Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

632 results about "X ray diffractogram" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

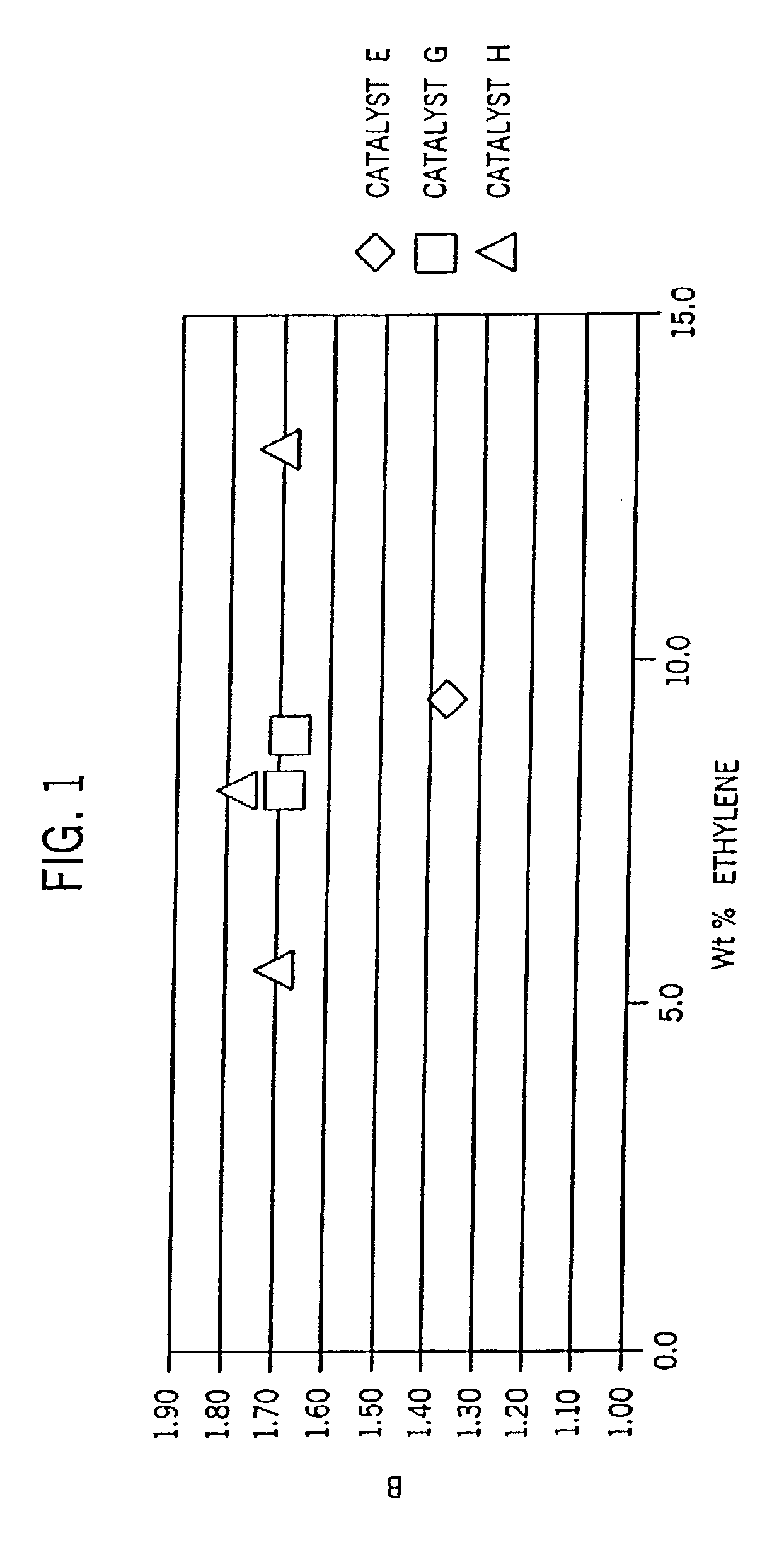

Isotactic propylene copolymers, their preparation and use

InactiveUS6960635B2Group 4/14 element organic compoundsOther chemical processesFiberZiegler–Natta catalyst

