Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

502 results about "Cytidine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

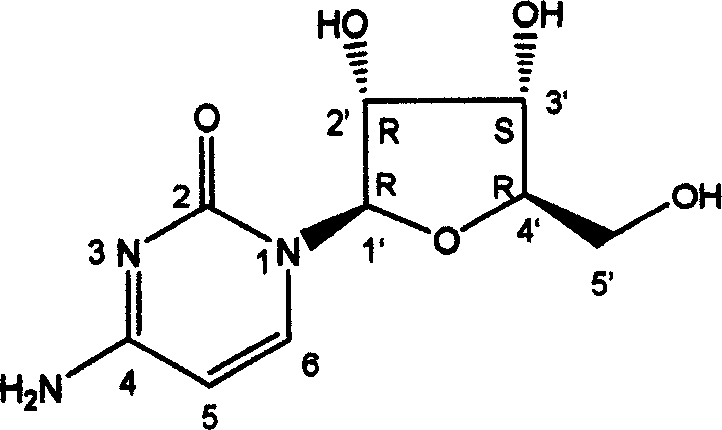

Cytidine is a nucleoside molecule that is formed when cytosine is attached to a ribose ring (also known as a ribofuranose) via a β-N₁-glycosidic bond. Cytidine is a component of RNA. If cytosine is attached to a deoxyribose ring, it is known as a deoxycytidine.

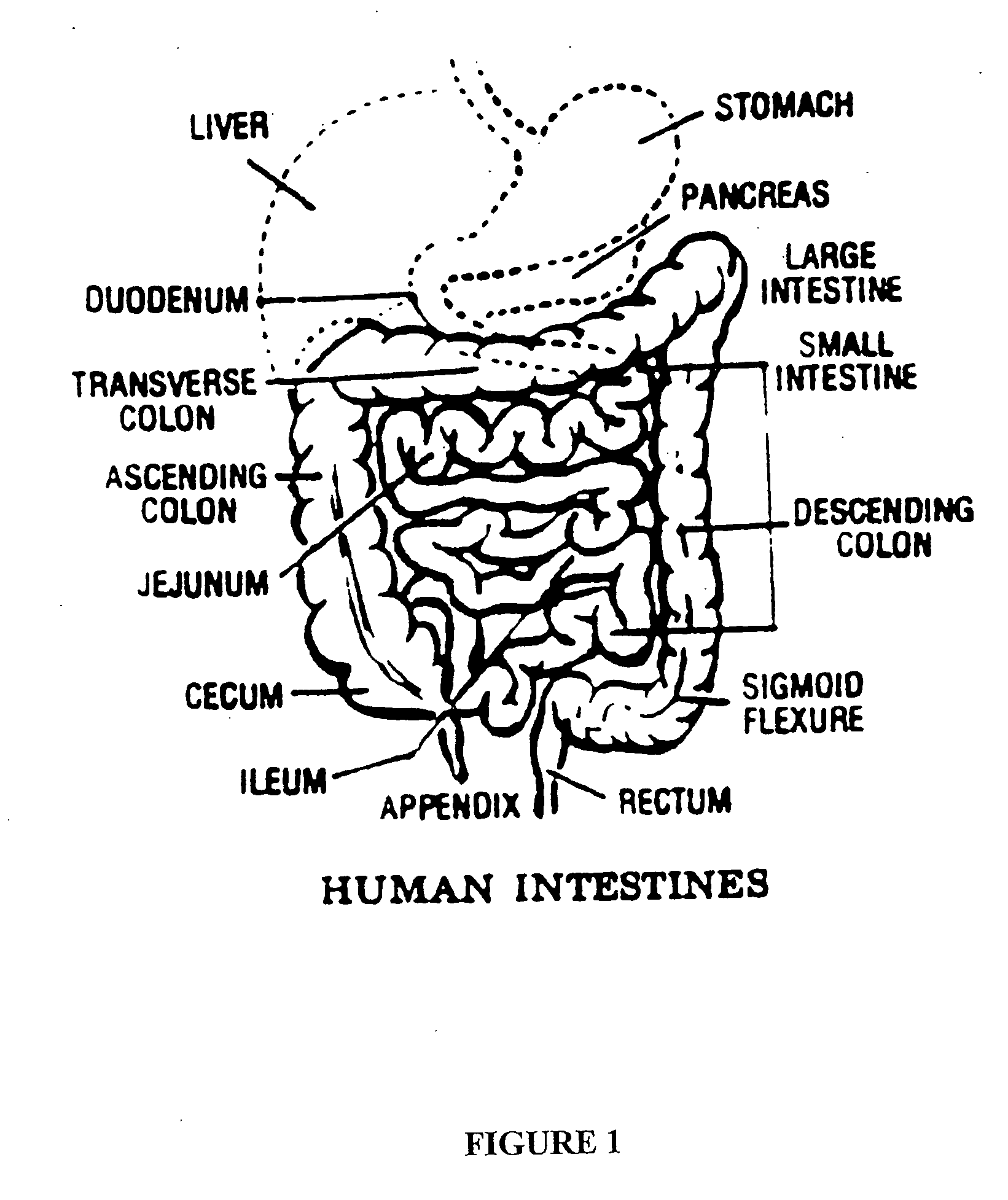

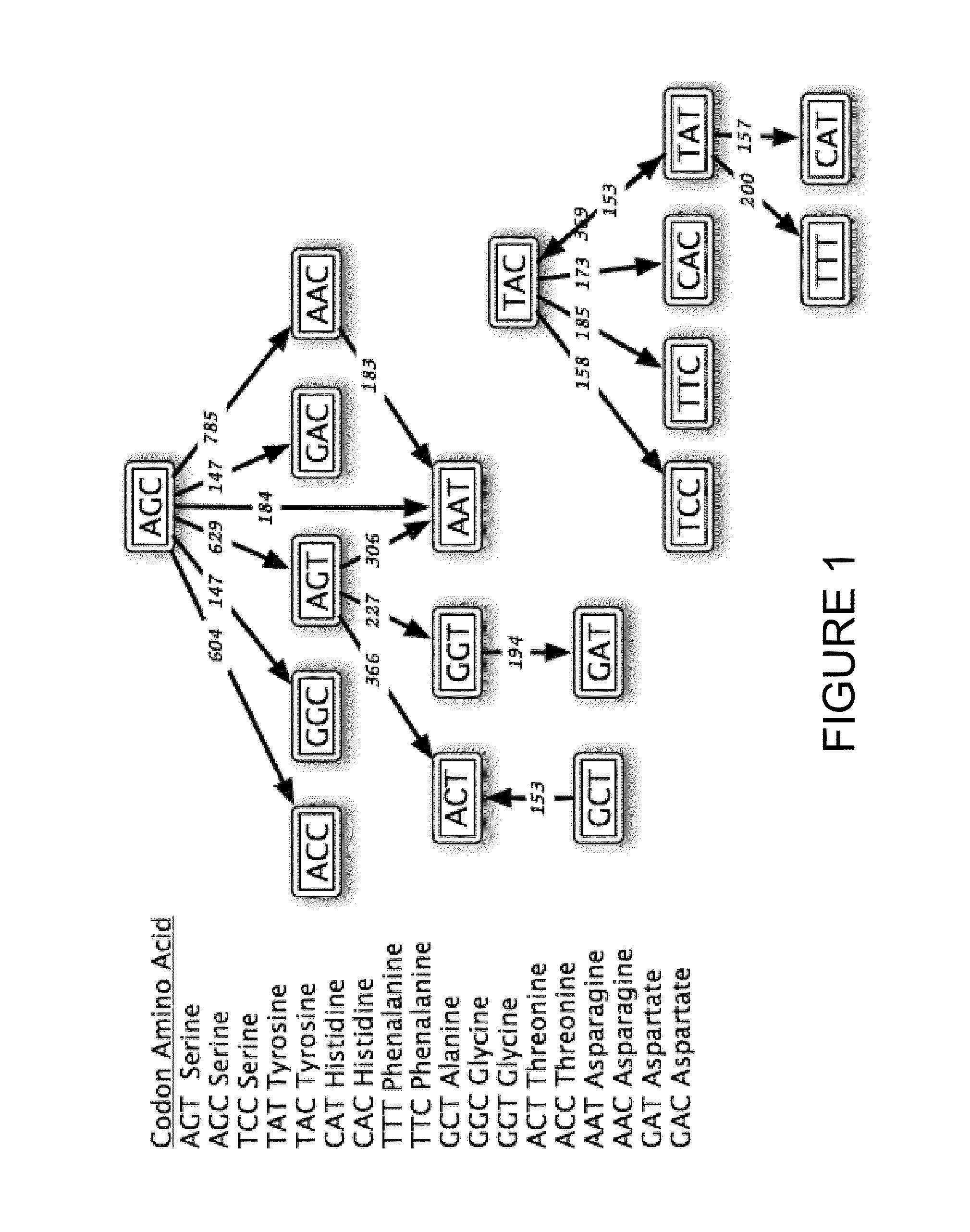

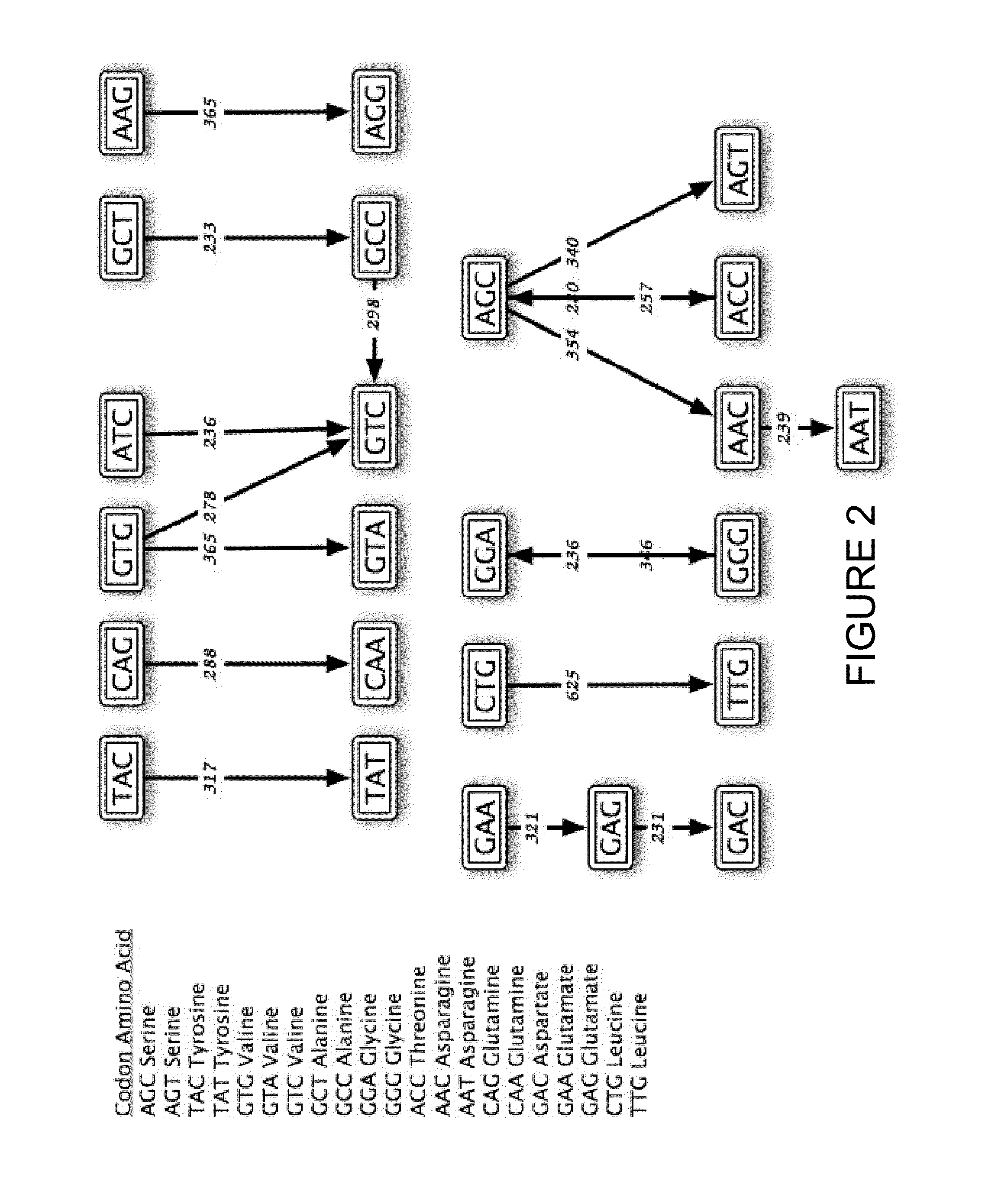

Colon-targeted oral formulations of cytidine analogs

InactiveUS20080057086A1Improve bioavailabilityBiocideCarbohydrate active ingredientsDiseaseLower Gastrointestinal Tract

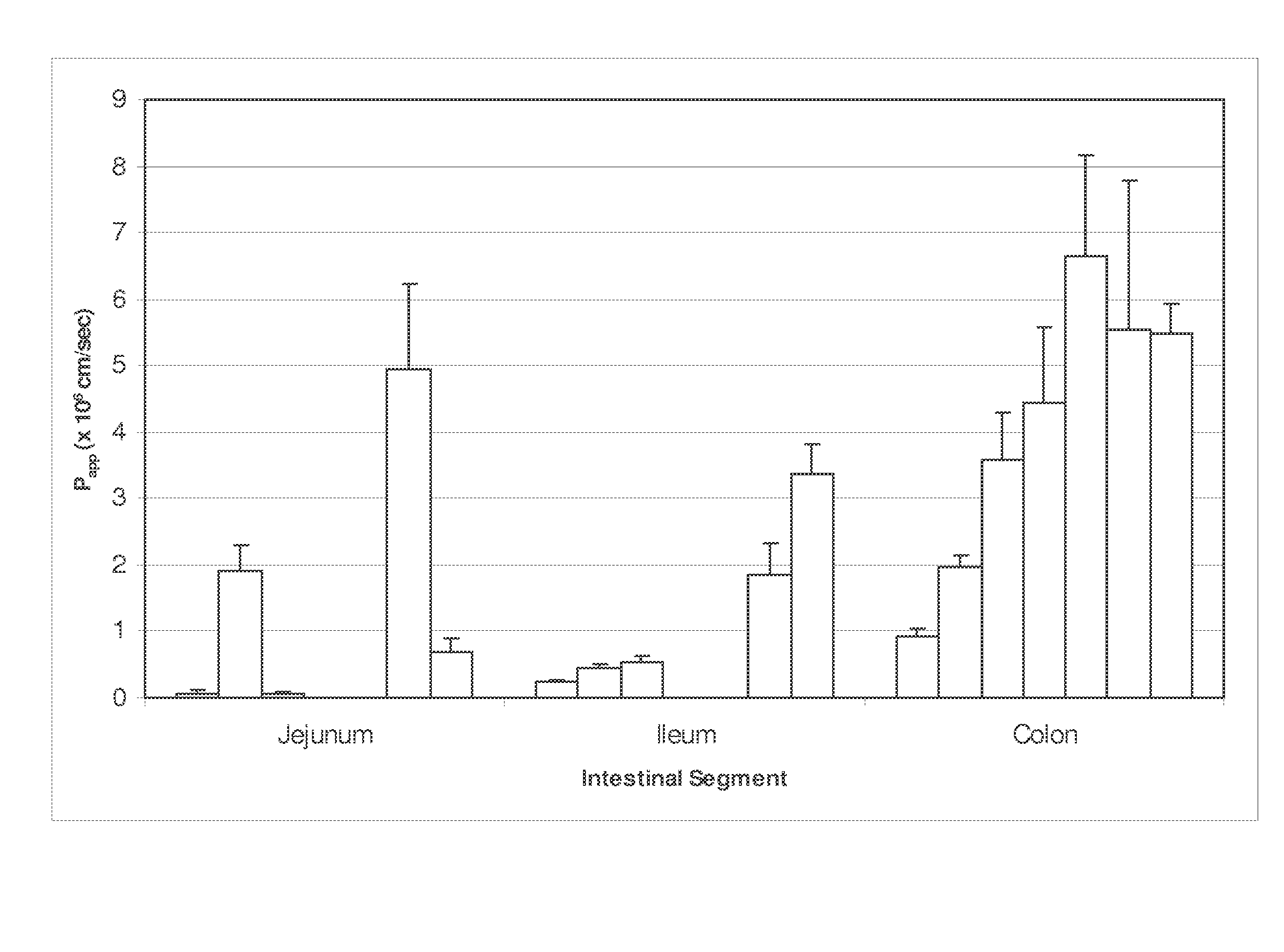

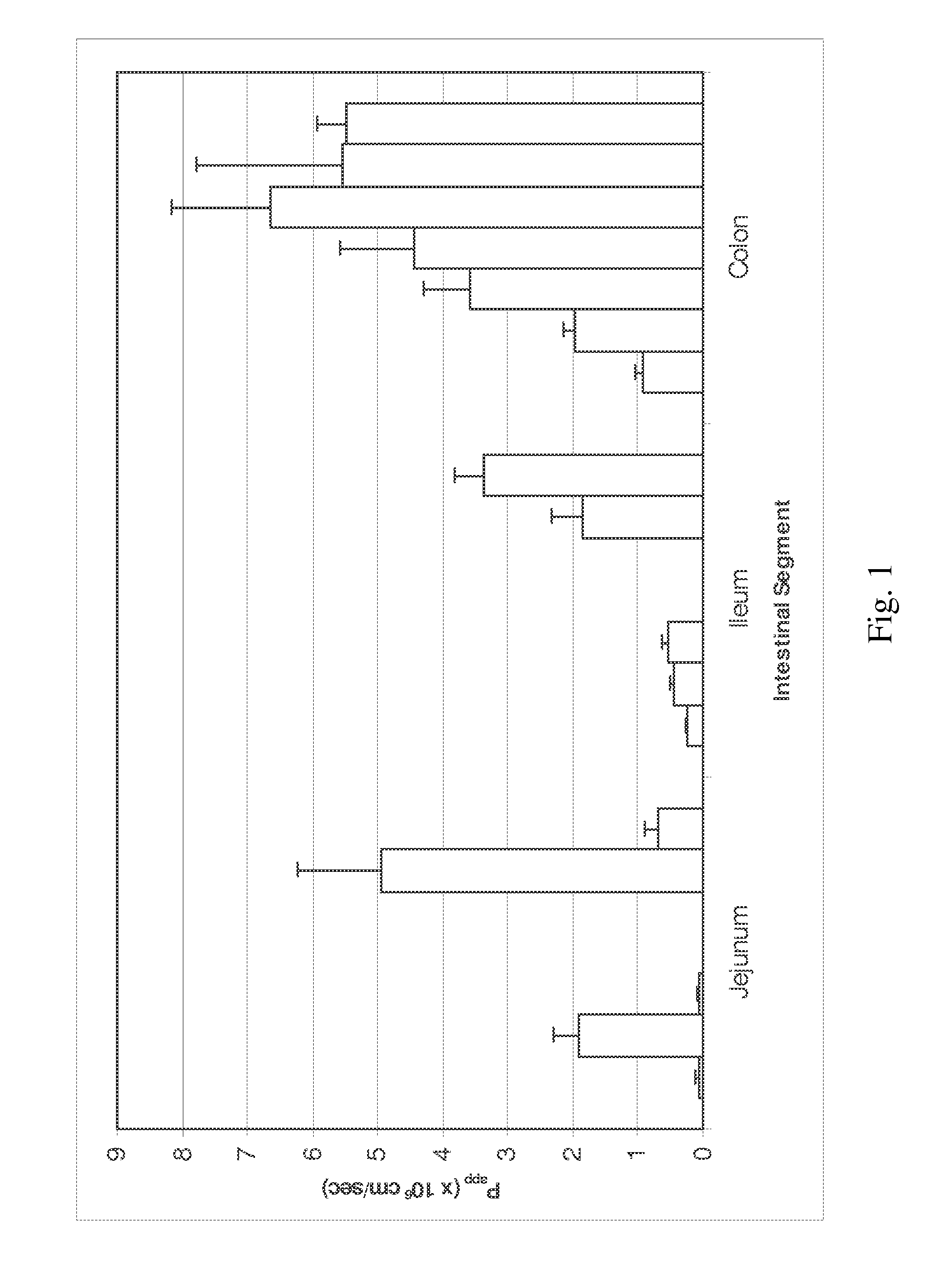

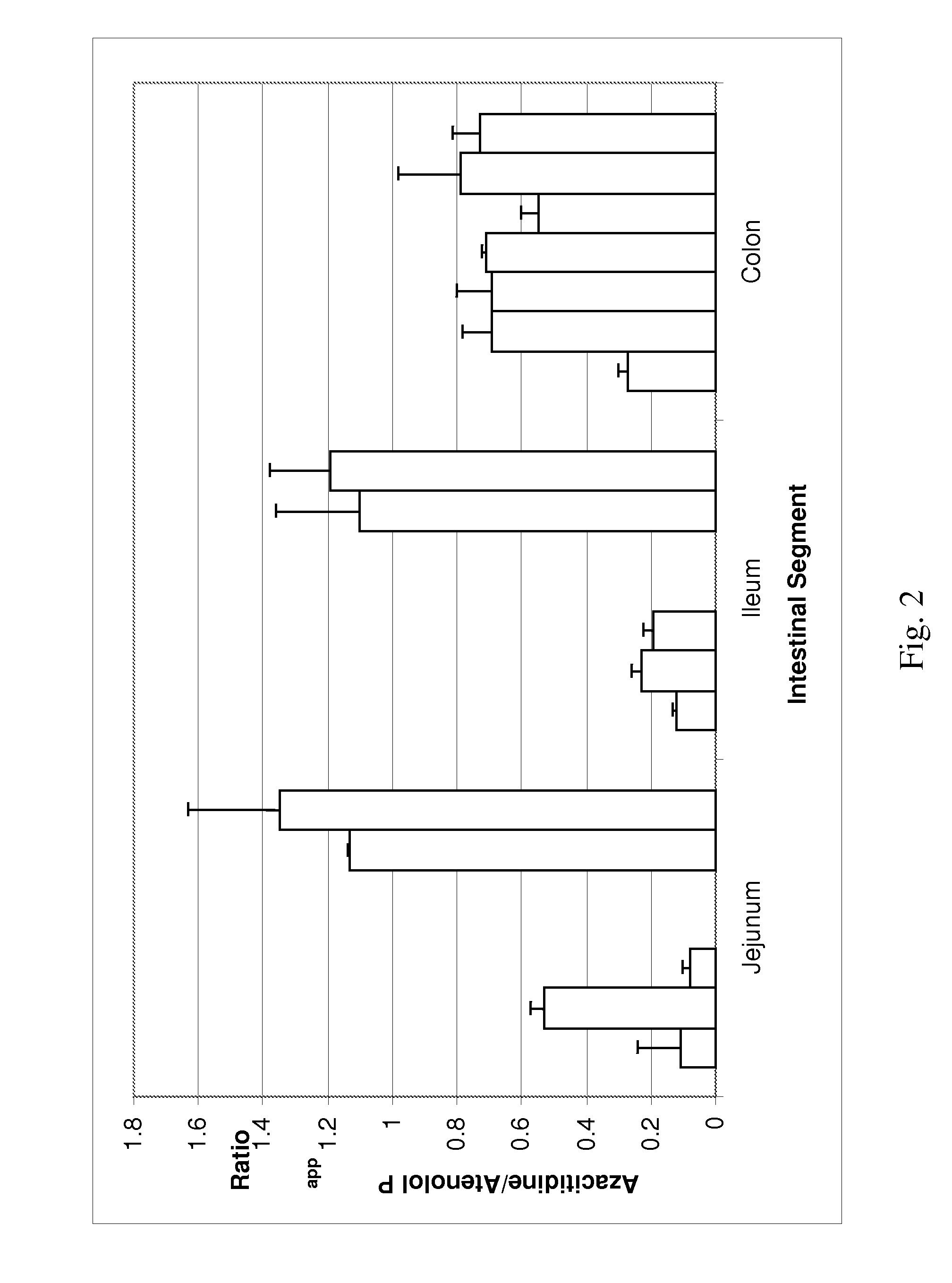

The present invention provides an oral formulation of a cytidine analog, including, 5-azacytidine, for delivery to the lower gastrointestinal tract, including, the large intestine; methods to treat diseases associated with abnormal cell proliferation by treatment with the oral formulations of the present invention; and methods to increase the bioavailability of a cytidine analog upon administration to a patient by providing an oral formulation of the present invention.

