Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

161 results about "Triphosphoric acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Triphosphoric acid (also tripolyphosphoric acid), with formula H₅P₃O₁₀, is a condensed form of phosphoric acid. In the family of phosphoric acids, it is the next polyphosphoric acid after pyrophosphoric acid, H₄P₂O₇, also called diphosphoric acid.

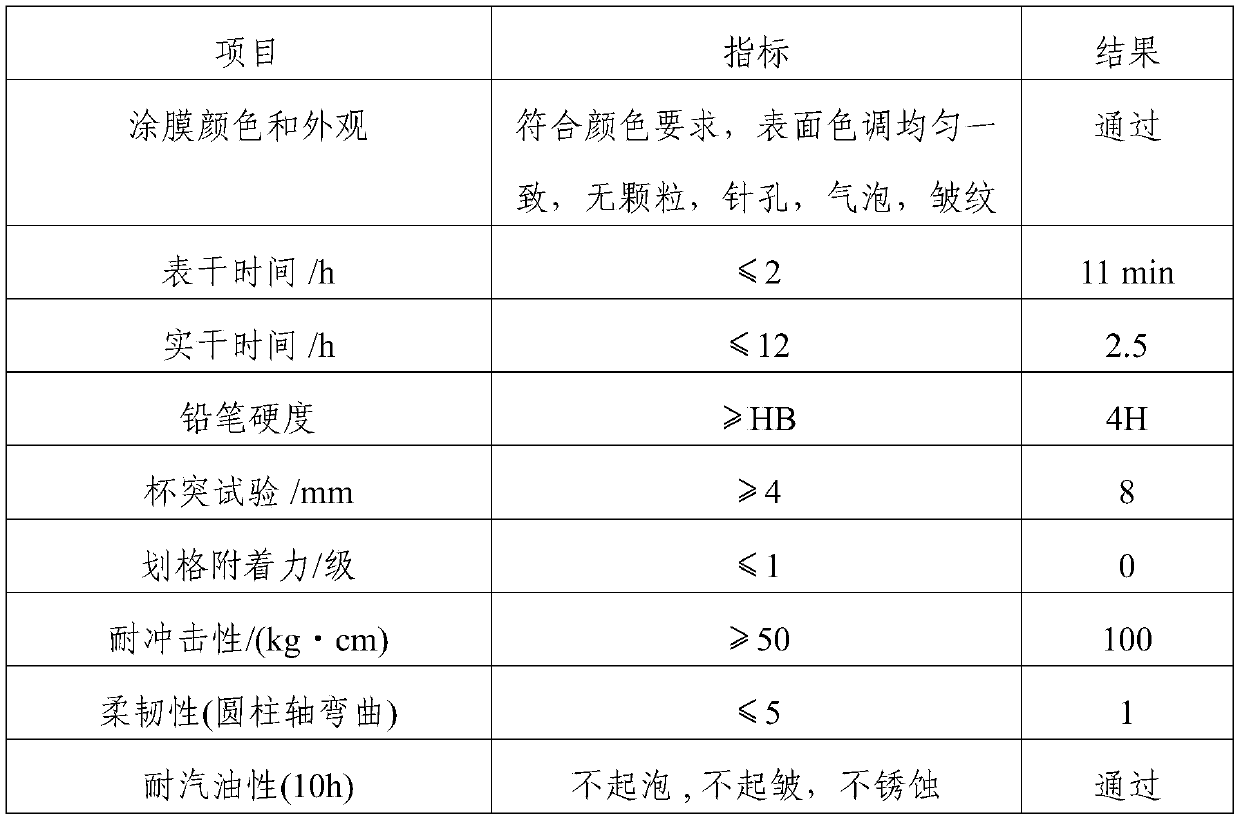

Drag-reducing abrasion-resisting solventless coating for pipeline as well as preparation method and application thereof

ActiveCN101974282AStrong adhesionGood flexibilityAnti-corrosive paintsPipe protection against damage/wearEpoxySolvent free

The invention relates to a drag-reducing abrasion-resisting solventless coating for a pipeline as well as a preparation method and application thereof. The drag-reducing abrasion-resisting solventless coating contains an A component and a B component, wherein the mass percentage of raw materials is as follows: the A component includes the following materials in percentage by weight: 30%-40% of epoxy resin, 5%-10% of toughening resin, 4%-8% of active diluents, 4%-8% of zinc phosphate, 0.2%-0.5% of levelling agents, 0.2%-0.5% of defoaming agents, 0.4%-0.8% of dispersing agents, 0.2%-1.0% of anti-settling thickening agents, 8%-20% of ferric oxide red powder, 5%-15% of aluminium triphosphate and 5%-15% of white pottery magnetic powder; the B component includes the following materials in percentage by weight: 5%-20% of modified amine and 2%-10% of modified polyamide; and the A component and the B component are matched for use according to the mass ratio of 3-5:1. The drag-reducing abrasion-resisting solventless coating is prepared through material blending, dispersion, grinding, filtration and packaging and can be applied in delivery pipelines of oil and natural gases. The drag-reducing abrasion-resisting solventless coating does not contain volatile solvents and has the advantages of good adhesive force, flexibility, salt spray resistance and solvent resistant property, smooth coating surface, good drag-reducing abrasion-resisting effect, convenient construction, resource saving and good popularization and application prospect.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL

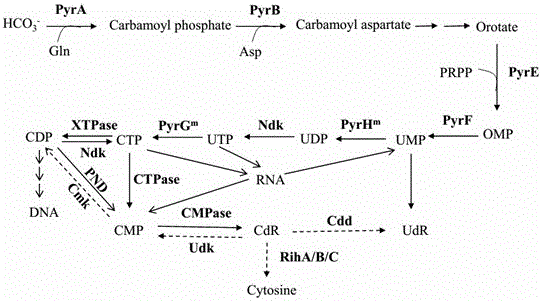

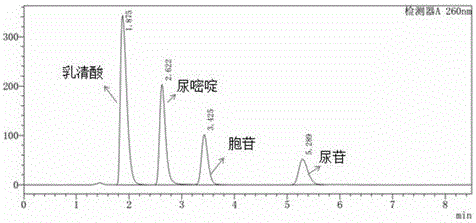

Recombinant microorganism for producing cytidine and method for producing cytidine

ActiveCN106754602ARealize large-scale industrial productionReduce manufacturing costBacteriaTransferasesRibonucleosideGenetic engineering

The invention provides a recombinant microorganism for producing cytidine and a method for producing the cytidine from the recombinant microorganism. A degradation and use gene of the cytidine is knocked off, and the gene encodes cytidine ammonialyase, ribonucleotide hydrolase, cytidine / uridine kinase and nucleoside transporter. Meanwhile key enzymes in biological synthesis process of the cytidine are over-expressed, including degrading cytidine triphosphoric acid to cytidine triphosphoric acid pyrophosphorylase of the cytidine monohosphoric acid, and catalyzing the cytidine monohosphoric acid to cytidine monohosphoric acid phosphorylase of the cytidine. In addition, pyrimidine nucleoside process is subjected to genetic engineering reform, and feedback inhibition of the synthesis process is relieved. By using a biological fermentation method, the cytidine yield greater than 20g / L can be achieved for a recombinant strain in a fermentation tank of 5L, industrial on-scale production can be achieved, and meanwhile the recombinant microorganism is low in cytidine production cost, small in pollution, green and environmental-friendly and relatively high in popularization and application value.

Owner:BIOSYNTHETICA INC

Disinfectant health-care aromatic hand paper towel and preparation method thereof

ActiveCN104846685ALow costReduce manufacturing costCosmetic preparationsToilet preparationsAntibacterial agentAntibacterial property

The invention discloses a disinfectant health-care aromatic hand paper towel and a preparation method thereof. The hand paper towel comprises the following components: softwood sulfite pulp, bamboo-pulp paper fiber, straw pulp, a cationic starch solution, a wet strength agent, a powerful antibacterial agent, an aromatic agent and titanium dioxide, wherein the wet strength agent is polyethylene ethylamine resin, the powerful antibacterial agent is composed of pure-oxygen-based quaternary ammonium salt, Sophora flavescens, common cnidium fruit, honeysuckle, borneol, isatis root, ethanol and distilled water, and the aromatic agent is composed of chitosan, ethanol, essence extract, deionized water, glycerin and triphosphoric acid. The prepared disinfectant health-care aromatic hand paper towel in the invention has the characteristics of no toxicity, harmlessness, environmental protection, highly-efficient antibacterial property and emission of aroma, can efficiently avoid contact-type cross infection with bacteria in public places and is safer and more secure to use.

