Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

678 results about "Sorbitan Monooleate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

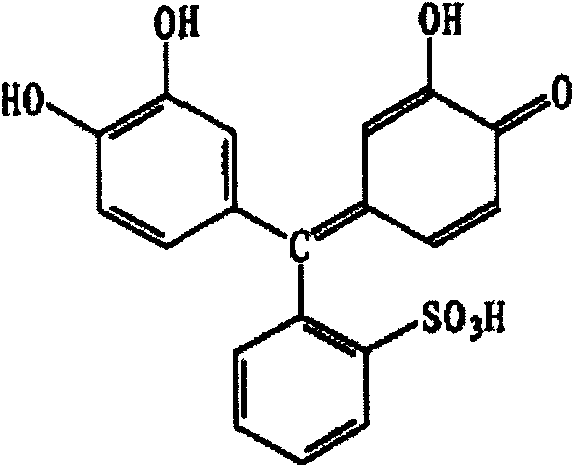

Sorbitan Monooleate. Excipient (pharmacologically inactive substance) Sorbitans are derived from dehydration of sorbitol or sorbose and related compounds in ester combination with fatty acids and with short oligo (ethylene oxide) side chains and an oleate terminus to form detergents and surfactants such as polysorbate 80.

Soft capsule preparation

A soft capsule preparation which comprises a dispersion of (2E,4E,6E,10E)-3,7,11,15-tetramethyl-2,4,6,10,14-hexadecapentaenoic acid in a vegetable oil filled in a soft capsule comprising a shell having a light blocking effect. The soft capsule preparation preferably comprises polyoxyethylene sorbitan monooleate and glycerol monostearate and the like as surfactants. As the vegetable oil, soybean oil, sesame oil, a mixture thereof, or the like may be used.

Owner:LEBER +1

Mitigation of Biomolecular Adsorption with Hydrophilic Polymer Additives

ActiveUS20090280251A1Reduce surface tensionInhibit bindingSludge treatmentVolume/mass flow measurementHydrophilic polymersPhenyl Ethers

Molecular adsorption to the microfluidic device surfaces can be passively and actively mitigated by mixing certain hydrophilic polymers (organic polymers with repeating hydrophilic groups—the preferred polymers being amphipathic surfactants—with the sample liquid during or prior to relevant microfluidic operations. Nonionic surfactants such as polyoxyethylene sorbitan monooleate and polyoxyethylene octyl phenyl ether are especially effective. High molecular weight polyethylene polymers are also effective. The hydrophilic polymers appear to prevent binding of the fouling molecules to the microfluidic by occupying the surface sites in place of the fouling molecules or by interacting with the fouling molecules to prevent binding of the fouling molecules the surface. When surface adsorption is thus mitigated, microfluidic devices can readily handle samples containing biomolecules to enable active sample concentration, filtering, washing, transport, mixing and other sample handling operations.

Owner:ADVANCED LIQUID LOGIC

Volatile rust preventive oil

InactiveCN102719302AInhibit corrosion and rustClean working environmentAdditivesGas phaseAntioxidant

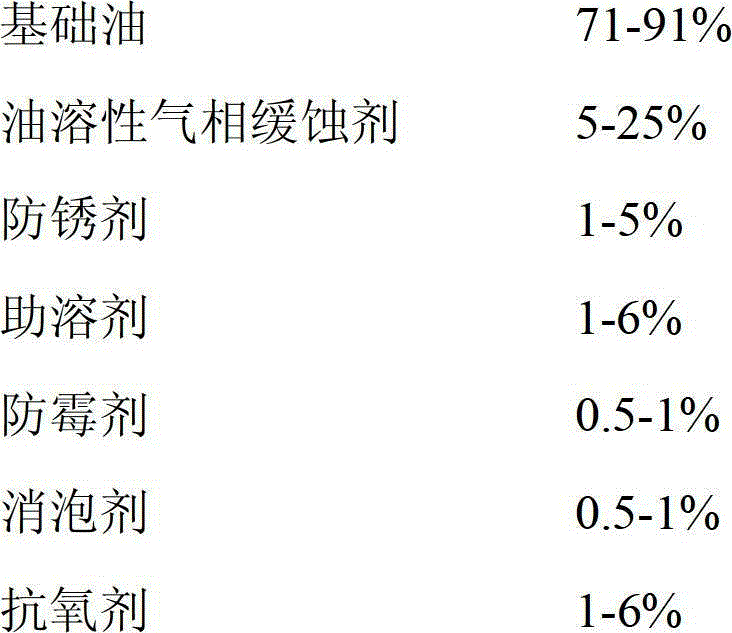

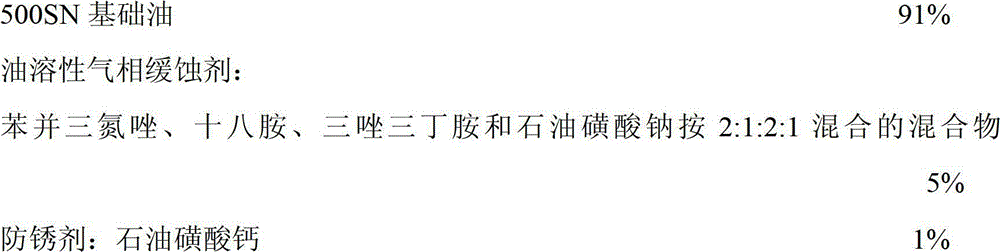

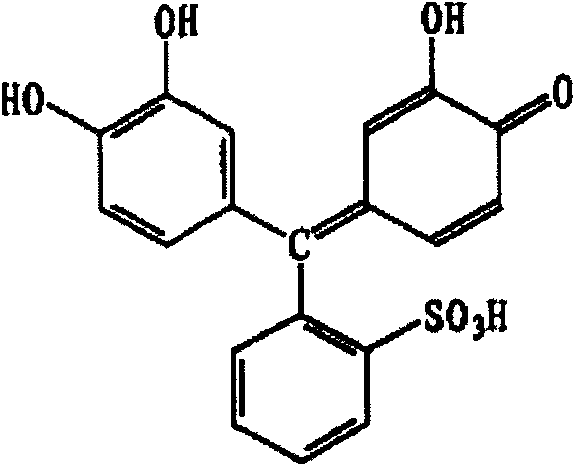

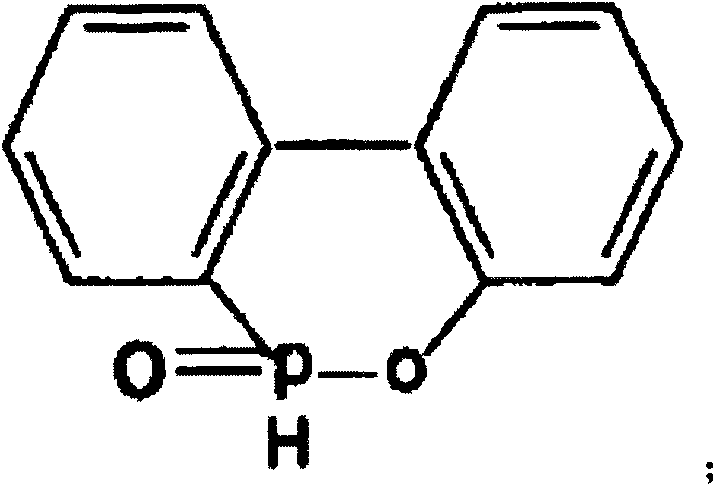

The invention discloses volatile rust preventive oil which comprises, by weight, 71-91% of base oil, 5-25% of an oil soluble volatile corrosion inhibitor, 1-5% of an antirusting agent, 1-6% of a cosolvent, 0.5-1% of a mildew-proof agent, 0.5-1% of an antifoaming agent and 1-6% of antioxidant, wherein the base oil is one of 500SN 46# machine oil, 32# machine oil, 600SN 150# machine oil and 100# machine oil; and the oil soluble volatile corrosion inhibitor is a mixture of four kinds of 2-heptadecenyl-imidalidine, octadecylamine, triazole tributylamine, dicyclohexylamine carbonate, dicyclohexylaminenitrite, benzotriazole, tert-butyl chromate, nephthenic soap, petroleum sodium sulfonate, sorbitan monooleate and stearic acid; and the antioxidant is sulfurphosphorousbutyloctyl zinc salt. The volatile rust preventive oil has good volatile rust preventive and corrosion resistant performances, metal which cannot be coated with rust preventive oil can achieve rust preventive protection, the operation is simple, and the cost is low.

Owner:上海福岛新材料科技有限公司

Water-in-oil microemulsions for oilfield applications

A well treatment microemulsion includes an oil external phase, an internal aqueous phase and a hydrophilic surfactant. The surfactant has a hydrophile lipophile balance of between 8-18. The oil external phase may include d-Limonene, xylenes, light mineral oil, or kerosene. The surfactant is configured to emulsify the water of the internal aqueous phase into the oil of the external (continuous) phase. The surfactant may include polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan tristearate, polyoxyethylene hydrogenated castor oil, polyoxyethylene sorbitan monostearate, polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan monolaurate or mixtures therebetween. The use of hydrophilic surfactants to emulsify an internal aqueous phase within an oil external microemulsion produces unexpected and beneficial results.

Owner:PNC BANK NAT ASSOC

Mitigation of biomolecular adsorption with hydrophilic polymer additives

ActiveUS8481125B2Inhibit bindingReduce surface tensionSludge treatmentVolume/mass flow measurementHydrophilic polymersPhenyl Ethers

Molecular adsorption to the microfluidic device surfaces can be passively and actively mitigated by mixing certain hydrophilic polymers (organic polymers with repeating hydrophilic groups—the preferred polymers being amphipathic surfactants—with the sample liquid during or prior to relevant microfluidic operations. Nonionic surfactants such as polyoxyethylene sorbitan monooleate and polyoxyethylene octyl phenyl ether are especially effective. High molecular weight polyethylene polymers are also effective. The hydrophilic polymers appear to prevent binding of the fouling molecules to the microfluidic by occupying the surface sites in place of the fouling molecules or by interacting with the fouling molecules to prevent binding of the fouling molecules the surface. When surface adsorption is thus mitigated, microfluidic devices can readily handle samples containing biomolecules to enable active sample concentration, filtering, washing, transport, mixing and other sample handling operations.

