Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

71results about How to "Excellent stress relaxation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper alloy sheet, manufacturing method of copper alloy sheet, and electric/electronic component

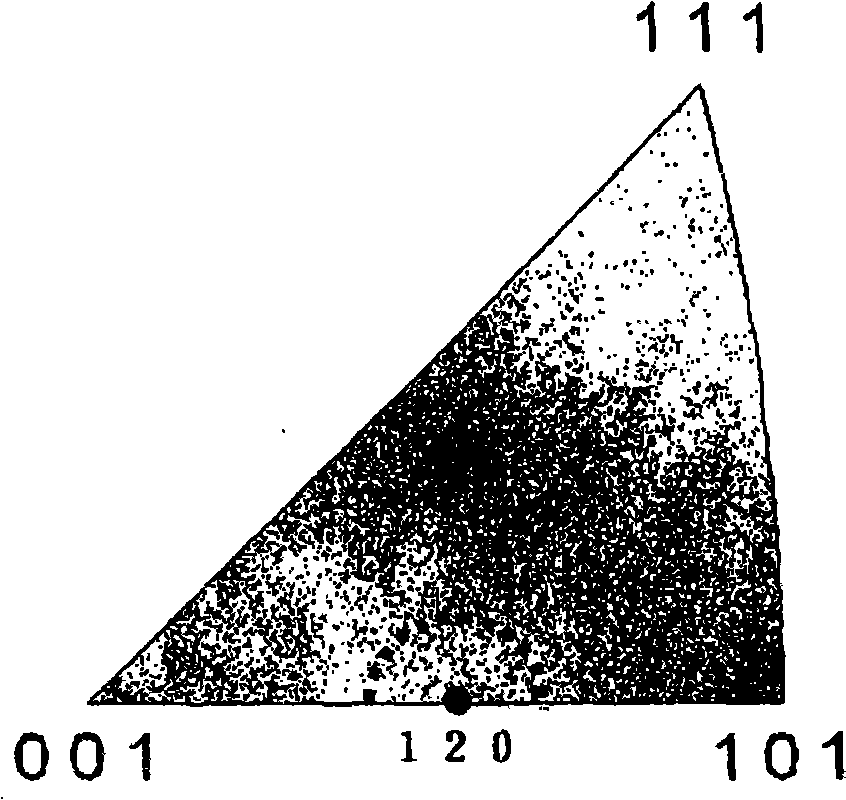

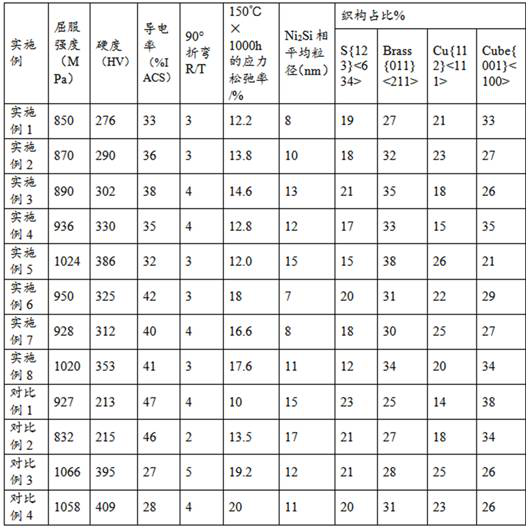

ActiveUS20110240180A1Excellent bending workabilityImprove conductivityConductive materialCrystal twinningCrystal orientation

There is provided a copper alloy sheet including 1.0 to 3.5 mass % Ni, 0.5 to 2.0 mass % Co, and 0.3 to 1.5 mass % Si, a Co / Ni mass ratio being 0.15 to 1.5, an (Ni+Co) / Si mass ratio being 4 to 7, and a balance being composed of Cu and an unavoidable impurity, wherein in observation results of a crystal grain boundary property and crystal orientation by EBSP measurement, a density of twin boundaries among all crystal grain boundaries is 40% or more and an area ratio of crystal grains with Cube orientation is 20% or more, on a rolled surface.

Owner:DOWA METALTECH CO LTD

Copper alloy sheet and method for producing same

ActiveUS20100269959A1Excellent bending workabilityExcellent stress relaxation resistanceCoupling contact membersChemical compositionX-ray

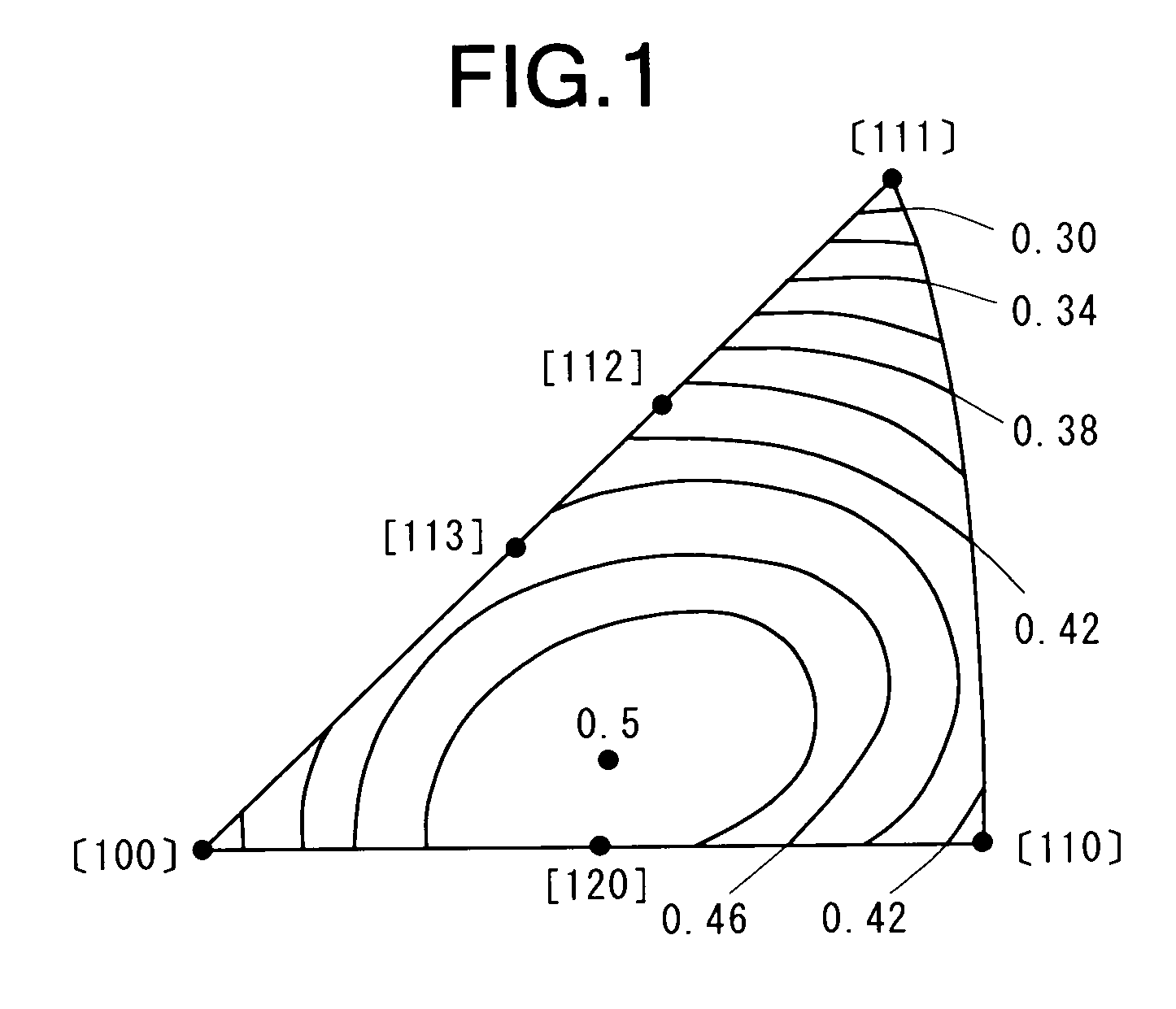

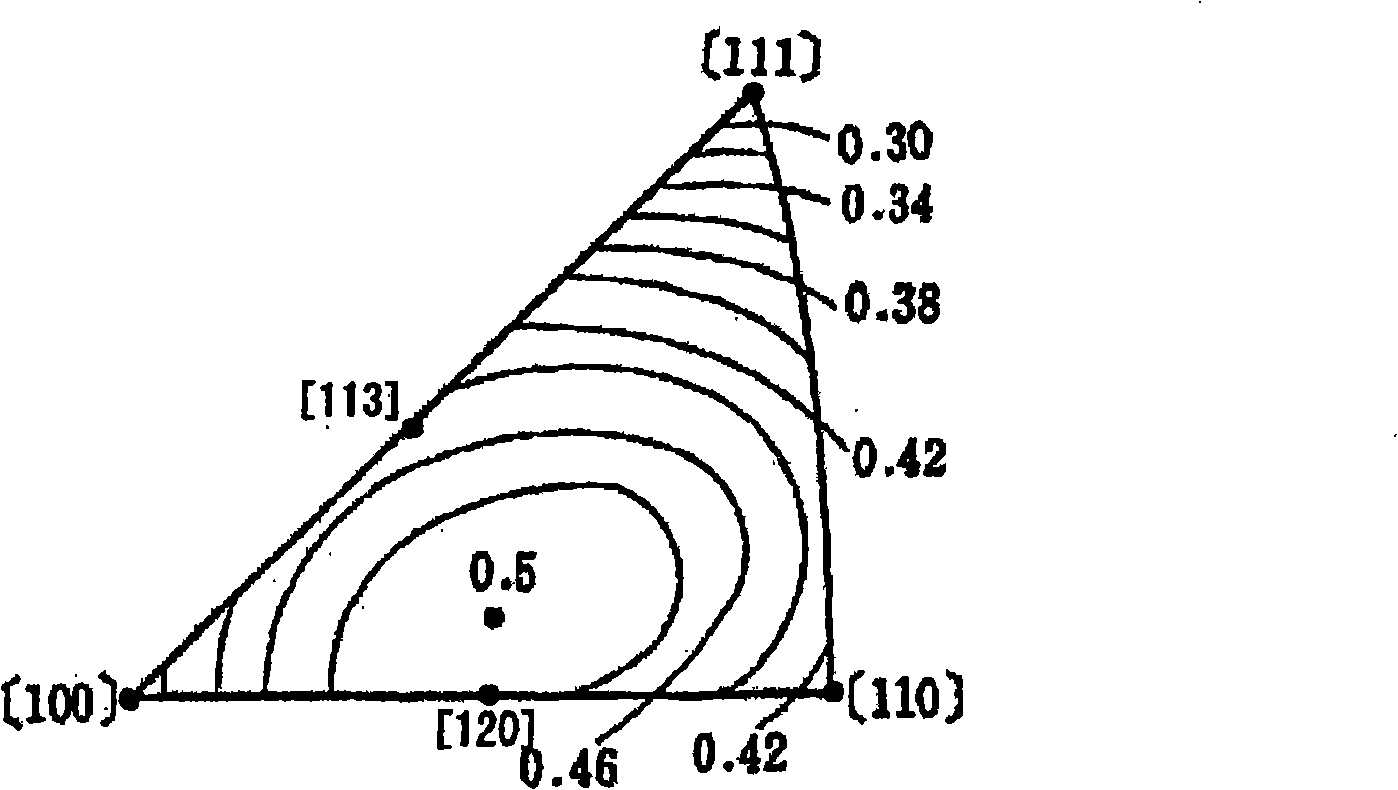

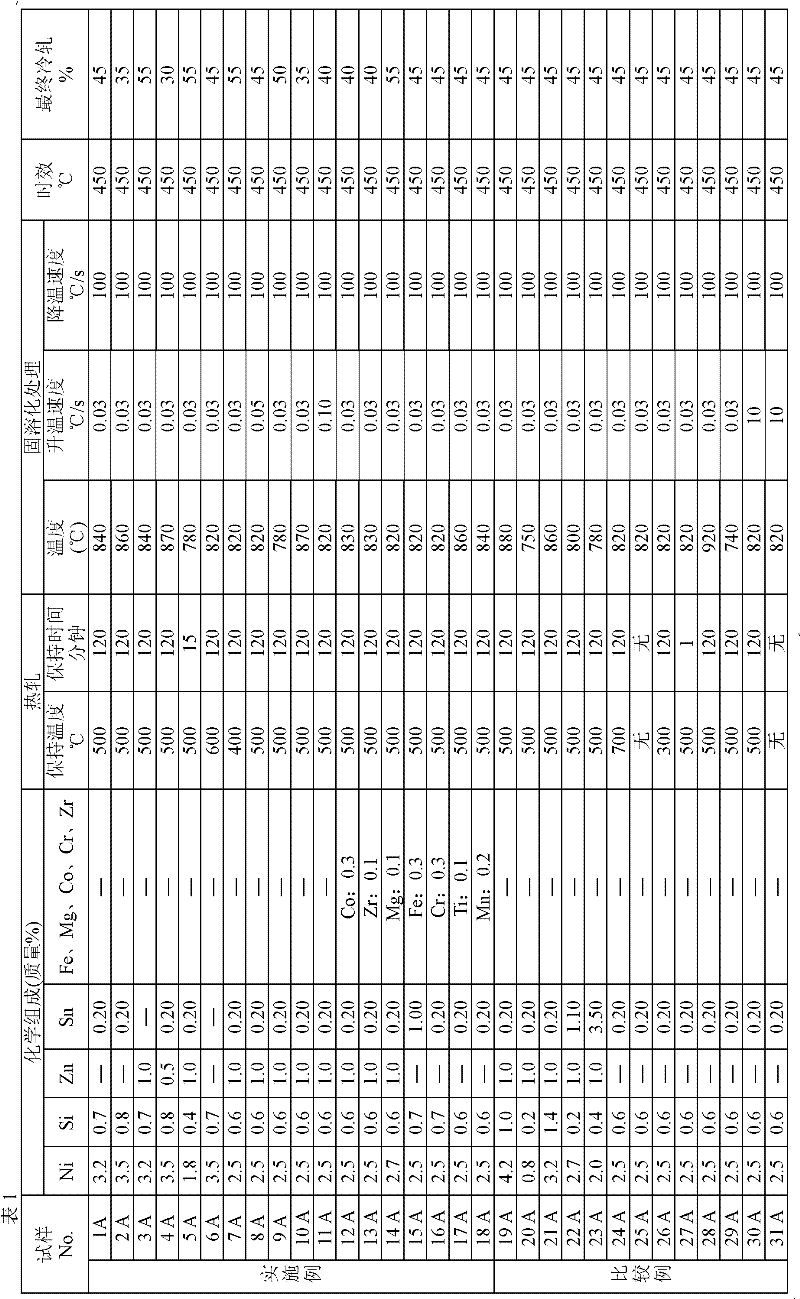

A copper alloy sheet has a chemical composition containing 0.7 to 4.0 wt % of Ni, 0.2 to 1.5 wt % of Si, and the balance being copper and unavoidable impurities, the copper alloy sheet having a crystal orientation which satisfies I{200} / I0{200}≧1.0, assuming that the intensity of X-ray diffraction on the {200} crystal plane on the surface of the copper alloy sheet is I{200} and that the intensity of X-ray diffraction on the {200} crystal plane of the standard powder of pure copper is I0{200}, and which satisfies I{200} / I{422}≧15, assuming that the intensity of X-ray diffraction on the {422} crystal plane on the surface of the copper alloy sheet is I{422}.

Owner:DOWA METALTECH CO LTD

Cu-Ni-Si-based copper alloy sheet material and method of manufacturing same

InactiveCN101245422AExcellent stress relaxation resistanceHigh strengthSolid-state devicesSemiconductor devicesX-rayCrystal orientation

Owner:DOWA METALTECH CO LTD

Method for preparing CuNiSiAl elastic copper alloy

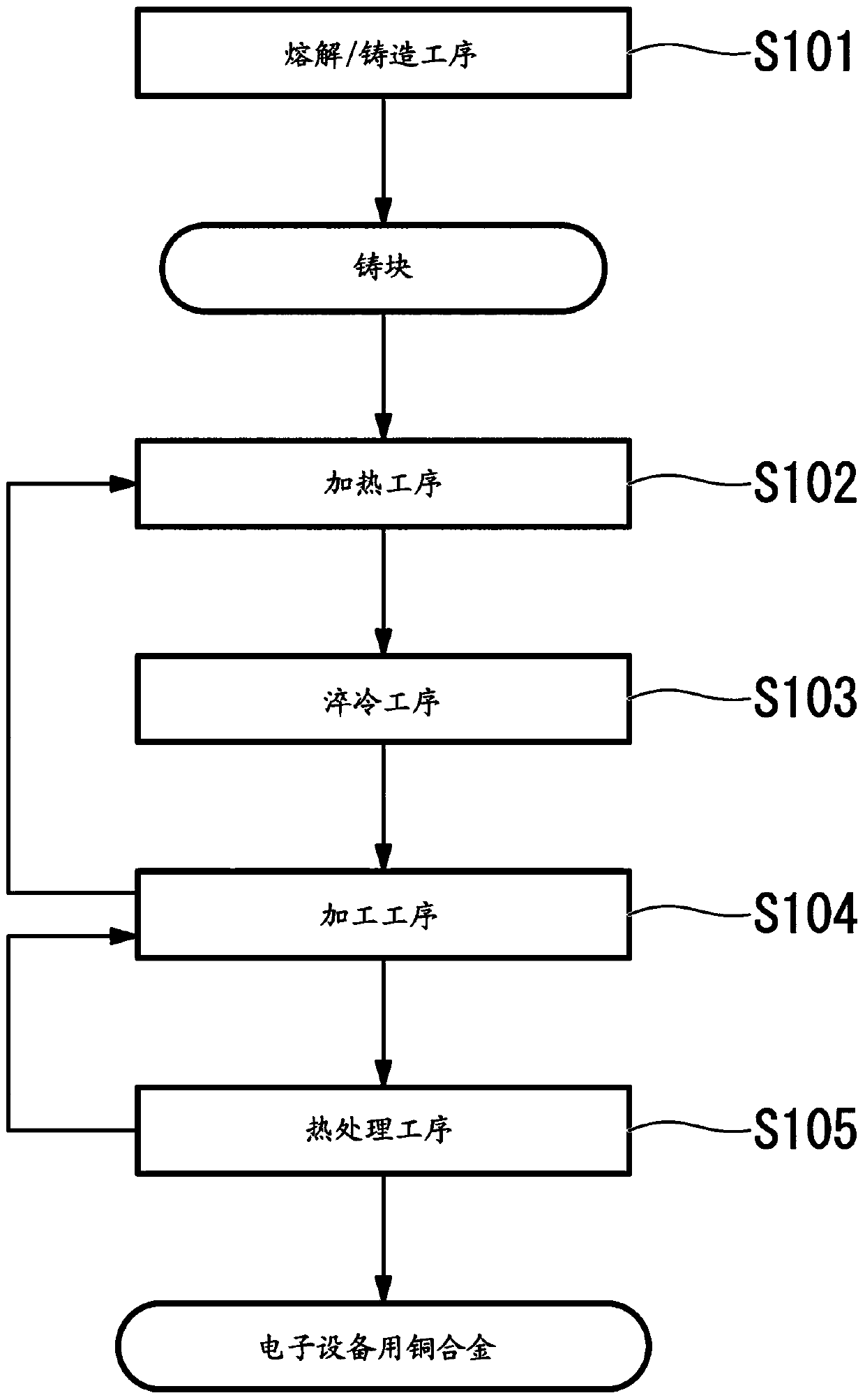

InactiveCN101984107AReasonable compositionHigh degree of alloyingSolution treatmentStress relaxation

The invention relates to a method for preparing a CuNiSiAl elastic copper alloy, comprising the steps of fusion casting, homogenizing treatment, hot rolling, solid solution treatment, cold rolling, ageing treatment, secondary cold rolling, etc. The alloy has reasonable components, high alloying degree, simple production process and low production cost and is convenient to operate. Compared with beryllium bronze, the alloy produced by the invention has the advantages of high strength, good conductivity, high stress relaxation resistance and no toxic elements such as beryllium. The CuNiSiAl elastic copper alloy prepared by the invention has ultrahigh strength and high stress relaxation resistance and can be suitable for the high performance conductive elastic devices in the aerospace and microelectronics industries, such as high power hermetically sealed electromagnetic relays, etc.