Owner:PHARMION

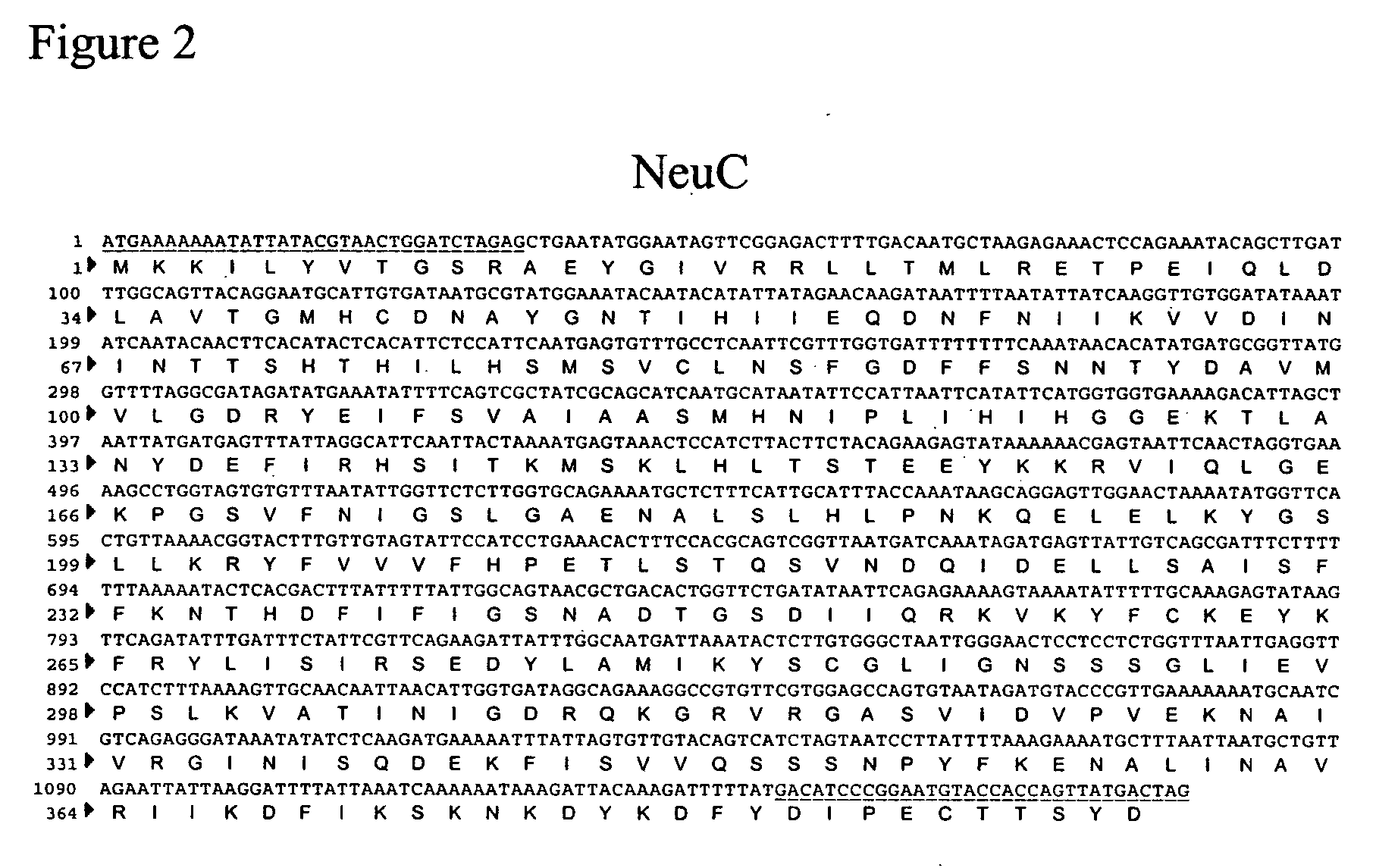

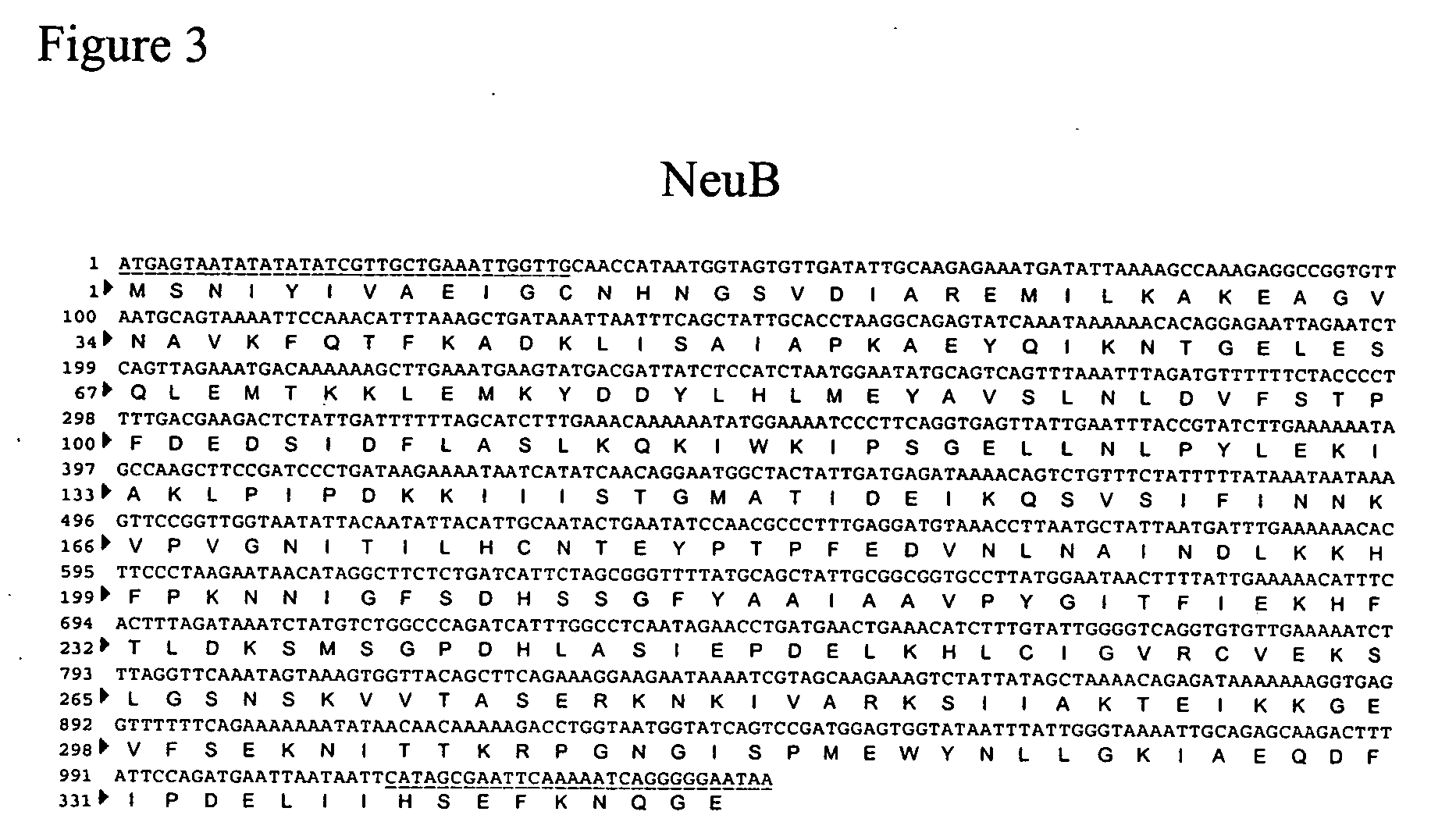

Method of engineering a cytidine monophosphate-sialic acid synthetic pathway in fungi and yeast

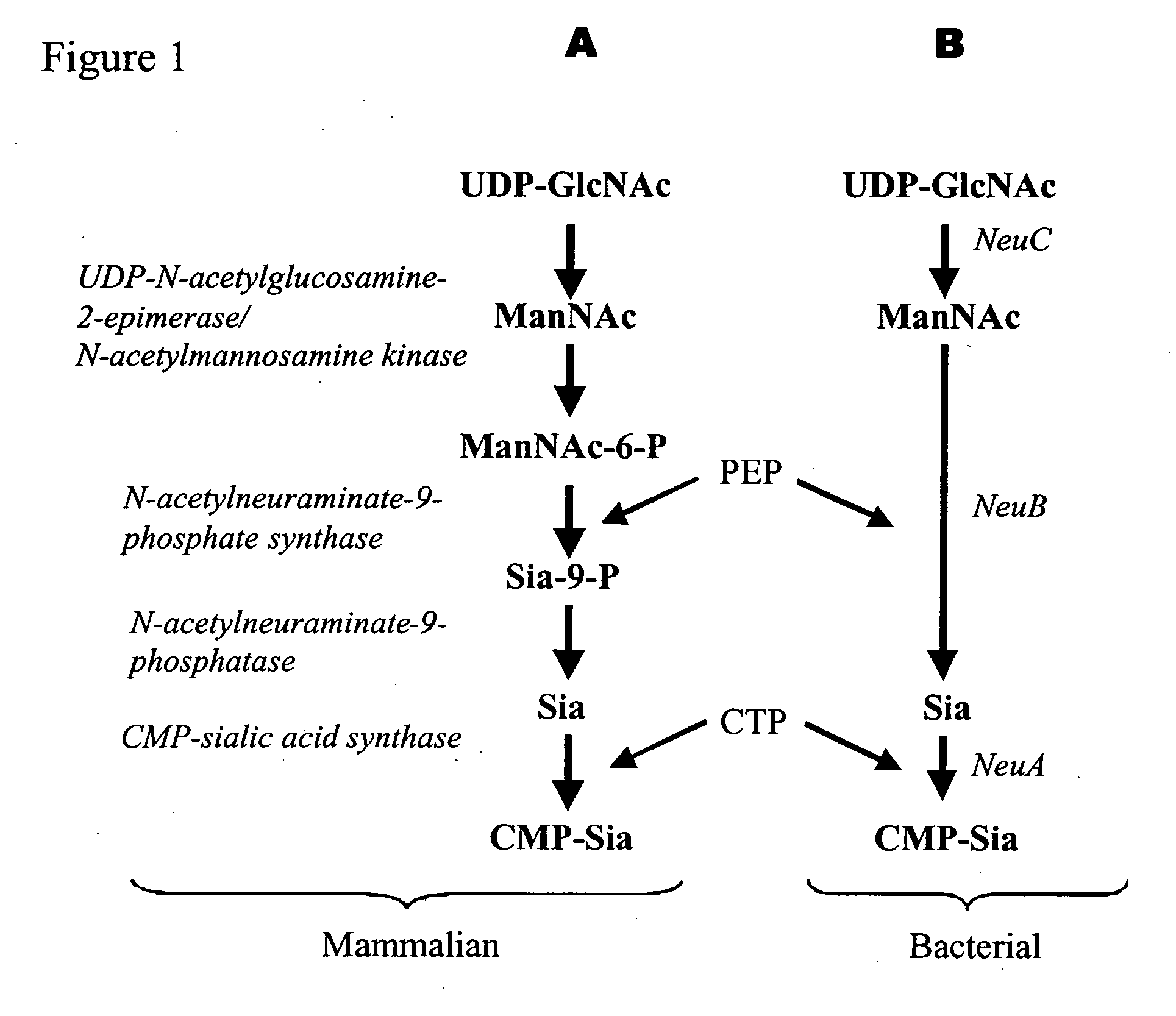

The present invention provides methods for generating CMP-sialic acid in a non-human host which lacks endogenous CMP-Sialic by providing the host with enzymes involved in CMP-sialic acid synthesis from a bacterial, mammalian or hybrid CMP-sialic acid biosynthetic pathway. Novel fungal hosts expressing a CMP-sialic acid biosynthetic pathway for the production of sialylated glycoproteins are also provided.

Owner:GLYCOFI

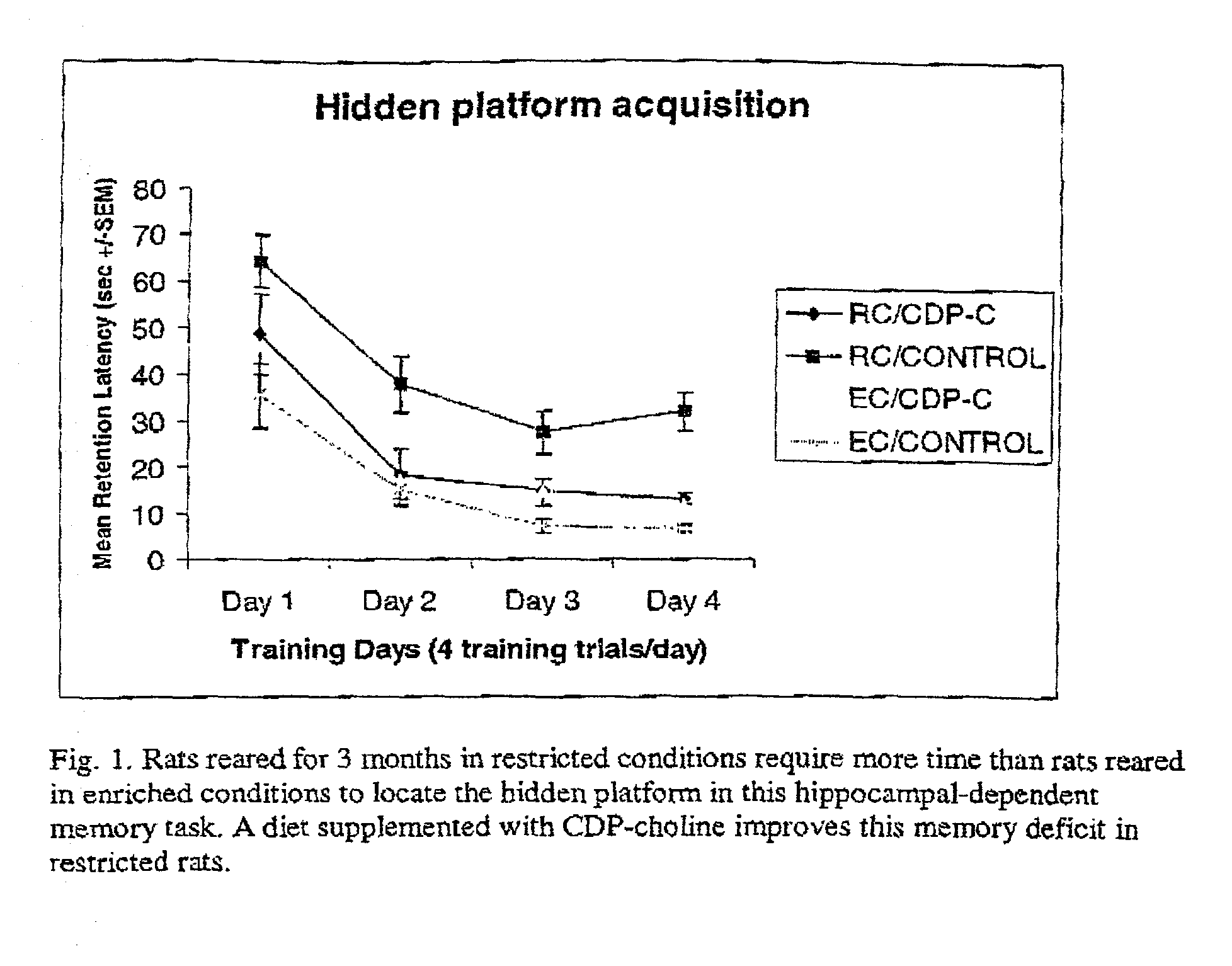

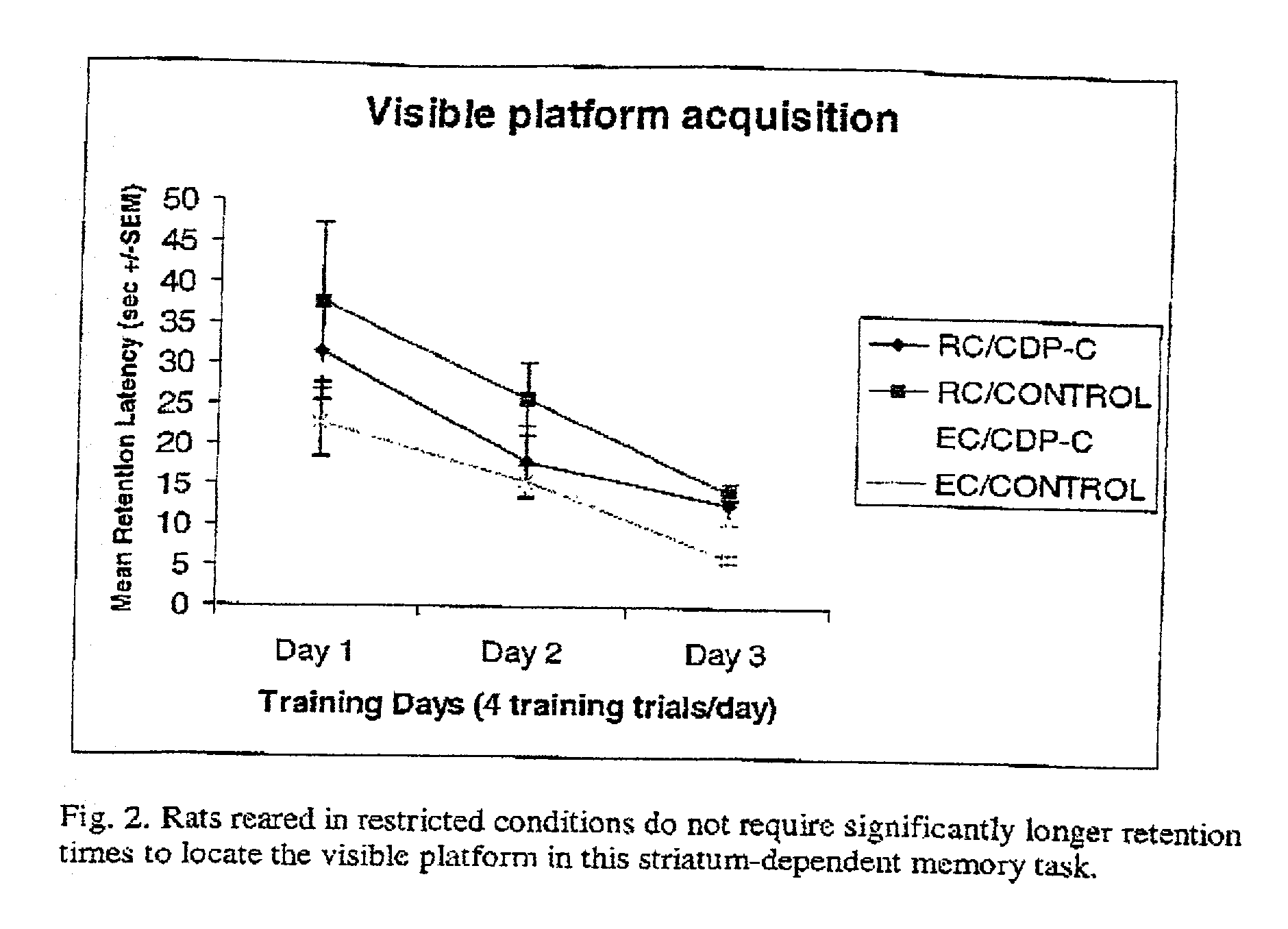

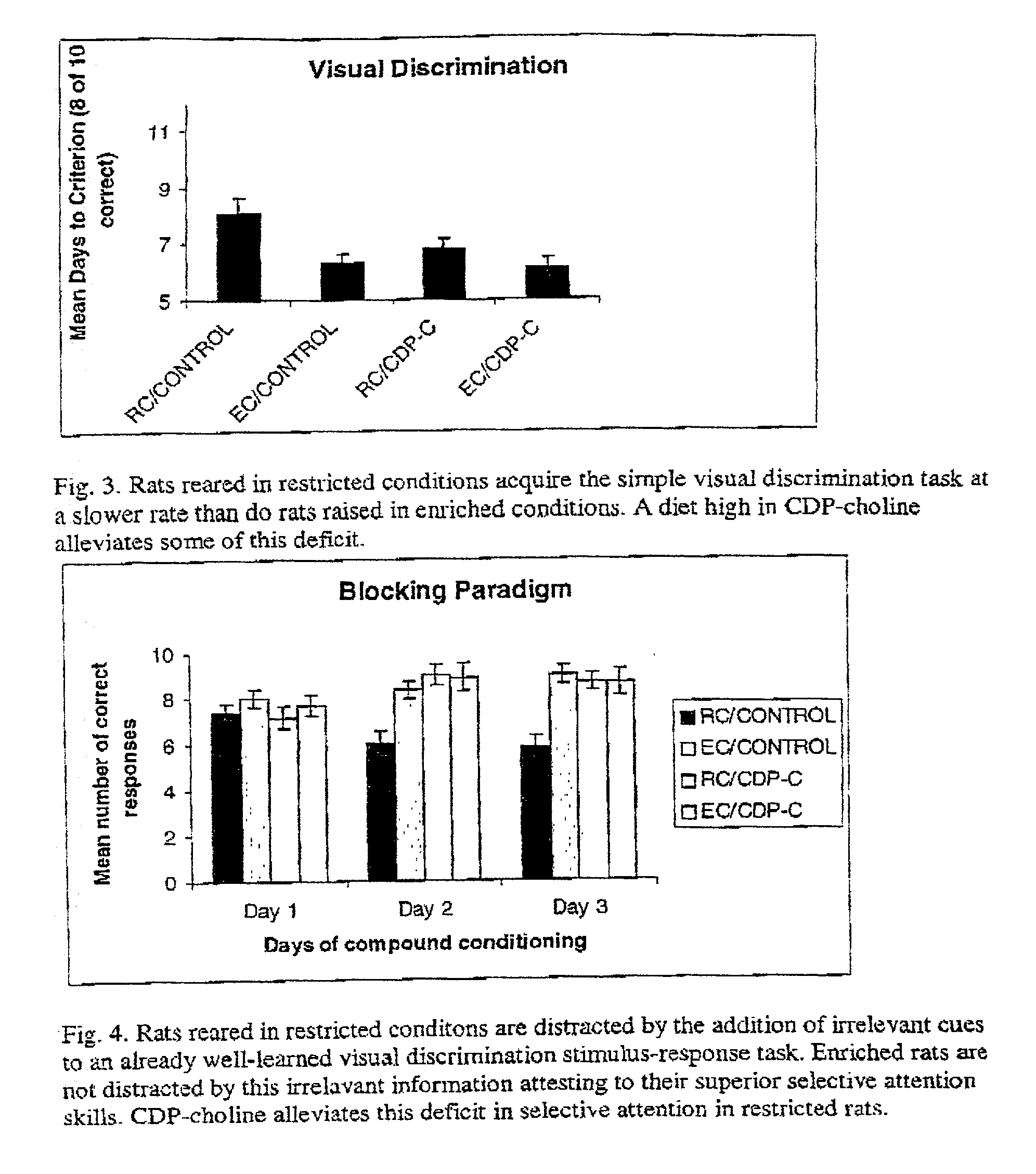

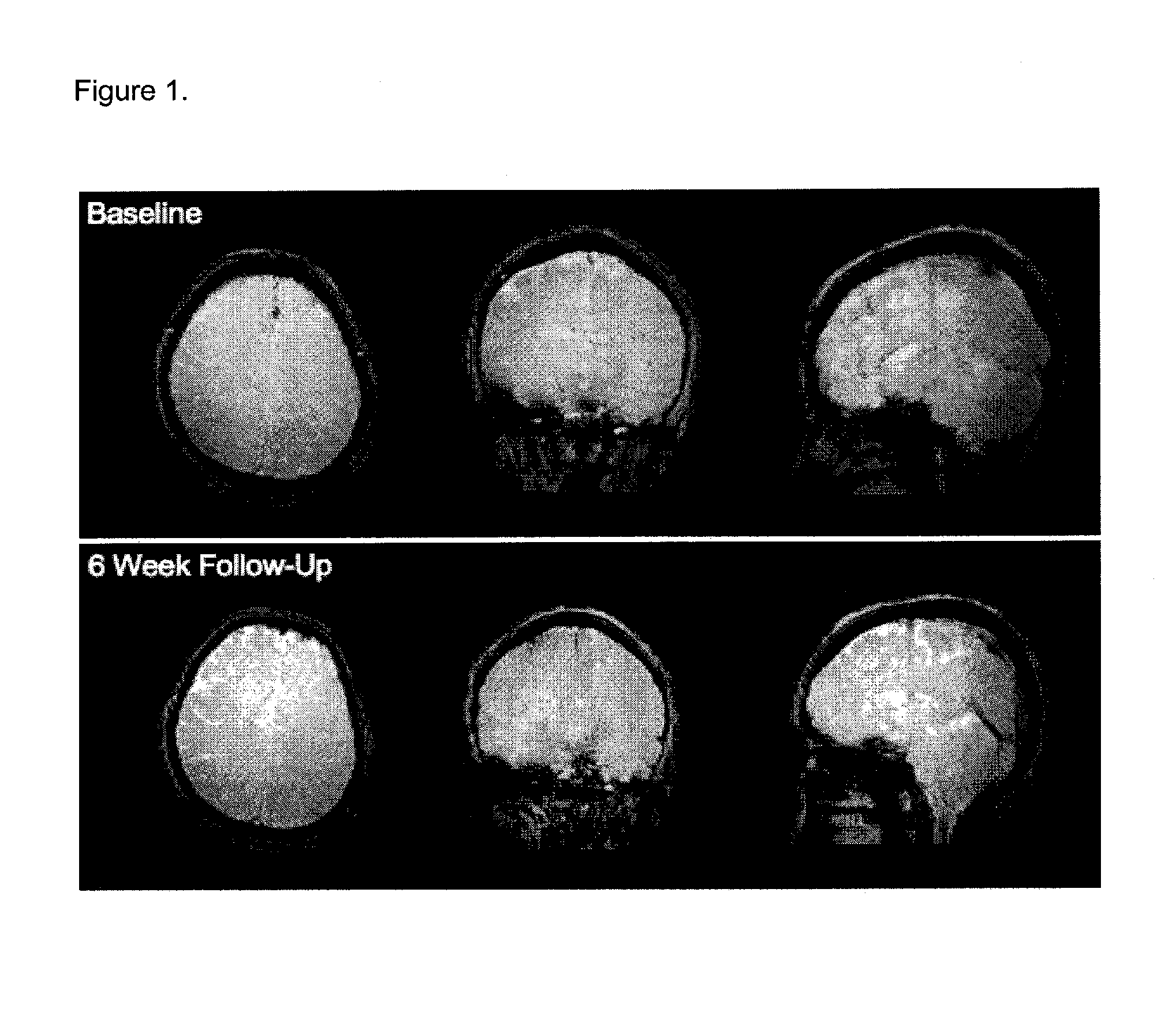

Compositions and methods for treating and preventing memory impairment using citicoline

InactiveUS20030114415A1Low toxicityAvoid damageBiocideCarbohydrate active ingredientsMemory disorderCiticoline

This invention relates to compositions and methods for preventing and treating cognitive dysfunction or memory impairment. The compositions include an effective amount of citicoline, or pharmaceutically-acceptable salts thereof, and one or more of the compounds selected from the group consisting of linoleic acid and linolenic acid. Other compositions of this invention include an effective amount of citicoline, or pharmaceutically-acceptable salt thereof, wherein said citicoline is metabolized to form at least one of cytidine, uridine, and choline. Still other compositions of this invention include effective amounts of choline, cytidine, and / or uridine, or their pharmaceutically-acceptable salts. This invention also encompasses methods for preparing these compositions.

