Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

232results about How to "Improved cycle life characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium-sulfur batteries

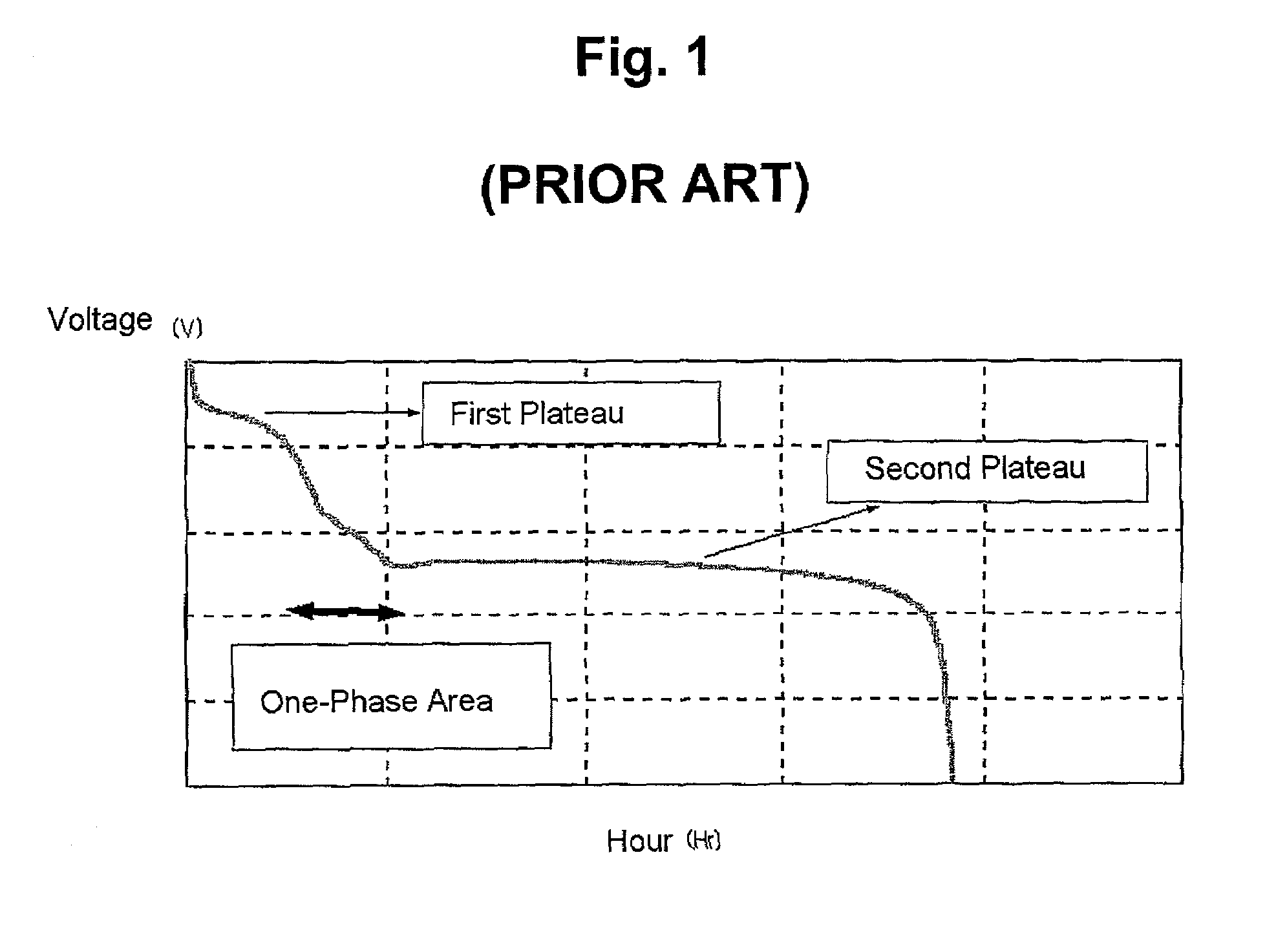

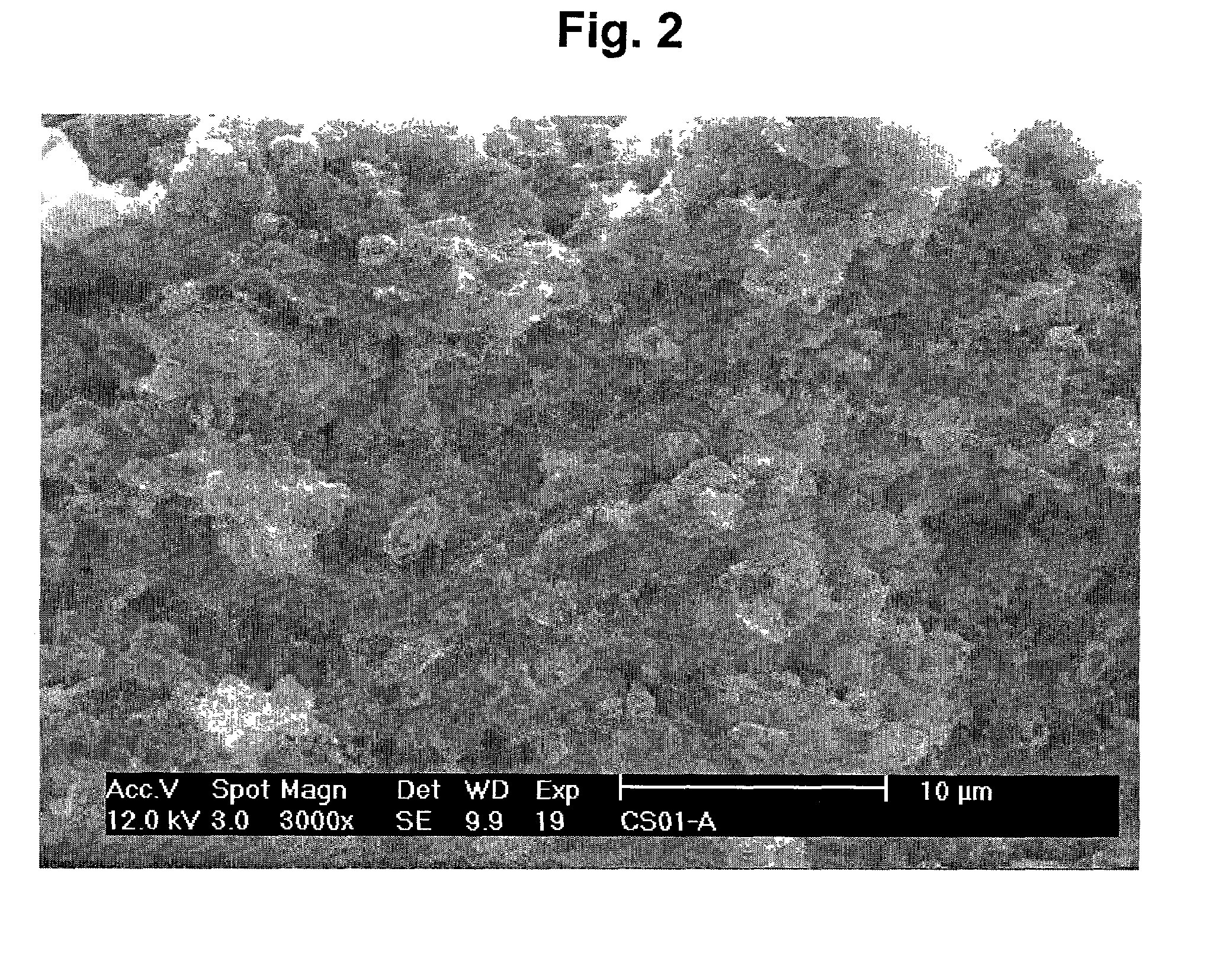

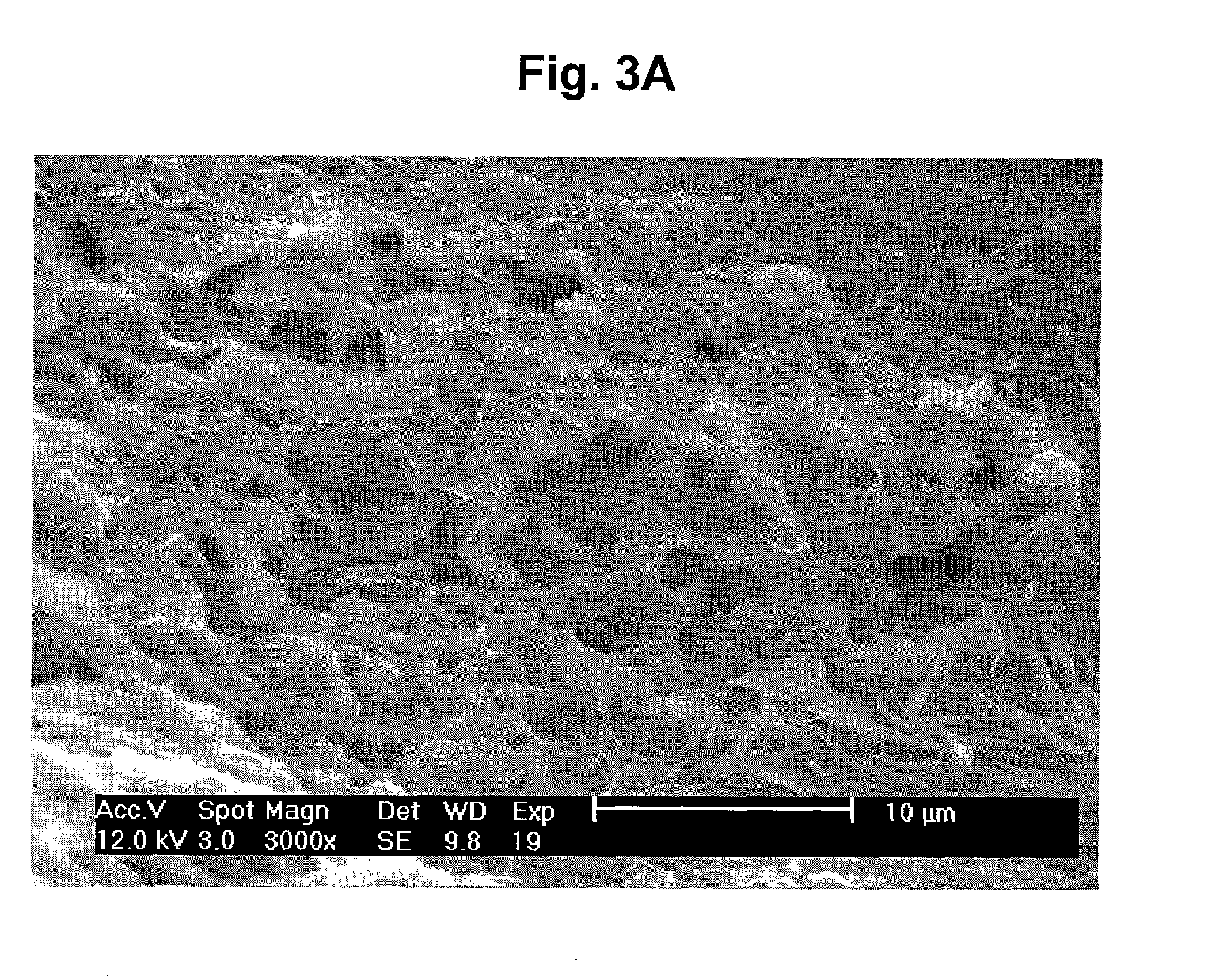

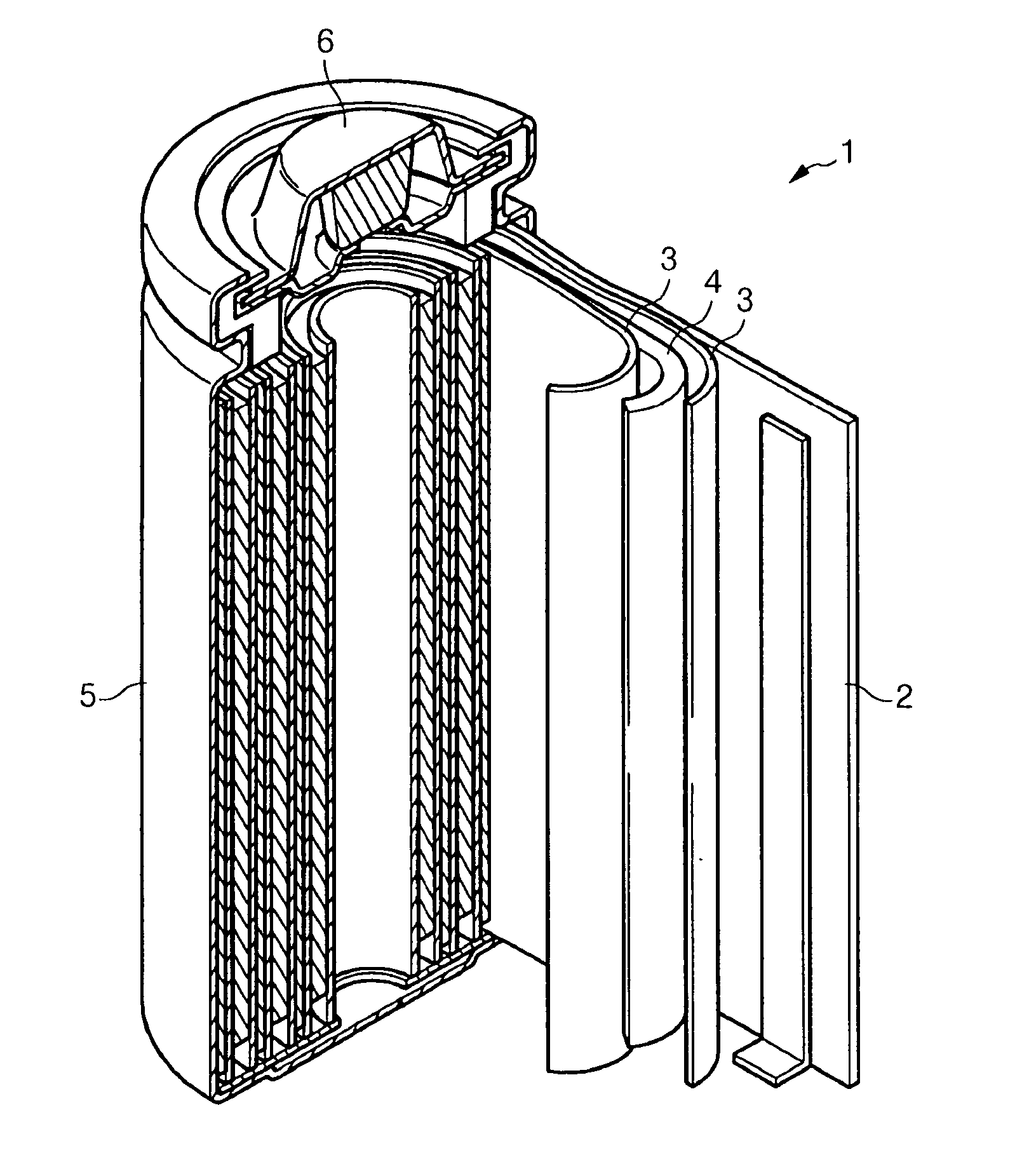

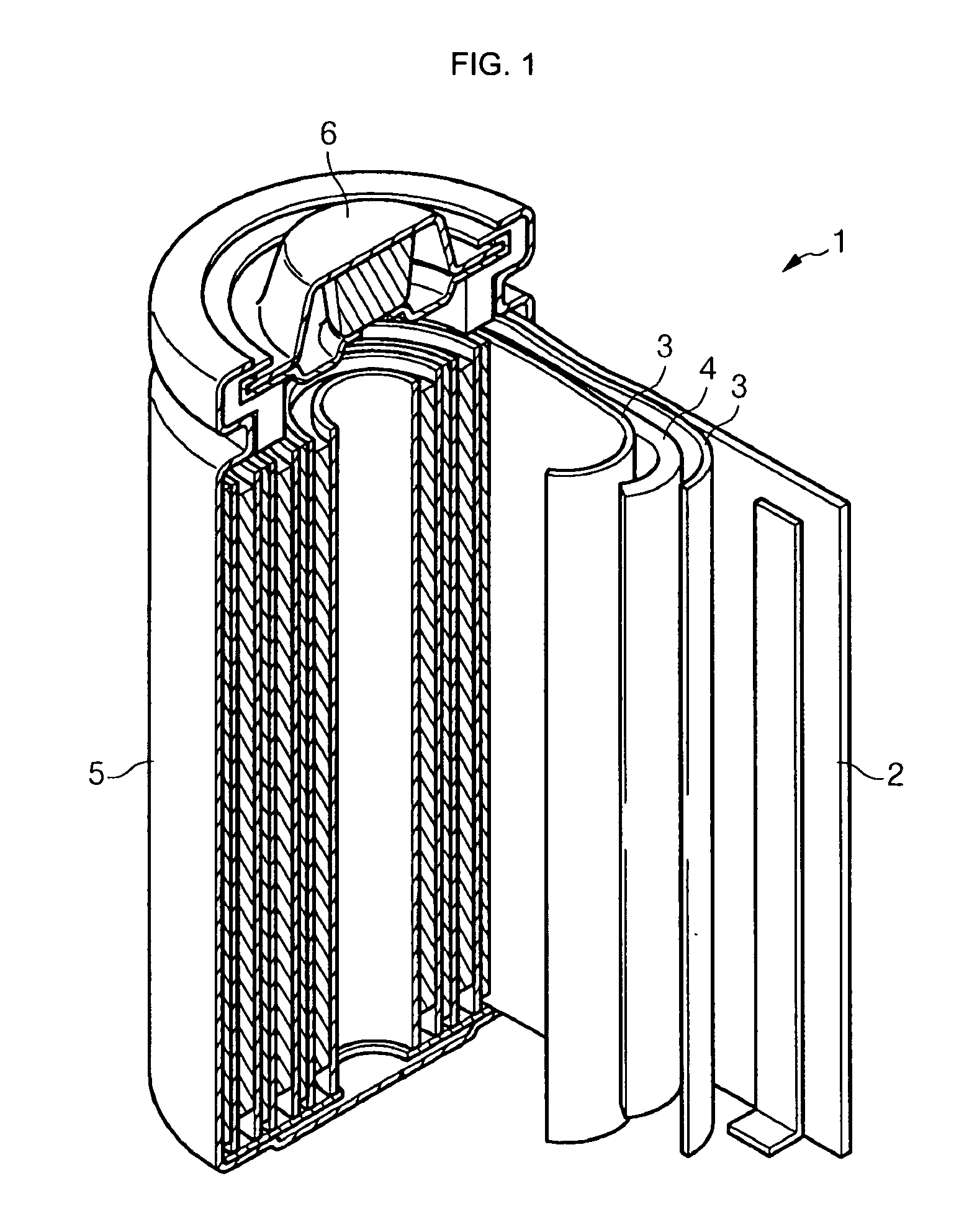

InactiveUS7250233B2Improved cycle life characteristicsElectrochemical processing of electrodesFinal product manufactureElectrochemical responseLithium–sulfur battery

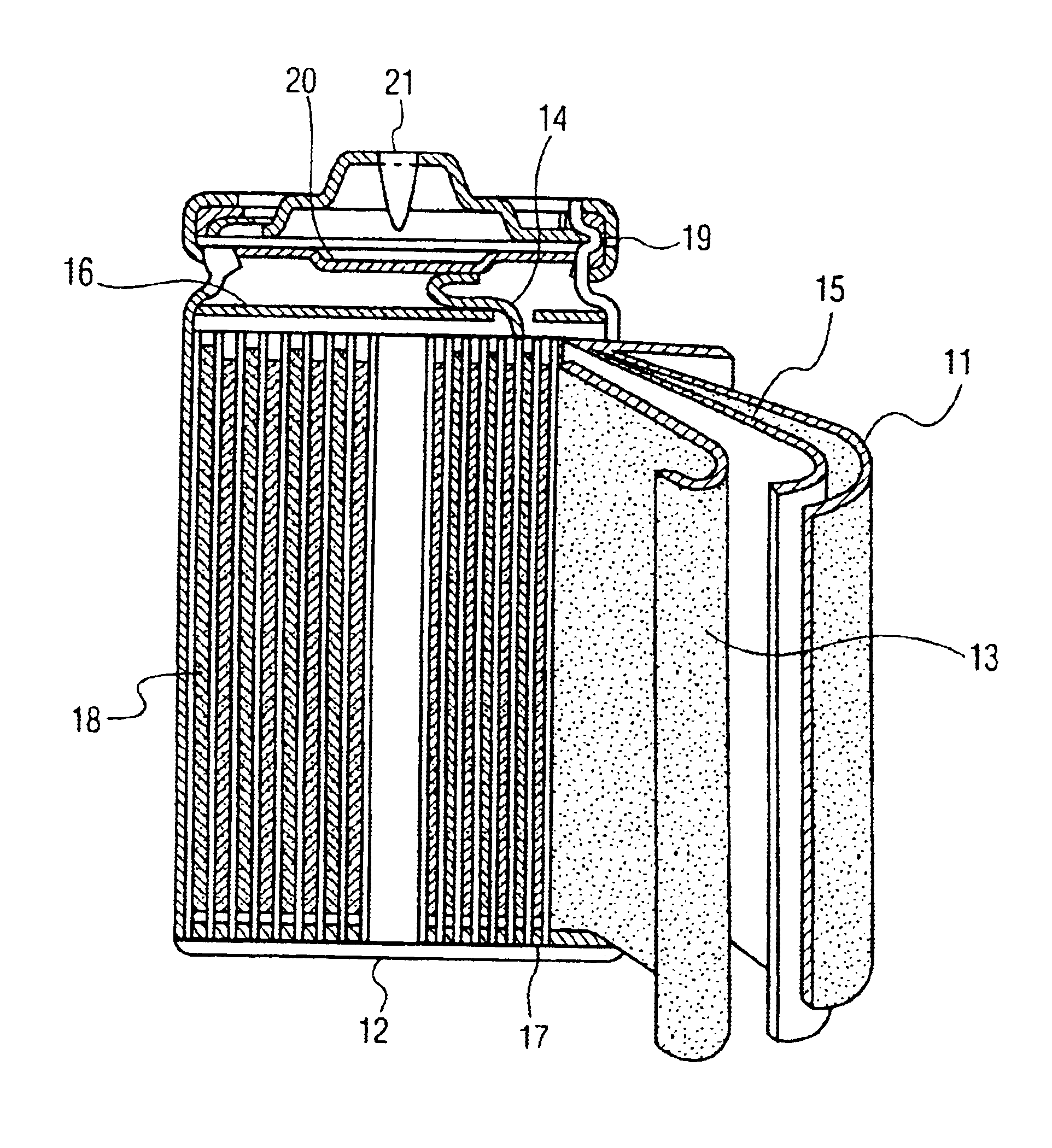

A lithium-sulfur battery having a positive electrode including a positive active material including an active sulfur, where the positive electrode comprises an electron-conductive path and an ion-conductive path, and includes active pores of the average size of up to 20 μm having both electron-conductive and ion-conductive properties, and are filled with the active sulfur during an electrochemical reaction of the battery.

Owner:SAMSUNG SDI CO LTD

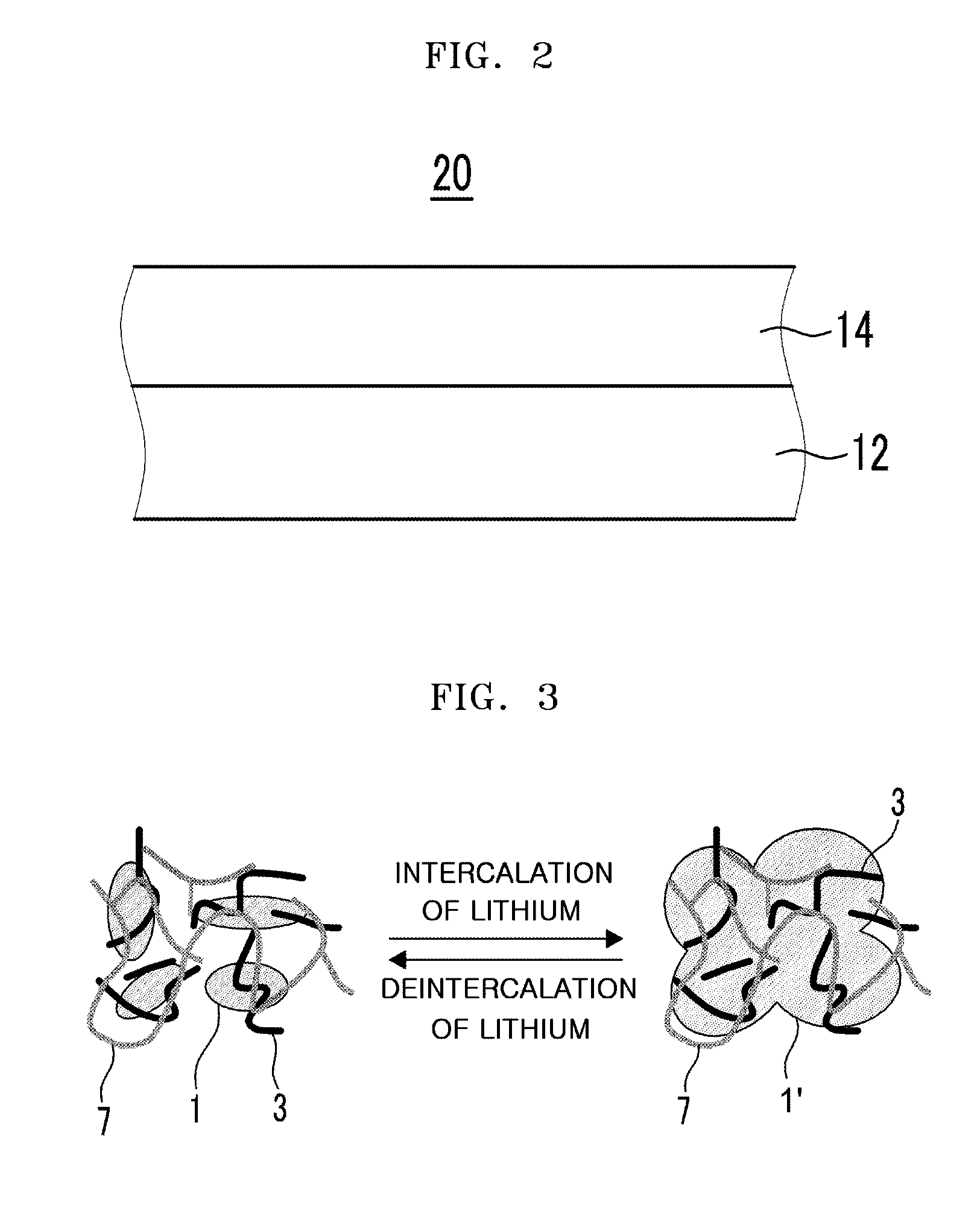

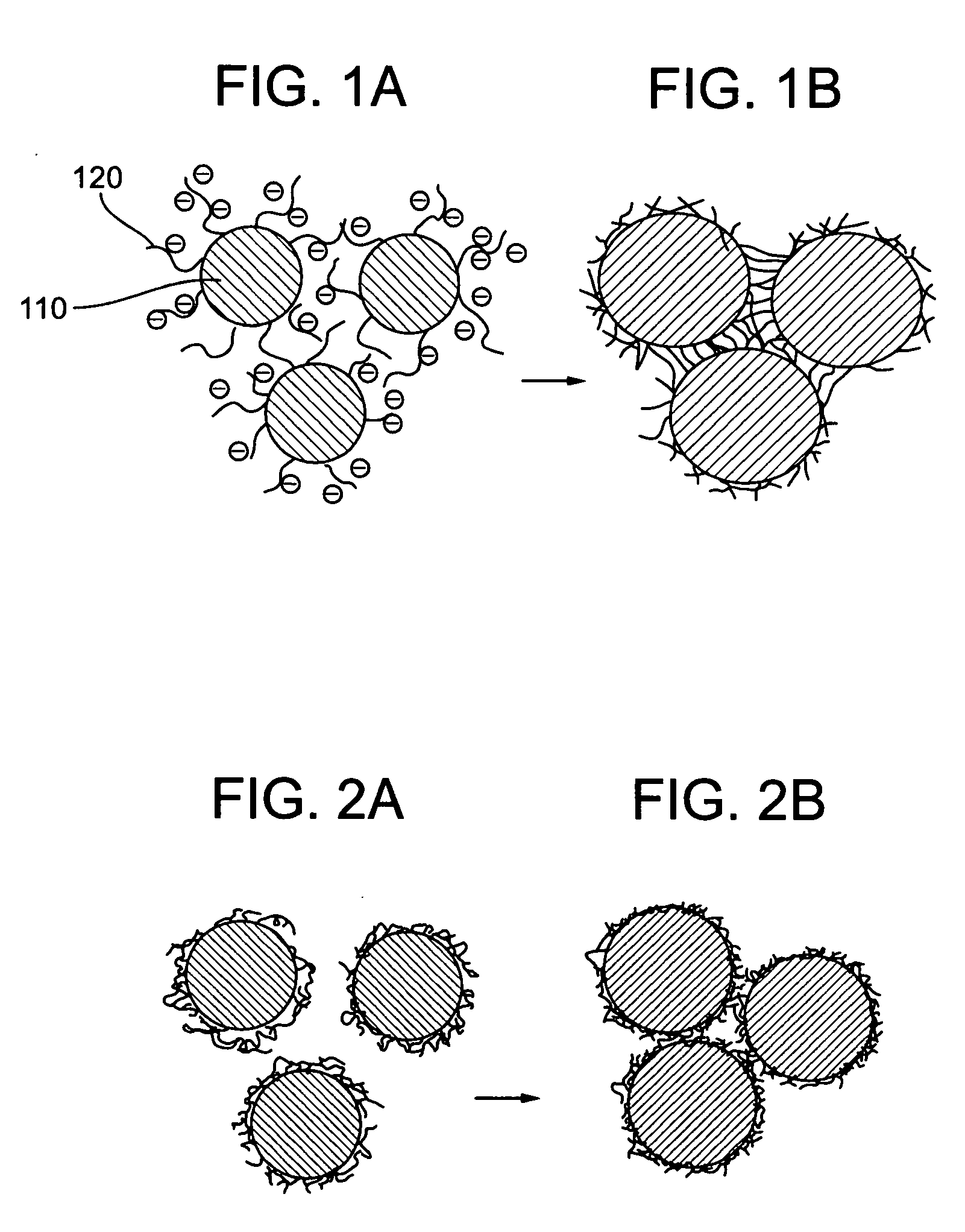

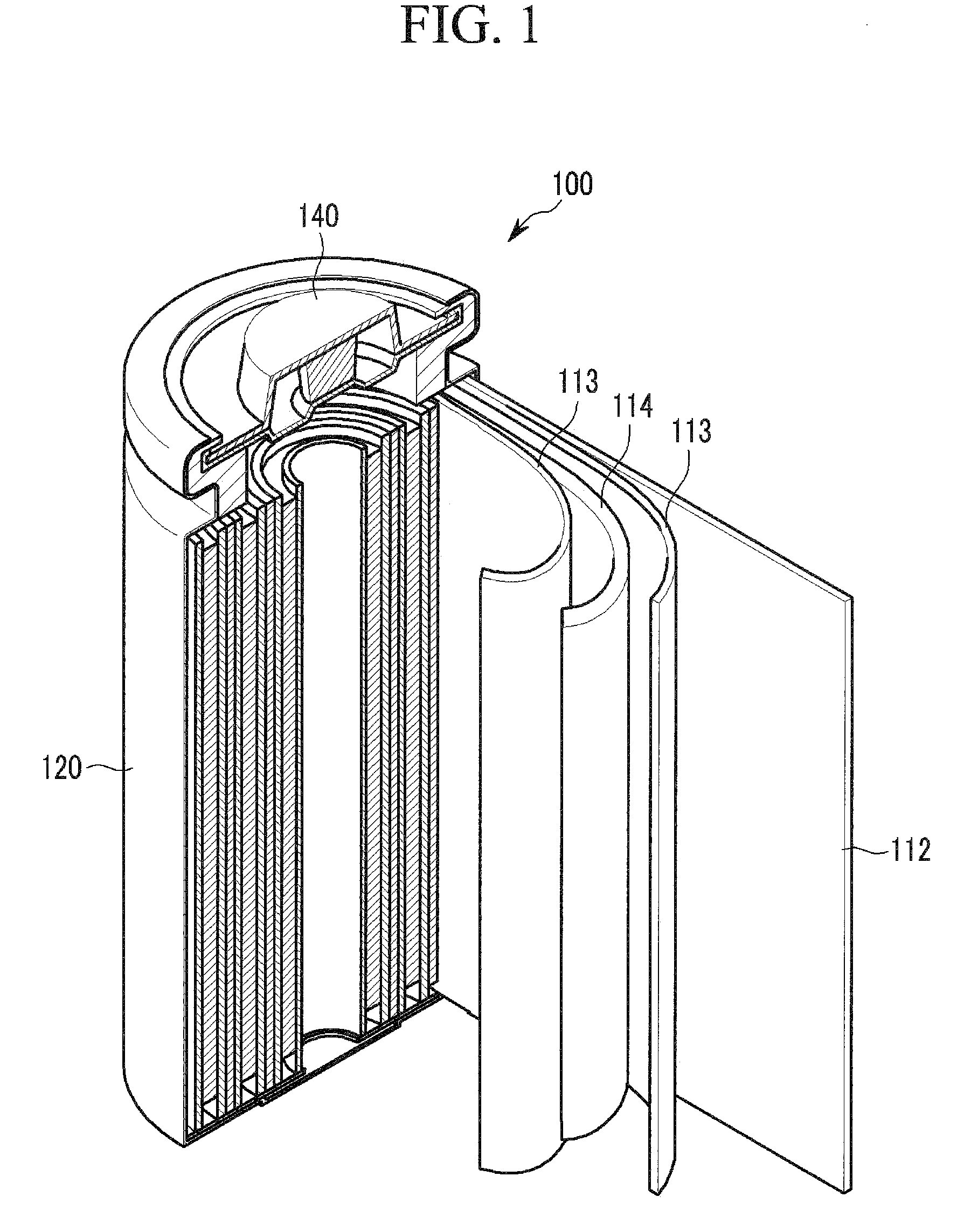

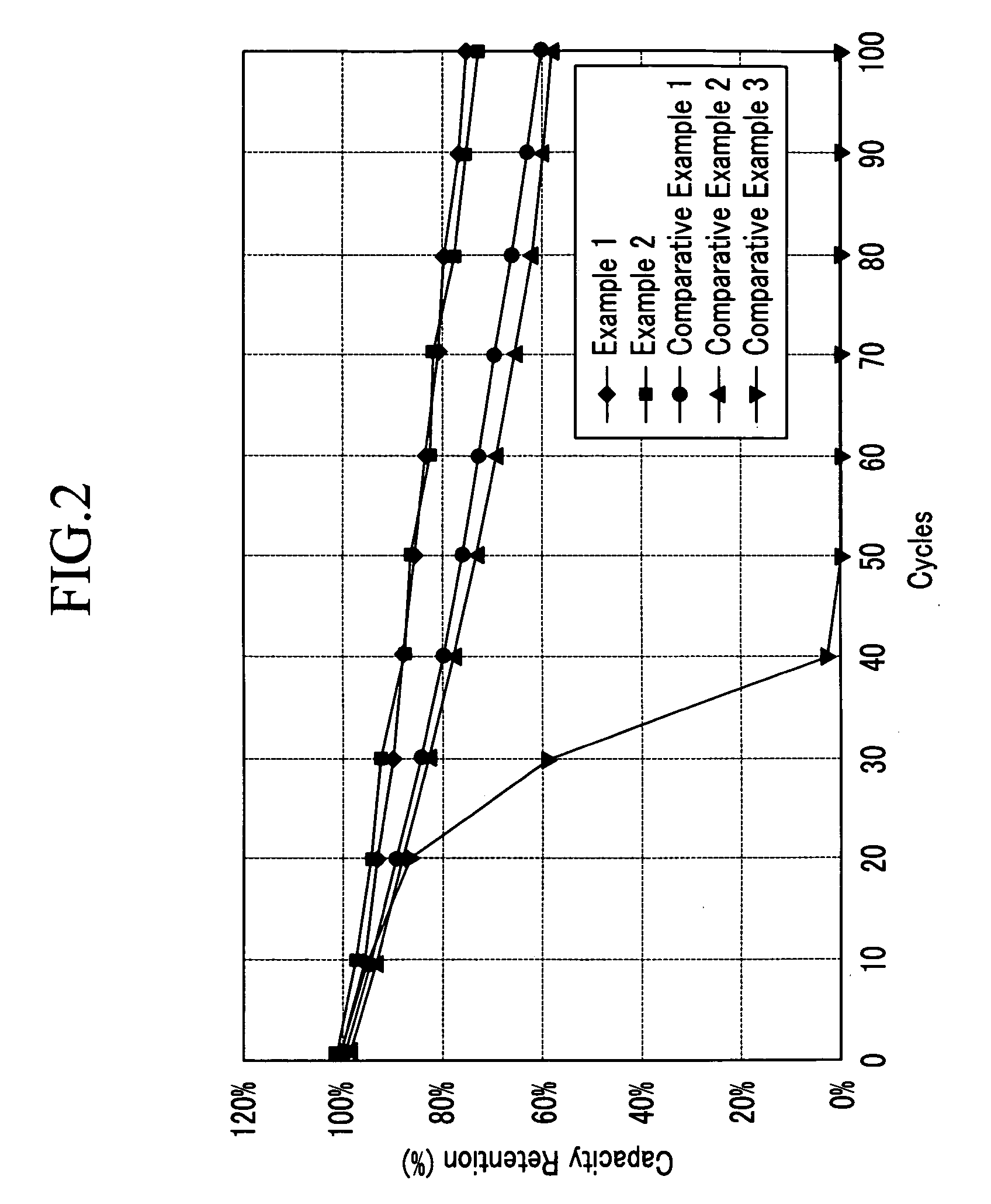

Active material for rechargeable lithium battery and rechargeable lithium battery including same