Owner:CENT SOUTH UNIV +1

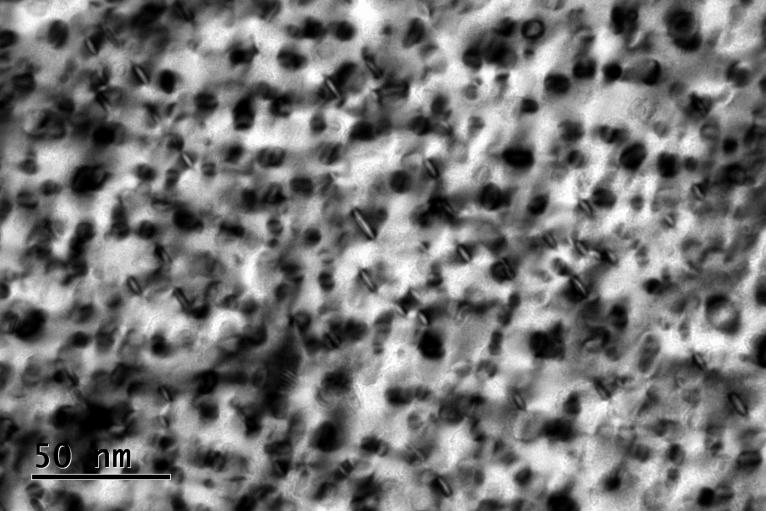

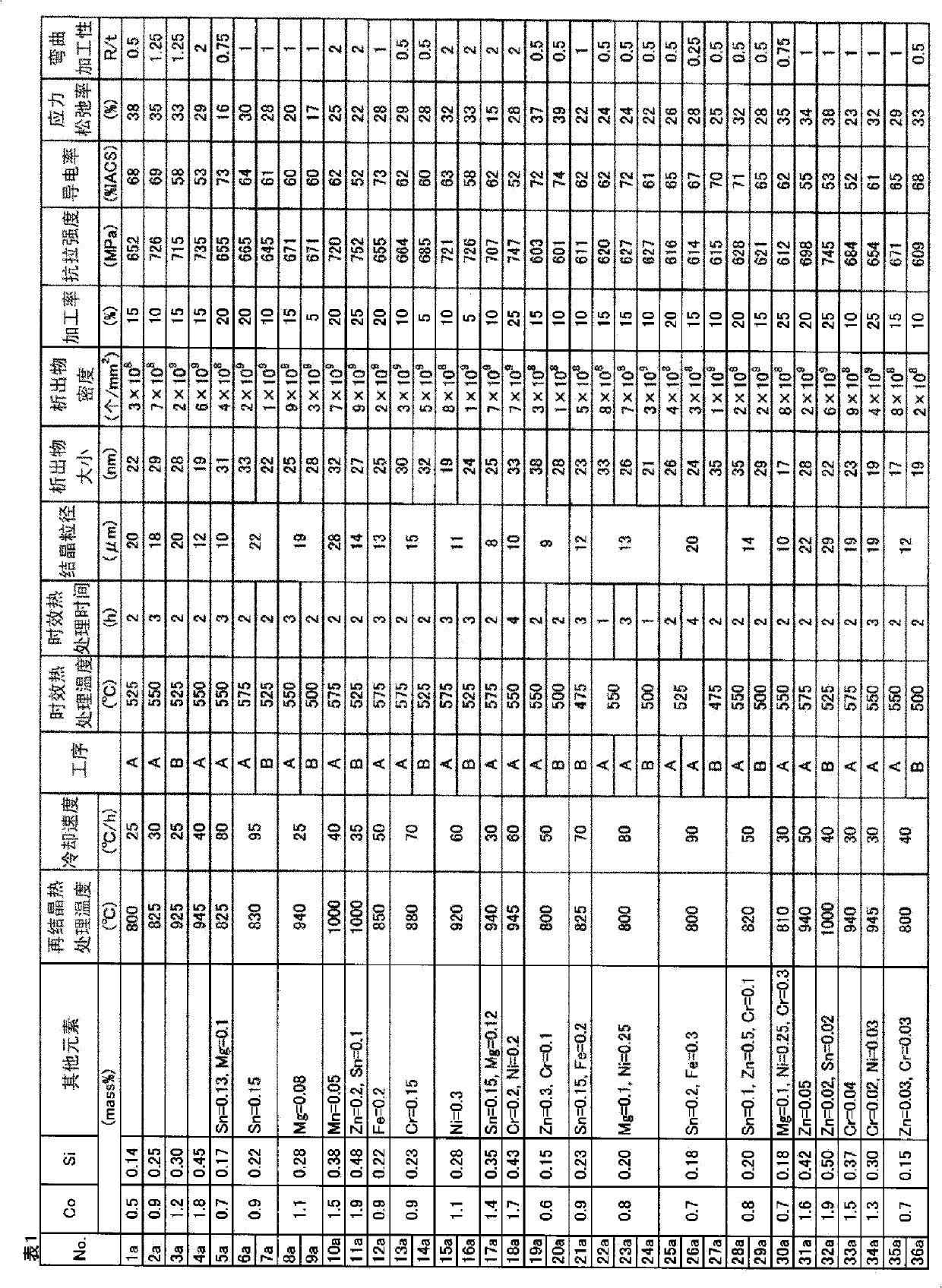

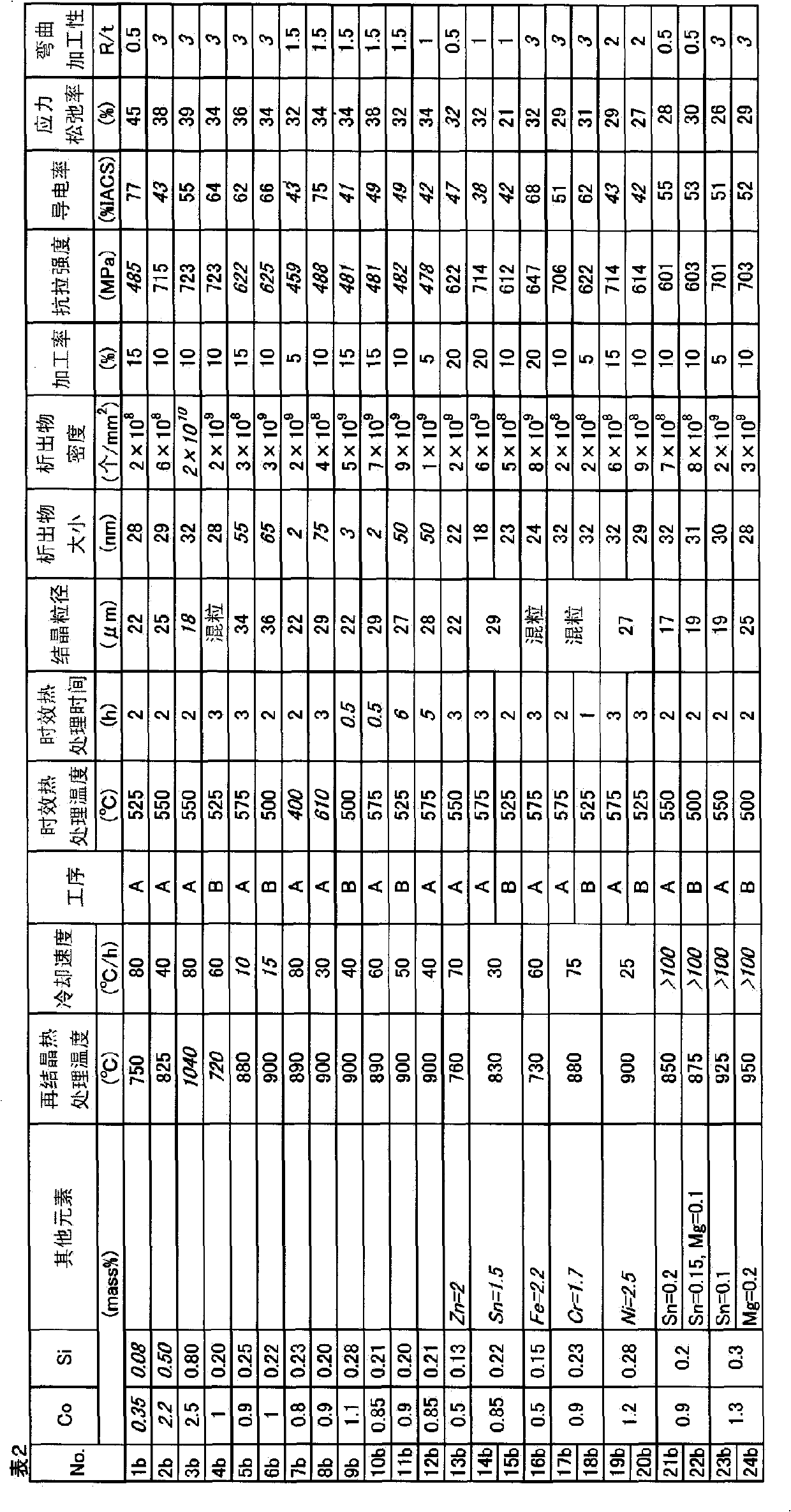

Copper alloy material for electric/electronic parts and method of producing the same

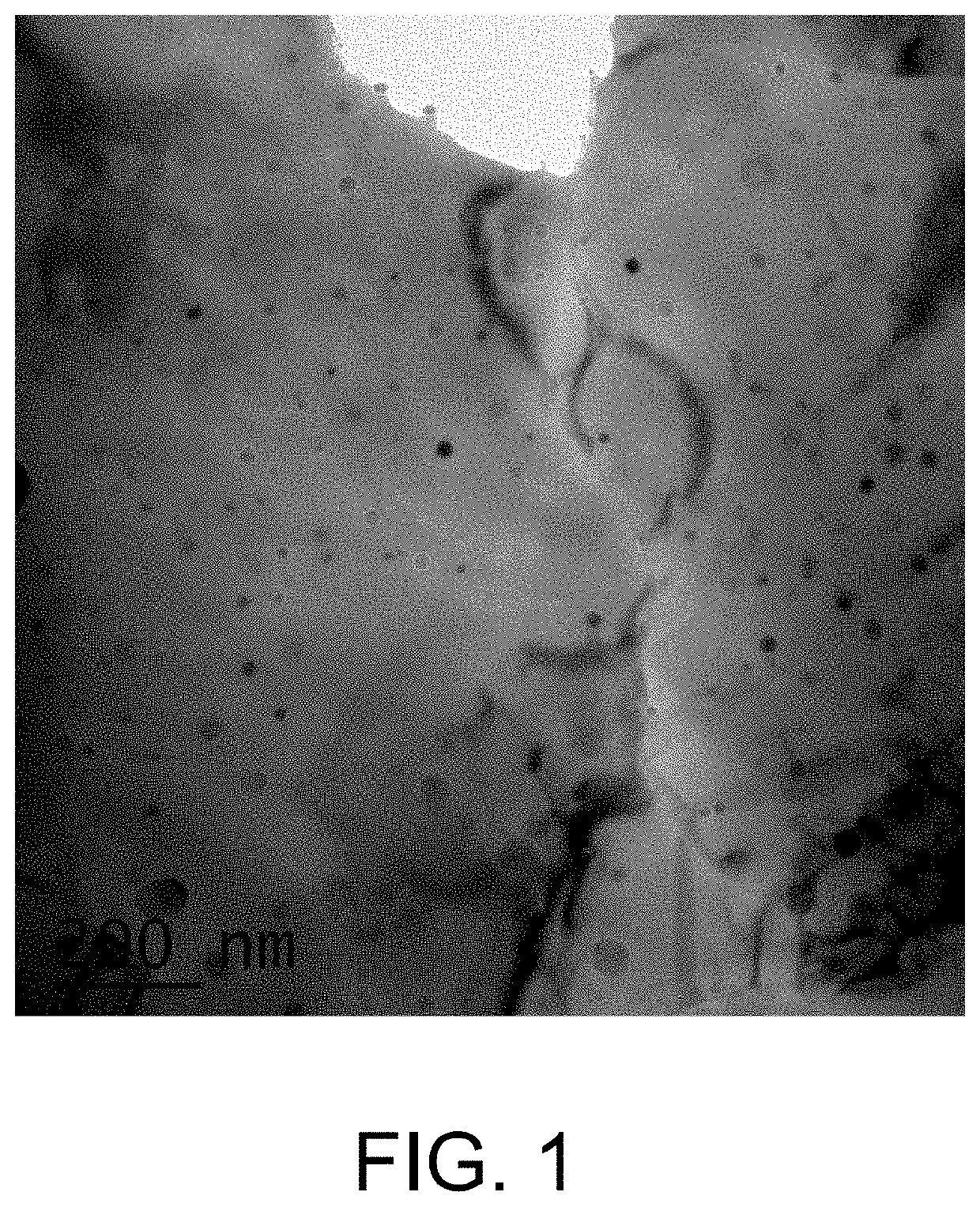

InactiveUS20110186192A1High mechanical strengthImprove conductivityConductive materialUltimate tensile strengthImpurity

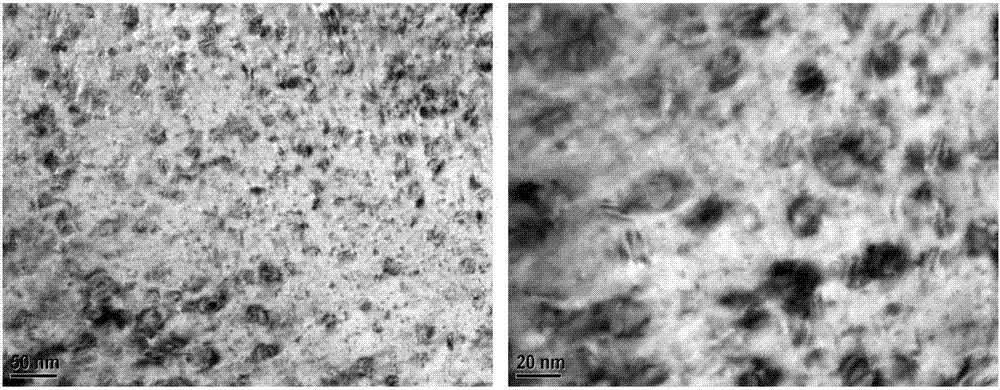

A copper alloy material for an electric / electronic part, having a composition comprising Co 0.5 to 2.0 mass % and Si 0.1 to 0.5 mass %, with the balance of Cu and inevitable impurities, in which a copper alloy of a matrix has a grain size of 3 to 35 μm, a precipitate composed of Co and Si has a particle size of 5 to 50 nm, the precipitate has a density of 1×108 to 1×1010 number / mm2, and the copper alloy material has a tensile strength of 550 MPa and an electrical conductivity of 50% IACS or more.

Owner:FURUKAWA ELECTRIC CO LTD

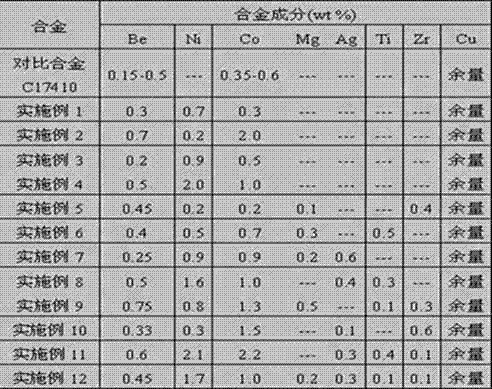

High-elasticity stress relaxation-resistant beryllium-copper alloy and its preparation and processing method

The invention relates to a high-elasticity stress relaxation-resistant beryllium-copper alloy and its preparation and processing method. The alloy comprises the following basic components by mass: 0.2-0.7% of Be, 0.5-2.0% of Co, 0.2-2.0% of Ni, and the balance Cu. The components of the copper alloy need to satisfy that: (a) the total content of Ni and Co is greater than or equal to 0.7% and less than or equal to 4%; and (b) the ratio of the sum of Ni and Co to Be is greater than or equal to 2 and less than or equal to 7. The preparation and processing method consists of: a. batching according to the mass percentage, charging, smelting and casting; b. surface milling; c. hot rolling; d. solid solution treatment; e. first cold rolling; f. first aging; g. second cold rolling; and h. second aging. The copper alloy provided in the invention has tensile strength sigmaB of 600-800MPa, plastic elongation delta of 4-10%, and electric conductivity of 35-50%IACS, and can be widely used in various elastic reeds, electrical contacts, spot welding poles, explosion-proof tools, electrical contact components, plug-in components and other occasions.

Owner:有研科技集团有限公司

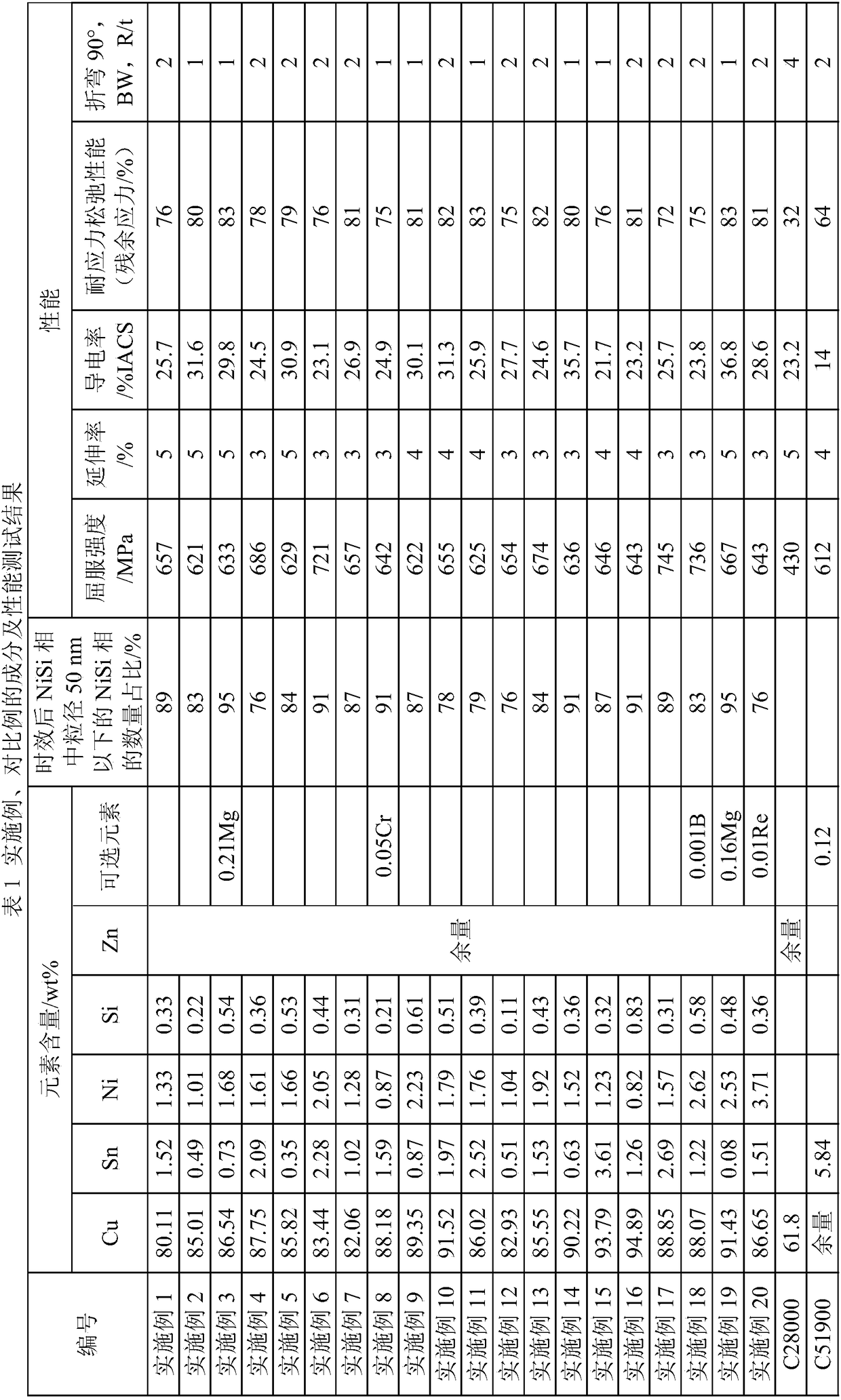

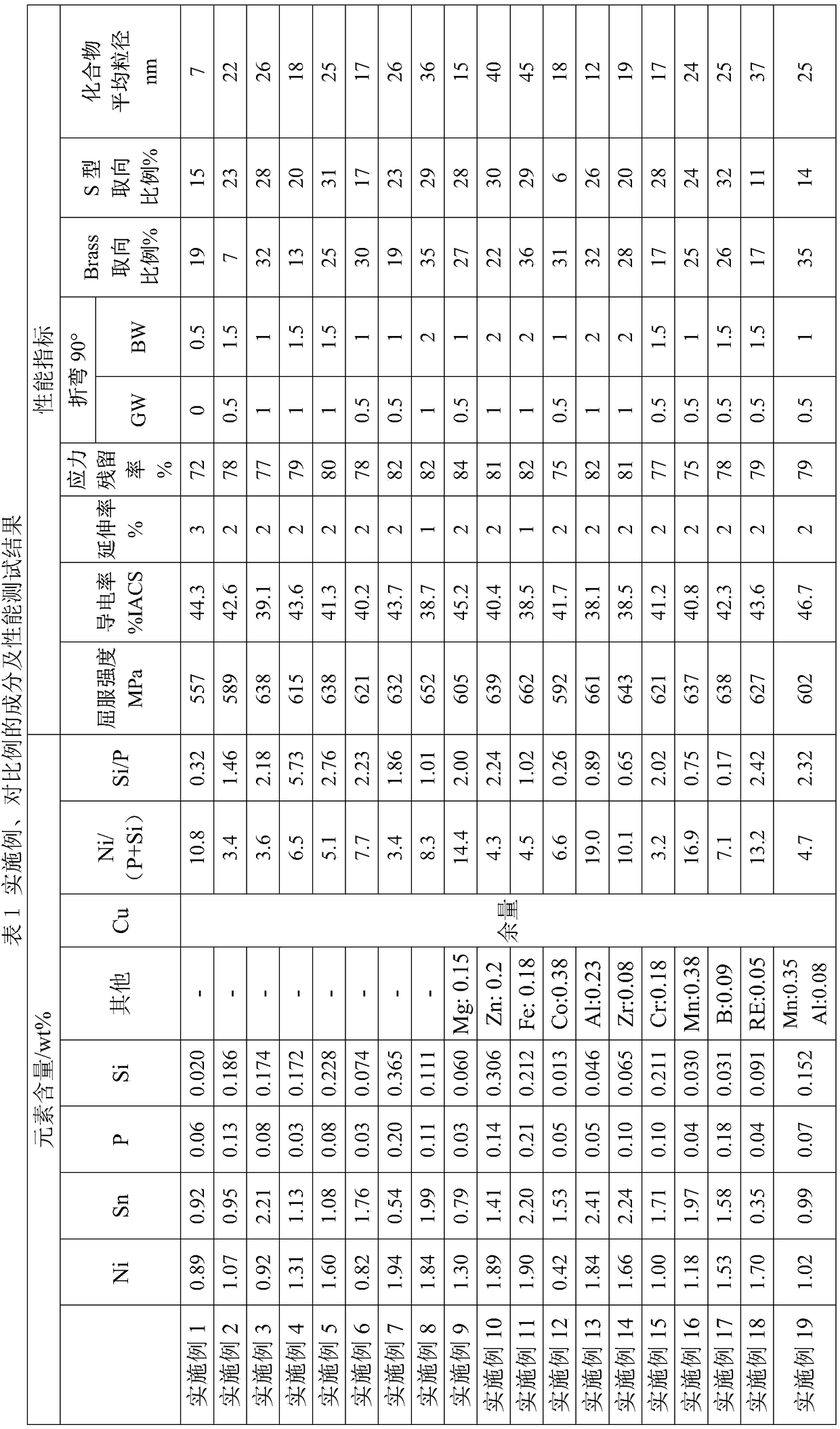

Precipitation-hardening copper alloy and application thereof

ActiveCN108285988AHigh strengthLittle effect on conductivityConductive materialMetal/alloy conductorsStress relaxationMatrix strength

