Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

238 results about "Chrome yellow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chrome yellow is lead(II) chromate (PbCrO₄). It occurs naturally as the mineral crocoite but the mineral ore was never used as a pigment for paint. After the French chemist Louis Vauquelin discovered the new element chromium in 1797 lead chromate was synthesized in the laboratory and used as a pigment beginning in the second decade of the nineteenth century.

High weather-resistant hot melting reflection type pavement marking paint

InactiveCN106883721AImprove crack resistanceResistant to large temperature difference between day and nightReflecting/signal paintsGlass ballCrack resistance

A hot-melt reflective pavement marking paint with high weather resistance, which is composed of thermoplastic resin, filler, reflective material, pigment and additives, wherein: Among them: thermoplastic resin is C 5 Petroleum resin; the filler is quartz sand and calcium carbonate powder with different particle size distribution; the reflective material is glass beads; the pigment is titanium dioxide or medium chrome yellow; the auxiliary agent is plasticizer, ultraviolet absorber, dispersant, thixotropic agent constitute, of which: The beneficial effect of the invention is that it is suitable for use in high-altitude areas, is resistant to large temperature differences between day and night, has strong anti-ultraviolet rays, and significantly improves the performance of anti-aging and anti-cracking of road marking coatings.

Owner:云南建投建材科技有限责任公司 +1

Aluminum-alloy anticorrosion coating and preparing method and application thereof

ActiveCN106280908AEasy to manufactureLow costAnti-corrosive paintsEpoxy resin coatingsEpoxyZinc phosphate

The invention discloses an aluminum-alloy anticorrosion coating and a preparing method and application thereof. The aluminum-alloy anticorrosion coating is mainly prepared from epoxy resin, titanium dioxide, talcum powder, strontium chrome yellow, tribasic zinc phosphate, graphene, a dispersing agent, an organic solvent, a flatting agent, an anti-settling agent, an epoxy hardener and the like. The aluminum-alloy anticorrosion coating is easy to prepare and low in cost, the adhesive force of a formed coating (a paint film) and aluminum alloy and magnesium alloy base materials is good, the flexibility is good, the comprehensive anticorrosion performance is excellent, and the aluminum-alloy anticorrosion coating has broad application prospects in the field of anticorrosion of aluminum alloy products and magnesium alloy products.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Anticorrosive environment-friendly spray paint formula

InactiveCN105199580ABright colorGood light fastnessAnti-corrosive paintsPolyurea/polyurethane coatingsDiacetone alcoholChemical industry

The invention discloses an anticorrosive environment-friendly spray paint formula, and relates to the field of chemical industries. The anticorrosive environment-friendly spray paint formula comprises the following components in parts by weight: 28 to 35 parts of glacial acetic acid, 3 to 7 parts of organic fluorine epoxy resin, 7 to 12 parts of epoxy modified organic silicon resin, 2 to 6 parts of glycol monomethyl ether, 6 to 9 parts of dimethyl sulfoxide, 8 to 13 parts of zinc phosphate, 8 to 13 parts of barium chromate, 1 to 4 parts of ethanol, 2 to 7 parts of polyacrylate, 1 to 4 parts of alcohol soluble resin, 7 to 13 parts of diacetone alcohol, 6 to 9 parts of zinc oxide, 8 to 13 parts of toluene diisocynate, 3 to 7 parts of n-butyl acetate, 12 to 16 parts of benzophenone, 9 to 13 parts of triethanolamine and 3 to 7 parts of diphenyl polysiloxane. The paint is bright in color and good in air-curing resisting effect, can substitute medium chrome yellow in inorganic pigment, is applicable to the outer wall paint, and has no harm of heavy metals, no harmful substances, good environment protection effect, little odor, no peculiar smell after being smeared on the wall, good mechanical performance, excellent electric insulation performance, dampness and water resistance, rust and cold resistance and ozone aging resistance.