Owner:ADVANCED LIQUID LOGIC

Thermoplastic food casing

A porous food casing consisting essentially of a film of food grade thermoplastic having a plurality of interconnected interstices therein. The interstices are defined by a porosity modifier selected from the group consisting of soybean oil, peanut oil, corn oil, glycerin, polyethylene glycol, monolaurate, mineral oil, polyoxyethylene, sorbitan monostearate, sorbitan monooleate and glycerol monooleate. The interstices are in a range of approximately 0.002 to 1 micron and the casing has a water vapor permeability in a range of about 1 to 1500 gms / m2 / min.

Owner:YEN WILLIAM W

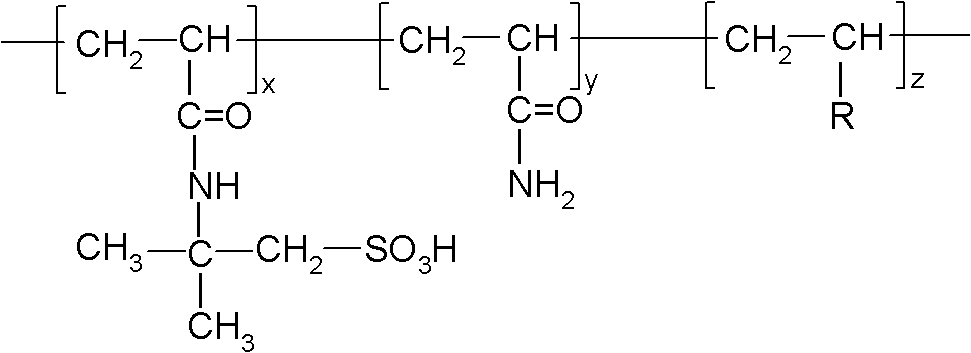

Preparation method of starch grafted copolymer inverse emulsion for drilling fluid

ActiveCN103113524AImprove the lubrication effectGood anti-collapse abilityDrilling compositionWater basedPotassium hydroxide

The invention relates to a preparation method of a starch grafted copolymer inverse emulsion for a drilling fluid. The method comprises the following steps of: adding an emulsifier sorbitan monooleate into white oil, and stirring, dissolving and introducing nitrogen to obtain an oil phase; dissolving potassium hydroxide in water, adding 2-acrylamidyl-2-methyl propanesulfonic acid, acrylamide, a vinyl monomer, a cationic monomer, polyoxyethylene sorbitan monooleate, ethylene diamine tetraacetic acid disodium salt and starch, and stirring to obtain an aqueous phase; adding the aqueous phase into the oil phase, adequately emulsifying, adjusting the pH value, introducing nitrogen, adding an initiator and a reducing agent; and stirring, heating, insulating heat, cooling, discharging and filtering under nitrogen protection to obtain the starch grafted copolymer inverse emulsion for the drilling fluid. The product serving as a drilling fluid treatment agent has good de-filtration effect, good thickening effect, a flow type regulating effect and good inhibition effect for dehydrating dispersion of clay and drillings, so that the quality of filter cakes is improved, the lubricity of the drilling liquid is improved and the processing cost of the drilling liquid is lowered, and the preparation method is suitable for various types of water-based drilling fluids.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flame-resistant and heat-resistant copper clad laminate preparation method

InactiveCN105172297AReasonable compositionUniform dispersionSynthetic resin layered productsLaminationMetal foilDimethyl phosphonate

The present invention relates to a flame-resistant and heat-resistant copper clad laminate preparation method, which comprises: adopting nanometer silica foam, dodecyl benzenesulfonic acid, bismuth nitrate pentahydrate, methyl trichlorosilane and polyoxyethylene sorbitan monooleate as a raw materials to obtain a filler; adopting DOPO, a bisphenol A cyanate ester monomer, a phenol compound, a m-nitrobenzene sulfonic acid pyridine salt, 2,3-epoxy cyclopentyl cyclopentyl ether and dimethyl phosphonate as raw materials to obtain a resin prepolymer; adding the filler to o-phthalic acid diglycidyl este to obtain an active filler; mixing the resin prepolymer and an indole compound, and then adding the active filler and isomeric undecanol polyoxyethylene ether phosphate potassium salt to obtain a composite system; and carrying out hot pressing molding on the composite system, a reinforced material and metal foil to obtain the flame-resistant and heat-resistant copper clad laminate, wherein the flame-resistant and heat-resistant copper clad laminate has characteristics of excellent flame retardant property and excellent heat resistance, and meets the development applications of the flame-resistant and heat-resistant copper clad laminate.

Owner:SUZHOU YIKETAI ELECTRONICS MATERIAL

Pumpable multiple phase compositions for controlled release applications downhole

Pumpable multiple phase vesicle compositions carry agents and components downhole or through a conduit, and controllably releasing them at a different place and time by breaking the compositions. In one non-limiting embodiment the pumpable multiple phase vesicles have a third phase containing a first phase which bears the agent to be controllably released. The first and third phases of the vesicles are separated by a surface active material bilayer that forms the second phase. The pumpable multiple phase vesicles may have internal and external phases that are both oil miscible, both aqueous miscible, or both alcohol miscible. The surface active material bilayer may be composed of compounds such as phospholipids, alkyl polyglycosides, gemini surfactants, sorbitan monooleate, sorbitan trioleate, and many others. The agent may be released by one or more of a variety of mechanisms.

Owner:BAKER HUGHES INC

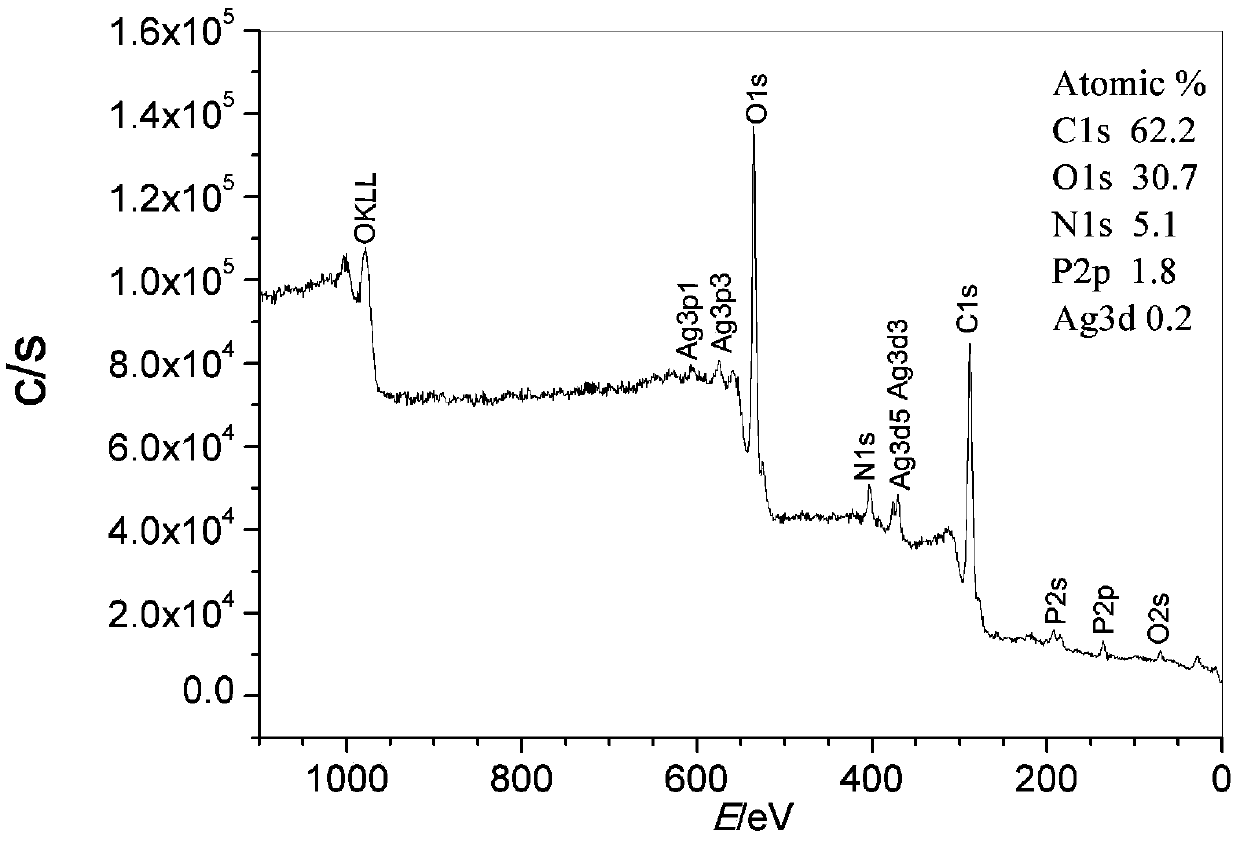

Silver-loaded low-molecular-weight chitosan composite microsphere antibacterial agent and preparation method thereof

ActiveCN105494430ABroad-spectrum bactericidalHigh antibacterial activityBiocideDead animal preservationEscherichia coliCross-link

The invention provides a silver-loaded low-molecular-weight chitosan composite microsphere antibacterial agent and a preparation method thereof. Low-molecular-weight chitosan is used as a raw material, and a low-molecular-weight chitosan acetic acid solution, a silver nitrate solution and a vanillic aldehyde ethanol solution are mixed to form composite sol; then paraffin is used as a continuous phase, sorbitan monooleate and alkylphenol ethoxylates are used as a compound emulsifier, a silver / low-molecular-weight chitosan sol is used as a monomer, and sodium tripolyphosphate is used as a cross-linking agent for preparing an emulsion system for emulsification crosslinking, and finally washing and drying are performed, so that the silver-loaded low-molecular-weight chitosan composite microsphere antibacterial agent is obtained. Due to the fact that the low-molecular-weight chitosan is used as the raw material, nanometer silver particles can enter microspheres, and the antibacterial activity of the composite antibacterial agent is obviously improved. The obtained antibacterial agent has the broad-spectrum bactericidal activity, and has the efficient fatality rate for both escherichia coli and staphylococcus aureus.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