The invention discloses a precipitation-hardening copper alloy which is prepared from the components in percentage by weight: 80 percent to 95 percent of Cu, 0.05 percent of to 4.0 percent of Sn, 0.01percent of to 3.0 percent of Ni, 0.01 to 1.0 percent of Si, and the balance Zn and inevitable impurities. According to the precipitation-hardening copper alloy provided by the invention, through solid solution strengthening and precipitation hardening, a combination performance of the alloy is improved, the matrix strength is improved, meanwhile, the influence on the conductivity of the alloy isless, a bending processing performance meets the requirement, and the alloy has a stress relaxation property as same as tin-phosphor bronze. The alloy provided by the invention has a better combination performance than C51900, is low in raw material cost, has remarkable advantages in welding and electroplating, can solve the utilization problem of multiple waste materials, and is widely applied toelectronic and electrical industry products such as connectors and connector assemblies.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Copper alloy with outstanding comprehensive performance and application thereof

ActiveCN109022900AGuaranteed electrical conductivityHigh strengthConductive materialMetal/alloy conductorsWire rodUltimate tensile strength

Owner:NINGBO POWERWAY ALLOY MATERIAL

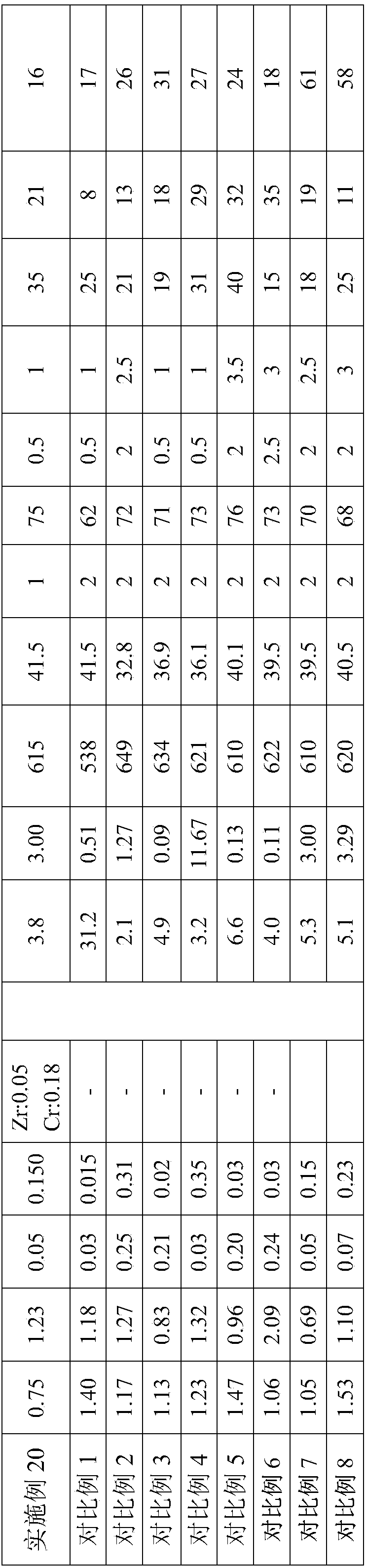

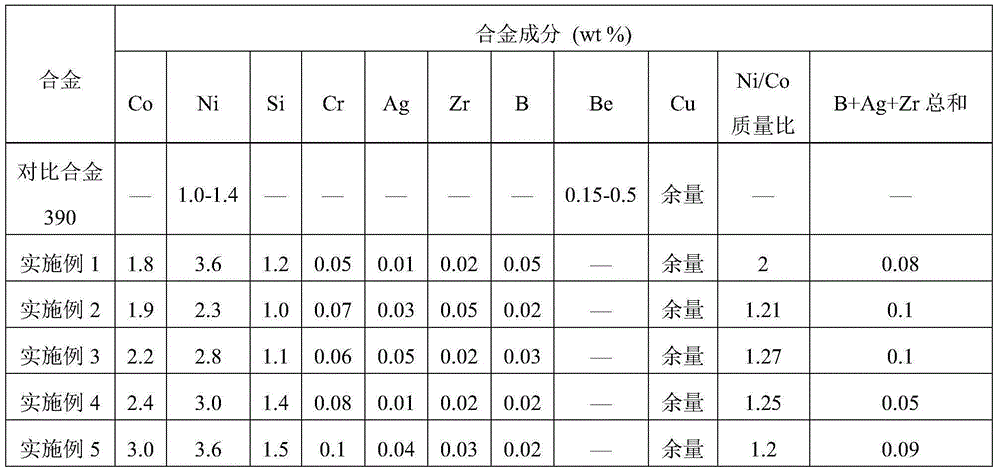

High-strength, high-electric-conductivity and high-stress relaxation-resistance copper alloy elastic material and preparation method thereof

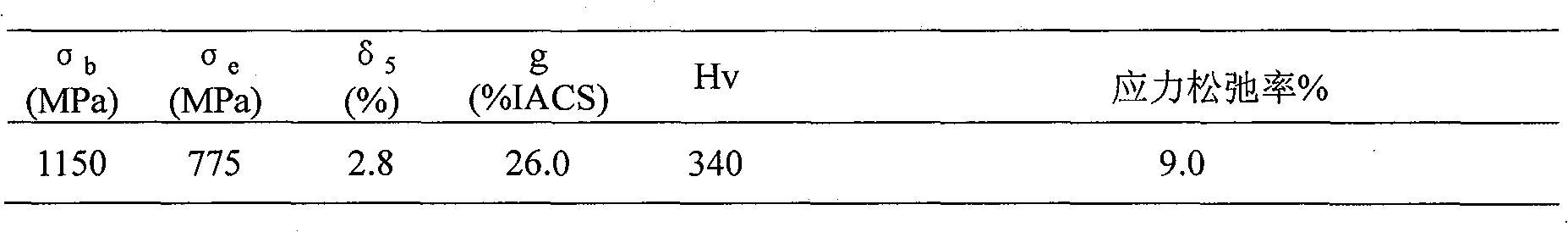

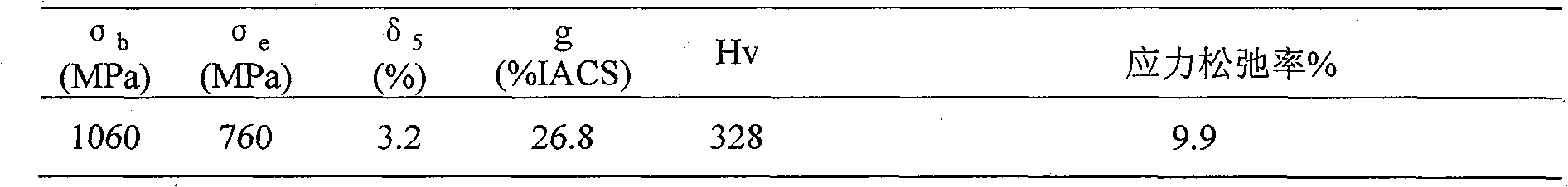

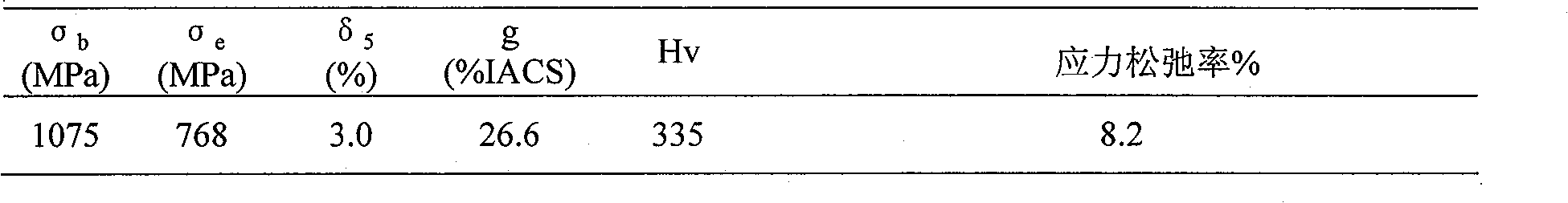

The invention relates to a high-strength, high-electric-conductivity and high-stress relaxation-resistance copper alloy elastic material and a preparation method thereof, and belongs to the field of machining of nonferrous metal. The material comprises the following components in percentage by weight: 1.8-3.0% of Co, 2.3-3.6% of Ni, 1.0-1.5% of Si, 0.05-0.1% of Cr, 0.01-0.05% of Ag, 0.02-0.05% of Zr, 0.02-0.05% of B, and the balance of Cu, wherein the mass ratio of Ni / Co is 1.2-2; and the mass sum of Ag, Zr and B is 0.05-0.1%. The material is prepared through smelting, casting, uniform heat treatment, hot rolling, solid solution treatment, primary cold rolling, first-grade aging treatment, secondary cold rolling and second-grade aging treatment. The tensile strength, the electric conductivity, the ductility and the stress relaxation resistance of the material can totally satisfy the use requirements of a vehicle high-current relay and a connector.

Owner:GRIMAT ENG INST CO LTD

Copper alloy and method for production thereof

InactiveCN101124345AHigh strengthExcellent bending workabilitySemiconductor/solid-state device detailsSolid-state devicesVolumetric Mass DensityImpurity

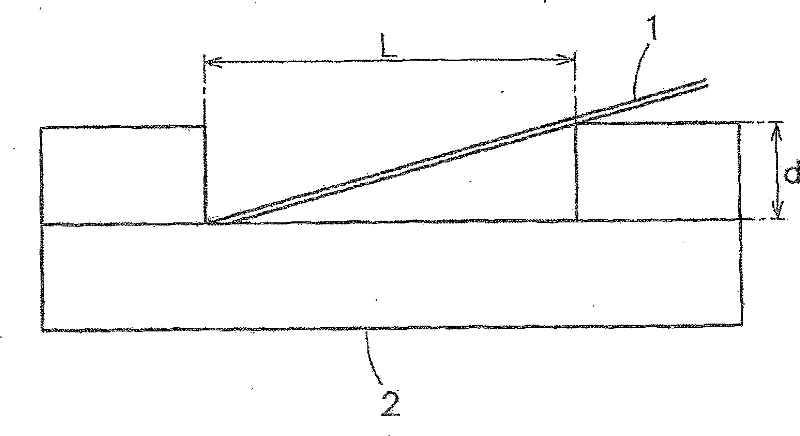

A copper alloy, having Sn 3.0 to 13.0 mass%, with the balance being Cu and unavoidable impurities, which copper alloy contains crystal grains whose diameter is 1.0 to 2.0 µm, and wherein the copper alloy has a precipitate X having a diameter of 1 to 50 nm and a density of 10 6 to 10 10 per mm 2 , and a precipitate Y having a diameter of 50 to 500 nm and a density of 10 4 to 10 8 per mm 2 ; and a method of producing the copper alloy, including the steps of: cold-working the recrystallized structure with an average crystal grain diameter of 1 to 15 µm at a working ratio of 40 to 70%; and heating the resultant to obtain a recrystallized structure with a crystal grain diameter of 1 to 2 µm.