Owner:王海平

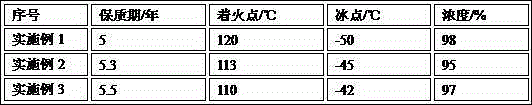

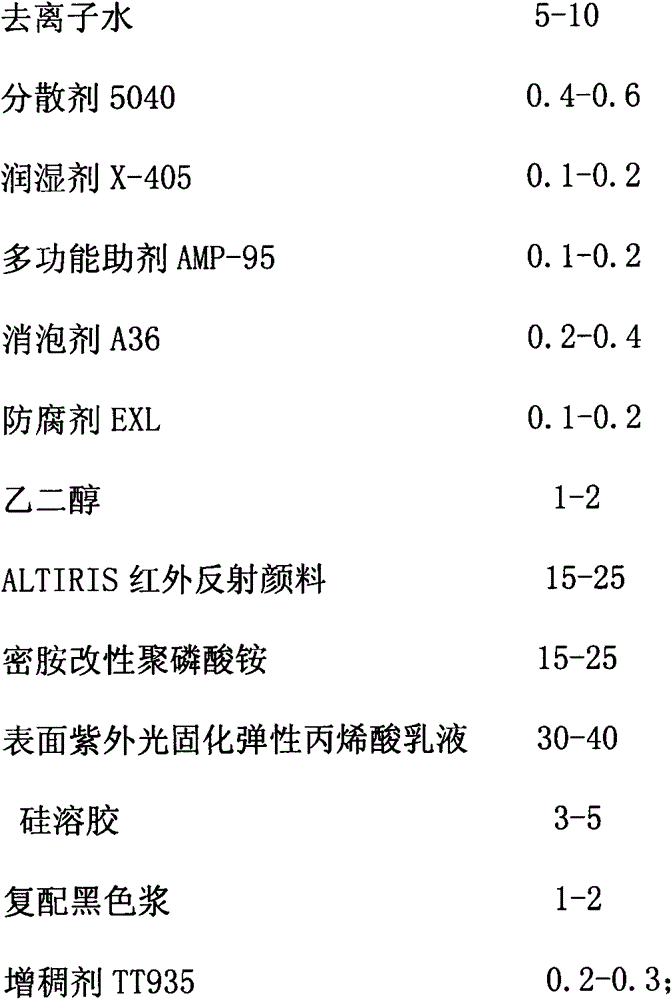

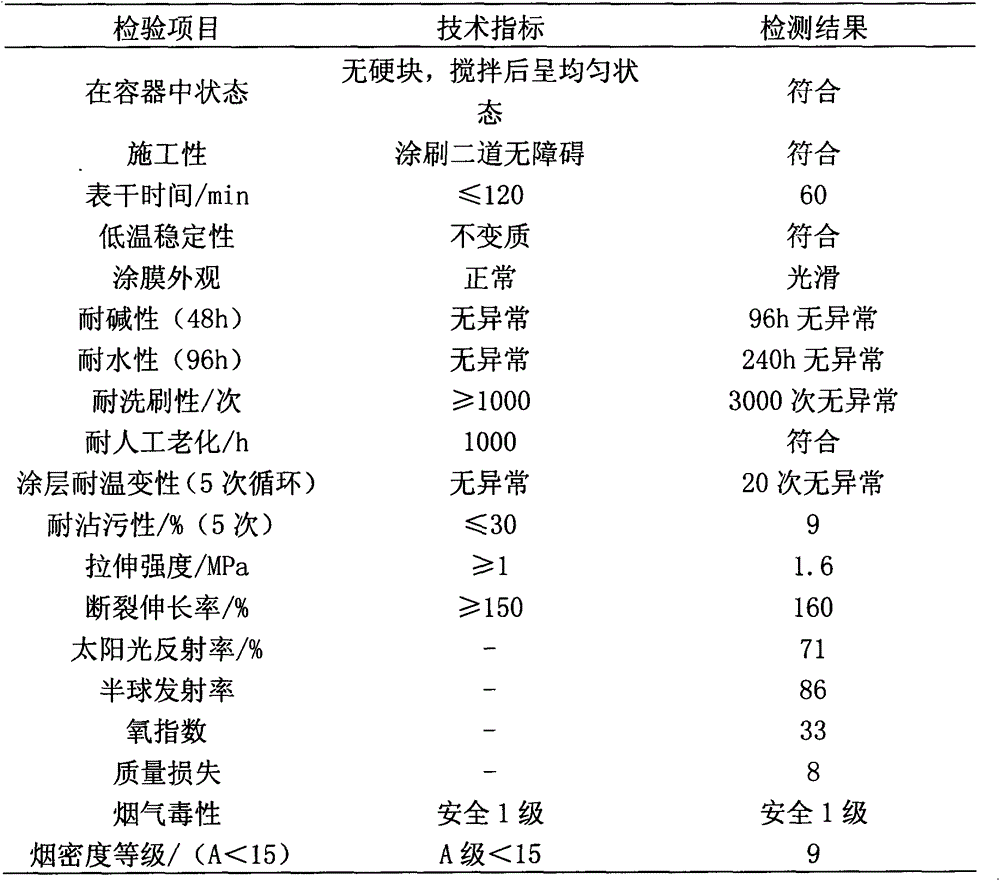

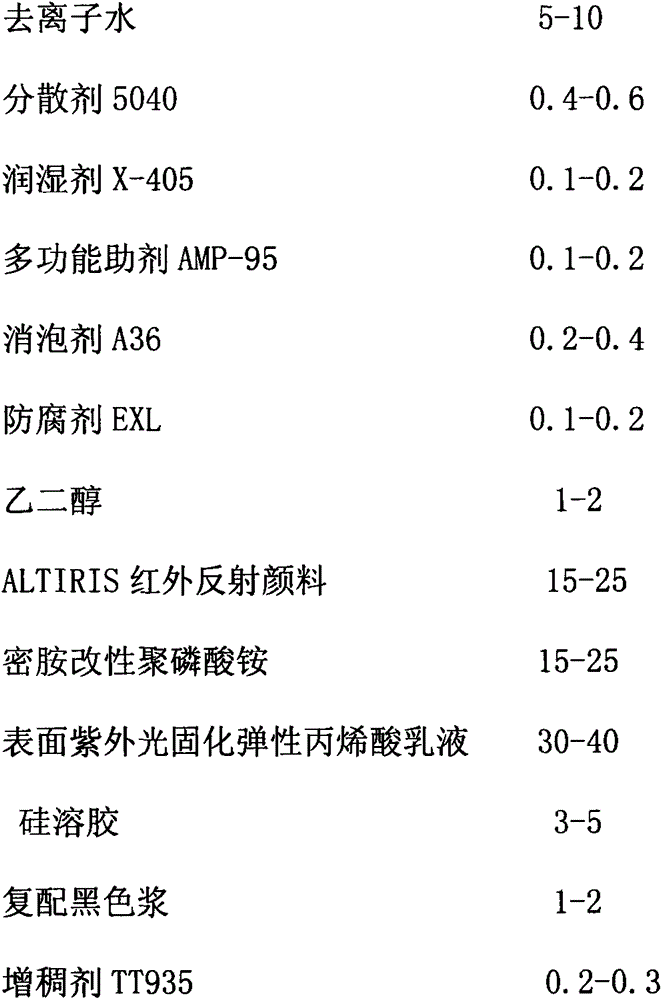

Grey heat-insulation flame-retardant external wall paint

InactiveCN103146275AElastic and crack-resistantWith fire performanceFireproof paintsReflecting/signal paintsPolymer scienceCrack resistance

The invention discloses a grey heat-insulation flame-retardant external wall paint. A surface ultraviolet-curing elastic acrylic emulsion and modified silica sol are compounded to obtain a film forming material, an ALTIRIS infrared reflection pigment is used as a white pigment, a compound black color paste is used as a coloring pigment, and melamine-modified ammonium polyphosphate is used as a flame retardant; and under the cooperation of deionized water and multiple assistants, dispersion, grinding, blending, and color matching are carried out to prepare the grey heat-insulation flame-retardant external wall paint. The compound black color paste is prepared by the following steps: compounding iron oxide red, titanium-chrome yellow and phthalocyanine blue into a black pigment, mixing with a proper amount of deionized water, dispersing agent, wetting agent and defoaming agent, dispersing and grinding. The invention has the characteristics of grey color, high solar reflection factor, cracking resistance due to high elasticity, heat insulation and control, flame retardancy and fire resistance, is suitable to be sprayed as a veneer paint for EPS, XPS and polyurethane hard foamed external wall external-thermal-insulation systems, and has wide popularization prospects.

Owner:BEIJING GUOTAI RUIHUA DIATOMS APPL TECH

High temp resistant electrostatic powdered paint and prodn. technique

This invention discloses a method for manufacturing a high temperature-resisting electrostatic powder coating, which is composed of organic silicon polyester resin 20-40 wt.%, epoxy resin 20-40 wt.%, specialty curing agent 1-5 wt.%, leveling agent 0.7-1.5 wt.%, titanium dioxide powders 0-25 wt.%, barium sulfate 0-25 wt.%, high temperature-resisting pigments (carbon black, chrome yellow, etc.) 0.1-2 wt.% and benzoin 0.2-0.8 wt.%. The powder coating is manufactured by: mixing the raw materials in a mixer, smelting in an extruder at 100-130 deg.C for 20-70 s, extruding, cooling the extruded sheets, pulverizing and grinding in a pulverizer to obtain high temperature-resisting electrostatic powder coating of 100-350 mesh. After curing of the coating, the coated surface can stand baking at 230-300 deg.C while still retains the previous appearance and physical and chemical properties. The coating can elongate the service life of the coated materials.

Owner:嘉兴维恩科技股份有限公司

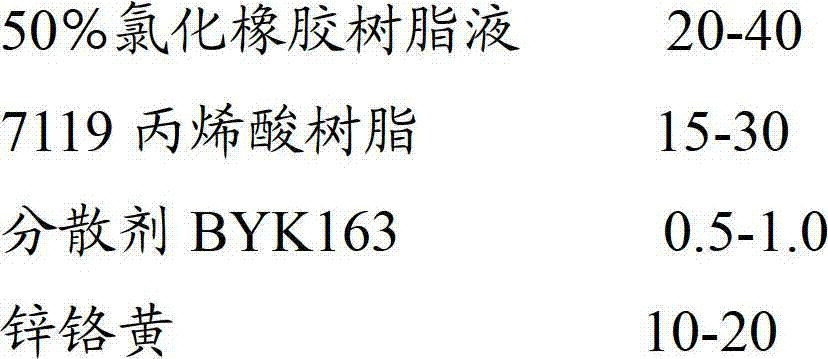

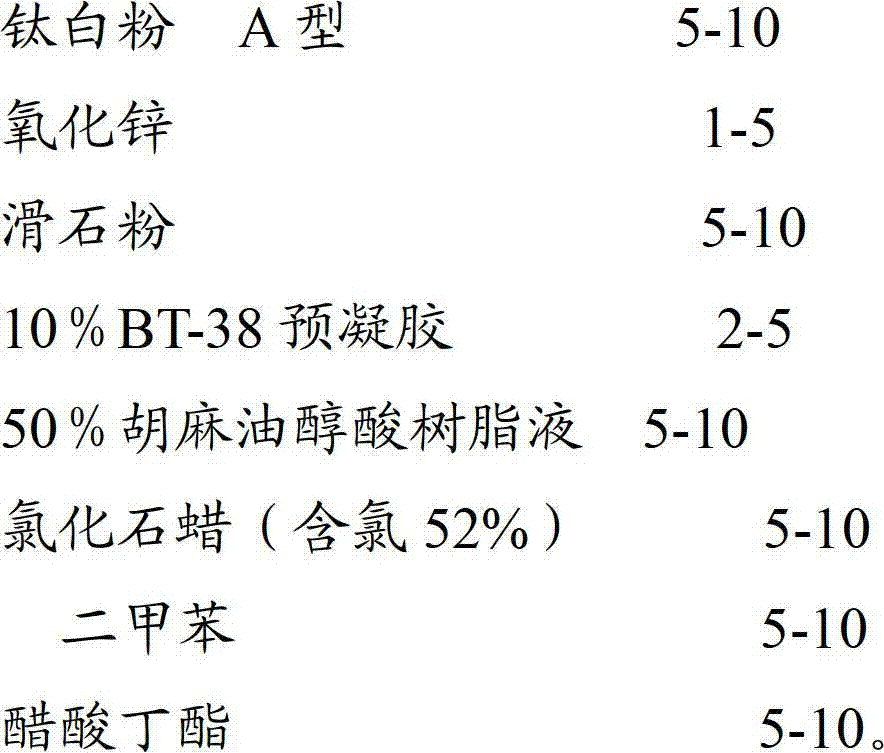

Seawater-resistant anticorrosive paint and preparation method of seawater-resistant anticorrosive paint

ActiveCN102786850AStrong adhesionExcellent adhesion and seawater resistance (the paint film has no abnormality after soaking in synthetic seawater for 100 daysRubber derivative coatingsAnti-corrosive paintsAcrylic resinChlorinated paraffins

The invention relates to a seawater-resistant anticorrosive paint, which comprises components in parts by weight as follows: 20-40 parts of 50% chlorinated rubber resin solution, 15-30 parts of 7119 acrylic resin, 0.5-1.0 part of dispersant BYK163, 10-20 parts of zinc chrome, 5-10 parts of A-type titanium dioxide, 1-5 parts of zinc oxide, 5-10 parts of talcum powder, 2-5 parts of 10% BT-38 pregel, 5-10 parts of 50% linseed alkyd resin solution, 5-10 parts of chlorinated paraffin (containing 52% of chlorine), 5-10 parts of dimethylbenzene, and 5-10 parts of butyl acetate. A preparation method of the seawater-resistant anticorrosive paint comprises the steps of preparing the chlorinated rubber resin solution, preparing the pregel, mixing and stirring. The seawater-resistant anticorrosive paint has the beneficial effects that the 50% linseed alkyd resin solution toughens and modifies the chlorinated rubber resin and the acrylic resin to endow excellent resistance against seawater, salt water, salt mist, oil, abrasion and chemicals.

