Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1710 results about "Zinc phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc phosphate is an Inorganic compound with the formula Zn₃(PO₄)₂)(H₂O)₄. This white powder is widely used as a corrosion resistant coating on metal surfaces either as part of an electroplating process or applied as a primer pigment (see also red lead). It has largely displaced toxic materials based on lead or chromium, and by 2006 it had become the most commonly used corrosion inhibitor. Zinc phosphate coats better on a crystalline structure than bare metal, so a seeding agent is often used as a pre-treatment. One common agent is sodium pyrophosphate.

Water industrial antirust paint and preparation method thereof

InactiveCN101045843AHigh hardnessStrong adhesionAnti-corrosive paintsEmulsion paintsEpoxyALUMINUM PHOSPHATE

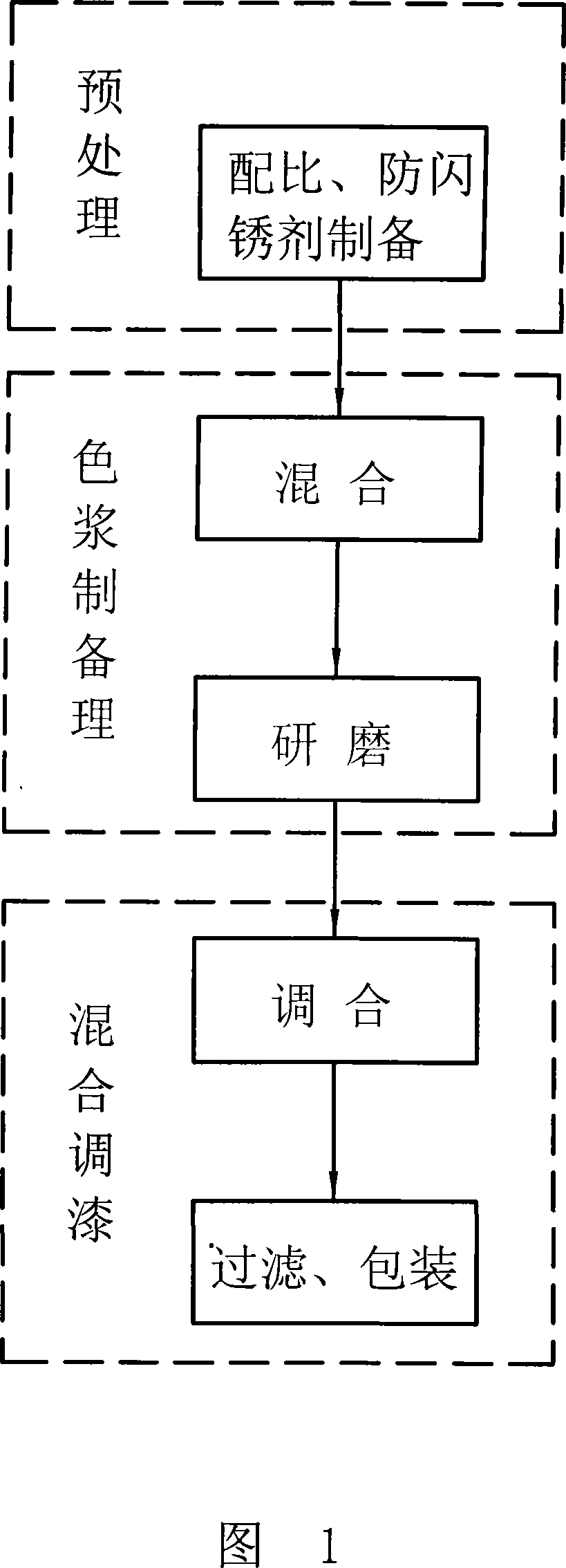

This invention relates to a aquosity industry anti-rust paint and its preparation method. According to weight it includes 8 to 11% aquosity acroleic acid modified epoxy, 33 to 40% acroleic acid latices, 0.1 to 0.3% defoamer, 0.05 to 0.15% wetting agent, 0.3 to 0.5% dispersant, 0.3 to 0.5% rust-resistant agent, 7.5 to 9% iron oxide red, 6 to 8% French chalk, 5 to 10% modified zinc phosphate, 2.5 to 10% trimerization aluminum phosphate, 3 to 3.5% precipitated baryte , 0.5 to 1% zinc oxide, 3 to 5% mica ferric oxide, alcohol ester twelve 1 to 2%, triethanolamine 1 to 2%, thickening agent 0.3 to 0.6%, preservative 0.05 to 0.1%, 5 to 20% de-ionized water, through pretreatment, color paste preparation and blending and adjusting to gain product.

