Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3730 results about "Cadmium Cation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The oxidation state +1 can be produced by dissolving cadmium in a mixture of cadmium chloride and aluminium chloride, forming the Cd22+ cation, which is similar to the Hg22+ cation in mercury(I) chloride.

Manufacturing apparatus and method for large-scale production of thin-film solar cells

ActiveUS20050109392A1Cheap productionLow costPV power plantsFinal product manufactureIndiumElectrical battery

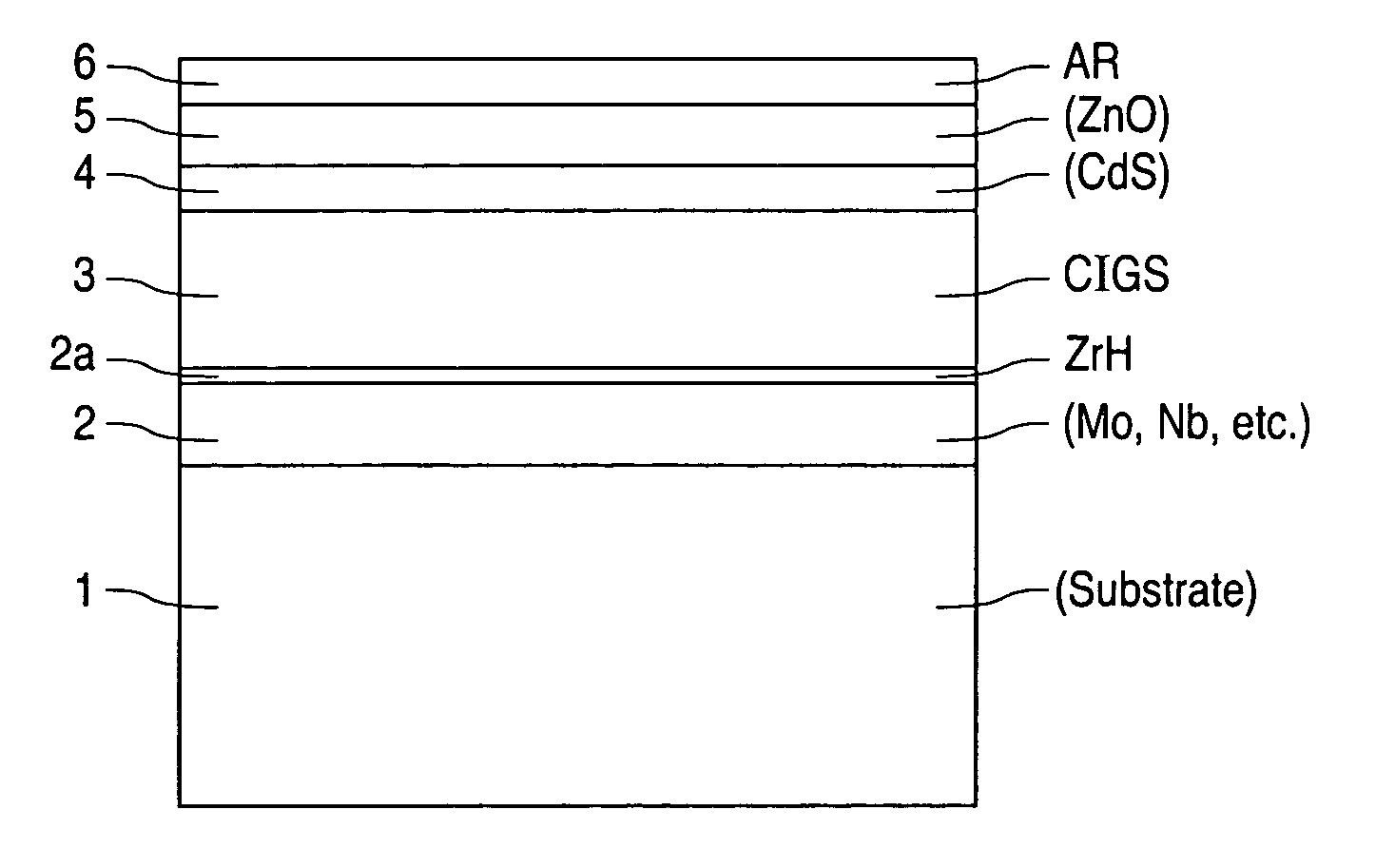

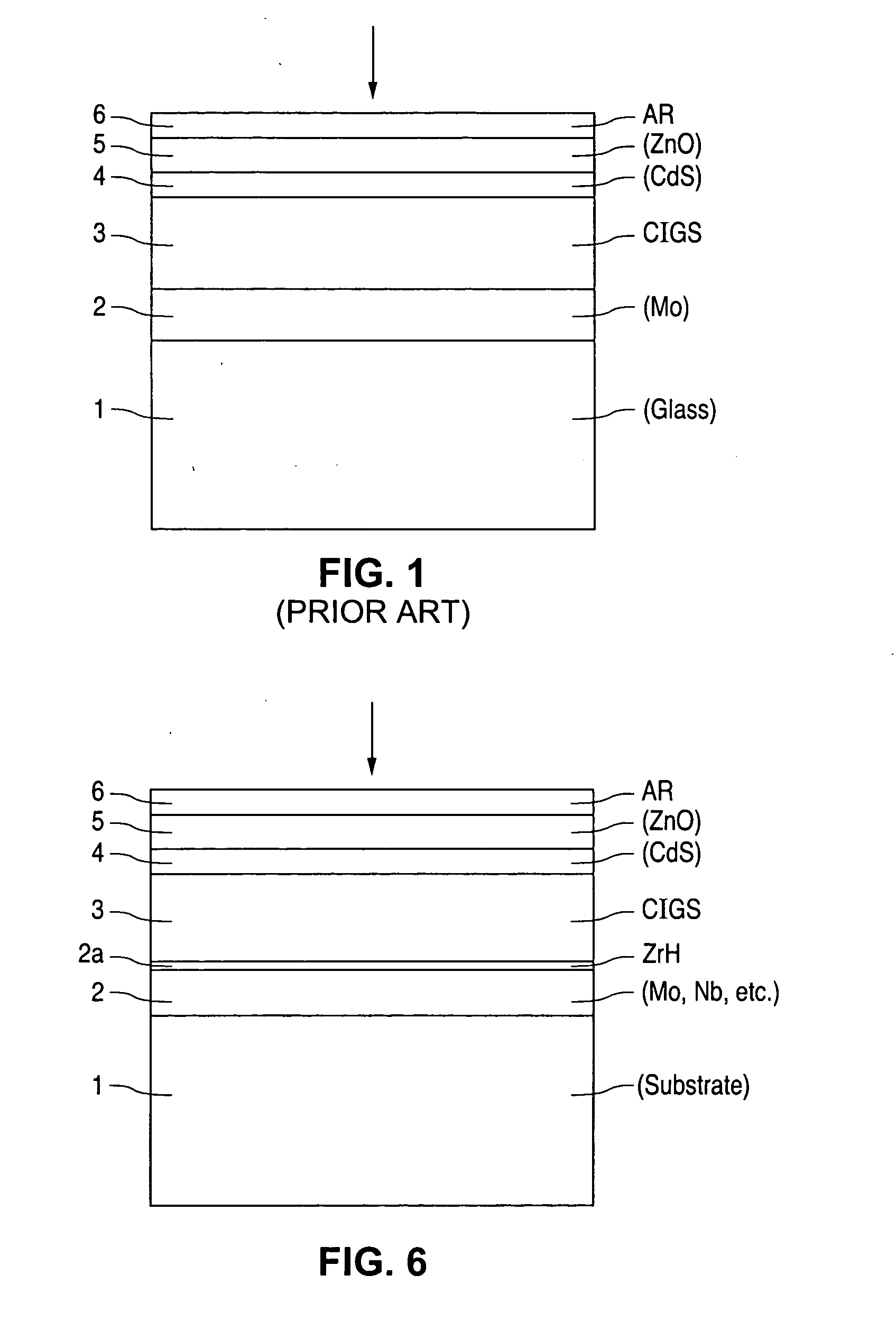

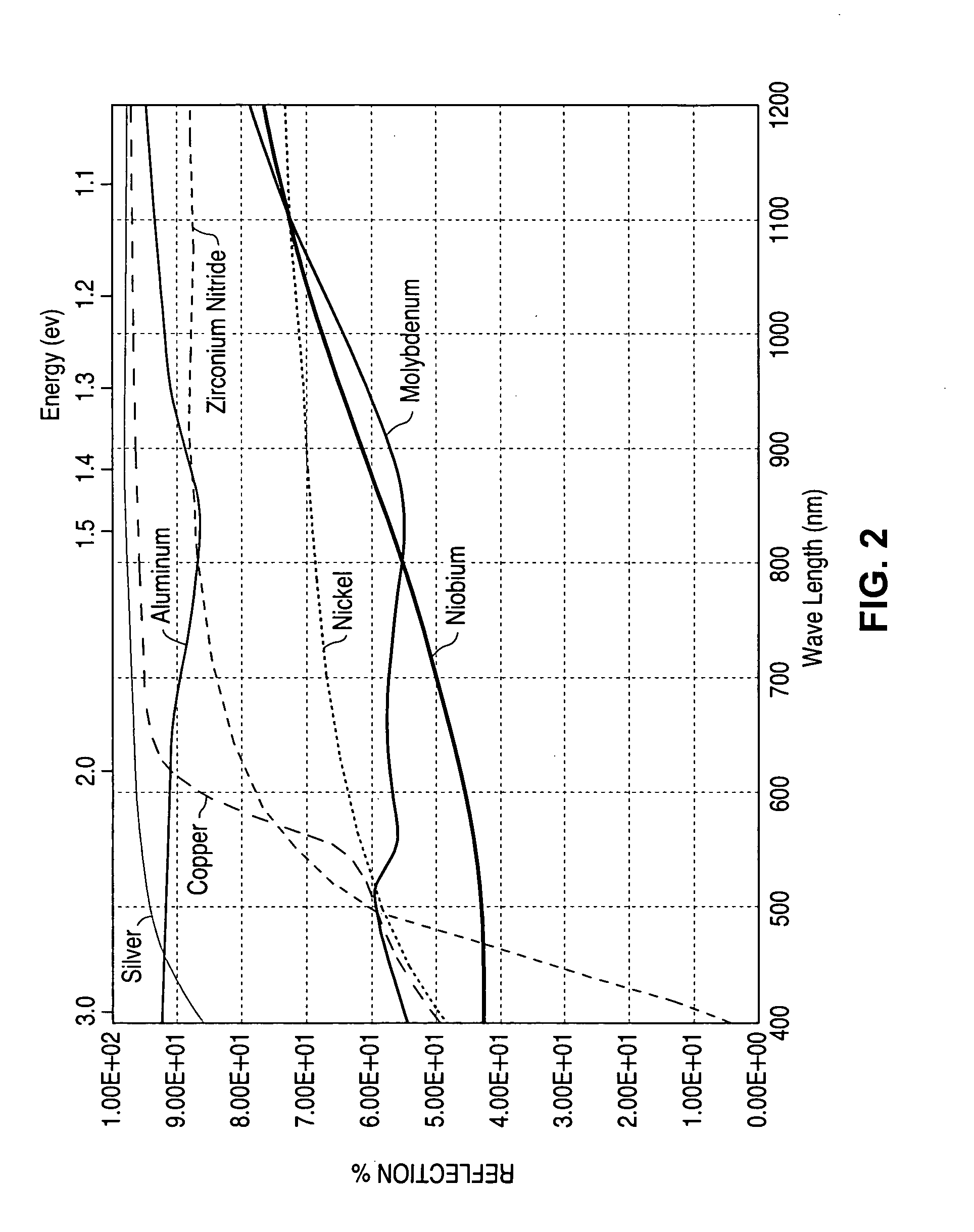

A method of manufacturing improved thin-film solar cells entirely by sputtering includes a high efficiency back contact / reflecting multi-layer containing at least one barrier layer consisting of a transition metal nitride. A copper indium gallium diselenide (Cu(InXGa1-x)Se2) absorber layer (X ranging from 1 to approximately 0.7) is co-sputtered from specially prepared electrically conductive targets using dual cylindrical rotary magnetron technology. The band gap of the absorber layer can be graded by varying the gallium content, and by replacing the gallium partially or totally with aluminum. Alternately the absorber layer is reactively sputtered from metal alloy targets in the presence of hydrogen selenide gas. RF sputtering is used to deposit a non-cadmium containing window layer of ZnS. The top transparent electrode is reactively sputtered aluminum doped ZnO. A unique modular vacuum roll-to-roll sputtering machine is described. The machine is adapted to incorporate dual cylindrical rotary magnetron technology to manufacture the improved solar cell material in a single pass.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

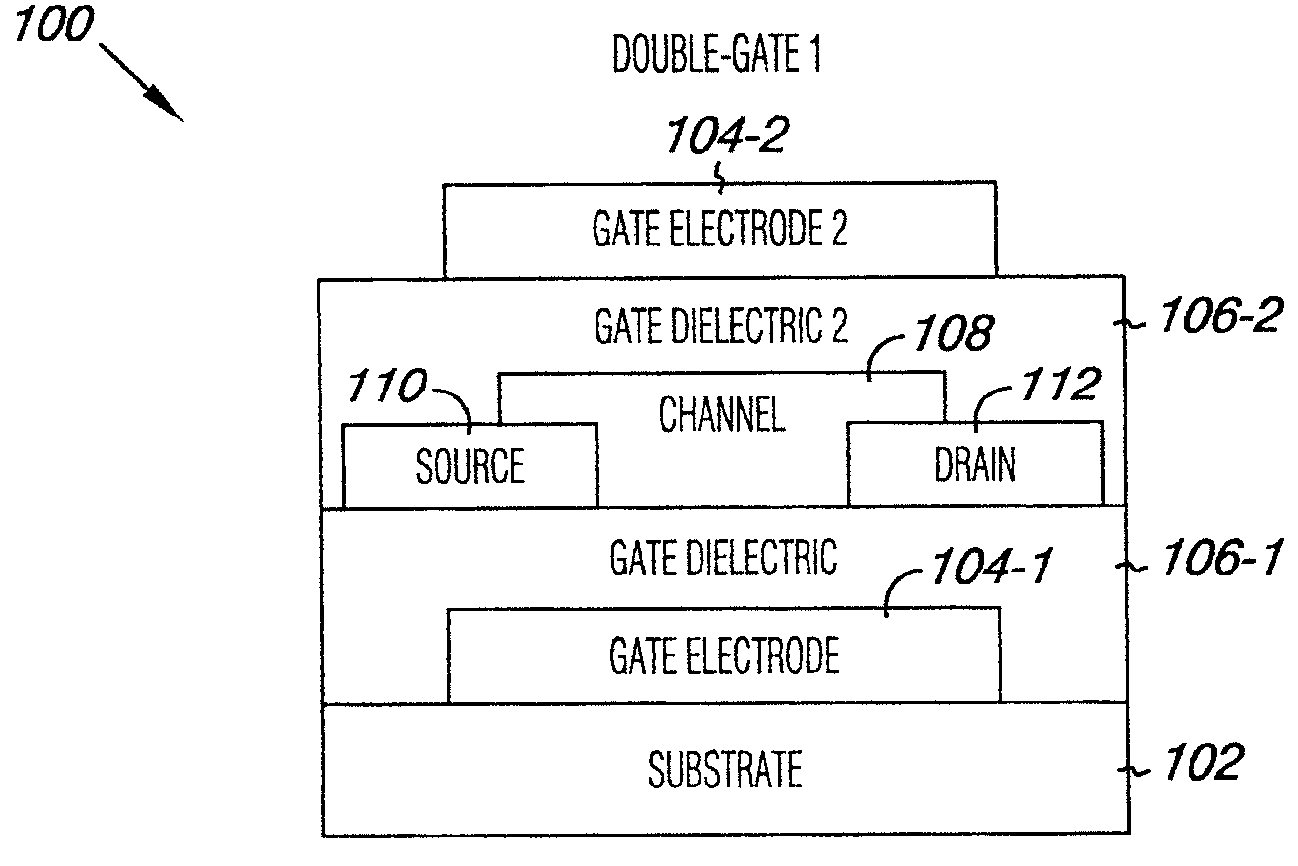

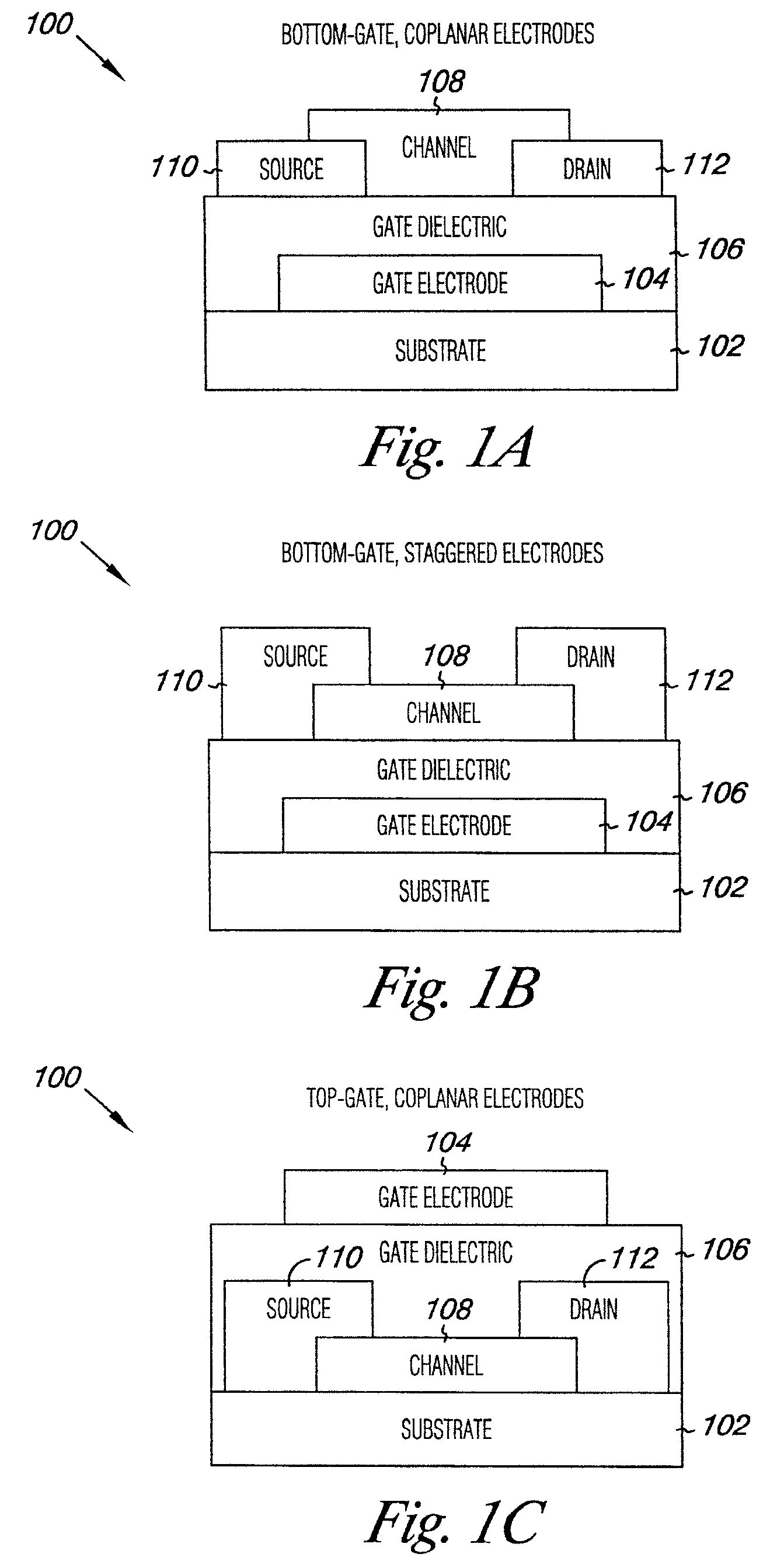

Method of making a semiconductor device having a multicomponent oxide

One exemplary embodiment includes a semiconductor device. The semiconductor device can include a channel including one or more of a metal oxide including zinc-gallium, cadmium-gallium, cadmium-indium.

