Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1264 results about "Chromic Ion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

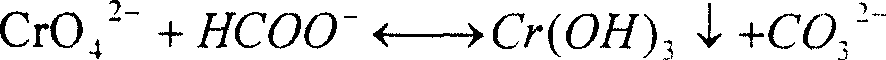

The chromate and dichromate ions are fairly strong oxidizing agents. Commonly three electrons are added to a chromium atom, reducing it to oxidation state +3. In acid solution the aquated Cr3+ ion is produced. In alkaline solution chromium(III) hydroxide is produced.

-Zn coated steel material, ZN coated steel sheet and painted steel sheet excellent in corrosion resistance, and method of producing the same

InactiveUS6465114B1Improve corrosion resistanceResistance to red rustHot-dipping/immersion processesLiquid surface applicatorsSheet steelAlloy coating

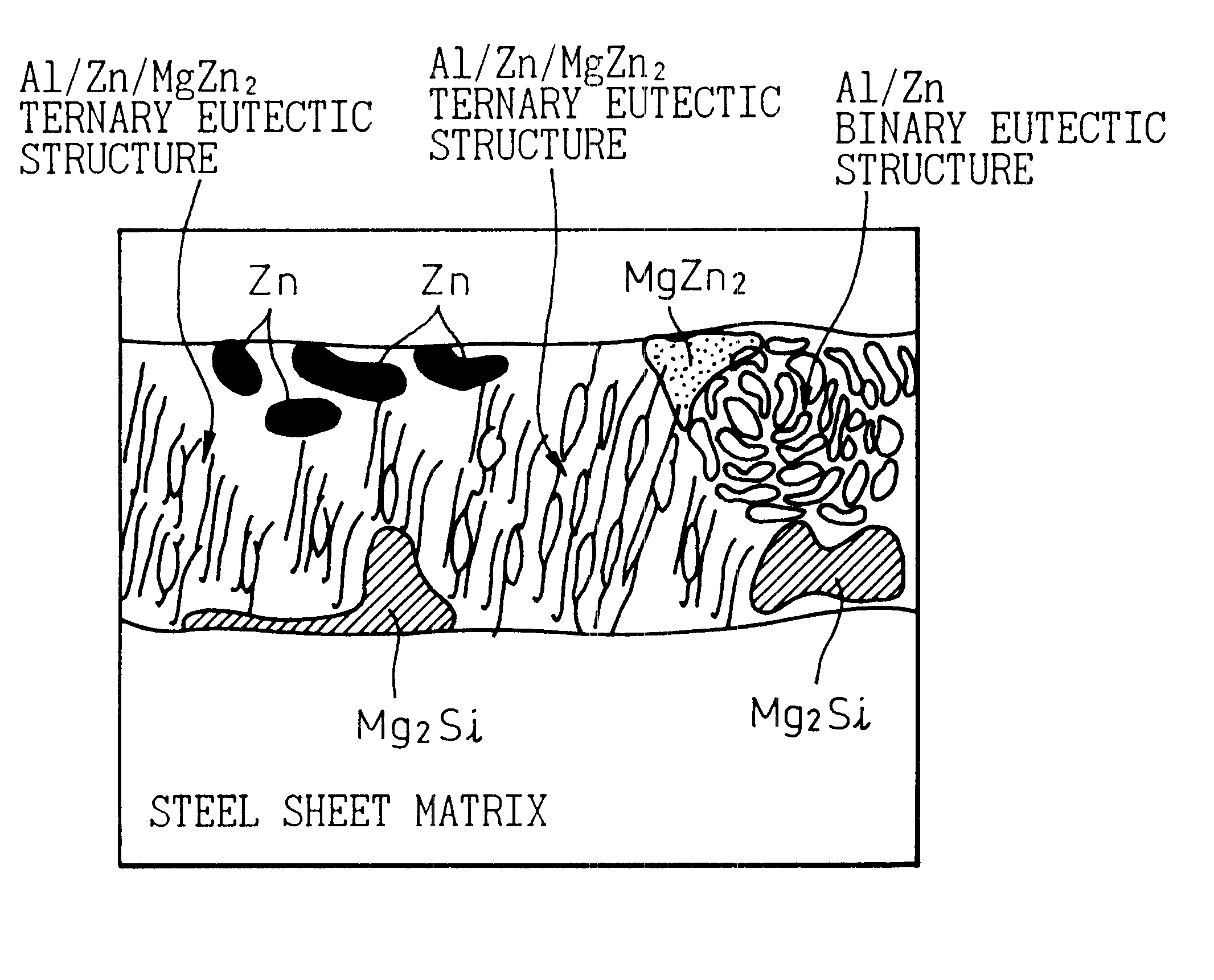

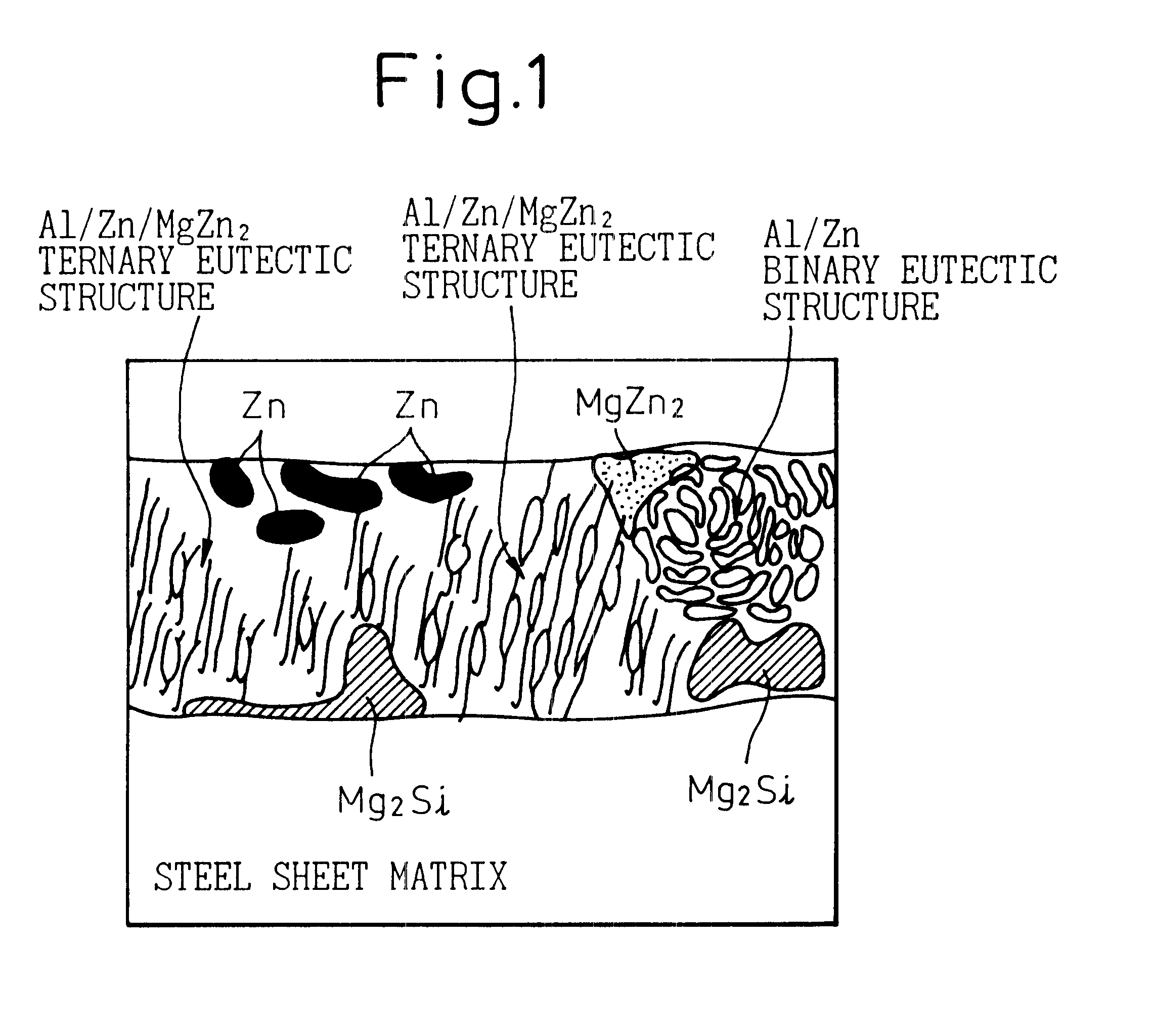

A coated steel material excellent in corrosion resistance and a method of producing the same, wherein a coated steel material has on the surface of the steel sheet a Zn-alloy coating layer containing 1-10 wt % of Mg, 2-19 wt % of Al and 0.01-2 wt % of Si, where Mg and Al satisfy Mg (%)+Al (%)<=20%, the balance being Zn and unavoidable impurities, and has a coating layer structure of a Mg intermetallic compound or the like. As a base metal treatment, it is preferably provided with a Ni coating layer. The coated Zn-alloy coated steel sheet may have provided on the coating layer, as an intermediate layer, a chromate film layer, and, as an upper layer, an organic coating layer. The Zn-alloy coating layer may further contain one or more of 0.01-1 wt % of In, 0.01-1 wt % of Bi and 1-10 wt % of Sn. The coated steel material may be painted.

Owner:NIPPON STEEL CORP

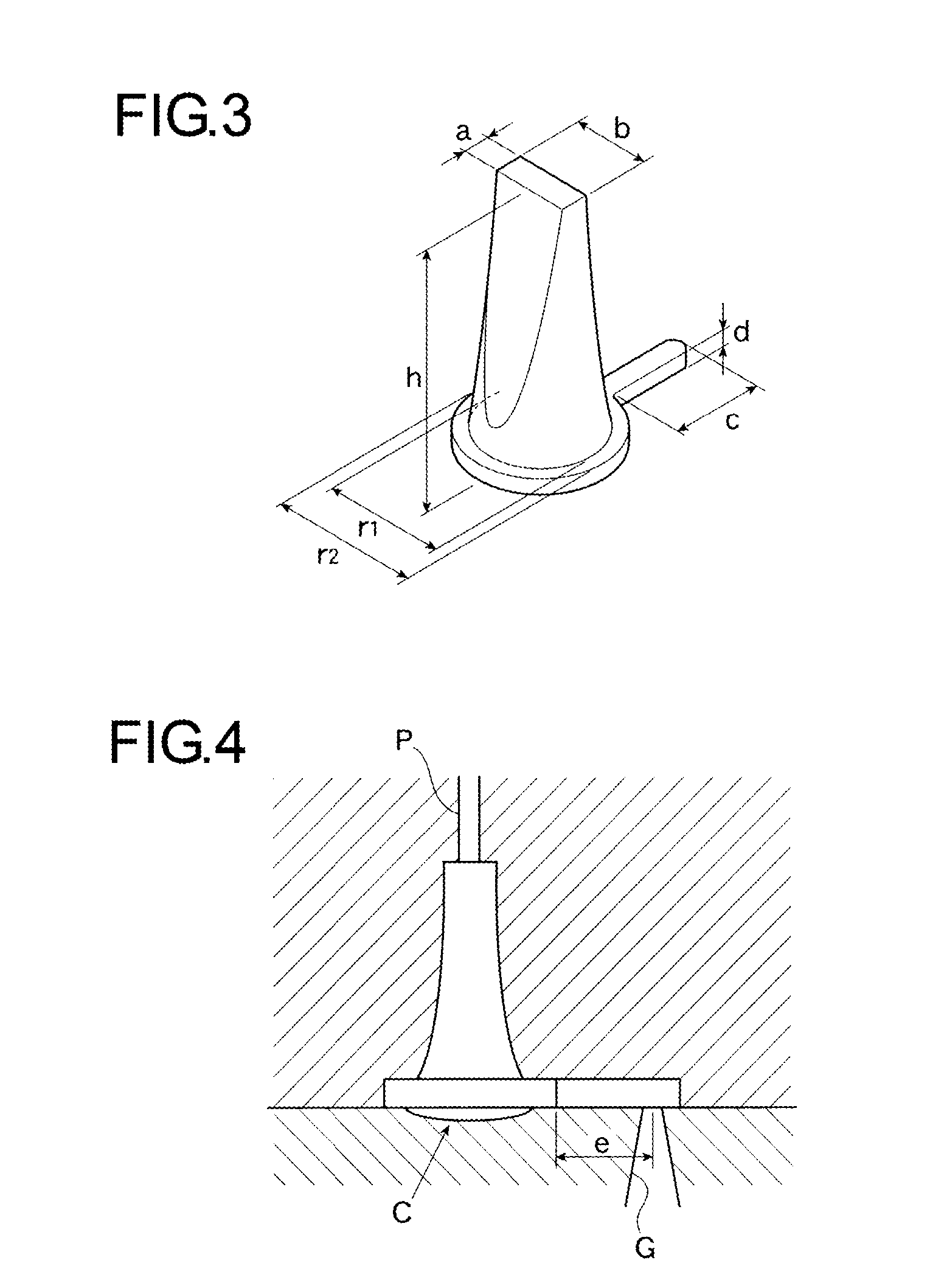

Bonded body of galvanized steel sheet and adherend, and manufacturing method thereof

InactiveUS20110008644A1Firmly connectedGood adhesionHot-dipping/immersion processesLiquid surface applicatorsPolyolefinSheet steel

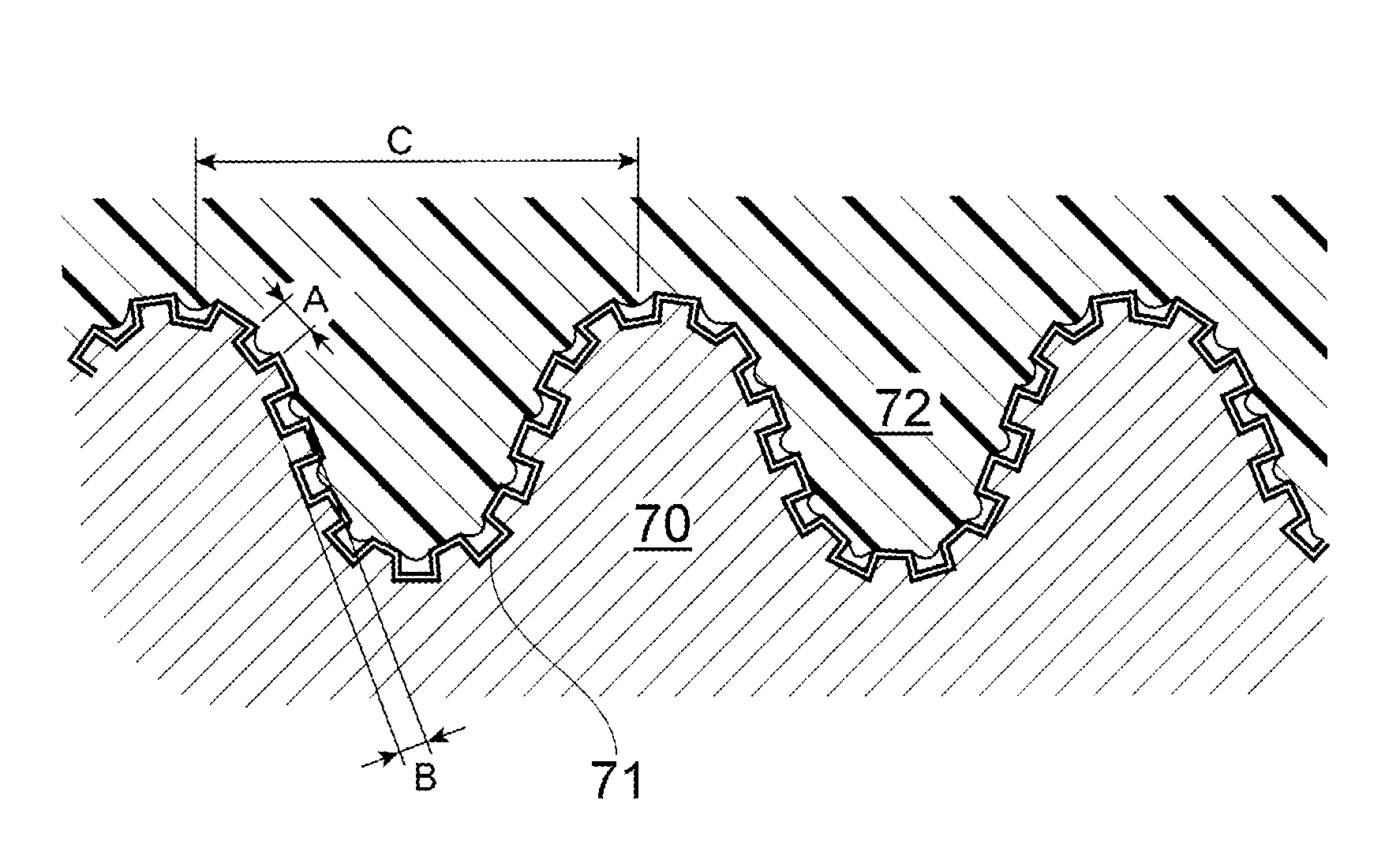

The invention is a technique for strongly integrating a galvanized steel sheet and a resin molded article. A hot-dip galvanized steel sheet “Z18” is immersed in an aqueous solution for aluminum degreasing at 75° C. for 7 minutes, to form roughness having an RSm of 0.8 to 2.3 μm and an Rz of 0.3 to 1.0 μm on the surface. The surface is covered with convex protrusions having a diameter of about 100 nm, and a chromate treatment layer appears in the surface. In other words, three conditions suitable for bonding are satisfied thereby. A resin composition comprising 70 to 97 wt % of polyphenylene sulfide and 3 to 30 wt % of a polyolefin resin is injected onto the surface. The resin composition penetrates into ultra-fine irregularities and is cured in that state, whereby a composite in which the galvanized steel sheet and the resin molded article are strongly integrated is obtained. The shear rupture strength of the composite is extremely high, in excess of 20 MPa.

