Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1442 results about "Beryllium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Beryllium is a chemical element with the symbol Be and atomic number 4. It is a relatively rare element in the universe, usually occurring as a product of the spallation of larger atomic nuclei that have collided with cosmic rays. Within the cores of stars, beryllium is depleted as it is fused into heavier elements. It is a divalent element which occurs naturally only in combination with other elements in minerals. Notable gemstones which contain beryllium include beryl (aquamarine, emerald) and chrysoberyl. As a free element it is a steel-gray, strong, lightweight and brittle alkaline earth metal.

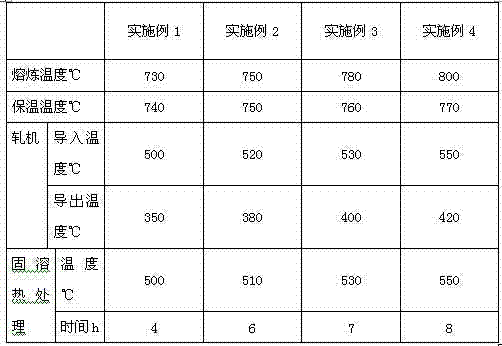

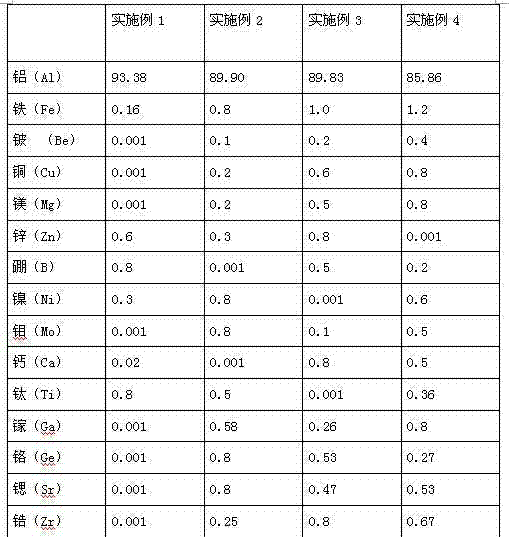

A kind of aluminum alloy material and preparation method thereof

The invention relates to an aluminum alloy material which is characterized in that the aluminum alloy material comprises the following components by weight percent: 0.16-1.2% of Fe, 0.001-0.8% of Cu, 0.001-0.8% of Mg, 0.001-0.8% of Zn, 0.001-0.8% of Ca, 0.001-1.0% of rare-earth elements, a trace amount of strontium, titanium, boron, nickel, chromium, zirconium, vanadium, beryllium, cobalt, lead, tin, bismuth, molybdenum, silver, indium, niobium and barium and the balance of aluminum. The alloy has excellent mechanical strength, processing performance and corrosion resistance and is suitable for the cable armored sheath.

Owner:GUANGDONG XINYI ALUMINUM ALLOY CABLE

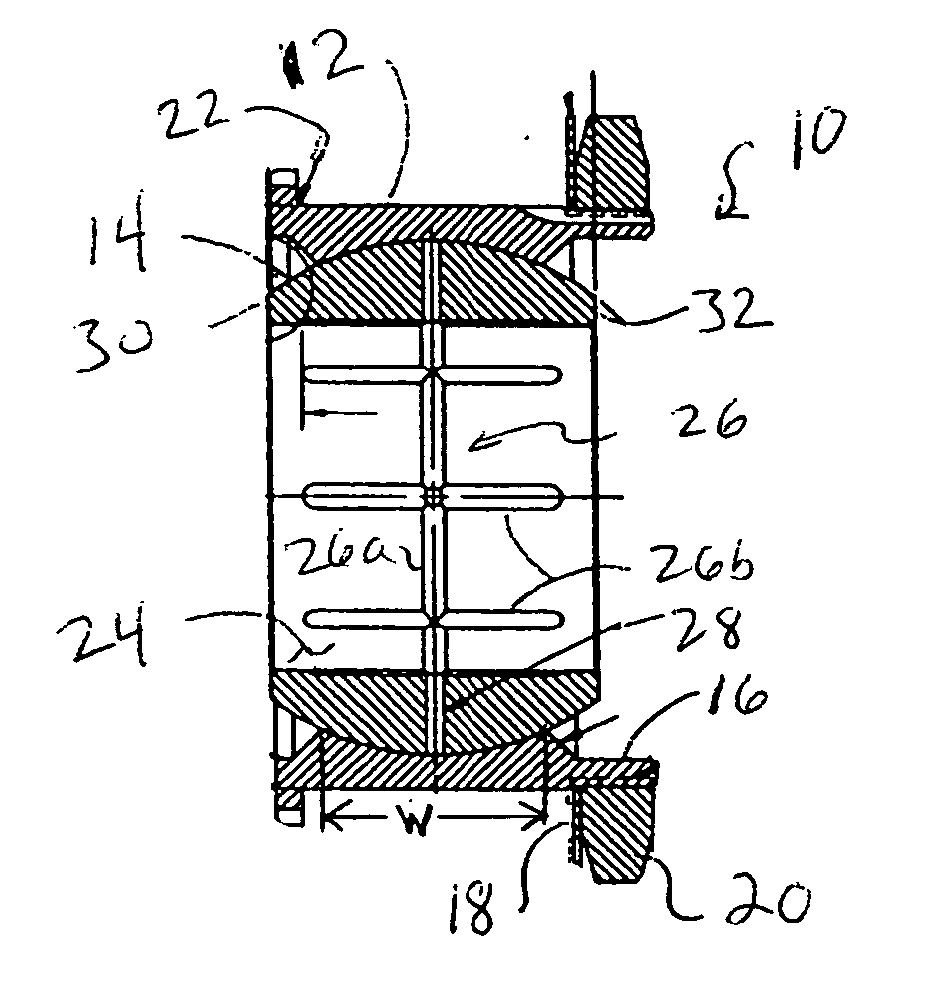

Bearing and hinge mechanism

A spherical plain bearing has an outer ring having a concave first bearing surface and an inner ring having a convex second bearing surface slidably disposed to the first bearing surface. The inner ring member also has a third bearing surface for engaging a pin to be mounted in the bearing. At least one bearing surface has a lubrication groove, and one of the outer ring and the inner ring is made from 440 stainless steel while the other is made from a precipitation-hardened martensitic stainless steel. Alternatively, the outer ring and the inner ring may be made from steel and a copper-beryllium alloy. In yet another alternative, the bearing need not have a lubrication groove, but may have a lubrication liner on the third bearing surface. A dropped hinge mechanism for a flap on a fixed wing aircraft has a hinge that includes such a bearing.

Owner:ROLLER BEARING OF AMERICA

Thermoplastically processable amorphous metals and methods for processing same

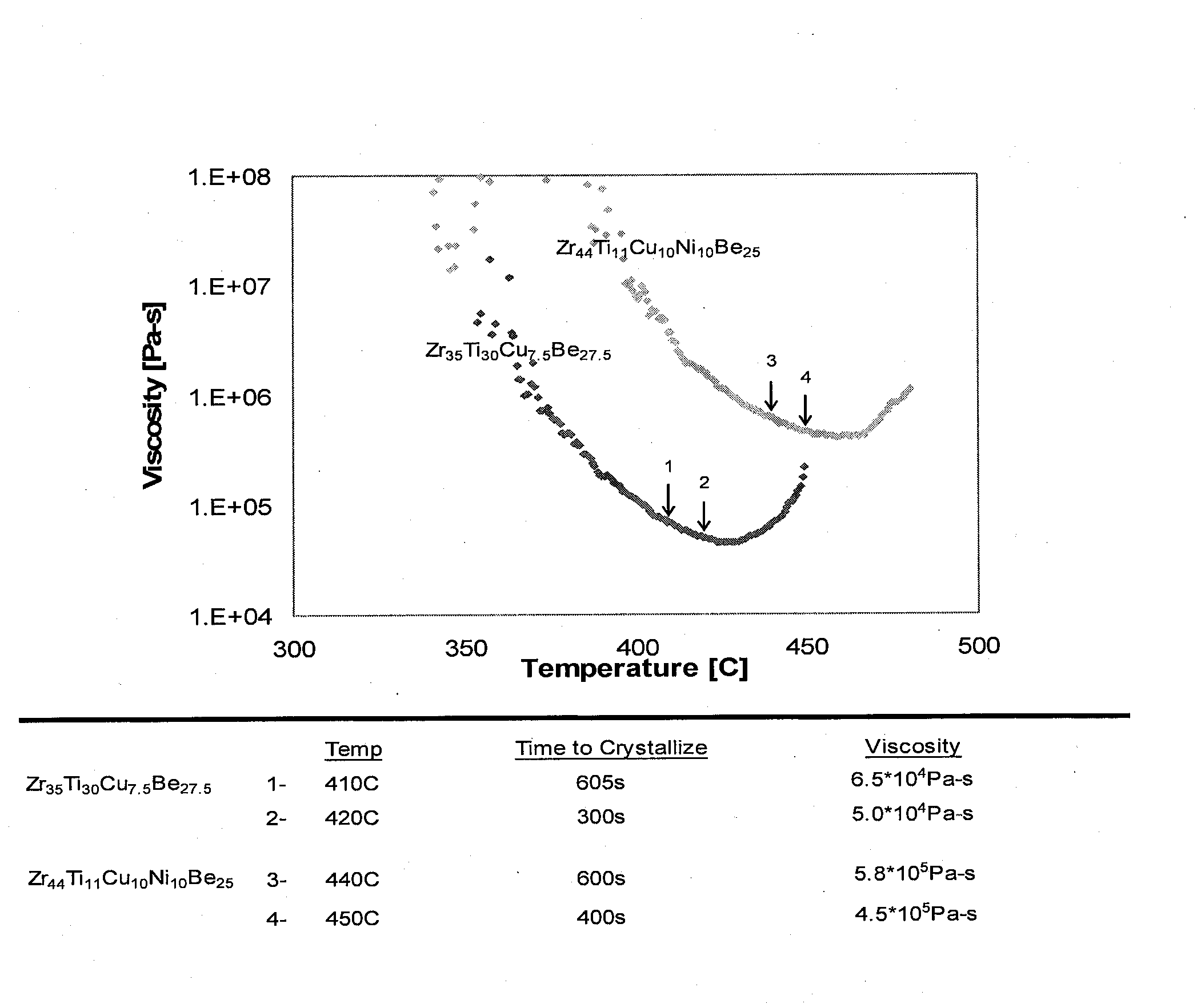

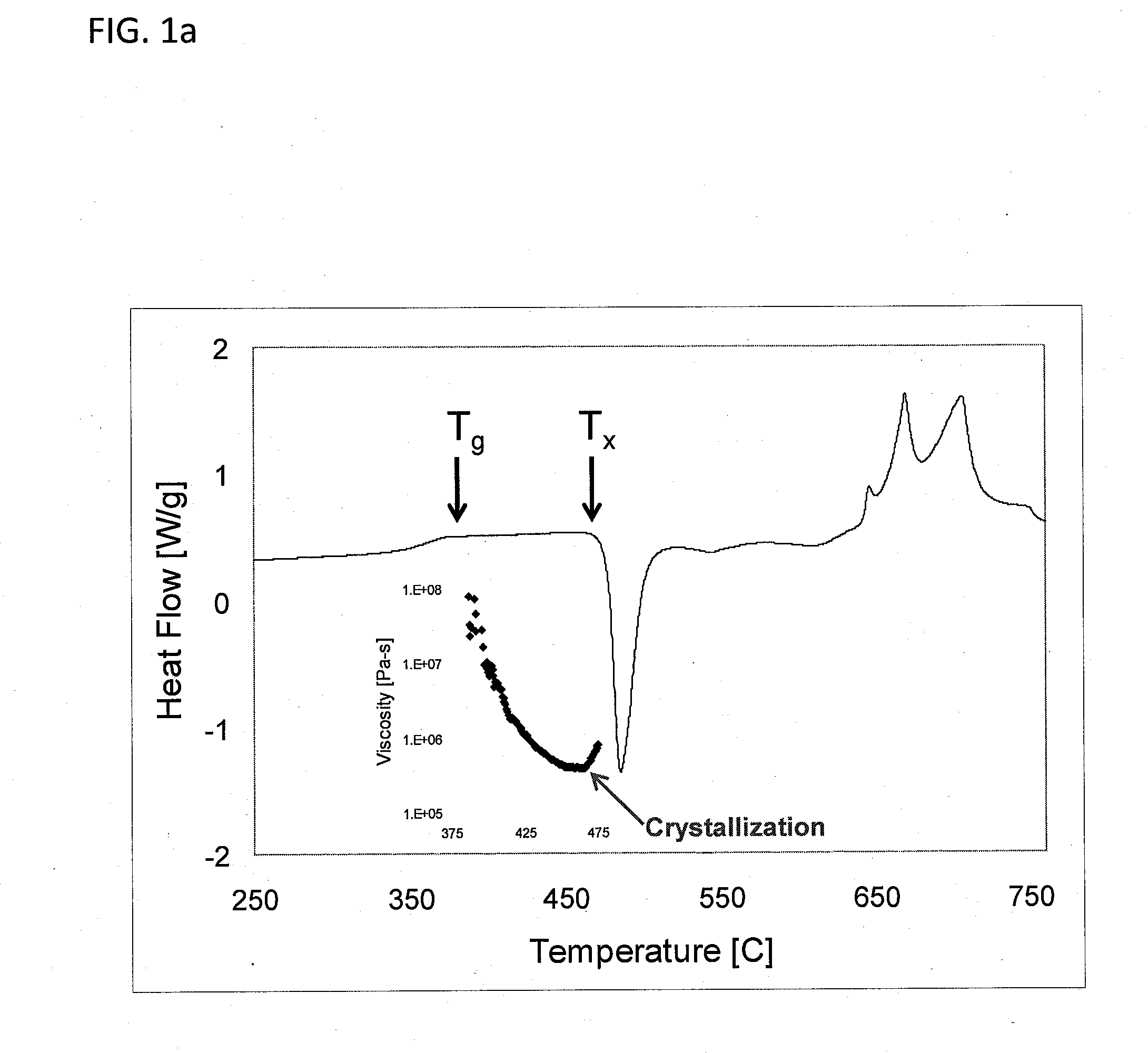

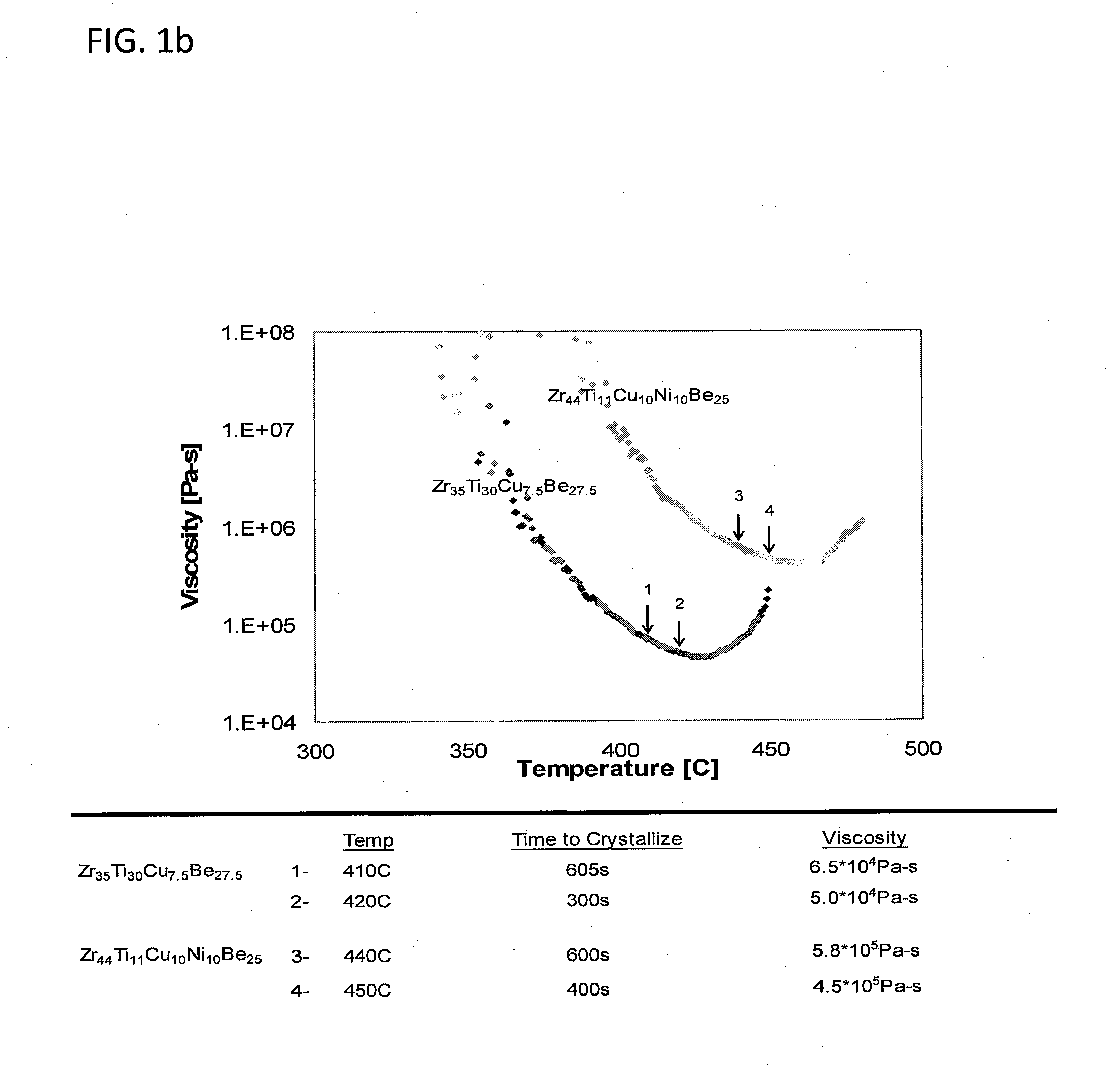

High strength, thermoplastically processable (TPF) amorphous alloys composed of Beryllium and at least one ETM and at least one LTM, as well as methods of processing such alloys are provided. The TPF alloys of the invention demonstrate good glass forming ability, low viscosity in the supercooled liquid region (SCLR), a low processing temperature, and a long processing time at that temperature before crystallization.