Owner:HEWLETT PACKARD DEV CO LP

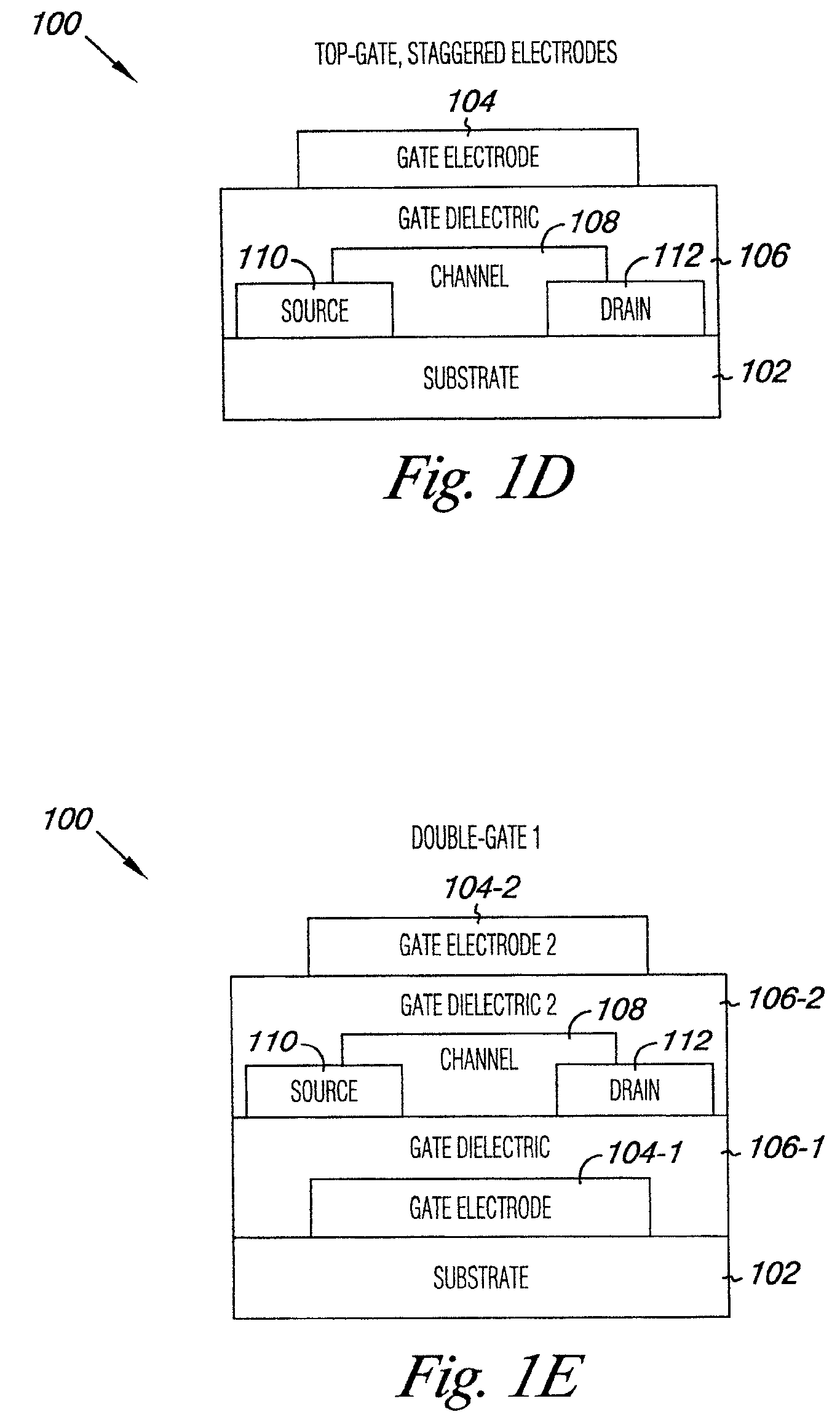

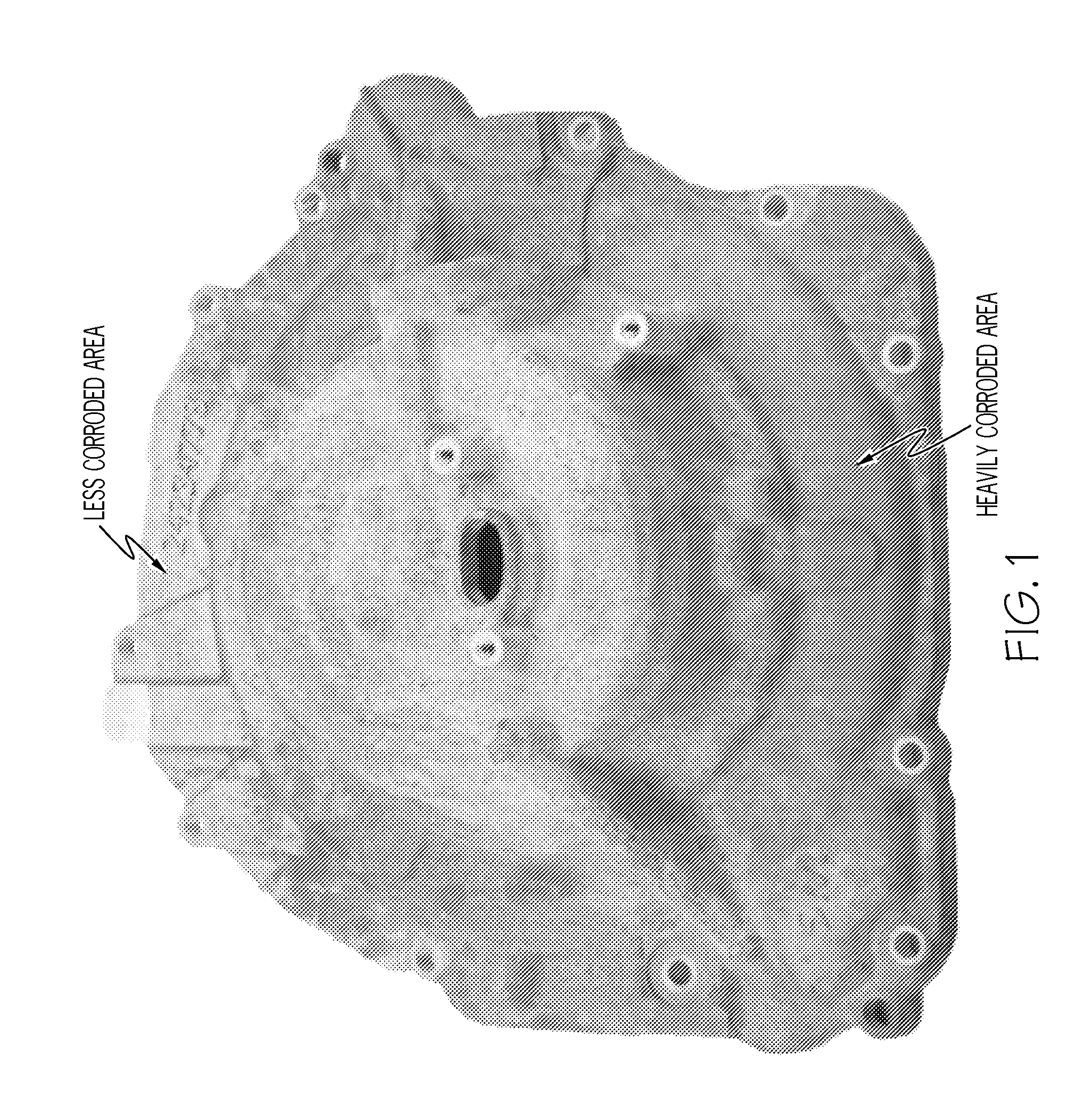

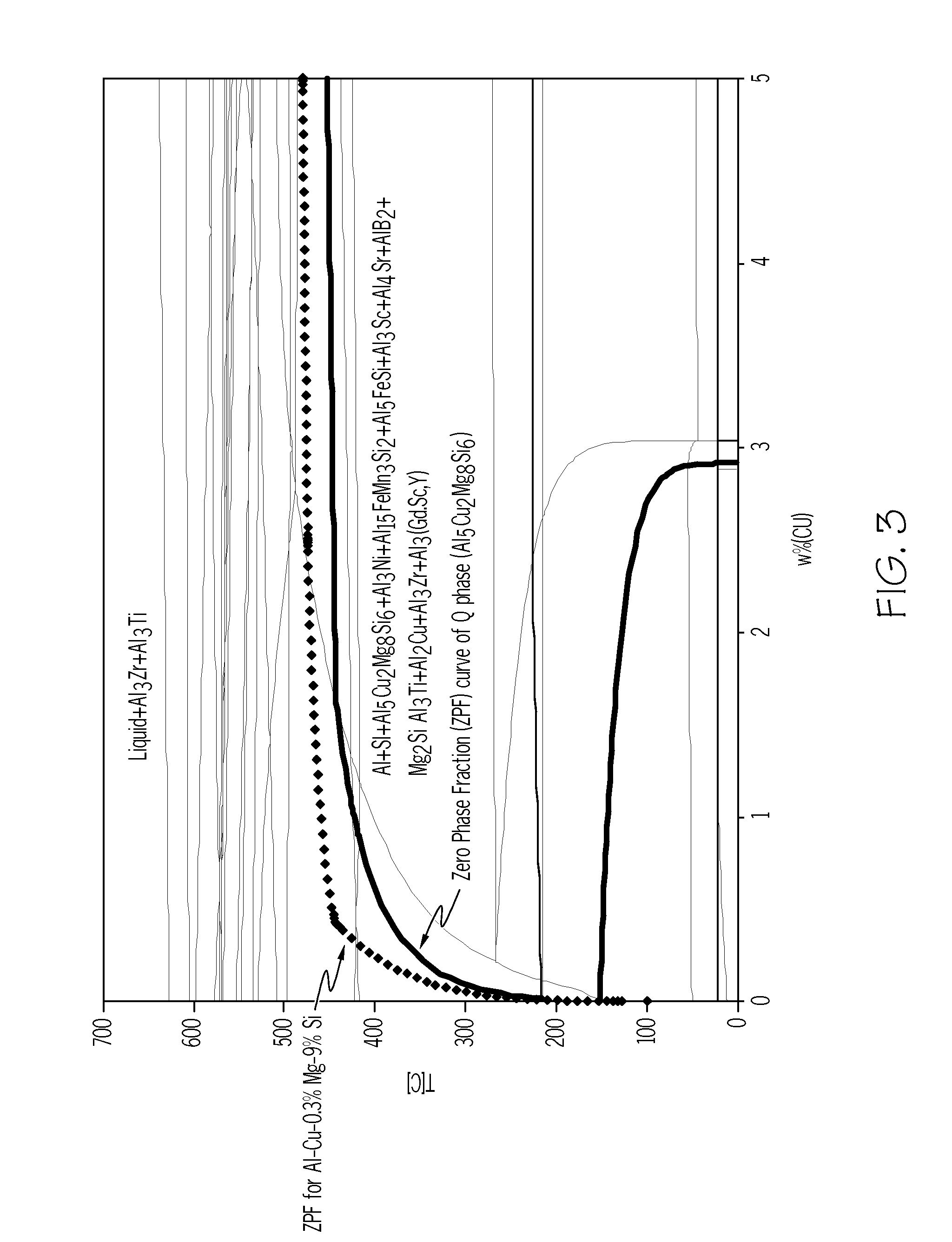

Cast aluminum alloys

ActiveUS20120000578A1Improve mechanical propertiesImprove corrosion resistanceAngiosperms/flowering plantsRare-earth elementIndium

Aluminum alloys having improved properties are provided. The alloy includes about 0 to 2 wt % rare earth elements, about 0.5 to about 14 wt % silicon, about 0.25 to about 2.0 wt % copper, about 0.1 to about 3.0 wt % nickel, approximately 0.1 to 1.0% iron, about 0.1 to about 2.0 wt % zinc, about 0.1 to about 1.0 wt % magnesium, 0 to about 1.0 wt % silver, about 0.01 to about 0.2 wt % strontium, 0 to about 1.0 wt % scandium, 0 to about 1.0 wt % manganese, 0 to about 0.5 wt % calcium, 0 to about 0.5 wt % germanium, 0 to about 0.5 wt % tin, 0 to about 0.5 wt % cobalt, 0 to about 0.2 wt % titanium, 0 to about 0.1 wt % boron, 0 to about 0.2 wt % zirconium, 0 to 0.5% yttrium, 0 to about 0.3 wt % cadmium, 0 to about 0.3 wt % chromium, 0 to about 0.5 wt % indium, and the balance aluminum. Methods of making cast aluminum parts are also described.

Owner:GM GLOBAL TECH OPERATIONS LLC

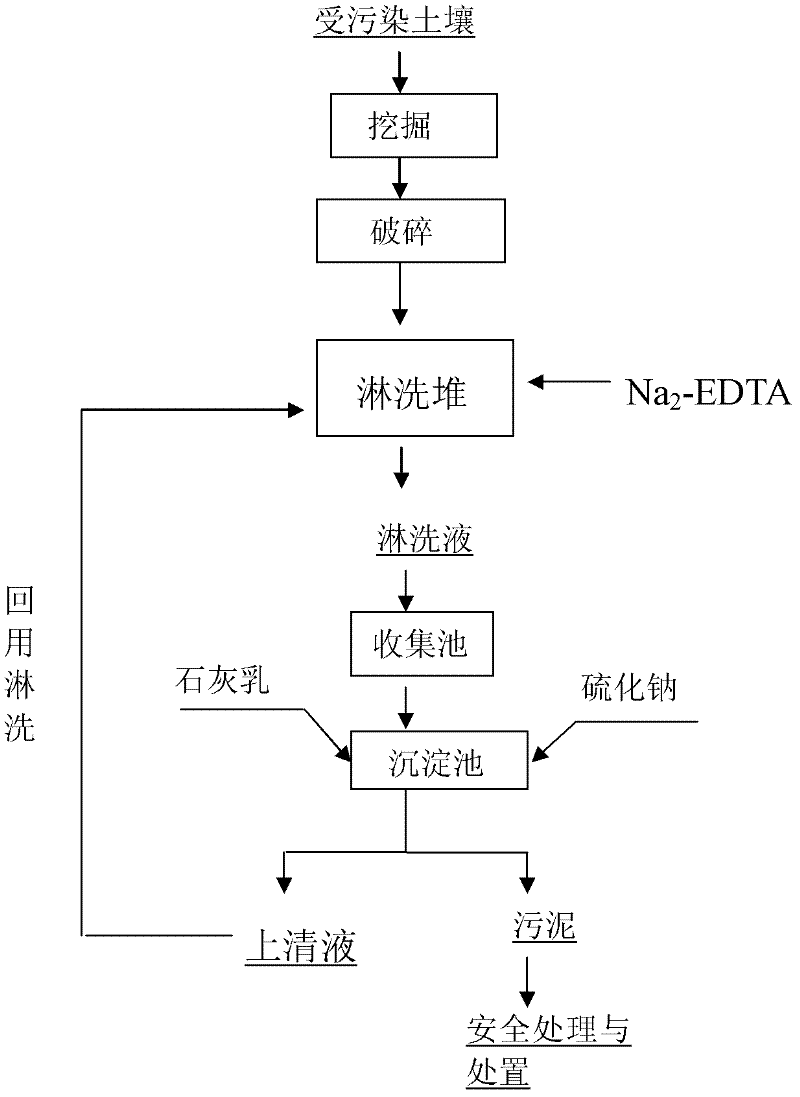

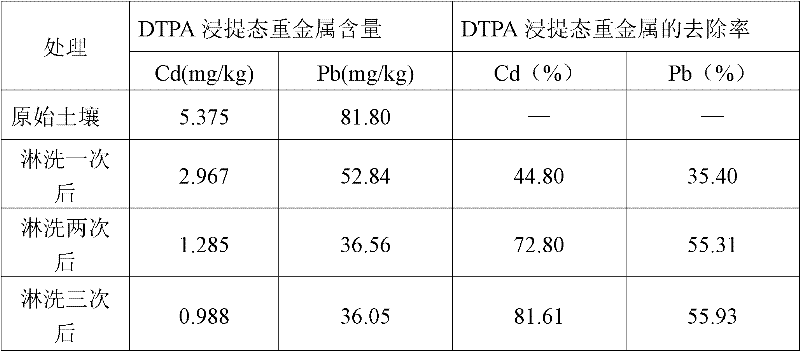

Chemical leaching restoring method for soil polluted by heavy metals

ActiveCN102500612AReduce Na

<sup>+</sup>

contentReduce operating costsContaminated soil reclamationPollution soilCadmium Cation

The invention discloses a chemical leaching restoring method for soil polluted by heavy metals. Na2EDTA solution is utilized to perform leaching to the soil polluted by the heavy metals, available cadmium and lead in the soil are effectively removed, Na2S.9H2O is utilized to precipitate the heavy metals in filtrate, Na2EDTA is released again, and repeated recycling of the Na2EDTA solution is achieved. After recycling, the Na2EDTA solution carries out leaching to the soil polluted by the heavy metals, the removing rate of available Cd in the polluted soil reaches 81.6-81.8%, and the removing rate of available Pb reaches 55.9-60.1%. The chemical leaching restoring method for the soil polluted by the heavy metals overcomes the shortcomings that an existing method for the Na2EDTA solution to perform leaching to the soil polluted by the heavy metals causes chemical cost to be large, generated filtrate is much, and the follow-up treatment is troublesome. Simultaneously, the chemical leaching restoring method for the soil polluted by the heavy metals has the advantages of being simple in process, becoming effective quickly, enabling a leaching agent to be reused, and enabling the heavy metals to be effectively eliminated.

Owner:CENT SOUTH UNIV +1

Process to make metal oxide thin film transistor array with etch stopping layer

The present invention generally relates to thin film transistors (TFTs) and methods of making TFTs. The active channel of the TFT may comprise one or more metals selected from the group consisting of zinc, gallium, tin, indium, and cadmium. The active channel may also comprise nitrogen and oxygen. To protect the active channel during source-drain electrode patterning, an etch stop layer may be deposited over the active layer. The etch stop layer prevents the active channel from being exposed to the plasma used to define the source and drain electrodes. The etch stop layer and the source and drain electrodes may be used as a mask when wet etching the active material layer that is used for the active channel.

Owner:APPLIED MATERIALS INC

Multicomponent composite flocculating setting agent and use in arsenic contamination water treatment

ActiveCN101503239AEfficient removalGood arsenic removal effectWater/sewage treatment by flocculation/precipitationArsenic pollutionEarth surface

The invention belongs to the technical field of river water body pollution control and in particular relates to a multiple-element compound flocculating settling agent and the application of the multiple-element compounded flocculating settling agent in arsenic pollution water body treatment. The multiple-element compounded flocculating settling agent is prepared by compounding malysite, aluminium salt, hypermanganate, polyacrylamide and aqueous solution. The multiple-element compounded flocculating settling agent can be applied in the arsenic pollution water body treatment to remove arsenic in the arsenic pollutant water body. The concentration of the arsenic in the treated water can meet or is superior to the specified requirement of three types of water on the arsenic concentration in the national earth surface water environment quality standard (less than 0.05 mg / L). The invention also can be used for removing heavy metals such as copper, chromium, cadmium, lead and the like in water by sedimentation. The multiple-element compounded flocculating settling agent can be used together with a multiple-element compounded metal oxide arsenic removal setting agent in static or flowing arsenic pollution water body treatment for removing the arsenic in the water body polluted by arsenic.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