Owner:天津灯塔涂料工业发展有限公司

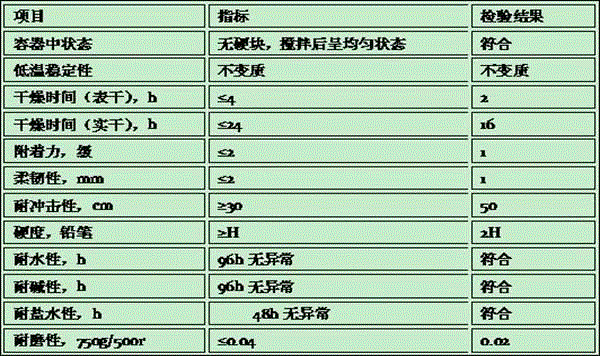

Epoxy organosilicon anticorrosion paint and preparing method thereof

InactiveCN101033370AImprove basic physical propertiesImprove corrosion resistanceAnti-corrosive paintsPolyamide coatingsTalcPhysical property

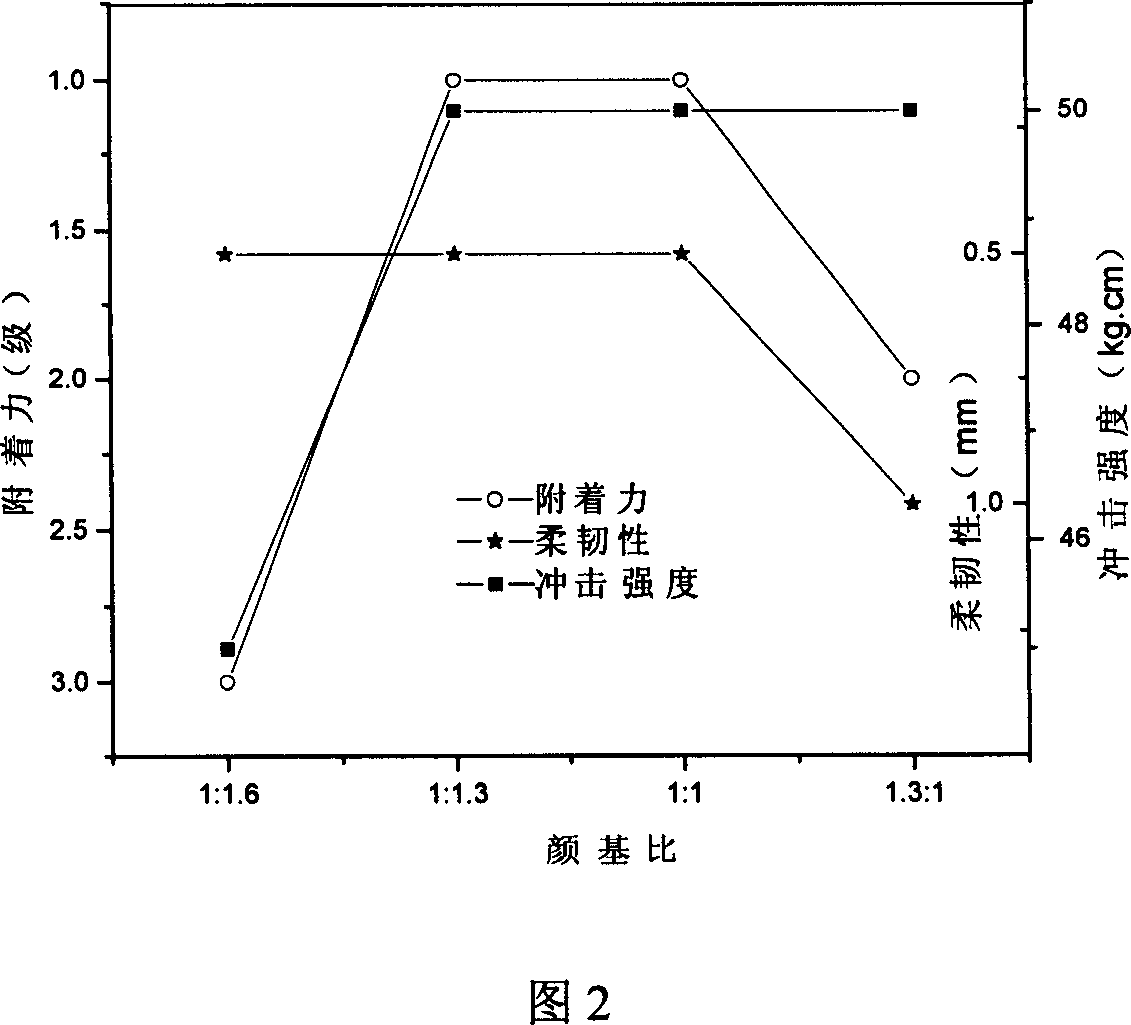

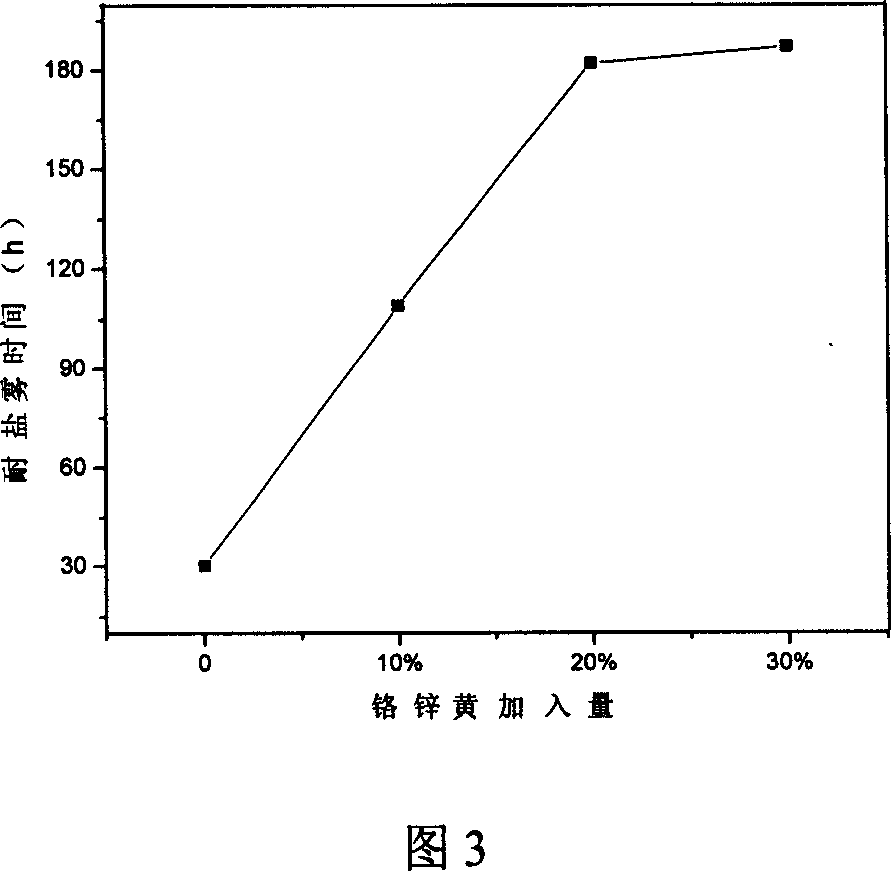

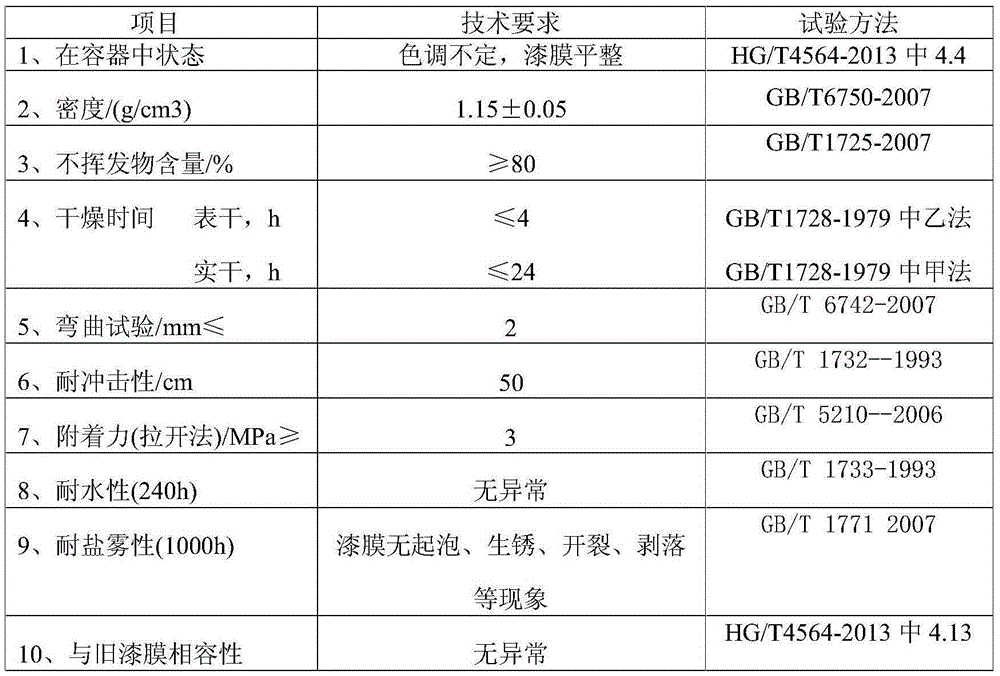

The invention relates to a kind of anti-corrosion epoxy-silicone resin coating and its preparation. In the invention, it takes the anti-corrosion epoxy-silicone resin ES-06 as material for the film, and polyamide 650 as curing agent, and it also includes anti-rust paint chrome yellow zinc, chromium and molybdenum acid strontium zinc, titanium dioxide pigments physique, mica, talc, defoamer 550, dispersant TM-950 and the solvent system of xylene and n-butyl alcohol. The advantage of the matiral is that the coating can be cured at room temperature, meanwhile, it has the properties such as the maximum adhesion of one class, a flexible of 0.5mm, a impact strength of 50kg.cm, a salt spray cumulative maximum time a 360 hours, and the coating has a good basic physical property and excellent corrosion resistance.

