Black surface treatment process of electrolytic copper foil

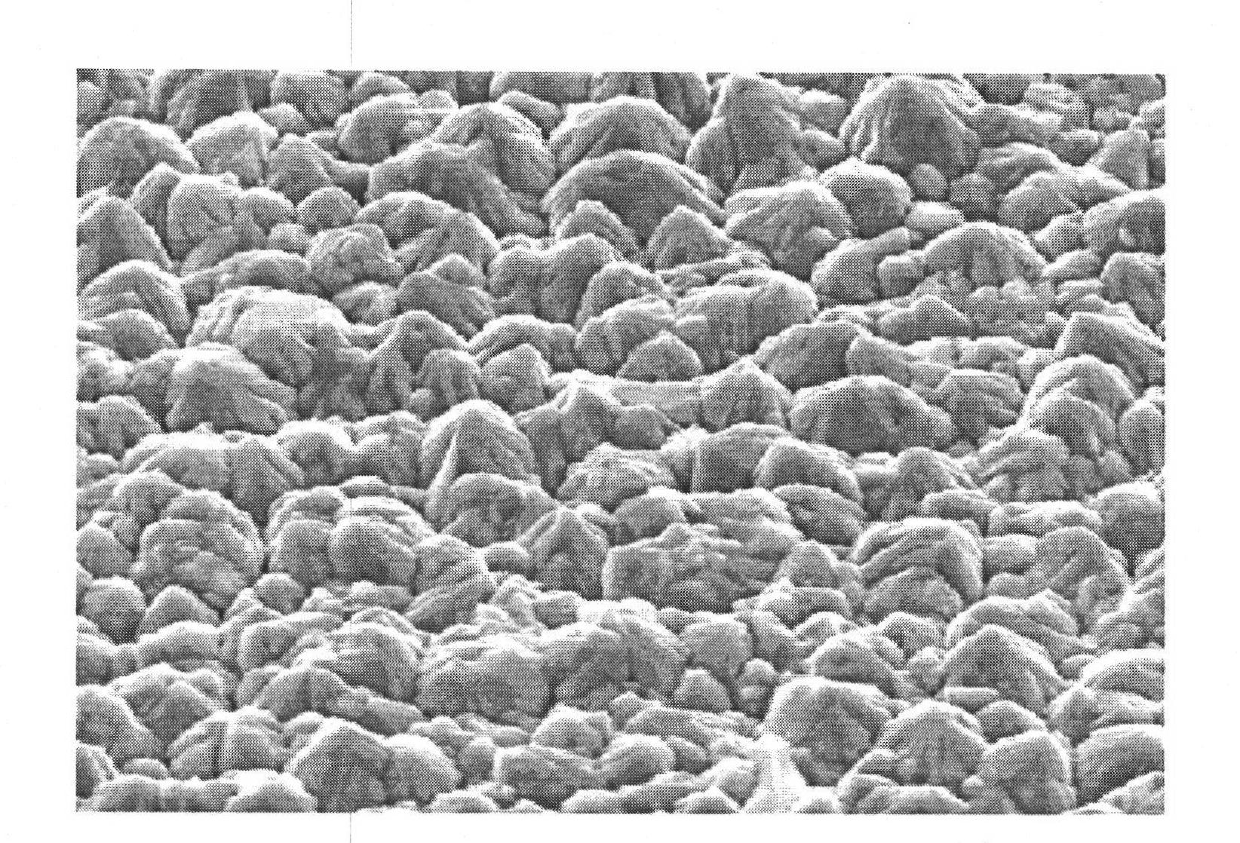

A technology for electrolytic copper foil and surface treatment, which is applied in the field of high-precision electrolytic copper foil production technology to achieve the effects of excellent oxidation resistance and good appearance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