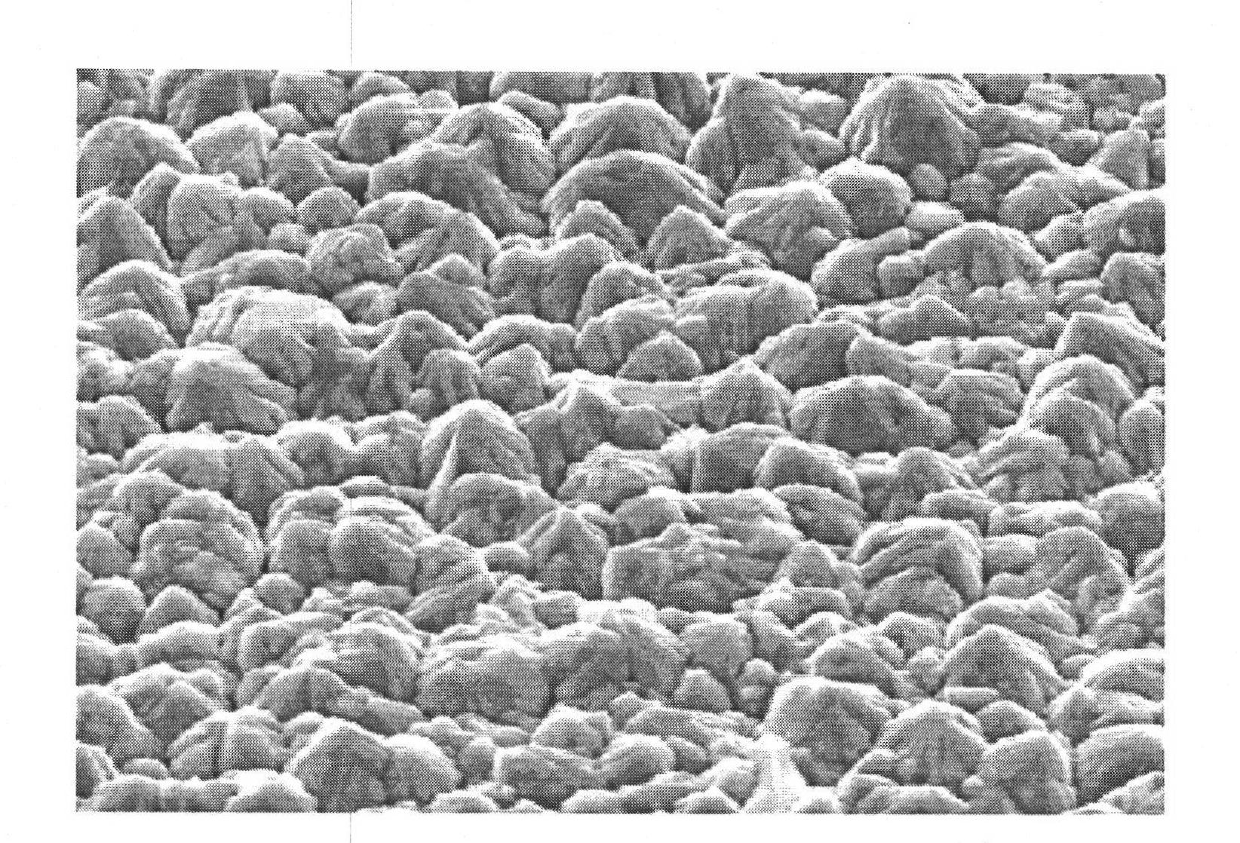

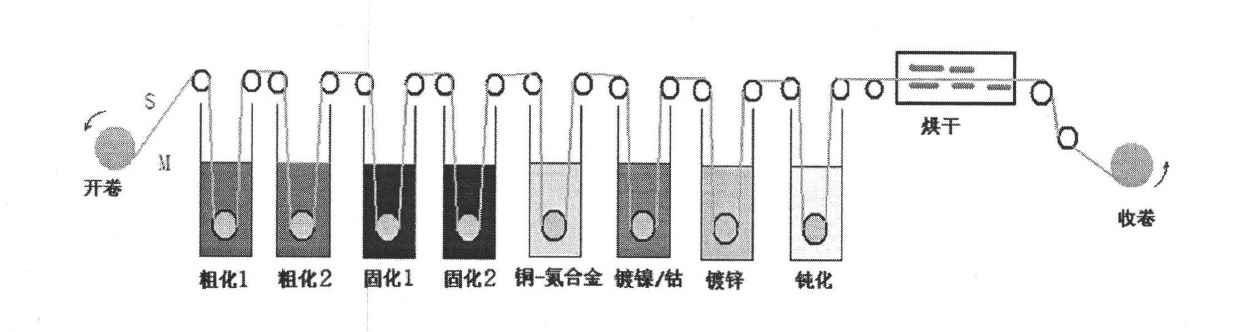

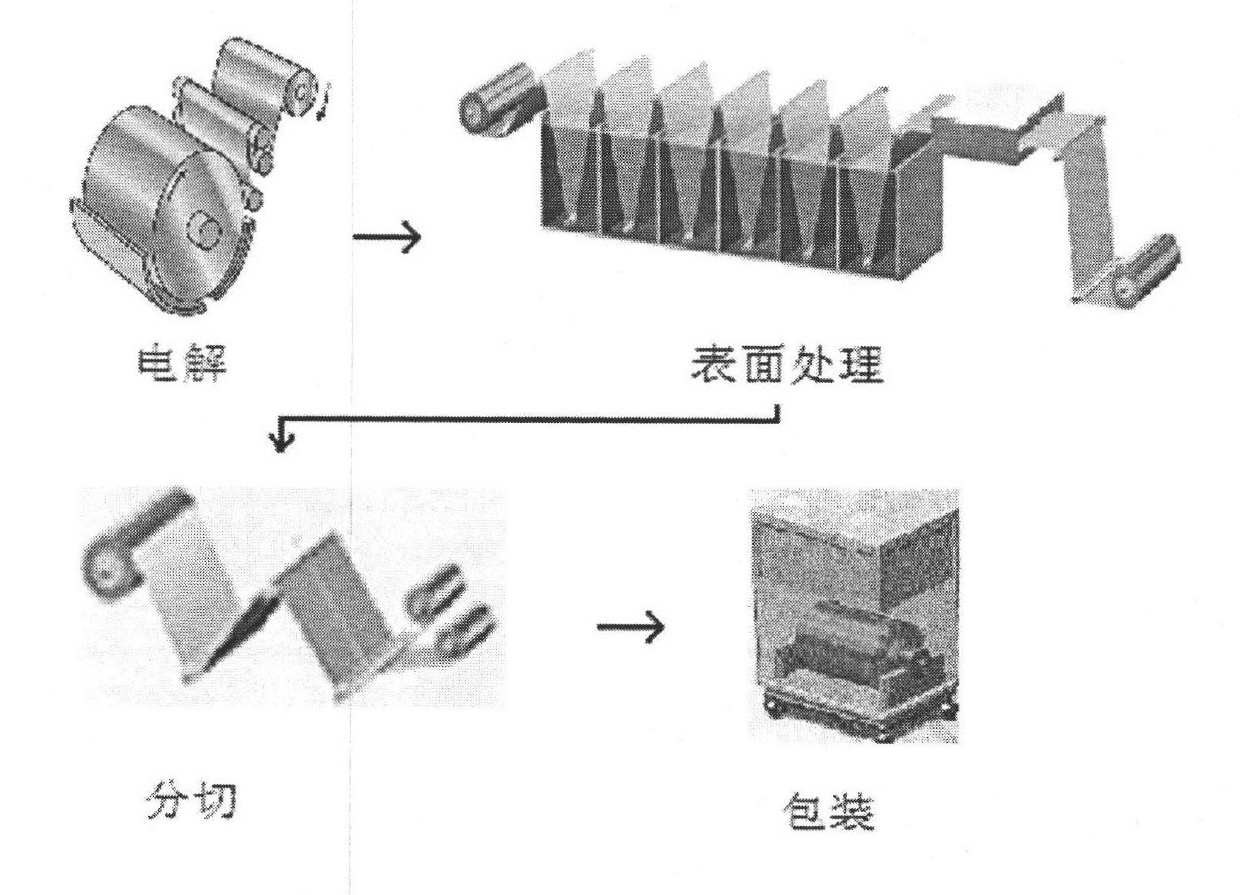

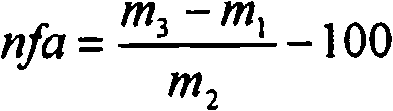

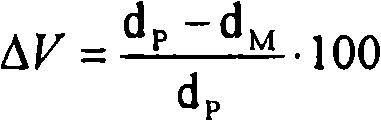

Black surface treatment process of electrolytic copper foil

ActiveCN101906630AImprove antioxidant capacityAccelerated corrosionSuperimposed coating processZinc alloysCopper foil

The invention relates to a black surface treatment process of an electrolytic copper foil, belonging to the technical field of production processes of high and precision electrolytic copper foils. The black surface treatment process of an electrolytic copper foil is characterized in that a VLP (Very Low Profile) electrolytic copper foil of 8-12 mu m is used as an electrode, and then copper or copper alloy is roughened, solidified, weakly roughened and electrically deposited at a running speed of 25.0+ / -0.1m / min; a layer of nano-scale nickel or cobalt alloy and a layer of nano-scale zinc alloy are sequentially and electrically deposited; and then alkaline chromate passivation is carried out and a layer of coupling agent is coated. In the invention, the black copper foil for an FPC (Flexible Printing Circuit) is obtained by carrying out a series of special surface treatments on the ultrathin and VLP electrolytic copper foil of 8-12 mu m, wherein the surface roughness Ra of the obtained copper foil is smaller than or equal to 0.30 mu m, Rz is smaller than or equal to 2.5 mu m; the thickness of the copper foil subjected to the surface treatments is increased by 1.40-1.80 mu m; the copper foil does not contain elements having serious damages to the human body, such as lead, mercury, cadmium, stibium, and the like and has excellent oxidation resistance as well as corrosion and etching resistance; the peel strength of the copper foil on a PI (Polyimide) film reaches higher than 1.0N / mm, and the folding strength on the PI film reach more than 100 thousand numbers of times; the copper foil has good appearance characteristics after the copper foil is microetched, and after the copper foil is made into an FCCL (Flexible Copper Clad Laminate), the copper foil has similar appearance characteristics to a rolled copper foil; and the properties of the copper foil product are equivalent to that of an electrolytic copper foil with the same specification for the FCCL.

Owner:SHANDONG JINBAO ELECTRONICS

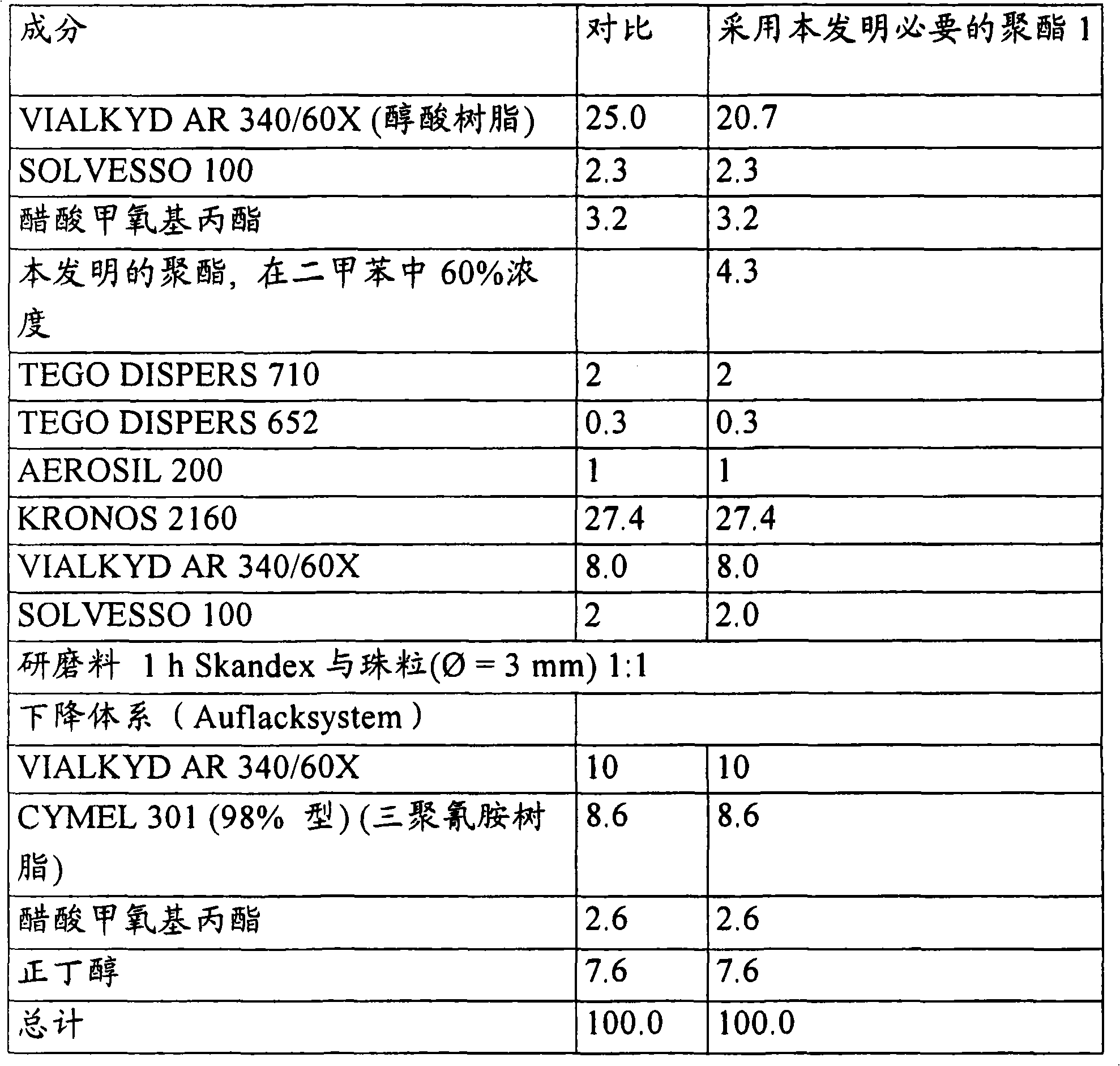

Coating material compositions

InactiveCN101353546AEffective adhesionImprove corrosion resistanceCosmetic preparationsLiquid surface applicatorsPolyesterAdditive ingredient

The invention relates to coating material compositions for, for example, metallic, mineral substrates or for substrates of wood, paper and plastics, which comprise yellowing-resistant, low-viscosity, unsaturated, amorphous polyesters which are very largely free of benzene and formaldehyde, as a result of which the adhesion of these coating material compositions is improved even under critical ambient conditions, and to a preparation process and use of said compositions. More specifically, the invention relates to coating material compositions, substantially including 1, yellowing-resistant, low-viscosity, unsaturated, amorphous polyesters which are very largely free of benzene and formaldehyde; 2, at least one other adhesive; 3, at least one accessory ingredient and / or additive; 4, at least one colorant and / or stuffing. The yellowing-resistant, low-viscosity, unsaturated, amorphous polyesters are composed by the following components: I. acid components, made up of A) at least one alpha, beta-unsaturated dicarboxilic acid, and B) at least one linear and / or branch fatty group and / or alicyclic and / or aromatic bifunctional and / or polyfunctional carboxyl acid, which is not provided with alpha, beta-unsaturated part; II. alcohol components, made up of C) bis(hydroxymethyl)tricyclo compounds and D) at least one bifunctional and / or polyfunctional alcohol, wherein, based on the polyesters, the content of benzene is lower than 10mg / kg and the content of formaldehyde is lower than 10mg / kg, the molecular weight distribution polydispersity of the polyesters is 1.3-4.5, the content of tricyclodecane(mono- / di-)aldehyde in the bis(hydroxymethyl)tricyclo compound C) is lower than 2 weight percent; mono(hydroxymethyl)tricyclo [5.2.1.0<2,6>] decane in the compound C) is lower than 10 weight percent, and the content of chromium, nickel, copper, cadmium and plumbum in the compound C) is lower than 2mg / kg.

Owner:EVONIK DEGUSSA GMBH

Continuous deposition process and apparatus for manufacturing cadmium telluride photovoltaic devices

InactiveUS20100184249A1Refined grain sizeAvoid condensationCellsVacuum evaporation coatingGas phaseSource material

A continuous deposition process and apparatus for depositing semiconductor layers containing cadmium, tellurium or sulfur as a principal constituent on transparent substrates to form photovoltaic devices as the substrates are continuously conveyed through the deposition apparatus is described. The film deposition process for a photovoltaic device having an n-type window layer and three p-type absorber layers in contiguous contact is carried out by a modular continuous deposition apparatus which has a plurality of processing stations connected in series for depositing successive layers of semiconductor films onto continuously conveying substrates. The fabrication starts by providing an optically transparent substrate coated with a transparent conductive oxide layer, onto which an n-type window layer formed of CdS or CdZnS is sputter deposited. After the window layer is deposited, a first absorber layer is deposited thereon by sputter deposition. Thereafter, a second absorber layer formed of CdTe is deposited onto the first absorber layer by a novel vapor deposition process in which the CdTe film forming vapor is generated by sublimation of a CdTe source material. After the second absorber layer is deposited, a third absorber layer formed of CdHgTe is deposited thereon by sputter deposition. The substrates are continuously conveyed through the modular continuous deposition apparatus as successive layers of semiconductor films are deposited thereon.

Owner:CHEN YUNG TIN

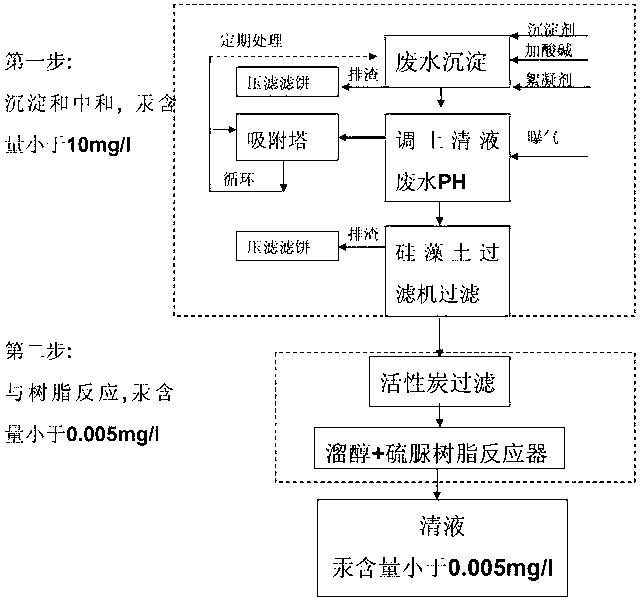

Method for treating mercury-containing wastewater during PVC (Polyvinyle Chloride) production through two-step process

InactiveCN102936070AEnsuring a circular economyImprove processing efficiencyMultistage water/sewage treatmentNature of treatment waterSlagGas phase

The invention discloses a method for treating mercury-containing wastewater during PVC (Polyvinyle Chloride) production through a two-step process. The method comprises the following steps of: firstly, completing primary removal of mercury, copper, ferrous and ferric iron, cadmium, zinc, manganese, lead and suspending impurities of above 10mg / l by using a precipitator and a flocculating agent, regulating PH to 6-8 and then adding the flocculating agent and stirring for 30 minutes, standing for above 1 hour, discharging slag and aerating, absorbing mercury carried away by a gas phase through a sulfide adsorber, purifying water by using a plate type kieselguhr filter, removing residual suspended matters; and 2, carrying out complete reaction on the mercury in the wastewater by using an active carbon and a mercaptan and thiourea resin combining method again for being removed, and finally reaching the standard that the content of the mercury is less than 0.005mg / l. The treated wastewater can be recycled to salt melting or an acetylene generator, so that zero emission of the treated wastewater is achieved; and the mercury-containing waste acid water of hydrochloric acid desorption in the industry of chlor-alkali can be treated, the consumption of acid is reduced, and the great popularization significance is achieved in the industry of chlor-alkali.