Owner:TAISEI PLAS CO LTD

Composite film chromium-free passivant

InactiveCN101886260AGood physical propertiesImprove corrosion resistanceMetallic material coating processesOrganic acidChemical treatment

The invention relates to a composite film chromium-free passivant, which mainly comprises the following components of: a waterborne resin film-forming substance, an organic acid film-forming substance, an inorganic film-forming substance, a film-forming auxiliary agent, an additive, water and the like. The formula of the composite film chromium-free passivant is scientific and reasonable, does not comprise toxic and harmful substances such as chromium and the like, and meets the requirements of ROHS environmental protection laws and regulations which have been implemented by European Union since July 2006, so that the composite film chromium-free passivant is an environmentally-friendly chemical treatment agent. The composite film chromium-free passivant is suitable for hot galvanizing and electrogalvanizing post-processing technology, and the passivation process is simple and easy to operate. An organic and inorganic composite film is formed on the surface of a galvanized part after passivation by using the composite film chromium-free passivant. The composite film is colorless and transparent, has high corrosion resistance and can substitute for the traditional chromate to perform the passivation.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

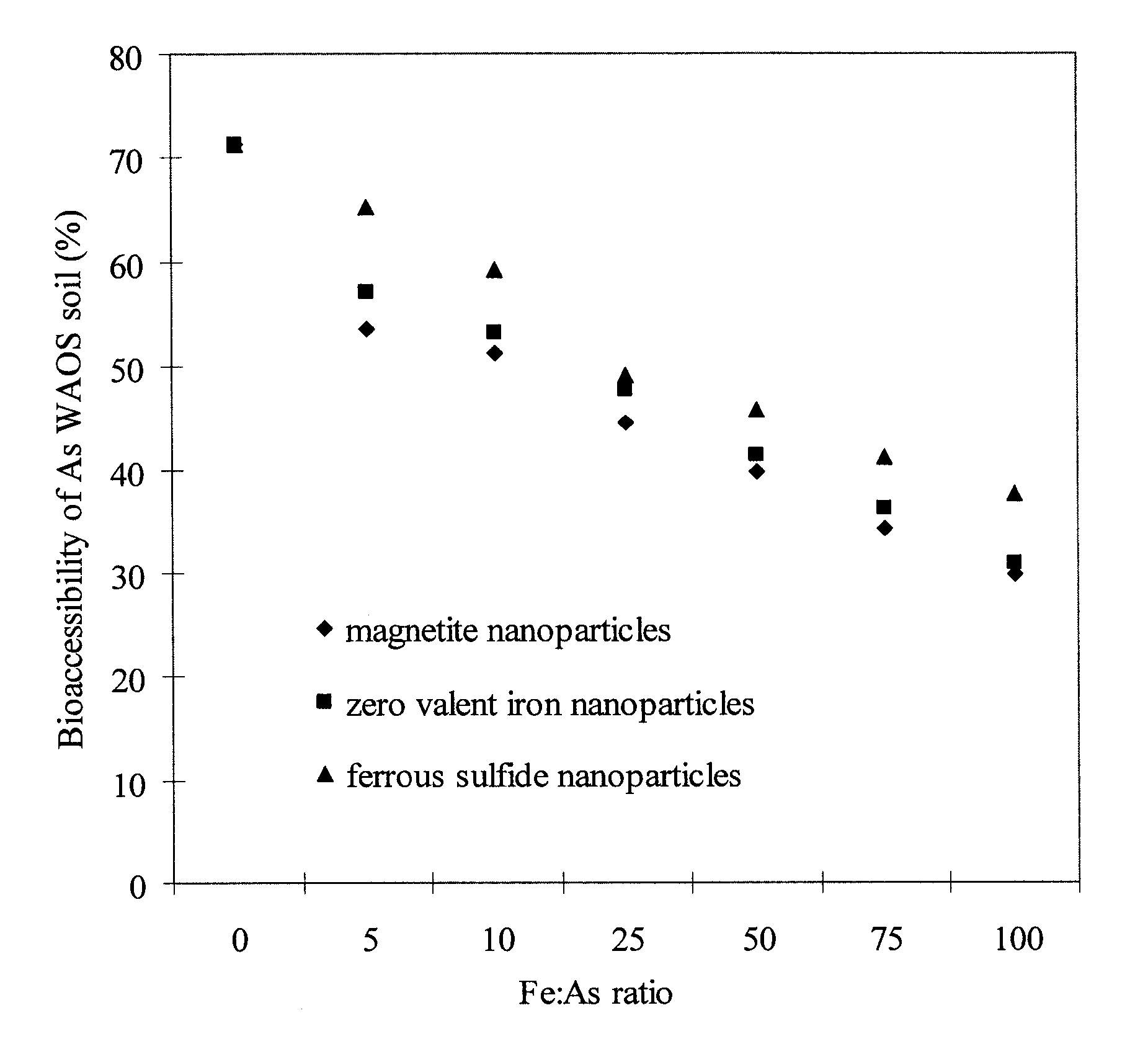

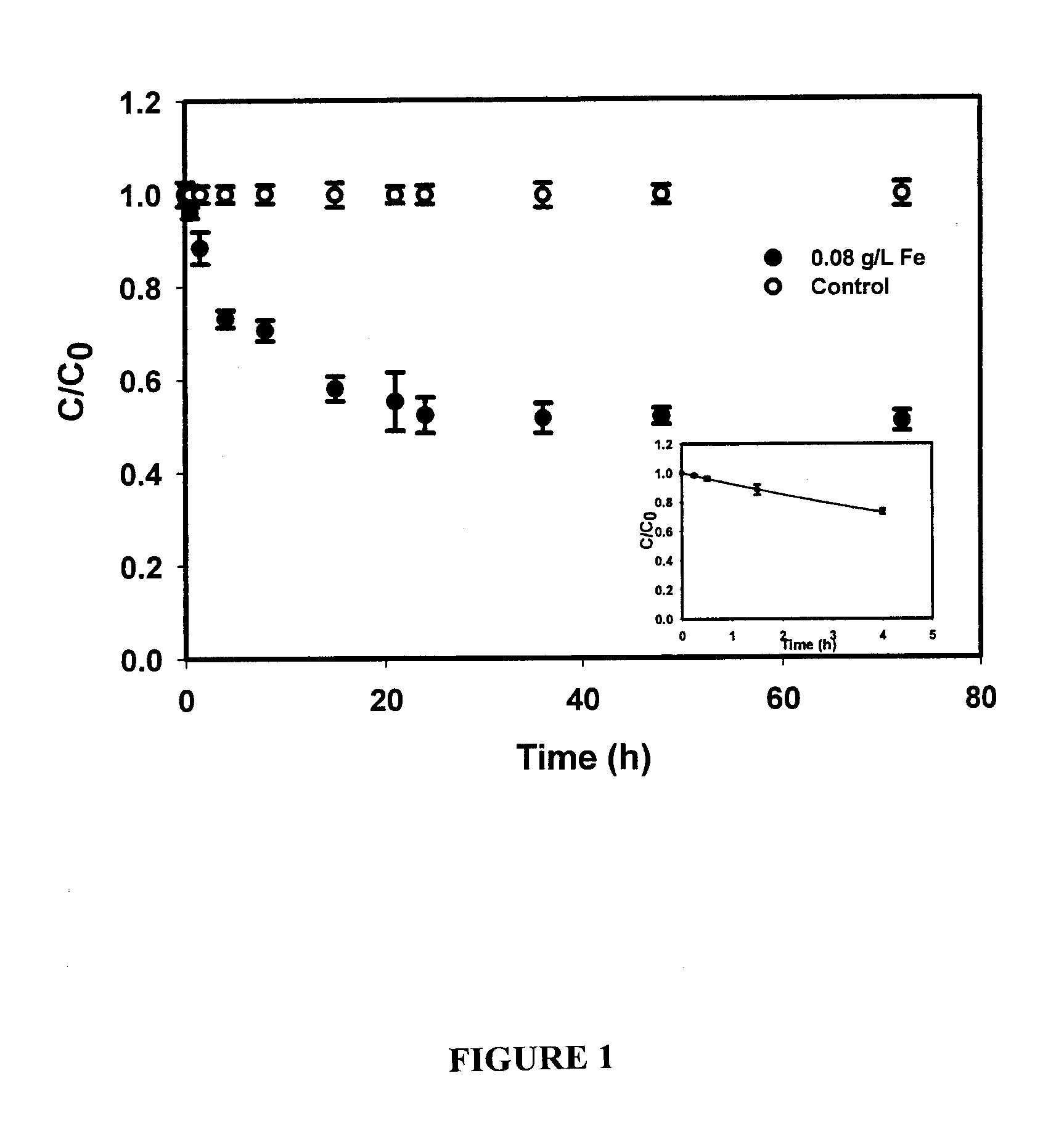

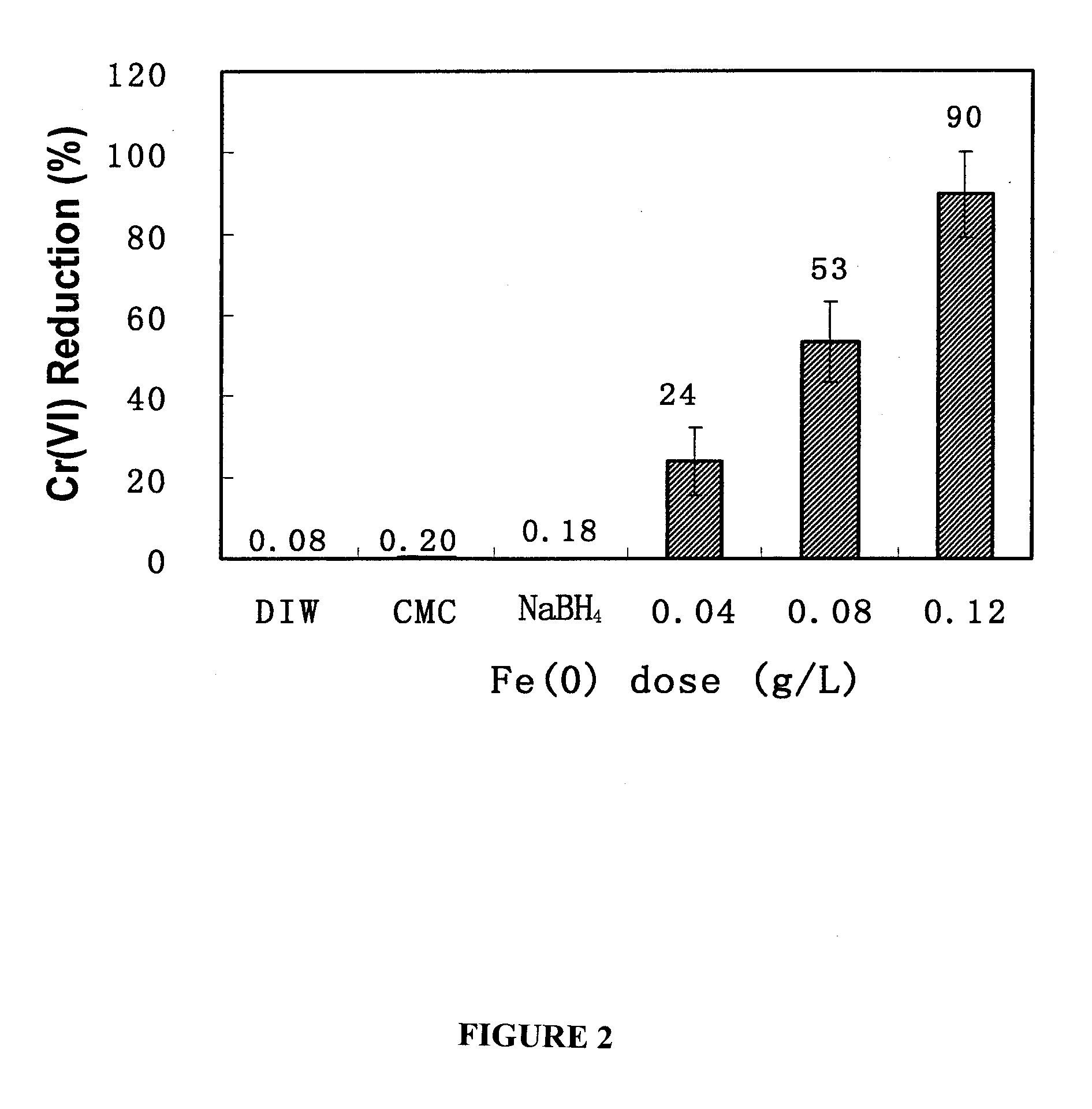

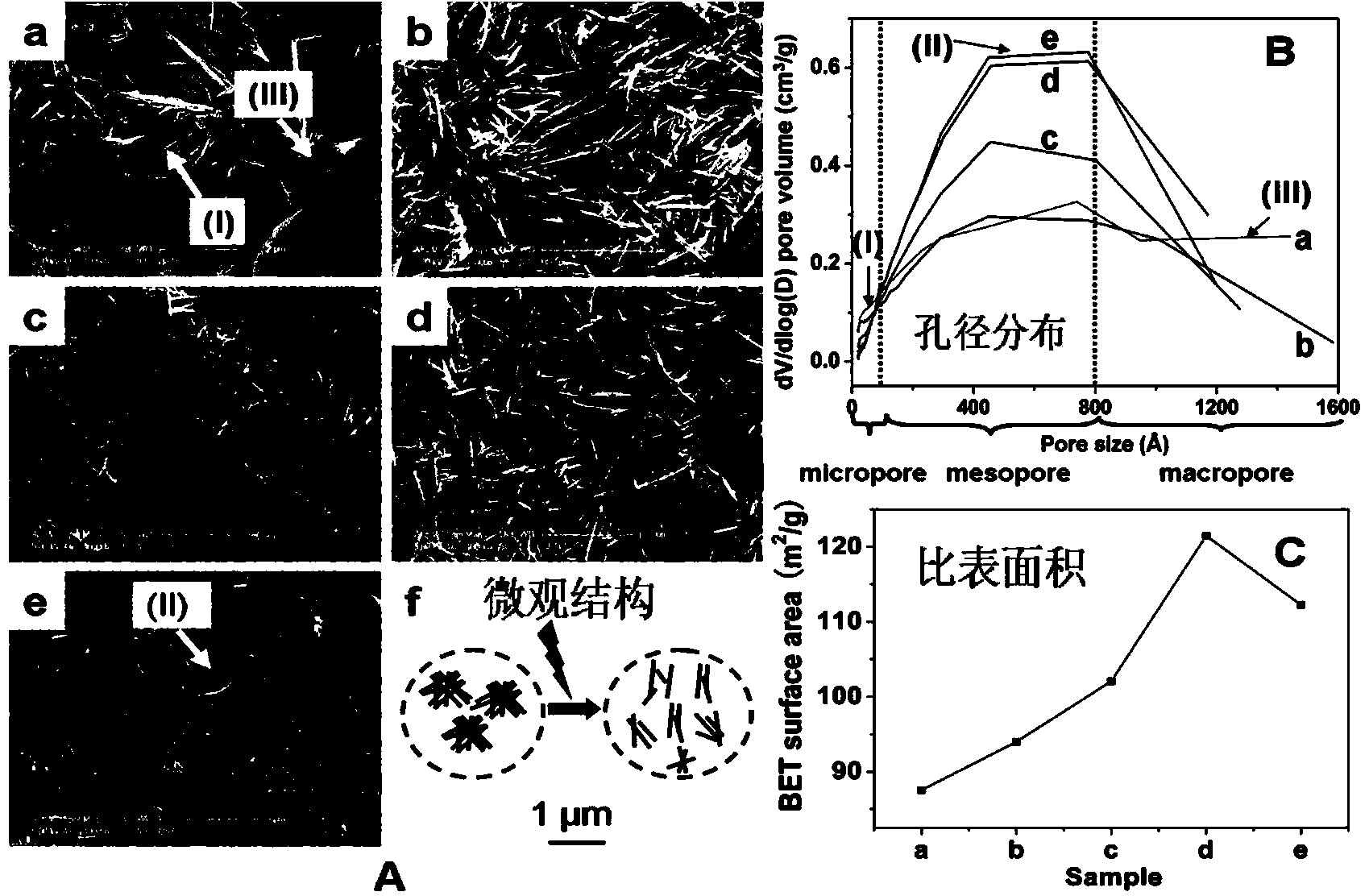

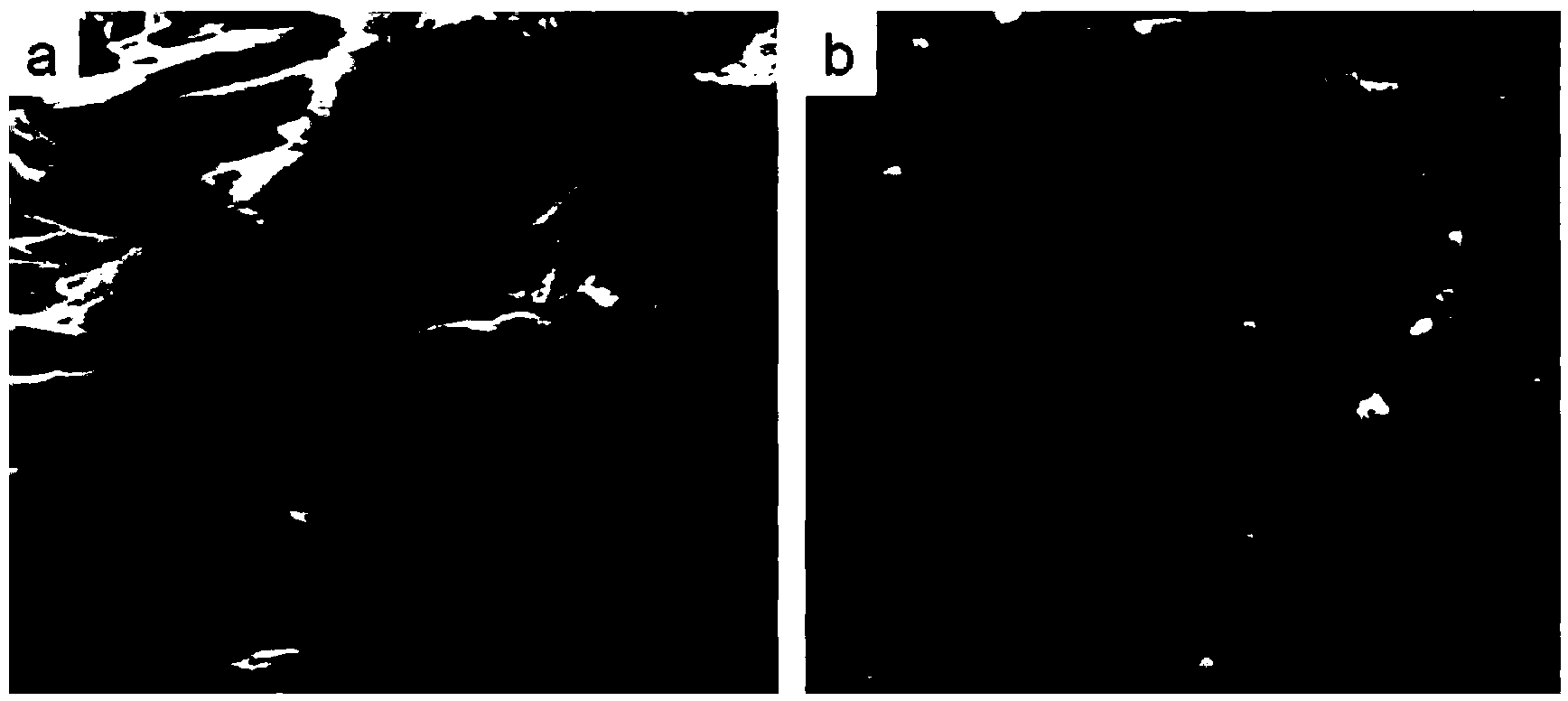

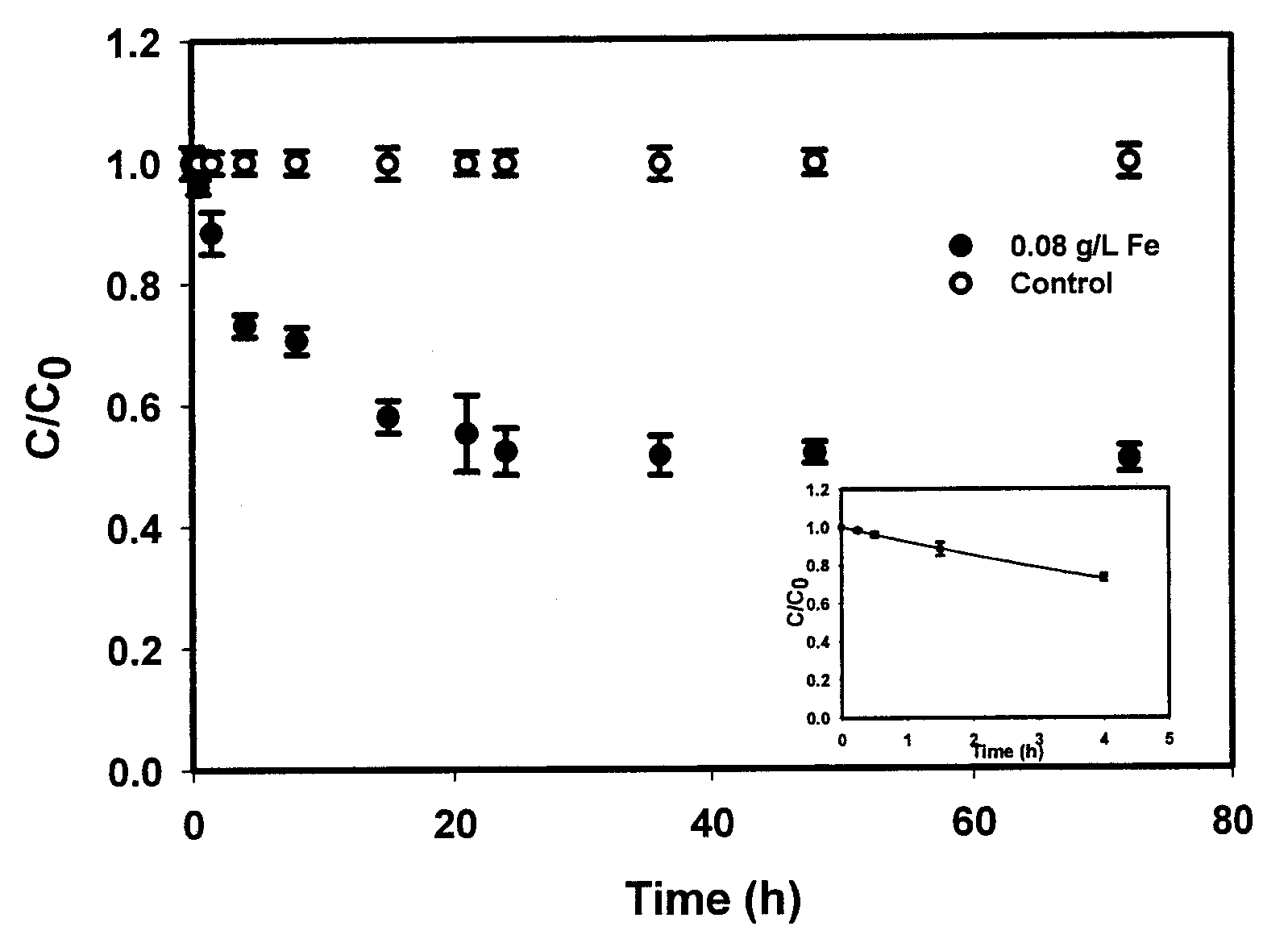

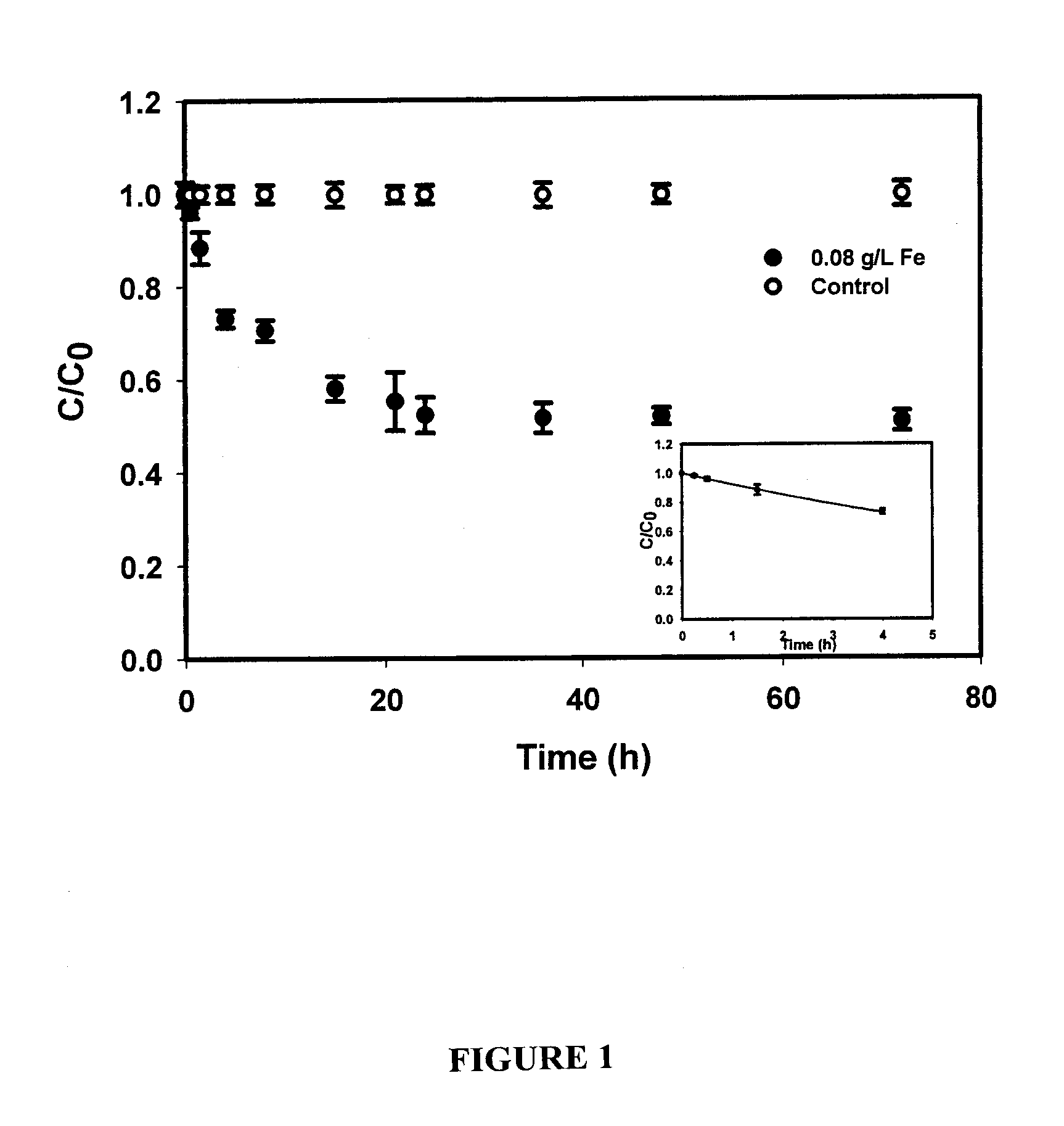

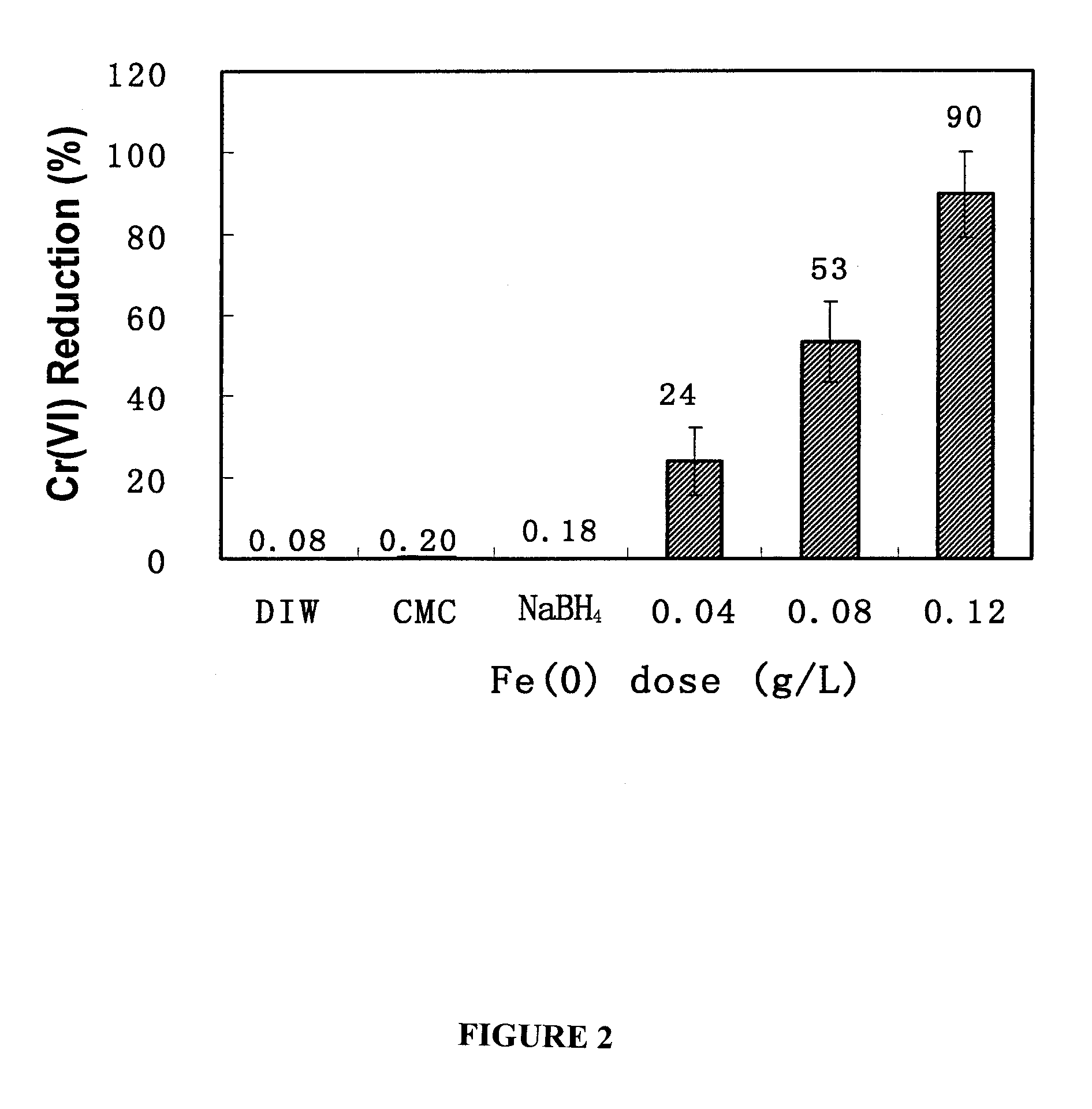

In Situ Remediation of Inorganic Contaminants Using Stabilized Zero-Valent Iron Nanoparticles

InactiveUS20070256985A1Low costProcess environmental protectionMaterial nanotechnologyWater treatment compoundsCelluloseMaterials science

A method for preparing highly stabilized and dispersible zero valent iron nanoparticles and using the nanoparticles as a remediation technology against inorganic chemical toxins in contaminated sites. The method employs a composition containing select polysaccharides (starch or cellulose) as a stabilizer for the iron nanoparticles in a liquid carrier, and results in suspensions of iron nanoparticles of desired size and mobility in water, brine, soils or sediments. The stabilizer facilitates controlling the dispersibility of the iron nanoparticles in the liquid carrier. An effective amount of the composition is delivered to a contaminated site so that the zero valent iron nanoparticles can remediate one or more toxins such as an arsenate, a nitrate, a chromate, or a perchlorate in the contaminated site.

