Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

399 results about "Methyltrichlorosilane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methyltrichlorosilane, also known as trichloromethylsilane, is an organosilicon compound with the formula CH₃SiCl₃. It is a colorless liquid with a sharp odor similar to that of hydrochloric acid. As methyltrichlorosilane is a reactive compound, it is mainly used a precursor for forming various cross-linked siloxane polymers.

Method of preparing methyl phenyl polysiloxane

ActiveCN101508776AWith high and low temperature resistanceWeather resistantReaction temperatureMethyl phenyl polysiloxane

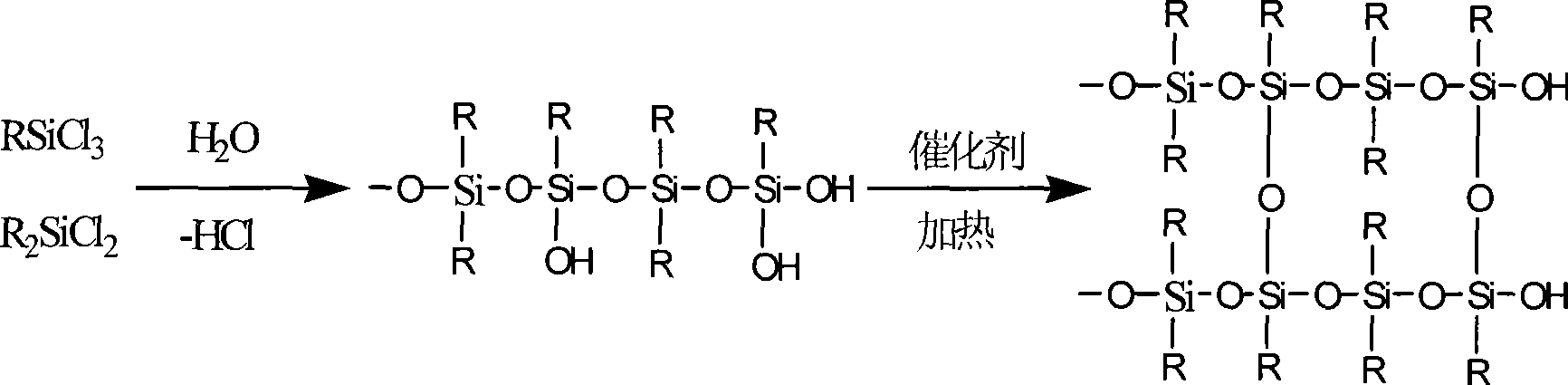

The invention discloses a method for synthesizing organic silicon, in particular provides a method for preparing methyl phenyl silicone resin which has low curing temperature by self and is not sticky repeatedly. The invention uses the monomers of methyl trichlorosilane, dimethyldichlorosilance, phenyl trichlorosilane, dichloromethylphenylsilane, diphenyl dichlorosilane and the like to obtain a methyl phenyl silicone resin with low curing temperature and a paint film which is not sticky repeatedly after being cured by the processes of adjusting the proportion of raw materials, controlling proper reaction temperature and polymerization time, carrying out hydrolysis reaction and polycondensation reaction, etc. The invention has the advantages that the methyl phenyl silicone resin prepared by the method has the characteristics of low curing temperature, being not sticky repeatedly, being clear and transparent, high and low temperature resistance, weather resistance, being insulating and the like; the methyl phenyl silicone resin is in particular fit for dip varnish higher than grade H; and the methyl phenyl silicone resin is used for confecting insulated paint, weather-resistant paint and heat resistant paint higher than grade H, is used for heat resistant parting agent and also can be used in the fields with rigorous using requirements, such as heat resistant water blocking and sand prevention for oil drilling, etc.

Owner:安徽比特海新材料股份有限公司

Preservative compositions for wood products

Preservative compositions for wood products is described. The compositions include at least one boron-containing material, such as but not limited to boric anhydride, and at least one silane-containing material, such as but not limited to methyltrichlorosilane. Optionally, at least one solvent, such as tetrahydrofuran, pentane, or water, may also be employed in the compositions. The compositions impart protection to the treated wood products, especially damage caused by exposure to water and insects.

Owner:PETRA INT HLDG

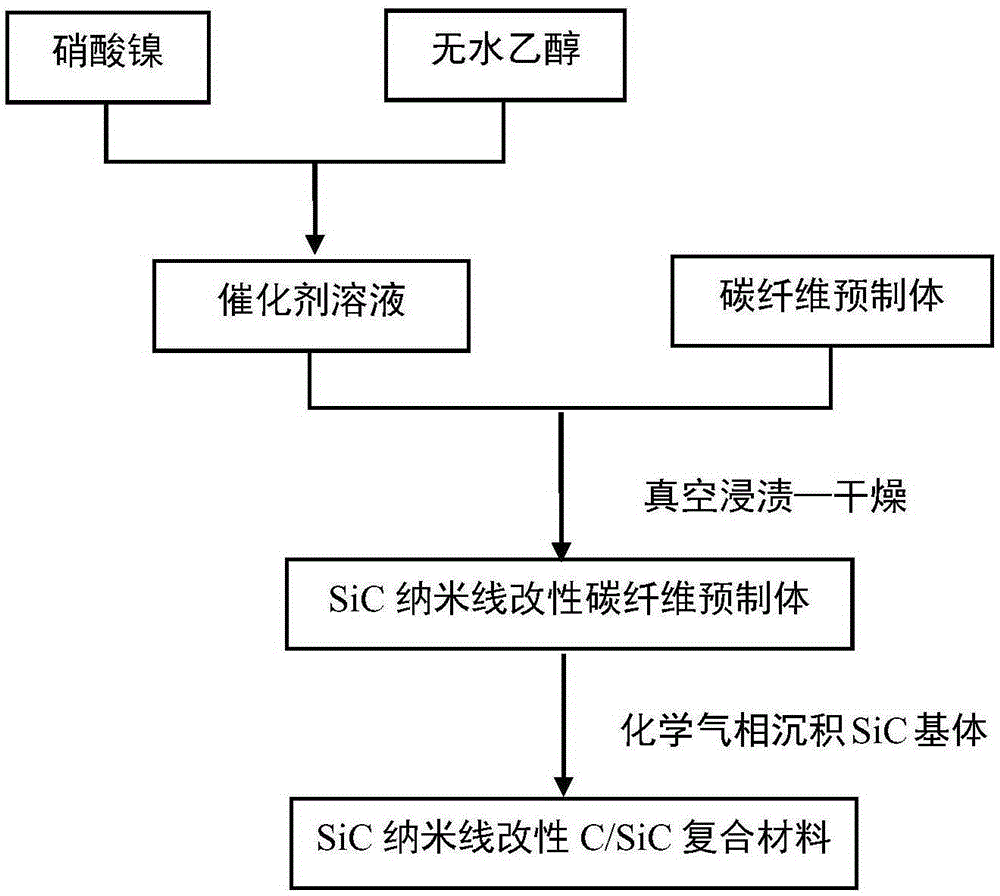

Method for preparing ceramic matrix composite material through SiC nano-wire modified ceramic matrix composite material interface

InactiveCN105237021AImprove mechanical propertiesImprove bending strengthHydrogenMethyltrichlorosilane

