Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

484 results about "Lean combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lean combustion is utilized in several types of engine designs including terrestrial gas turbine, steam furnaces, and aero engines. The use of wide range of lean combustion is because of low. temperature combustion process, fuel economy and reduced emissions.

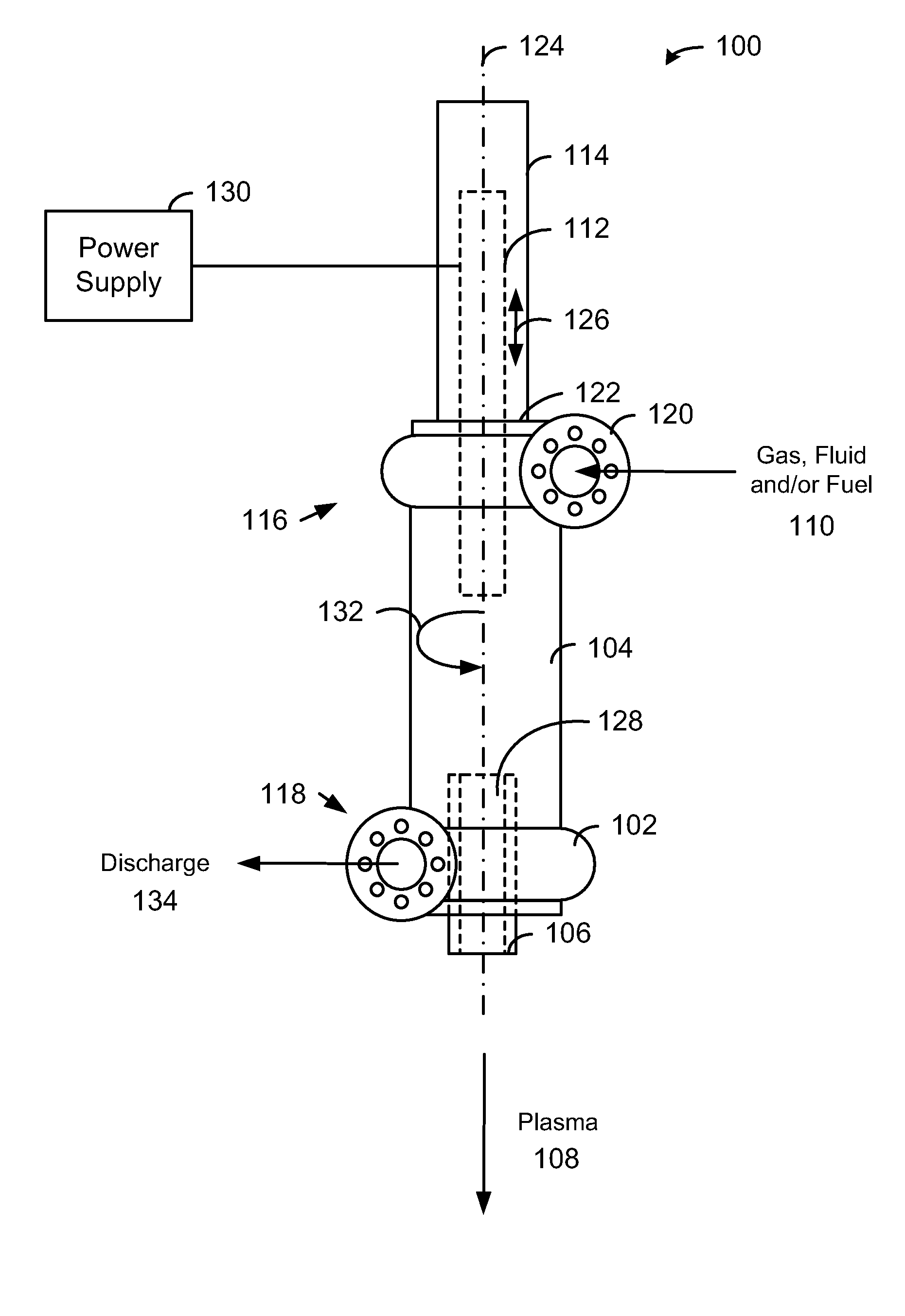

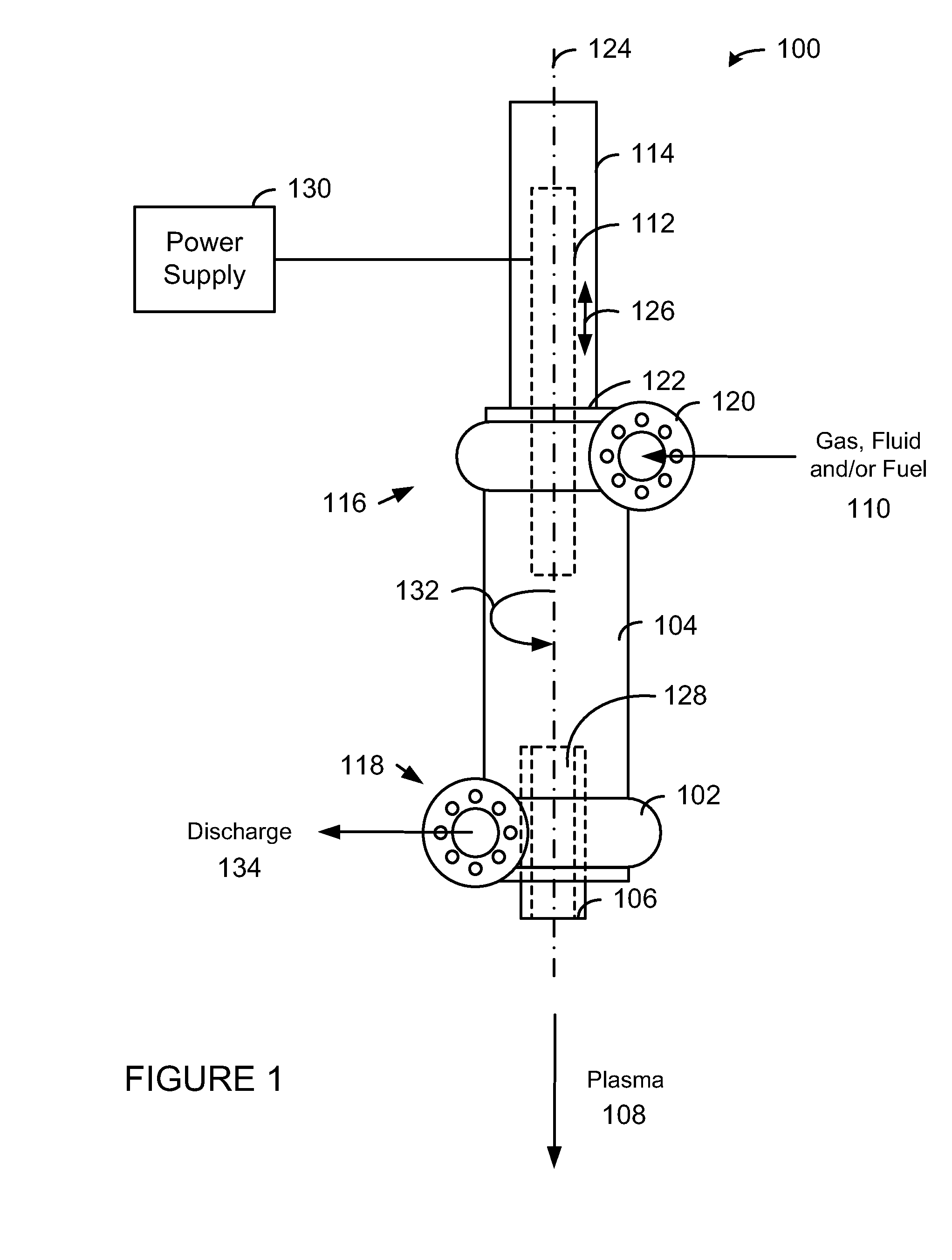

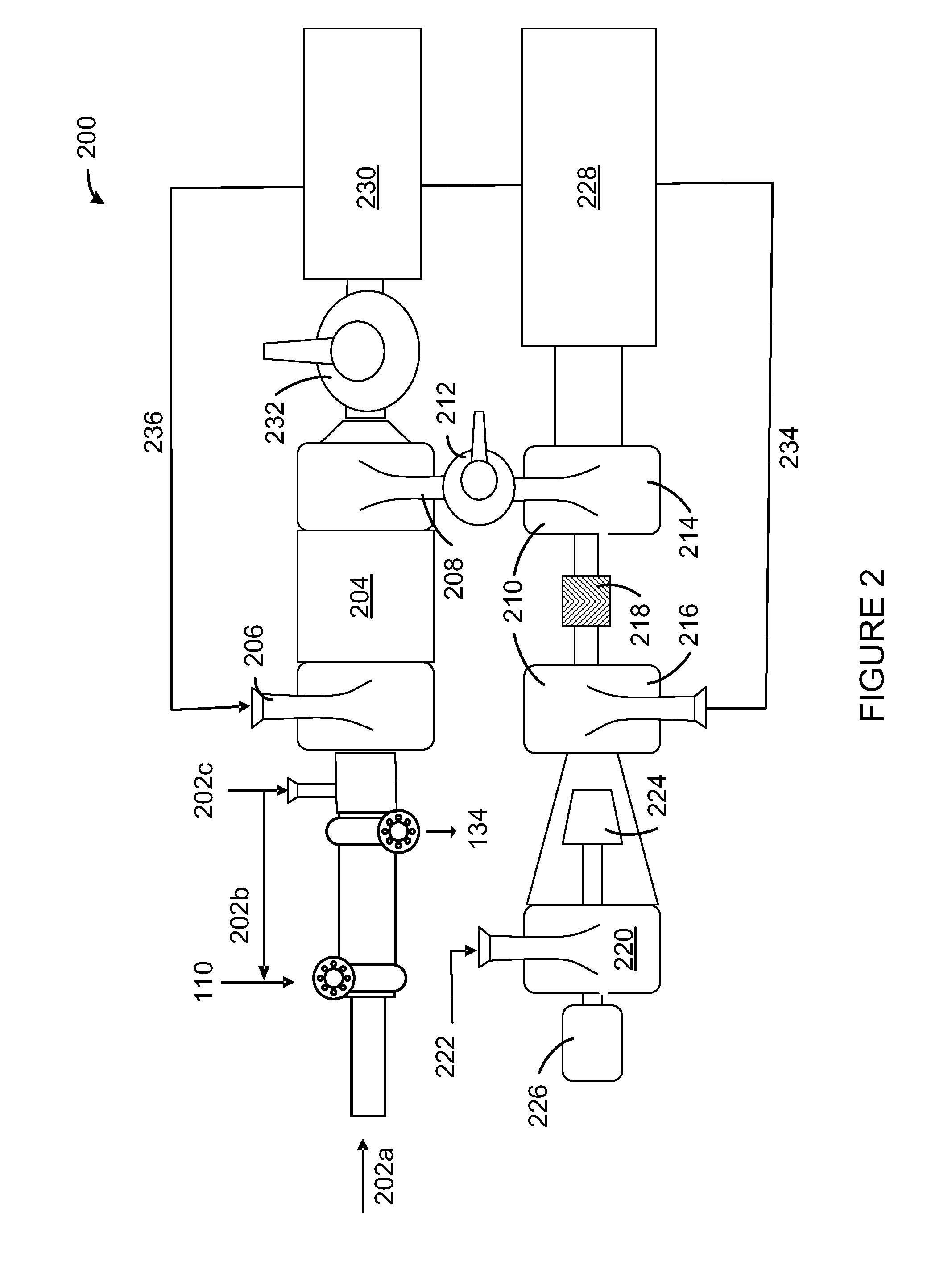

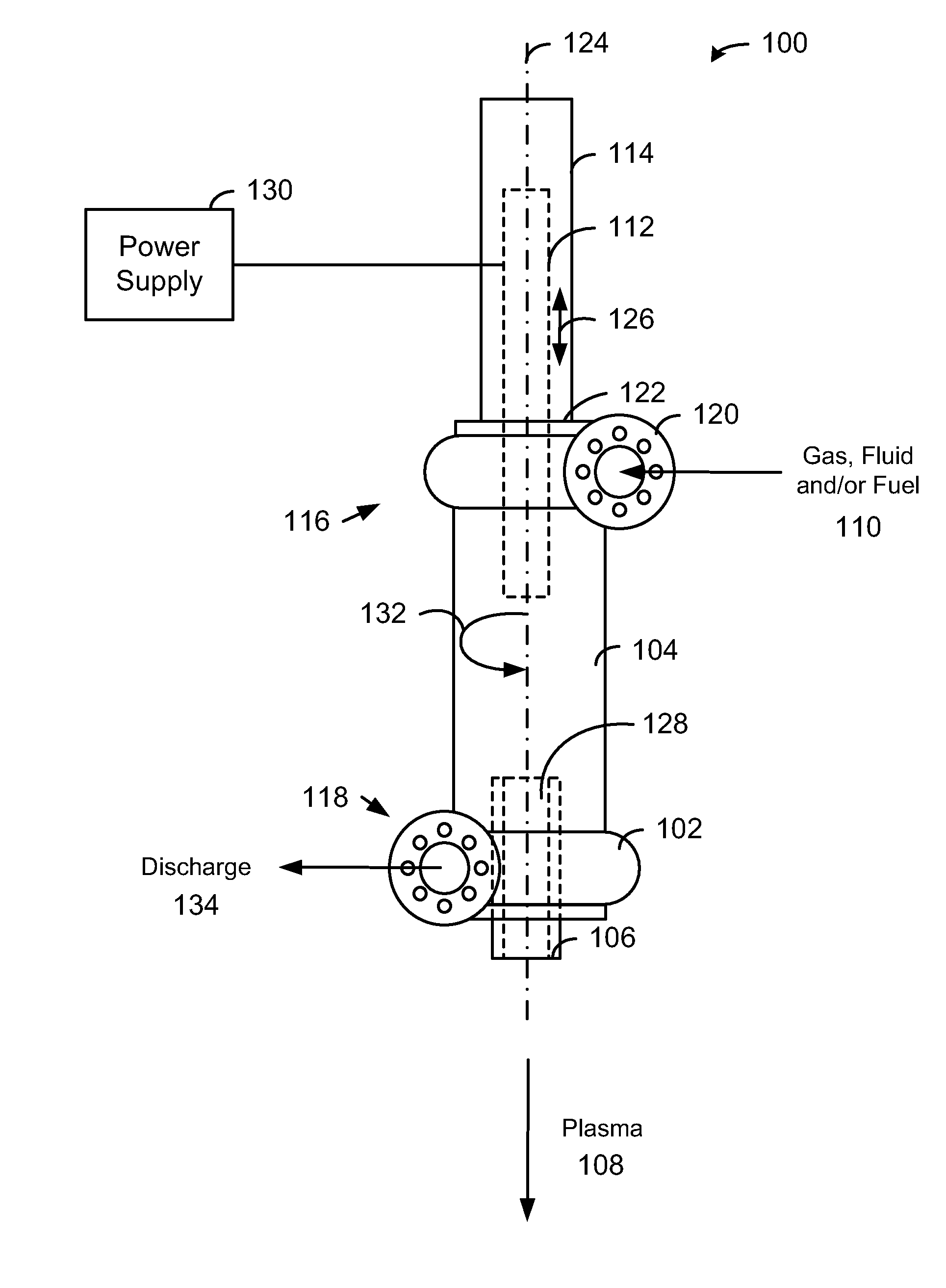

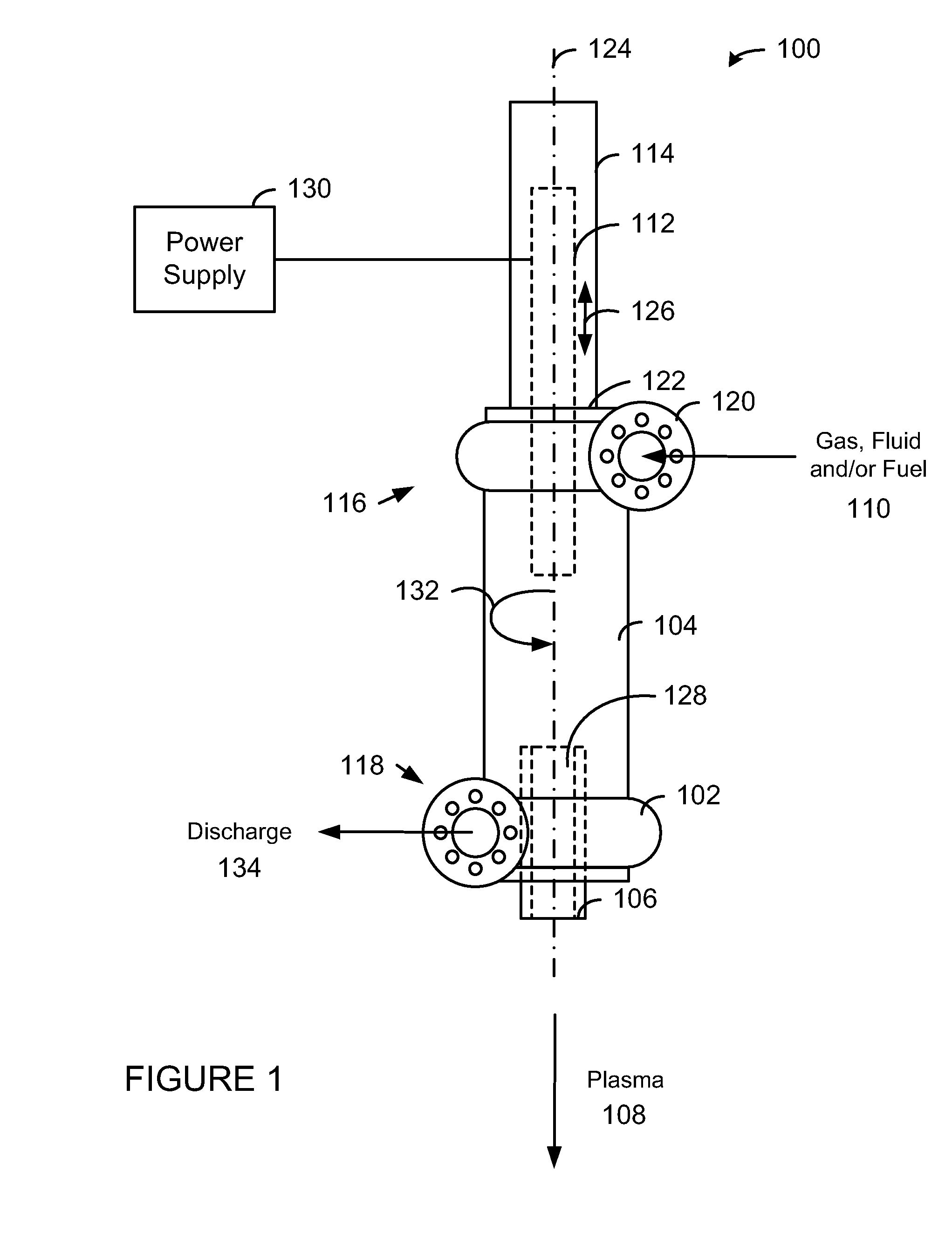

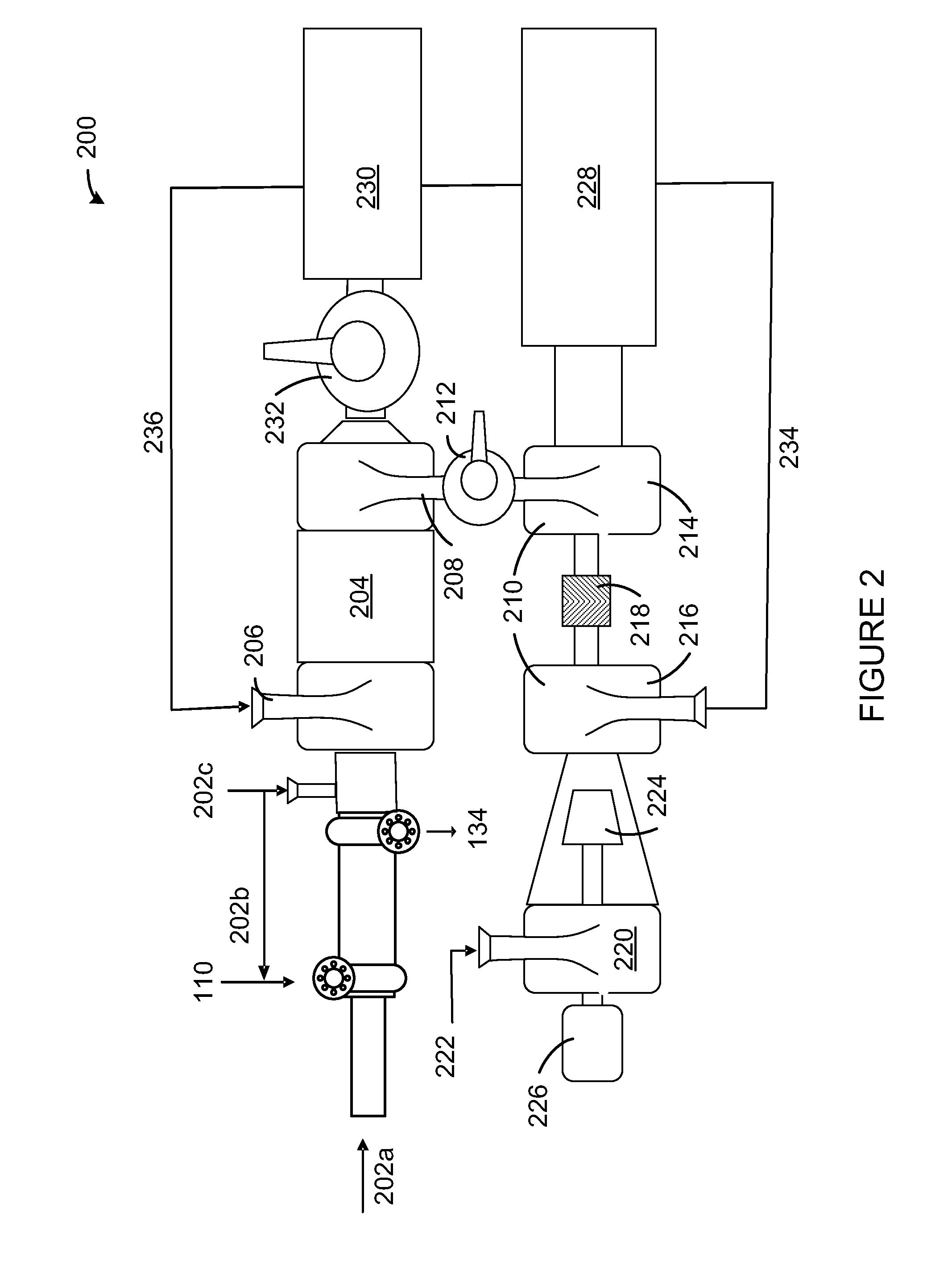

System, method and apparatus for lean combustion with plasma from an electrical arc

The present invention provides a plasma arc torch that can be used for lean combustion. The plasma arc torch includes a cylindrical vessel, an electrode housing connected to the first end of the cylindrical vessel such that a first electrode is (a) aligned with a longitudinal axis of the cylindrical vessel, (b) extends into the cylindrical vessel, and (c) can be moved along the longitudinal axis, a linear actuator connected to the first electrode to adjust a position of the first electrode, a hollow electrode nozzle connected to the second end of the cylindrical vessel such that the center line of the hollow electrode nozzle is aligned with the longitudinal axis of the cylindrical vessel, and wherein the tangential inlet and the tangential outlet create a vortex within the cylindrical vessel, and the first electrode and the hollow electrode nozzle creates a plasma that discharges through the hollow electrode nozzle.

Owner:FORET PLASMA LABS

System, method and apparatus for lean combustion with plasma from an electrical arc

The present invention provides a plasma arc torch that can be used for lean combustion. The plasma arc torch includes a cylindrical vessel, an electrode housing connected to the first end of the cylindrical vessel such that a first electrode is (a) aligned with a longitudinal axis of the cylindrical vessel, (b) extends into the cylindrical vessel, and (c) can be moved along the longitudinal axis, a linear actuator connected to the first electrode to adjust a position of the first electrode, a hollow electrode nozzle connected to the second end of the cylindrical vessel such that the center line of the hollow electrode nozzle is aligned with the longitudinal axis of the cylindrical vessel, and wherein the tangential inlet and the tangential outlet create a vortex within the cylindrical vessel, and the first electrode and the hollow electrode nozzle crate a plasma the discharges through the hollow electrode nozzle.

Owner:FORET PLASMA LABS

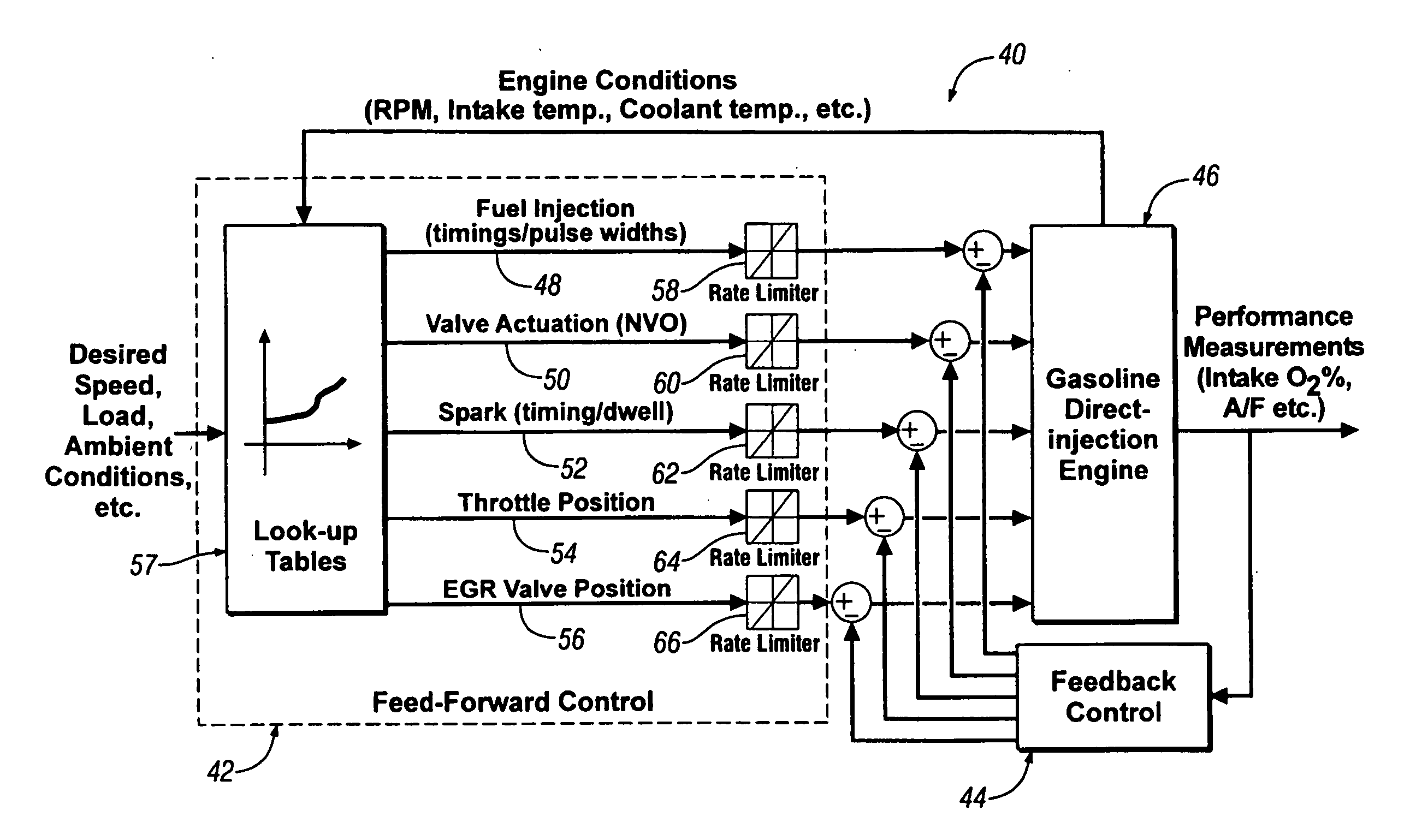

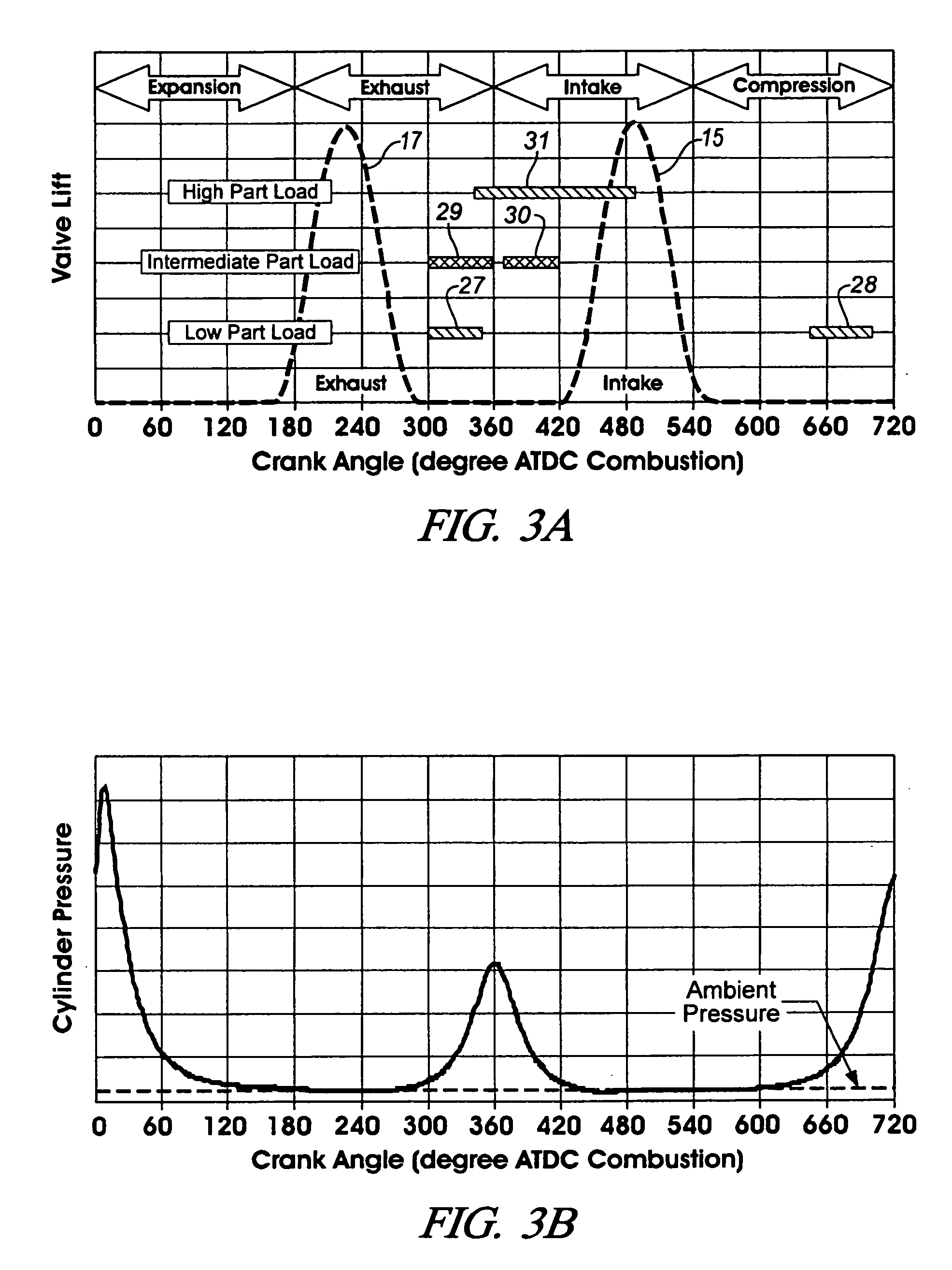

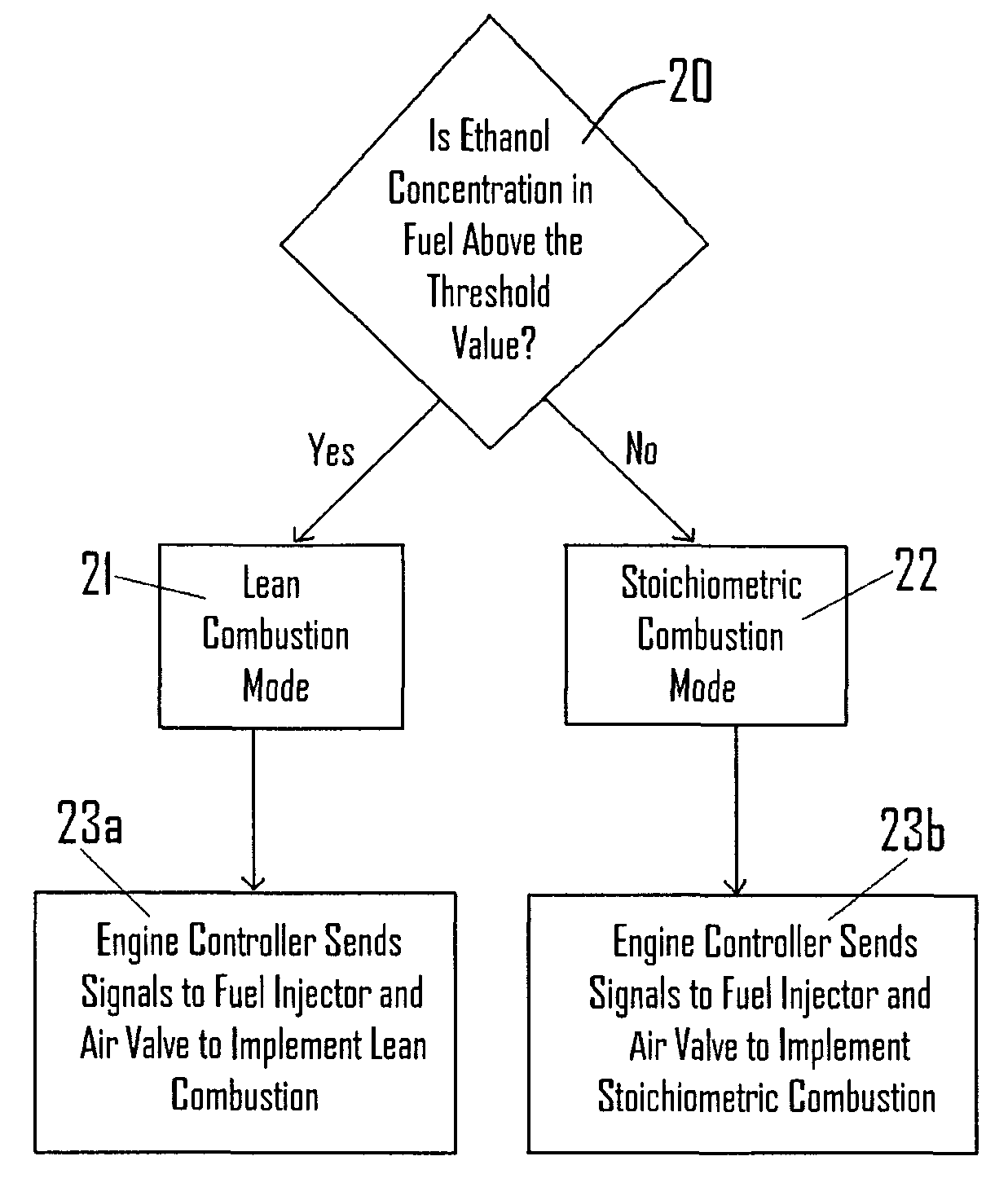

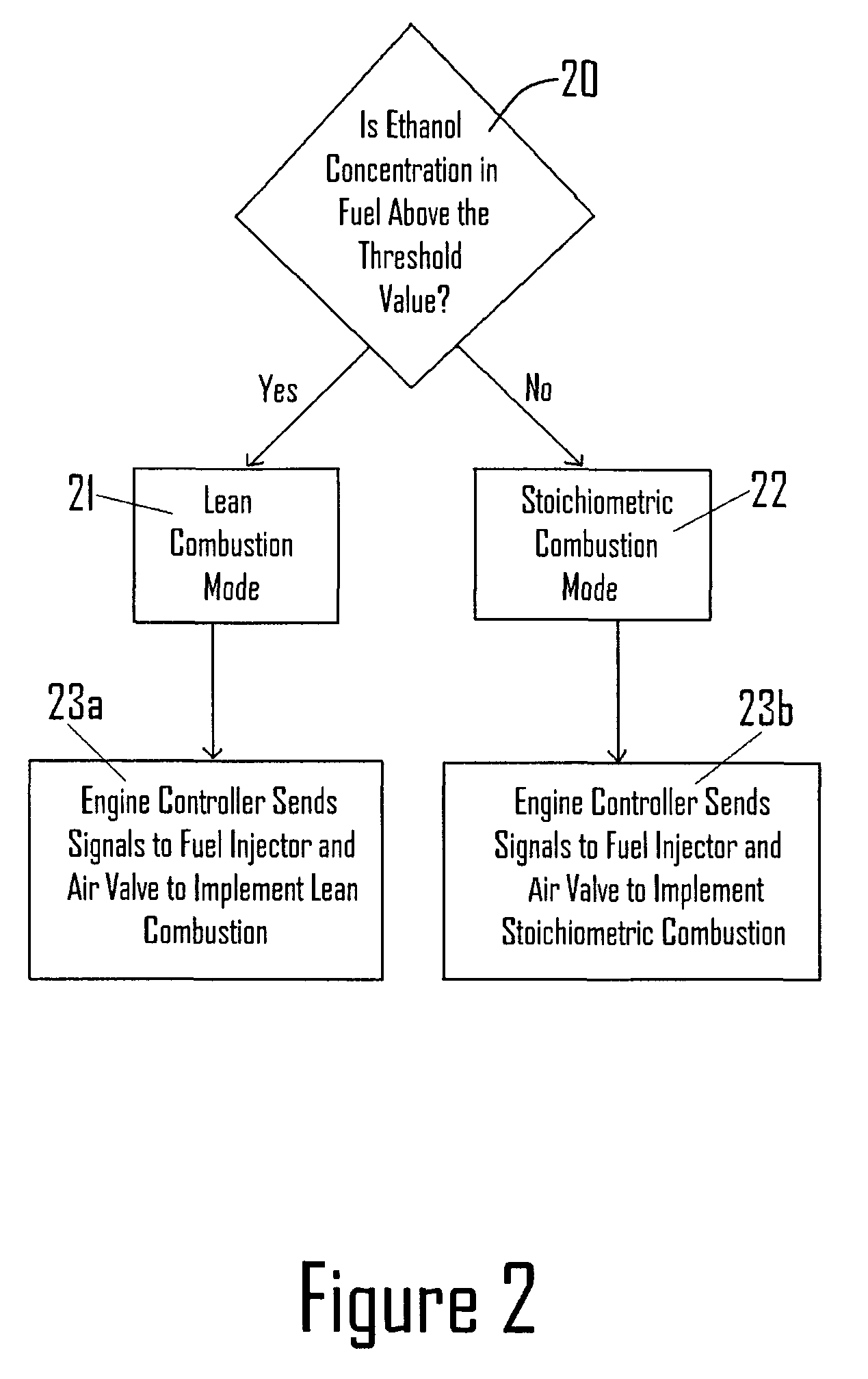

Method for load transient control between lean and stoichiometric combustion modes of direct-injection engines with controlled auto-ignition combustion

InactiveUS20060196469A1Electrical controlNon-fuel substance addition to fuelStable stateHomogeneous charge compression ignition