Owner:赵建军

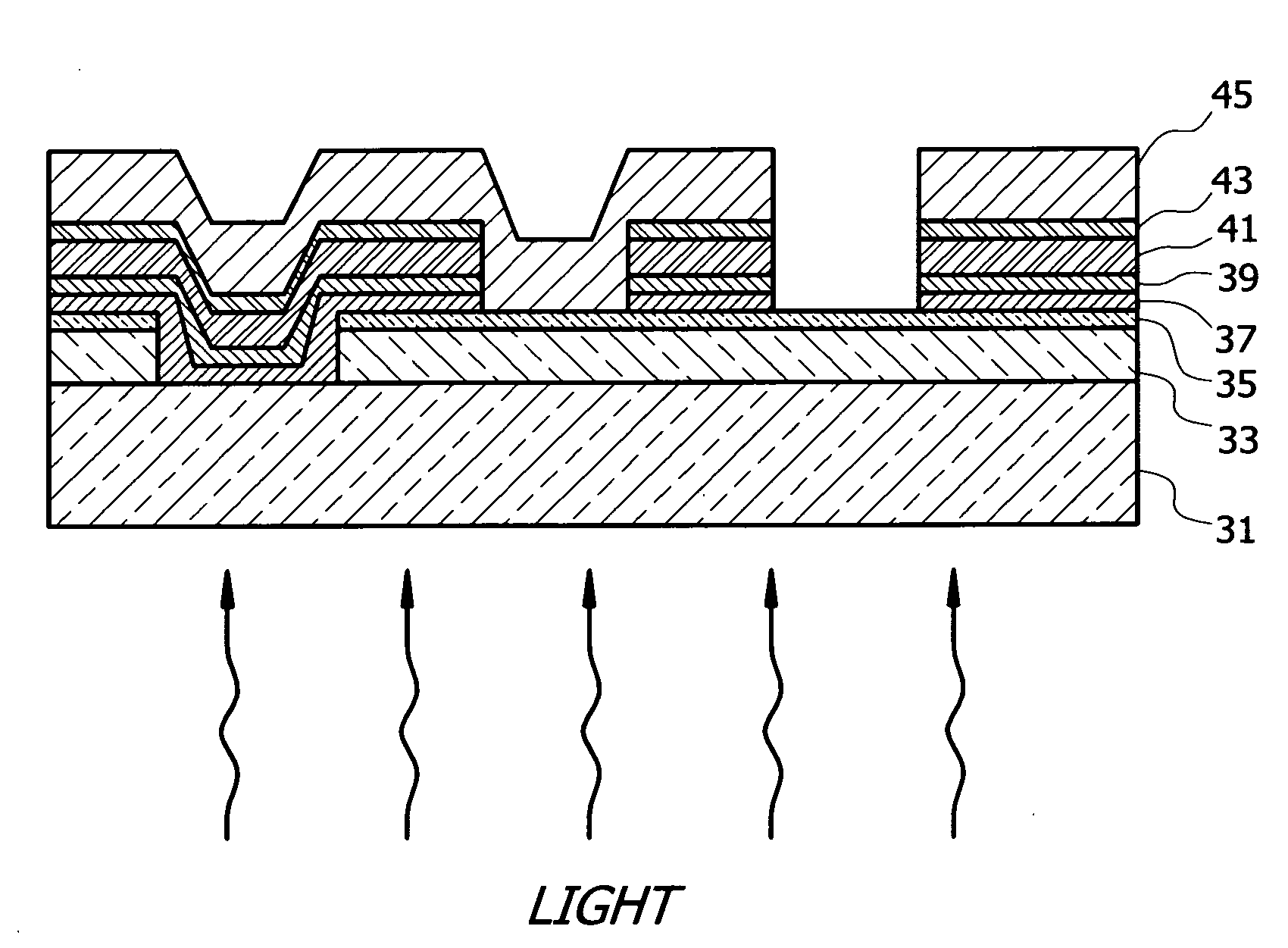

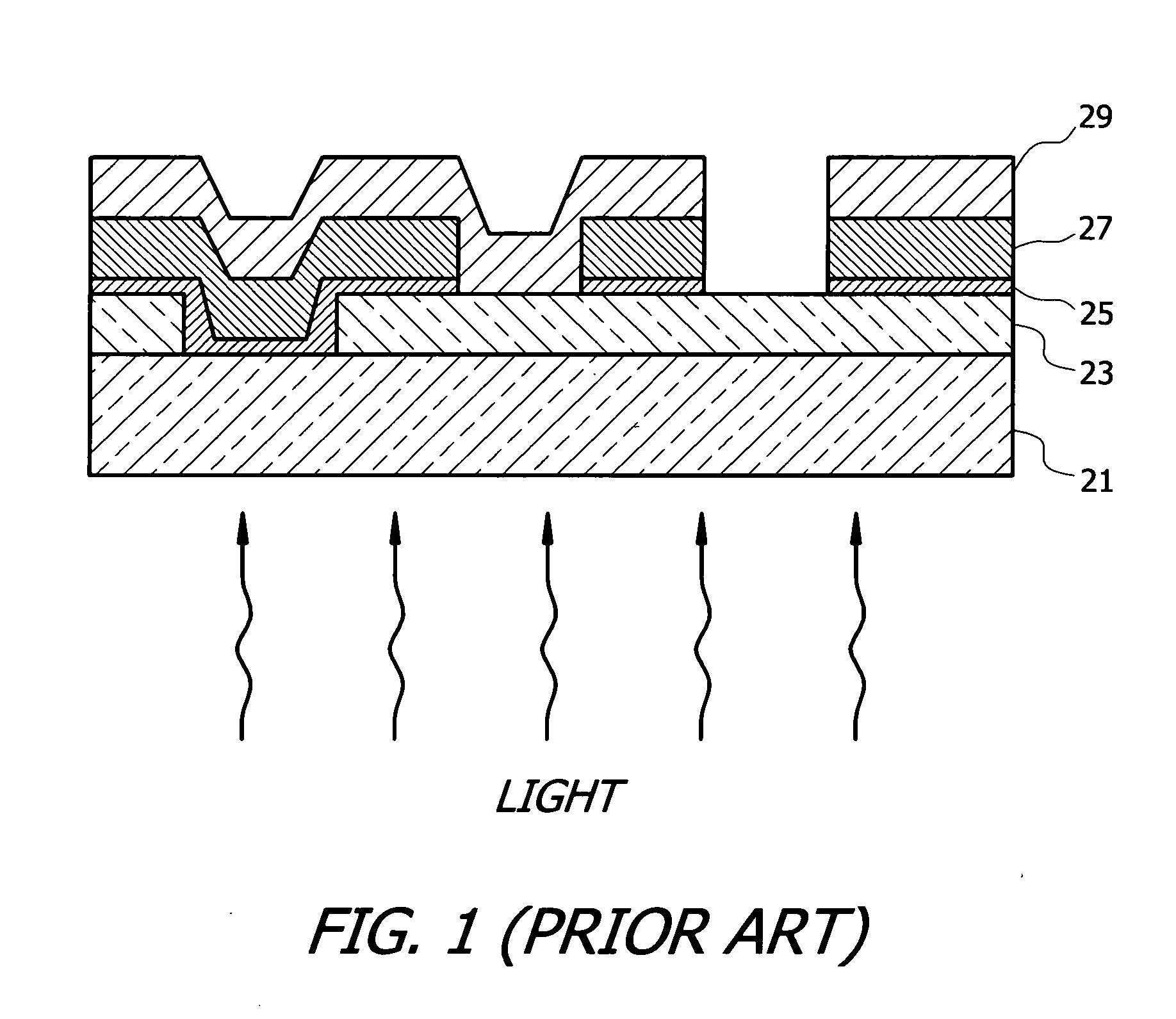

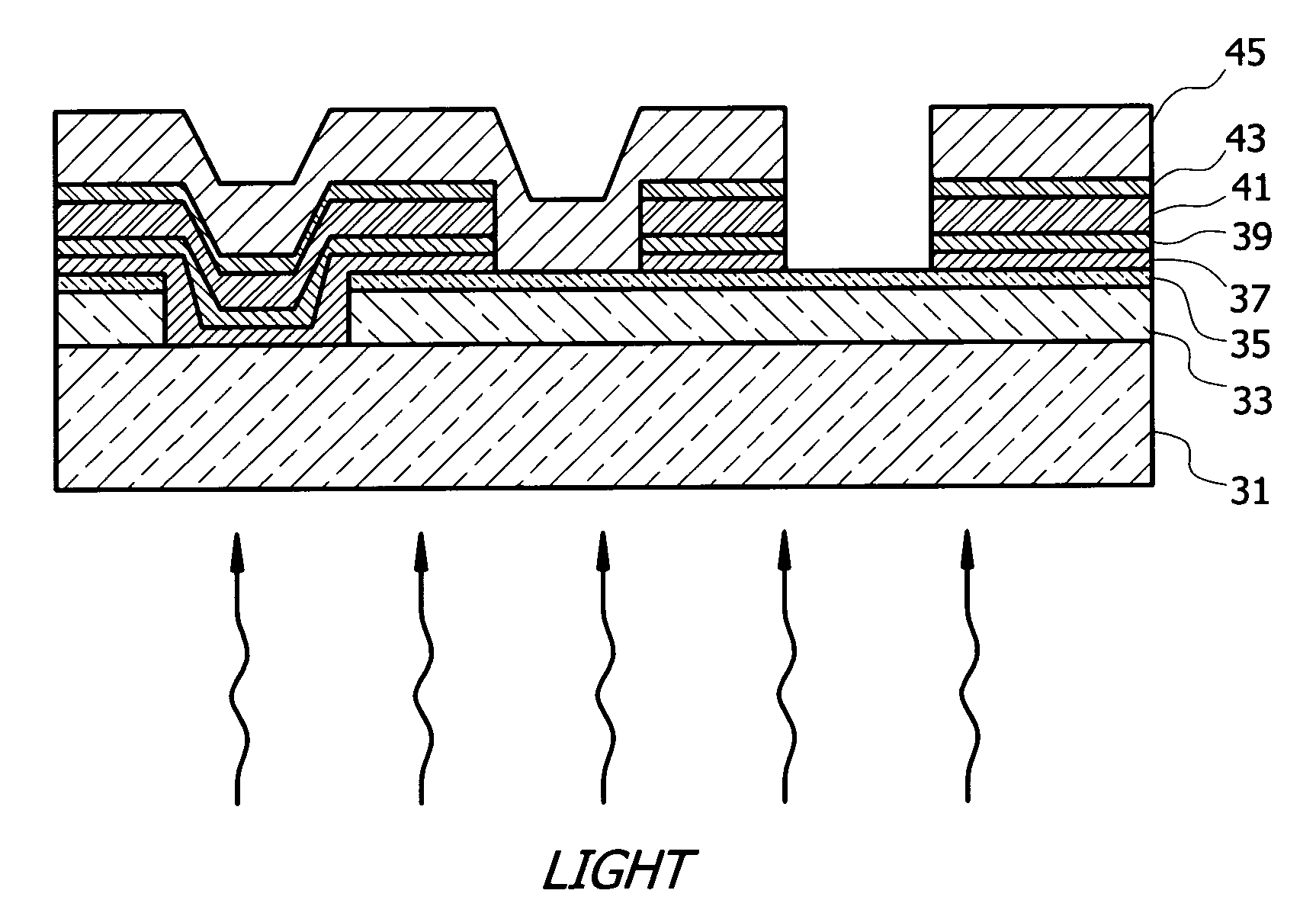

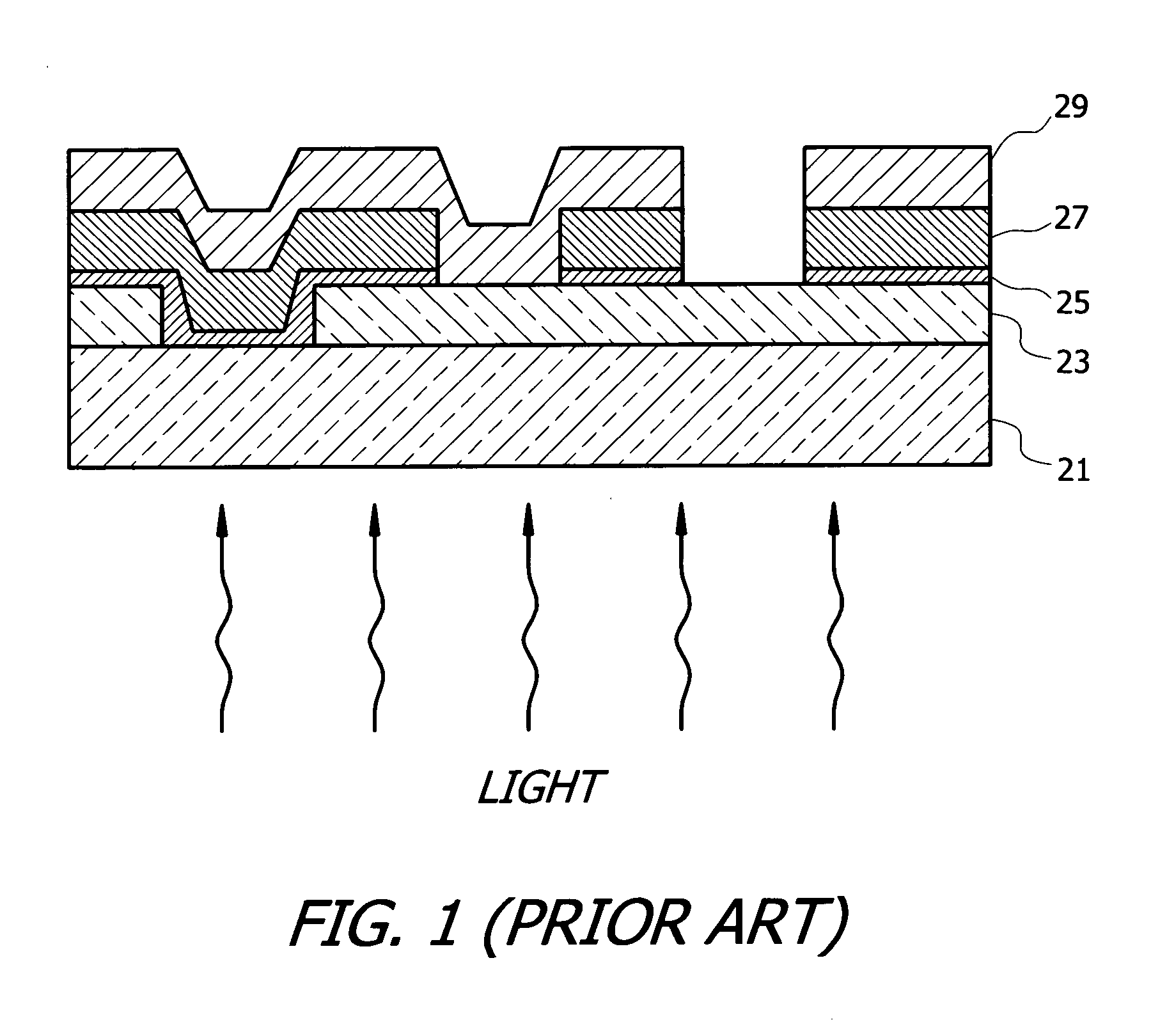

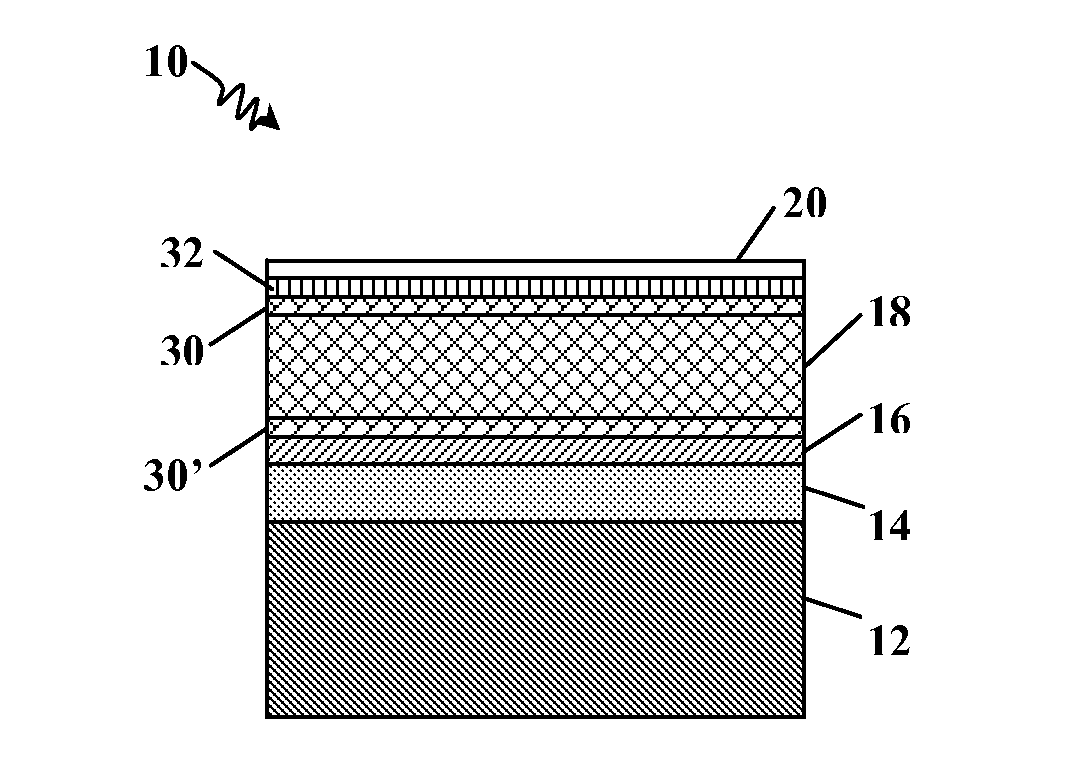

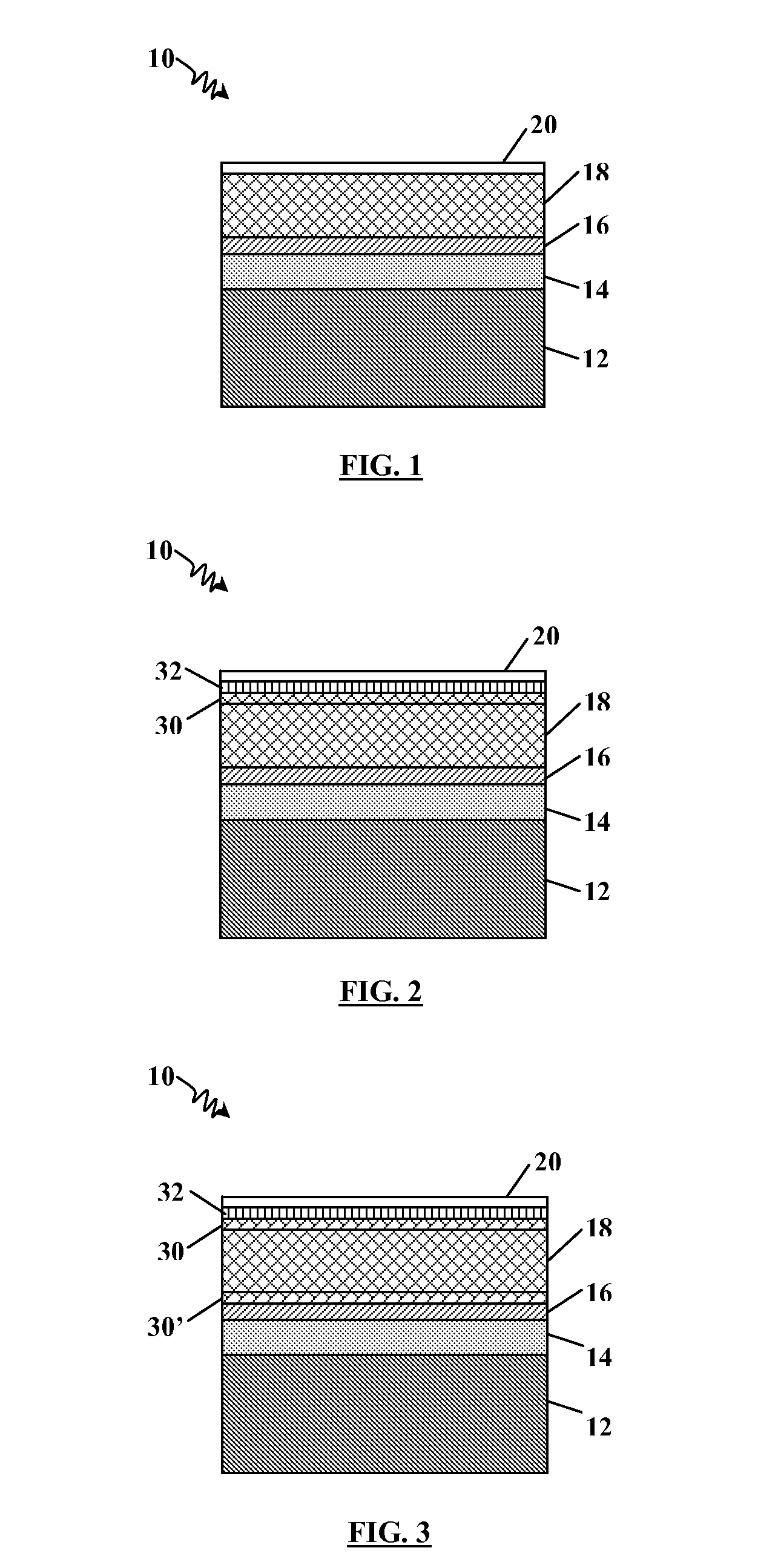

Multiple band gapped cadmium telluride photovoltaic devices and process for making the same

ActiveUS20100180935A1Improve conversion efficiencyImprove efficiencyFinal product manufactureVacuum evaporation coatingHeterojunctionCharge carrier

A heterojunction photovoltaic device for the production of electrical energy in response to the incident light includes an optically transparent substrate, a front contact formed of an transparent conductive oxide for collecting light generated charge carriers, an n-type window layer formed of cadmium sulfide or zinc sulfide, a p-type absorber structure disposed on the window layer, thereby forming a rectification junction therebetween, and a back contact comprising at least one metal layer. The p-type absorber structure has a plurality of p-type absorber layers in contiguous contact. Each absorber layer contains cadmium as a principal constituent and has a different composition and a different band gap energy. The first absorber layer is in contiguous contact with the n-type window layer. The band gap energy progressively decreases from the first absorber layer to the last absorber layer in the p-type absorber structure.

Owner:AUCMOS TECH USA INC

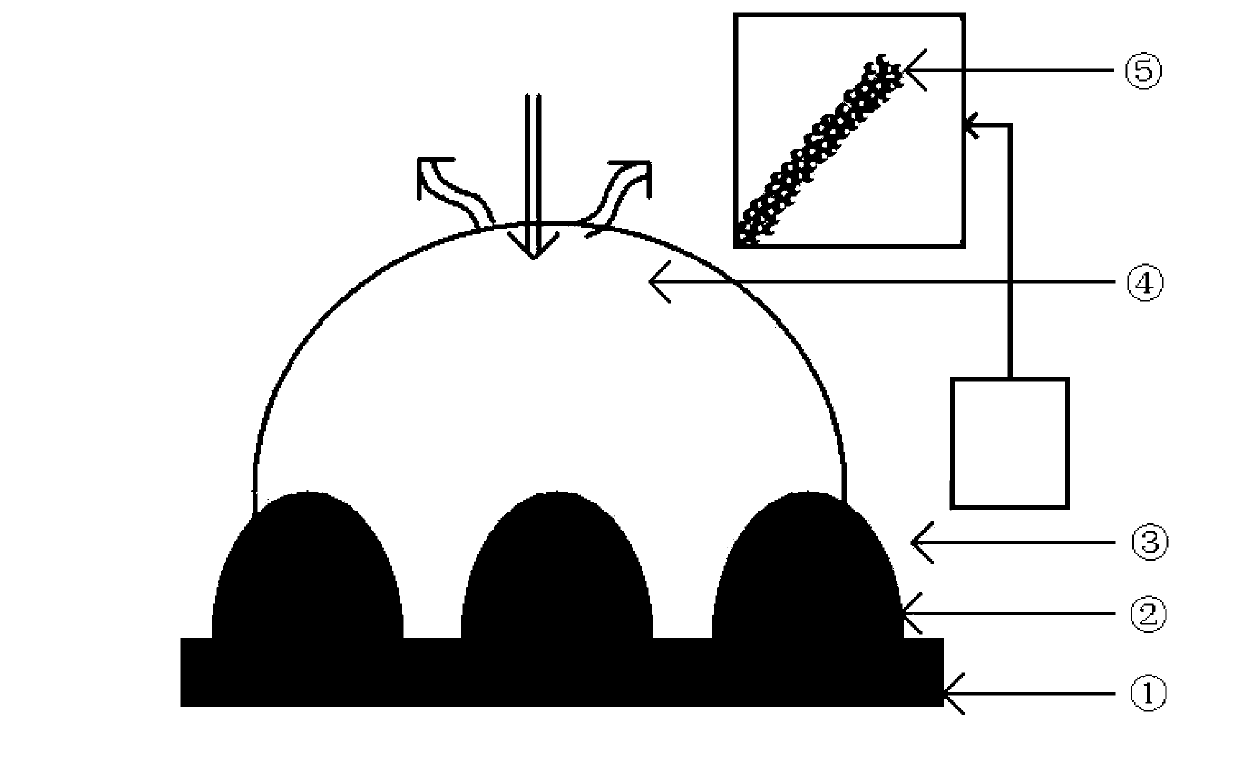

Method for controlling the accumulation of the heavy metal cadmium in the rice corn

InactiveCN101133710AWide variety of sourcesReduce use costContaminated soil reclamationHorticulture methodsManganesePaddy field

The present invention relates to a method for controlling heavy metal cadmium content in the rice, belonging to the field of paddy rice planting technology. It is characterized by that in the course of land preparation before rice field seedling transplantation the ferrochelate can be applied into the soil, and said ferrochelate and the soil are uniformly mixed; and in the spike formation stage and filling stage of rice the ferrochelate also can be respectively applied in the rice field. Said method can make cadmium content in the rice be less than 0.2mg / kg.

