Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

147 results about "Volatile corrosion inhibitor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Volatile corrosion inhibitors (VCI) are a type of corrosion inhibitor that are used to protect ferrous materials and non ferrous metals against corrosion or oxidation where it is impractical to apply surface treatments. They slowly release chemical compounds within a sealed airspace that actively prevents surface corrosion. A typical application is to protect stored tools or parts inside bags, boxes or cupboards, one advantage of VCIs being that if the container is opened and reclosed, levels of inhibitor will recover.

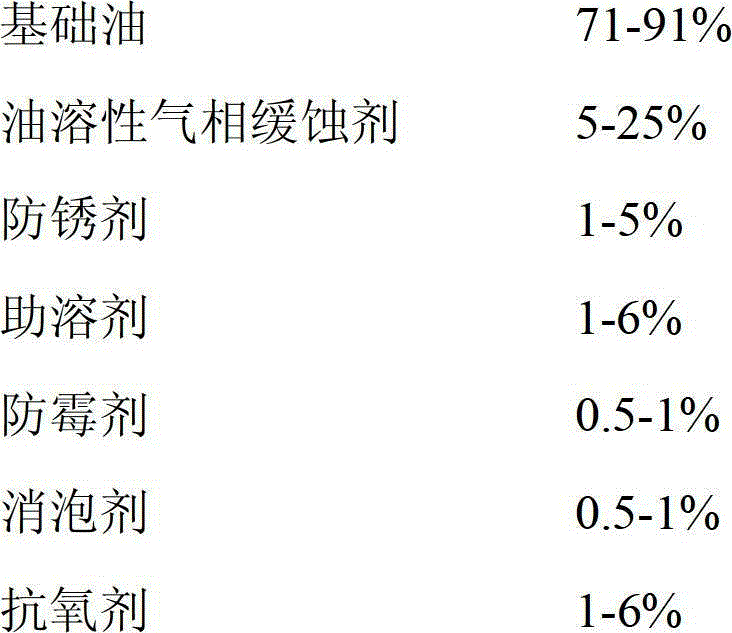

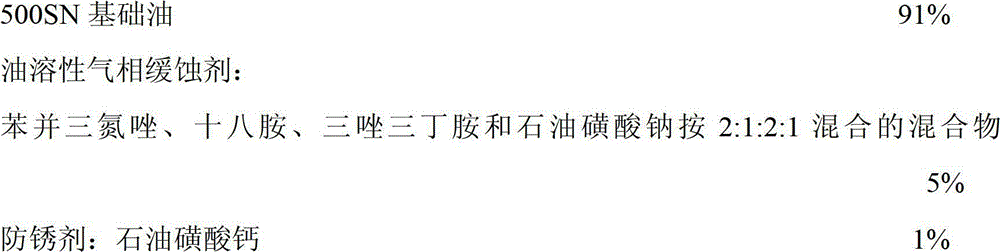

Volatile rust preventive oil

InactiveCN102719302AInhibit corrosion and rustClean working environmentAdditivesGas phaseAntioxidant

The invention discloses volatile rust preventive oil which comprises, by weight, 71-91% of base oil, 5-25% of an oil soluble volatile corrosion inhibitor, 1-5% of an antirusting agent, 1-6% of a cosolvent, 0.5-1% of a mildew-proof agent, 0.5-1% of an antifoaming agent and 1-6% of antioxidant, wherein the base oil is one of 500SN 46# machine oil, 32# machine oil, 600SN 150# machine oil and 100# machine oil; and the oil soluble volatile corrosion inhibitor is a mixture of four kinds of 2-heptadecenyl-imidalidine, octadecylamine, triazole tributylamine, dicyclohexylamine carbonate, dicyclohexylaminenitrite, benzotriazole, tert-butyl chromate, nephthenic soap, petroleum sodium sulfonate, sorbitan monooleate and stearic acid; and the antioxidant is sulfurphosphorousbutyloctyl zinc salt. The volatile rust preventive oil has good volatile rust preventive and corrosion resistant performances, metal which cannot be coated with rust preventive oil can achieve rust preventive protection, the operation is simple, and the cost is low.