Owner:MASSACHUSETTS INST OF TECH

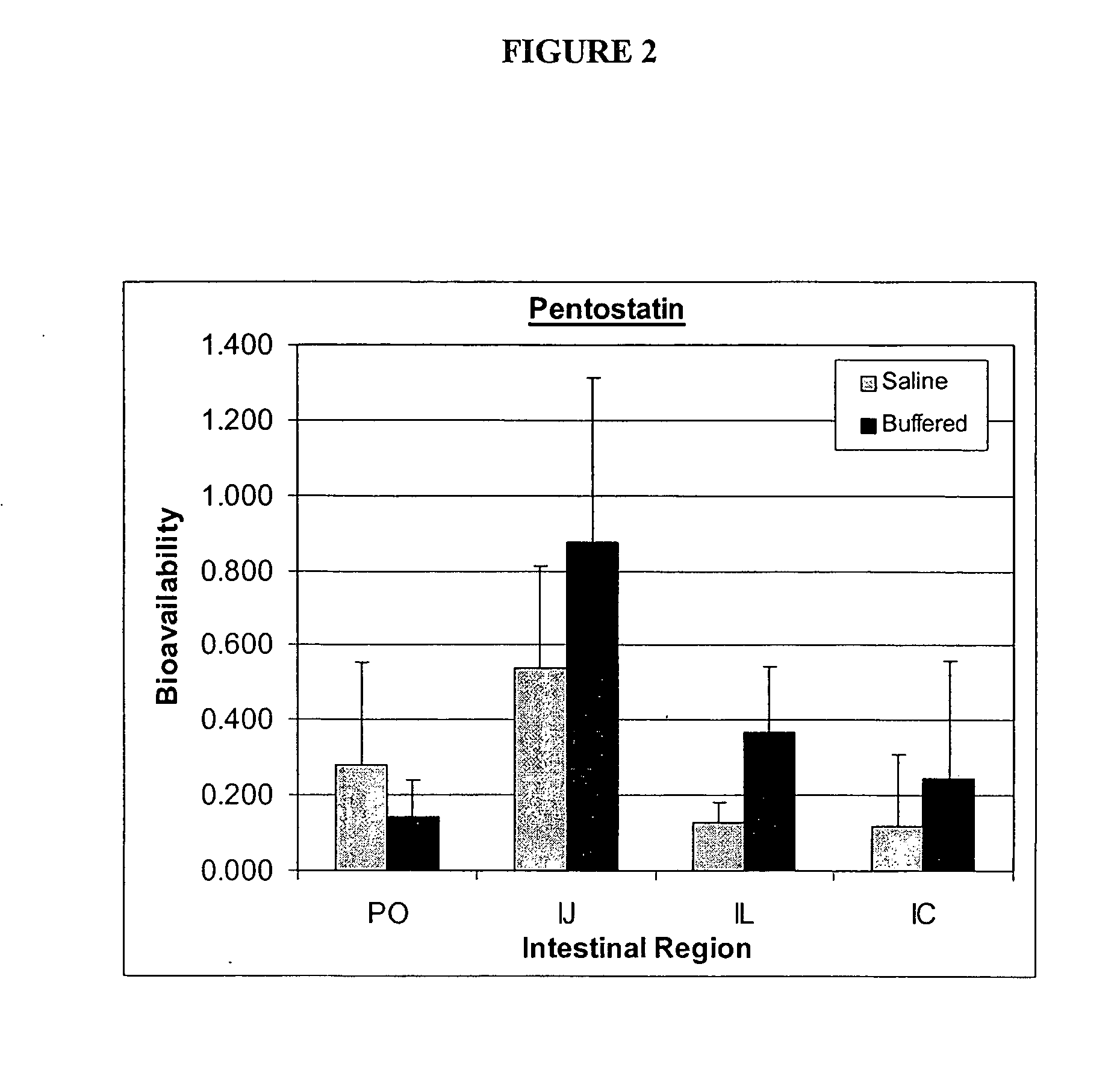

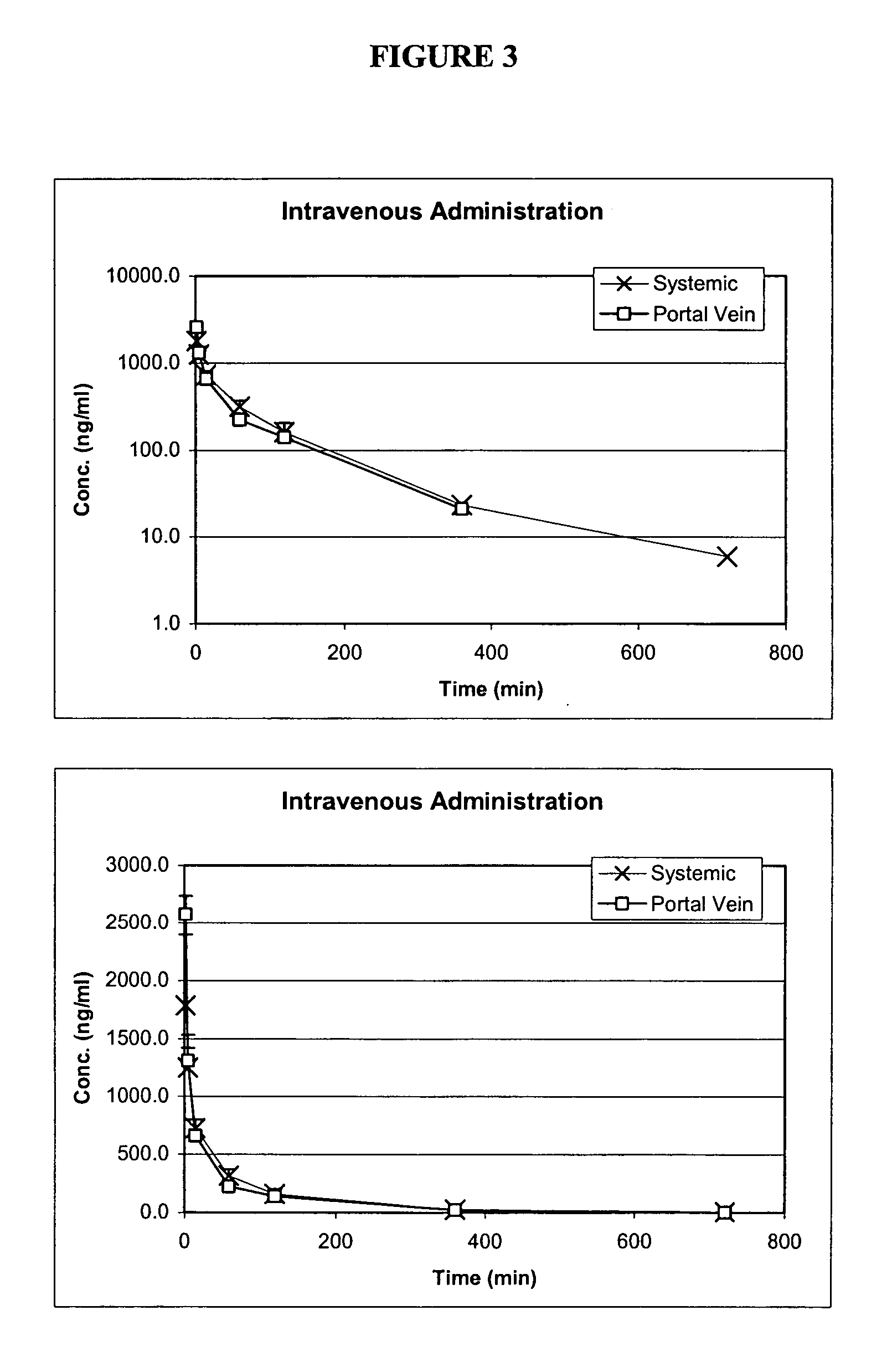

Pharmaceutical formulations targeting specific regions of the gastrointesinal tract

Oral formulations of pharmaceuticals are provided with enhanced bioavailability by targeting specific regions of the gastrointestinal tract. Particularly, water soluble and acid-labile drugs such as cytidine analogs (e.g., decitabine) and 2'-deoxyadenosine analogs (e.g., pentostatin) are formulated with pH-sensitive polymers so that these drugs are preferably absorbed in the upper regions of the small intestine, such as the jejunum. In addition, drugs with poor oral bioavailability such as camptothecin compounds (e.g., 9-nitro-camptothecin) can also be formulated using similar strategies in order to significantly improve their oral bioavailability. These formulations can be used to treat a wide variety of diseases or conditions, such hematological disorders, benign tumors, cancer, restenosis, inflammatory diseases, and autoimmune diseases.

Owner:MAYNE PHARMA USA

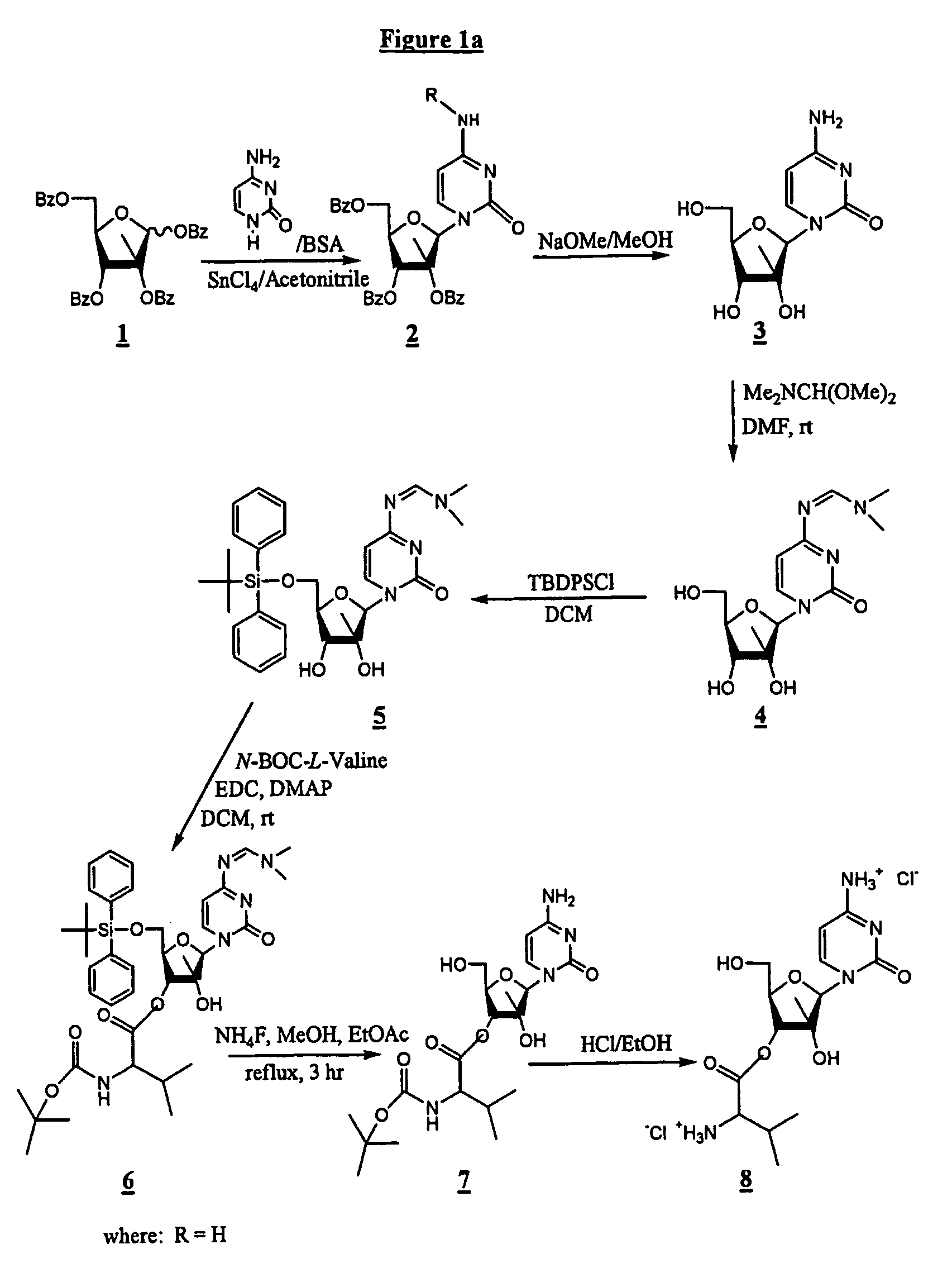

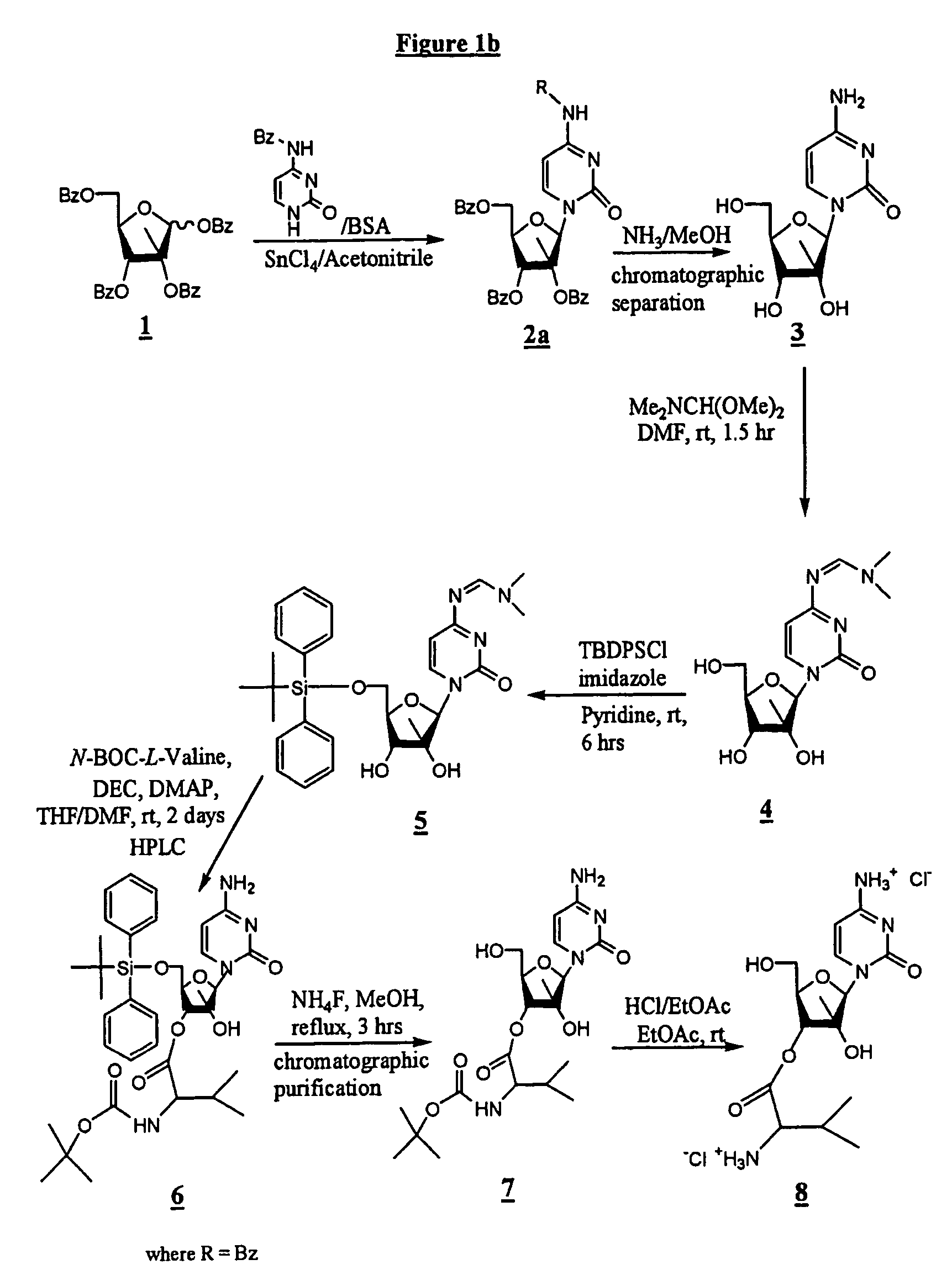

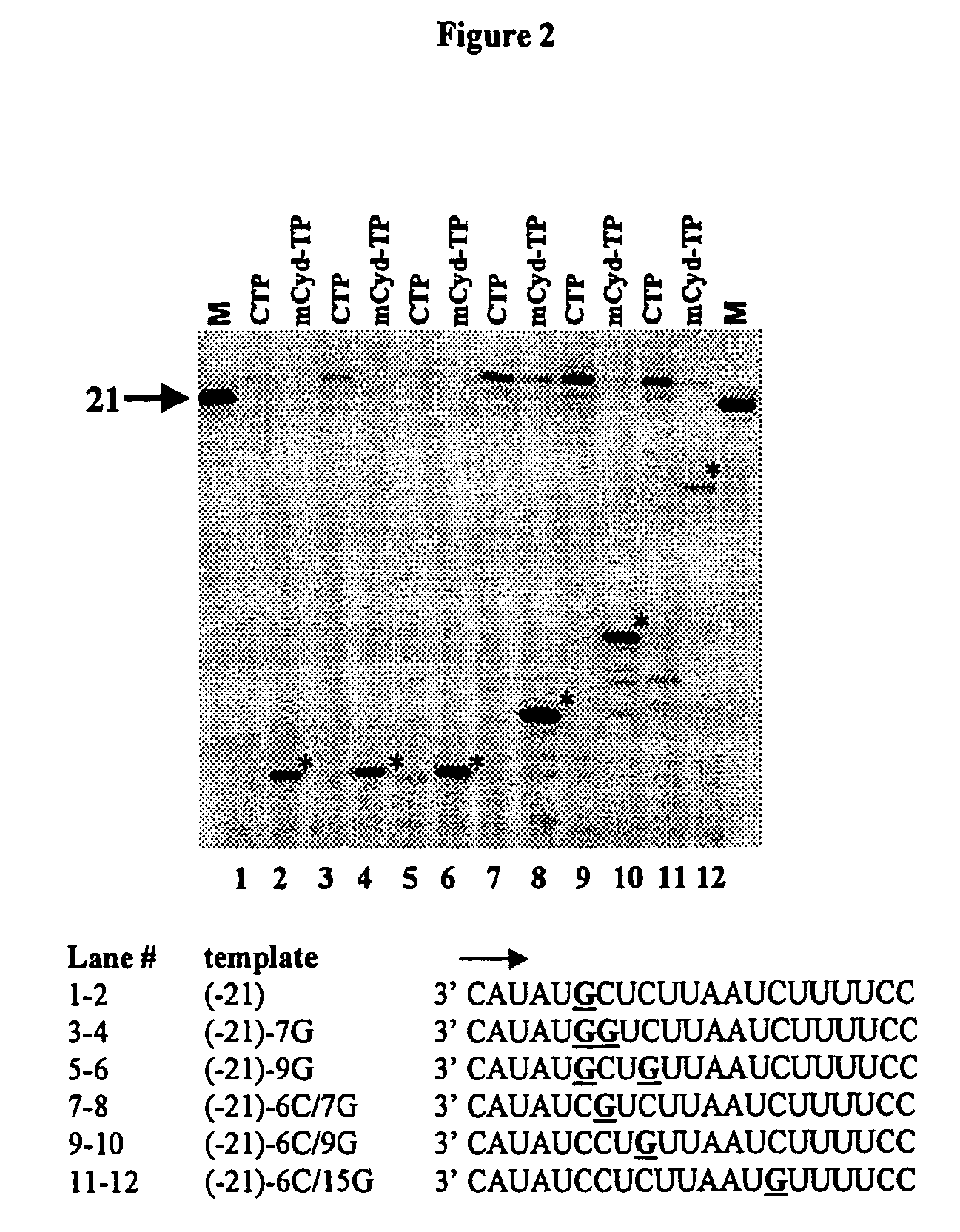

2'-C-methyl-3'-O-L-valine ester ribofuranosyl cytidine for treatment of flaviviridae infections

The 3′-L-valine ester of β-D-2′-C-methyl-ribofuranosyl cytidine provides superior results against flaviviruses and pestiviruses, including hepatitis C virus. Based on this discovery, compounds, compositions, methods and uses are provided for the treatment of flaviviridae, including HCV, that include the administration of an effective amount of val-mCyd or its salt, ester, prodrug or derivative, optionally in a pharmaceutically acceptable carrier. In an alternative embodiment, val-mCyd is used to treat any virus that replicates through an RNA-dependent RNA polymerase.

Owner:INDENIX PHARM LLC +3

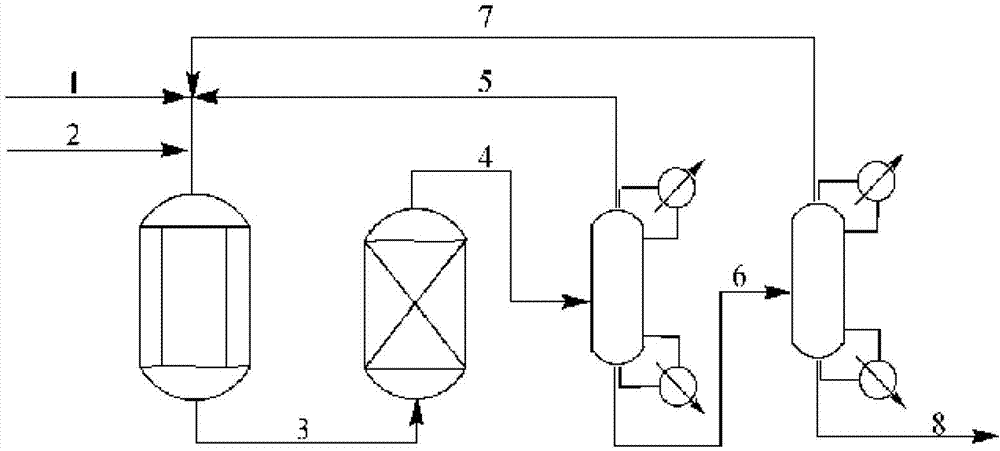

Method for continuous production of polyformaldehyde dimethyl ether

InactiveCN102786397ARealize industrial productionImprove stabilityOrganic chemistryOrganic compound preparationPtru catalystDistillation

The invention provides a method for continuous production of polyformaldehyde dimethyl ether. The method is characterized by comprising the following steps: a) feeding dimethoxymethane and hot-melted paraformaldehyde into a fixed bed reactor and adopting an acidic resin catalyst, so as to prepare polyformaldehyde dimethyl ether (DMM3-8), wherein the reaction temperature is 120-180 DEG C and the pressure is 0.1-10 MPa; b) cooling the reaction product, and then performing adsorptive separation through a dehydrating tower, so as to obtain polyformaldehyde dimethyl ether of which most water, cytidine glycol and hemiacetal are desorbed; c) feeding the polyformaldehyde dimethyl ether subjected to desorption into a distillation tower for separation, wherein most of a low-boiling component (dimethoxymethane (DMM)), poly-di-formaldehyde dimethyl ether (DMM2), a by-product (methanol) and triformol are extracted first, and then the materials in a tower kettle are fed into a rectifying tower in the next step, so as to extract the rest of the DMM2 and the triformol; and d) returning the low-boiling component (dimethoxymethane (DMM)), the methanol, the DMM2 and the triformol, which are evaporated out by the distillation tower and the rectifying tower in the last step, into the fixed bed reactor to continue to react to prepare polyformaldehyde dimethyl ether.

Owner:CHINA NAT OFFSHORE OIL CORP +1

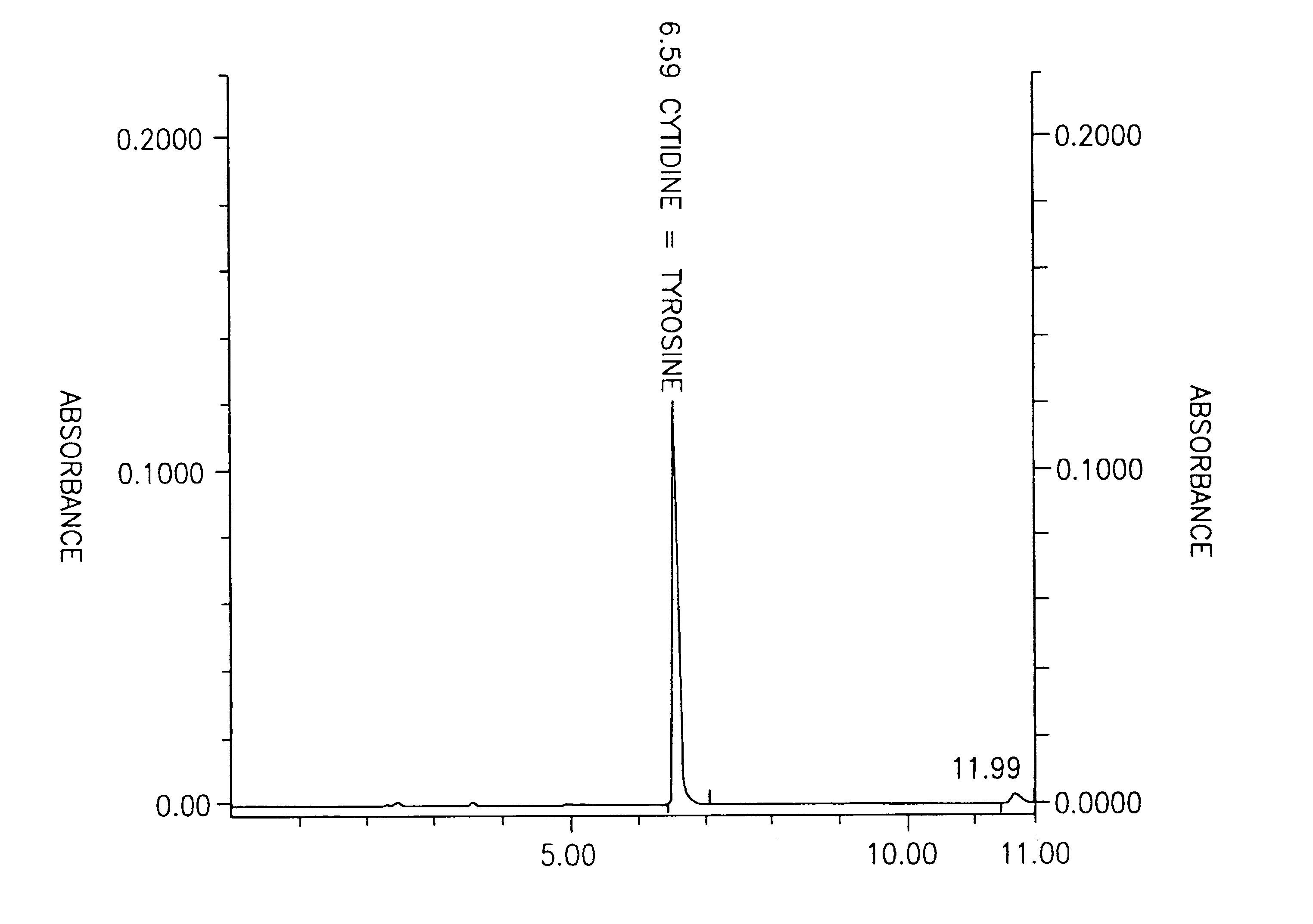

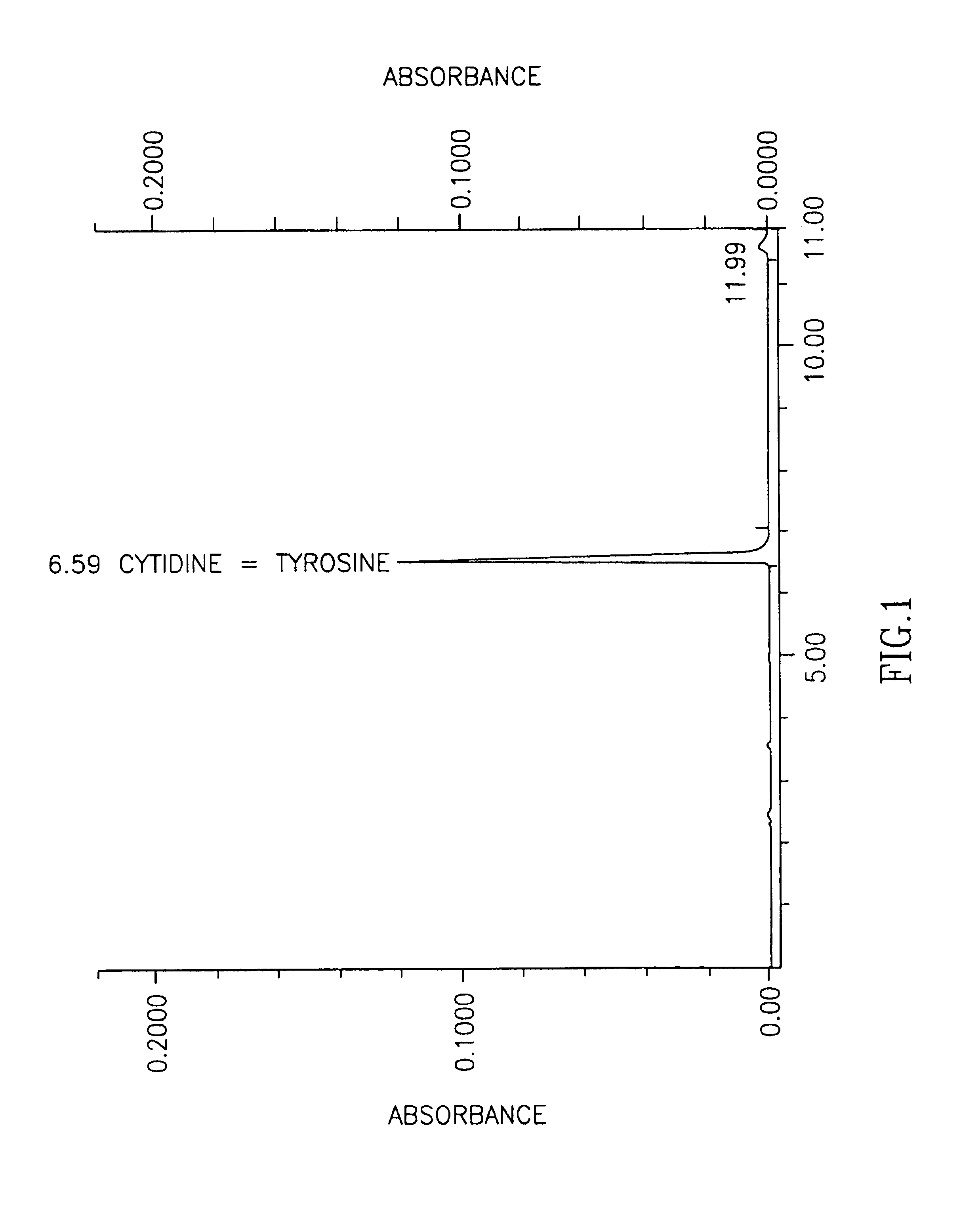

Methods for increasing blood cytidine and/or uridine levels and treating cytidine-dependent human diseases

InactiveUS6989376B2Enhancing uridine bioavailabilityBiocideNervous disorderMedicineUridine Nucleotides

Methods of treating certain neurological diseases using exogenous uridine or a uridine source alone as a precursor of endogenous cytidine, particularly in the human brain, are disclosed. Methods are also disclosed wherein exogenous uridine or a uridine source is combined either with drugs increasing uridine availability or with compounds that serve as a source of choline in phospholipid synthesis.

