Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

477 results about "Ziegler–Natta catalyst" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Ziegler–Natta catalyst, named after Karl Ziegler and Giulio Natta, is a catalyst used in the synthesis of polymers of 1-alkenes (alpha-olefins). Two broad classes of Ziegler–Natta catalysts are employed, distinguished by their solubility...

Isotactic propylene copolymers, their preparation and use

InactiveUS6960635B2Group 4/14 element organic compoundsOther chemical processesFiberZiegler–Natta catalyst

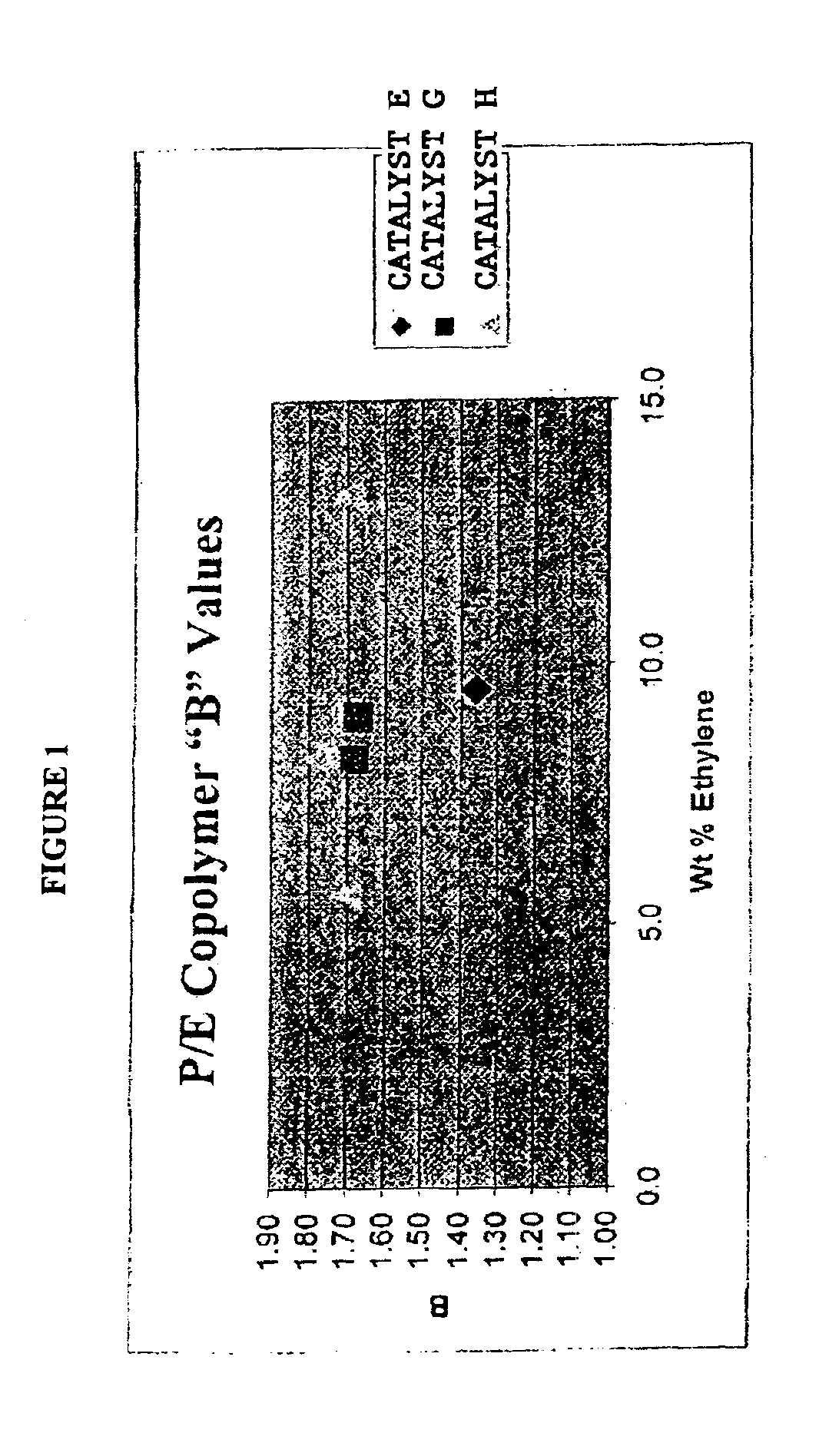

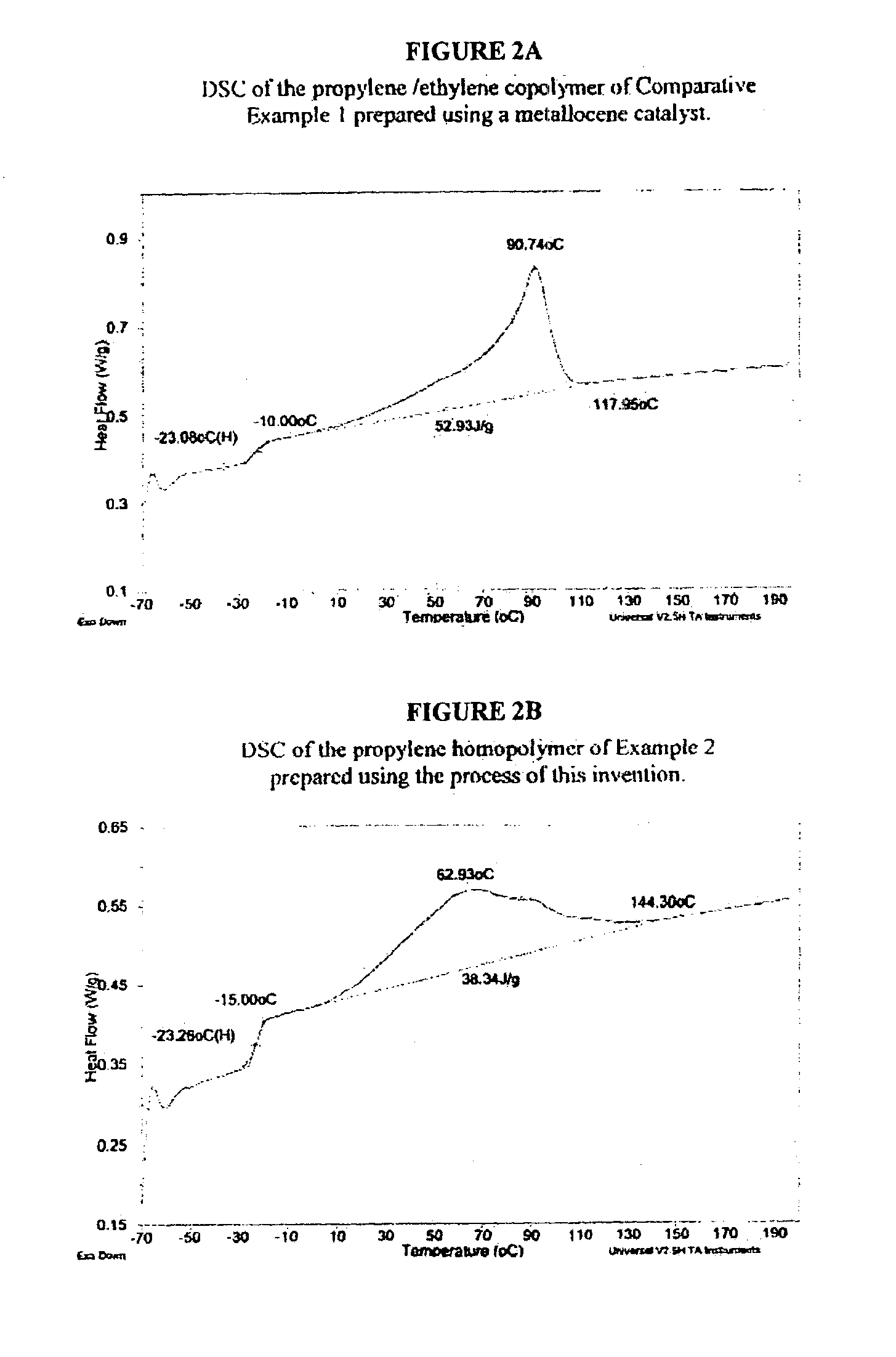

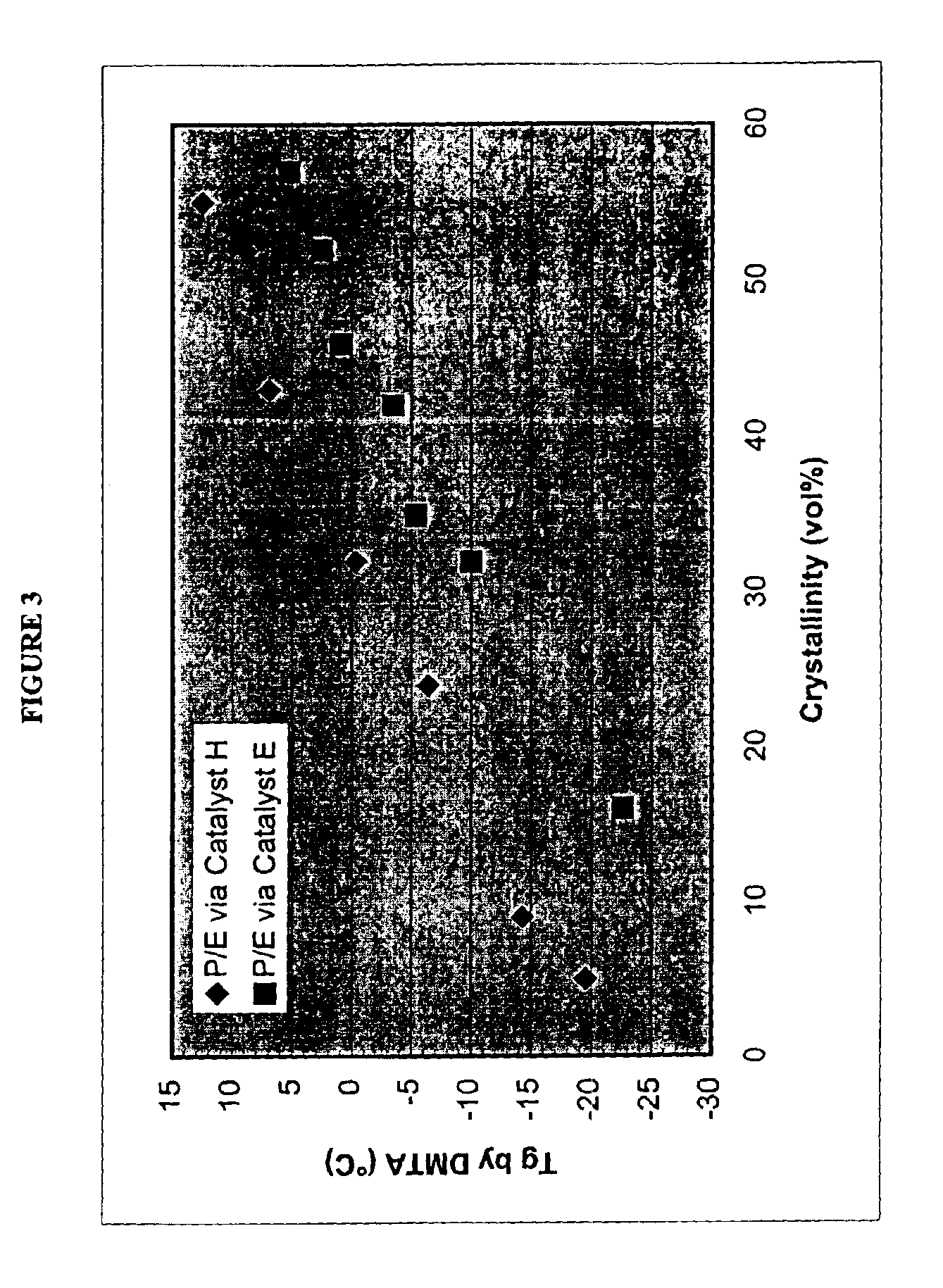

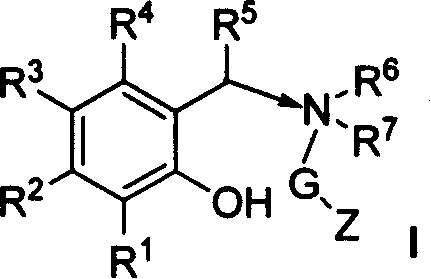

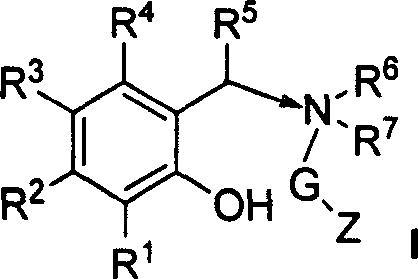

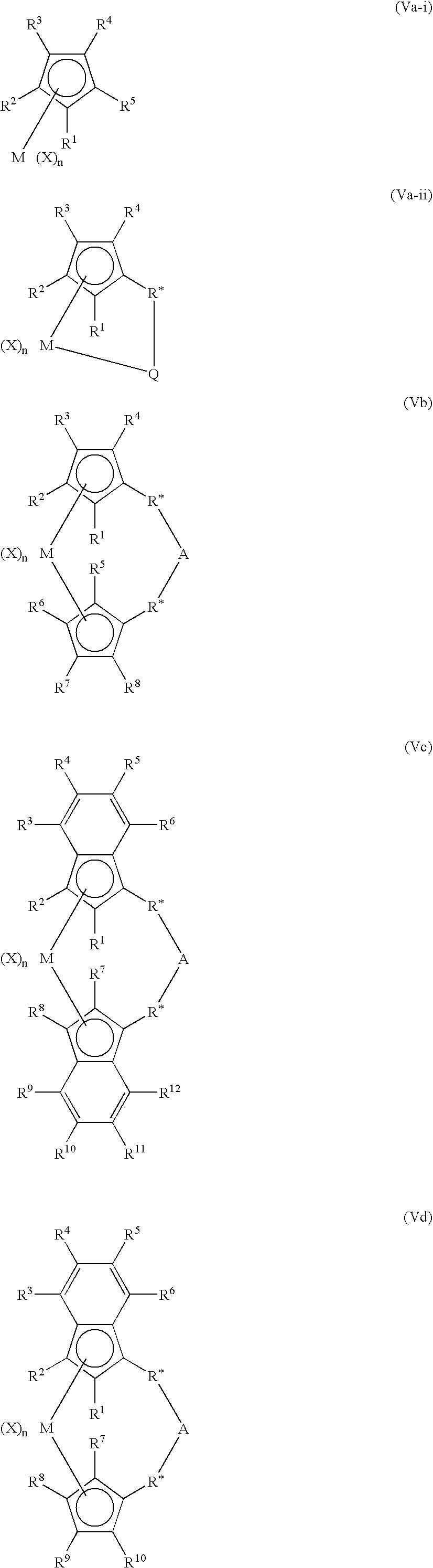

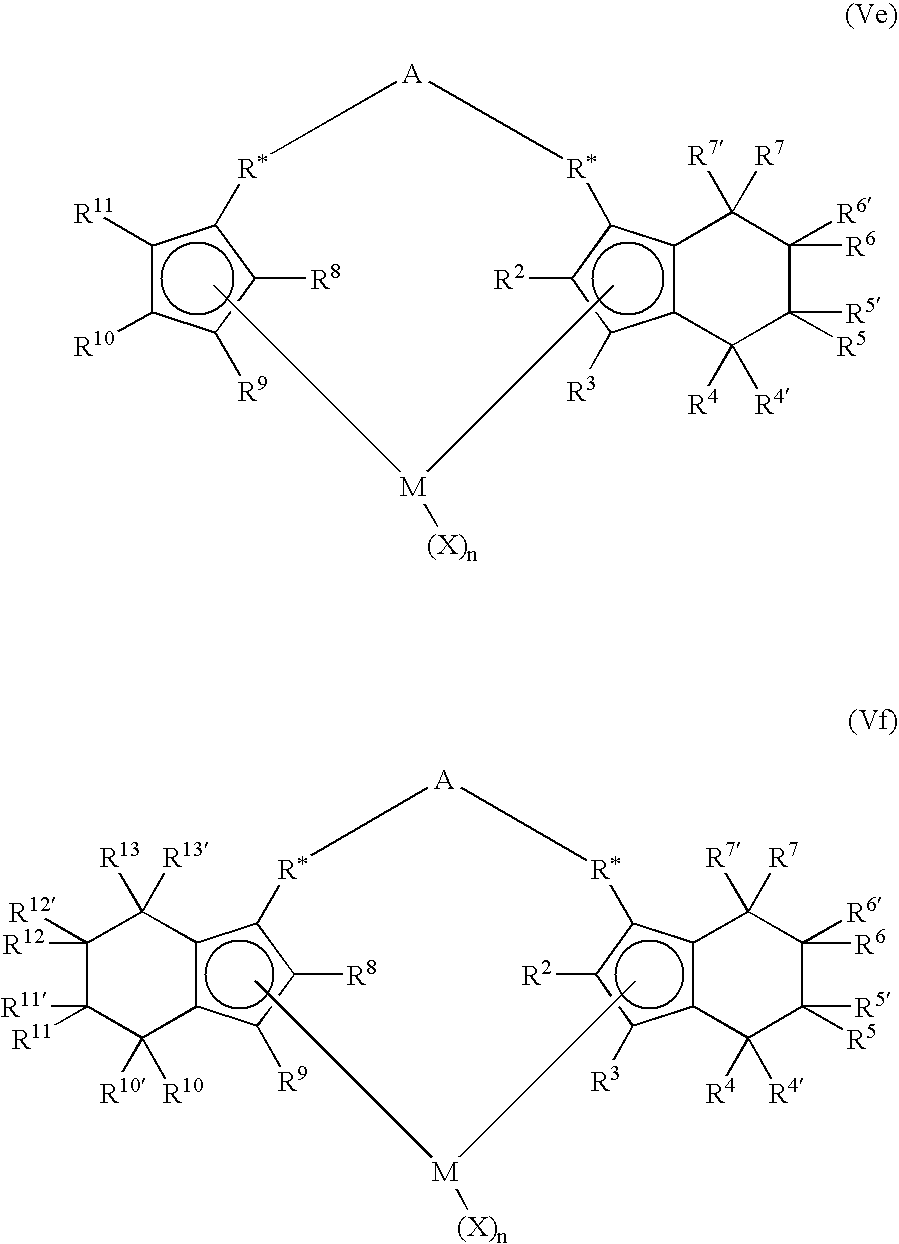

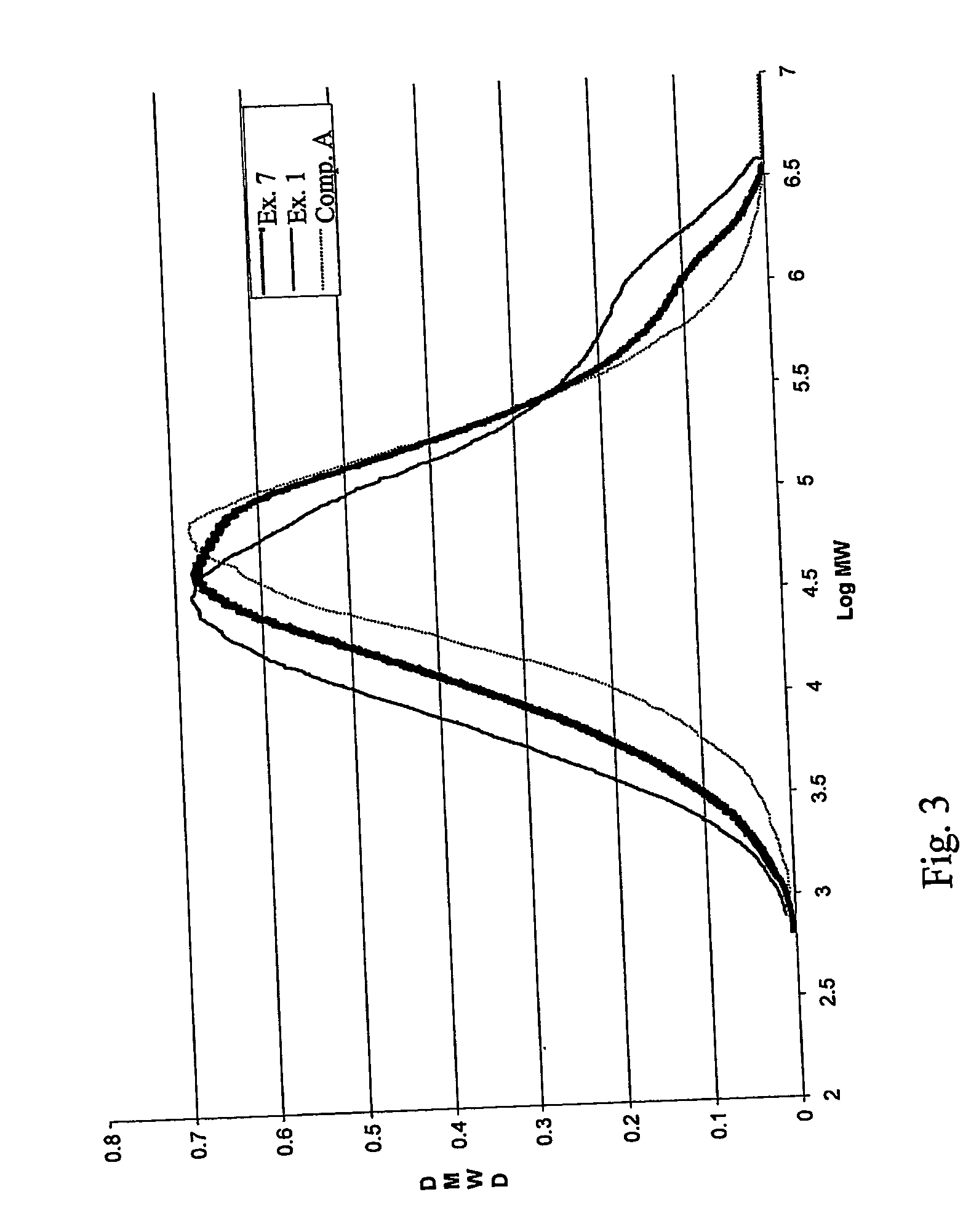

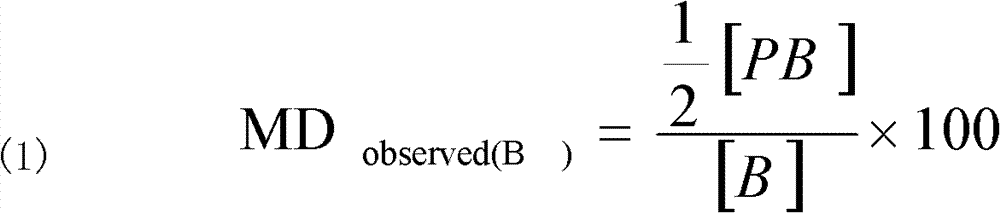

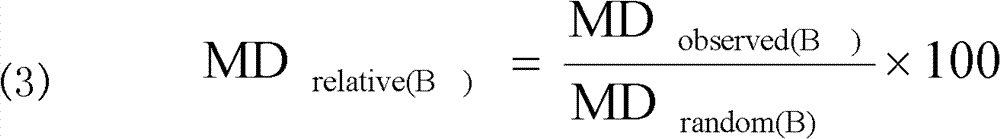

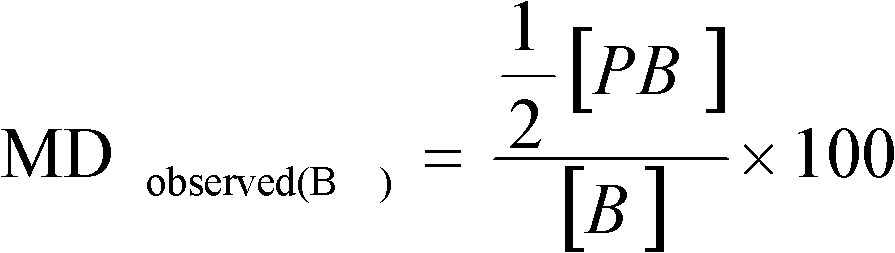

Unique copolymers comprising propylene, ethylene and / or one or more unsaturated comonomers are characterized as having: at least one, preferably more than one, of the following properties: (i) 13C NMR peaks corresponding to a regio-error at about 14.6 and about 15.7 ppm, the peaks of about equal intensity, (ii) a B-value greater than about 1.4 when the comonomer content of the copolymer is at least about 3 wt %, (iii) a skewness index, Six, greater than about −1.20, (iv) a DSC curve with a Tme that remains essentially the same and a Tmax that decreases as the amount of comonomer in the copolymer is increased, and (v) an X-ray diffraction pattern that reports more gamma-form crystals than a comparable copolymer prepared with a Ziegler-Natta catalyst. These polypropylene polymers are made using a nonmetallocene, metal-centered, heteroaryl ligand catalyst. These polymers can be blended with other polymers, and are useful in the manufacture of films, sheets, foams, fibers and molded articles.

