Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

128results about How to "Large flow cross-sectional area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

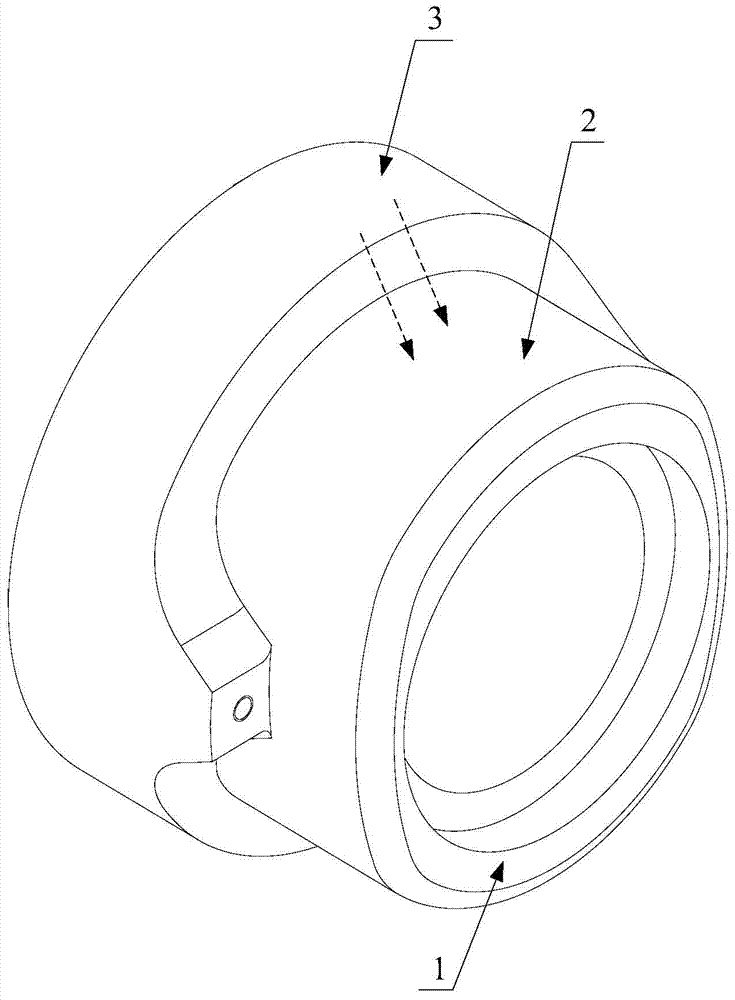

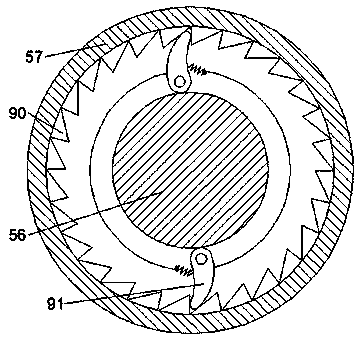

Devices for reducing left atrial pressure having biodegradable constriction, and methods of making and using same