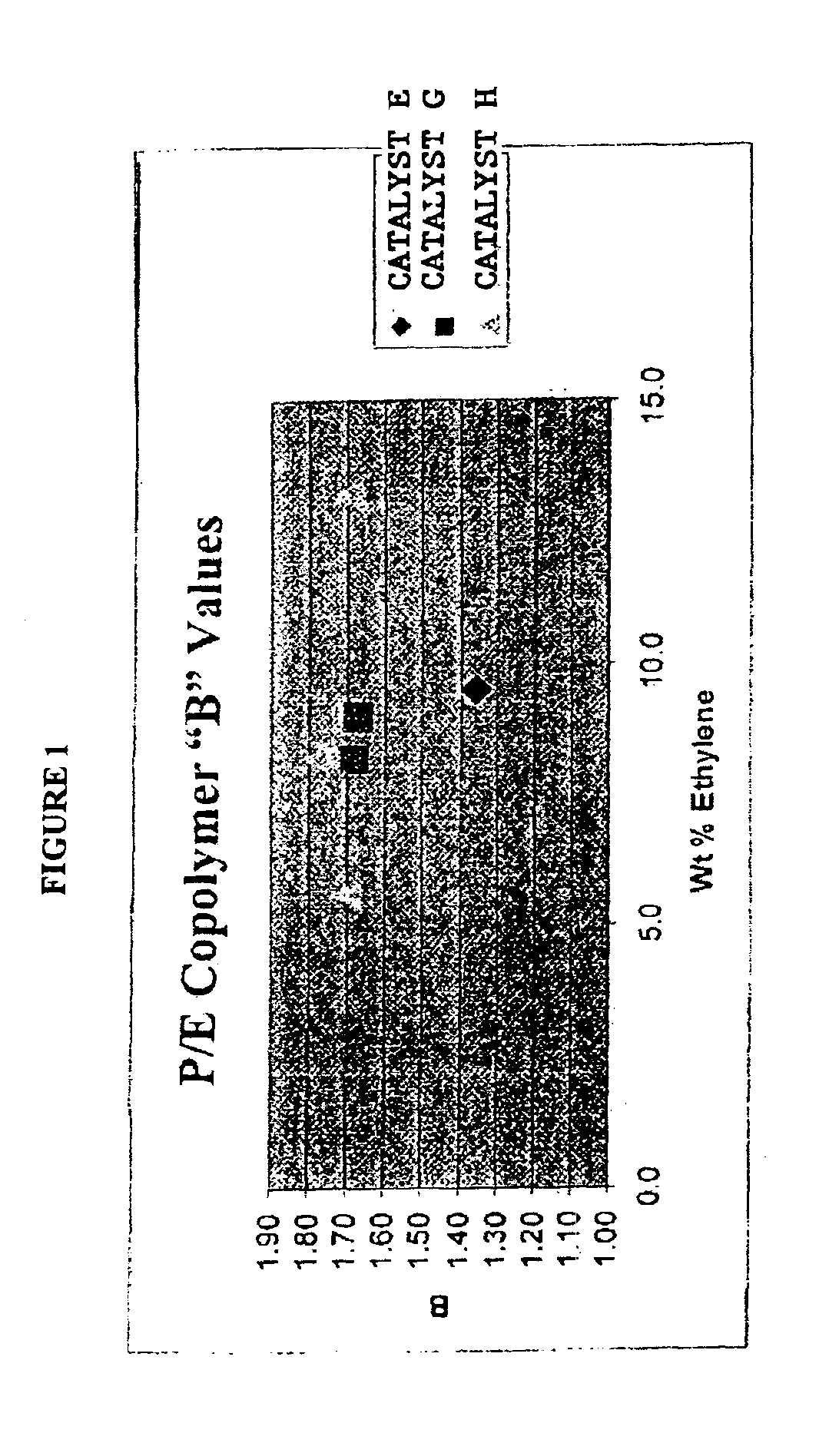

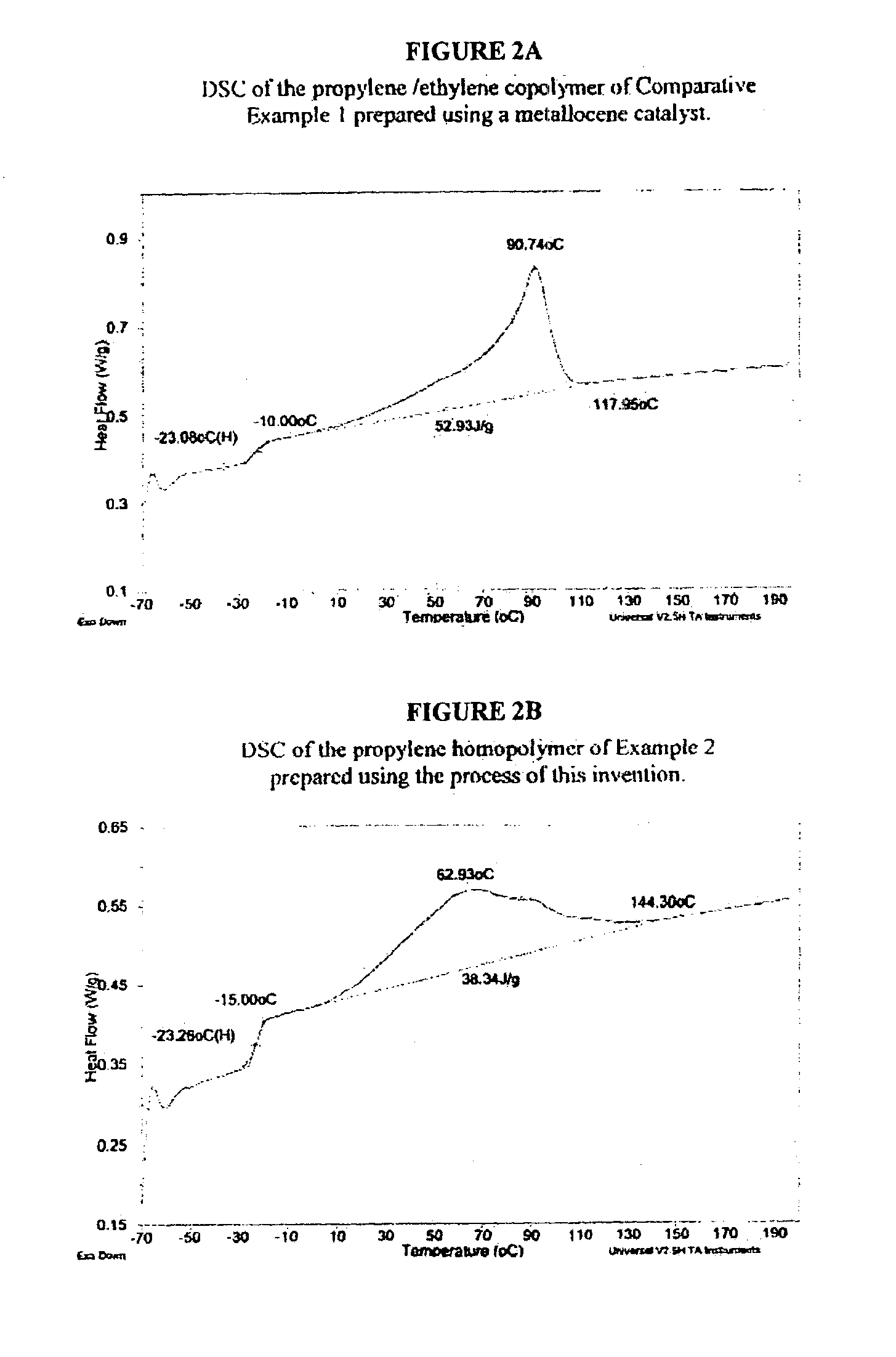

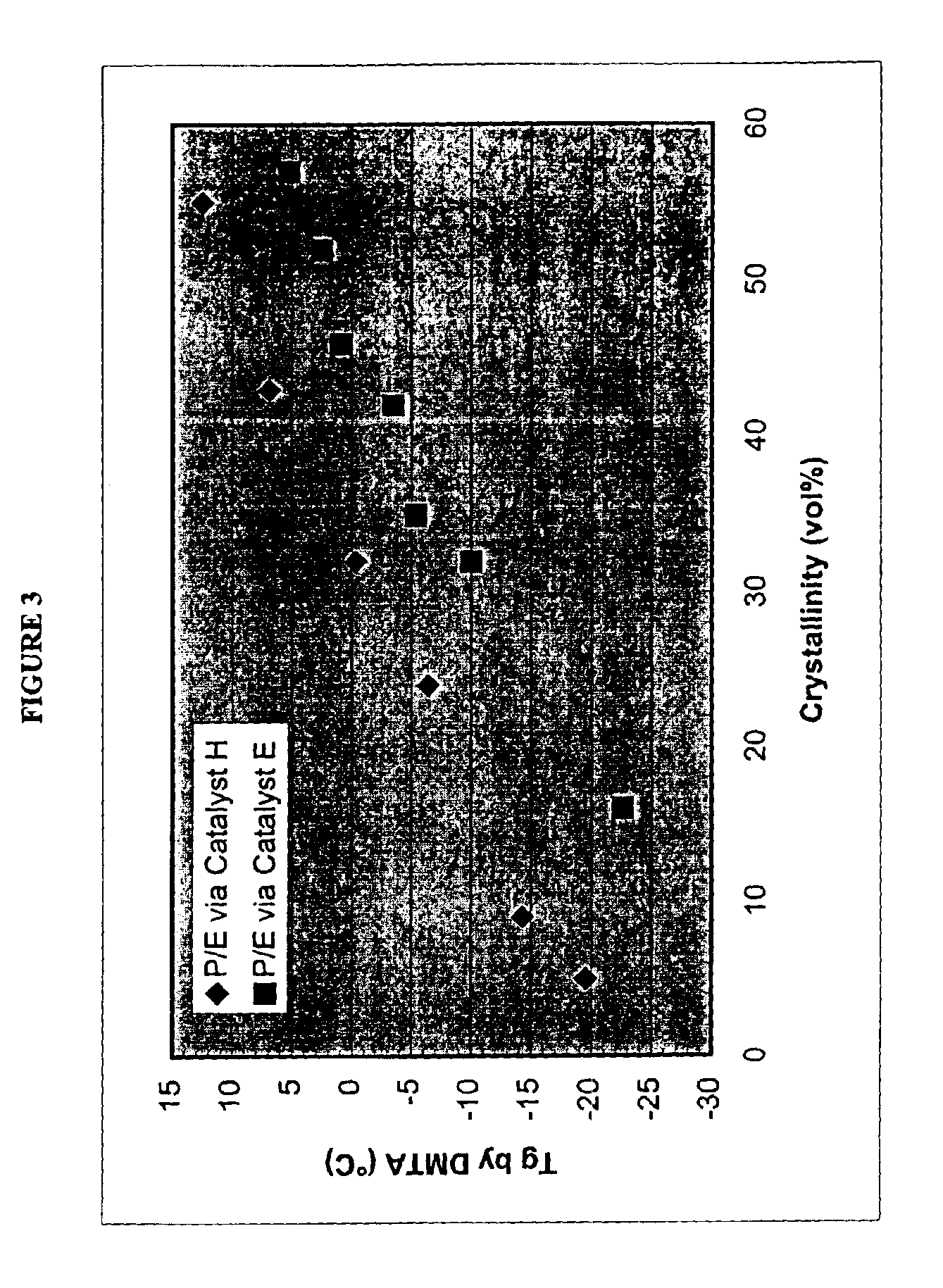

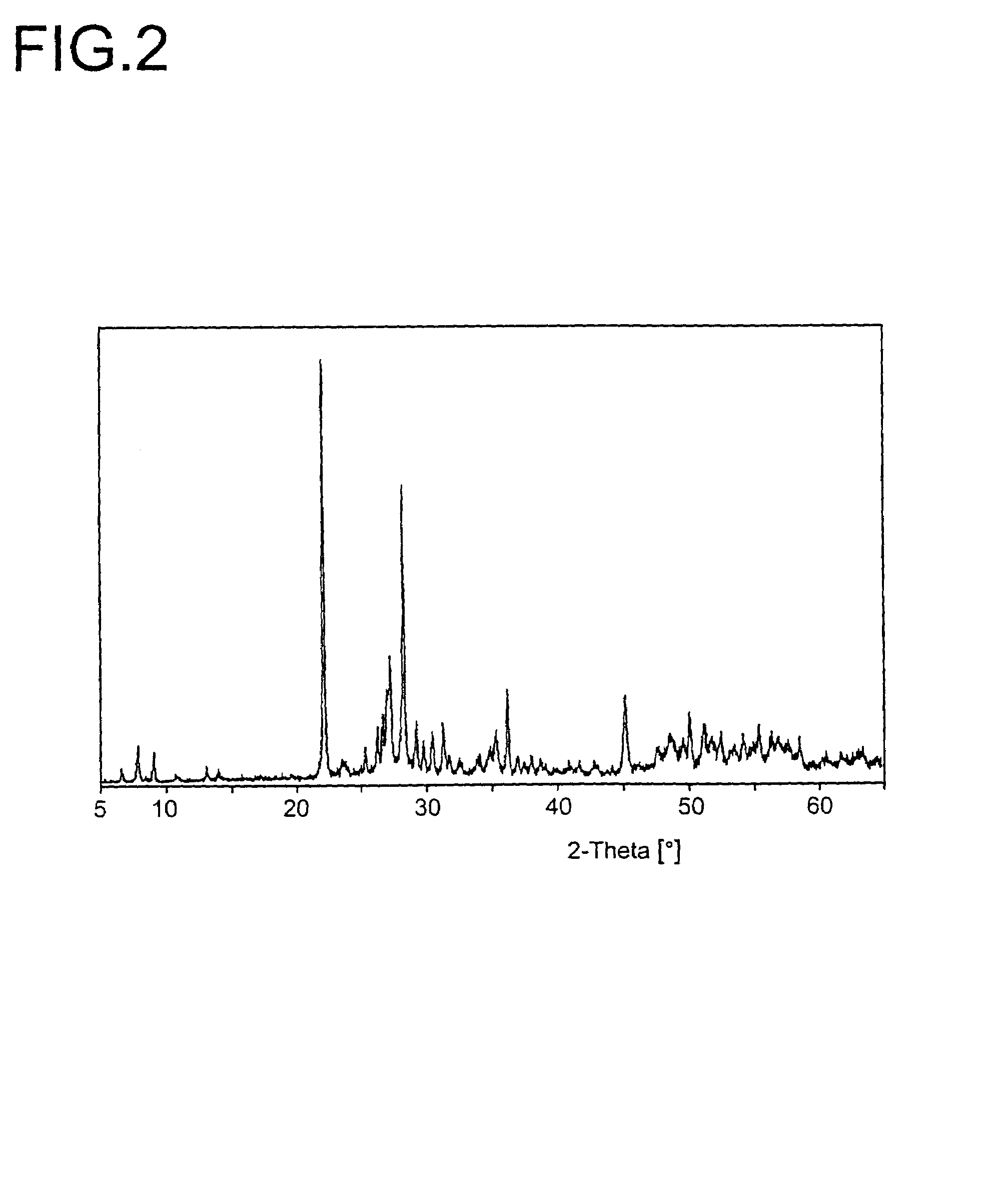

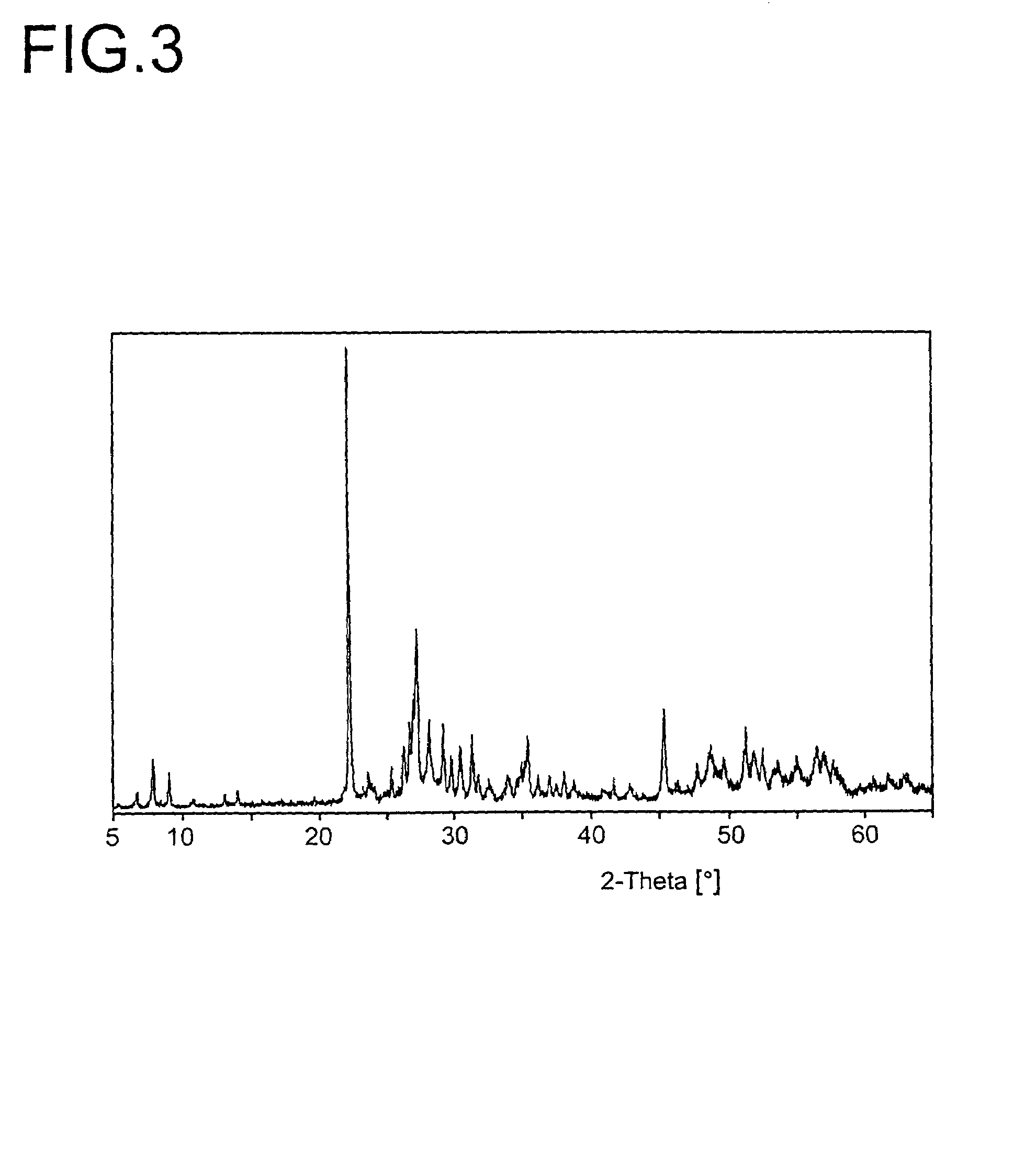

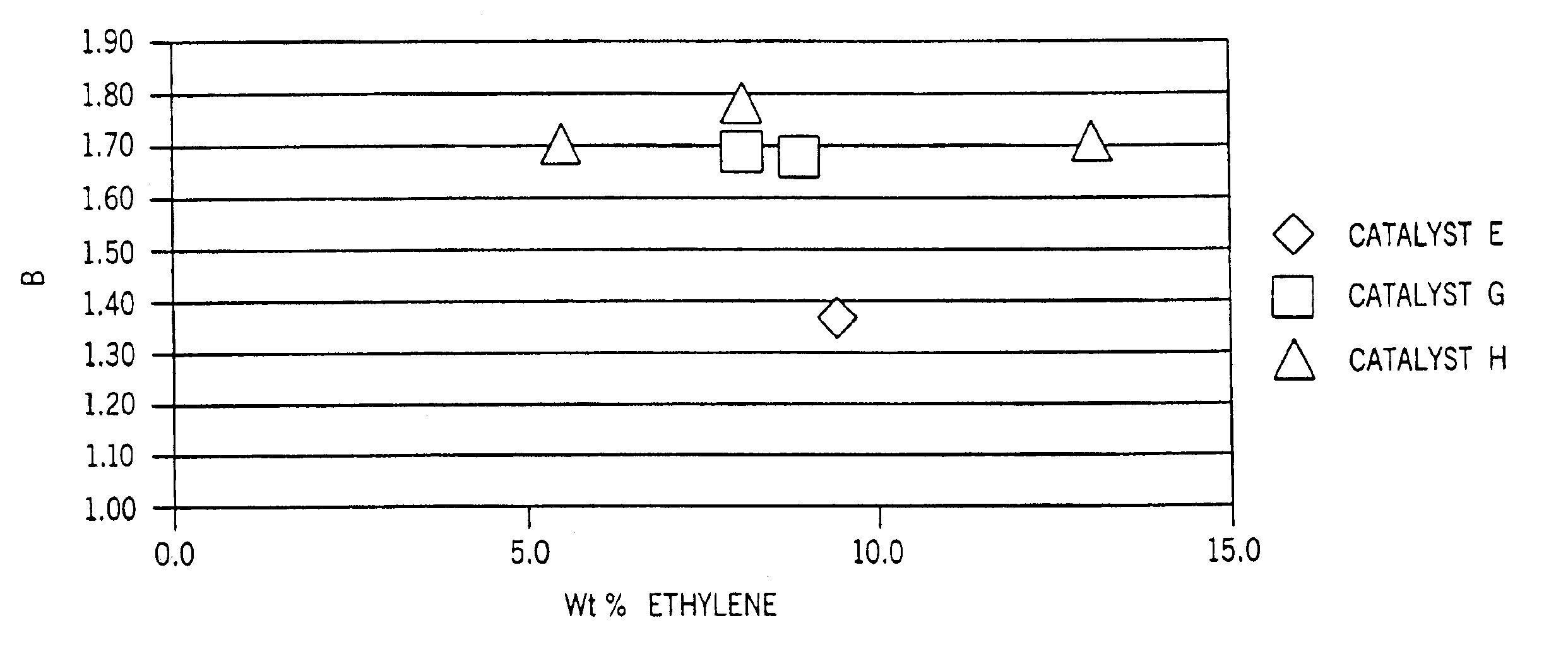

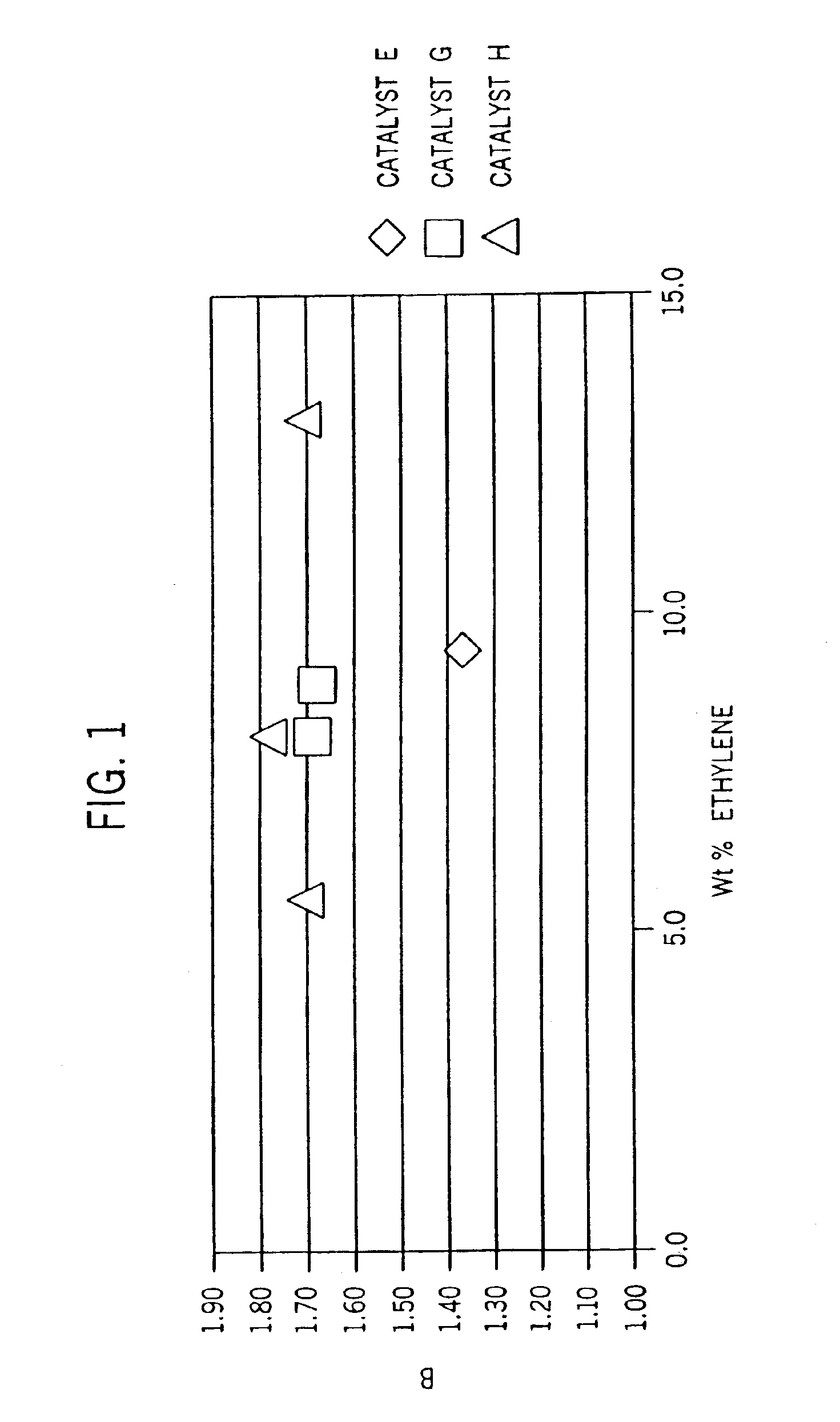

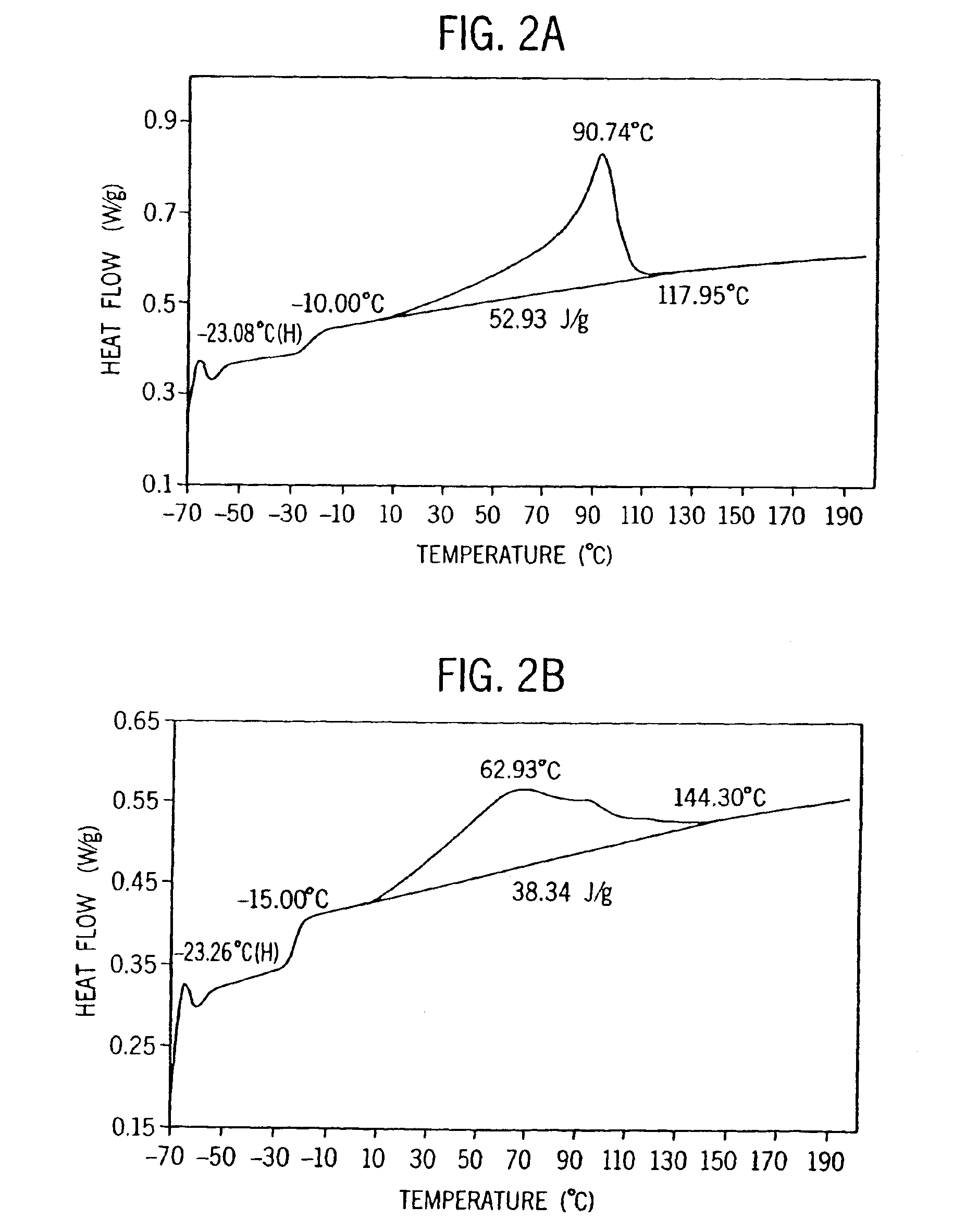

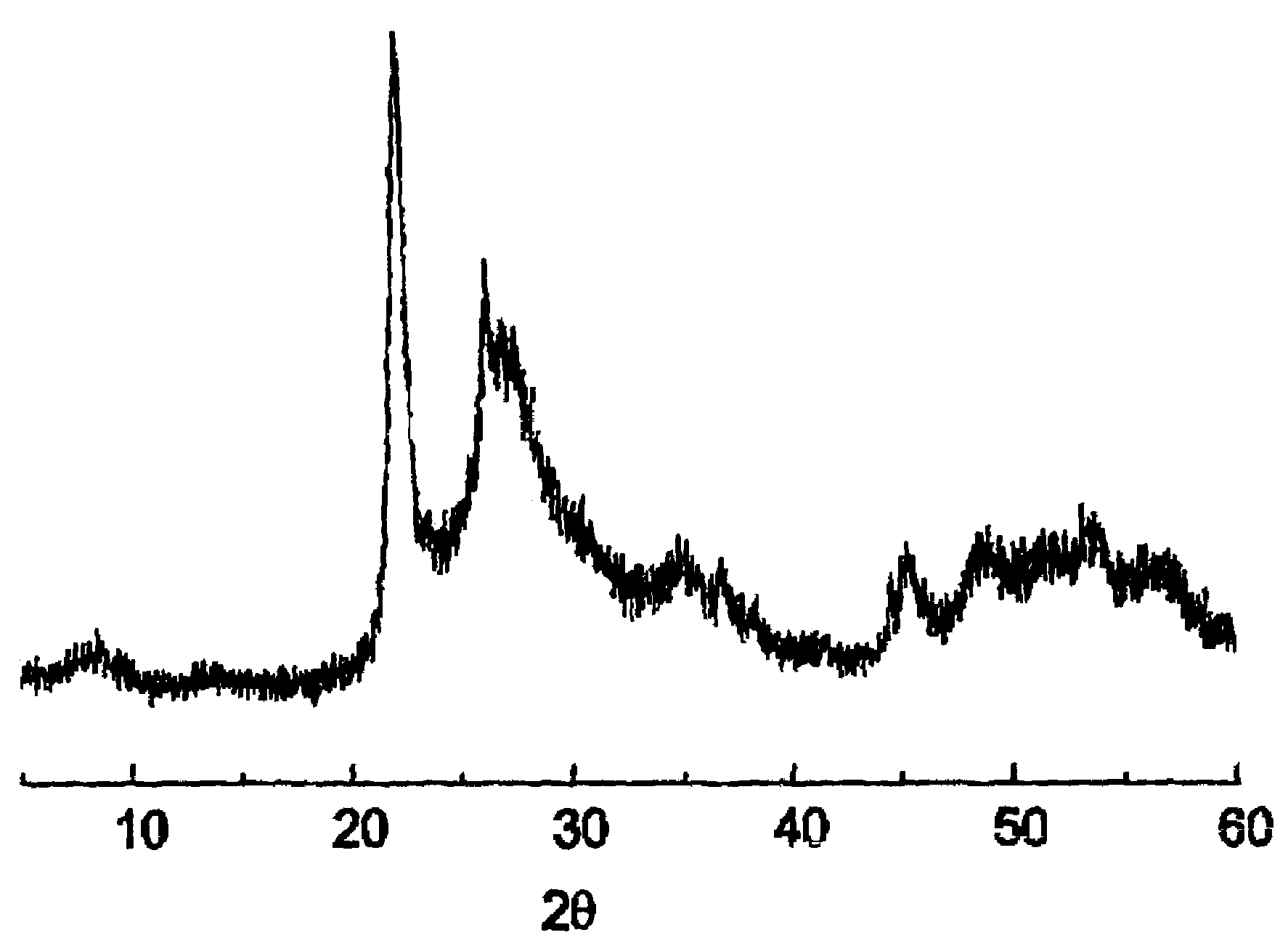

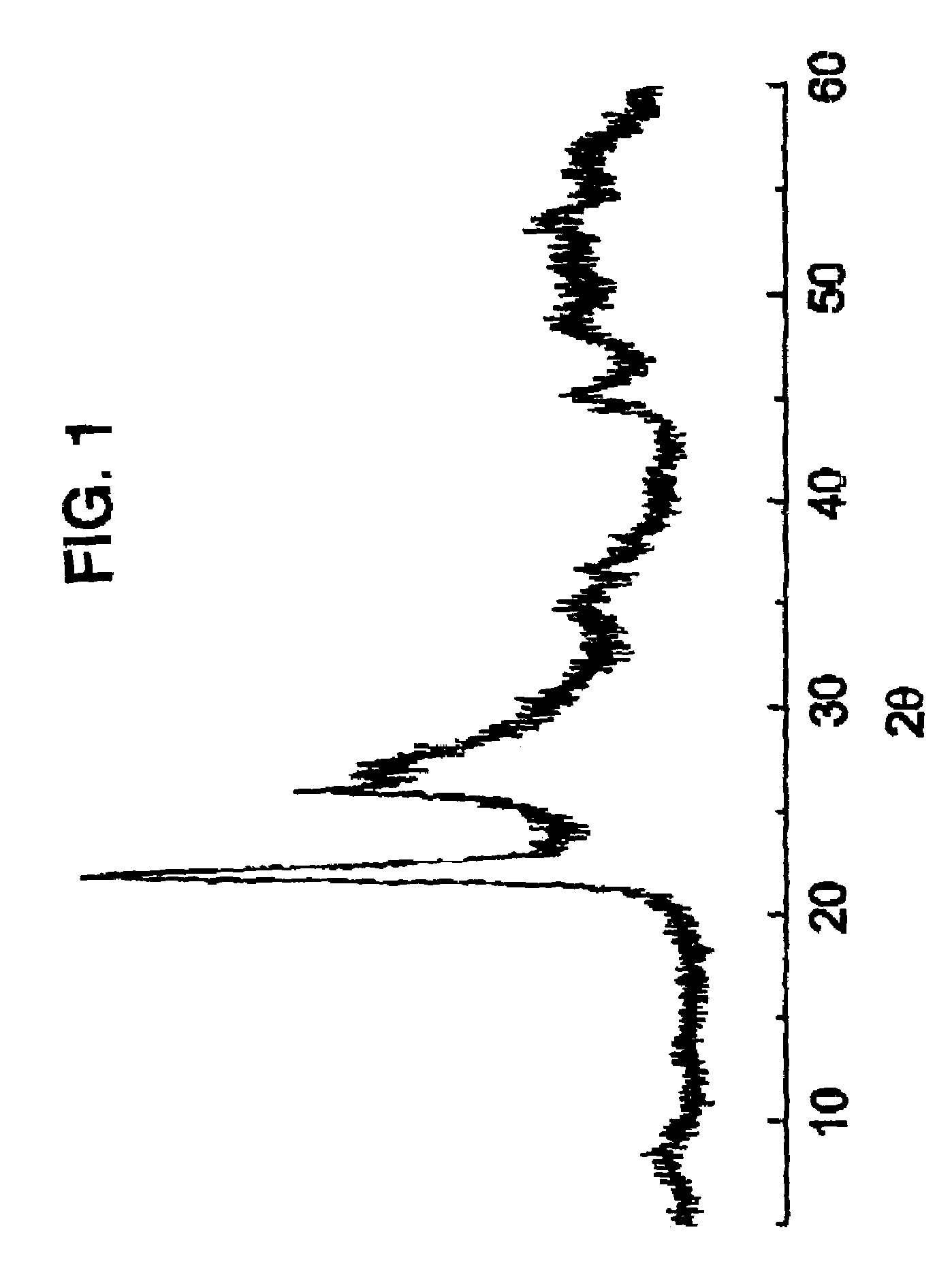

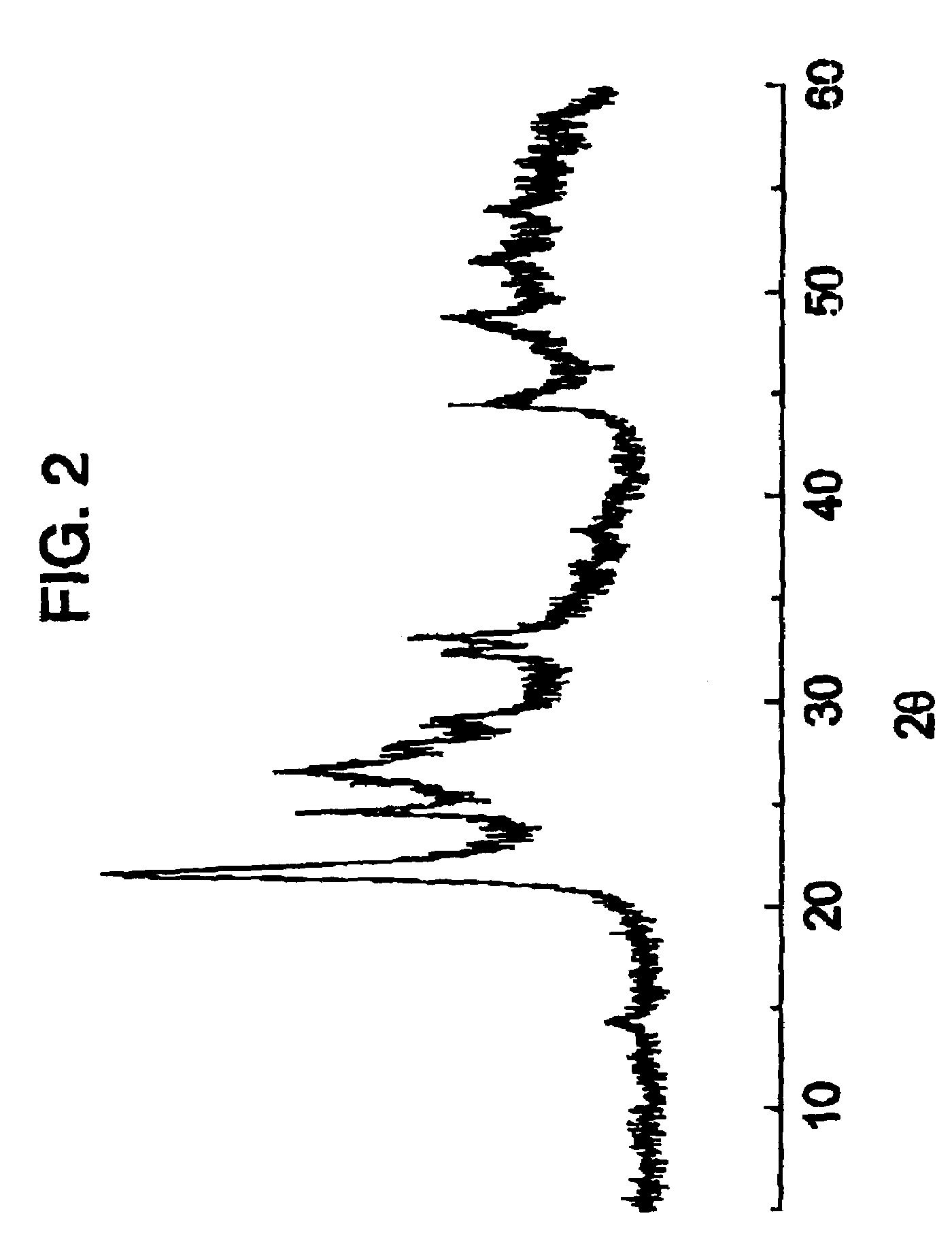

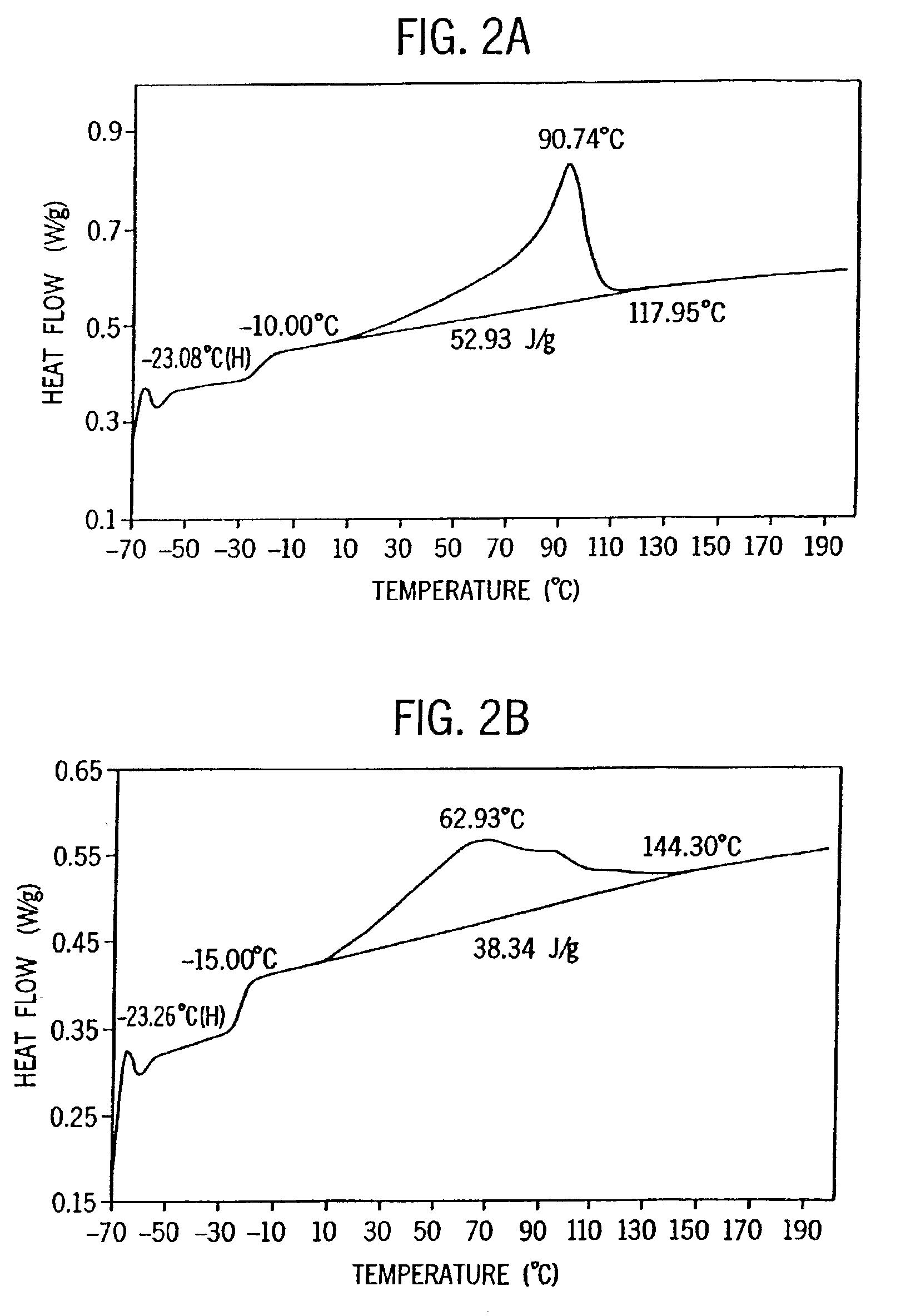

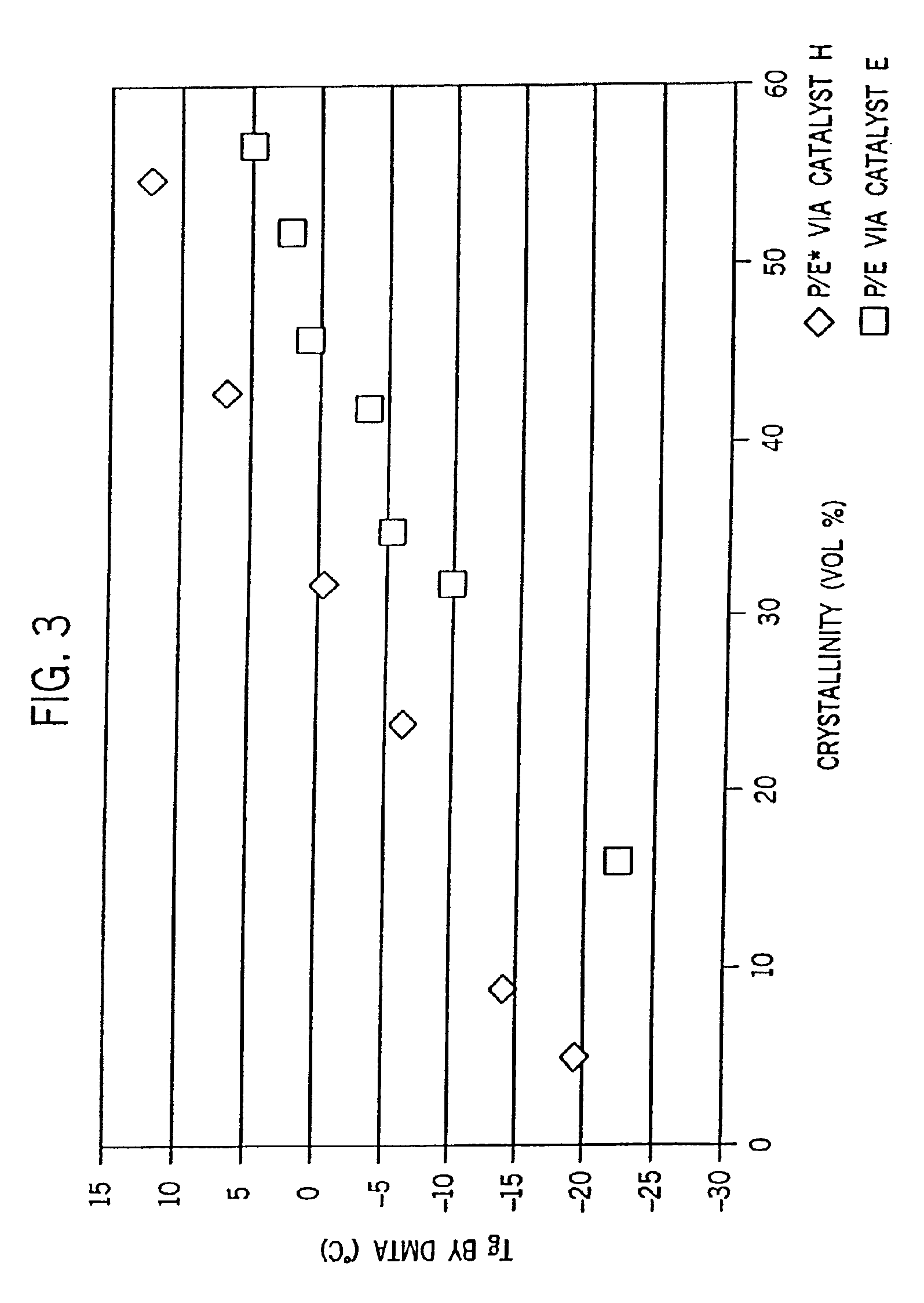

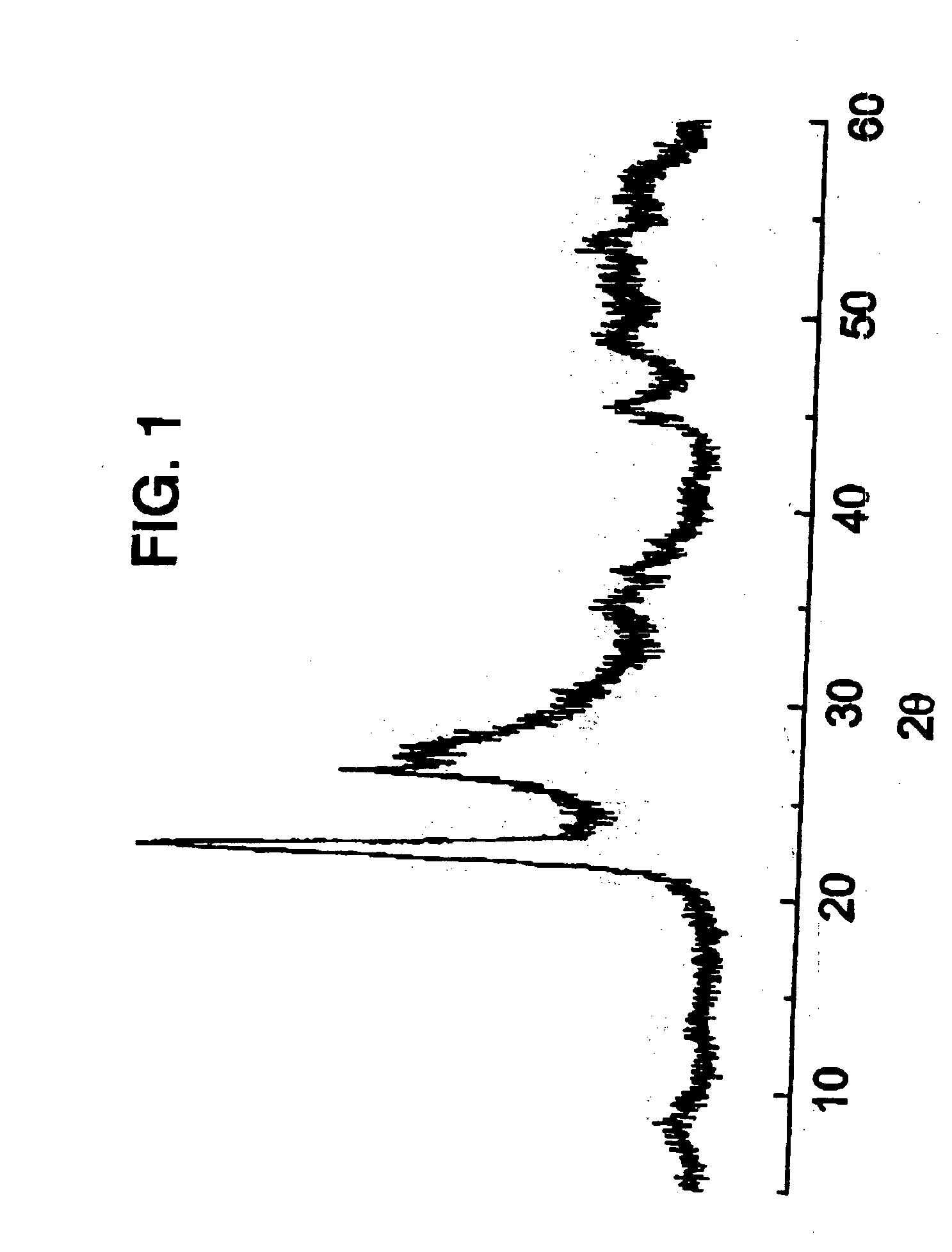

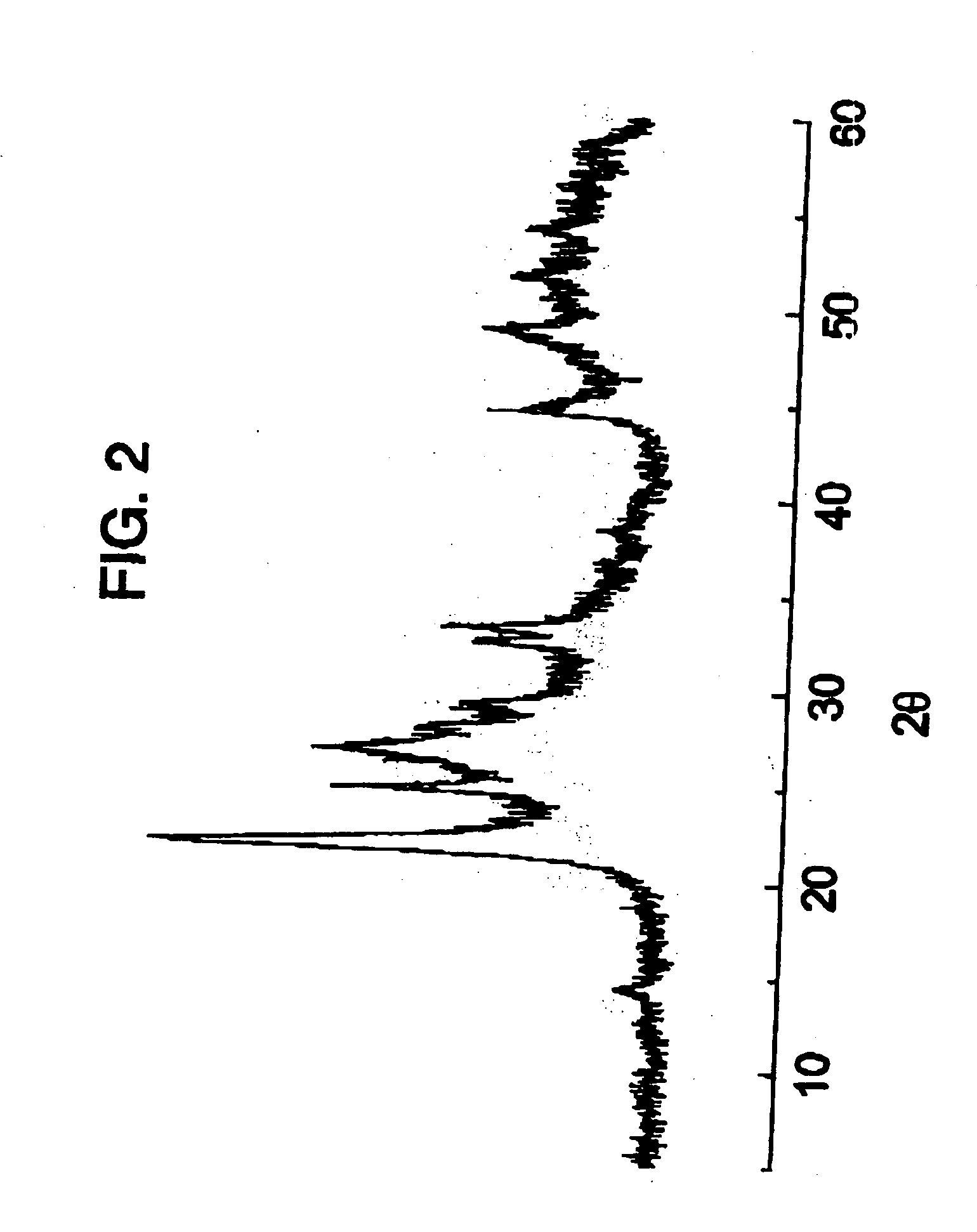

Unique copolymers comprising propylene, ethylene and / or one or more unsaturated comonomers are characterized as having: at least one, preferably more than one, of the following properties: (i) 13C NMR peaks corresponding to a regio-error at about 14.6 and about 15.7 ppm, the peaks of about equal intensity, (ii) a B-value greater than about 1.4 when the comonomer content of the copolymer is at least about 3 wt %, (iii) a skewness index, Six, greater than about −1.20, (iv) a DSC curve with a Tme that remains essentially the same and a Tmax that decreases as the amount of comonomer in the copolymer is increased, and (v) an X-ray diffraction pattern that reports more gamma-form crystals than a comparable copolymer prepared with a Ziegler-Natta catalyst. These polypropylene polymers are made using a nonmetallocene, metal-centered, heteroaryl ligand catalyst. These polymers can be blended with other polymers, and are useful in the manufacture of films, sheets, foams, fibers and molded articles.

Owner:DOW GLOBAL TECH LLC

Hydroalkylation of aromatic hydrocarbons

InactiveUS6730625B1High activityHigh selectivityMolecular sieve catalystsMolecular sieve catalystBenzeneX-ray

There is described a process and a catalyst for the hydroalkylation of an aromatic hydrocarbon, particularly benzene, wherein the catalyst comprises a first metal having hydrogenation activity and a crystalline inorganic oxide material having a X-ray diffraction pattern including the following d-spacing maxima 12.4±0.25, 6.9±0.15, 3.57±0.07 and 3.42±0.07.

Owner:EXXONMOBIL CORP (US)

Multimetal oxide materials

Owner:BASF SE

Blends and sealant compositions comprising isotactic propylene copolymers

Films with excellent machine direction (MD) tear properties comprise at least one layer made from a polymer comprising:(A) at least 50 weight percent (wt %) propylene; and(B) at least 5 wt % ethylene and / or one or more unsaturated comonomers.Representative of component (B) unsatuarated comonomers are the C4-20 α-olefins, C4-20 dienes, styrenic compounds, and the like. Preferably, the film has at least one of a (i) haze value of less than about 10, (ii) 45 degree gloss of greater than about 65, and (iii) dart value of greater than about 100 g / mil. In one preferred embodiment, the layer comprises a compolymer characterized as having at least one of the following properties: (i) 13C NMR peaks corresponding to a regio-error at about 14.6 and about 15.7 ppm, the peaks of about equal intensity, (ii) a B-value greater than about 1.4 when the comonomer content, i.e., the units derived from ethylene and / or the unsaturated comonomer(s), of the copolymer is at least about 3 wt %, (iii) a skewness index, Six, greater than about −1.20, (iv) a DSC curve with a Tme that remains essentially the same and a Tmax that decreases as the amount of comonomer, i.e., the units derived from ethylene and / or the unsaturated comonomer(s), in the copolymer is increased, and (v) an X-ray diffraction pattern that reports more gamma-form crystals than a comparable copolymer prepared with a Ziegler-Natta (Z-N) catalyst.