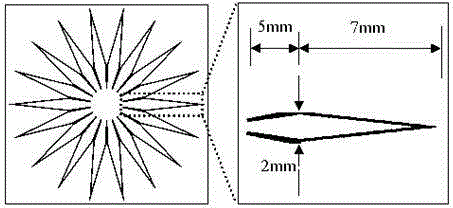

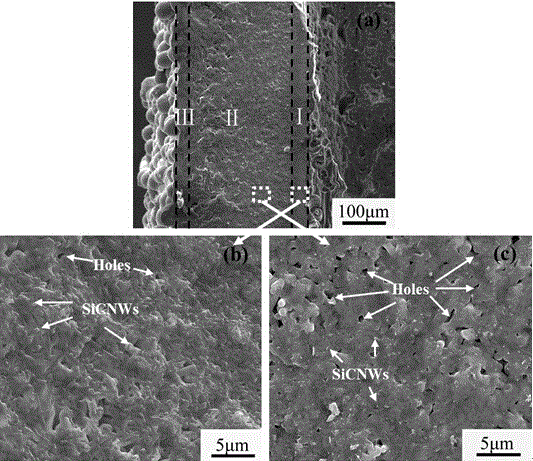

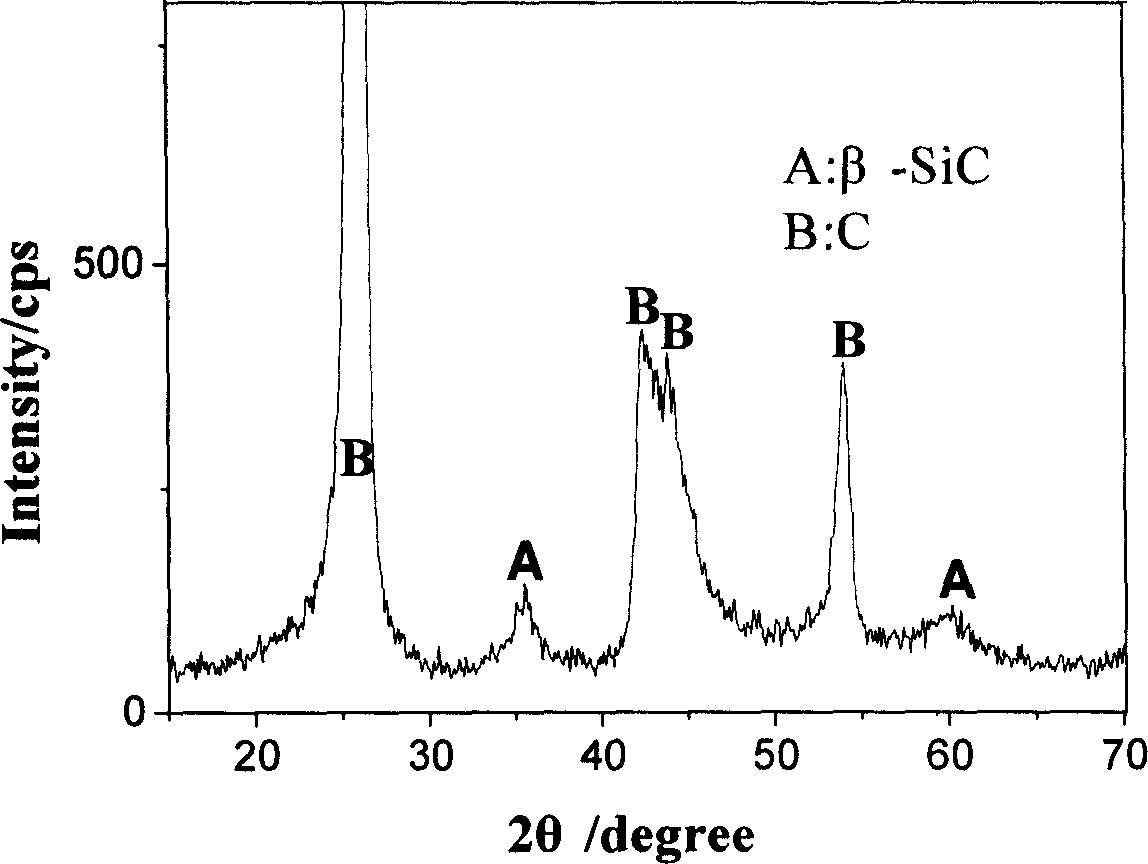

The present invention relates to a method for preparing a ceramic matrix composite material through a SiC nano-wire modified ceramic matrix composite material interface. The method comprises: immersing a porous fiber preform in a catalyst solution; in a CVD furnace, carrying out in-situ SiC nano-wire deposition by using methyltrichlorosilane MTS as a silicon source, using argon Ar as a dilution gas, and using hydrogen as a carrier gas, wherein the dilution ratio is 30-90; and preparing a SiC matrix by using a CVI process, using methyltrichlorosilane MTS as a silicon source, and using argon Ar as a dilution gas so as to obtain the compact SiC nano-wire modified ceramic matrix composite material, wherein the dilution ratio is 9-11. According to the present invention, the reinforcing and toughening mechanism of the SiC nano-wire is used to improve the mechanical property of the material; and the bending strength of the composite material adopting the SiC nano-wires as the interface is increased by 26.7% (Figure 6) compared with the PyC interface composite material under the same process, and the interface antioxidant property of the interface can be improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Flame-resistant and heat-resistant copper clad laminate preparation method

InactiveCN105172297AReasonable compositionUniform dispersionSynthetic resin layered productsLaminationMetal foilDimethyl phosphonate

The present invention relates to a flame-resistant and heat-resistant copper clad laminate preparation method, which comprises: adopting nanometer silica foam, dodecyl benzenesulfonic acid, bismuth nitrate pentahydrate, methyl trichlorosilane and polyoxyethylene sorbitan monooleate as a raw materials to obtain a filler; adopting DOPO, a bisphenol A cyanate ester monomer, a phenol compound, a m-nitrobenzene sulfonic acid pyridine salt, 2,3-epoxy cyclopentyl cyclopentyl ether and dimethyl phosphonate as raw materials to obtain a resin prepolymer; adding the filler to o-phthalic acid diglycidyl este to obtain an active filler; mixing the resin prepolymer and an indole compound, and then adding the active filler and isomeric undecanol polyoxyethylene ether phosphate potassium salt to obtain a composite system; and carrying out hot pressing molding on the composite system, a reinforced material and metal foil to obtain the flame-resistant and heat-resistant copper clad laminate, wherein the flame-resistant and heat-resistant copper clad laminate has characteristics of excellent flame retardant property and excellent heat resistance, and meets the development applications of the flame-resistant and heat-resistant copper clad laminate.

