Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8365results about "Laminated elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

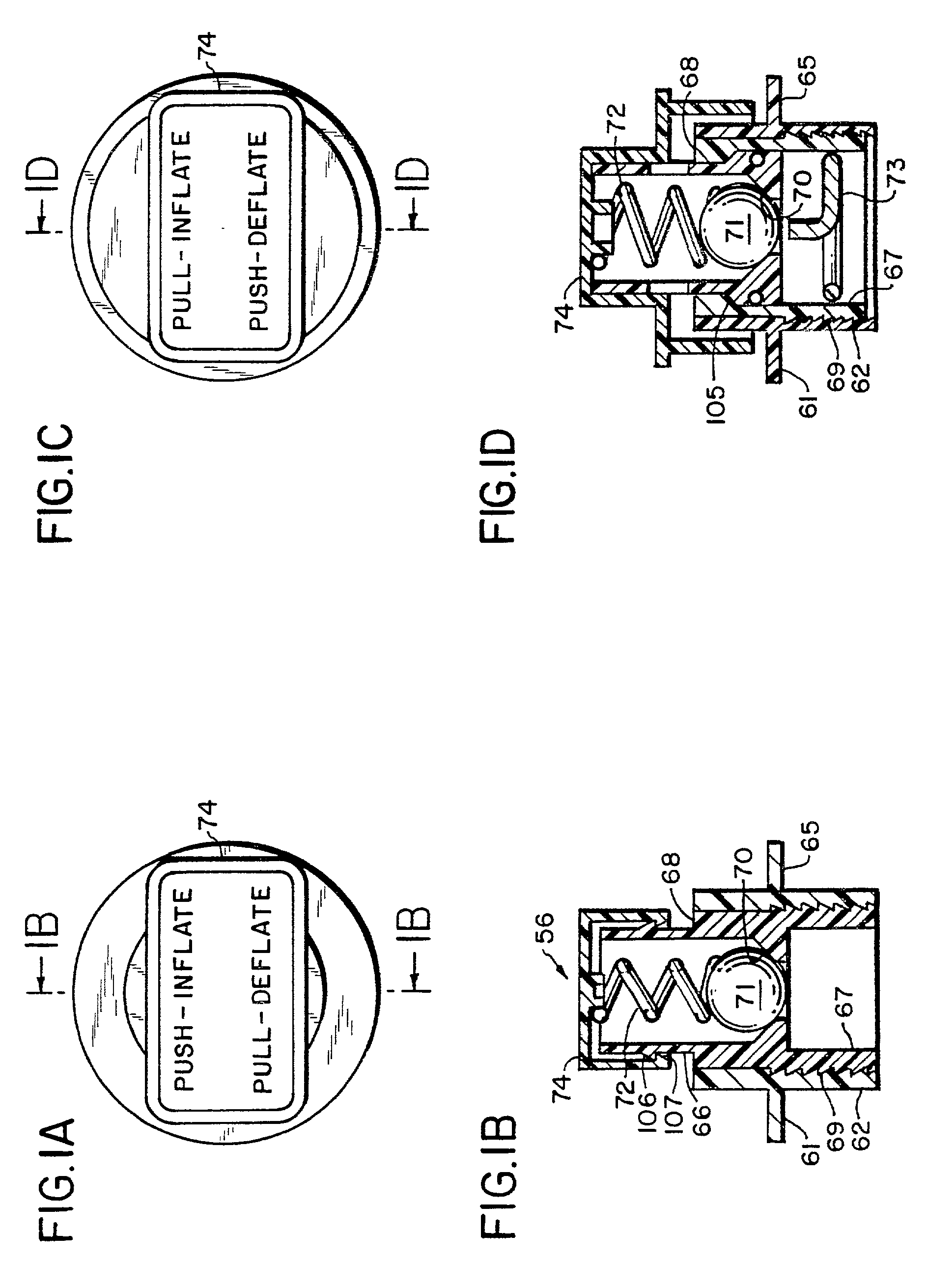

Ergonomic systems and methods providing intelligent adaptive surfaces and temperature control

InactiveUS6230501B1Reduce the possibilityReduce removalVehicle seatsSolesTemperature controlEngineering

Ergonomic systems which provide medical therapy, comfort and enhanced function are provided. Surfaces are provided with adjustable contour, transient force damping and temperature. The technologies are applied to footwear, seating surfaces an cryotherapy devices. The cooling and cryotherapy system employ an evaporator in close proximity to skin, and therefore employ methods to reduce risk of frostbite. Advanced control and power supply options are disclosed.

Owner:PROMDX TECH

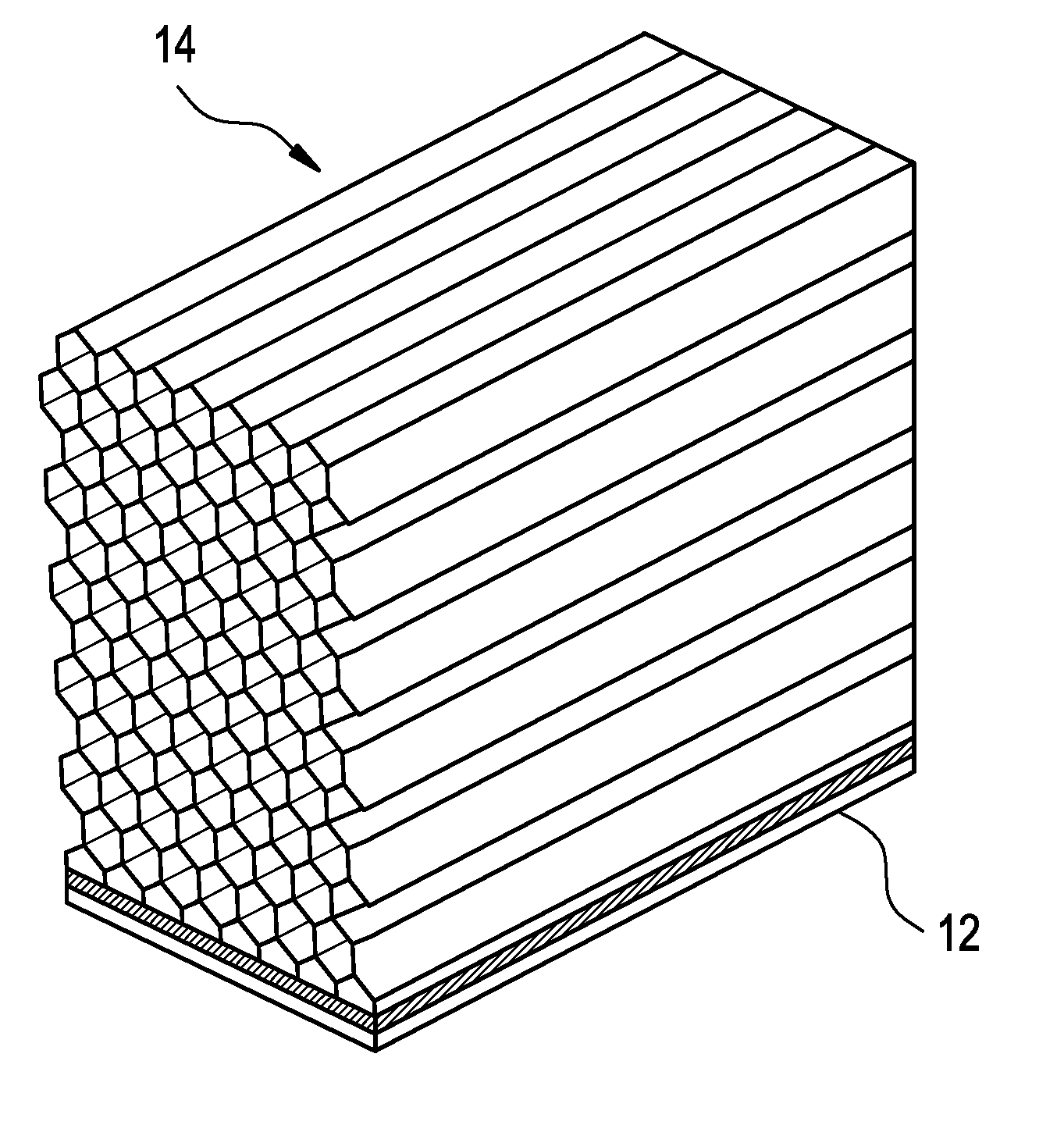

Thermal management system

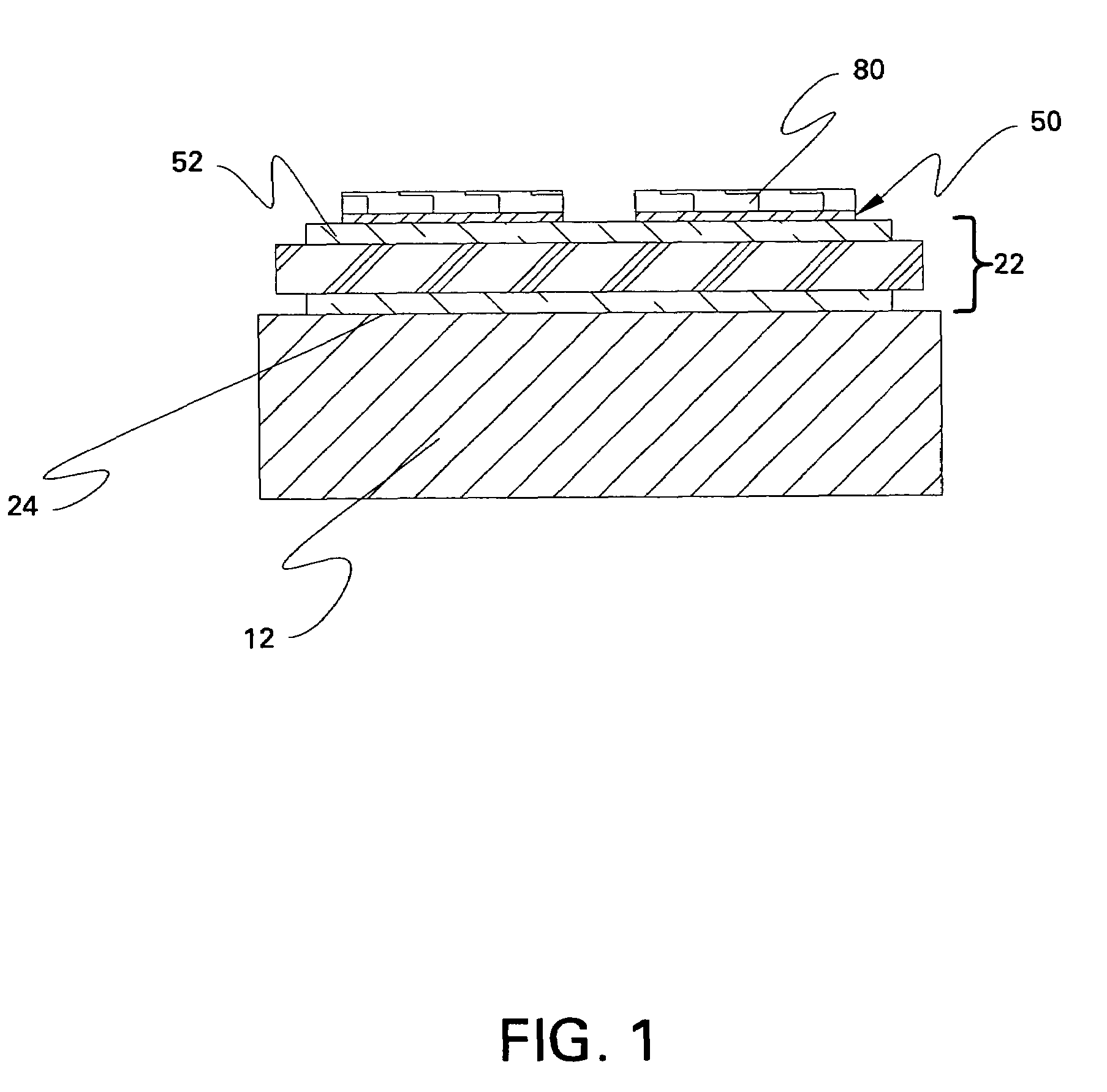

InactiveUS6482520B1Improve cooling effectIncreased anisotropyLayered productsSemiconductor/solid-state device detailsEngineeringThermal management system

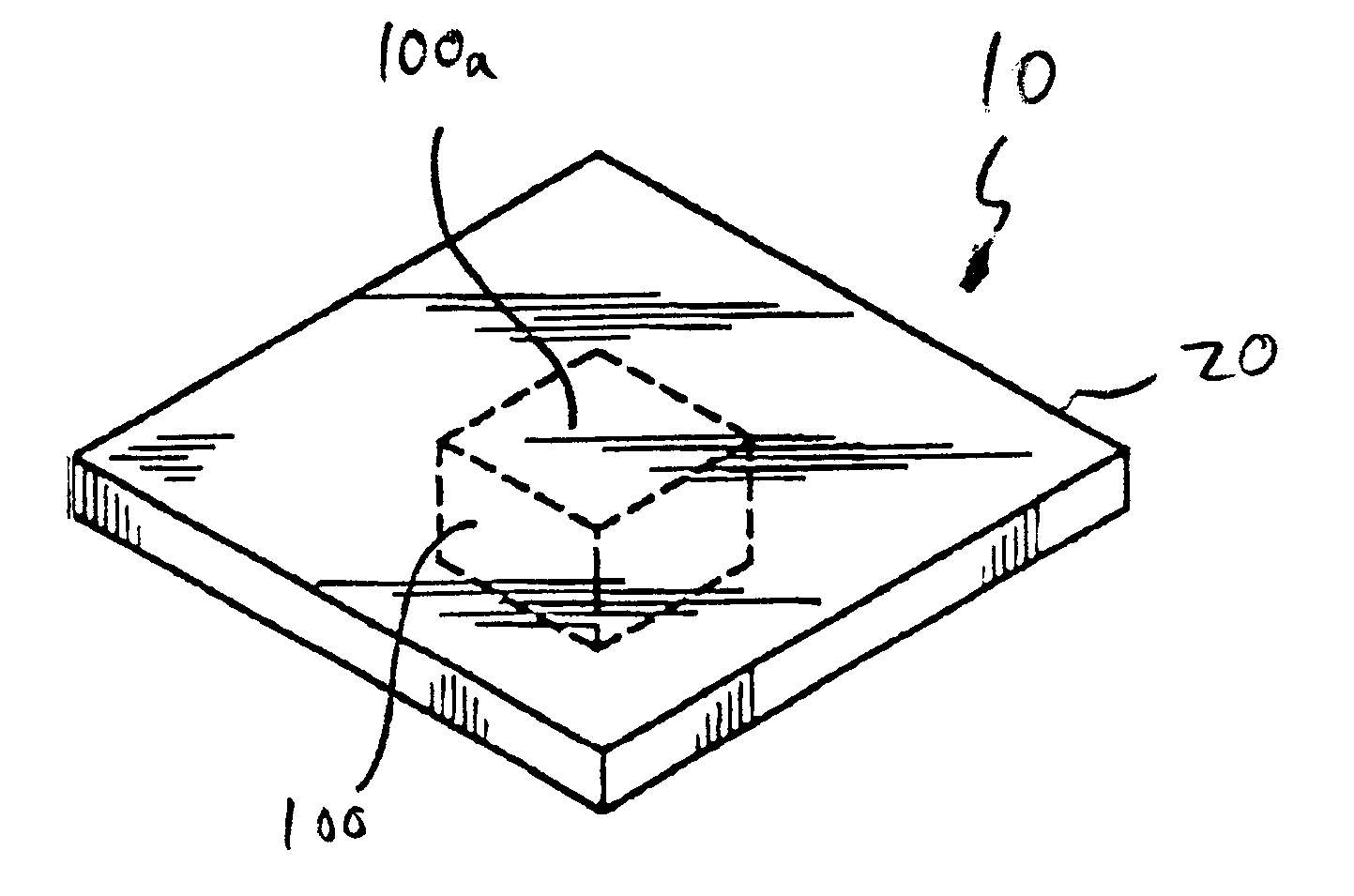

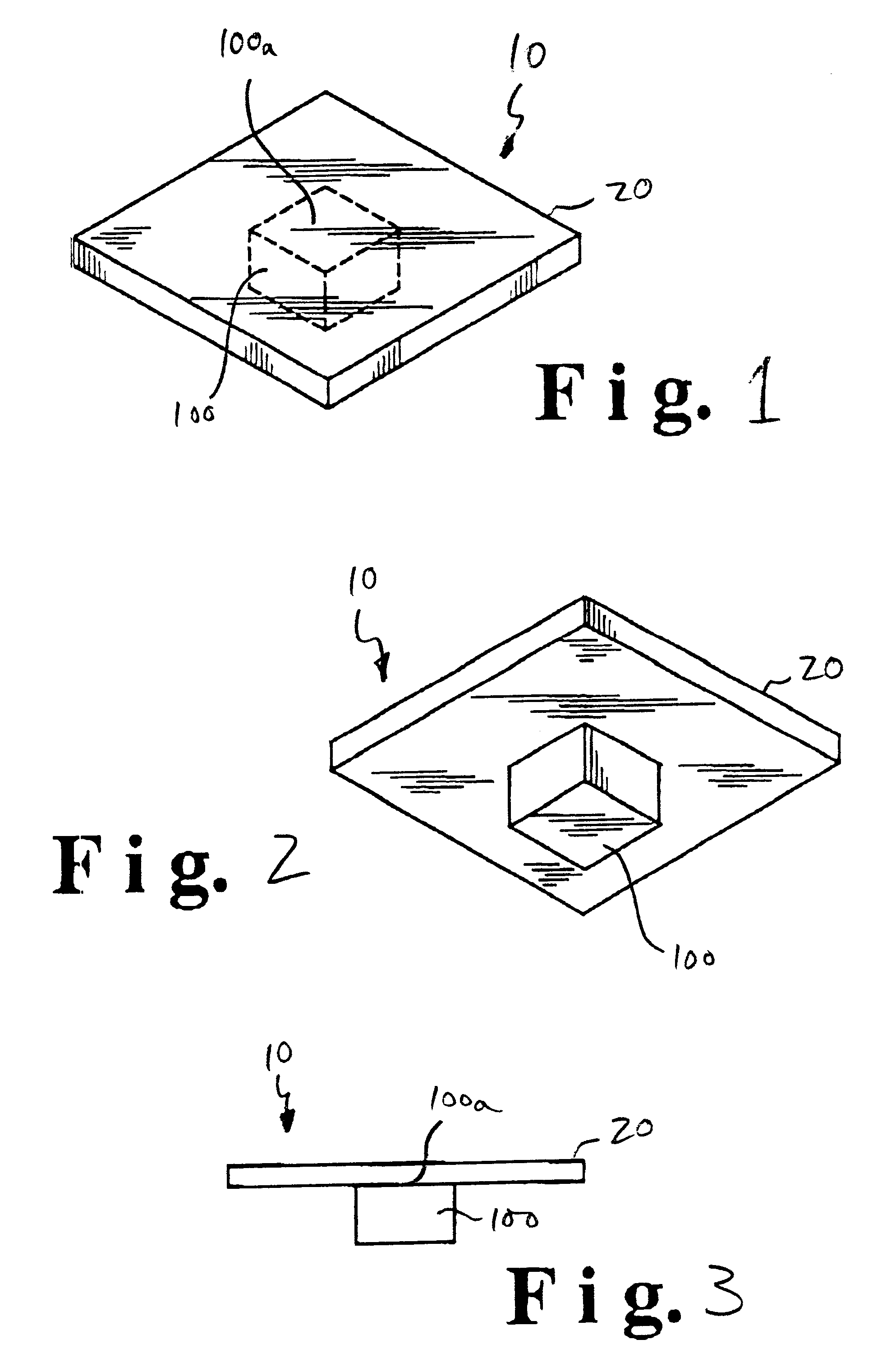

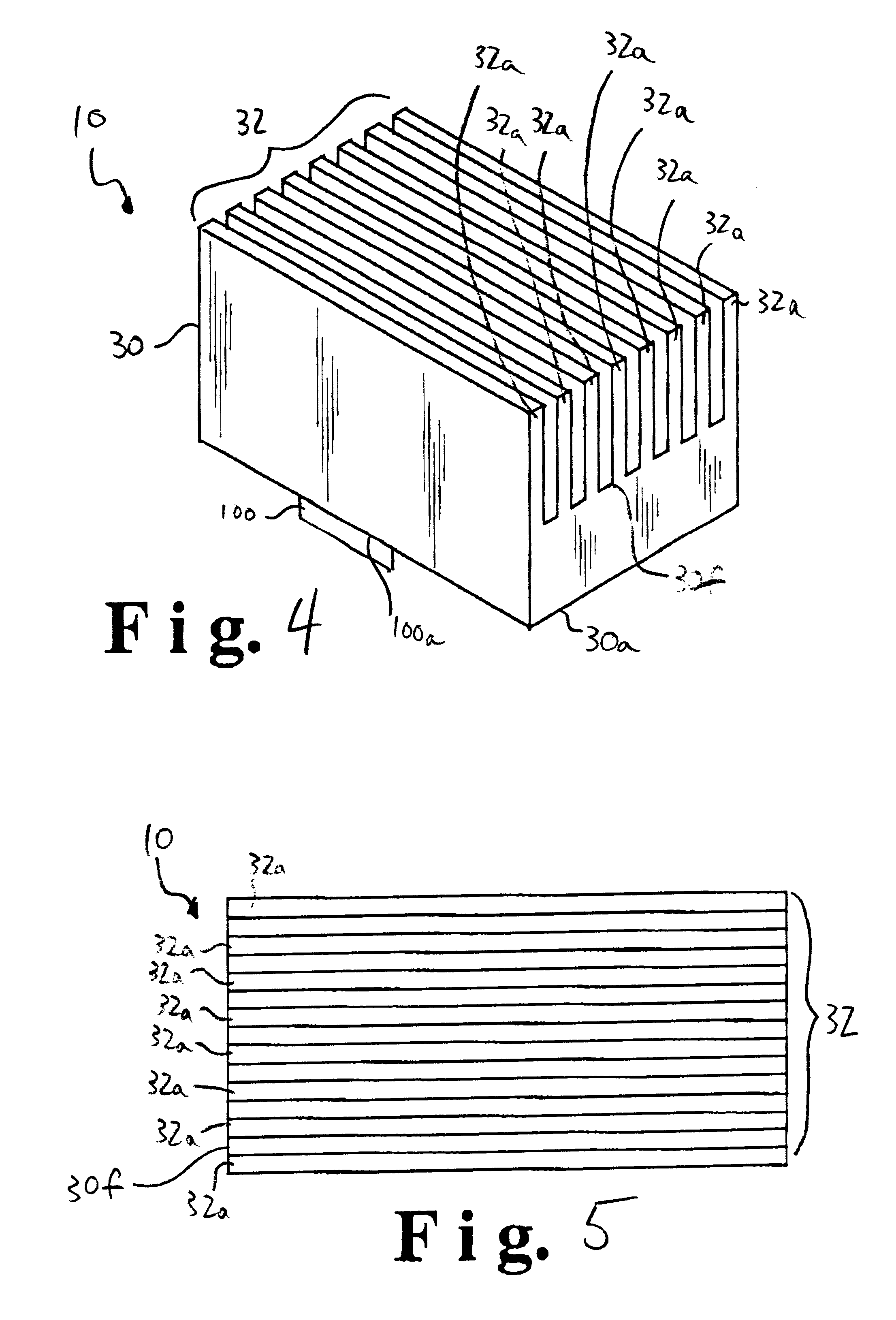

The present invention relates to a system for managing the heat from a heat source like an electronic component. More particularly, the present invention relates to a system effective for dissipating the heat generated by an electronic component using a thermal management system that includes a thermal interface formed from a flexible graphite sheet and / or a heat sink formed from a graphite article.

Owner:NEOGRAF SOLUTIONS LLC

Method for producing a three-dimensional object

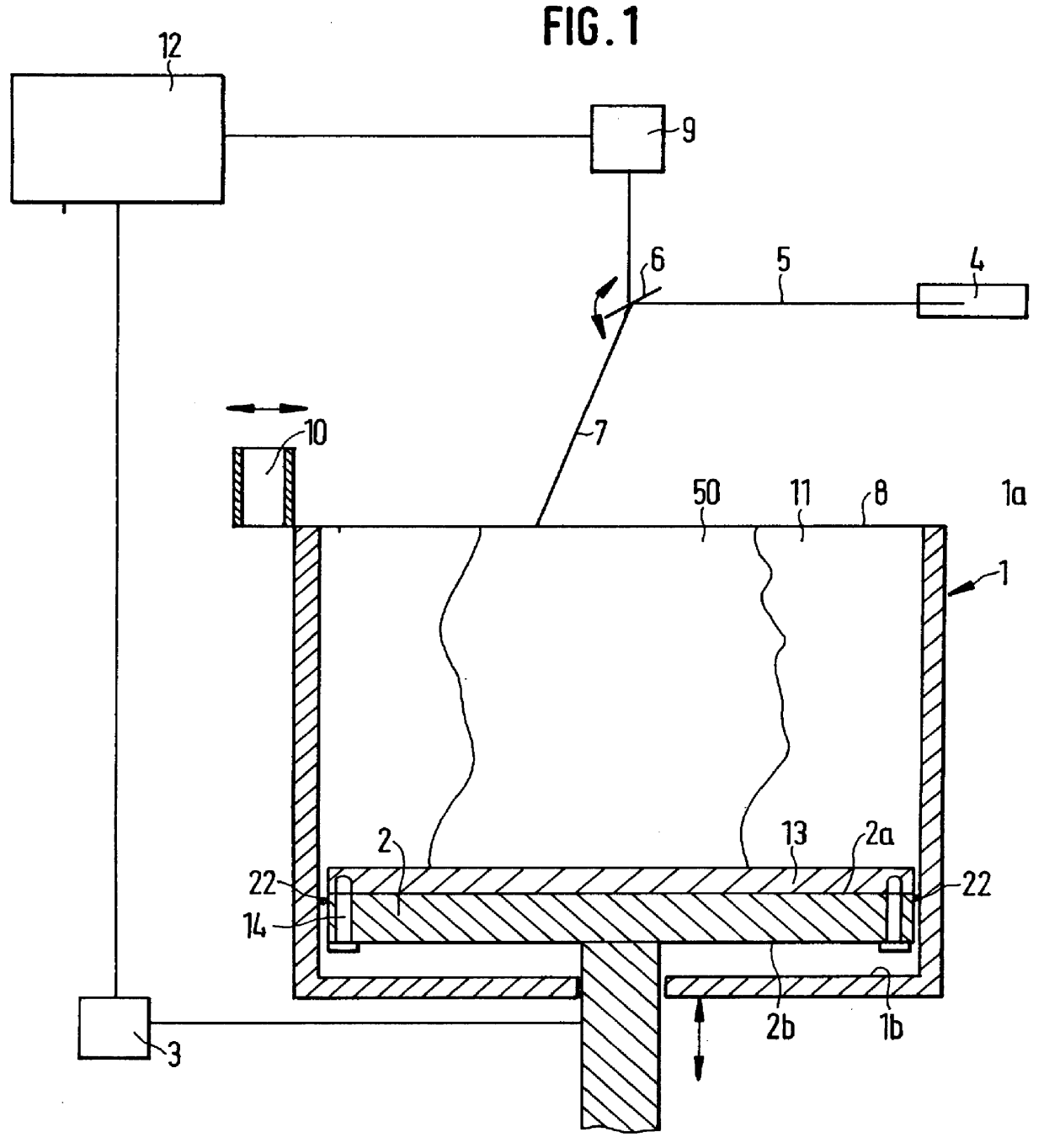

InactiveUS6042774AShorten production timeAdditive manufacturing apparatus3D object support structuresIrradiationMaterials science

A method of producing an object by successive solidification of layers of a powder material is disclosed. The method provides a preformed base plate having a metal plate with a solidified layer of a powder material formed thereon. Then, successive layers of said powder material are applied and solidified on the solidified layer of the base plate to form the object. In further detail, the method for produces a three-dimensional by providing a support and a preformed base plate having an upper surface for supporting the object. The base plate is removably attached to the support. Means are provided for adjusting the elevation of said upper surface. A layer of the powder material is applied to the upper surface of the base plate. The powder material is solidified at points corresponding to a cross-section of the object by irradiation with electromagnetic or particle radiation. Then, the applying and solidifying steps are repeated for completing the object.

Owner:EOS ELECTRO OPTICAL SYST

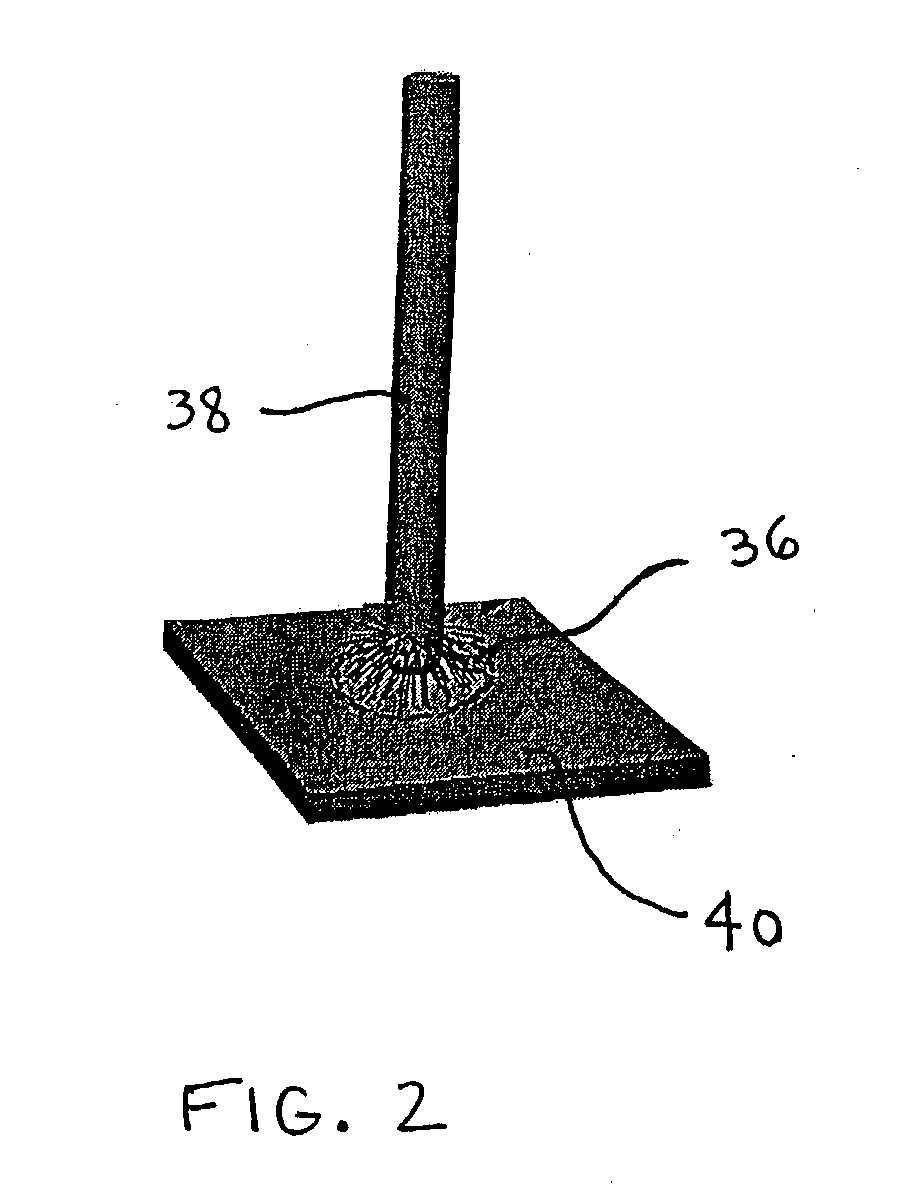

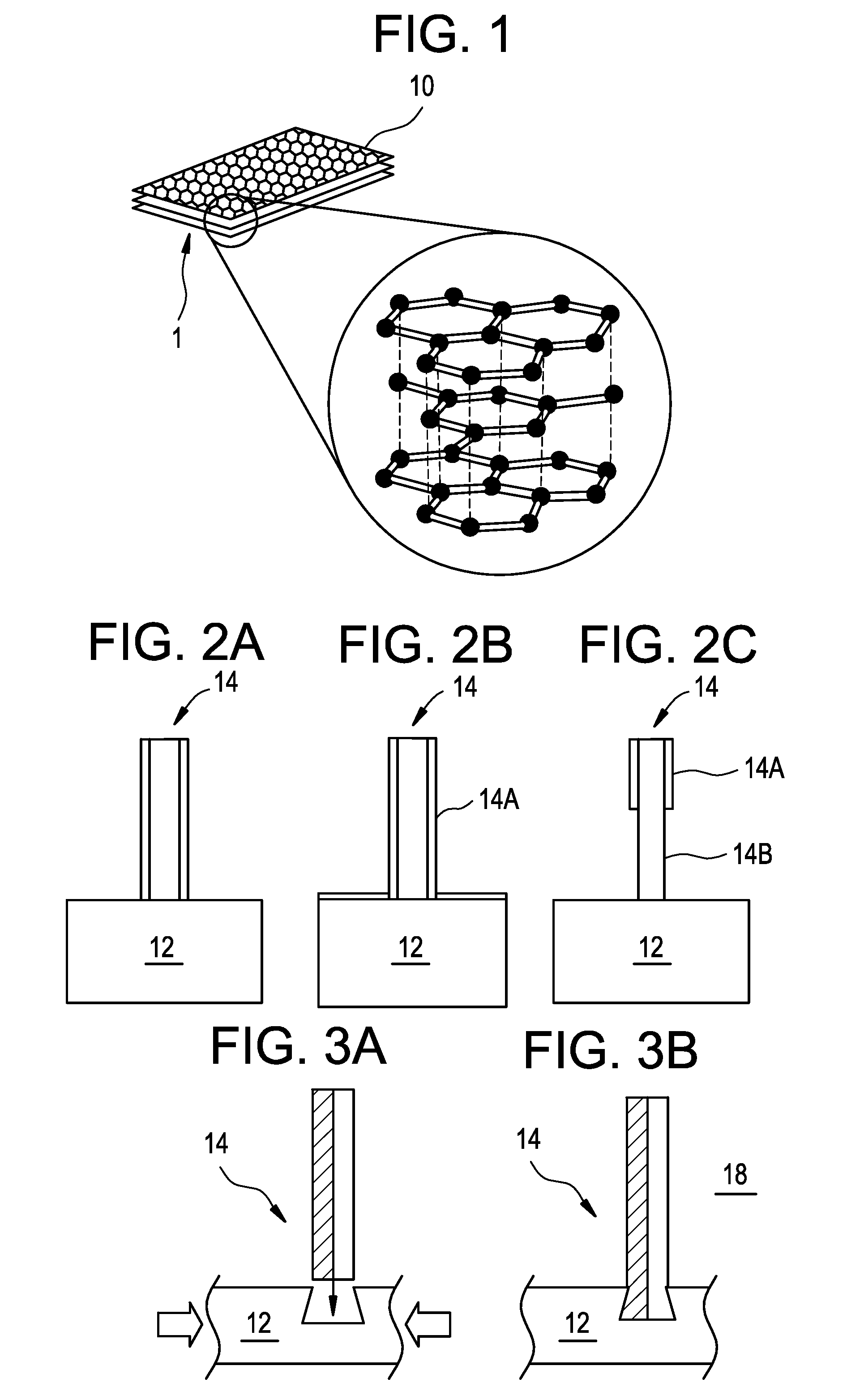

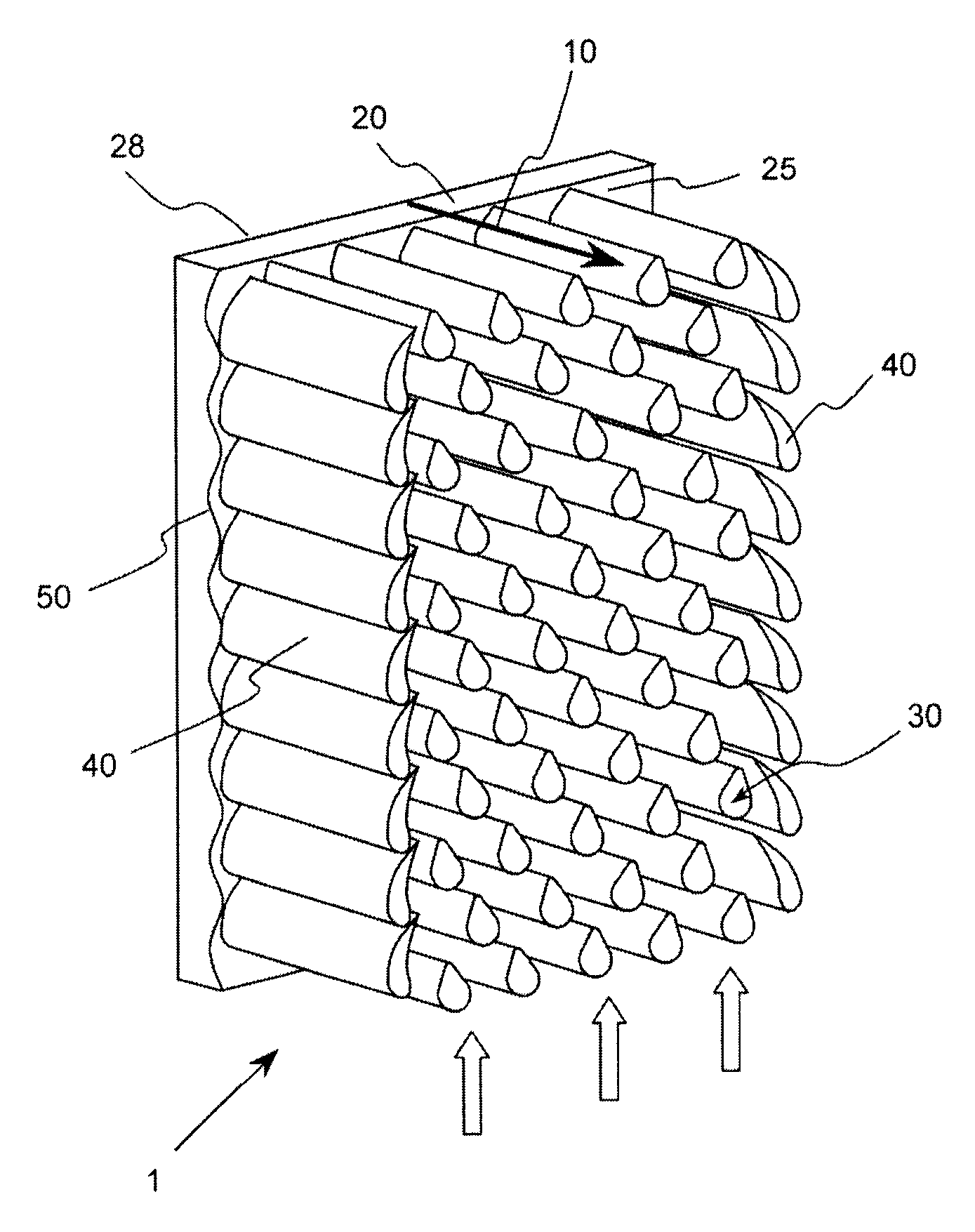

Nanotube/metal substrate composites and methods for producing such composites

InactiveUS20050238810A1Simplified and advantageous mannerReduce productionMaterial nanotechnologyIndirect heat exchangersHydrogen fuel cellChemical vapor deposition

Carbon nanotubes are grown directly on metal substrates using chemical vapor deposition. Metal substrates are comprised of catalysts which facilitate or promote the growth of carbon nanotubes. The nanotube coated metal substrates have applications including, but not limited to, heat transfer and thermal control, hydrogen storage, fuel cell catalytic reformers, electronics and semiconductors, implantable medical devices or prostheses, and tribological wear and protective coatings.