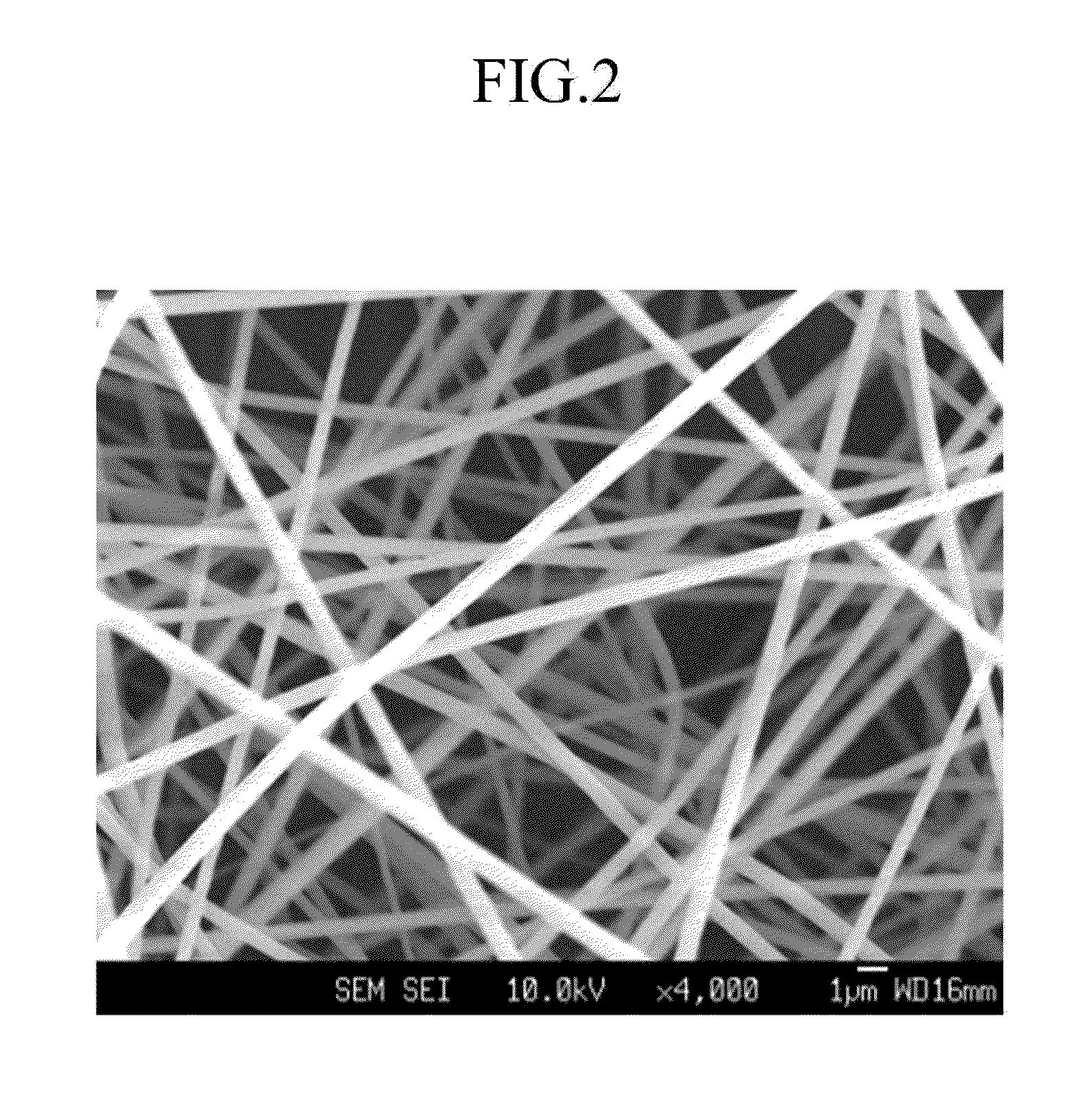

InactiveUS20080038635A1Improved cycle life characteristicsImprove conductivityMaterial nanotechnologyElectrode manufacturing processesFiberEngineering

The present invention relates to an active material for a rechargeable lithium battery and a rechargeable lithium battery including the same. The active material includes an active material and a fiber-shaped or tube-shaped carbon conductive material attached to the surface of the active material. The active material includes a conductive shell including a fiber-shaped or tube-shaped carbon conductive material and increases discharge capacity due to improved conductivity and improves cycle-life efficiency by maintaining paths between active material particles during charge and discharge cycles.

Owner:SAMSUNG SDI CO LTD

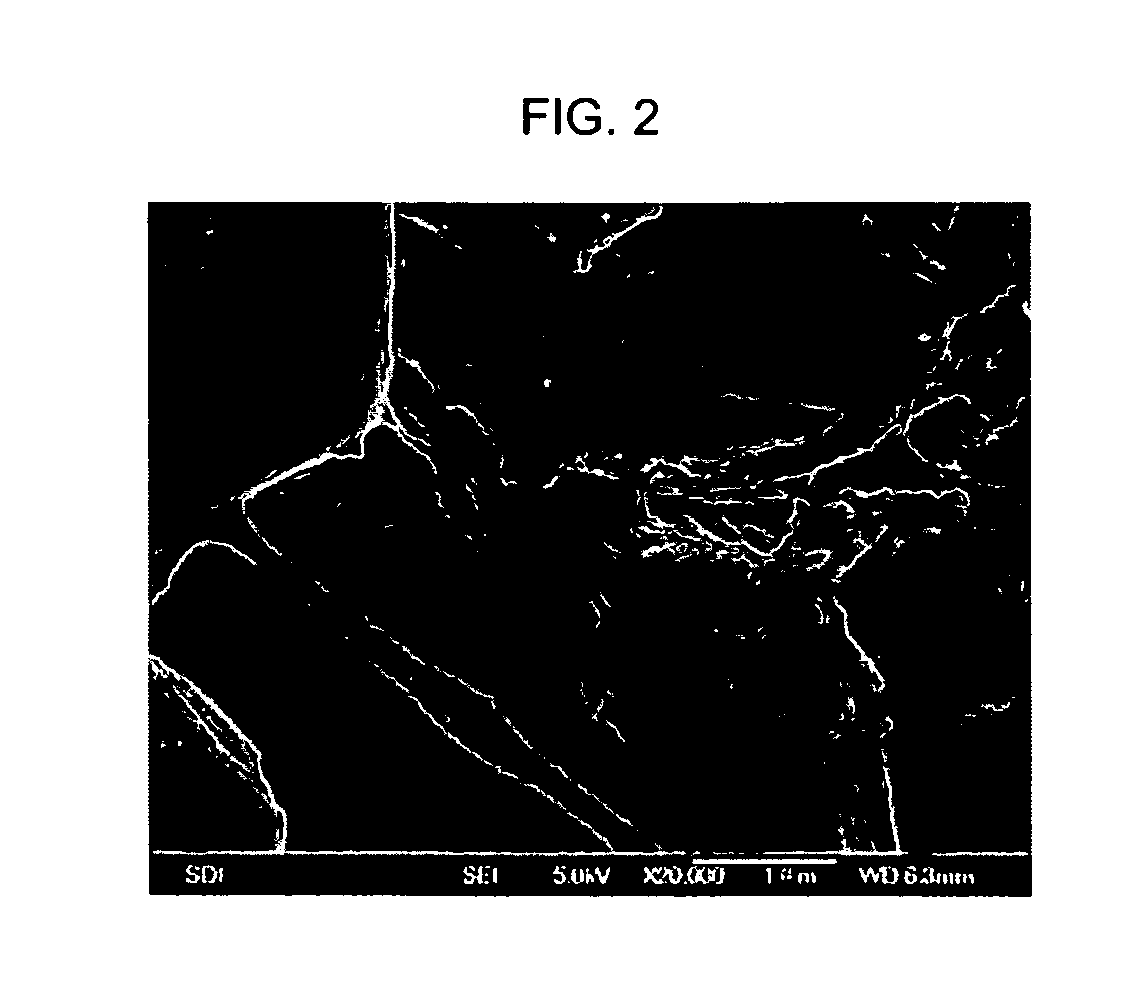

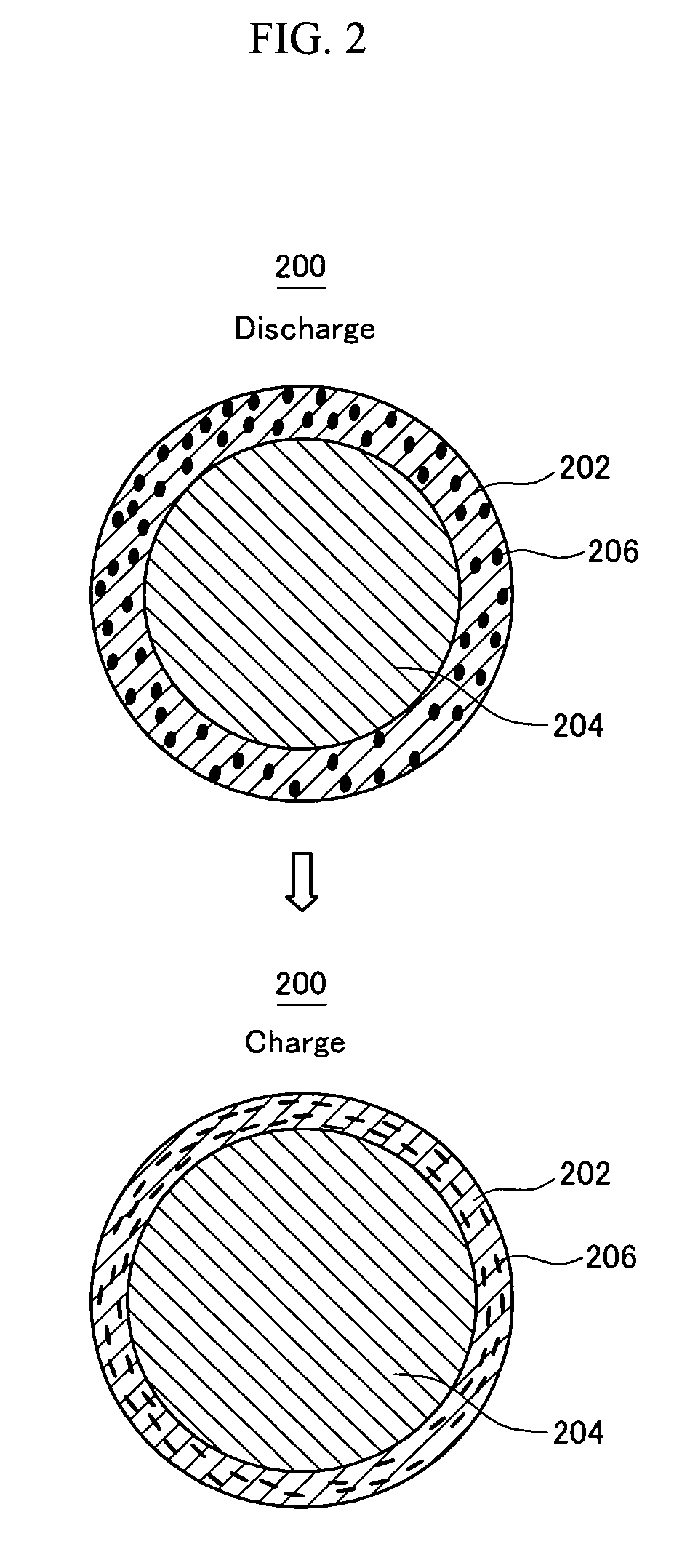

Negative active material for rechargeable lithium battery, method of preparing same and rechargeable lithium battery including same

InactiveUS20070099085A1Excellent reversible characteristicImproved cycle life characteristicsNegative electrodesNon-aqueous electrolyte accumulator electrodesEngineeringLithium battery

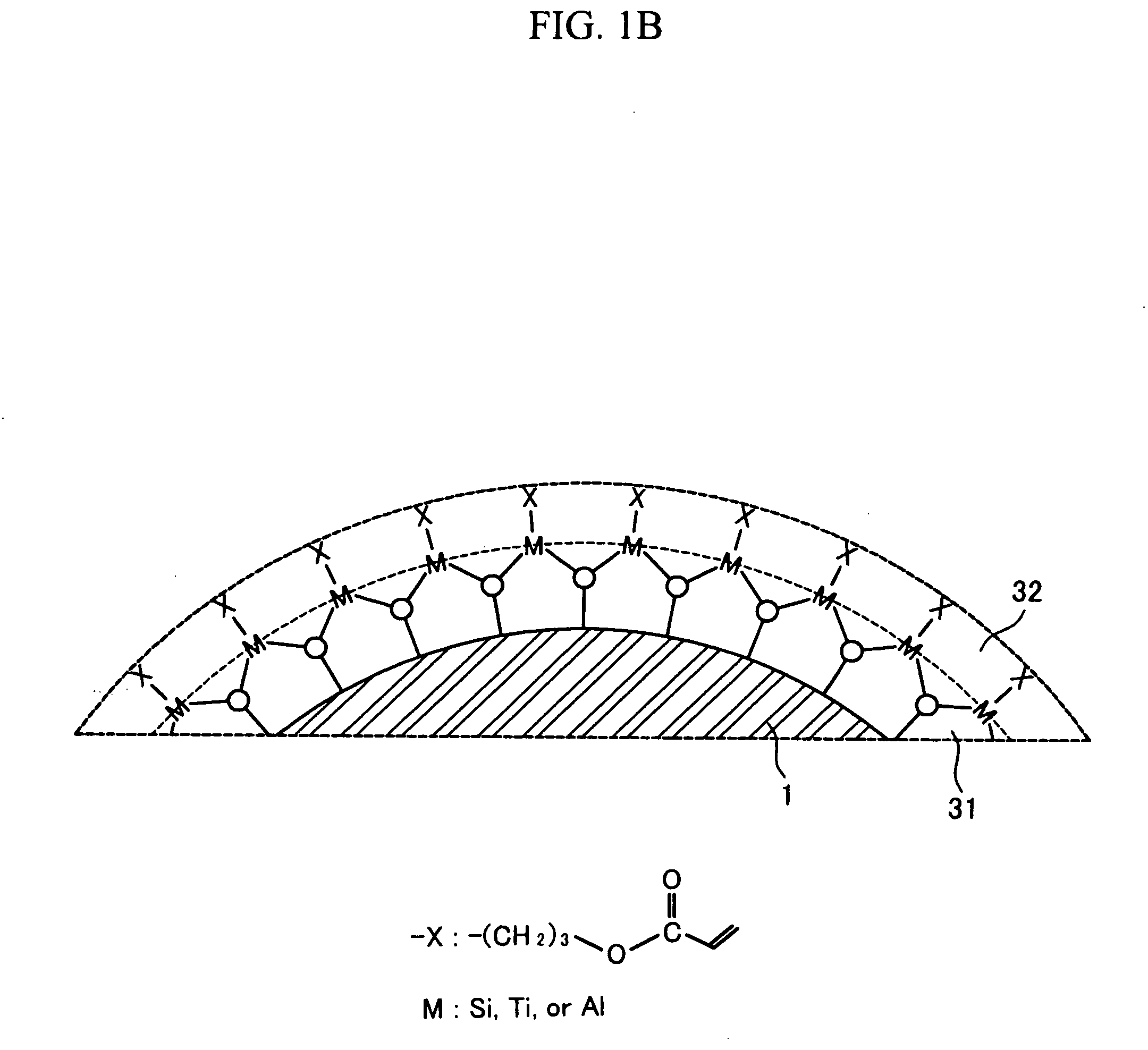

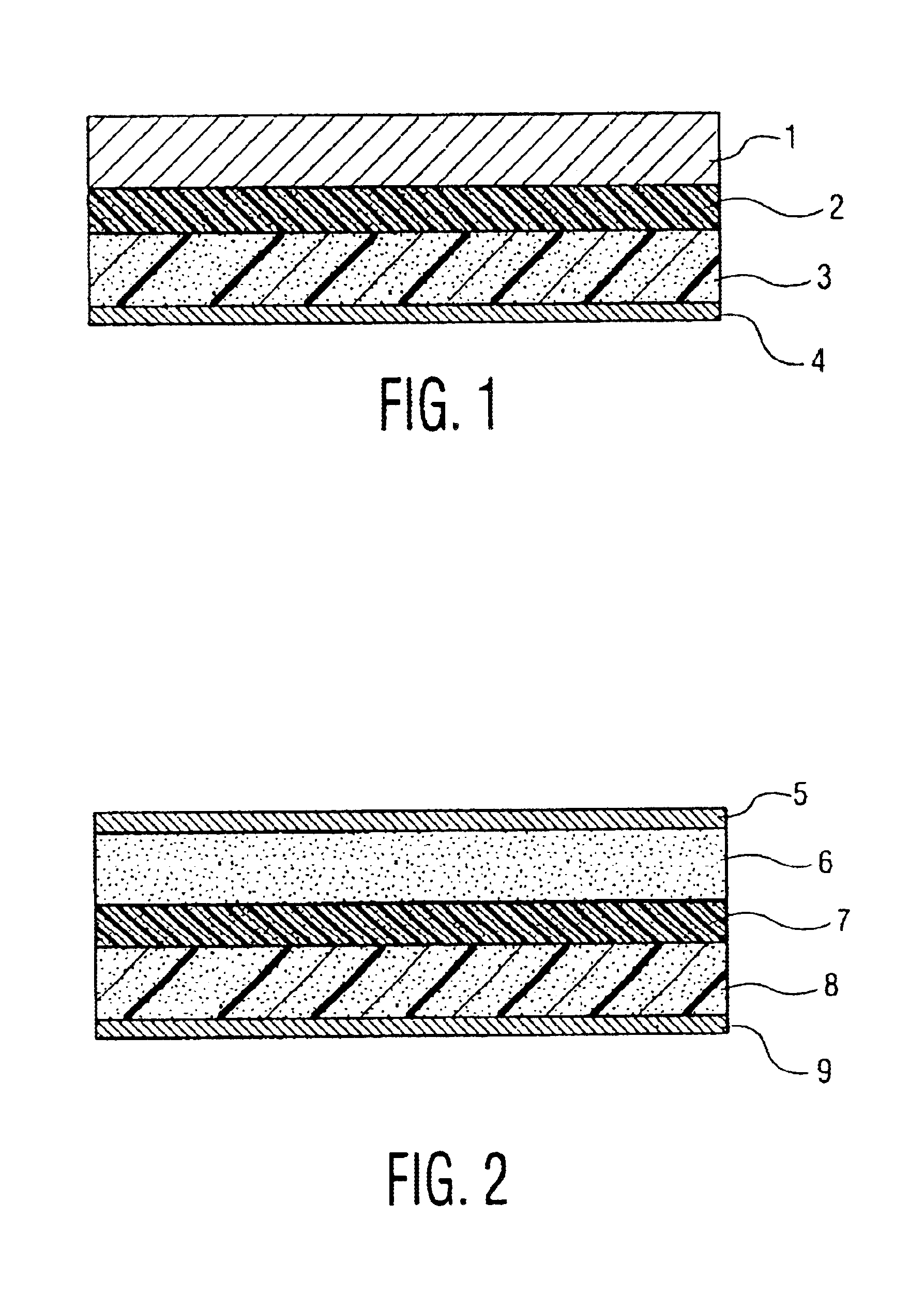

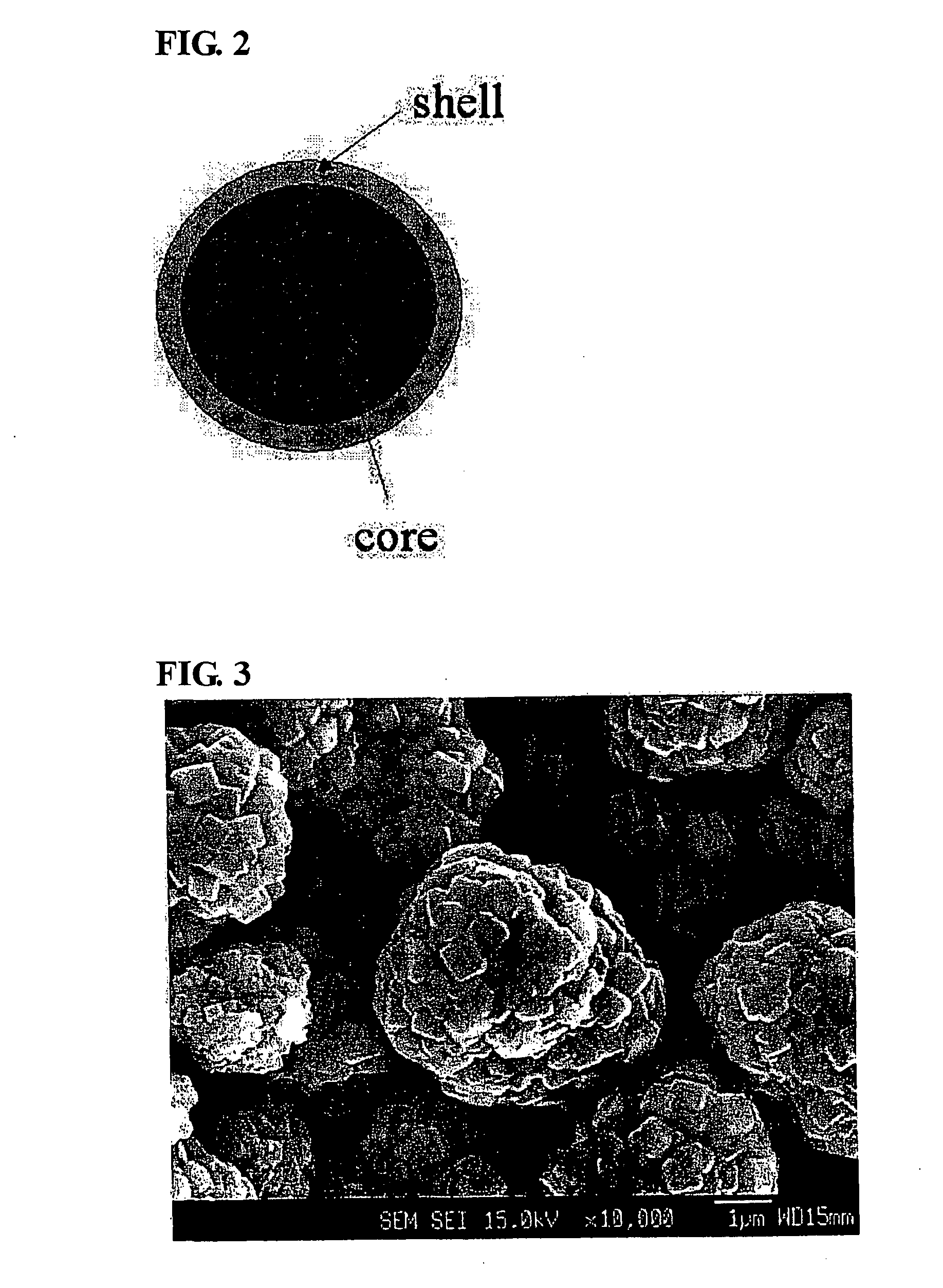

The present invention relates to negative active materials for rechargeable lithium batteries, manufacturing methods thereof, and rechargeable lithium batteries including the negative active materials. A negative active material for a rechargeable lithium battery includes a core including a material capable of carrying out reversible oxidation and reduction reactions and a coating layer formed on the core. The coating layer has a reticular structure.