Owner:SUZHOU YIKETAI ELECTRONICS MATERIAL

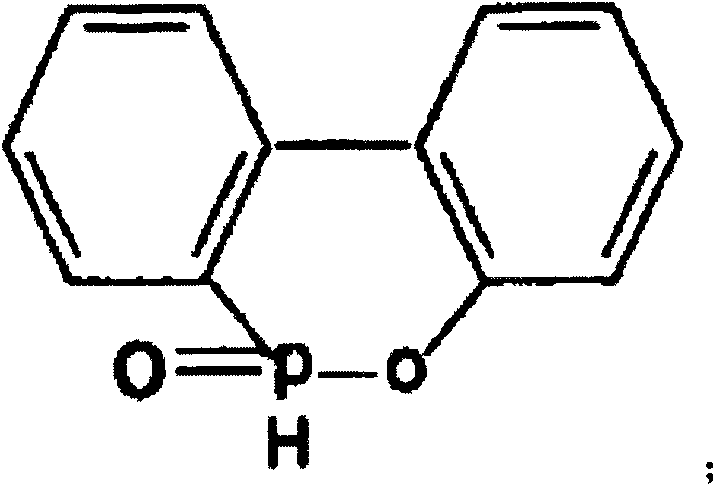

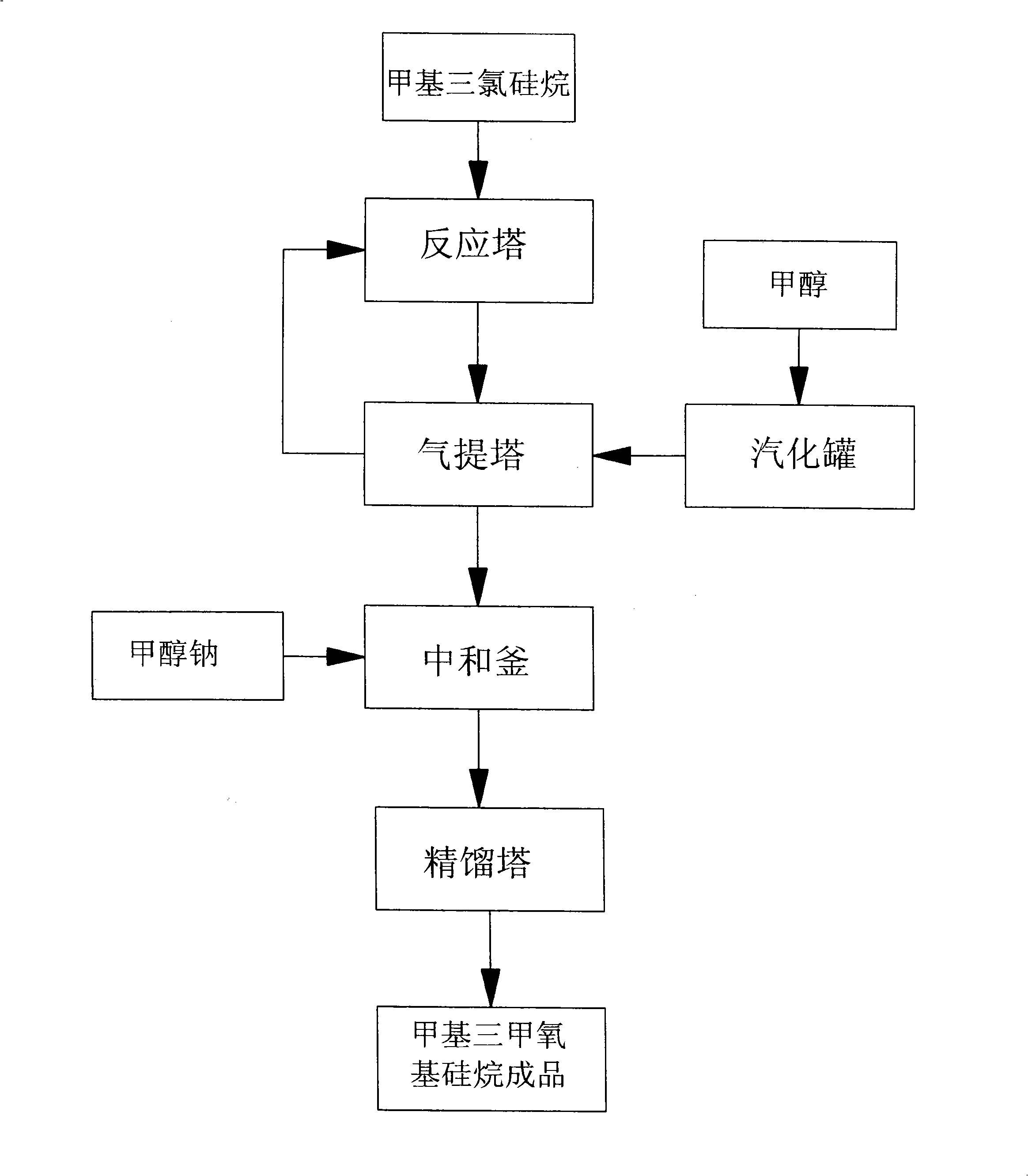

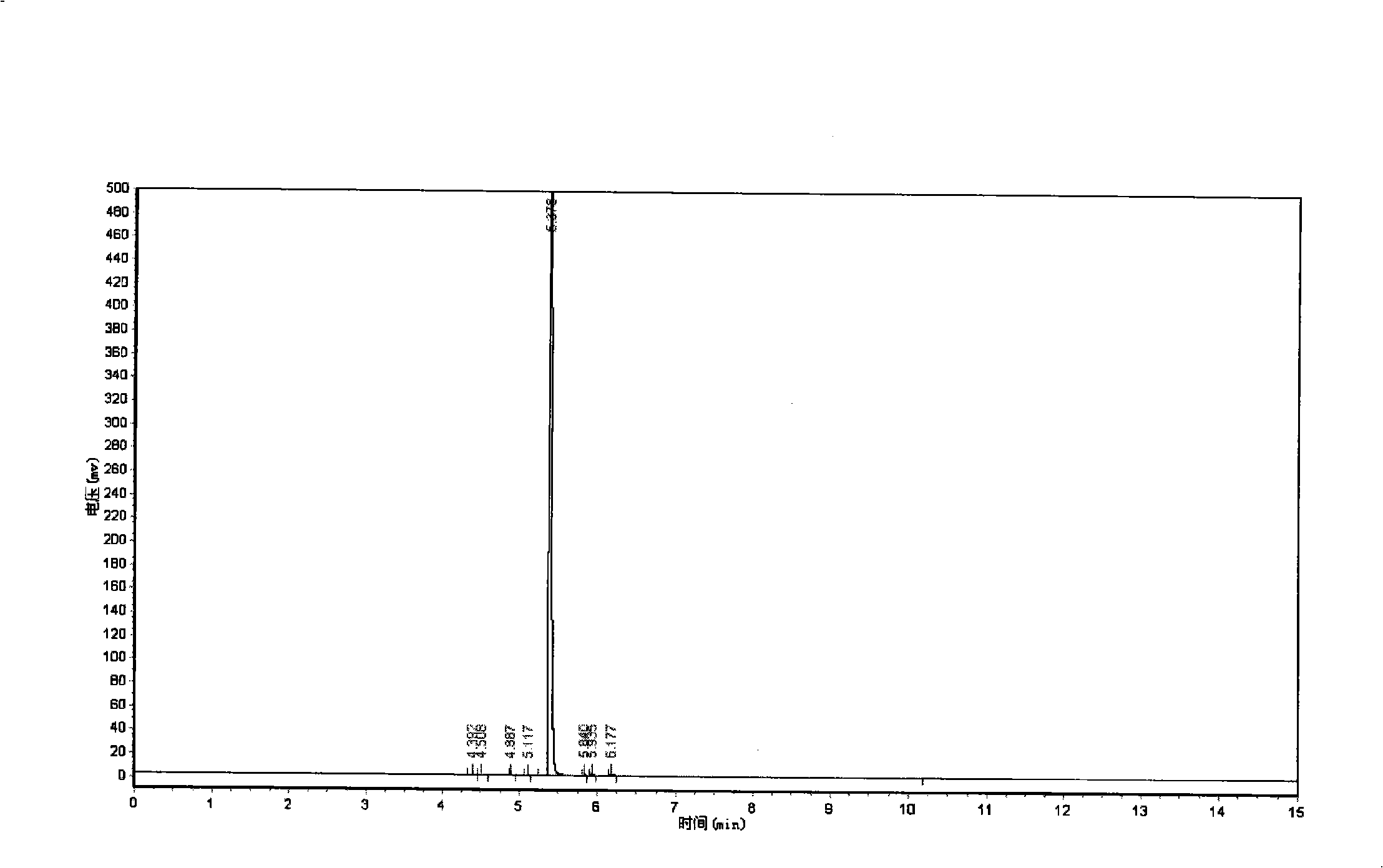

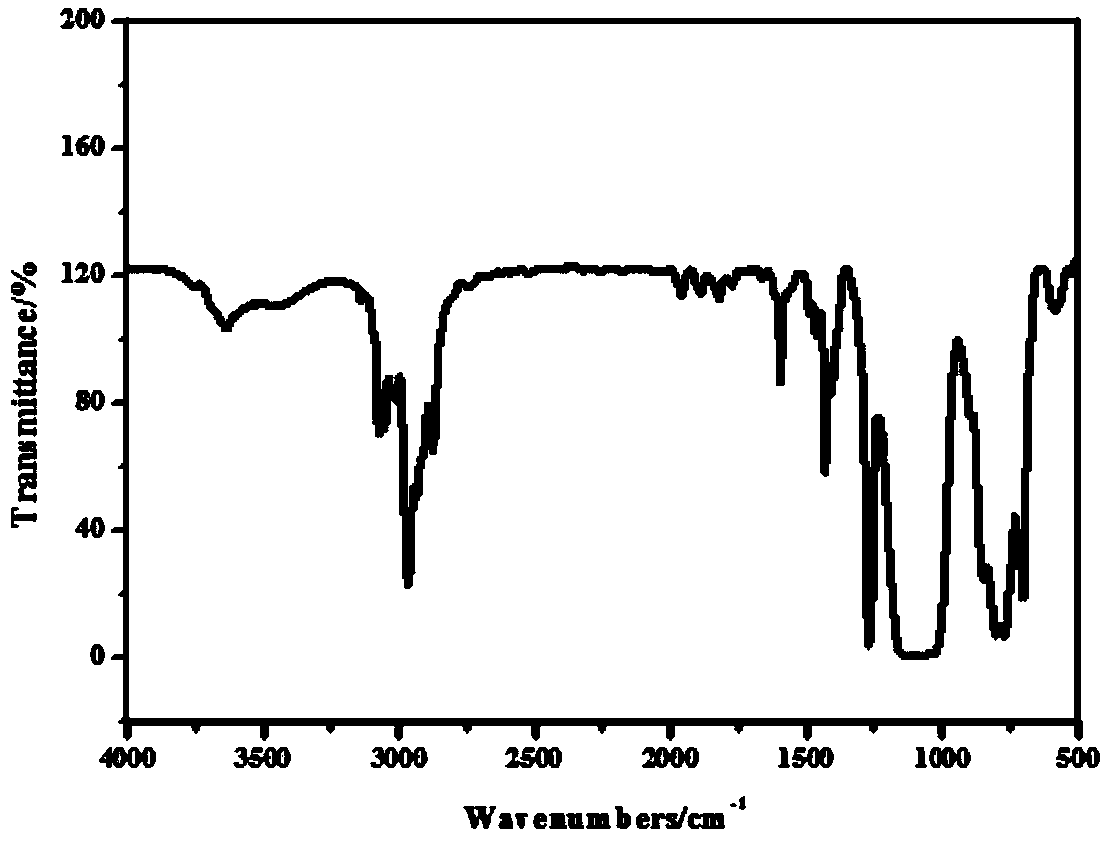

Preparation technique of methyl trimethoxysilane

ActiveCN101348497AEfficient removalAvoid it happening againGroup 4/14 element organic compoundsMethyltrichlorosilaneSilanes