Owner:MAINSTREAM ENG

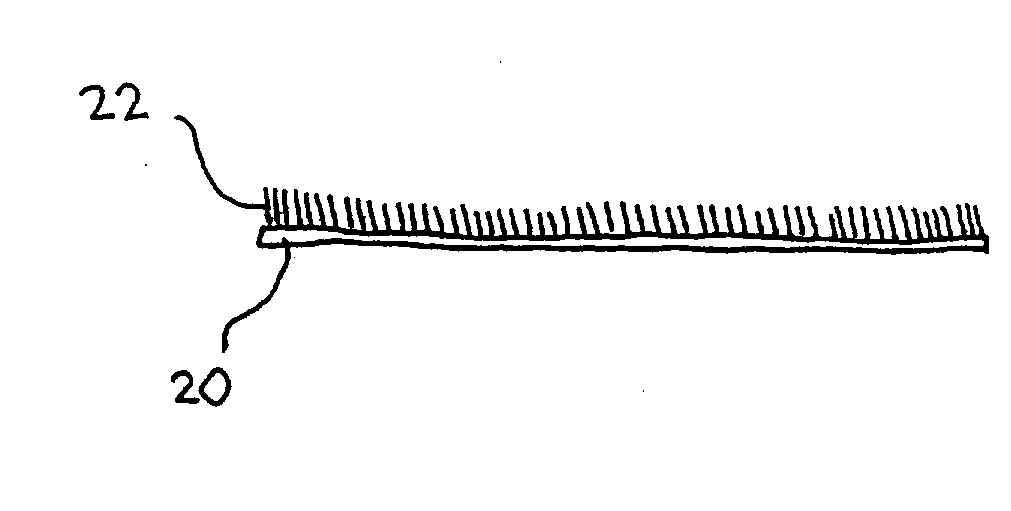

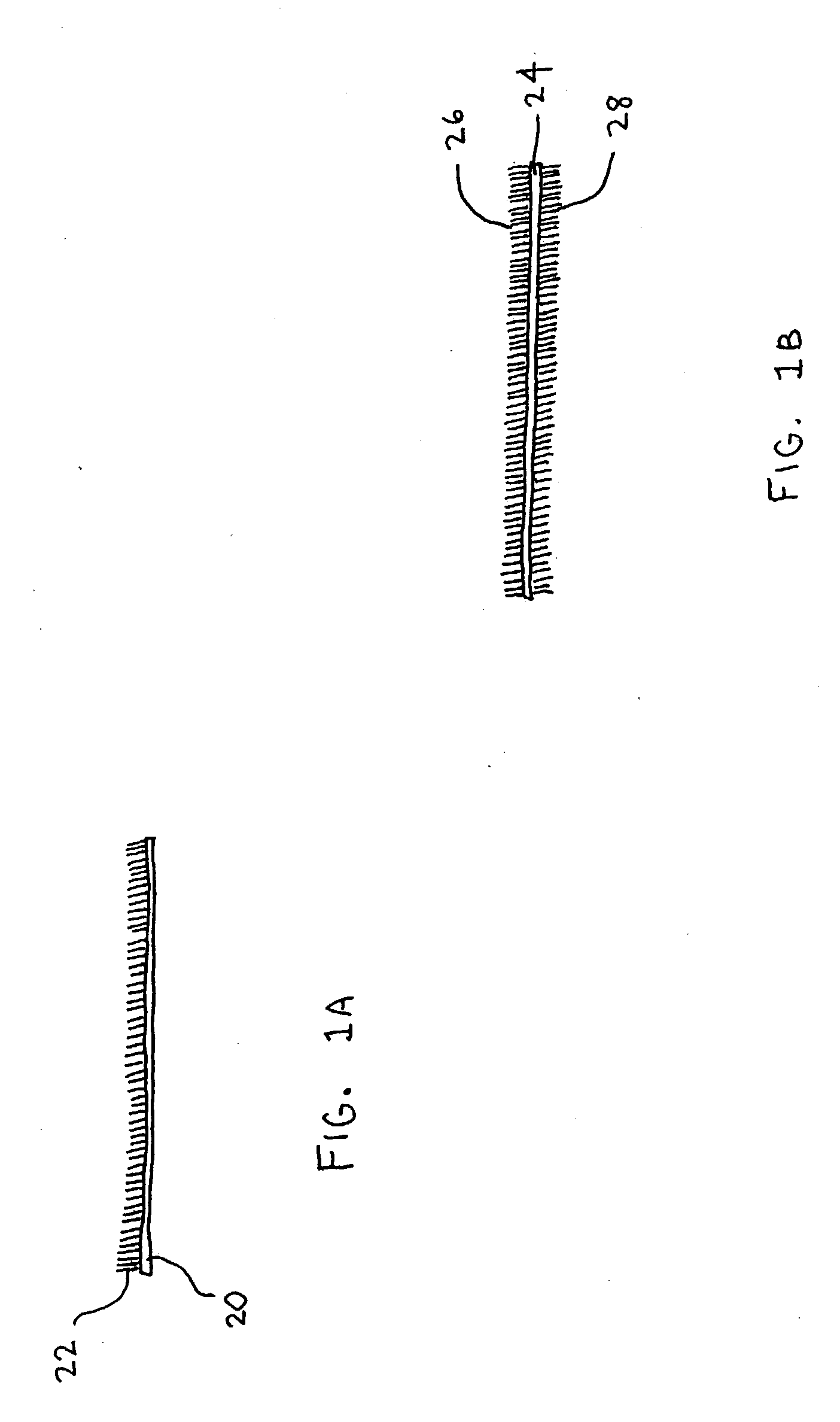

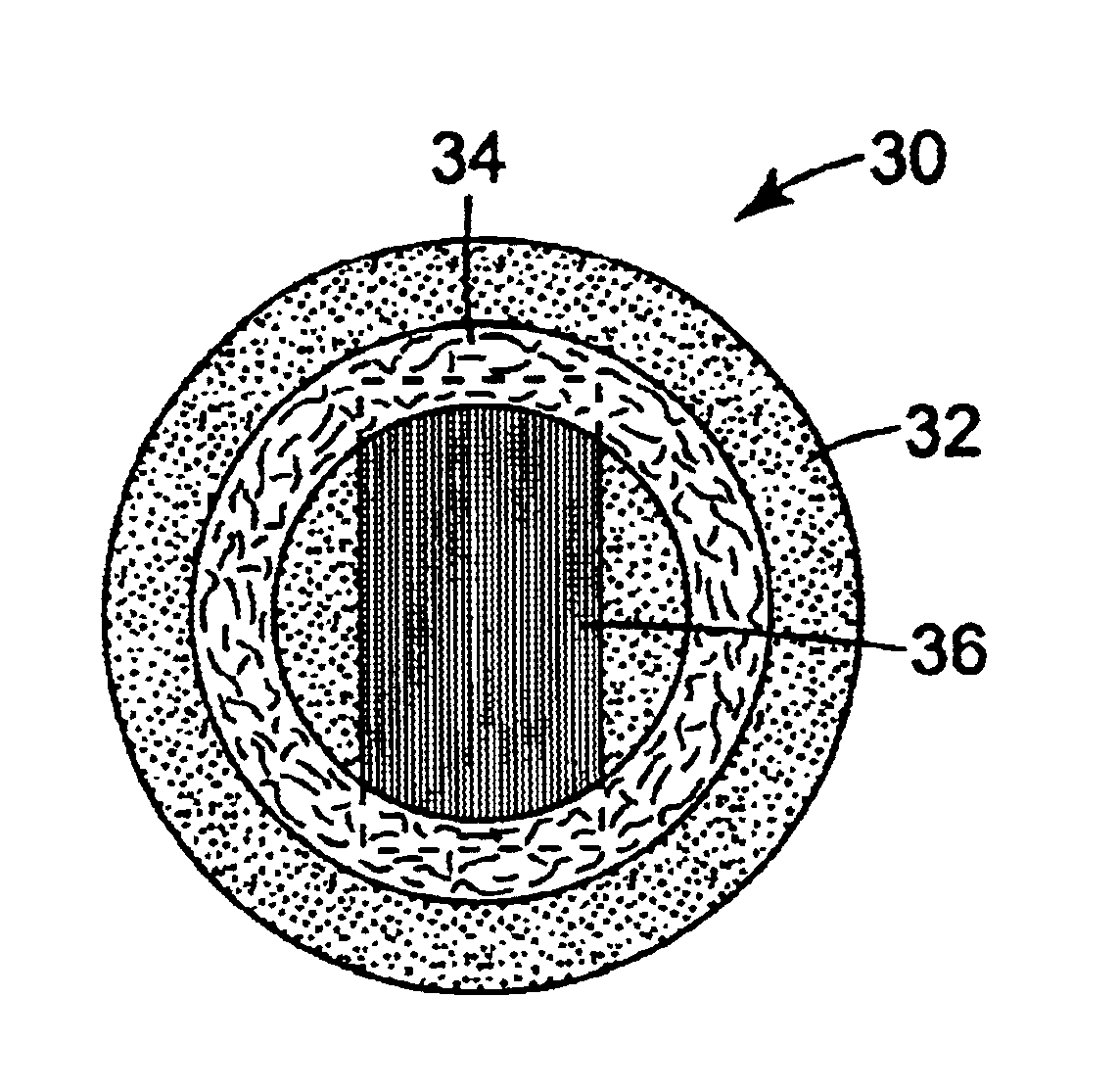

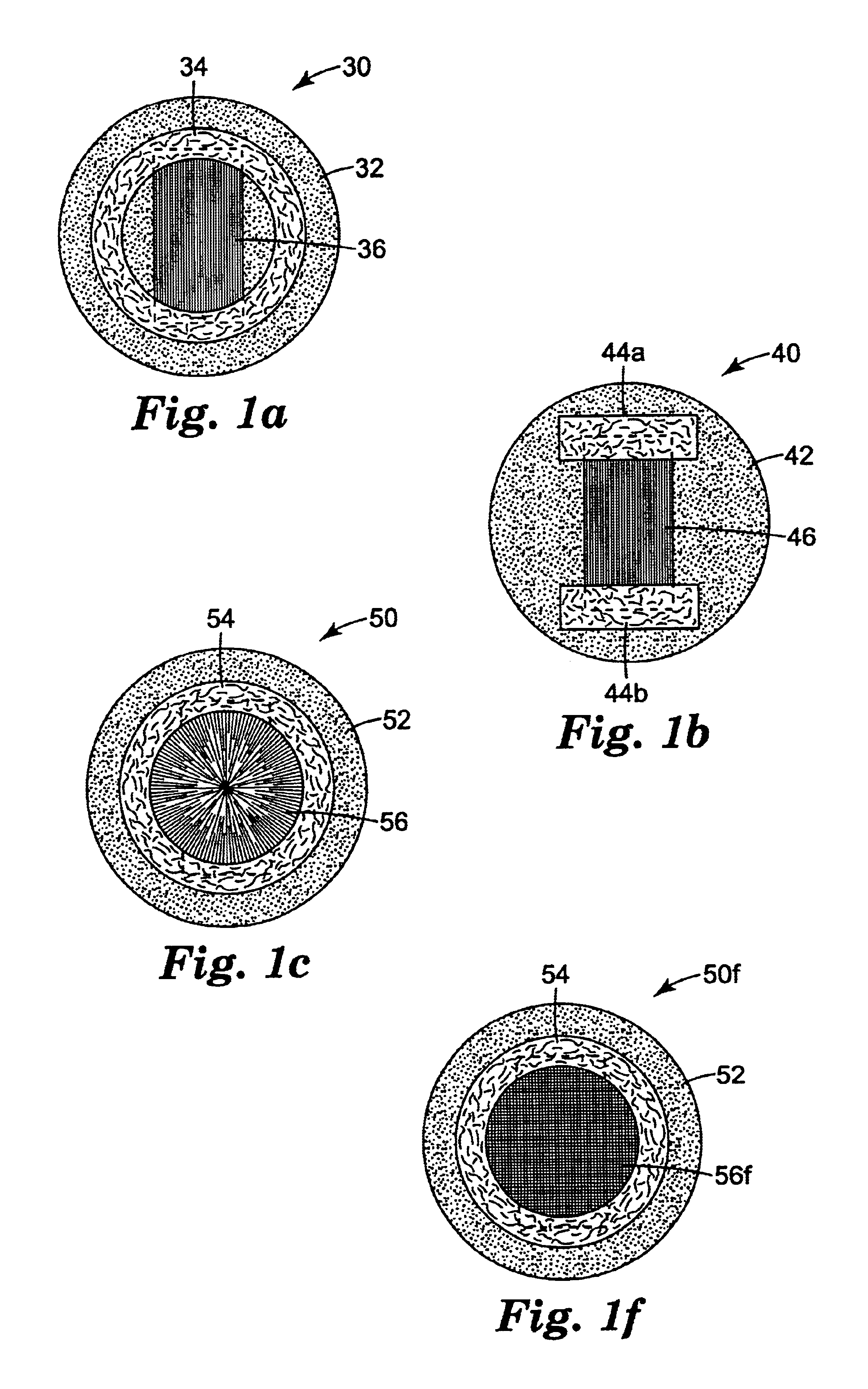

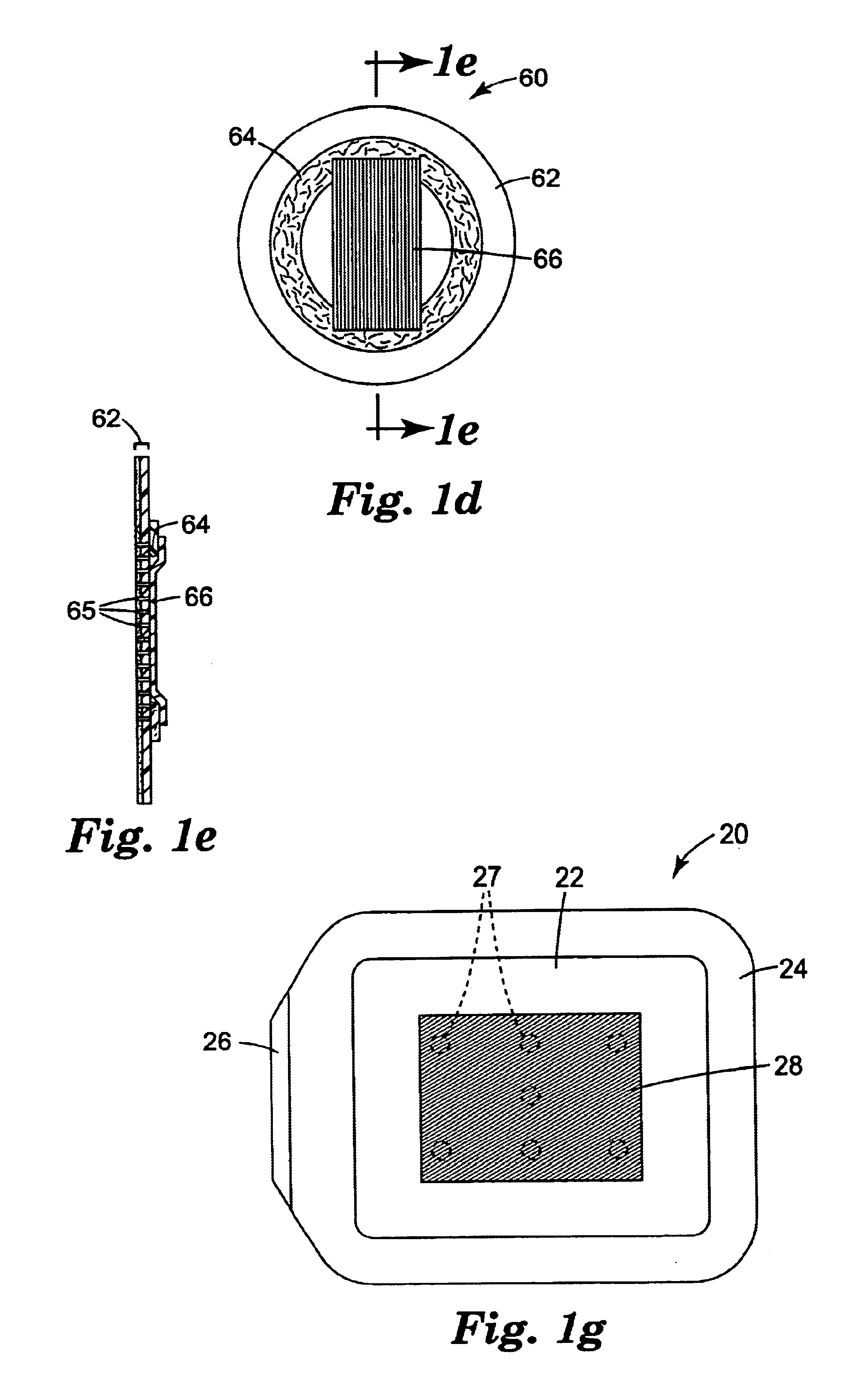

Fiber adhesive material

InactiveUS20040071870A1Improve adhesion performanceMaterial nanotechnologySemiconductor/solid-state device detailsDielectricFiber

A fiber velvet comprising nano-size fibers or nanofibrils attached to micro-size fibers is disclosed. Methods of manufacturing the velvet as well as various uses of the velvet are also described. For example, the fiber velvet can be used as a thermal interface or as an adhesive material. The nanofibrils may be attached to a flat base or membrane, or may be attached to the tip portions of the micro-size or larger diameter fibers. Various attributes of the micro-size fibers and of the nano-size fibers, for example, geometry (e.g. size, length, packing density) material type (e.g. carbon, metal, polymer, or ceramic) and properties (e.g. conductivity, modulus, surface energy, dielectric constant, surface roughness) can be selected depending on the desired attributes of the fiber velvet. The nanofibrils have a diameter of less than about 1 micron, and may advantageously be formed from single walled and / or multi-walled carbon nanotubes.

Owner:KULR TECH

Advanced heat sinks and thermal spreaders

InactiveUS20070053168A1Material nanotechnologyDigital data processing detailsGraphiteMaterials science

A heat sink assembly for an electronic device or a heat generating device(s) is constructed from an ultra-thin graphite layer. The ultra-thin graphite layer exhibits thermal conductivity which is anisotropic in nature and is greater than 500 W / m° C. in at least one plane and comprises at least a graphene layer. The ultra-thin graphite layer is structurally supported by a layer comprising at least one of a metal, a polymeric resin, a ceramic, and a mixture thereof, which is disposed on at least one surface of the graphite layer.

Owner:GENERAL ELECTRIC CO

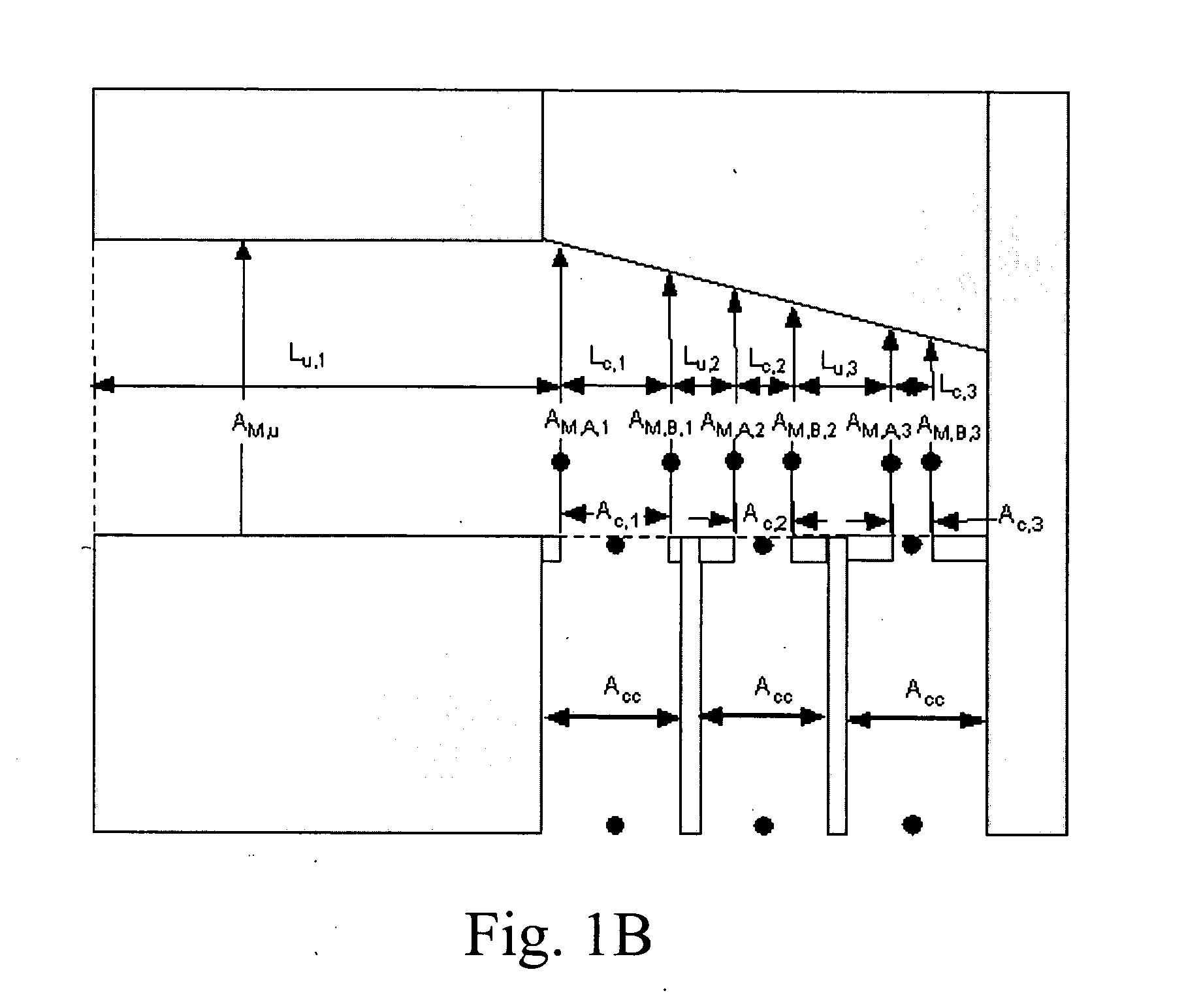

Manifold designs, and flow control in multichannel microchannel devices

InactiveUS20050087767A1Equally distributedLow costChemical/physical/physico-chemical microreactorsSemiconductor/solid-state device manufacturingEngineering

Owner:VELOCYS CORPORATION

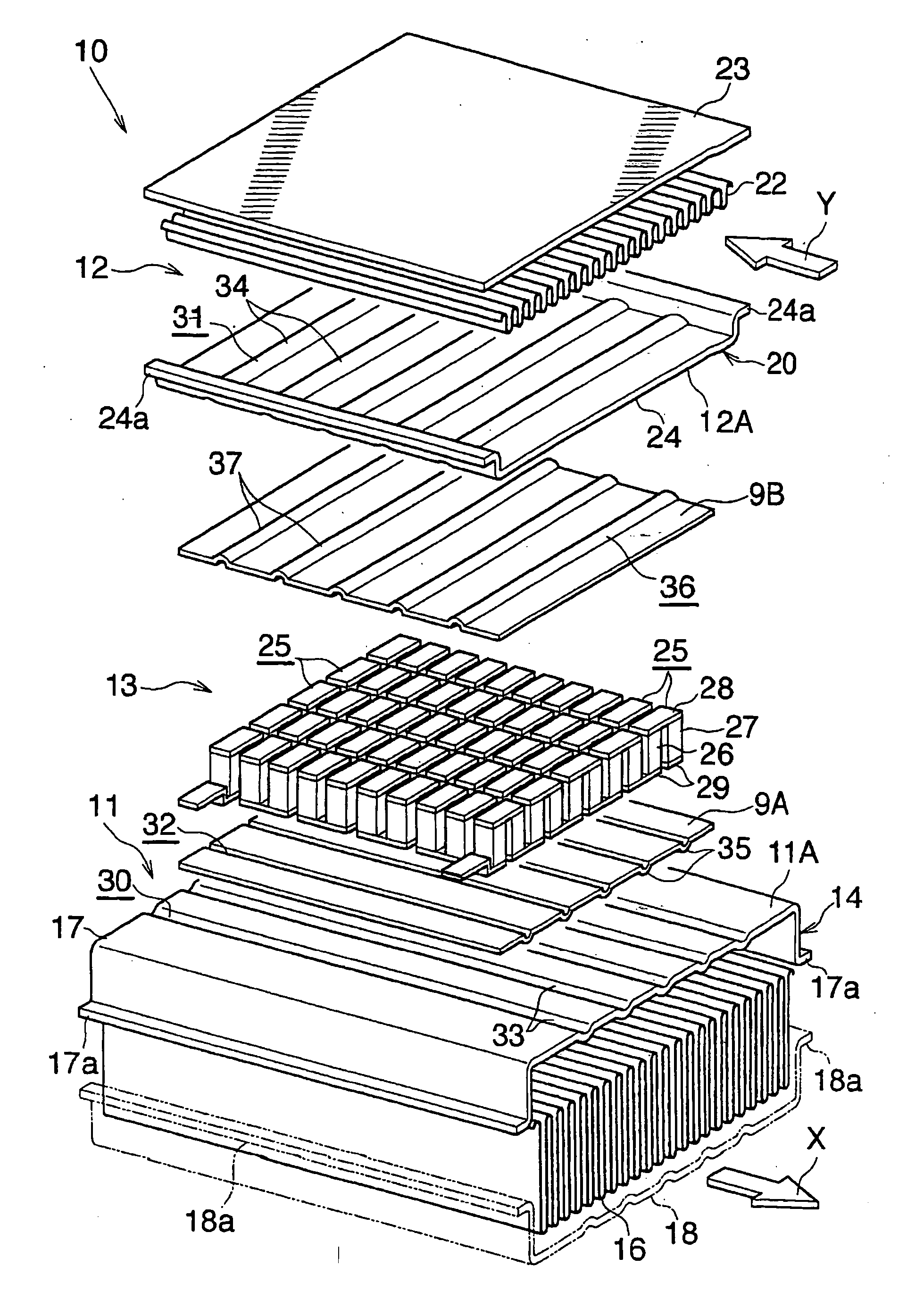

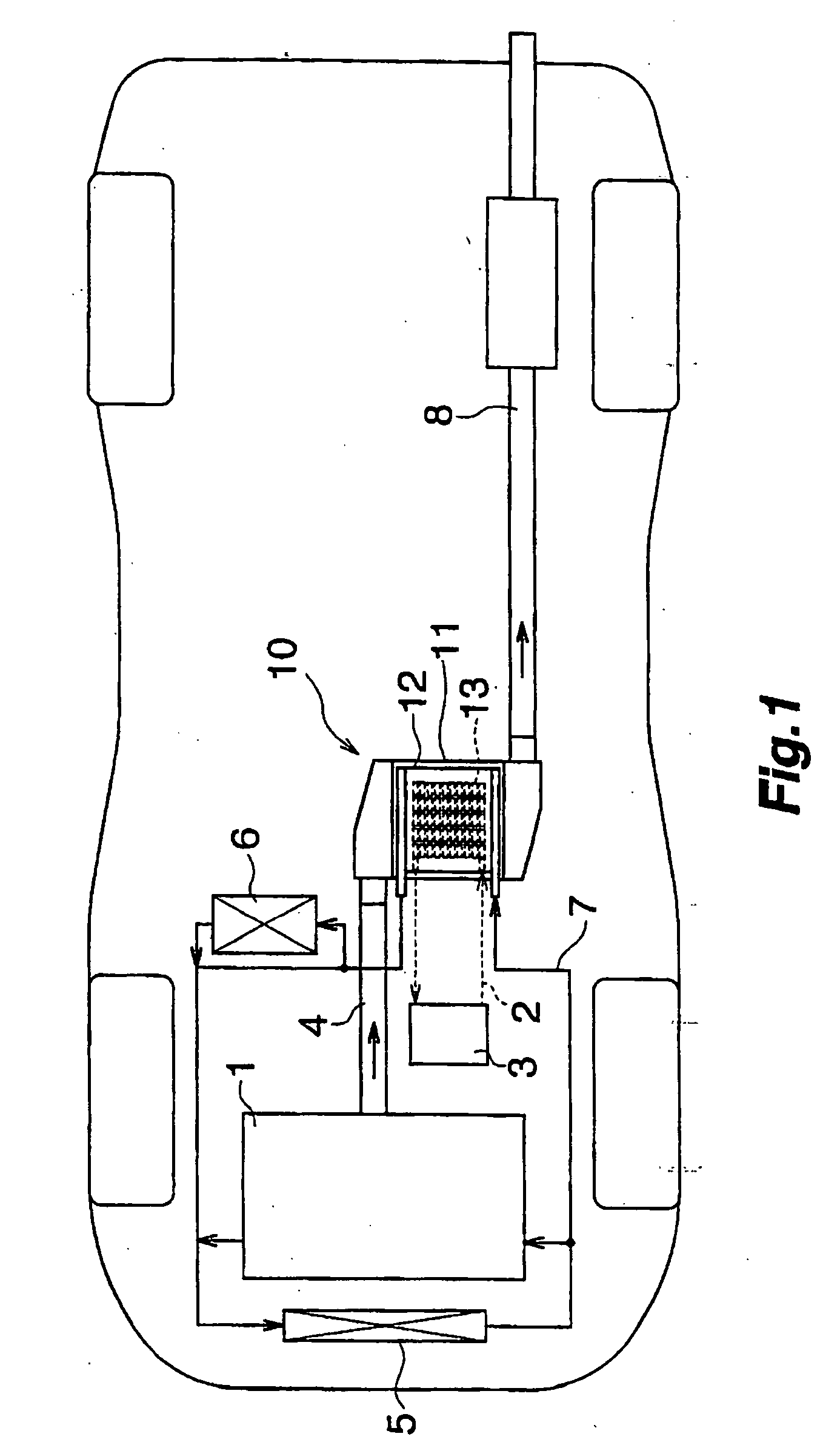

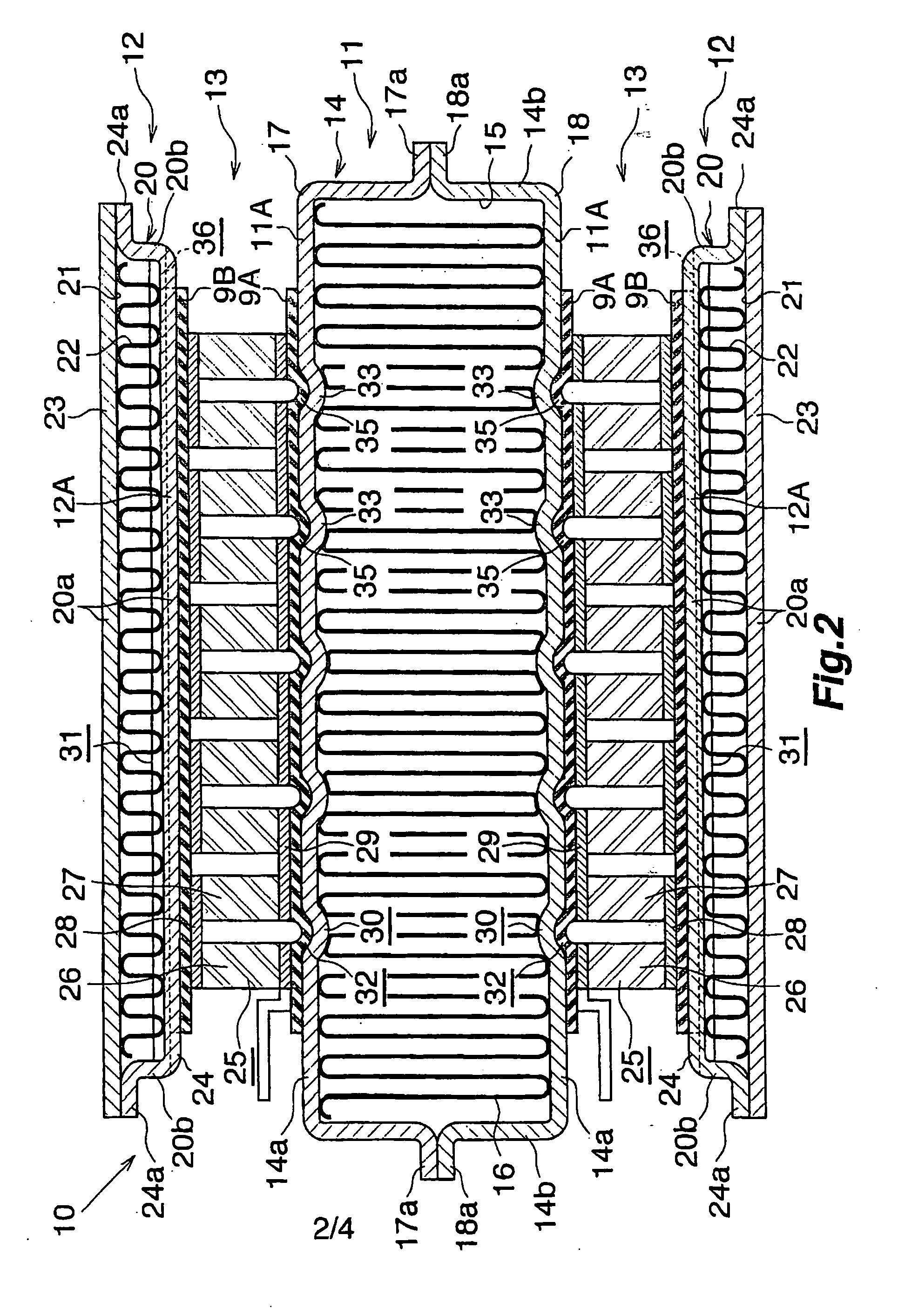

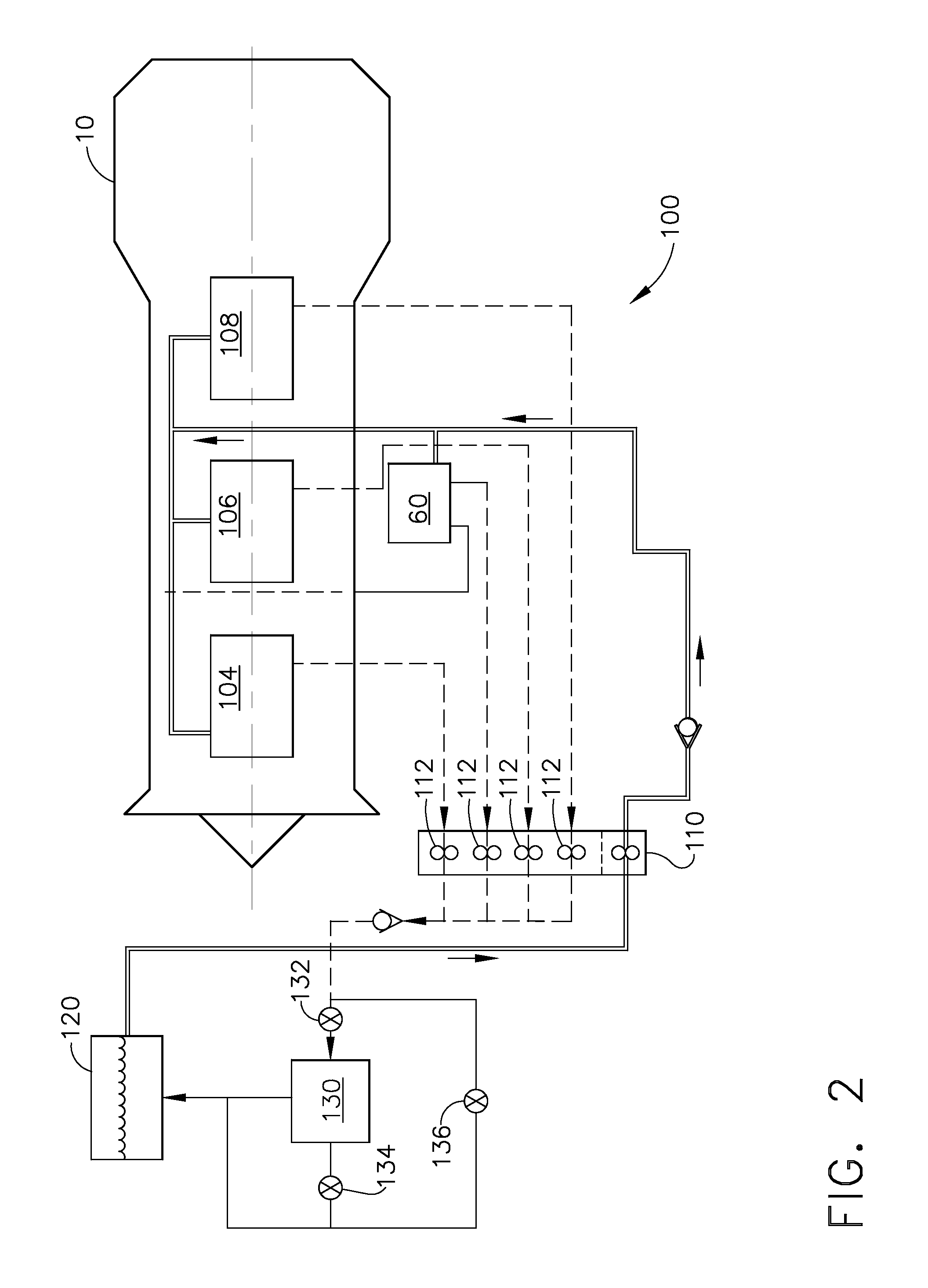

Waste heat recovery system and thermoelectric conversion system

InactiveUS20060157102A1Increase powerImprove efficiencyInternal combustion piston enginesThermoelectric device with peltier/seeback effectWaste heat recovery unitFuel cells

A waste heat recover system includes a mechanism for supplying power by use of a thermoelectric conversion unit, and a mechanism for utilizing heat released from the thermoelectric conversion unit. Heat released from the thermoelectric conversion unit is utilized for, for example, heating, defrosting, defogging, temperature keeping of fuel, temperature keeping of an internal combustion engine, and temperature keeping of a fuel cell. The waste heat recovery system is equipped in, for example, cars, incinerators, fuel cells, and industrial machinery.

Owner:SHOWA DENKO KK

Drug delivery dressing having fluid control film

The present invention provides drug delivery dressings having a fluid control film component that comprise a sheet having microchannels that permit directional flow of a liquid.