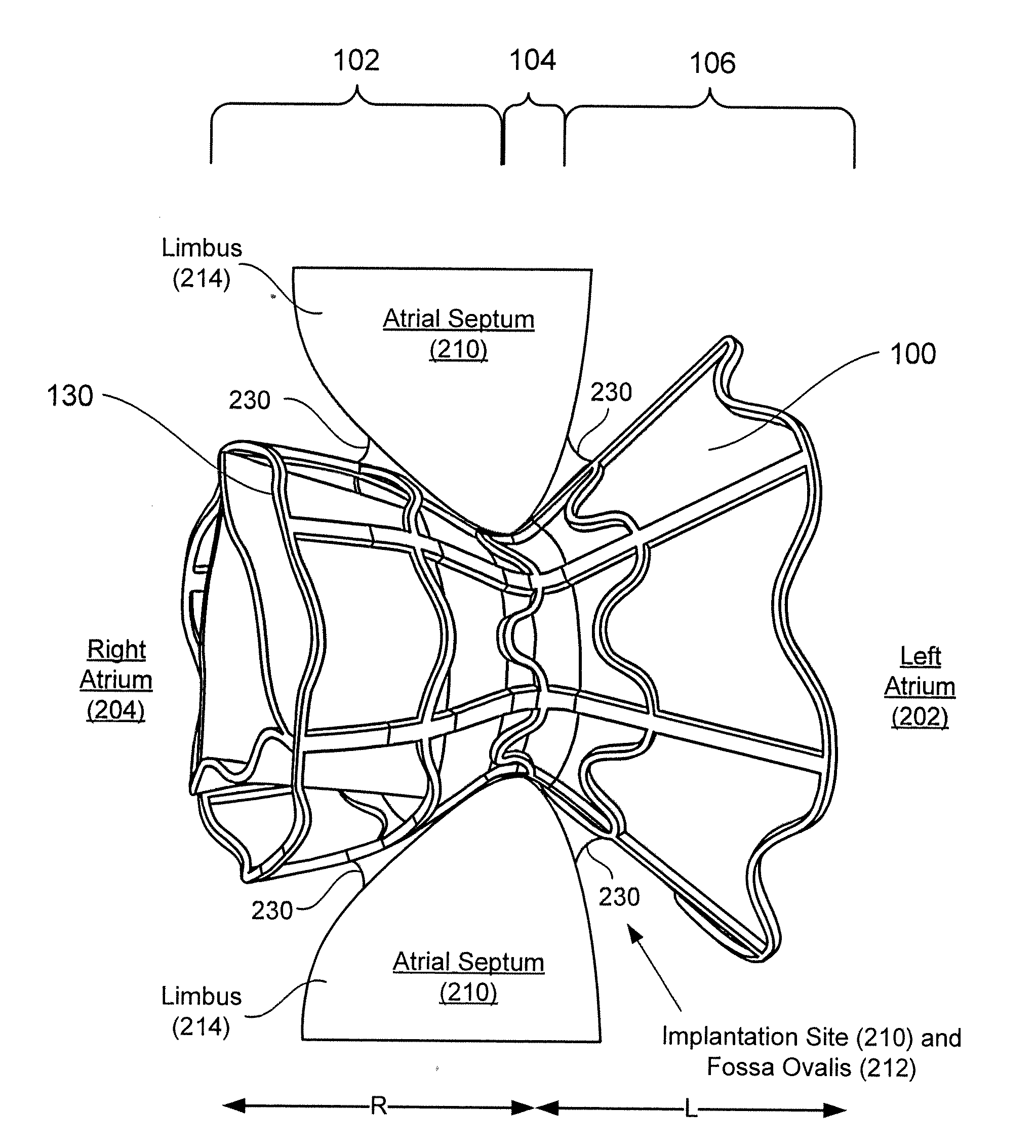

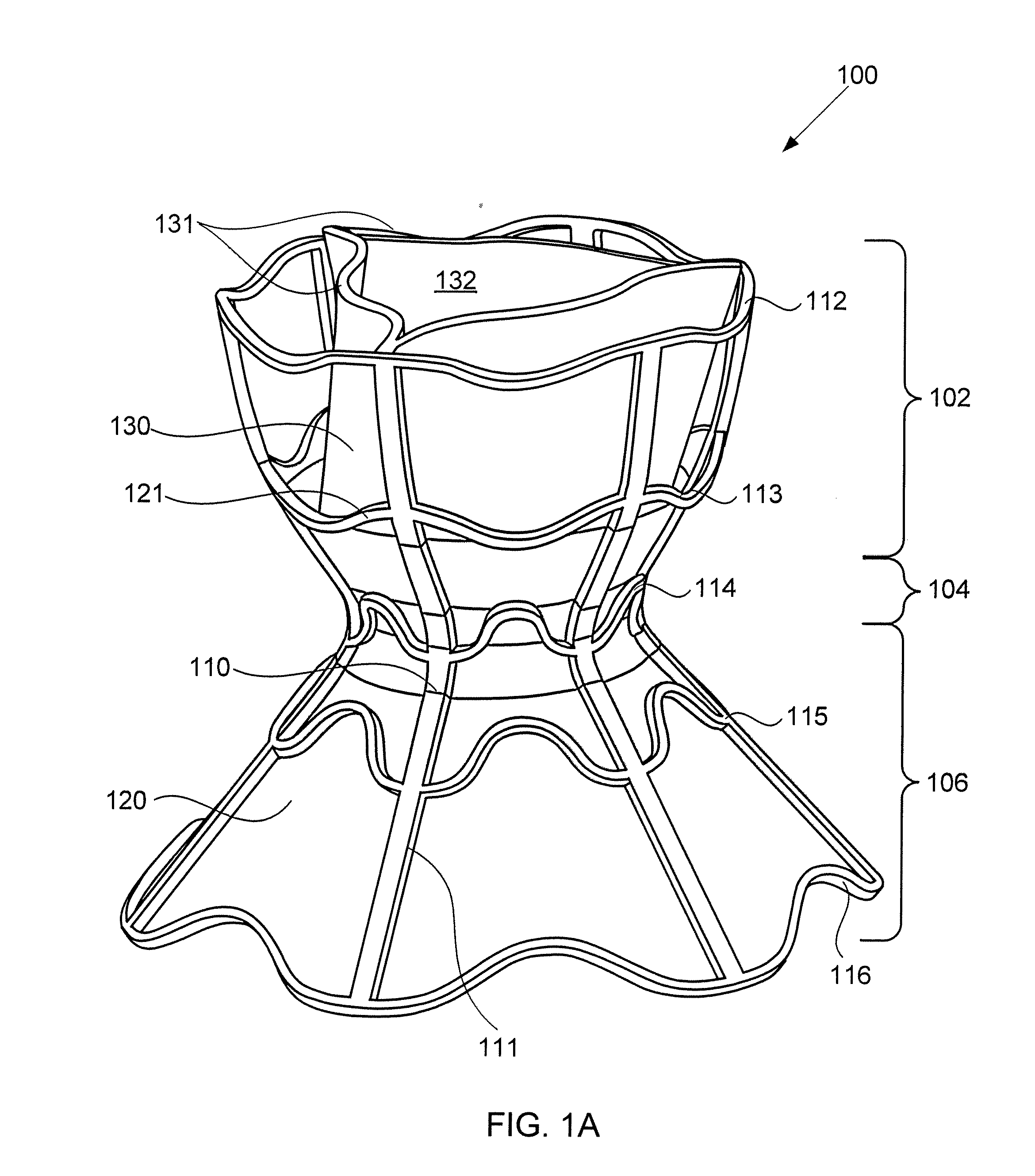

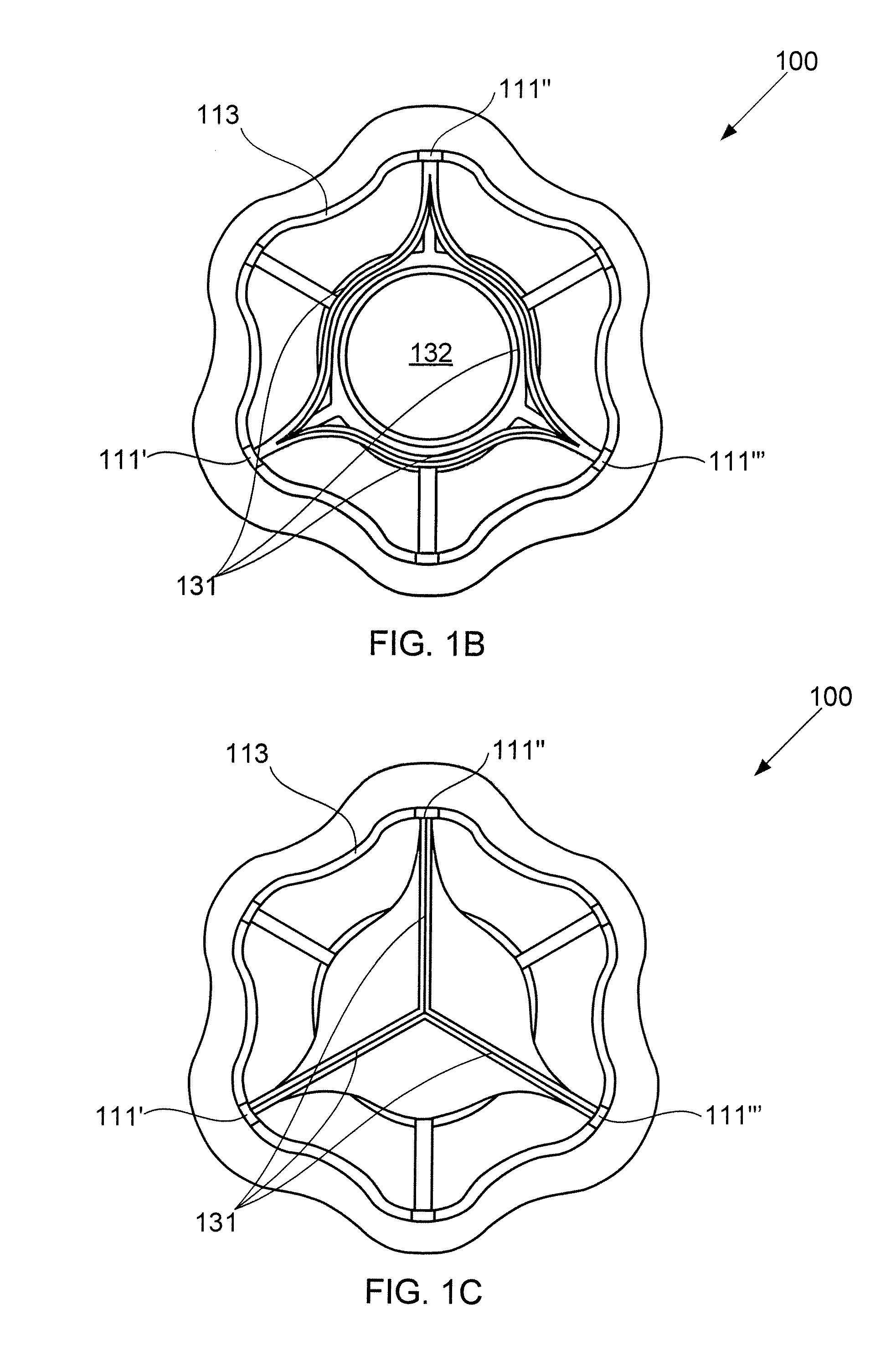

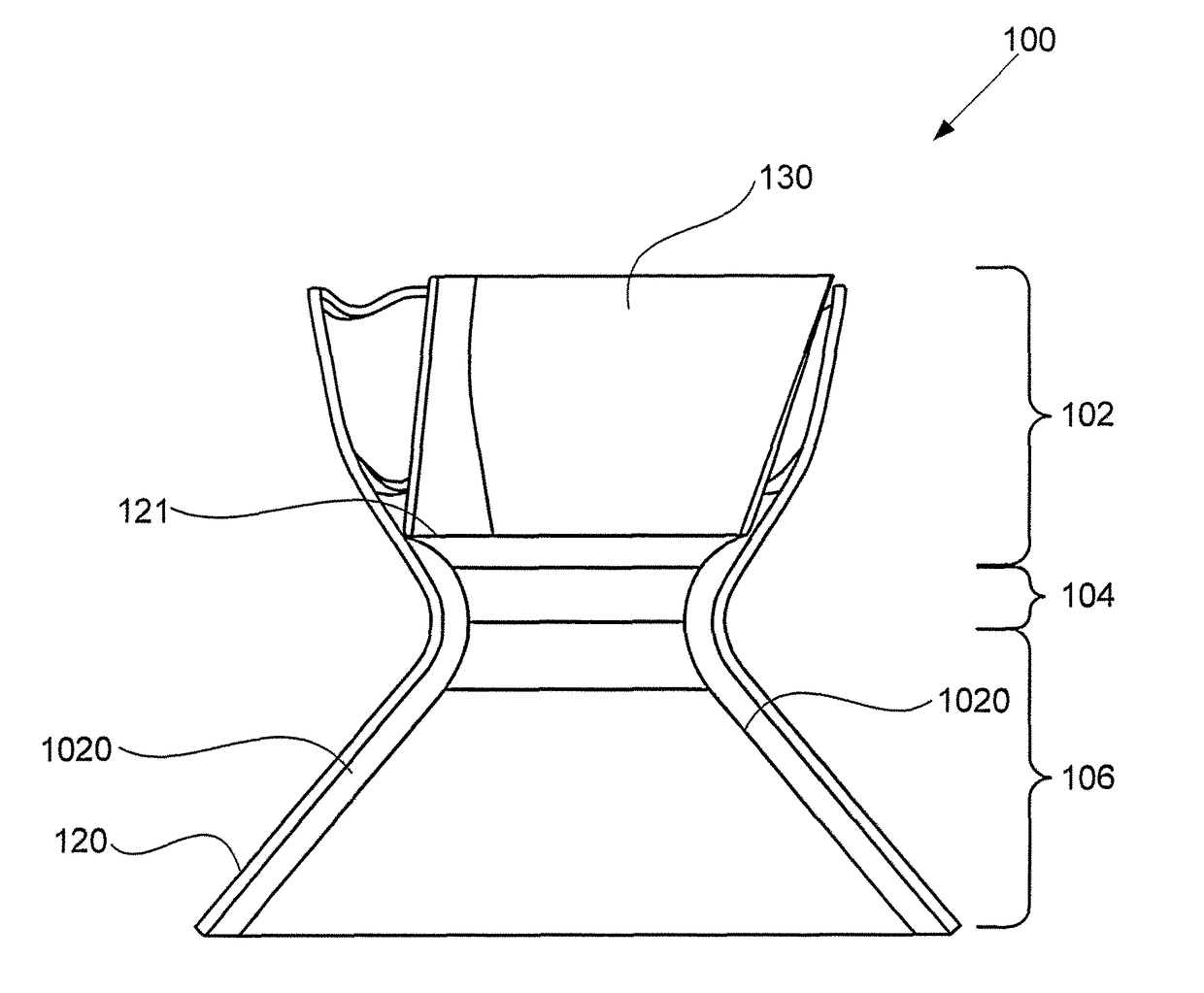

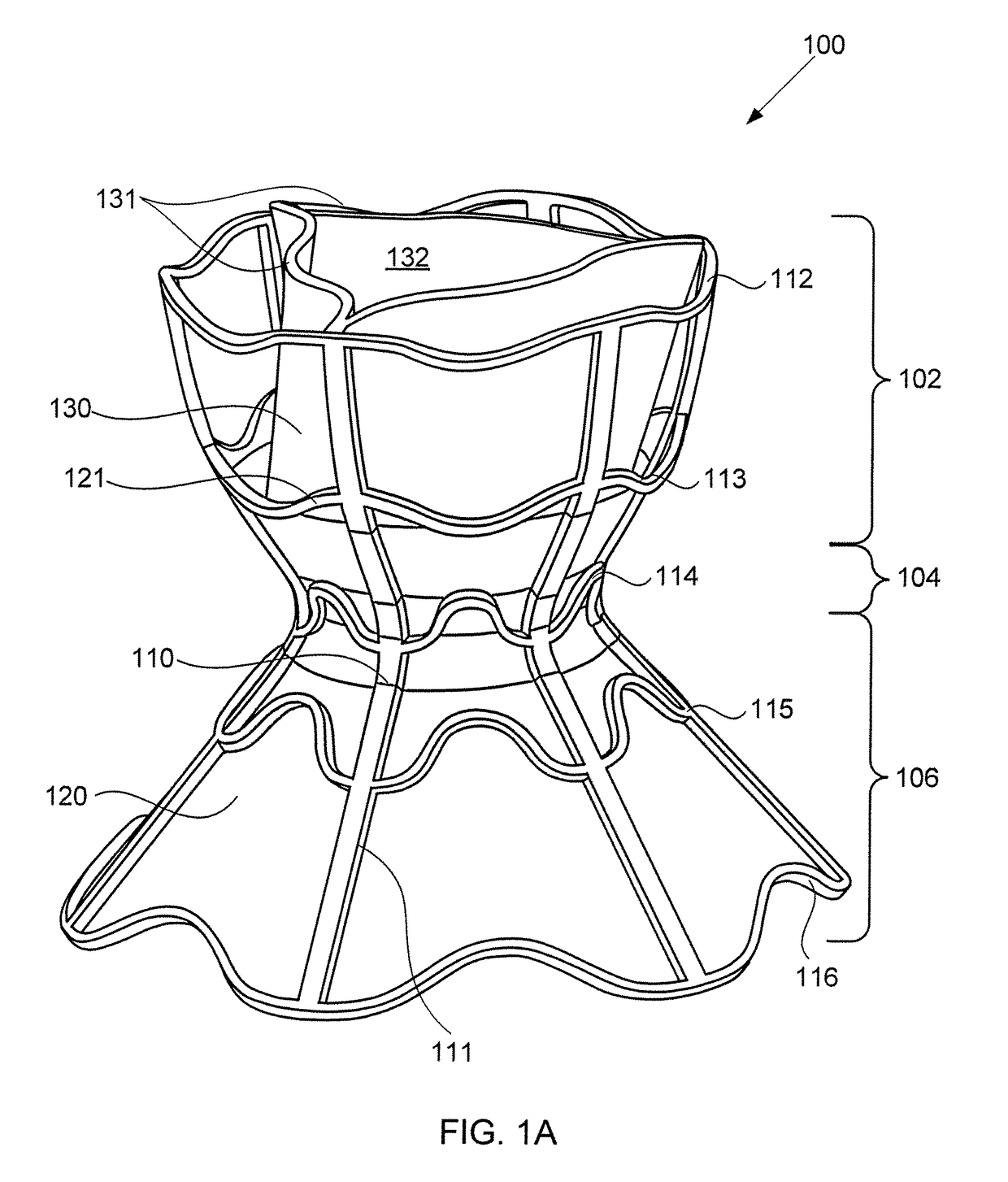

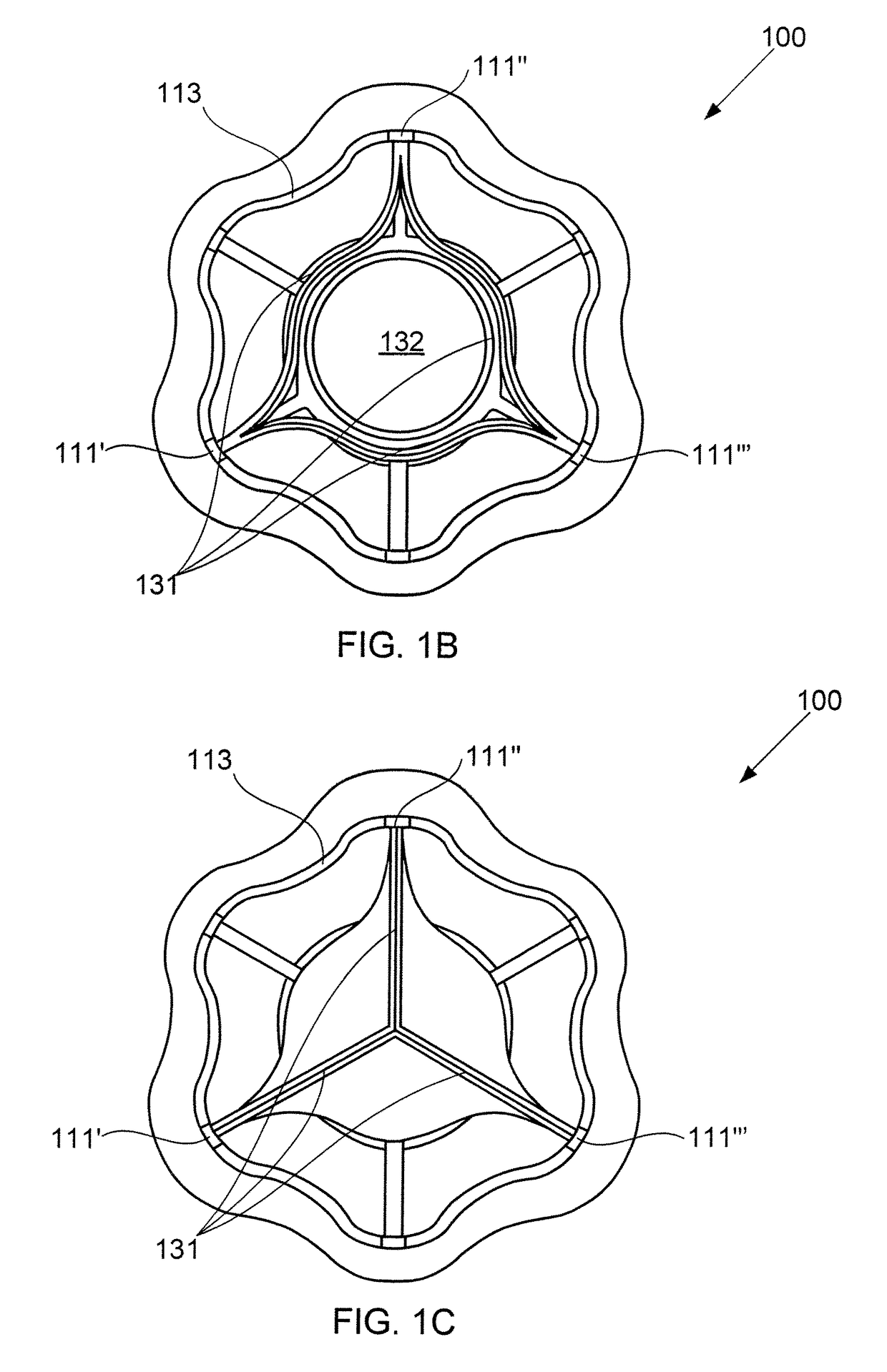

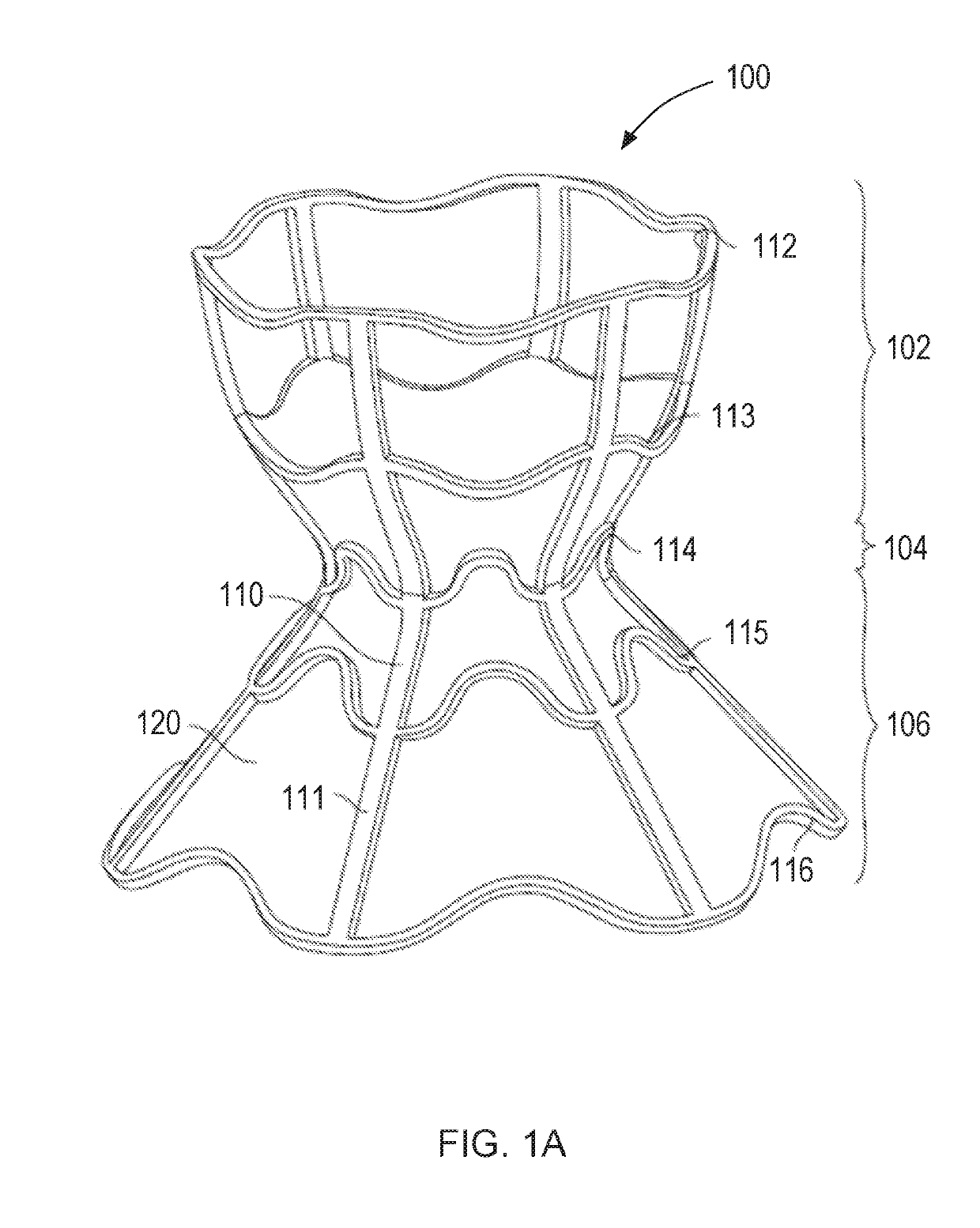

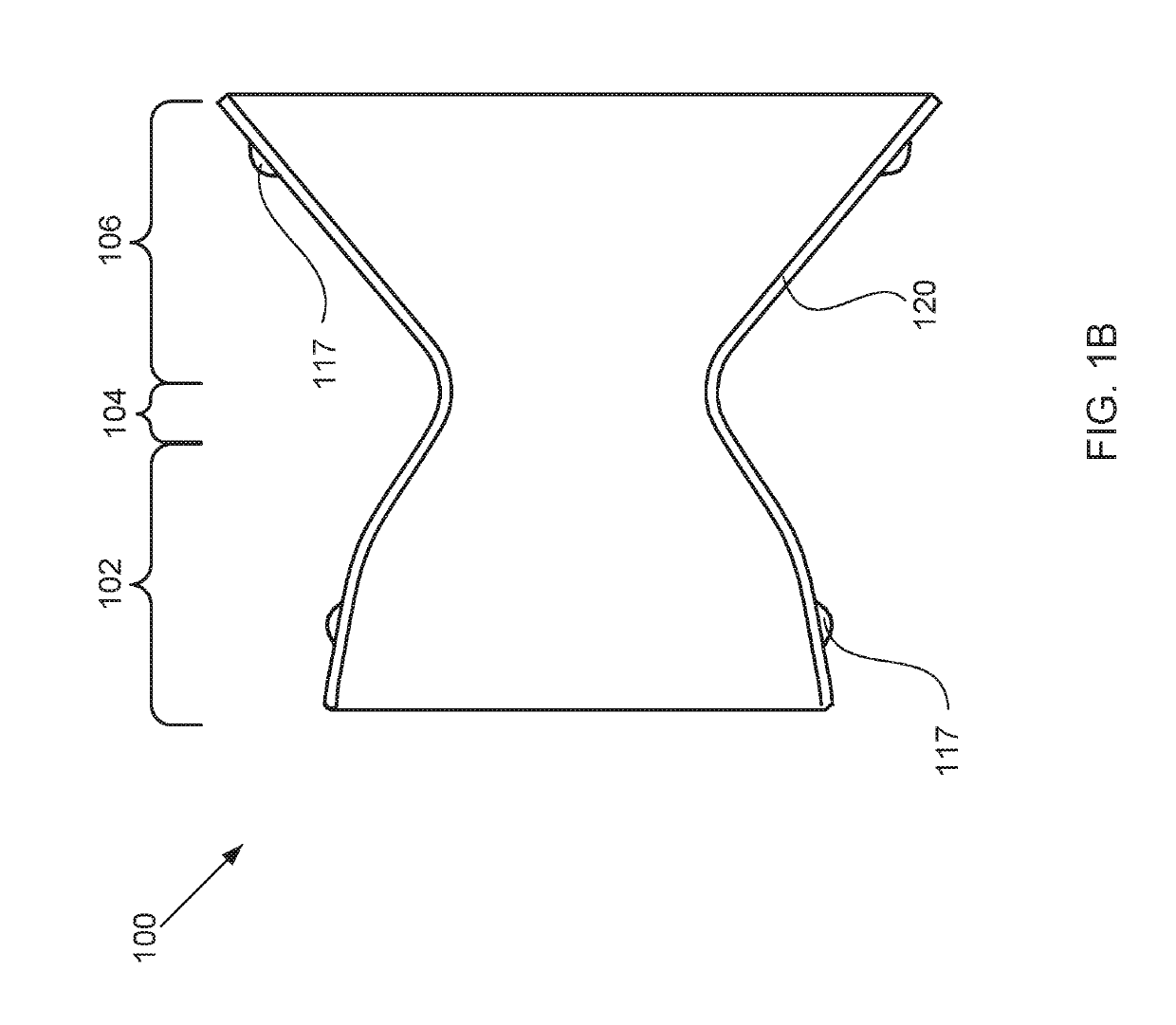

ActiveUS20130030521A1Reducing left atrial pressureIncrease cardiac outputHeart valvesSurgeryLeft ventricular sizeLeft atrial pressure

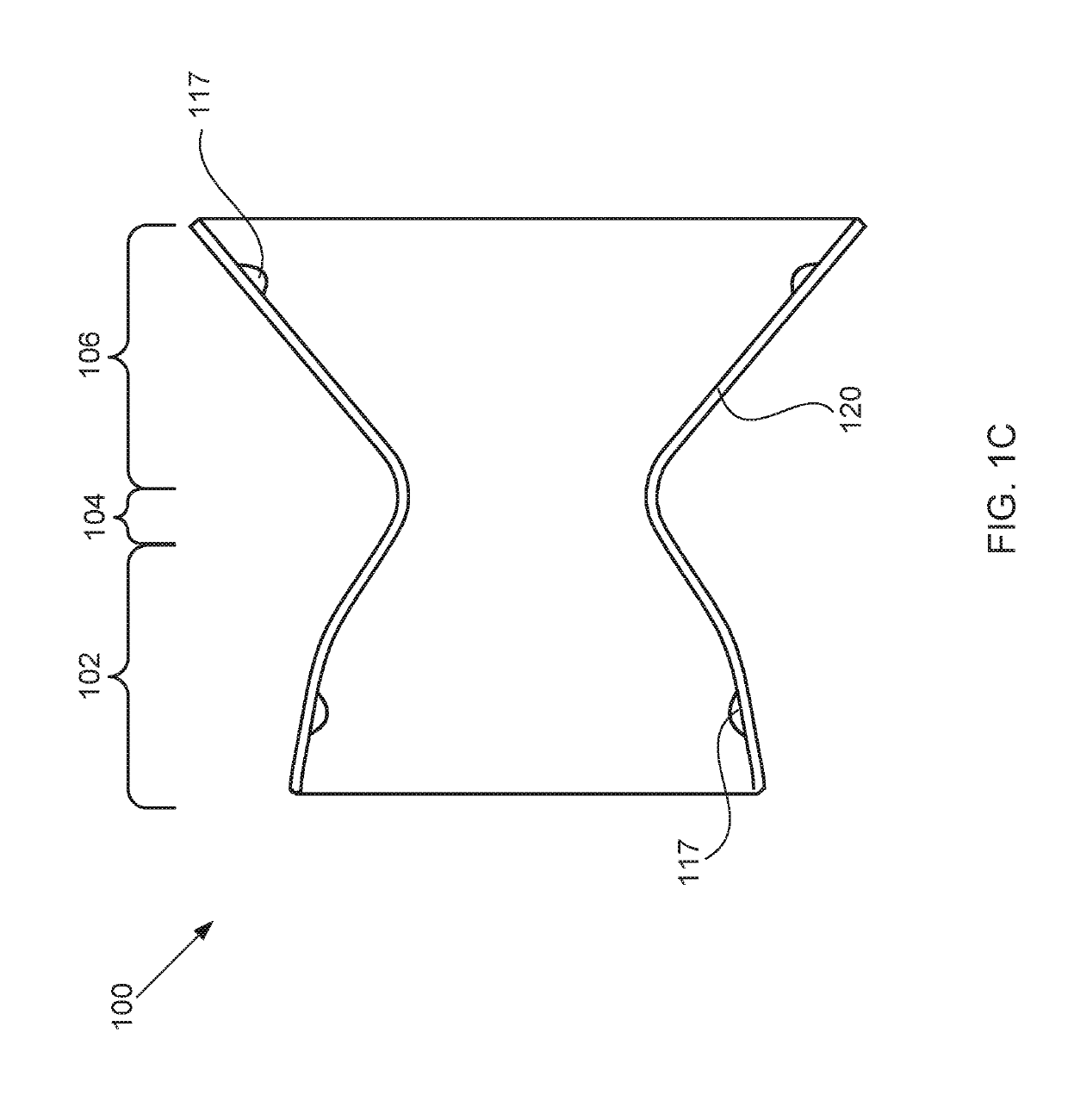

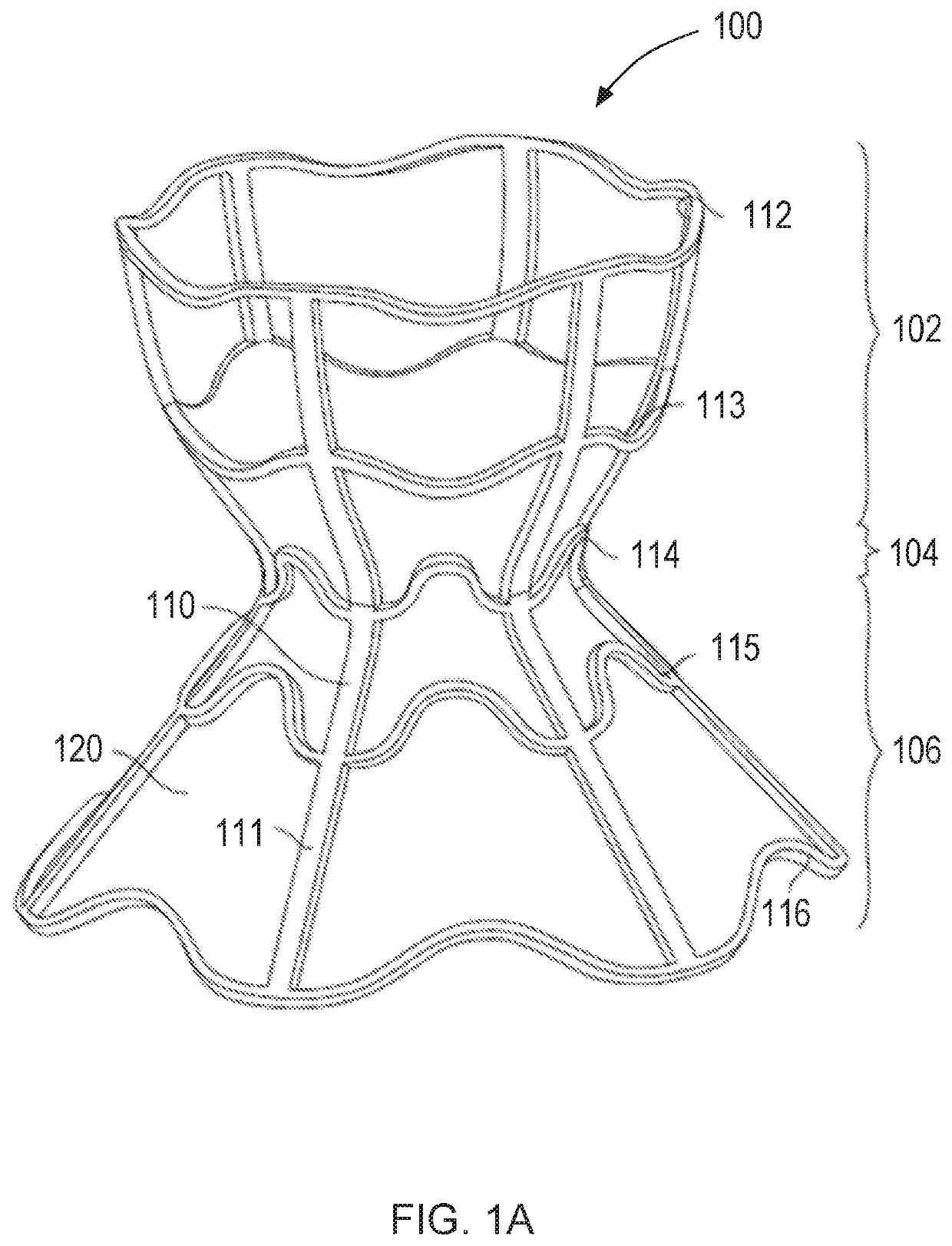

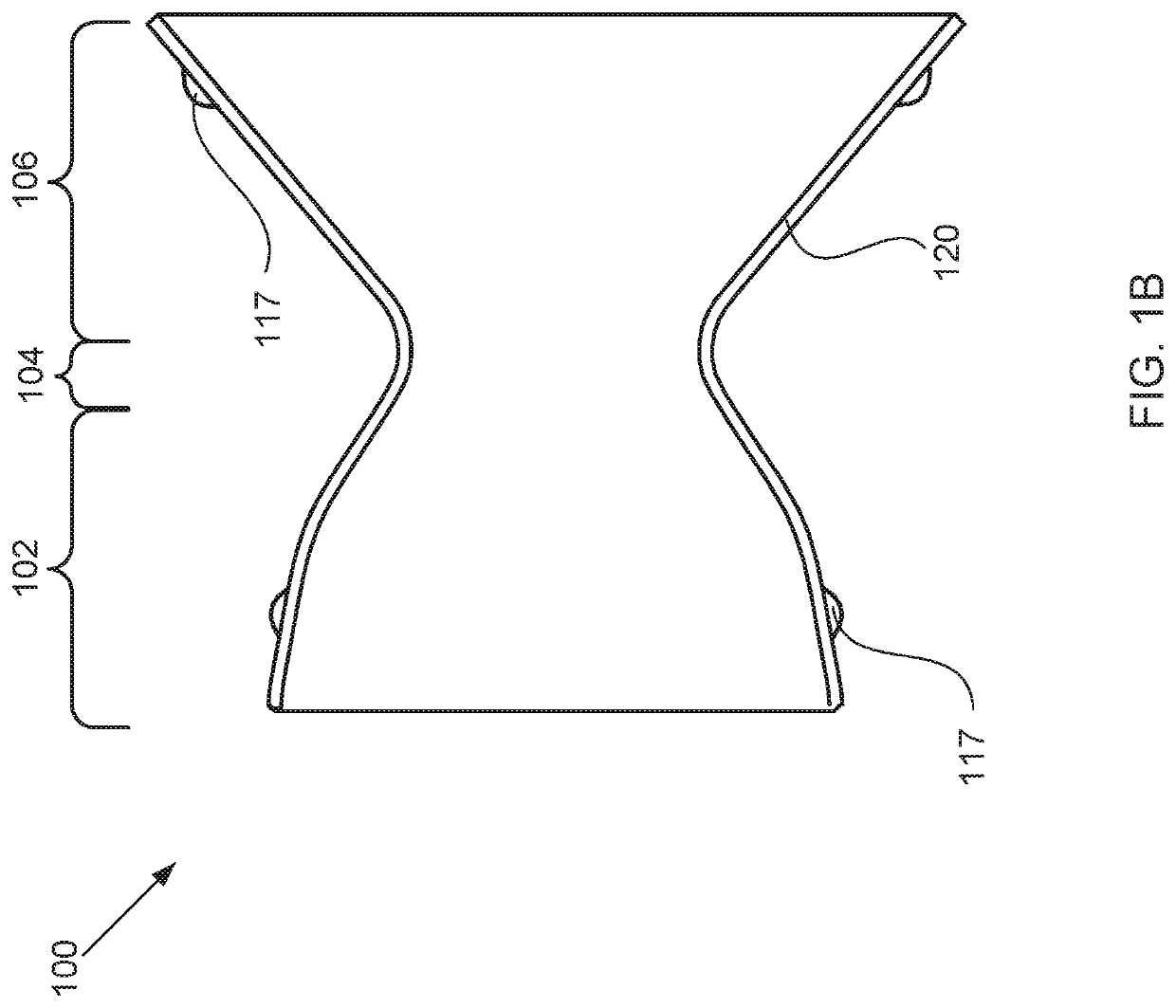

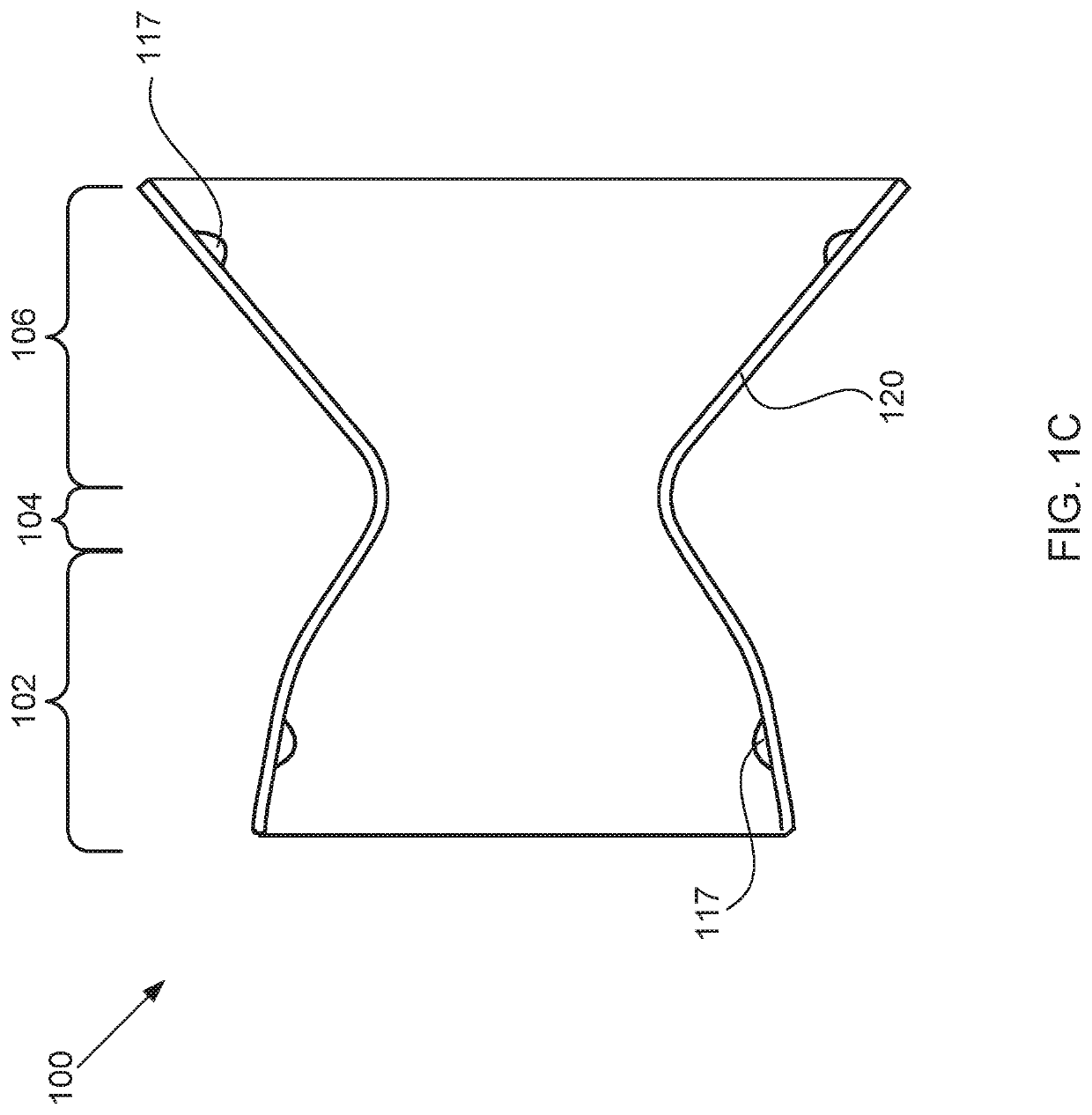

A device for regulating blood pressure between a patient's left atrium and right atrium comprises an hourglass-shaped stent comprising a neck region and first and second flared end regions, the neck region disposed between the first and second end regions and configured to engage the fossa ovalis of the patient's atrial septum; and a one-way tissue valve coupled to the first flared end region and configured to shunt blood from the left atrium to the right atrium when blood pressure in the left atrium exceeds blood pressure in the right atrium. The inventive device may include a biodegradable material that biodegrades to offset flow changes caused by tissue ingrowth. The inventive device may reduce left atrial pressure and left ventricular end diastolic pressure, and may increase cardiac output, increase ejection fraction, relieve pulmonary congestion, and lower pulmonary artery pressure, among other benefits.

Owner:WAVE LTD V

Devices for reducing left atrial pressure having biodegradable constriction, and methods of making and using same

ActiveUS9629715B2Large flow cross-sectional areaReduce pressureStentsHeart valvesLeft ventricular sizeLeft atrial pressure

A device for regulating blood pressure between a patient's left atrium and right atrium comprises an hourglass-shaped stent comprising a neck region and first and second flared end regions, the neck region disposed between the first and second end regions and configured to engage the fossa ovalis of the patient's atrial septum; and a one-way tissue valve coupled to the first flared end region and configured to shunt blood from the left atrium to the right atrium when blood pressure in the left atrium exceeds blood pressure in the right atrium. The inventive device may include a biodegradable material that biodegrades to offset flow changes caused by tissue ingrowth. The inventive device may reduce left atrial pressure and left ventricular end diastolic pressure, and may increase cardiac output, increase ejection fraction, relieve pulmonary congestion, and lower pulmonary artery pressure, among other benefits.