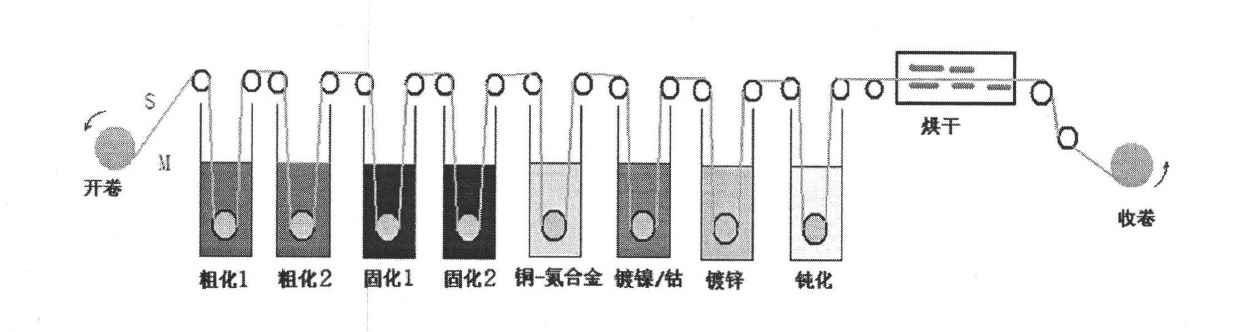

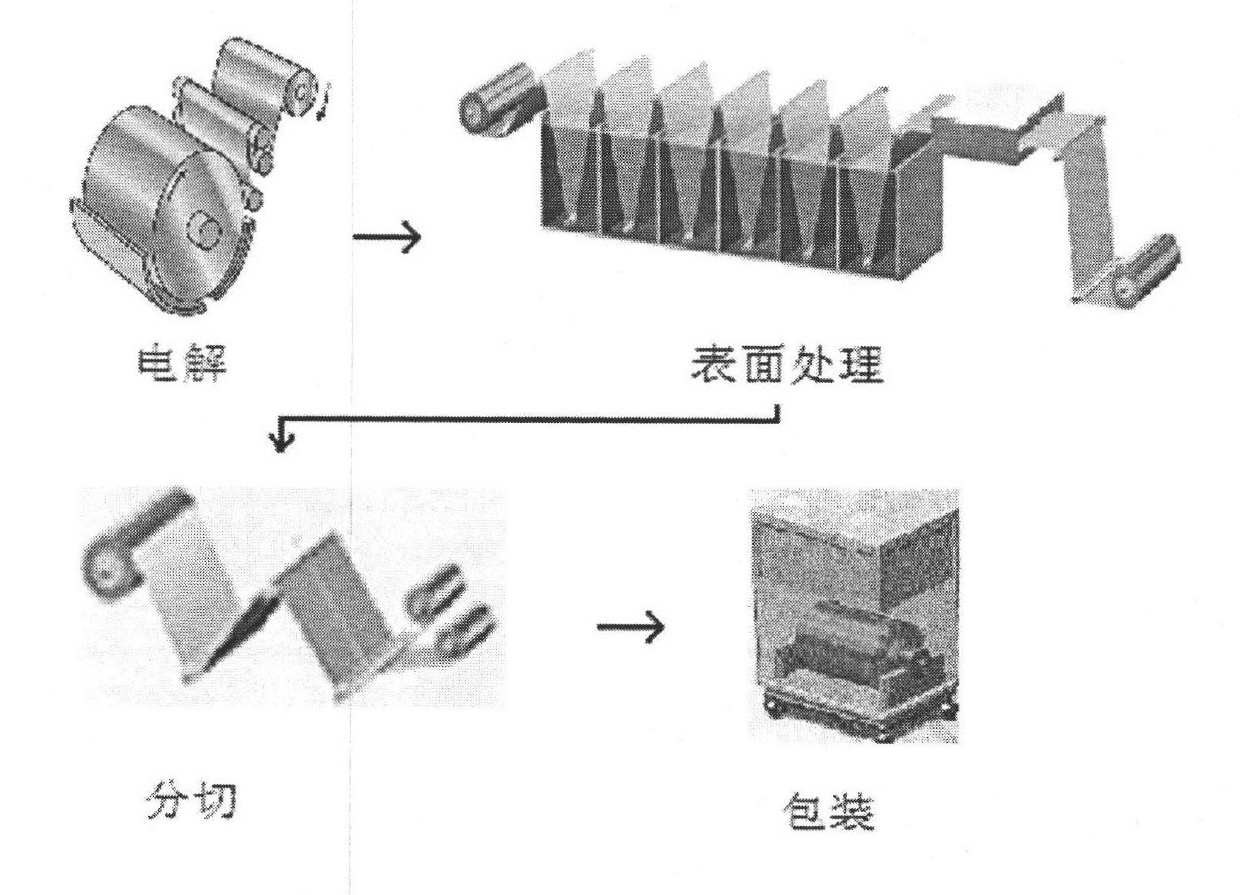

[0037] The black surface treatment process of electrolytic copper foil, the specific process is as follows