Owner:CALIFORNIA INST OF TECH

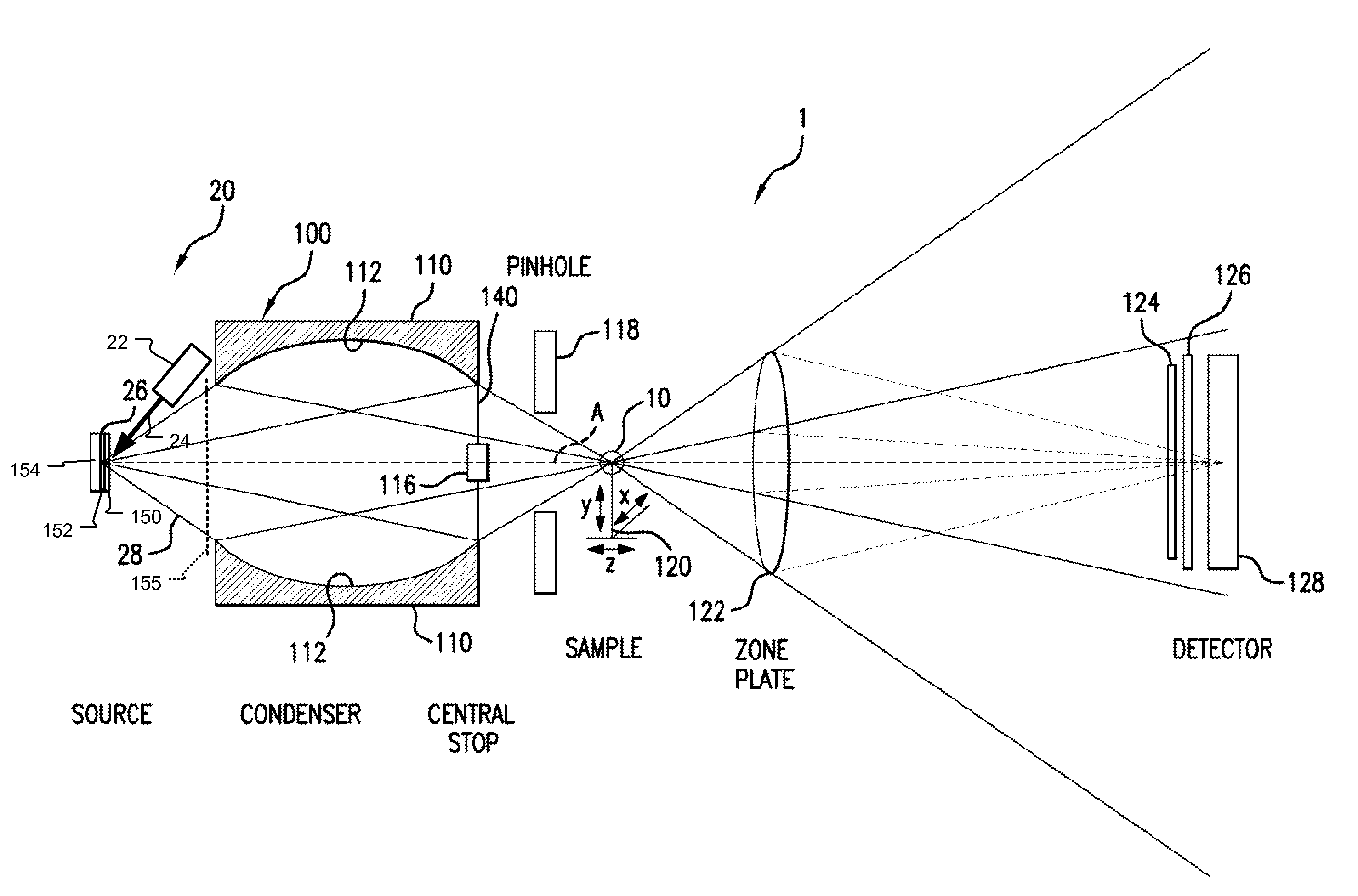

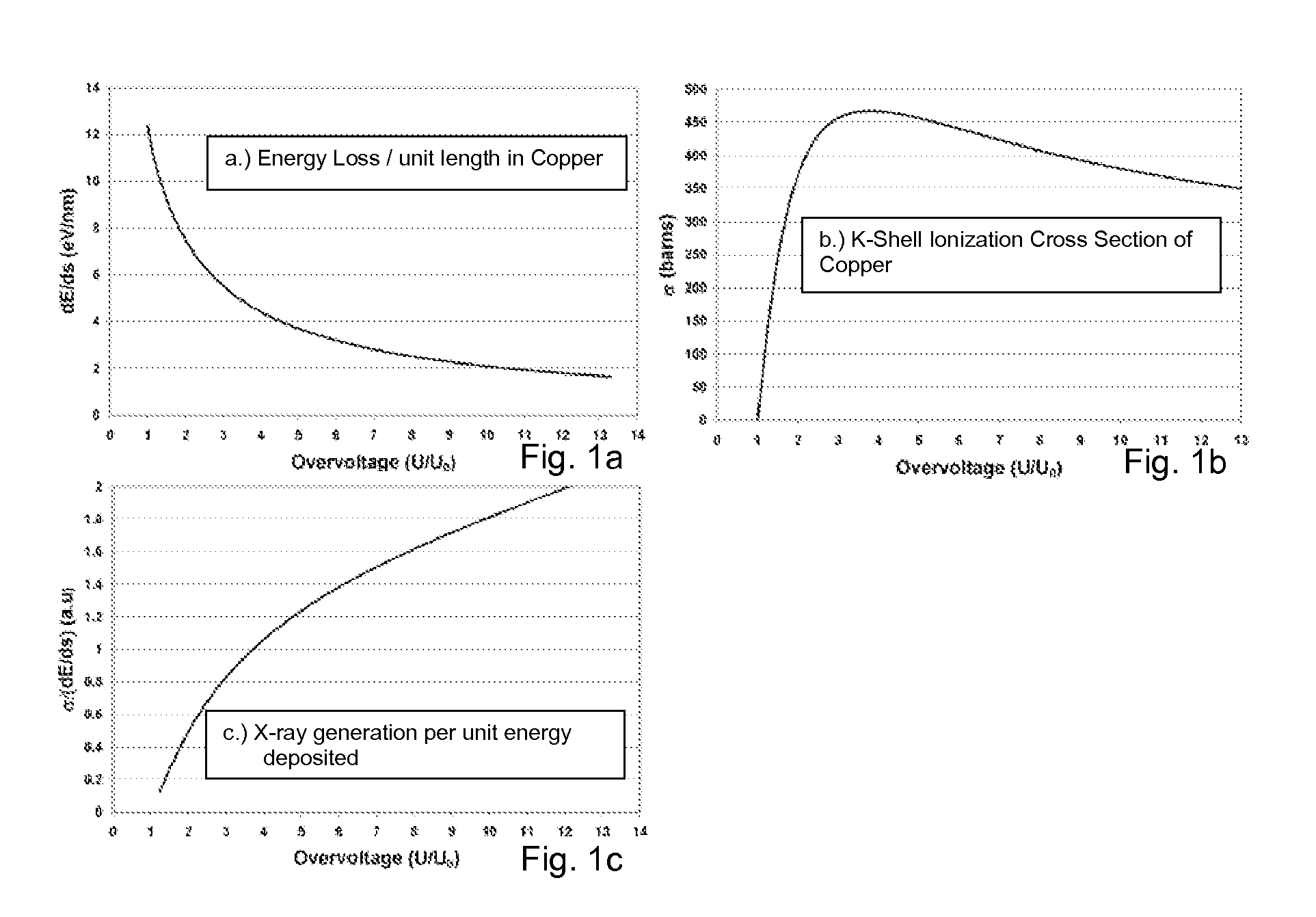

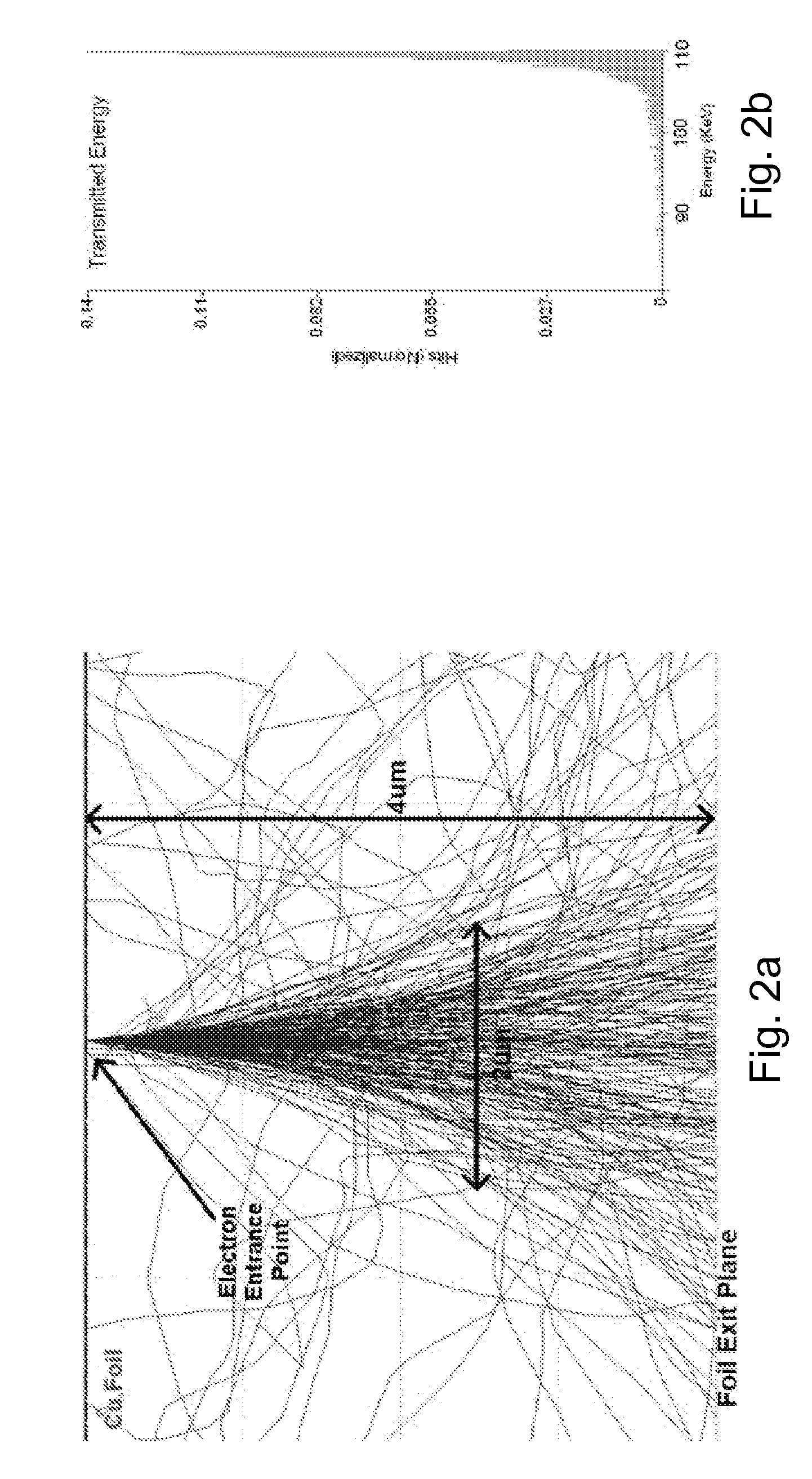

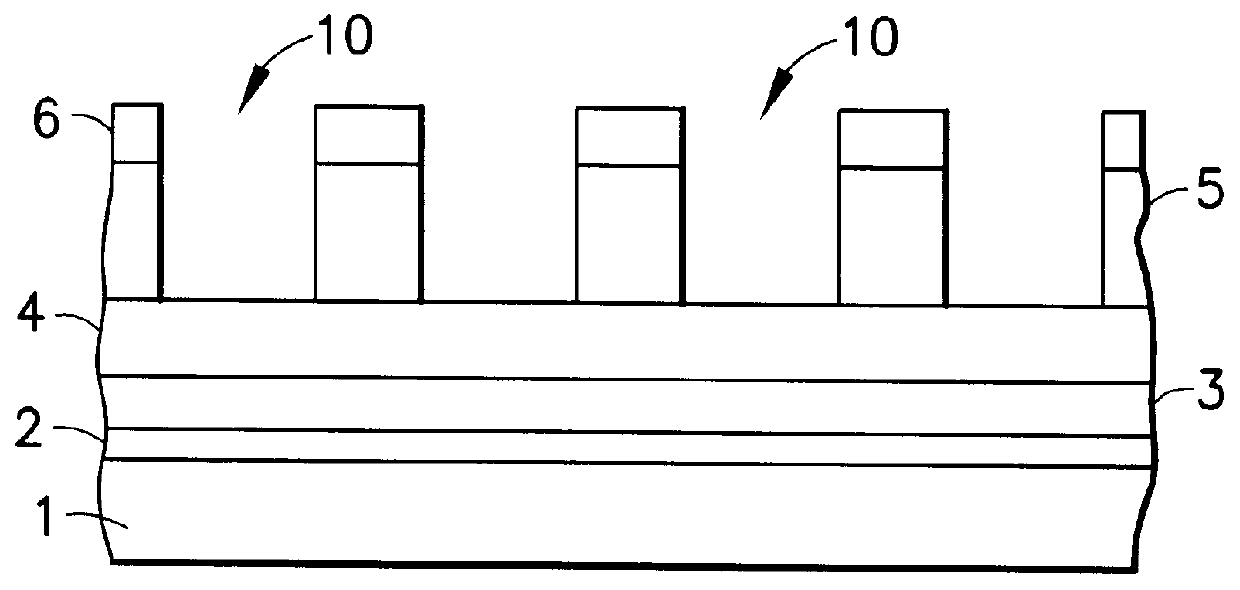

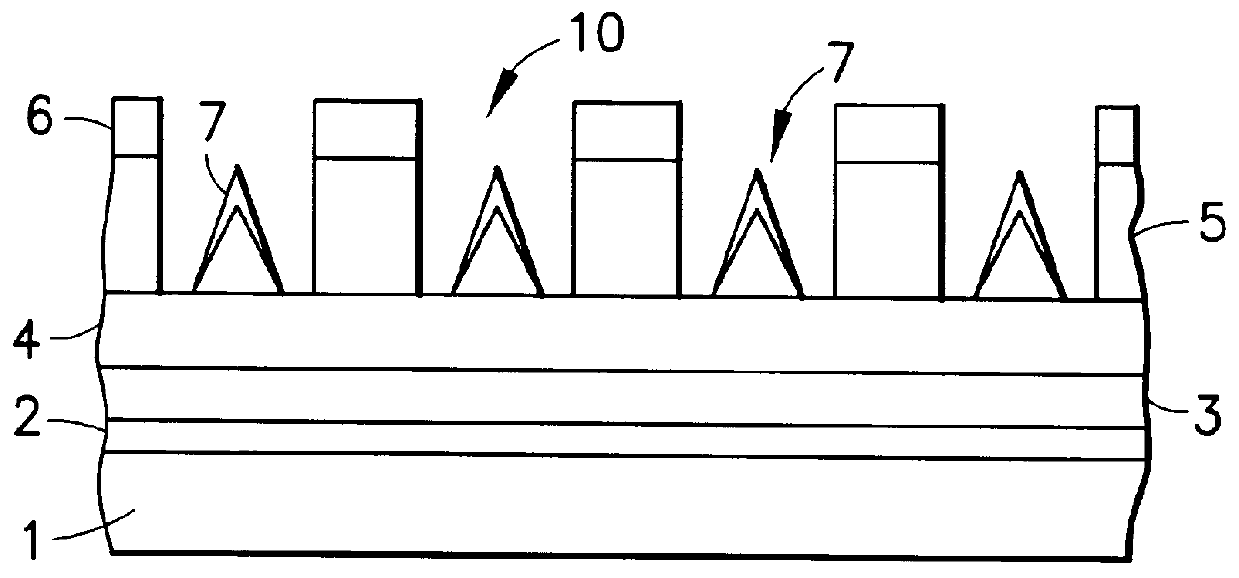

Structured anode X-ray source for X-ray microscopy

ActiveUS7443953B1Improve performanceImprove thermal performanceX-ray tube laminated targetsX-ray tube electrodesHigh energyX-ray

An x-ray source comprises a structured anode that has a thin top layer made of the desired target material and a thick bottom layer made of low atomic number and low density materials with good thermal properties. In one example, the anode comprises a layer of copper with an optimal thickness deposited on a layer of beryllium or diamond substrate. This structured target design allows for the use of efficient high energy electrons for generation of characteristic x-rays per unit energy deposited in the top layer and the use of the bottom layer as a thermal sink. This anode design can be applied to substantially increase the brightness of stationary, rotating anode or other electron bombardment-based sources where brightness is defined as number of x-rays per unit area and unit solid angle emitted by a source and is a key figure of merit parameter for a source.

Owner:CARL ZEISS X RAY MICROSCOPY

Integrated circuit devices and methods employing amorphous silicon carbide resistor materials

InactiveUS6031250AReduce the temperatureLow implementation costSolid-state devicesSemiconductor/solid-state device manufacturingField emission deviceOxygen

Integrated circuits, including field emission devices, have a resistor element of amorphous SixC1-x wherein 0<x<1, and wherein the SixC1-x incorporates at least one impurity selected from the group consisting of hydrogen, halogens, nitrogen, oxygen, sulphur, selenium, transition metals, boron, aluminum, phosphorus, gallium, arsenic, lithium, beryllium, sodium and magnesium.

Owner:ENTEGRIS INC +1

Cast Aluminium Alloy

Cast aluminium alloys comprising 1.0-8.0% in weight magnesium (Mg), >1.0-4.0% in weight silicon (Si), 0.01-<0.5% in weight scandium (Sc), 0.005-0.2% in weight titanium (Ti), 0-0.5% in weight of at least one element or selected from the group consisting of zirconium (Zr), hafnium (Hf), molybdenum (Mo), terbium (Tb), niobium (Nb), gadolinium (Gd), erbium (Er) and vanadium (V), 0-0.8% in weight manganese (Mn), 0-0.3% in weight chromium (Cr), 0-1.0% in weight copper (Cu), 0-0.1% in weight zinc (Zn), 0-0.6% in weight iron (Fe), 0-0.004% in weight beryllium (Be), and the remainder of aluminium with further impurities to an individual maximum of 0.1% in weight and totally maximally 0.5% in weight.