Owner:ZHEJIANG HUACHUAN IND GRP

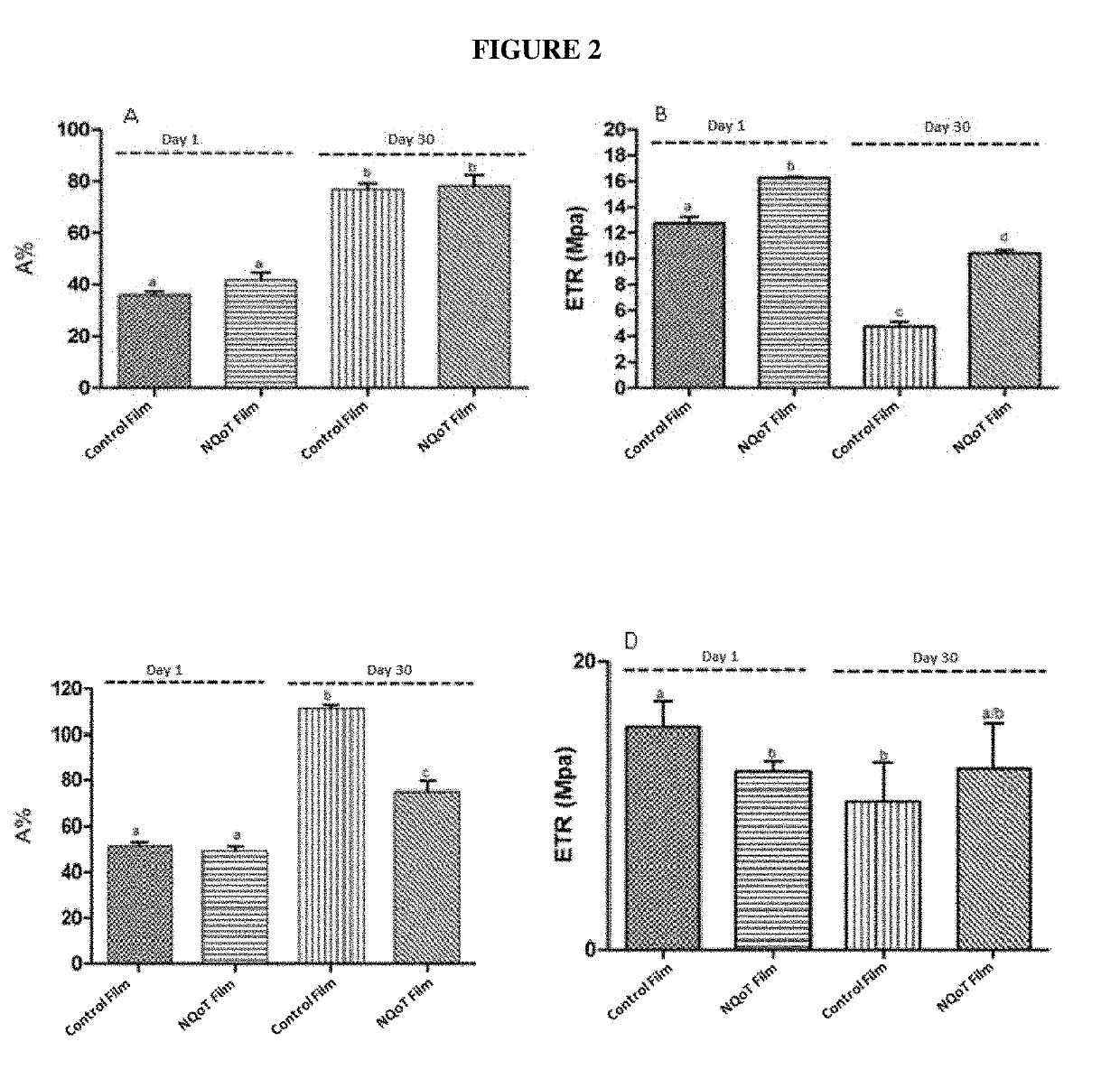

Edible bio-active films based on chitosan or a mixture of quinoa protein-chitosan; sheets having chitosan-tripolyphosphate-thymol nanoparticles; production method; bio-packaging comprising same; and use thereof in fresh fruit with a low ph

InactiveUS20190281845A1Extended shelf lifeImprove mechanical propertiesFlexible coversWrappersNanoparticleFilm base

Owner:UNIVERSITY OF CHILE

Reagents for reversibly terminating primer extension

This invention relates to the field of nucleic acid chemistry, more specifically to the field of compositions of matter that comprise triphosphates of modified 2'-deoxynucleosides and oligonucleotides that are formed when these are appended to the 3'-end of a primer, wherein said modifications comprise NH2 moiety attached to their 3'-hydroxyl group and a fluorescent species in a form of a tag affixed to the nucleobase via a linker that can be cleaved. Such compositions and their associated processes enable and improve the sequencing of oligonucleotides using a strategy of cyclic reversible termination, as outlined in US Patent 6,664,079. Most specifically, the invention concerns compositions of matter that are 5'-triphosphates of ribo- and 2'- deoxyribonucleosides carrying detectable tags and oligonucleotides that might be derived from them. The invention also concerns processes wherein a DNA polymerase, RNA polymerase, or reverse transcriptase synthesizes said oligonucleotides via addition of said triphosphates to a primer.

Owner:动态组合化学技术有限责任公司

Epoxy anticorrosion decoration paint

ActiveCN102911586AEffective isolationLow Molecular TG ValueAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer science

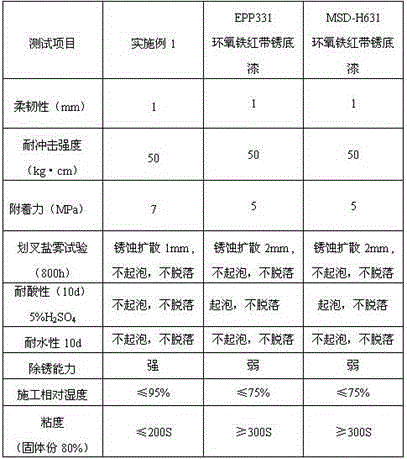

The invention provides an epoxy anticorrosion decoration paint. The epoxy anticorrosion decoration paint is characterized by being prepared by mixing a component A and a component B according to the weight ratio of 4:1, wherein the component A contains 30-50% of low molecular weight epoxy resin, 5-10% of zinc phosphate, 5-10% of packing, 5-10% of aluminium triphosphate, 20-30% of iron oxide red, 0.2-0.5% of tetra-n-propyl zirconate, 0.1-0.3% of silane coupling agent and 5-20% of butyl cellosolve, and the component B contains 30-50% of amino-terminated epoxy-amine affixture, 0.1-0.5% of penetrant, 0.1-0.5% of phytic acid, 30-48% of ethanol and 30-48% of n-butyl alcohol. The paint has excellent corrosion resistance, strong base material adhesion, good flexibility and shock resistance, high solid content, low viscosity, strong tolerance to environment humidity and strong construction adaptability.

Owner:江苏纽克莱涂料有限公司

Epichlorophdrin resinous varnish and preparation method thereof

InactiveCN101294017AImprove water resistanceExcellent chemical corrosion resistanceWax coatingsParaffin waxSodium Bentonite

The invention relates to a chlorinated polyether resin coating and a production method thereof. The coating contains 1 weight part of chlorinated polyether resin, 0.025-0.5 weight parts of chlorinated paraffin wax with chlorine content of 52%, 0.008-0.5 weight parts of acrylic acid-modified fluorocarbon resin, 0.05-3.0 weight parts of dimethylbenzene, 0.01-1.2 weight parts of heavy aromatic solvent, 0.005-0.01 weight parts of dimethyl silicon oil, 0.005-0.25 weight parts of aluminum tripolyphosphate, 0.006-0.5 weight parts of titanium white powder, 0.01-0.4 weight parts of talc powder and 0.005-0.05 weight parts of organic bentonite. The coating is characterized in that: the components are packaged independently and are dried at room temperature to form coating. The coating is excellent in physical property, chemical resistance, salt spray resistance and light fastness, and can be used for the surface protection and coating of steel structure and concrete in corrosive marine environments.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

Aqueous fire retardation antirust coating material

InactiveCN103409011AStrong adhesionAvoid pollutionFireproof paintsAnti-corrosive paintsEpoxyDimethyl methylphosphonate

The present invention relates to an aqueous fire retardation antirust coating material, which is characterized by comprising the following raw materials, by weight: 100-120 parts of a styrene-acrylate emulsion, 8-10 parts of an epoxy resin, 15-25 parts of glass flakes, 0.1-0.3 part of zinc phosphate, 4-10 parts of dimethyl methylphosphonate, 2-4 parts of aluminum tripolyphosphate, 0.5-2 parts of sorbitan monooleate, 0.2-0.3 part of polyoxy ethylene nonyl phenyl ether, 0.1-0.2 part of triethylamine, 0.1-1 part of a dispersing agent, 0.1-0.5 part of an antifoaming agent, and 10-20 parts of deionized water. The product has characteristics of good corrosion resistance, strong adhesion to the substrate, substrate protection, rust resistance and good fire retardation, adopts water as a solvent so as to overcome pollution of the solvent type coating material on the environment, and is a green environmental protection coating material.

Owner:WUJIANG JUNDA ELEVATOR PARTS

Ammonia diagnosis/determination reagent kit and ammonia concentration determination method

InactiveCN101169411AFast measurementImprove accuracyMaterial analysis by observing effect on chemical indicatorMicrobiological testing/measurementWavelengthGlyceraldehyde 3-phosphate

The invention relates to an ammonia diagnosing / measuring reagent box which utilizes the technique of the enzyme contrasting color method and the enzyme jointing method, and belongs to the technical field of the medicine / food / environment test. The main components of the reagent box of the invention mainly include cushion liquid, coenzyme, glutamic acid, adentosine triphosphoric acid, glyceraldehyde-3-phosphate, glutamine synthetase, glyceraldehyde-3-phosphate dehydrogenase and stabilizing agent; the reagent box generates a series of enzymic reactions through the mixing of the samples and the reagent at a certain cubage rate, and then the reactants are positioned under an ultraviolet / visible light analyzer which tests the reducing speed of the absorbency at the main wave length of 340nm, thereby measuring the concentration size of the enzyme. The invention can absolutely get needed measuring result through the ultraviolet / visible light analyzer.