Owner:DOW GLOBAL TECH LLC

Mono-active center Ziegler-Natta catalyst for olefinic polymerization

The invention relates to a new catalyst for single active central Ziegler-Natta alkene polymerization. Said catalyst takes salicylal containing dentate or substituted salicylal derivatives as electrons, and is prepared by adding pretreated carrier, metallic compound and electrons into magnesium compound / tetrahydrofuran solution. The catalyst can produce ethane homopolymer and copolymer with narrow molecular weight distribution (1.6-3.8) and even comonomer distribution, with high activity and under action of adjuvant catalyst of alkyl aluminium and alkyl aluminoxanes. The ethane polymerization, homopolymerization or combined polymerization of ethane and 1- olefin, ring olefin and polar monomer through slurry method or gas phase method by using said catalyst can be realized.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

Production of polyethylene having a broad molecular weight distribution

InactiveUS6221982B1High densityImprove mechanical propertiesOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer scienceZiegler–Natta catalyst

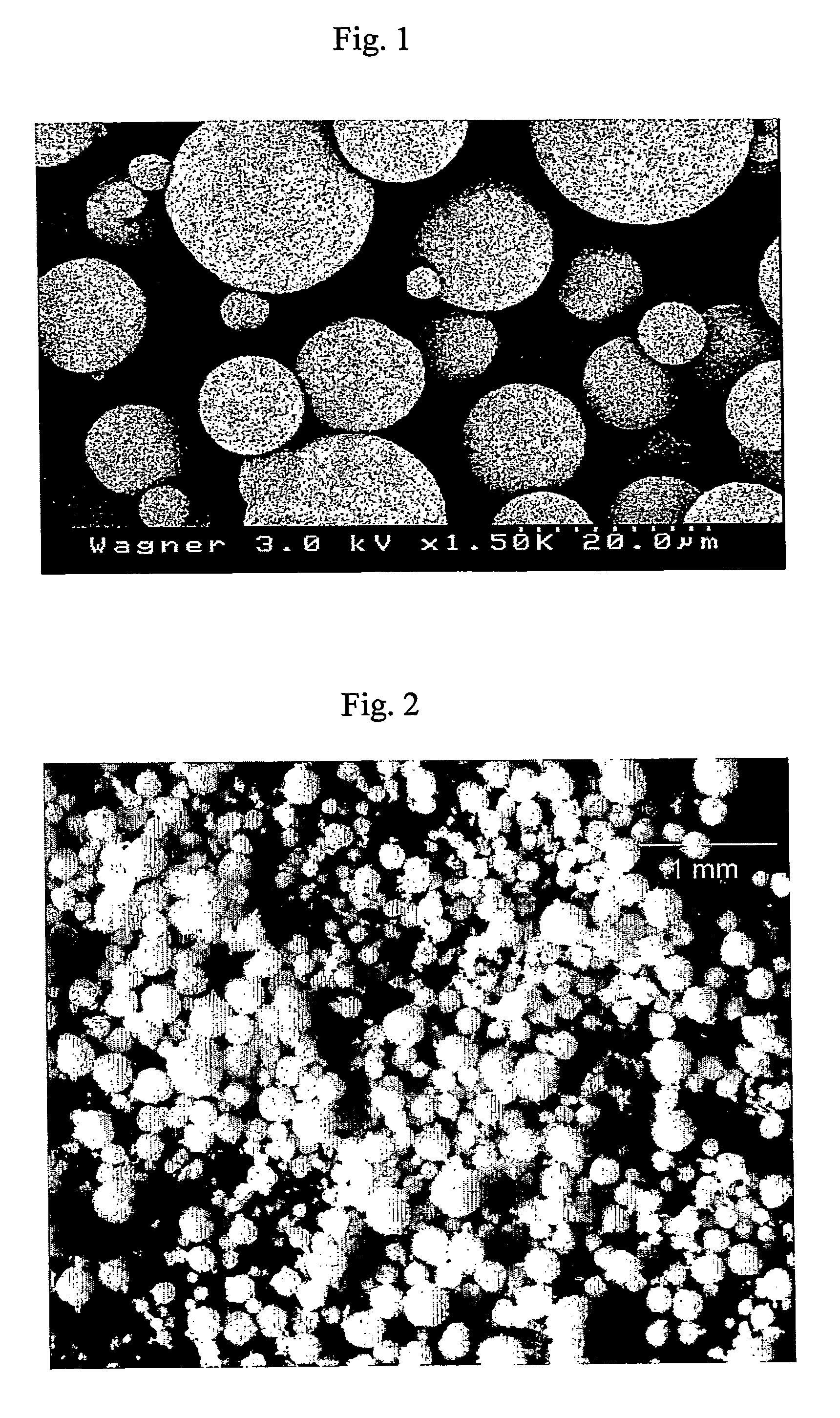

A process for producing high density polyethylene in the presence of a Ziegler-Natta catalyst system in two liquid full loop reactors in series, wherein in a first reactor a first polyethylene product is polymerized substantially by homopolymerization of ethylene and hydrogen, optionally with a minor degree of copolymerization of ethylene with an alpha-olefinic comonomer comprising from 3 to 8 carbon atoms, and in a second reactor serially connected to the first reactor downstream thereof a second polyethylene product is copolymerized from ethylene and an alpha-olefinic comonomer comprising from 3 to 8 carbon atoms, and a hydrogenation catalyst is introduced into the reactants downstream of the first reactor.