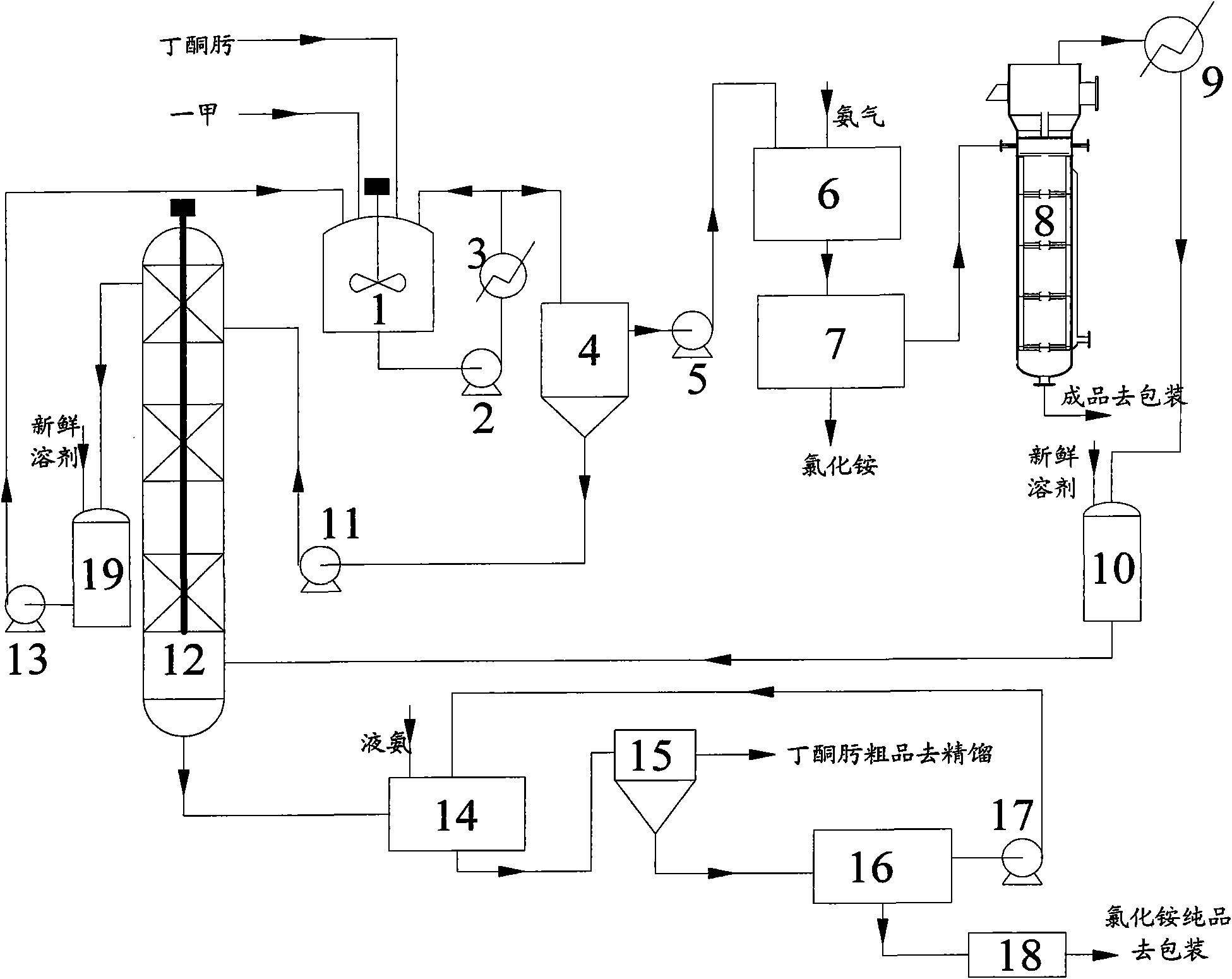

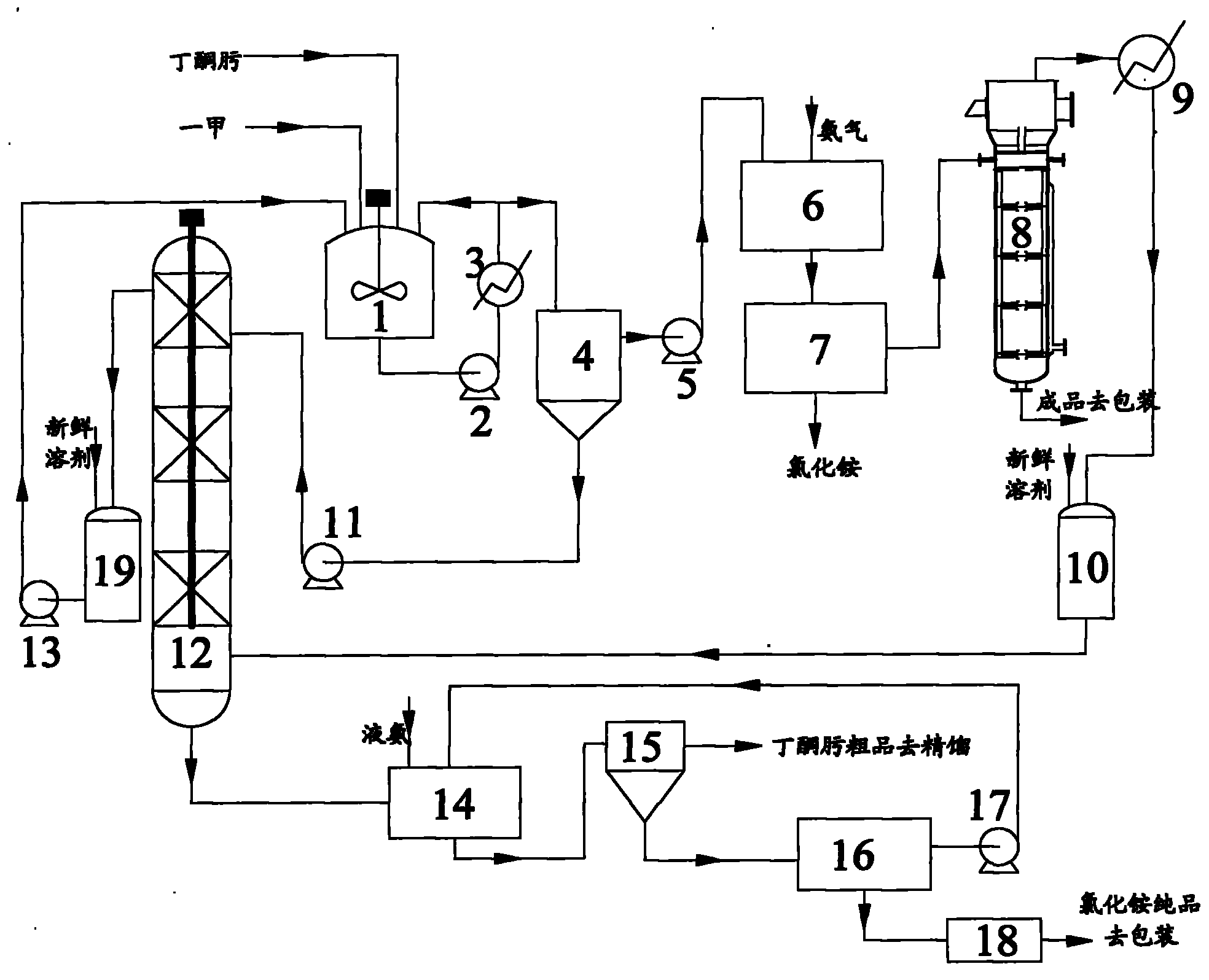

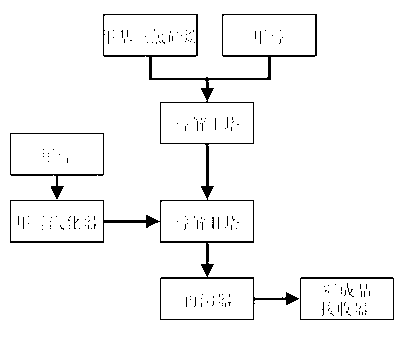

The invention provides a process for preparing methyltrimethoxy silane. The process comprises the following steps that: a. methanol is subjected to vaporization by a vaporizing cylinder and passes through a stripping tower, and enters the bottom part of a reaction tower, methyl trichlorosilane enters the reaction tower from the top and is sprayed downward, and methanol reacts with methyl trichlorosilane by counter current contact; b. a primary product is pumped in the top part of the stripping tower and subjected to steam stripping by methanol gases passing by the stripping tower, after falling onto the bottom part of the stripping tower, the primary product is pumped in a neutralization kettle, and the saturated sodium methylate solution is added in the neutralization kettle for neutralization; c. the coarse product of methyltrimethoxy silane is pumped in a rectification tower for rectification. The process has the characteristics of high working efficiency, stable process and big output, etc. Because the process of the invention is continuously carried out, the process has the advantages of having few operators, ensuring safe production and being capable of easily realizing the control of DCS computers; moreover, the product yield is 90 percent, the effective content of the product is high, and the content of methyltrimethoxy silane is more than 99 percent.

Owner:湖北新蓝天新材料股份有限公司

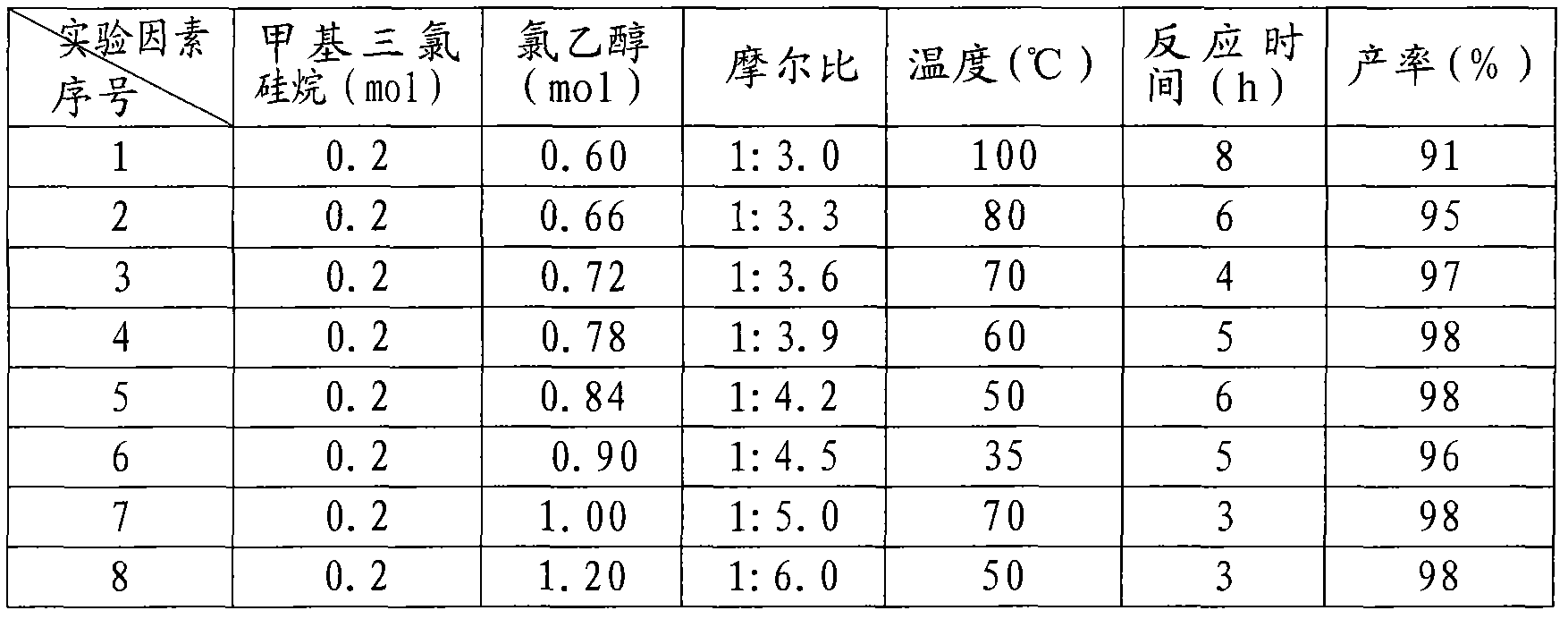

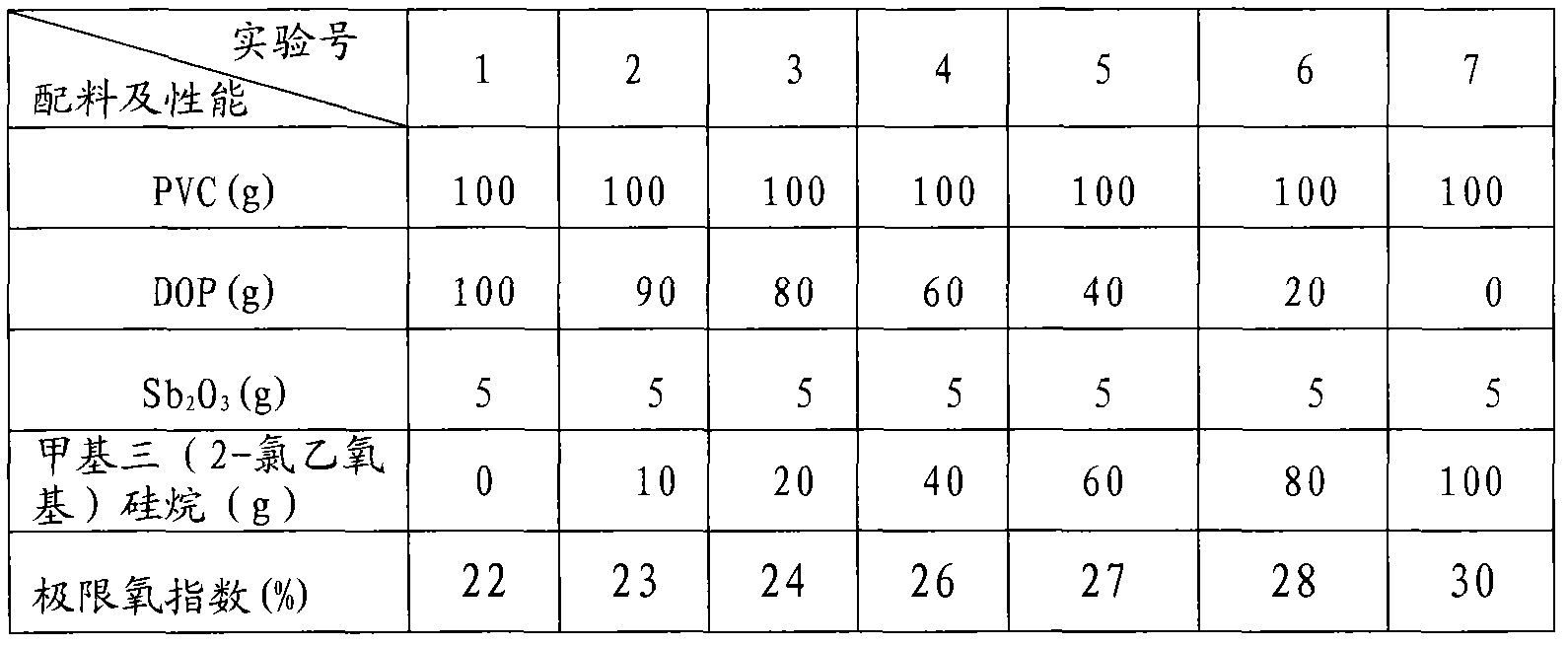

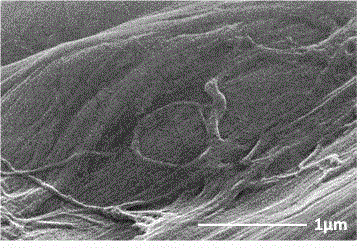

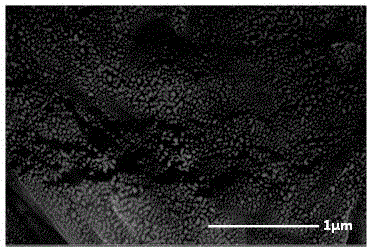

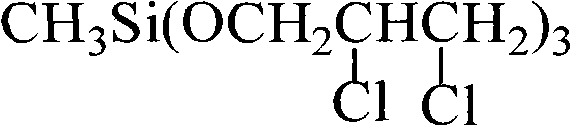

Methyl tri(2-chloroethoxy) silane compound and preparation method thereof

ActiveCN102174055AStabilize the C-Si bond structureSymmetrical ester structureGroup 4/14 element organic compoundsSilane compoundsHalogen

The invention relates to a methyl tri(2-chloroethoxy) silane compound which is used as a silicon-halogen synergistic flame-retardant plasticizer and a preparation method thereof. The methyl tri(2-chloroethoxy) silane compound has the following structural formula: CH3Si(OCH2CH2Cl)3. The preparation method of the methyl tri(2-chloroethoxy) silane compound comprises the following steps: dropwise adding and stirring chloroethanol at a certain molar ratio to methyl trichlorosilane, carrying out a reaction on the chloroethanol and the methyl trichlorosilane for a certain time at a certain temperature, and purifying after finishing hydrogen chloride release and reaction to obtain methyl tri(2-chloroethoxy) silane. The methyl tri(2-chloroethoxy) silane can be used as the good flame-retardant plasticizer, and the process for producing the methyl tri(2-chloroethoxy) silane is simple, has low equipment investment and cost and is easy to realize industrial production.