Owner:DOW GLOBAL TECH LLC

Olefin epoxidation catalysts

A method of synthesizing an olefin epoxidation catalyst comprises the step of treating a porous crystalline aluminosilicate material having an X-ray diffraction pattern including d-spacing maxima at 12.4+ / -0.25, 6.9+ / -0.15, 3.57+ / -0.07 and 3.42+ / -0.07 Angstrom, such as MCM-22, with a dealuminating agent under conditions effective to remove framework aluminium from the material and produce a dealuminated product. The dealuminated product is then treated with a titanium-containing material under conditions effective to insert titanium into the dealuminated product and produce a titanium-containing, dealuminated catalyst composition. The resultant catalyst is useful in the epoxidation of olefins, such as propylene and cyclohexene, with hydrogen peroxide and organic hydroperoxides.

Owner:MOBIL OIL CORP

Method for the oxidative dehydrogenation of ethane

InactiveUS7319179B2Organic compound preparationHeterogenous catalyst chemical elementsAlkaline earth metalDehydrogenation

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC) +1

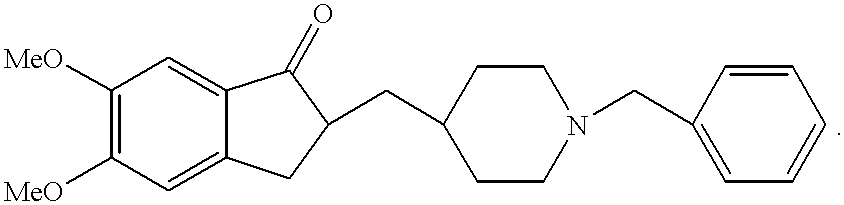

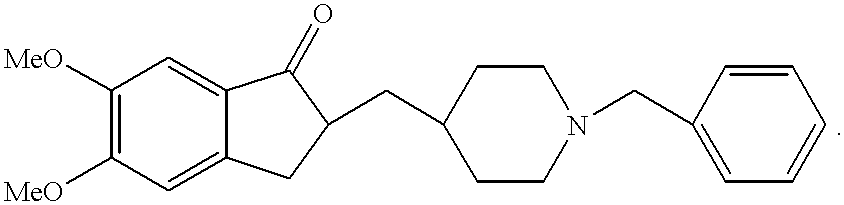

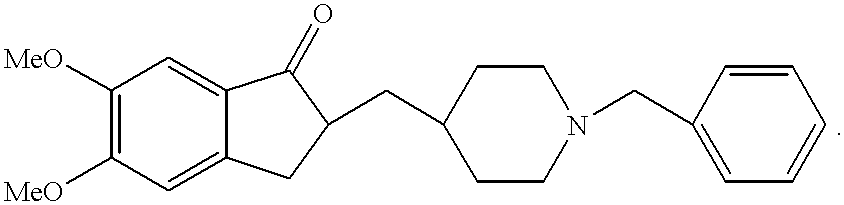

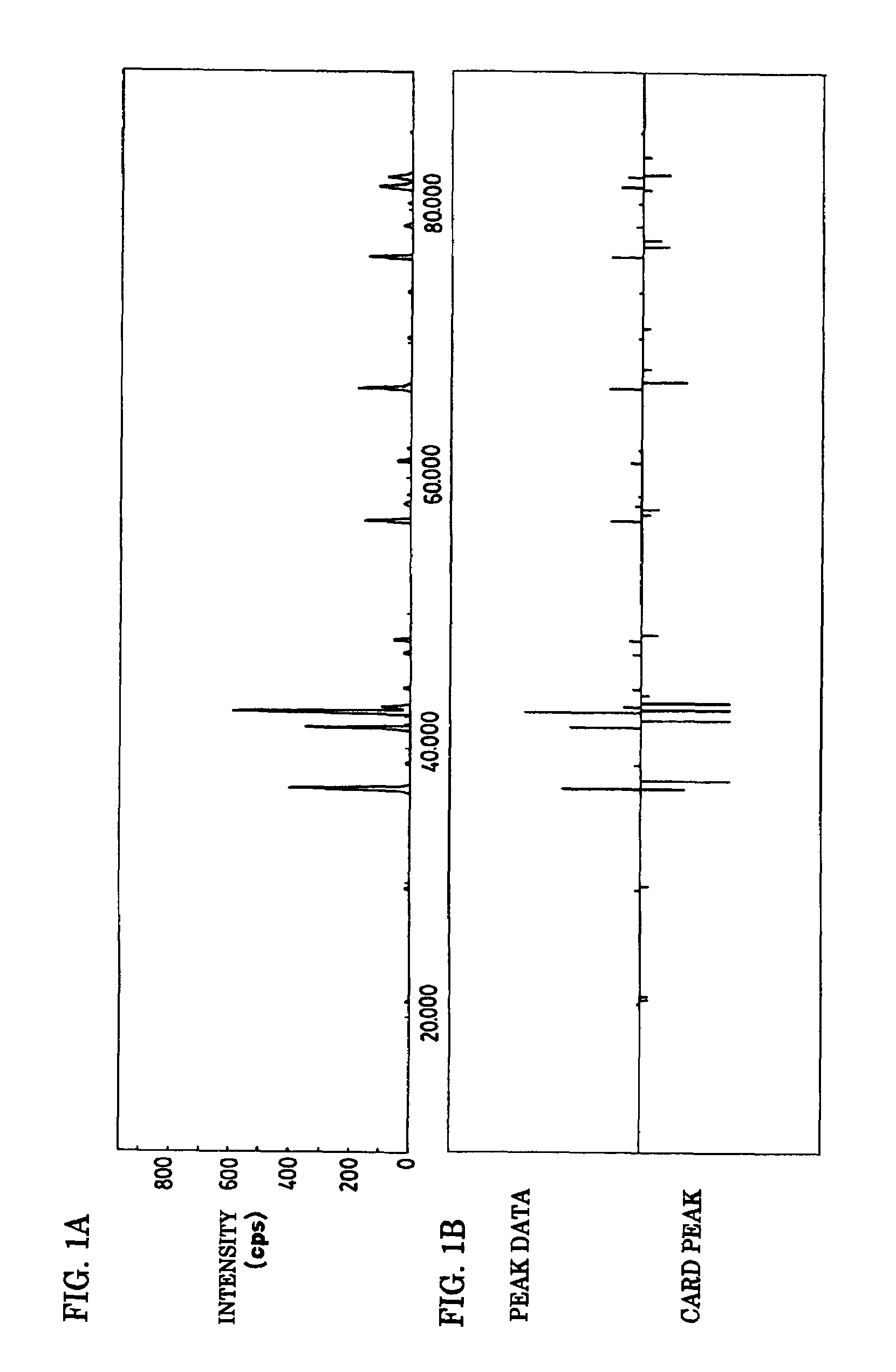

Donepezil polycrystals and process for producing the same

The present invention provides novel polymorphic crystals (A) to (C) having excellent handling properties and an extremely low content of residual solvent of donepezil used as a precursor for production of donepezil hydrochloride having an excellent action as a medicament, and an industrial process for producing the same. Further, the novel polymorphic crystals (A) to (C) according to the present invention are characterized by the powder X-ray diffraction pattern and / or IR absorption peaks of donepezil represented by the following formula:

Owner:EISAI CO LTD

Isotactic propylene copolymer fibers, their preparation and use

Fibers comprising a propylene homopolymer or a copolymer of propylene and at least one of ethylene and one or more unsaturated comonomers exhibit desirable properties. The homopolymers are characterized as having 13C NMR peaks corresponding to a regio-error at about 14.6 and about 15.7 ppm, the peaks of about equal intensity. The copolymers are characterized as (A) comprising at least about 60 weight percent (wt %) of units derived from propylene, and (B) having at least one of the following properties: (i) 13C NMR peaks corresponding to a regio-error at about 14.6 and about 15.7 ppm, the peaks of about equal intensity, (ii) a B-value greater than about 1.4 when the comonomer content of the copolymer is at least about 3 wt %, (iii) a skewness index, Six, greater than about −1.20, (iv) a DSC curve with a Tme that remains essentially the same and a Tmax that decreases as the amount of comonomer in the copolymer is increased, and (v) an X-ray diffraction pattern that reports more gamma-form crystals than a comparable copolymer prepared with a Ziegler-Natta (Z-N) catalyst.