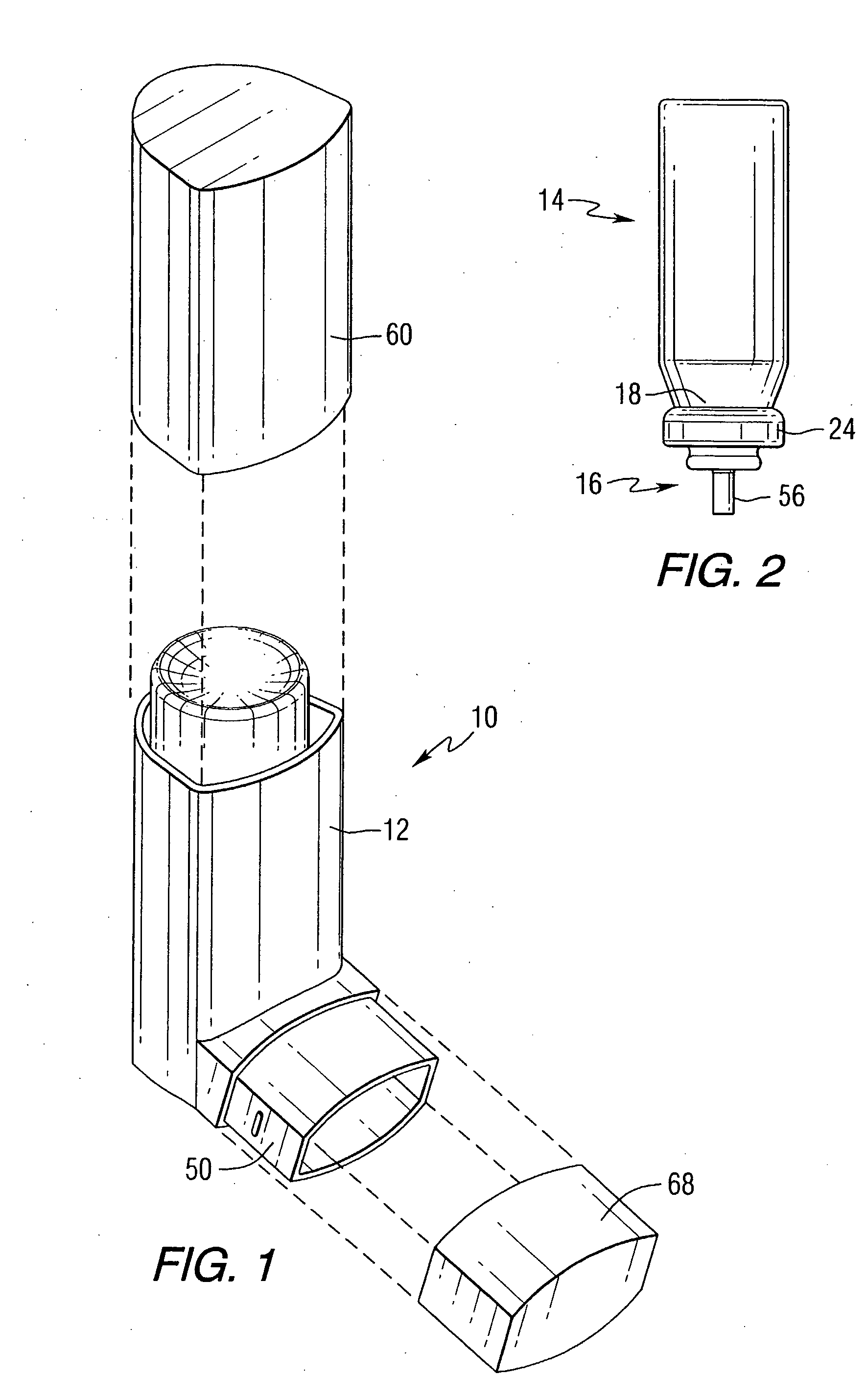

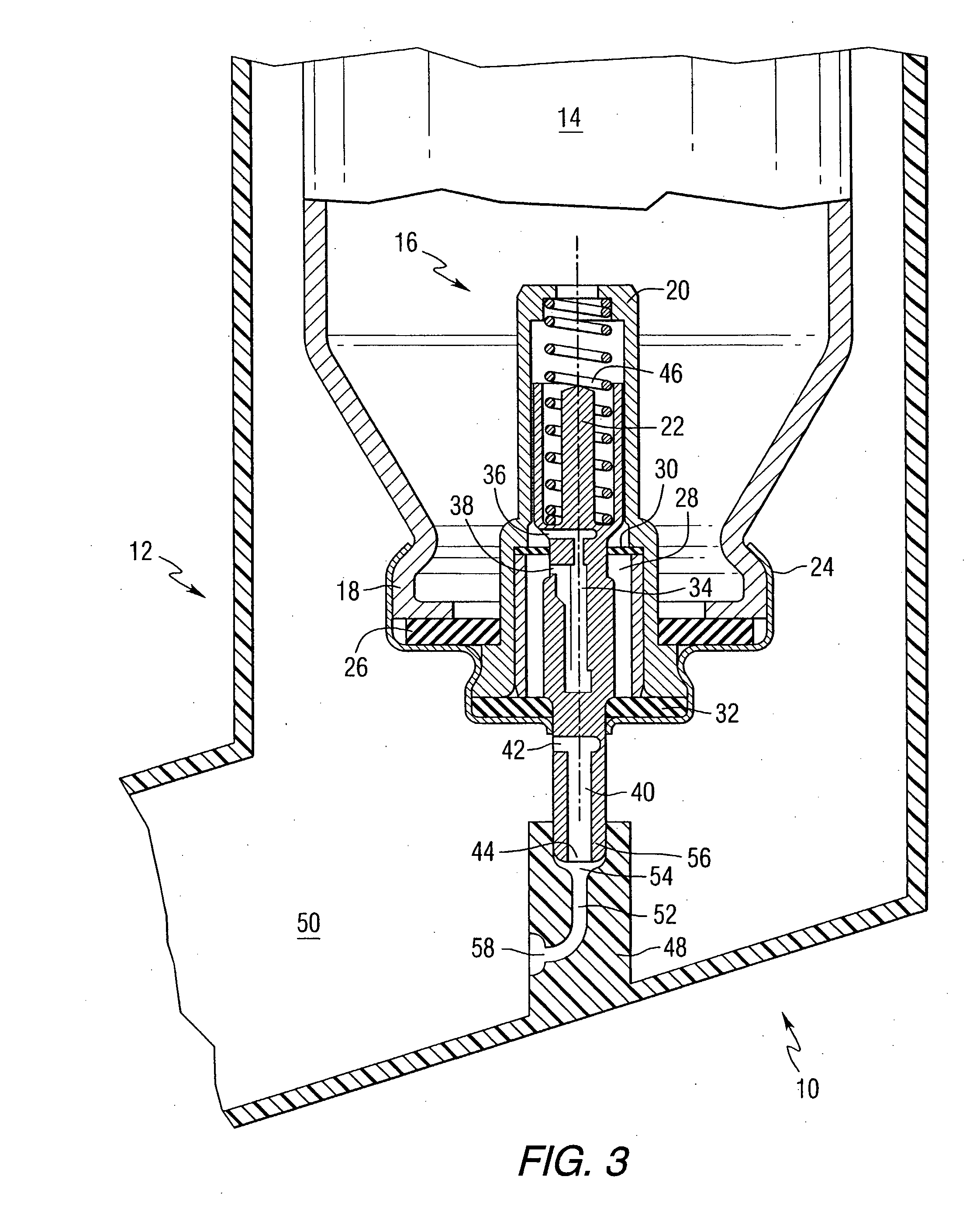

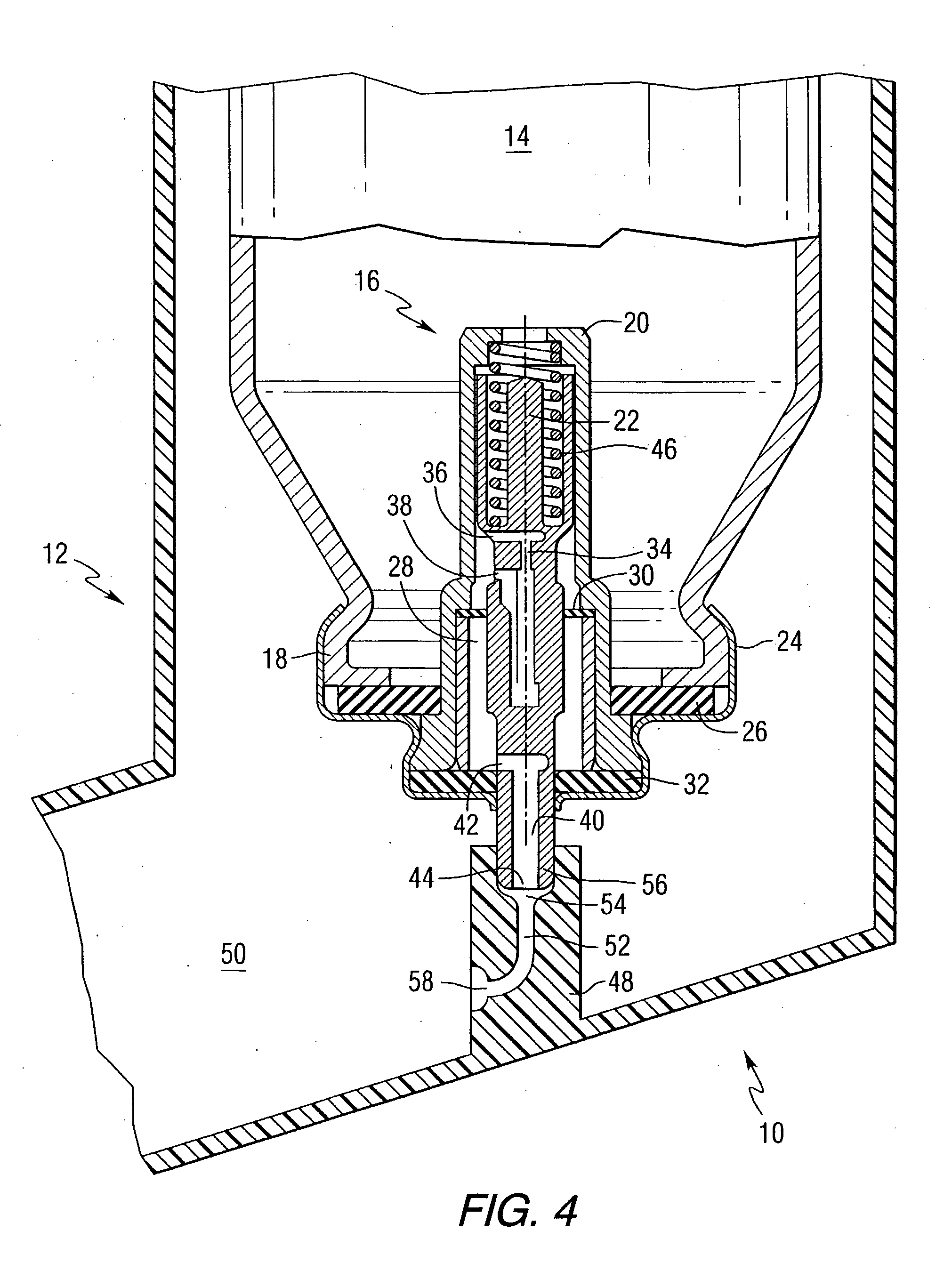

Orally Absorbed Pharmaceutical Formulation and Method of Administration

InactiveUS20090214657A1The process is simple and convenientIncrease glucose levelsPowder deliveryPeptide/protein ingredientsSolventSplit dose

A pharmaceutical formulation for absorption through oral mucosae comprising an effective amount of (a) a pharmaceutical agent in mixed micellar form, (b) at least one micelle-forming compound selected from the group comprising an alkali metal alkyl sulfate and a polyoxyethylene sorbitan monooleate, (c) a block copolymer of polyoxyethylene and polyoxypropylene, (d) at least one additional micelle-forming compound, and (e) a suitable solvent. The invention also provides a metered dose dispenser (aerosol or non-aerosol) containing the present formulation and a method of administering insulin using the metered dose dispenser comprising administering split doses of a formulation containing insulin before and after each meal.