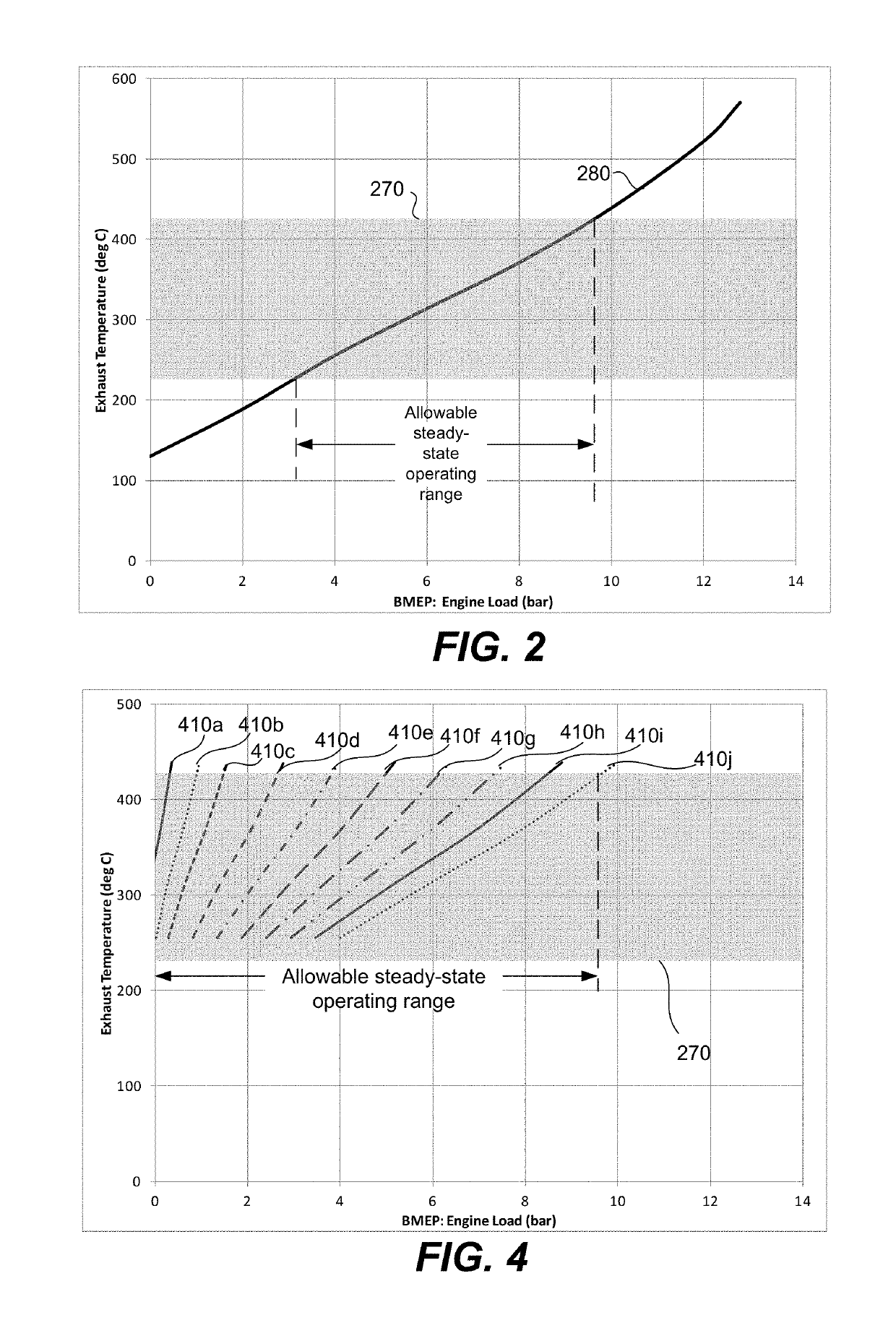

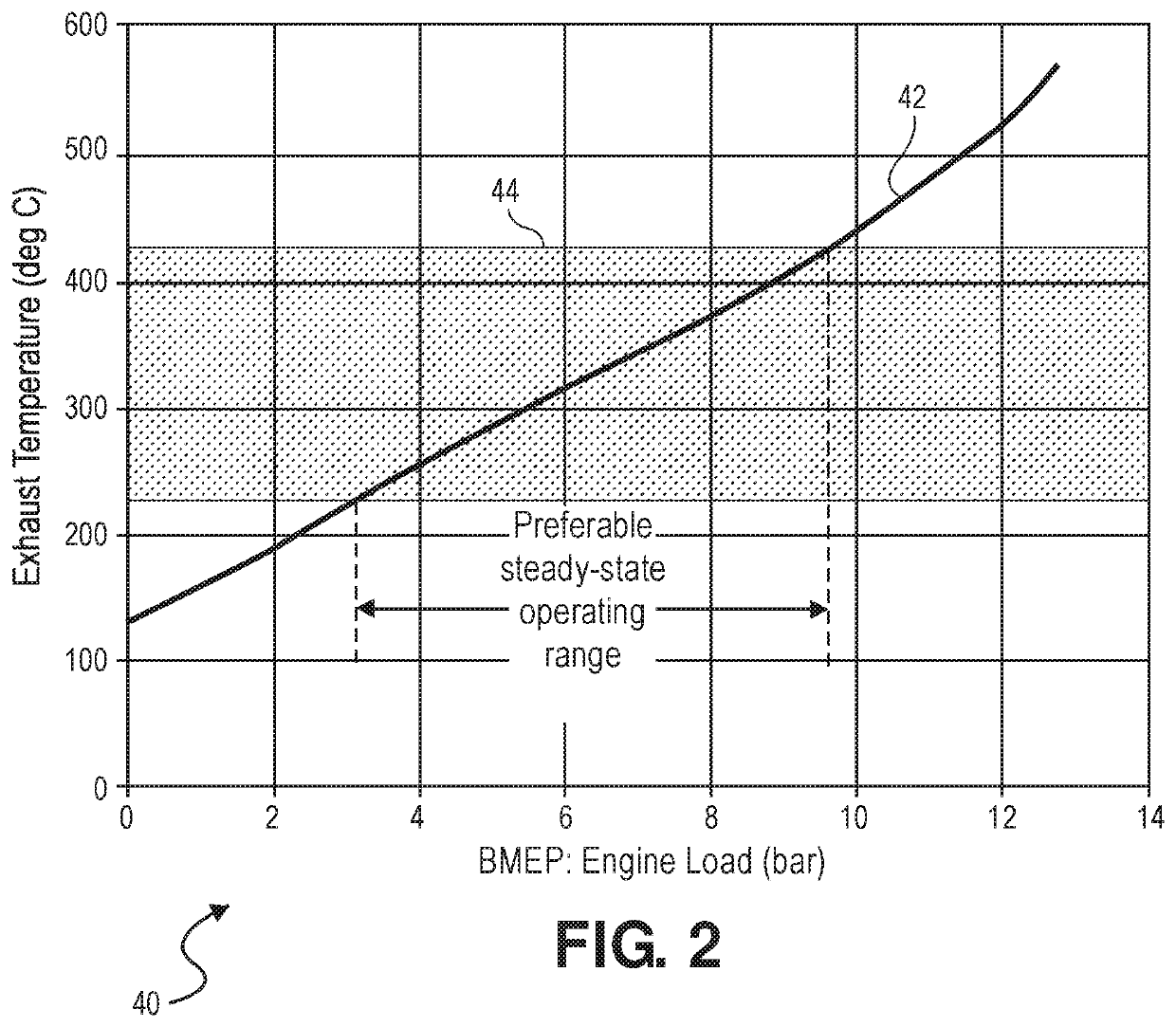

A method is provided for control of a direct-injection engine operated with controlled auto-ignition (HCCI) during load transient operations between modes of lean combustion low load (HCCI / Lean) and stiochiometric combustion medium load (HCCI / Stoich.). The method includes 1) operating the engine at steady state, within a homogeneous charge compression-ignition (HCCI) load range, with fuel-air-exhaust gas mixtures at predetermined conditions, for each speed and load, and controlling the engine during changes of operating mode between one to another of the HCCI / Stoich. medium load mode and the HCCI / Lean lower load mode by synchronizing change rates of predetermined controlled inputs to the current engine fueling change rate.

Owner:GM GLOBAL TECH OPERATIONS LLC

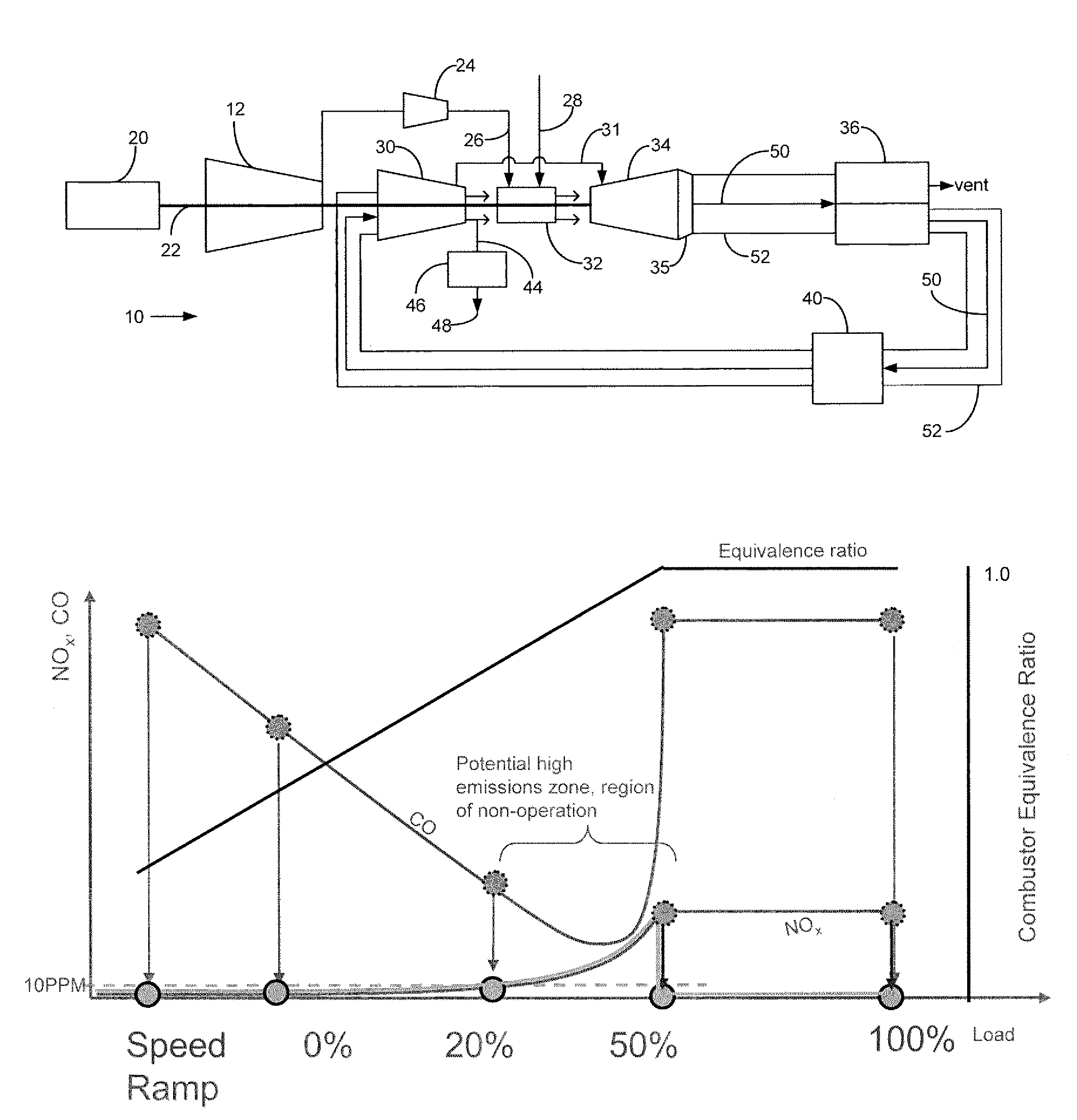

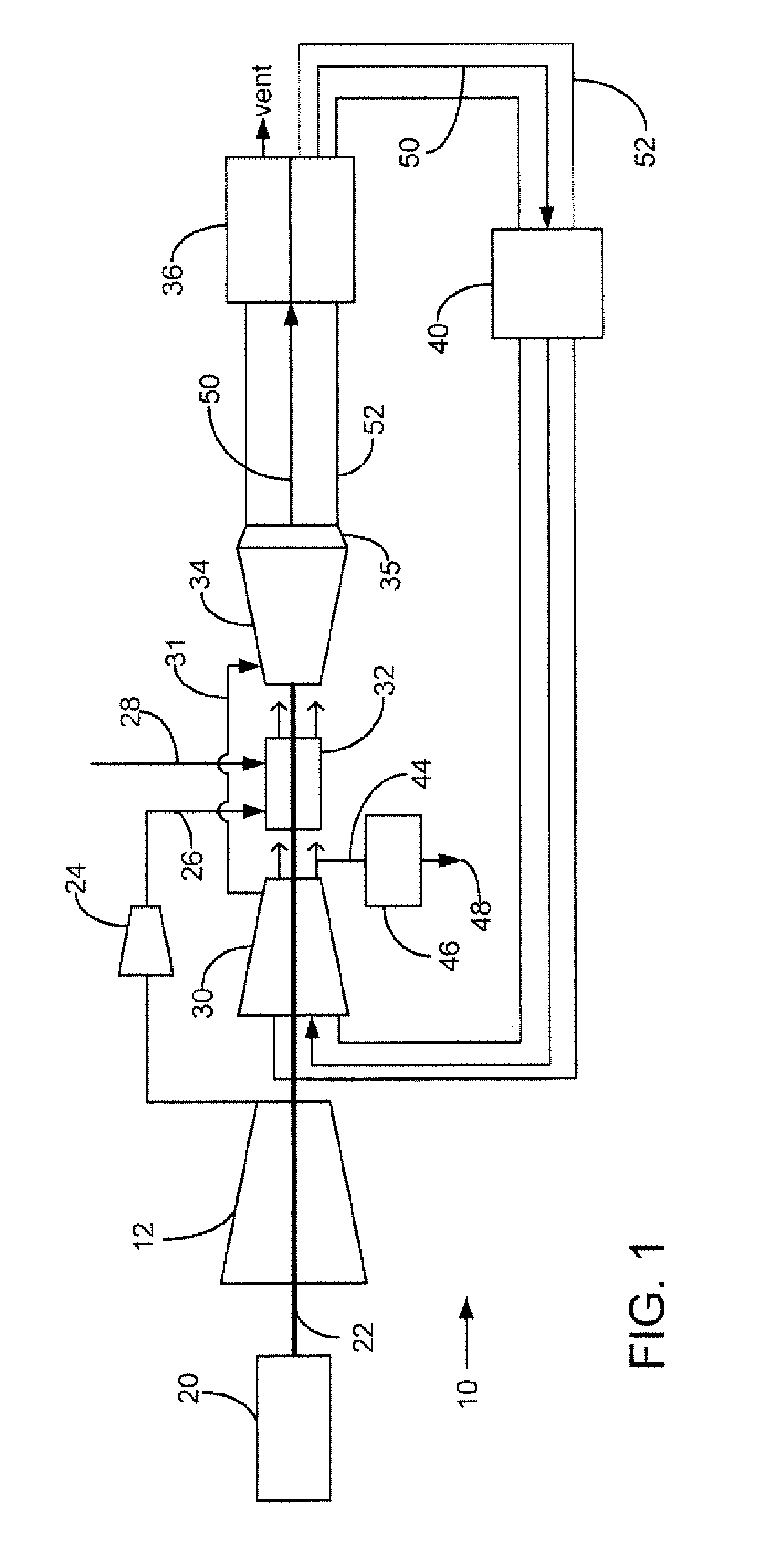

Power plant and method of operation

A main air compressor delivers a compressed ambient gas flow with a compressed ambient gas flow rate to a turbine combustor. A fuel stream with a flow rate is delivered to the turbine combustor and mixed with the compressed ambient gas flow and an exhaust gas flow and burned with substantially stoichiometric combustion to form the exhaust gas flow and drive a turbine, thus operating the power plant at a first load. A portion of the exhaust gas flow is recirculated from the turbine to the turbine compressor and a portion is delivered to an exhaust path. The fuel stream flow rate and the compressed ambient gas flow rate are reduced, and substantially stoichiometric combustion is maintained and the power plant is operated at a second load. The fuel stream flow rate is further reduced and lean combustion is achieved and the power plant is operated at a third load.

Owner:GENERAL ELECTRIC CO

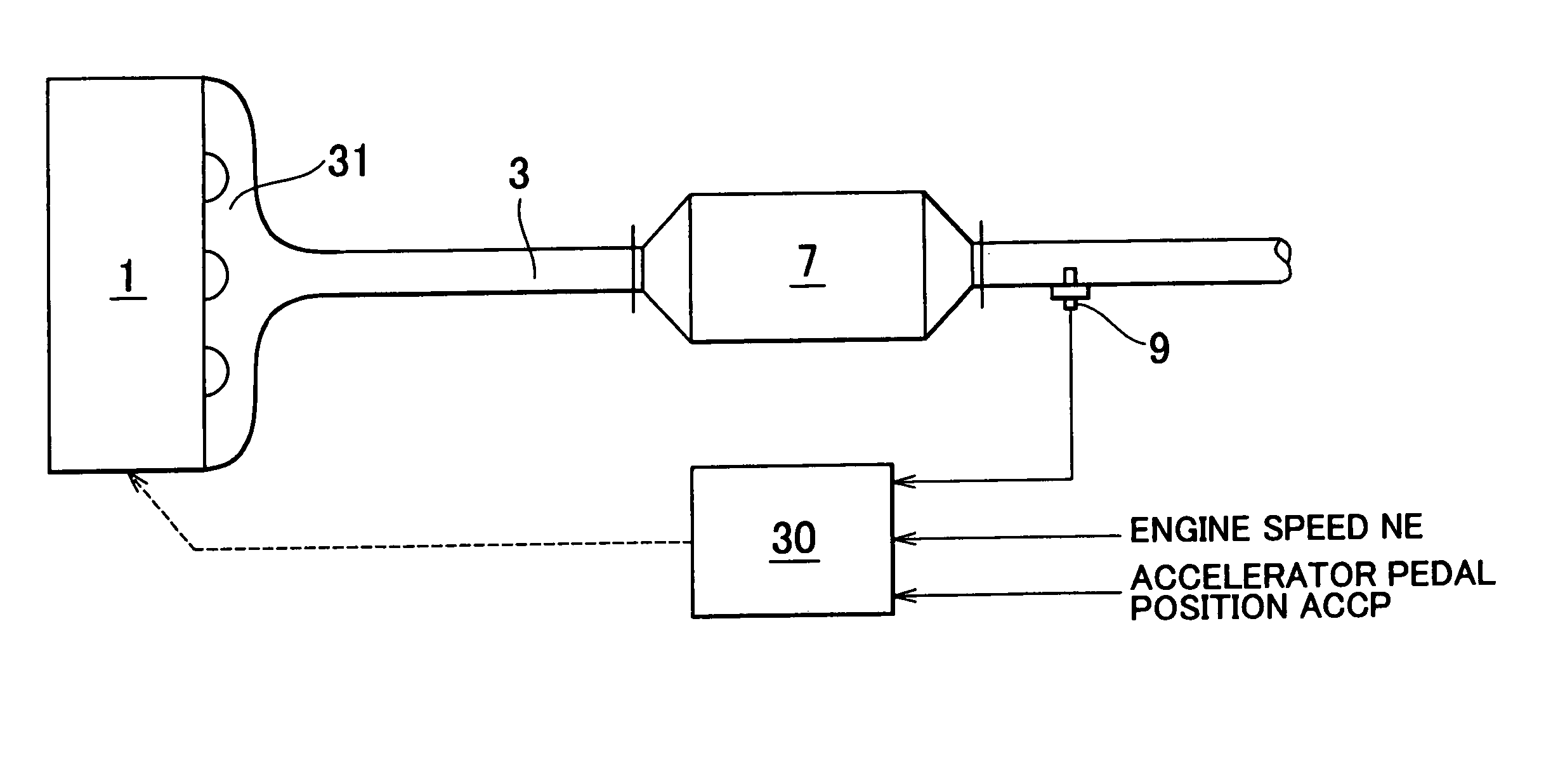

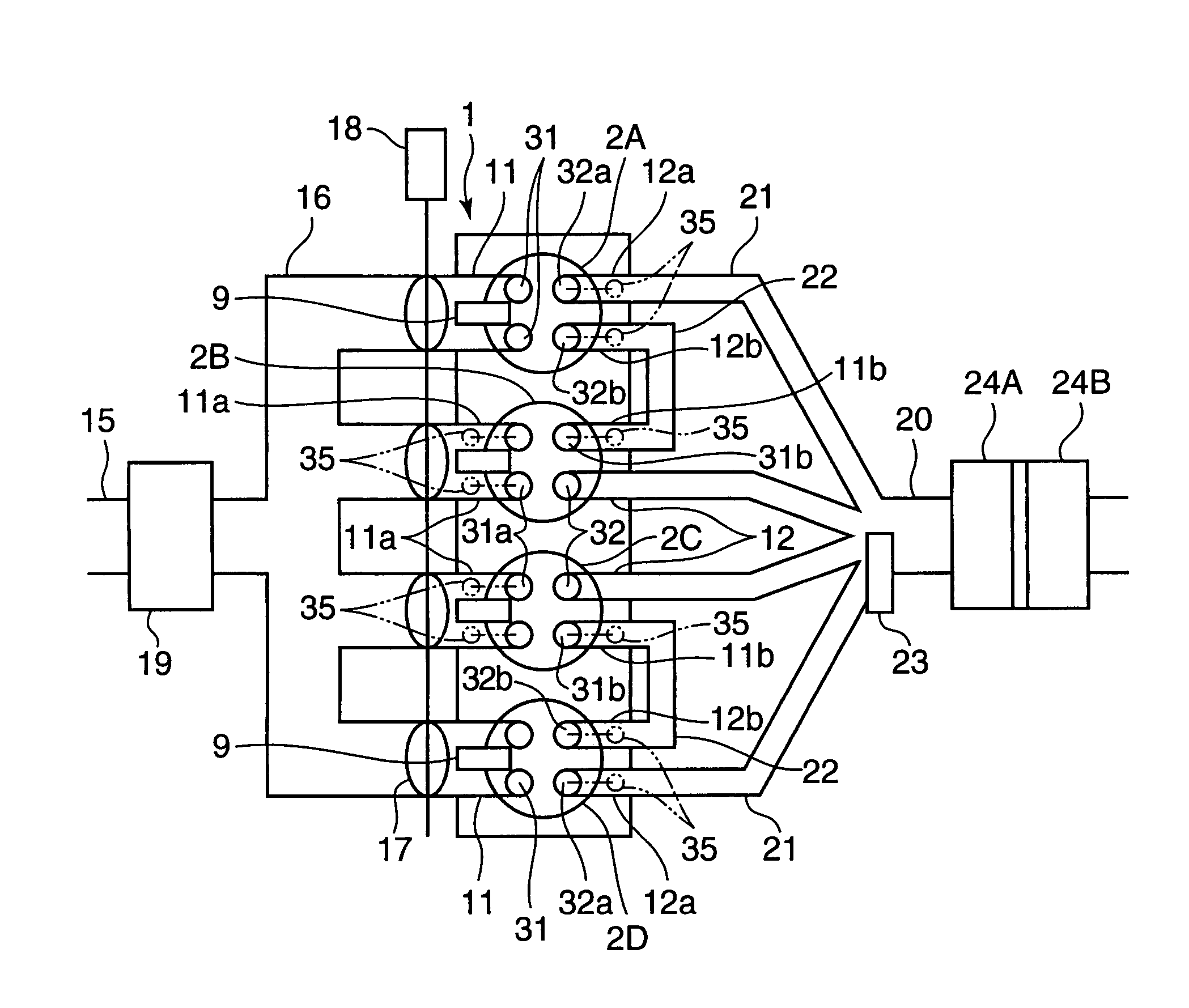

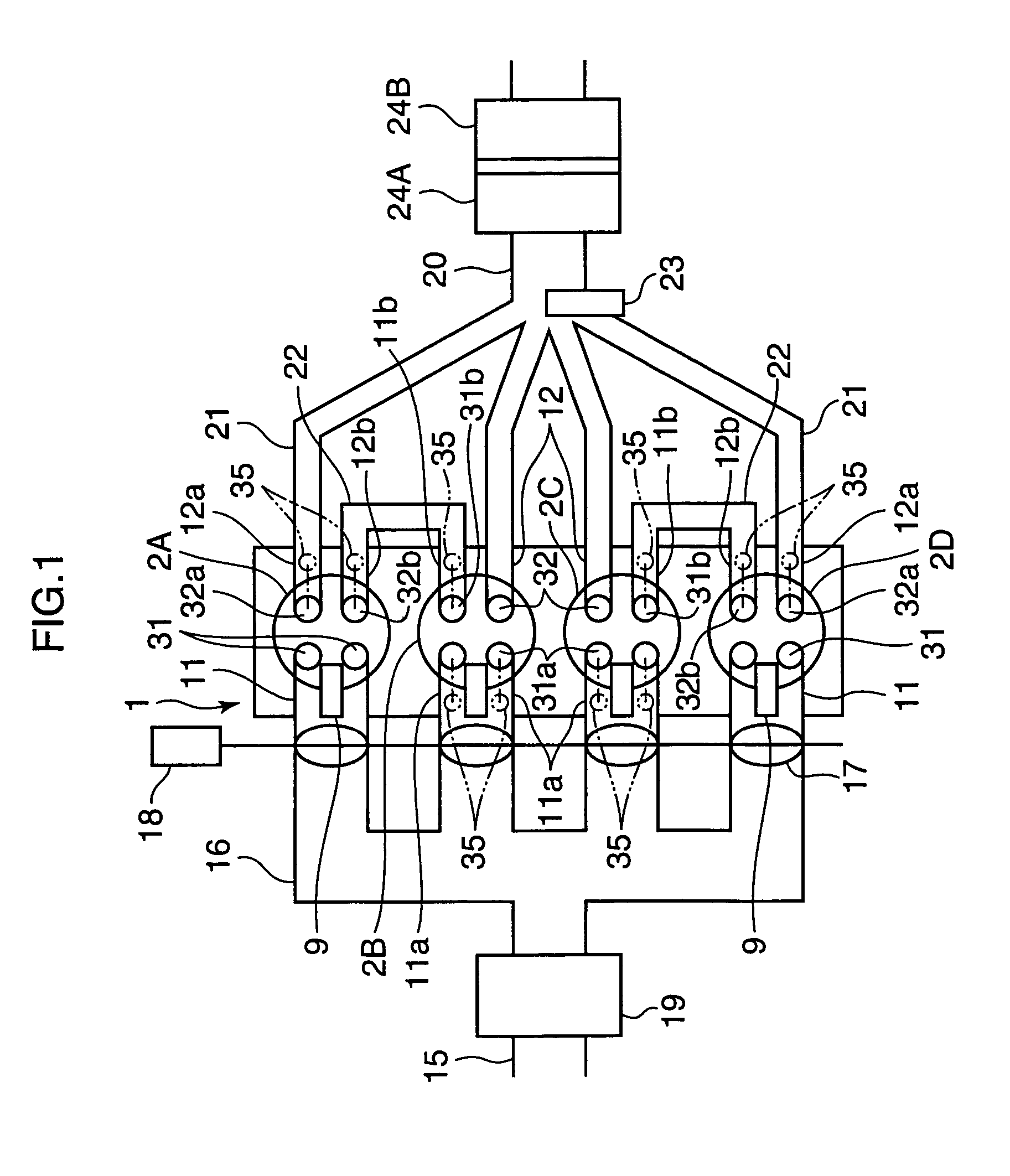

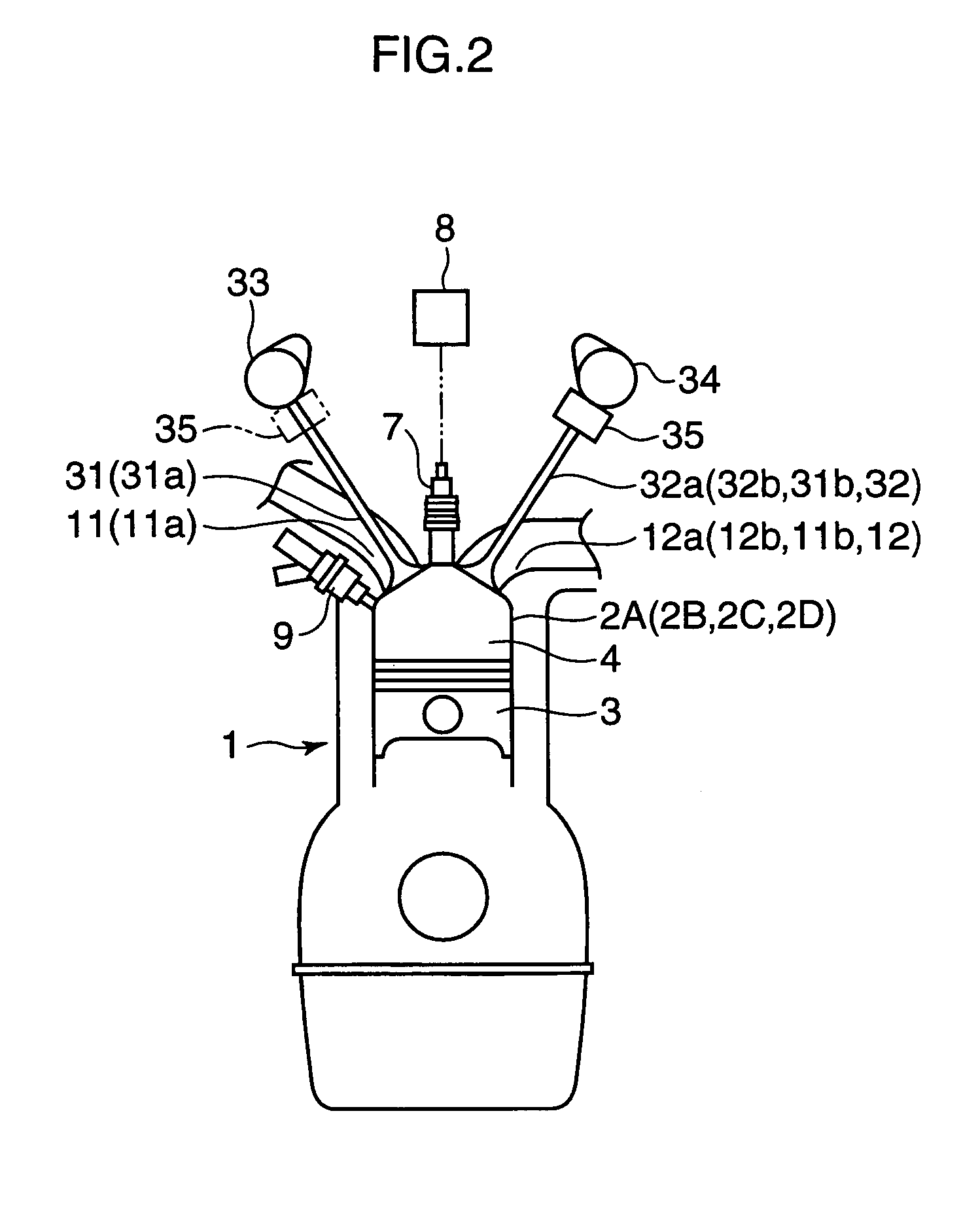

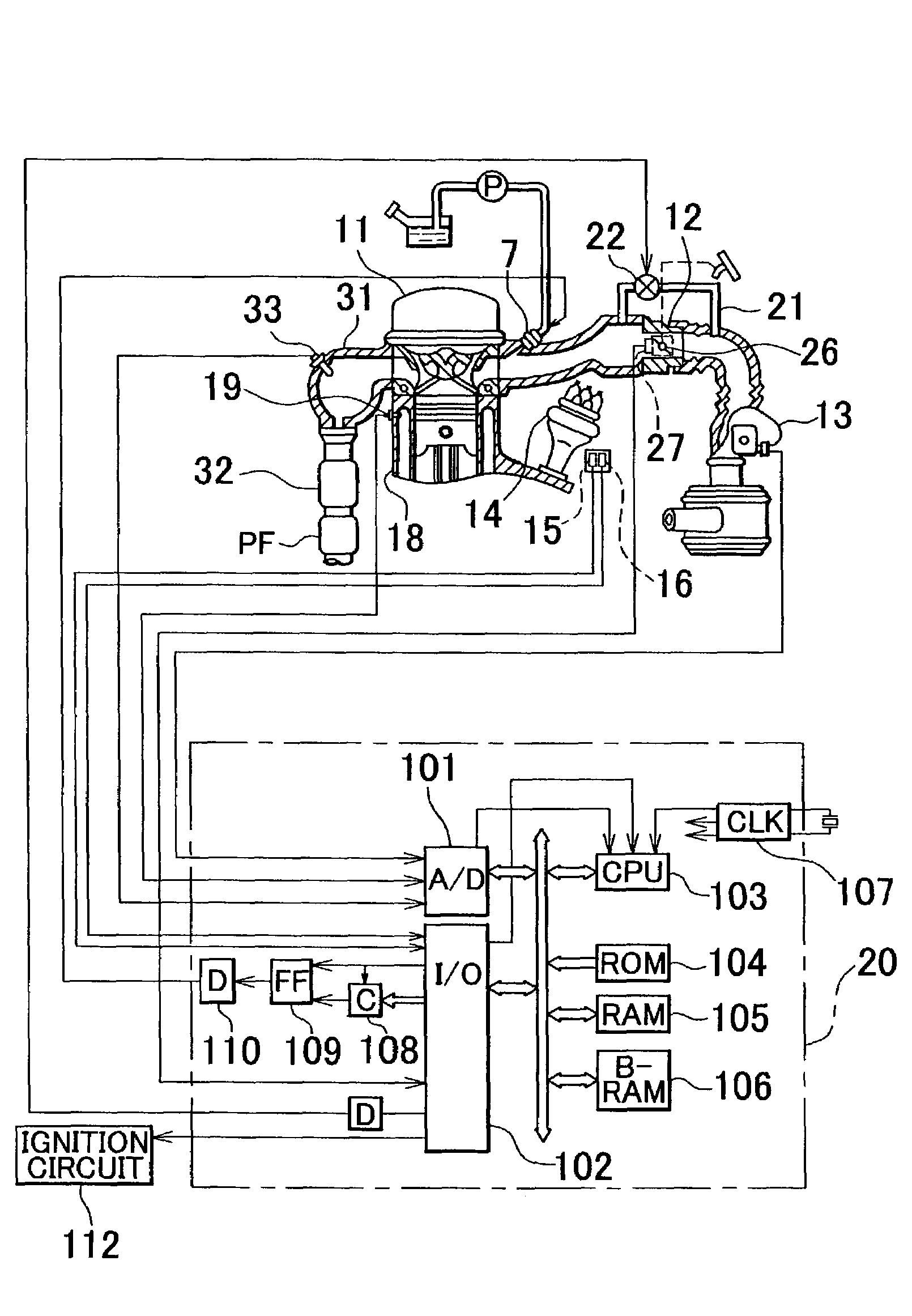

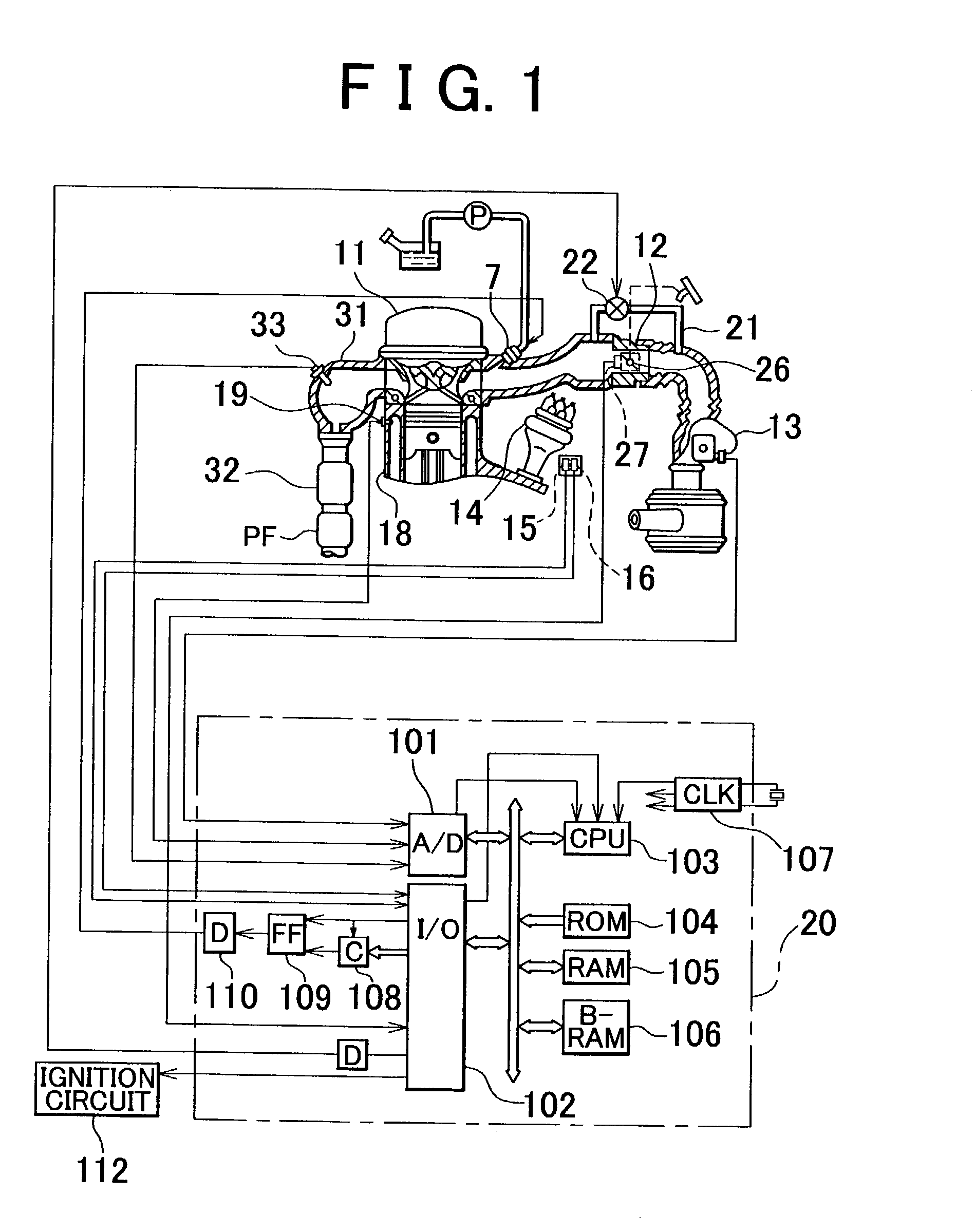

Spark ignition engine control device

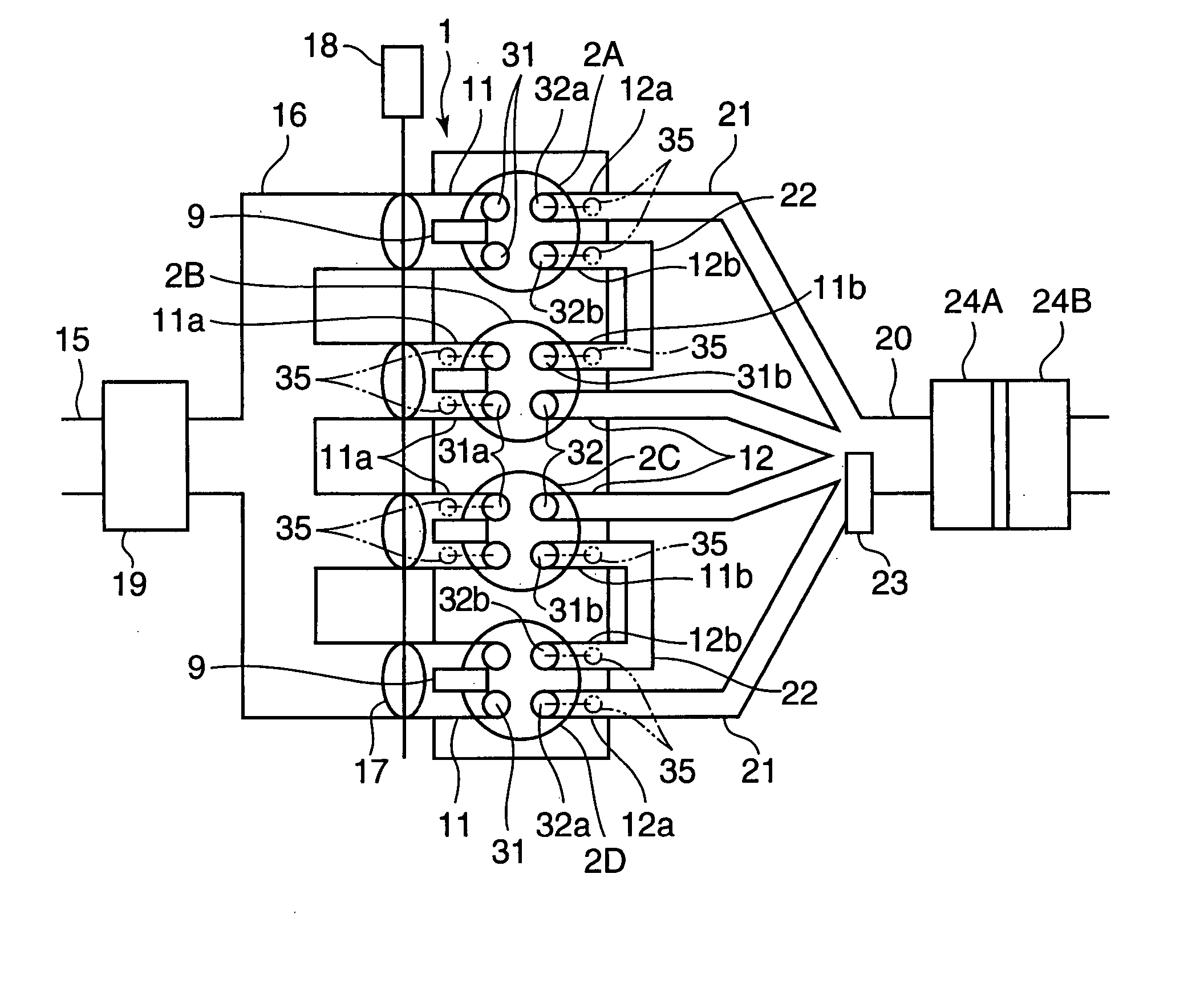

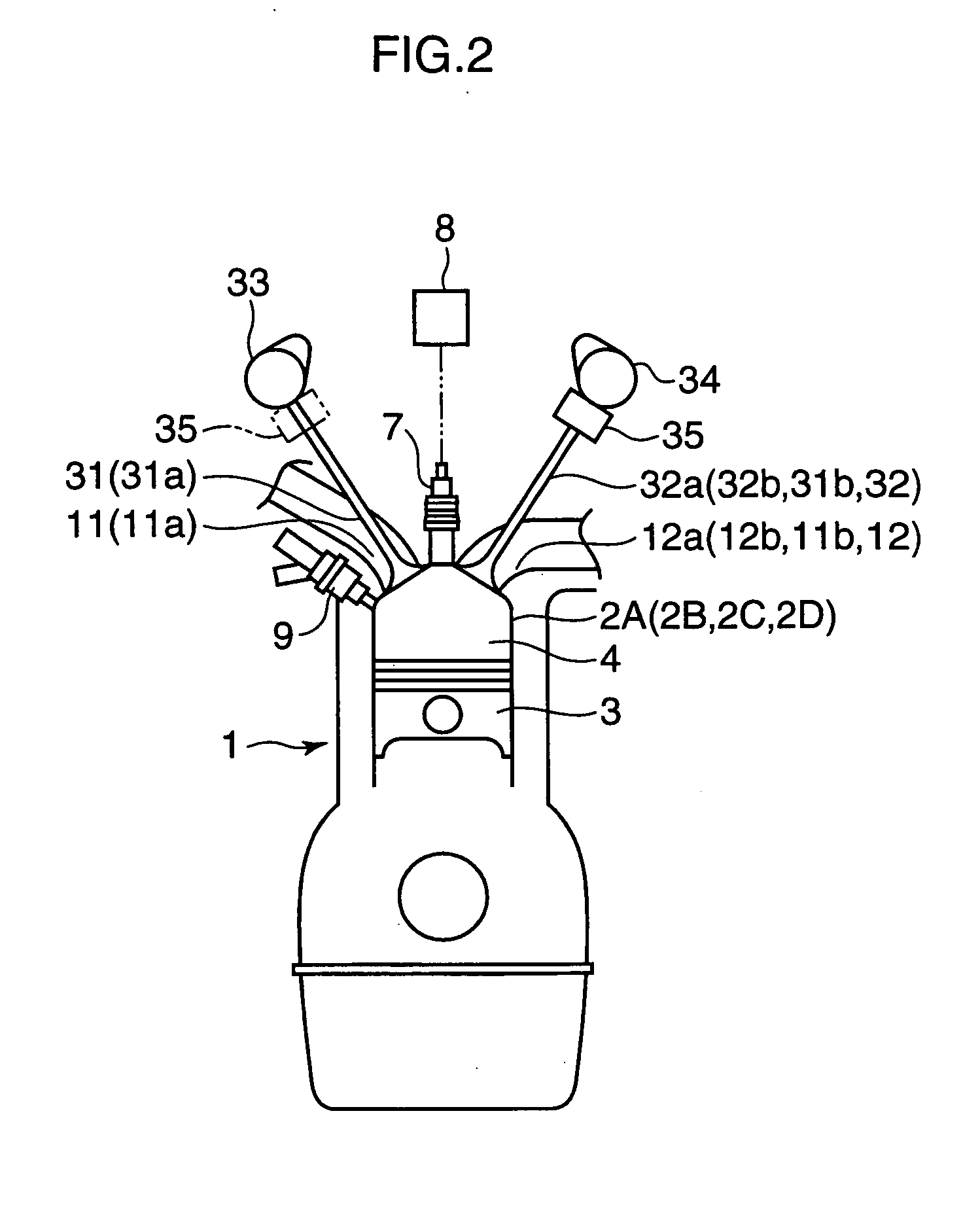

InactiveUS20050022755A1Expand operating regionIncreased fuel costValve arrangementsElectrical controlLean combustionSpark-ignition engine