Owner:DOW GLOBAL TECH LLC

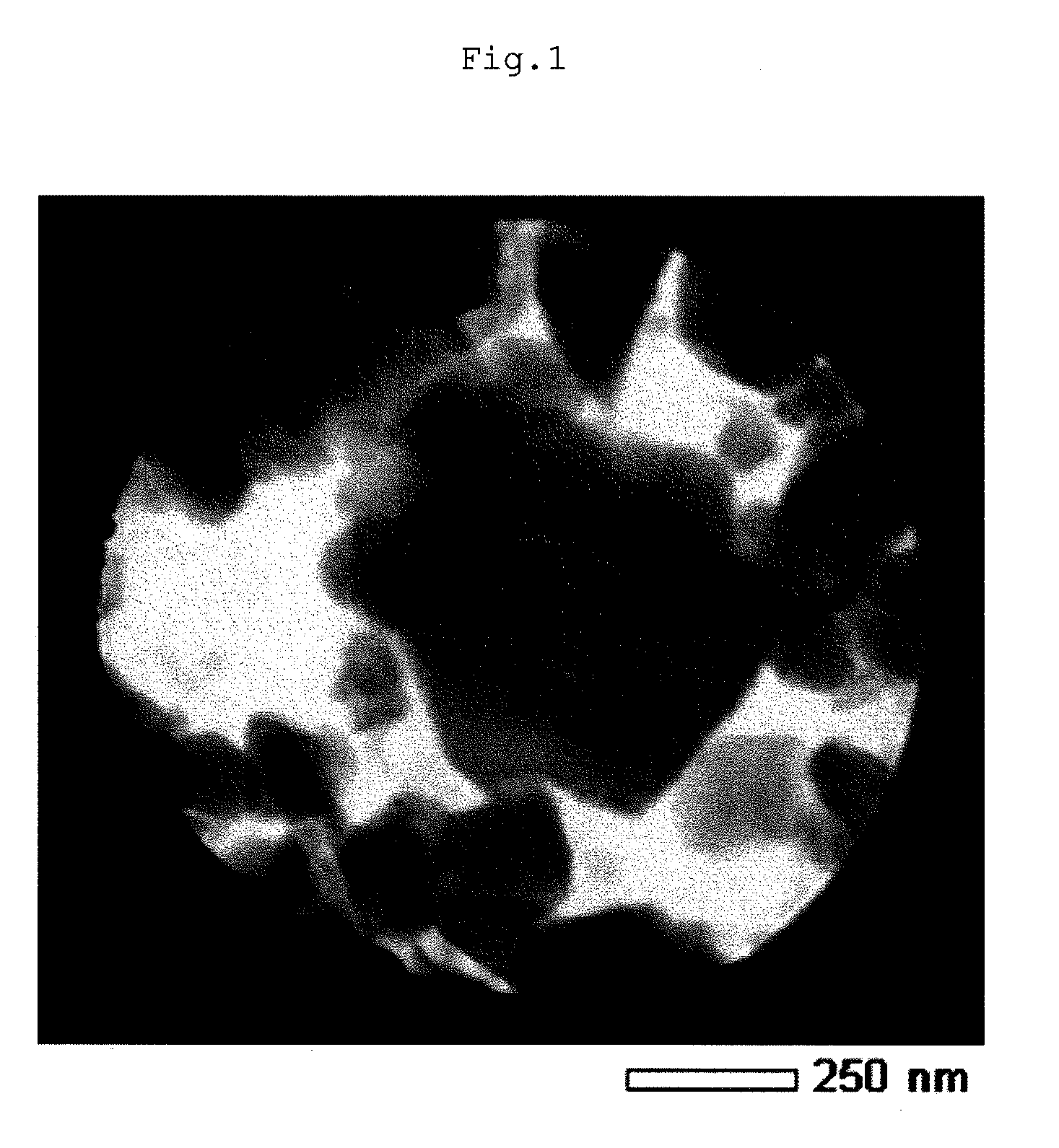

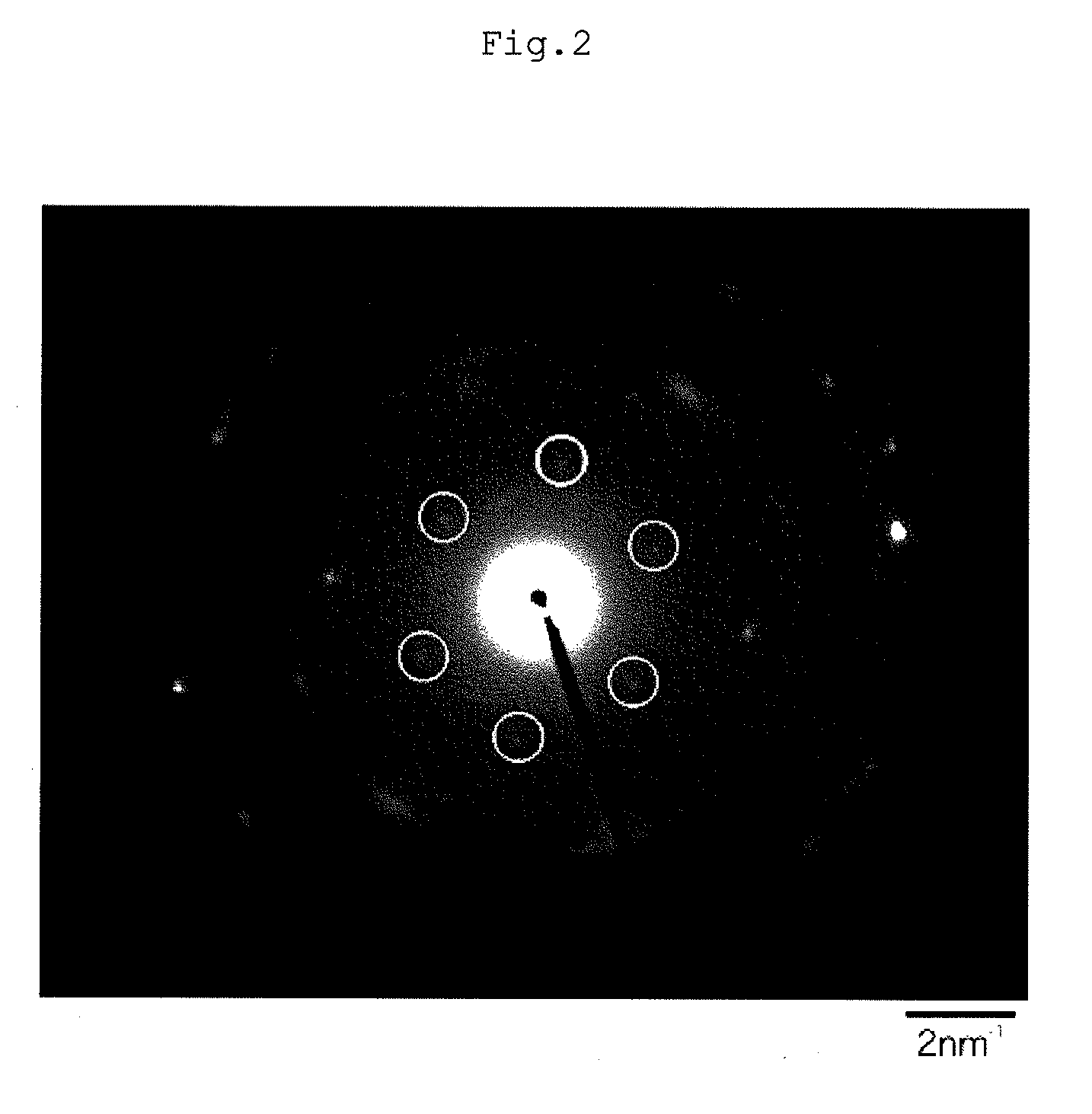

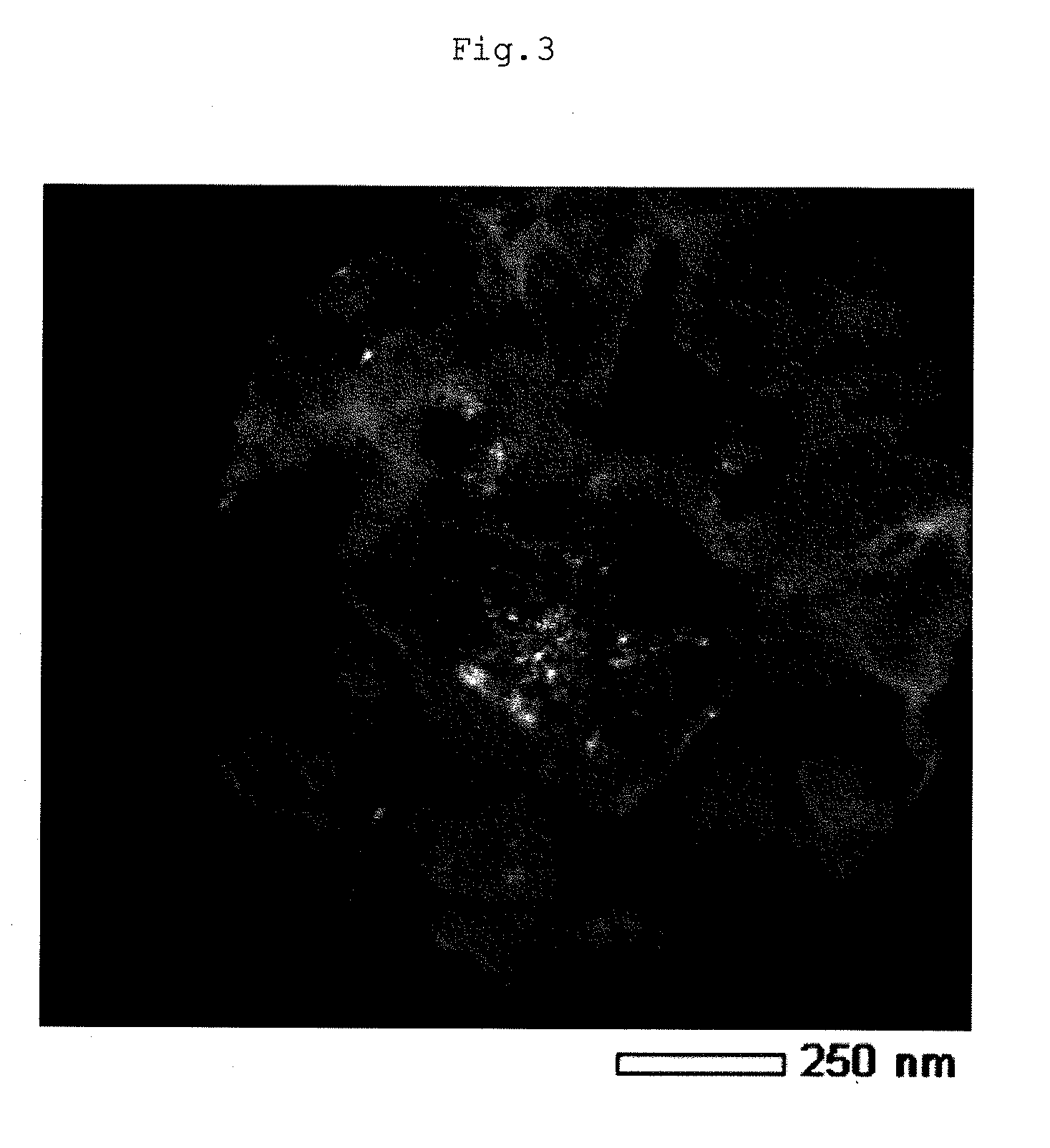

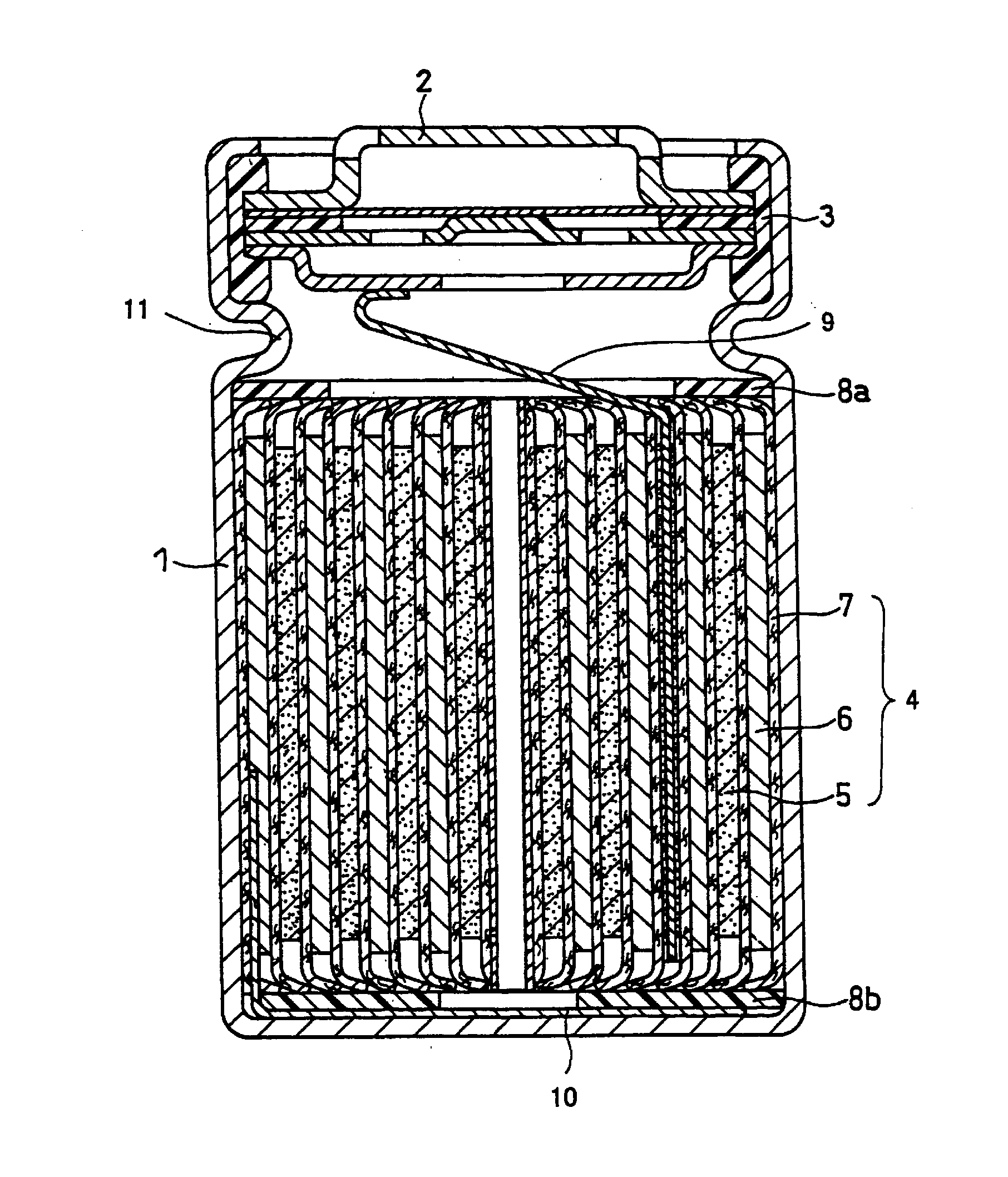

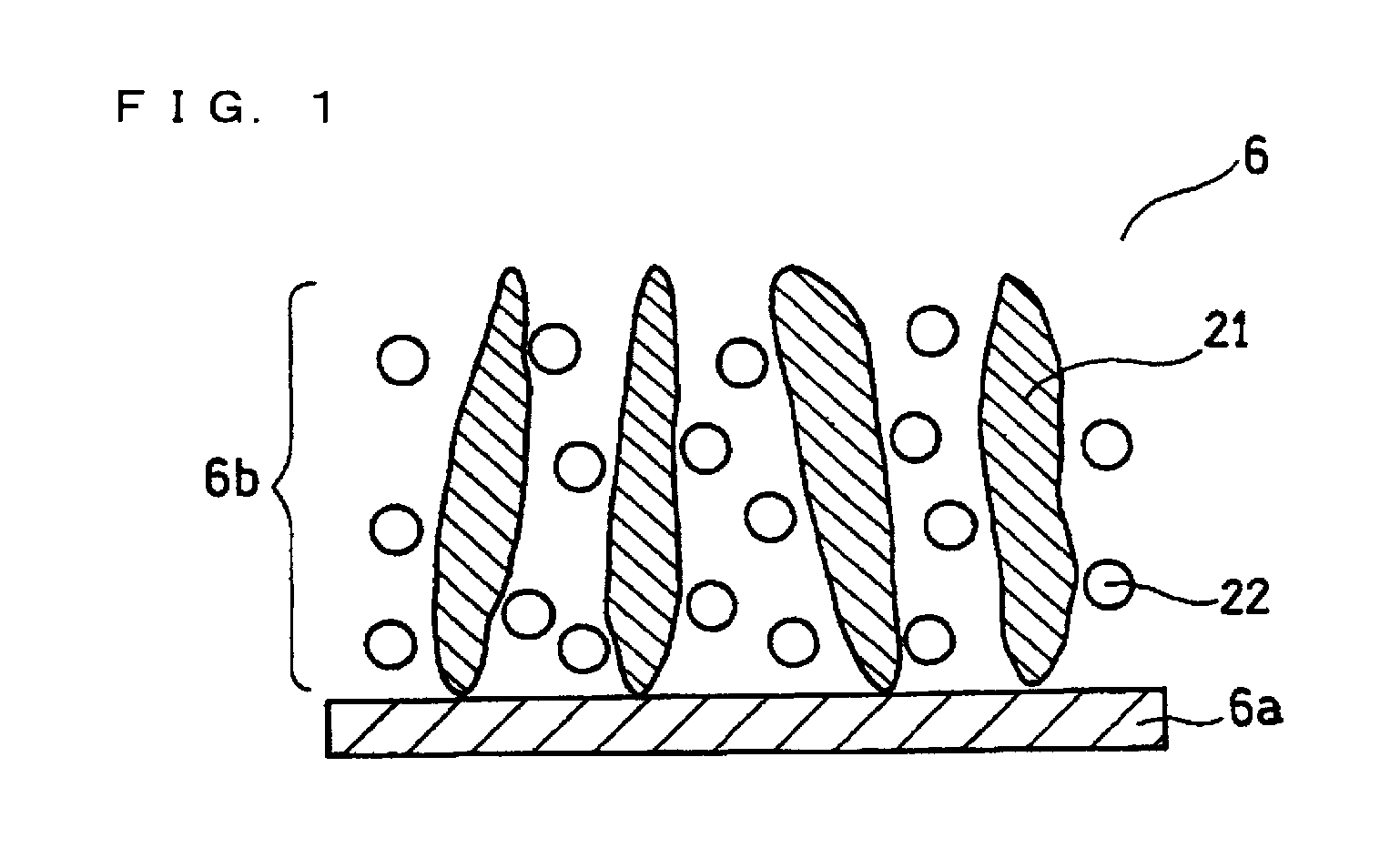

Active material for non-aqueous electrolyte secondary battery and manufacturing method therefore

ActiveUS20080268347A1Increase capacityReduces electron conductivity and lithium diffusing abilityElectrode manufacturing processesNon-aqueous electrolyte accumulatorsDesorptionX-ray

An active material for a non-aqueous electrolyte secondary battery including a lithium-containing transition metal oxide containing nickel and manganese and having a closest-packed structure of oxygen, wherein an atomic ratio MLi / MT between the number of moles of lithium MLi and the number of moles of transition metal Mt contained in the lithium-containing transition metal oxide is greater than 1.0; the lithium-containing transition metal oxide has a crystal structure attributed to a hexagonal system, and the X-ray diffraction image of the crystal structure has a peak P003 attributed to the (003) plane and a peak P104 attributed to the (104) plane; an integrated intensity ratio I003 / I104 between the peak P003 and the peak P104 varies reversibly within a range from 0.7 to 1.5 in association with absorption and desorption of lithium by the lithium-containing transition metal oxide; and the integrated intensity ratio varies linearly and continuously.

Owner:PUBLIC UNIVERSITY CORPORATION OSAKA CITY UNIVERSITY +1

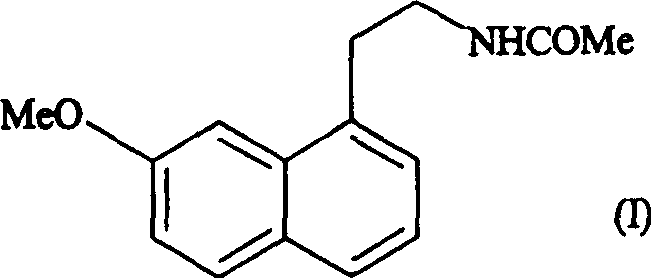

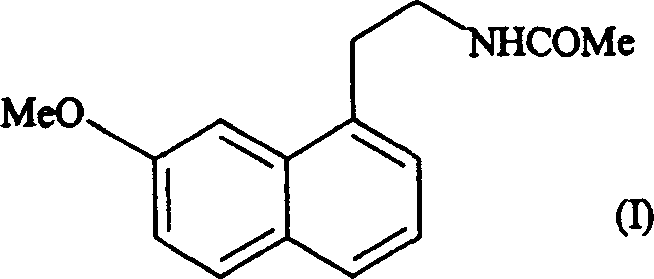

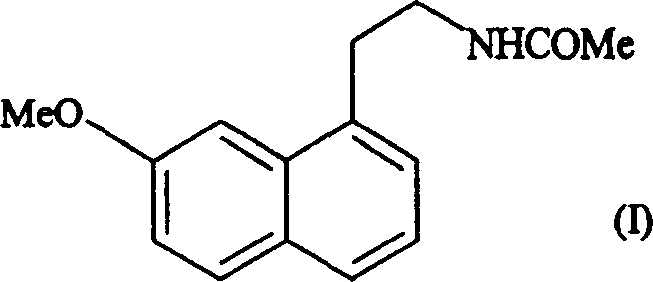

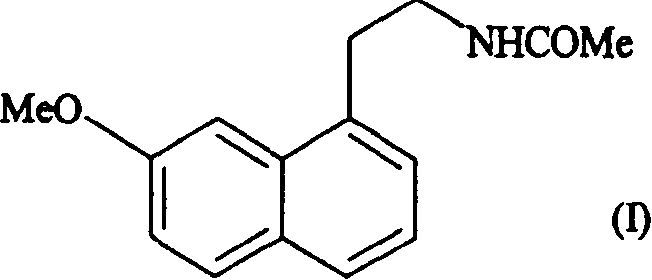

New crystalline form v of agomelatine, a process for its preparation and pharmaceutical compositions containing it

The crystalline form V of a compound of formula (I) is characterised by the X diffraction diagram thereof on a powder.

