Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

541results about How to "Increased anisotropy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

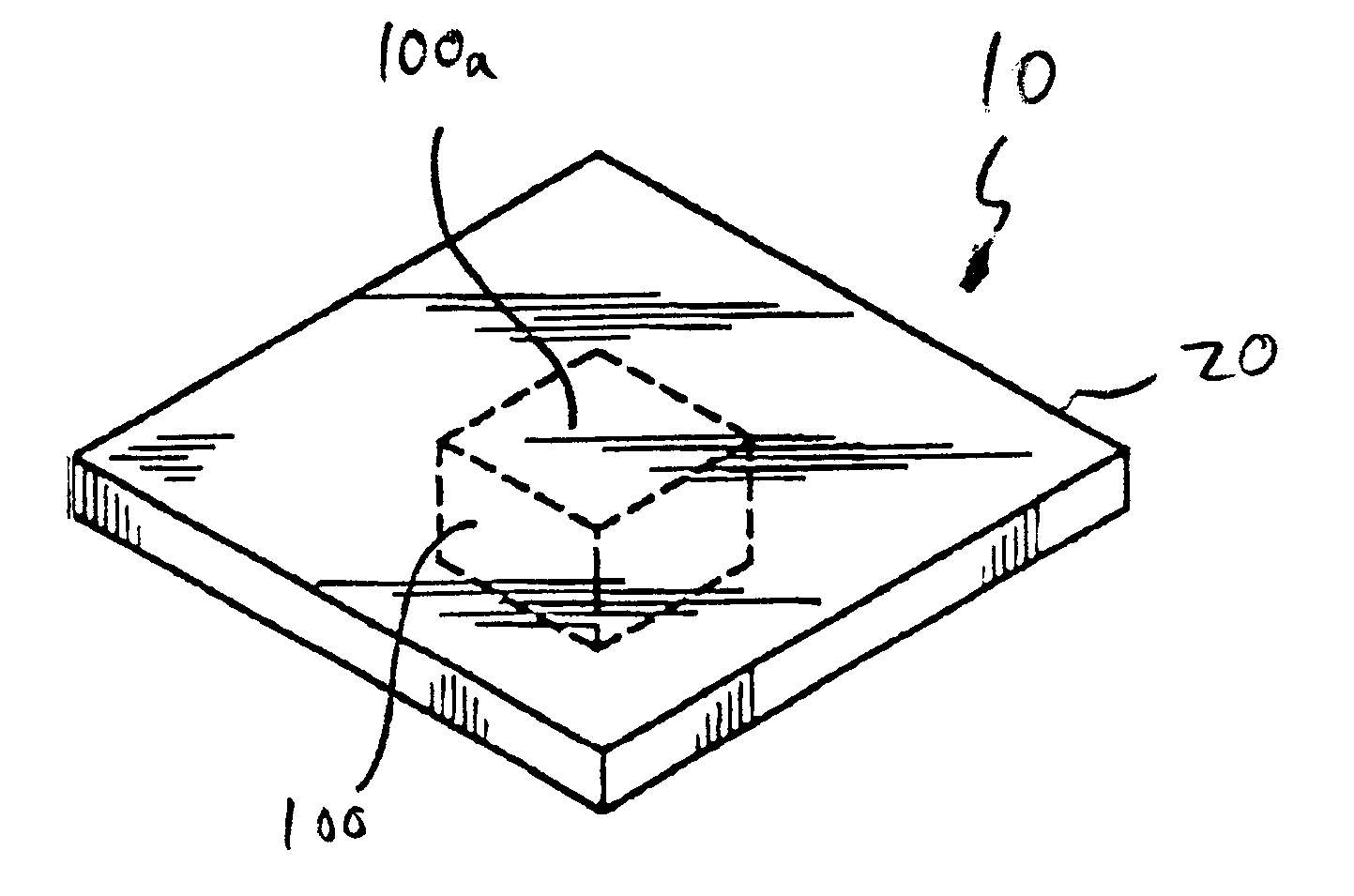

Thermal management system

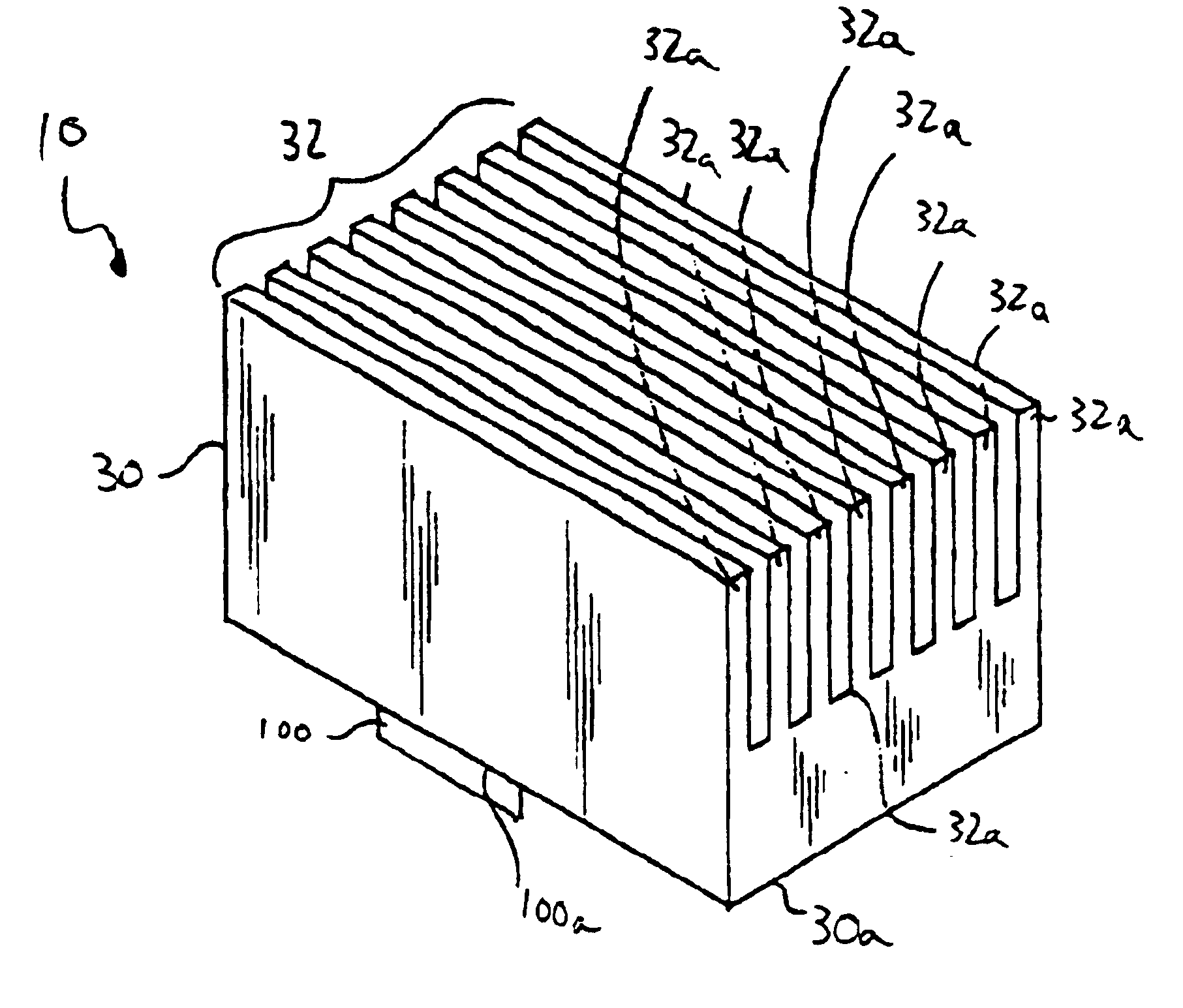

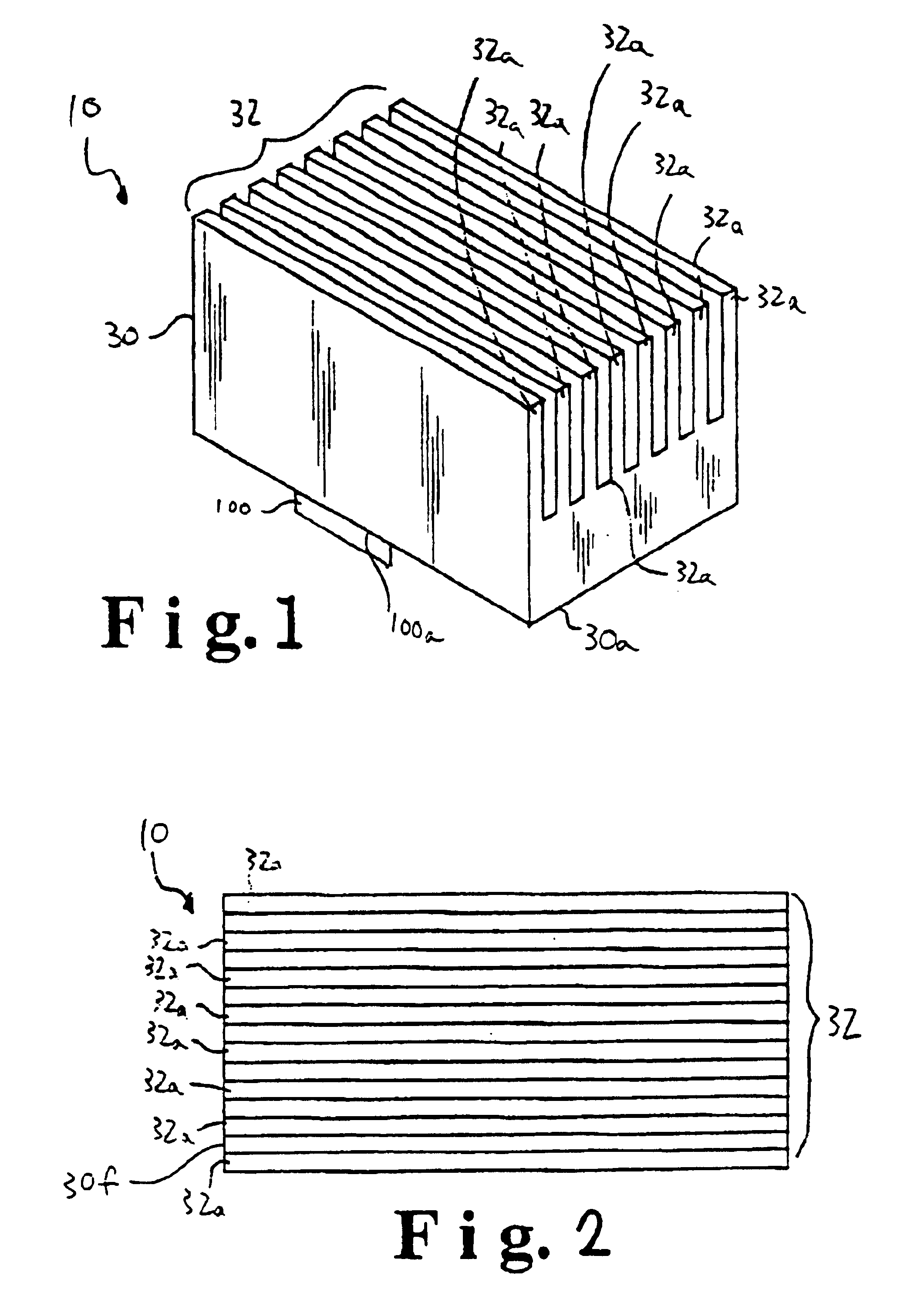

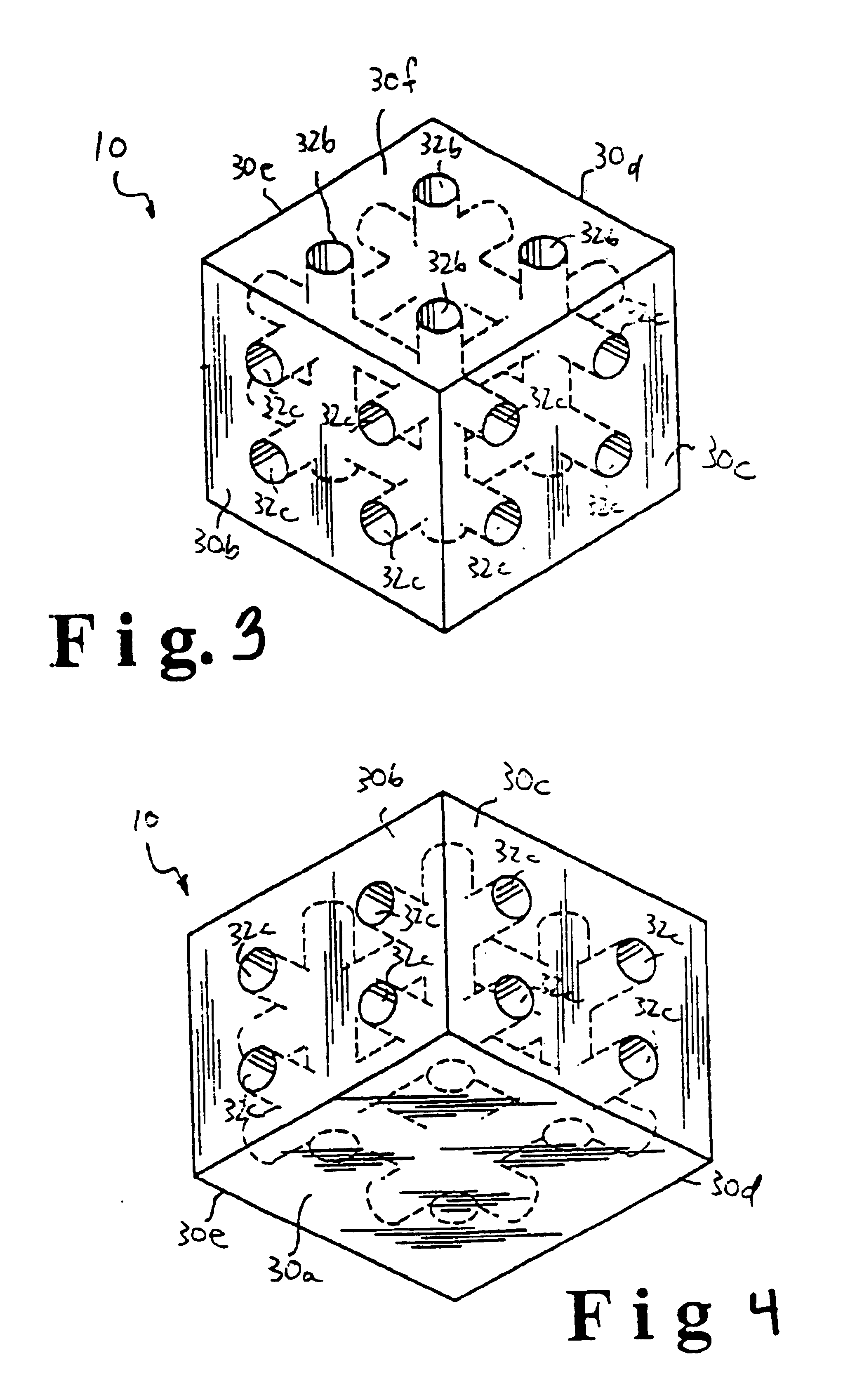

InactiveUS6482520B1Improve cooling effectIncreased anisotropyLayered productsSemiconductor/solid-state device detailsEngineeringThermal management system

The present invention relates to a system for managing the heat from a heat source like an electronic component. More particularly, the present invention relates to a system effective for dissipating the heat generated by an electronic component using a thermal management system that includes a thermal interface formed from a flexible graphite sheet and / or a heat sink formed from a graphite article.

Owner:NEOGRAF SOLUTIONS LLC

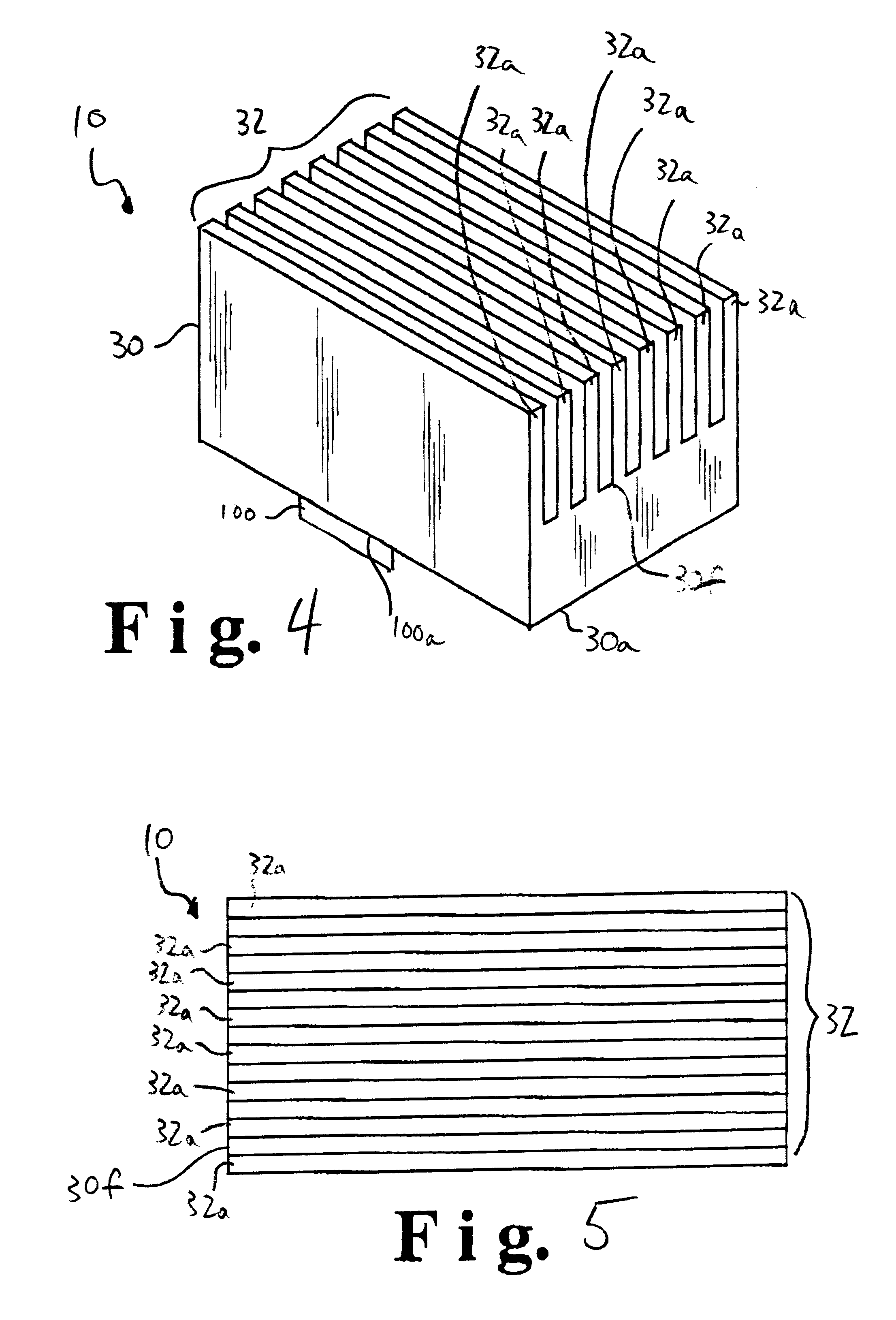

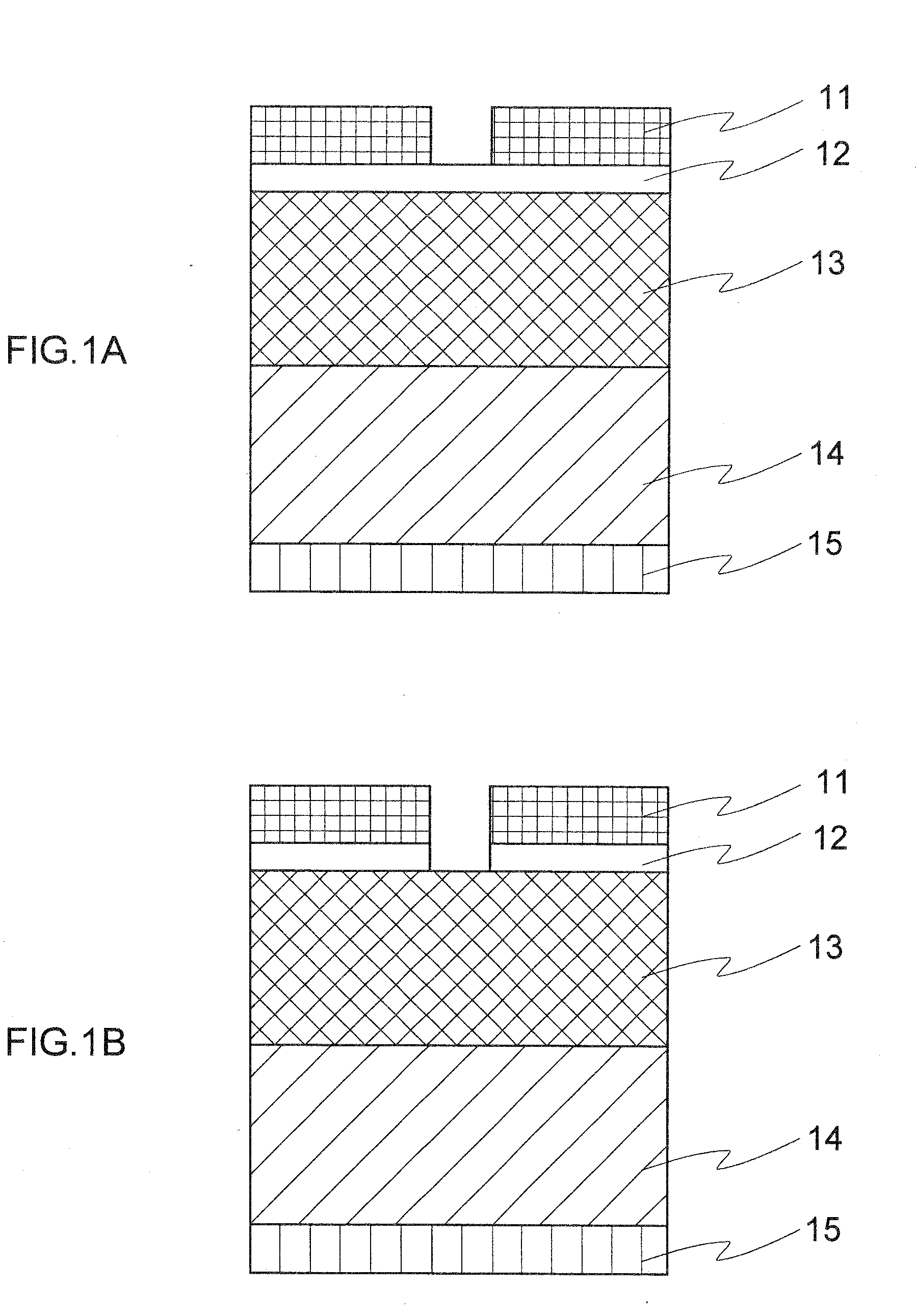

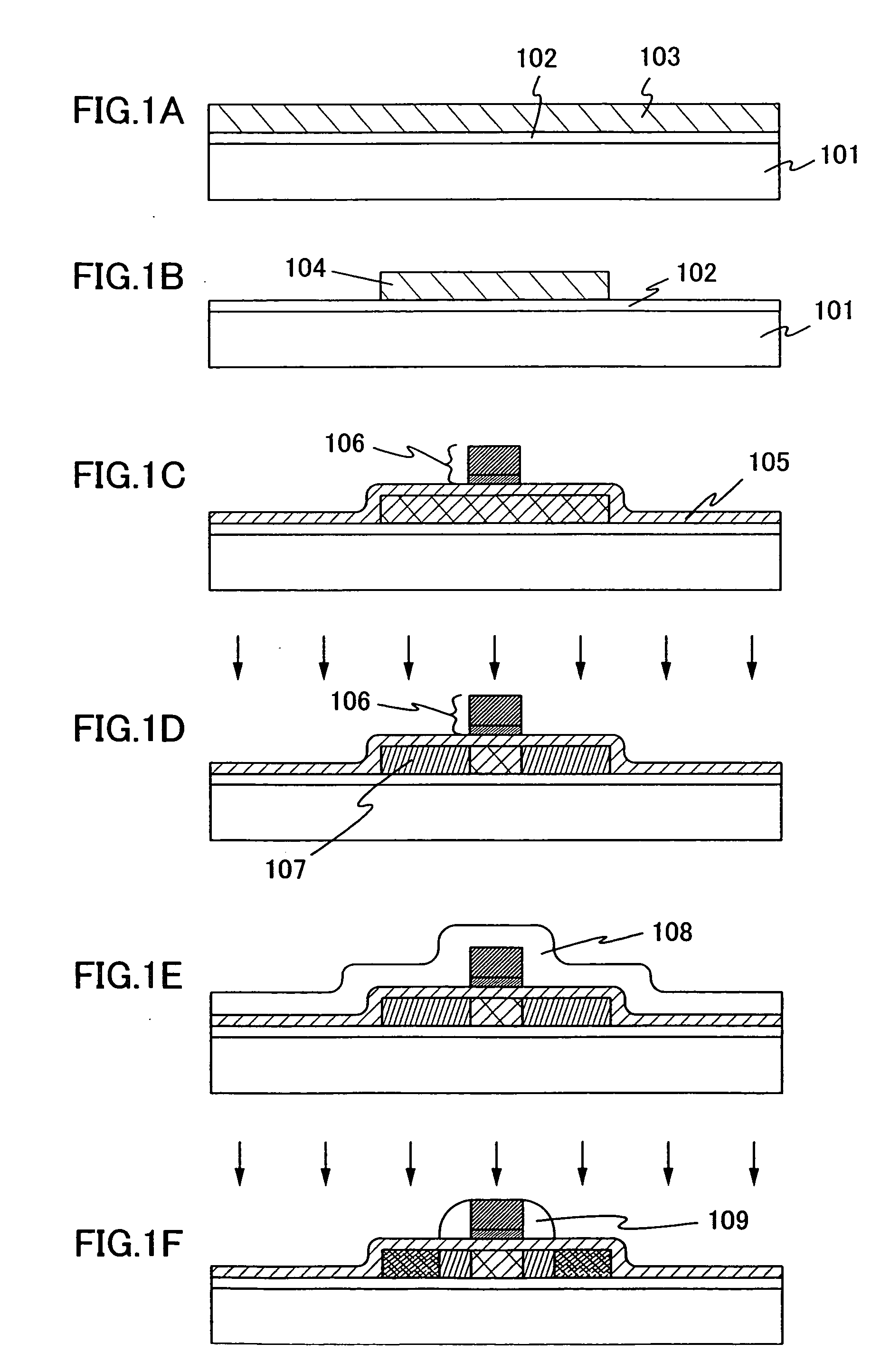

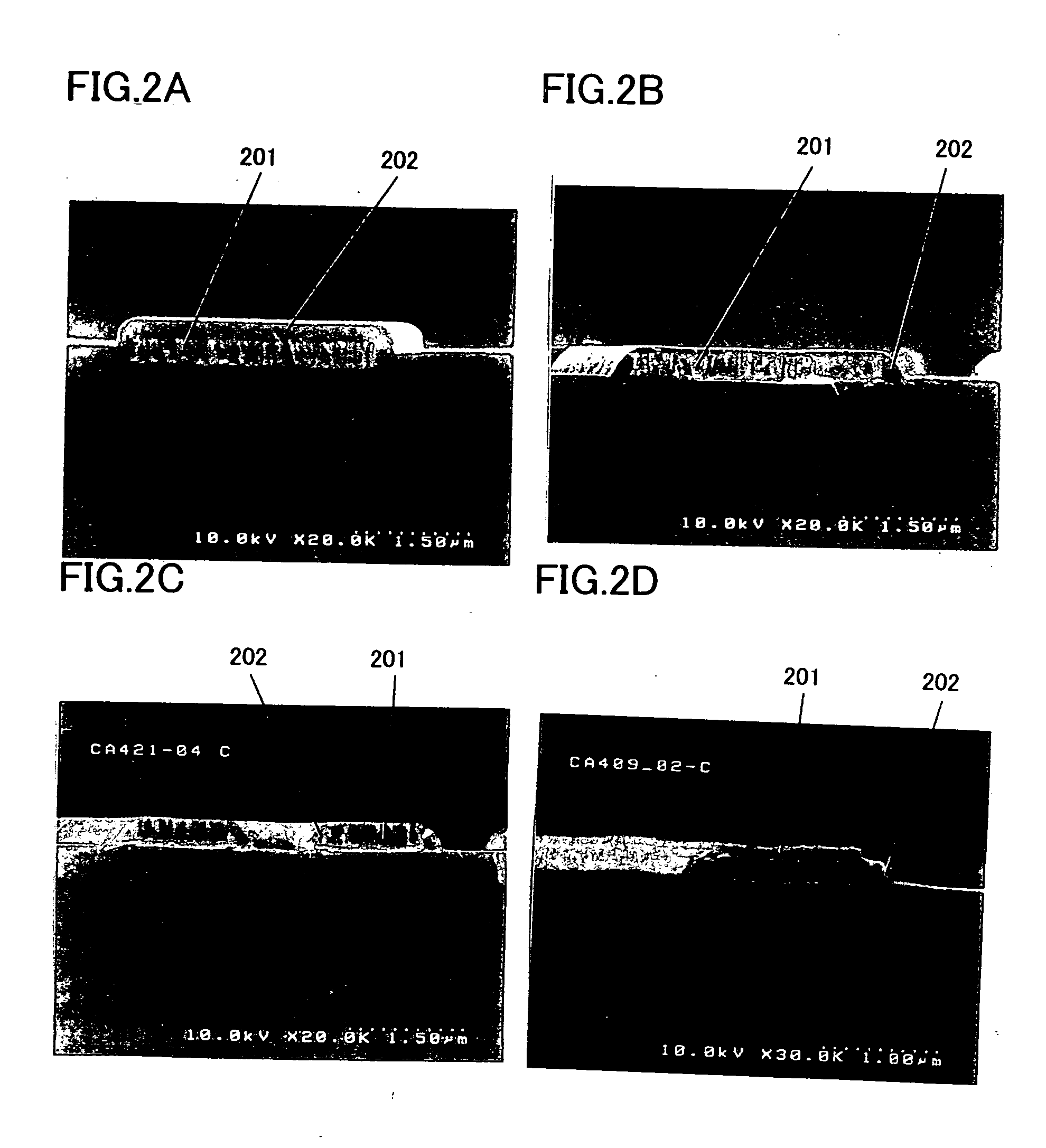

Method for manufacturing semiconductor device

InactiveUS20090081879A1Increased anisotropySemiconductor/solid-state device manufacturingSilicon oxideSemiconductor

There is provided a method for manufacturing a semiconductor device including processing a substrate to be processed by using an amorphous carbon hard mask that includes processing an amorphous carbon film formed on the substrate to be processed to provide a hard mask, and forming a protective film comprising a silicon oxide film on a sidewall of the amorphous carbon film exposed during or after processing the amorphous carbon film; and the protective film preferably formed by sputtering an intermediate mask comprising at least a silicon oxide on the amorphous carbon film.