Owner:COSCO KANSAI PAINT & CHEM TIANJIN

FBE pnenolic aldehyde modified epoxy powder coating and its preparation method

InactiveCN1733853ASimple construction processIncrease crosslink densityPowdery paintsEpoxy resin coatingsEpoxyPhthalocyanine

The FBE phenolic modified epoxy powder comprises, 25~50% phenolic modified epoxy resin, 0~25% E-12 epoxy resin, 10~15% curing agent, 0.5~2.0% levelling agent, 0.2~0.3% degasifier, 0.02~0.05% curing accelerant, 0.5% chrome yellow, 0.05% phthalocyanine, 2.5% phthalocyanine, and 25~30% deposited barium sulfate. Wherein, mixing rapidly the resins, curing agent, and levelling agent for 1~2min; adding others to mix for 3~5min; fusion extruding the mixed material; tabletting the fused material; cooling to smash in frain mill and classify; separating fine powder by cyclone, and sieving the powder to obtain product.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Epoxy primer realizing rusty construction and preparation method of epoxy primer

InactiveCN105273571AWell mixedImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsCyclohexanoneWax

The invention discloses epoxy primer realizing rusty construction. The epoxy primer comprises a component A and a component B and is characterized in that the component A is prepared from ingredients in parts by weight as follows: 17.6-26.4 parts of E51 epoxy resin, 24-36 parts of 60% 601 epoxy resin, 5.6-8.4 parts of a Lite-2020 resin modifier, 2.4-3.6 parts of an epoxy based reactive diluent, 0.4-0.6 parts of polyamide wax, 0.4-0.6 parts of a dispersing agent, 8-12 parts of a pigment, 3.2-4.8 parts of tetrabasic zinc chrome yellow, 4.8-7.2 parts of zinc phosphate, 4.8-7.2 parts of aluminum triphosphate, 5.6-8.4 parts of cyclohexanone, 2.6-4.0 parts of mixed butanol, 0.4-0.6 parts of a KBM403 silane coupling agent and 0.16-0.24 parts of a leveling agent; the component B is an amine curing agent; a weight ratio of the component A to the component B is 5:1. The invention further discloses a preparation method of the epoxy primer. The surface in a non-ideal state can be directly coated with the epoxy primer; according to the epoxy primer, the limitation that common paint requires higher derusting grade is overcome, rusty coating can be realized, the coating process is simplified, and the epoxy primer can be matched with various kinds of finish paint; the epoxy primer is suitable for bottom coating of large steel products such as a bridge, a ship, a derrick, a storage tank, a pipeline and the like.

Owner:重庆南方漆业有限公司

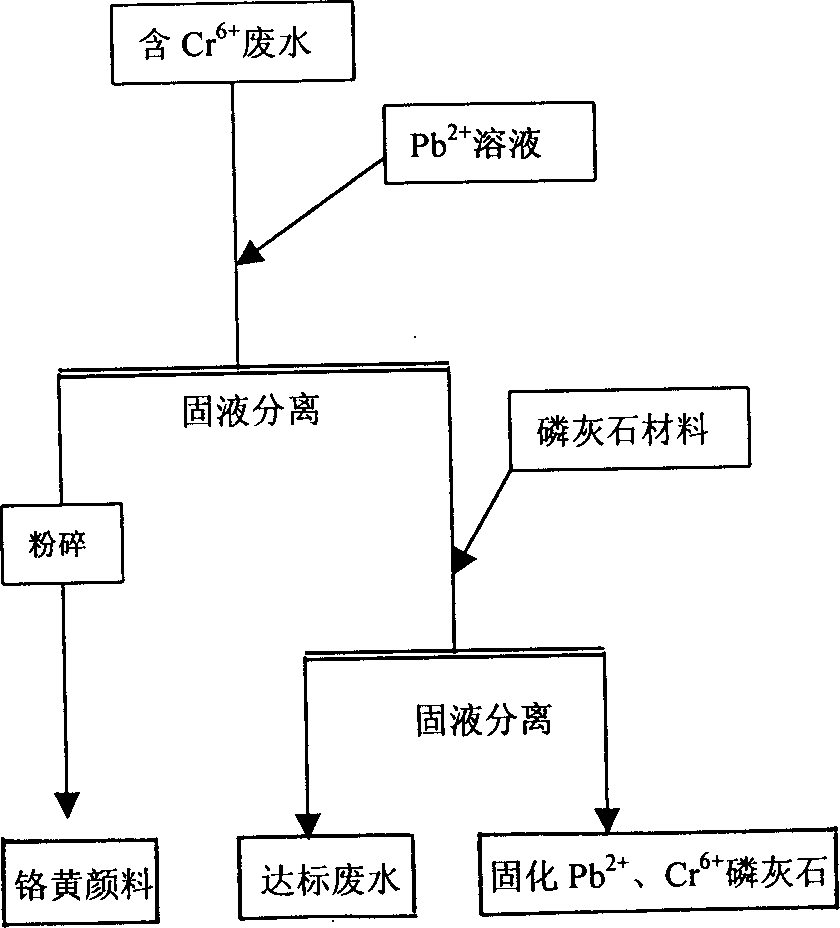

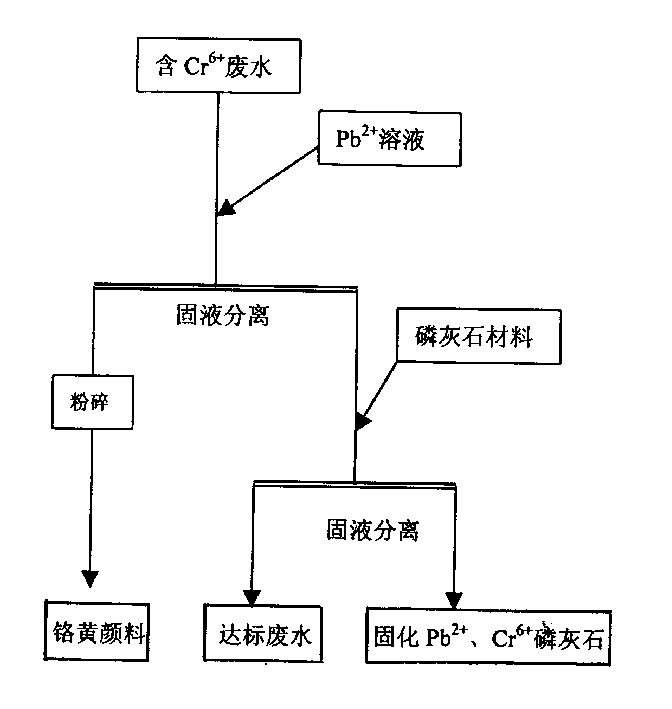

Process for recovering chrome yellow from chrome containing sewage

InactiveCN1373094AAvoid secondary pollutionOptimal treatment processPigmenting treatmentChromates/bichromatesWastewaterSewage

A process for recovering chrome yellow from the Cr-containing waste water and removing metallic ions includes adding the solution containing Pb (2+) ions to said waste water to generate PbCrO4 precipitate and reduce the Cr (6+) concentration to lower than 0.5 mg / L, solid-liquid separation, drying the solid, cooling, pulverizing to obtain chrome yellow powder, adding francolite to the liquid to adsorb Cr (6+) and Pb (2+) ions, solid-liquid separation, and draining the liquid.