Owner:GENEREX PHARMA

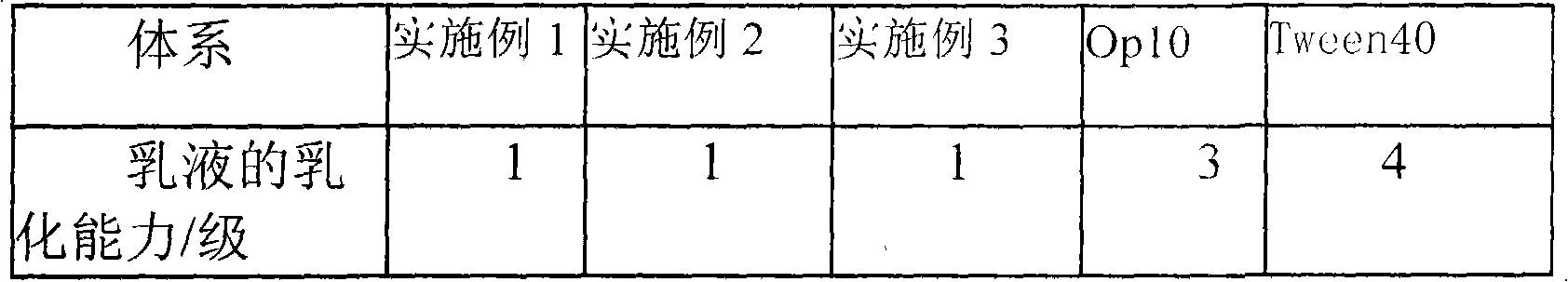

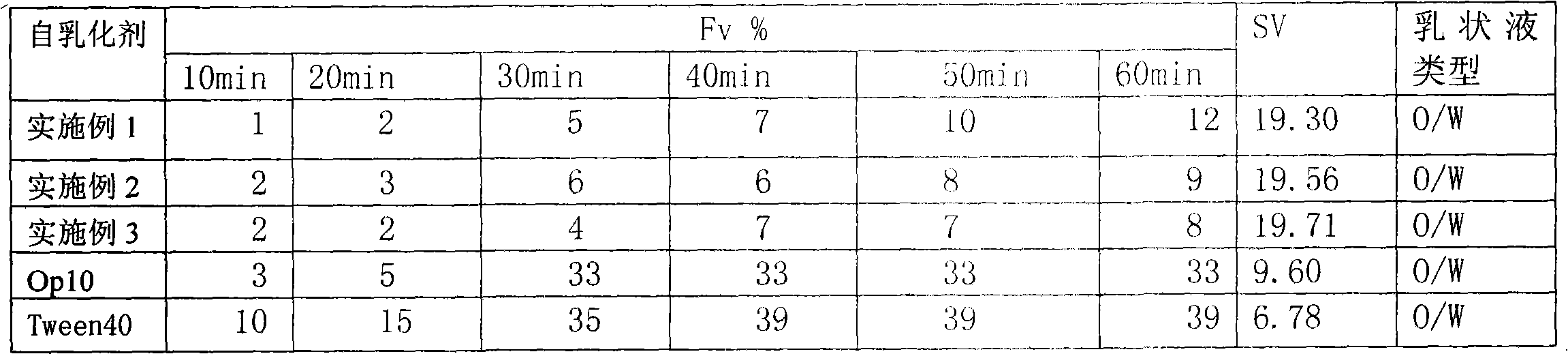

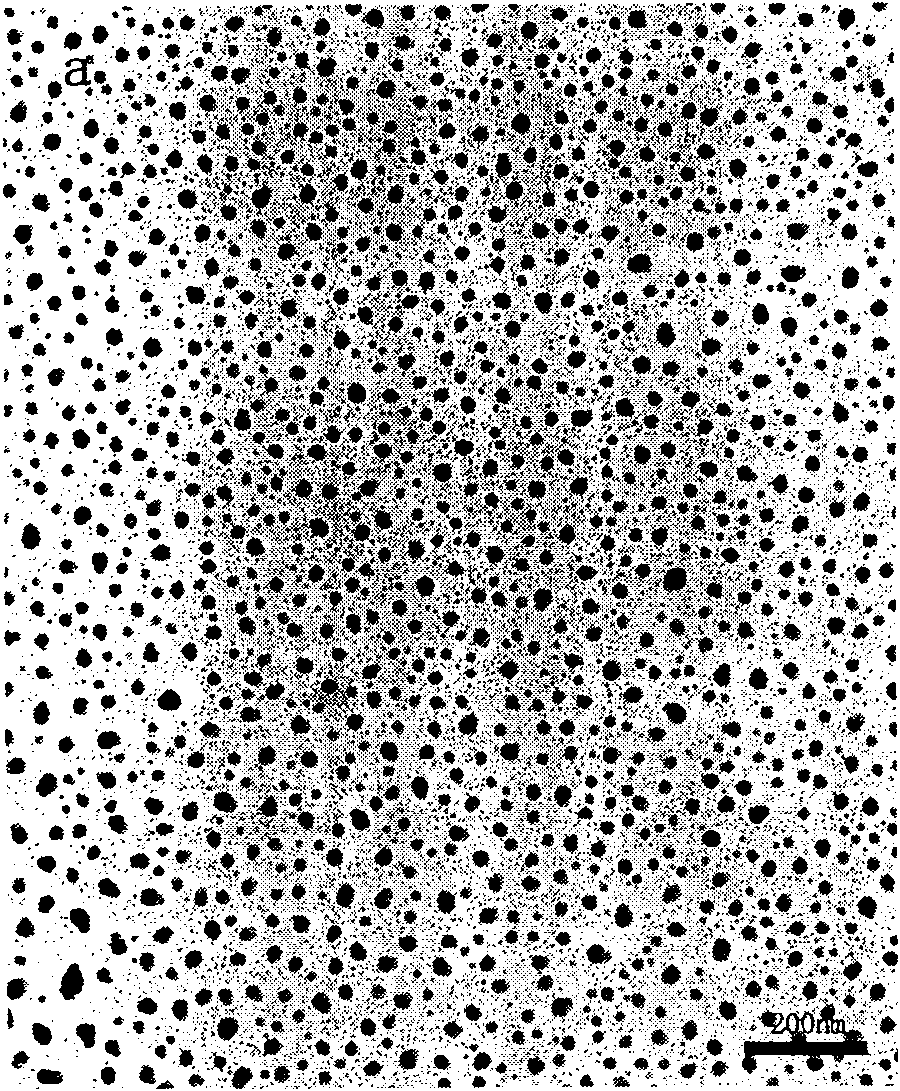

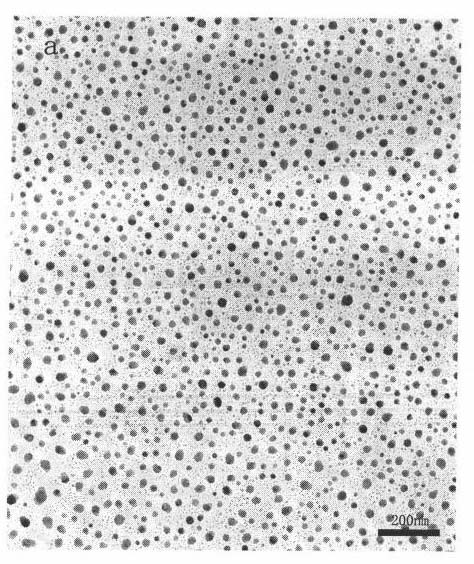

Self-emulsifier and use thereof in tertiary oil recovery

ActiveCN101927139AReduce manufacturing costEasy to operateTransportation and packagingMixingBetainePalmitates

The invention discloses a self-emulsifier and use thereof in binary compound tertiary oil recovery. The emulsifier comprises the following components in percentage by mass: 24 to 30 percent of alkyl amido betaine, 9 to 24 percent of carboxylic amino acid type amphoteric nonionic surfactant, 5 to 14 percent of amine oxide surfactant, 1 to 5 percent of fatty alcohol-polyoxyethylene ether, 0.7 to 3.7 percent of polyoxyethylene sorbitan monooleate, 1 to 2.3 percent of nonyl hydroxybenzene polyethoxylate ether, 0.5 to 1.5 percent of fatty acid methyl ester ethoxylate, 0.6 to 3.7 percent of C6 to C8 fatty alcohol , 0.4 to 2.3 percent of triethanolamine, 0.5 percent of monoglycerylester palmitate and the balance of water. The emulsifier prepared by the method emulsifies crude oil under the condition of low shearing force or no external force of a binary compound system and makes an emulsifying system stable.

Owner:大庆高新区华龙祥化工有限公司

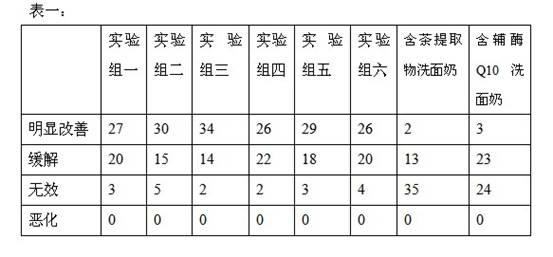

Tea extract facial cleanser and preparation method thereof

ActiveCN102091006AMild performanceImprove smoothnessAntibacterial agentsCosmetic preparationsFine lineAllergy

The invention provides a tea extract facial cleanser and a preparation method thereof. The tea extract facial cleanser is prepared from the following effective components: tea extract, coenzyme Q10, fructus phyllanthi juice, lecithin, citric acid, TWEEN 80 polyoxyethylene sorbitan monooleate, cocamidopropyl betaine (CAB-35), amino acid laurinol ester, deionized water and the like. The facial cleanser provided by the invention is weakly acidic, purely natural, phosphorus-free, non-toxic, harmless, non-irritant, non-corrosive and pollution-free, integrates multiple functions of resisting ultraviolet rays, resisting oxidation, shrinking pores, resisting bacteria, diminishing inflammation, removing acnes, removing grease, resisting radiation, resisting allergy, removing excess fat, preserving moisture, delaying senility, enhancing smoothness and elasticity, preventing and restoring wrinkles and fine lines, clearing free radicals and the like, can keep vigorous metabolism of the skin and can enhance the immunity of the skin after being used for a long time, thereby protecting the skin in the harmful environment so that the skin is healthy and tender.