Owner:MASSACHUSETTS INST OF TECH

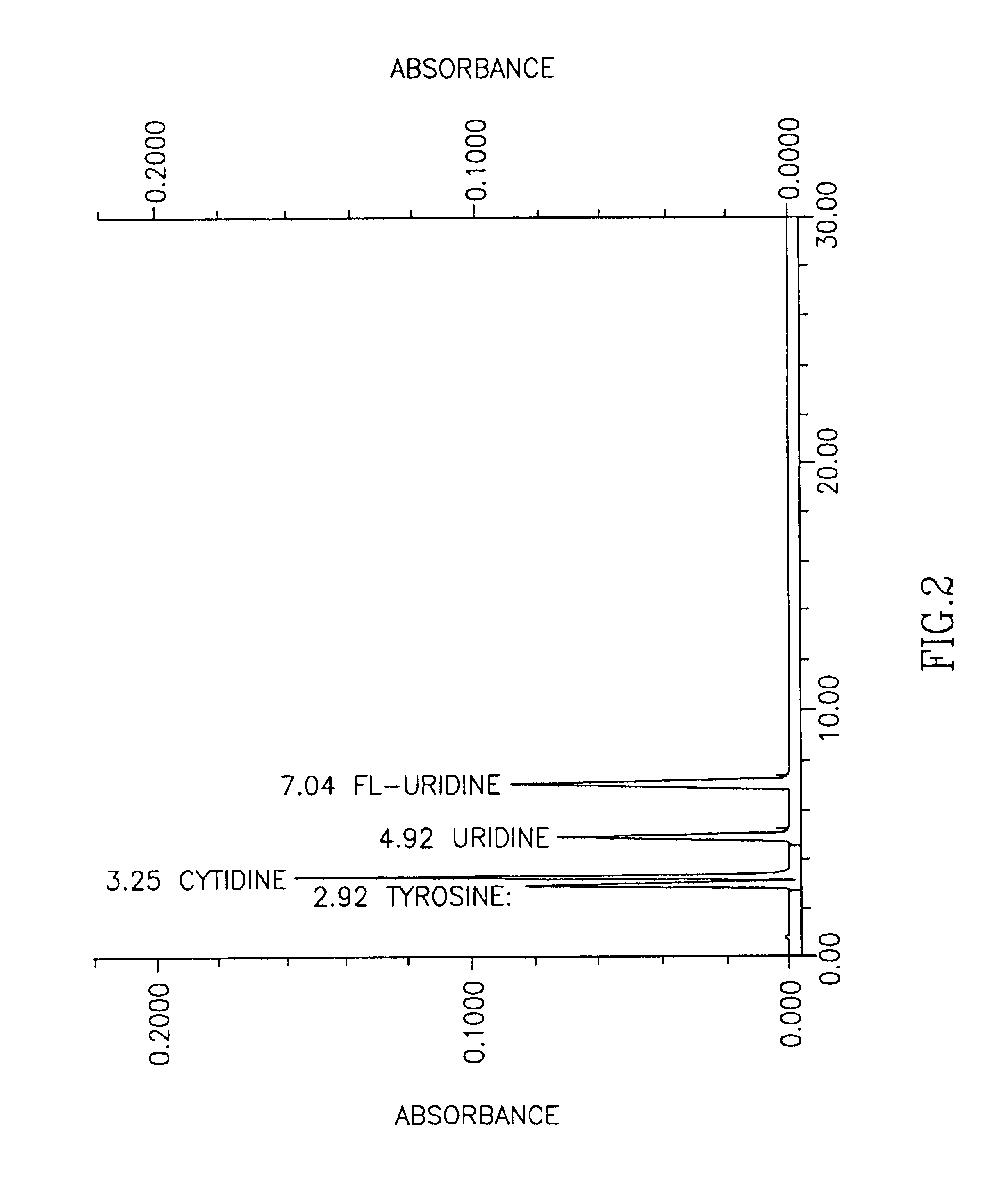

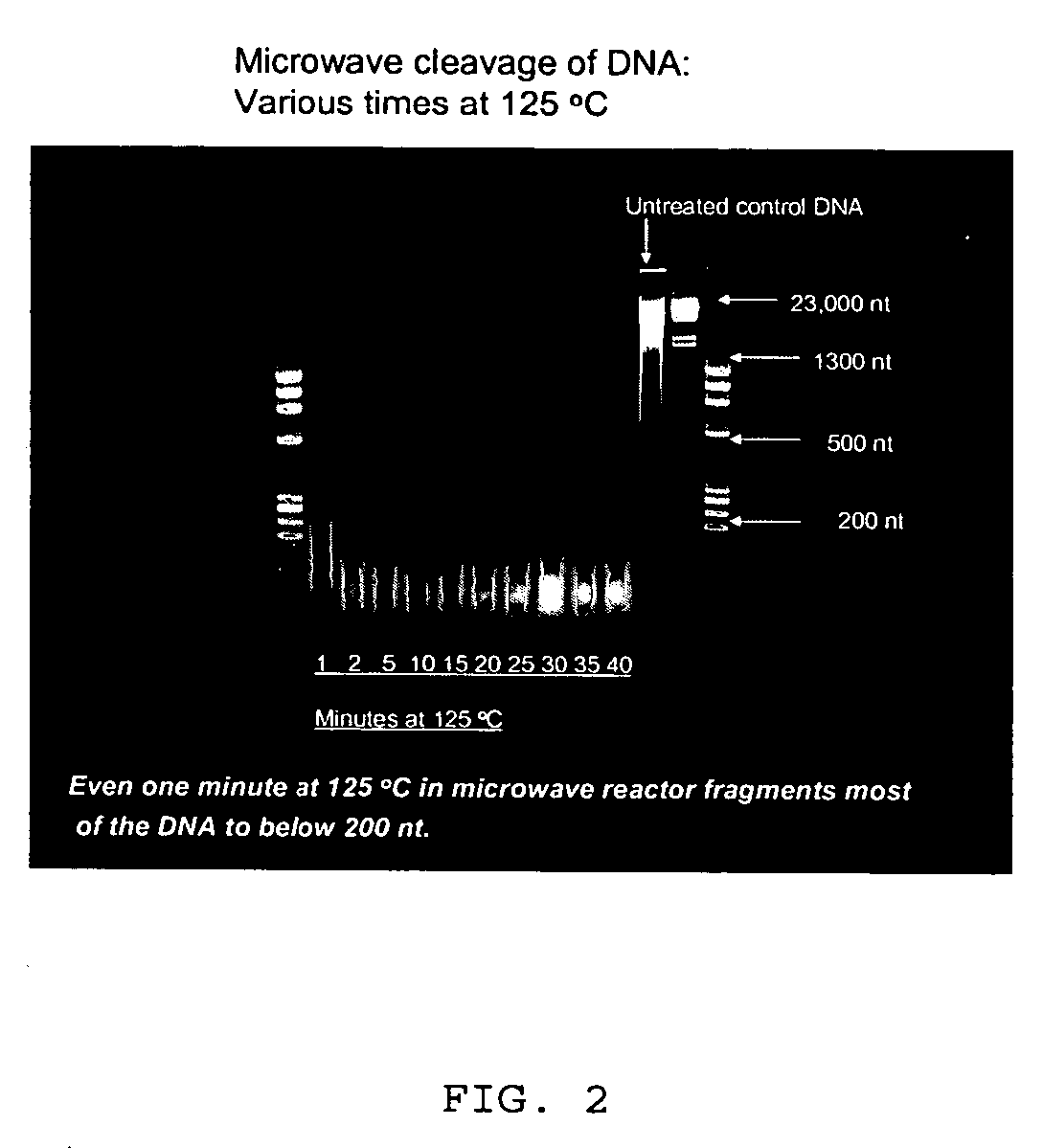

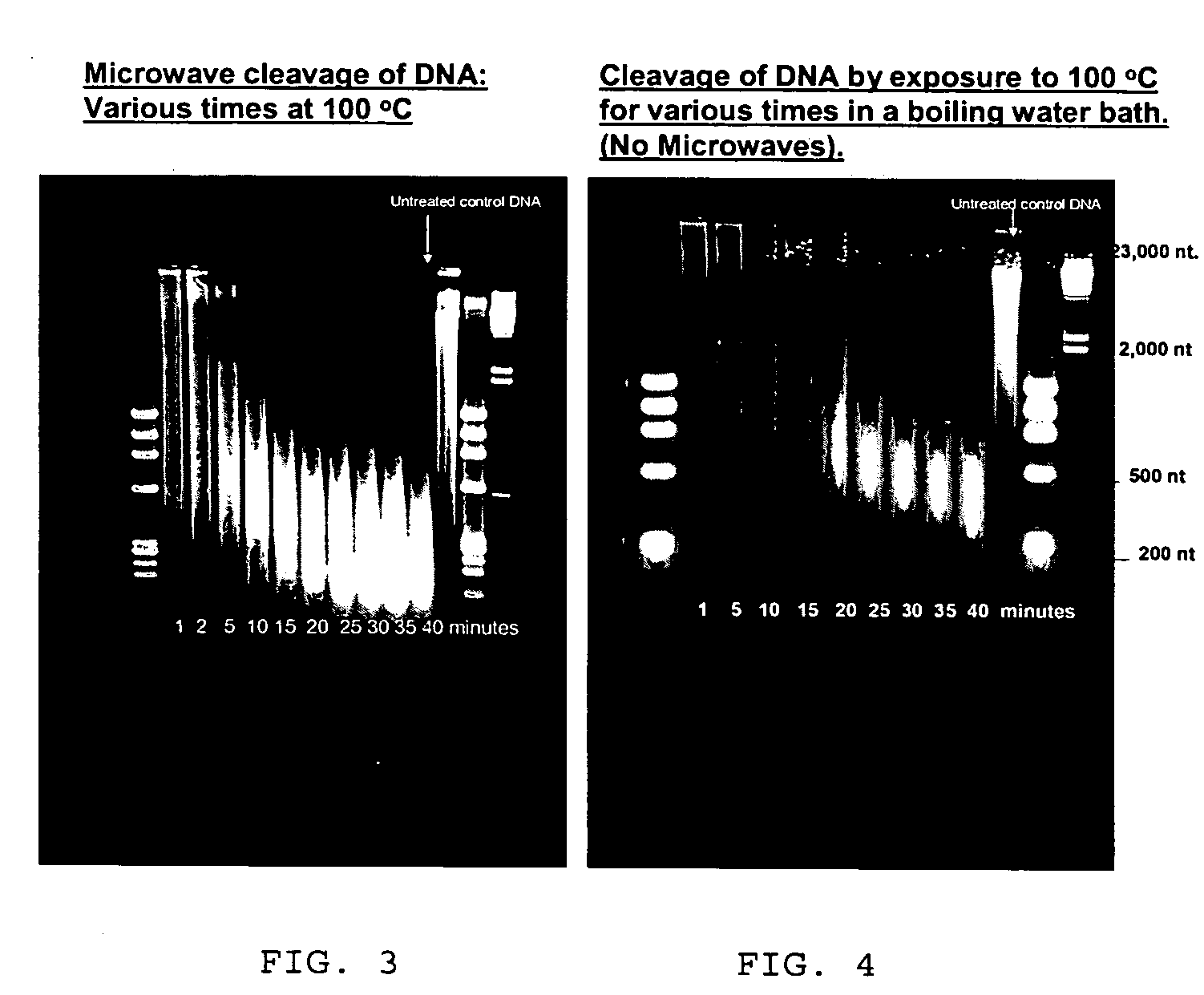

Microwave mediated synthesis of nucleic acid probes

A method for preparing a nucleic acid probe is provided. The method comprises forming an activated cytosine or cytidine by a bisulfite catalyzed reaction; and covalently linking a reporter molecule to the activated cytosine or cytidine, wherein said activating step, said covalently linking step, or both are conducted in the presence of microwave energy. Also provided by the invention are nucleic acid probes.

Owner:VENTANA MEDICAL SYST INC

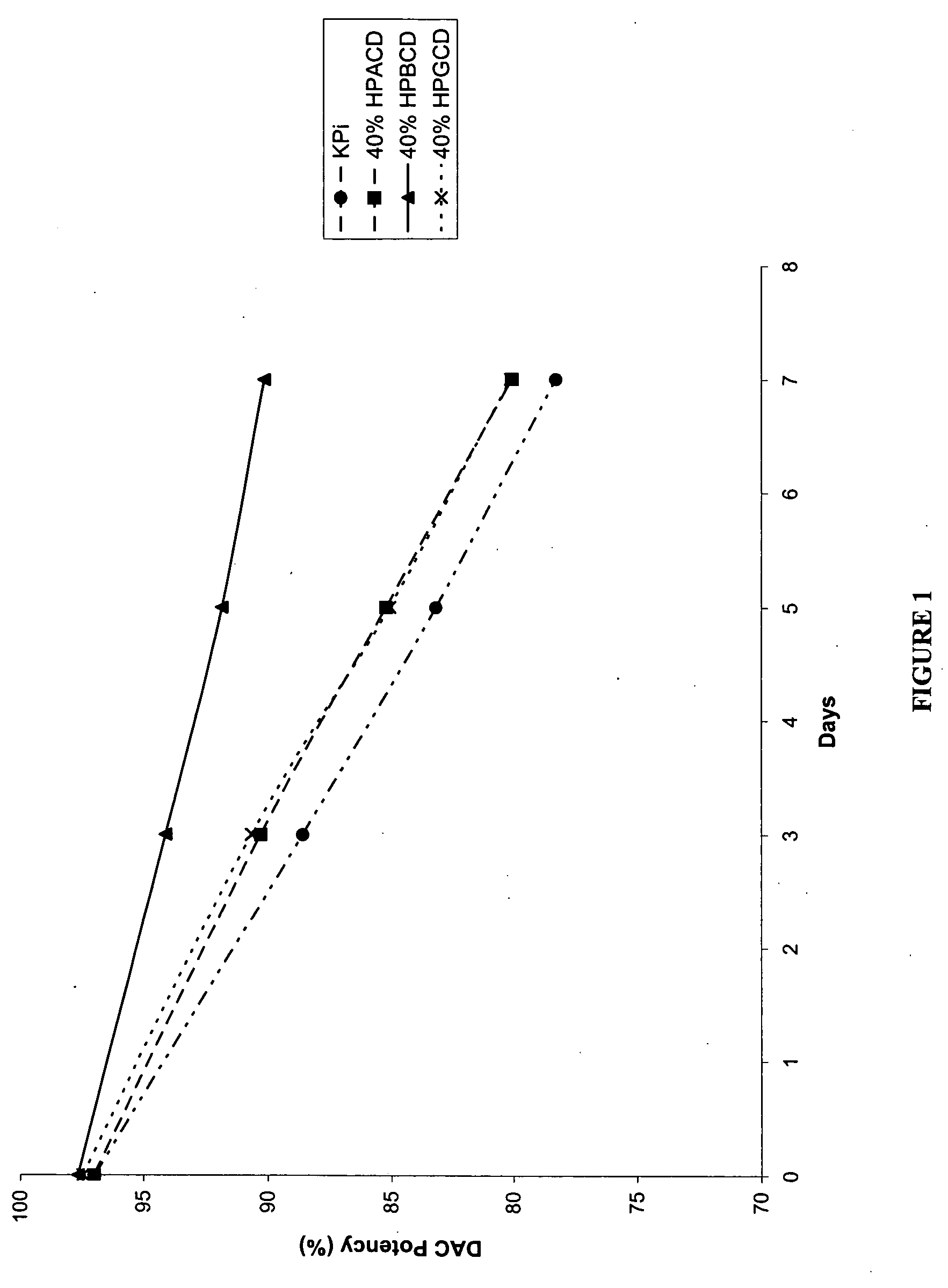

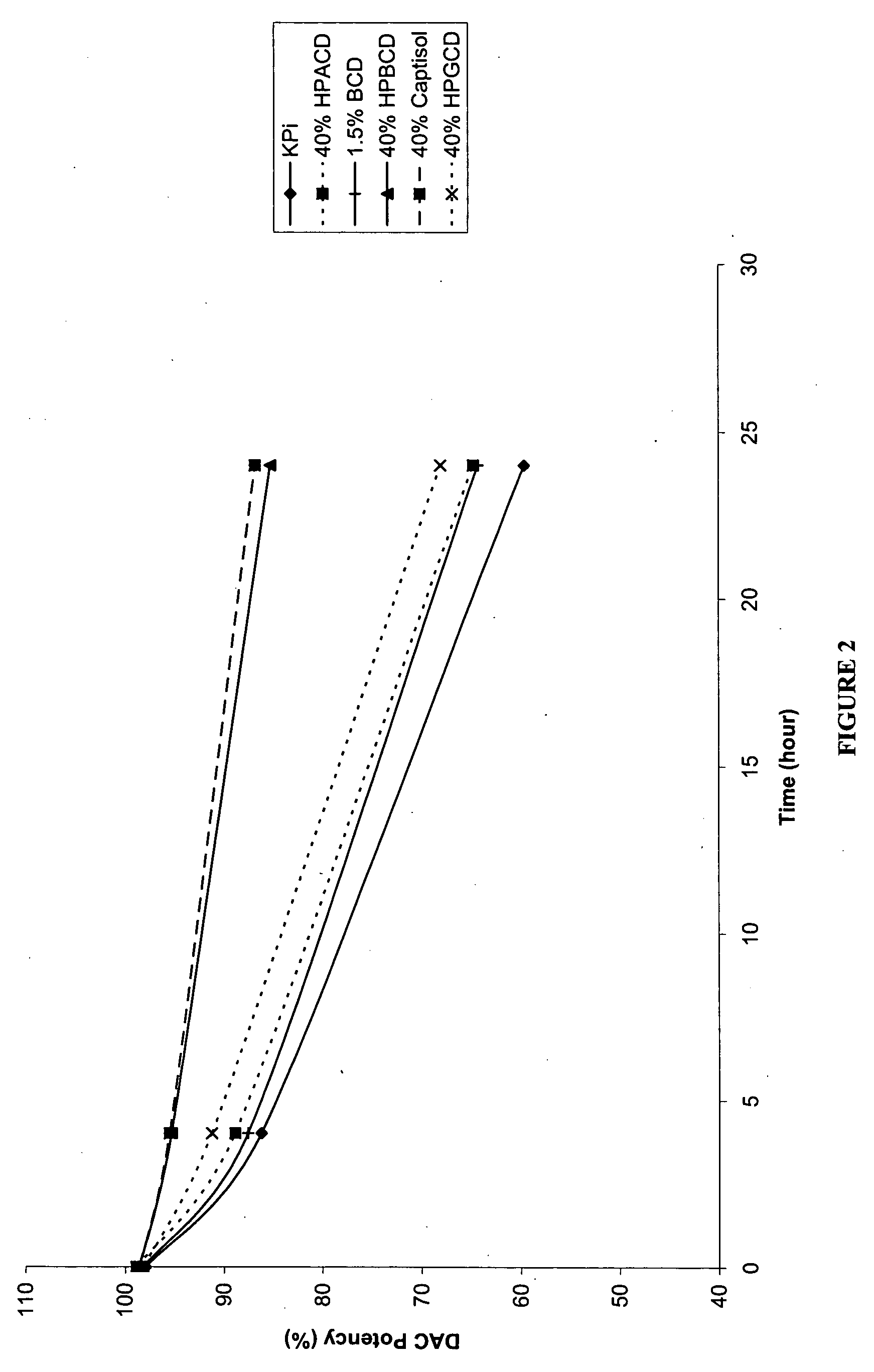

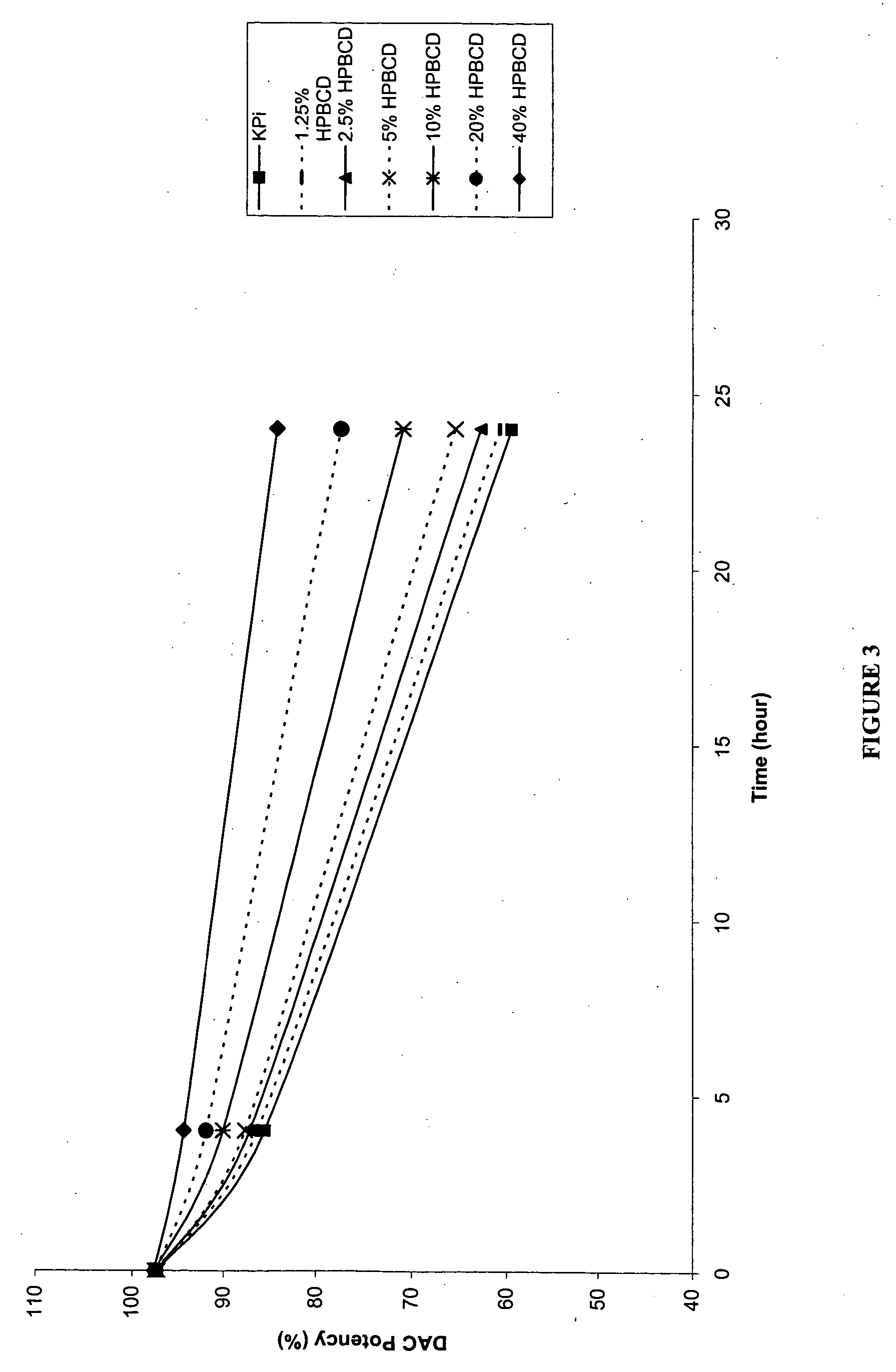

Pharmaceutical formulation of cytidine analogs and derivatives

InactiveUS20060128654A1Reduce decompositionImprove solubilityBiocideCarbohydrate active ingredientsSolubilityCytosine

The present invention provides pharmaceutical formulations of cytidine analogs and derivatives, such as 5-azacytidine, 5-aza-2′-deoxy-2′,2′-difluorocytidine, 5-aza-2′-deoxy-2′-fluorocytidine, 2′-deoxy-2′,2′-difluorocytidine, and cytosine 1-β-D-arabinofuranoside, as well as methods of manufacturing the formulations. In particular, the cytidine analog or derivative is formulated with a cyclodextrin compound to stabilize and / or enhance solubility of the drug. Kits and methods for using the pharmaceutical formulations are also provided, including methods of administering the cytidine analog or derivative to treat conditions or diseases, such as cancer and hematological disorders.