Owner:AUBURN UNIV

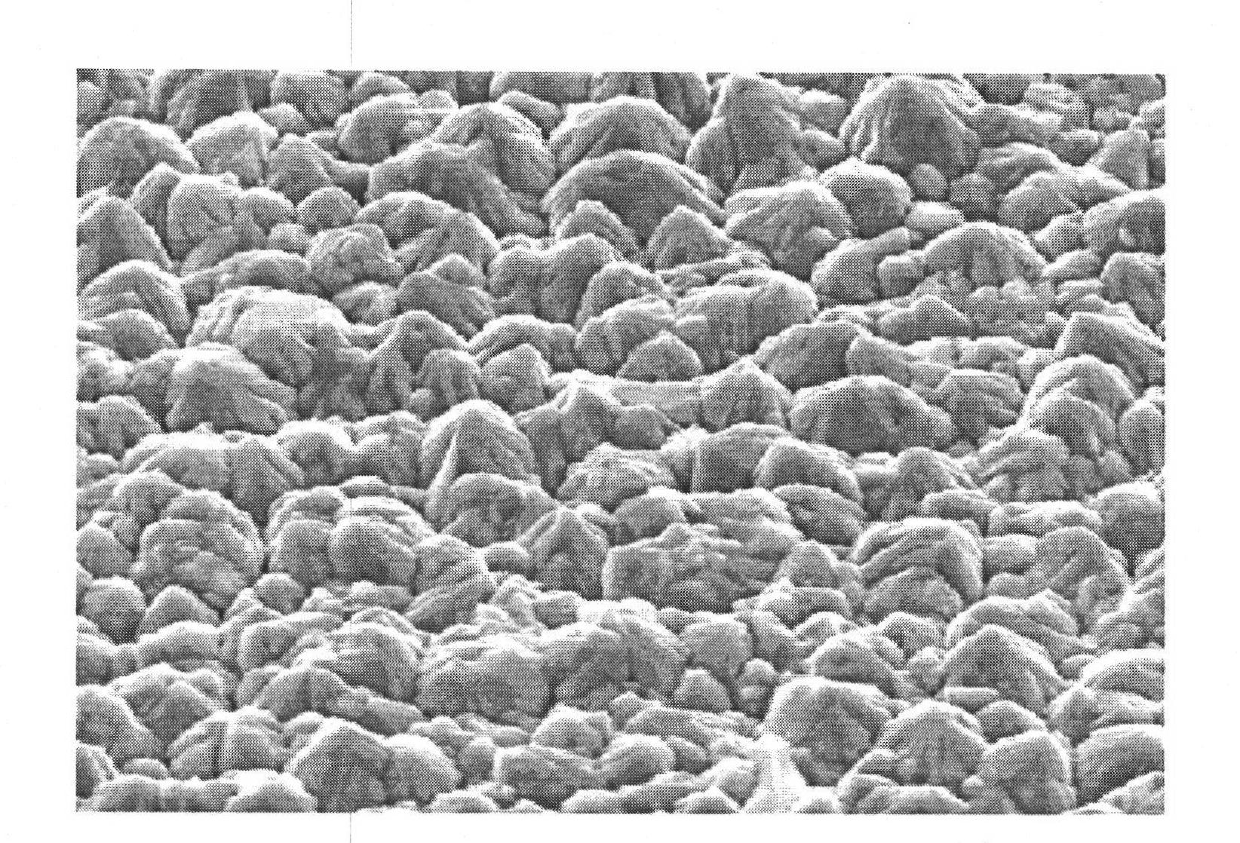

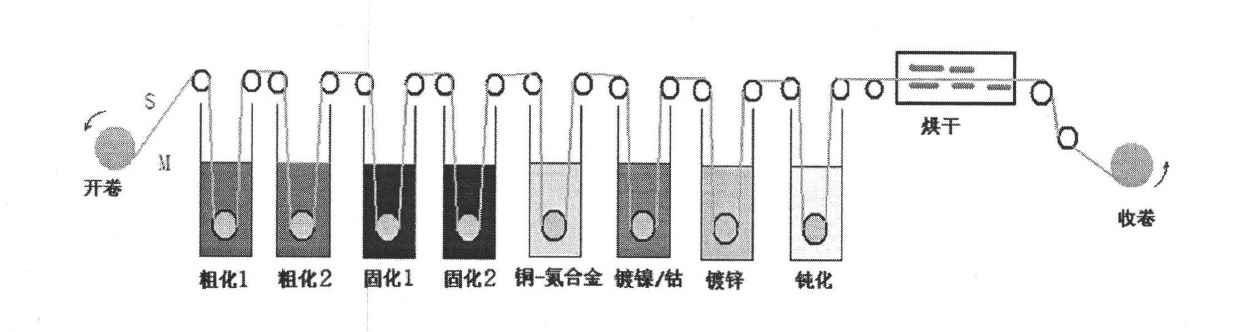

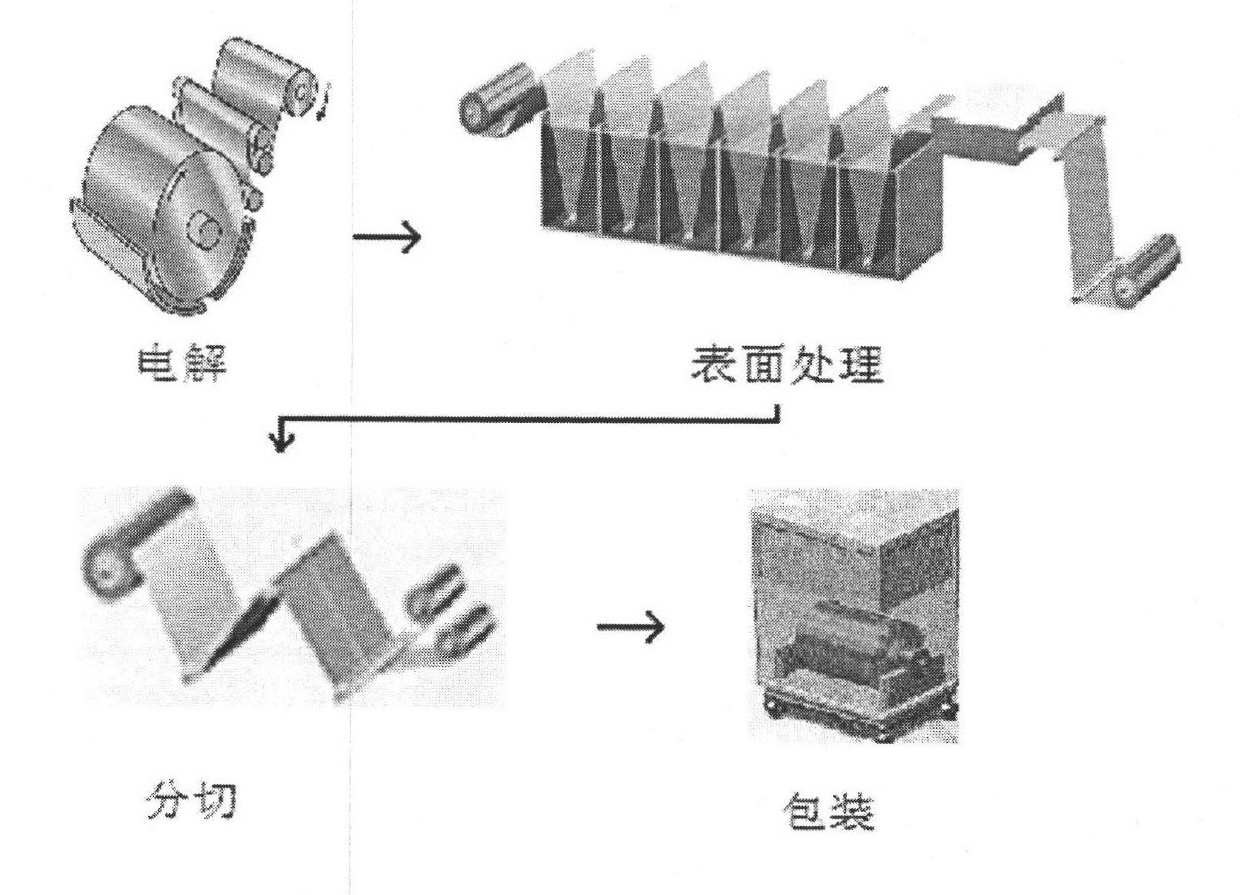

Black surface treatment process of electrolytic copper foil

ActiveCN101906630AImprove antioxidant capacityAccelerated corrosionSuperimposed coating processZinc alloysCopper foil

The invention relates to a black surface treatment process of an electrolytic copper foil, belonging to the technical field of production processes of high and precision electrolytic copper foils. The black surface treatment process of an electrolytic copper foil is characterized in that a VLP (Very Low Profile) electrolytic copper foil of 8-12 mu m is used as an electrode, and then copper or copper alloy is roughened, solidified, weakly roughened and electrically deposited at a running speed of 25.0+ / -0.1m / min; a layer of nano-scale nickel or cobalt alloy and a layer of nano-scale zinc alloy are sequentially and electrically deposited; and then alkaline chromate passivation is carried out and a layer of coupling agent is coated. In the invention, the black copper foil for an FPC (Flexible Printing Circuit) is obtained by carrying out a series of special surface treatments on the ultrathin and VLP electrolytic copper foil of 8-12 mu m, wherein the surface roughness Ra of the obtained copper foil is smaller than or equal to 0.30 mu m, Rz is smaller than or equal to 2.5 mu m; the thickness of the copper foil subjected to the surface treatments is increased by 1.40-1.80 mu m; the copper foil does not contain elements having serious damages to the human body, such as lead, mercury, cadmium, stibium, and the like and has excellent oxidation resistance as well as corrosion and etching resistance; the peel strength of the copper foil on a PI (Polyimide) film reaches higher than 1.0N / mm, and the folding strength on the PI film reach more than 100 thousand numbers of times; the copper foil has good appearance characteristics after the copper foil is microetched, and after the copper foil is made into an FCCL (Flexible Copper Clad Laminate), the copper foil has similar appearance characteristics to a rolled copper foil; and the properties of the copper foil product are equivalent to that of an electrolytic copper foil with the same specification for the FCCL.