For the purpose of improving the fuel efficiency by lean combustion and enhancing the fuel efficiency improvement effects by performing compression ignition efficiently in some cylinders, a multi-cylinder spark ignition engine is constructed such that exhaust gas, that is exhausted from preceding cylinders 2A, 2D on the exhaust stroke side among pairs of cylinders whose exhaust stroke and intake stroke overlap in a low load, low rotational speed region, is directly introduced through an inter-cylinder gas passage 22 into following cylinders 2B, 2C on the intake stroke side and only gas exhausted from the following cylinders 2B, 2C is fed to an exhaust passage 20, which is provided with a three-way catalyst 24. Combustion controller is provided that controls the combustion of each of the cylinders such that combustion is conducted by forced ignition in a condition in which the air / fuel ratio is a lean air / fuel ratio which is larger by a prescribed amount than the stoichiometric air / fuel ratio in the preceding cylinders 2A, 2D and, in the following cylinders 2B, 2C, fuel is supplied to burnt gas of lean air / fuel ratio introduced from the preceding cylinders 2A, 2D and combustion is conducted by compression ignition.

Owner:MAZDA MOTOR CORP

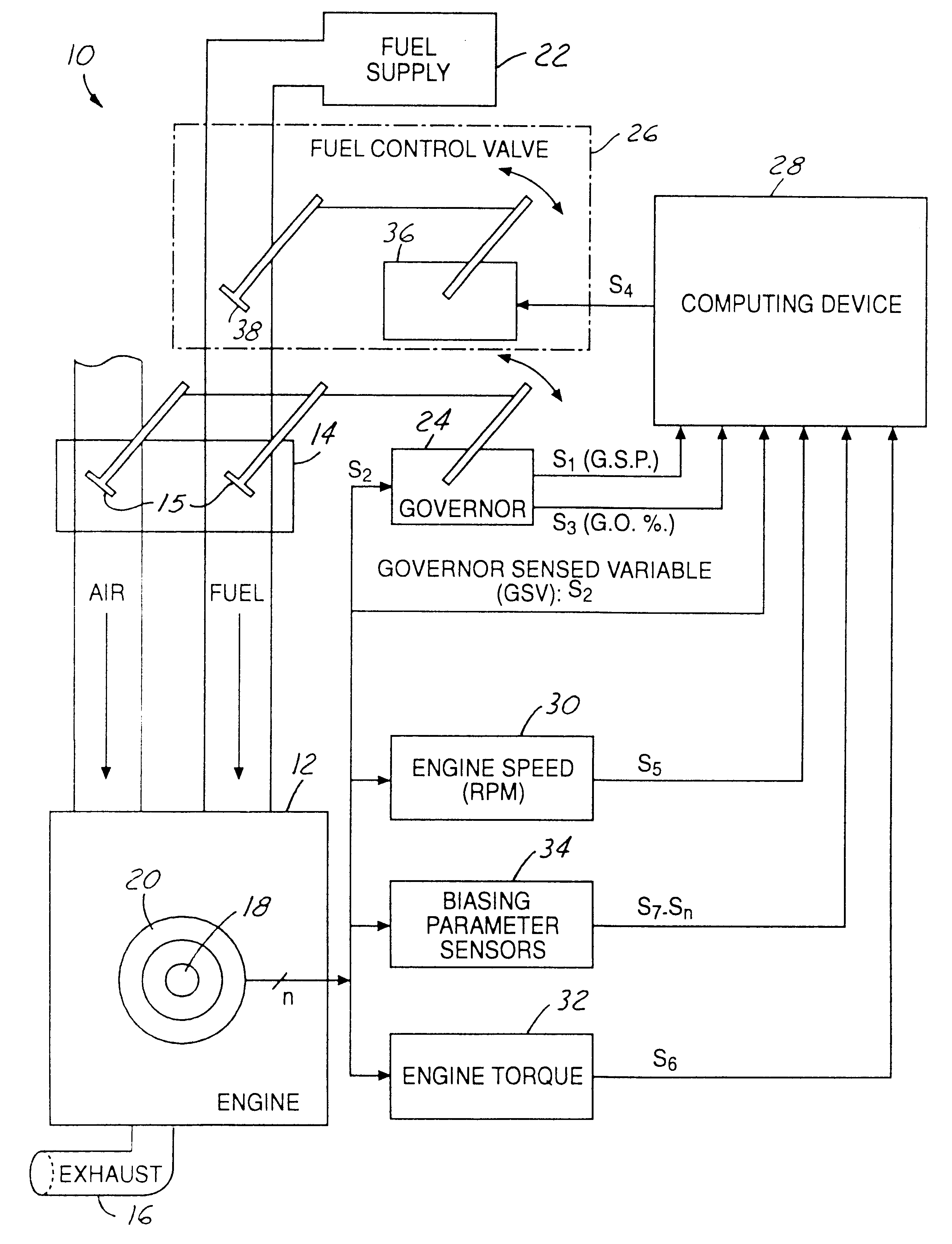

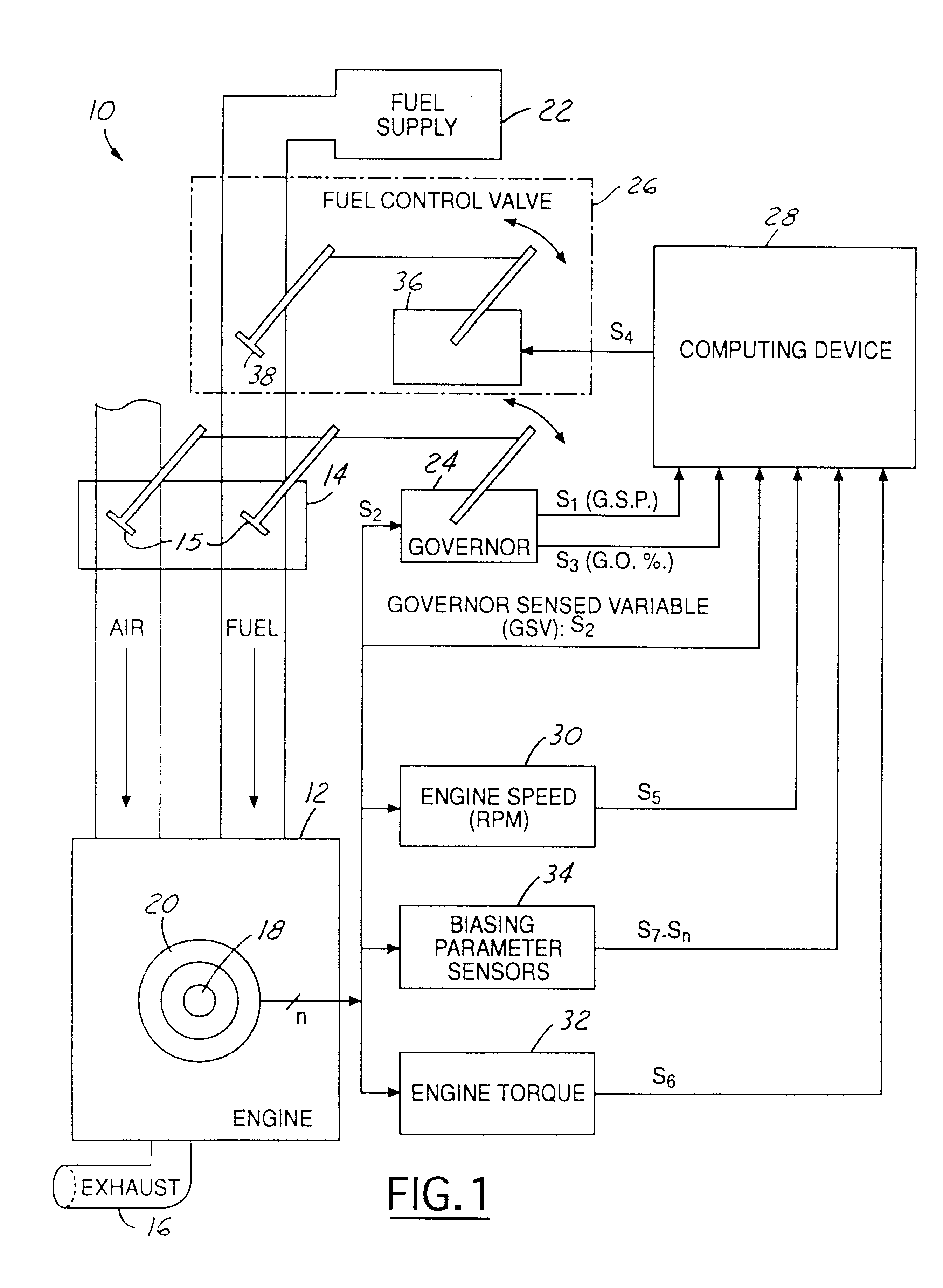

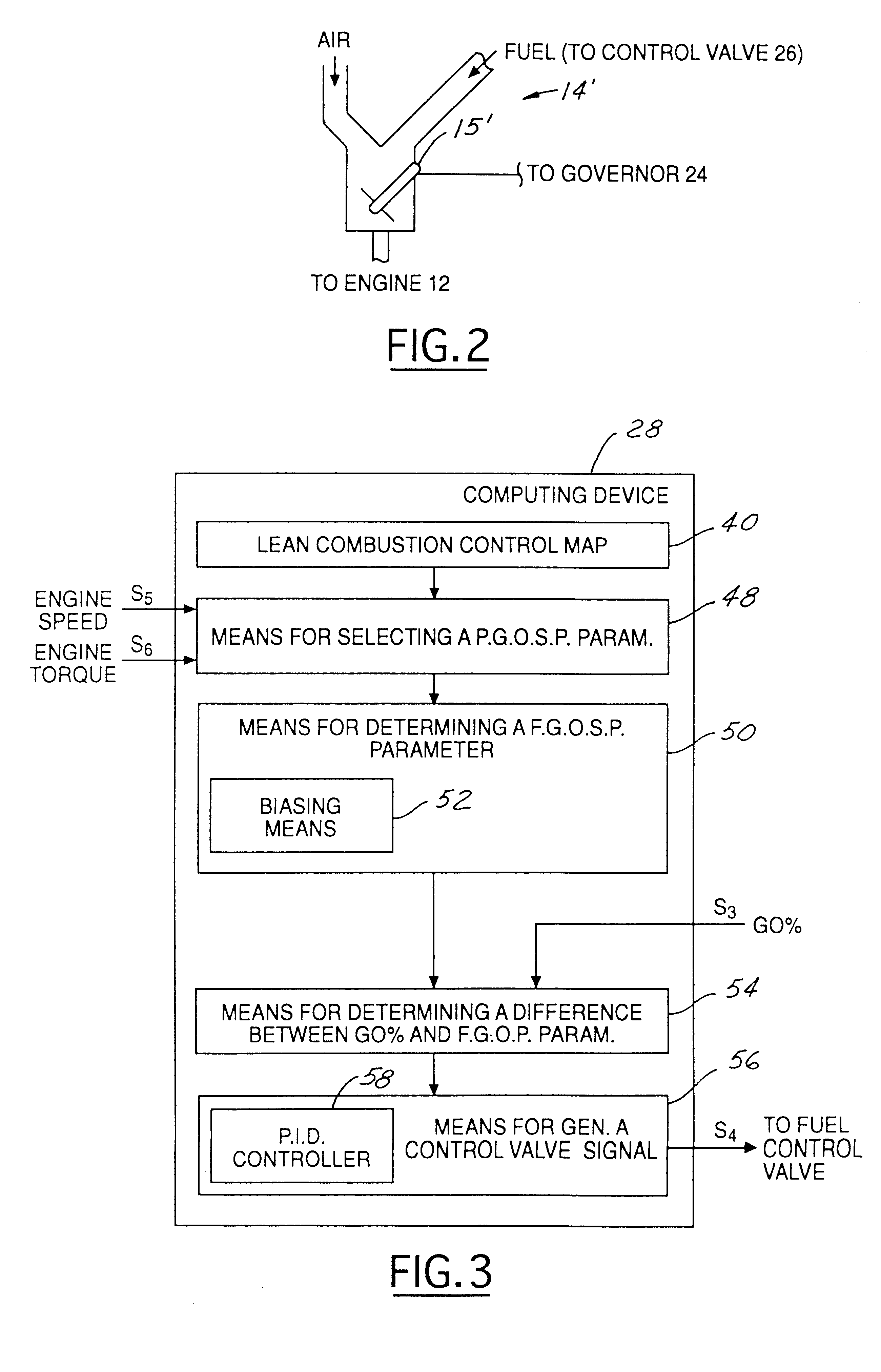

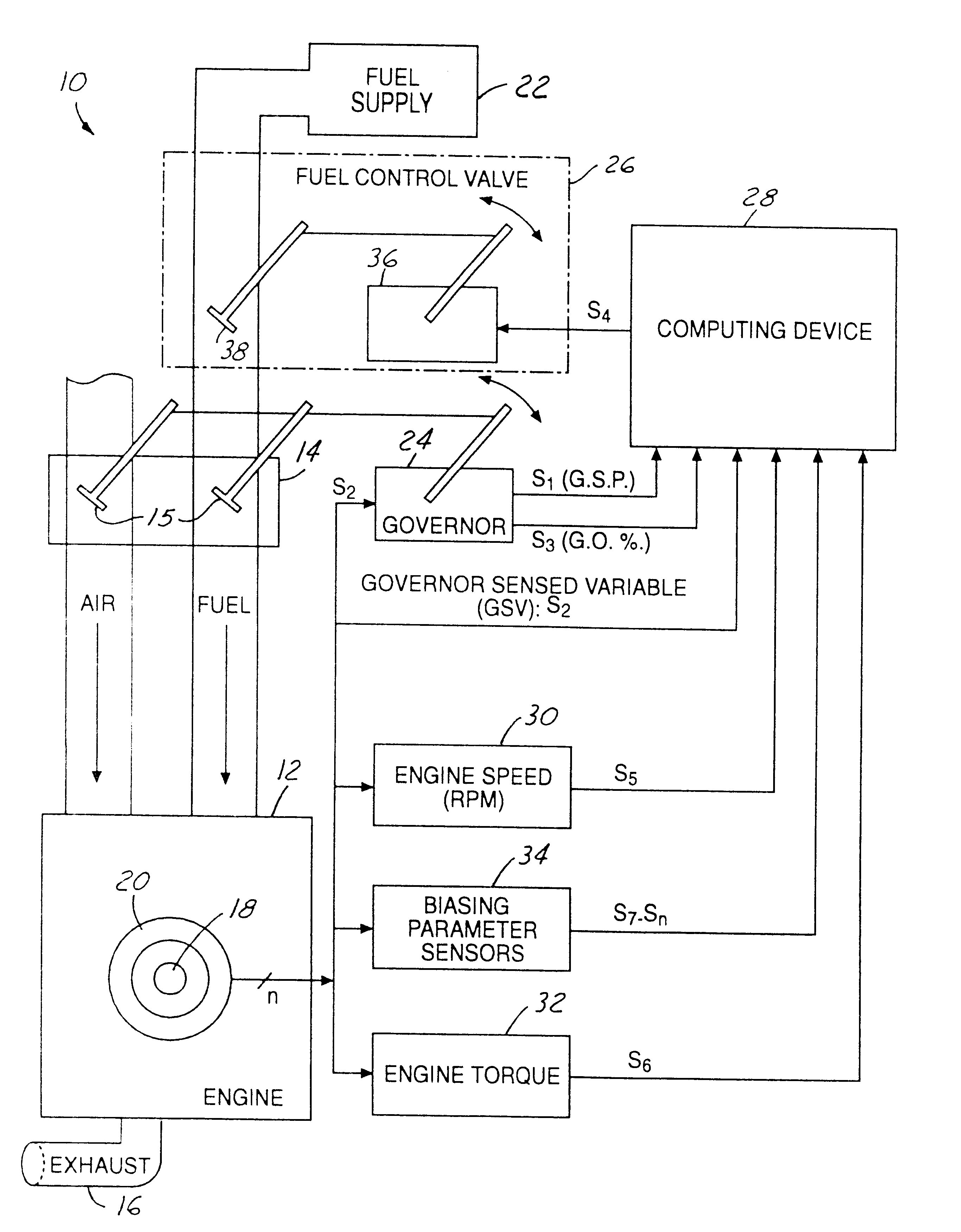

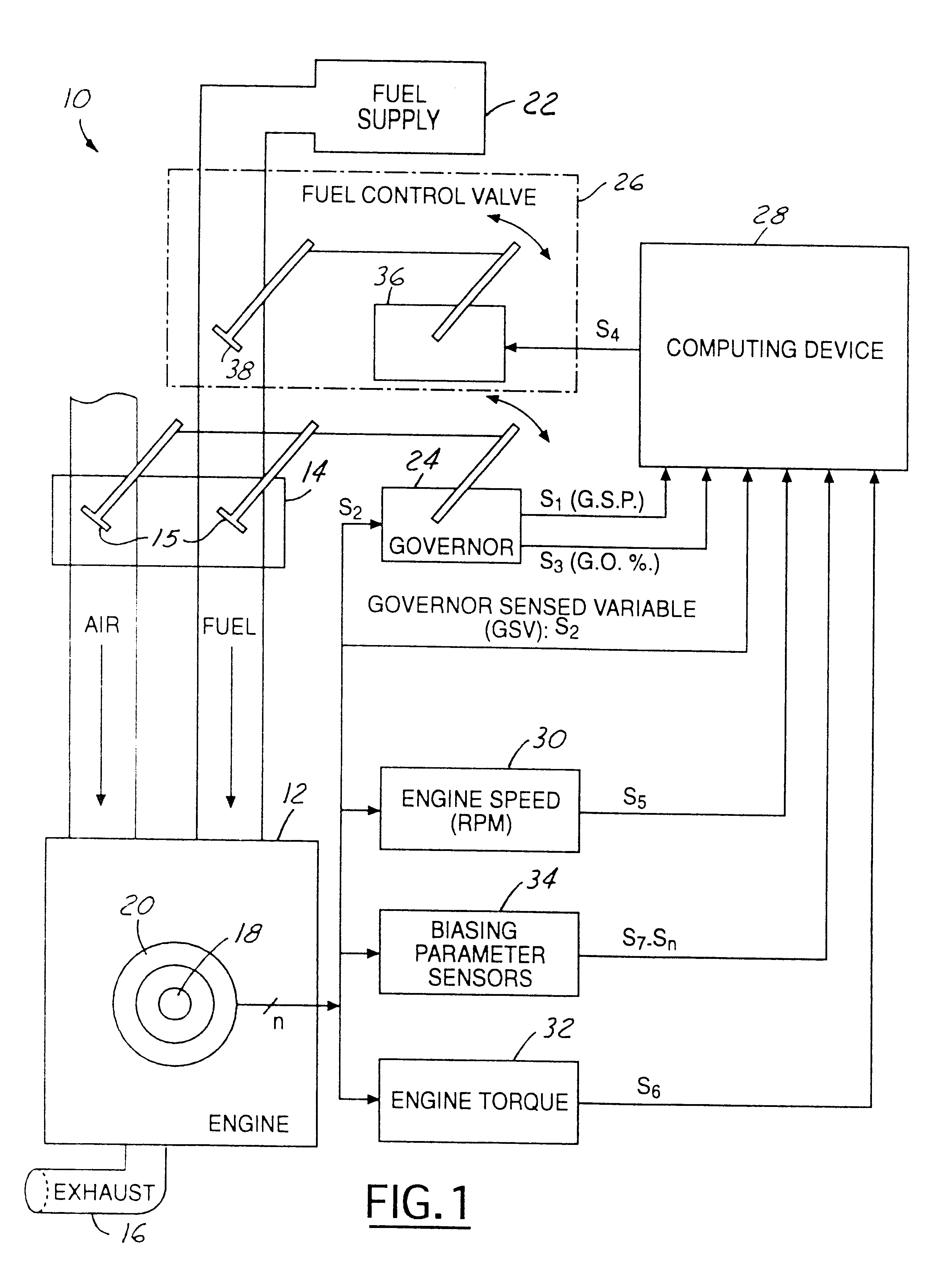

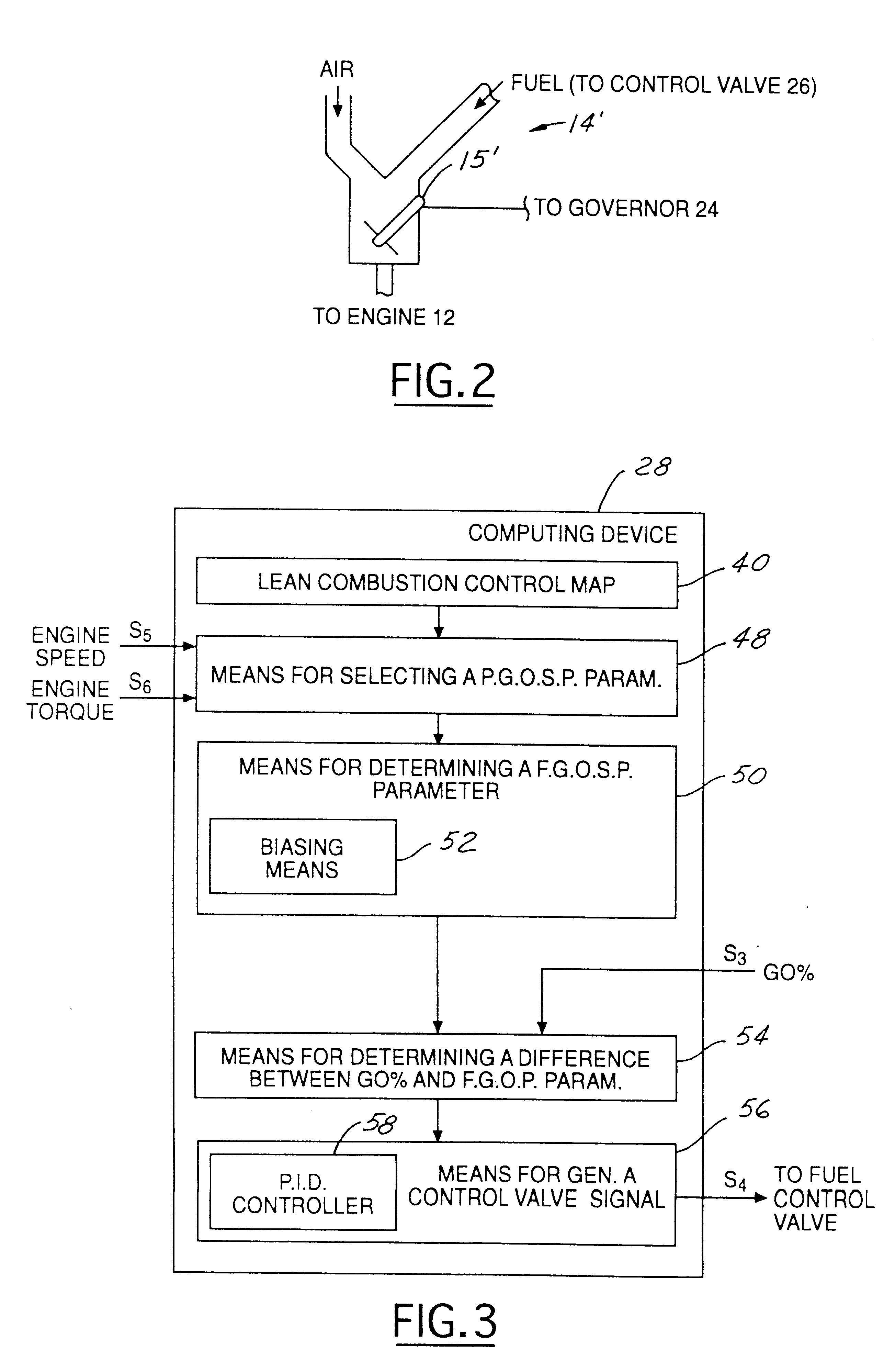

Method and system for controlling an air-to-fuel ratio in a non-stoichiometric power governed gaseous-fueled stationary internal combustion engine

InactiveUS6189523B1Reduces "pumping losses.Less importantAnalogue computers for vehiclesElectrical controlControl signalExhaust fumes

A gaseous-fueled reciprocating internal combustion engine includes a carburetor having a throttle valve that is controlled by a speed governor. A proportional fuel control valve is disposed intermediate a fuel supply and the carburetor, and is controlled by an air fuel computing device. The computing device generates a control signal to adjust the fuel control valve based on a governor sensed variable indicative of engine speed, sensed engine torque, a governor output signal from the governor indicative of an opening position of the throttle valve wherein 100% corresponds to a wide open throttle position, and 0% corresponds to a closed position, and a lean combustion control map containing predetermined set point values stored in memory. During operation, the control valve is responsive to the control signal generated by the computing device for adjustment of a fuel flow therethrough so as to obtain a ratio of air to fuel provided to the engine that is substantially at a lean misfire limit of the engine, thereby reducing fuel consumption, NOx emissions, and reducing exhaust gas temperatures. Alternatively, the control signal is generated using engine speed alone.