Owner:CHINA NAT RICE RES INST

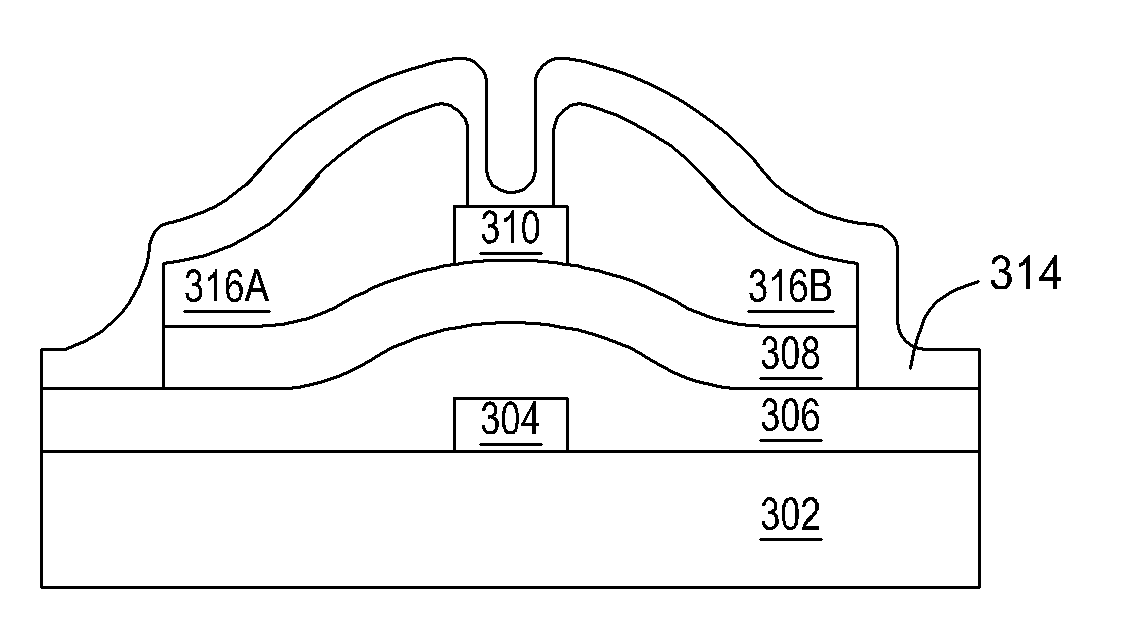

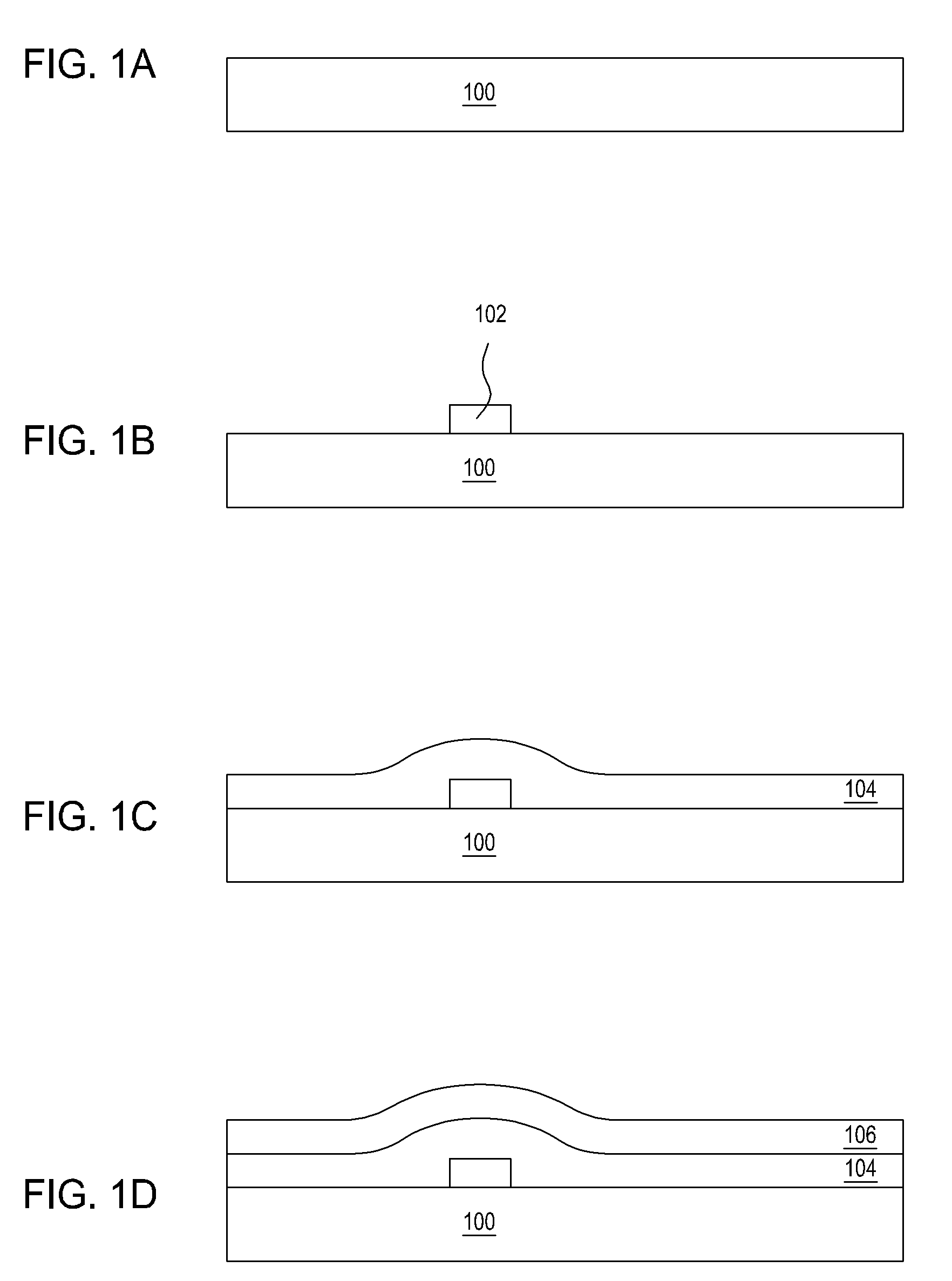

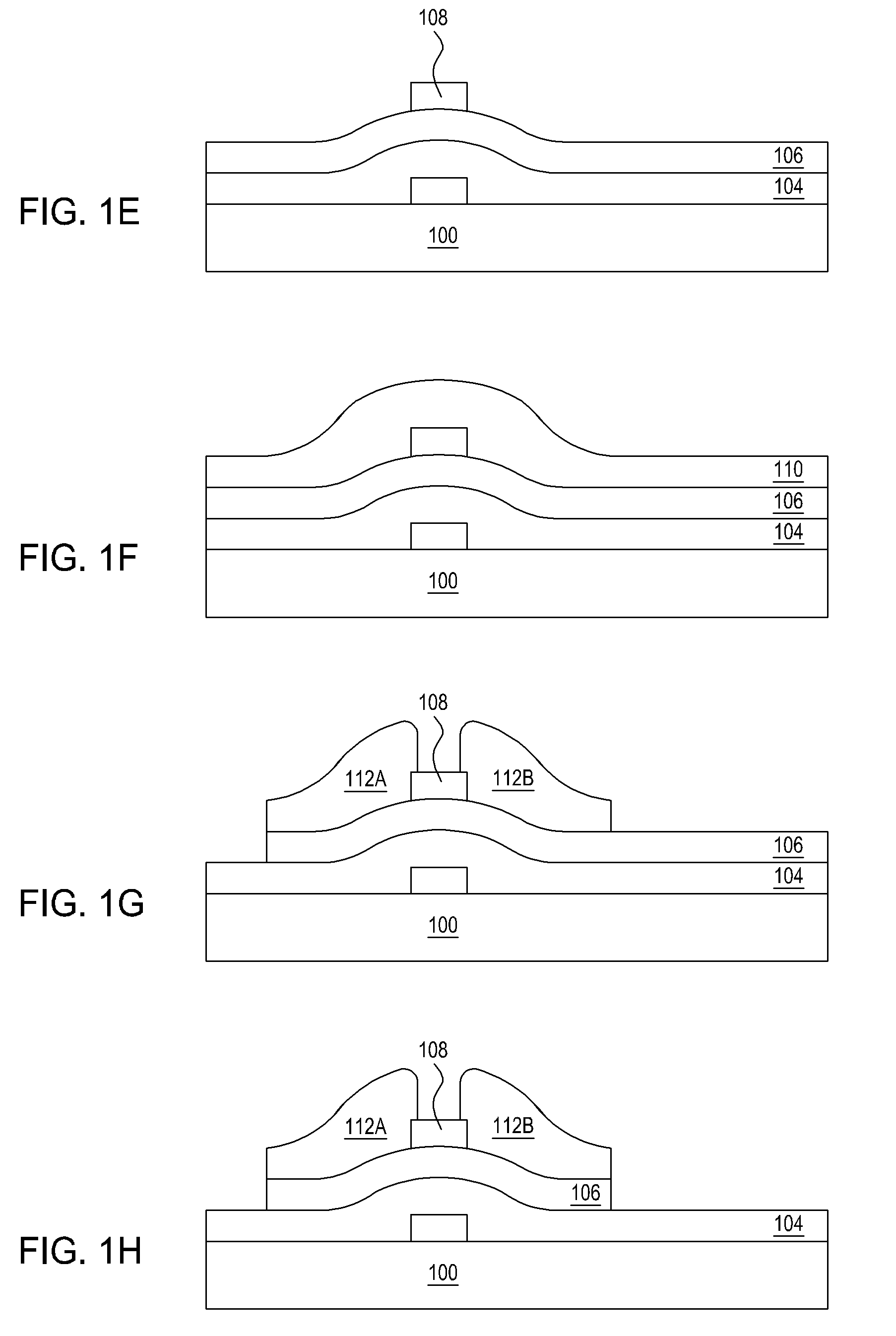

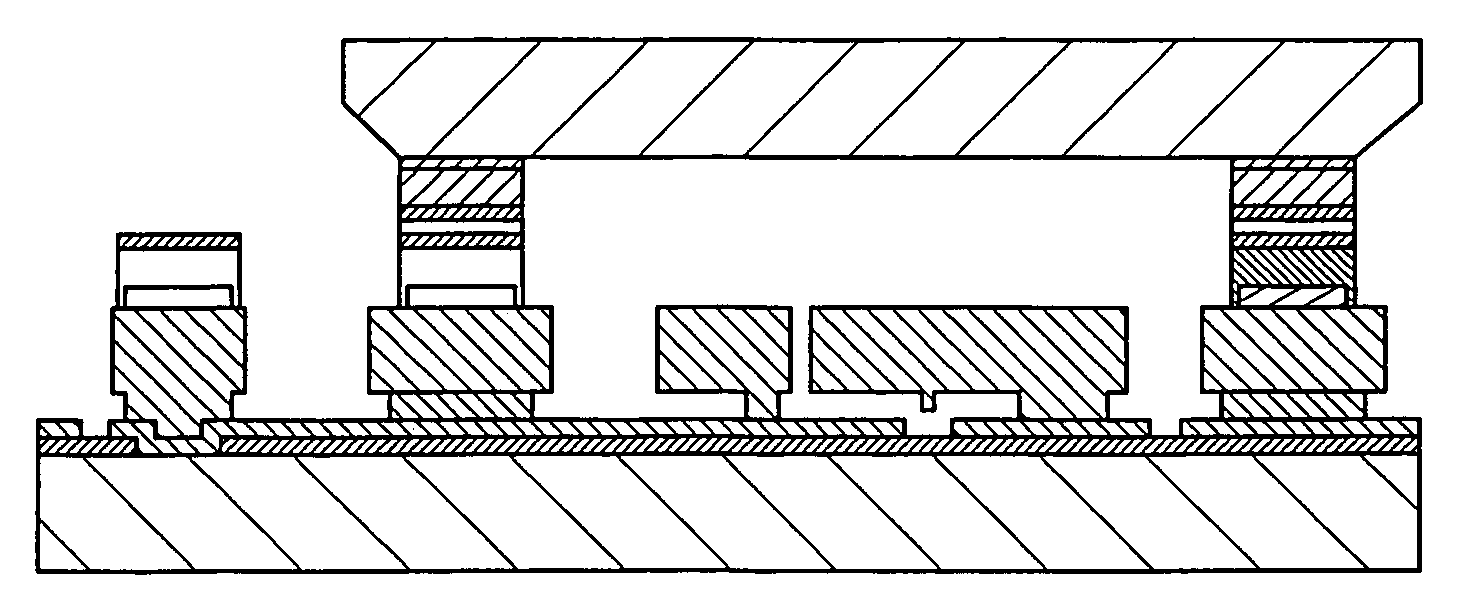

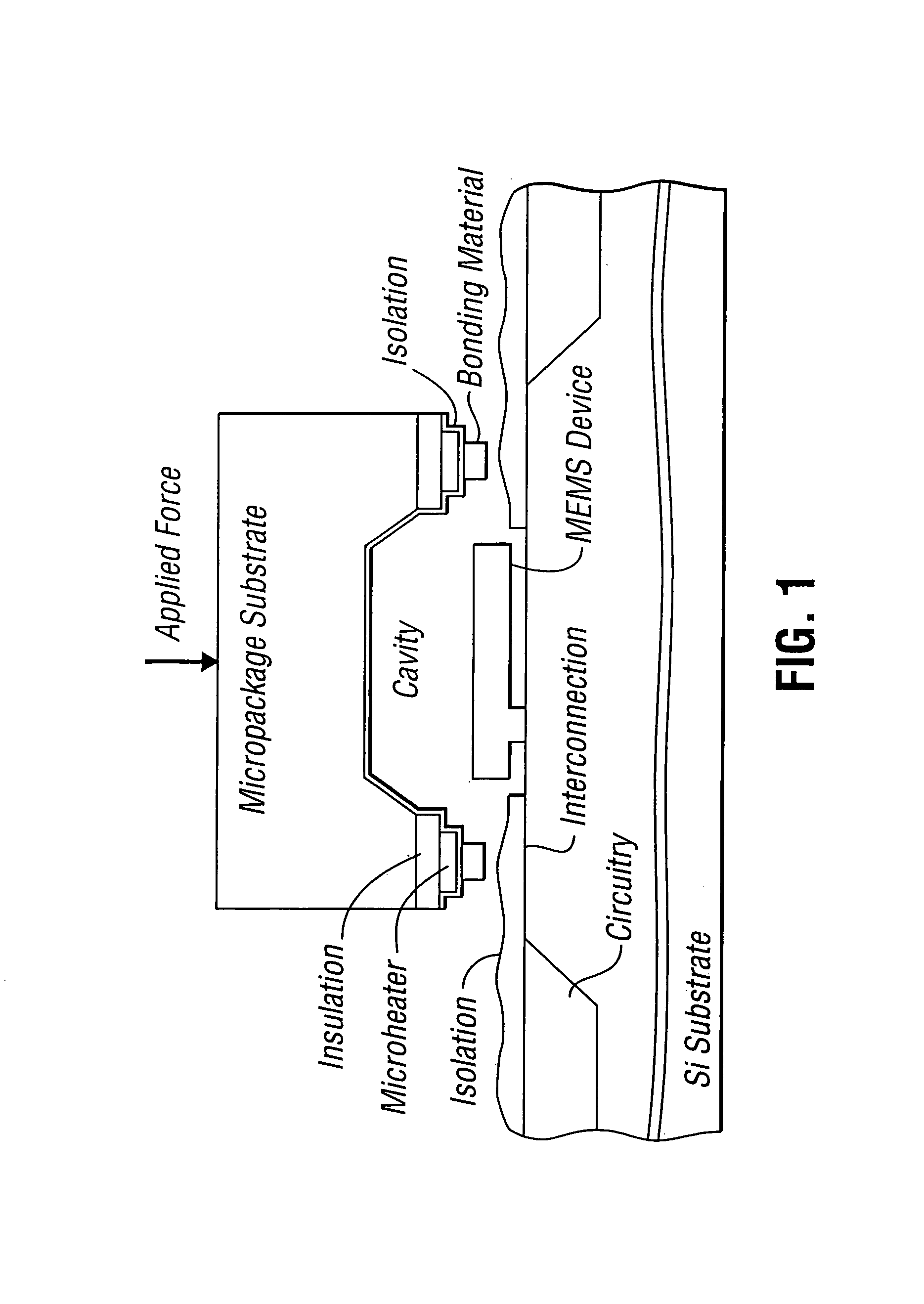

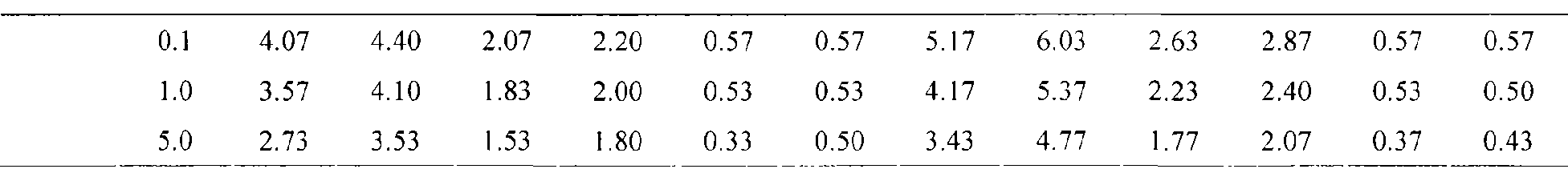

Wafer level packaging technique for microdevices

InactiveUS7138293B2Low cost processingLow costDecorative surface effectsSemiconductor/solid-state device detailsCadmium CationTin

A method is disclosed for fabricating a integrated device, such as a MEMS device. A first wafer is provided on an exposed surface with a layer of gold, gold alloy or gold compound. A second wafer is provided on its exposed surface with under-layer of gold, gold alloy or gold compound; and an over- of bismuth, bismuth alloy, a compound of bismuth, cadmium, cadmium alloy, a compound of cadmium compound, tin, tin alloy, or a compound of tin. The wafers are then brought into contact and bonded at their surfaces through the deposited layers.

Owner:TELEDYNE DIGITAL IMAGING INC

Process for preparing bitumen compositions with reduced hydrogen sulfide emission

InactiveUS20050145137A1Reduce evolutionEmission reductionRefining with metalsRefining with metal saltsScavengerCadmium Cation

In methods of preparing asphalt including asphalt / elastomeric polymer compositions, it has been discovered that the emission or evolution of H2S can be reduced by adding certain H2S scavengers to the asphalt mixture, but that not every known H2S scavenger can be effective in this method. Particularly helpful H2S scavengers include inorganic metal salts. Suitable inorganic or organic metal salt H2S scavengers include, but are not necessarily limited to those where the metal of the salt is zinc, cadmium, mercury, copper, silver, nickel, platinum, iron, or magnesium, and mixtures of these salts.