Owner:ELPIDA MEMORY INC

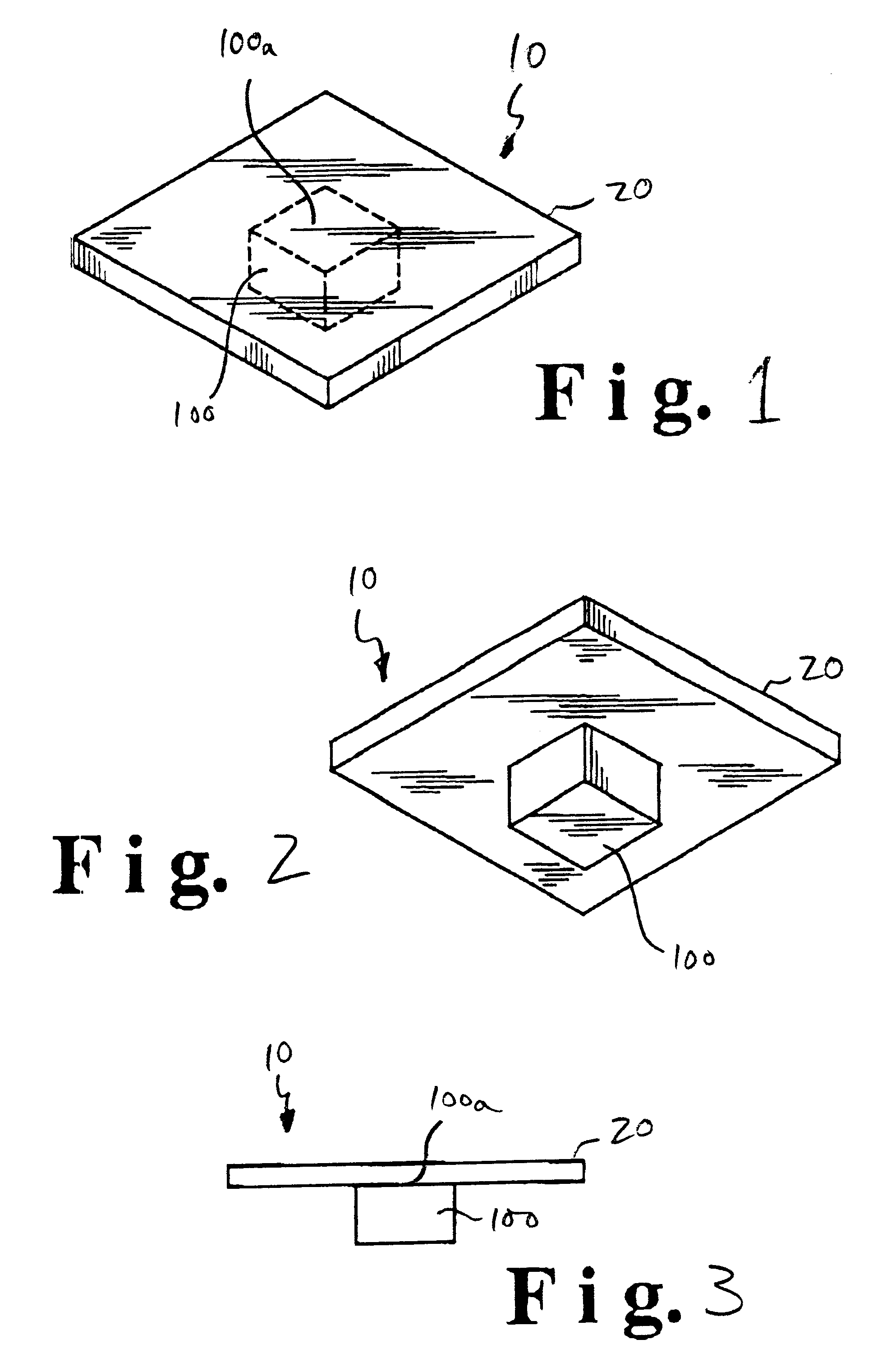

Graphite-based heat sink

InactiveUS6503626B1Improve cooling effectIncreased anisotropyLayered productsSemiconductor/solid-state device detailsNuclear engineeringGraphite

The present invention relates to a system for managing the heat from a heat source like an electronic component. More particularly, the present invention relates to a system effective for dissipating the heat generated by an electronic component using a heat sink formed from a compressed, comminuted particles of resin-impregnated flexible graphite mat or sheet.

Owner:GRAFTECH INT HLDG INC

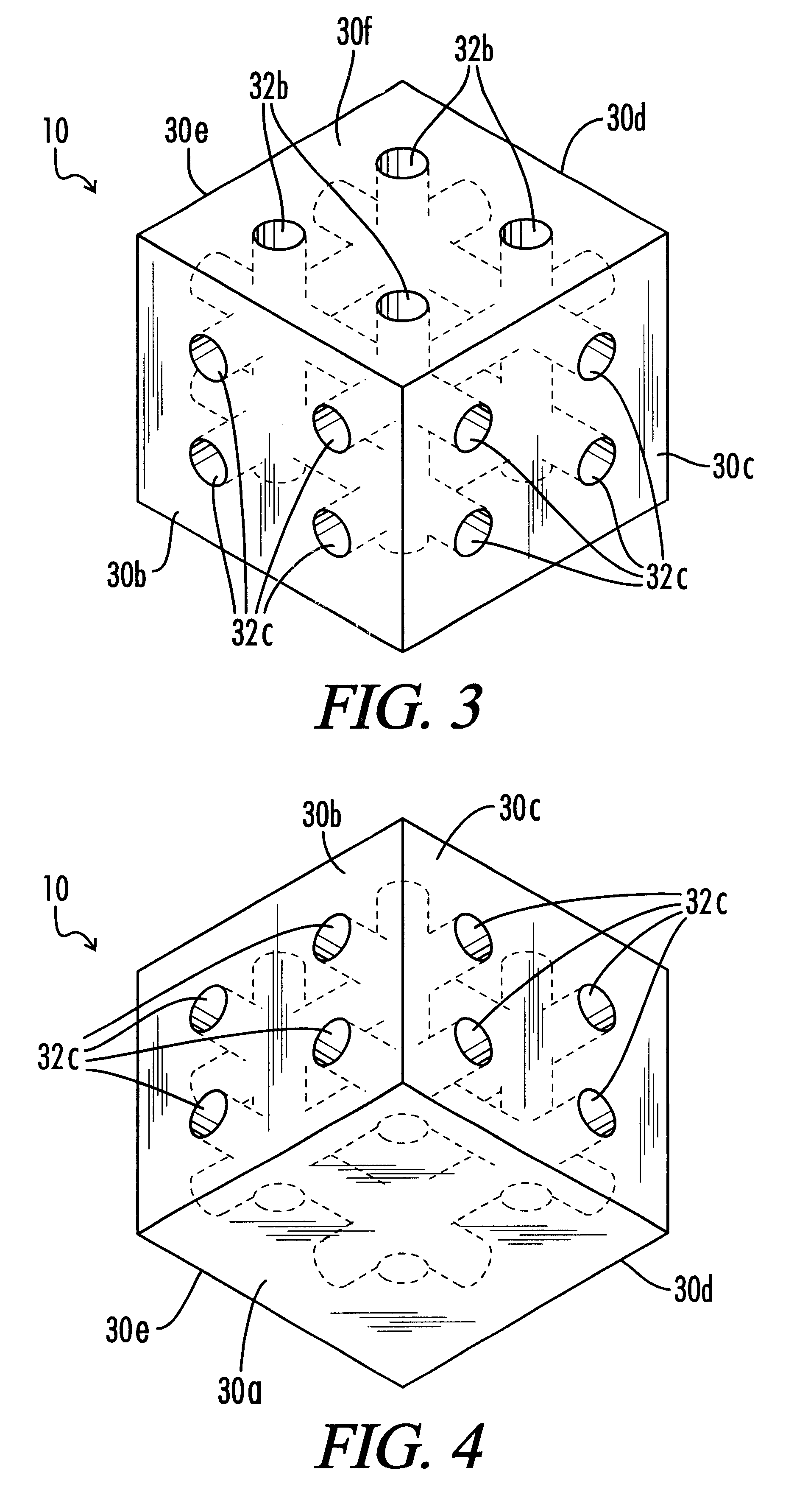

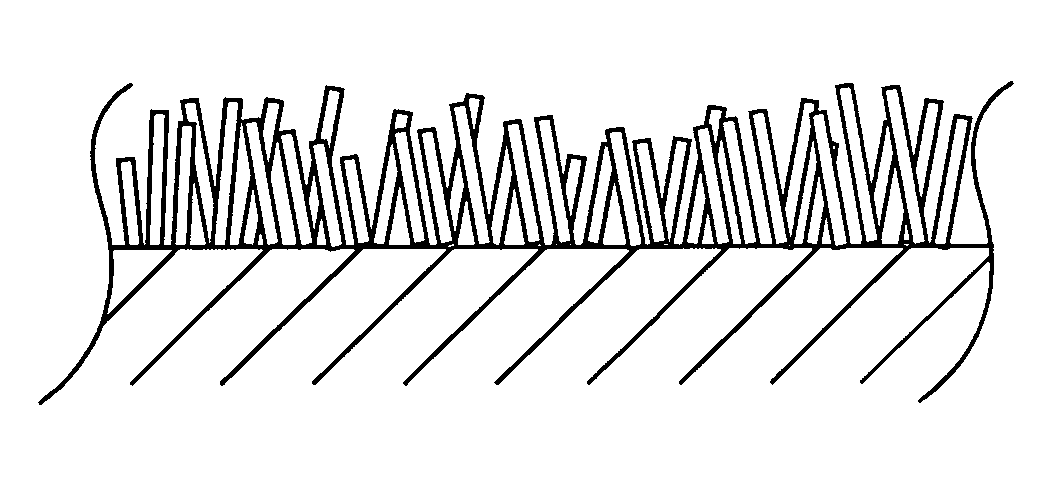

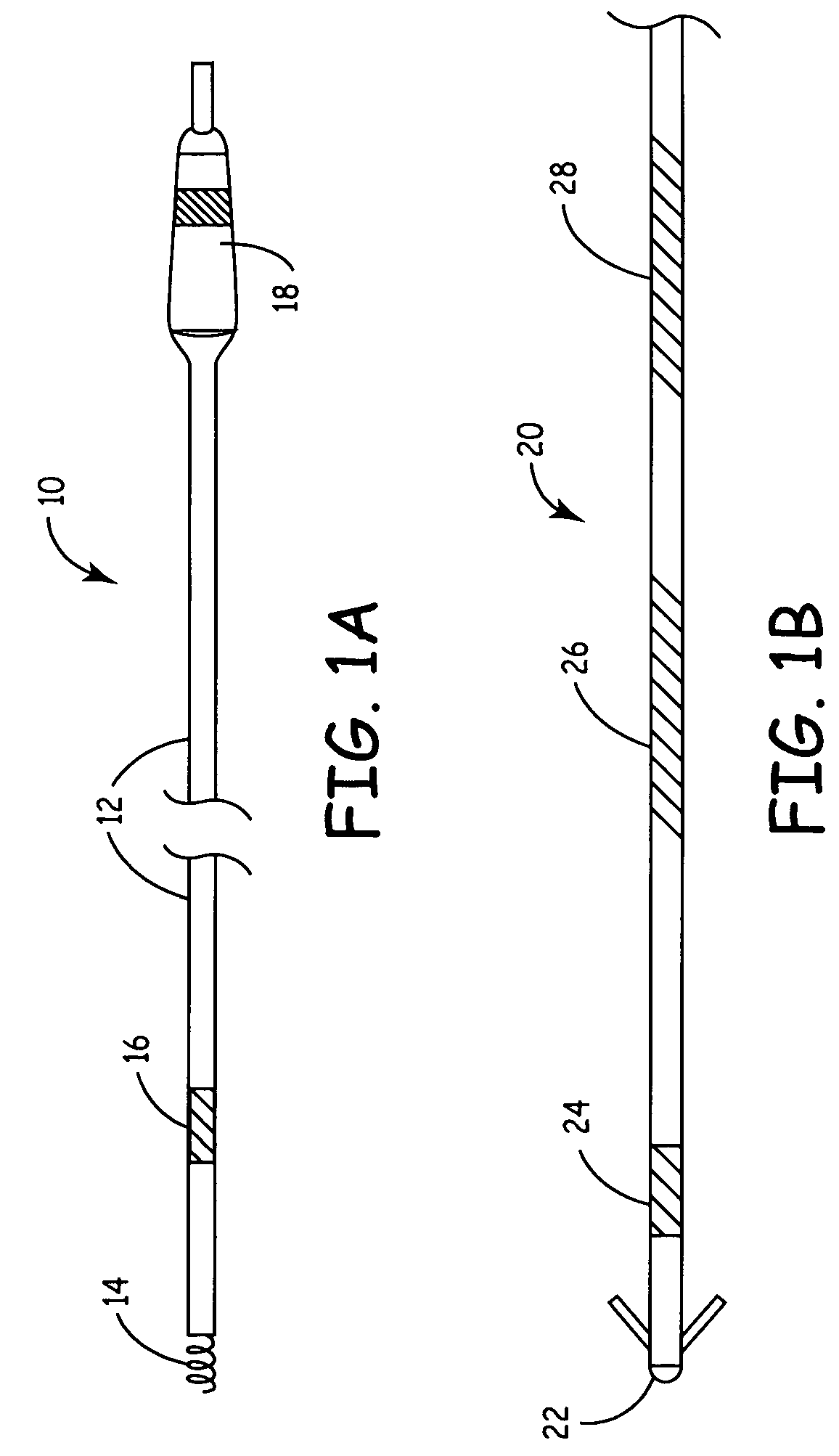

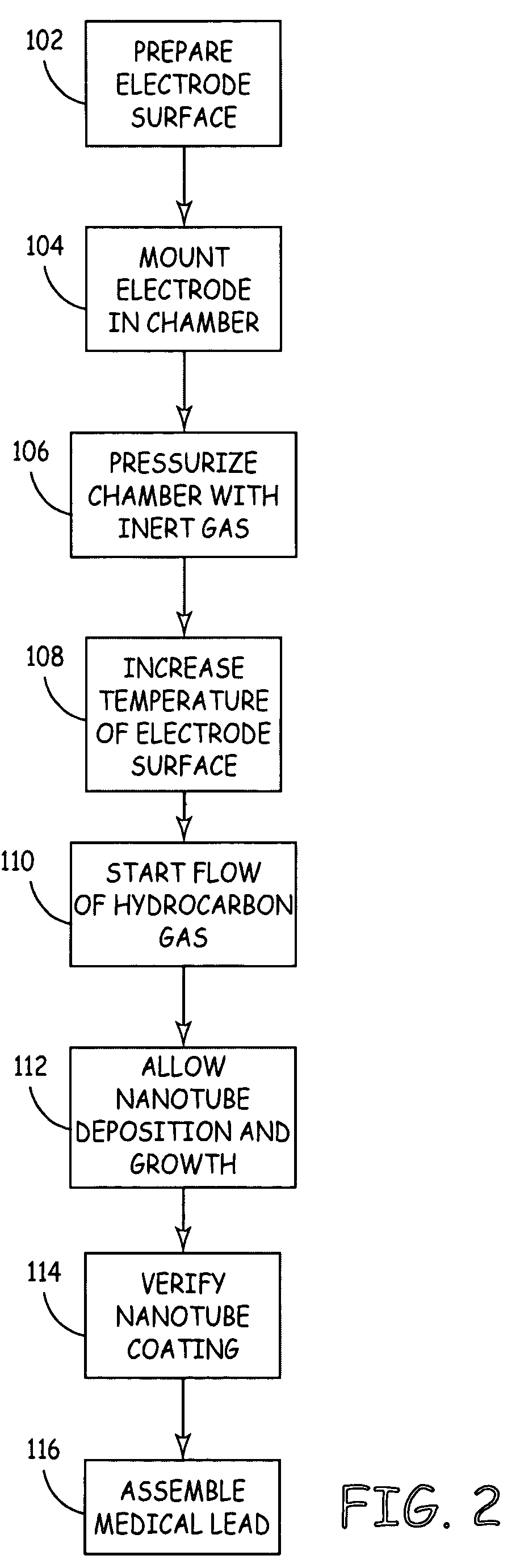

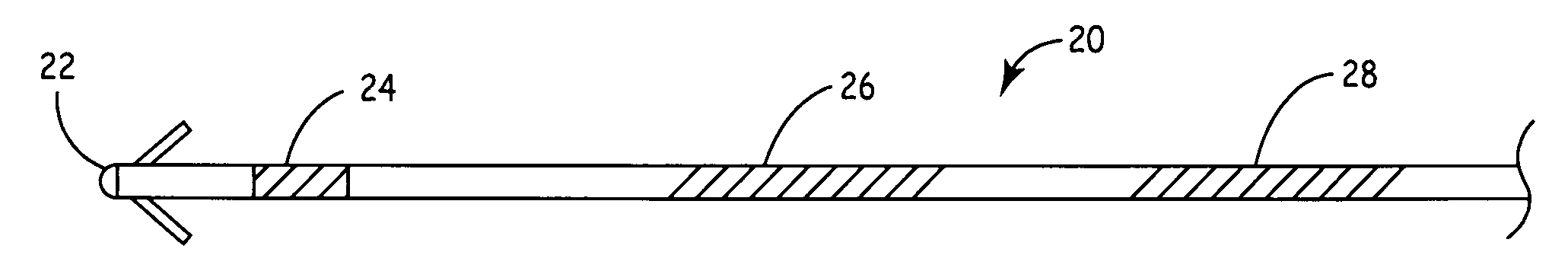

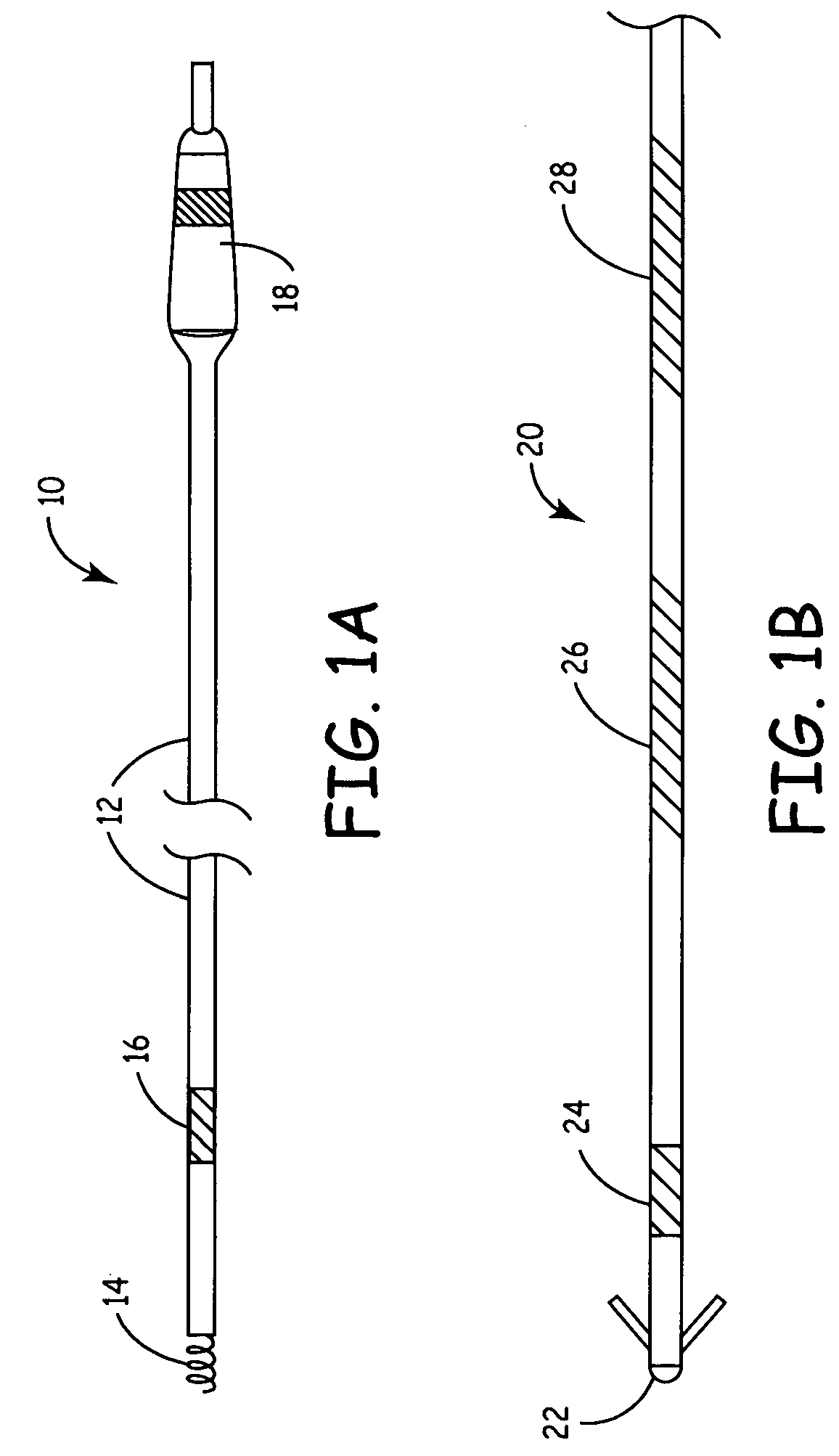

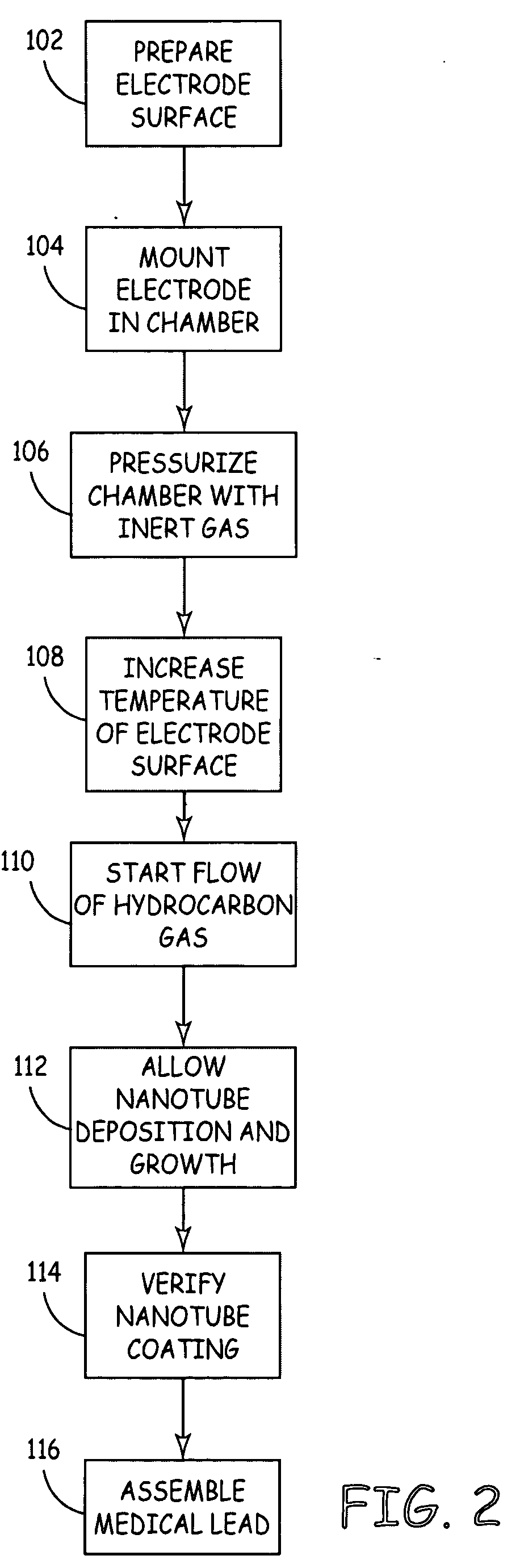

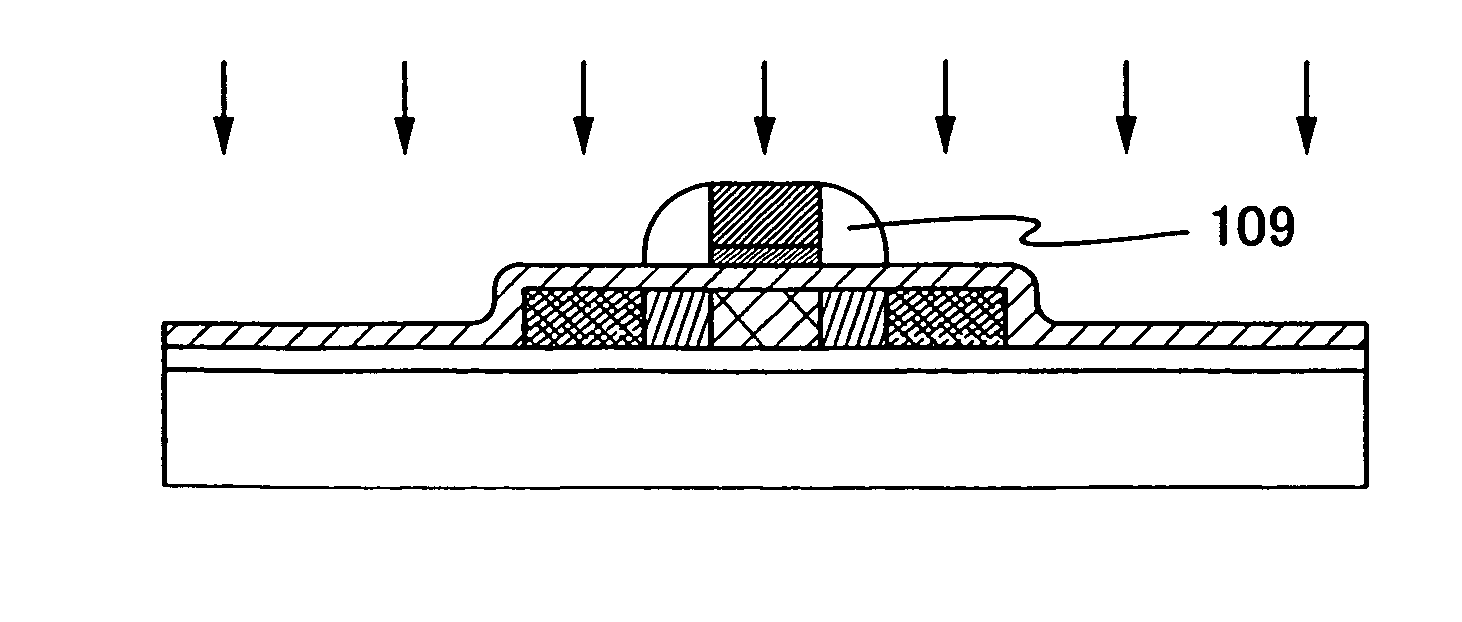

Medical devices incorporating carbon nanotube material and methods of fabricating same

InactiveUS7596415B2High strengthStable stateNanotechTransvascular endocardial electrodesMuscle tissueCarbon nanotube

The present invention relates generally to medical devices; in particular and without limitation, to unique electrodes and / or electrical lead assemblies for stimulating cardiac tissue, muscle tissue, neurological tissue, brain tissue and / or organ tissue; to electrophysiology mapping and ablation catheters for monitoring and selectively altering physiologic conduction pathways; and, wherein said electrodes, lead assemblies and catheters optionally include fluid irrigation conduit(s) for providing therapeutic and / or performance enhancing materials to adjacent biological tissue, and wherein each said device is coupled to or incorporates nanostructure or materials therein. The present invention also provides methods for fabricating, deploying, and operating such medical devices.