Owner:3M INNOVATIVE PROPERTIES CO

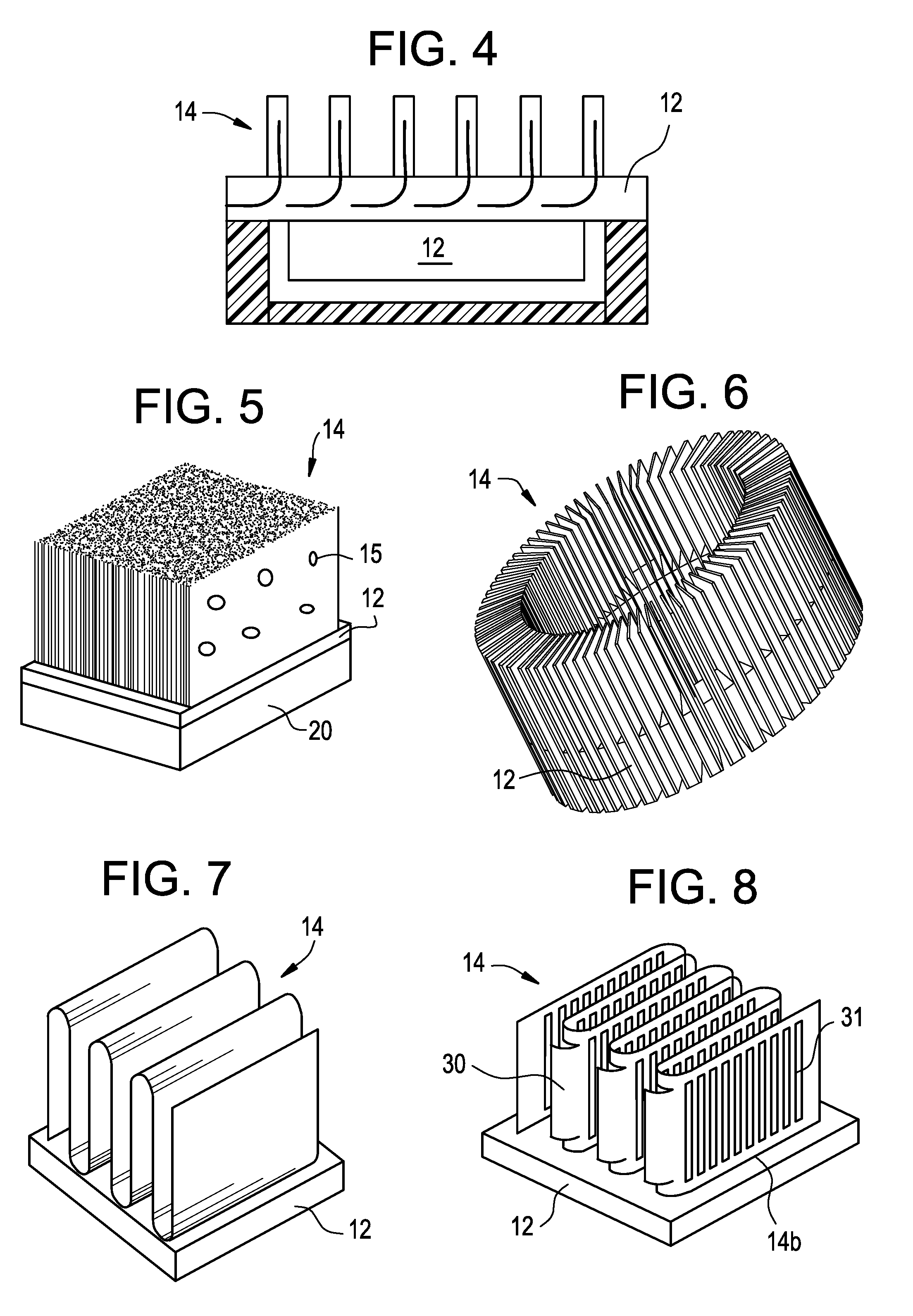

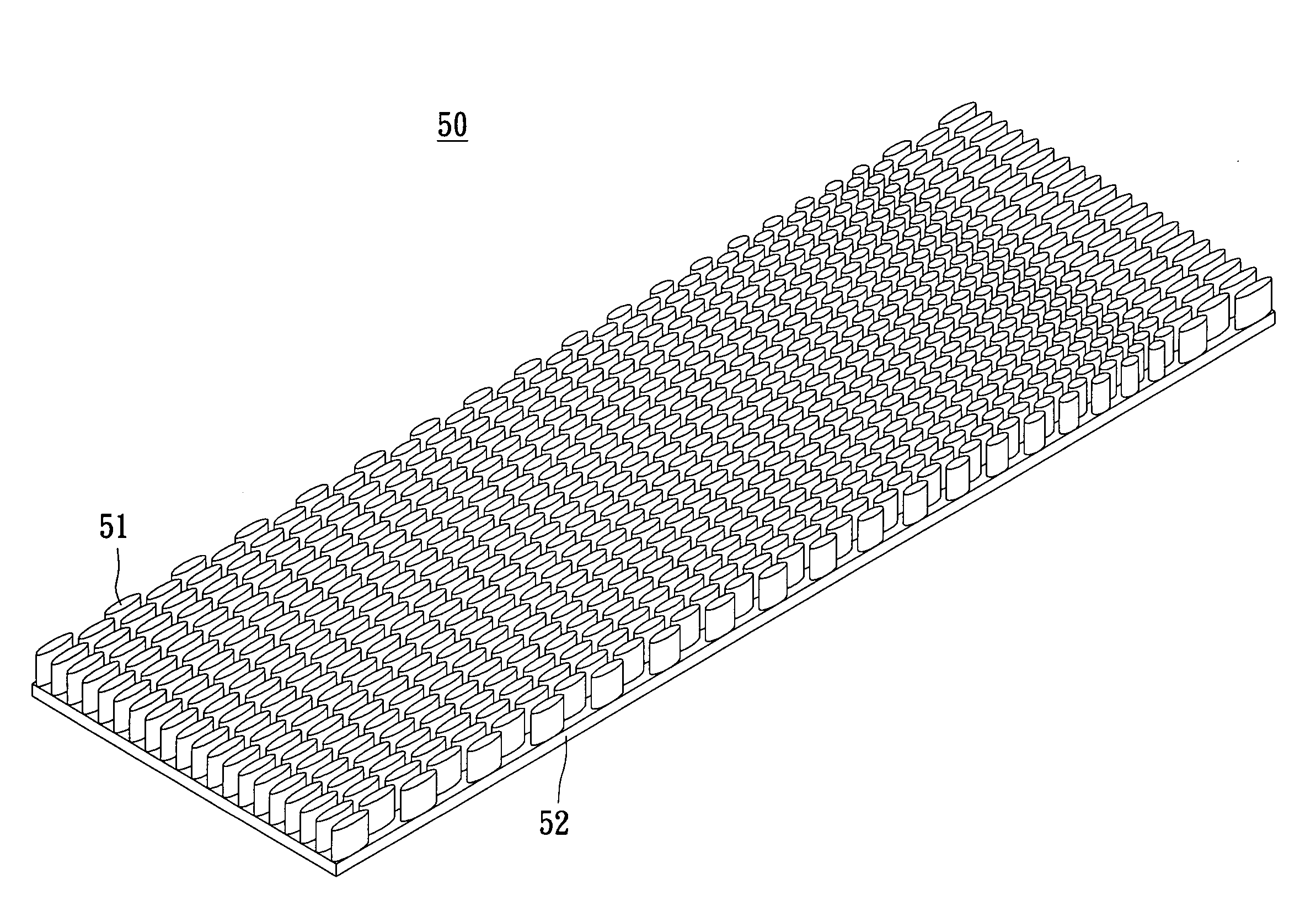

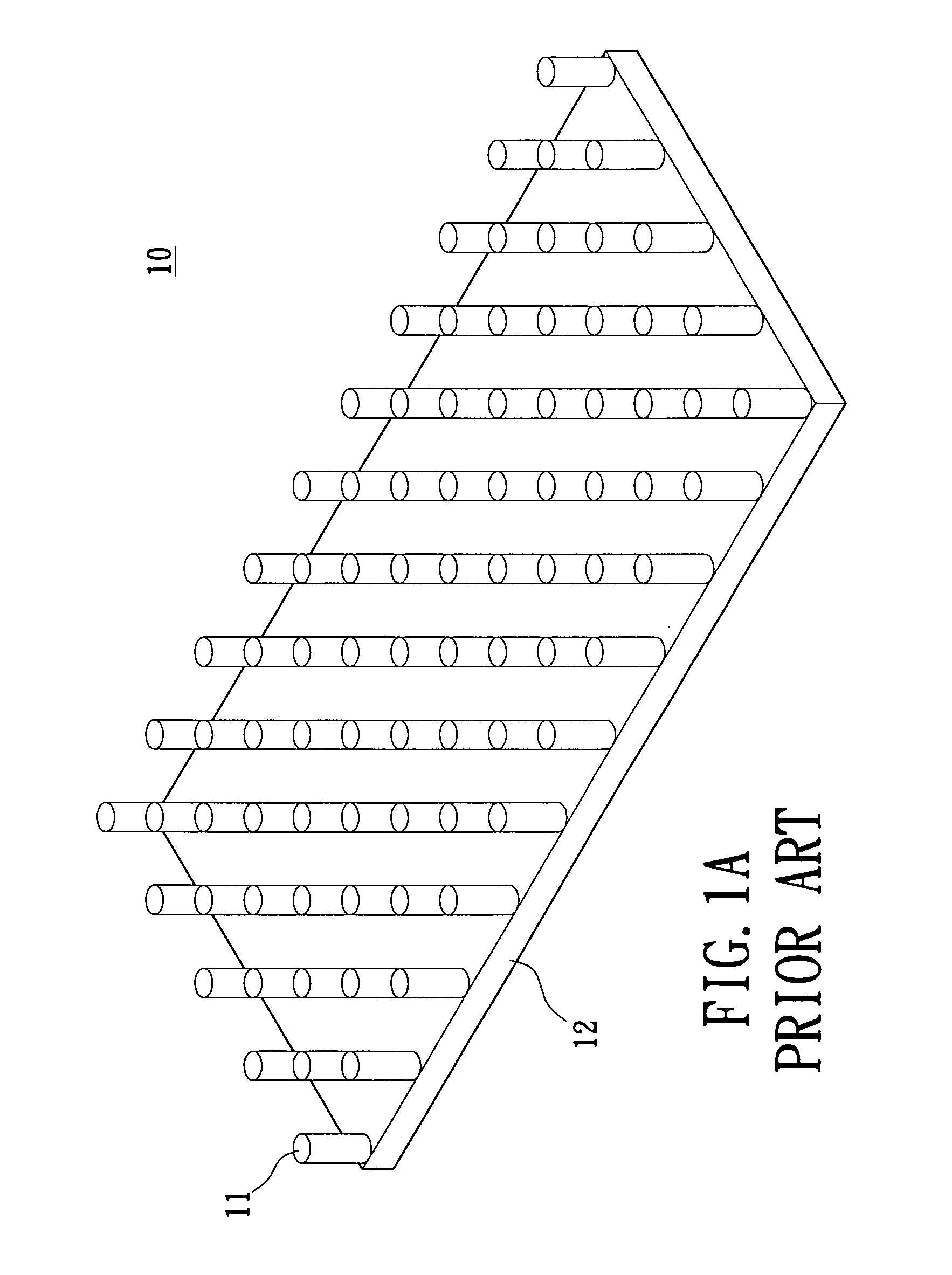

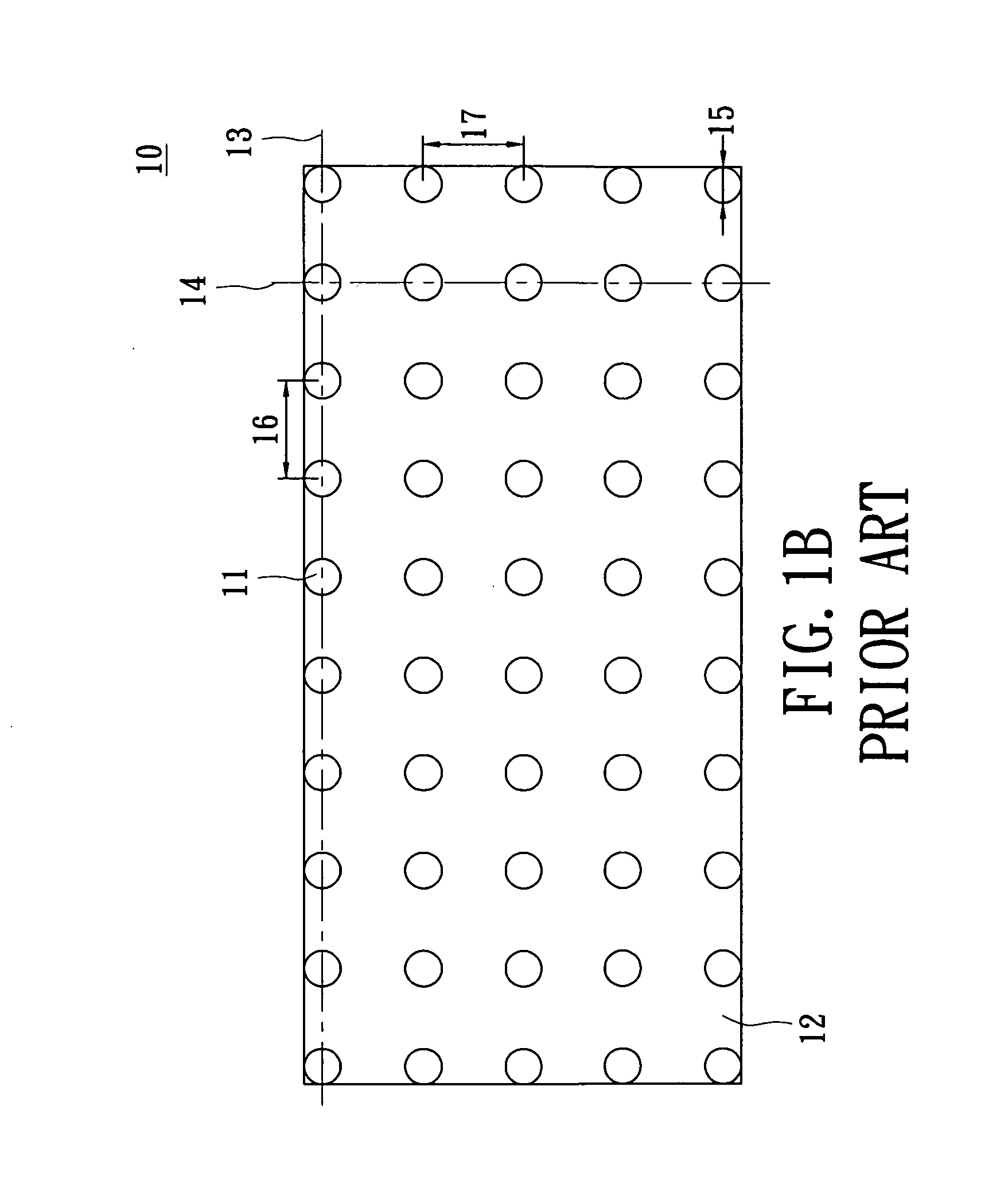

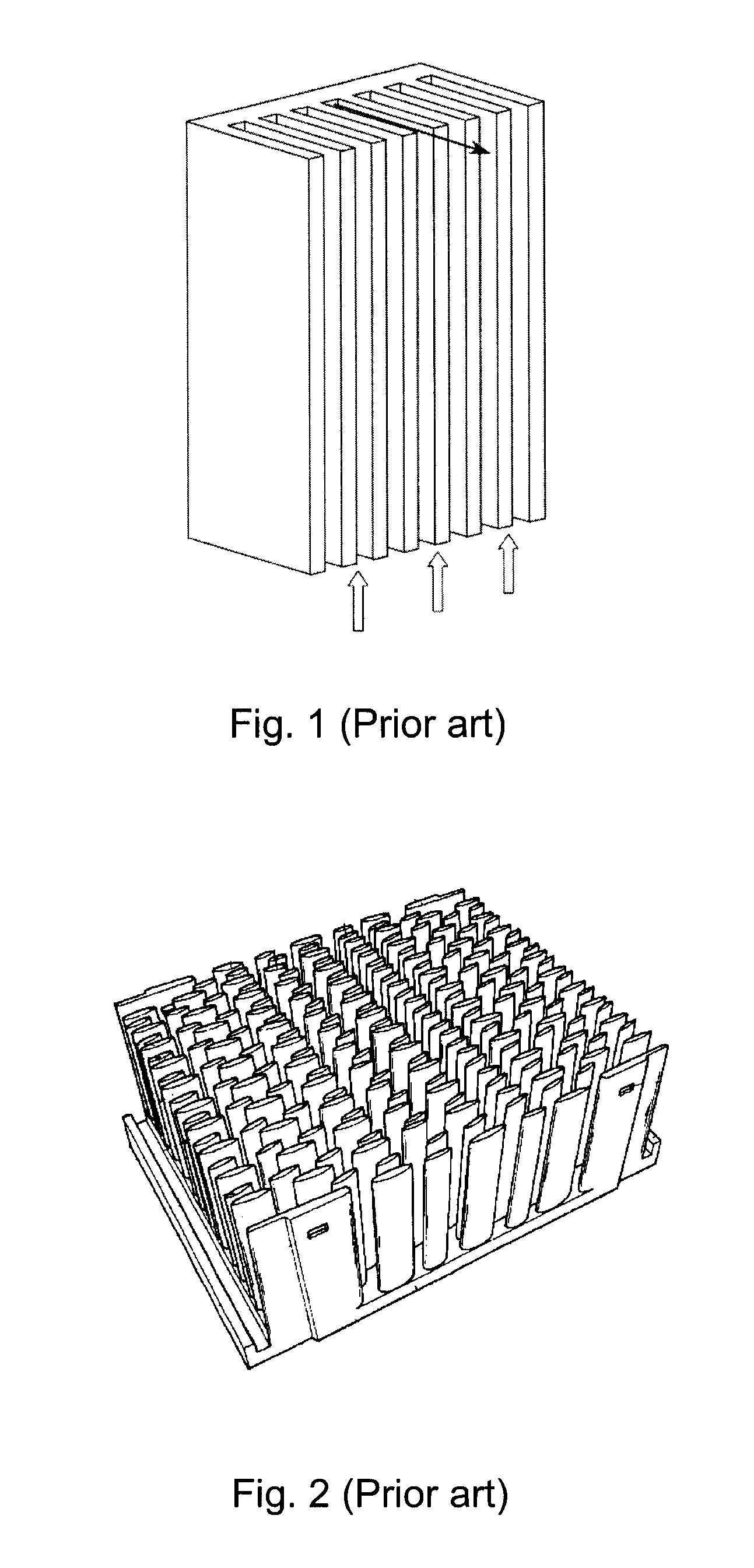

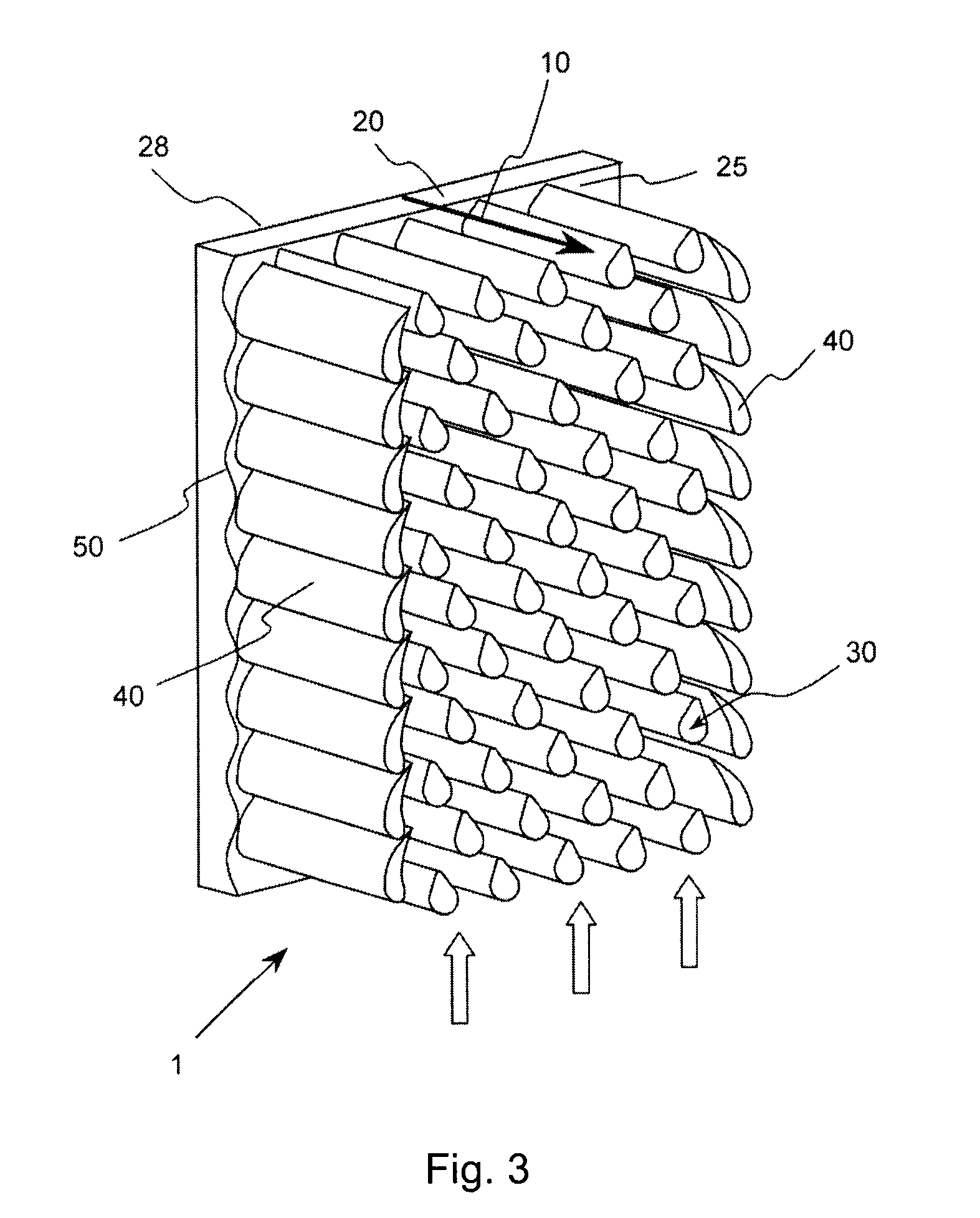

Non-linear fin heat sink

InactiveUS20090145581A1Improve power densityDissipating/removing heatSemiconductor/solid-state device detailsSolid-state devicesCoolant flowEngineering

A non-linear fin heat sink is provided for dissipating / removing heat uniformly from a device, where the heat generation is non-uniform over that device, while also providing a small and relatively lightweight heat sink. The heat sink has extended surface protrusions that are optimally shaped in recognition of convective heat transfer, conductive heat transfer, and flow resistance allowing the heat sink to offset the temperature rise of a coolant media and provide enhanced cooling for the coolant temperature, deliver optimized cooling efficiency per the local physical properties of the coolant media, be used with a fluid for effectuating heat transfer; either liquid coolant, gas coolant or a combination thereof. Furthermore the heat sink features turbulence enhancement of the coolant stream by a pin array through which coolant stream passes, such fin array featuring a non-linear shape, spacing, and height pattern to provide optimal cooling while simultaneously reducing volume and flow resistance.

Owner:THERMAL TECH

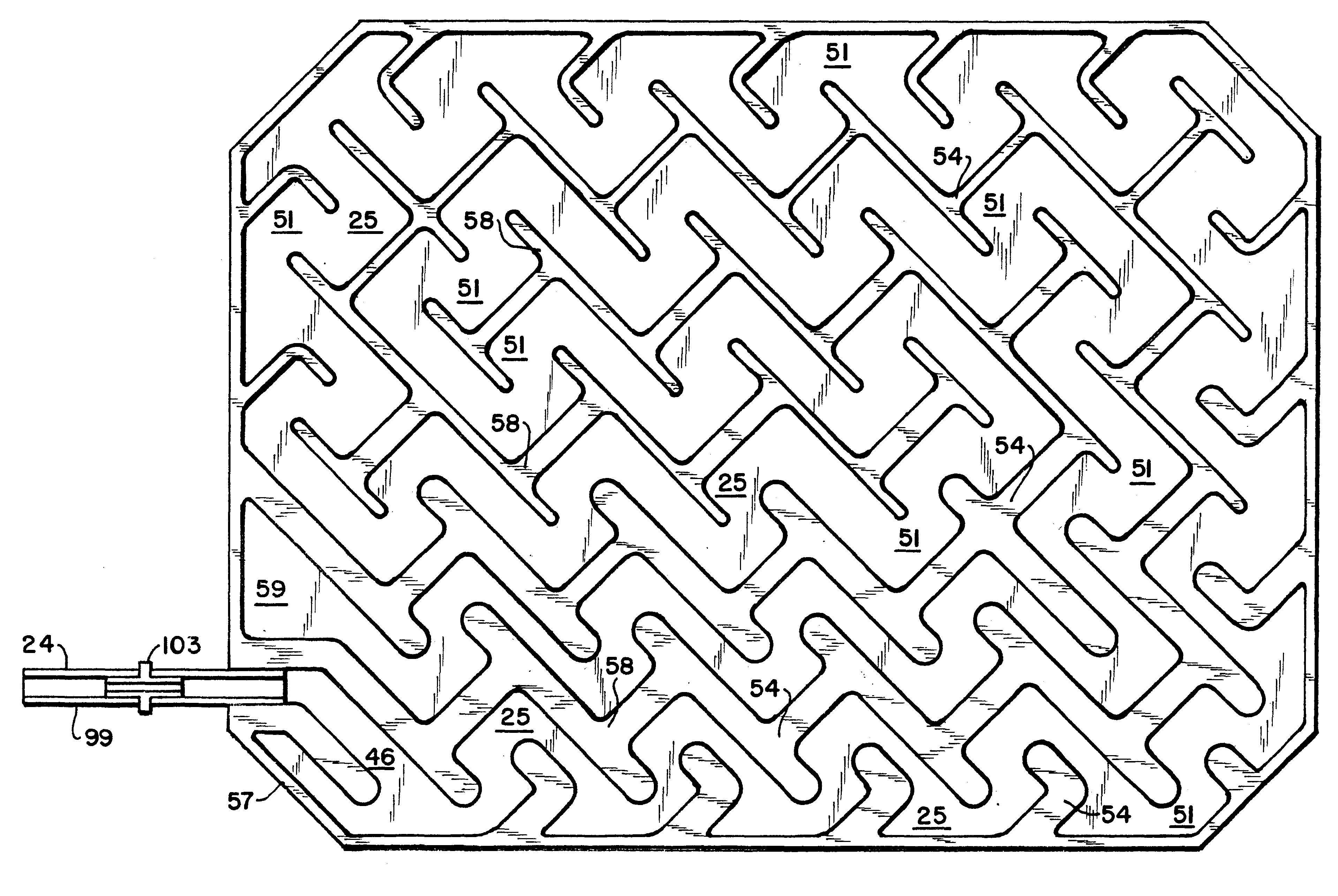

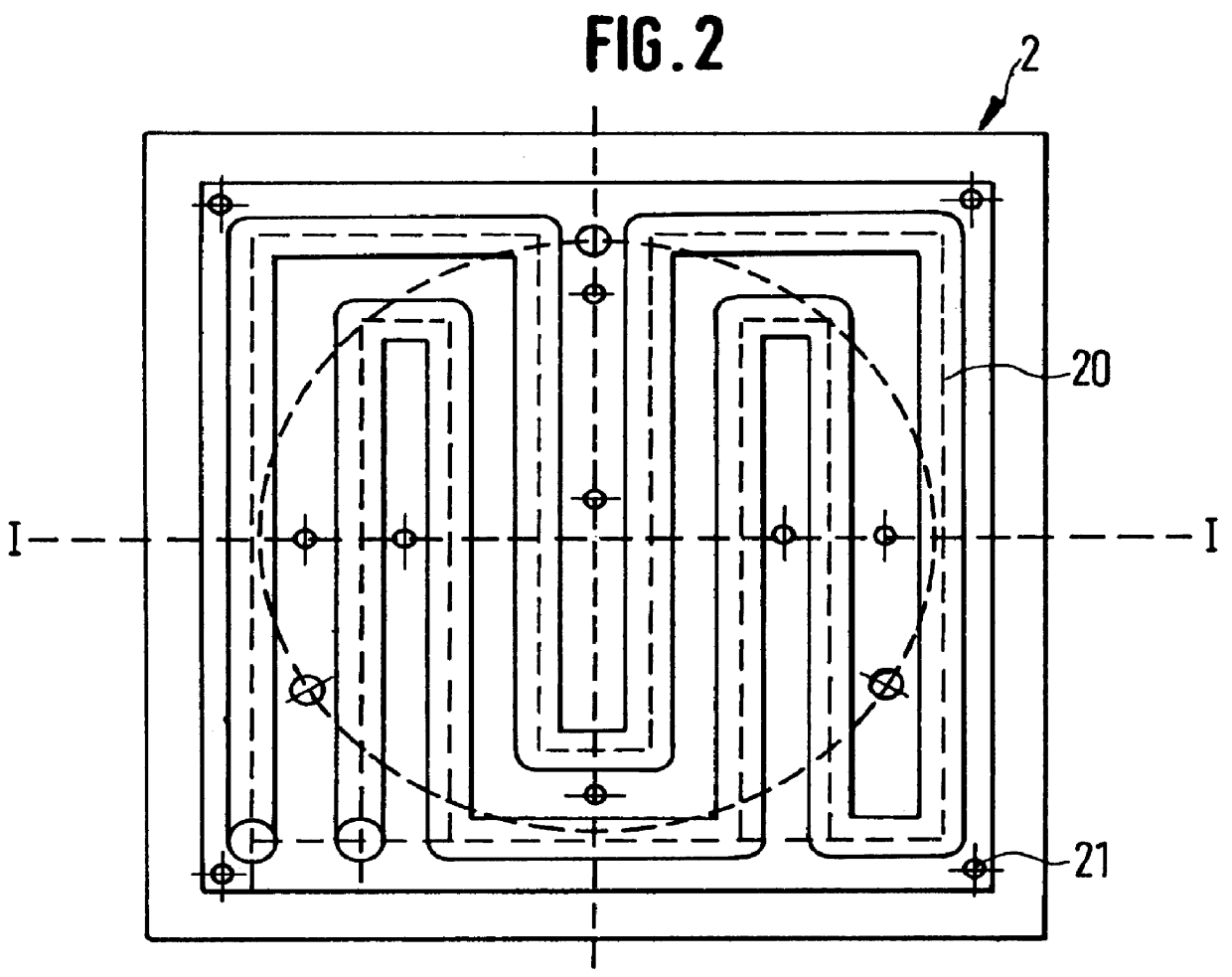

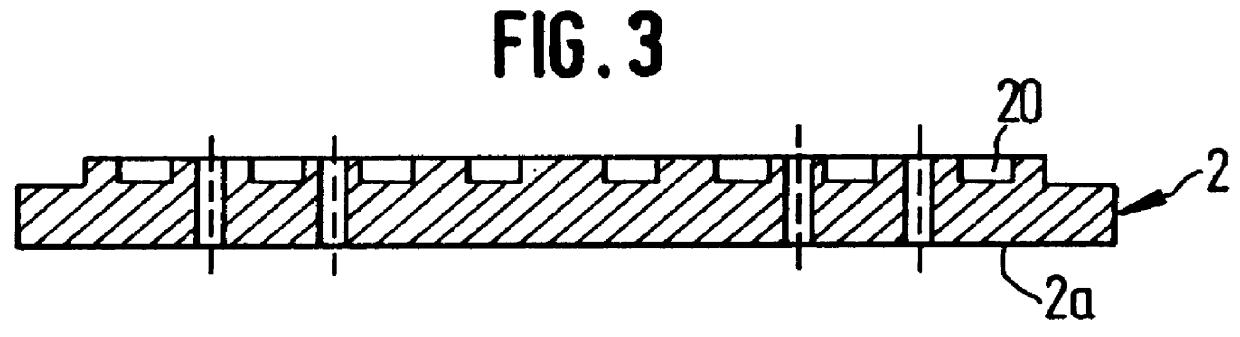

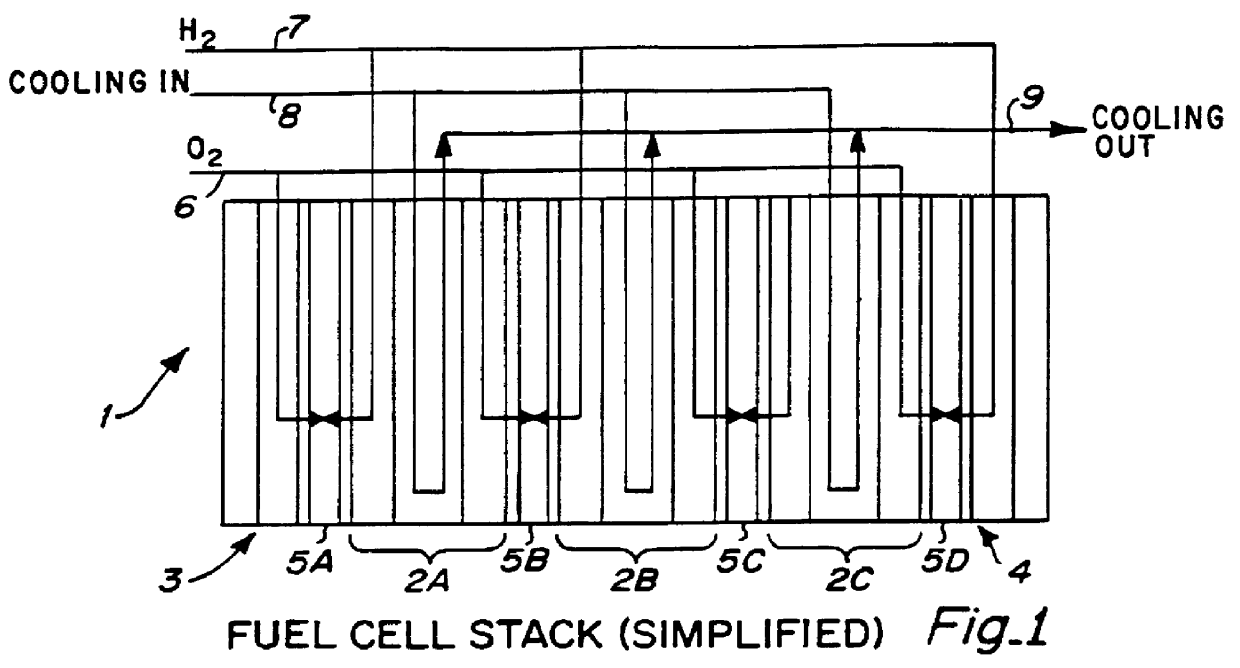

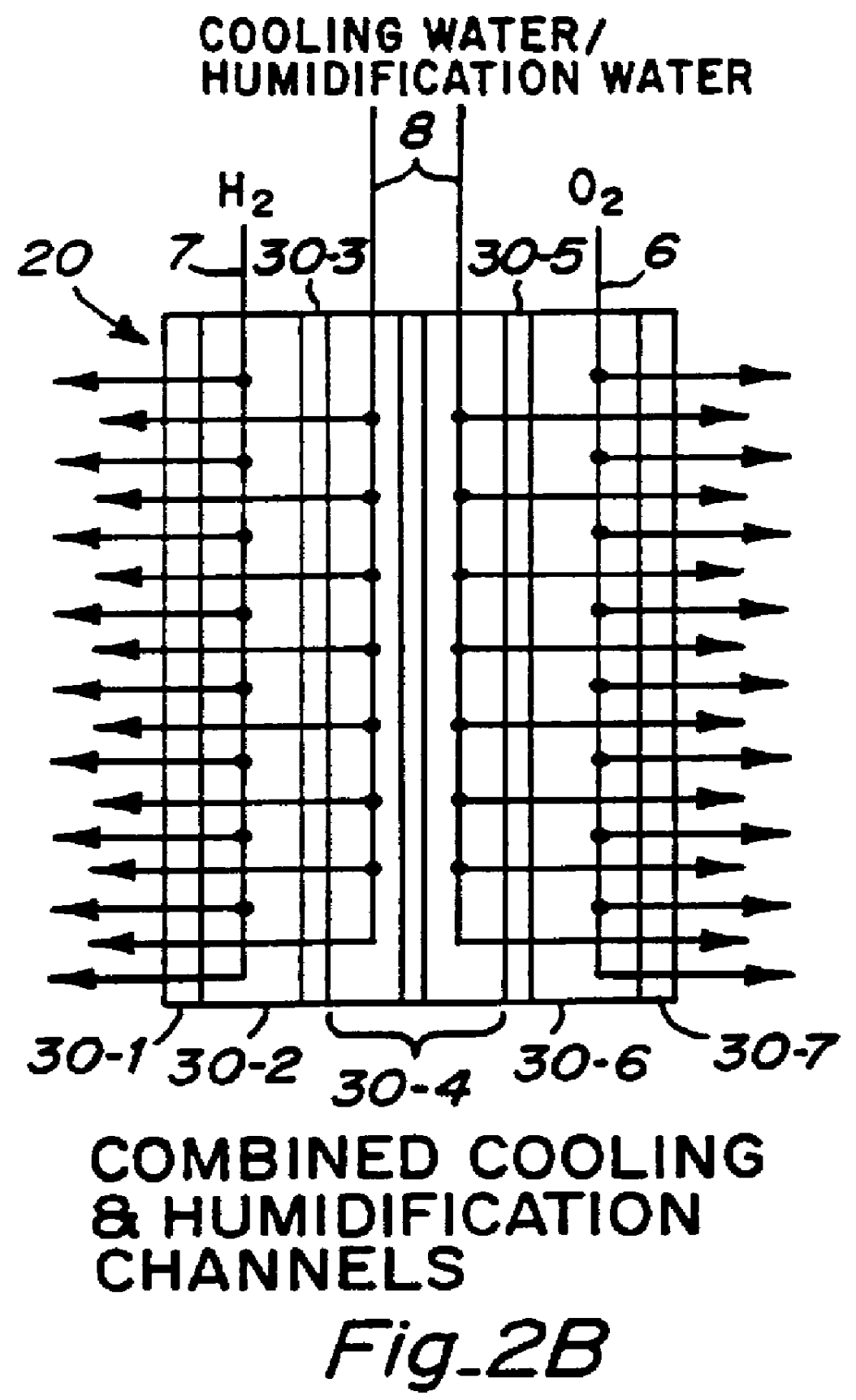

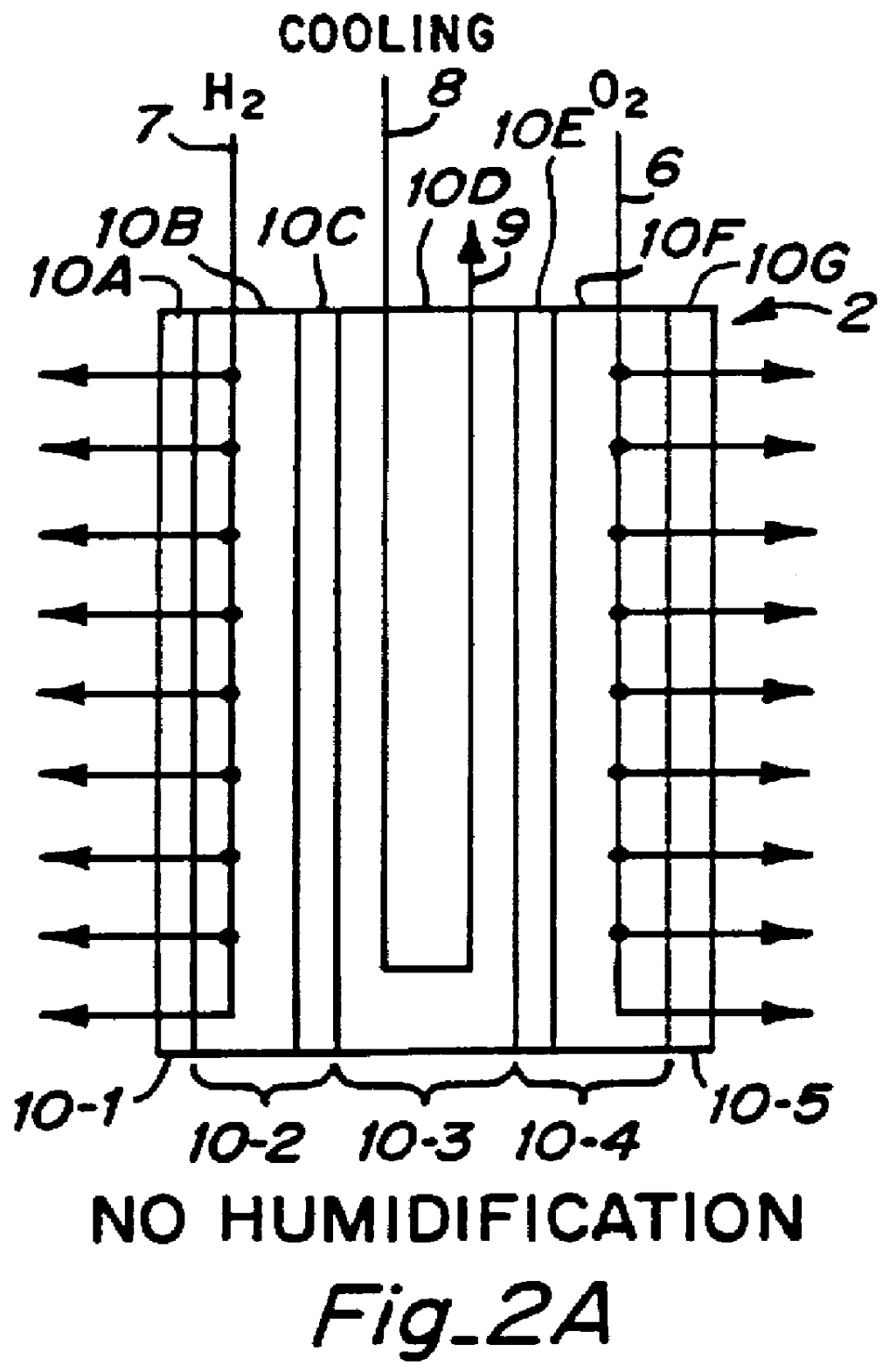

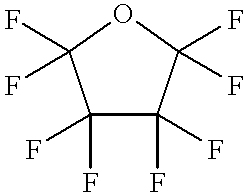

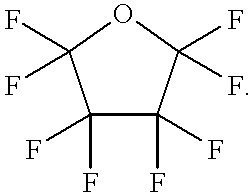

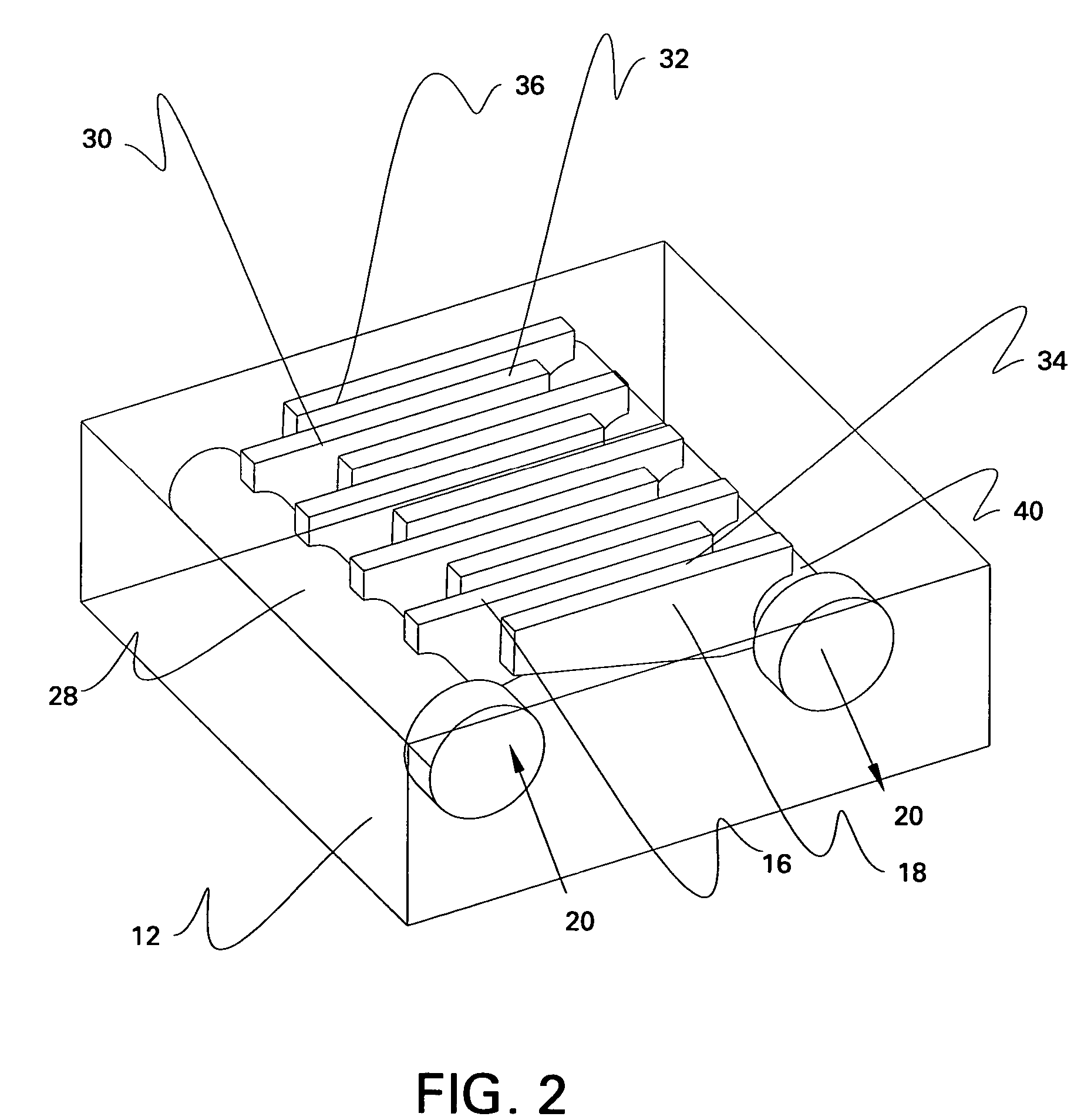

Fuel cell platelet separators having coordinate features

InactiveUS6051331ASimple designEvenly distributedSolid electrolytesFuel cells groupingLaser etchingFuel cells

PCT No. PCT / US95 / 13325 Sec. 371 Date Sep. 28, 1997 Sec. 102(e) Date Sep. 28, 1997 PCT Filed Oct. 10, 1995 PCT Pub. No. WO96 / 12316 PCT Pub. Date Apr. 25, 1996Fuel cell stacks comprising stacked separator / membrane electrode assembly fuel cells in which the separators comprise a series of thin sheet platelets, having individually configured serpentine micro-channel reactant gas humidification active areas and cooling fields therein. The individual platelets are stacked with coordinate features aligned in contact with adjacent platelets and bonded to form a monolithic separator. Post-bonding processing includes passivation, such as nitriding. Preferred platelet material is 4-25 mil Ti, in which the features, serpentine channels, tabs, lands, vias, manifolds and holes, are formed by chemical and laser etching, cutting, pressing or embossing, with combinations of depth and through etching preferred. The platelet manufacturing process is continuous and fast. By employing CAD based platelet design and photolithography, rapid change in feature design can accommodate a wide range of thermal management and humidification techniques. One hundred H2-O2 / PEM fuel cell stacks of this IFMT platelet design will exhibit outputs on the order of 0.75 kW / kg, some 3-6 times greater than the current graphite plate PEM stacks.

