Method for preparing silicon carbide reflecting mirror material and CVI forming device thereof

A reflective mirror and silicon carbide technology, applied in metal material coating technology, mirrors, gaseous chemical plating, etc., can solve the problems of easy cracks in the substrate and coating, low overall density of the material, and low preparation cost, and achieve thermal The effect of consistent performance, shortened time, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

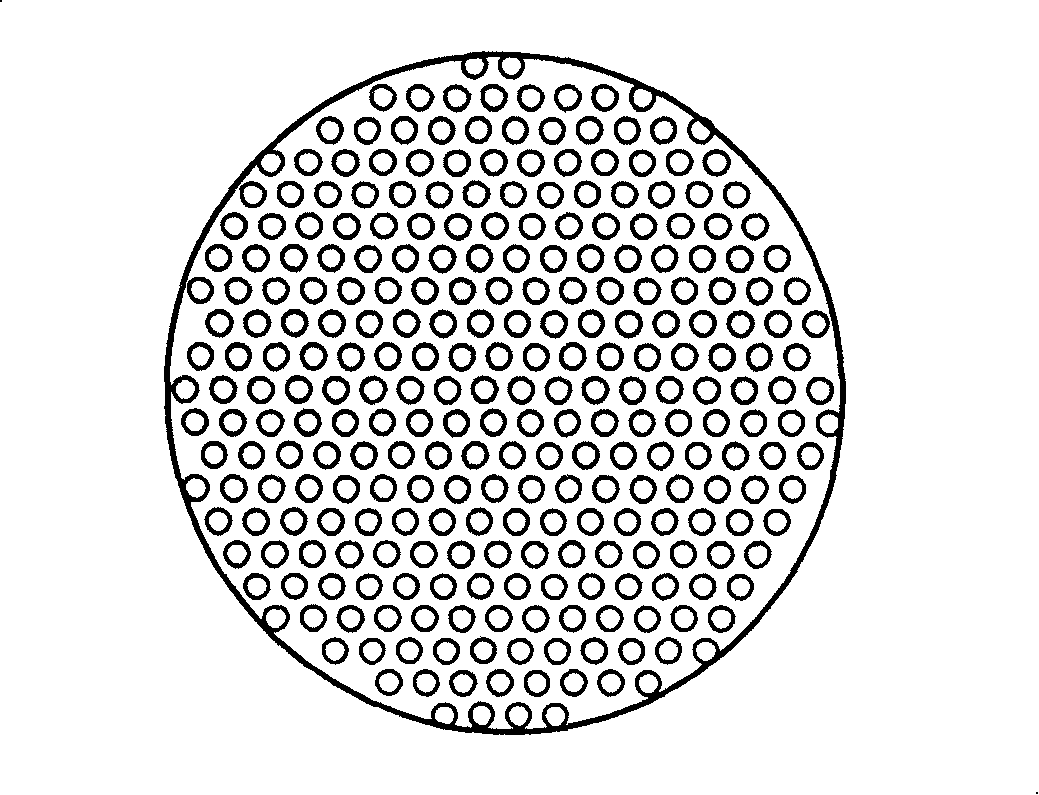

[0021] The CVI forming device is formed by adding a graphite chamber to a conventional CVI deposition furnace. The graphite cavity 2 is composed of two semi-cylinders and two upper and lower gas-conducting graphite gaskets 4. In order to facilitate demoulding, the contact surface is covered with graphite paper 5, and the graphite cavity 2 is tightened by the graphite outer mold sleeve 1. Between the SiC powder 3 and the inner wall of the graphite cavity 2 is a layer of graphite paper 5 to prevent the SiC powder 3 from adhering to the inner wall of the graphite cavity 2 during the CVI process. Since the pore diameter of the gas-conducting graphite gasket 4 is larger than that of the SiC powder, the SiC powder may be carried out by the air flow during the CVI process. There is a layer of carbon fiber mesh tire 7 between the SiC powder 3 and the gas-conducting graphite gasket 4, also for the convenience of Demoulding, the carbon fiber net tire 7 and the gas-conducting graphite ga...

Embodiment 2

[0023] A SiC mirror material with a size of φ150×20mm is prepared. The preparation process and related parameters are as follows: (1) β-SiC powder with a particle size of 50 mesh is loaded into a graphite cavity. (2) CVI deposited SiC densification at 1100°C to form SiC powder. The process parameters are: MTS: H 2 =1:12, the Ar gas flow rate is 200ml / min, the deposition pressure is 300Pa, and the deposition time is 50h; (3) After removing the graphite cavity, CVI is densified again for 50h; (4) SiC blank is processed on a diamond grinding machine Preliminary mechanical processing to increase the surface porosity and make the green body have a certain flatness; (5) Repeat CVI deposition SiC densification twice, each deposition time is 50h, deposition temperature is 1300°C, MTS:H 2 =1:8, the Ar flow rate is 300ml / min, the deposition pressure is controlled at about 5kPa, and the surface of the green body needs to be machined before each densification; (6) Deposit a layer of CVD...

Embodiment 3

[0028] SiC mirror materials made of SiC powders of different particle sizes and the same CVI deposition process were prepared, and the sample size was φ50×15mm. The preparation process and related parameters are as follows: (1) SiC powder with a particle size of 50 mesh and 200 mesh is loaded into a graphite cavity. (2) SiC densification by CVI deposition at 1100°C to shape the matrix additive. The process parameters are: MTS: H 2 =1:12, the Ar flow rate is 200ml / min, the deposition pressure is 300Pa, and the deposition time is 50h; (3) After removing the graphite cavity, CVI is densified again for 50h; Mechanical processing to increase the surface porosity and make the green body have a certain flatness; (5) Repeat the densification twice, each deposition time is 50h, the deposition temperature is 1300°C, MTS:H 2 =1:8, the Ar flow rate is 300ml / min, the deposition pressure is controlled at about 5kPa, and the surface of the green body needs to be machined before each densif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com