Owner:ANR PIPELINE

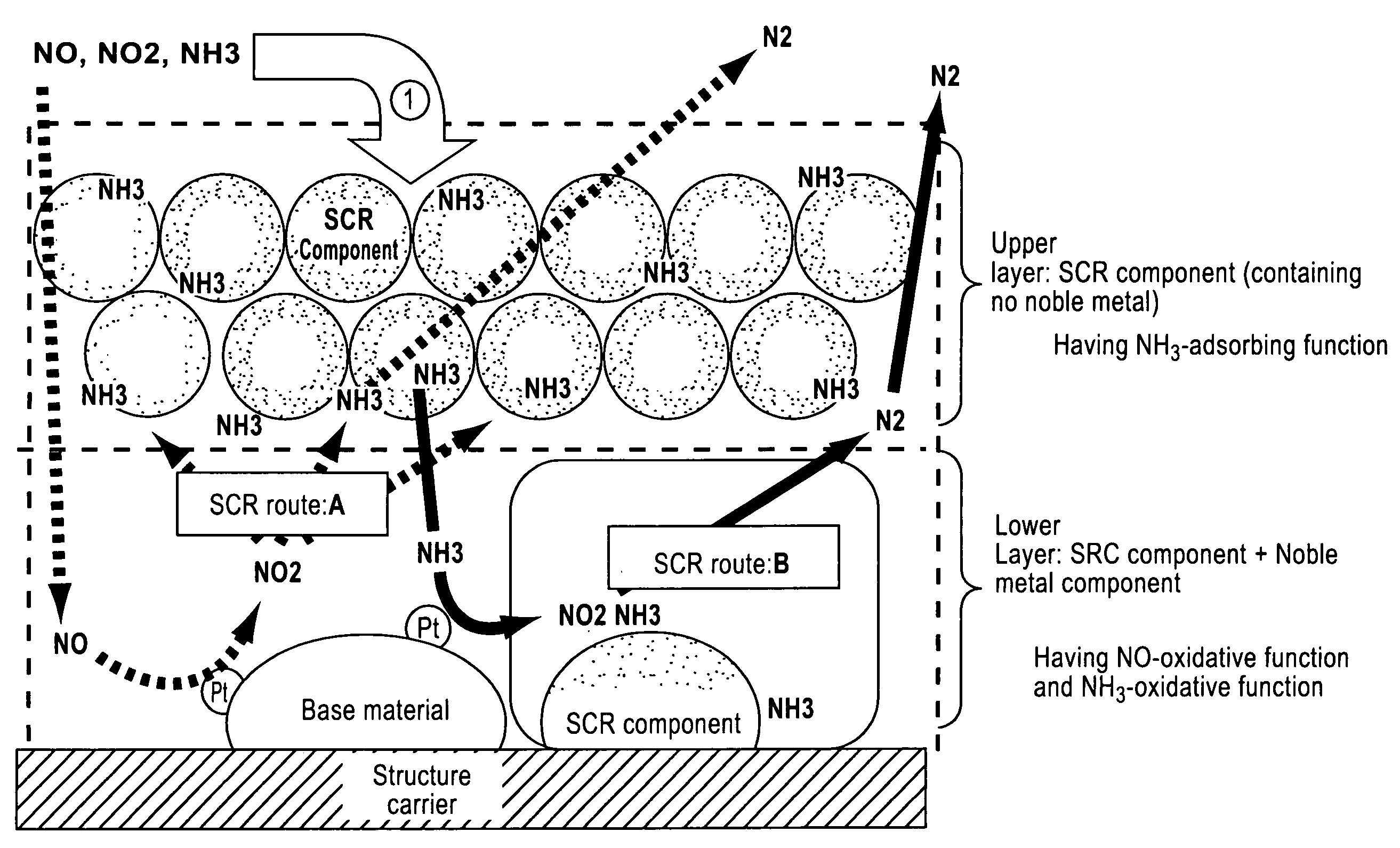

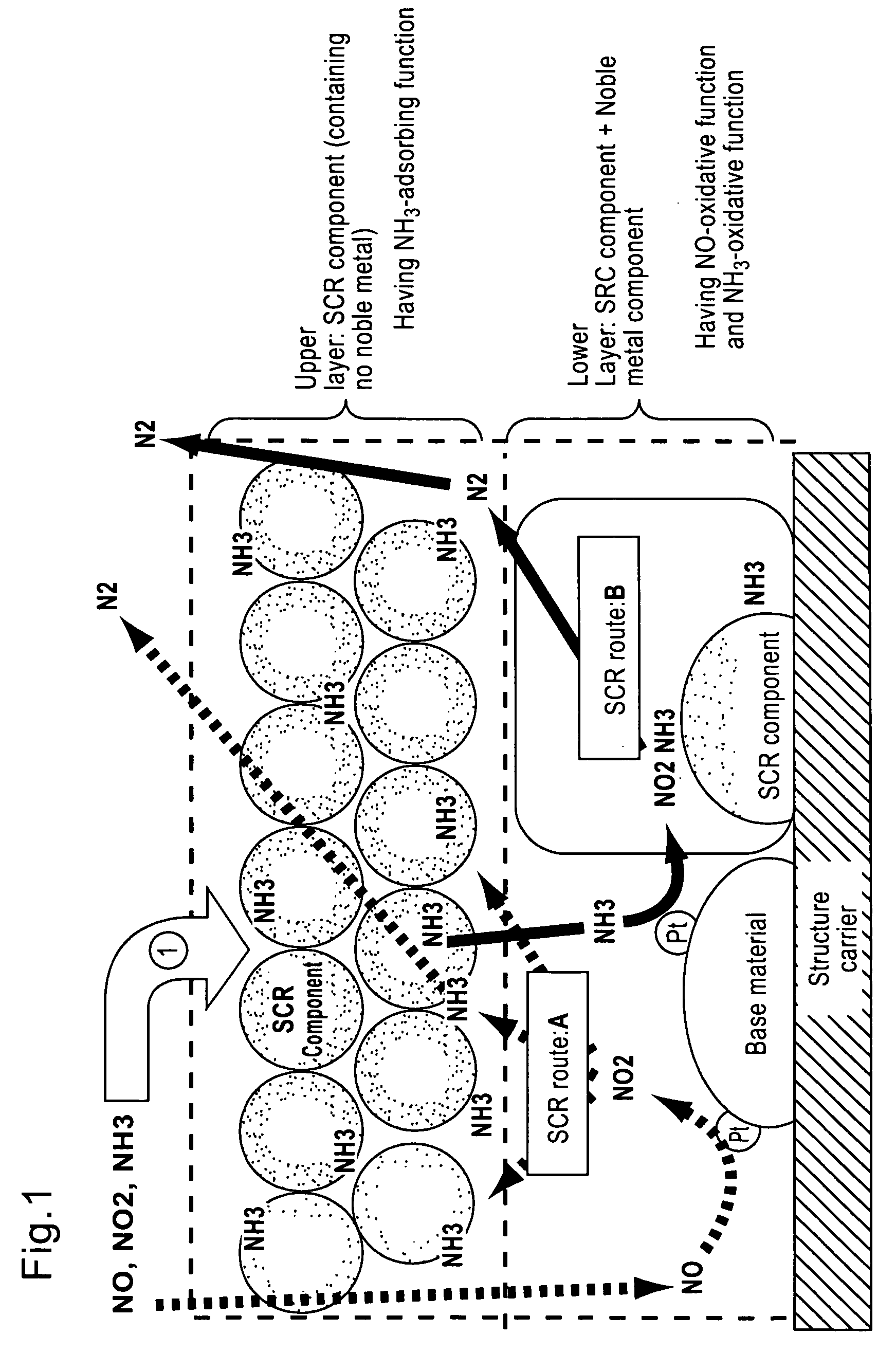

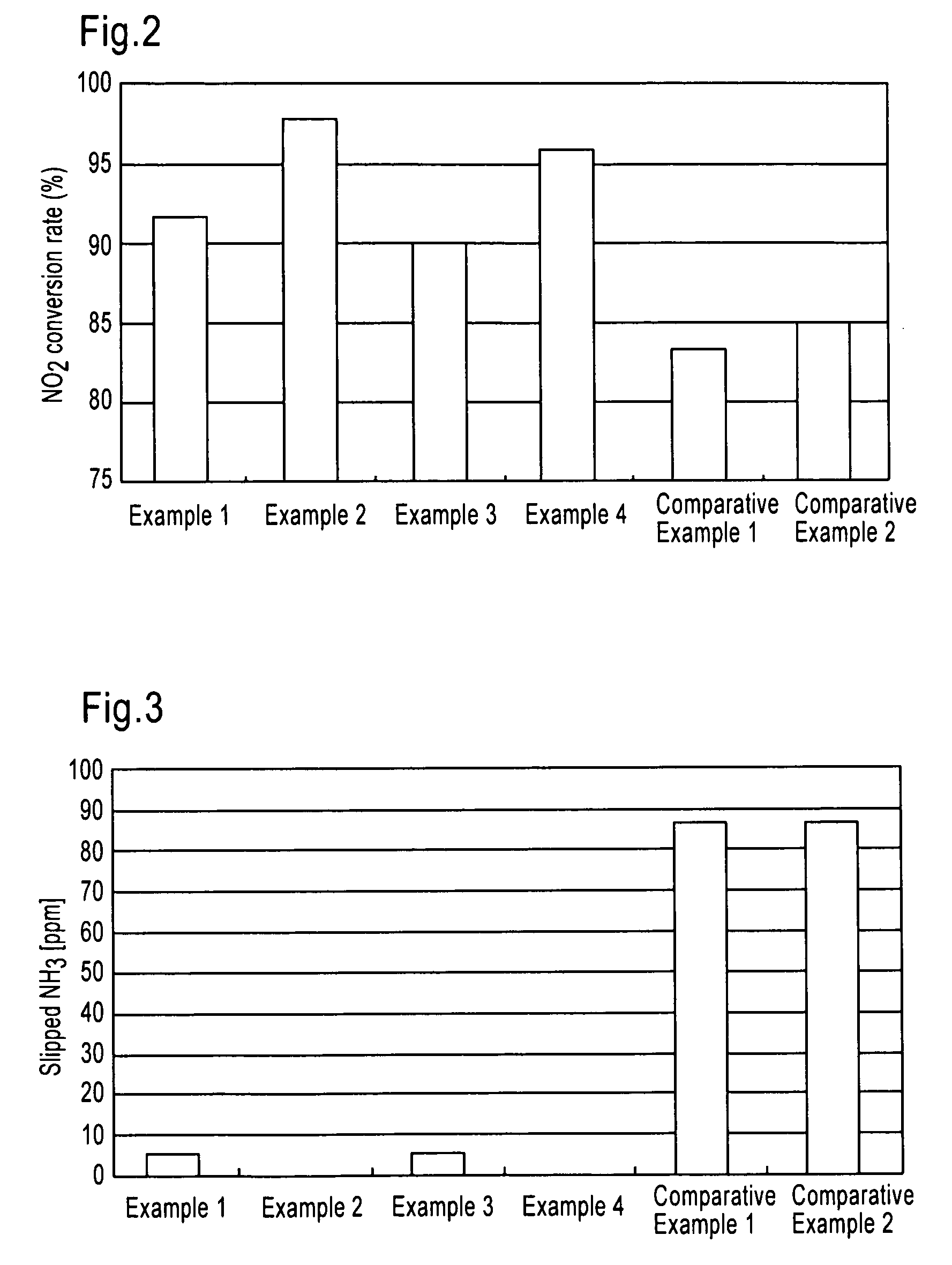

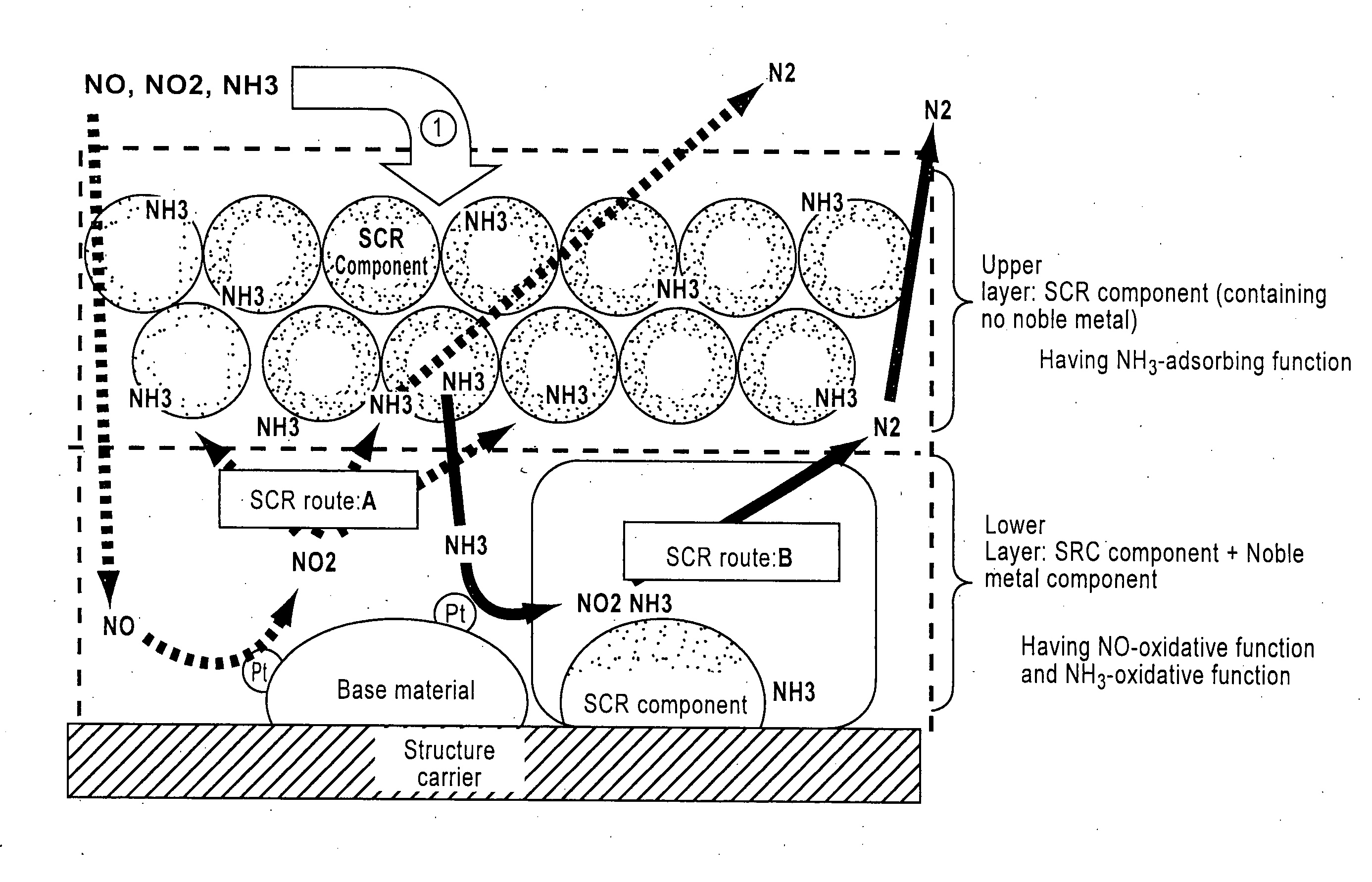

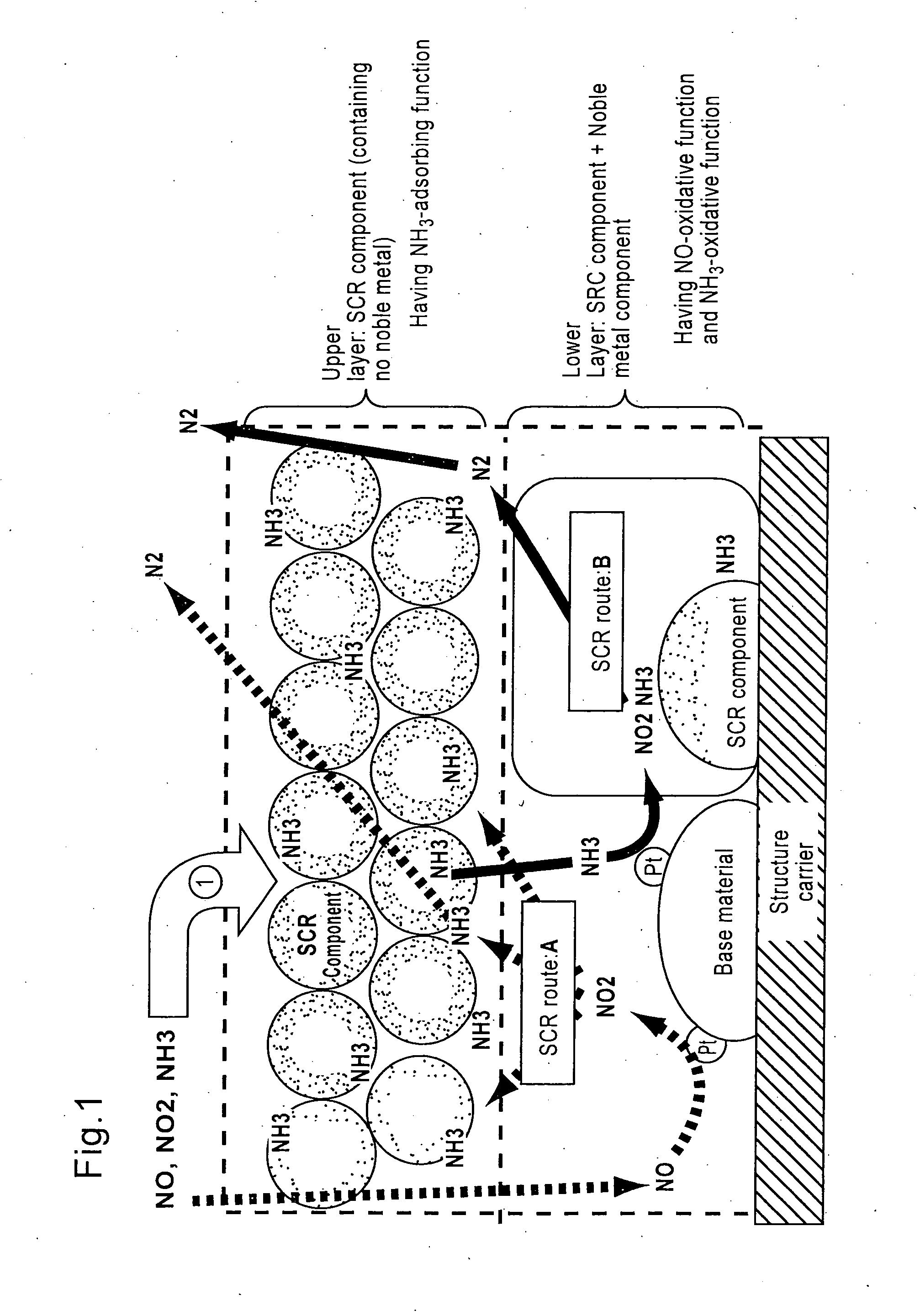

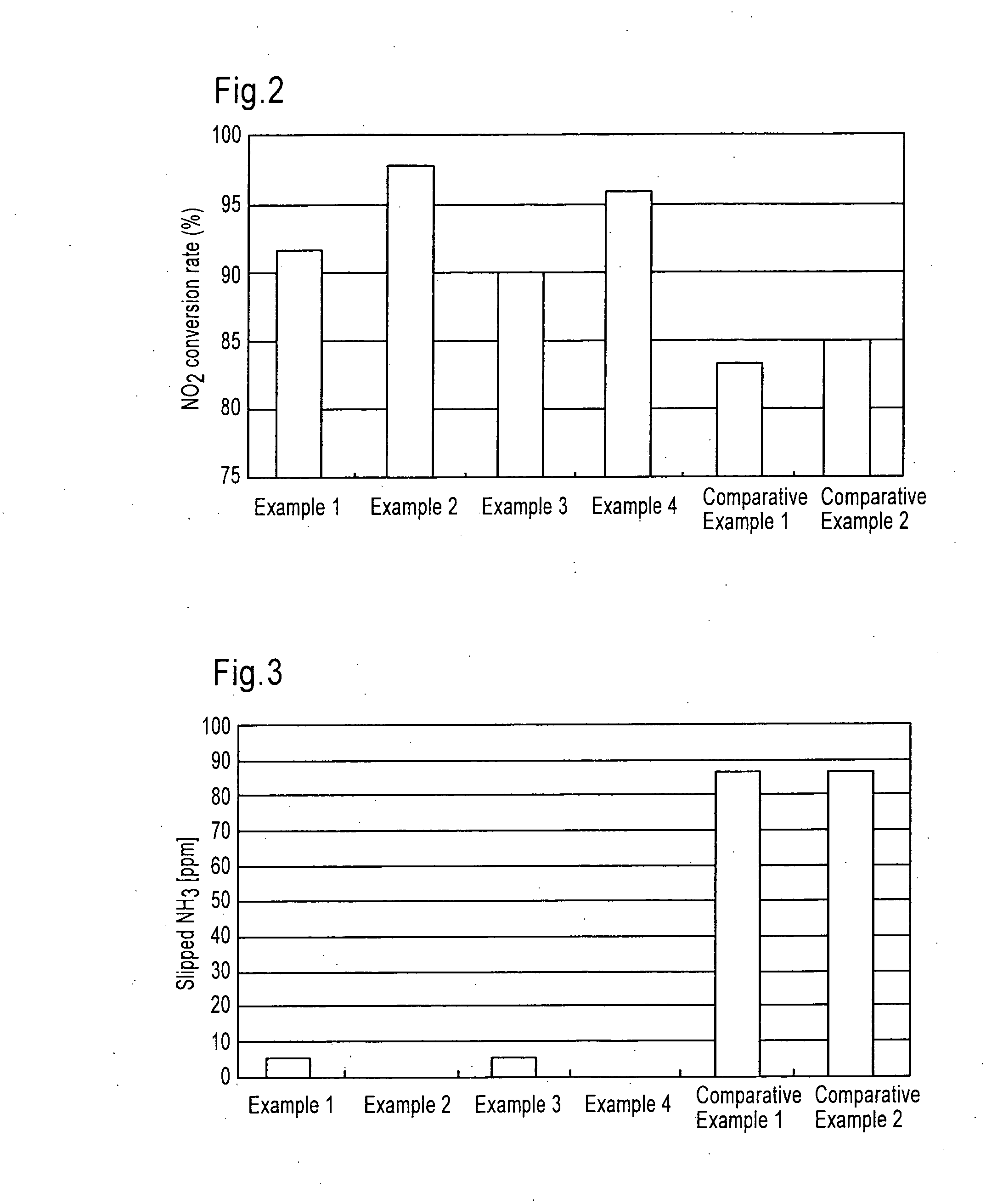

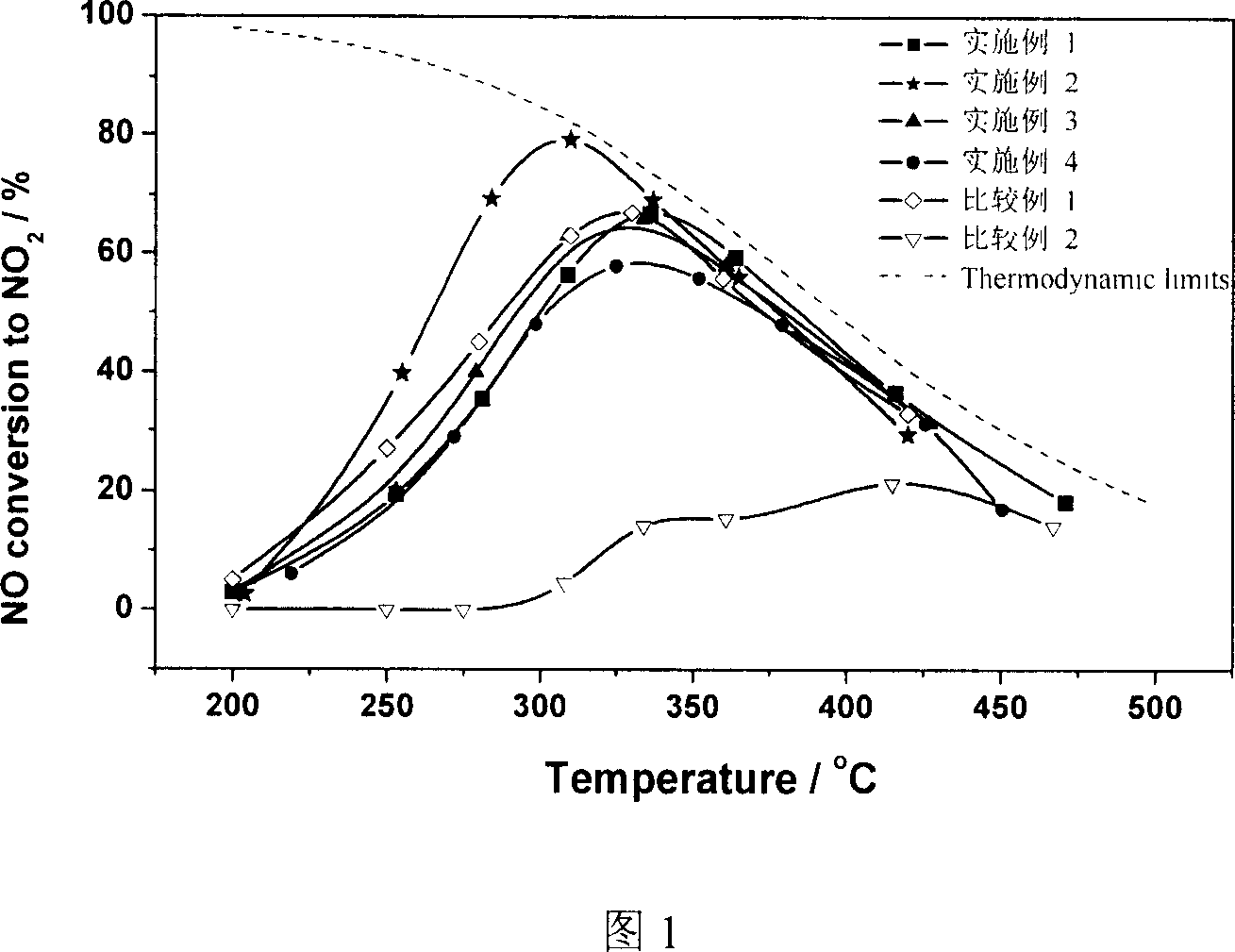

Selective catalytic reduction type catalyst, and exhaust gas purification equipment and purifying process of exhaust gas using the same

ActiveUS20080286184A1Improve purification effectImprove efficiencyGas treatmentNitrogen compoundsDiesel engineReducing agent

The present invention relates to a technology to purify nitrogen oxides contained in exhaust gas exhausted from lean combustion engines such as diesel engine with ammonia and a selective catalytic reduction type catalyst, and an object of the present invention is to provide a selective catalytic reduction type catalyst which can effectively purify nitrogen oxides even at a low temperature as well as inhibit leak of ammonia, and an exhaust gas purification equipment and a purifying process of exhaust gas using the same.The present invention is a selective catalytic reduction type catalyst for purifying nitrogen oxides in exhaust gas exhausted from lean combustion engines using ammonia or urea as a reducing agent, it is provided with a selective catalytic reduction type catalyst, characterized in that said catalyst comprises a lower-layer catalyst layer (A) having an oxidative function for nitrogen monoxide (NO) in exhaust gas and an upper-layer catalyst layer (B) having an adsorbing function for ammonia on the surface of a monolithic structure type carrier (C), and that the lower-layer catalyst layer (A) comprises a noble metal component (i), an inorganic base material constituent (ii) and zeolite (iii), and the upper-layer catalyst layer (B) comprises substantially none of component (i) but the component (iii).

Owner:N E CHEMCAT

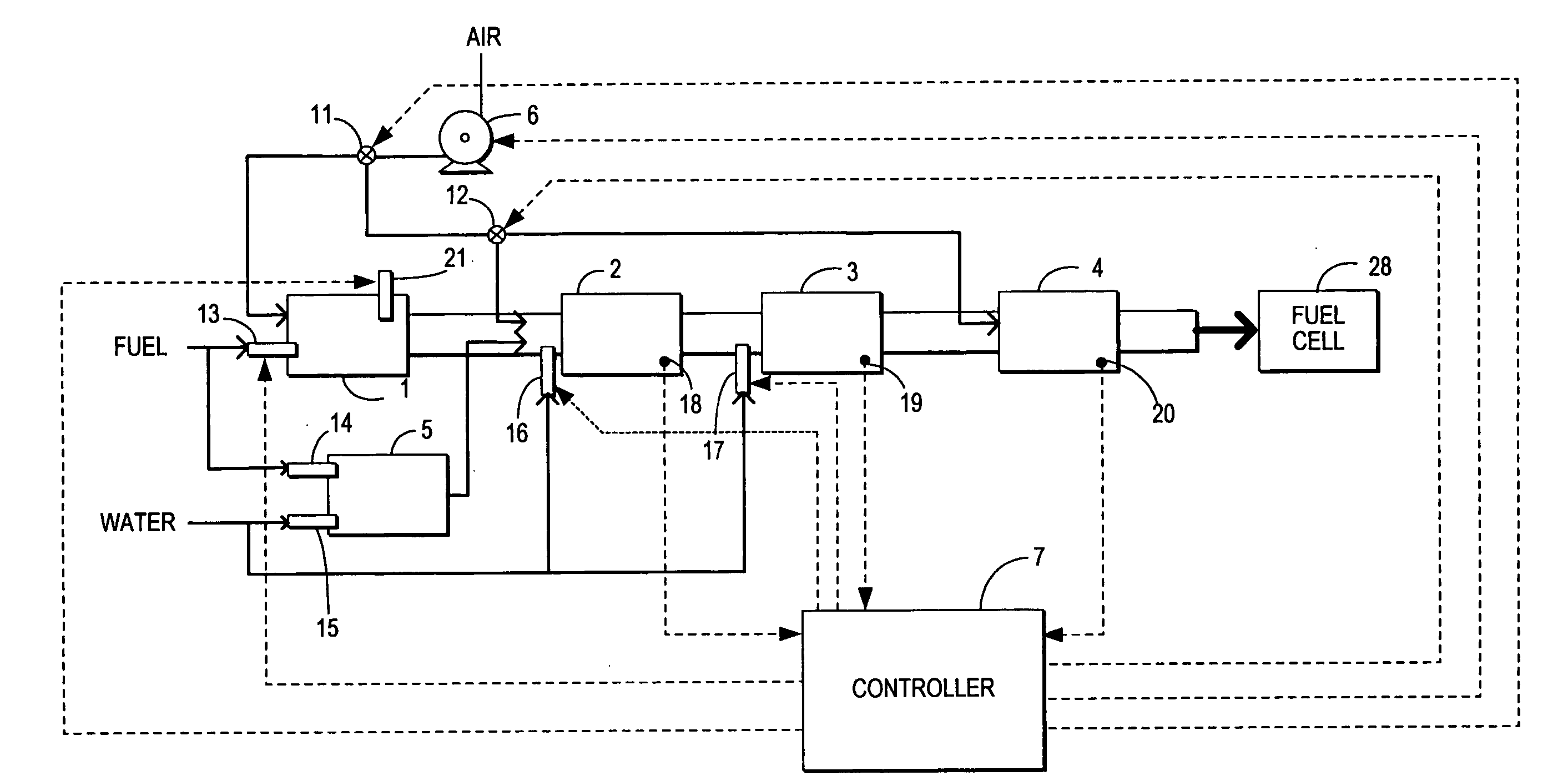

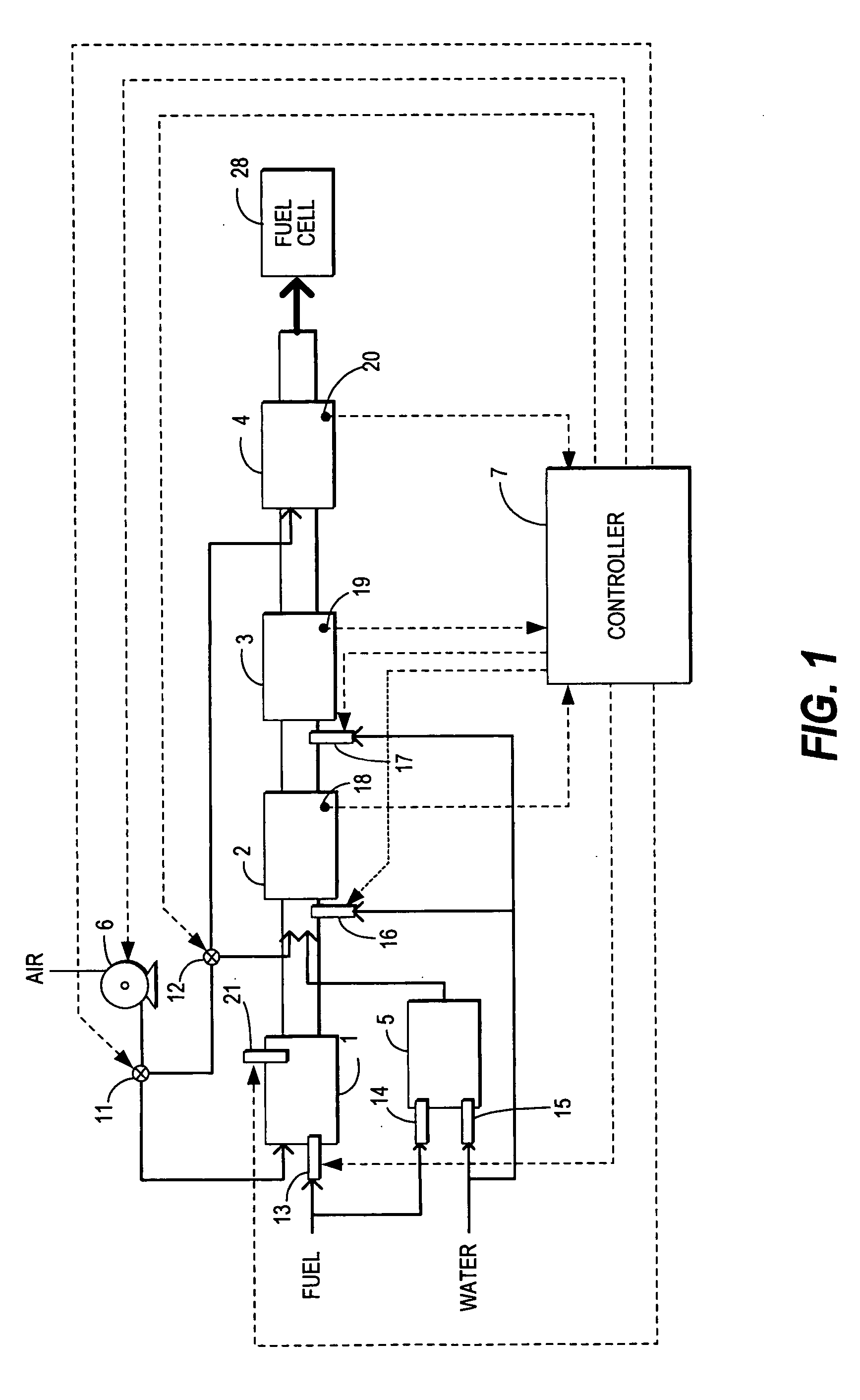

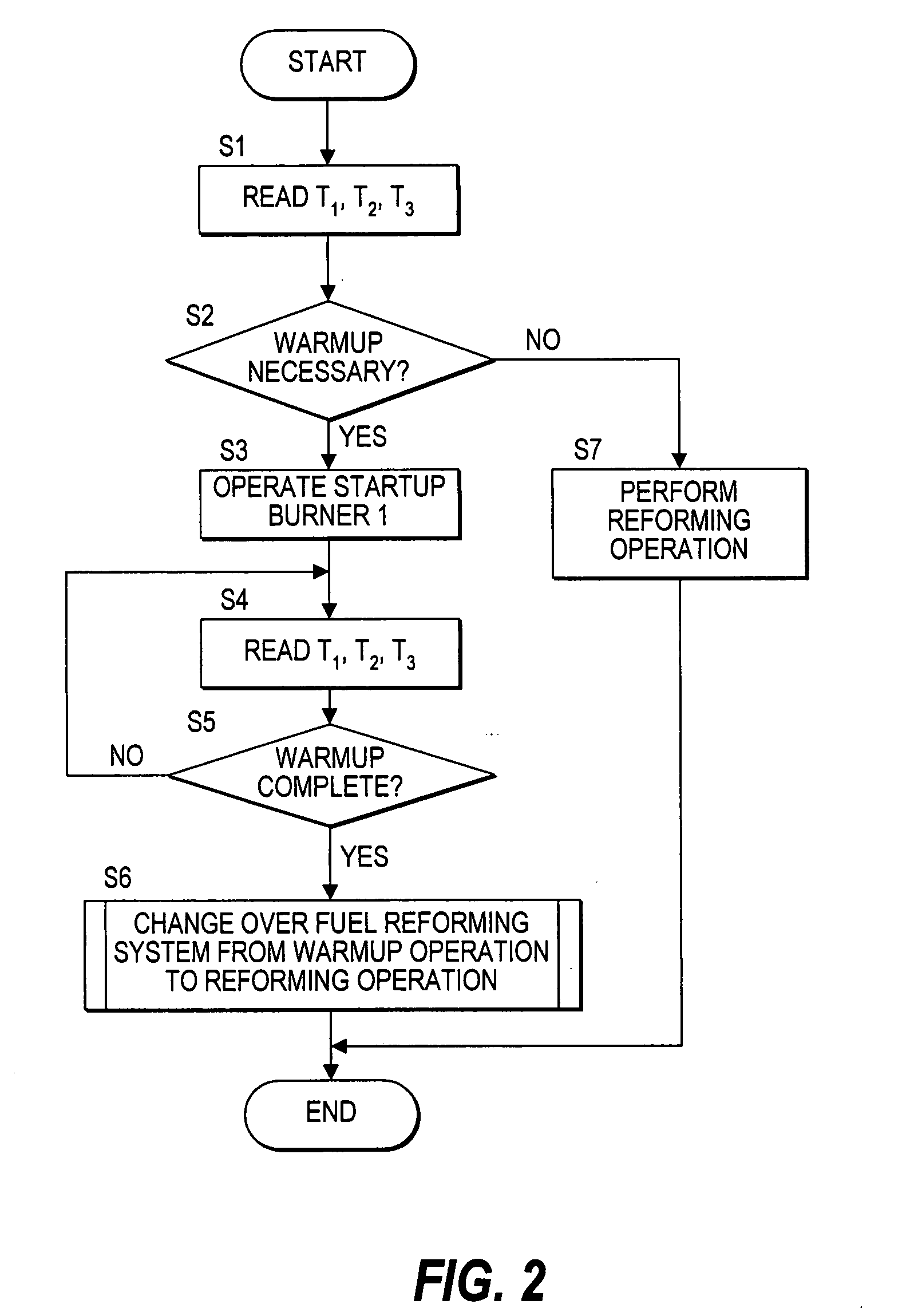

Fuel reforming system and fuel cell system having same

InactiveUS20050089732A1Process control/regulationFuel cell heat exchangeAutomotive engineeringLean combustion

A fuel reforming system, comprising a reformer (2, 3, 4) which produces reformate gas from rich raw fuel gas, and supplies the reformate gas to the fuel cell (28) during a reforming operation, a burner (1) which produces lean combustion gas, and supplies the lean combustion gas to the reformer (2, 3, 4) during a warmup operation of the reformer (2, 3, 4), and a nonflammable fluid supply apparatus which supplies a nonflammable fluid other than fuel and air to the reformer (2, 3, 4). During the warmup operation of the reformer (2, 3, 4), the lean combustion gas is supplied from the burner (1) to the reformer (2, 3, 4), and when warmup of the reformer (2, 3, 4) is complete, the nonflammable fluid is supplied from the nonflammable fluid supply apparatus to the reformer (2, 3, 4), and the reforming operation of the reformer (2, 3, 4) then starts.

Owner:NISSAN MOTOR CO LTD

Selective catalytic reduction type catalyst, and exhaust gas purification equipment and purifying process of exhaust gas using the same

The present invention is an exhaust gas purification catalyst equipment, and a method of use thereof, formed by arranging a selective catalytic reduction type catalyst for purifying nitrogen oxides in exhaust gas exhausted from lean combustion engines using ammonia or urea as a reducing agent, it is provided with a selective catalytic reduction type catalyst, characterized in that said catalyst comprises a lower-layer catalyst layer (A) having an oxidative function for nitrogen monoxide (NO) in exhaust gas and an upper-layer catalyst layer (B) having an adsorbing function for ammonia on the surface of a monolithic structure type carrier (C), and that the lower-layer catalyst layer (A) comprises a noble metal component (i), an inorganic base material constituent (ii) and zeolite (iii), and the upper-layer catalyst layer (B) comprises substantially none of component (i) but the component (iii), in a flow path of exhaust gas, characterized in that a spraying means to supply an urea aqueous solution or an aqueous ammonia solution is arranged in the downstream of the aforementioned oxidation catalyst and in the upstream of aforementioned selective catalytic reduction type catalyst.

Owner:N E CHEMCAT

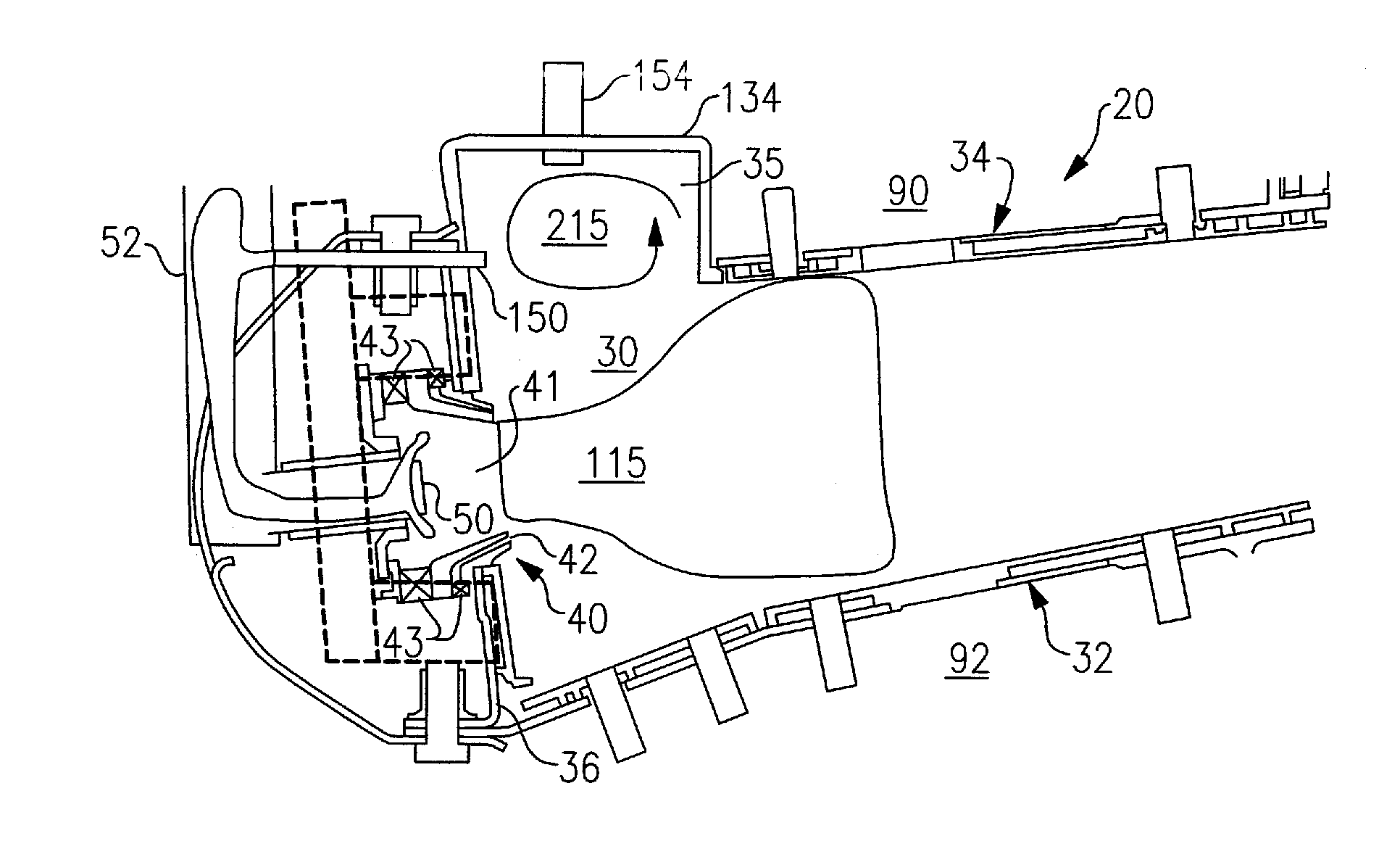

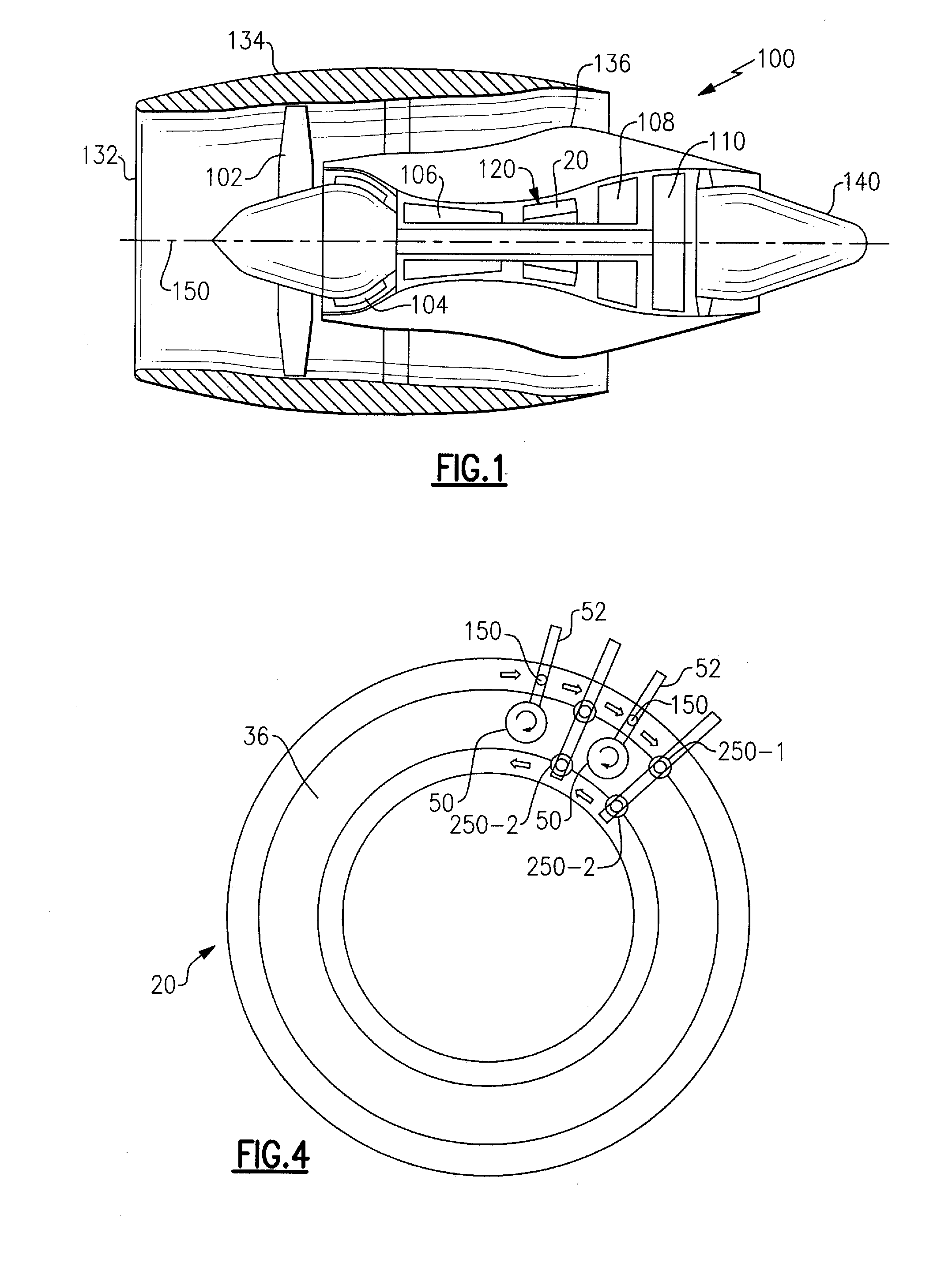

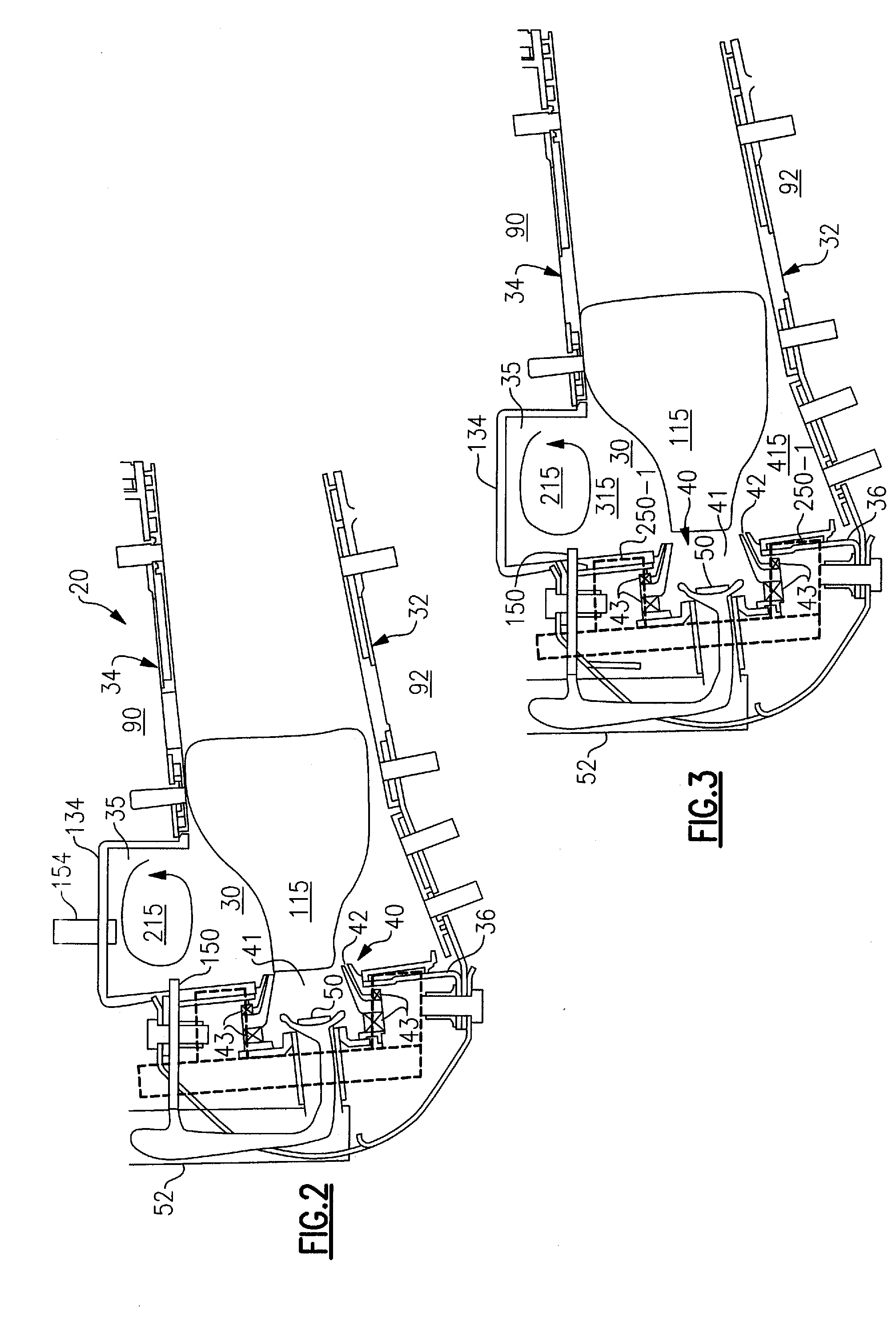

Gas turbine combustor with staged combustion

ActiveUS20110185735A1Easy to optimizeExpand the scope of operationTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorStaged combustion

An annular combustor for a gas turbine engine is provided that facilitates staged combustion in a lean direct ignition (LDI) mode over an extended range of operating fuel air ratios. A method is also provided for operating a gas turbine engine over a power demand range that facilitates staged combustion in a lean direct ignition (LDI) mode over an extended range of operating fuel air ratios.