Owner:H POWER

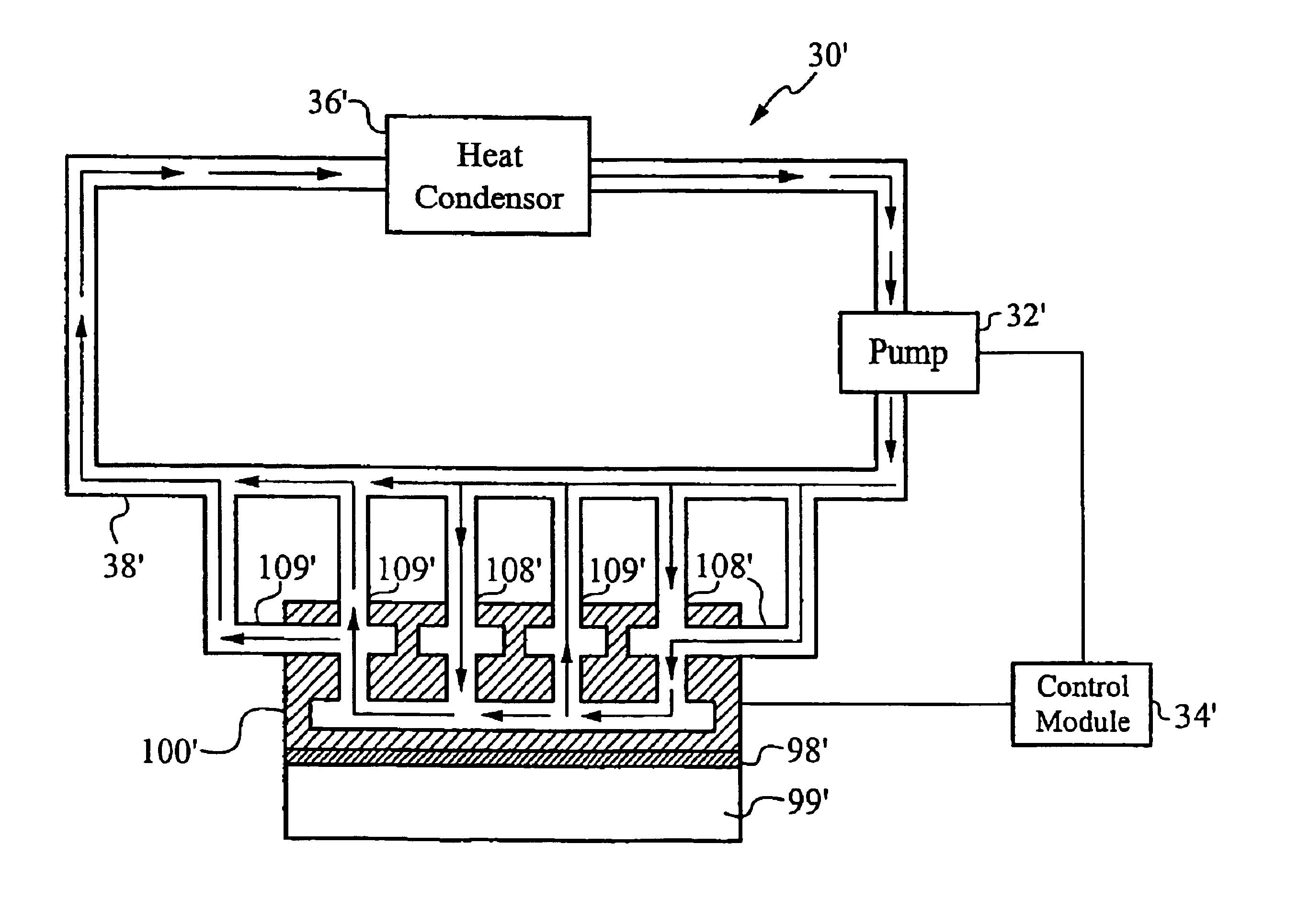

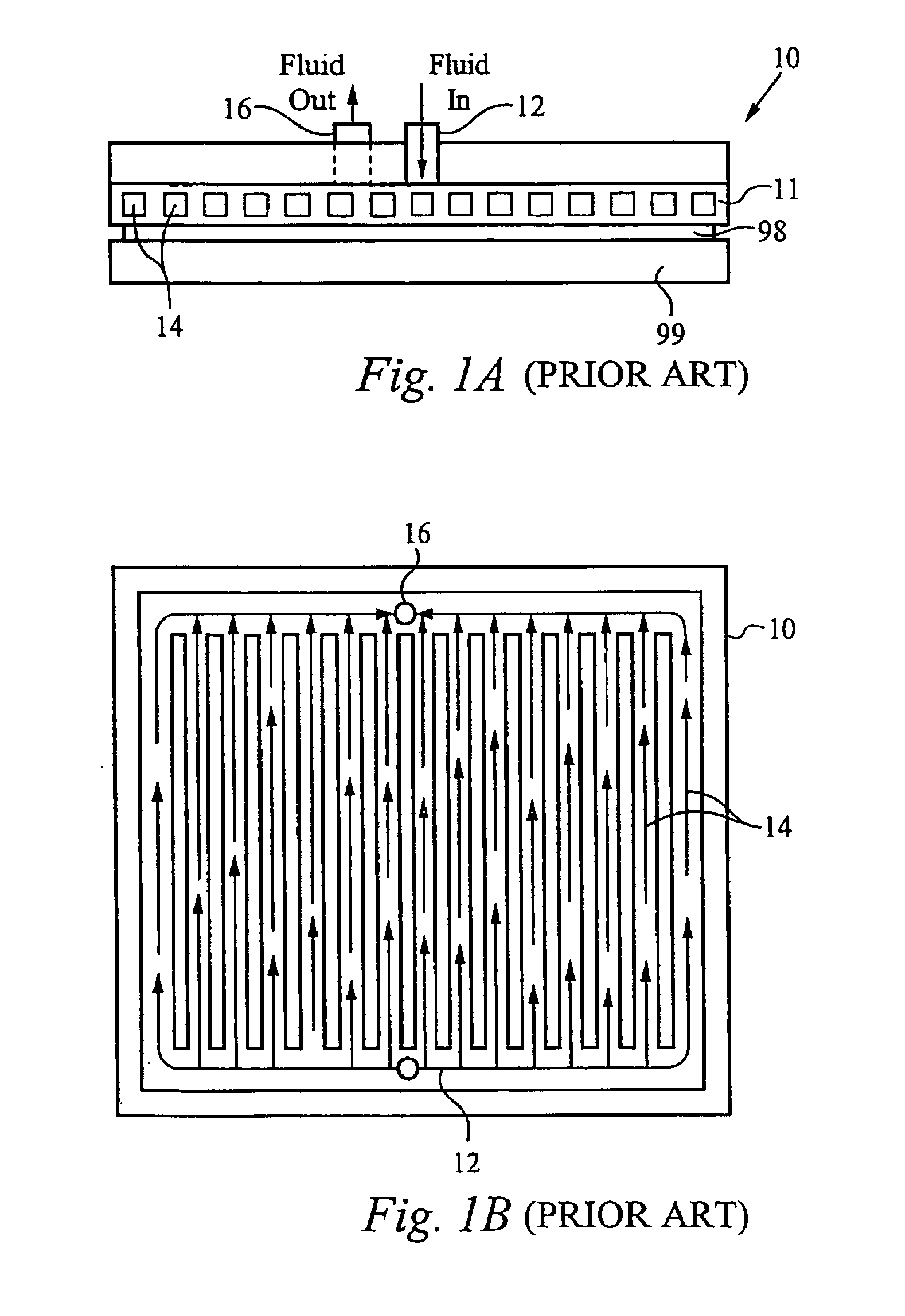

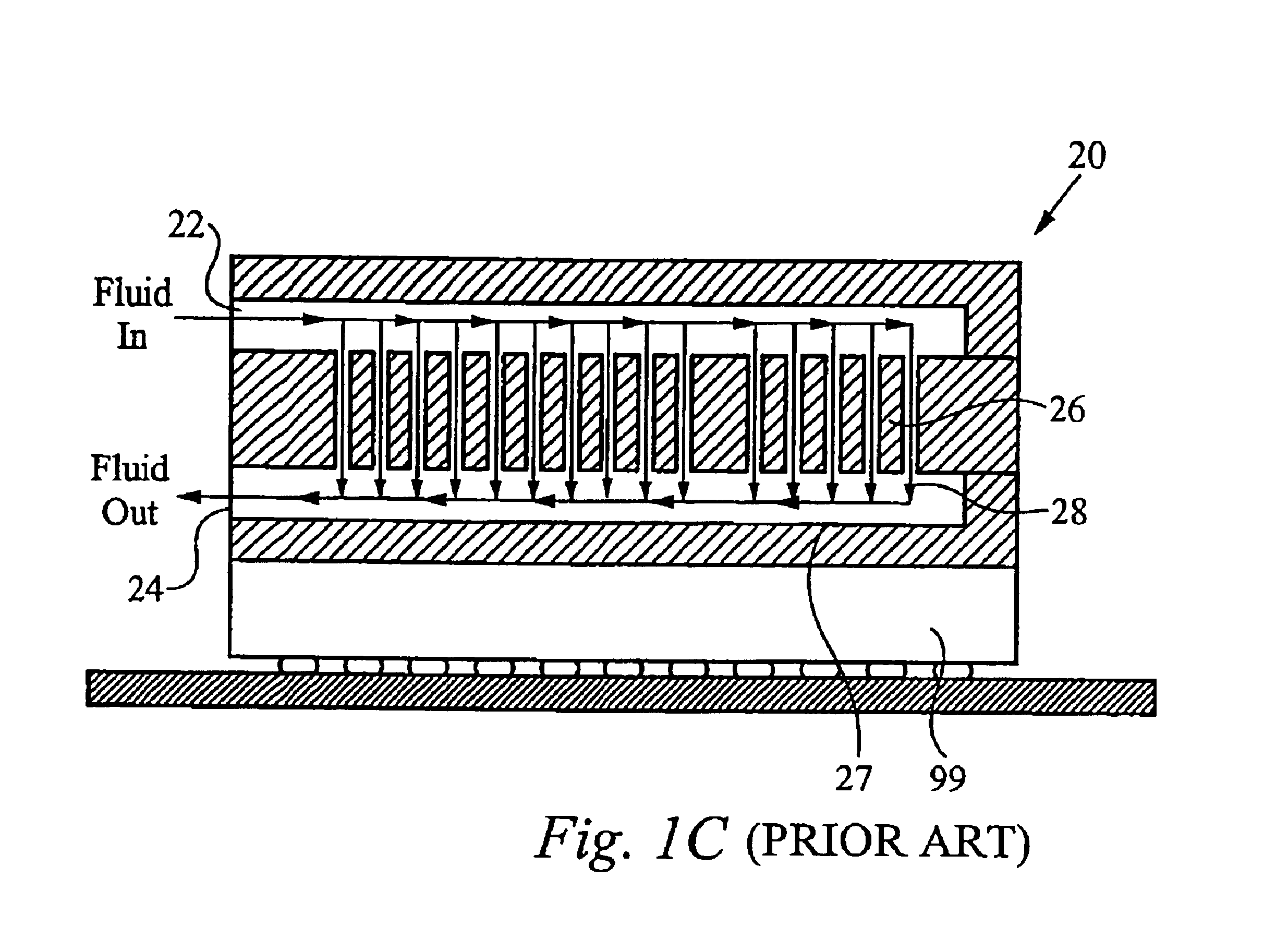

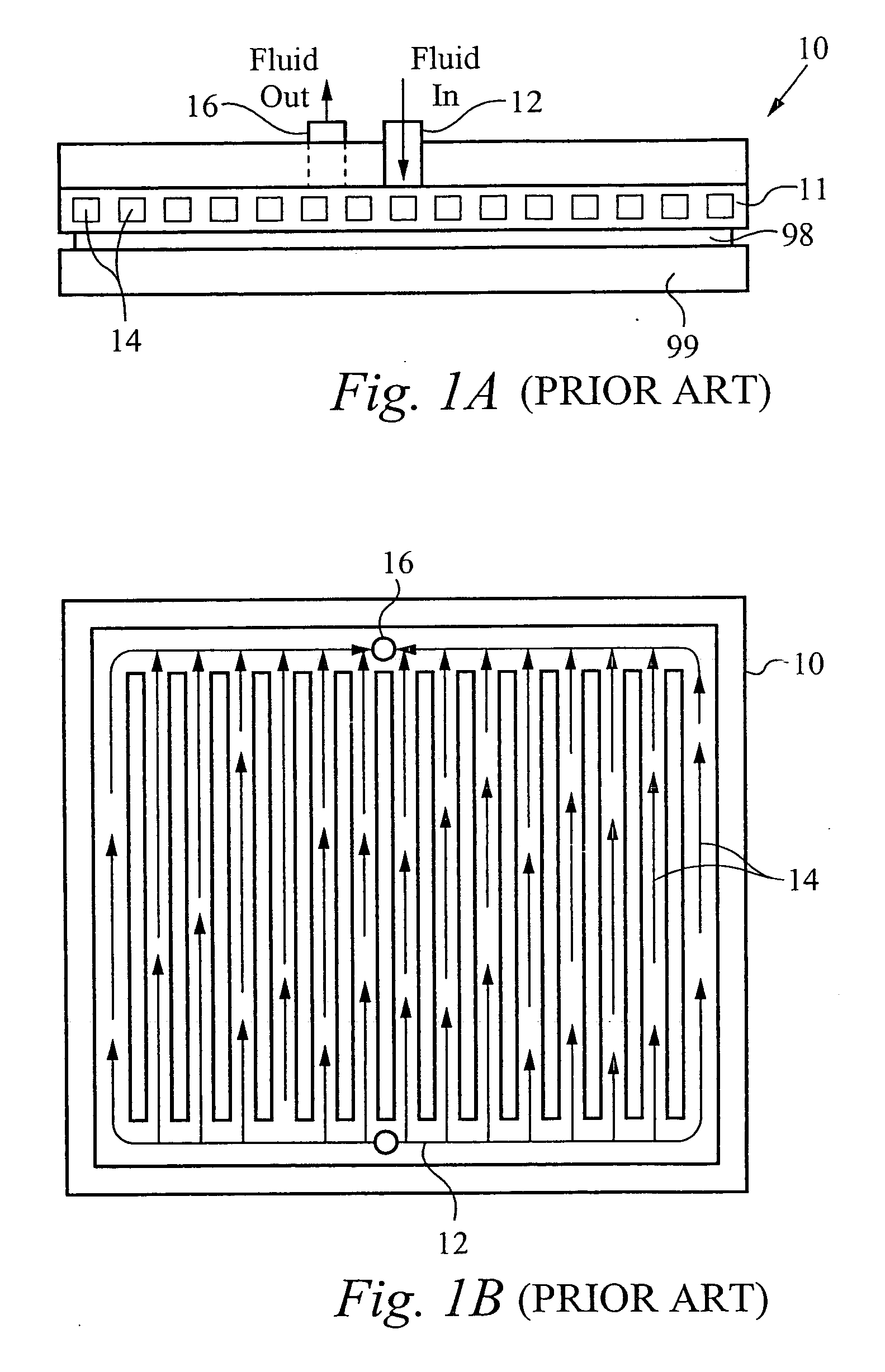

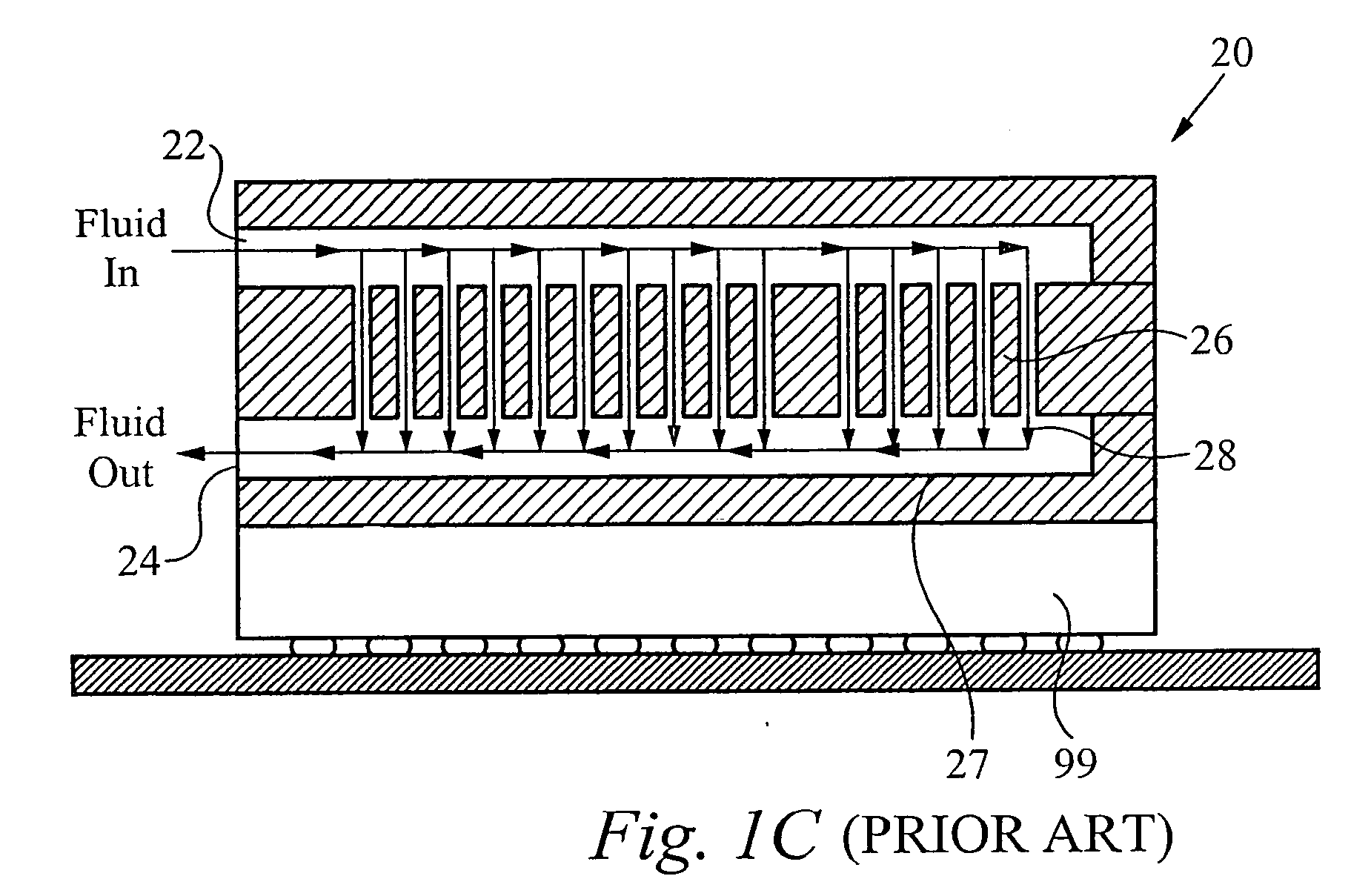

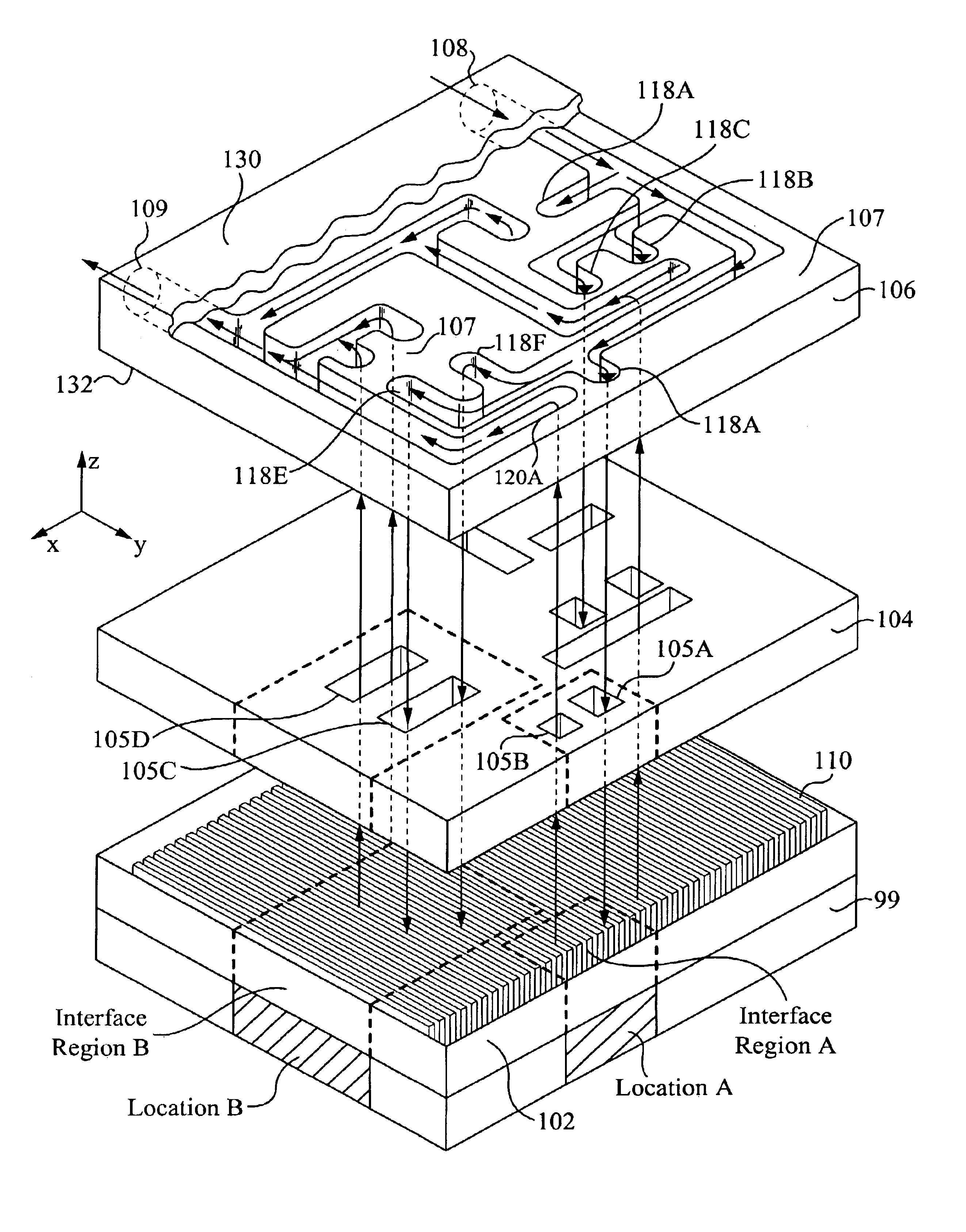

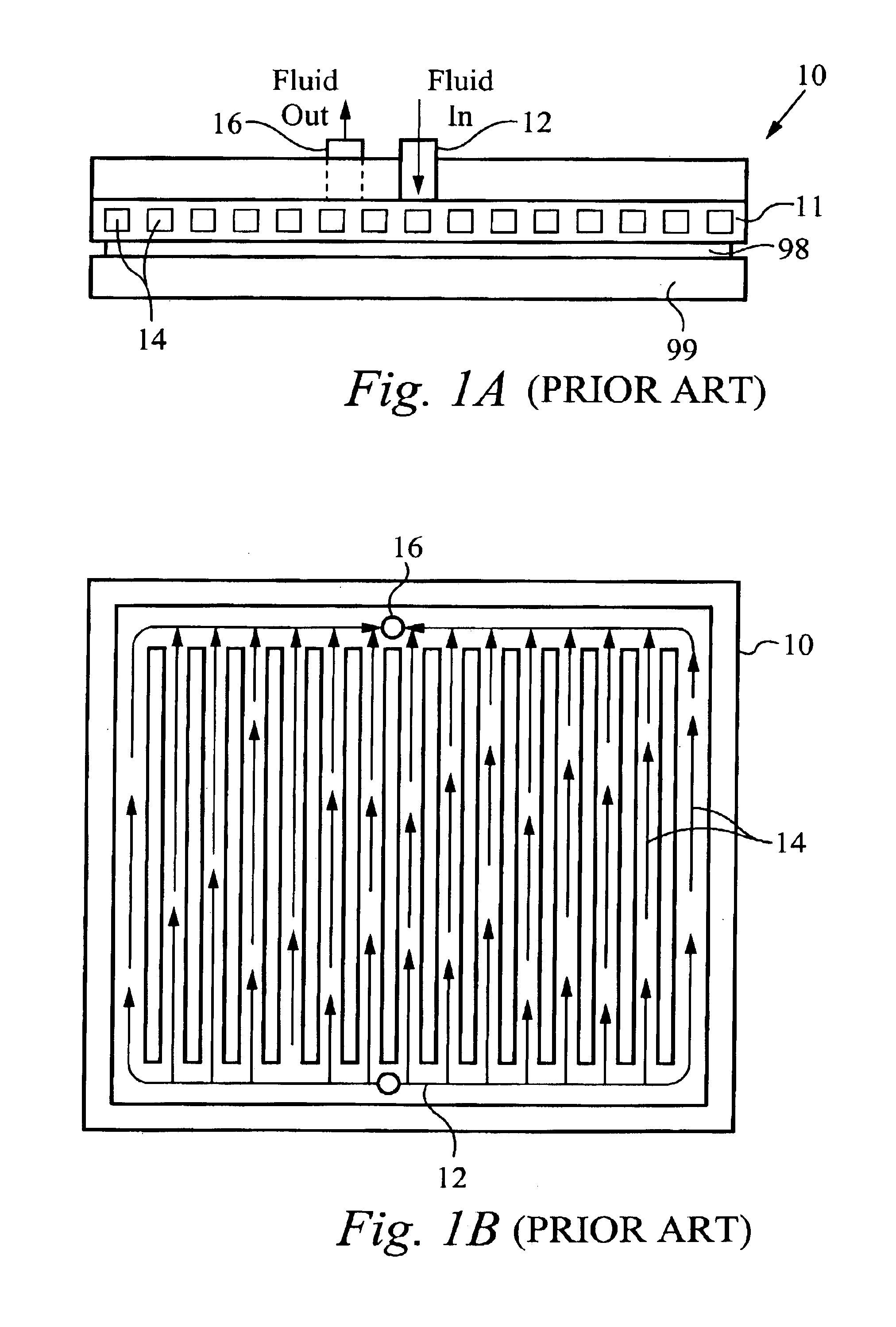

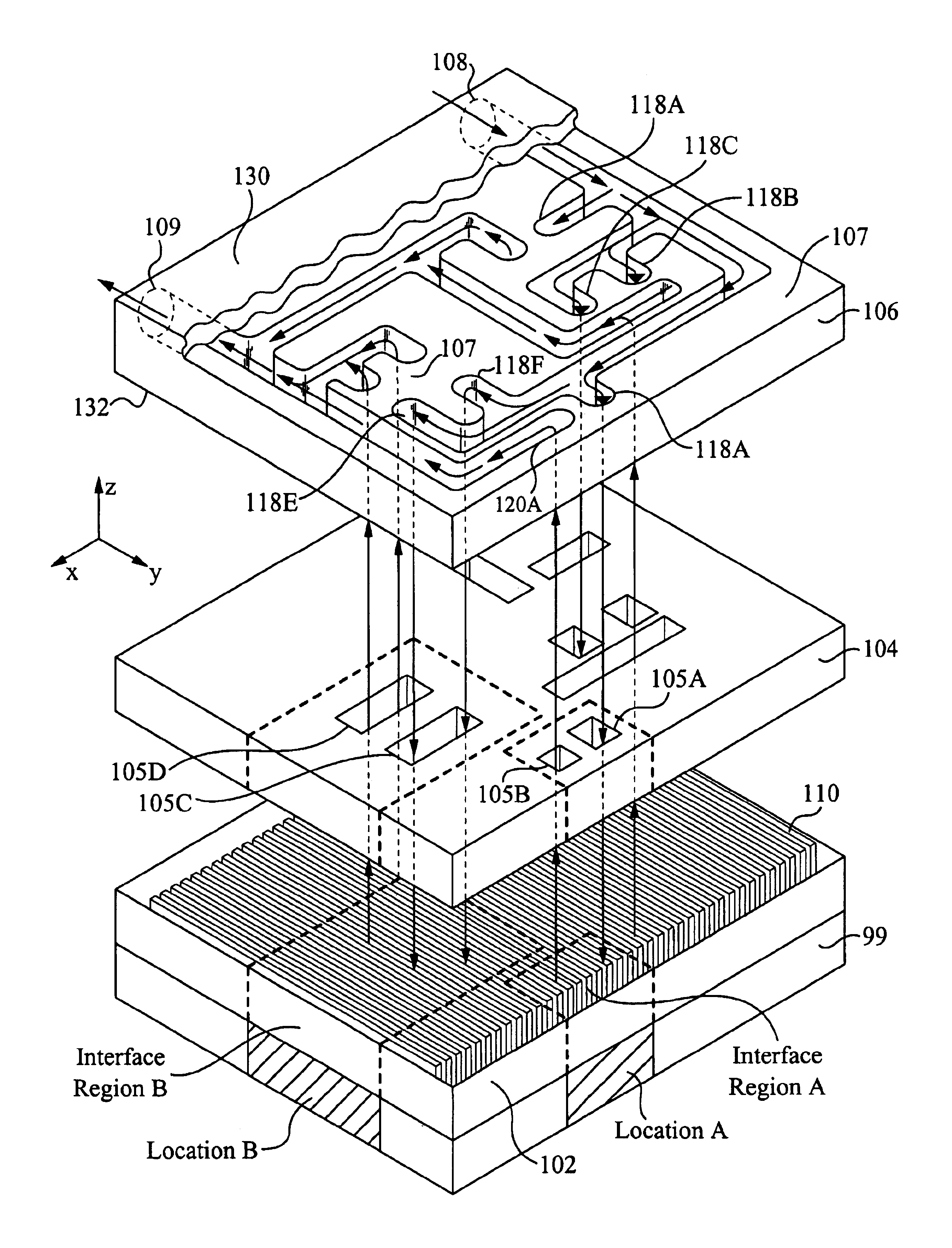

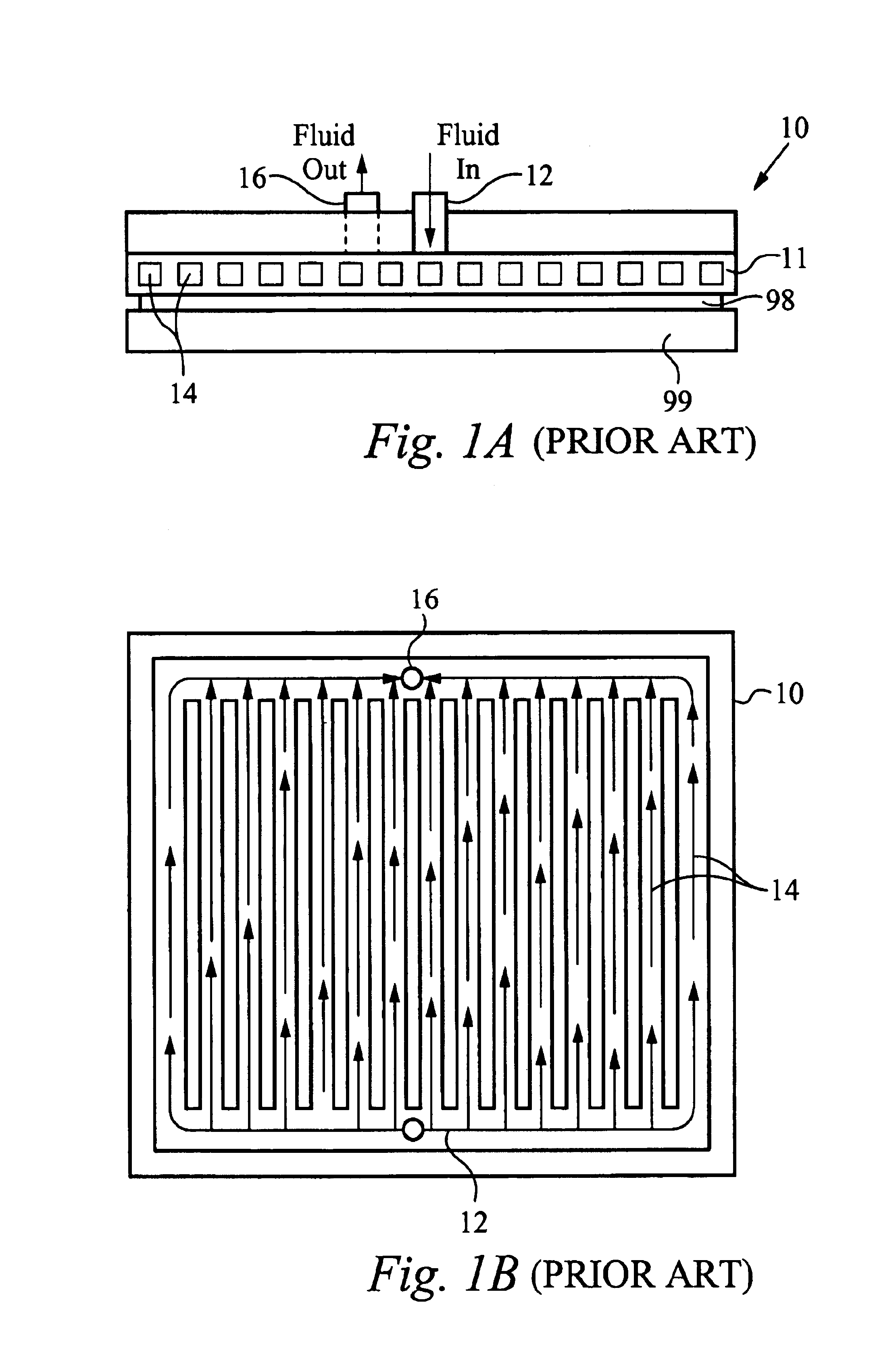

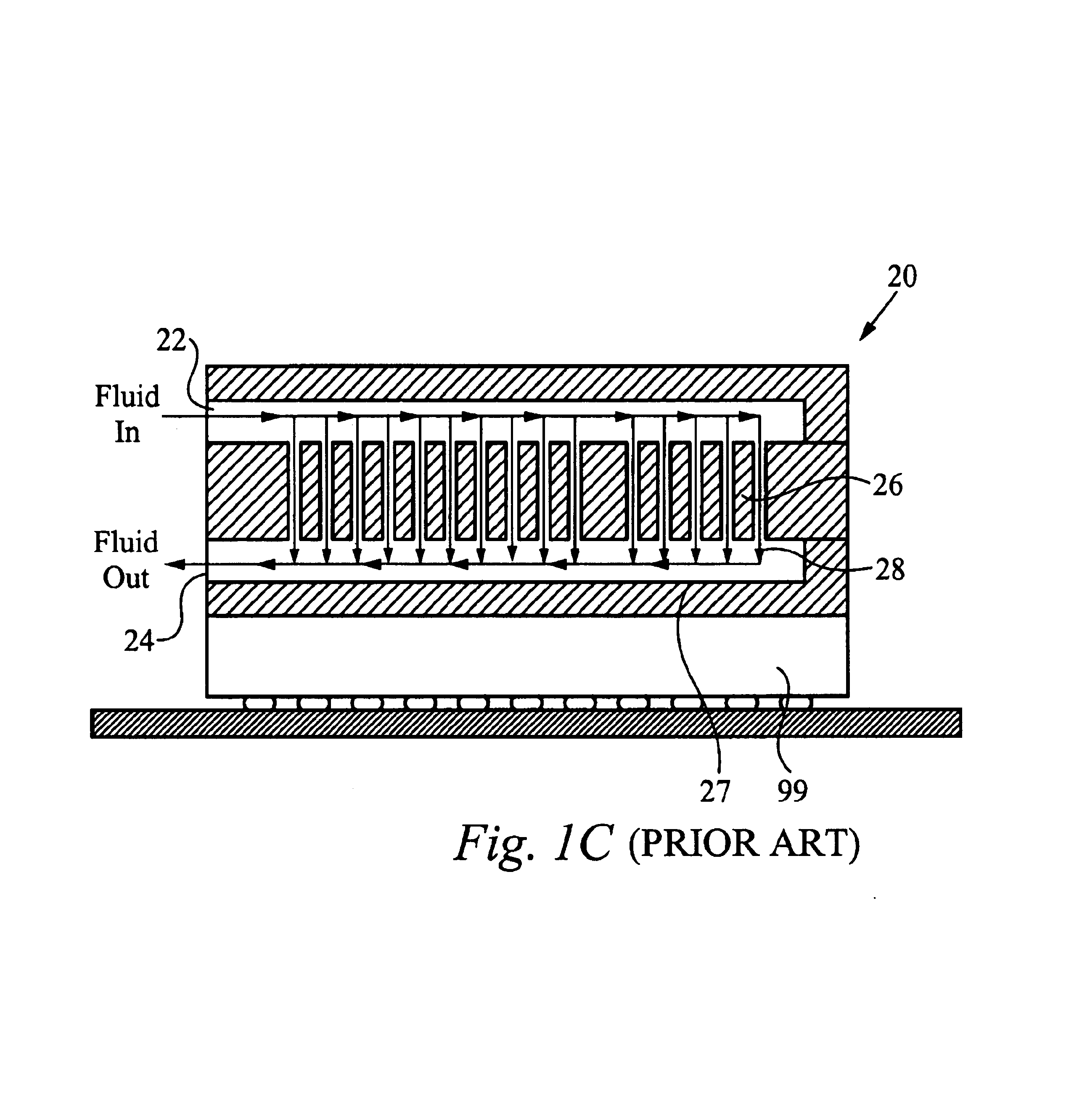

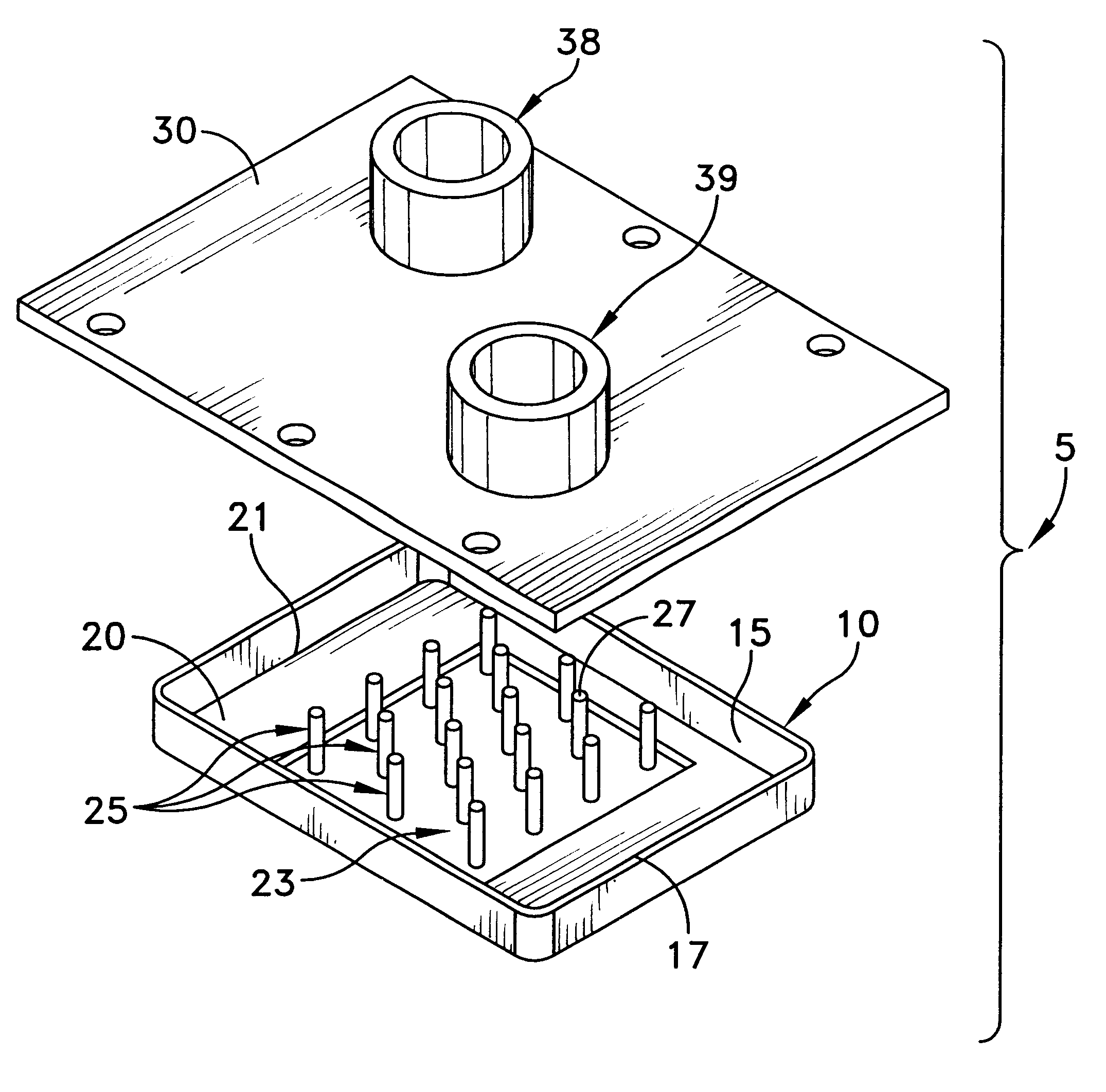

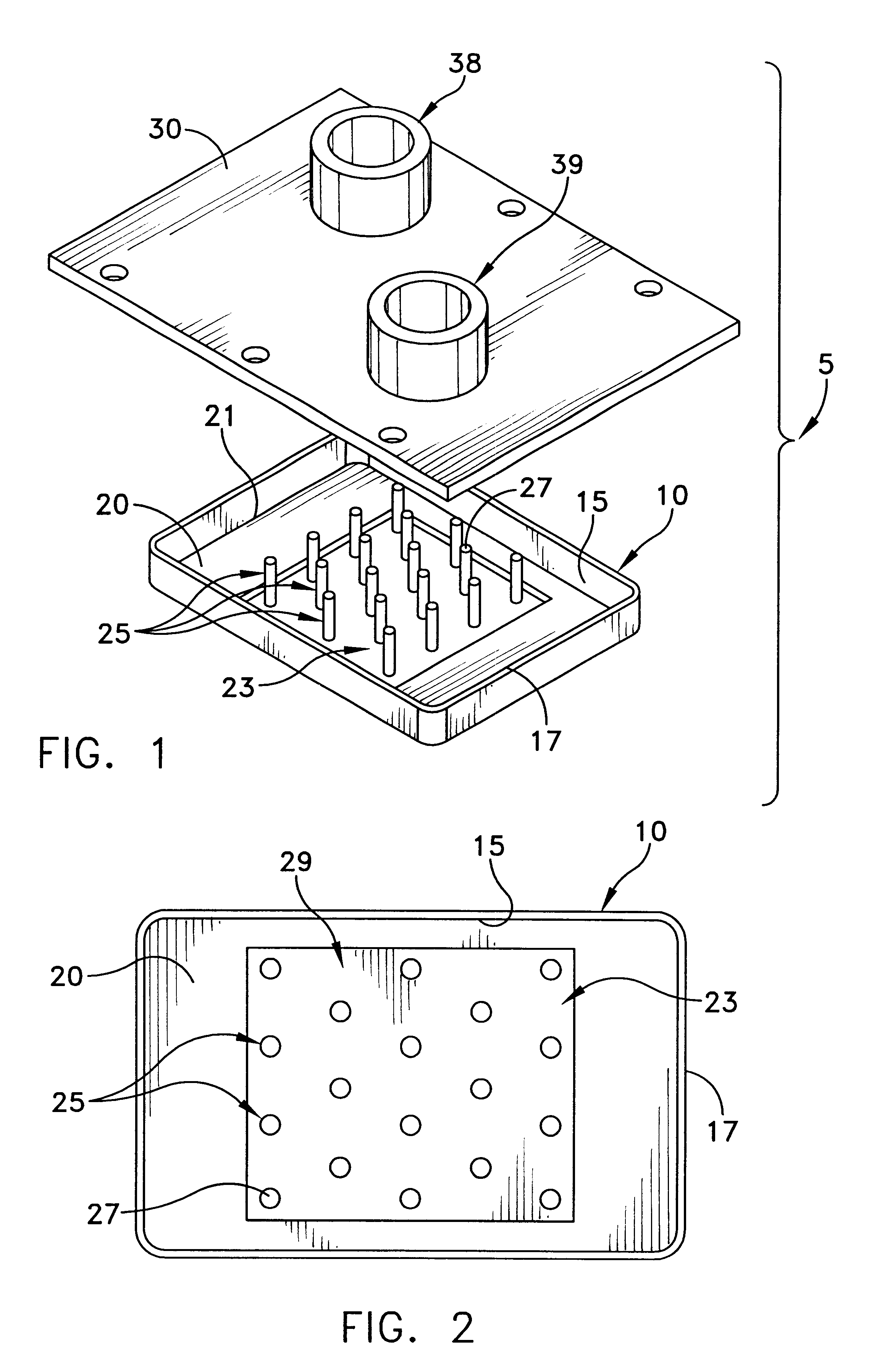

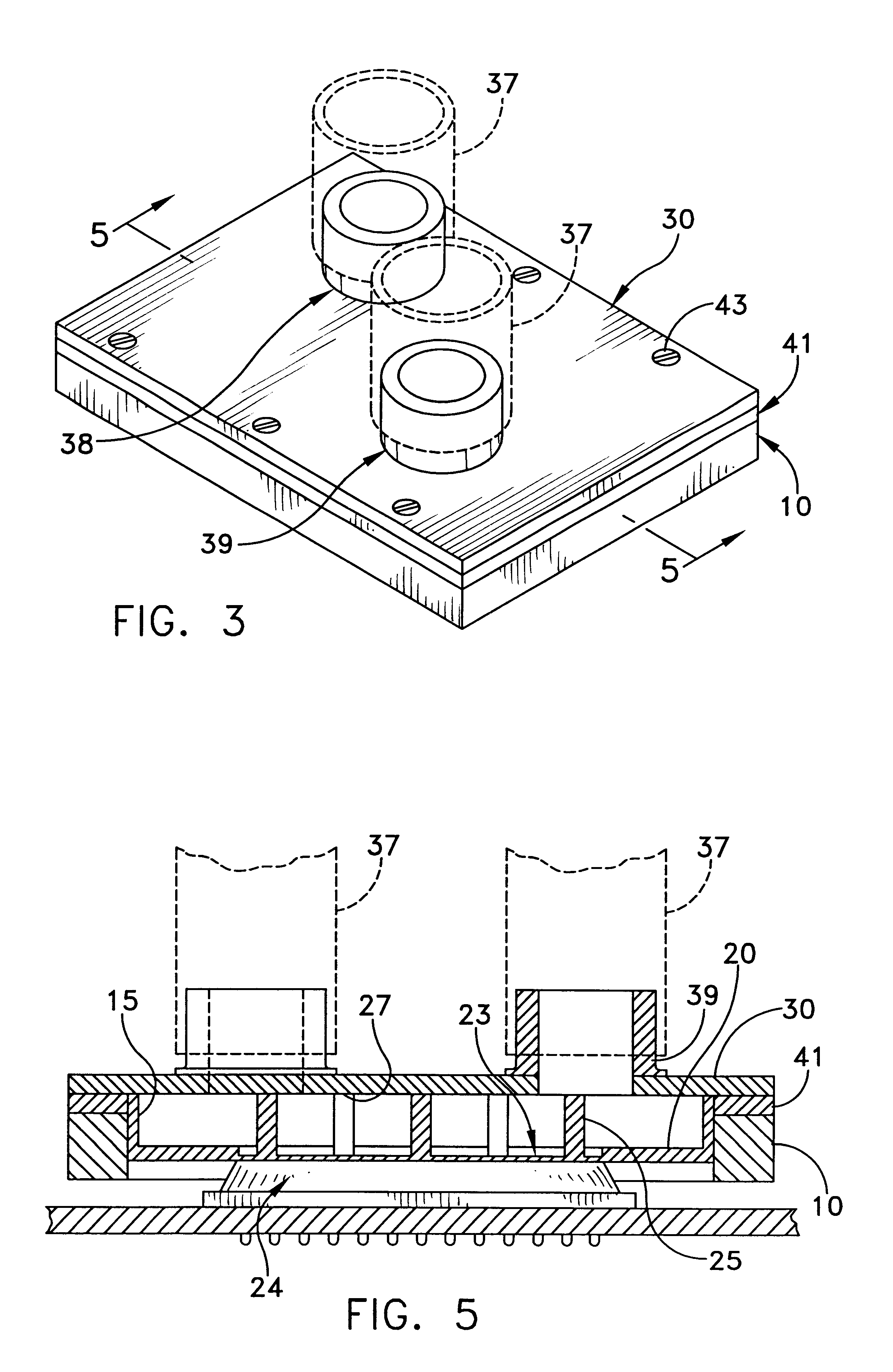

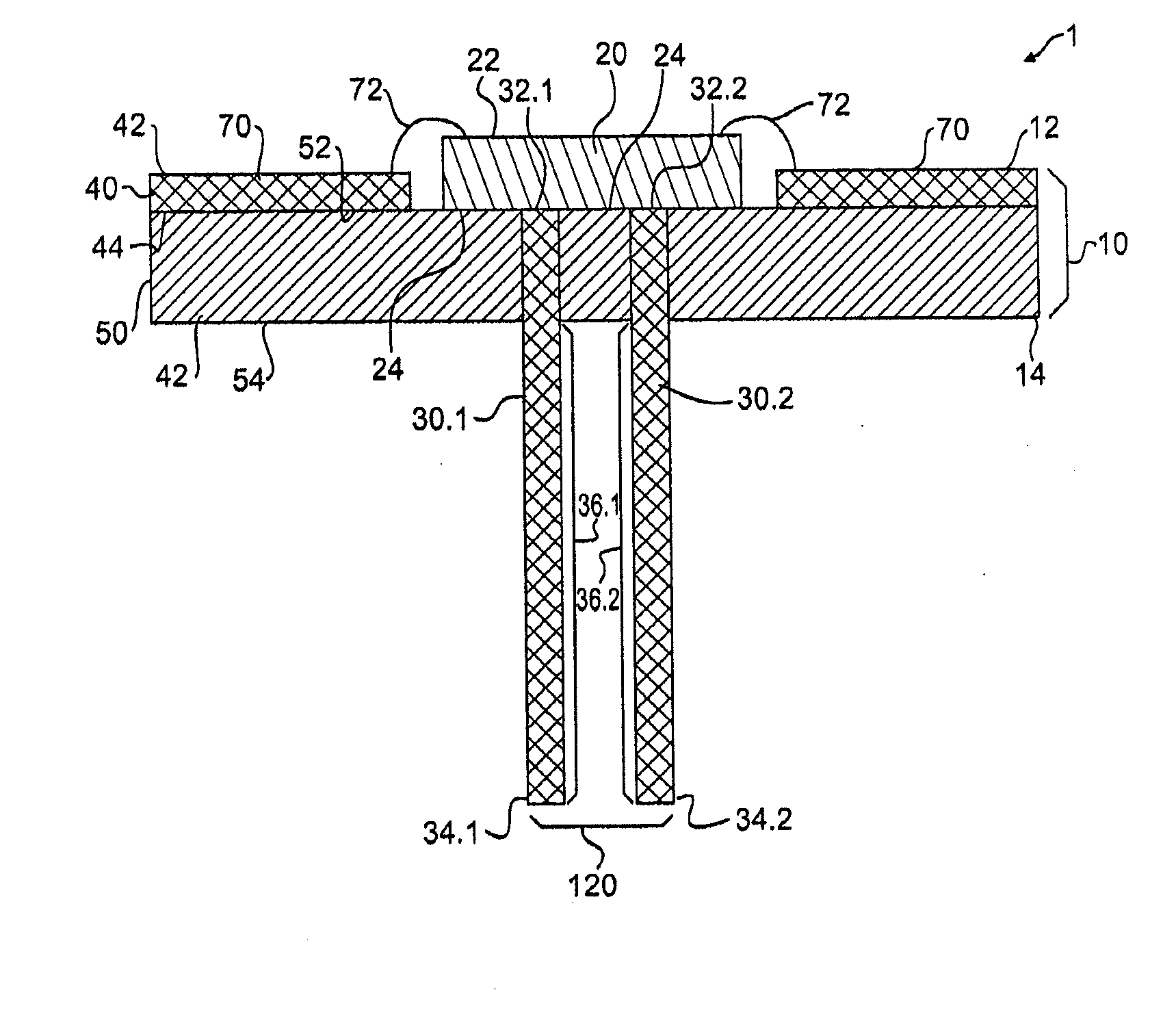

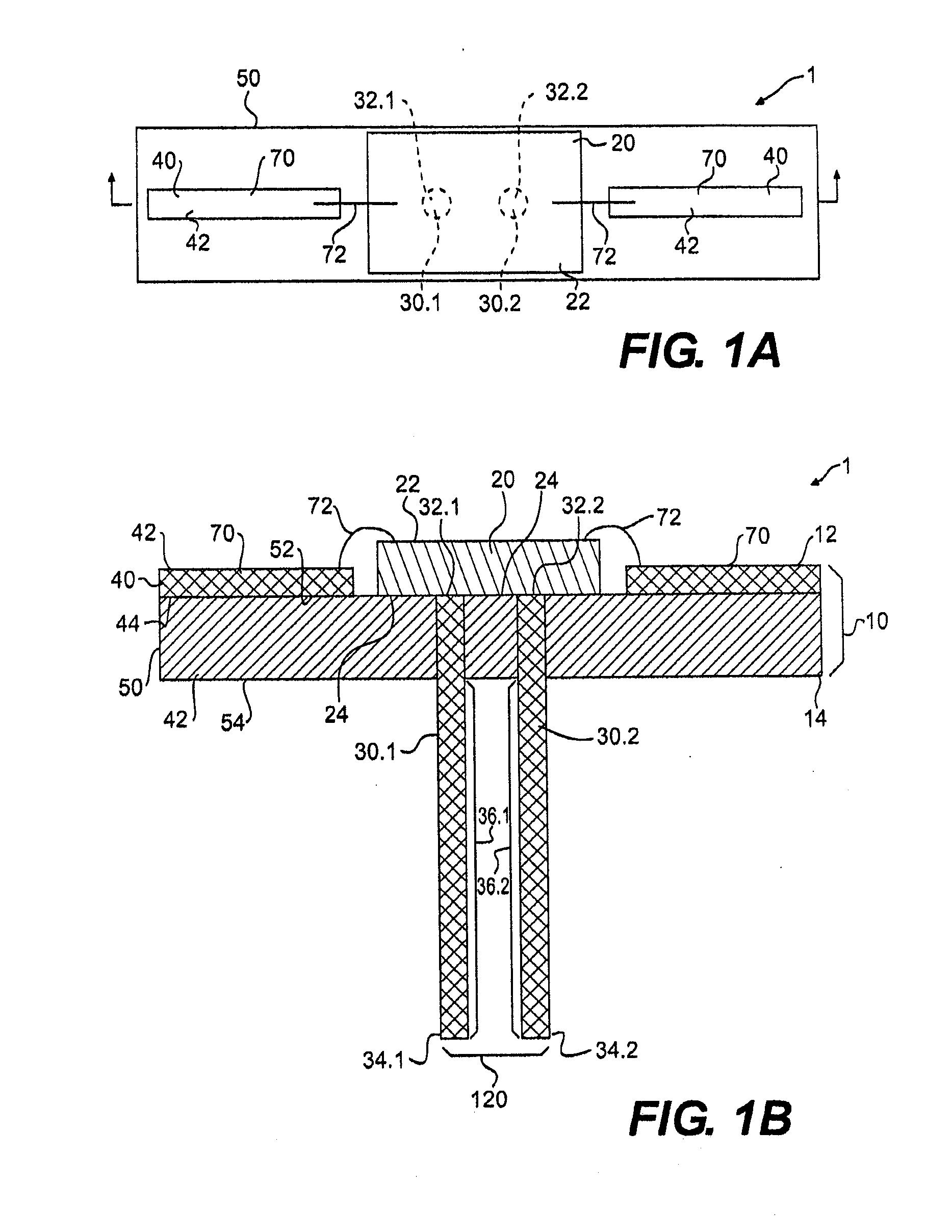

Method and apparatus for efficient vertical fluid delivery for cooling a heat producing device

InactiveUS7000684B2Minimized fluid path distanceImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesInterface layerPath distance

A heat exchanger and method of manufacturing thereof comprises an interface layer for cooling a heat source. The interface layer is coupled to the heat source and is configured to pass fluid therethrough. The heat exchanger further comprises a manifold layer that is coupled to the interface layer. The manifold layer includes at least one first port that is coupled to a first set of individualized holes which channel fluid through the first set. The manifold layer includes at least one second port coupled to a second set of individualized holes which channel fluid through the second set. The first set of holes and second set of holes are arranged to provide a minimized fluid path distance between the first and second ports to adequately cool the heat source. Preferably, each hole in the first set is positioned a closest optimal distance to an adjacent hole the second set.

Owner:VERTIV CORP

Cooling systems incorporating heat exchangers and thermoelectric layers

ActiveUS20070034356A1Thermoelectric device with peltier/seeback effectDigital data processing detailsEngineeringThermal contact

A method and system for cooling a heat source are presented. The system includes a fluid heat exchanger, a pump, a thermoelectric device having a cooling portion and a heating portion, and a heat rejector configured to be in thermal contact with at least a portion of the heating portion of the thermoelectric device. The pump is coupled with the fluid heat exchanger and configured to pass a fluid therethrough. The thermoelectric device is configured along with the heat exchanger in a cooling system to enhance the cooling efficiency of the system.

Owner:VERTIV CORP

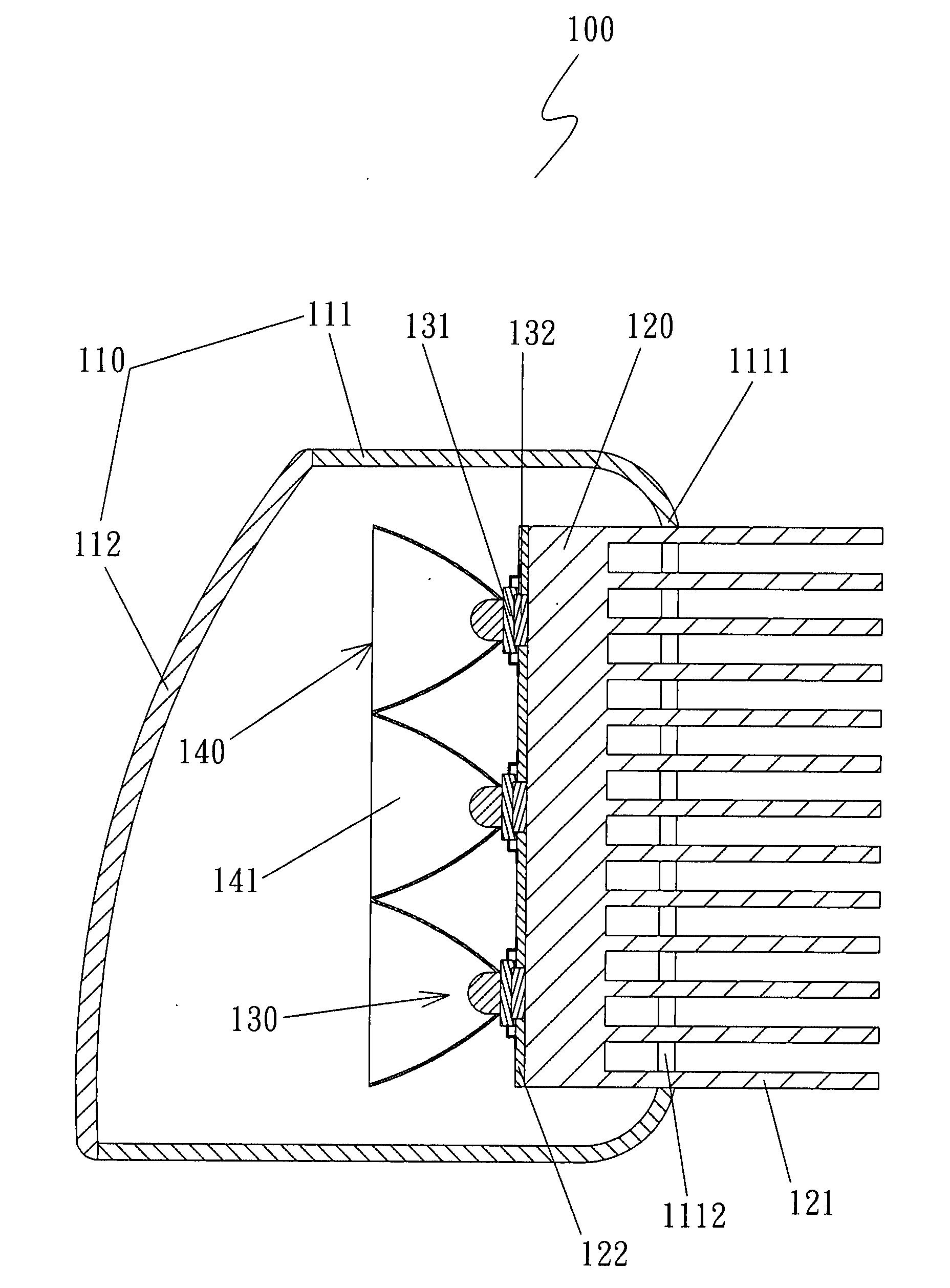

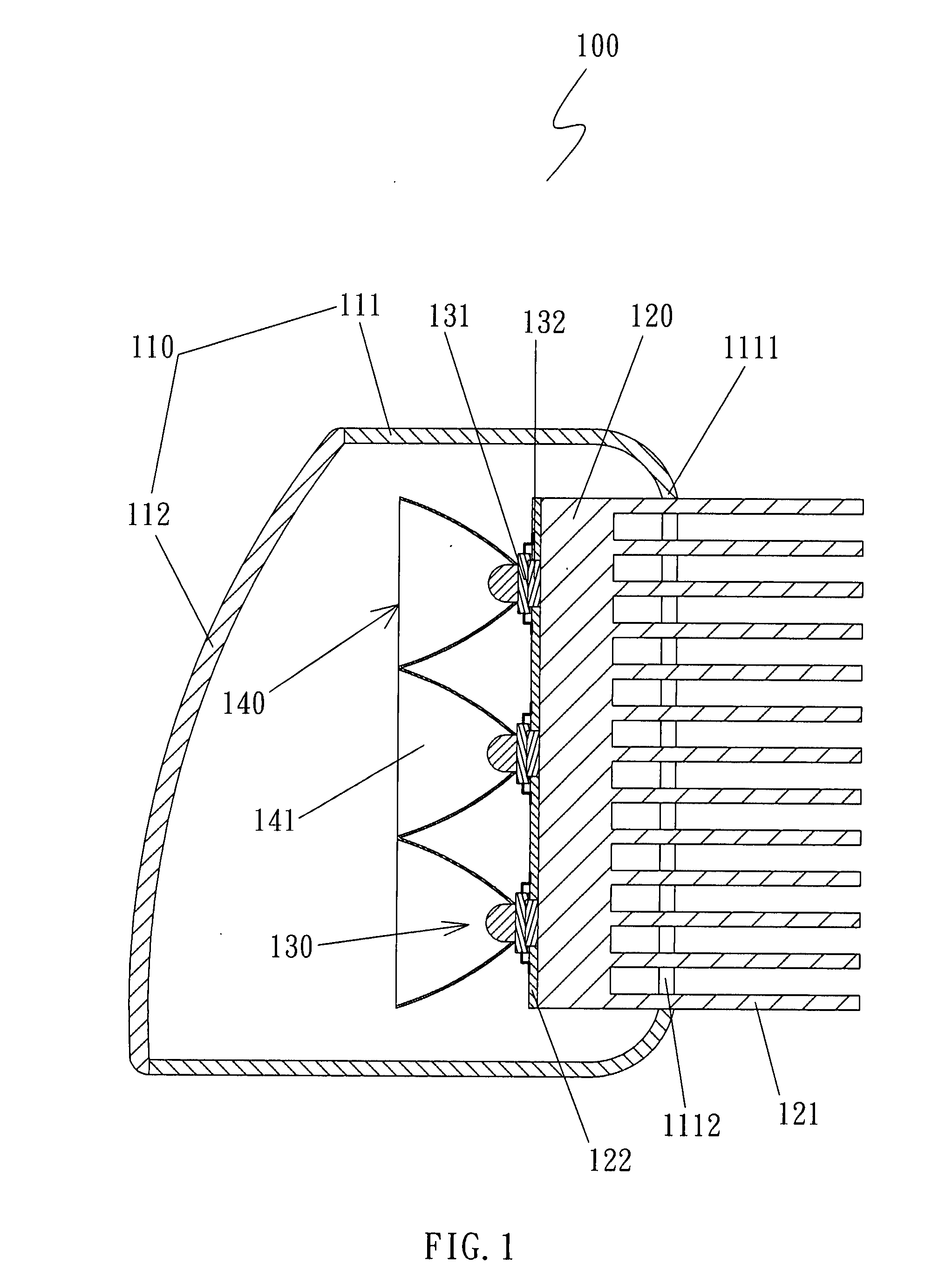

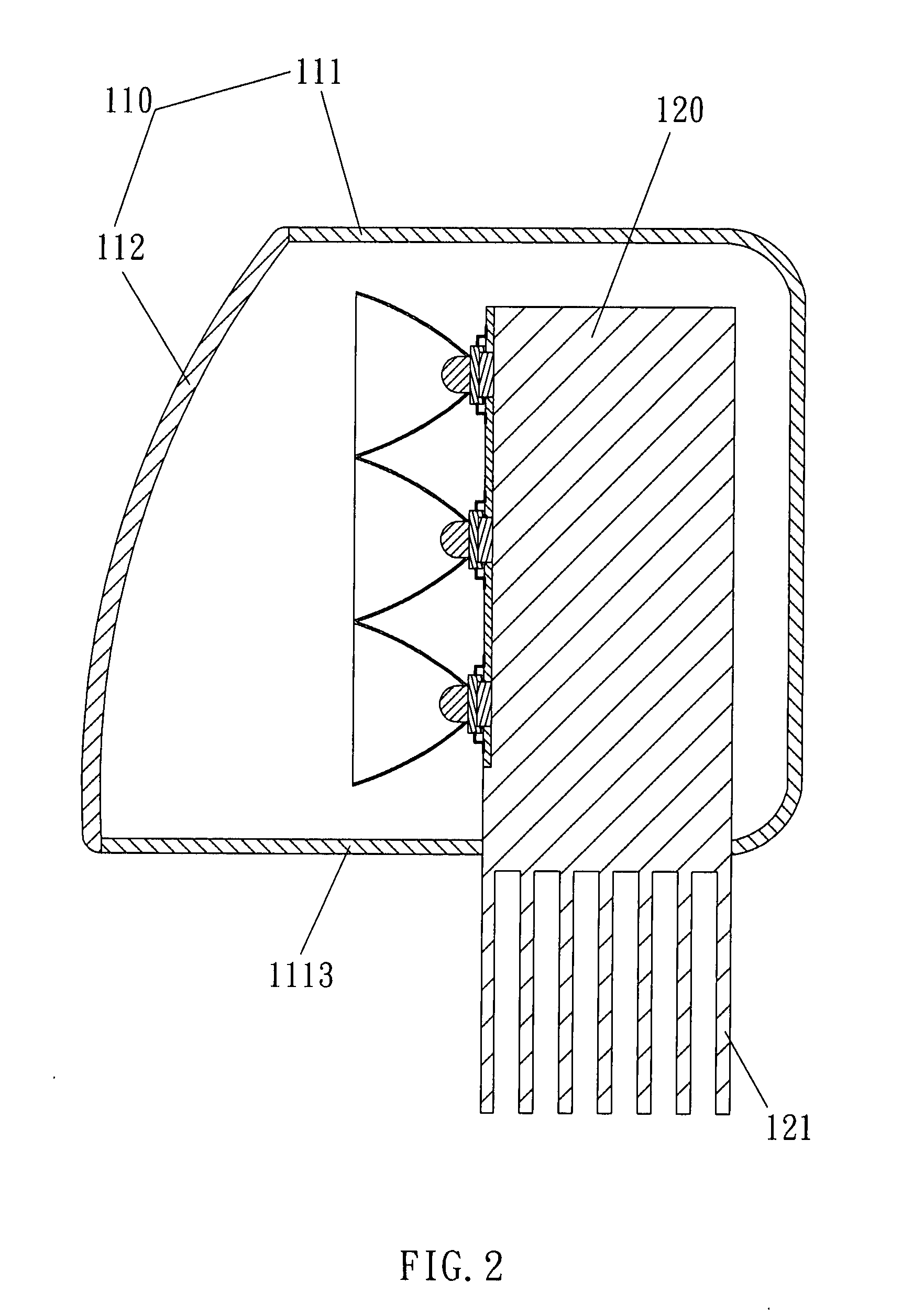

Heat dissipating apparatus for automotive LED lamp

InactiveUS20090059594A1Reduce the temperatureAvoid overall overheatingVehicle headlampsPoint-like light sourceCold airThermal energy

