Absorption tower with wet type electric demister

A demister and wet electric technology, applied in the field of absorption towers, can solve the problems that the wet electric demister cannot be built in, and achieve the effect of effectively using the site space, saving water resources, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with embodiment, but protection scope of the present invention is not limited to this:

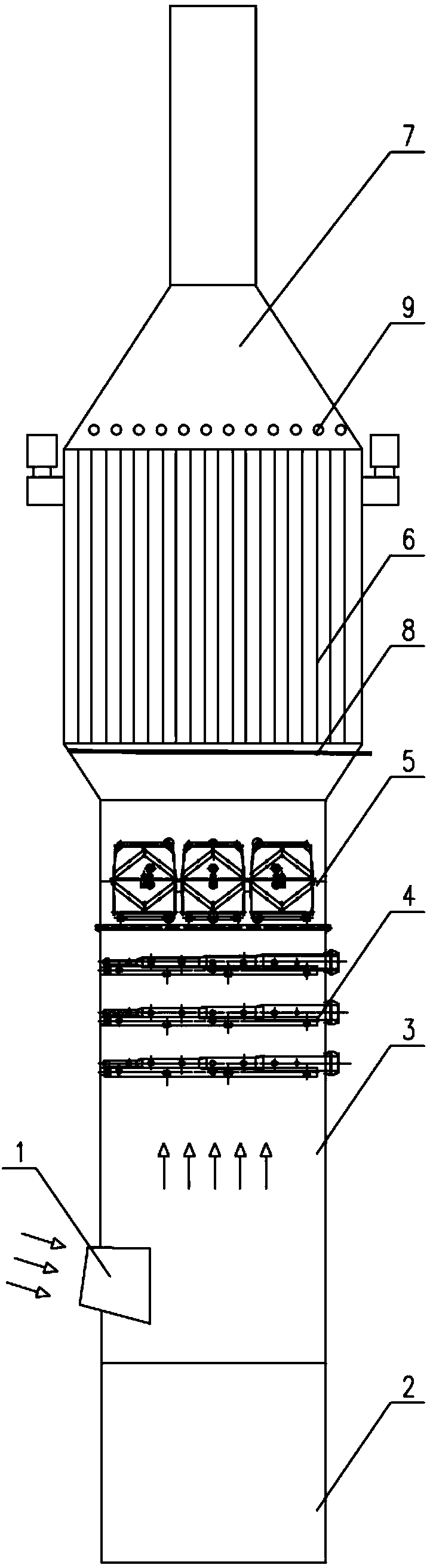

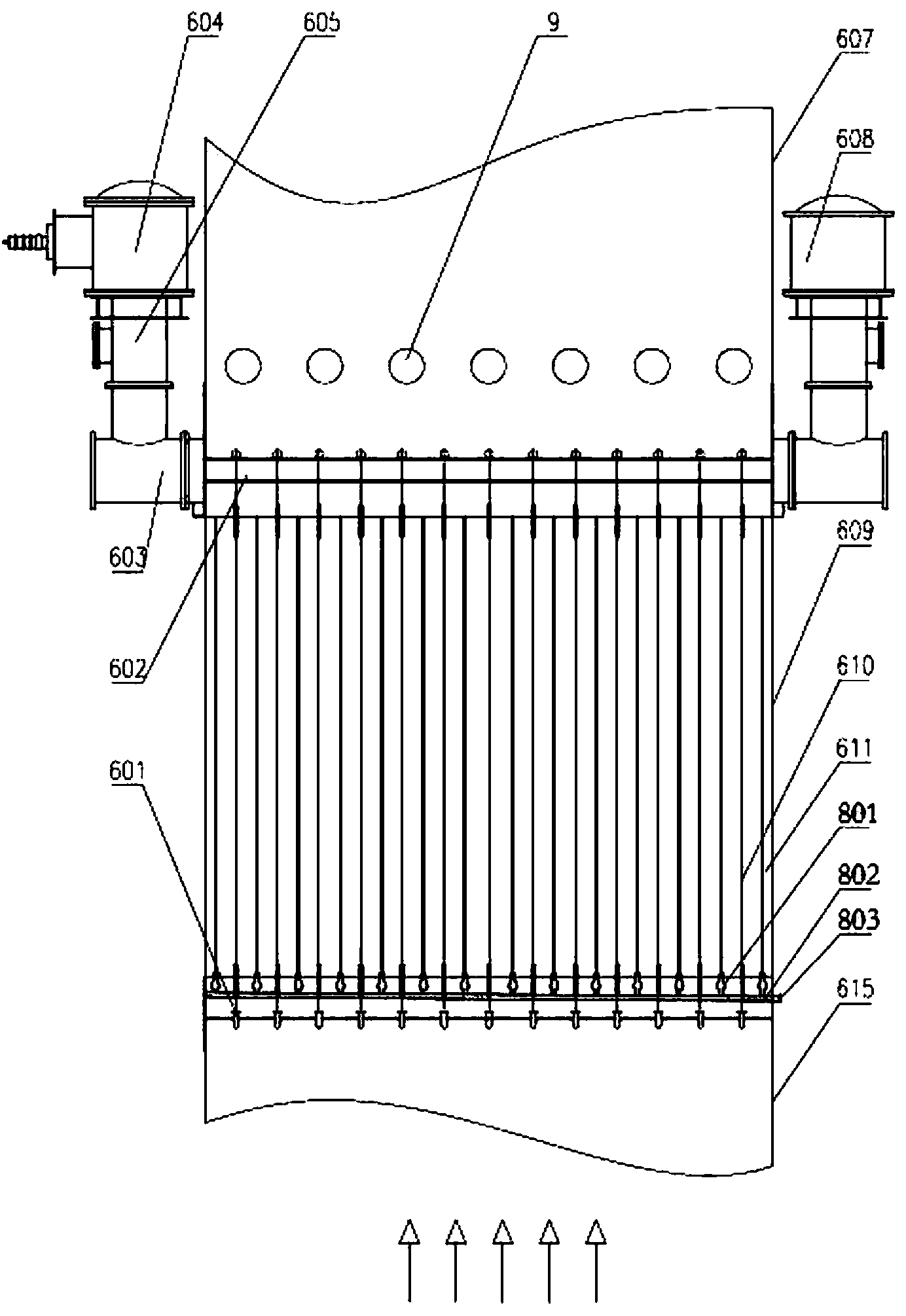

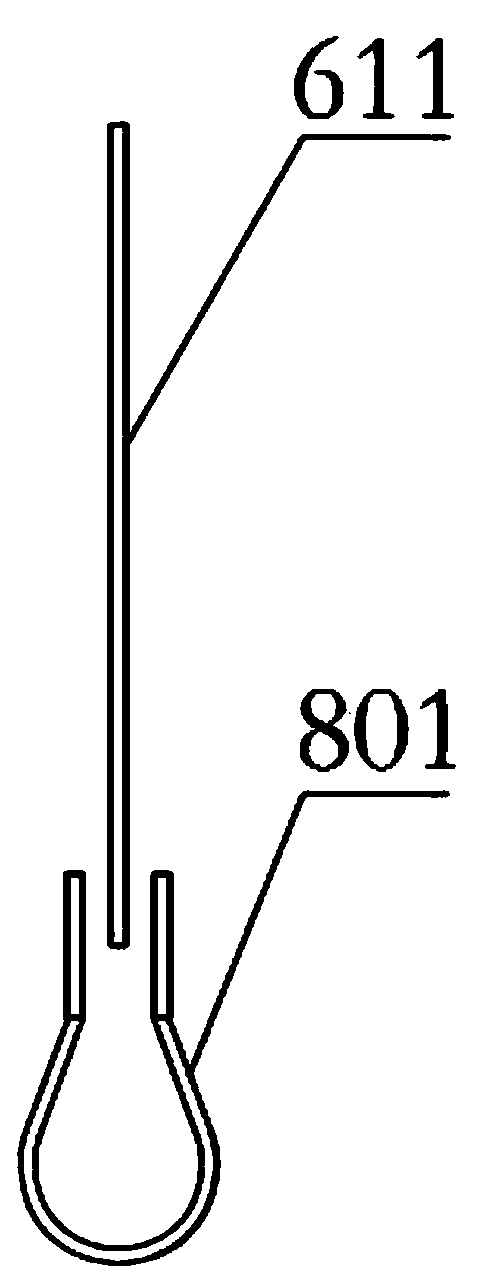

[0060] Such as Figure 1-Figure 11 An absorption tower including a wet electrostatic demister according to the present invention is shown. The specific structure is as shown in the summary of the invention, and will not be described again.

[0061] combined with Figure 12 , a kind of absorption tower work flow that comprises wet electrostatic demister of the present invention is described:

[0062] After the flue gas enters the absorption tower from the entrance 1 of the absorption tower, it is first pre-wetted in the spray layer 4 of the absorption zone 3, and the pre-wetted gas is demisted in the mechanical demister 5.

[0063] The principle of mechanical demisting is: the mechanical demister 5 includes multiple baffles, and the baffles divide the flue into several small flues (further, grooves can be provided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com