Owner:SAMSUNG SDI CO LTD

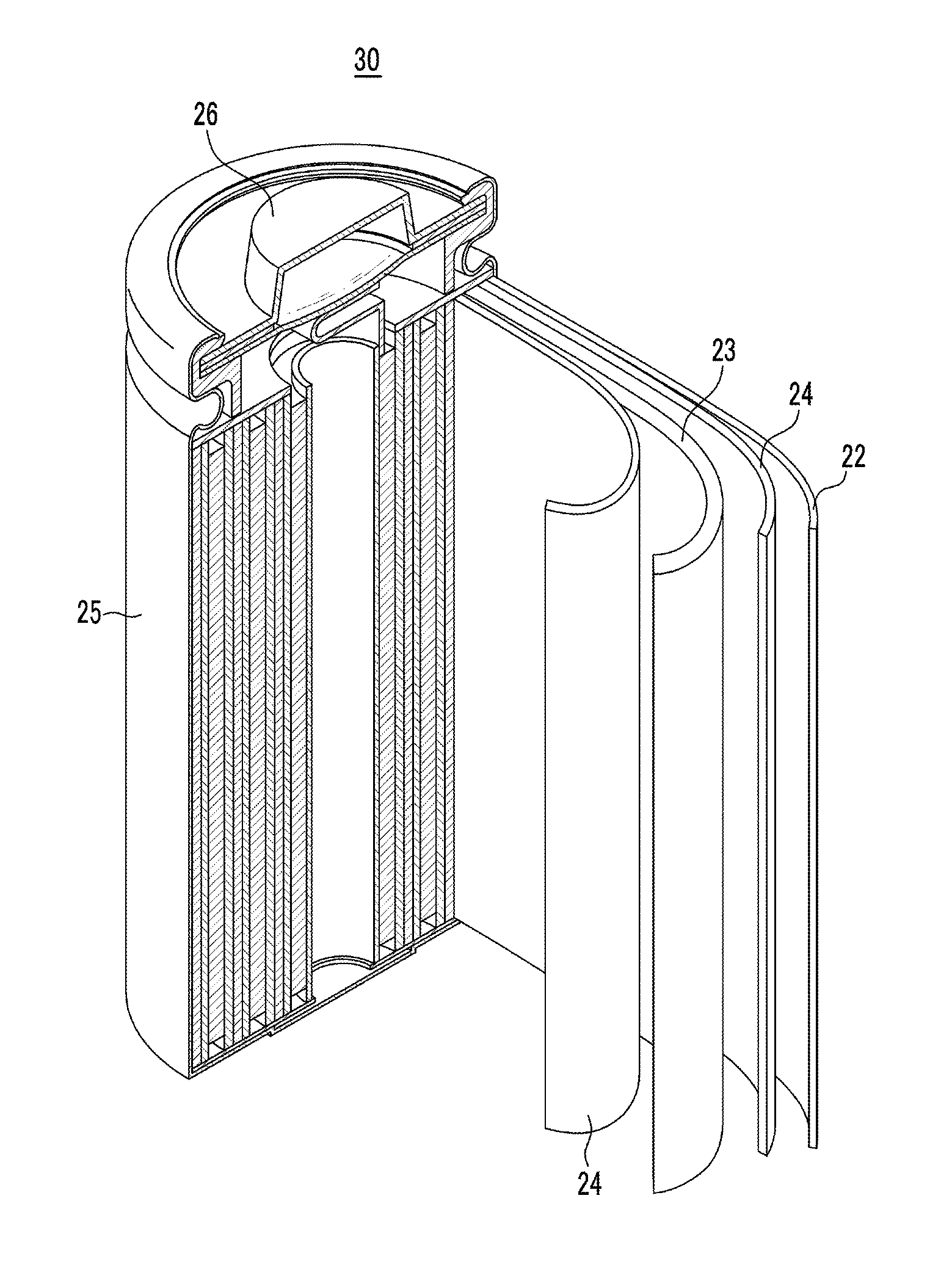

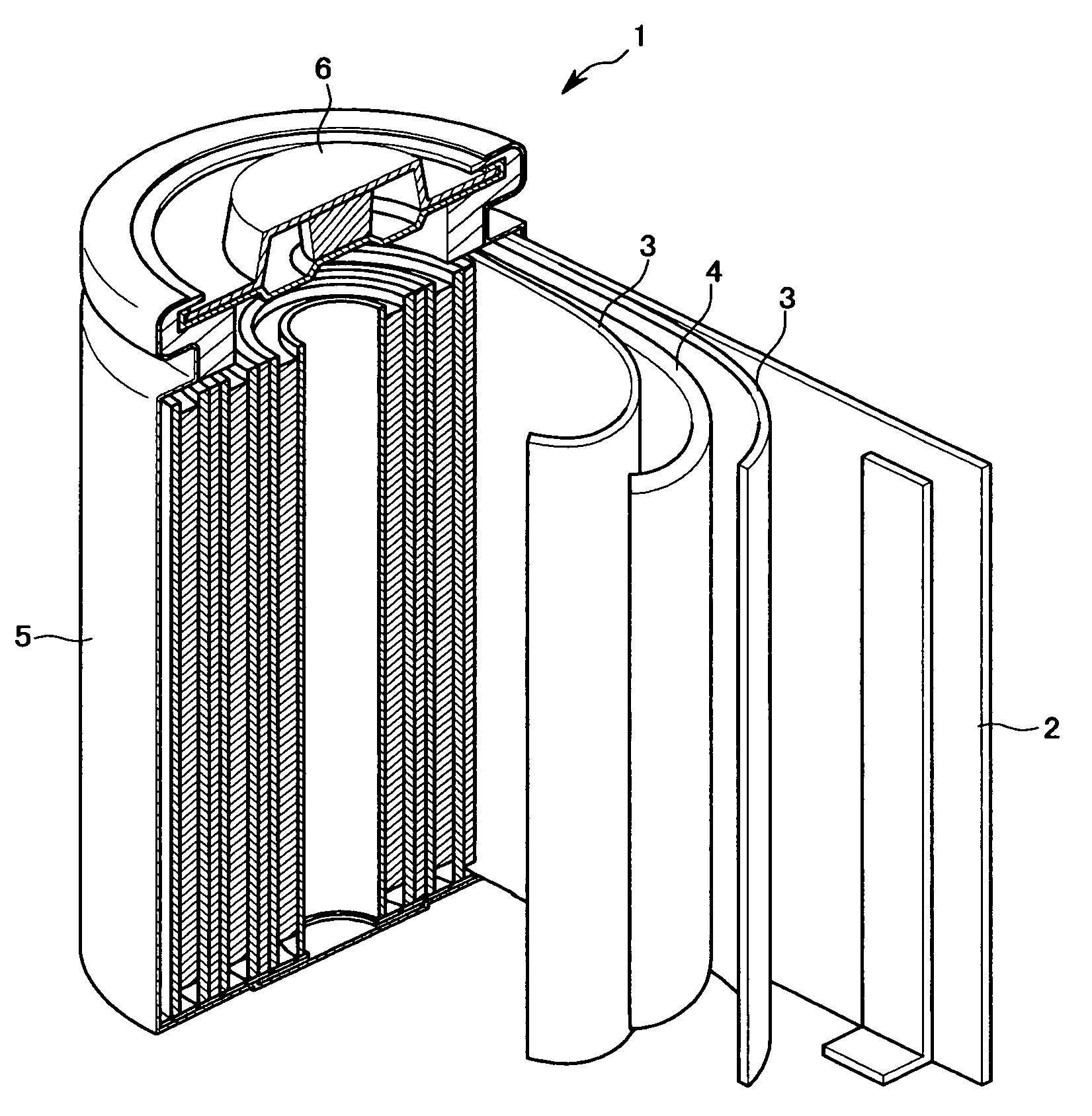

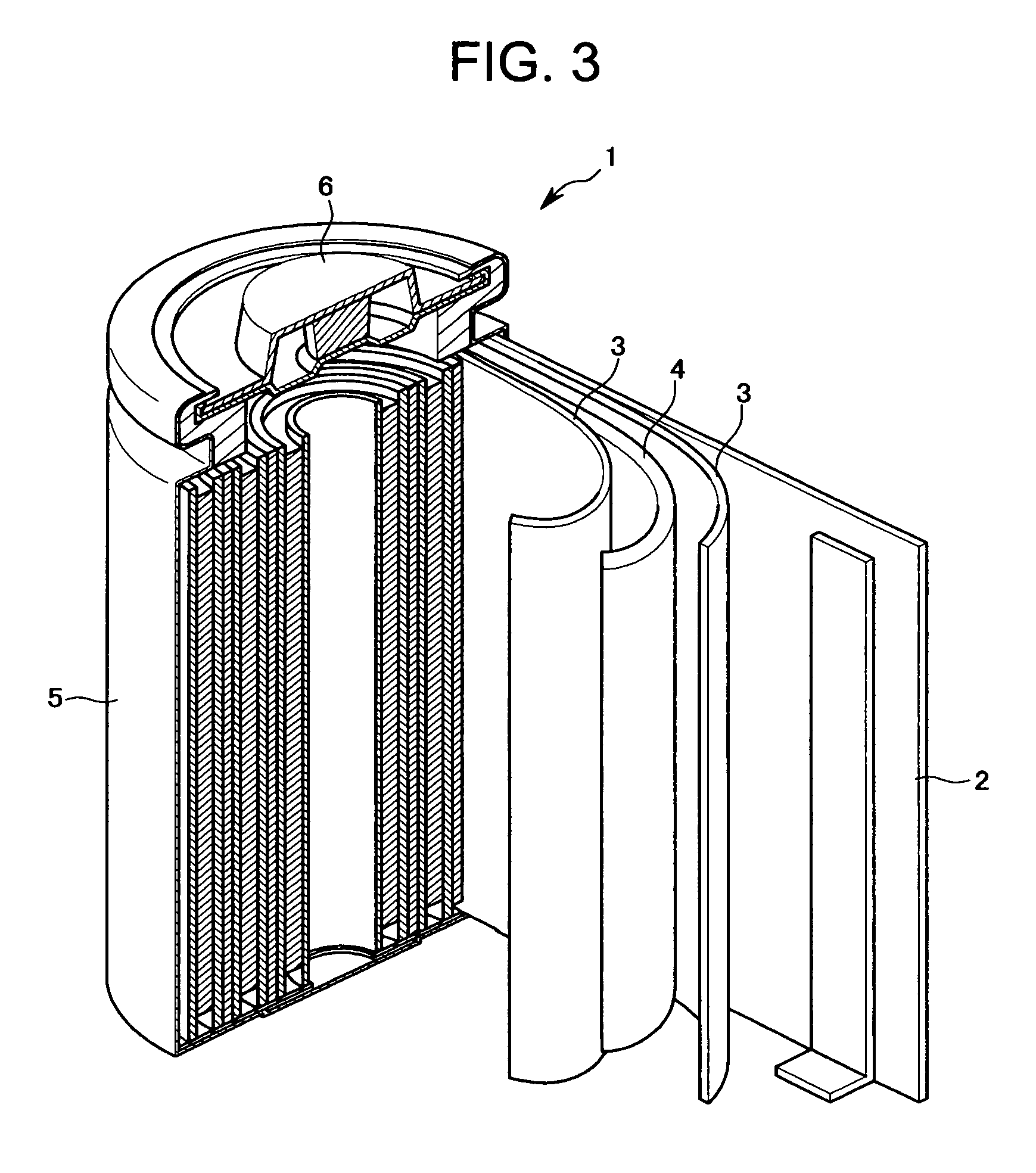

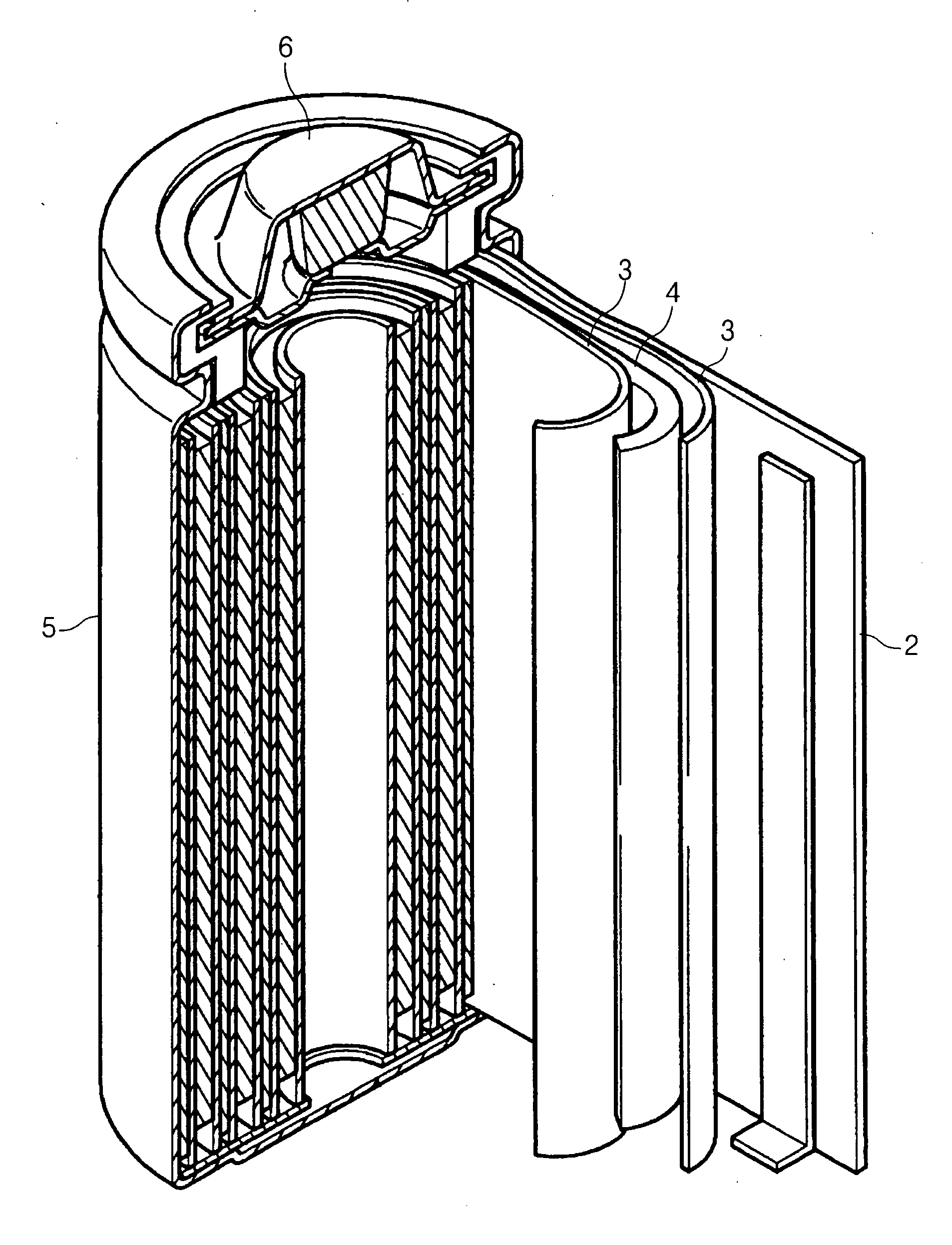

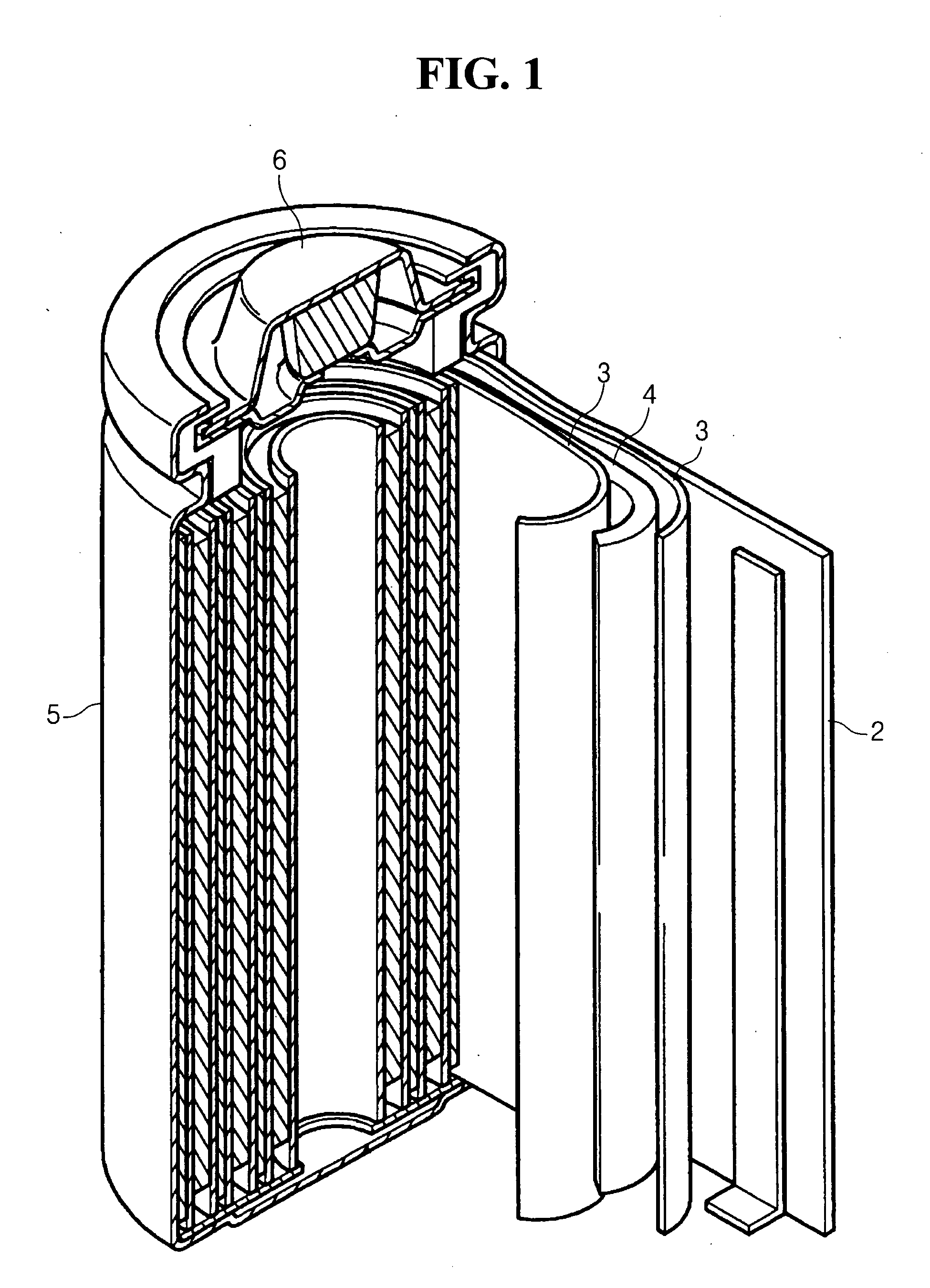

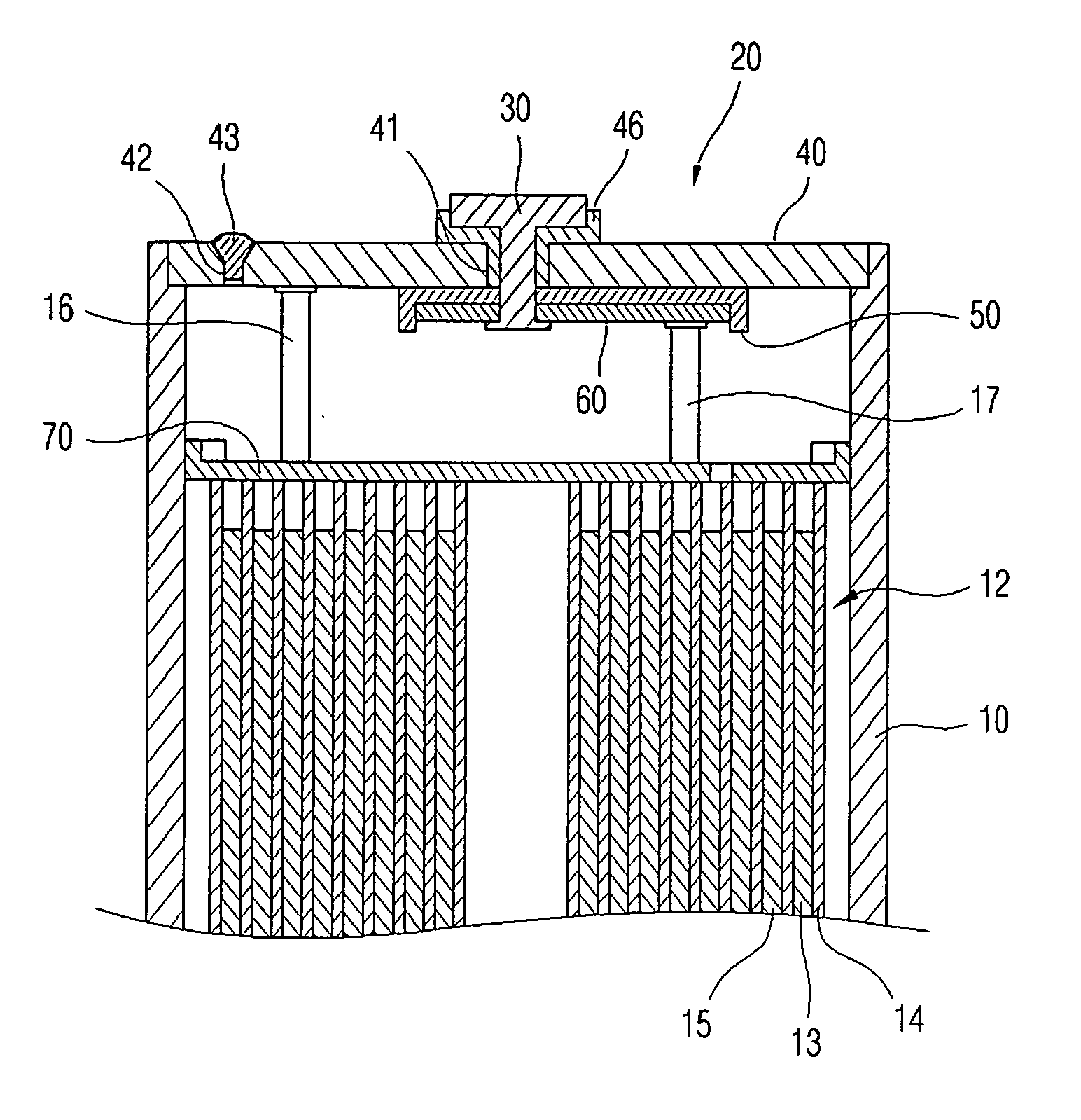

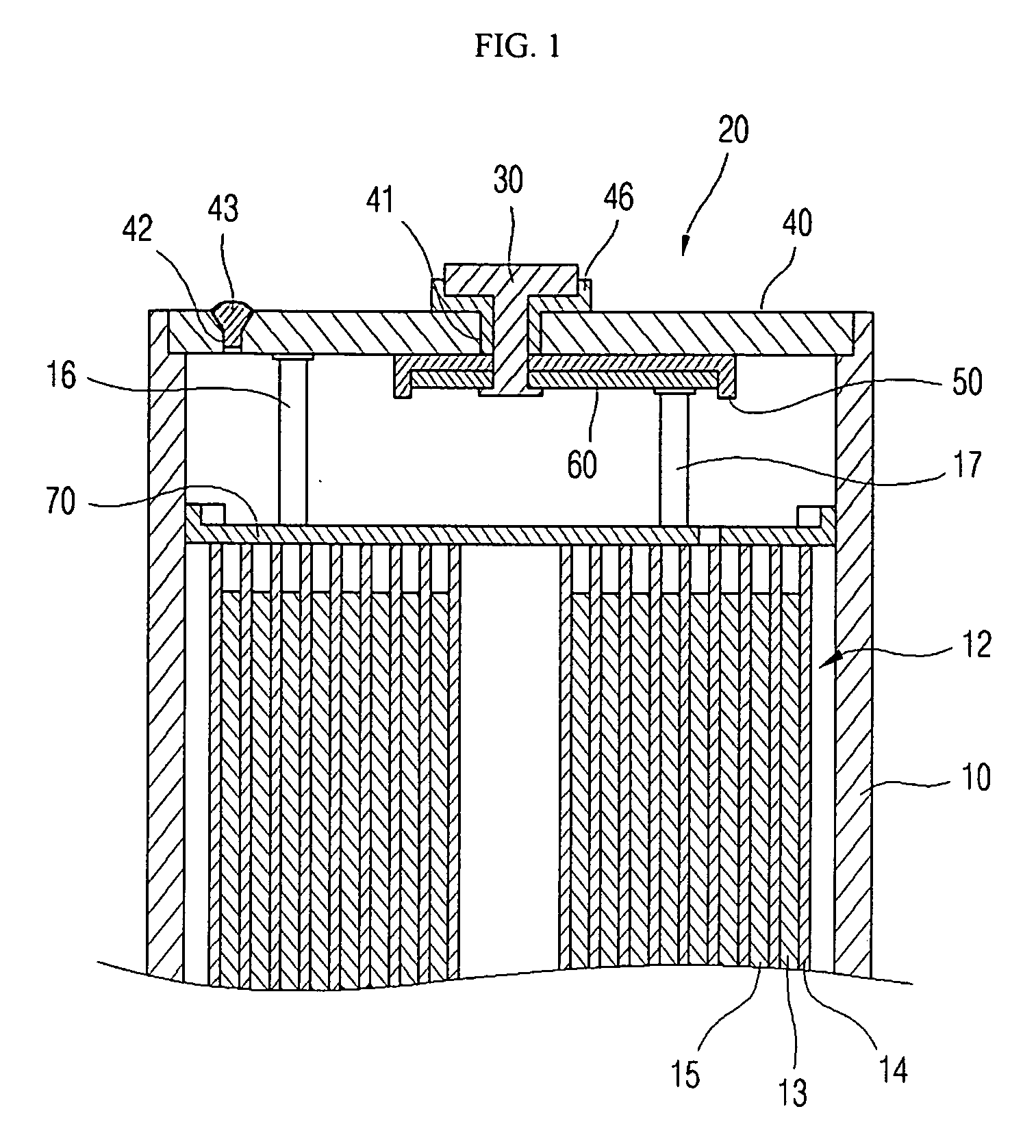

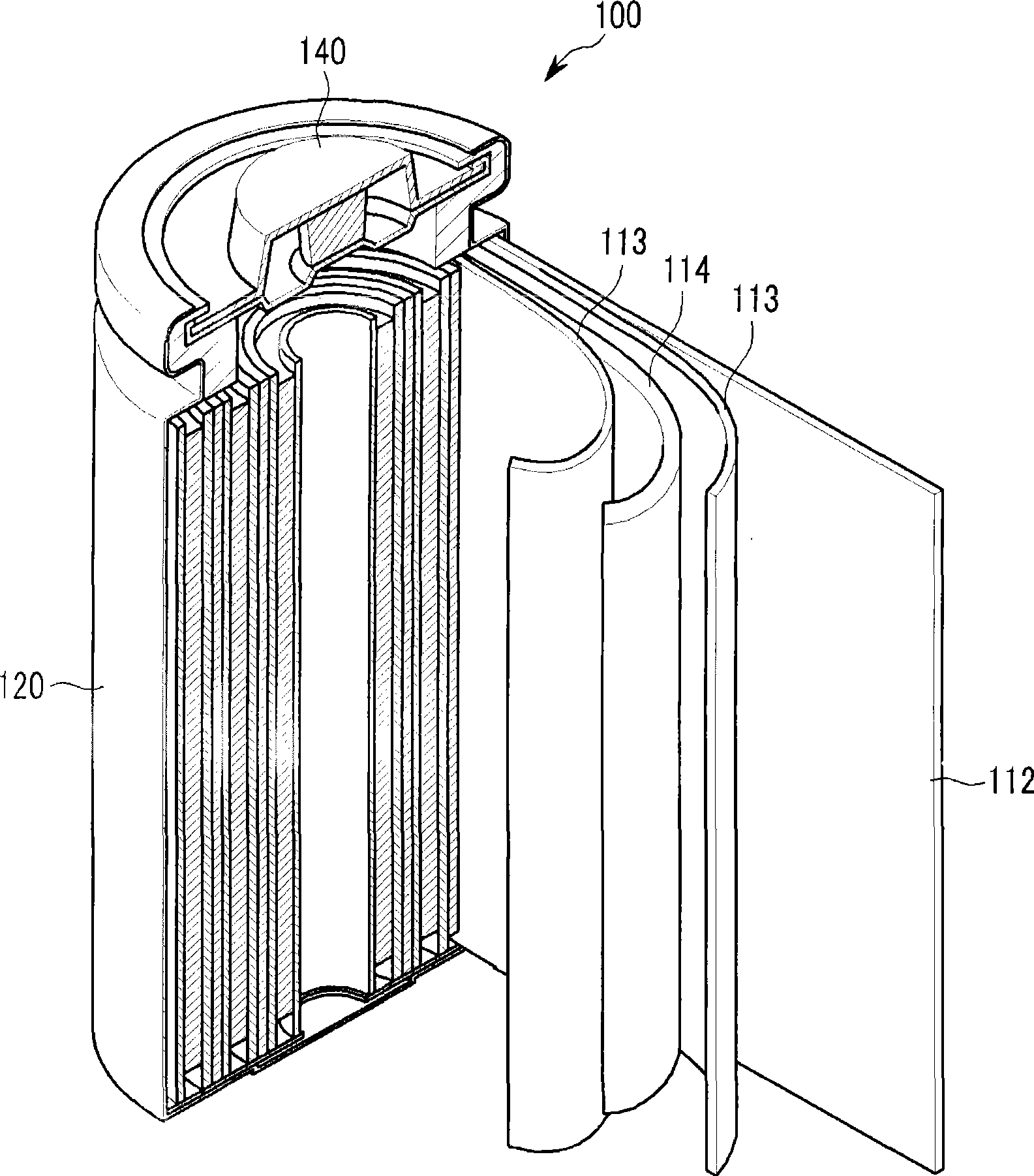

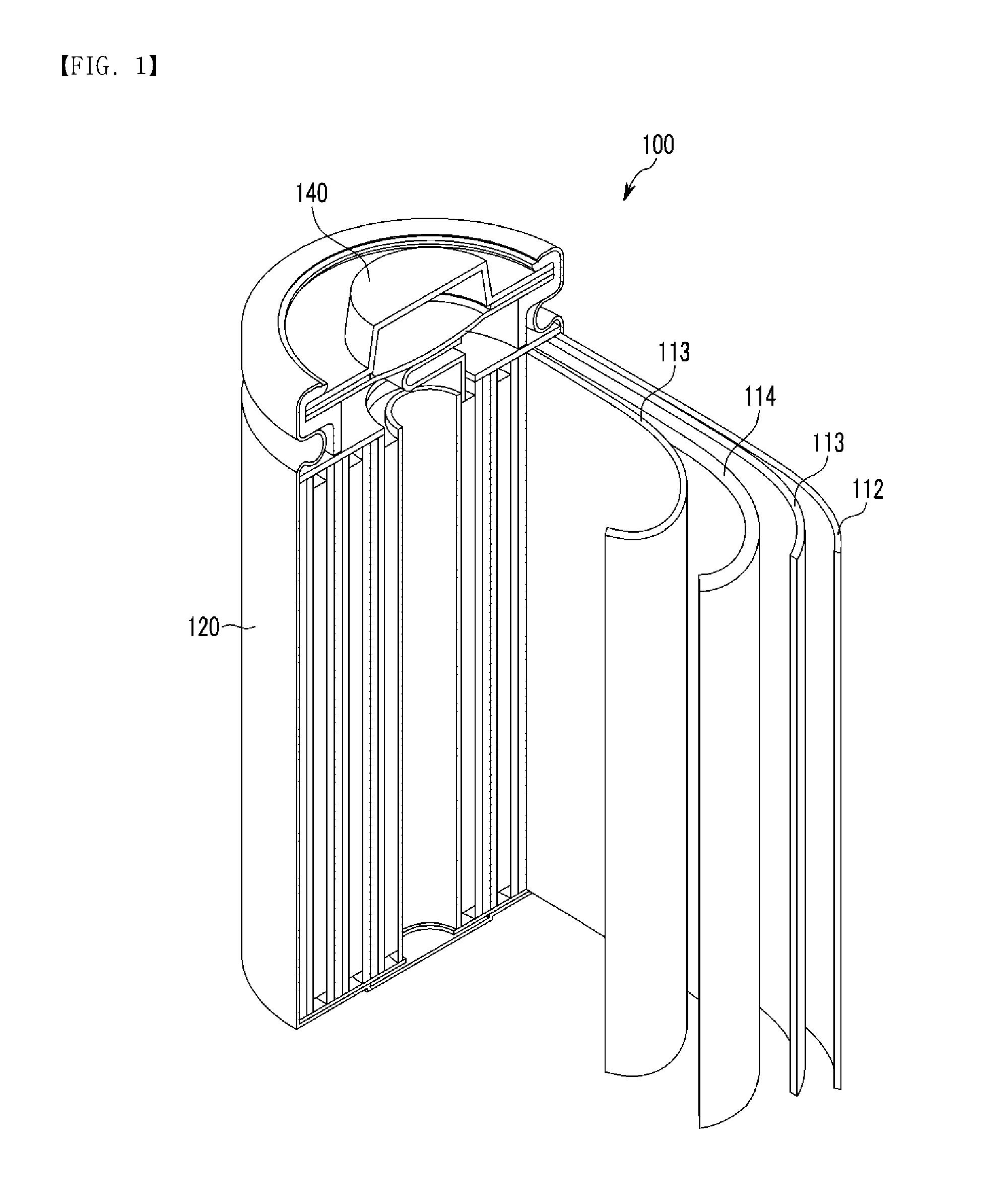

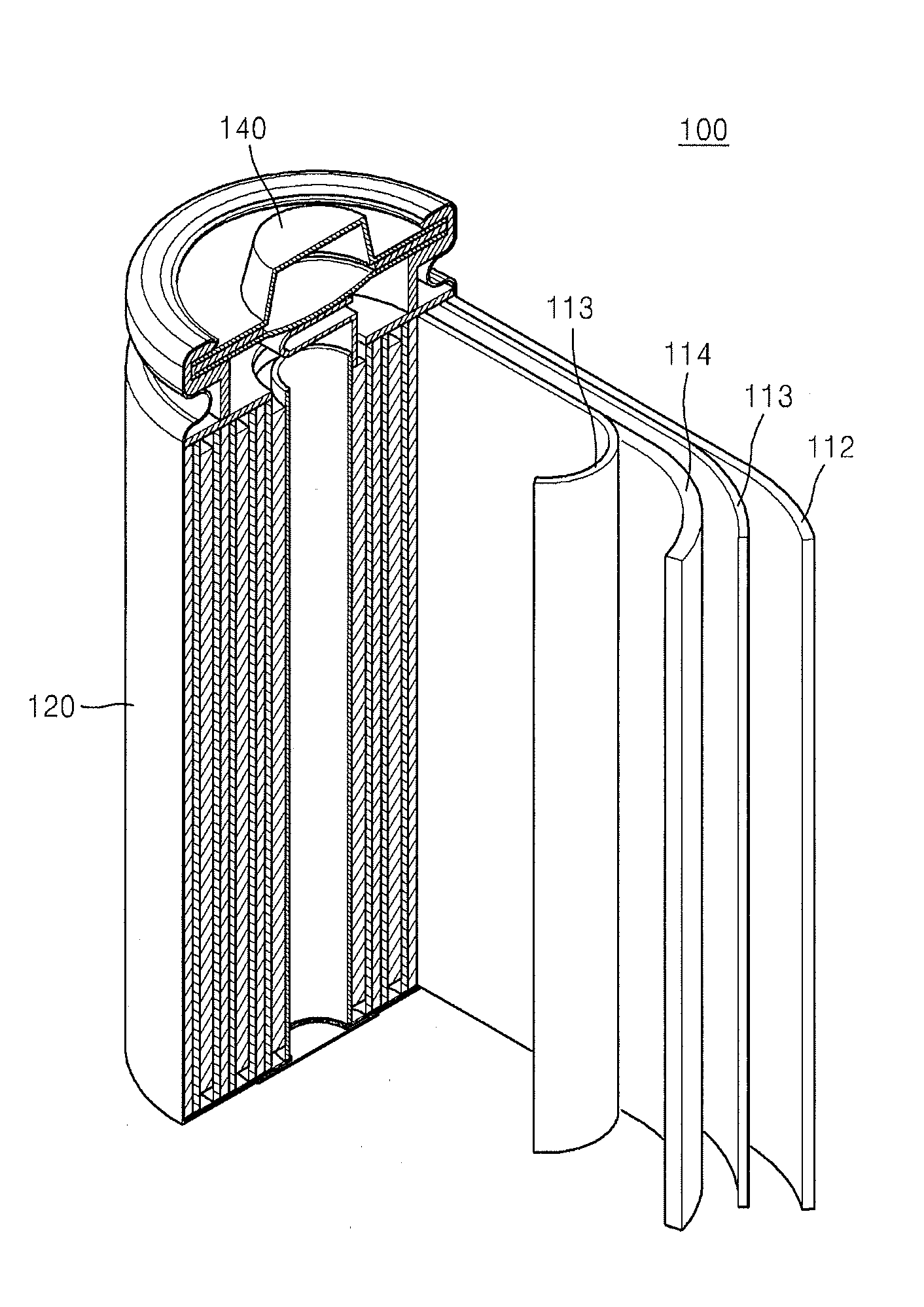

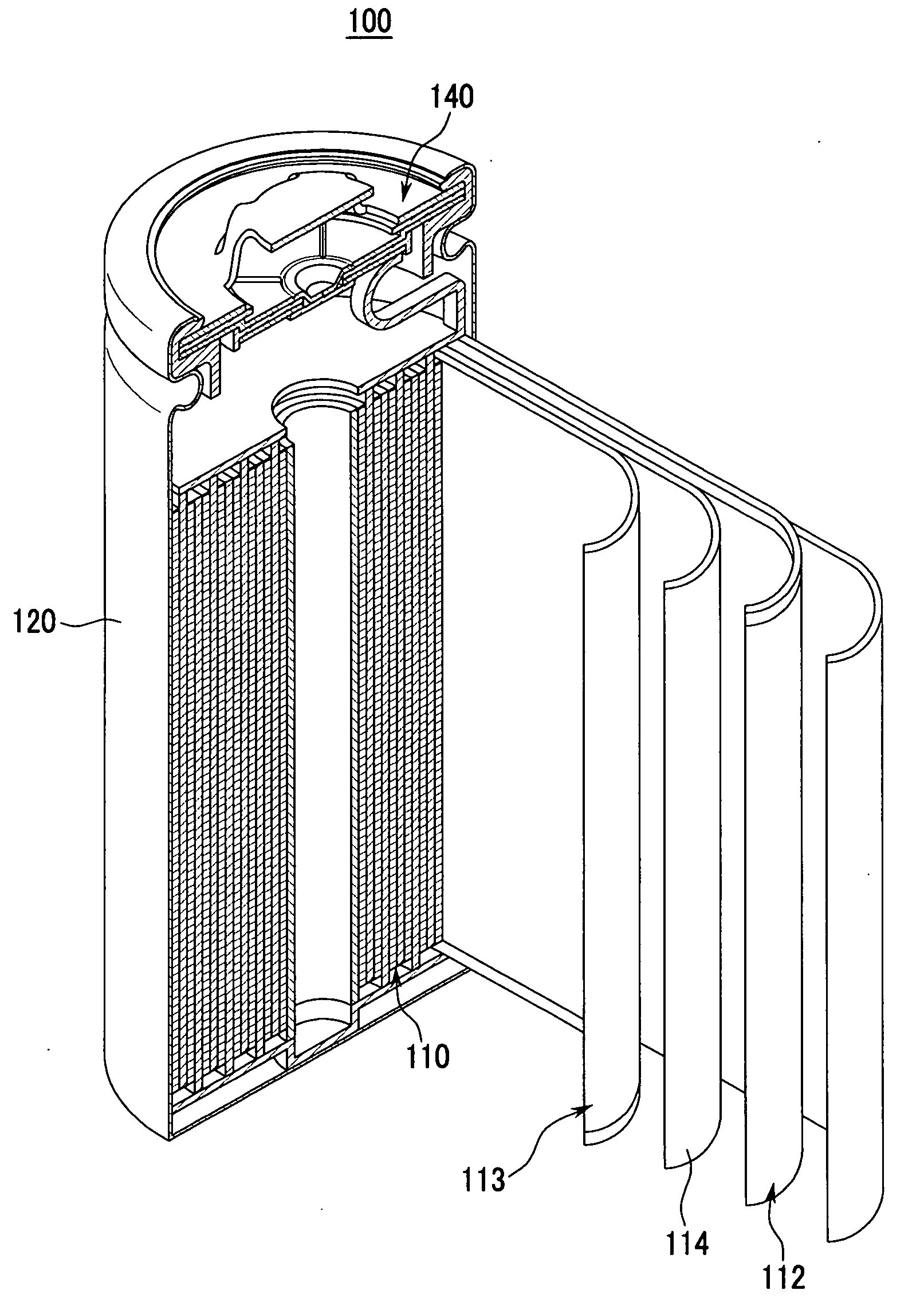

Lithium secondary battery

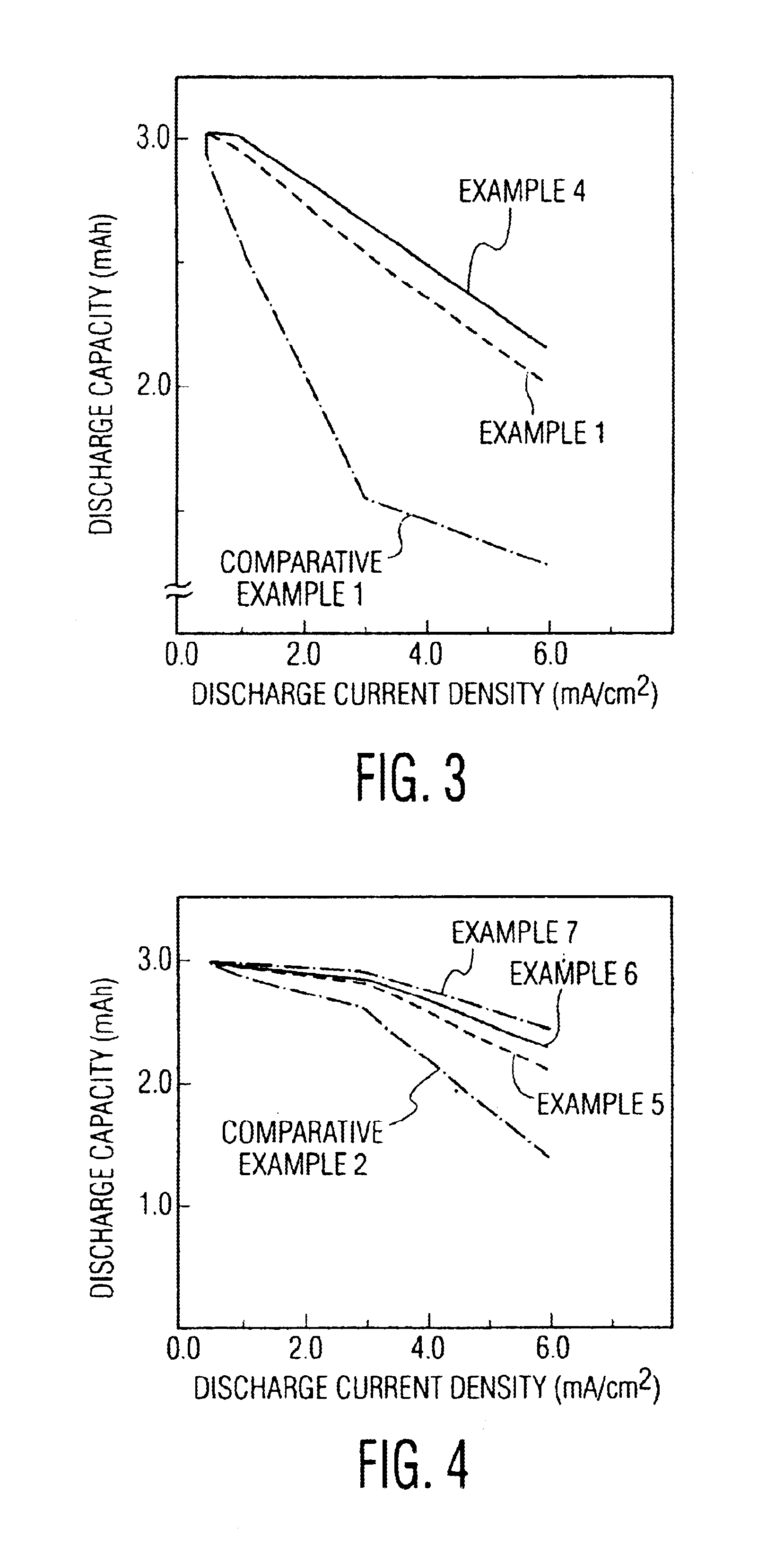

InactiveUS6905796B2Large capacityImprove ionic conductivityOrganic electrolyte cellsNegative electrodesHigh rateInternal resistance

A lithium secondary battery has high capacity and excellent current characteristics. The lithium battery comprises of a positive electrode, a negative electrode and an electrolyte; the negative electrode comprising Al2O3 particles not relating to the charge-and discharge reactions of the battery. The presence of the ceramics particles in the electrode leads to a decrease in the internal resistance of the battery because of the enhancement of ion conductivity in the electrode, resulting in higher capacity at high rate discharge of the lithium secondary battery.