Owner:WAVE LTD V

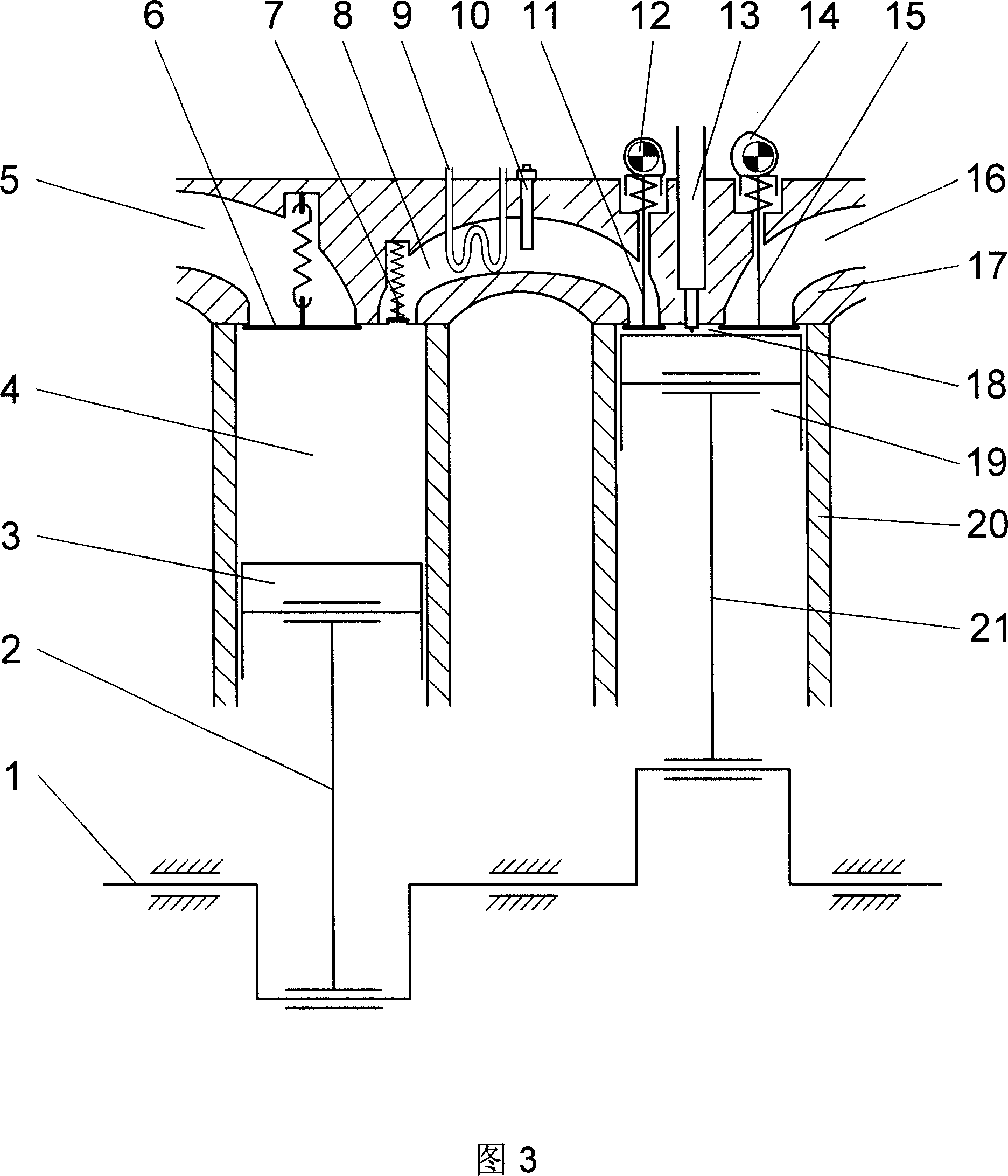

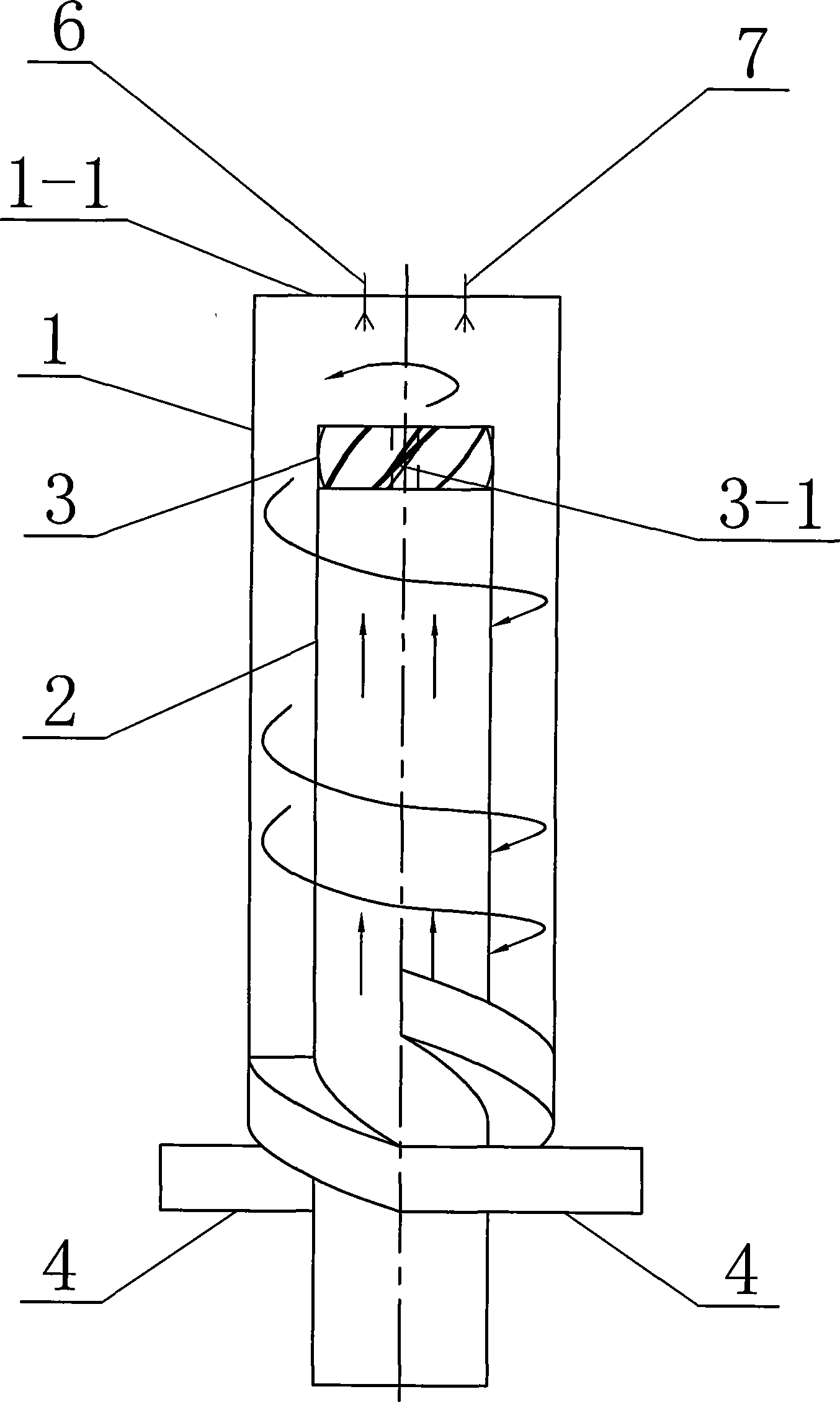

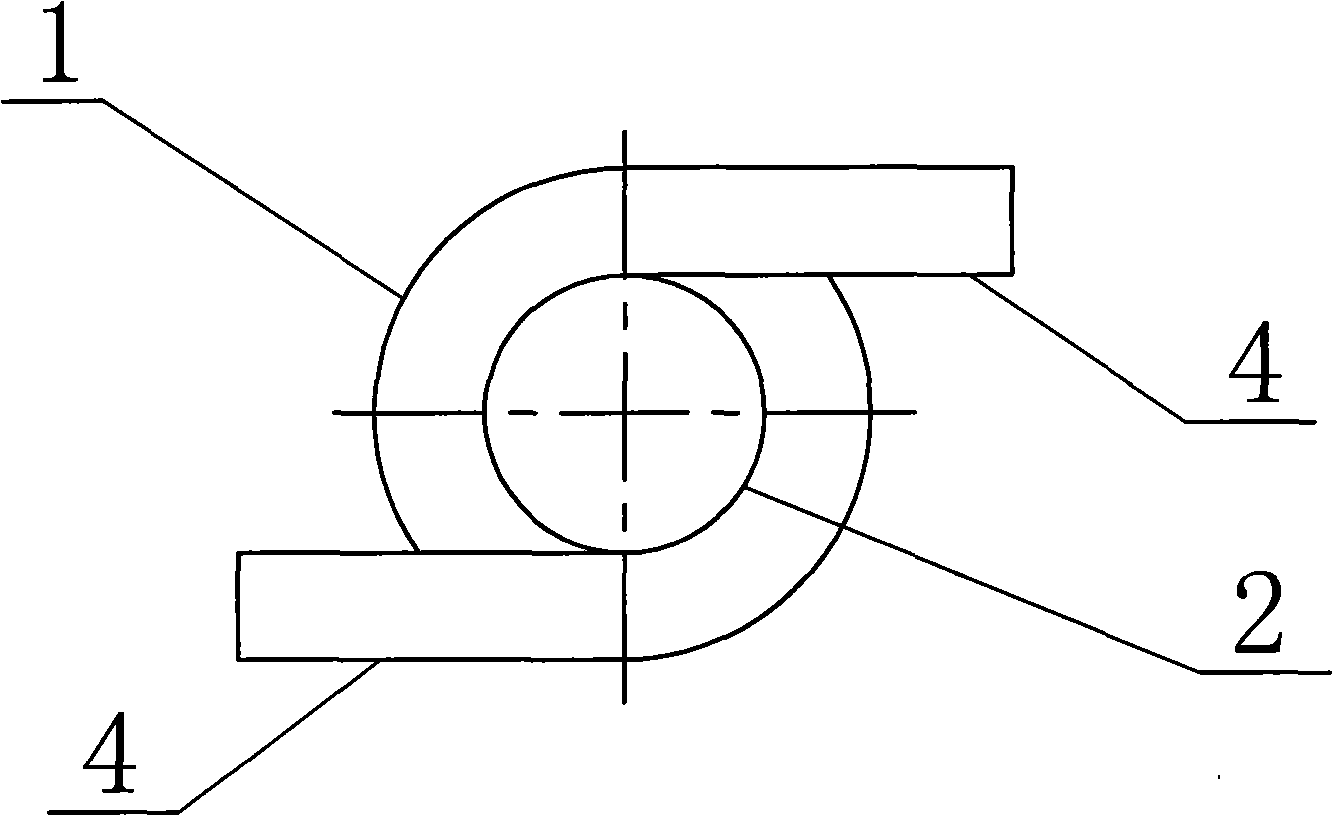

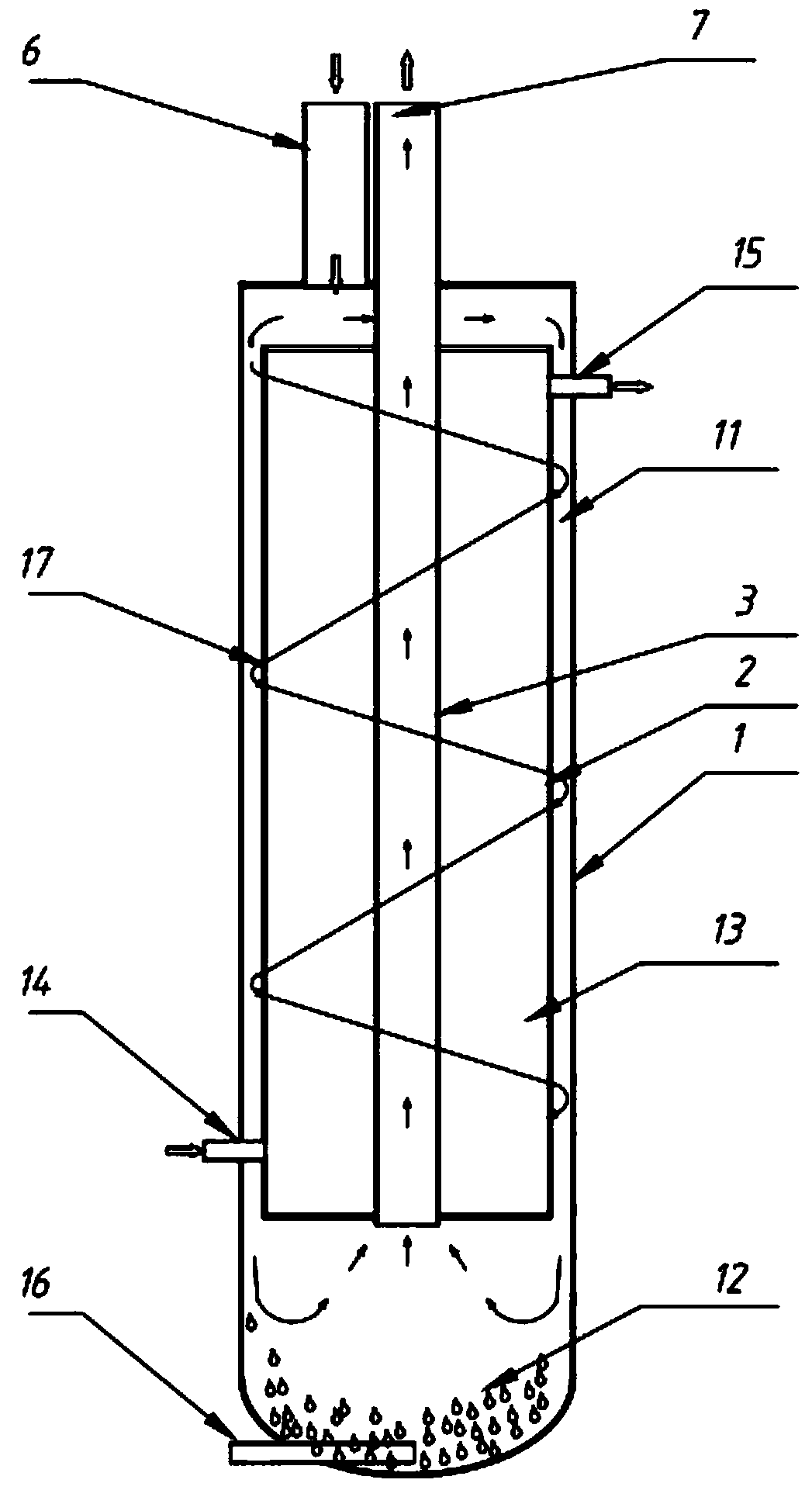

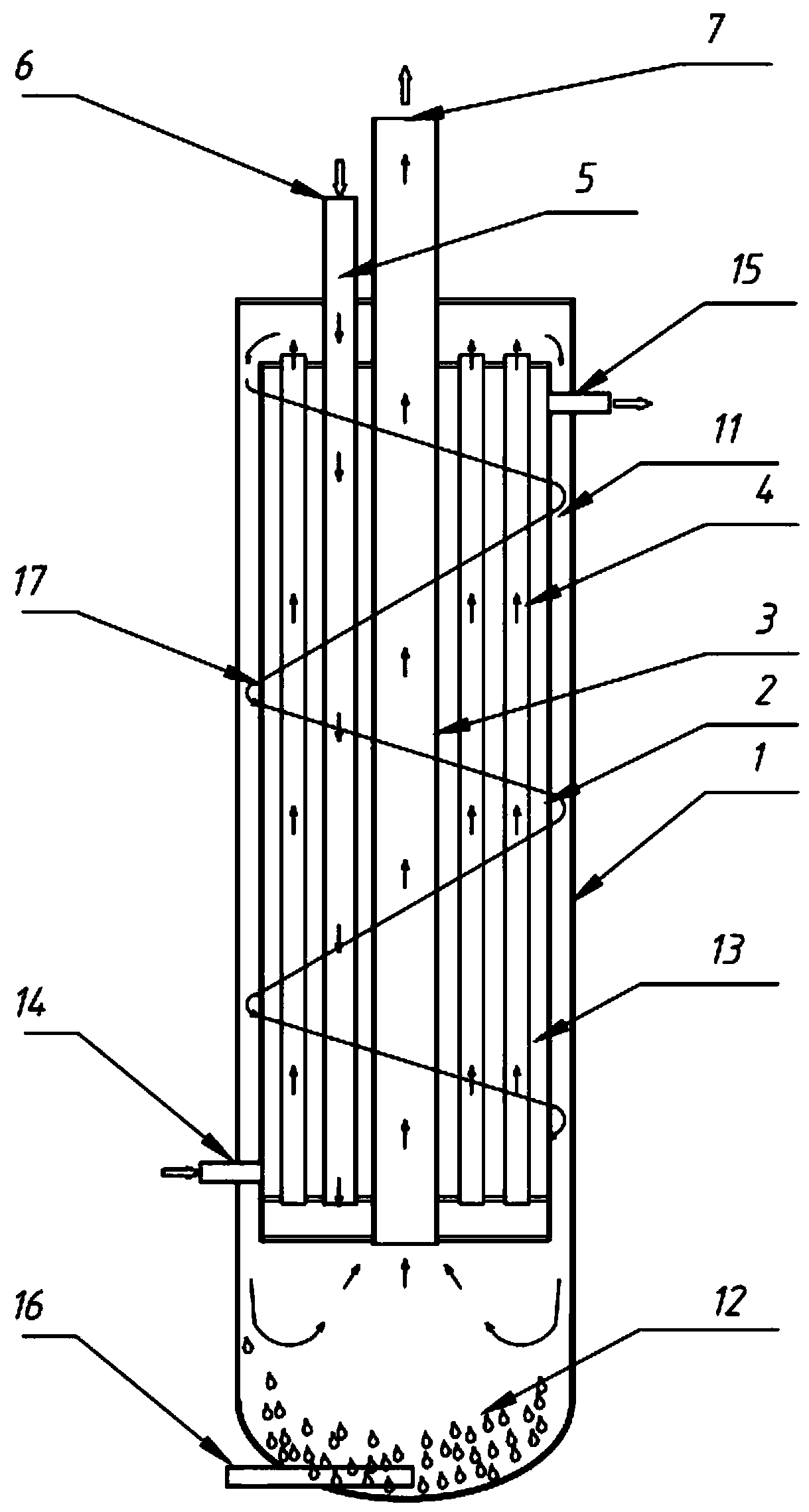

All natural circulation-type modular small reactor

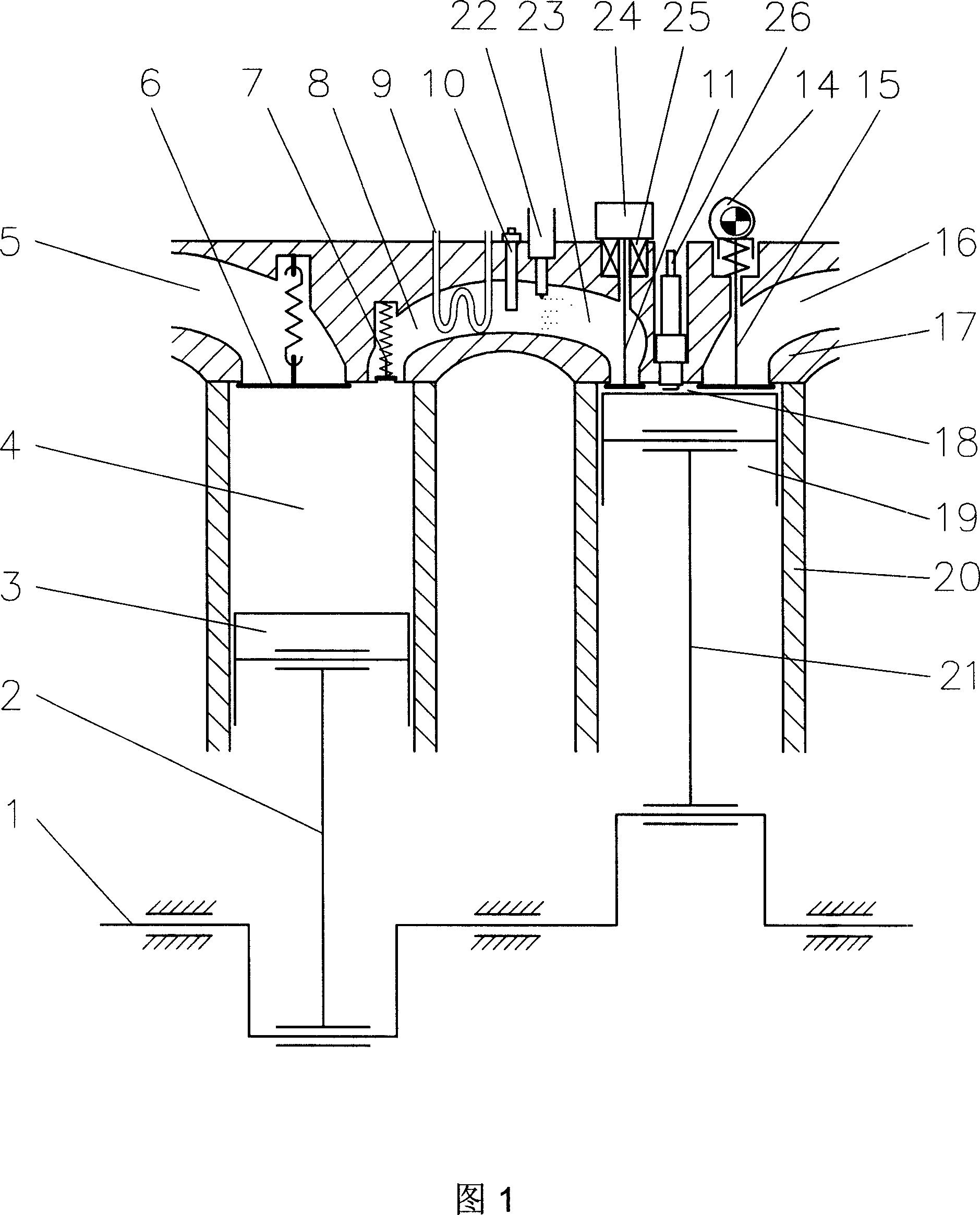

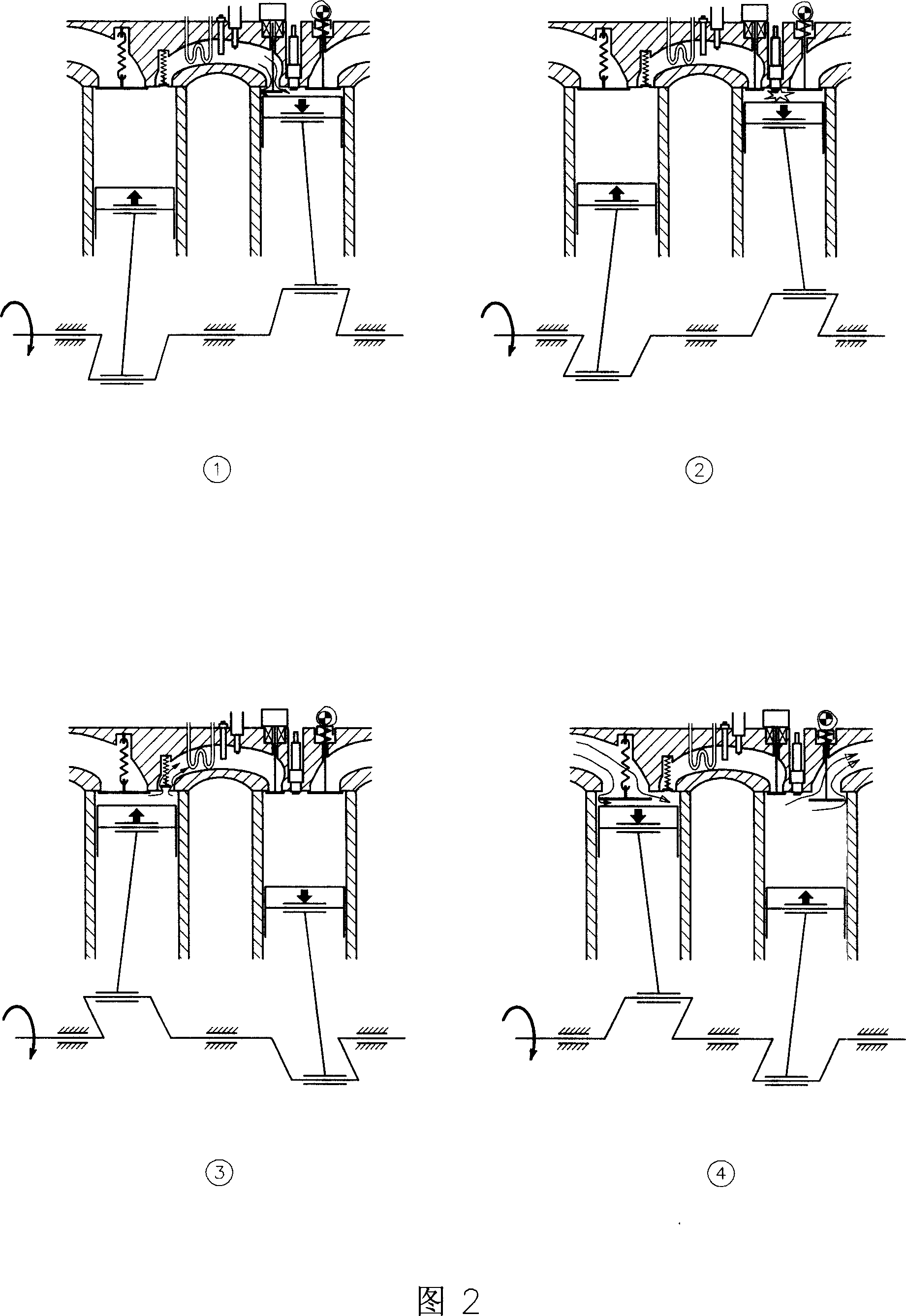

ActiveCN108648837AReduce resistanceImprove natural circulationNuclear energy generationCooling arrangementPotential differenceHeat transmission

The invention discloses an all natural circulation-type modular small reactor. The all natural circulation-type modular small reactor comprises a reactor main body, a safe shell, a water tank and a passive safety system. The reactor main body comprises a pressure vessel. A reactor core, a direct current steam generator and a voltage stabilizer are orderly arranged in the pressure vessel from bottom to top. One end of a control rod driving mechanism matched with the reactor core is arranged at a top cover of the pressure vessel. The pressure vessel is arranged in the safe shell. The safe shellis immersed in the water tank. The passive safety system comprises a passive residual heat removal system and a passive safe shell heat transmission system. The reactor is free of forced circulation of a path of a cooling agent driven by a main pump, and utilizes density contrast of cooling agents between the direct current steam generator and the reactor core and cold and hot core potential difference to drive the cooling agents to all naturally circulate in the pressure vessel so that the reactor safety is improved. The passive safety system realizes a lasting submerged state of the reactorcore and carries out the residual heat of the reactor core to prevent core damage.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Interatrial shunts having biodegradable material, and methods of making and using same

ActiveUS20190254814A1Reducing left atrial pressureIncreased cardiac outputStentsHeart valvesAtrial cavityAtrial septum

A device for regulating blood pressure between a patient's left atrium and right atrium comprises an hourglass-shaped stent comprising a neck region and first and second flared end regions, the neck region disposed between the first and second end regions and configured to engage the fossa ovalis of the patient's atrial septum, and a drug-eluting biodegradable material that biodegrades over time to release a drug that limits tissue overgrowth. The inventive device also may include a biodegradable material that biodegrades to offset flow changes caused by tissue overgrowth. The inventive device may reduce left atrial pressure and left ventricular end diastolic pressure, and may increase cardiac output, increase ejection fraction, relieve pulmonary congestion, and lower pulmonary artery pressure, among other benefits.