Owner:SHANDONG JINBAO ELECTRONICS

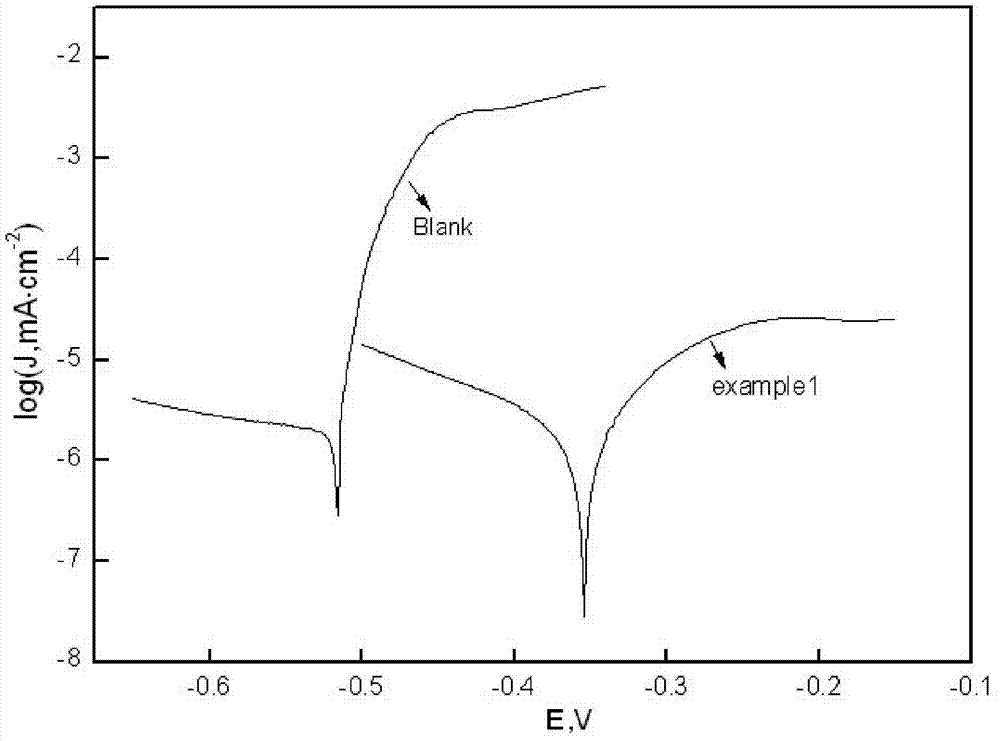

Non-toxic polyaniline modified anti-corrosive coating and preparation method thereof

ActiveCN101643618AAchieve passivationImprove corrosion resistanceRubber derivative coatingsAnti-corrosive paintsAfter treatmentPhytic acid

The invention relates to coating technology, in particular to a non-toxic polyaniline modified anti-corrosive coating and a preparation method thereof to solve the problems that that prior antirust pigment has poor corrosion resistance, and the coating is matched with harmful lead-containing and chromate-containing pigment in the manufacturing process. The non-toxic polyaniline modified anti-corrosive coating comprises a film forming matter, polyaniline modified antirust pigment, and the like. A polyaniline coating layer is formed on the surface of the antirust pigment by an oxidative polymerization method; the antirust pigment after treatment has passivating effect on metal; and a phytic coating layer on the surface of the antirust pigment also has corrosion inhibiting effect on the metal. The non-toxic polyaniline modified anti-corrosive coating has strong corrosion resistance and permeability resistance, and can be applied to anti-corrosive projects such as petrochemical equipment,pipelines, offshore oil platforms, wharf facilities, shipping and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Functional fertilizer and repair agents for repairing soil heavy metal

ActiveCN103788960AReduce the content of high-priced heavy metal ionsLow ion contentAgriculture tools and machinesOrganic fertilisersSolubilitySoil heavy metals

The invention discloses functional fertilizer and repair agents for repairing soil heavy metal. Modified attapulgite, chitosan, biochar and sodium thiosulfate are compounded, and on one hand, the absorption performance of the attapulgite and the biochar and the chelation of the chitosan are used for fixing heavy metal ions in soil and preventing the heavy metal ions in the soil from migrating through leaching and runoff. On the other hand, the sodium thiosulfate is used for restoring the high-valence-state heavy metal ions (like hexavalent chromium ions) to low-valence-state ions (like trivalent chromic ions), and therefore virulence and solubleness of the ions are reduced.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

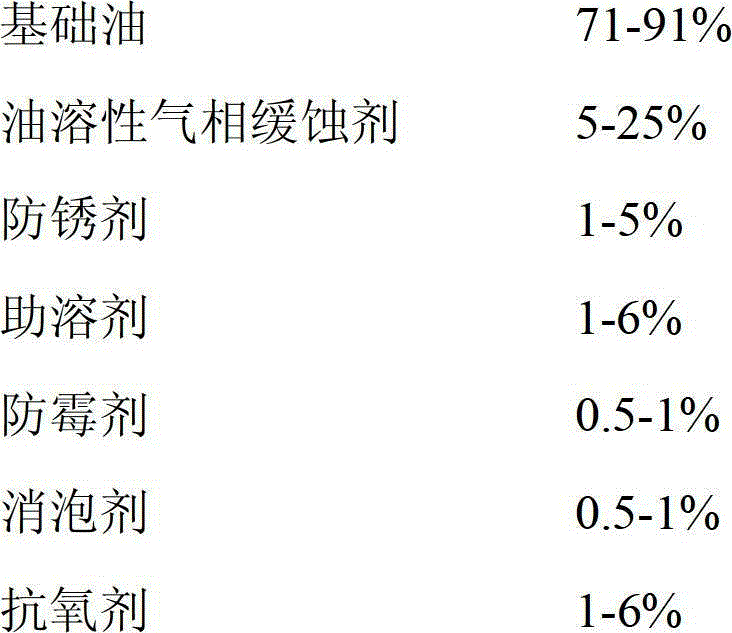

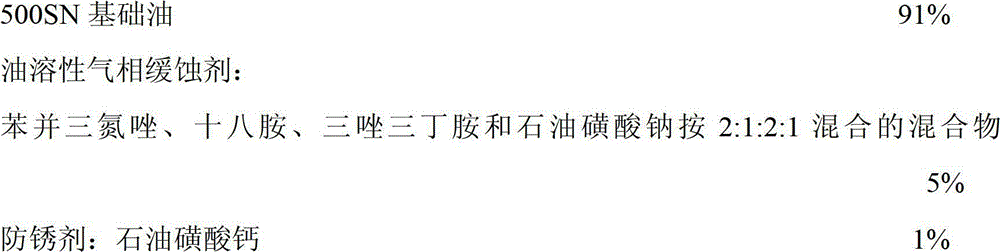

Volatile rust preventive oil

InactiveCN102719302AInhibit corrosion and rustClean working environmentAdditivesGas phaseAntioxidant

The invention discloses volatile rust preventive oil which comprises, by weight, 71-91% of base oil, 5-25% of an oil soluble volatile corrosion inhibitor, 1-5% of an antirusting agent, 1-6% of a cosolvent, 0.5-1% of a mildew-proof agent, 0.5-1% of an antifoaming agent and 1-6% of antioxidant, wherein the base oil is one of 500SN 46# machine oil, 32# machine oil, 600SN 150# machine oil and 100# machine oil; and the oil soluble volatile corrosion inhibitor is a mixture of four kinds of 2-heptadecenyl-imidalidine, octadecylamine, triazole tributylamine, dicyclohexylamine carbonate, dicyclohexylaminenitrite, benzotriazole, tert-butyl chromate, nephthenic soap, petroleum sodium sulfonate, sorbitan monooleate and stearic acid; and the antioxidant is sulfurphosphorousbutyloctyl zinc salt. The volatile rust preventive oil has good volatile rust preventive and corrosion resistant performances, metal which cannot be coated with rust preventive oil can achieve rust preventive protection, the operation is simple, and the cost is low.

Owner:上海福岛新材料科技有限公司

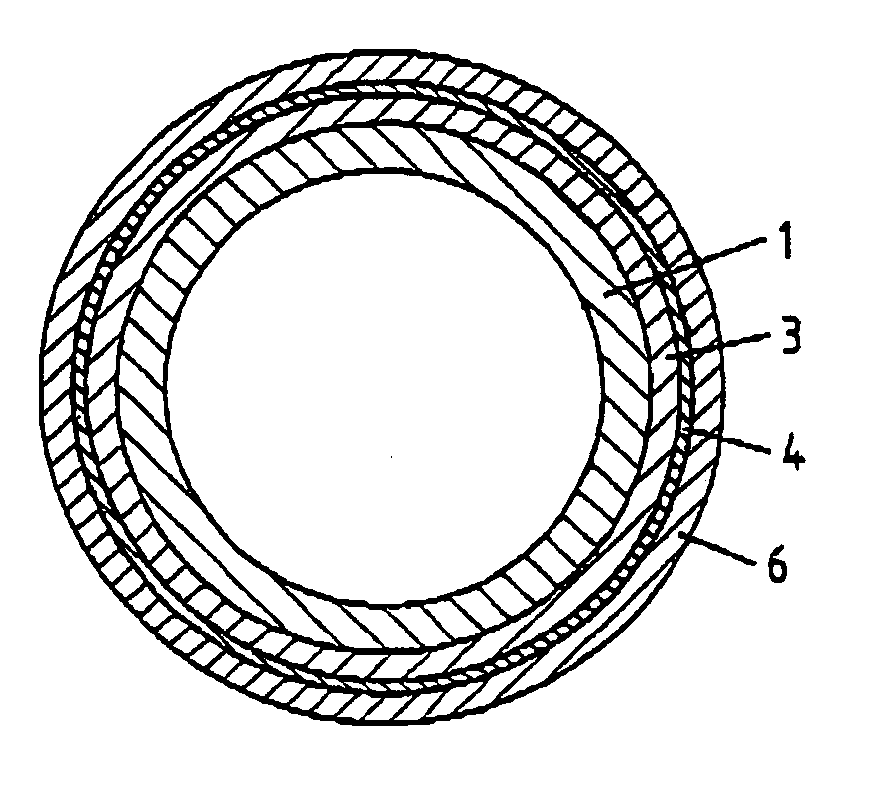

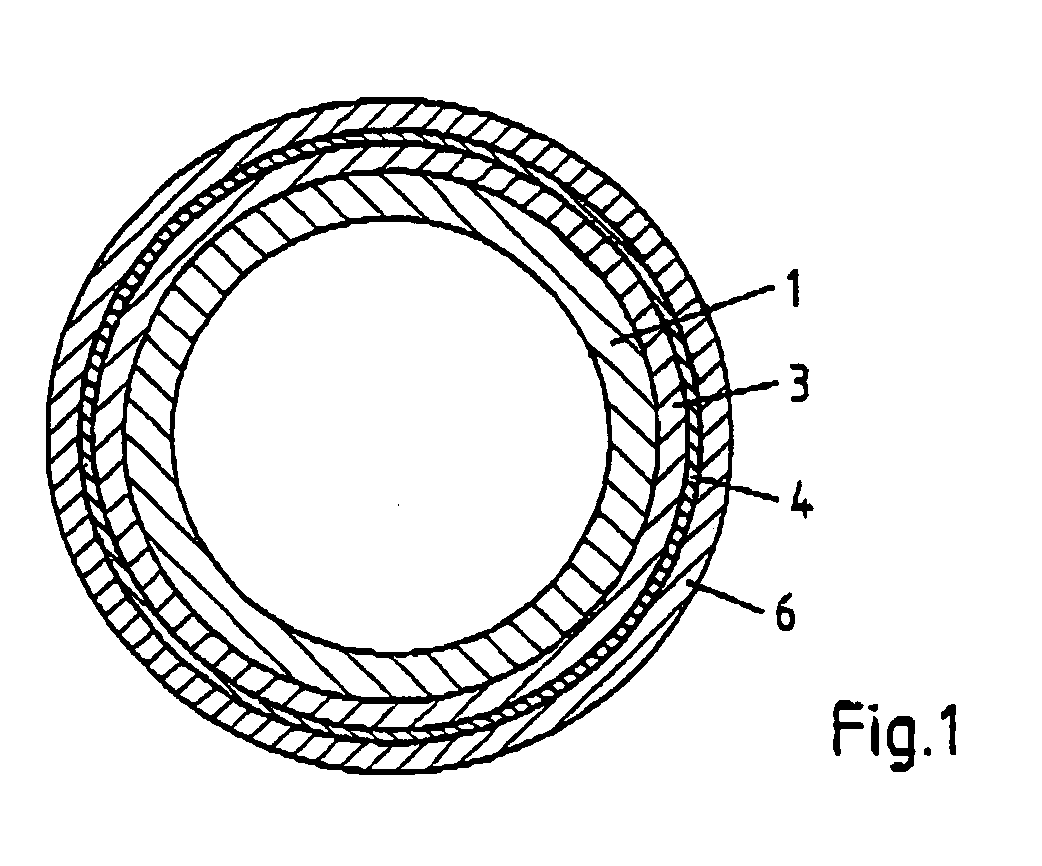

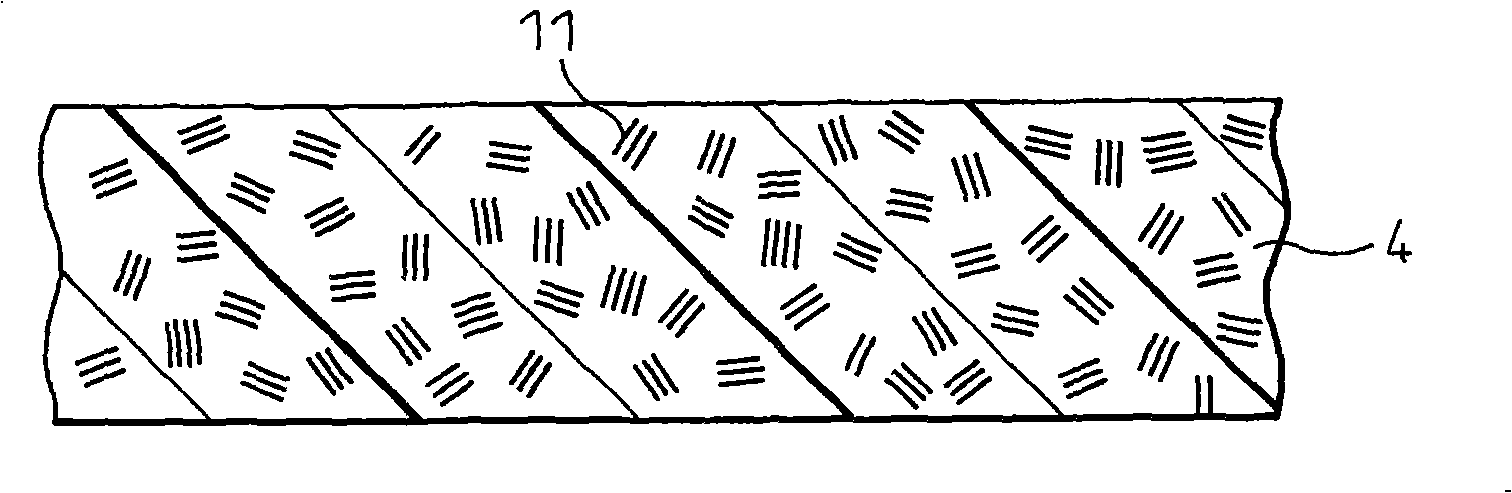

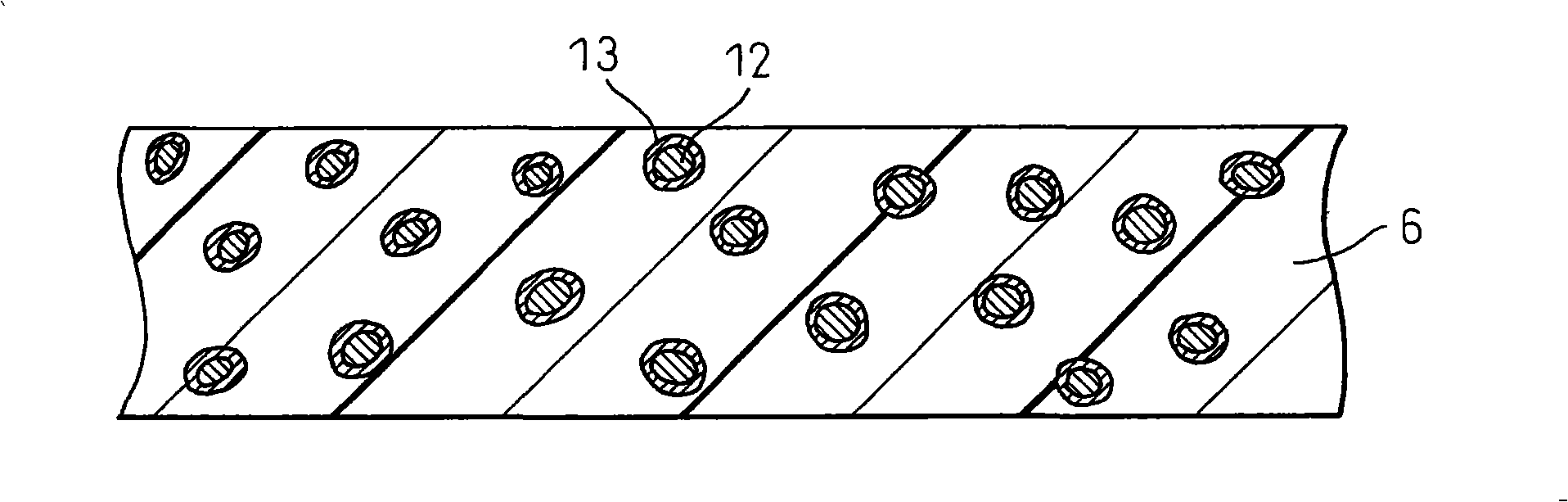

Multilayer coated corrosion resistant article and method of production thereof

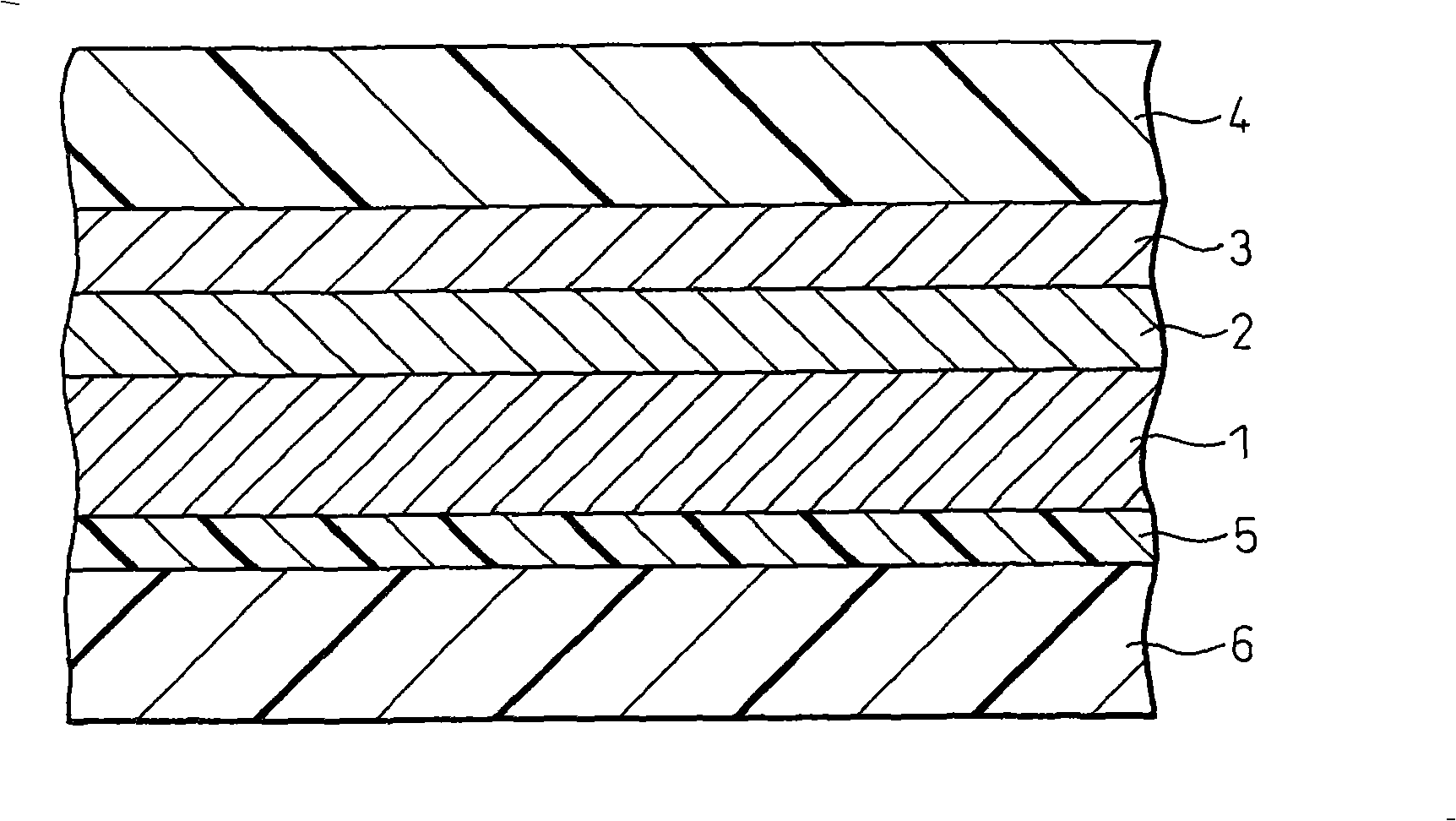

InactiveUS20050031894A1Increase heightImprove heat resistanceSynthetic resin layered productsCoatingsPhosphateZinc

The disclosure relates to a corrosion resistant article comprising a metal body 1 and a protective coating applied on at least one surface of said metal body 1, said protective coating comprising: (a) a zinc layer 3 comprising metallic zinc; (b) a silicate layer 4 comprising at least one silicate; and (c) a synthetic resin layer 6 comprising at least one fluoroplastic material such as, for example, polyvinylfluoride. In particular, the disclosure relates to a corrosion resistant brake pipe or fuel pipe having a protective coating for use in motor vehicles. The protective coating is substantially free of chromates and phosphates and, hence, environmentally acceptable.