Owner:MEDTRONIC INC

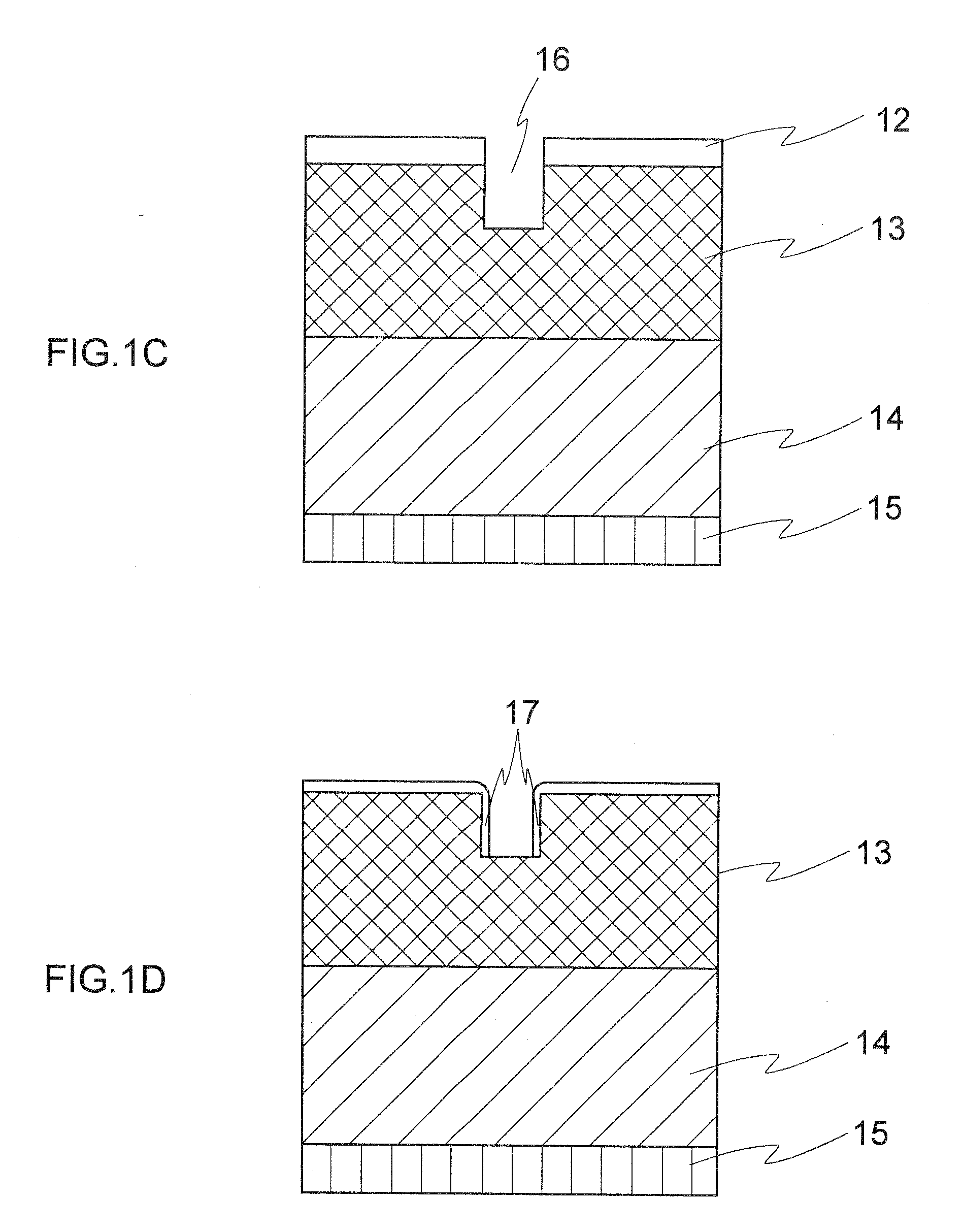

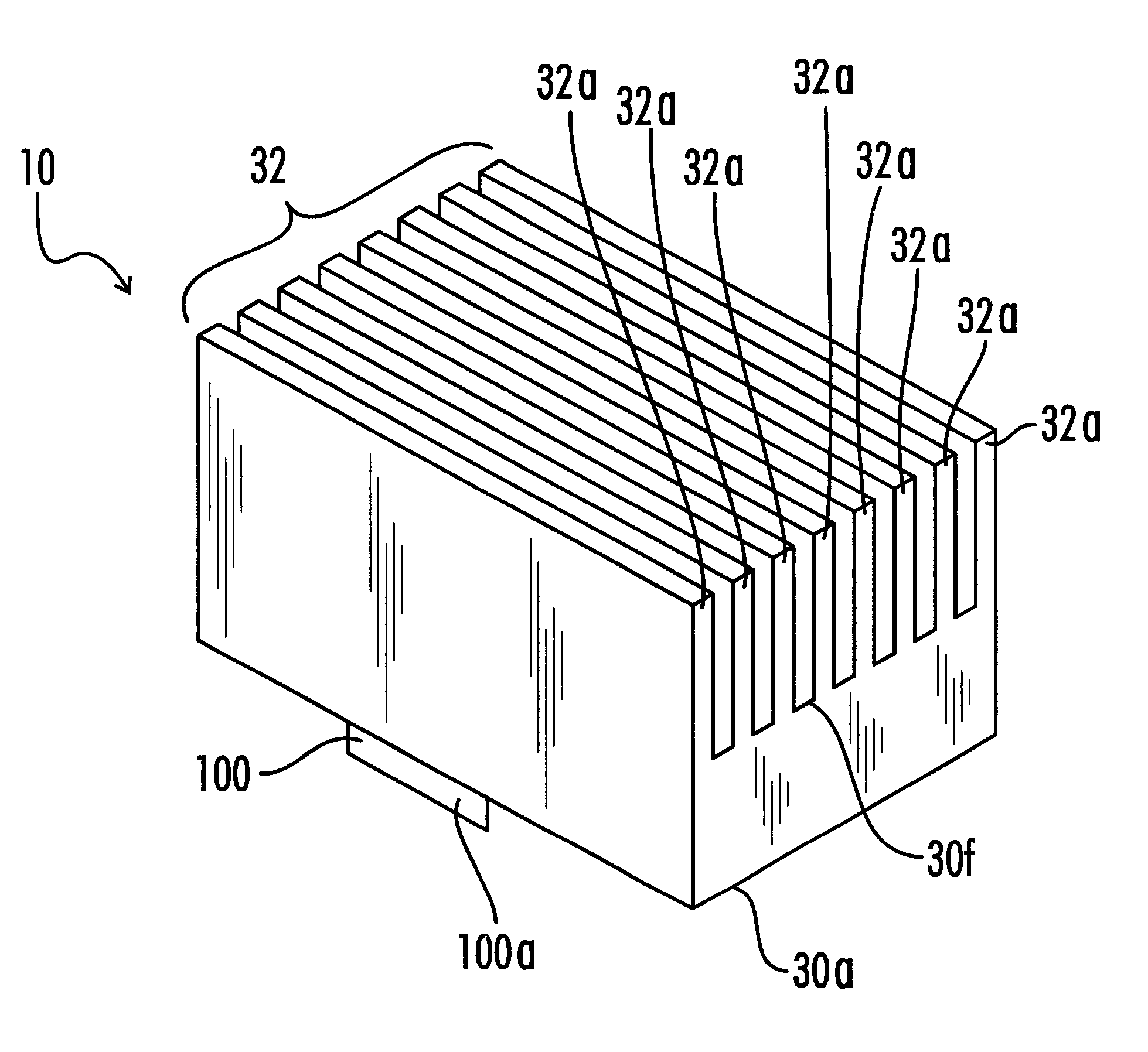

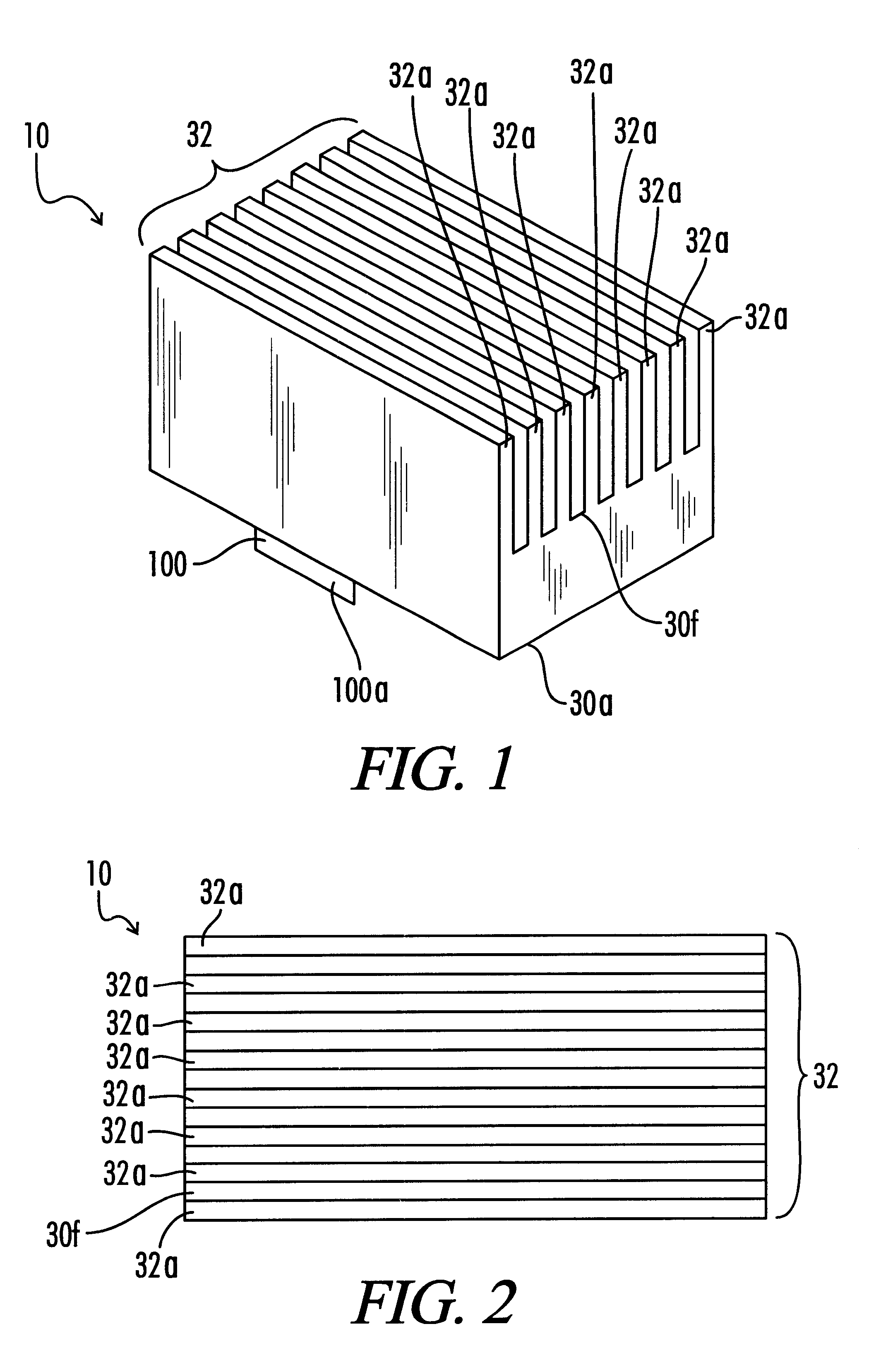

Thermal management system

InactiveUS6841250B2Improve cooling effectIncreased anisotropyLayered productsSemiconductor/solid-state device detailsGraphiteThermal management system

The present invention relates to a system for managing the heat from a heat source like an electronic component. More particularly, the present invention relates to a system effective for dissipating the heat generated by an electronic component using a thermal management system that includes a heat sink formed from a graphite article.

Owner:NEOGRAF SOLUTIONS LLC

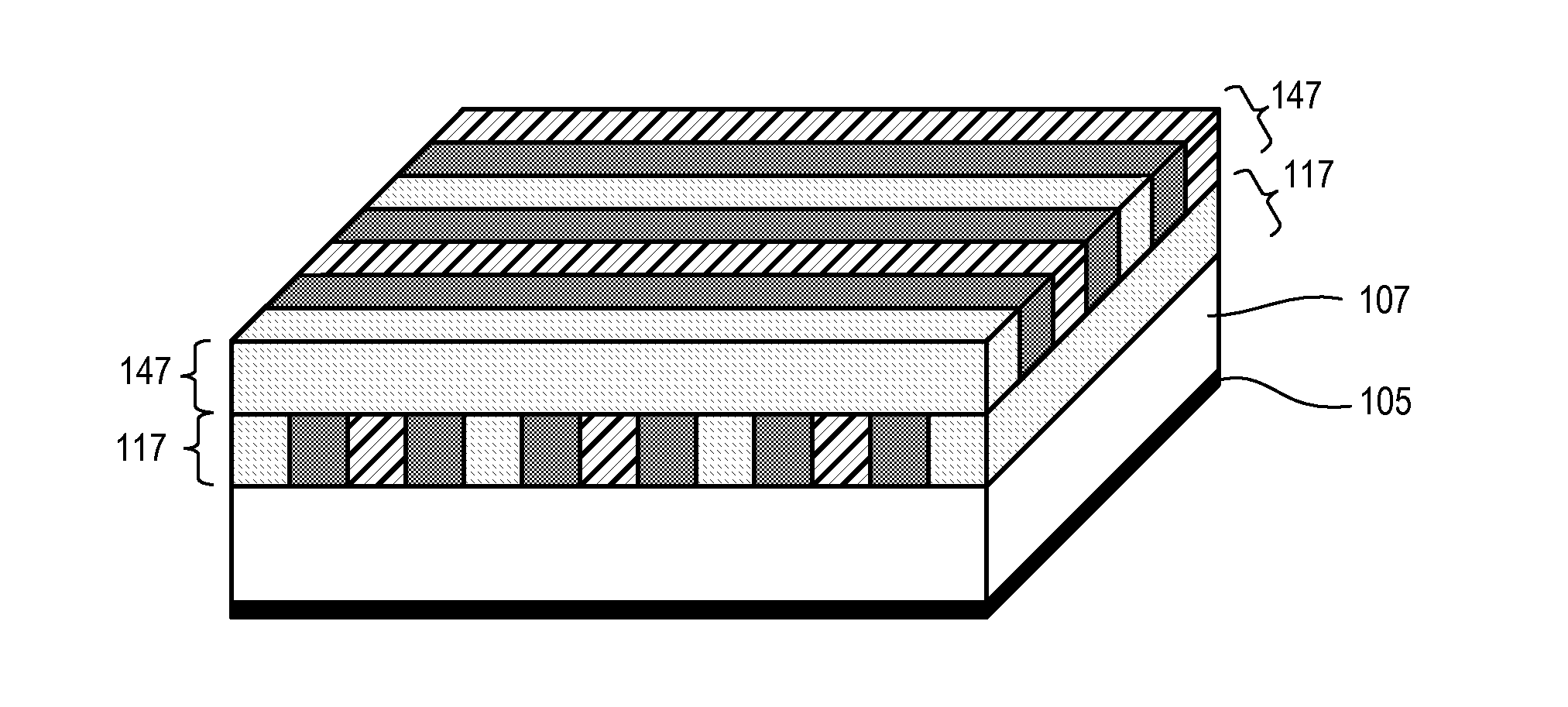

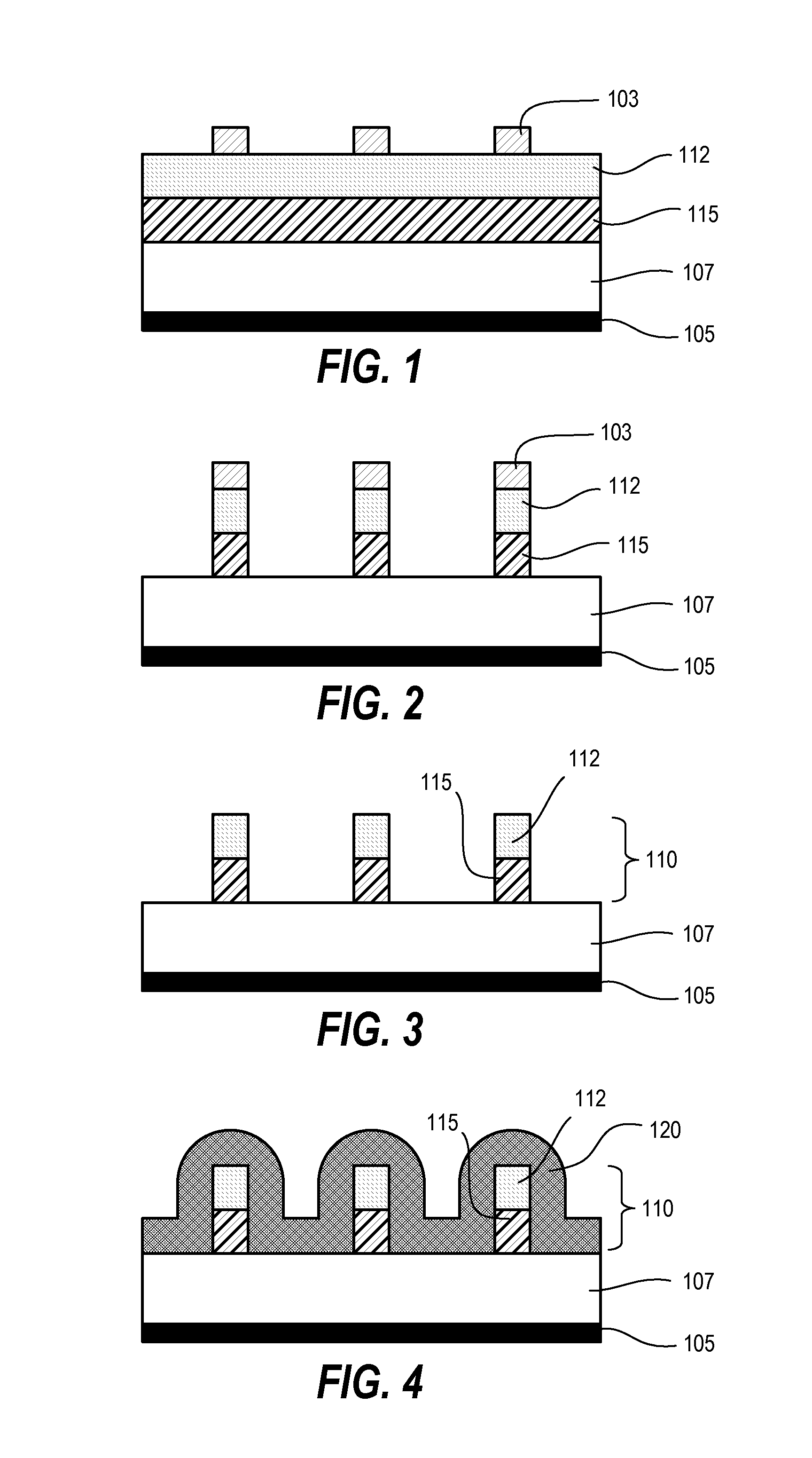

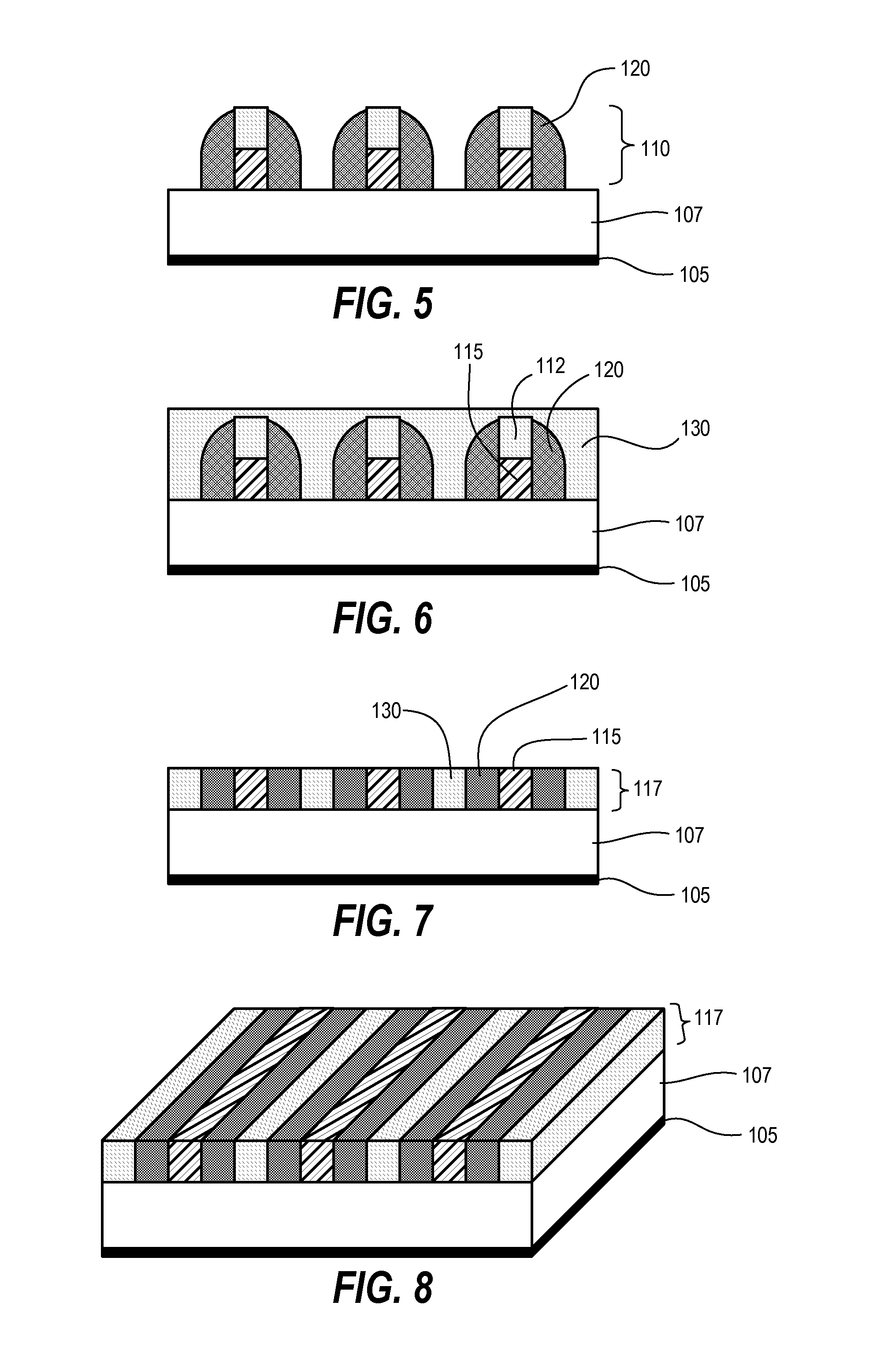

Method for multiplying pattern density by crossing multiple patterned layers

ActiveUS20150243518A1High uniformity and fidelityHigh densitySemiconductor/solid-state device manufacturingImage transferComputational physics

Techniques disclosed herein include increasing pattern density for creating high-resolution contact openings, slots, trenches, and other features. A first line-generation sequence creates a first layer of parallel lines of alternating and differing material by using double-stacked mandrels, sidewall image transfer, and novel planarization schemes. This line-generation sequence is repeated on top of the first layer of parallel lines, but with the second layer of parallel lines of alternating and differing material being oriented to elevationally cross lines of the first layer. Etching selective to one of the materials within the double stack of parallel lines results in defining a pattern of openings, slots, etc., which can be transferred into underlying layers. Such patterning techniques herein can quadruple a density of features in a given pattern, which can be described as created a pitch quad.

Owner:TOKYO ELECTRON LTD

Medical devices incorporating carbon nanotube material and methods of fabricating same

InactiveUS20050203604A1High strengthStable stateNanotechTransvascular endocardial electrodesMuscle tissueCarbon nanotube

The present invention relates generally to medical devices; in particular and without limitation, to unique electrodes and / or electrical lead assemblies for stimulating cardiac tissue, muscle tissue, neurological tissue, brain tissue and / or organ tissue; to electrophysiology mapping and ablation catheters for monitoring and selectively altering physiologic conduction pathways; and, wherein said electrodes, lead assemblies and catheters optionally include fluid irrigation conduit(s) for providing therapeutic and / or performance enhancing materials to adjacent biological tissue, and wherein each said device is coupled to or incorporates nanostructure or materials therein. The present invention also provides methods for fabricating, deploying, and operating such medical devices.

Owner:MEDTRONIC INC

Method for manufacturing semiconductor device

InactiveUS20060205129A1Avoid changeAvoid low process precisionSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialInductively coupled plasma

In a gas containing a fluorine atom in the molecule, etching of a SiN film is performed isotropically; therefore, the width of a sidewall gets smaller and it is difficult to widen the width of an LDD region. A silicon nitride film is formed over a gate electrode, a hydrogen bromide is mainly used as an etching gas, the silicon nitride film only over the gate electrode and the surface of a substrate are removed by an etching method such as ICP (Inductively Coupled Plasma), and the silicon nitride film is simultaneously left only on the side surface part of the gate electrode.