Owner:上海福岛新材料科技有限公司

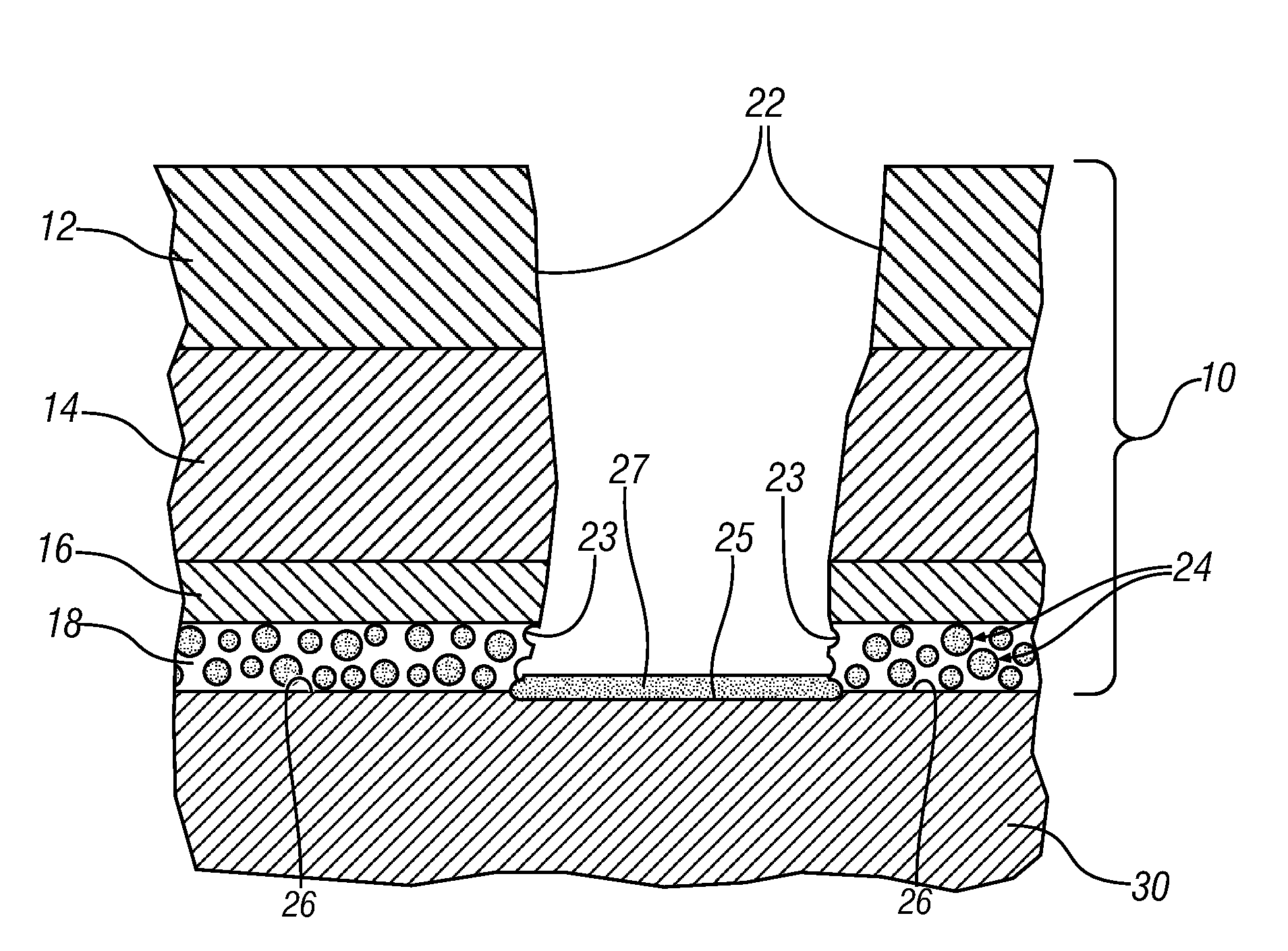

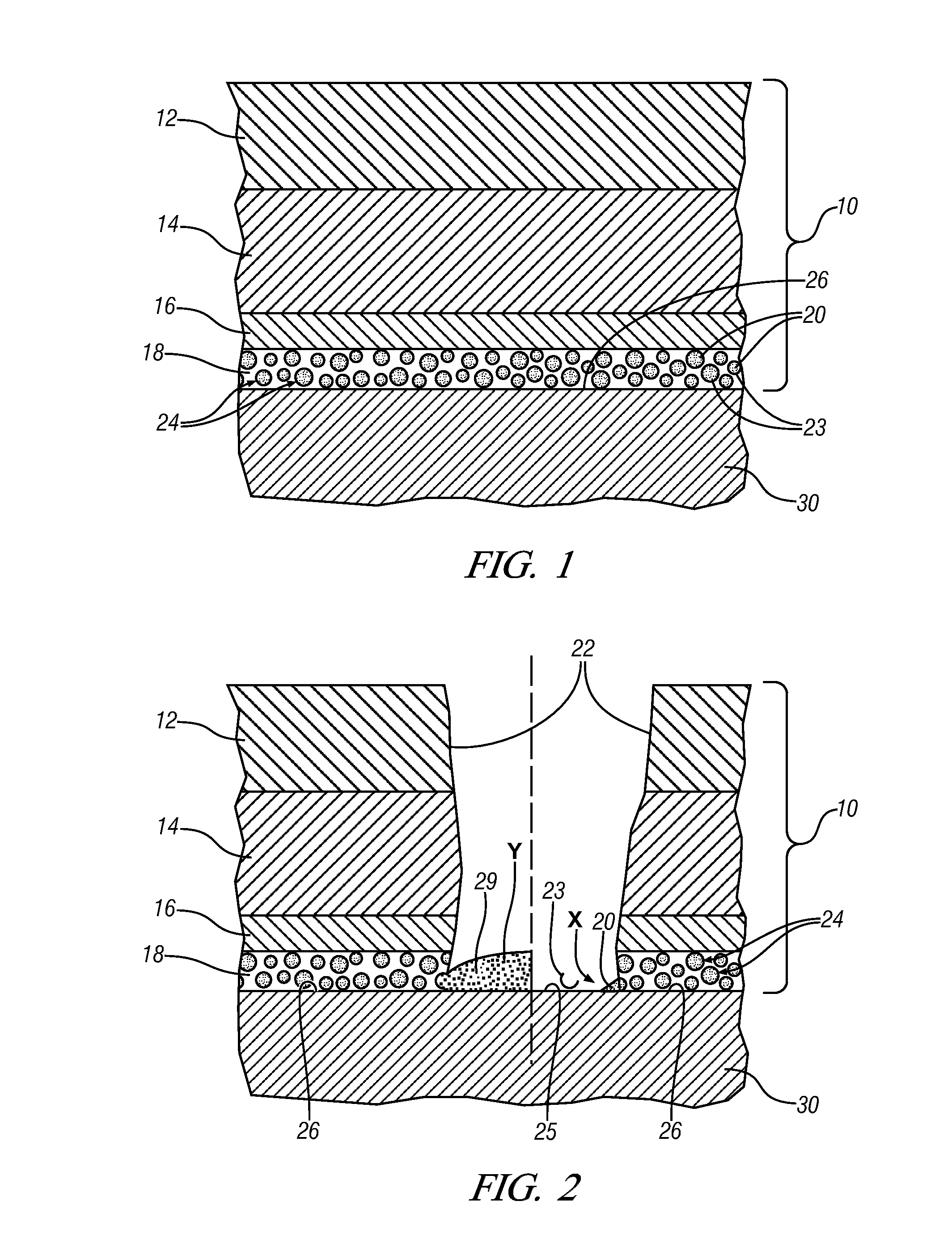

Corrosion inhibitors in breakable microcapsules to passivate scratched metals

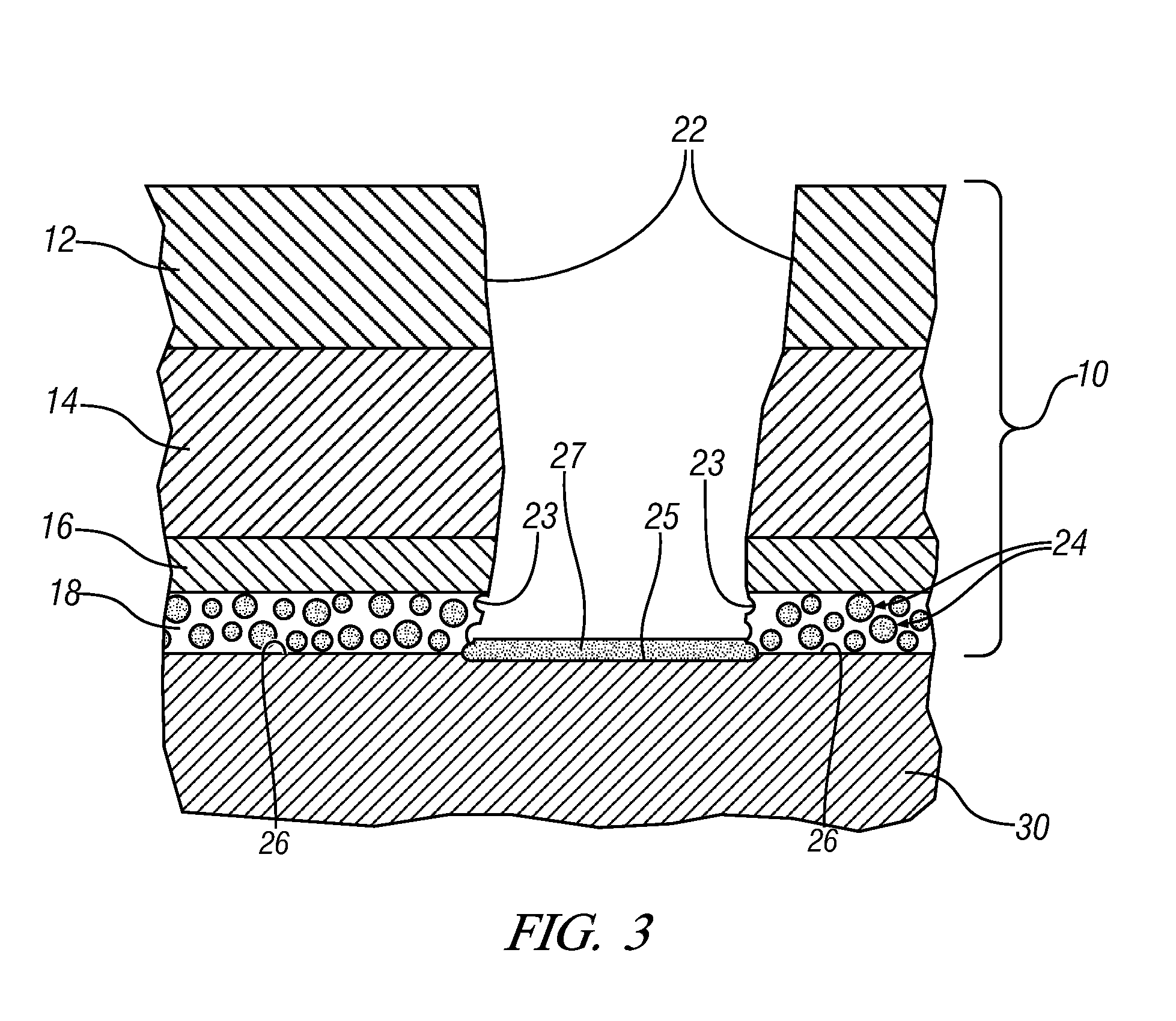

ActiveUS20110064941A1Promoting passivating layer formationUnwanted color changeLayered productsPretreated surfacesAmbient waterVolatile corrosion inhibitor

Microencapsulated chemical(s), as water-soluble solid particles, are embedded in at least one the paint layers on the surface of a magnesium article used in an automobile. If the protective paint film is scratched or otherwise mechanically disturbed to expose the surface of the magnesium article the capsules will be ruptured. This will expose the encapsulated chemical(s) to ambient water enabling them to dissolve and form an aqueous solution capable of reacting with the exposed magnesium to form a protective passivating layer on the exposed magnesium to resist corrosion. In a second embodiment the encapsulated chemicals include a deliquescing compound for extraction of moisture from the atmosphere sufficient to induce dissolution of the passivating layer-forming chemical(s) and trigger the formation of the passivating layer in the absence of ambient water.

Owner:GM GLOBAL TECH OPERATIONS LLC

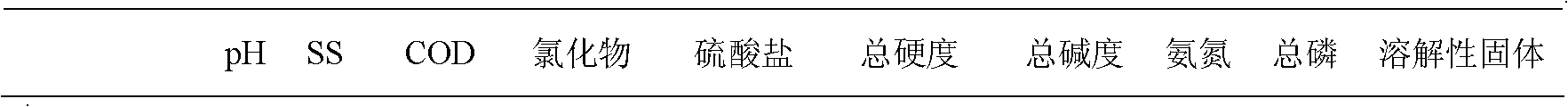

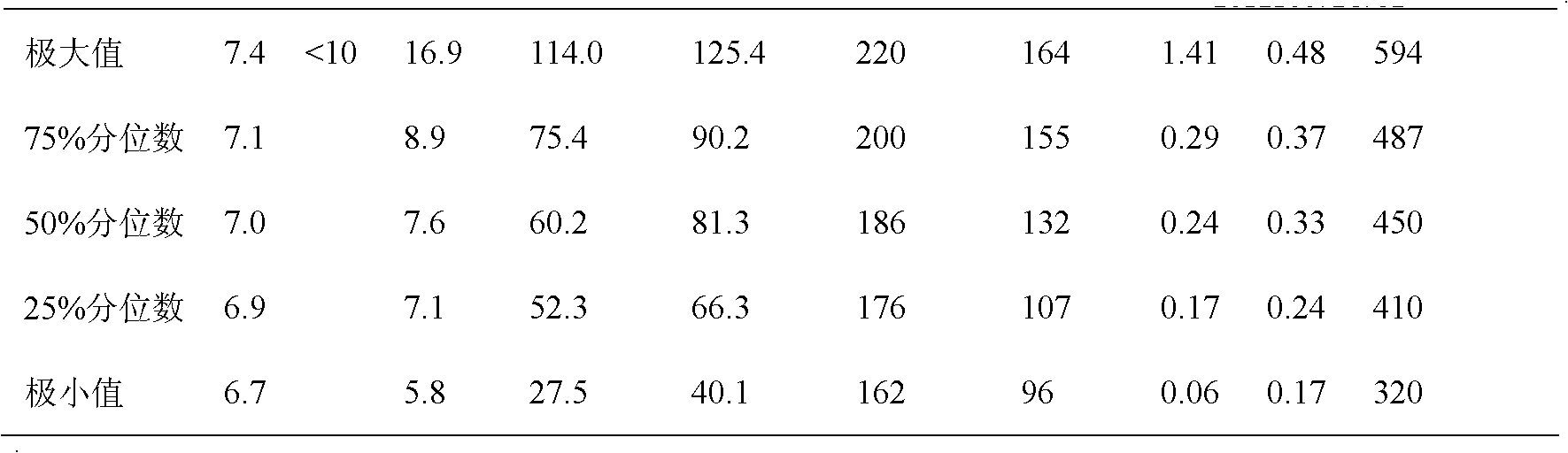

Scale and corrosion inhibitor

InactiveCN103319010AReduce eutrophication pollutionImprove protectionScale removal and water softeningEutrophicationFluorescence

The invention relates to a scale and corrosion inhibitor, comprising organic phosphonate, an inorganic scale and corrosion inhibition component, a carboxylic acid containing copolymer, zinc salt, a heterocyclic compound and a fluorescence tracing component. The scale and corrosion inhibitor is easy to compound, has good stability, and has good scale and corrosion inhibition performances for reusing tail water of a sewage plant into a circulating cooling system under a low addition amount; the scale and corrosion inhibitor can be directly added into a reclaimed water reusing pipeline, without needing to supplement calcium and alkali into the tail water in advance and regulating a pH value, and has a good treating effect; the scale and corrosion inhibitor does not contain a toxic compound and inorganic phosphatic, contains little phosphor, can reduce eutrophication pollution of a water body, and is in favor of environment protection.

Owner:常州市排水管理处 +1

Intelligent response self-repairing anticorrosive coating material and preparation method thereof

ActiveCN110079140AKeep aliveImprove bindingAnti-corrosive paintsEpoxy resin coatingsVolatile corrosion inhibitorZinc

The invention discloses an intelligent response self-repairing anticorrosive coating material and a preparation method. The coating material comprises zinc oxide microcapsules and a coating matrix; each zinc oxide microcapsule comprises a capsule core and a capsule core carrier, the capsule core is a corrosion inhibitor, and the capsule core carrier is porous zinc oxide; and the outer surface of the capsule core carrier is coated with a ZIF-8 membrane. The porous inorganic material ZnO ensures the activity of the corrosion inhibitor, and the ZIF-8 membrane formed on the surface of the ZnO cannot only improve the bonding performance, but also serve as a hole sealing material to prevent premature release of the corrosion inhibitor. The invention successfully constructs the anticorrosive coating material with double effects of pH response and self-repairing. When the coating cracks, the microcapsules rupture and release the corrosion inhibitor, thereby realizing a self-repairing function; when no obvious damage is caused to the coating, and internal corrosion has already occurred, the microcapsules can be degraded and automatically release the corrosion inhibitor according to the change of pH value around a corrosion site, thereby realizing the self-repairing function.

Owner:SUN YAT SEN UNIV

Corrosion inhibitor for after polishing detergent

ActiveCN101525563AFree from erosive propertiesFree from oxidationNon-surface-active detergent compositionsDetergent compounding agentsVolatile corrosion inhibitorPhysical chemistry

The invention relates to a corrosion inhibitor for an after polishing detergent. A creatine compound which is taken as the corrosion inhibitor is creatine and a salt compound thereof. The corrosion inhibitor is used in the after polishing detergent for chemical mechanical polishing, and can protect the surface of a processing object from corrosion when the after CMP (chemical mechanical polishing) cleaning is carried out. A chemical formula which can best display the characteristics of the corrosion inhibitor is shown.