Owner:PANASONIC CORP

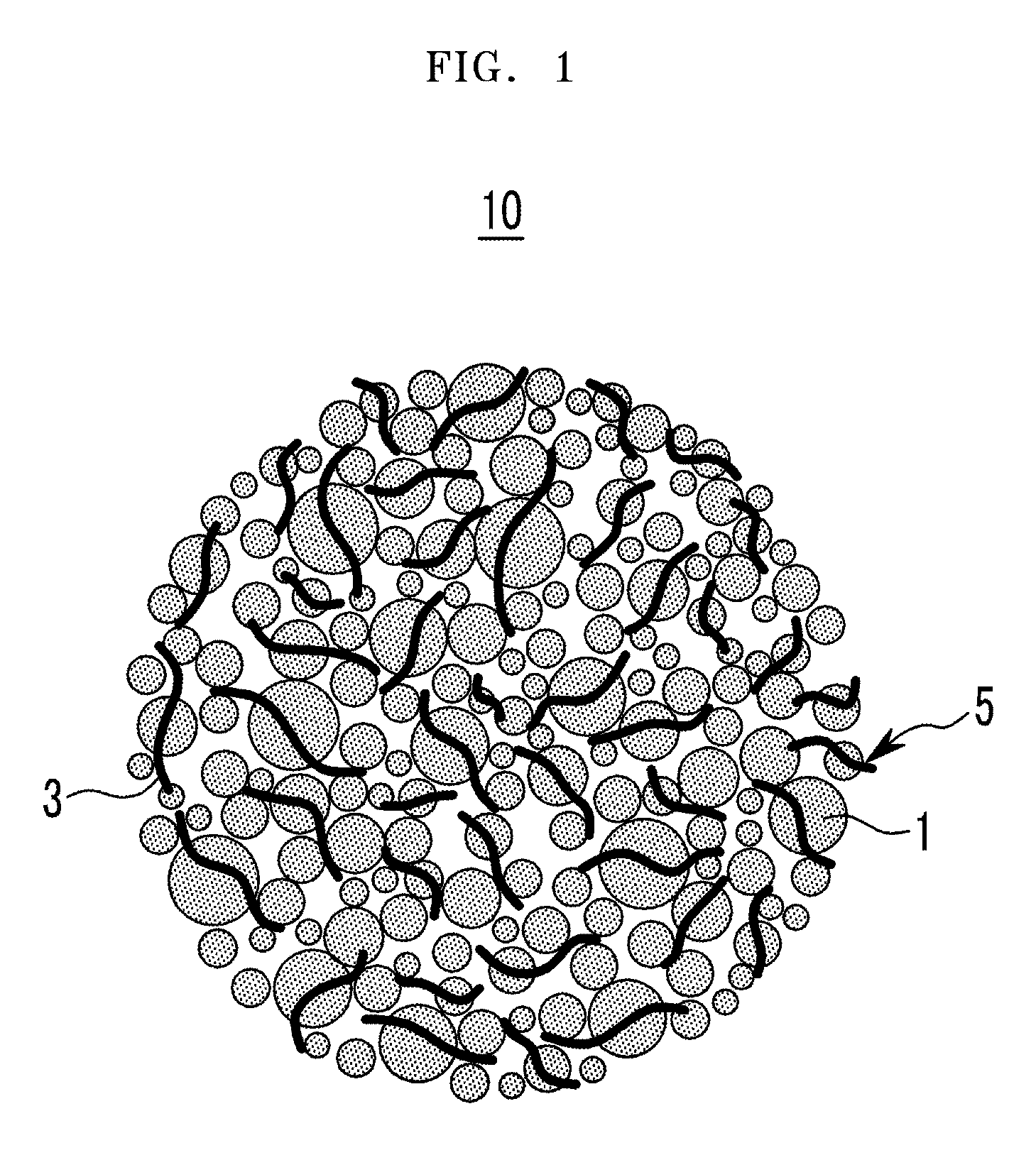

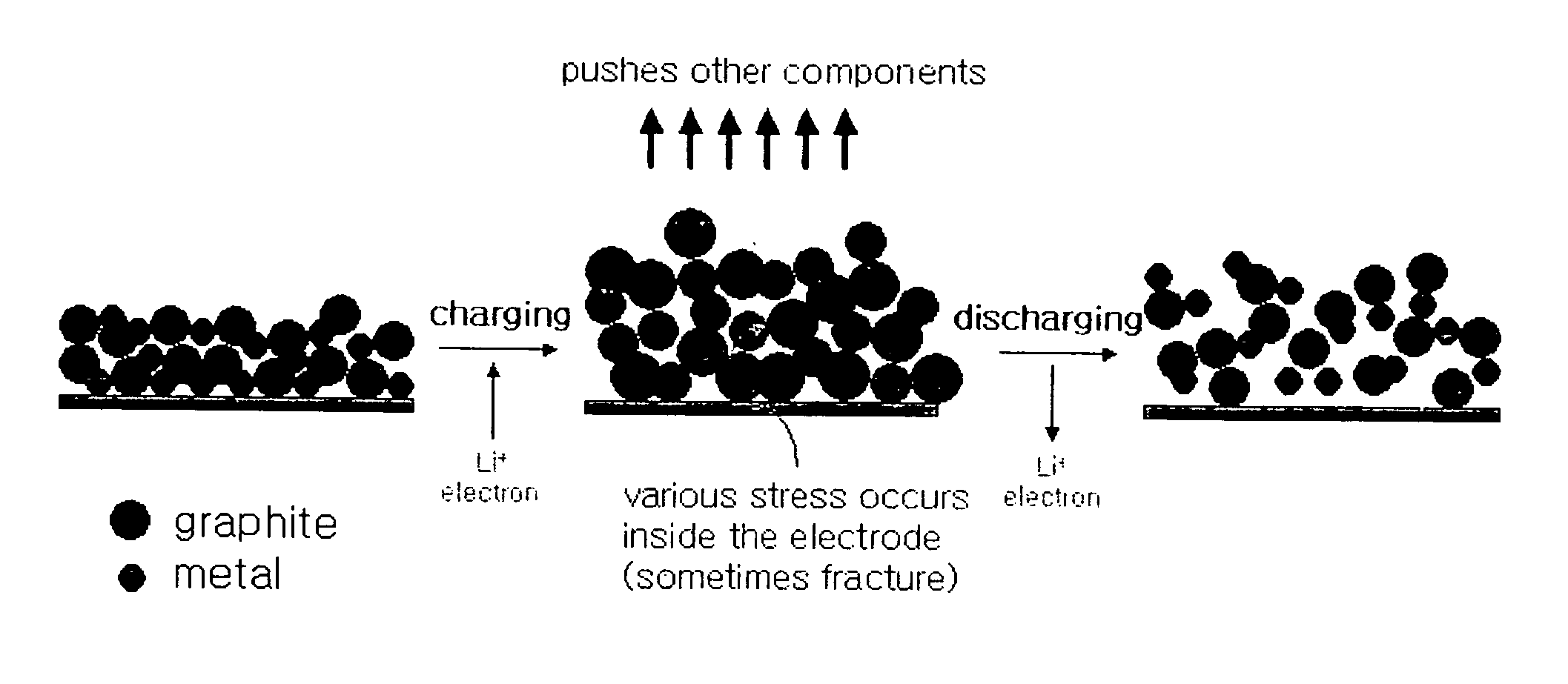

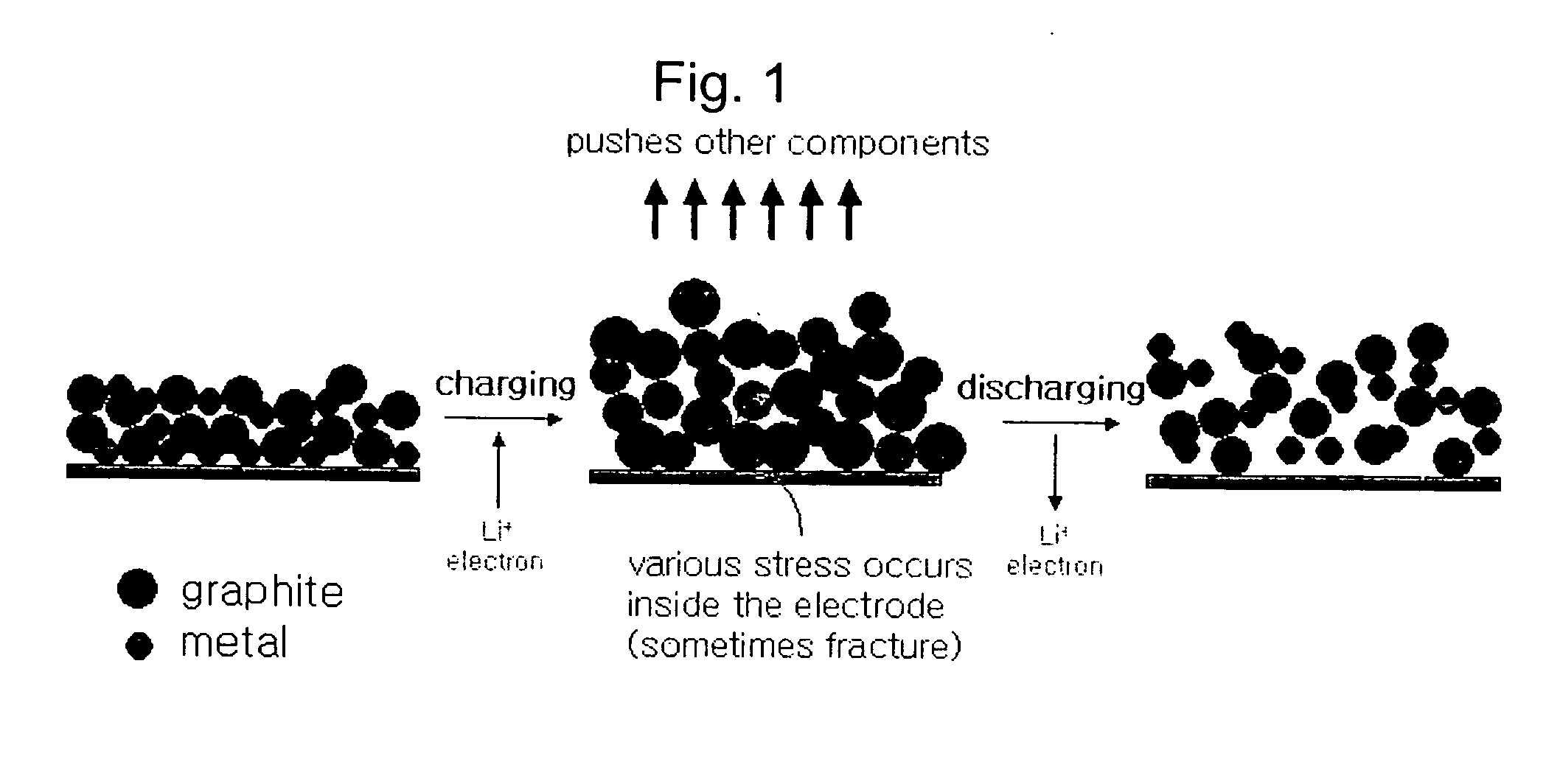

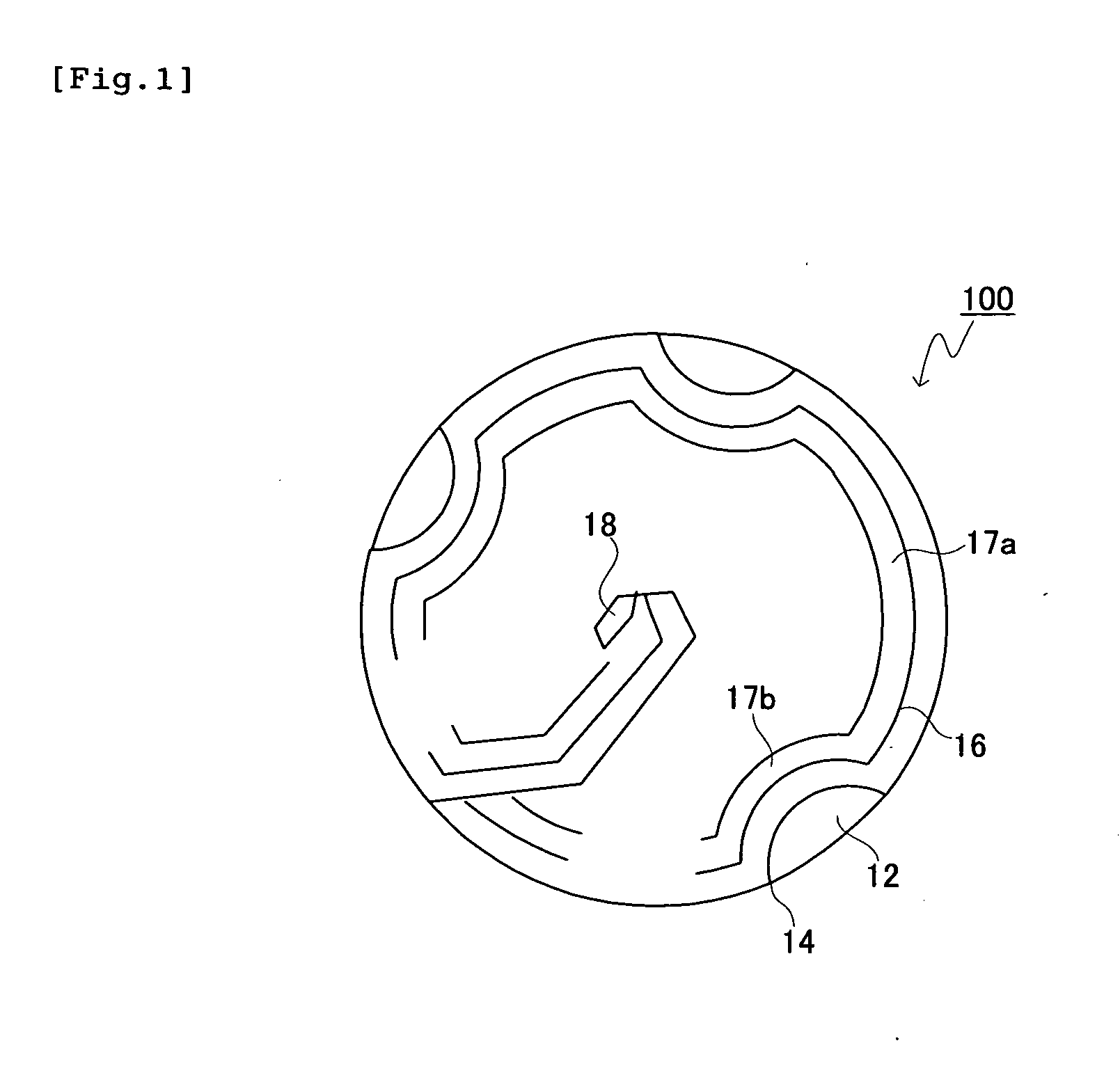

Anode active material, anode including the anode active material, method of manufacturing the anode, and lithium battery including the anode

InactiveUS20100136431A1Improved cycle life characteristicsMaterial nanotechnologyNon-aqueous electrolyte accumulatorsFiberElectron donor

An anode active material for lithium batteries, an anode including the anode active material, a method of manufacturing the anode, and a lithium battery including the anode. The anode active material includes secondary particles formed of agglomerated primary nanoparticles. The primary nanoparticles include a non-carbonaceous material bound with hollow carbon nanofibers. The anode includes the anode active material and a polymeric binder having an electron donor group.

Owner:SAMSUNG ELECTRONICS CO LTD

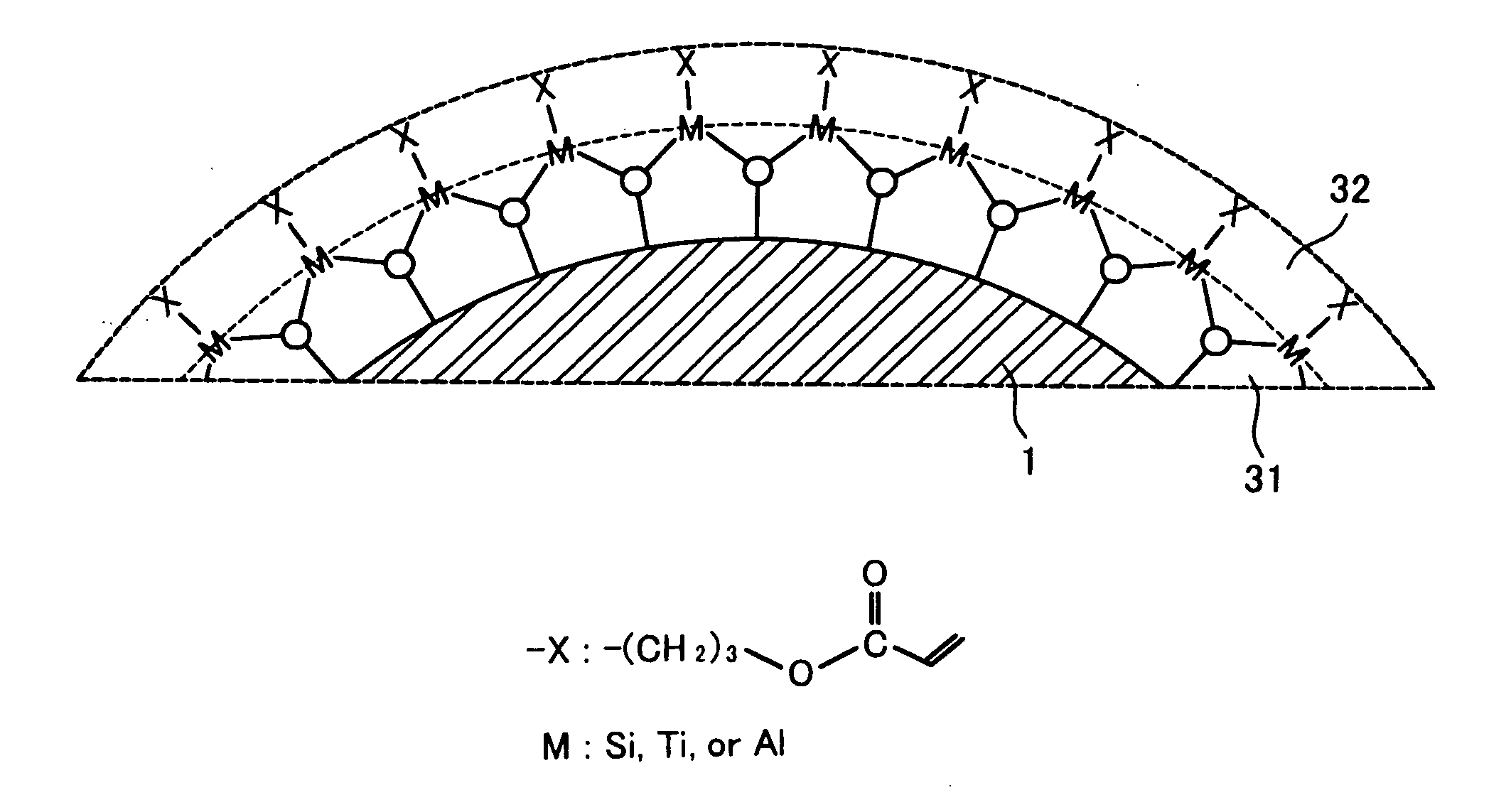

Negative active material for a rechargeable lithium battery, a method of preparing the same, and a rechargeable lithium battery comprising the same

ActiveUS20070122712A1Improved cycle life characteristicsImprove featuresElectrode manufacturing processesSecondary cellsMaterials scienceCarbon substrate

Negative active materials for rechargeable lithium batteries, methods of manufacturing the negative active materials, and rechargeable lithium batteries including the negative active materials are provided. One negative active material includes an active metal core and a crack inhibiting layer formed on the core. The crack inhibiting layer includes a carbon-based material.

Owner:SAMSUNG SDI CO LTD

Active material for rechargeable lithium battery and rechargeable lithium battery including the same

ActiveUS20090142665A1Improved cycle life characteristicsImprove conductivityMaterial nanotechnologyLi-accumulatorsNanofiberOxygen

An active material for a rechargeable lithium battery is provided with a non-carbon-based material on which nanofiber-shaped carbon having an oxygen-included functional group is grown. The negative active material for a rechargeable lithium battery has good conductivity and cycle life characteristics.

Owner:SAMSUNG SDI CO LTD

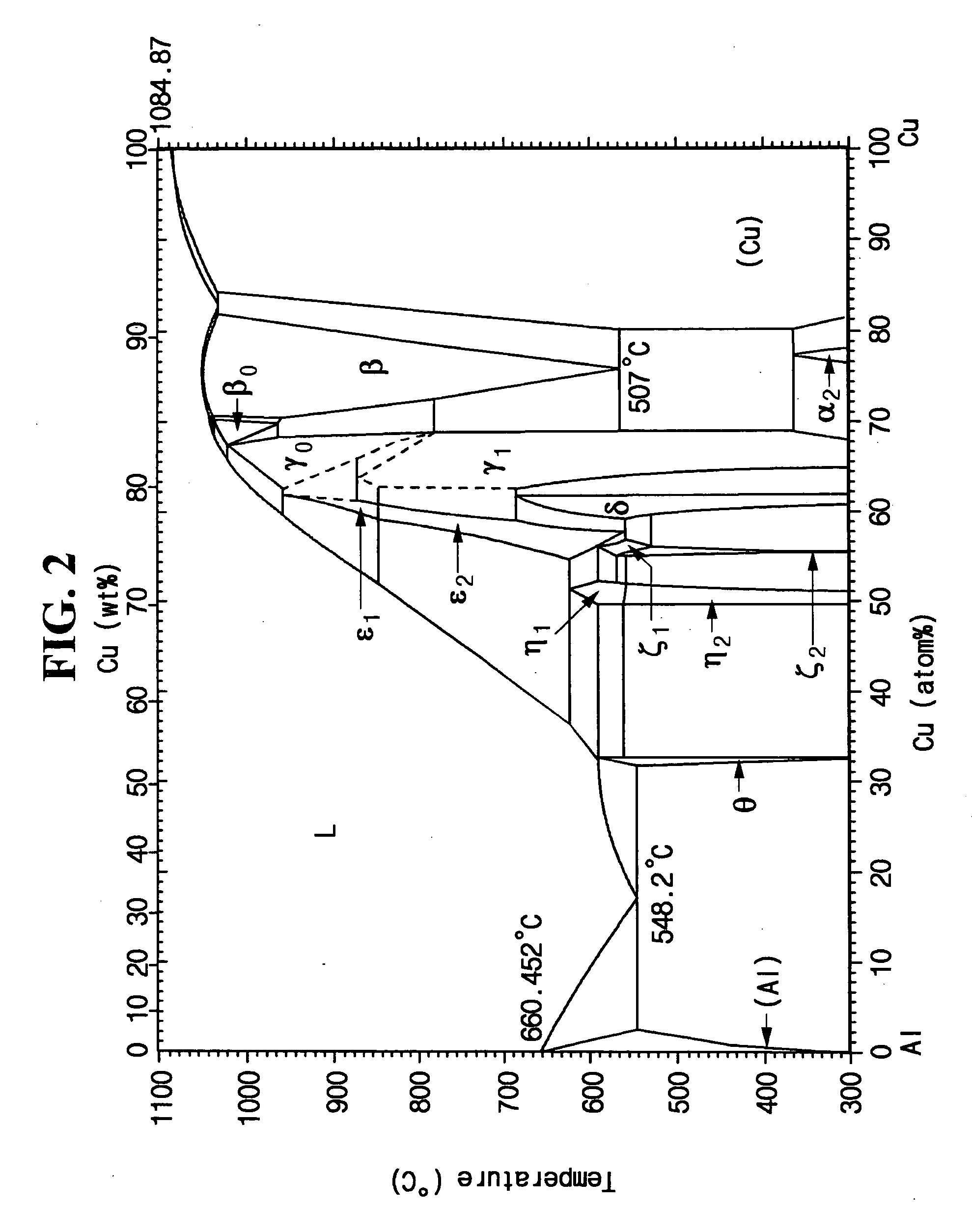

Negative active material and rechargeable lithium battery including negative active material

ActiveUS20070122702A1Large capacityImproved cycle life characteristicsFinal product manufactureActive material electrodesMaterials scienceMetal

A negative active material for a rechargeable lithium battery and a rechargeable lithium battery including the negative active material have a negative active material including either Si or Sn active metal grains and a metal matrix composed of at least two metal elements that surrounds the active metal grains but does not react therewith.