Owner:SEMICON ENERGY LAB CO LTD

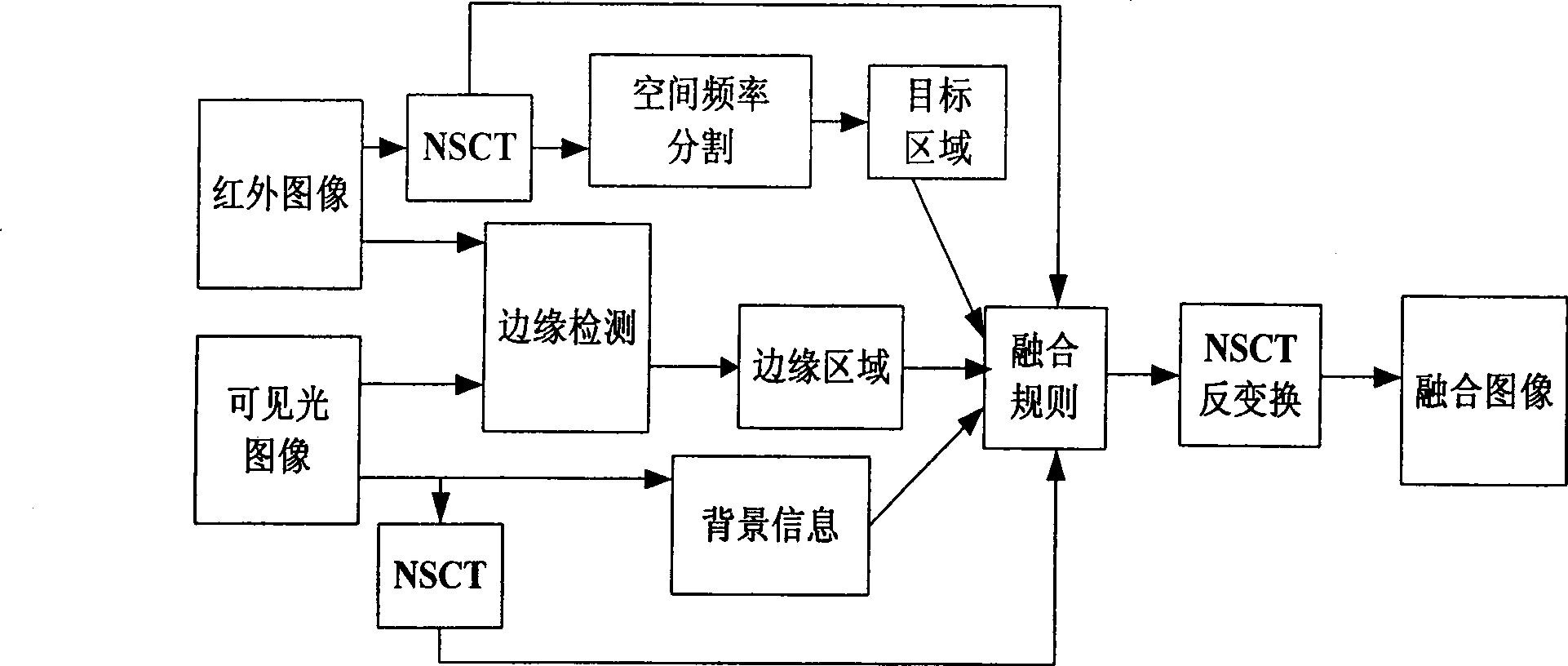

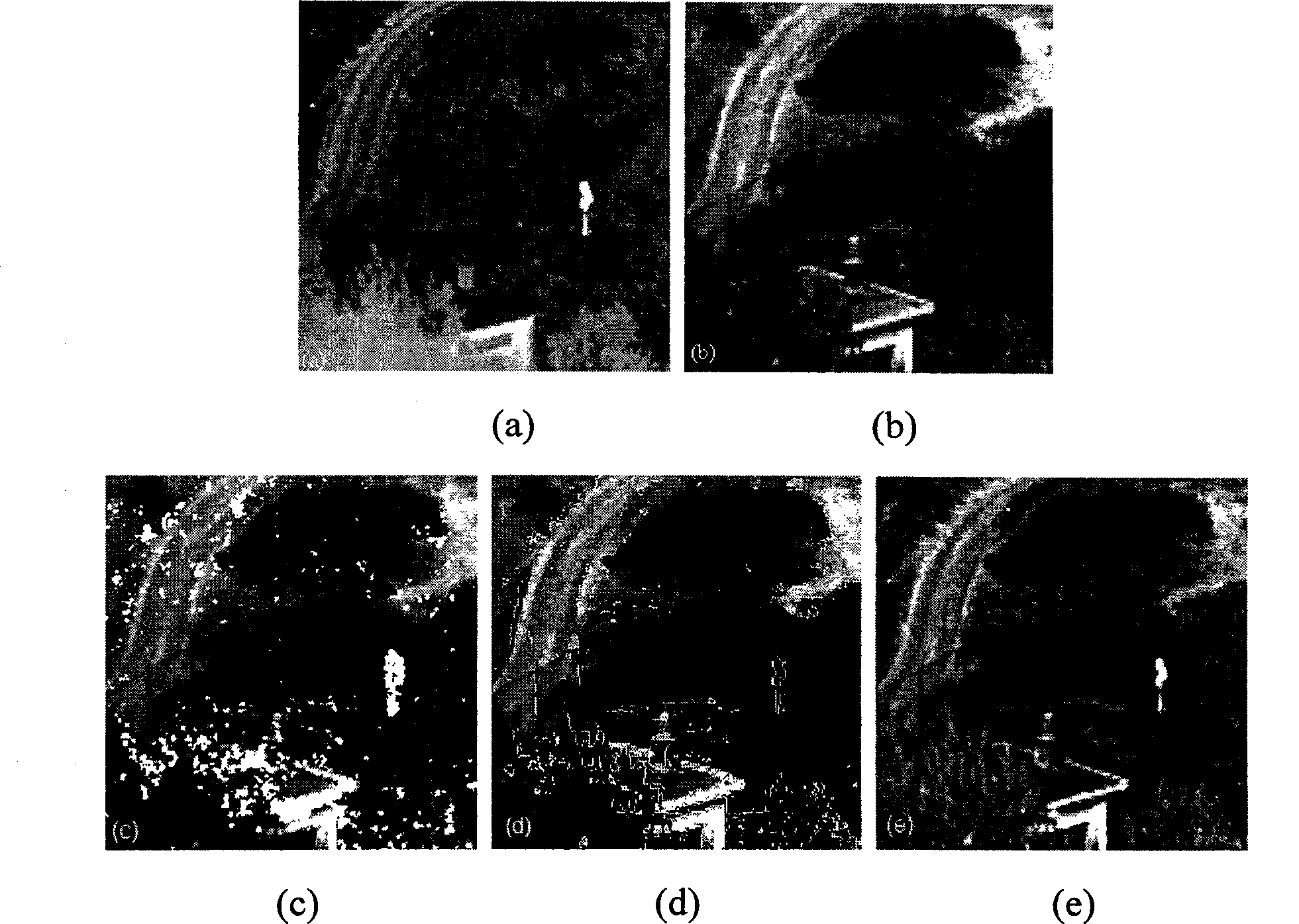

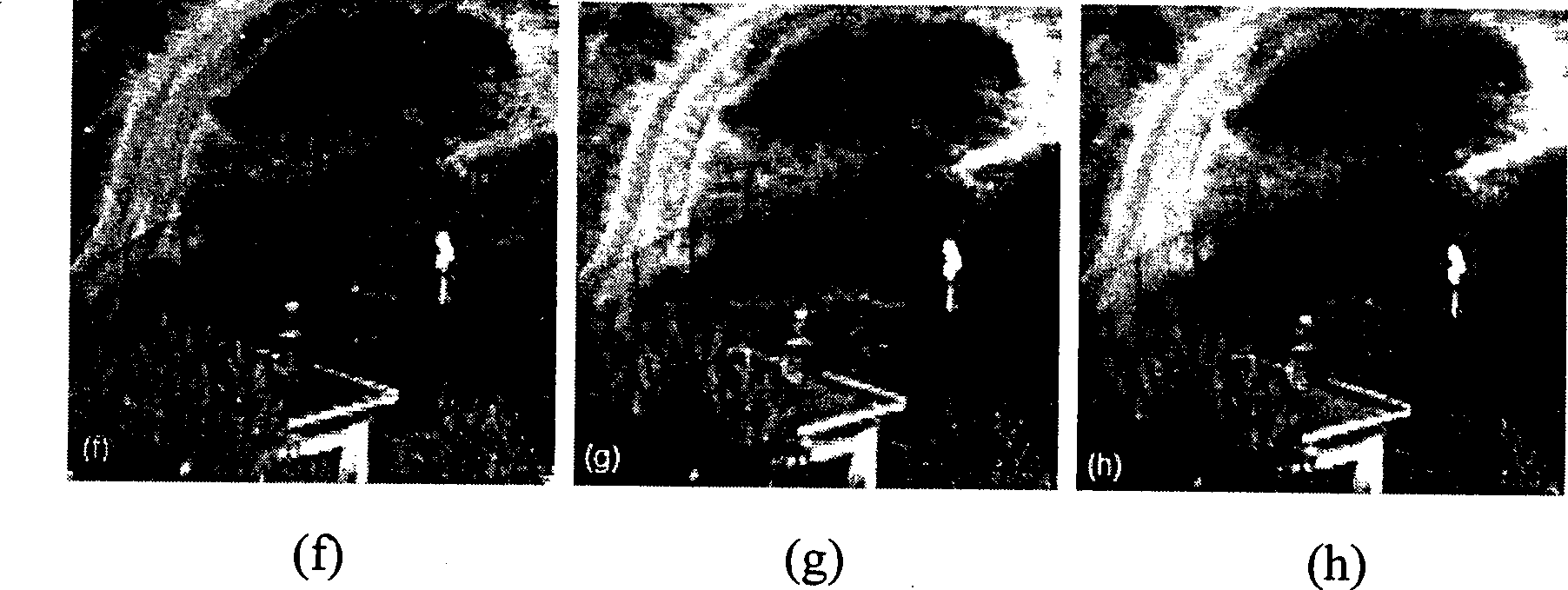

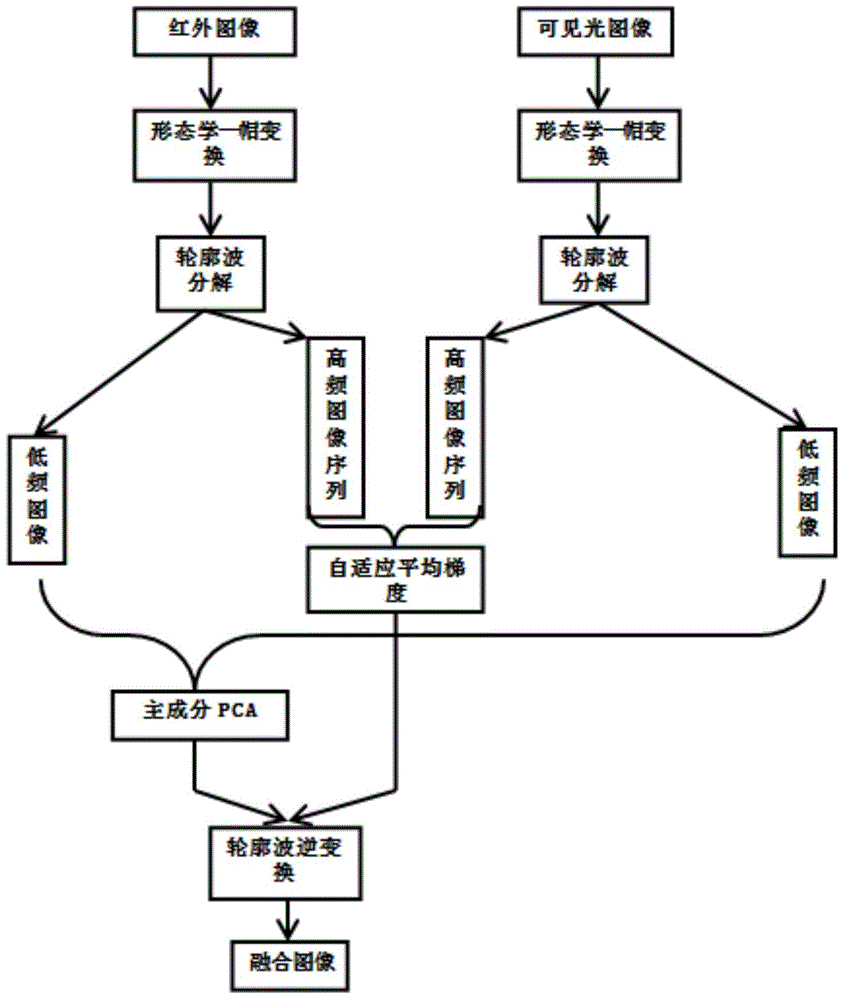

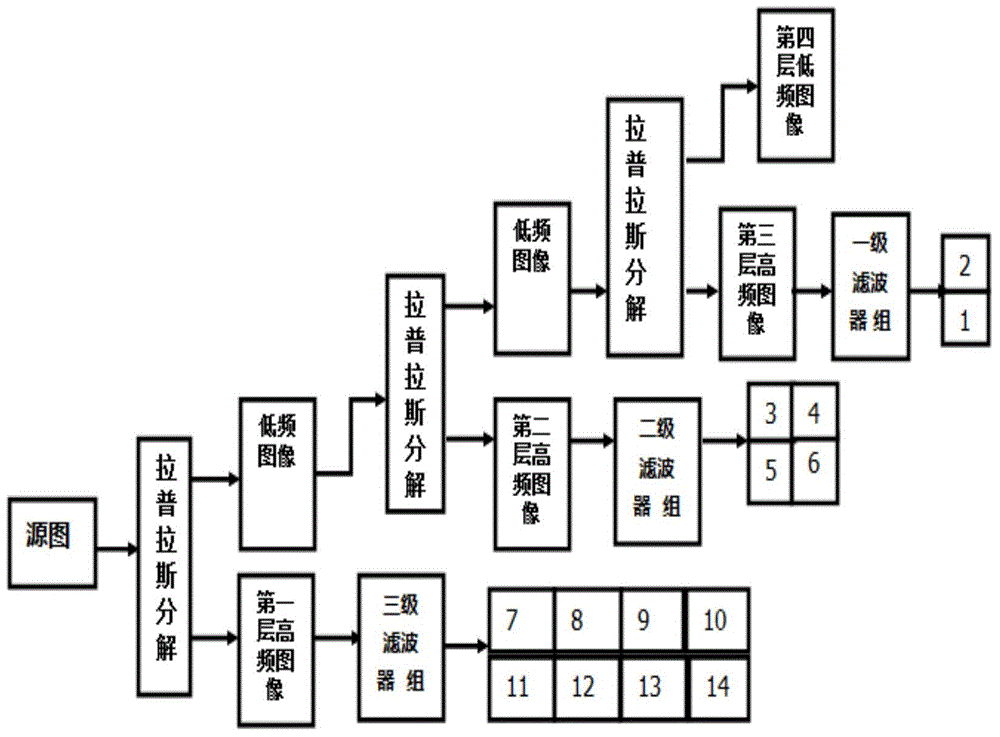

Image fusion of sequence infrared and visible light based on region segmentation

ActiveCN101546428AEfficient captureGood multi-resolutionImage enhancementImage analysisContourletImage fusion

The invention relates to an image fusion of sequence infrared and visible light based on region segmentation. The invention is characterized in that infrared images are segmented into different regions according to the interframe objective change situation and gray scale change degree thereof; the images are dissembled to different frequency domains in the different directions by utilizing non-sub-sampling Contourlet transform; different fusion rules are selected based on the characteristics of different regions in the different frequency domains; and image reformation is carried out for the processed coefficients to obtain the final fusion result. The method takes the information of the characteristics in one of the regions into consideration, so the algorithm is capable of effectively reducing the rate of fusion image error due to the noise and low matching precision, and has stronger robustness.

Owner:JIANGSU HUAYI GARMENT CO LTD +1

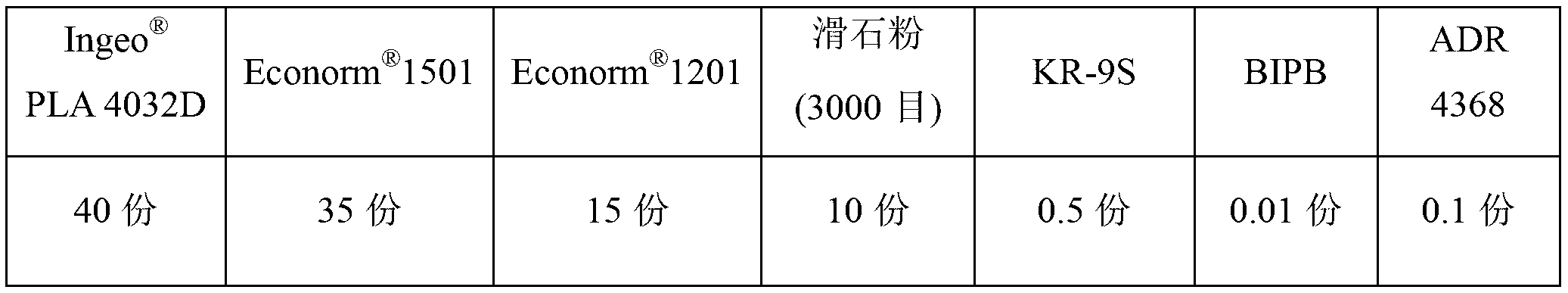

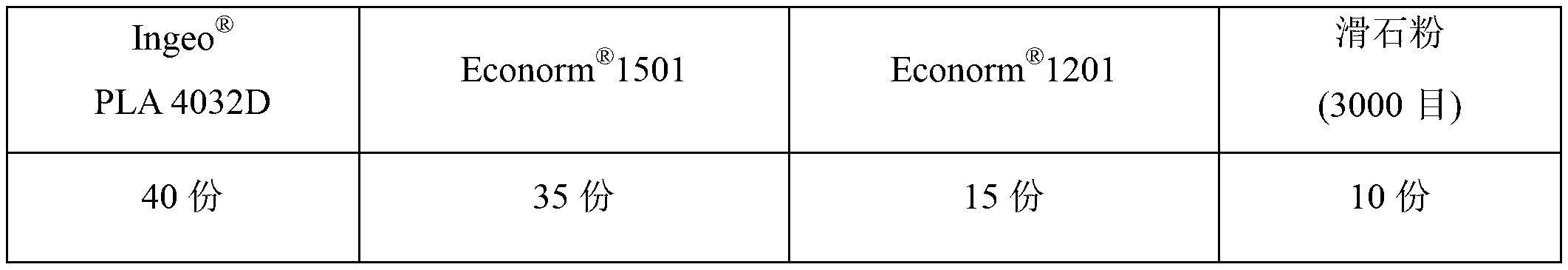

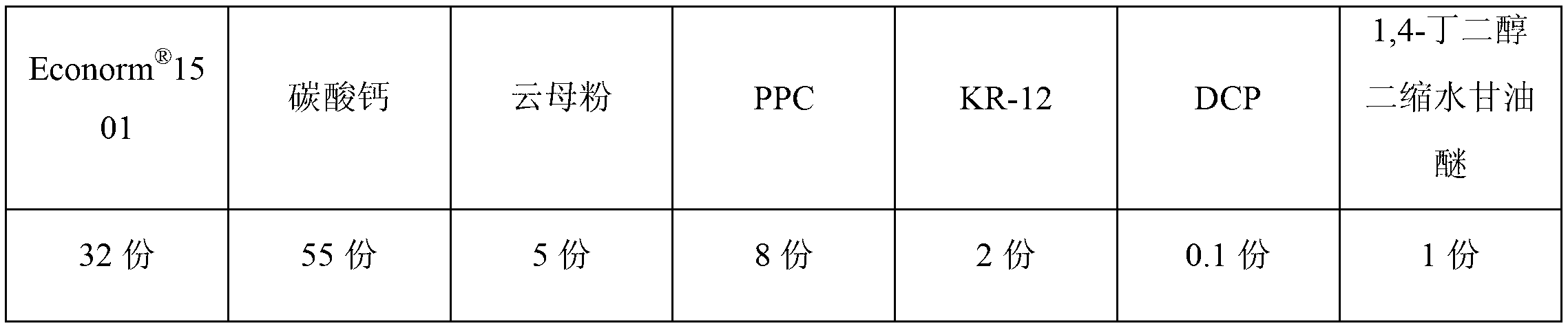

Method for increasing capacity of biodegradable polyester blend film

The invention relates to a biodegradable polyester blend film, and in particular relates to a method for increasing the capacity of a biodegradable polyester blend film. The method for increasing the capacity of the biodegradable polyester blend film comprises the steps of: adding a high-activity titanate coupling agent, a free radical cross-linking agent and a multi-epoxy group compound into a blending compound system of two or more than two biodegradable polyesters and an inorganic or organic filler; initiating and promoting transesterification, proper intermolecular cross-linking reaction and end-group chain extension in a double-screw extruder with the length-diameter ratio of more than or equal to 48 and the total kneading blocks of more than or equal to 16 under the action of high temperature and high shear strength, thus increasing the capacity of blending polyester. Through utilizing the double-screw extruder with the high length-diameter ratio and high shear strength and introducing the titanate coupling agent, the free radical cross-linking agent and the multi-epoxy group compound are introduced, on-line capacity increasing of a biodegradable polyester / filler blend compound system is carried out, so that the anisotropy of the mechanical property of the film is greatly improved.

Owner:山东悦泰生物新材料有限公司

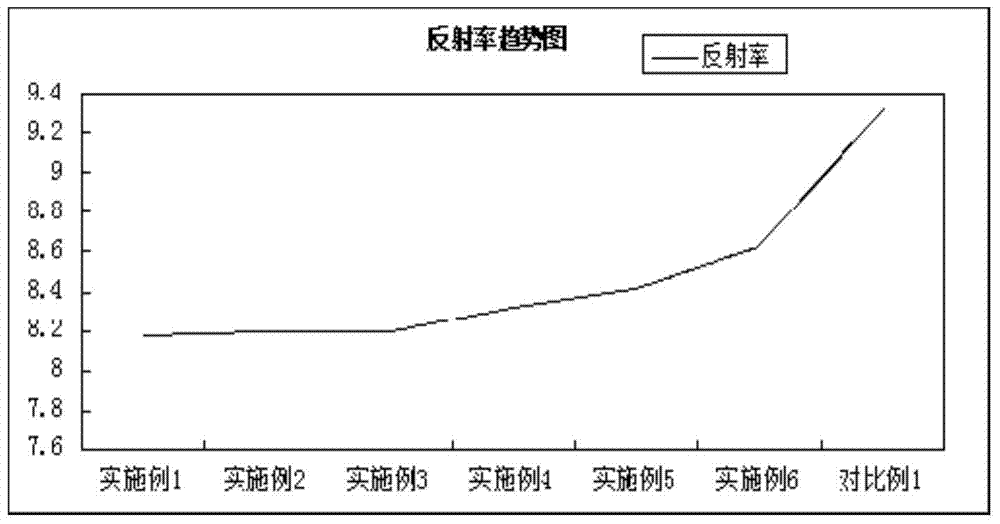

Alcohol-free alkaline texturing solution for mono-crystalline silicon wafer, texturing method for mono-crystalline silicon wafer, solar cell and manufacturing method for solar cell

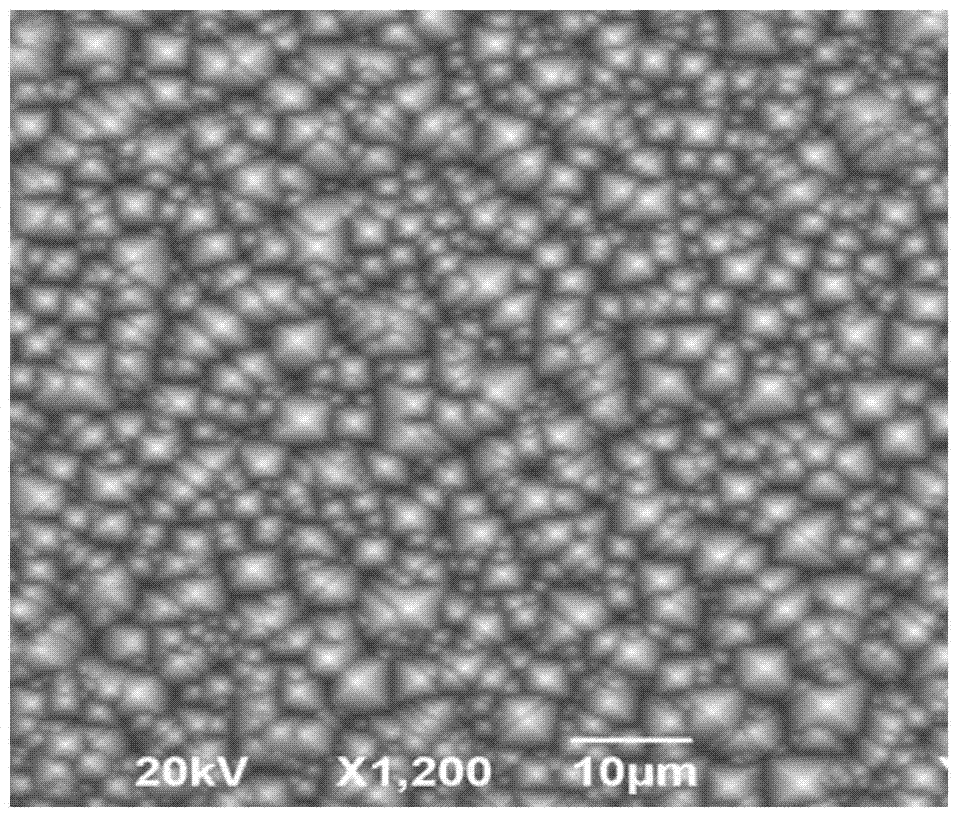

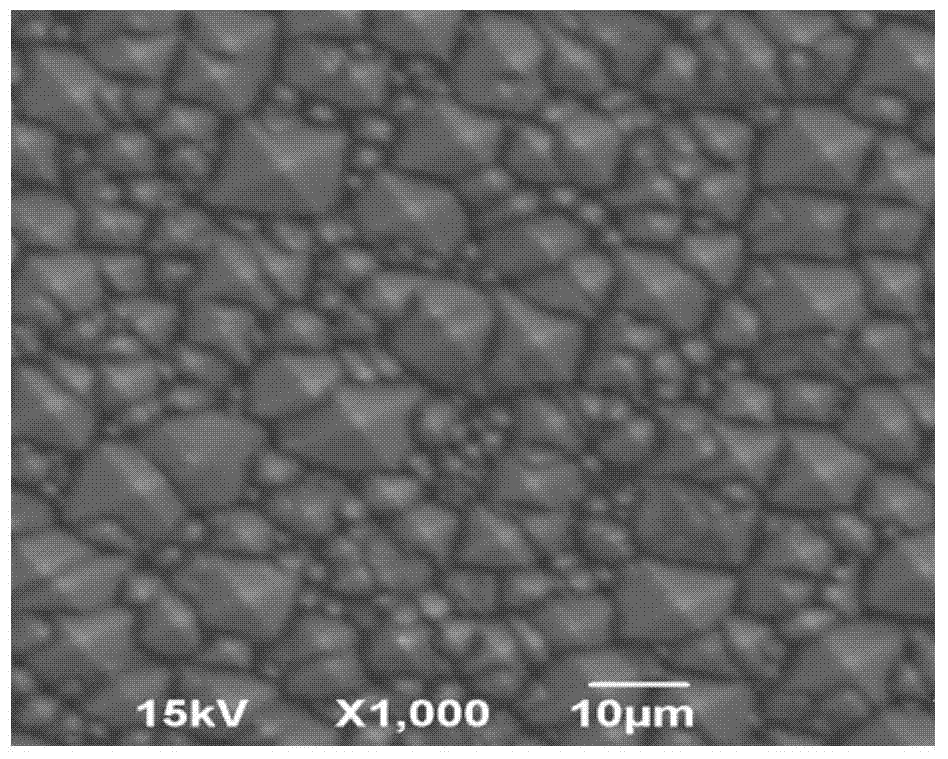

InactiveCN103614778AReduce reflectivityIncreased anisotropyAfter-treatment detailsFinal product manufactureAlcohol freeAbsorption capacity

The invention discloses an alcohol-free alkaline texturing solution for a mono-crystalline silicon wafer, a texturing method for the mono-crystalline silicon wafer, a solar cell and a manufacturing method for the solar cell. The alcohol-free alkaline texturing solution for the mono-crystalline silicon wafer comprises an alkaline solution and a texturing additive, wherein the texturing additive is an alcohol-free additive. According to the alcohol-free alkaline texturing solution, isopropanol which is harmful to human bodies and the environment adopted in the conventional alkaline texturing solution is abandoned; the corrosion depth of the surface of a silicon wafer can be controlled within the range of 5 to 7.5 mu m easily by performing surface texturing on the mono-crystalline silicon wafer obtained by performing linear cutting on a diamond by only adopting the alcohol-free alkaline texturing solution consisting of the alkaline solution and the alcohol-free additive; meanwhile, the corrosion speed is guaranteed; the anisotropy of corrosion is enhanced; pyramid structures on the surface of the silicon wafer obtained after the texturing are small and uniform in size, so that the reflectivity of the surface of the silicon wafer is reduced by about 1 percent; the light absorption capacity of the surface of the silicon wafer is increased; the conversion efficiency of the solar cell is improved.

Owner:YINGLI ENERGY CHINA

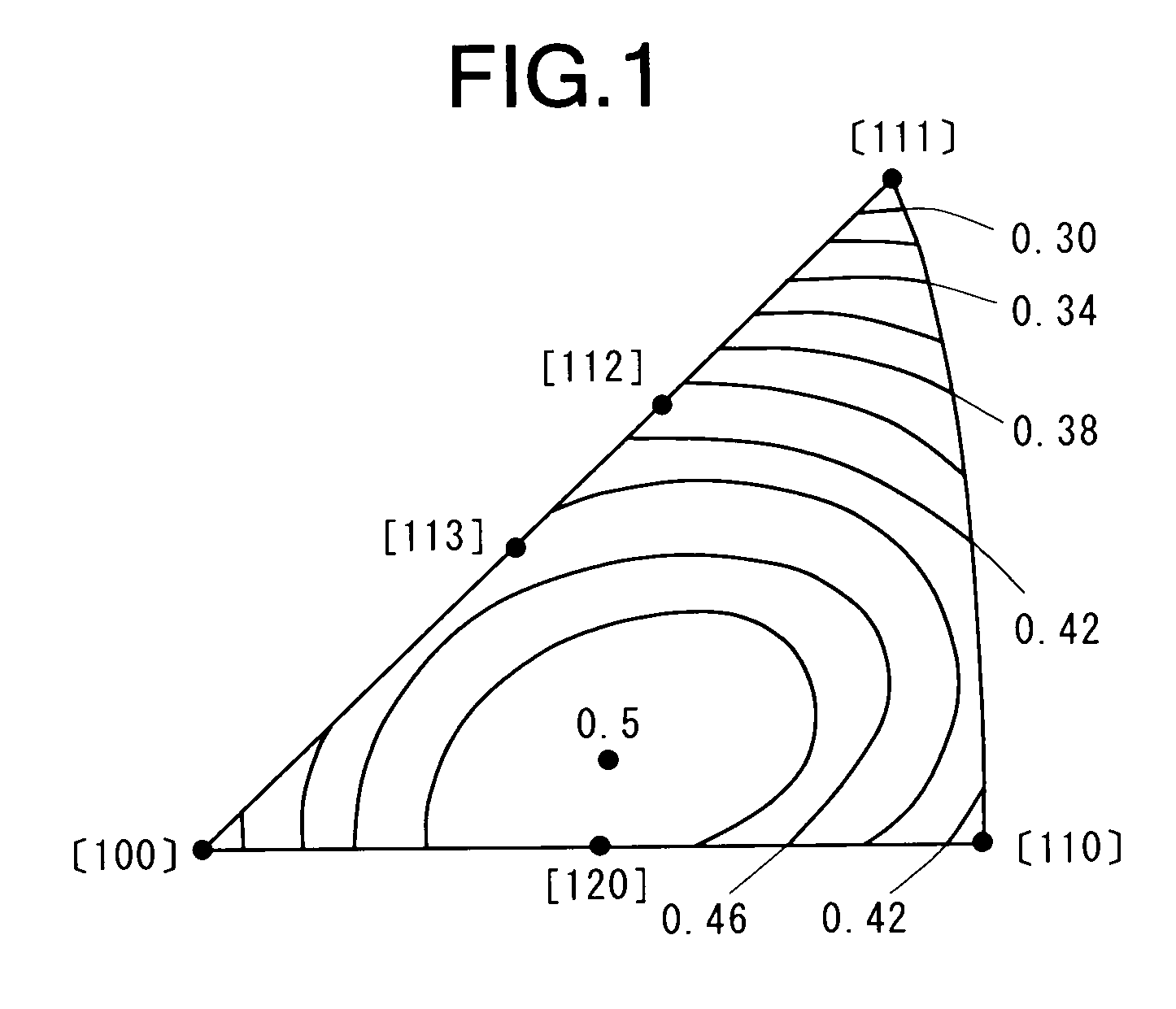

Copper alloy sheet, manufacturing method of copper alloy sheet, and electric/electronic component

ActiveUS20110240180A1Excellent bending workabilityImprove conductivityConductive materialCrystal twinningCrystal orientation

There is provided a copper alloy sheet including 1.0 to 3.5 mass % Ni, 0.5 to 2.0 mass % Co, and 0.3 to 1.5 mass % Si, a Co / Ni mass ratio being 0.15 to 1.5, an (Ni+Co) / Si mass ratio being 4 to 7, and a balance being composed of Cu and an unavoidable impurity, wherein in observation results of a crystal grain boundary property and crystal orientation by EBSP measurement, a density of twin boundaries among all crystal grain boundaries is 40% or more and an area ratio of crystal grains with Cube orientation is 20% or more, on a rolled surface.