Owner:ELISHA HLDG LLC

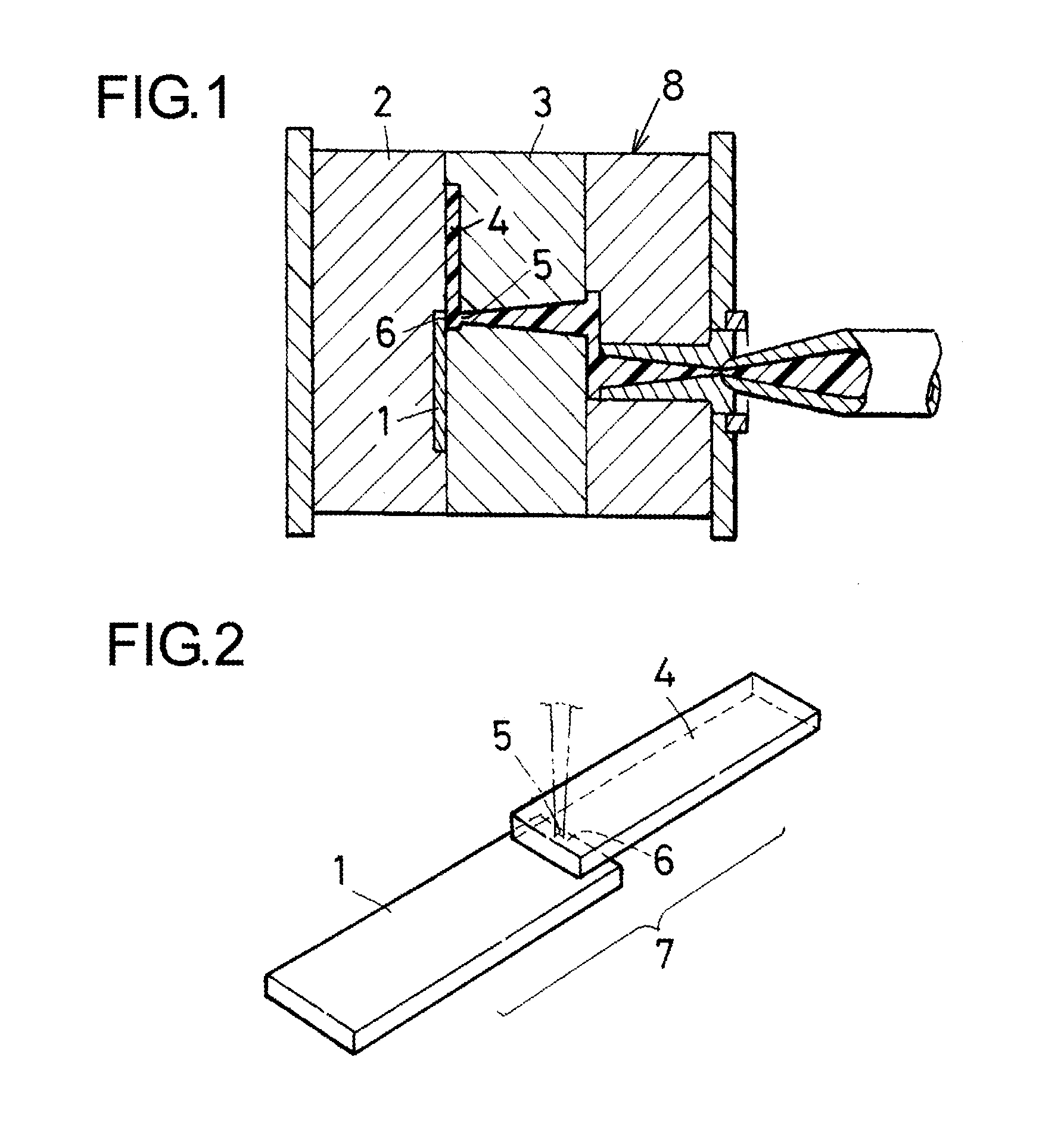

Non-chromate metallic surface-treating agent, method for surface treatment, and treated steel material

InactiveUS6475300B2Easy to processIncrease resistancePretreated surfacesSolid state diffusion coatingWater dispersibleAcrylic resin

A non-chromate metallic surface treating agent comprising (a) a silane coupling agent and / or a hydrolytic condensation product thereof, (b) water-dispersible silica, and (c) a zirconium compound and / or a titanium compound, and further comprising (d) a thiocarbonyl-containing compound and / or (e) a water-soluble acrylic resin is disclosed.

Owner:NIPPON PAINT CO LTD

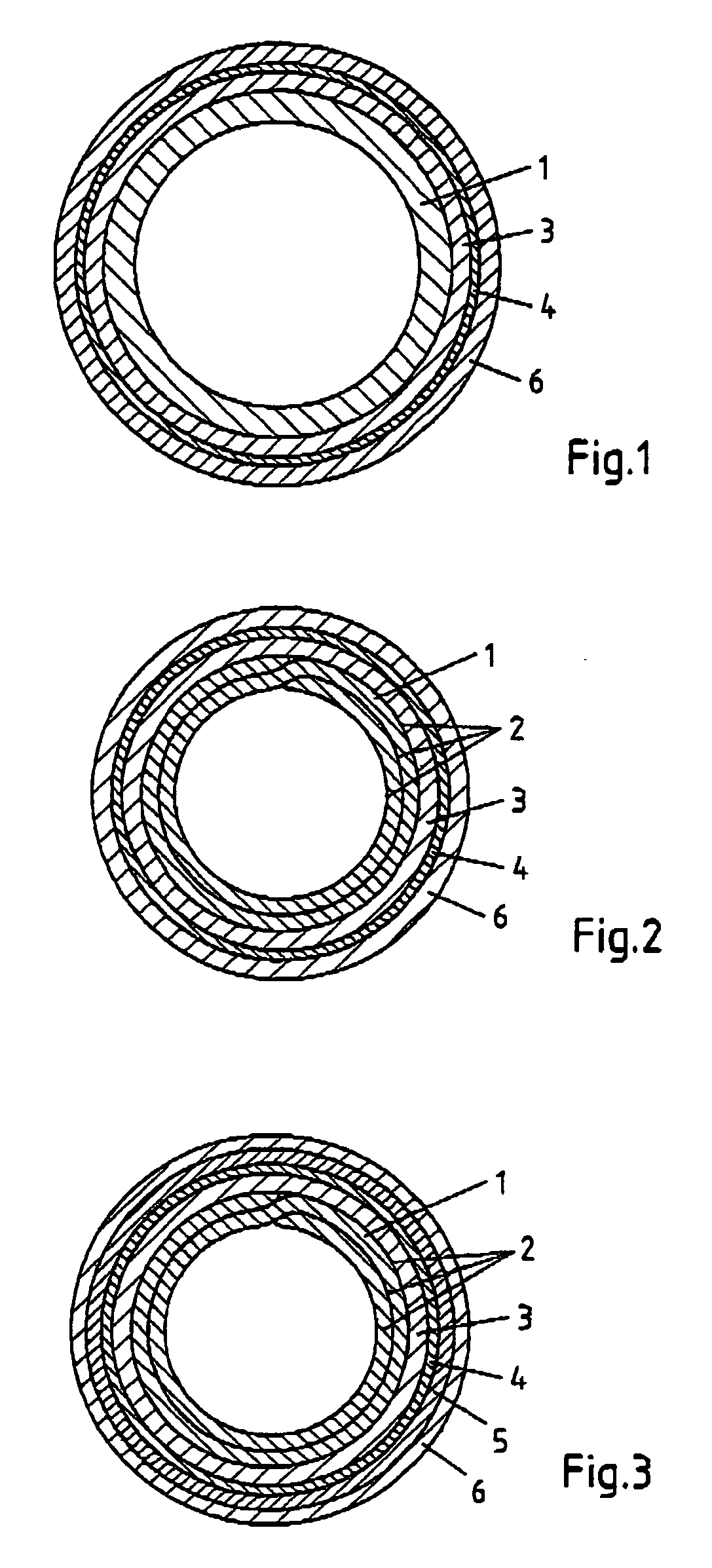

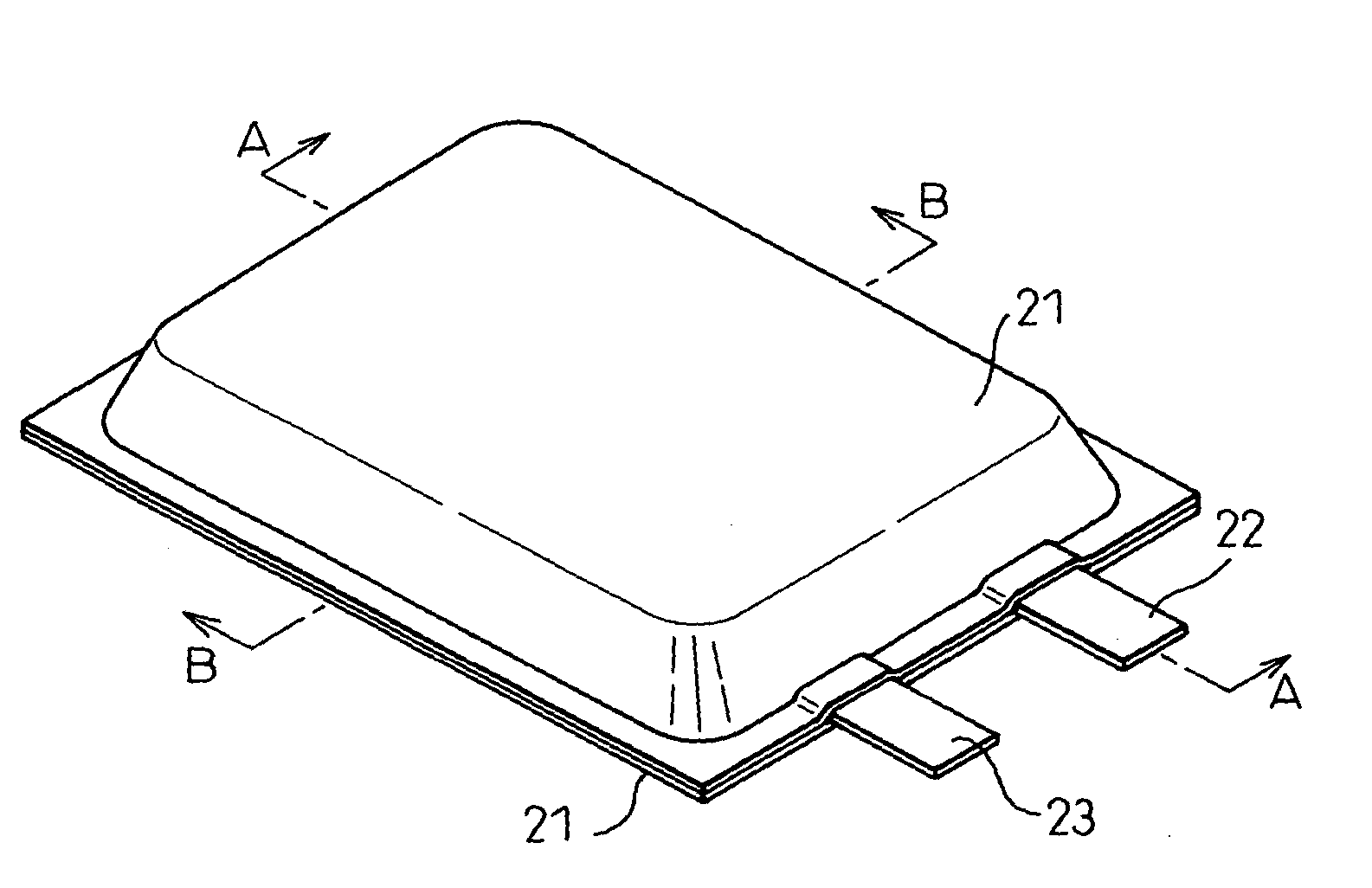

Resin-Coated Stainless Steel Foil, Container and Secondary Battery

ActiveUS20090029245A1Strong adhesionImprove corrosion resistanceEnvelopes/bags making machineryChromatisationPolyolefinMachinability

The present invention provides a resin-coated stainless steel foil capable of maintaining a strong adherence force to the film even in an electrolytic solution to exhibit good corrosion resistance and excellent in the workability, design property and piecing resistance, and a container and a secondary battery each using the resin-coated stainless steel foil. According to the present invention, a resin-coated stainless steel foil having a chromate treatment layer of 2 to 200 nm in thickness on at least one surface of a stainless steel foil and having at least a polyolefin-based resin (A) layer containing a functional group having polarity on the chromate treatment layer; and a container and a secondary battery each using the resin-coated stainless steel foil are provided.

