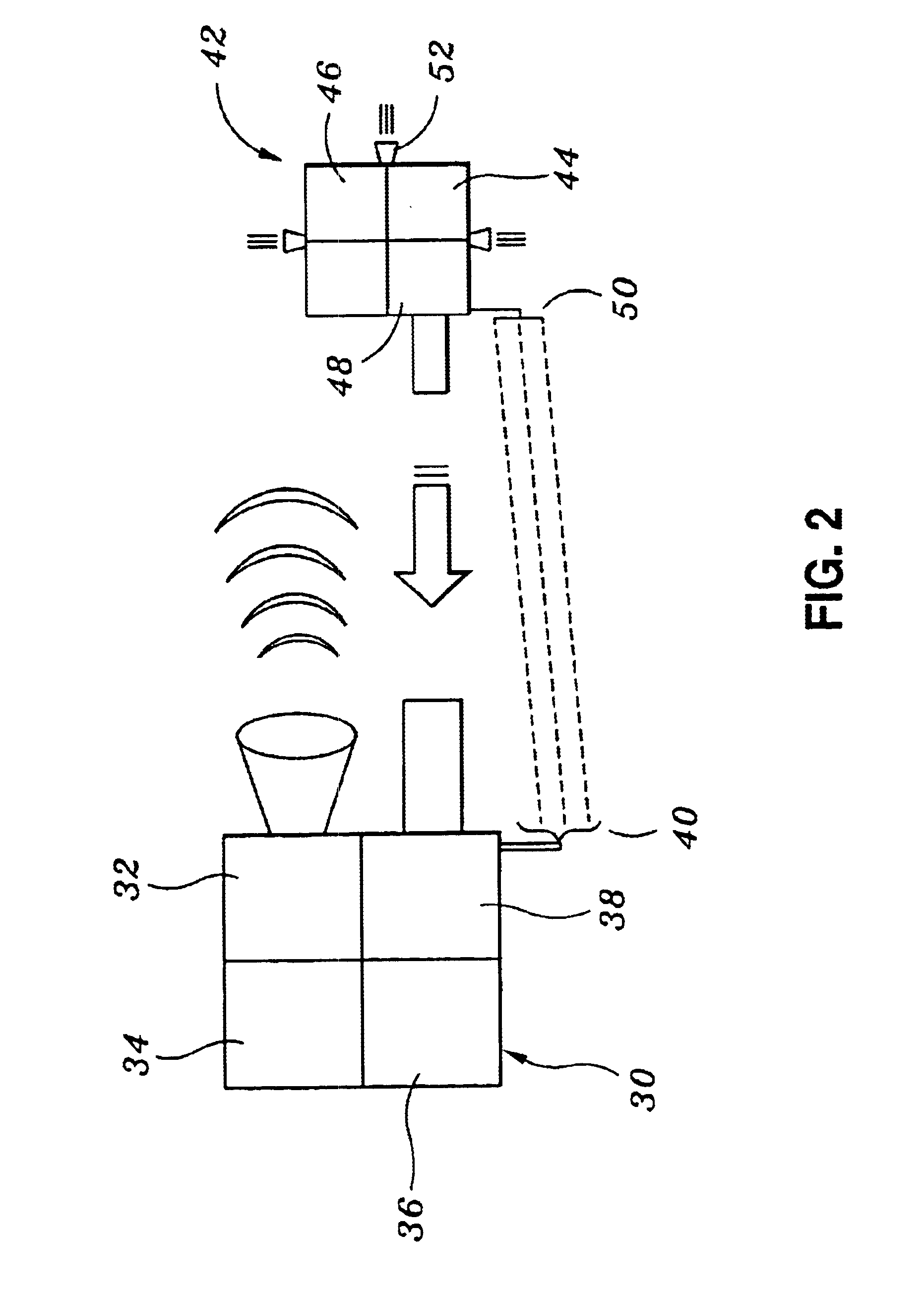

Micro-satellite and satellite formation for inverse and distributed proximity operations

