Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5228 results about "Acylation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, acylation (or alkanoylation) is the process of adding an acyl group to a compound. The compound providing the acyl group is called the acylating agent. Because they form a strong electrophile when treated with some metal catalysts, acyl halides are commonly used as acylating agents.

Quaternary Ammonium Salt Detergents for Use in Fuels

A quaternary ammonium salt detergent made from the reaction product of the reaction of: (a) a hydrocarbyl substituted acylating agent and a compound having an oxygen or nitrogen atom capable of condensing with said acylating agent and further having a tertiary amino group; and (b) a quaternizing agent suitable for converting the tertiary amino group to a quaternary nitrogen and the use of such quaternary ammonium salt detergents in a fuel composition to reduce intake valve deposits.

Owner:THE LUBRIZOL CORP

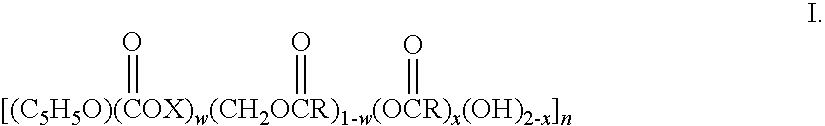

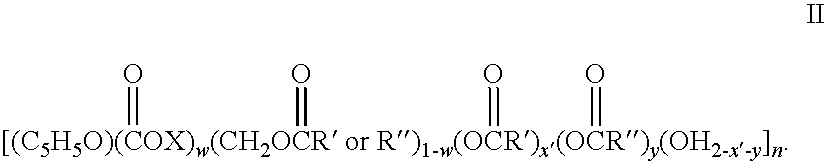

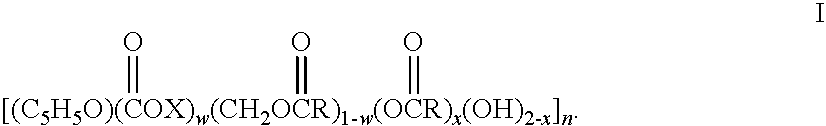

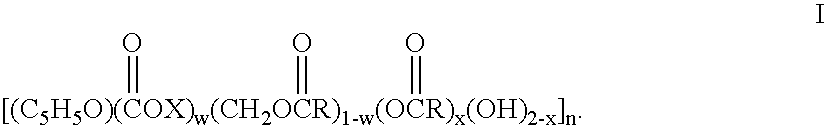

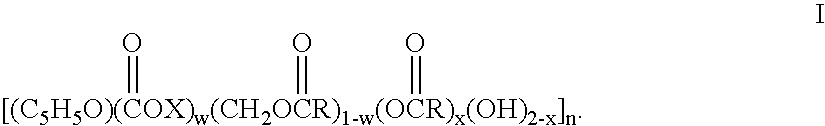

Biodegradable oxidized cellulose esters

Owner:UNIV OF IOWA RES FOUND

Biodegradable oxidized cellulose esters

The present invention relates to the preparation of a series of oxidized cellulose esters suitable for use as a drug carrier in the development of biodegradable controlled and / or sustained release pharmaceutical, agricultural, and veterinary compositions, such as films, compacts, microspheres, and pellets. The esters are prepared by acylation of oxidized cellulose having at least 3% carboxyl groups. The resulting oxidized cellulose esters are soluble in aqueous alkaline solutions, water, and a variety of organic solvents.

Owner:UNIV OF IOWA RES FOUND

Oral osmotic controlled drug delivery system for a sparingly soluble drug

InactiveUS6534090B2Control swellingIncrease in sizePowder deliveryPill deliveryCelluloseHydrophilic polymers

The present invention is for an oral osmotic controlled drug delivery system for a sparingly soluble drug comprising:a. a core comprising (i) finely particulate anhydrous carbamazepine (ii) a polymeric swelling agent consisting of one or more swellable hydrophilic polymers selected such that the polymeric swelling agent exhibits controlled swelling and the wall does not rupture or burst, (iii) a crystal habit modifier in whose presence, upon contact with an aqueous medium, the anhydrous carbamazepine being transformed into cuboidal or rod-shaped crystals of the dihydrate of carbamazepine, or mixtures thereof, and (iv) water-soluble compounds for inducing osmosis,b. a wall made of acylated cellulose which is impermeable to the components of the core, but permeable to water, andc. a passageway through the wall for releasing the components present in the core to the surrounding environment.

Owner:SUN PHARMA INDS

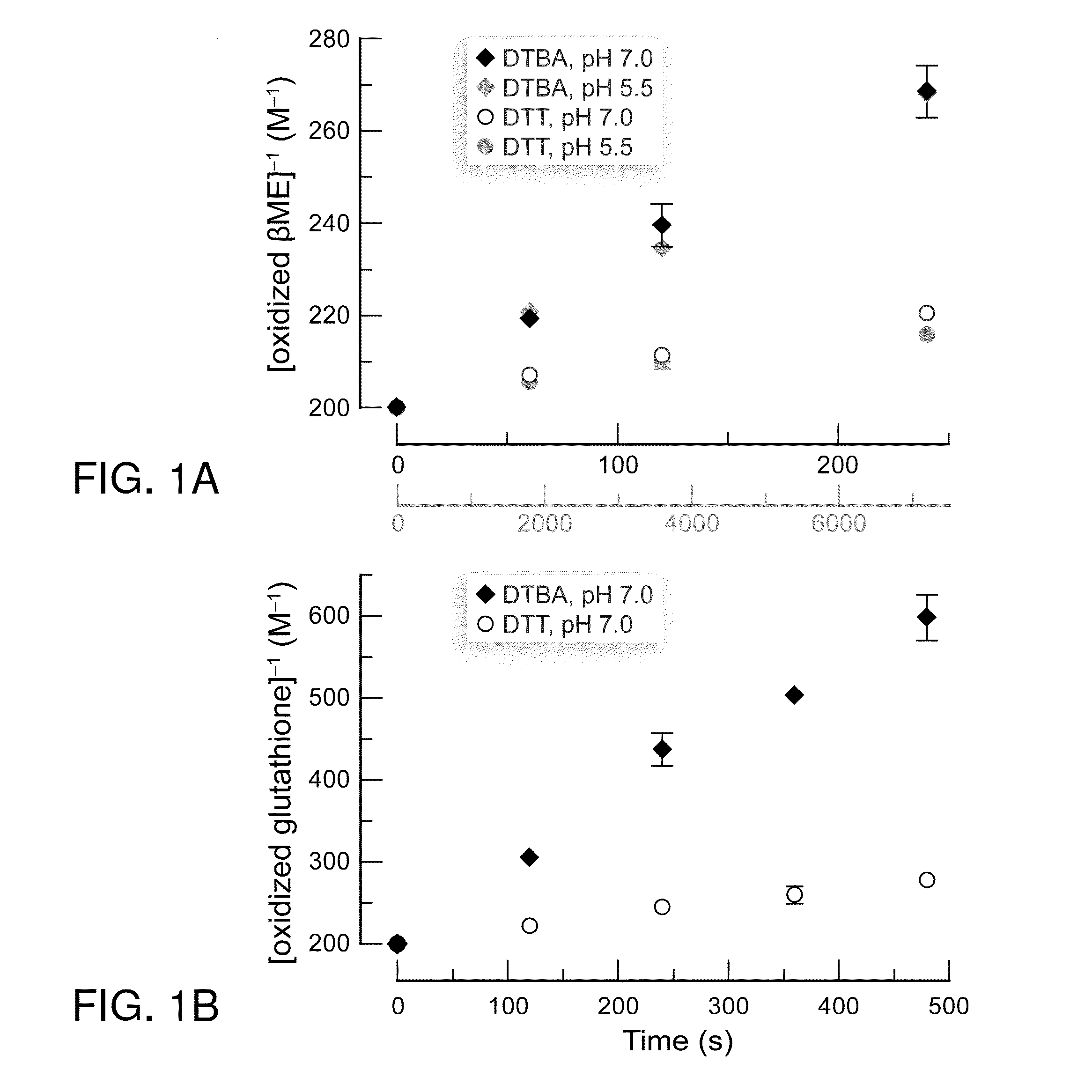

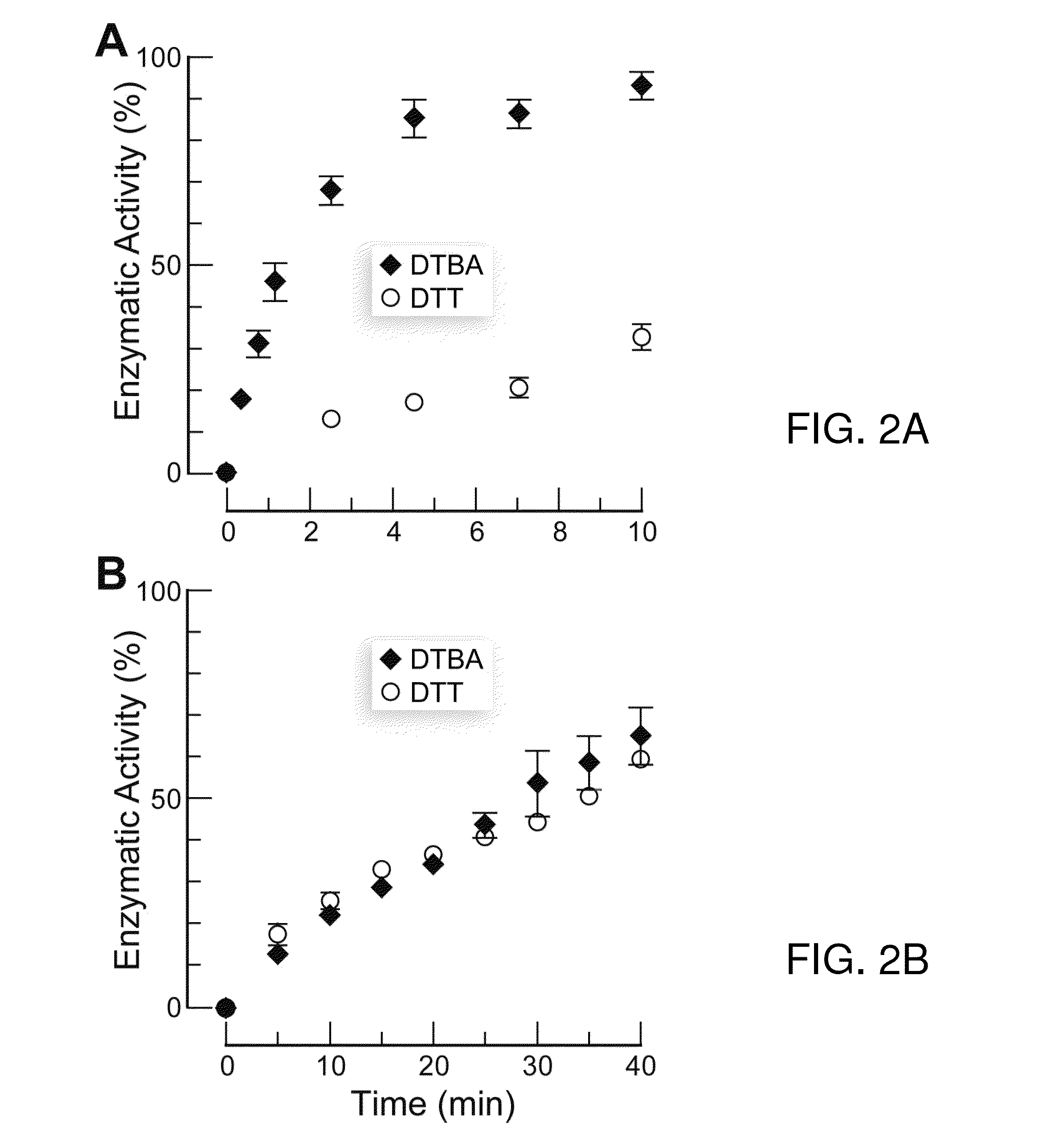

Dithioamine reducing agents

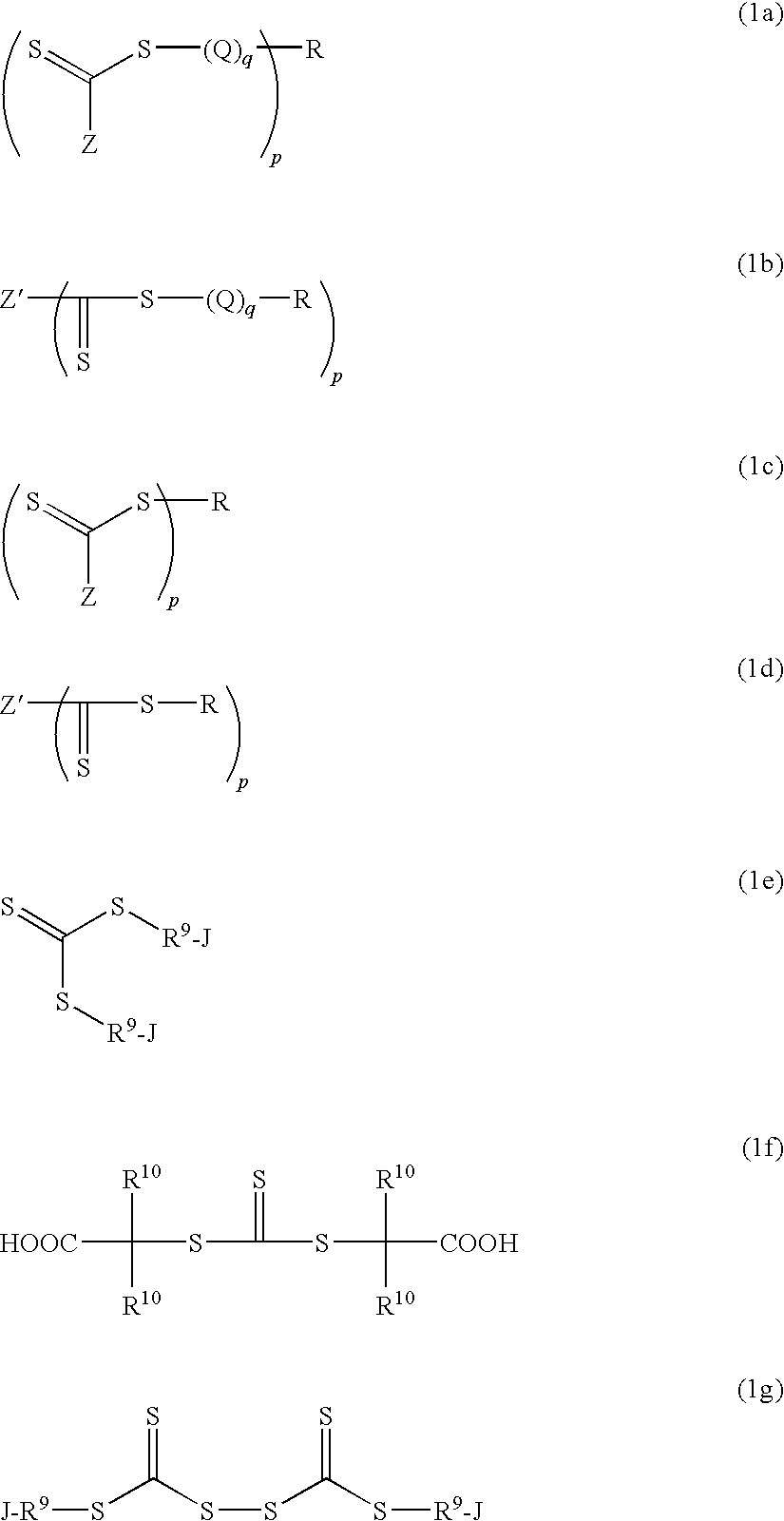

ActiveUS20130211055A1Reduce disulfide bondPrevent formation of disulfide bondSugar derivativesOrganic chemistry methodsDithianeNanoparticle