Owner:EADS DEUT GMBH +1

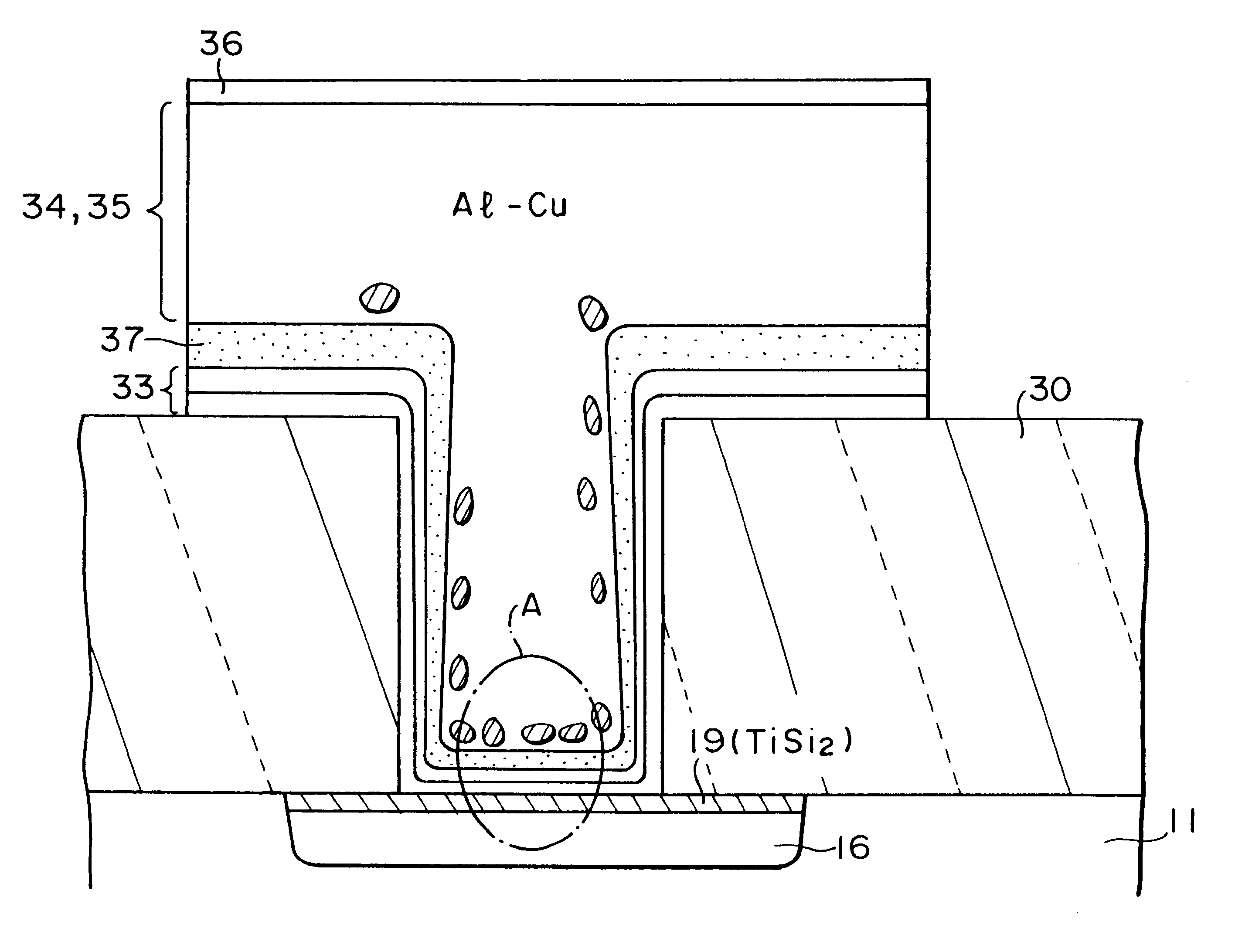

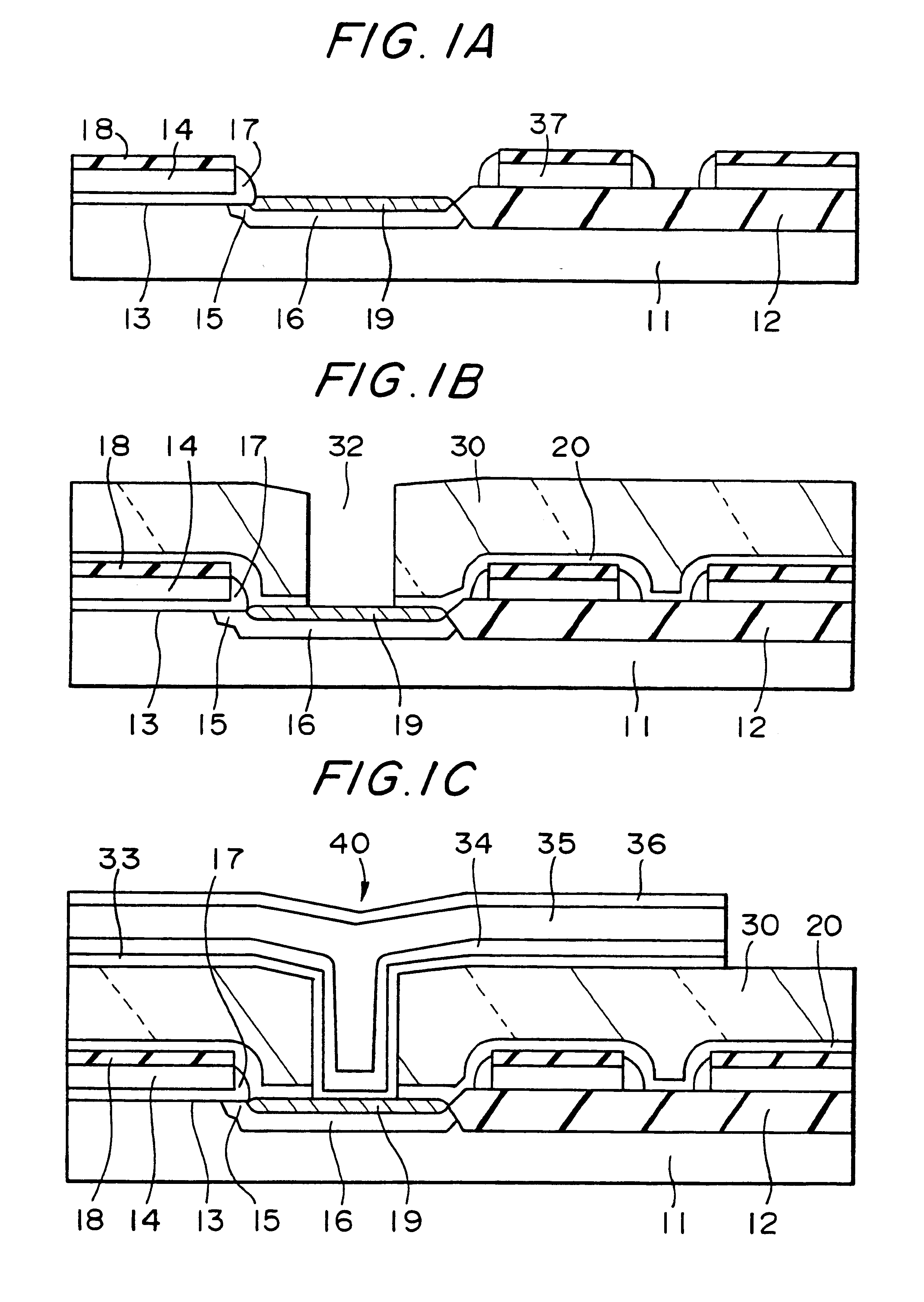

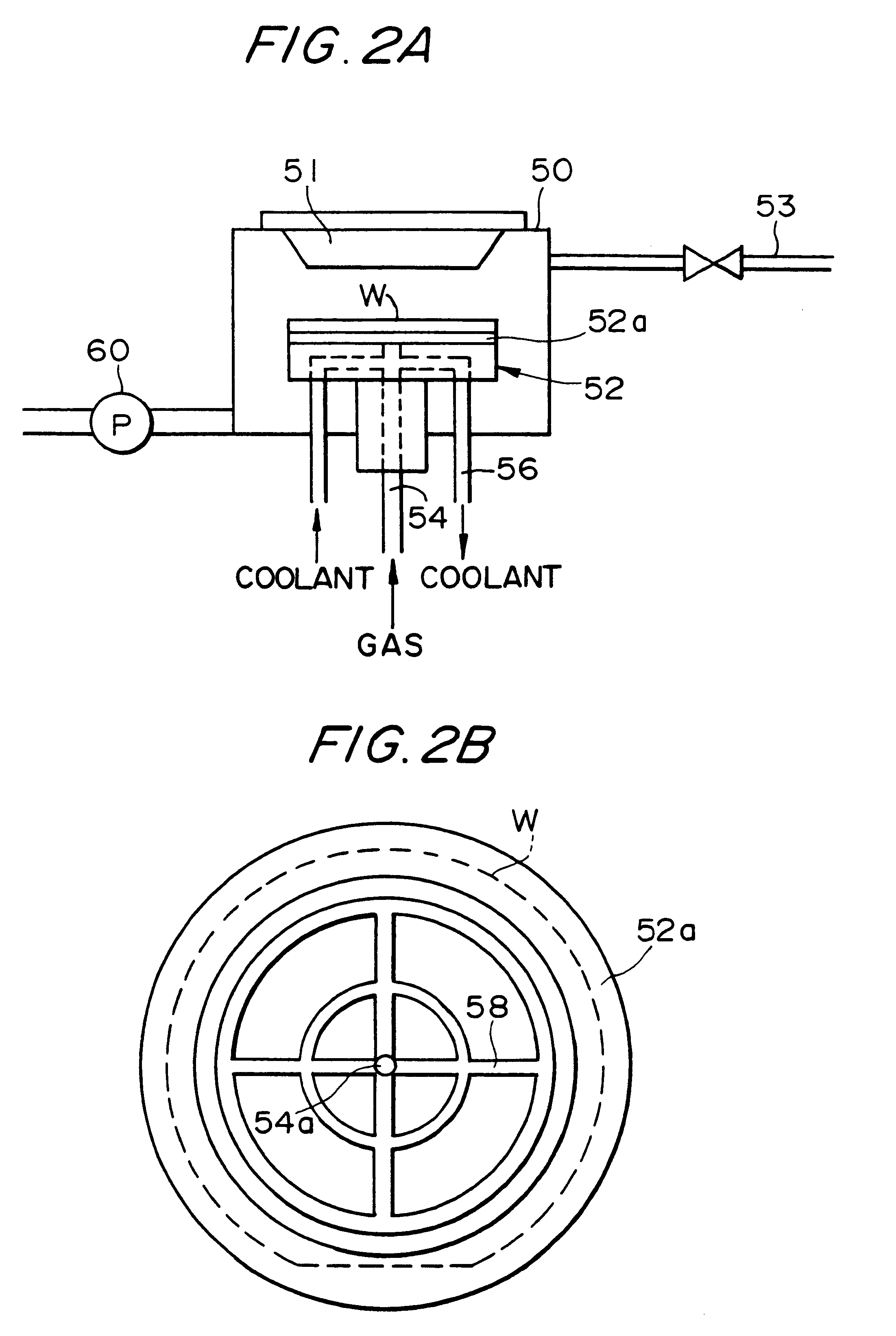

Semiconductor device and method of fabricating the same

InactiveUS6326287B1Improve liquidityLow wettabilitySemiconductor/solid-state device detailsSolid-state devicesMOSFETDielectric

A semiconductor device comprising a semiconductor substrate including an electronic element such as a MOSFET, interlayer dielectric (silicon oxide layer or BPSG layer) formed on the semiconductor substrate, a through-hole formed in the interlayer dielectric, a barrier layer formed on a surface of the interlayer dielectric and on a surface of the through-hole, and a metal wiring layer formed on the barrier layer. The metal wiring layer contains aluminum as its major component and 0.1 wt % to 3 wt % of beryllium. An aluminum alloy can be embedded in the through-hole without creation of any void or breaking of wire, and the semiconductor device is highly resistant to electro-migration.

Owner:SEIKO EPSON CORP

Non ionic/electrolyte, liquid/gaseous, mechanically refined/nanoparticle dispersion Building Materials/High Wear-Heat Resistant Part Brushes, Windings, Battery Cells, Brake Pads, Die Cast Molding, Refrigeration, Polarized/Integrated Optical, Spectrometric Processors, Central Processor Unit Processors, Electronic Storage Media, Analogous Series/Parallel Circuit Generators/Transceivers, Particulate Matter PM Carbonaceous-Polyamide, Crystalline Silica, and Cellulosic Filament Extraction/Miners Suit

InactiveUS20140178513A1High wear-heat resistant partAuxillary shaping apparatusShaping pressTransceiverTransformer

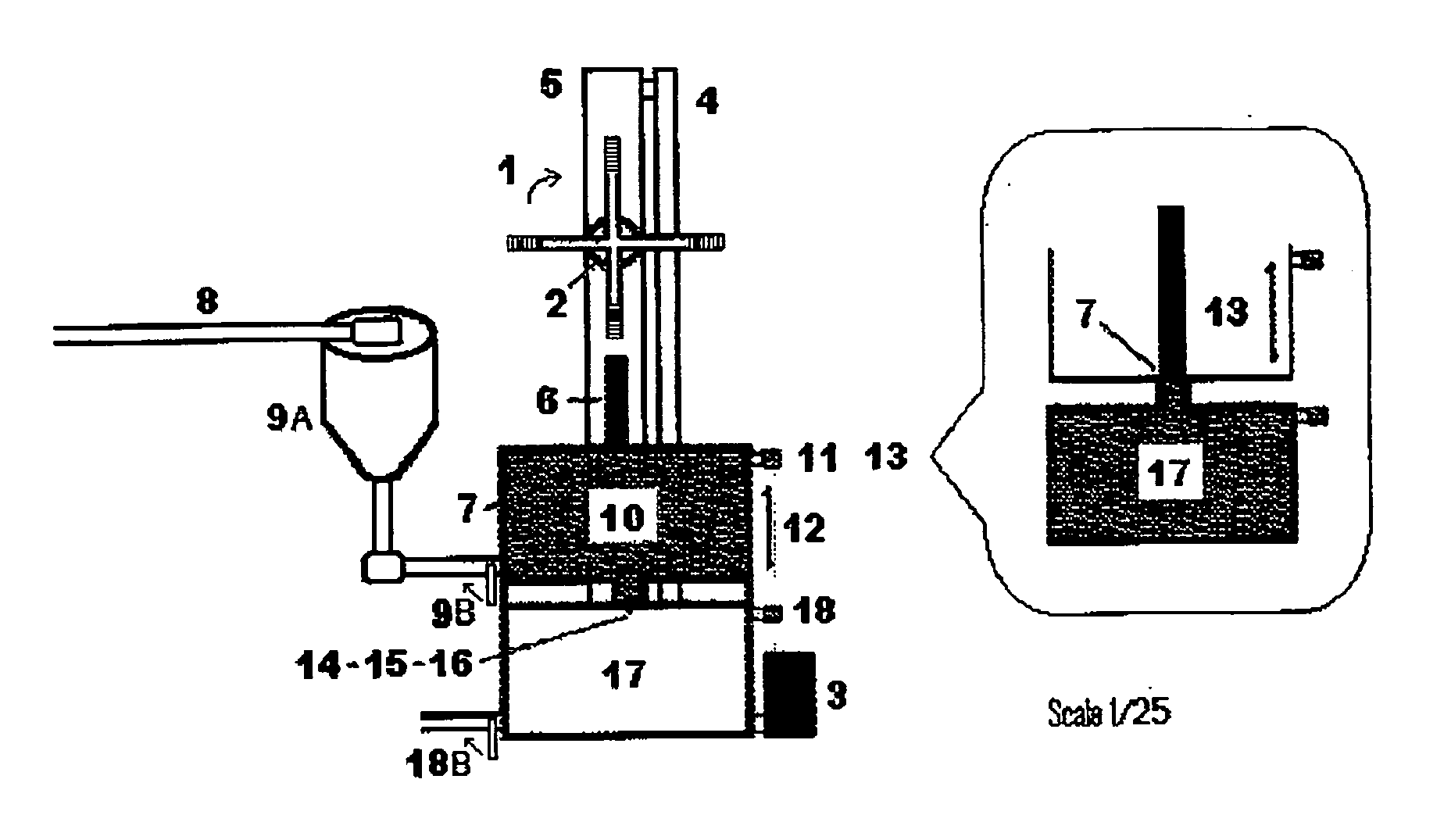

The variable hydraulic press and distillation reservoir process scientific formula non ionic or electrolyte mechanically refined and nanoparticle dispersion preform slurry extrusion with or without ionic suspension Preform slurry high wear-heat resistant parts electronic composite coils, windings, annealing, drawn, spun, coils, windings, wire, woven textile mesh, shielding, parts brushes, inductors, antinode couplers, electric rheostats, starters, motors, alternators, generators, ionic suspension enhanced composite coils, composite windings, spun wound coils and windings beryllium Be4, magnesium Mg12, copper Cu29 and carbon nanofoam C6, electronic parts capacitors, ionic suspension circuit battery cells, electronic parts rheostats, resistors, transformers, transducers, rectifiers, power supplies, or heat sinks Preform slurry high wear-heat resistant parts aerospace, automotive, and transportation brake calipers, rotors, pads, and bushings Preform slurry non ionic or electrolyte mechanically refined and nanoparticle high wear-heat resistant parts precision casting molds 2.5 phase die cast molding Building Materials fine concrete, mortar, brick, and tiles.

Owner:MATTHEWS ROBERT RICHARD

High-strength die-casting aluminum alloy for pressure casting

The invention relates to the field of alloy material, and discloses a high-strength die-casting aluminum alloy for pressure casting. The aluminum alloy is Al-Mg-Si-Mn series, and comprises 4.5-6.3 wt% of magnesium, 1.4-2.8 wt% of silicon, 0.4-1.0 wt% of manganese, no more than 0.22 wt% of iron, no more than 0.20 wt% of titanium, no more than 0.05 wt% of copper, no more than 0.0045 wt% of beryllium, no more than 0.30 wt% of unavoidable impurity, and the balance of aluminum. The die-casting aluminum alloy provided by the invention has excellent casting property and good mechanical property, and the tensile strength and the yield strength are greatly promoted; the die-casting aluminum alloy has large elongation percentage and high rigidity, and also has good corrosion resistance without solid solution heat treatment; and the high-strength die-casting aluminum alloy for pressure casting can be used for safety spare parts on passenger cars, and satisfies the requirement of light weight development for passenger cars.

Owner:GUANGDONG HONGTAI TECH HLDG +1

Metal alloys for the reflective or the semi-reflective layer of an optical storage medium

InactiveUS6852384B2Improve reflectivitySimilar sputtering characteristicPhotomechanical apparatusRecord information storageIndiumCadmium Cation

A silver-based alloy thin film is provided for the highly reflective or semi-reflective layer of optical discs. Alloy additions to silver include gold, rhodium, ruthenium, osmium, platinum, palladium, copper, silicon, cadmium, tin, lithium, nickel, cobalt, indium, chromium, antimony, gallium, boron, molybdenum, zirconium, beryllium, titanium, and zinc. These alloys have moderate to high reflectivity and reasonable corrosion resistance in the ambient environment.

Owner:TARGET TECH

Metal alloys for the reflective or the semi-reflective layer of an optical storage medium

InactiveUS6841219B2Improve reflectivitySimilar sputtering characteristicLayered productsPhotomechanical apparatusIndiumCobalt

A silver-based alloy thin film is provided for the highly reflective or semi-reflective layer of optical discs. Alloy additions to silver include gold, rhodium, ruthenium, osmium, platinum, palladium, copper, silicon, cadmium, tin, lithium, nickel, cobalt, indium, chromium, antimony, gallium, boron, molybdenum, zirconium, beryllium, titanium, magnesium, and zinc. These alloys have moderate to high reflective and reasonable corrosion resistance in the ambient environment.

