Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

663 results about "Methyltrimethoxysilane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

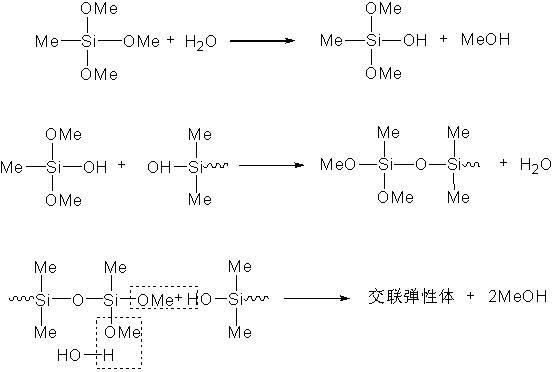

Methyltrimethoxysilane is an organosilicon compound with the formula CH₃Si(OCH₃)₃. It is a colorless, free-flowing liquid. It is a crosslinker in the preparation of polysiloxane polymers.

Glass fiber reinforced silicon dioxide aerogel composite material and preparation method thereof

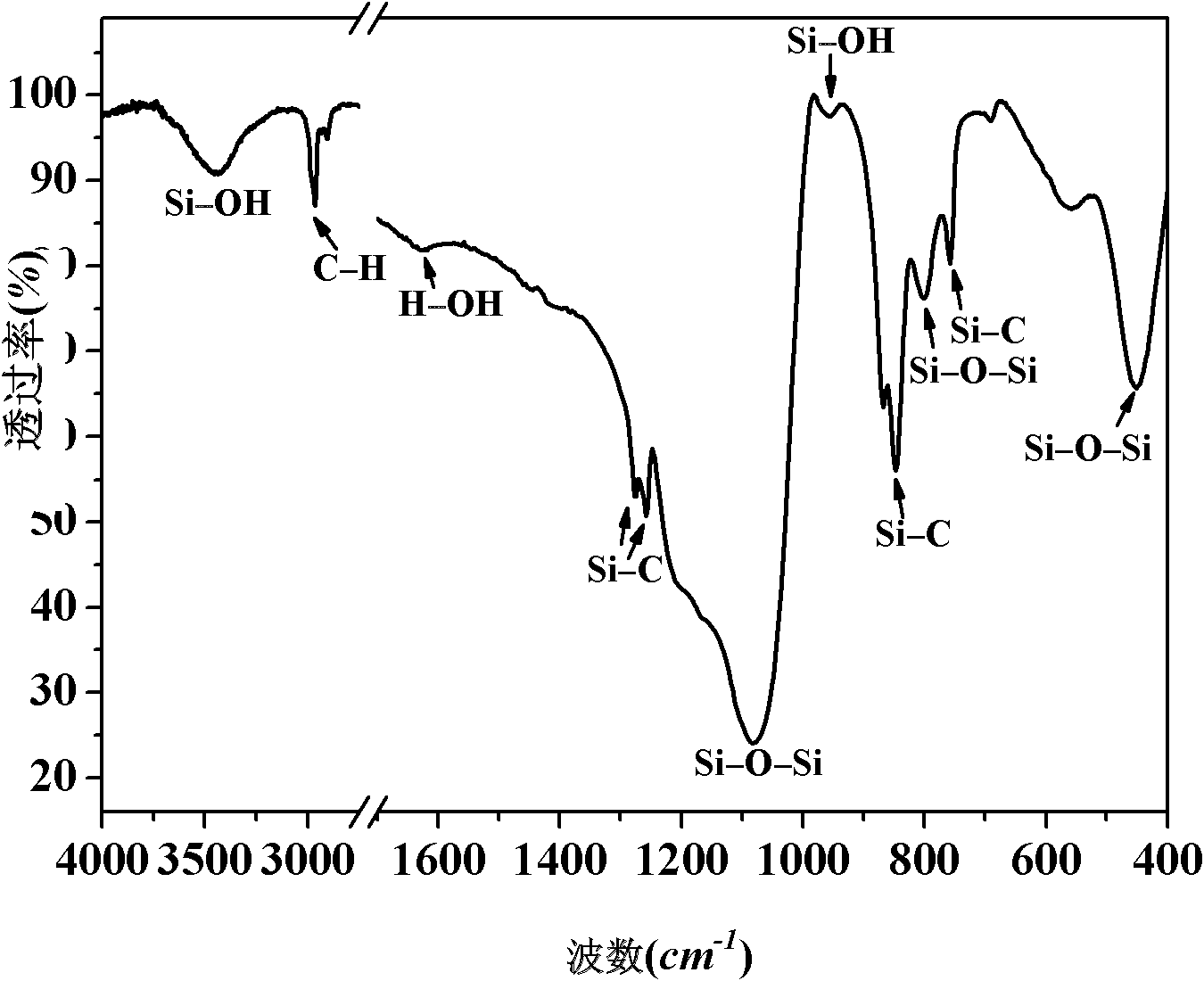

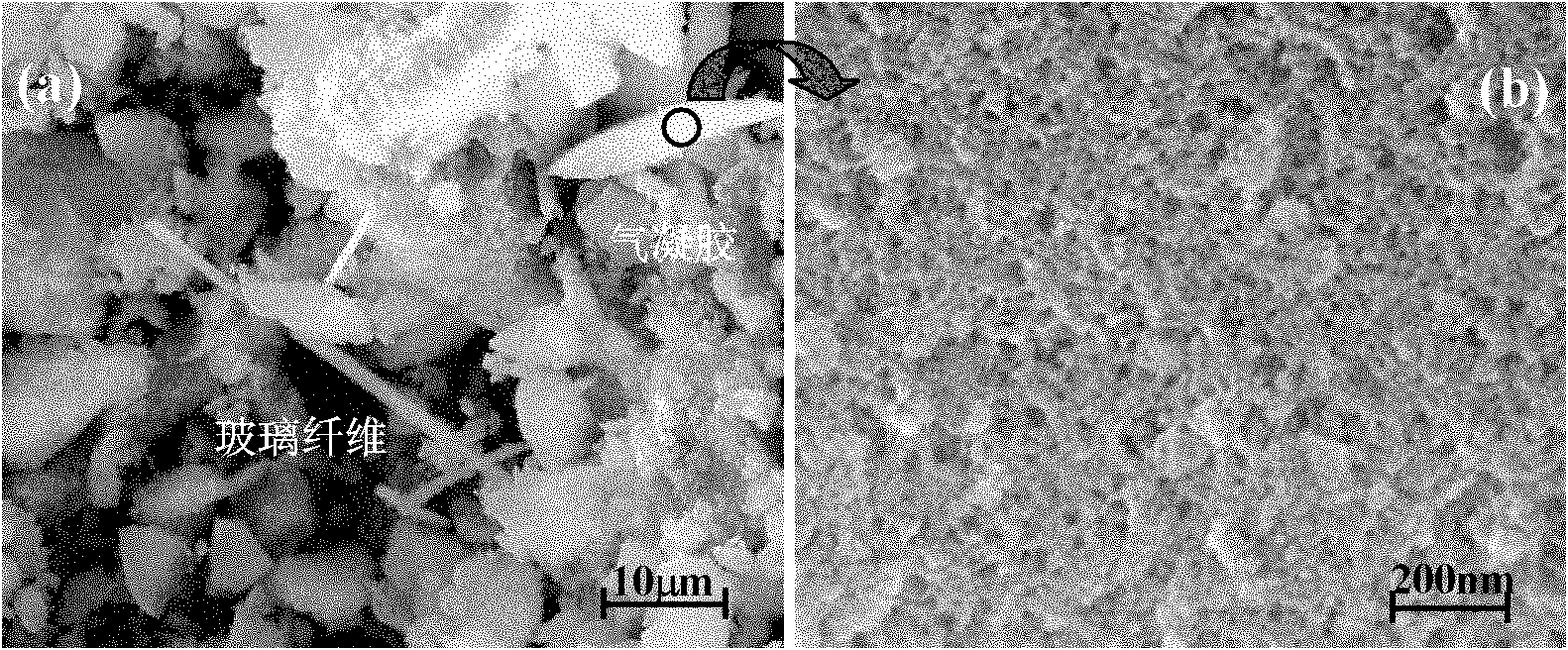

The invention relates to an aerogel composite material, in particular to a glass fiber reinforced silicon dioxide aerogel composite material and a preparation method thereof. The excellent properties of aerogel are maintained, the mechanical properties of the aerogel are reinforced, and the glass fiber reinforced silicon dioxide aerogel composite material has good integrity and certain strength. The glass fiber reinforced silicon dioxide aerogel composite material is prepared by compounding glass fiber and silicon dioxide aerogel, wherein the glass fiber is a reinforcement, and the content ofthe glass fiber accounts for 1-15% total mass of a sample; the silicon dioxide aerogel is a matrix, tetraethoxysilane is a silicon source material, and methyltrimethoxysilane or methyltriethoxysilaneis used as a silicon source co-precursor. The preparation method comprises the following steps of: firstly, pretreating the glass fiber; then, preparing glass fiber reinforced silicon dioxide composite wet gel; and finally, aging, secondarily modifying and drying the silicon dioxide composite wet gel.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

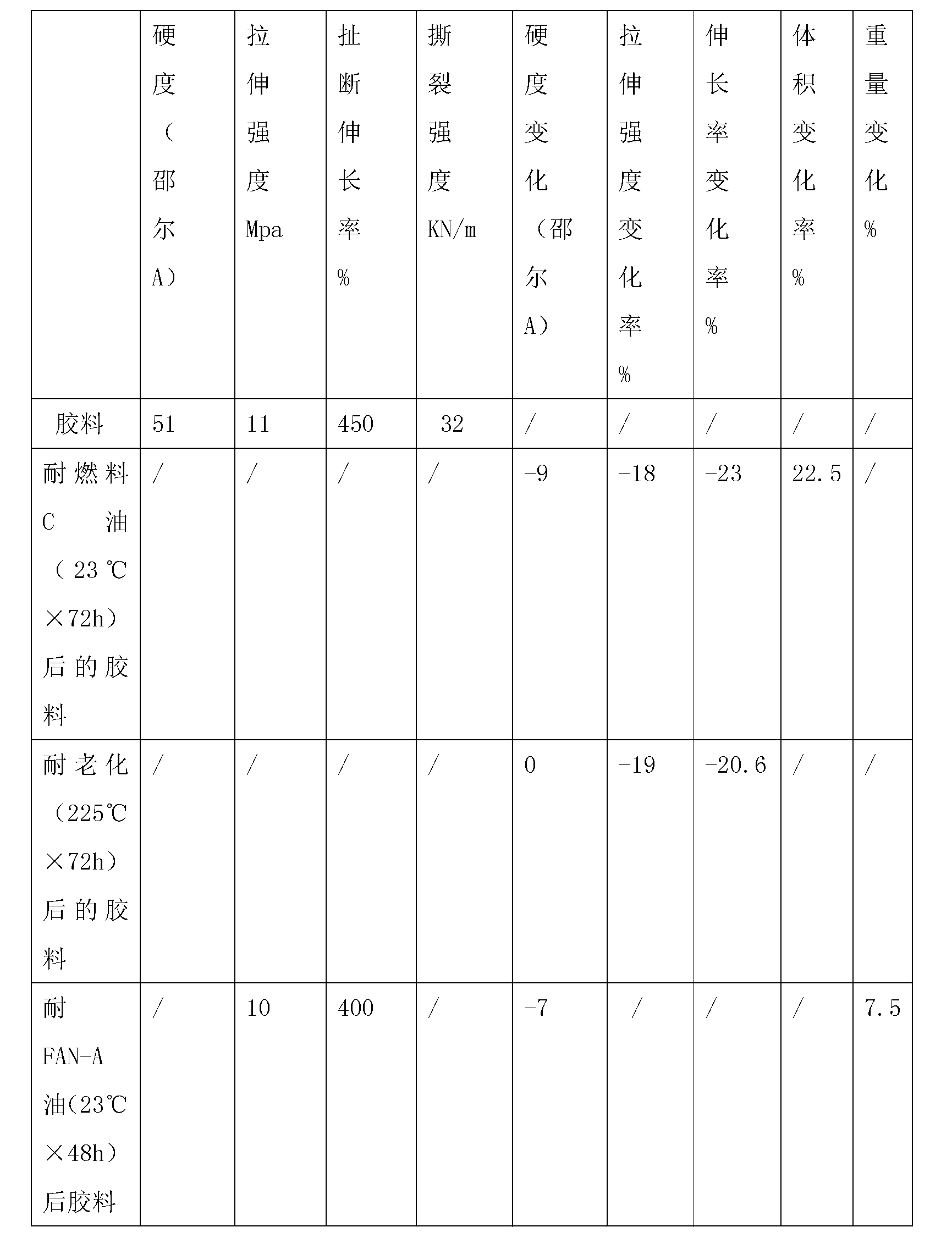

Valve sealing gasket sizing material and preparation method thereof

ActiveCN103012891AImprove performanceGood high and low temperature resistanceDiphenylsilanediolSolvent

The invention discloses a valve sealing gasket sizing material, which is prepared from the following raw materials in parts by weight: 20-30 parts of fluorosilicone rubber, 50-60 parts of hydrogenated nitrile-butadiene rubber, 15-25 parts of chlorosulfonated polyethylene rubber TS-320 (TOSOH, Japan), 2-3 parts of gamma-methacryloxypropyltrimethoxysilane, 1-2 parts of diphenyl silandiol, 14-16 parts of modified tree ash, 2-3 parts of ferrocene, 0.2-0.6 part of dicumyl peroxide (DCP), 20-30 parts of high-abrasion resistant carbon black N330, 20-25 parts of precipitated white carbon black, 5-7 parts of light calcium carbonate, 2-4 parts of zinc oxide, 1-3 parts of calcium stearate, 1-3 parts of aluminium oxide, 5-8 parts of dolomite, 13-15 parts of modified iron tailing powder, 0.1-0.3 part of accelerating agent MBTS, 1-2 parts of sulphur, 1-2 parts of anti-aging agent RD, 1-2 parts of anti-aging agent MB, 1-2 parts of benzimidazole-2-thiol, 1-3 parts of methyltrimethoxy silane, and 2-3 parts of paraffin. The sizing material of the rubber has excellent high and low temperature-resistant, oil-proof, solvent-resistant and chemical-resistant performance, and at the same time is good in mechanical property and low in cost.

Owner:平湖市博宏塑料制品厂

Preparation method of flexible silica aerogel

The invention discloses a preparation method of a flexible silica aerogel, relating to a silica aerogel. The invention provides the preparation method of the flexible silica aerogel, which takes methyl alkoxy-series silane as a silicon source precursor. The preparation method comprises the steps of mixing methyl trimethoxysilane or methyl trimethoxysilane, an anhydrous ethanol solution and water, further adding hydrochloric acid, regulating the pH value of the solution to 2-2.5, then adding ammonia water to obtain a sol, standing, then preparing a wet gel, further aging the wet gel, and then drying to prepare the flexible silica aerogel. The prepared flexible silica aerogel has the advantages of low density and high porosity, and simultaneously overcomes the shortcomings of poor integrity and great brittleness. According to the preparation method, the complicated steps of complex solvent exchange and gel modification are not required, so that the operation is simple and easy, the process is controllable, the cost is low, the period is short, and the continuous production can be realized.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

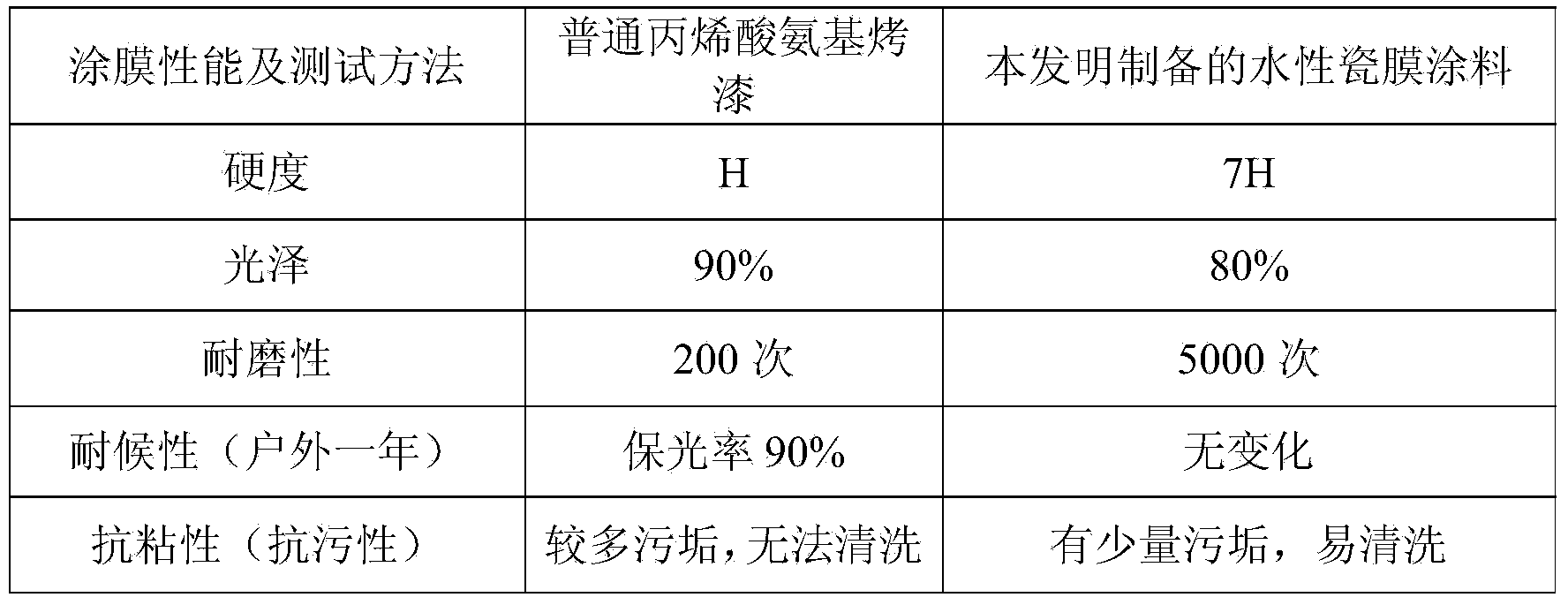

Water-based porcelain film coating and preparation method thereof

The invention provides a water-based porcelain film coating. The formula of the water-based porcelain film coating comprises the following components in parts by weight: 45% to 55% of colloidal silica dispersion liquid, 30% to 45% of a silane coupling agent, 5% to 15% of an inorganic pigment, 2% to 5% of alumina packing, 0.5% to 1% of a flatting agent, 1% to 2% of hydroxy silicone oil with low molecular weight and 1% to 1.5% of an organic acid catalyst, wherein the colloidal silica dispersion liquid is prepared by mixing colloidal silica with big and small particle diameters according to the mass ratio of (1-3):1, wherein the particle diameters of the colloidal silica with the small particle diameters are distributed within 10nm to 15nm while the particle diameters of the colloidal silica with the big particle diameters are distributed within 40nm to 50nm; the silane coupling agent is prepared by mixing methyl trimethoxysilane and methyl triethoxysilane according to the mass ratio of (1-2):1; the organic acid catalyst can be a formic acid or an acetic acid or can be a mixture of the formic acid and the acetic acid. The water-based porcelain film coating has the good adhesive force and the good waterproof and cohesive-proof on an aluminum alloy substrate.