Dithioamine reducing agents useful for the reduction of disulfide bonds. The reducing agents of this invention are useful, for example, to reduce disulfide bonds, particularly in proteins, or to prevent the formation of disulfide bonds, particularly in proteins and other biological molecules. Reducing agents of this invention are useful and suitable for application in a variety of biological applications, particularly as research and synthetic reagents. The invention provides S-acylated dithioamines which can be selectively activated reducing agents by removal of the S-acyl groups enzymatically or chemically. The invention further provides dithiane precursors of thioamino reducing agents. The invention provides dithioamine reducing agents, S-acylated dithioamines and dithianes which are immobilized on surfaces, including among others, glass, quartz, microparticles, nanoparticles and resins.

Owner:WISCONSIN ALUMNI RES FOUND

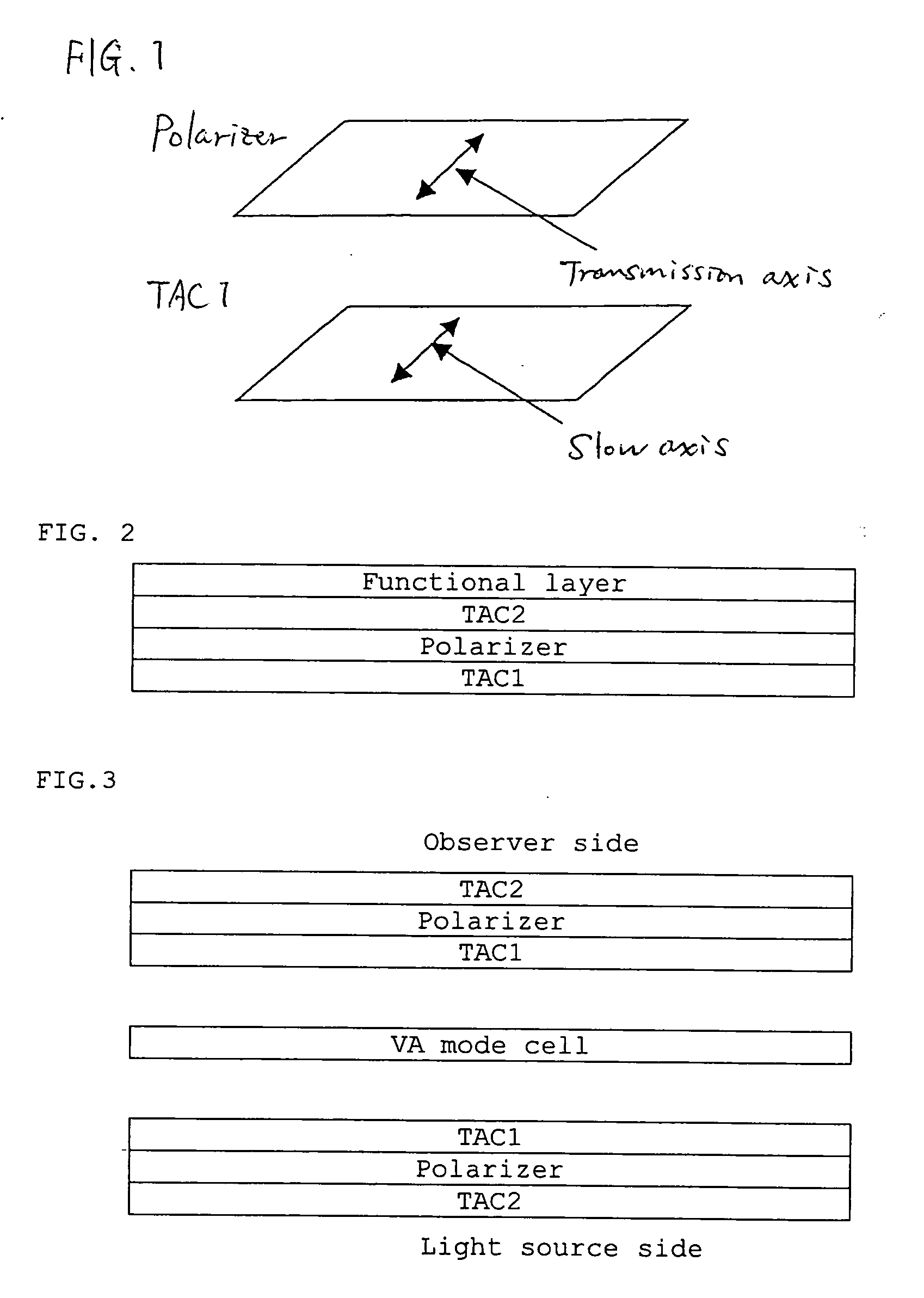

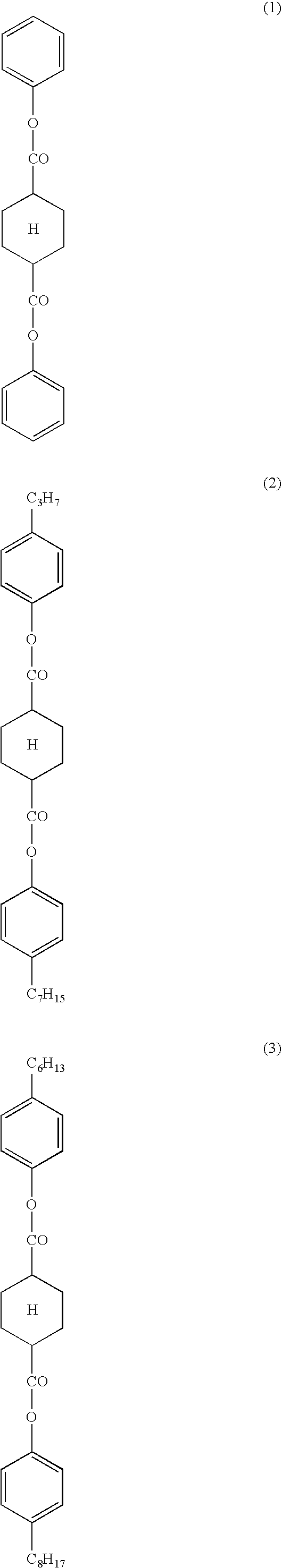

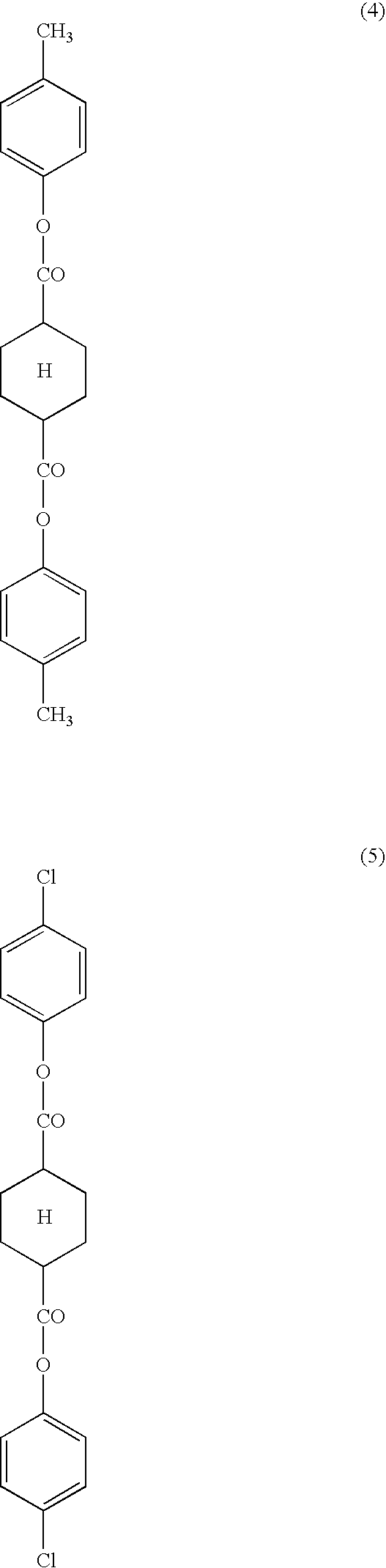

Cellulose acylate laminate film, method for producing same, polarizer and liquid crystal display device

InactiveUS20100055356A1High degree of substitutionExcellent releasabilityLiquid crystal compositionsCellulosic plastic layered productsPolarizerLiquid-crystal display

A stretched cellulose acylate laminate film having a skin layer containing a cellulose acylate with a total degree of acyl substitution of more than 2.7 and a core layer containing a cellulose acylate with a total degree of acyl substitution of 2.0-2.7 wherein the core layer is thicker than the skin B layer and at least one of these layers contains a retardation-controlling agent, is excellent in high expressibility, little optical unevenness and good releasability from a support.

Owner:FUJIFILM CORP

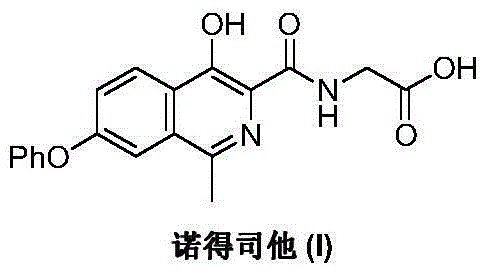

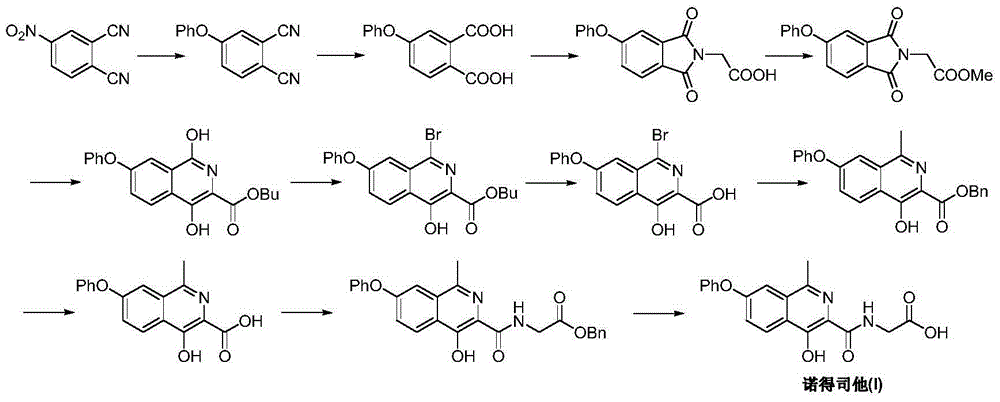

Preparation method of Roxadustat

ActiveCN104892509AEase of industrial productionRaw materials are easy to getOrganic chemistryDehydrogenationTyrosine

The invention discloses a preparation method of Roxadustat. The preparation steps are as follows: the Roxadustat is prepared from tyrosine through esterification, etherification, cyclization, dehydrogenation, oxidative rearrangement and acylation reaction. The preparation method has the advantages that the raw materials are easily obtained; the process is simple; and the preparation method is economic and environmental-friendly, and is suitable for industrialized production.

