Large-area and high-thermal-conductivity light and thin microgroove flat heat tube

A flat plate heat pipe, high thermal conductivity technology, used in indirect heat exchangers, lighting and heating equipment, etc., can solve the limitations of flat heat pipe flatness and maximum width, wire mesh heat pipes limit maximum heat flux, void space and number of through holes Limitation and other issues to achieve the effect of improving repeatability, meeting the heat dissipation requirements of large heat flux density and high power, and avoiding the risk of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

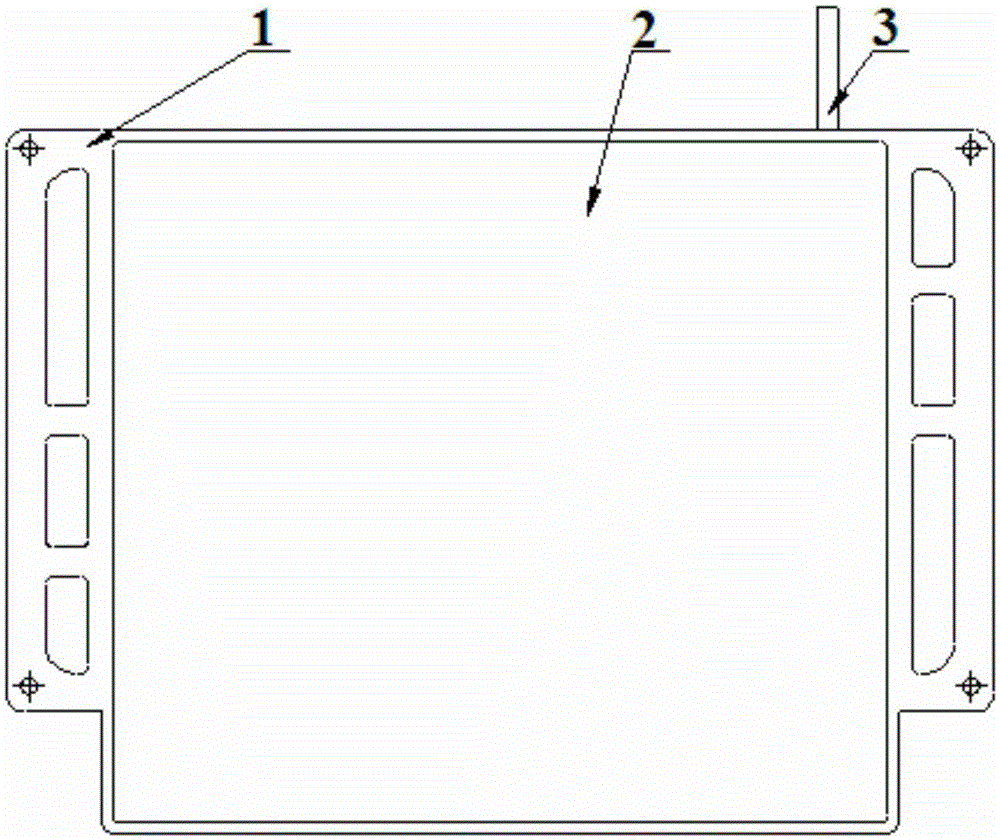

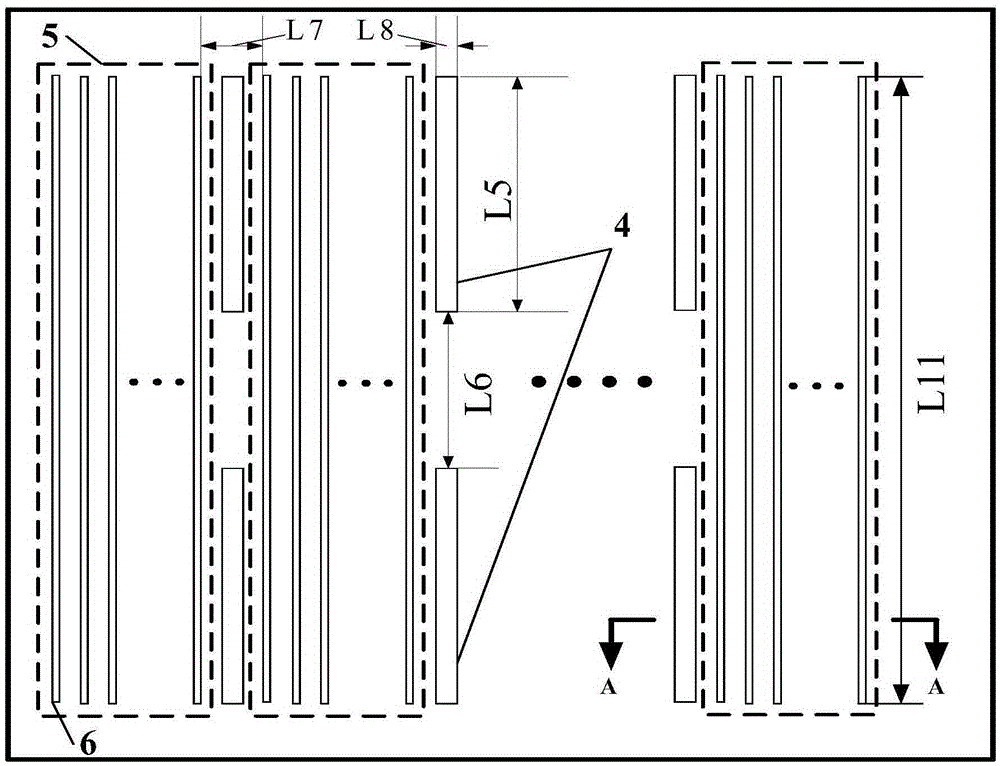

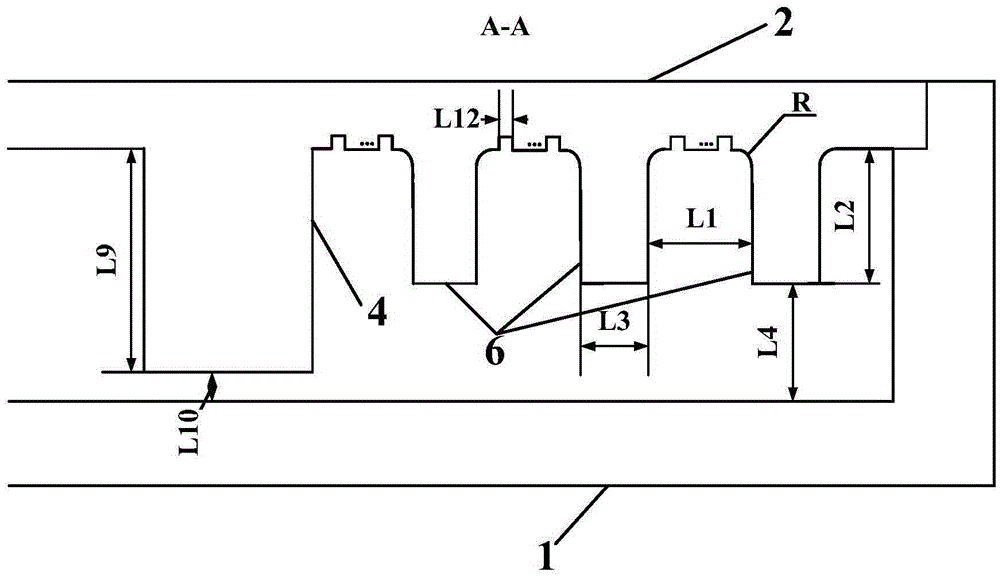

[0027] Such as figure 1 Shown is a schematic diagram of the structure of a large-area light and thin high-thermal conductivity micro-groove plate heat pipe. It can be seen from the figure that it includes a micro-groove shell 1, a micro-groove cover 2 and a liquid filling tube 3; the micro-groove cover 2 is fixedly installed in the micro-groove The upper surface of the housing 1 and the lower surface of the microgroove cover 2 are provided with reinforcing ribs 4; the liquid filling tube 3 is fixedly installed on one side of the microgroove housing 1.

[0028] The three form a closed space and fill a certain amount of liquid working medium inside. Through the air cavity formed by the micro-groove cover plate 1 and the micro-operating shell 2, the internal working medium is evaporated and condensed by heating and cooling. The array provides the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com