Owner:LES LAB SERVIER

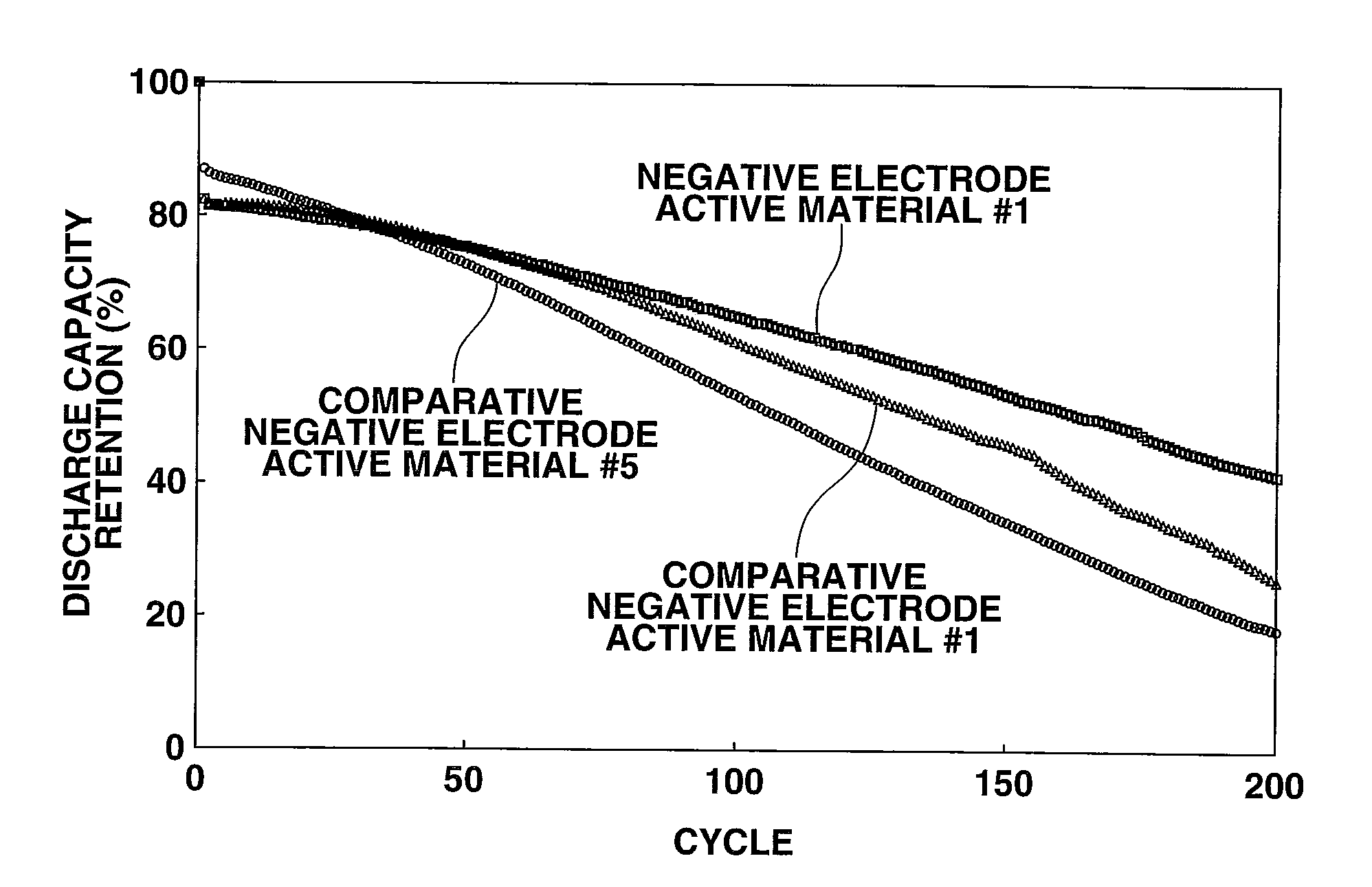

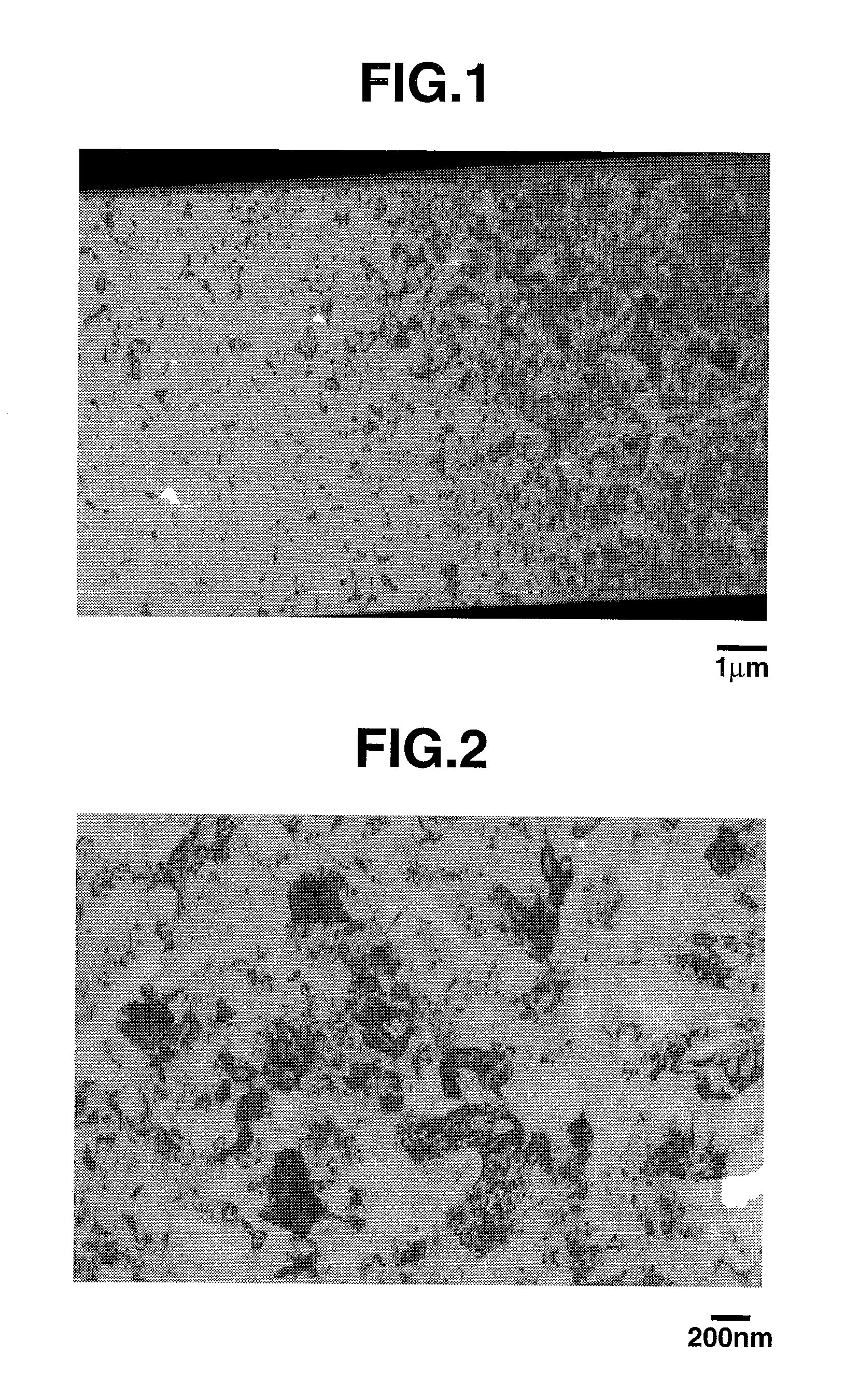

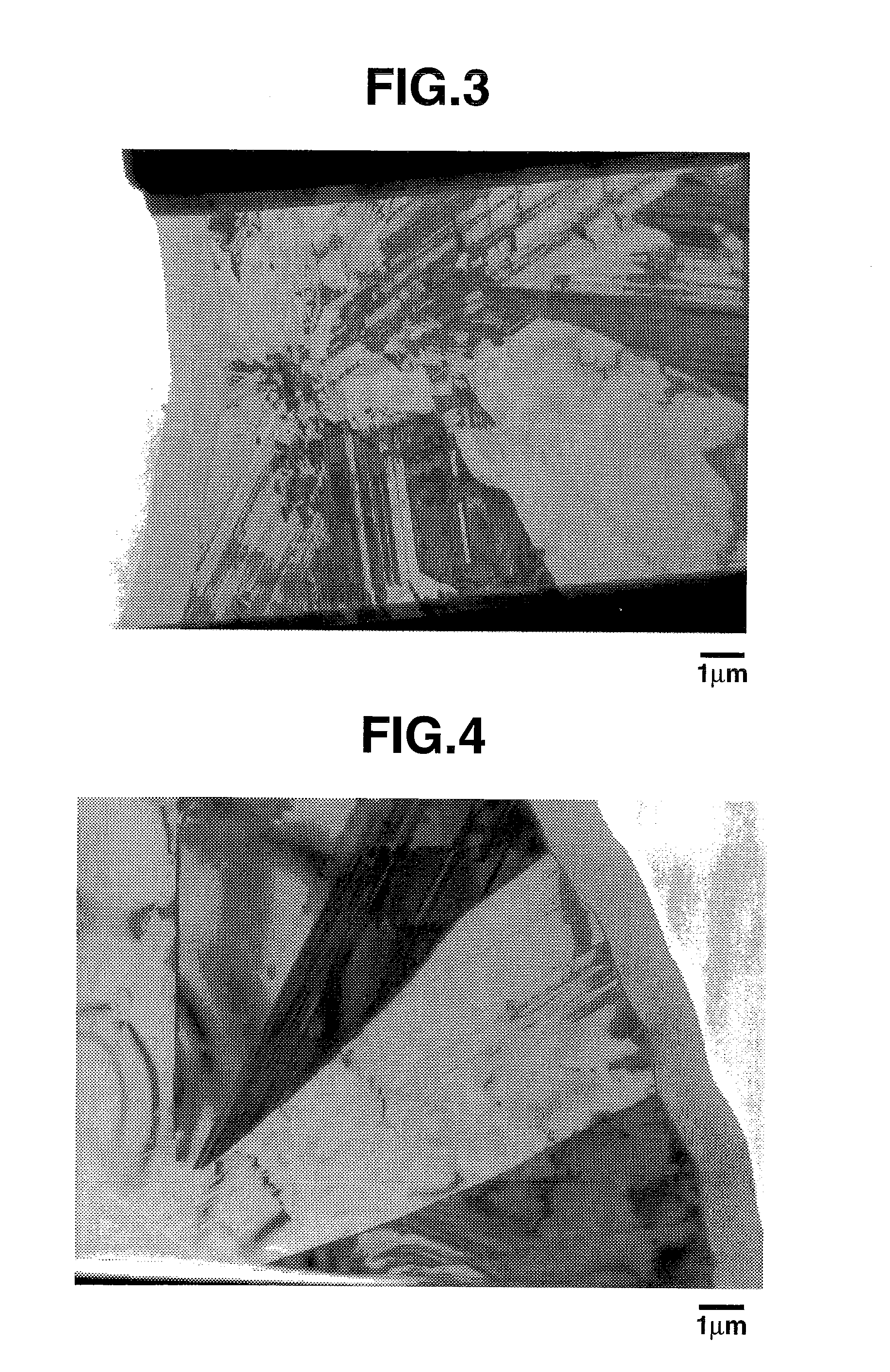

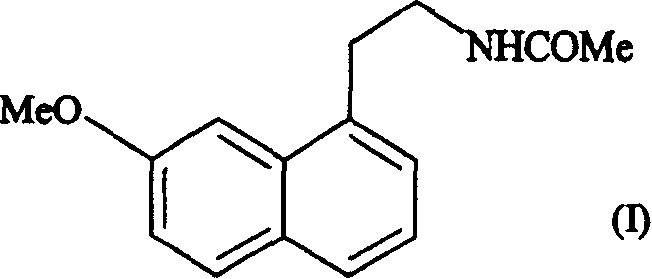

Negative electrode material for rechargeable battery with nonaqueous electrolyte, negative electrode for rechargeable battery with nonaqueous electrolyte, rechargeable battery with nonaqueous electrolyte, and process for producing polycrystalline silicon particles for active material for negative electrode material for rechargeable battery with nonaqueous electrolyte

ActiveUS20100266902A1Increase capacityImprove efficiencyMaterial nanotechnologySiliconX-rayFull width at half maximum

This invention provides a negative electrode material for a rechargeable battery with a nonaqueous electrolyte, characterized in that the negative electrode material contains polycrystalline silicon particles as an active material, the particle diameter of crystallites of the polycrystalline silicon is not less than 20 nm and not more than 100 nm in terms of a crystallite size determined by the Scherrer method from the full width at half maximum of a diffraction line attributable to Si (111) around 2θ=28.4° in an x-ray diffraction pattern analysis, and the true specific gravity of the silicon particles is 2.300 to 2.320.

Owner:PANASONIC ENERGY CO LTD +1

Crystalline form iv of agomelatine, a process for its preparation and pharmaceutical compositions containing it

The crystalline form IV of a compound of formula (I) is characterised by the X diffraction diagram thereof on a powder.

Owner:SERVIER LAB

New crystalline form iii of agomelatine, a process for its preparation and pharmaceutical compositions containing it

The crystalline form III of a compound of formula (I) is characterised by the X diffraction diagram thereof on a powder, and the drugs contains it.

Owner:LES LAB SERVIER

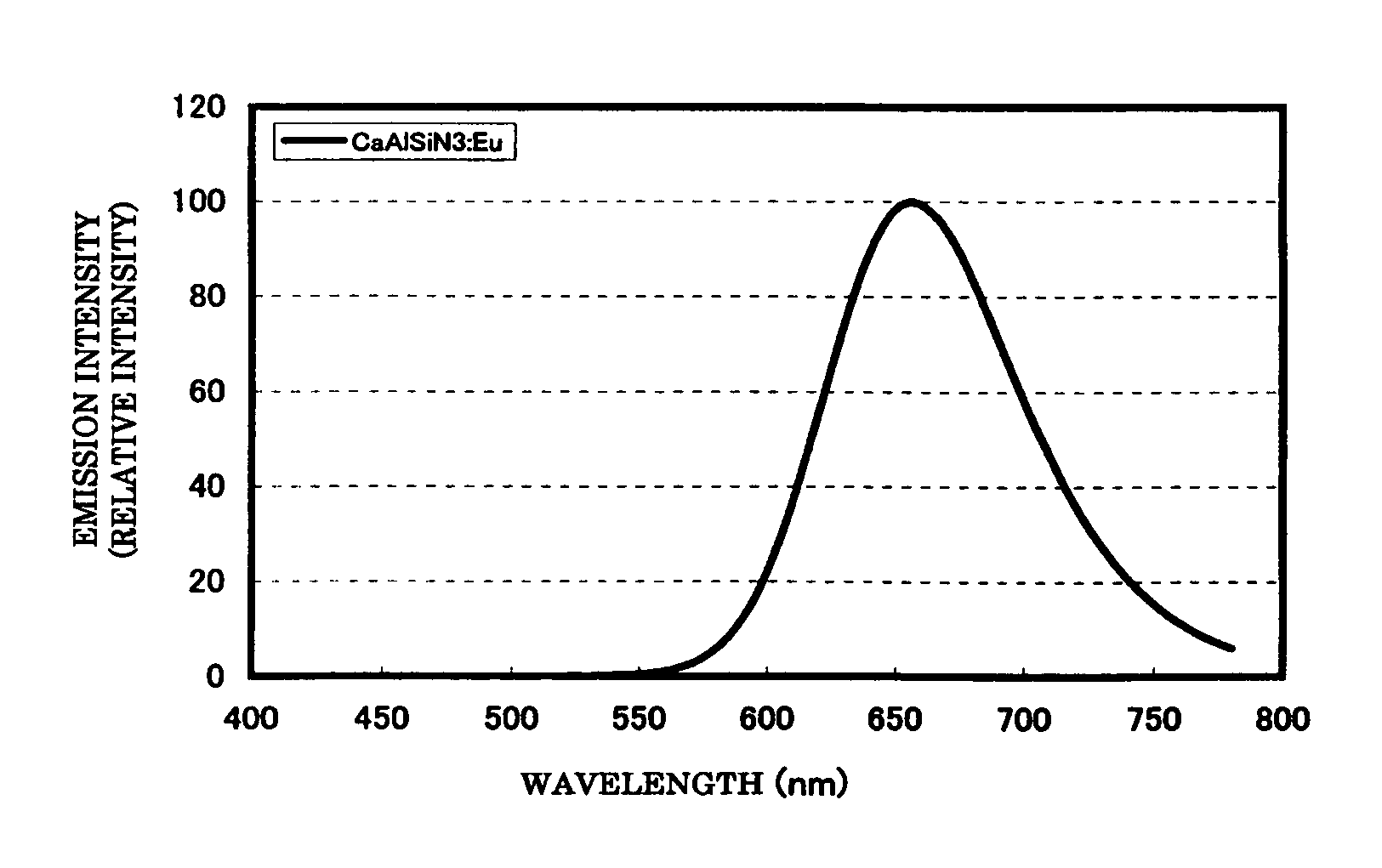

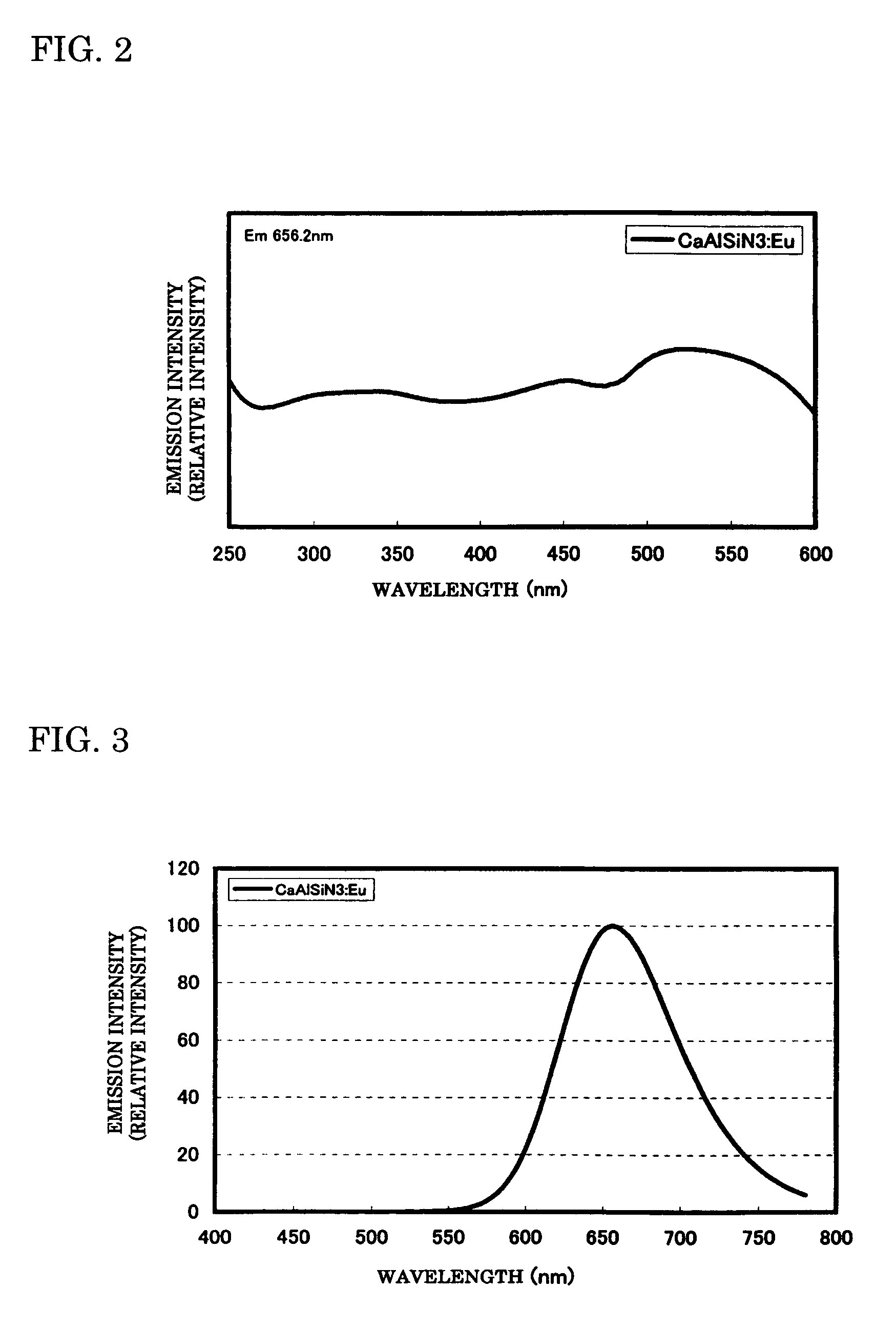

Phosphor and manufacturing method for the same, and light source

ActiveUS7476337B2Easy to manufactureReduce manufacturing costElectrical apparatusElectroluminescent light sourcesPhosphorX-ray

To provide a phosphor having an emission characteristic such that a peak wavelength of light emission is in a range from 580 to 680 nm, and having a high emission intensity, and having a flat excitation band with high efficiency for excitation light in a broad wavelength range from ultraviolet to visible light (wavelength range from 250 nm to 550 nm). For example, Ca3N2(2N), AlN(3N), Si3N4(3N), Eu2O3(3N) are prepared, and after weighing and mixing a predetermined amount of each raw material, raw materials are fired at 1500° C. for 6 hours, thus obtaining the phosphor including a product phase expressed by a composition formula CaAlSiN3:Eu and having an X-ray diffraction pattern satisfying a predetermined pattern.