Owner:FURUKAWA ELECTRIC CO LTD

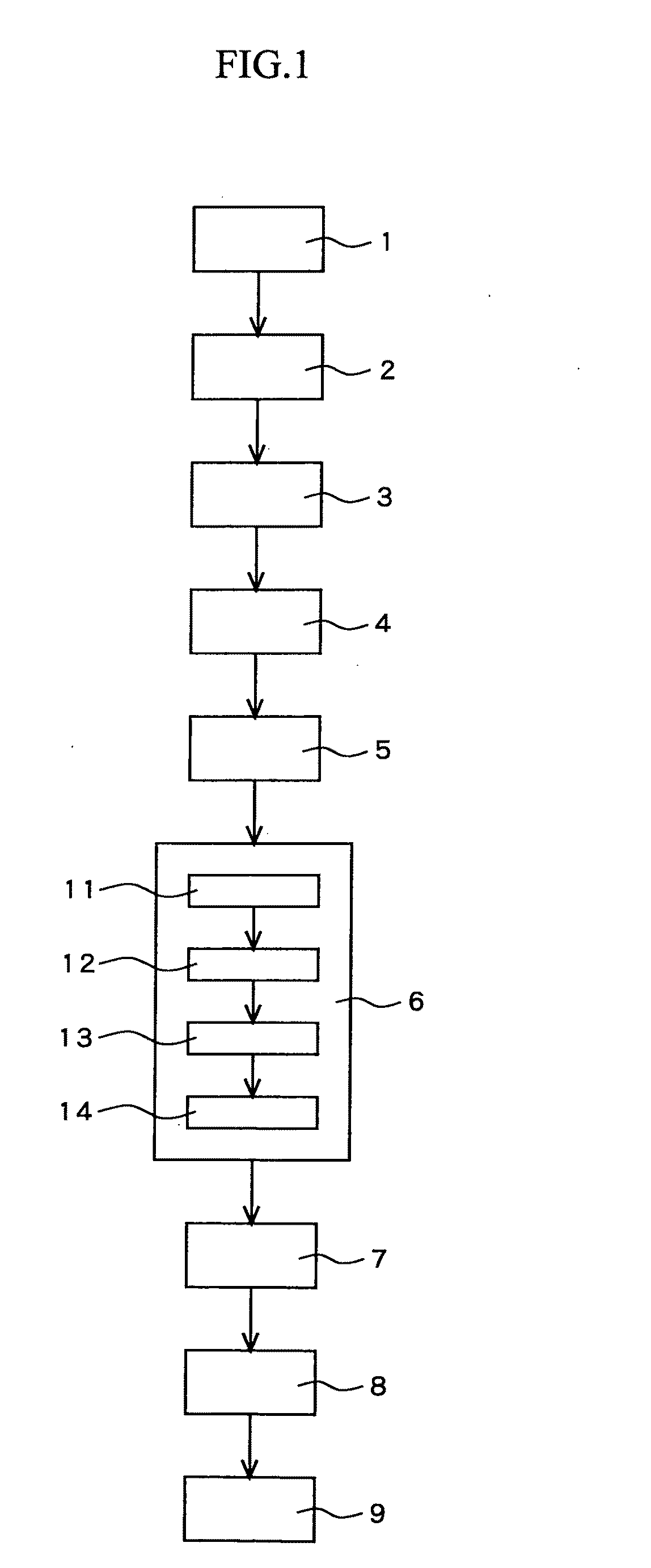

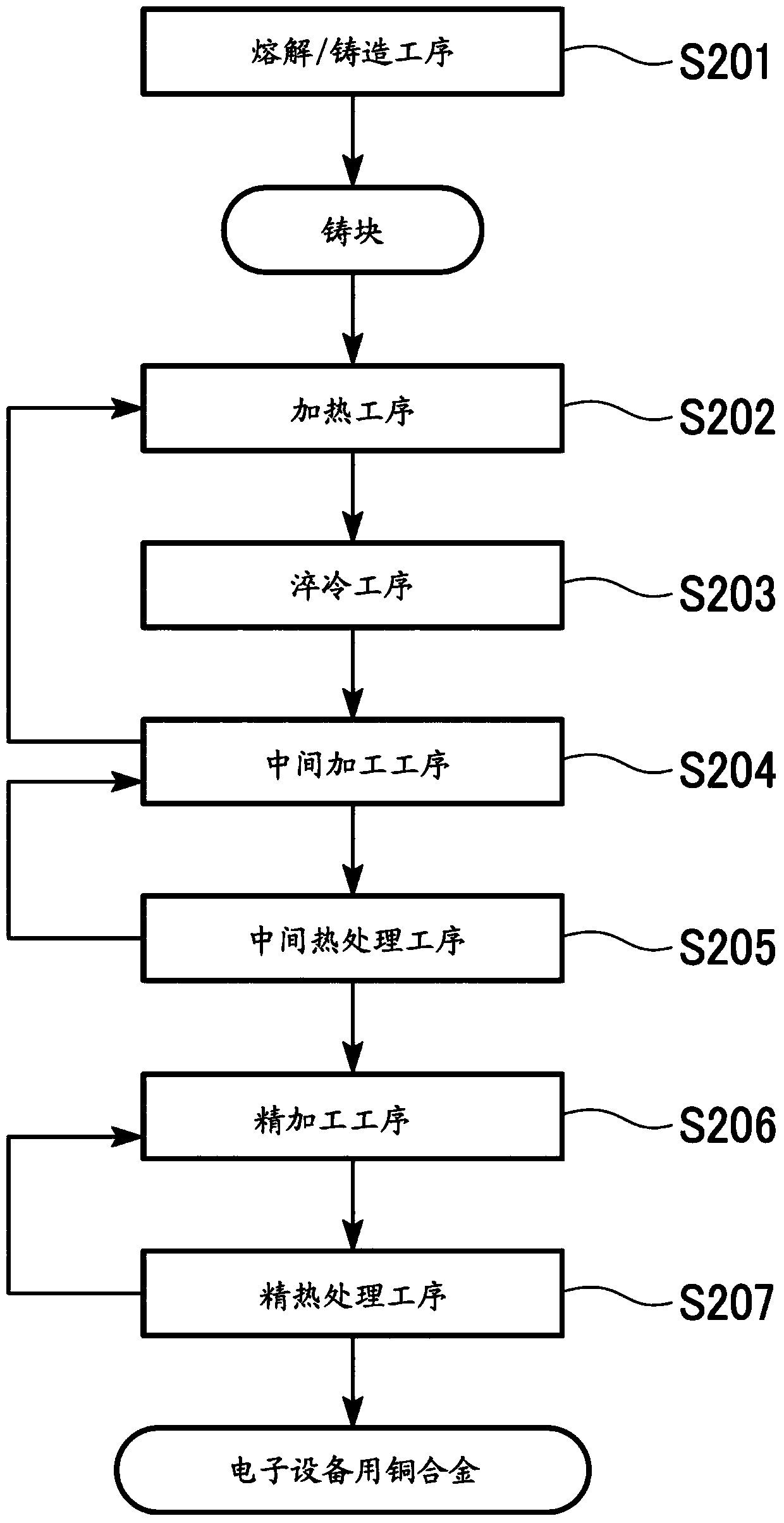

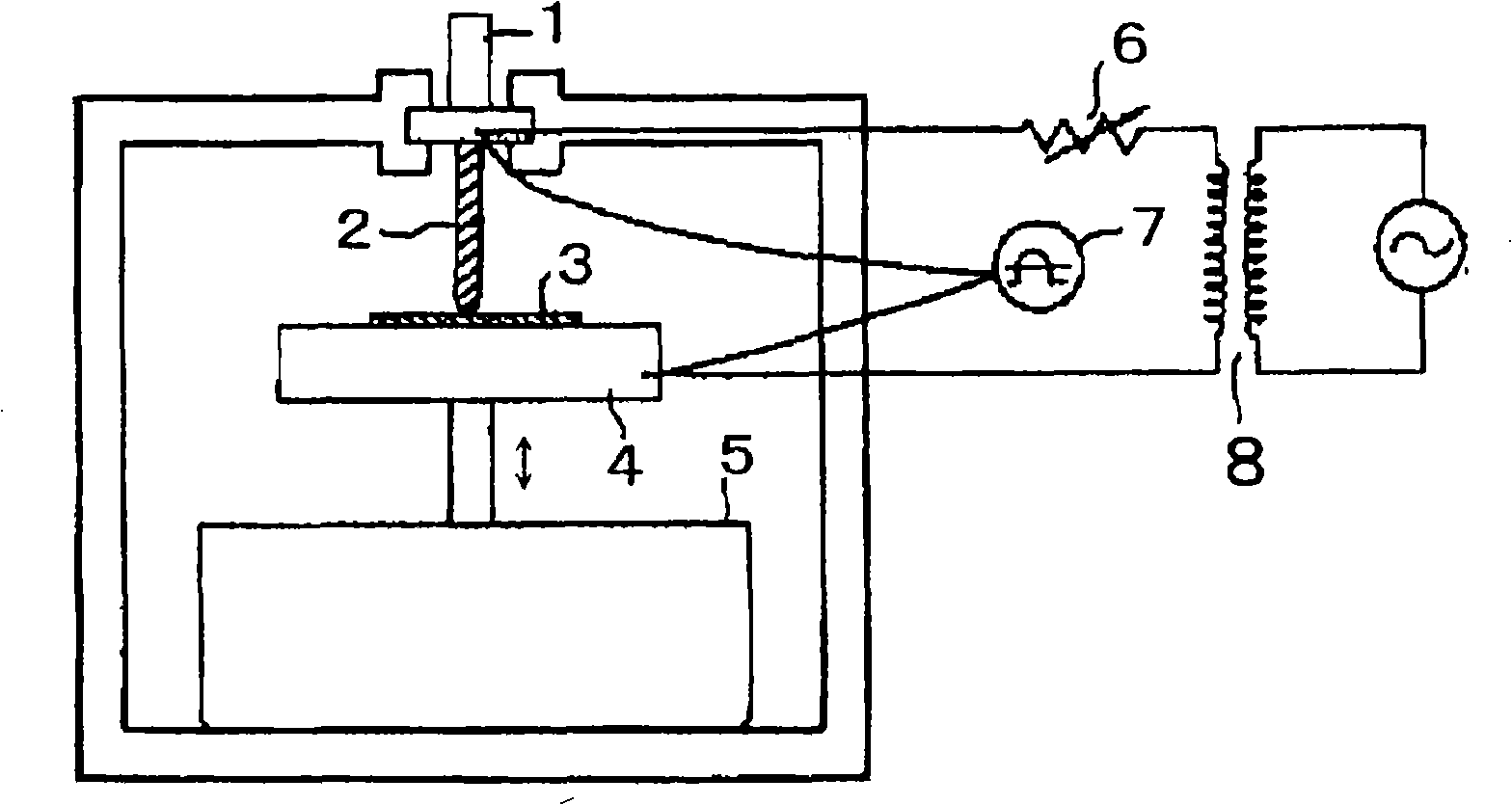

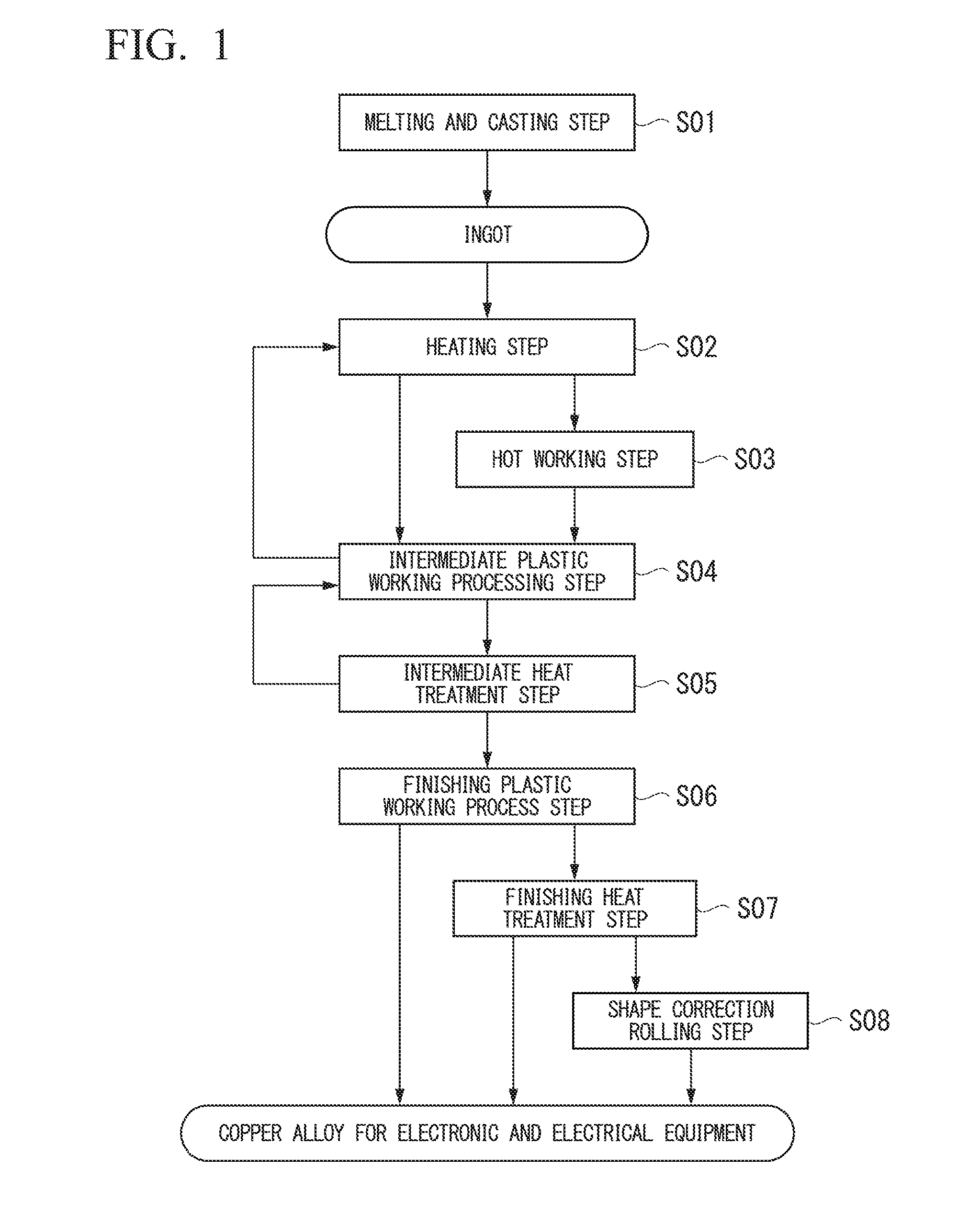

Manufacturing method of copper alloy sheet

ActiveUS20150053314A1High strengthAvoid great stressConductive materialMetal/alloy conductorsQuenchingImpurity

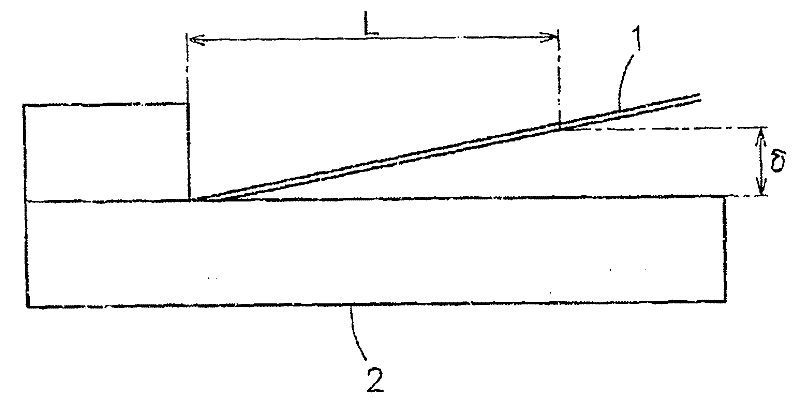

Manufacturing method of a copper alloy sheet including melting and casting a raw material of a copper alloy having a composition containing 1.0 mass % to 3.5 mass % Ni, 0.5 mass % to 2.0 mass % Co, and 0.3 mass % to 1.5 mass % Si with a balance being composed of Cu and an unavoidable impurity. The method includes the steps of first cold rolling, intermediate annealing, second cold rolling, a solution heat treatment and aging. The solution heat treatment includes: heating at 800° C. to 1020° C.; first quenching to 500° C. to 800° C.; maintaining the 500° C. to 800° C. temperature for 10 seconds to 600 seconds; and second quenching to 300° C. or lower.

Owner:DOWA METALTECH CO LTD

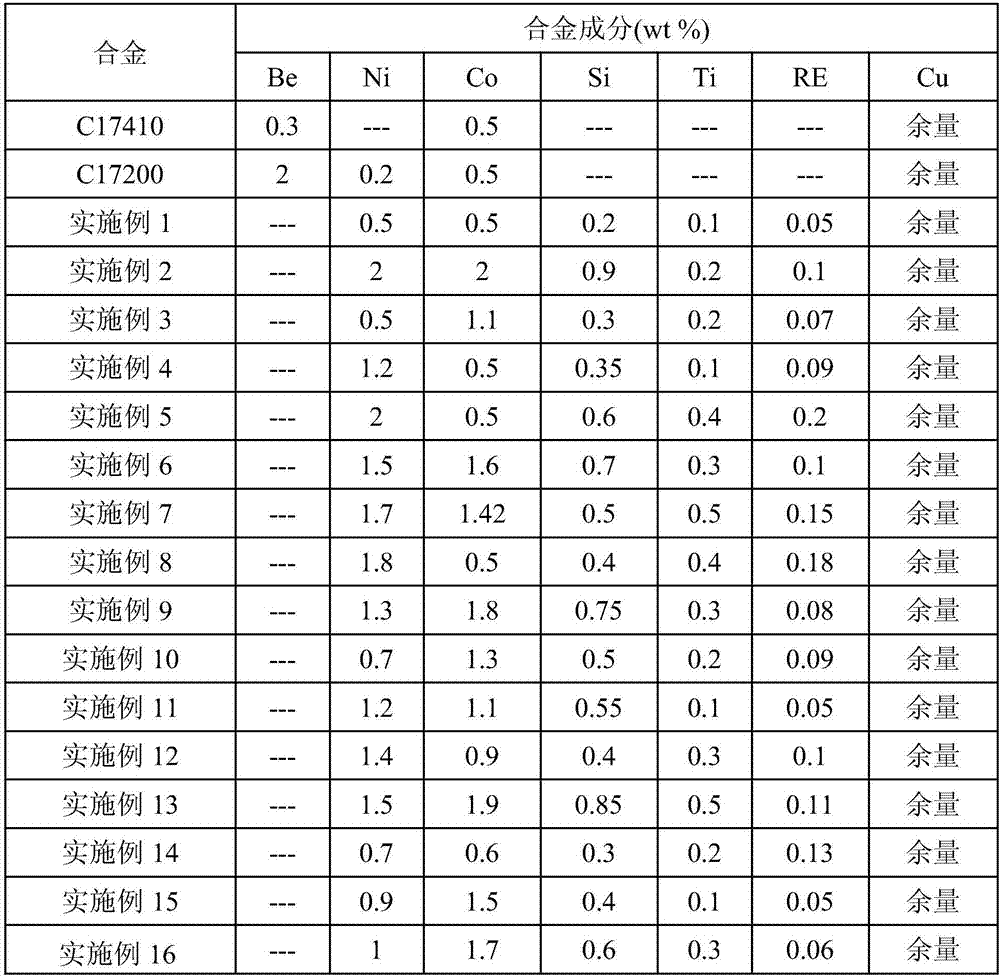

Cu-Ni-Si-Co-Ti-RE copper alloy and preparation method thereof

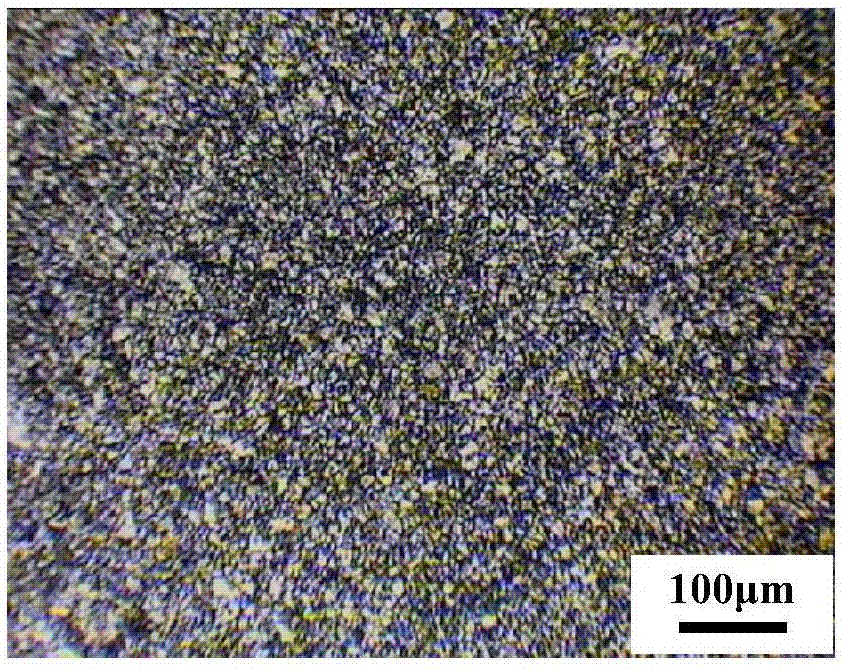

The invention discloses a Cu-Ni-Si-Co-Ti-Re copper alloy. The Cu-Ni-Si-Co-Ti-Re copper alloy comprises the following components in percentage by weight: 0.5%-2.0% of Ni, 0.2%-0.9% of Si, 0.5%-2.0% of Co, 0.1%-0.5% of Ti, 0.05%-0.2% of RE and the balance Cu, wherein RE is one or more of Ce, La and Y. The Cu-Ni-Si-Co-Ti-Re copper alloy has tensile strength sigma b which can reach 800-1000 MPa, plastic ductility sigma of 3-10%, electrical conductivity of 45%-55% of IACS, anti-stress-relaxation property greater than or equal to 80% (working for 1000 hours at a temperature of 200 DEG C). The invention further discloses a preparation method for the Cu-Ni-Si-Co-Ti-Re copper alloy.

Owner:JIANGXI UNIV OF SCI & TECH +1

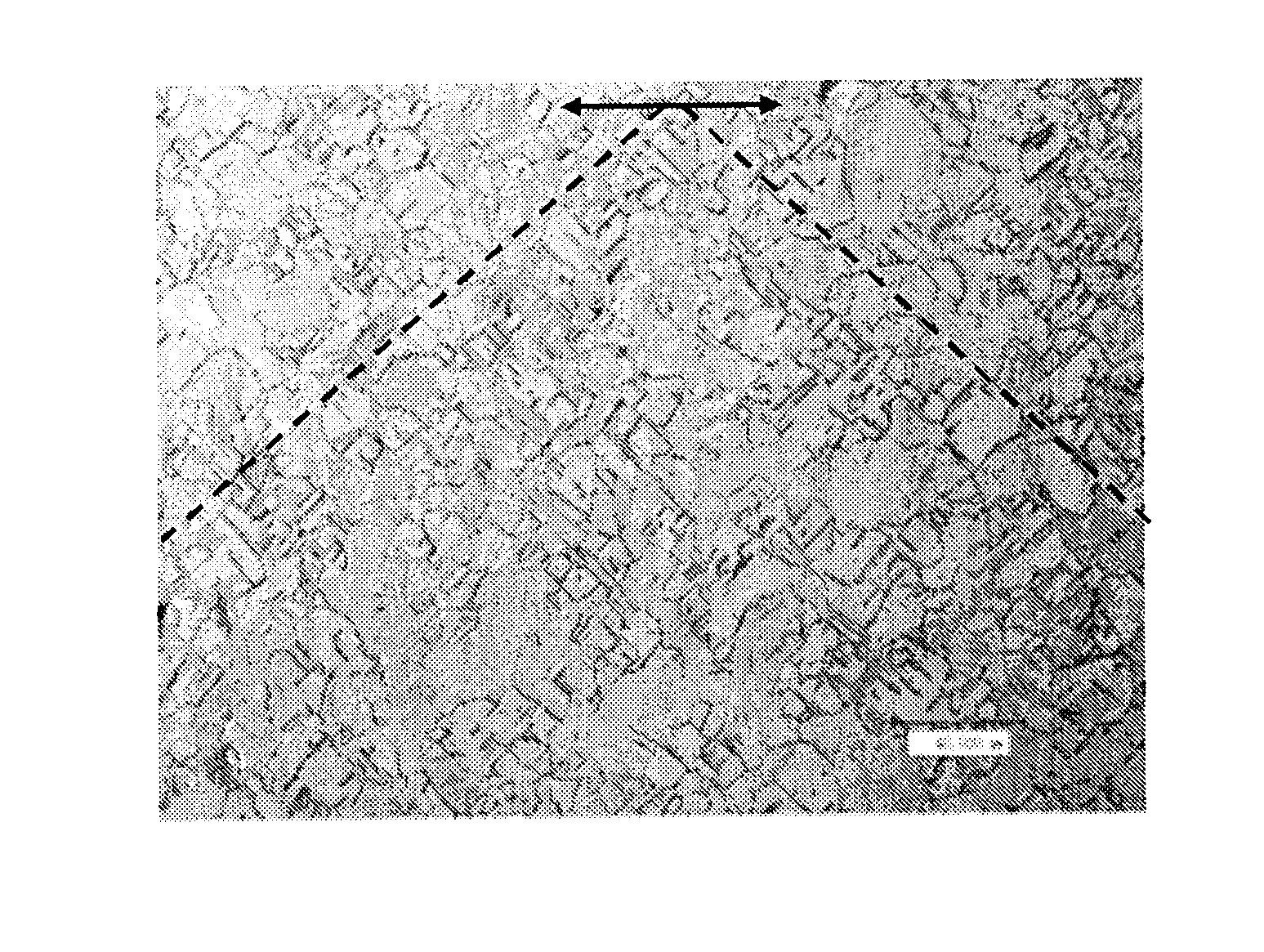

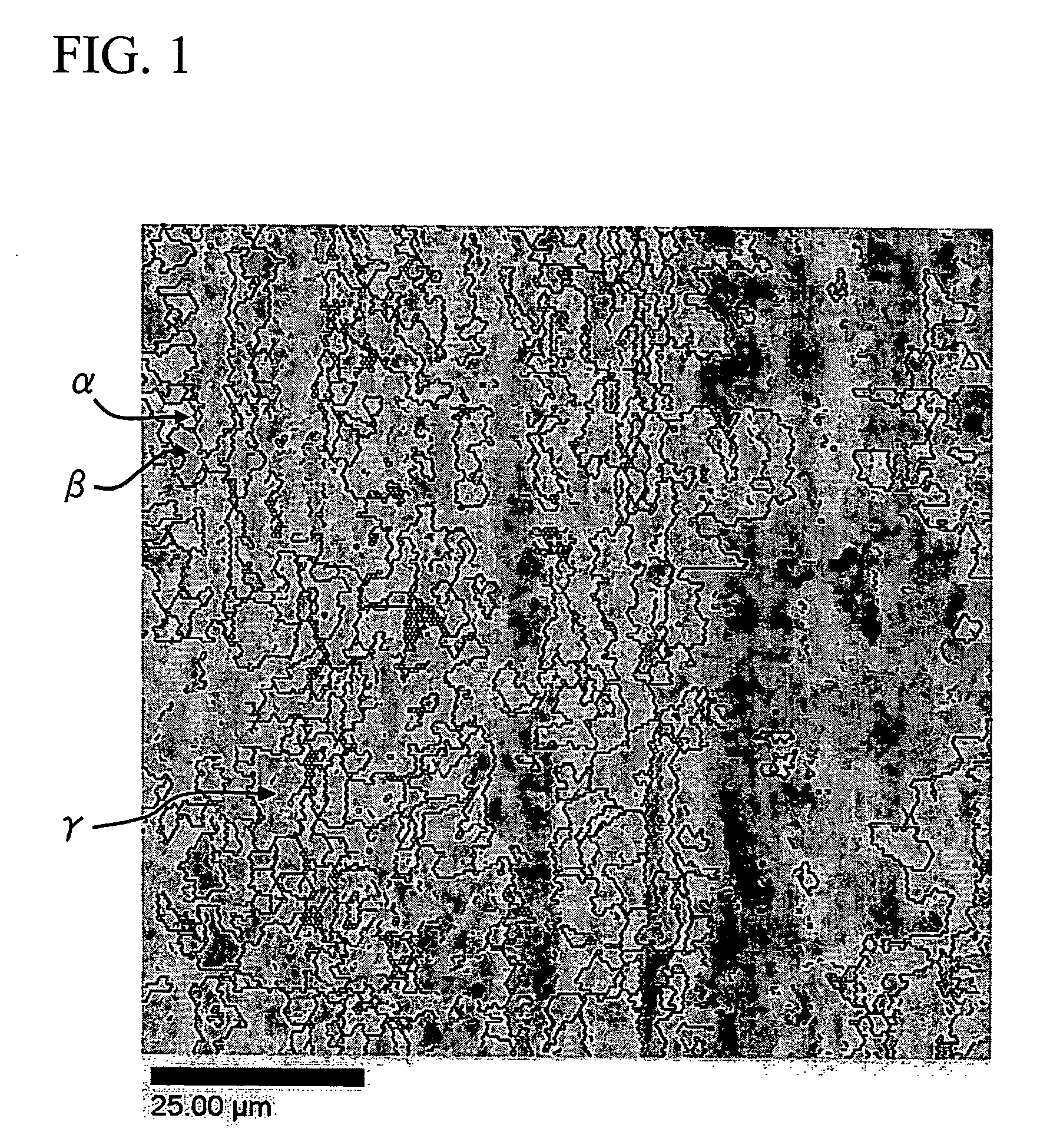

Copper alloy

InactiveCN102534298AHigh strengthExcellent bending workabilityConductive materialMetallic pattern materialsHigh intensityImpurity

A copper alloy containing Ni: 1.5% - 3.6% and Si: 0.3% - 1.0% in terms of mass percent with the remainder consisting of copper and unavoidable impurities, wherein: the average crystal grain size of the crystal grains in the copper alloy is 5 to 30 [mu]m; the area ratio of the crystal grains having crystal grain sizes not less than twice the average crystal grain size is not less than 3%; and the ratio of the area of cube orientation grains to the area of the crystal grains having crystal grain sizes not less than twice the average crystal grain size is not less than 50%.