Owner:UWIZ TECH

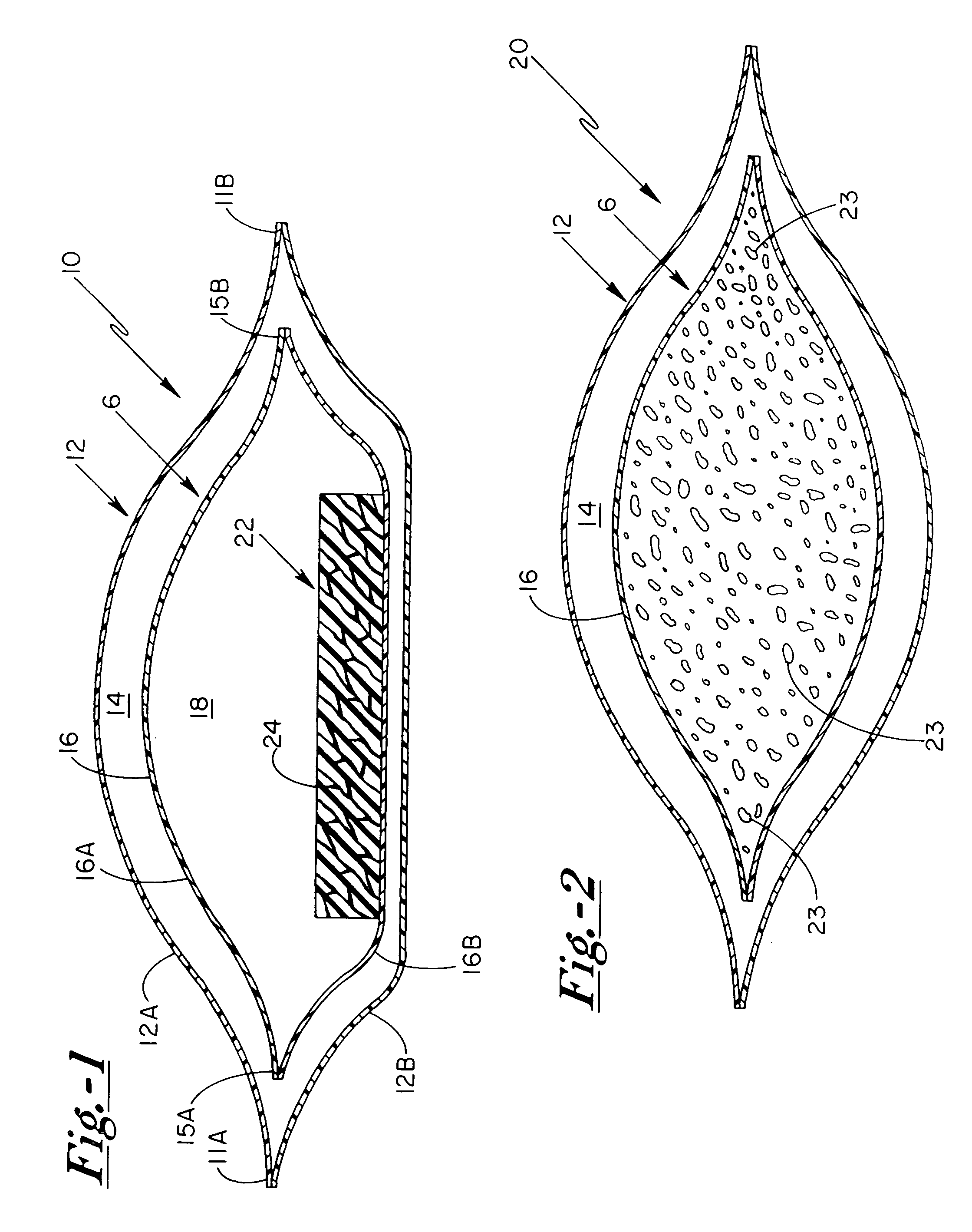

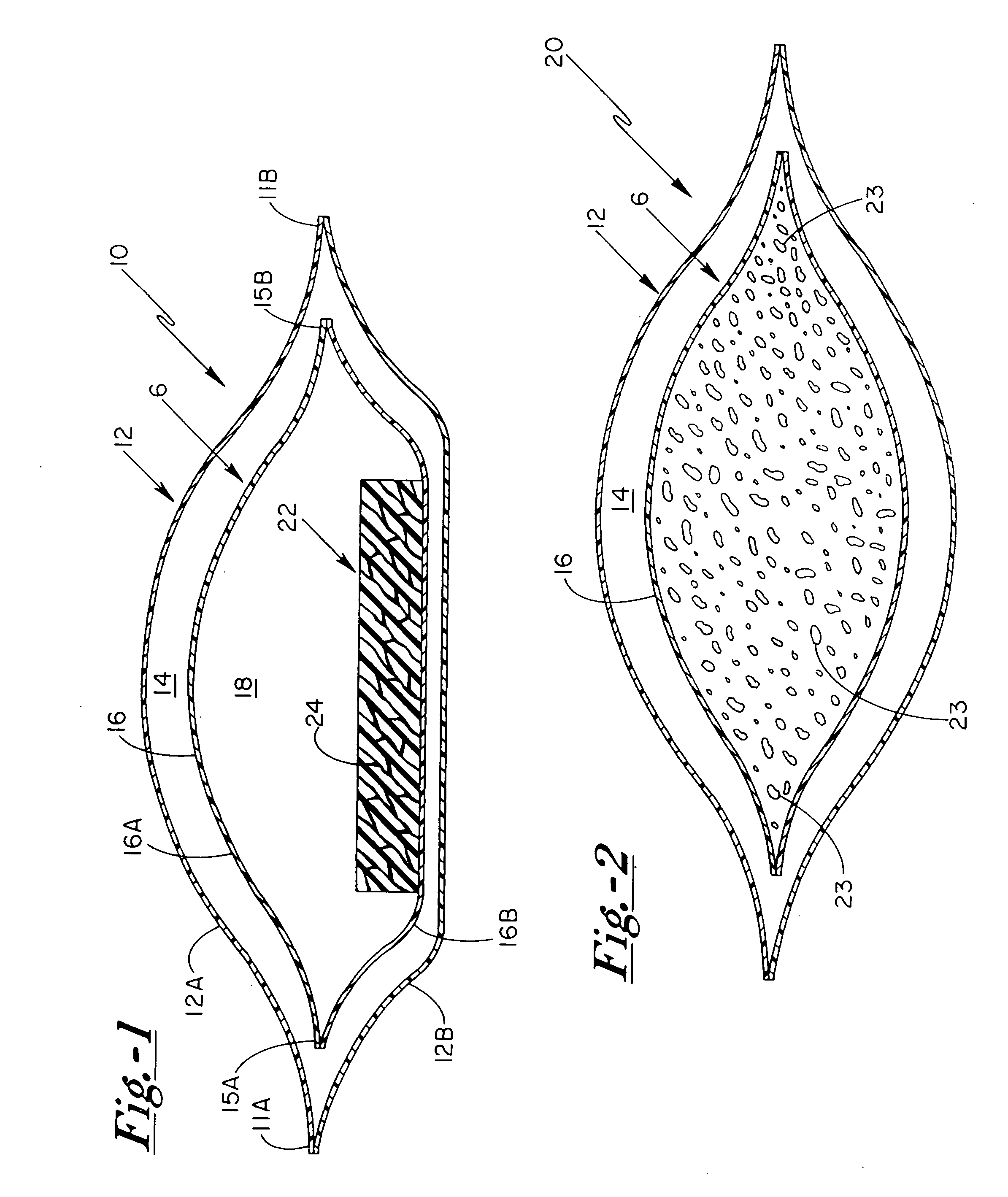

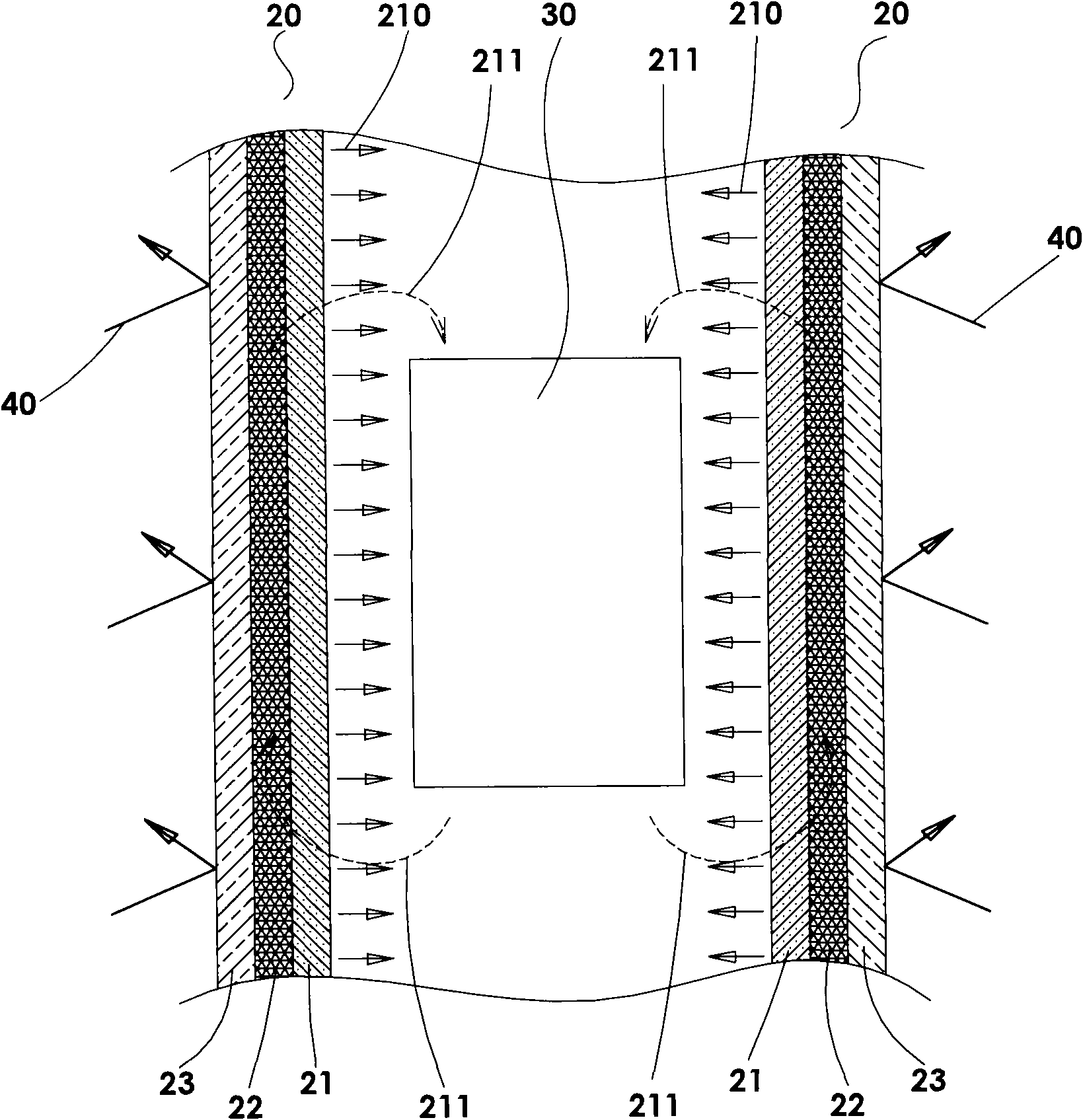

Volatile corrosion inhibitor packages

ActiveUS7763213B2Enhanced emission surface areaFacilitated releasePackage sterilisationContainer/bottle contructionVolatile corrosion inhibitorSolid particle

Owner:NXP USA INC +1

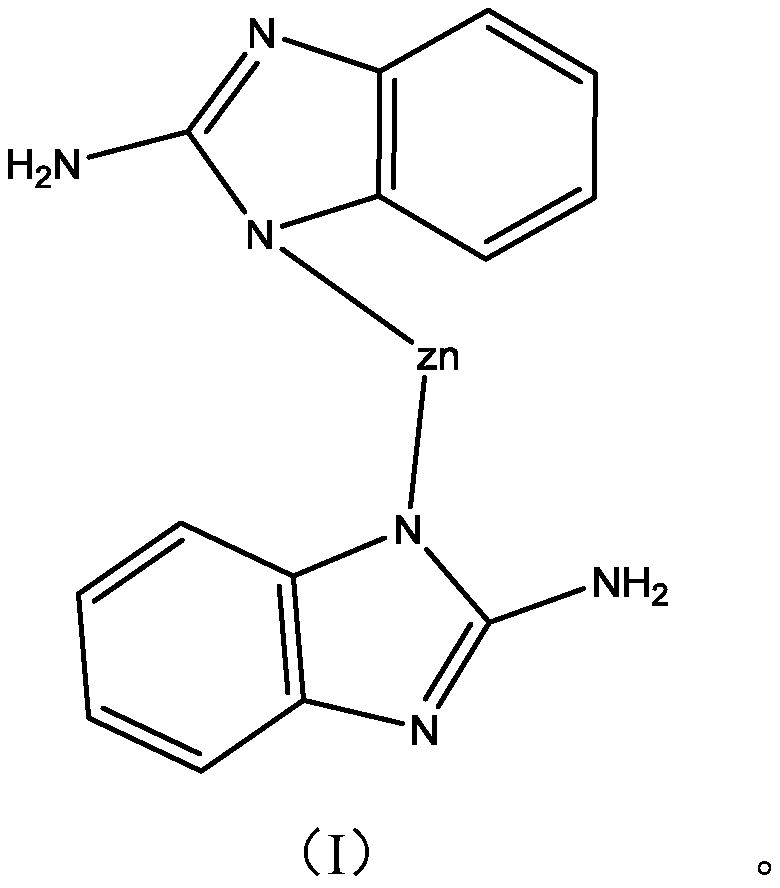

Copper corrosion inhibitor based on metal organic frame material MOFs and preparation method thereof

ActiveCN110129803AGood corrosion inhibitionStable structureVolatile corrosion inhibitorHexamethylphosphoramide

The invention belongs to the field of metal material corrosion inhibitors, and discloses a copper corrosion inhibitor based on metal organic frame material MOFs and a preparation method thereof. The copper corrosion inhibitor is prepared from the components in part by weight: 20-40 parts of aminobenzimidazole / Zn<2+>MOFs, 30-50 parts of small molecule alcohol with a molecular weight not exceeding 60, and 10-40 parts of strong polarity organic solvent, polarity of the strong polarity organic solvent is not weaker than hexamethylphosphamide, wherein the aminobenzimidazole / Zn<2+>MOFs have a structural formula shown in the following equation (I). According to the copper corrosion inhibitor based on the metal organic frame material MOFs and the preparation method thereof, key main materials of the copper corrosion inhibitor are improved, the aminobenzimidazole / Zn<2+>MOFs are used as the main materials, the characteristics of strong hydrophobicity of an adsorption group and structural stability of the aminobenzimidazole / Zn<2+>MOFs are used, and the good corrosion inhibition effect on a copper elementary substance or copper alloy materials is realized.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Compound antirust packaging material and manufacturing method thereof

InactiveCN102975437ASolve metal corrosion problemsImprove protectionFlexible coversWrappersVolatile corrosion inhibitorGas phase

Owner:沈阳防锈包装材料有限责任公司

Volatile corrosion inhibitor packages

ActiveUS20070138031A1Enhanced emission surface areaFacilitated releasePackage sterilisationContainer/bottle contructionVolatile corrosion inhibitorSolid particle

A package for enclosing volatile corrosion inhibiting materials includes a first enclosure barrier being fabricated from one or more gas-impermeable materials and defining a first enclosed space. The package further includes a substrate having one or more volatile corrosion inhibitor materials disposed thereon, with the substrate being disposed within the first enclosed space. In some embodiments, a second enclosure barrier being fabricated from a gas-permeable, solid particle-impermeable material is disposed in the first enclosed space, and defines a second enclosed space inside of the first enclosed space. In such embodiments, the substrate is preferably disposed within the second enclosed space.