Owner:邹磊

Fire-retardant paint with steel structure

ActiveCN101857756AExtend fire resistance timeImprove fire resistanceFireproof paintsPolyurea/polyurethane coatingsPhosphoric acidComposite substrate

The invention relates to fire-retardant paint with a steel structure, which is prepared from the following raw materials proportioning by weight: 45 to 60 of composite substrate resin, 6 to 8 of melamine, 6 to 8 of pentaerythritol, 16 to 20 of ammonium polyphosphate, 4 to 10 of expansible graphite, 2 to 5 of nano magnesium hydroxide, 1 to 3 of zinc phosphate, 1 to 3 of zinc borate, 2 to 5 of aluminum hydroxide, 3 to 5 of aluminum polyphosphate, 6 to 9 of titanium dioxide, 0.5 to 0.8 of flatting agent and 15 to 20 of acetone. The paint has excellent capabilities of fire prevention and corrosion prevention.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

Drag-reducing abrasion-resisting solventless coating for pipeline as well as preparation method and application thereof

ActiveCN101974282AStrong adhesionGood flexibilityAnti-corrosive paintsPipe protection against damage/wearEpoxySolvent free

The invention relates to a drag-reducing abrasion-resisting solventless coating for a pipeline as well as a preparation method and application thereof. The drag-reducing abrasion-resisting solventless coating contains an A component and a B component, wherein the mass percentage of raw materials is as follows: the A component includes the following materials in percentage by weight: 30%-40% of epoxy resin, 5%-10% of toughening resin, 4%-8% of active diluents, 4%-8% of zinc phosphate, 0.2%-0.5% of levelling agents, 0.2%-0.5% of defoaming agents, 0.4%-0.8% of dispersing agents, 0.2%-1.0% of anti-settling thickening agents, 8%-20% of ferric oxide red powder, 5%-15% of aluminium triphosphate and 5%-15% of white pottery magnetic powder; the B component includes the following materials in percentage by weight: 5%-20% of modified amine and 2%-10% of modified polyamide; and the A component and the B component are matched for use according to the mass ratio of 3-5:1. The drag-reducing abrasion-resisting solventless coating is prepared through material blending, dispersion, grinding, filtration and packaging and can be applied in delivery pipelines of oil and natural gases. The drag-reducing abrasion-resisting solventless coating does not contain volatile solvents and has the advantages of good adhesive force, flexibility, salt spray resistance and solvent resistant property, smooth coating surface, good drag-reducing abrasion-resisting effect, convenient construction, resource saving and good popularization and application prospect.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL

Nano-structured inorganic zinc phosphate corrosion protective coating for metal alloys

ActiveUS20090192251A1Trend downSuperior metal to resin adhesiveLiquid surface applicatorsEfficient propulsion technologiesZinc phosphateOrganic acid