Owner:WAVE LTD V

Chip suction drill

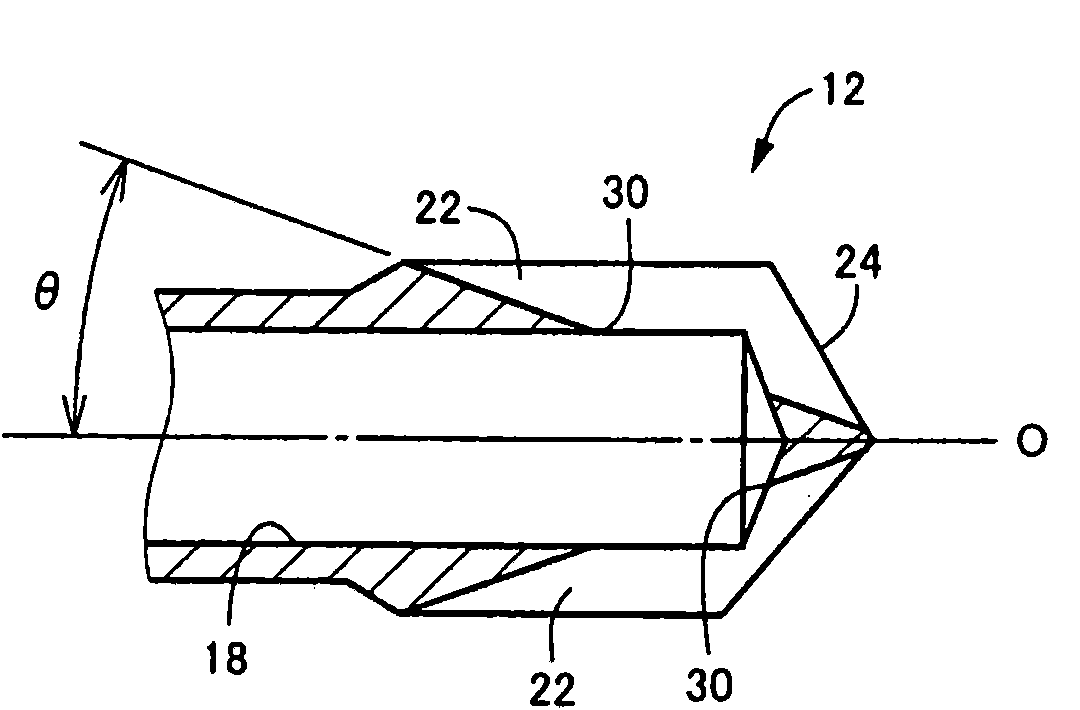

ActiveCN101959634AExcellent Chip Attraction PerformanceReduce resistanceTransportation and packagingMetal working apparatusChips intakeHole making

A chip suction drill (10) performs a hole making process to a material to be ground (42) such as a casting using a cutting blade (24). A chip generated is suctioned in a chip suction path (18) from a chip intaking hole (30) formed in a cutting blade groove (22) and ejected to a shank (16) side. In this case, since an air introduction groove (32) is provided in the outer periphery surface of a blade (12), air is excellently introduced into the leading end of a tool at which the chip is generated by the cutting blade (24) and the air introduced into the leading end of the tool upon the suction of air by the chip suction path (18) is excellently suctioned in the chip intaking hole (30) together with the chip. Particularly, since only one chip suction path (18) is provided in the tool, its cross section area can be sufficiently secured and the chip intaking hole (30) can be enlarged along with the enlargement of the chip suction path (18). Thus, the generation of chip packing can be suppressed and excellent chip suction performance can be obtained.

Owner:OSG

Internal-combustion engine

InactiveCN1928333AEasy to controlEmission reductionInternal combustion piston enginesOutput powerCombustion chamberInlet valve

The invention relates to an internal-combustion engine with piston reciprocating, comprising body, cover, piston, crankshaft and connecting bar. The piston moves advance and return and is connected with crankshaft through connecting bar. The space on the top of piston sealed by cover is formed blast chamber. Intake valve, air outlet valve and spark plug are set in cover at the top of blast chamber. In said body except blast chamber air compressed unit is set, which comprises inhalation valve, air outlet valve, assistant piston, which can move advance and return, and be connected with said crank shaft through assistant connecting bare, and assistant connecting bar. The outlet of air outlet valve is connected to hollow air conversation room withstanding pressure, in which thermal converter, temperature sensor, fuel nozzle and fuel evaporating and mixing room. The outlet of air conversation room is connected to said inlet of intake valve in blast chamber. The invention can decrease harmful gas NOx released largely because of low temperature, improve work efficiency of gas and decrease burning noise.

Owner:袁辉

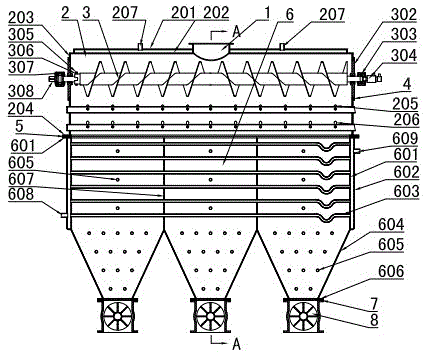

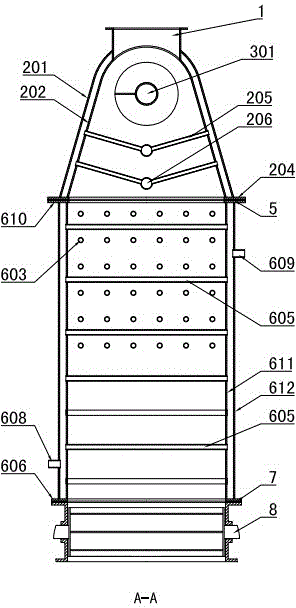

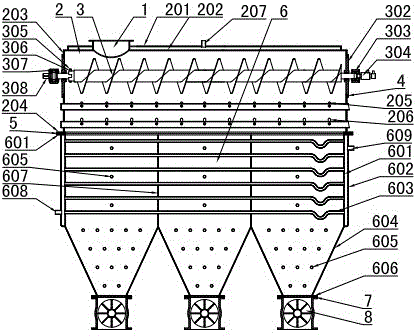

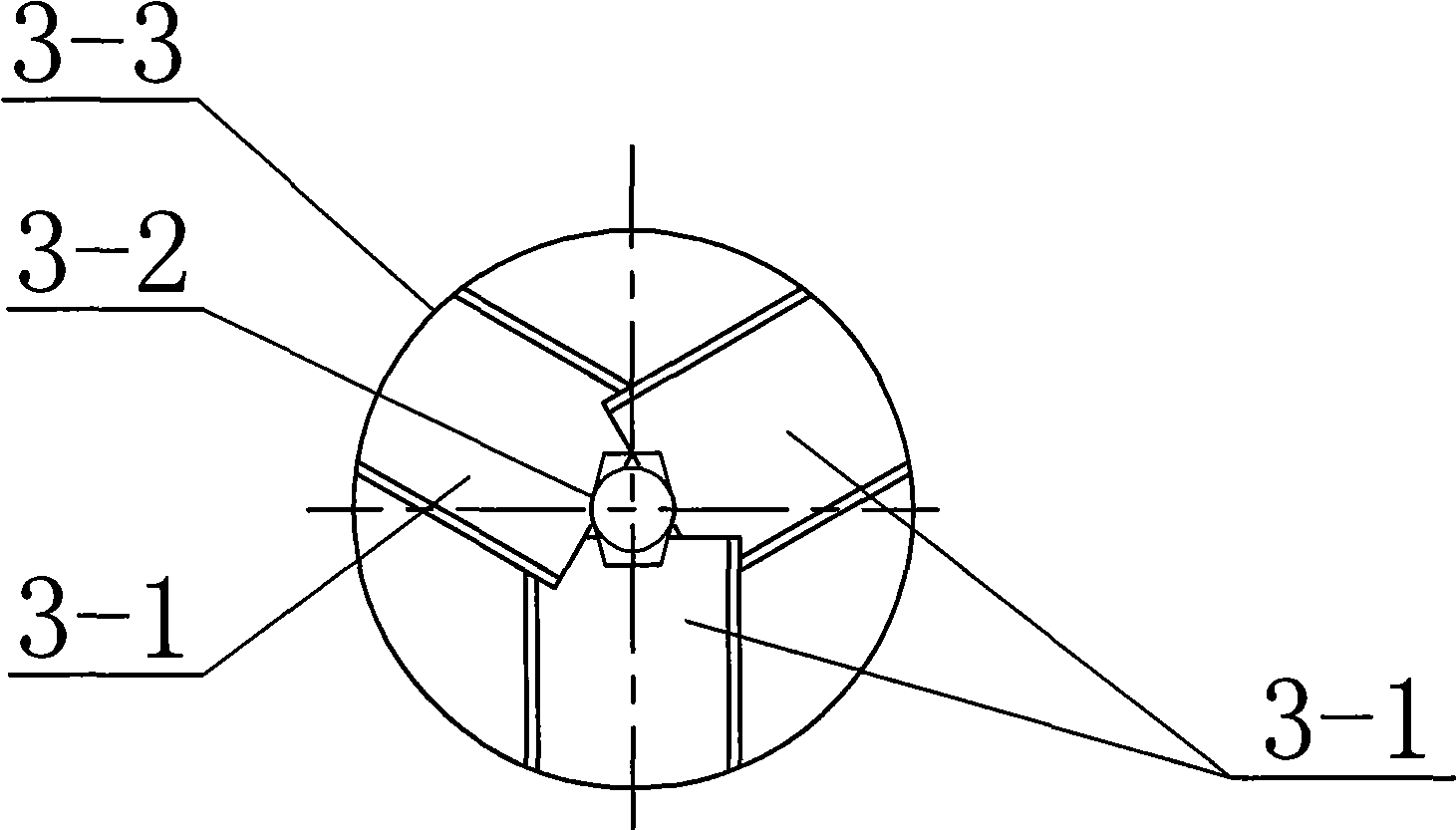

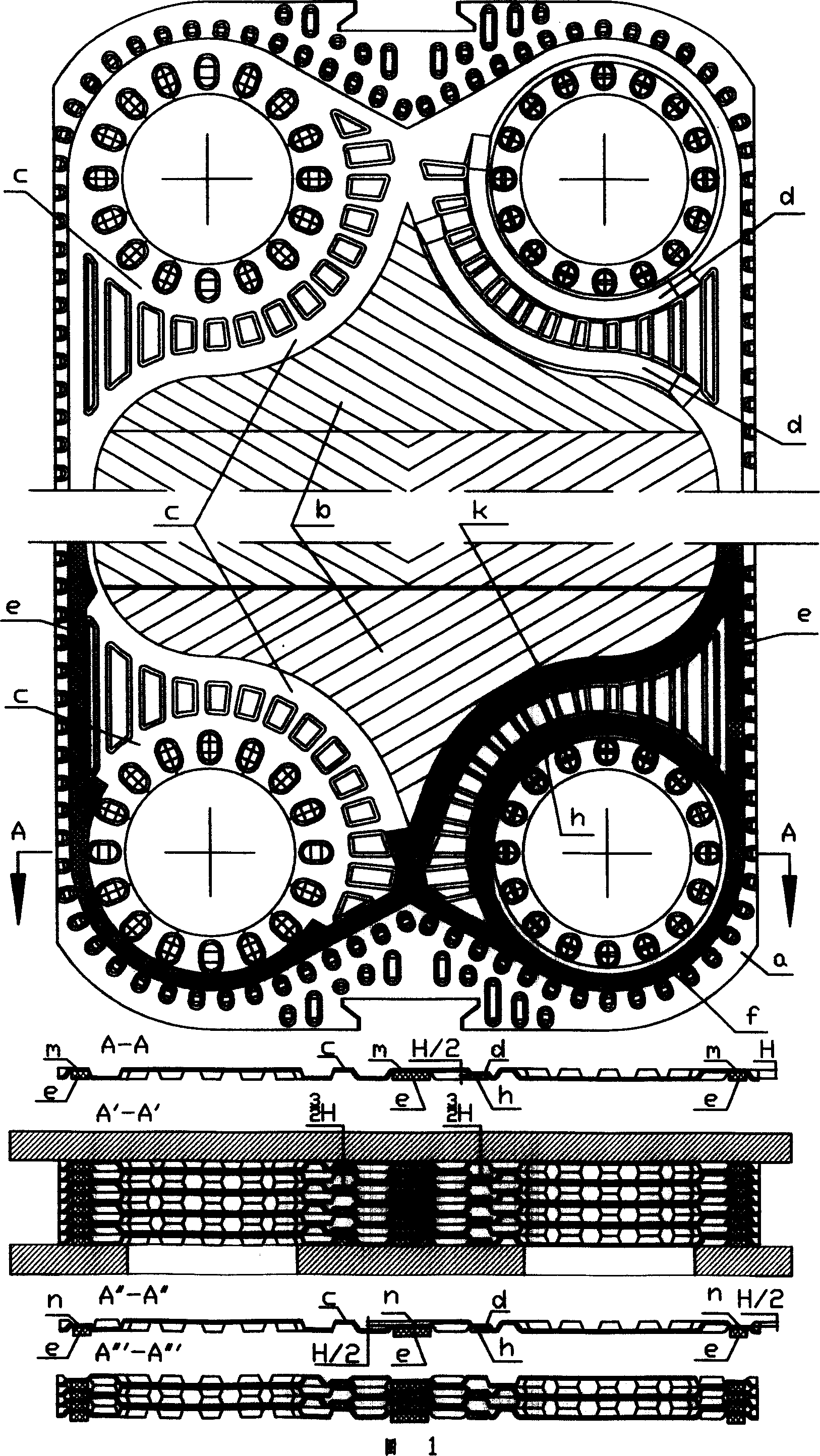

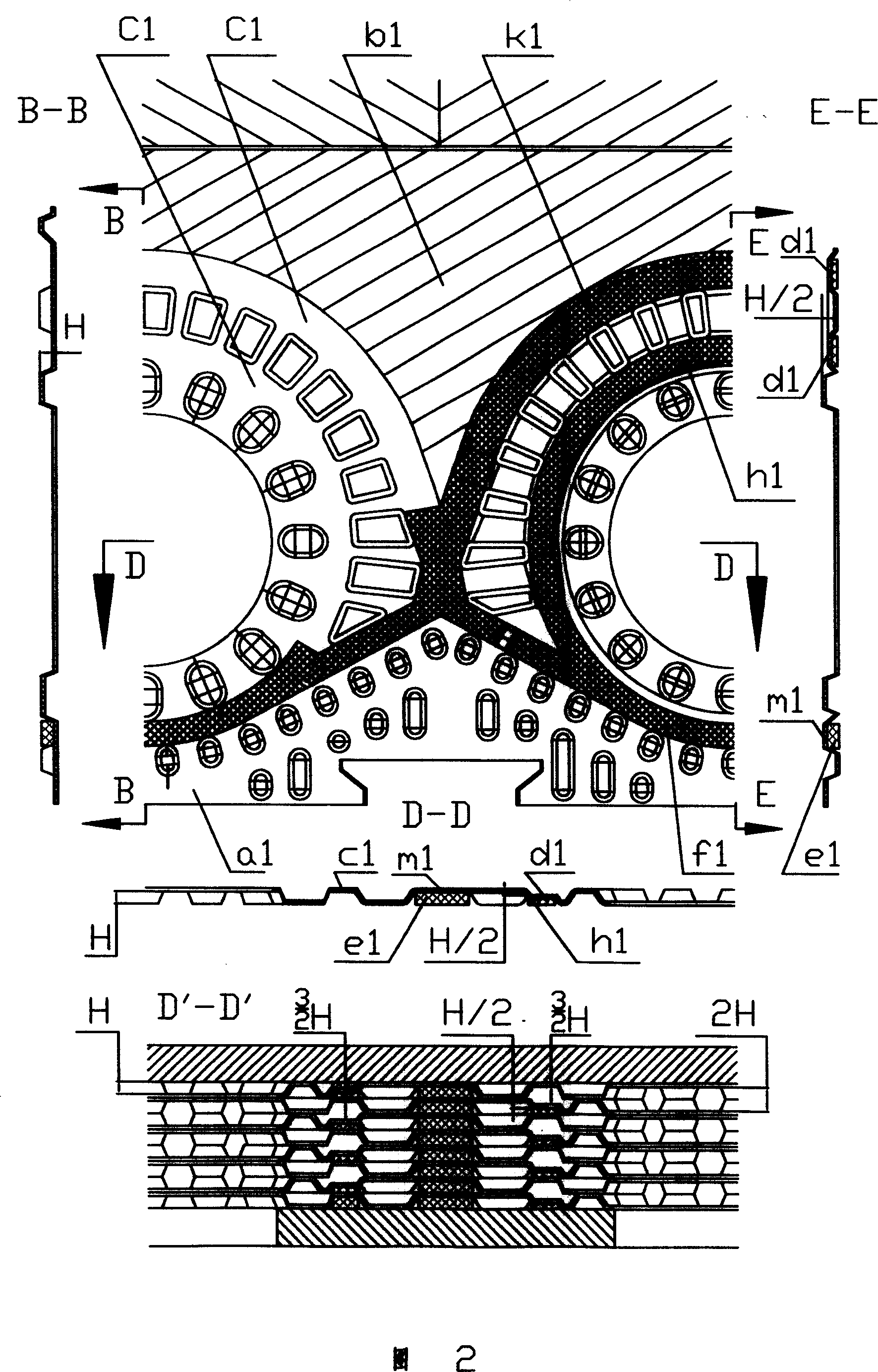

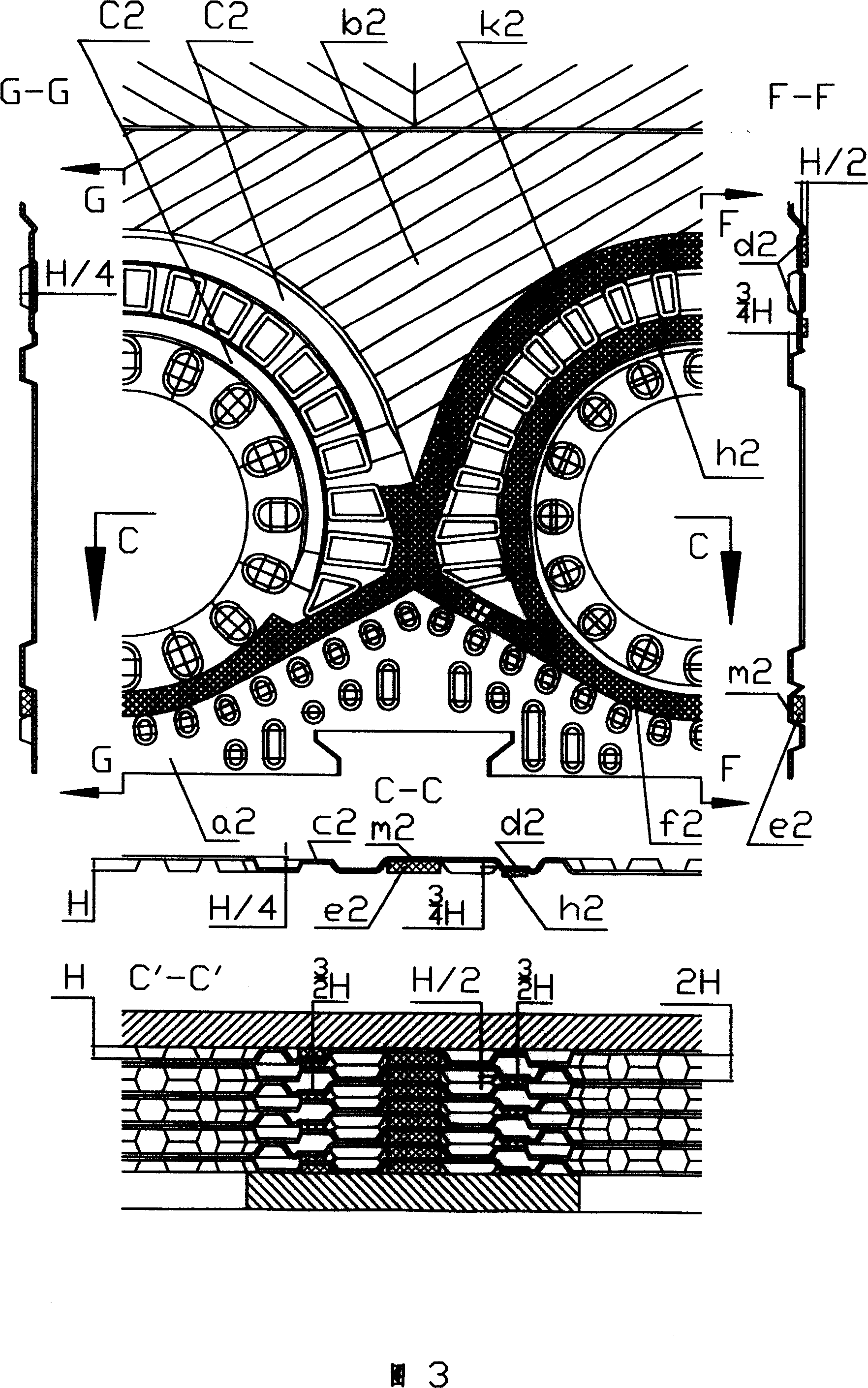

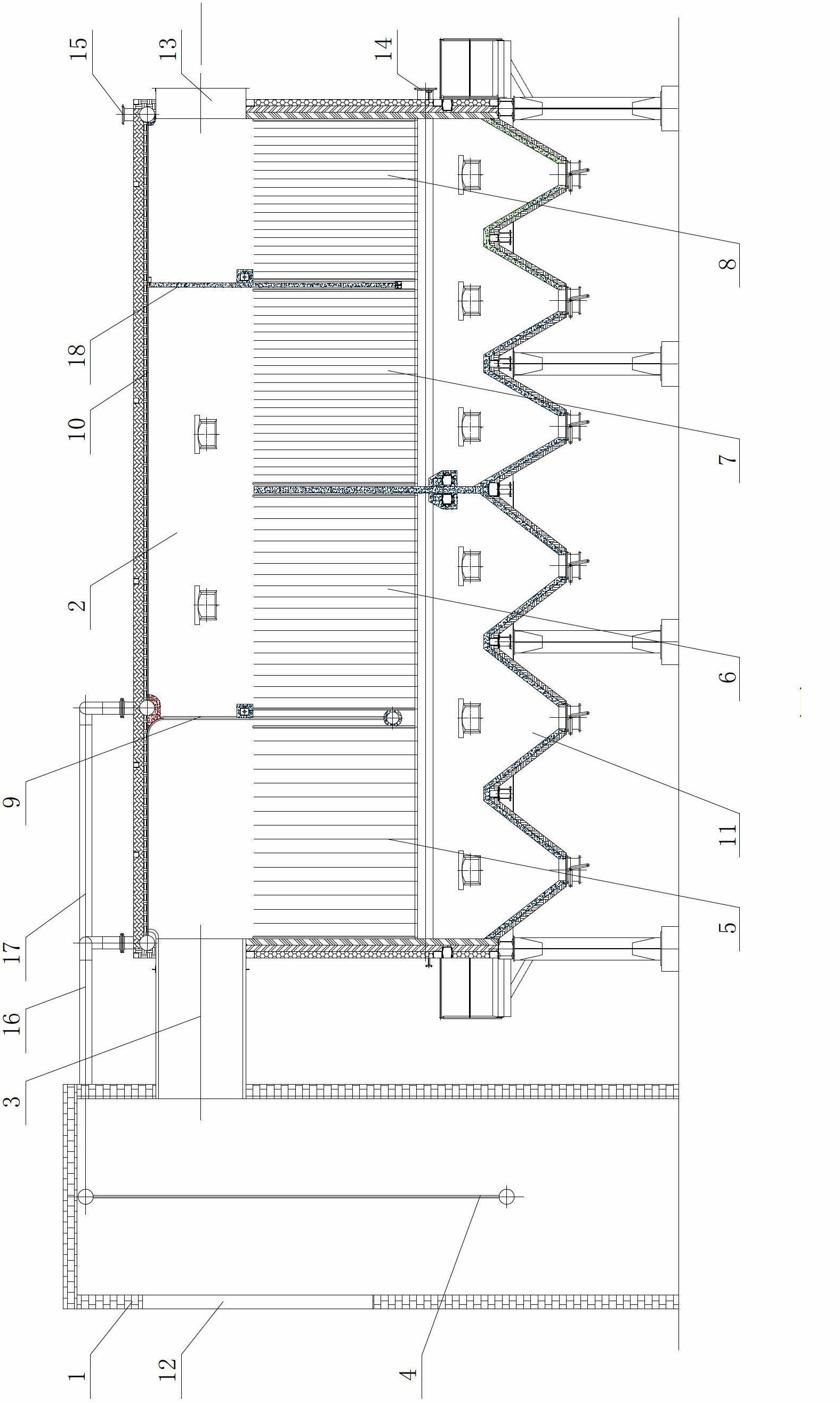

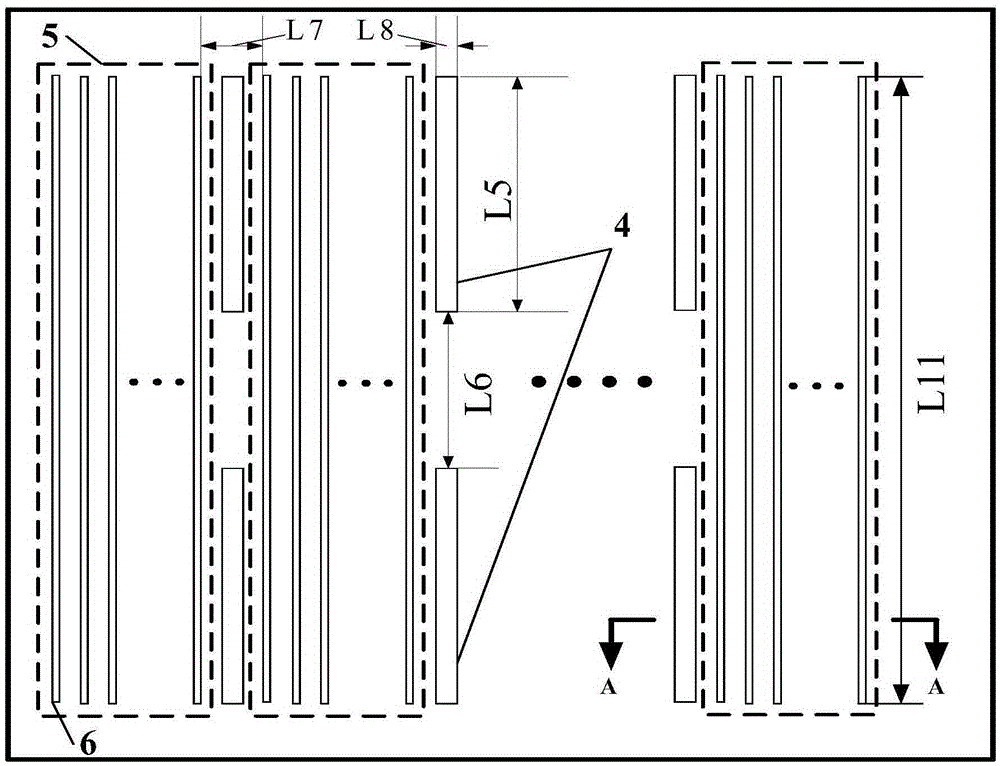

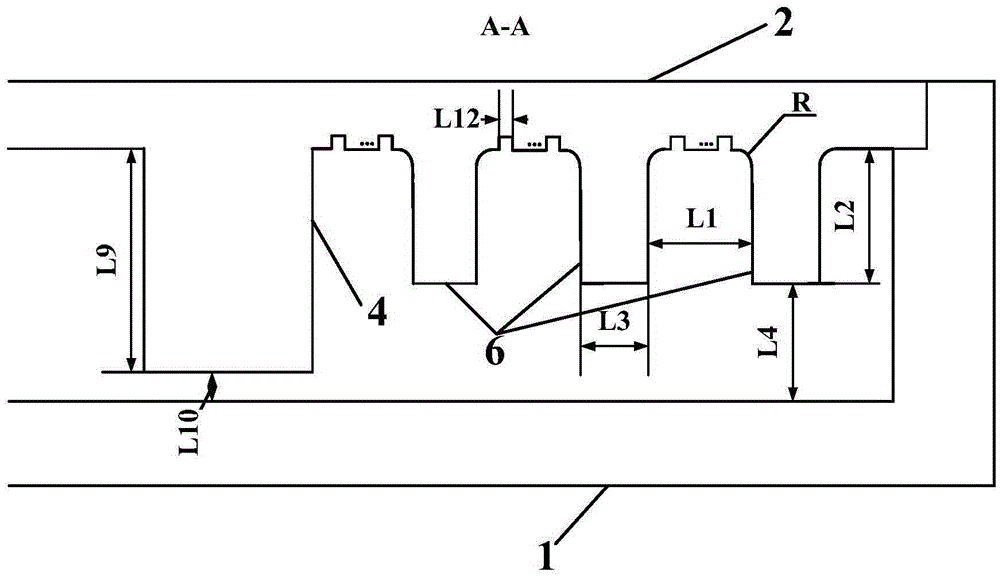

Large box type high-temperature material heat exchanger

ActiveCN104697371ALarge flow cross-sectional areaLarge cooling capacityMoving conduit heat exchangersImpellerEngineering

The invention provides a large box type high-temperature material heat exchanger, and belongs to the field of high-temperature solid material cooling equipment. The large box type high-temperature material heat exchanger is characterized by sequentially comprising a water cooling box cover (2), a heat exchanging box (6) and necking-down type hoppers from top to bottom, wherein a water cooling jacket is arranged on a wall of the water cooling box cover (2); end water cavities and / or side water cavities are formed in the wall of the heat exchanging box (6) and the walls of the necking-down hoppers; a plurality of heat exchanging pipelines are respectively arranged in the water cooling box cover (2), the heat exchanging box (6) and cavities of the necking-down type hoppers; a feeding opening (1) is formed in the upper portion of the water cooling box cover (2); a water cooling spiral distributor (3) which can convey and cool down materials is arranged in the water cooling box cover (2); the necking-down type hoppers are arranged side by side; and an impeller discharging valve (8) is arranged at an outlet of the bottom of each necking-down type hopper. The large box type high-temperature material heat exchanger is large in material cooling amount, low in energy consumption and long in service life; and abrasion of heat exchanging components is small.