Owner:NXP USA INC +1

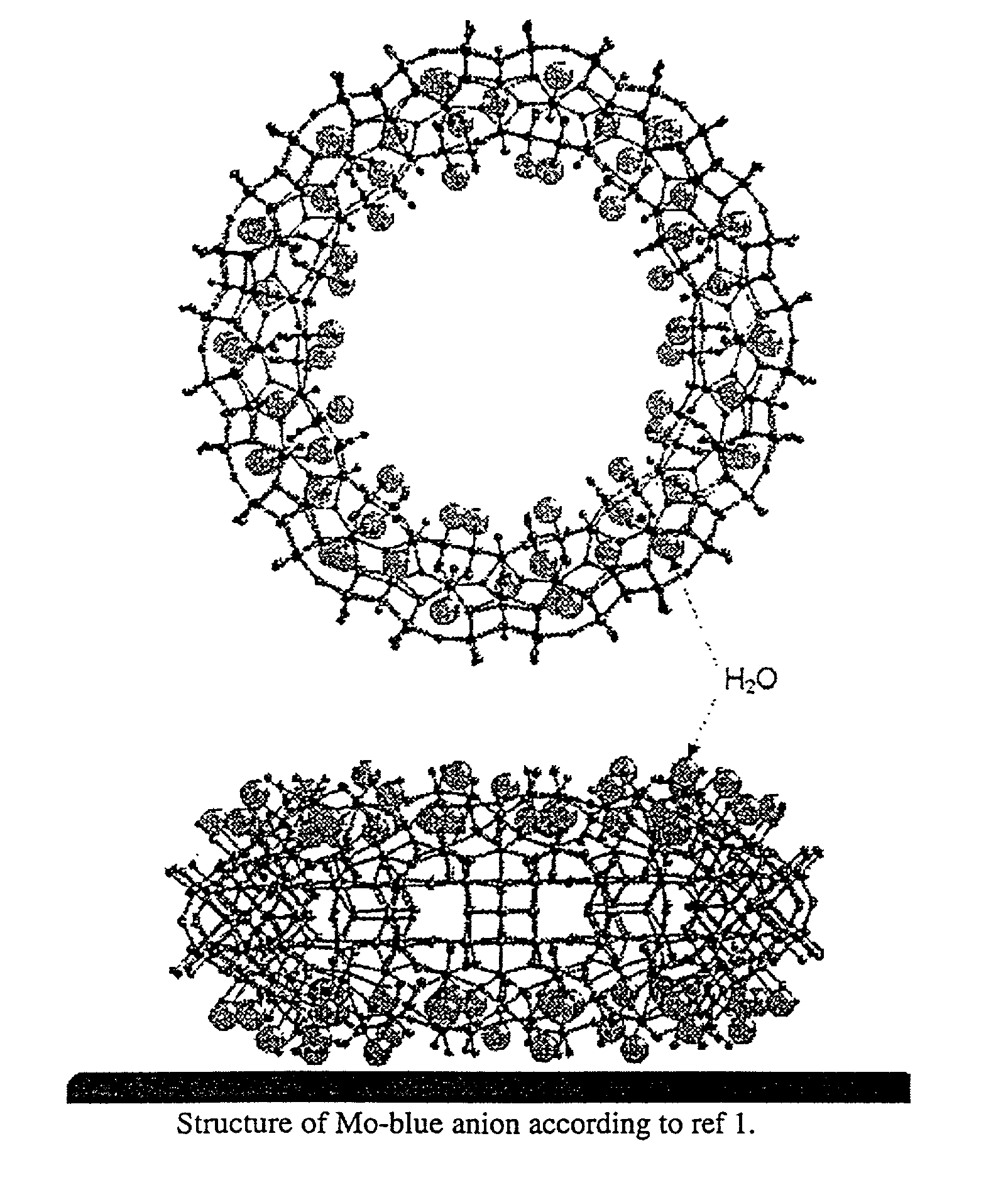

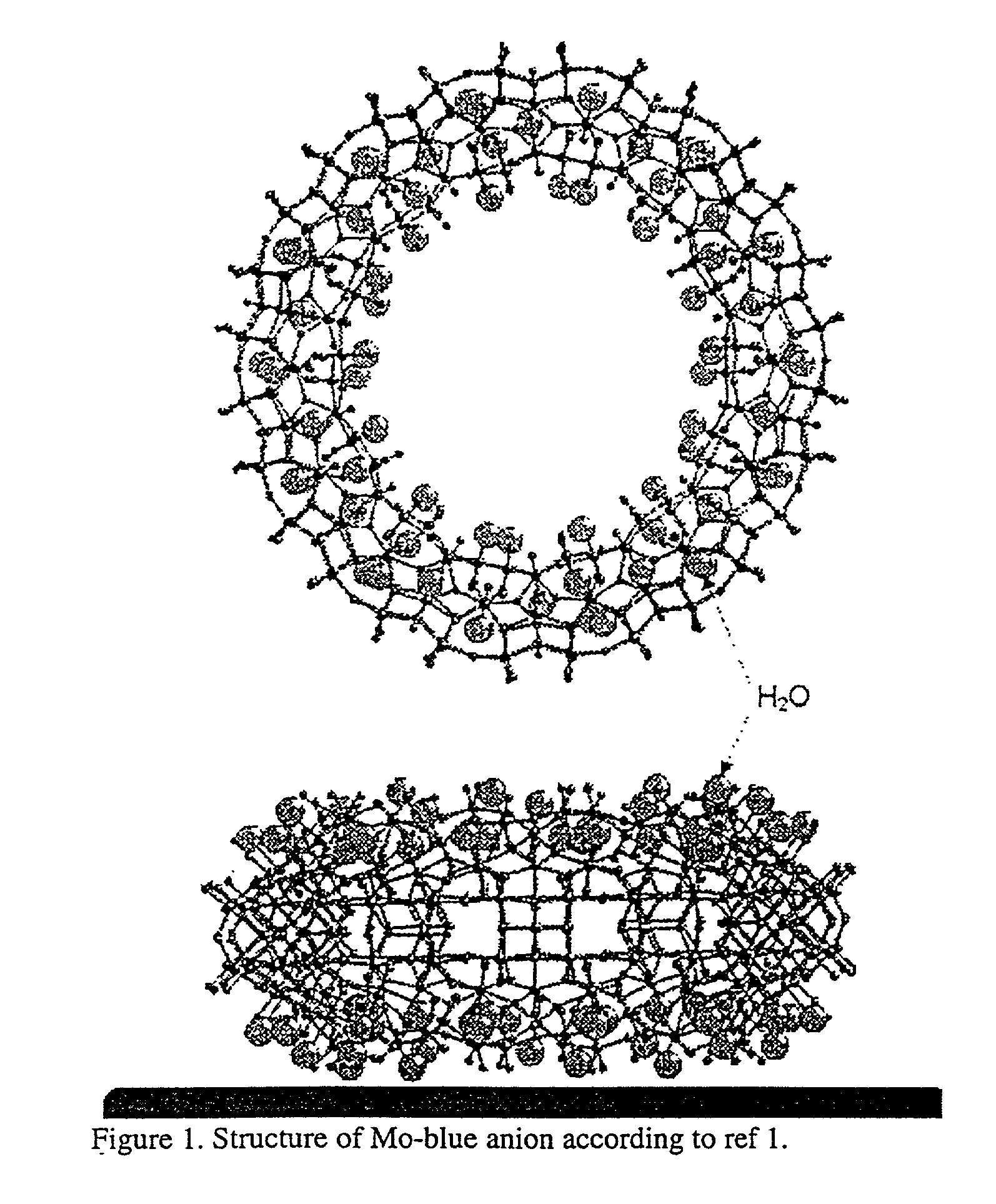

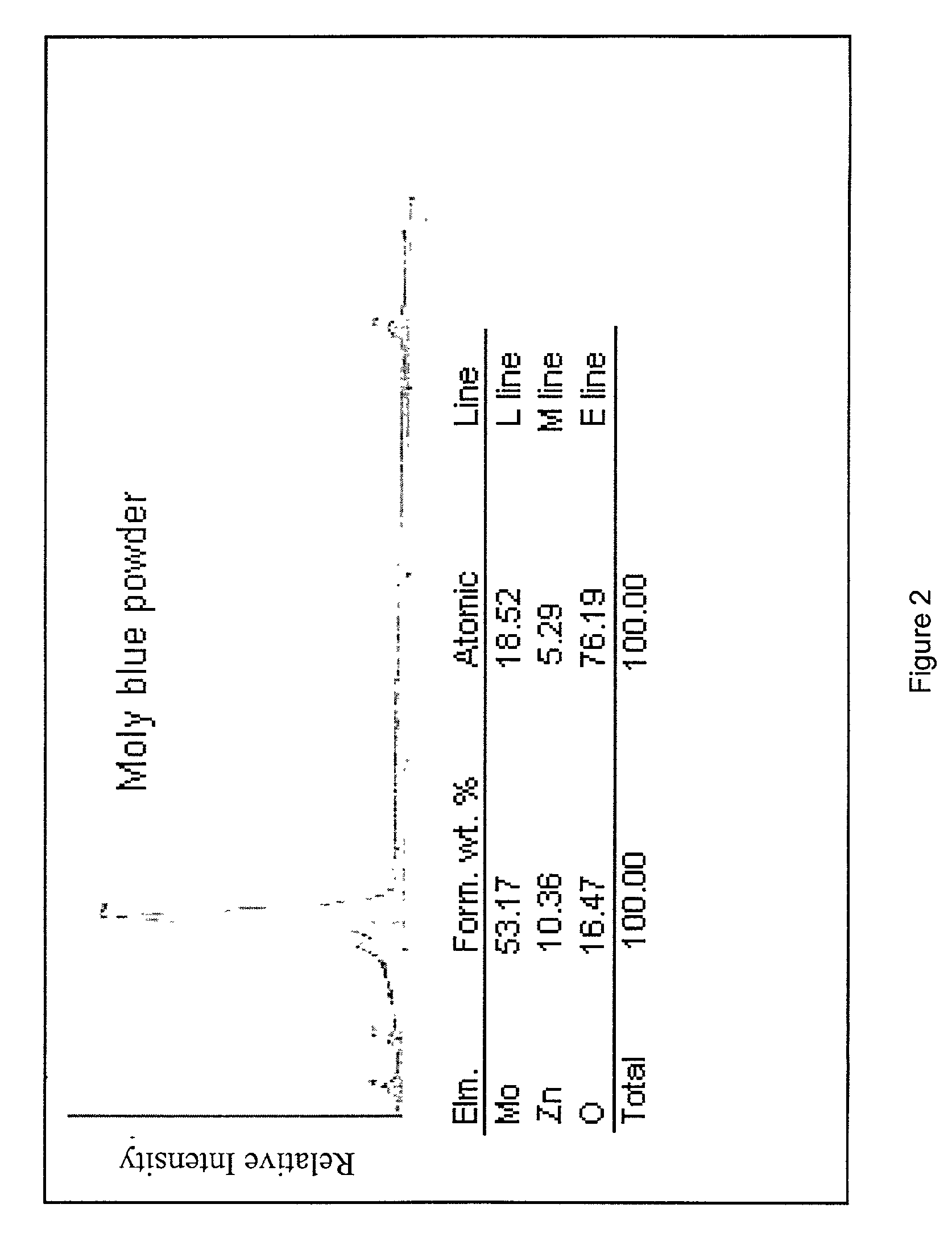

Supramolecular oxo-anion corrosion inhibitors

InactiveUS20030019391A1Hinders its propagationOther chemical processesSurface reaction electrolytic coatingVolatile corrosion inhibitorOxyanion

A corrosion inhibitor is described which includes several supramolecular oxo-anion compositions useful for preventing the propagation of pit corrosion on aluminum and aluminum alloys. The oxo-anion compositions preferably include soluble polymeric oxidic acids comprising combinations of molybdenum, phosphorous, tungsten, and silicon. These compositions are useful as corrosion inhibitors in high-moisture, corrosive environments, such as radiators and cooling systems. For low-moisture environments, these oxo-anion compositions can be reacted with a counter-ion, such as various metals, including, but not limited to the rear earth metals, to form a soluble salt. The salt can then be adsorbed onto a carrier, such as paint pigments, which can then be applied to the surfaces of aluminum and aluminum alloys. These surface adsorbates then become sparingly soluble and are gradually released over time in the presence of an aqueous corrosive agent so as to prevent propagation of pit corrosion.