Owner:KOBE STEEL LTD

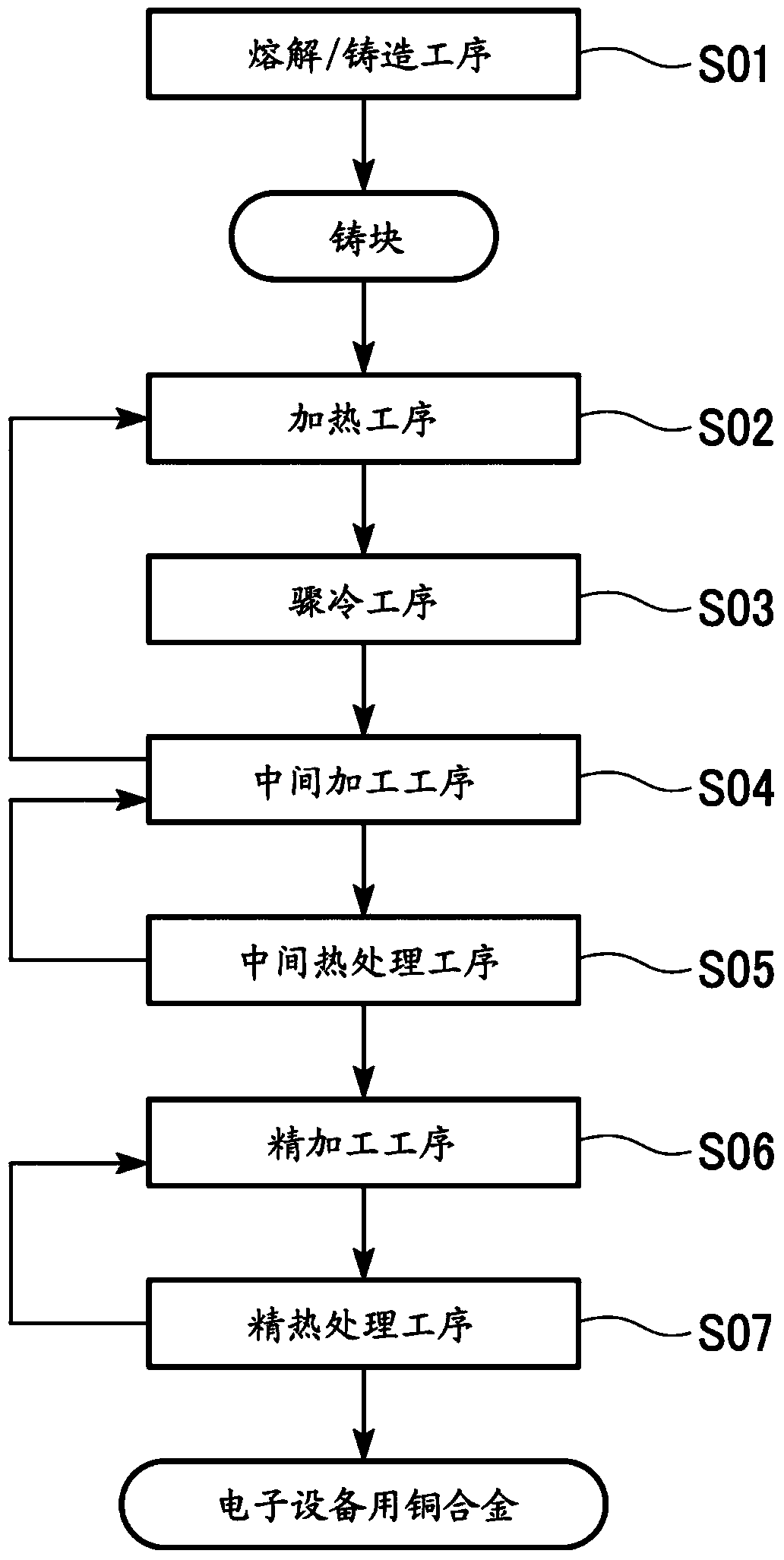

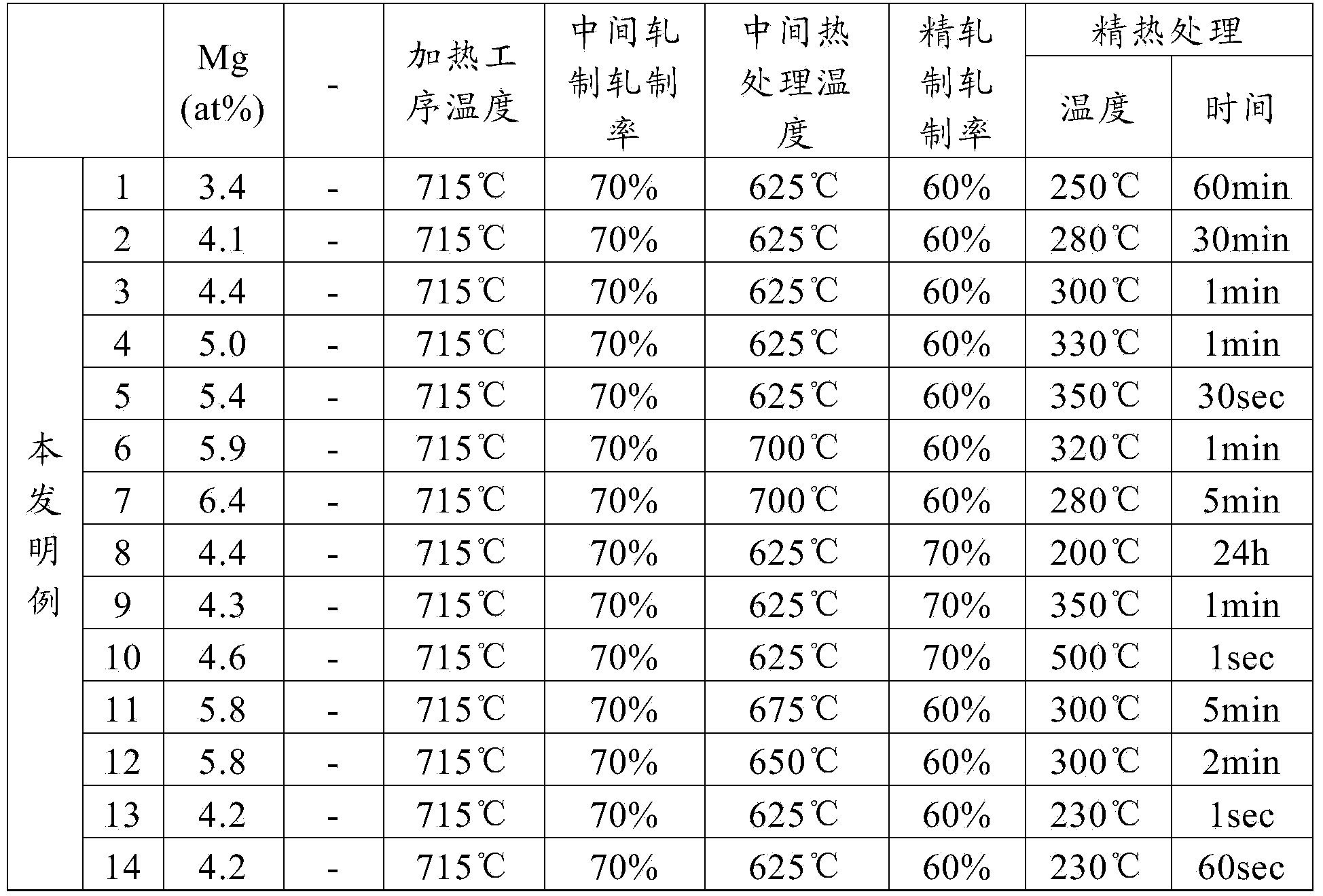

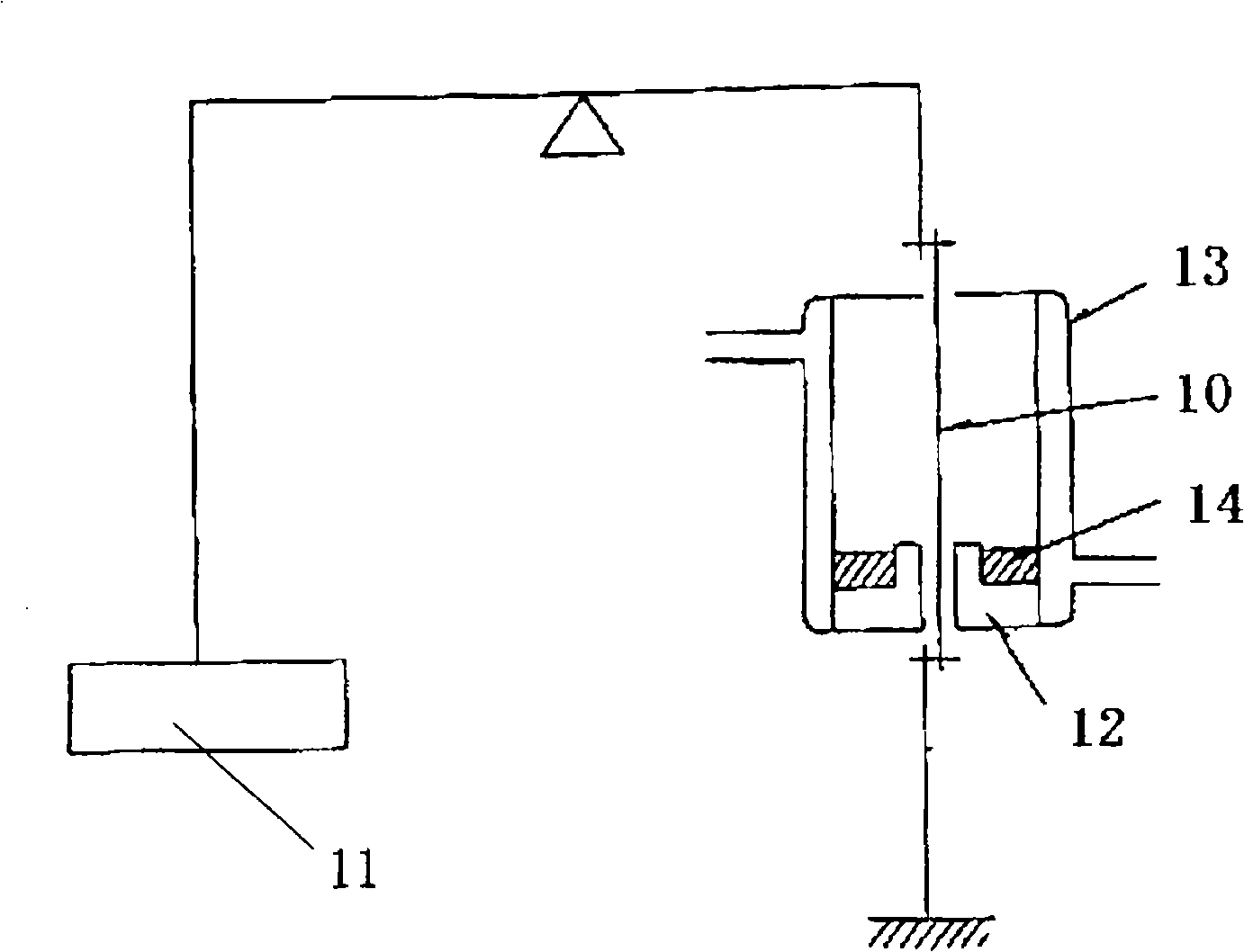

Copper alloy for electronic devices, method for producing copper alloy for electronic devices, copper alloy plastic working material for electronic devices, and component for electronic devices

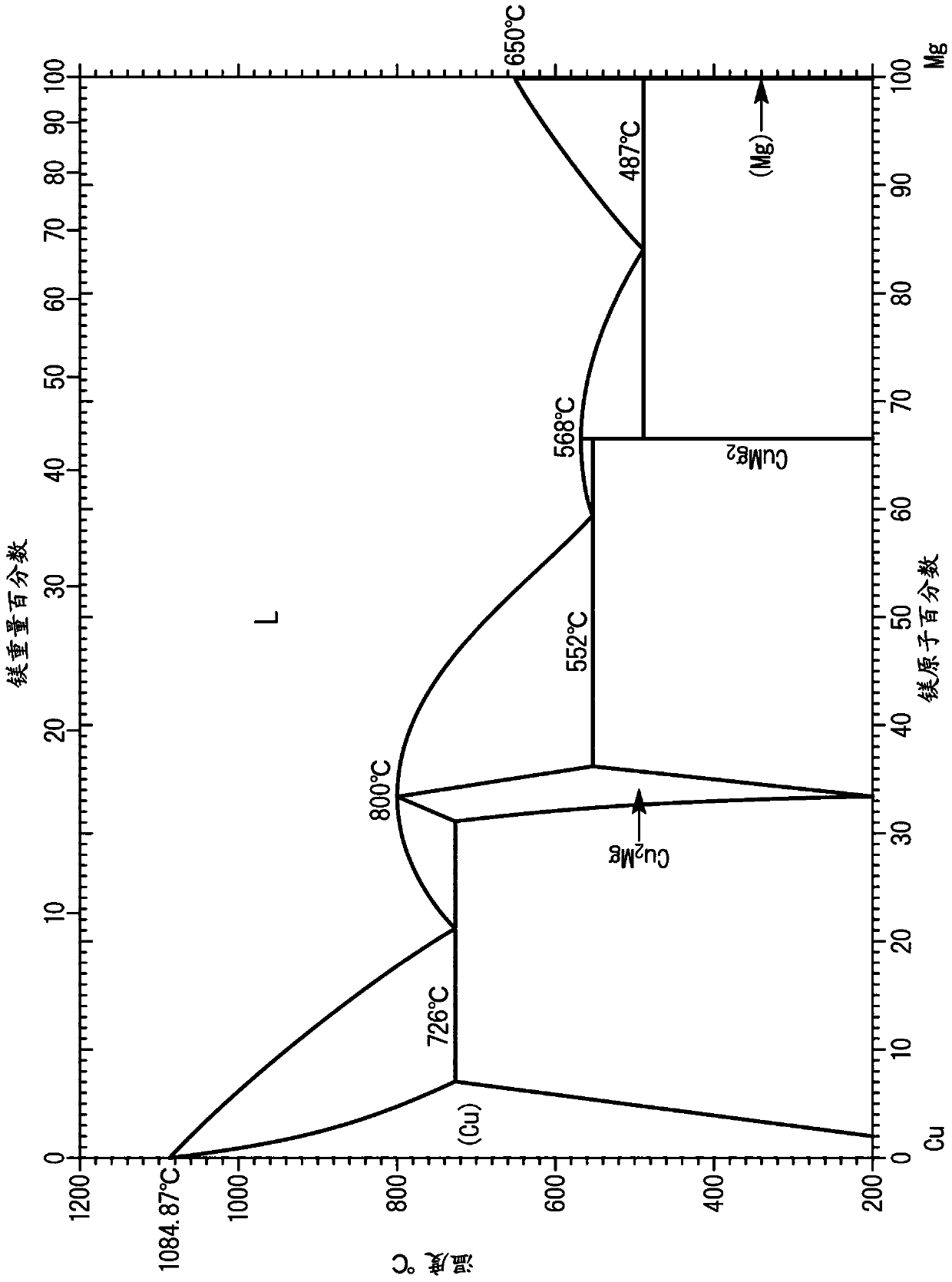

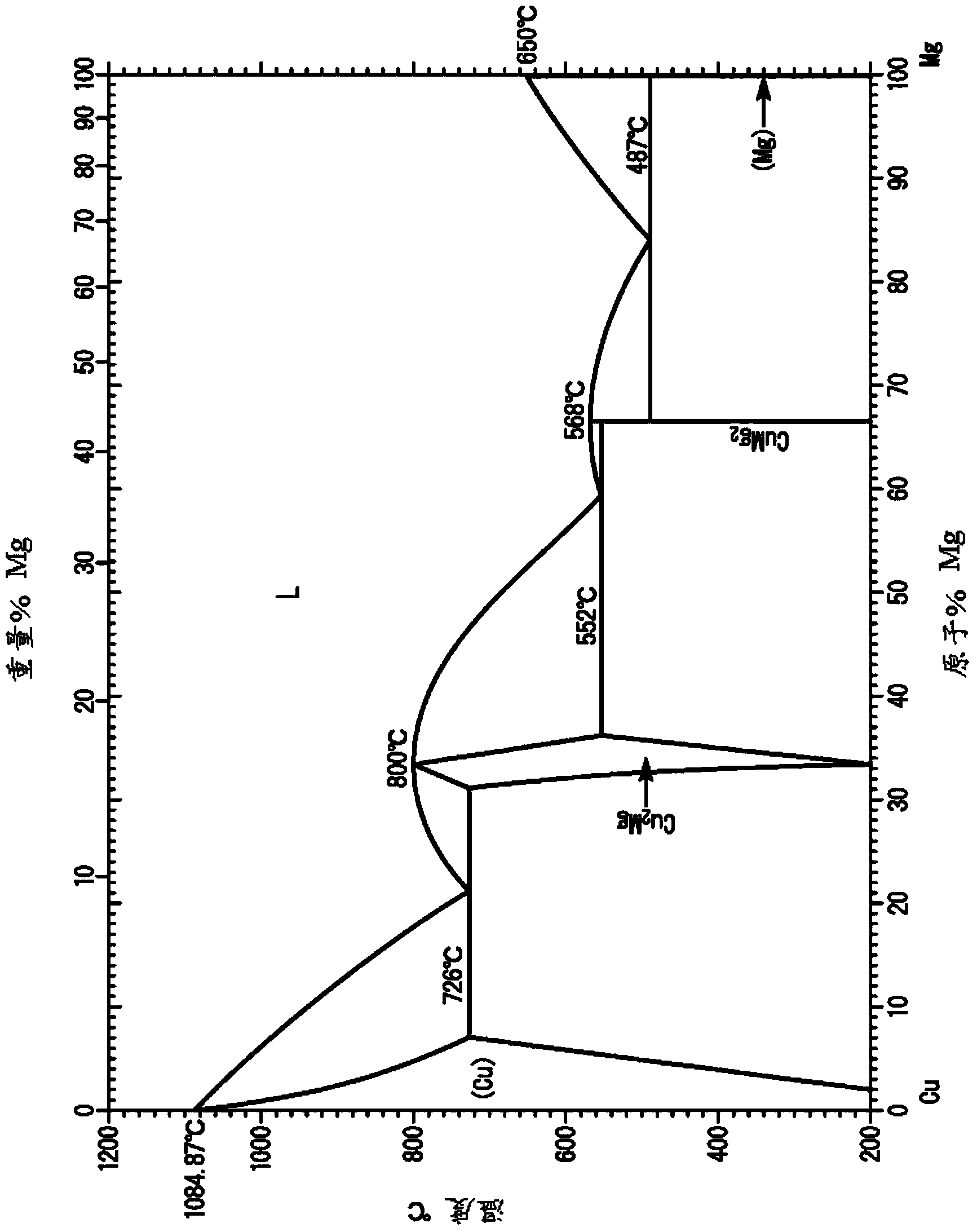

ActiveCN103502487ALow Young's modulusExcellent stress relaxation resistanceConductive materialMetal/alloy conductorsElectric devicesElectric equipment

One embodiment of this copper alloy contains Mg in an amount within the range from 3.3% by atom (inclusive) to 6.9% by atom (exclusive) and Cr and / or Zr respectively in an amount within the range from 0.001% by atom (inclusive) to 0.15% by atom (inclusive), with the balance made up of Cu and unavoidable impurities. When the Mg concentration is represented by A% by atom, the electrical conductivity s (% IACS) satisfies the following formula (1). s = {1.7241 / (-0.0347 × A2 + 0.6569 × A + 1.7)} × 100 (1) One embodiment of this method for producing a copper alloy comprises: a step wherein a copper material having the composition of the above-described copper alloy is heated to a temperature within the range from 300°C to 900°C (inclusive); a step wherein the heated copper material is quenched to 200°C or less at a cooling rate of 200°C / min or more; and a step wherein the quenched copper material is worked.

Owner:MITSUBISHI MATERIALS CORP

Copper alloy

InactiveUS20120148439A1Improve conductivityHigh strengthConductive materialMetallic pattern materialsArea ratioImpurity

A copper alloy containing Ni: 1.5%-3.6% and Si: 0.3%-1.0% in terms of mass percent with the remainder consisting of copper and unavoidable impurities, wherein: the average crystal grain size of the crystal grains in the copper alloy is 5 to 30 μm; the area ratio of the crystal grains having crystal grain sizes not less than twice the average crystal grain size is not less than 3%; and the ratio of the area of cube orientation grains to the area of the crystal grains having crystal grain sizes not less than twice the average crystal grain size is not less than 50%.