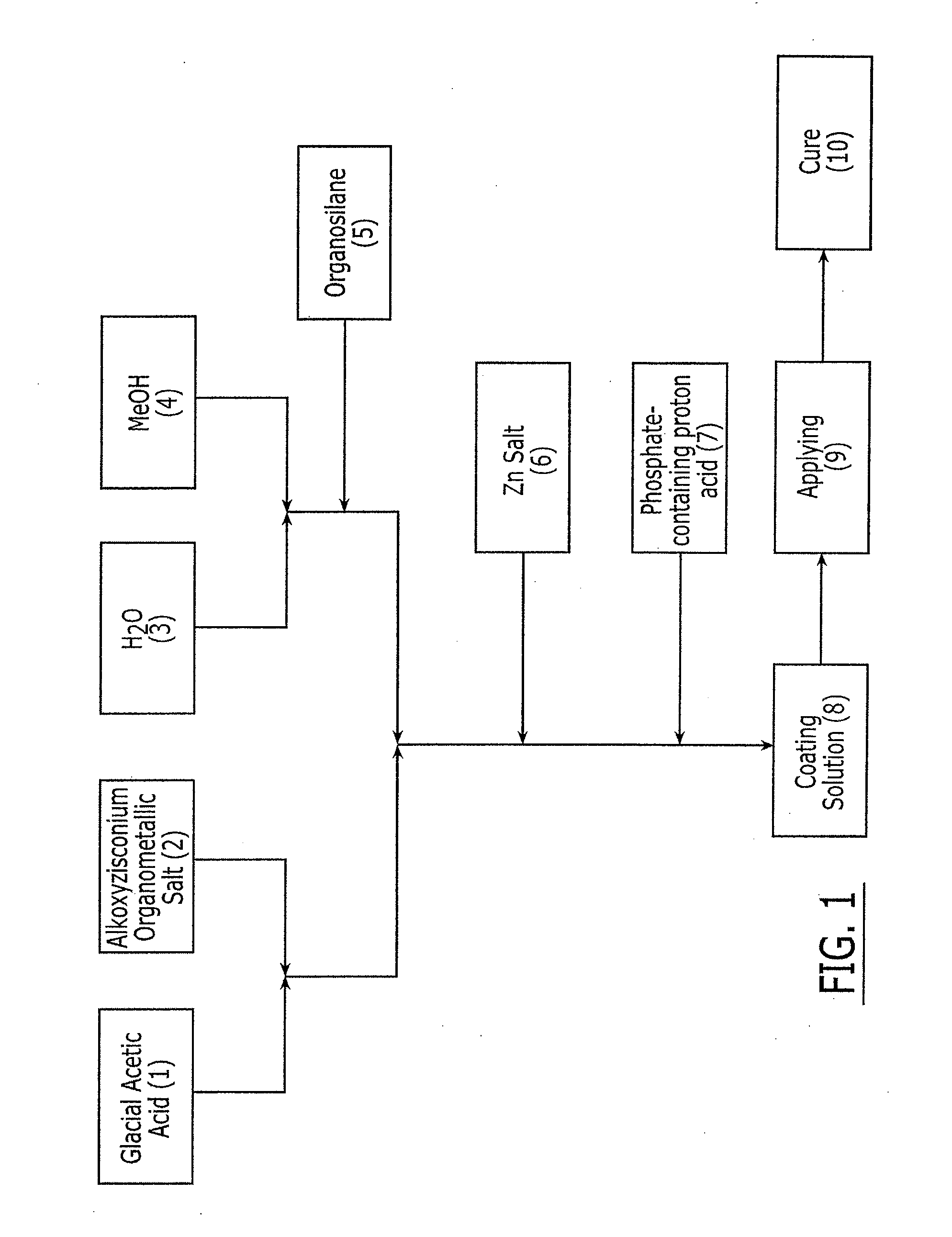

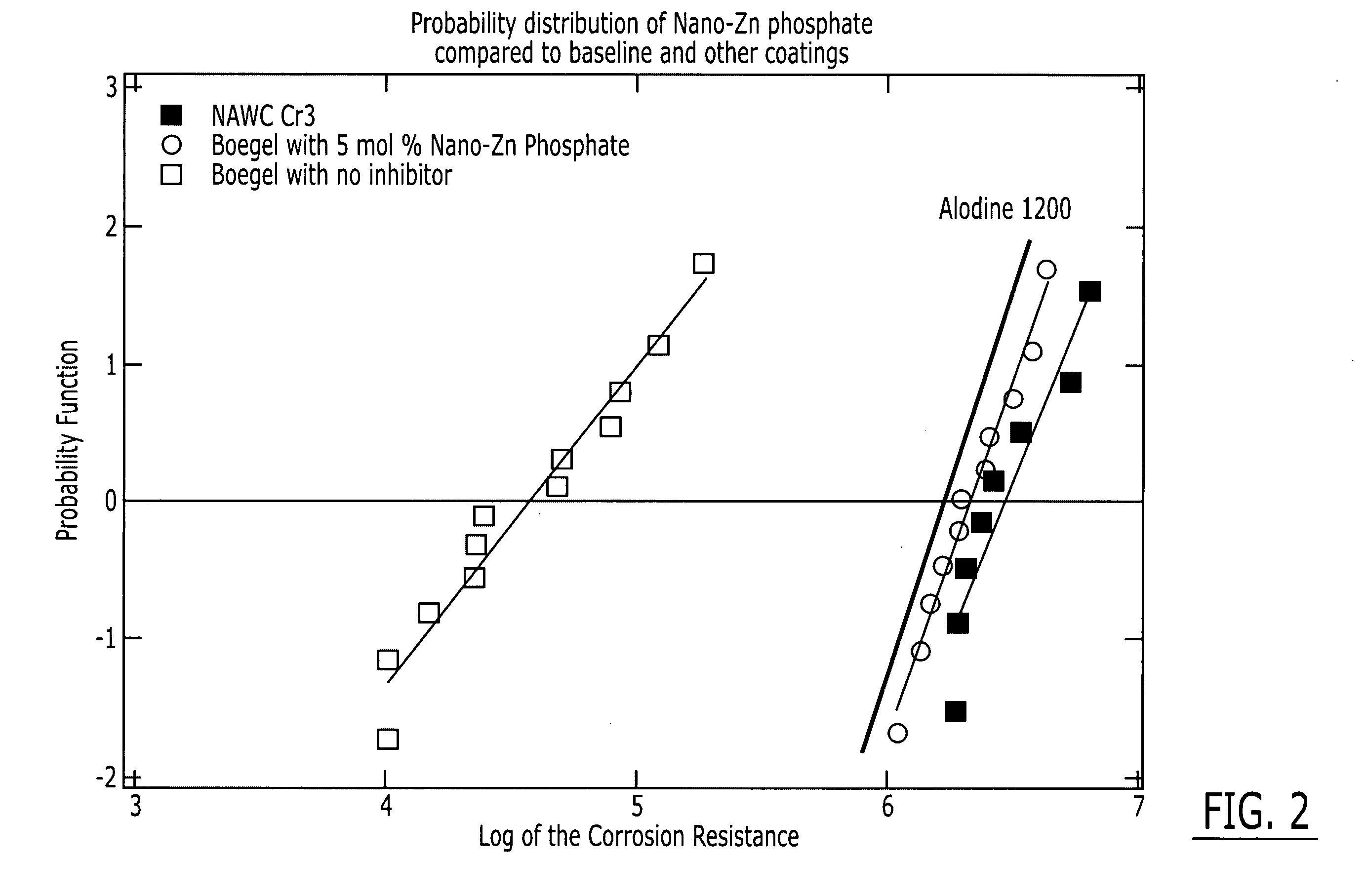

A method is provided for enhancing corrosion resistance of a metal surface that includes the step of forming a sol-gel coating in which nanostructured zinc phosphate (Zn3(PO4)2) and zinc oxide (ZnO) phases are present in the mixture. The method may include the steps of mixing an organosilane, organometallic, organic acid, water, and alcohol and allowing the components of the mixture to partially hydrolyze, followed by adding at least one component having zinc functionality and at least one component having phosphate functionality to the partially hydrolyzed mixture, wherein the zinc component and phosphate component are added in a molar ratio of from about 1.5:1 to about 5:1 (Zn:PO4). The resulting mixture can be applied as a coating to a metal surface to improve the corrosion resistance of the metal and to enhance the adhesion of resinous materials to the metal surface.

