Sludge reflux type three-phase separator used in anaerobic reactor

An anaerobic reactor and three-phase separator technology, which is applied in the field of sludge return three-phase separator, can solve the problem of affecting sludge settlement and gas-solid separation, disturbing sludge return, and failing to maintain reactor sludge concentration, etc. problems, to achieve the effect of ensuring high-efficiency treatment, expanding the flow cross-sectional area, and mitigating disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

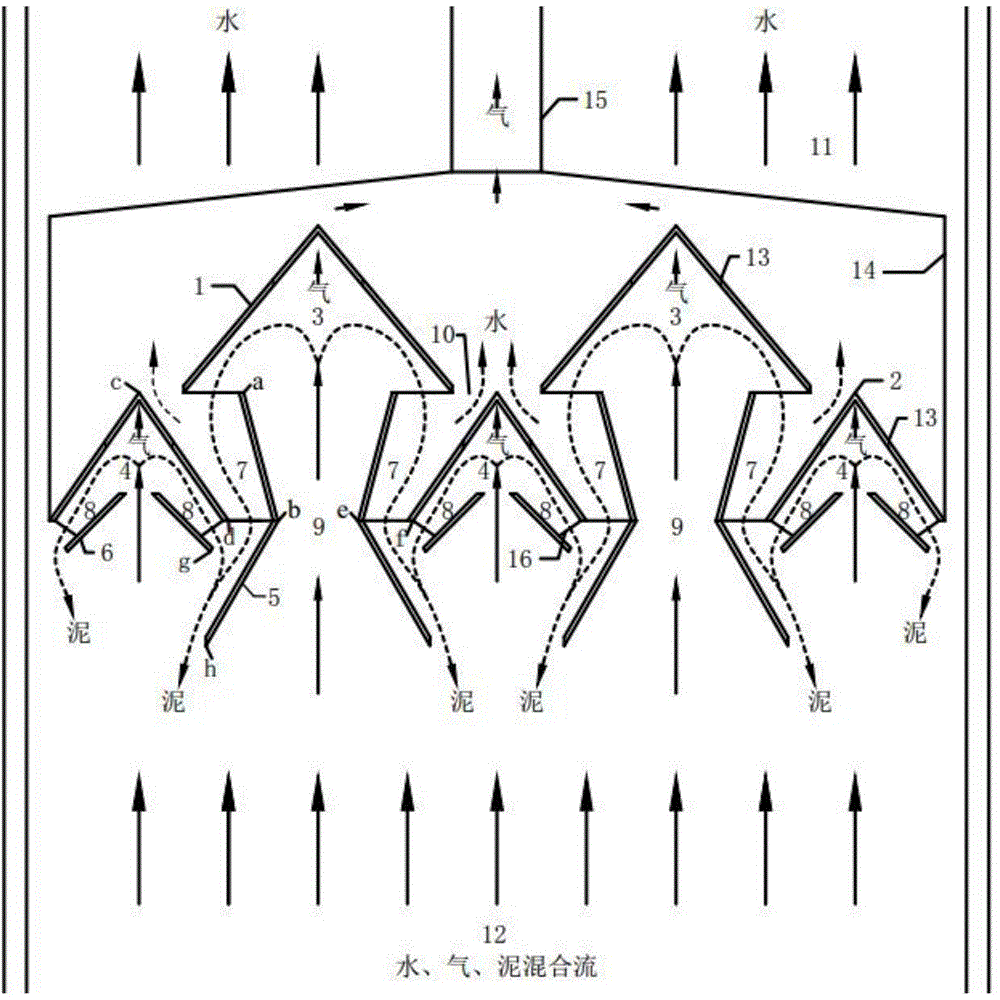

Embodiment 1

[0046] The separator of the present invention used in the verification process is compared with the traditional three-phase separator, and its structure and size are exactly the same as the traditional three-phase separator except that the separation parts are different. By monitoring the COD of the effluent (measured by the potassium dichromate method, the same below), the SS concentration of the suspended solids in the effluent and the biogas generation rate during the operation of the reactor, it is shown that the new three-phase separator has a better performance than the traditional three-phase separator. Three-phase separation effect.

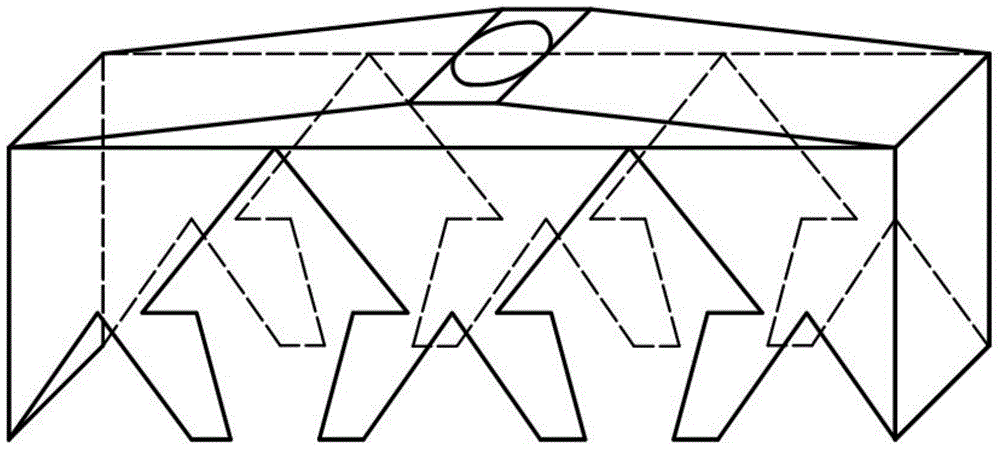

[0047] The processed anaerobic reactor of present embodiment is as Figure 5 , Figure 6 shown. in, Figure 5 For inserting the anaerobic reactor of three-phase separator of the present invention, denoted as No. 1 reactor, Figure 6 It is an anaerobic reactor equipped with a traditional three-phase separator, which is recorded as No. ...

Embodiment 2

[0058] The connection relationship of the sludge return type three-phase separator used in the anaerobic reactor used in this embodiment is the same as that of Example 1, except that its specific parameters in the separator are: the two sides of the lower three-phase separation plate and the The angle between the horizontal line is 50°, the angle between the plates on both sides of the upper three-phase separation plate and the horizontal line is 45°, the angle between the plate surface of the upper half of the upper sludge return plate and the horizontal line is 65°, and the angle between the lower plate surface and the horizontal line The included angle is 55°, and the included angle between the lower sludge return short board and the horizontal line is 35°.

[0059] The angle between the plane where the upper half of the plate in the upper sludge return plate is located and the plane where the upper half of the plate in the lower three-phase separation plate is close to the ...

Embodiment 3

[0065] The connection relationship of the sludge return type three-phase separator used in the anaerobic reactor used in this embodiment is the same as that of Example 1, except that its specific parameters in the separator are: the two sides of the lower three-phase separation plate and the The angle between the horizontal line is 60°, the angle between the plates on both sides of the upper three-phase separation plate and the horizontal line is 55°, the angle between the plate surface of the upper half of the upper sludge return plate and the horizontal line is 80°, and the angle between the lower plate surface and the horizontal line The included angle is 75°, and the included angle between the lower sludge return short board and the horizontal line is 47.5°.

[0066] The angle between the plane of the upper half of the plate in the upper sludge return plate and the plane of the upper half of the plate in the lower three-phase separation plate close to the upper sludge retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com