Owner:KOBE STEEL LTD

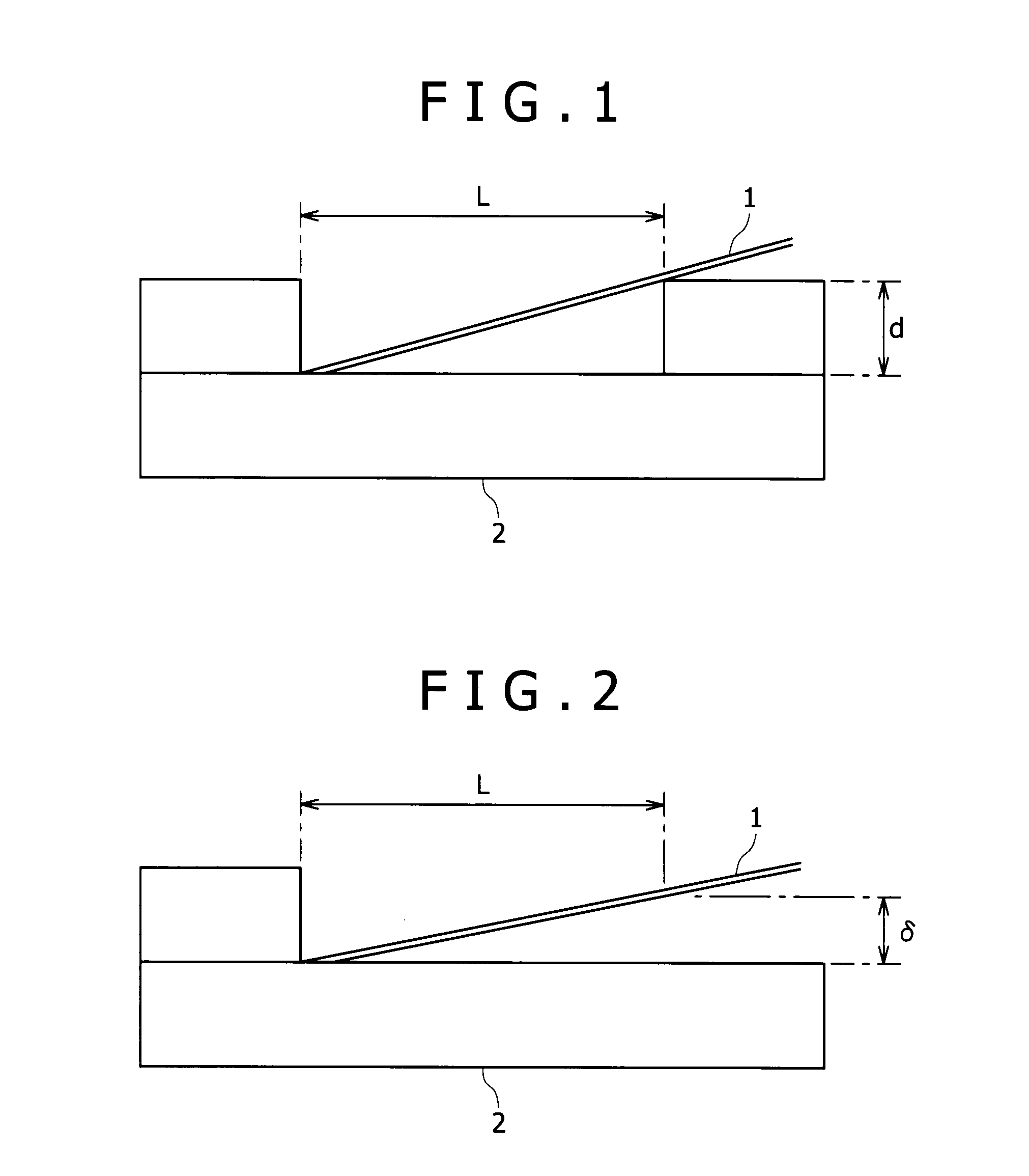

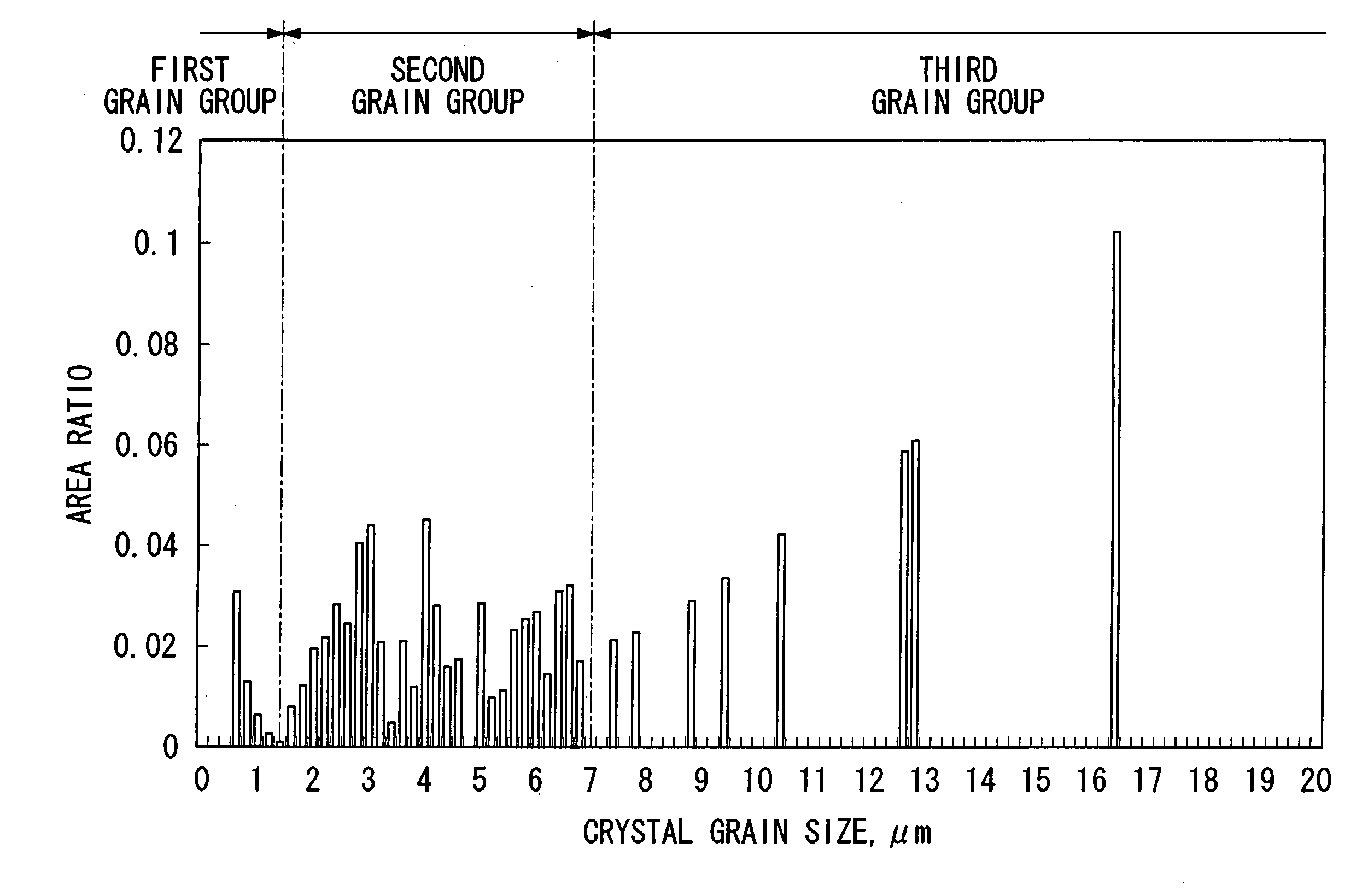

Copper alloy and method of manufacturing the same

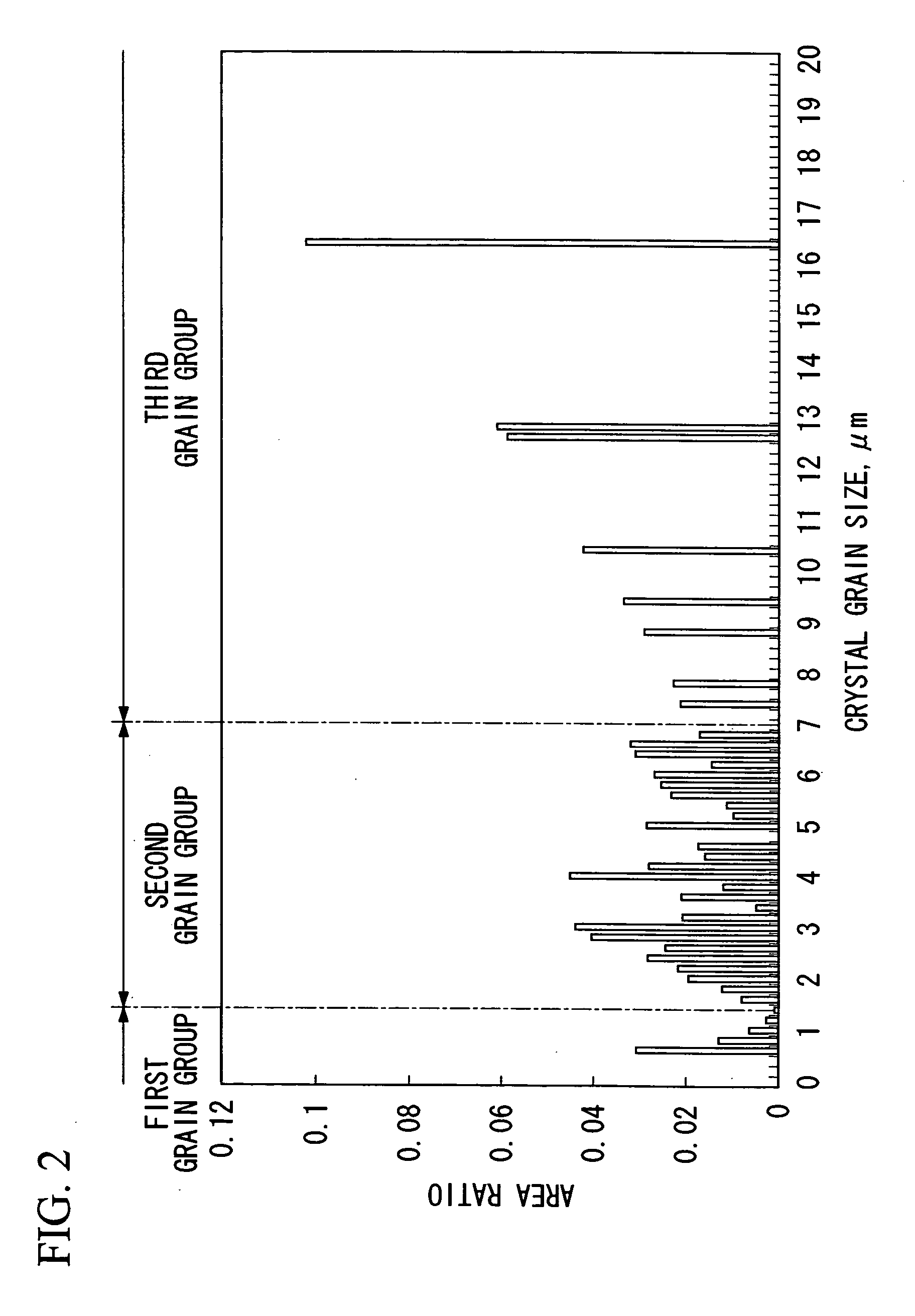

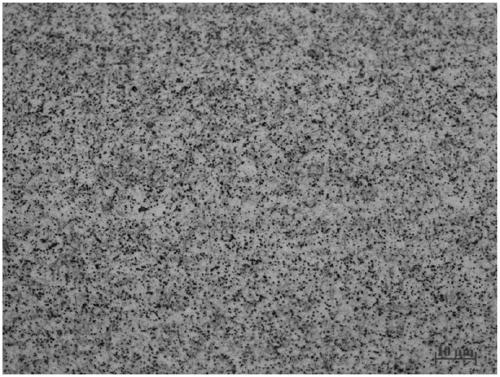

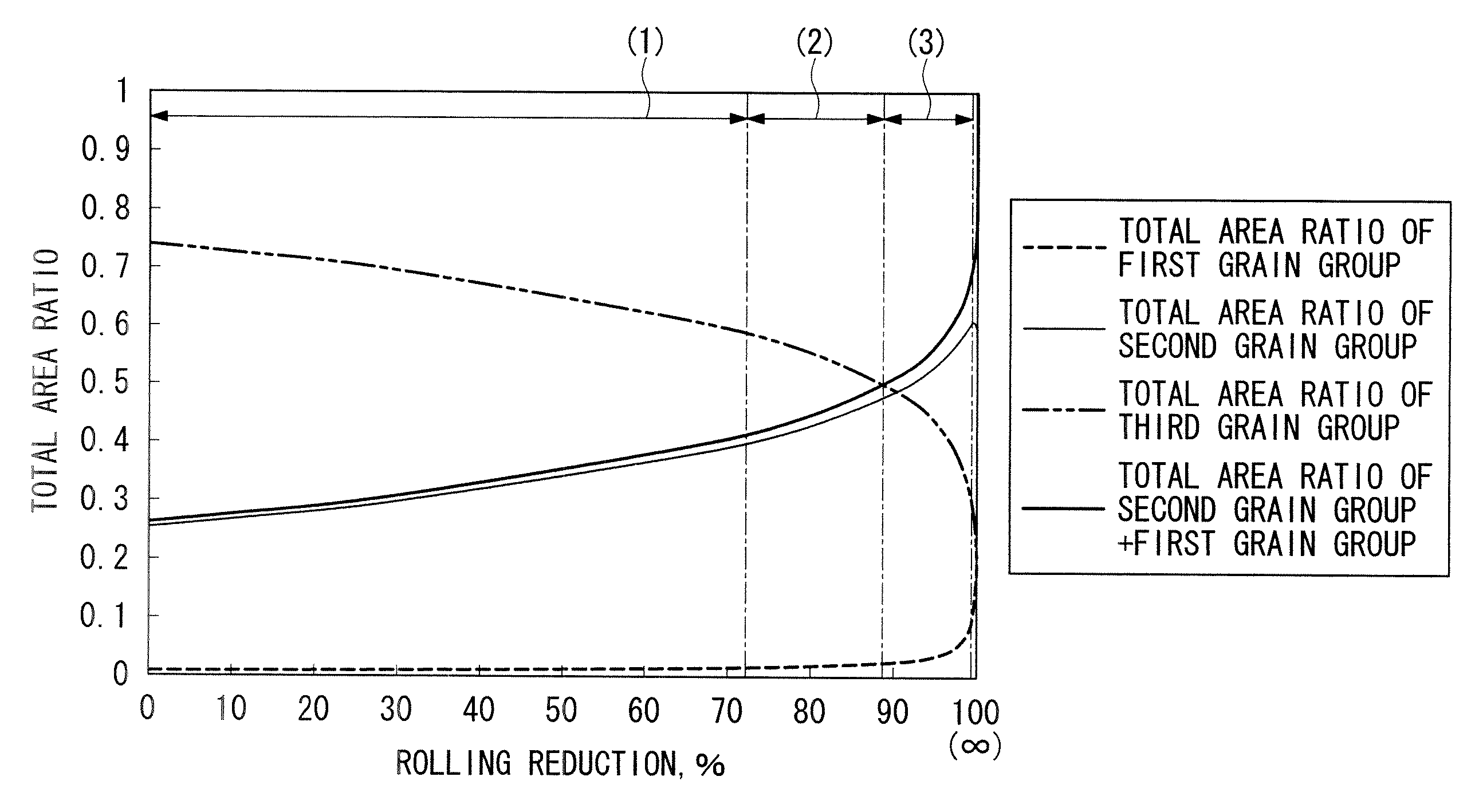

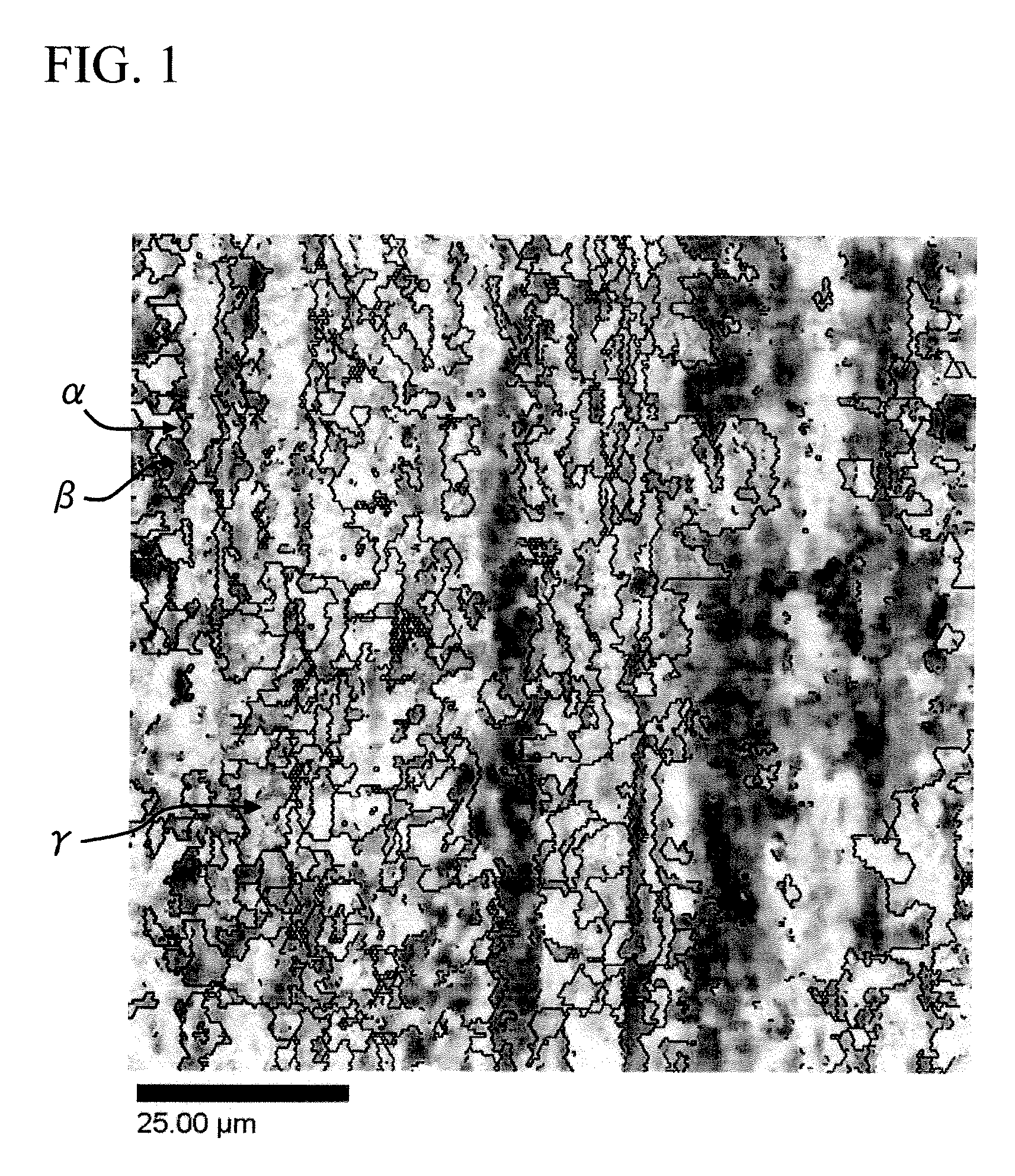

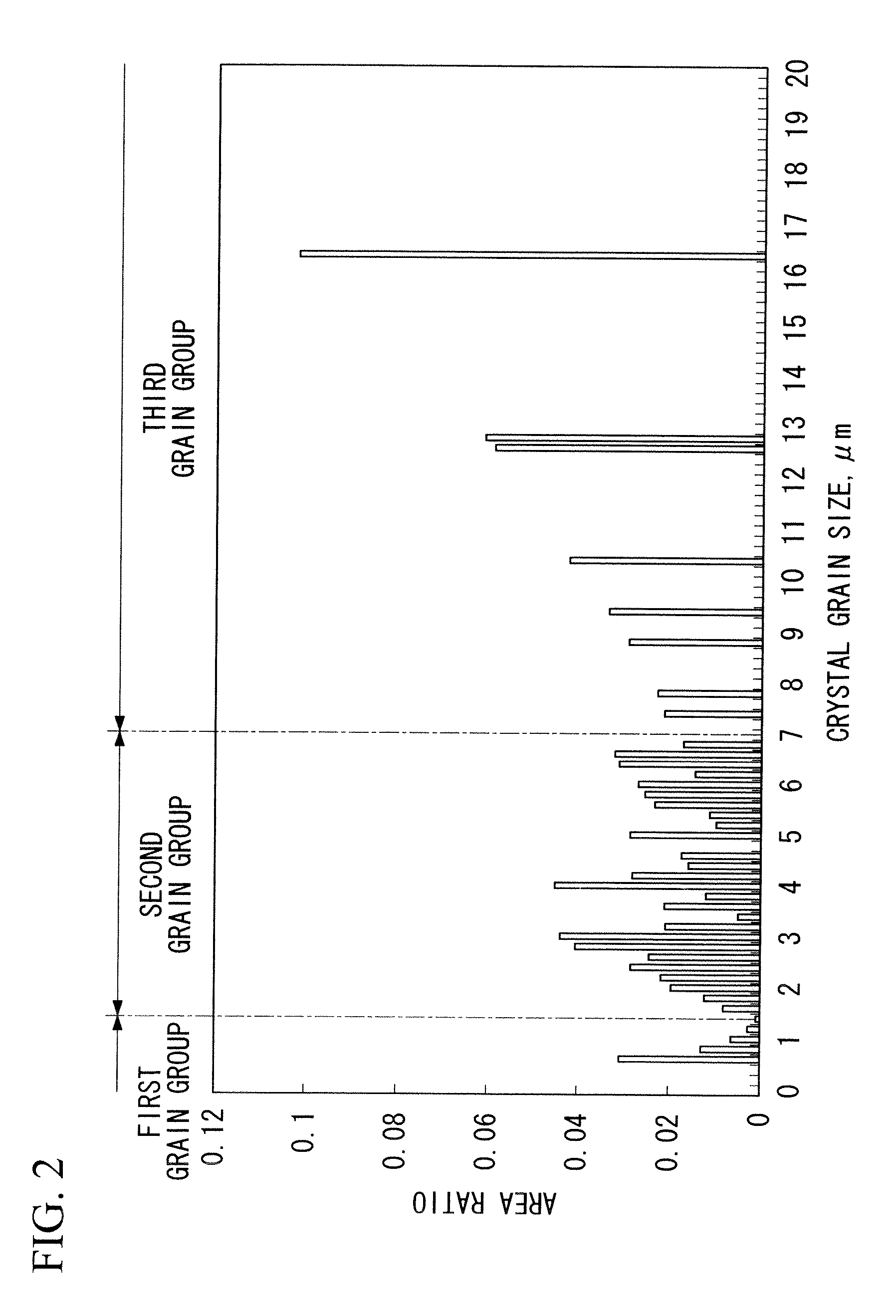

ActiveUS20050230014A1High elongationHigh strengthMetal rolling arrangementsArea ratioMaterials science

This copper alloy contains at least zirconium in an amount of not less than 0.005% by weight and not greater than 0.5% by weight, includes a first grain group including grains having a grain size of not greater than 1.5 μm, a second grain group including grains having a grain size of greater than 1.5 μm and less than 7 μm, the grains having a form which is elongated in one direction, and a third grain group including grains having a grain size of not less than 7 μm, and also the sum of α and β is greater than γ, and α is less than β, where α is a total area ratio of the first grain group, β is a total area ratio of the second grain group, and γ is a total area ratio of the third grain group, based on a unit area, and α+β+γ=1.