Owner:FINA RES SA

Bimetallic catalyst, method of polymerization and bimodal polyolefins therefrom

InactiveUS7172987B2Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyolefinZiegler–Natta catalyst

Bimetallic catalysts, and methods of producing a bimetallic catalyst comprising a modified Ziegler-Natta catalyst and a metallocene are provided, in one embodiment the method including combining: (a) a Ziegler-Natta catalyst comprising a Group 4, 5 or 6 metal halide and / or oxide, optionally including a magnesium compound, with (b) a modifier compound (“modifier”), wherein the modifier compound is a Group 13 alkyl compound, to form a modified Ziegler-Natta catalyst. Also provided is a method of olefin polymerization using the bimetallic catalyst of the invention. The modified Ziegler-Natta catalyst is preferably non-activated, that is, it is unreactive towards olefin polymerization alone. In one embodiment, the molar ratio of the Group 13 metal (of the modifier) to the Group 4, 5 or 6 metal halide and / or oxide is less than 10:1 in one embodiment. The bimetallic catalysts of the present invention are useful in producing bimodal polymers, particularly bimodal polyethylene, having a Polydispersity (Mw / Mn) of from 12 to 50. These bimodal polyolefins are useful in such articles as pipes and films.

Owner:UNIVATION TECH LLC

Thermoplastic vulcanizate composition

The instant disclosure is directed to a thermoplastic vulcanizate composition comprising a dynamically-cured rubber; from about 20 to about 300 parts by weight of a thermoplastic resin per 100 parts by weight rubber and from about 30 to about 250 parts by weight additional oil per 100 parts by weight rubber; wherein the rubber comprises a multimodal polymer composition cured with a curing agent, the multimodal polymer composition comprising 45 to 75 wt% of a first polymer fraction and 25 to 55 wt % of a second polymer fraction, each comprising ethylene, a C3-C10 alpha-olefin, and a non-conjugated diene, wherein the polymer fractions have been polymerized using a Ziegler-Natta catalyst system, wherein the first polymer fraction has a Mooney viscosity of greater than or equal to about 150 ML(1+4@125° C.), and the second polymer fraction has a Mooney viscosity of about 20 ML to about 120 ML; and about 10 phr to about 50 phr of an extender oil. A method of producing the thermoplastic vulcanizate is also disclosed.

Owner:CELANESE INT CORP

Spray-dried, mixed metal ziegler catalyst compositions

ActiveUS20070060725A1Improve productivityImproved catalyst homogeneityMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsZiegler–Natta catalystTitanium

A Ziegler-Natta catalyst composition comprising a solid mixture formed by halogenation of: Al) a spray-dried catalyst precursor comprising the reaction product of a magnesium compound, a non-metallocene titanium compound, and at least one non-metallocene compound of a transition metal other than titanium, with A2) an organoaluminium halide halogenating agent, a method of preparing, precursors for use therein, and olefin polymerization processes using the same.

Owner:UNION CARBIDE CORP

Method for transitioning between Ziegler-Natta and metallocene catalysts in a bulk loop reactor for the production of polypropylene

InactiveUS6916892B2High temperature rangeChemical/physical/physico-chemical processesFeed devicesScavengerZiegler–Natta catalyst

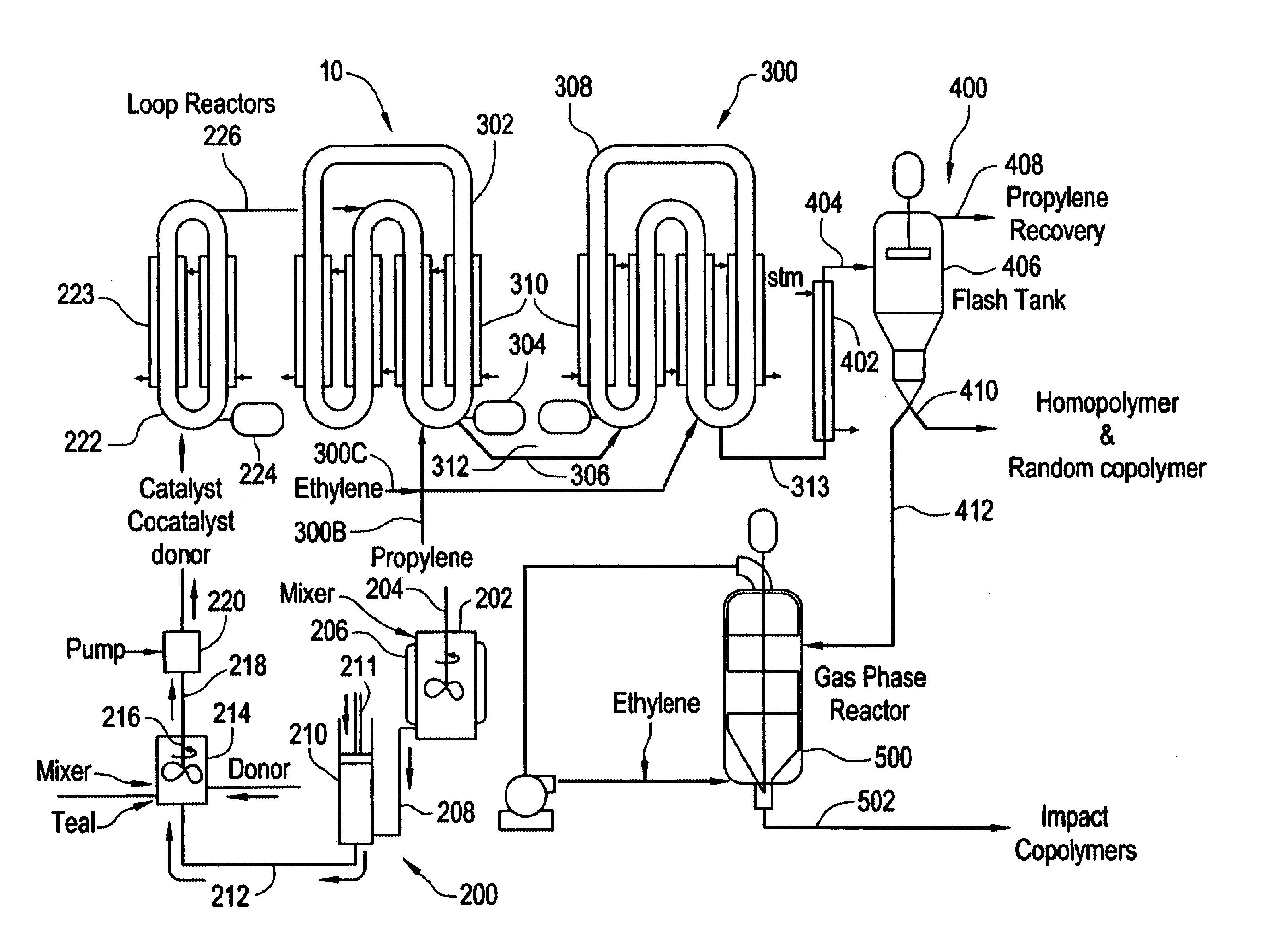

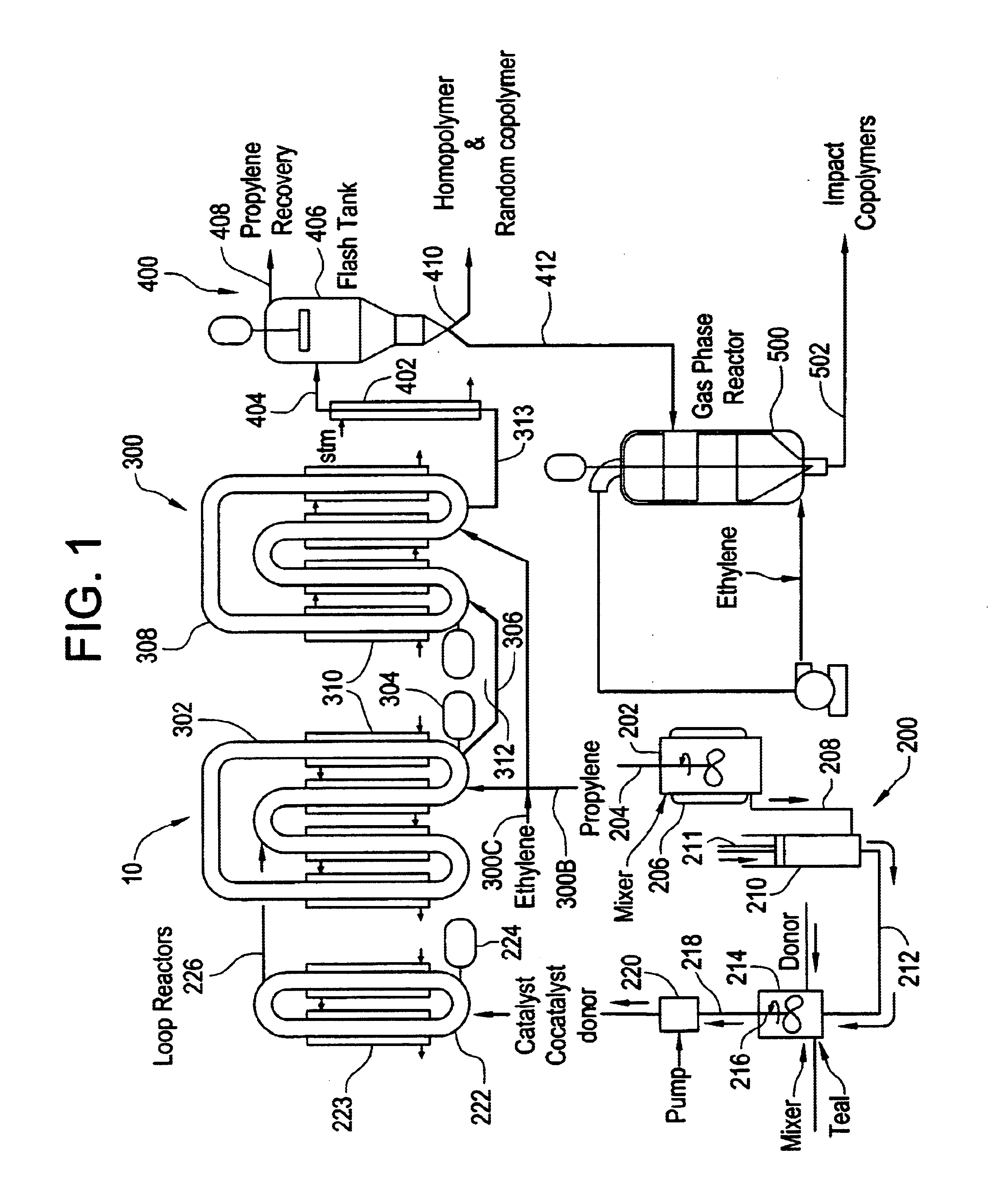

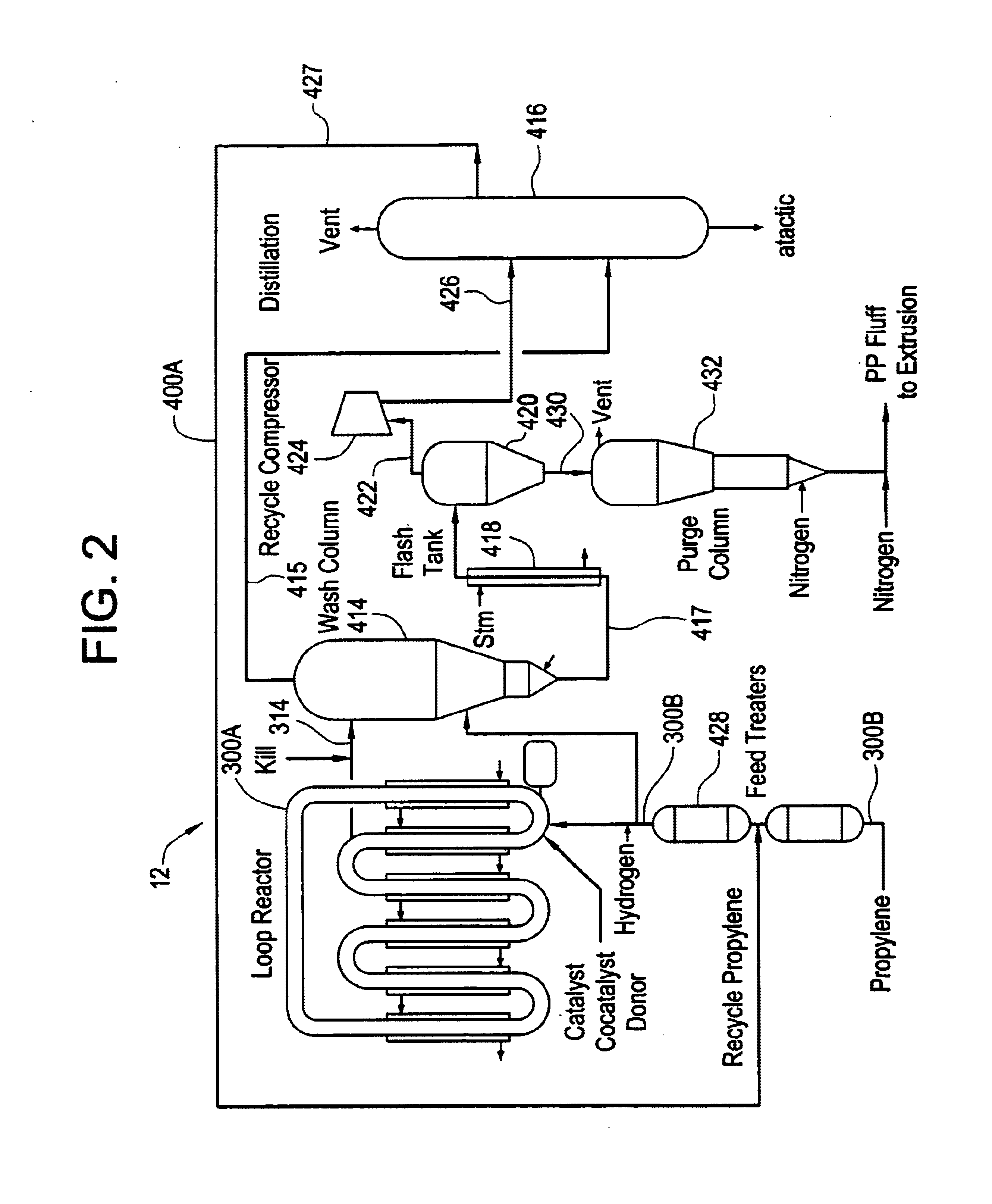

The present invention relates to propylene polymerization process in a bulk loop reactor, and particularly to propylene polymerization process for polymerizing commercial quantities of polypropylene in a bulk loop reactor by sequentially introducing Ziegler-Natta and metallocene catalyst systems into the bulk loop reactor. In one embodiment, separate catalyst mixing systems are used to introduce a quantity of metallocene catalyst and Ziegler-Natta catalyst into the bulk loop reactor. The frequency rate at which the quantity of metallocene catalyst is introduced into the bulk loop reactor may be higher than the frequency rate at which the quantity of Ziegler-Natta catalyst is introduced. In another embodiment, a method of polymerizing propylene in a bulk loop reactor is provided which includes contacting a quantity of supported metallocene catalyst with a first quantity of scavenger, such as TEAL and or TIBAL, prior to injecting the supported metallocene catalyst into the bulk loop reactor and contacting a quantity of Ziegler-Natta catalyst system with a second quantity of scavenger prior to injecting the Ziegler-Natta catalyst system into the bulk loop reactor, wherein the second quantity of scavenger is greater that the first quantity of scavenger. In another embodiment, a method of contacting a flow of metallocene with a flow of propylene is provided. This method includes directing the flow of metallocene towards a junction, directing the flow of propylene towards the junction and maintaining a portion of the flow of metallocene separate from a portion of the flow propylene within a portion of the junction downstream of the flow of propylene into the junction. In another embodiment, a method of introducing a quantity of antifouling agent into a catalyst mixing system is provided. In this embodiment a portion of the antifouling agent is introduced at or downstream of a point of contact of a stream of propylene with a stream of catalyst. The antifouling agent may be a member, alone or in combination with other members, selected from the group consisting of Stadis 450 Conductivity Improver, Synperonic antifouling agent, and Pluronic antifouling agent.