Owner:SUZHOU ANJ BIOTECHNOLOGY CO LTD

High-temperature wear-resistant coating

InactiveCN104610789AImprove mechanical propertiesImprove impact resistanceCoatingsCarbon monofluorideO-Phosphoric Acid

The invention relates to a fire-resistant material and particularly relates to a high-temperature wear-resistant coating. The high-temperature wear-resistant coating is prepared from the following raw materials: 13-22 parts of white corundum micro-powder, 6-11 parts of cement, 4-14 parts of carbon fluoride, 8-13 parts of titanium dioxide, 9-14 parts of Mohr's salt, 5-7 parts of barium sulfate, 3-9 parts of magnesium hexasilicate, 4-9 parts of aluminum triphosphate, 2.3-4.5 parts of sodium persulfate, 0.7-1.3 parts of PA-80 cement gum, 6-8 parts of aluminium oxide, 0.3-1.5 parts of silica micro-powder and 3-5 parts of phosphoric acid. The high-temperature wear-resistant coating provided by the invention has the advantages of very good mechanical property and shock resistance, high temperature resistance and excellent adhesive force and can resist wear and hardly fall off when used in a high-temperature furnace.

Owner:YIXING GUOQIANG FURNACE IND

Rust-proof paint

InactiveCN103483937AImprove rust resistanceStrong color fixing abilityAnti-corrosive paintsPolycarbonate coatingsPhosphoric acidTriphosphoric acid

The invention discloses rust-proof paint. The rust-proof paint comprises the following components in parts by weight: 75-80 parts of acrylic emulsion, 20-30 parts of iron red, 5-10 parts of polycarbonate, 10-15 parts of inositol hexaphosphate, 1-3 parts of aluminum dihydrogen tripolyphosphate, 0.5-2 parts of iron phosphating agent, 0.02-1 part of silicon dioxide and 100 parts of water. Compared with the ordinary water-based rust-proof paint, the rust-proof paint provided by the invention has a better rust-proof effect, has a very strong color fixing effect, still does not lose the color and luster after being affected by high temperature and harsh environment for a long time under, and is low in cost.

Owner:佛山市顺德区明邦化工实业有限公司

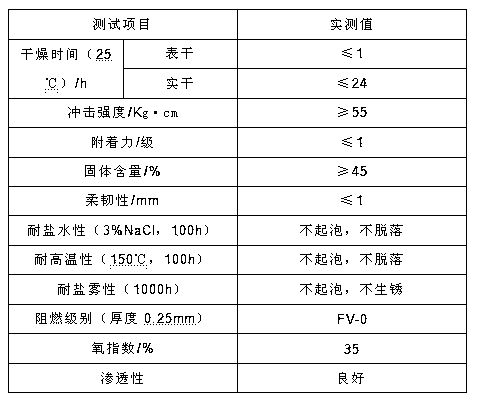

High-performance two-component epoxy primer for rail transit and preparation process thereof

InactiveCN110894392AHigh solid contentEmission reductionAnti-corrosive paintsEpoxy resin coatingsPhosphomolybdic acidXylylene

The invention provides a high-performance two-component epoxy primer for rail transit and a preparation process thereof, belonging to the technical field of paints. The high-performance two-componentepoxy primer comprises a component A and a component B in a weight ratio of 10: (2.3-2.8). The component A is prepared from the following components: solid epoxy resin, liquid epoxy resin, graphene, epoxy silane coupling agent modified nanometer silicon dioxide, pigment and filler, zinc-calcium modified aluminum triphosphate, zinc phosphomolybdate, a thixotropic agent, a wetting dispersant, a leveling agent, an antifoaming agent and a mixed solvent. The component B is prepared from cashew nut shell oil modified phenolic aldehyde amine resin, cardanol modified polyamide resin, xylene, n-butyl alcohol, propylene glycol methyl ether acetate and an amino silane coupling agent. The epoxy primer prepared by the invention has excellent mechanical properties, corrosion resistance, weather resistance and adhesive force, and has good application prospects in rail transit.

Owner:安徽壹信通讯科技有限公司

Freeze-dried microsphere of PCR reaction agent and preparing method thereof

PendingCN110452956AStable storageSolving Quantitative ProblemsMicrobiological testing/measurementFreeze-dryingMicrosphere

The invention provides a freeze-dried microsphere of a PCR reaction agent. The freeze-dried microsphere comprises an enzyme reaction liquid, desoxyribonucleic acid triphosphoric acid, a primer, a template, a biological buffer solution, glucan, trehalose, bovine serum albumin, gelatin, glycerinum, dimethyl sulfoxide, a surfactant, a defoaming agent, a preservative and the like. By means of the freeze-dried microsphere of the PCR reaction agent and the preparing method thereof, the problem that a PCR agent cannot be preserved or transported at a normal temperature in the prior art is solved; theproblems that the PCR agent can hardly be packaged or stored and a freeze-dried powder agent can hardly be quantified are solved. The freeze-dried product comprises a PCR reaction main agent and is convenient to use and saves time, and the contamination introduced in the experiment operation process and the errors of reducing the addition of reaction components are effectively avoided.

Owner:INTEGRATED BIOSYSTEMS CO LTD

Acrylic acid-polyaniline composite modified polyurethane coating

InactiveCN105602440AImprove corrosion resistanceGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsGlycerolFire resistance

The invention discloses an acrylic acid-polyaniline composite modified polyurethane coating which is prepared from modified polyurethane emulsion, waterborne acrylic emulsion, waterborne polyaniline emulsion, diphenylmethane diisocyanate, nano-zinc oxide, nano-zinc phosphate, aluminum oxide, wollastonite, boron nitride, barium sulfate, aluminum triphosphate, diethyl aluminum phosphinic acid, calcium chloride, N-methyl pyrrolidone, a defoaming agent, a dispersing agent, a wetting agent, a flatting agent, glycerol, 8-hydroxyquinoline, epoxy resin, a silane coupling agent, polyethylene wax and water. The acrylic acid-polyaniline composite modified polyurethane coating is good in water resistance and corrosion resistance, excellent in heat resistance and weather resistance, high in strength, high in adhesive force with a base material and long in service life, and has the certain fire resistance.

Owner:ANHUI ANDA HUATAI NEW MATERIALS CO LTD

Whitening and anti-aging aqueous coating for glass sliding doors and preparation method of whitening and anti-aging aqueous coating

InactiveCN104341999AEasy to prepareStrong aging resistanceAntifouling/underwater paintsPaints with biocidesEpoxyPolymer science

The invention discloses a whitening and anti-aging aqueous coating for glass sliding doors. The whitening and anti-aging aqueous coating is characterized by being prepared from the following raw materials in parts by weight: 40-50 parts of aqueous polyurethane resin, 15-20 parts of an E-20 epoxy resin emulsion, 7-10 parts of a modified pure acrylic emulsion, 2-3 parts of nano-calcium carbonate, 1-3 parts of dipropylene glycol dimethyl ether, 0.3-0.6 part of alcoholamine diphosphoryloxy glycolic acid titanate, 0.2-0.4 part of fluoro-alkyl polyether modified polysiloxane, 0.5-1.0 part of alkylaryl polyether alcohol, 0.2-0.4 part of dimethicone, 0.3-0.6 part of propyl trimethoxy siloxane, 0.3-0.5 part of nano-montmorillonite, 0.4-0.7 part of vermiculite powder, 0.3-0.4 part of aluminum tripolyphosphate, 0.4-0.8 part of high-gloss powder, 1-2 parts of brightening titanium dioxide and 10-15 parts of deionized water. The aqueous glass coating disclosed by the invention is simple in preparation method, good in adhesion against a glass substrate and high in aging resistance; by adding the brightening titanium dioxide and the high-gloss powder, the brightness is improved; the added modified pure acrylic emulsion has the characteristics of excellent stain resistance, bactericidal property, scrub resistance, weather resistance and the like; and the coating disclosed by the invention is fast in drying speed and a paint film is smooth.

Owner:凤阳徽亨商贸有限公司

Efficient and environment-friendly chromate-free passivation solution and preparation method thereof

The invention discloses an efficient and environment-friendly chromate-free passivation solution and a preparation method thereof. The efficient and environment-friendly chromate-free passivation solution comprises the following components of 35-40 g / L of molybdenum phosphate, 10-20 g / L of sodium vanadate, 8-12 g / L of sodium tungstate, 10-100 g / L of phytic acid, 3-30 g / L of tartaric acid, 5-50 g / L of gallotannic acid, 10-50 g / L of poly trimethyl ethyoxyl modified epoxy resin, 6-8 g / L of corrosion and scale inhibitor, 3-6 g / L of sealant, 10-15 g / L of film-forming agent, 0.5-3 g / L of anti-oxidant or oxidation inhibiter and 3-7 g / L of aluminium triphosphate. Through reasonable formula design, the passivation solution contains no chromium ions of any valence state, and has the characteristics of safety and environment friendliness, meanwhile, the passivation solution has the excellent passivation performance, film forming performance and rust resistance, and comprehensive and efficient corrosion resistance is given to a zinc coating. The characteristic of the low cost is achieved from the formula technology to the preparation technology, and the development and application prospects are wide.