Owner:NIPPON STEEL & SUMIKIN MATERIALS CO LTD

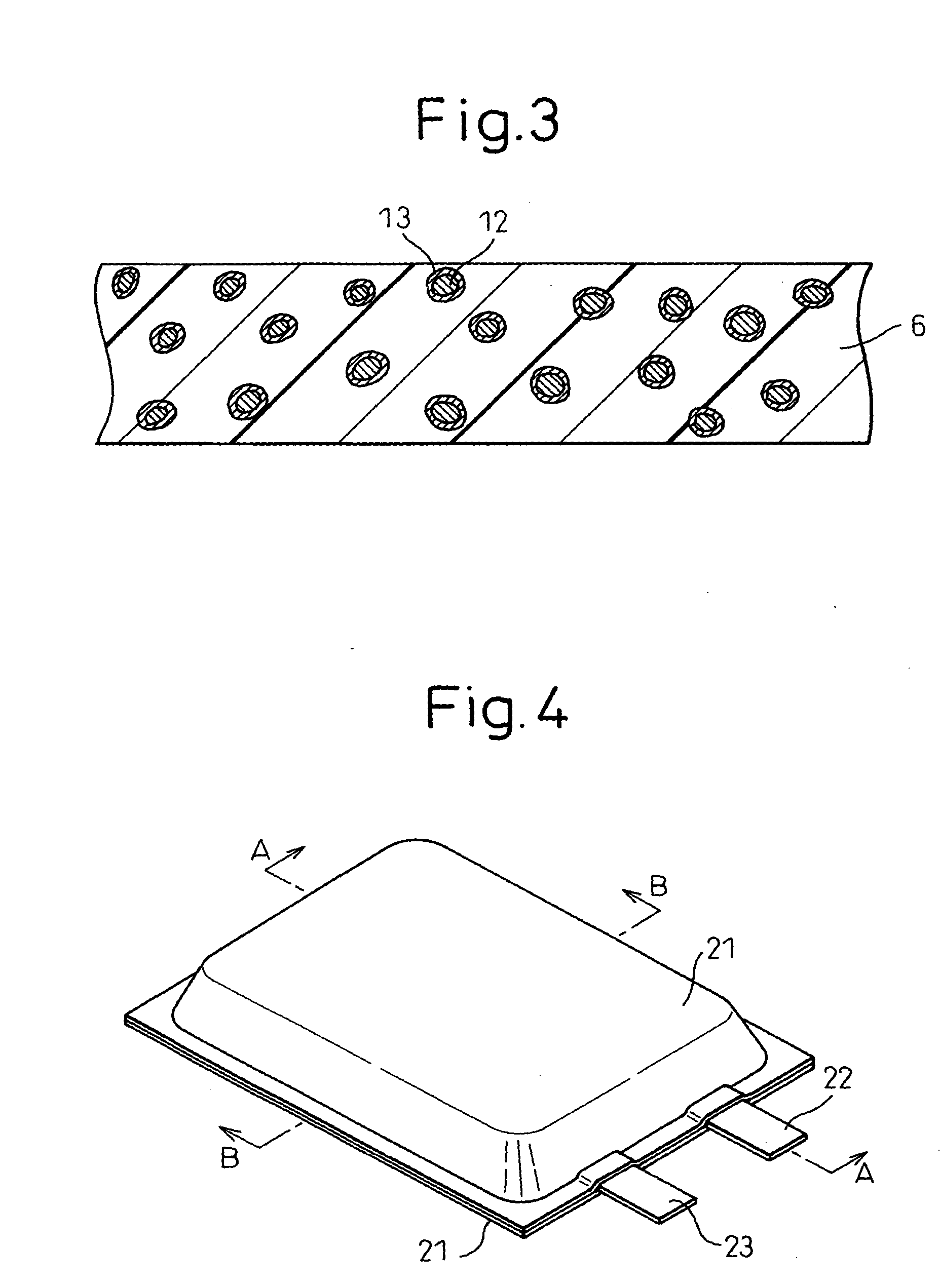

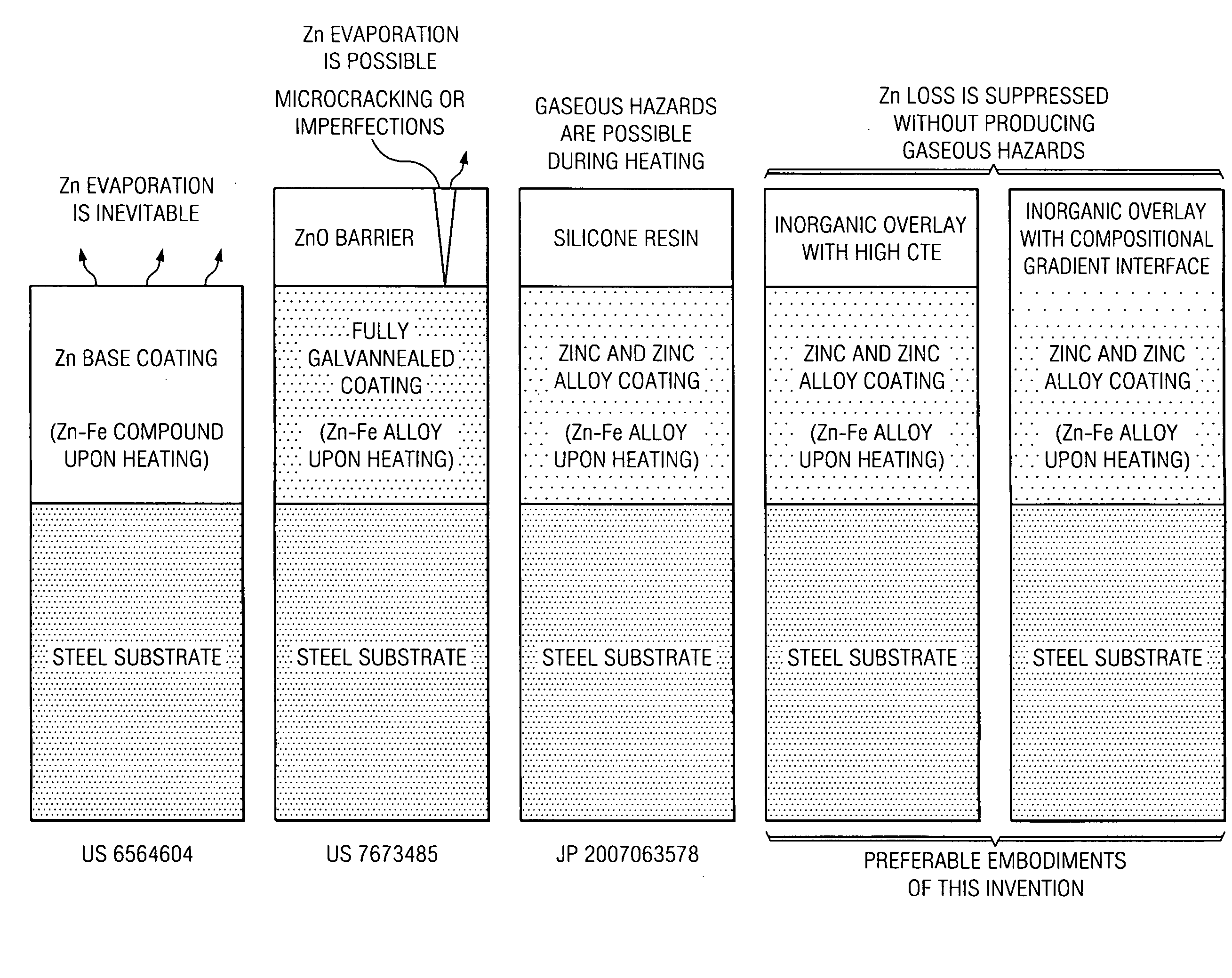

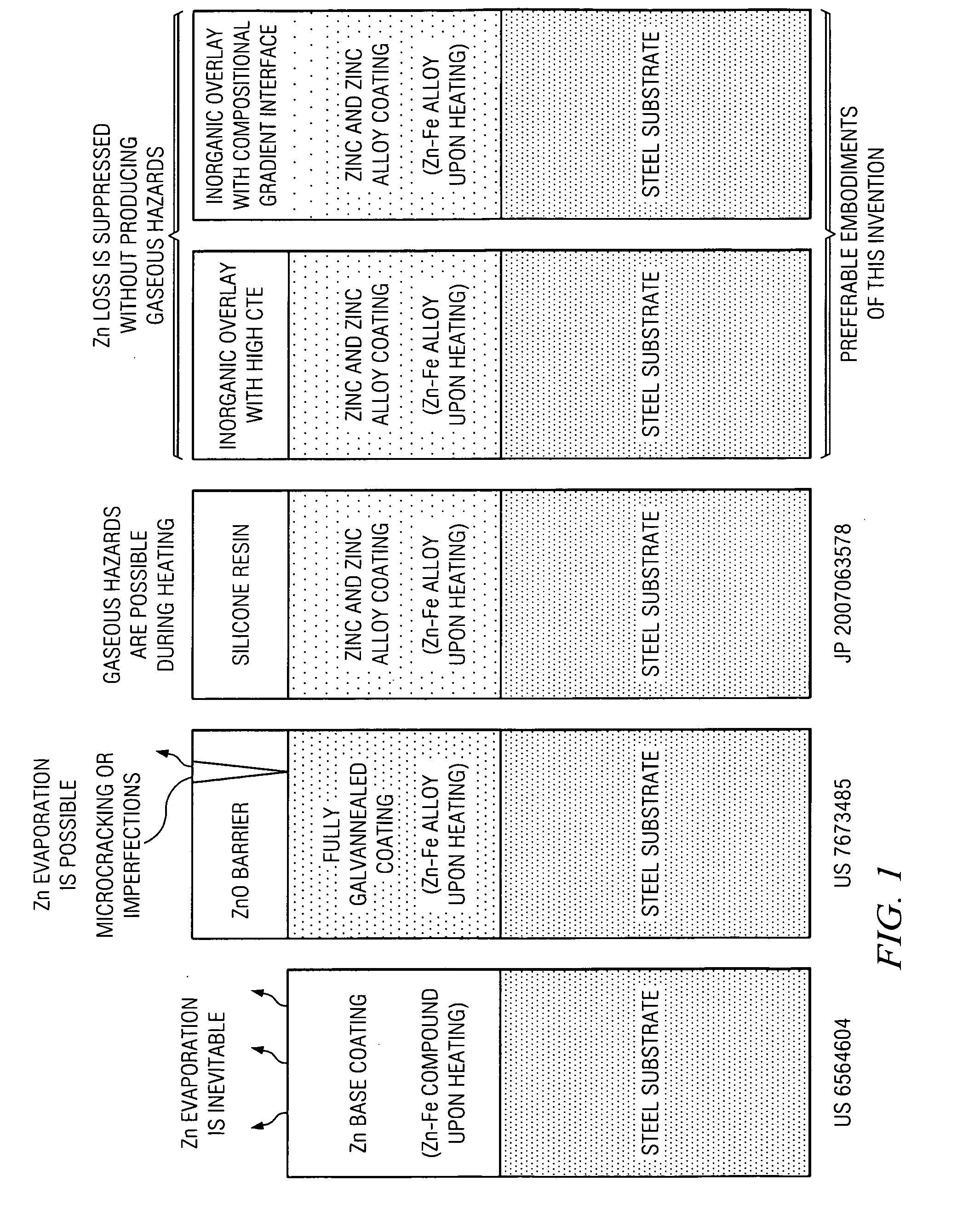

Zinc coated steel with inorganic overlay for hot forming

InactiveUS20120118437A1Retard and restrict lossReduce hardnessHot-dipping/immersion processesPretreated surfacesTungstatePhosphate

The present invention is of zinc or zinc alloy coated steel for hot forming having an inorganic overlay covering the zinc or zinc alloy coating to prevent loss of zinc during heating and hot forming. In one embodiment, the inorganic overlay has a coefficient of thermal expansion greater than the coefficient of thermal expansion of zinc oxide. In another embodiment, the inorganic overlay has a compositional gradient interface with the zinc or zinc alloy coating. Preferably the inorganic overlay may be comprised of material selected from phosphates, oxides, nitrates, carbonates, silicate, chromate, molybdate, tungstate, vanadate, titanate, borate, fluoride and mixtures thereof. A method of preparing the steel for hot forming and a method for hot forming the steel are provided.

Owner:WANG JIAN +1

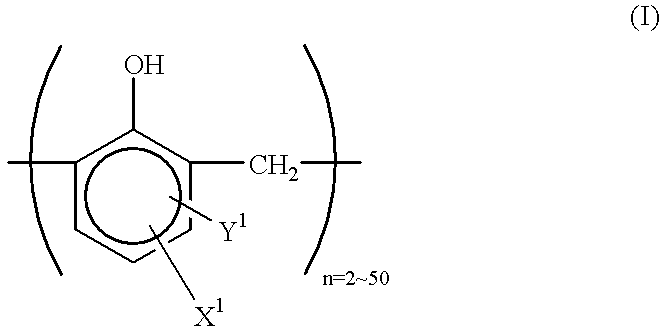

Surface treatment composition for metallic material and method for treatment

InactiveUS6180177B1Good adhesivenessIncrease resistancePretreated surfacesMetallic material coating processesMetallic materialsHafnium

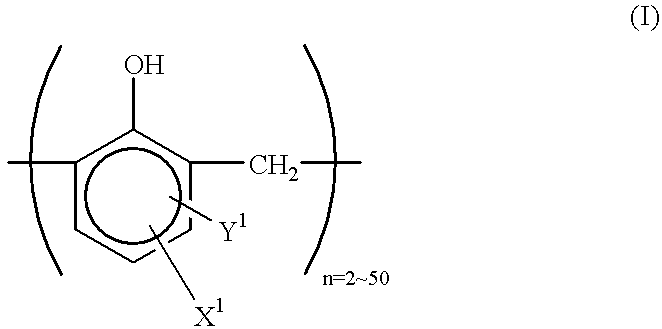

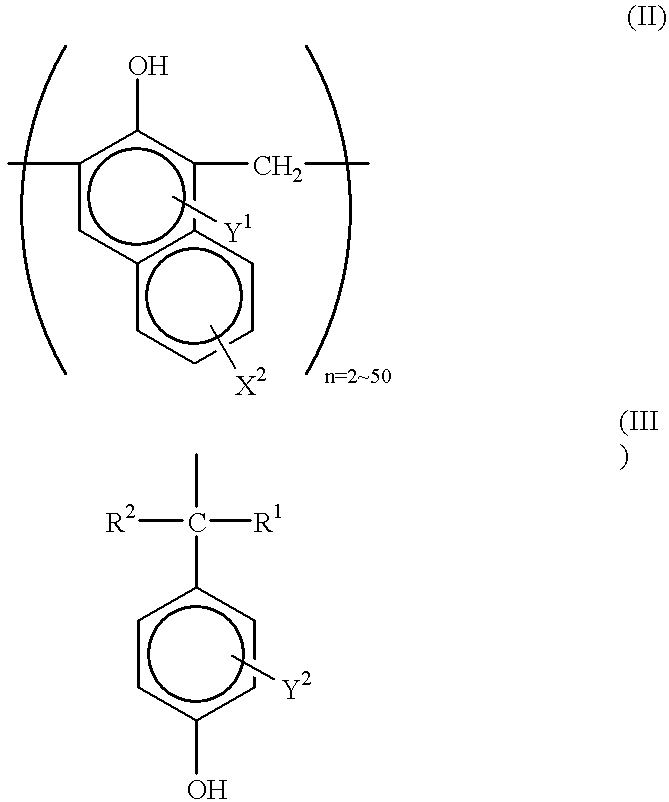

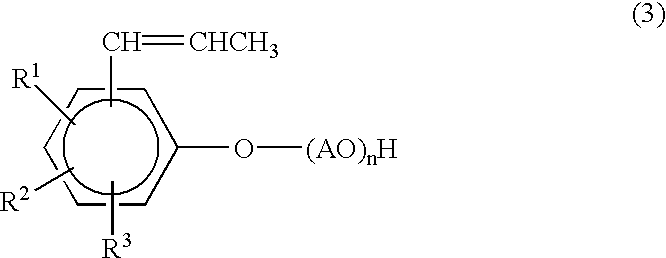

In the composition of the surface-treatment agent used for metallic material, a composition having such high corrosion-resistance as to replace the chromate coating is provided. In the composition of the surface-treatment agent provided for the metallic material, fingerprint resistance, blackening resistance and adhesiveness of paint coating are also improved. The metallic material is treated by an acidic surface-treating agent comprising the following components:(A) a cationic component, which consists of divalent or higher valent metallic ions selected from the group consisting of manganese, cobalt, zinc, magnesium, nickel, iron, titanium, aluminum and zirconium;(B) at least one acid component selected from the group consisting of (1) fluoro-acid which contains four or more fluorine atoms, and one or more elements selected from the group consisting of titanium, zirconium, silicon, hafnium, aluminum and boron, (2) phosphoric acid, and (3) acetic acid;(C) a silane coupling-agent component which consists of one or more compounds which contain at least one reactive functional group selected from an amino group containing active hydrogen, an epoxy group, a vinyl group, a mercapto group and a methacryloxy group;(D) one or more water-soluble polymer components which are expressed by the following general formula (I) and has a polymerization degree of from 2 to 50 of the polymeric unit.