Owner:云南龙润茶业集团有限公司

Lubricating oil wear resistant additive, and preparation method and application thereof

InactiveCN104711077AImprove anti-wear performanceWith repair functionAdditivesMolybdateWear resistant

The invention discloses a lubricating oil wear resistant additive. The lubricating oil wear resistant additive comprises, by mass, 70-80% of base oil, 5-10% of organic molybdate, 1-3% of sorbitan monooleate, 0.7-0.8% of zinc diamyldithiocarbamate, 1-3% of nanometer graphene, and the balance of additives. The lubricating oil wear resistant additive has wear resistance and reduction effects on various lubricating oils, has a restoration function, can reduce the mechanical work noise and power loss, and is suitable for any brand of machine oils, gear oils, hydraulic oils, track oils and other lubricating oils. The invention also discloses a preparation method of the lubricating oil wear resistant additive. The method comprises the following steps: mixing nanometer graphene with sorbitan monooleate, carrying out ultrasonic dispersion, adding base oil, organic molybdate, zinc diamyldithiocarbamate and the additives, and uniformly stirring. The preparation method has the advantages of simple process steps, low cost, and suitableness for industrial production.

Owner:上海恒扬新能源科技发展有限公司

Method for preparing nano copper powder

The invention discloses a method for preparing nano copper powder, which comprises the following steps of: compounding copper sulfate, lauryl sodium sulfate and polyoxyethylene sorbitan monooleate in a molar ratio of 1:0.5-2:0.05-0.3, dissolving the mixture in water, blending the aqueous solution and lauryl mercaptan-containing benzene solution in a molar ratio of copper sulfate to lauryl mercaptan of 1:0.5-2, and uniformly stirring; pouring the emulsion fluid into an electrolytic bath, taking pure copper as an anode and stainless steel as a cathode, and regulating the pH value to between 0.5 and 4; supplying direct current to the anode and the cathode to ensure that the lauryl mercaptan dissolved in an electrolyte performs in-situ clad on precipitated copper atoms, the generated copper powder loosely attaches to the surface of the cathode, copper ions near the anode are continuously migrated to the place near the cathode under the action of diffusion and directional migration of electric charge at the same time, and the electrolytic time is 30 to 120 minutes; adding the cathode to which the copper powder is attached into absolute ethyl alcohol, and putting the cathode in an ultrasonic cleaner for desorption by using ultrasonic waves for 5 to 20 minutes to obtain dark purple copper solution; and filtering the solution, and drying the filtrate for 1 to 3 hours at the temperature of between 60 and 100 DEG C in a vacuum environment to obtain brown powder, namely a nano copper composite.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

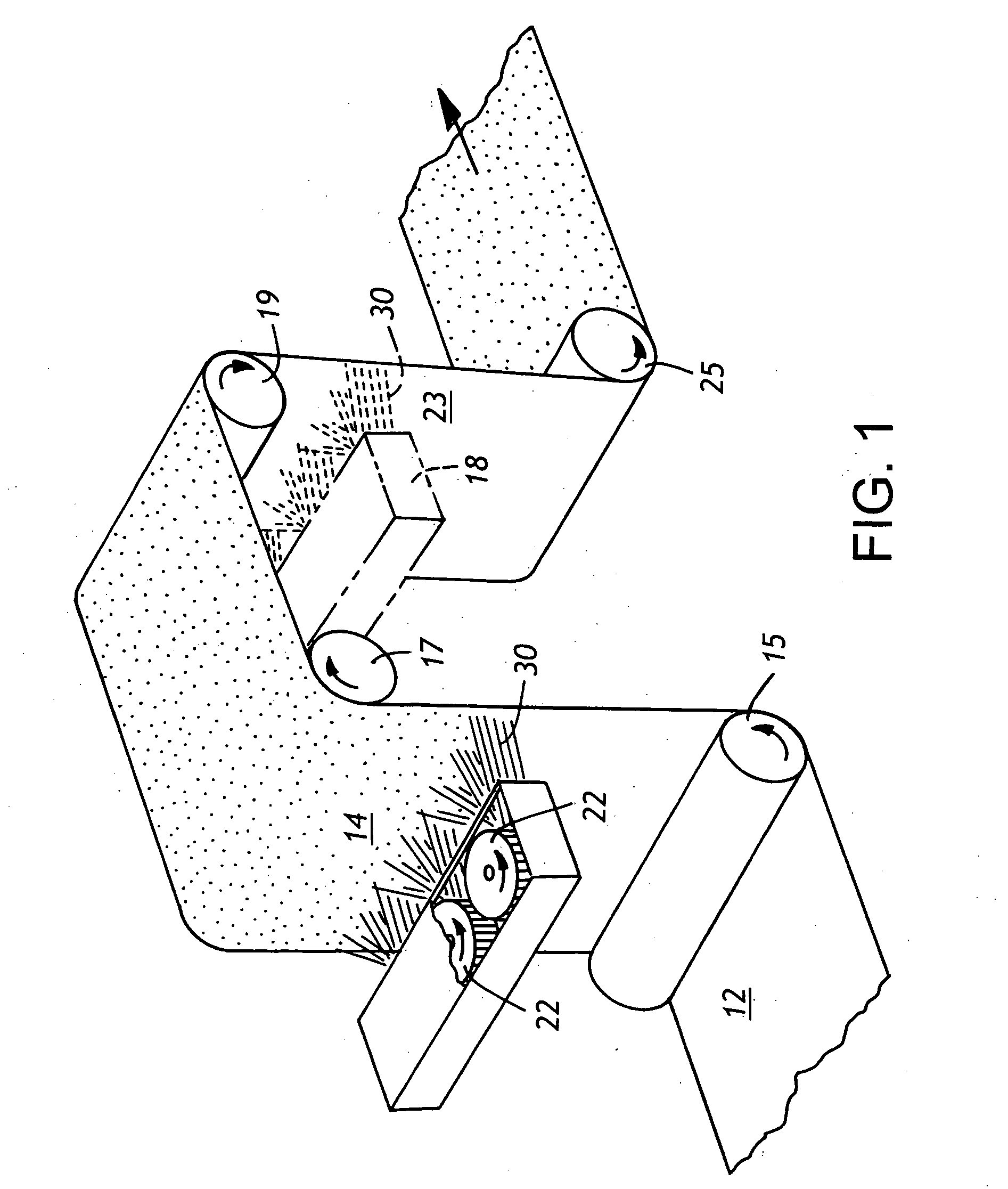

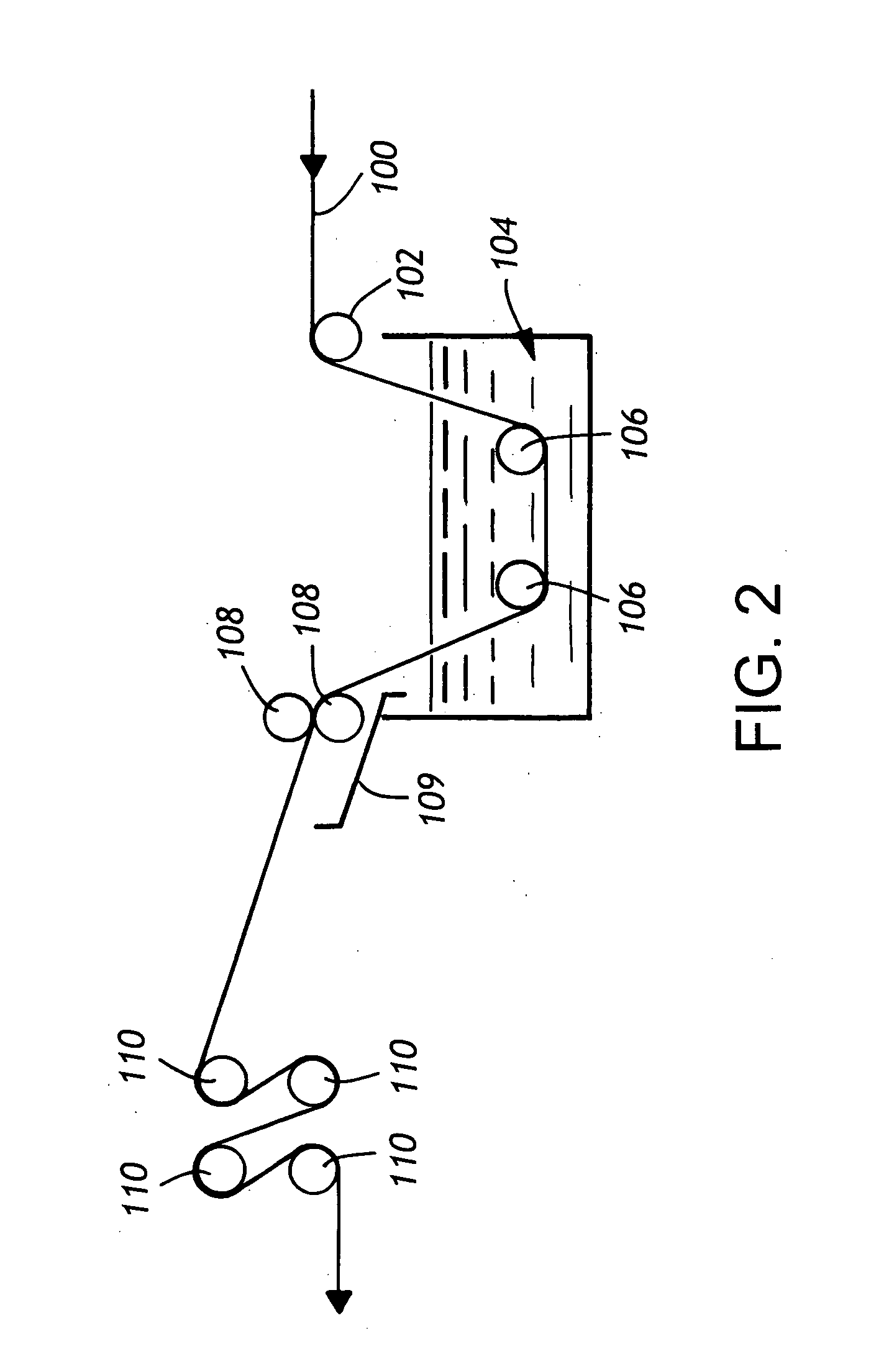

Treatment of substrates for improving ink adhesion to substrates

InactiveUS20060003150A1Improve ink adhesionImprove adhesionDecorative surface effectsDuplicating/marking methodsSorbitan MonooleateSURFACTANT BLEND