Owner:南通华宇化工科技有限公司

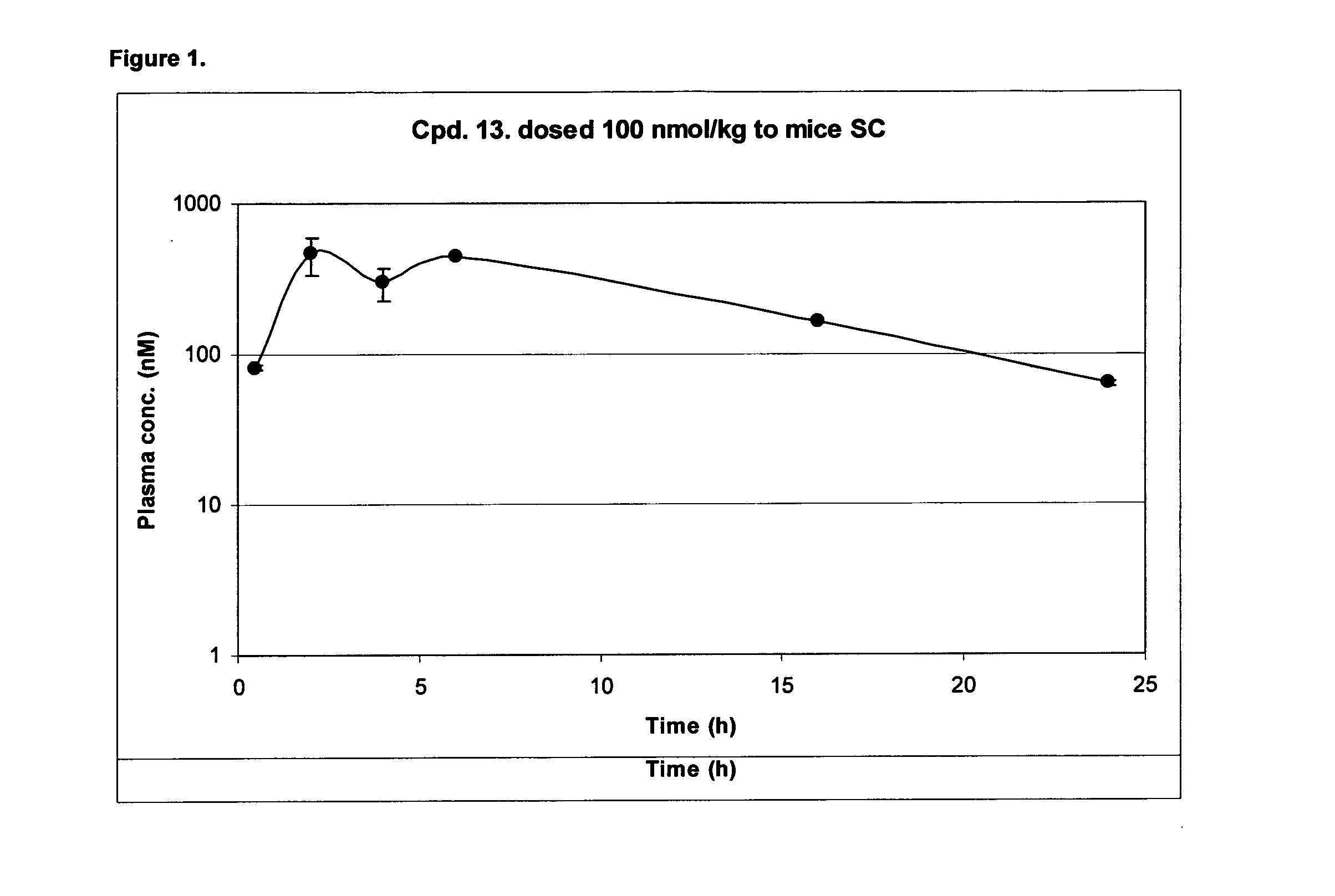

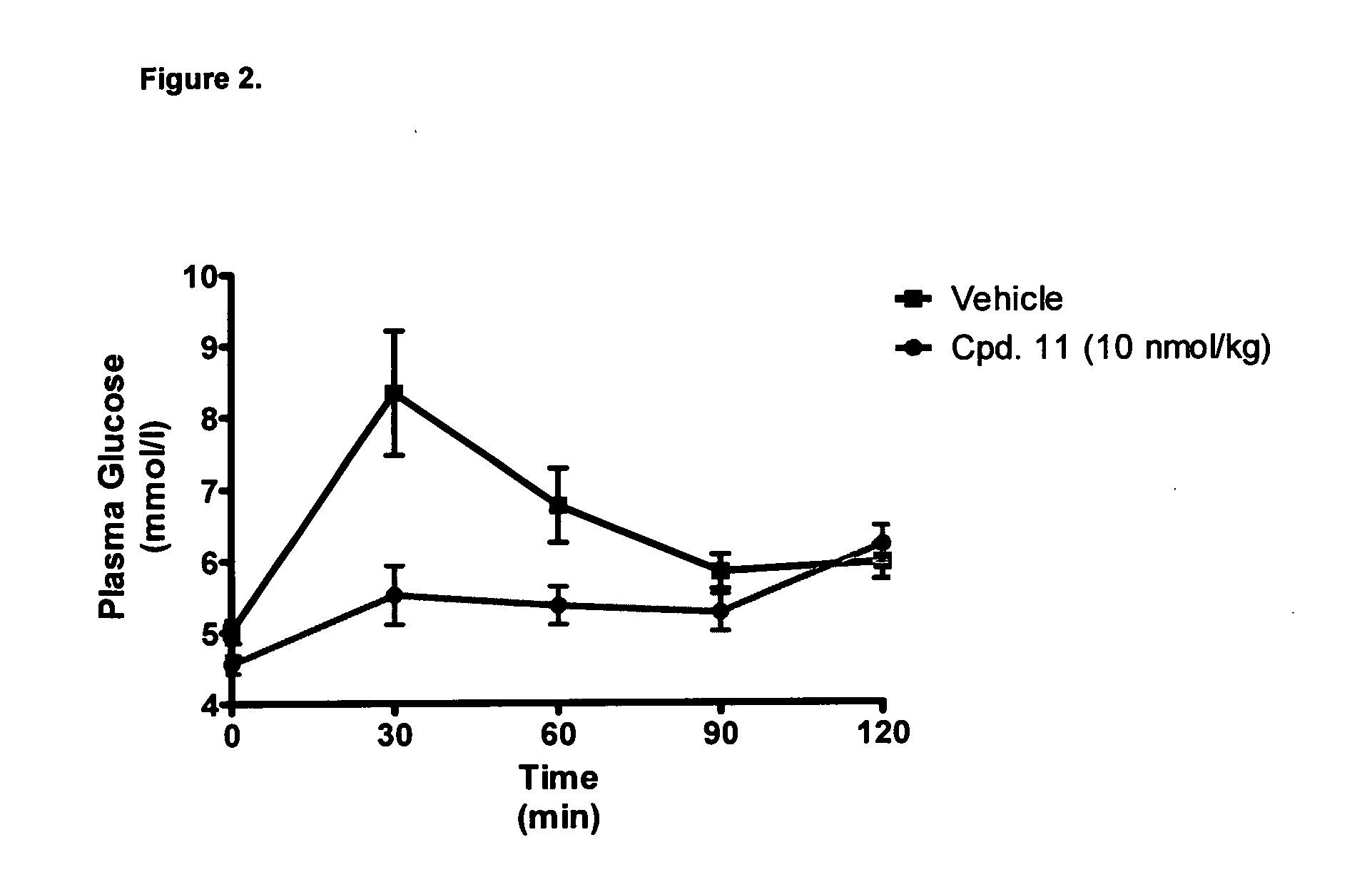

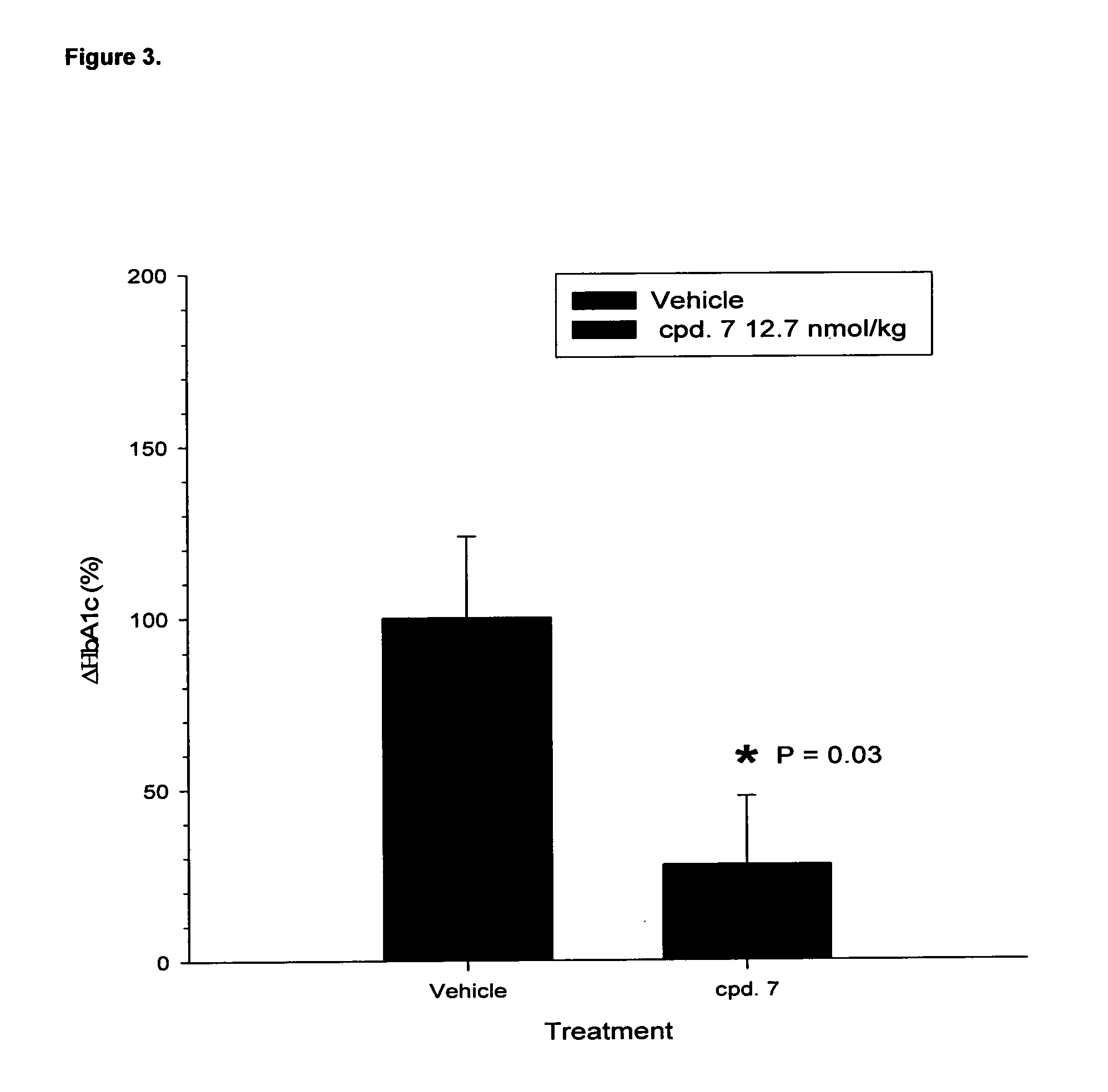

Acylated glucagon analogues

InactiveUS20120178670A1Avoid weight gainGood for weight lossPeptide/protein ingredientsAntipyreticDiabetes mellitusWeight gain prevention

The invention provides materials and methods for promoting weight loss or preventing weight gain, and in the treatment of diabetes and associated metabolic disorders. In particular, the invention provides novel acylated glucagon analogue peptides effective in such methods. The peptides may mediate their effect by having increased selectivity for the GLP-1 receptor as compared to human glucagon.