Owner:广东四方威凯新材料有限公司

Novel crosslinker of single-component de-alcoholized room temperature vulcanized silicone rubber and preparation method thereof

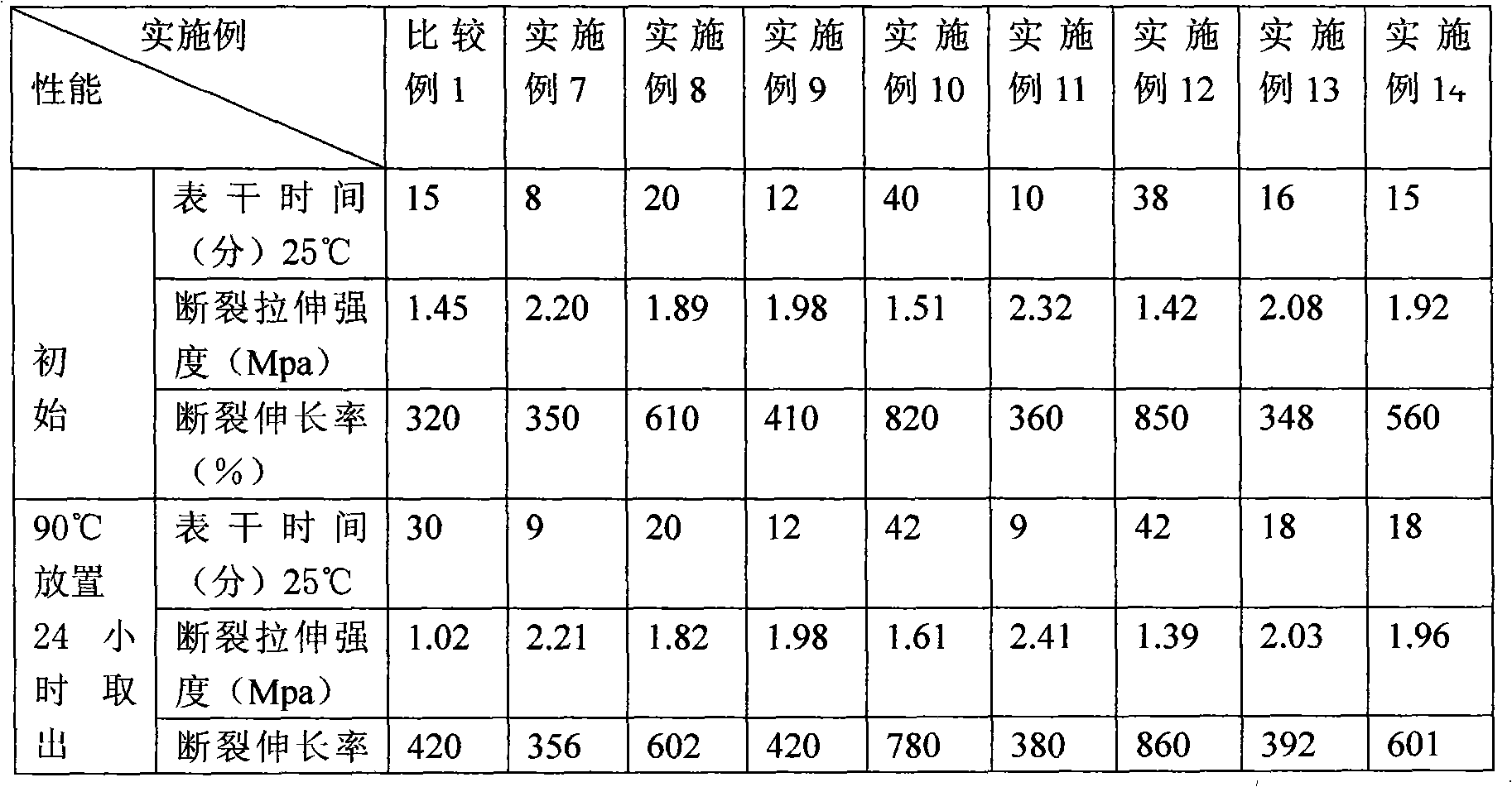

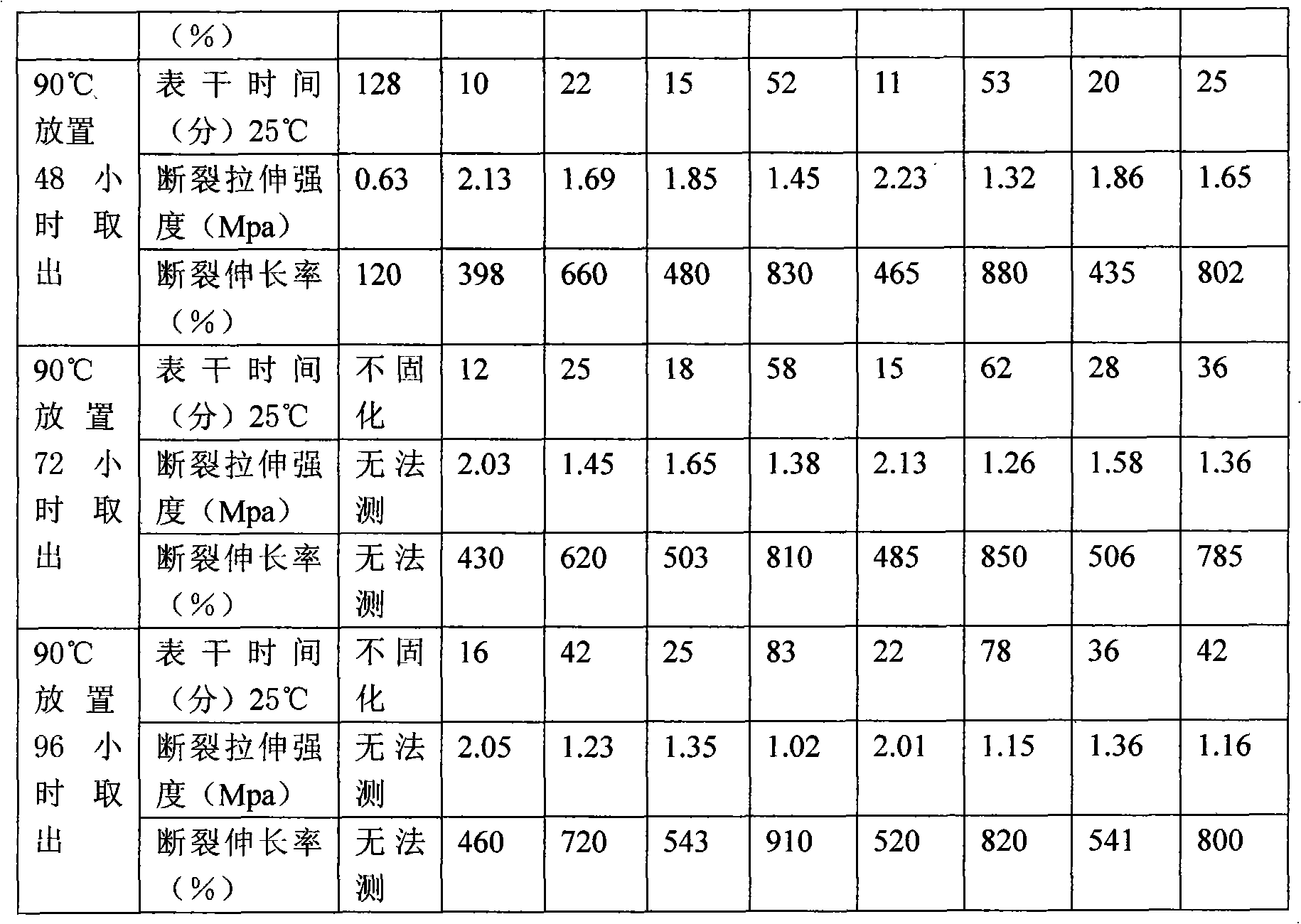

InactiveCN101624446AGood storage stabilityGood physical and mechanical propertiesPolymer scienceVulcanization

The invention relates to a method for synthesizing poly alkyl methoxy silane by taking alkylchlorosilane or alkyl methoxy silane as main raw materials, or the poly alkyl methoxy silane replaces methyl trimethoxy silane and other crosslinkers partially or wholly for being used as a novel crosslinker of single-component de-alcoholized room temperature vulcanized silicone rubber, so as to lead the storage stability and the physical mechanical properties (fracture tensile strength and fracture elongation) after being solidified to be improved.

Owner:朱旭 +2

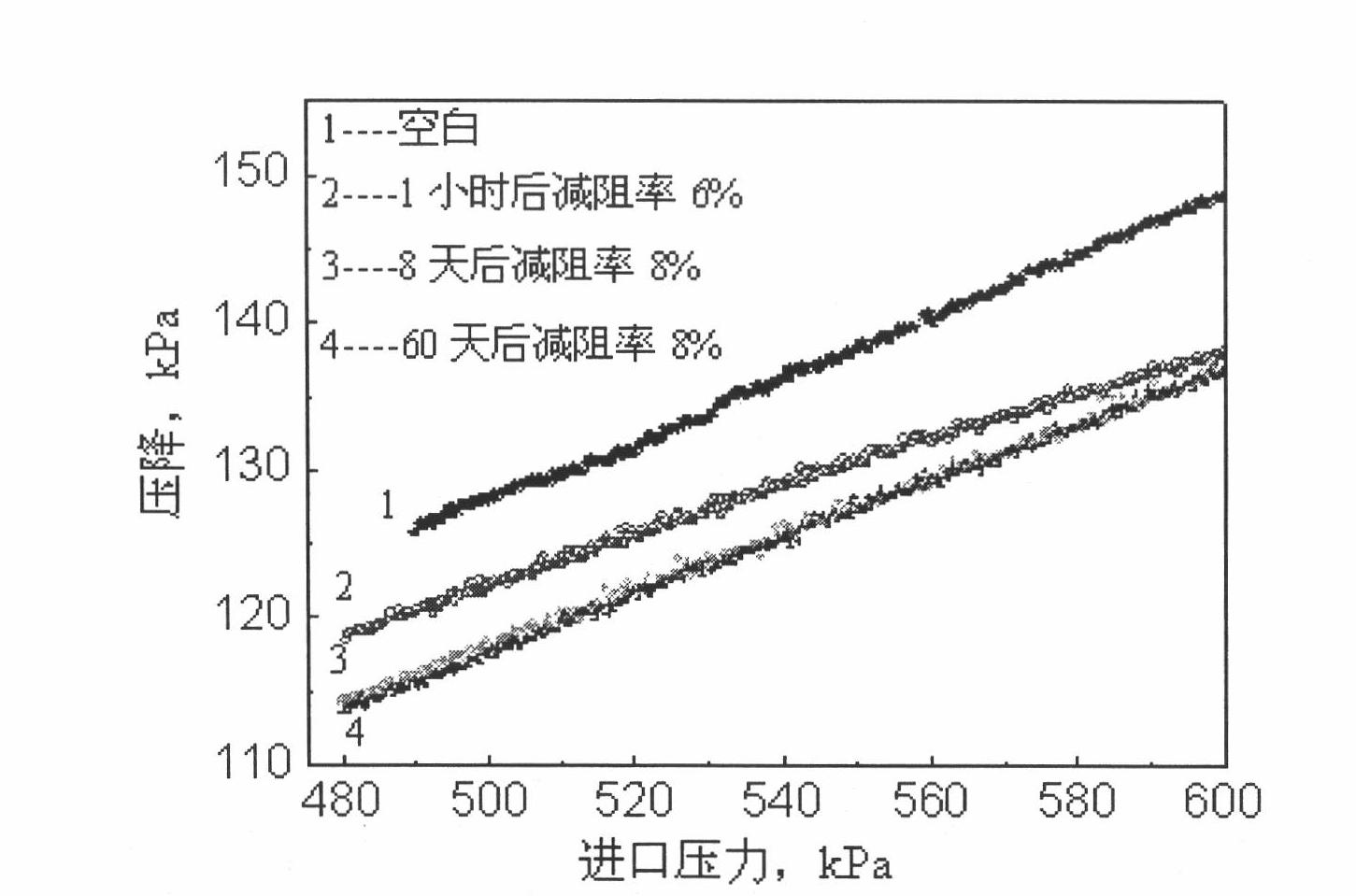

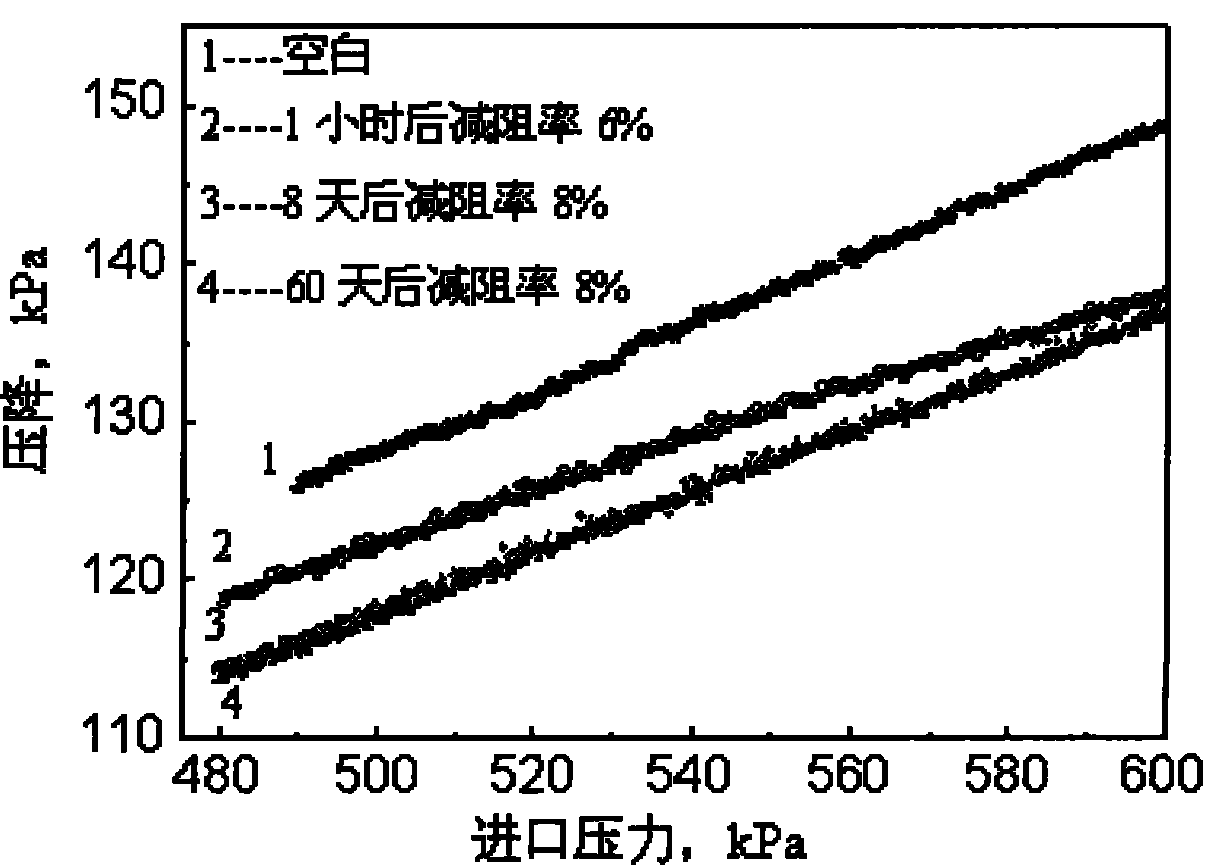

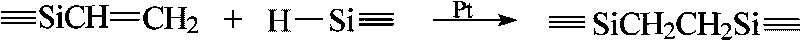

Antisepsis and antidrag chemical additive of natural gas pipeline and preparation method thereof

ActiveCN102040908AEase of application for pipingGood anti-corrosion functionCorrosion preventionAnti-corrosive paintsSilanesChemical compound

The invention discloses an antisepsis and antidrag chemical additive of natural gas pipeline and a preparation method thereof, and relates to the technical field of anticorrosion of common metal material, composition of macromolecular compound and pipeline system. Dodecyl trimethoxy silane is prepared by trimethoxy silane and Alpha-laurylene of which the mole ratio is 1:1-1.3:1 and a platinum catalyst under catalyzing, wherein the mole ratio of the platinum catalyst to Alpha-laurylene is 10*10-6:1-12*10-6:1; and the methyltrimethoxy silane and the synthetic dodecyl trimethoxy silane are successively added to a solvent normal hexane with the mole ratio as 0:1-0.1:1 and mixed and configured into a solution of 40-60wt%. In the invention, the pipe wall has strong adsorption force, functions are multiple, the process is simple, and the effect is preferable.

