Compressed gas refrigerated dryer heat exchanging water removal structure

A technology of compressing gas and drying machine, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., it can solve the problem that liquid is easily taken away by air flow, condensate is easy to freeze, and plate gap is small problems, to achieve the effects of reducing the risk of corrosion leakage and solder joint leakage, good gas-liquid separation effect, and high material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

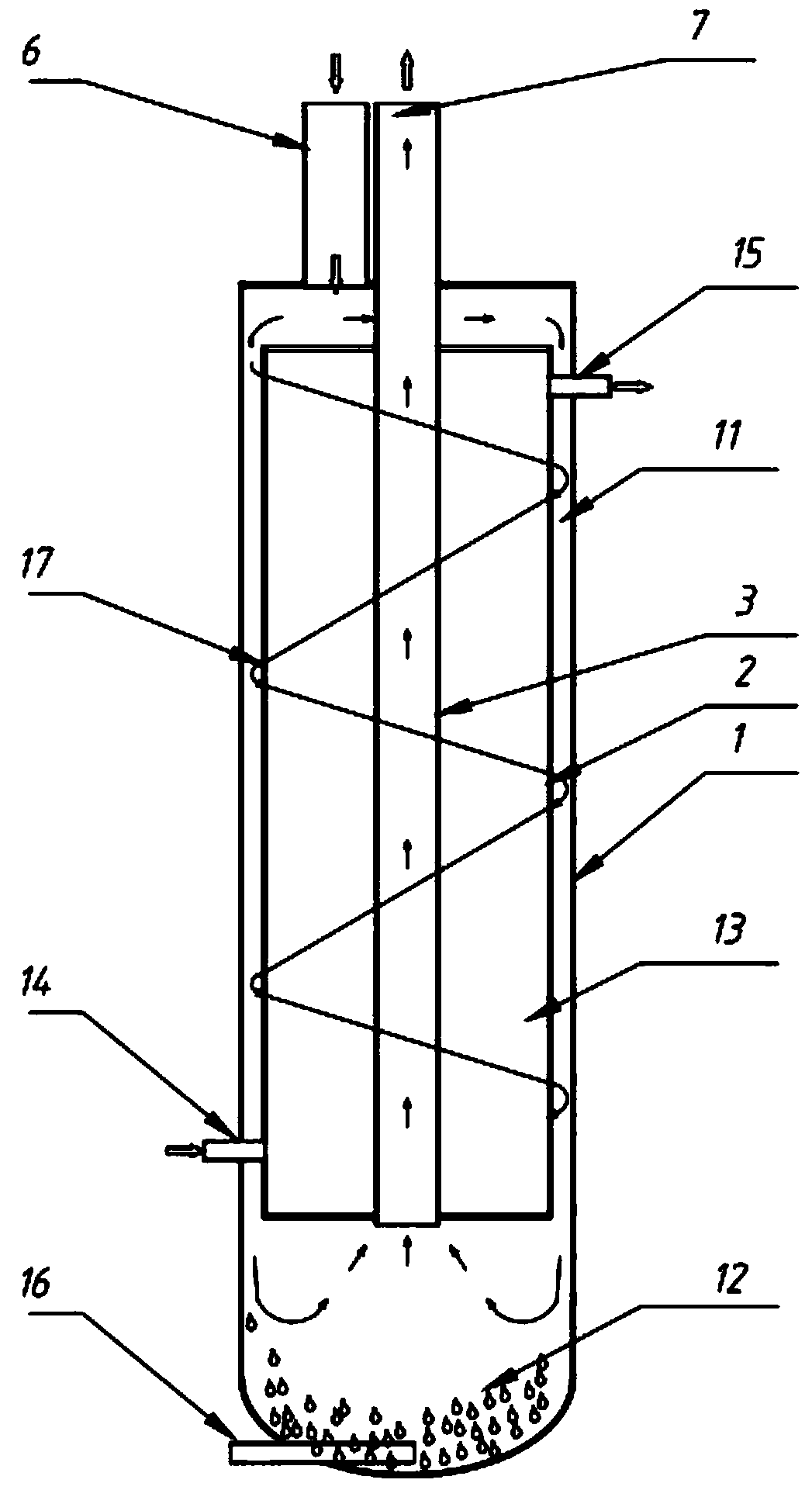

[0032] Embodiment 1: refer to figure 1 , the present invention provides a heat exchange and water removal structure for a compressed gas refrigeration dryer, which includes a vertically arranged first tube 1 and a second tube 2 inside the first tube 1. The outer diameter of the second tube 2 is Smaller than the inner diameter of the first tube 1, and the second tube 2 is preferably coaxially arranged with the first tube 1, the bottom of the second tube 2 does not touch the bottom of the first tube 1, the first tube 1 and the second tube 2 A gas-liquid separation chamber 11 is formed between them, and a spiral piece 17 is arranged in the gas-liquid separation chamber 11 . The liquid collecting chamber 12 is formed at the bottom of the gas-liquid separation chamber 11, the bottom of the second pipe 2 is closed, and the top is also closed, and a cooling chamber 13 is arranged inside, and the cooling chamber 13 is respectively provided with a cooling source outlet 15 and a The c...