Owner:FINA TECH

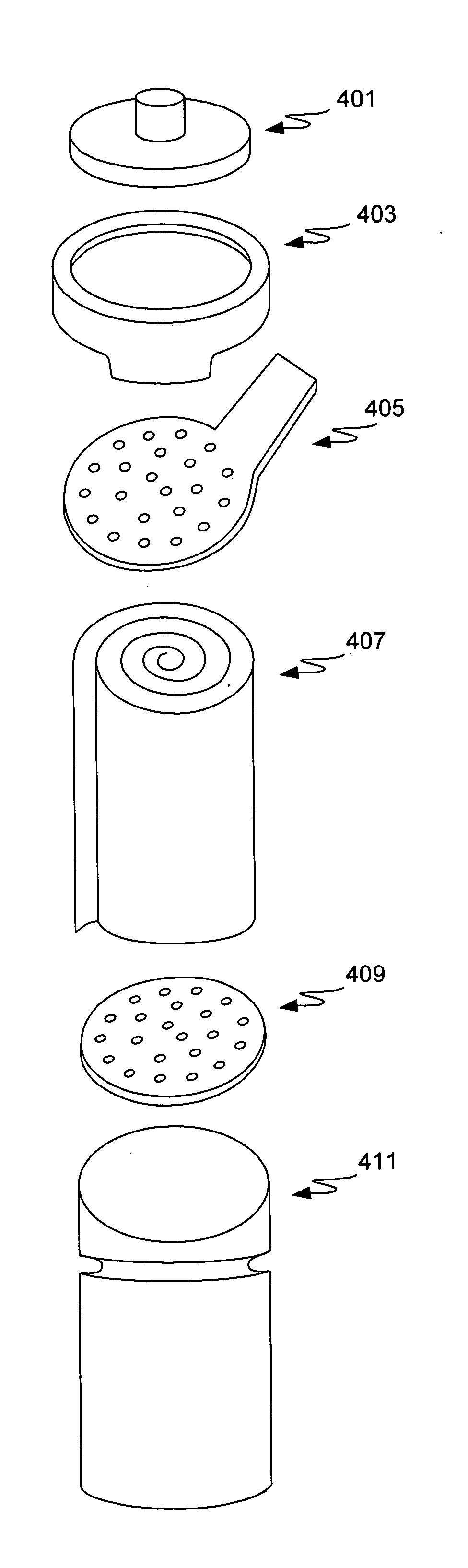

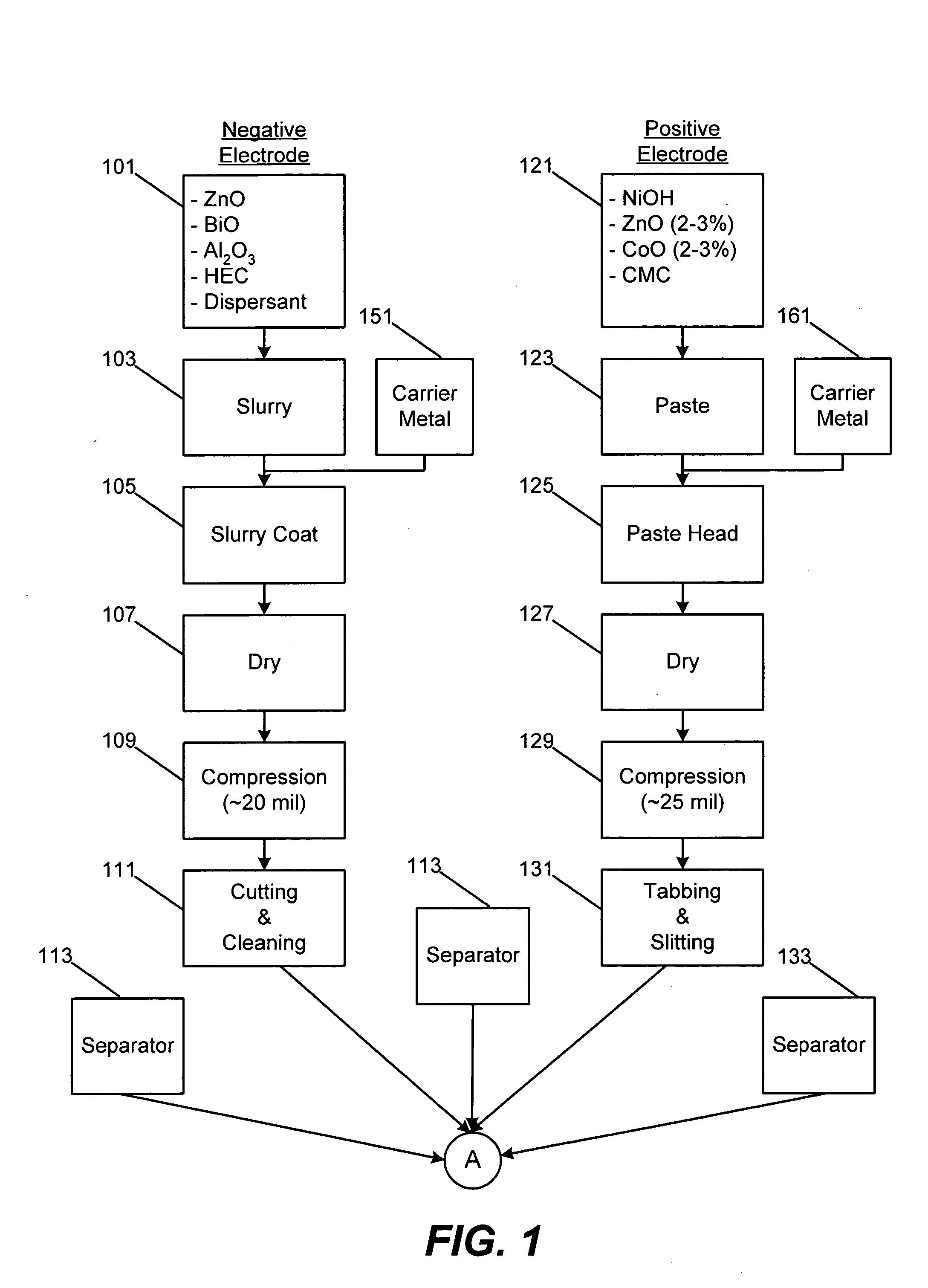

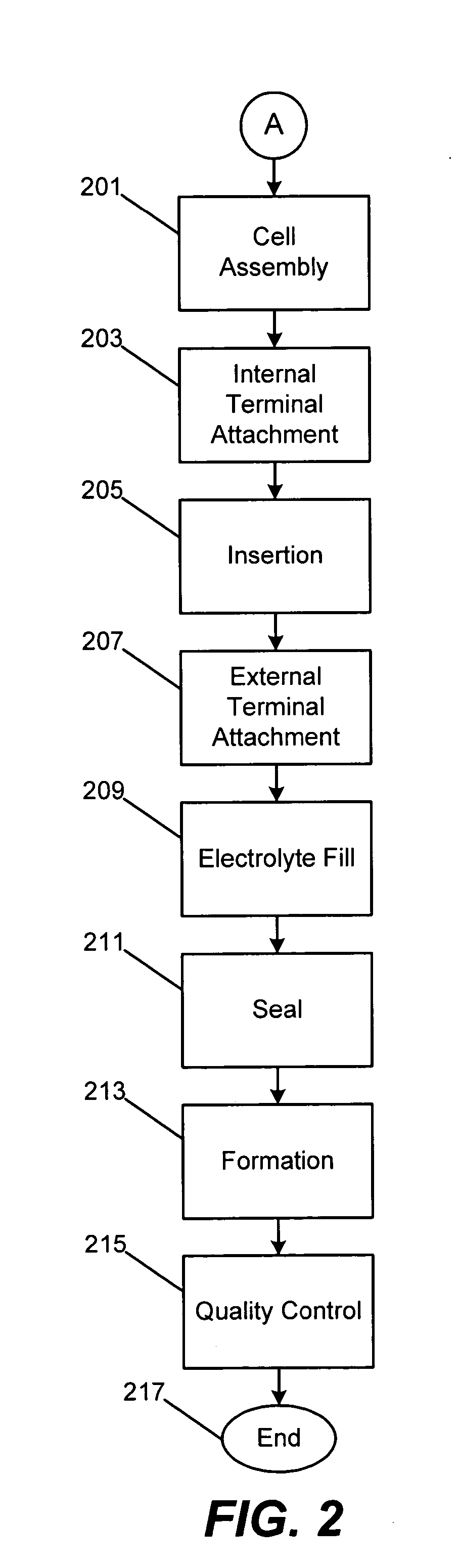

Method of manufacturing nickel zinc batteries

ActiveUS20050064292A1Improve efficiencyFinal product manufactureElectrode carriers/collectorsZinc compoundsSlurry

Methods of manufacturing a rechargeable power cell are described. Methods include providing a slurry or paste of negative electrode materials having low toxicity and including dispersants to prevent the agglomeration of particles that may adversely affect the performance of power cells. The methods utilize semi-permeable sheets to separate the electrodes and minimize formation of dendrites; and further provide electrode specific electrolyte to achieve efficient electrochemistry and to further discourage dendritic growth in the cell. The negative electrode materials may be comprised of zinc and zinc compounds. Zinc and zinc compounds are notably less toxic than the cadmium used in NiCad batteries. The described methods may utilize some production techniques employed in existing NiCad production lines. Thus, the methods described will find particular use in an already well-defined and mature manufacturing base.

Owner:ZINCFIVE POWER INC

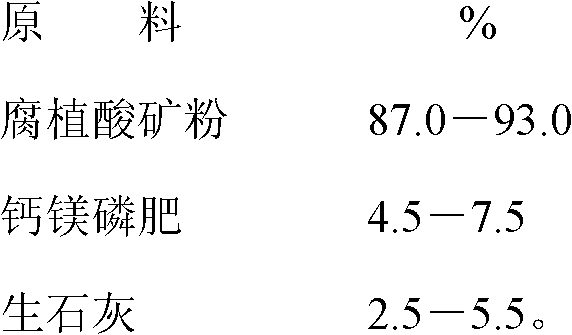

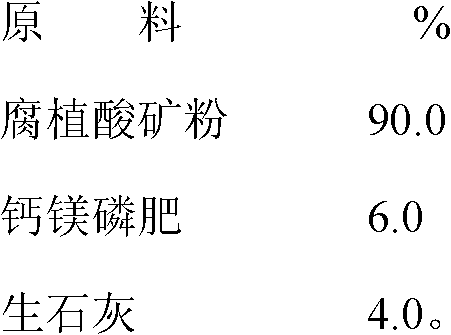

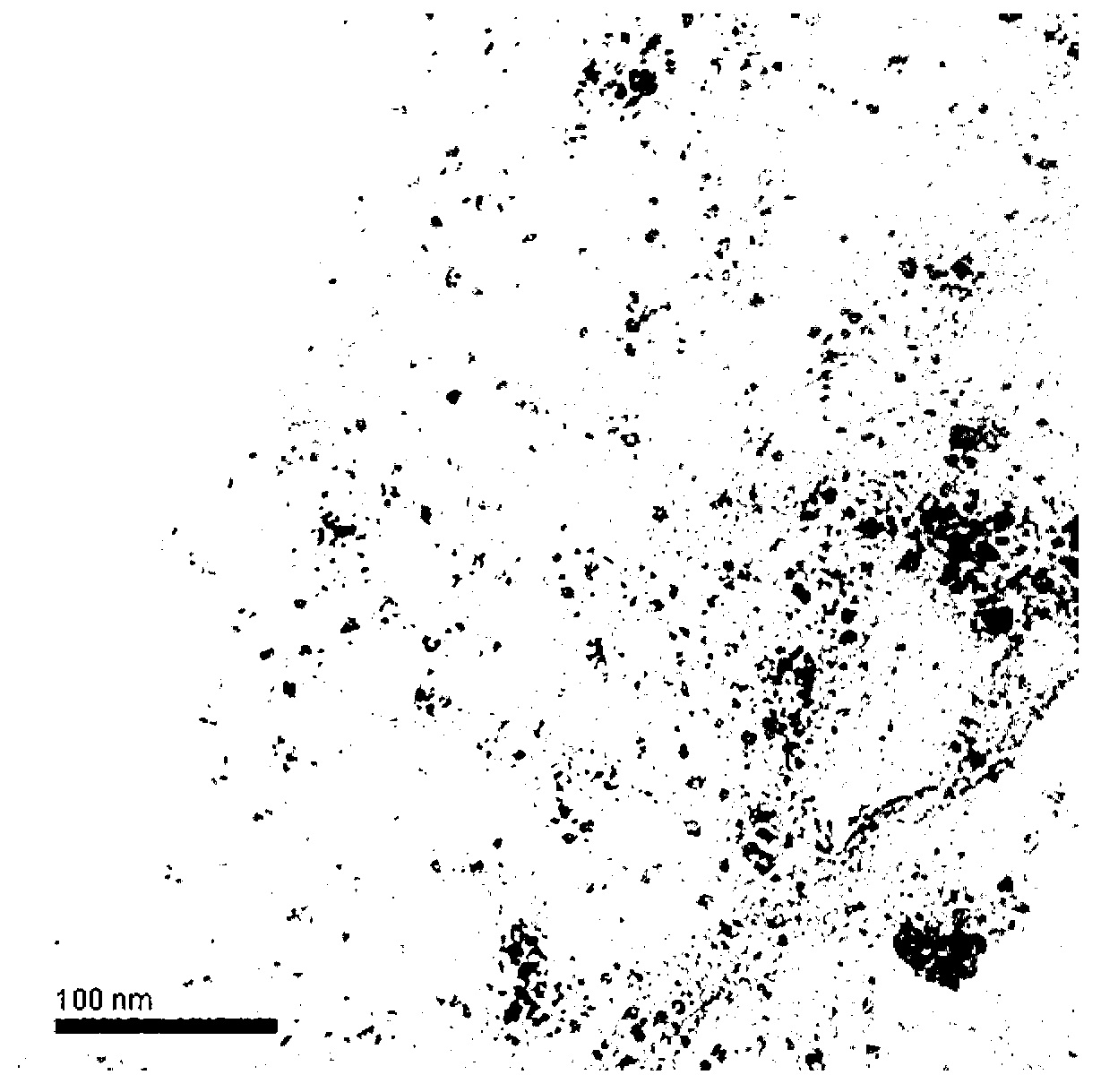

Preparation method of active radical with surface-enhanced Raman scattering (SERS) effect

InactiveCN102759520AQuick checkIncrease surface areaRaman scatteringChemical vapor depositionCadmium Cation

The invention provides a preparation method of an active radical with a surface-enhanced Raman scattering (SERS) effect, belongs to the technical field of spectrum detection, and relates to the preparation technology of the SERS active radical, which is rapid, has high sensitivity and performs a low trace detection function. The preparation method is characterized in that firstly, a nano porous silicon columnar array with a large specific surface area is prepared by utilizing a hydrothermal etching technology; afterwards, a nanowire structure of an II-VI group compound semiconductor (such as zinc oxide, titanium dioxide, cadmium sulfide, cadmium selenide, cadmium telluride, and the like) by utilizing a chemical vapor deposition method; and finally, nano particles of precious metal (such as gold, silver, copper and the like) are finally prepared on the nanowire structure by using a chemical reduction method, so as to obtain an active radical material. The preparation method has a wide application prospect in the aspects of clinical biomolecular fast recognition, trace chemical substance detection, biological sample analysis, and the like. The preparation method has the advantages that the preparation process of each material is simple, the condition is mild and the repetition rate reaches 100 percent.

Owner:BEIJING UNIV OF CHEM TECH

Layers that impede diffusion of metals in group vi element-containing materials

InactiveUS20080251119A1Improve efficiencyContact stabilityFinal product manufactureSemiconductor/solid-state device manufacturingElectrical resistance and conductanceCadmium fluoride

A method of making thermodynamically stable, diffusion-impeded barrier layers within, for example, a photovoltaic cell with a metal-containing electrical contact using exposure to fluorine. Exposing the cadmium telluride surface to fluorine creates a Te-poor barrier layer of cadmium fluoride. Once that barrier layer is formed, the metal-containing electrical contact may be applied or formed. The barrier layer allows tunneling current to occur between the p-type layer and the metal-containing electrical contact establishing a low-resistance, highly uniform, and thermally stable electrical contact.

Owner:FOREHAND DAVID

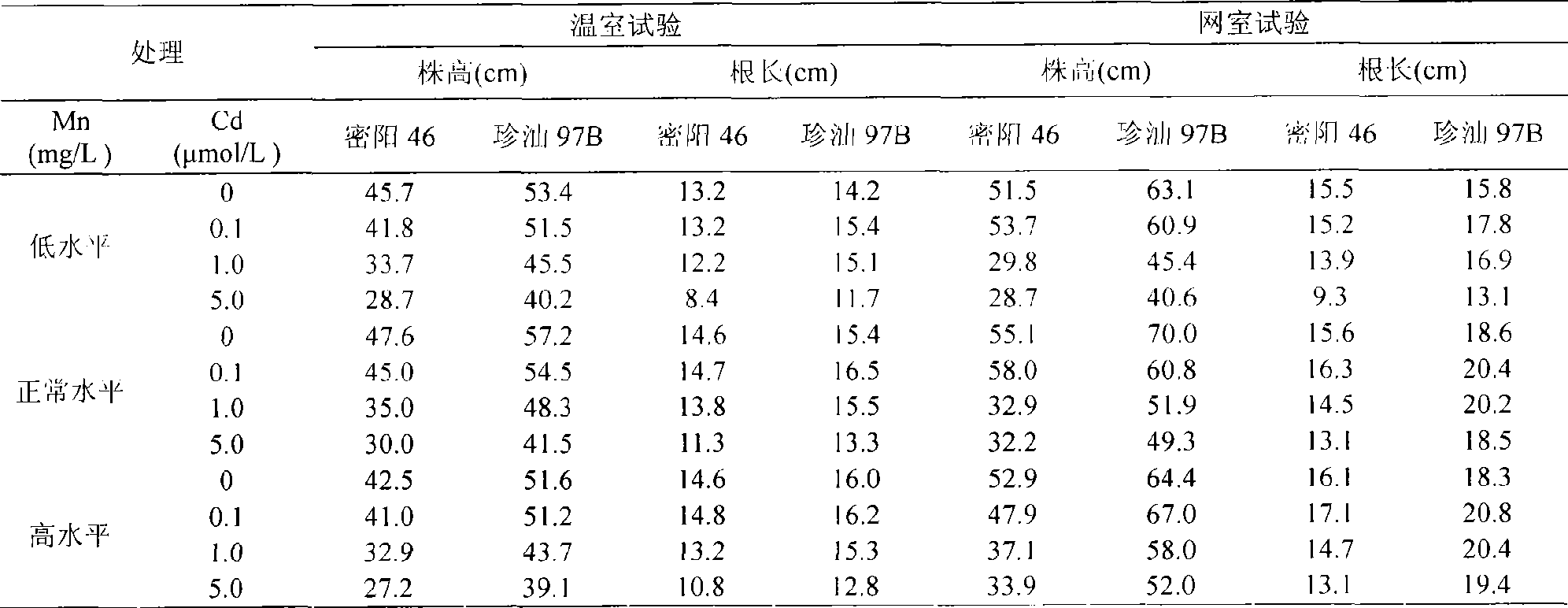

Method of controlling heavy metal cadmium accumulation of paddy

InactiveCN101507400AWide variety of sourcesReduce usageFertilising methodsHorticulture methodsManganeseCadmium Cation

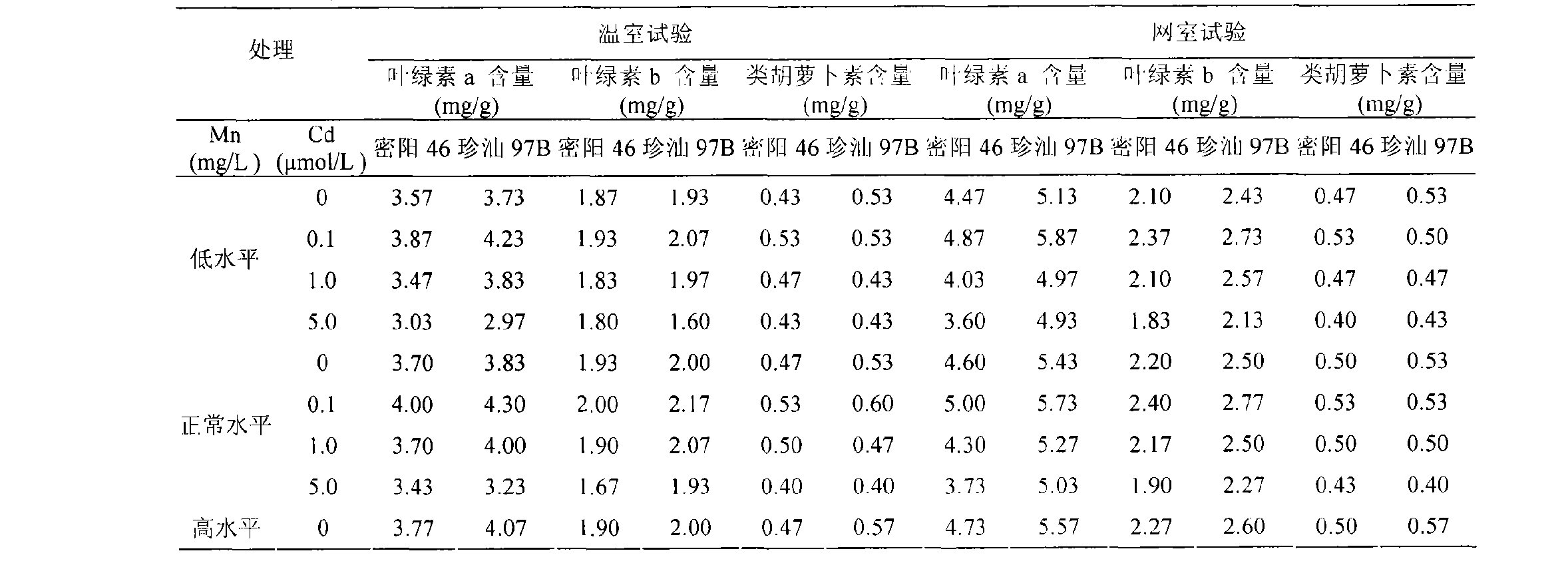

The invention discloses a method for controlling the accumulation of heavy metal cadmium in rice, and belongs to the technical field of rice planting. The method comprises the following steps of: (1) before the land preparation for seedling transplanting, applying a divalent manganese chelate in soil and uniformly mixing the divalent manganese chelate and the soil; (2) during a period from 15 to 20 days after seedling transplanting to 35 to 45 days after the seedling transplanting, spraying aqueous solution of a divalent manganese fertilizer once every other 7 to 10 days; (3) spreading the divalent manganese chelate in the early booting stage and the grouting stage of the rice respectively; (4) irrigating the paddy land within 3 to 5 days after the soil application of the divalent manganese chelate; (5) from the earing period of the rice to the ripening period of the rice, spraying the aqueous solution of the divalent manganese fertilizer once every other 7 to 10 days; and (6) after the soil application of the divalent manganese chelate, applying the divalent manganese chelate in the same way each year, but with an application rate which is reduced by half or three quarters. The method adopts soil application and leaf surface spraying application of the divalent manganese fertilizer and is more effective. The method is wider in application range, more economic and effective and is capable of improving the mineral nutrient element content of the rice and overcoming the adverse effects of the prior art.