Owner:FINA TECH

Gas-phase polymerization method and polymer of polybutene-1

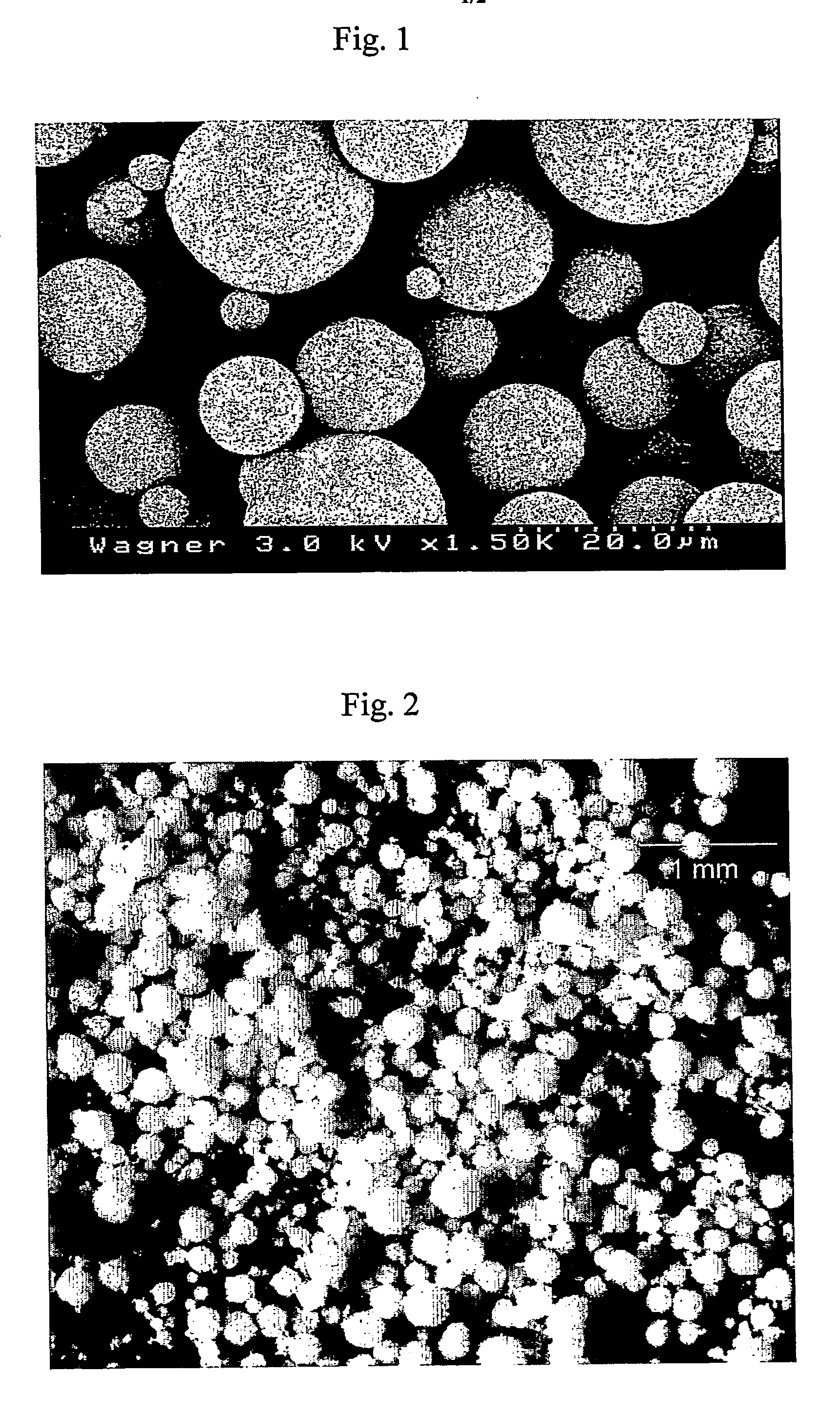

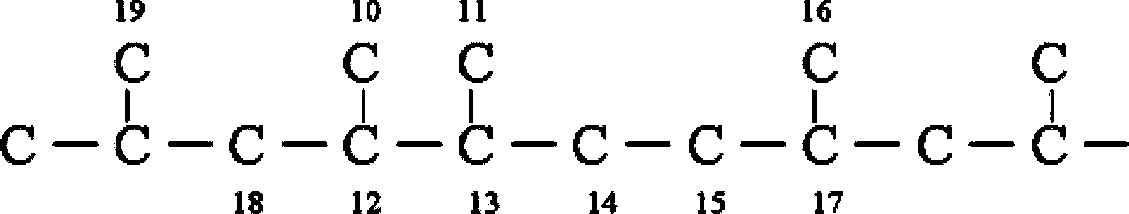

The invention provides a gas-phase polymerization method of polybutene-1 for preparing high-quality butene-1 polymer, which comprises: performing homopolymerization of butene-1 serving as a monomer and a reaction medium or copolymerization of butene-1 and other alpha-olefins in a gas-phase polymerization reactor at a reaction temperature of 0 to 110 DEG C in the presence of a Ziegler-Natta catalyst with high stereoselectivity, and standing for 1 to 6 hours optimally. The method is simple in process, easy in operation and low in cost. The prepared polybutene-1 product is sphere-like or spherical particles and contains little fine powder, thereby contributing to the long-term operation o devices.

Owner:CHINA PETROLEUM & CHEM CORP +1

Film

InactiveUS20100304062A1Easy to processIncrease chanceSynthetic resin layered productsLaminationLow-density polyethyleneLinear low-density polyethylene

The present invention provides a uniaxially oriented multilayer film comprising at least (i) a layer (A) and (ii) a layer (B), wherein said layer (A) comprises a linear low density polyethylene (LLDPE) comprising (e.g. selected from):—a multimodal LLDPE produced using a Ziegler Natta catalyst (znLLDPE), or—a LLDPE produced using a single site catalyst (mLLDPE) or—a mixture of a mLLDPE and a multimodal znLLDPE, said layer (B) comprises a multimodal LLDPE, and said multilayer film is in the form of a stretched film which is uniaxially oriented in the machine direction (MD) in a draw ratio of at least 1:3.

Owner:BOREALIS TECH OY

Method of making a Ziegler-Natta catalyst

ActiveUS20060046927A1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationZiegler–Natta catalystFumed silica