Owner:PIPECHINA SOUTH CHINA CO

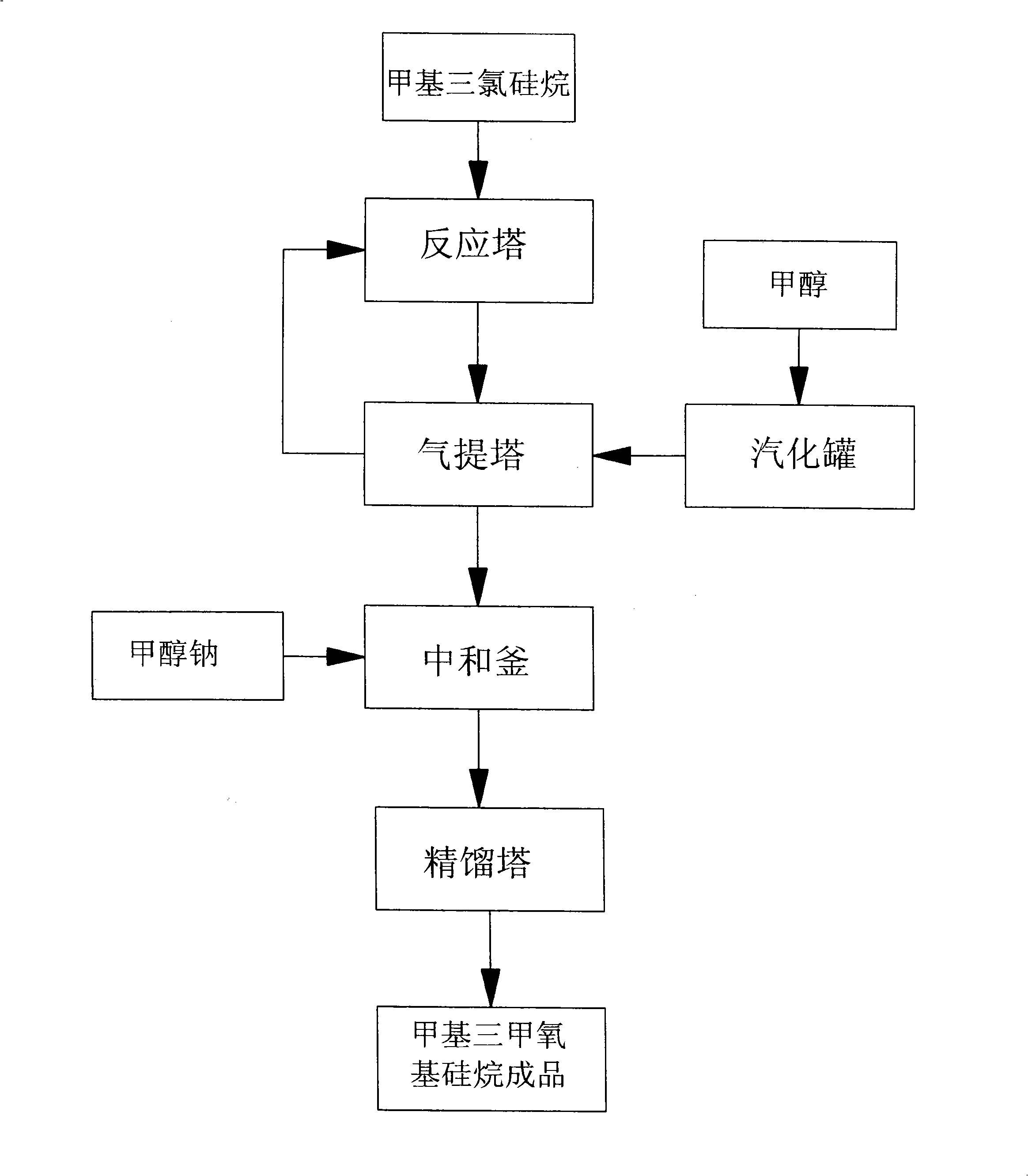

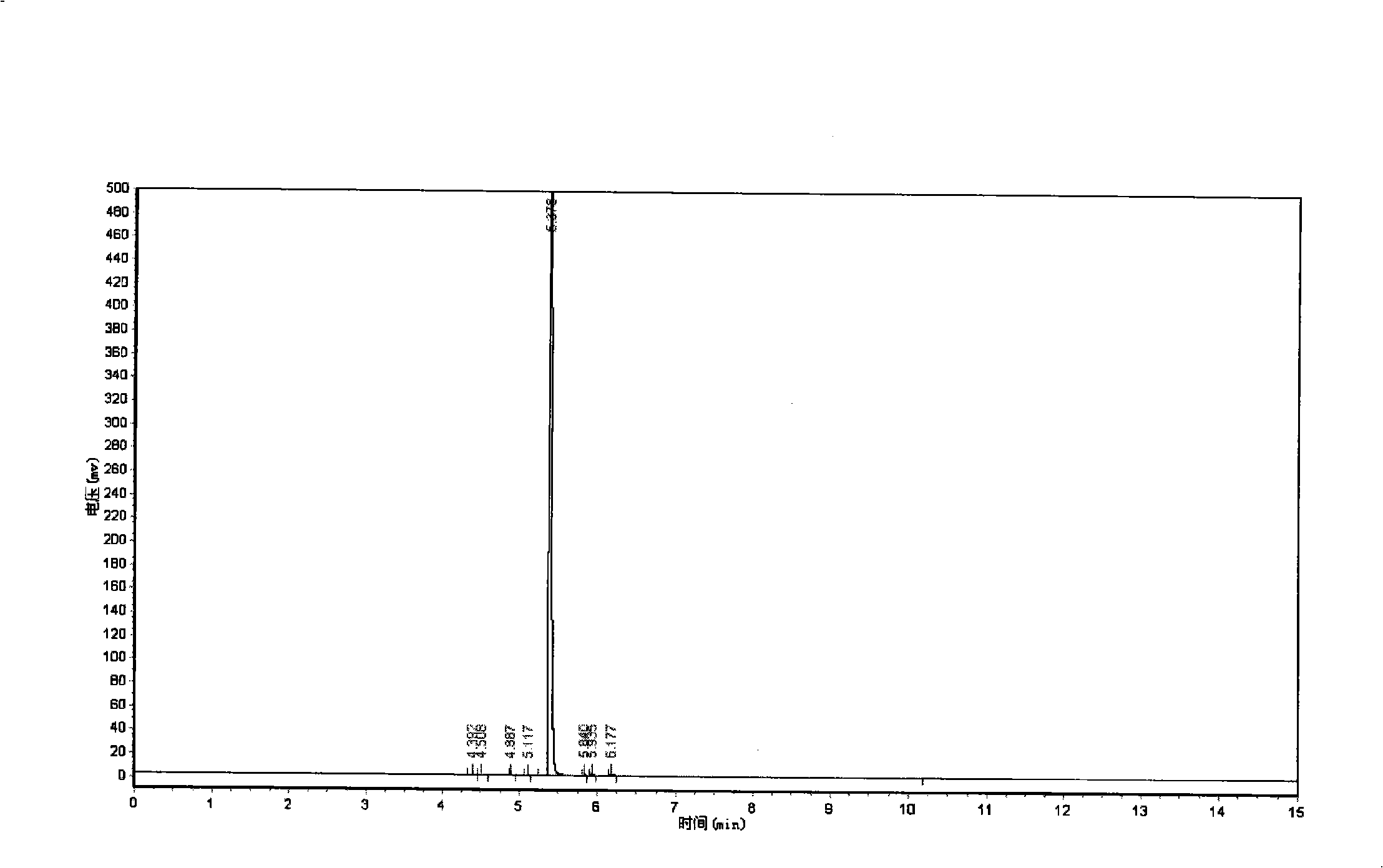

Preparation technique of methyl trimethoxysilane

ActiveCN101348497AEfficient removalAvoid it happening againGroup 4/14 element organic compoundsMethyltrichlorosilaneSilanes

The invention provides a process for preparing methyltrimethoxy silane. The process comprises the following steps that: a. methanol is subjected to vaporization by a vaporizing cylinder and passes through a stripping tower, and enters the bottom part of a reaction tower, methyl trichlorosilane enters the reaction tower from the top and is sprayed downward, and methanol reacts with methyl trichlorosilane by counter current contact; b. a primary product is pumped in the top part of the stripping tower and subjected to steam stripping by methanol gases passing by the stripping tower, after falling onto the bottom part of the stripping tower, the primary product is pumped in a neutralization kettle, and the saturated sodium methylate solution is added in the neutralization kettle for neutralization; c. the coarse product of methyltrimethoxy silane is pumped in a rectification tower for rectification. The process has the characteristics of high working efficiency, stable process and big output, etc. Because the process of the invention is continuously carried out, the process has the advantages of having few operators, ensuring safe production and being capable of easily realizing the control of DCS computers; moreover, the product yield is 90 percent, the effective content of the product is high, and the content of methyltrimethoxy silane is more than 99 percent.

Owner:湖北新蓝天新材料股份有限公司

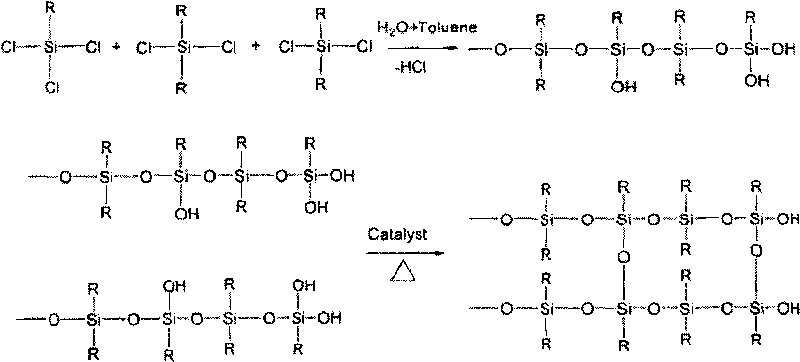

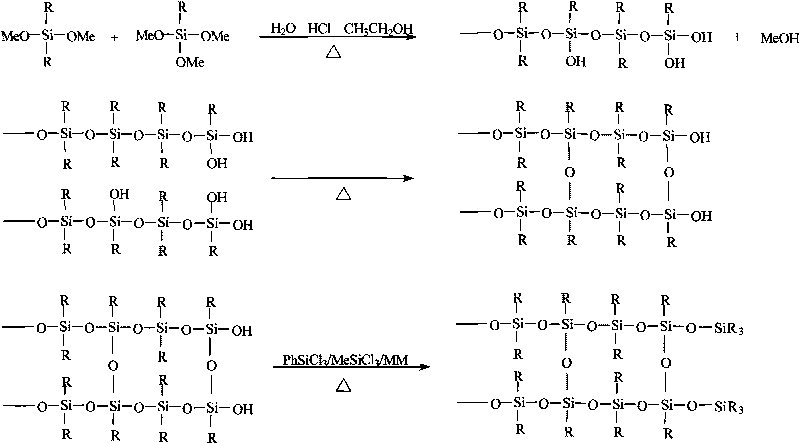

Method for preparing methyl phenyl vinyl silicone resin

The invention discloses a method for preparing a methyl phenyl vinyl silicone resin, which comprises the following steps of: under a condition of a nitrogen atmosphere at the temperature of between 30 and 45 DEG C, dissolving a certain amount of methyl trimethoxy silane, vinyl trimethoxy silane and alkyl dimethoxy silane in ethanol; adjusting the pH of the system to between 2.8 and 3.5; after full reaction, adding the methyl trimethoxy silane, the vinyl trimethoxy silane, the alkyl dimethoxy silane and deionized water into the mixture to perform isothermal reaction for 0.5 to 1 hour at the temperature of between 50 and 60 DEG C; raising the temperature to between 72 and 78 DEG C, performing the isothermal reaction again for 8 to 10 hours, and then dropping an end capping agent and deionized water into the mixture; performing reaction at the temperature of between 72 and 78 DEG C for 6 to 10 hours to obtain a white emulsion; and standing the mixture until complete demixing, separating the mixture to obtain an oily matter at a lower layer, and performing vacuum drying on the oily matter to obtain a product of the methyl phenyl vinyl silicone resin. In the method, the process is simple, the product is easy to separate and purify, the reactions are mild and are easy to control, and the processability is greatly improved.

Owner:SUZHOU UNIV

Flame-retardant dealcoholization type room-temperature curing silicon rubber

ActiveCN102002240AImprove stabilityGood adhesionOther chemical processesAdhesivesSilanesBinding force

The invention provides a flame-retardant dealcoholization type room-temperature curing silicon rubber, comprising: (1) polysiloxane, wherein the end of the polysiloxane is trimethoxy; (2) reinforcing fillers such as white carbon black, calcium carbonate and the like; (3) flame-retardant fillers such as aluminum hydroxide, zinc carbonate, carbon black and the like; (4) platinum compound added after the mixing; and (5) a condensation curing agent which comprises methyltrimethoxy silane, a silane coupling agent, organic titanate or organic tin compounds. The flame retardant dealcoholization type room-temperature curing silicon rubber of the invention has the characteristics of quick curing, excellent binding force to various base materials, good flame retardance, no halogen and the like.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS

Cage-shaped organic silicon flame retardant charring agent and preparation method thereof

ActiveCN102146093ACompact and stable structureStrong insulationGroup 4/14 element organic compoundsCoatingsMethyltrimethoxysilanePhysical chemical

The invention relates to a cage-shaped organic silicon flame retardant charring agent, i.e. a 1,4-dimethyl-1-sila-2,6,7-trioxabicyclo[2,2,2]-octane compound, and a preparation method thereof. The compound has a structure shown as the following formula in the specification. The preparation method comprises the step of: reacting methyl trichlorosilane or methyltrimethoxysilane with trimethylolethane in an organic solvent to prepare 1,4-dimethyl-1-sila-2,6,7-trioxabicyclo[2,2,2]-octane. The cage-shaped organic silicon flame retardant charring agent is a novel halogen-free non-toxic flame retardant charring agent, which has high flame retardant performance and good charring performance, can effectively prevent the melting and the dropping of high polymer during combustion, and is stable in physical and chemical properties, good in compatibility with macromolecular materials, high in raw material availability, simple in process and easy for industrial production.

Owner:SUZHOU UNIV OF SCI & TECH

Metallic cathode electrophoretic paint and preparation method thereof

ActiveCN104312246AImprove stabilityImprove acid resistancePaints for electrolytic applicationsEpoxySilanes

The invention discloses metallic cathode electrophoretic paint and a preparation method thereof. The metallic cathode electrophoretic paint comprises the following components: modified epoxy resin, methyl trimethoxy silane, hydroxy propyl cellulose acetic ester, 2-cyan ethyl acrylate, acrylamide, 2-acrylamide-2-methyl propanesulfonic acid, propanesulfonic acid and zinc stearate. The preparation method comprises the following steps: adding modified epoxy resin, hydroxy propyl cellulose acetic ester and 2-cyan ethyl acrylate into a reaction kettle, heating till the above components are molten, adding hydroxypropyl methylcellulose and methyl trimethoxy silane, heating, stirring to react, further adding deionized water, further reacting at certain temperature and vacuum degree, finally adding acrylamide, heating, stirring, subsequently cooling, adding 2-acrylamide-2-methyl propanesulfonic acid and zinc stearate, stirring, reacting, and finally cooling to room temperature, thereby obtaining the metallic cathode electrophoretic paint. By adopting the metallic cathode electrophoretic paint disclosed by the invention, the properties of a coated paint membrane are greatly improved, and the use range of the cathode electrophoretic paint is further widened and expanded.