Owner:THE BOEING CO

Graphene anticorrosive paint and preparation method thereof

InactiveCN106675336AEffective dispersionAvoid harmAnti-corrosive paintsEpoxy resin coatingsZinc phosphateTitanium

The invention provides a graphene anticorrosive paint. The graphene anticorrosive paint is composed of the following components in parts by mass: 0.01-5 parts of graphene, 25-70 parts of epoxy resin, 5-15 parts of reactive diluent, 5-30 parts of titanium white, 5-30 parts of barium sulfate, 5-30 parts of zinc phosphate, 3-10 parts of aid and 5-30 parts of curing agent. The invention also provides a preparation method of the graphene anticorrosive paint.

Owner:NINGBO MORSH TECH

Glaze for fast-fired crystal glaze ceramic tile, and preparation method and applications of ceramic tile

ActiveCN104829268AReduce granularity requirementsSimple manufacturing processManufacturing technologyBrick

The invention provides a glaze for fast-fired crystal glaze ceramic tile and a preparation method and applications of ceramic tile. The glaze comprises basic crystal glaze and a color developing agent, wherein the basic crystal glaze comprises the following raw materials: zinc oxide, titanium dioxide, quartz, cryolite, zinc phosphate, kaolin, and lead frit. A proper amount of zinc phosphate is introduced into the glaze to avoid the raw material frit treatment, which is carried out to ensure the residual amount of nucleating agent, the requirements on the glaze granularity are reduced, the manufacture technologies of crystal glaze and ceramic tiles are simplified, and the technical difficulties that the crystal glaze sintering technology is complicated, the crystal patterns are difficult to control, and the production cost is high are solved. Moreover, the addition amount of quartz and lead frit is precisely controlled to obtain crystal glaze art ceramic tiles which have the advantages of good crystallization effect, strong three-dimensional effect, and good artistic effect. The provided preparation method has the advantages of simpleness, lower sintering temperature, shorter period, and suitability for massive industrial production.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

Environment-friendly solvent-free humidified and rusted anticorrosive paint

InactiveCN101747825AEasy pretreatmentConvenient anti-corrosion solutionAnti-corrosive paintsEpoxy resin coatingsOrganic filmSolvent free