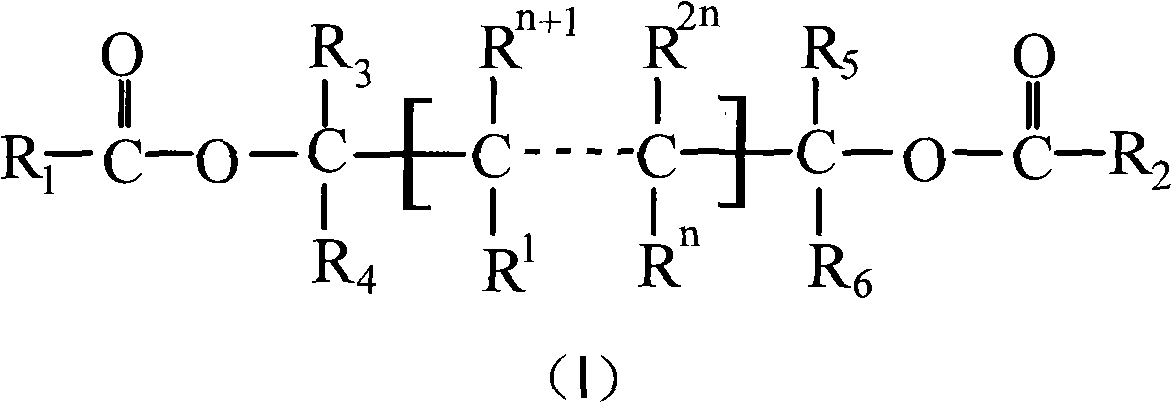

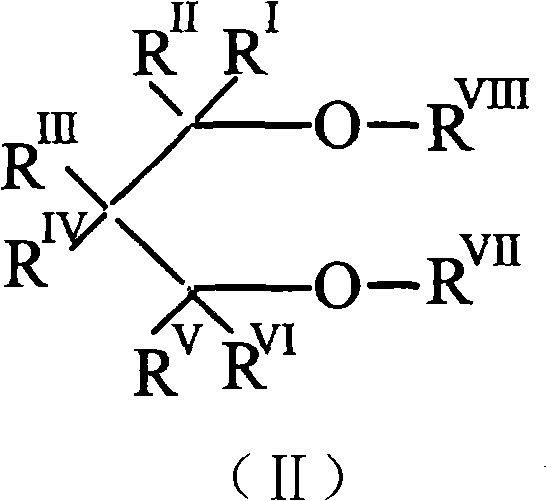

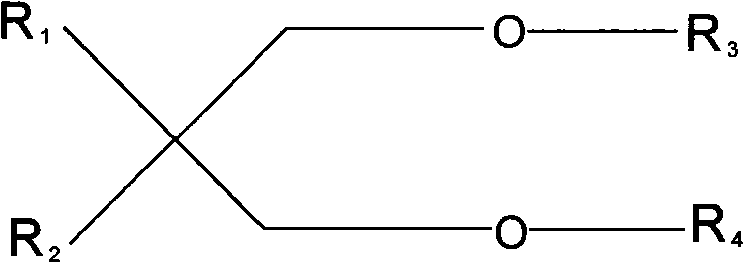

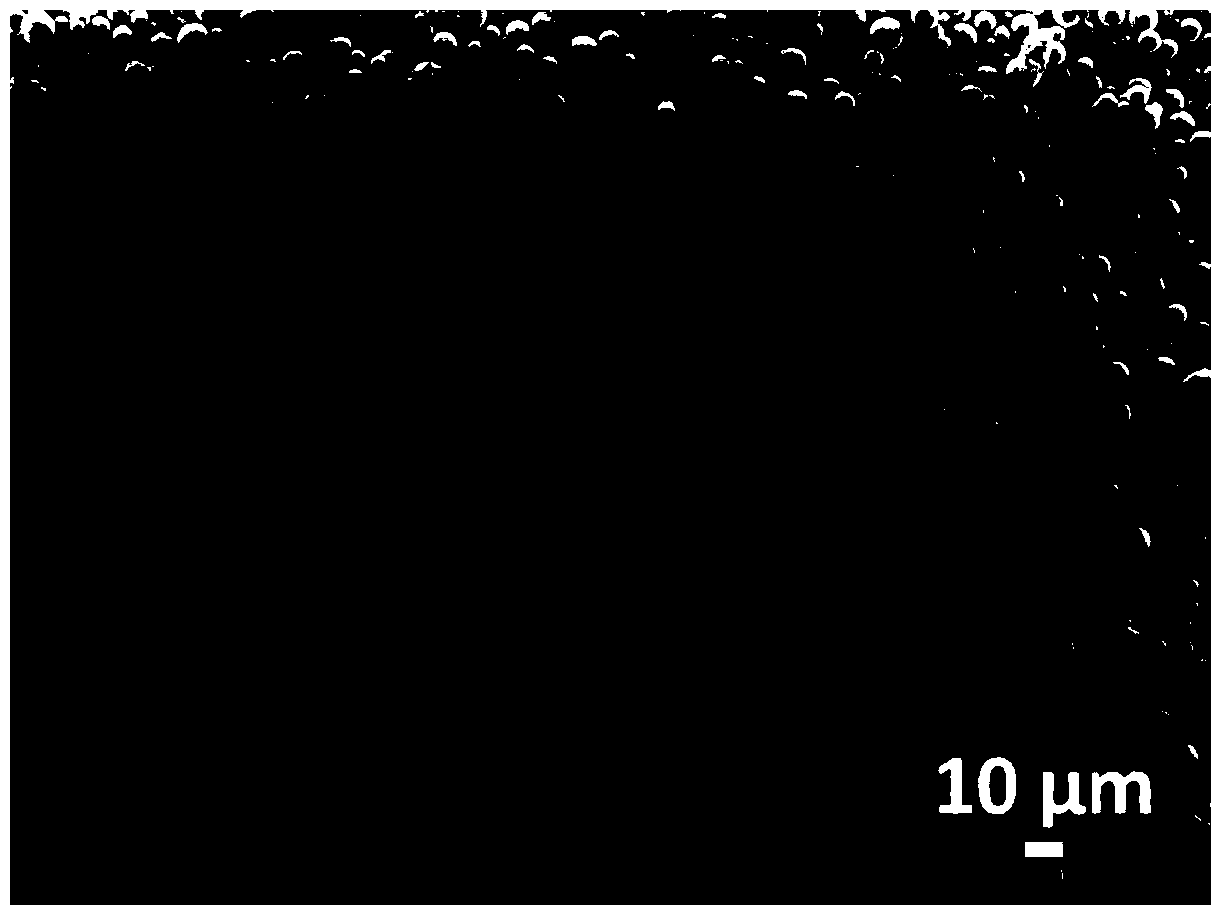

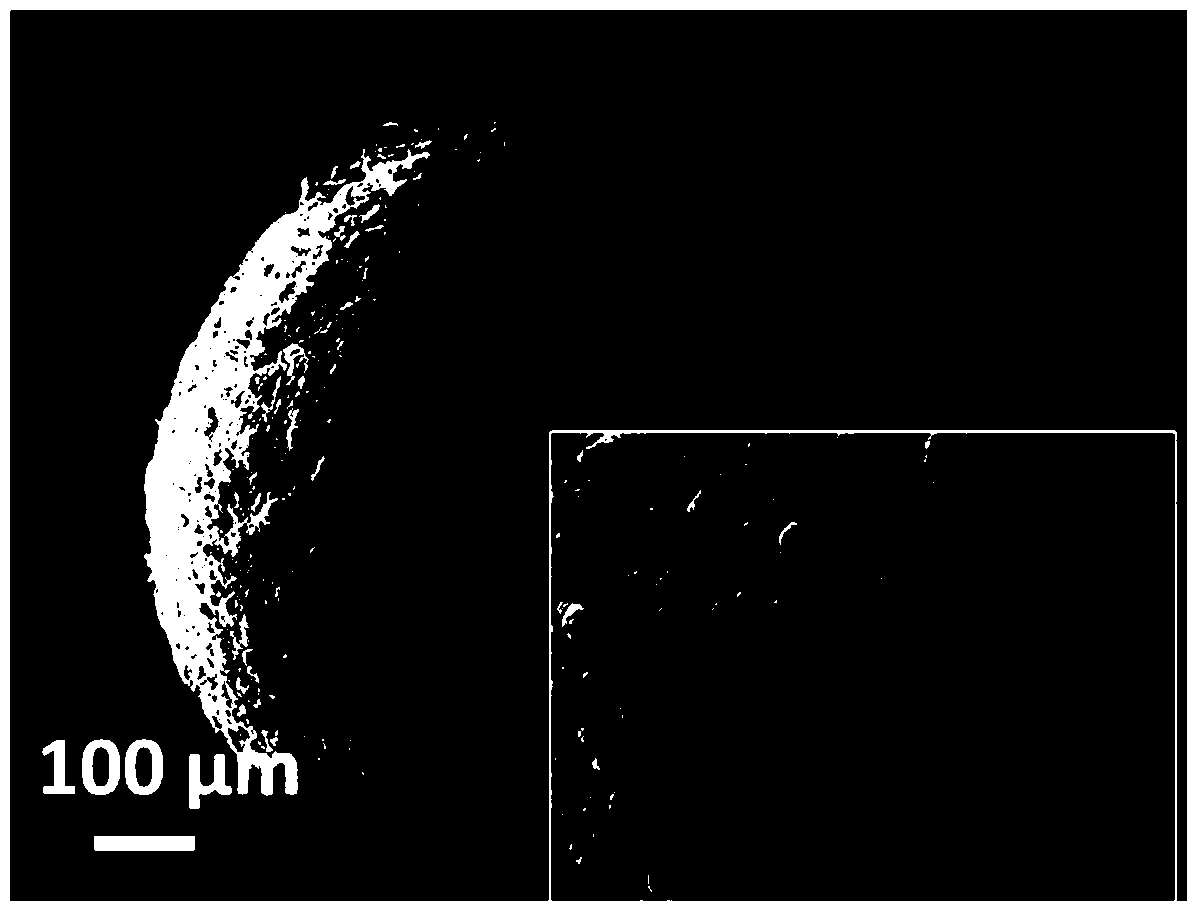

A method for making a Ziegler-Natta catalyst support includes the steps of contacting a fumed silica with a surface modifying agent such as a compound having the formula RMgX MgR′R″ wherein R, R′ and R″ are each individually a moiety selected from an alkyl group, cycloalkyl, aryl or alkaryl group, and X is a halogen selected from the group consisting of chlorine, bromine and iodine, to provide a pretreated silica seeding agent. The pretreated silica seeding agent is then dispersed in a non-aqueous liquid magnesium halide / alkanol complex, and the magnesium halide is crystallized onto the silica particles to form-catalyst support particles especially suitable for Ziegler-Natta catalysts.

Owner:LUMMUS NOVOLEN TECH

Processes for transitioning between various polymerization catalysts

ActiveUS6858684B2Increase heightReduce the overall heightChemical/physical processesZiegler–Natta catalystOlefin polymerization

This invention relates to processes for transitioning among polymerization catalyst systems, preferably catalyst systems, which are incompatible with each other. Particularly, the invention relates to processes for transitioning among olefin polymerization reactions utilizing Ziegler-Natta catalyst systems, metallocene catalyst systems and chromium-based catalyst systems.

Owner:UNIVATION TECH LLC

Processes for transitioning between metallocene and Ziegler-Natta polymerization catalysts

ActiveUS6949612B2Efficient activationReducing electricityZiegler–Natta catalystOlefin polymerization

Processes for transitioning among polymerization catalyst systems, preferably catalyst systems that are incompatible with each other. In particular, the processes relate to transitioning from olefin polymerizations utilizing metallocene catalyst systems to olefin polymerizations utilizing traditional Ziegler-Natta catalyst systems.

Owner:UNIVATION TECH LLC

Preparation method of propylene random copolymer

The invention relates to a preparation method of a propylene-butylene-1 random copolymer. The preparation method comprises a step that the propylene-butylene-1 random copolymer is obtained through carrying out a copolymerization reaction of propylene and butylene-1 by adjusting the addition amount of the copolymerization monomer butylene-1 in a reactor at a polymerization temperature under a proper hydrogen content in the presence of a selected Ziegler-Natta catalyst. The preparation method has an easy polymerization process and can avoid the appearance of sticky kettle, caking, incompletely-removed residual monomers and the like, and the prepared propylene-butylene-1 random copolymer has a high relative butylene-1 dispersion degree and a low room-temperature xylene soluble substance content.

Owner:CHINA PETROLEUM & CHEM CORP +1

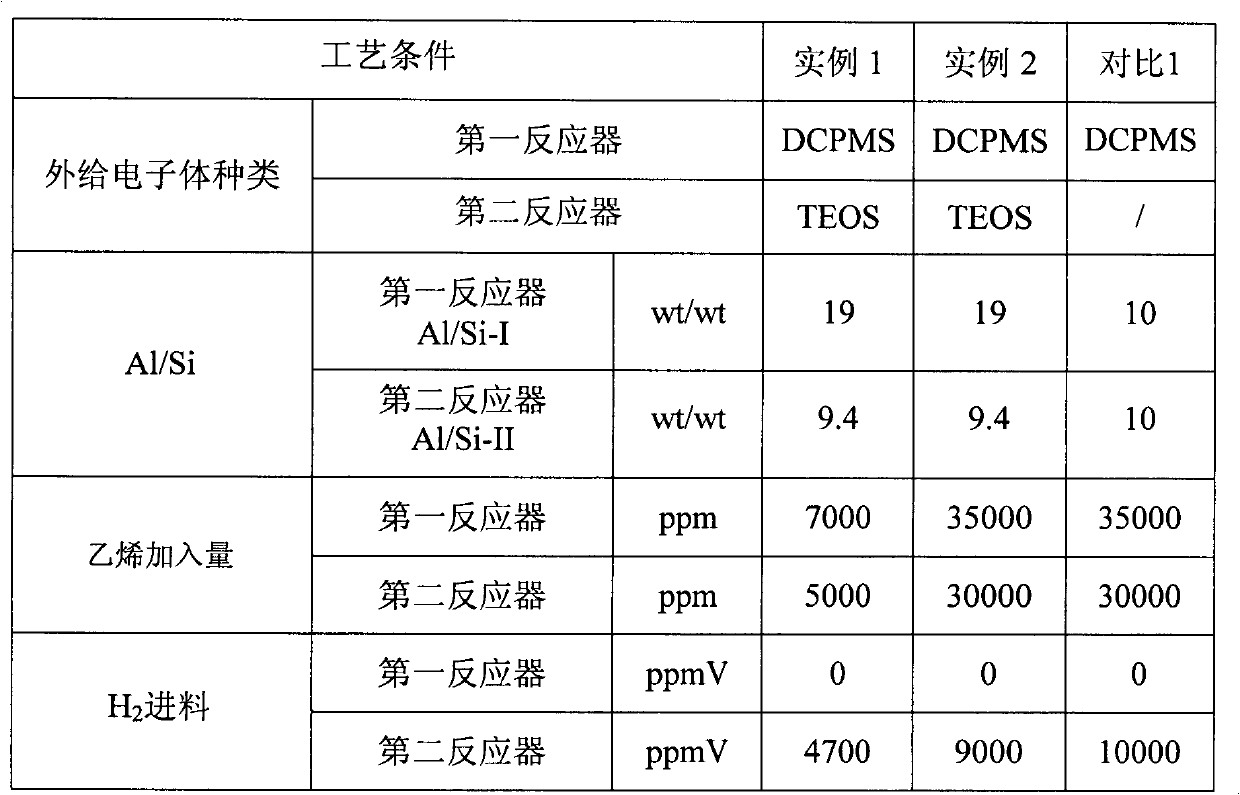

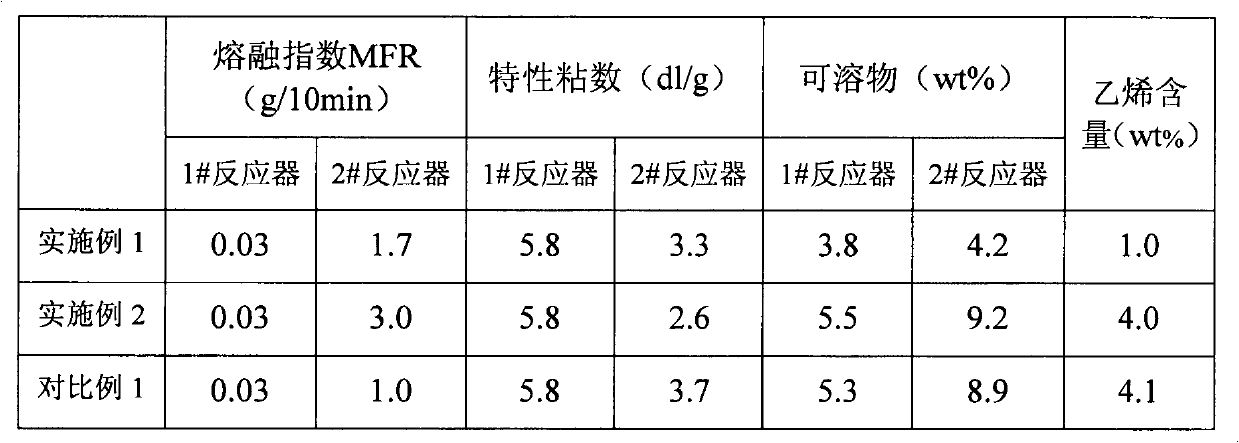

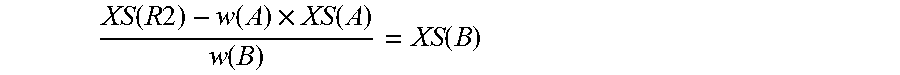

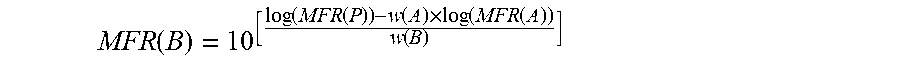

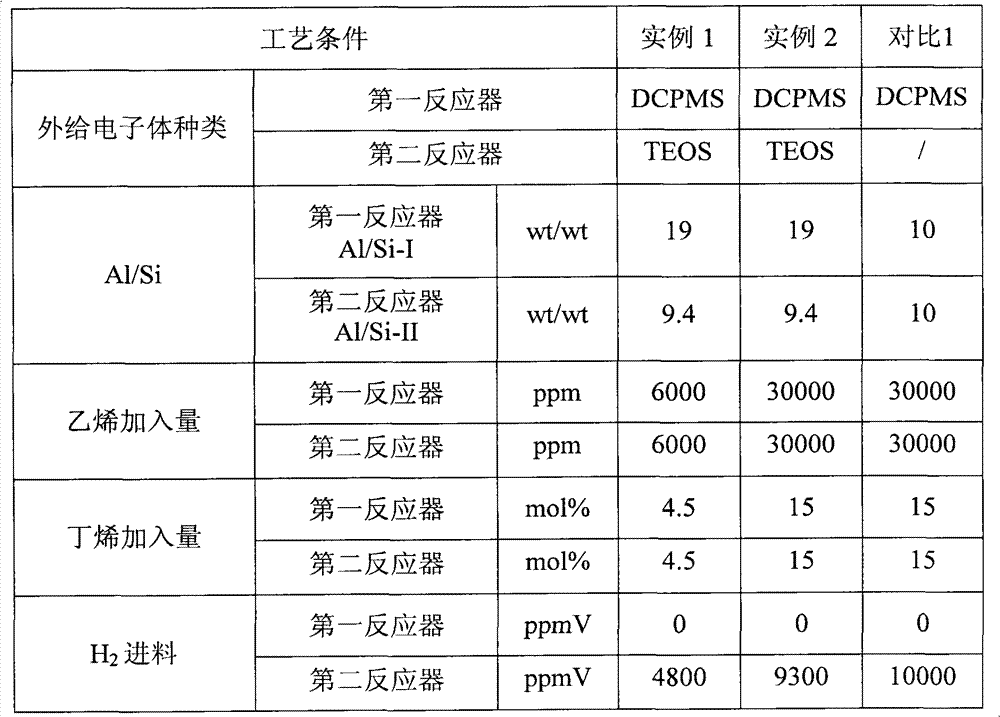

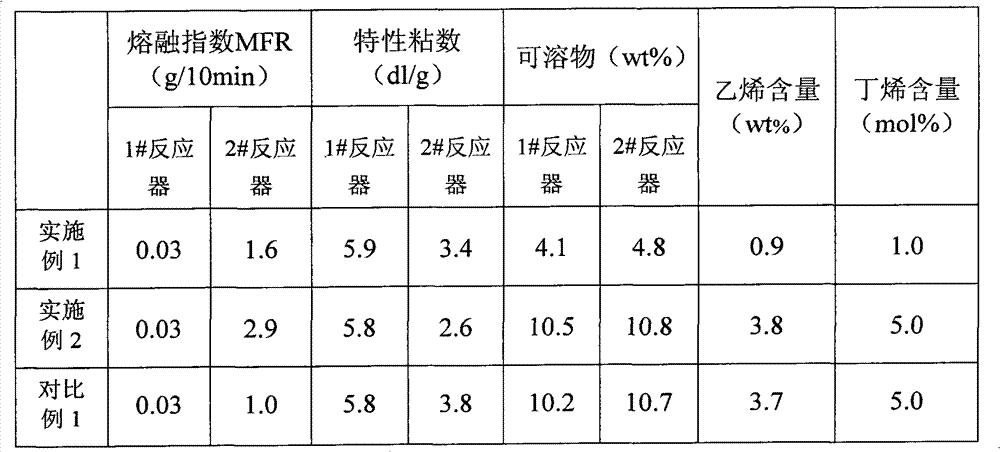

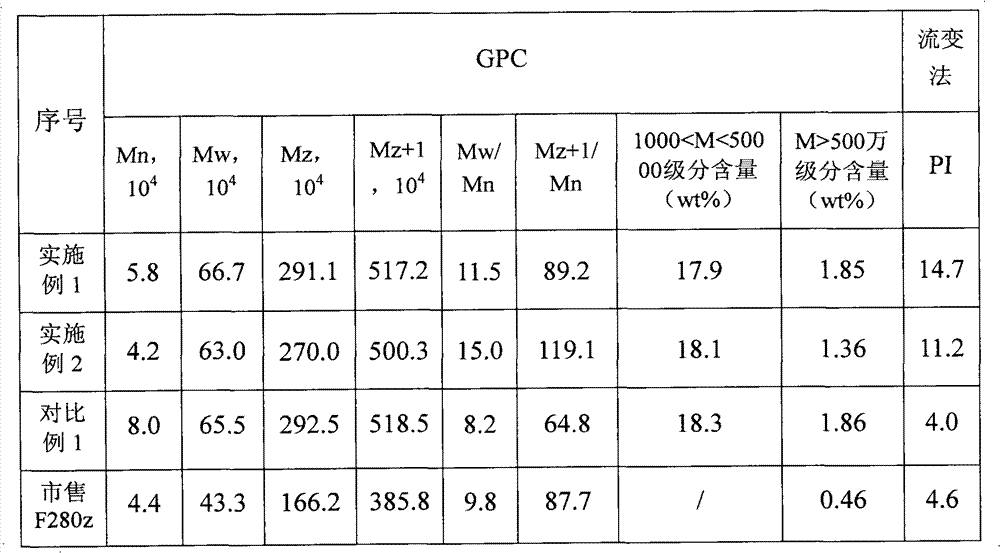

High-melt-strength propylene/ethylene copolymer and preparation method thereof

The invention provides a method for preparing random high-melt-strength propylene / ethylene copolymer by direct polymerization. The method includes that during different serially operated polymerization reaction steps, according to requirements of different molecular grades, the propylene / ethylene copolymers with wide molecule distribution and 'overhigh molecular weight grade' can be prepared by controlling types and proportions of electron donor components in a Ziegler-Natta catalyst system in different reaction steps. The invention further provides random high-melt-strength propylene / ethylene copolymer which has great mechanical property, optical performance, in particular high impact strength, low melting point and high melt strength. Compared with homopolymer high-melt-strength polypropylene, the copolymerized high-melt-strength polypropylene is more applicable to preparation of multiplying-power foaming products and can be utilized in post processing for molding multiplying-power foaming beads with lower energy consumption, and the foaming beads are higher in cohesive strength and better in toughness.