A method and apparatus for conducting proximity operations is disclosed. The method called inverser proximity operations includes maneuvering an active vehicle into general proximity to a target vehicle, transmitting from the target vehicle to the active vehicle data representing relative position and velocity between the target vehicle and the active vehicle, and maneuvering the active vehicle in accordance with the data to effect a desired proximity operation. Another method called distributed proximity operations includes maneuvering a carrier vehicle into general proximity to a target vehicle, releasing one or more active vehicles from the carrier vehicle, transmitting from the carrier vehicle to the active vehicle(s) data representing relative position and velocity between the target vehicle and the active vehicle, and maneuvering the active vehicle(s) in accordance with the data to effect a desired proximity operation. The proximity operations are similarly suitable for aeronautical systems, such as when using an active aircraft to re-fuel a target aircraft, such as a drone. Whether for space, air, or other environments, the proximity operations described can be used for re-fueling, repairing, and replacing components and / or systems.

Owner:LOCKHEED MARTIN CORP

Bypass duct fluid cooler

ActiveUS20060042225A1Light weightCosmonautic vehiclesCosmonautic propulsion system apparatusTurbineChiller

A method and apparatus for cooling a fluid in a bypass gas turbine engine involves directing the fluid to the bypass duct of the engine to allow for heat exchange from the fluid to bypass air passing through the bypass air duct.