Owner:DOWA METALTECH CO LTD

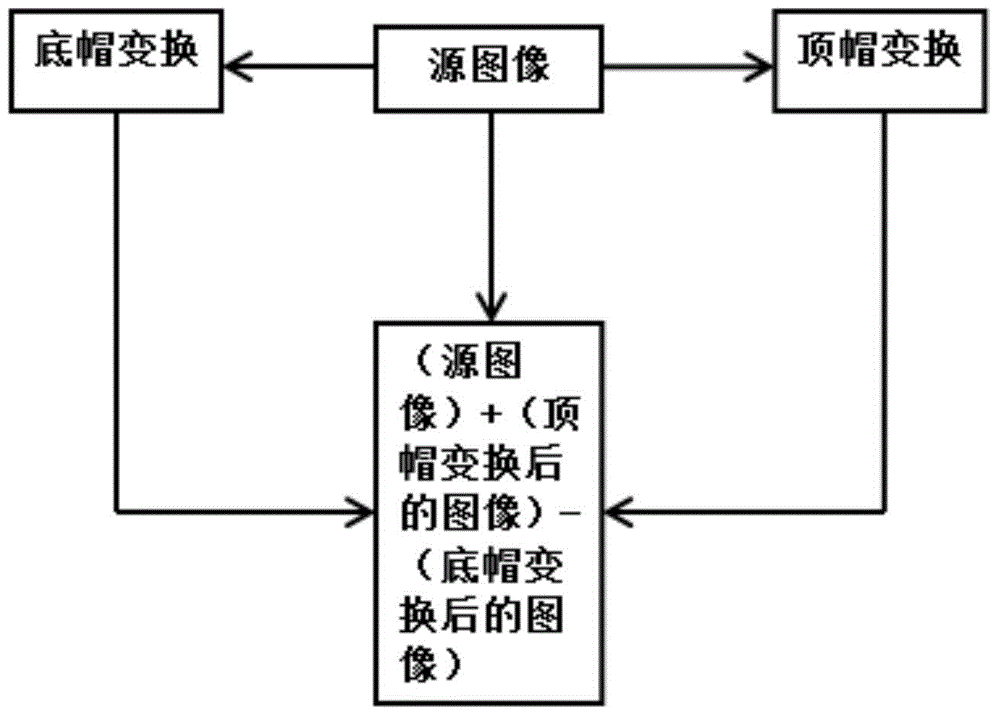

Morphology and PCA (principal component analysis) based contourlet fusion method for infrared and visible light images

InactiveCN104408700AIncrease contrastPromote localizationImage enhancementGeometric image transformationDecompositionPrincipal component analysis

The invention discloses a morphology and PCA (principal component analysis) based contourlet fusion method for infrared and visible light images. The method includes: firstly, subjecting two images to morphology-hat transformation respectively and subjecting the two obtained images to contourlet decomposition to form a high-frequency image and a low-frequency image respectively; then, fusing the low-frequency image by a PCA method; fusing the high-frequency image by means of average gradient adaptive weighted processing; reconstructing a fused image by means of contourlet reverse transformation. The morphology and PCA based contourlet fusion method for the infrared and visible light images is used for image fusion of the infrared and visible light images, so that the fused image is high in contrast ratio, rich in information and clear in texture detail.

Owner:NANJING UNIV OF SCI & TECH

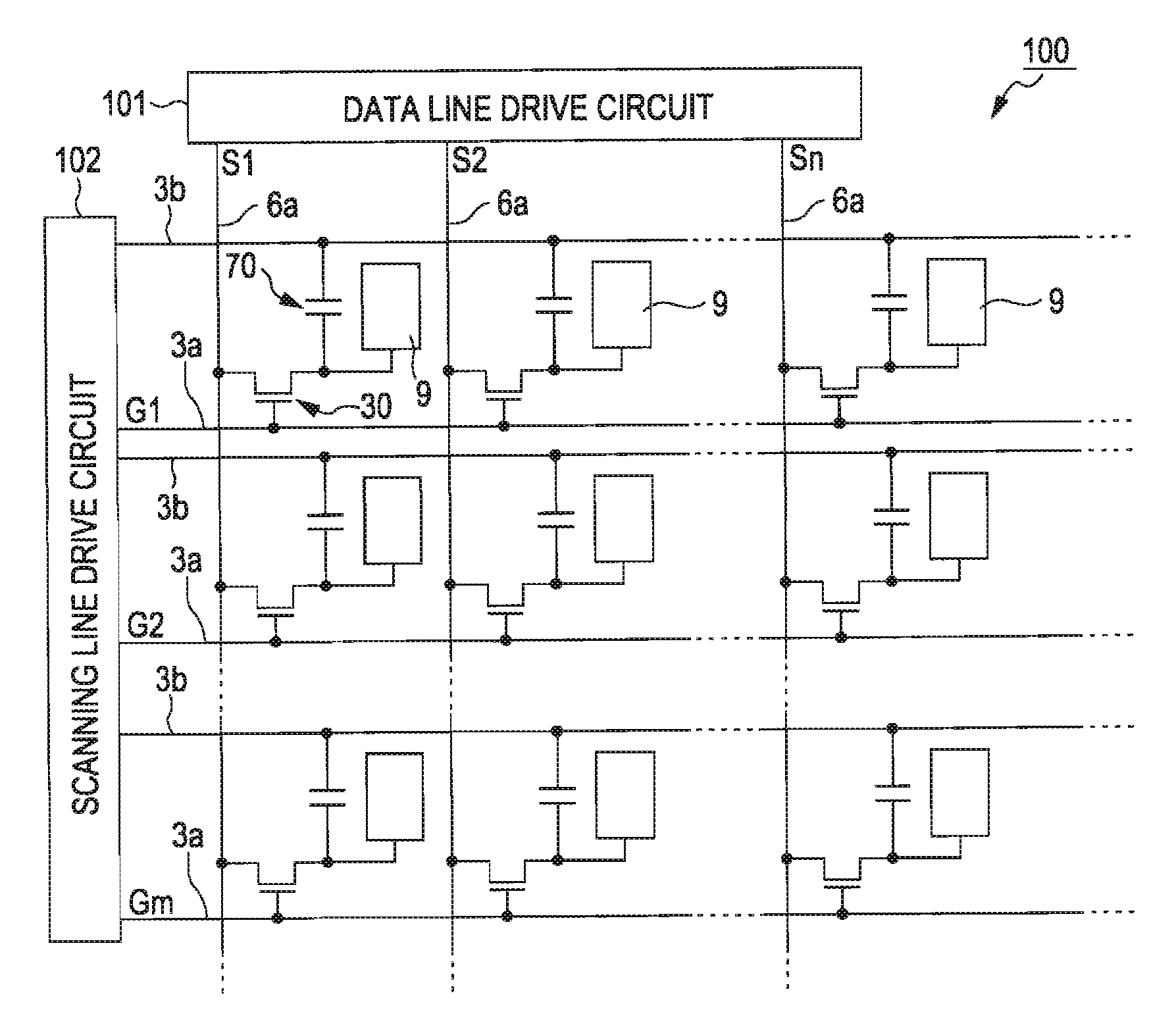

Liquid crystal device and electronic equipment

InactiveUS20080100764A1Reduce displayReduce widthNon-linear opticsElectrical field strengthLiquid-crystal display

A liquid crystal device including a liquid crystal layer having liquid crystal which demonstrates an optically isotropic property when no electric field is applied and demonstrates an optically anisotropic property which is proportional to the square of the electric field strength when electric field is applied, and a pair of substrates which sandwich the liquid crystal layer, including sub-pixel areas each including a reflective display area for reflective display and a transmissive display area for transmissive display; and first and second electrodes provided in both of the reflective display area and the transmissive display area, wherein the liquid crystal layer is driven by an electric field generated between the first electrode and the second electrode, and wherein the distance between the first electrode and the second electrode in the transmissive display area is smaller than the distance between the first electrode and the second electrode in the reflective display area.

Owner:JAPAN DISPLAY WEST

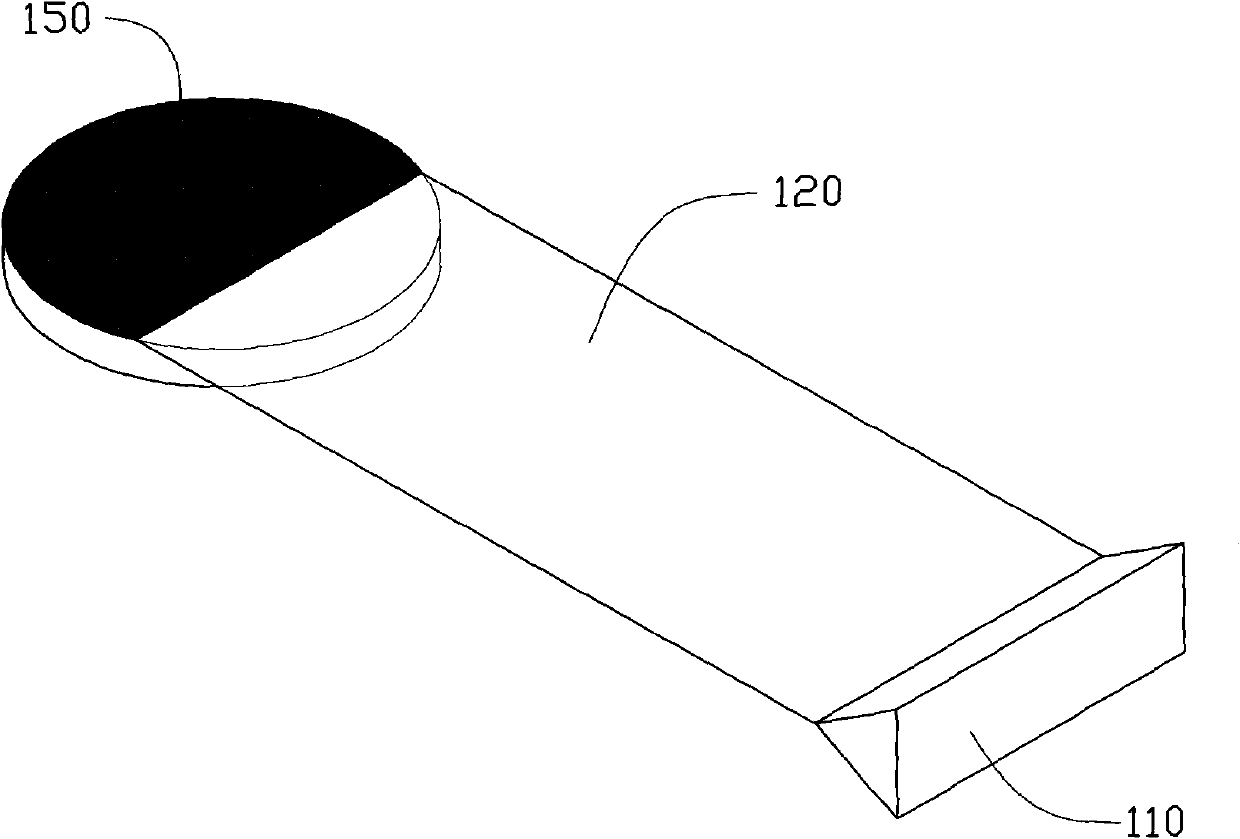

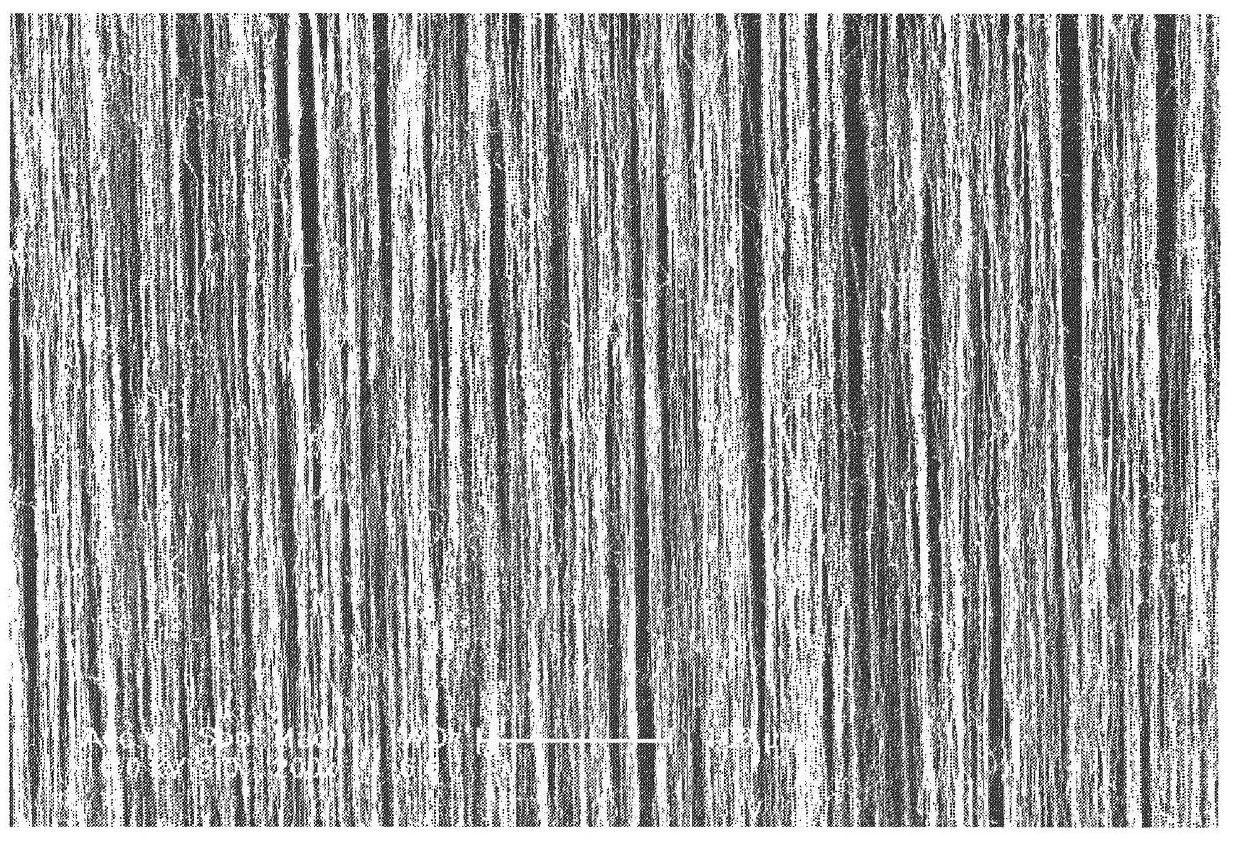

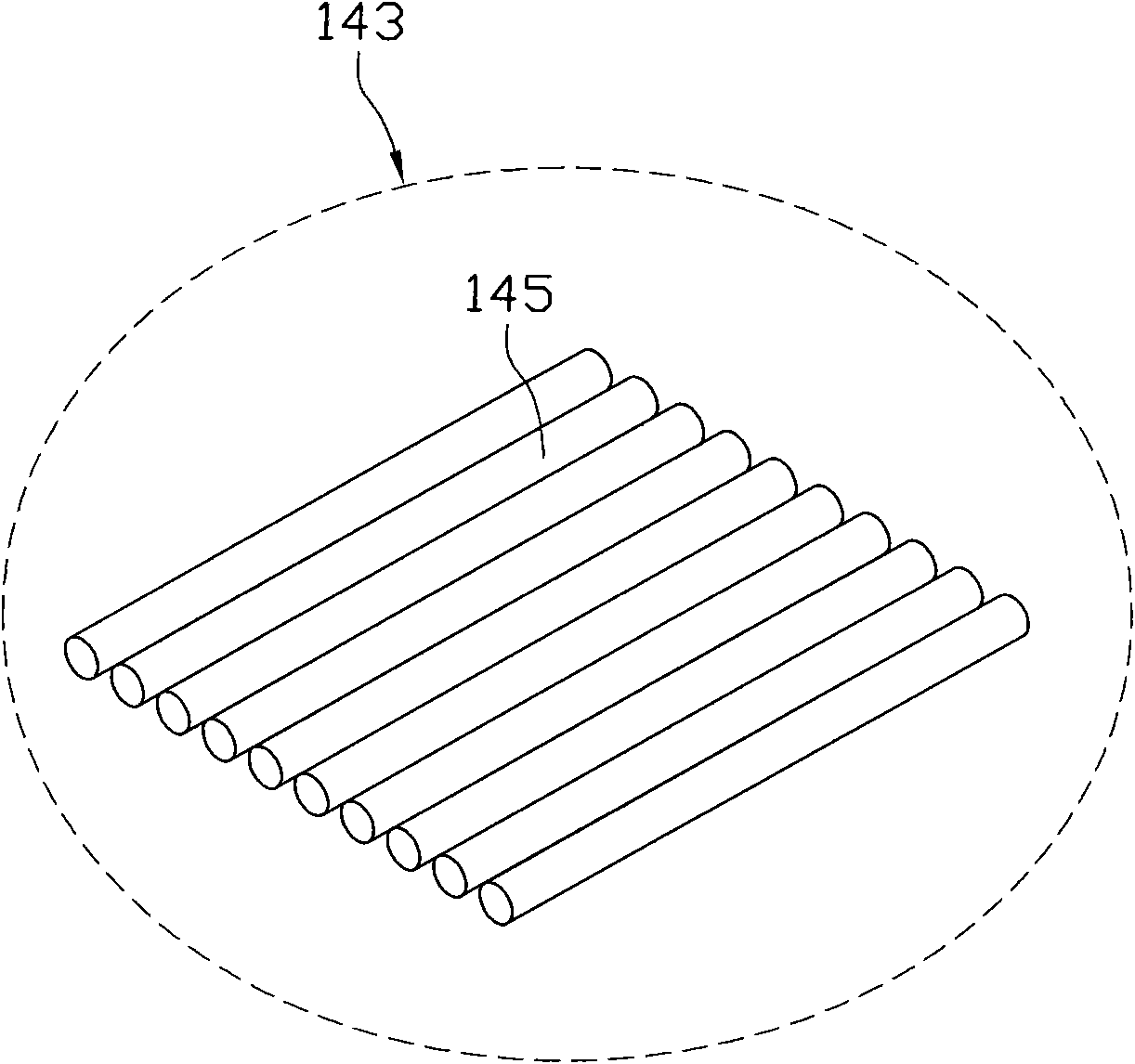

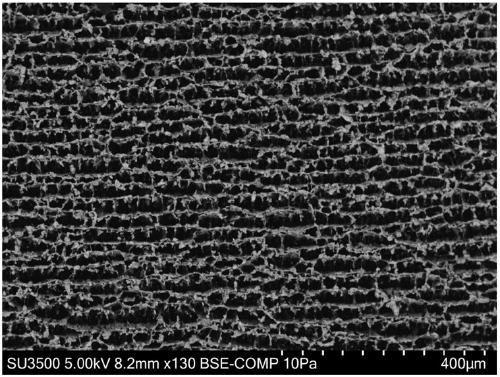

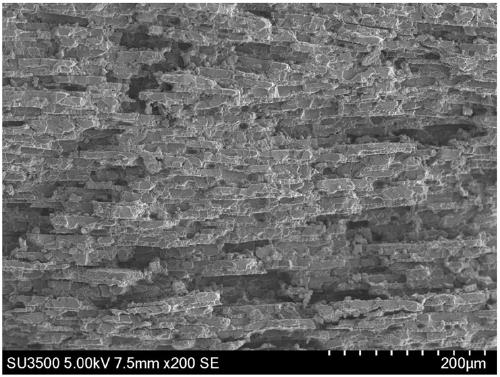

Carbon-nano-tube film and preparation method thereof

ActiveCN102086035AReduce distribution densityGood light transmissionMaterial nanotechnologyNanostructure manufactureCarbon nanotubeEngineering

The invention relates to a method for preparing a carbon-nano-tube film. The method comprises the following steps of: providing a carbon-nano-tube primary film which is formed by a plurality of carbon-nano-tubes, wherein the plurality of carbon-nano-tubes are arranged along the same direction in a preferential orientation mode; and scanning the carbon-nano-tube primary film row by row along the preferential orientation direction parallel to the plurality of carbon-nano-tubes by adopting a laser beam so as to form a plurality of thinning areas in the partial position in the carbon-nano-tube primary film, wherein the plurality of thinning areas are arranged into at least one row along the preferential orientation direction of the plurality of carbon-nano-tubes. The invention also relates toa carbon-nano-tube film which can be applied to the fields of transparent electrodes, thin-film transistors, touch screens, and the like.

Owner:BEIJING FUNATE INNOVATION TECH

Manufacturing method of silver-tungsten carbide-carbon electrical contact material

InactiveCN1658346AImprove compactnessHigh hardnessContact materialsManufacturing technologyCircuit breaker

This invention relates to a manufacturing method of a silver-tungsten carbide-carbon electric contactor. It adopts silver powder, tungsten carbide and graphite powder as the raw materials and manufactures the silver-tungsten carbide-carbon electric contactor material through chemical coating and solid agglomeration techniques, and belongs to the field of electric components breaker switch manufacturing technology. The characteristic of this invention is: adopt silver powder, slab tungsten carbide powder, graphite powder and a little additive metal powder as the raw materials. At first mix the slab tungsten carbide powder, the graphite powder and the additive metal powder, and use chemical coating technique to get silver coating compound powder, and then pass through cold roll forming, agglomeration, re-rolling to get AgWC12C3 electric contactor material with tungsten carbide grains arrayed directionally. The AgWC12C3 electric contactor material made by this invention has fine compactness, high rigidity and conductive power. This material can be applied to many kinds of breakers with large capacity, the breakers with plastic covers and automatic switches.

Owner:SHANGHAI UNIV

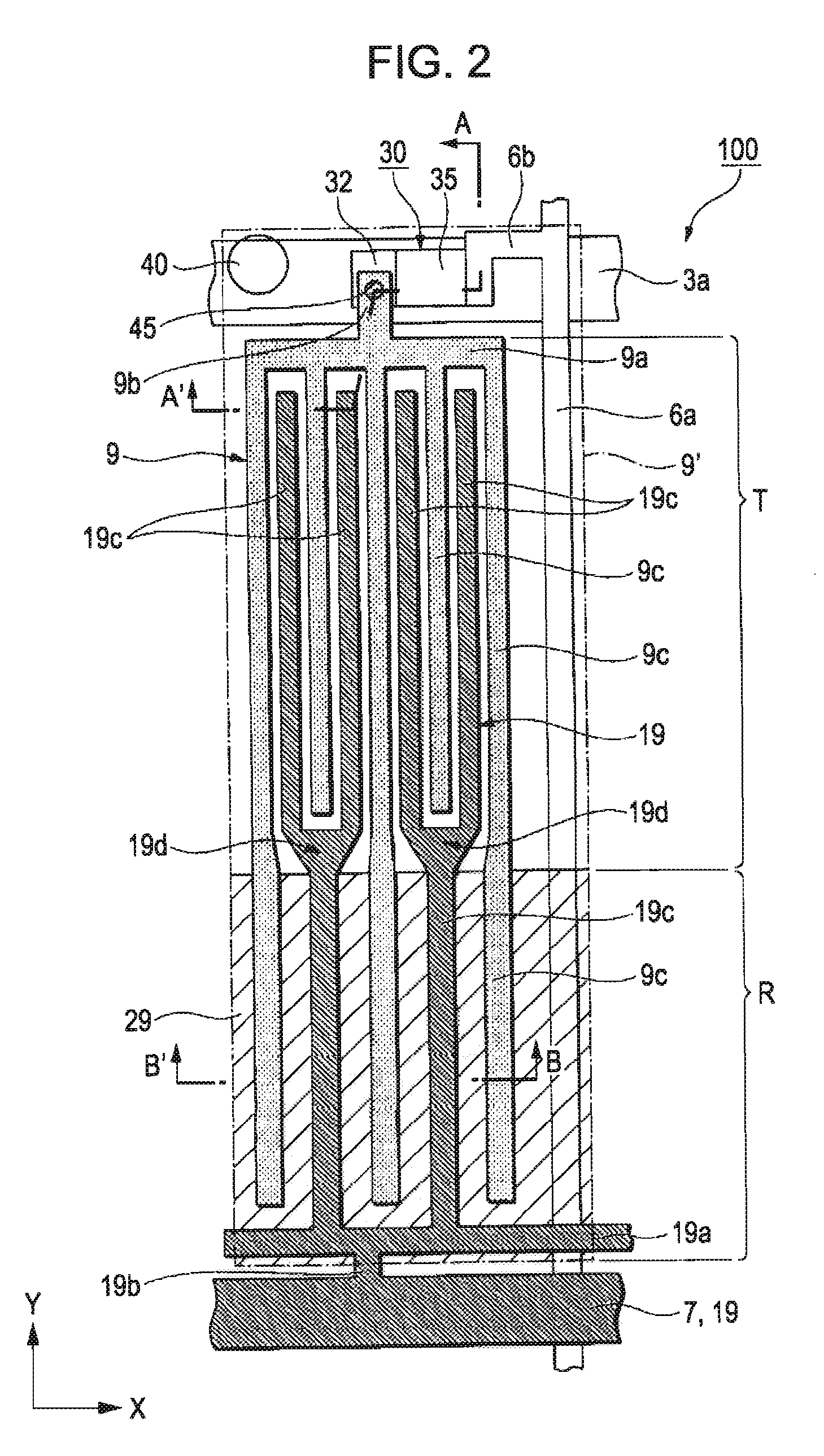

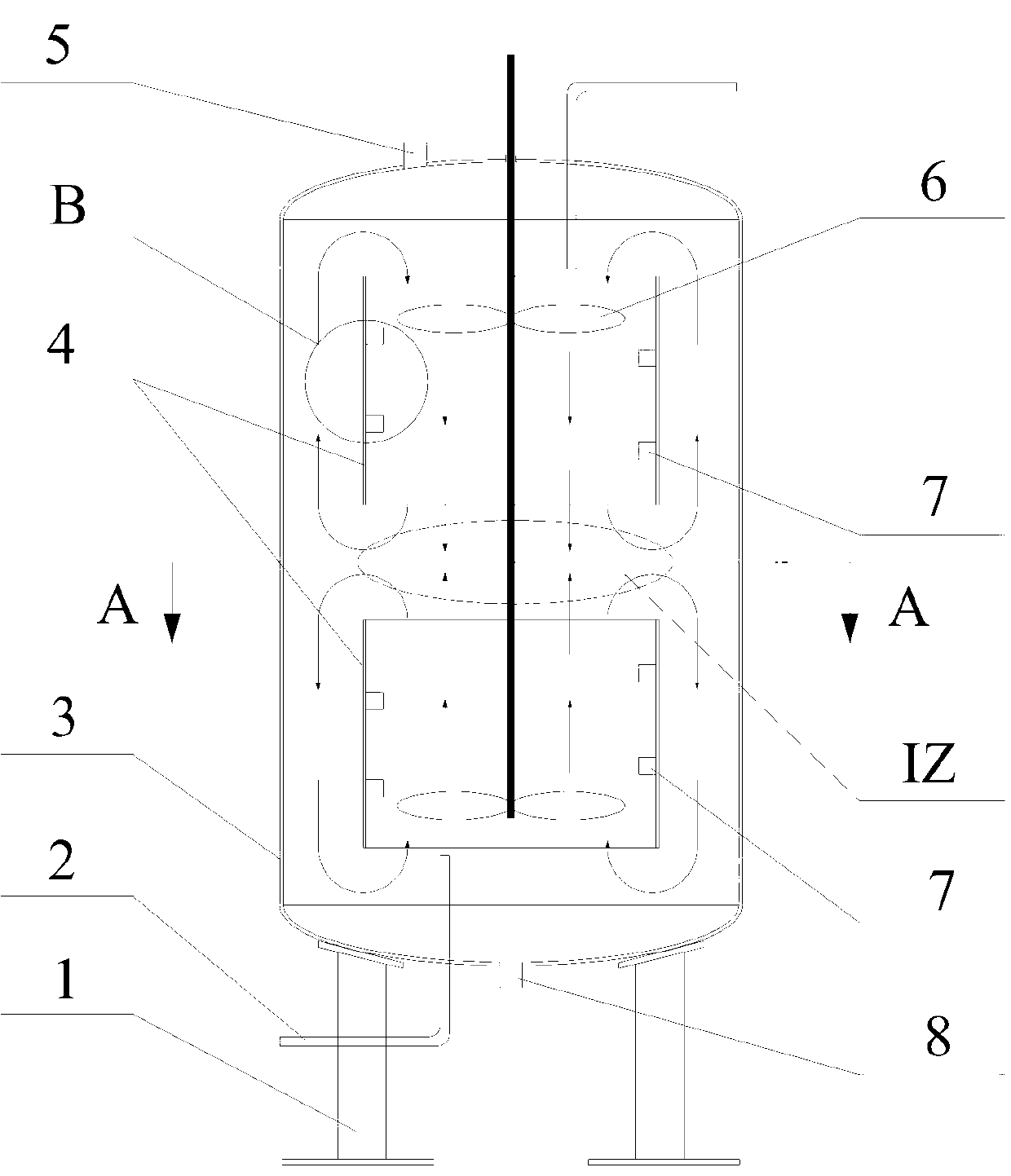

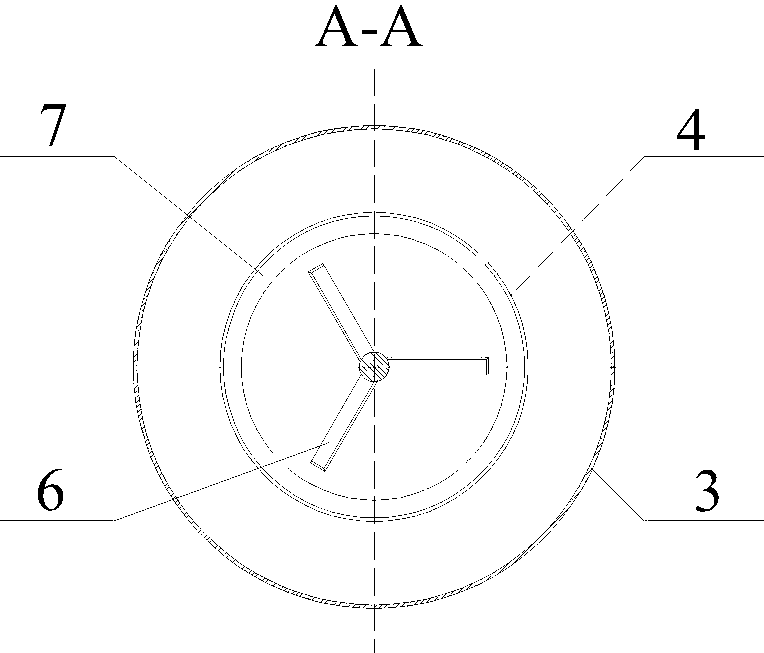

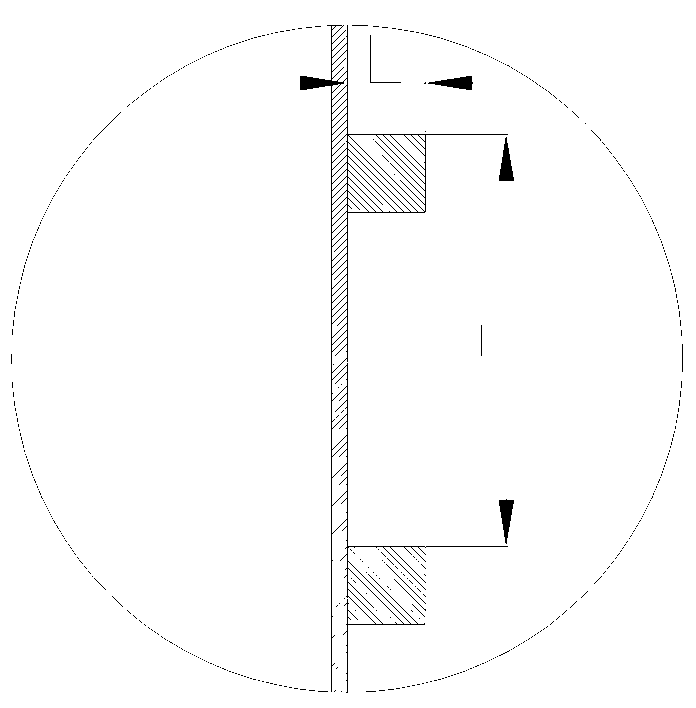

Impinging stream reactor

InactiveCN102989404AWell mixedIncreased anisotropyChemical/physical/physico-chemical stationary reactorsPropellerProcess engineering

The invention discloses an impinging stream reactor. The impinging stream reactor is provided with a material inlet and a material outlet; two guide cylinders are arranged inside the reactor; a fluid impinging area is formed between the outlets of the guide cylinders; each guide cylinder is internally provided with propellers correspondingly; the spiral directions of the propellers are opposite; and the propellers are respectively used for pushing fluid to flow from the material inlet to the impinging area through the guide cylinders. The impinging stream reactor is characterized in that the inner wall of each guide cylinder is provided with spiral type guide blades. Strong micromixing and continuous circulation flow of liquid are maintained, mixing during impinging and outside the impinging area is strengthened, the time for the fluid inside the reactor to achieve uniform mixing is shortened, the production efficiency is enhanced remarkably and good economic performance can be obtained.