Owner:CHINA PETROLEUM & CHEM CORP +1

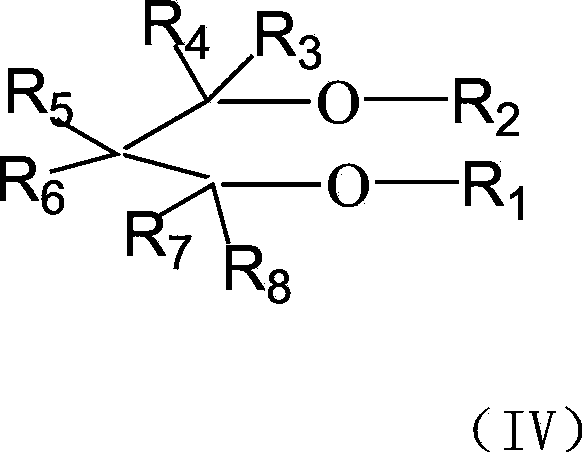

Process for forming a ziegler-natta catalyst system having a controlled morphology

InactiveUS7169727B2Molecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsAlcoholZiegler–Natta catalyst

A pre-catalyst is formed by reacting butylethylmagnesium with an alcohol to form a magnesium alkoxide compound, followed by contacting the magnesium alkoxide compound with a phosphorous compound to form a magnesium alkoxide phosphorous compound mixture. The magnesium alkoxide phosphorous compound mixture is subsequently reacted with TiCl4 to form a MgCl2 support. The MgCl2 support is then contacted with an internal donor while being heated to form a first catalyst slurry, which is then contacted with TiCl4 while being heated to form a second catalyst slurry. The second catalyst slurry is next contacted with TiCl4 while being heated to form a third catalyst slurry, which is washed and dried, resulting in a highly active pre-catalyst with controlled morphology. The pre-catalyst may be combined with one or more co-catalysts and optionally one or more external electron donors to form an active catalyst system, which may be used for the polymerization of olefins.

Owner:FINA TECH

Catalyst for olefin high-temperature polymerization and preparation and use thereof

The present invention discloses catalyst for high temperature olefin polymerization and its preparation process and use. The catalyst includes: supported Ziegler-Natta catalyst of titanium halide compound and organic electron donor compound supported with MgCl2 alcoholate carrier; aluminoxane prepared with trialkyl aluminum and water; and one kind of organic electron donor, such as organosilicon compound R2Si(OCH3)2, where R is phenyl, isopropyl, isobutyl or cyclopentyl. The said catalyst can catalyze propylene polymerizing reaction at 50-120 deg.c in excellent catalytic activity, and the prepared polymer has isotactivity index of 85-99 %, number average molecular weight of 43000-104000 g / mol, molecular weight distribution index of 4.5-10.6.

Owner:ZHEJIANG UNIV

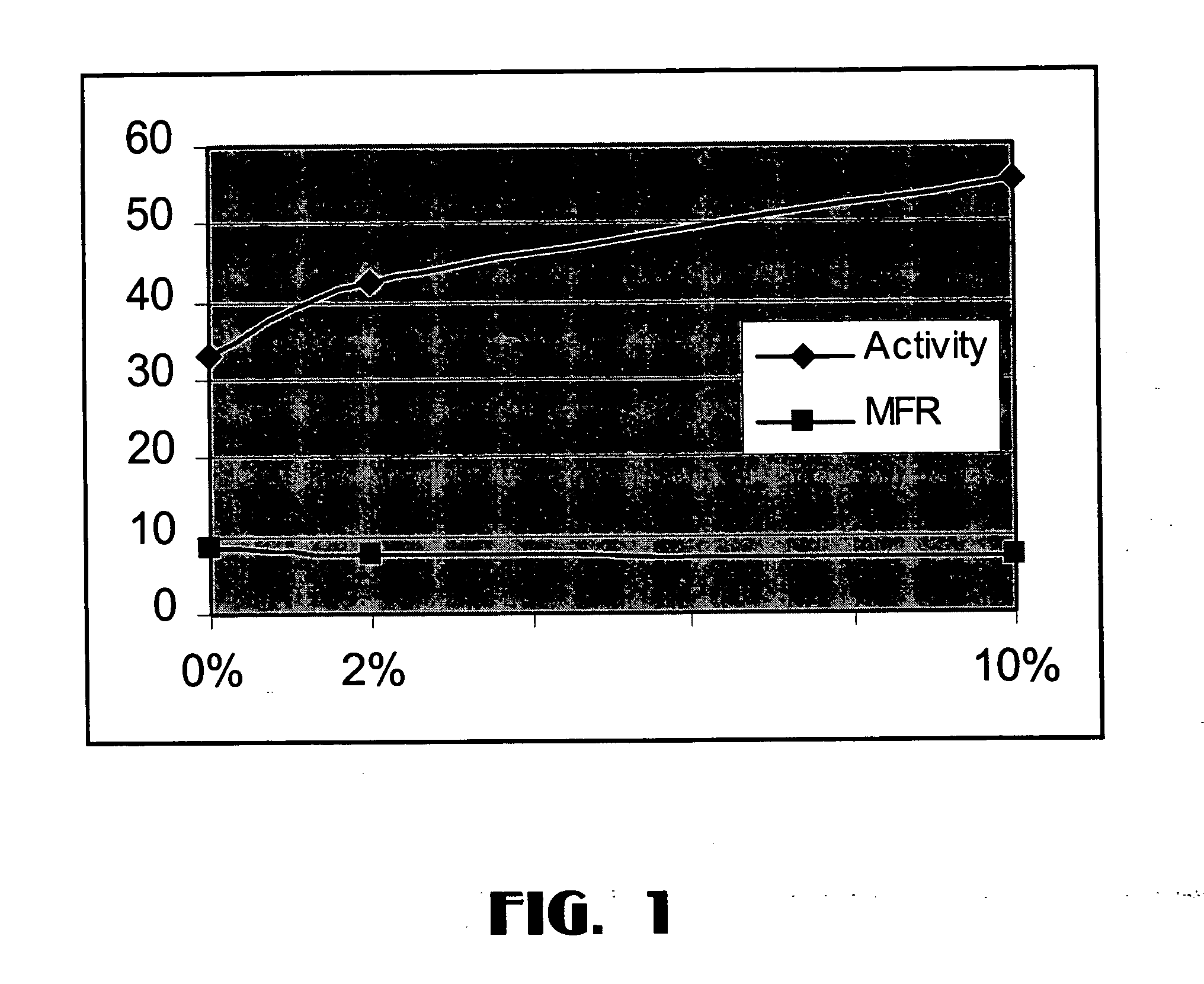

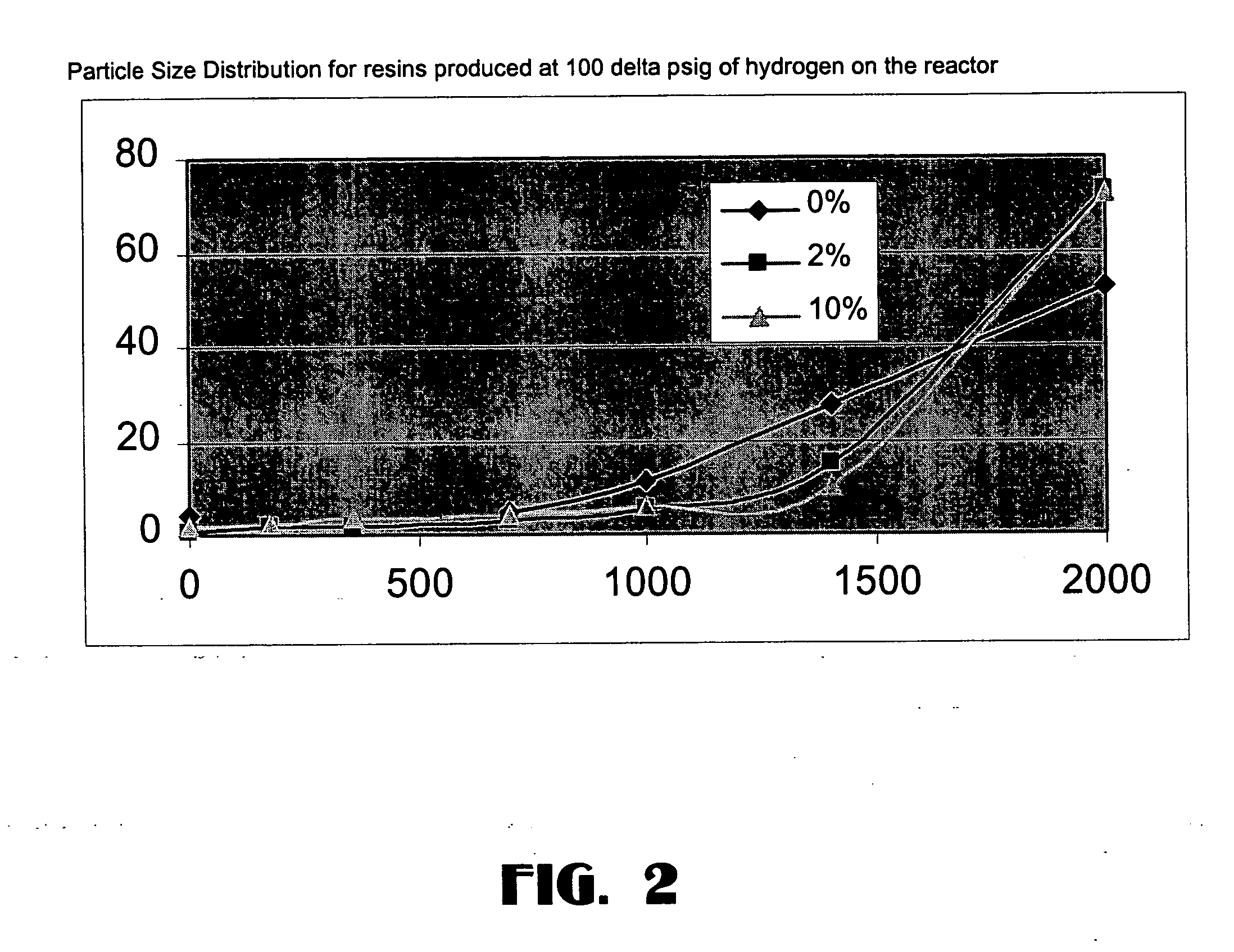

Process for the polymerization of ethylene and interpolymers thereof

A novel continuous gas phase polymerization process for producing polyethylene and interpolymers of ethylene and at least one other olefin is provided wherein a non-aromatic halogenated hydrocarbon(s) is used in a specified amount such that the activity of the titanium, zirconium and / or hafnium containing Ziegler-Natta catalyst is increased.