Embodiment 2

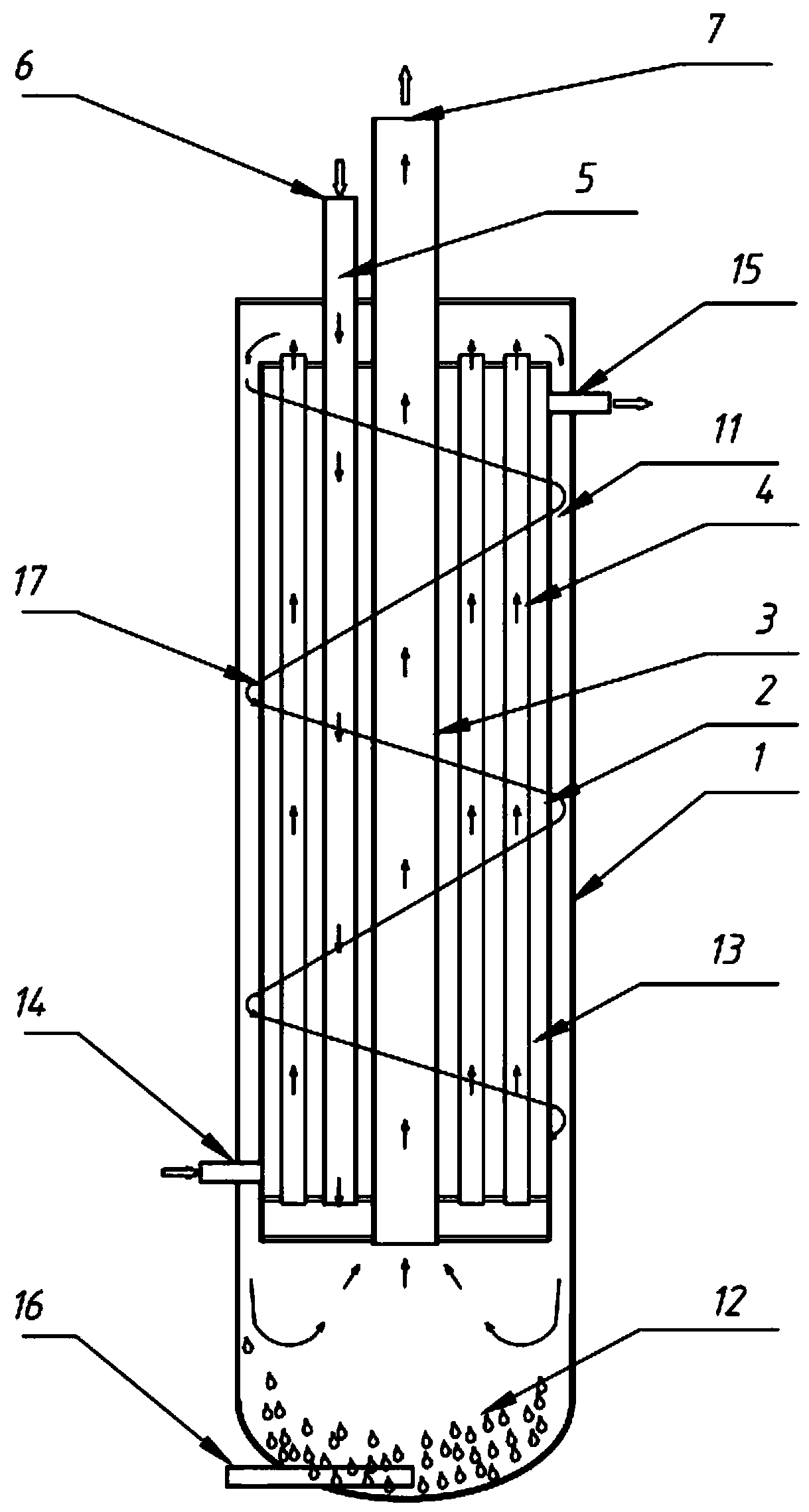

[0042] Embodiment 2: refer to figure 2Compared with Embodiment 1, the difference is that one or more fourth tubes 4 are provided in the refrigeration chamber 13 to increase the heat exchange area, and the upper part of the gas-liquid separation chamber 11 passes through the fourth pipe 4. The pipe 4 communicates with the gas inlet 6 , wherein the gas inlet 6 communicates with the bottom of the refrigeration chamber 13 through the fifth pipe 5 . In this way, the gas enters the bottom of the refrigeration chamber 13 through the fifth pipe 5, and then enters the fourth pipe 4. The gas performs a heat exchange with the cooling source on the inside of the fourth pipe 4 and the outside of the fourth pipe 4, and then reaches the upper part of the gas-liquid separation chamber 11. , flowing downward from the upper part of the gas-liquid separation chamber 11, under the action of the spiral piece 17, the compressed gas descends in a spiral manner, the compressed gas contacts the outer...

Embodiment 3

[0051] Embodiment 3: refer to image 3 Compared with Embodiment 2, the difference is that the upper part of the refrigeration chamber 13 is not closed, but the bottom is closed, the fourth pipe 4 is arranged in the refrigeration chamber 13, and the two ends of the fourth pipe 4 are respectively connected to the refrigeration source outlet 15 and the refrigeration source inlet 14 , the low-temperature refrigeration source flows in the fourth pipe 4 , and the compressed gas flows outside the fourth pipe 4 . In this way, the gas enters the bottom of the refrigeration chamber 13 through the fifth pipe 5, flows upwards in the refrigeration chamber 13, conducts a heat exchange with the low-temperature refrigeration source inside the fourth pipe 4, and then lowers the temperature, and then reaches the upper part of the gas-liquid separation chamber 11, from The upper part of the gas-liquid separation chamber 11 flows downward, and the compressed gas generates centrifugal force during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com