In a heat dissipating apparatus for an automotive LED lamp, the automotive LED lamp includes an automotive lamp set, a heat dissipating module, a plurality of LEDs, and a reflecting unit. The heat dissipating module is wrapped to form an insulation circuit for separating heat energy and electric power of the insulation circuit and heat dissipating module. The LED is electrically connected to the insulation circuit, and a main base of the LED installs a metal conducting plate for conducting the heat produced by the LED to the heat dissipating module. The reflecting unit is installed in the automotive lamp set, so that the heat dissipating module can use a cold air or a liquid coolant as the heat dissipating medium for dissipating heat, preventing a drop of light output caused by an overheat, and avoiding damages to the LED to extend the life expectancy of the automotive LED lamp.

Owner:YIH IND

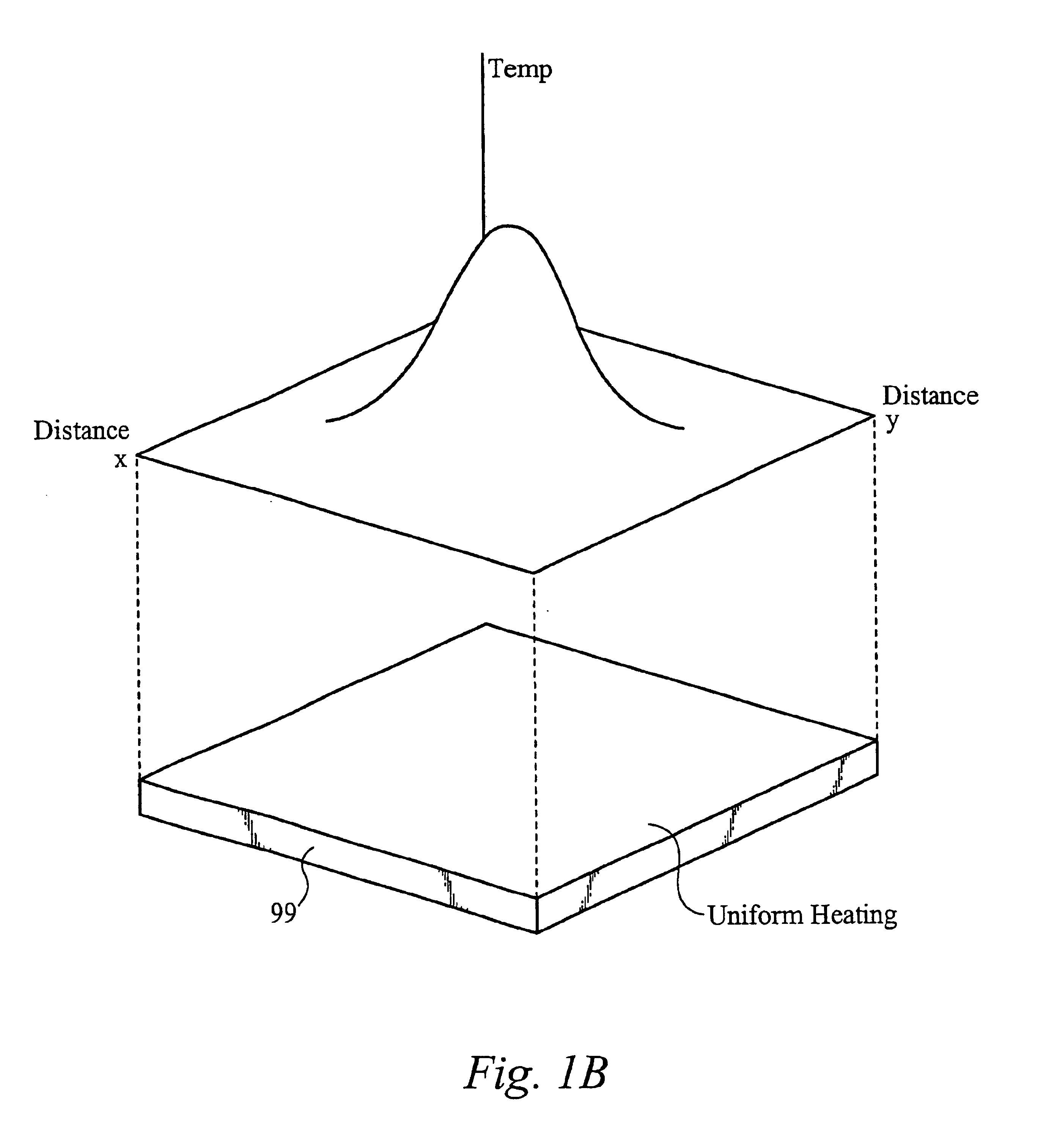

Method and apparatus for achieving temperature uniformity and hot spot cooling in a heat producing device

ActiveUS7104312B2Minimize temperature differenceTemperatue controlSemiconductor/solid-state device detailsTemperature differenceEngineering

A method of controlling temperature of a heat source in contact with a heat exchanging surface of a heat exchanger, wherein the heat exchanging surface is substantially aligned along a plane. The method comprises channeling a first temperature fluid to the heat exchanging surface, wherein the first temperature fluid undergoes thermal exchange with the heat source along the heat exchanging surface. The method comprises channeling a second temperature fluid from the heat exchange surface, wherein fluid is channeled to minimize temperature differences along the heat source. The temperature differences are minimized by optimizing and controlling the fluidic and thermal resistances in the heat exchanger. The resistances to the fluid are influenced by size, volume and surface area of heat transferring features, multiple pumps, fixed and variable valves and flow impedance elements in the fluid path, pressure and flow rate control of the fluid, and other factors.

Owner:VERTIV CORP

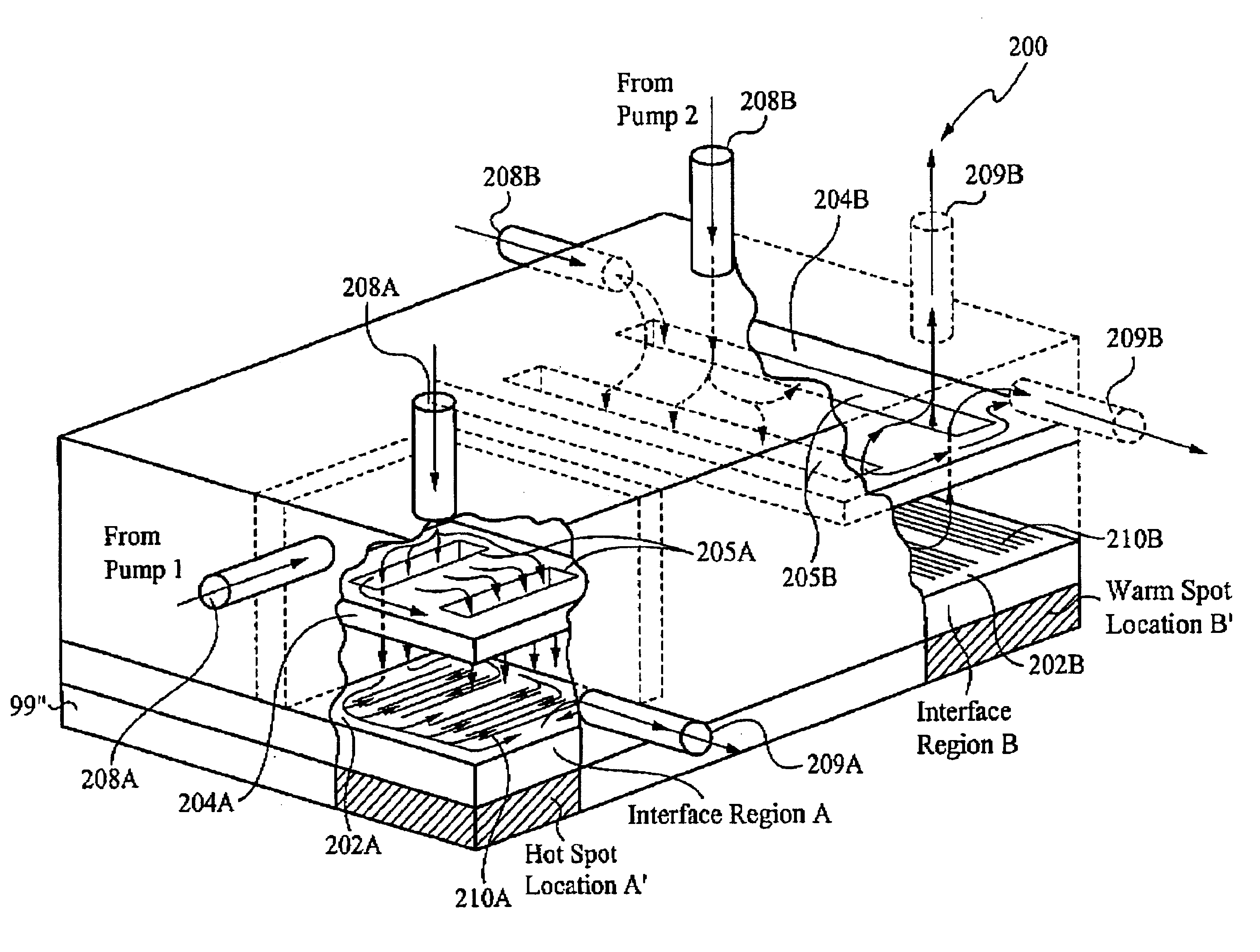

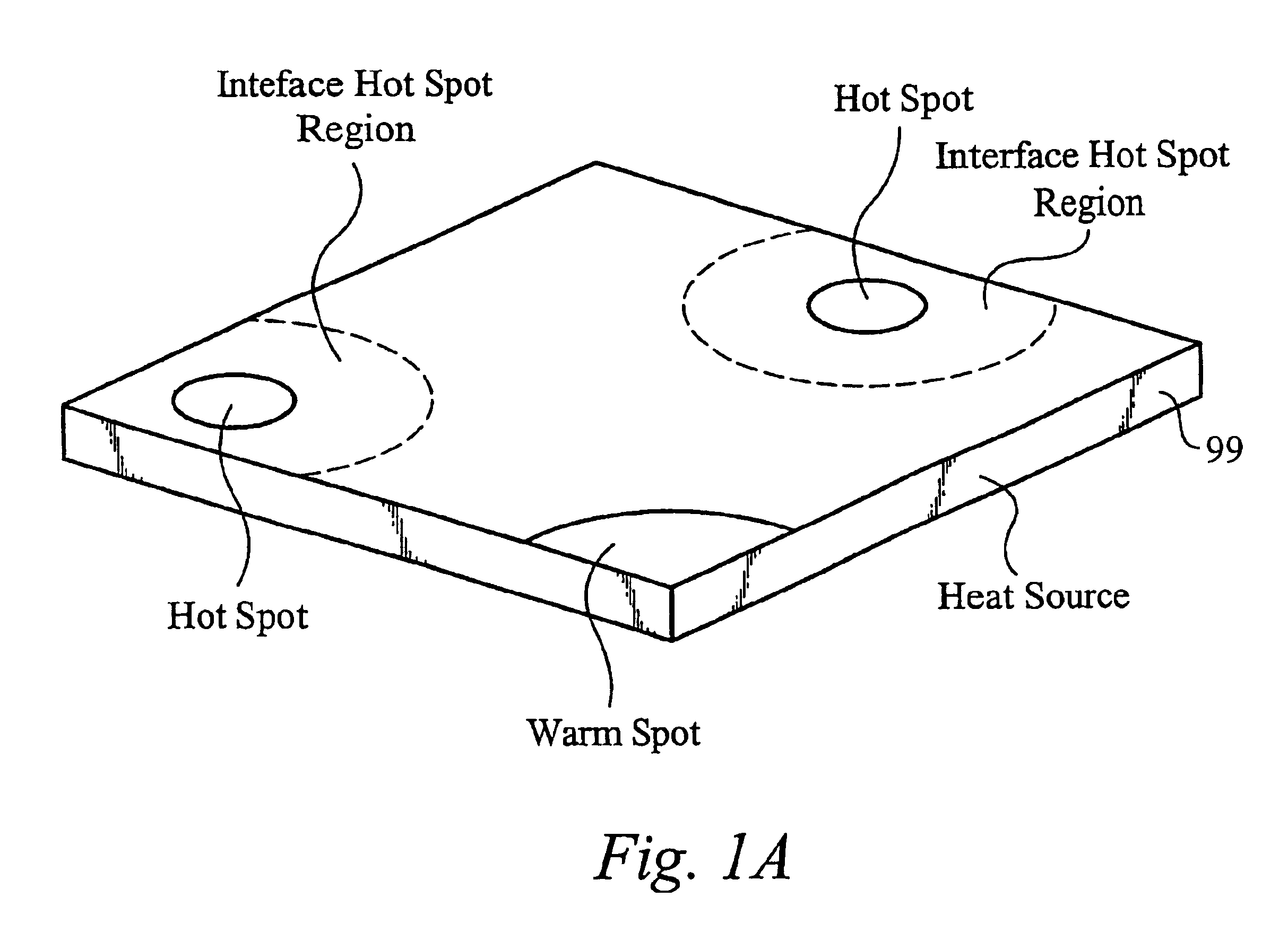

Method and apparatus for flexible fluid delivery for cooling desired hot spots in a heat producing device

InactiveUS6988534B2Temperatue controlSemiconductor/solid-state device detailsInter layerInterface layer

A heat exchanger apparatus and method of manufacturing comprising: an interface layer for cooling a heat source and configured to pass fluid therethrough, the interface layer having an appropriate thermal conductivity and a manifold layer for providing fluid to the interface layer, wherein the manifold layer is configured to achieve temperature uniformity in the heat source preferably by cooling interface hot spot regions. A plurality of fluid ports are configured to the heat exchanger such as an inlet port and outlet port, whereby the fluid ports are configured vertically and horizontally. The manifold layer circulates fluid to a predetermined interface hot spot region in the interface layer, wherein the interface hot spot region is associated with the hot spot. The heat exchanger preferably includes an intermediate layer positioned between the interface and manifold layers and optimally channels fluid to the interface hot spot region.