Owner:THE BOEING CO

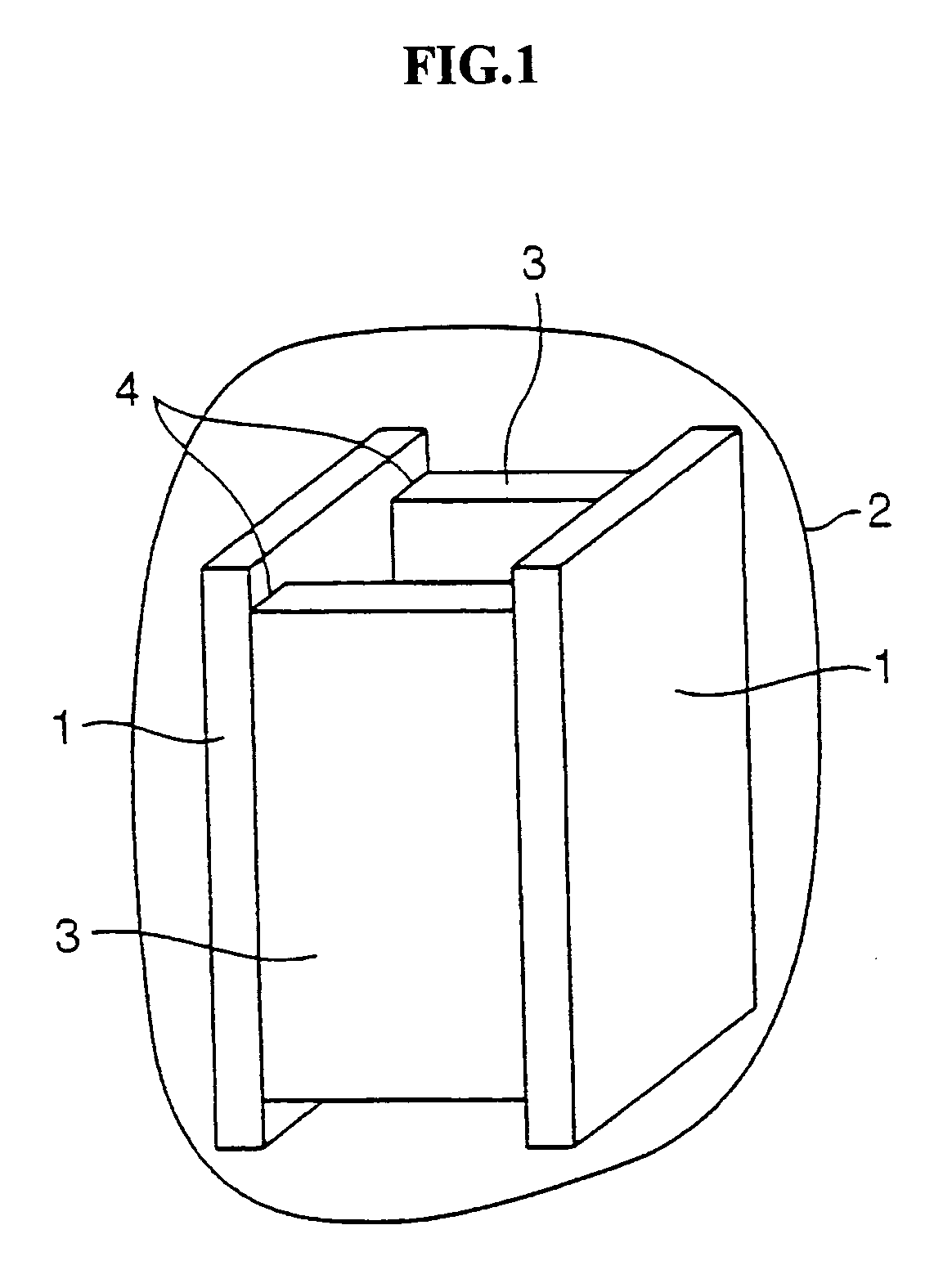

Volatile corrosion inhibitor and molding material and molded article using the same

A volatile corrosion inhibitor to be kneaded into a resin of the present invention comprises a nitrous acid metal salt, a benzoic acid metal salt, a saturated polycarboxylic acid or a metal salt thereof, and an anticorrosive component for nonferrous metals. The volatile corrosion inhibitor to be kneaded into a resin does not cause melting, gasification, decomposition, vaporization even when exposed to a high temperature condition for molding a thermoplastic resins into an article in a form of films, sheets or fibers. Further, the volatile corrosion inhibitor is free of generation of offensive odor or dust caused by sublimation. As the result, working environment does not deteriorate, and superior anticorrosive ability with respect to nonferrous metal materials such as copper as well as to iron based metal materials is exhibited. In addition, the present invention relates also to a volatile anticorrosive molding material obtained by kneading the volatile corrosion inhibitor into a resin.