Owner:SHANDONG UNIV OF TECH

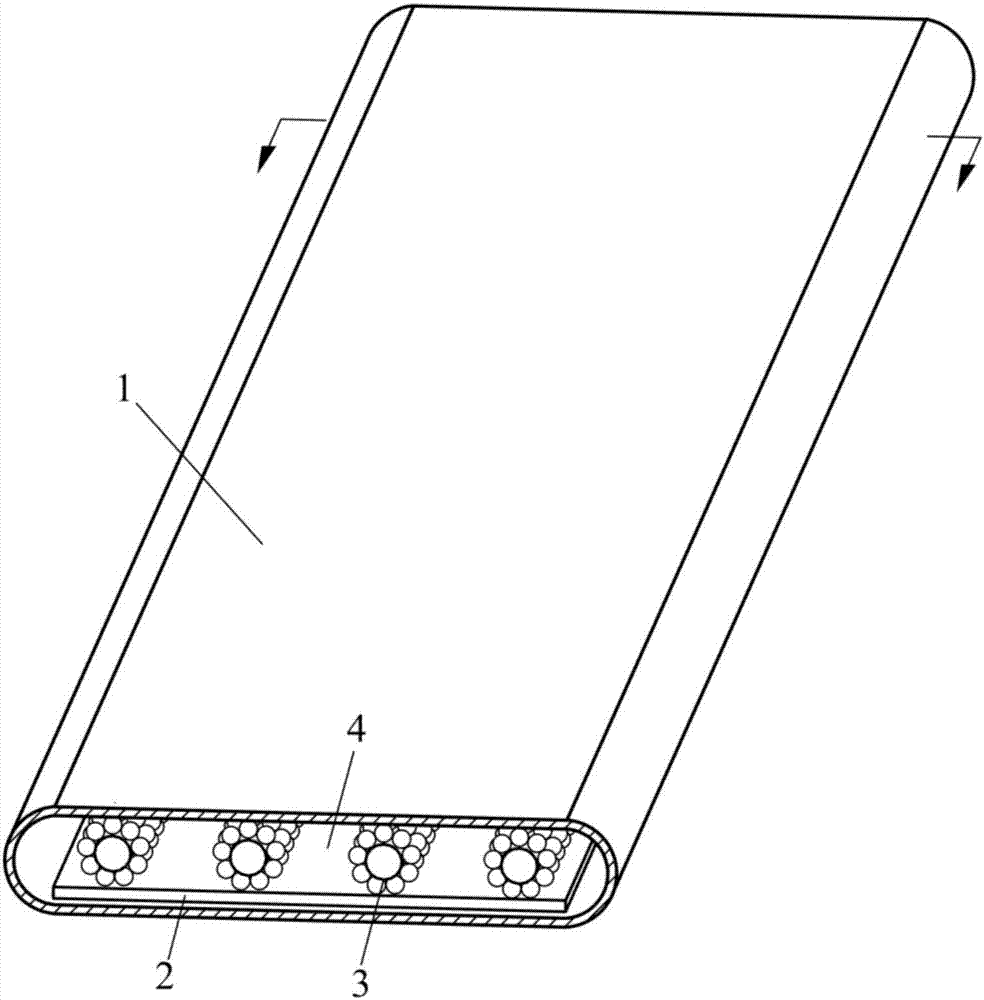

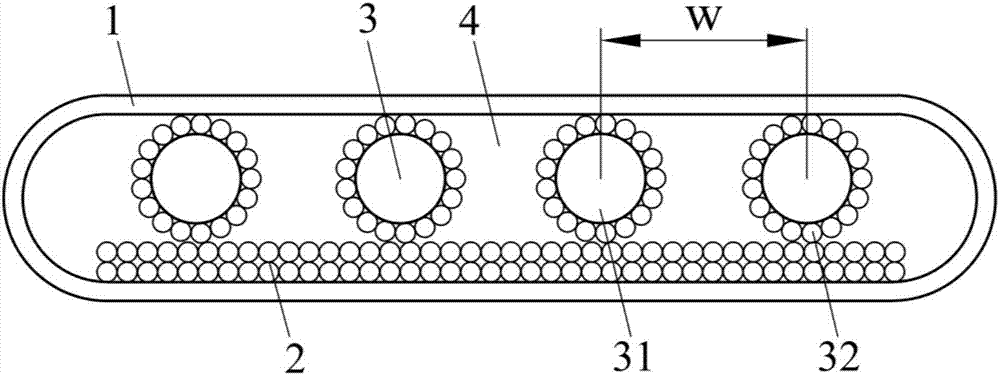

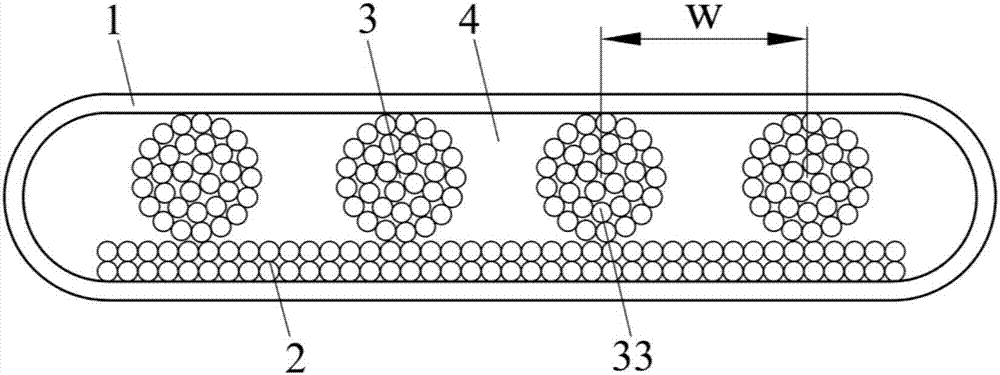

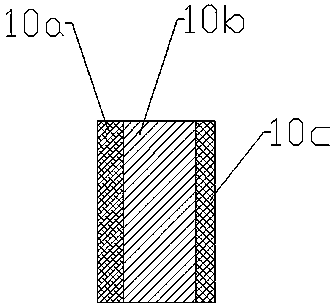

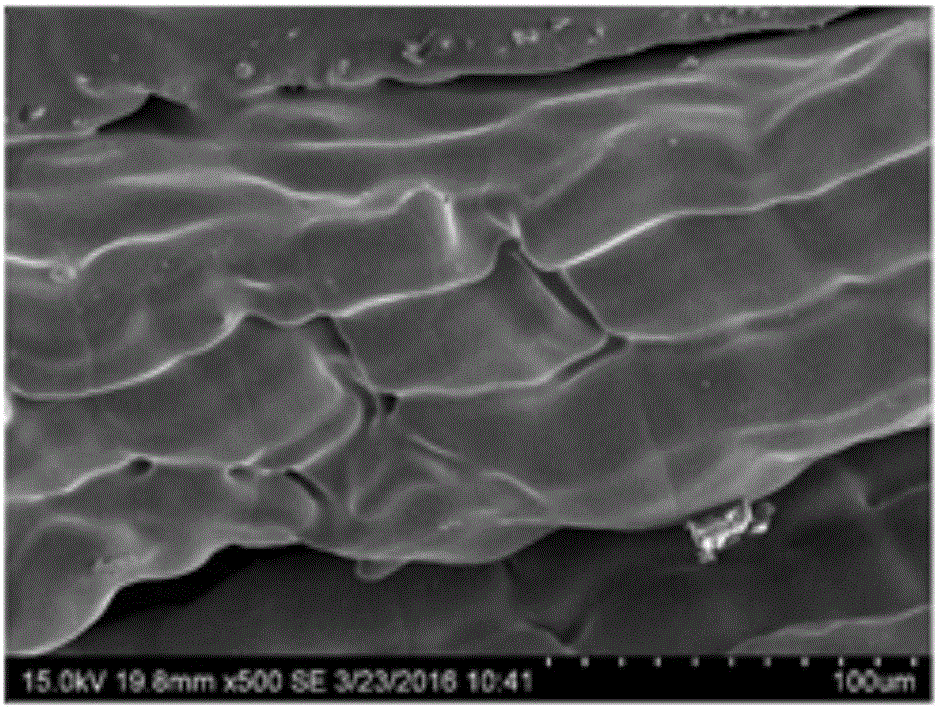

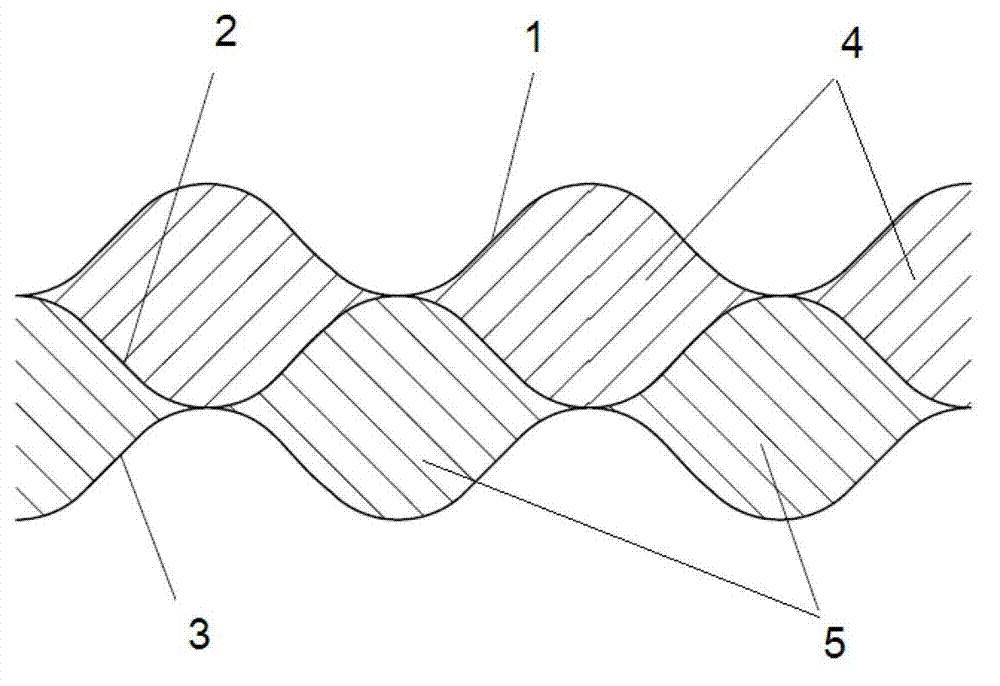

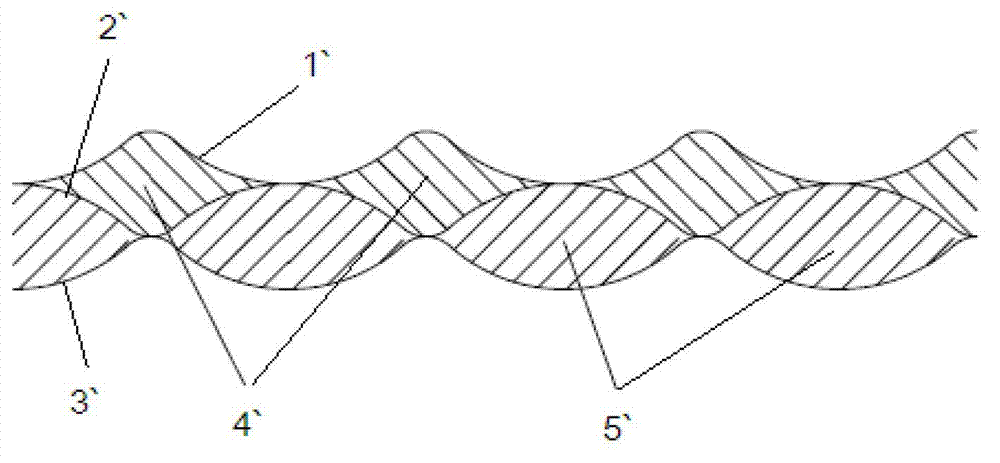

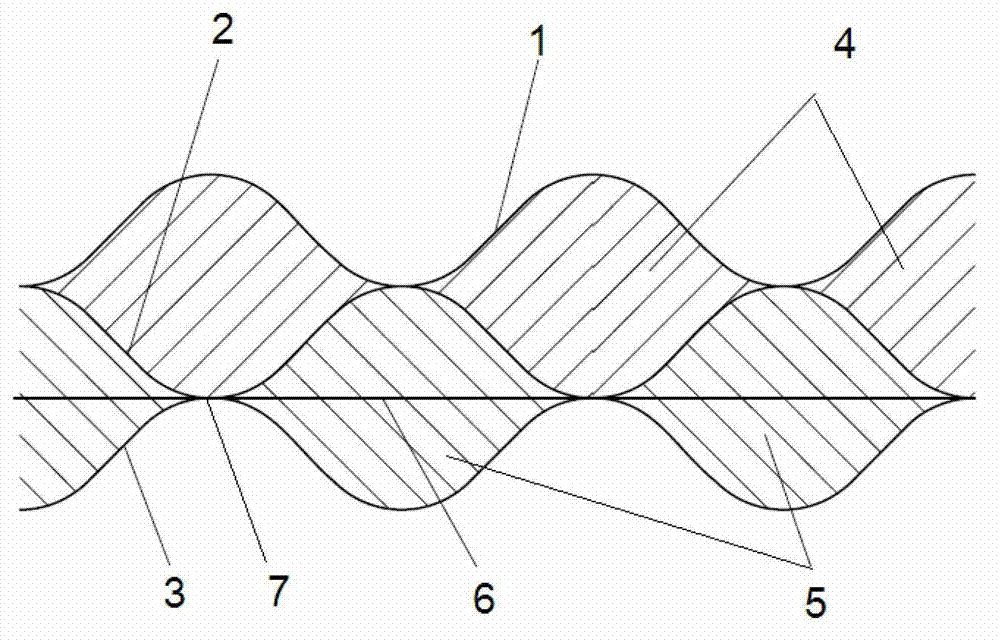

Ultra-thin flat panel heat pipe and manufacturing method thereof

ActiveCN107167008AEasy to moveIncrease heat transfer limitIndirect heat exchangersVapor liquidHeat flux

The invention relates to an ultra-thin flat heat pipe and a manufacturing method thereof. A wick comprises a porous medium bottom layer and a plurality of porous medium filaments arranged side by side; the porous medium filaments make contact with the top of a tube shell; the wick inside the heat pipe, a sharp angled area between the porous medium filaments and the upper surface of the tube shell, and a sharp angled area between the porous medium filaments and the porous medium bottom layer provide liquid return capillary driving force which is large enough in a limited space; spaces formed between the porous medium filaments provide steam flow channels, and the steam flow channels communicate with one another; and reasonable matching of vapor-liquid phase distribution is achieved, and steam and condensed liquid can flow easily. According to the ultra-thin flat heat pipe, efficient operation can be maintained at various angles, the performance of anti-gravity operation is excellent, the heat flux which can be borne by the heat pipe is high, and the heat transfer performance of the heat pipe is remarkably improved after further modification treatment.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

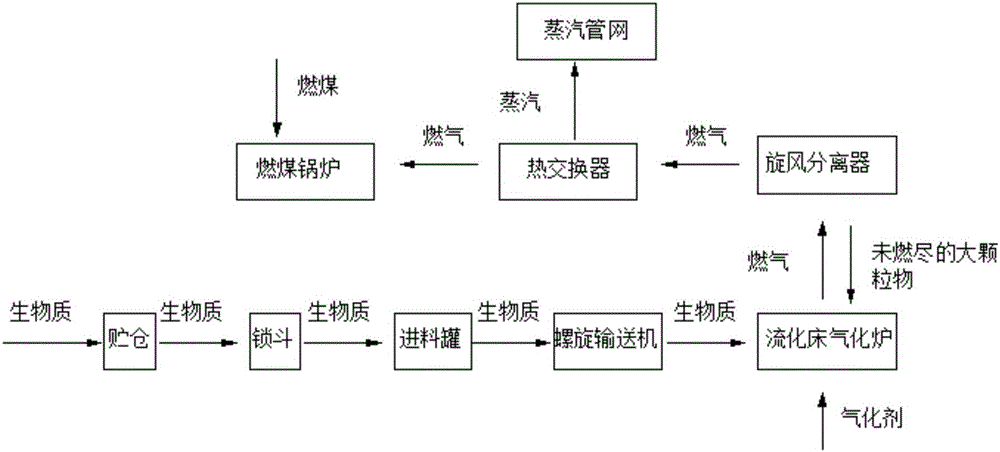

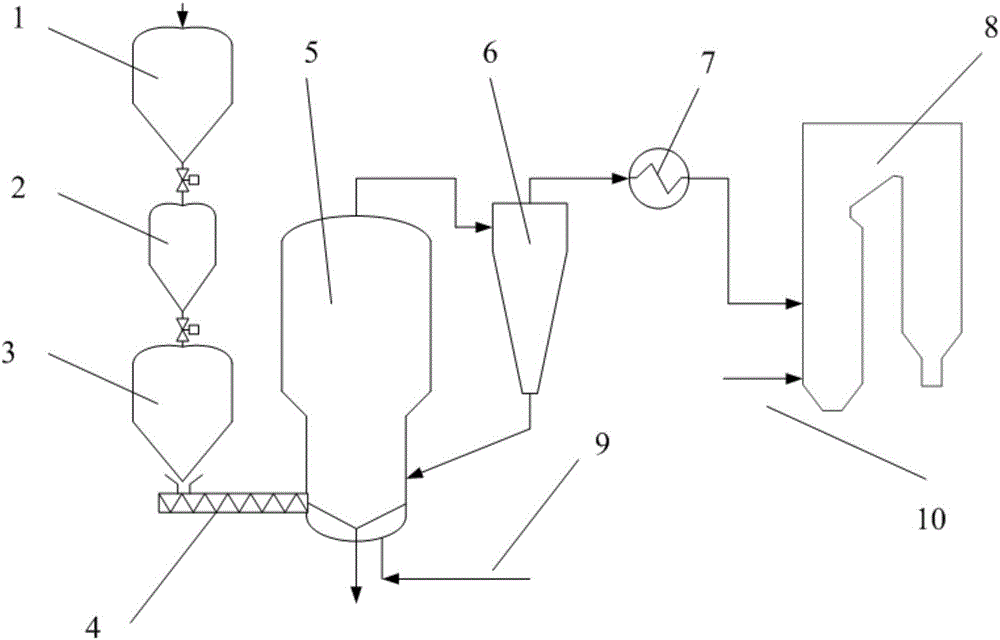

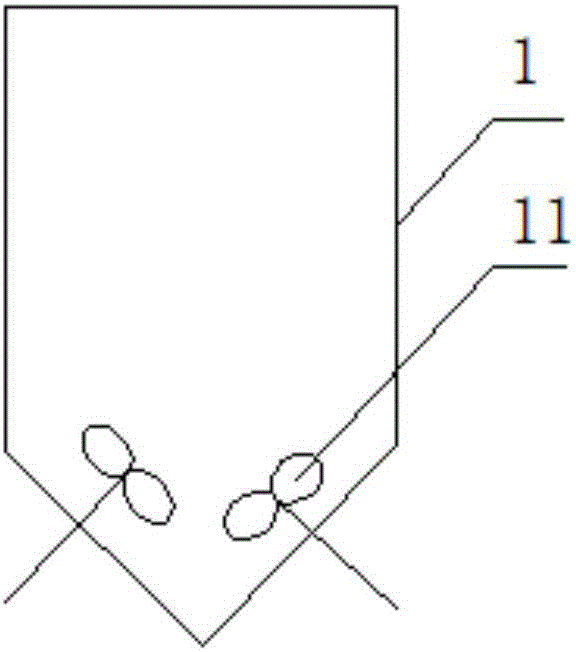

Biomass gasification power-generation process

InactiveCN106244246AHigh strengthImprove gasification efficiencyGasifier feeding meansGasification processes detailsParticulatesFood consumption

The invention discloses a biomass gasification power-generation process. The biomass gasification power-generation process comprises the following steps of step (I), pressurizing biomass granules until the gauge pressure is 0.1-4.0Mpa, then discharging materials to a charging tank, then conveying the discharged materials to a fluidized-bed gasifier, and performing a gasification reaction with a gasification agent so as to obtain fuel gas for standby application; step II, performing cyclone dust removal on the fuel gas prepared in step (I) through a cyclone separator, performing separation to obtain large particles which are not burn-out, and returning the large particles to the fluidized-bed gasifier for gasifying once again; and step (III), cooling the flue gas which is subjected to dust removal by the cyclone separator to 300-700 DEG C through a heat exchanger, and enabling the cooled flue gas to be led into a coal boiler to be subjected to mixed combustion with the coal for power generation. According to the biomass gasification power-generation process disclosed by the invention, the biomass granules are sent to a large-scale coal boiler through the fuel gas generated by gasification to be subjected to combined combustion with the coal for power generation, so that the coal consumption required for power generation is reduced, the amount of CO2 generated during combustion is reduced, greenhouse effects caused by CO2 can be alleviated, and emission of NOX by power plants is reduced.