Owner:RAYTHEON TECH CORP

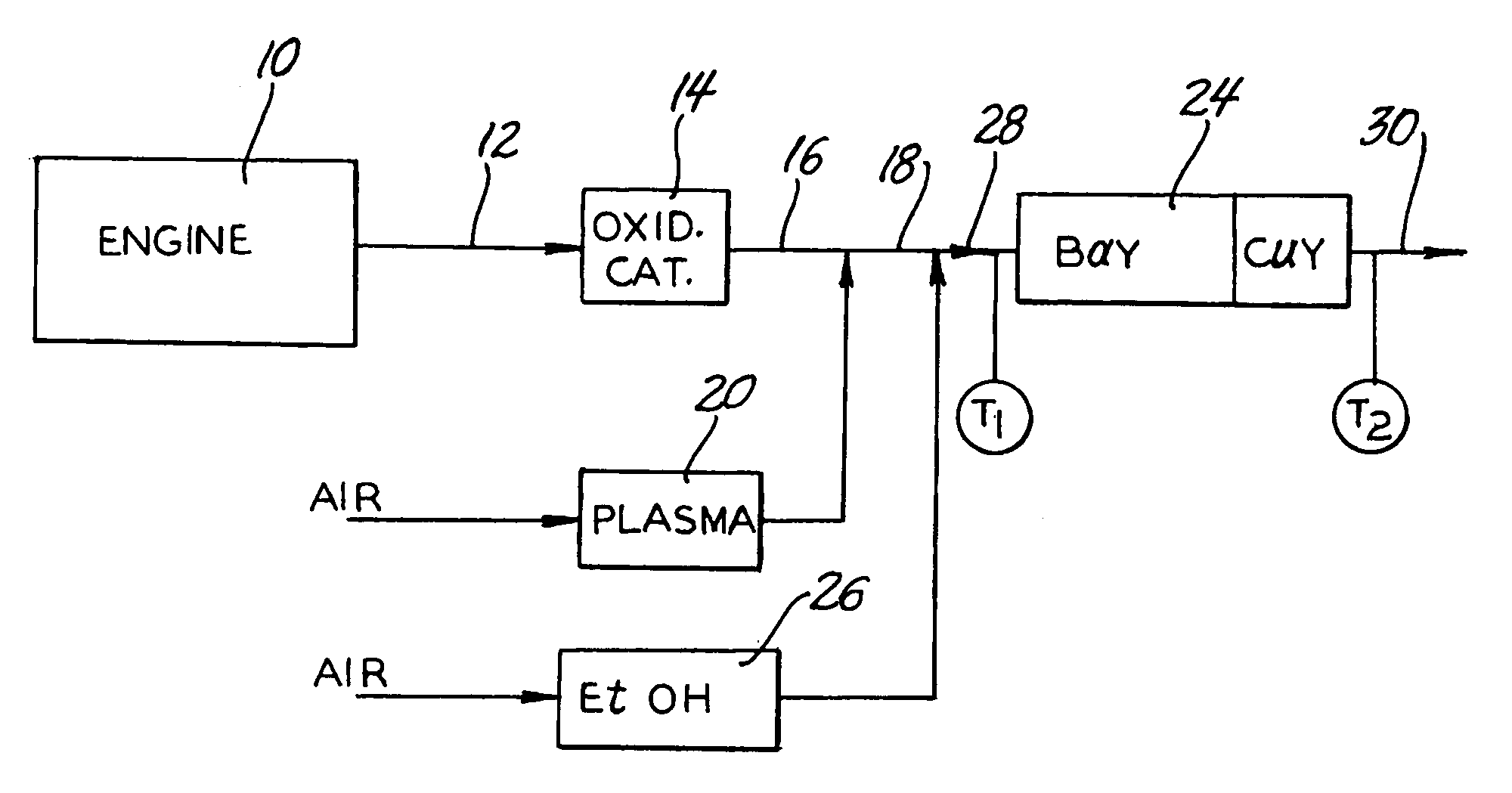

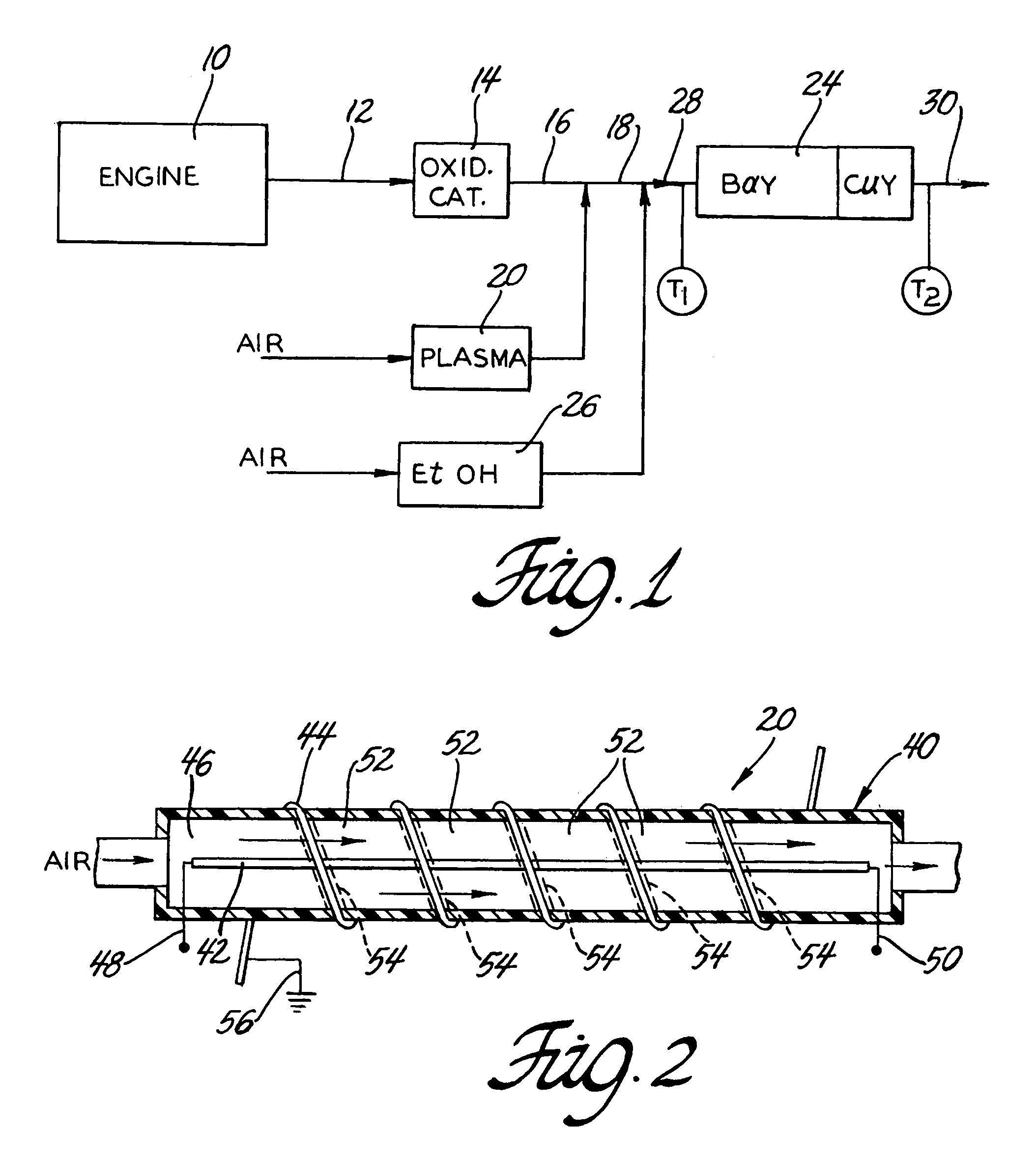

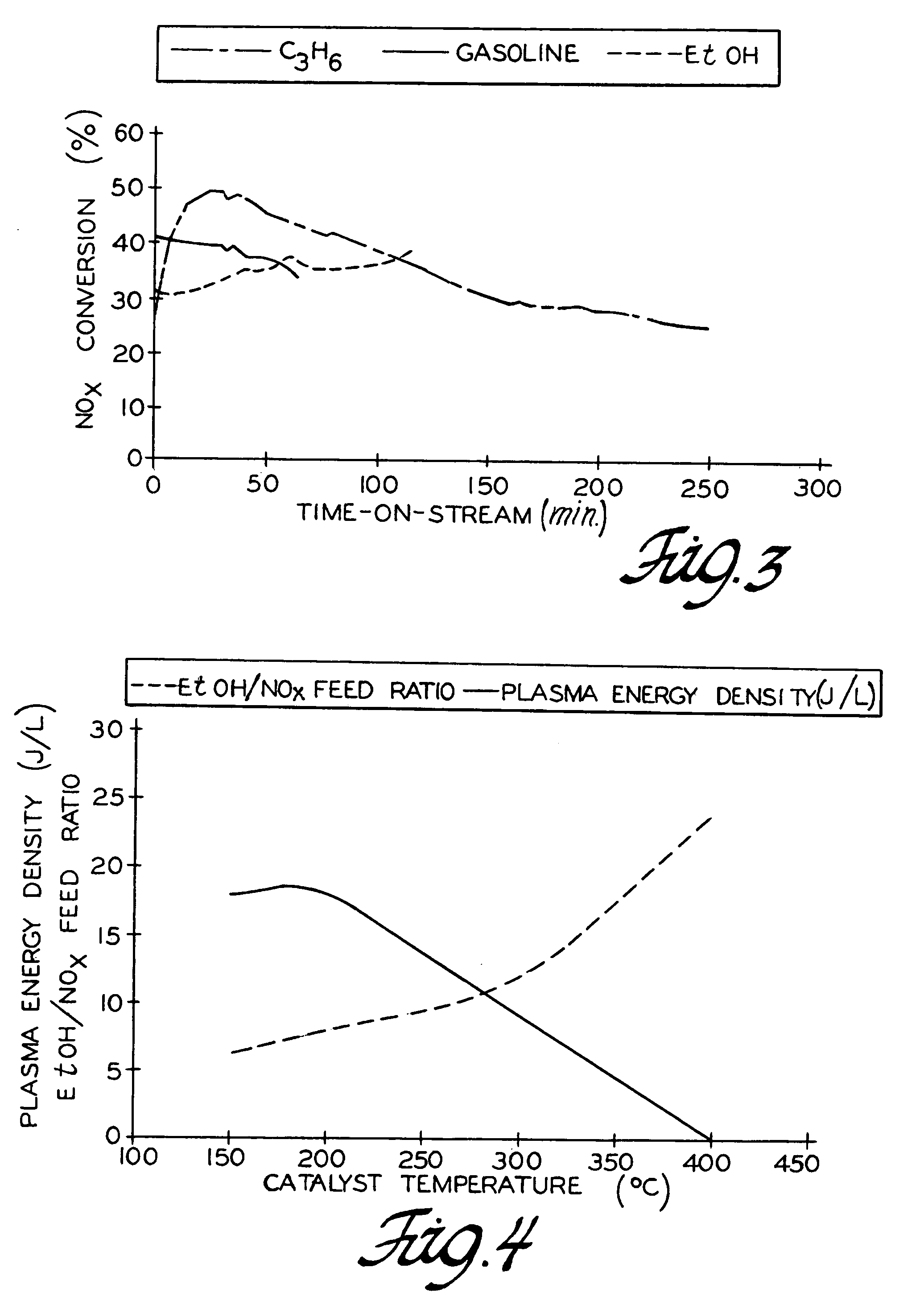

Method of reducing NOx in diesel engine exhaust

InactiveUS7090811B2Improve efficiencyHigh activityNitrogen compoundsInternal combustion piston enginesOxygenPlasma reactor

This invention provides a method of reducing nitrogen oxides in an oxygen containing exhaust stream using ethanol as a reductant for plasma-assisted selective catalytic reduction. The exhaust gas, generated from a diesel engine or other lean-burn power source, comprises nitrogen oxides, especially NO. Ozone generated from a plasma reactor is injected into the exhaust stream to convert NO to NO2 and the plasma injection is followed by the addition of ethanol. The NO2 is then reduced by contacting the exhaust stream with a dual-bed catalytic reactor comprising BaY (or NaY) and CuY zeolite catalysts in the presence of ethanol as the reductant. The plasma power density and the molar ratio of ethanol to NOx fed to the catalytic reactor are controlled as a function of the catalyst temperature for the best performance of the plasma-catalyst system. An average conversion of NOx to N2 of at least 90% is achieved over the temperature range of 200–400° C.

Owner:GM GLOBAL TECH OPERATIONS LLC

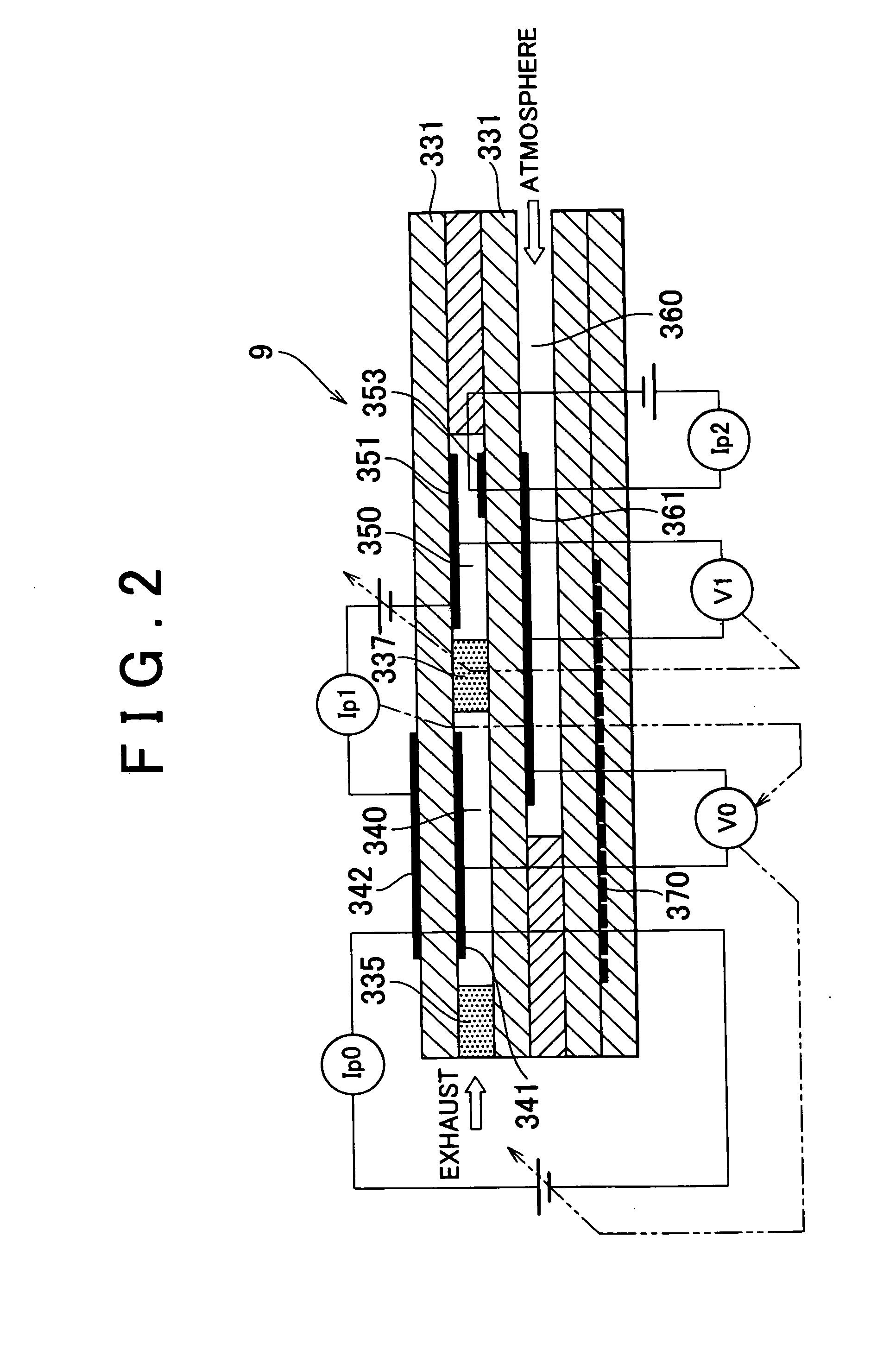

Exhaust emission control system and method

ActiveUS20040074226A1Solution value is not highLong intervalElectrical controlInternal combustion piston enginesControl systemExhaust fumes

An exhaust emission control system for an internal combustion engine is provided which includes a NOx storage / reduction catalyst disposed in an exhaust passage of the engine, and a NOx sensor positioned in the exhaust passage downstream of the catalyst. A controller of the system performs a rich-spike operation to temporarily operate the engine at a rich air / fuel ratio each time a NOx storage state of the catalyst satisfies a predetermined rich-spike condition during a lean-burn operation. When the degree of degradation of the catalyst is determined by comparing the output of the NOx sensor with a predetermined evaluation value, the rich-spike condition is changed so that the amount of NOx stored in the catalyst at the time of a start of the rich-spike operation during a degradation determination period is made larger than that reached during a period other than the determination period.

Owner:TOYOTA JIDOSHA KK

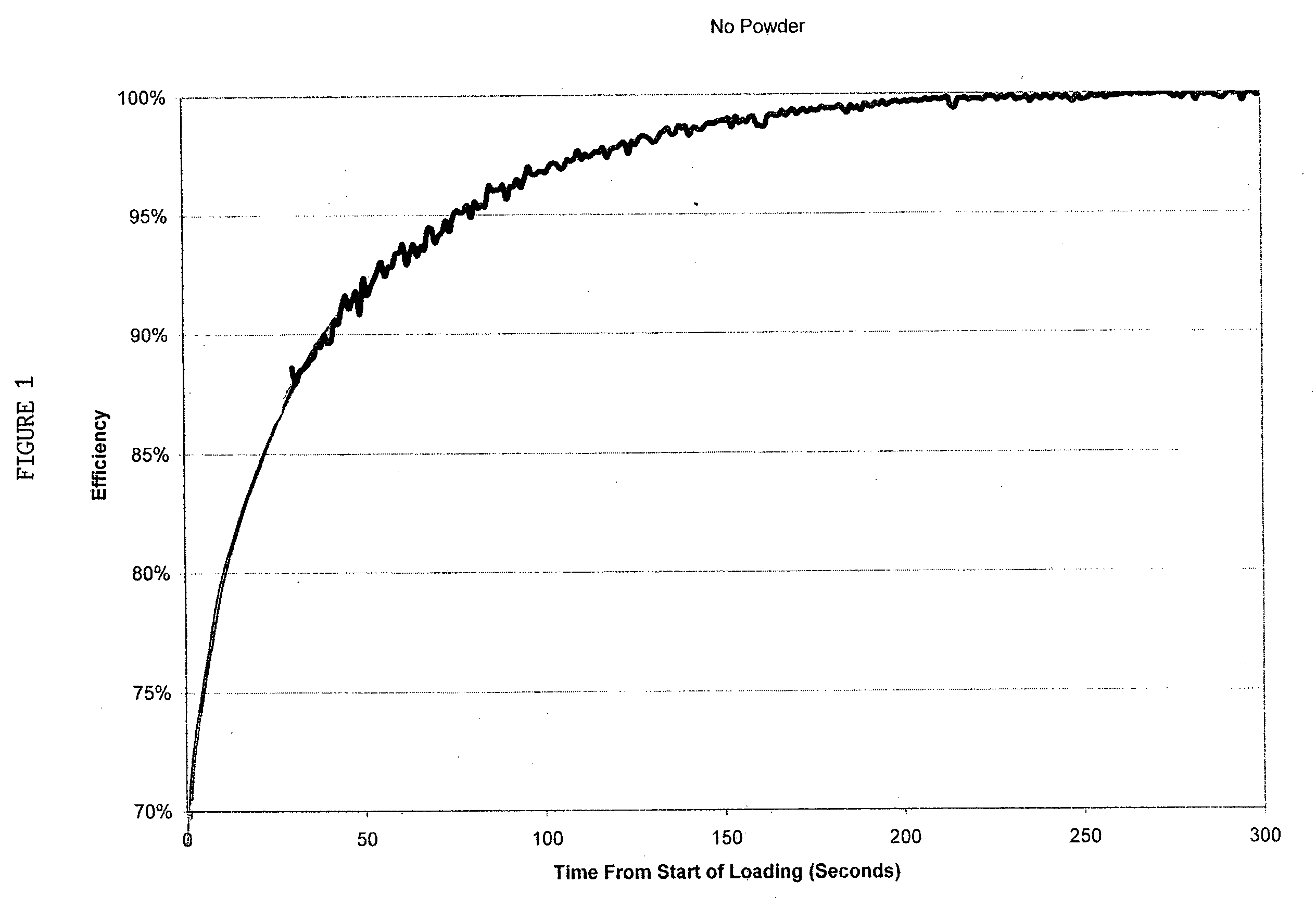

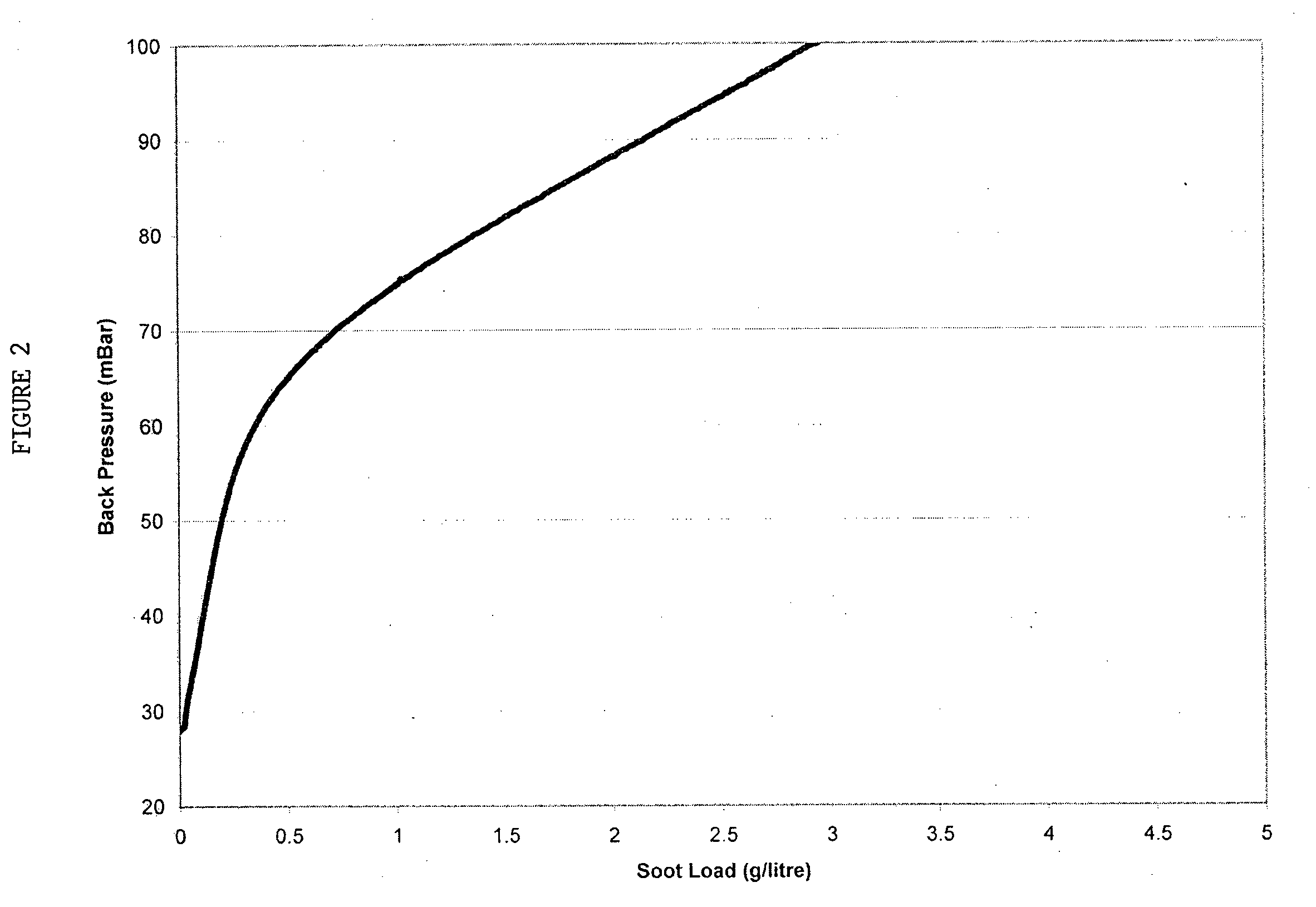

Diesel particulate filter

ActiveUS20130243659A1Excessive backpressureHigh platinum group metal loadingCombination devicesLiquid surface applicatorsPorous substrateExhaust fumes

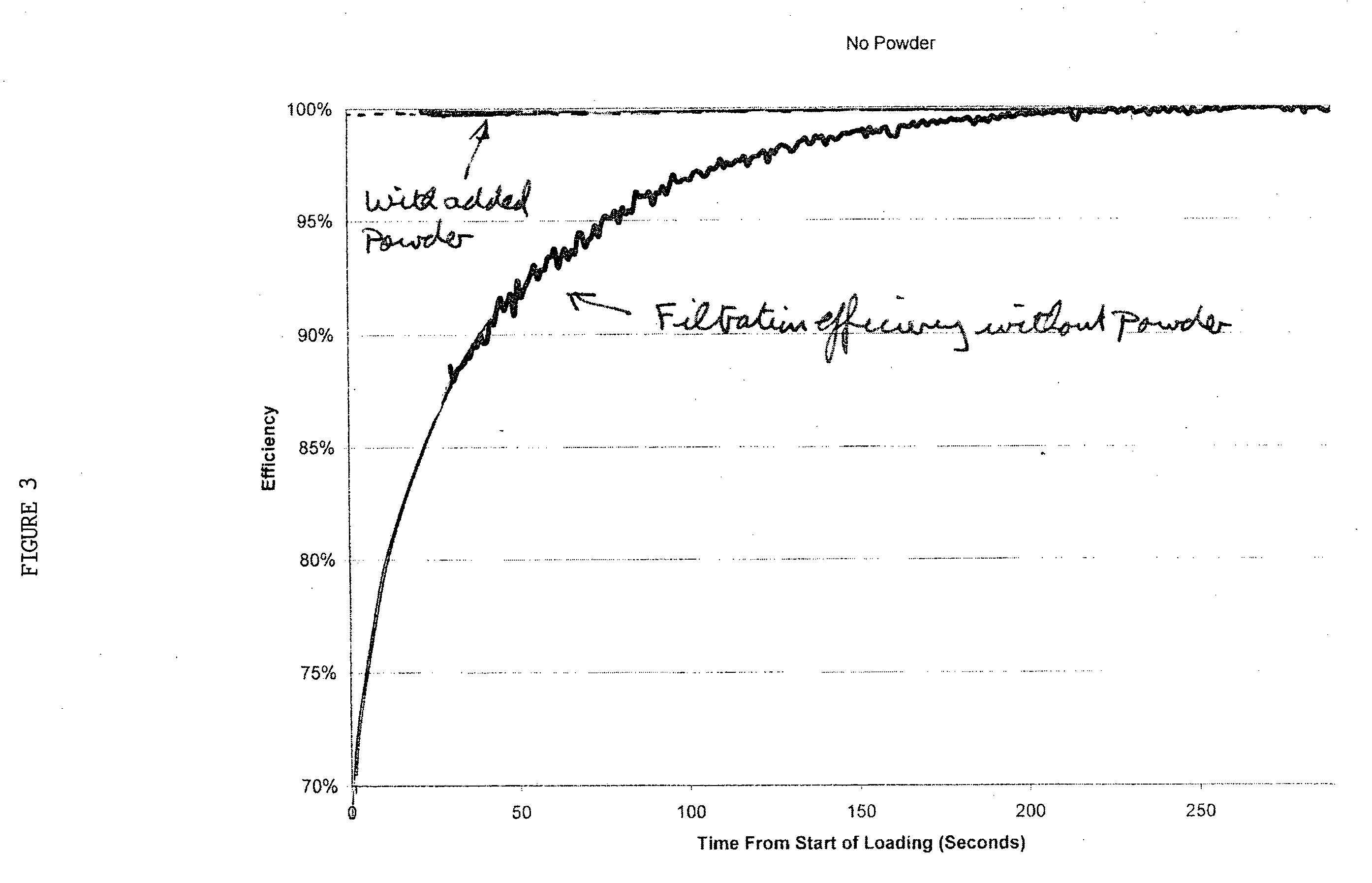

A method of making a filter for filtering particulate matter from exhaust gas emitted from a lean-burn internal combustion engine, which filter comprising a porous substrate having inlet surfaces and outlet surfaces, wherein the inlet surfaces are separated from the outlet surfaces by a porous structure containing pores of a first mean pore size, wherein the inlet surfaces comprise a bridge network comprising interconnected particles of refractory material over the pores of the porous structure, which method comprising the step of contacting inlet surfaces of the filter substrate with an aerosol comprising refractory material in dry powder form. The invention also relates to a filter obtainable by such method.

Owner:JOHNSON MATTHEY PLC

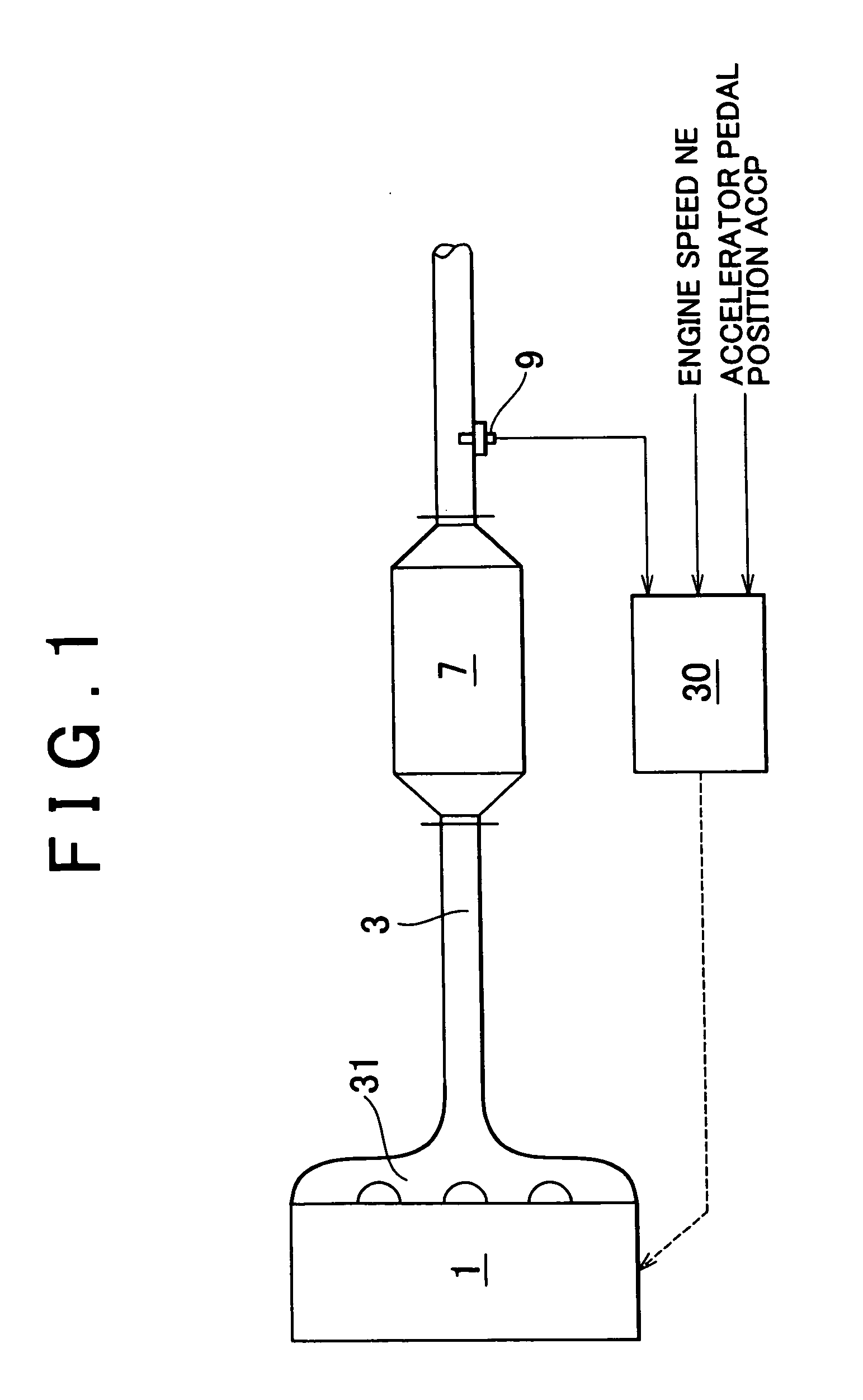

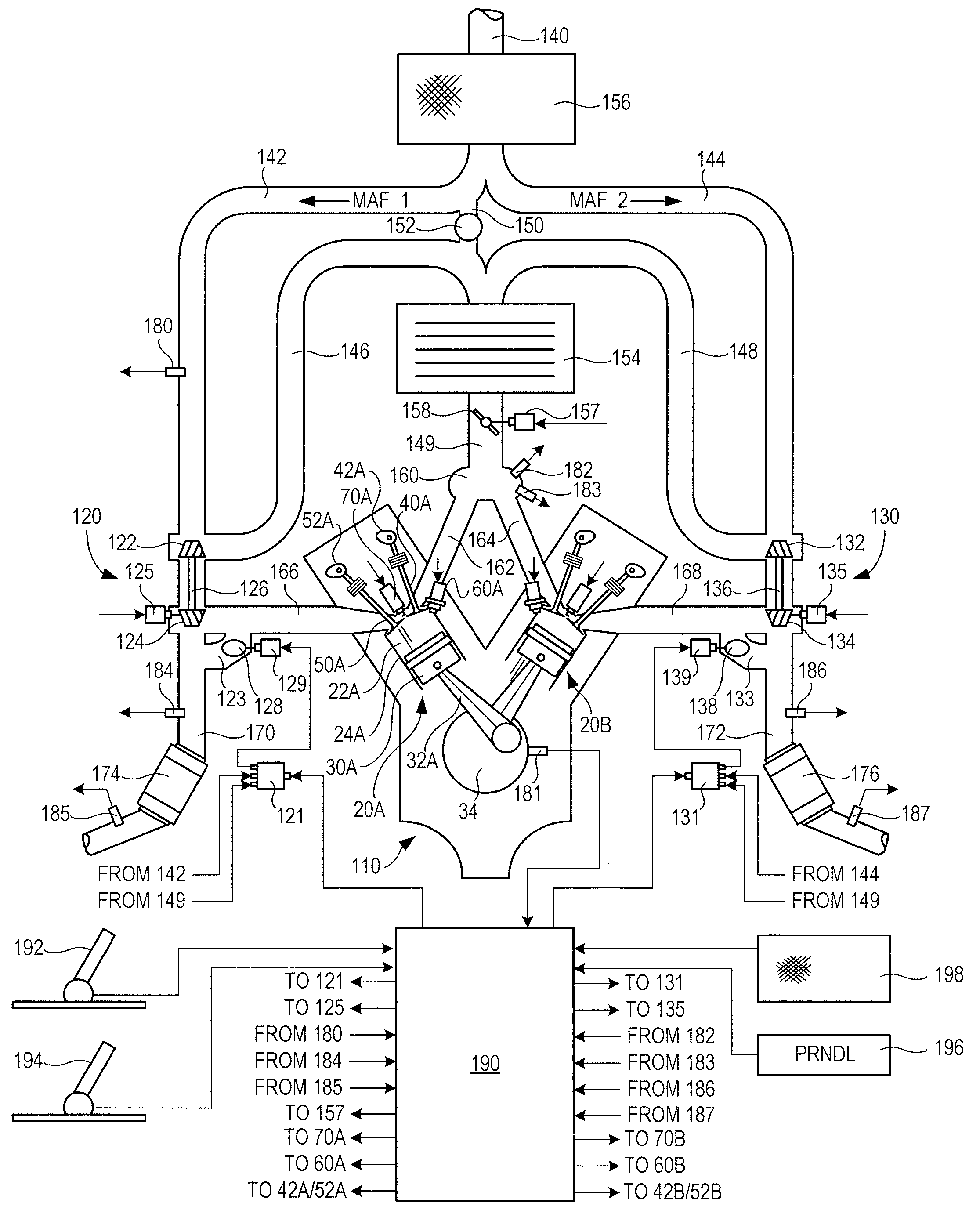

Internal combustion engine and internal combustion engine control method

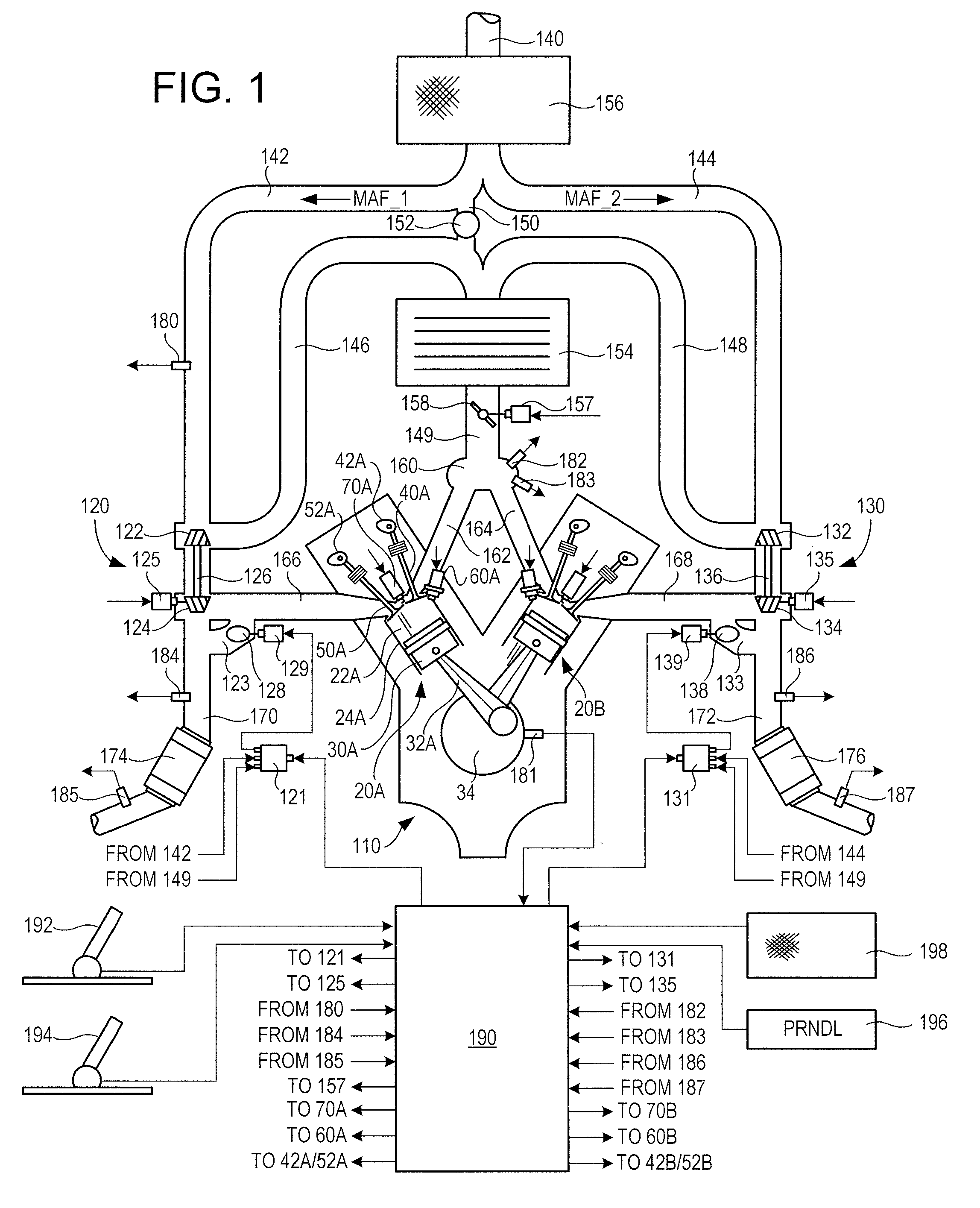

ActiveUS20100071658A1Improve drivabilityPrevent pressureElectrical controlInternal combustion piston enginesExternal combustion engineTurbocharger

In a V-type six-cylinder engine, turbo-superchargers are provided for compressing intake air and feeding the compressed air into combustion chambers, and an ECU is operable to switch the combustion mode from a non-supercharged stoichiometric combustion mode to a supercharged lean combustion mode, depending on the engine operating conditions. When switching from the non-supercharged stoichiometric combustion mode to the supercharged lean combustion mode, the ECU retards the ignition timing, and keeps the retard amount of the ignition timing at a constant value if the increasing actual boost pressure becomes equal to or higher than a pre-set target boost pressure.

