Flame-resistant and heat-resistant copper clad laminate preparation method

A copper-clad laminate, heat-resistant technology, applied in chemical instruments and methods, lamination, electronic equipment, etc., can solve the problems of high water absorption, high dielectric constant, low heat and humidity resistance, low shrinkage, etc., to achieve good fluidity , Improve compatibility, narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0030] Synthesis example 1 preparation of filler

[0031] Disperse 1Kg of nano-silica foam in deionized water, then add 200g of dodecylbenzenesulfonic acid, 200g of bismuth nitrate pentahydrate and 350g of methyltrichlorosilane; then hydrothermally react at 150°C for 2 hours; then filter the reaction Liquid, the filter cake was added to ethanol, dispersed evenly and then added 50g of polyoxyethylene sorbitan monooleate, stirred at 60°C for 2 hours, and finally dried to obtain filler (particle size: 560-880nm).

Embodiment 1

[0032] Embodiment 1 A method for preparing a flame-retardant and heat-resistant copper-clad laminate, comprising the following steps:

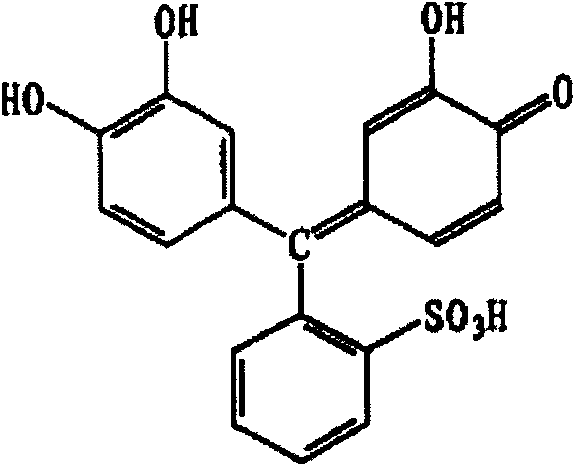

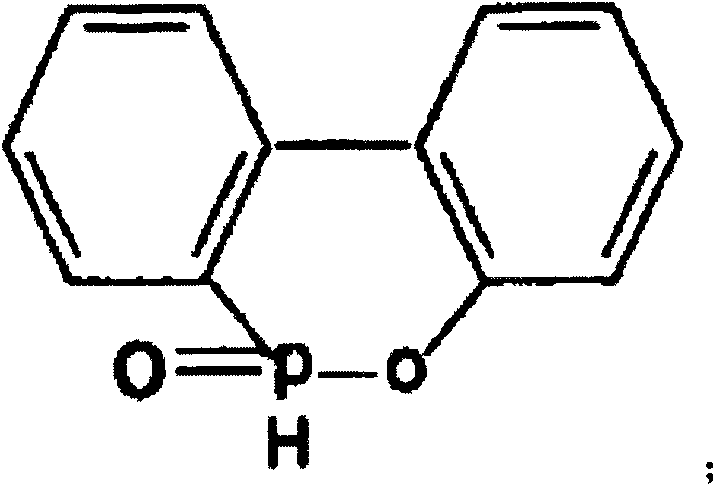

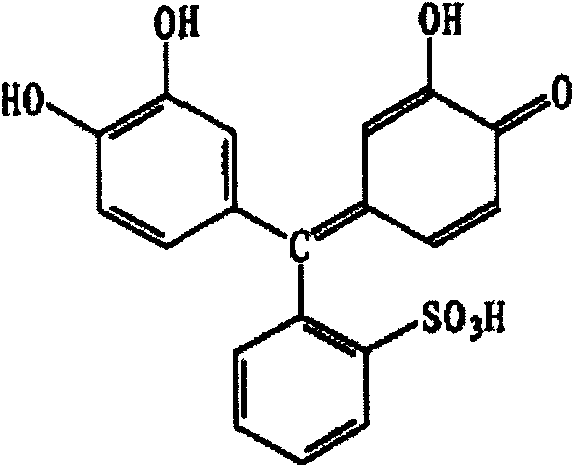

[0033] Mix 5g DOPO and 100g bisphenol A cyanate monomer, stir at 95°C for 25 minutes, add 20g phenol compound, continue stirring for 30 minutes; then add 8g m-nitrobenzenesulfonic acid pyridinium salt, 58g Cyclopentyl ether, continue to stir for 20 minutes; add 9g dimethyl phosphite, stir at 100°C for 30 minutes; obtain resin prepolymer; add 32g filler to 12g diglycidyl phthalate, stir at 125°C 1 hour, obtain active filler; With 100g resin prepolymer and 9g indole compound (R 1 for hydrogen, R 2 is methyl, R 3 Amino) mixed, stirred at 120°C for 30 minutes; then added active filler, stirred at 130°C for 30 minutes; then added 1.5g of isomeric undecyl alcohol polyoxyethylene ether phosphate potassium salt, stirred at 140°C for 50 minutes to obtain a compound system; the above composite system was dissolved in a butanone / ethylene glycol methyl...

Embodiment 2

[0034] Embodiment 2 A method for preparing a flame-retardant and heat-resistant copper-clad laminate, comprising the following steps:

[0035] Mix 5g DOPO and 100g bisphenol A cyanate monomer, stir at 95°C for 25 minutes, add 30g phenolic compound, and continue stirring for 30 minutes; then add 8.2g m-nitrobenzenesulfonic acid pyridinium salt, 63g Pentyl cyclopentyl ether, continue stirring for 20 minutes; add 12g dimethyl phosphite, stir at 100°C for 30 minutes; obtain resin prepolymer; add 45g filler to 14g diglycidyl phthalate, 125°C Stir for 1 hour to obtain active filler; 100g resin prepolymer and 8.5g indole compound (R 1 for hydrogen, R 2 is methyl, R 3 For cyano group) mixed, stirred at 120°C for 30 minutes; then added active filler, stirred at 130°C for 30 minutes; then added 1.5g of isomeric undecyl alcohol polyoxyethylene ether phosphate potassium salt, stirred at 140°C for 50 minutes to obtain Composite system; the above composite system is dissolved in a butano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com