Owner:TARGET TECH

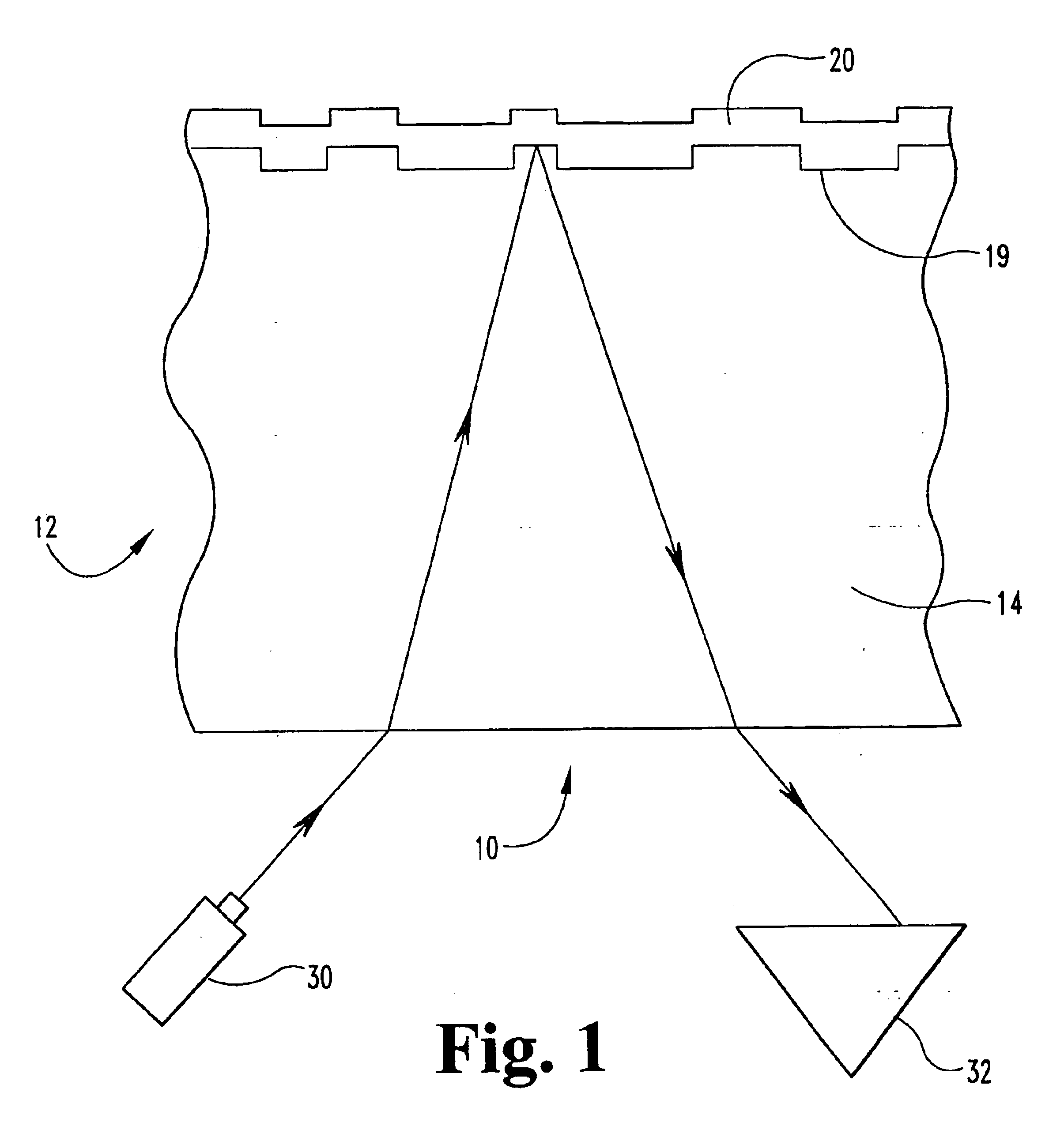

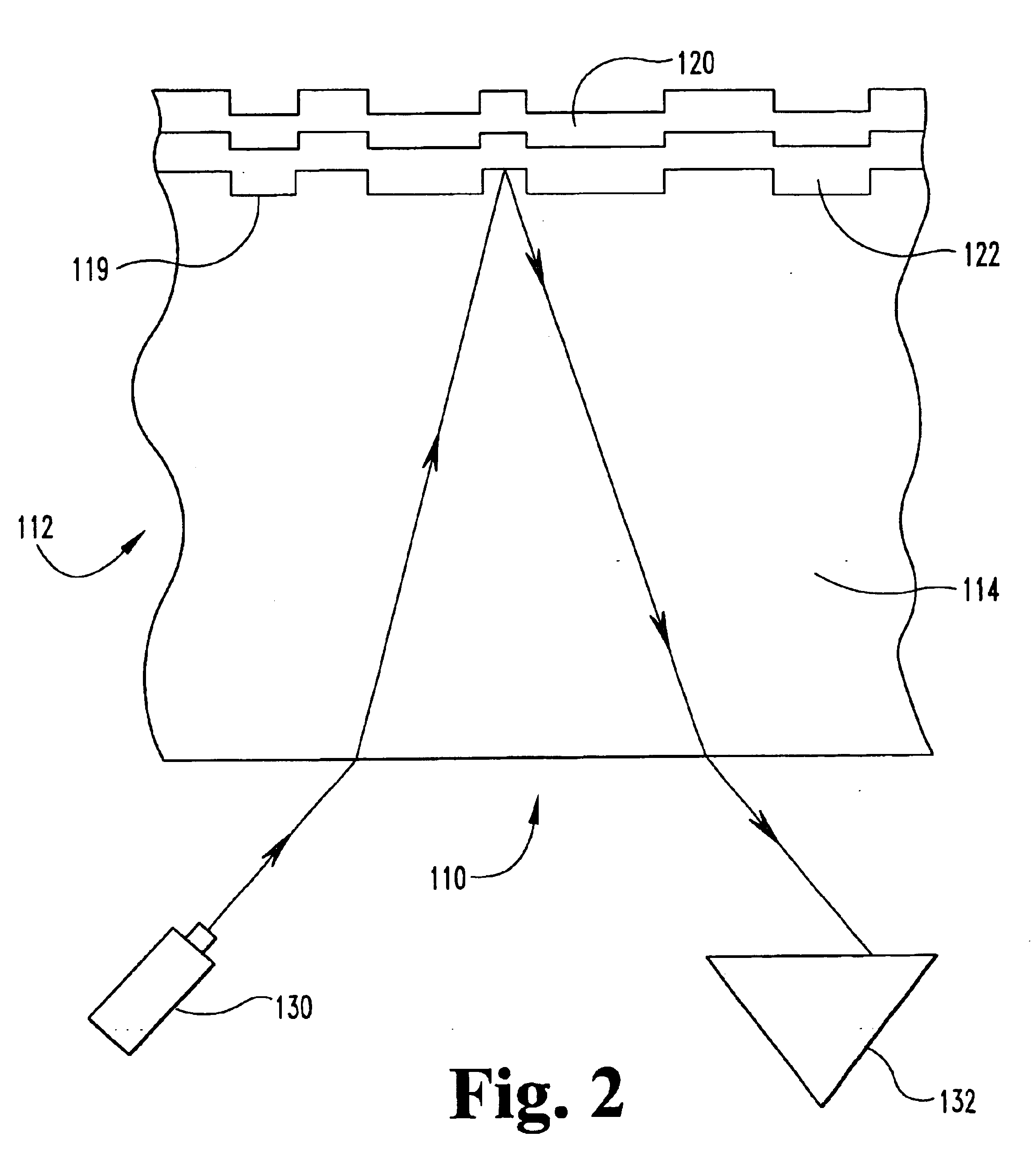

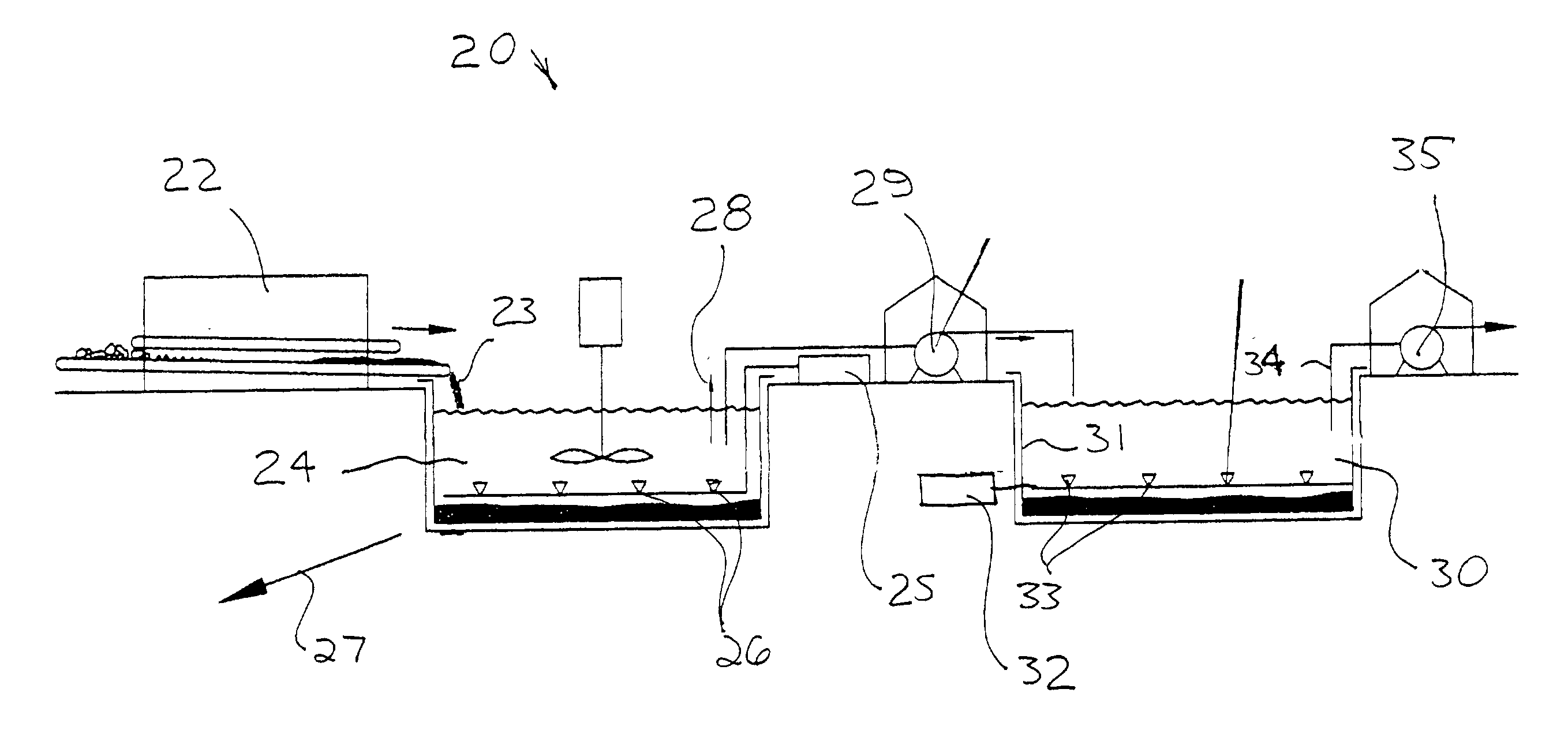

Remediation of metal contaminants with hydrocarbon-utilizing bacteria

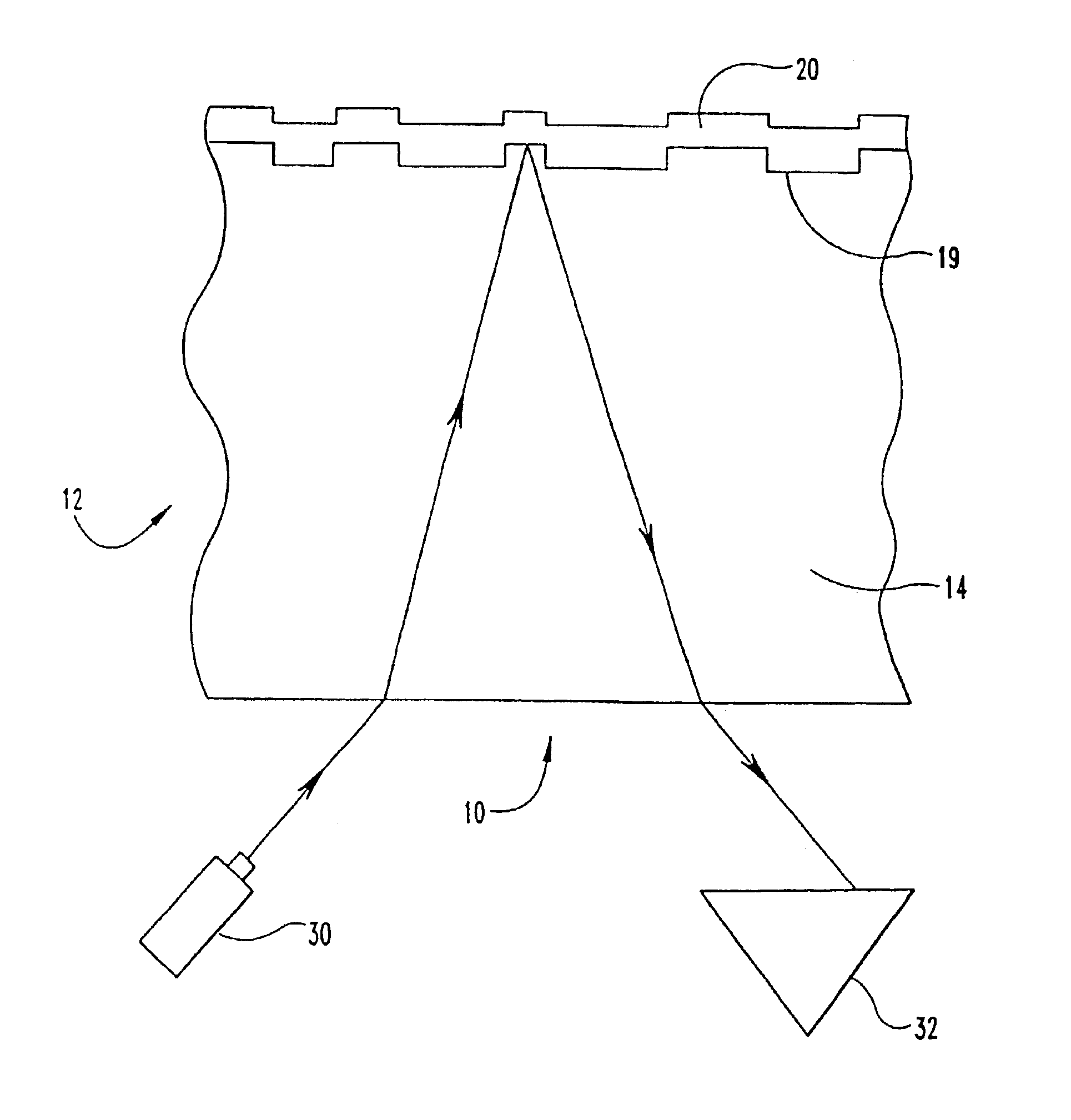

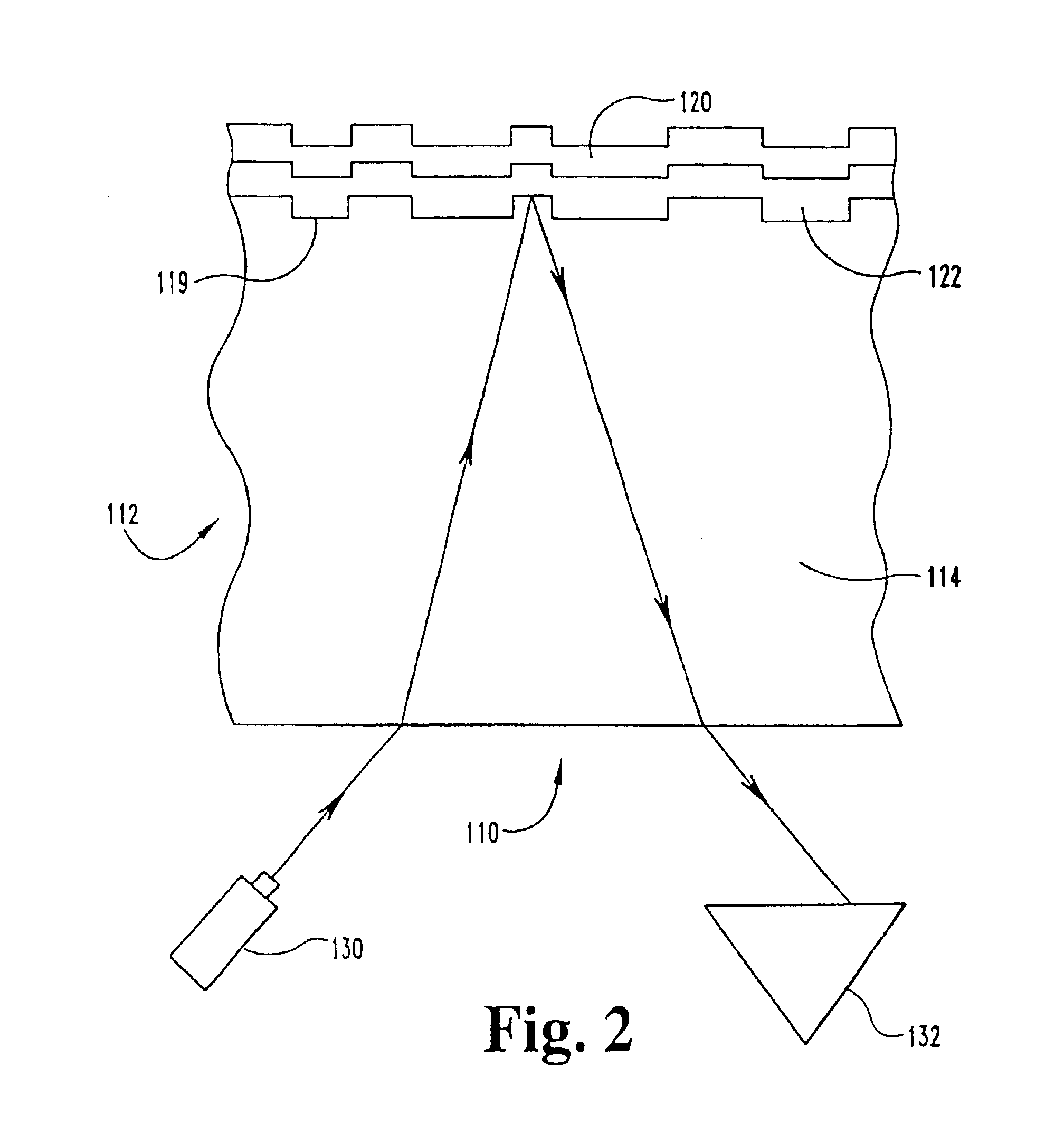

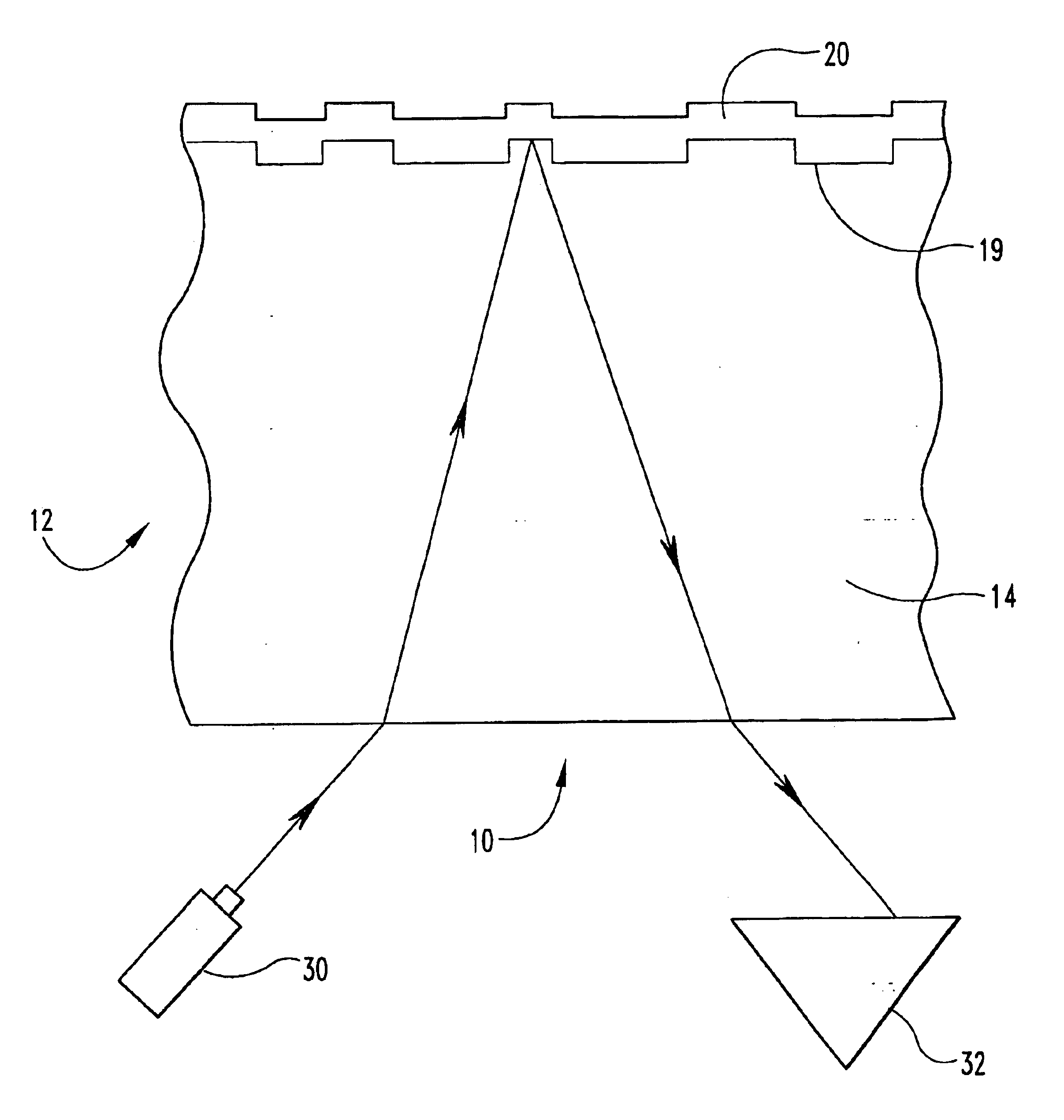

Methods and apparatus are disclosed for remediating metal contaminants using hydrocarbons which stimulate the growth of hydrocarbon-utilizing bacteria. The metal contaminants may include heavy metals such as arsenic, antimony, beryllium, cadmium, chromium, copper, lead, mercury, iron, manganese, magnesium, radium, nickel, selenium, silver, thallium and zinc. The hydrocarbon may include alkanes, alkenes, alkynes, poly(alkene)s, poly(alkyne)s, aromatic hydrocarbons, aromatic hydrocarbon polymers and aliphatic hydrocarbons. Butane is a particularly suitable hydrocarbon which stimulates the growth of butane-utilizing bacteria. Remediation may occur in-situ or ex-situ, and may occur under aerobic, anaerobic or dual aerobic / anaerobic conditions. Examples of applications include the remediation of heavy metals, the remediation of arsenic impacted surface water, groundwater and / or soil, the remediation of acid mine drainage, and the treatment of spent metal plating solutions.

Owner:GLOBAL BIOSCI

Fuel compositions exhibiting improved fuel stability

InactiveUS6652608B1Enhanced combustion structureImprove stabilityNon-fuel substance addition to fuelCombustion enginesIndiumCobalt

A fuel composition of the present invention exhibits minimized hydrolysis and increased fuel stability, even after extended storage at 65° F. for 6-9 months. The composition, which is preferably not strongly alkaline (3.0 to 10.5), is more preferably weakly alkaline to mildly acidic (4.5 to 8.5) and most preferably slightly acidic (6.3 to 6.8), includes a lower dialkyl carbonate, a combustion improving amount of at least one high heating combustible compound containing at least one element selected from the group consisting of aluminum, boron, bromine, bismuth, beryllium, calcium, cesium, chromium, cobalt, copper, francium, gallium, germanium, iodine, iron, indium, lithium, magnesium, manganese, molybdenum, nickel, niobium, nitrogen, phosphorus, potassium, palladium, rubidium, sodium, tin, zinc, praseodymium, rhenium, silicon, vanadium, or mixture, and a hydrocarbon base fuel.

Owner:OCTANE INT

Metal alloys for the reflective or the semi-reflective layer of an optical storage medium

InactiveUS6905750B2Improve reflectivitySimilar sputtering characteristicLayered productsPhotomechanical apparatusIndiumCadmium Cation

A silver-based alloy thin film is provided for the highly reflective or the semi-reflective layer of optical discs. Alloy additions to silver include gold, rhodium, ruthenium, osmium, platinum, palladium, copper, silicon, cadmium, tin, lithium, nickel, cobalt, manganese, indium, chromium, antimony, gallium, boron, molybdenum, zirconium, beryllium, titanium, aluminum, germanium and zinc. These alloys have moderate to high reflectivity and reasonable corrosion resistance in ambient environments.