Owner:河南森远科技有限公司

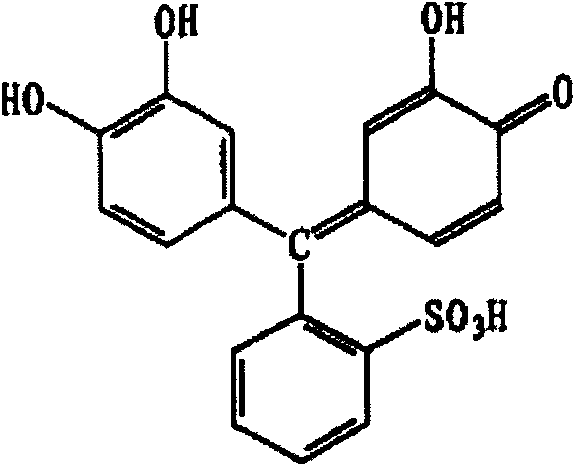

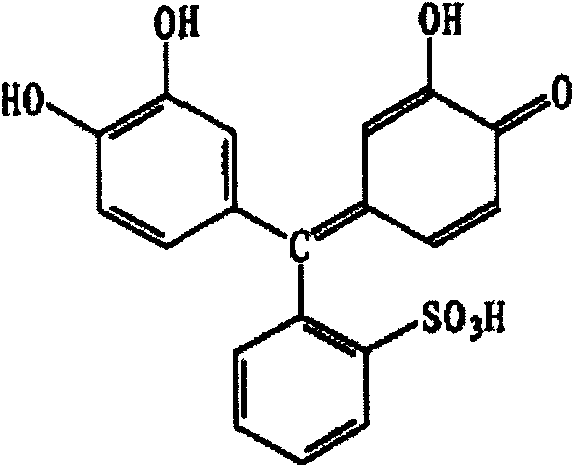

Preparation and application of paper-based microfluidic chip for colorimetric analysis

InactiveCN104677896AReduce manufacturing costEasy to operateMaterial analysis by observing effect on chemical indicatorLaboratory glasswaresOctadecyltrichlorosilaneColorimetric analysis

The invention relates to preparation and application of a paper-based microfluidic chip for colorimetric analysis; the preparation comprises the step of enabling a hydrophilic channel to be jointed on a hydrophobic substrate, wherein the hydrophilic channel is obtained by printing the pattern of the channel on a piece of filter paper and then shearing the pattern, and the hydrophobic substrate is obtained by treating the filter paper with a normal hexane solution containing methyl trichlorosilane and octadecyl trichlorosilane; the paper-based microfluidic chip is combined with a colorimetric analysis method, so that rapid quantitative detection can be realized. The preparation method is simple and fast, short in production cycle, low in cost, low in energy consumption and free from pollution. The preparation and the application of the paper-based microfluidic chip for colorimetric analysis are suitable for the fields such as clinical diagnosis, food hygiene, environmental monitoring and biochemistry, thus having very wide application scope.

Owner:TAIYUAN UNIV OF TECH

Cage-shaped organic silicon flame retardant charring agent and preparation method thereof

ActiveCN102146093ACompact and stable structureStrong insulationGroup 4/14 element organic compoundsCoatingsMethyltrimethoxysilanePhysical chemical

The invention relates to a cage-shaped organic silicon flame retardant charring agent, i.e. a 1,4-dimethyl-1-sila-2,6,7-trioxabicyclo[2,2,2]-octane compound, and a preparation method thereof. The compound has a structure shown as the following formula in the specification. The preparation method comprises the step of: reacting methyl trichlorosilane or methyltrimethoxysilane with trimethylolethane in an organic solvent to prepare 1,4-dimethyl-1-sila-2,6,7-trioxabicyclo[2,2,2]-octane. The cage-shaped organic silicon flame retardant charring agent is a novel halogen-free non-toxic flame retardant charring agent, which has high flame retardant performance and good charring performance, can effectively prevent the melting and the dropping of high polymer during combustion, and is stable in physical and chemical properties, good in compatibility with macromolecular materials, high in raw material availability, simple in process and easy for industrial production.

Owner:SUZHOU UNIV OF SCI & TECH

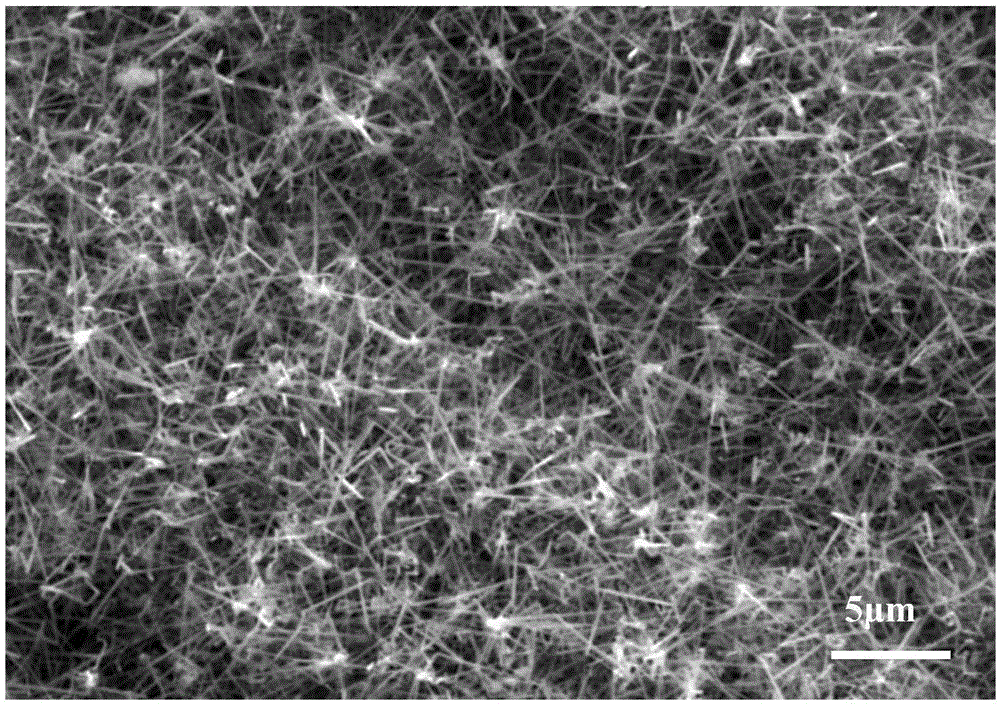

Preparation method of SiC nanowire-toughened SiC ceramic coating on surface of C/C composite

The invention discloses a preparation method of a SiC nanowire-toughened SiC ceramic coating on the surface of a C / C composite. The method includes the steps of putting the ground, polished and dried C / C composite in a deposition furnace, introducing carrier gas hydrogen into a bubbling bottle containing methyl trichlorosilane after the furnace is powered on and heated to a preset temperature, bringing a reaction gas source into a hearth for reaction, obtaining SiC nanowires, depositing the SiC coating after the temperature is raised to the preset temperature, conducting cooling after deposition ends, and obtaining the SiC coating. The compact SiC nanowire-toughened SiC ceramic coating of a sandwich structure is prepared in situ through a one-step CVD method, the cracking tendency of the SiC coating is reduced through the toughening effect of the SiC nanowires, and the oxidation resistance is remarkably improved; the weight loss of the C / C composite with the prepared ceramic coating is only 0.48% when the C / C composite is oxidized in static air at the temperature of 1400 DEG C for 420 hours. The technological process is simple and easy to achieve, and the problems that SiC nanowire-toughened SiC ceramic coatings prepared through an existing method are complex in process and not remarkable in effect are solved.

Owner:NANJING INST OF TECH

Preparation method of methyl tris-methylethylketoxime silane

ActiveCN102079753ANothing producedNo pollution in the processGroup 4/14 element organic compoundsSilanesMethyltrichlorosilane

The invention discloses a preparation method of methyl tris-methylethylketoxime silane, comprising the following steps of: a, respectively and continuously pumping monomethyl trichlorosilane, diacetylmonoxime and a solvent No. 120 into a kettle type stirring reactor by a feeding pump via a flowmeter, circulating one part of discharged reaction materials to the kettle type reactor, and recovering the other part of discharged reaction materials, precipitating and separating the recovered materials through a two-phase separator for demixing to obtain a solvent, as well as crude products of methyl tris-methylethylketoxime silane, unreacted diacetylmonoxime and a little included diacetylmonoxime hydrochloride in the upper layer, and a diacetylmonoxime hydrochloride precipitate in the lower layer; and b, neutralizing the crude products in the upper layer with ammonia gas in a neutralizer to obtain solid ammonium chloride, filtering, distilling a filtered crude solution through a film evaporator, and circulating the distilled solvent to an extraction tower for use, wherein a finished product of the high-purity methyl tris-methylethylketoxime silane can be obtained at the bottom in the film evaporator. The method can be used for realizing the continuous production of the methyl tris-methylethylketoxime silane and has the advantages of high reaction conversion rate, high product recover rate and no pollution to the environment, wherein the obtained product yield reaches 95% and the content of the methyl tris-methylethylketoxime silane exceeds 97%.