Owner:江苏悠谷未来科技有限公司

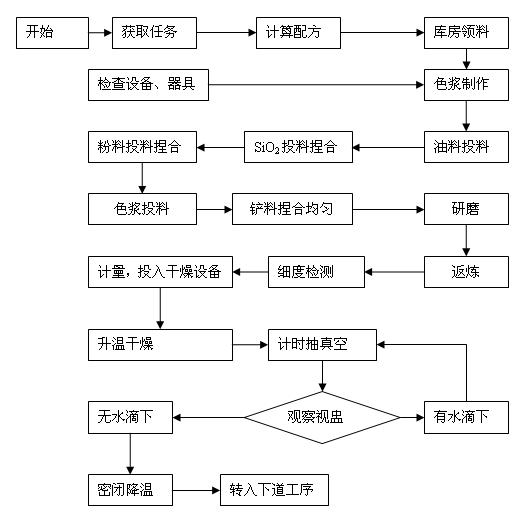

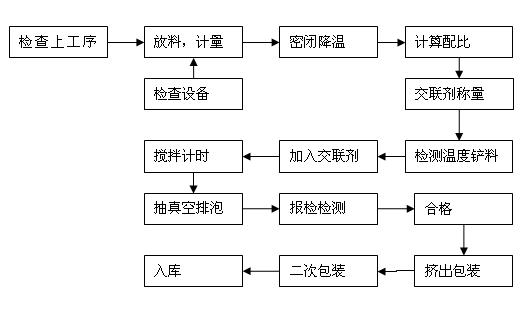

Dealcoholized one-component room temperature vulcanized silicone rubber and preparation method thereof

The invention belongs to the field of room temperature vulcanized silicone rubber and in particular relates to one-component room temperature vulcanized silicone rubber and a preparation method thereof. The one-component room temperature vulcanized silicone rubber is characterized by being prepared by taking alpha, omega-dihydroxypolydimethylsiloxane as base rubber, an organic titanate chelate asa catalyst and methyltrimethoxysilane as a crosslinking agent, and adding linear polydimethylsiloxane and a filler. According to the formula, the one-component room temperature vulcanized silicone rubber comprises 90 to 120 parts of alpha, omega-dihydroxypolydimethylsiloxane, 1 to 10 parts of linear polydimethylsiloxane with a hydroxyl group which is taken as a terminal group, 5 to 15 parts of white carbon black, 1 to 3 parts of organic titanate chelate and 4 to 10 parts of methyltrimethoxysilane. The preparation method comprises the following steps of: weighing raw materials, mixing rubber, drying, preparing and the like. The invention mainly aims at the requirements on the assembly of liquid crystal display modules, starts from the formula and a manufacturing process, can ensure that the flowability of a product is appropriate, and can also accelerate the curing speed of the product. The dealcoholized one-component room temperature vulcanized silicone rubber has the characteristics of low viscosity, no solvent, high flowability, fast curing and environment friendliness.

Owner:CHENGDU TALY TECH CO LTD

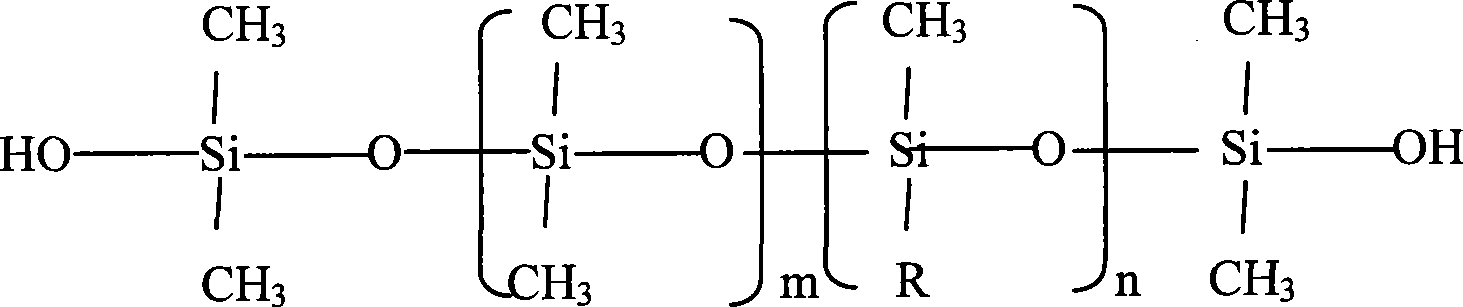

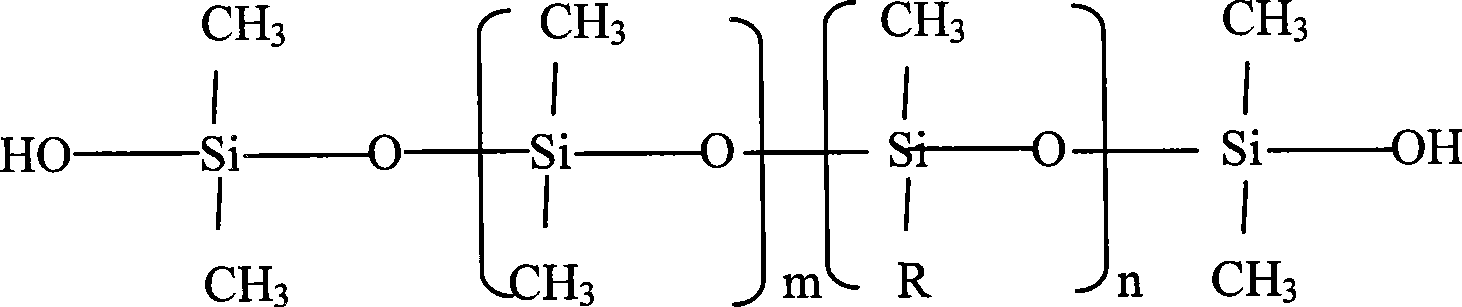

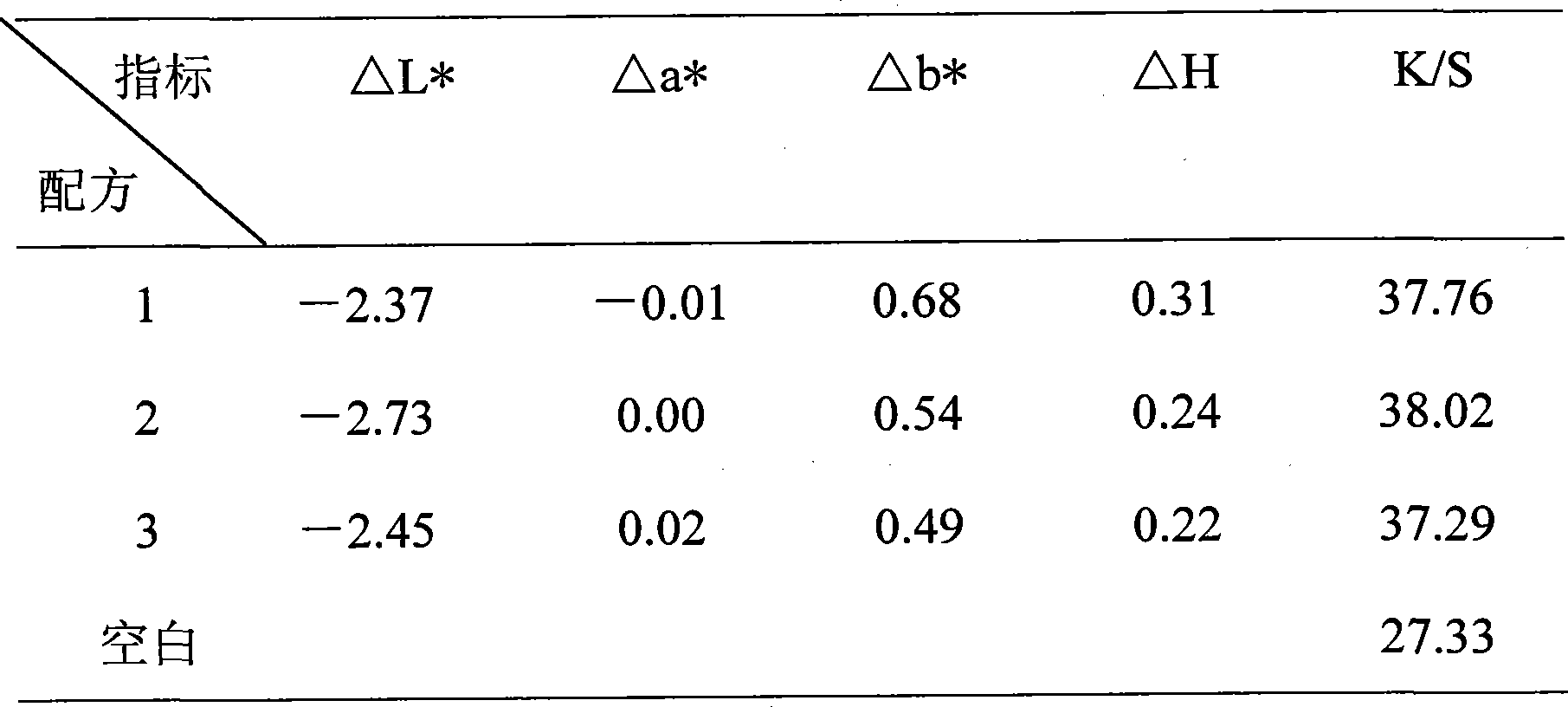

Fiber deep dyeing promoter

The invention relates to the technical field of textile finishing agent, in particular to a fiber deep dyeing promoter. According to weight percentage, the fiber deep dyeing promoter comprises 10-30% of hydroxyl-terminated amino silicone oil, 1-10% of part hydrolysate of methyl trimethoxysilane, 3-20% of nonionic emulsifier, 0.5-5% of acetic acid, and 55-85% of deioned water; after textile finishing, the fiber deep dyeing promoter is attached to the surface of the fiber textile and generates moist crosslinking reaction during the heat treatment process so as to form a single-molecule organosilicon polysiloxane film layer; by virtue of the extremely low reflectivity of the rganosilicon polysiloxane film layer, the light radiating on the surface of the textile generates refraction and diffuse reflection on the fiber surface, the absorption quantity of the incident light of the textile is greatly increased and the reflective light is reduced, thus achieving the effect of deepening dyeing.