Owner:TOYOTA JIDOSHA KK

RE perovskite type catalyst for oxidizing NO

InactiveCN1973962AEasy to makeEasy to operateDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationNitric oxide

The present invention relates to provides one kind of RE perovskite type catalyst for catalytic oxidation of NO into NO2, and features that the catalyst includes the perovskite type active component A1-xA'xB1-yB'yO3, where, A represents RE metal element La, A' includes Zr, Ce, Sr, Ca, Ba and Pr, B and B' represent transition metal element Fe, Co, Ni, Mn, Cu or Ti, x is 0-0.9, and y is 0-1.0. The catalyst of the present invention has simple preparation process, low cost, and NO oxidizing activity up to 80 % at 300 deg.c. It may be used to replace noble metal catalyst for oxidizing NO in lean combustion tail gas into NO2 to raise the NOx eliminating rate.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Spark ignition engine control device

InactiveUS7219634B2Effective contributionShorten speedValve arrangementsElectrical controlLow loadFuel efficiency

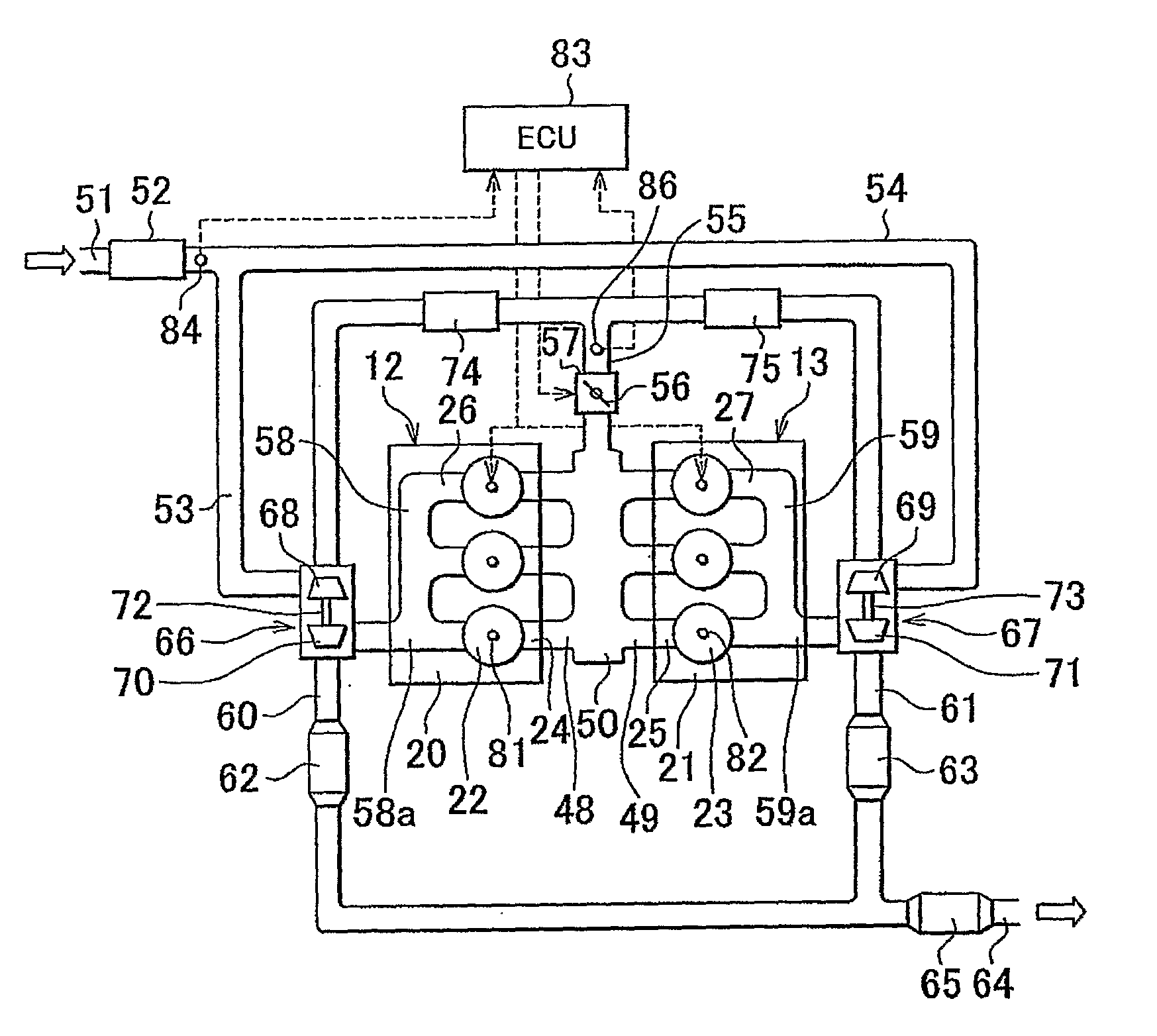

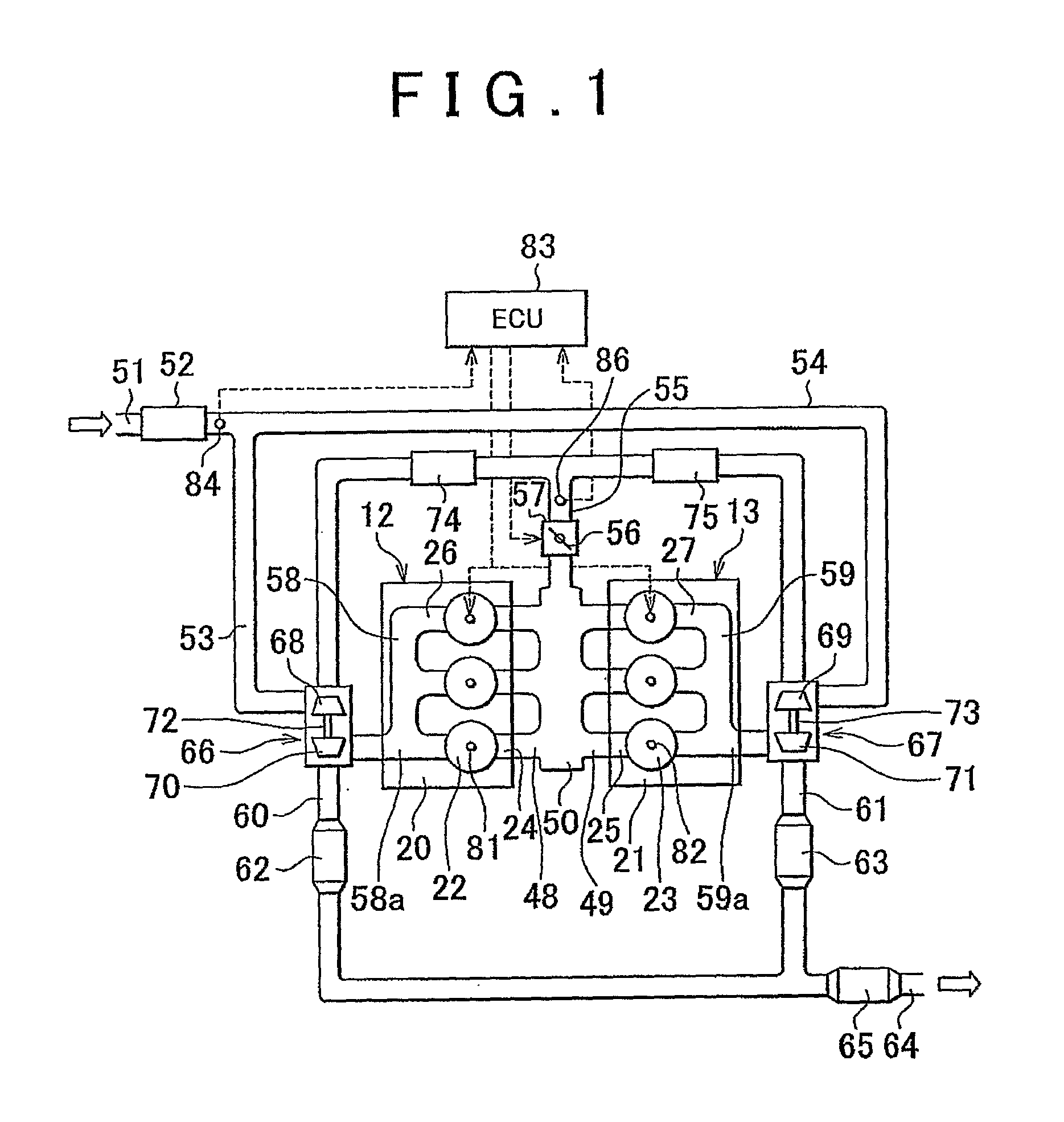

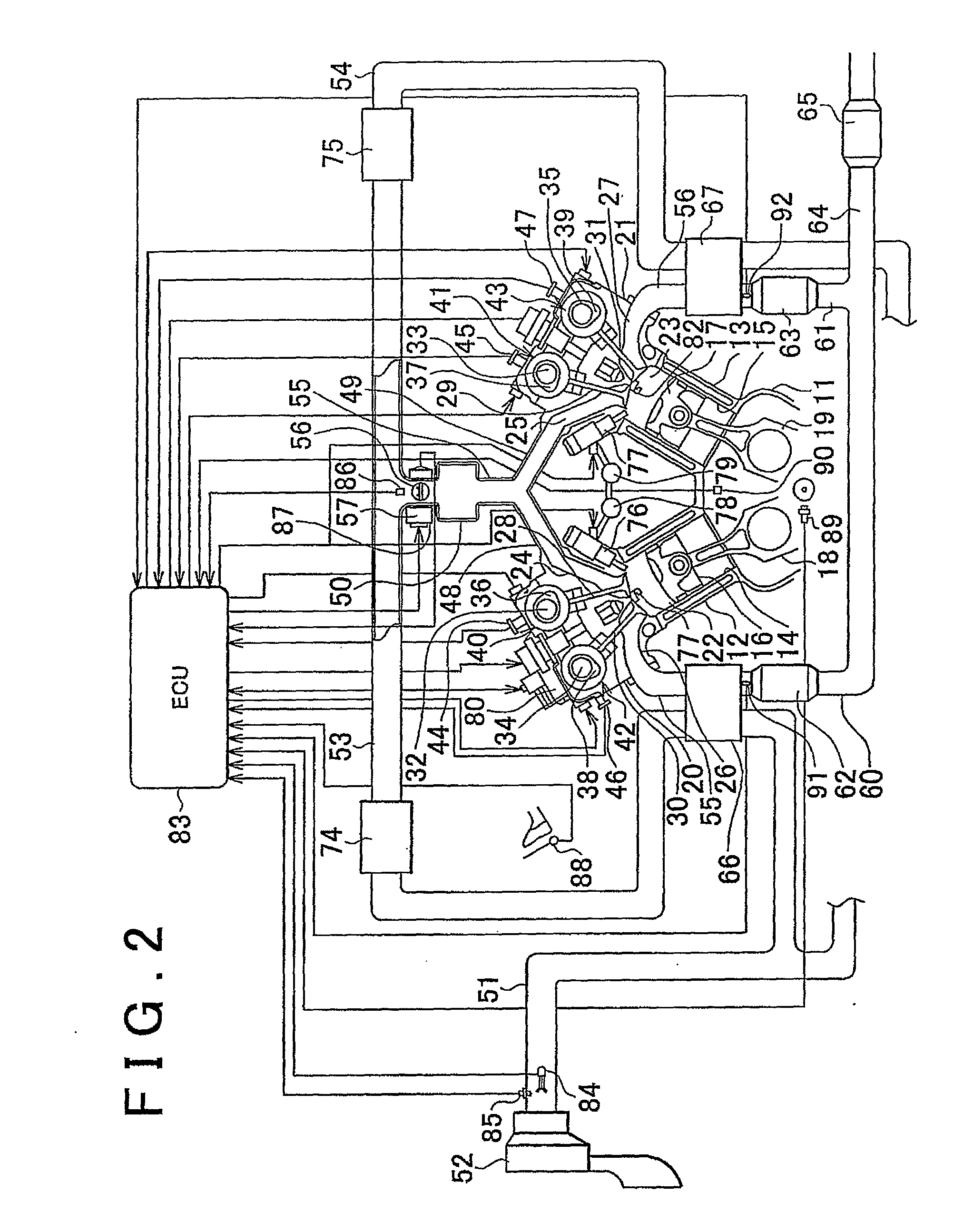

For the purpose of improving the fuel efficiency by lean combustion and enhancing the fuel efficiency improvement effects by performing compression ignition efficiently in some cylinders, a multi-cylinder spark ignition engine is constructed such that exhaust gas, that is exhausted from preceding cylinders 2A, 2D on the exhaust stroke side among pairs of cylinders whose exhaust stroke and intake stroke overlap in a low load, low rotational speed region, is directly introduced through an inter-cylinder gas passage 22 into following cylinders 2B, 2C on the intake stroke side and only gas exhausted from the following cylinders 2B, 2C is fed to an exhaust passage 20, which is provided with a three-way catalyst 24. Combustion controller is provided that controls the combustion of each of the cylinders such that combustion is conducted by forced ignition in a condition in which the air / fuel ratio is a lean air / fuel ratio which is larger by a prescribed amount than the stoichiometric air / fuel ratio in the preceding cylinders 2A, 2D and, in the following cylinders 2B, 2C, fuel is supplied to burnt gas of lean air / fuel ratio introduced from the preceding cylinders 2A, 2D and combustion is conducted by compression ignition.

Owner:MAZDA MOTOR CORP

Lean hc conversion of twc for lean burn gasoline engines

The present invention relates to a catalyst composition comprising a carrier substrate, a layer (i) coated on said carrier substrate comprising at least one precious group metal, a layer (ii) comprising Rh, and a layer (iii) comprising Pd and / or Pt and being substantially free of Ce, Ba and Rh, wherein the layer (iii) has a lower weight than the layer (i) or the layer (ii). Furthermore, the present invention relates to a method for treating an exhaust gas stream using said catalyst composition.

Owner:BASF CORP

Stripping ethanol from ethanol-blended fuels for use in NOx SCR

InactiveUS7257945B2Efficient systemMaximize controlNon-fuel substance addition to fuelExhaust apparatusEmulsionLean combustion

A method to use diesel fuel alchohol micro emulsions (E-diesel) to provide a source of reductant to lower NOx emissions using selective catalytic reduction. Ethanol is stripped from the micro emulsion and entered into the exhaust gasses upstream of the reducing catalyst. The method allows diesel (and other lean-burn) engines to meet new, lower emission standards without having to carry separate fuel and reductant tanks.

Owner:UT BATTELLE LLC

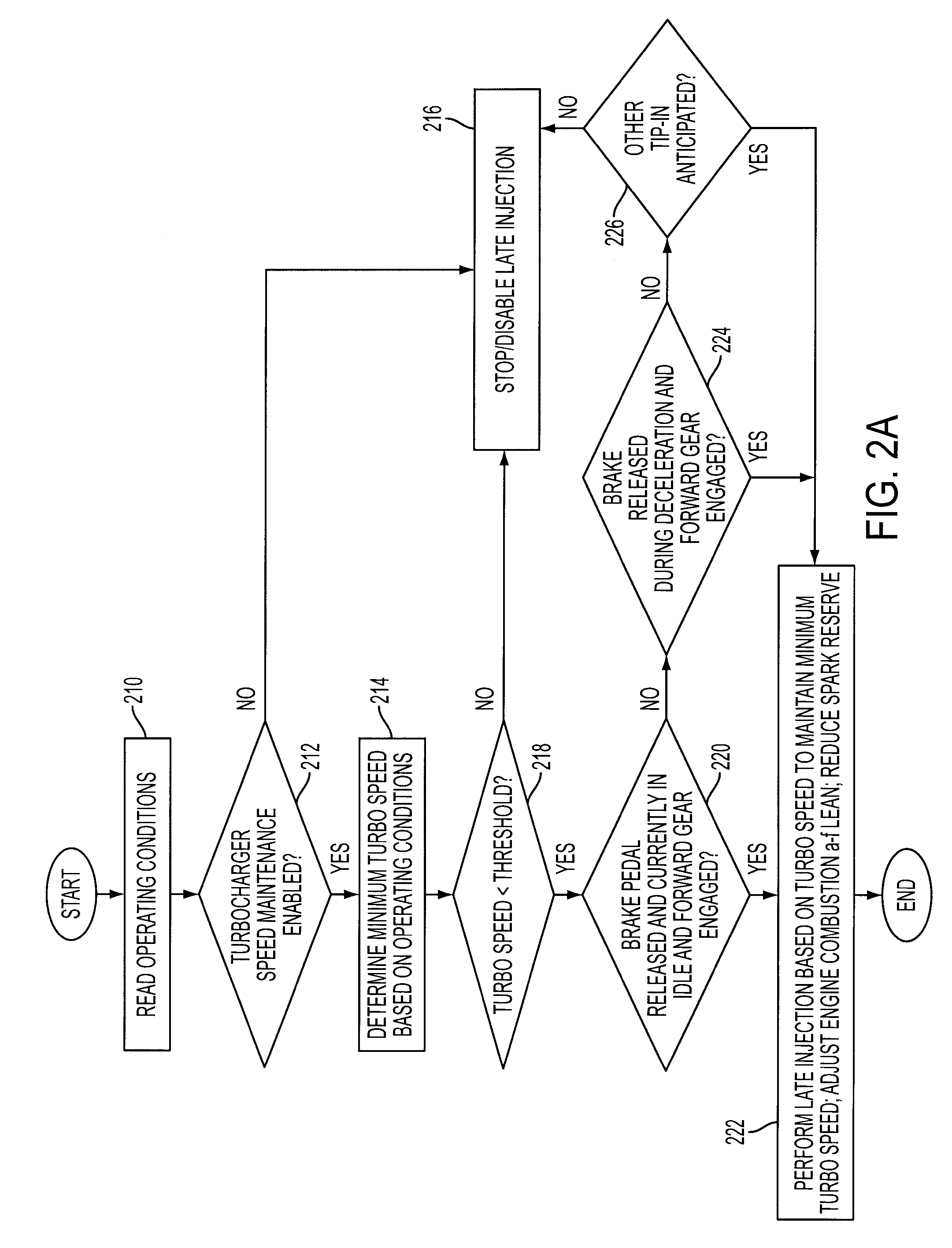

Engine idle speed and turbocharger speed control

ActiveUS20090107456A1Quick responseReduce fuel usageElectrical controlInternal combustion piston enginesCombustionTurbocharger

Various methods are described for controlling engine operation for an engine having a turbocharger and direction injection. One example method includes performing at least a first and second injection in response to a driver action. The first and second injection may be performed during a cylinder cycle, the first injection generating a lean combustion and the second injection injected after combustion such that it exits the cylinder unburned into the exhaust upstream of a turbine of the turbocharger.

Owner:FORD GLOBAL TECH LLC

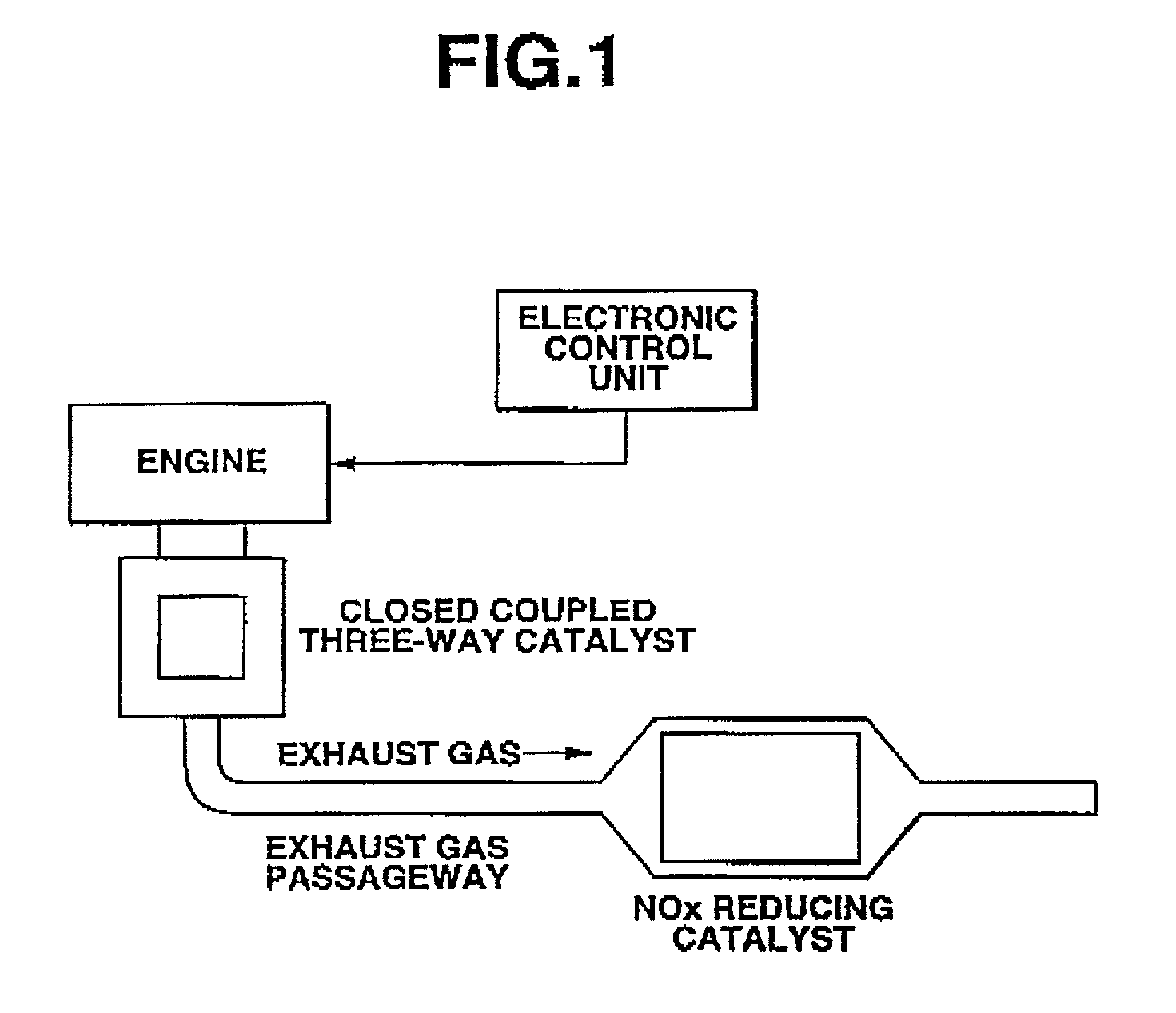

Exhaust gas control device-equipped internal combustion engine and exhaust gas control method

InactiveUS6978603B2Efficient removalElectrical controlDispersed particle filtrationParticulatesExternal combustion engine

In an exhaust gas control device-equipped internal combustion engine, particulate matter produced in conjunction with combustion of gasoline in a combustion chamber is oxidized by an exhaust gas control device provided in an exhaust passage. The engine includes air-fuel ratio control changer that changes between a feedback control toward a stoichiometric air-fuel ratio whereby an amount of oxygen in exhaust gas is reduced and a feedback control toward a lean-burn combustion side whereby the amount of oxygen in exhaust gas is increased, if the oxidation speed of particulate matter in the exhaust gas control device provided in the exhaust passage is slow, or if the amount of deposit of particulate matter is great.

Owner:TOYOTA JIDOSHA KK

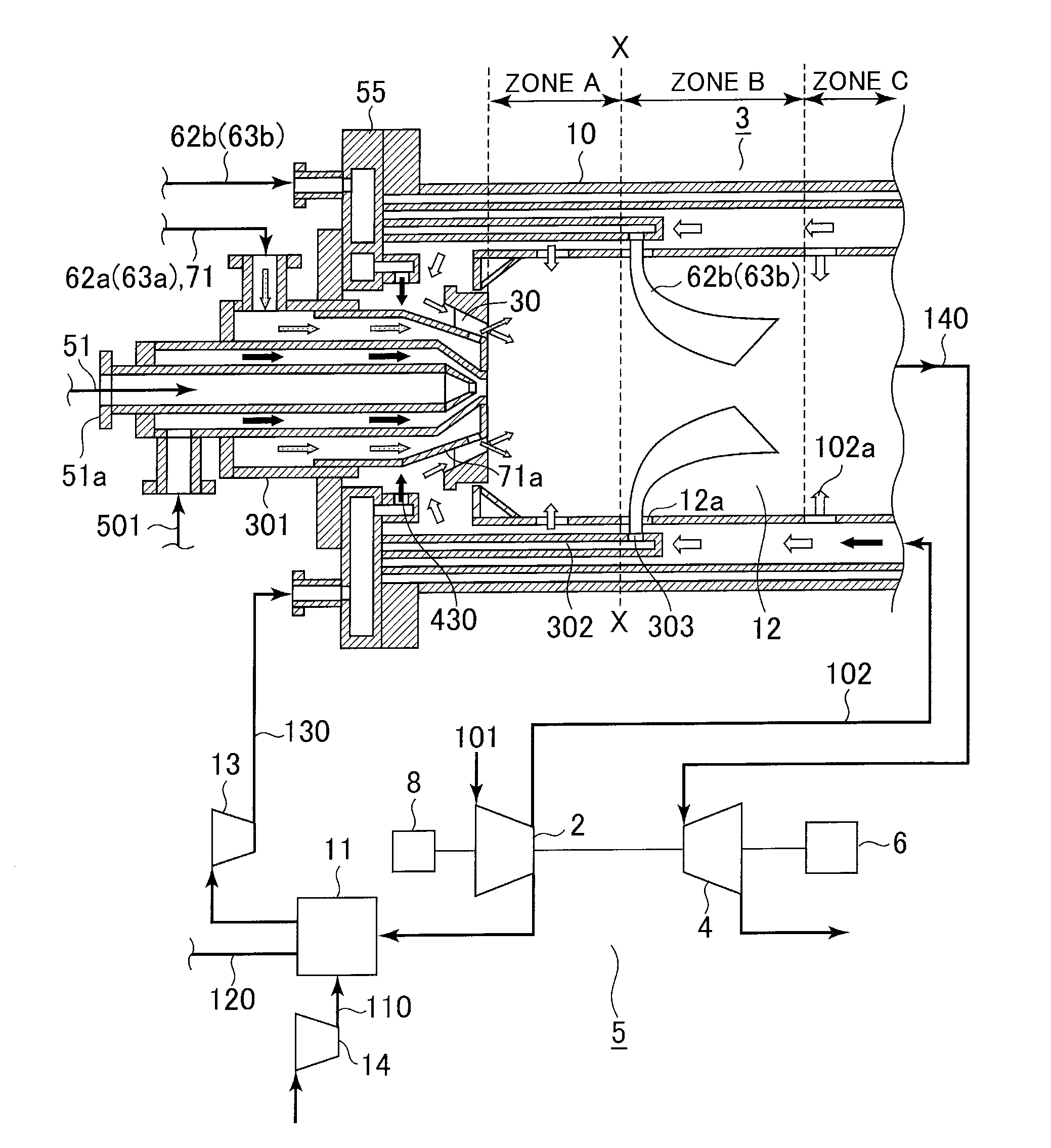

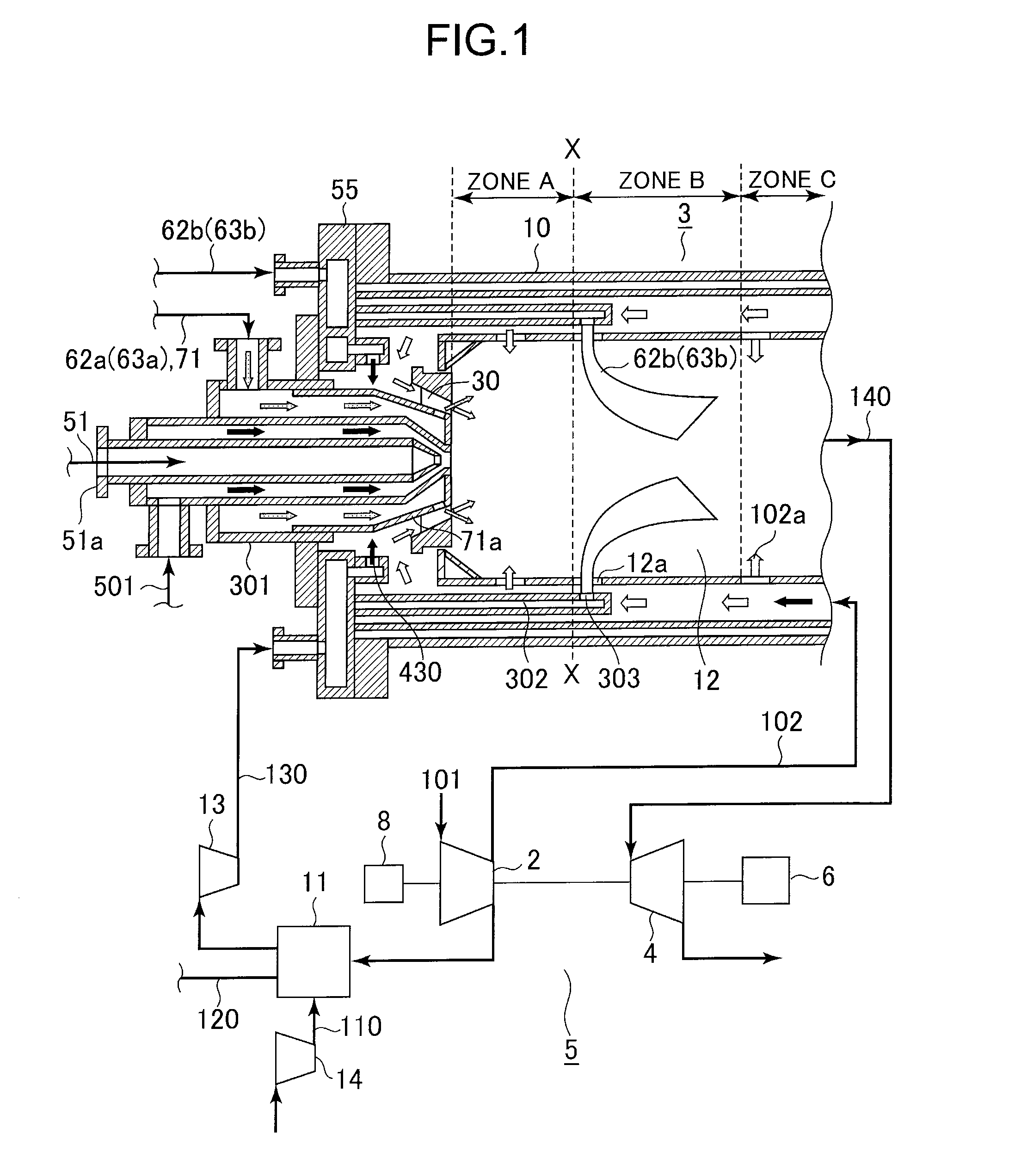

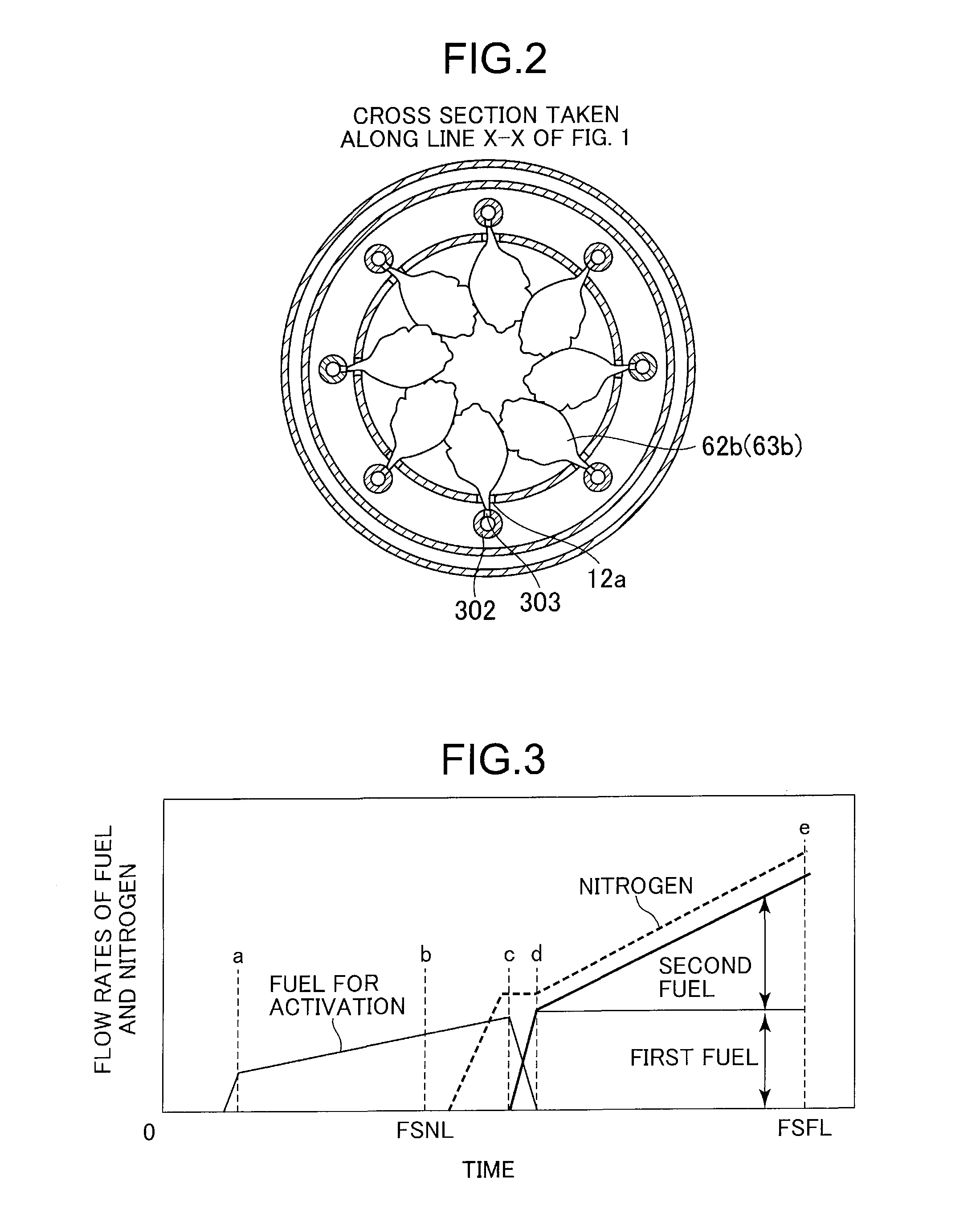

Low NOx Combustor for Hydrogen-Containing Fuel and its Operation

ActiveUS20110094239A1Suppressing NOx emissionEnsure reliabilityContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustion chamberCombustor

An object of the present invention is to provide a gas turbine combustor that supports hydrogen-containing gas having a high burning velocity and is capable of performing low NOx combustion without reducing reliability of a burner. A first fuel nozzle is provided upstream of a combustion chamber and supplies fuel for activation and hydrogen-containing gas. The combustor has a primary combustion zone, a reduction zone and a secondary combustion zone. In the primary combustion zone, the fuel supplied from the first fuel nozzle is combusted under a fuel rich condition to form a burned gas containing a low concentration of oxygen. In the reduction zone, a hydrogen-containing gas is injected into the combustion chamber through a second fuel injection hole from a second fuel nozzle so that NOx generated in the primary combustion zone is reduced by an oxygen reaction of the hydrogen. In the secondary combustion zone, air for lean combustion is supplied into the combustion chamber so that unburned part of fuel is combusted under a fuel lean condition.

Owner:MITSUBISHI POWER LTD

Exhaust gas purifying system and catalyst

InactiveUS20010004832A1Efficient removalHigh fuel economy improvement effectNitrous oxide captureGas treatmentPorous substratePlatinum

An exhaust gas purifying system for an automotive internal combustion engine which discharges oxygen-excessive exhaust gas under lean-burn operation. The exhaust gas purifying system comprises a NOx reducing catalyst for reducing NOx in the presence of at least hydrogen serving as reducing agent. The NOx reducing catalyst is disposed in an exhaust gas passageway of the engine. The NOx reducing catalyst includes a porous substrate, and platinum and cesium carried on the porous substrate. A catalyst is disposed in the exhaust gas passageway in order to produce hydrogen so as to enrich the oxygen-excessive exhaust gas with hydrogen before the oxygen-excessive exhaust gas reaches the NOx reducing catalyst. The oxygen-excessive exhaust gas enriched with hydrogen is introduced through the exhaust gas passageway to the NOx reducing catalyst. Here, the oxygen-excessive exhaust gas enriched with hydrogen is brought into contact with the NOx reducing catalyst under a condition in which temperature of at least one of the NOx reducing catalyst and the oxygen-excessive exhaust gas enriched with hydrogen is within a range of from 250 to 600° C.