Owner:SUPERGEN

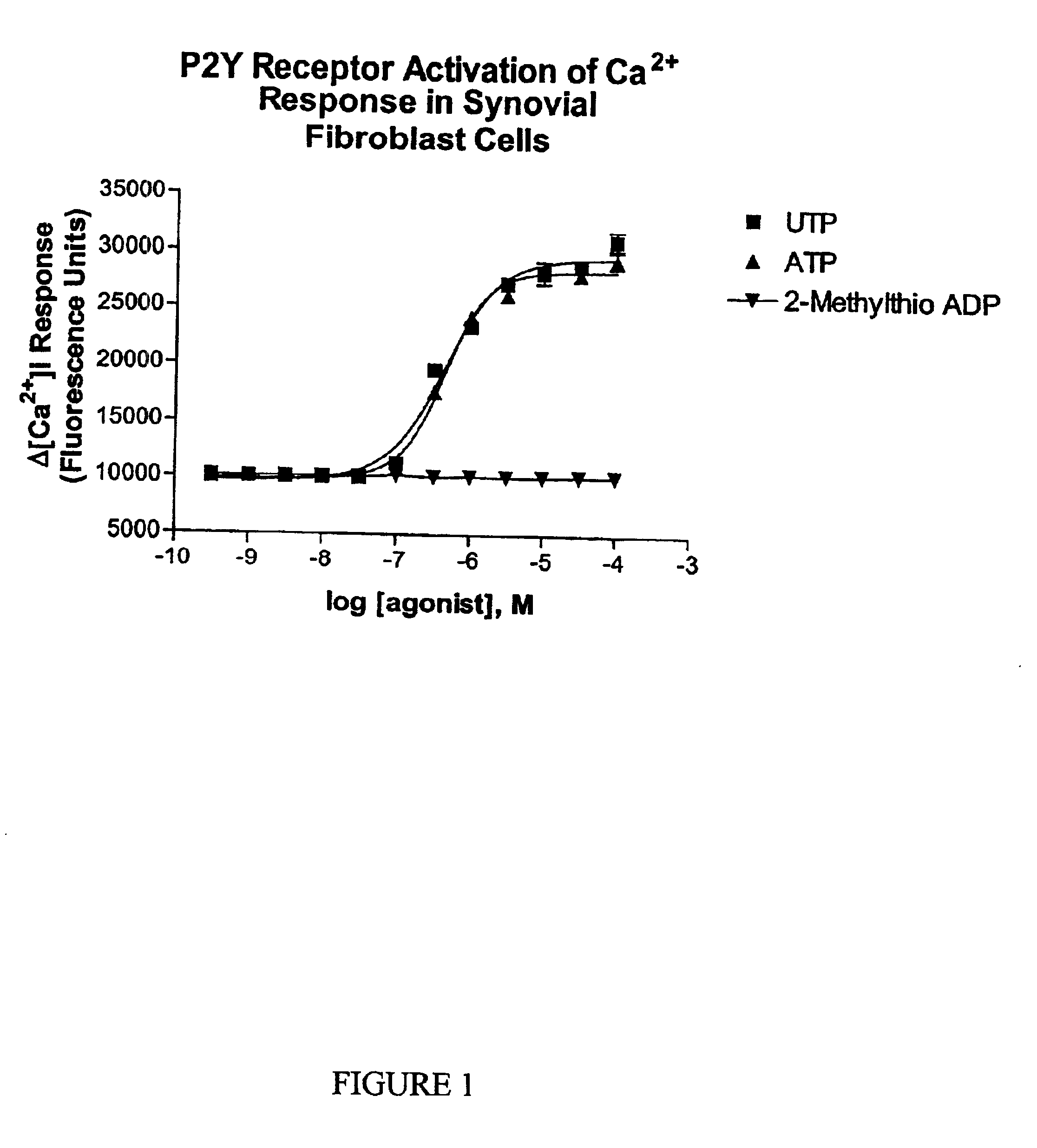

Method of treating gastrointestinal tract disease with purinergic receptor agonists

InactiveUS20020052336A1Increase secretionBiocideCarbohydrate active ingredientsDiseaseDisease irritable bowel

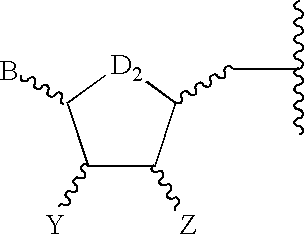

The invention provides a method of regulating water and mucin secretions and fluid transport in the gastrointestinal tract. The invention also provides a method for treating a gastrointestinal disease in which the mucosal barrier of the gastrointestinal system is impaired. The invention additionally provides a method for correcting disorders of fluid secretion or absorption in the gastrointestinal system. The method comprises administering to a patient a pharmaceutical composition comprising a purinergic P2Y receptor agonist, in an amount effective to regulate water and mucin secretions or to correct abnormal fluid transport in the gastrointestinal tract. The pharmaceutical composition used in this invention comprises a P2Y purinergic receptor agonist such as uridine 5'-diphosphate (UDP), uridine 5'-triphosphate (UTP), cytidine 5'-diphosphate (CDP), cytidine 5'-triphosphate (CTP), adenosine 5'-diphosphate (ADP), adenosine 5'-triphosphate (ATP), and their analogs; and dinucleotide polyphosphate compounds of general Formula (IV). Said compound is prepared in an oral form, an injectable form, or a suppository form, and administered to a patient.

Owner:INSPIRE PHARMA

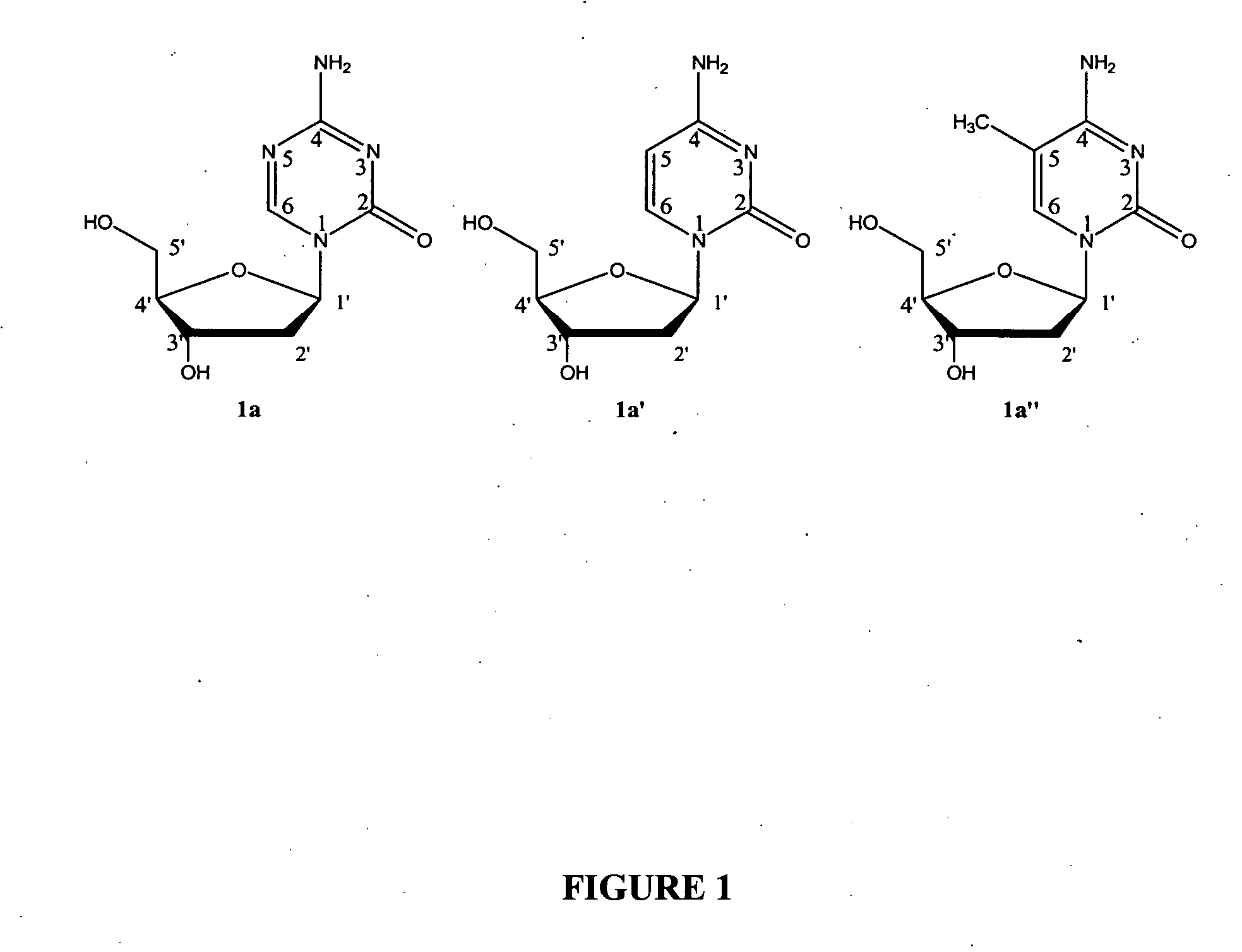

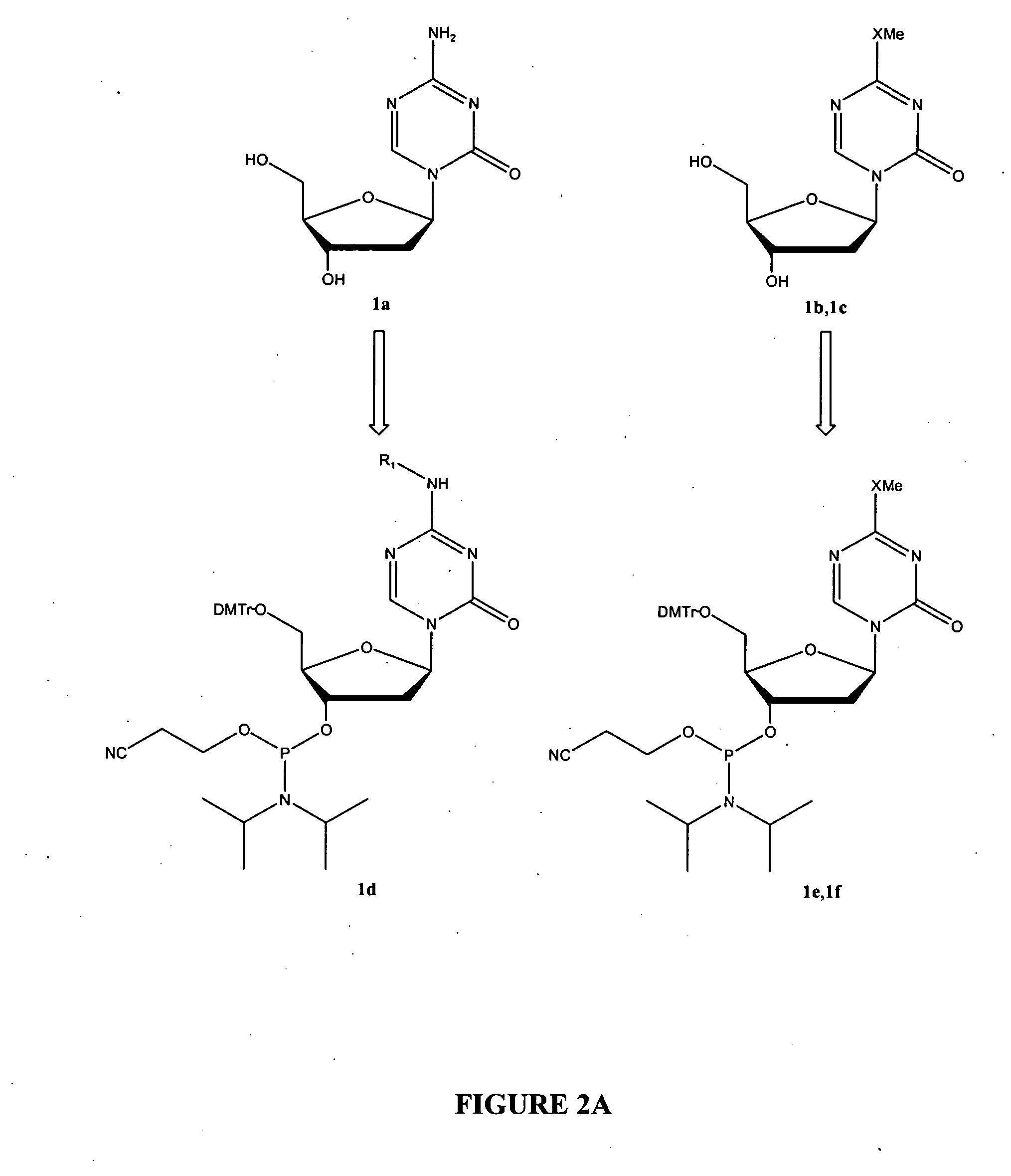

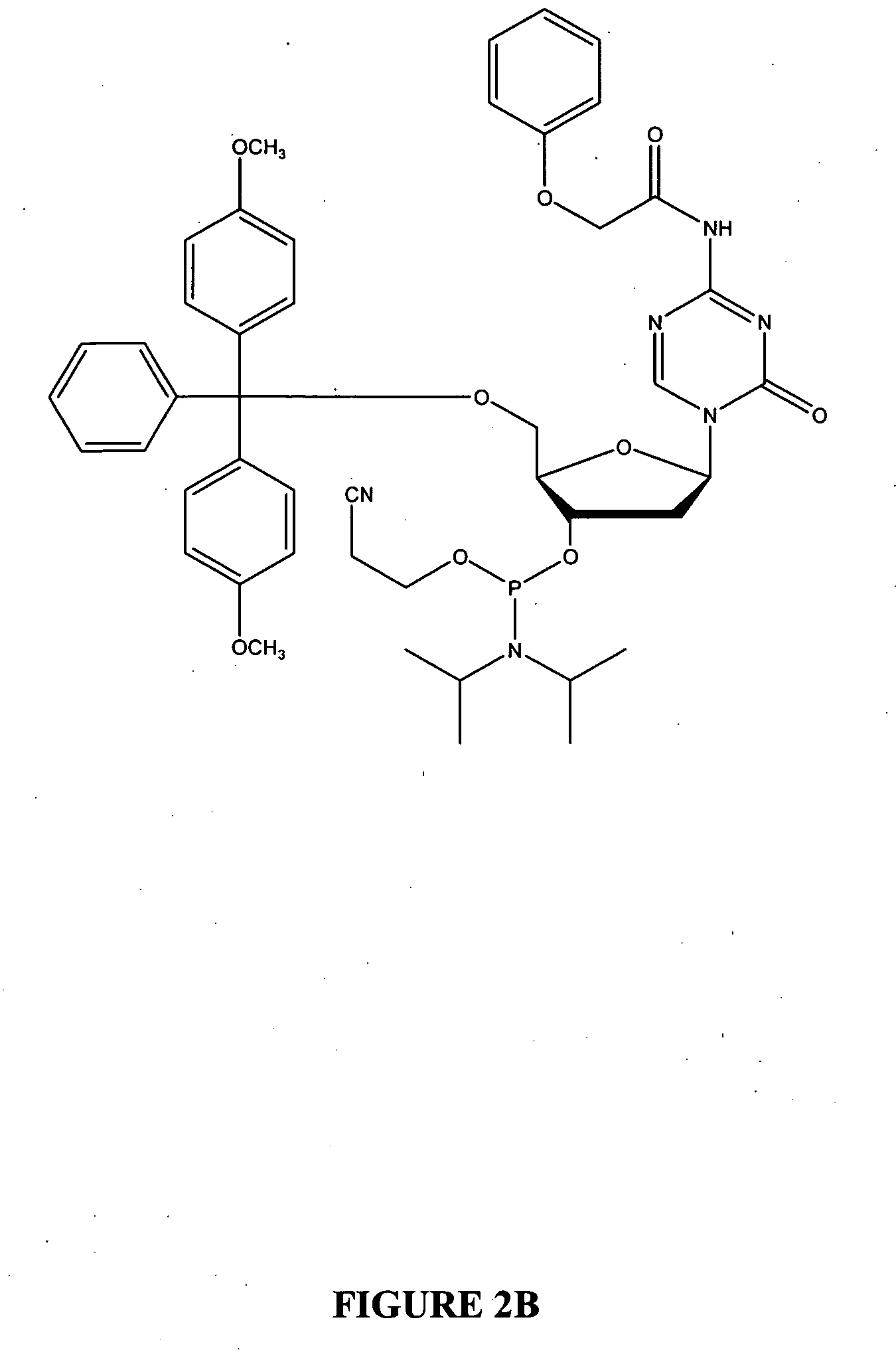

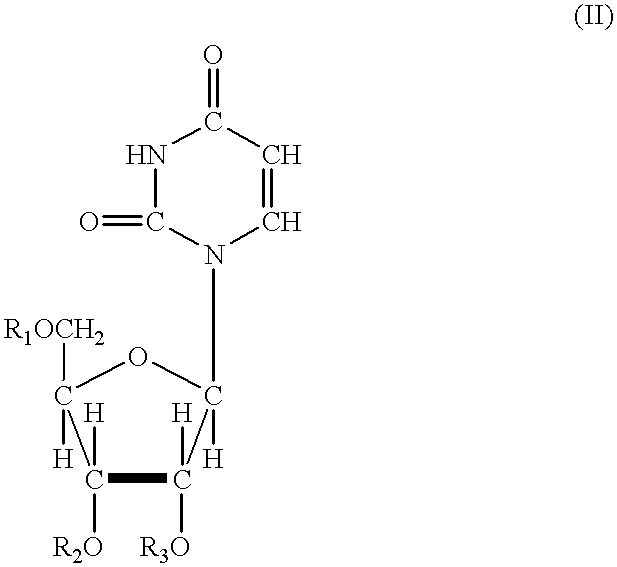

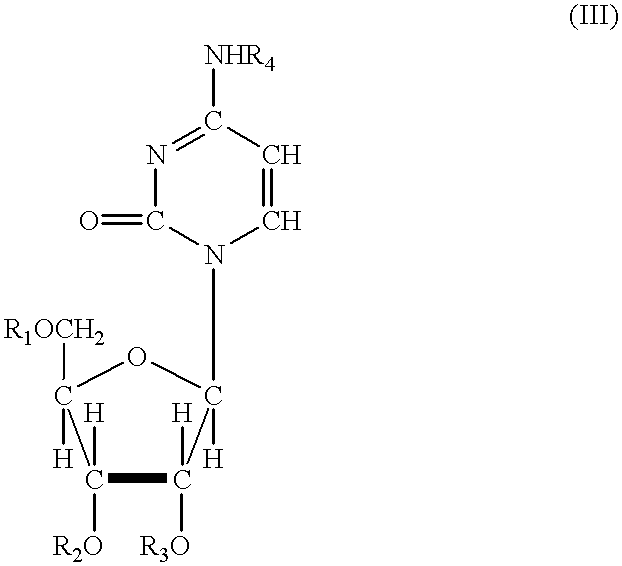

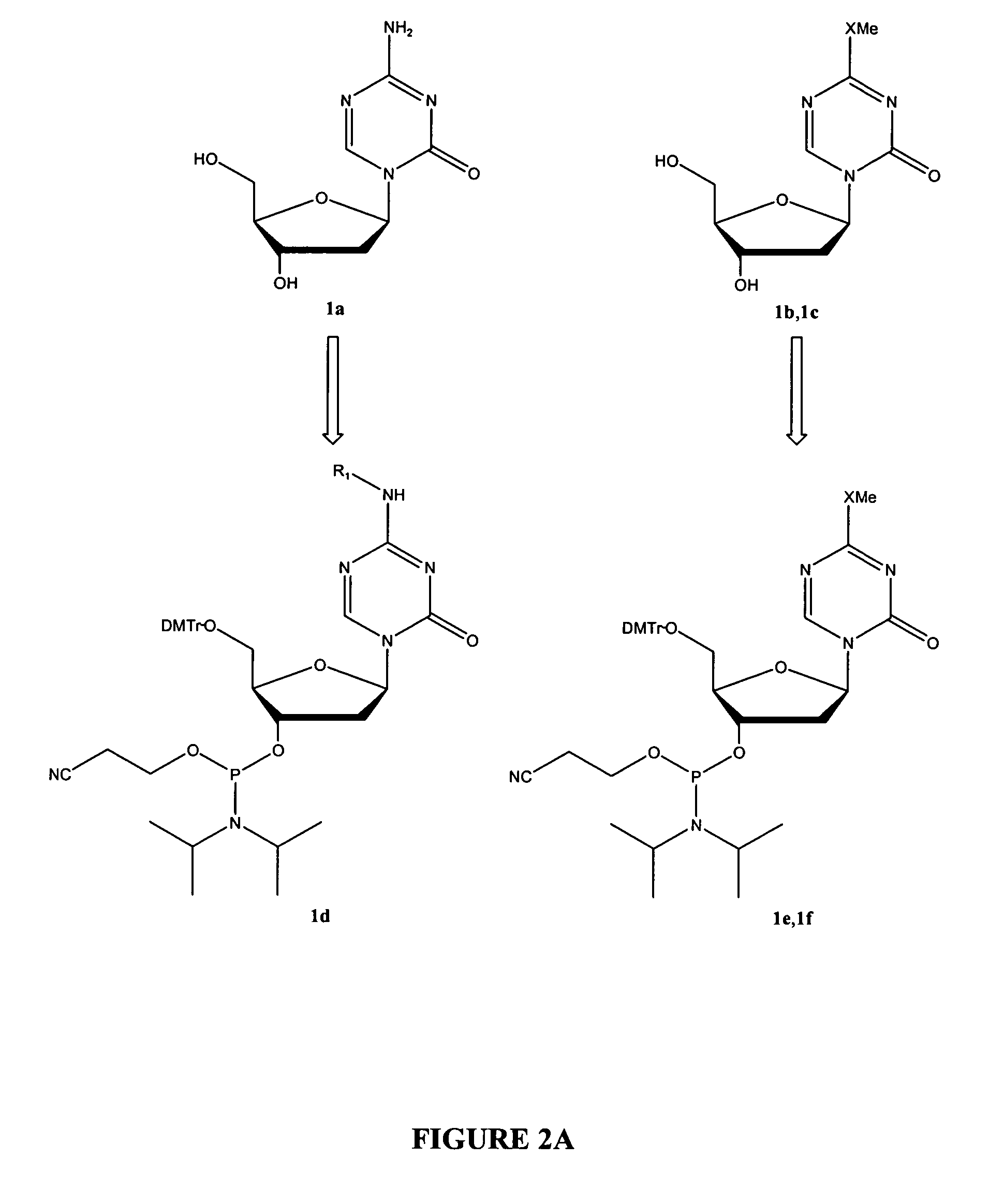

Oligonucleotide analogues incorporating 5-aza-cytosine therein

Oligonucleotide analogues are provided that incorporate 5-aza-cytosine in the oligonucleotide sequence, e.g., in the form of 5-aza-2′-deoxycytidine (decitabine) or 5-aza-cytidine. In particular, oligonucleotide analogues rich in decitabine-deoxyguanosine islets (DpG and GpD) are provided to target the CpG islets in the human genome, especially in the promoter regions of genes susceptible to aberrant hypermethylation. Such analogues can be used for modulation of DNA methylation, such as effective inhibition of methylation of cytosine at the C-5 position. Methods for synthesizing these oligonucleotide analogues and for modulating nucleic acid methylation are provided. Also provided are phosphoramidite building blocks for synthesizing the oligonucleotide analogues, methods for synthesizing, formulating and administering these compounds or compositions to treat conditions, such as cancer and hematological disorders.