Owner:WUHAN CHEM COLLEGE

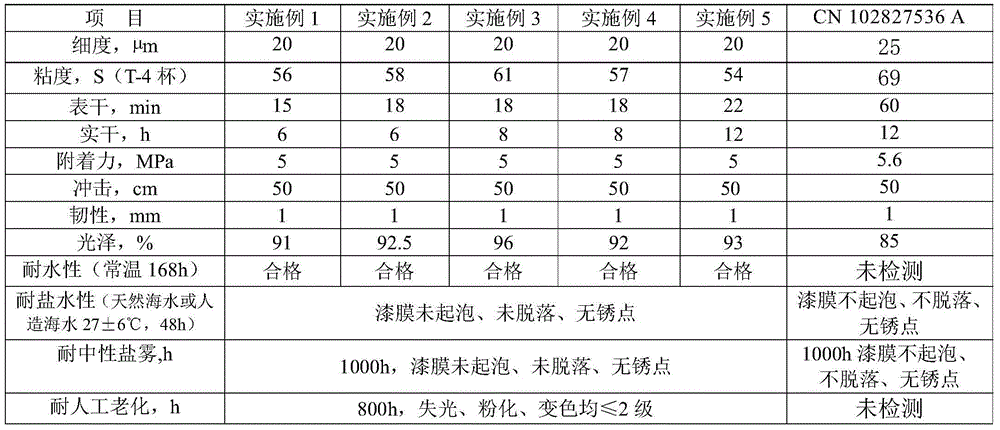

Novel water-based epoxy floor paint and preparation technique thereof

InactiveCN106675314AHigh hardnessImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsWater basedBound property

The invention relates to a novel water-based epoxy floor paint and a preparation technique thereof. The invention is characterized in that the novel water-based epoxy floor paint is composed of a component A and a component B. The component A is prepared from the following raw materials in parts by mass: 80 parts of water-based epoxy resin and 20 parts of reactive diluent. The component B is prepared from the following raw materials in parts by mass: 20-25 parts of water-based epoxy curing agent, 25-35 parts of deionized water, 0.2-0.6 part of RS610 wetting and dispersing agent, 0.3-0.5 part of DF681F defoaming agent, 0.5-1 part of scratch-resistant aid, 0.2-0.4 part of A401 alkali swelling thickener, 4-6 parts of titanium white, 2-3 parts of BGS phthalocyanine blue, 1-1.5 parts of 801 strontium chrome yellow, 10-15 parts of light calcium carbonate, 20-25 parts of precipitated barium sulfate and 10-15 parts of ultrafine talcum powder. By using water as the dispersion medium, the floor paint is free of volatile organic solvents (such as methylbenzene and xylene), so that abundant resources are saved, the fire hazard during construction is eliminated, the atmosphere pollution is lowered, and the working environment conditions are improved; and the coating has high adhesion and high binding property for most substrates.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

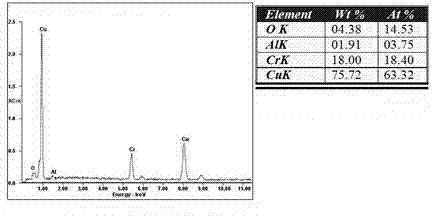

Preparation method of copper-chrome alloy

Owner:SHENZHEN YUANSIDACHENG TECH

Polyvinyl chloride (PVC) hard modified plastic

InactiveCN103265777AImprove mechanical propertiesImprove impact resistanceParaffin waxPolymer science

The invention discloses a polyvinyl chloride (PVC) hard modified plastic which is characterized in that a general PVC plastic raw material, a stabilizer, a lubricant, a coloring agent and a filler are mixed and granulated, wherein the stabilizer is tribasic lead sulfate, dibasic lead phosphite, barium stearate or cadmium stearate; the lubricant is stearic acid, paraffin or mineral oil; the coloring agent includes rutile type titanium dioxide, chrome yellow and channel black; and the filler includes calcium carbonate, argil and glass fiber. Through the way, the PVC hard modified plastic disclosed by the invention has better mechanical properties and good heat resistance, resists impact and aging, and is particularly suitable for the buildings such as doors / windows, pipelines, plates and the like and the related industries.

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

Coating for outer walls and preparation method thereof

The invention relates to a coating for outer walls and a preparation method thereof. The coating contains following components in parts by weight: 60 to 90 parts of acrylic acid ester emulsion, 25 to 40 parts of silica sol, 12 to 20 parts of pearl essence, 0.3 to 1 part of light chrome yellow, 25 to 45 parts of ash calcium powder, 20 to 40 parts of powdered steatile, 2 to 5 parts of hectorite, 1.3 to 3.2 parts of clay, 1.5 to 4 parts of aluminum sulfate, 0.6 to 1.5 parts of antifoaming agent, 4.5 to 12 parts of Texanol alcohol ester, 0.1 to 0.7 part of cuprous oxide and 50 to 85 parts of water. The coating for outer walls has the functions of water resistance, acid resistance, alkali resistance, freezing and thawing resistance, pollution and dust resistance, aging resistance and fire resistance, and also has the effects of mildew resistance and sterilization.

Owner:WUJIANG WUHUA HARDWARE PROD

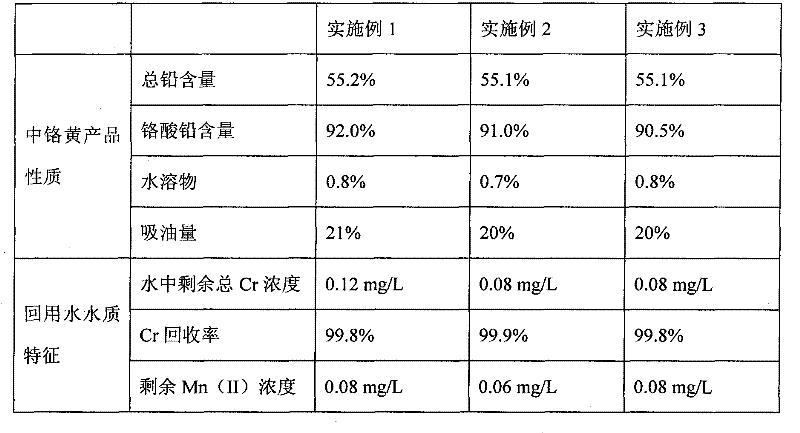

Method for recycling chromium from chromium passivation wastewater of electrolytic manganese factory

ActiveCN102249443ALow costAvoid pollutionWater contaminantsMultistage water/sewage treatmentElectrolysisSludge

The invention discloses a method for recycling chromium from chromium passivation wastewater of an electrolytic manganese factory. The method is characterized by comprising the following steps of: adding hydrogen peroxide into the chromium passivation wastewater, oxidizing Cr(III) into Cr(VI), adding sodium hydroxide into liquid to remove impurities, such as Mn and other metal ions, adjusting pH and adding Pb<2+>, washing the obtained precipitate part by using water, drying and preparing powder to obtain chrome yellow, adjusting pH of supernate, adding aluminum sulfate, stirring, reacting andperforming solid-liquid separation, wherein the obtained supernate is used for washing the negative plate of the discharged manganese of the electrolytic manganese factory. By the method, the chromium recycling rate is over 99 percent, the impurities, such as manganese and other metal ions are removed, purity of chrome yellow in the product and the product quality are improved, the chromium content in sludge is reduced through recycling and recovering of chromium in wastewater, the sludge does not belong to risky solid wastes, the wastewater can be used for washing the negative plate of the discharged manganese of the electrolytic manganese factory, the policy of energy conservation and emission reduction, recycling of resource, and cyclic utilization is met, and economic benefit is brought to relative industry.

Owner:DAXIN MANGANESE MINE BRANCH OF CITIC DAMENG MINING IND +1

Single-component primer-topcoat paint commonly used on stainless steel, galvanized sheet and aluminum alloy and preparation method of single-component primer-topcoat paint commonly used on stainless steel, galvanized sheet and aluminum alloy

The invention discloses a single-component primer-topcoat paint commonly used on stainless steel, a galvanized sheet and an aluminum alloy, and a preparation method for the single-component primer-topcoat paint commonly used on the stainless steel, the galvanized sheet and the aluminum alloy. The single-component primer-topcoat paint commonly used on the stainless steel, the galvanized sheet and the aluminum alloy is prepared from the following components: epoxy modified acrylate resin, dimethylbenzene, butyl acetate, a flatting agent, a defoaming agent, an adhesion promoter, chlorinated paraffin, precipitated barium sulfate, rutile type titanium dioxide, carbon black powder, medium chrome yellow powder and polyamide wax. The paint prepared by the preparation method disclosed by the invention can meet the needs of a stainless steel substrate, a galvanized sheet bottom substrate and an aluminum alloy substrate, and really achieves multiple purposes. Meanwhile, the prepared paint is convenient to construct, stable in performance and great in quantity demand. As primer, the single-component primer-topcoat paint is excellent in adhesion with the three substrates, can be coated with polyurethane acrylate finish, fluorocarbon finish, and the like, and is good in covering power while being used as finish, and excellent in weather resistance.

Owner:WUXI HUHUANG PAINT

Waterborne undercoat-topcoat integrated paint applied to type-25 passenger trains

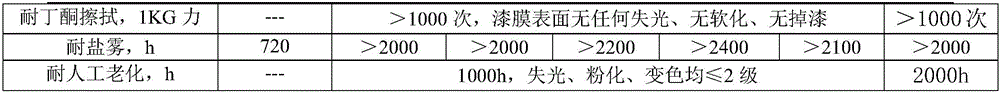

The invention provides a waterborne undercoat-topcoat integrated paint applied to type-25 passenger trains. The paint comprises a component A and a component B; the component A is prepared from waterborne hydroxy acrylic resin emulsion, waterborne organic silicon modified epoxy resin emulsion, waterborne chlorinated polypropylene emulsion, rutile titanium dioxide, phthalocyanine green, phthalocyanine blue, medium chrome yellow, carbon black, nano barium sulfate, surface treatment silicon powder, waterborne zinc phosphate, a waterborne dispersing agent, a waterborne foam inhibitor, a waterborne defoaming agent, a waterborne leveling agent, a surfactant, a neutralizing agent, a waterborne ultraviolet absorbing agent, waterborne polyamide wax slurry, a mould-proof bactericide, deionized water and a solubilizer; the component B is a hydrophilic isocyanate curing agent. The waterborne undercoat-topcoat integrated paint is high in drying speed, hardness and sagging resistance and excellent in chemical resistance, weatherability can reach 2000h or above, butanone resistance reaches 1000 times or above, and salt spray resistance reaches 2000h or above.