Owner:VERTIV CORP

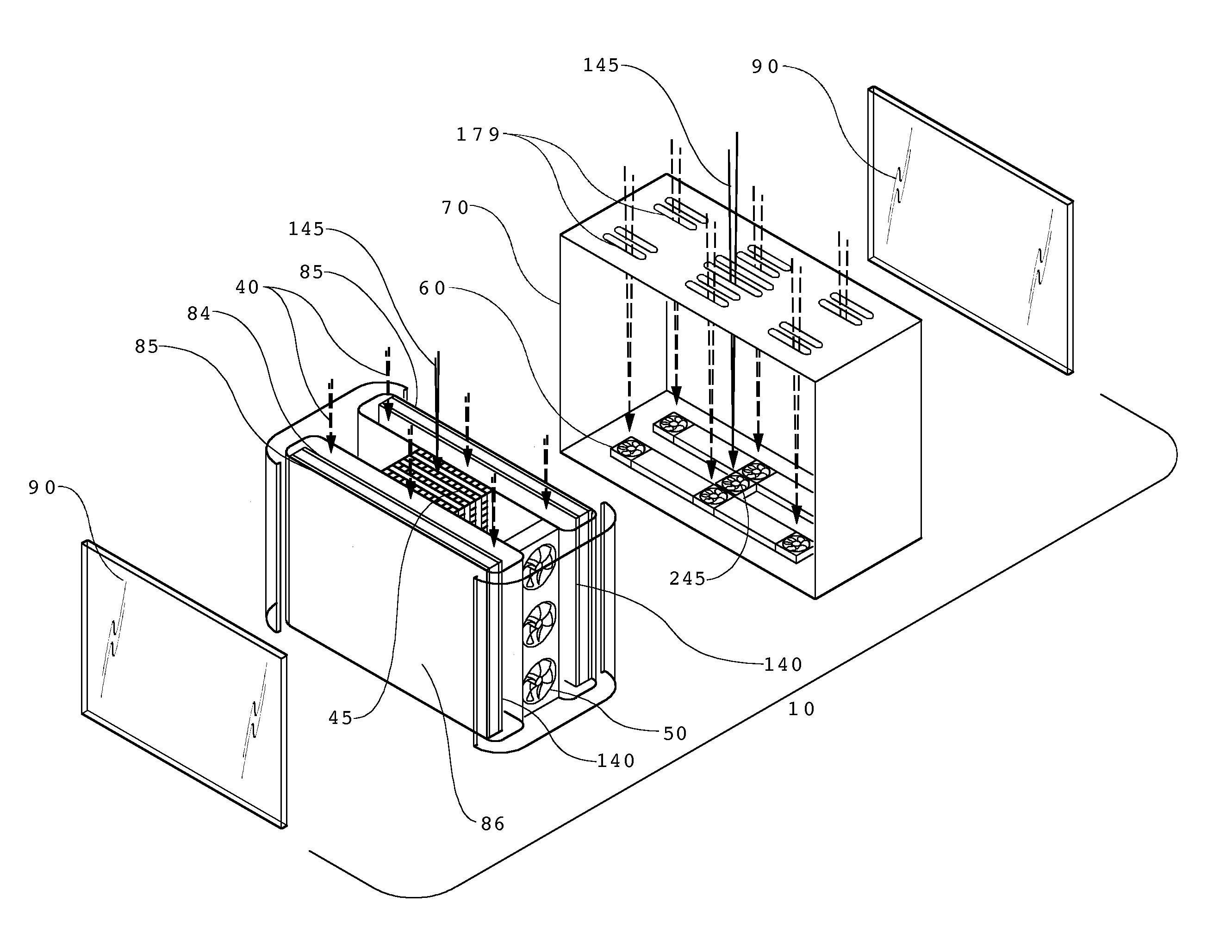

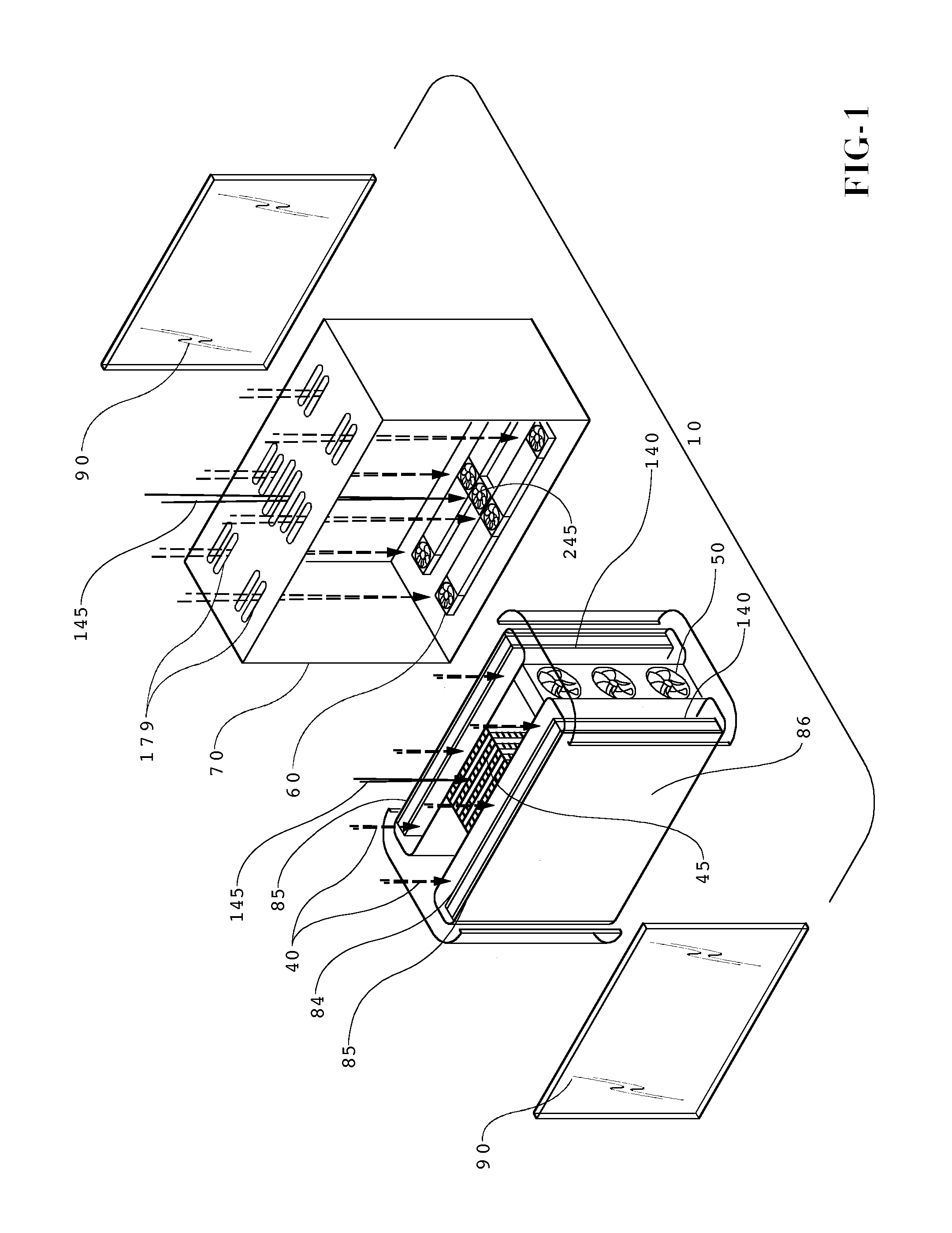

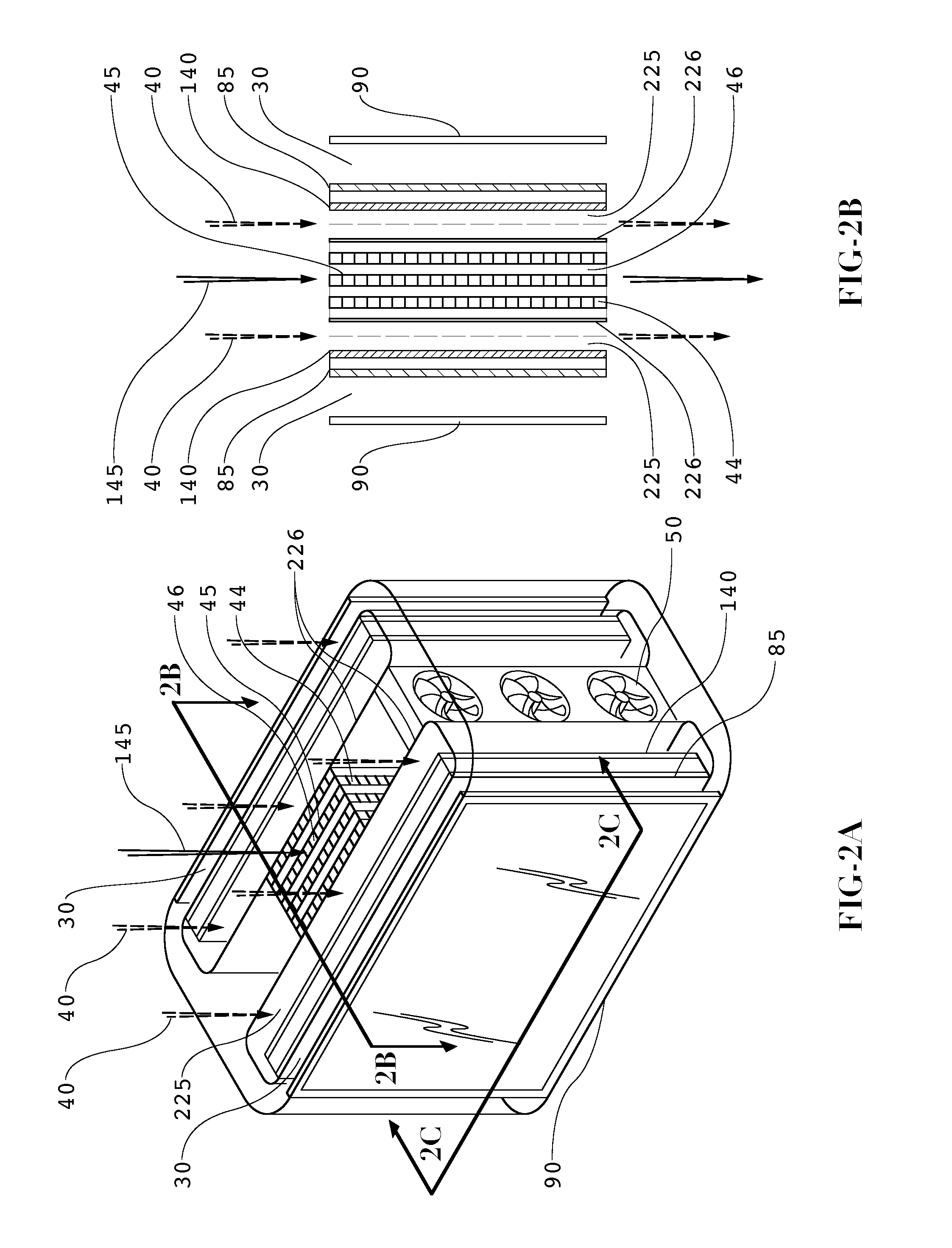

Heat Exchanger for Back to Back Electronic Displays

ActiveUS20110085301A1Digital data processing detailsLighting heating/cooling arrangementsEngineeringElectronic assemblies

A cooling assembly for a dual electronic image assembly having an open and closed gaseous loop. A closed gaseous loop allows circulating gas to travel across the front surface of a pair of electronic image assemblies and through a heat exchanger. An open loop allows ambient gas to pass through the heat exchanger and extract heat from the circulating gas. An optional additional open loop may be used to cool the back portion of the electronic image assembly (optionally a backlight). The cooling assembly can be used with any type of electronic assembly for producing an image. Some embodiments use cross-flow heat exchangers comprised of corrugated plastic.