Owner:TARGET TECH

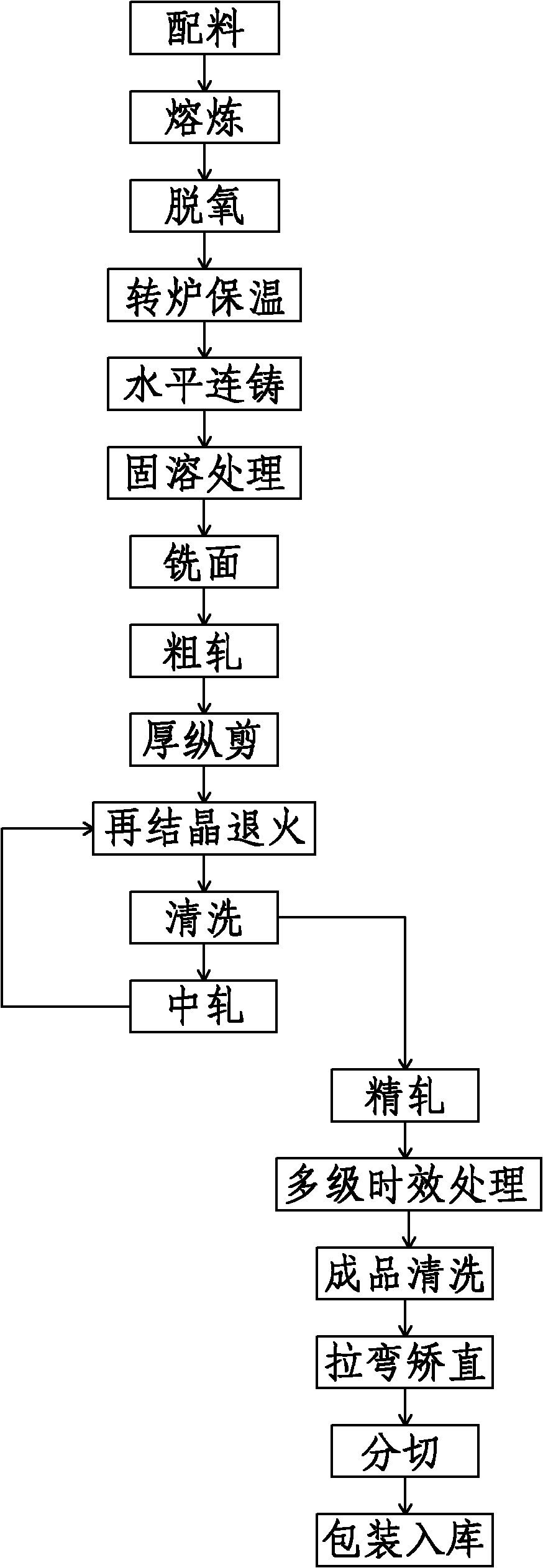

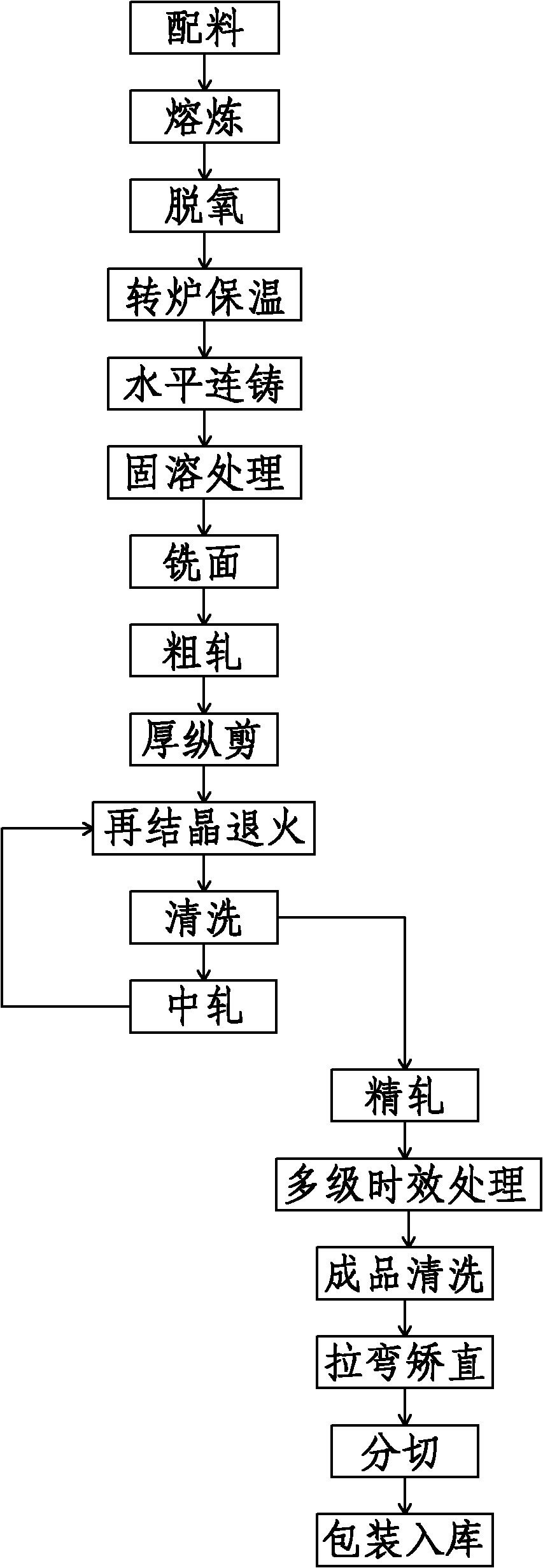

Formula of copper nickel tin alloy strip and production process

The invention discloses a formula of a copper nickel tin alloy strip and a production process. The formula of the alloy strip comprises the following components in percentage by weight: 19.0 to 21.0 percent of Ni, 4.0 to 6.0 percent of Sn, 0.01 to 0.05 percent of Zr and the balance of Cu. The production process comprises the following steps of: proportioning, smelting, bath analysis, deoxidation, converter heat preservation, horizontal continuous casting, solution treatment, surface milling, rough rolling, thickness longitudinal shearing, strong convection bright annealing, cleaning, precision rolling, multistage ageing, bending, straightening and slitting. The production process has no pollution, the production flow is short, the alloy strip blank has small specification size and high quality, cold rolling is directly performed, a hot rolling process is saved, and the production efficiency is improved; the obtained copper nickel tin alloy has the properties of high strength, high elongation, high hardness, high elasticity, stress corrosion resistance and the like, the performance of the copper nickel tin alloy is close to that of beryllium bronze, and the copper nickel tin alloy can partially replace the beryllium bronze to manufacture elastic elements.

Owner:江苏富威科技股份有限公司

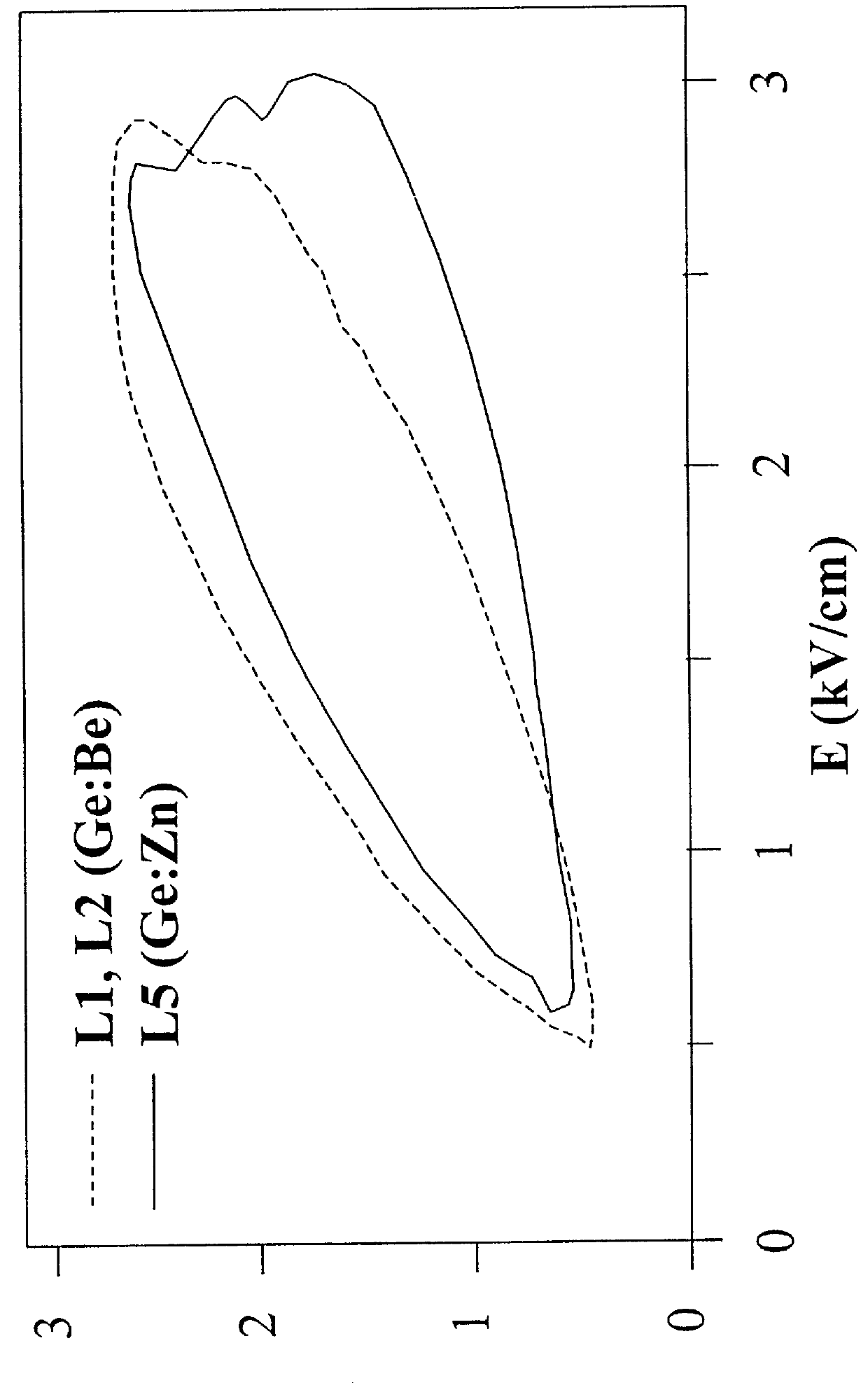

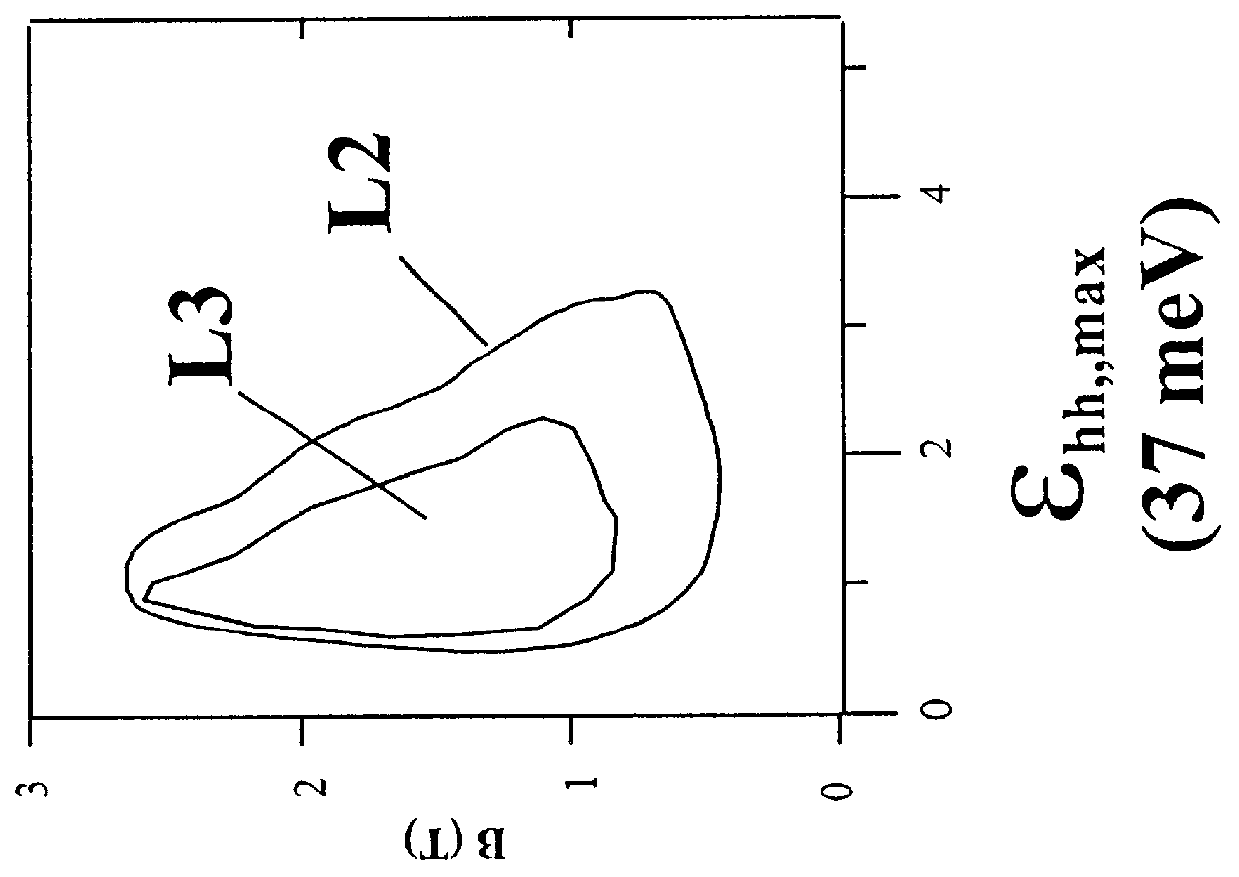

Doping of germanium and silicon crystals with non-hydrogenic acceptors for far infrared lasers

InactiveUS6011810AIncrease powerHigh duty cycleLaser detailsLaser active region structureAcceptor dopantFar infrared

A method for doping semiconductors used for far infrared lasers with non-hydrogenic acceptors having binding energies larger than the energy of the laser photons. Doping of germanium or silicon crystals with beryllium, zinc or copper. A far infrared laser comprising germanium crystals doped with double or triple acceptor dopants permitting the doped laser to be tuned continuously from 1 to 4 terahertz and to operate in continuous mode. A method for operating semiconductor hole population inversion lasers with a closed cycle refrigerator.

Owner:LAWRENCE BERKELEY NAT LAB

Thermonuclear plasma reactor for rocket thrust and electrical generation

InactiveUS20090000268A1Easy to triggerDownsize working reactionCosmonautic vehiclesNuclear energy generationHigh energyNuclear engineering