Owner:MITSUBISHI SHINDOH CO LTD

Copper alloy for electronic and electrical equipment and application

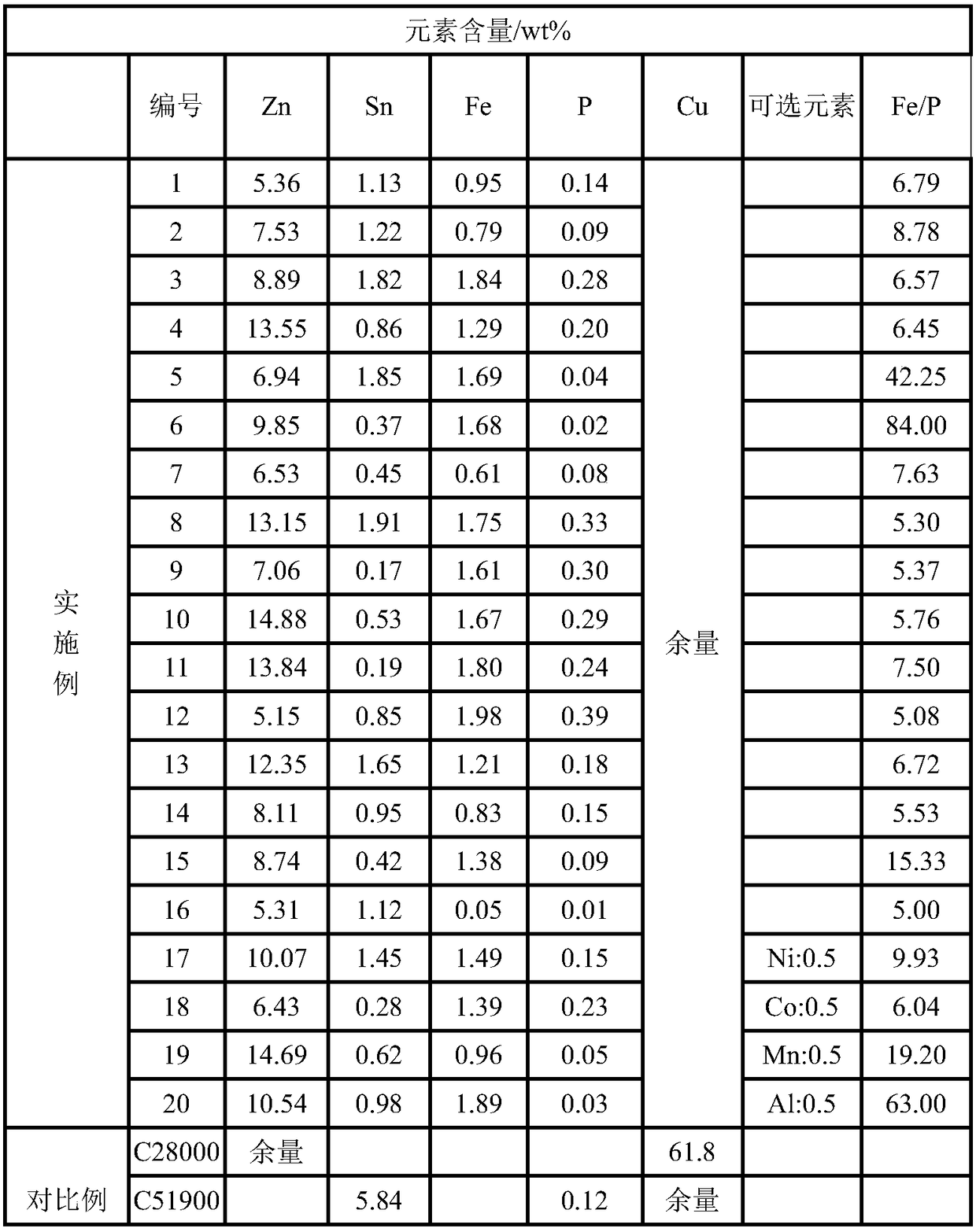

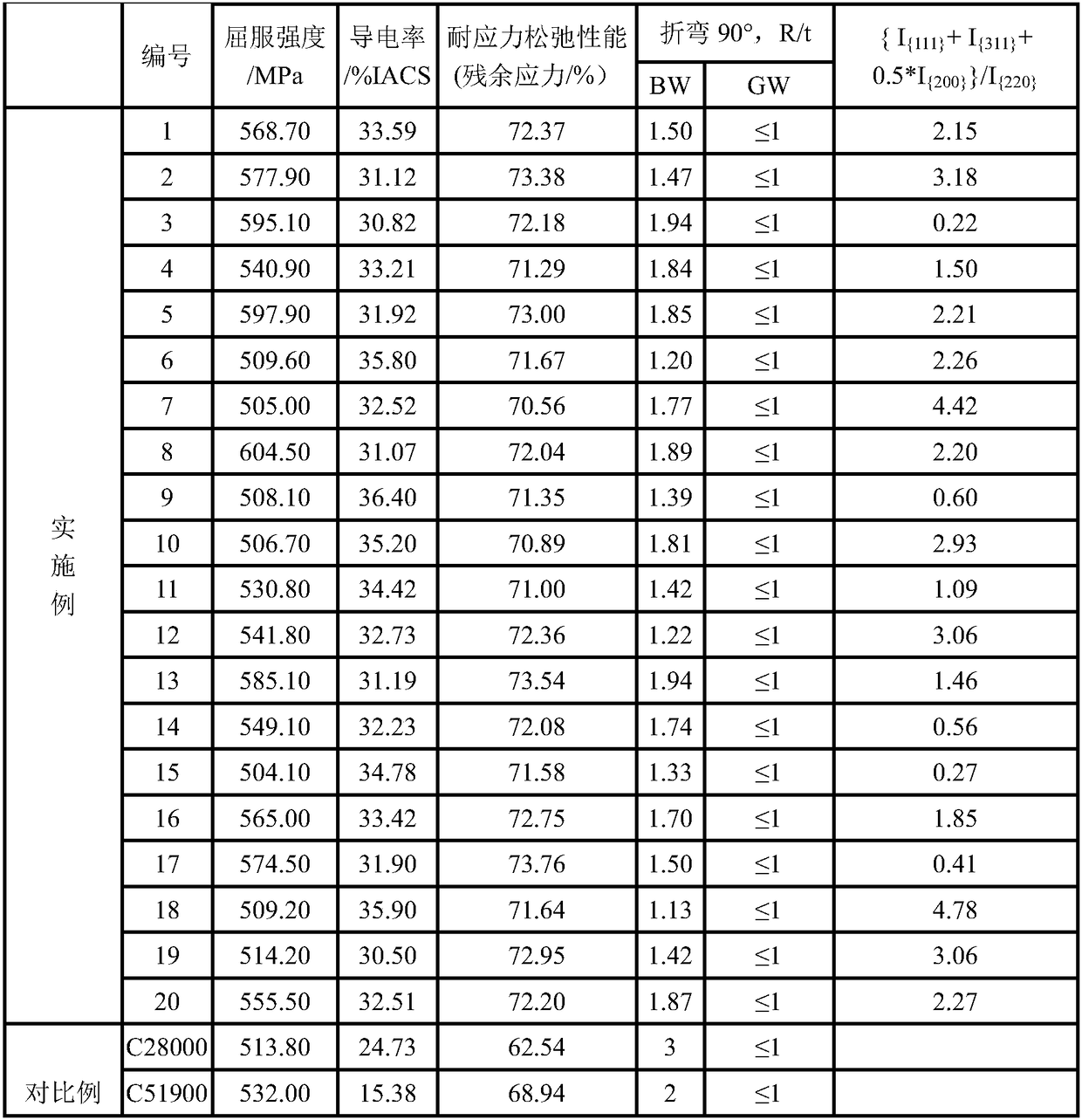

ActiveCN109338151AHigh strengthImprove utilizationConductive materialMetal/alloy conductorsMetallurgyImpurity

The invention relates to a copper alloy for electronic and electrical equipment and application. The copper alloy is characterized by comprising, by weight, 5.01 wt%-15.0 wt% of Zn, 0.1 wt%-2.0 wt% ofSn, 0.01 wt%-2.0 wt% of Fe, 0.01 wt%-0.5 wt% of P, the balance Cu and unavoidable impurities, and preferably, the weight percentage of Fe and P meets the formula: 5<=Fe / P<=100.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Copper alloy for electronic equipment, method for producing copper alloy for electronic equipment, rolled copper alloy material for electronic equipment, and part for electronic equipment

ActiveCN103842551AInhibition of power failureLow tensile modulusSingle bars/rods/wires/strips conductorsApparatus for heat treatmentMetallurgyStress relaxation

A copper alloy for electronic equipment comprises between 3.3 at% and 6.9 at% of Mg, with the balance being substantially Cu and inevitable impurities. When the Mg concentration is X at%, the conductivity sigma (% IACS) is within a range of sigma < {1.7241 / (-0.0347 X2 + 0.6569 X + 1.7)} 100, and the stress relaxation percentage after 1,000 hours at 150 C is 50% or less.

Owner:MITSUBISHI MATERIALS CORP

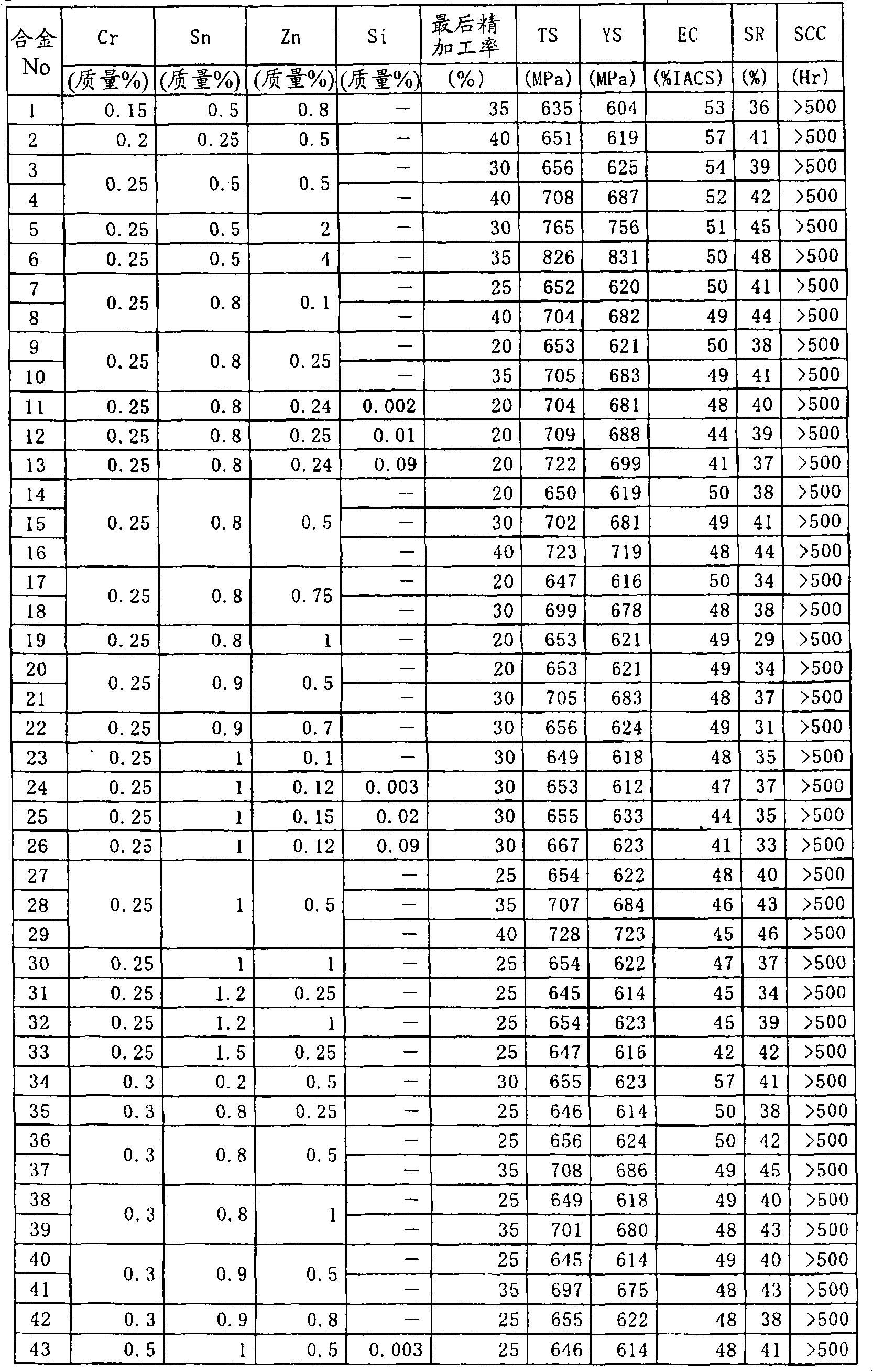

Copper alloy for an electric connecting device

InactiveCN101268206AHigh strengthImprove conductivityConductive materialCoupling contact membersStress corrosion crackingUltimate tensile strength

A copper alloy for electrical connecting device of 600 MPa or higher tensile strength (TS), 560 MPa or higher 0.2% yield strength (YS), 40%IACS or higher electrical conductivity (EC) and 500 hr or longer breaking time exhibited in a stress corrosion cracking test (SCC) under loading of 80% of 0.2% yield strength (YS), which copper alloy is composed of 0.1 to 1 mass% Cr, 0.1 to 5.0 mass% Zn, 0.1 to 2.0 mass% Sn and the balance unavoidable impurities and Cu.

Owner:FURUKAWA ELECTRIC CO LTD

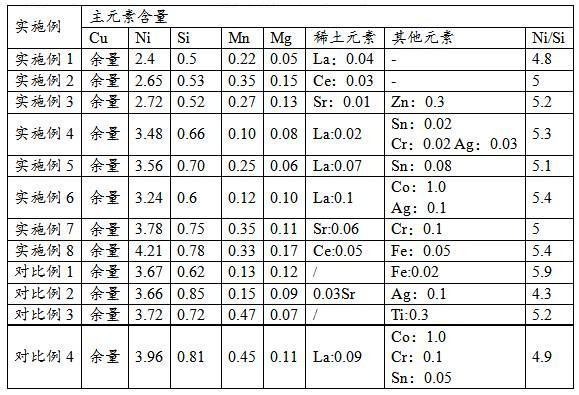

Environment-friendly conductive elastic copper alloy and preparation method thereof and application in connectors

PendingCN112111671AImprove high temperature resistanceAccelerated corrosionConductive materialMetal/alloy conductorsSolution treatmentRare-earth element

The invention belongs to the technical field of non-ferrous metal processing, and provides an environment-friendly conductive elastic copper alloy and a preparation method and application thereof. Thecopper alloy comprises, by weight, 2.0-4.3% of Ni, 0.5-0.85% of Si, 0.05-0.4% of Mn, 0.01-0.2% of Mg, 0.01-1.0% of rare earth element and the balance of Cu. The copper alloy can keep high conductivity while having ultrahigh strength, has the characteristics of being high-temperature-resistant, stress-relaxation- resistant, complex-environment-corrosion-resistant and high in elasticity, is excellent in forming performance and high in reliability, can meet the use requirements of connectors in different application scenes, and is a new generation of alloy material for the connectors. Accordingto the preparation method, the copper alloy is prepared through smelting, casting, hot rolling, primary rolling, intermediate annealing, intermediate rolling, rapid solution treatment, finish rollingand aging treatment, so that the microstructure of the copper alloy can be effectively controlled, and various properties of the copper alloy are guaranteed.

Owner:NINGBO XINGYE SHENGTAI GROUP

Copper alloy material for electrical and electronic components, and manufacturing method therefof

InactiveCN102112639AHigh strengthImprove conductivityConductive materialMetal/alloy conductorsElectronic componentCobalt

Disclosed is a copper alloy material for electrical and electronic components that has a composition comprising 0.5-2.0 mass% Co, 0.1-0.5 mass% Si, and the remainder Cu and unavoidable impurities. The crystal grain diameter of the base material copper alloy is 3-35 mm, the particle diameter of a precipitate composed of Co and Si is 5-50 nm, and the density of the precipitate is 1108 to 11010 particles / mm2. The tensile strength of the copper alloy material is at least 550 MPa, and the conductivity is at least 50% IACS.

Owner:FURUKAWA ELECTRIC CO LTD

Ultra-high strengthen, high-conductivity CuNiSi series elastic copper alloy and method for preparing same

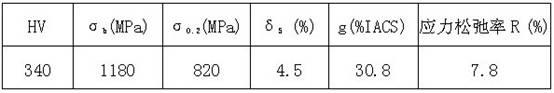

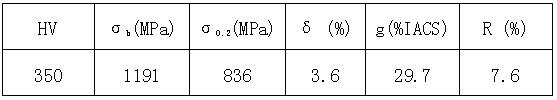

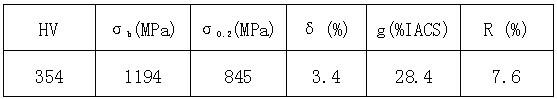

Disclosed is a CuNiSi system elastic copper alloy with ultra high strength and high conductivity as well as a method for the production thereof, having (in weight percent ): Ni: 6.4 to 8.2wt percent; Si: 1.2 to 1.8wt percent; Sn: 0.3 to 0.5wt percent; Mg: 0.1 to 0.2wt percent; Zr: 0.1 to 0.2wt percent; and balance Cu, and the method for the production thereof comprises five steps of: (1) CuNiSi non-vacuum secondary remelting and ingot casting; (2) homogenizing treatment and hot rolling; (3) twin-stage solution treatment; (4) cold rolling; and (5) time effect treatment. The elastic copper alloy and the method have advantages of reasonable alloy constituents, high alloying degree, simple production process, convenient operation, low production cost, high alloy strength, high conductivity and good stress relaxation resistance, and can realize the preparation of large specification billet, and Ni and Si content in the prepared target alloy system is high, and the process method of the invention is suitable for the industrialized production, and can replace the current aerospace high-power hermetically sealed electromagnetic relays, as well as raw materials and production processes of high performance conductive elastic devices in the electronic industry.

Owner:CENT SOUTH UNIV

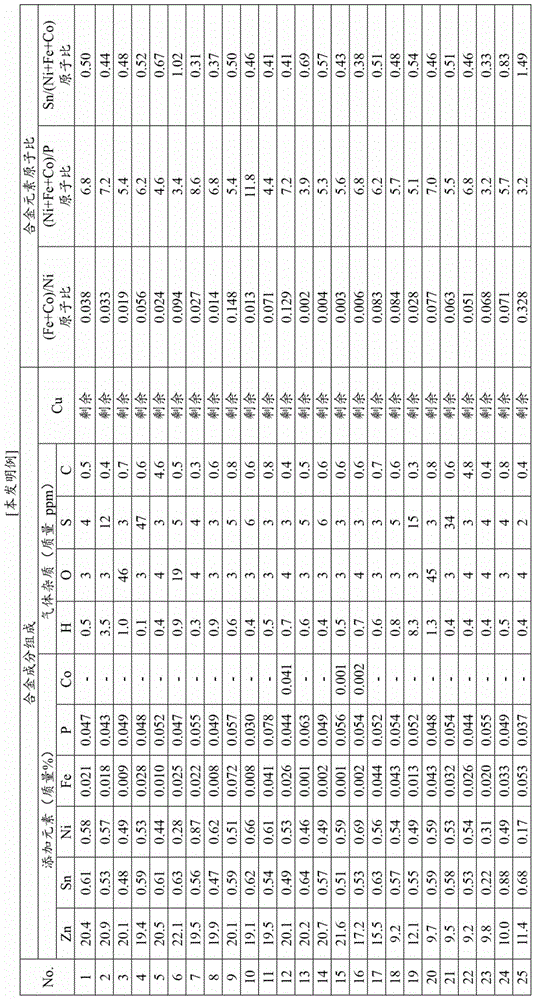

Copper alloy for electronic and electrical equipment, copper alloy thin sheet for electronic and electrical equipment, and conductive component for electronic and electrical equipment, terminal

ActiveUS20160369374A1Excellent stress relaxation resistanceGood formabilityConductive materialMetal/alloy conductorsUltimate tensile strengthImpurity

One aspect of this copper alloy for an electronic and electrical equipment contains: more than 2.0 mass % to 36.5 mass % of Zn; 0.10 mass % to 0.90 mass % of Sn; 0.15 mass % to less than 1.00 mass % of Ni; and 0.005 mass % to 0.100 mass % of P, with the balance containing Cu and inevitable impurities, wherein atomic ratios of amounts of elements satisfy 3.00<Ni / P<100.00 and 0.10<Sn / Ni<2.90, and a strength ratio TSTD / TSLD of tensile strength TSTD in a direction perpendicular to a rolling direction to tensile strength TSLD in a direction parallel to the rolling direction exceeds 1.09.