Owner:湖北新蓝天新材料股份有限公司

Method of preparing carbon-carbon composite material surface silicon carbide nano wire

InactiveCN1834287AEffective control of morphologyEffective control of purityChemical vapor deposition coatingFiberCarbon composites

This invention relates to a method for manufacturing SiC nanowires on the surface of C / C composite, which comprises the steps of: (1) polishing the C / C composite, washing with distilled water, and drying; (2) binding the treated C / C composite with carbon fibers, and suspending in a vertical chemical vapor deposition furnace; (3) evacuating the furnace, pumping Ar into the furnace to normal pressure, and repeating for three times; (4) applying electricity, heating, and pumping H2 for pretreatment; (5) adjusting the flow rates of Ar, H2 and methyl trichlorosilane when the furnace temperature reaches the predetermined deposition temperature, keeping the temperature for deposition, the turning off the power and cooling naturally to obtain a layer of SiC nanowires on the surface of the material. The method has such advantages as simple process, no additive, low deposition pressure and temperature. The morphology and purity of the synthesized SiC nanowires can be effectively controlled by adjusting the deposition factors.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

High-durability concrete

The invention discloses a high-durability concrete which comprises the following raw materials: cement, river sand, macadam, water, fly ash, nano microbead, natural zeolite micropowder, aluminum oxide, sodium sulfate, diethanolamine, sodium hydroxide, methyl trichlorosilane, ethanol, an air entraining agent, a lignosulfonate water reducing agent, polyvinyl alcohol, mixed fiber, sodium nitrate and polyvinylpyrrolidone. The mixed fiber is the combination of carbon fiber, steel fiber, polypropylene fiber and polyvinyl alcohol fiber in a weight ratio of 1:(2-5):(3-7):(3-6). The high-durability concrete has the advantages of high strength, favorable water impermeability, favorable freezing resistance and favorable durability, and has long service life when being applied to hydrotechnics, harbors, roads and other projects.

Owner:WUWEI HENGJI COMML CONCRETE

Methyl chlorosilane parallel double-effect distillation method

ActiveCN101857606AReduce tower diameterRealize secondary useSilicon organic compoundsChemical industryGas phaseReboiler

The invention discloses a methyl chlorosilane parallel double-effect distillation method. The method comprises the following steps: the synthetic product of methyl chlorosilane passes through a heavy component removing tower for removing heavy components and a light component removing tower for removing light components, the mixture of dimethyldichlorosilane and methyltrichlorosilane can be obtained, the mixture is divided to two parts to be sent to two parallel distillation systems of high-pressure refining and low-pressure refining, wherein one part enters in a high-pressure refining distillation system composed of a methyltrichlorosilane high-pressure tower and a dimethyldichlorosilane high-pressure tower, the other part enters in a low-pressure refining distillation system composed of a methyltrichlorosilane low-pressure tower and a dimethyldichlorosilane low-pressure tower, and the overhead gas phases of the methyltrichlorosilane high-pressure tower and the dimethyldichlorosilane high-pressure tower are separately used as the heat sources of the tower bottom reboilers of the methyltrichlorosilane low-pressure tower and the dimethyldichlorosilane low-pressure tower. By adopting two parallel processing lines, energy consumption can be reduced by more than 20%- 40% and the amount of circulating water can be saved.

Owner:TIANJIN UNIV

Method for generating dimethyldichlorosilance by utilizing disproportionation reaction

ActiveCN101824046AImprove resource utilizationReasonable designGroup 4/14 element organic compoundsResource utilizationReaction temperature

The invention relates to a method for generating dimethyldichlorosilance by utilizing disproportionation reaction, which belongs to the technical field of the comprehensive utilization of three wastes in the production process of methyl chlorosilane. The invention is characterized by comprising the following steps: generating the dimethyldichlorosilance by using methyl trichlorosilane and trimethylchlorosilane as organic silicon monomers, or a high boiling object and a low boiling object as the organic silicon monomers, or the mixture of the methyl trichlorosilane, the trimethylchlorosilane, the high boiling object and the low boiling object as the organic silicon monomers as raw materials under the single or combined catalytic action of aluminum powder and anhydrous aluminum trichloride as catalysts. In the invention, reaction is generated in a high-pressure agitating kettle at the temperature of 180 to 350 DEG C, and in the reaction, the reaction pressure is controlled by the reaction temperature, i.e. the higher the reaction temperature is, the higher the reaction pressure is, and the maximum conversion rate of a target product can reach more than 70 percent. The invention improves the resource utilization level of methyl organic silicon monomer production, the dimethyldichlorosilance is produced in lower cost, and the invention has simple and easy operation and is suitable for large-scale popularization and utilization.

Owner:HANGZHOU JINFADA CHEM IND

Preparation of methyl tributanoximo silane

ActiveCN101348498AImprove solubilityGood volatilization effectGroup 4/14 element organic compoundsSilanesDistillation

The invention provides a method for preparing methyltris(methylethylketoxime)silane. The method comprises the following steps that: a. methyl trichlorosilane, butanone oxime, alkaline air and 120#solvent naphtha are simultaneously pumped in a reaction kettle by a measuring pump and reacted for 30m under the normal pressure and at a temperature of between 35 to 40 DEG C, and reactants are picked up and filtered by a centrifuge so as to obtain a filtrate and ammonium chloride deposit; b. the filtrate passes through a falling-film evaporator to distill off 120#solvent naphtha, and the coarse product of methyltris(methylethylketoxime)silane is obtained; c. the coarse product of methyltris(methylethylketoxime)silane is put in a scraper evaporator for distillation, the remained butanone oxime is distilled off, and the refined product is obtained. The process of the invention has the characteristics of big productivity, low energy consumption, simple control and greenness and environmental protection, etc.; moreover, the product yield is 95 percent, the effective content of the product is high, and the content of methyltris(methylethylketoxime)silane is more than 96 percent.