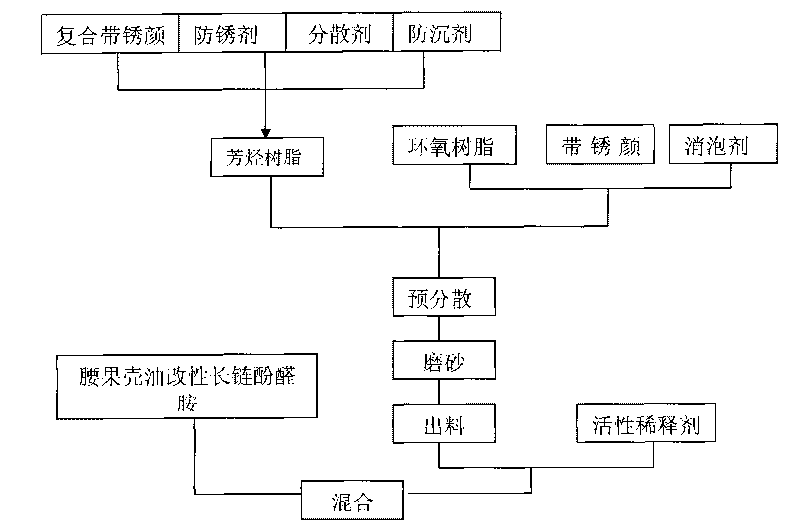

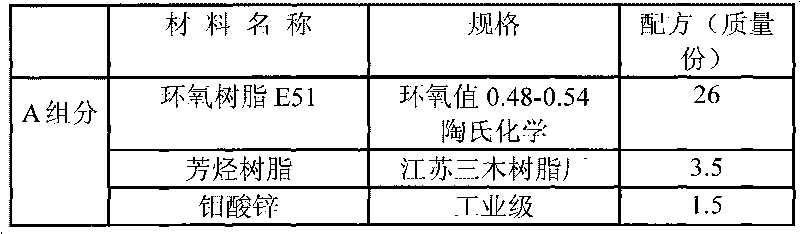

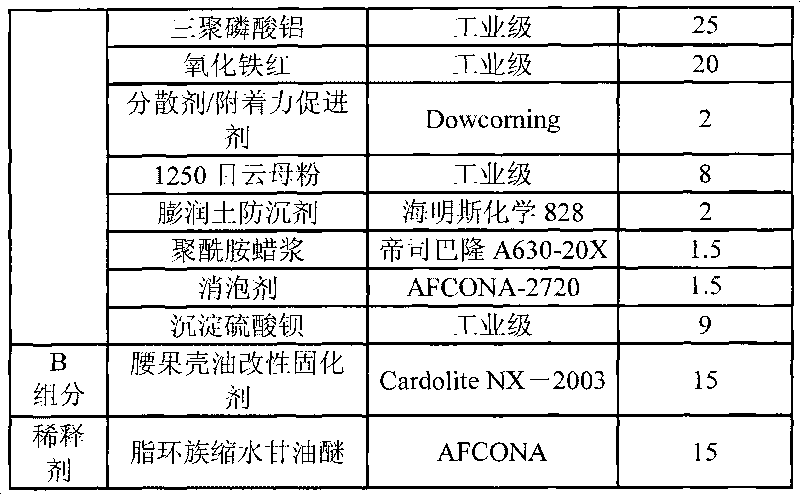

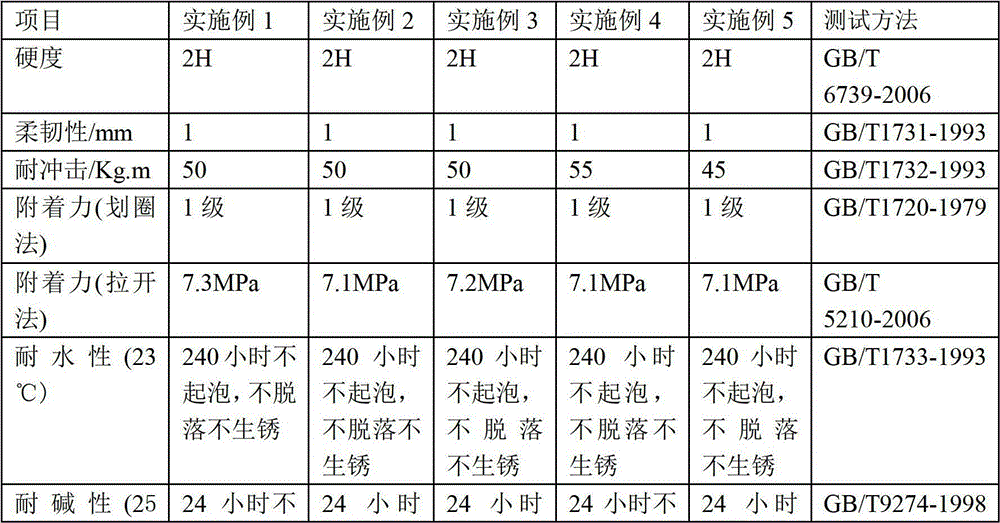

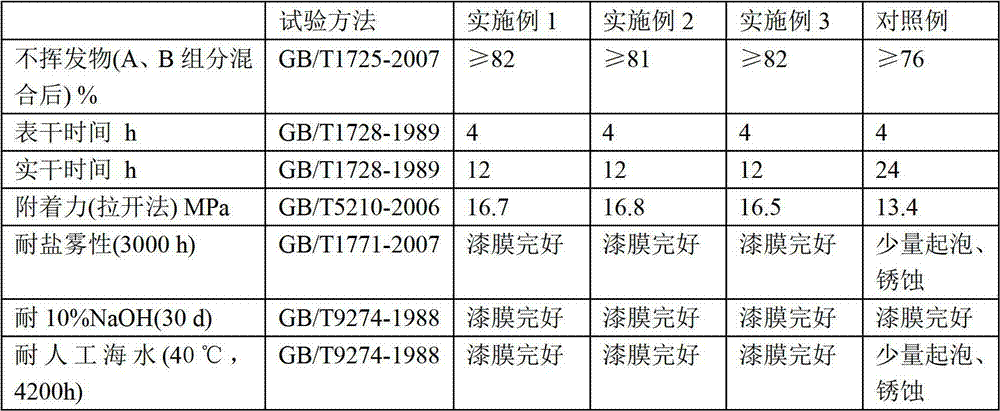

The invention relates to a paint material with formed organic film, in particular to an epoxy solvent-free anticorrosive paint applied to low surface treatment steel structure. The anticorrosive paint is prepared by efficiently compounding rusted coating pigments such as zinc molybdate, zinc phosphate, aluminium trippolyhosphate, iron oxide red and the like, using cashew nut oil modified long-chain amine phenolic aldehyde as, alicyclic glycidyl ether as active diluent, thus overcoming the problems that surface treatment technique in coating construction costs high and heavy anticorrosive paint with high solvent content pollutes the environment, having easy preparation and construction, low cost, fast solidification at high temperature, good mechanical and anticorrosive performance, solvent-free and environment-friendly properties, and being applicable to heavy anticorrosive projects of steel structures such as ship, train, bridge and the like.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Process for treating steel-, zinc- and aluminum-based metals using a two-step coating system

InactiveUS6733896B2Effective treatmentPretreated surfacesSolid state diffusion coatingZinc phosphateCeramic composite

The present invention comprises a method for treating one or more multi-metal articles. The method comprises exposing the one or more articles to a first treatment composition capable of providing a conversion coating on steel- and zinc-based metal, and exposing the one or more articles to a second treatment coating composition suitable for providing a conversion coating on aluminum-based metal articles. Preferably, the first treatment composition comprises a zinc-phosphate conversion coating comprising, zinc ion, phosphate ion, manganese ion, and fluoride ion. Preferably, the second treatment composition comprises a ceramic composite treatment composition.