Owner:CHANGSHU FENGFAN POWER EQUIP

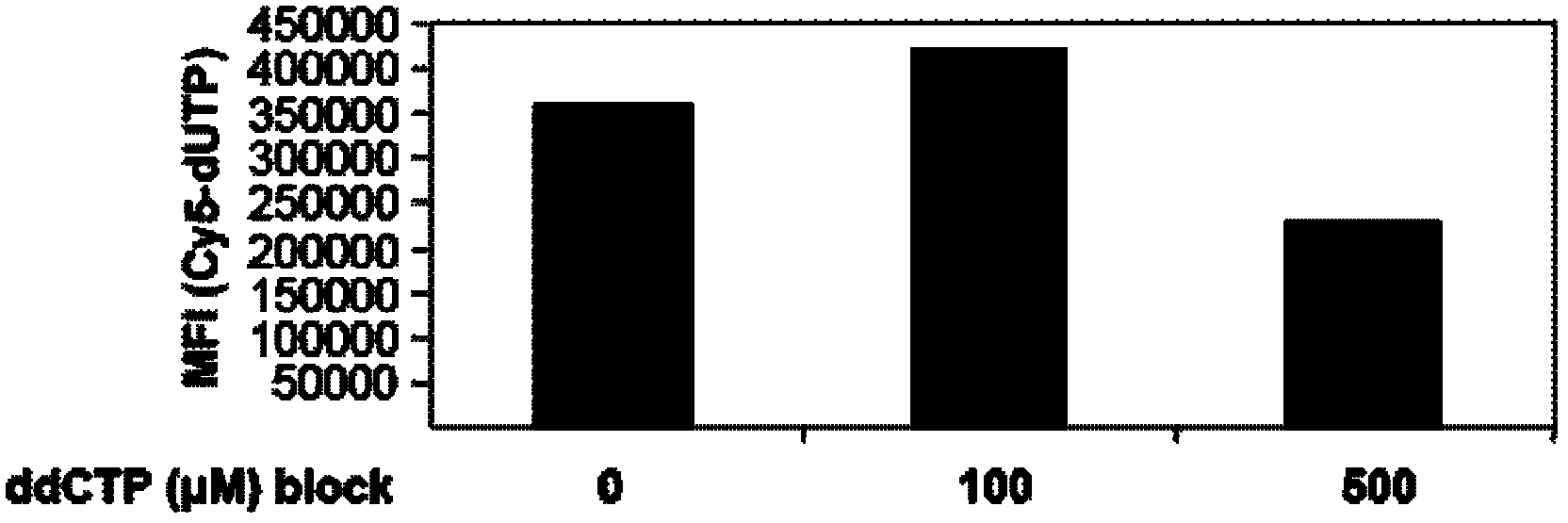

Specificity quantitive detection for cell apoptosis

InactiveCN102382893AStrong specificityReliable Guiding PrinciplesMicrobiological testing/measurementNucleotideCell membrane

The invention discloses a cell pre-incubation reagent box for detecting cell apoptosis and is characterized in that the cell pre-incubation reagent box comprises a terminal transferase (TdT) for marking a terminal 3' of a DNA, and a dideoxy nucleotide triphosphoric acid (ddNTP) or a triphosphoric acid deoxyribonucleoside (dNTP); the dideoxy nucleotide triphosphoric acid (ddNTP) or the triphosphoric acid deoxyribonucleoside (dNTP) is not marked and is marked in advance as a basic group in a dideoxy nucleotide triphosphoric acid (ddNTP) pair or a triphosphoric acid deoxyribonucleoside (dNTP) pair is added at the terminal3' of a fractured DNA segment after a cell membrane is penetrated through. The method provides a more specific way for detecting cell apoptosis.

Owner:PERSONGEN BIOMEDICINESUZHOUCO +1

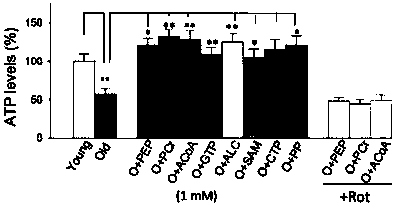

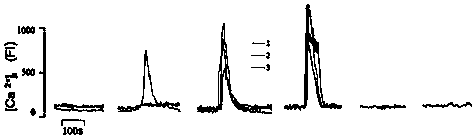

High-energy substance for preventing and treating neurodegenerative disease of old people and medical application of substance

InactiveCN103520190ABoost energy levelsReasonable treatmentOrganic active ingredientsNervous disorderS-Adenosyl-l-methionineHigh energy

The invention relates to a high-energy substance for preventing and treating a neurodegenerative disease of old people. The high-energy substance comprises one or more of compounds and derivatives of the compounds of phosphoenolpyruvic acid, creatine phosphoric acid, acetyl coenzyme A, adenosine triphosphoric acid, L-carnitine, s-adenosylmethionine, guanosine triphosphate, cytidine triphosphate, pyrophosphoric acid, 1,3-diphosphoglycerate and succinyl coenzyme A. The high-energy substance has the benefits as follows: the high-energy substance is used for treating the neurodegenerative disease of the old people, particularly the aged population, so as to delay and prevent dementia; and the high-energy substance is proved to be a novel medicine which is reasonable, safe and economical and used for treating the neurodegenerative disease, particularly senile dementia.

Owner:陈铭

Medical rust-removal and antirust paint and preparation method therefor

The invention discloses medical rust-removal and antirust paint and a preparation method therefor. The paint is prepared from the following raw materials: styrene, zinc phosphate, phosphoric acid, zinc oxide, zinc chrome yellow, organobentonite, a polyvinyl acetate emulsion, deionized water, ammonium persulfate and aluminum triphosphate. The paint which is applied to medical apparatuses is antirust, the viscosity of the paint is 60-80, the fineness of the paint is 40-60 [mu]m, the flexibility of the paint is 0.2-0.8mm and the adhesive force of the paint is level 1-2; the paint has good antiseptic property, impact resistance within 60-80cm, impact strength of 500-550N / cm, and salt water resistance of not blistering and not falling within 1-3 days; the surface-drying time is 0.1-0.5 hour, the hard-drying time is 8-12 hours and the covering power is 95-115g / cm<2>.

Owner:SUZHOU JONATHAN NEW MATERIALS TECH

Anti-rust paint for coating surfaces of ships

InactiveCN103483938AImprove protectionGood color fixing effectAnti-corrosive paintsWater immersionPhosphoric acid

The invention discloses an anti-rust paint for coating the surfaces of ships. The anti-rust paint comprises the following components in parts by weight: 25-35 parts of a styrene-acrylic emulsion, 10-30 parts of inositol hexaphosphate, 2-5 parts of copper powder, 1-3 parts of quartz powder, 2-3 parts of aluminum dihydrogen tripolyphosphate, 0.2-0.5 part of silicon dioxide, 0.05-1 part of calcium oxalate and 100 parts of water. Experimental analysis shows that the anti-rust paint for coating the surfaces of ships can work 20 years under the condition of high salinity, has a better color-fixing effect than the general anti-rust paint, is free from dropping after being subject to long-term water immersion, has strong adhesiveness, can better protect the ships and increase the use value of the ships and has a very broad commercial prospect.

Owner:WUXI YANGGONG MACHINERY MFG

Method for preparing phosphorus oxide modified microporous molecular sieve shape-selective catalyst

InactiveCN104437600AHigh activityHigh shape selectivityMolecular sieve catalystsHydrocarbonsTriphosphoric acidPyrophosphoric acid

The invention relates to a method for preparing a phosphorus oxide modified microporous molecular sieve shape-selective catalyst. by the method, a microporous molecular sieve ZSM-5 or MCM-22 is used as a matrix, pyrophosphorous acid, hypophosphoric acid, iso-hypophosphoric acid, pyrophosphoric acid, triphosphoric acid or peroxydiphosphoric acid is used as the precursor of a phosphorus oxide, and the phosphorus oxide is loaded on the outer surface of the microporous molecular sieve in an impregnation and temperature programmed calcination method, wherein the mass ratio of the phosphorus oxide to the microporous molecular sieve is (1:6) to (1:20). The obtained shape-selective catalyst provided by the invention has good shape-selection catalytic performance on toluene disproportionation and ethylbenzene disproportionation processes, and the preparation method of the catalyst is simple.

Owner:CHANGZHOU UNIV

Anticorrosive paint

InactiveCN104387923AStrong resistance to salt waterGood weather resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyCellulose

The invention discloses an anticorrosive paint which comprises 4-9 parts of zinc-rich epoxy powder, 5-8 parts of sodium hexametaphosphate, 22-26 parts of water-based acrylic acid modified epoxy resin, 12-16 parts of alkyd resin, 20-30 parts of aluminum tripolyphosphate, 6-9 parts of hydroxyethyl cellulose, 18-24 parts of talcum powder and 4-8 parts of thickener. The anticorrosive paint has the advantages of high brine resistance, favorable weather resistance, favorable corrosion resistance, high adhesive force, high wear resistance and the like.

