Anticorrosive environment-friendly spray paint formula

A paint and environmental protection technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as spraying workers' health hazards, affecting users' health, environmental pollution, etc., and achieves good environmental protection effects, good light resistance, and gloss high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] An anti-corrosion and environment-friendly spray paint formula, the composition ratio (parts by mass) of the anti-corrosion and environment-friendly spray paint formula includes 28 parts of glacial acetic acid, 3 parts of organic fluorine epoxy resin, 7 parts of epoxy modified silicone resin solution Parts, 2 parts of ethylene glycol monomethyl ether, 6 parts of dimethyl sulfoxide, 8 parts of zinc phosphate, 8 parts of barium chromate, 1 part of ethanol, 2 parts of polyacrylate, 1 part of alcohol-soluble resin, 7 parts of diacetone alcohol , 6 parts of zinc oxide, 8 parts of toluene diisocyanate, 3 parts of butyl acetate, 12 parts of benzophenone, 9 parts of triethanolamine and 3 parts of diphenylpolysiloxane.

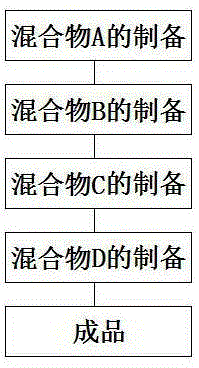

[0020] The preparation process of the anti-corrosion and environmentally friendly spray paint is carried out according to the following steps: Preparation of mixture A: take a heatable container, pour glacial acetic acid and epoxy-modified silicone resin liquid i...

Embodiment 2

[0021] Example 2: The rest are the same as in Example 1, except that 29 parts of glacial acetic acid, 4 parts of organic fluorine epoxy resin, 8 parts of epoxy-modified silicone resin liquid, 2 parts of ethylene glycol monomethyl ether, and 7 parts of dimethyl sulfoxide 9 parts of zinc phosphate, 9 parts of barium chromate, 2 parts of ethanol, 3 parts of polyacrylate, 2 parts of alcohol-soluble resin, 8 parts of diacetone alcohol, 7 parts of zinc oxide, 9 parts of toluene diisocyanate, 4 parts of butyl acetate parts, 13 parts of benzophenone, 10 parts of triethanolamine and 4 parts of diphenyl polysiloxane; in the step (1), the heating temperature is 85°C; in the step (5), at 40°C Add water for dilution, the amount of added water is 8 parts, and then continue to stir for a period of time, and the duration of stirring is 37 minutes.

Embodiment 3

[0022] Example 3: The rest are the same as in Example 1, except that 30 parts of glacial acetic acid, 5 parts of organic fluorine epoxy resin, 9 parts of epoxy-modified silicone resin liquid, 3 parts of ethylene glycol monomethyl ether, dimethyl methylene 8 parts of sulfone, 10 parts of zinc phosphate, 10 parts of barium chromate, 3 parts of ethanol, 4 parts of polyacrylate, 3 parts of alcohol-soluble resin, 9 parts of diacetone alcohol, 8 parts of zinc oxide, 10 parts of toluene diisocyanate, butyl acetate 5 parts of ester, 14 parts of benzophenone, 11 parts of triethanolamine and 5 parts of diphenylpolysiloxane; in the step (1), the heating temperature is 90°C; Add water at ℃ for dilution, the amount of water added is 9 parts, and then continue to stir for a period of time, and the duration of stirring is 39 minutes.

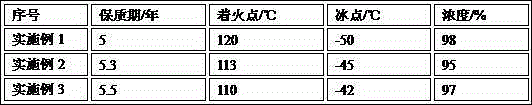

[0023] After the above process steps, the paint sample is taken out to be tested:

[0024]

[0025] From the above data, it can be known that the shelf ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com