Owner:东莞市嘉宏纺织助剂有限公司

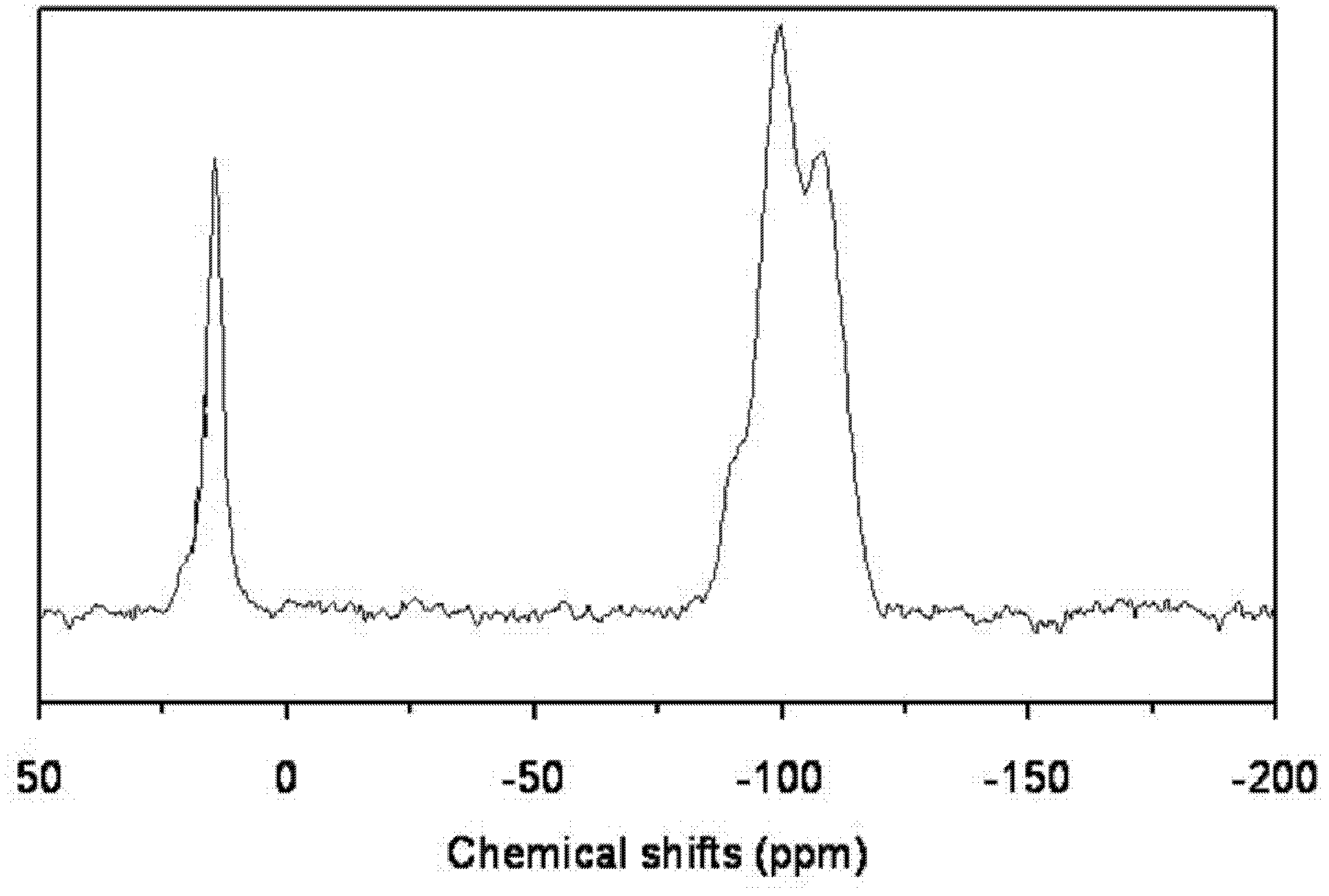

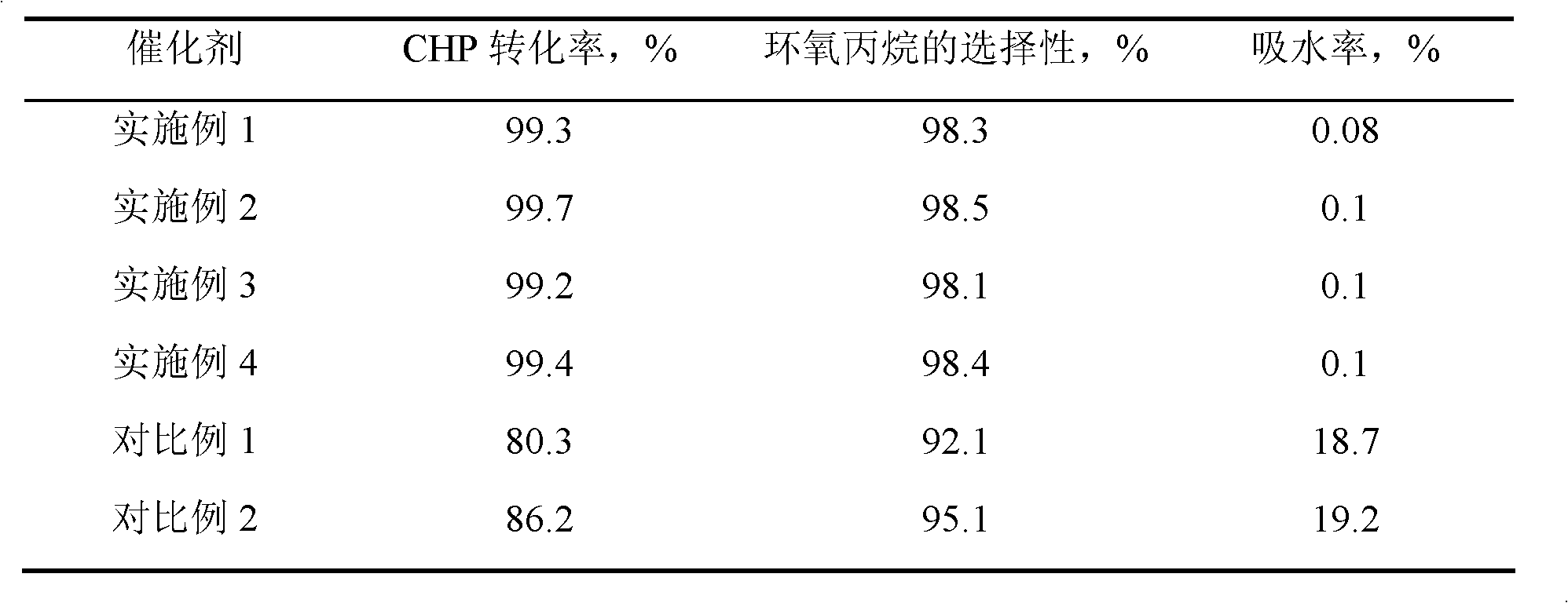

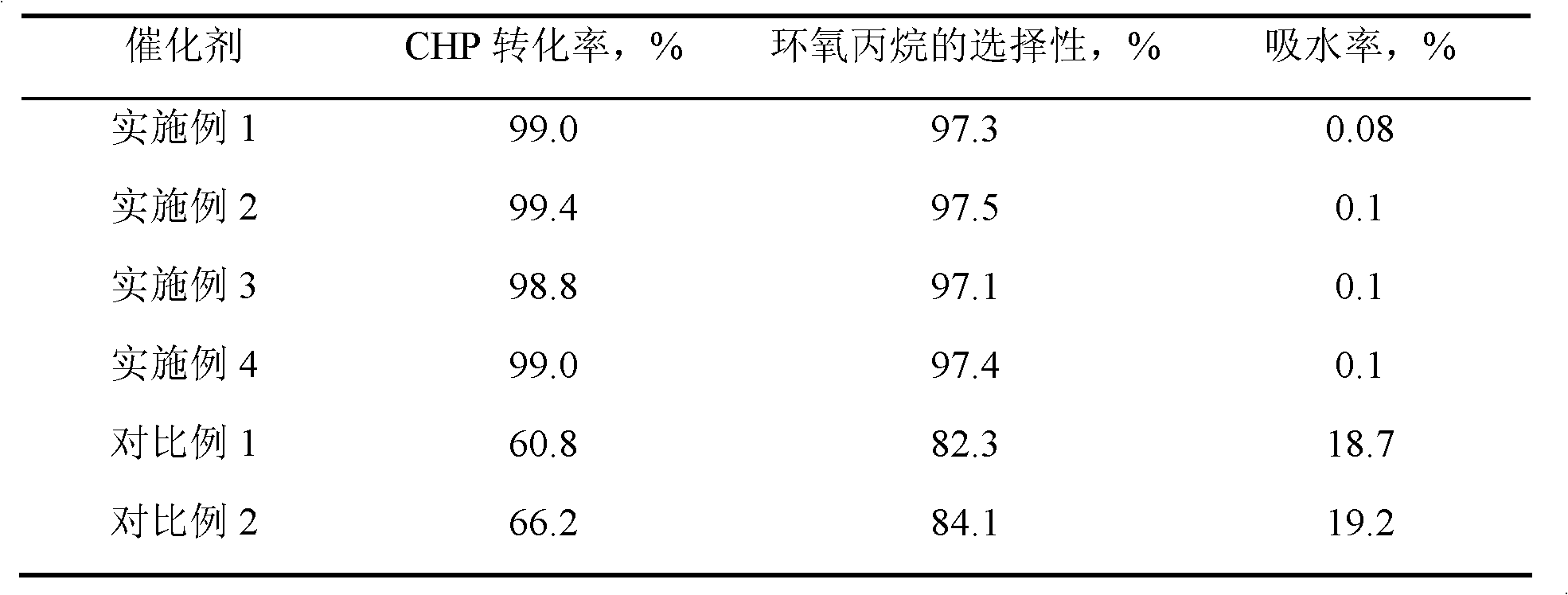

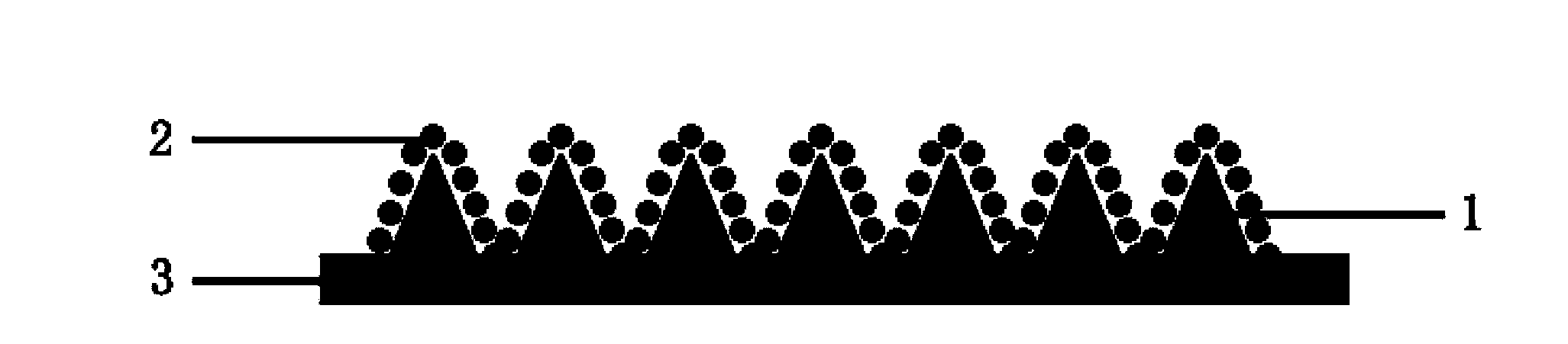

Method for producing epoxypropane through reaction between cumyl hydroperoxide and propylene

ActiveCN103030612AImprove catalytic performanceReduce in quantityOrganic chemistryMolecular sieve catalystsSilanesReaction temperature

The invention relates to a method for producing epoxypropane through reaction between cumyl hydroperoxide and propylene, mainly aiming at solving the problems of low catalyst activity, low epoxypropane selectivity and poor reaction stability existing in the prior art. Reaction raw materials are in contact with catalyst to produce the epoxypropane by using the cumyl hydroperoxide and the propylene as the raw materials under the conditions that the molar ratio of the cumyl hydroperoxide to the propylene is 1:1 to 1:10, the reaction temperature is 50-100DEG C, the reaction pressure is 1-5MPa and the mass space velocity of the cumyl hydroperoxide is 1-30h<-1>. The catalyst is prepared by adopting a method which comprises the following steps of: a) evenly mixing organic silicon sources, inorganic silicon sources, titanium sources and organic templates with water, and filtering, water-washing, drying and roasting the product to obtain precursors I, wherein the inorganic silicon sources are selected from at least one of silica sol, silicate ester and solid silicon oxide, and the organic silicon sources are methyltrimethoxysilane; and b) by taking inert gas as carriers, feeding silanization agent into the precursors I for reaction to obtain the catalyst, wherein the silanization agent is selected from at least one of organic silane, organic silicylamine, organic silicylamide and organic silazane. By adopting the technical scheme, the problems are better solved and the method can be used for the industrial production of the epoxypropane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrophobic high-elasticity methylsilsesquioxane aerogel block and preparation method thereof

The invention discloses a hydrophobic high-elasticity methylsilsesquioxane aerogel block and a preparation method thereof. The aerogel block is a compound with methyltrimethoxysilane and dimethoxydimethylsilane as a co-precursor, a hydrochloric acid solution HCl as a solvent and a catalyst and cetyltrimethylammonium chloride as a dispersant. The preparation method includes the following steps: adding cetyltrimethylammonium chloride into the hydrochloric acid solution, then adding the precursor, carrying out magnetic stirring under a closed condition, adding a gel accelerator, then stirring again, placing in a drying oven, gelling and aging; carrying out solvent replacement of the gel formed in the step 1) with isopropanol for at least two times, to obtain a gel after solvent replacement; and placing the gel after solvent replacement in a drying oven, and drying to obtain the complete hydrophobic high-elasticity methylsilsesquioxane aerogel block. Through the way, the methylsilsesquioxane aerogel block with good hydrophobicity and high elasticity can be obtained under the condition of ambient pressure drying.

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

Thin ceramic coating and production method thereof

InactiveCN101445677AWith qualityHigh temperature resistantFireproof paintsHigh densityCeramic coating

The invention provides a thin ceramic coating and a production method thereof, belonging to the field of functional coatings, in particular to the filed of high temperature resistant coatings. The thin ceramic coating is realized mainly through materials such as water dispersive nanometer alumina, pigments, fillers, potassium titanate whisker, methyl trimethoxysilane and the like. The coating produced by the invention has the qualities of an enamel surface, is complete harmless to a human body, and has the advantages of burning resistance, high temperature resistance, high hardness, high density, and good weatherability.

Owner:上海瓷龙贸易有限公司

Surface treatment of nanoparticles to control interfacial properties and method of manufacture

InactiveUS20050222325A1Material nanotechnologySynthetic resin layered productsPersonal care3-mercaptopropyltrimethoxysilane

A surface treated particle comprising a plurality of inorganic, metallic, semi-metallic, and / or metallic oxide particles and a star-graft copolymer with looped and / or linear polymeric structure on a star-graft copolymer, obtainable by a heterogeneous polymerization reaction in the particle surface proximity, encapsulating at least a portion of said particles and a method for making the same. The surface treatment comprises: Si (w, x, y, z), where: w, x, y, and z are mole percent tetrafunctional, trifunctional, difunctional, and monofunctional monomeric units, respectively; w, x, y, and z are about 0-50, 0-50, 5-99, and 0-5, respectively; w is tetraethylorthosilicate; x is selected from the group consisting of γ-glycidoxypropyltrimethoxysilane, γ-methacryloxypropyltrimethoxysilane, methyltrimethoxysilane, n-propyltrimethoxysilane, isobutyltrimethoxysilane, n-hexyltrimethoxysilane, n-octyltrimethoxysilane, n-octadecyltrimethoxysilane, phenyltrimethoxysilane, 3-(trimethoxysilyl)propylsuccinic anhydride, heptadecafluorotrimethoxysilane, 3-isocyanatopropyltrimethoxysilane, 2-(diphenylphosphino)ethyltrimethoxysilane, 3-aminopropyltrimethoxysilane, 3-mercaptopropyltrimethoxysilane, n-(trimethoxysilylpropyl)EDTA, pentafluorophenylpropyltrimethoxysilane, trifluoropropyltrimethoxysilane, and the triethoxy-containing counterparts of these monomers; y is selected from the group consisting of dicyclohexyldimethoxysilane, diethyldiethoxysilane, dimethyldichlorosilane, dimethyldiethoxysilane, dimethyldimethoxysilane, diphenyldiethoxysilane, diphenyldimethoxysilane, di-n-hexyldichlorosilane, n-hexylmethyldichlorosilane, methyldodecyldiethoxysilane, n-octylmethyldimethoxysilane, and the diethoxy-containing counterparts of these monomers; and z is selected form the group consisting of n-octadecyldimethylmethoxysilane, triethylsilanol, trimethylethoxysilane, trimethylmethoxysilane, and the ethoxy-containing counterparts of these monomers. Product(s) per se, defined as surface treated ZnO and / or TiO2, and the use of the product(s) per se in personal care formulations are excluded.

Owner:NANOPHASE TECH CORP

Novel combinations of silane electron donors for use in catalyst compositions

Disclosed is a process for preparing an olefinic polymer comprising contacting at least one olefinic C3+ monomer and a catalyst composition comprising a Ziegler-Natta catalyst, dicyclopentyl dimethoxysilane as a first electron donor, and a second electron donor selected from the group consisting of methyl trimethoxysilane, methyl triethoxysilane, dimethyl dimethoxysilane, and mixtures thereof, under reaction conditions suitable to form an olefinic polymer. The polymer prepared using this method may exhibit significantly broadened molecular weight distribution than that achieved using any of the silane compounds alone, and may also exhibit desirable melt flow characteristics and xylene solubles levels.

Owner:FINA TECH

Ketoxime type room temperature vulcanized silicone rubber with long storage period and preparation method thereof

The invention belongs to the field of building sealing materials, and particularly relates to ketoxime type room temperature vulcanized silicone rubber with long storage period and a preparation method thereof. The rubber comprises the following components in part by weight: 10 to 100 parts of fundamental substance, 3 to 20 parts of crosslinking agent, 0.1 to 2 parts of catalyst, 10 to 100 parts of filler, 1 to 10 parts of thixotropic agent, 2 to 4 parts of pigment, 0.5 to 2 parts of hydroxyl scavenger and 0.5 to 2 parts of tackifier. In the method, an organic silicon-oxygen polymer is adopted as the fundamental substance, and the hydroxyl scavenger is introduced to improve the storage period, wherein the crosslinking agent is methyl-trithoxysilicane and 2-butanone oxime, and is prepared by reacting for 20h at the temperature of between 100 and 150 DEG C in the absence of the catalyst. The ketoxime type room temperature vulcanized silicone rubber with long storage period is steady in storage and strong in cohesive force; and the corrosion on metal materials is reduced by replacing the conventional tin catalysts with a titanium complex.

Owner:GLEIHOW NEW MATERIALS CO LTD

Titanium-containing ceramic paint and protective coating

ActiveUS20140170425A1Maintain good propertiesHigh temperature resistanceLayered productsPaints with free metalsZirconium dioxideAluminium

Disclosed is a titanium-containing ceramic paint, including 100 parts by weight of silica sol, 50 to 100 parts by weight of organic silane, 0.3 to 1 parts by weight of a catalyst, 5 to 20 parts by weight of titanium powder, and 1 to 5 parts by weight of a silicone oil. The organic silane can be methyltrimethoxy silane and / or methyltriethoxy silane. The catalyst can be formic acid, acetic acid, hydrochloric acid, citric acid, methyl formate, ethyl acetoacetate, maleic anhydride, or combinations thereof. The titanium-containing ceramic paint may further include 30 to 50 parts by weight of filler, such as silica, alumina, zirconium dioxide, silicon carbide, aluminum nitride, boron nitride, kaolin, talcum powder, mica powder, silicate of aluminum or zirconium, barium sulfate, metal fiber, stainless powder, or combinations thereof. The titanium-containing ceramic paint may further include 30 to 40 parts by weight of a color powder.