Owner:HENKEL KGAA

Water-based epoxy anti-corrosive coating and preparation method thereof

ActiveCN102311695AHas neutral salt spray resistanceLimit the spreadFireproof paintsAnti-corrosive paintsWater basedEpoxy

The invention discloses a water-based epoxy anti-corrosive coating and a preparation method thereof, and relates to a ship antirust and cabin inside and outside antirust fireproof paint. The invention provides a water-based epoxy coating with the VOC lower than 10g / l, and the coating belongs to an environment-friendly coating, which not only has the antirust performance of anti-corrosive coating,but also has low flame propagation of cabin inside finish paint, meets the requirement of cabin inside smoke and toxin, resists aging, and is a multifunctional water-based coating, and the bottom andthe surface are combined. Zhejiang Ampang AB-EP-20 is used as the epoxy resin, Zhejiang Ampang AD-HGF is used as the curing agent, and fluorocarbon emulsion (the model of which is Beijing Baowei PF-1) is used as the base material. Wetting dispersant, defoamer I, defoamer II, flash rust inhibitor, thickener, defoamer and substrate wetting agent are used as additives, rutile titanium white powder, compound zinc phosphate, ferrotitanium powder, talcum powder, ultra-fine aluminum hydroxide, precipitated barium sulfate, mica powder and aluminum tripolyphosphate are used as pigment fillers.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Water -borne anticorrosion paint and method for preparing same

ActiveCN102746766AImprove adhesionImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyZinc phosphate

The invention provides a water -borne anticorrosion paint and a method for preparing the same, and belongs to the paint technical field. The paint comprises, by weight, 10% to 45% of water-borne epoxy resins, 5% to 20% of silica sol, 5% to 15% of anticorrosion pigments, 20% to 40% of pigment fillers, 0.5% to 5% of additives and 10% to 15% of water. The anticorrosion pigments are selected from one of zinc phosphate, modified zinc phosphate and zinc molybdate or a mixture formed by any of the three in any proportion; and the additives are a mixture formed by wetting agents, dispersing agents, film forming additives, pH modifiers, antifoaming agents and rheological additives in any proportion. The water -borne anticorrosion paint has a good adhesive force with metals, and excellent anticorrosion performance, rigidity and chemical resistant performances, and the salt mist resistant performance is more than1000 hours.

Owner:JIANGSU HUAXIA PAINT MAKING

Temperature-resistance thermal-insulation heavy-duty anticorrosion coating

InactiveCN102134444AImprove adhesionImprove media resistanceAnti-corrosive paintsEpoxy resin coatingsZinc phosphatePolymer science

The invention relates to the technical field of coating, in particular to temperature-resistance thermal-insulation heavy-duty anticorrosion coating, which comprises the following raw material components in percentage by mass: 10 to 40 percent of epoxy modified organosilicon resin, 5 to 20 percent of novolac epoxy resin, 8 to 20 percent of modified amine curing agent, 2 to 10 percent of flexibilizer, 0.1 to 1 percent of modified polysiloxane flatting agent, 0.01 to 0.1 percent of polysiloxane defoaming agent, 0.1 to 1 percent of polyacrylate dispersant, 4 to 11 percent of zinc phosphate, 4 to 10 percent of barite powder, 3 to 8 percent of titanium white, 0.01 to 0.1 percent of carbon black, 15 to 40 percent of potassium titanate whiskers and 2 to 20 percent of nano porous material. The organosilicon-modified epoxy resin adopted by the invention combines the high performance of epoxy resin and organosilicon resin, and the organosilicon-modified epoxy resin and the novolac epoxy resin compensate for respective defects. The coating has high anticorrosion performance, high high-temperature-resistance performance and high insulating performance, and the adhesion force, medium-resistance performance and thermal-insulation and heat-preservation performance of the coating are improved considerably.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL

Seawater corrosion-resistant paint

InactiveCN102876192AStrong resistance to seawater corrosionChloropene polymer coatingsAnti-corrosive paintsEpoxyCerium nitrate

The invention provides seawater corrosion-resistant paint which comprises component A and component B. The component A comprises the following materials by weight: 20-30 parts of epoxy resin, 10-20 parts of petroleum resin, 5-10 parts of chloroprene rubber, 3-6 parts of polytetrafluoroethylene, 2-8 parts of polyvinyl acetate, 2-4 parts of a coupling agent, 1-2 parts of a defoaming agent, 5-8 parts of silica sol, 1-2 parts of cerium nitrate, 1-2 parts of montmorillonite, 1-2 parts of iron red, 4-6 parts of zinc phosphate, 2-3 parts of barium sulfate, 3-4 parts of aluminum tripolyphosphate, 1-2 parts of titanium oxide, 4-7 parts of zinc oxide, 25-35 parts of and solvent. The component B comprises the following materials by weight: 20-35 parts of a curing agent, and 15-20 parts of butanol. The inventive paint has excellent seawater corrosion resistance, salt fog resistance above 2,000 hr, 10% NaOH solution resistance above 30 days, and artificial seawater resistance above 4,200 hr.