Owner:NIHON PARKERIZING

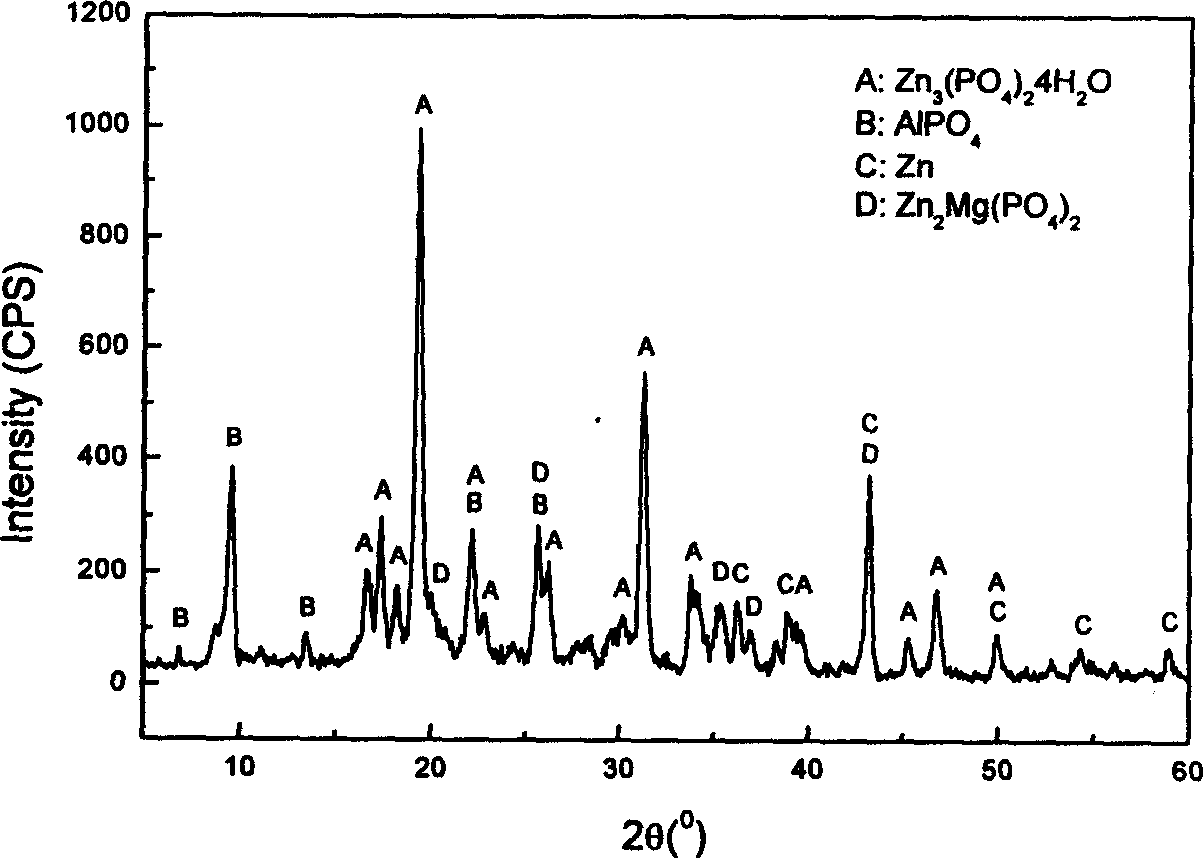

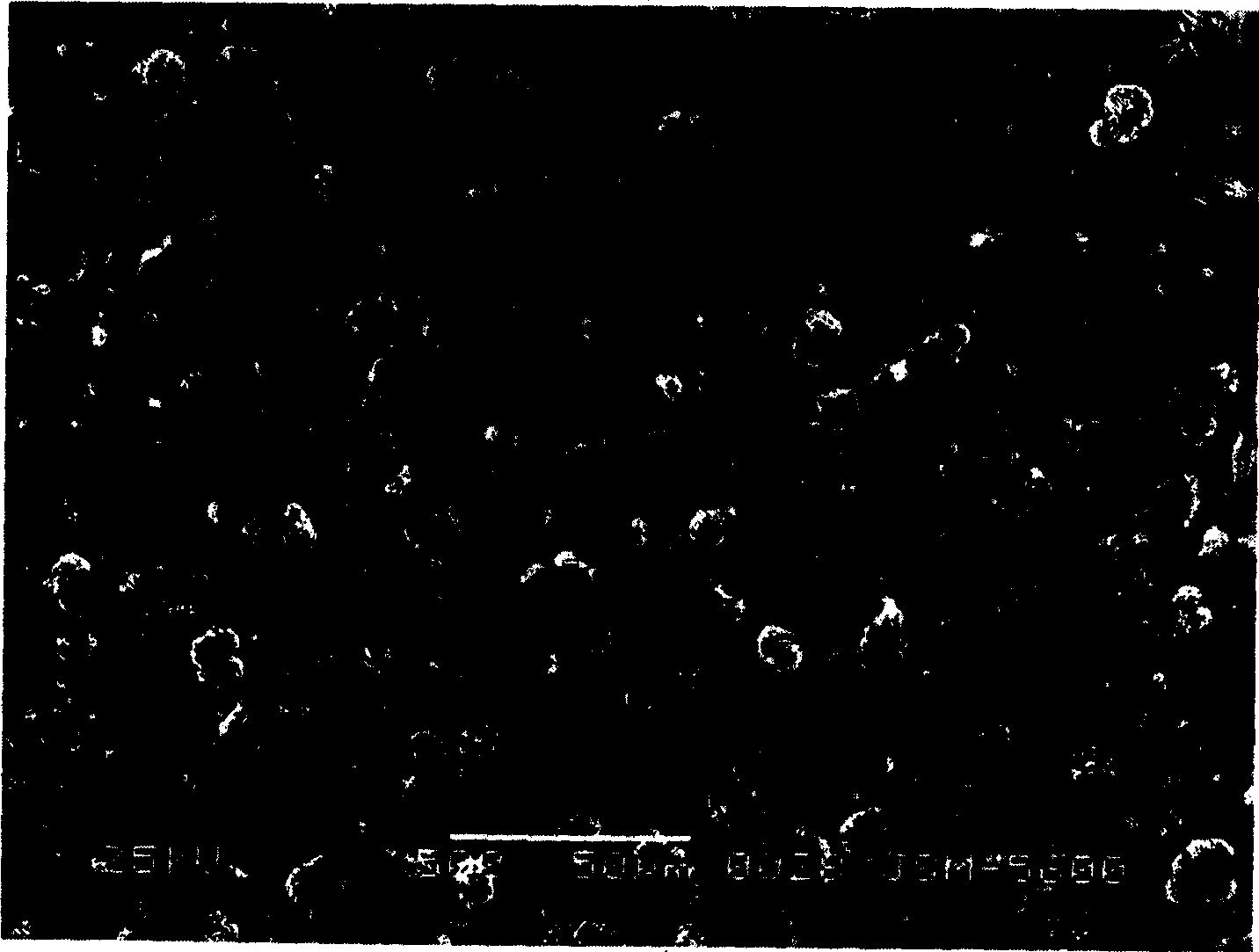

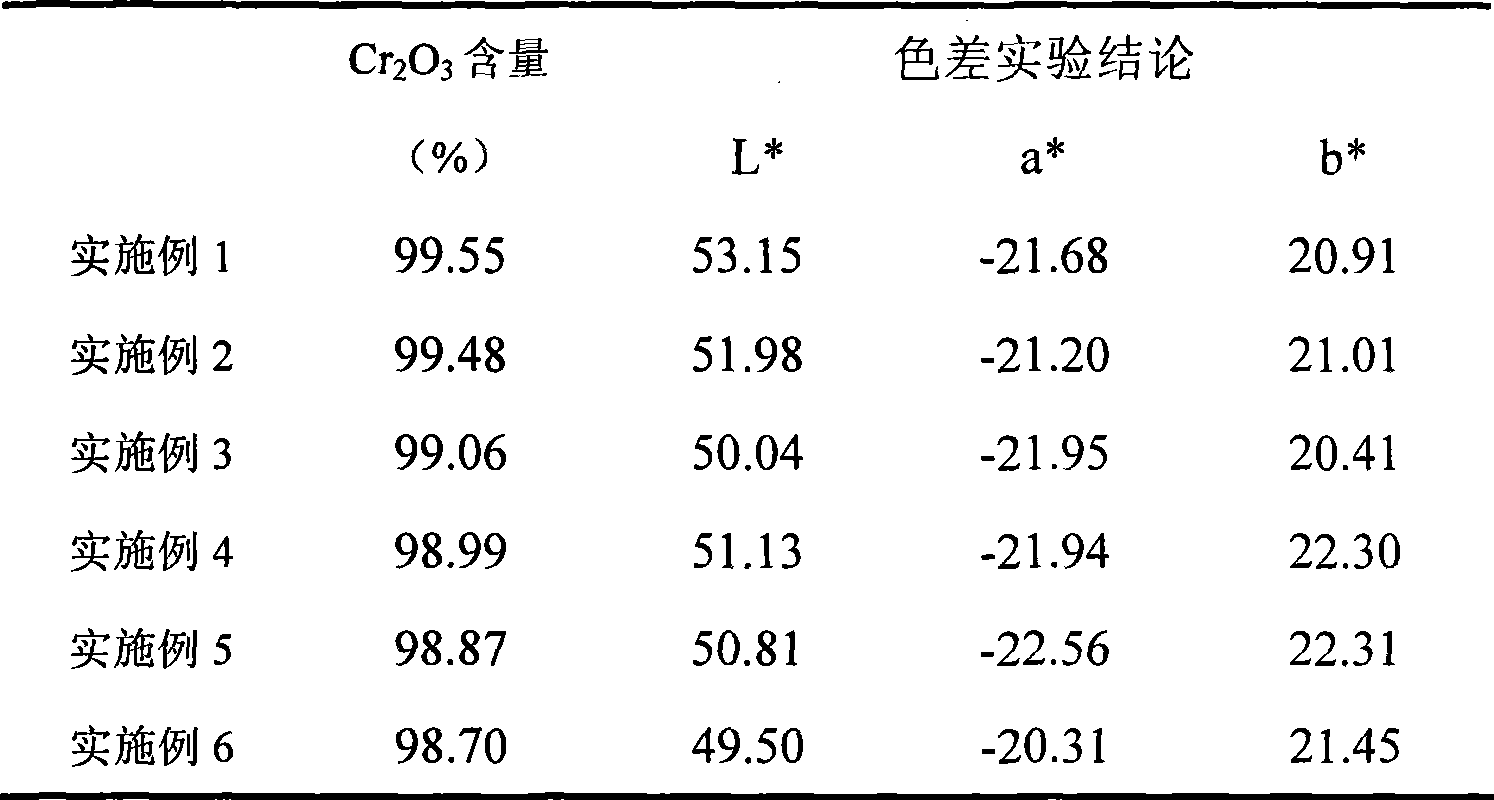

Method of preparing chromium oxide powder using water heat reducing chromate

InactiveCN100999335AControl particle size distributionGood dispersionChromium trioxideSlurrySurface-active agents

This invention relates to a preparation method that prepares chromic oxide powder by using water heat to deoxidize chromate. Use chromate water solution as raw material, CO2 as acidifying agent, process by surface active agent, directly deoxidize at condition of heat water, get hydrated Cr2O3 slurry, centrifugalize, separate, dry, calcinate hydrated Cr2O3 at different temperature, prepare globular Cr2O3 micropowder. Its grade size is between submicron and nanometer. This invention utilizes surface active agent to control sexavalent chromic salt which can be directly deoxidized to get trivalence chrome crystal. It can control hydrated chromic oxide calcinating temperature to prepare globular Cr2O3 micropowder of which grade size can be controlled.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Composition for metal surface treatment and surface treated metallic material

InactiveUS6514357B1Improve corrosion resistanceLow costSolid state diffusion coatingAnti-corrosive paintsAluminum IonSheet steel

A composition for metal surface treatment which comprises an aluminum ion, a magnesium ion, a manganese ion, a water-soluble organic resin, an acid and water; and a surface treated metal material which has been treated with the composition. The resultant surface treated metal material is free from the danger of water contamination owing to chromium, since the composition is free of chromium, and also is excellent in both electrical conductivity and corrosion resistance. Accordingly, the metal material can be used in a wide variety of applications in place of a conventional chromate-treated steel sheet and the like.

Owner:50 DAI NIPPON TORYO

Resin-coated stainless steel foil, container and secondary battery

ActiveCN101331020AStrong adhesionImprove corrosion resistanceAlkaline accumulatorsChromatisationPolyolefinElectrical polarity

A resin-coated stainless steel foil that can maintain strong adherence to films even in an electrolyte solution and exhibit good corrosion resistance, excelling in processability, designability and stab resistance; and, making use of the same, a container and secondary battery. There is provided a resin-coated stainless steel foil characterized by having a chromate-treated layer of 2 to 200nm superimposed on at least one major surface of stainless steel foil and having, superimposed on the chromate-treated layer, at least a layer of polyolefin resin (A) containing a polar functional group. Further, there are provided, making use of the same, a container and secondary battery.

Owner:NIPPON STEEL CHEM &MATERIAL CO LTD

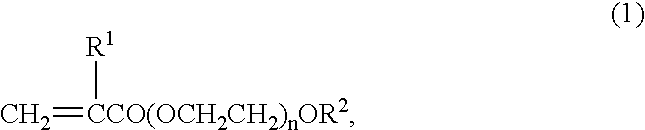

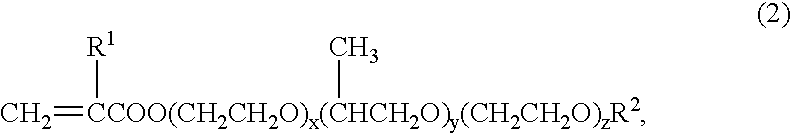

Water-based surface-treating agent for metallic material

InactiveUS6447620B1Raise the ratioIncreased insolubilityOther chemical processesSolid state diffusion coatingWater basedMetallic materials

A water-based surface-treating agent for metallic materials which gives a film highly satisfactory in corrosion resistance, blackening resistance, wet secondary adhesion to topcoatings, low-pollution characteristics (amount of fixed chromium), chemical resistance (especially acid resistance and alkali resistance), etc., while retaining the intact practical liquid stability of conventional chromate-containing resinous coating agents. The water-based surface-treating agent comprises a synthetic resin emulsion and hexavalent chromium ions and has a pH of 5 or lower, the synthetic resin emulsion being one obtained by emulsion-polymerizing the following ingredients using a nonionic polymerizable emulsifier and a nonionic nonpolymerizable emulsifier: (1) an ethylenic carboxylic acid, (2) a functional acrylic monomer having at least one of N-((un)substituted methylol)carbamoyl, phosphonate, alkoxy, cyano, and carbamoyl groups, and (3) a third monomer which is different from the ingredients (1) and (2) and forms the skeleton of the copolymer to be obtained.

Owner:HENKEL CORP

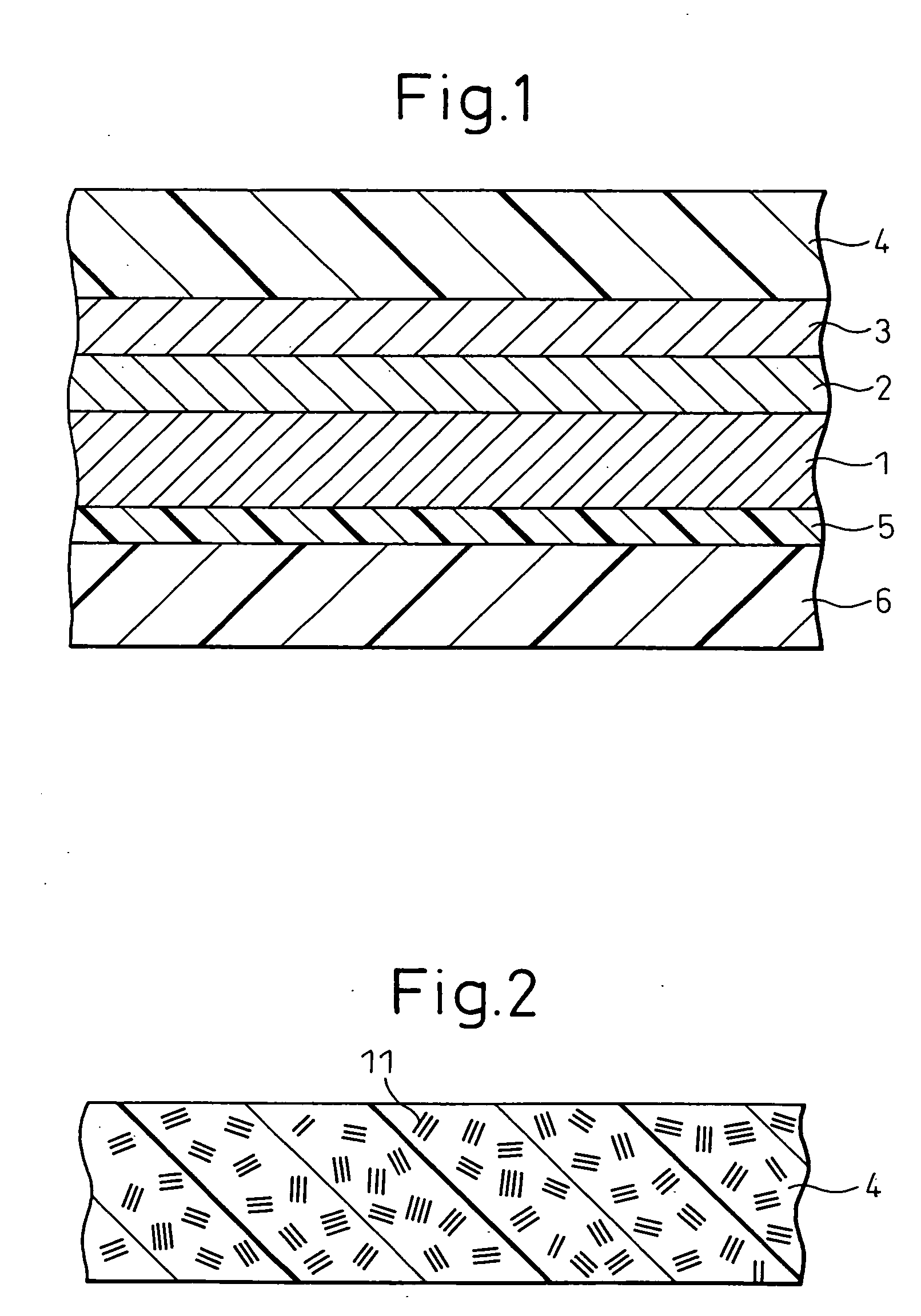

Copper foil for printed wiring board having excellent chemical resistance and heat resistance

InactiveUS6329074B1Bond strength is sufficientHigh bonding strengthInsulating substrate metal adhesion improvementChromatisationAcrylic resinAlloy

This invention provides a copper foil for a printed wiring board, which comprises a copper foil, an alloy layer (A) comprising copper, zinc, tin and nickel which is formed on a surface of the copper foil, said surface to be brought into contact with a substrate for a printed wiring board, and a chromate layer which is formed on a surface of the alloy layer (A,. The copper foil for a printed wiring board has the following features: even if a printed wiring board is produced using a long-term stored copper foil, the interface between the copper foil and the substrate is only slightly corroded with chemicals; even if the copper foil contacts a varnish containing an organic acid, e.g., a varnish for an acrylic resin, in the formation of a copper-clad laminate, the bond strength is sufficient. Even if a printed circuit board made by using the copper foil is placed in a high temperature environment, e.g., in an engine room of an automobile, for a long period of time, blistering of the copper circuit from the substrate due to deterioration of the interface between the copper circuit and the substrate does not take place.

Owner:MITSUI MINING & SMELTING CO LTD

High temperature resistant annealing treated single-component chromium-free water-based silicon steel sheet insulating coating solution

InactiveCN101486866AGood coating appearanceGood adhesionEpoxy resin coatingsPolyester coatingsChromium freeWater based

A high-temperature annealing treatment resistant single-component chromium-free aqueous silicon steel sheet insulated masking liquid is characterized in that the main ingredients include organic resin, inorganic water dispersion liquid, curing agent and other additives. The weight ratio of the components is as follows: 100 parts of the organic resin, 100-400 parts of inorganic matter, 5-30 parts of the curing agent, 1-20 parts of additive surface active agent and the rest of water, and the solid content of the masking liquid is 30-50 percent. The masking liquid does not contain toxic organic solvent and chromate, has excellent performances of coating appearance, adhesion, salt spray resistance, insulativity and the like, and can still keep good insulativity after going through high-temperature stress annealing process. After a high-temperature annealing experiment (nitrogen atmosphere, 750 DEG C / 2h), the interface resistance retention value is more than 70 percent. The curing speed of the masking liquid is fast, the curing is thorough, and the surface of the membranous layer does not turn sticky for a long time of placement after curing. The masking liquid is in the form of single component, has convenient use and can be stored for long time.

Owner:NANJING UNIV +1

Chromium-free Dyclo paint

InactiveCN101260252AGood effectNo pollution in the processLiquid surface applicatorsAnti-corrosive paintsChromium freeZinc

The invention relates to a non-chromate Dacromet paint belonging to the metal anticorrosion technical field. The non-chromate Dacromet paint is prepared by the following steps that: after mixing a component B with a component C based on the weight ratio of 3-5:1.5-2.4, mixing the mixture with a component A based on the weight ratio of 1:16-32, stirring evenly and controlling pH value between 3.5 and 5.5; the non-chromate Dacromet paint has the characteristics of non-environmental pollution and non-public nuisance, high permeability, high adhesion, high antifriction, high weatherability, high chemical stability and so on. And the anticorrosion of the non-chromate Dacromet paint improves 7-10 folds of zinc electroplating.