Owner:INNOTEK TECH CHINA

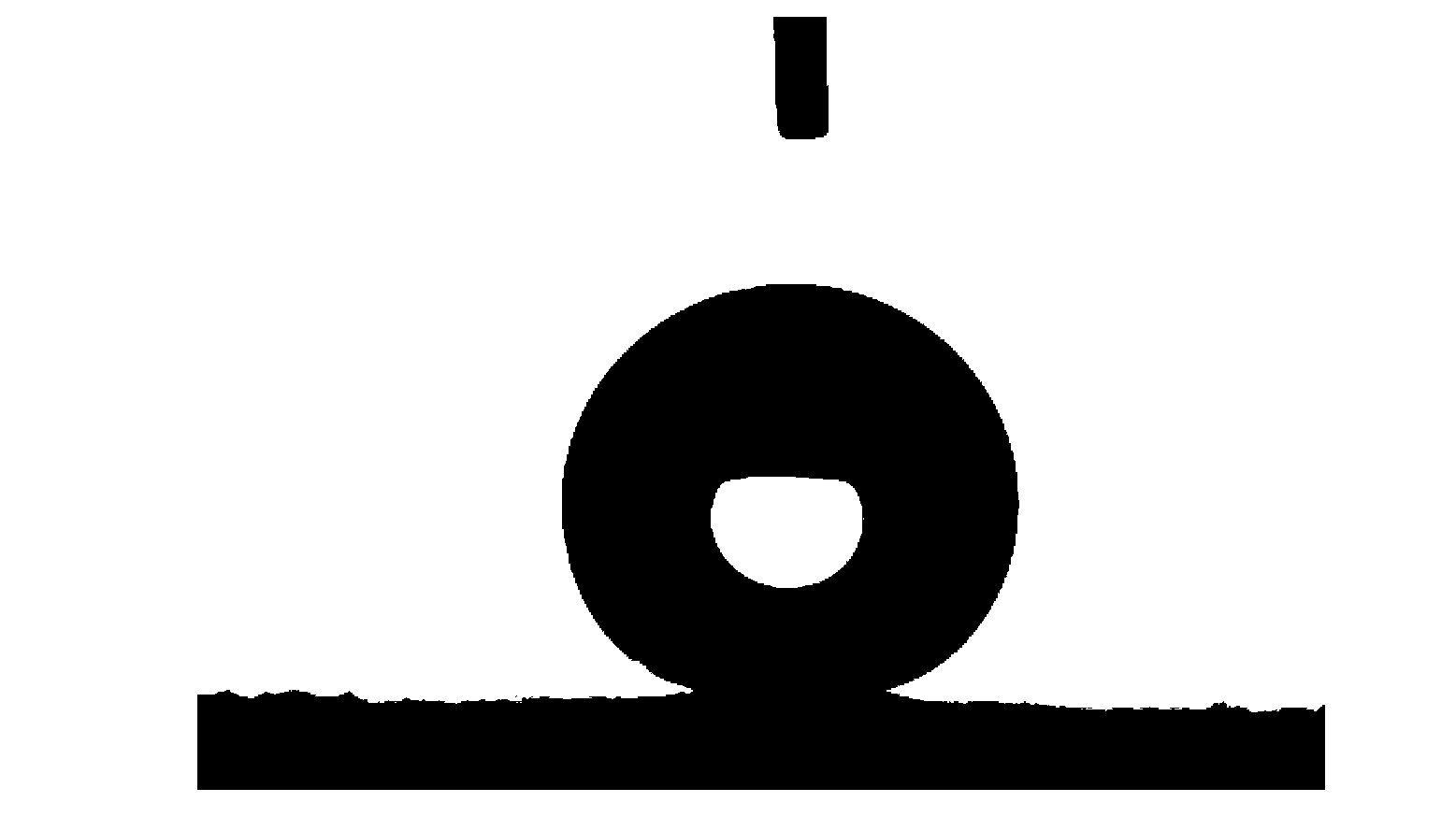

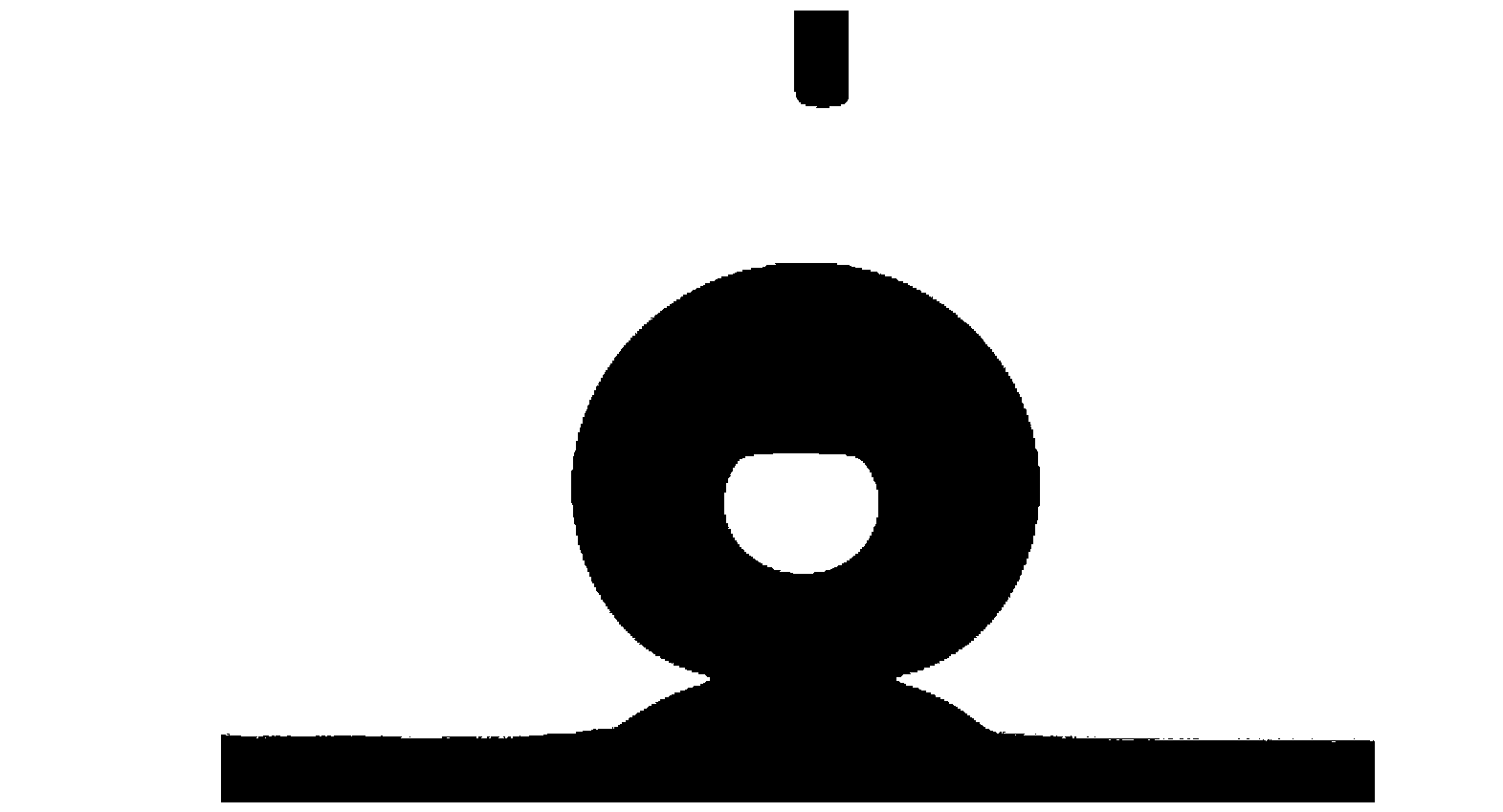

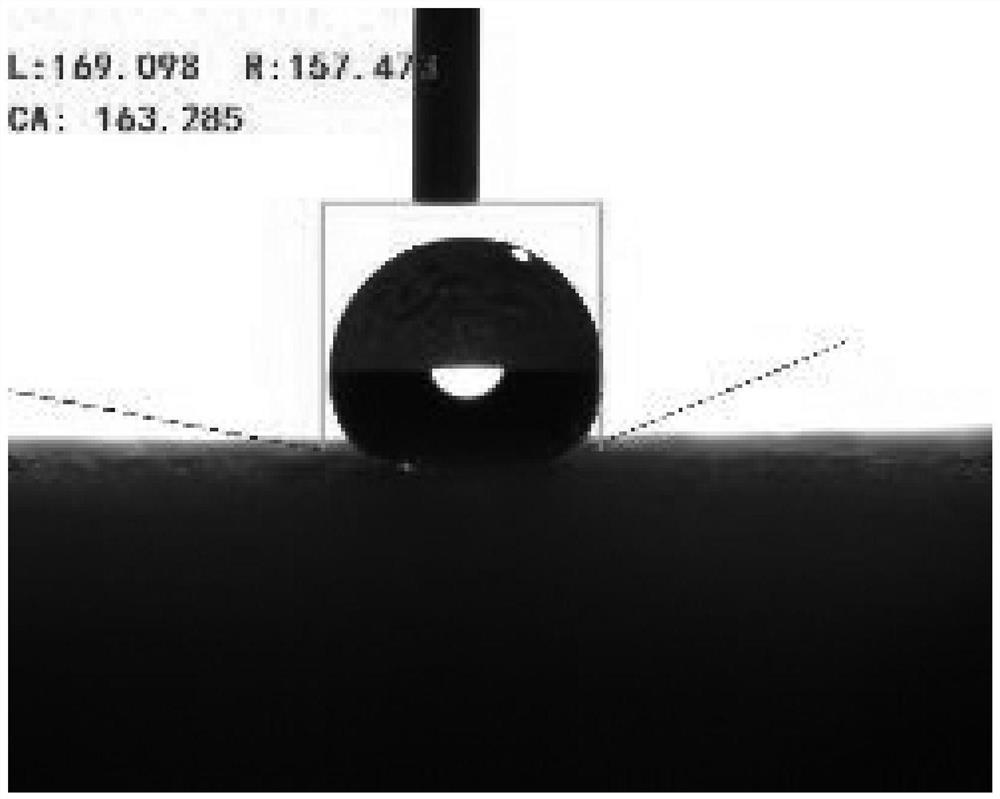

Preparation method for super-hydrophobic coating

ActiveCN103818069AHigh strengthImprove wear resistanceSynthetic resin layered productsOXALIC ACID DIHYDRATEAlcohol

The invention discloses a preparation method for a super-hydrophobic coating. The preparation method comprises the following steps: 1, mixing hydrophobic resin and modified particles, and dissolving the mixture in a solvent to prepare a solution I; 2, adding methyltrimethoxysilane and tetraethyl orthosilicate into alcohol to form a mixed solution, adding water into the mixed solution, adding an oxalic acid aqueous solution, stirring and standing, adding ammonia water, stirring and standing to obtain super-hydrophobic hydrogel, and performing ultrasonic treatment to prepare a solution II; 3, coating a substrate with the coating solution I in a spraying or rolling way, obtaining a coating I after the coating solution I is cured, dip-coating the surface of the coating I with a coating solution II, and obtaining a super-hydrophobic surface after the coating solution II is dried. According to the method, the problem of poor abrasion resistance of the super-hydrophobic coating is solved; in addition, the super-hydrophobic coating has the advantages of simplicity in repair and strong strength.

Owner:无锡市耐密特新材料有限公司

Cavity corrosion proof zinc-rich paint and preparing method thereof

InactiveCN101100569AAnti-corrosive paintsPolyurea/polyurethane coatingsCarbon nanotubeSODIUM SILICATE SOLN

A zinc-enriched coating against cavity corrosion and its production are disclosed. The coating consists of carbon nanometer tube: 0.3-4 wt%, nanometer zinc powder 3-8 wt%, and organic resin additive 12-30 wt%. The process is carried out by reflux decontaminating for carbon nanometer tube by mixed acid, soaking in diluted lithium aqueous glass, centrifugal treating, collecting or mixing carbon nanometer tube with silicon acid, ball grinding, adding carbon nanometer tube into lithium silicate-sodium silicate solution, adding into organic resin, heavy potassium chromate solution, FC80, methyl-methoxide, multifunctional accessories and de-foaming agent while agitating to obtain coating component A, mixing ordinary zinc powder with nanometer zinc powder proportionally to obtain coating component B, and mixing component A with component B proportionally to obtain final product.

Owner:HUAZHONG NORMAL UNIV

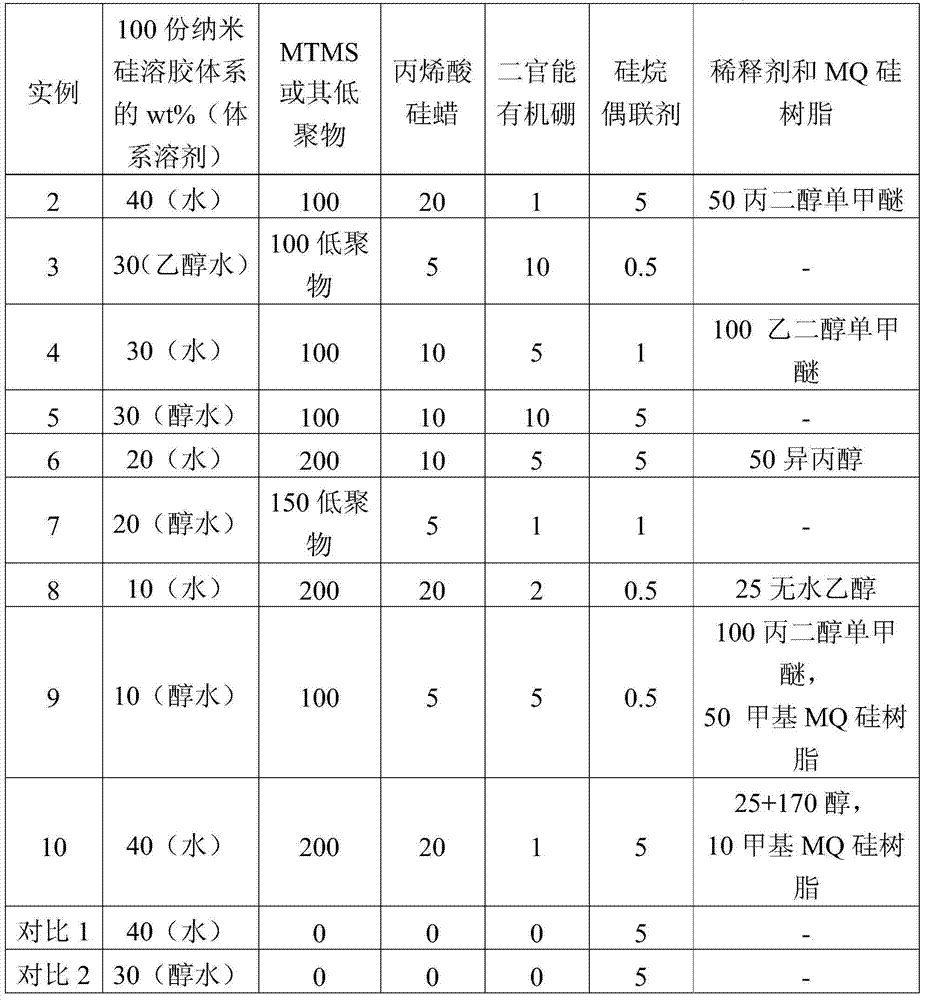

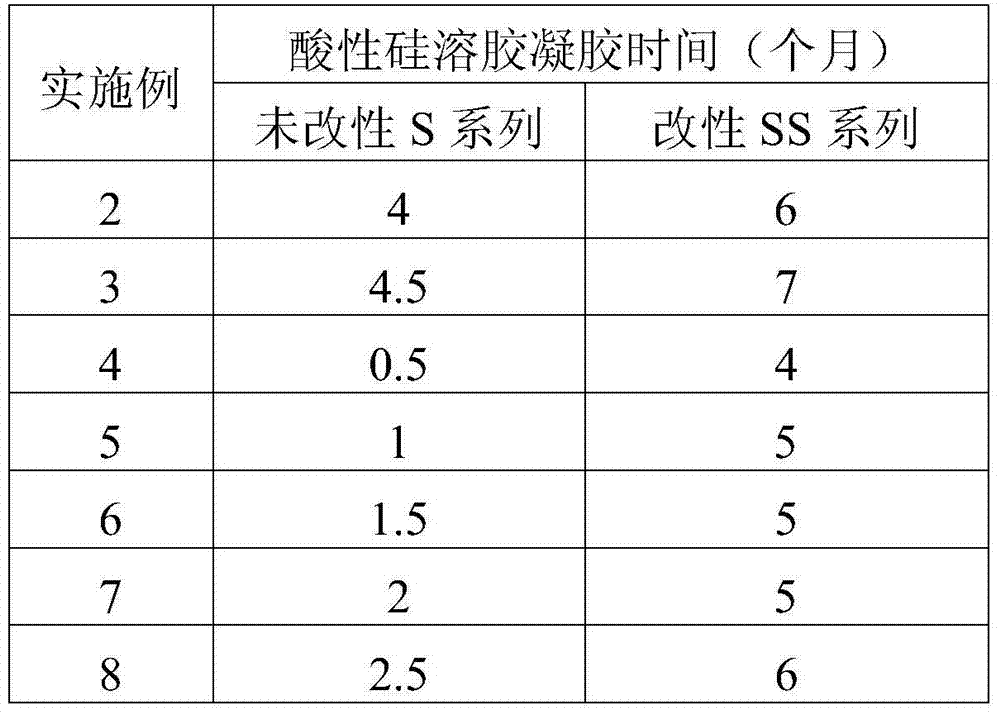

Room-temperature-curing acrylic heteropolysiloxane nano-ceramic protection coating and preparation method thereof

ActiveCN103589336AImproved storage stability at room temperatureImprove waterproof performanceCoatingsSilanesStain

The invention discloses a room-temperature-curing acrylic heteropolysiloxane nano-ceramic protection coating and a preparation method thereof, and belongs to the coating field. The preparation method comprises the followings steps: uniformly mixing 5-20 parts by weight of acrylic organosilicon wax, 1-10 parts by weight of a bifunctional organoboron compound and parts of an alcoholic dilutent, adding the obtained mixture to 100 parts of a nanometer silica sol system having a concentration of 10-40wt%, adding 100-200 parts by weight of methyltrimethoxy silane or its oligomer, 0.5-5 parts by weight of a silane coupling agent, residual parts of the alcoholic diluent and 0-50 parts by weight of a methyl MQ silicone resin mixed solution under stirring, and continuously stirring at room temperature for 1-2h to prepare a nano-ceramic protection coating; and the coating is coated on the surface of a substrate, and the formed coat is naturally dried to form a high-hardness high temperature resistant ceramic protection coat. The completely cured coat has a hardness reaching above 6H, can resistant a high temperature of 400DEG C, and has excellent water and stain resistances.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