Owner:SUZHOU MINGXUAN FLOORING COATINGS

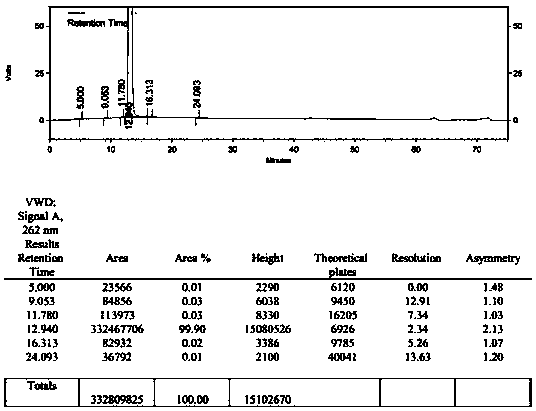

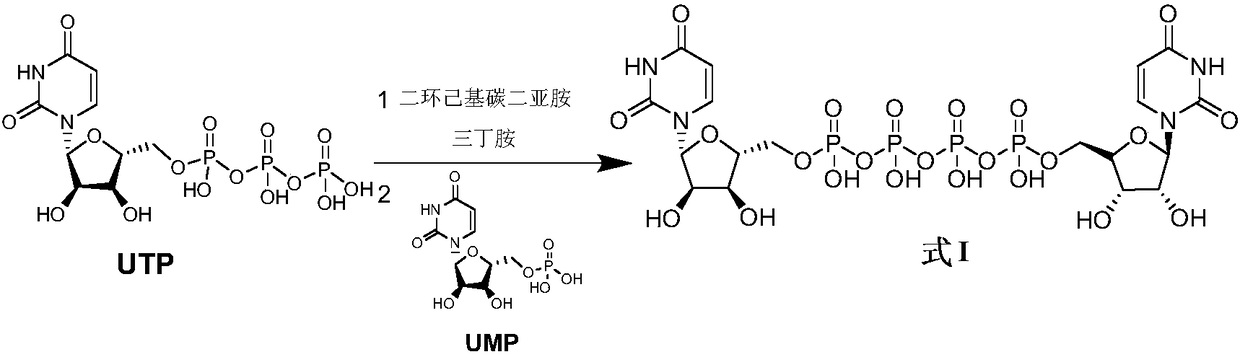

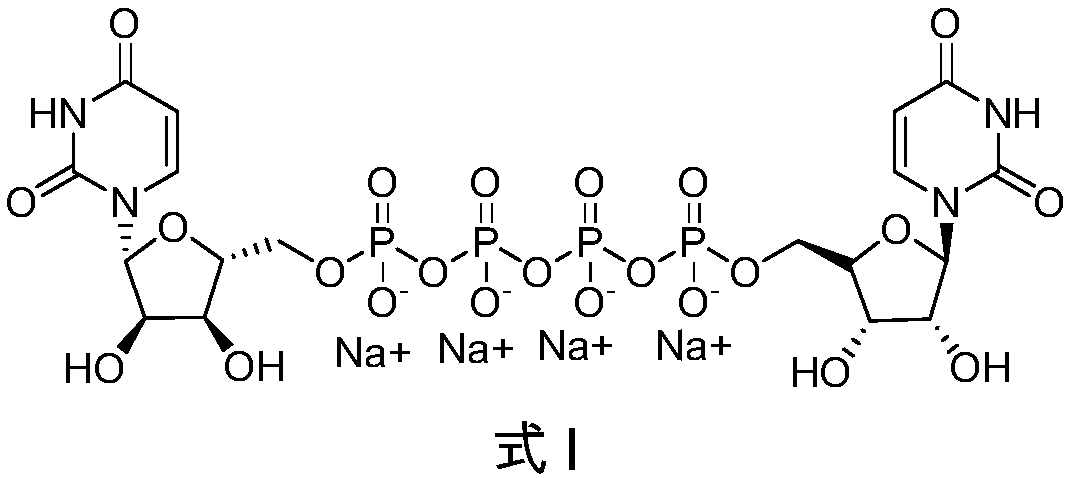

An industrial preparation process of tetrasodium P<1>,P<4>-di(uridine-5')tetraphosphate

An industrial preparation process of tetrasodium P<1>,P<4>-di(uridine-5')tetraphosphate is provided. The process includes preparing cyclic triphosphoric acid from a tributylamine salt of UTP by utilizing a carbodiimide type condensating agent; reacting the cyclic triphosphoric acid with a tributylamine salt of UMP to synthesize P<1>,P<4>-di(uridine-5')tetraphosphoric acid; directly salifying the reaction solution, without concentration, with a salt of an organic acid; performing crystallization; performing gradient elution with anion exchange resin after dissociation; subjecting the eluate, without the need of water concentration, to salt removing and water removing through membrane filtration; and then salifying to obtain the high-purity tetrasodium P<1>,P<4>-di(uridine-5')tetraphosphate.The tetrasodium P<1>,P<4>-di(uridine-5')tetraphosphate meeting officinal requirements can be prepared in a large scale by the process.

Owner:GUANGDONG ZHONGSHENG PHARMA +1

Environmental-friendly anti-rusting paint for equipment and preparation method thereof

ActiveCN103773142AImprove adhesionImprove rust resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsMeth-Polyvinyl alcohol

The invention provides environmental-friendly anti-rusting paint for equipment and a preparation method thereof. The environmental-friendly anti-rusting paint comprises the following components in parts by weight: 19-30 parts of polyvinyl butyral resin, 10-20 parts of organic silicon modified acrylate emulsion, 0.3-0.6 part of methyl benzene sulfonic acid, 0.04-0.08 part of chlorinated paraffin, 2-5 parts of zinc chrome yellow, 2-5 parts of mica iron oxide, 2-5 parts of calcium tripolyphosphate, 1-3 parts of aluminium phosphate, 2-4 parts of bentonite, 3-6 parts of nepheline, 0.6-1.5 parts of carbon black, 0.07-0.12 part of emulsified silicone oil, 0.2-0.5 part of dibutyl phthalate, 0.2-0.4 part of diatomite, 0.1-0.3 part of polyurethane and 32-45 parts of water. The environmental-friendly anti-rusting paint provided by the invention is safe and non-toxic, high in adhesive force and good in anti-rusting performance, wear resistance and impact resistance, and also can remove harmful substances such as free formaldehyde, benzene and VOC (volatile organic compounds) out of the air.