Owner:ZEALAND PHARM AS

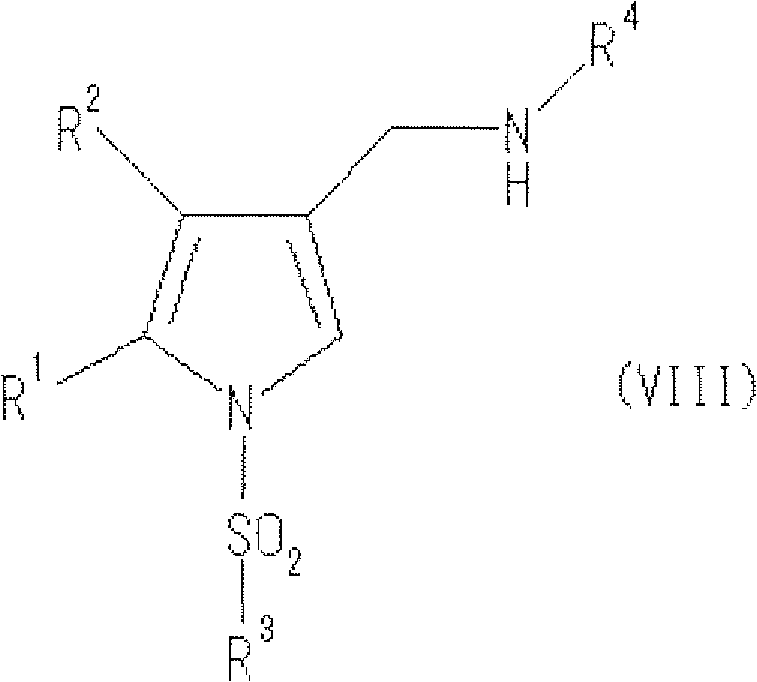

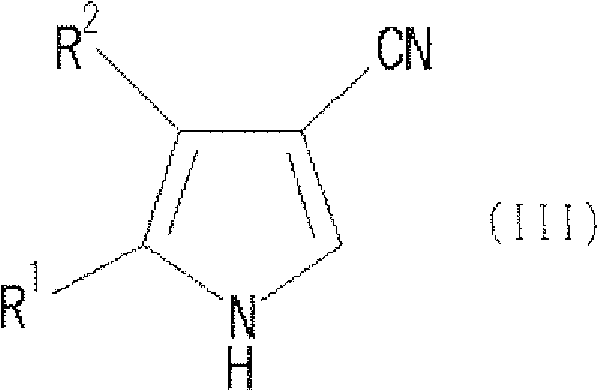

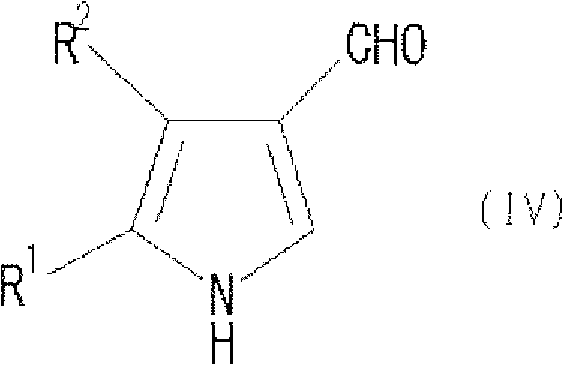

Process for producing pyrrole compound

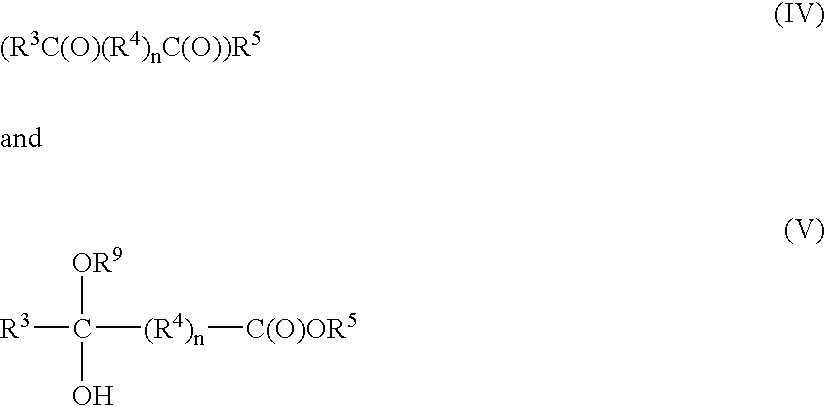

A process for producing a sulfonylpyrrole compound useful as a medicine, a process for producing an intermediate for use in the process, and a novel intermediate. The process for producing a sulfonylpyrrole compound (VIII) comprises reducing a compound (III), subsequently hydrolyzing the compound to obtain a compound (IV), sulfonylating the compound (IV) to obtain a compound (VI), and aminating the compound (VI) to thereby produce the compound (VIII).

Owner:TAKEDA PHARMA CO LTD

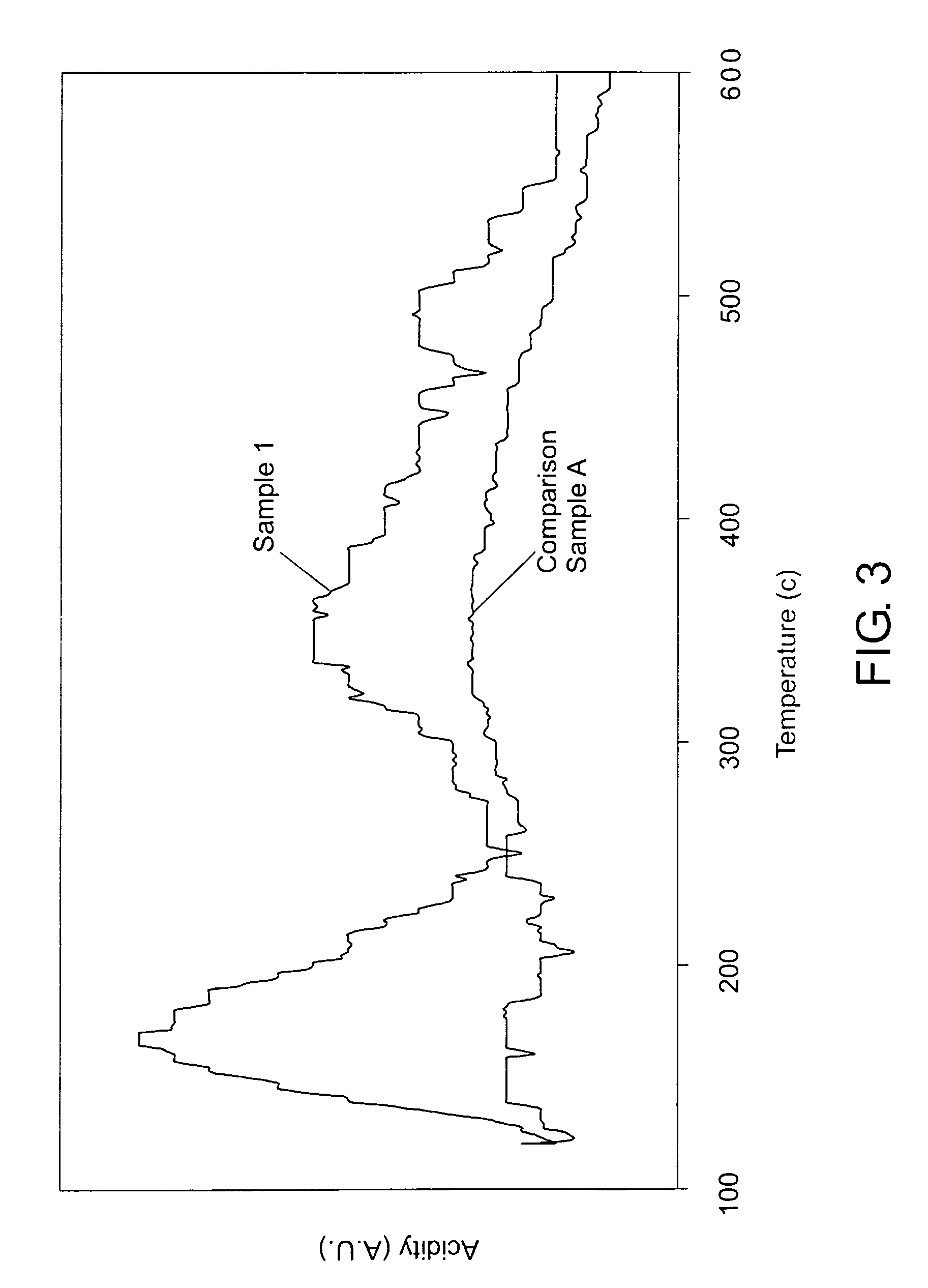

Zeolite composite, method for making and catalytic application thereof

A catalytic material includes microporous zeolites supported on a mesoporous inorganic oxide support. The microporous zeolite can include zeolite Beta, zeolite Y (including “ultra stable Y”—USY), mordenite, Zeolite L, ZSM-5, ZSM-11, ZSM-12, ZSM-20, Theta-1, ZSM-23, ZSM-34, ZSM-35, ZSM-48, SSZ-32, PSH-3, MCM-22, MCM-49, MCM-56, ITQ-1, ITQ-2, ITQ-4, ITQ-21, SAPO-5, SAPO-11, SAPO-37, Breck-6, ALPO4-5, etc. The mesoporous inorganic oxide can be e.g., silica or silicate. The catalytic material can be further modified by introducing some metals e.g. aluminum, titanium, molybdenum, nickel, cobalt, iron, tungsten, palladium and platinum. It can be used as catalysts for acylation, alkylation, dimerization, oligomerization, polymerization, hydrogenation, dehydrogenation, aromatization, isomerization, hydrotreating, catalytic cracking and hydrocracking reactions.

Owner:ABB LUMMUS GLOBAL INC

Biodegradable oxidized cellulose esters

InactiveUS20060093672A1Less-expensive to produceOrganic active ingredientsBiocideOrganic solventMicrosphere

The present invention relates to the preparation of a series of oxidized cellulose esters suitable for use as a drug carrier in the development of biodegradable controlled and / or sustained release pharmaceutical, agricultural, and veterinary compositions, such as films, compacts, microspheres, and pellets. The esters are prepared by acylation of oxidized cellulose having at least 3% carboxyl groups. The resulting oxidized cellulose esters are soluble in aqueous alkaline solutions, water, and a variety of organic solvents.

Owner:UNIV OF IOWA RES FOUND

Sulfenylation process of pyrozole compound with trifluoromethanesulfonyl radical

InactiveCN1374298AEasy to manufactureHigh reactivityOrganic chemistryAcyl groupCombinatorial chemistry

The present invention relates to one sulfenylation process of pyrazole compound with CF3SO2K or the mixed salt of CF3SO2K and CF3SO2Na. CF3SO2K or the mixed salt of CF3SO2K and CF3SO2Na are made to react first with reagent A and then with pyrazole compound to obtain pyrazole compound with trifluoromethanesulfonyl radical, where the reagent A is selected from phosgene, TCF, POCl3, PC1 and SOC12. The present invention finds one new sulfenylation reagent, and is easy to prepare, high in reaction, activity, easy to use and high in yield.

Owner:JIANGSU PESTICIDE RES INST

Quaternary ammonium salt detergents for use in fuels

A quaternary ammonium salt detergent made from the reaction product of the reaction of: (a) a hydrocarbyl substituted acylating agent and a compound having an oxygen or nitrogen atom capable of condensing with said acylating agent and further having a tertiary amino group; and (b) a quaternizing agent suitable for converting the tertiary amino group to a quaternary nitrogen and the use of such quaternary ammonium salt detergents in a fuel composition to reduce intake valve deposits.

Owner:THE LUBRIZOL CORP

Detergent mixture

InactiveUS20040048766A1Good cleaning and foaming propertyProcess economyCationic surface-active compoundsOrganic detergent compounding agentsActive agentSugar amine

A process for making a surfactant composition involving: (a) providing a starting mixture containing: (i) an aqueous alkali solution; (ii) at least one amino acid and / or a salt thereof; (iii) a fatty acid chloride; (iv) an acylatable surfactant precursor selected from the group consisting of a protein hydrolyzate, a polyamino acid, an aminosulfonic acid, an amino sugar, a nonionic surfactant, and mixtures thereof; and (v) up to about 15% by weight, based on the weight of the starting mixture, of a polyol component; (b) providing a stirring mechanism; and (c) reacting (ii) and (iii), with stirring, to form the surfactant composition.