Owner:湖北新蓝天新材料股份有限公司

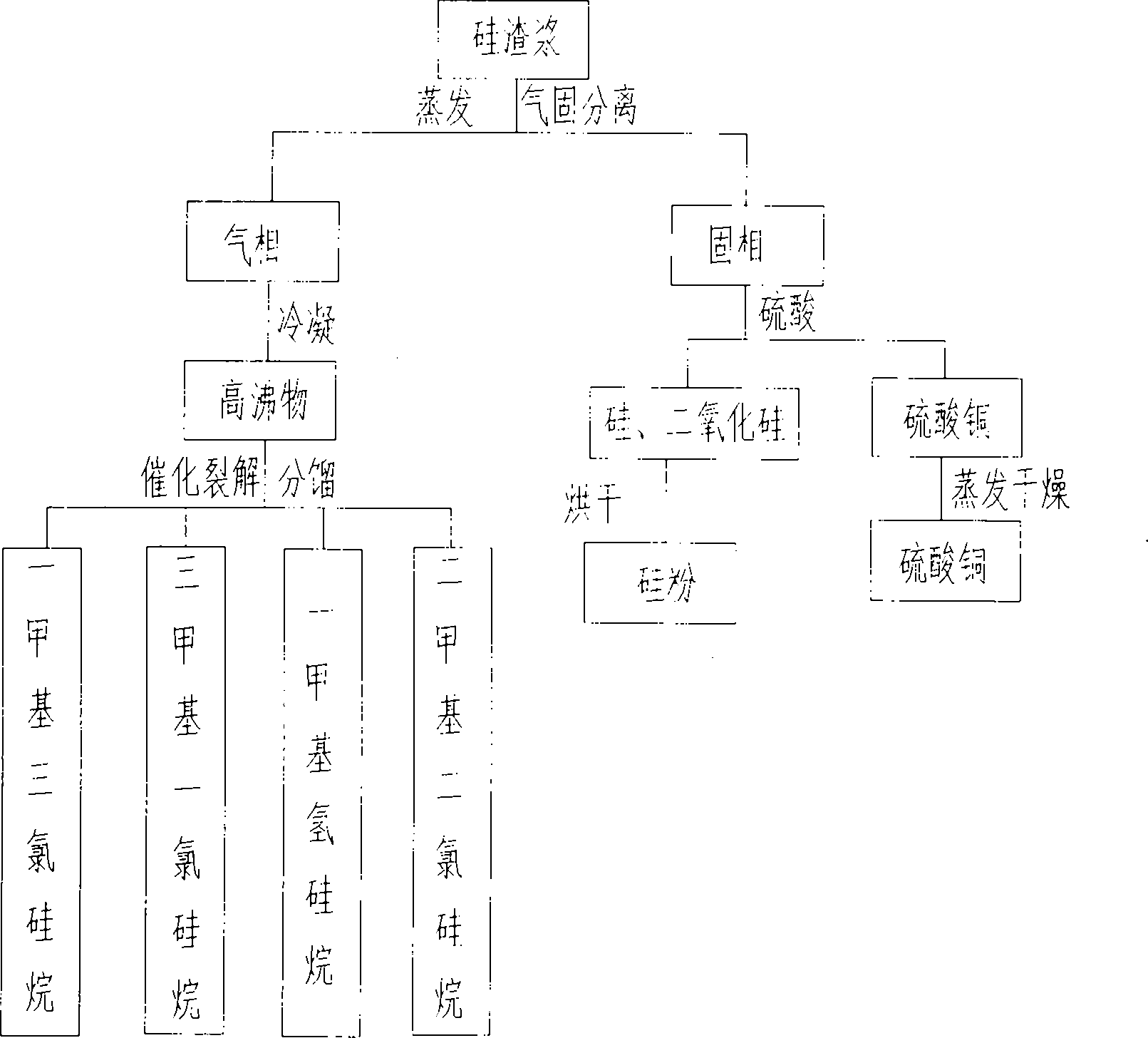

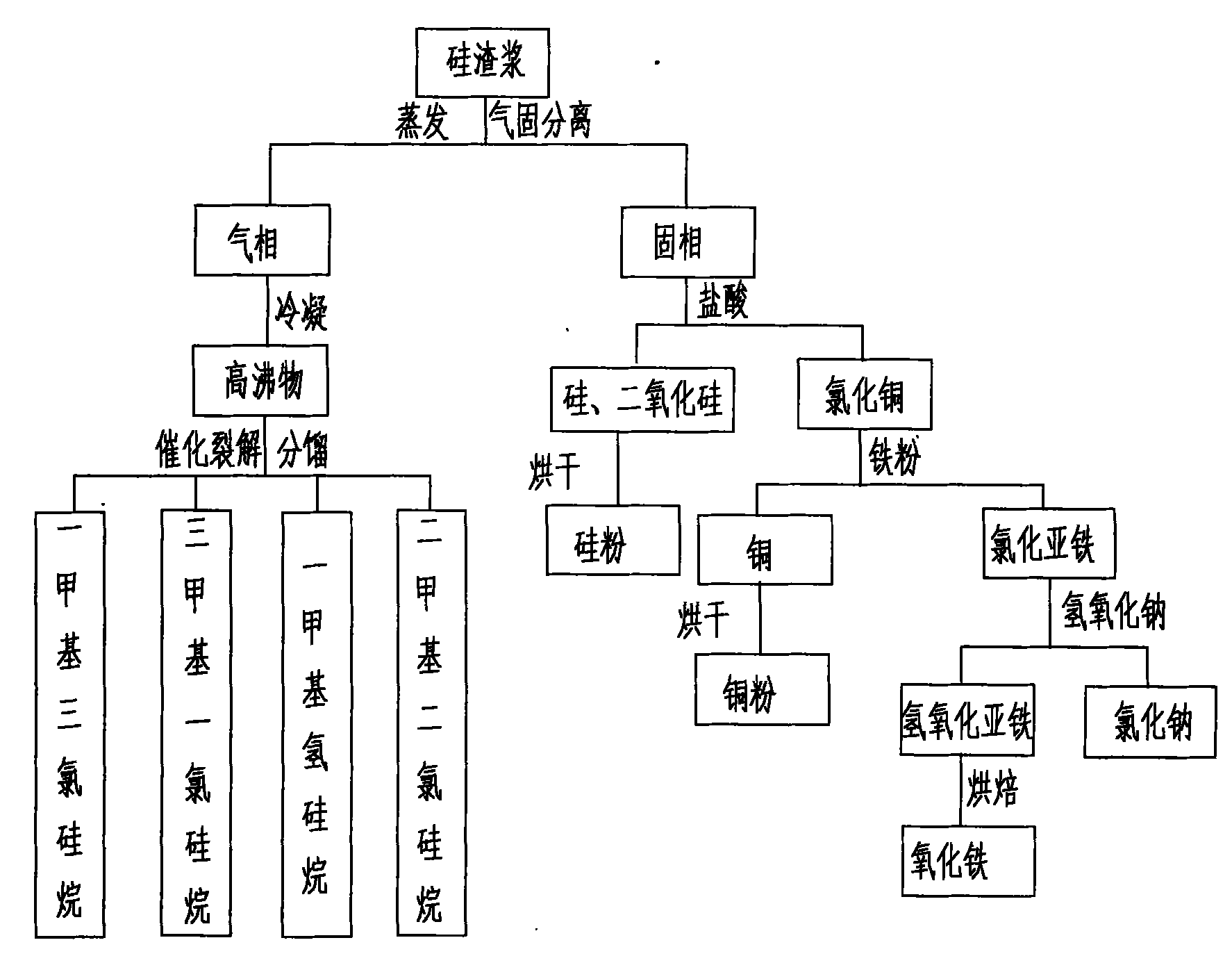

Processing and recycling process for silicon slurry

PendingCN102174674AGuaranteed to drive normallyEliminate pollutionSilicon organic compoundsFerrous oxidesGas phaseSilanes

The invention provides a processing and recycling process for silicon slurry, which comprises the steps as follows: silicon slurry is evaporated for gas and solid separation; high boiling point substances are obtained after the gas phase is condensed; the high boiling point substances react with hydrogen chloride to be cracked into mixed monomers such as methyl trichloro silicane, trimethyl chloro silicane, methyl silane, dimethyl dichloro silicane and the like; and after the fractionation, each pure monomer product can be obtained. The solid phase separated through evaporation mainly contains cuprous oxide, silicon, silicon dioxide and the like; hydrochloric acid (or sulfuric acid) is added into the solid phase to extract copper chloride (or copper sulfate, which can be sold directly) by a chemical method; and silicon and silicon dioxide are separated out. Iron powder is added into a copper chloride solution for extracting copper and ferrous chloride, and sodium hydroxide is added into the ferrous chloride solution for extracting ferrous oxide. The processing and recycling process is environment-friendly and can eliminate pollution, and meanwhile can recover various by-products from silicon slurry, thereby having well economic benefits.

Owner:上海竟茨环保科技有限公司

Method for preparing carbon-silicon carbide composite material by using chemical gas-phase permeation method

InactiveCN102344294AMake up for mechanicsMake up for the shortcomings of easy layeringWater bathsSilanes

The invention provides a method for preparing a carbon-silicon carbide composite material by using a chemical gas-phase permeation method. The method is characterized in steps that: a carbon fiber weaved body is placed in a deposition chamber, and deposed carbon particles are adopted as a dividing surface, wherein methane is adopted as a reaction gas, argon is adopted as a diluting gas, a deposition pressure in the deposition chamber is 6 to 7kPa, a deposition temperature is 900 to 1000 DEG C, and a deposition time is 3 to 12 hours; then silicon carbide crystal whiskers are deposed, wherein methyl trichloro silane is adopted as a reaction gas, hydrogen is adopted as a carrier gas, methyl trichloro silane is positioned in a evaporation vessel for water bath heating, a water bath temperature is 35 to 40 DEG C, a pressure in the evaporation vessel is controlled at 0.2 to 0.3MPa, a total flow of hydrogen and methyl trichloro silane is controlled at 200 to 300ml / min, methyl trichloro silane is delivered into the deposition chamber by hydrogen through a bubbling method, argon is used as a diluting gas, a deposition pressure in the deposition chamber is 6 to 7kPa, a deposition temperature is 1100 to 1150 DEG C, and a deposition time is 1 to 7 days, such that the carbon-silicon carbide composite material is obtained. The composite material provided by the invention has good toughness and high anti-interlaminar shear strength.

Owner:SHANDONG UNIV OF TECH

Cracking process of organosilicon high-boiling components

The invention relates to a cracking process of organosilicon high-boiling components.. The cracking process is characterized in that organosilicon high-boiling components are used as raw materials and are subjected to impurity removal, N,N-dimethylaniline, N,N-diethylformamide or tri-n-butylamine are selected as a catalyst, the catalytic cracking is performed inside a reaction vessel to which hydrogen chloride gas is introduced, and finally, dimethyldichlorosilane, monomethyltrichlorosilane, monomethyldichlorosilane and trimethylchlorosilane are respectively recovered through a layered cooling tower at different temperatures. The cracking process has the advantages that the matching is reasonable, the operation is simple, the recovery ratio is high, and more than 60% of dimethyldichlorosilane product with high added value can be obtained.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

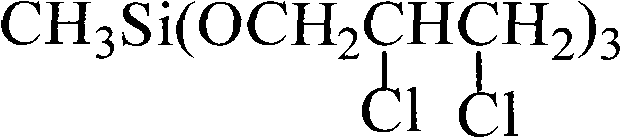

Methyl silicic acid tri(2,3-dichloropropyl) ester compound and preparation method thereof

InactiveCN102140114AImprove flame retardant performanceStabilize the C-Si bond structureGroup 4/14 element organic compoundsMethyltrichlorosilaneSilicic acid

The invention relates to a Si and Cl synergistic fire retardant methyl silicic acid tri(2,3-dichloropropyl) ester compound and a preparation method thereof. The structure of the compound is shown in the specification. The preparation method comprises the following steps: dropwise adding dichloropropanol with a certain molar ratio in methyl trichlorosilane at the temperature of 25 DEG C; heating to react for a period of time; after discharging hydrogen chloride, and purifying, so as to obtain the methyl silicic acid tri(2,3-dichloropropyl) ester. The methyl silicic acid tri(2,3-dichloropropyl)ester is high in inflaming retarding efficiency and is good in compatability with polymer materials, and has the advantages of simple process, less equipment investment and low cost. The preparation method is easy to achieve industrial production.

Owner:枣阳市佳宝硅助剂有限公司

Organosilicone water soluble long-acting compound fertilizer and preparation method thereof

The invention belongs to the technical field of enveloping type slow controlled release long-acting compound fertilizers, adopts organosilicone to clad compound fertilizer particles, forms an environment-friendly slow controlled release compound fertilizer, and further relates to a preparation method of the compound fertilizer. The organosilicone water soluble long-acting compound fertilizer is formed by a water soluble particle core and a hydrophobicity polymer outer enveloping layer. The preparation method is 1 preparing the water soluble particle core, enabling urea, triple superphosphate and potassium chloride to serve as main nutrient elements, smashing, mixing, prilling and drying to obtain particle fertilizers and enabling the particle fertilizers to serve as cores of enveloping fertilizers; 2 preparing an enveloping agent, enabling monomethyl trichlorosilane to serve as main raw materials, conducting cohydrolysis and condensation, and preparing modified organosilicone methyl silicone resin polymers after washing and disacidification; and 3 enveloping, putting the water soluble particle core in an enveloping machine, preheating, spraying the enveloping agent at interval, heating and keeping warm, conducting dehydration polycondensation crosslinking solidification, and forming a hydrophobicity methyl silicone resin film on the surface of the particle core of the fertilizer. The organosilicone water soluble long-acting compound fertilizer is free of the three wastes and free of toxic and side effects and environmental contamination in the whole manufacture and using processes, and belongs to environment-friendly products.

Owner:河北硅谷肥业有限公司

Method for preparing methyl chlorosilane by cracking organic silicon high boiling point substance

InactiveCN101824047AHigh selectivitySolve the use problemGroup 4/14 element organic compoundsBoiling pointMethyltrichlorosilane

The invention discloses a method for preparing methyl chlorosilane by cracking organic silicon high boiling point substance, which takes the organic silicon high boiling point substance produced by organic silicon mixed monomer as raw material, and comprises the steps of: when the organic silicon high boiling point substance is forged to 2 / 3 of the liquid level in a cracking kettle by a pump, adding catalyst triethylamine and tributylamine; filling chloromethane gas into the cracking reaction kettle with rising temperature, and preparing methyl chlorosilane mixed monomer; and cooling the mixed monomer, leading the mixed monomer enter a rectifying tower, and then preparing monomethyl dichlorsilane, dimethyl dichlorsilane, monomethyl trichlorosilane and trimethyl monochlorosilane. The method can improve the selectivity of the dimethyl dichlorsilane, increases the product yield, generates less residual waste, solves the problem of the utilization of the high boiling point substance, reduces the environmental pollution, is low in cost, has higher profit space, can be used for continuously cracking the high boiling point substance, and is suitable for popularization and application.

Owner:山东中创钢构有限公司

Method for preparing SiC coating on surface of spherical graphite material

The invention provides a method for preparing a SiC coating on the surface of a spherical graphite material. The method comprises the steps of (1) mixing Si powder, SiC powder, Al2O3 powder and graphite powder, so as to obtain embedding powder; (2) embedding the spherical graphite material into the embedding powder, and jolt-ramming an embedded mixture, so as to obtain the embedded mixture after jolt-ramming; (3) performing sintering treatment on the embedded mixture after jolt-ramming in an argon atmosphere, so as to obtain sintering treatment products; (4) performing chemical vapor deposition on the sintering treatment products in a spouted fluidized bed in the condition that methyl trichlorosilane, hydrogen and argon are introduced, so as to form the SiC coating on the surface of the spherical graphite material. By utilizing the method, the SiC coating which has the advantages of integrity in coating, uniformity in thickness, good transitivity and high bonding strength with a substrate can be rapidly and effectively prepared on the surface of the spherical graphite material.