Printed substrates and methods for treating substrates to improve the adhesion of an ink composition to a hydrophobic substrate are provided. The printed substrates include are treated with a surfactant, for example an ethoxylated hydrogenated castor oil or sorbitan monooleate. The method involves contacting at least a portion of a hydrophobic substrate with a composition that comprises an ethoxylated hydrogenated castor oil or sorbitan monooleate or a mixture thereof; and then printing a pattern or other indicia on at least a portion of the portion of the hydrophobic substrate that was contacted with surfactant.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Micro-emulsified cutting fluid production additive package and preparation method and application thereof

ActiveCN102807912AStrong emulsifying abilityImprove emulsification efficiencyLubricant compositionAlkaneSolubility

The invention relates to a micro-emulsified cutting fluid production additive package and a preparation method and the application thereof. The additive package is composed of, by weight, 5-25 parts of higher fatty acid, 10-35 parts of alkylol amine, 3-15 parts of sodium alkane sulfonate, 5-20 parts of sorbitan monooleate, 2-15 parts of fatty alcohol-polyoxyethylene ether, 3-15 parts of coconutt diethanol amide, 3-15 parts of butyl carbitol, 1-5 parts of polyether, 0.1-0.6 part of benzotriazole, 1-5 parts of antiseptic bactericide and 3-10 parts of water. The additive package is high in emulsifying ability, high in emulsifying efficiency, and fine in hard water resistance and bubble inhibition performance in preparation of cutting fluid, and micro-emulsified cutting fluid is high in water solubility and free of coagulation, caking and precipitation.

Owner:JINAN COOLANT TECH CO LTD

Cation emulsion asphalt anti-collapse agent for well drilling fluid and its producing method

InactiveCN1749350AHigh strengthQuality improvementDrilling compositionPotassium hydroxideDibenzoyl Peroxide

The cation emulsified asphalt as collapse-preventing agent for well drilling fluid consists of asphalt 20-40wt%, potassium hydroxide 4-9 wt%, ammonium cetyl trimethyl chloride 1-3wt%, industrial assistant oil 15-30wt%, acrylic acid monomer 5-8wt%, deionized water 15-30wt%, dibenzoyl peroxide 0.1-0.2wt%, ammonium epoxypropyl trimethyl chloride 5-8wt% and sorbitan monooleate. The preparation process of the cation emulsified asphalt as collapse-preventing agent includes the steps of preparation of polymer emulsion, preparation of cation asphalt emulsion and compounding of polymer-cation asphalt emulsion. The collapse-preventing agent can be compounded well to cation polymer well drilling fluid to form stable well drilling fluid with obviously improved performance.