Owner:COGNIS DEUT GMBH & CO KG

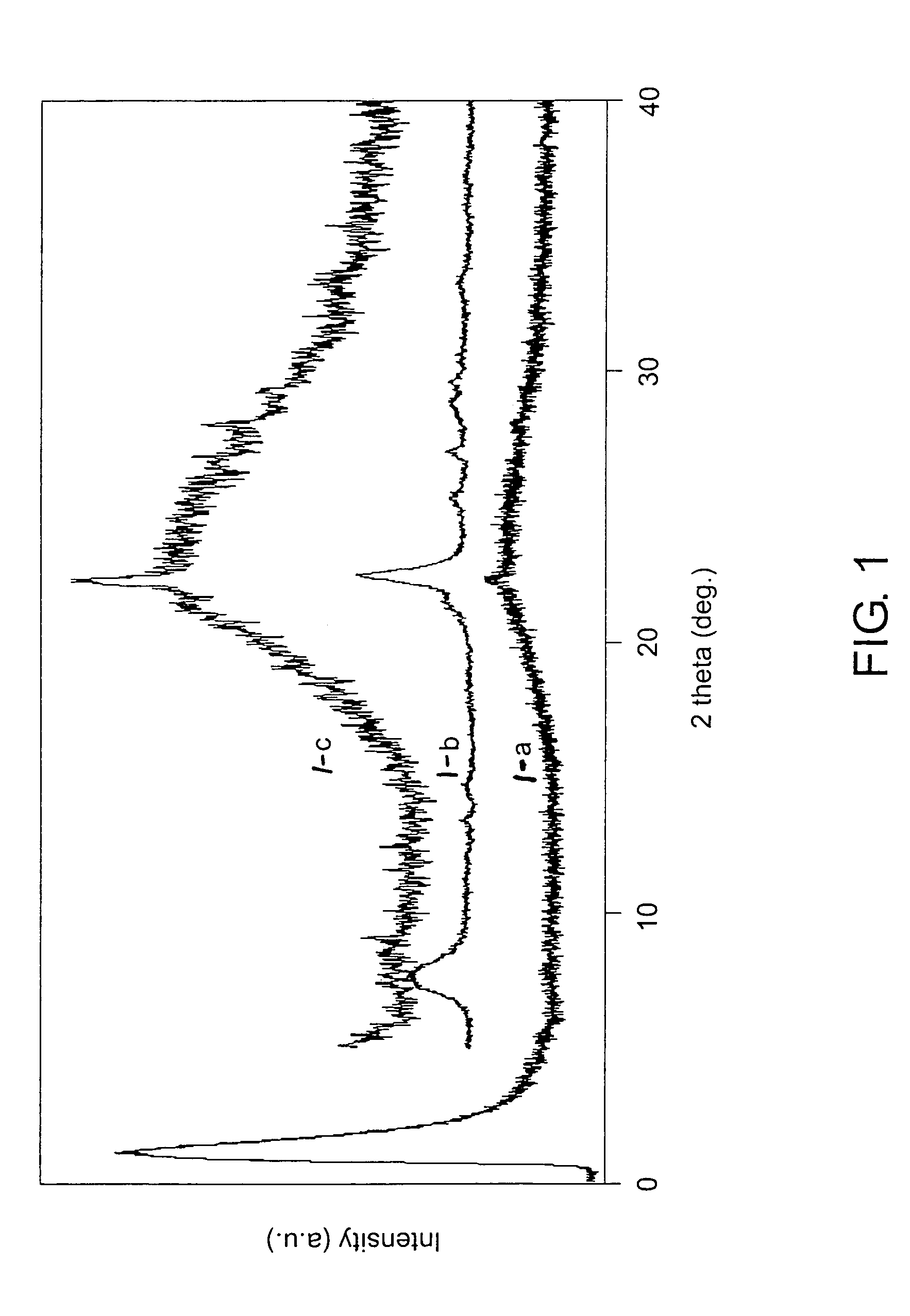

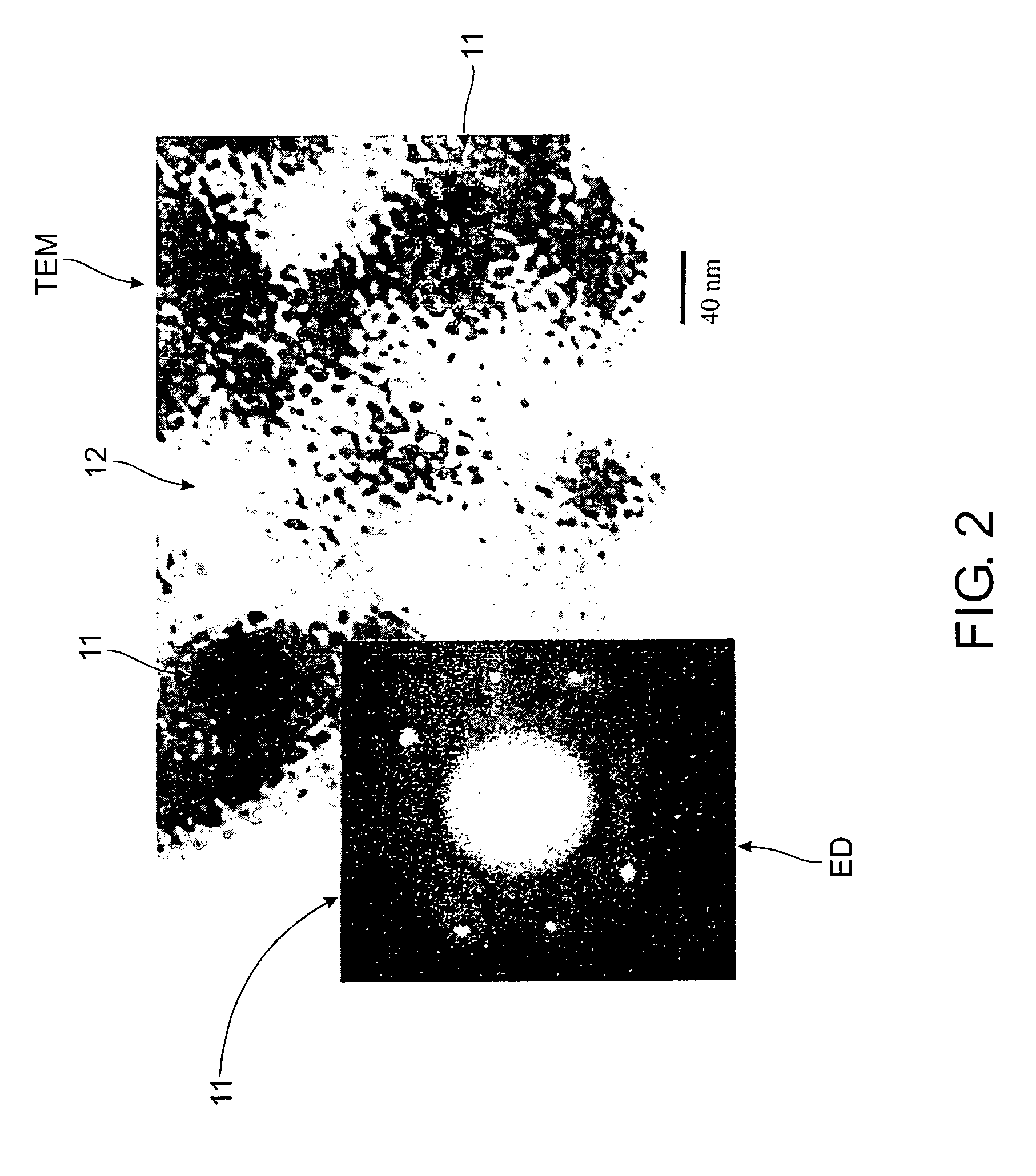

Mesoporous material with active metals

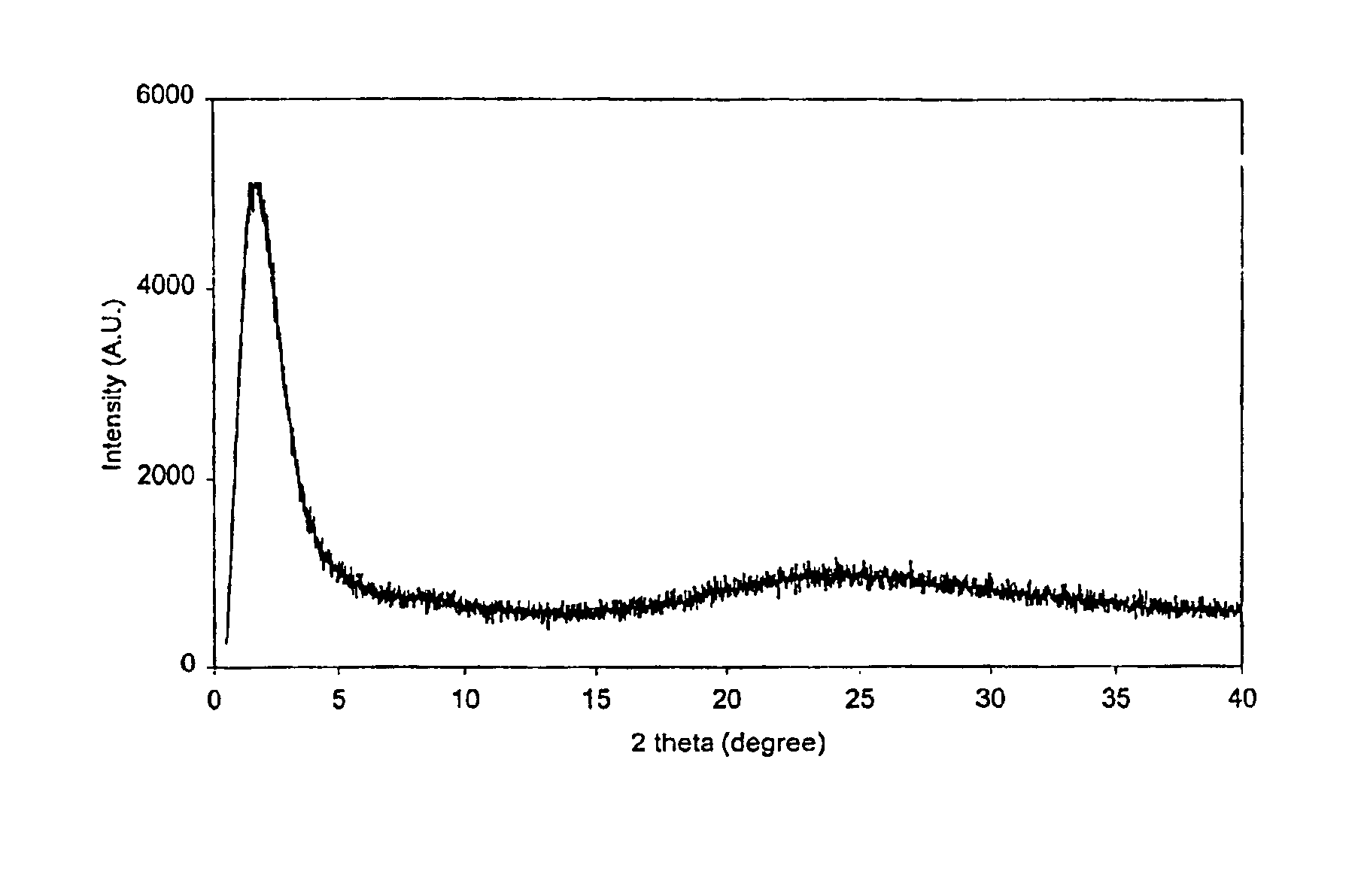

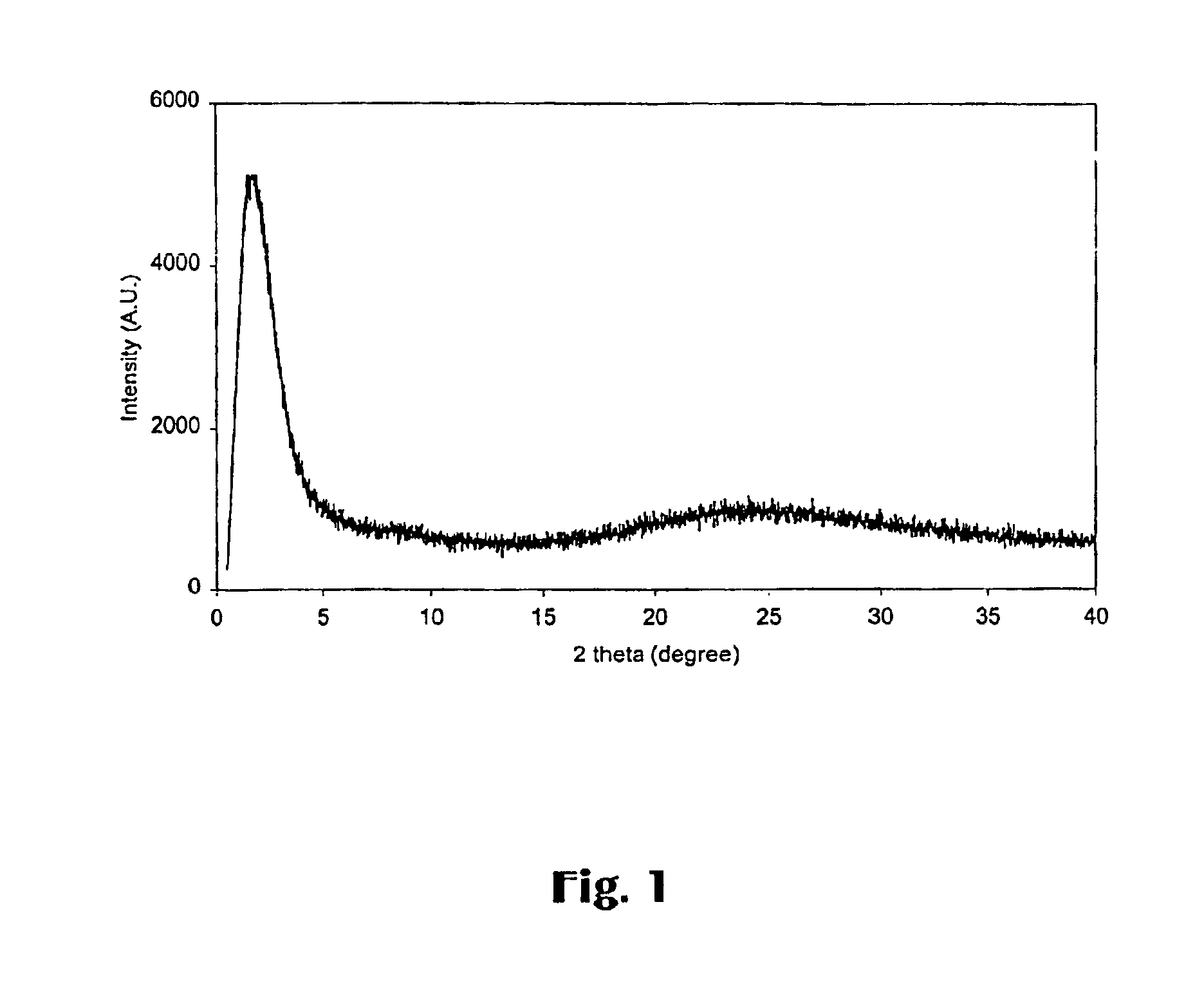

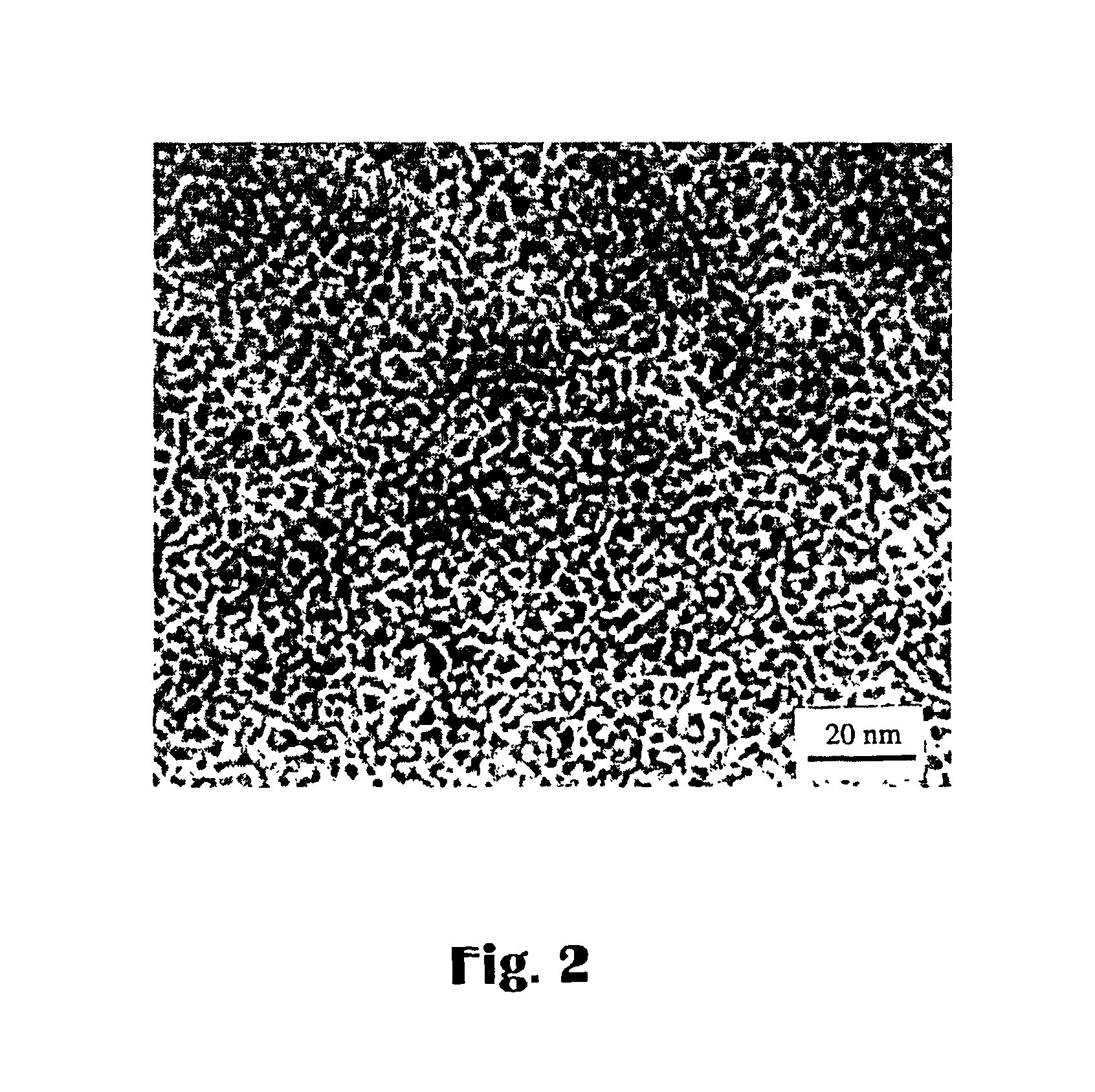

A process for treating organic compounds includes providing a composition which includes a substantially mesoporous structure of silica containing at least 97% by volume of pores having a pore size ranging from about 15 Å to about 30 Å and having a micropore volume of at least about 0.01 cc / g, wherein the mesoporous structure has incorporated therewith at least about 0.02% by weight of at least one catalytically and / or chemically active heteroatom selected from the group consisting of Al, Ti, V, Cr, Zn, Fe, Sn, Mo, Ga, Ni, Co, In, Zr, Mn, Cu, Mg, Pd, Pt and W, and the catalyst has an X-ray diffraction pattern with one peak at 0.3° to about 3.5° at 2θ. The catalyst is contacted with an organic feed under reaction conditions wherein the treating process is selected from alkylation, acylation, oligomerization, selective oxidation, hydrotreating, isomerization, demetalation, catalytic dewaxing, hydroxylation, hydrogenation, ammoximation, isomerization, dehydrogenation, cracking and adsorption.

Owner:ABB LUMMUS GLOBAL INC

Acylated cyclodextrin: guest molecule inclusion complexes

InactiveUS20020025946A1Improve processing efficiencyImprove stabilityBiocideOrganic chemistryCyclodextrinAqueous medium

The present invention is directed to a method of making an inclusion complex comprising an acylated cyclodextrin host molecule and a guest molecule, wherein the method comprises the steps of: a)contacting the acylated cyclodextrin host molecule and the guest molecule to form an inclusion complex; and b) precipitating the inclusion complex in an aqueous medium. The present invention is further directed to an inclusion complex comprising an acylated cyclodextrin host molecule and a guest molecule, wherein the guest molecule comprises from about 2% (wt.) to about 15% (wt.) of the inclusion complex. Moreover, the present invention relates to a composition comprising a polymer and an inclusion complex, wherein the inclusion complex comprises an acylated cyclodextrin host molecule and a guest molecule and medical devices and solid pharmaceutical compositions comprised thereof.

Owner:EASTMAN CHEM CO

Anti-wrinkle composition

ActiveUS20070166267A1Easy to superviseAccurate balanceBiocideOrganic active ingredientsWrinkle skinDimethyl isosorbide

A composition is disclosed for treating the skin comprising an acylated short chain bioactive peptide and Lycium barbarum extract product. Also disclosed is a method for topically administering the composition in an amount therapeutically effective to reduce wrinkles by building the dermal fibroblast matrix. The composition may contain dimethylisosorbide or ethoxydiglycol as solubilizing and penetration enhancers for the hydrophobically modified peptide.

Owner:GRANT INDS

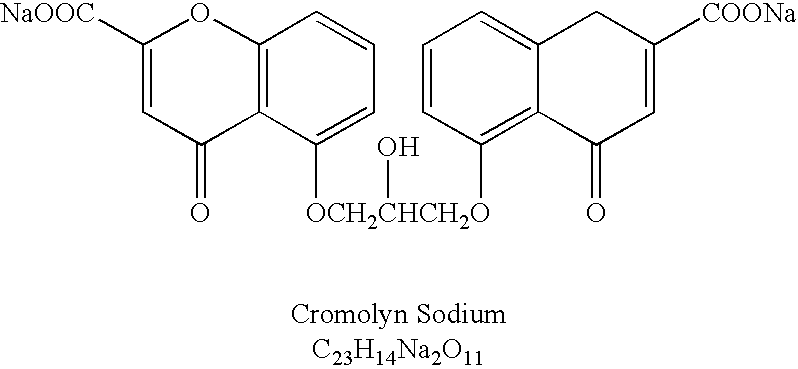

Formulations for oral administration of cromolyn sodium

InactiveUS20040259952A1High activityImprove absorption rateBiocideAntipyreticOral medicationCromolyn Sodium

An oral dosage form comprises cromolyn sodium (sodium or disodium cromoglycate), and an acylated amino acid delivery agent.

Owner:NOVO NORDISK NORTH AMERICA OPERATIONS AS

Optical cellulose acylate film, polarizing plate and liquid crystal display

ActiveUS20050142304A1Favorable retardation valueLittle changeLiquid crystal compositionsPolarising elementsCelluloseMixed fatty acid

To provide an optical film which exhibits excellent retardation values both in the film plane and along the direction perpendicular to the film plane and shows little change in retardation values depending on environmental factors such as humidity, a liquid crystal display showing little change in viewing angle characteristics due to an environmental (humidity) change, and a polarizing plate to be used in the liquid crystal display, the cellulose acylate contains a cellulose acylate which is a mixed fatty acid ester of a cellulose and satisfies formulae specified in the specification, and a polarizing plate and a liquid crystal display using this cellulose acylate film.