Owner:SUPERGEN

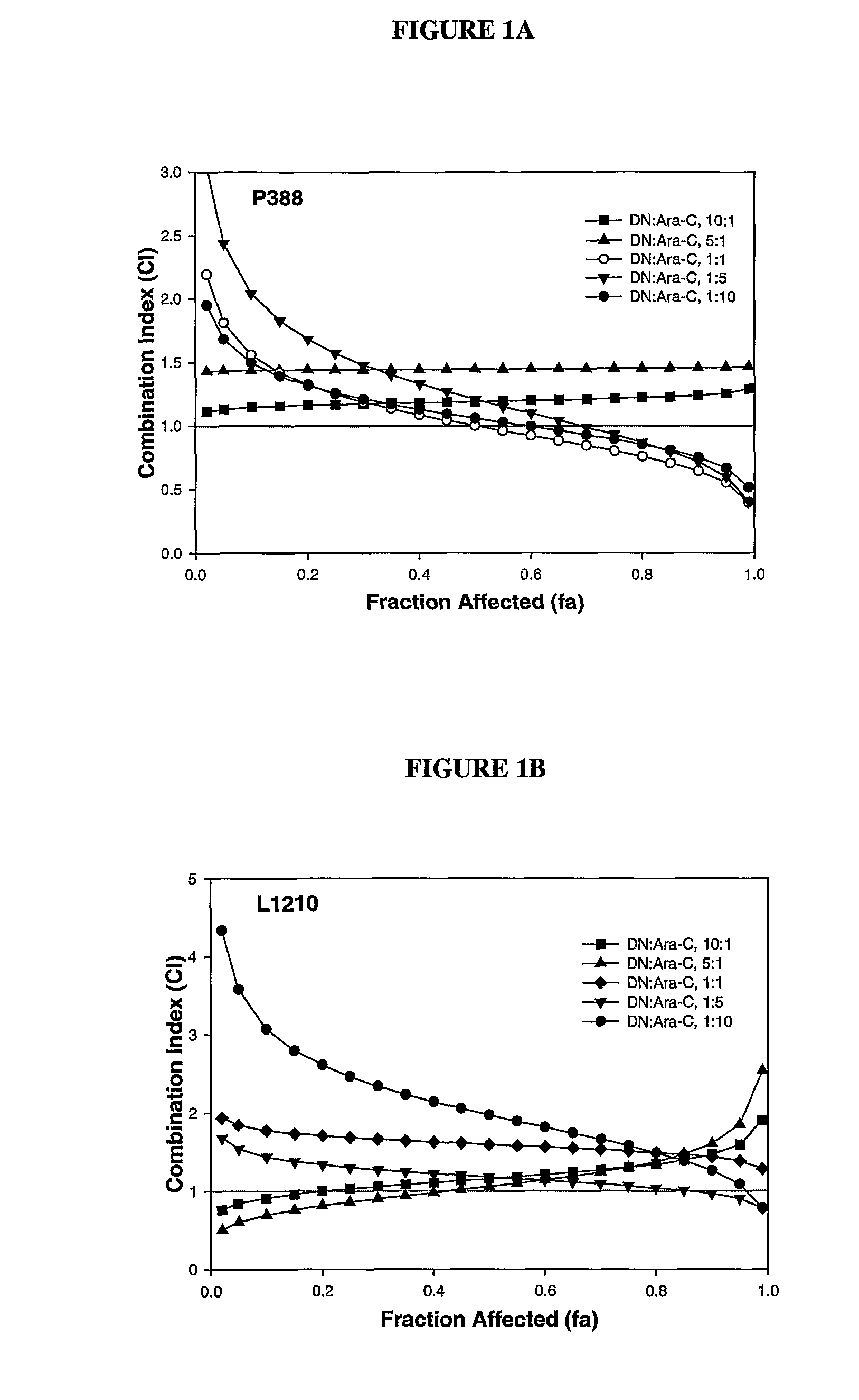

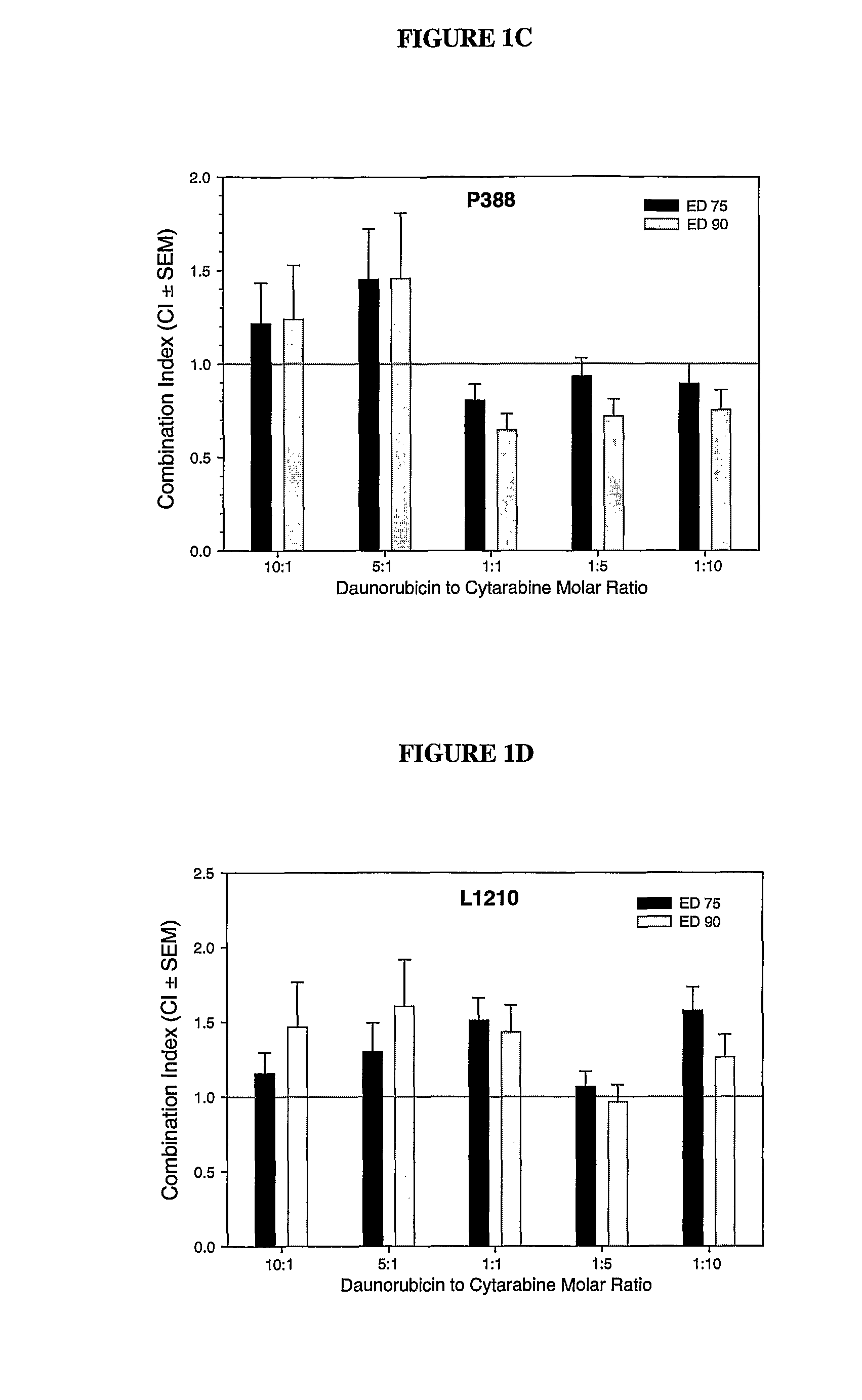

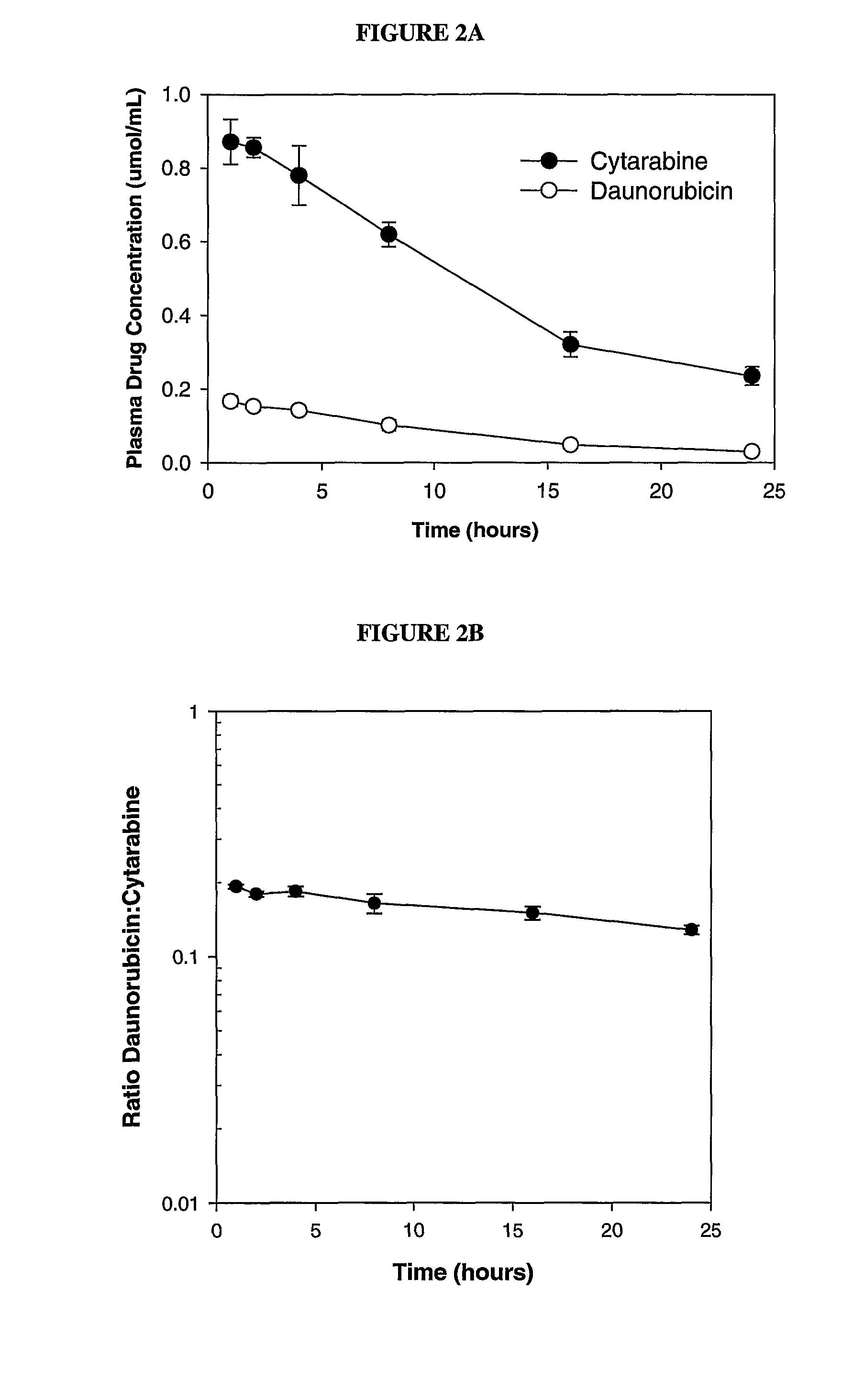

Liposomal formulations of anthracycline agents and cytidine analogs

Compositions which comprise an anthracycline agent, and a cytidine analog are encapsulated in liposomal carriers. The preferred anthracycline agent is selected from the group of daunorubicin, doxorubicin, and idarubicin, while the preferred cytidine analog is selected from the group of cytarabine, gemcitabine, or 5-azacytidine. The combination of the anthracycline agent and cytidine analog encapsulated in said liposomal carriers are useful in achieving a drug retention and a sustained drug release for each therapeutic agent.

Owner:CELATOR PHARMA INC

Acylated uridine and cytidine and uses thereof

ActiveUS6258795B1No untoward pharmaceutical effectEfficient managementBiocideSugar derivativesDiseaseDiabetes mellitus

The invention relates to compositions comprising acyl derivatives of cytidine and uridine. The invention also relates to methods of treating hepatopathies, diabetes, heart disease, cerebrovascular disorders, Parkinson's disease, infant respiratory distress syndrome and for enhancement of phospholipid biosynthesis comprising administering the acyl derivatives of the invention to an animal.

Owner:WELLSTAT THERAPEUTICS

Oligonucleotide analogues incorporating 5-aza-cytosine therein

Oligonucleotide analogues are provided that incorporate 5-aza-cytosine in the oligonucleotide sequence, e.g., in the form of 5-aza-2′-deoxycytidine (decitabine) or 5-aza-cytidine. In particular, oligonucleotide analogues rich in decitabine-deoxyguanosine islets (DpG and GpD) are provided to target the CpG islets in the human genome, especially in the promoter regions of genes susceptible to aberrant hypermethylation. Such analogues can be used for modulation of DNA methylation, such as effective inhibition of methylation of cytosine at the C-5 position. Methods for synthesizing these oligonucleotide analogues and for modulating nucleic acid methylation are provided. Also provided are phosphoramidite building blocks for synthesizing the oligonucleotide analogues, methods for synthesizing, formulating and administering these compounds or compositions to treat conditions, such as cancer and hematological disorders.

Owner:SUPERGEN

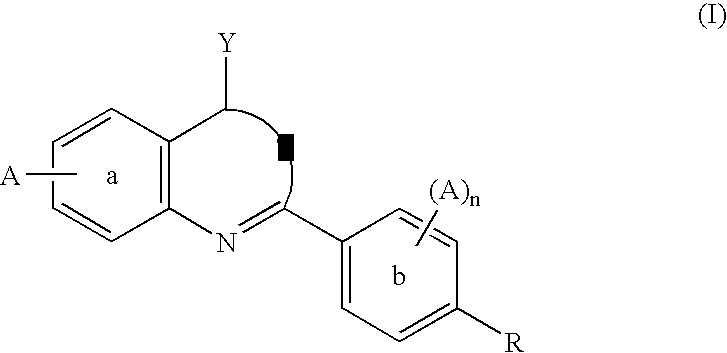

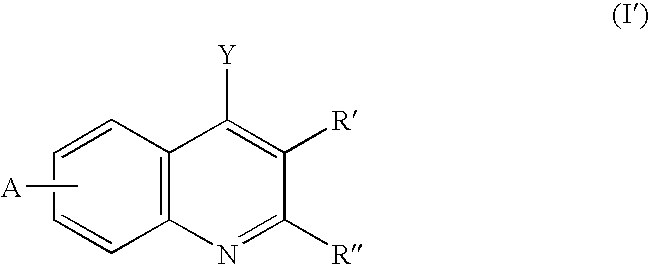

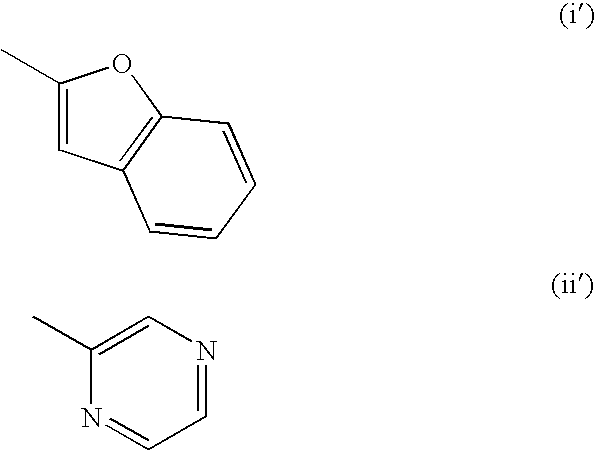

Dihydroorotate dehydrogenase inhibitors for the treatment of viral-mediated diseases

InactiveUS6841561B1Potent activityBiocideOrganic chemistryDiseaseDihydroorotate Dehydrogenase Inhibitor

Flavivirus, rhabdovirus and paramyxovirus infections may be treated by administering an inhibitor of the enzyme dihydroorotate dehydrogenase such as 6-fluoro-2-(2′-fluoro-1,1′-biphenyl-4-yl)-3-methyl-4-quinolinearcarboxylic acid sodium salt (Brequinar). A synergistic effect can be obtained if an interferon such as interferon α2, interferon α8 or interferon β, or an inhibitor of a second enzyme selected from inosine monophosphate dehydrogenase, guanosine monophosphate synthetase, cytidine triphosphate synthetase and S-adenosylhomocysteine hydrolase, is also administered.

Owner:INST OF MOLECULAR & CELL BIOLOGY

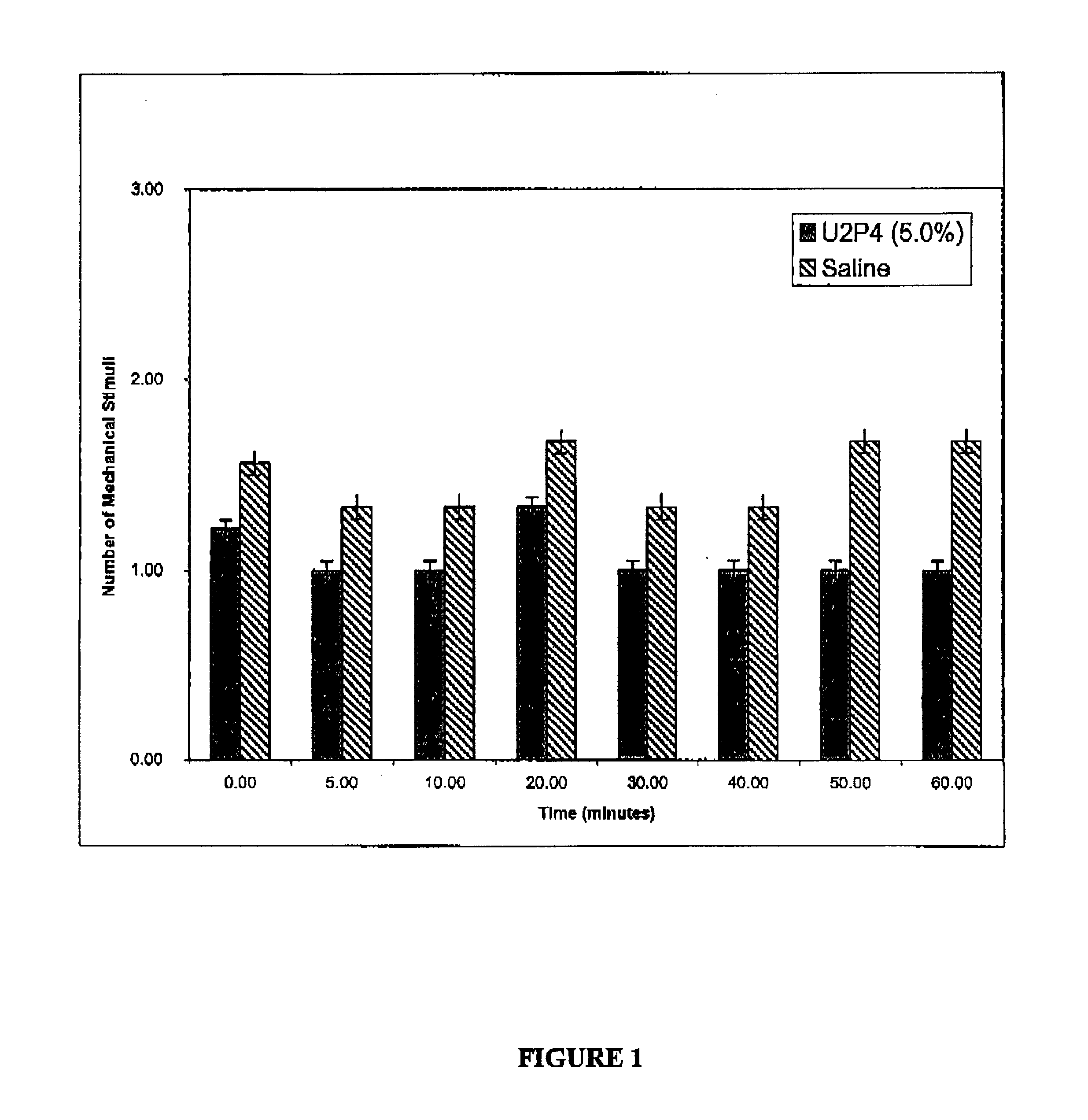

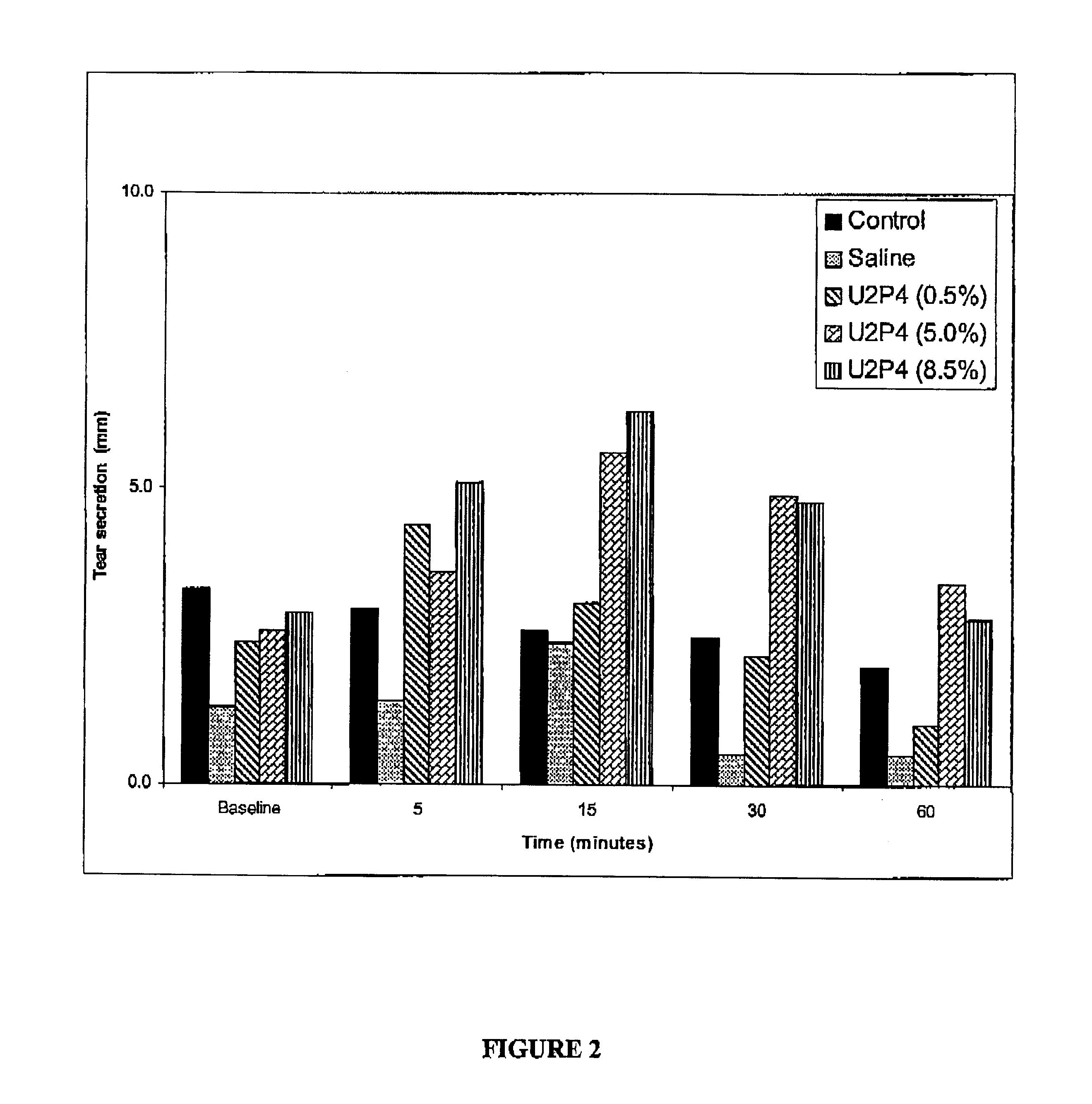

Method of treating dry eye disease with purinergic receptor agonists

A method and preparation for the stimulation of tear secretion in a subject in need of such treatment is disclosed. The method comprises administering to the ocular surfaces of the subject a purinergic receptor agonist such as uridine 5′-triphosphate [UTP], dinucleotides, cytidine 5′-triphosphate [CTP], adenosine 5′-triphosphate [ATP], or their therapeutically useful analogs and derivatives, in an amount effective to stimulate tear fluid secretion and enhance drainage of the lacrimal system. Pharmaceutical formulations and methods of making the same are also disclosed. Methods of administering the same would include: topical administration via a liquid, gel, cream, or as part of a contact lens or selective release membrane; or systemic administration via nasal drops or spray, inhalation by nebulizer or other device, oral form (liquid or pill), injectable, intra-operative instillation or suppository form.

Owner:MERCK SHARP & DOHME CORP

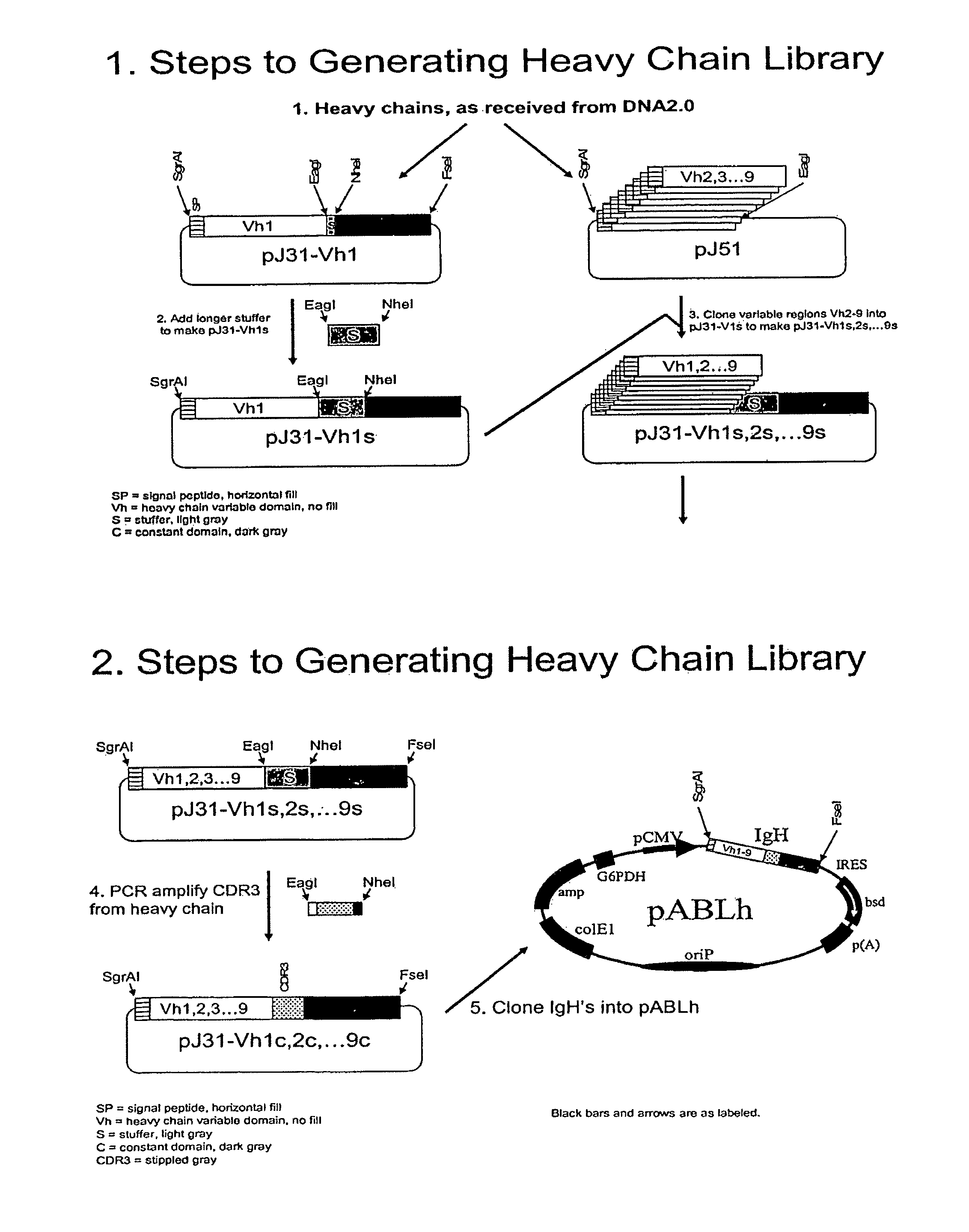

Methods of generating libraries and uses thereof

ActiveUS8685897B2High affinityHigh reactivityImmunoglobulins against growth factorsFermentationHeavy chainActivation-induced (cytidine) deaminase

This invention relates to methods for the generation of humanized antibodies, particularly a humanized antibody heavy chain protein and a humanized antibody light chain protein. The method comprises using cells that express or can be induced to express Activation Induced Cytidine Deaminase (AID).

Owner:ANAPTYSBIO INC

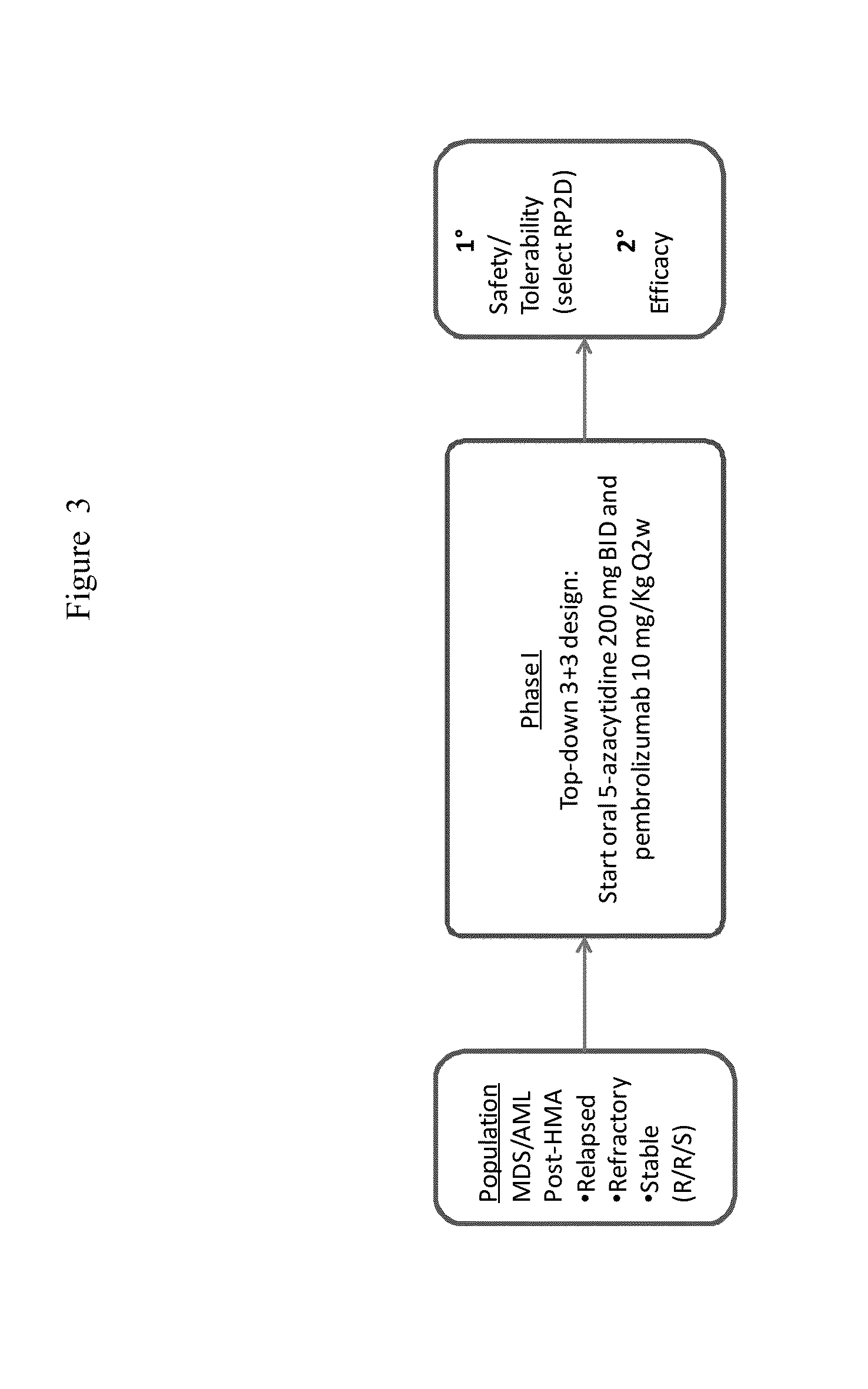

Methods for treating a disease or disorder using oral formulations of cytidine analogs in combination with an Anti-pd1 or Anti-pdl1 monoclonal antibody

InactiveUS20160067336A1Improve survivalOrganic active ingredientsAntibody ingredientsDiseaseMonoclonal antibody

The present disclosure provides methods of treating diseases or disorders with oral cytidine analogs (e.g., 5-azacytidine) in combination with anti-PD1 / anti-PDL1 antibodies (e.g., pembrolizumab or durvalumab). The diseases or disorders include, but are not limited to, relapsed or refractory myelodysplastic syndromes, acute myeloid leukemia, ovarian cancer, or non-small cell lung cancer.