Owner:SAMSUNG SDI CO LTD

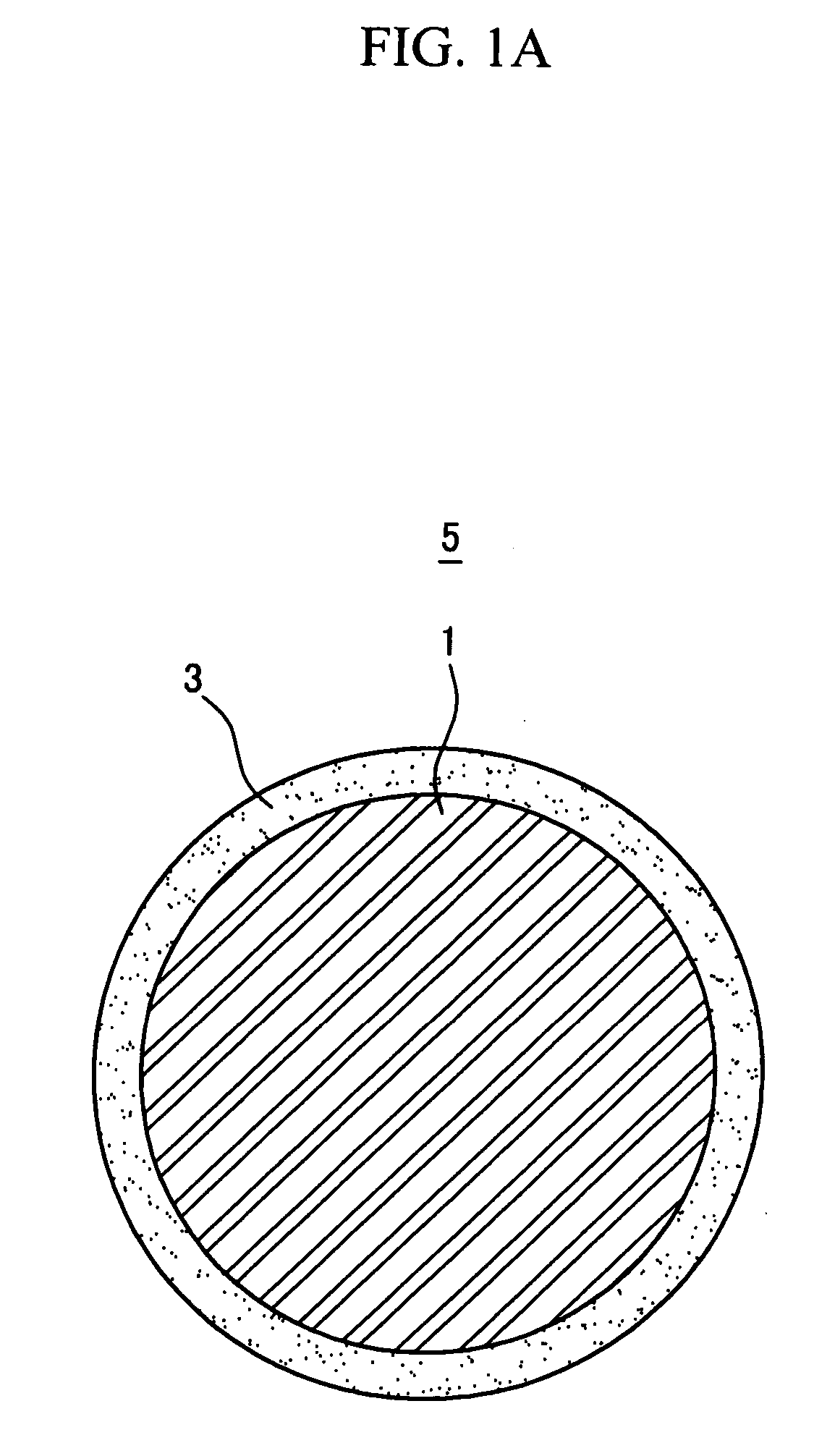

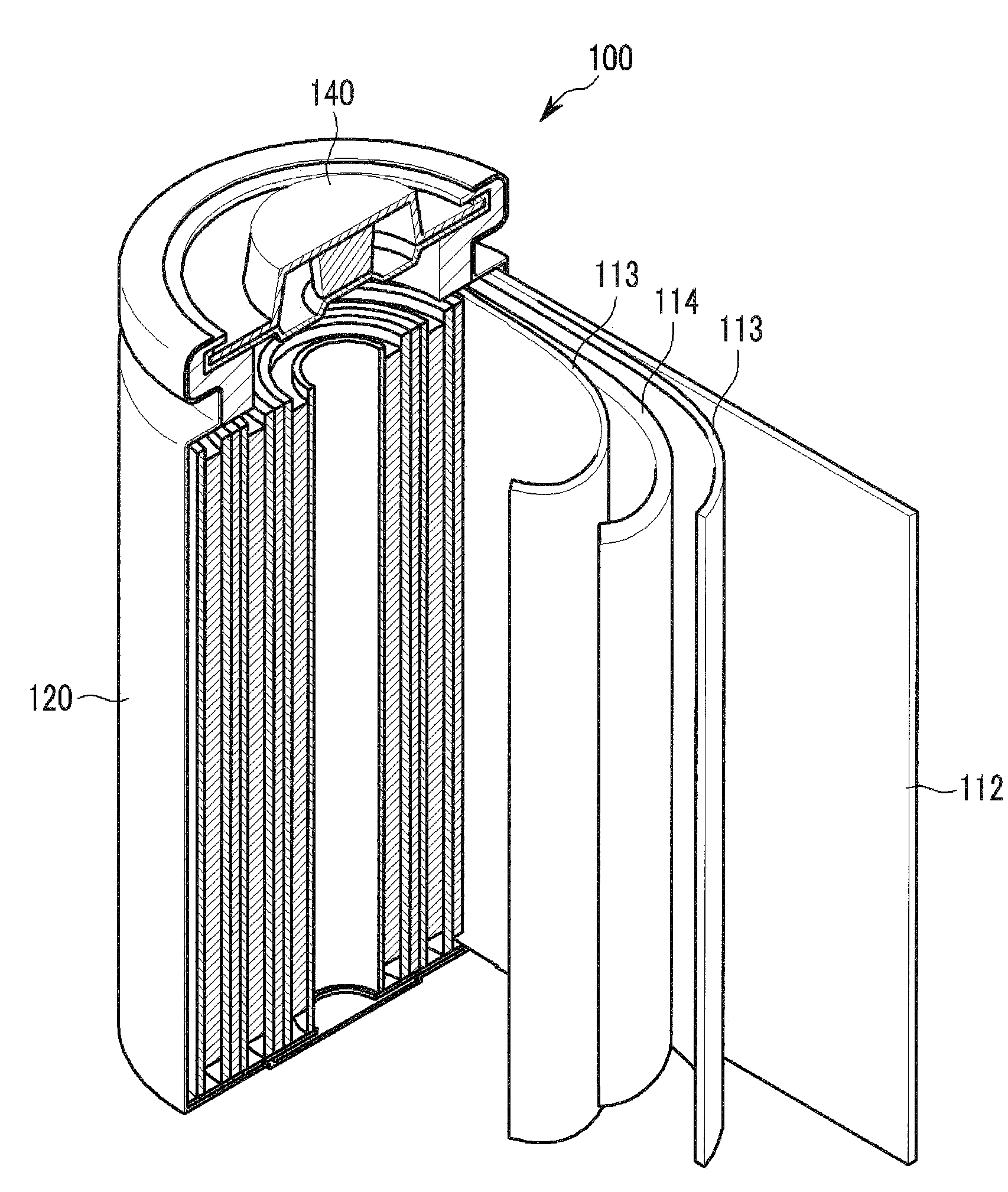

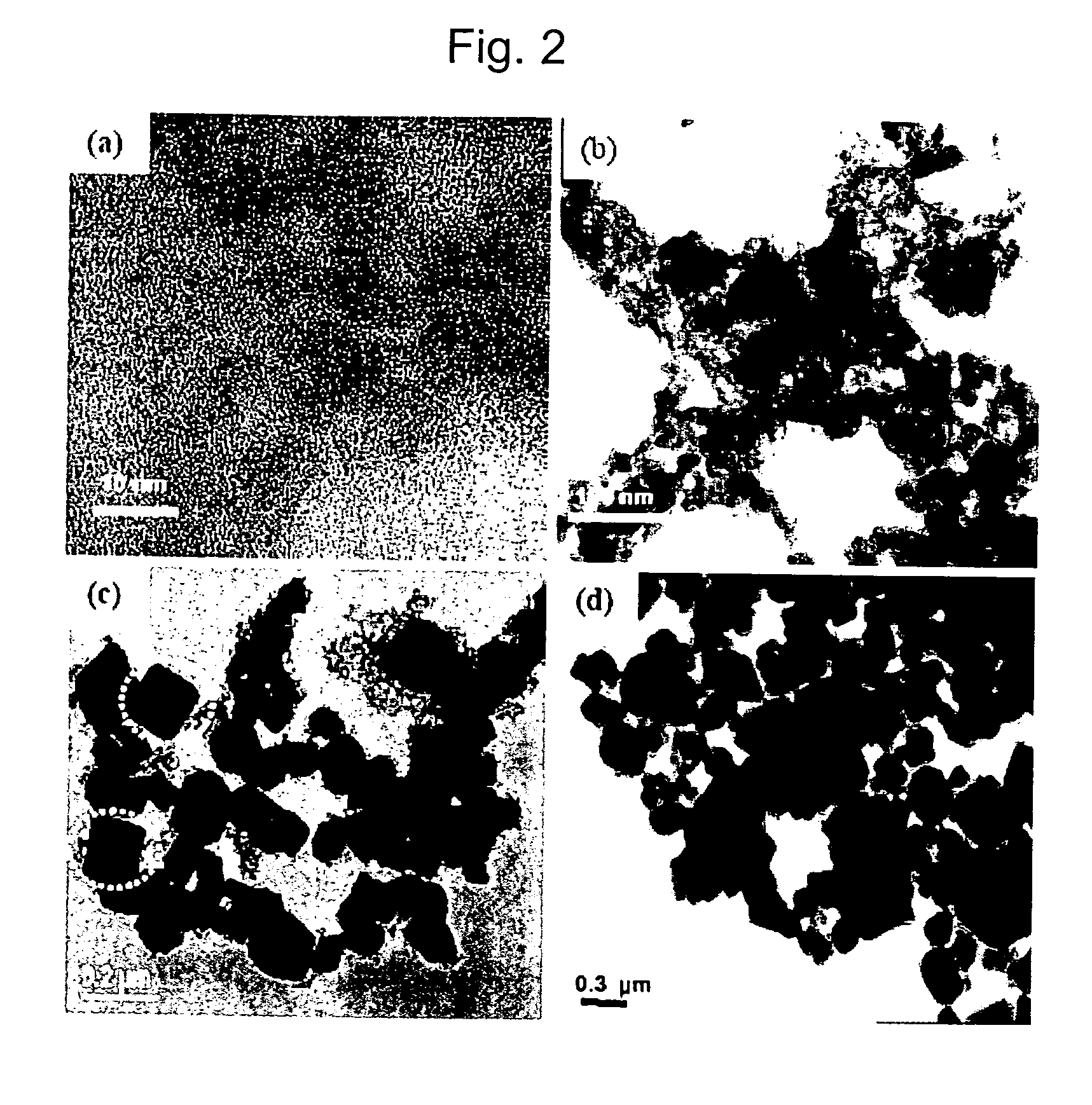

Negative electrode for rechargeable lithium battery, and rechargeable lithium battery including the same

ActiveUS20090136845A1Improved initial formation efficiency and cycle-life characteristicImproved cycle life characteristicsNon-fibrous pulp additionElectrode thermal treatmentCross-linkEngineering

A negative electrode for a rechargeable lithium battery and a rechargeable lithium battery including the same are provided. The negative electrode for a rechargeable lithium battery includes a current collector, and a negative active material layer on the current collector. The negative active material layer includes an interpenetrating network network, and a negative active material in the interpenetrating network network. The interpenetrating network is formed by cross-linking a first polymer having a hydroxyl or amine group and a second polymer having a carboxylic acid group. The negative electrode for a rechargeable lithium battery minimizes volume expansion and imparts good cycle-life characteristics and initial formation efficiency.

Owner:SAMSUNG SDI CO LTD

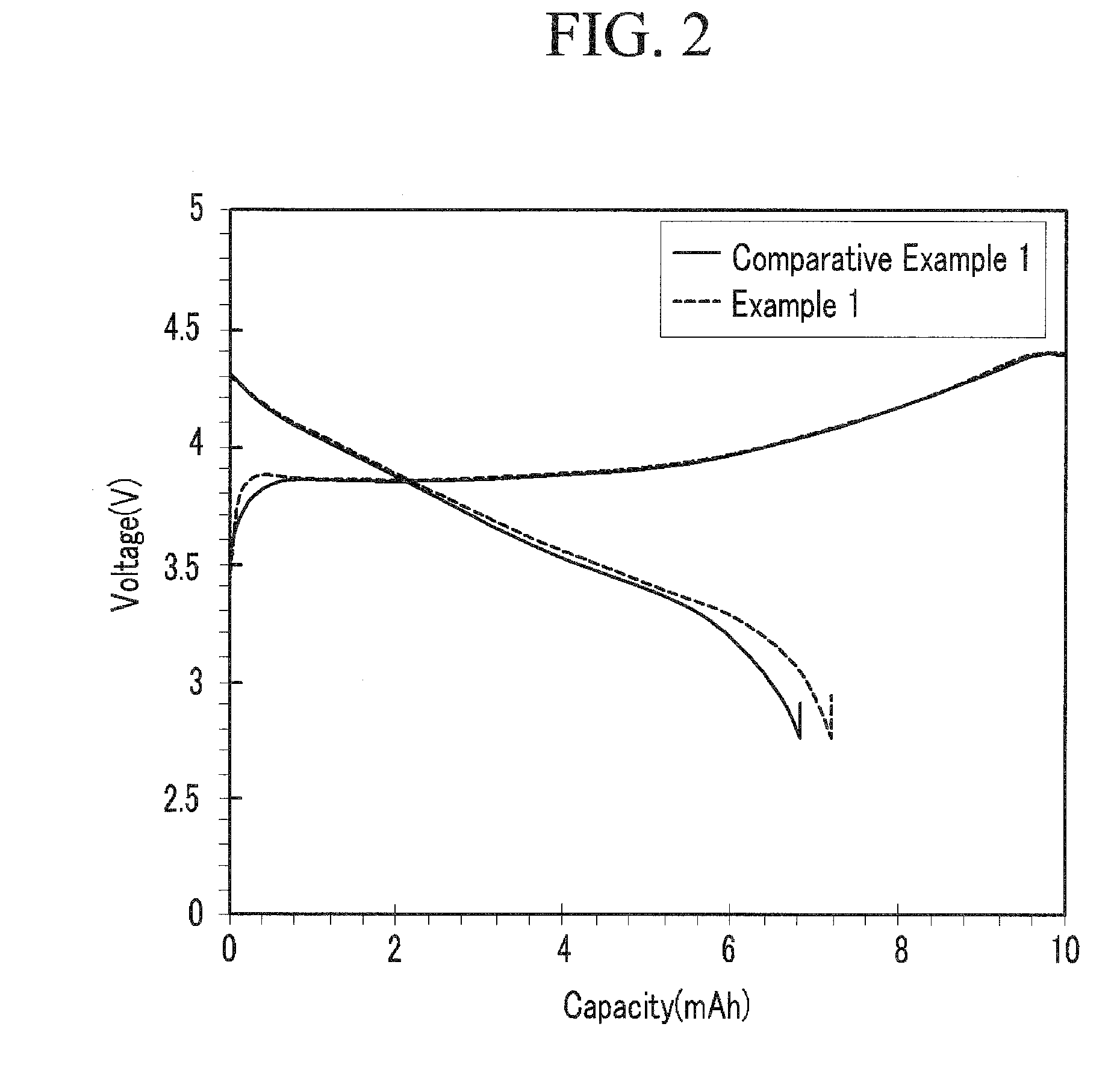

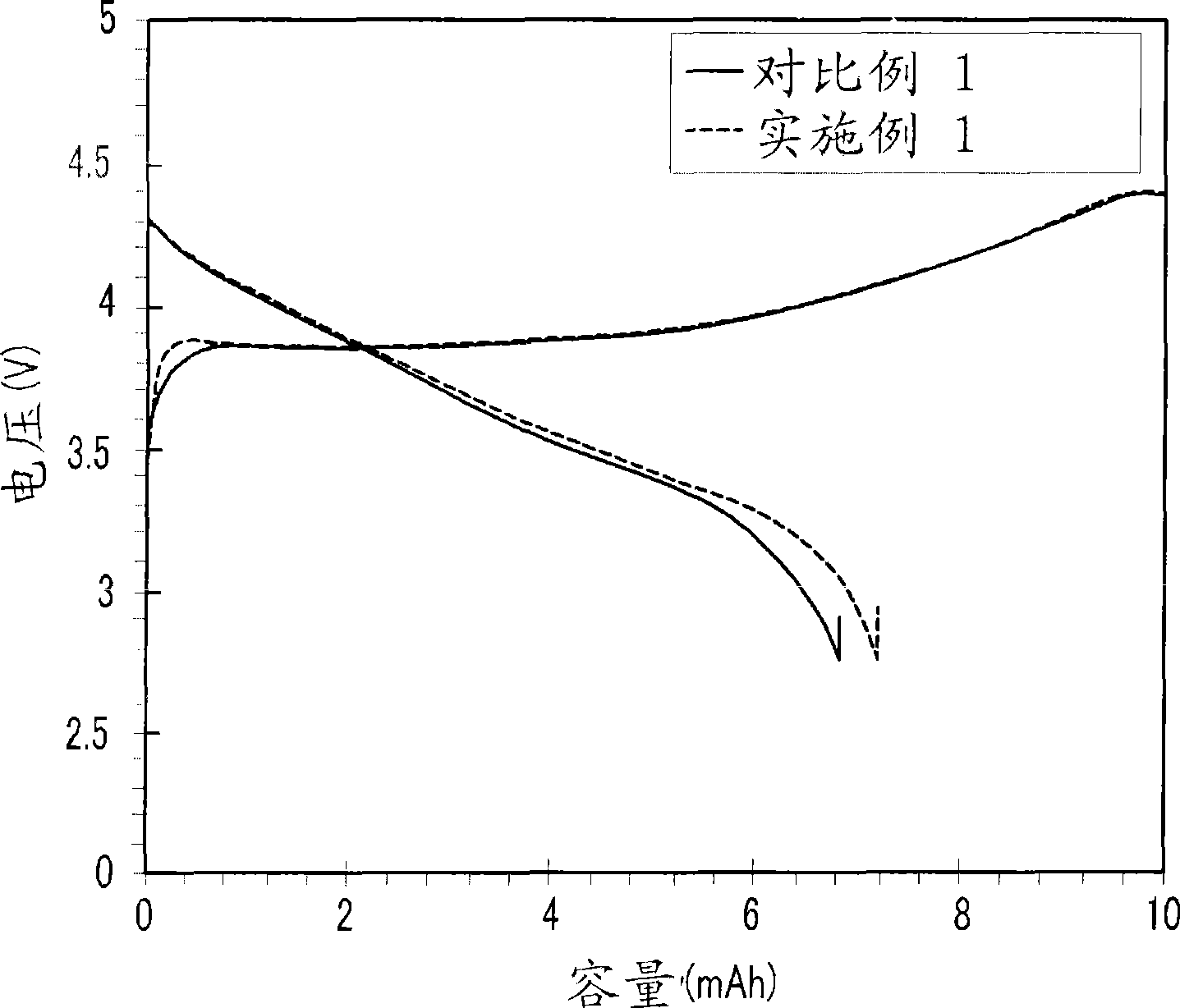

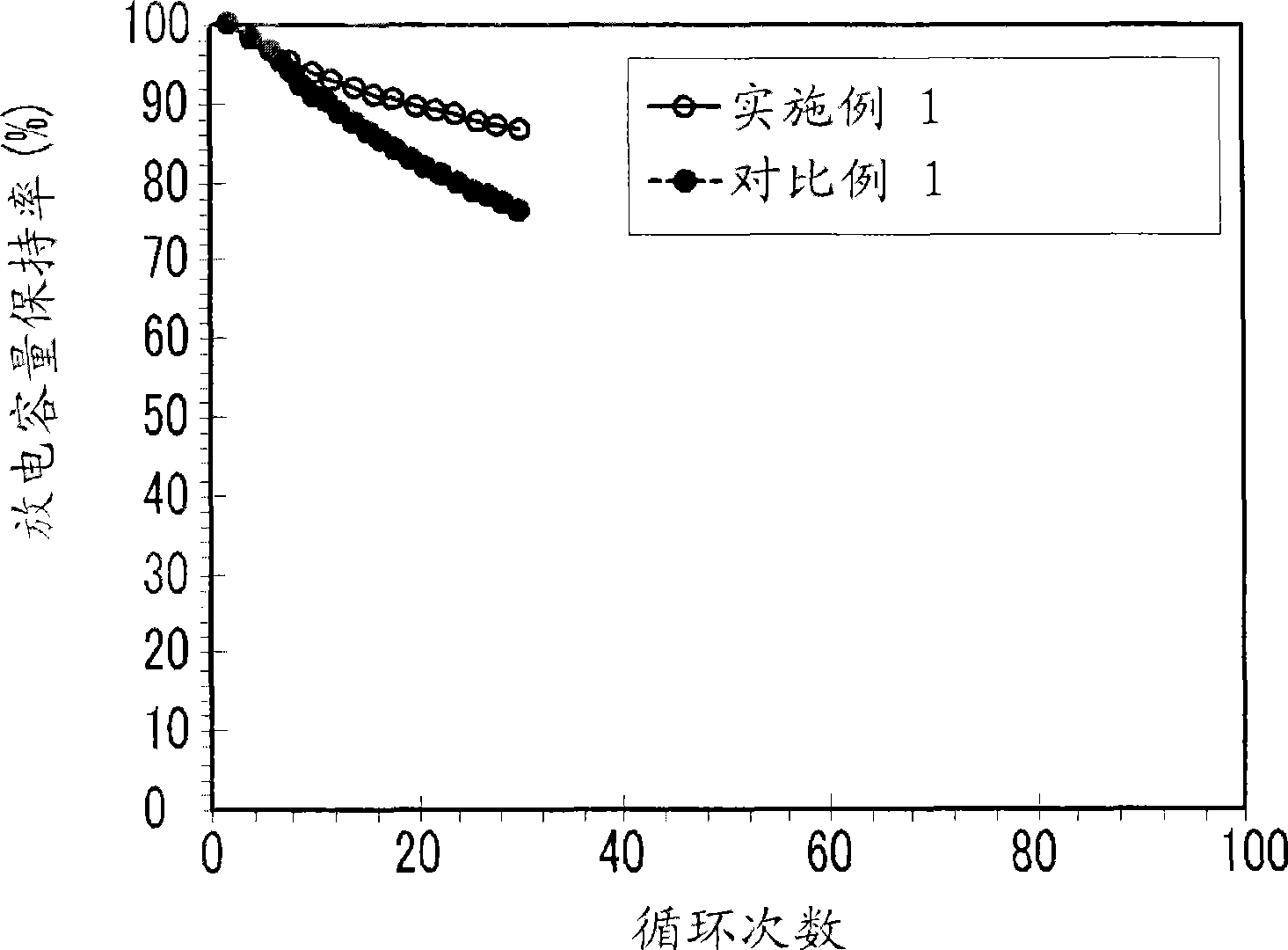

Electrolyte for lithium ion rechargeable battery and lithium ion rechargeable battery including the same

ActiveUS20050287442A1Improved cycle life characteristicsPrevents drop in discharge capacityOrganic electrolyte cellsActive material electrodesHigh temperature storageLithium

The present invention is an electrolyte for a lithium ion rechargeable battery and a lithium ion rechargeable battery that includes the same. More particularly, the present invention discloses an electrolyte for a lithium ion rechargeable battery that provides excellent cycle life characteristics and high-temperatures storage stability and prevents a drop in discharge capacity of a battery at low temperature, and a lithium ion rechargeable battery including the same. The lithium ion rechargeable battery including the electrolyte provides improved cycle life characteristics and prevents the problems of a drop in discharge capacity at low temperature and high-temperature swelling through the formation of a stable SEI film at the initial charge cycle.

Owner:SAMSUNG SDI CO LTD

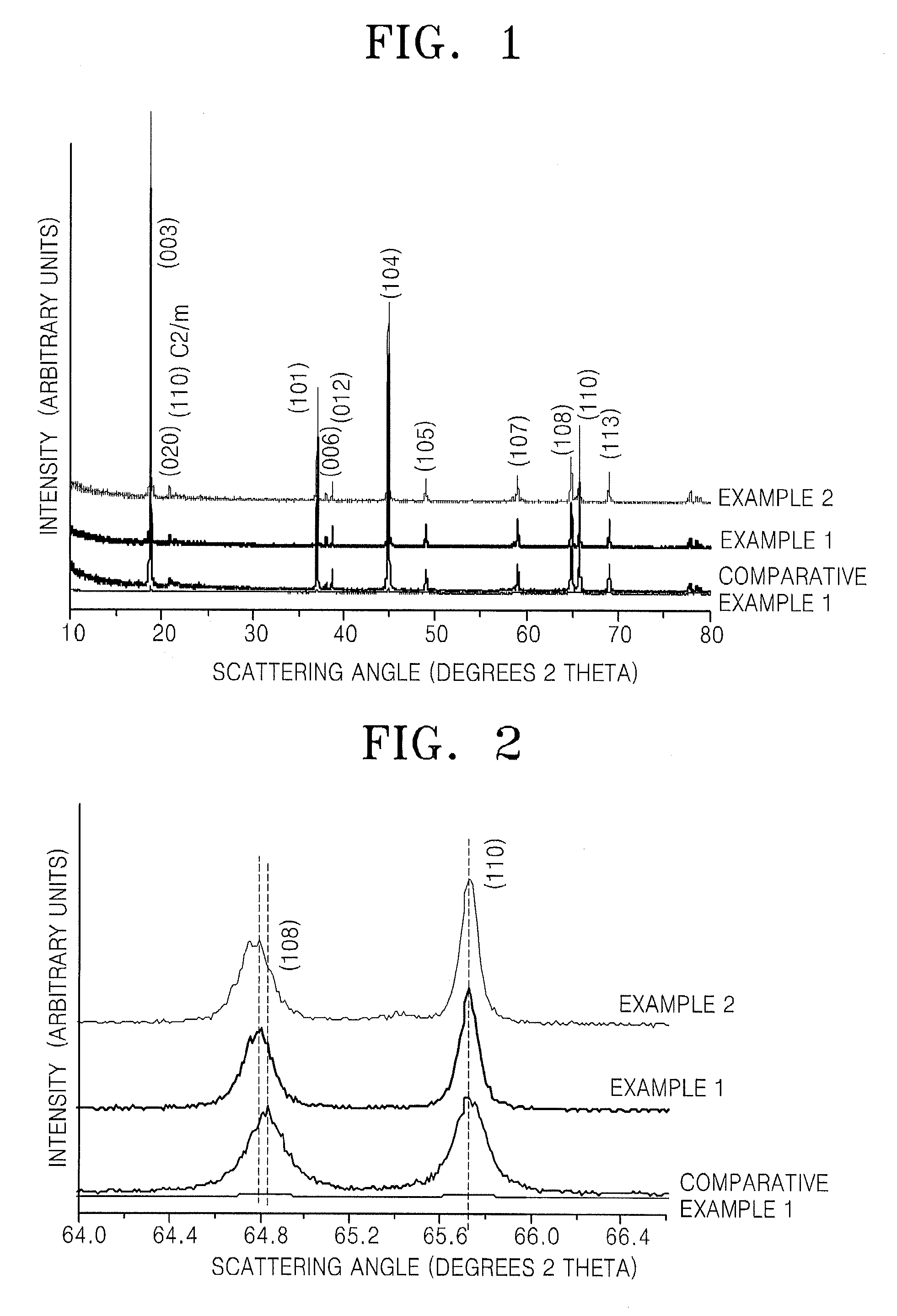

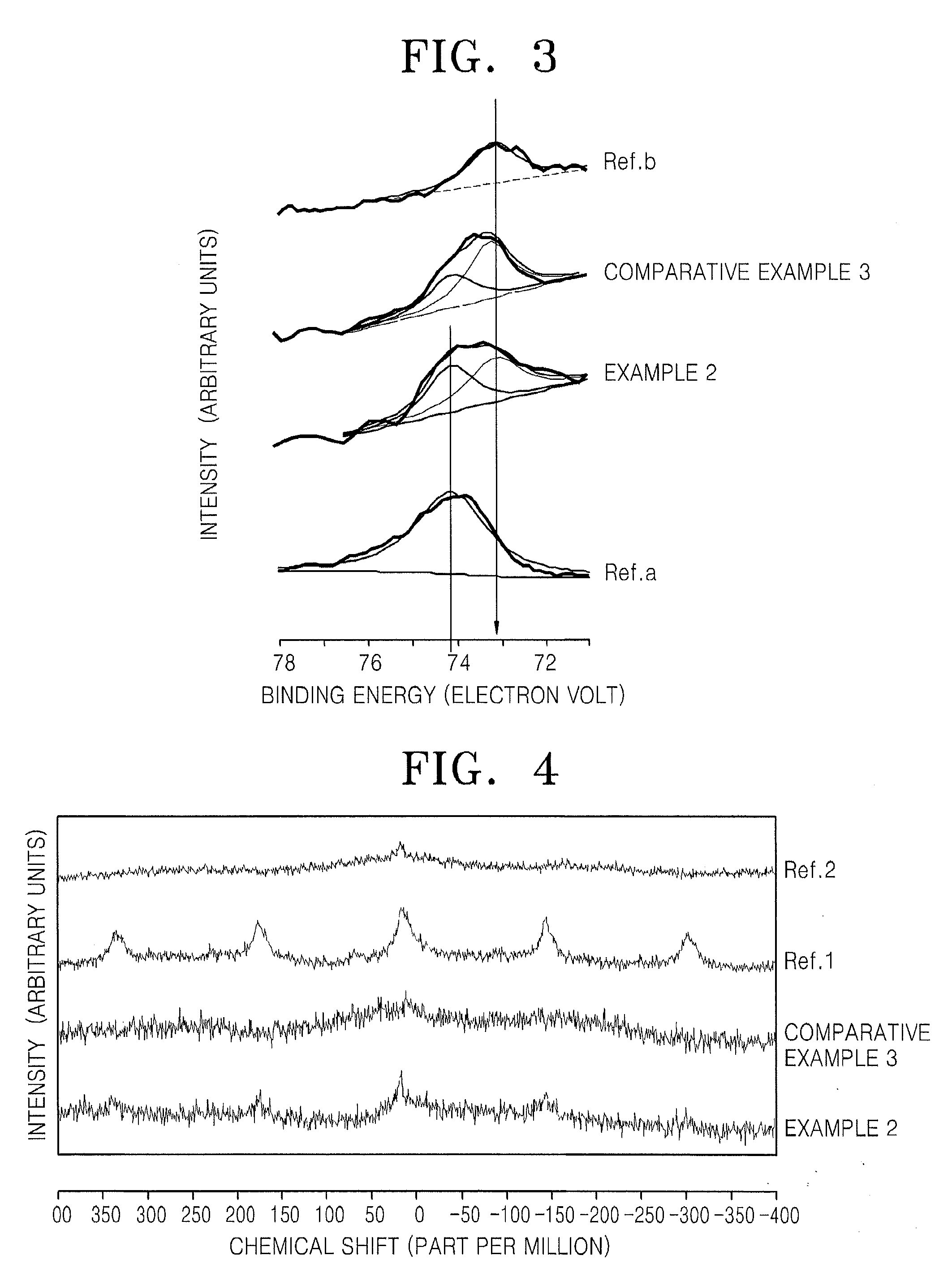

Positive active material for rechargeable lithium battery, method of preparing same, and rechargeable lithium battery comprising same

ActiveUS20050014065A1Large capacityImproved cycle life characteristicsNon-aqueous electrolyte accumulatorsAlkali metal oxidesCrystallographyX-ray

Disclosed is a positive active material for a lithium rechargeable battery, a method of preparing the same, and a lithium rechargeable battery comprising the same. The positive active material has an I(003) / I(104) intensity ratio of between 1.15 to 1 and 1.21 to 1 in an X ray diffraction pattern using CuKα ray, wherein I(003) / I(004) is the X-ray diffraction intensity of the (003) plane divided by the X-ray diffraction intensity of the (104) plane. The compound is represented by the formula: LixNiyCozMn1-y-z-qXqO2 wherein x≧1.05, 0<y<0.35, 0<z<0.35, X is Al, Mg, Sr, Ti or La, and 0≦q<0.1.

Owner:SAMSUNG SDI CO LTD

Anode active material, manufacturing method thereof and lithium battery using the anode active material

InactiveUS20070020519A1Large capacityImproved cycle life characteristicsMaterial nanotechnologyElectrode manufacturing processesOptoelectronicsMonomer

Provided are an anode active material for a lithium secondary battery, a manufacturing method of the anode active material, and a lithium secondary battery using the anode active material. More particularly, an anode active material for a lithium secondary battery having a high capacity and an excellent cycle lifetime, a manufacturing method of the anode active material, and a lithium secondary battery using the anode active material are provided. In the anode active material, monomers are coated on a tin nanopowder. The anode active material has a higher capacity and a higher cycle lifetime than a conventional anode active material.

Owner:SAMSUNG SDI CO LTD

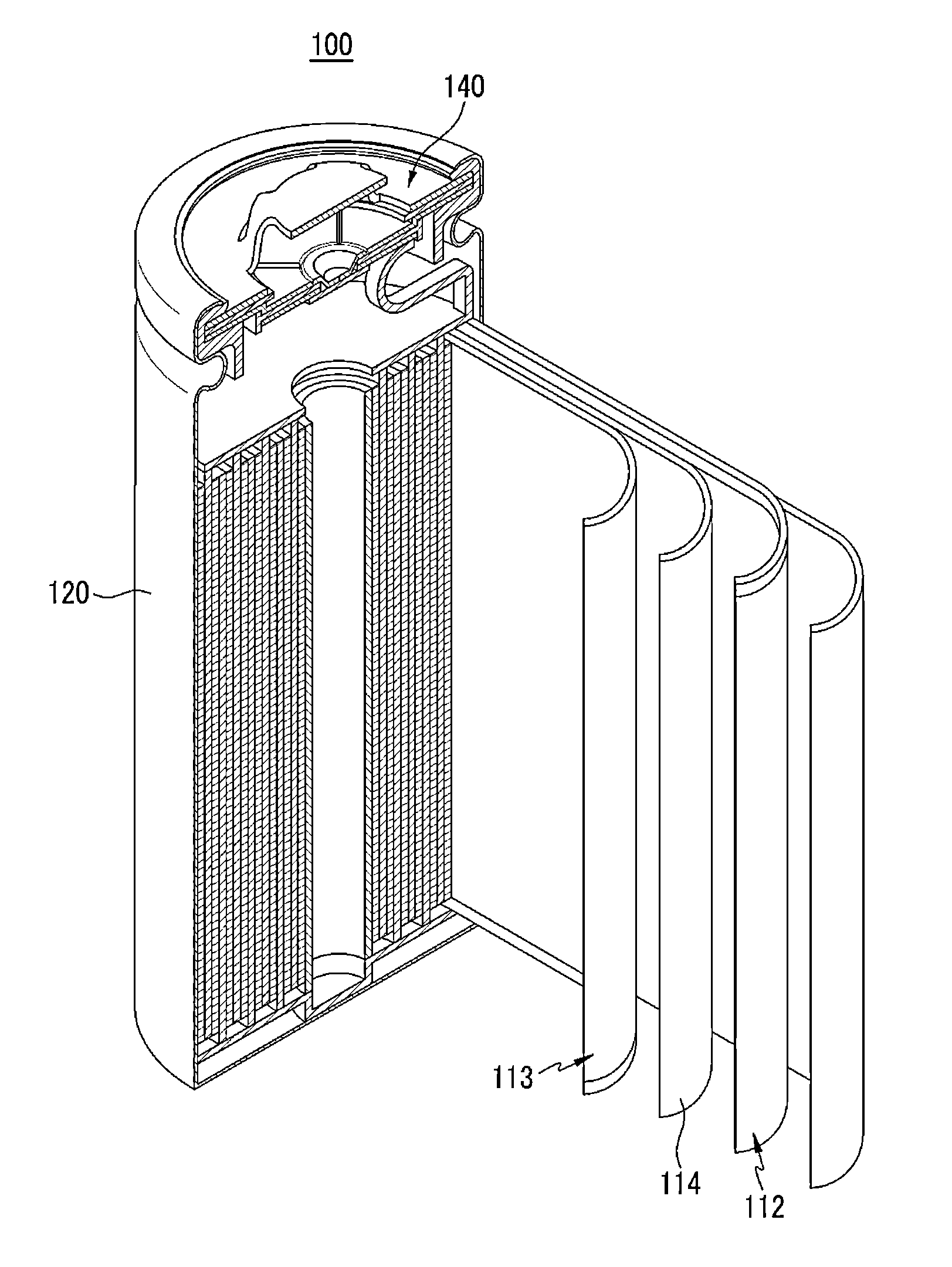

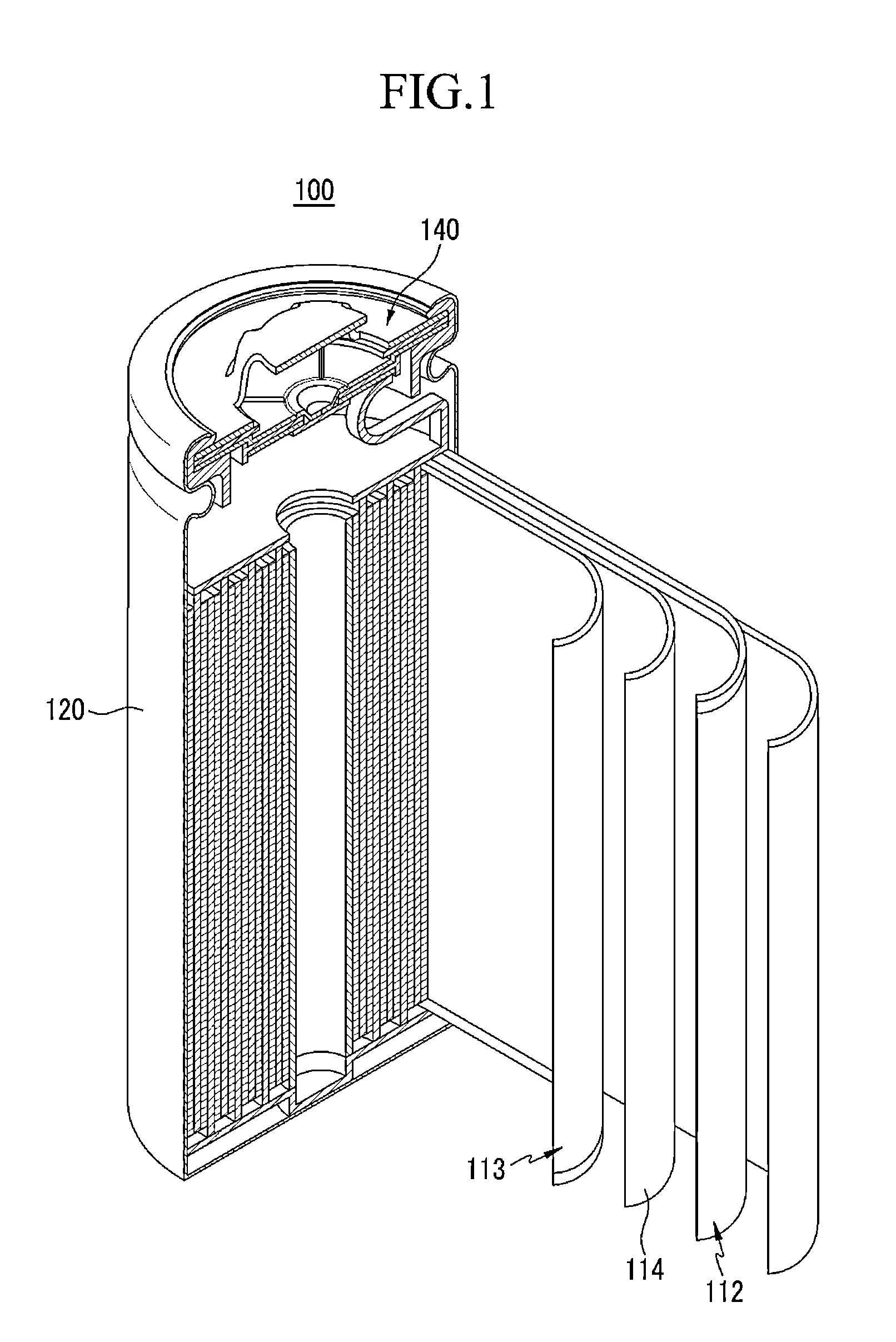

Negative electrode for rechargeable lithium battery, and rechargeable lithium battery including the same

ActiveCN101447561AImproved cycle life characteristicsIncrease capacityFinal product manufactureElectrode carriers/collectorsCurrent collectorEngineering

A negative electrode for a rechargeable lithium battery and a rechargeable lithium battery including the same are provided. The negative electrode for a rechargeable lithium battery includes a current collector, and a negative active material layer on the current collector. The negative active material layer includes an interpenetrating network, and a negative active material in the interpenetrating network. The interpenetrating network is formed by cross-linking a first polymer having a hydroxyl or amine group and a second polymer having a carboxylic acid group. The negative electrode for a rechargeable lithium battery minimizes volume expansion and imparts good cycle-life characteristics and initial formation efficiency.