[0038] 1. Preparation of roughening solution: mix and dissolve cathode copper, concentrated sulfuric acid, soft water, and steam to form a copper sulfate solution, then add additive A, mix well, pump it into the roughening tank for electroplating; among them, Cu 2+ 15g / L,H 2 SO 4 150g / L, Additive A 50ppm, temperature 40℃, current density 25A / dm 2 , Additive A selects thiourea for use.

[0039] 2. Preparation of curing solution: mix and dissolve cathode copper, concentrated sulfuric acid, soft water and steam to generate copper sulfate solution, pump it into the curing tank for electroplating; where Cu 2+ 65g / L, H 2 SO 4 85g / L, temperature is 80℃, current density is 32A / dm 2 .

[0040] 3. Weak coarsening: mix and dissolve cathode copper, concentrated sulfuric acid, soft water, and steam to form a copper sulfate solution, then add additive C to the copper sulfa...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is:

[0047] 1. Coarsening: Cu 2+ 20g / L, H 2 SO 4 150g / L, additive A 10ppm, temperature 26°C, current density 30A / dm 2 , Additive A selects gelatin for use.

[0048] 2. Curing: Cu 2+ 58g / L,H 2 SO 4 160g / L, the temperature is 40℃; the current density is 25A / dm 2 .

[0049] 3. Weak coarsening: Cu 2+ 8g / L, H 2 SO 4 180g / L, additive C 1.2g / L, temperature 40°C, current density 7.5A / dm 2 , additive C is NaAsO 3 .

[0050] 4. Cobalt-plated alloy: K 4 P 2 o 7 140-300g / L, Co 2+ 15g / L, Zn 2+ 1.5g / L, additive M 420ppm, additive N 8.5g / L, pH 9.2, temperature 35°C, current density 12A / dm 2 , the additive M is Ag 2 SO 4 , the additive N is NH 4 AC.

[0051] 5. Galvanized alloy: K 4 P 2 o 7 220g / L, Zn 2+ 6.8g / L, additive D 145ppm, pH 9.6, temperature 40°C, current density 1.6A / dm 2 , the additive D chooses CuSO 4 .

[0052] 6. Passivation: potassium chromate 8.5g / L, pH 10.6, temperature 35...

Embodiment 3

[0055] The difference between this embodiment and embodiment 1 is:

[0056] 1. Coarsening: Cu 2+ 12g / L,H 2 SO 4 142g / L, Additive A 5.5ppm, temperature 45℃, current density 25 A / dm 2 , Additive A selects hydroxyethyl cellulose for use.

[0057] 2. Curing: Cu 2+ 70g / L, H 2 SO 4 95g / L, the temperature is 52℃; the current density is 30A / dm 2 .

[0058] 3. Weak coarsening: Cu 2+ 14g / L,H 2 SO 4 180g / L, additive C 1.8g / L, temperature 50°C, current density 9.2A / dm 2 , Additive C chooses NH 4 Cl.

[0059] 4. Nickel-plated alloy: K 4 P 2 o 7 180g / L, Ni 2+ 12g / L, Zn 2+0.5g / L, additive M 120ppm, additive N 3g / L, pH 10.8, temperature 40°C, current density 12A / dm 2 , the additive M chooses CoSO 4 ·7H 2 O, the additive N is triammonium citrate.

[0060] 5. Galvanized alloy: K 4 P 2 o 7 260g / L, Zn 2+ 5g / L, additive D 140ppm, pH 10.6, temperature 39°C, current density 0.68A / dm 2 , the additive D chooses NiSO 4 ·6H 2 O.

[0061] 6. Passivation: sodium chr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com