Owner:CITIZEN ELECTRONICS CO LTD +1

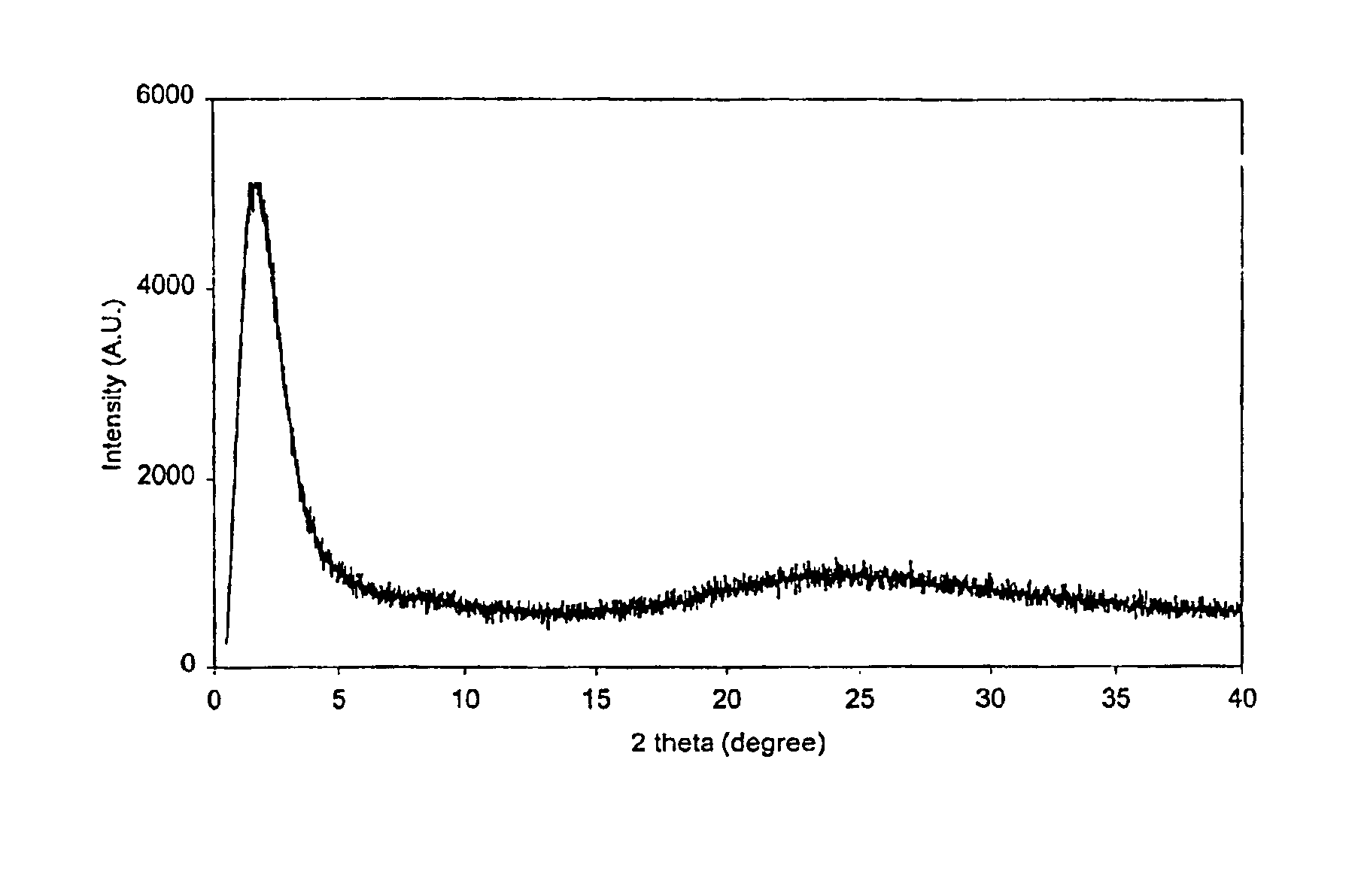

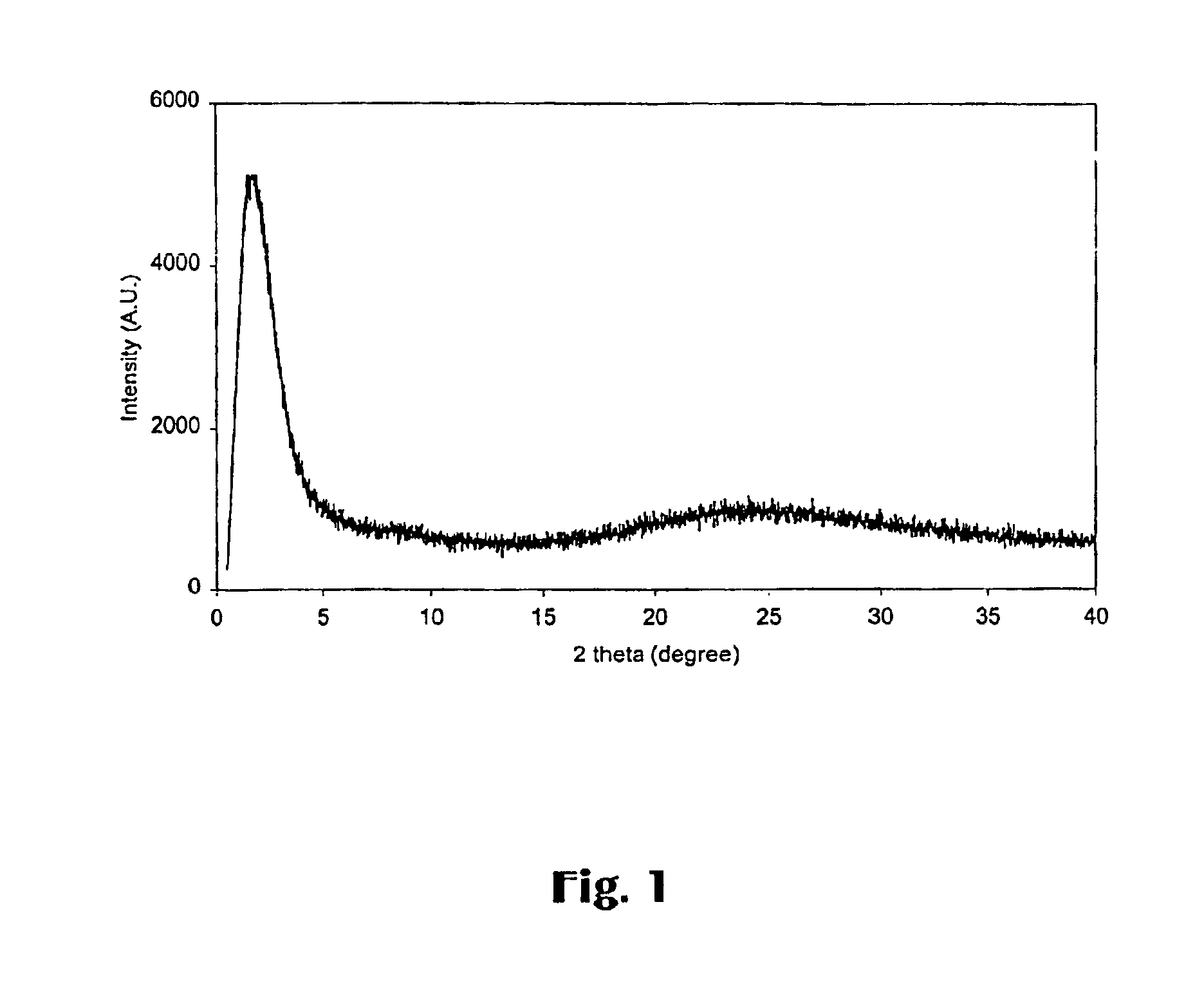

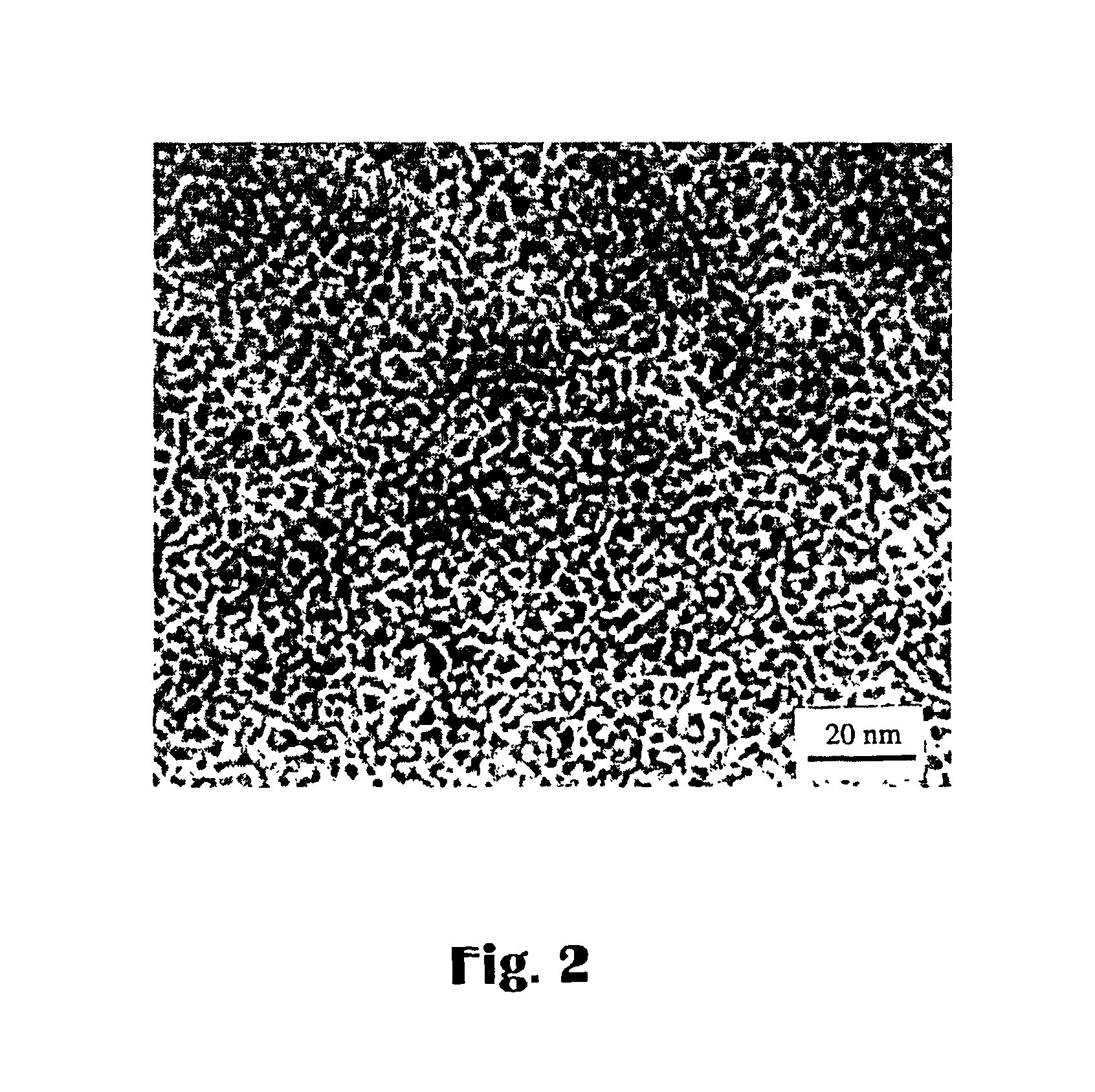

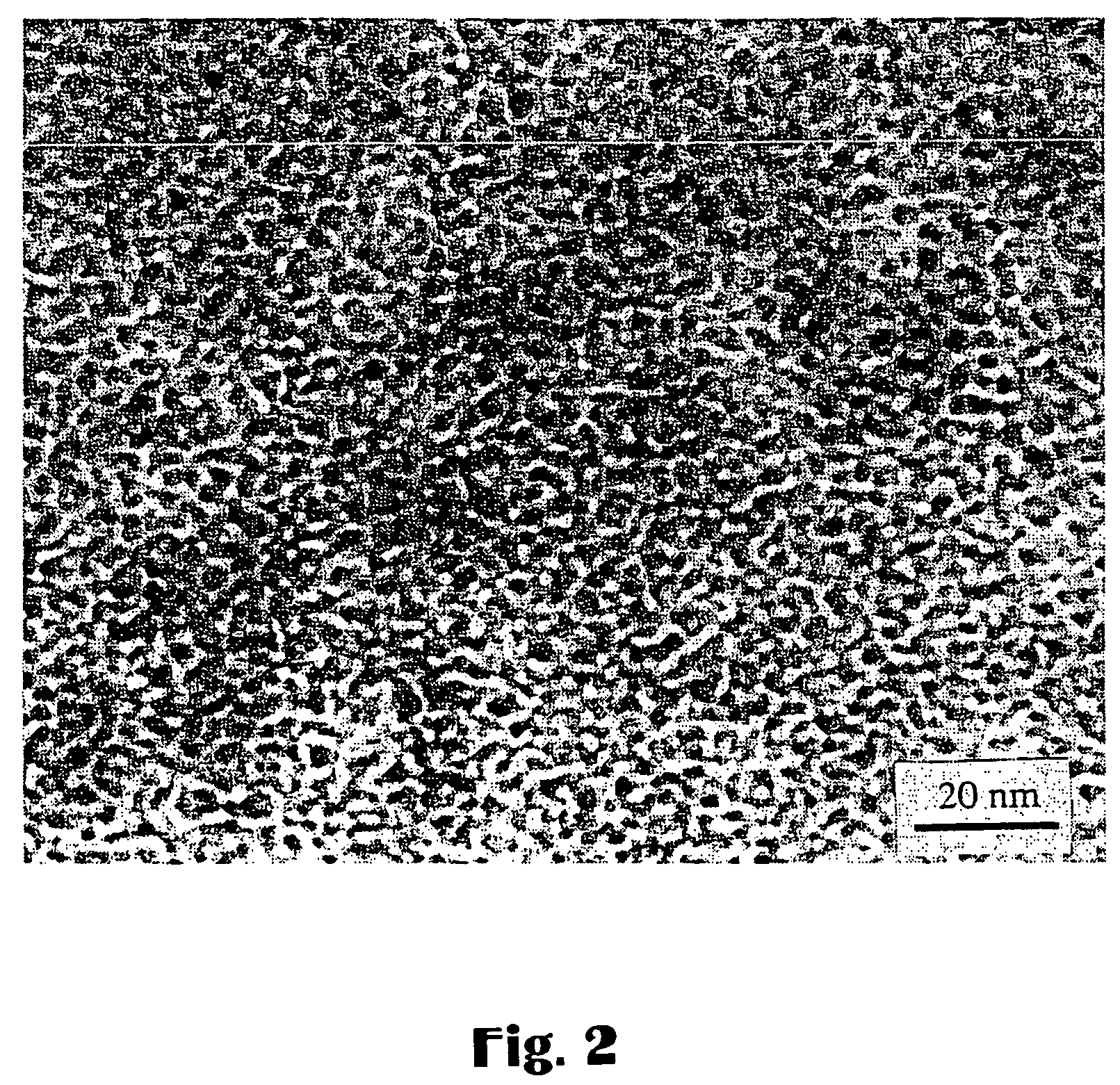

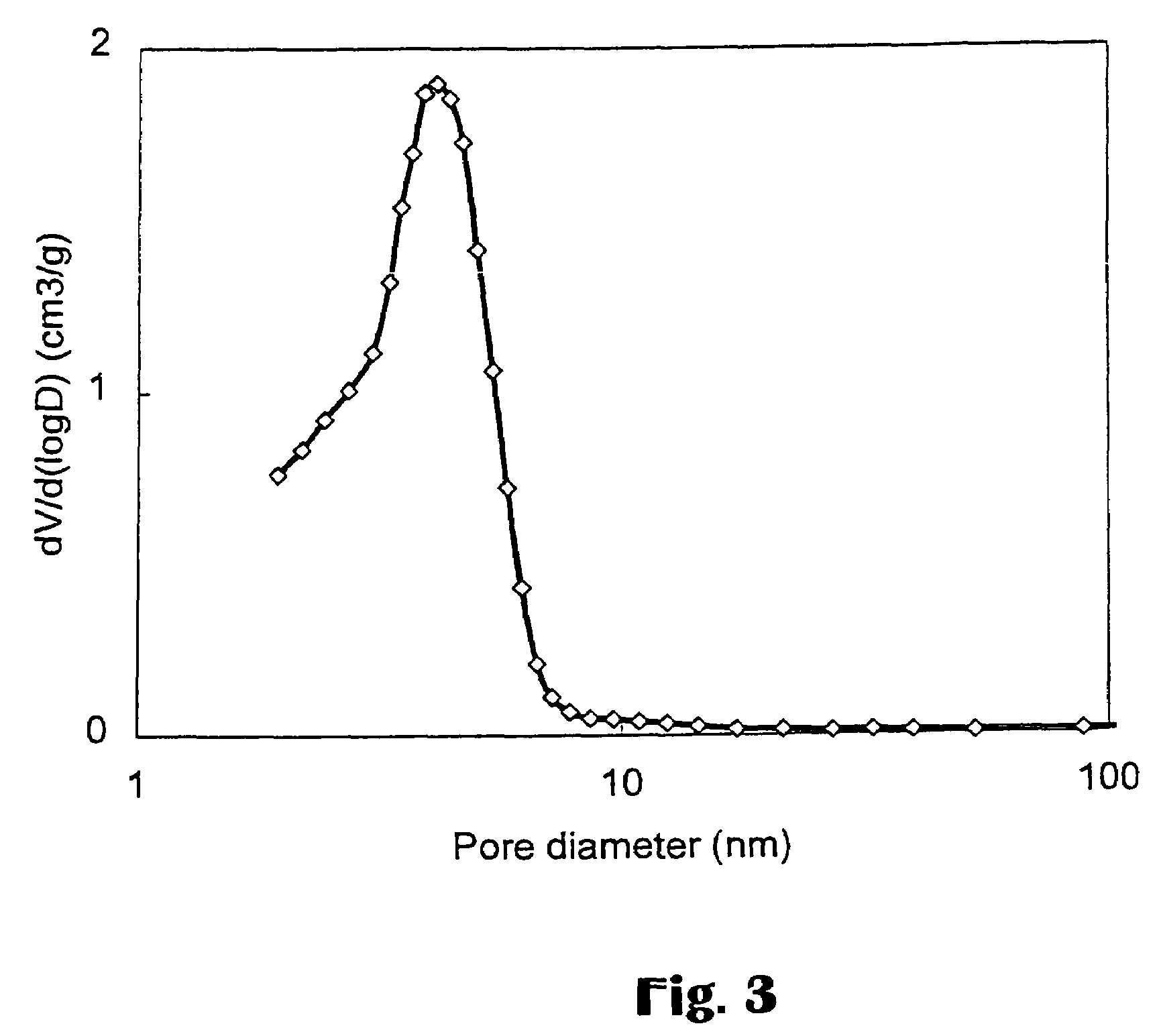

Mesoporous material with active metals

A process for treating organic compounds includes providing a composition which includes a substantially mesoporous structure of silica containing at least 97% by volume of pores having a pore size ranging from about 15 Å to about 30 Å and having a micropore volume of at least about 0.01 cc / g, wherein the mesoporous structure has incorporated therewith at least about 0.02% by weight of at least one catalytically and / or chemically active heteroatom selected from the group consisting of Al, Ti, V, Cr, Zn, Fe, Sn, Mo, Ga, Ni, Co, In, Zr, Mn, Cu, Mg, Pd, Pt and W, and the catalyst has an X-ray diffraction pattern with one peak at 0.3° to about 3.5° at 2θ. The catalyst is contacted with an organic feed under reaction conditions wherein the treating process is selected from alkylation, acylation, oligomerization, selective oxidation, hydrotreating, isomerization, demetalation, catalytic dewaxing, hydroxylation, hydrogenation, ammoximation, isomerization, dehydrogenation, cracking and adsorption.

Owner:ABB LUMMUS GLOBAL INC

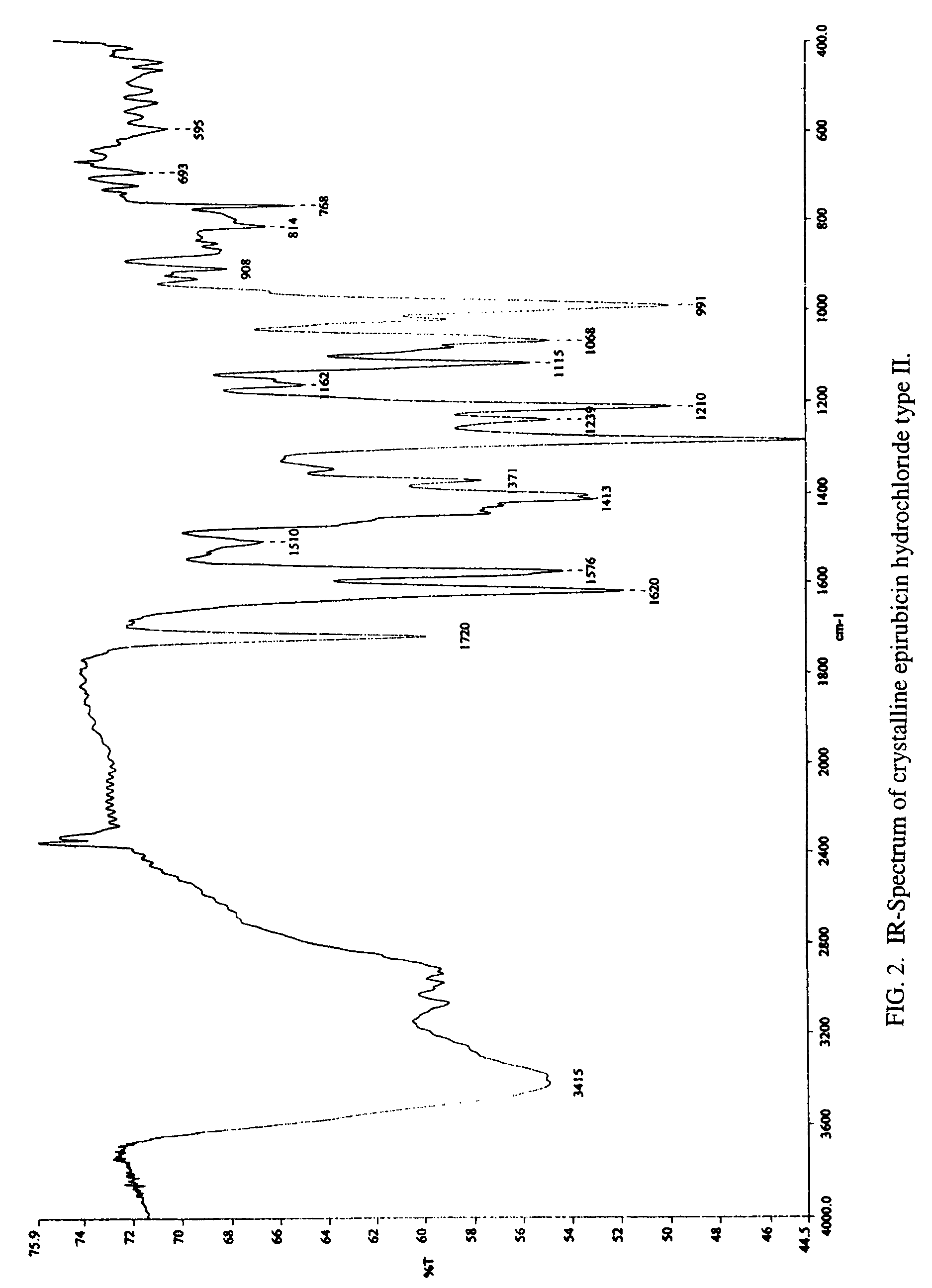

Thermally stable crystalline epirubicin hydrochloride and method of making the same

ActiveUS7485707B2Improve thermal stabilityImprove featuresSugar derivativesMedical preparationsCrystallographyThermal stability

A crystalline form of epirubicin hydrochloride, named herein as “type II” crystalline epirubicin hydrochloride, has excellent thermal stability. Type II crystalline epirubicin hydrochloride has a powder X-ray diffraction pattern having average values of diffraction angle (2θ) and relative intensity P(%) as presented in the following table:DiffractionAngleRelative Intensity2ΘP (%)5.2369.89.21212.513.73215.516.4464.818.234521.1149.722.52925.524.07129.925.87918.427.76216.529.75710.134.3924.438.15713.144.2935.964.6997.777.815100.

Owner:SYNBIAS PHARMA

Silicide compositions containing alkali metals and methods of making the same

The invention relates to a method of making alkali metal silicide compositions, and the compositions resulting from the method, comprising mixing an alkali metal with silicon and heating the resulting mixture to a temperature below about 475° C. The resulting compositions do not react with dry O2. Also, the invention relates to sodium silicide compositions having a powder X-ray diffraction pattern comprising at least three peaks with 2Theta angles selected from about 18.2, 28.5, 29.5, 33.7, 41.2, 47.4, and 56.2 and a solid state 23Na MAS NMR spectra peak at about 18 ppm. Moreover, the invention relates to methods of removing a volatile or flammable substance in a controlled manner. Furthermore, the alkali metal silicide compositions of the invention react with water to produce hydrogen gas.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