Owner:SAMSUNG SDI CO LTD

Separator for lithium secondary battery and method for manufacturing same

InactiveUS20130115519A1Improve cycle life characteristicExcellent thermal stability and wettabilityCell seperators/membranes/diaphragms/spacersFinal product manufactureAromatic diamineOrtho position

Provided is a separator for a rechargeable lithium battery including a porous support including a polymer derived from polyamic acid or a polymer derived from polyimide, wherein the polyamic acid and the polyimide include a repeating unit prepared from aromatic diamine including at least one ortho-positioned functional group relative to an amine group and dianhydride.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

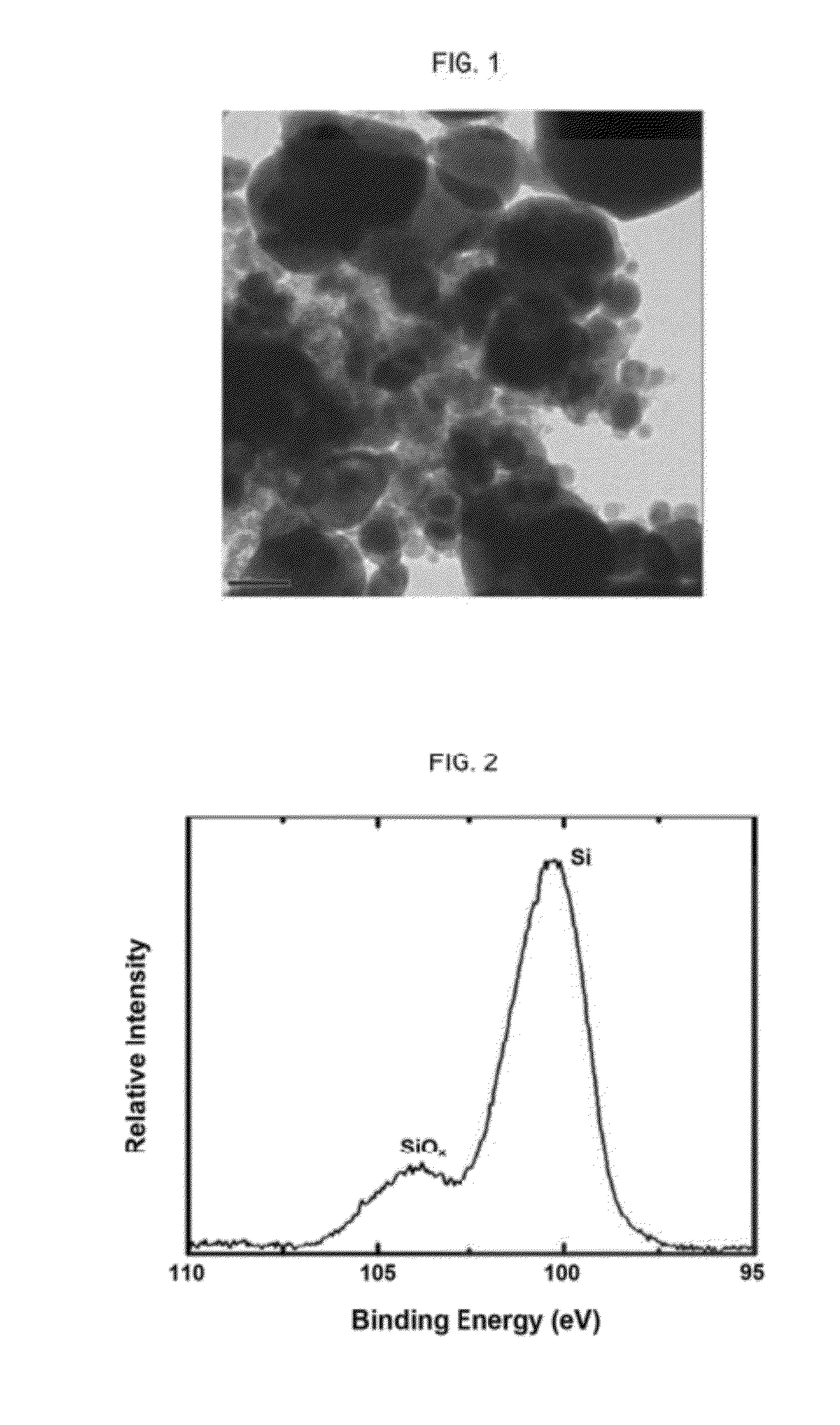

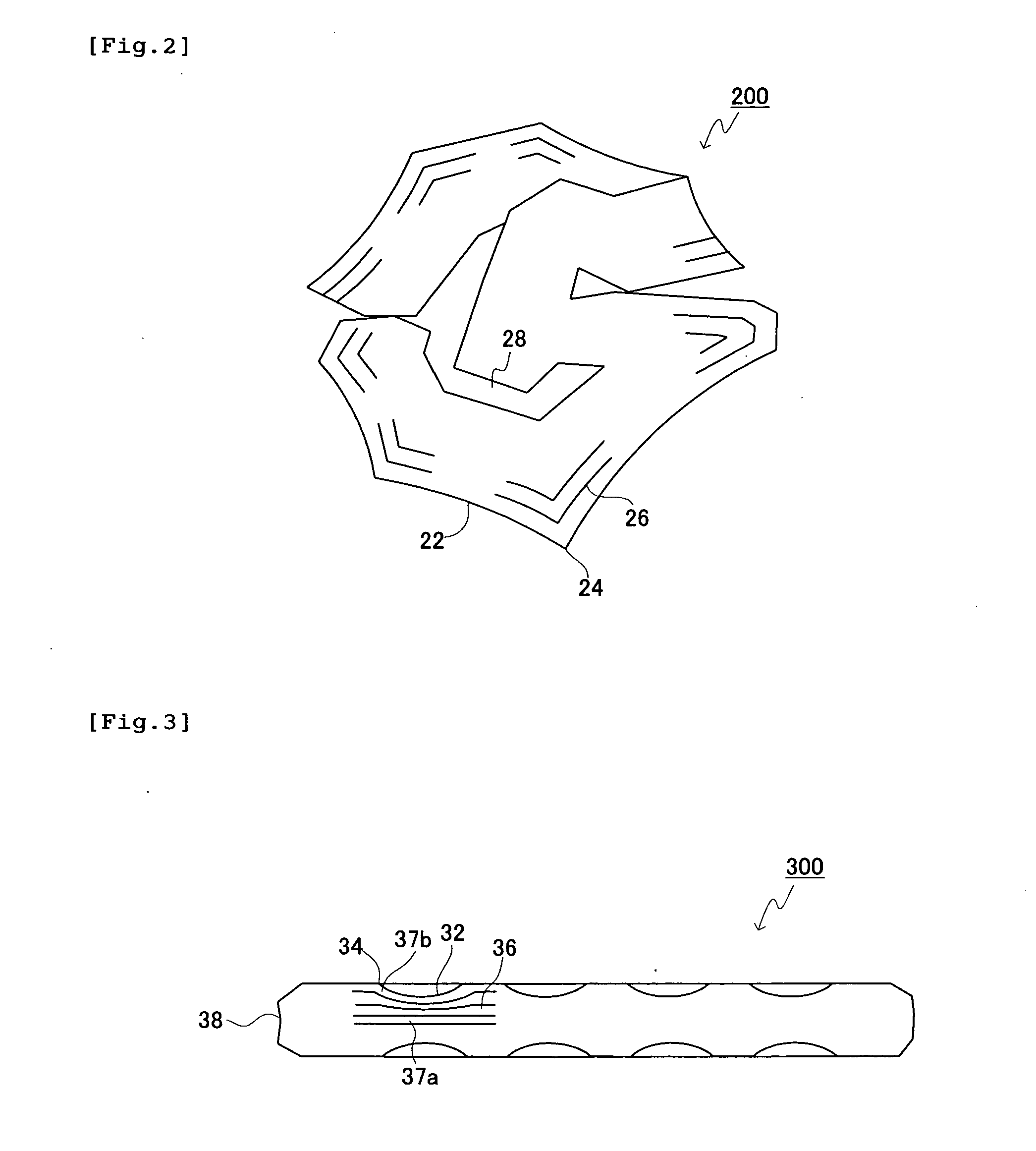

Negative-electrode active material for rechargeable lithium battery

ActiveUS20120077087A1Improved cycle life characteristicsSilver accumulatorsMaterial nanotechnologyCarbon layerMaterials science

The present invention relates to negative-electrode active material for rechargeable lithium battery comprising: a core comprising material capable of doping and dedoping lithium; and, a carbon layer formed on the surface of the core, wherein the carbon layer has a three dimensional porous structure comprising nanopores regularly ordered on the carbon layer with a pore wall of specific thickness placed therebetween.

Owner:LG ENERGY SOLUTION LTD +1

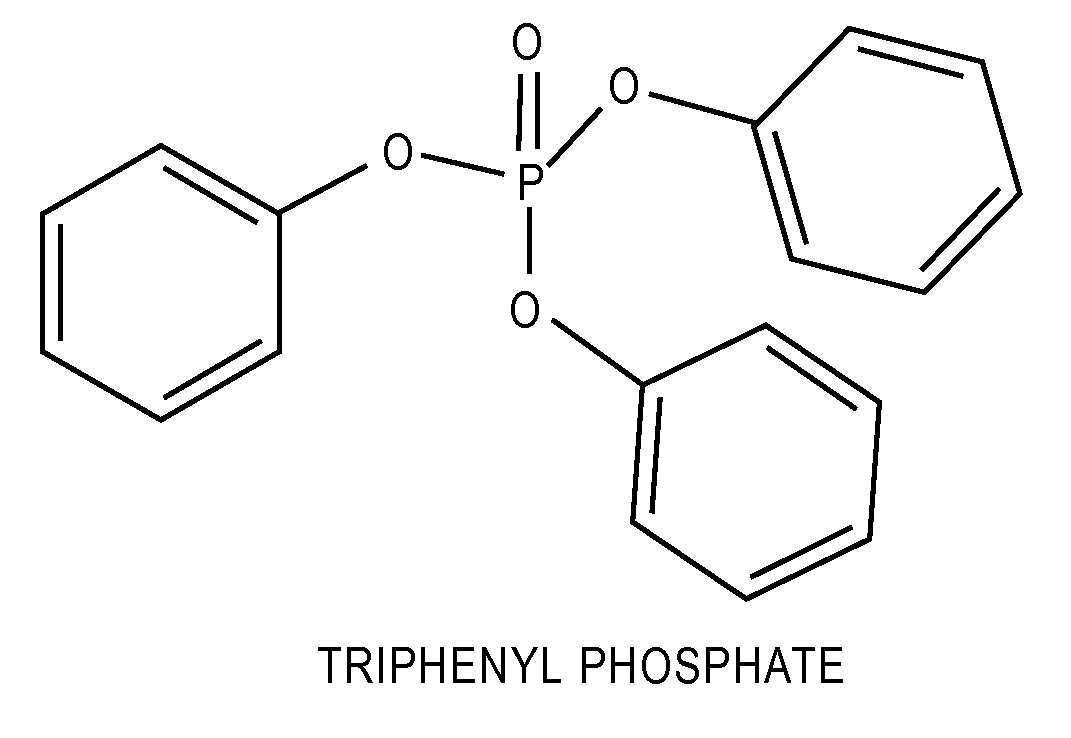

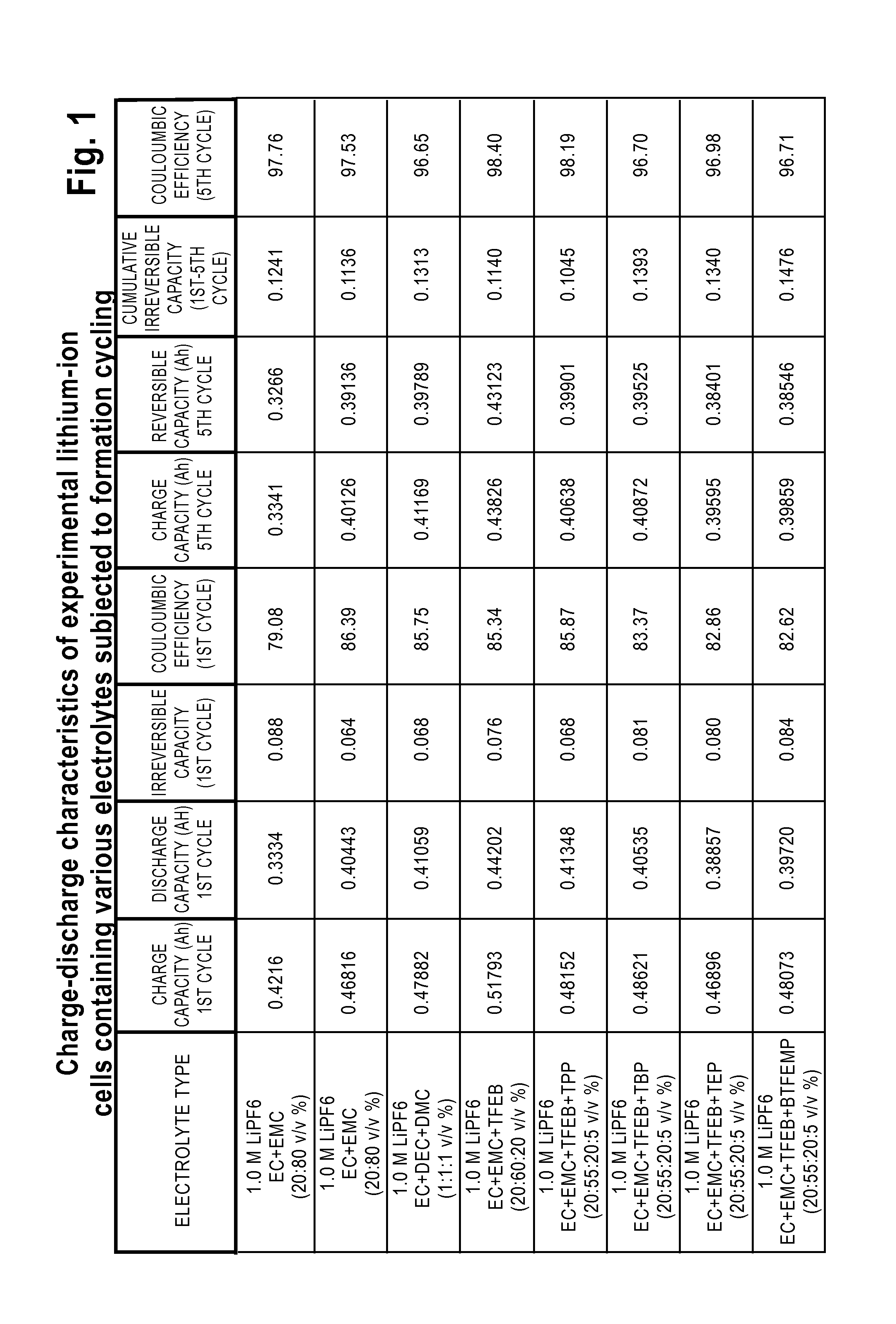

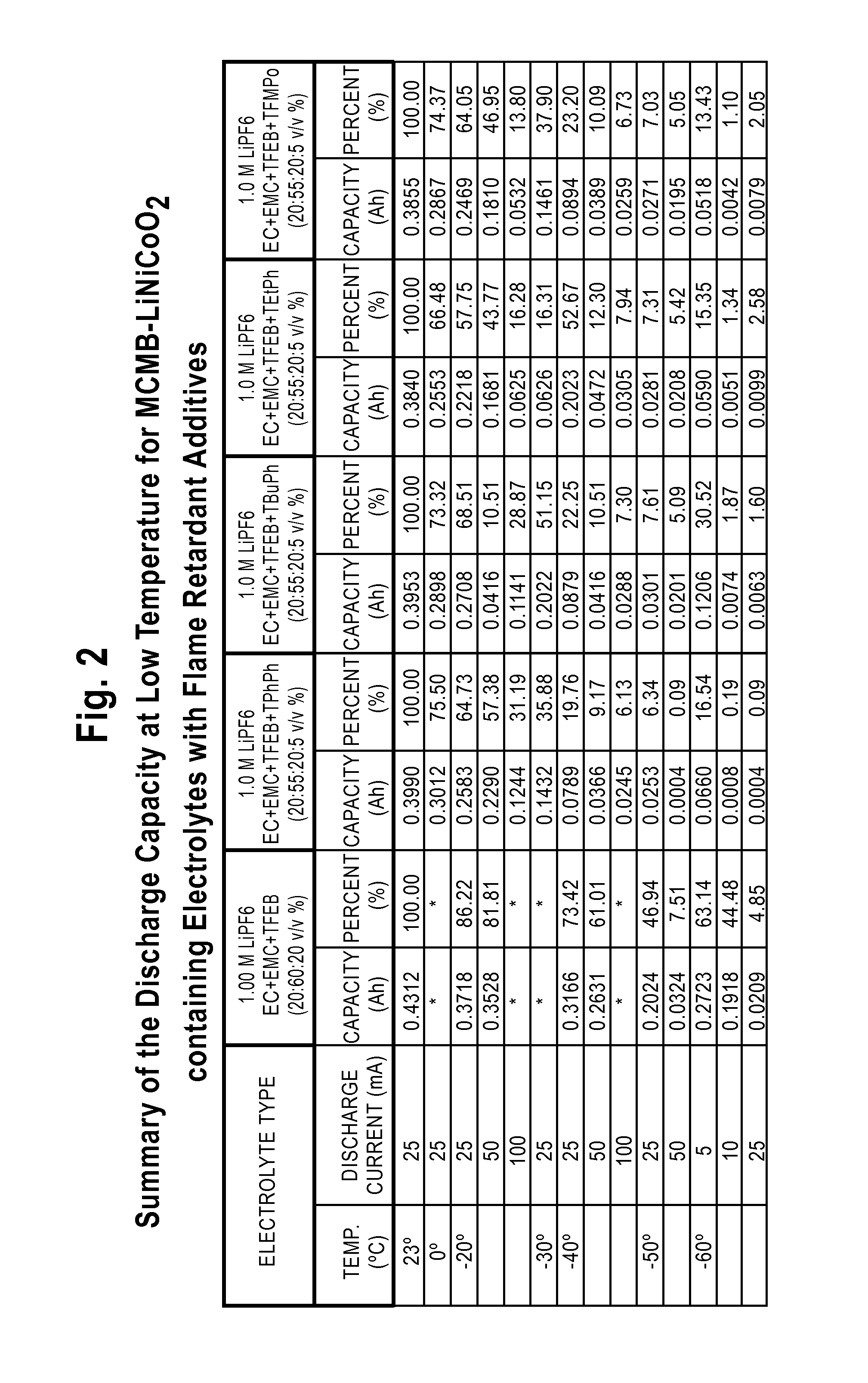

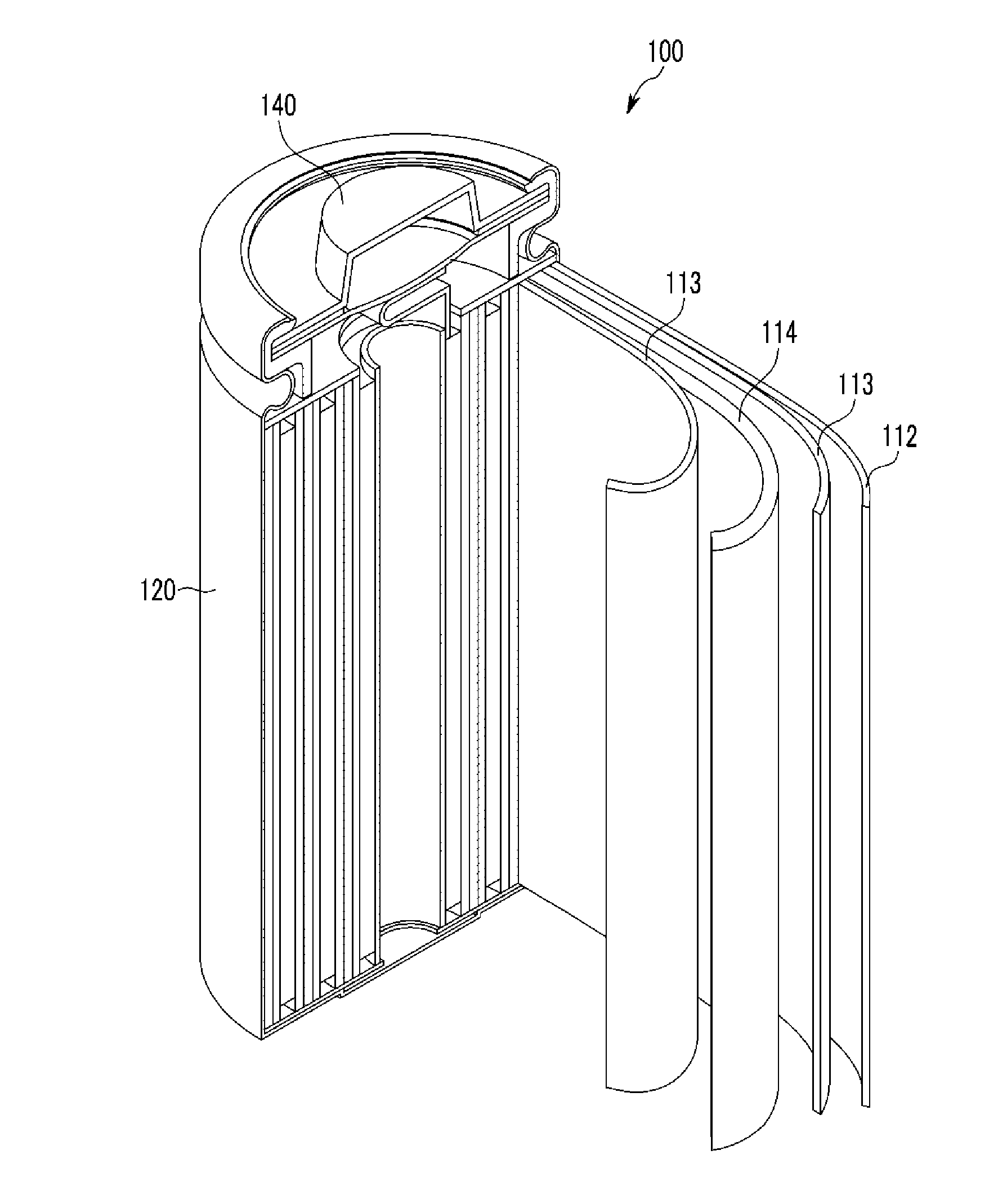

Lithium-ion electrolytes containing flame retardant additives for increased safety characteristics

InactiveUS8795903B2Improve featuresImprove performanceElectrolytic capacitorsOrganic electrolyte cellsMethyl carbonatePhysical chemistry

The invention discloses various embodiments of Li-ion electrolytes containing flame retardant additives that have delivered good performance over a wide temperature range, good cycle life characteristics, and improved safety characteristics, namely, reduced flammability. In one embodiment of the invention there is provided an electrolyte for use in a lithium-ion electrochemical cell, the electrolyte comprising a mixture of an ethylene carbonate (EC), an ethyl methyl carbonate (EMC), a fluorinated co-solvent, a flame retardant additive, and a lithium salt. In another embodiment of the invention there is provided an electrolyte for use in a lithium-ion electrochemical cell, the electrolyte comprising a mixture of an ethylene carbonate (EC), an ethyl methyl carbonate (EMC), a flame retardant additive, a solid electrolyte interface (SEI) film forming agent, and a lithium salt.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

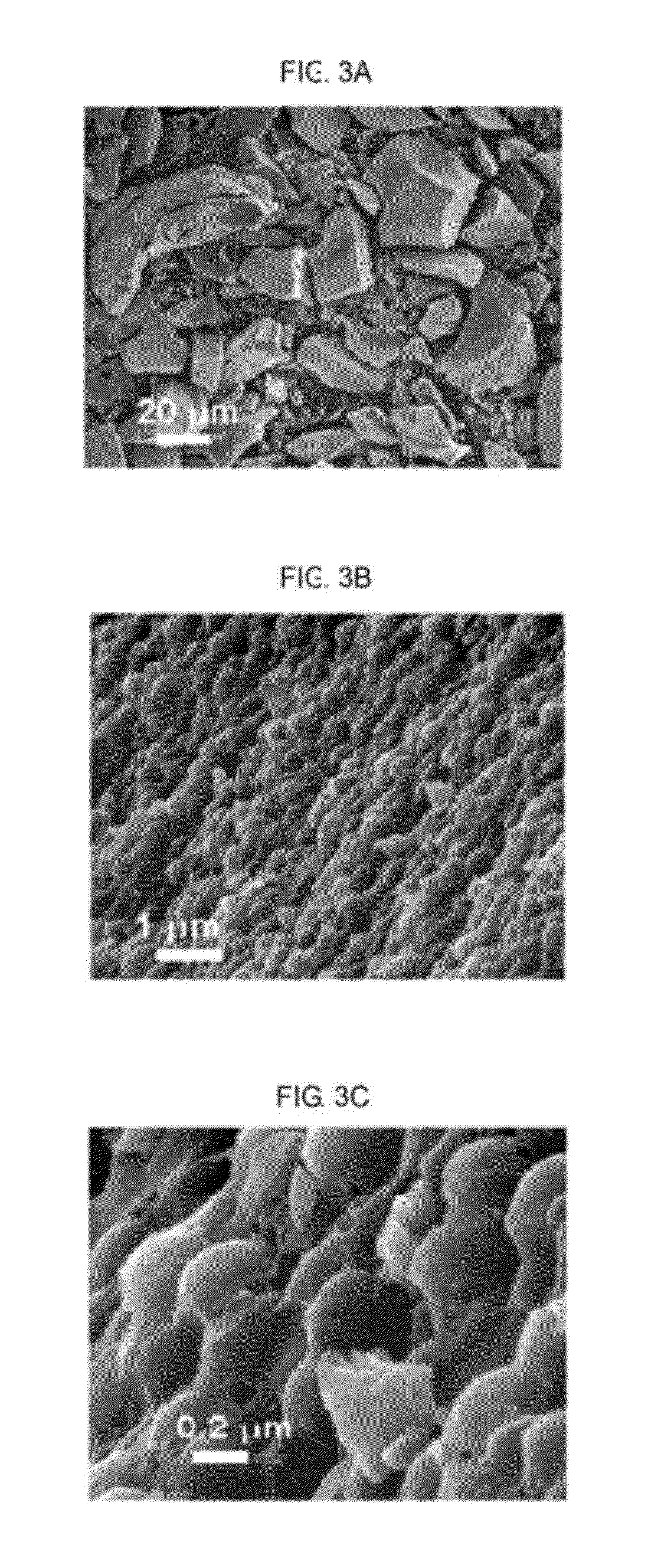

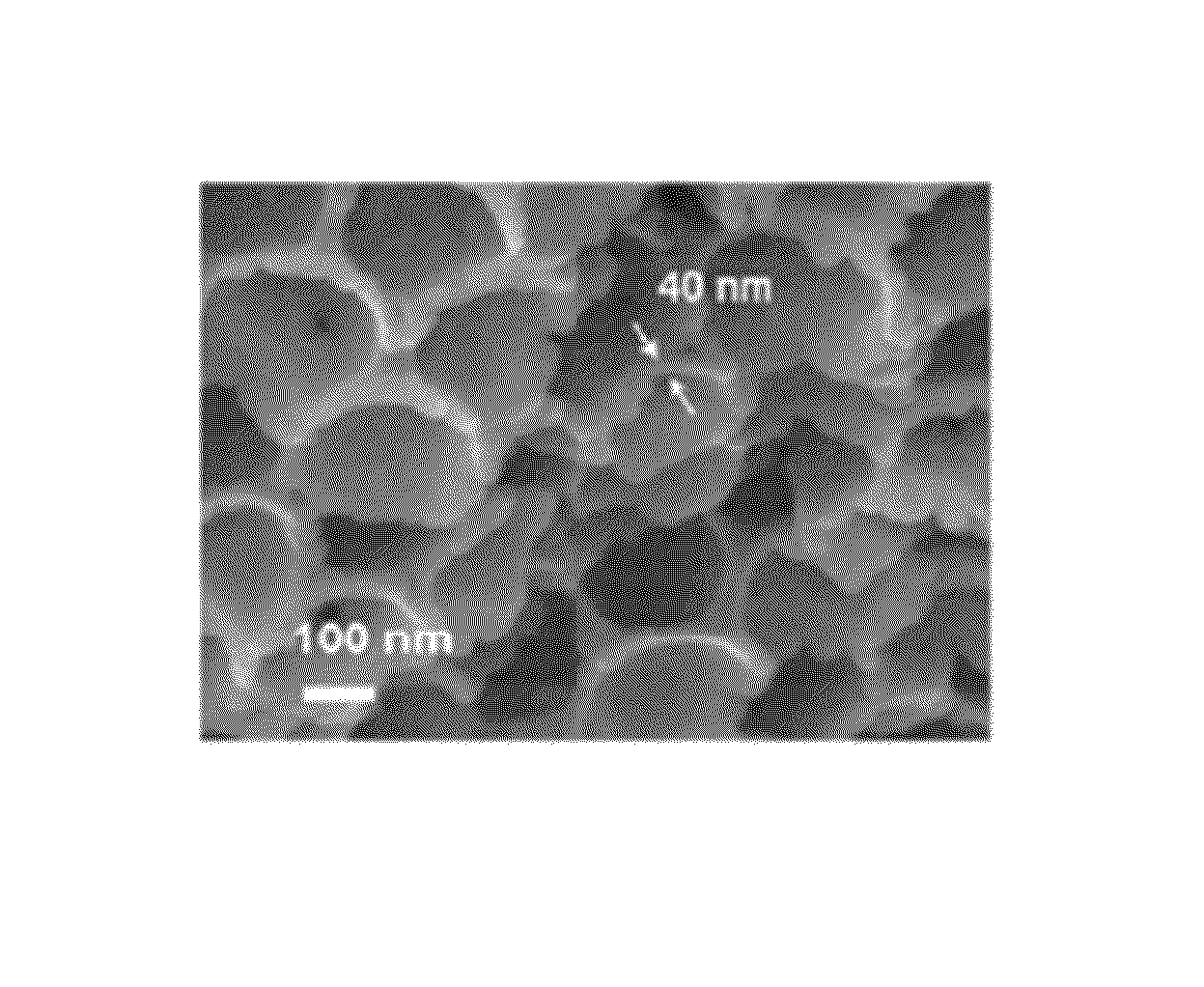

Negative electrode active material for rechargeable lithium battery, method for preparing the same and rechargeable lithium battery including the same

InactiveUS20140356707A1Improved cycle life characteristicsInhibition of irreversible reactionsLi-accumulatorsNon-aqueous electrolyte accumulator electrodesGraphiteSpherical form

The present invention relates to a negative electrode active material for a rechargeable lithium battery, a method for preparing the same, and a rechargeable lithium battery including the same. This invention provides a negative electrode active material for a rechargeable lithium battery, comprising a core part including a spherical graphite, and a coating layer containing a low crystalline carbon material and coated on a surface of the core part, wherein a pore volume of less than or equal to 2000 nm is 0.08 ml / g or less, and a tap density is 1.1 g / cm3 or more.

Owner:POSCO CHEMTECH CO LTD

Cathode active material, cathode and lithium battery including cathode active material, and method of preparing the cathode active material

ActiveUS20140193714A1Large capacityImproved cycle life characteristicsLi-accumulatorsNon-aqueous electrolyte accumulator electrodesNiobiumLithium metal

A cathode active material including a lithium metal oxide composite having a first domain and a second domain and represented by Formula 1:x[Li2-y(M1)1-z(M2)y+zO3]-(1−x)[LiMeO2] Formula 1wherein0<x<1,0≦y<1,0≦z<1,0<y+z<1,M1 includes at least one transition metal,M2 includes at least one metal selected from magnesium (Mg), aluminum (Al), vanadium (V), zinc (Zn), molybdenum (Mo), niobium (Nb), lanthanum (La), and ruthenium (Ru), andMe includes at least one metal selected from nickel (Ni), cobalt (Co), manganese (Mn), iron (Fe), chromium (Cr), titanium (Ti), copper (Cu), aluminum (Al), magnesium (Mg), zirconium (Zr), and boron (B).

Owner:SAMSUNG SDI CO LTD

Positive active material for rechargeable lithium battery and method of preparing same

InactiveUS20050084757A1Good cycle life characteristicImproved cycle life characteristicsElectrode manufacturing processesNon-aqueous electrolyte accumulatorsOxideMaterials science

A positive active material for rechargeable lithium batteries includes an active material component processed from a manganese-based compound. The transition metal compound is selected from LixMnO2, LixMnF2, LixMnS2, LixMnO2-zFz, LixMnO2-zSz, LixMn1-yMyO2, LixMn1-yMyF2, LixMn1-yMyS2, LixMn1-yMyO2-zFz, LixMn1-yO2-zSz, LixMn2O4, LixMn2F4, LixMn2S4, LixMn2O4-zFz, LixMn2O4-zSz, LixMn2-yMyO4, LixMn2-yMyF4, LixMn2-yMyS4, LixMn2-yMyO4-zFz, or LixMn2-yMyO4-zSz where 0<x≦1.5, 0.05≦y≦0.3, z≦1.0 and M is selected from Al, Co, Cr, Mg, Fe or La. A metallic oxide is coated on the active material component.