Owner:FUJIFILM CORP

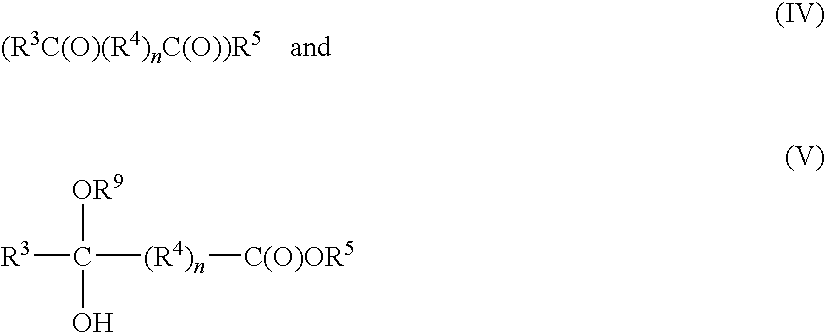

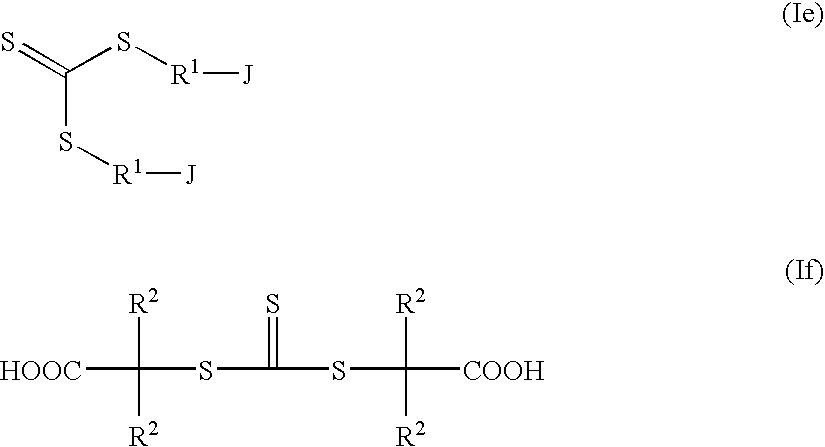

Process for Preparing Polymers and Compositions Thereof

The present invention provides a process for preparing a polymer, employing the steps of: (1) contacting a free radical initiator; a chain transfer agent containing a thiocarbonyl thio group and a free radical leaving group; and a radically polymerisable monomer, to form a polymer chain; and (2) contacting the polymer chain of step (1) with at least one of a polyvalent coupling agent, a polymerisation inhibitor, a grafting acylating agent, an amine and an oil of lubricating viscosity. The invention further provides compositions and uses for the polymer.

Owner:THE LUBRIZOL CORP

L-Threonine derivatives of high therapeutic index

The present invention is directed to a derivative comprised of an L-Threonine bonded to a medicament or drug having a hydroxy, amino, carboxy or acylating derivative thereon. The derivative has the same utility as the drug from which it is made, but it has enhanced therapeutic properties. In fact, the derivatives of the present invention enhance at least one or more therapeutic qualities, as defined herein. The present invention is also directed to pharmaceutical compositions containing same.

Owner:SIGNATURE R & D HLDG LLC

Polymer microsphere and preparation method thereof

InactiveCN101798372AHigh mechanical strengthImprove stress resistanceMicroballoon preparationMicrocapsule preparationMicrosphereAtom-transfer radical-polymerization

The invention discloses a polymer microsphere and preparation method thereof. The microsphere comprises a core and surface graft; wherein the core is monodispersed polystyrene-divinyl benzene microsphere with crosslinking degree of 60-90% and grain diameter of 2-20 microns, and the surface graft is polyglycidyl methacrylate or derivate thereof. Friedel-Crafts acylation is utilized, alpha-halogenacyllhalide is taken as acylation agent, initiator molecule is bonded on the surface of the microsphere; conventional atom transfer radical polymerization method is utilized to initiate monomers glycidyl methacrylate to condense; then different nucleopilic reagent is utilized for opening ring, and amino, hydroxyl, hydrazine, carboxyl and sulfydryl groups are introduced onto the surface of the microsphere. The polymer microsphere can be used as separation material for different chromatographs for high efficiency ion exchange, chelation and high efficiency affiliation, also can be used as carrier for fixing enzyme and catalyst and is an excellent functional microsphere.

Owner:SUZHOU UNIV +2

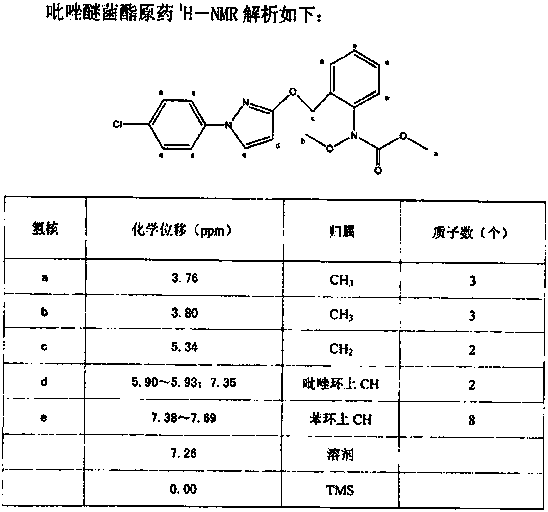

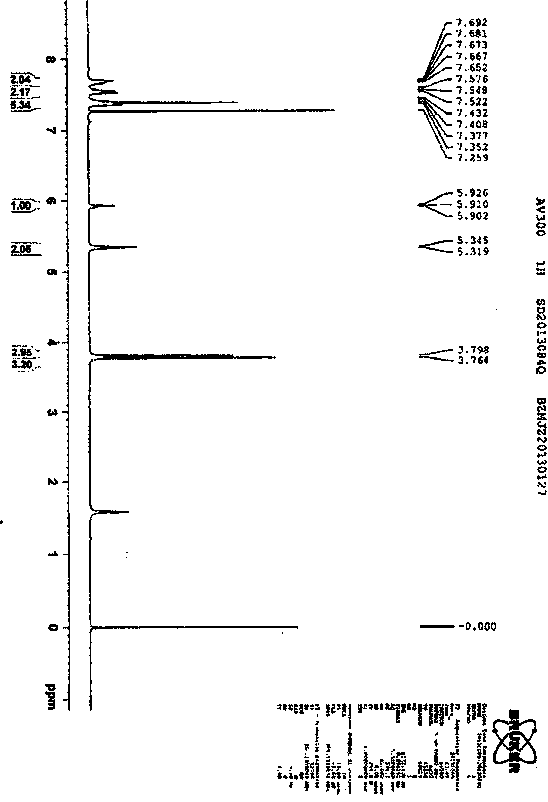

Synthetic technology for pyraclostrobin

ActiveCN104211641AFormation reaction is easy to controlSmooth responseOrganic chemistryMethylanilineChlorobenzene

The invention concretely relates to a synthetic technology for pyraclostrobin. The synthetic technology comprises: firstly performing cyclization to obtain 1-(4-chlorophenyl)-pyrazol-3-one, oxidizing the pyrazol ring under the effect of an oxidant to generate 1-(4-chlorophenyl)-3-hydroxypyrazole, then using 2-nitrobenzyl bromide to performing etherification to generate 1-(4-chlorophenyl)-3-[2-(nitrophenyl)methoxy]-1H-pyrazole, then using a reducing agent to perform nitro reducing, so as to generate N-hydroxyl-2-[N'-(4-chlorophenyl)pyrazol-3'-yloxymethyl]aniline, then using ClCO2CH3 to perform N-acylation reaction to generate methyl N-hydroxyl-N-2-{[N'-(4-chlorophenyl)pyrazol-3'-yloxymethyl]phenyl}formate, and finally performing hydroxyl methylation under an alkaline condition to generate pyraclostrobin. The technology enables all operations in the pyraclostrobin preparation process to be relatively controllable, helps to improve the stability of the preparation process and improve the product yield, successfully employs low-cost reagents and substantially reduces production cost, and also the employed reagents are relatively small in toxicity, is relatively beneficial for environment protection, and has no corrosivity on plastic pipes, so that the production safety is improved.