Owner:CHINA NAT RICE RES INST

Durable glass and glass enamel composition for glass coatings

The present invention provides glass compositions and glass coating systems for use on glass substrates in several industrial applications. It relates to a lead-free and cadmium-free glass enamel coating made primarily by utilizing at least one or more of lead-free and cadmium-free glass compositions comprising in weight percent from about 26% to about 63% SiO2, from about 2% to about 10.5% ZnO, from about 8% to about 20% B2O3, from about 0.1% to about 10% Bi2O3, up to about 12% Na2O, from about 0.1% to about 17% K2O, up to about 6% Li2O, from about 0.1% to about 22% of Ta2O5, from about 0.0% to about 22% of Nb2O5, up to about 8% from each of Al2O3, TiO2, ZrO2, BaO and SrO, from about 0.1% to about 7% Sb2O3, up to about 7% F2, up to about 4% from each of CaO, Mo2O3 and MgO, and from about 0.1% to about 4% of one or more of La2O3, Nd2O3, Pr2O3 and Ce2O3.

Owner:SHEPHERD COLOR COMPANY

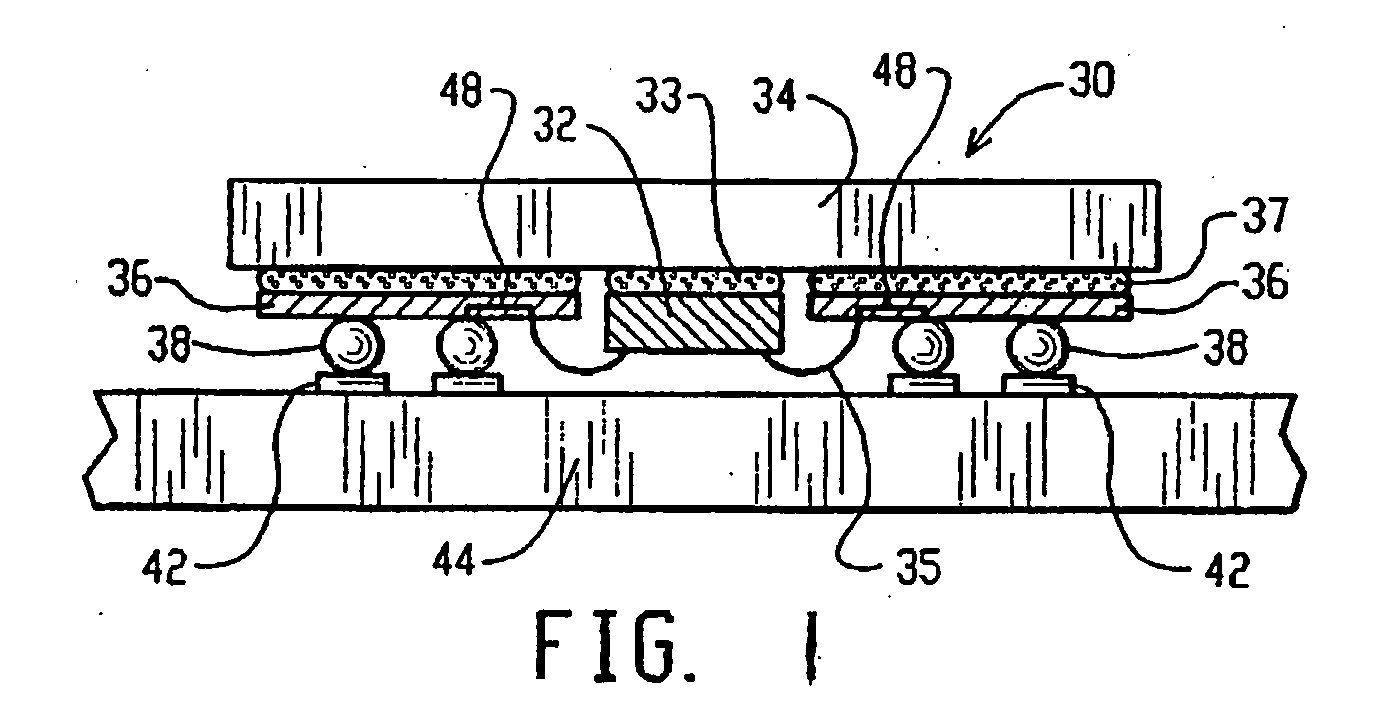

Electronic Package Formed Using Low-Temperature Active Solder Including Indium, Bismuth, and/or Cadmium

InactiveUS20070228109A1Increase concentrationHigh-strength, high-thermal conductivity jointsCooking-vessel materialsExhaust apparatusIndiumNiobium

An active solder alloy, an electronic device package including the active solder alloy bonding an electronic device to a substrate, and a method of forming high-strength joints by soldering using the solder alloy. The alloy contains up to about 10% by weight of an element or a mixture of elements selected from the group consisting of titanium, zirconium, hafnium, vanadium, niobium, or tantalum; between about 0.1 and 5% by weight of an element or a mixture of elements selected from the group of the lanthanides (rare earths); between about 0.01 and 1% by weight of gallium up to about 10% by weight of silver; up to about 2% by weight of magnesium; and a remainder consisting of tin, bismuth, indium, cadmium, or a mixture of two or more of these elements. The alloy enables low-temperature (less than about 180° C.) soldering within relatively narrow melting ranges (less than about 10° C.).

Owner:S BOND TECH

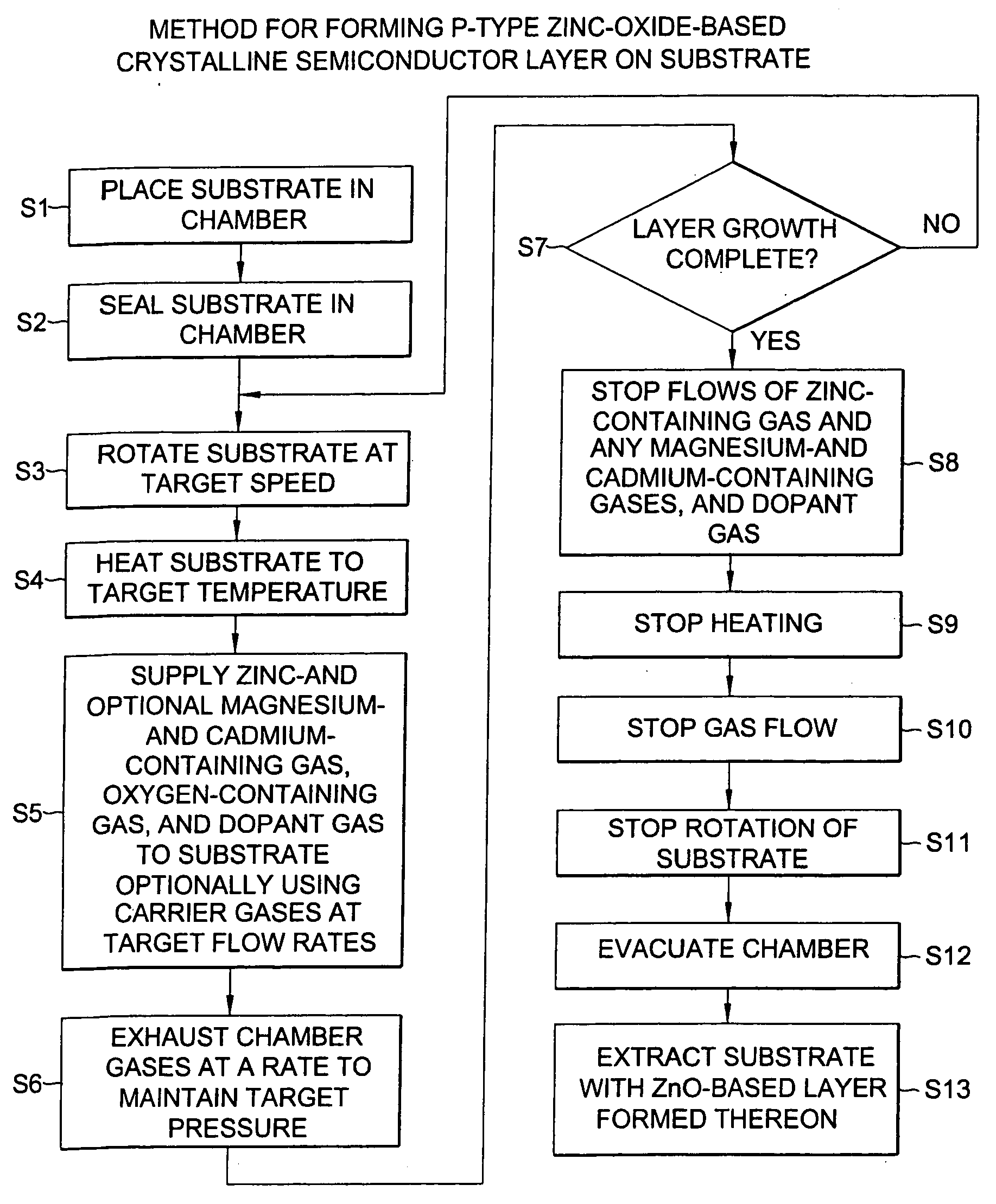

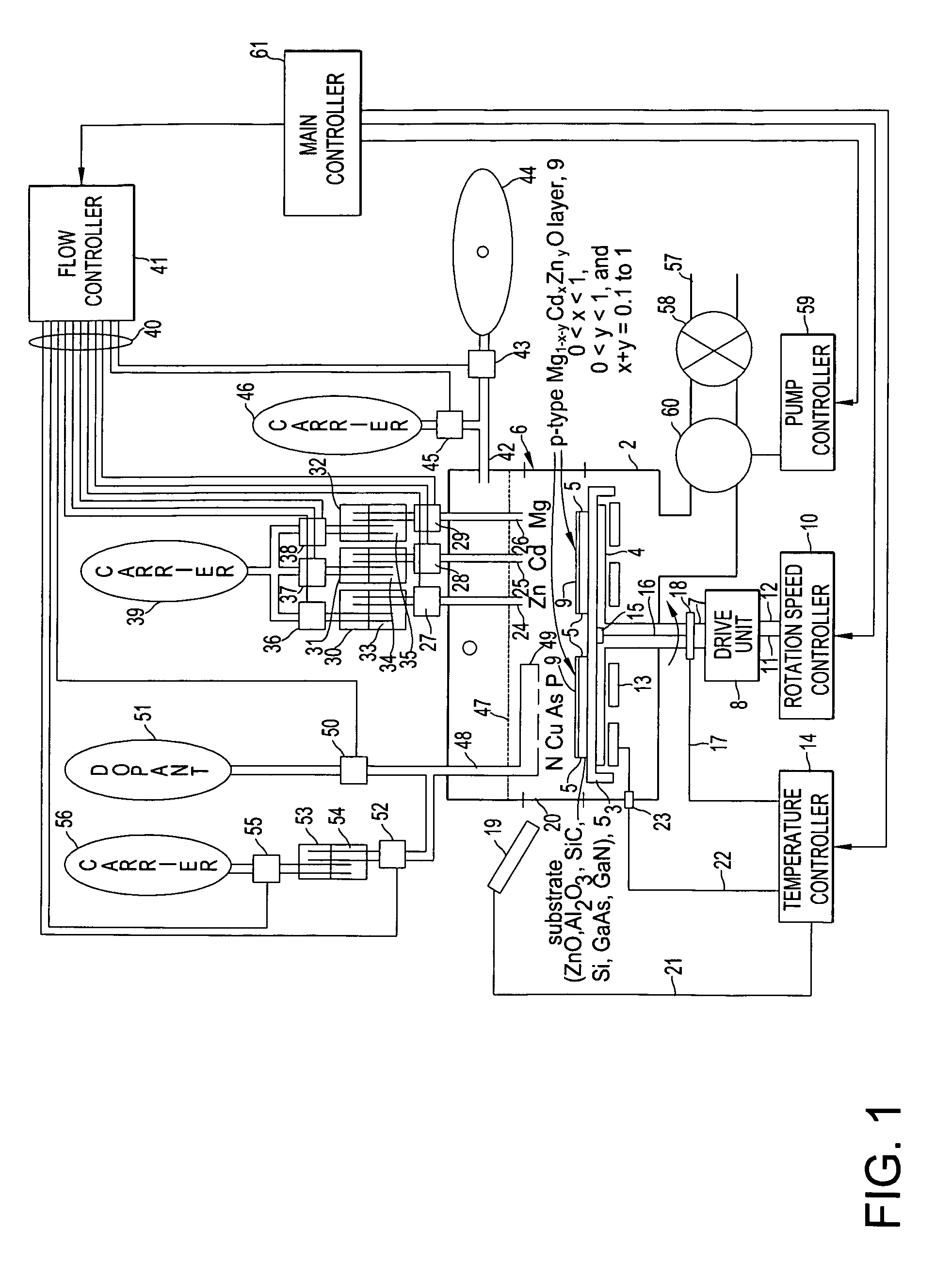

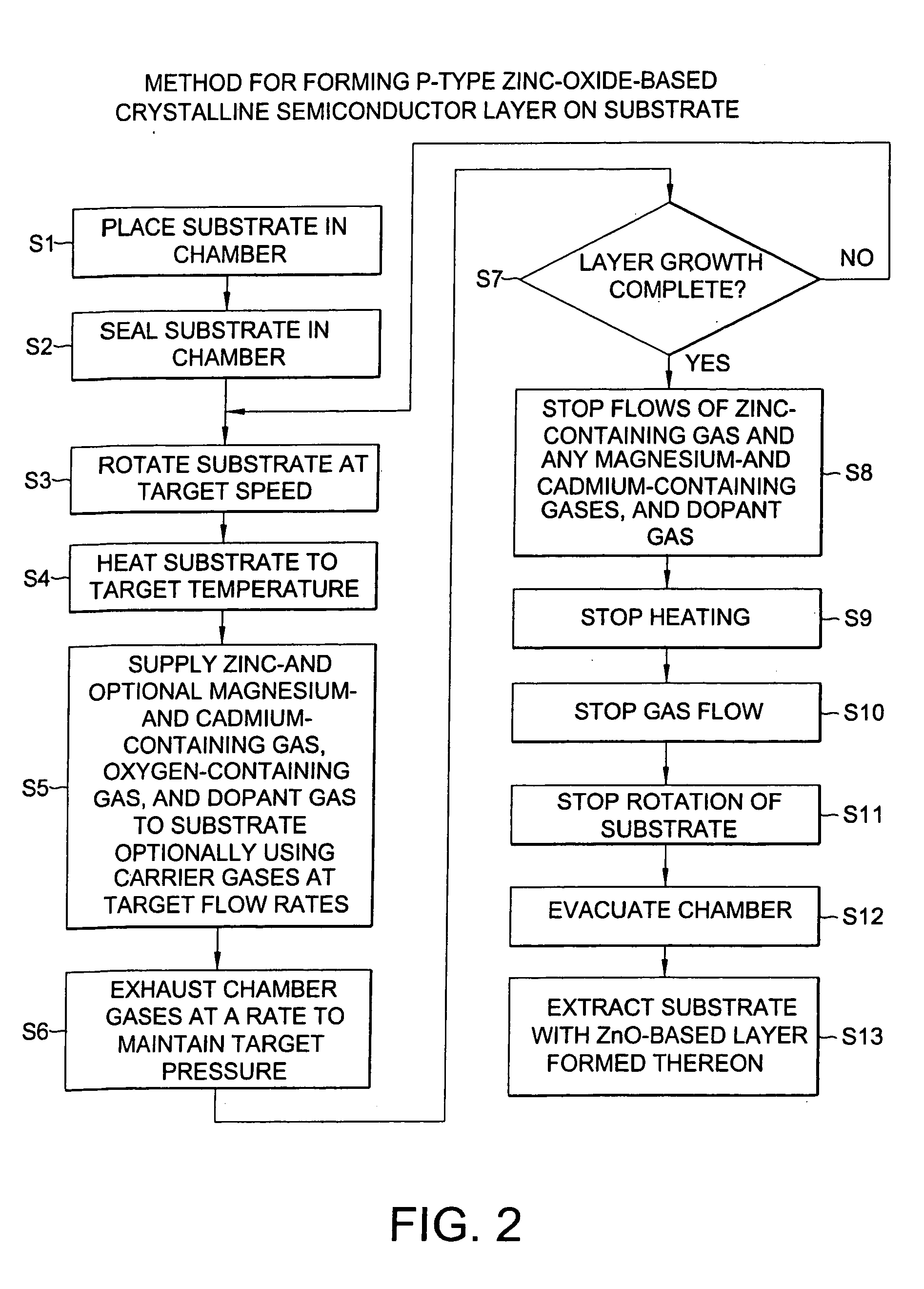

Method of forming a p-type group II-VI semiconductor crystal layer on a substrate

InactiveUS20050020035A1Overcome disadvantagesQuality improvementPolycrystalline material growthSemiconductor/solid-state device manufacturingChemical vapor depositionCadmium Cation

A method of depositing a p-type magnesium-, cadmium- and / or zinc-oxide-based II-VI Group compound semiconductor crystal layer over a substrate by a metalorganic chemical vapor deposition technique. A reaction gas is supplied to a surface of a heated substrate in a direction parallel or oblique to the substrate. The p-type magnesium-, cadmium- and / or zinc-oxide-based II-VI Group compound semiconductor crystal layer is grown on the heated substrate, while introducing a pressing gas substantially in a vertical direction toward the substrate to press the reaction gas against the entire surface of the substrate.

Owner:CERMET

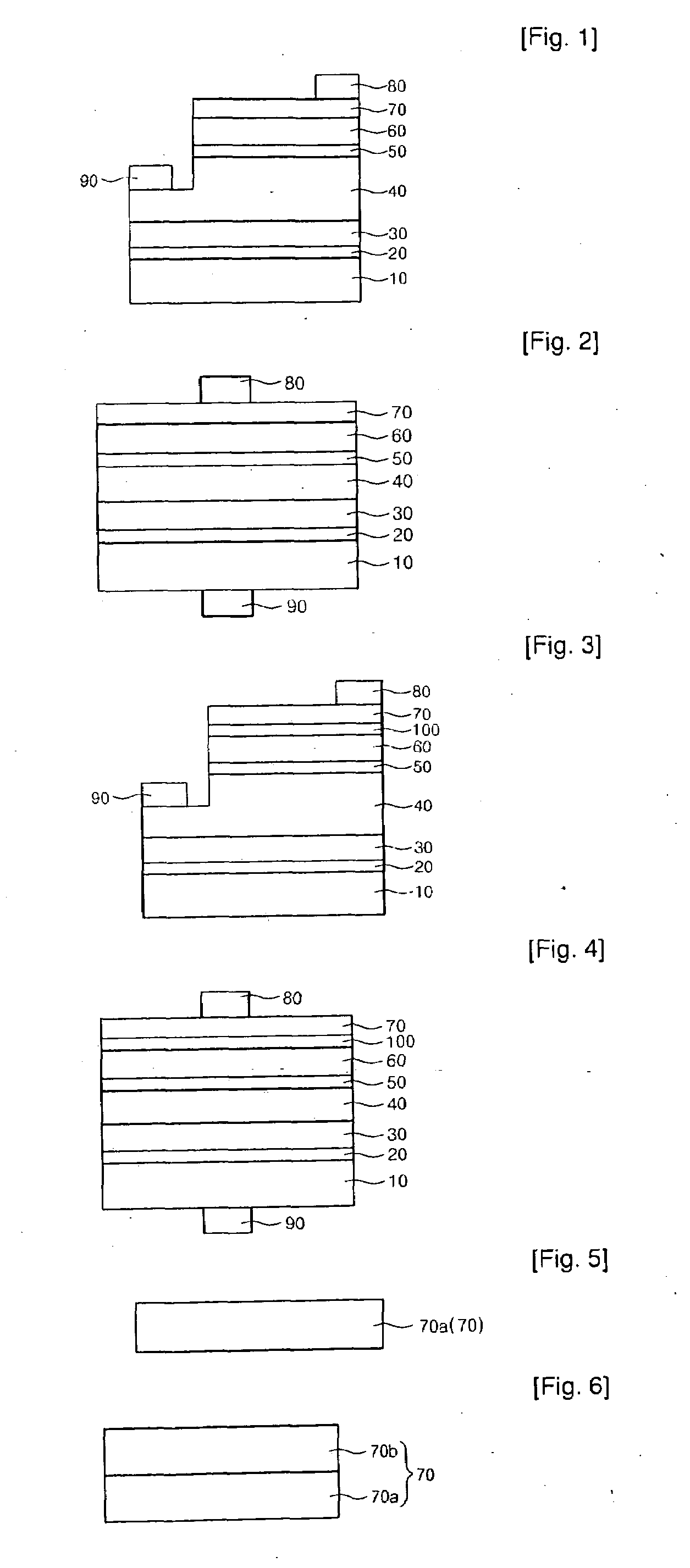

Optical Device and Method of Fabricating the Same

ActiveUS20080258174A1Improve efficiencyImproved ohmic contact characteristicsSemiconductor/solid-state device manufacturingOxide conductorsIridiumIndium

Disclosed is an optical device including an optical member and a contact layer stacked on at least one of top and bottom surfaces of the optical member. The contact layer has at least one transparent conducting oxynitride (TCON) layer. The TCON consists of at least one of indium (In), tin (Sn), zinc (Zn), cadmium (Cd), gallium (Ga), aluminum (Al), magnesium (Mg), titanium (Ti), molybdenum (Mo), nickel (Ni), copper (Cu), silver (Ag), gold (Au), platinum (Pt), rhodium (Rh), iridium (Ir), ruthenium (Ru), and palladium (Pd).