Owner:CELGENE CORP

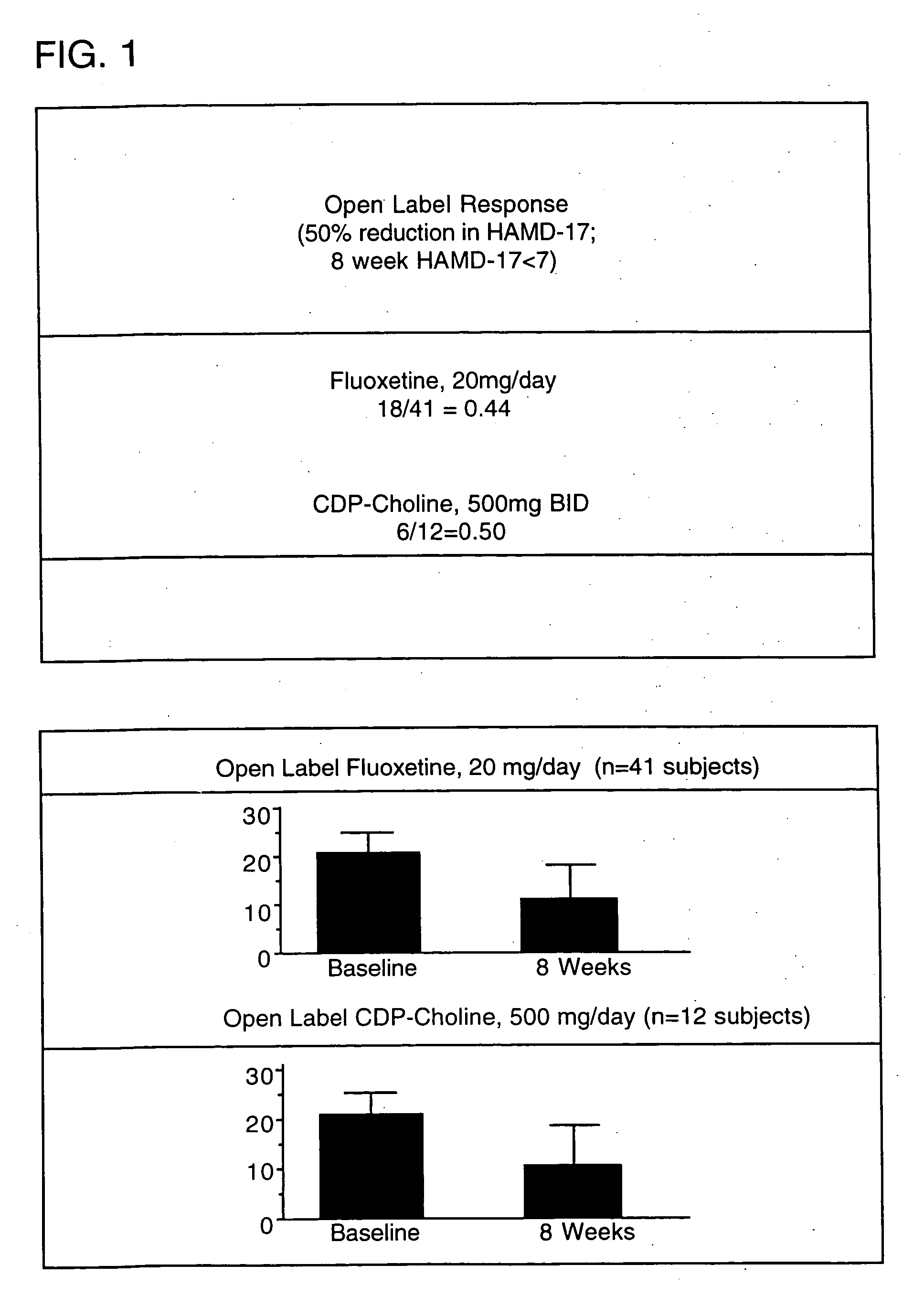

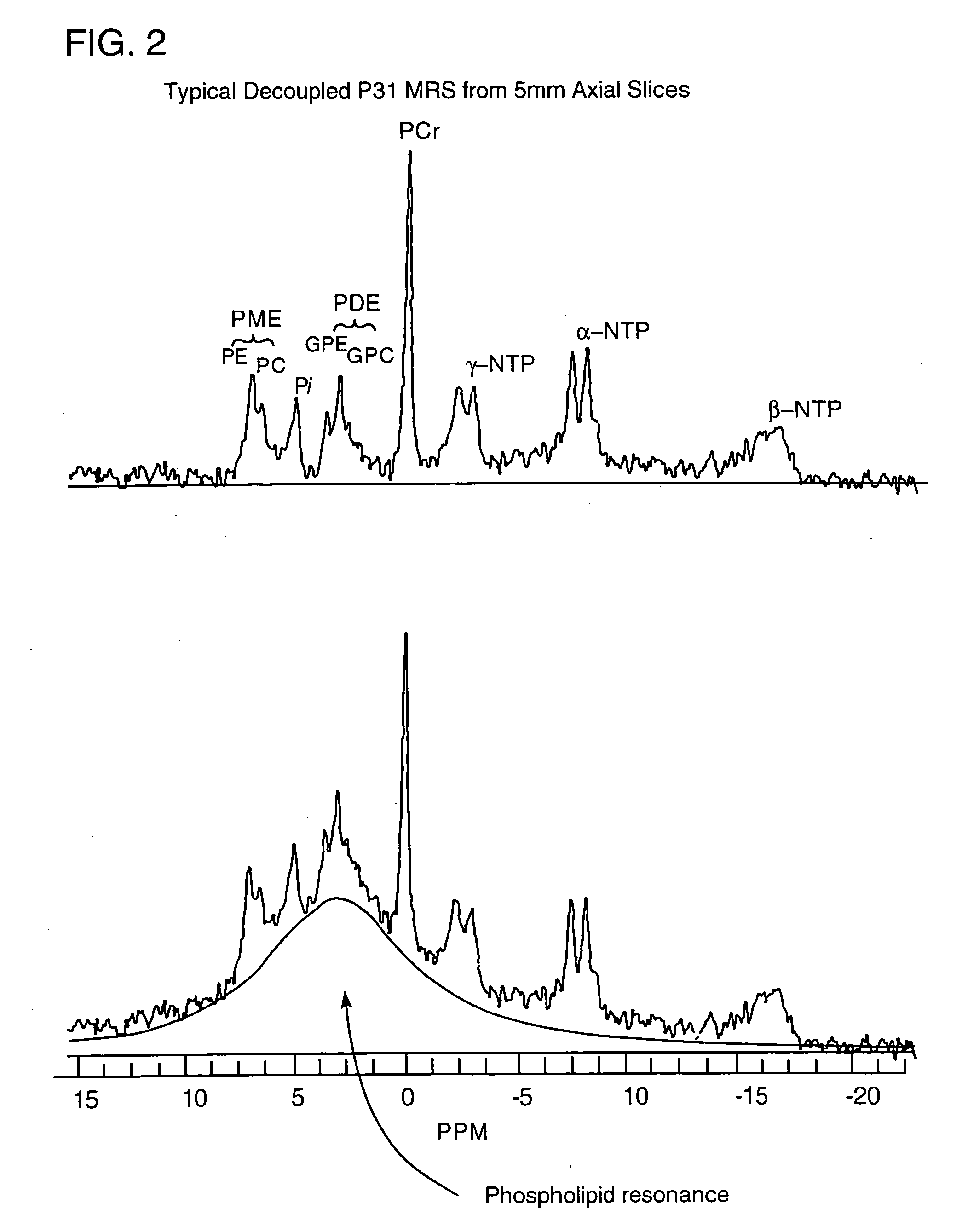

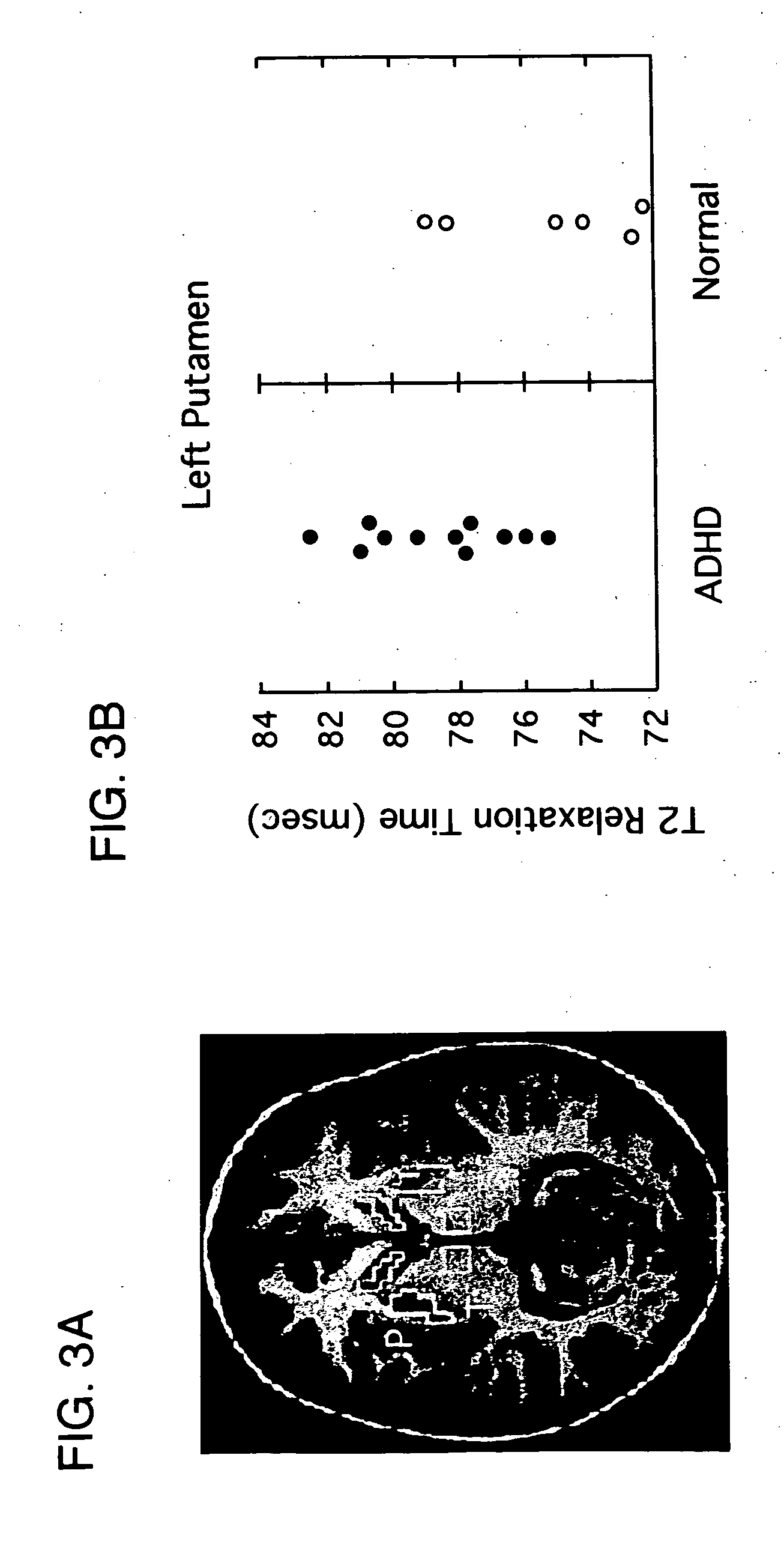

Methods of treating psychiatric substance abuse, and other disorders using combinations containing omega-3 fatty acids

The invention provides methods for treating or preventing psychiatric disorders, substance abuse disorders, and other conditions, e.g., cardiovascular disease and cancer, involving administration of a therapeutically-effective amount of a cytosine-containing or cytidine-containing compound, creatine-containing compound, adenosine-containing, adenosine-elevating compound, omega-3 fatty acids, or combinations thereof to a mammal. The invention further provides methods of enhancing neurodevelopment and delaying premature pregnancy by administration of an effective amount of a cytosine-containing or cytidine-containing compound, creatine-containing compound, adenosine-containing, adenosine-elevating compound, omega-3 fatty acids, or combinations thereof to a mammal.

Owner:MCLEAN HOSPITAL THE

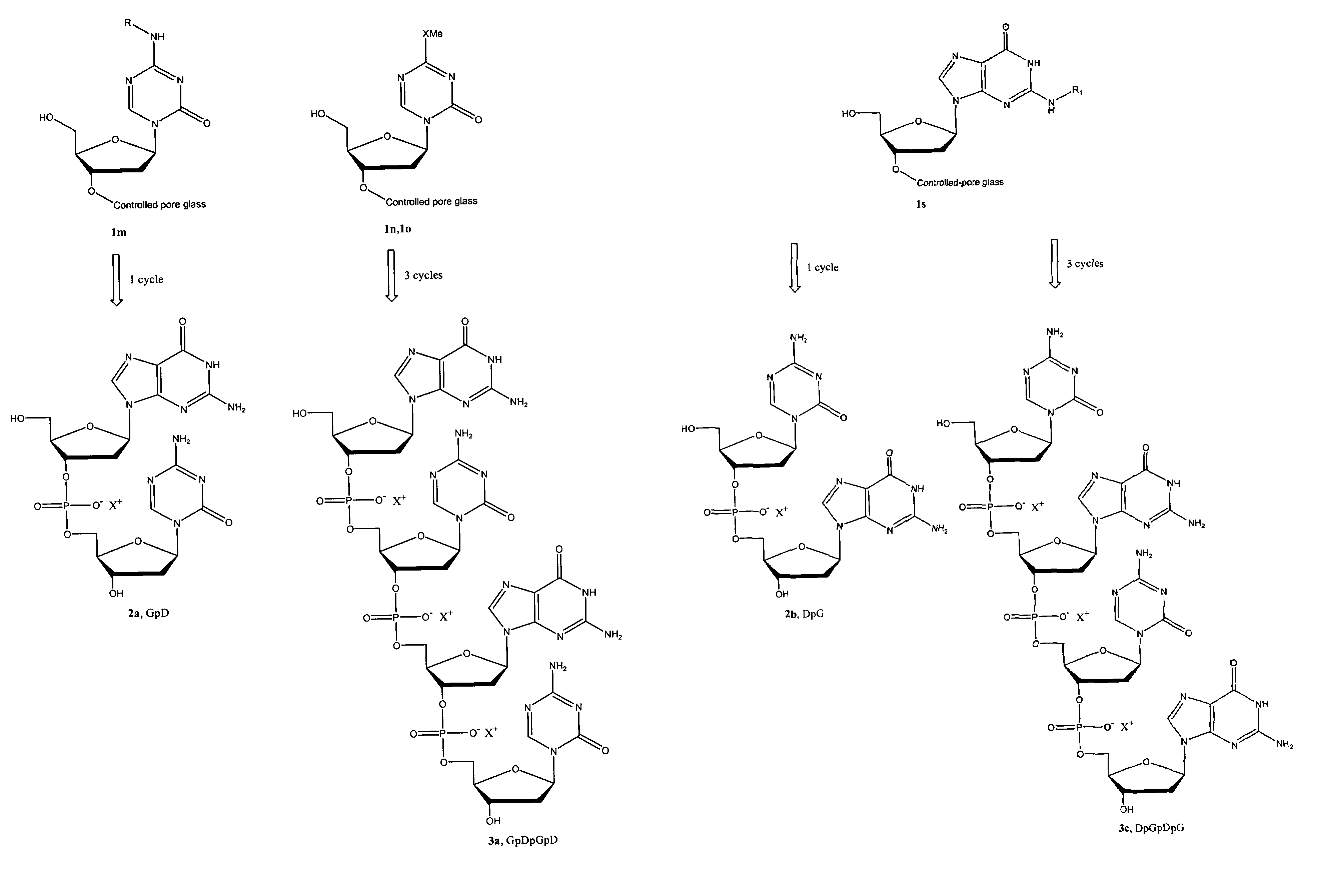

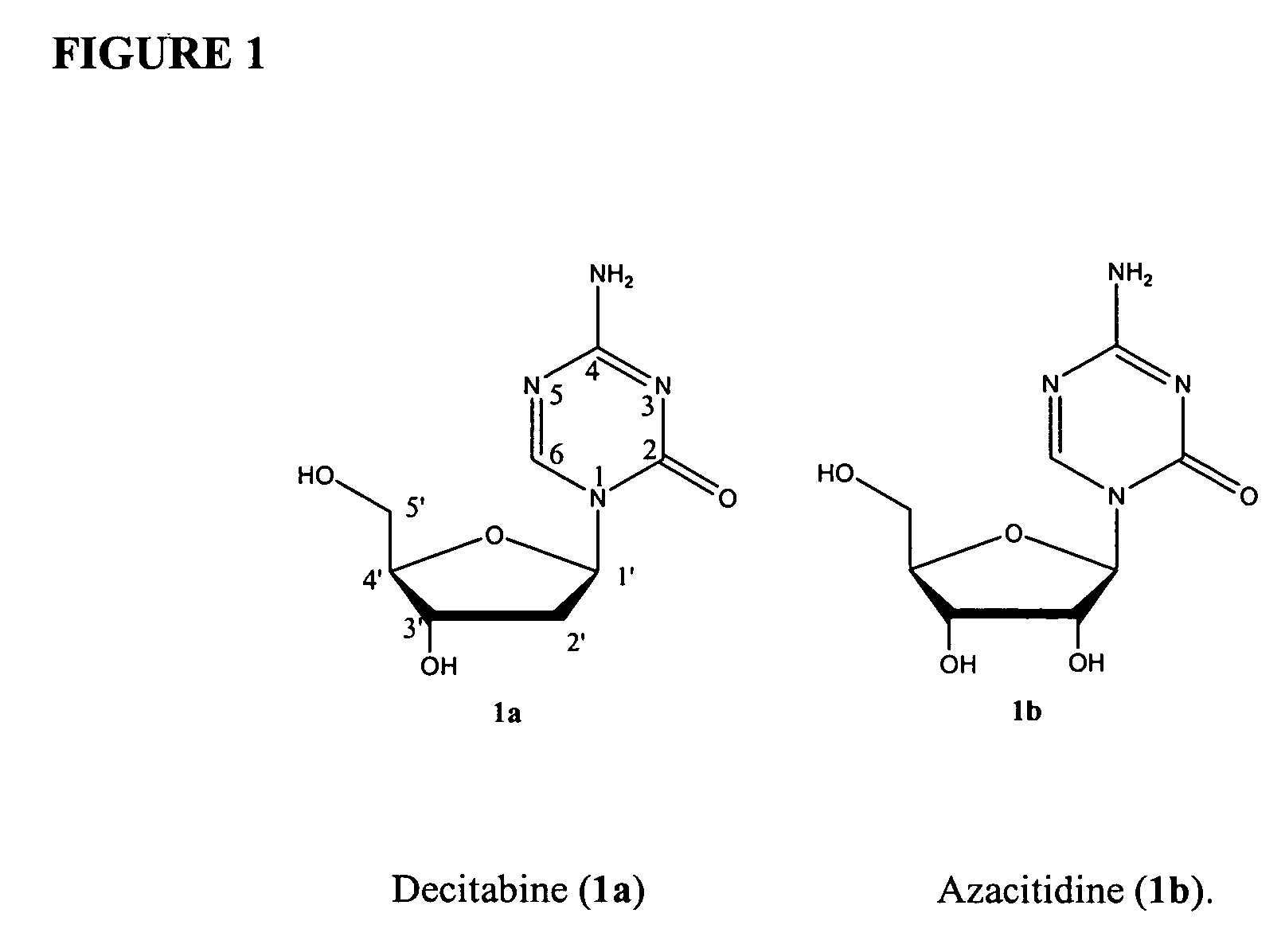

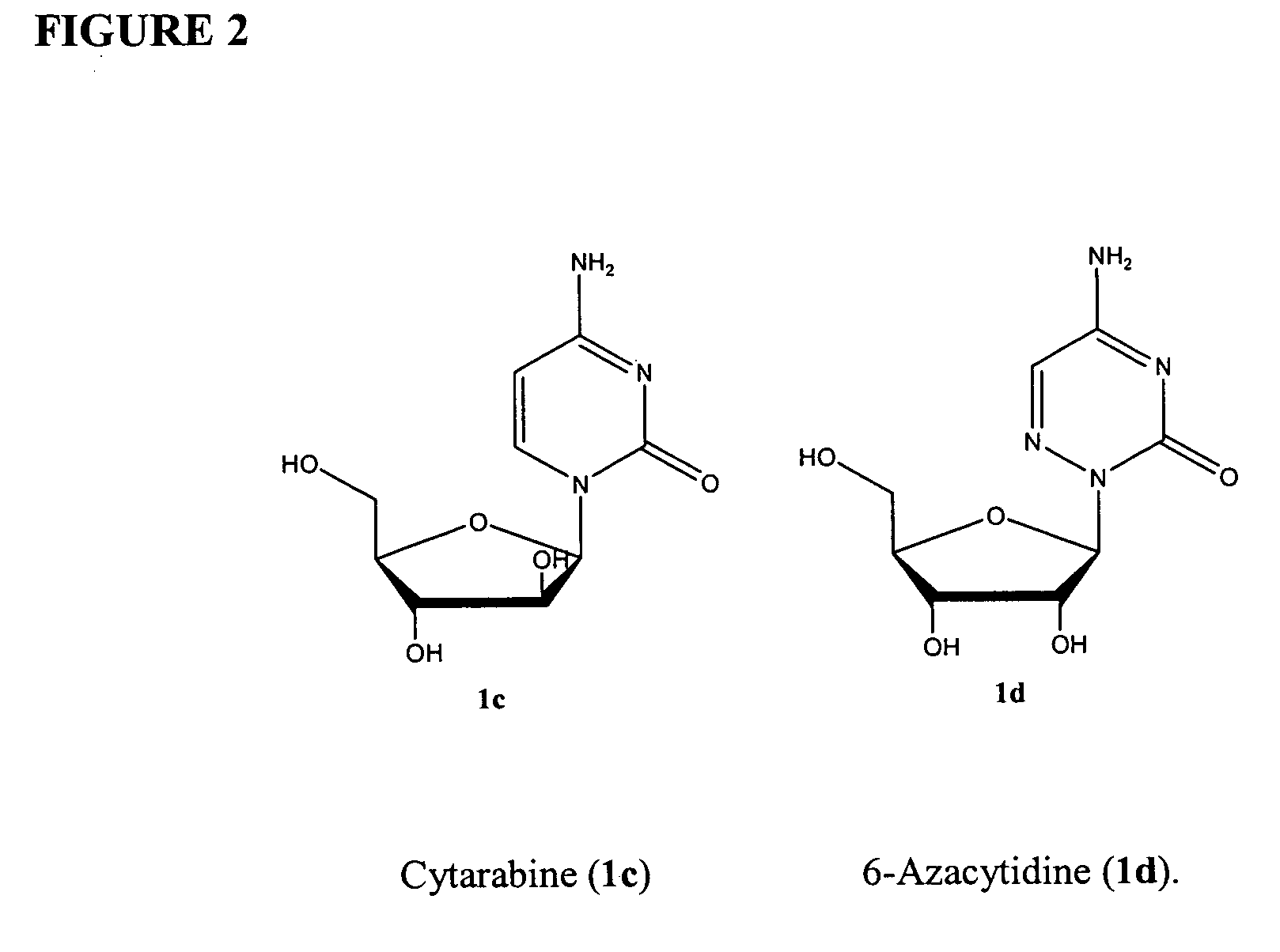

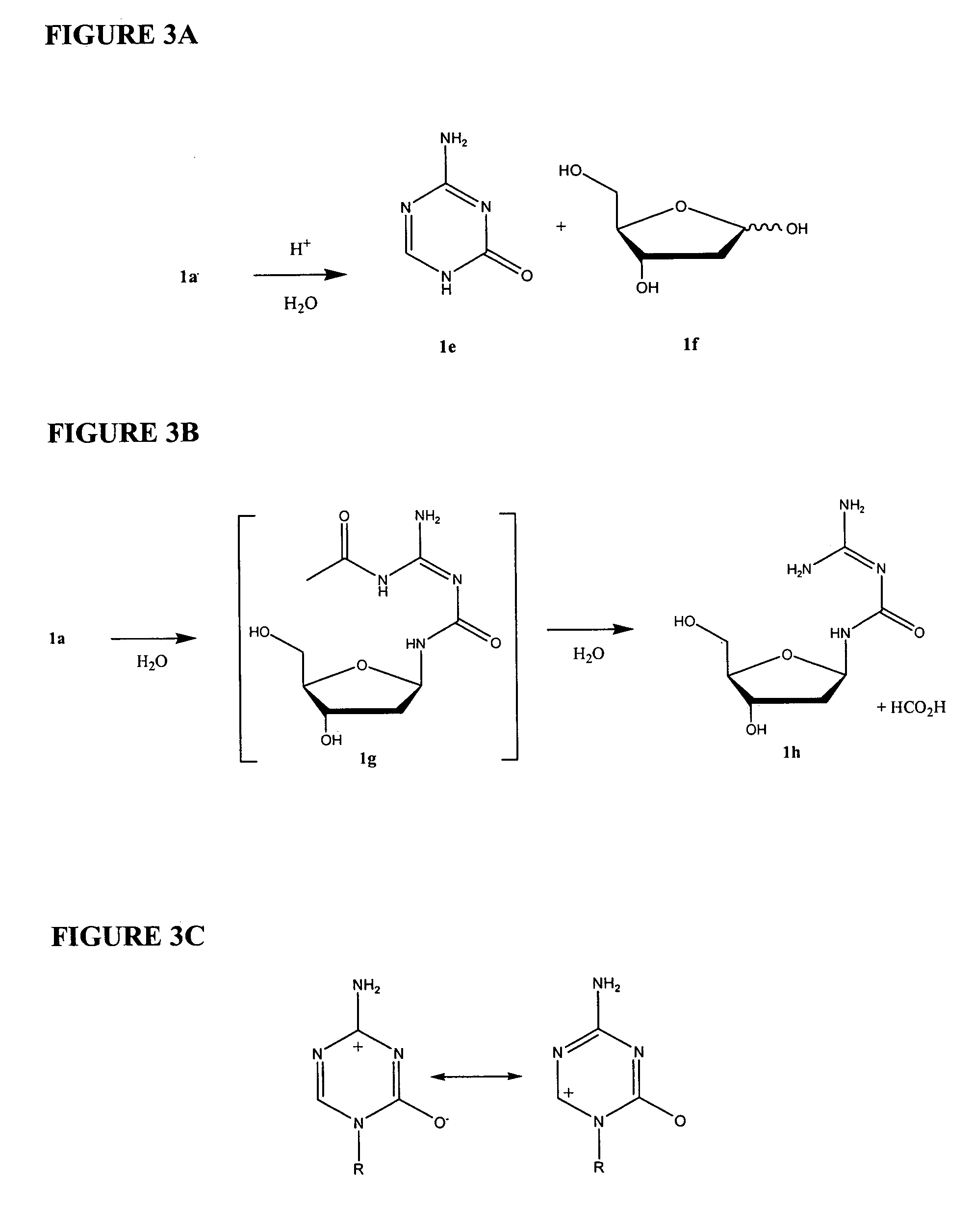

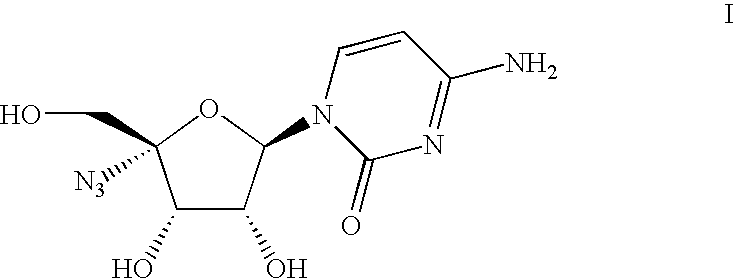

Azacytosine analogs and derivatives

Compounds and compositions of azacytosine analogs and derivatives are provided. In one aspect of the invention, analogs or derivatives of decitabine and azacitidine are provided with modification at the 4- and 6-position of the triazine ring, at the 1′–6′ position of the ribose ring, or combinations thereof. Methods of synthesizing and manufacturing these analogs and derivatives are also provided. These compounds can be formulated into pharmaceutical compositions that can be used for treating any disease that is sensitive to the treatment with decitabine or azacitidine, such as hematological disorders and cancer.