Owner:CHUBU KIRESUTO +1

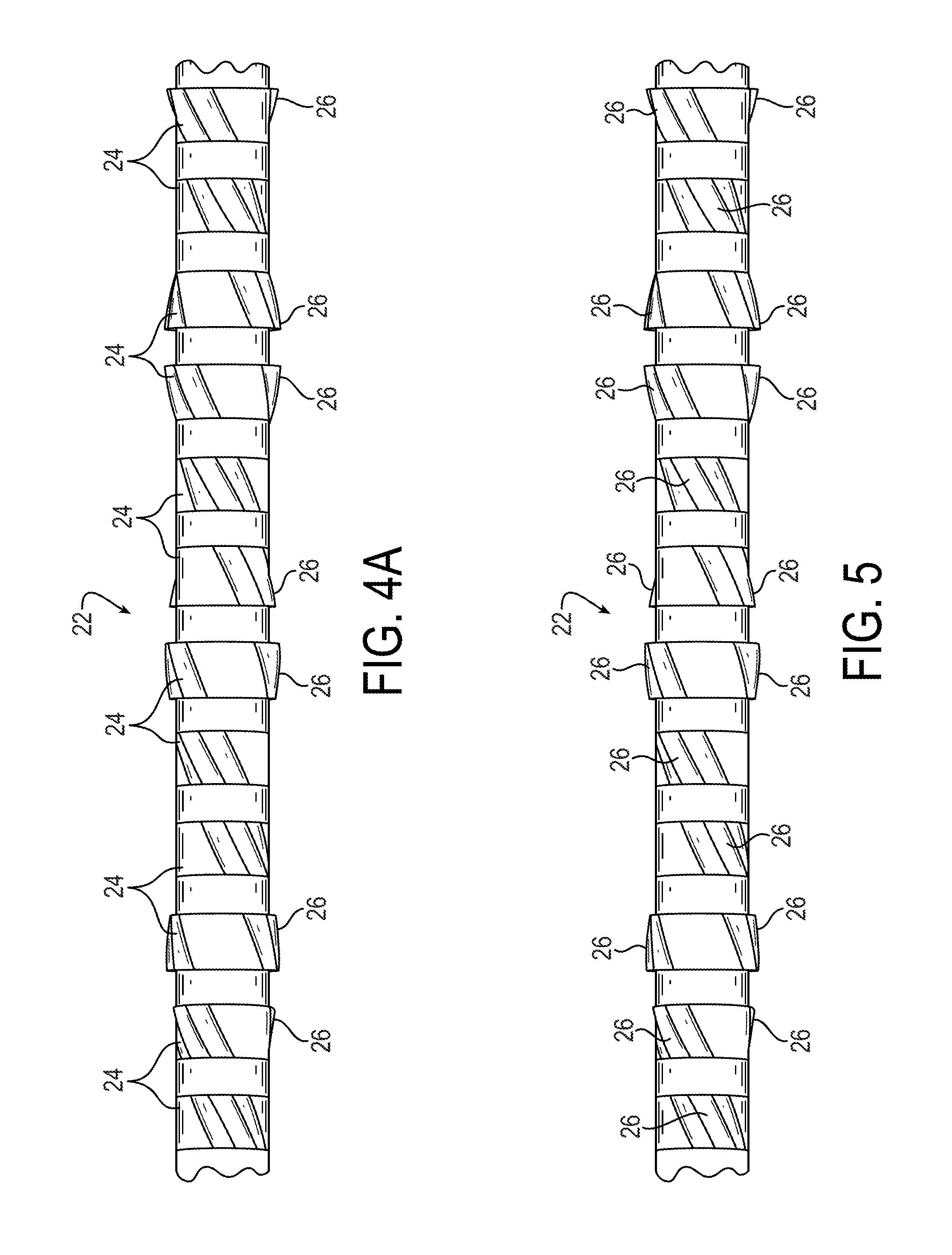

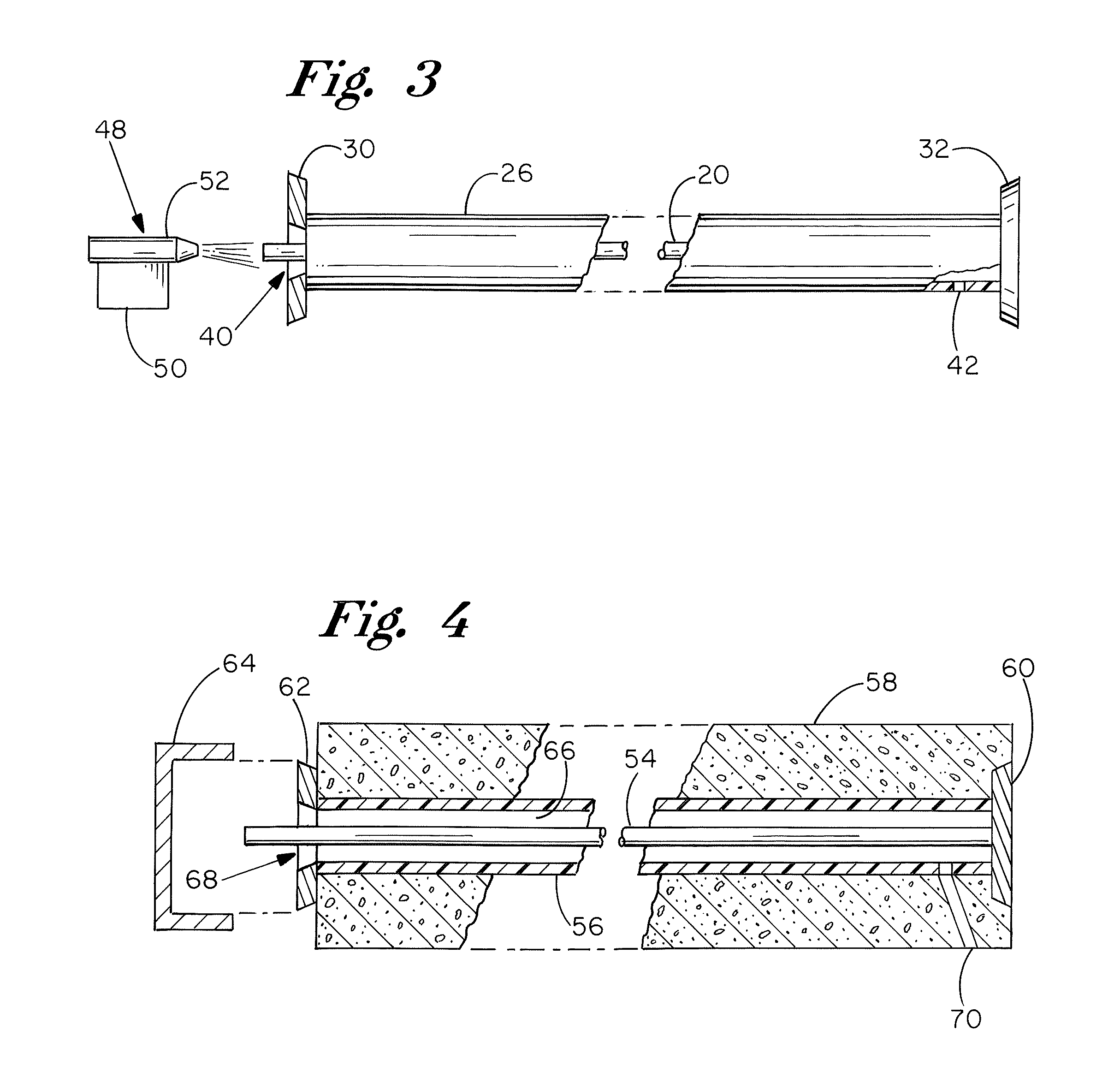

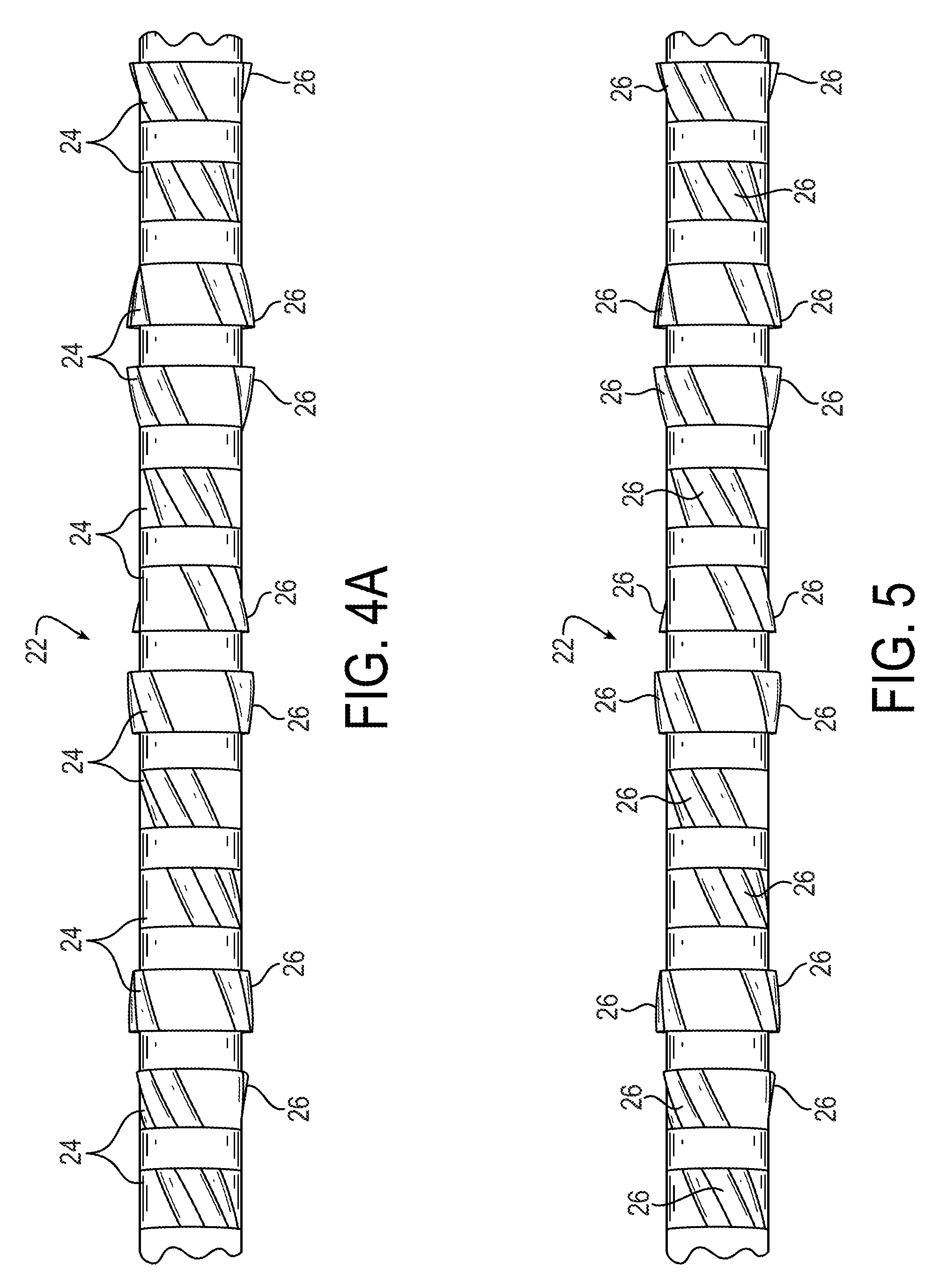

Apparatus and method for cleaning the barrel of a firearm

ActiveUS20140123530A1Avoid corrosionHollow article cleaningEndoscopesVolatile corrosion inhibitorEngineering

A cleaning device for preserving a barrel of a firearm includes a central member defining a core and having a longitudinal length, a leading end and a trailing end. A tubular woven sheath surrounding the central member and has a lead end and a trailing end. A radial protrusion formed of a polymer is disposed about the central member between the central member and the sheath. A volatile corrosion inhibiter (VCI) is disposed on or in the cleaning device and configured to off-gas to cause a substantial part of an interior of the barrel to become lined with a protective coating to resist corrosion. The cleaning device is configured to be stored within the barrel of the firearm. A method for storing a cleaning device within a barrel of a firearm for preserving a barrel of a firearm is also described.

Owner:OTIS PROD

Organic film-forming amine corrosion inhibitor and application thereof

The invention belongs to the technical field of metal anticorrosion, and in particular relates to an organic film-forming amine corrosion inhibitor and an application method thereof. An organic film-forming amine corrosion inhibitor of the present invention is prepared from the following substances according to the concentration ratio: organic amine: passivator: surfactant: water=12~20:2~5:2~5:40~ 60. An organic film-forming amine corrosion inhibitor prepared by the invention has no odor, good water solubility, good fluidity, high anti-corrosion efficiency of more than 93%, and small emulsification tendency, and it is compatible with fungicides, corrosion inhibitors, and purifiers commonly used in oil fields. and other chemical reagents have good compatibility, for H 2 S, CO 2 , Cl, O 2 It can be widely used in downhole oil casings, surface equipment, technical system pipelines, refinery processes and metal equipment for water injection stations and sewage treatment stations for oil and gas wells. Corrosion of pipelines.

Owner:CHENGDU ENERGY ENG

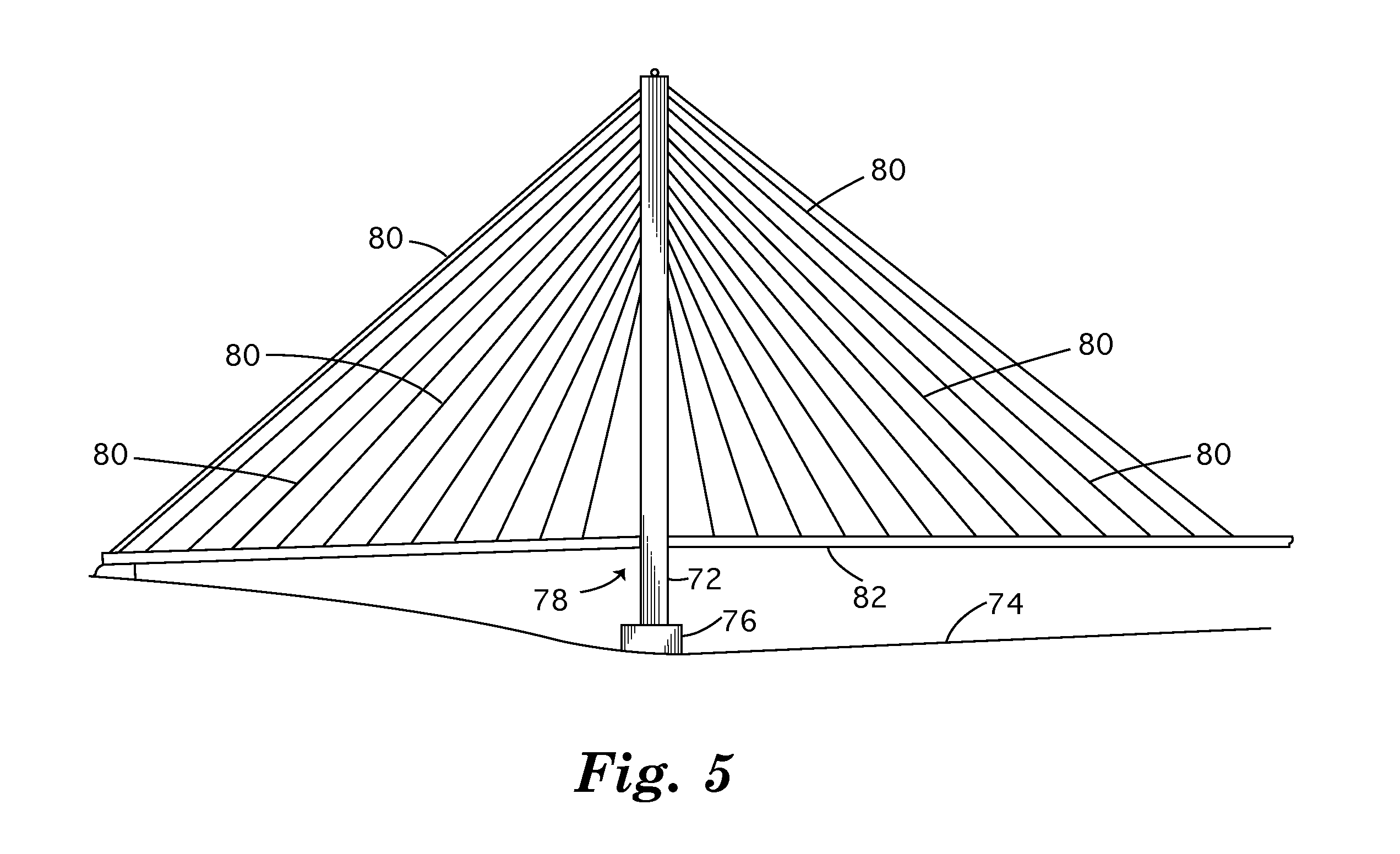

Method for treating elongate metal tension member with volatile corrosion inhibitors

ActiveUS9435037B2Improve protectionEffective characterizationLiquid surface applicatorsBuilding reinforcementsVolatile corrosion inhibitorEngineering

A volatile corrosion inhibiting agent is provided for dispersion of a vapor phase corrosion inhibitor in a vapor stream that is passed into a sheath or other casing enclosing a metal bar, cable, or other tension member to protect said tension member from corrosion.

Owner:CORTEC CORP

Application of 1-myristyl-3-methylimidazolium chloride ionic liquid serving as steel corrosion inhibitor

InactiveCN101818349AMake up for the lack of toxic side effectsInhibit corrosion reactionCorrosion reactionVolatile corrosion inhibitor

The invention discloses application of 1-myristyl-3-methylimidazolium chloride ionic liquid serving as a steel corrosion inhibitor. The method of the application comprises the step of: immersing steel in acid liquor containing the corrosion inhibitor of the 1-myristyl-3-methylimidazolium chloride ionic liquid to clean the steel. The invention has the advantages that the ionic liquid is used as the corrosion inhibitor and is extremely easy to dissolve in common solutions in production, such as water and the like, which is beneficial to the penetration in the use of the corrosion inhibitor; compared with common inorganic corrosion inhibitors, the corrosion inhibitor of the invention does not have toxic action on the environment and organisms and makes up the defect of big toxic and side effects on the traditional corrosion inhibitors. The corrosion inhibitor can effectively restrain the corrosion reaction of steel materials in acid media and has good corrosion inhibition efficiency.