Owner:武汉高斯生态能源技术有限公司

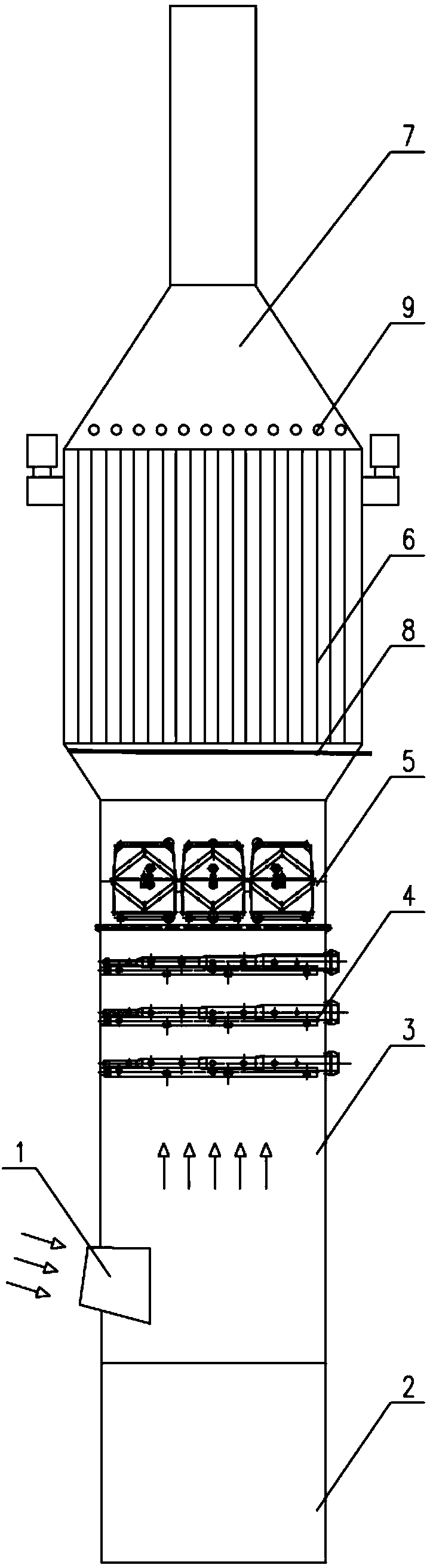

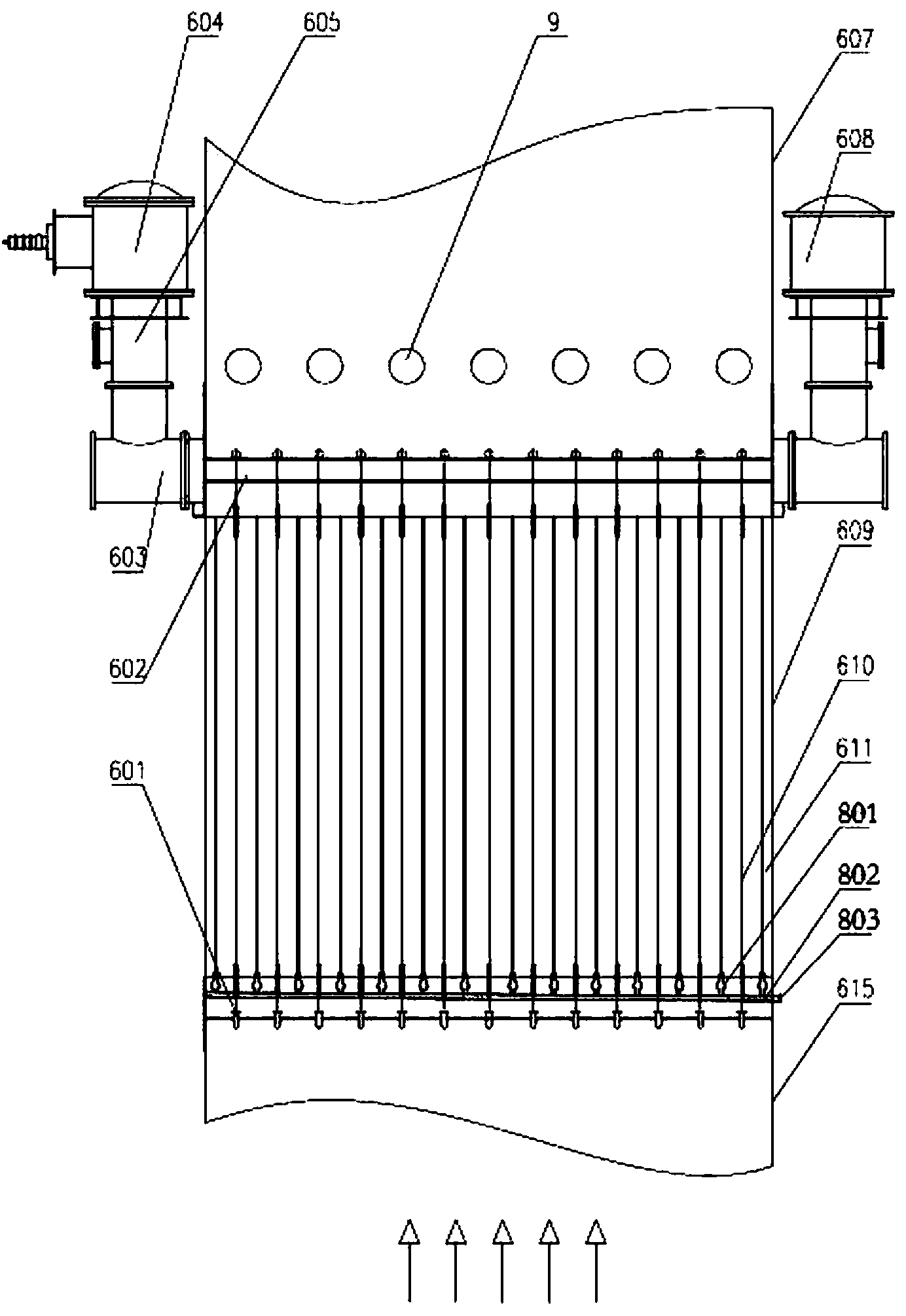

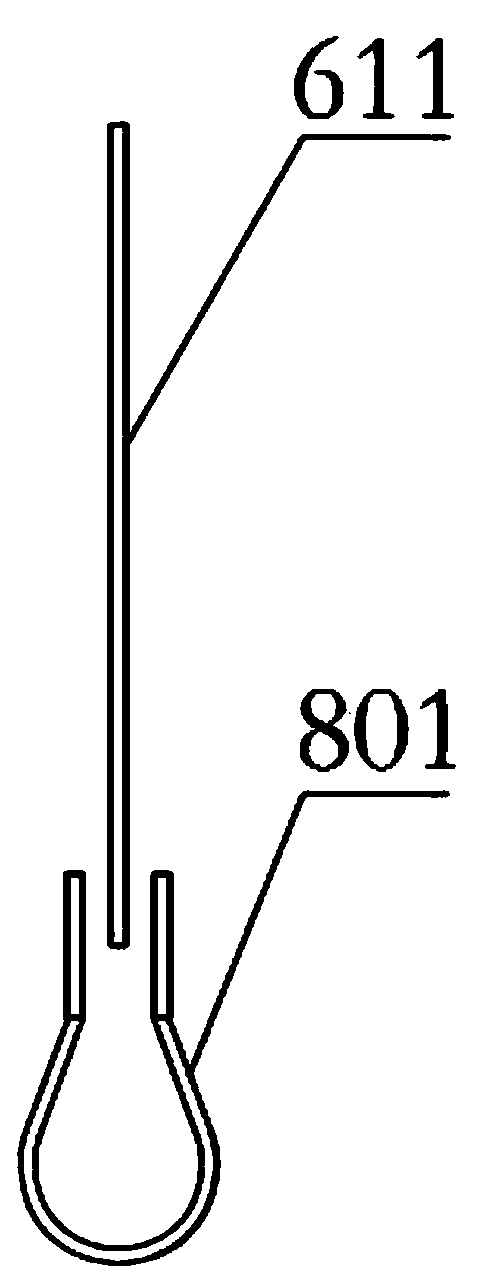

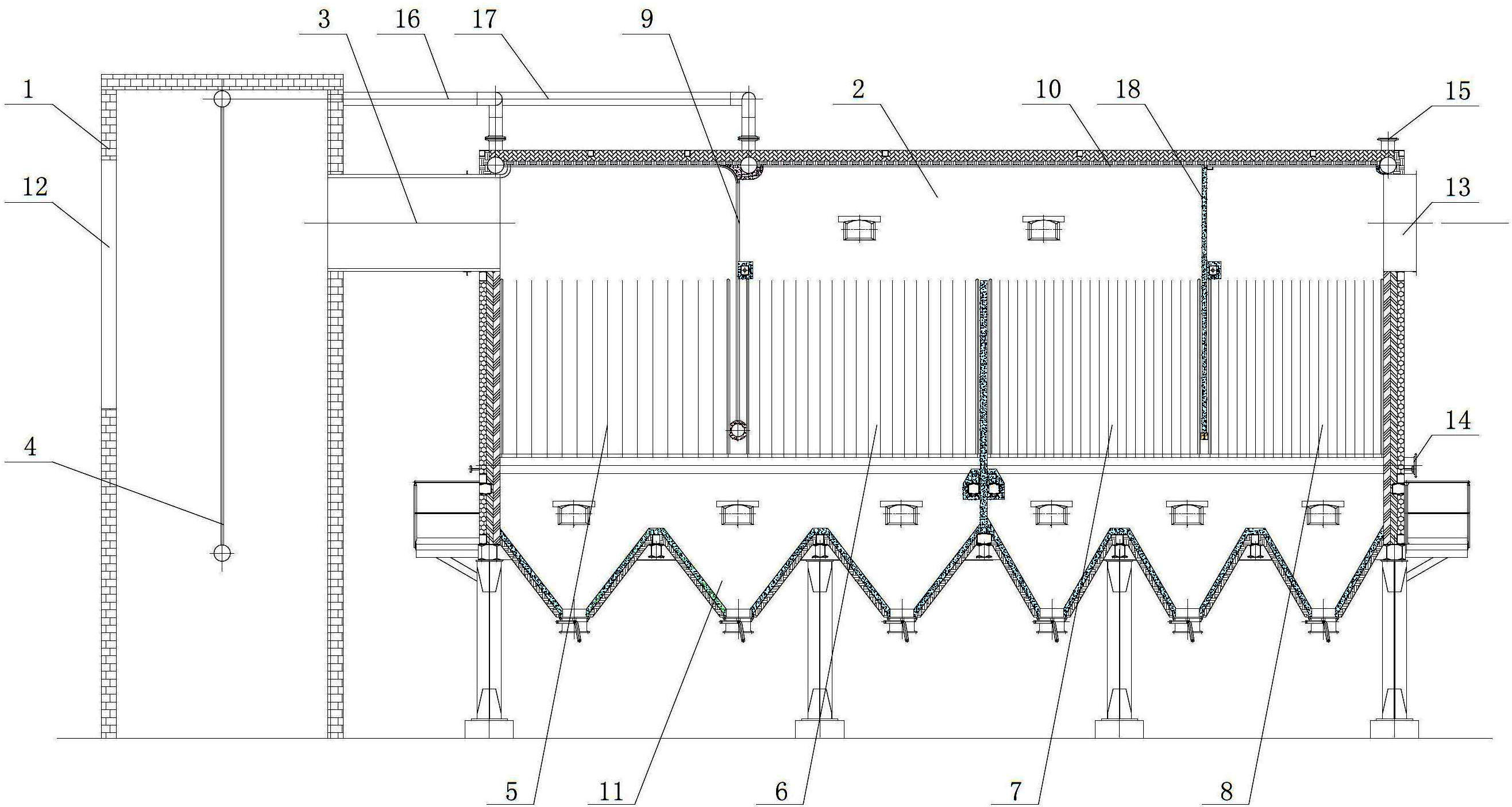

Absorption tower with wet type electric demister

ActiveCN103816771AEffective use of venue spaceSmall footprintCombination devicesSmall footprintEngineering

The invention discloses an absorption tower with a wet type electric demister. The absorption tower comprises a slurry pool (2), an absorption zone (3) and an absorption tower top part (7), which are communicated in sequence from bottom to up along the flowing direction of smoke, wherein the absorption zone (3) is provided with an absorption tower entrance (1), a spraying layer (4) and a mechanical demister (5) in sequence along the flowing direction of smoke; the wet type electric demister (6) is arranged between the mechanical demister (5) and the absorption tower top part (7); a spraying washing device (9) is arranged right above the wet type electric demister (6) and a washing water collection device (8) is arranged right below the wet type electric demister (6). By additionally arranging the washing water collection device below the wet type electric demister, the technical bottleneck that a wet type electric demister with receiving electrodes cannot be arranged in the upper part of a cooling tower is overcome; the site space is effectively utilized and the occupied area is small; washing water is recycled and thus the water resource is saved.

Owner:南京宇行环保科技有限公司

Coalescence degreaser for oilfield sewage treatment

ActiveCN111348769AThe number of deployments increasedSolve the problem of stable loweringWaste water treatment from quariesFatty/oily/floating substances removal devicesFiberYarn

The invention provides a coalescence degreaser for oilfield sewage treatment. The coalescence degreaser comprises a tank body, a flow stabilizing device, a rectifying device, a primary filtering device and an oil gathering device; the tank body sequentially comprises a lining layer formed by jet yarns in a jet molding mode, a structural layer formed by resin and fiber material composite materialsin an enveloping and winding mode and an outer surface layer formed by gel coat resin in a spraying mode from inside to outside in the thickness direction of the tank wall. The oil gathering device comprises a coalescence separation corrugated plate and a supporting piece. The thickness of corrugated plates in the prior art is reduced to increase the cross sectional area of a water flow channel between the adjacent corrugated plates, so that the sewage treatment capacity is greatly improved; and on the premise that the sewage treatment efficiency is not reduced, namely, the cross section of the water flow channel is kept unchanged, the arrangement number of the corrugated plates is greatly increased, so that the contact area of the corrugated plates and sewage is increased, and the oil gathering efficiency and effect are improved.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

Micro-channel reactor

PendingCN107626271AIncrease the reaction areaImprove reaction efficiencyChemical/physical/physico-chemical processesPlunger pumpExothermic reaction

The invention discloses a micro-channel reactor which comprises a shell body, wherein a plurality of micro-channel reaction modules which are sequentially in serial connection are arranged in the shell body, a discharging pipe is arranged at the tail end of the micro-channel reaction module at the most downstream, mixers are arranged between every two adjacent micro-channel reaction modules, a first feeding plunger pump and a second feeding plunger pump which are communicated with the micro-channel reaction module at the most upstream are arranged on the shell body, a sampling pipe communicated with a reaction cavity of the micro-channel reaction module is arranged each micro-channel reaction module, the sampling pipes are connected with sampling valves, and the sampling valves are arranged on the shell body. By means of a unique structural design, the micro-channel reactor has many excellent technological effects, can be applied to processes of high-efficiency heat exchange, high-efficiency mixing and strong exothermic reaction and production processes of high-added-value fine chemicals, extremely toxic substances, superfine / nano particles and high-energy explosives and has good application potential and industrial production value.

Owner:FRAPPS CHEM IND SUICHANG CO LTD

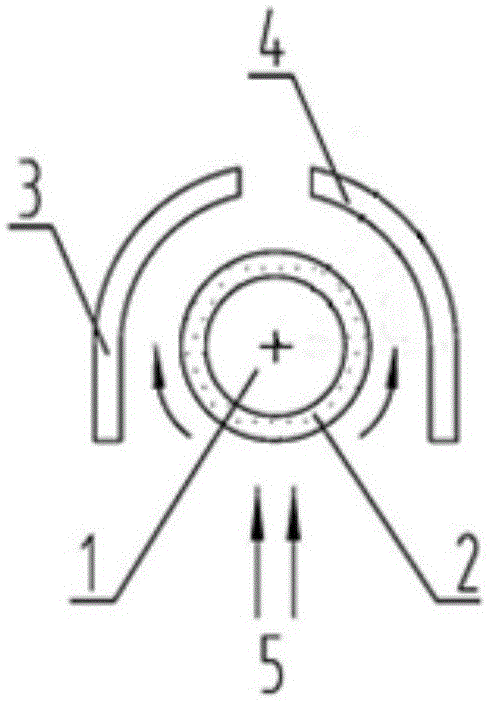

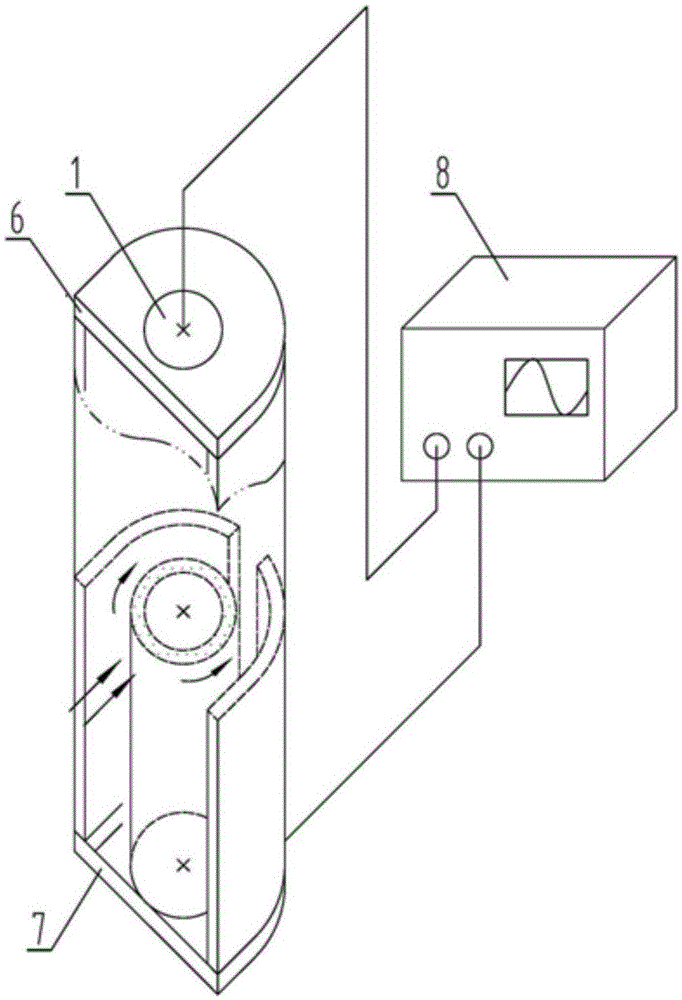

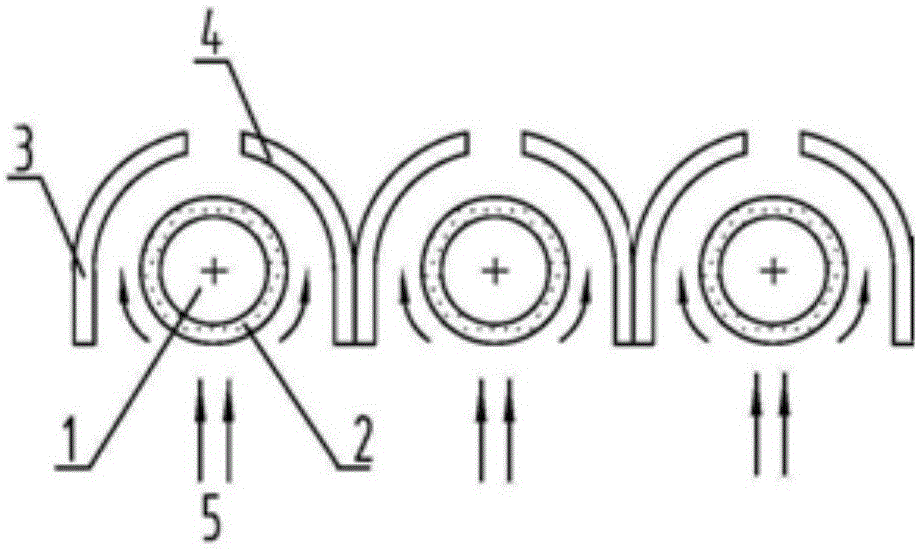

Upper straight-down rotating dry-type circulating fluidized bed desulfurization reactor

InactiveCN101496991AIncreased cross-sectional area of flue gas flowExtended stayDispersed particle separationChemical/physical processesEngineeringFluidized bed

The invention discloses a desulphurization reactor of an upper direct-lower rotary dry-type circulating fluidized bed and relates to a desulphurization reactor of the circulating fluidized bed. The reactor solves the problems that the prior desulphurization reactor has low working efficiency and particles are easy to cling to the wall surface and the prior desulphurization reactor has large height. An inner cylinder is arranged in an outer cylinder; the lower end of the inner cylinder is positioned on the lower part of the outer cylinder; a swirler is arranged at the upper end of the inner cylinder; one to four tangential cyclone smoke exhaust pipes are positioned on the lower part of the outer cylinder and are evenly distributed on the outer sidewall of the inner cylinder along the tangential direction; each tangential cyclone smoke exhaust pipe is communicated with a cavity between the outer cylinder and the inner cylinder; the upper end of the shell is communicated with an inner cavity of the outer cylinder; the lower end of the shell is communicated with the inner cylinder; one side of each cyclone plate is connected with a central shaft; and the other side of each cyclone plate is connected with the inner wall of the shell. The desulphurization reactor has a compact structure, strong applicability of load change and low cost and is convenient for general layout and operating maintenance of the system; and the desulphurization efficiency is improved over 10 percent.

Owner:HARBIN INST OF TECH

U-shaped plate type dielectric-barrier-discharge-based low-temperature plasma reactor and reactive system

ActiveCN105050304AFlow adjustableChange the size of the flow cross-sectional areaPlasma techniqueGas passingEngineering

The invention relates to a U-shaped plate type dielectric-barrier-discharge-based low-temperature plasma reactor and reactive system. The reactor comprises a core electrode, a U-shaped plate electrode housing, an insulating medium and a driving power. The core electrode is installed inside the U-shaped plate electrode housing; and gas outlet channel parallel to the core electrode is arranged at the arc position of the U-shaped plate electrode housing. The insulating medium is installed between the core electrode and the U-shaped plate electrode housing. The driving power is respectively connected with the core electrode and the U-shaped plate electrode housing. Gas enters the reactor through a U-shaped opening of the U-shaped plate electrode housing; and the processed gas leaves the reactor through the gas outlet channel. According to the reactor, large-flow gas can be processed; the gas disturbance can be enhanced and the plasma catalysis can be strengthened; the mixed uniform degree of several kinds of gas can be improved; the dielectric barrier discharge (DBD) breakdown voltage and discharging power are low and the waste gas treatment cost can be lowered; and the reactor can work separately or work in a matrix arrangement mode.

Owner:SHANDONG ELECTRIC POWER ENG CONSULTING INST CORP

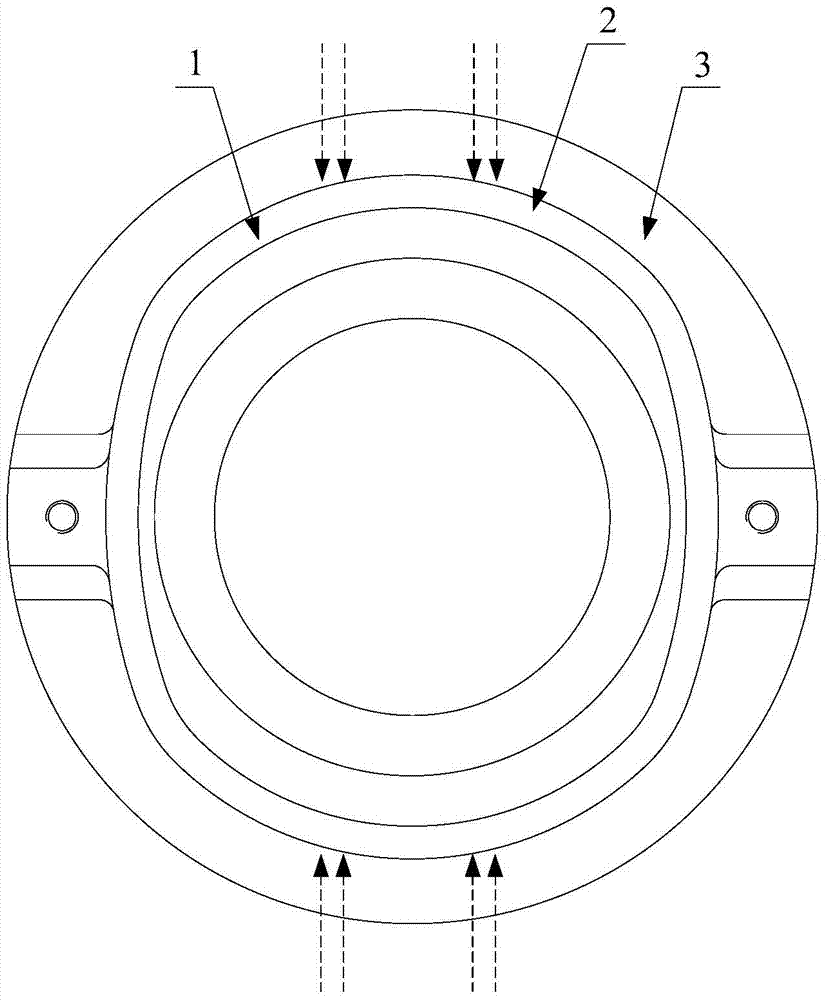

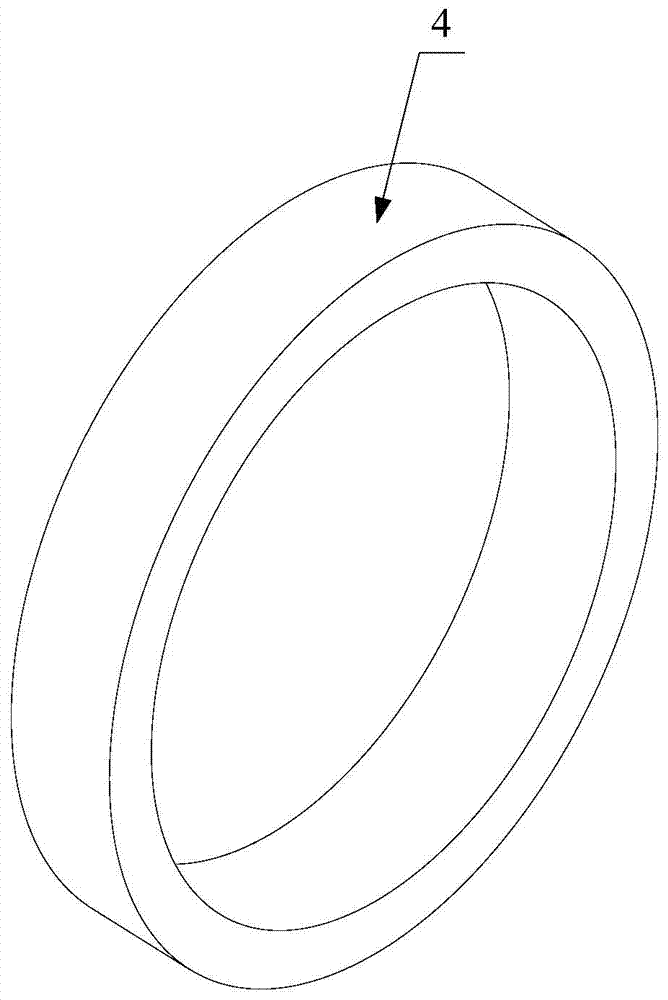

Plate-type heat exchanger with low current-resistance at angled hole and secondary sealing groove

InactiveCN1979076AReduce resistanceLarge flow cross-sectional areaLaminated elementsStationary plate conduit assembliesFlutePlate heat exchanger

The invention relates to a board type exchanger that has low flow resistance at the flute of angle hole and second sealing. The feature is that the layer location of flute bottom layer bearing sealing spacer is different between different group angle hole sealing structure and corresponding angle hole second sealing structure. When the heat exchanging board stacking together, the interval channel height between boards formed by angle holes sealing spacer flute and corresponding second sealing spacer flute exceeds the height of buckle ripple. Thus, the flow resistance would be decreased.

Owner:缪志先

Villous fin fiber composite groove type special-shaped heat pipe and manufacturing method thereof

InactiveCN106767071AImprove heat transfer performanceImprove capillary suctionIndirect heat exchangersTubular elementsMetal fibersHeat pipe

The invention discloses a villous fin fiber composite groove type special-shaped heat pipe. The villous fin fiber composite groove type special-shaped heat pipe comprises a heat pipe body with a special-shaped section. Grooves are formed in the inner wall of the heat pipe body. A villous fin fiber layer is laid on the inner wall of the heat pipe body. Villous fin fibers are metal fibers which are provided with irregular protrusions and / or pits on surfaces and are of a villous fin structure. The invention further discloses a manufacturing method of the villous fin fiber composite groove type special-shaped heat pipe. According to the villous fin fiber composite groove type special-shaped heat pipe, the capillarity attraction of a heat pipe wick is effectively improved, split-flow of liquid and steam inside the heat pipe is realized, the heat transfer performance of the heat pipe is effectively enhanced, the defect that groove type heat pips are low in threshold power is overcome, liquid permeability is improved, the resistance of working medium backflow is reduced, and the defect that traditional groove type heat pipes cannot be bent or flattened is overcome; and the heat pipe is a special-shaped pipe, so that the air flow section area is increased, air resistance is effectively reduced, the cooling air flow quantity is increased, and heat exchange performance is improved.