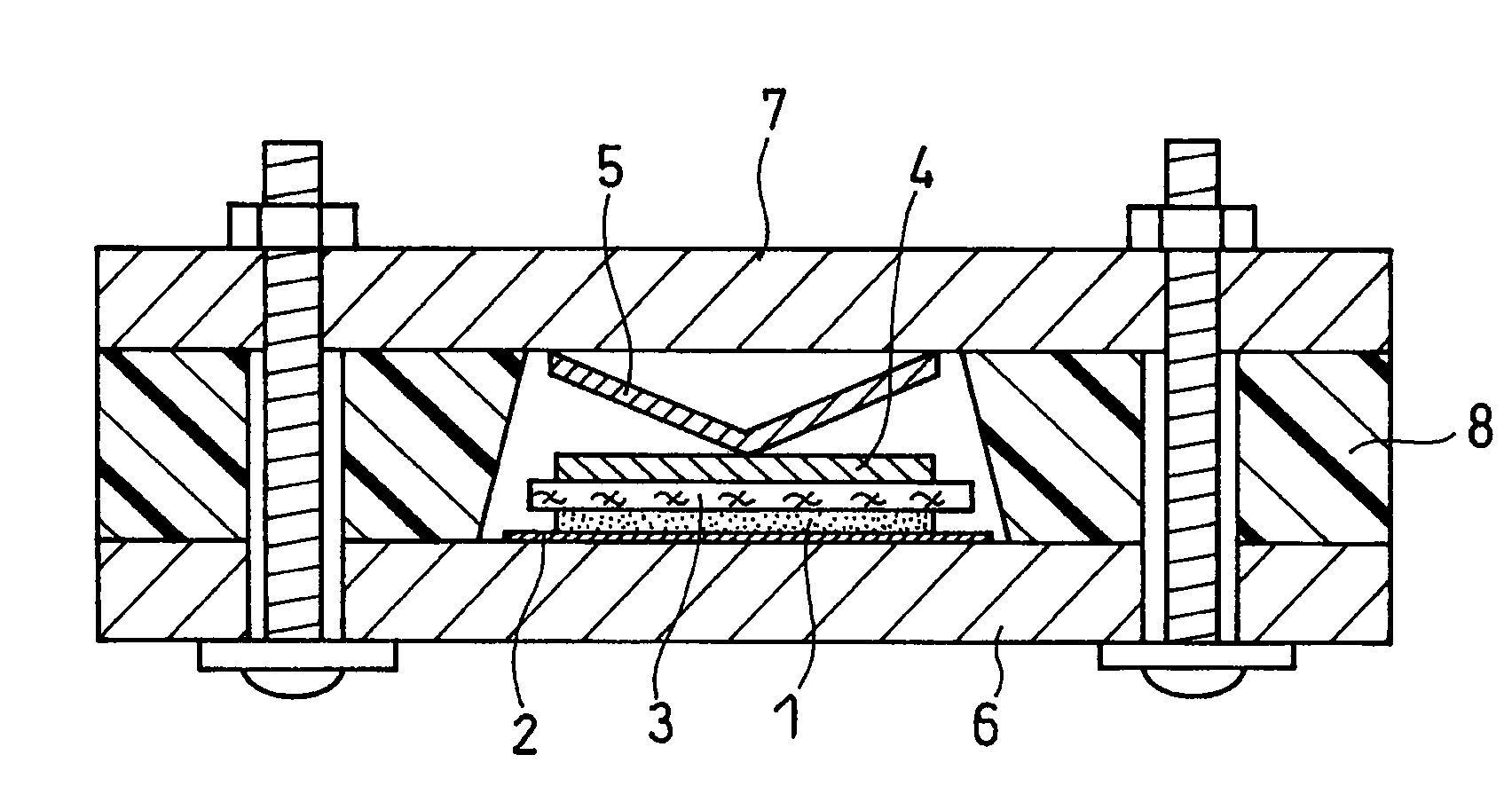

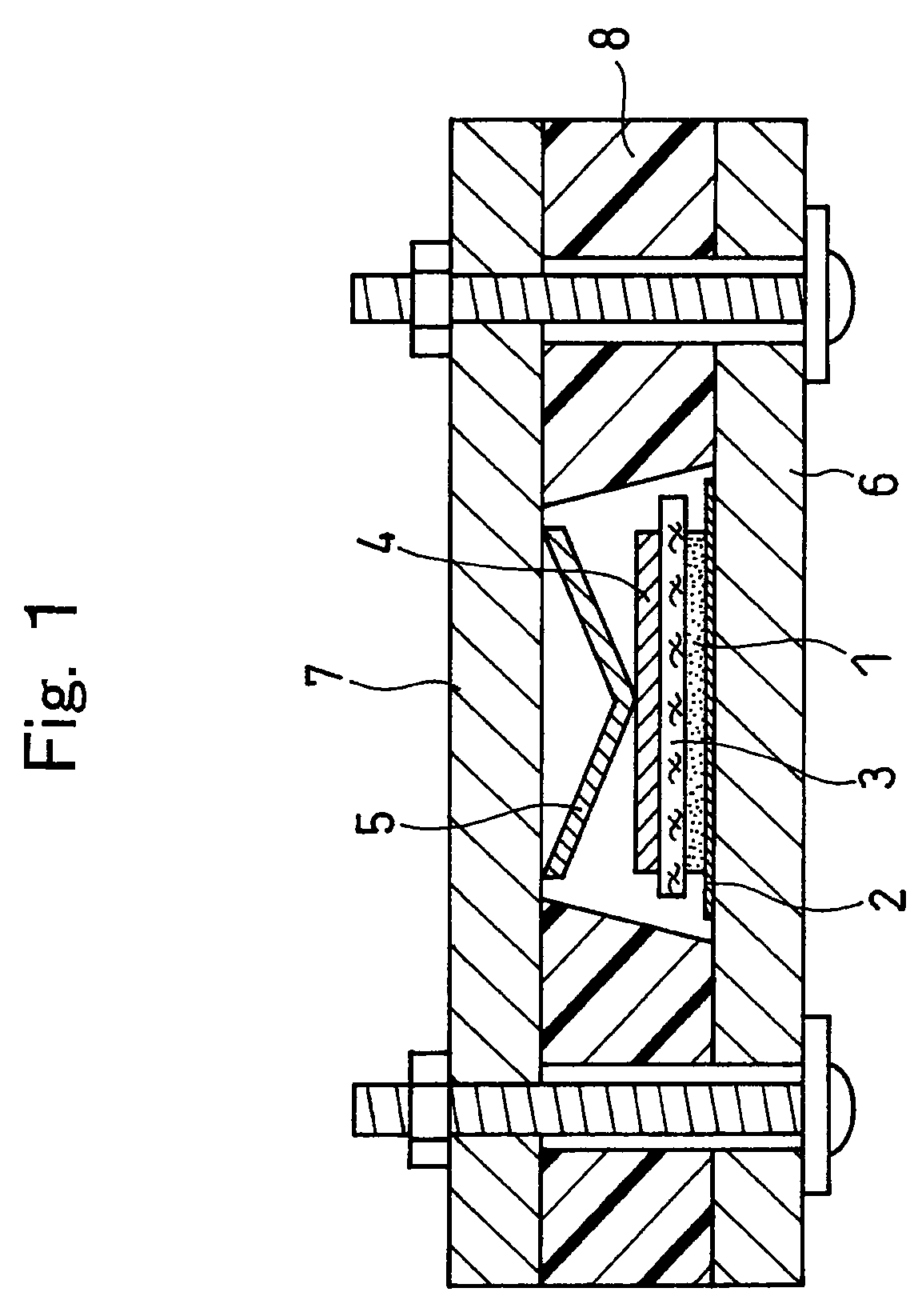

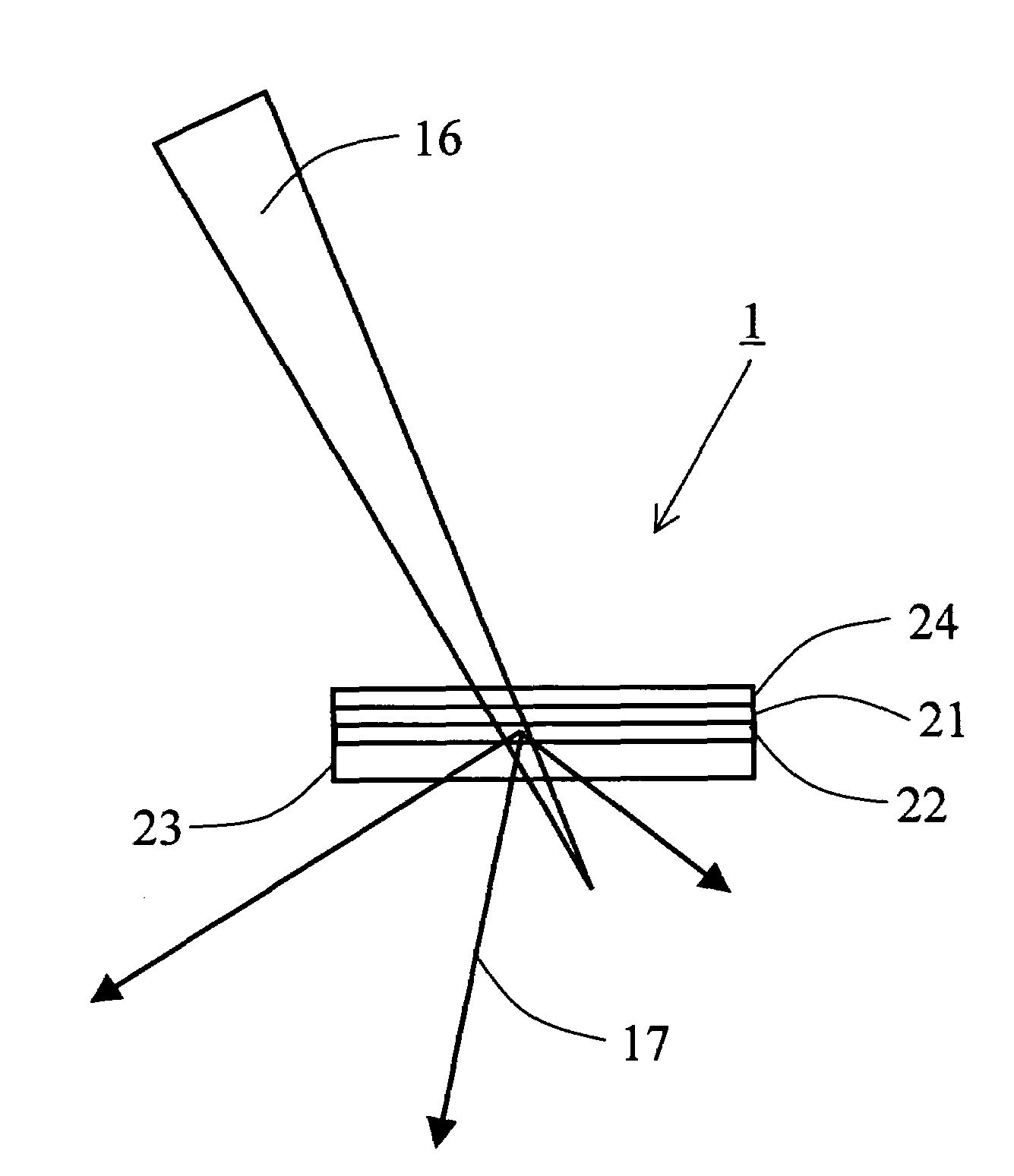

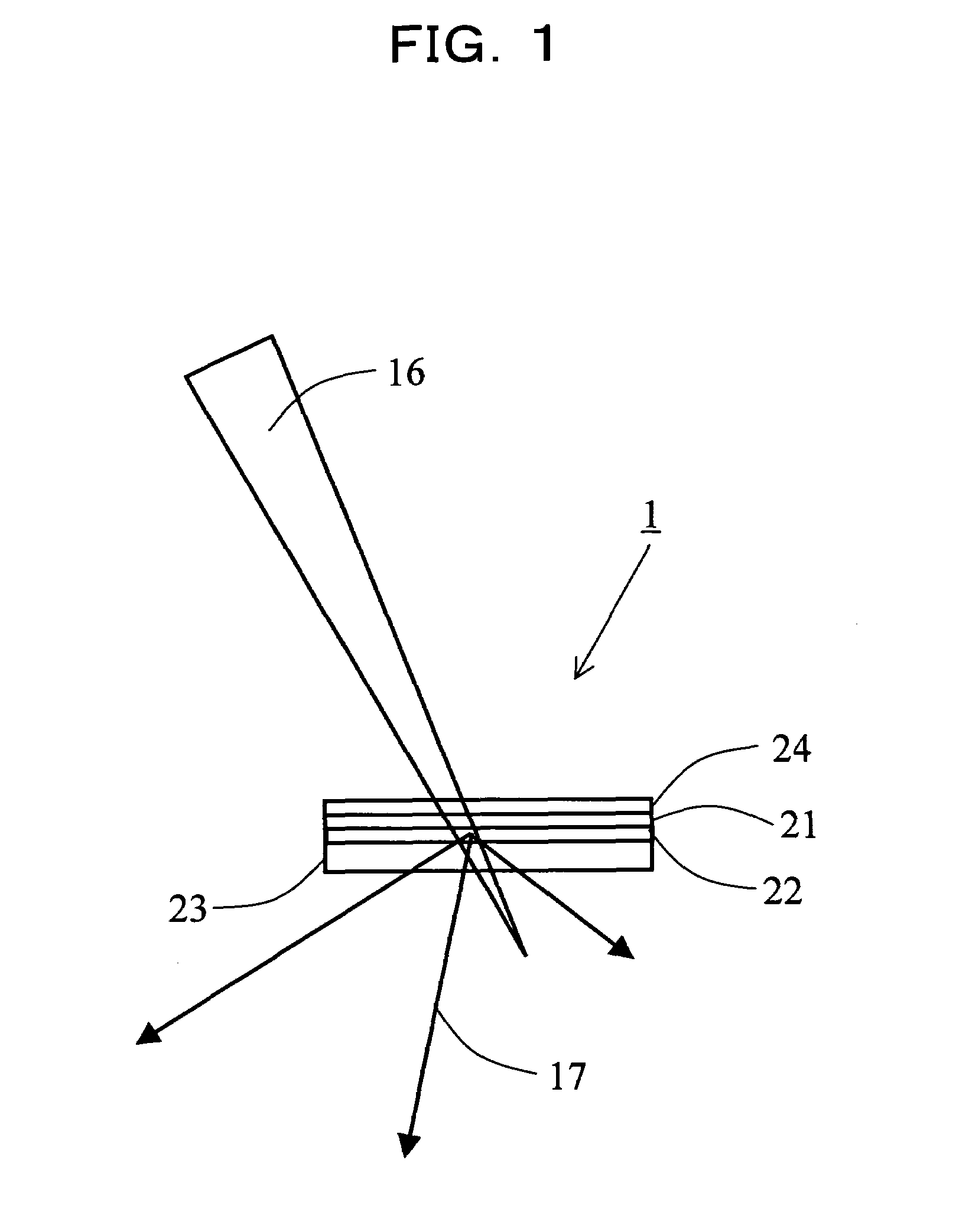

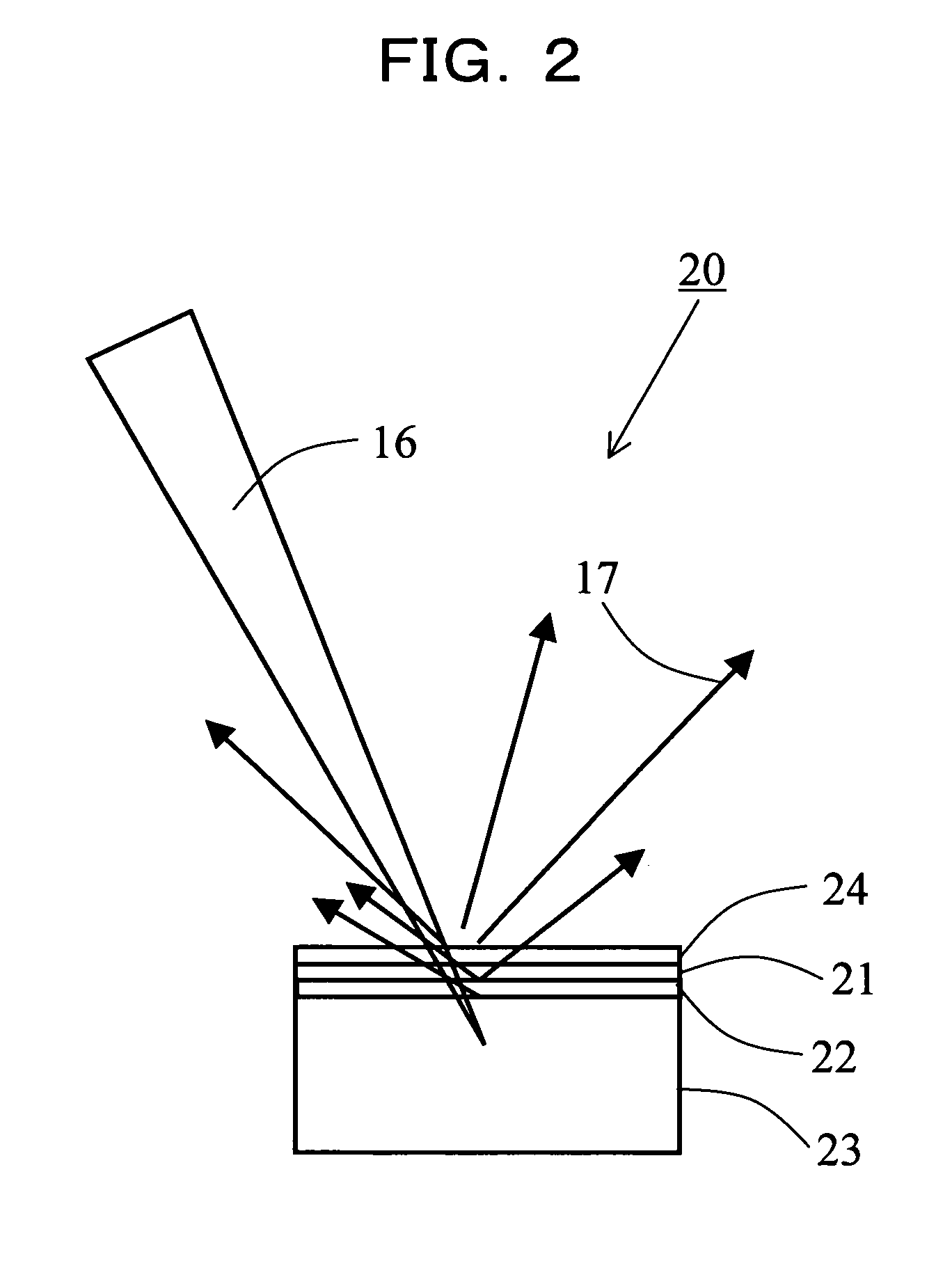

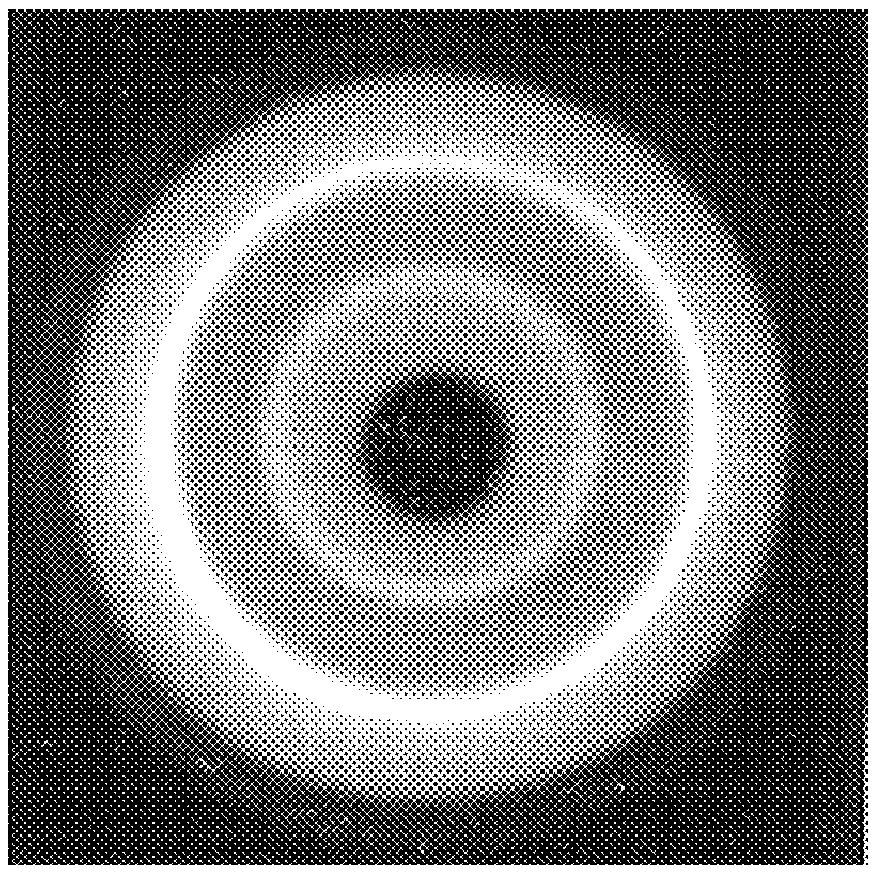

Method and apparatus for labeling using optical identification elements characterized by X-ray diffraction

ActiveUS20070121181A1Made smallPaper-money testing devicesMaterial analysis using radiation diffractionMulti materialFiber

An optical identification element for identifying an item comprises a binder material and one or more materials embedded in the binder material. The one or more materials provide an encoded composite X-ray diffraction pattern when illuminated by an X-ray beam. The encoded composite X-ray diffraction pattern is indicative of the item. The one or more materials are preferably powdered crystal materials. The optical identification element may be shaped as a microbead or a macrobead. Alternatively, the binder material may be in the form of a thread or fiber. The labeled item may be selected from the group, comprising: large or small objects, products, solids, powders, liquids, gases, plants, pharmaceuticals, currency, ID cards, minerals, cells and / or animals. The item may be a chemical or a DNA sequence. The optical identification element may be used for many different purposes, such as for sorting, tracking, identification, verification, authentication, anti-theft / anti-counterfeit, security / anti-terrorism, or for other purposes. In a manufacturing environment, the elements 8 may be used to track inventory for production information or sales of goods / products.

Owner:ILLUMINA INC

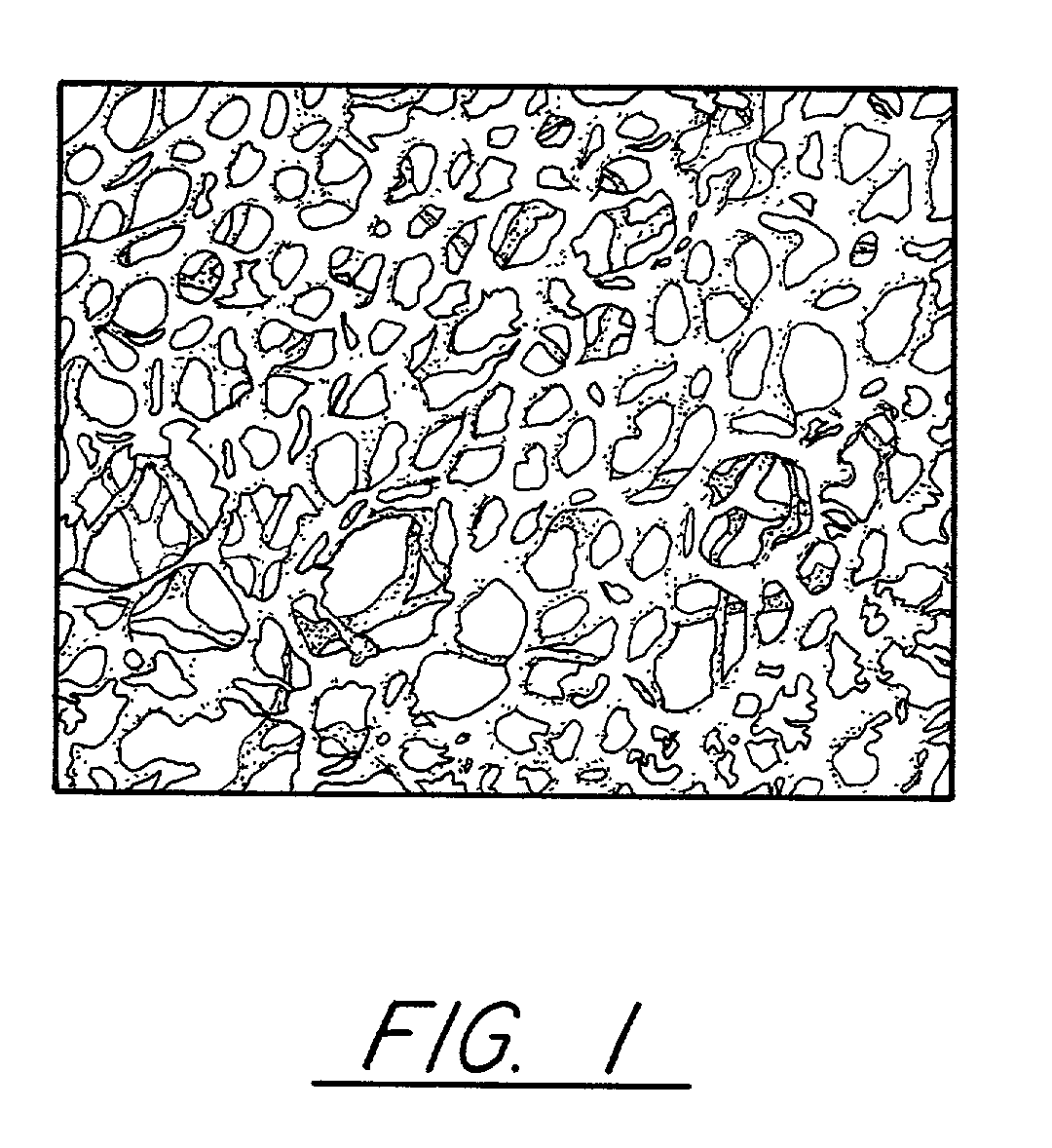

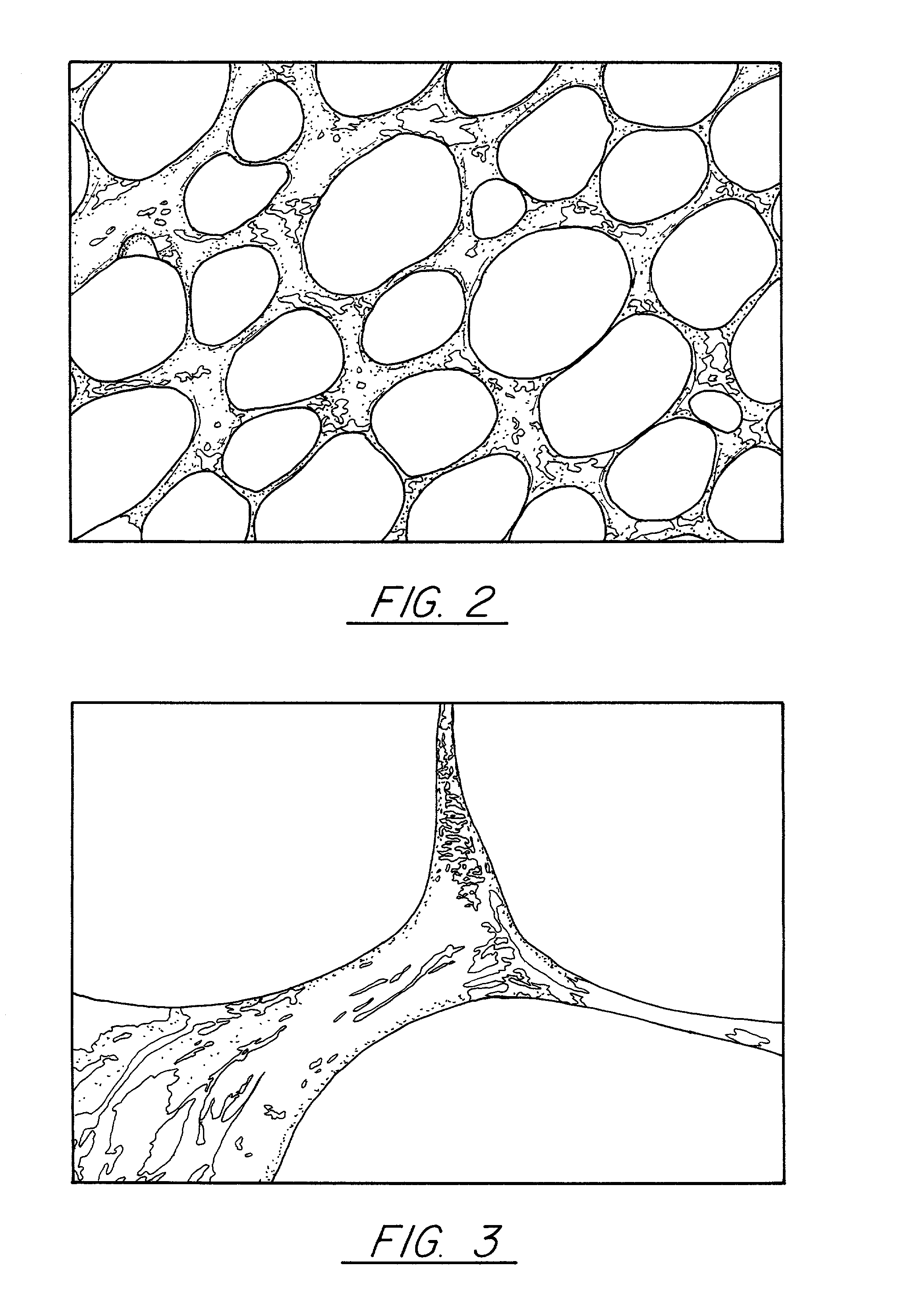

Pitch-based carbon foam and composites and use thereof

InactiveUS7070755B2Speed up evaporationImprove cooling effectCarbon compoundsHeat storage plantsX-rayVolumetric Mass Density

A thermally conductive carbon foam is provided, normally having a thermal conductivity of at least 40 W / m·K. The carbon foam usually has a specific thermal conductivity, defined as the thermal conductivity divided by the density, of at least about 75 W·cm3 / m·° K·gm. The foam also has a high specific surface area, typically at least about 6,000 m2 / m3. The foam is characterized by an x-ray diffraction pattern having “doublet” 100 and 101 peaks characterized by a relative peak split factor no greater than about 0.470. The foam is graphitic and exhibits substantially isotropic thermal conductivity. The foam comprises substantially ellipsoidal pores and the mean pore diameter of such pores is preferably no greater than about 340 microns. Other materials, such as phase change materials, can be impregnated in the pores in order to impart beneficial thermal properties to the foam. Heat exchange devices and evaporatively cooled heat sinks utilizing the foams are also disclosed.