Owner:成都拜迪新材料有限公司

Plastic dehumidifying staining master batch and preparation method thereof

InactiveCN101186731AOvercome the large amount of additionOvercoming dispersionLinear low-density polyethylenePolymer science

The invention discloses a plastic dehumidifying coloring mother particle, which is characterized in that the dehumidifying coloring mother particle comprises one or a plurality of calcium oxide, magnesium oxide and tin oxide 11-60 parts by weight, one or a plurality of biphenyl aniline yellow, permanent yellow, indigo, pigment yellow, permanent orange, orange chrome yellow, pigment scarlet, golden light red, scarlet powder, jade lime and carbon black (pigment black) 5-45 parts by weight, one or a plurality of stearate adjuvant, paraffin, coupler, polyethylene wax, brightening agent and brightening agent 8-65 parts by weight, one or a plurality of high-density polyvinyl resin, linear low-density polyvinyl resin, polyacryl resin, ethylene-vinyl acetate copolymer 15-75 parts by weight.

Owner:李守本

Environment-friendly type special adhesion primer for nonferrous metal surface

InactiveCN101693802AStrong support abilityLess consumption per unit areaAnti-corrosive paintsPolyvinyl butyralPolyvinyl alcohol

The invention relates to an environment-friendly type special adhesion primer for nonferrous metal surface which is exclusively used for the surface of nonferrous metal, such as stainless steel, aluminum alloy and the like, to serve as the primer. The environment-friendly type special adhesion primer for nonferrous metal surface comprises a component A and a component B, wherein the formula of the component A comprises the following components: 1-20 parts of zinc chrome yellow, 1-5 parts of talcum powder, 2-20 parts of polyvinyl butyral, 5-70 parts of isopropanol and 1-25 parts of butanol; the formula of the component B comprises the following components: 1-30 parts of phosphoric acid, 10-40 parts of purified water and 30-70 parts of isopropanol. A coating is ultrathin and has strong matching property, wide use range, little consumption of unit area and high drying speed; and the thickness of a dry film is only 5-20 microns, and subsequent matching paint can be sprayed after 10-20 minutes. The polyvinyl butyral and the zinc chrome yellow which are innoxious and inodorous are used as main raw materials, the properties of high transparence and superior flexibility and deflection of the polyvinyl butyraldehyde after being dissolved in alcohol solvents and the like are utilized, the adhesion force is increased, the zinc chrome yellow and the phosphoric acid generate a phosphating reaction on the surface of the metal to act as the functions of phosphatization and passivation, the bonding force between the paint and a substrate of the metal is improved, and the environment-friendly type special adhesion primer for nonferrous metal surface has a certain corrosion-prevention function and effect.

Owner:袁泉利

Anti-corrosive paint formula

InactiveCN104559760ABright colorGood light fastnessAnti-corrosive paintsEpoxy resin coatingsDiacetone alcoholEpoxy

The invention relates to an anti-corrosive paint formula which comprises components in parts as follows: 40 parts of titanium dioxide, 50 parts of glacial acetic acid, 5 parts of organic fluorine epoxy resin, 10 parts of epoxy modified organic silicon liquid resin, 4 parts of ethylene glycol monomethyl ether, 8 parts of dimethyl sulfoxide, 10 parts of zinc phosphate, 10 parts of barium chromate, 6 parts of aluminium triphosphate, 3 parts of diethyl phosphinic acid aluminum, 4 parts of N-methyl-2-pyrrolidone, 1 part of ethanol, 4 parts of polyacrylate, 1 part of alcohol-soluble resin, 10 parts of diacetone alcohol, 8 parts of zinc oxide and 9 parts of toluene diisocyanate. Paint prepared with the formula has bright color and good sun-proof effect, medium chrome yellow in inorganic pigment can be replaced, and the paint is applicable to an exterior wall coating material and is free of heavy metal harm.

Owner:QINGDAO JIASHANG CREATIVE CULTURE

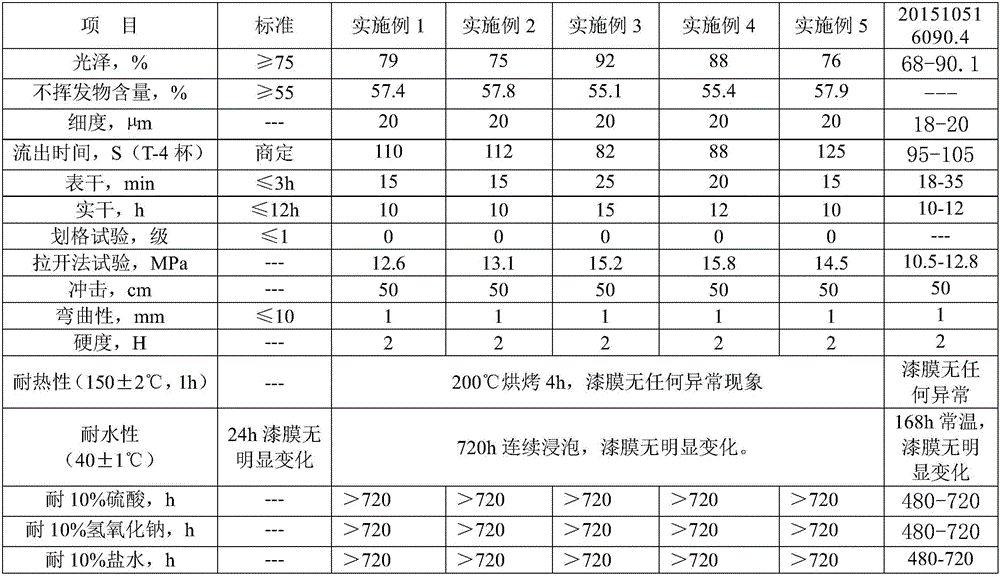

High-gloss aqueous modified polyurethane finish coat and preparation method thereof

InactiveCN104403540AImprove anti-corrosion performanceImprove fullnessAnti-corrosive paintsPolyurea/polyurethane coatingsDisinfectantChemistry

The invention discloses a high-gloss aqueous modified polyurethane finish coat. The finish coat comprises the following components in percentage by weight: 40-53% of aqueous polyurethane dispersoid, 15-25% of an epoxy modified acrylic emulsion, 12-16% of medium chrome yellow, 5-10% of nanometer barium sulfate, 0.2-0.3% of an aqueous dispersing agent, 0.1-0.2% of an aqueous foam inhibitor, 0.1-0.2% of an aqueous antifoaming agent, 0.2-0.3% of an aqueous flatting agent, 0.1-0.2% of an aqueous wetting agent, 0.6-1% of a neutralizer, 0.5-1% of hydrated magnesium silicate, 0.2-0.4% of an aqueous rheologic addition agent, 0.3-0.5% of an antimildew disinfectant, 6.8-10.7% of deionized water and 1-2% of a film forming addition agent. The coat disclosed by the invention adopts traditional aqueous polyurethane for modifying epoxy acrylic acids, so that the purposes of obviously strengthening gloss and antiseptic property are realized, and the coat can be widely used for industries of various tower cranes, steel structures, bridges, machinery, machine tools and the like. The product of the coat has the advantages of high drying speed, high hardness, high gloss (wherein the gloss can reach more than 91%), excellent fullness, good weather resistance and good excellent water resistance, and the salt mist resistant property can reach more than 1000 hours.

Owner:成都拜迪新材料有限公司

Preparation method of inorganic and organic composite yellow pigment

ActiveCN104194392AStrong UV Absorbing PropertiesGood visible light-infrared reflection performanceOrganic dyesThermal stabilityInorganic pigments

The invention provides a preparation method of an inorganic and organic composite yellow pigment. The preparation method comprises the following steps: in a preparation process of a C.I. pigment yellow 13 and 83 compound, adding an inorganic mixture of white carbon black / titanium dioxide in a certain proportion to prepare the inorganic and organic composite yellow pigment which takes inorganic matters as a main body. The preparation method comprises the following steps: preparing a coupling component; carrying out a tetra-nitriding reaction; and carrying out a coupled reaction. According to the preparation method provided by the invention, by using the inorganic and organic composite yellow pigment which takes inorganic matters as the main body, the prepared composite yellow pigment more shows characteristics of inorganic matters and has good heat stability and light stability. Compared with the inorganic yellow pigment lead chromate yellow, the prepared composite pigment shows more excellent coloring properties such as high coloring force, brighter color and purer yellow and the like and can become a potential substituent of the yellow inorganic pigment containing toxic heavy metals such as lead chromate yellow.