Owner:PRATT & WHITNEY CANADA CORP

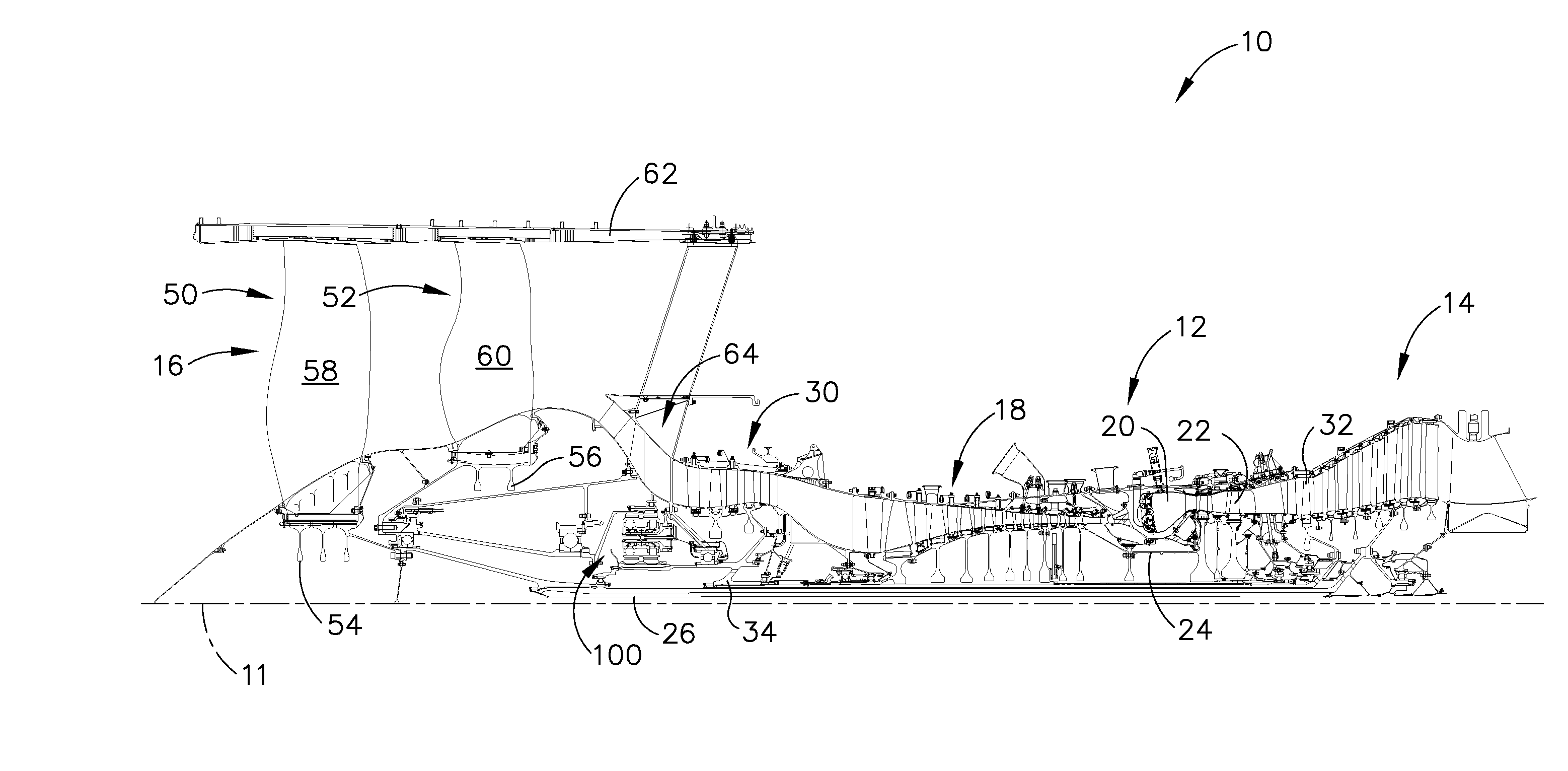

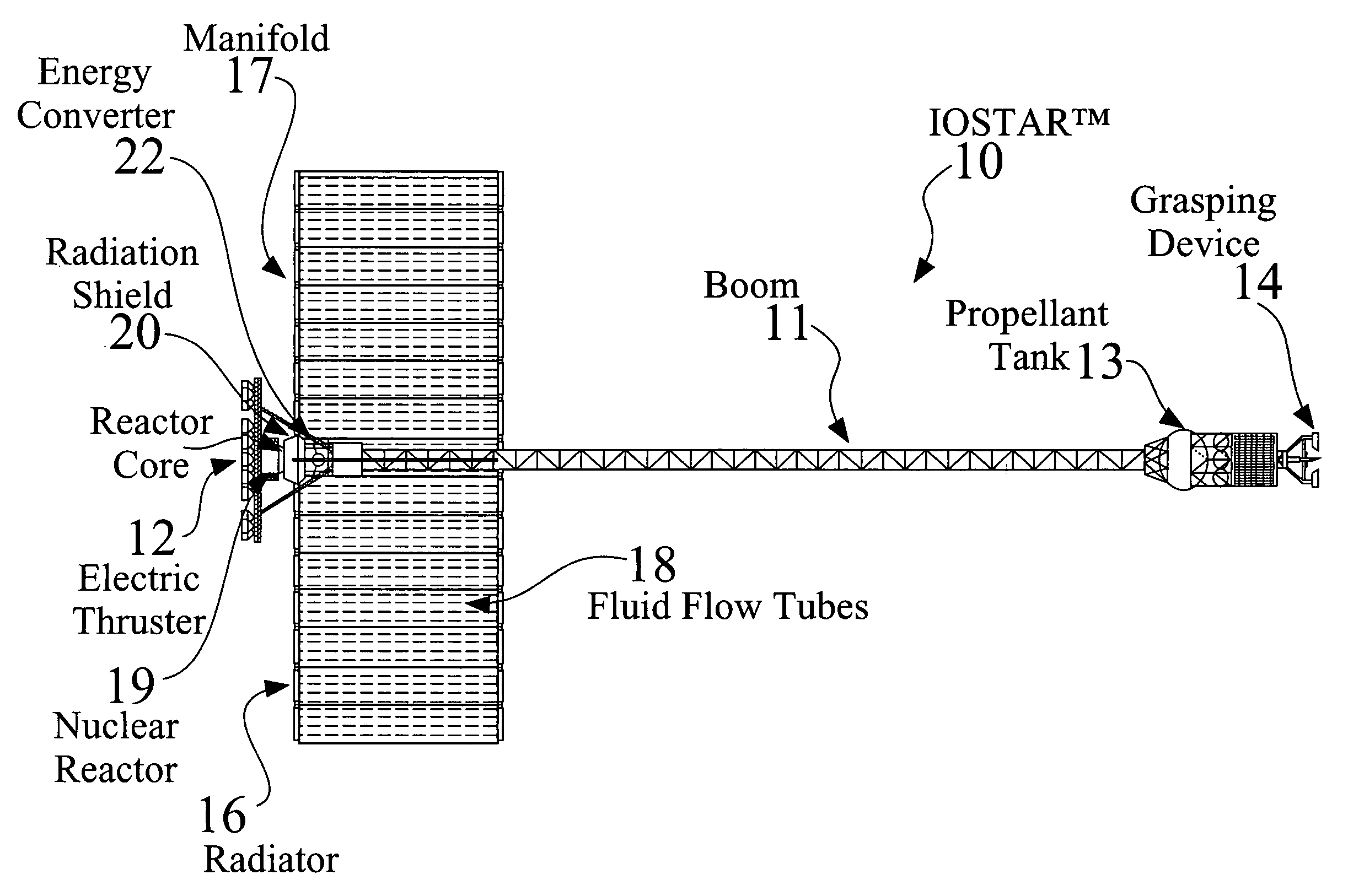

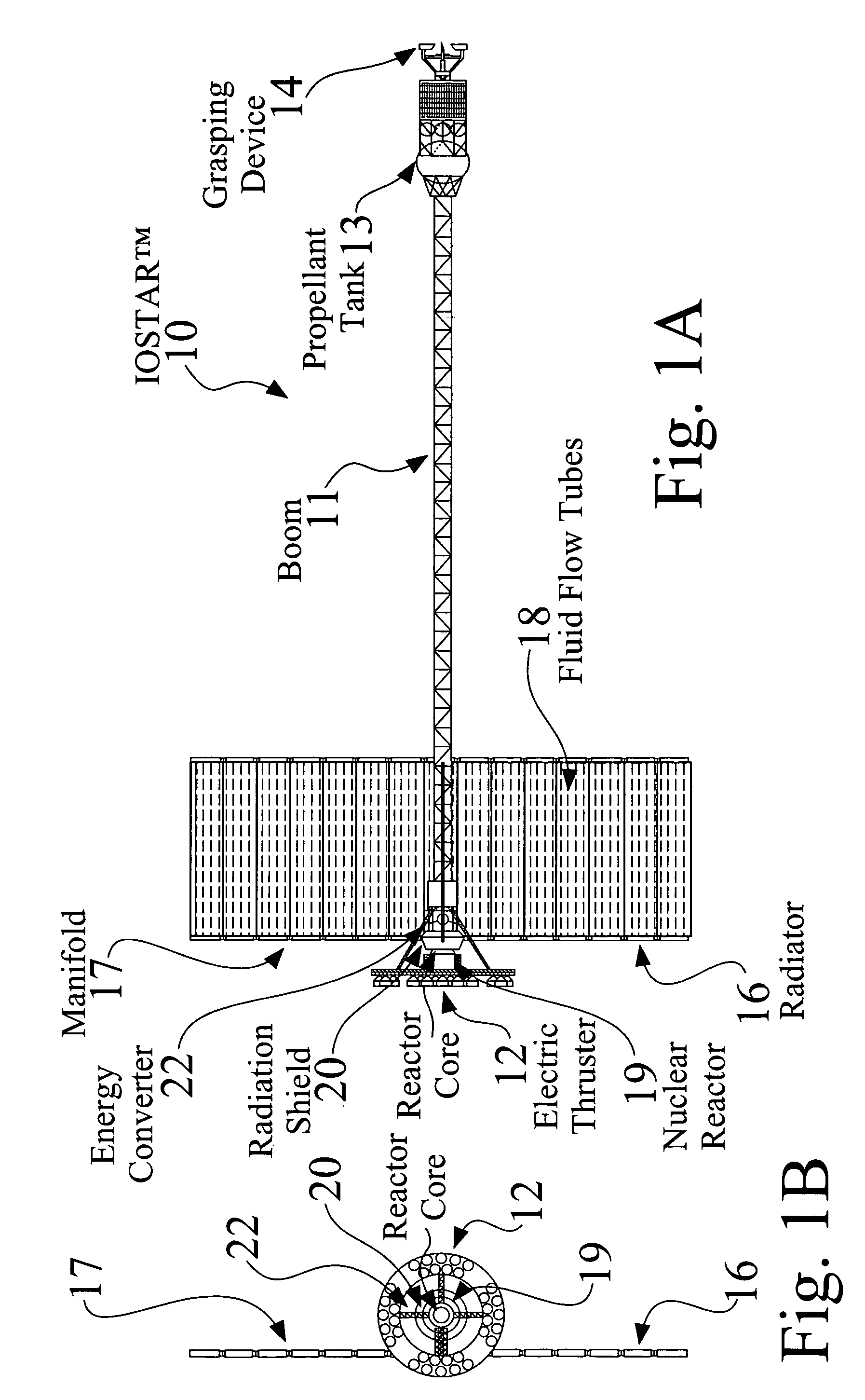

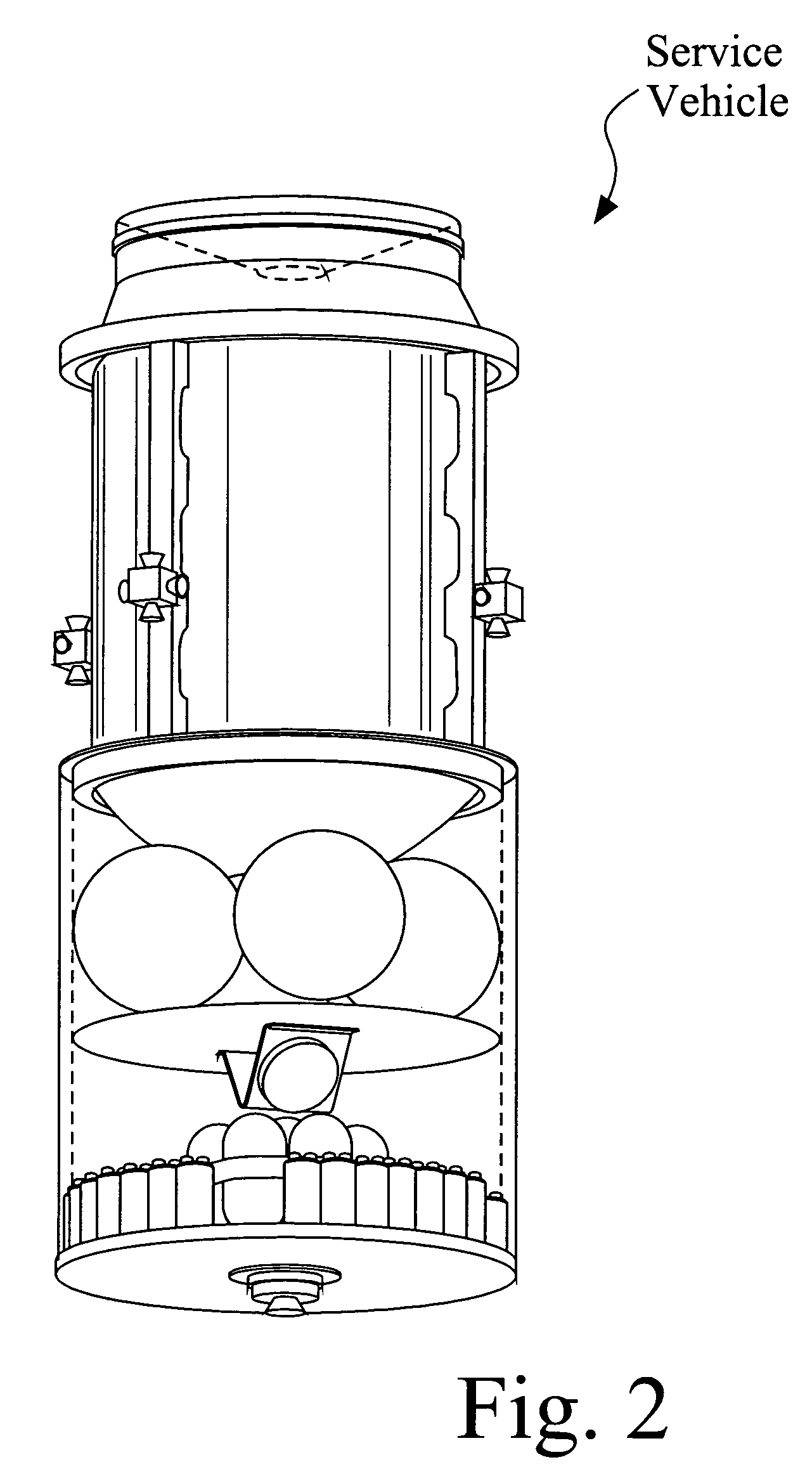

In orbit space transportation and recovery system

InactiveUS7216833B2Low costCosmonautic environmental control arrangementLaunch systemsNuclear reactorPropellant tank

An In Orbit Transportation & Recovery System (IOSTAR™) (10). One preferred embodiment of the present invention comprises a space tug powered by a nuclear reactor (19). The IOSTAR™ includes a collapsible boom (11) connected at one end to a propellant tank (13) which stores fuel for an electric propulsion system (12). This end of the boom ( 11) is equipped with docking hardware (14) that is able to grasp and hold a satellite (15) and as a means to refill the tank (13). Radiator panels (16) mounted on the boom (11) dissipate heat from the reactor (19). A radiation shield (20) is situated next to the reactor (19) to protect the satellite payload (15) at the far end of the boom (11). The IOSTAR™ (10) will be capable of accomplishing rendezvous and docking maneuvers which will enable it to move spacecraft between a low Earth parking orbit and positions in higher orbits or to other locations in our Solar System.