Owner:WUJIANG HUACHENG COMPOSITE MATERIAL SCI & TECH

Epoxy anti-corrosive paint used for underwater concrete

InactiveCN102719173AStrong adhesionExcellent abrasion resistanceAnti-corrosive paintsEpoxy resin coatingsMicrosphereSolvent free

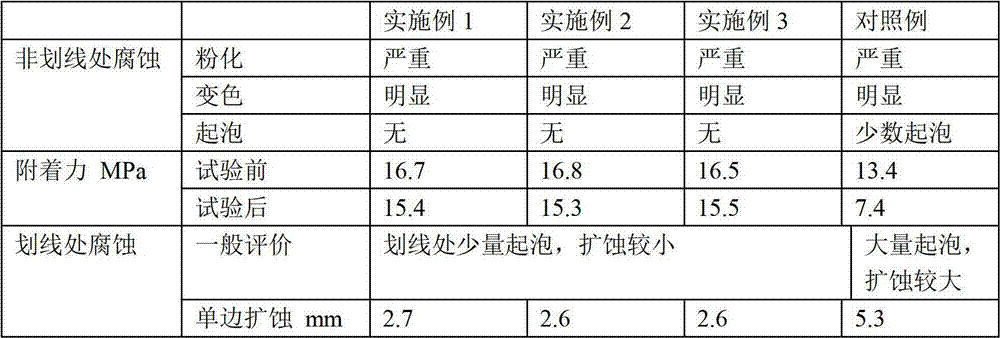

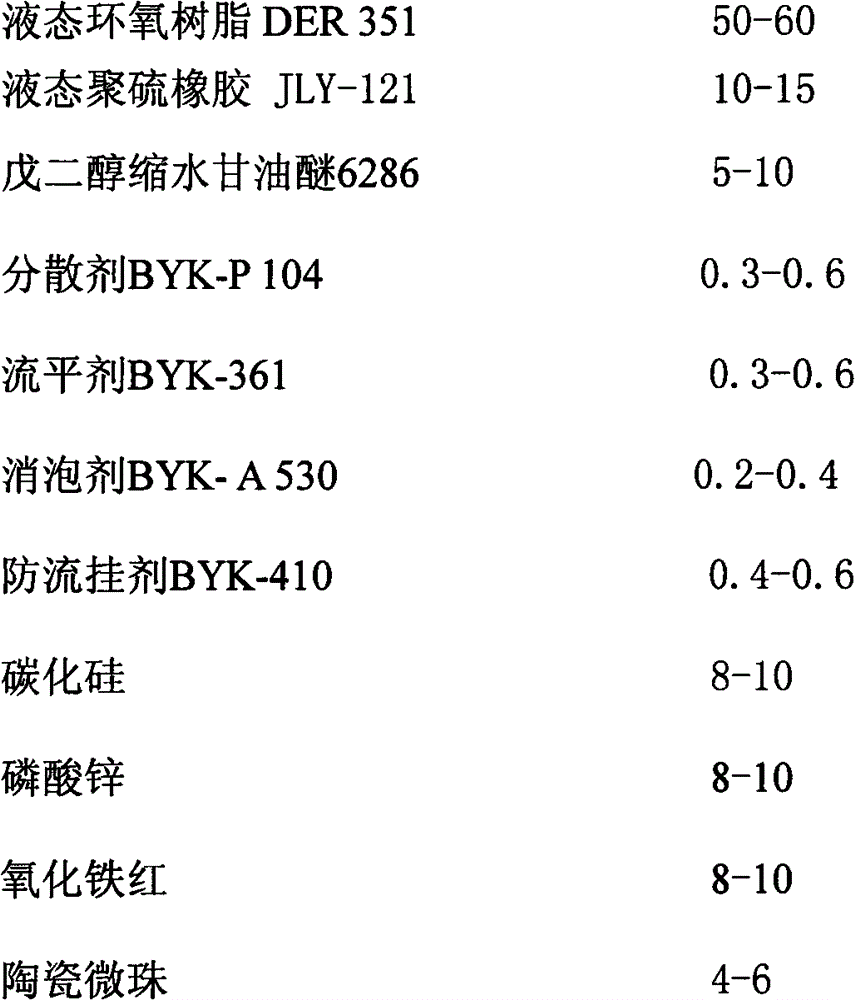

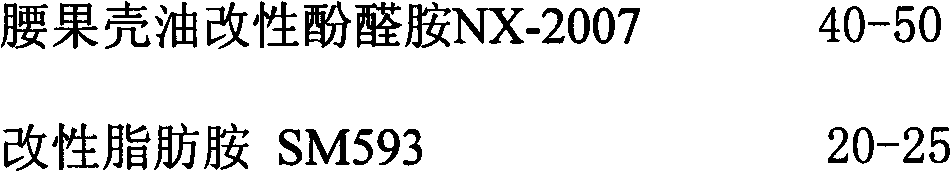

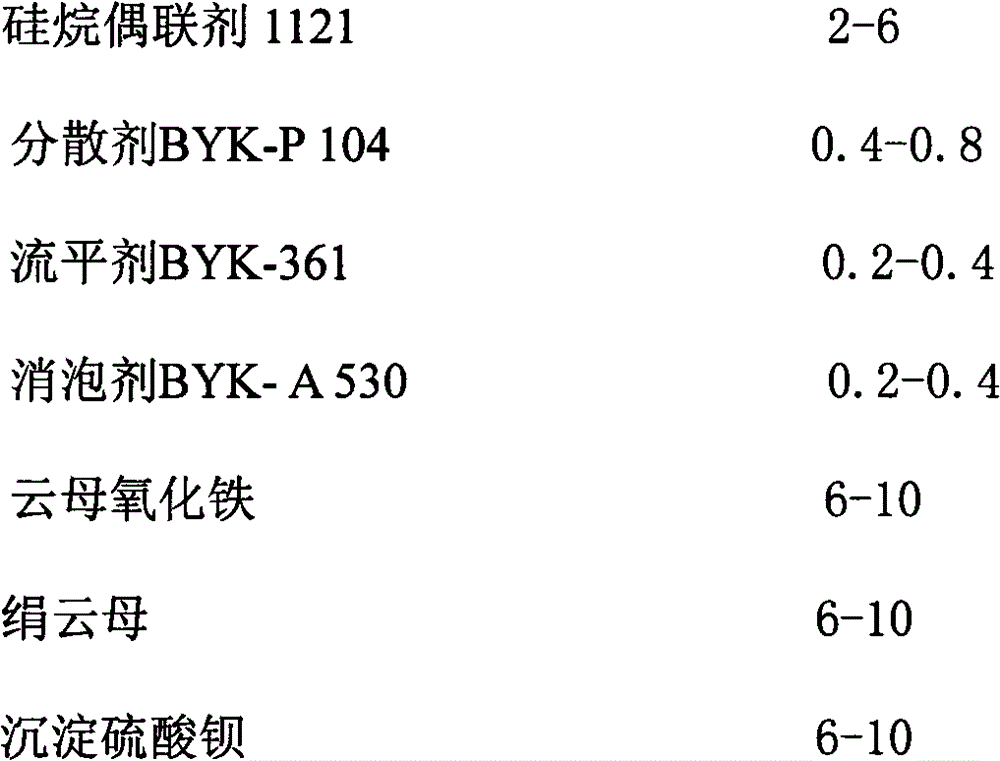

The invention discloses epoxy anti-corrosive paint used for underwater concrete. Liquid epoxy resin DER351 is used as a base material; polysulfide rubber is used as a flexibilizer; pentanediol diglycidyl ether 6286 is used as a diluent; zinc phosphate and iron oxide red are used as active anti-corrosive pigment; spherical silicon carbide, ceramic microspheres, mica iron oxide, sericite and precipitate vitriolic barium are used as fillings; cashew shell oil, modified phenolic aldehyde amine and modified aliphatic amine are used as curing agents; and a silane coupling agent 1121 is used as an adhesion promoter. With the cooperation of functional promoters, the raw materials are made into solvent-free double-component epoxy anti-corrosive paint used for underwater concrete through conventional preparation technique equipment. The epoxy anti-corrosive paint used for underwater concrete is highly environmental-friendly and can be directly painted or smeared on damp interfaces of underwater concrete and rapidly solidified into films; the coating has great adhesion and strong abrasion resistance and corrosion prevention. The epoxy anti-corrosive paint used for underwater concrete is widely applied to the corrosion prevention of various underwater concrete facilities.