Owner:WESTLAKE LONGVIEW

Polypropylene composite and preparation method thereof

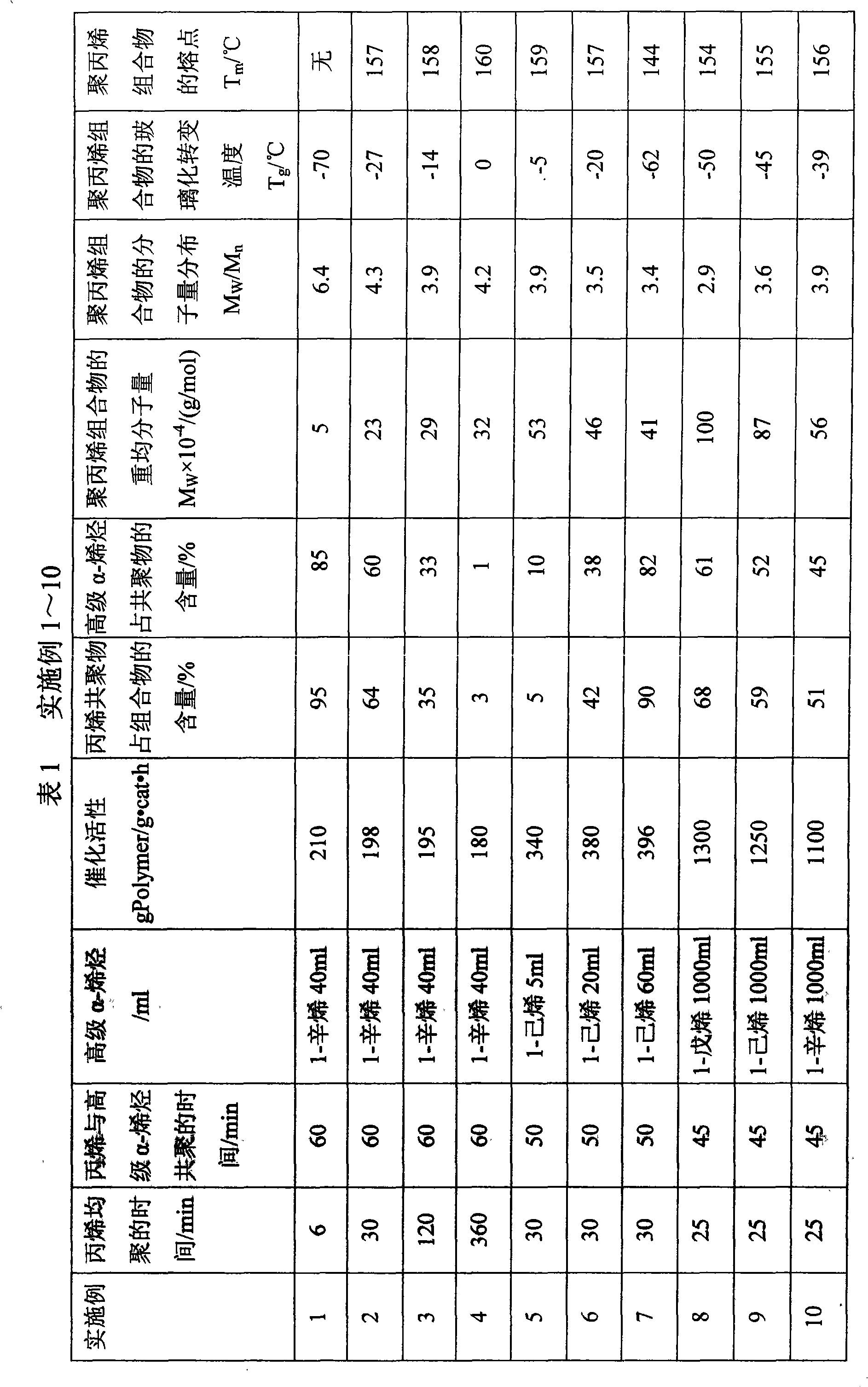

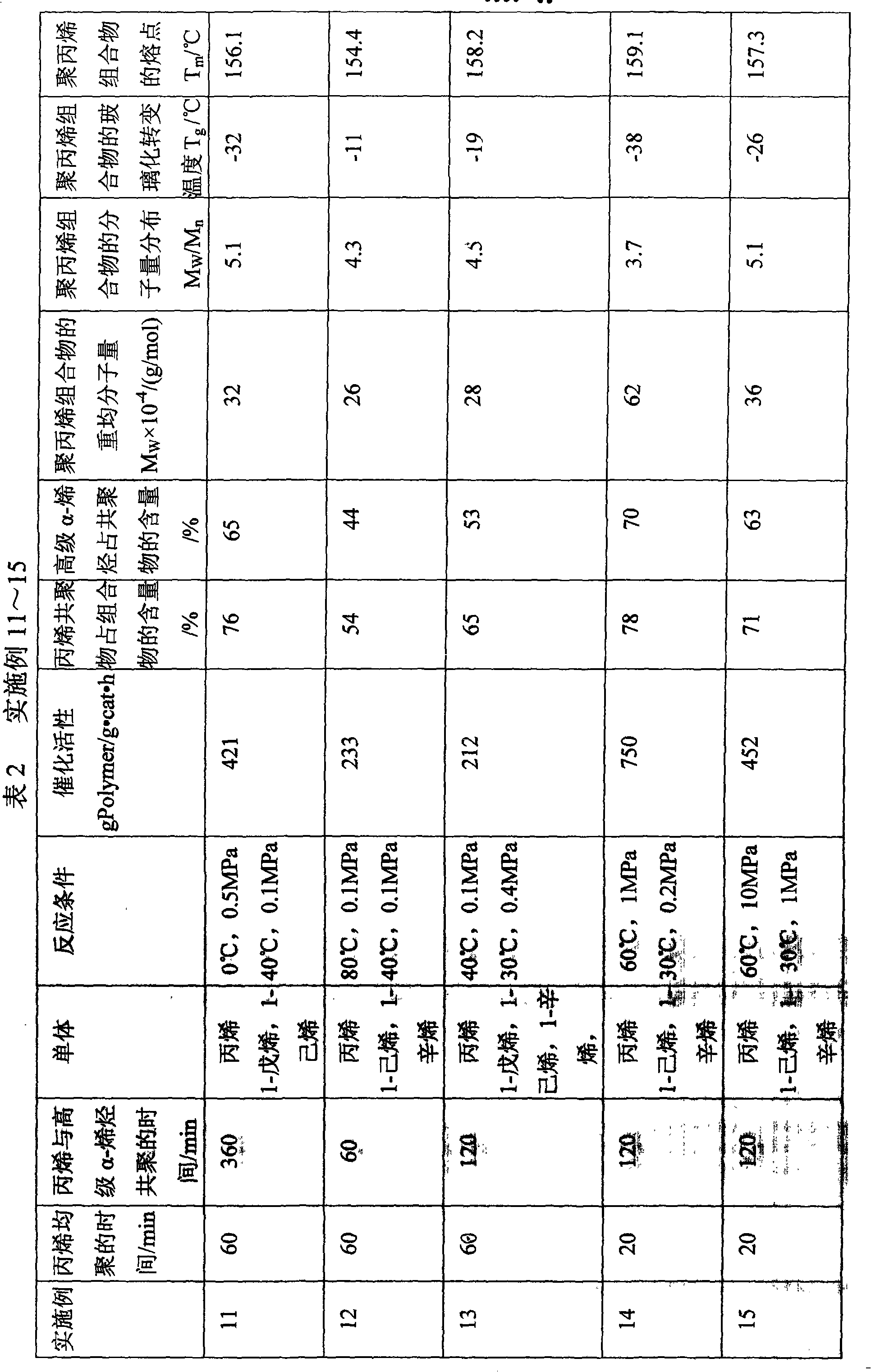

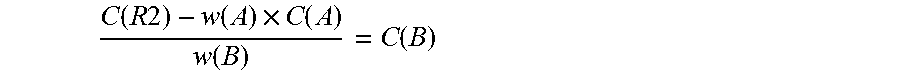

The invention belongs to the polyolefin material field, in particular relates to a preparation method of polypropylene composite and the polypropylene composite obtained by the preparation method. The invention adopts single heterogeneous Ziegler-Natta catalyst to carry out staging polymerization in a kettle, so as to prepare polypropylene composite, and homopolymerization time of propylene and copolymerization time of propylene and high grade alpha-olefin as well as monomer charging ratio are controlled to regulate content of propylene and high grade alpha-olefin copolymer in polypropylene composite, thus obtaining polypropylene composite with adjustable structure and property. The polypropylene composite is composed of propylene homopolymer and propylene copolymer; wherein the propylene copolymer is obtained by propylene and high grade alpha-olefin by copolymerization, the mass content of high grade alpha-olefin in the propylene copolymer is 1-85%, and propylene copolymer accounts for 3-95% of total mass of polypropylene composite.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Process for producing propylene terpolymer

InactiveUS20160312018A1Lower melting temperatureReduce volatilityPolymer scienceZiegler–Natta catalyst

Owner:BOREALIS AG

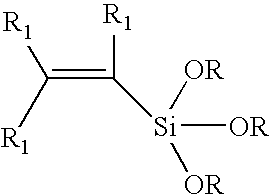

Process for copolymerizing ethylene with vinylsilanes

Owner:EQUSR CHEM LP

Polypropylene with narrow distribution of molecular weight

The invention relates to polypropylene with narrow distribution of molecular weight and a preparation method, and especially relates to a propylene polymer with narrow distribution of molecular weight by employing a Ziegler-Natta catalyst through direct reactor polymerization. The polymer has high and adjustable isotacticity, the molecular weight distribution is narrow, and the high-molecular trailing index is high. propylene is not contained in a locational isomeric structure, the melting point and crystallization temperature are high, compared with a traditional degradation method for producing the polypropylene with narrow distribution, the polypropylene with narrow distribution of molecular weight has the advantages of economy, energy saving and environmental protection. The product is especially suitable for the fields with high fluidity requirement such as spinning, injecting by a thin wall, casting the transparent material. In addition, due to characteristic of narrow distribution of molecular weight, the polymer has a certain advantage on transparency application aspect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for the polymerization of ethylene and interpolymers thereof

InactiveUS20030027952A1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationZiegler–Natta catalystGas phase

A novel continuous gas phase polymerization process for producing polyethylene and interpolymers of ethylene and at least one other olefin is provided wherein a non-aromatic halogenated hydrocarbon is used in a specified amount such that the activity of the titanium, zirconium and / or hafnium containing Ziegler-Natta catalyst is increased.

Owner:WESTLAKE LONGVIEW

Preparation process of catalyst for ethylene polymerization

InactiveCN1861650AHigh titanium contentImprove particle size distributionPolymer scienceZiegler–Natta catalyst

A process for preparing a Ziegler-Natta catalyst used for the sludge polymerization of ethene features that in its preparing procedure the ultrasonic wave technique is used for increasing the content of Ti and improving the granularity distribution of polymer.

Owner:北京燕化高新催化剂有限公司

Spray-dried, mixed metal ziegler catalyst compositions

ActiveUS7348383B2Improve productivityImprove homogeneityMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsZiegler–Natta catalystTitanium

A Ziegler-Natta catalyst composition comprising a solid mixture formed by halogenation of: Al) a spray-dried catalyst precursor comprising the reaction product of a magnesium compound, a non-metallocene titanium compound, and at least one non-metallocene compound of a transition metal other than titanium, with A2) an organoaluminium halide halogenating agent, a method of preparing, precursors for use therein, and olefin polymerization processes using the same.