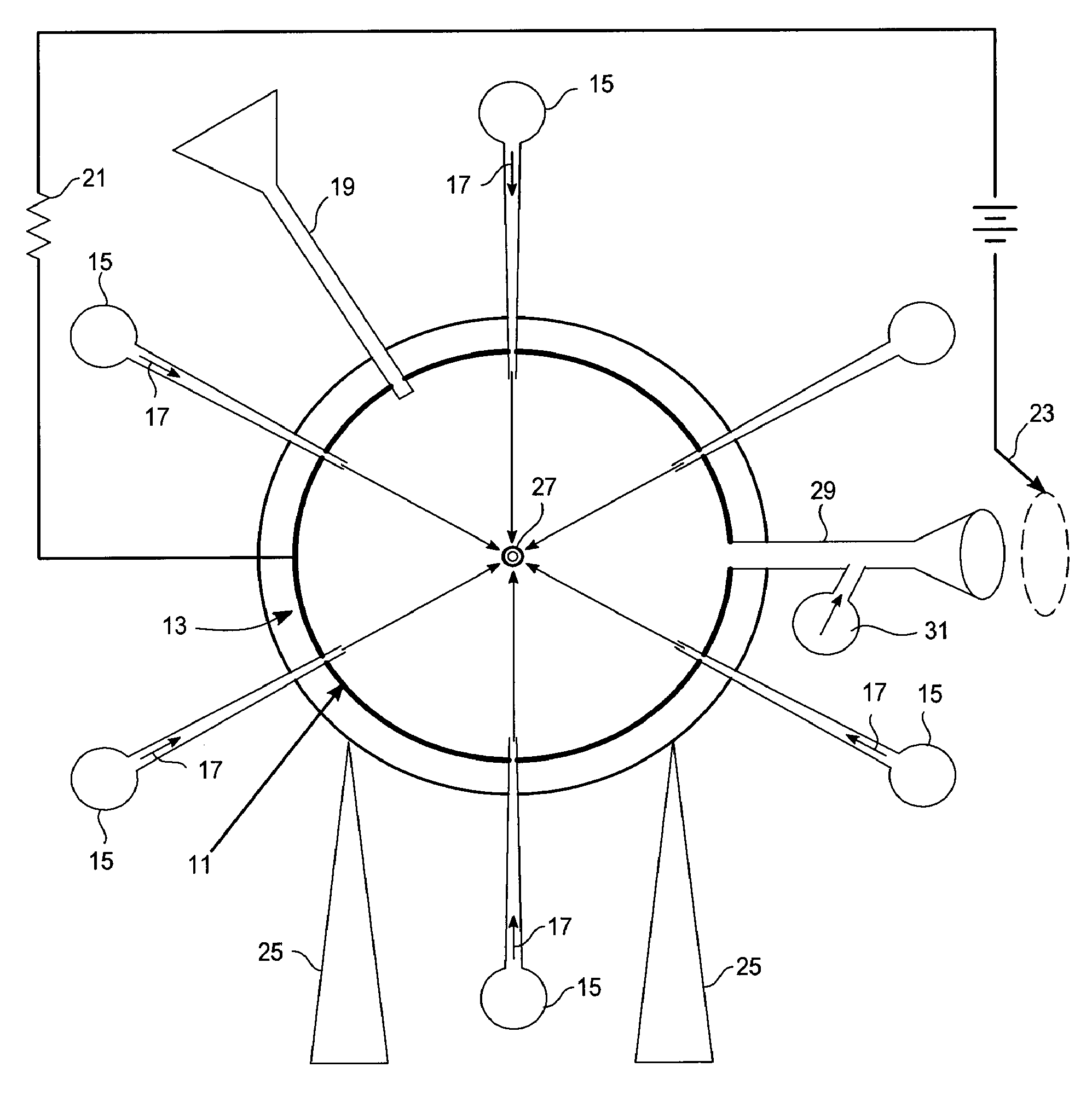

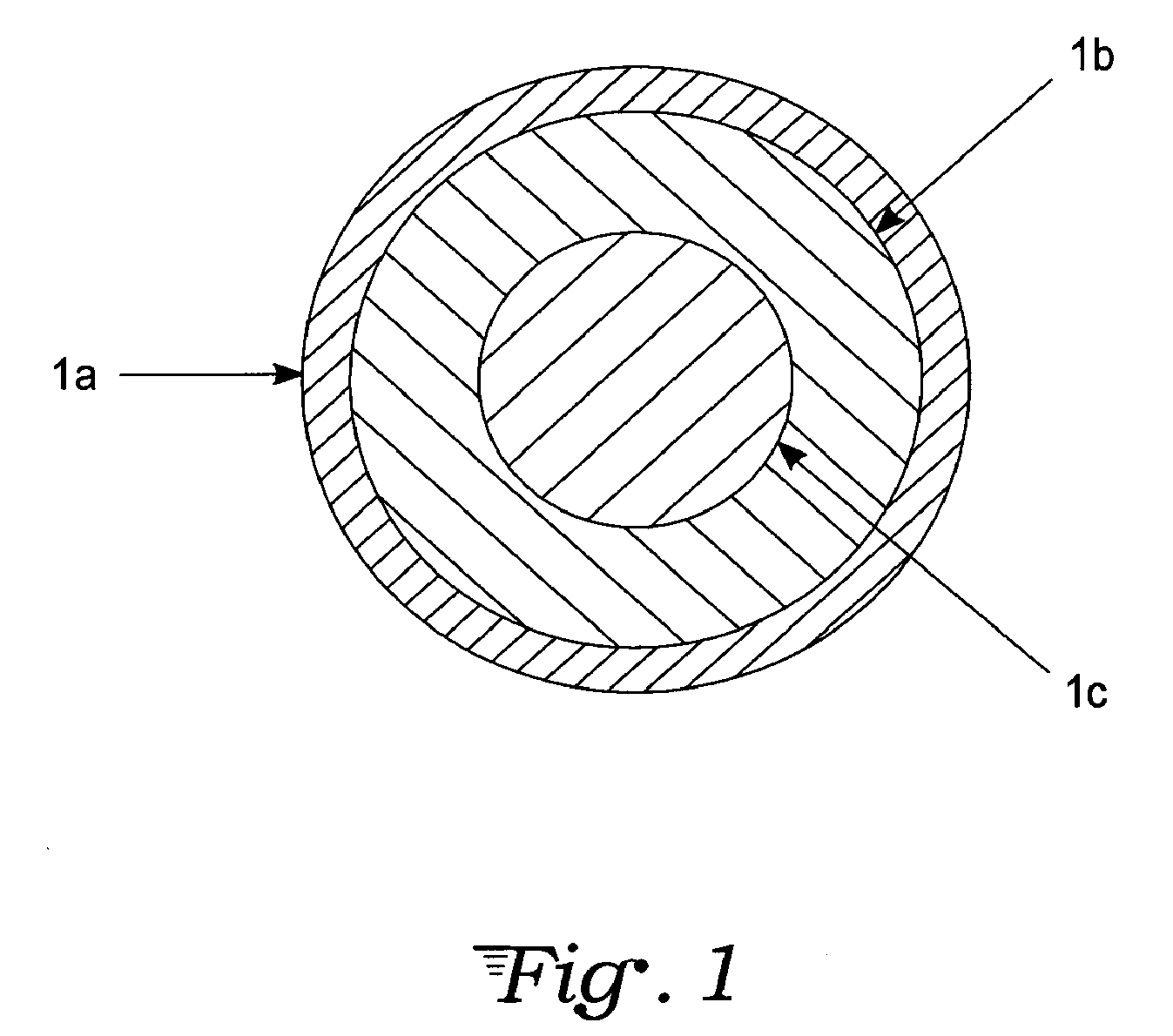

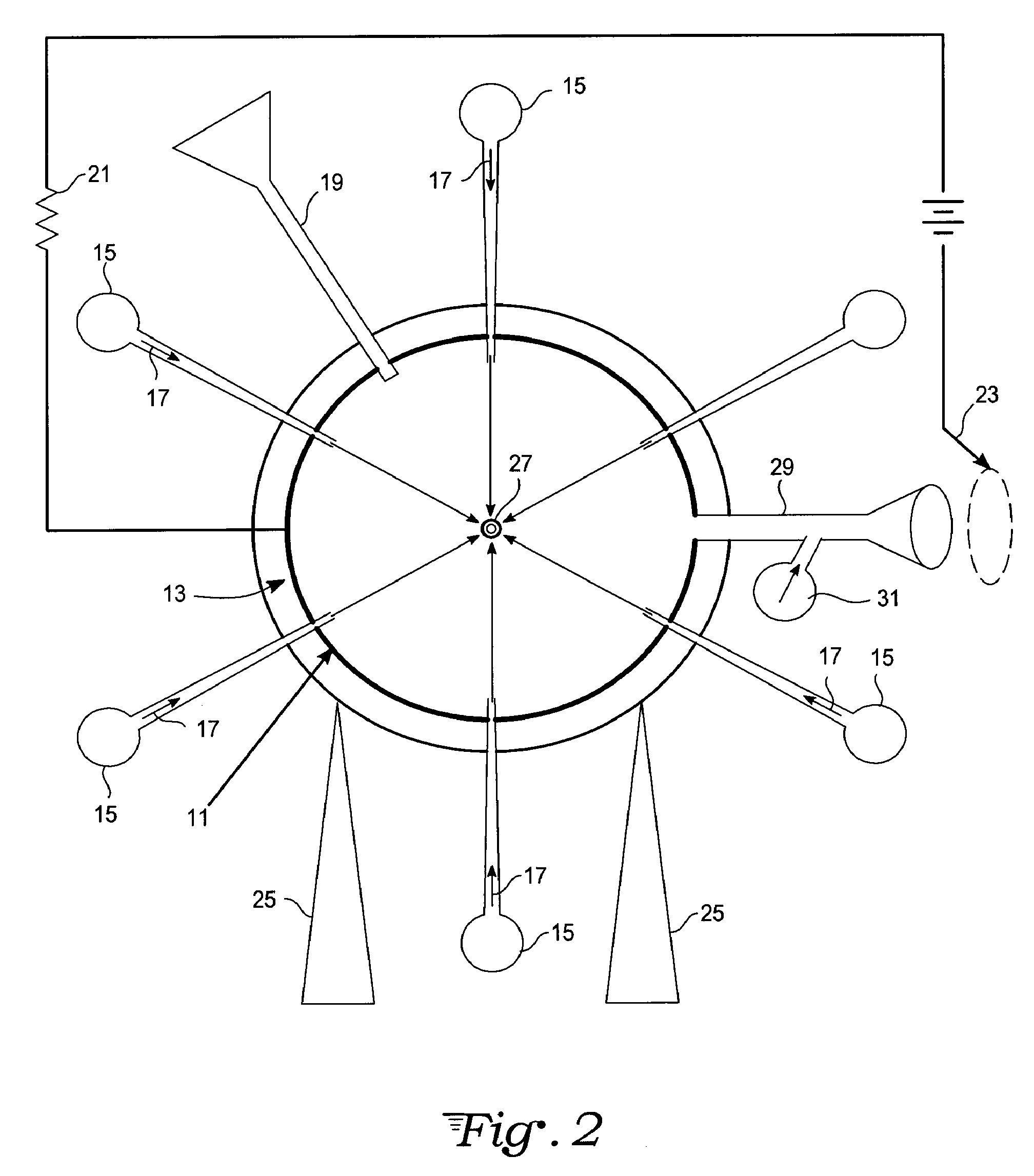

A reactor system produces plasma rocket thrust using alpha-initiated atomic fuel pellets without the need for a critical mass of fissionable material. The fuel pellets include an outer layer reactive material to alpha particles to generate neutrons (e.g., porous lead or beryllium), an under-layer of fissionable material (e.g., thorium or enriched uranium), and an optional inner core of fusion material (e.g., heavy water ice, boron hydride). The pellets are injected one at a time into a charged reaction chamber containing a set of alpha beam channels, possibly doubling as ion accelerators, all directed toward a common point. Alpha particles converging on each successive pellet initiate an atomic reaction in the fissionable under-layer, via a neutron cascade from the pellet outer layer, producing plasma that is confined within the chamber. This may be enhanced by atomic fusion of the optional inner core. The resulting high-energy plasma creates electrostatic pressure on the chamber and is allowed to exit the chamber through a port. An ion accelerator at the exhaust port of the chamber accelerates outgoing plasma ions, possibly with added reaction mass, to generate the rocket thrust. An electric circuit that includes the charged chamber may collect the electrons in the plasma to help power the ion accelerator(s).

Owner:YURASH GREG J

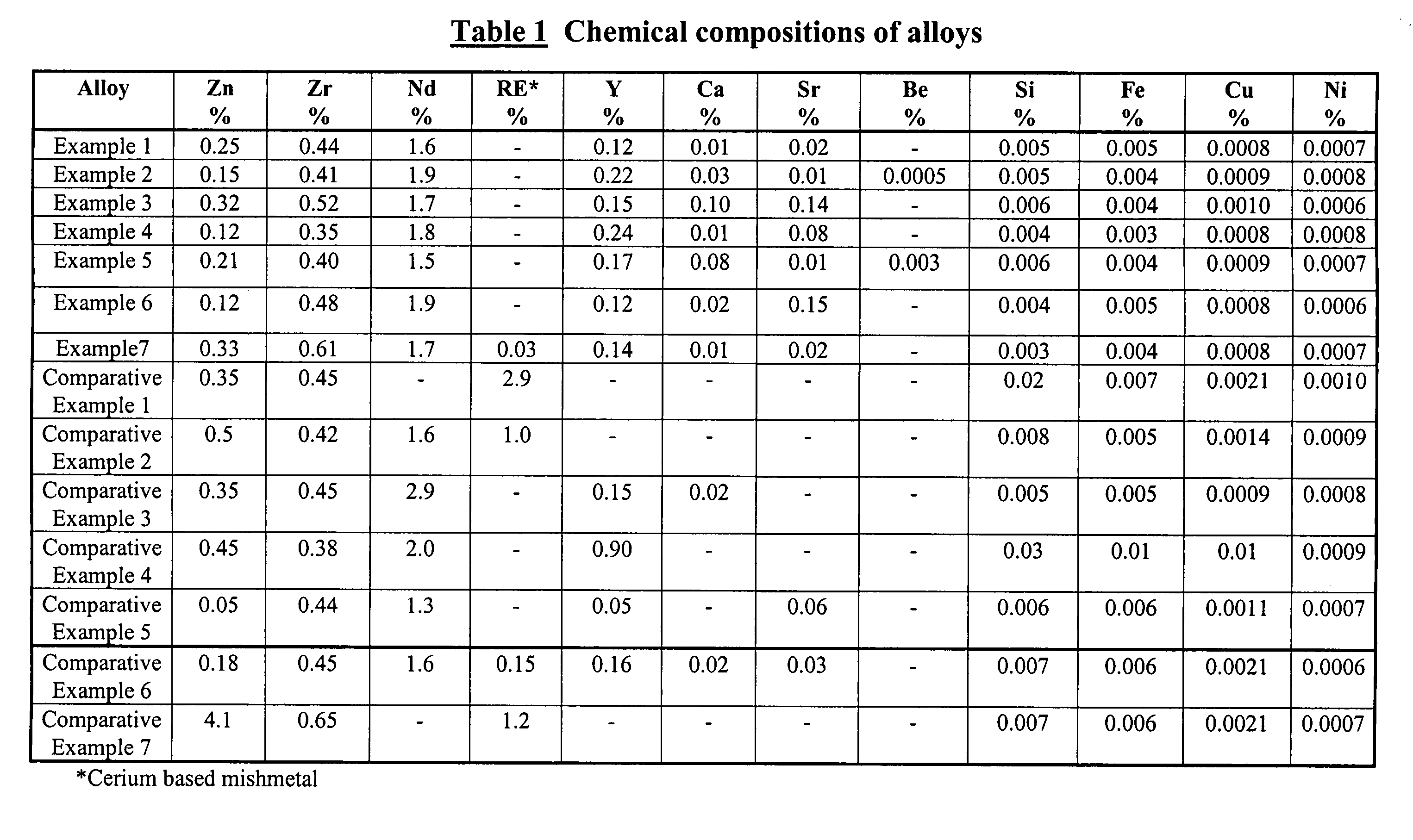

Creep resistant magnesium alloy with improved ductility and fracture toughness for gravity casting applications

The present invention relates to creep-resistant magnesium-based alloys with low susceptibility to hot tearing, and with improved ductility, impact strength and fracture toughness, and corrosion resistance. The alloys contain at least 96 wt % magnesium, 1.5 to 1.9 wt % neodymium, 0.10 to 0.30 wt % yttrium, 0.35 to 0.70 wt % zirconium, 0.05 to 0.35 wt % zinc, 0.01 to 0.10 wt % calcium, 0.01 to 0.15 wt % strontium, and 0.0000 to 0.0005 wt % beryllium, and they are suitable for low pressure and gravity castings. Articles, that are castings of the alloys, are suitable for applications at temperatures as high as 175-250° C.

Owner:DEAD SEA MAGNESIUM +1

High strength hot-dip galvanized or galvannealed steel sheet having improved plating adhesion and press formability and process for producing the same

InactiveUS6911268B2Improve stamping formabilityImprovement in surface corrosionHot-dipping/immersion processesFurnace typesCeriumAustenite

Disclosed are a high strength hot-dip galvanized or galvannealed steel sheet, which has improved press formability and plating adhesion and is useful as a member for automobile, building, electric or other members, and a process for producing the same.This high strength hot-dip galvanized or galvannealed steel sheet comprises: (a) a steel sheet substrate comprising, by weight, carbon (C): 0.05 to 0.2%, silicon (Si): 0.2 to 2.0%, manganese (Mn): 0.2 to 2.5%, and aluminum (Al): 0.01 to 1.5%, the silicon and the aluminum having a mutual relationship represented by formula 0.4(%)≦Si+0.8 Al (%)≦2.0(%), the steel sheet substrate further comprising at least one member selected from the group consisting of (i) 0.003 to 1.0% of tin (Sn), (ii) 0.005 to 1.0% in total of at least one member selected from antimony (Sb), bismuth (Bi), and selenium (Se), (iii) 0.005 to 1.0% in total of at least one member selected from beryllium (Be), magnesium (Mg), calcium (Ca), and zirconium (Zr), and (iv) 0.005 to 1.0% in total of at least one member selected from scandium (Sc), yttrium (Y), lanthanum (La), and cerium (Ce), with the balance consisting of iron (Fe) and unavoidable impurities, the volume fraction of retained austenite in the steel structure being 2 to 20%; and (b) a zinc (Zn) coating layer provided on said steel sheet substrate.

Owner:NIPPON STEEL CORP

Electroluminescent materials and devices

InactiveUS7887933B2Desirable hueImprove efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesIndiumCadmium Cation

An electroluminescent composition is provided comprising: (a) a compound of the general chemical formula (I):wherein M is lithium, sodium, potassium, rubidium, caesium, beryllium, magnesium, calcium, strontium, barium, copper, silver, gold, zinc, boron, aluminum, gallium, indium, germanium, tin, antimony, lead, manganese, iron, ruthenium, osmium, cobalt, rhodium, iridium, nickel, palladium, platinum, cadmium or chromium; n is the valence of M; and R1, R2 and R3 can be the same or different, and are selected from hydrogen, a substituted or unsubstituted aliphatic group, a substituted or unsubstituted aromatic, heterocyclic or polycyclic ring structure, a fluorocarbon, a halogen or a nitrile group; and (b) a suitable dopant. The composition may be used in forming electroluminescent devices.

Owner:MERCK PATENT GMBH

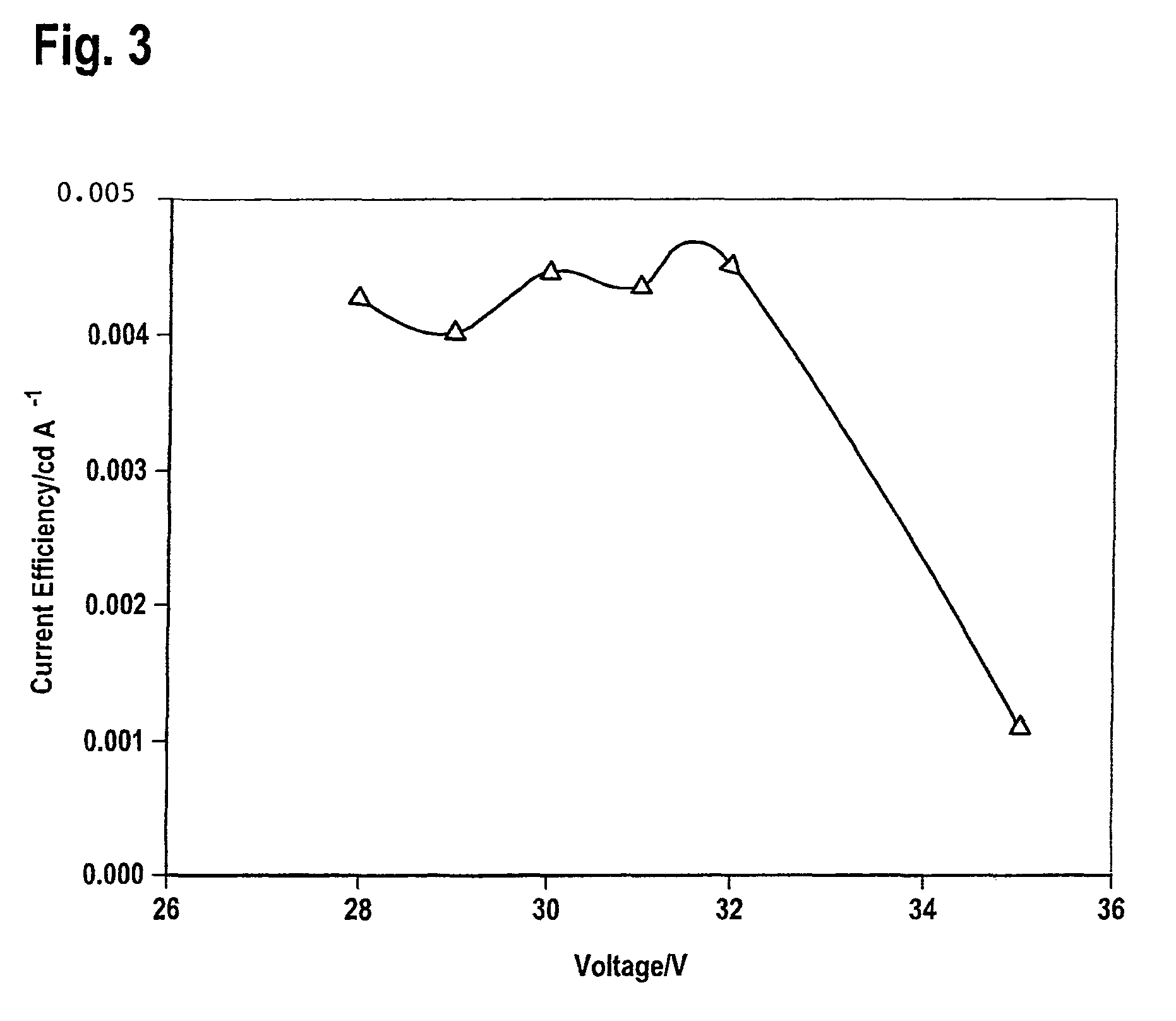

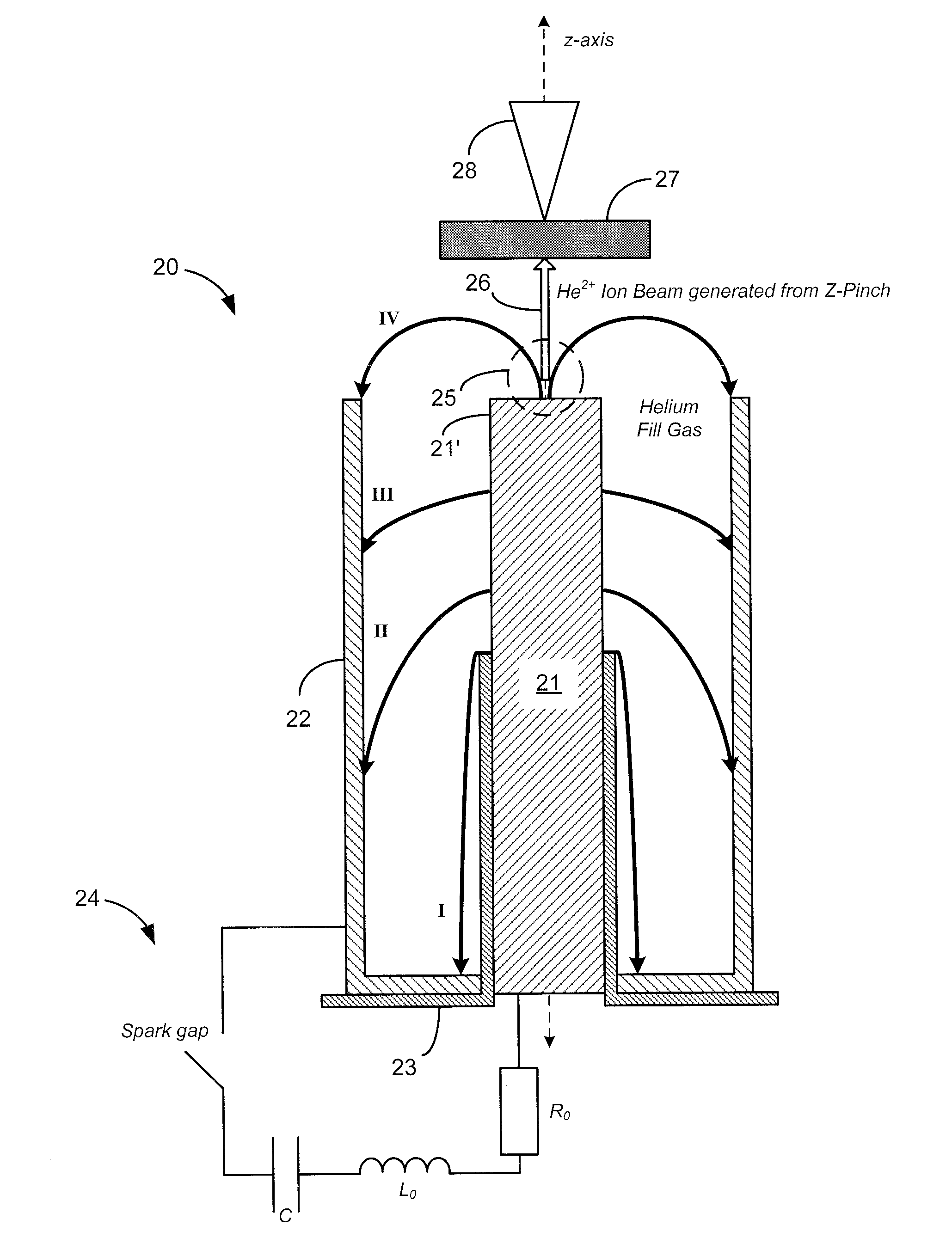

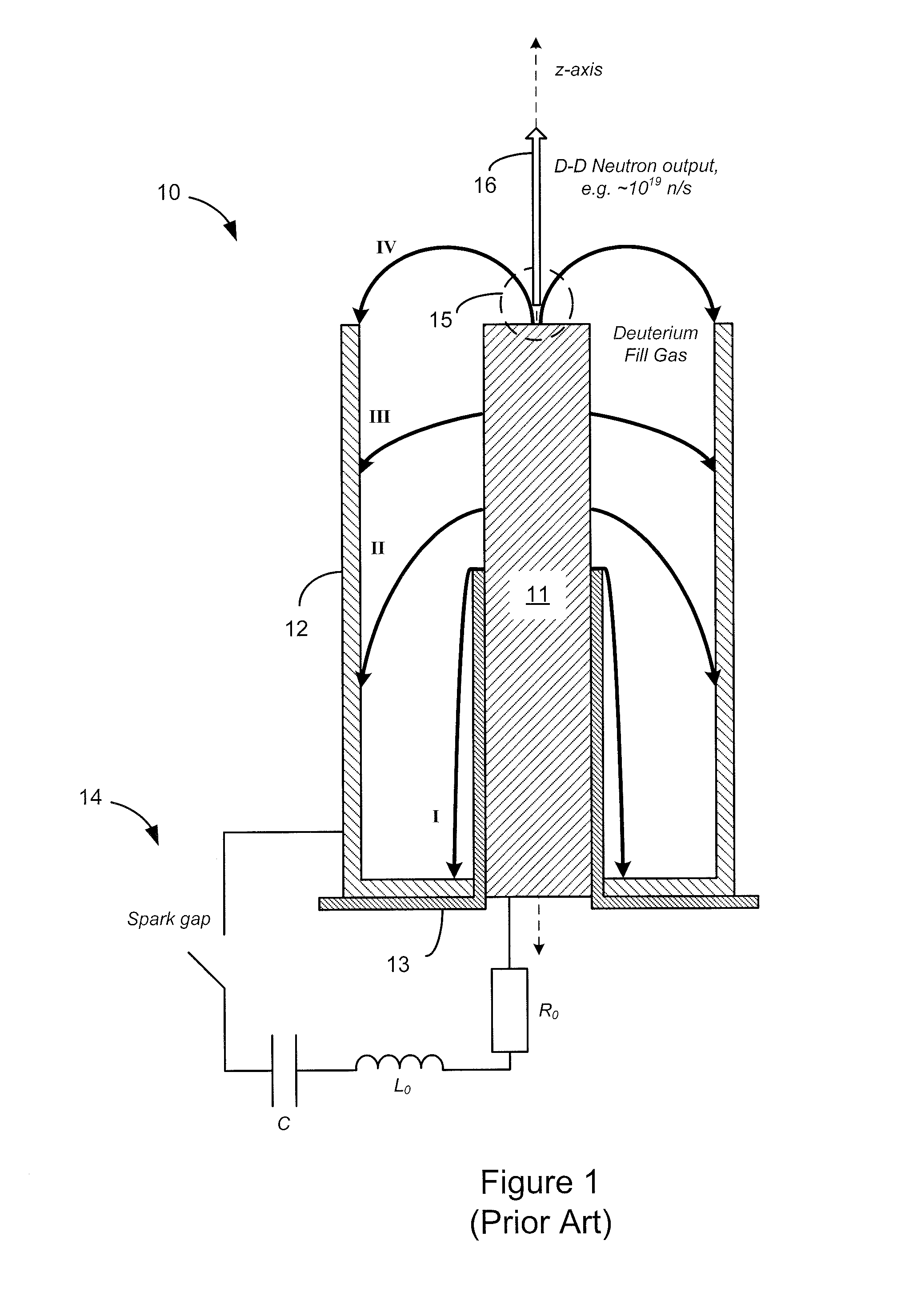

Dense plasma focus (DPF) accelerated non radio isotopic radiological source

ActiveUS20100215136A1High strengthEasy to adaptNuclear energy generationDirect voltage acceleratorsNeutron emissionIon beam