Owner:玉门石油管理局有限公司

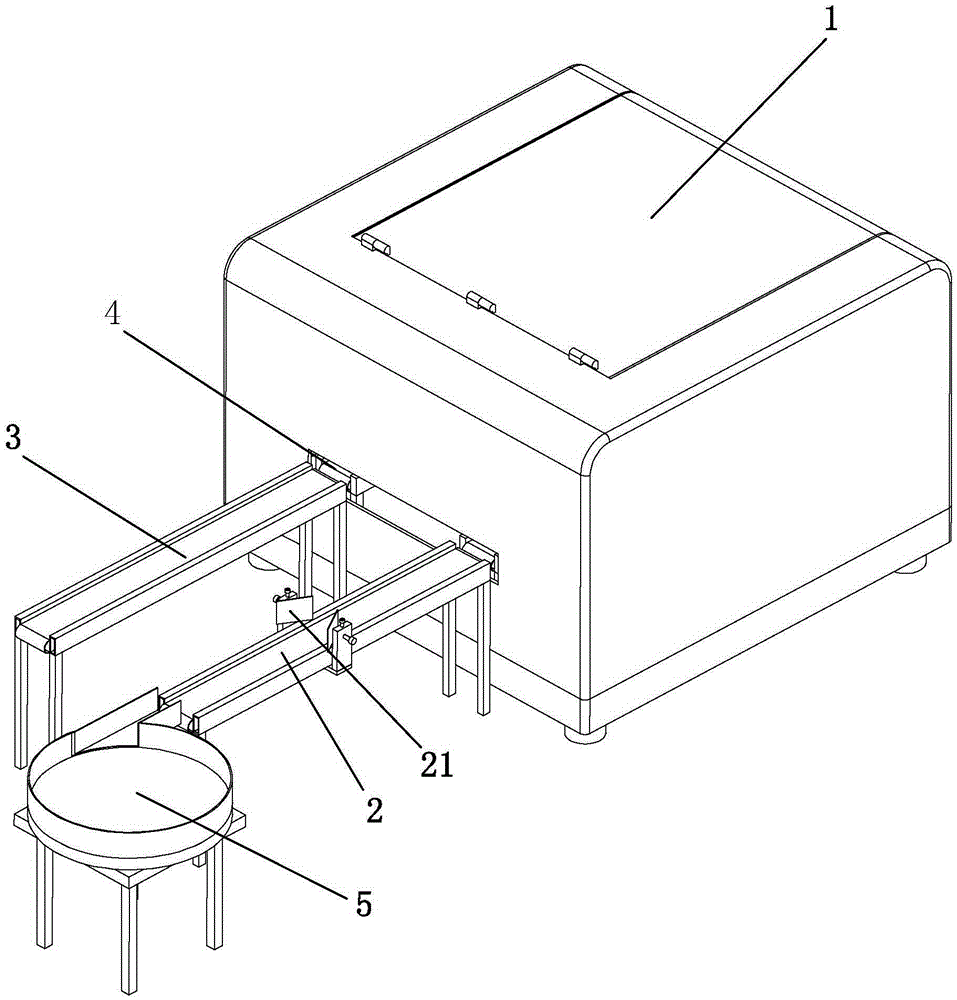

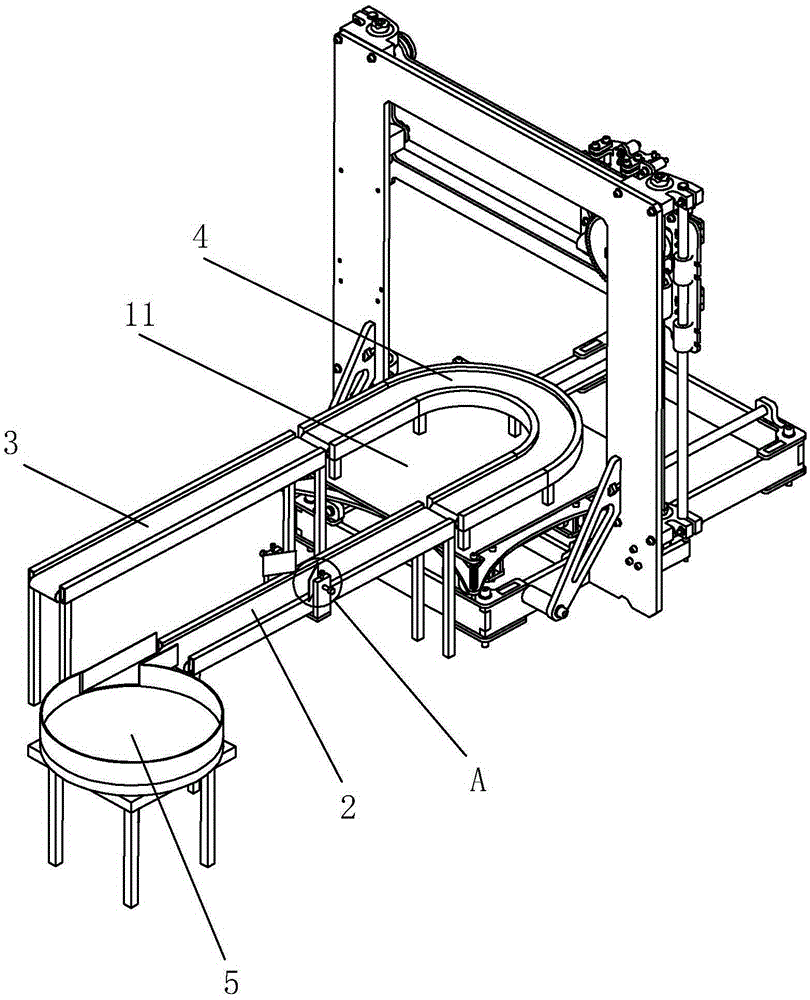

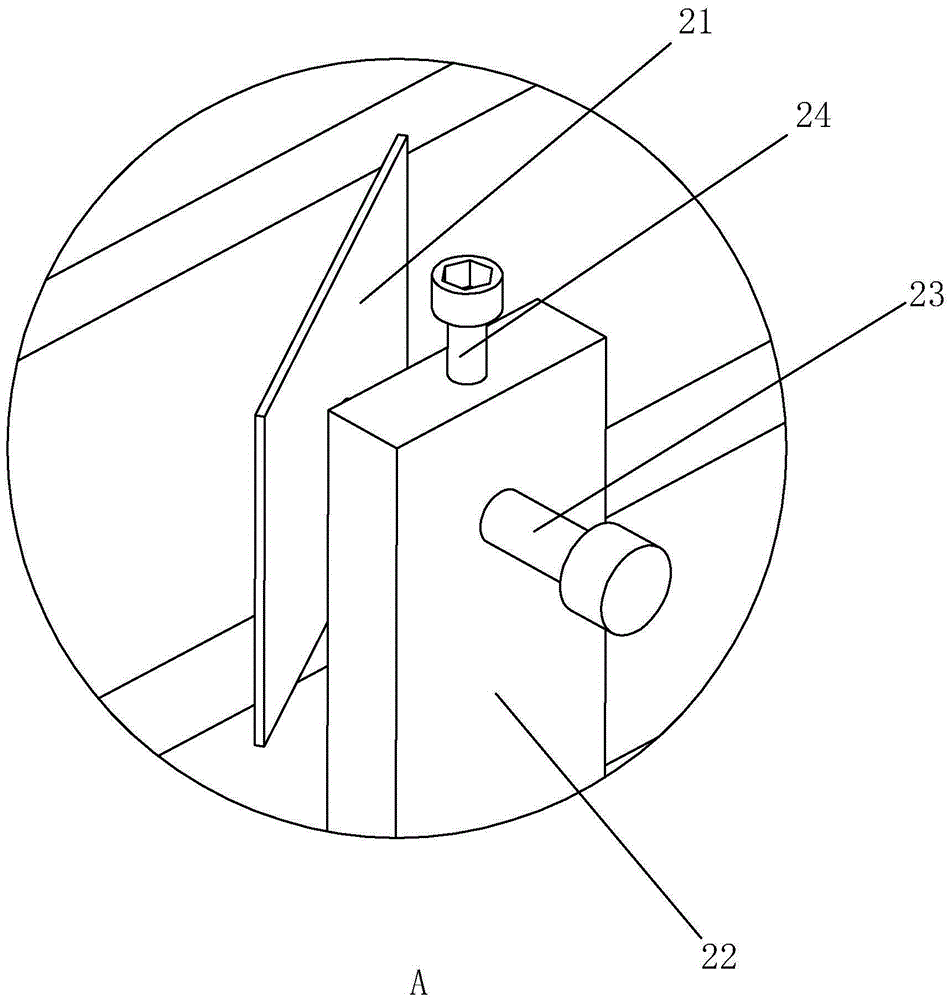

Edible printing ink and food printer

The invention discloses edible printing ink which comprises components in percentage by mass as follows: 65%-75% of water, 8%-12% of ethyl alcohol, 7%-13% of glycerol, 0.5%-3.5% of sorbitan monooleate ethoxylate and 6%-10% of edible pigment. According to the edible printing ink, high definition is acquired in the aspect of food printing patterns. The invention further discloses a food printer. The technical scheme is as follows: the food printer comprises a printer body, an automatic feeding device and an automatic discharging device, the printer body uses the edible printing ink and comprises a printing head and a printing platform allowing food to be placed on; the automatic feeding device is located at the upper portion of the printer body and conveys the food onto the printing platform; and the automatic discharging device is located at the lower portion of the printer body and outputs the food from the printing platform. The food printer solves the problems that an existing food printer is low in definition and cannot achieve mass production.

Owner:苏州明锦机械设备有限公司

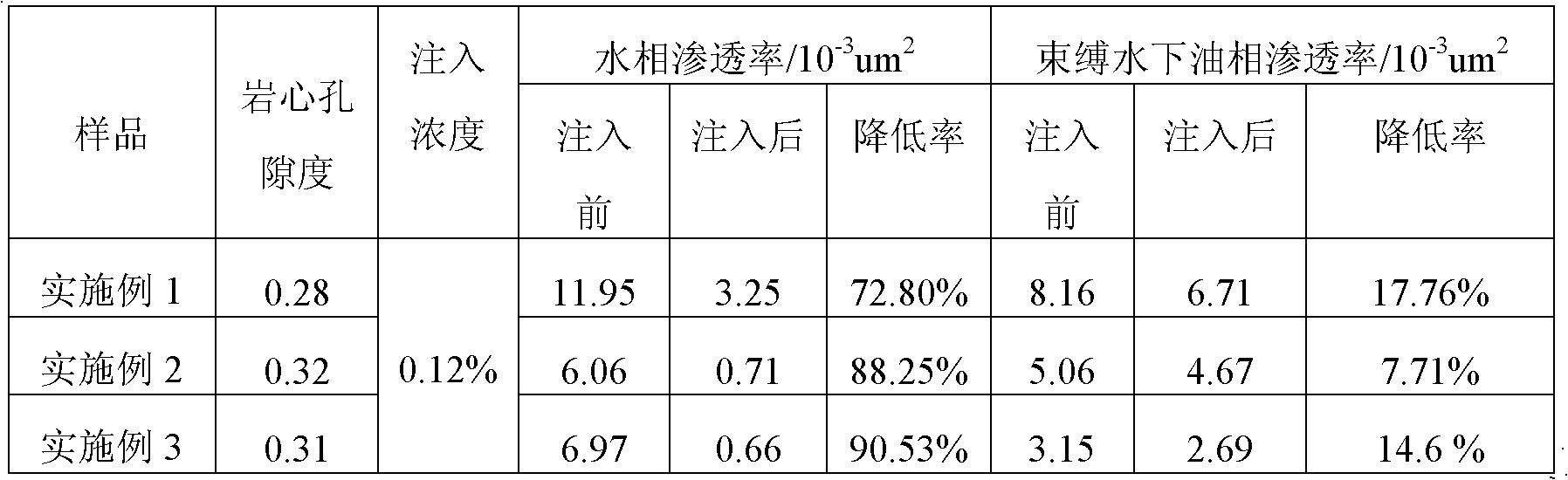

Water control agent for oil well and preparation method thereof

The invention relates to a water control agent for an oil well and a preparation method thereof. The method comprises the steps of: mixing sorbitan monooleate, a hydrophobic monomer and an oil phase solvent to form a continuous phase; adding ammonium persulfate serving as an oxidant into acrylamide and 2-acrylamido-2-methyl propane sulfonic acid serving as comonomers, and dissolving into water together to form a dispersed phase; adding the dispersed phase into the continuous phase to form inverse emulsion; and dripping a reducing agent, namely sodium hydrogen sulfite into the inverse emulsion step by step, and raising the temperature to initiate polymerization, wherein a generated terpolymer can be taken as the water control agent for the oil well and can also be taken as a water control fracturing thickener for the oil well. The product is simple in preparation technology; reaction conditions are easy to control; and the water control agent for the oil well is particularly suitable for water control and oil production increase of waterside or high-water-content and low-permeability oil reservoirs.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

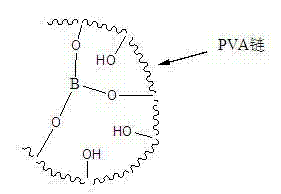

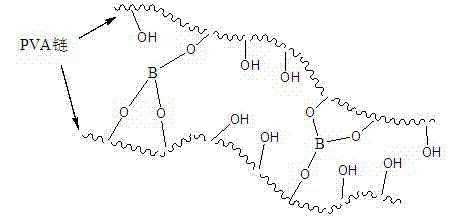

Polyvinyl alcohol-borax microsphere and preparation method thereof

ActiveCN102964612AEasy and efficient to prepareImprove thermal stabilitySodium phosphatesMicrosphere

The invention relates to a polyvinyl alcohol-borax microsphere and a preparation method thereof. In particular, the technical method adopts borax as the crosslinking agent to prepare a polyvinyl alcohol microsphere by means of water-in-oil reversed phase suspension polymerization. The method consists of: taking liquid paraffin-sorbitan monooleate system as the dispersion phase, adopting a polyvinyl alcohol water solution as the polymerization phase, and using borax as the crosslinking agent, subjecting them and polyvinyl alcohol to an esterification crosslinking reaction in an acidic condition, employing sodium phosphate as the pH adjusting agent and the curing agent, and leaving a microsphere to cure, thus obtaining the polyvinyl alcohol-borax microsphere. In the invention, borax is adopted as the crosslinking agent, which is non-toxic and non-simulating to human bodies, thus avoiding using dialdehyde, diacyl chloride and other crosslinking agents having toxicity to human bodies and stimulation to the skin, as well as potential safety hazards. The prepared polyvinyl alcohol microsphere has good thermal stability, no bacterium, no toxicity, no pyrogen, and good biocompatibility.

Owner:IMEIK TECH DEV CO LTD

Washing agent for wash oil for well cementation and preparation method thereof

The invention discloses a washing agent for wash oil for well cementation and a preparation method thereof. The washing agent comprises the following materials in percentage by weight: 0%-10% of soap bases, 10%-20% of fatty alcohol-polyoxyethylene ether sodium sulfate, 4.0%-6.0% of fatty alcohol polyethenoxy ether, 7.0%-10% of alkylphenol polyoxyethylene ether, 2.0%-4.0% of sorbitan monooleate and the balance of water. The washing agent disclosed by the invention has washing and diluting functions, can solve the problem of pollution caused by the contact of cement paste and an oil-based drilling fluid, and plays a role of isolating and cleaning the stratum and the sleeve pipe interface, thereby achieving the purpose of enhancing well cementation quality.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Microencapsulated acidity regulator and preparation method thereof

The invention relates to the technical field of food additives, in particular to a microencapsulated acidity regulator and a preparation method thereof. The microencapsulated acidity regulator is composed of a wall material and an acidity regulator core material in a weight ratio of 1-30:3-1; the wall material wraps a swelling agent core material and is at least one of distilled glycerin monostearate, sorbitan monooleate, hydrogenated vegetable oil, glycerol monolaurate, diacetyl tartaric acid ester of mono(di)glycerides, polyglycerol fatty acid ester, sodium stearoyl lactate and calcium stearoyl lactate; the acidity regulator core material is at least one of gluconic acid-delta-lactone, malic acid, citric acid and fumaric acid. The microencapsulated acidity regulator has advantages that release speed of the acidity regulator can be controlled under certain conditions, and accordingly reactions of the acidity regulator with other substances in advance in certain environment can be reduced; the microencapsulated acidity regulator is less prone to damping and convenient to store and transport.

Owner:GUANGDONG GUANGYI TECH IND

Lubricant For Conveyor Chains For Packaged Products

A lubricant for conveyor chains of bottled products, set for lubricating through direct application without dilution and in a discontinual way, in prolonged intervals, leaving a layer or film on the surface of the conveyor chain. The lubricant is composed of an homogeneous mixture of one or more fluids of silicon such as emulsified polydimethylsiloxane; one or more fatty acids such as the oleic acid; one or more amines such as the tensoactive product derived from an ethoxylated amine; one or more hydrocarbons such as the white mineral oils; one or more emulsifiers such as the sorbitan monooleate; and one or more polyglycols such as the polyalkylene-glycol, and alternatively a microbicide.

Owner:QUIMIPROD S A DE

Active dry yeast protectant and application thereof

ActiveCN102168016AHigh retention rateImprove fermentation effectMicroorganism based processesMicroorganism preservationFood additiveMicroorganism

The invention relates to an active dry yeast dehydration protectant and application thereof and belongs to the technical field of microorganism products and food additives. The active dry yeast protectant comprises the following components: glyceryl monostearate, sorbitan monostearate, sorbitan monooleate (Span80) and glycerin. The active dry yeast protectant can obviously increase the living cell rate of active dry yeast to 86 to 90 percent, obviously increase the preserving rate of active dry yeast to 88 to 90 percent and obviously increase the fermentation ability of active dry yeast to 530 to 550mL / h.