Owner:湖北恒信石化设备有限公司

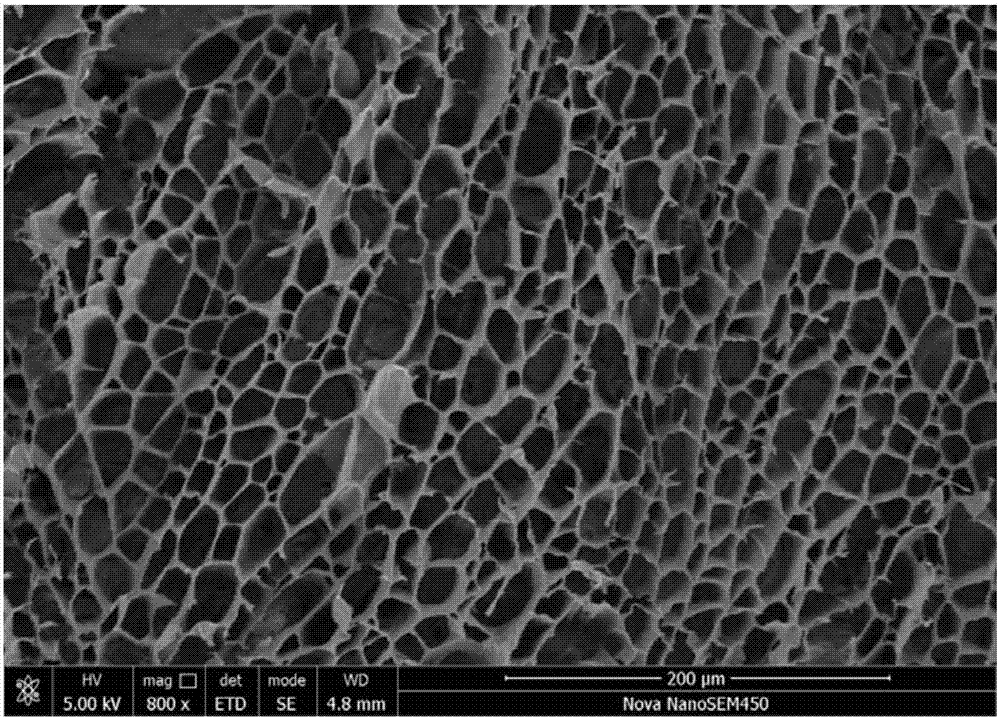

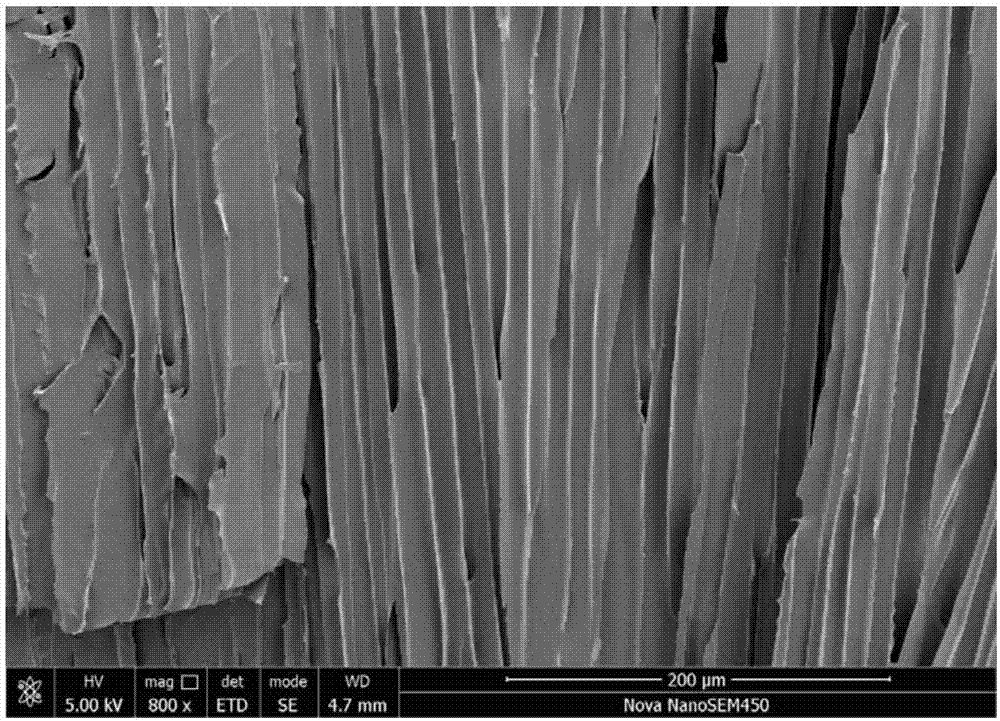

Anisotropic polyimide aerogel material and preparation method thereof

The invention provides an anisotropic polyimide aerogel material and a polyimide / inorganic nanoparticle composite aerogel material as well as preparation methods thereof. The anisotropic polyimide aerogel material and the polyimide / inorganic nanoparticle composite aerogel material are prepared with a freezing method, a freezing solution is used for freezing, the freezing direction is controlled, and the prepared aerogel material has anisotropy and has wide application prospects in low dielectric materials, matter adsorption, matter separation, thermal insulation protection, acoustic damping, catalysts, drug carriers and other fields.

Owner:SICHUAN UNIV

Copper alloy sheet and method for producing same

ActiveUS20100269959A1Excellent bending workabilityExcellent stress relaxation resistanceCoupling contact membersChemical compositionX-ray

A copper alloy sheet has a chemical composition containing 0.7 to 4.0 wt % of Ni, 0.2 to 1.5 wt % of Si, and the balance being copper and unavoidable impurities, the copper alloy sheet having a crystal orientation which satisfies I{200} / I0{200}≧1.0, assuming that the intensity of X-ray diffraction on the {200} crystal plane on the surface of the copper alloy sheet is I{200} and that the intensity of X-ray diffraction on the {200} crystal plane of the standard powder of pure copper is I0{200}, and which satisfies I{200} / I{422}≧15, assuming that the intensity of X-ray diffraction on the {422} crystal plane on the surface of the copper alloy sheet is I{422}.

Owner:DOWA METALTECH CO LTD

Boron nitride/epoxy resin composite and preparation method and application thereof

ActiveCN109666263AImprove thermal conductivityIncreased anisotropyHeat-exchange elementsEpoxyBoron nitride

The invention relates to boron nitride / epoxy resin composite and a preparation method and application thereof. The preparation method includes: 1) dispersing boron nitride nanosheet and a binder in water to form a mixed solution; 2) subjecting the mixed solution to bidirectional freezing, and removing ice crystal by lyophilization to obtain boron nitride aerogel with lamellar oriented structure; 3) filling the lamellar oriented structure of the boron nitride aerogel with cured epoxy resin to obtain the boron nitride / epoxy resin composite. The preparation method is simple to perform, is available to large-scale preparation and is suitable for industrial scaled application.

Owner:ZHEJIANG UNIV

Anisotropic nanocomposite hydrogel

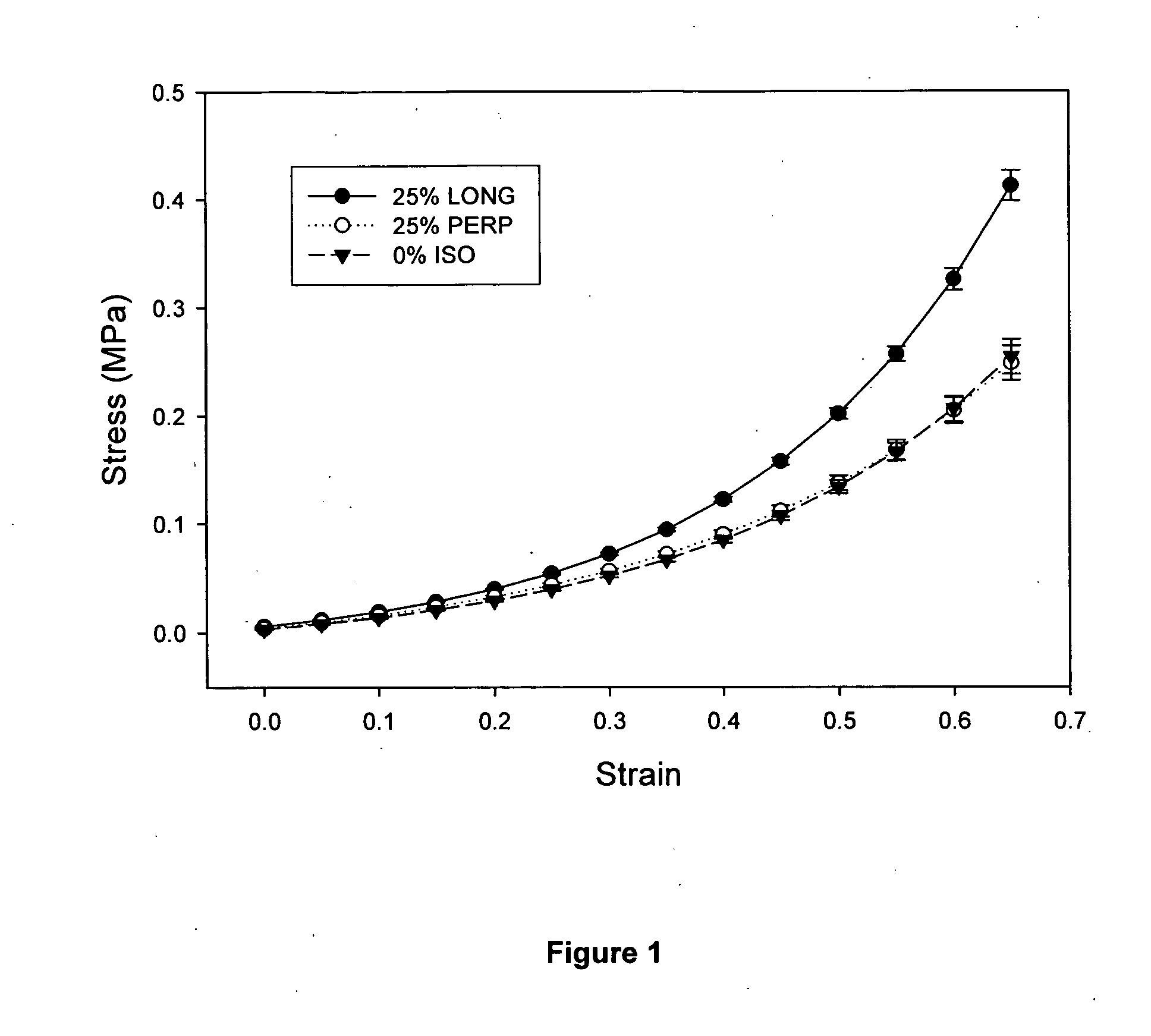

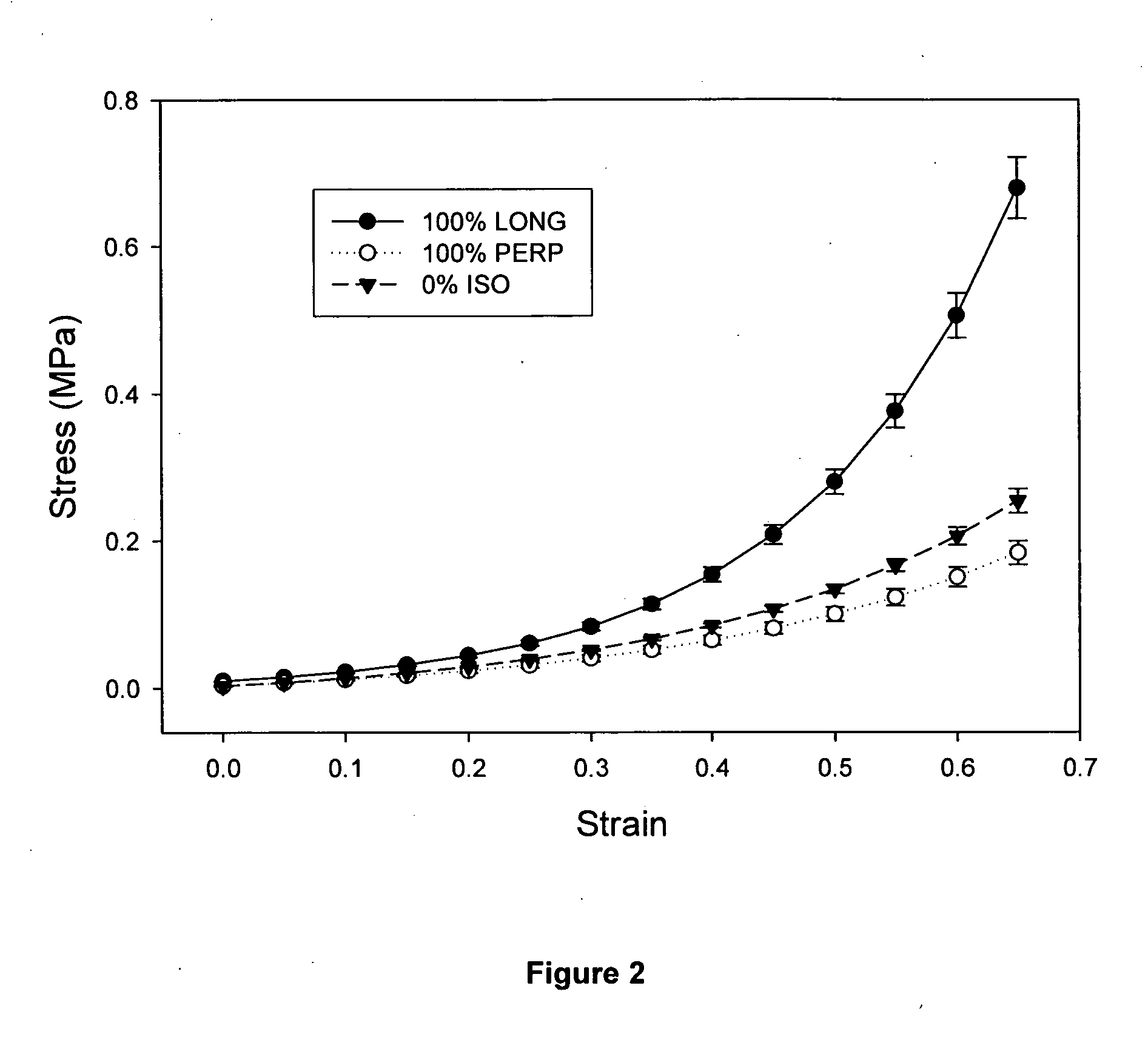

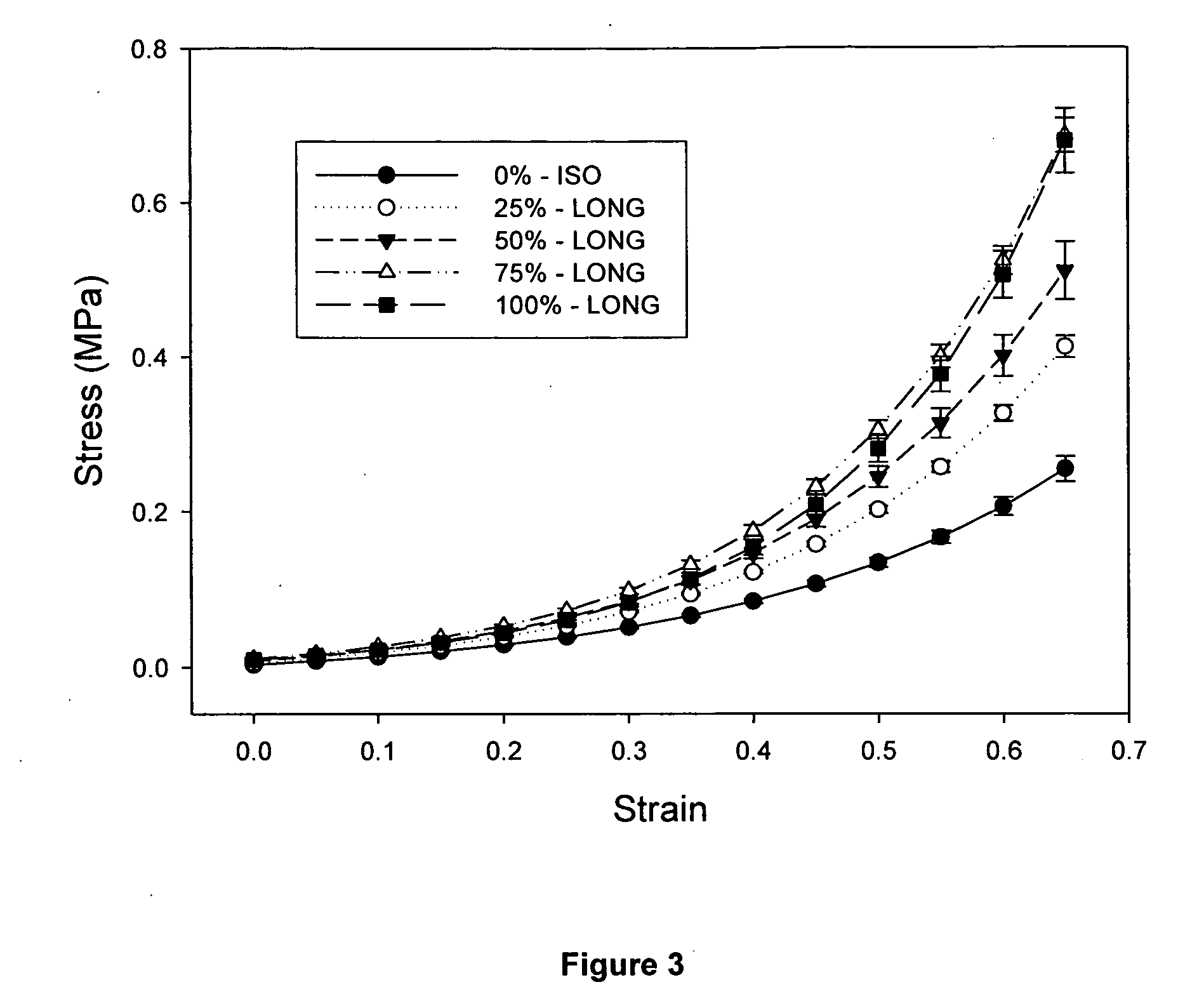

ActiveUS20090252800A1Increased anisotropyIncrease stiffnessPowder deliveryOn/in organic carrierCelluloseActive agent

Anisotropic nanocomposite hydrogel materials are created using a process in which a hydrogel-forming material is crosslinked in the presence of nanoscale cellulose and subsequently thermally cycled under an applied tensile strain. Such materials are capable of exhibiting high mechanical and viscoelastic anisotropy, increased stiffness when subjected to large strain, and are suitable for a broad range of soft tissue replacement applications. In addition controlled release of bioactive agents properties can be designed into medical devices fabricated from such nanocomposite materials.

Owner:AXCELON BIOPOLYMERS COPRORATION

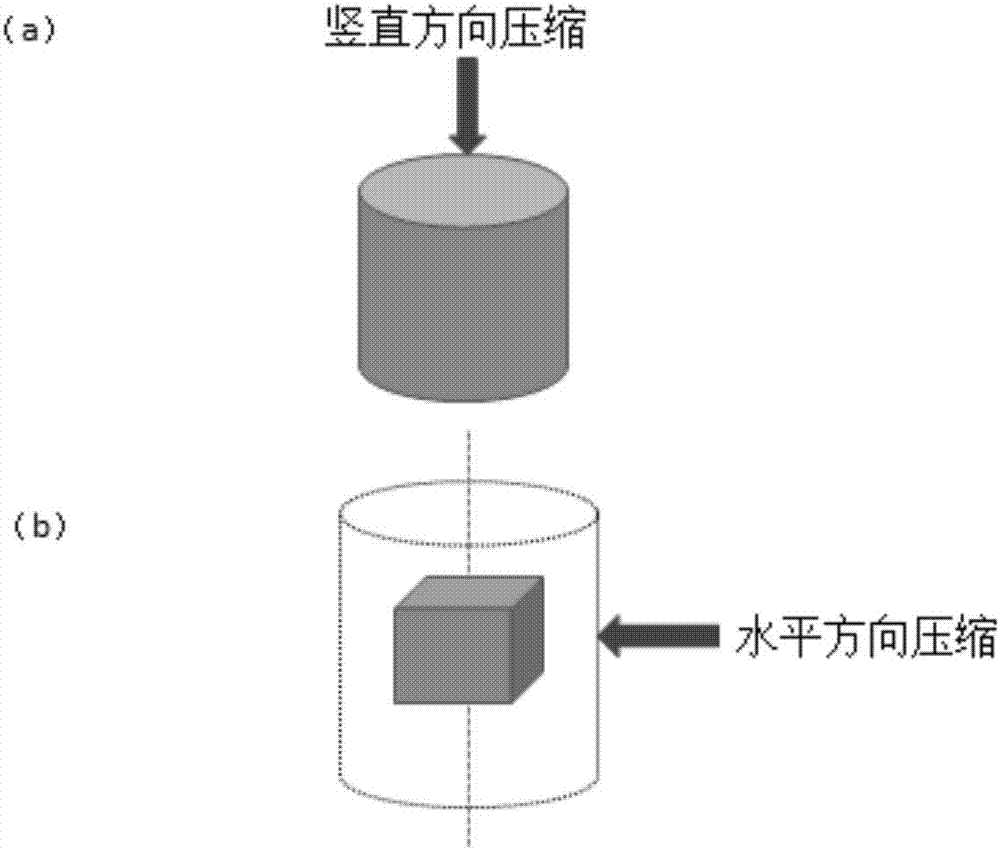

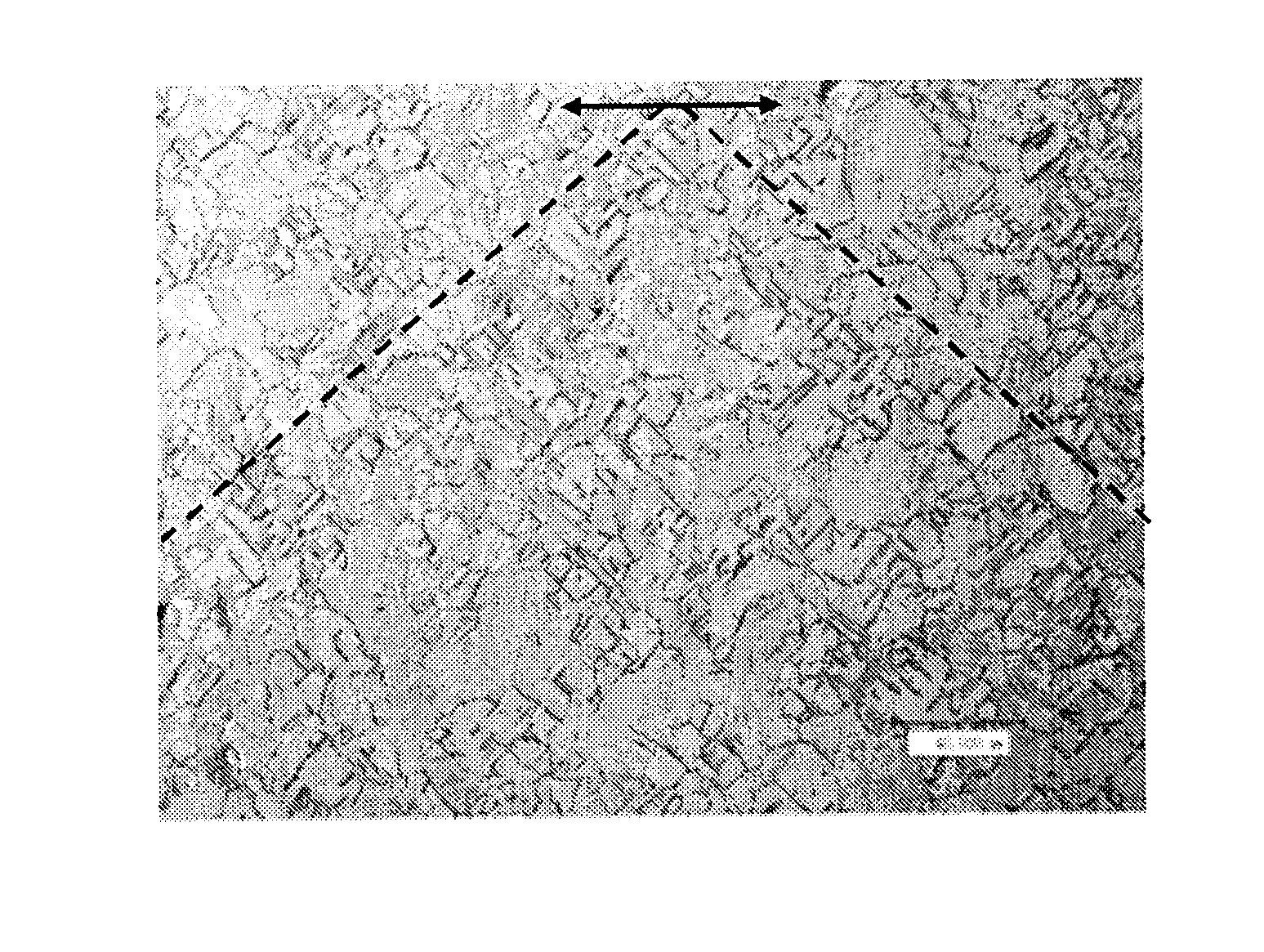

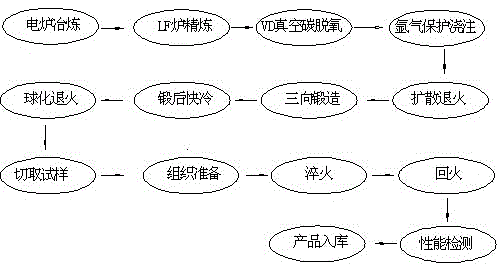

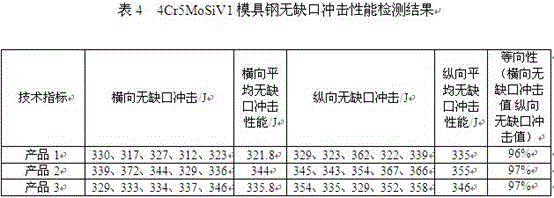

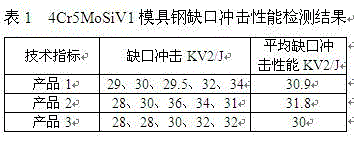

Preparation method for improving performance of 4Cr5MoSiV1 hot work die steel

ActiveCN105525078ALow steel total oxygen contentReduce oxygen contentHeating/cooling devicesSlagHot work