Owner:CRRC +1

Interatrial shunts having biodegradable material, and methods of making and using same

ActiveUS11135054B2Large flow cross-sectional areaReduce pressureStentsHeart valvesLeft ventricular sizeLeft atrial pressure

Owner:WAVE LTD V

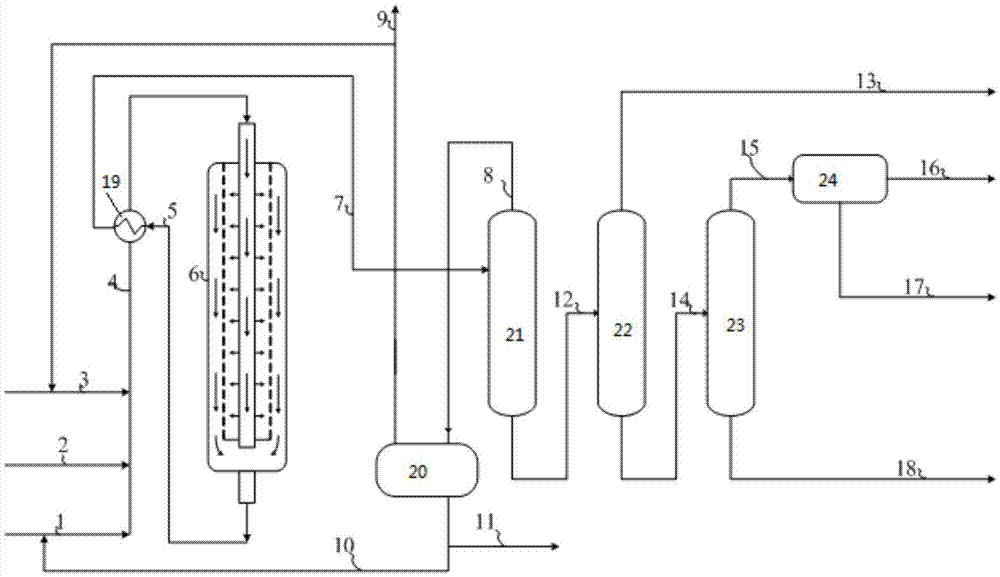

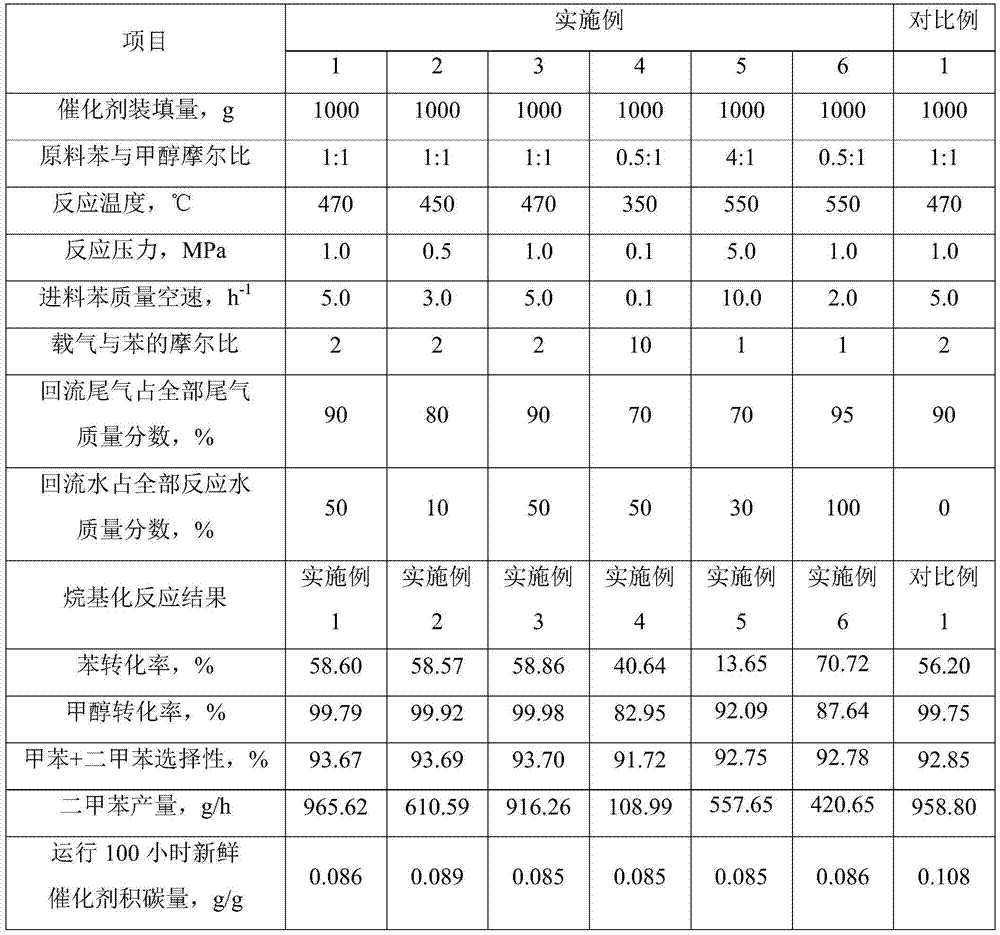

Method for preparing p-xylene from benzene and methanol through alkylation

ActiveCN106854135ASame loadingUniform axial temperature distributionHydrocarbon by isomerisationHydrocarbonsAlkyl transferHigh energy

The invention provides a method for preparing p-xylene from benzene and methanol through alkylation on a fixed-bed radial-flow reactor with a multichannel structure. The method mainly overcomes the problems of small raw material treating capacity of a unit catalyst within unit time, inadequate usage of the catalyst, high energy consumption in separation, low production efficiency of reactors and the like in the prior art. According to the invention, the fixed-bed radial-flow reactor is employed, and a separation process of separation at first and condensation next is beneficial for reduction of energy consumption; and the process of recovering a part of water produced in reaction is beneficial for heat removal of catalyst beds and inhibition of carbon formation of the catalyst.

Owner:PETROCHINA CO LTD

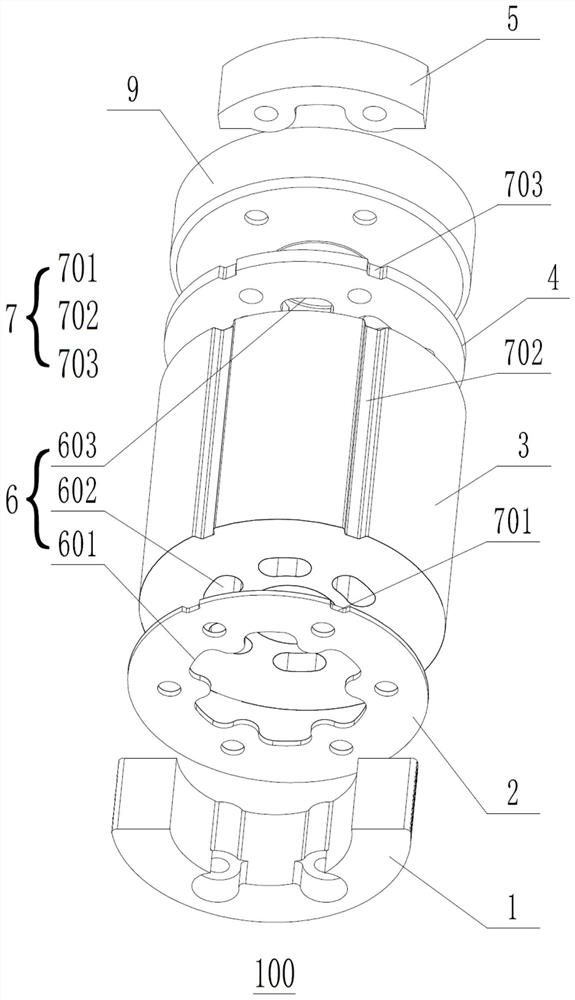

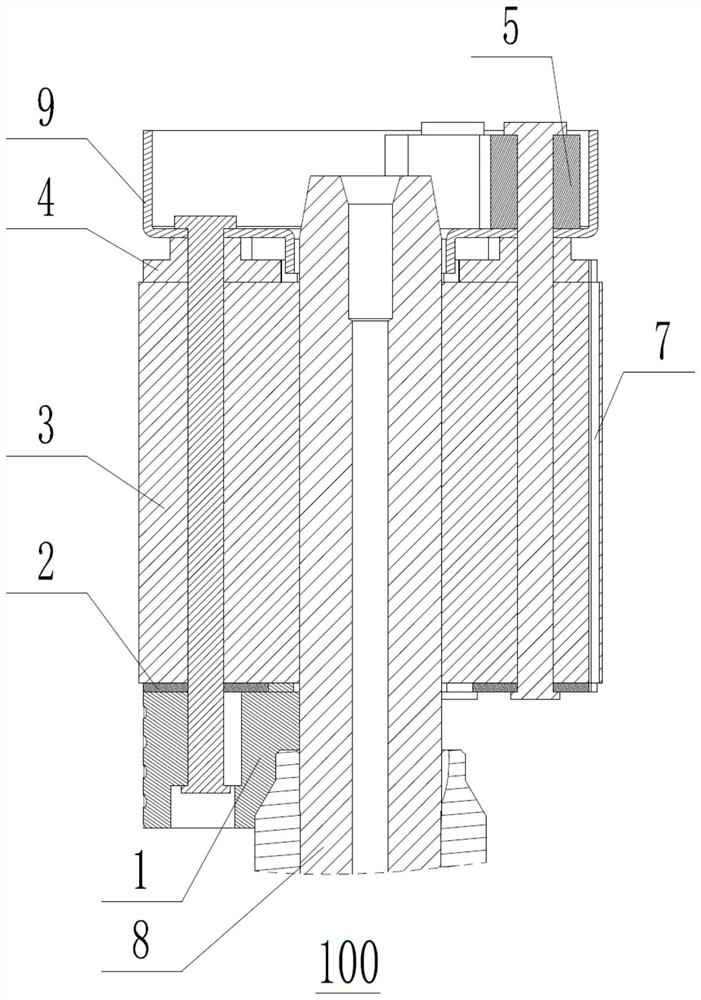

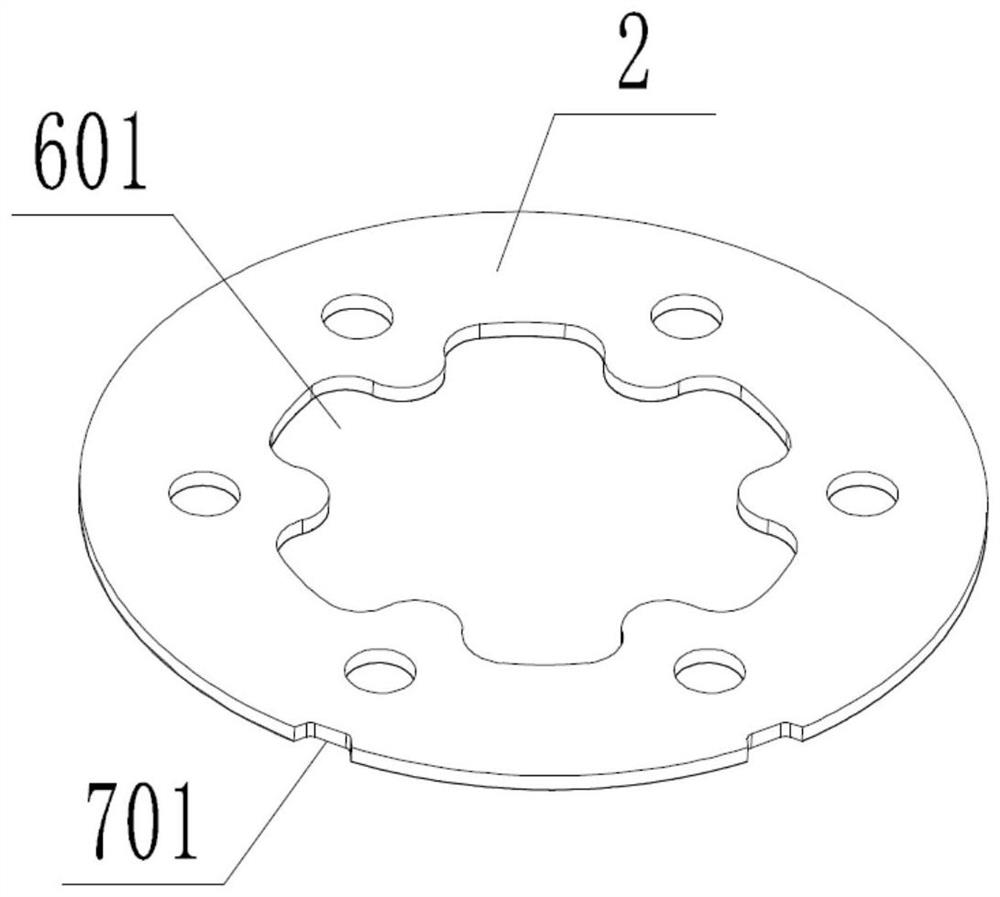

Rotor assembly, compressor and air conditioner

PendingCN112360743AIncreased edge return flowQuality improvementRotary/oscillating piston combinations for elastic fluidsMechanical energy handlingElectric machineryOil separation

The invention relates to the technical field of gas compression devices, in particular to a rotor assembly, a compressor and an air conditioner. A plurality of main circulation channels are evenly formed in a first magnetic baffle, a rotor iron core and a second magnetic baffle of the rotor assembly around the central axis, auxiliary circulation channels which are through in the axial direction are formed in the first magnetic baffle, the rotor iron core and the second magnetic baffle, a main balance block is located on one side of the central axis, and auxiliary circulation channels are located on the other side of the central axis. The auxiliary circulation channels improve a balance system, the height of the main balance block in the axial direction can be reduced, then the windward area of the main balance block is reduced, the clapping effect on exhaust gas flow is weakened, tiny liquid drops are reduced, and then the amount of oil entering an upper cavity of a motor along with flowing of a refrigerant is reduced. The auxiliary circulation channels increase the flow flowing through the circulation channels, improves the internal circulation of the compressor, increases the stator trimming return flow, and realizes secondary oil separation. The effects of two oil separation are integrated, and the oil spitting rate of the compressor is effectively reduced.

Owner:GREE ELECTRIC APPLIANCES INC

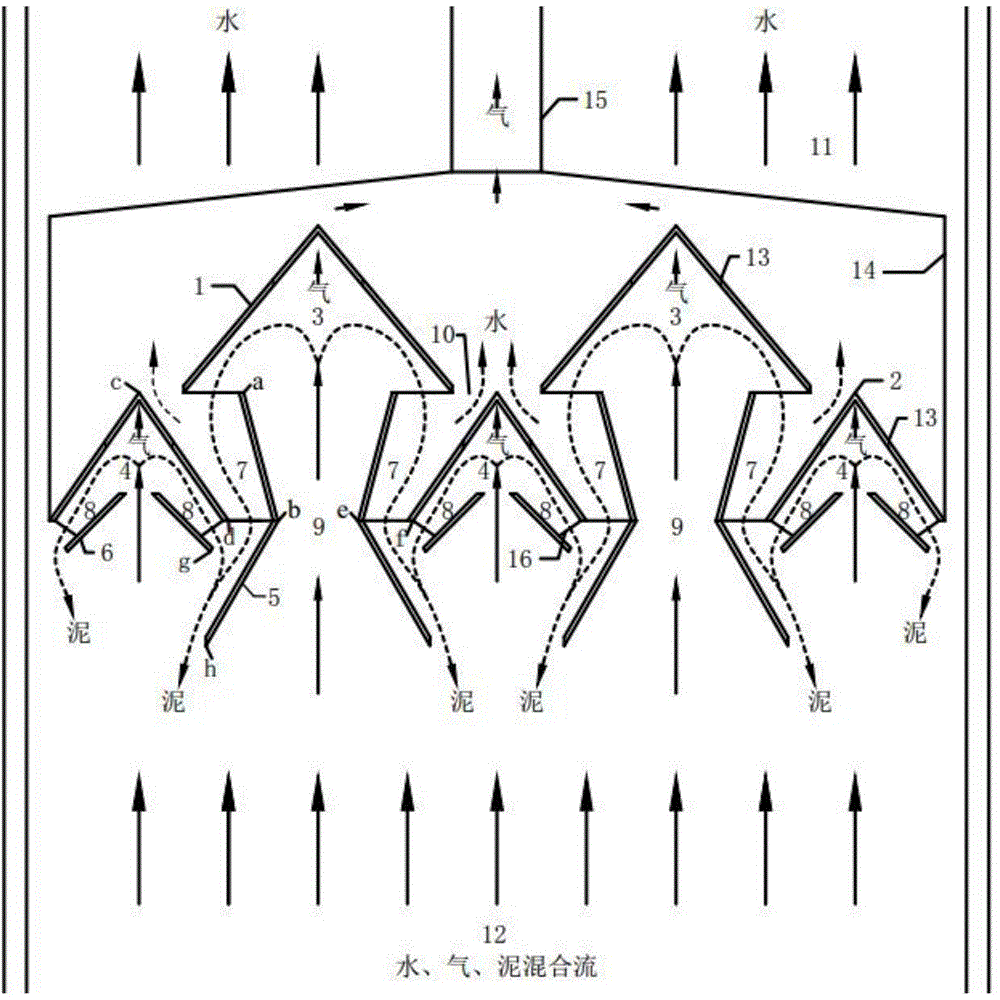

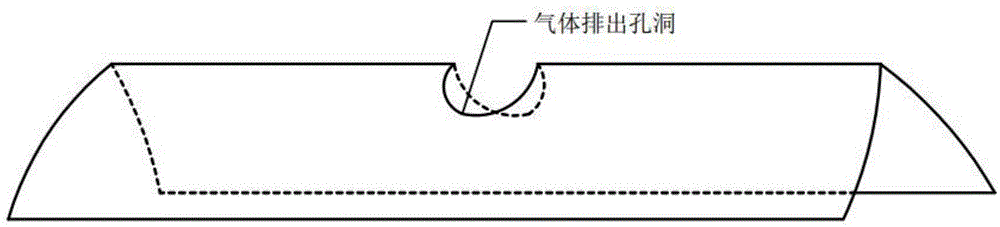

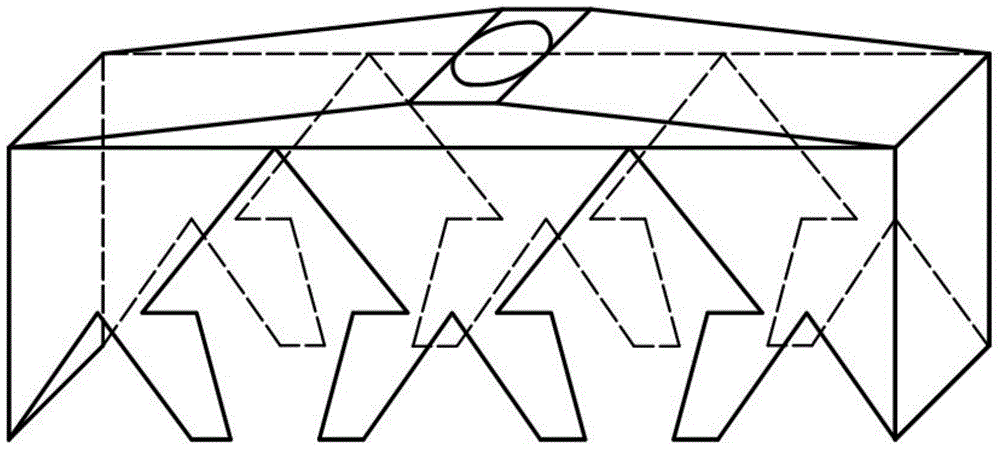

Sludge reflux type three-phase separator used in anaerobic reactor

ActiveCN104386811AIncrease concentrationDisadvantages of changing coincidenceSpecific water treatment objectivesWaste based fuelRefluxEngineering

The invention discloses a sludge reflux type three-phase separator used in an anaerobic reactor. The separator comprises an upper three-phase separation plate, a lower three-phase separation plate, an upper sludge reflux plate and a lower sludge reflux short plate, wherein an upper sludge reflux channel is formed between the upper sludge reflux plate and the lower three-phase separation plate, and a lower sludge reflux channel is formed between the lower sludge reflux plate and the lower three-phase separation plate; the upper sludge reflux channel and the lower sludge reflux channel are joined at the edge of the lower separation plate to form a sludge joined reflux channel, so that the sludge reflux channels are independent of and separated from a gas-liquid-solid three-phase mixed liquid ascending channel. The sludge reflux type three-phase separator can be used for improving the gas-liquid-solid three-phase separation effect in sewage anaerobic biological treatment and guaranteeing the anaerobic effluent quality, is simple in structure, and has strong practicality.

Owner:SOUTH CHINA UNIV OF TECH

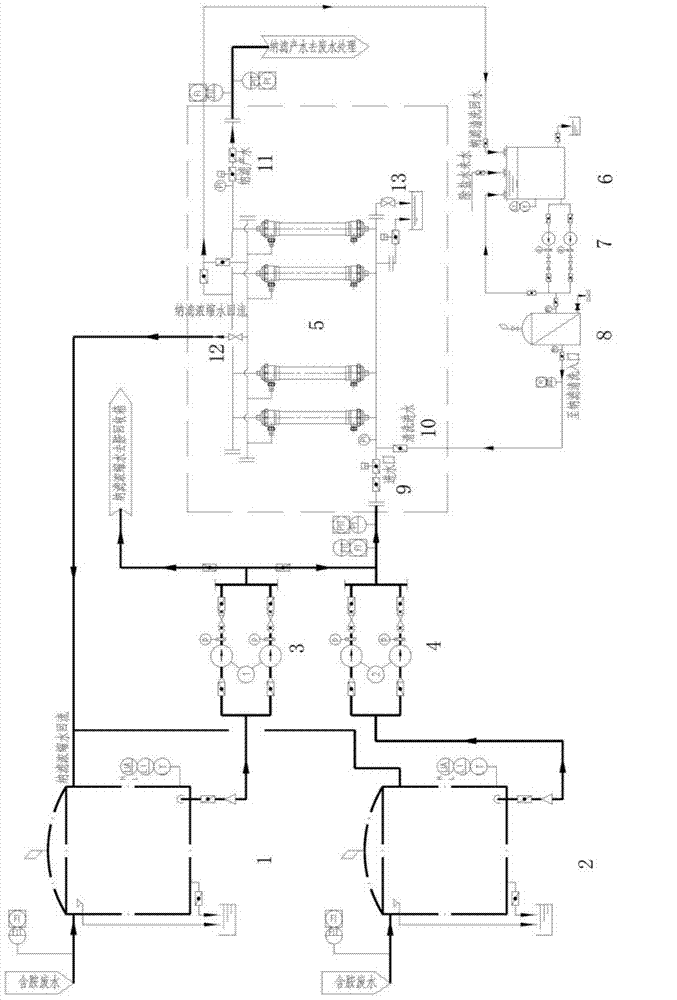

Device and method for recycling treatment of amino containing waste water

InactiveCN104229941AHigh amine contentHigh in amineWater contaminantsWater/sewage treatment bu osmosis/dialysisWater treatment systemFiltration membrane

The invention relates to a device and a method for recycling treatment of amino containing waste water and belongs to the field of alcohol-amine desulfurization liquid purification. The recycling treatment device mainly comprises a recycling tank, a pressurizing pump and a nano-filtration membrane assembly, wherein the recycling tank, the pressurizing pump and the nano-filtration membrane assembly are sequentially connected through pipelines and valves, a concentrated water outlet of the nano-filtration membrane assembly is connected to the recycling tank through a pipeline, and a yield water outlet of the nano-filtration membrane assembly is connected to a waste water treatment system through a pipeline. Planer nano-filtration membranes are used for filtering, are convenient to assemble and easy to wash and exchange, the waste water circulation cross section area is large, blockage cannot easily occur, and different number of membranes can be assembled according to waste water properties and waste water quantity. Cross-flow filtration is adopted in the invention, part of amine fluid can be refluxed, the pollution of waste water to the nano-filtration membranes can be reduced, and the concentrating rate can be improved.