Owner:NISSAN MOTOR CO LTD

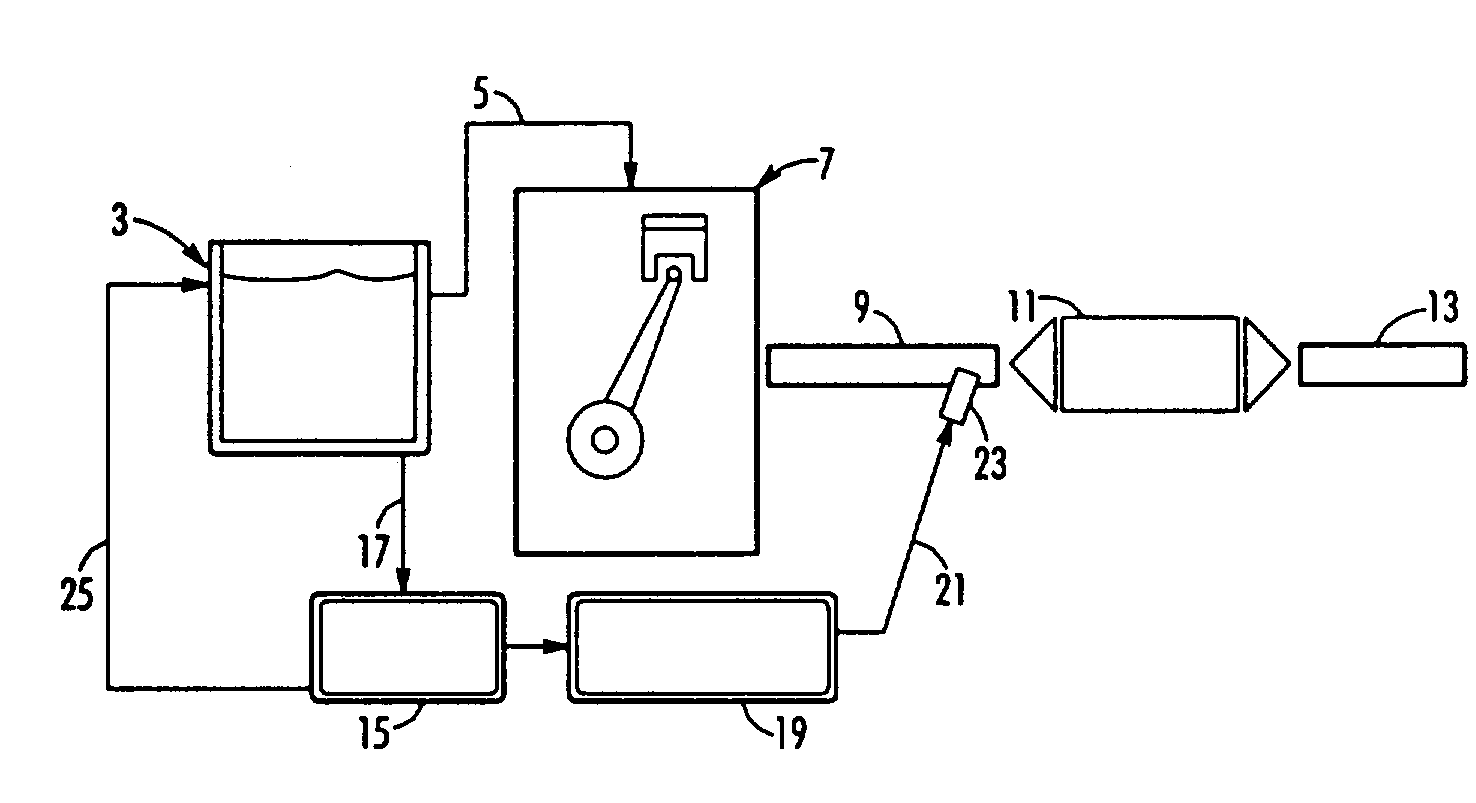

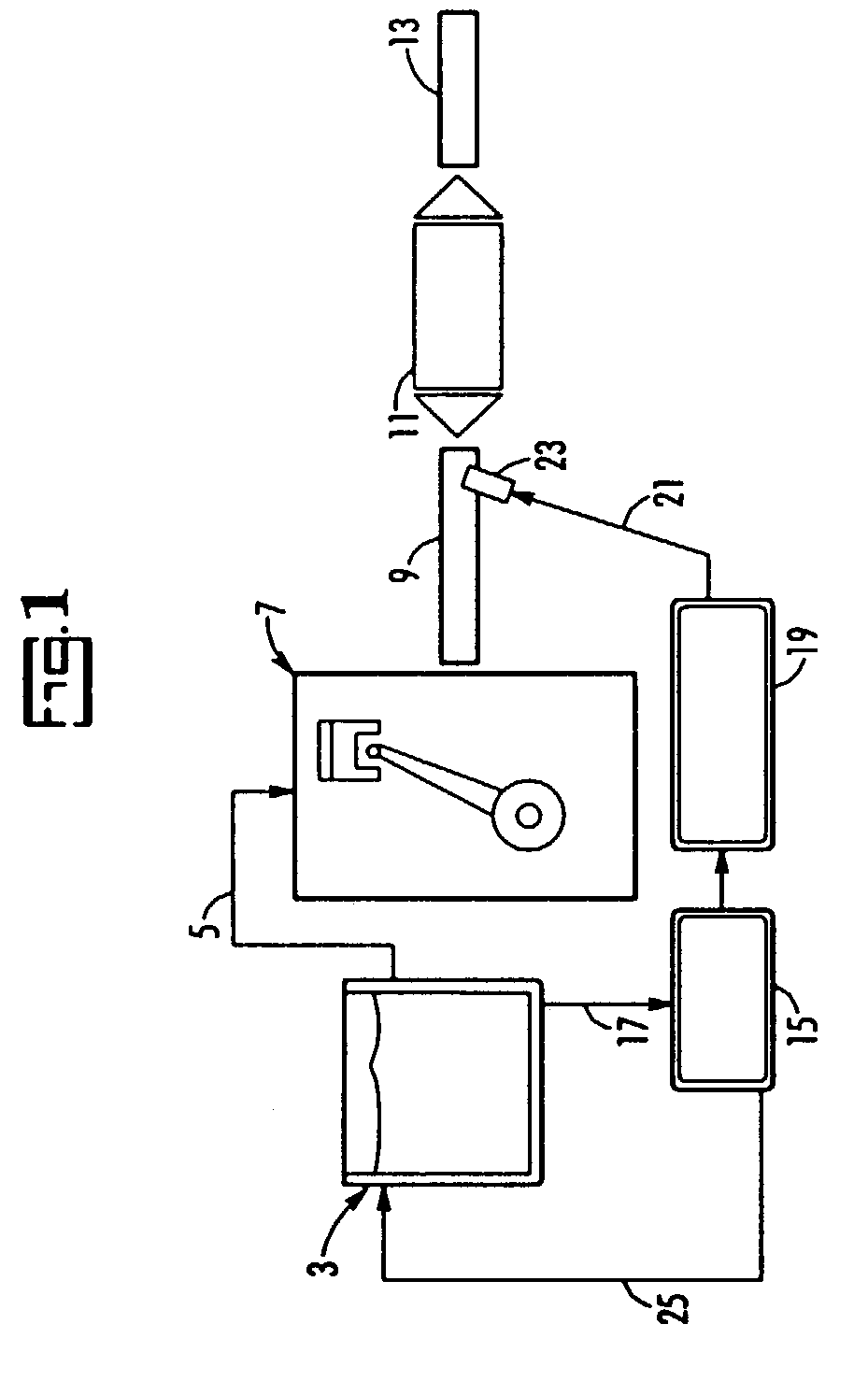

Method and system for controlling an air-to-fuel ratio in a non-stoichiometric power governed gaseous-fueled stationary internal combustion engine

InactiveUS6289877B1Reduces "pumping losses.Less importantAnalogue computers for vehiclesElectrical controlControl signalCarburetor

A gaseous-fueled reciprocating internal combustion engine includes a carburetor having a throttle valve that is controlled by a speed governor. A proportional fuel control valve is disposed intermediate a fuel supply and the carburetor, and is controlled by an air fuel computing device. The computing device generates a control signal to adjust the fuel control valve based on a governor sensed variable indicative of engine speed, sensed engine torque, a governor output signal from the governor indicative of an opening position of the throttle valve wherein 100% corresponds to a wide open throttle position, and 0% corresponds to a closed position, and a lean combustion control map containing predetermined set point values stored in memory. During operation, the control valve is responsive to the control signal generated by the computing device for adjustment of a fuel flow therethrough so as to obtain a ratio of air to fuel provided to the engine that is substantially at a lean misfire limit of the engine, thereby reducing fuel consumption, NOx emissions, and reducing exhaust gas temperatures. Alternatively, the control signal is generated using engine speed alone.

Owner:ANR PIPELINE

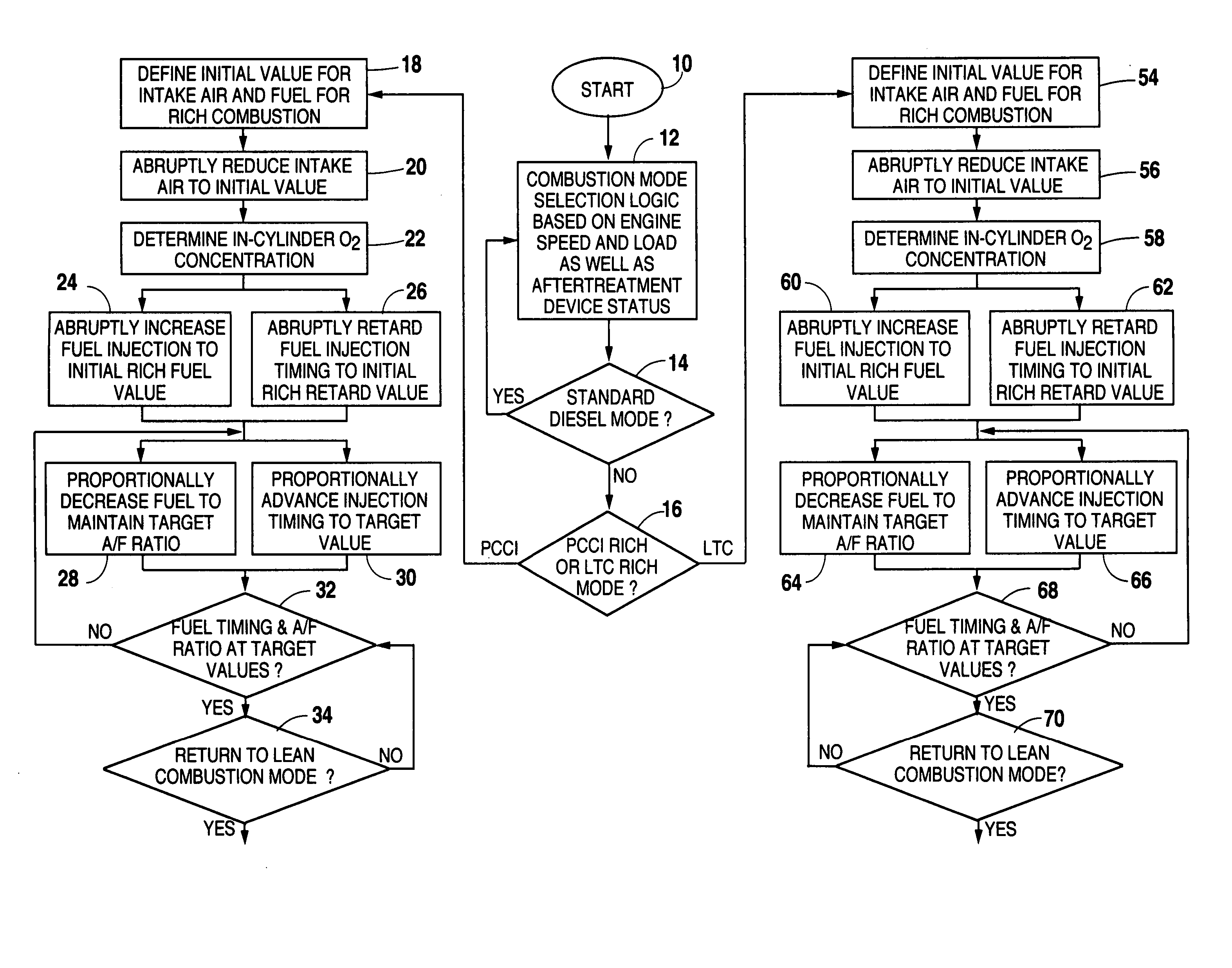

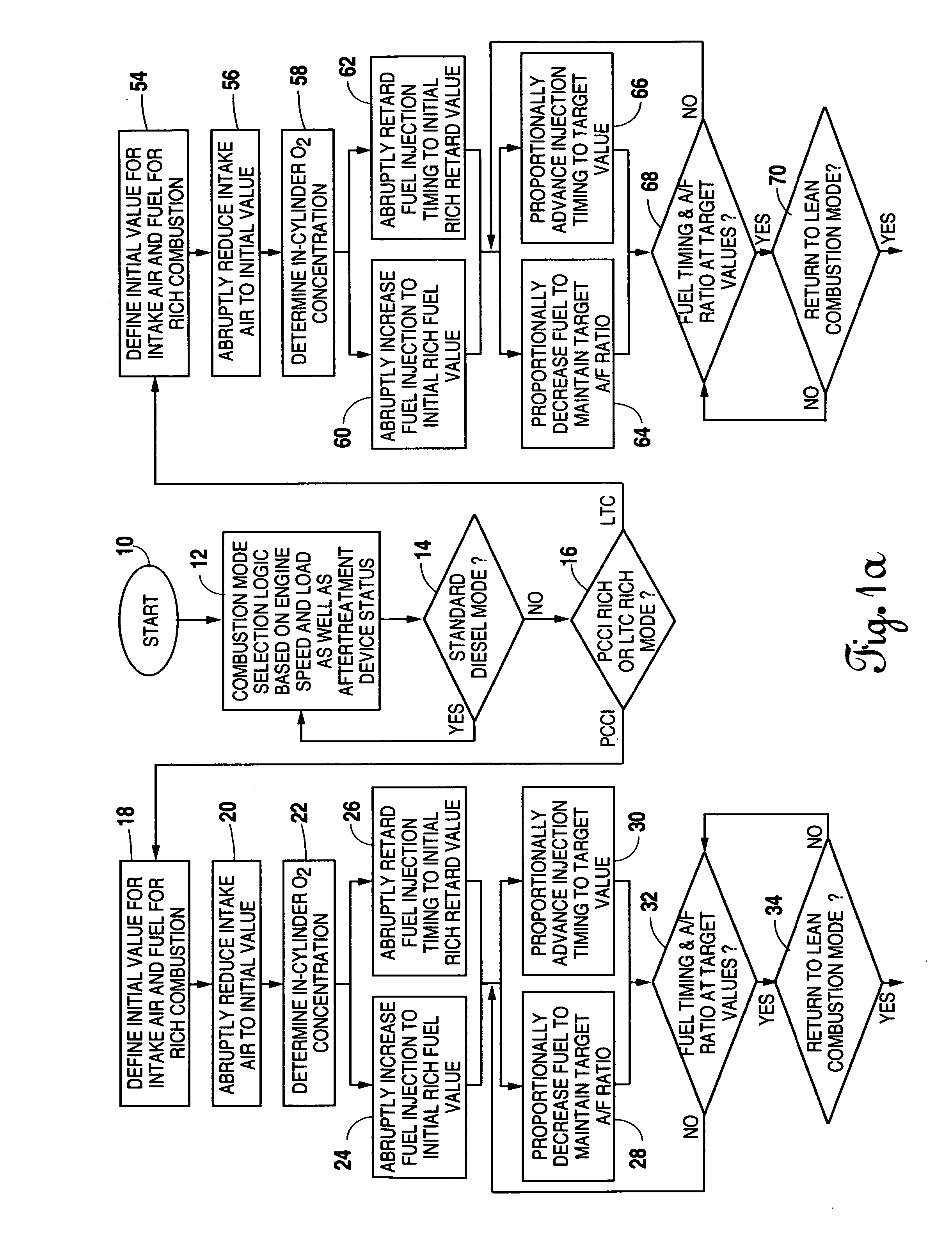

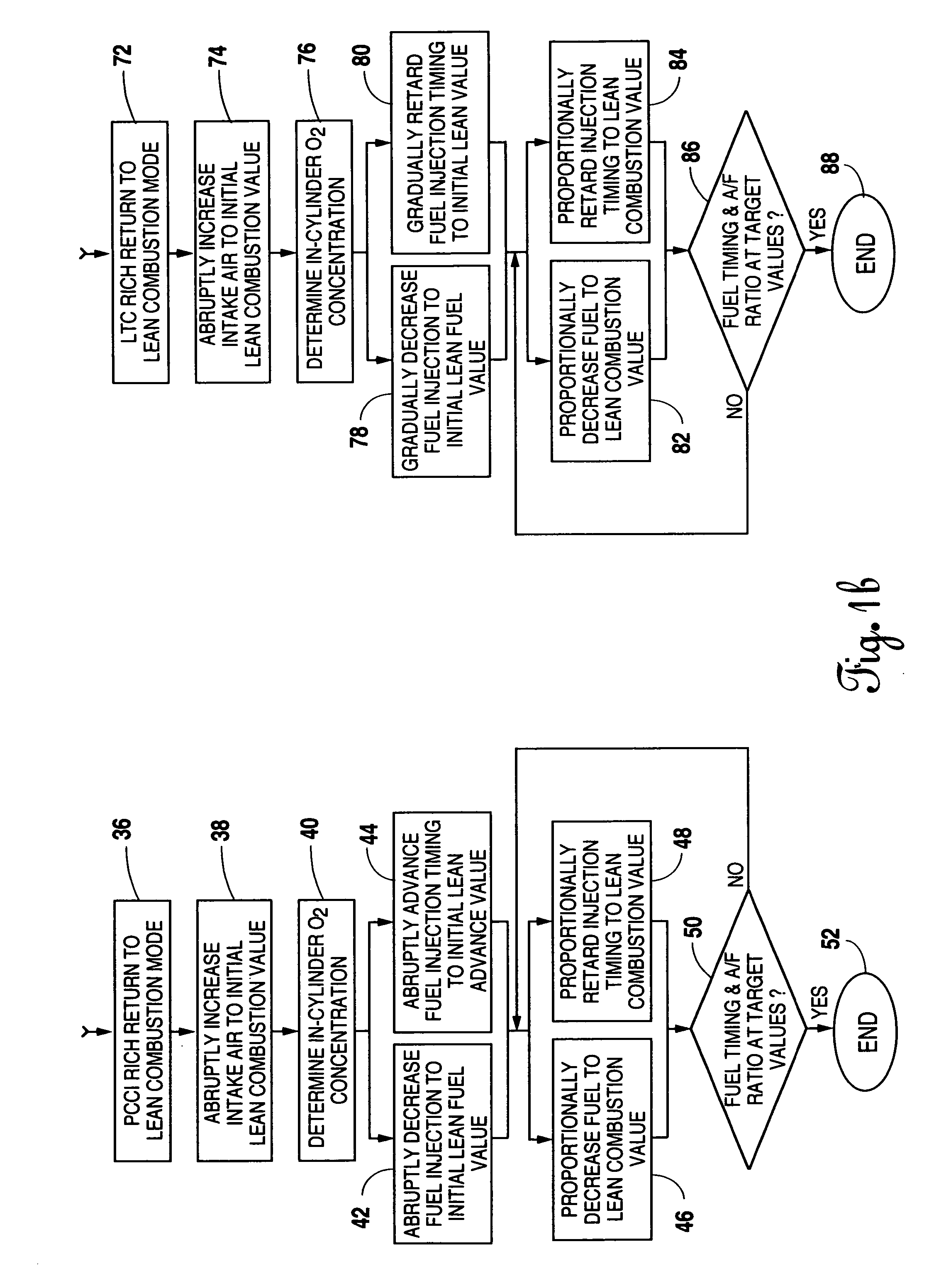

Method for rapid, stable torque transition between lean rich combustion modes

ActiveUS20060064228A1Torque stabilizationReduce the amount requiredElectrical controlInternal combustion piston enginesCombustionNuclear engineering

A method for rapidly transitioning from a lean combustion mode to a rich combustion mode, such as often required for the regeneration of aftertreatment devices, is provided by abrupt intake air reduction and a concurrent abrupt increase in fuel injection quantity with accompanying retardation of fuel injection timing. The abrupt increase in fuel quantity is to a maximum value sufficient to immediately provide a defined initial rich air / fuel ratio for a coexistent oxygen concentration in the cylinder. The fuel quantity is then proportionally reduced from the maximum value to a target fuel quantity to maintain a target air / fuel ratio during the transition. Simultaneously, injection timing is abruptly retarded to a value sufficient to avoid torque increase as a result of the increased injected fuel. The injection timing is subsequently proportionally advanced from the abruptly retarded timing value when the target fuel quantity and air / fuel ratio values are achieved.