Owner:MFG RESOURCES INT INC

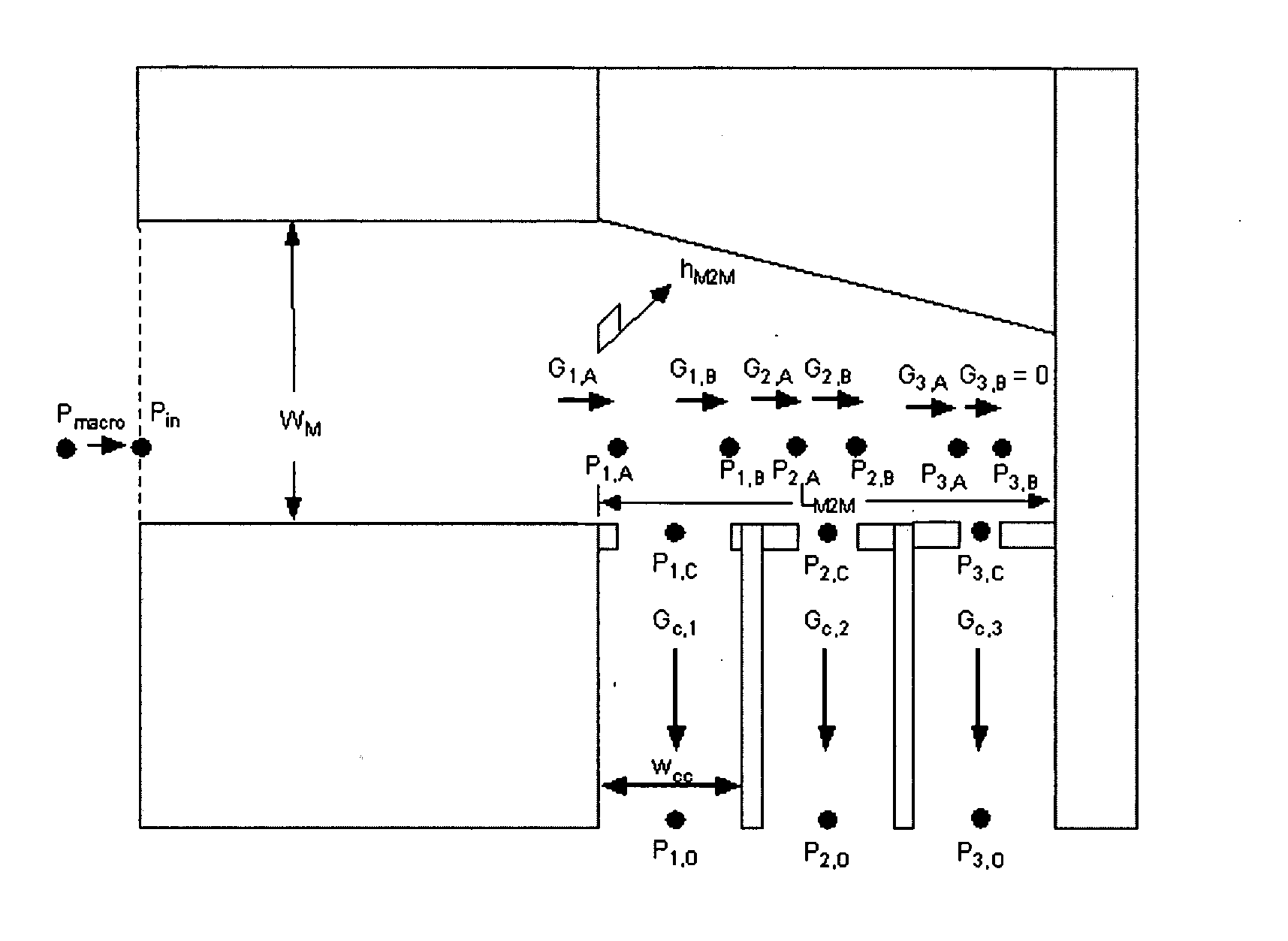

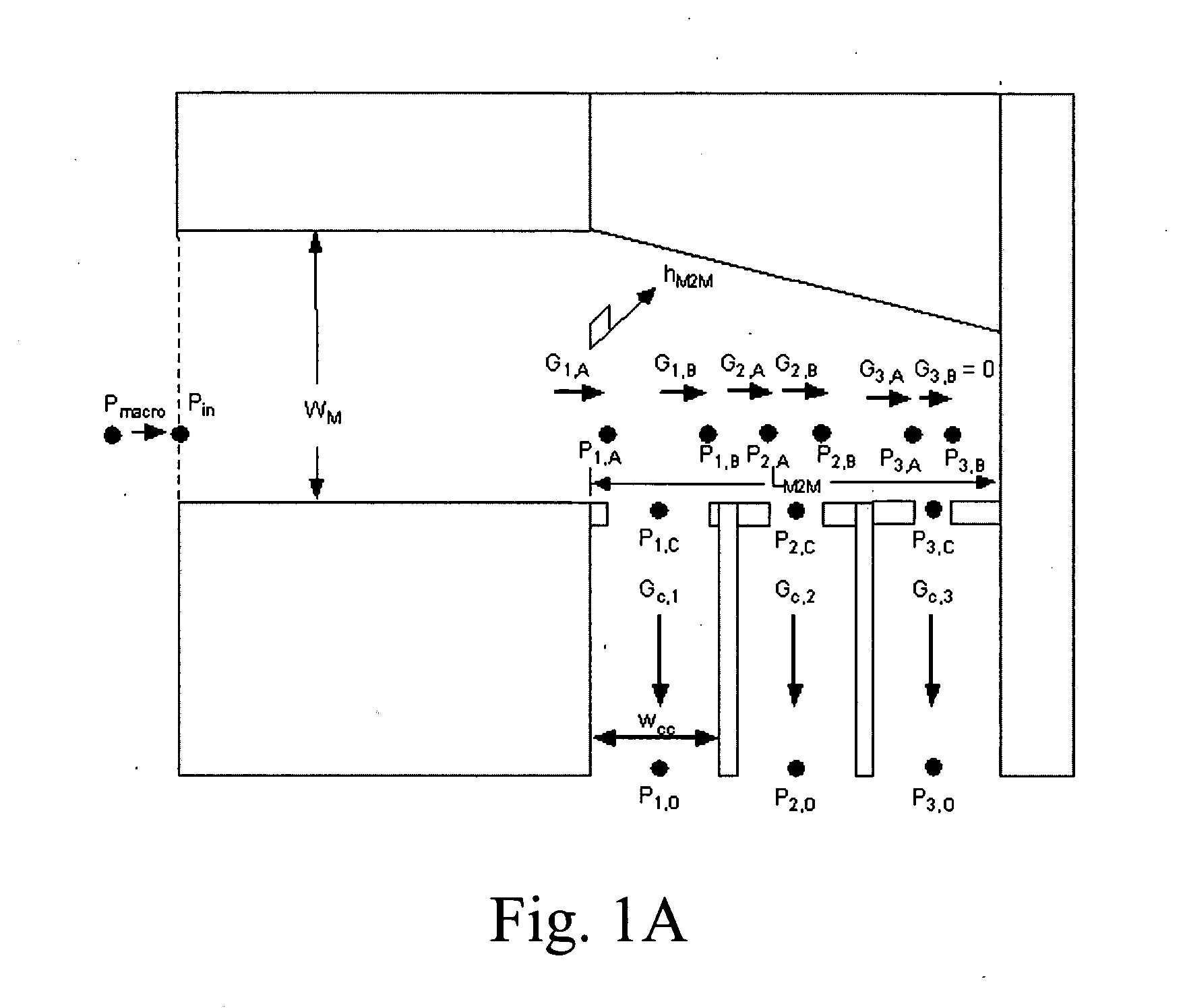

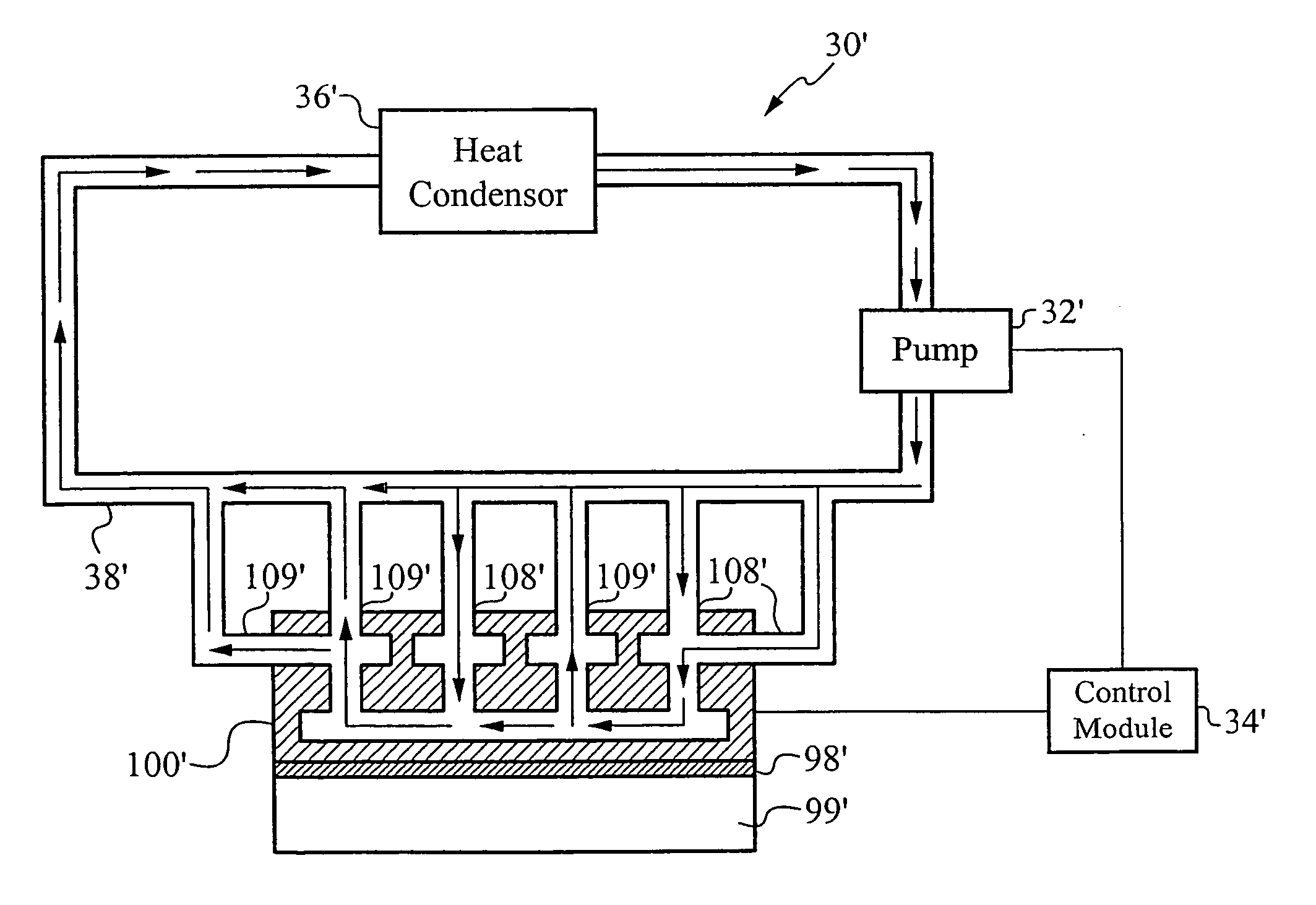

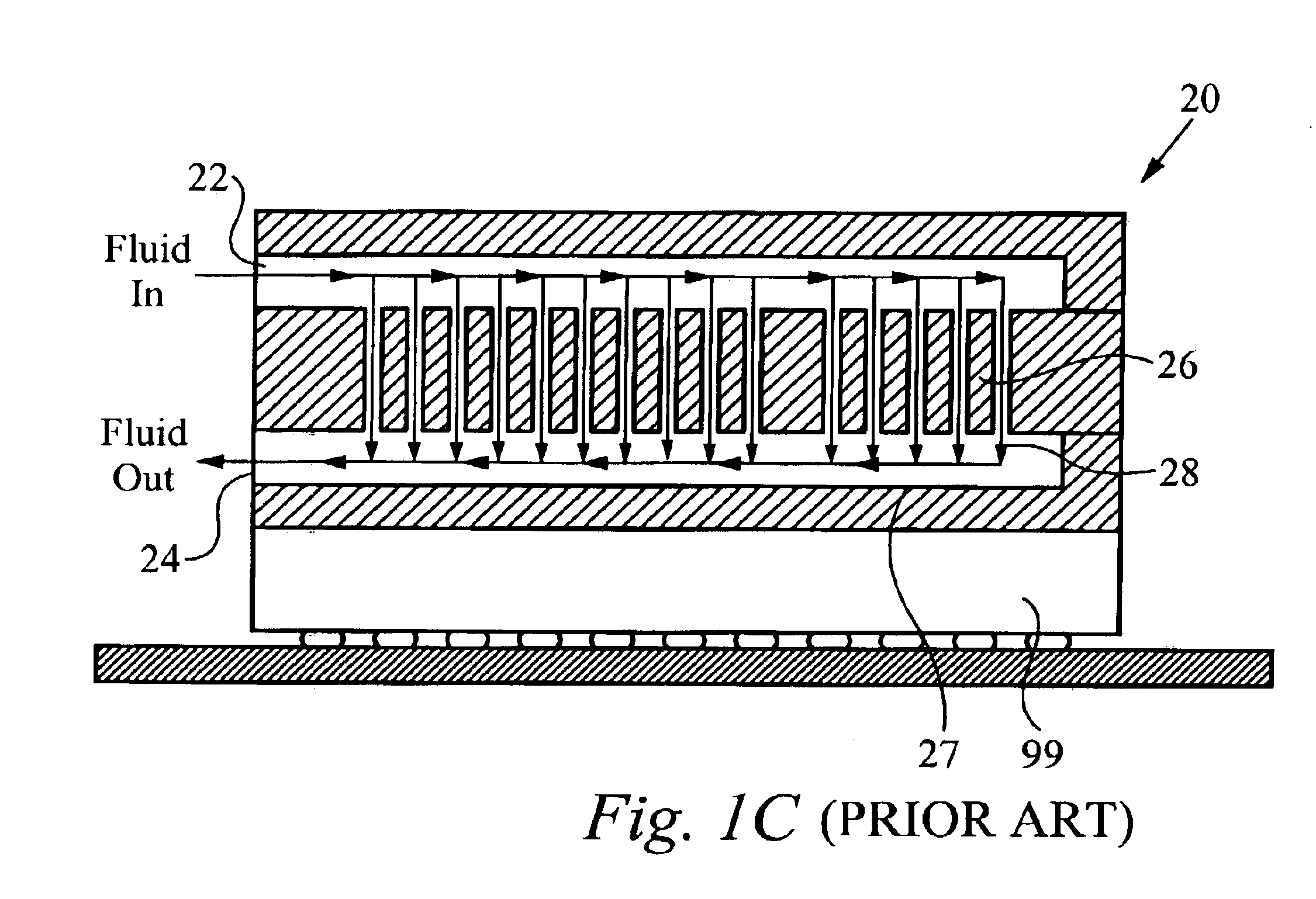

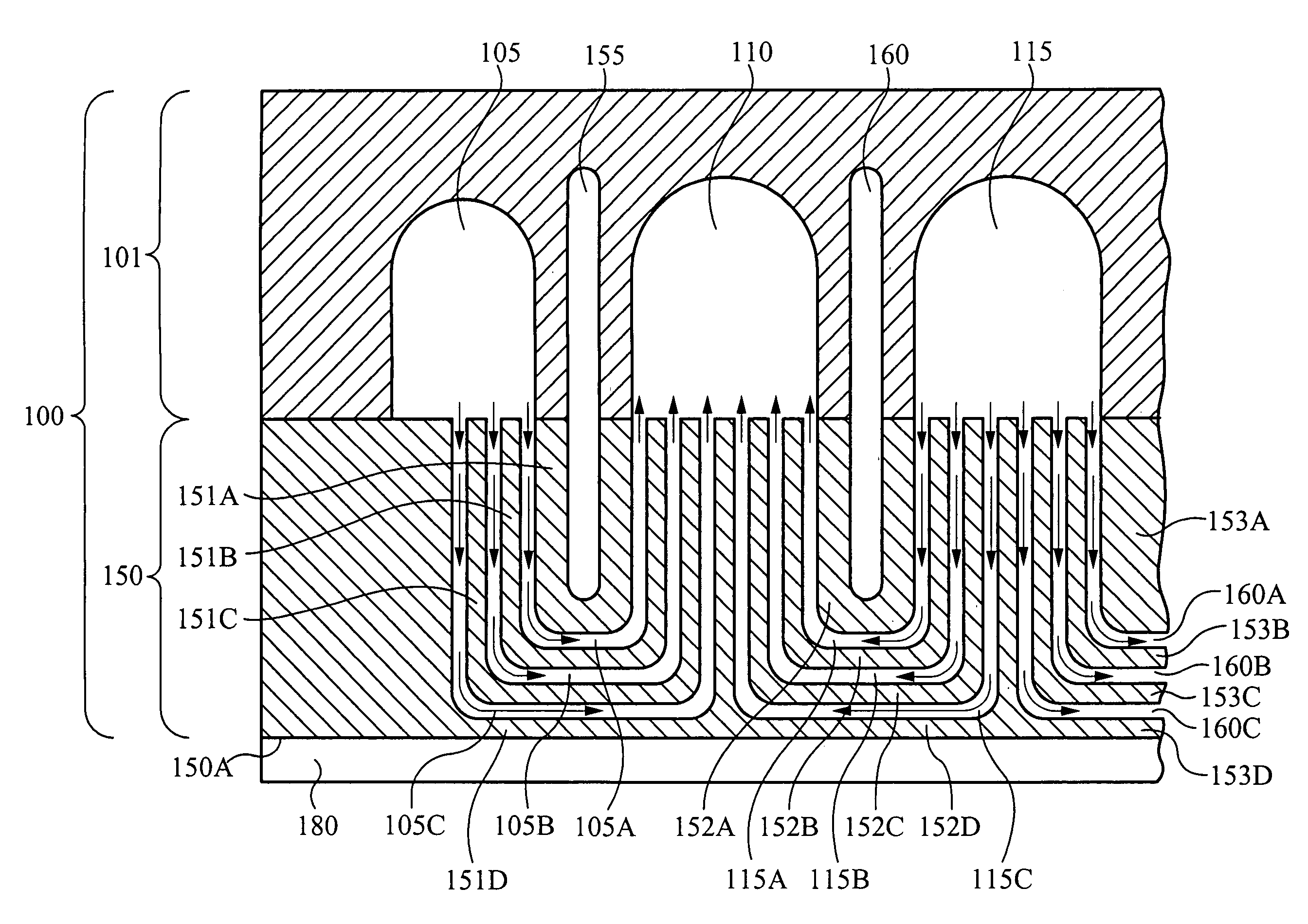

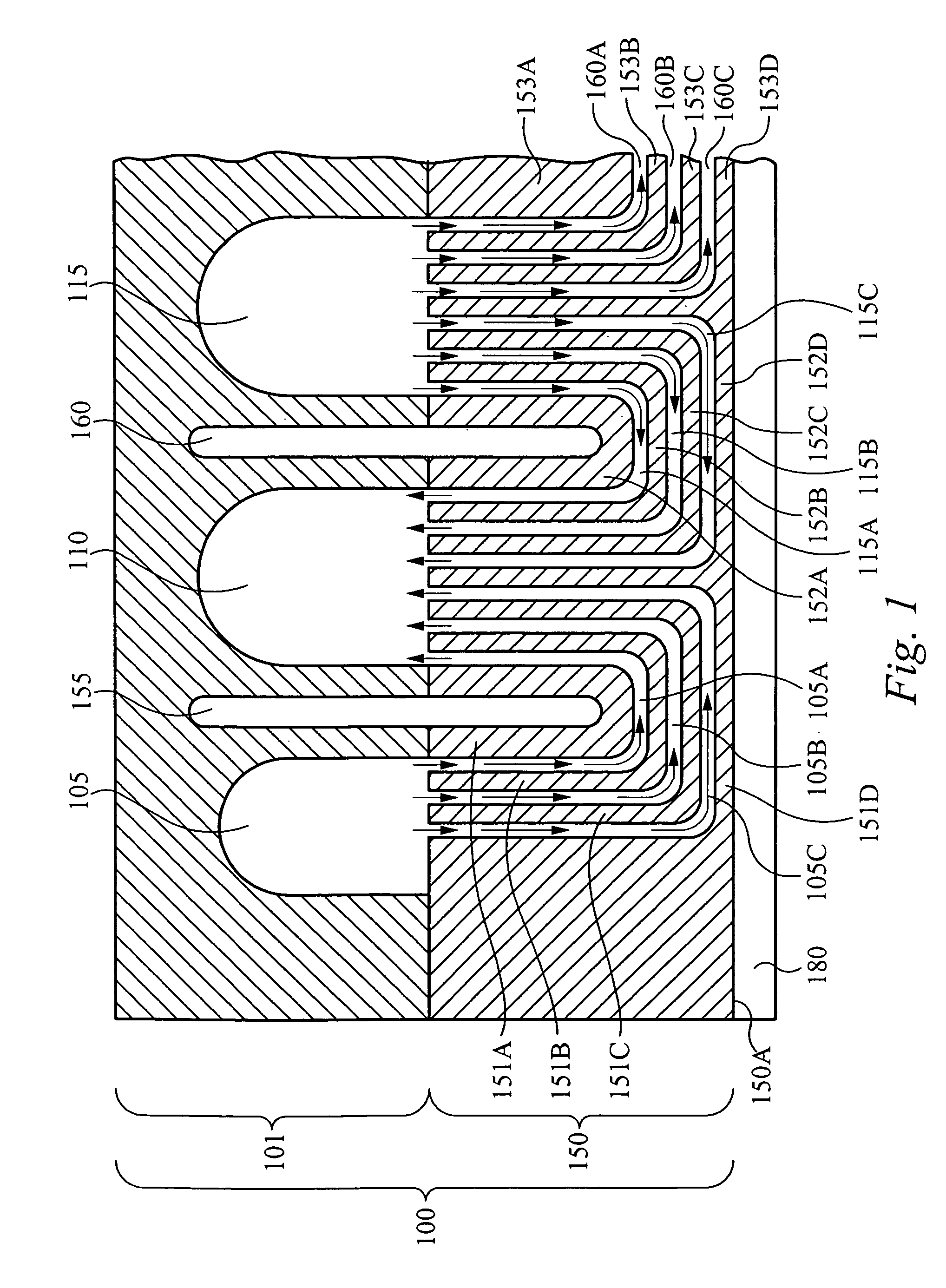

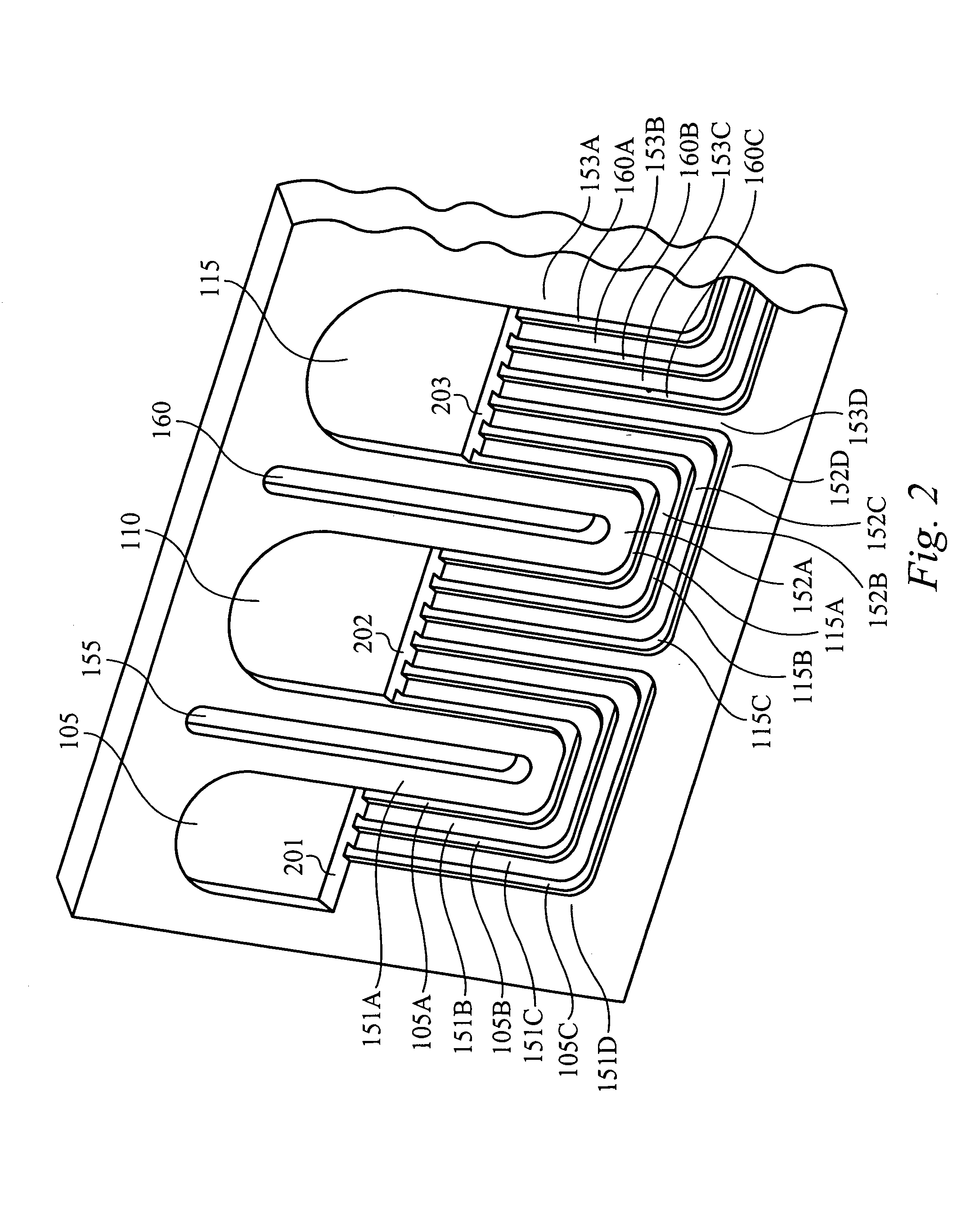

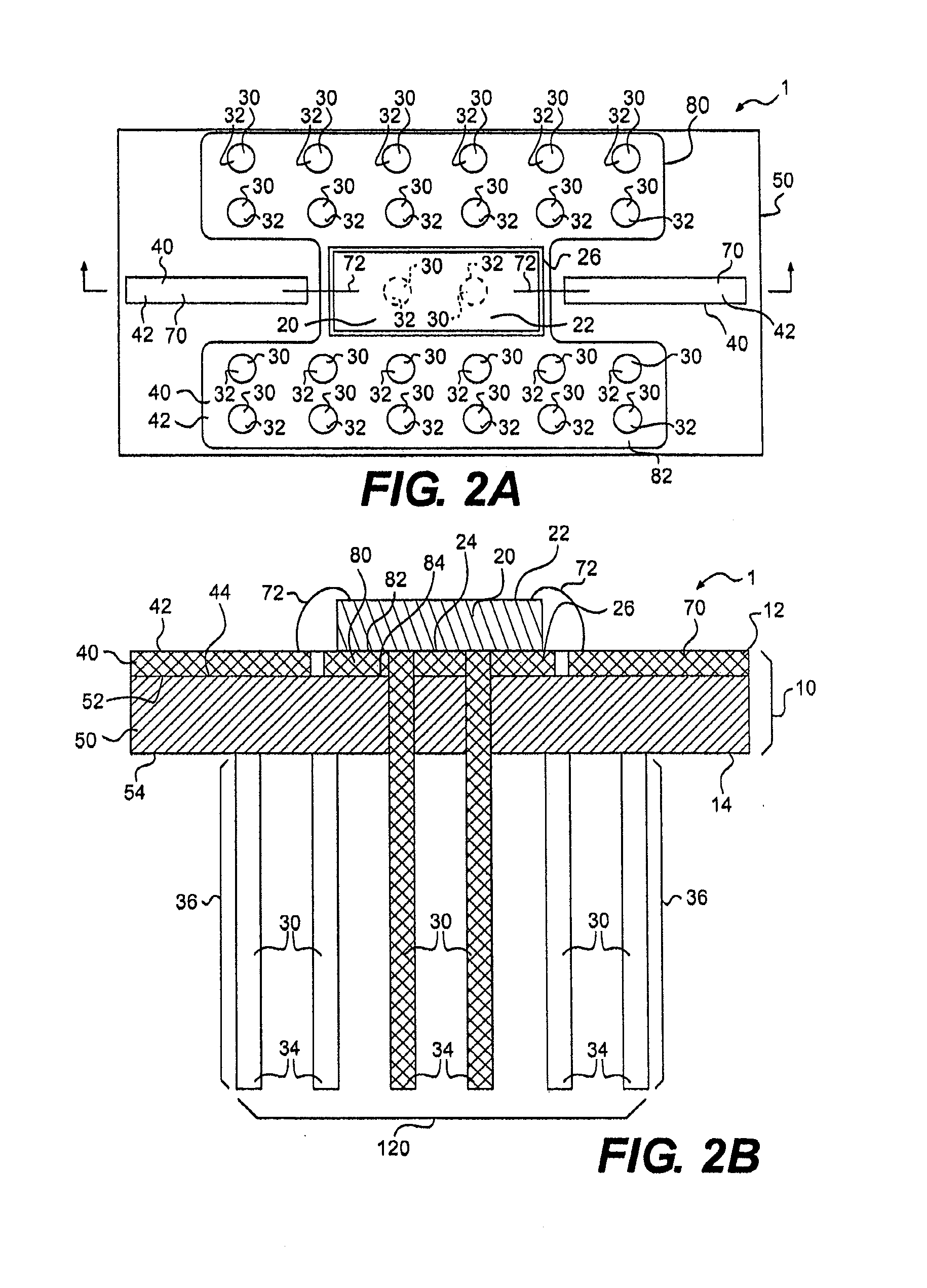

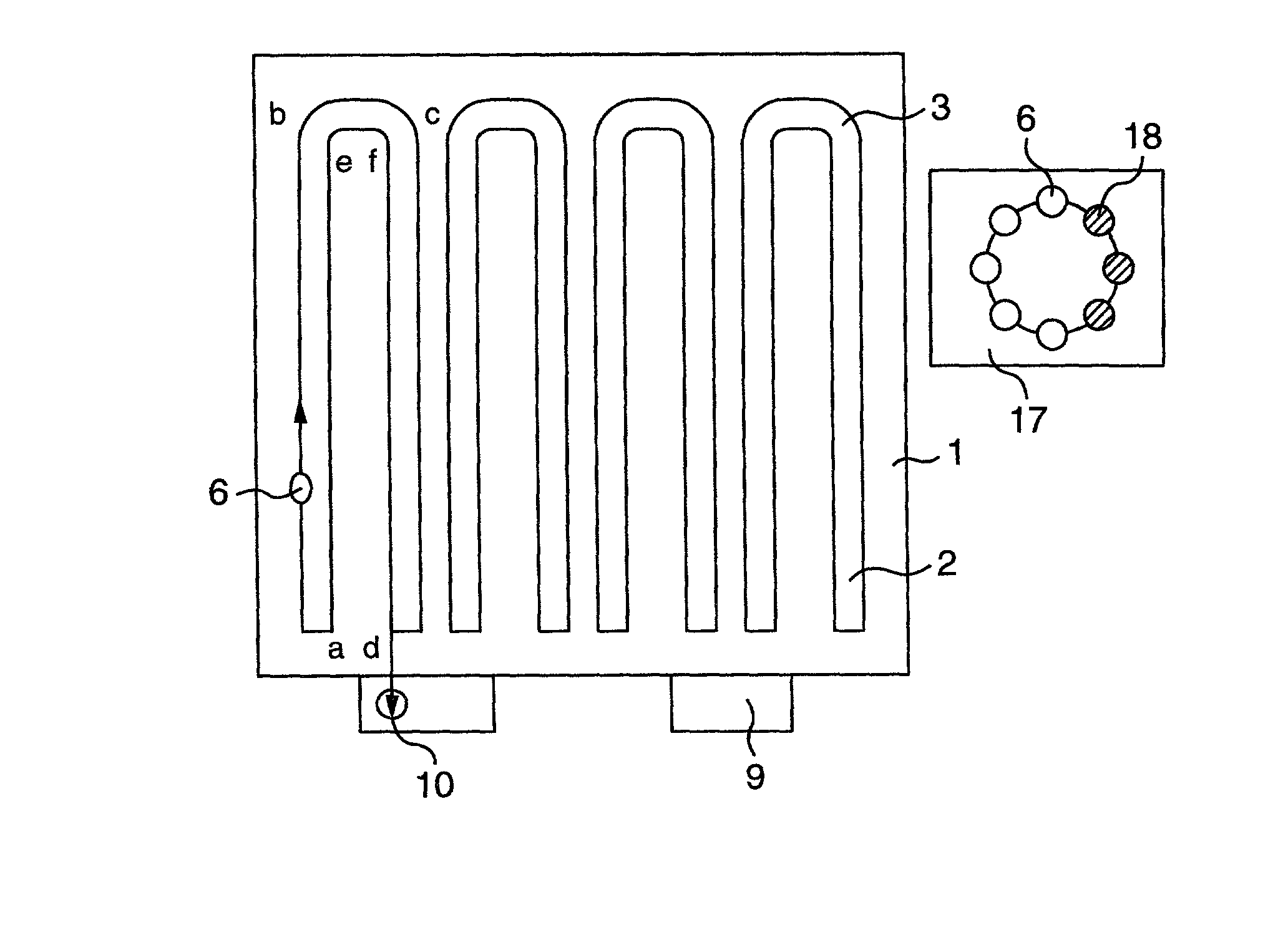

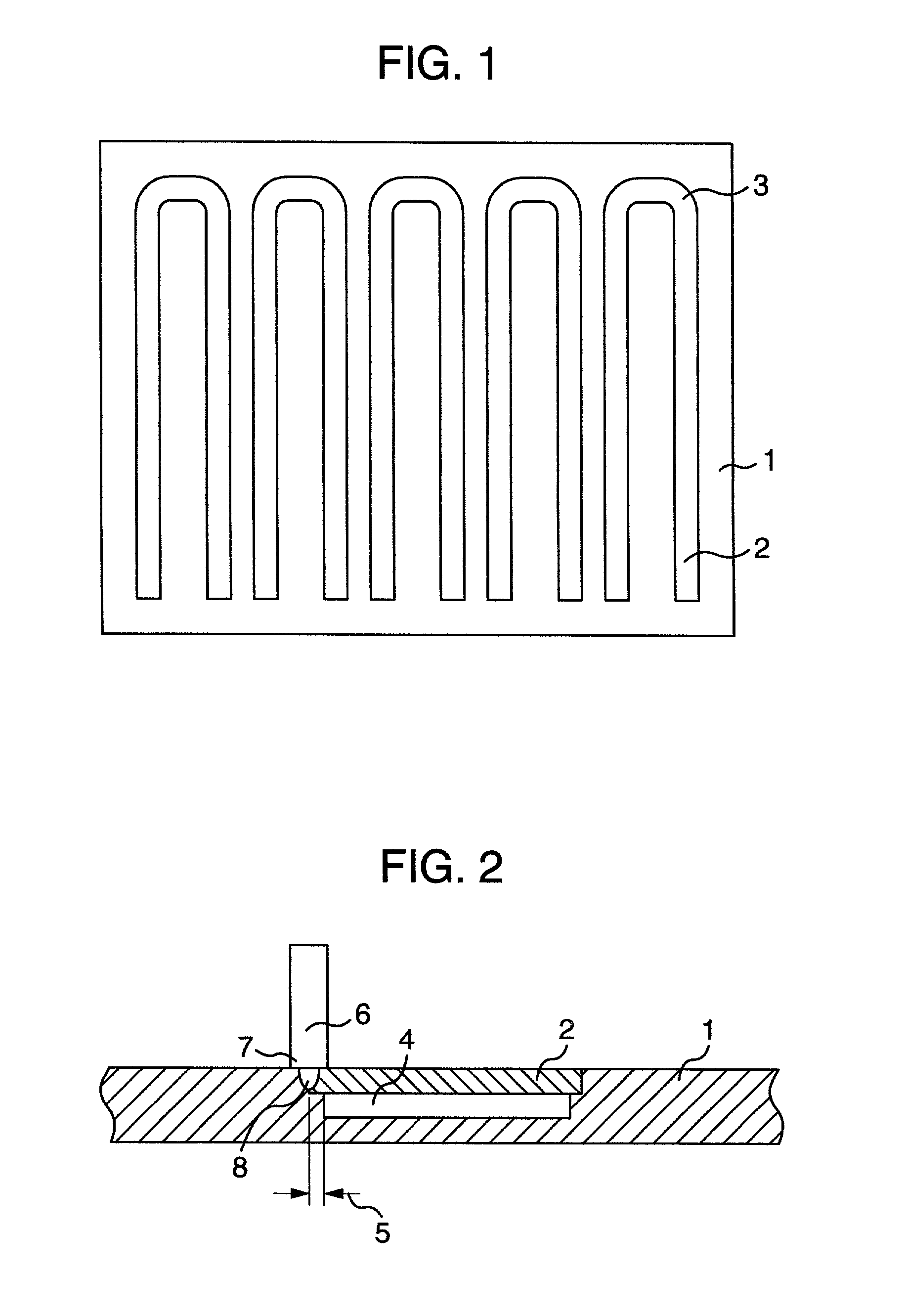

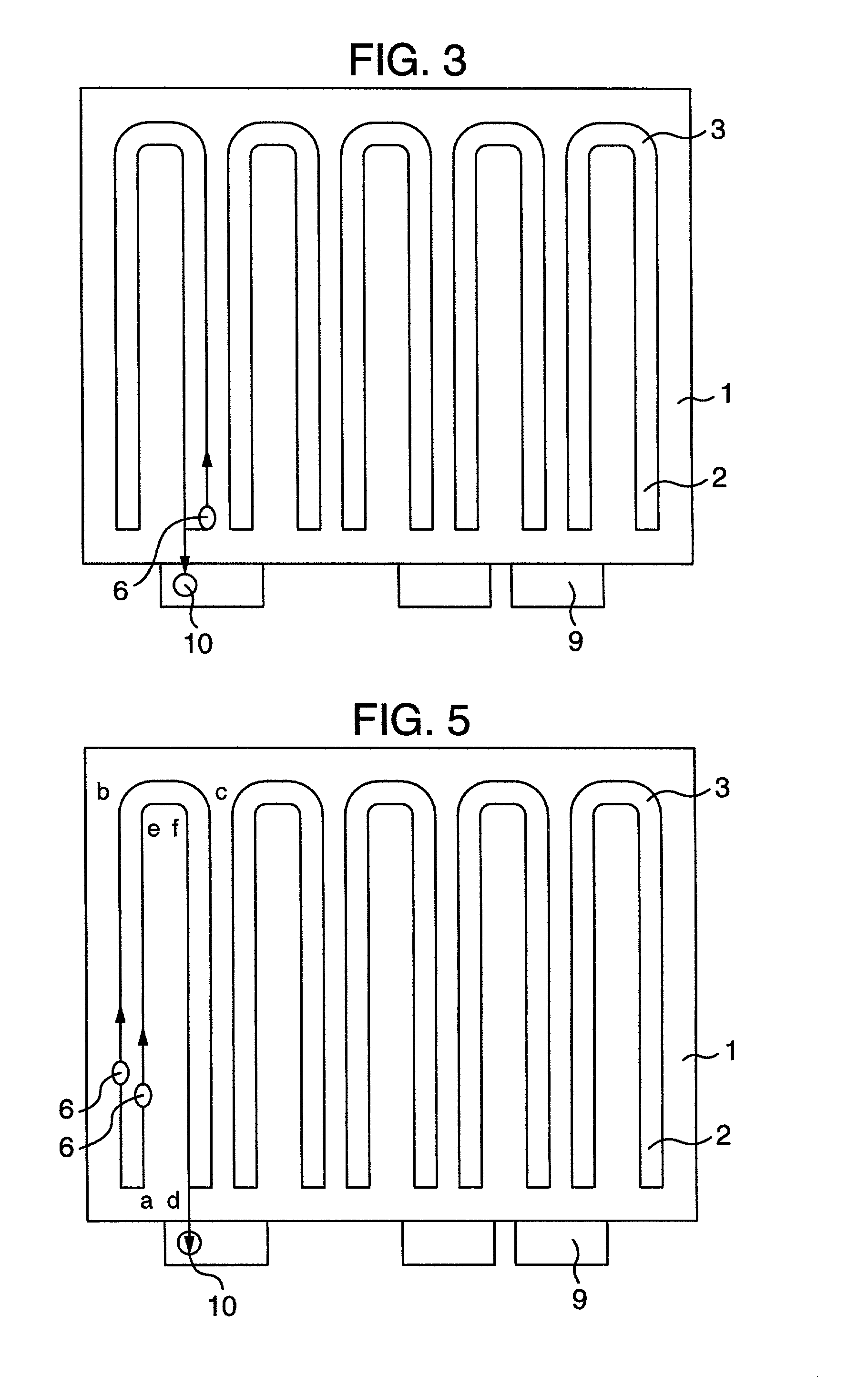

Multi-level microchannel heat exchangers

ActiveUS7156159B2Uniform pressure flowAccurate concentrationThermal insulationSemiconductor/solid-state device detailsInterface layerInlet manifold

An apparatus and method of circulating a heat-absorbing material within a heat exchanger. The apparatus comprises a manifold layer coupled to an interface layer. The manifold layer comprises an inlet manifold and an outlet manifold. The interface layer comprises a plurality of channels that extend from the inlet manifold, toward a heat-exchanging plane, and turn away from the heat-exchanging plane, terminating at the outlet manifold. The plurality of channels are stacked in a plane non-parallel to the heat-exchanging plane. Each of the channels is adjacent to another, thus allowing heat radiated from a heat-generating device to be conducted to a cooling material circulating within the channels, away from the heat-generating device. Preferably, each of the channels has a U-shape or an elongated U-shape.

Owner:VERTIV CORP

Interwoven manifolds for pressure drop reduction in microchannel heat exchangers

InactiveUS6986382B2Semiconductor/solid-state device detailsSolid-state devicesInterface layerEngineering

A microchannel heat exchanger coupled to a heat source and configured for cooling the heat source comprising a first set of fingers for providing fluid at a first temperature to a heat exchange region, wherein fluid in the heat exchange region flows toward a second set of fingers and exits the heat exchanger at a second temperature, wherein each finger is spaced apart from an adjacent finger by an appropriate dimension to minimize pressure drop in the heat exchanger and arranged in parallel. The microchannel heat exchanger includes an interface layer having the heat exchange region. Preferably, a manifold layer includes the first set of fingers and the second set of fingers configured within to cool hot spots in the heat source. Alternatively, the interface layer includes the first set and second set of fingers configured along the heat exchange region.

Owner:VERTIV CORP

Ergonomic systems and methods providing intelligent adaptive surfaces and temperature control

Owner:PROMDX TECH

Liquid-cooled heat sink with thermal jacket

A liquid-cooled heat sink is provided having a cooling housing including a peripheral side wall extending from the perimeter of a bottom wall and a lid sized to engage the peripheral side wall so as to form a chamber. A fluid inlet port and a fluid outlet port are defined through the lid, and disposed in fluid communication with the chamber. In one embodiment, a plurality of pins project outwardly from the bottom wall so as to be positioned within the chamber and arranged in a staggered pattern. The pins include an end that engages the undersurface of the lid. In an alternative embodiment, a corrugated fin having a plurality of corrugations is positioned within the chamber so that at least one of the corrugations engages the bottom wall and at least one of the corrugations engages the under surface of the lid.

Owner:THERMAL

Heat sink with microchannel cooling for power devices

InactiveUS7353859B2Semiconductor/solid-state device detailsSolid-state devicesEngineeringThermal contact

An apparatus for cooling at least one heated surface includes a base plate defining a number of inlet and outlet manifolds. The inlet manifolds are configured to receive a coolant, and the outlet manifolds exhaust the coolant. The inlet and outlet manifolds are interleaved. The apparatus also includes at least one substrate having inner and outer surfaces. The inner surface is coupled to the base plate and defines a number of microchannels that receive the coolant from the inlet manifolds and deliver the coolant to the outlet manifolds. The microchannels are oriented substantially perpendicular to the inlet and outlet manifolds. The outer surface is in thermal contact with the heated surface. The apparatus also includes an inlet plenum that supplies the coolant to the inlet manifolds, and an outlet plenum that exhausts the coolant from the outlet manifolds. The inlet plenum and outlet plenum are oriented in a plane of the base plate.

Owner:GENERAL ELECTRIC CO

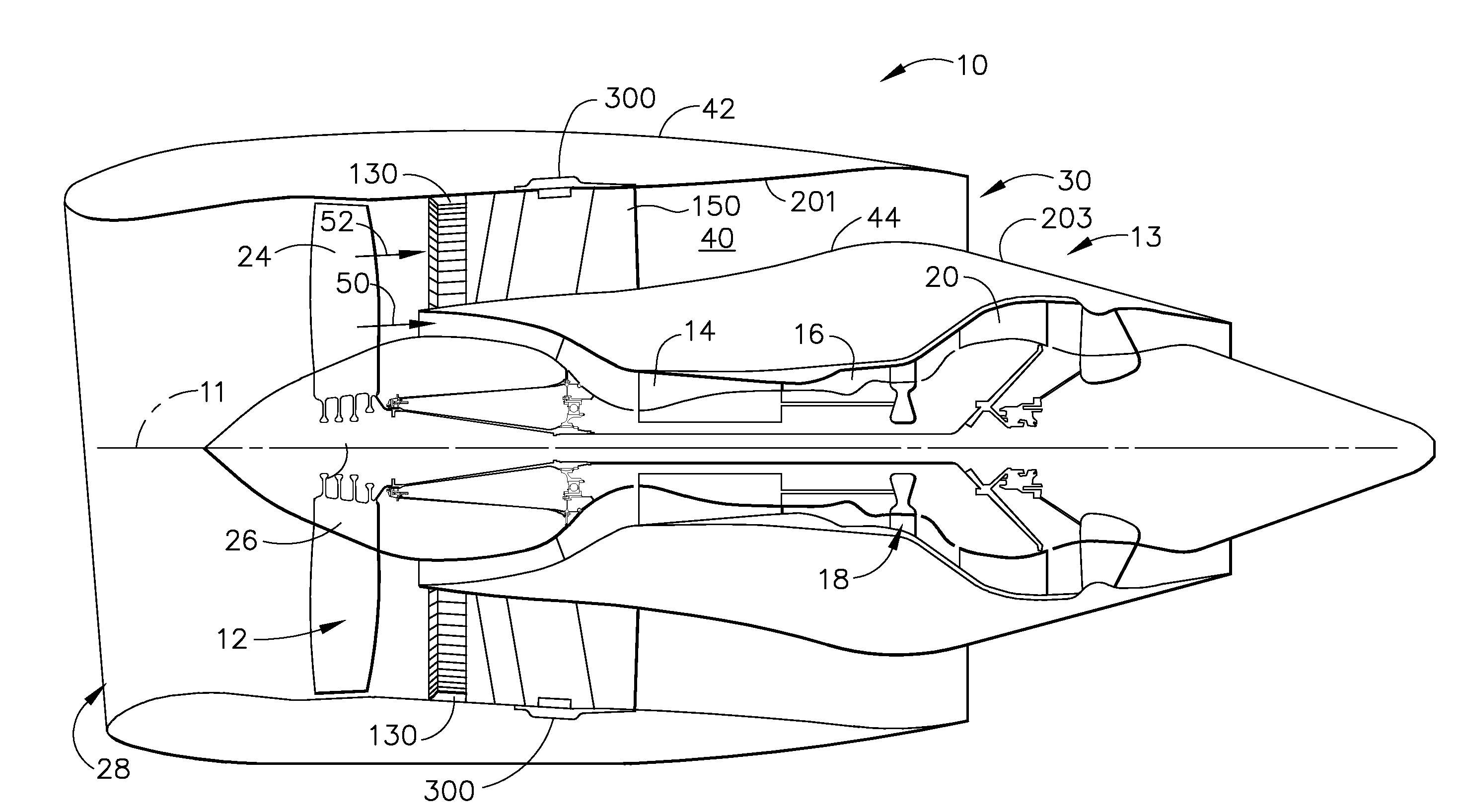

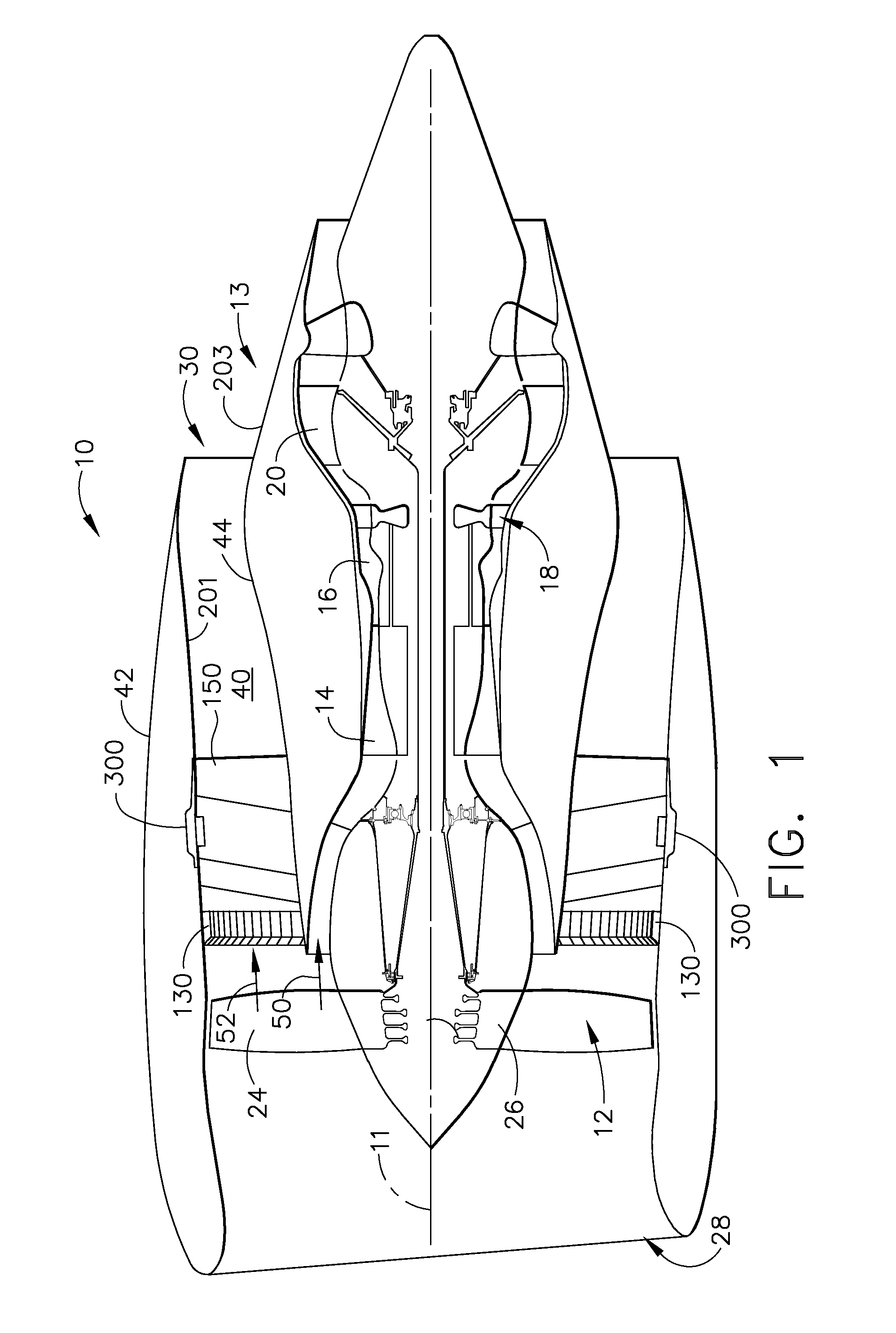

Method and apparatus for operating gas turbine engine heat exchangers

ActiveUS20080095611A1Turbine/propulsion engine coolingEfficient propulsion technologiesEngineeringTurbine

A method for assembling a turbine engine includes assembling a heat exchanger assembly that includes at least a radially inner plate, a radially outer plate, and a heat exchanger coupled between the radially inner and outer plates, forming the heat exchanger assembly such that the heat exchanger assembly has a substantially arcuate shape, and coupling the heat exchanger to a fan casing such that the heat exchanger is positioned upstream or downstream from the fan assembly.

Owner:UNISON INDUSTRIES +1

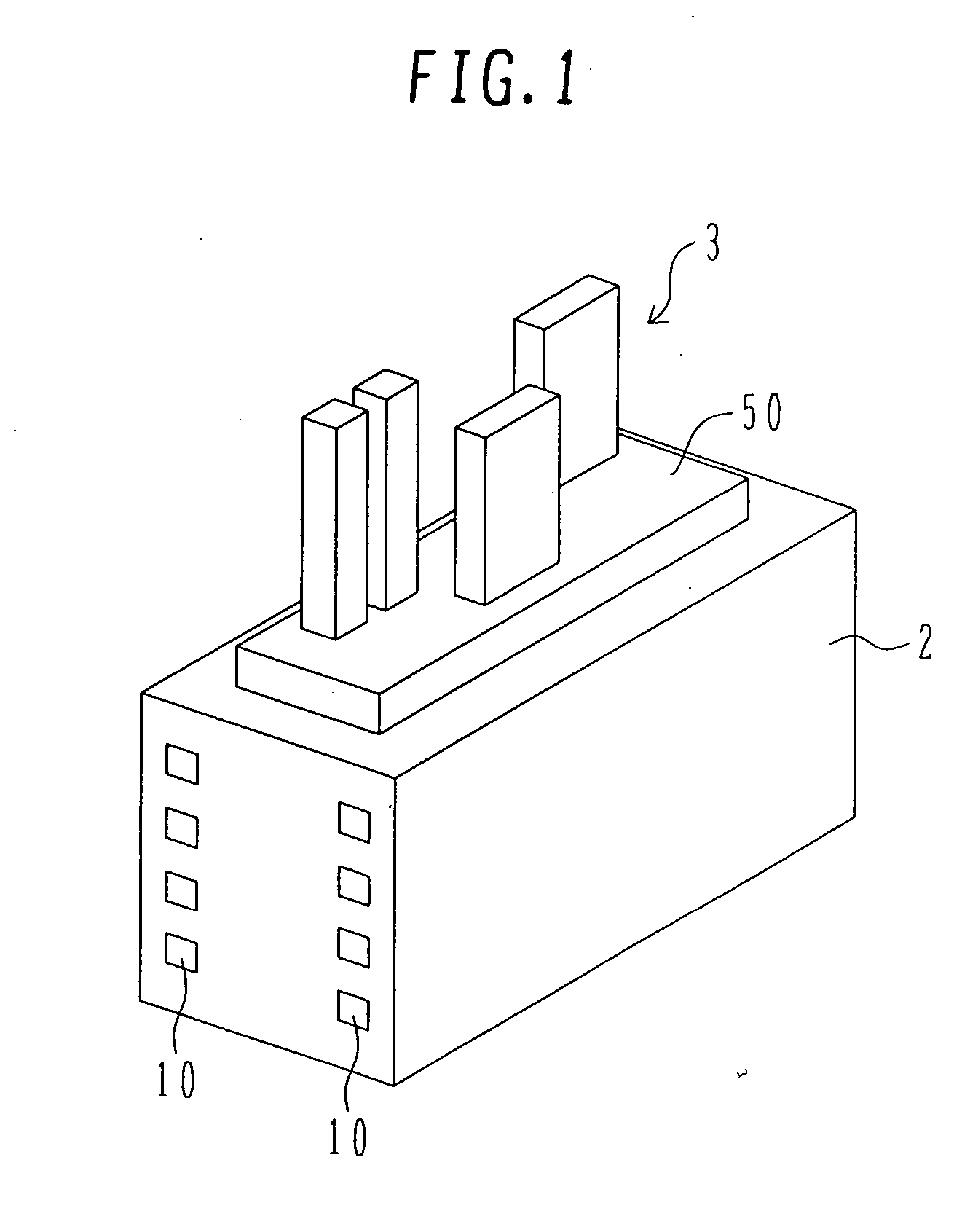

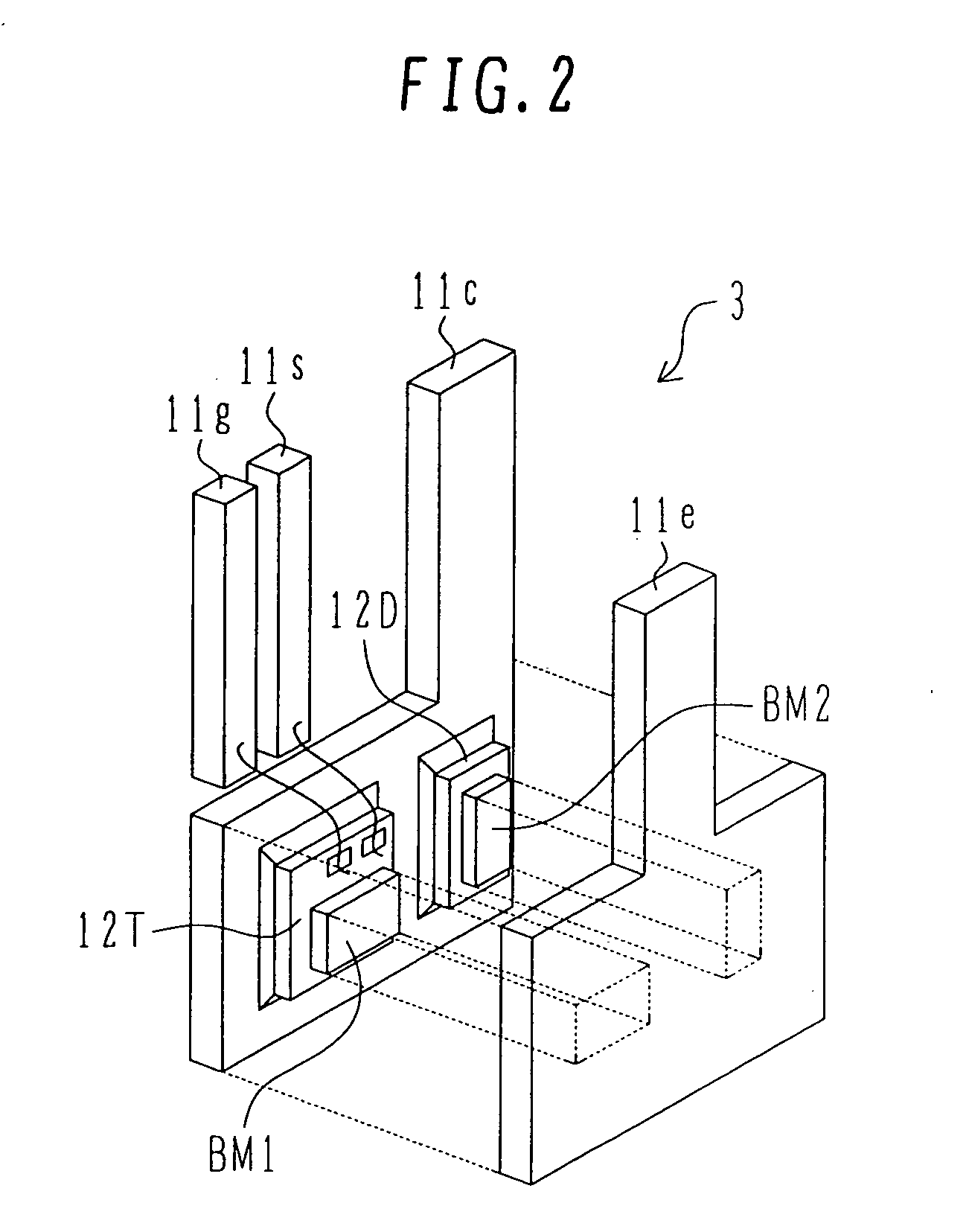

Semiconductor unit, and power conversion system and on-vehicle electrical system using the same

InactiveUS20070096278A1Improve insulation performanceReduce thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipElectric power

A semiconductor device includes a semiconductor chip and leads electrically connected to the electrodes of the semiconductor chip. A hollow radiator base houses the semiconductor device which is molded with high-thermal-conductivity resin having an electrical insulating property. The radiator base has a cooling-medium channel therein or radiating fins on the outside. Alternatively, the radiator base is housed in a second radiator base.

Owner:HITACHI LTD

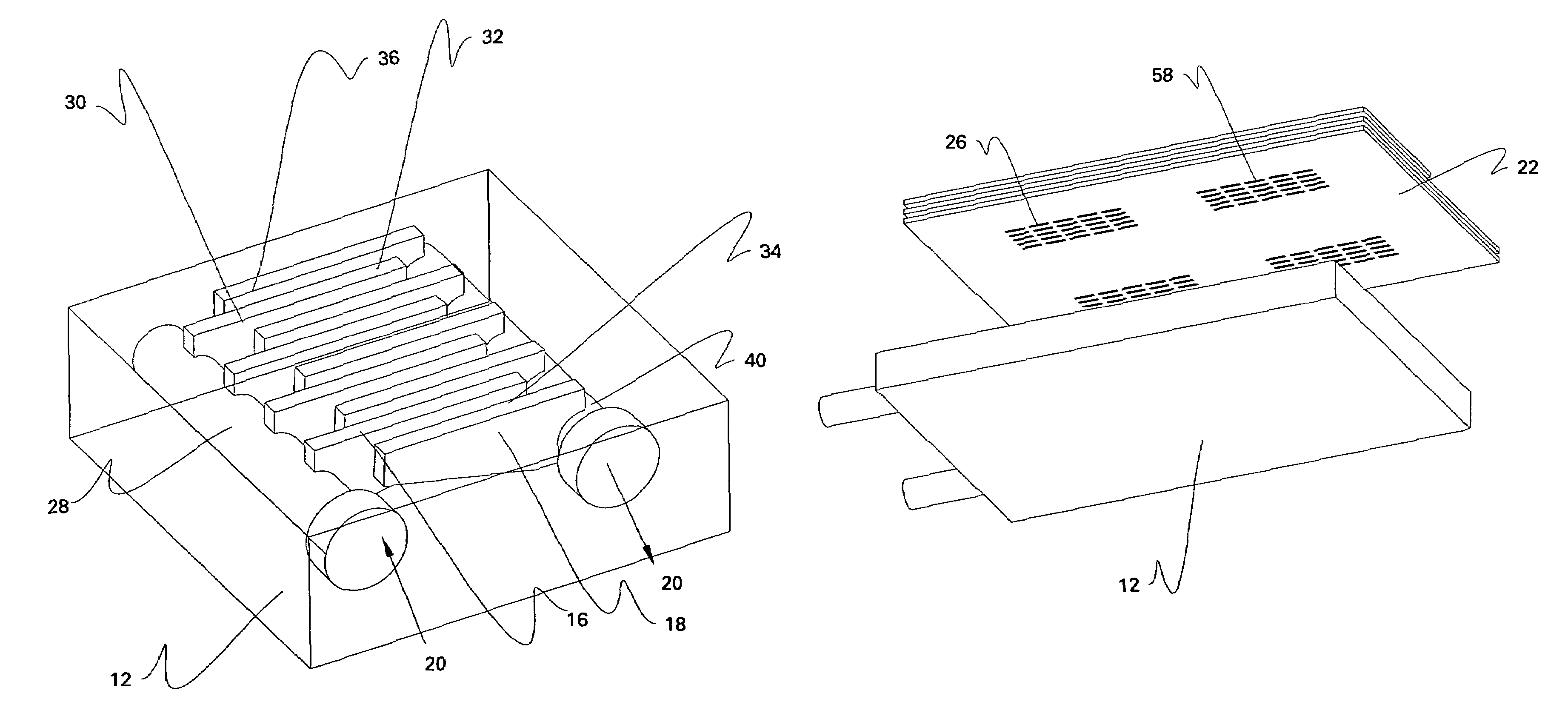

Apparatus and method for thermal dissipation in a light

A device is disclosed for producing light that may include one or more printed circuit boards (PCBs), an electronics package may be disposed about the first surface of one or more of the PCBs and a housing. The PCBs may include a metal layer and a core, and, in some aspects, may include multiple cores interposed between multiple metal layers, and in some embodiments a backplane may be disposed along the core(s). A plurality of PCB's may be set apart and connected by pins to dissipate heat from one PCB to another, and / or to convey electrical connectivity. Pins may be configured to pass through or into one or both the PCBs including the cores to conduct heat generated by the electronics package away for dispersion. In some embodiments, the pins may pass into the backplane. The PCBs may include LEDs, lights, computer devices, memories, telecommunications devices, or combinations of these. The device may also include a housing to contain the plurality of PCBs such that air flow may enter the housing and pass by the pins for cooling of the PCBs and electronics thereof. The housing may also be configured to permit external power to be applied to the PCBs within the apparatus.

Owner:NEXXUS LIGHTING

Heat sink

InactiveUS20080066888A1Minimized pressure dropImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesRADIUSHeat spreader

A heat sink comprises a base panel having a top surface and a bottom surface. A plurality of pin fins extend outwardly from the top surface and each fin has a cross-sectional configuration with two radiuses, a first radius and a second radius, wherein the first radius is larger than the second radius. The first and second radiuses are tangentially interconnected by intermediate portions, giving the pin fin cross-sectional configuration a raindrop shape, thereby generating low pressure drop across the heat sink by minimizing the drag force effects and maintaining large exposed surface area available for heat transfer.

Owner:DANAHER MOTION STOCKHOLM AB

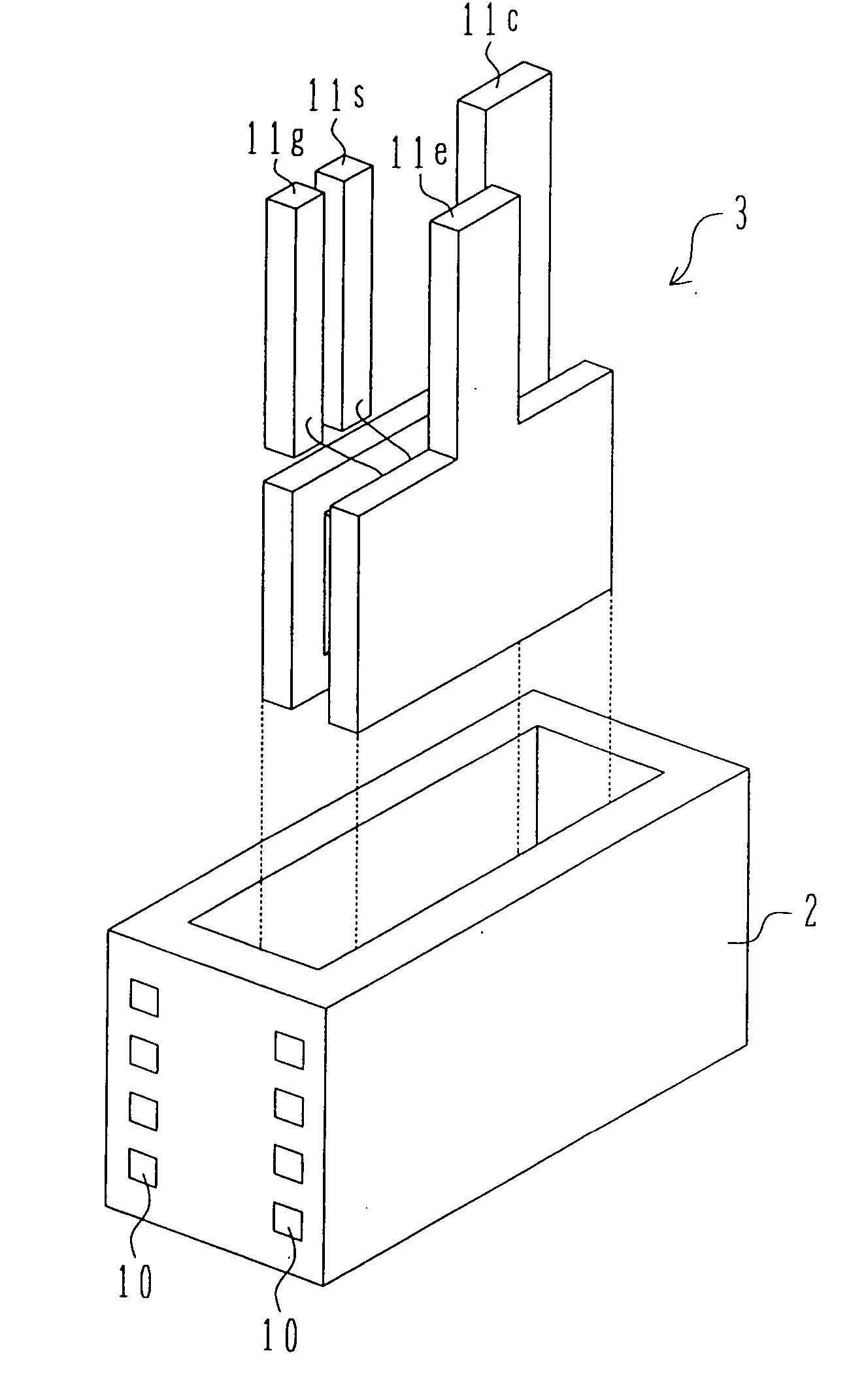

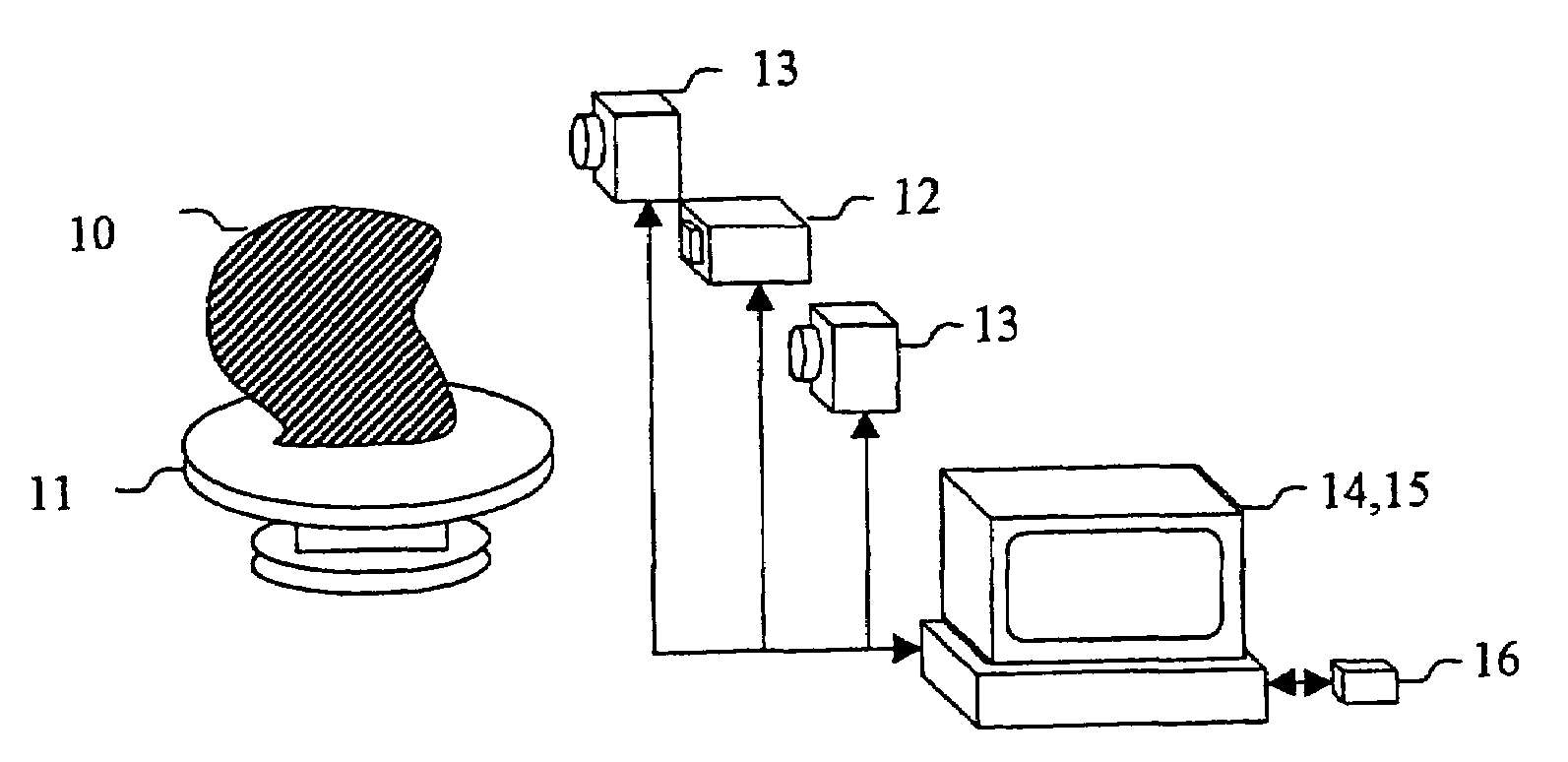

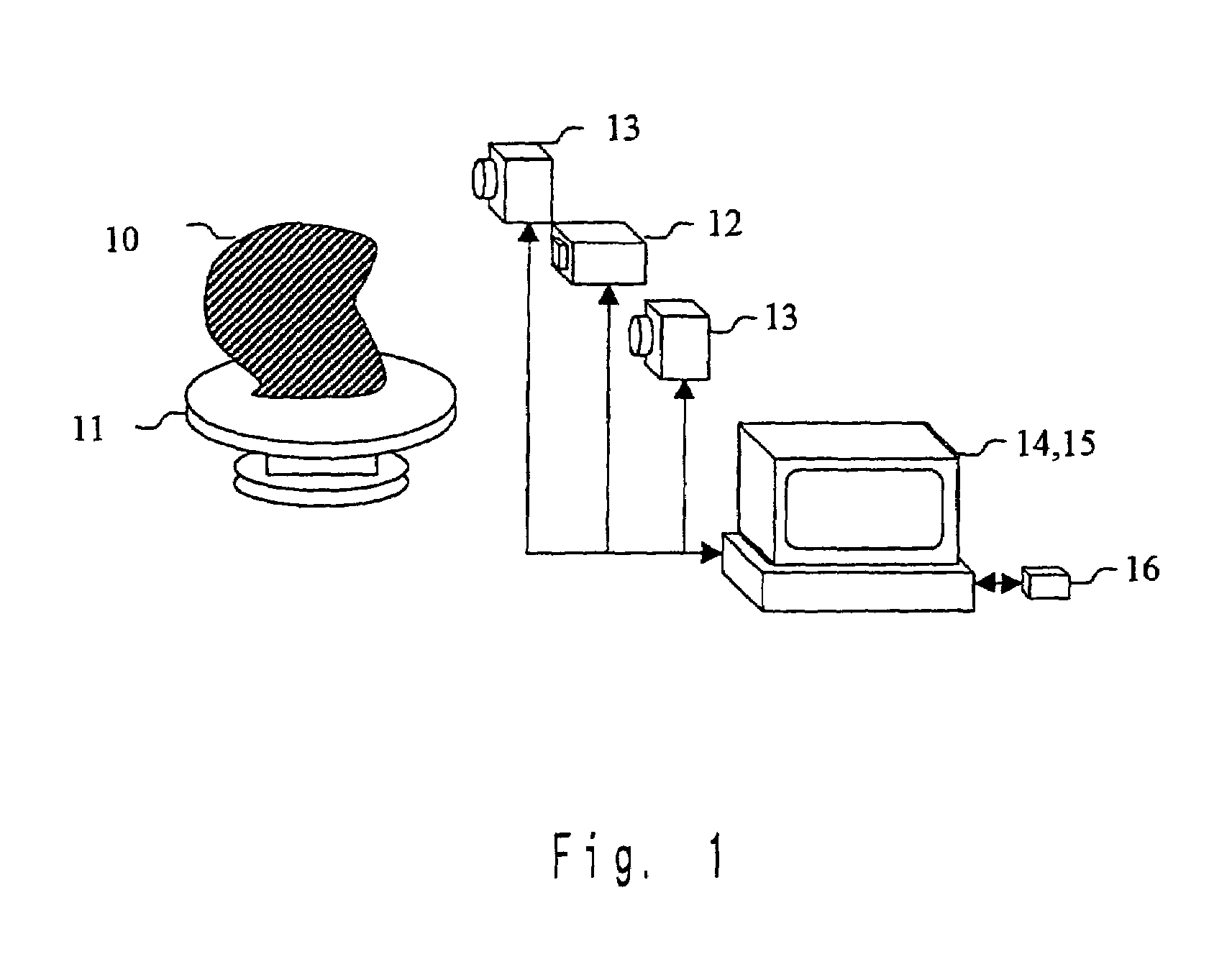

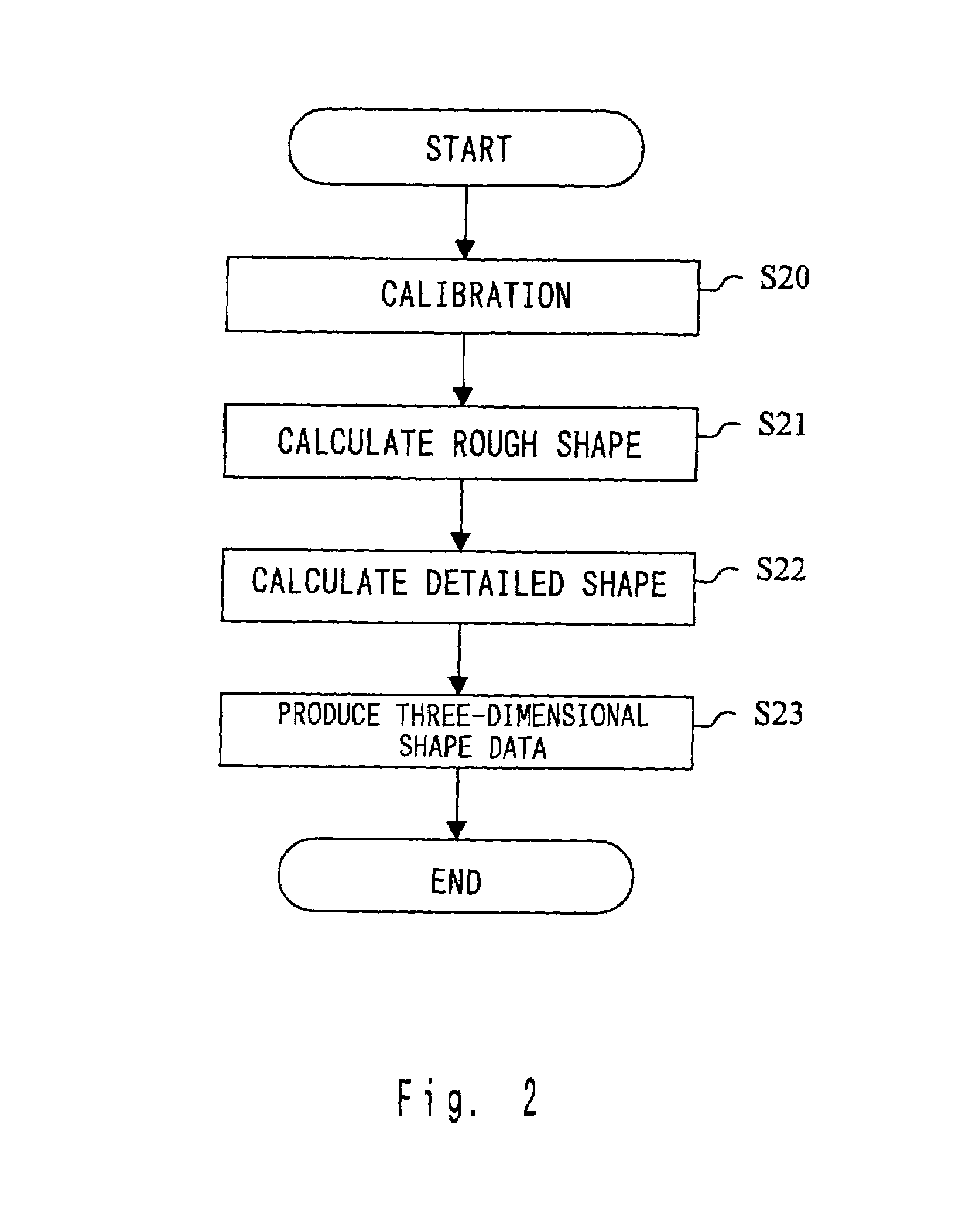

Three-dimensional modeling apparatus, method, and medium, and three-dimensional shape data recording apparatus, method, and medium

InactiveUS6965690B2Increase investmentOptical rangefindersFuel cell auxillariesTriangulationThree dimensional shape

A three-dimensional shape modeling of a real object that reduces the limitations on the target shape and color. The rough shape of the target object is determined by a silhouette method (which has limitation on the target shape) and, at the same time, the detailed shape of the target object is determined by a triangulation method or the like (which has limitation on the target color). By using both sets of information, the consistency between the rough and detailed shape information are checked. For the portions where the consistency is not satisfied (points where detailed shape information is absent or points where detailed shape section is present outside the rough shape), rough shape is assumed to be the final object information and for other portions, the detailed shape is taken as the final object information. In this manner, three-dimensional shape modeling with reduced limitations on the target shape and color can be performed.