Owner:NANTONG HUAXIN ENVIRONMENTAL ENG EQUIP

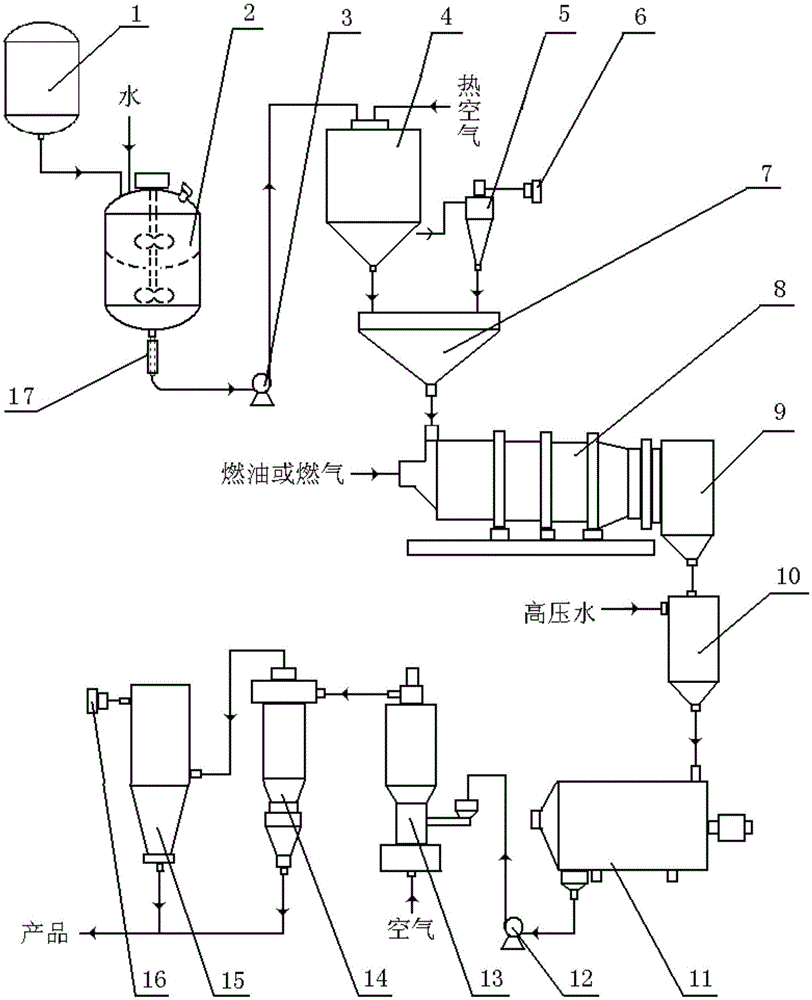

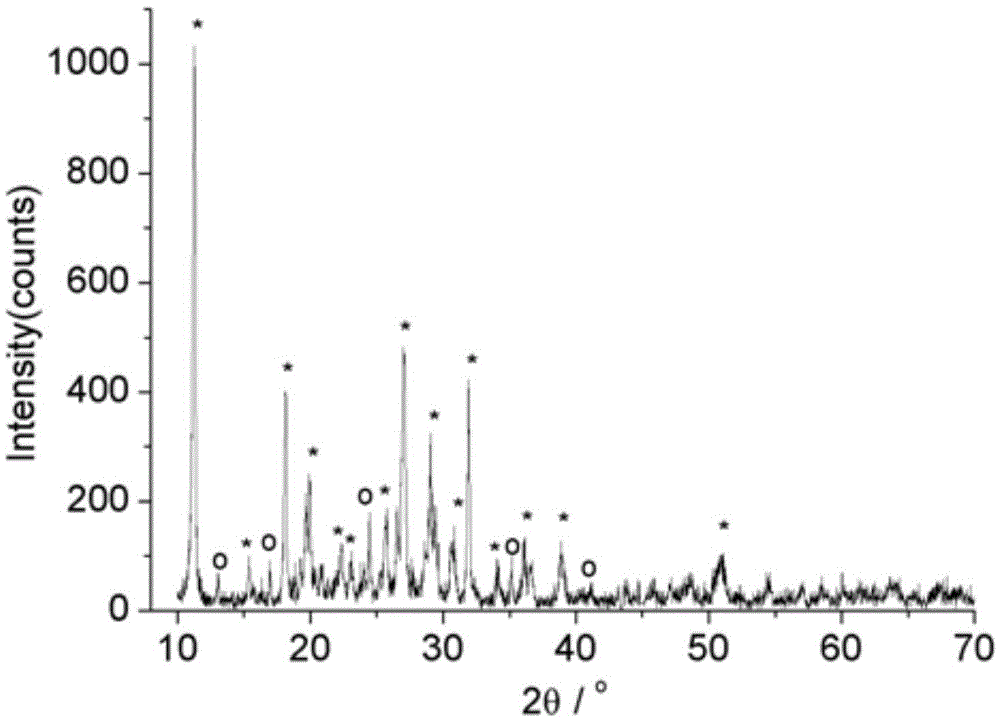

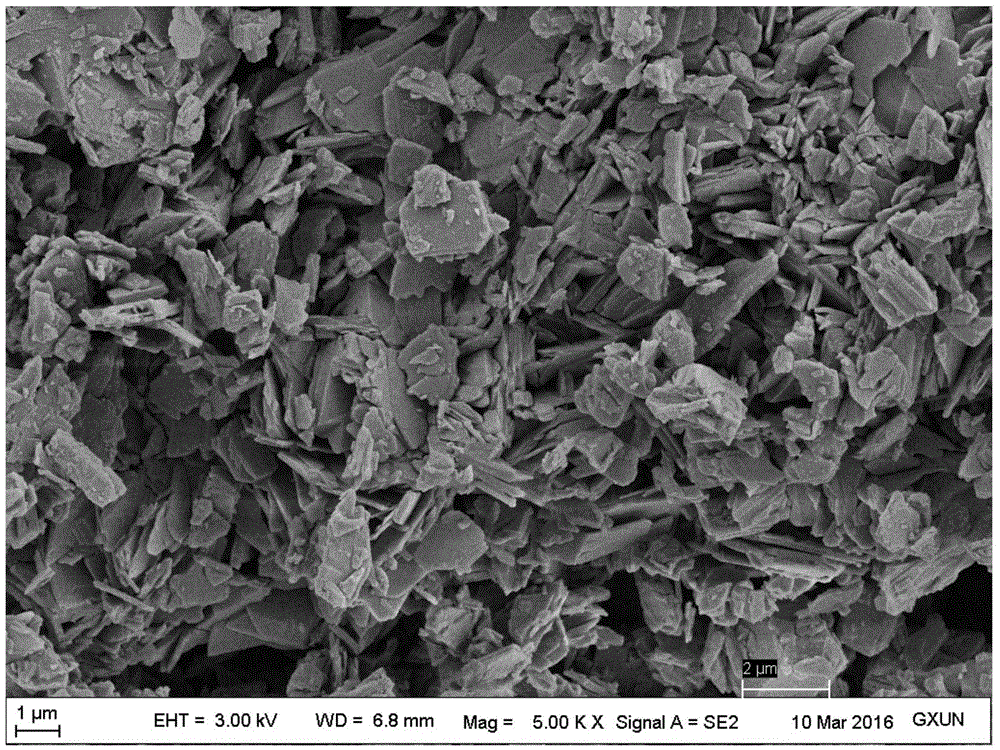

Aluminum dihydrogen tripolyphosphate continuous production method and device

The invention provides an aluminum dihydrogen tripolyphosphate continuous production method and device. The production method comprises the steps: preparing liquid aluminum dihydrogen phosphate by adopting activated aluminum oxide and 85% industrial phosphoric acid, centrifugally atomizing and drying to obtain aluminum dihydrogen phosphate powder, calcining, condensing, hydrating, drying and crushing to obtain aluminum dihydrogen tripolyphosphate powder. The aluminum dihydrogen tripolyphosphate continuous production method is an automatically-controlled continuous production process and is convenient in production and stable in product quality by virtue of digitalized control; and the prepared aluminum dihydrogen tripolyphosphate particles are uniform in size, the purity reaches 92 percent or more, compared with the prior art, the purity is increased by 15 to 18, and the problems of the existing two-step-method intermittent process that the automation degree is not high, the product quality is unstable and the purity is large in fluctuation are solved.

Owner:GUANGXI UNIV FOR NATITIES

Reagent (kit) for measuring formaldehyde and method for measuring concentration of formaldehyde

InactiveCN101793788AFast measurementImprove accuracyMicrobiological testing/measurementColor/spectral properties measurementsAdditive ingredientPhosphoric acid

The invention relates to a reagent (kit) for measuring formaldehyde by using an enzyme-multiplied method, an enzyme colorimetric method and an enzyme coupling method as well as a method for measuring the concentration of the formaldehyde, and composition and ingredients of the reagent, belonging to the technical field of food / environmental test. The reagent (kit) comprises the main ingredients of buffer solution, coenzyme, adenosine triphosphoric acid, tetrahydrofolic acid, glyceric aldehyde-3-phosphoric acid, formaldehyde dehydrogenase, formic acid-dihydrofolic acid ligase, glyceric aldehyde-3-glycerol phosphate dehydrogenase and stabilizing agent. The concentration of the formaldehyde is measured by mixing a sample and the reagent according to a certain volume ratio to carry out a series of enzymatic reaction, placing the reactant under an ultraviolet / visible light analyzer and detecting the ascending degree of absorbance at a dominant wavelength of 340nm.

Owner:SUZHOU ANJ BIOTECHNOLOGY CO LTD

Epoxy polyurethane root-resistant waterproof coating and preparation method thereof

InactiveCN104277668AObvious root blocking effectNo damagePolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyPolymer science

The invention discloses an epoxy polyurethane root-resistant waterproof coating. The epoxy polyurethane root-resistant waterproof coating is characterized by being prepared from the following raw materials in parts by weight: 0.3-0.6 part of a defoamer BYK-354, 0.2-0.4 part of polyester modified polydimethylsiloxane, 20-30 parts of epoxy resin, 7-9 parts of locked polyurethane, 0.1-0.3 part of blocked p-toluenesulfonic acid, 2-3 parts of micro-powder wax, 0.2-0.4 part of a dispersant EFKA015, 30-40 parts of linear-chain polyester resin, 4-6 parts of heavy calcium carbonate powder, 3-4 parts of antimonous oxide, 5-7 parts of fine stone powder, 8-10 parts of neoprene latex, 3-5 parts of silicon oxide, 2-3 parts of aluminum triphosphate, 0.5-1.0 part of phenyltrimethoxysilane, 4-6 parts of calcium carbonate whisker powder, 3-4 parts of polyisocyanate, 5-7 parts of root-resistant auxiliary, 4-6 parts of methyl isobutyl ketone, 5-7 parts of ethylene glycol butyl ether and 8-11 parts of S-1508. The epoxy polyurethane root-resistant waterproof coating has excellent adhesive force, wear resistance, weather fastness, corrosion resistance and the like; the added root-resistant auxiliary has an obvious root resisting effect and is unharmful to the plant root systems and excellent in compatibility with a resin; the epoxy polyurethane root-resistant waterproof coating is simple to prepare, high in adaptability and worthy of popularization.