Owner:SUPERGEN

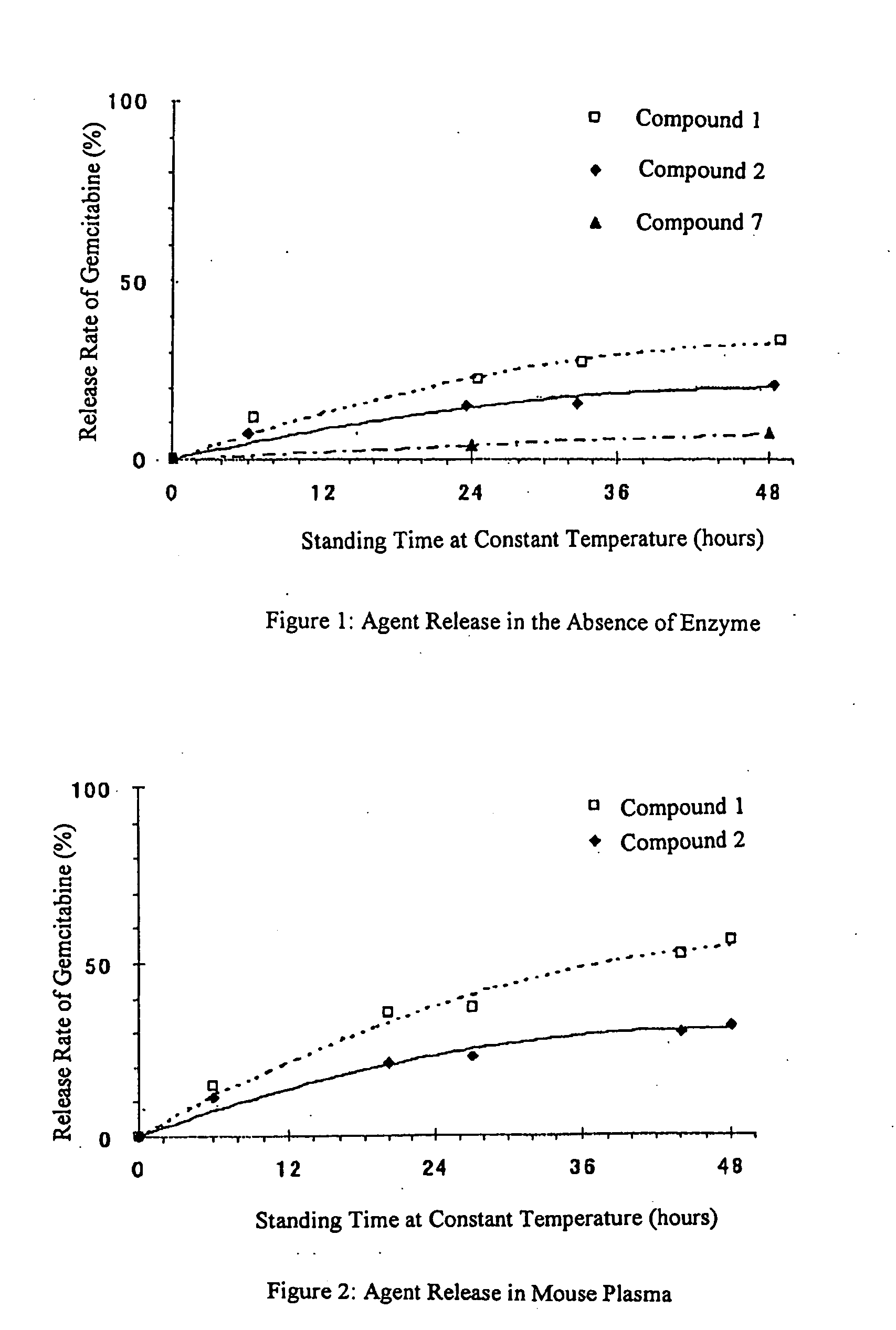

Polymeric Derivative of Cytidine Metabolic Antagonist

InactiveUS20090012252A1Improve efficacyEliminate side effectsPeptide/protein ingredientsAntiviralsSide chainPolyethylene glycol

[PROBLEMS] To provide a derivative of a cytidine metabolic antagonist which can exert a high therapeutic effect at a low dose.[MEANS FOR SOLVING PROBLEMS] A polymeric derivative of a cytidine metabolic antagonist which comprises a polymeric compound having a polyethylene glycol moiety and a polymer moiety having a carboxyl group in a side chain and a cytidine metabolic antagonist, which has such a structure that the carboxyl group in the side chain of the polymeric compound and an amino group in the cytidine metabolic antagonist are bound together to form an amide bond.

Owner:NIPPON KAYAKU CO LTD

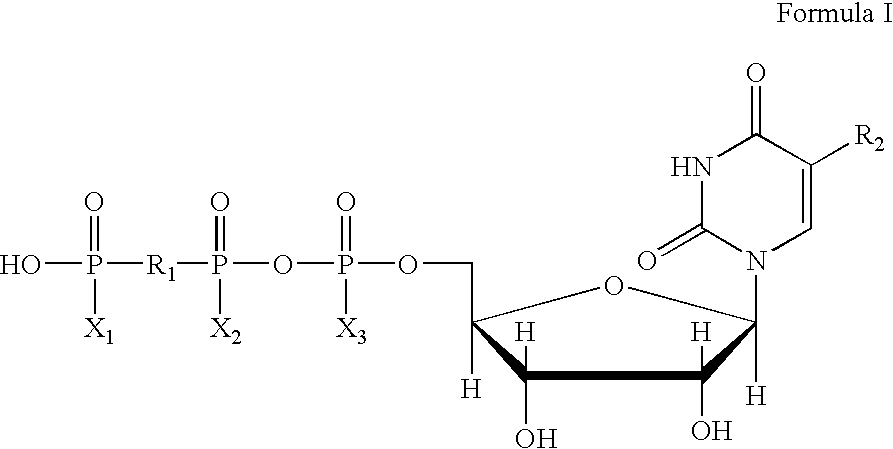

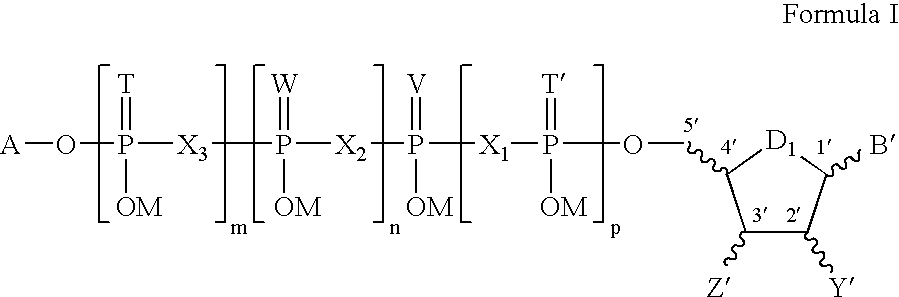

Joint lubrication with P2Y purinergic receptor agonists

InactiveUS7109181B2Enhance joint lubricationTreat osteoarthritisBiocideAerosol deliveryPhospholipidUridine Nucleotides

The present invention is directed to a method of altering the amount or composition of synovial fluids secreted from joints in a subject in need of such treatment. The method comprises administering to a subject a pharmaceutical composition comprising a P2Y purinergic receptor agonist in an amount effective to alter the amount or composition of synovial fluids. The P2Y purinergic receptor agonist is administered in an amount effective to stimulate secretion of synovial fluid, lubricin, hyaluronic acid, or surface-active phospholipids; to enhance joint lubrication; or to treat osteoarthritis. The pharmaceutical compositions useful in the present invention comprise a P2Y purinergic receptor agonist of Formula I and include, but are not limited to: uridine-, adenosine-, cytidine-5′-di- or triphosphates, dinucleoside polyphosphates, and analogs thereof. The invention is useful for treating conditions associated with reduced joint lubrication and joint stiffness, such as osteoarthritis.

Owner:INSPIRE PHARMA

Composition and method for enhancing neuromuscular facilitation and cognitive functions

InactiveUS20070248696A1Function increaseIncrease in the neurotransmitter acetylcholineBiocideCarbohydrate active ingredientsGriffonia simplicifoliaDietary supplement

A composition and a method for improving neuromuscular facilitation, also known as “muscle memory,” and enhancing cognitive functions, such as memory and mental focus. The dietary supplement, and the method for the administration thereof, increases acetylcholine levels, which improves neuromuscular facilitation. In various embodiments, factors other than increasing acetylcholine levels within the body further contribute to the overall effect of the dietary supplement composition. In a preferred embodiment, the invention is a composition, and a method for the administration thereof, comprising effective amounts of choline, dimethylaminoethanol, cytidine 5′-diphosphocholine, turmeric extract, decaffeinated green tea extract, vitamin B1, vitamin B5, vitamin B6, vitamin B12, folic acid, dimethylglycine, huperzine A, Griffonia simplicifolia extract, and 1-phenylalanine, magnesium stearate, and silicon dioxide.

Owner:MIND SPORTS NUTRITION

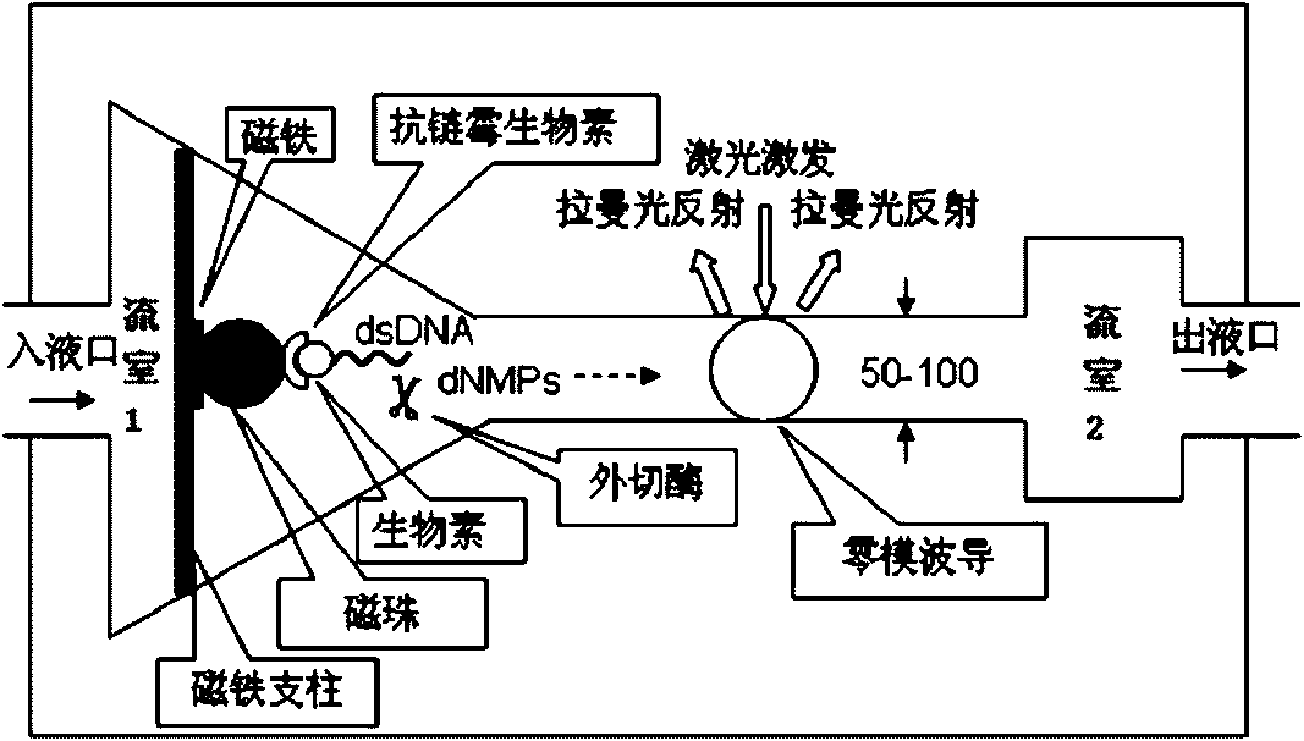

Method for testing sequence of nucleic acid single molecule

InactiveCN101654712AFast measurementHigh assay qualityMicrobiological testing/measurementRaman scatteringPhosphoric acidWaveguide

The invention relates to a method for testing a sequence of a nucleic acid single molecule in the technical field of biology, which comprises the following steps: respectively detecting Raman spectrumsignals of deoxyadenosine 5'-phosphoric acid, deoxyguanosine 5'-phosphoric acid, deoxycytidine 5'-phosphoric acid, deoxythymidine 5'-phosphoric acid, methyldeoxycytidine 5'-phosphoric acid, adenosine5'-phosphoric acid, vernine 5'-phosphoric acid, cytidine 5'-phosphoric acid and uridine 5'-phosphoric acid and establishing a standard curve; cutting a nucleic acid molecule to be detected by exonclease and detecting the Raman spectrum signal transmitted by a cut product when passing through a zero mode waveguide by the trigger of a laser; converting the Raman spectrum signal obtained in the step2 into concrete ribotide according to the standard curve obtained in the step 1 and obtaining the concrete sequence of the nucleic acid molecule to be detected by combining the cutting direction of the exonclease. The method can directly detect a natural nucleic acid sequence without a mark and has high detecting speed and detecting quality and low detecting cost.

Owner:SHANGHAI JIAO TONG UNIV

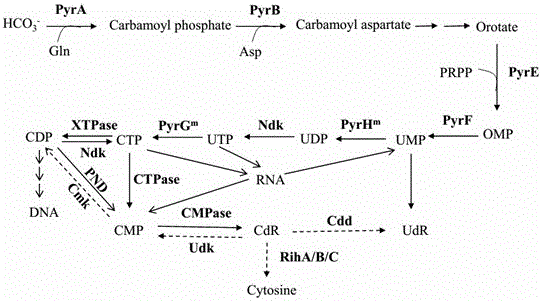

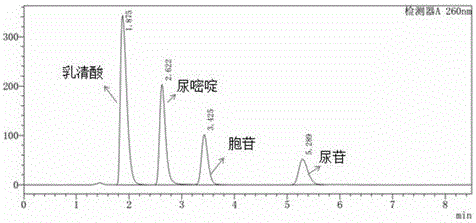

Recombinant microorganism for producing cytidine and method for producing cytidine

ActiveCN106754602ARealize large-scale industrial productionReduce manufacturing costBacteriaTransferasesRibonucleosideGenetic engineering

The invention provides a recombinant microorganism for producing cytidine and a method for producing the cytidine from the recombinant microorganism. A degradation and use gene of the cytidine is knocked off, and the gene encodes cytidine ammonialyase, ribonucleotide hydrolase, cytidine / uridine kinase and nucleoside transporter. Meanwhile key enzymes in biological synthesis process of the cytidine are over-expressed, including degrading cytidine triphosphoric acid to cytidine triphosphoric acid pyrophosphorylase of the cytidine monohosphoric acid, and catalyzing the cytidine monohosphoric acid to cytidine monohosphoric acid phosphorylase of the cytidine. In addition, pyrimidine nucleoside process is subjected to genetic engineering reform, and feedback inhibition of the synthesis process is relieved. By using a biological fermentation method, the cytidine yield greater than 20g / L can be achieved for a recombinant strain in a fermentation tank of 5L, industrial on-scale production can be achieved, and meanwhile the recombinant microorganism is low in cytidine production cost, small in pollution, green and environmental-friendly and relatively high in popularization and application value.

Owner:BIOSYNTHETICA INC

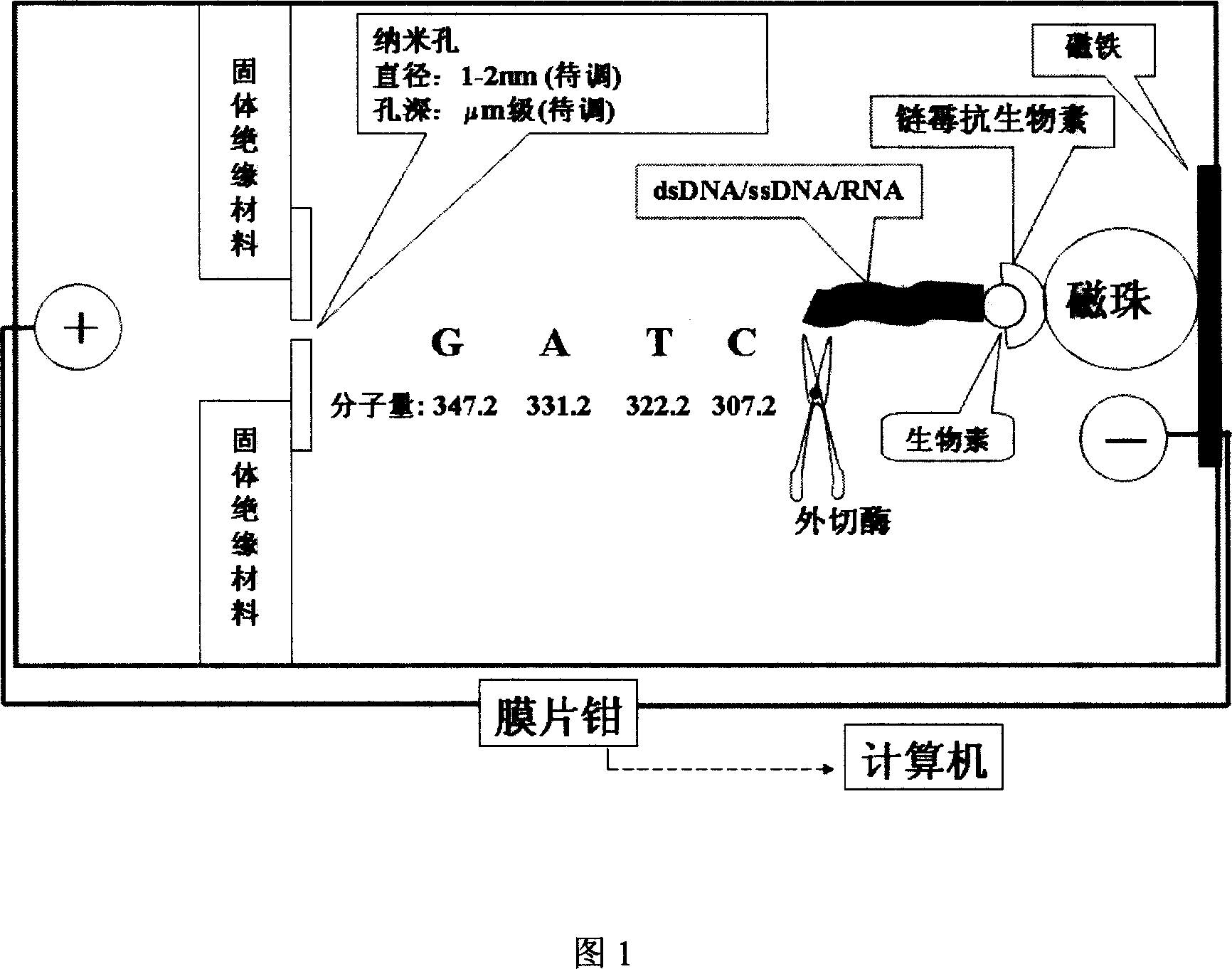

Single molecular nucleic acid sequencing process for exonuclease-nanometer hole

InactiveCN1932039AImprove recognition accuracyHigh hardnessMicrobiological testing/measurementPhosphateNucleotide

The present invention relates to biotechnology, and is single molecular nucleic acid sequencing process for exonuclease-nanometer hole. The process includes the following steps: 1. detecting electric signal of single molecular nucleotide to set up standard curve; 2. fixing nucleic acid in the negative pole of electrophoresis tank, degrading nucleotides with exonuclease and detecting the electric signal with the patch clamp while passing through the nanometer hole; and 3. converting the electric signal into specific nucleotide based on the standard curve and obtaining the base sequence of the nucleotide according to the cutting direction of the exonuclease. The present invention has high nucleoside and deoxynucleoside-phosphate recognizing accuracy, and may be used in detecting nucleoside and deoxynucleoside5'-phosphate, nucleoside and deoxynucleoside3'-phosphate and methylated cytidine in natural eukaryote DNA.

Owner:SHANGHAI JIAO TONG UNIV

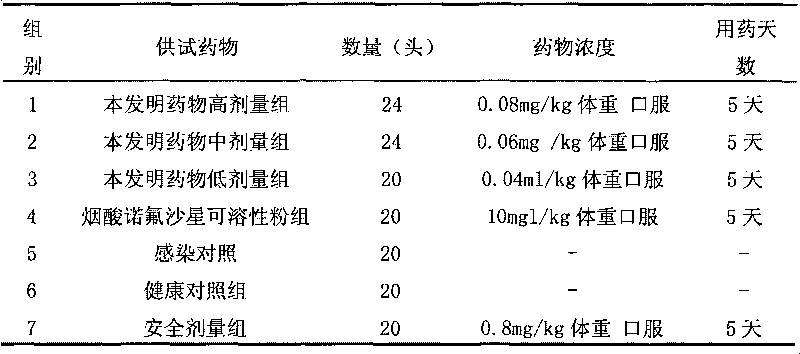

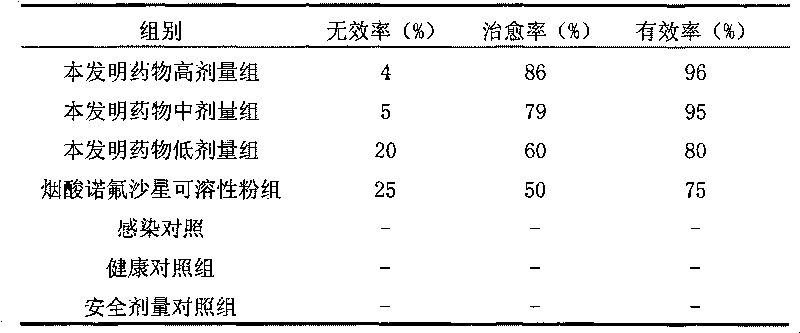

Polyinosinic powder for livestock and preparation method thereof

The invention aims to provide veterinary polyinosinic powder which mainly comprises poly cytidine acid, poly inosinic acid and auxiliary material, is prepared through a series of processes, such as mixing, dissolving, granulating, drying, grinding and the like, and is mainly used to prevent and treat the virus diseases of the livestock. Through the clinical therapeutic effect test we find that the medicine is characterized by good therapeutic effect, little dosage and high efficiency in preventing and treating the virus diseases of the livestock, and is suitable to be popularized and applied in the livestock industry.

Owner:TIANJIN RINGPU BIO TECH

Extract of traditional Chinese medicine having alpha-glucosidase inhibitor activity and its application

ActiveCN101007017AInhibitory activityLower blood sugarMetabolism disorderPill deliveryGlycosidase inhibitorAdditive ingredient

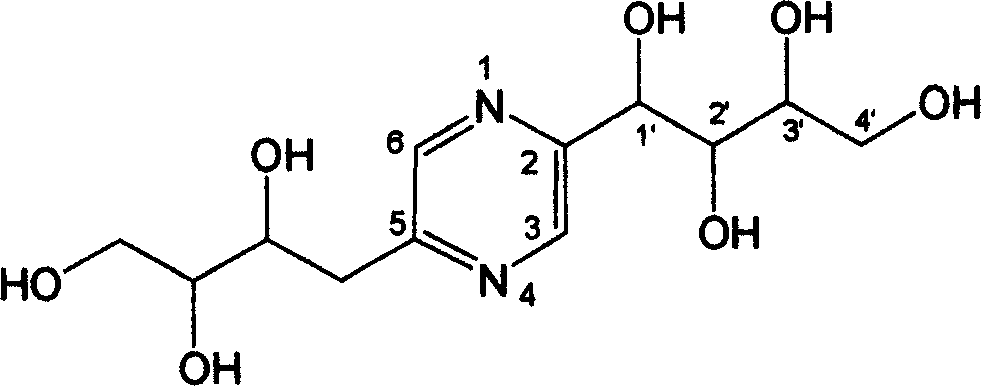

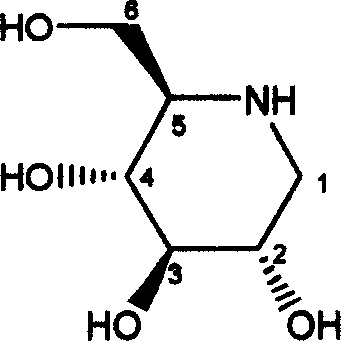

The invention discloses anextract of Chinese herbs containing alpha-glycoside enzyme inhibitor, which comprises cytidine, 2-(1',2',3',4'-tetrahydroxylbutyl)-5-(2'',3'',4''-trihydroxybutyl)-pyrazine and 1-deoxynojirimycin. The extract can be obtained from leaves, branches and peels of mulberries. The extract can be used for preparing medicament for treating diabetes.

Owner:JINAN UNIVERSITY

Methods and compositions for improving cognitive performance

PendingUS20100041621A1Improve performanceRaise attentionBiocideCarbohydrate active ingredientsPsychiatryCognitive skill

Owner:THE MCLEAN HOSPITAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com