Owner:QILU UNIV OF TECH

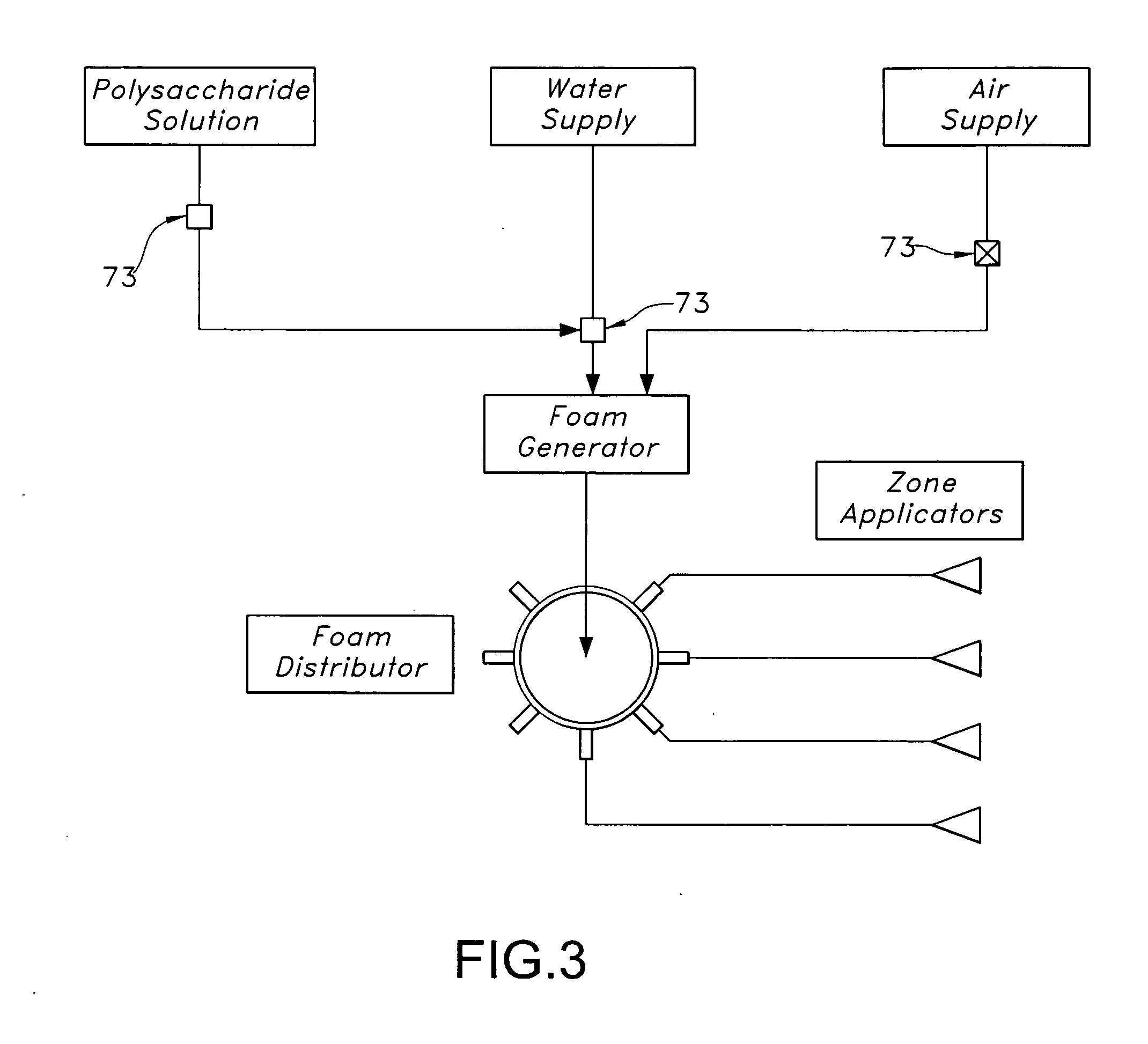

Water-in-oil microemulsions for oilfield applications

A well treatment microemulsion includes an oil external phase, an internal aqueous phase and a hydrophilic surfactant. The surfactant has a hydrophile lipophile balance of between 8-18. The oil external phase may include d-Limonene, xylenes, light mineral oil, or kerosene. The surfactant is configured to emulsify the water of the internal aqueous phase into the oil of the external (continuous) phase. The surfactant may include polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan tristearate, polyoxyethylene hydrogenated castor oil, polyoxyethylene sorbitan monostearate, polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan monolaurate or mixtures therebetween. The use of hydrophilic surfactants to emulsify an internal aqueous phase within an oil external microemulsion produces unexpected and beneficial results.

Owner:FLOTEK CHEM LLC

Yellowtop extract weedicide emulsion and preparation technology thereof

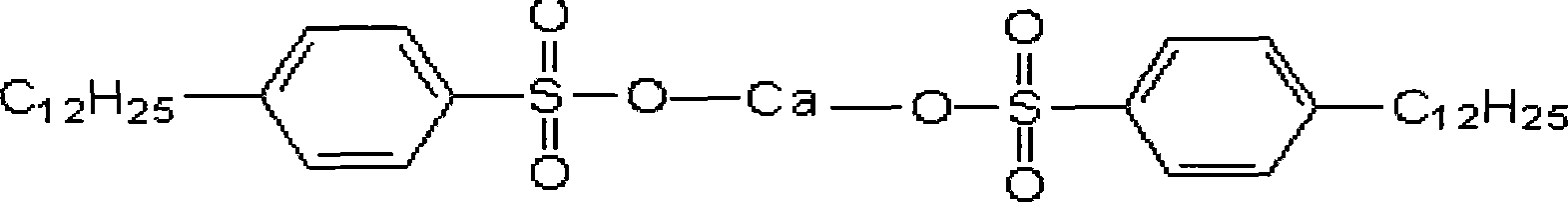

The invention discloses a herbicide emulsifiable concentrate extracted from chrysanthemum chrysanthemum, which is characterized in that the weight percentage of each component of the chrysanthemum chrysanthemum extract is 5%-50% of chrysanthemum chrysanthemum extract, 10%-20% of pesticide adjuvant, and 30% of solvent ~85%, the pesticide adjuvant is: Nongru No. 500: a mixed emulsifier of Tween-80=1: 1~3 (weight ratio); said Nongru No. 500 is calcium dodecylbenzenesulfonate, Tween -80 is ethylene oxide adduct of sorbitan monooleate; solvent: xylene. The invention also discloses a preparation process of the herbicide emulsifiable concentrate extracted from the chrysanthemum chrysanthemum. The herbicide emulsifiable concentrate has a good control effect on weeds such as crabgrass, retroverted amaranthus, barnyardgrass, and quinoa. In the case of the same control effect on the four tested weeds, the dosage of the extract of the chrysanthemum was 40-50 times lower than that without processing.

Owner:HEBEI AGRICULTURAL UNIV.

Water-based metal rust inhibitor and preparation method thereof

The invention provides a water-based metal rust inhibitor and a preparation method thereof. The rust inhibitor comprises sorbitan monooleate, inositol hexaphosphate, zinc dihydrogen phosphate, acrylamide, glutamic acid, dinonyl-naphthalenesulfonate, dicyclohexylamine, octadecylamine oleyl sarcosinate, oxidized barium petrotate, sodium ethylenediamine teramethylene phosphonate, 1-hydroxyethylidene, dimethylaminoethyl acrylate, sulfomethylated polyacrylamide, a film forming agent and deionized water. The preparation method comprises the steps of firstly, mixing sorbitan monooleate, inositol hexaphosphate, zinc dihydrogen phosphate and water, and adding octadecylamine oleyl sarcosinate; then, adding acrylamide, glutamic acid, dinonyl-naphthalenesulfonate, dicyclohexylamine and oxidized barium petrotate into the deionized water, and adding 1-hydroxyethylidene; and mixing a mixture I and a mixture II, and adding the left components to obtain the water-based metal rust inhibitor. The rust inhibitor can be attached to the surface of metal, so that the metal has better wear resistance and corrosion resistance.

Owner:NINGBO SHEN XIN ELECTRONICS CO LTD

Micro-emulsion cutting fluid for aluminum alloy, and preparation method of micro-emulsion cutting fluid

The invention discloses a micro-emulsion cutting fluid for aluminum alloy and a preparation method of the micro-emulsion cutting fluid. The micro-emulsion cutting fluid comprises the following raw materials in parts by weight: 12-16 parts of paraffin-based oil, 3-5 parts of star anise oil, 4-7 parts of eucalyptus oil, 5-7 parts of sorbitan fatty acid, 3-4 parts of triethanolamine oleate, 3-4 parts of petroleum sodium sulfonate, 7-8 parts of sorbitan monooleate, 3-4 parts of monoethanolamine, 6-7 parts of zinc sulfate, 4-7 parts of sodium oleate, 6-8 parts of dimethicone, 2-4 parts of sodium molybdate, 4-7 parts of octylphenol polyoxyethylene ether, 4-7 parts of chlorinated paraffin, 4-5 parts of ricinoleic acid, 0.5-1.5 parts of dodecanol, 1.2-1.5 parts of imidazolidinyl urea, 10-15 parts of additives and 15-25 parts of deionized water. The micro-emulsion cutting fluid for aluminum alloy also has the outstanding performances on the aspects of corrosion inhibition property, corrosion resistance, lubrication, rust resistance, defoaming property, service life and the like.

Owner:江苏悠谷未来科技有限公司

Water-in-oil microemulsions for oilfield applications

A well treatment microemulsion includes an oil external phase, an internal aqueous phase and a hydrophilic surfactant. The surfactant has a hydrophile lipophile balance of between 8-18. The oil external phase may include d-Limonene, xylenes, light mineral oil, or kerosene. The surfactant is configured to emulsify the water of the internal aqueous phase into the oil of the external (continuous) phase. The surfactant may include polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan tristearate, polyoxyethylene hydrogenated castor oil, polyoxyethylene sorbitan monostearate, polyoxyethylene sorbitan monooleate, polyoxyethylene sorbitan monolaurate or mixtures therebetween. The use of hydrophilic surfactants to emulsify an internal aqueous phase within an oil external microemulsion produces unexpected and beneficial results.

Owner:FLOTEK CHEM LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com