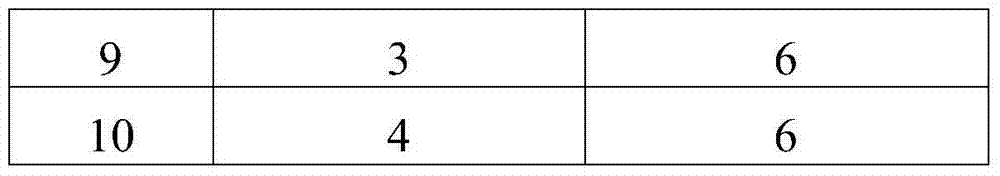

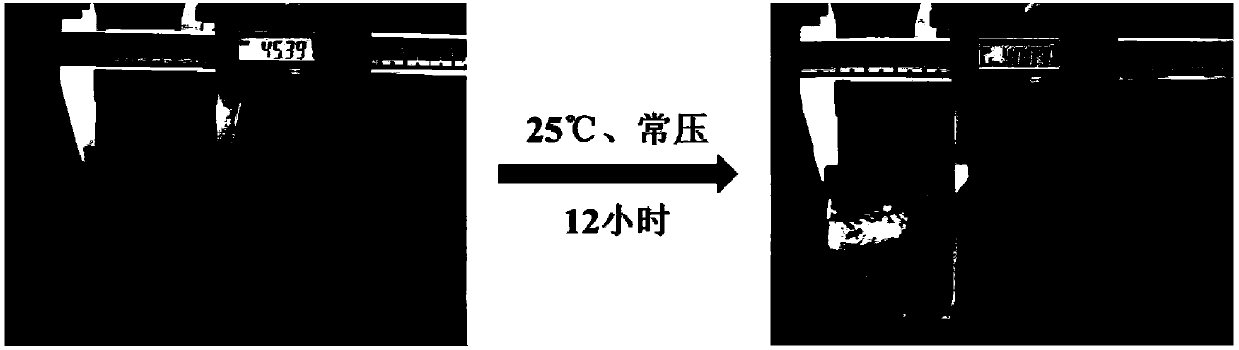

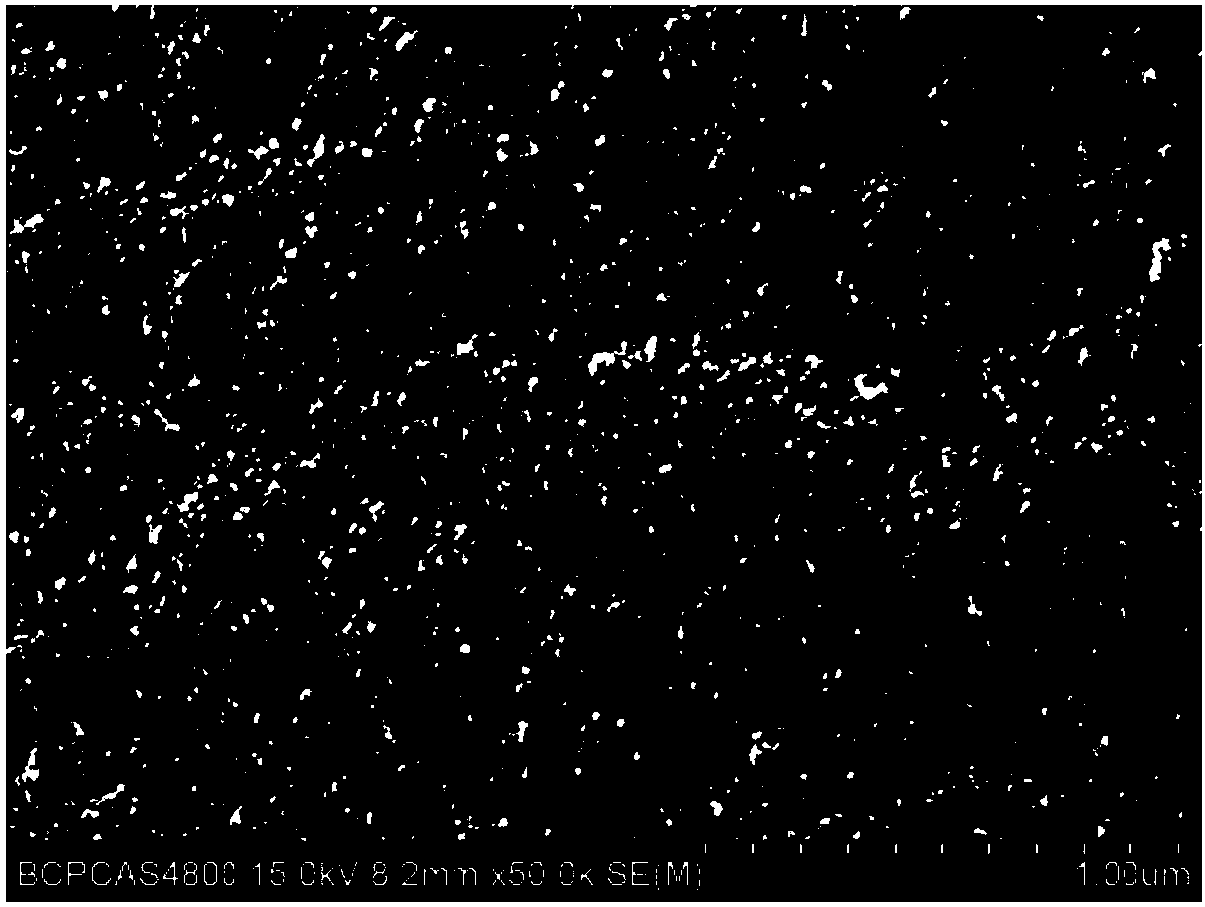

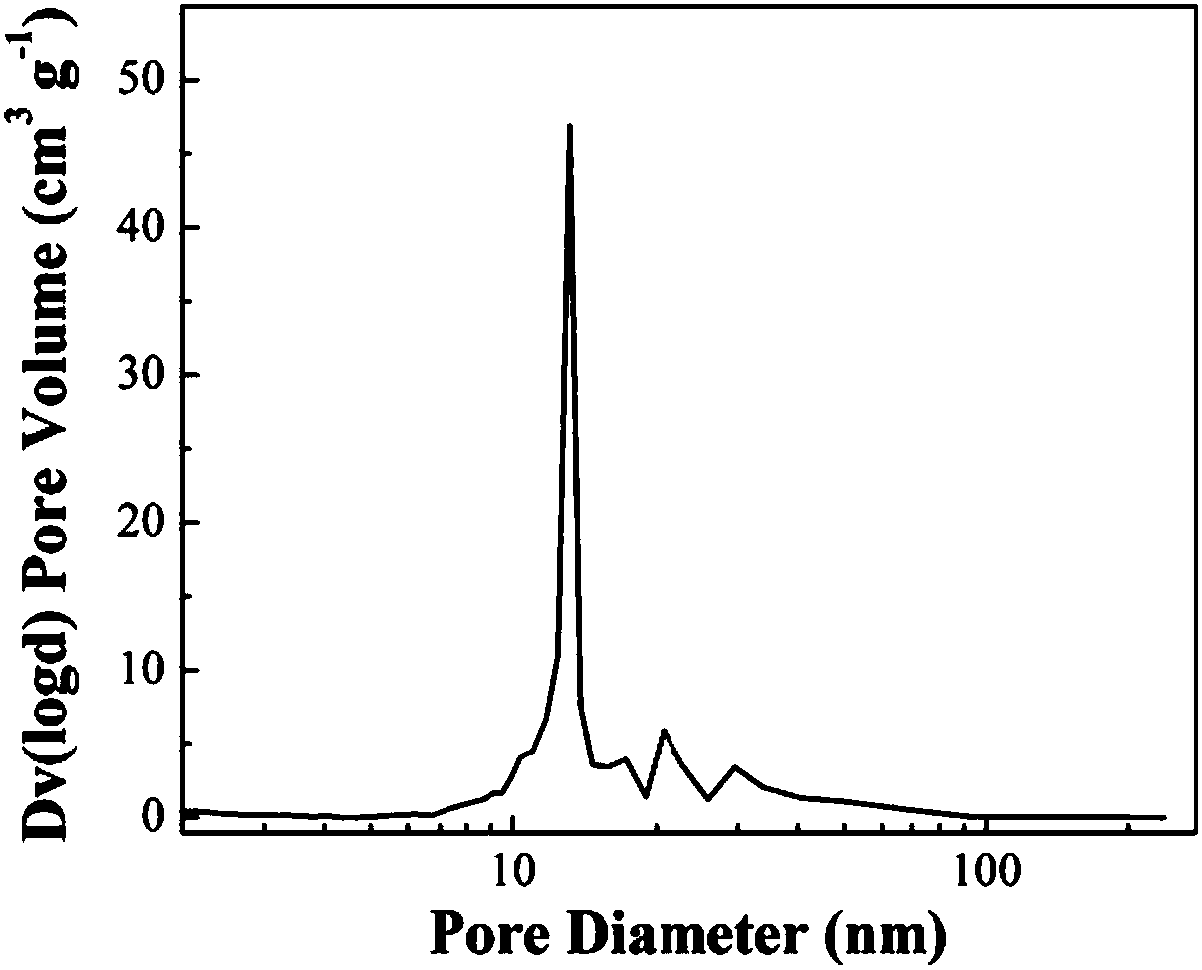

Preparation method of silicon dioxide aerogel

The invention discloses a preparation method of silicon dioxide aerogel, and belongs to the technical field of a nano-porous material. The preparation method includes steps of performing hydrolytic polymerization on methyl trimethoxy silane to obtain a wet gel; staying the wet gel under a certain temperature and acquiring a contracted wet gel; sealing and aging the contracted wet gel through solvent; drying the aged wet gel and acquiring the aerogel. Through applying the methyl trimethoxy silane and the surface active agent to prepare the wet gel, the wet gel can bear heavy contraction and deformation; through staying, fluid in the wet gel hole is volatilized, and the wet gel is contracted; under the condition of low addition of the methyl trimethoxy silane, the aerogel with high density can be acquired; meanwhile, the aerogel grain has small dimension, the hole structure is more uniform, and the contact area between grains is bigger; thus the optical transparency and the mechanical performance of the aerogel are promoted.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Ceramic paint and coating having stereoscopic effect

The invention relates to ceramic paint having a stereoscopic effect, which is characterized by comprising the following components in parts by weight: 100 parts of silica sol, 50-100 parts of organosilane, 0.3-1 part of catalyst, and 1-20 parts of magnetic powder, wherein the organosilane is methyltrimethoxy silane and / or methyltriethoxy silane; and the catalyst is one or a combination of formic acid, acetic acid, hydrochloric acid, citric acid, methyl formate, ethyl acetoacetate and maleic anhydride. The ceramic paint further comprises 1-5 parts by weight of silicone oil and 5-10 parts by weight of additional organosilane, wherein the additional organosilane is one or a combination of tetramethoxyl silane, tetraethoxy silane, dimethyldimethoxy silane, dimethyldiethoxy silane and phenyltrimethoxy silane. The ceramic paint provided by the invention has favorable cold / hot hardness and wear resistance; and the magnetic powder in the paint can form a coating having multiple stereoscopic patterns, thereby achieving good decorative effect.

Owner:INNOTEK TECH CHINA

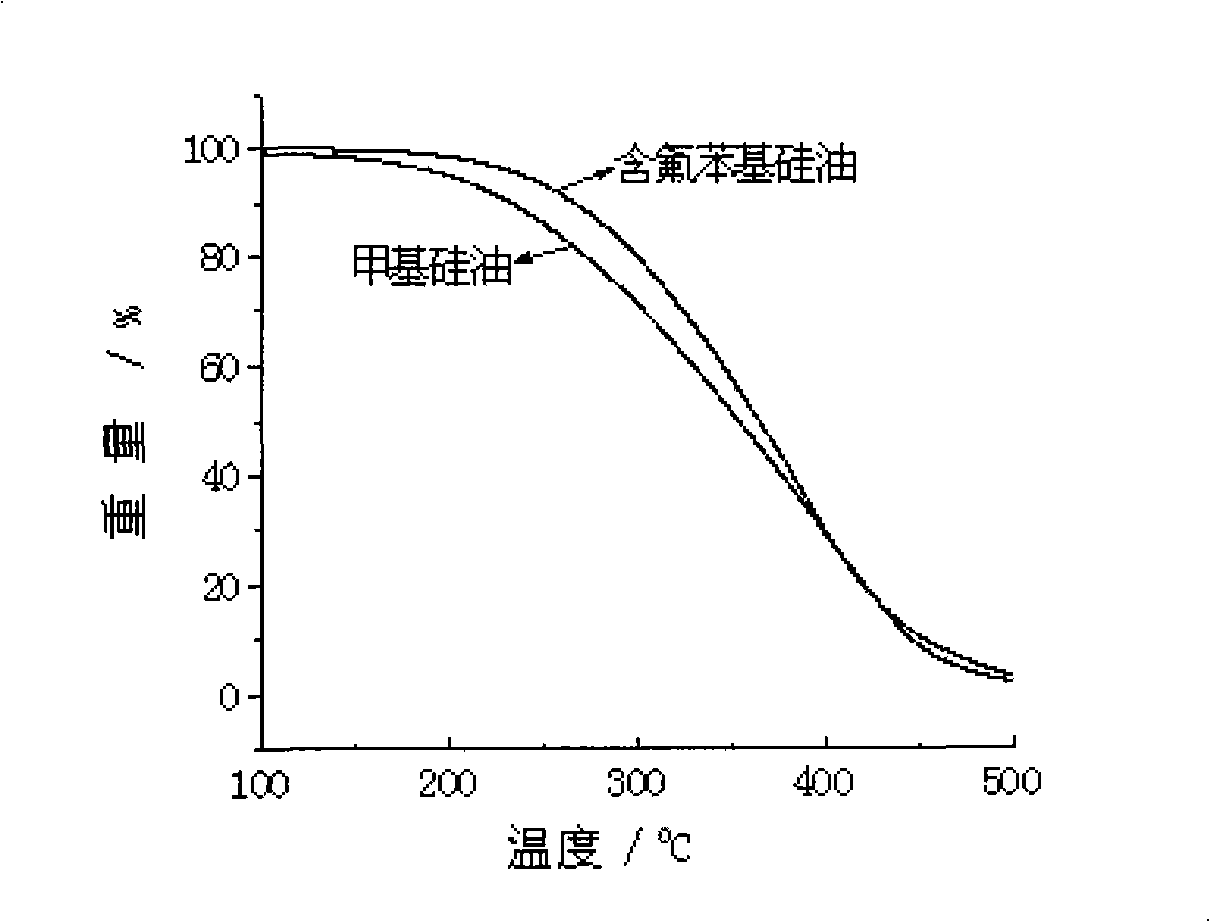

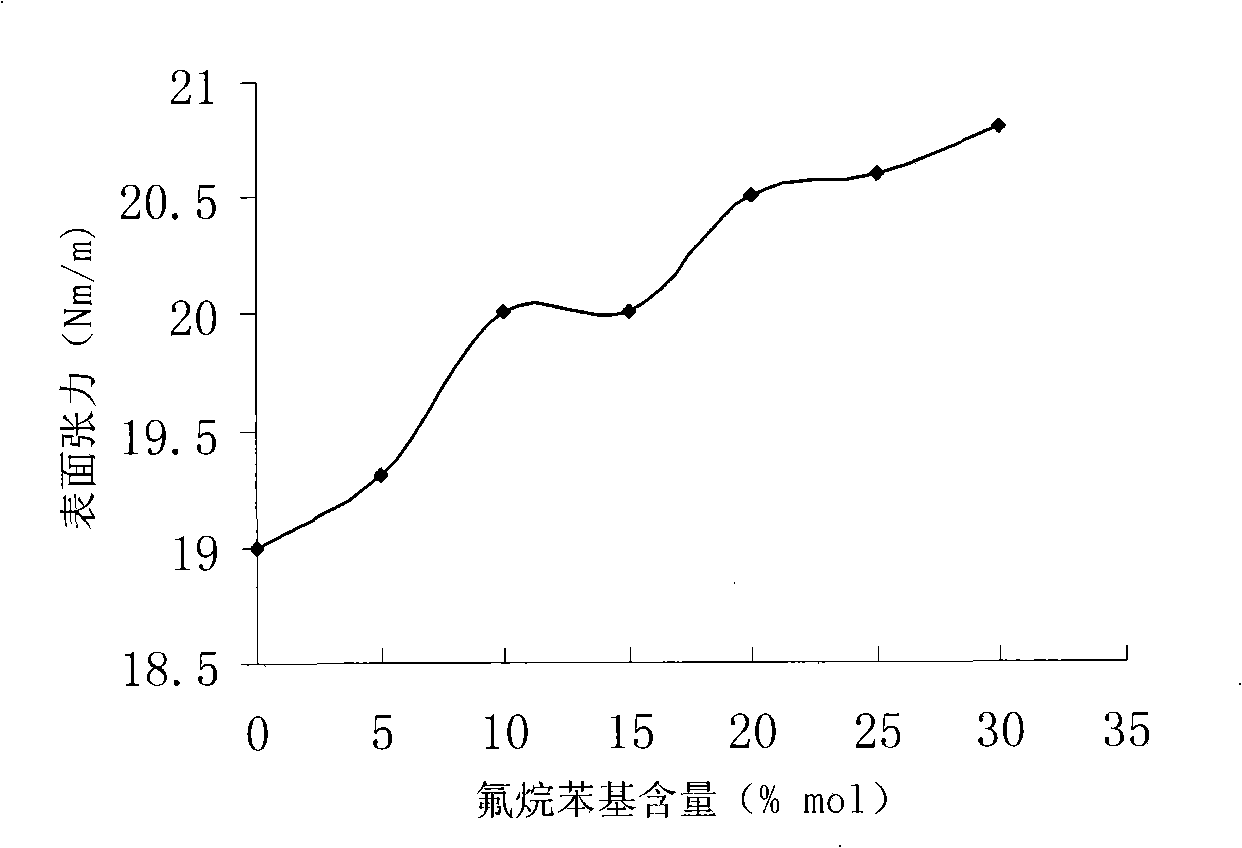

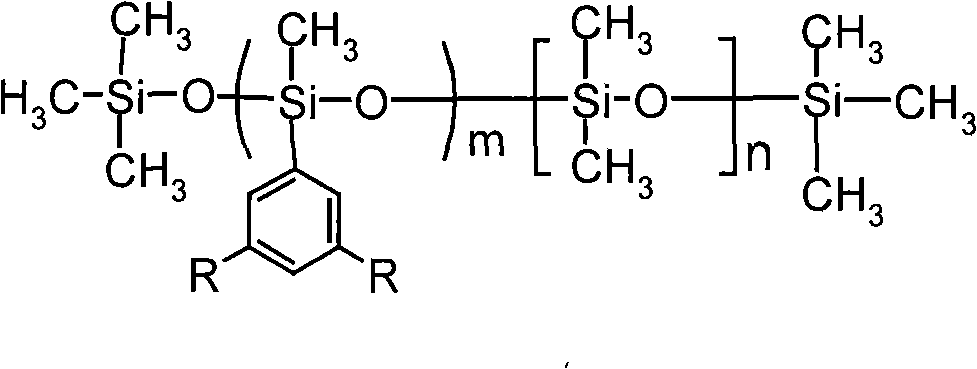

Novel fluorine phenyl-containing silicone oil and method of producing the same

InactiveCN101402733AImprove heat resistanceRaw materials are easy to getHeat-exchange elementsBase-materialsChemical synthesisHeat conducting

The invention discloses novel fluoride phenyl silicone oil and a preparation method thereof, pertaining to the technical field of chemical synthesis and special-typed high molecular material. The silicone oil takes 3, 5-difluoride substituent-1-halogeno benzene and methyl-trimethoxy silicane as raw materials and prepares fluoride organoxilicon monomer 3, 5-difluoride substituent phenyl-methyl-dimethoxy-silicane monomer through grignard reaction and substitution reaction. Hydrolysis and equilibrium polymerization are imposed on the fluoride organoxilicon monomer synthesized and dimethyl-dimethoxy silicane together to prepare 3, 5-di (trifluoromethyl) phenyl silicone oil. The novel fluoride phenyl silicone oil product has good heat resistance, is supposed to be applied as heat conducting oil, hydraulic oil, surface treatment materials and the like, and has advantages of easy access to raw materials, easy realization of preparation technology and facilitation for promotion and application.