Owner:ANHUI LENCAQI BUILDING MATERIAL

Preparation and application methods of antirust and antibacterial aluminum triphosphate pigment

InactiveCN107603312AReduce performanceLow water resistanceAntifouling/underwater paintsPaints with biocidesPolyesterALUMINUM PHOSPHATE

The invention provides antirust and antibacterial aluminum triphosphate pigment and a preparation method thereof. The preparation method comprises the following steps: (1) preparing aluminum triphosphate sol; (2) preparing aluminum triphosphate powder from the sol; (3) activating the aluminum triphosphate powder with sodium hydroxide; (4) loading silver ions; (5) performing surface treatment of the antirust and antibacterial aluminum triphosphate with a silane coupling agent. The pigment can be applied to ultraviolet curing coating; the formula of the coating comprises the following components: 4-10% of epoxy acrylate, 15-25% of polyester acrylate, 15-27% of monofunctional (methyl) acrylate, 25-35% of bifunctional (methyl) acrylate, 5-15% of trifunctional (methyl) acrylate, 3-7% of adhesion promoter, 4-15% of modified aluminum phosphate, 0.5-2.5% of antirust and antibacterial aluminum triphosphate, 0.5-1.5% of triethanolamine, 1-3% of diphenylketone and 3-6% of photoinitiator.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

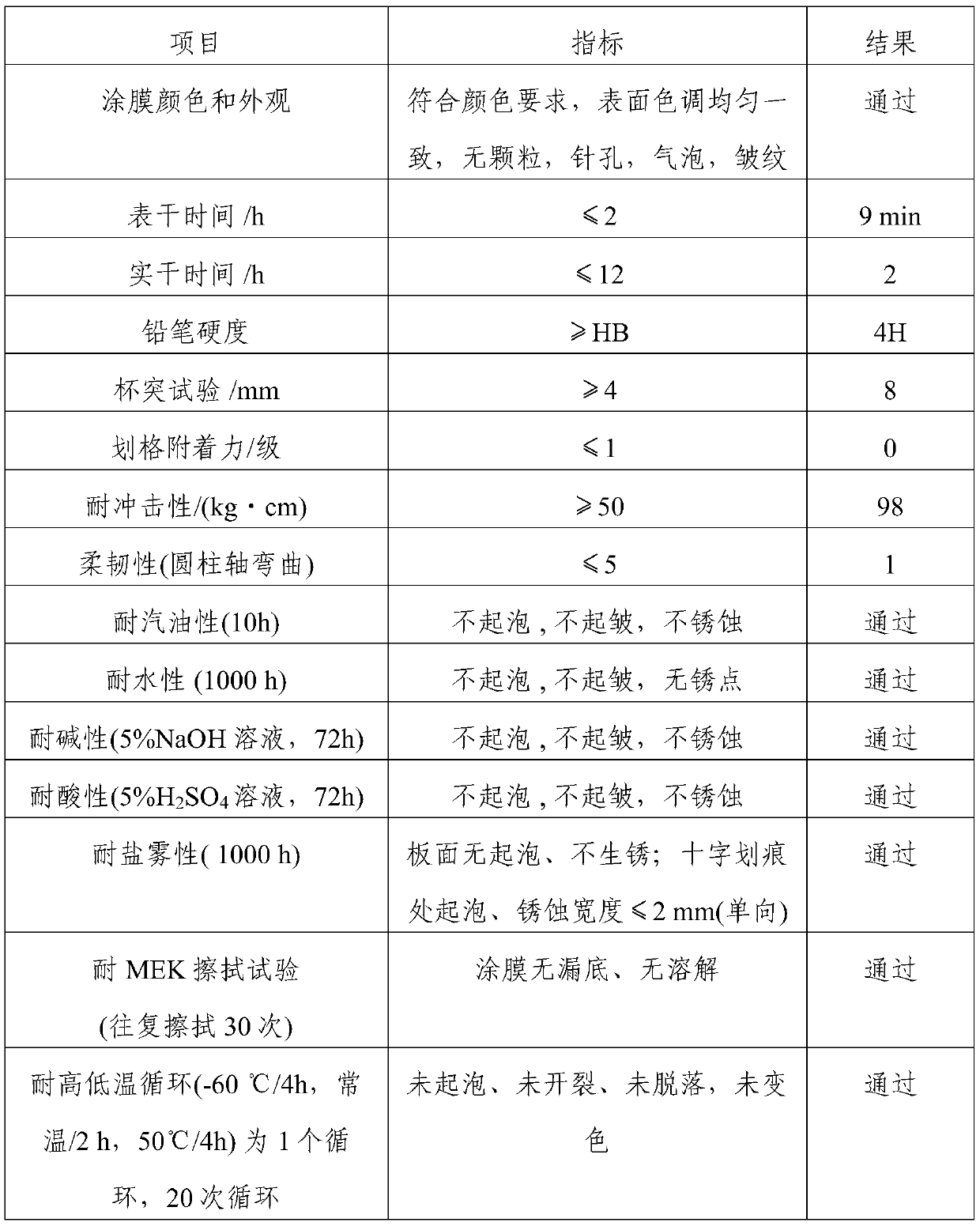

Waterborne over-rust coating for steel and preparation method thereof

InactiveCN105925092AThe appearance of the coating film is uniform, flat and brightDurable coating appearanceAnti-corrosive paintsVinyl etherEthyleneglycol monobutyl ether

The invention discloses a waterborne over-rust coating for steel and a preparation method thereof. The preparation method comprises the following steps: weighing acrylic resin, gallic acid, tannic acid, 2-(2-ethoxyethoxy)ethyl acetate, dioctyl phthalate, aluminum dihydrogen tripolyphosphate, zinc yellow, sodium carboxymethyl cellulose, ammonium citrate, ethylene glycol monobutylether, potassium hexacyanoferrate, sodium tetraborate, cetyl vinyl ether and potassium polyoxyethylene laurylether phosphate; stirring the raw materials and grinding, wherein the appearance of a costing film is uniform, flat and bright and the coating film is durable and has good resistance; carrying out surface drying for 5min to 25min and carrying out complete drying for 20h to 24h, wherein the viscosity is 40s to 60s, the flexibility is 0.5mm to 0.9mm, the adhesive force is grade 1 to grade 2 and the moisture resistance and the salt fog resistance are good; immersing into water at 30 DEG C to 40 DEG C for 5d to 9d, wherein the coating film has no bubbles and is not released and the impact resistance strength is 50cmkN / cm to 70cmkN / cm, the coating is used for protecting the surface of metal steel, the solid content is 45 percent to 55 percent and the hardness is 0.6 to 1.