Owner:SHANDONG KANGQIAO BIO TECH CO LTD

Optical film, polarizing plate and display

InactiveUS20060078754A1Easy to produceImprove production efficiencyElectric discharge tubesSynthetic resin layered productsCelluloseBenzene

A method for producing an optical film comprising steps of mixing a heated and molten cellulose ester having an acylated degree for from 2.5 to 2.9 and at least one of a UV absorbent having at least two benzotriazole skeletons and a UV absorbent having a weight average molecular weight of from 2,000 to 50,000 to form a mixture, and extruding the mixture to form a film.

Owner:KONICA MINOLTA OPTO

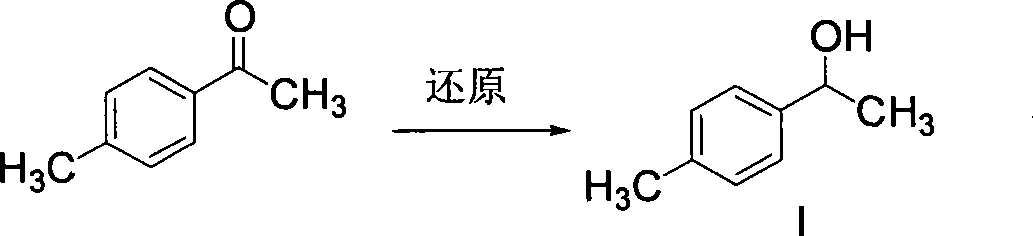

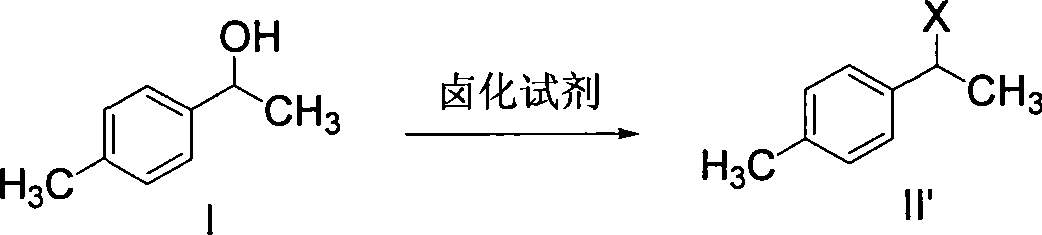

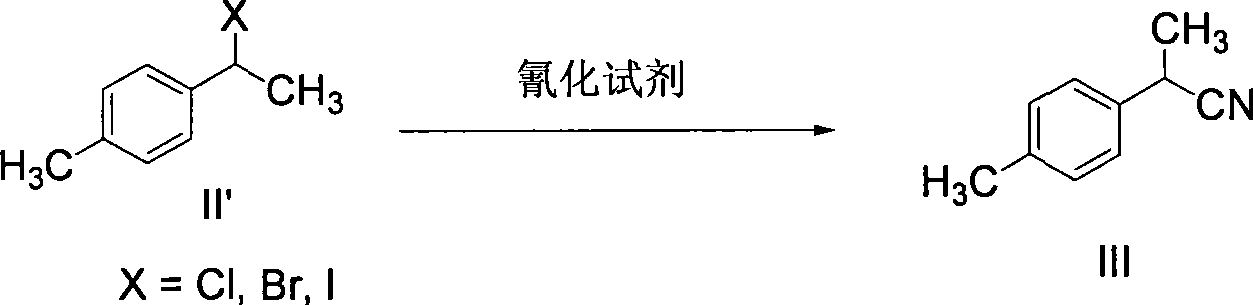

Method for synthesizing loxoprofen sodium

ActiveCN101412670ARaw materials are easy to getUnique craftOrganic compound preparationCarboxylic compound preparationSolventHydrolysis

The invention discloses a synthetic method for loxoprofen sodium, which is prepared by taking methyl acetophenone as an initial raw material through reduction, acylation or halogen substituent, cyanation, hydrolysis, bromination, condensation, decarboxylation and salifying. The method has the advantages of easily obtained raw material, unique technology, simple and stable operation, and high productive rate in each step of reaction; and all solvents used in the synthesis process can be recycled, so the production cost is reduced greatly. Tests show that the obtained product has reliable quality and stable performance, and can be further used for making preparation of non-steroidal anti-inflammatory drugs such as the loxoprofen sodium.

Owner:ZHEJIANG APELOA JIAYUAN PHARMA +1

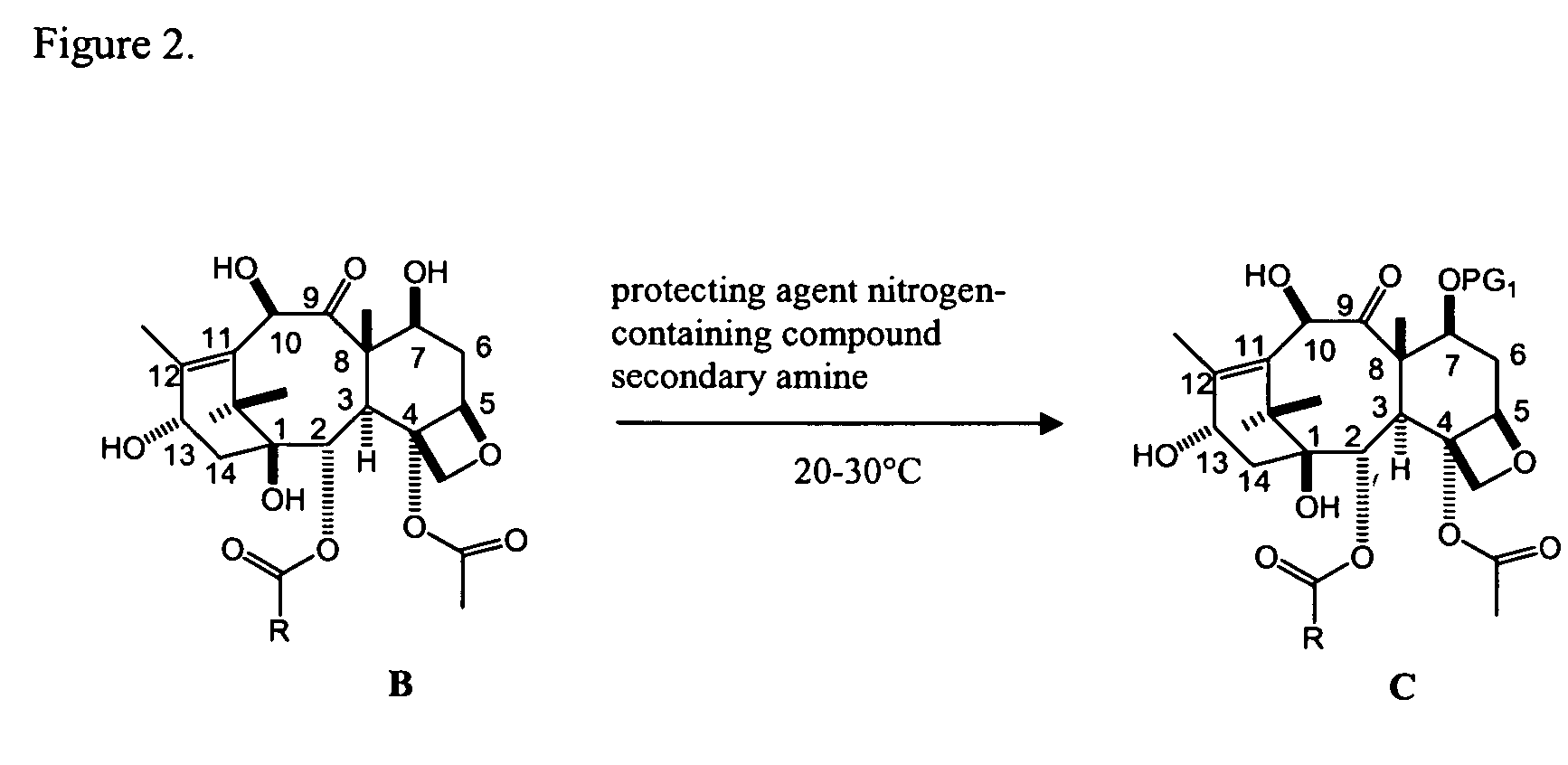

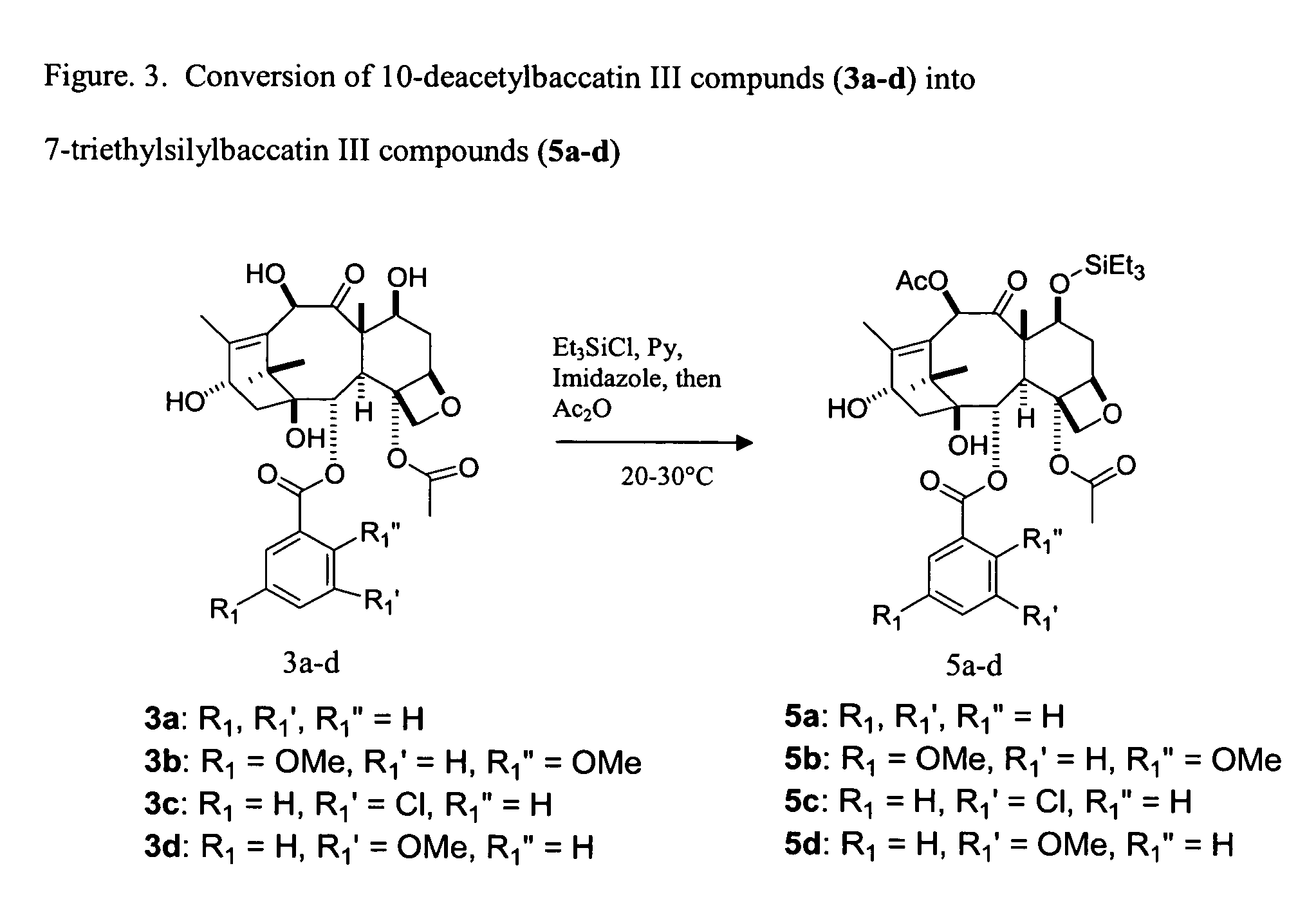

Facile method for synthesizing baccatin III compounds

A process for synthesizing a C-7 protected baccatin III compound represented by formula (A), which comprises reacting a 10-deacetylbaccatin III compound represented by formula (B) with a protecting agent and an acylating agent in the presence of a secondary amine and a nitrogen-containing compound. Also, a process for synthesizing a C-7 protected 10-deacetylbaccatin III compound represented by formula (C), which comprises reacting a 10-deacetylbaccatin III compound represented by formula (B) with a protecting agent in the presence of a secondary amine and a nitrogen-containing compound. In both processes the nitrogen-containing compound is selected from a nitrogen-containing heterocycle or a trialkylamine. When the nitrogen-containing heterocycle is selected, it may be an unsubstituted or a substituted pyridine or an unsubstituted or a substituted pyrazine. When a trialkylamine is selected, it may be, for example, triethylamine or diisopropylethylamine.wherein PG1 represents the organic residue of the protecting agent, PG2 represents the organic residue of the acylating agent, and R represents a simple or substituted aryl group or a heterocyclic group.

