Copper alloy for an electric connecting device

A copper alloy, electrical connection technology, applied in the direction of metal/alloy conductors, circuits, conductive materials, etc., can solve problems such as poor strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

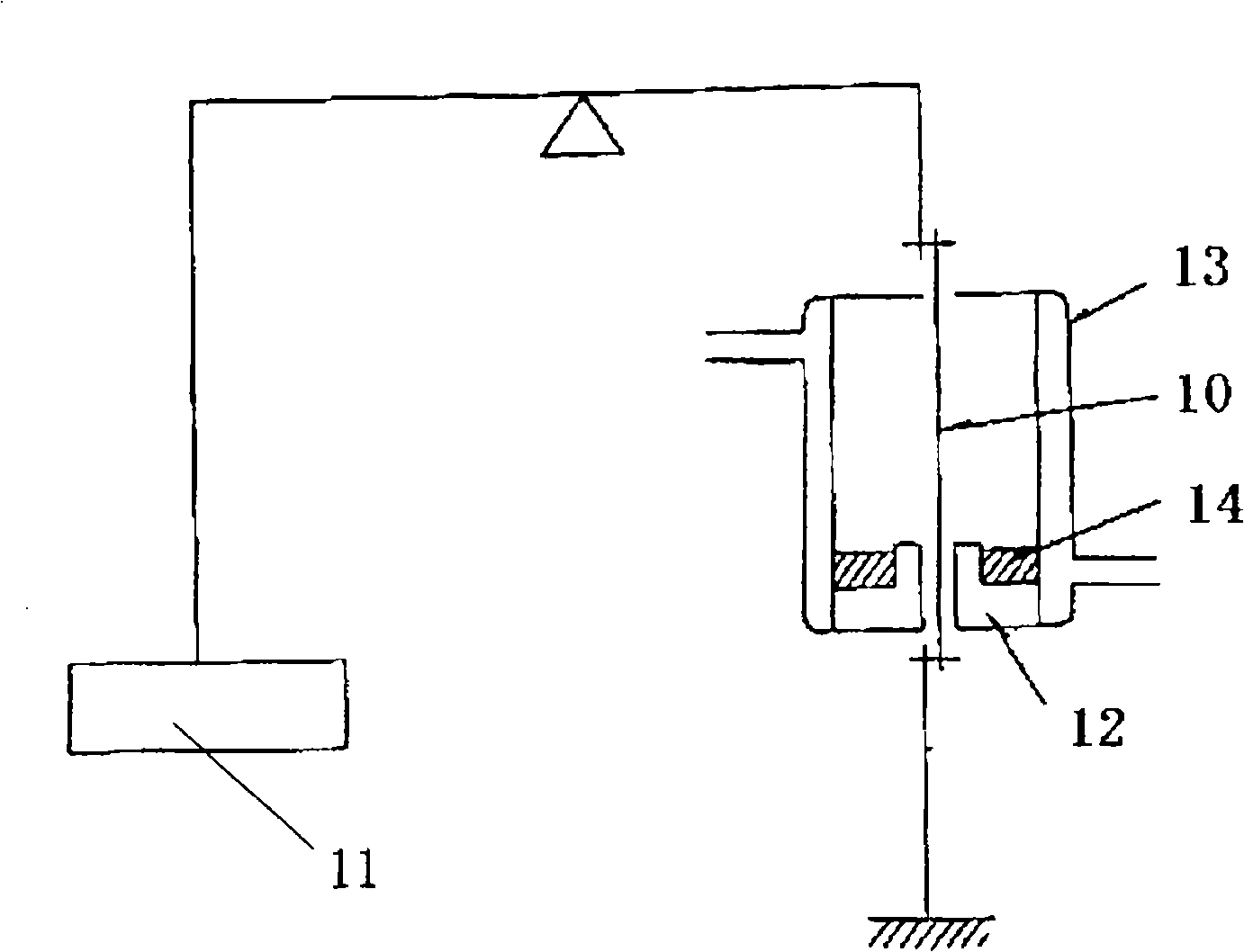

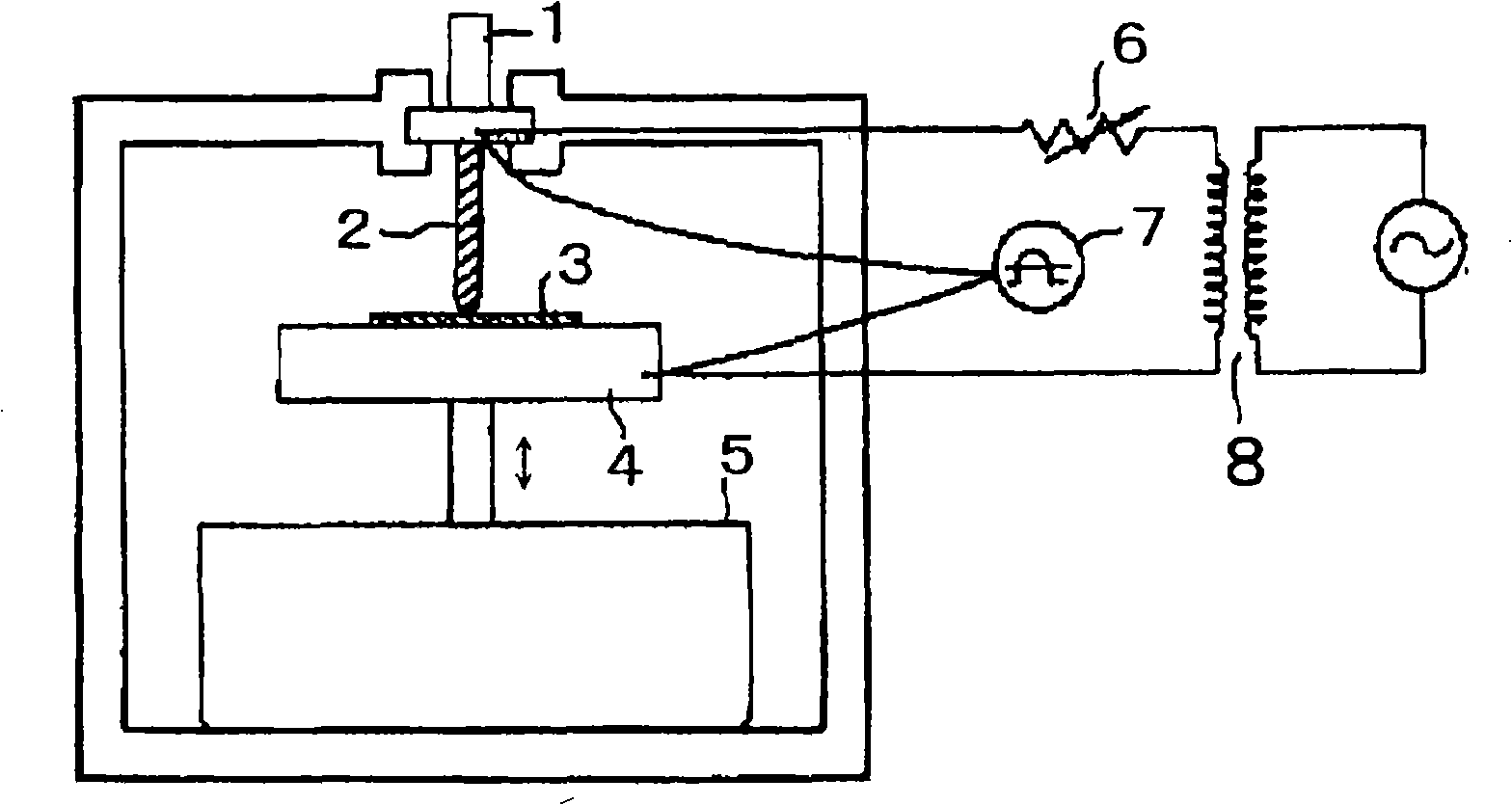

Method used

Image

Examples

Embodiment

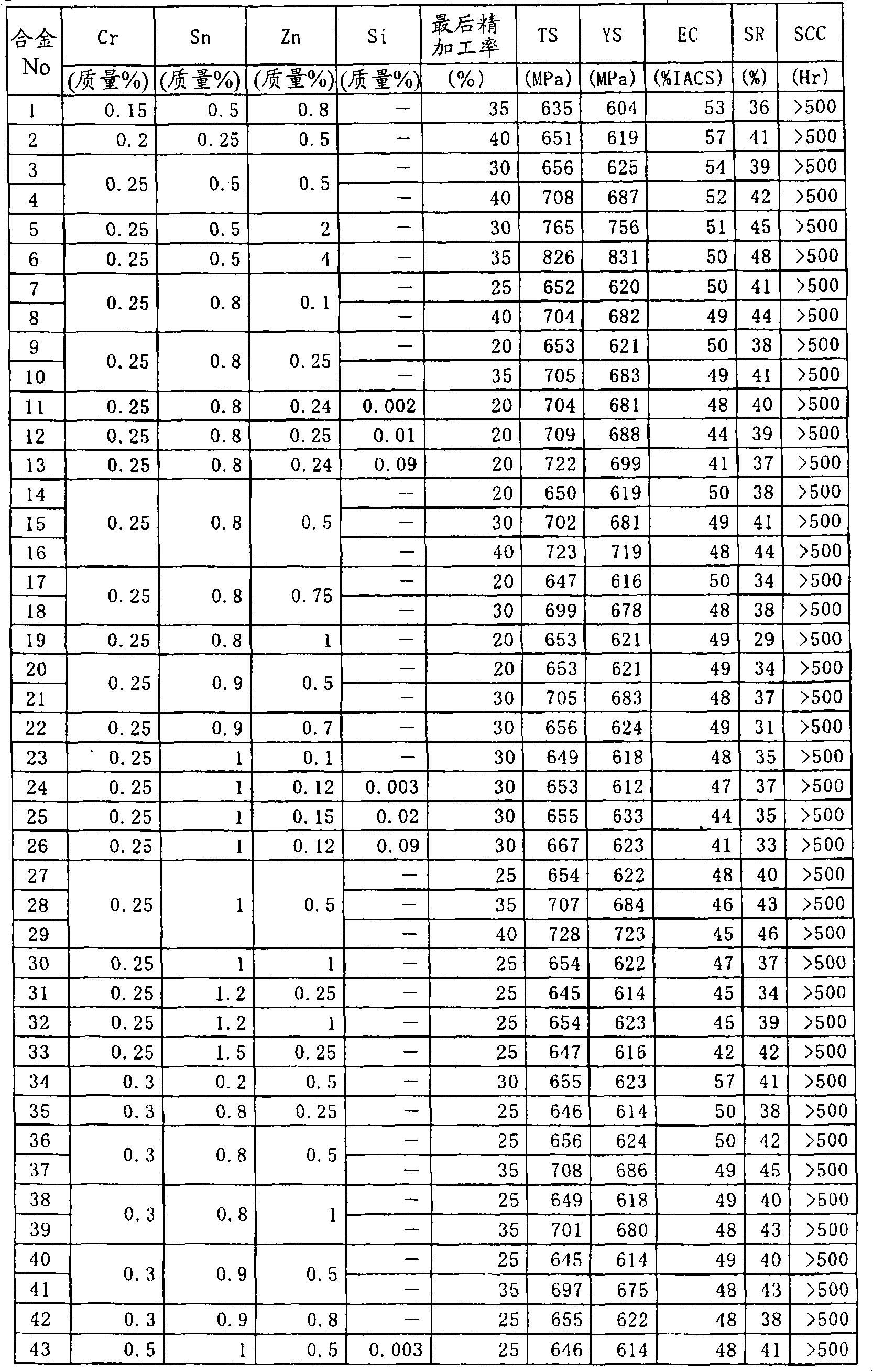

[0037] Various copper alloys are cast into book-shaped molds with a thickness of 30 mm x width 120 mm x length 180 mm in a high-frequency air melting furnace at a melting temperature of about 1200-1250 °C and a furnace temperature of about 1200 °C. The obtained ingot is kept at about 950-1000° C. for 1 hour in an air heating furnace, and then processed by hot rolling to a thickness of about 12-13 mm. And this hot-rolled sheet was surface-cut, and it processed into the sheet|seat of thickness about 10mm.

[0038] Cold working and heat treatment were repeated, and a flat plate (strip) with a thickness of 0.5 mm was produced from this plate. The Cr precipitation treatment is heat treatment at a temperature of 400-450° C. for 2-5 hours, and the final finishing rate is 10-40%.

[0039] In addition, commercially available copper alloys and non-ferrous materials were obtained with a plate thickness of 0.5 mm. The copper alloys are C2600, C2680, C5111, C5191 and C7701, and the stain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com