A non-radio-isotopic radiological source using a dense plasma focus (DPF) to produce an intense z-pinch plasma from a gas, such as helium, and which accelerates charged particles, such as generated from the gas or injected from an external source, into a target positioned along an acceleration axis and of a type known to emit ionizing radiation when impinged by the type of accelerated charged particles. In a preferred embodiment, helium gas is used to produce a DPF-accelerated He2+ ion beam to a beryllium target, to produce neutron emission having a similar energy spectra as a radio-isotopic AmBe neutron source. Furthermore, multiple DPFs may be stacked to provide staged acceleration of charged particles for enhancing energy, tenability, and control of the source.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

A kind of conductive paste for front electrode of crystalline silicon solar cell and preparation method thereof

InactiveCN102280161AImprove conductivityFirmly attachedNon-conductive material with dispersed conductive materialCable/conductor manufactureIndiumCerium

The invention discloses a conductive paste for a positive electrode of a crystal silicon solar cell and a preparation method of the conductive paste. The paste is prepared by mixing and grinding conductive metal powder, alloy powder which is formed by two or more elements selected from silver, zinc, tin, silicon, copper, magnesium, germanium, gold, beryllium, aluminum, indium, cerium, lanthanum, gallium, bismuth, and nickel, an organic carrier, and one or a mixture of transition metal oxide, lead oxide, stannic oxide, zinc oxide, organic compounds of zinc, and organic compounds of titanium according to a certain weight part. In the conductive paste, glass powder is not used as an inorganic binder, the problems of low electrical properties, low weldability and welding resistance, silicon chip bending and the like caused by adding the glass powder into the conductive paste for the positive electrode of thecrystal silicon solar cell in the prior art are solved, the positive electrode of the crystal silicon solar cell prepared from the paste has firm adhesive force, high ohmic contact, high weldability and high welding resistance, and the solar cell has a high electrical property and low deformability.

Owner:陈晓东

Preparation method of bonded gold-silver alloy wire

ActiveCN102776405AImprove conductivityStable chemical propertiesSemiconductor/solid-state device detailsSolid-state devicesCeriumTechnical design

The invention relates to a preparation method of a bonded gold-silver alloy wire, and belongs to the technical field of bonded wire processing processes. The bonded gold-silver alloy wire comprises the following metal materials by weight: 20-30% of silver, 5-1000 ppm of palladium, 5-1000 ppm of calcium, 5-1000 ppm of beryllium, 5-1000 ppm of cerium and the balance of gold; the preparation method comprises the following steps: 1), preparing materials; 2) smelting an alloy ingot; 3) pulling and casting an alloy rod; 4) wire-drawing; 5) annealing; 6) coiling; and 7) packaging. The preparation method of the bonded gold-silver alloy wire, provided by the invention, has the advantages of reasonable and standard technical design, and simple operation, the produced bonded gold-silver alloy wire has the advantages of strong conductivity, stable chemical performance, good oxidation resistance, flowability and plasticity, higher breaking force and better elongation, and moderate cost, and requirements of semiconductor package industry and LED (Light Emitting Diode) illumination technology on the performances of the bonded gold-silver alloy wire can be completely satisfied.

Owner:烟台招金励福贵金属股份有限公司

Remediation of metal contaminants with hydrocarbon-utilizing bacteria

Methods and apparatus are disclosed for remediating metal contaminants using hydrocarbons which stimulate the growth of hydrocarbon-utilizing bacteria. The metal contaminants may include heavy metals such as arsenic, antimony, beryllium, cadmium, chromium, copper, lead, mercury, iron, manganese, magnesium, radium, nickel, selenium, silver, thallium and zinc. The hydrocarbon may include alkanes, alkenes, Aalkynes, poly(alkene)s, poly(alkyne)s, aromatic hydrocarbons, aromatic hydrocarbon polymers and aliphatic hydrocarbons. Butane is a particularly suitable hydrocarbon which stimulates the growth of butane-utilizing bacteria. Remediation may occur in-situ or ex-situ, and may occur under aerobic, anaerobic or dual aerobic / anaerobic conditions. Examples of applications include the remediation of heavy metals, the remediation of arsenic impacted surface water, groundwater and / or soil, the remediation of acid mine drainage, and the treatment of spent metal plating solutions.

Owner:GLOBAL BIOSCI

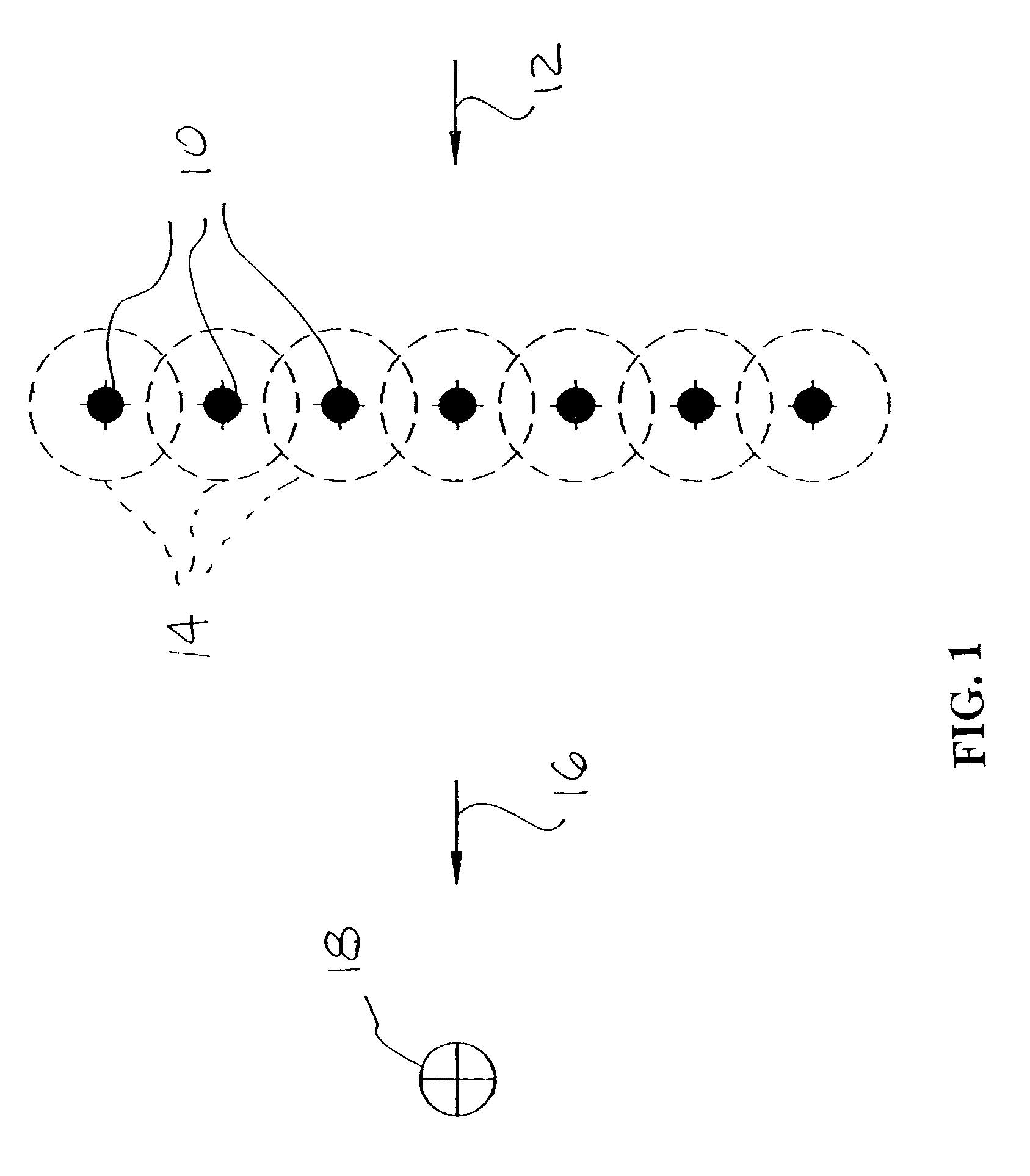

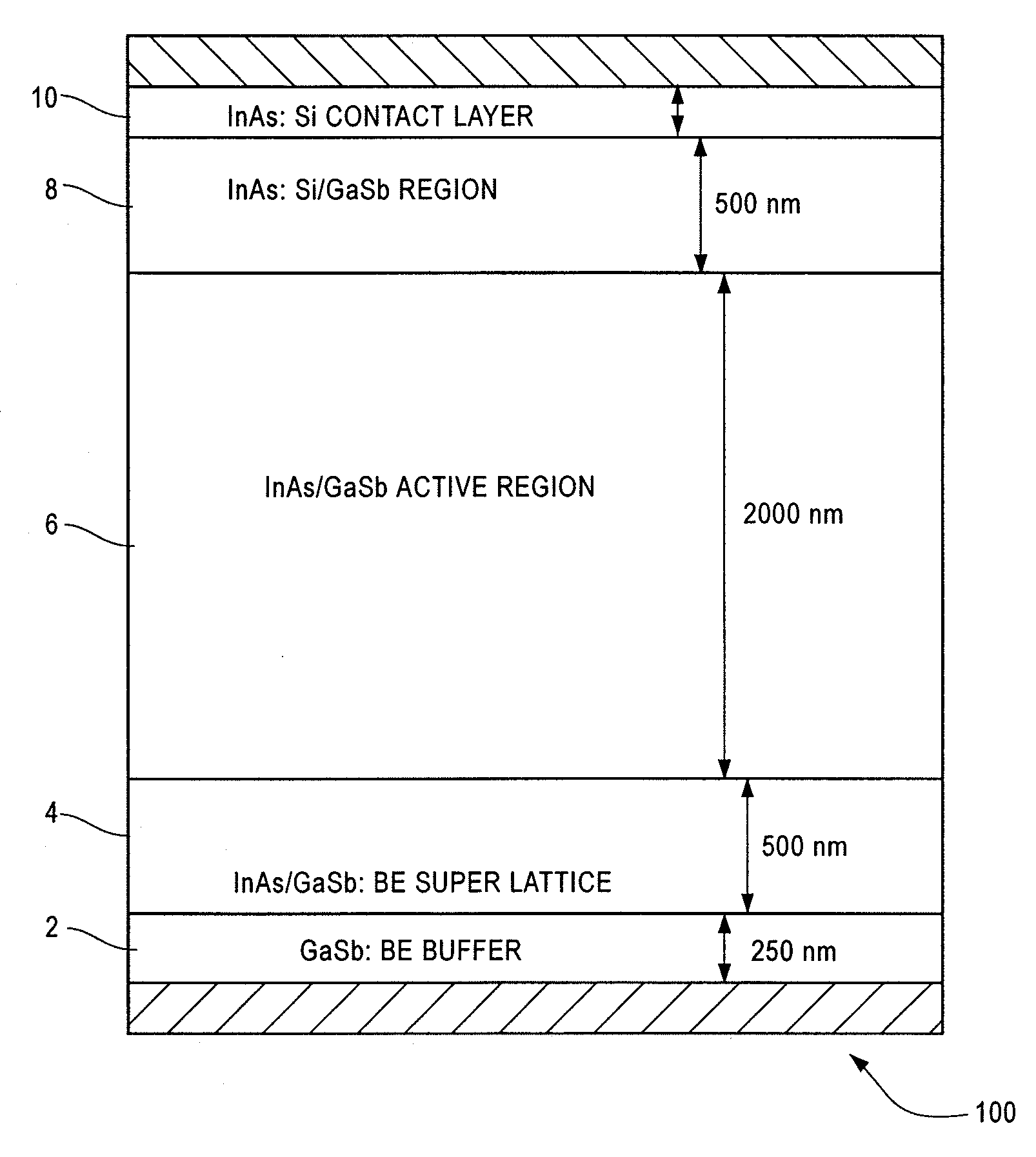

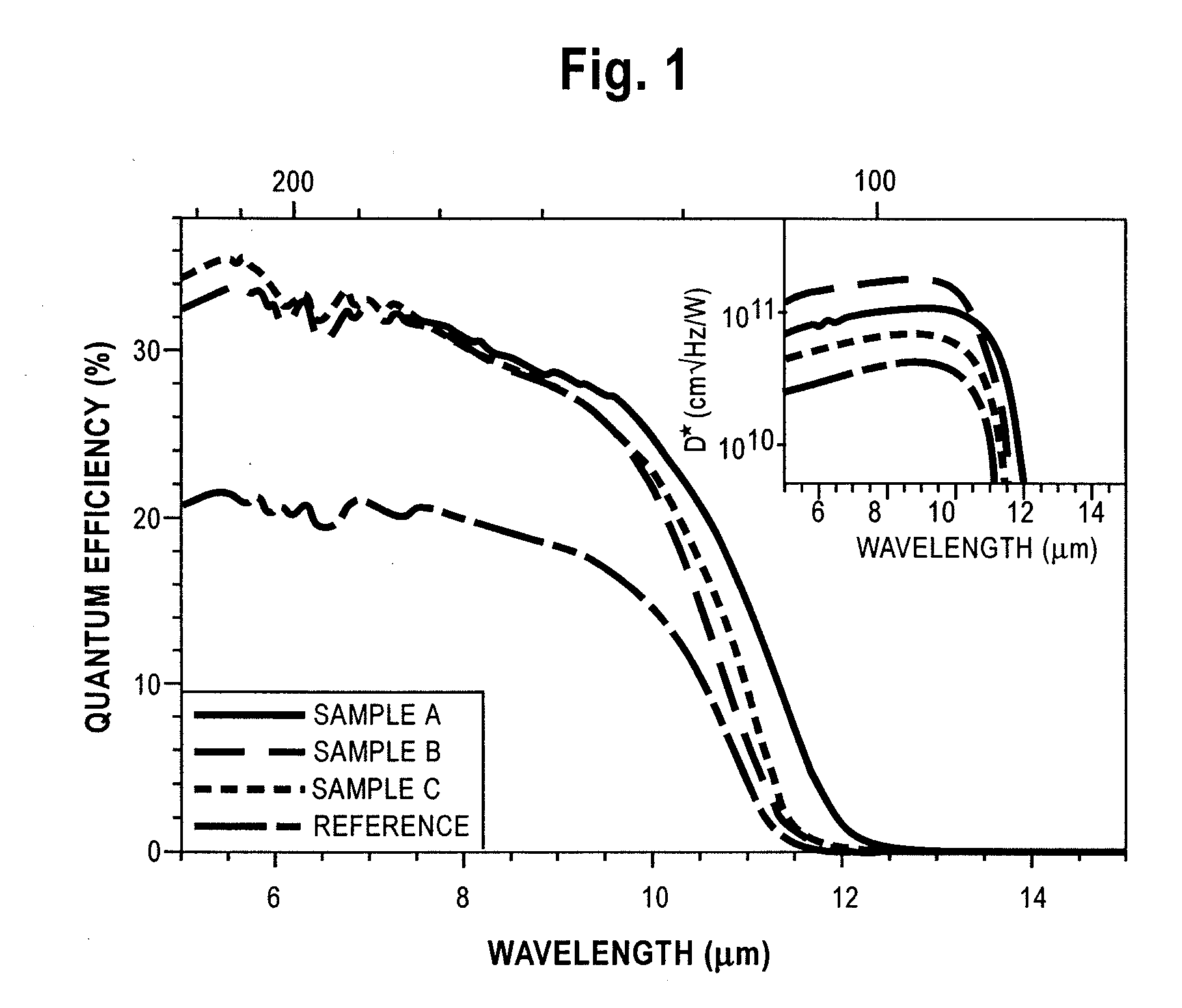

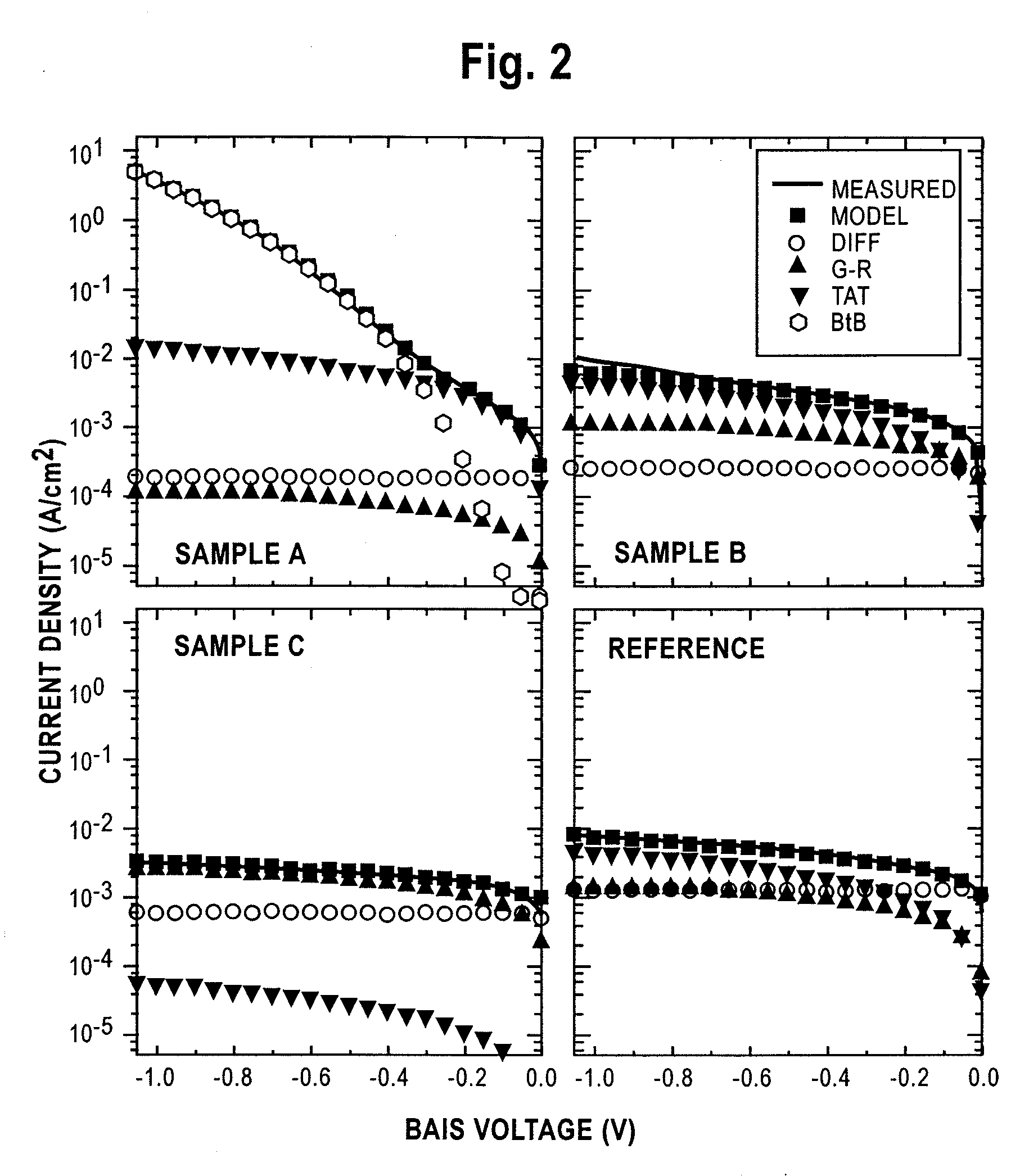

InAs/GaSb Infrared Superlattice Photodiodes Doped with Beryllium

ActiveUS20090224228A1Improve performanceImprove equipment efficiencySolid-state devicesSemiconductor/solid-state device manufacturingQuantum efficiencyPhotodiode

An improved photodiode and method of producing an improved photodiode comprising doping an InAs layer of an InAs / GaSb region situated on top of an InAs / GaSb:Be superlattice and below an InAs:Si / GaSb regions such that the quantum efficiency of the photodiode increases and dominant dark current mechanisms change from diffusion to band-to-band tunneling as the InAs layer is doped with Beryllium.