The invention relates to 4Cr5MoSiV1 hot work die steel, in particular to a preparation method for improving the performance of the 4Cr5MoSiV1 hot work die steel. The preparation method comprises the steps of producing highly-clean steel ingots with the total oxygen content being 12 ppm by adopting electric furnace smelting, vacuum carbon deoxidizing and slag surface diffusing and deoxidization refining, adding the pure rare earth La and Ce on the oxygen control condition and carrying out argon shield pouring; carrying out diffusing and homogenizing annealing on the steel ingots and upsetting and drawing forging on the steel ingots in the three-dimensional directions three times, fast cooling the steel ingots through water and air alternately after forging, carrying out the processes of fast cooling after ultrahigh-temperature austenitizing and spheroidizing annealing before quenching, carrying out tempering with the temperature not lower than 590 DEG C 2-3 times after quenching, and finally obtaining the stable tempered structure of the 4Cr5MoSiV1 hot work die steel. According to the invention, the single notched impact property KV2 of the 4Cr5MoSiV1 hot work die steel is greater than or equal to 25 J, the average notched impact property KV2 is greater than or equal to 30 J, the single non-notched impact energy is greater than or equal to 280 J, the average non-notched impact energy is greater than or equal to 320 J, the ratio of the transverse non-notched impact energy to the longitudinal non-notched impact energy is greater than or equal to 93%, and the isotropy is excellent.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

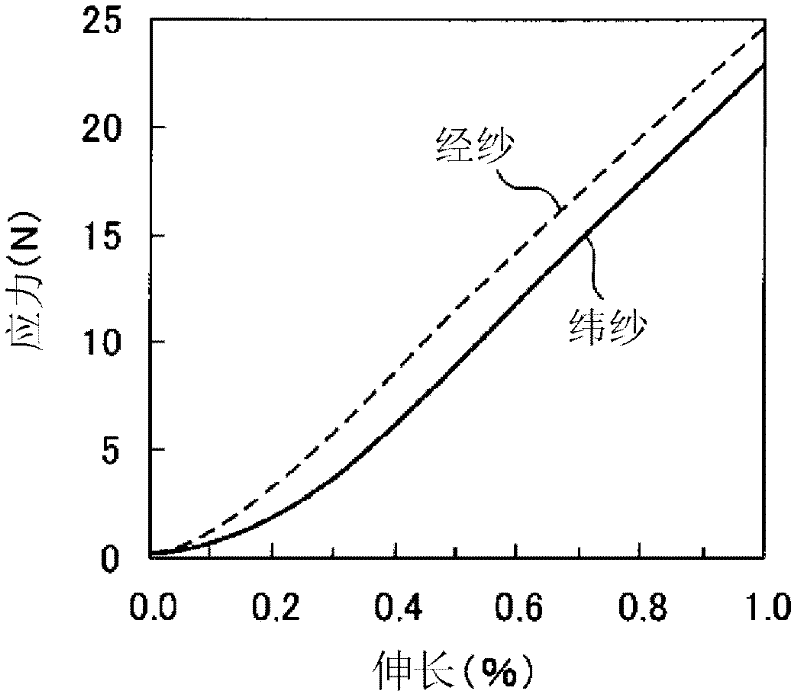

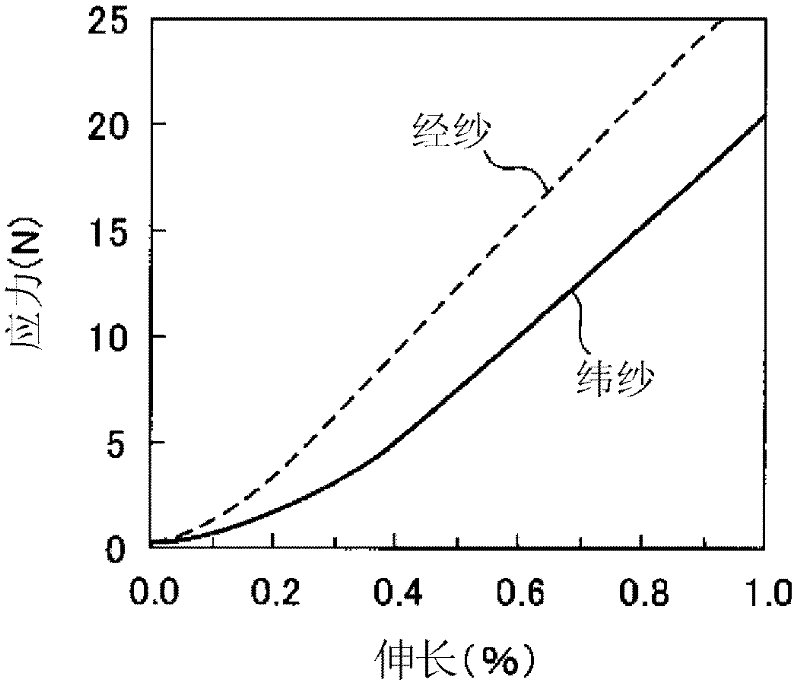

Glass cloth for printed wiring board

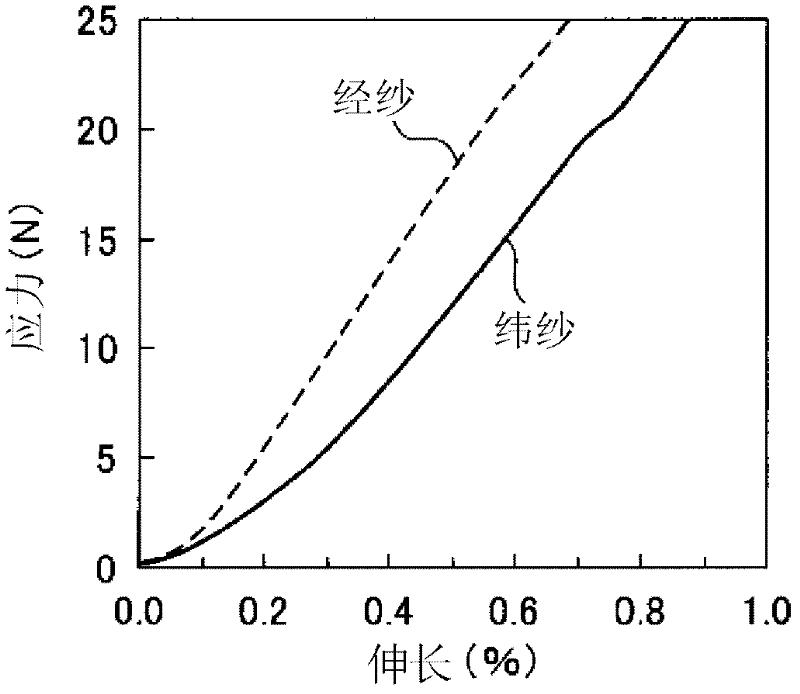

ActiveCN102482809AIncreased anisotropyNo warping/twistingPrinted circuit aspectsWoven fabricsGlass fiberYarn

Disclosed are: a glass cloth, which has small anisotropy of dimensional change, while being free from warp and twist, and which is suitable for the production of a printed wiring board that is used in electronic / electrical fields; a prepreg using the glass cloth; and a printed wiring board using the glass cloth. The glass cloth is characterized in that the warp and the weft are configured of glass yarn of from 1.8 10-6 kg / m to 14 10-6 kg / m, the ratio of the average filament diameter of the weft to the average filament diameter of the warp (the weft / warp ratio) is 1.01 or more but less than 1.27, and the glass cloth has a thickness of 10-40 [mu]m (inclusive).

Owner:ASAHI KASEI KK

Anisotropic film and method of manufacturing anisotropic film

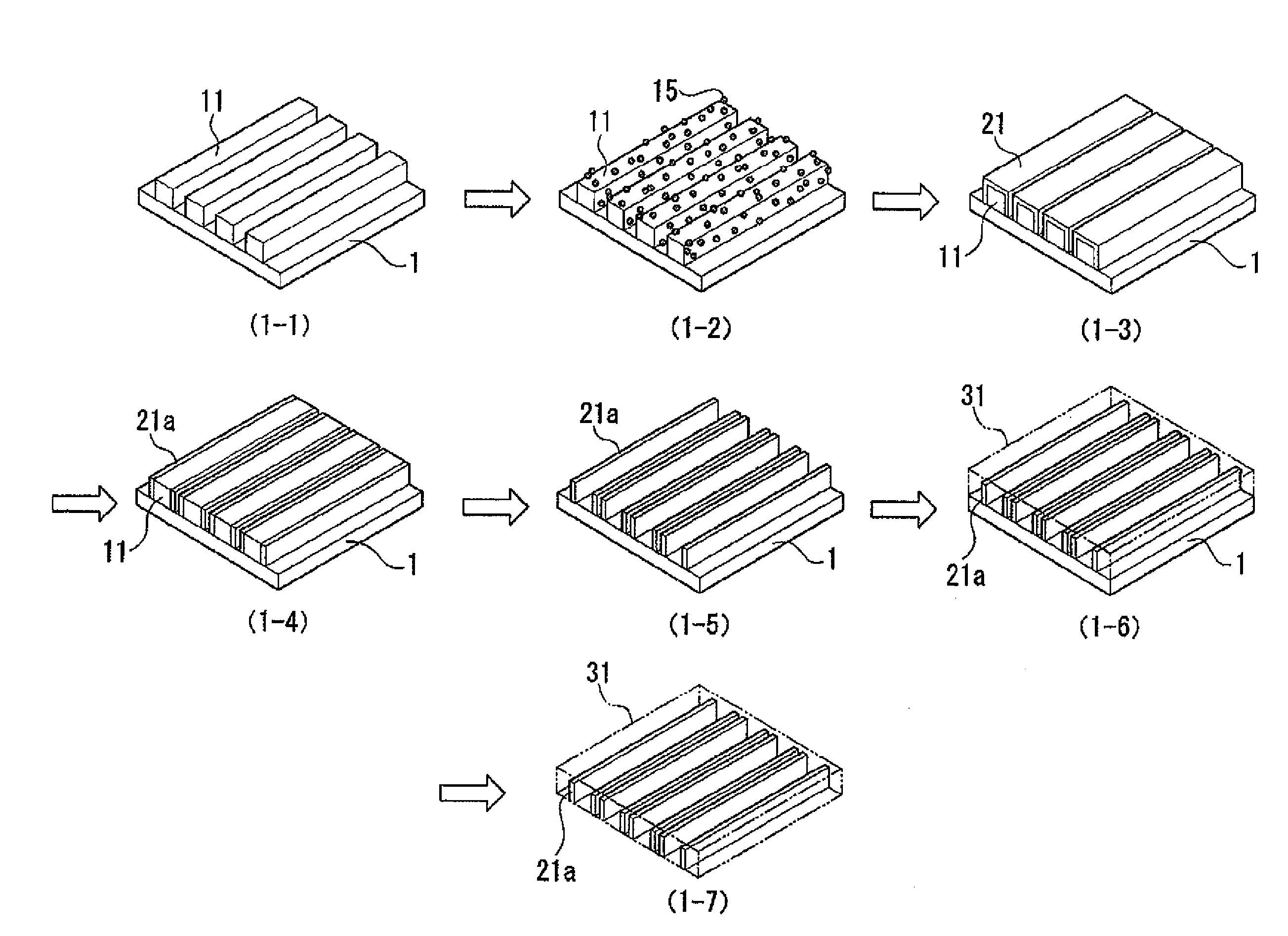

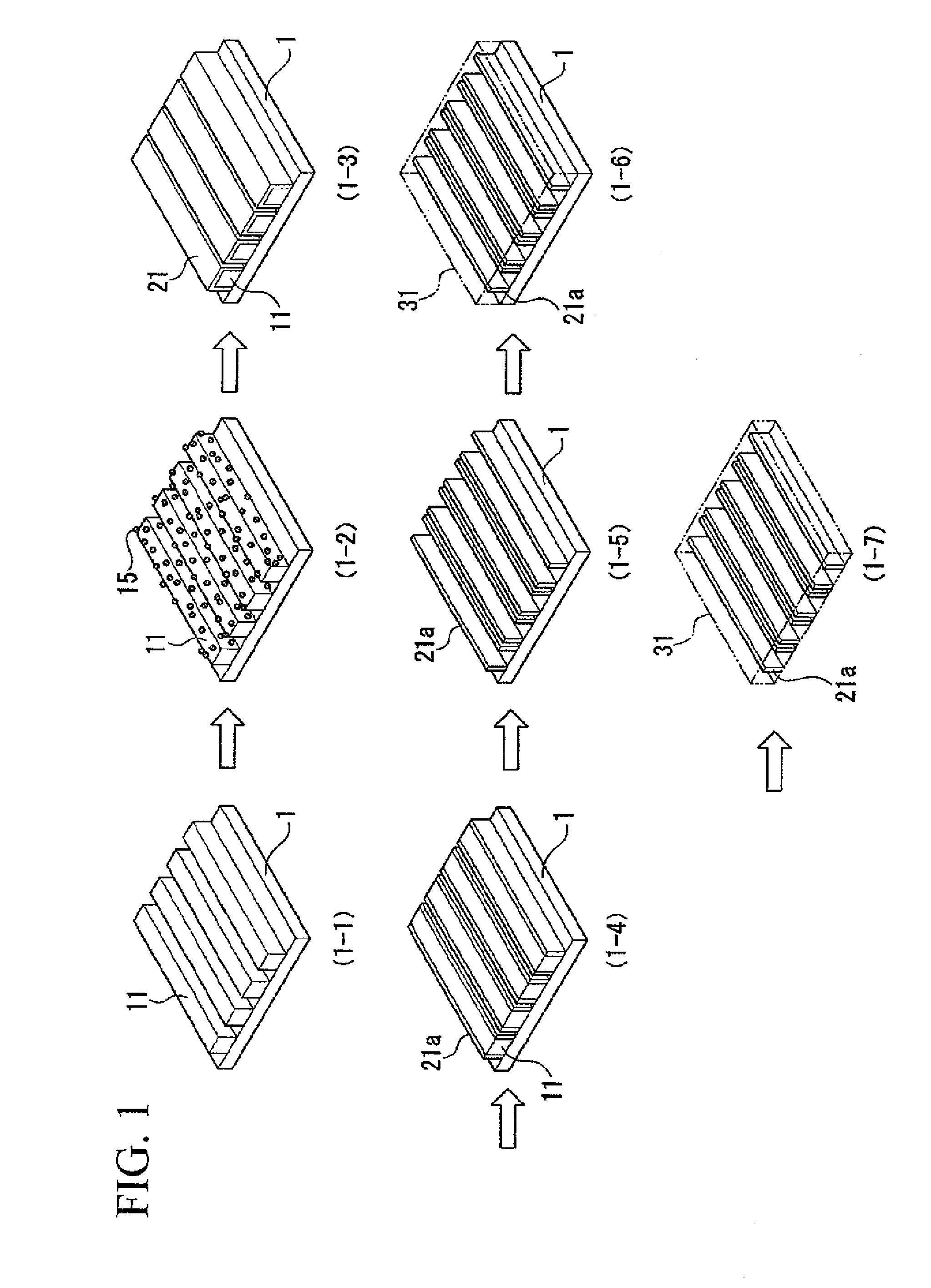

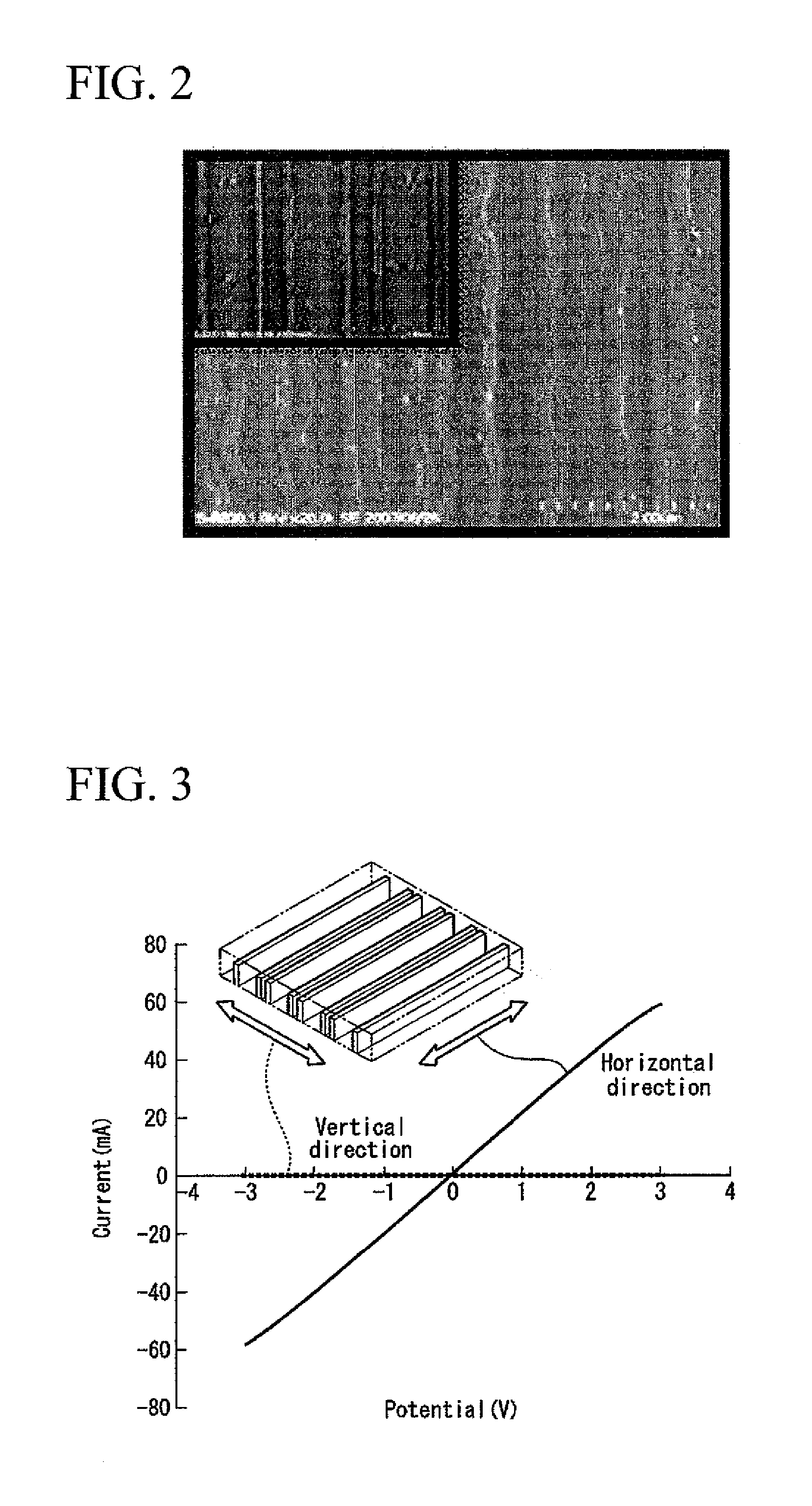

InactiveUS20090061170A1Increased anisotropySuperior workability and handling propertyLayered productsDecorative surface effectsNanostructureNanometre

An anisotropic film is disclosed in which a line-shaped nanostructure is disposed inside a resin film. Also disclosed is a method of producing an anisotropic film that includes: forming a metal nanostructure on a substrate, forming a resin film that embeds the metal nanostructure, and detaching the resin film from the substrate, wherein the step of forming the metal nanostructure on the substrate includes: at least, forming a coating film on the surface of a template provided on the substrate, the coating film including a metal layer formed by electroless plating; and removing a portion or all of the template while retaining a portion or all of the coating film, or removing a portion of the coating film. Also disclosed is an anisotropic film produced using the method of producing an anisotropic film.

Owner:TOKYO OHKA KOGYO CO LTD +1

Samarium and cobalt sintered permanent magnet material and preparation method thereof

ActiveCN104637642ASpeed up coolingIntegrity guaranteedInorganic material magnetismCobaltCritical magnetic field

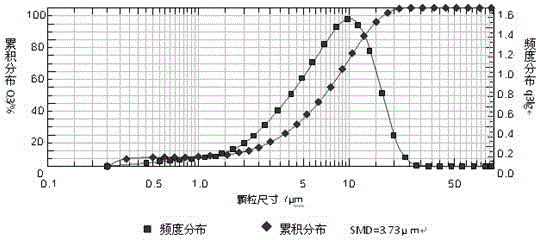

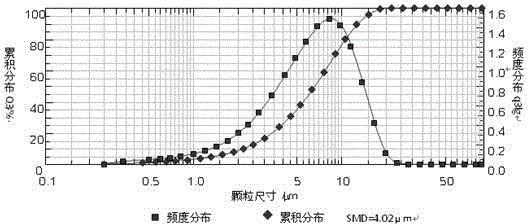

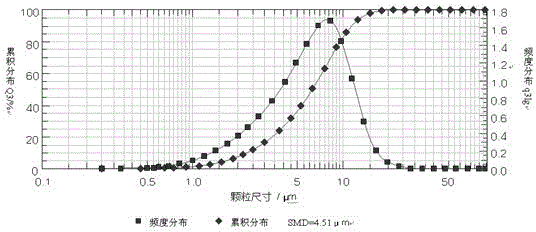

A samarium and cobalt sintered permanent magnet material comprises, in weight percent, 25-27%wt of samarium, 49-51%wt of cobalt, 5-6.5%wt of copper, 3-3.5%wt of zirconium and 15-18%wt of iron. A preparation method includes the steps: smelting; casting an ingot; absorbing hydrogen for the cast ingot; making powder; performing orientation forming and sintering. In the smelting process, the thickness of a casting mould cavity is decreased, cooling water is filled into the wall of the mould cavity, cooling of the cast ingot is accelerated, element composition segregation is decreased, the production process is stabilized, a dendrite crystal is restrained by adding a zirconium element, hydrogen absorbing is performed for the cast ingot in the smelting process, production steps are saved, and energy consumption is reduced. In the subsequent milling process, the cast ingot absorbed hydrogen is crystallized into particles, the particles fracture along crystal boundaries in the milling process of airflow, the integrality of crystal particles is ensured, the anisotropy of the crystal particles is improved, magnetic powder particles are obtained, particle size distribution is concentrated with the range of 3.5-4.5 micrometers, the sintering temperature needed by the magnetic powder particle of each point of a blank is the same in the later sintering process, the sizes of the sintered crystal particles are the same and uniform, and the performances, particularly, such as residual magnetism Br, maximum magnetic energy product (BH) max and critical magnetic field Hk of a sintered permanent magnet are improved.

Owner:NINGBO NINGGANG PERMANENT MAGNETIC MATERIALS

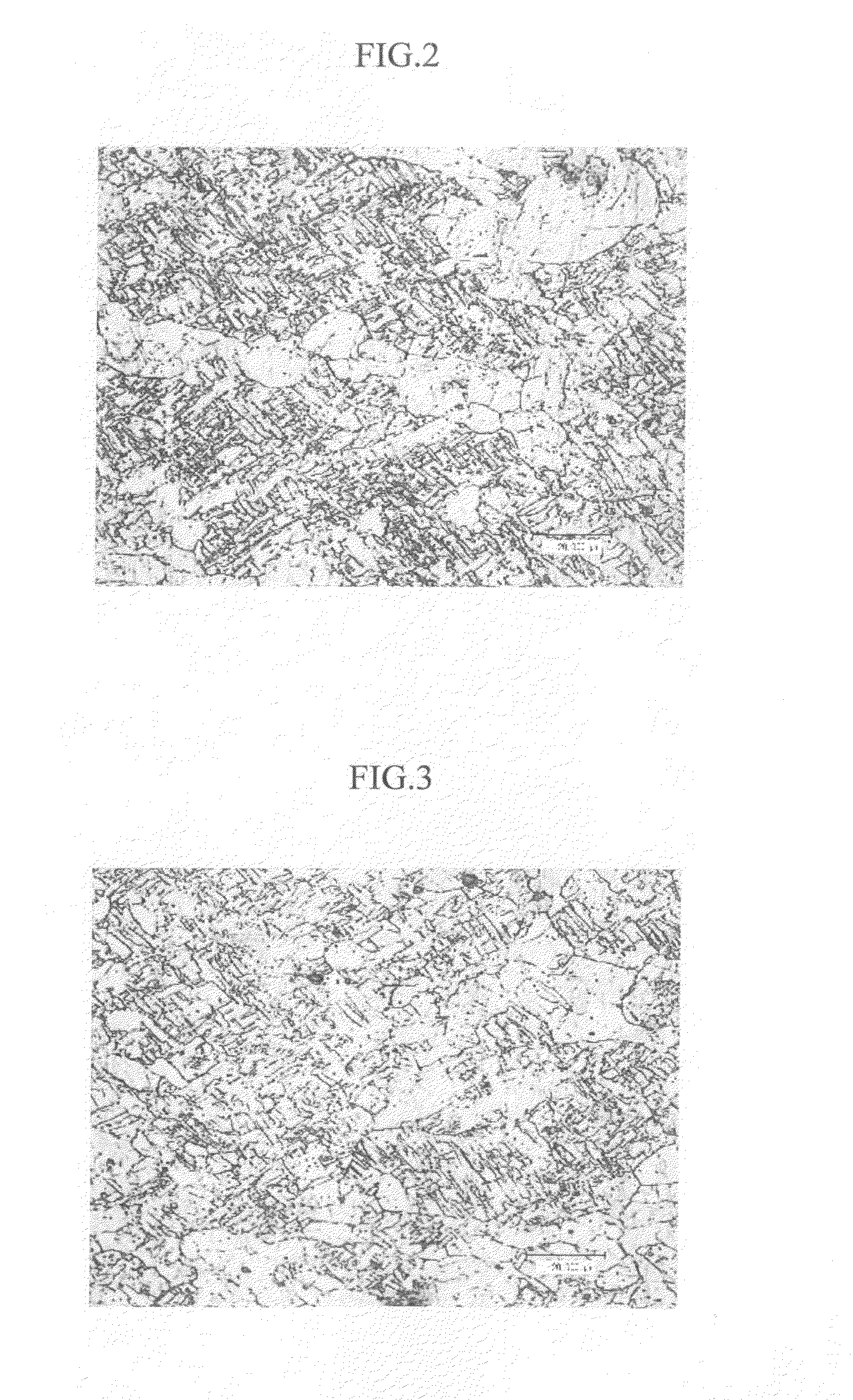

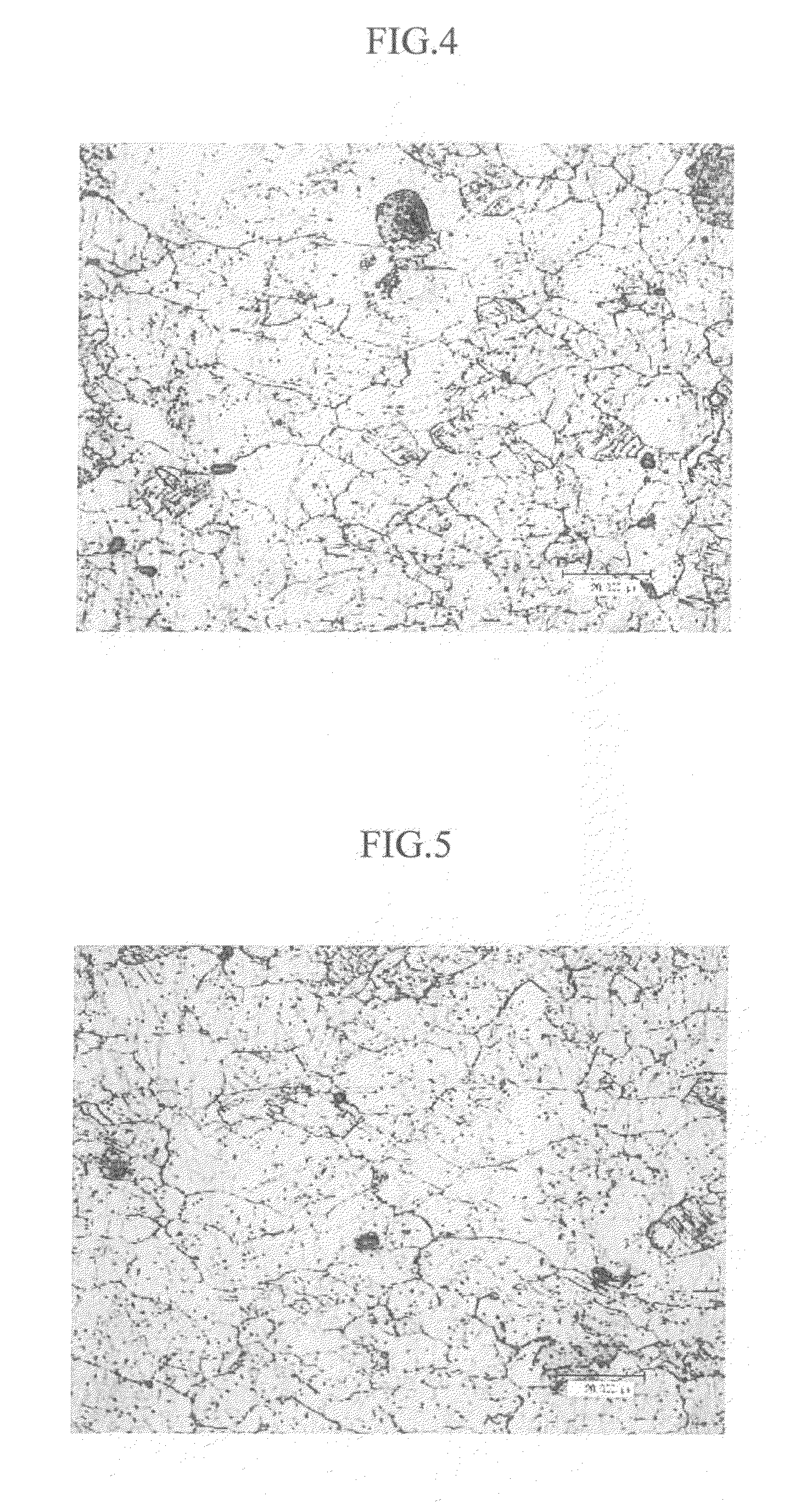

High-toughness and high-thermal-stability hot work die steel and preparation method thereof

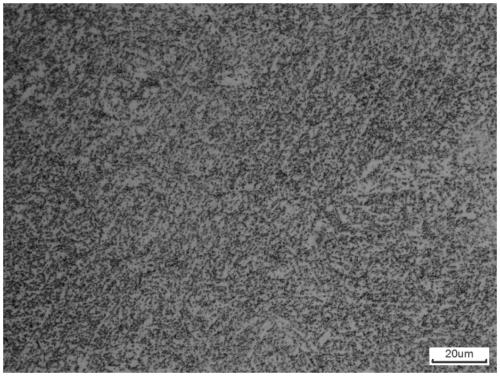

ActiveCN111593257AImprove toughnessImprove thermal stabilityProcess efficiency improvementMaterials scienceMicrostructure

The invention relates to a preparation method of high-toughness and high-thermal-stability hot work die steel. The preparation method comprises the following steps of optimizing alloy components, andstrictly controlling the production process; and the specific process route is as follows, electric furnace smelting, ladle refining furnace refining, vacuum refining furnace refining, electrode blankcasting, protective atmosphere electroslag furnace remelting, forging, ultrafine treatment and spheroidizing annealing production processes are adopted at the same time. The invention further relatesto the high-toughness and high-thermal-stability hot work die steel prepared through the preparation method. The product has the advantages of uniform annealed microstructure, favorable spheroidizedstructure, fine and uniform grain distribution and uniform quenched and tempered structure, and the fine precipitated phases of the Mo and Cr carbides have the dispersion strengthening action in the use process, thereby enhancing the properties of the material and endowing the material with high toughness and high isotropy. The product can be widely used for manufacturing hot extrusion dies, mandrels, hammer dies of die forging hammers, dies of forging presses and dies for precision forging machines, and particularly can be used as a high-end die-casting die made of aluminum, copper and alloysthereof.