Owner:UNIV OF JINAN

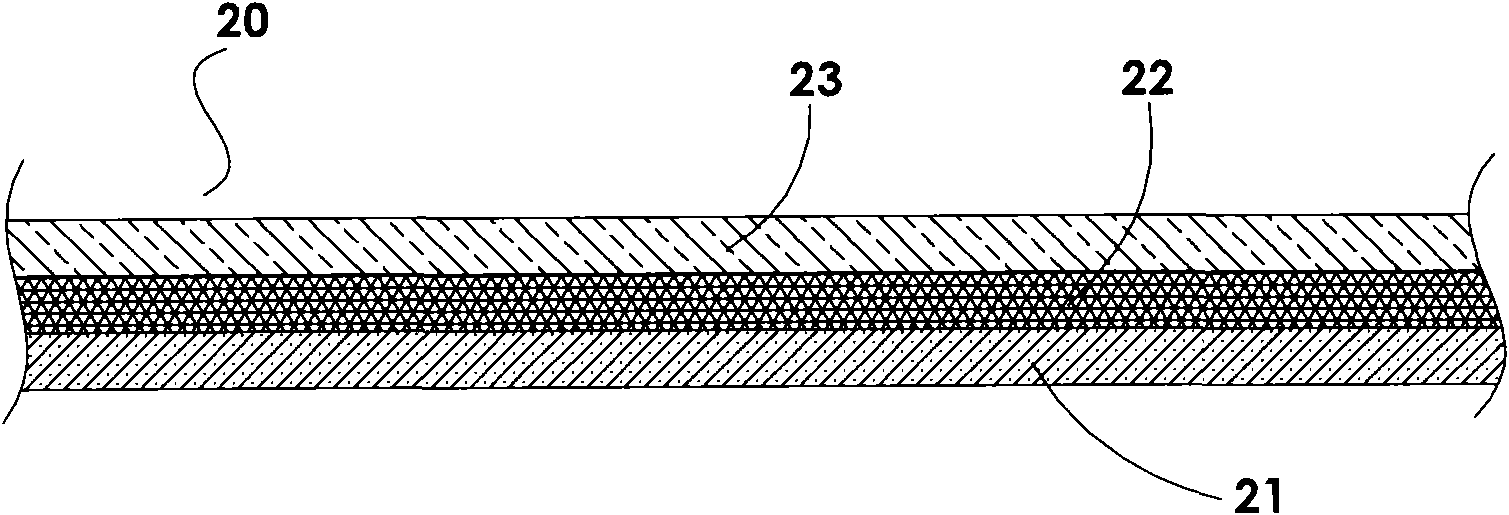

Corrosion resistant tube for secondary battery and secondary battery comprising the same

ActiveUS20160099439A1Extend the lifespanImprove securityFinal product manufactureSmall-sized cells cases/jacketsVolatile corrosion inhibitorBattery cell

Provided is a corrosion resistant tube for a secondary battery including a volatile corrosion inhibitor (VCI) and a base resin, and a secondary battery including the same. The corrosion resistant tube of the present invention prevents the occurrence of rust or the occurrence of corrosion in a battery cell, and therefore, is capable of enhancing stability of the battery.

Owner:LG ENERGY SOLUTION LTD

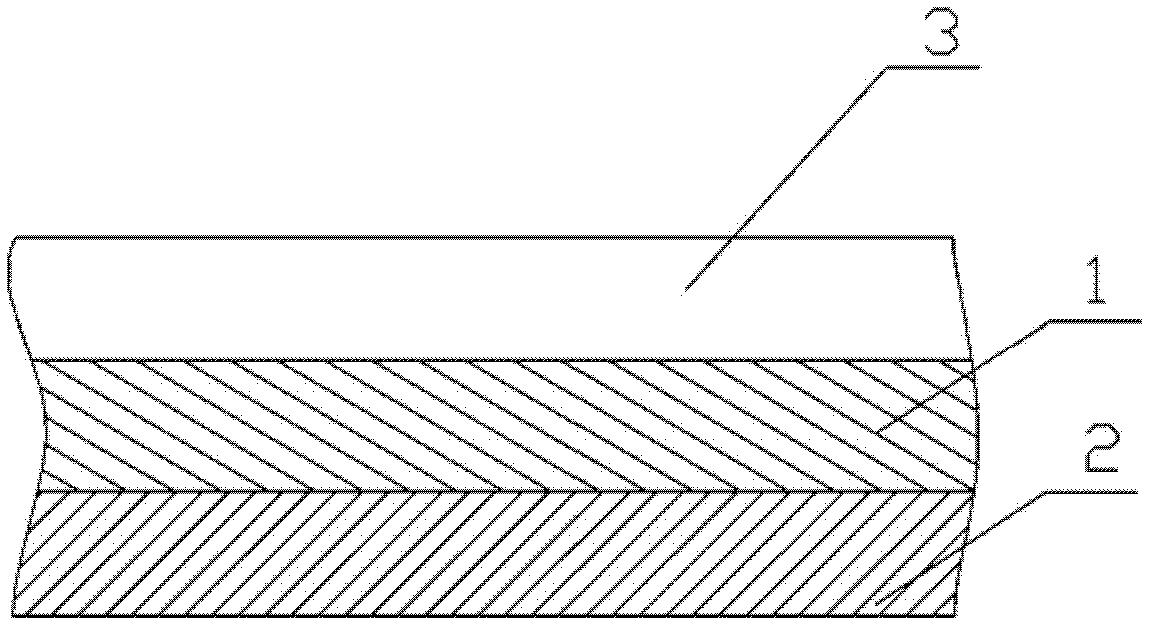

High-strength oxidation-resisting anti-rust film

InactiveCN102173151AIncrease productivityReduce manufacturing costFlexible coversWrappersVolatile corrosion inhibitorAlcohol

The invention discloses a high-strength oxidation-resisting anti-rust film which is prepared through the following steps: completing the preparation of an inner-layer material, a middle-layer material and an outer-layer material in an independent dispensing procedure; and then forming a three-layer compound film by extruding the inner-layer material, the middle-layer material and the outer-layer material in a multi-layer coextrusion mode by using an extrusion machine, wherein the inner-layer material contains a volatile corrosion inhibitor VCI (accounting for about 5wt% of the inner-layer material), through uniformly mixing the volatile corrosion inhibitor with a polyethylene PE master batch, an inner VCI anti-rust layer is formed; the middle-layer material contains 4,4'-Isopropylidenediphenol C12-15 alcohol phosphite (accounting for 3wt% of the middle-layer material), through uniformly mixing the 4,4'-Isopropylidenediphenol C12-15 alcohol phosphite with a polyethylene PE master batch, a middle bridging layer is formed; and the outer-layer material contains a polypropylene PP (accounting for 13wt% of the outer-layer material) and a metalized polypropylene MPP (accounting for 30wt% of the outer-layer material), through uniformly mixing the PP and the MPP with a polyethylene PE batch, an outer isolation layer is formed. The film disclosed by the invention has the economic effect of low manufacturing cost, and can be applied to metal product packaging; and meanwhile, the film also has the effects of weather fastness, tear resistance, antioxidation, waterproofing moisture-proofing and rust protection.

Owner:HON BOUW

Composite scale and corrosion inhibitor, and applications thereof in circulated cooling water treatment

ActiveCN105621634AGood scale inhibitionGood corrosion inhibition effectScale removal and water softeningVolatile corrosion inhibitorPolyaspartic acid

The invention discloses a composite scale and corrosion inhibitor. The composite scale and corrosion inhibitor contains carboxymethylinulin, cyclodextrin and / or a cyclodextrin derivative, and polyaspartic acid and / or polyepoxysuccinic acid at a weight ratio of (12-100):(2-25):(5-25). The invention also discloses applications of the composite scale and corrosion inhibitor in circulated cooling water treatment. The composite scale and corrosion inhibitor possesses excellent corrosion and scale inhibition comprehensive performance; and when the composite scale and corrosion inhibitor is applied to circulated cooling water treatment, requirements of circulated cooling water on scale and corrosion inhibition are satisfied, and environmental problems caused by phosphorus-containing chemicals in phosphorus-containing circulated cooling water are avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

Volatile corrosion inhibiting mixture with tracing agent

ActiveUS20090020034A1Liquid surface applicatorsOther chemical processesVolatile corrosion inhibitorElectromagnetic spectrum

A corrosion inhibiting mixture is disclosed comprising a carrier, a volatile corrosion inhibitor and a tracing agent which absorbs light in the ultraviolet and violet region of the electromagnetic spectrum, and re-emits light in the blue region of the electromagnetic spectrum.

Owner:SKS INDS

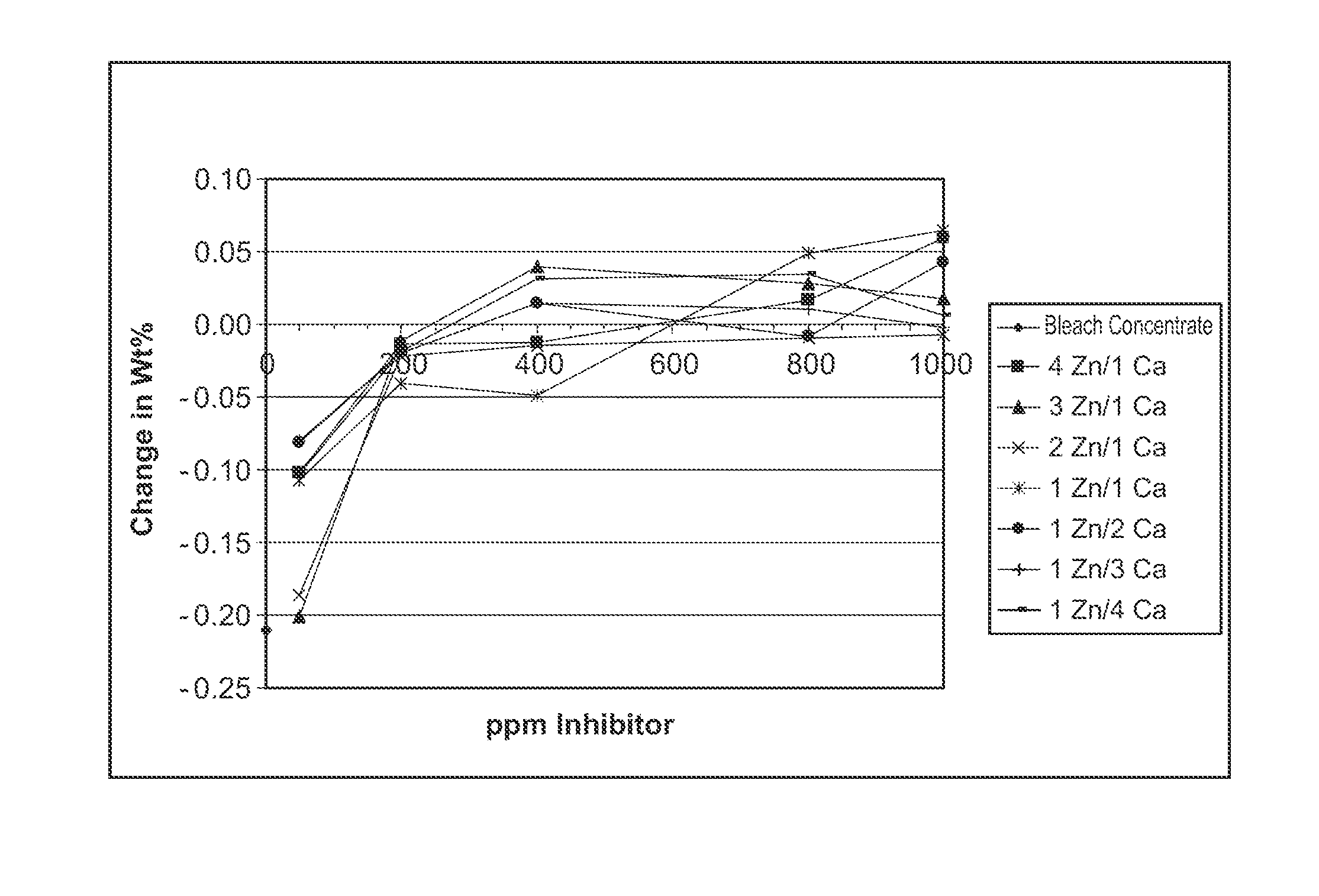

Corrosion inhibition of hypochlorite solutions using Zn and Ca

ActiveUS8114343B1Not adversely stabilityReduce corrosionOther chemical processesDetergent bleaching agentsVolatile corrosion inhibitorHypochlorite

Owner:ECOLAB USA INC

Environmental-friendly volatile corrosion inhibitor for carbon steel and preparation method of environmental-friendly volatile corrosion inhibitor

An environmental-friendly volatile corrosion inhibitor for carbon steel comprises sodium silicate with the mass-volume concentration of 0.8 g / L-1.2 g / L, alanine with the mass-volume concentration of 1.8 g / L-2.3 g / L, sodium benzoate with the mass-volume concentration of 6.8 g / L-8.3 g / L, and ammonium benzoate with the mass-volume concentration of 3.8 g / L-4.5 g / L, dissolved in distilled water. A preparation method of the environmental-friendly volatile corrosion inhibitor comprises the following steps: respectively weighing the sodium silicate, alanine, sodium benzoate and ammonium benzoate according to the mass-volume concentrations; respectively dissolving in distilled water with the volumes of 1 / 4 of those of the solutes, and uniformly stirring; after the four solutions are stilled, mixing and uniformly stirring. The environmental-friendly volatile corrosion inhibitor is formed by compounding the sodium silicate, alanine, sodium benzoate and ammonium benzoate, is environmental-friendly and efficient, has little pollution to the environment, has a good synergistic effect, and solves the problems that the conventional volatile corrosion inhibitor is poor in corrosion-inhibition performance and generates more pollution, adopts the simple preparation method, is convenient to use, and can prolong the service life of the carbon steel.