Owner:SAMSUNG DISPLAY CO LTD +1

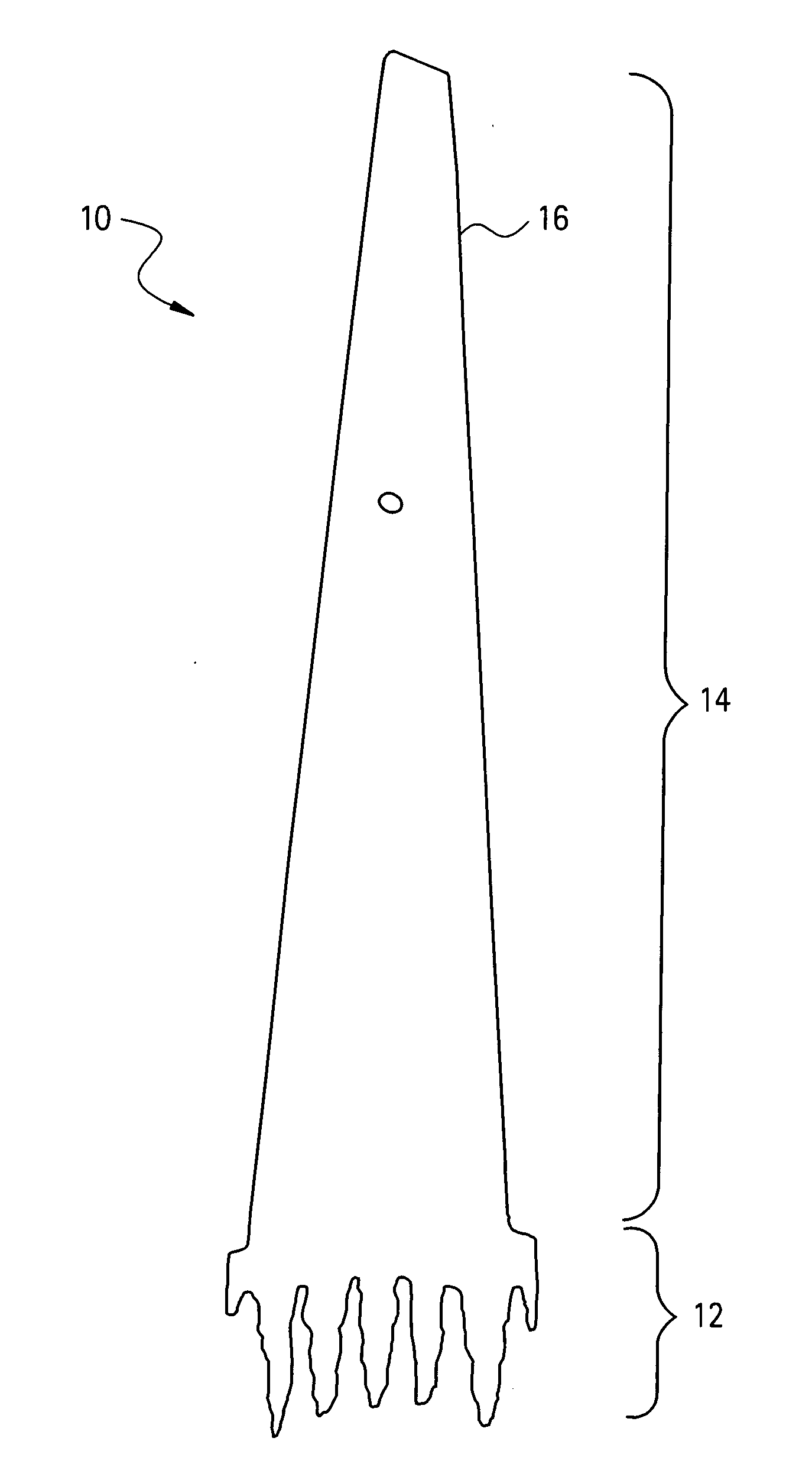

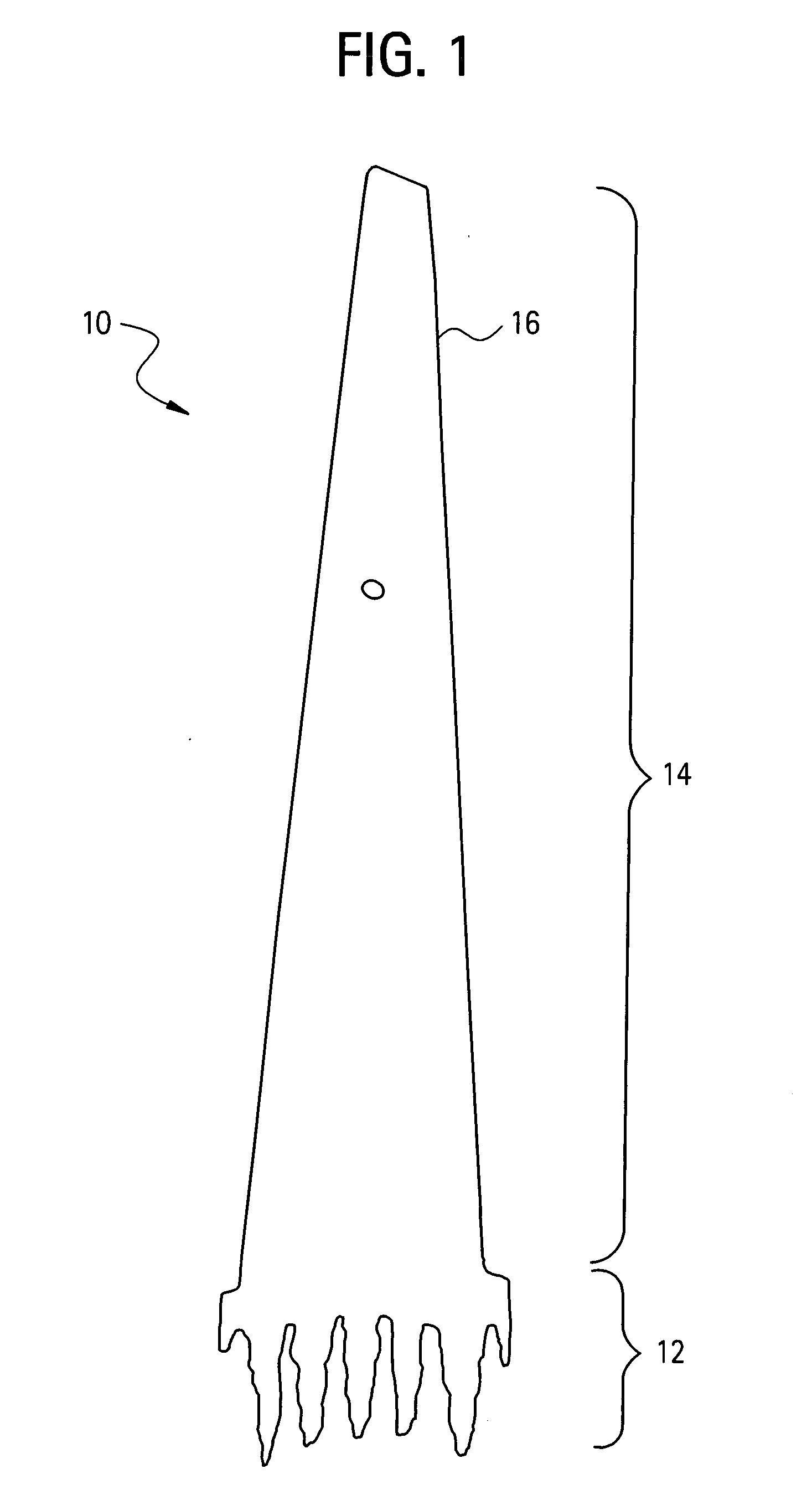

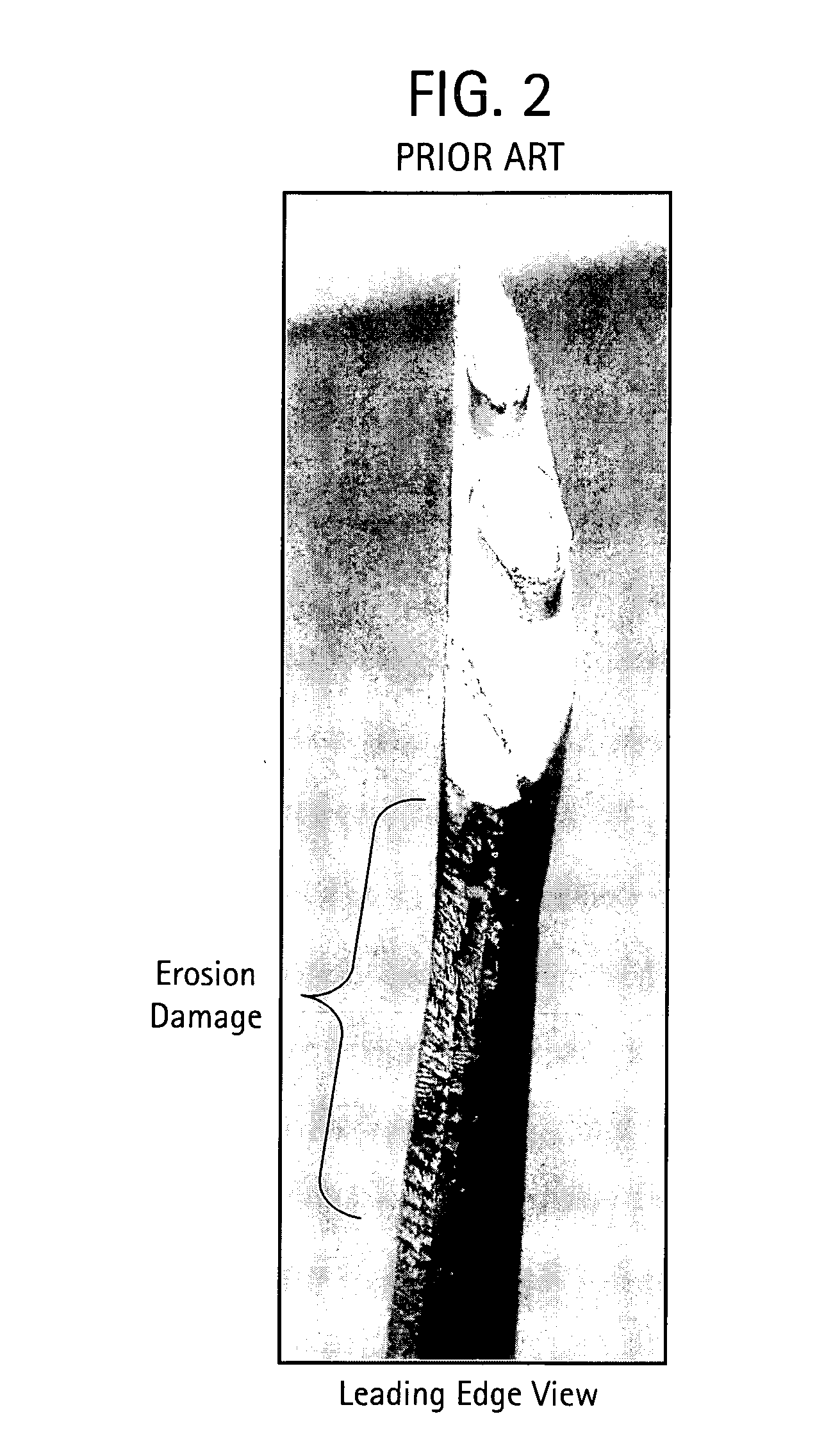

Erosion and wear resistant protective structures for turbine engine components

An erosion resistant protective structure for a turbine engine component comprises a shape memory alloy. The shape memory alloy includes nickel-titanium based alloys, indium-titanium based alloys, nickel-aluminum based alloys, nickel-gallium based alloys, copper based alloys, gold-cadmium based alloys, iron-platinum based alloys, iron-palladium based alloys, silver-cadmium based alloys, indium-cadmium based alloys, manganese-copper based alloys, ruthenium-niobium based alloys, ruthenium-tantalum based alloys, titanium based alloys, iron-based alloys, or combinations comprising at least one of the foregoing alloys. Also, disclosed herein are methods for forming the shape memory alloy onto turbine component.

Owner:GENERAL ELECTRIC CO

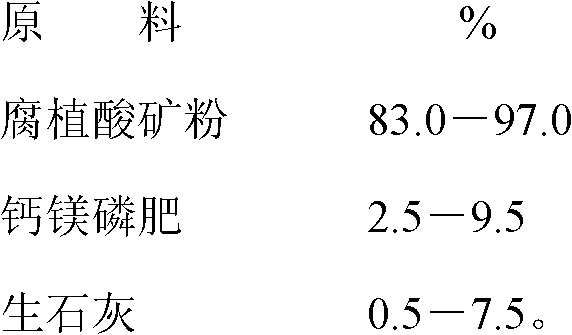

Soil heavy metal composite passivator with humic acid minerals and preparation method thereof

ActiveCN102220136AImprove adsorption capacityTake advantage of multiple functionsAgriculture tools and machinesOrganic fertilisersSoil heavy metalsCadmium Cation

The invention discloses a soil heavy metal composite passivator with humic acid minerals and a preparation method thereof. The soil heavy metal composite passivator is prepared by humic acid mineral powder, fused calcium magnesium phosphate and quick lime according to a certain proportion. The preparation method comprises the following steps: A, preparing the humic acid mineral powder: taking humic acid raw ore, carrying out ball-milling to the humic acid raw ore, and sieving the humic acid raw ore by a 110-140-mesh sieve for standby; and B, uniformly mixing the raw material prepared in the step A, fused calcium magnesium phosphate and quick lime, adjusting the water content of the mixture to be 10% counting by H2O, and stacking the mixture for five-seven days to obtain the soil heavy metal composite passivator with the humic acid minerals, so that the operation is simple and the method is easy to implement. By the invention, the available cadmium content of red sand mud soil with thefull-cadmium content of 10mg / kg (by exogenous adding) is reduced by 0.36-2.25mg / kg within ninety-day culture time, the reduction amplitude reaches up to 4.7-25.7%, the efficiency of the soil heavy metal composite passivator with the humic acid minerals under a water condition of 45% WHC (Water-holding Capacity) is better than that under a flooded condition, and the soil heavy metal composite passivator with the humic acid minerals also has the functions of passivating heavy metal in soil, soil fertility and the like and has significant popularization and application values in vast heavy metalpollution regions.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

Heavy metal treating agent and heavy metal pollutants treating method

ActiveCN101947381AGood storage stabilityInhibitionSludge treatmentWater contaminantsHigh concentrationSludge

Provided is a heavy metal treating agent and a heavy metal pollutants treating method. The invention provides a medicament and a treating method thereof. The medicament is used for treating heavy metal pollutants, like burning ash and fly ash discharged from a garbage burning field, soil polluted by heavy metal, sludge generated from waste water treatment, and heavy metal contained in the waste water discharged by factories. Heavy metal treating agent comprising piperazine dithiocarboxylic acids salt and reductible composition is used. In terms of reductible composition, water soluble bivalent iron compound and aliphatics Alpha - hydroxycarboxylic acid and / or salt, or sulfurated bi-alkali metal salt are preferably used. With the heavy metal treating agent, harmful cation species heavy metal like lead, zincum, cadmium, mercury, arsenic, selenium, and hexavalent chromium can be treated by encapsulation in a high concentration, and harmful anion species heavy metal like hexavalent chromium, arsenic and selenium can be treated by encapsulation in a high concentration.

Owner:TOSOH CORP

Method of preparing cadmium sulfide nanocrystals emitting light at multiple wavelengths, and cadmium sulfide nanocrystals prepared by the method

A method for preparing cadmium sulfide nanocrystals emitting light at multiple wavelengths. The method comprises the steps of (a) mixing a cadmium precursor and a dispersant in a solvent that weakly coordinates to the cadmium precursor, and heating the mixture to obtain a cadmium precursor solution, (b) dissolving a sulfur precursor in a solvent that weakly coordinates to the sulfur precursor to obtain a sulfur precursor solution, and (c) feeding the sulfur precursor solution to the heated cadmium precursor solution maintained at a high temperature to prepare cadmium sulfide crystals, and growing the cadmium sulfide crystals. Further, cadmium sulfide nanocrystals prepared by the method. The cadmium sulfide nanocrystals have uniform size and shape and can emit light close to white light simultaneously at different wavelengths upon excitation. Due to these characteristics, the cadmium sulfide nanocrystals can be applied to white light-emitting diode devices.

Owner:SAMSUNG ELECTRONICS CO LTD

Chemical leaching repairing method for heavy metal and arsenic mercury contaminated soil

ActiveCN101362145AGood removal effectImprove repair efficiencyContaminated soil reclamationRestoration methodSoil heavy metals

The invention relates to soil heavy metal pollution treatment technology, in particular to a chemical leaching restoration method used for heavy metal and arsenic mercury polluted soil. Prior soil chemical leaching restoration methods concentrate on the polluted soil caused by one or a plurality of heavy metals (cadmium, copper, lead and zinc, etc.,), which do not have ideal restoration effect to soil with the pollution of both arsenic in the form of negative ions and mercury which is volatile metal. Aiming at the problem, the method uses the combination of three reagents, namely, Na2EDTA, oxalic acid and KI and leaching method with fractional steps for realizing the chemical restoration of the cadmium, the copper, the lead, the zinc, the arsenic and the mercury, etc., in the polluted soil so that the heavy metal in the polluted soil can reach the environmental safety standards. The soil after the leaching treatment is washed by water, and then is refilled in the original position; therefore, no secondary pollution can be caused.

Owner:SUN YAT SEN UNIV

Multiple element composite metal oxidate arsenic removal settling agent and use method thereof

The invention belongs to the material field for removing the arsenic in water by settlement, more particularly relates to polyelement composite metal oxide arsenic removal settlement agent and an application method thereof based on iron oxide, manganese oxide, and aluminum oxide. The invention uses an ectopic preparation method or situ preparation method for preparing and obtaining polyelement composite metal oxide arsenic removal settlement agent which comprises hydrated iron oxide, hydroxyl-hydrated ferric hydroxide, hydrated aluminum oxide, hydroxyl-hydrated alumina, hydrated manganese oxide and the like. The polyelement composite metal oxide arsenic removal settlement agent can be used for removing the arsenic pollutants in water bodies such as lakes, reservoirs, rivers, groundwater, drinking water, industrial waste water, and the like; in addition, the settlement agent can also be used for removing the heavy metals such as copper, chromium, cadmium, lead, and the like, and the pollutants such as iron, manganese, phosphates, and the like in water by settlement.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Metal alloys for the reflective or the semi-reflective layer of an optical storage medium

InactiveUS6852384B2Improve reflectivitySimilar sputtering characteristicPhotomechanical apparatusRecord information storageIndiumCadmium Cation

A silver-based alloy thin film is provided for the highly reflective or semi-reflective layer of optical discs. Alloy additions to silver include gold, rhodium, ruthenium, osmium, platinum, palladium, copper, silicon, cadmium, tin, lithium, nickel, cobalt, indium, chromium, antimony, gallium, boron, molybdenum, zirconium, beryllium, titanium, and zinc. These alloys have moderate to high reflectivity and reasonable corrosion resistance in the ambient environment.

Owner:TARGET TECH

Sulfonylation graphene oxide magnetic adsorbent, and preparation method and application thereof

InactiveCN102989420AWide variety of sourcesLow priceOther chemical processesAlkali metal oxides/hydroxidesSorbentAniline

The invention relates to a sulfonylation graphene oxide magnetic adsorbent, and a preparation method and application thereof. The adsorbent uses graphene oxide nanosheet as a substrate; the substrate surface is loaded with magnetic ferrite nanoparticles, and contains a large amount of sulfonic acid. The method comprises the following specific steps: first subjecting a graphite powder to pre-oxidation and deep oxidation, and conducting ultrasonic separation to obtain a graphene oxide solution; then adding a mixed solution of iron ions and ferrous ions; rapidly adding ammonia solution while stirring to obtain magnetic graphene oxide; and finally grafting aminobenzene sulfonic acid to magnetic graphene oxide matrix, washing and determining a constant volume to obtain a final product. The product has good adsorption effect on the heavy metals, copper and cadmium, and organic aniline. The product has the advantages of low cost, large specific surface area, high adsorption capacity and easy separation and recovery. The invention can be used for treating wastewater from smelting factory, electronics factory, chemical plant and electroplating plant.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com