Owner:IOSTAR CORP

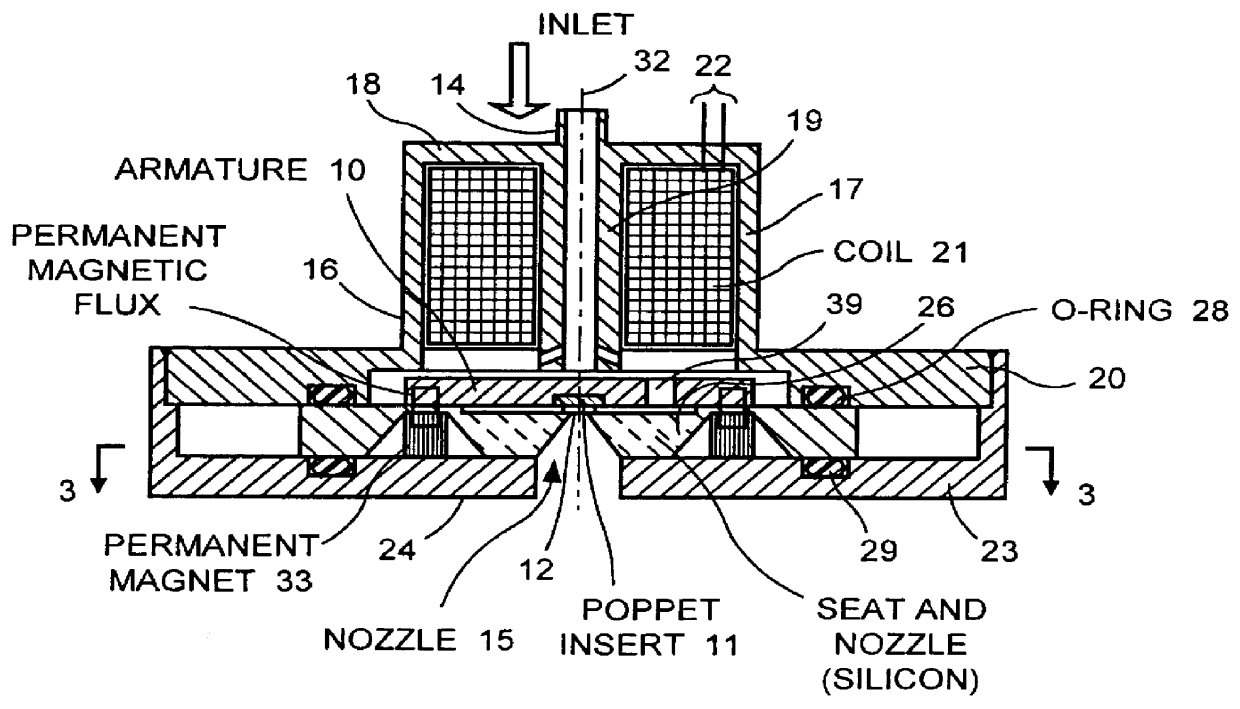

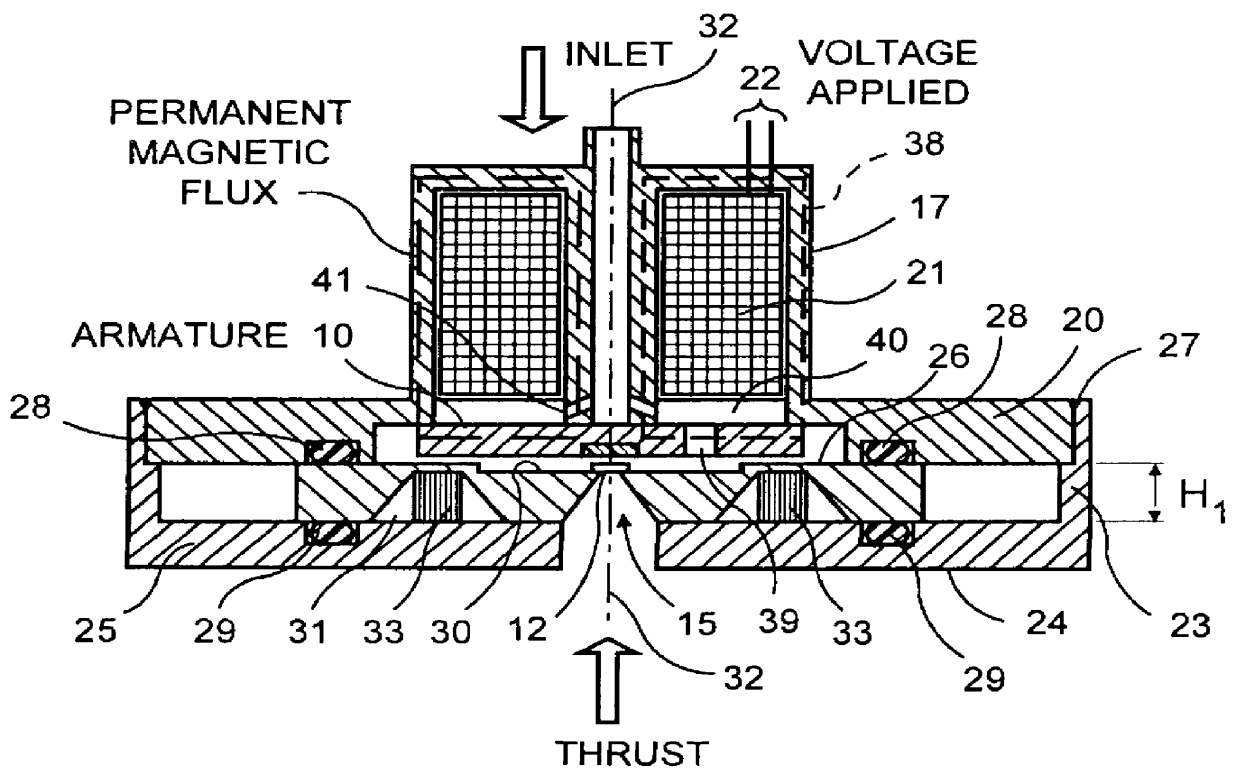

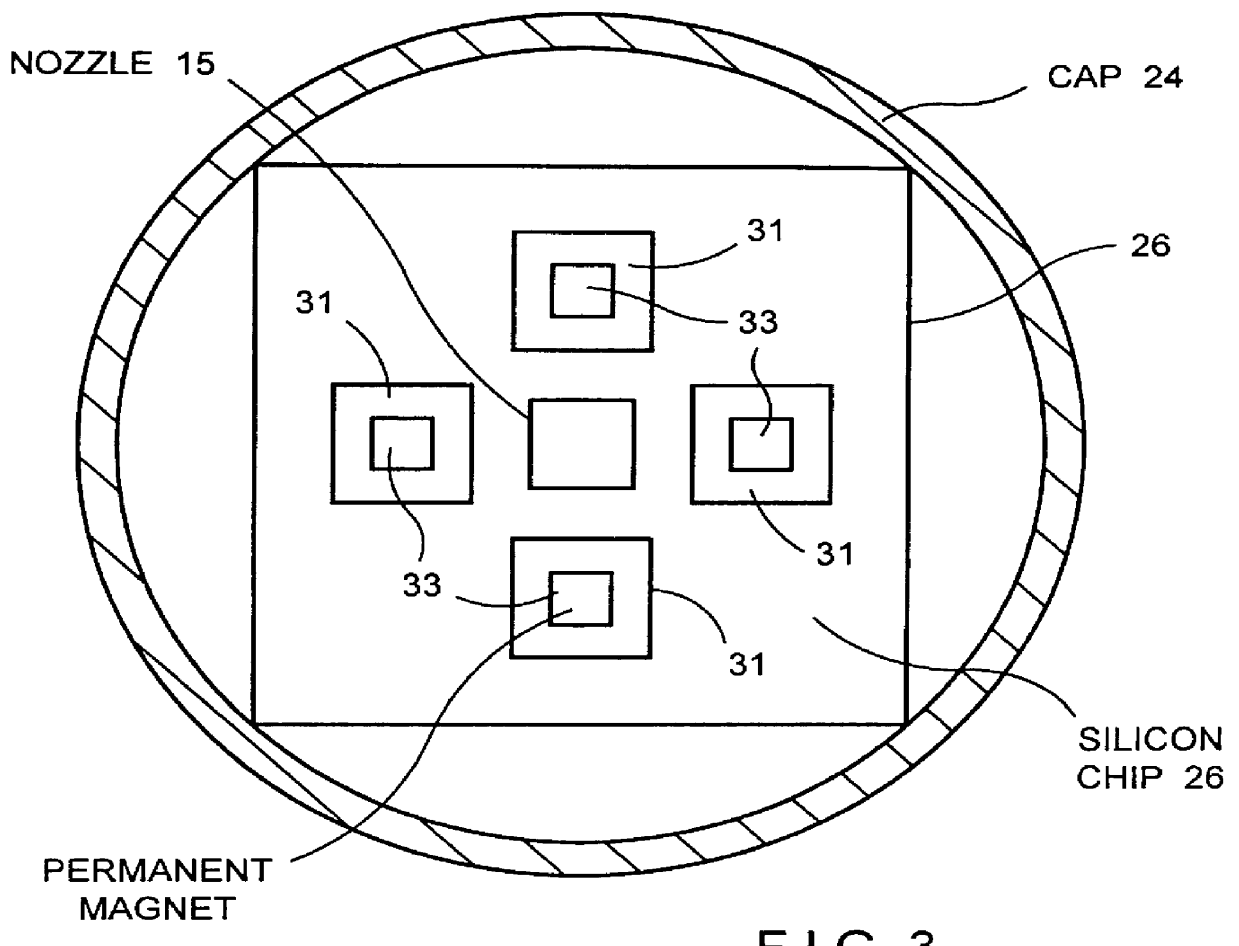

Microvalve and microthruster for satellites and methods of making and using the same

InactiveUS6068010ASmall sizeLight weightCosmonautic vehiclesEngine manufactureElectromagnetic valveVALVE PORT

A microvalve and microthruster are provided. Both include a housing with an interior in which an armature can travel and abut a valve seat to provide an electromagnetic valve. The armature acts as a valve body that is maintained in a or normally closed position by a permanent magnet, and is opened by interaction with a selectively activatable electromagnet. A microthruster is provided by fashioning the valve discharge as a nozzle, preferably of a material that is permanently and selectively magnetizable, so that the nozzle functions as the permanent magnet and which magnetism can be adjusted to assure proper opening and closing of the valve portion. The valve body is guided without any sliding fit mechanism and is suitable for controlling gas or liquid fluid flows.

Owner:MAROTTA SCI CONTROLS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com