Owner:OL SECURITY LIABILITY CO

Cooling plate and manufacturing method thereof, and sputtering target and manufacturing method thereof

InactiveUS20020153130A1Improve accuracyAccurate stepElectric discharge tubesVacuum evaporation coatingSputteringEngineering

The present invention is a cooling plate including a groove, which becomes a passage of a coolant, inside a body, wherein one or more fins are provided inside the groove, wherein the groove is covered with a lid having width larger than the groove, wherein the lid is joined to the body by friction stir welding, and wherein a weld bead formed by the joining is outside the passage, and the weld bead formed by the joining is formed within the body and further, is characterized by a manufacturing method of a cooling plate that has a first groove, which becomes a passage of a coolant, and a second groove, which has width larger than the first groove and receives a lid on the first groove, inside a body, receives the lid on the second groove, and is joined to the body, the manufacturing method of a cooling plate wherein, while the lid and the body are joined together by the friction stir welding owing to insertion of a rotation tool having a shoulder and a pin, the joining is performed so that a weld bead formed by the joining may become out of the passage, and furthermore, is characterized in that a target for sputtering is joined to the cooling plate.

Owner:HITACHI CABLE

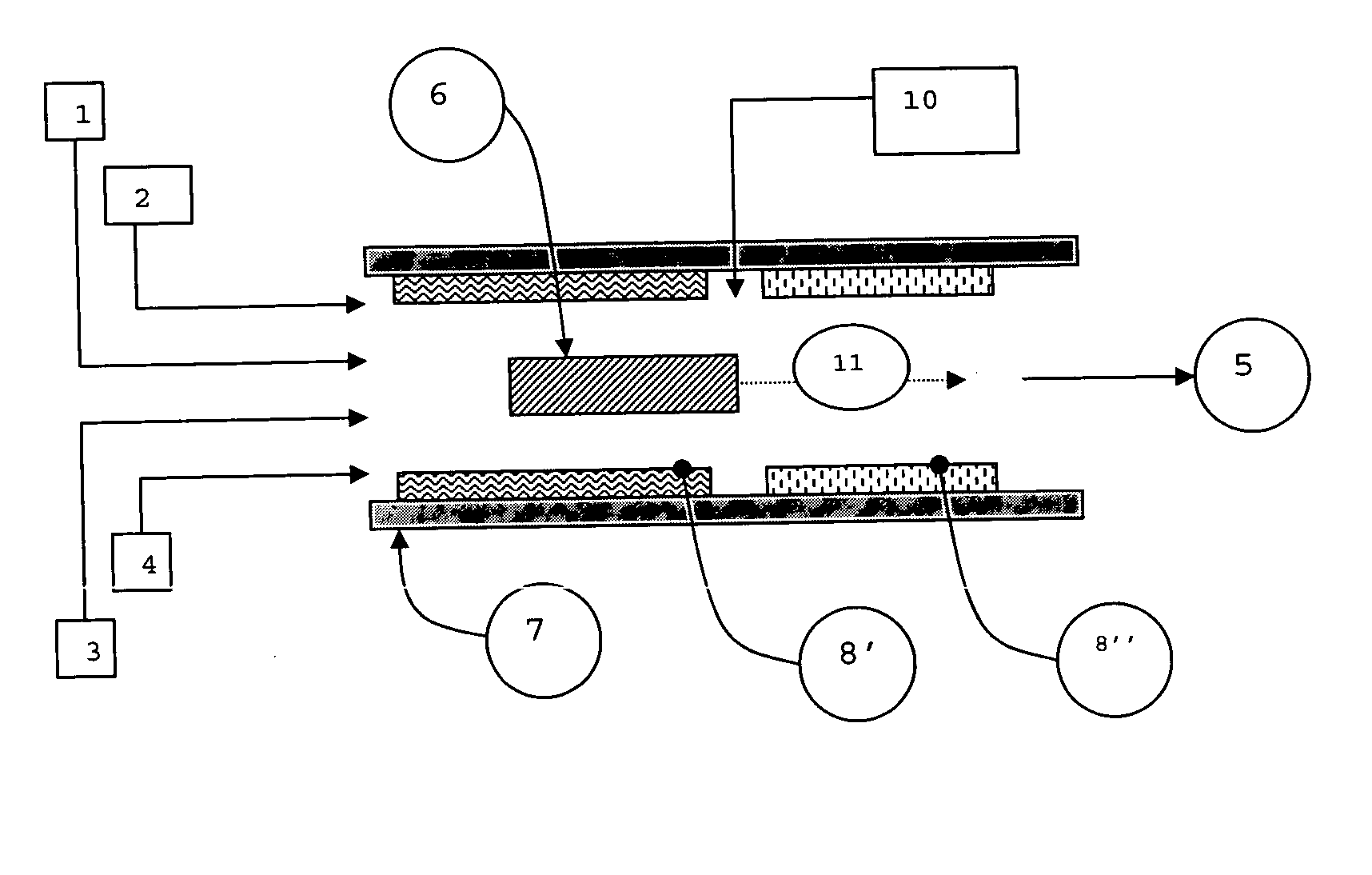

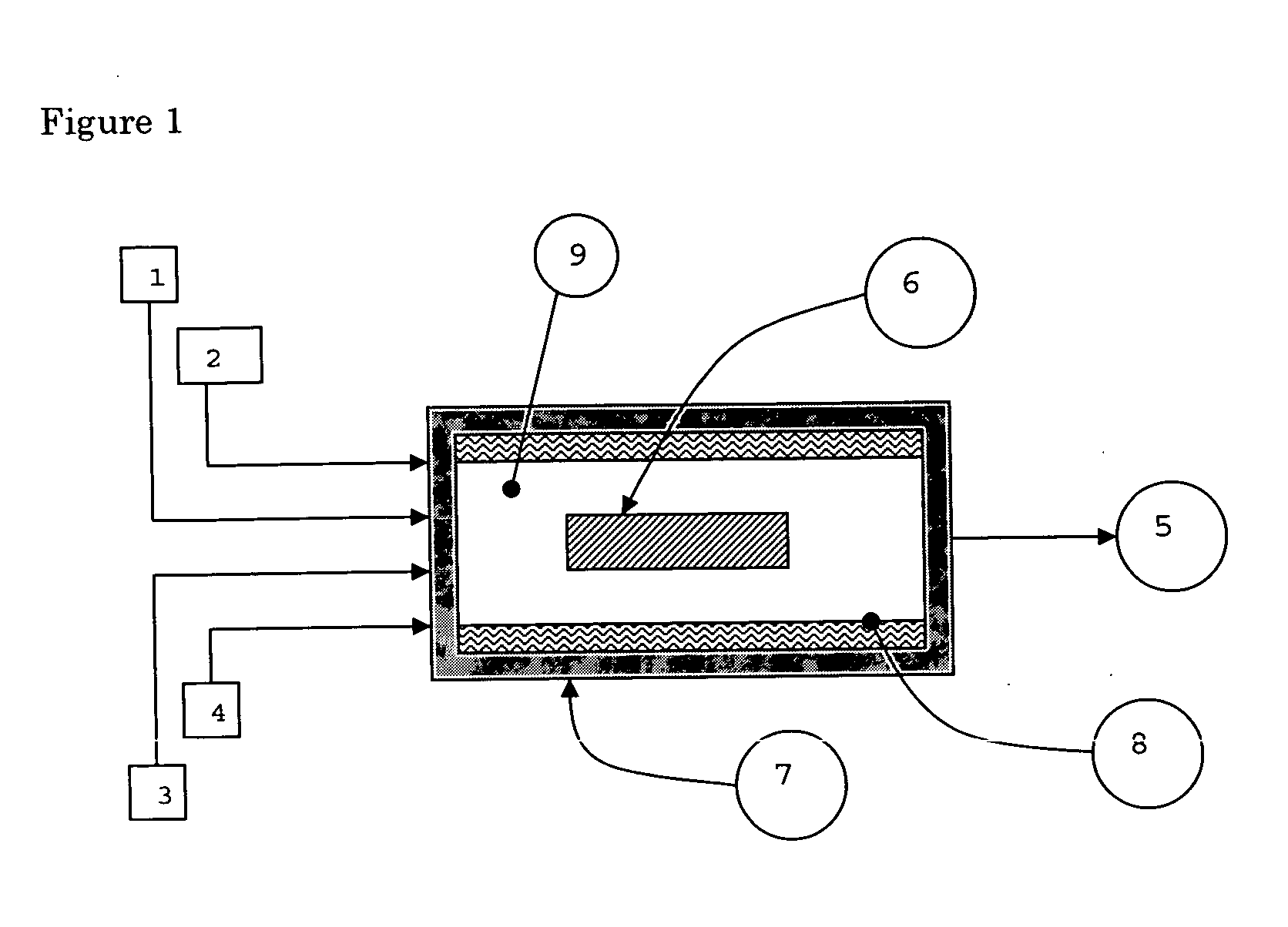

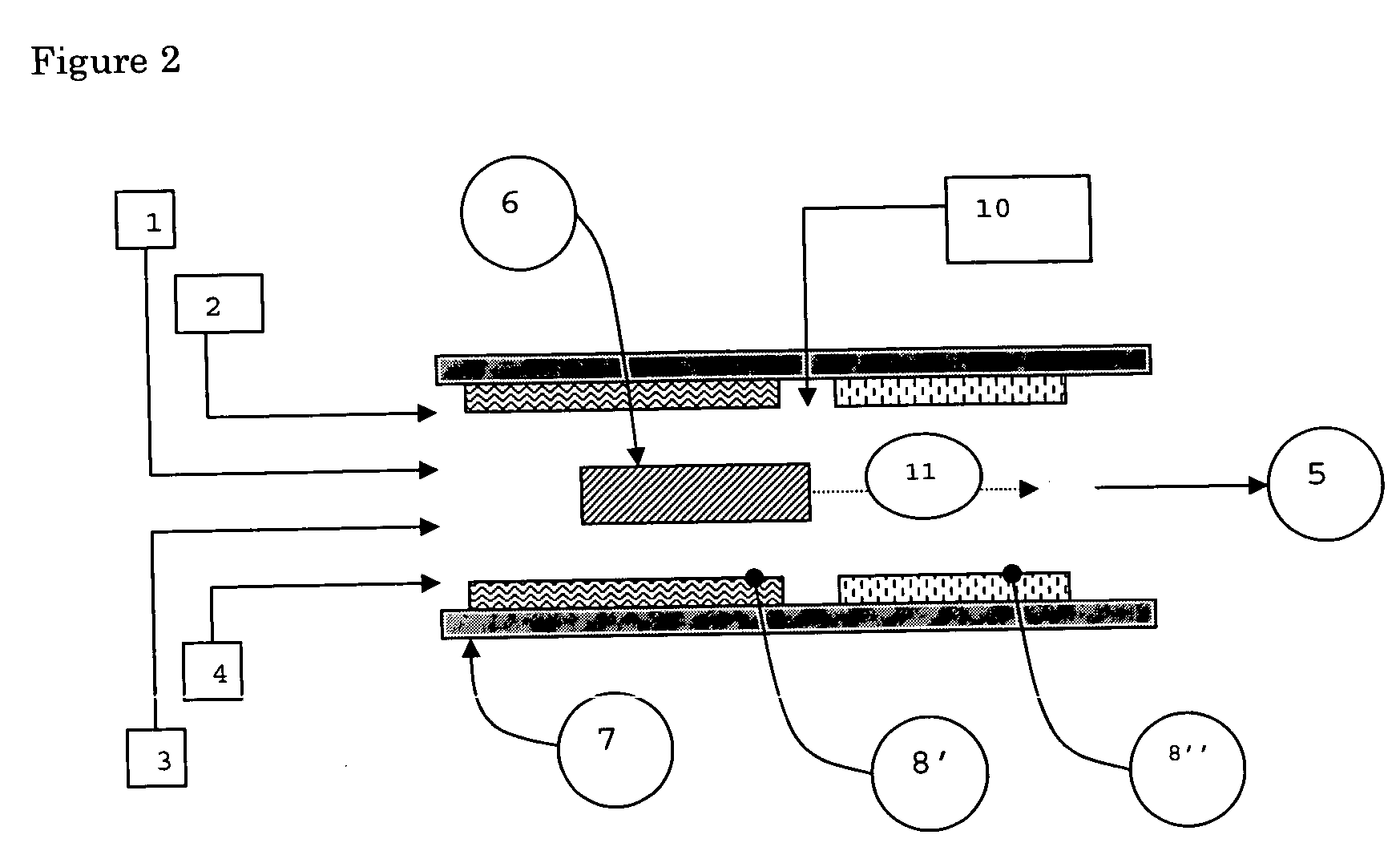

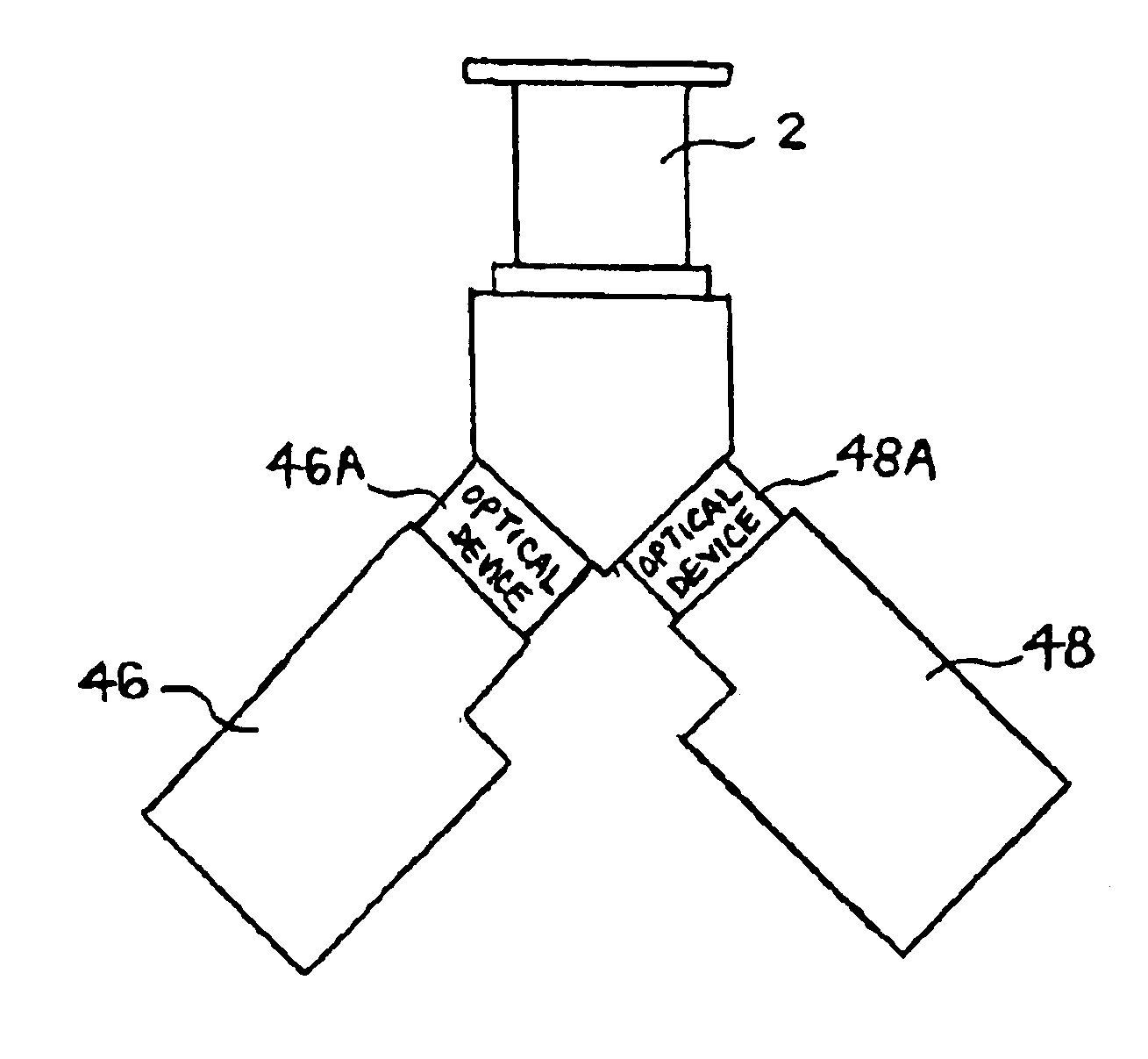

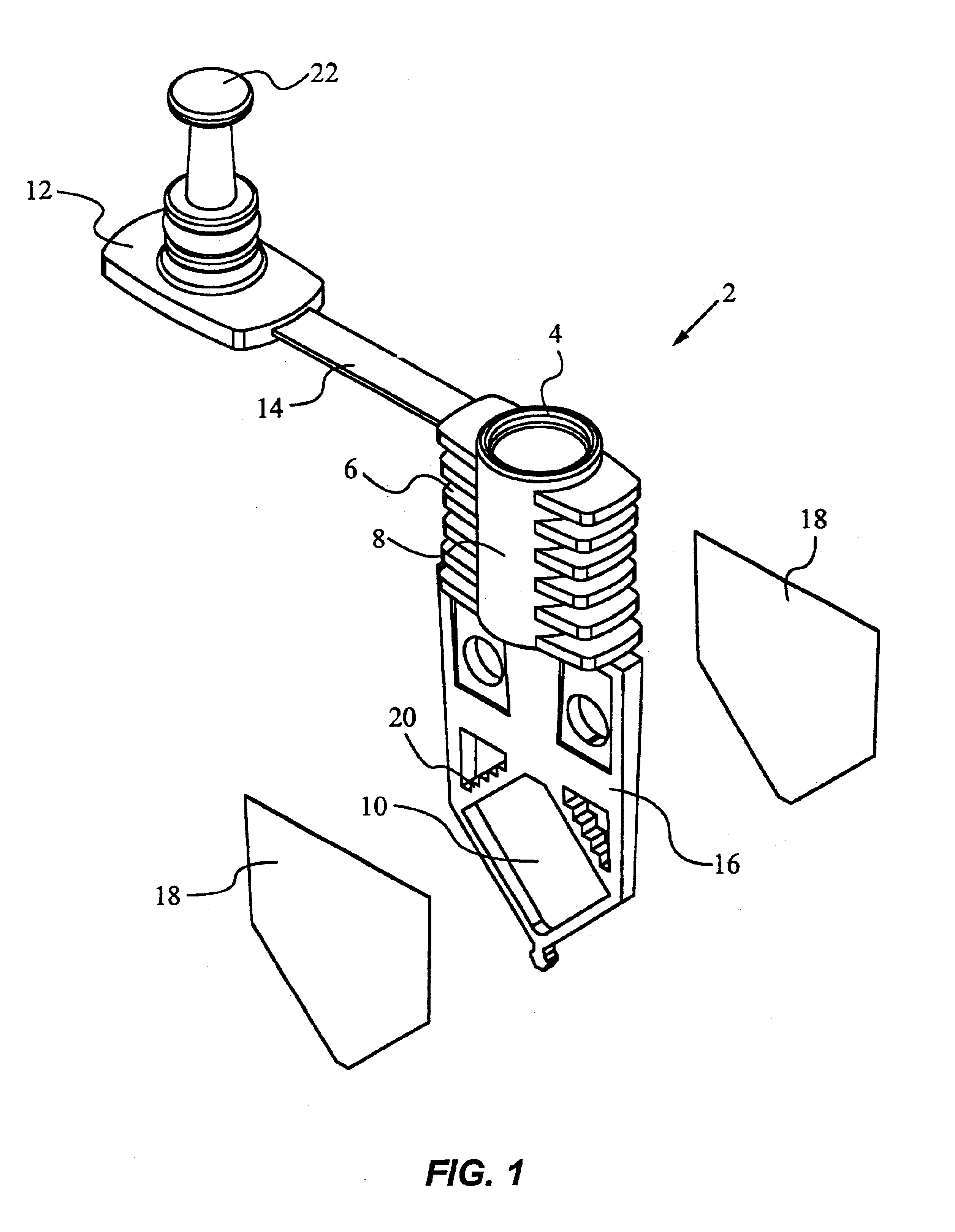

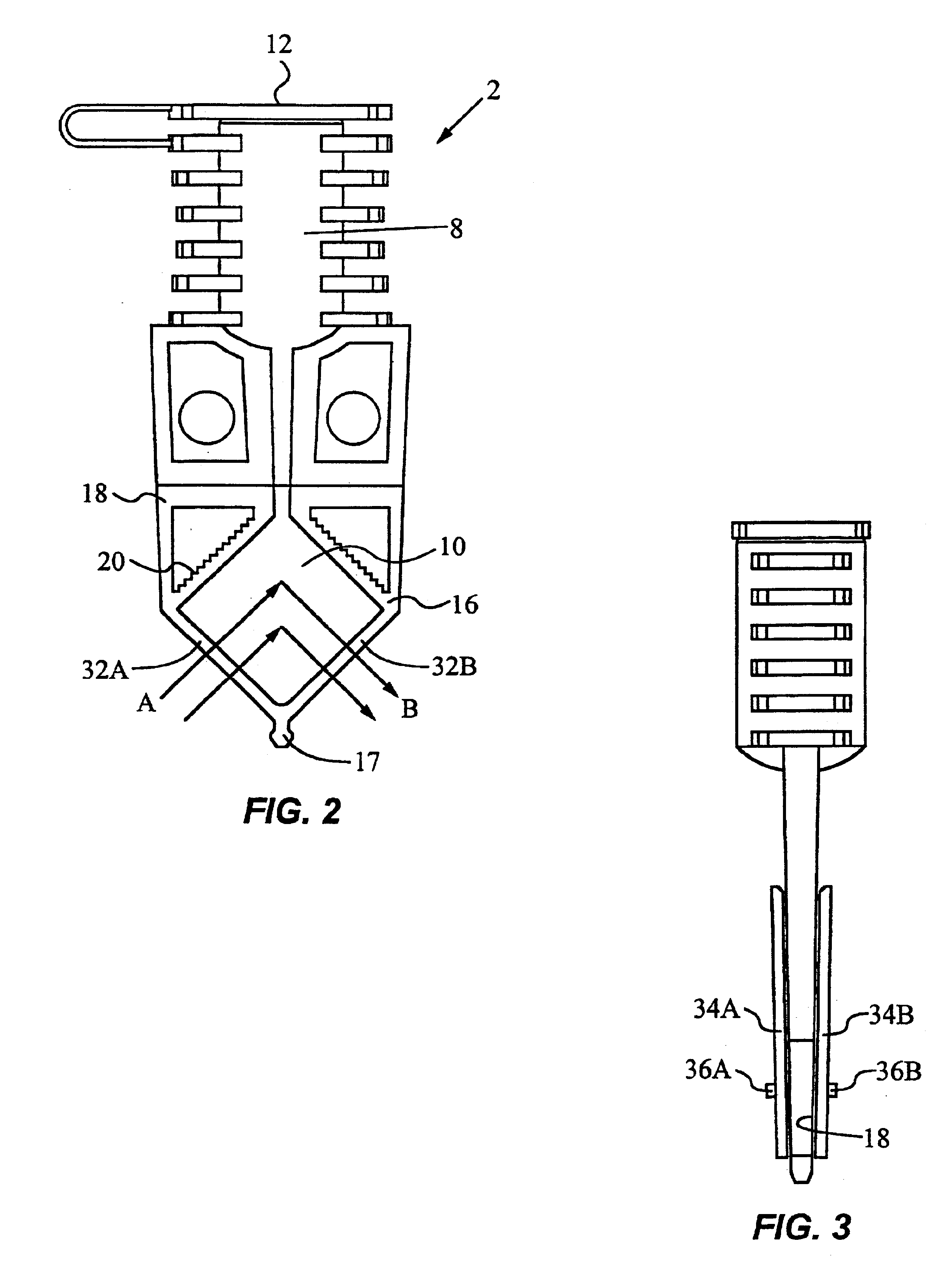

Multi-channel optical detection system

InactiveUS6940598B2Low costReduce maintenanceOptical radiation measurementHeating or cooling apparatusExcitation beamAnalyte

An apparatus for thermally controlling and optically interrogating a reaction mixture includes a vessel [2] having a chamber [10] for holding the mixture. The apparatus also includes a heat-exchanging module [37] having a pair of opposing thermal plates [34A, 34B] for receiving the vessel [2] between them and for heating / and or cooling the mixture contained in the vessel. The module [37] also includes optical excitation and detection assemblies [46,48] positioned to optically interrogate the mixture. The excitation assembly [46] includes multiple light sources [100] and a set of filters for sequentially illuminating labeled analytes in the mixture with excitation beams in multiple excitation wavelength ranges. The detection assembly [48] includes multiple detectors [102] and a second set of filters for detecting light emitted from the chamber [10] in multiple emission wavelength ranges. The optics assemblies [46,48] thus provide a multi-channel system for detecting a plurality of different target analytes in the mixture.

Owner:CEPHEID INC

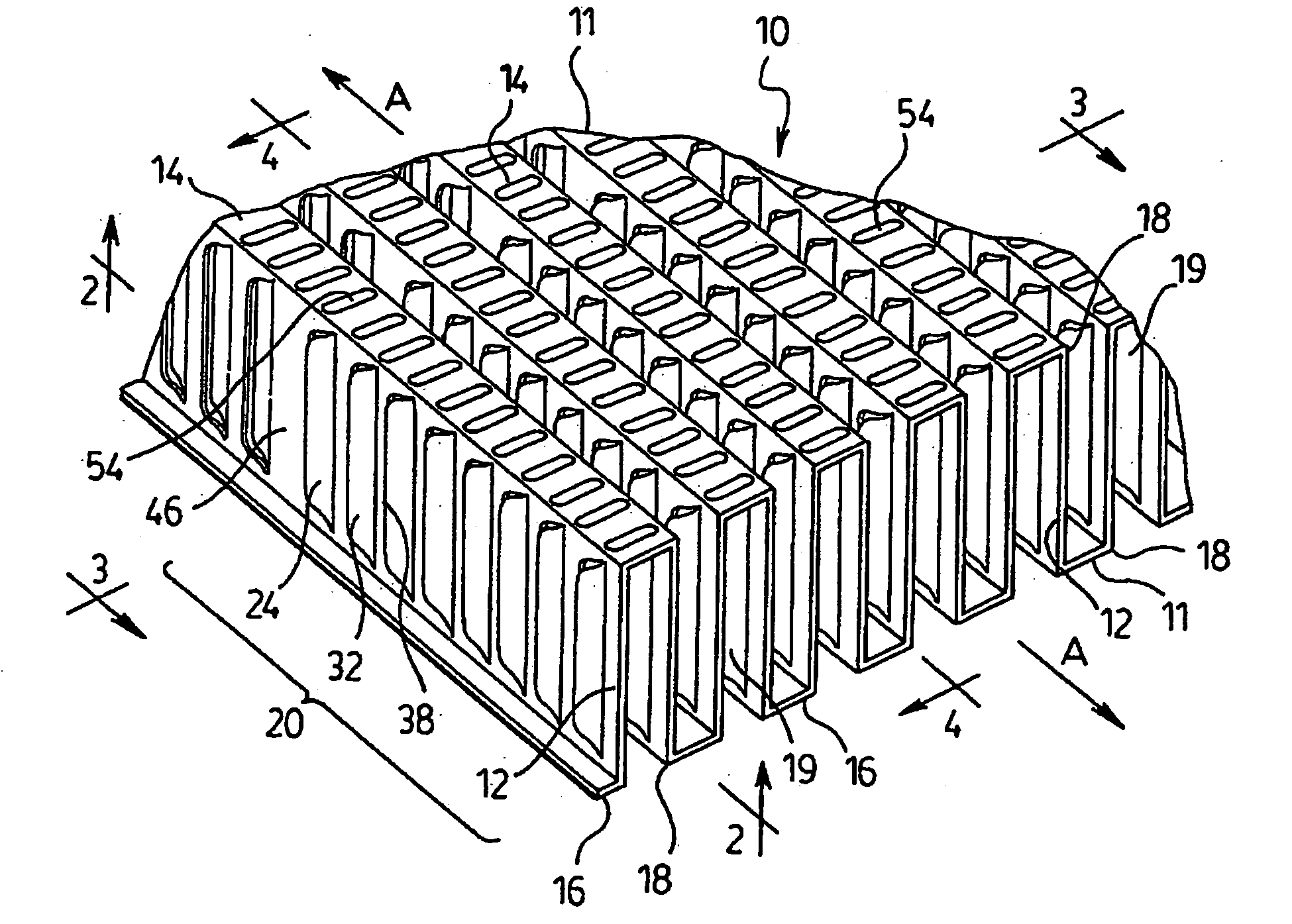

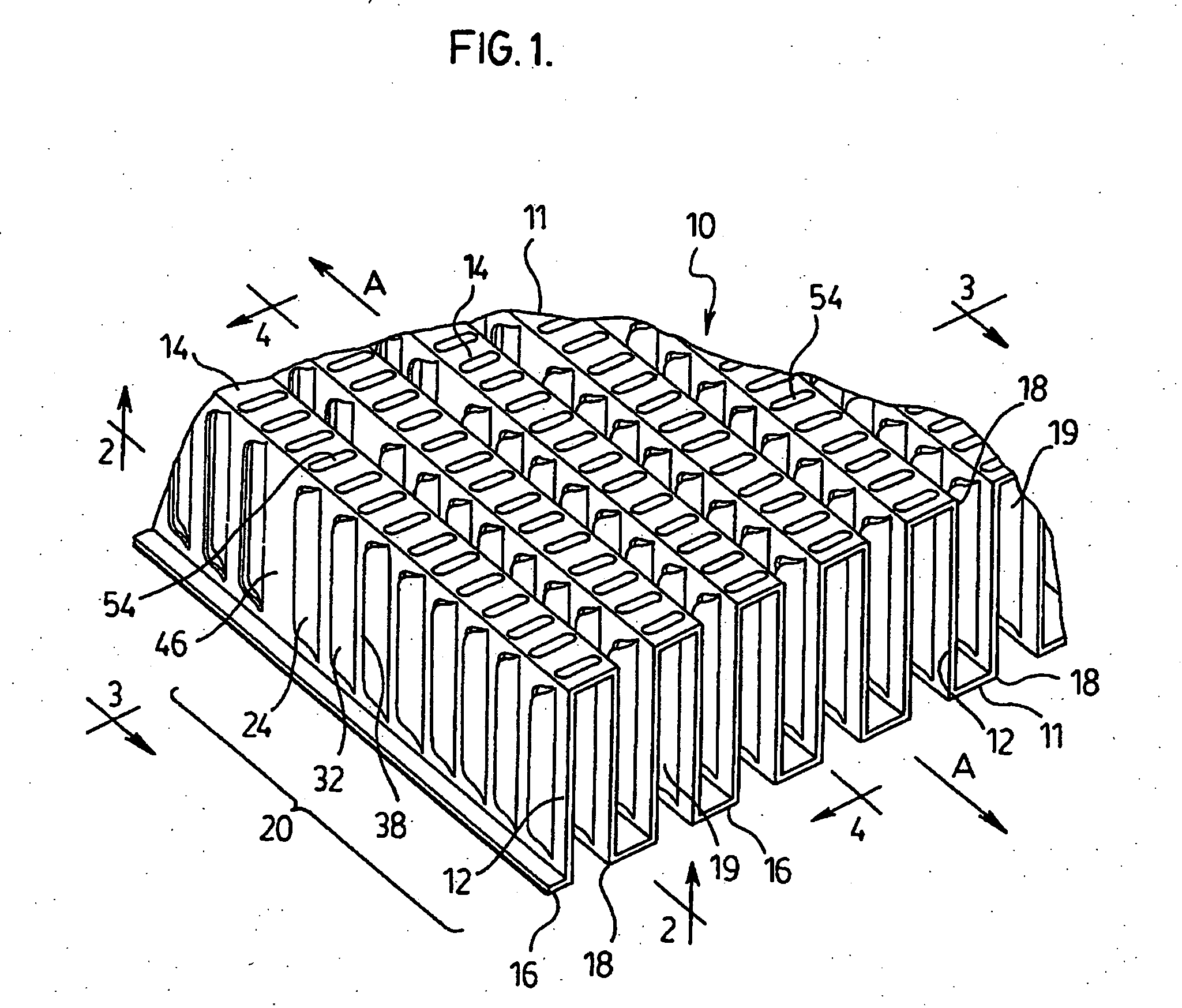

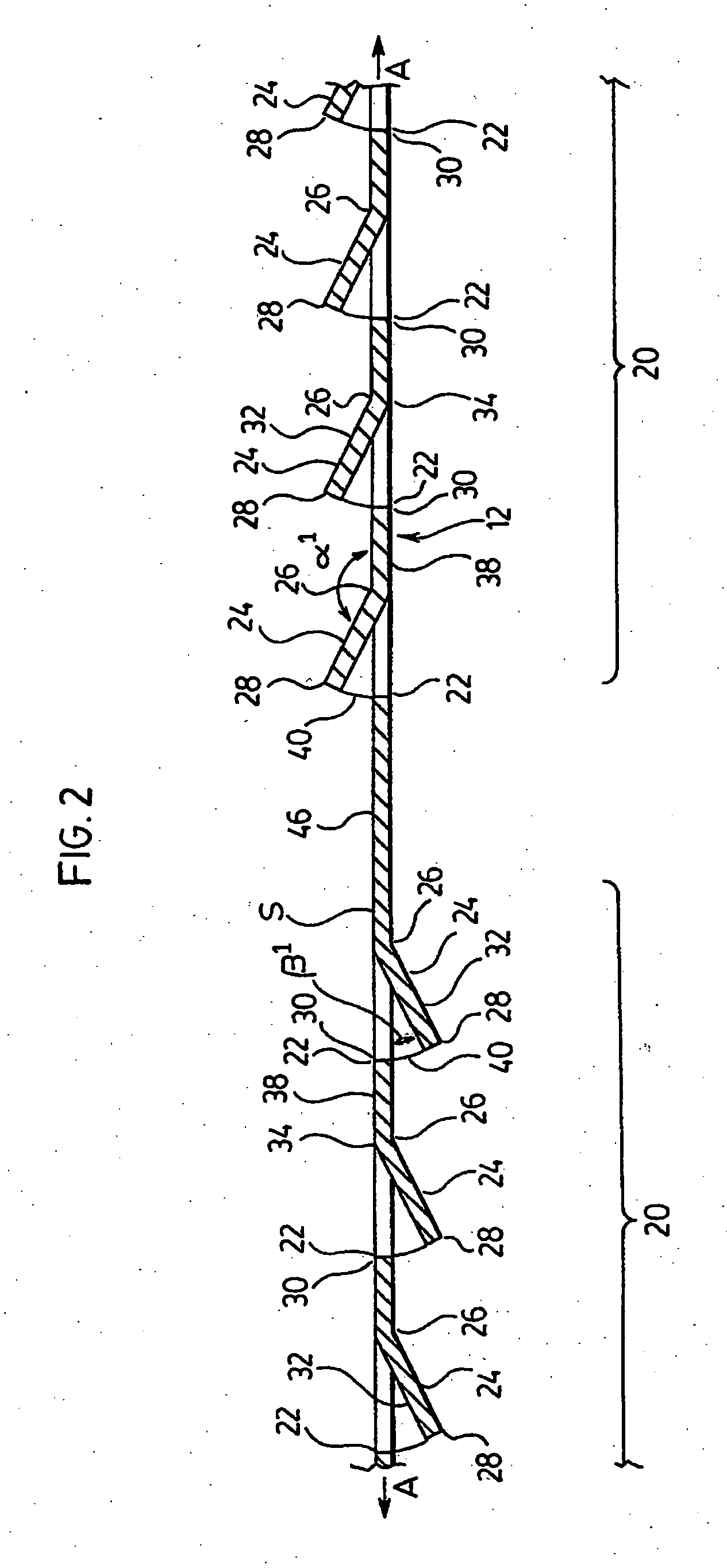

Heat exchangers with corrugated heat exchange elements of improved strength

InactiveUS20070012430A1Heat transfer modificationLaminated elementsEngineeringUltimate tensile strength

A corrugated fin or turbulizer for a heat exchanger comprises a series of corrugations with parallel side walls. The side walls are provided with a series of parallel slits between which one-sided or two-sided louvers are defined. Each of the louvers has first and second edges extending along an adjacent pair of slits, and at least one bend located between the edges, thereby causing at least one of the edges of the louver to project outwardly of the plane of the side wall, and providing the side wall with improved crush resistance. The corrugations may preferably be rectangular or trapezoidal in form, having generally flat top and bottom surfaces defined by two closely-spaced bends. The top and bottom surfaces may preferably be provided with protrusions, at least some of which extend close to the bends. This assists in creating localized areas of weakness along which the bends can be formed cleanly.

Owner:DANA CANADA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com