Efficient heat exchange structure of compressed air refrigeration dryer

A technology of compressed air and heat exchange structure, which is applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc. It can solve the problems that moisture is easily taken away by the air flow, the structure cannot be compacted, and the production is complicated. Achieve the effect of reducing the risk of corrosion leakage and solder joint leakage, reducing leakage, and simplifying procurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

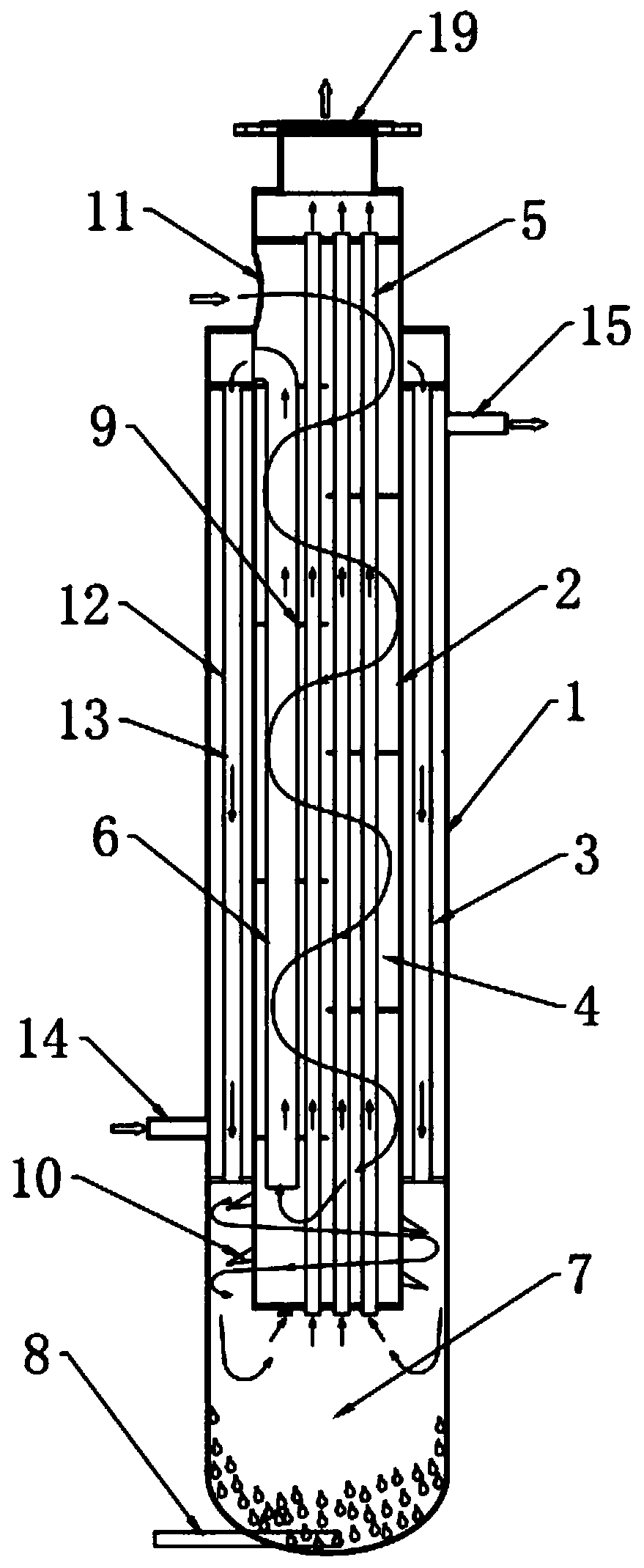

[0029] Embodiment 1: as figure 1 As shown, a high-efficiency heat exchange structure of a compressed air refrigeration dryer includes a vertically arranged first tube 1, and also includes a second tube 2 arranged in the inner cavity of the first tube 1, and the first The tube 1 and the second tube 2 are coaxially arranged, and the structure is symmetrical. The upper and lower ends of the first tube 1 and the second tube 2 are sealed, and the top of the first tube 1 protrudes from the top of the second tube 2. A first cavity 3 is formed between the inner wall of the tube 1 and the outer wall of the second tube 2, the inner cavity of the second tube 2 forms a second cavity 4, and an air inlet 11 is opened on the upper part of the second tube 2 and communicated with the The second cavity 4, the second tube 2 is provided with a plurality of first heat exchange tubes 5 up and down, and the plurality of first heat exchange tubes 5 are evenly distributed in the second cavity 4, and ...