Owner:江苏宏晟模具钢材料科技有限公司

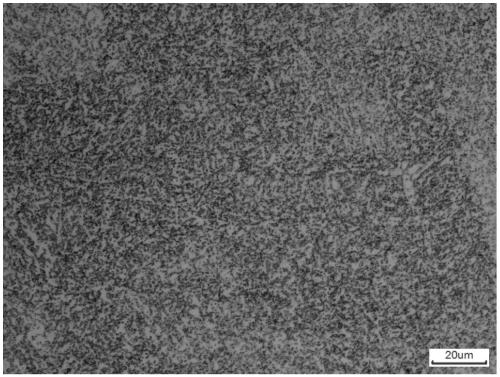

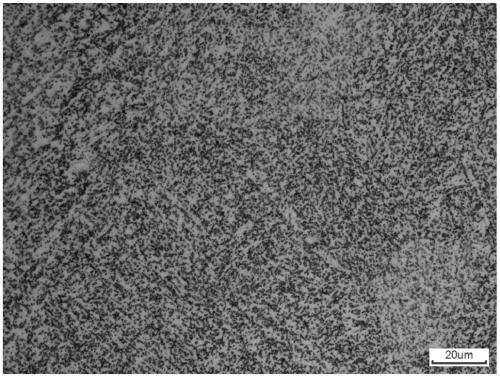

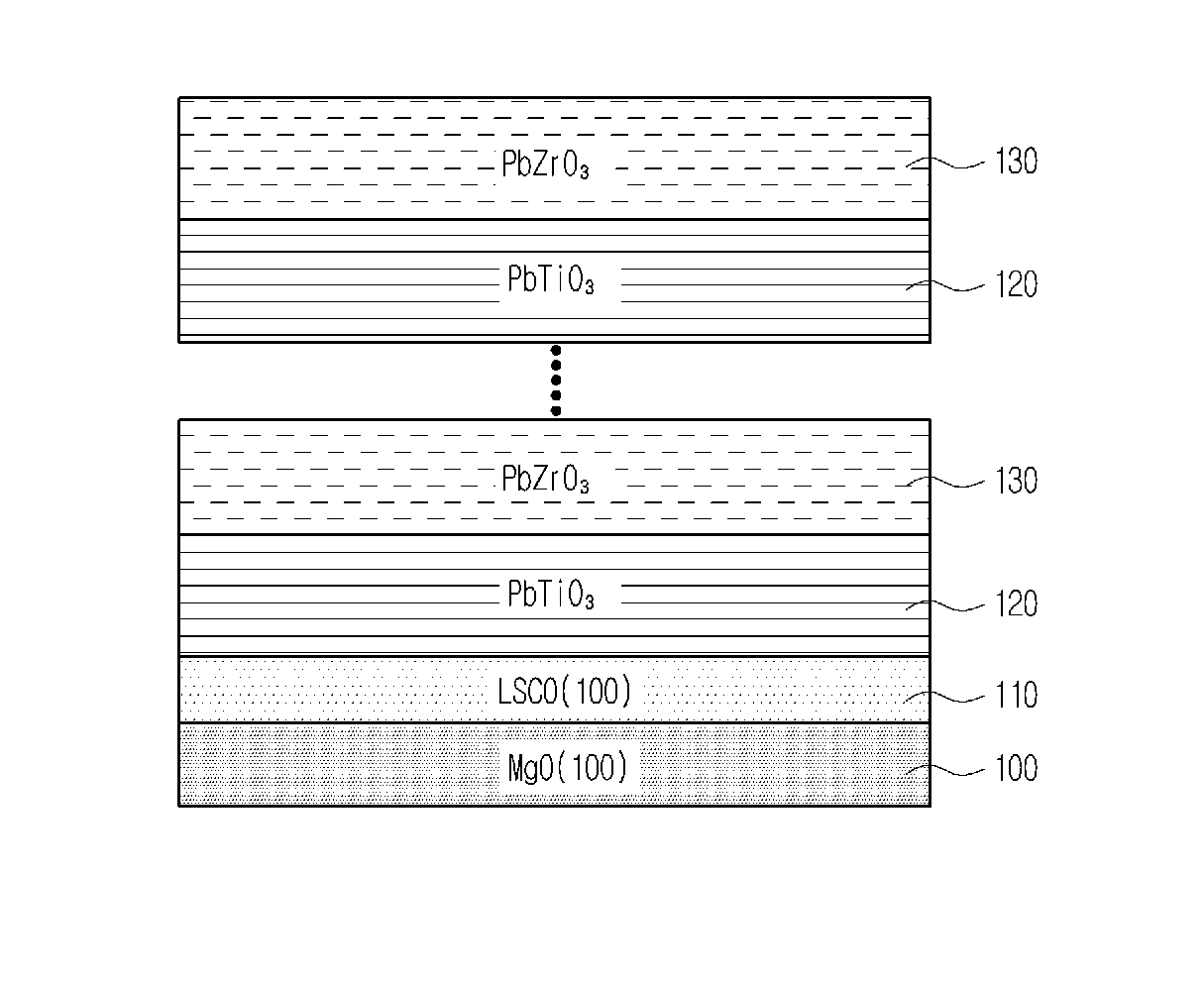

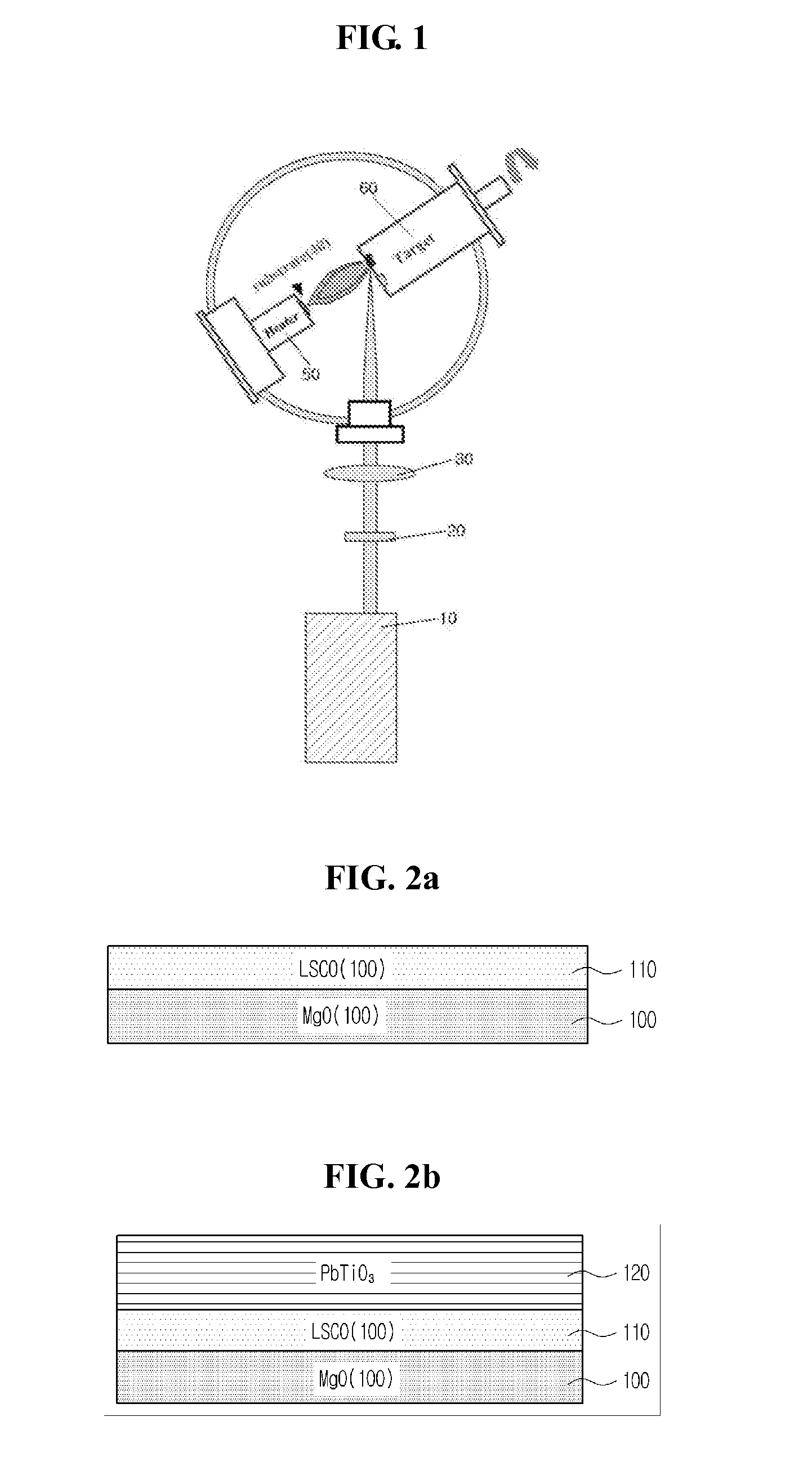

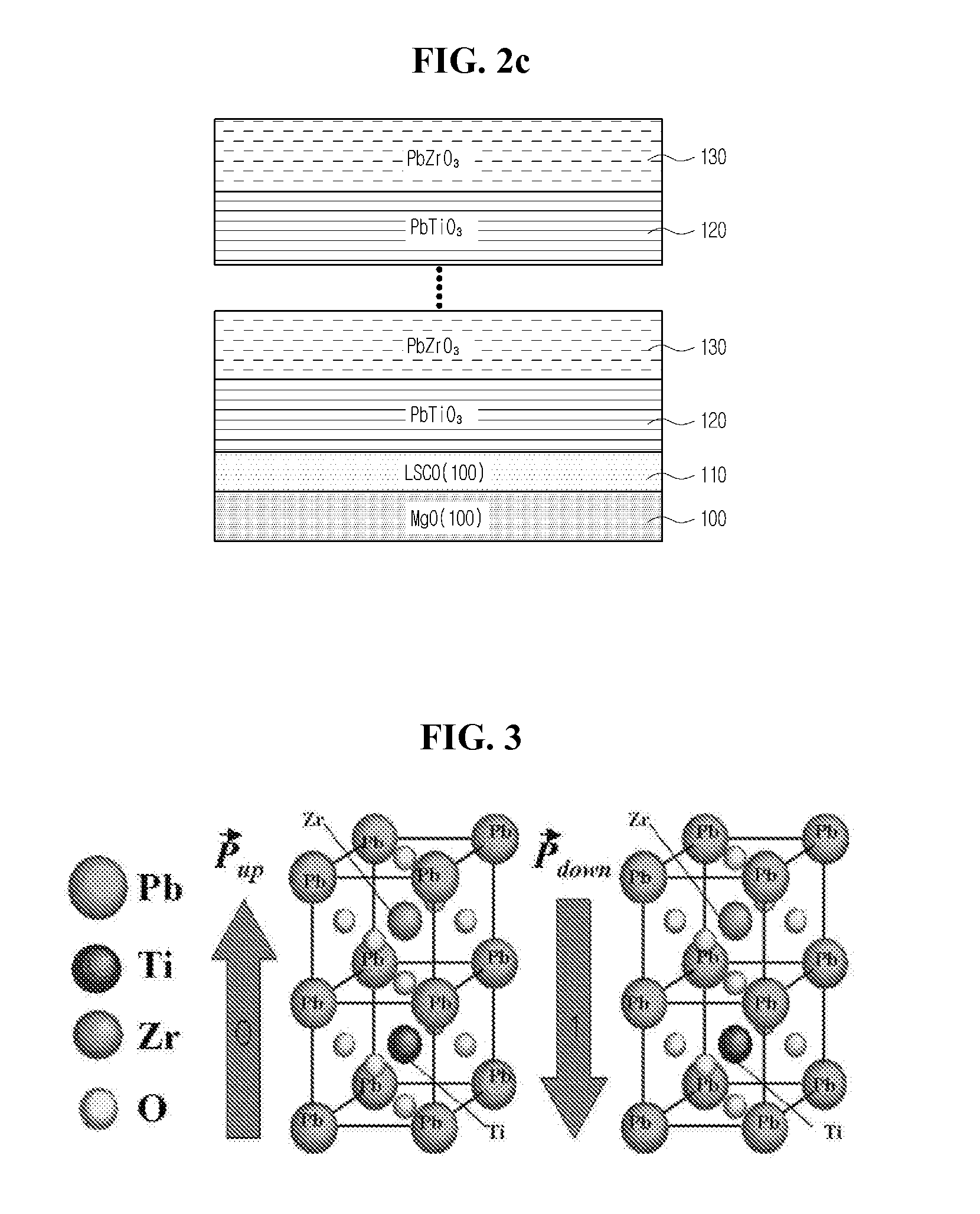

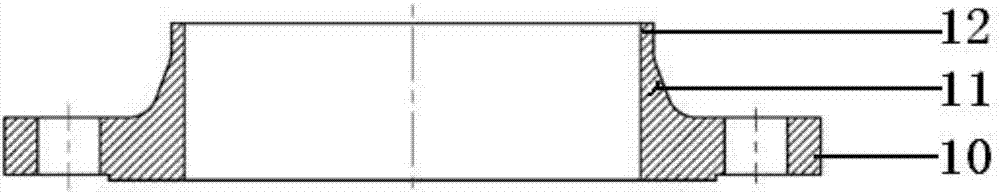

Ferroelectric Oxide Artificial Lattice, Method For Fabricating The Same And Ferroelectric Storage Medium For Ultrahigh Density Data Storage Device

ActiveUS20070152253A1Increased anisotropyOvercome problemsSemiconductor/solid-state device detailsSolid-state devicesLong term dataCrystal structure

The present invention is related to a ferroelectric storage medium for ultrahigh density data storage device and a method for fabricating the same. A supercell having high anisotropy is formed by controlling crystal structure and symmetry of unit structure (supercell) of artificial lattice by using an ordered alignment of predetermined ions having orientation of (perpendicular) deposition direction. Unit atomic layers of oxides having different polarization characteristic are deposited so that the supercell itself shows electric polarization having only two, upward and downward directions as one block of supercell having single-directional polarization. Oxide artificial lattices can be formed so as to have solely 180 degree domain structure, thus a single electric domain having improved anisotropic characteristic can be formed, thereby allowing capability of ultrahigh density data storage and long term data retention.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

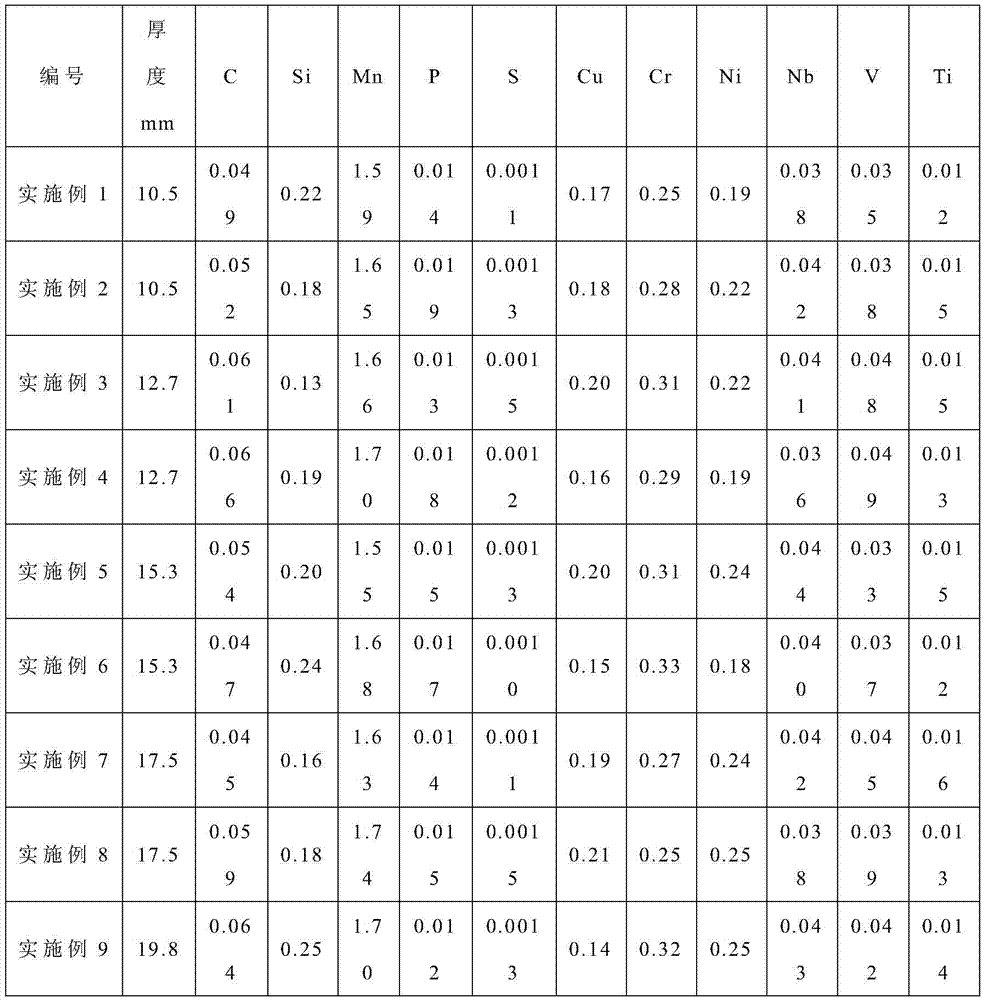

Electric arc additive manufacturing method for flange part

ActiveCN107470620AMeet the qualityFulfil requirementsAdditive manufacturing apparatusIncreasing energy efficiencyShielding gasWater cooling

The invention relates to an electric arc additive manufacturing method for a flange part. The electric arc additive manufacturing method for the flange part comprises the steps that a base plate, a wire, protective gas and equipment are selected; multi-layer and multi-pass accumulation is completed on the base plate from inside to outside along a spiral path through the electric arc additive manufacturing method, so that a bottom surface and a lower neck of the flange part are manufactured; multi-layer and single-pass accumulation is completed on the lower neck along a circular path, so that an upper neck of the flange part is manufactured, and the temperature, current, overlap rate and advancing speed between the layers and the passes are controlled; and redundant portions of the base plate are cut off, solid solution treatment is conducted, the temperature and the constant-temperature time are controlled, and water cooling is conducted. According to the electric arc additive manufacturing method for the flange part, restrains from complex tools, molds and special tools are avoided, only a small degree of finish machining needs to be conducted on a formed blank, the machining procedure is greatly simplified, the manufacturing cycle of products is shortened, and customized individual production can be achieved; and the nondestructive detection quality of the formed flange part is qualified, metal is pure, the structure, the plasticity and the toughness are optimized, the anisotropy phenomenon is improved, and the performance of the flange part can meet the quality and performance requirements for similar forged pieces.

Owner:SUZHOU NUCLEAR POWER RES INST +3

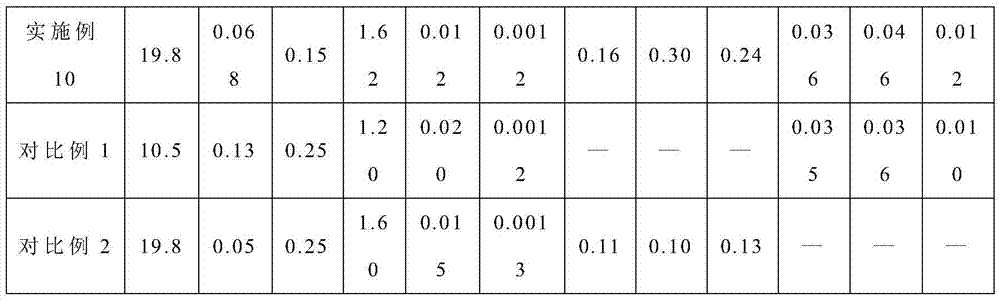

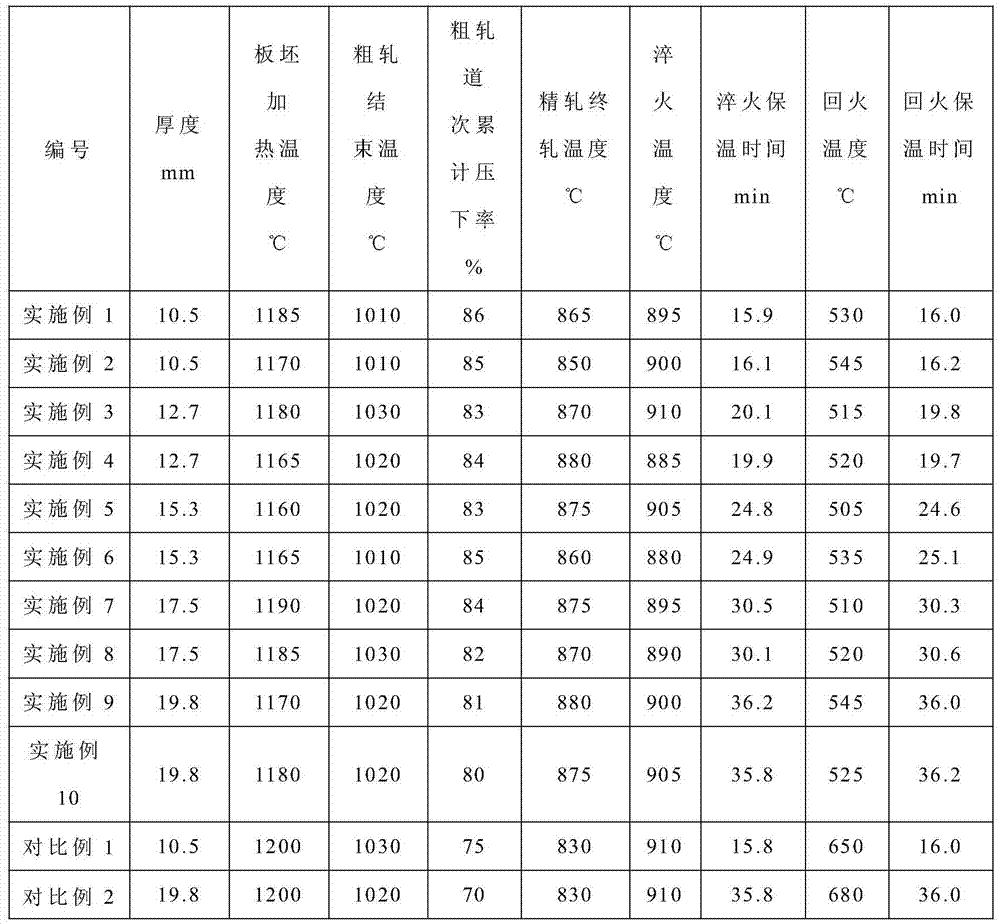

High-toughness and low-yield-ratio quenched and tempered steel plate used in low-temperature environment and manufacturing method of high-toughness and low-yield-ratio quenched and tempered steel plate

The invention discloses a high-toughness and low-yield-ratio quenched and tempered steel plate used in a low-temperature environment. The high-toughness and low-yield-ratio quenched and tempered steel plate comprises, by weight, 0.045-0.068% of C, 0.13-0.25% of Si, 1.55-1.74% of Mn, smaller than or equal to 0.020% of P, smaller than or equal to 0.0015% of S, 0.25-0.33% of Cr, 0.14-0.21% of Cu, 0.18-0.25% of Ni, 0.035-0.044% of Nb, 0.033-0.049% of V, 0.010-0.016% of Ti and the balance Fe and inevitable impurities. The invention further discloses a manufacturing method of the high-toughness and low-yield-ratio quenched and tempered steel plate used in the low-temperature environment. A proper number of alloy elements such as Cu, Cr and Ni are added to the steel plate on the basis of a low-C and high-Mn system, and Nb, V and Ti are adopted for microalloying. Due to a pass reduction schedule and an offline heat treatment regime in the hot rolling process are optimized, quenched and tempered type pipeline steel which is high in low-temperature-environment toughness and low in yield ratio and is used for a straight seam welded pipe is finally obtained.

Owner:武汉钢铁有限公司

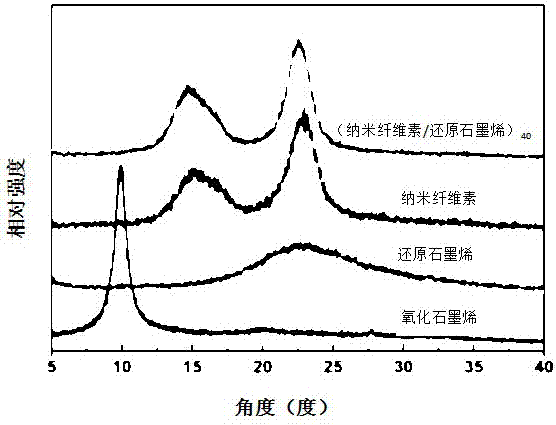

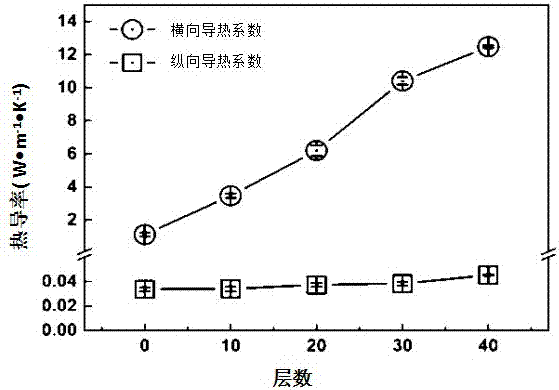

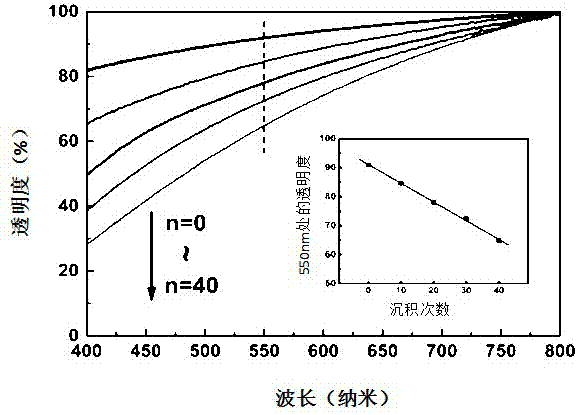

Transparent and insulating graphene composite heat-conducting film and preparation method thereof

InactiveCN106893128ASmall coefficient of thermal expansionEnvironmentally friendly and degradableHeat-exchange elementsCoatingsComposite filmHeat conducting

The invention relates to a method for preparing a transparent and insulating graphene composite heat-conducting film. According to the method, the heat-conducting film is prepared through the compositing of nanocellulose, graphene and boron nitride. Through filtration drying of nanocellulose dispersion liquid, a nanocellulose film is obtained, the nanocellulose film is immersed in graphene oxide solution, the obtained film is immersed in the nanocellulose dispersion liquid, and a nanocellulose - graphene oxide composite film is obtained by repeating the two-step operations many times, the composite film is placed in a solution to be restored, and a nanocellulose-graphene film is obtained. Mixed solution of the nanocellulose and boron nitride is prepared through an ultrasonic mixing method. The obtained film is immersed in the mixed solution of the cellulose and boron nitride, and a nanocellulose - graphene - boron nitride heat-conducting film is obtained. The film has superhigh anisotropy and is suitable for horizontal heat dissipation of a modern electronic device. The film is good in transparency. Since an outer layer is a mixed film of boron nitride and cellulose, an electric insulation effect can be achieved, and requirements of special electronic devices are met.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com