Owner:王建军

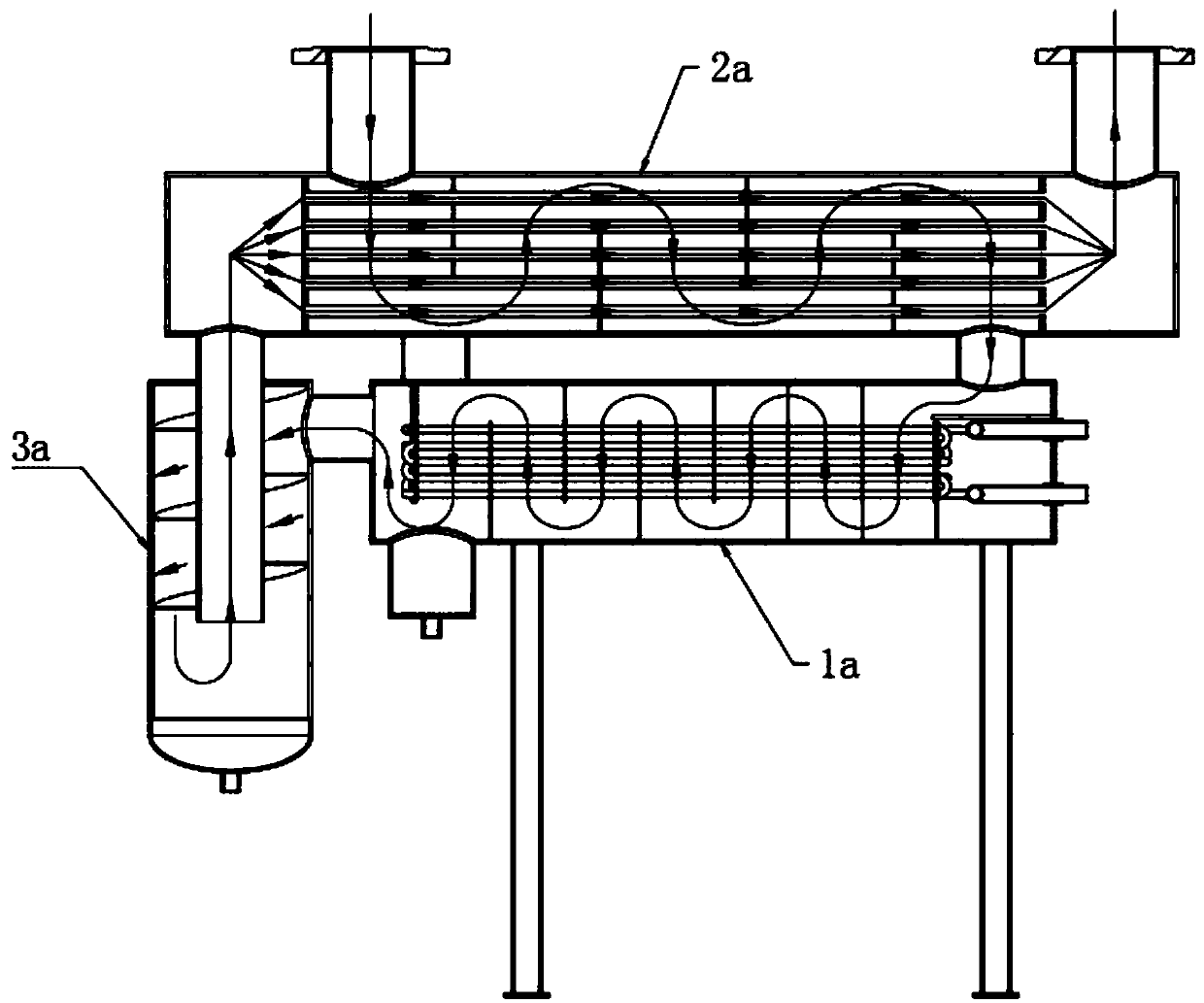

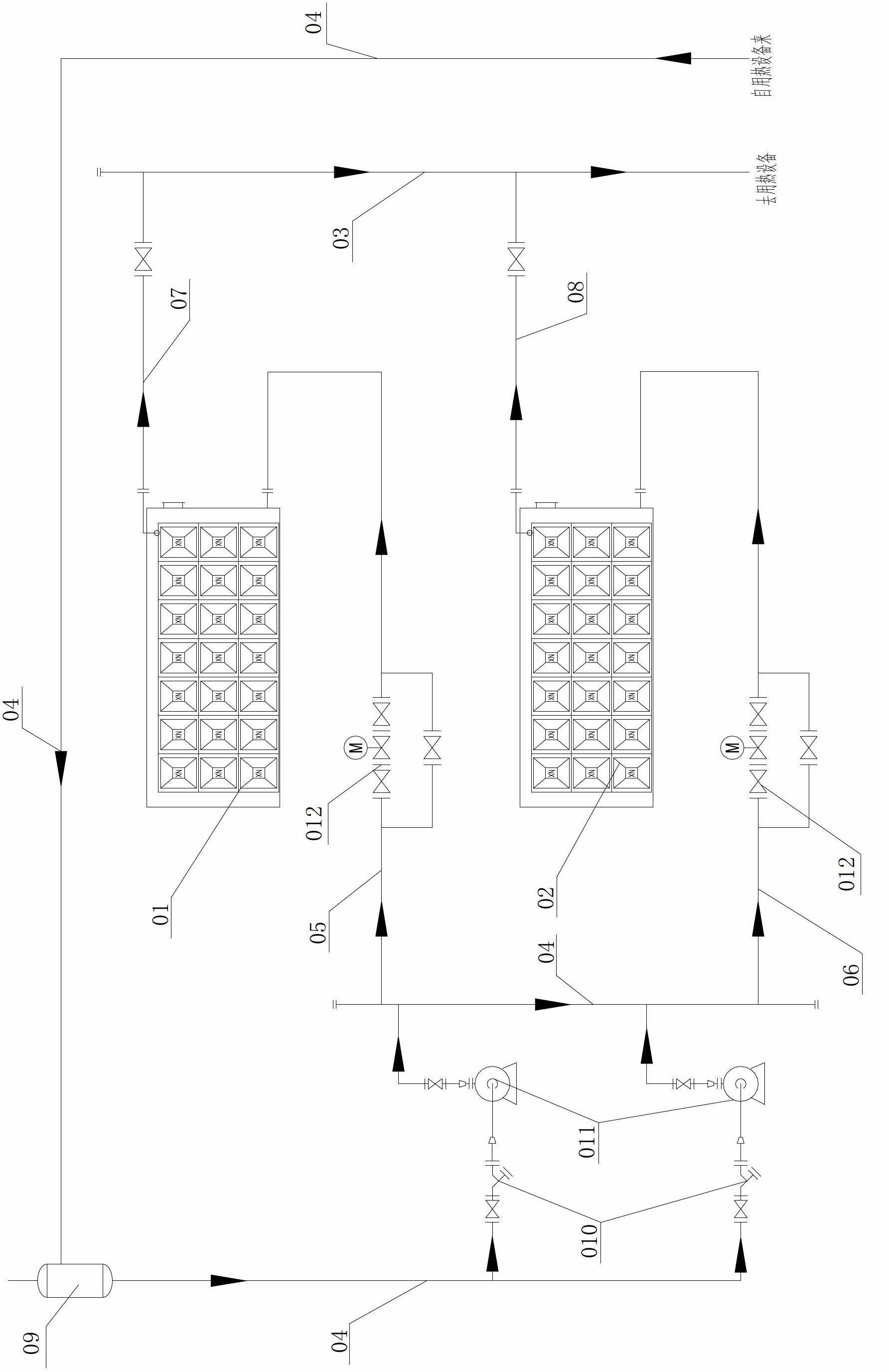

Efficient heat exchange structure of compressed air refrigeration dryer

InactiveCN109556433AConvenient sourceReduce leakageDispersed particle separationCorrosion preventionAir separationEngineering

The invention provides an efficient heat exchange structure of a compressed air refrigeration dryer. The problems that according to existing equipment, ice blockage is prone to occurring, the structure is incompact, and the drying effect is poor can be solved. The efficient heat exchange structure comprises a vertically-arranged first pipe and further comprises a second pipe arranged in an inner cavity of the first pipe; a first cavity is formed between the inner wall of the first pipe and the outer wall of the second pipe; an inner cavity of the second pipe forms a second cavity, and the upper portion of the second pipe is provided with an air inlet and communicates with the second cavity; the second pipe is provided with a plurality of first heat exchange pipes in a vertical penetratingmode, and bottom ends of the first heat exchange pipes communicate with the first cavity; a connection pipe is arranged in the second pipe, the top end of the connection pipe communicates with the upper portion of the first cavity, and the bottom end of the connection pipe communicates with the lower portion of the second cavity; and the bottom of the first pipe is provided with a water collectingtank and a drain pipe. The efficient heat exchange structure is compact in structure, resistant to corrosion, free of secondary pollution, small in pressure loss, capable of reducing ice blockage andleakage phenomena, simple in technology, low in cost and good in water-air separation effect.

Owner:FOSHAN TIANDI YUANYI PURIFICATION EQUIP

Ultra-low-nitrogen combustion equipment with post-premixing cold flame combustion coupling matrix tube mode wall structure

ActiveCN112815312AGuaranteed stabilityReduce the temperatureGaseous fuel burnerCombustion chamberAir volume

The invention relates to ultra-low-nitrogen combustion equipment with a post-premixing cold flame combustion coupling matrix tube mode wall structure. The ultra-low-nitrogen combustion equipment comprises a fuel gas regulation and control device, an air volume regulation and control device, an air-gas mixing device, a cold flame combustion device, a matrix tube and mode wall device and a comprehensive controller. The fuel gas regulation and control device provides fuel gas for the air-gas mixing device; the air volume regulation and control device provides combustion-supporting air for the air-gas mixing device; the air-gas mixing device conducts jet flow mixing on combustible gas provided by the fuel gas regulation and control device and the combustion-supporting air provided by the air volume regulation and control device, and the combustible gas and the combustion-supporting air are evenly mixed through the air-gas mixing device and then injected into the cold flame combustion device; the mixed gas sequentially passes through a double-layer rectifying plate, a hexagonal heat pipe type cooling fire-retardant tube nest and a flame cooling tube nest in the cold flame combustion device and then enters a combustion chamber for combustion; and after combustion, high-temperature flue gas is subjected to radiation and convective heat exchange in the combustion chamber, then exchanges heat with a medium in the matrix tube and mode wall device and then is discharged into a flue.

Owner:BEIJING BOOSTER BOILER

Extrusion die for metal tube

The invention provides an extrusion die for a metal tube. The extrusion die comprises a mold core seat, wherein the outer peripheral surface of the mold core seat is free of a runner, a shape formed by enclosure of the outer peripheral surface is elliptical on the cross section of the mold core seat, and the feeding part of the mold core seat is close to the long axis end position of the ellipse. The extrusion die provided by the invention balances the distribution amount of a molten metal material at each position of the elliptical outer peripheral surface, enables the extrusion amount of the molten metal material at each position of the circumference of a discharging outlet to be balanced to a greatest extent, reduces, even avoids the phenomena of different thickness of different positions at the circumference of the metal tube and an irregular excircle shape of the metal tube, and substantially improves production quality of the metal tube.

Owner:HEFEI SMARTER TECH GROUP CORP

Plate type heat exchanger

InactiveCN102767979AImprove the overall heat transfer coefficientLarge flow cross-sectional areaLaminated elementsStationary plate conduit assembliesEngineeringConvection heat

The invention provides a plate type heat exchanger. The plate type heat exchanger comprises at least three folded plate sheets for form at least two flowing channels, wherein at least one layer of reinforcing sheets is arranged in at least one flow channel. The reinforcing pieces are plate sheets, perforated plate sheets or screens. The plate type heat exchanger can improve flow area and actual heat exchange area of convection heat exchange coefficient on the small side, surface heat exchange coefficient by adding the reinforcing piece in a targeted mode on a basis that the turbulence strength of the plate type heat exchanger is kept to be constant and is even improved, accordingly improves total heat exchange coefficient, enables the efficiency to be improved during liquid-liquid heat exchange, air-liquid heat exchange and air-air heat exchange, especially during the air-liquid heat exchange, and widens the application range.

Owner:覃新川

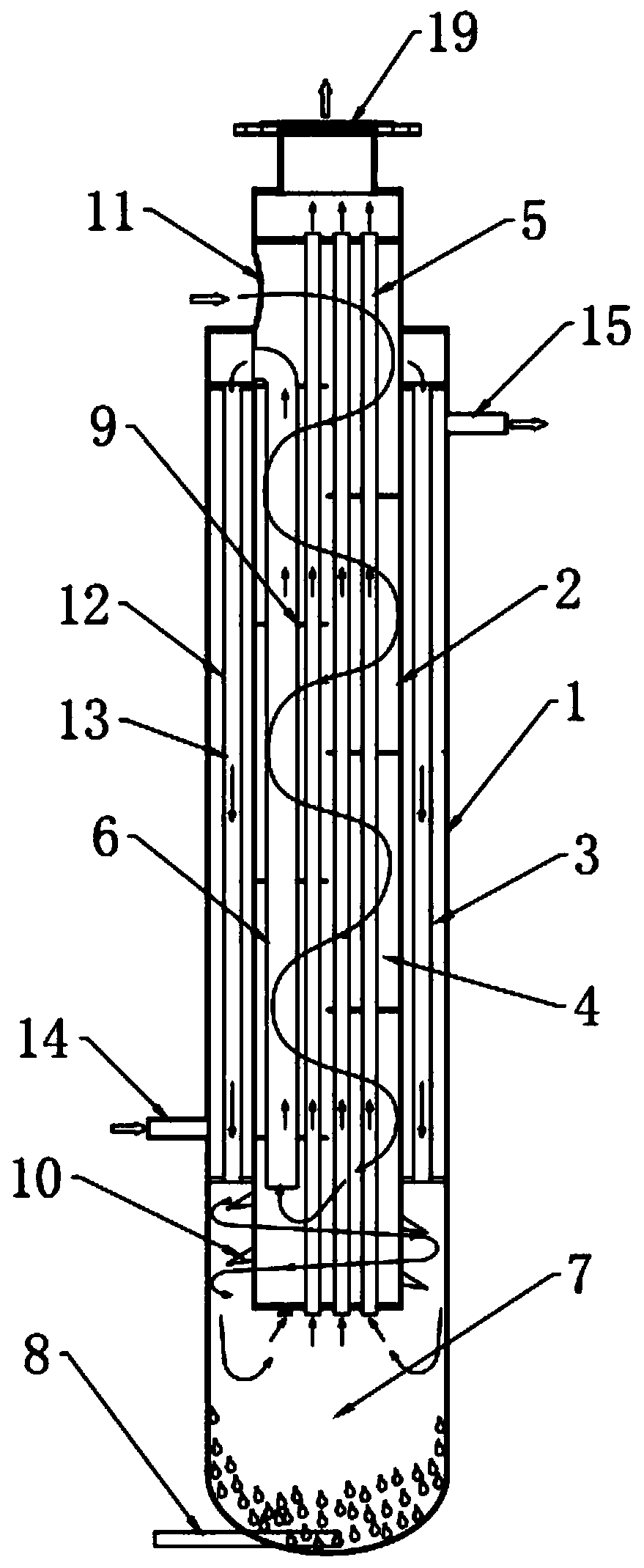

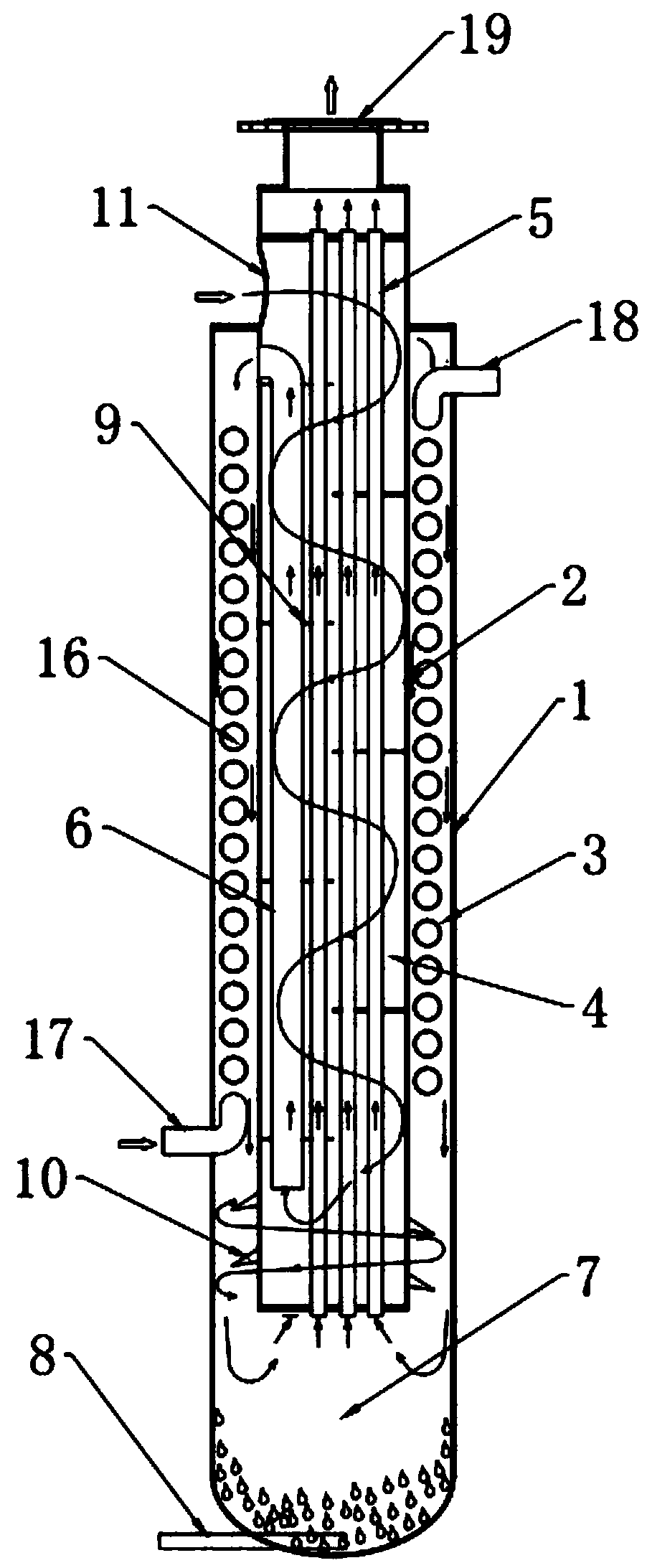

Organic heat carrier waste-heat furnace and waste-heat furnace system

ActiveCN102679751AIncrease disturbanceLarge flow cross-sectional areaIncreasing energy efficiencyWaste heat treatmentFlueConvection

The invention discloses an organic heat carrier waste-heat furnace which comprises a waste-heat furnace body and a settling chamber, wherein one side wall of the settling chamber is provided with a smoke inlet, and the other side wall of the settling chamber is connected with one side of the waste-heat furnace body through a flue; the other side wall of the waste-heat furnace body is provided with a smoke outlet, the settling chamber is internally provided with a settling chamber diaphragm-type wall pipe screen, the top of the settling chamber diaphragm-type wall pipe screen is connected with the top of the settling chamber, and the bottom of the settling chamber diaphragm-type wall pipe screen is provided with a smoke channel; the waste-heat furnace body is internally provided with a plurality of mutually parallel convection sections, each adjacent convection sections are separated by smoke folding devices, each adjacent smoke folding devices are arranged in a stagger manner, and smoke entering the adjacent convection sections turns; and the convection sections comprise a plurality of pipe screens which are mutually parallel arranged, the spacing between each adjacent pipe screens is more than 100 mm, the design can be used for ensuring the smoke entering the adjacent convection sections to turn, increasing the disturbance of the smoke, realizing the effective segregation of the smoke, reducing the smoke flow rate and reducing the abrasion of a heating surface.

Owner:WUXI XINENG BOILER

Compressed gas refrigerated dryer heat exchanging water removal structure

PendingCN110375563ACompact structureImprove the effect of gas-liquid separationDispersed particle separationHeat exchanger casingsDifferential pressureProcess engineering

The invention provides a compressed gas refrigerated dryer heat exchanging water removal structure which can improve the problems that the existing equipment is not impact in structure, and poor in gas and water separating effect and can cause ice blockage easily, and the inlet and outlet differential pressure of compressed gas is large. The compressed gas refrigerated dryer heat exchanging waterremoval structure comprises a first pipe vertically arranged, and a second pipe arranged in the first pipe, wherein the bottom of the second pipe is not in contact with the bottom of the first pipe; agas-liquid separation cavity is formed between the first pipe and the second pipe; a liquid collecting cavity is formed in the bottom of the gas-liquid separation cavity; a refrigerating cavity is formed in the second pipe and is provided with a refrigerating source outlet and a refrigerating source inlet; the refrigerating cavity communicates with a gas inlet; the compressed gas refrigerated dryer heat exchanging water removal structure further comprises one or more third pipes; one end of the third pipe communicates with the external world and serves as a gas outlet; the other end of the third pipe communicates with the upper part of the liquid collecting cavity; the gas enters from the gas inlet, is cooled through the refrigerating cavity and is subjected to gas-water separation through the gas-liquid separation cavity, then, condensate separates out and flows to the liquid collecting cavity, and the gas is discharged out of the gas outlet through the third pipe.

Owner:FOSHAN TIANDI YUANYI PURIFICATION EQUIP

Undisturbed switching control method of pneumatic regulation valve

InactiveCN109058473AIncrease elastic potential energyReduce elastic potential energyOperating means/releasing devices for valvesEqualizing valvesHandoff controlEngineering

The invention discloses an undisturbed switching control method of a pneumatic regulation valve. The undisturbed switching control method of the pneumatic regulation valve relates to a device body anda first cavity formed in the device body. A first rotary shaft which extends upwards and downwards is rotatably arranged in the first cavity. The tail end of the top of the first rotary shaft is in power connection with a motor fixedly arranged in the top end wall of the first cavity. According to the undisturbed switching control method of the pneumatic regulation valve, the structure of a device is simple, the performance is reliable, and mounting, maintenance and repair are convenient; the device can automatically detect the rate of flow passing through the device and compares the flow rate with an initial setting, automatic dynamic regulation is conducted according to the flow rate, and thus, it is ensured that the rate of flow passing through the valve is constant; meanwhile, the device can be switched into a manual mode according to requirements, the flow data and the operating state of the device are not changed in the switching process, and thus, undisturbed switching betweenthe automatic mode and the manual mode is achieved; and in addition, the device can generate compressed gas through a micro gas pump, and an external gas source is not needed, so that the mounting procedure is greatly simplified, and the maintenance cost of the device is reduced.

Owner:俞李娜

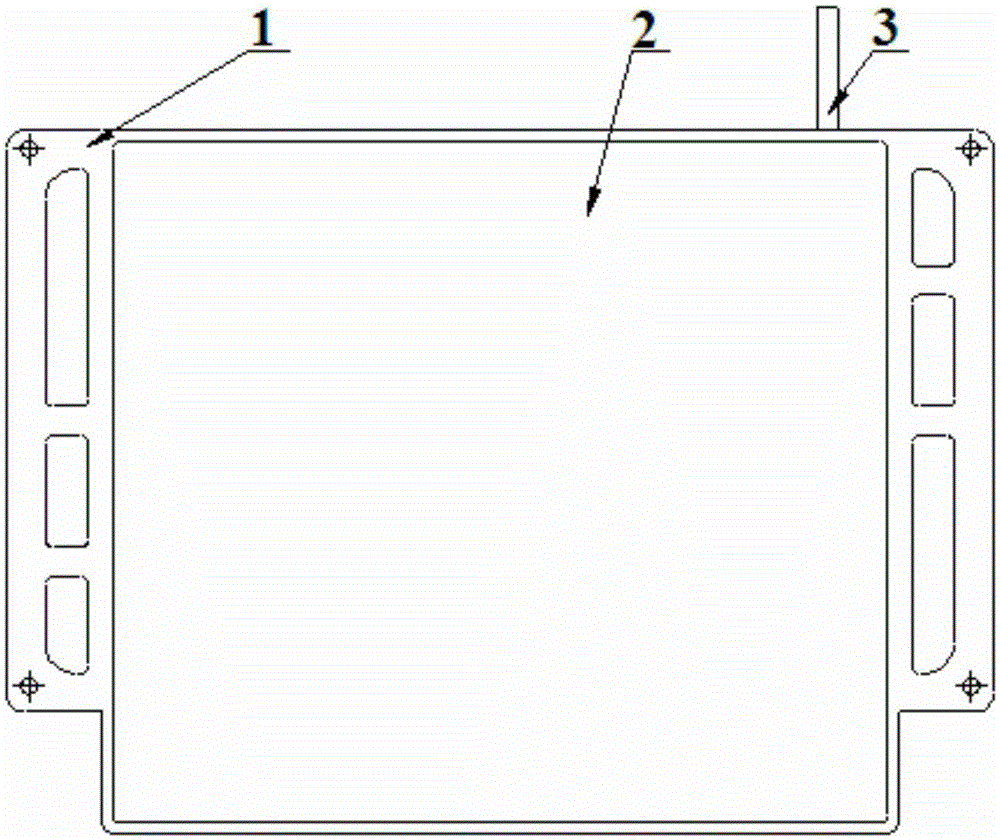

Large-area and high-thermal-conductivity light and thin microgroove flat heat tube

InactiveCN105403084ALarge flow cross-sectional areaReduce frictional resistanceIndirect heat exchangersEngineeringUltimate tensile strength

The invention discloses a large-area and high-thermal-conductivity light and thin microgroove flat heat tube, and belongs to the field of microgroove flat thermal control engineering. The large-area and high-thermal-conductivity light and thin microgroove flat heat tube comprises a microgroove shell, a microgroove cover plate and a liquid filling pipe, wherein the microgroove cover plate is fixedly mounted at the upper part of the microgroove shell; a reinforcing rib is arranged at the lower part of the microgroove cover plate; and the liquid filling pipe is fixedly mounted at the right side of the upper end of the microgroove shell. The invention provides the large-area and high-thermal-conductivity light and thin microgroove flat heat tube; firstly, a capillary structure, the cover plate and the shell are connected to form a complete sealing structure through modes of electronic beam welding, TIG welding and dissimilar metal brazing, so that the high heating flux can be realized, and the heat transfer on the larger heat transfer contact area is efficient and reliable; and the large-area and high-thermal-conductivity light and thin microgroove flat heat tube is relatively lighter in whole weight and higher in structural strength, can serve as a structural part and a bearing part, and is convenient for use. The large-area and high-thermal-conductivity light and thin microgroove flat heat tube reduces the system complexity, and improves the system reliability.

Owner:BEIJING SATELLITE MFG FACTORY

Blast furnace gas dry method bag type dust removing mechanical type pressure dust unloading process and device thereof

ActiveCN106636507ALarge flow cross-sectional areaLess load interval changesBlast furnace detailsProcess efficiency improvementEngineeringGas chamber

Disclosed is a blast furnace gas dry method bag type dust removing mechanical type pressure dust unloading process and device. A first gas pressure relief valve is arranged on a dust and gas chamber located on the lower portion of each cloth bag dust removing box body. Each first gas pressure relief valve of the corresponding cloth bag dust removing box body is connected to a concentration dust bin through a first gas pressure relief pipe, so that dust and gas with pressure in the concentration dust bin enter the dust and gas chambers located on the lower portions of the cloth bag dust removing box bodies through the first gas pressure relief valves. A second gas pressure relief valve is arranged on a gas purifying chamber located on the upper portion of each cloth bag dust removing box body. Each second gas pressure relief valve of the corresponding cloth bag dust removing box body is connected to a low pressure purified gas main pipe through a second gas pressure relief pipe, so that gas in gas purifying chambers located on the upper portions of the cloth bag dust removing box bodies enters the low pressure purified gas main pipe through the second gas pressure relief valves. Cloth bag dust removing box body dust unloading is conducted by utilizing gas pressure energy of a dust removing system. The blast furnace gas dry method bag type dust removing mechanical type pressure dust unloading process and device have the advantages that the mechanical dust unloading and conveying process is adopted and meanwhile pneumatic dust unloading and conveying are utilized, and the pneumatic dust unloading and conveying process is adopted and meanwhile mechanical power dust unloading and conveying are utilized.

Owner:LIUZHOU IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com