Owner:MITSUBISHI MATERIALS CORP +1

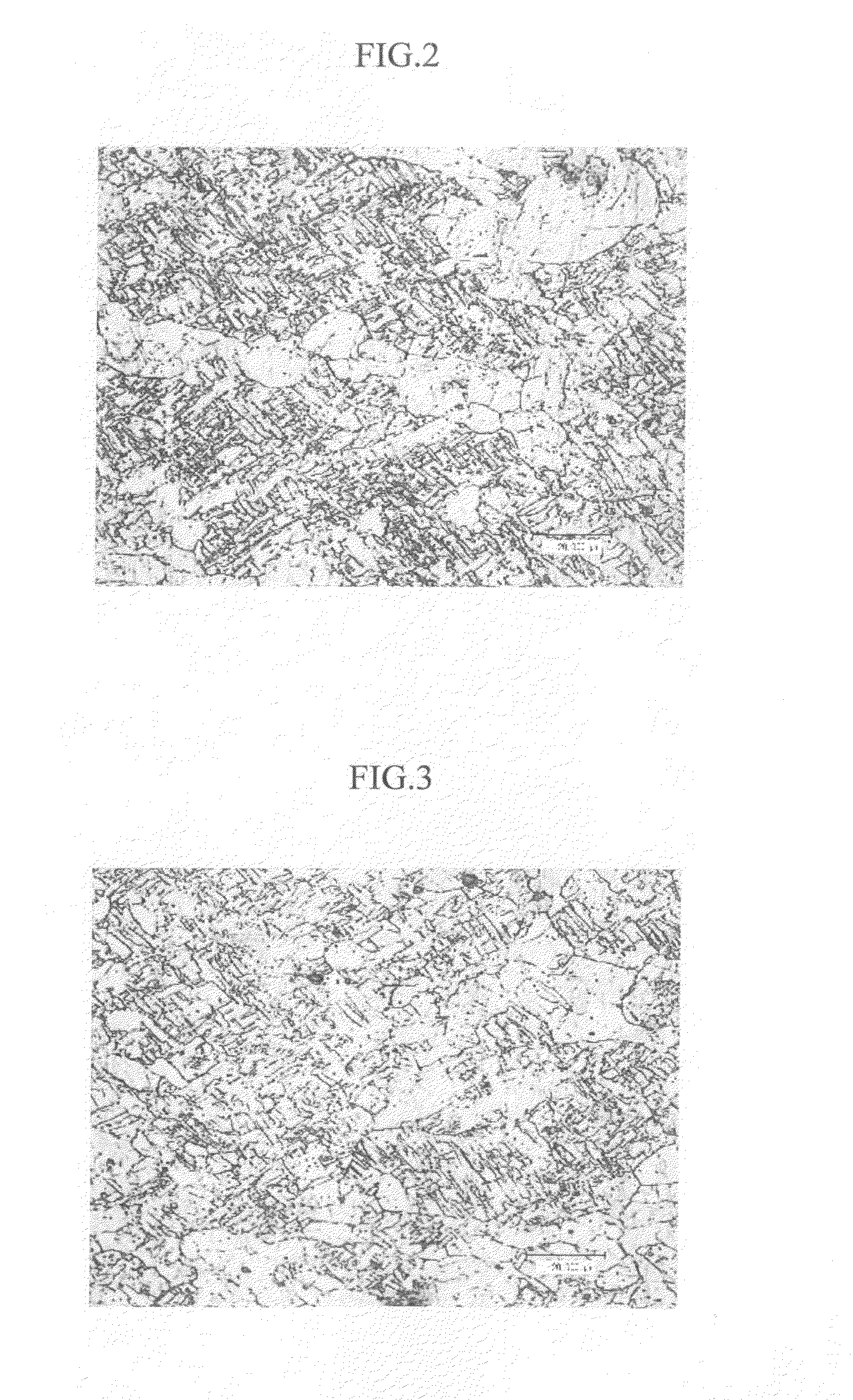

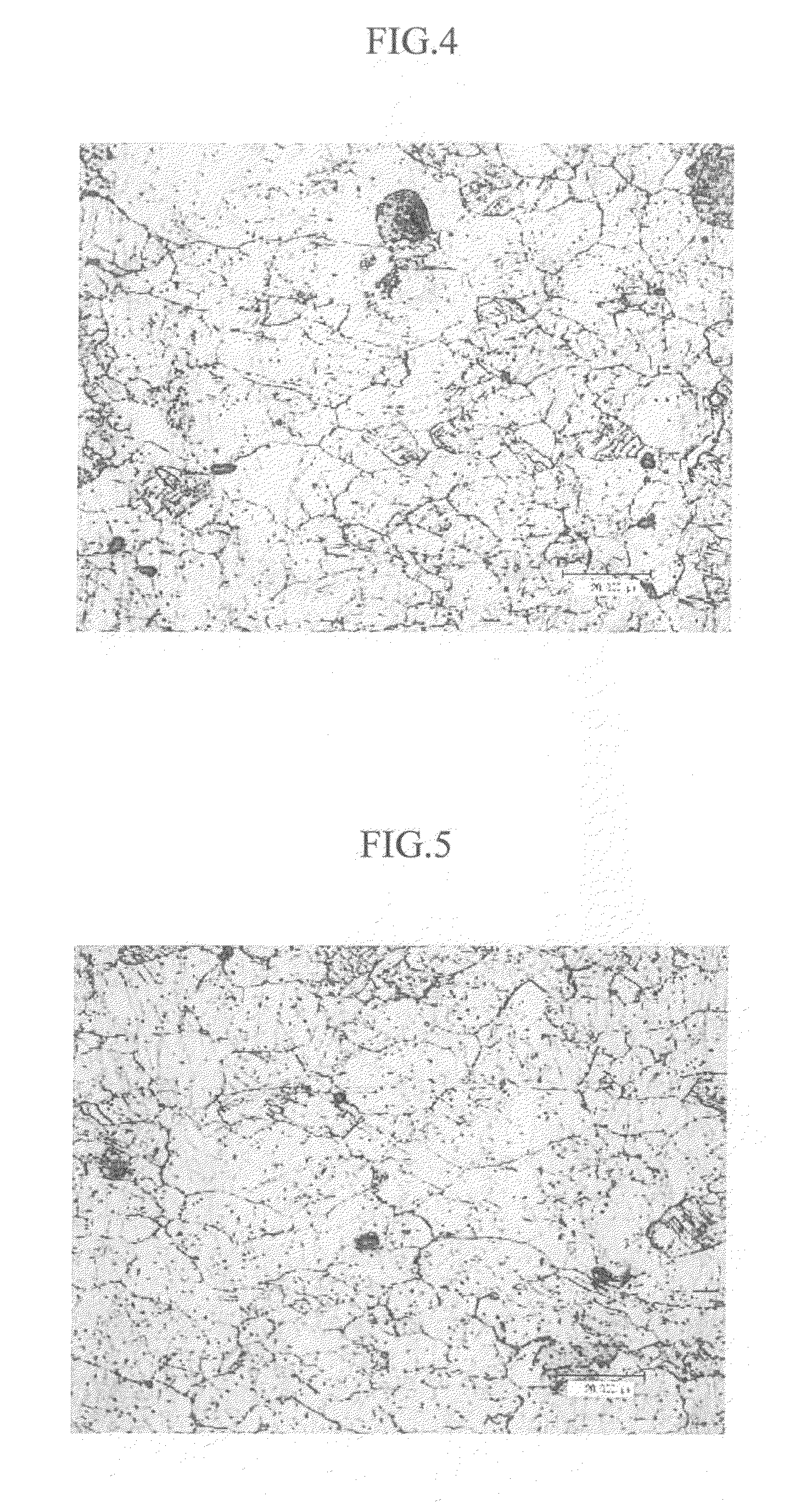

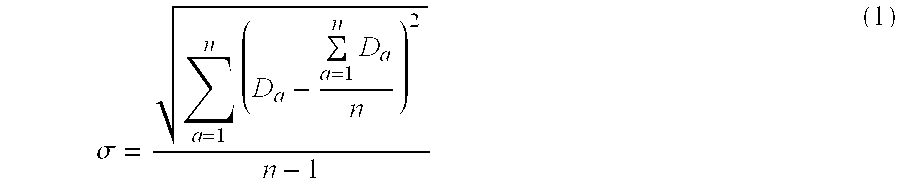

Electric and electronic part copper alloy sheet with excellent bending workability and stress relaxation resistance

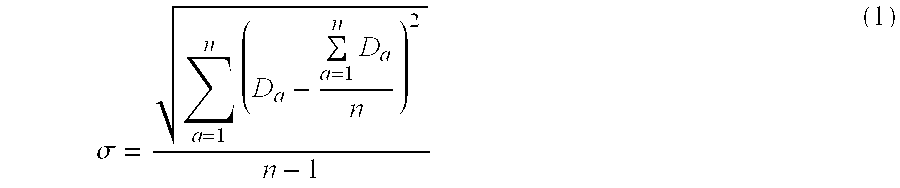

ActiveUS20130255838A1Excellent stress relaxationImprove workabilitySolid-state devicesSemiconductor devicesStress relaxationImpurity

An electric and electronic part copper alloy sheet with excellent bending workability and stress relaxation resistance is made from a copper alloy containing 1.5 to 4.0 percent by mass of Ni, Si satisfying a Ni / Si mass ratio of 4.0 to 5.0, 0.01 to 1.3 percent by mass of Sn, and the remainder composed of copper and incidental impurities, wherein the average crystal grain size is 5 to 20 μm, the standard deviation of the crystal grain size satisfies 2σ<10 μm, and the proportion of the number of particles having a particle diameter of 90 to 300 nm in Ni—Si dispersed particles having a particle diameter of 30 to 300 nm is 20% or more, where the particles are observed in a cross-section defined by a direction perpendicular to a sheet surface and a direction parallel to a rolling direction.

Owner:KOBE STEEL LTD

Copper alloy and application thereof

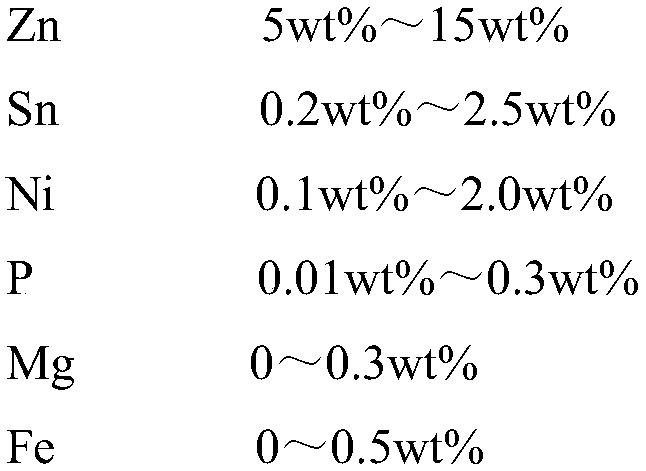

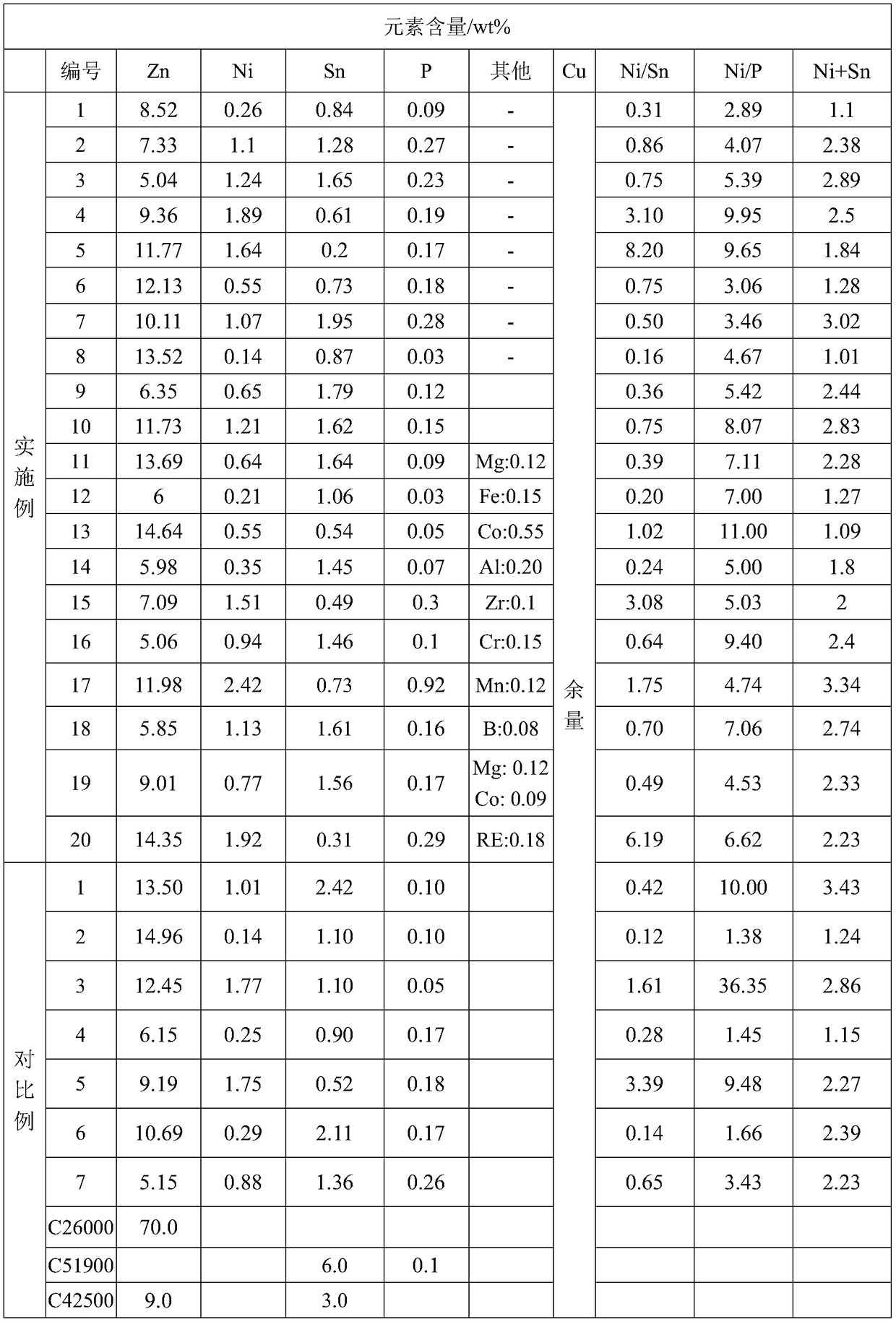

The invention relates to a copper alloy and application thereof. The copper alloy comprises 5-15 wt% of Zn, 0.2-2.5 wt% of Sn, 0.1-2.0 wt% of Ni, 0.01-0.3 wt% of P, 0-0.3 wt% of Mg, 0-0.5 wt% of Fe, and the balance Cu and inevitable impurities. Preferably, Ni, Sn and P meet that the sum of Ni and Sn is larger than or equal to 1.0 wt% and smaller than or equal to 3.5 wt%, the weight ratio of Ni toSn is 0.08-10, the weight ratio of Ni to P is 2-15, and Ni and P form a NiP compound in a base body. In crystal orientation analysis measured by EBSD, the Brass orientation deviation angles (011)(211)are smaller than 15 degrees, and the area proportion is 10-25%. Meanwhile, the yield strength is larger than or equal to over 600 MPa, the electric conductivity is larger than or equal to 25% IACS, the bending machining performance is excellent, namely, a value R / t in the GW direction is smaller than or equal to 1, and a value R / t in the BW direction is smaller than or equal to 2. The copper alloy is applicable to connectors such as electric parts, car parts and communication devices, terminals and switch parts.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Copper alloy plate and method for producing same

ActiveUS20200407824A1Excellent stress relaxation resistanceHigh strengthConductive materialChemical compositionCrystal orientation

There are provided an inexpensive copper alloy plate having excellent bending workability, excellent stress corrosion cracking resistance and excellent stress relaxation resistance while maintaining the high strength thereof, and a method for producing the same. The copper alloy plate has a chemical composition which contains 17 to 32% by weight of zinc, 0.1 to 4.5% by weight of tin, 0.5 to 2.0% by weight of silicon, 0.01 to 0.3% by weight of phosphorus and the balance being copper and unavoidable impurities, wherein the total of the content of silicon and six times as much as the content of phosphorus is 1% by weight or more and wherein the copper alloy plate has a crystal orientation satisfying I{220} / I{420}≤2.0 assuming that the X-ray diffraction intensity on {220} crystal plane on the plate surface of the copper alloy plate is I{220} and that the X-ray diffraction intensity on {420} crystal plane thereon is I{420}.

Owner:DOWA METALTECH CO LTD

Electric and electronic part copper alloy sheet with excellent bending workability and stress relaxation resistance

ActiveUS9194026B2Excellent stress relaxation resistanceExcellent bending workabilitySolid-state devicesSemiconductor devicesStress relaxationImpurity

An electric and electronic part copper alloy sheet with excellent bending workability and stress relaxation resistance is made from a copper alloy containing 1.5 to 4.0 percent by mass of Ni, Si satisfying a Ni / Si mass ratio of 4.0 to 5.0, 0.01 to 1.3 percent by mass of Sn, and the remainder composed of copper and incidental impurities, wherein the average crystal grain size is 5 to 20 μm, the standard deviation of the crystal grain size satisfies 2σ<10 μm, and the proportion of the number of particles having a particle diameter of 90 to 300 nm in Ni—Si dispersed particles having a particle diameter of 30 to 300 nm is 20% or more, where the particles are observed in a cross-section defined by a direction perpendicular to a sheet surface and a direction parallel to a rolling direction.

Owner:KOBE STEEL LTD

Precipitation-strengthened copper alloy and application thereof

ActiveUS20200071805A1Low costReduce conductivityConductive materialMetal/alloy conductorsPhosphor bronzeSolid solution strengthening

The invention is a precipitation-strengthened copper alloy, including the following components in percentage by weight: 80 wt %-95 wt % of Cu, 0.05 wt %-4.0 wt % of Sn, 0.01 wt %-3.0 wt % of Ni, 0.01 wt %-1.0 wt % of Si, and the balance of Zn and unavoidable impurities. According to the invention, the comprehensive performance of the alloy is improved by solution strengthening and precipitation strengthening; while the strength of the matrix is improved, the electrical conductivity of the alloy is hardly affected, the bending workability meets the requirements, and the stress relaxation resistance comparable to that of tin phosphor bronze is achieved. The comprehensive performance of the alloy of the invention is superior to that of the tin phosphor bronze C51900. Furthermore, the alloy of the invention is low in raw material cost, has obvious advantages in welding and plating.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Copper alloy for electrical and electronic equipment, copper alloy thin sheet for electrical and electronic equipment, and conductive part and terminal for electrical and electronic equipment

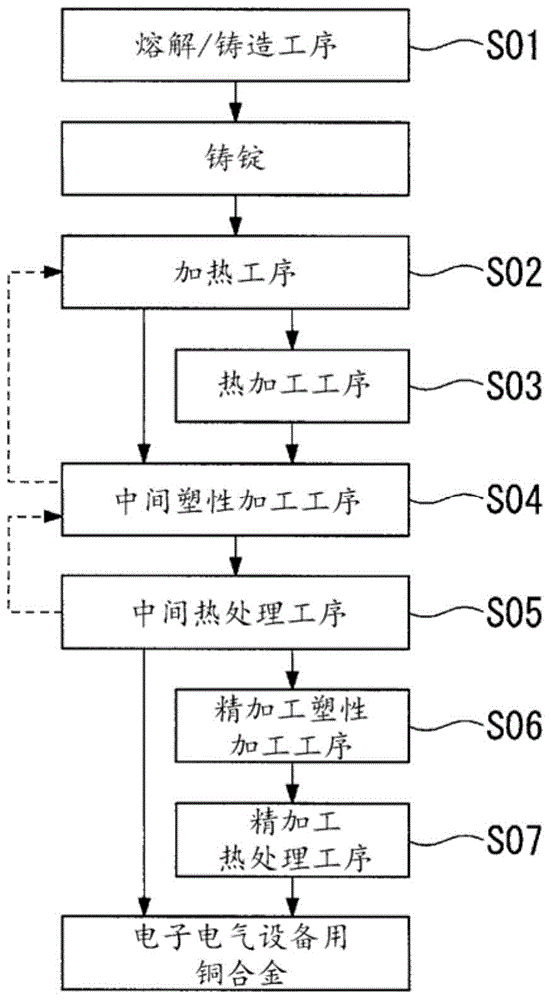

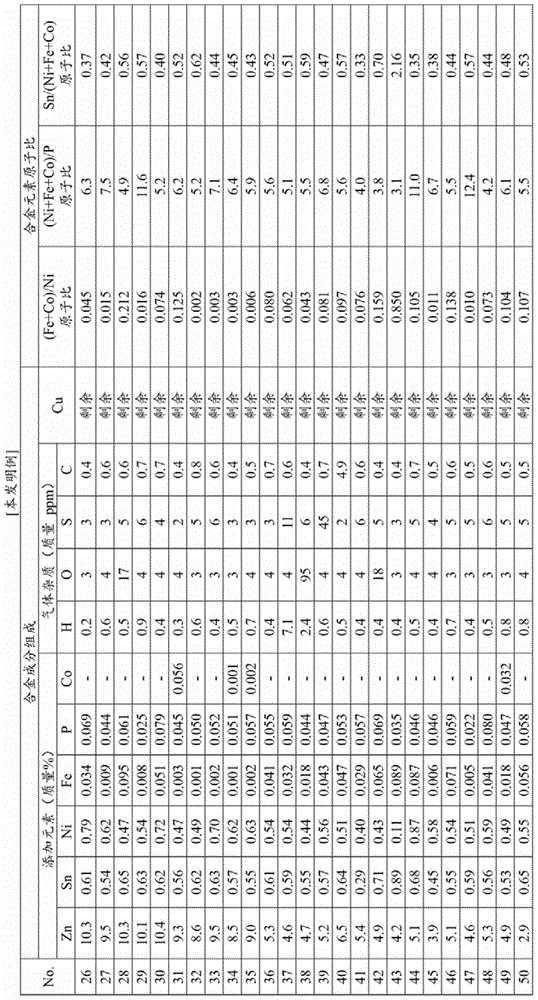

ActiveCN104822854AReliable and sufficiently excellent stress relaxation resistanceHigh strengthSingle bars/rods/wires/strips conductorsConductive materialOxygenImpurity

The present invention pertains to a copper alloy for electrical and electronic equipment, a copper alloy thin sheet for electrical and electronic equipment, and a conductive part and terminal for electrical and electronic equipment. The copper alloy for electrical and electronic equipment contains more than 2.0 mass% but less than 23.0 mass% of zinc, 0.10 mass% to 0.90 mass% of tin, 0.05 mass% to less than 1.00 mass% of nickel, 0.001 mass% to less than 0.100 mass% of iron, and 0.005 mass% to 0.100 mass% of phosphorus, with the remainder comprising copper and unavoidable impurities. The copper alloy satisfies 0.002 ≤ Fe / Ni < 1.500, 3.0 < (Ni + Fe) / P < 100.0, and 0.10 < Sn / (Ni + Fe) < 5.00 in terms of atomic ratios. The content of hydrogen is not more than 10 mass ppm, the content of oxygen is not more than 100 mass ppm, the content of sulfur is not more than 50 mass ppm, and the content of carbon is not more than 10 mass ppm.

Owner:MITSUBISHI MATERIALS CORP +1

Copper alloy and method of manufacturing the same

This copper alloy contains at least zirconium in an amount of not less than 0.005% by weight and not greater than 0.5% by weight, includes a first grain group including grains having a grain size of not greater than 1.5 μm, a second grain group including grains having a grain size of greater than 1.5 μm and less than 7 μm, the grains having a form which is elongated in one direction, and a third grain group including grains having a grain size of not less than 7 μm, and also the sum of α and β is greater than γ, and α is less than β, where α is a total area ratio of the first grain group, β is a total area ratio of the second grain group, and γ is a total area ratio of the third grain group, based on a unit area, and α+β+γ=1.

Owner:MITSUBISHI SHINDOH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com