Owner:SHANDONG UNIV

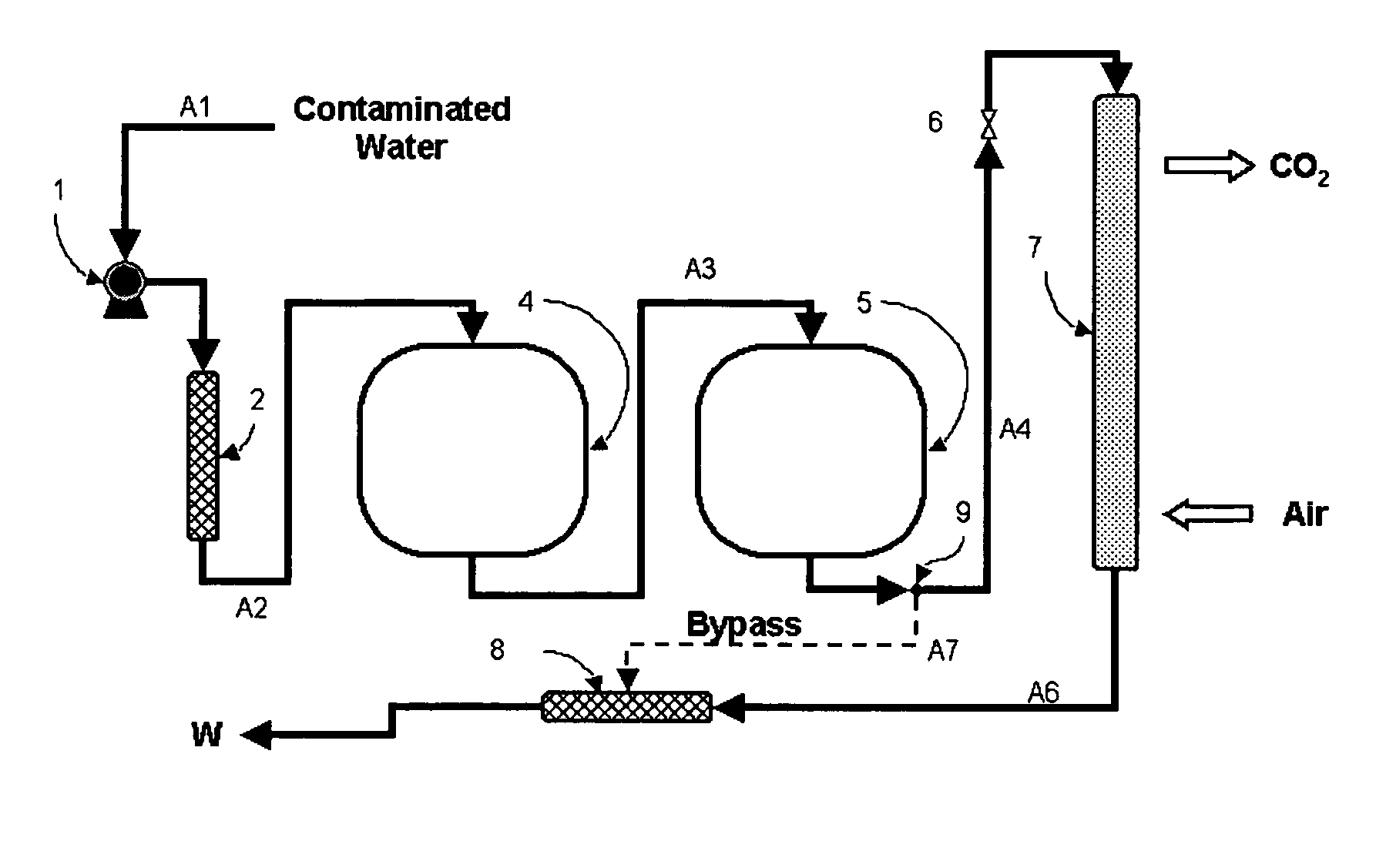

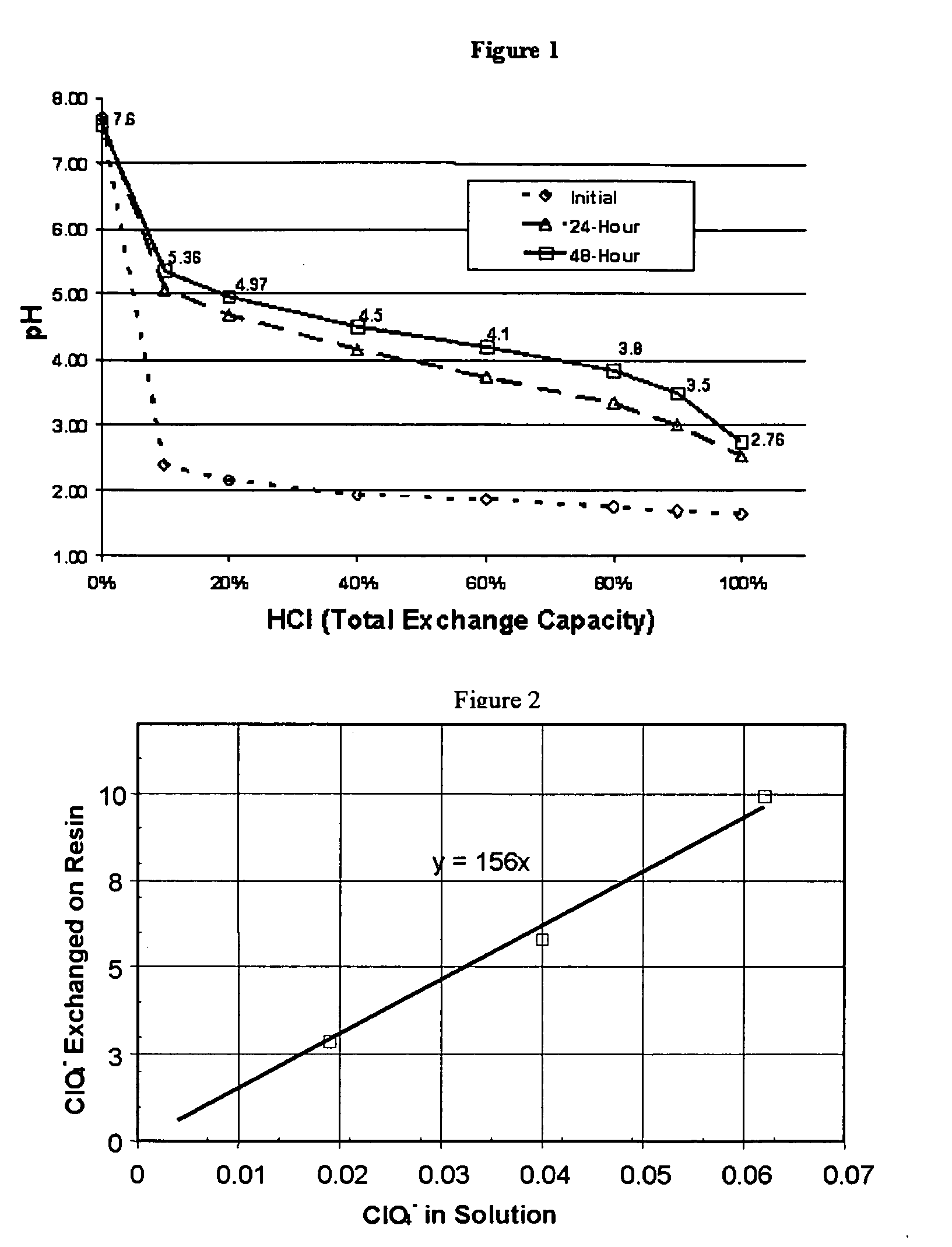

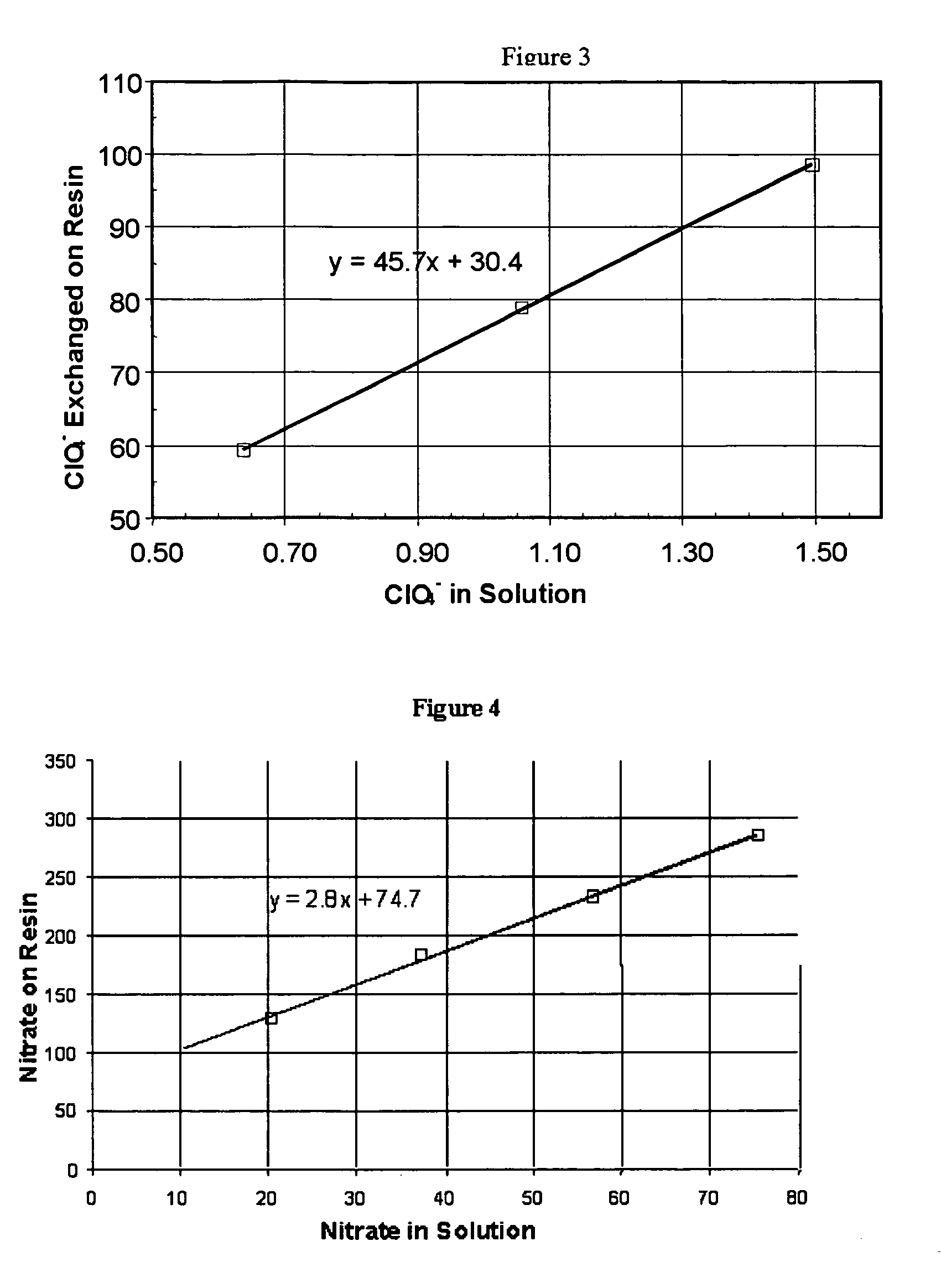

Water treatment process for perchlorate, nitrate, chromate, arsenate and other oxyanions for using weak-base anion exchange resins

ActiveUS20070114178A1Reduce pumping costsImprove chemical efficiencyOrganic anion exchangersIon-exchanger regenerationSelenateIon exchange

The invention consists of a water treatment process using selective and regenerable weak base anion exchange resins to remove any number of complex anions, especially oxyanions including perchlorate, nitrate, chlorate, arsenate, selenate, and chromate, from aqueous solutions. The treatment process is comprised of three key processes including 1) pretreatment to lower pH, 2) ion exchange, and 3) post treatment to adjust pH and alkalinity. The invention also includes processes for regenerating weak base anion resins and treatment of the residuals generated. This invention employs pressurized treatment, carbon dioxide management, and reuse of regenerating solution to minimize pumping and treatment costs.

Owner:APPLIED RES ASSOCS INC +1

Method for extracting vanadium and chromium from materials containing vanadium or/and chromium

InactiveCN105420519AEasy to separateHigh recovery rateProcess efficiency improvementPregnant leach solutionVanadate

A method for extracting vanadium and chromium from materials containing the vanadium or / and the chromium is characterized by comprising the following steps: taking salt and alkali of alkali metal or the alkali of the alkali metal as an oxidation transformation medium of the materials containing the vanadium or / and the chromium; carrying out treating for 0.5-6 hours at the temperature of 160-600 DEG C under the effect of an oxidizing agent and enabling the vanadium and the chromium in the materials to be converted into soluble vanadate and soluble chromate; carrying out water leaching to obtain leaching liquor containing the vanadium or / and the chromium; adding a precipitant A in the leaching liquor containing the vanadium or / and the chromium to selectively precipitate the vanadium at first, and adding a precipitant B to precipitate the chromium to obtain vanadium-rich residues and chromium-rich residues; and then separating and recycling the vanadium and the chromium from the vanadium-rich residues and the chromium-rich residues respectively. The vanadium and the chromium are separated and recycled effectively, and moreover, the effect of removing impurities simultaneously is achieved; liquor obtained after chromium precipitation is subjected to oxidization regeneration, evaporated and concentrated to obtain media, and the media are returned to an oxidation transformation procedure for the materials containing the vanadium or / and the chromium and are recycled. The method has the advantages of the simple technology, easiness and convenience in operation, the good vanadium and chromium separating effect, a high metal recovery rate, low production cost, environmental friendliness and the like, and is suitable for industrial application of extracting the vanadium and the chromium from the materials containing the vanadium or / and the chromium.

Owner:CENT SOUTH UNIV

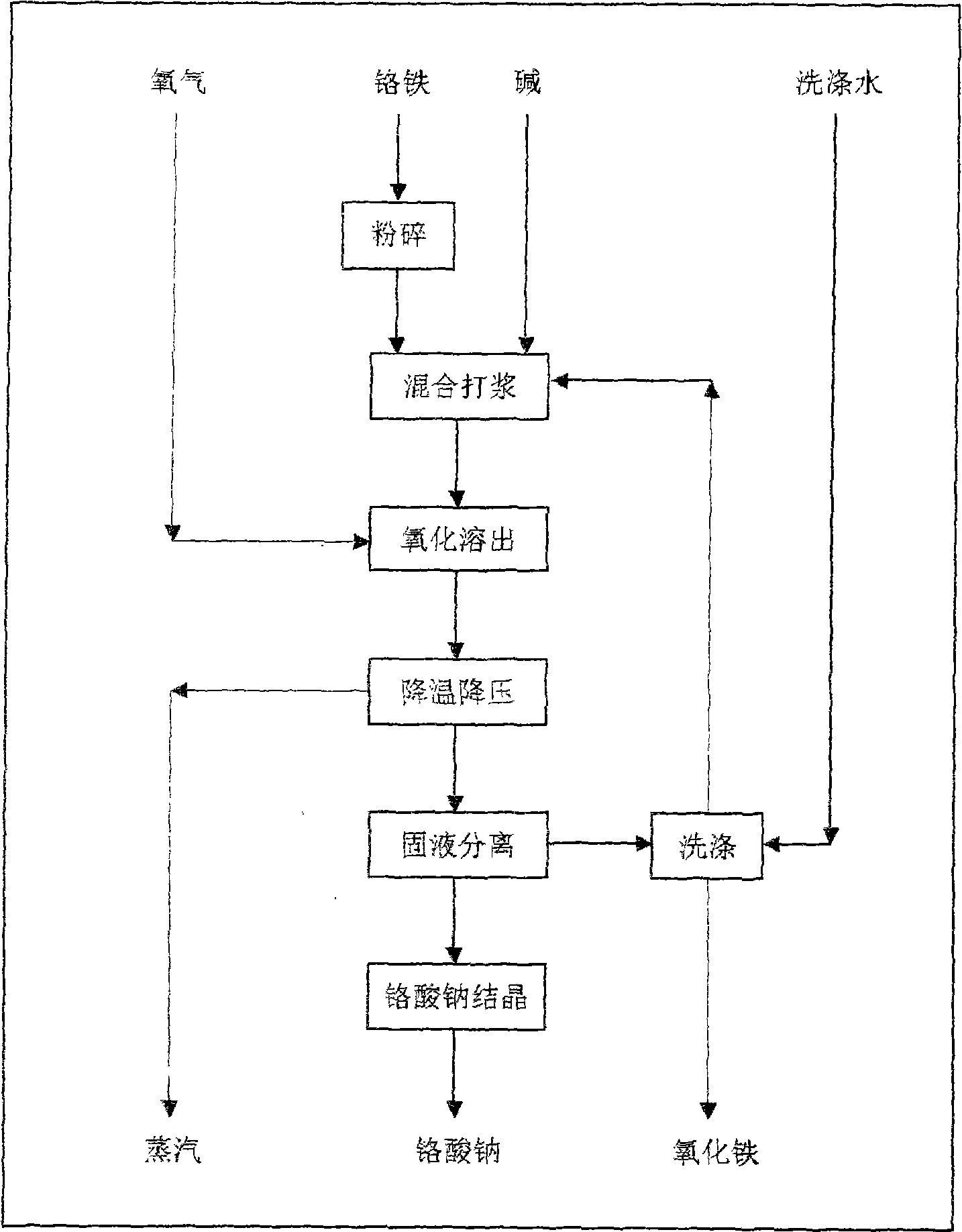

High-efficiency, energy-conservation and clean method for producing chromate

ActiveCN101508466ASolve pollutionAchieving the purpose of cleaner productionChromates/bichromatesWastewaterCleaning methods

The invention provides a method for producing chromate with high efficiency, energy conservation and cleanness. The method uses chromium iron as a raw material, and carries out oxidation dissolution in high-temperature high-pressure aqueous alkali to separate solid and liquid after temperature and pressure reduction so as to obtain a chromate solution, water and ferric oxide or mixture of the water, ferric oxide and chrome oxide. A high-temperature high-pressure reactor is used as the reactor of the method so as to greatly improve equipment efficiency and production efficiency. The method realizes autothermal reaction by system reaction heat to achieve the aim of energy conservation, and is an energy-saving process of chromate production. The method does not need external fuel to supply heating and does not generate waste gas, and the reaction precipitate is the water and the ferric oxide or the mixture of the water, the ferric oxide and the chrome oxide, wherein the water and the ferric oxide or the mixture of the water, the ferric oxide and the chrome oxide can be used for preparing chromium iron paint without generating waste residue; and washing of the precipitate adopts countercurrent washing, and washing water is used for preparing a reaction initial solution without generating waste water. The method does not generate the three wastes, and is a clean process for producing the chromate.

Owner:青海省博鸿化工科技股份有限公司

Magnesium alloy phosphorization solution and its phosphorized technology

InactiveCN1598055AProcess stabilityThe process is simple and easy to controlMetallic material coating processesPhosphatePhosphoric acid

Owner:JILIN UNIV

Methods for coating a metal substrate and related coated metal substrates

Disclosed are methods for treating metal substrates, including ferrous substrates, such as cold rolled steel and electrogalvanized steel. The methods include depositing an electropositive metal onto at least a portion of the substrate, and then contacting the substrate with a pretreatment composition that is substantially free of crystalline phosphates and chromates. The present invention also relates to coated substrates produced thereby.

Owner:PPG IND OHIO INC

Method for preparing titanium-alloy surface micro-arc oxidation antifriction compound film layer

InactiveCN102021629AGood anti-frictionReduce pollutionSurface reaction electrolytic coatingElectrolytic agentMicro arc oxidation

The invention relates to a method for preparing a titanium-alloy surface micro-arc oxidation antifriction compound film layer, which is characterized by comprising the following steps of: (1) micro-arc oxidation of an electrolyte; and (2) preparation of a compound film. The invention has the technical effects that: 1. the method provided by the invention is used for preparing the micro-arc oxidation compound film layer with an antifriction effect by introducing a solid lubricant and experimenting on a one-step method in the titanium-alloy micro-arc oxidation process on the premise of not destroying a micro-arc oxidation film layer, and the antifriction effect is remarkable; and 2. the composition raw materials of a sodium-silicate system electrolyte adopted by the invention are simply and easily obtained, a solution is neutral or weakly alkaline, the solution does not contain heavy metal ions, such as chromium ions and the like or environment-friendly constraint elements and does not contain substances harmful to human bodies and environments, the environmental pollution is small, and the requirements of high-quality clean production are satisfied.

Owner:NANCHANG HANGKONG UNIVERSITY

Batch hot-dip galvanizing chromium-free passivator and application method thereof

ActiveCN104018148AAchieve qualityAchieve corrosion resistanceMetallic material coating processesOrganic filmChromium free

The invention discloses a batch hot-dip galvanizing chromium-free passivator and an application method thereof. According to the invention, toxic and harmful hexavalent chromium and trivalent chromium used in a traditional passivation process are replaced with an organic film-former, so that a chromium-free passivator which does not contain chromates, can be used at room temperature, is low in cost, good in corrosion resistance and easy to use, and can be practically applied to industrial production is provided for passivation treatment in the batch hot-dip galvanizing industry. The chromium-free passivator mainly comprises an organic film-former, an organic corrosion inhibitor, an oxidant, a surfactant and water. The chromium-free passivator disclosed by the invention is easy to use and simple in operation, and has no change in existing processes.

Owner:宁波华印表面工程材料科技有限公司 +1

Method for preparing pigment grade chromium hemitrioxide green by using gaseous reducing agent low temperature reduction chromate salt

The invention discloses a method for preparing pigment-grade chromium oxide green. The method comprises the steps of taking reducing gas as a reducing agent, allowing chromic salt to react with the reducing gas for 0.5 to 3 hours at a temperature between 300 and 800 DEG C, cooling, using water to wash and hydrolyzing a reaction mixture, mixing the reaction mixture with additives at a temperature between 700 and 1,300 DEG C, activating and sintering the reaction mixture and the additives for 0.5 to 3 hours, washing, drying and grading the sintered material to obtain the pigment-grade chromium oxide green, wherein the chromic salt is chromate or bichromate; the reducing gas is hydrogen, natural gas, ammonia gas, coal gas or a mixture thereof; and the additives are silicon compounds, titanium compounds, boron compounds, phosphorus compounds, aluminum compounds, barium compounds, zinc compounds and other compounds, such as SiO2, K2SiO3, Na2SiO3, TiO2, K2TiO3, B2O3, H2BO3, H3PO4, P2O3, Al2O3, Al(OH)3, Al2(SO4)3, AlCl3, Al(NO3)3, BaO, Ba(OH)2, BaSO4, BaCl2, Ba(NO3)2, ZnO, ZnCl2, ZnSO4, Zn(NO)3, Sb2O3 and other substances.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

In situ remediation of inorganic contaminants using stabilized zero-valent iron nanoparticles

InactiveUS7635236B2Good dispersionEasy to remedyMaterial nanotechnologyWater treatment compoundsMaterials scienceChromic Ion

A method for preparing highly stabilized and dispersible zero valent iron nanoparticles and using the nanoparticles as a remediation technology against inorganic chemical toxins in contaminated sites. The method employs a composition containing select polysaccharides (starch or cellulose) as a stabilizer for the iron nanoparticles in a liquid carrier, and results in suspensions of iron nanoparticles of desired size and mobility in water, brine, soils or sediments. The stabilizer facilitates controlling the dispersibility of the iron nanoparticles in the liquid carrier. An effective amount of the composition is delivered to a contaminated site so that the zero valent iron nanoparticles can remediate one or more toxins such as an arsenate, a nitrate, a chromate, or a perchlorate in the contaminated site.

Owner:AUBURN UNIV

Deformed steel bar compound corrosion-inhibited quenching agent and usage method thereof

The invention discloses a deformed steel bar compound corrosion-inhibited quenching agent and a usage method thereof. The compound corrosion-inhibited quenching agent is obtained by mixing the following compositions in parts by weight: 0-1 part of sodium carboxy methyl cellulose, 0-1 part of sodium polyacrylate, 0.1-1 part of sodium benzoate, 0.1-2 parts of triethanolamine, 0-0.1 part of sodium molybdate, 0-5 parts of sodium hydroxide, 0-10 parts of sodium carbonate, 5-15 parts of sodium silicate, and 70-90 parts of water. In use, the non-rusted deformed steel bar is subjected to quenching treatment in the corrosion-inhibited quenching agent for 1-2s at 100-200 DEG C, thereby being capable of slowing down the corrosion of the deformed steel bar under the atmosphere. The corrosion-inhibited quenching agent does not contain nitrite and chromate, has no S and P atoms, and is green and environment-friendly, low in cost, and recyclable.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com