Owner:WUXI EPIC TECH

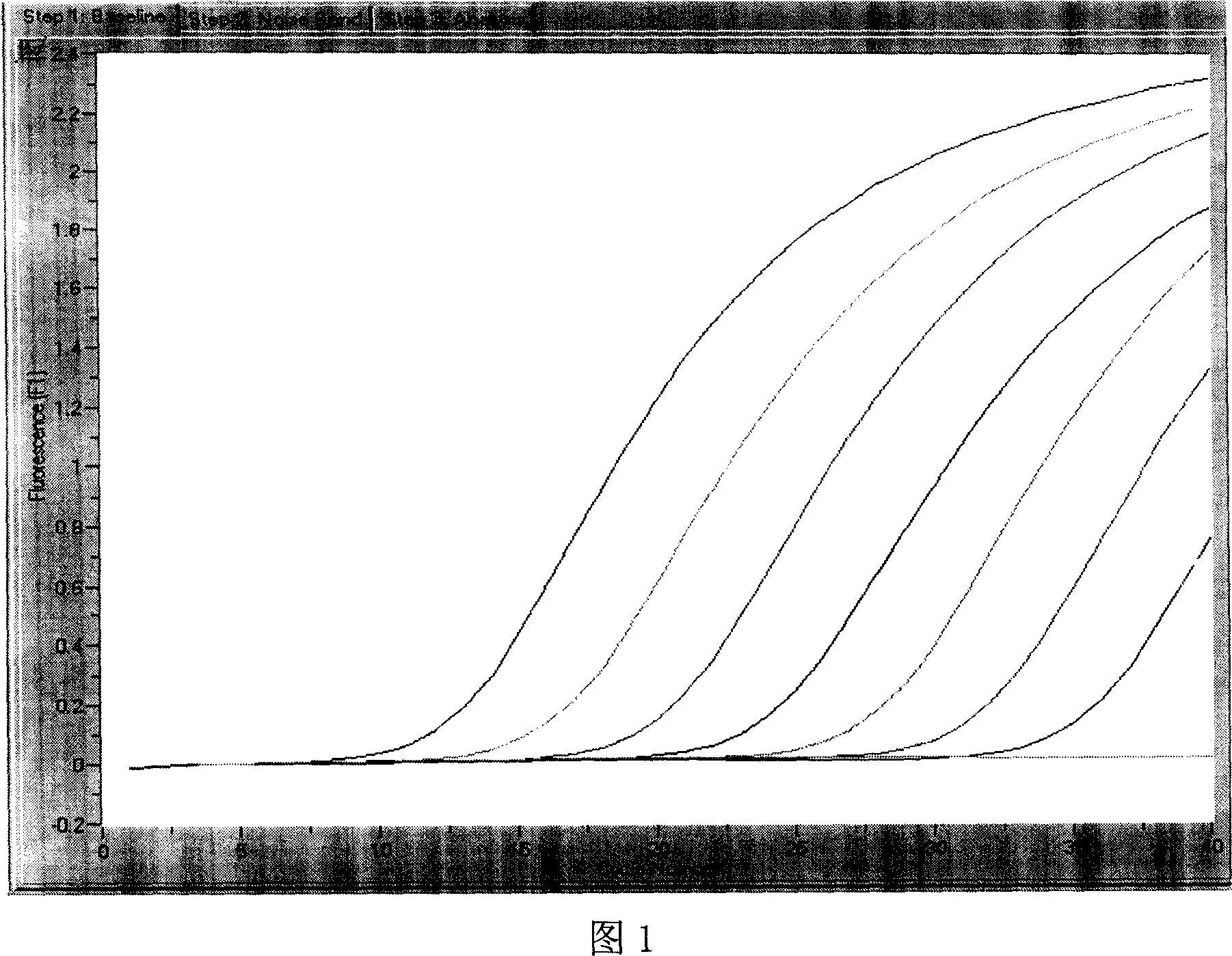

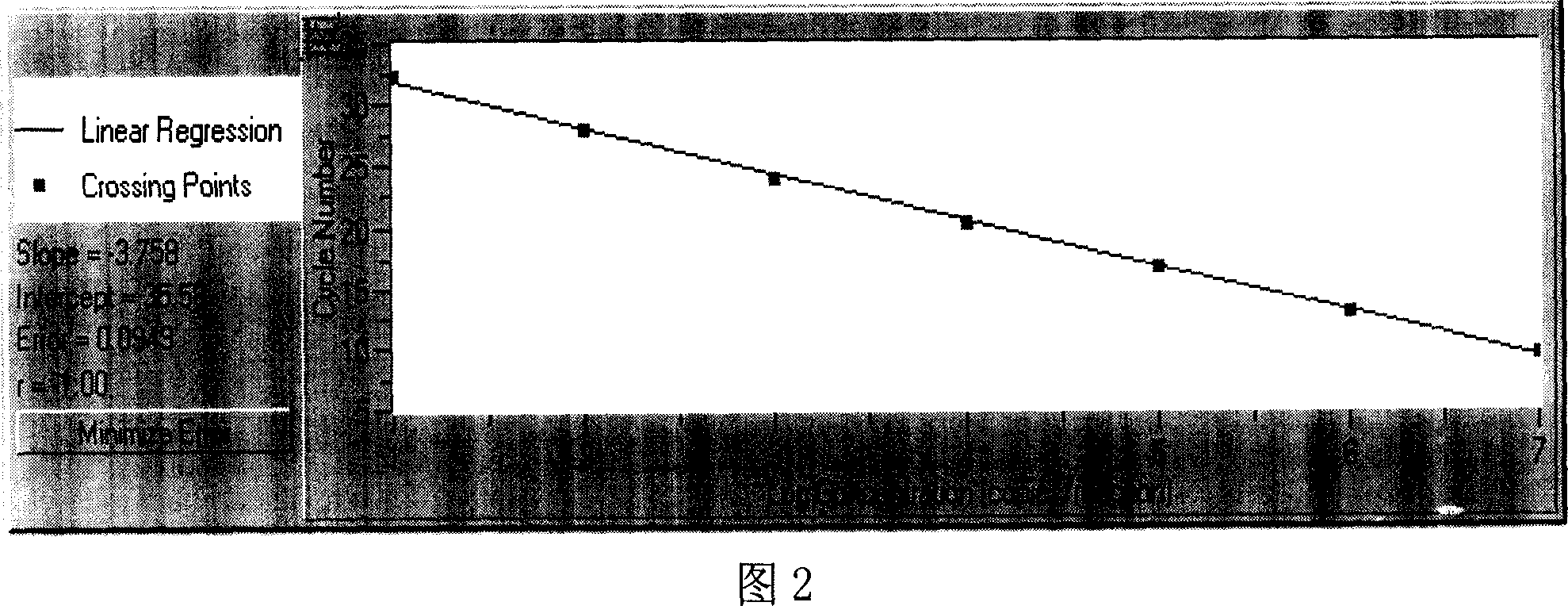

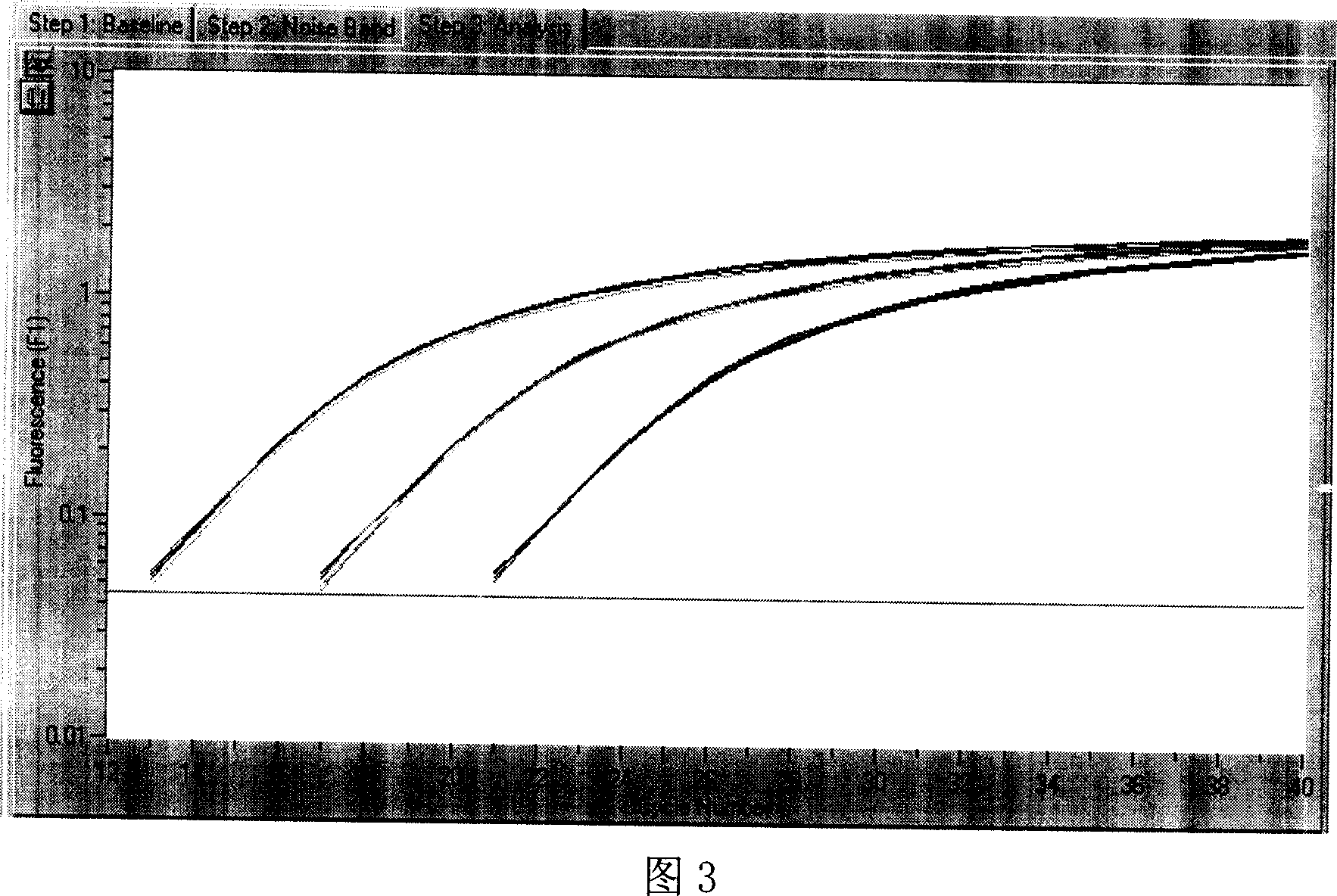

Parotiditis virus fluorencent amplification detection reagent box and detection method

InactiveCN1948507AImprove isolationEasy diagnosisMicrobiological testing/measurementFluorescence/phosphorescenceDiseaseHemagglutinin

The invention offers detecting reagent boxes for fluorescent augment of mumps virus, which include hemagglutinin gene standards of mumps virus, detecting reagent of fluorescent augment, DNA polymerase and reverse transcriptase. The detecting reagent of fluorescent augment mainly contains buffer solution of one-step RT-PCR, specificity exciters and probes, mixture of deoxidizing triphosphoric acid and nucleoside. The partial sequence of hemagglutinin gene standards of mumps virus is 5'- CTCAAGGACTGTTTGCCTCTTACACCACAACCACCTGCTTTCAAGATACCGGTGATGCTAGTG-3'. The specificity exciters have two sequences: the sequence of upstream exciters is 5'-CTCAAGGACTRTYTGCYTCSTA-3'and the sequence of downstream exciters is 5'-CTCTRGCAT CACCGGTATCTTGAA-3'. The equence of specificity probes is 5'-FAM-ACCACAACCACCTGC-NFQ-MGB-3', in which FAM is reporting fluorescent metakliny, NFQ is non-fluorescent annihilation metakliny, MGB is modifying metakliny. The detecting reagent boxes can detect pathogen nucleic acid directly. At the early stage of mumps disease, specificity gene of mumps virus can be detected, which facilitates early isolation, diagnosis and therapy.

Owner:ZHEJIANG CENT FOR DISEASE CONTROL & PREVENTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com