Owner:UT BATTELLE LLC

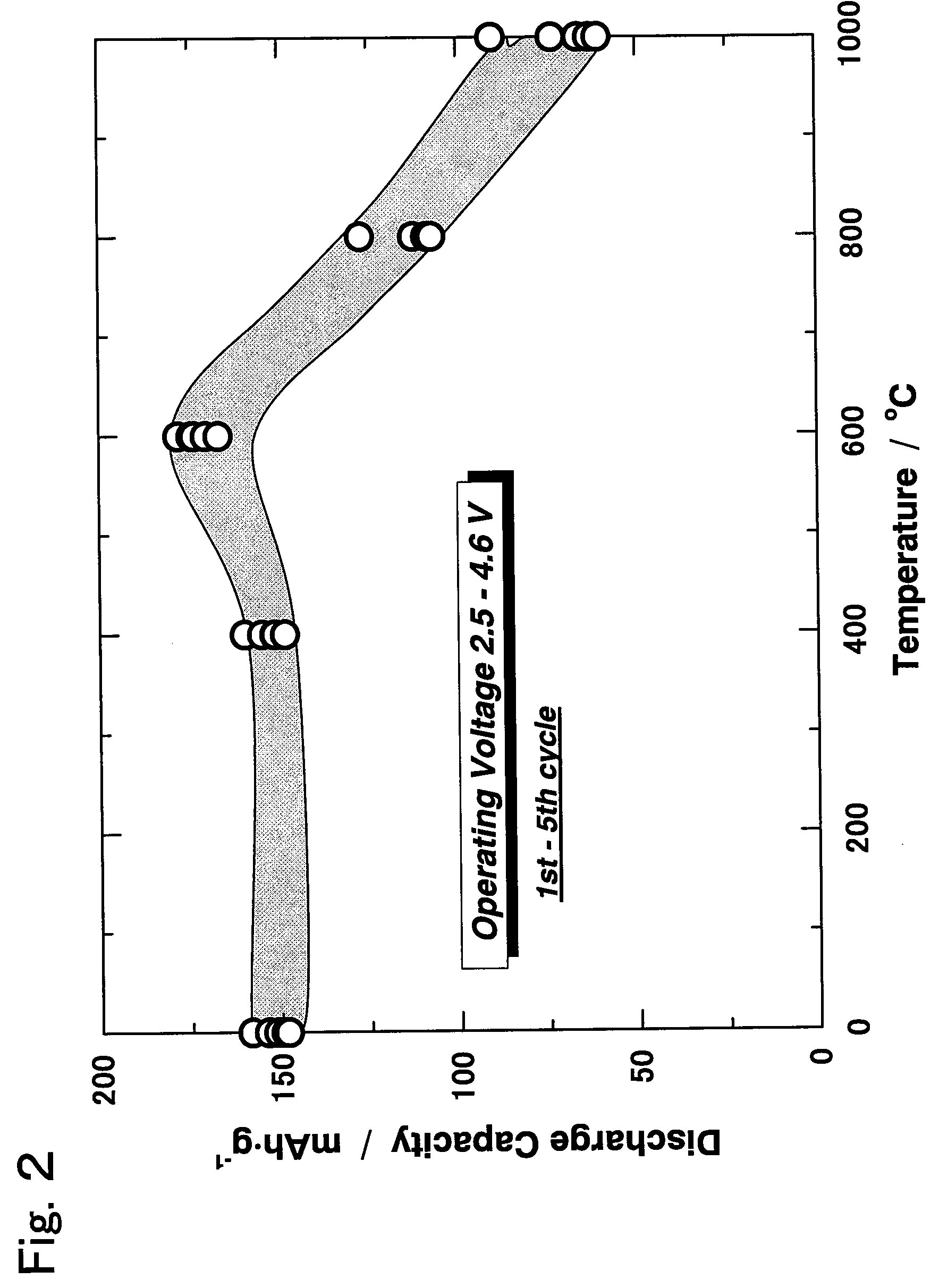

Positive active material for rechargeable lithium battery, method of preparing same, and rechargeable lithium battery comprising same

ActiveUS20050014065A1Large capacityImproved cycle life characteristicsNon-aqueous electrolyte accumulatorsAlkali metal oxidesCrystallographyX-ray

Disclosed is a positive active material for a lithium rechargeable battery, a method of preparing the same, and a lithium rechargeable battery comprising the same. The positive active material has an I(003) / I(104) intensity ratio of between 1.15 to 1 and 1.21 to 1 in an X ray diffraction pattern using CuKα ray, wherein I(003) / I(004) is the X-ray diffraction intensity of the (003) plane divided by the X-ray diffraction intensity of the (104) plane. The compound is represented by the formula: LixNiyCozMn1-y-z-qXqO2 wherein x≧1.05, 0<y<0.35, 0<z<0.35, X is Al, Mg, Sr, Ti or La, and 0≦q<0.1.

Owner:SAMSUNG SDI CO LTD

Method for the oxidative dehydrogenation of ethane

InactiveUS20050085678A1Organic compound preparationHeterogenous catalyst chemical elementsChemistryX ray diffractogram

The invention relates to a method for the oxidative dehydrogenation of ethane. The inventive method is characterized in that it consists of bringing the ethane into contact with the catalyst containing Mo, Te, V, Nb and at least a fifth element A which is selected from Cu, Ta, Sn, Se, W, Ti, Fe, Co, Ni, Cr, Zr, Sb, Bi, an alkali metal, an alkaline-earth metal and a rare earth, in which at least Mo, Te, V and Nb are present in the form of at least one oxide, said catalyst presenting, in calcined form, an X-ray diffractogram with more than ten intense diffraction lines, typically, the most intense lines corresponding to diffraction angles 2Θ of 7.7°±0.4, 8.9°±0.4, 22.1°+0.4, 26.6°±0.4, 26.9°±0.4, 27.1°±0.4, 28.1°±0.4, 31.2°±0.4, 35.0°±0.4 and 45.06°±0.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC) +1

Positive Electrode Active Material for Lithium Ion Battery, Positive Electrode for Secondary Battery, and Lithium Ion Battery

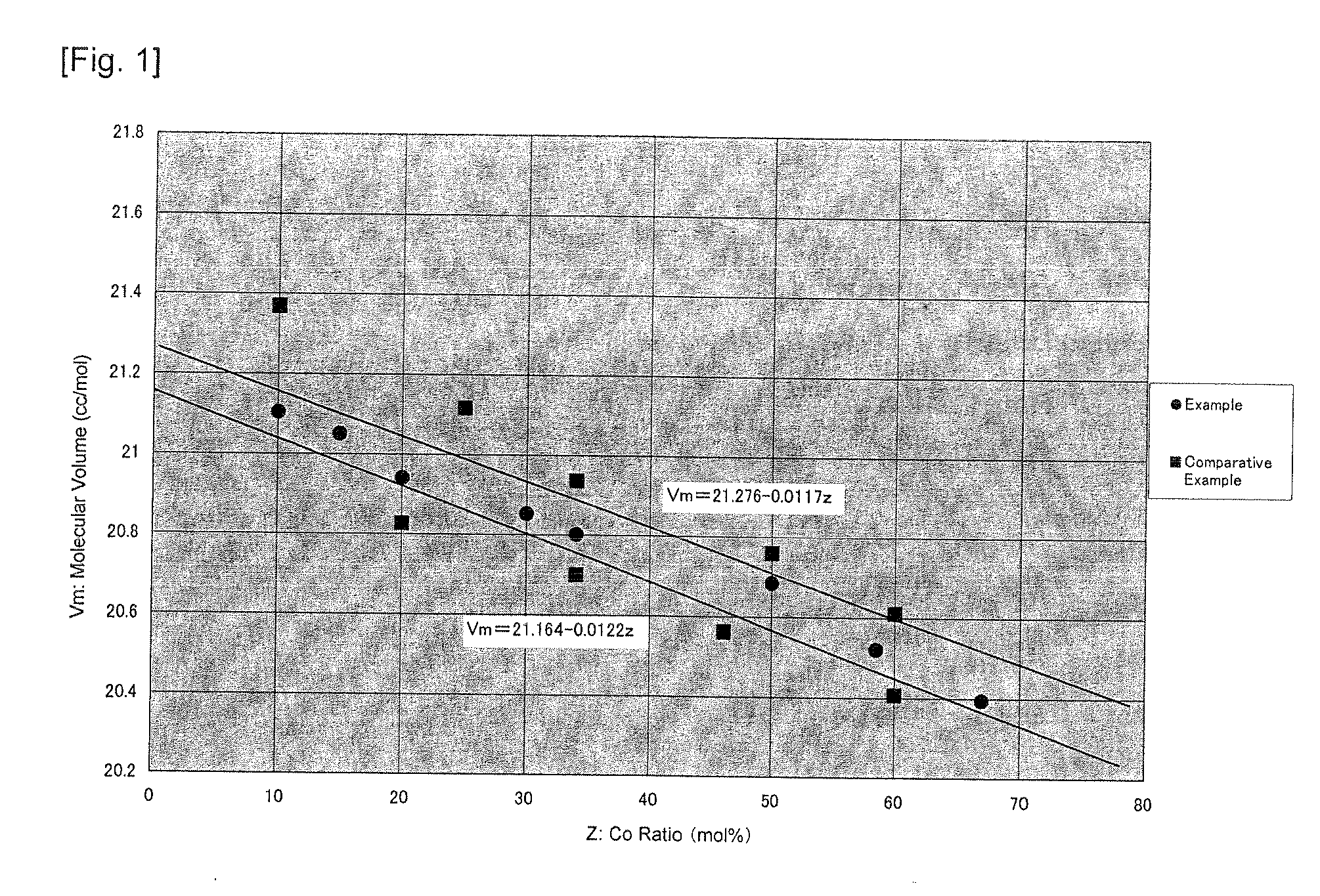

ActiveUS20110031437A1High crystallinityEnsure characteristicPositive electrodesLi-accumulatorsHorizontal axisManganese

Provided is a positive electrode active material for a lithium ion battery positive electrode material made of lithium-containing nickel-manganese-cobalt composite oxide of a layered structure represented with LiaNixMnyCozO2 (1.0<a<1.3, 0.8<x+y+z<1.1), wherein, in a region with a molar volume Vm that is estimated from a lattice constant calculated from a (018) plane and a (113) plane in a powder X-ray diffraction pattern using CuK alpha rays as a vertical axis and Co ratio z (molar %) in metal components as a horizontal axis, the relationship thereof is within a range of Vm=21.276-0.0117z as an upper limit and Vm=21.164-0.0122z as a lower limit, and a half value width of both the (018) plane and the (113) plane is 0.200° or less. As a result of studying and defining the relationship of the cobalt (Co) ratio and the lattice constant, which are considered to influence the crystal structure, obtained was a positive electrode active material having high crystallinity, high capacity and high security. By using this material, it is possible to obtain a positive electrode active material for a lithium ion battery that is able to further ensure the characteristics and safety of the lithium ion battery.

Owner:JX NIPPON MINING& METALS CORP

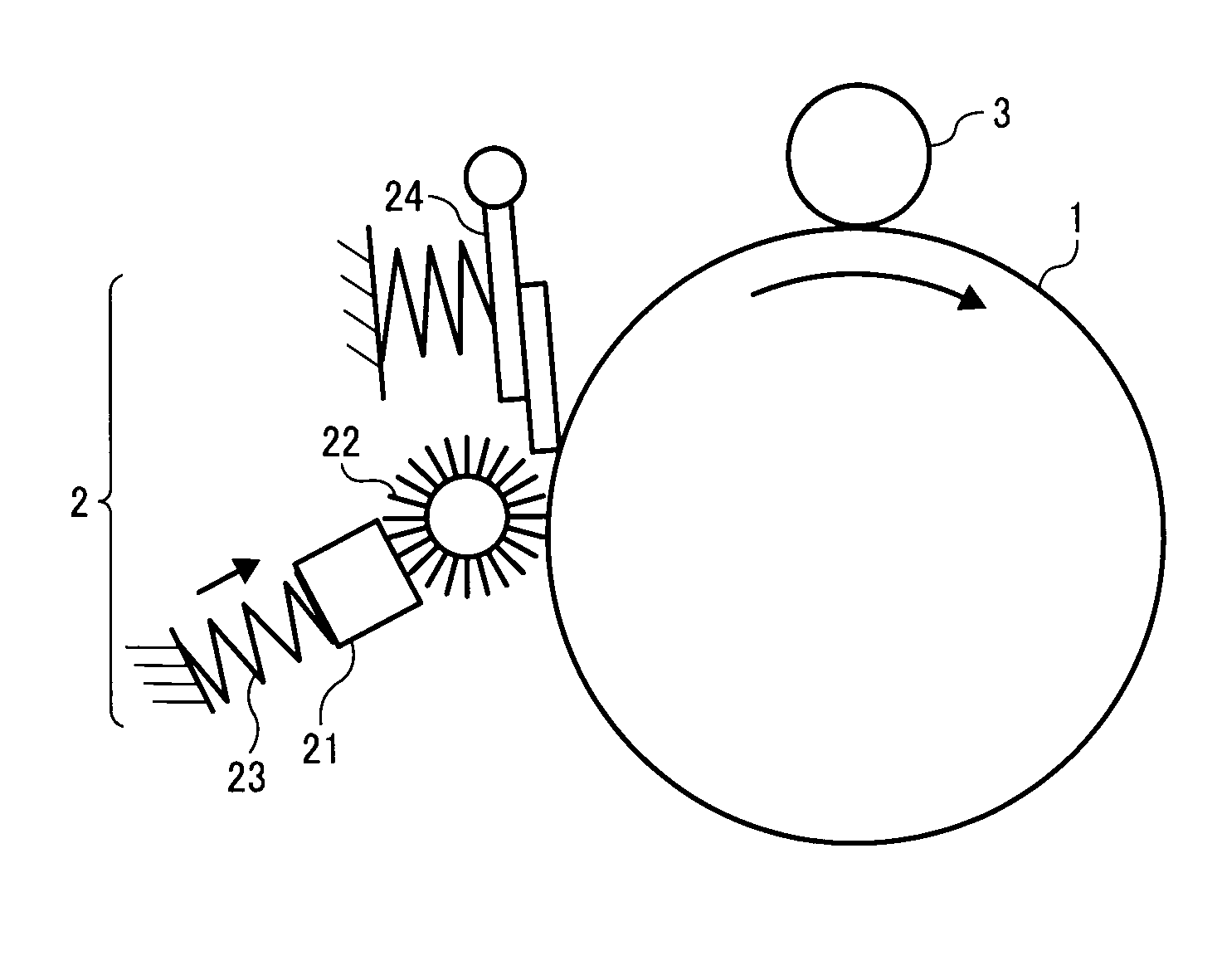

Protective material and image forming apparatus using the protective material

A protective material block including a metal soap, wherein the surface of the protective material block has an X-ray diffraction pattern wherein a ratio (P2 / P1) of a maximum peak height (P2) on a surface separation of from 3.6 to 5.0 Å to a maximum peak height (P1) on a surface separation of from 11 to 16 Å not greater than 0.5.

Owner:RICOH KK

Mesoporous material with active metals

A process for treating organic compounds includes providing a composition which includes a substantially mesoporous structure of refractory oxide containing at least 97% by volume of pores having a pore size ranging from about 15 Å to about 30 Å and having a micropore volume of at least about 0.01 cc / g, wherein the mesoporous structure has incorporated therewith at least about 0.02% by weight of at least one catalytically and / or chemically active heteroatom selected from the group consisting of Al, Ti, V, Cr, Zn, Fe, Sn, Mo, Ga, Ni, Co, In, Zr, Mn, Cu, Mg, Pd, Pt and W, and the catalyst has an X-ray diffraction pattern with one peak at 0.3° to about 3.5° at 2 theta (θ). The catalyst is contacted with an organic feed under reaction conditions wherein the treating process is selected from alkylation, acylation, oligomerization, selective oxidation, hydrotreating, isomerization, demetalation, catalytic dewaxing, hydroxylation, hydrogenation, ammoximation, isomerization, dehydrogenation, cracking and adsorption.

Owner:LUMMUS TECH INC

Active material for lithium secondary battery, electrode for lithium secondary battery, and lithium secondary battery

ActiveUS20130146808A1Improve discharge capacityCobalt compoundsNon-aqueous electrolyte accumulator electrodesMiller indexX-ray

[Object]There is provided an active material for a lithium secondary battery, which has a high initial efficiency and a high discharge capacity, and particularly has a high discharge capacity at a low temperature (excellent low-temperature characteristic), and a lithium secondary battery using the active material.[Solution]An active material for a lithium secondary battery, which contains a solid solution of a lithium transition metal composite oxide having an α-NaFeO2 crystal structure, wherein the composition ratio of metal elements contained in the solid solution satisfies, Li1+x−yNayCoaNibMncO2+d (0<y≦0.1, 0.4≦c≦0.7, x+a+b+c=1, 0.1≦x≦0.25, −0.2≦d≦0.2), the active material has an X-ray diffraction pattern attributable to a space group R3-m (P3112), and in the Miller index hkl, the half width of the diffraction peak of the (003) is 0.30° or less and the half width of the diffraction peak of the (114) plane is 0.50° or less. Further, the average of three oxygen position parameters determined from crystal structure analysis by the Rietveld method on the basis of the X-ray diffraction pattern is preferably 0.264 or less.

Owner:GS YUASA INT LTD

Coated cutting tool and method for producing the same

ActiveUS20080057280A1Improve fracture resistanceReduce machining accuracyPigmenting treatmentOther chemical processesX-rayWear resistance

Provided are a coated cutting tool having excellent wear resistance and excellent resistance to chipping as well as excellent fracture resistance such that the coated cutting tool is unlikely to cause backward movement of the tool edge position due to wear or chipping, and a method for producing the same.A coated cutting tool comprising a base material having a surface coated with a coating film, wherein the coating film comprises at least one layer comprised of a TiCN columnar crystal film, wherein the TiCN columnar crystal film has an average grain size of 0.05 to 0.5 μm, as measured in the direction parallel to the surface of the base material, and exhibits an X-ray diffraction pattern having a peak at a diffraction angle 2θ in the range of from 121.5 to 122.6° wherein the peak is ascribed to the (422) crystal facet of the TiCN columnar crystal as measured using CuKα radiation.

Owner:TUNGALOY CORP

X-ray target and apparatuses using the same

InactiveUS7551722B2Electron beam absorptivitySmall in focus sizeX-ray tube laminated targetsImaging devicesHigh intensityX ray analysis

Owner:JAPAN SCI & TECH CORP

Material for activating epidermal cell multiplication

InactiveUS6440740B1Improve propertiesEpidermal cells/skin cellsArtificial cell constructsAdhesion processCell adhesion

The present invention provides a novel material for activating epidermal cell multiplication on which not only effective adhesion and multiplication of human and mammalian epidermal cells is accomplished also intercellular adhesion is promoted to form a plain cellular layer. The present invention provides a material for activating epidermal cell multiplication which contains silk fibroin of alpha-type or alpha-helix X-ray diffraction pattern as a principal constituent. The present material fulfills the principal requirements for activating epidermal cells of greatly improved cellular adhesion rate, multiplication, intercellular adhesion and growth of cell layers.

Owner:NAT INST OF AGROBIOLOGICAL SCI

Lithium composite metal oxide and nonaqueous electrolyte secondary battery

ActiveUS20090280412A1High capacity retentionIncrease productionActive material electrodesNon-aqueous electrolyte accumulator electrodesLithiumX-ray

The present invention provides a lithium composite metal oxide containing Li and at least one transition metal element, wherein at least one lithium composite metal oxide particle constituting the lithium composite metal oxide has both hexagonal and monoclinic crystal structures. Further, the present invention also provides a lithium composite metal oxide containing Li, Ni and M (where, M represents one or more kinds of transition metal elements selected from the group consisting of Mn, Co and Fe), having a diffraction peak (diffraction peak A) at an angle 2θ in a range from 20° to 23° in a powder X-ray diffraction pattern of a lithium composite metal oxide which is obtained by powder X-ray diffraction measurement made in the condition that CuKα is used as a radiation source and the measurement range of diffraction angle 2θ is in a range from 10° to 90°.

Owner:SUMITOMO CHEM CO LTD

Negative electrode for nonaqueous electrolyte secondary battery, method for producing same, and nonaqueous electrolyte secondary battery

InactiveUS20120164530A1Easy to insertEasy extractionElectrode carriers/collectorsNegative electrodesX-rayGraphite particle

An object of the invention is to provide a negative electrode capable of improving the large current characteristics of a nonaqueous electrolyte secondary battery while maintaining the battery capacity. A negative electrode includes a sheet-like current collector and a negative electrode mixture layer disposed on a surface of the current collector. The negative electrode mixture layer includes graphite particles and ceramic particles interposed between the graphite particles. The mean particle size of the ceramic particles is smaller than that of the graphite particles. In an X-ray diffraction pattern of the negative electrode mixture layer, the ratio R of the intensity I110 of a peak attributed to a (110) plane of the graphite particles to the intensity I002 of a peak attributed to a (002) plane, i.e., the ratio I110 / I002, is 0.05 or more. The negative electrode mixture layer has a density of 1.1 to 1.8 g / cm3.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com