Owner:NORTHWESTERN UNIV

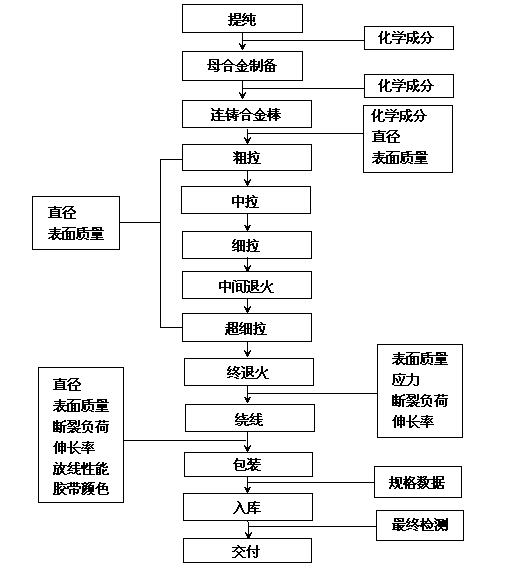

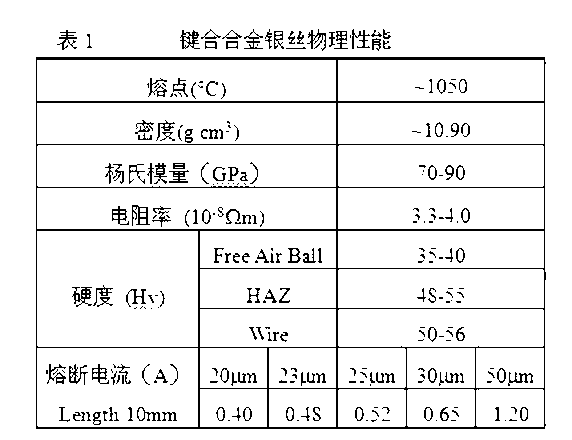

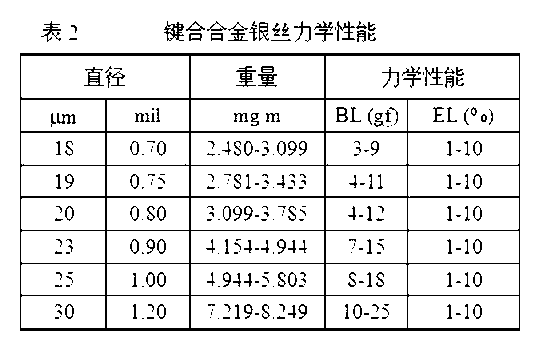

Bonding alloy filamentary silver and preparation method thereof

ActiveCN103194637AImprove conductivityAntioxidantSolid-state devicesSemiconductor devicesCeriumSemiconductor package

The invention relates to bonding alloy filamentary silver and a preparation method thereof, and belongs to the technical field of processing of a bonding wire. The bonding alloy filamentary silver comprises the following metal materials by mass ratio: less than 90wt% of silver, 3.0-10.0wt% of gold, and 3.0-8.0wt% of palladium; and the bonding alloy filamentary silver also comprises at least two of following metals of 10-100ppm of calcium, 4-10ppm of beryllium, 10-100ppm of cerium, and 50-500ppm of copper. The preparation method comprises the steps of 1) preparing materials; 2) smelting mother alloy; 3) continuously casting an alloy rod; 4) roughly working, intermediately drawing, and finely drawing; 5) carrying out middle annealing; 6) ultra-finely drawing; 7) finally annealing; 8) winding; and 9) packaging. The technology disclosed by the invention is specified and reasonable in design, and simple and convenient to operate; the obtained product is strong in electrical conductivity, has certain inoxidizability, good plasticity, high rupturing load, good elongation and low cost, can meet the demands of the semiconductor encapsulation industry and a light-emitting diode (LED) illumination technology on performance of the bonding alloy filamentary silver, and can be used as a substitute for a bonding alloy wire.

Owner:烟台招金励福贵金属股份有限公司

P-type group II-VI semiconductor compounds

InactiveUS7161173B2Diminish desired electronic propertyInhibit single crystal formationPolycrystalline material growthSemiconductor/solid-state device manufacturingAlkaline earth metalSemiconductor materials

A persistent p-type group II-VI semiconductor material is disclosed. The group II-VI semiconductor includes atoms of group II elements, atoms of group VI elements, and one or more p-type dopants. The p-type dopant concentration is sufficient to render the group II-VI semiconductor material in a single crystal form. The semiconductor resistivity is less than about 0.5 ohm·cm, and the carrier mobility is greater than about 0.1 cm2 / V·s. Group II elements include zinc, cadmium, the alkaline earth metals such as beryllium, magnesium calcium, strontium, and barium, and mixtures thereof. Group VI elements include oxygen, sulfur, selenium, tellurium, and mixtures thereof. P-type dopants include, but are not limited to, nitrogen, phosphorus, arsenic, antimony, bismuth, copper, chalcogenides of the foregoing, and mixtures thereof.

Owner:ZENO MATERIALS LLC

Method for in-situ preparation of TiBO2 reinforced magnesium-based composite material

The invention relates to a method of in-situ preparing TiB2 granule strengthening Mg-based composite material in the composite material technical field. The steps are that: powder of K2TiF6, KBF4 and Na3AlF6 are mixed uniformly and then put into a kiln for drying, thus obtaining waterless powder. Aluminum ingot is melted in a resistance furnace with heat preservation and uniformity; the waterless powder after dried is added to the melting Al melt liquid by batch and then is stirred with a graphite disc, and scum on the surface of the melt liquid is removed after stirred and stewed, thus obtaining TiB2-Al intermediate alloy; magnesium alloy is smelted with the protection of SF6 and CO2 mixing gas, and flame retardant element beryllium is added; the TiB2-Al intermediate alloy is added into the magnesium alloy melting solution slowly, stirred, stewed and cast. The technology of the invention is comparatively simple, has low cost, and the density of TiB2 / Mg composite material is between 1.8-2.0g / cm<3> and tensile strength thereof is increased by more than 60 percent than base alloy.

Owner:SHANGHAI JIAO TONG UNIV

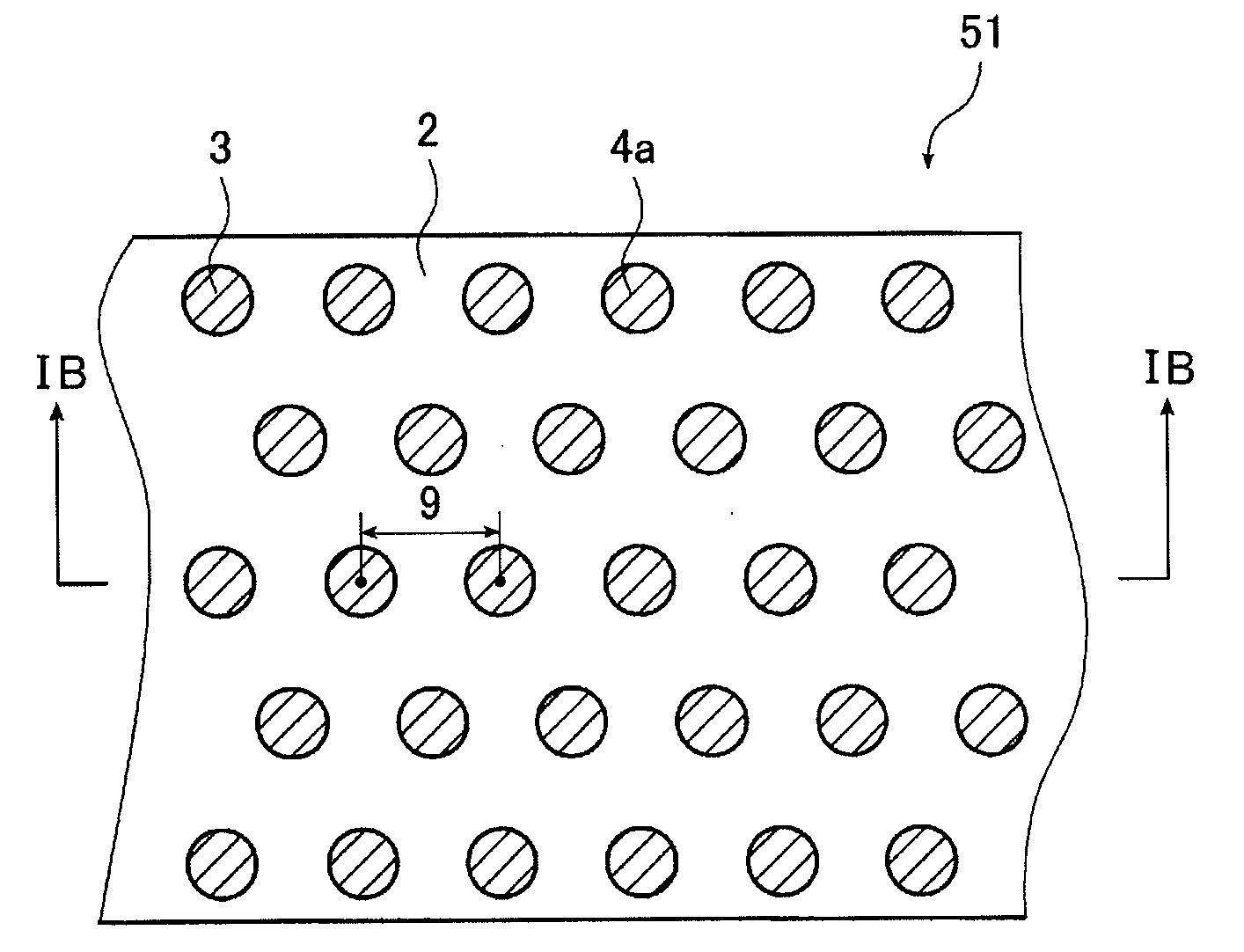

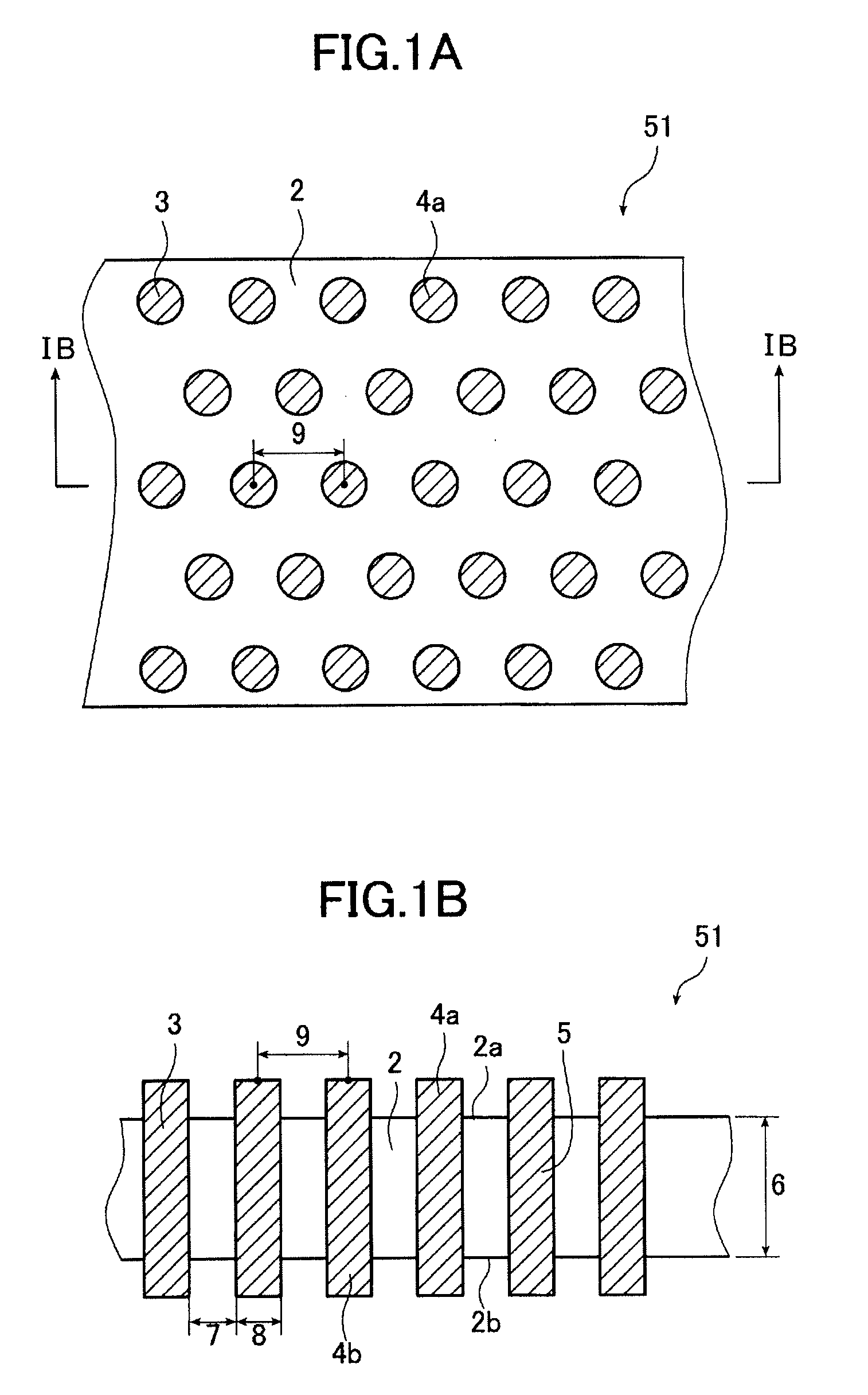

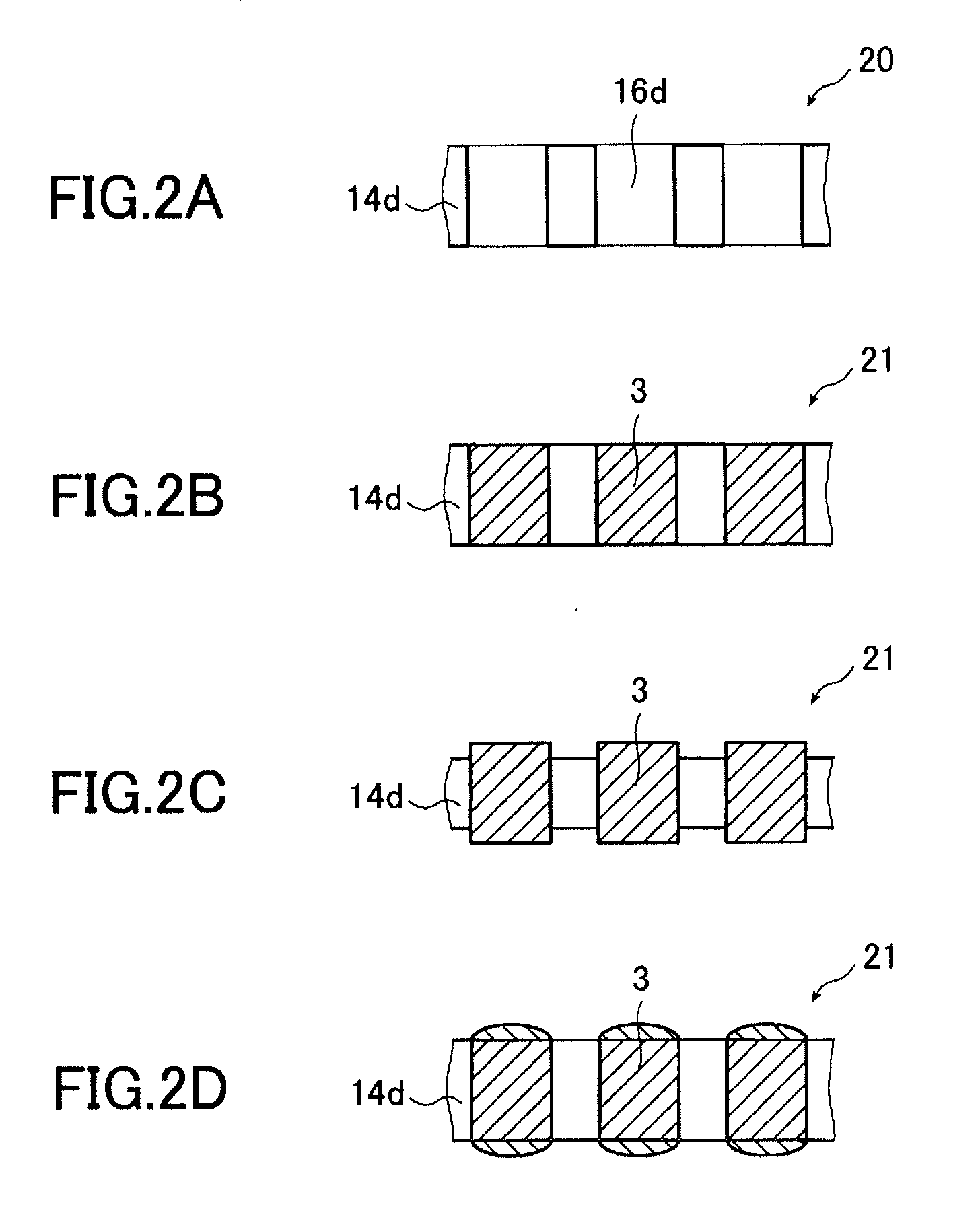

Anisotropic conductive joint package

ActiveUS20100294547A1High densityHighly integratedPrinted circuit assemblingLine/current collector detailsAnisotropic conductive filmRhenium

An anisotropic conductive joint package in which an anisotropic conductive film is joined to at least one conductive material selected from among the group consisting of gold (Au), silver (Ag), copper (Cu), aluminum (Al), magnesium (Mg), nickel (Ni), a tin oxide doped with indium (ITO), molybdenum (Mo), iron (Fe), palladium (Pd), beryllium (Be), and rhenium (Re). The package is characterized in that: the anisotropic conductive film has an insulating base and conductive paths composed of conductive members, insulated from one another, and extending through the insulating base in the direction of the thickness of the insulating base, one ends of the conductive paths are exposed from one side of the insulating base, the other ends are exposed from the other side, the density of the conductive paths is 3,000,000 pieces / mm2 or more, the insulating base is a structural body composed of an anodic oxide film of an aluminum substrate having micropores, and each micropore does not have a branch structure along the depth. The package can be used as an anisotropic conductive member of an electronic component of a semiconductor device or the like or a connector for inspection even if the structure has a much higher degree of integration realized by drastically improving the installation density of the conductive paths.

Owner:FUJIFILM CORP

Methanation catalyst and preparation method thereof

ActiveCN102463119AHigh catalytic activityImprove catalytic stabilityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsCooking & bakingNickel salt

The invention discloses a methanation catalyst and a preparation method thereof. The methanation catalyst comprises the following components: a) nickel oxide, wherein nickel content is 5-50wt%; b) manganese oxide, wherein manganese content is 0.1-15wt%; c) at least one of oxides of beryllium, manganese, calcium, strontium, barium, lanthanum and cerium, wherein metal content is 0.5-20wt%; the components a) and b) are distributed within the range from the surface of carrier particles to a position 1 / 2 radius away from the center, and the component c) is distributed into the whole carrier particles. The preparation method disclosed by the invention comprises the following steps of: 1) mutually dissolving nickel salt and / or manganese salt with organic acid, preparing salt of the component c) into aqueous solution; and 2) dipping supported components nickel, manganese and the component c), wherein the component c) is independently supported, and baking and sintering decomposition treatment are carried out after supporting every time. The catalyst disclosed by the invention can maintain better catalytic activity and stability in a wider temperature range and has good catalytic effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com