Owner:西安宇坤实业有限公司

Apparatus and method for cleaning the barrel of a firearm

ActiveUS9115947B2Avoid corrosionHollow article cleaningEndoscopesVolatile corrosion inhibitorEngineering

Owner:OTIS PROD

Volatile corrosion inhibitor containing natural gas with carbon dioxide

The invention relates to a volatile corrosion inhibitor containing natural gas with carbon dioxide and mainly solves the problem that carbon dioxide contained in natural gas severely corrodes steel so as to greatly minimize the lifetime of oil and gas well. The volatile corrosion inhibitor comprises the following components of: by weight, 10-20% of N-methyl diethanolamine, 1-3% of Penetrant JFC-2, 3-10% of benzotriazol, 4-15% of 5,7 dinitrogen-8-hydroxyquinoline, and 52-82% of anhydrous ethanol. The content of each component is the weight percent of the gross weight of the corrosion inhibitor. The volatile corrosion inhibitor containing natural gas with carbon dioxide has high inhibition efficiency and will not influence the lifetime of the oil and gas well.

Owner:大庆中浮石油技术开发有限公司

Damp-proof and wear-resistant switch and preparation method thereof

InactiveCN106700832AGood corrosion inhibition effectImprove protectionAnti-corrosive paintsEpoxy resin coatingsEpoxyWear resistant

The invention discloses a damp-proof and wear-resistant switch. A component A comprises constituents in parts by mass as follows: 9-13 parts of poly(aryl ether sulfone ketone) modified resin, 21-27 parts of silicon carbide micro-powder, 5-9 parts of graphite fluoride, 18-23 parts of black silicon carbide, 10-16 parts of fine-grain aluminum oxide, 2-7 parts of zinc oxide, 17-21 parts of modified epoxide resin, 4-9 parts of a flatting agent and 16-22 parts of auxiliary materials; a component B comprises constituents in parts by mass as follows: 11-16 parts of a binder, 9-12 parts of a suspending agent, 13-26 parts of silicon carbide, 11-17 parts of aluminum oxide, 40-45 parts of a solvent, 20-23 parts of epoxy resin, 11-19 parts of vinyltriethoxysilane, 19-22 parts of a curing agent, 2-8 parts of a coupling agent and 3-8 parts of a fire retardant; a wear-resistant layer comprises components as follows: 13-22 parts of a wetting agent, 14-19 parts of deionized water, 9-16 parts of a leveling agent, 2-7 parts of plasticizing resin, 13-18 parts of a volatile corrosion inhibitor, 18-24 parts of a solvent, 18-34 parts of a curing agent, 27-30 parts of a defoaming agent and 22-27 parts of a coalescing agent.

Owner:苏州富艾姆工业设备有限公司

Corrosion-resistant washer, and secondary battery comprising same

ActiveCN103959514AImprove securityPrevent rustSmall-sized cells cases/jacketsBattery isolationVolatile corrosion inhibitorEngineering

According to one embodiment of the present invention, provided are a corrosion-resistant washer for a secondary battery, and a secondary battery comprising same, wherein the corrosion-resistant washer is characterized by including a volatile corrosion inhibitor (VCI) and a base resin. The corrosion-resistant washer of the present invention can improve the stability in a battery by preventing the occurrence of corrosion or the occurrence of rust in the crimping part of a battery cell.

Owner:LG ENERGY SOLUTION LTD

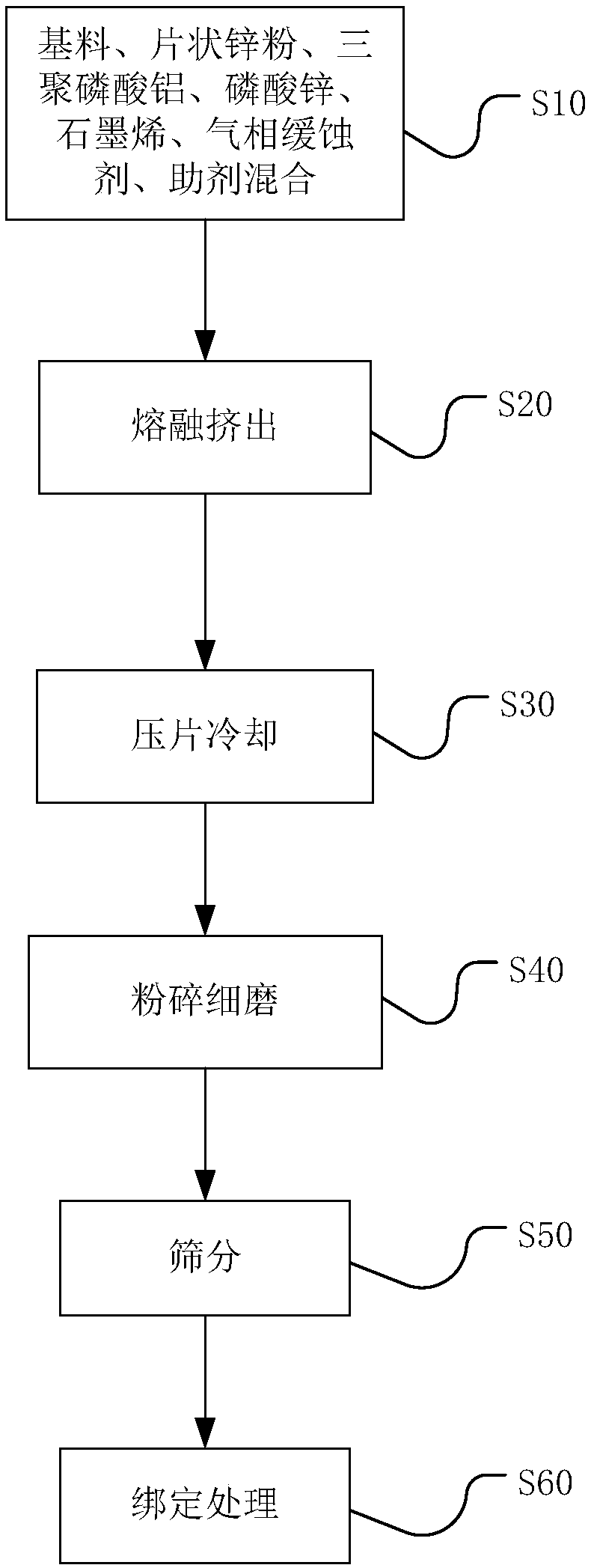

Graphene powder bimetallic paint and preparation method thereof

InactiveCN109486343AImprove shielding effectImprove the protective effectAnti-corrosive paintsPolyether coatingsUltravioletElectrochemistry

The invention discloses a graphene powder bimetallic paint. The graphene powder bimetallic paint is composed of base materials, filler, volatile corrosion inhibitor and auxiliaries, wherein the base materials are composed of, by weight part, 30-50 parts of epoxy resin powder, 5-30 parts of phenolic hydroxyl resin, 5-15 parts of polytetrafluoroethylene resin and 5-15 parts of fluorocarbon powder resin; the filler is composed of 30-60 parts of flake zinc powder, 1-5 parts of flake aluminum powder, 5-10 parts of aluminum tripolyphosphate, 5-10 parts of zinc phosphate and 0.05-1 part of graphene.The graphene powder bimetallic paint is high in shielding effects, the added graphene can significantly increase conductivity of flake metals, enhance the electrochemical protecting effects as well asthe utilization rate of the zinc powder of coatings and accordingly greatly enhance the anti-corrosion effects of the coatings; the added flake aluminum powder can enhance the shielding effects of the coatings and endow the coatings with a silver gray metal appearance so that the graphene powder bimetallic paint can be applied as a finishing coating, and meanwhile, the metal appearance can achieve reflecting effects on ultraviolet rays to corresponding increase the anti-ageing effects of the coatings.

Owner:AVIC BIAM NEW MATERIALS TECH ENG

Double-layer environment protection gas-phase rust-proofing film membrane and preparation method thereof

InactiveCN101249903ANo pollutionWill not emitFlexible coversWrappersVolatile corrosion inhibitorGas phase

Disclosed are a double-layer environmental friendly volatile corrosion inhibitor film and a process for preparation thereof. The film is formed by co-extruding and film-blowing of an outer shielding layer and an inner release layer, in the inner release layer according to the weight ratio, plastics and modified plastics or combination of the plastics and the modified plastics takes 90-95%, and additive takes 5-10%. The additive is composed of volatile corrosion inhibitor of 65-80%, dispersing lubricant of 2-5% and carrier plastic of 15-30% according to the weight ratio. The volatile corrosion inhibitor employs combination of sodium borate, ammonium molybdate and cyclohexylamine laurate. The process of preparation of the invention is composed of firstly mixing and granulating raw material of the volatile corrosion inhibitor, the dispersing lubricant and the carrier plastic of the additive, then uniformly mixing additive particles and plastic raw material of the inner release layer, inputting in an inner layer of a plastic blowing machine to extrude to a bucket, simultaneously inputting raw material of the outer shielding layer into an outer layer of the plastic blowing machine to extrude to the bucket, then co-extruding and film-blowing, and manufacturing out the double-layer environmental friendly volatile corrosion inhibitor film. The double-layer environmental friendly volatile corrosion inhibitor film has the advantages of zero toxic component, good rust-proofing effect and low cost, and is adaptable to rustproof packaging of various metal materials.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

Durable volatile antirust nonwoven fabric and preparation method thereof

ActiveCN107858856AGood slow releaseIncreased durabilityFilament/thread formingPaper coatingVolatile corrosion inhibitorEmulsion

The invention relates to the technical field of metal corrosion resistance and in particular relates to a durable volatile antirust nonwoven fabric and a preparation method thereof. The preparation method comprises the steps: encapsulating a volatile corrosion inhibitor, further, carrying out spinning, and carrying out fixation on cellulose fibers; and then, forming a mesh, and sealing the mesh bycoating zeolite powder and a resin emulsion to form the volatile antirust nonwoven fabric. The durable volatile antirust nonwoven fabric is not only good in slow release feature, but also excellent in packaging performance, good in durability, beneficial to long-term slow release and capable of sustainably and slowly volatilizing the corrosion inhibitor at normal temperature and adsorbing the corrosion inhibitor to an exposed metal surface to effectively prevent an environmental atmosphere such as oxygen and moisture from corroding metal so as to achieve a good antirust effect.

Owner:山东冠骏清洁材料科技有限公司

Corrosion inhibition of hypochlorite solutions using polyacrylate and Ca

ActiveUS8105531B1Not adversely stabilityReduce corrosionOther chemical processesDetergent bleaching agentsVolatile corrosion inhibitorHypochlorite

Owner:ECOLAB USA INC

Volatile corrosion inhibitor, and forming material and formed article using the same

A volatile corrosion inhibitor to be kneaded into a resin of the present invention comprises a nitrous acid metal salt, a benzoic acid metal salt, a saturated polycarboxylic acid or a metal salt thereof, and an anticorrosive component for nonferrous metals. The volatile corrosion inhibitor to be kneaded into a resin does not cause melting, gasification, decomposition, vaporization even when exposed to a high temperature condition for molding a thermoplastic resins into an article in a form of films, sheets or fibers. Further, the volatile corrosion inhibitor is free of generation of offensive odor or dust caused by sublimation. As the result, working environment does not deteriorate, and superior anticorrosive ability with respect to nonferrous metal materials such as copper as well as to iron based metal materials is exhibited. In addition, the present invention relates also to a volatile anticorrosive molding material obtained by kneading the volatile corrosion inhibitor into a resin.

Owner:CHUBU KIRESUTO +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com