Owner:TSINGHUA UNIV

Preparation method for methylphenyl silicone resin and coating

The invention provides a preparation method for a methylphenyl silicone resin and a coating. The preparation method comprises the following steps: using total or partial methyl trichlorosilane, dimethyldichlorosilance, phenyl trichlorosilane and dichlorodiphenylsilane to be combined as a monomer raw material, performing cohydrolysis in the presence of an organic solvent incompatible with water, generating organic siloxane alcohol, adding a nucleophilic reaction catalyst to 8% of tetramethylammonium hydroxide butanol solution, performing catalytic condensation, finally preparing an organic silicon resin polymer with a specific structure and high reactivity, weighing 20 g of the prepared methylphenyl silicone resin, adding a curing agent of butyl titanate, uniformly stirring for 1 h, uniformly coating on a substrate of an iron material, curing for 2-3 days in a room temperature, successfully constructing the methylphenyl silicone resin coating. The provided preparation method is capableof improving the yield, completely solving a fundamental defect of a thermal condensation silicone resin that the viscosity is returned after curing, and completely curing in the room temperature, hasthe good high-temperature and low-temperature resistance, and has the extensive application prospect.

Owner:HARBIN ENG UNIV

Organic silicon residue slurry treatment device and treatment method

InactiveCN104262379AAvoid pollutionAvoid it happening againGroup 4/14 element organic compoundsSlagMethyltrichlorosilane

The invention relates to an organic silicon residue slurry treatment device and treatment method. The treatment device comprises a suspension separator, wherein the side wall of the suspension separator is connected with a slag slurry inlet pipeline; the top of the suspension separator is connected with a clear solution outlet pipeline; the bottom of the suspension separator is connected with a bottom solution outlet pipeline; the end part of the clear solution outlet pipeline is connected with a pressurization leaf filter; the bottom of the pressurization leaf filter is connected with a filtrate outlet pipeline; and the end part of the filtrate outlet pipeline is connected with an organic-silicon high-boiling clear solution storage tank. When the slag slurry treated by the technique is used for catalytic cracking, the cracked crude product contains about 20% of dimethyl dichlorosilane, 36% of methyl trichlorosilane, 40% of methyl dichlorosilane and less than 1% of organic silicon high-boiling substance. Compared with the slag slurry hydrolysis technique adopted by most organic silicon manufacturers at present, the method provided by the invention avoids discharging abundant acid mist in the hydrolysis process, and reasonably reutilizes the valuable high-boiling substances from the generated solid waste slag.

Owner:浙江恒业成有机硅有限公司

Alcoholysis process for methyltrimethoxysilane

ActiveCN103012460AGuarantee normal productionAvoid cloggingGroup 4/14 element organic compoundsAlcoholMethyltrichlorosilane

The invention relates to a continuous alcoholysis process for methyltrimethoxysilane. Alcoholysis is accomplished by double towers. Methyl trichlorosilane and methanol are dropwise added to the tower I for alcoholysis reaction at a room temperature; incomplete alcoholysate generated by the reaction flows into the tower II and is subjected to the alcoholysis with vaporized methanol; and a crude finish product of methyltrimethoxysilane enters a crude finish product receiver. The process is stable and easy to operate, the product quality is high, the yield of the crude finish product of methyltrimethoxysilane is greater than 95%, the content is greater than 96%, and the acid content is less than 30ppm.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Metal powders with improved flowability

ActiveUS7943084B1Improve flow behaviorNot readily wetted by waterTransportation and packagingMetal-working apparatusMean diameterMethyltrichlorosilane

The present invention demonstrates a superior, more economical, and scalable process to increase the fluidity of metal powders by surface modification with alkylsilane reagents. This invention discloses that the most efficient process results from treatment with methyltrichlorosilane in hexane. In particular, the fluidity of aluminum powders having mean diameters smaller than 10 micrometers was considerably improved by the process of the present invention. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope of the claims.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

New technology of synthesizing dimethyldichlorosilance

ActiveCN103709187AEmission reductionEasy to operateGroup 4/14 element organic compoundsPhysical/chemical process catalystsNitrogen gasReactions stress

The invention relates to a new technology of synthesizing dimethyldichlorosilance with methyl chlorosilane byproducts through disproportionation. The method comprises the following steps: by taking gama-Al2O3 immobilized AlCl3 as a catalyst, simultaneously adding the mixture of zinc chloride and stannic chloride, or adding methyl trichlorosilane and trimethylchlorosilane in a raw material tank at a low-boiling point, feeding to a preheating section with nitrogen, gasifying raw materials to enter a reaction section, keeping the temperature of the reaction section to be 200-400 DEG C, wherein the reaction pressure is 0-0.6 MPa; standing for 10-40s, cooling products through a condenser after reaction, feeding monomers after being cooled in a collection tank, and absorbing tail gas with alkali liquor. The new technology has the advantages that the content of dimethyldichlorosilance synthesized through the technology is higher than the level of existing patents and related articles; and moreover, the technology is simple in operation, can effectively reduce the emission of three wastes, and can continuously process methyl chlorosilane by products in a large scale.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Preparation method of methyltrialkoxysilane

InactiveCN104262380AImprove efficiencyHigh yieldGroup 4/14 element organic compoundsAmmonium halidesAlcoholMethyltrichlorosilane

The invention provides a preparation method of methyltrialkoxysilane. The preparation method comprises the following steps of adding anhydrous alcohol into a reaction container A, arranging one end of a gas-guide tube under the liquid level in the reaction container A, introducing the other end of the gas-guide tube into a container B with methyltrichlorosilane, heating the anhydrous alcohol in the reaction container A to a temperature of 55-63 DEG C for a reaction, heating the methyltrichlorosilane in the container B to a temperature of 62-68 DEG C, feeding N2 into the container B, heating the mixed solution in the reaction container A to a temperature of 75-88 DEG C, carrying out a backflow thermal-insulation reaction process for 1-4h, then stopping heating, collecting the product, and feeding ammonia gas into the product to adjust product pH to 8-9 so that methyltrialkoxysilane is obtained. Dry neutral gas and an ammonia gas neutralizer are used under the conditions of normal pressure and low temperature. The preparation method utilizes simple technical equipment, is convenient for operation, and has a low cost and a high yield. Ammonium chloride obtained by neutralization of the preparation method can be used as fertilizer and is conducive to green production.

Owner:HUBEI XINGFA CHEM GRP CO LTD

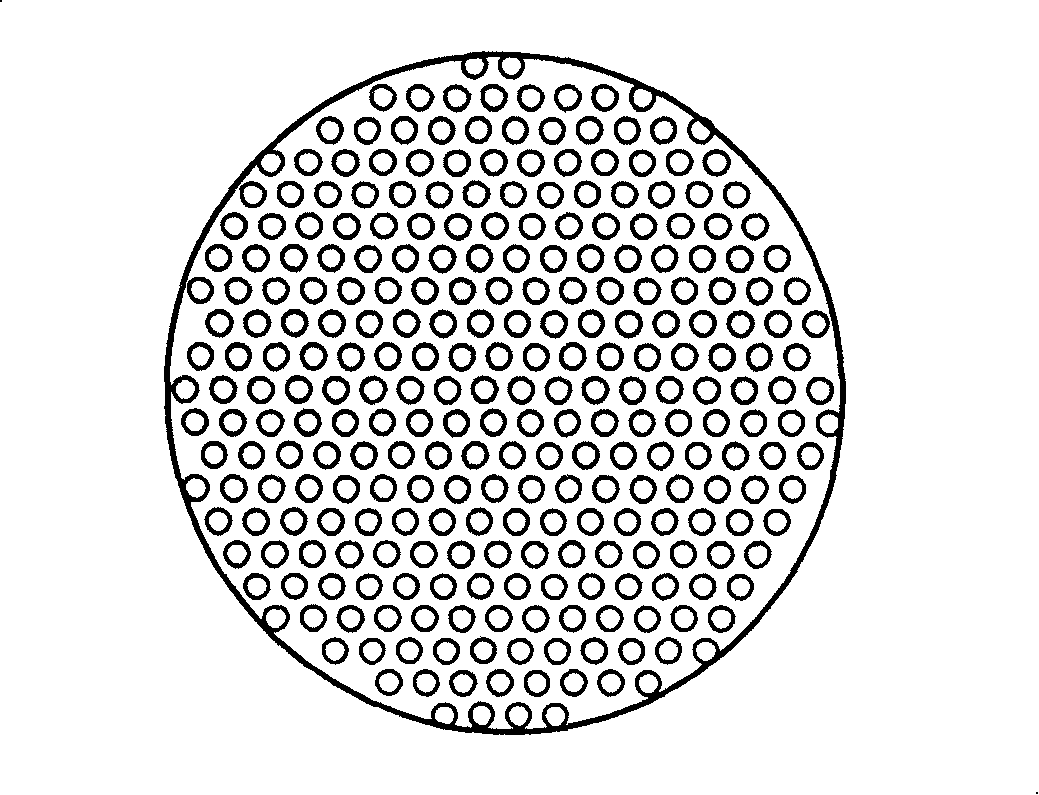

Method for preparing silicon carbide reflecting mirror material and CVI forming device thereof

InactiveCN101240417AAvoid crackingSame deposition effectMirrorsChemical vapor deposition coatingMethyltrichlorosilaneShielding gas

The invention discloses a preparing method for SiC reflector material and a CVI forming device for the preparing method. The method is: using 50 to 200 mesh Sic power as raw material put in the graphite cavity of the CVI forming device, methyltrichlorosilane as Sic gas source, H2 as eluant gas and diluent gas, Ar as protective gas, under a temperature of 1000 to 1300 DEG C, depositing SiC to form a blank by CVI method; after shucking off the graphite cavity, repeatedly CVI depositing SiC to intensify the blank and mechanically processing for several times; and preparing SiC reflecting layer on the surface of the SiC blank by CVD method. For reflector material prepared by the invention, crackle is not easy to appear, since the base and coating have same heat performance, the production period is greatly reduced, the production cost is lowered, and multiple workpieces can be deposited at the same time.

Owner:CENT SOUTH UNIV

Method for preparing methylchlorosilane with high boiling organosilicon

InactiveCN101314606AHigh selectivitySimple processGroup 4/14 element organic compoundsDimethylaniline N-oxideMethyltrichlorosilane

The invention relates to a method for preparing methyl chlorosilane from organosilicon high-boiling products. The method comprises the steps as follows: the whole composition of the high-boiling products which are the byproduct in the production process of dimethyl dichlorosilane as the organosilicon monomer is adopted as the raw material and reacts with hydrogen chloride in the presence of N,N-dimethylanlilne and tri-n-butylamine as a catalyst in a cracking kettle with a fractionating tower to obtain a mixed monomer mainly containing dimethyl dichlorosilane, trimethylchlorosilane, methyldichlorosilane and methyltrichlorosilane; and the mixed monomer is collected via the overhead condenser of the fractionating tower. The method can improve the conversion of the high-boiling products. The conversion is higher than 90%, the dimethyl dichlorosilane allows a selectivity of higher than 50%, and the selectivety of trimethylchlorosilane reaches 10%. The organosilicon monomer can be prepared at low cost.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com