Owner:UNION CARBIDE CORP

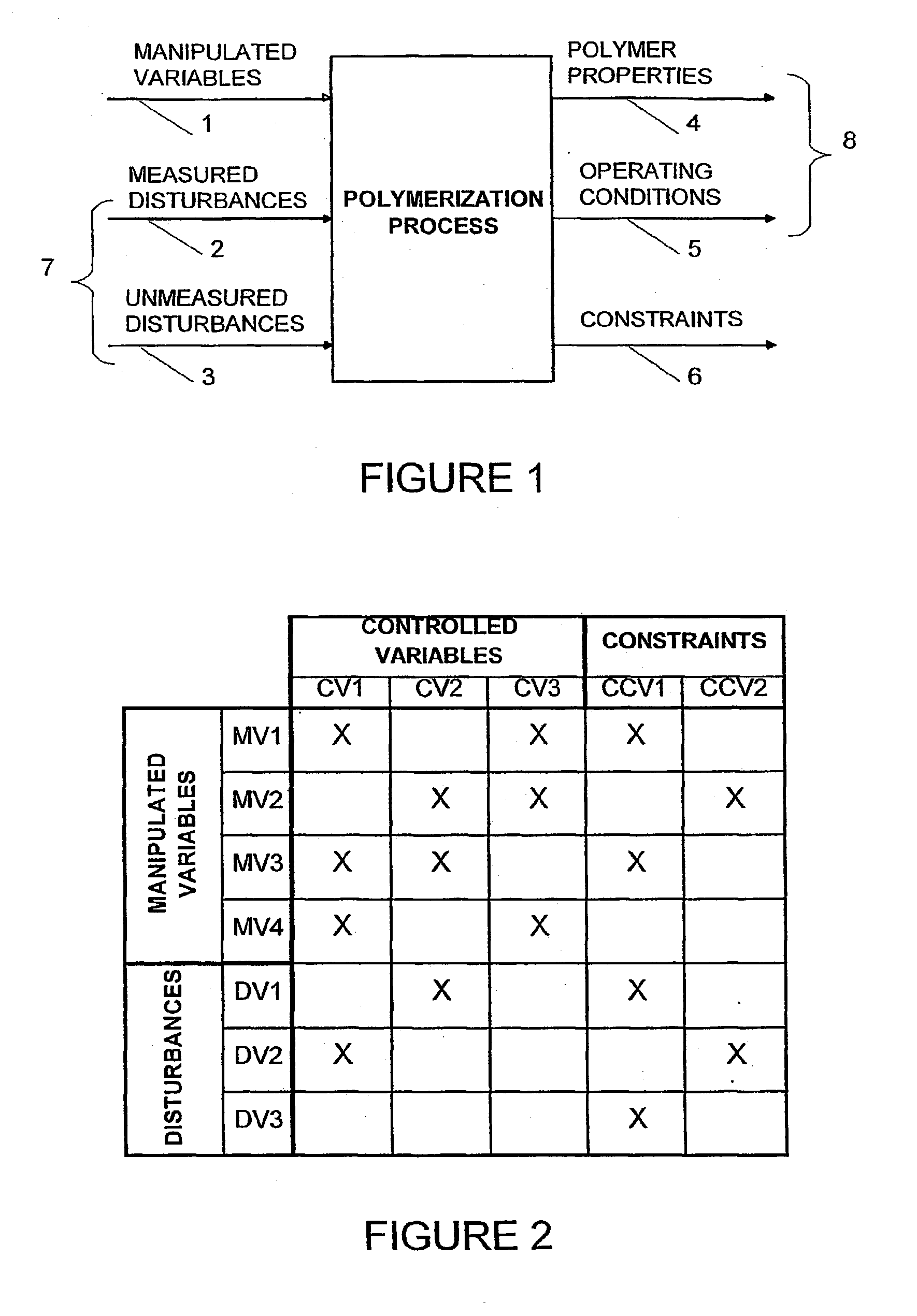

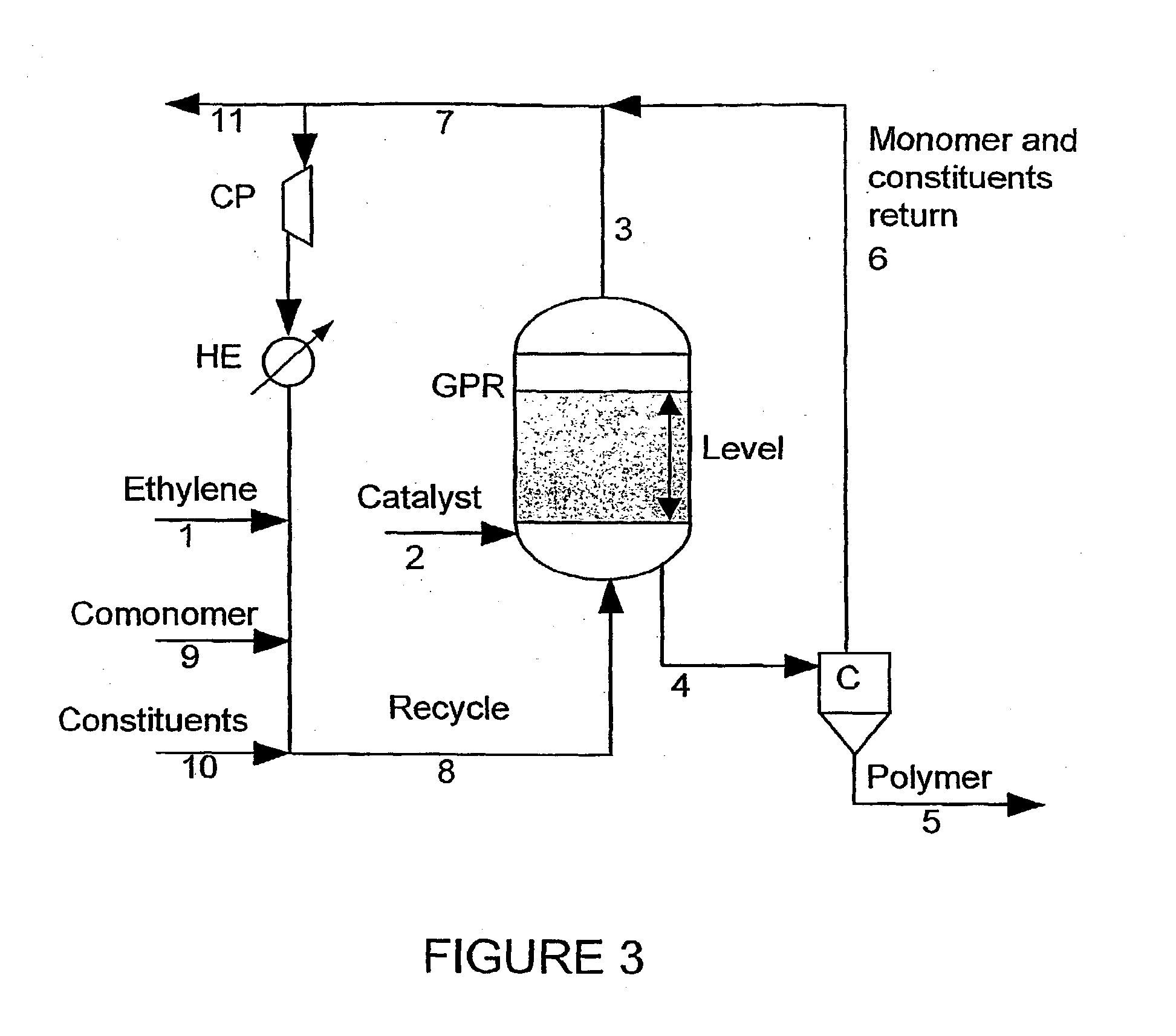

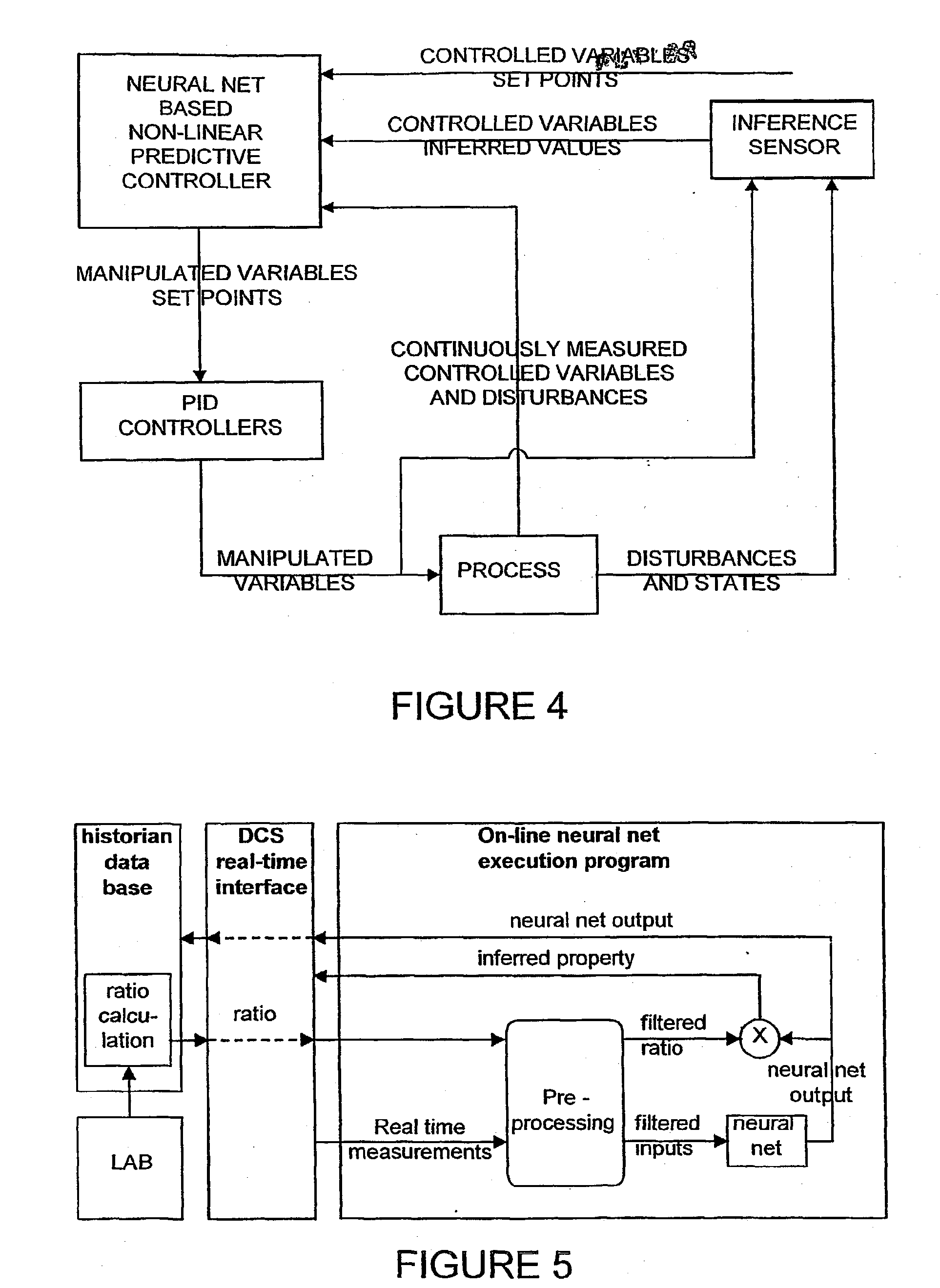

Process for the controlled production of polyethylene and its copolymers

InactiveUS20030105247A1Speed maximizationControlling ratio of multiple fluid flowsChemical variable controlLinear low-density polyethyleneProduction rate

A process for producing high density polyethylene (HDPE) or linear low density polyethylene (LLDPE) in gas phase reactors, isolated or combined, using chromium or Ziegler-Natta catalysts, provided with on-line control of certain process variables as well as physical properties of the produced resin is described. Such process comprises the use of models for the inference of the physical properties and of the process variables that are not continuously measured as well as models which are relevant for the control of said properties and of the operating conditions of the process. The control of the process variables provides further the maximization of the production rate and of the catalyst productivity in the polymerization reaction.

Owner:BRASKEM SA

High-melt-strength propylene/ethylene/butene copolymer and preparation method thereof

ActiveCN102816271AImprove mechanical propertiesGood optical performancePolymer scienceZiegler–Natta catalyst

The invention provides a method for adopting a direct polymerization method to prepare a high-melt-strength propylene / ethylene / butene random copolymer. The method comprises during different polymerization reaction stages of series connection operation, controlling categories and proportions of external electron donor components in a Ziegler-Natta catalyst system at different reaction stages according to the requirements of different molecular weight fractions, so that the propylene / ethylene / butene random copolymer with wide molecular weight distribution and extremely high molecular weight fractions can be prepared. The invention further correspondingly provides the propylene / ethylene / butene random copolymer with high melt strength. Compared with homopolymerized high-melt-strength polypropylene, the propylene / ethylene / butene random copolymer has good mechanical property and optical performance, extremely low melting point and extremely high melt strength and is suitable for preparing high-magnification foaming products, post processing energy consumption is low when the propylene / ethylene / butene random copolymer is applied to molding of high-magnification foaming beads, and the foaming beads are high in adhesion strength and good in toughness.

Owner:CHINA PETROLEUM & CHEM CORP +1

High barrier multilayer film

InactiveUS6458470B1Improve moisture resistanceGood dimensional stabilitySynthetic resin layered productsDomestic containersZiegler–Natta catalystOptoelectronics

The present invention is a high barrier multilayer film particularly suitable for packaging. The high barrier multilayer film is a film including (a) a core substrate layer having an isotactic polypropylene produced from Ziegler-Natta catalysts, and (b) an adjacent layer on at least one surface of the core substrate layer, wherein the adjacent layer (b) comprises an isotactic polypropylene produced from metallocene catalysts; or the high barrier multilayer film includes (a') a core substrate layer having an isotactic polypropylene produced from metallocene catalysts, and (b') an adjacent layer on at east one surface of the core substrate layer, wherein the adjacent layer (b') comprises an isotactic polypropylene produced from Ziegler-Natta catalysts.

Owner:EXXONMOBIL CORP (US)

Thermoplastic vulcanizate composition

The instant disclosure is directed to a thermoplastic vulcanizate composition comprising a dynamically-cured rubber; from about 20 to about 300 parts by weight of a thermoplastic resin per 100 parts by weight rubber and from about 30 to about 250 parts by weight additional oil per 100 parts by weight rubber; wherein the rubber comprises a multimodal polymer composition cured with a curing agent, the multimodal polymer composition comprising 45 to 75 wt % of a first polymer fraction and 25 to 55 wt % of a second polymer fraction, each comprising ethylene, a C3-C10 alpha-olefin, and a non-conjugated diene, wherein the polymer fractions have been polymerized using a Ziegler-Natta catalyst system, wherein the first polymer fraction has a Mooney viscosity of greater than or equal to about 150 ML(1+4@125° C.), and the second polymer fraction has a Mooney viscosity of about 20 ML to about 120 ML; and about 10 phr to about 50 phr of an extender oil. A method of producing the thermoplastic vulcanizate is also disclosed.

Owner:CELANESE INT CORP

High-rubber polypropylene polyphase copolymer resin used for 3D printing, and preparation method and application thereof

ActiveCN103992560AAdjustable Molecular CompositionAdjustable structureMonocomponent synthetic polymer artificial filamentAdditive manufacturing with liquidsZiegler–Natta catalystEthylene Homopolymers

The invention discloses a high-rubber polypropylene polyphase copolymer resin used for 3D printing, and a preparation method and an application thereof. The copolymer resin is composed of a propylene homopolymer and crosslinked ethylene-propylene-diolefin diolefin copolymer rubber, and is prepared through sequentially catalyzing propylene monomer homopolymerization and ethylene / propylene / diolefin monomer copolymerization by a catalyst containing a carrier type Ziegler-Natta catalyst. The content of rubber in the copolymer resin reaches above 70%, the obtained polymer product is particles with the particle diameter of 50-1500mum, and a heat stabilizer is added to make the resin form an high-impact-resistance and high-toughness product through 3D printing molding.

Owner:INST OF CHEM CHINESE ACAD OF SCI

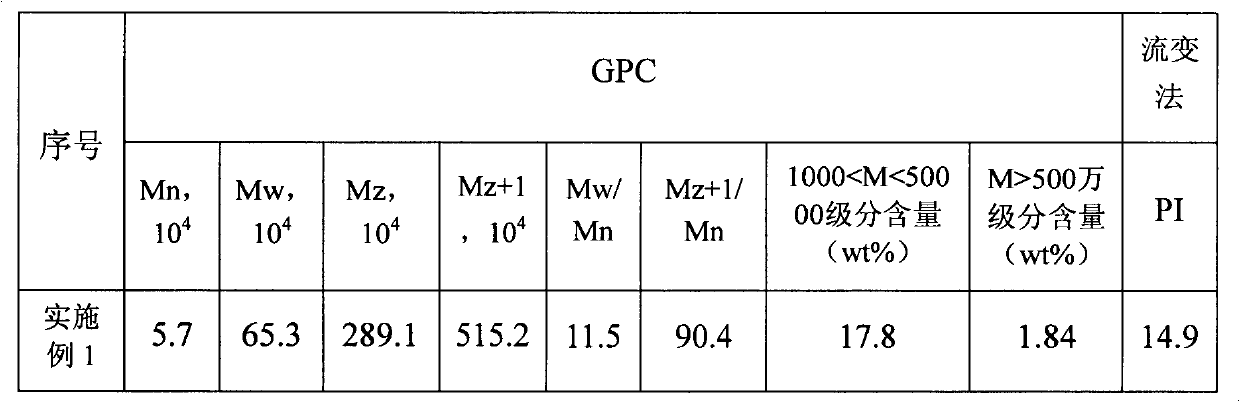

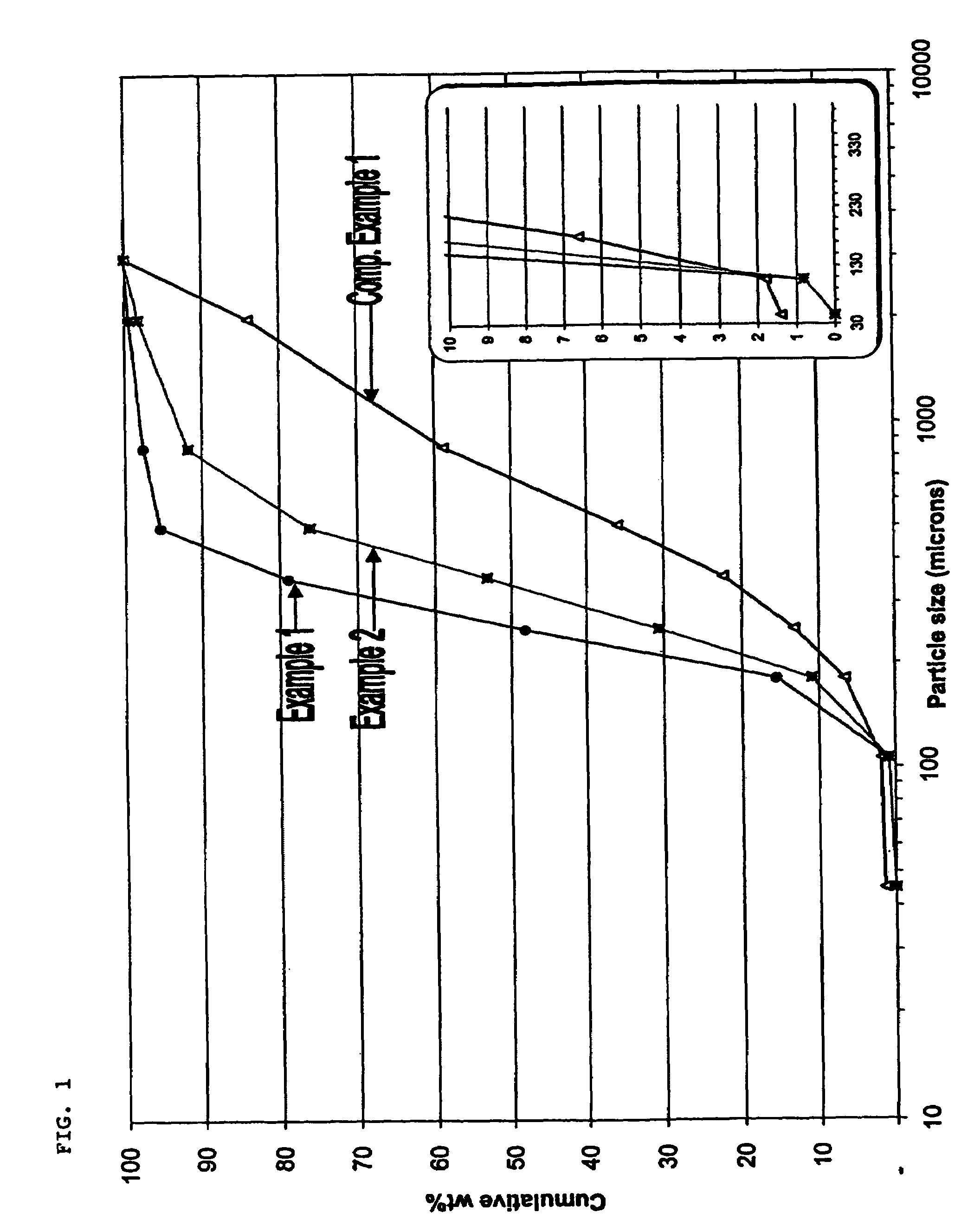

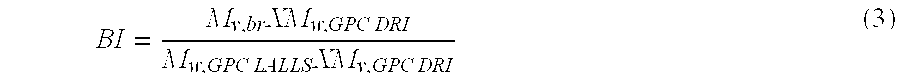

Propylene homopolymer having high melt strength and preparation method thereof

ActiveUS9068030B2High molecular weightImprove mechanical propertiesZiegler–Natta catalystElectron donor

The present invention provides a process for preparing high melt strength propylene polymer by direct polymerization, comprising that a propylene polymer with wide molecular weight distribution and containing “very high molecular weight fraction” can be prepared by controlling the species and ratios of the external electron donors in the Ziegler-Natta catalyst system at different reaction stages according to the requirement for different molecular weight fractions in the different propylene polymerization stage of the series operation, and said polymer has excellent mechanical properties, especially with very high melt strength. The present invention also provides a propylene homopolymer with high melt strength, comprising the following features: (1) the MFR is 0.2-10 g / 10 min at 230° C. with a load of 2.16 kg; (2) the molecular weight distribution Mw / Mn is 6-20; (3) the content of the fraction with a molecular weight higher than 5,000,000 is higher than or equal to 0.8 wt %; (4) Mz+1 / Mn is higher than or equal to 70. Said homopolymer can be used in the preparation of foam products, thermoforming products, biaxial stretching films, blown films and blow-molded products.

Owner:CHINA PETROCHEMICAL CORP +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com