Owner:浙江永合新材料科技有限公司

Chlorinated rubber coating used for marine environment and production method

InactiveCN105315796AHigh glossEliminate Bubble ProblemsRubber derivative coatingsAnti-corrosive paintsEpoxyPolymer science

The invention relates to a chlorinated rubber coating used for a marine environment and a production method. The production method includes the steps of adding modified chlorinated rubber resin, modified hydrogenated bisphenol F-type epoxy resin and epoxidized soybean oil to a mixed solvent composed of dimethylbenzene and solvent oil, adding modified titanium dioxide, feldspar powder, talcum powder, silicon micro-powder, mica powder, phthalocyanine green, chrome yellow, polyamide wax, chlorinated paraffin, a hydroxyl triazine derivative and epoxy chloropropane and the like to the mixed solution, mixing, stirring and grinding the mixed solution to obtain the high-glossiness weather-resistant chlorinated rubber coating used for the marine environment. The marine environment can be uniformly stirred and directly used for coating surfaces. The coating allows construction at -20 DEG C, is excellent in storage stability, anti-ultraviolet light aging property, adhesive force, corrosion resistance of acids, alkalis and salts and sea water scouring resistance, and can be used for corrosion resistance of offshore structures such as ships, ocean platforms, docks and the like.

Owner:CNPC RES INST OF ENG TECH +2

Novel refractory coating capable of preventing powder from falling

ActiveCN103319978AWith mattingHigh bonding strengthFireproof paintsEpoxy resin coatingsEpoxyAluminum silicate

The invention relates to a novel refractory coating capable of preventing powder from falling. The novel refractory coating is characterized by comprising the following components in mass ratio: 10 to 15 parts of epoxy resin, 0.5 to 0.9 part of antibacterial agent, 1 to 4 parts of mildew preventive, 10 to 25 parts of modified sericite, 10 to 20 parts of water, 5 to 10 parts of titanium dioxide, 9 to 15 parts of alumina powder, 1 to 2 parts of flexibilizer, 1 to 3 parts of flatting agent, 10 to 15 parts of chrome yellow, 10 to 15 parts of falling preventing agent, 5 to 10 parts of nickel iron chromite black spinel, 3 to 5 parts of coupling agent, 2 to 4 parts of expanded perlite, 1 to 2 parts of coalescing agent, 8 to 12 parts of quartz powder, 15 to 25 parts of melamine, 20 to 30 parts of aluminium silicate, 8 to 15 parts of monox, 1 to 3 parts of barium sulfate, 1 to 3 parts of antifoaming agent, 1 to 3 parts of wetting agent, 20 to 30 parts of mixed solvent, 5 to 10 parts of zinc oxide, 10 to 20 parts of zinc phosphate, 15 to 25 parts of aluminium triphosphate, 5 to 10 parts of sodium hydroxide, and 1 to 8 parts of hydrochloric acid.

Owner:安徽格锐新材料科技有限公司

Yellow-gray quick-drying anti-corrosive paint for galvanized stainless pipe fitting and preparation method thereof

InactiveCN104031497AImprove adhesionImprove anti-corrosion performanceAnti-corrosive paintsButyl acetatePipe fitting

The invention provides a yellow-gray quick-drying anti-corrosive paint for galvanized stainless pipe fittings. The yellow-gray quick-drying anti-corrosive paint is prepared from the following components in percentage by weight: 35%-45% of acrylic resin, 10%-15% of modified resin, 10%-12% of titanium dioxide, 3%-5% of medium chrome yellow, 0.2%-0.3% of high-pigment carbon black, 0.5%-1% of dispersing agents, 0.2%-0.5% of flatting agents, 1%-1.5% of adhesive force auxiliary agents, 0.5%-1% of anti-corrosion agents, 10%-15% of butyl acetate and 15%-20% of dimethyl benzene. The invention also provides a preparation method of the yellow-gray quick-drying anti-corrosive paint for the galvanized stainless pipe fittings. 10%-15% by weight of the modified resin, the adhesive force auxiliary agents and the anti-corrosion agents are additionally used for the formula of the yellow-gray quick-drying anti-corrosive paint, so that a composition formed by the components and other components is increased in adhesive force and improved in anti-corrosive property; the galvanized stainless pipe fittings show the yellow-gray and are attractive in appearance after being coated with the yellow-gray quick-drying anti-corrosive paint.

Owner:SHANDONG RUIBANG COATING TECH

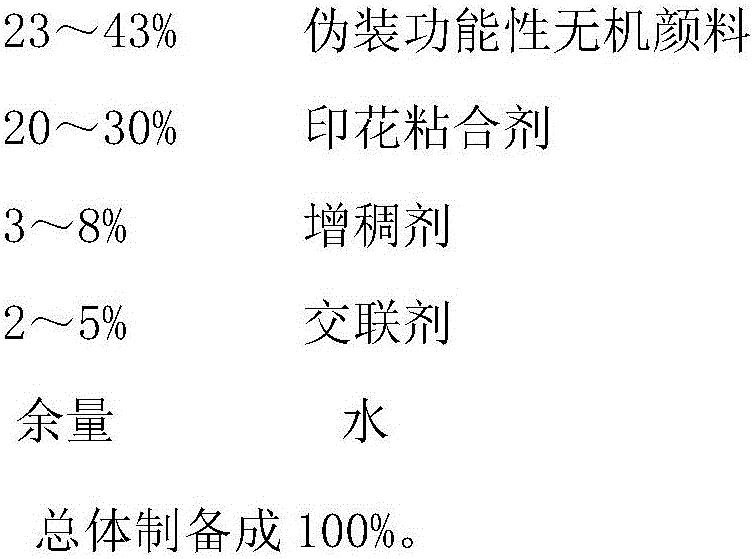

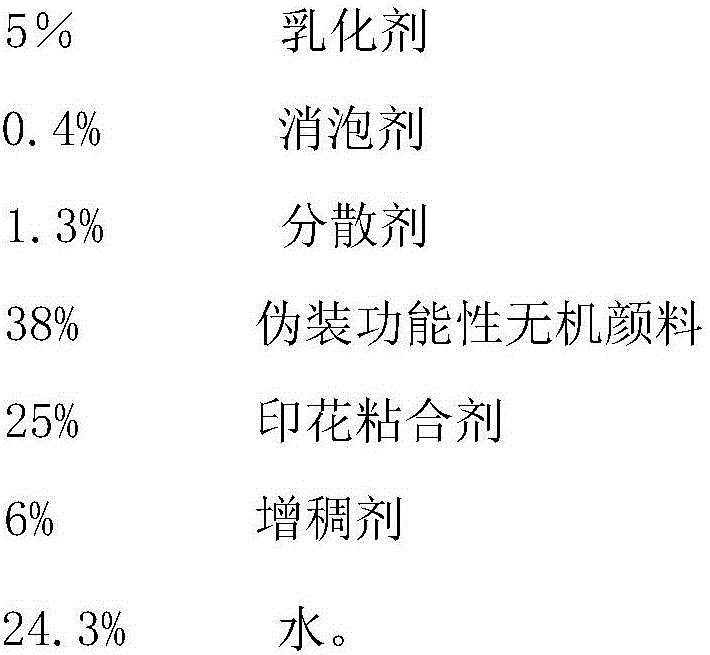

Counterreconnaissance pretending functional inorganic pigment, inorganic printing coating and fabric

ActiveCN106436377AImprove absorbing performanceImprove light fastnessDyeing processProtective garmentManganeseUltraviolet

The invention provides a counterreconnaissance pretending functional inorganic pigment, an inorganic printing coating and a fabric; the counterreconnaissance pretending functional inorganic pigment includes mixtures of any several types of titanium chrome yellow, titanium manganese brown, cobalt blue, titanium cobalt green, titanium nickel yellow, copper eriochrome black or iron eriochrome black; after adding the emulgator, the dispersing agent, the flame retardant, and water or solvent type PU glue and others, the reflectivity of near infrared ray corresponding to the color block required and the lightness L, a, and b values can be obtained; moreover, more metal elements are applied to improve the wave absorbing effect and also improve the fastness , and guarantee no color fading under the ultraviolet irradiation for thousands of hours. The front face of the fabric layer using the coating can be coated with digital camouflage pattern; the opposite face can be coated through the coating; the dual-faced coating can make that the static water pressure resistance index is over double to the fabric in the past; thus the fabric has higher waterproof and wet penetration, and the overall performance is better.

Owner:ZHEJIANG SHENGFA TEXTILE PRINTING & DYEING

Carbon nanotube anticorrosive paint

InactiveCN112574606AImprove water resistanceImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyNanotube

The invention discloses an anticorrosive paint for carbon nanotube-containing metal. The anticorrosive paint is composed of epoxy resin, organic bentonite, dibutyl phthalate, titanium dioxide, mediumchrome yellow, talcum powder, barium sulfate, zinc oxide, carbon nanotubes, temperature-sensitive powder and matched assistants. According to the invention, a special high-strength one-dimensional linear structure of the carbon nanotubes is utilized to form a high-strength interlaced reticular structure in the coating, so that the coating is more compact; and meanwhile, by utilizing the nano effect of the carbon nanotubes, the binding force between the coating and the material is improved, pores in the coating are reduced, and a solution is prevented from entering the coating, so that the weather resistance and the corrosion resistance of the coating are effectively improved. The material is environmentally friendly, the production process is environmentally friendly, the obtained paint film is excellent in water resistance and corrosion resistance, high in bonding strength and excellent in alkali resistance and corrosion resistance, the application range of the paint is greatly widened, and the cost performance of the paint is greatly improved.