Owner:KWEON HO JIN +3

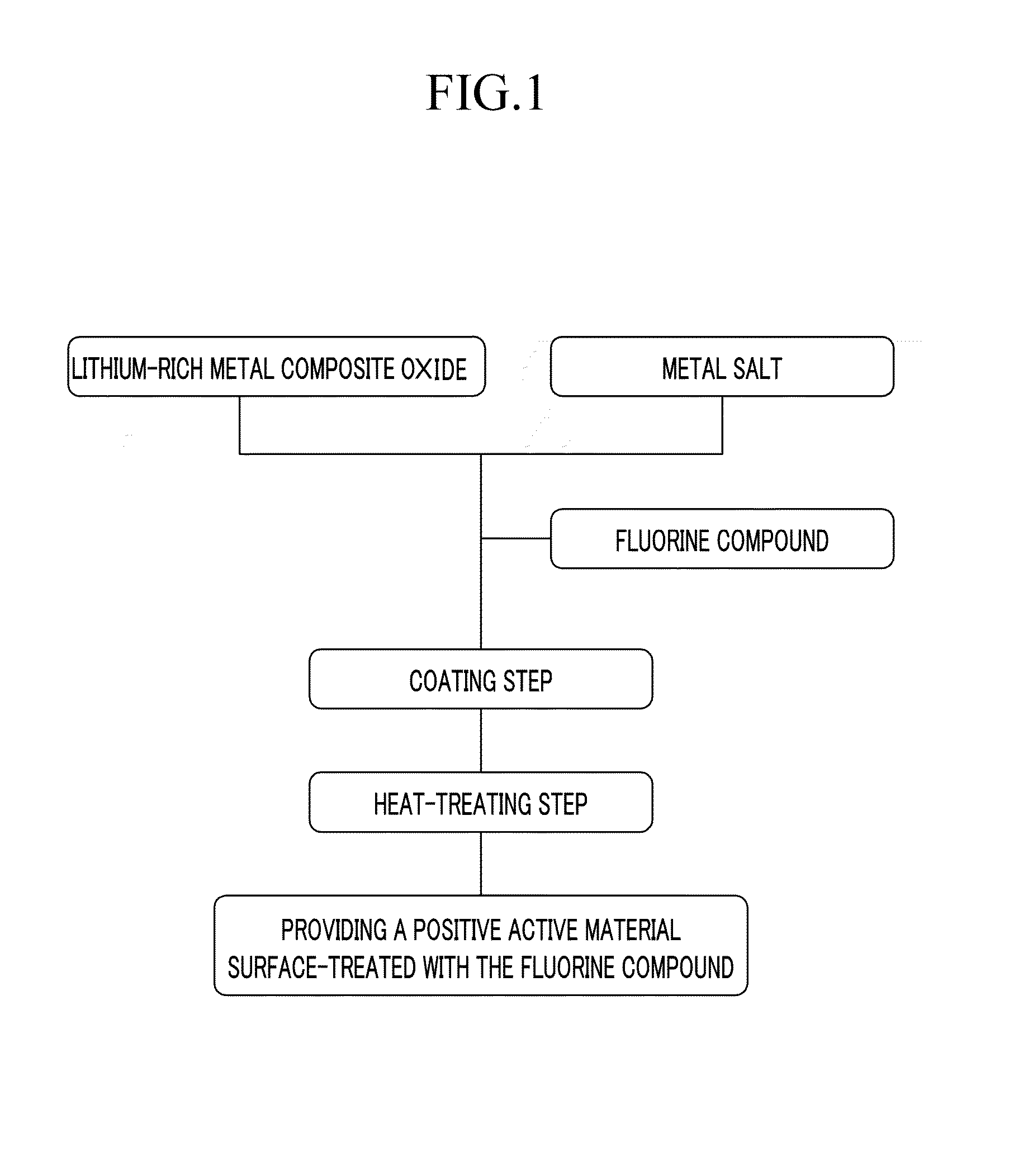

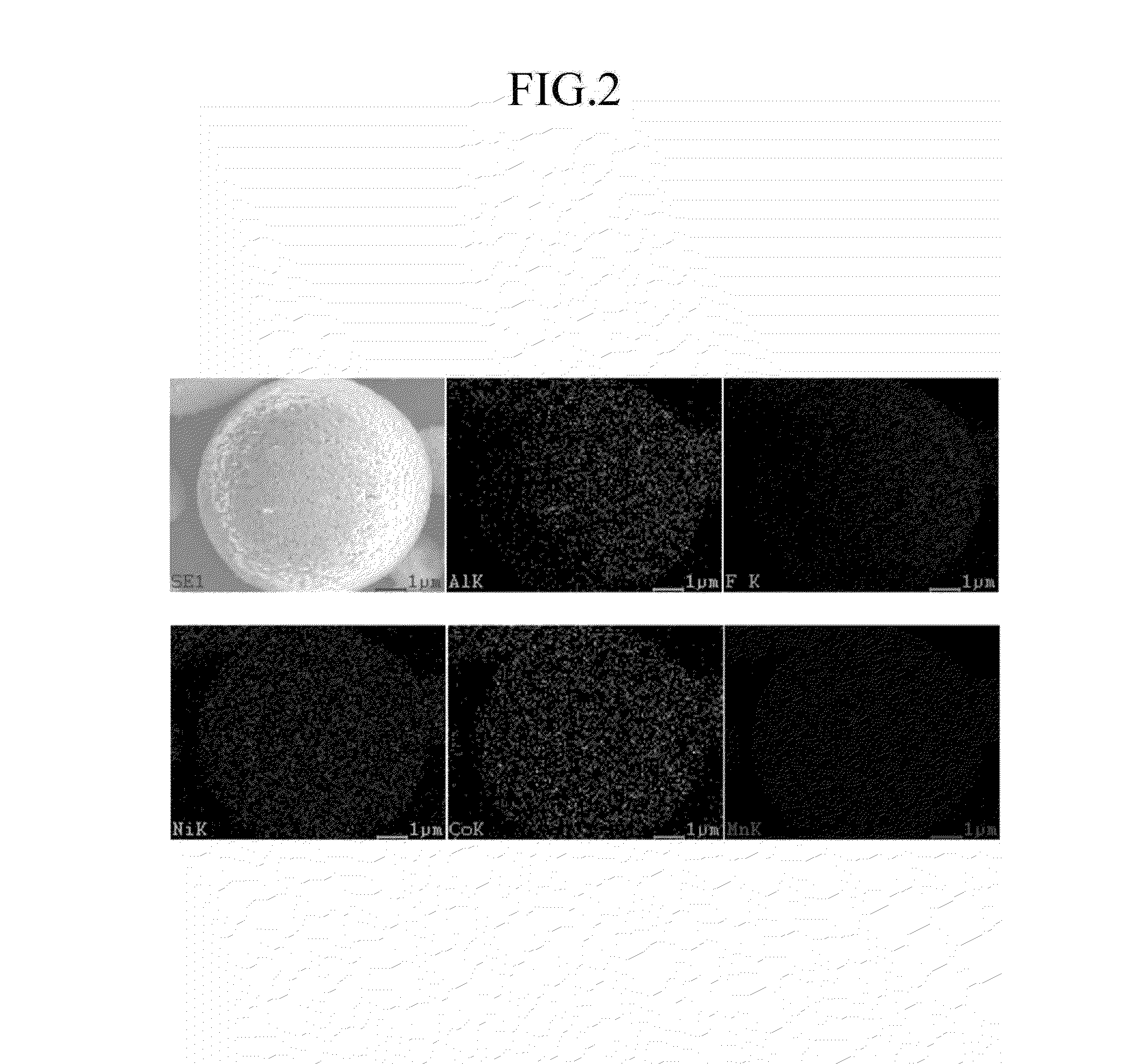

Cathode active material for a lithium secondary battery, method for manufacturing same, and lithium secondary battery including same

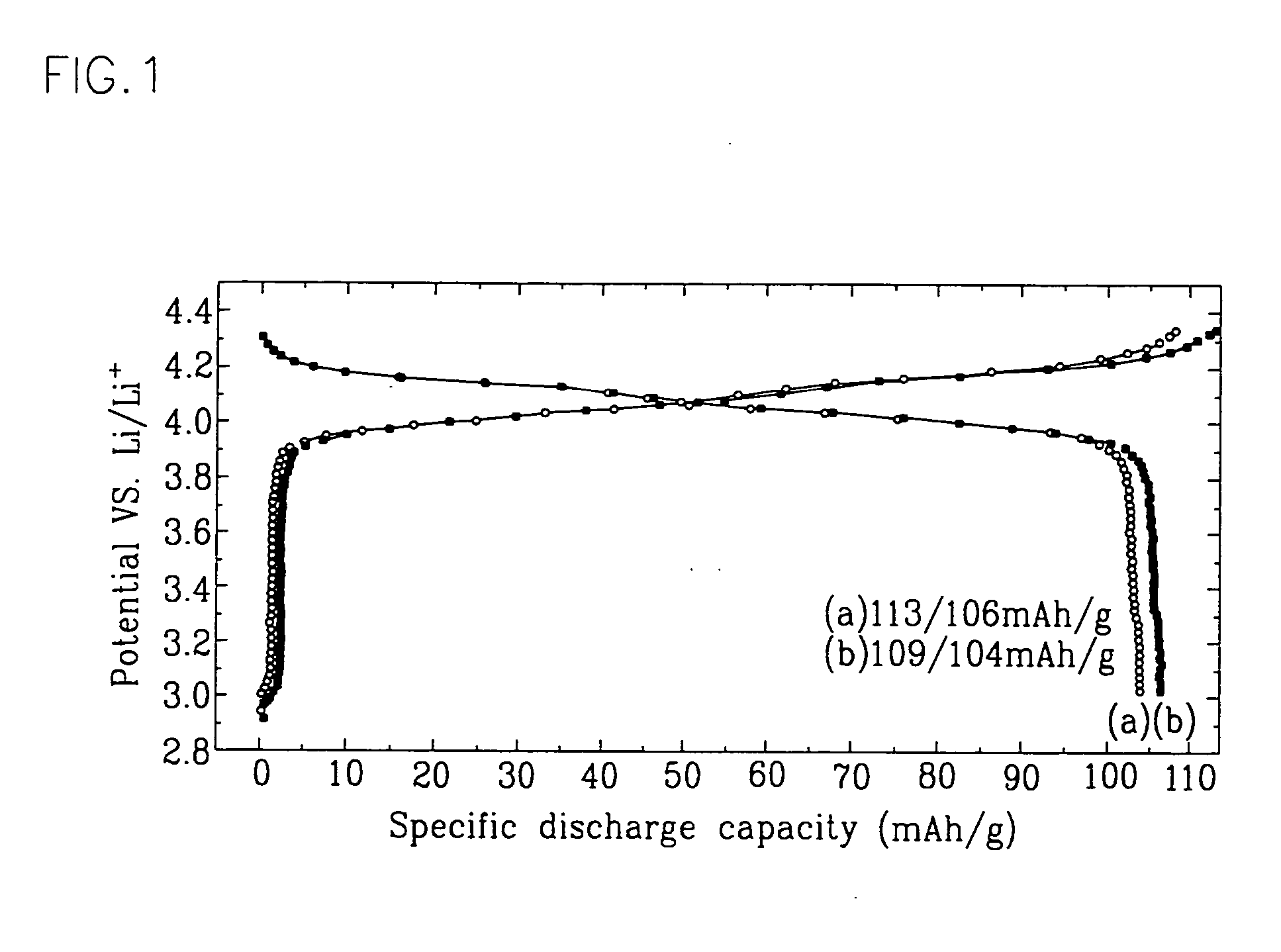

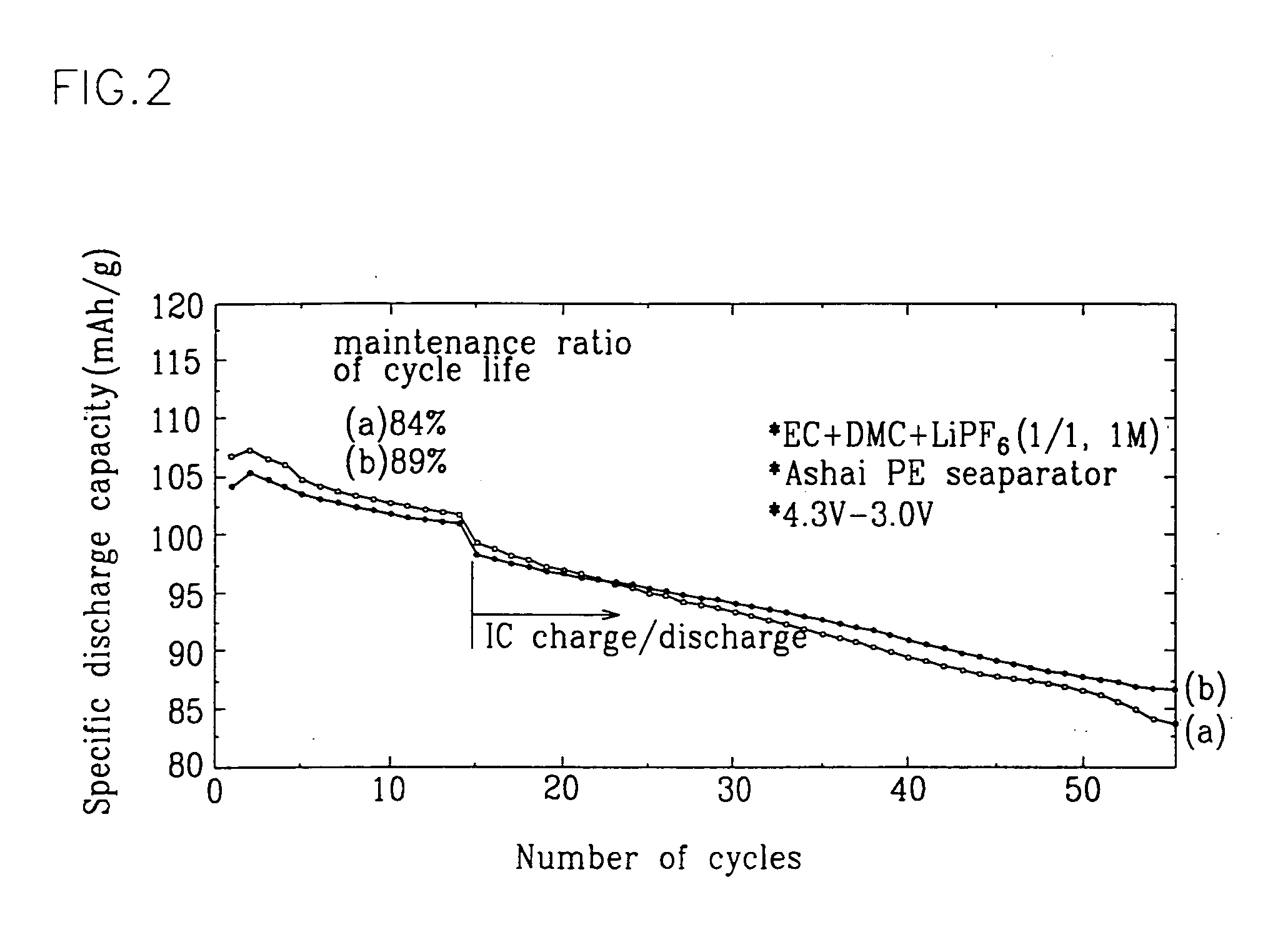

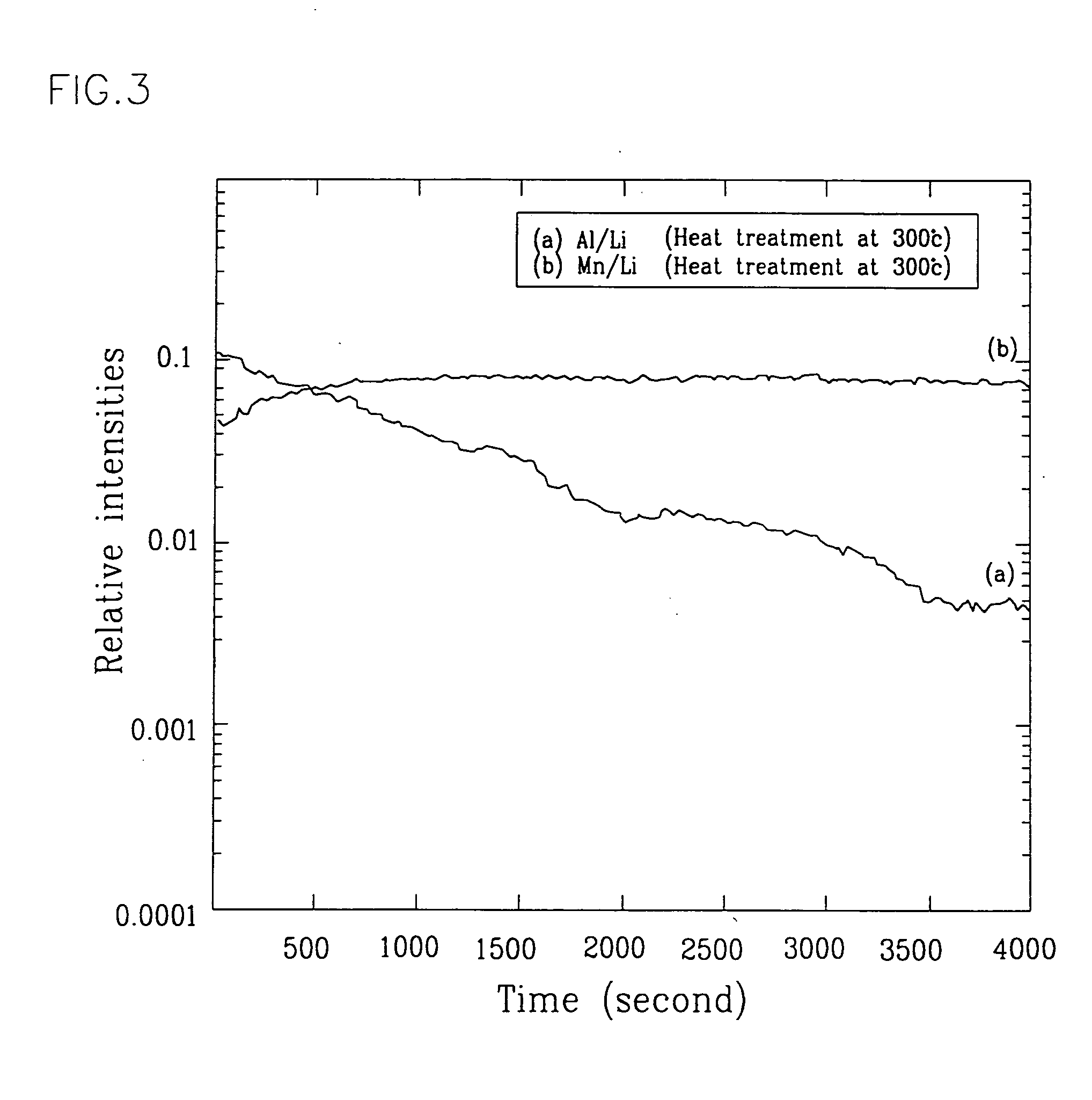

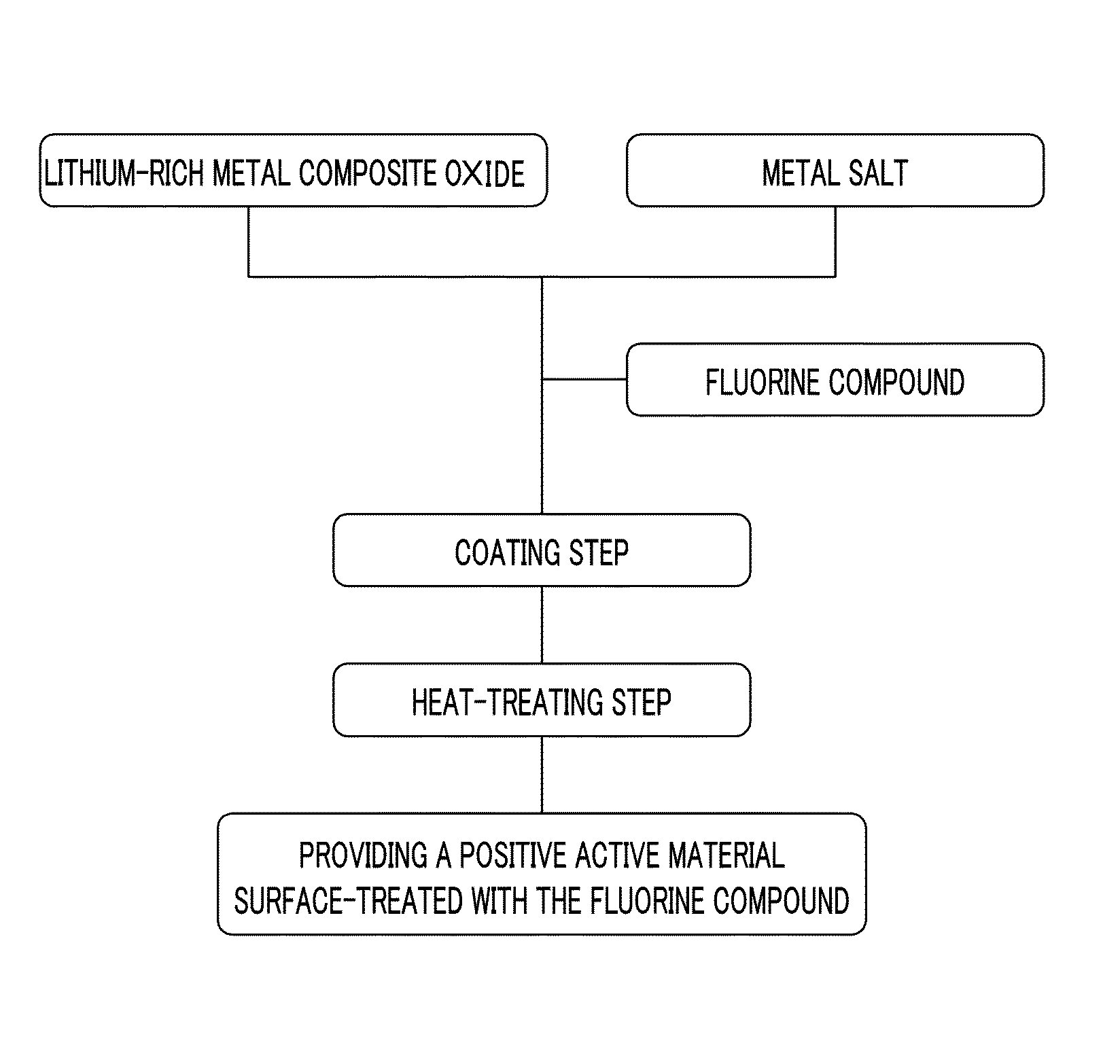

InactiveUS20140242463A1Improved cycle life characteristicsSuppressing deterioration and manganese elutionSilver accumulatorsElectrode thermal treatmentElectrical batteryLithium metal

The present invention provides a positive active material for a secondary lithium battery, a method of preparing the positive active material, and a secondary lithium battery including the positive active material, wherein the positive active material includes a lithium metal composite oxide core represented by the following Chemical Formula 1, and a coating layer including a fluorine compound and positioned at a shell of the lithium metal composite oxide core.LiwNixCoyMn1-x-y-zMzO2 [Chemical Formula 1](1.2≦w≦1.5, 0<x<1, 0≦y<1, 0.5≦1-x-y-z, and M is at least one metal selected from the group consisting of Al, Mg, Fe, Cu, Zn, Cr, Ag, Ca, Na, K, In, Ga, Ge, V, Mo, Nb, Si, Ti, and Zr).

Owner:KOREA ELECTRONICS TECH INST

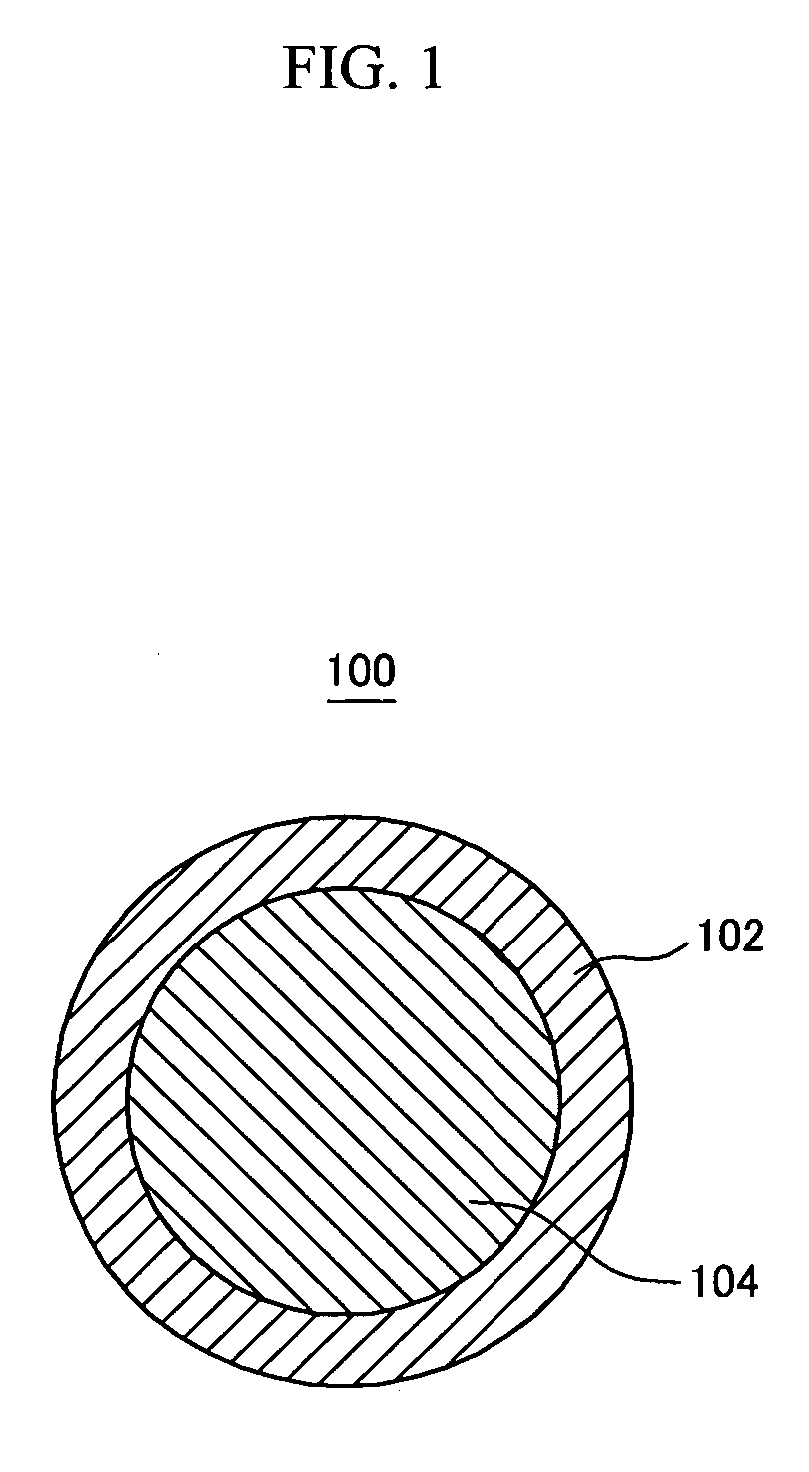

Core-shell spinel cathode active materials for lithium secondary batteries, lithium secondary batteries using the same and method for preparing thereof

ActiveUS20090272939A1Improved cycle life characteristicsLow-cost and high-output characteristicsSolid electrolyte cellsActive material electrodesLithiumSulfur

Disclosed herein is a core-shell spinel cathode active material for lithium secondary batteries. The core portion of the active material is made of a spinel manganese-containing material substituted with fluorine or sulfur, having 4V-grade potential and showing low-cost and high-output characteristics, and the shell portion, which comes into contact with an electrolyte, is made of a spinel transition metal-containing material, having excellent thermal stability and cycle life characteristics and showing low reactivity with the electrolyte. Thus, the cathode active material shows significantly improved cycle life characteristics and excellent thermal stability.

Owner:SK ON CO LTD

Negative active material for rechargeable lithium battery, method of preparing the same, and rechargeable lithium battery including the same

ActiveUS20080145758A1Large capacityImproved cycle life characteristicsSilver accumulatorsElectrode manufacturing processesHigh rateMaterials science

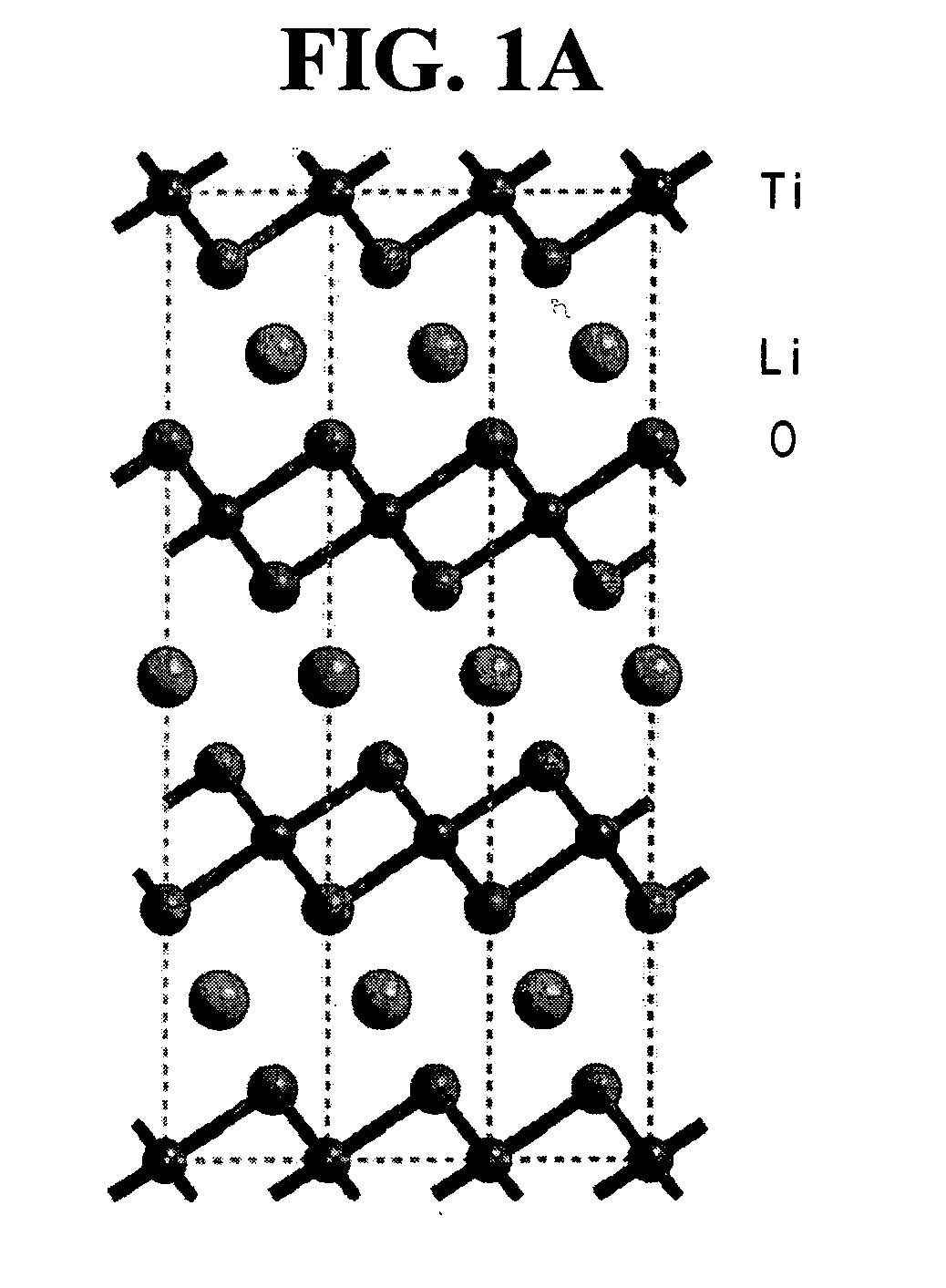

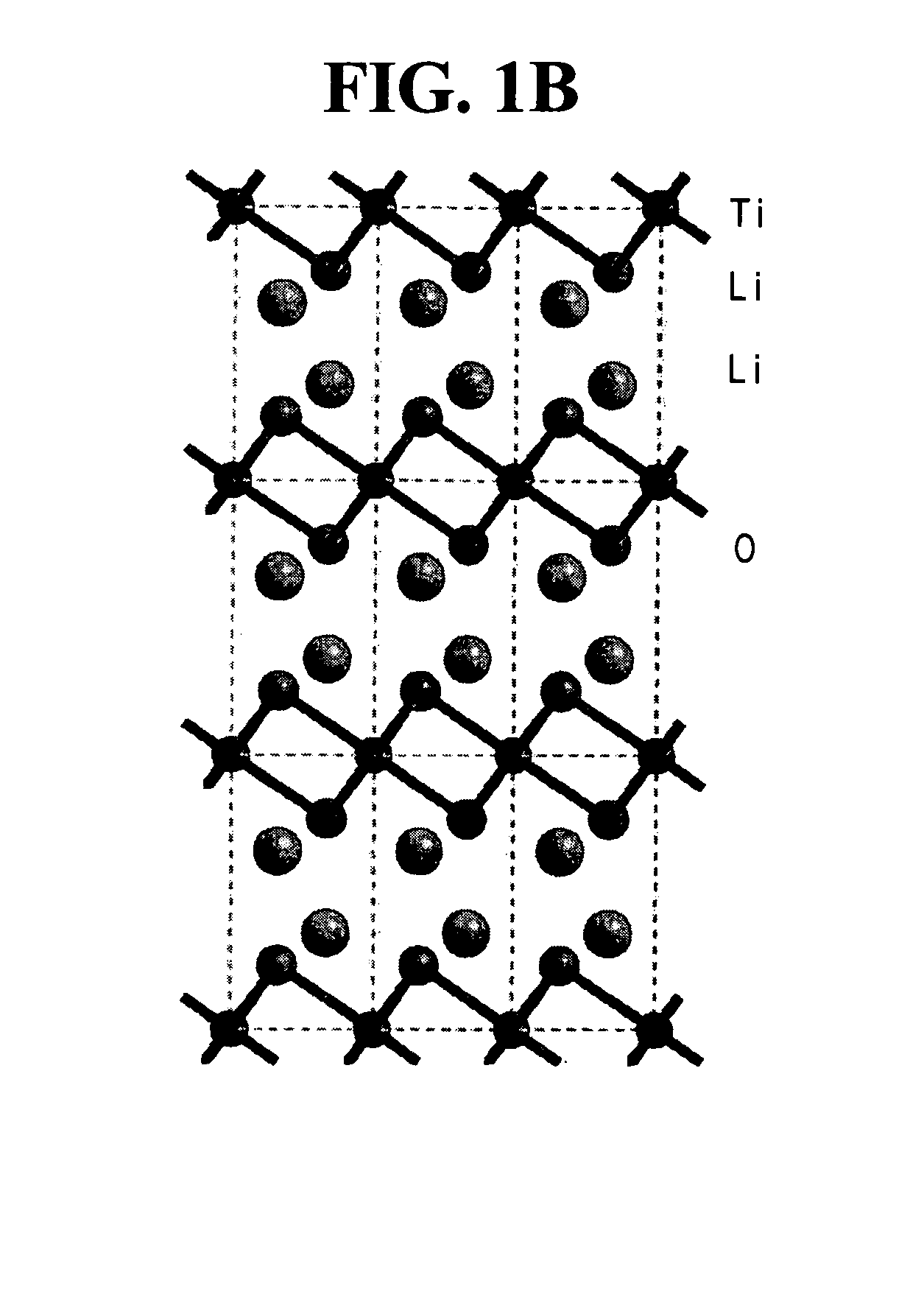

A negative active material for a rechargeable lithium battery includes a compound represented by the following Formula 1:Li1+xTi1−x−yMyO2+z (1)wherein, in the above Formula 1, 0.01≦x≦0.5, 0≦y≦0.3, −0.2≦z≦0.2, and M is an element selected from the group consisting of V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Zr, Nb, Mo, W, Ag, Sn, Ge, Si, Al, and combinations thereof. The negative active material has high capacity and excellent cycle-life characteristics, and particularly, can provide a rechargeable lithium battery having high capacity at high-rate charge and discharge.