Owner:SUZHOU UNIV

Aluminium wiredrawing lubricant and preparation method thereof

The invention provides an aluminium wiredrawing lubricant and a preparation method thereof. The lubricant is characterized by comprising the following raw materials by weight parts: 0.3-0.4 parts of monoethanolamine, 0.6-0.8 parts of triethanolamine, 0.2-0.3 parts of mercapto benzimidazole, 1-2 parts of caprylic-capric acid blend, 1-2 parts of sodium dodecyl sulfate, 1-2 parts of dibutyltin dilaurate, 1-2 parts of zinc acetate, 1-2 parts of tung oil, 2-3 parts of methyl trimethoxy silane, 3-4 parts of a film forming auxiliary agent and 150-160 parts of water. According to the invention, the tung oil is added to promote lubricity, water base is used to play a relatively good heat dissipating effect, the triethanolamine is added to improve an anti-corrosion effect, and the methyl trimethoxy silane is combined with the mercapto benzimidazole, the caprylic-capric acid blend and the film forming agent to improve a film forming performance and prolong an anti-corrosion time of the aluminium conductor after the wiredrawing.

Owner:安徽富华电子集团有限公司

Cosmetic composition containing hydrophilic spherical polymethylsilsesquioxane powder

InactiveUS20080118537A1Narrowing particleFeel smoothCosmetic preparationsImpression capsSuspending AgentsAqueous solution

A cosmetic composition is disclosed containing hydrophilic, spherical powder of polymethylsilsesquioxane having a particle size ranged from 1-20 microns with a narrow particle size distribution. The hydrophilic, spherical powder in the composition is prepared by a process comprising (1) hydrolyzing and condensing methyltrimethoxysilane in water in the presence of a thickener as suspending agent, an oil as surface tension modifier and an acid or base as catalyst to form spherical particles, (2) post-hydrolyzing the spherical particles in an aqueous NaOH solution and (3) purifying the spherical particles by repeated washing and vacuum stripping.

Owner:GRANT INDS

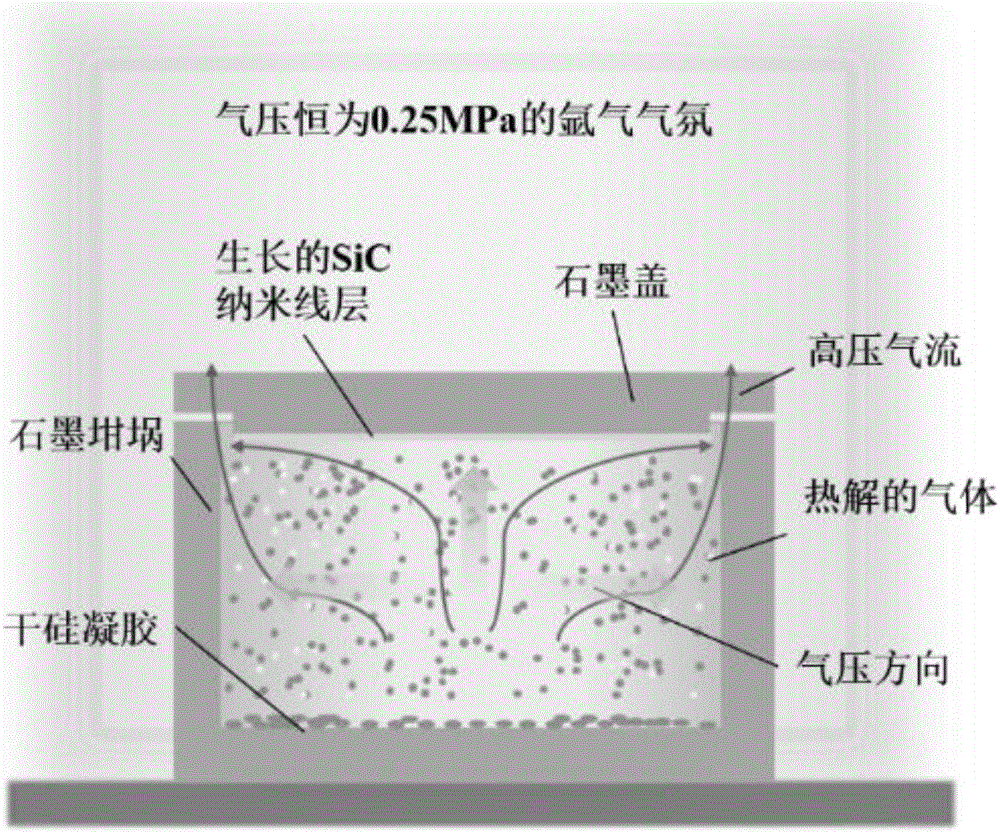

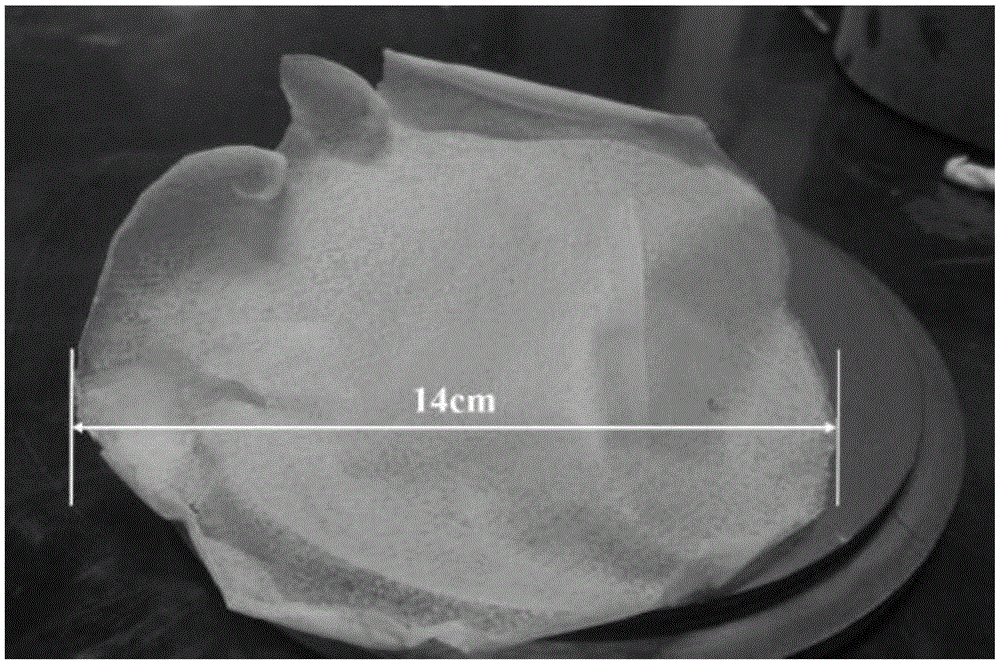

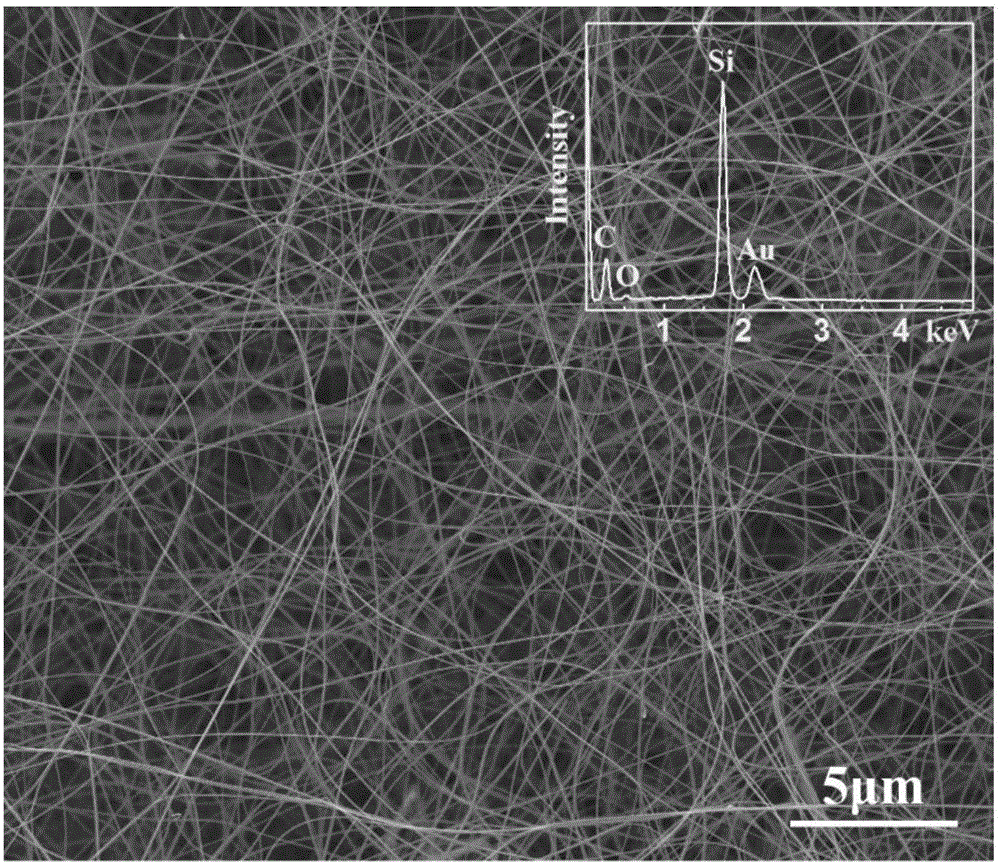

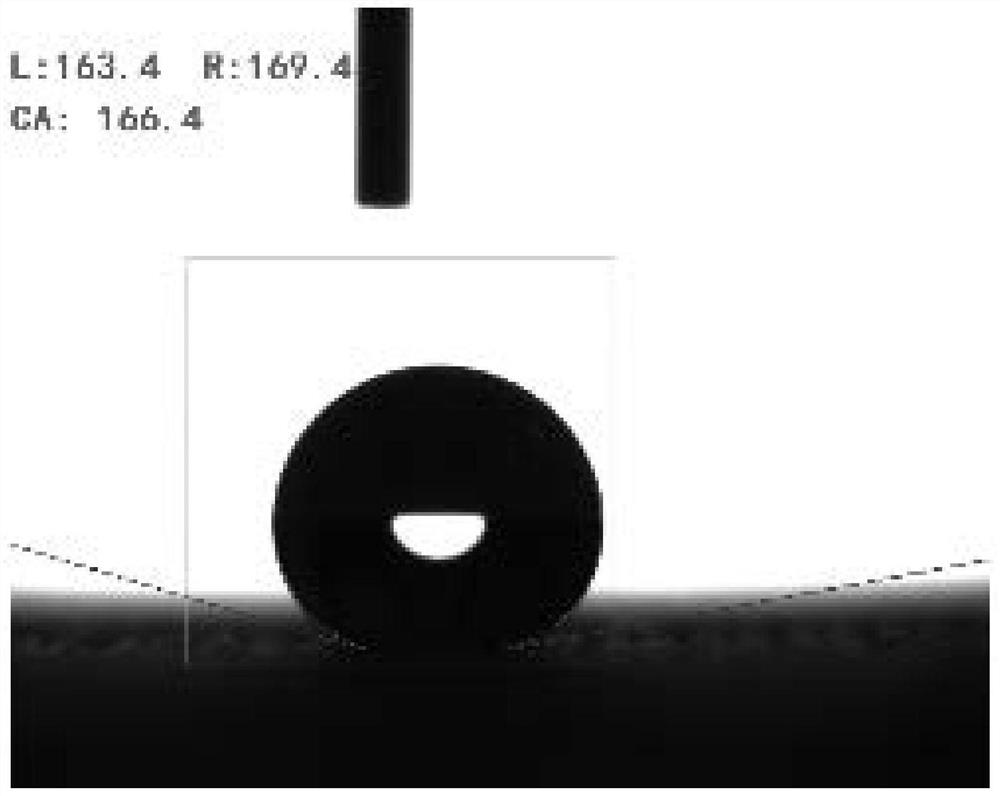

Self-supporting silicon carbide nanowire paper and preparing method thereof

The invention discloses self-supporting silicon carbide nanowire paper and a preparing method thereof, and belongs to the field of nanomateiral preparing and self-assembly technology thereof. The preparing method includes the following steps that methyl trimethoxy silane and dimethyl dimethoxysilane are used as raw materials, nitric acid is used as a crosslinking catalyst, a cohydrolysis method is adopted to prepare silica gel, and then the silica gel is dried to prepare xerogel; the xerogel is put into a graphite crucible with a graphite cover, the graphite crucible is put in an air pressure sintering furnace, air of the air pressure furnace is pumped until the air pressure is 0.1 Pa or below, the air pressure furnace is filled with high-purity argon, the air pressure furnace is heated to 1320-1500 DEG C at the speed of 2-10 DEG C / min, and the temperature is kept for 1 h; the product is cooled to the room temperature along with the furnace, a greyish-green nanowire layer can grow on a graphite substrate and is striped from the graphite substrate to prepare the self-supporting silicon carbide nanowire paper. Self-assembly of nanowires can be achieved in the process of nanowire growth, the thickness of the nanowire paper prepared through the method is adjustable, and the area of the nanowire paper prepared each time is large.

Owner:XI AN JIAOTONG UNIV

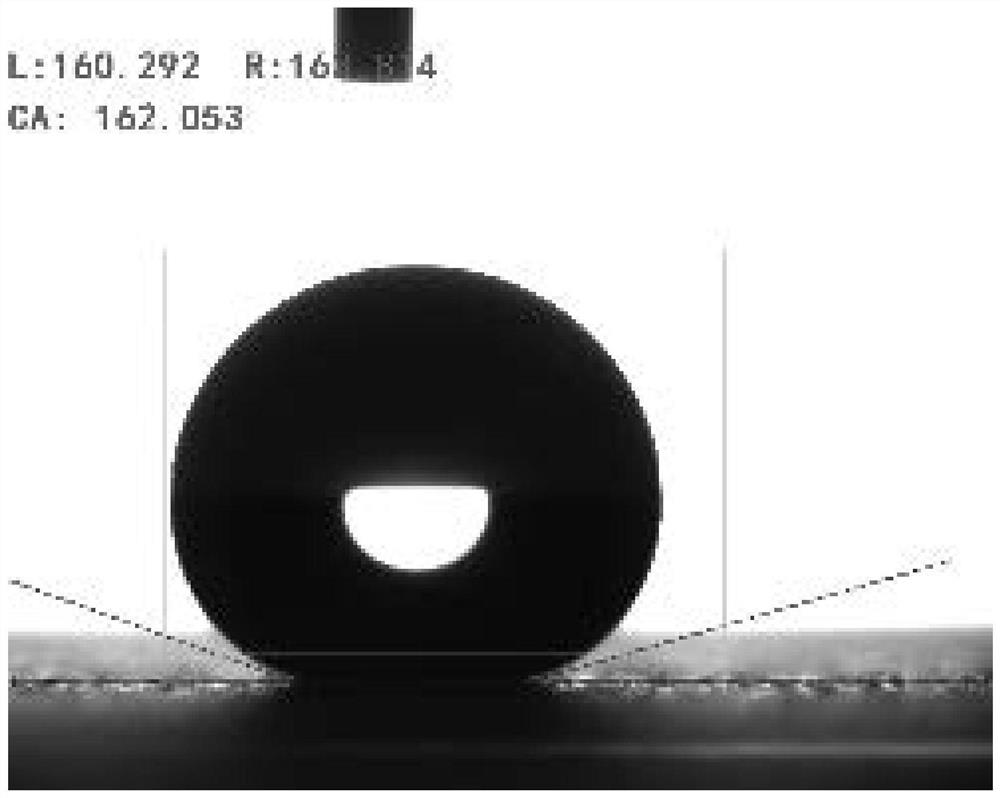

Fluorine-free super-hydrophobic modified silicon dioxide composite resin coating and preparation method thereof

InactiveCN112876983AIncrease roughnessStrong adhesionAnti-corrosive paintsPolymer scienceSilicic acid

The invention relates to the technical field of super-hydrophobic surface treatment, and particularly discloses a fluoride-free super-hydrophobic modified silicon dioxide composite resin coating, which is prepared from the following raw materials: modified hydrophobic silicon dioxide sol and an organic silica polymer, wherein the modified hydrophobic silicon dioxide sol is prepared from the following raw materials: tetraethyl orthosilicate, a first silane coupling agent and a second siloxane coupling agent, the first silane coupling agent is one of methyltriethoxysilane, hexamethyldisilazane and methyltrimethoxysilane which contain a methyl functional group, and the second siloxane coupling agent is hexadecyl trimethoxy silane containing medium and long carbon chains or n-octyl triethoxy silane containing medium and long carbon chains. The invention further provides a preparation method of the fluoride-free super-hydrophobic modified silicon dioxide composite resin coating, wherein the process is simple, the good cost advantage is achieved, and the prepared modified silicon dioxide composite resin coating has the super-hydrophobic characteristic while has good abrasion resistance.

Owner:FOSHAN SPRING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com