Owner:JIANGSU KEHUI ENVIRONMENTAL TECH CO LTD

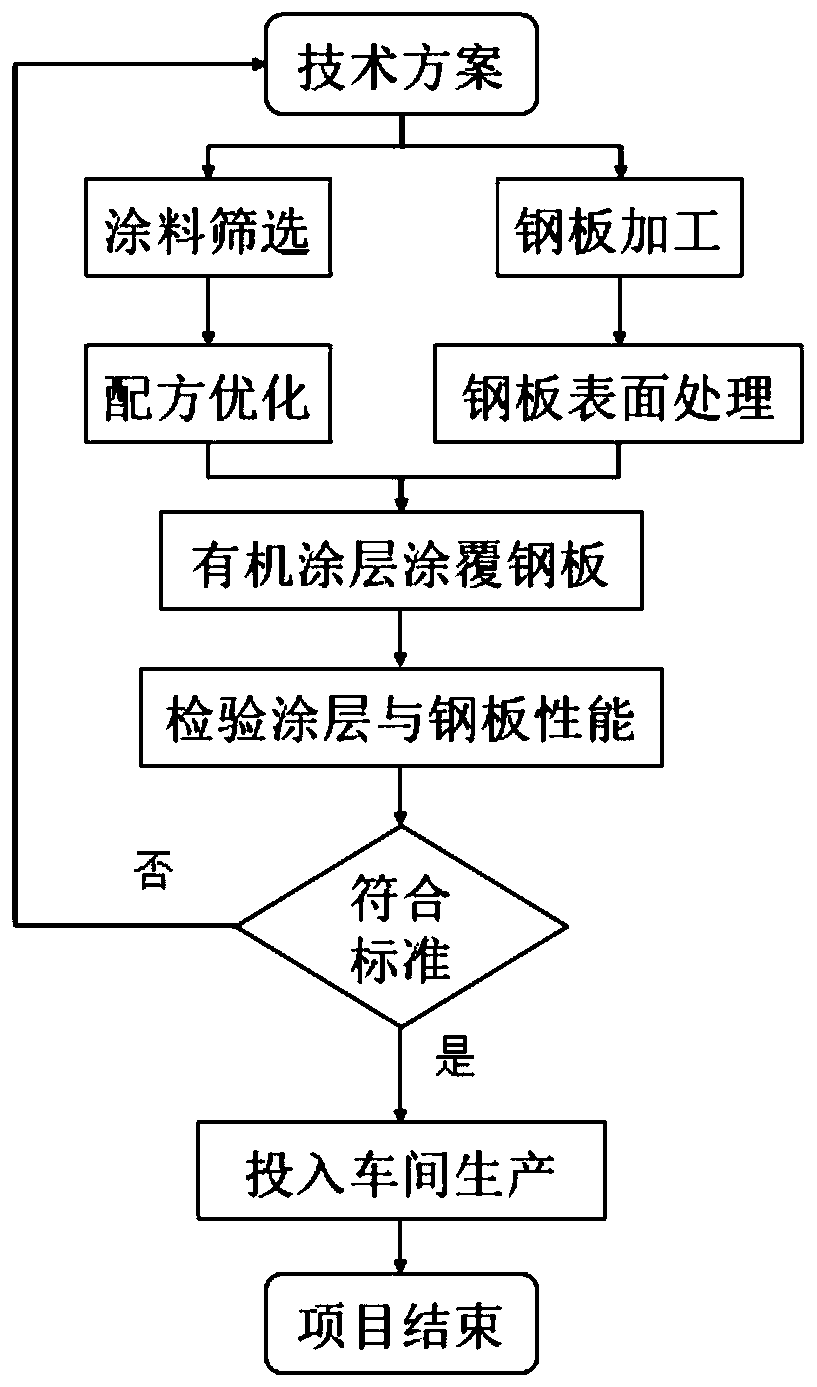

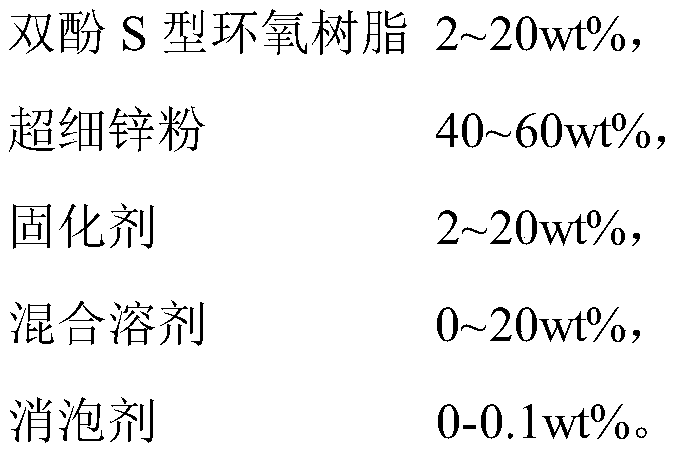

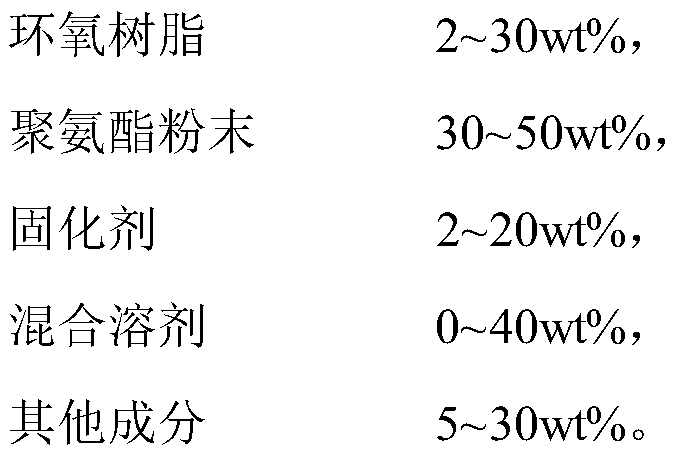

Organic coated steel sheet, manufacturing method and application thereof

ActiveCN110669415AImprove conductivityGood flexibilityPretreated surfacesAnti-corrosive paintsFirming agentBisphenol AF

The invention discloses an organic coated steel plate, a manufacturing method and application thereof. The organic coated steel plate is composed of a steel plate, primer and finish paint. The epoxy zinc-rich primer is composed of bisphenol S epoxy resin, superfine zinc powder, a mixed solvent, a curing agent and a defoaming agent. The epoxy-polyurethane composite finish paint is composed of epoxyresin, polyurethane powder, a mixed solvent, a curing agent and other components. And the epoxy resin is bisphenol S type epoxy resin, bisphenol A type epoxy resin or bisphenol AF type epoxy resin; and the other components can be one or more of titanium dioxide, talcum powder, mica iron oxide, medium chrome yellow and zinc phosphate. The preparation method of the organic coated steel plate includes: firstly carrying out surface treatment on the steel plate, then coating the steel plate with the primer, performing high-temperature curing at 100-280DEG C for 0.1-0.5h, then coating the steel plate with the finish paint, and conducting high-temperature curing. The obtained organic coated steel plate has the characteristics of good toughness, high strength, good paint film adhesiveness, friction resistance and long service life, and is particularly suitable for manufacturing bolt connection tanks.

Owner:BEIJING YINGHERUI ENVIRONMENTAL ENG

Water soluble industry paint and its prepn process

InactiveCN1609151AGood for physical and mental healthImprove protectionEmulsion paintsHigh resistanceAcrylic resin

The present invention relates to paint technology and is one kind of water soluble industrial paint. The water soluble industrial paint consists of deionized water, dispersant, wetting agent, defoaming agent, corrosion retardant, triethanolamine, Fe2O3, zinc chrome yellow, mica powder, aluminum tripolyphosphate, talcum powder, barite, glycol, CS-12, alcoholic acid modified styrene-acrylic resin, preservative, bactericide, WT-105A and 113. Compared with available technology, the present invention has the advantages of water solvent, no toxicity, no smell, no burning and exploding, no pollution, high resistance to acid, alkali, salt, oil and other corrosive medium, etc.

Owner:广东泰锋环保涂料股份有限公司

Medical rust-removal and antirust paint and preparation method therefor

The invention discloses medical rust-removal and antirust paint and a preparation method therefor. The paint is prepared from the following raw materials: styrene, zinc phosphate, phosphoric acid, zinc oxide, zinc chrome yellow, organobentonite, a polyvinyl acetate emulsion, deionized water, ammonium persulfate and aluminum triphosphate. The paint which is applied to medical apparatuses is antirust, the viscosity of the paint is 60-80, the fineness of the paint is 40-60 [mu]m, the flexibility of the paint is 0.2-0.8mm and the adhesive force of the paint is level 1-2; the paint has good antiseptic property, impact resistance within 60-80cm, impact strength of 500-550N / cm, and salt water resistance of not blistering and not falling within 1-3 days; the surface-drying time is 0.1-0.5 hour, the hard-drying time is 8-12 hours and the covering power is 95-115g / cm<2>.

Owner:SUZHOU JONATHAN NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com