Owner:SAMSUNG SDI CO LTD

Rechargeable lithium battery

ActiveUS20100159336A1Improve reliabilityExcellent cycle-life characteristicNon-aqueous electrolyte accumulatorsElectrolytic capacitorsHalogenPhysical chemistry

Owner:SAMSUNG SDI CO LTD

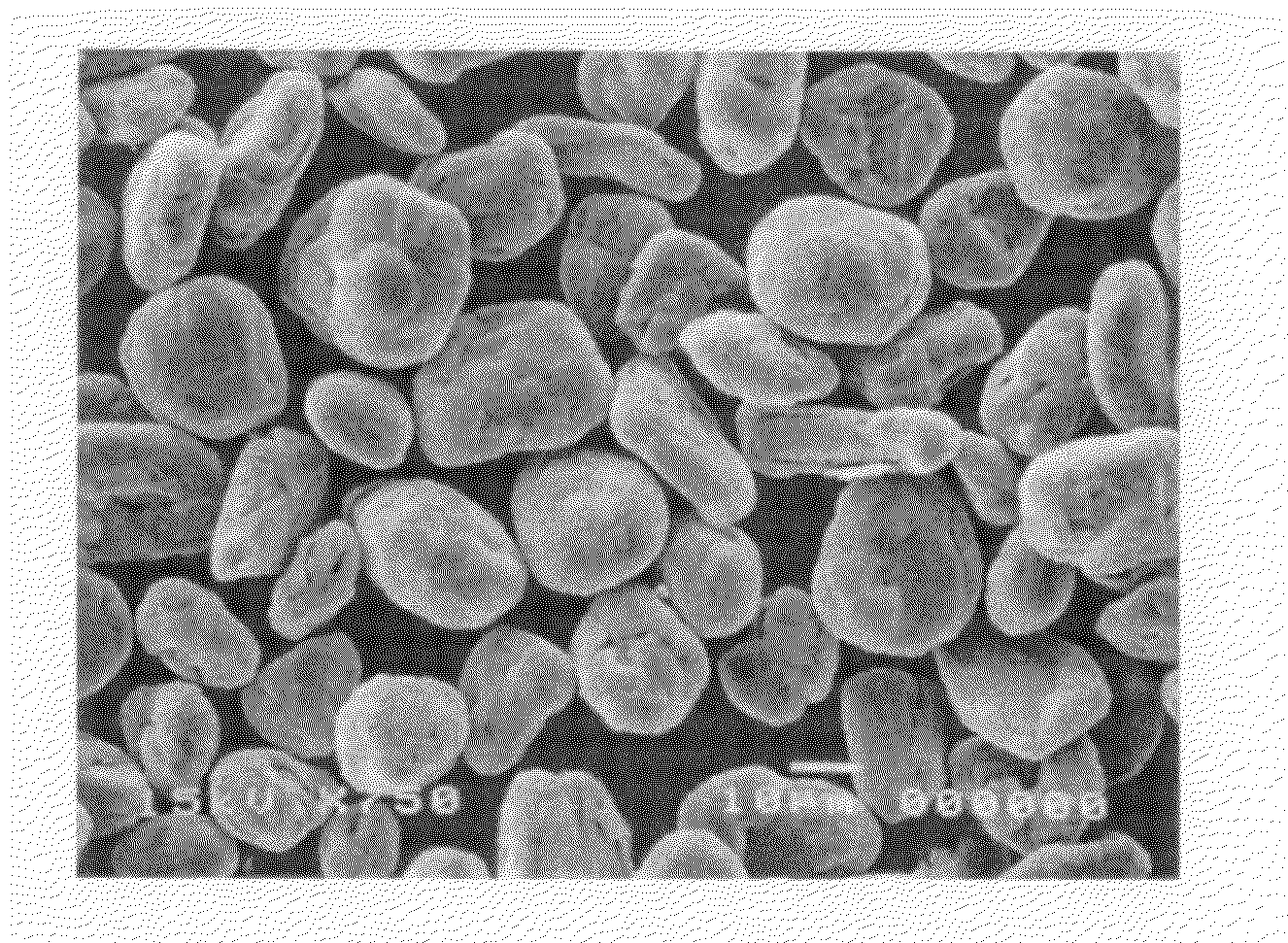

Graphite Particle, Carbon-Graphite Composite Particle and Their Production Processes

ActiveUS20090258298A1Improved cycle life characteristicsLarge capacityGraphiteElectrode carriers/collectorsCarbon layerLithium

The present invention relates to a graphite particle and a carbon-graphite composite particle both suitable for use in electrode for lithium ion secondary battery, as well as to processes for producing these particles.The graphite particle of the present invention has an average particle diameter of 5 to 50 μm, wherein one or more recesses having a depth of 0.1 to 10 μm are formed in the surface. The graphite particle is produced by a mixing step for mixing raw material graphite particles and recess-forming particles, a press molding step for press-molding the mixture composed of the raw material graphite particles and the recess-forming particles to obtain a molded article, a pulverization step for pulverizing the molded article, and a separation step for separating and removing the recess-forming particles from the pulverized molded article. The carbon-graphite composite particle of the present invention is produced by performing a thermal CVD step which comprises covering the surface of the above-mentioned graphite particle with a carbon layer.

Owner:NIPPON POWER GRAPHITE CO LTD

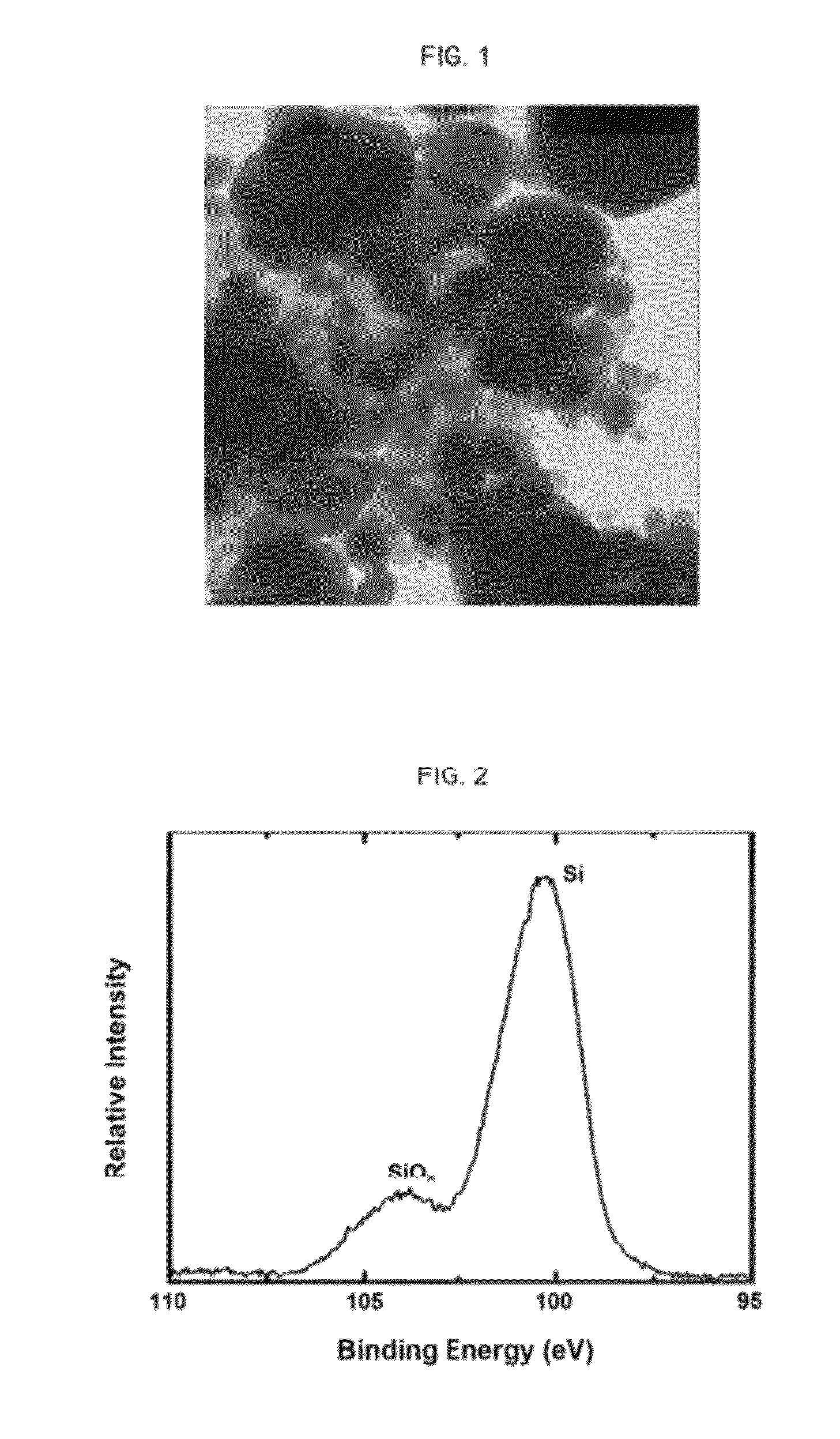

Negative-electrode active material for rechargeable lithium battery

ActiveUS8669008B2Improved cycle life characteristicsSilver accumulatorsMaterial nanotechnologyCarbon layerNanopore

The present invention relates to negative-electrode active material for rechargeable lithium battery comprising: a core comprising material capable of doping and dedoping lithium; and, a carbon layer formed on the surface of the core, wherein the carbon layer has a three dimensional porous structure comprising nanopores regularly ordered on the carbon layer with a pore wall of specific thickness placed therebetween.

Owner:LG ENERGY SOLUTION LTD +1

Rechargeable lithium battery

InactiveUS20090068562A1Increased initial formation efficiencyImproved cycle life characteristicsOrganic electrolyte cellsSecondary cellsOrganic solventMetal

A rechargeable lithium battery includes a positive electrode including a positive active material that can reversely intercalate / deintercalate lithium ions, a negative electrode including a negative active material that can reversely intercalate / deintercalate lithium ions, and a non-aqueous electrolyte including includes a non-aqueous organic solvent, a lithium salt, and at least one additive including a dinitrile-based compound. The negative active material includes a compound represented by LixMyVzO2+d wherein 0.1≦x≦2.5, 0≦y≦0.5, 0.5≦z≦1.5, 0≦d≦0.5, and M is a metal selected from the group consisting of Al, Cr, Mo, Ti, W, Zr, and combinations thereof.

Owner:SAMSUNG SDI CO LTD

Electrolyte for lithium ion rechargeable battery and lithium ion rechargeable battery including the same

ActiveUS7235334B2Improved cycle life characteristicsPrevents drop in discharge capacityOrganic electrolyte cellsActive material electrodesHigh temperature storageLithium

The present invention is an electrolyte for a lithium ion rechargeable battery and a lithium ion rechargeable battery that includes the same. More particularly, the present invention discloses an electrolyte for a lithium ion rechargeable battery that provides excellent cycle life characteristics and high-temperatures storage stability and prevents a drop in discharge capacity of a battery at low temperature, and a lithium ion rechargeable battery including the same. The lithium ion rechargeable battery including the electrolyte provides improved cycle life characteristics and prevents the problems of a drop in discharge capacity at low temperature and high-temperature swelling through the formation of a stable SEI film at the initial charge cycle.

Owner:SAMSUNG SDI CO LTD

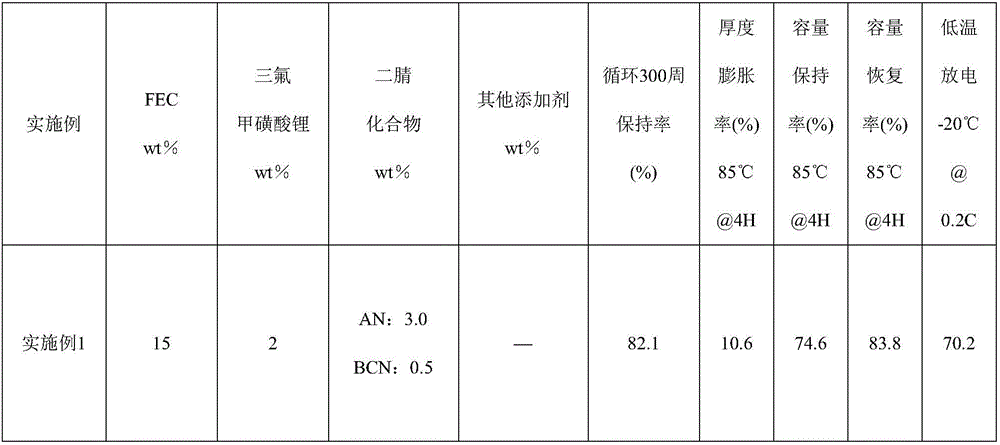

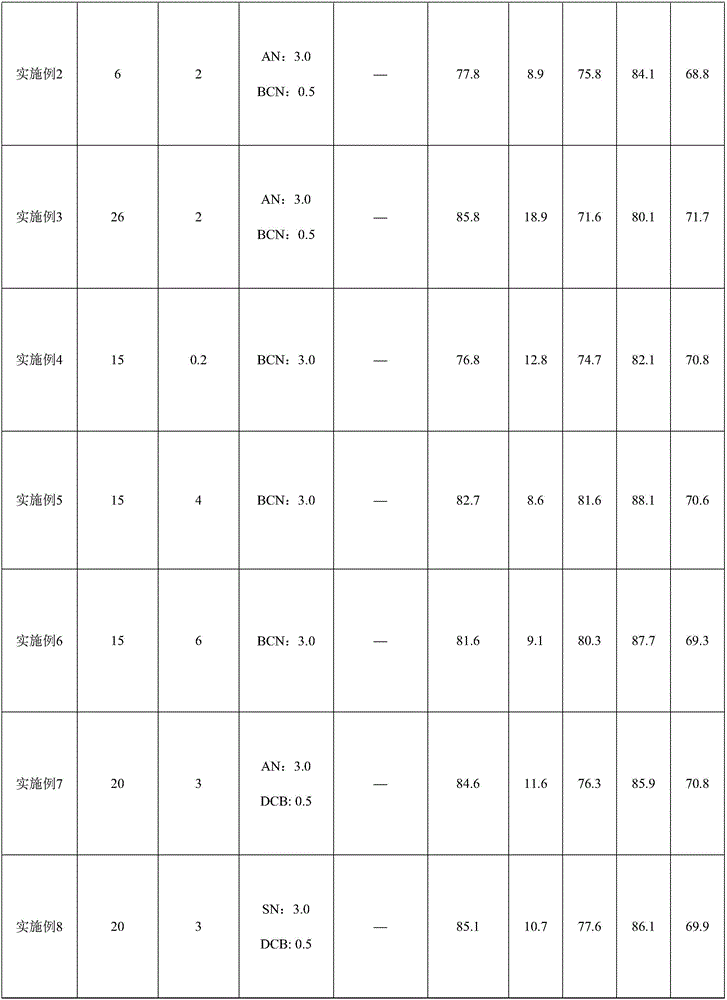

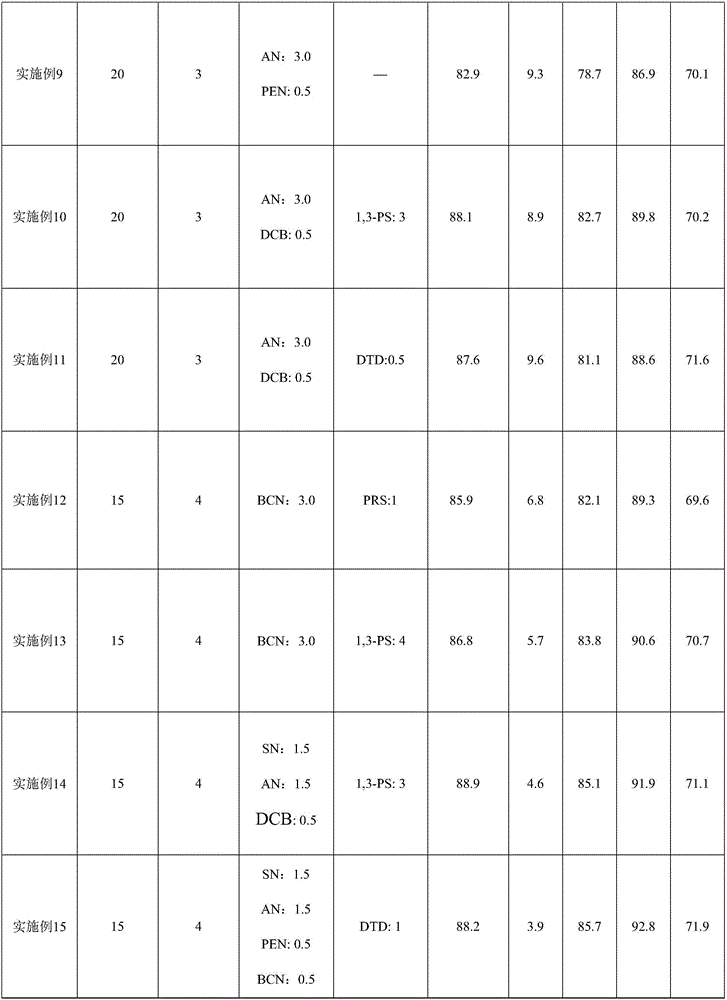

Silicon-based cathode high-voltage lithium ion battery

InactiveCN106099174AImprove cycle performanceImprove cycle lifeSecondary cellsOrganic electrolytesHigh temperature storageTriflic acid

The invention discloses a silicon-based cathode high-voltage lithium ion battery which comprises a negative pole, positive pole, a diaphragm arranged between the negative pole and the positive pole and a nonaqueous electrolyte. An active ingredient of the negative pole is lithium transition metal oxide, an active ingredient of the positive pole is a substance based on Si, the diaphragm is a ceramic diaphragm, the nonaqueous electrolyte comprises a nonaqueous organic solvent, lithium salt and additives, and the additives include fluoroethylene carbonate (FEC), trifluoromethanesulfonic acid (Li SO3F3) and a dinitrile compound. Compared with the prior art, the silicon-based cathode high-voltage lithium ion battery has the advantages that due to synergistic effect generated by combined use of the three additives, an SEI film formed on the surface of an electrode is more stable and compact, and physical and chemical structural stability of the surface of a silicon-carbon cathode is improved, so that a silicon-carbon cathode battery has high high-temperature storage performance and circulating performance.

Owner:GUANGZHOU TINCI MATERIALS TECH

Negative Electrode Material for Lithium Secondary Battery and its Manufacturing Method, and Negative Electrode for Lithium Secondary Battery, and Lithium Secondary Battery

ActiveUS20140054492A1Easy to deal withExcellent cycle characteristicsFinal product manufactureElectrode carriers/collectorsOptoelectronicsWater resistant

[Object] The object is to provide a negative electrode material for a lithium secondary battery, wherein a sulfide-based negative electrode with water-resistant properties can exert excellent cycle characteristics and high output performance while maintaining a high discharge capacity and there is no precipitation of lithium dendrites during charge at low temperature.[Means for Solving Problems] A negative electrode material for a lithium secondary battery comprising sulfur and sulfide glass including the following components (i) and (ii):(i) at least one or more elements selected from a group consisting of Sb, As, Bi, Ge, Si, Cu, Zn, Pd, In and Zr; and(ii) at least one or more elements selected from a group consisting of Se, Te, Ga, Sn, Pb, Cd, Al, Fe, Mg, Ca, Co, Ag, Sr, P and Ba,wherein the ratio of the above components is sulfur: 40-80 mol %, (i): 1-50 mol % and (ii): 1-50 mol %, respectively.

Owner:ISUZU GLASS +1

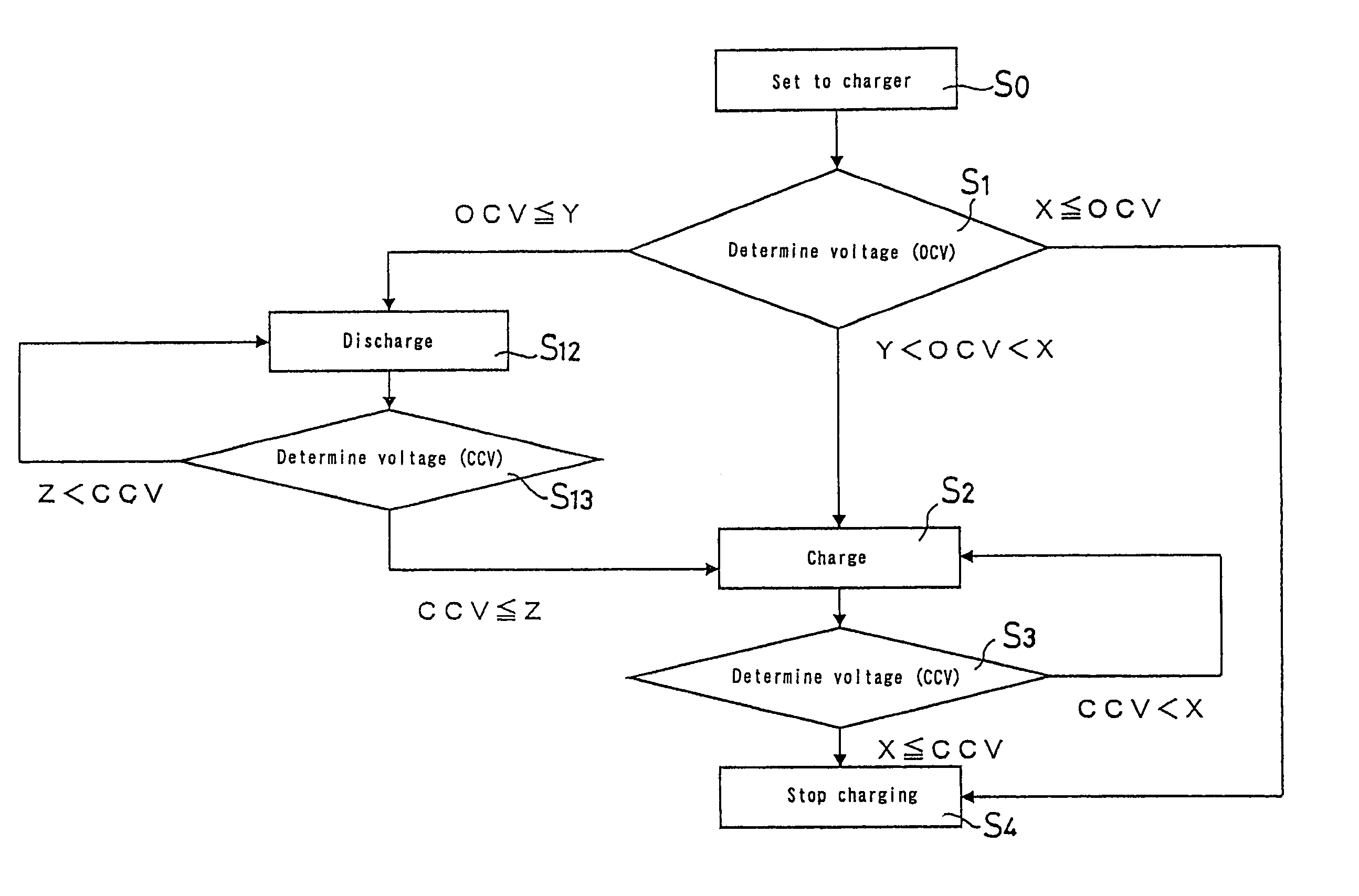

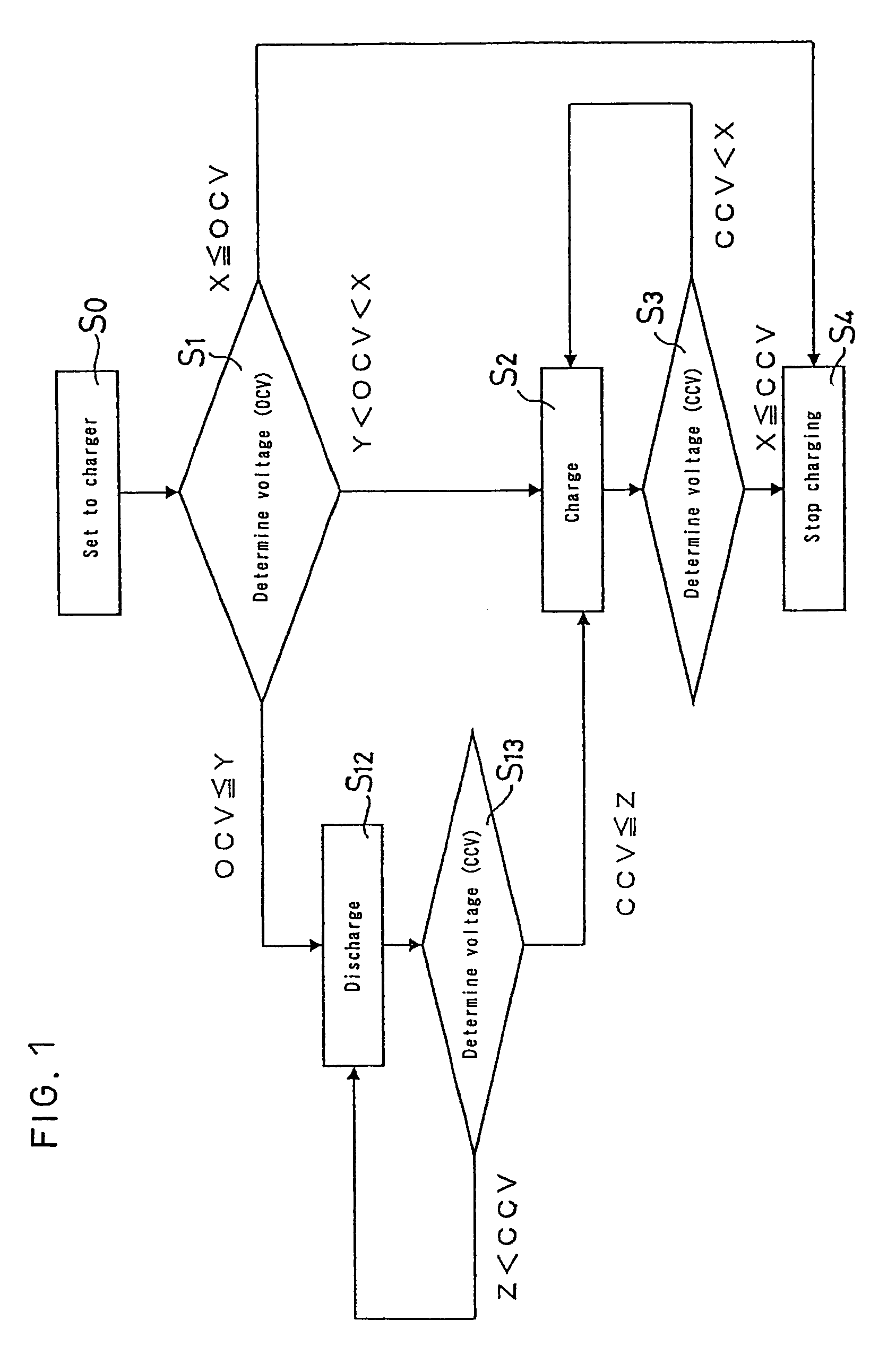

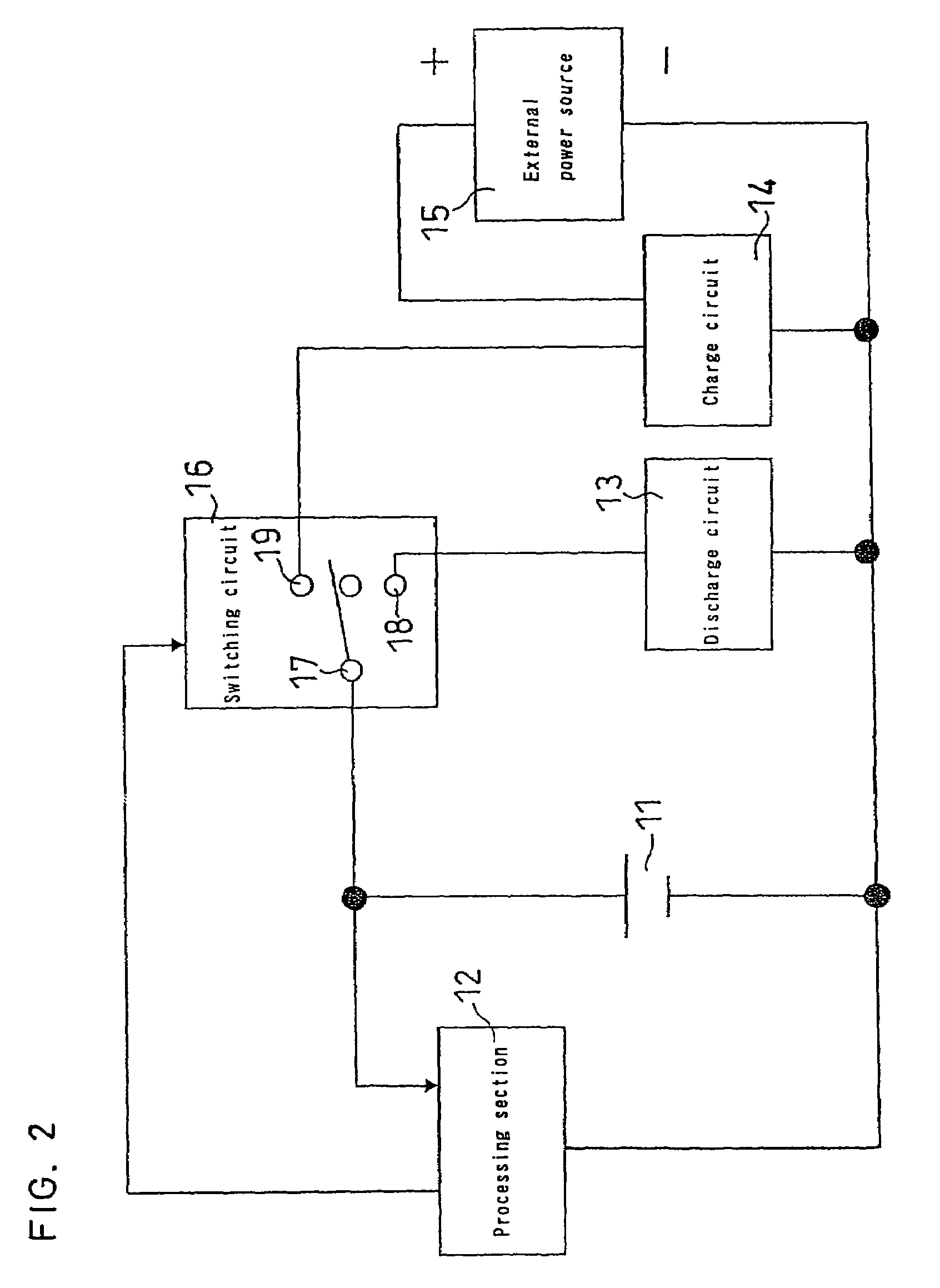

Method for charging a non-aqueous electrolyte secondary battery and charger therefor

InactiveUS7071653B2Improved cycle life characteristicsBatteries circuit arrangementsSecondary cells charging/dischargingEngineeringComposite oxide

A method for charging a non-aqueous electrolyte secondary battery, the battery comprising a positive electrode that comprises a lithium-containing composite oxide, a negative electrode, and a non-aqueous electrolyte. The method comprises the step of detecting an open-circuit-voltage of the battery to determine which of voltage regions A, B and C the detected value is included in. The region A is not smaller than a prescribed value X. The region B is smaller than the prescribed value X and larger than a prescribed value Y (Y<X). The region C is not larger than the value Y. According to the determination, charging is stopped when the detected value is included in the region A, charging is conducted when the detected value is included in the region B, or discharging is conducted until a closed-circuit-voltage of the battery becomes not larger than a prescribed value Z and then charging is conducted, when the detected value is included in the region C.

Owner:GK BRIDGE 1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com