Owner:IMMUNOGEN INC

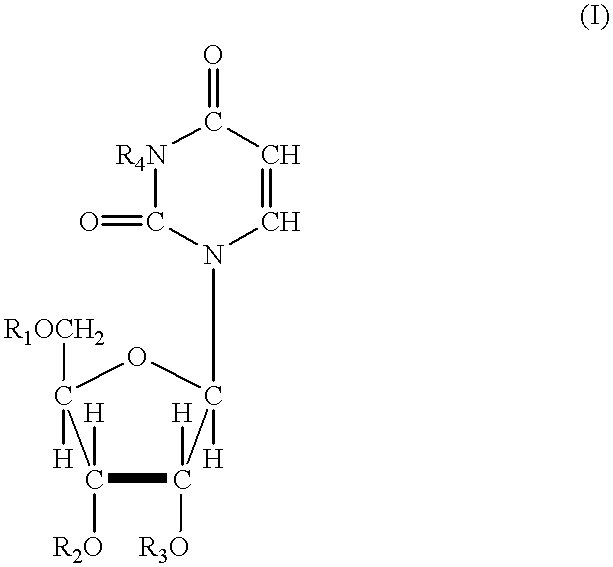

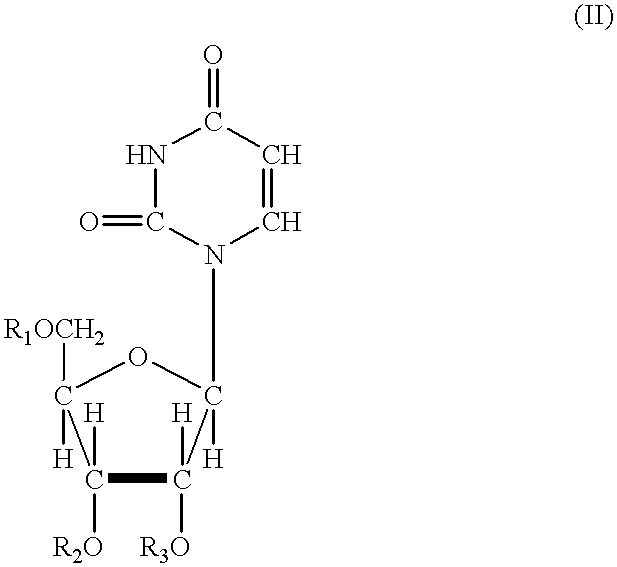

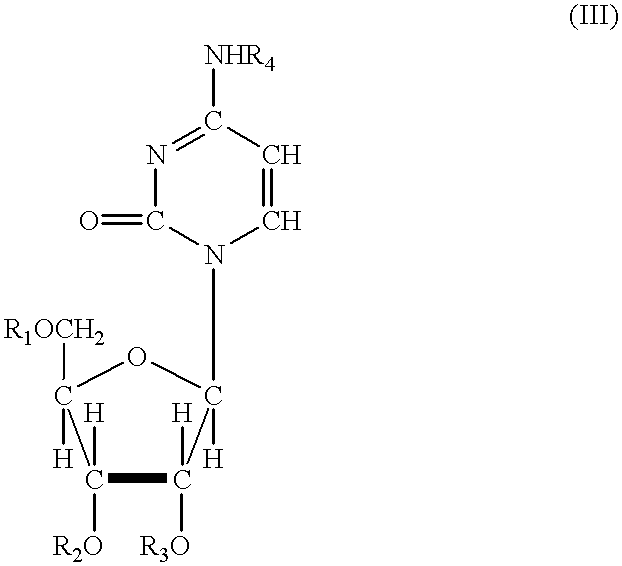

Acylated uridine and cytidine and uses thereof

ActiveUS6258795B1No untoward pharmaceutical effectEfficient managementBiocideSugar derivativesDiseaseDiabetes mellitus

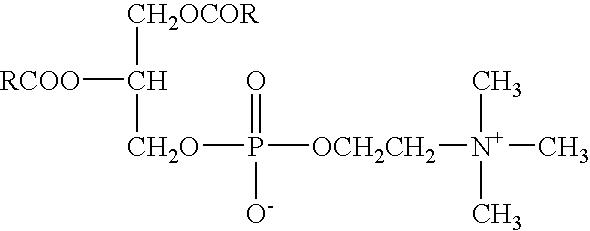

The invention relates to compositions comprising acyl derivatives of cytidine and uridine. The invention also relates to methods of treating hepatopathies, diabetes, heart disease, cerebrovascular disorders, Parkinson's disease, infant respiratory distress syndrome and for enhancement of phospholipid biosynthesis comprising administering the acyl derivatives of the invention to an animal.

Owner:WELLSTAT THERAPEUTICS

Anti-wrinkle cosmetic composition

ActiveUS20090136595A1Improving dermal fibroblast regulationEasy to superviseHeavy metal active ingredientsCosmetic preparationsWrinkle skinAdditive ingredient

The present invention relates to a composition for treating skin comprising an acylated short chain bioactive peptide and fulvic acid, and optionally colloidal gold. The invention further relates to a method for topically administering the composition in an amount therapeutically effective to reduce wrinkles by building the dermal fibroblast matrix. The invention further relates to a method of treating wrinkled skin by topically administering the composition to an individual in need of such treatment.

Owner:GRANT INDS

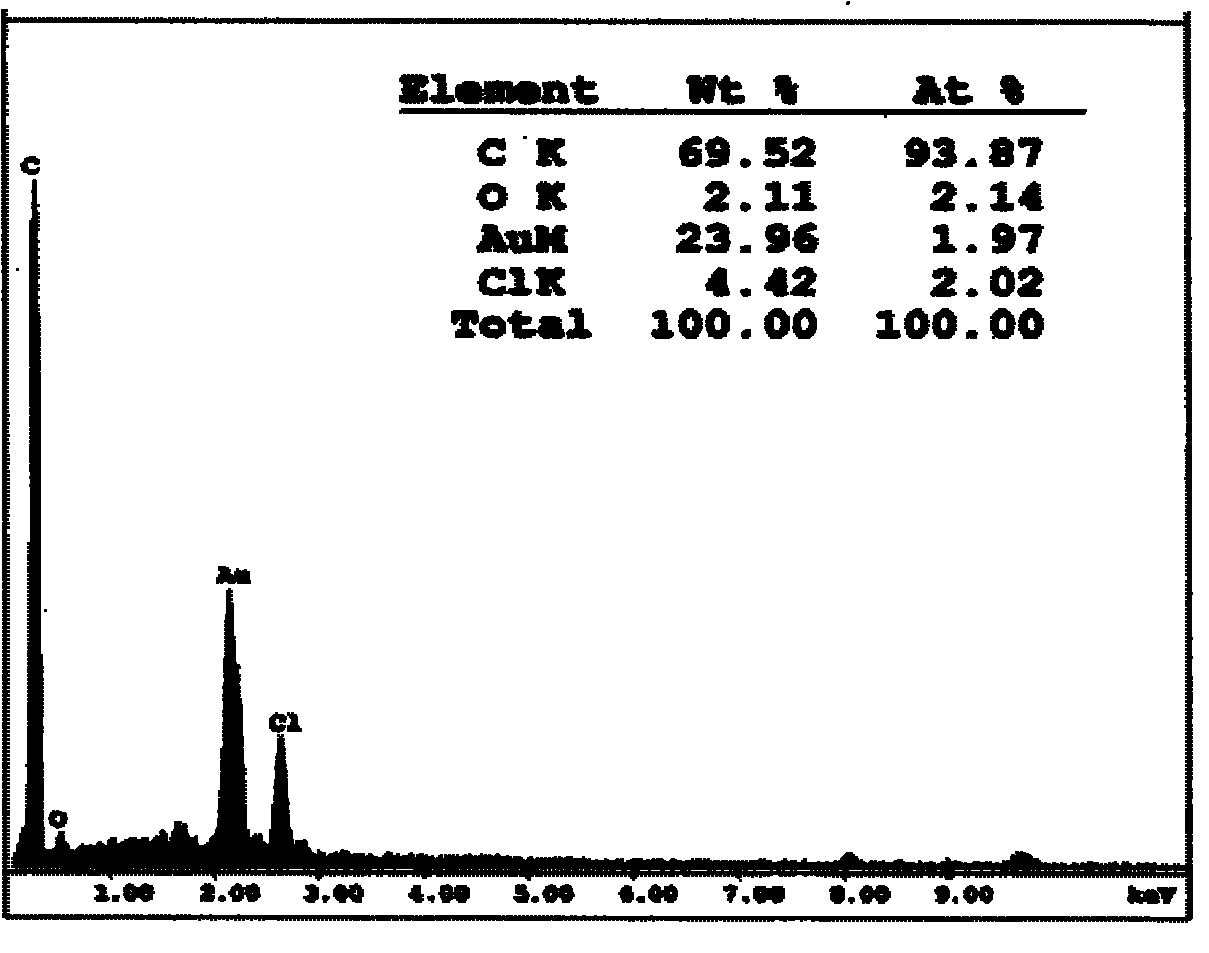

Preparation method of carbon fiber reinforcement grafted by graphene oxide

A preparation method of a carbon fiber reinforcement grafted by graphene oxide relates to a preparation method of a carbon fiber reinforcement grafted by graphene oxide. The invention solves the problems of harsh process conditions, long process period, toxic process, and difficult industrial production for current carbon fiber surface modification methods. The invention adopts a 'grafting' method, and grafts graphene oxide on acidified carbon fiber surfaces through an acylation reaction by using polyamide-amine with a lot of amido active groups; the invention has low cost, is simple, practical, environment-friendly, and nontoxic, and can be completed within a short period. The method particularly comprises the following steps: mixing acidified carbon fibers and a polyamide-amine methanolsolution, reacting to prepare carbon fibers modified by polyamide-amine, adding the prepared carbon fibers in a graphene oxide acetone suspension, mixing, reacting, filtering, drying the precipitatestill the weight is constant. The obtained carbon fiber reinforcement has interfacial shear strength with epoxy resin of up to 79.77-105.50 MPa which is improved.

Owner:HARBIN INST OF TECH

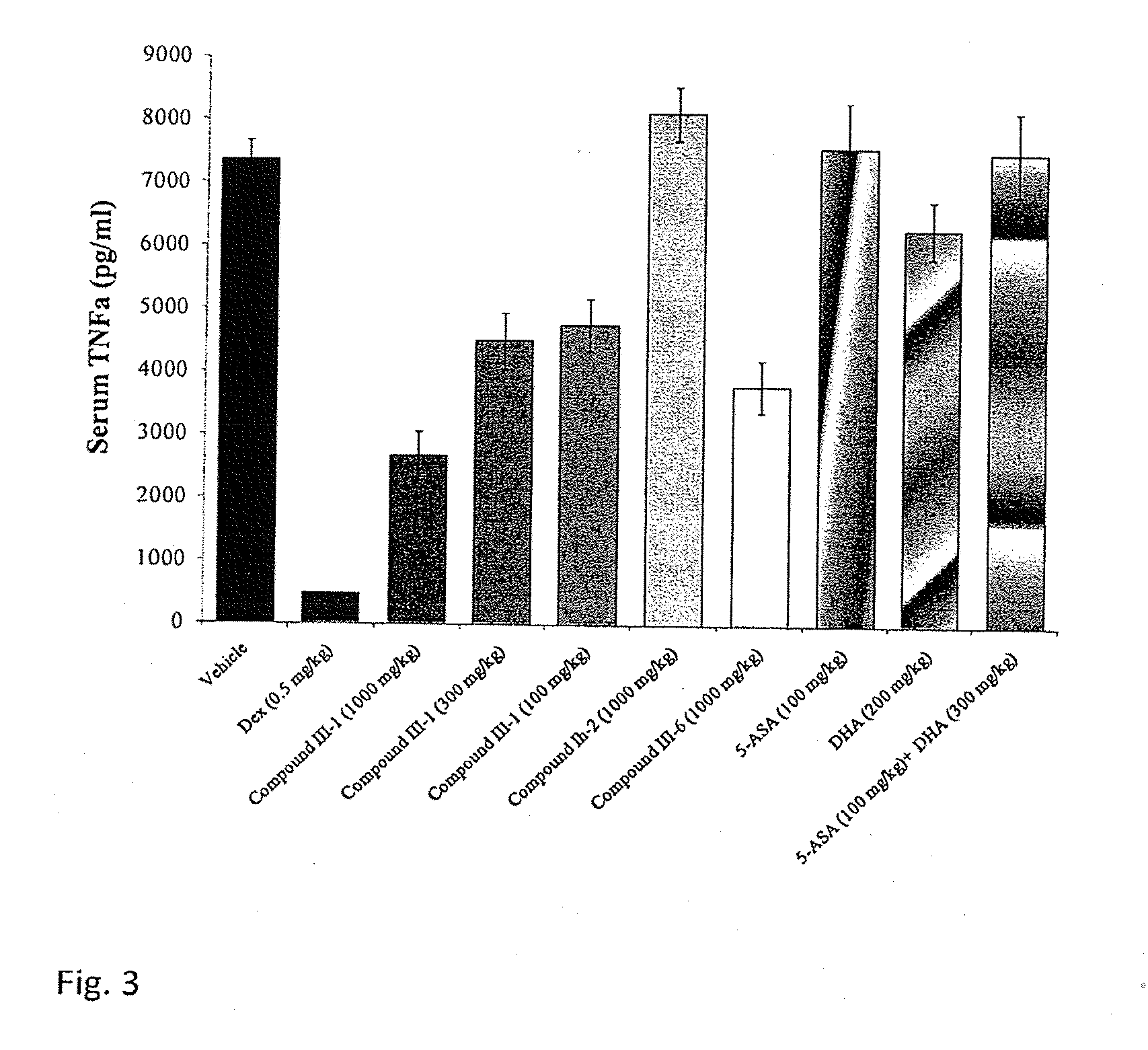

Fatty Acid Acylated Salicylates and Their Uses

ActiveUS20100184730A1Blunt proinflammatoryInhibiting pro-inflammatory pathwayBiocideNervous disorderSalicylic acid esterPerylene derivatives

The invention relates to fatty acid acylated salicylate derivatives; compositions comprising an effective amount of a fatty acid acylated salicylate derivative; and methods for treating or preventing an inflammatory disorder comprising the administration of an effective amount of a fatty acid acylated salicylate derivative.

Owner:CATABASIS PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com