Embodiment 2

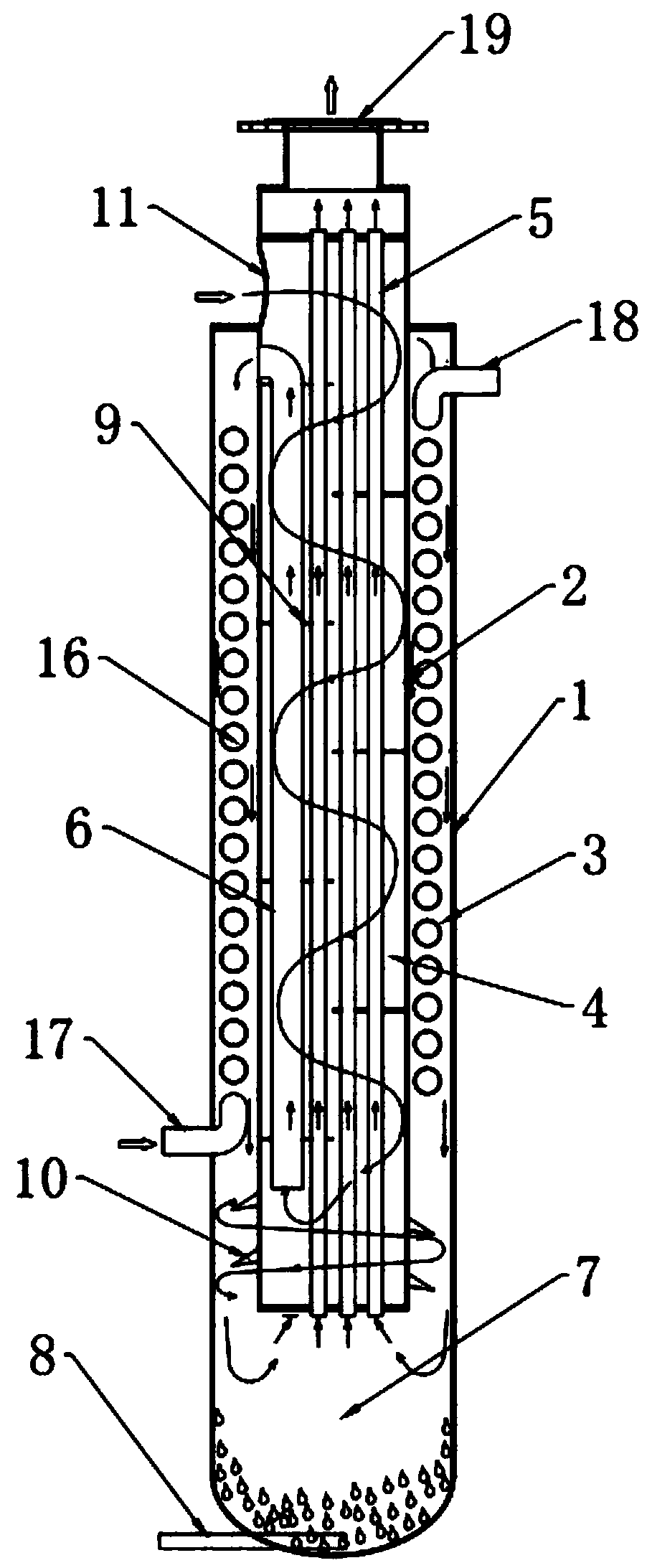

[0032] Embodiment 2: refer to figure 2 , a high-efficiency heat exchange structure for a compressed air refrigeration dryer, comprising a vertically arranged first tube 1, and also including a second tube 2 arranged in the inner cavity of the first tube 1, and the first tube 1 Set coaxially with the second pipe 2, the structure is symmetrical and reasonable, the upper and lower ends of the first pipe 1 and the second pipe 2 are sealed, the top of the first pipe 1 protrudes from the top of the second pipe 2, and the top of the first pipe 2 A first cavity 3 is formed between the inner wall of the second tube 2 and the outer wall of the second tube 2, and the inner cavity of the second tube 2 forms a second cavity 4. An air inlet 11 is opened on the upper part of the second tube 2 and communicated with the first cavity. The second cavity 4, the second tube 2 is provided with a plurality of first heat exchange tubes 5 up and down, the plurality of first heat exchange tubes 5 are ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com