Owner:SOUTHWEST RES INST

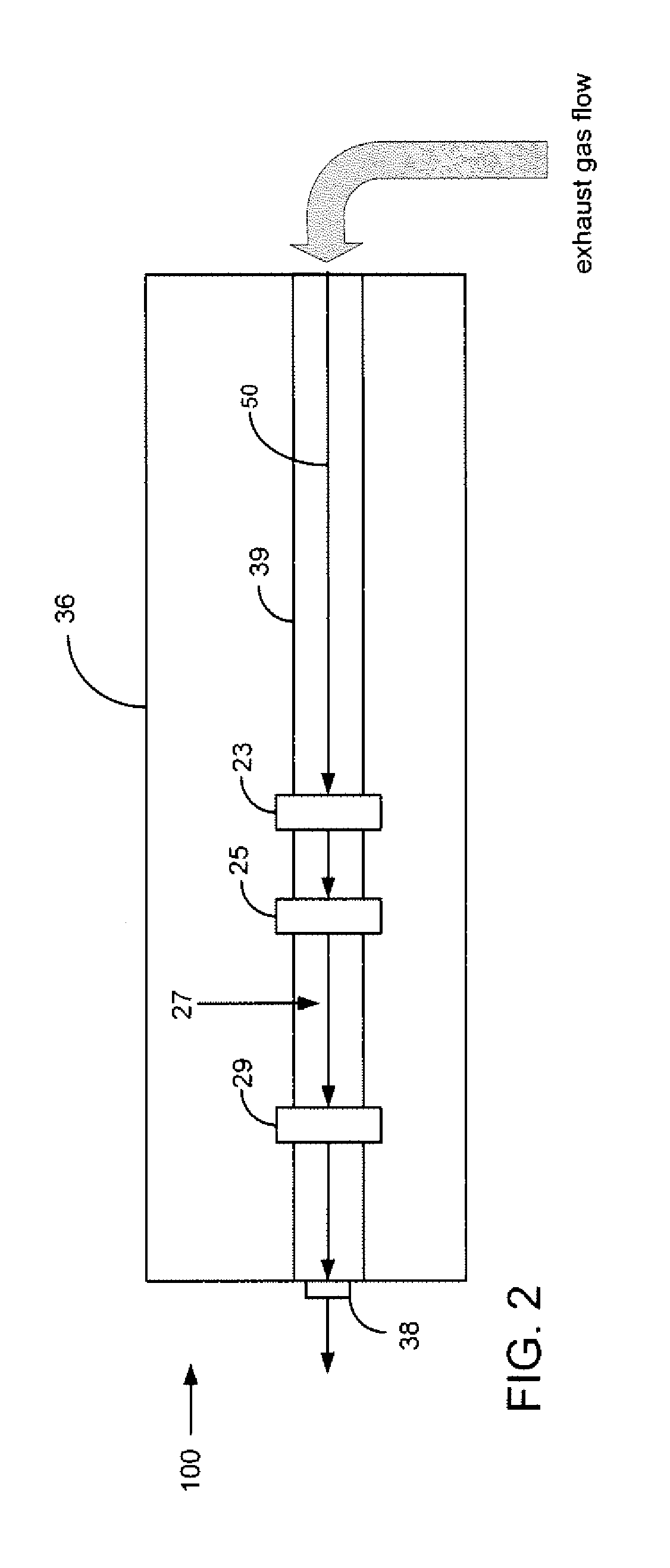

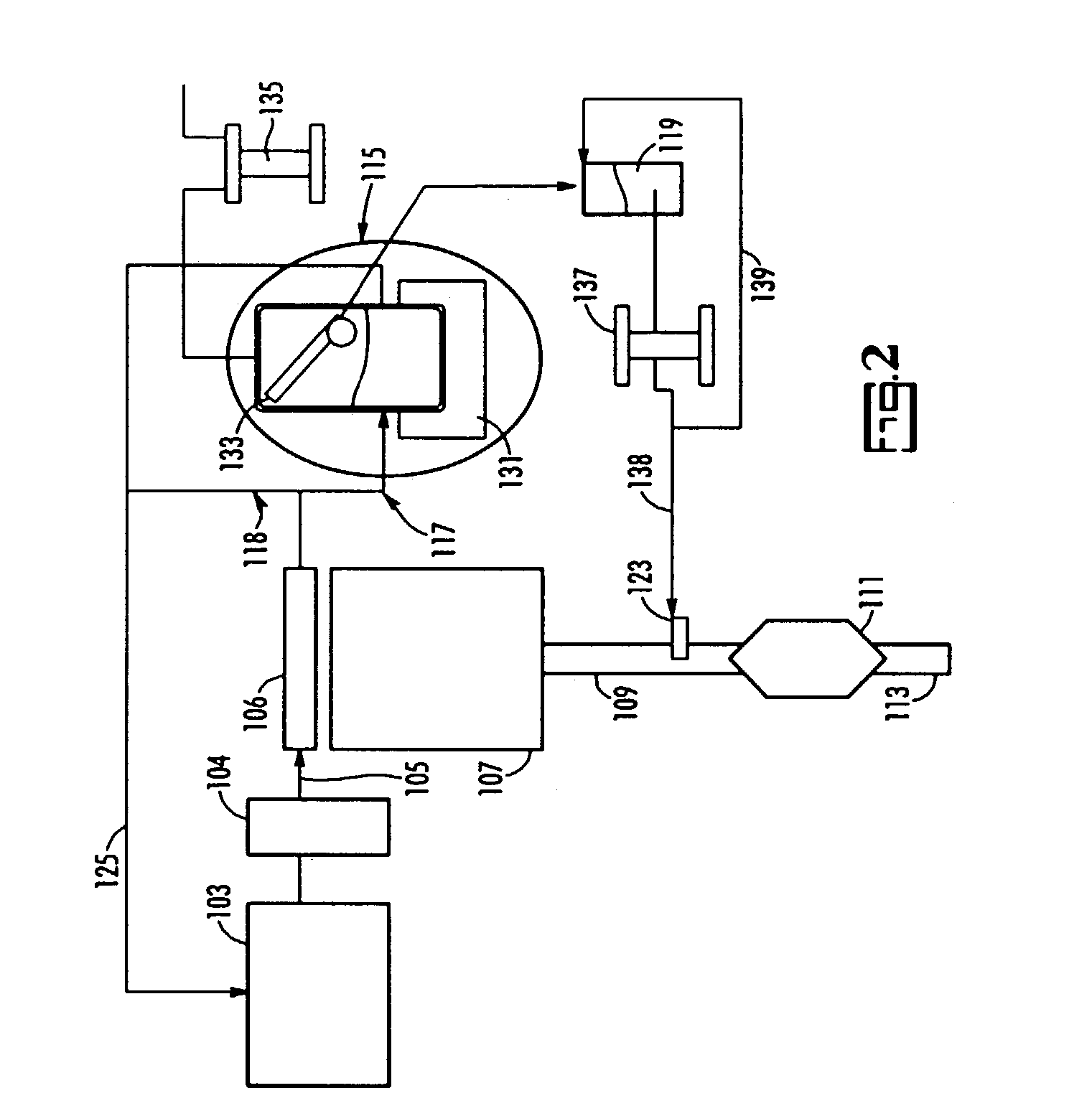

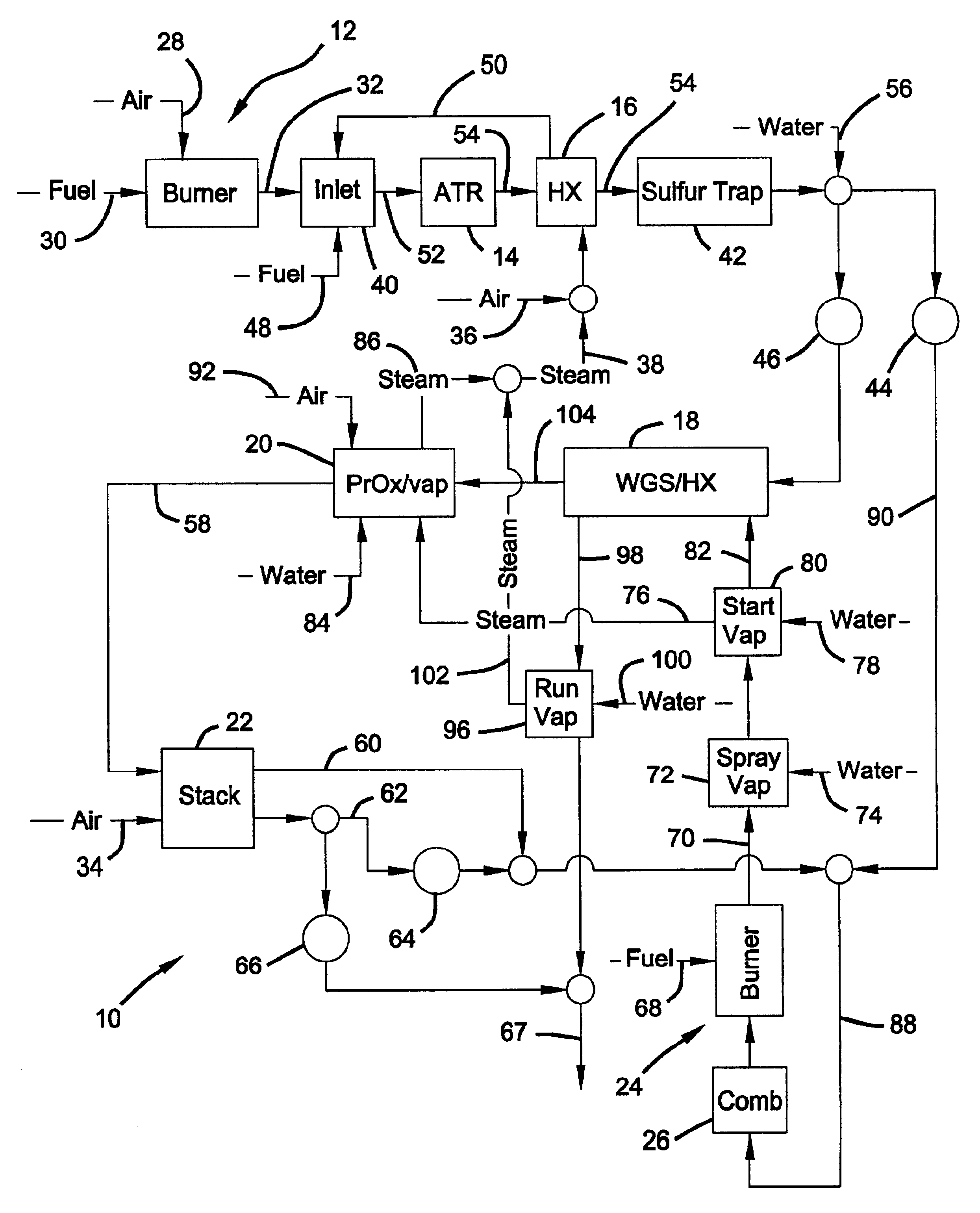

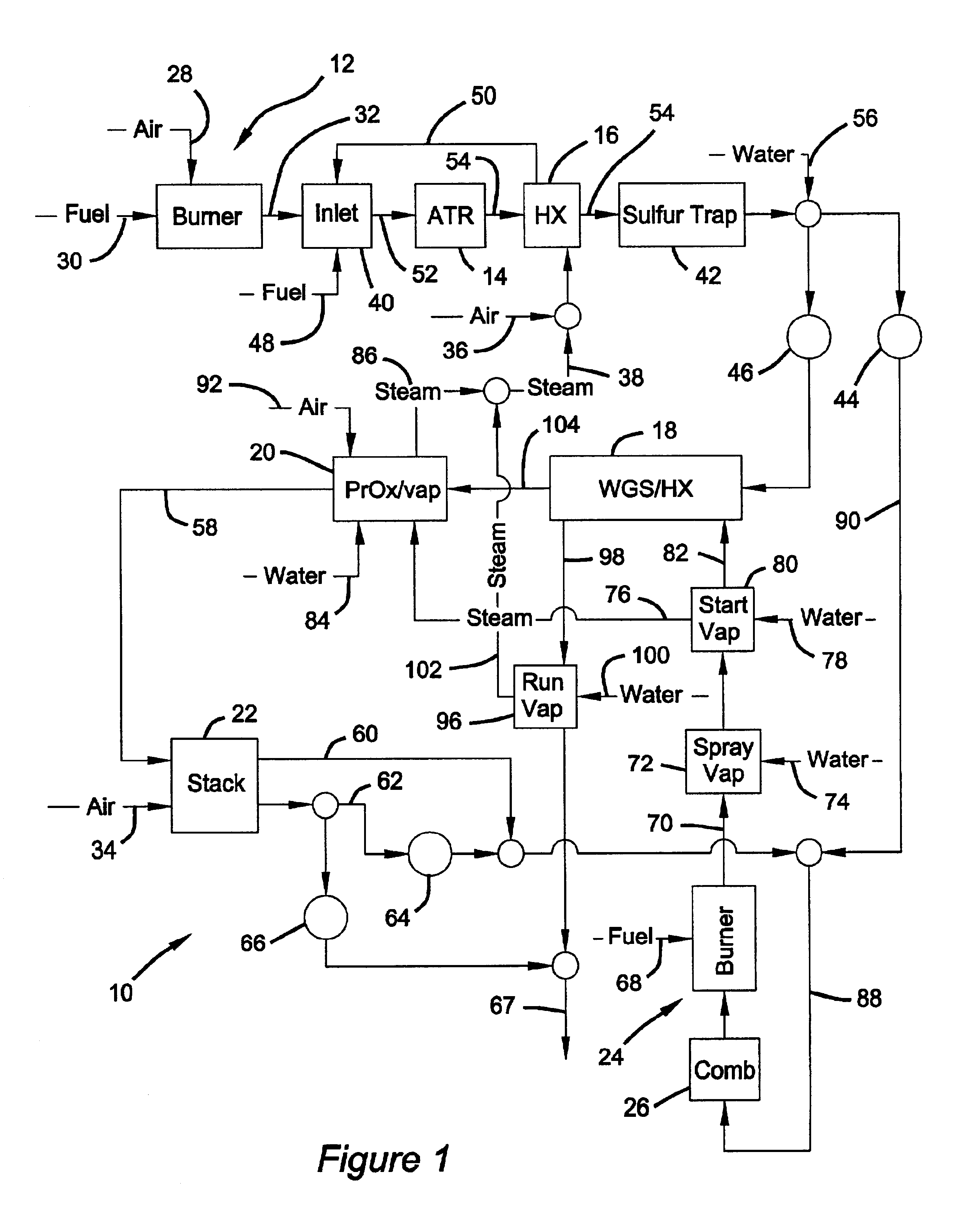

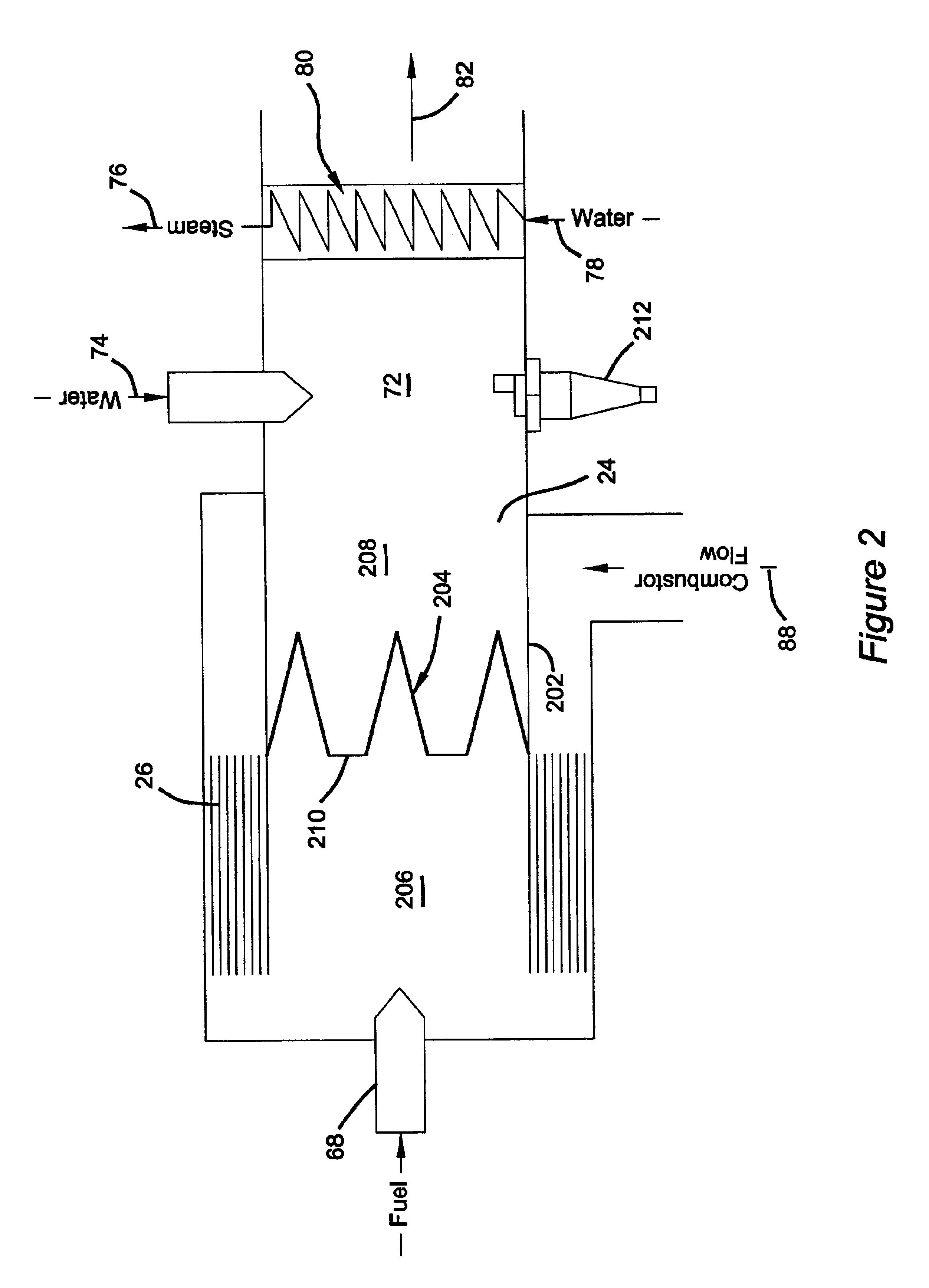

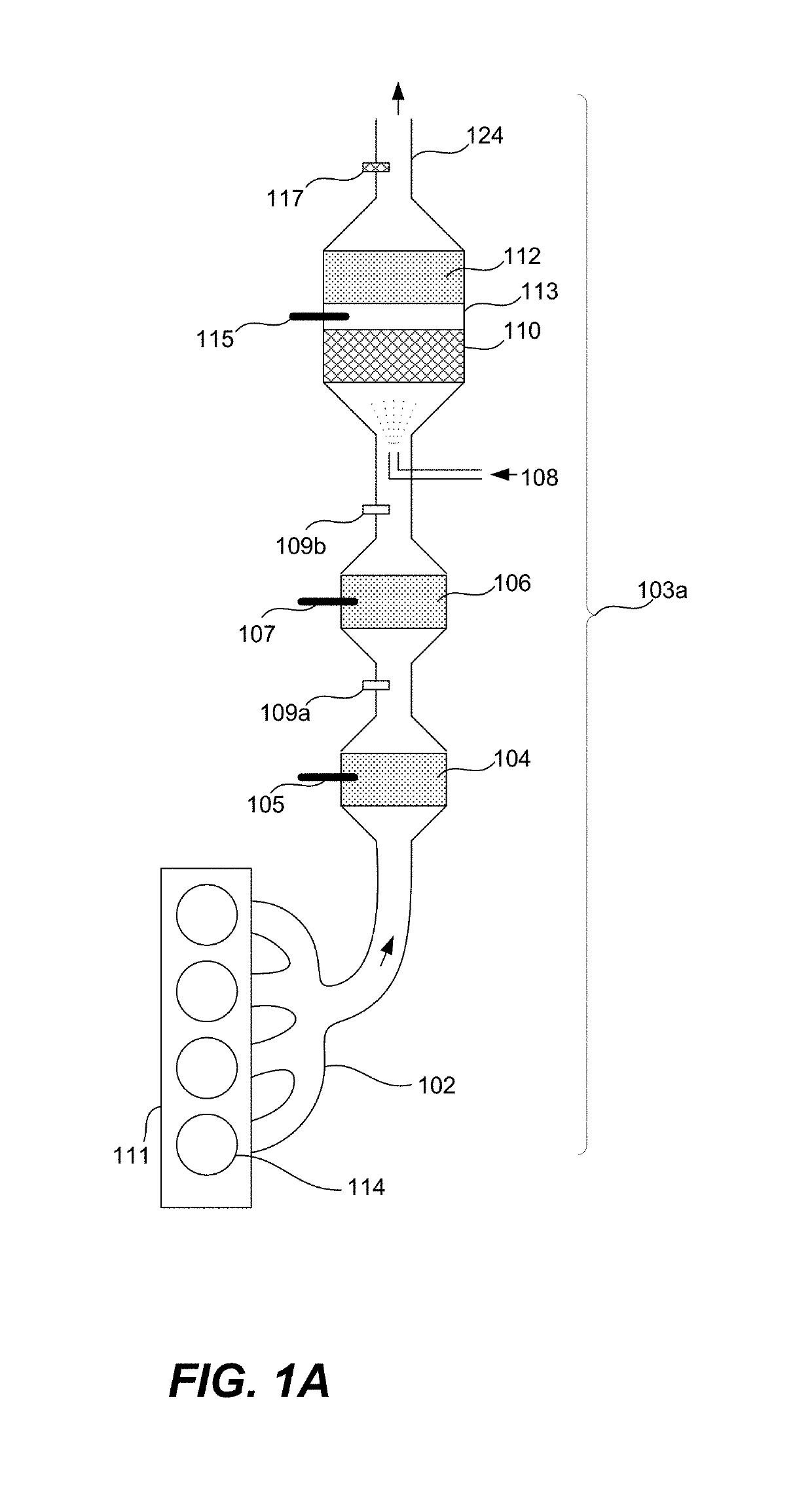

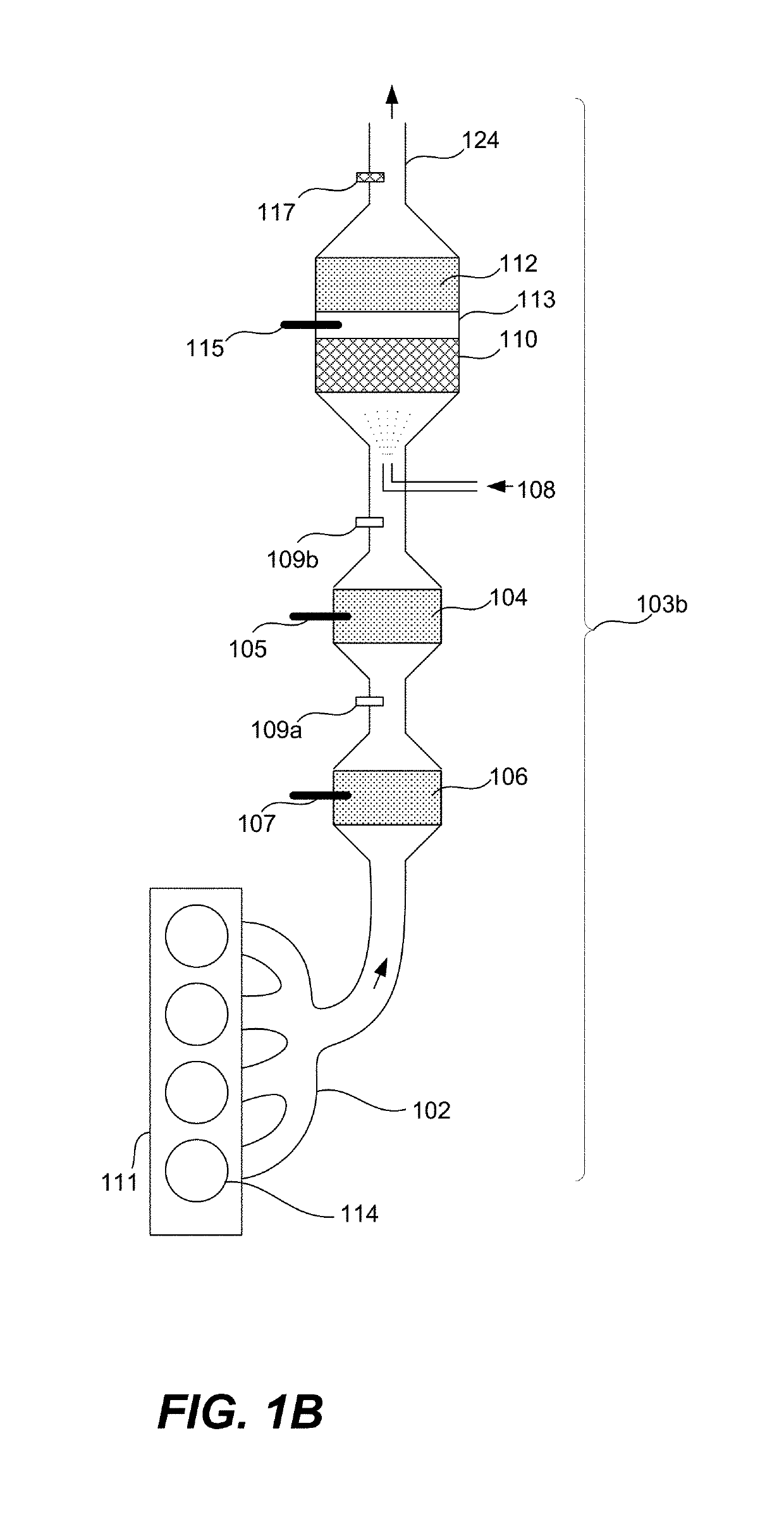

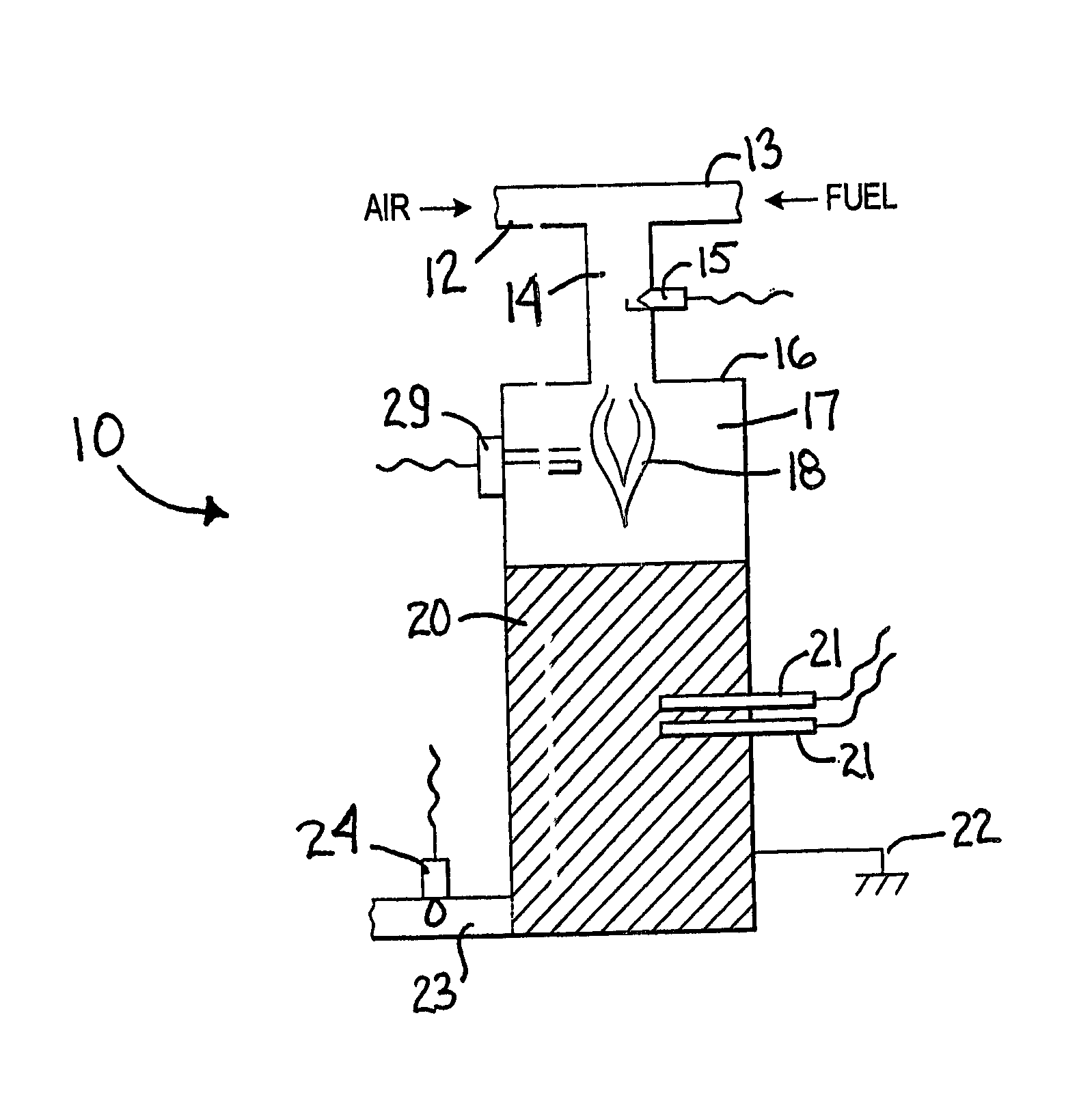

Staged lean combustion for rapid start of a fuel processor

InactiveUS6926748B2Achieve operating temperatureHydrogenPhysical/chemical process catalystsThermal energyFuel cells

A fuel processor for rapidly achieving operating temperature during startup. The fuel processor includes a reformer, a shift reactor, and a preferential oxidation reactor is provided for deriving hydrogen for use in creating electricity in a plurality of fuel cells. A first combustion heater system is coupled to at least one of the reformer, the shift reactor, and the preferential oxidation reactor to preheat the component during a rapid startup sequence. That is, the first combustion heater system is operable to produce thermal energy as a product of the combustion of air and fuel in the form of a first heated exhaust stream. This first heated exhaust stream is then used to heat the component directly or by using a heat exchanger type system. The first heated exhaust stream is also used by a second combustion device as a source of oxygen or diluent.

Owner:GM GLOBAL TECH OPERATIONS LLC

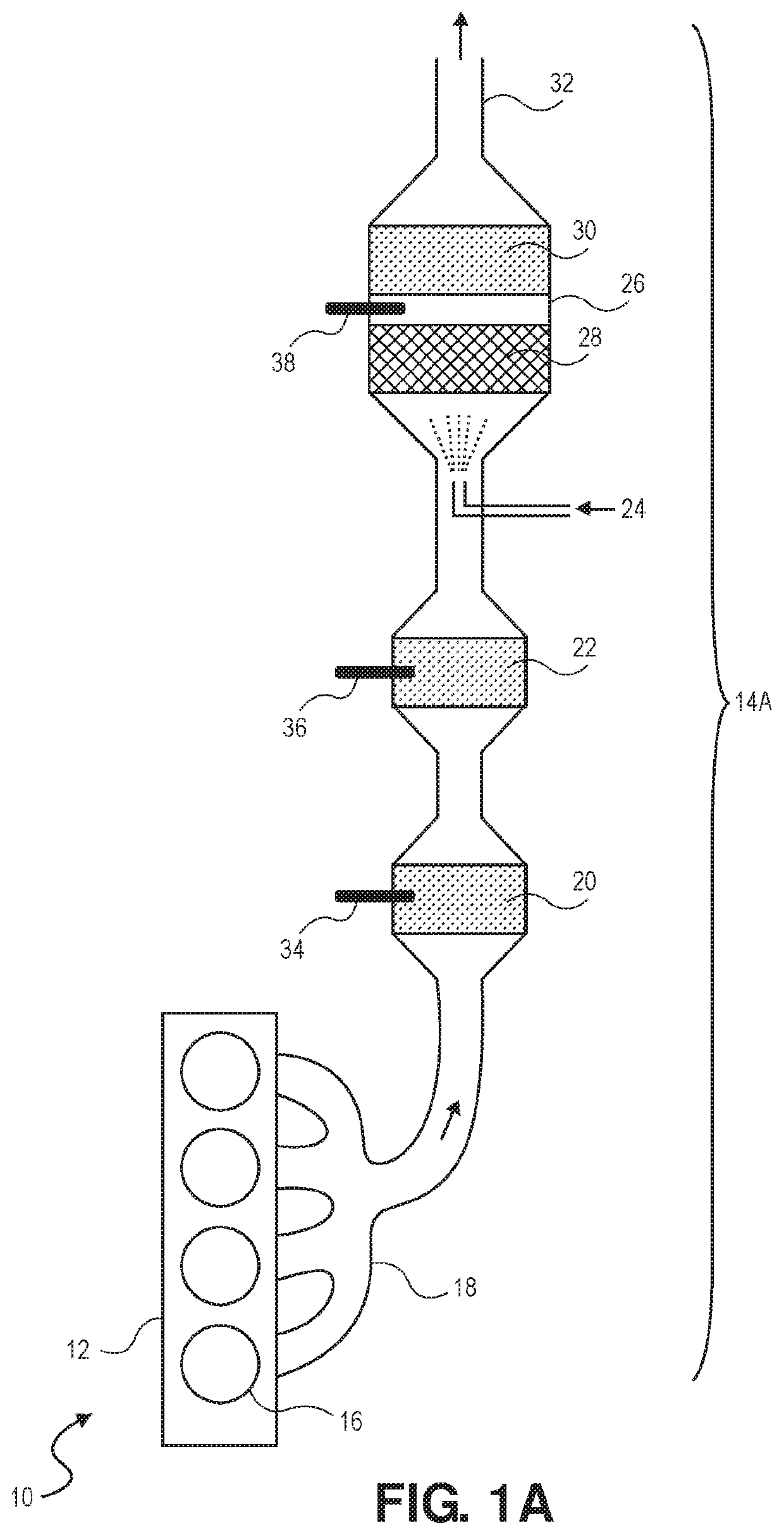

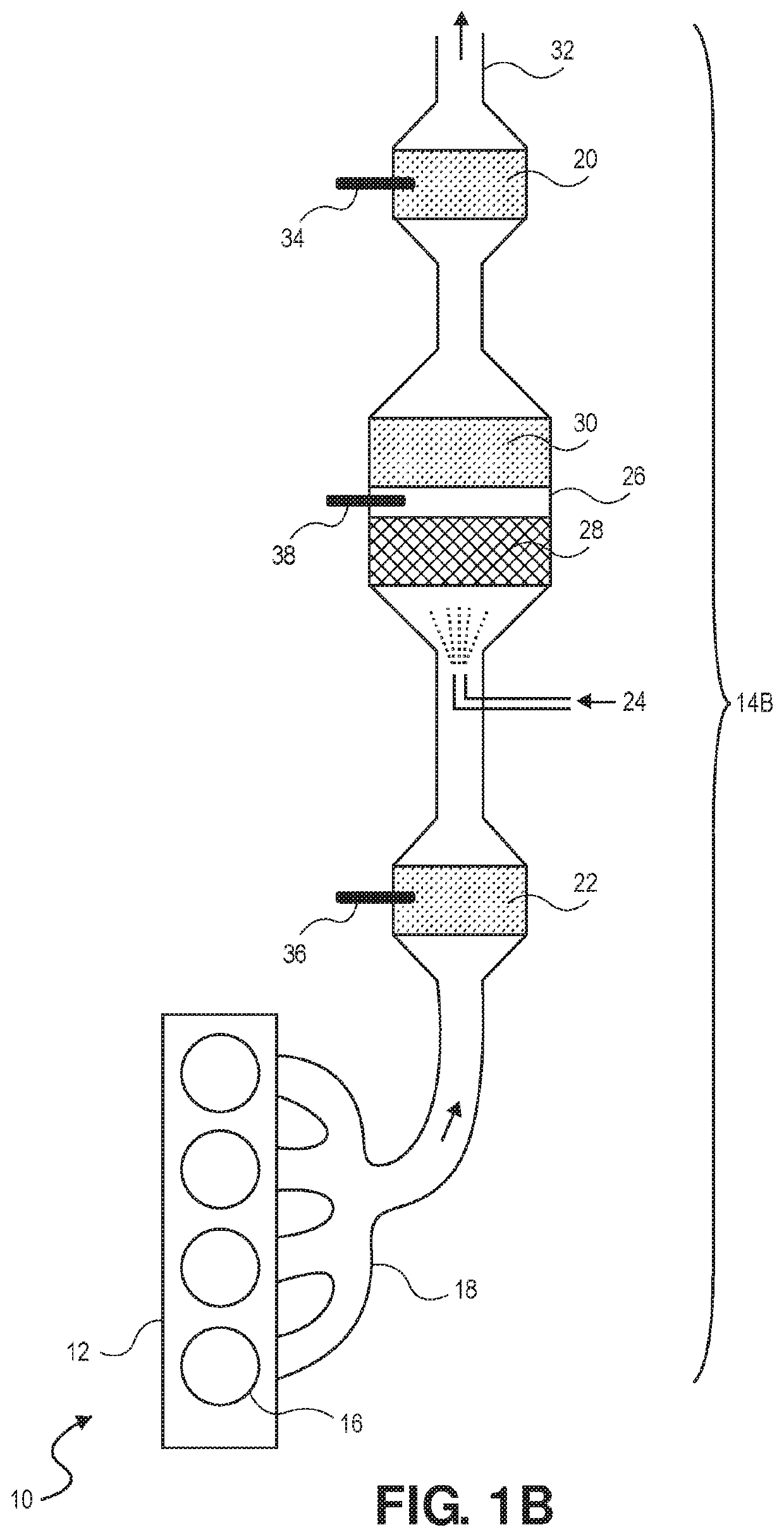

Lean burn internal combustion engine exhaust gas temperature control

ActiveUS10247072B2Electrical controlInternal combustion piston enginesTemperature controlExternal combustion engine

A variety of methods and arrangements for controlling the exhaust gas temperature of a lean burn, skip fire controlled internal combustion engine are described. In one aspect, an engine controller includes an aftertreatment system monitor and a firing timing determination unit. The aftertreatment monitor obtains data relating to a temperature of one or more aftertreatment elements, such as a catalytic converter. Based at least partly on this data, the firing timing determination unit generates a firing sequence for operating the engine in a skip fire manner such that the temperature of the aftertreatment element is controlled within its effective operating range.

Owner:TULA TECH INC

Burner Control Sensor Configuration

In domestic installations of any type of furnace or equivalent, proof of lean combustion is necessary to satisfy requirements of certification agencies. Exhibiting proof of lean combustion during the operation of an integrated fuel reformer and fuel cell system can be problematic because the point of combustion and its nature may shift during operation. In addition, the preferred ratio of fuel to air in these fuel-reforming systems is often near a stoichiometry of one. In the present invention, the combination of a flame-detecting device, a temperature sensing device and an oxygen or hydrocarbon sensor is used to verify the occurrence of combustion, and show proof of lean combustion.

Owner:NUVERA FUEL CELLS

Separately determining firing density and pumping density during firing density transitions for a lean-burn internal combustion engine

ActiveUS20200025050A1Control of ratioAvoid adversely affecting emissionElectrical controlInternal combustion piston enginesEngineeringLean combustion

A skip fire engine controller and method of control is described wherein during transitions from a first firing density to a second firing density, a firing density and a pumping density are separately set so as to balance the conflicting demands of (a) torque control, (b) Noise, Vibration and Harshness (NVH), (c) air flow through the engine and (d) air-fuel ratio.

Owner:TULA TECH INC

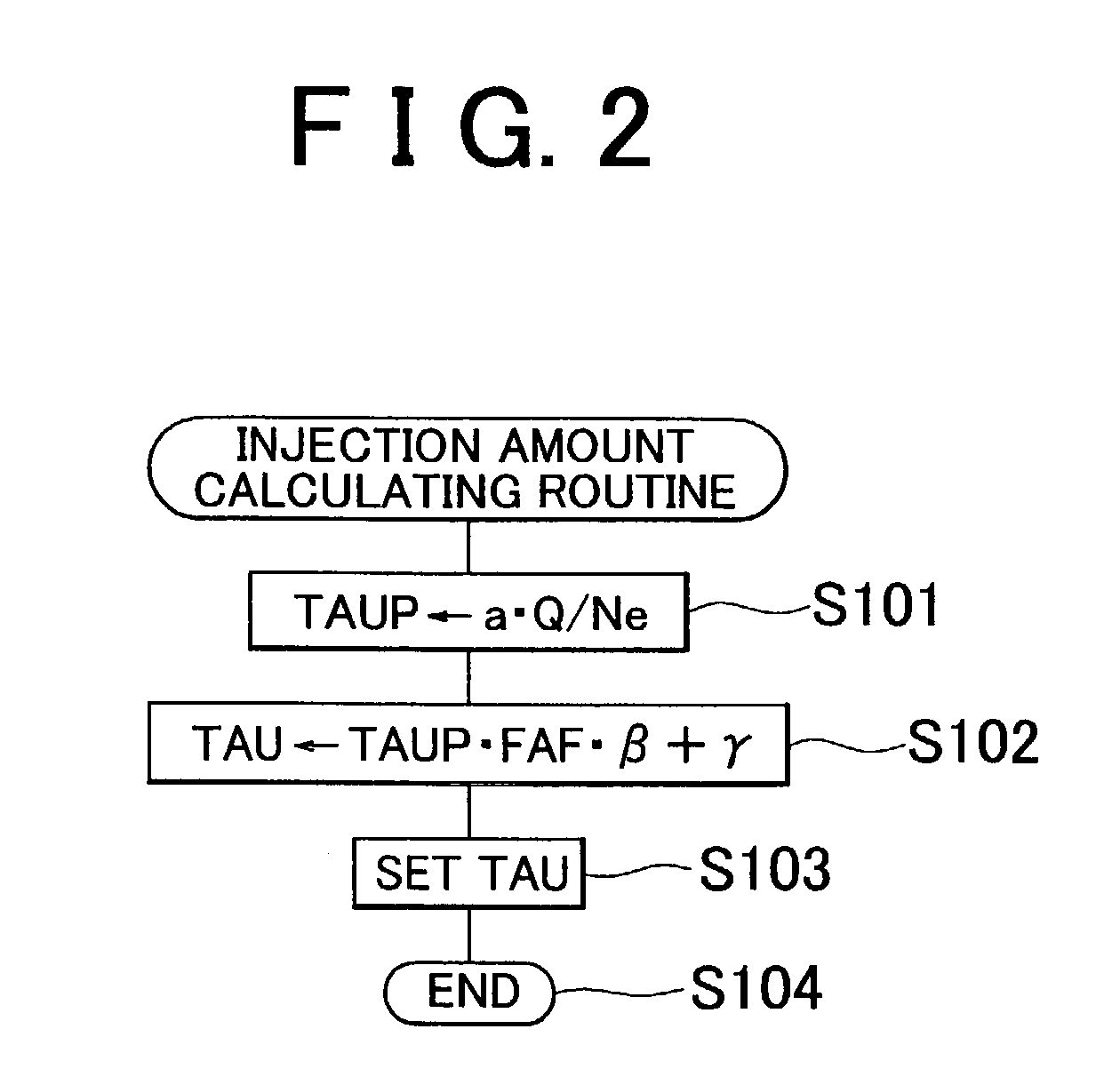

Fuel injection control apparatus and fuel injection control method for internal combustion engine

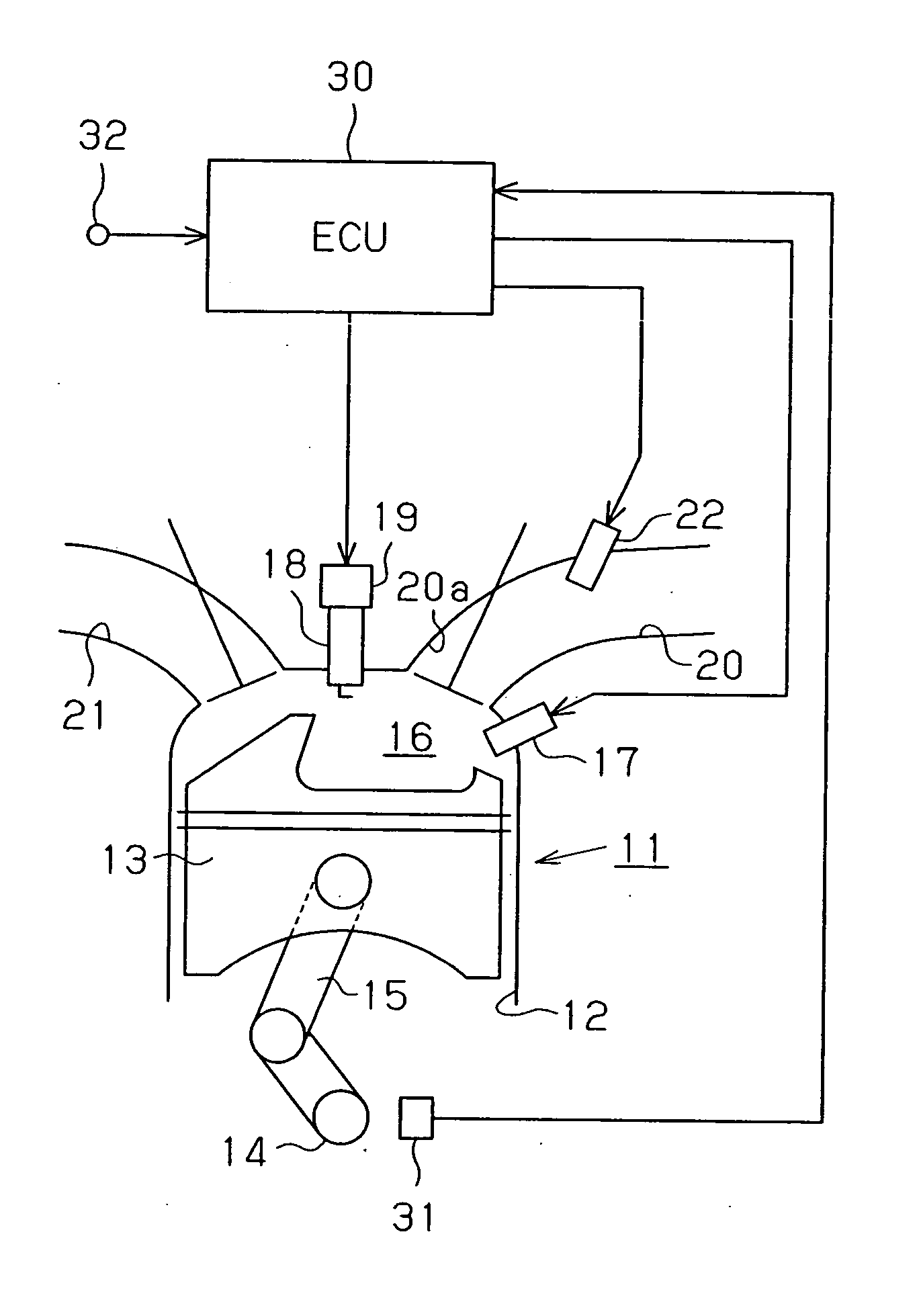

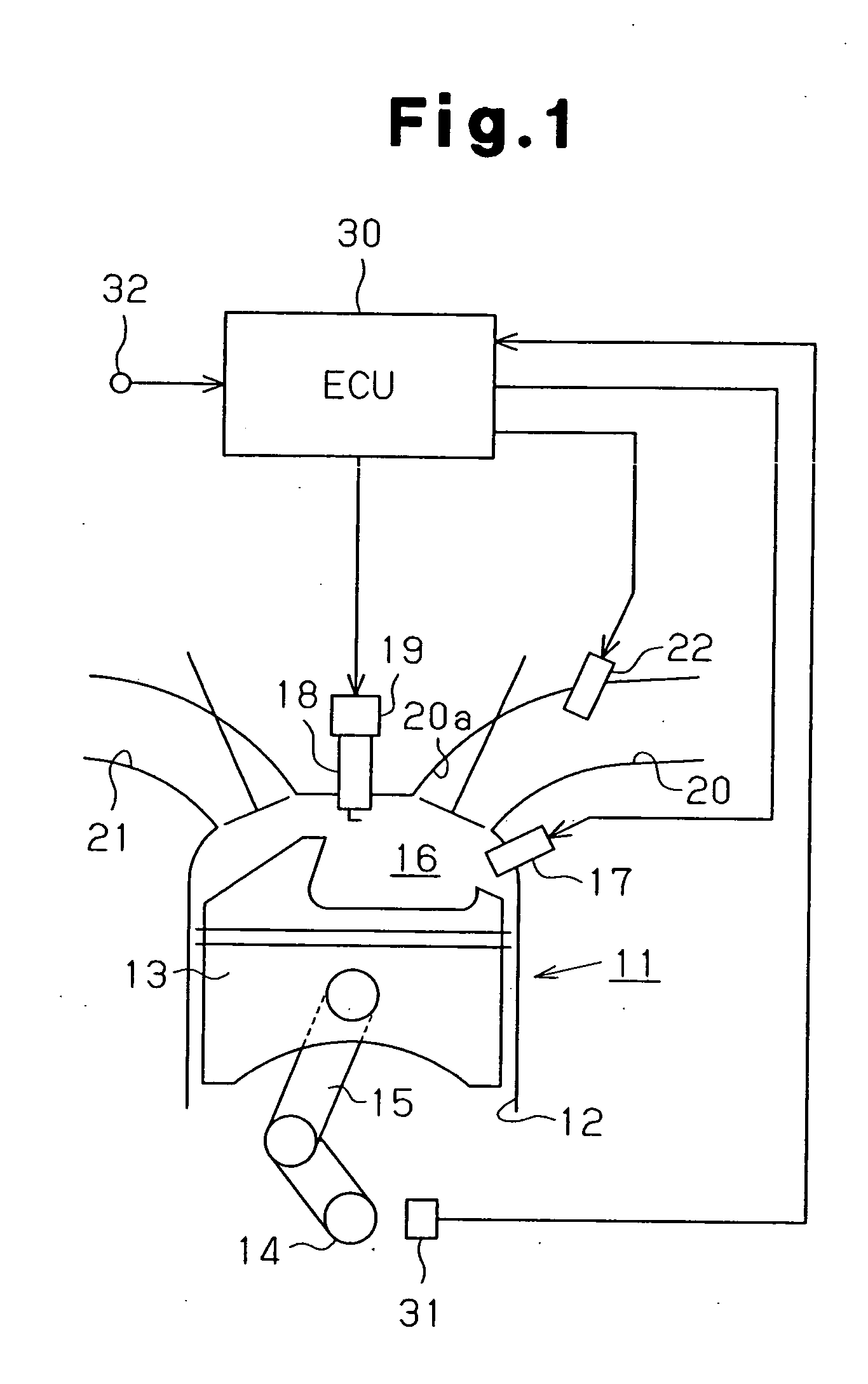

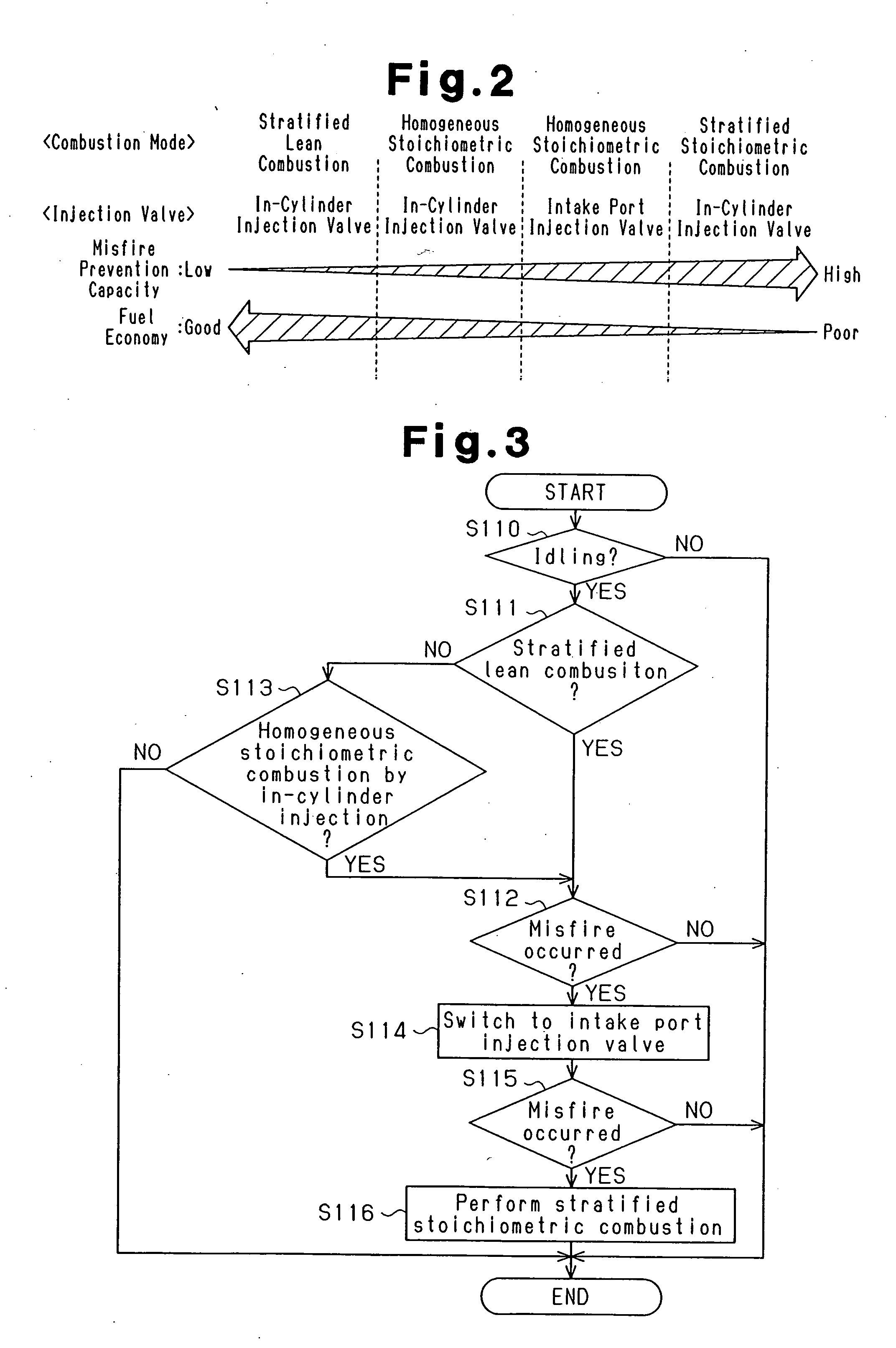

InactiveUS20050098154A1Easy to solveReduced fuel economyElectrical controlCombustion enginesCombustionInternal combustion engine

An internal combustion engine includes an in-cylinder injection valve and an intake port injection valve. The engine is operated in a combustion mode that is selected from at least stratified lean combustion and homogeneous combustion. An ECU selects the combustion mode according to the operational state of the engine, and controls the fuel injection valves in a fuel injection mode that corresponds to the selected combustion mode. When a misfire is detected while the engine is operated in the stratified lean combustion or the homogeneous combustion, the ECU switches the fuel injection mode such that the ratio of the amount of fuel injected from the intake port injection valve to the entire amount of fuel supplied into the cylinder is increased. As a result, misfires are suppressed while preventing the fuel economy from deteriorating.

Owner:TOYOTA JIDOSHA KK

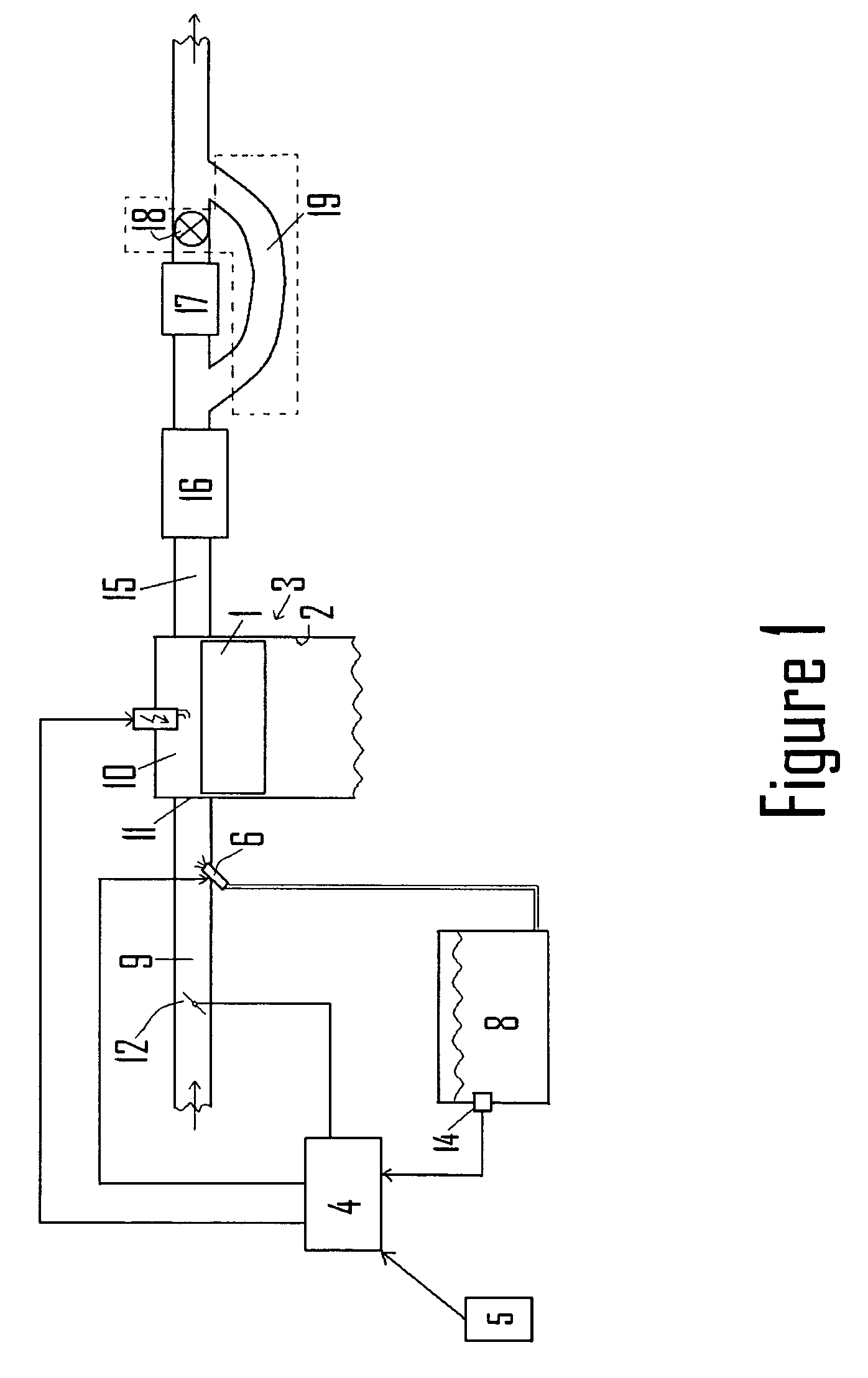

Flex fuel internal combustion engine system

InactiveUS8061121B2Efficient combustionElectrical controlInternal combustion piston enginesInternal combustion engineLean combustion

Owner:ENVIRONMENTAL PROTECTION AGENCY US

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com