Owner:北京国泰瑞华精藻硅特种材料有限公司

Epoxy anticorrosive paint for underwater steel

InactiveCN102719174AStrong adhesionPromote environmental protectionAntifouling/underwater paintsPaints with biocidesSolvent freeSolvent

The invention discloses epoxy anticorrosive paint for underwater steel. Liquid epoxy resin DER351 is used as base materials, liquid polysulfide rubber JLY-121 is used as toughening agent, pentanediol glycidyl ether 6286 is used as diluents, aluminum tripolyphosphate, zinc phosphate and iron oxide red are used as active rustproofing pigment, micaceous iron oxide, sericite and precipitated barium sulphate are used as filler, cashew shell oil modified phenolic aldehyde and modified fatty amine are used as curing agents, silane coupling agent 1121 is used as adhesion promoter, and solvent-free bicomponent epoxy anticorrosive paint for underwater steel is prepared by the normal preparation process under the cooperation of functional auxiliaries. The epoxy anticorrosive paint for underwater steel has fine environment friendliness, can be brushed or scraped at rusted damp interfaces of underwater steel, can be quickly cured to form films, excellent in coating adhesive power, capable of removing, converting and stabilizing rusts, high in resistance to impact, abrasion and corrosion and widely applicable to corrosion resistance of various underwater steel facilities.

Owner:BEIJING GUOTAI RUIHUA DIATOMS APPL TECH

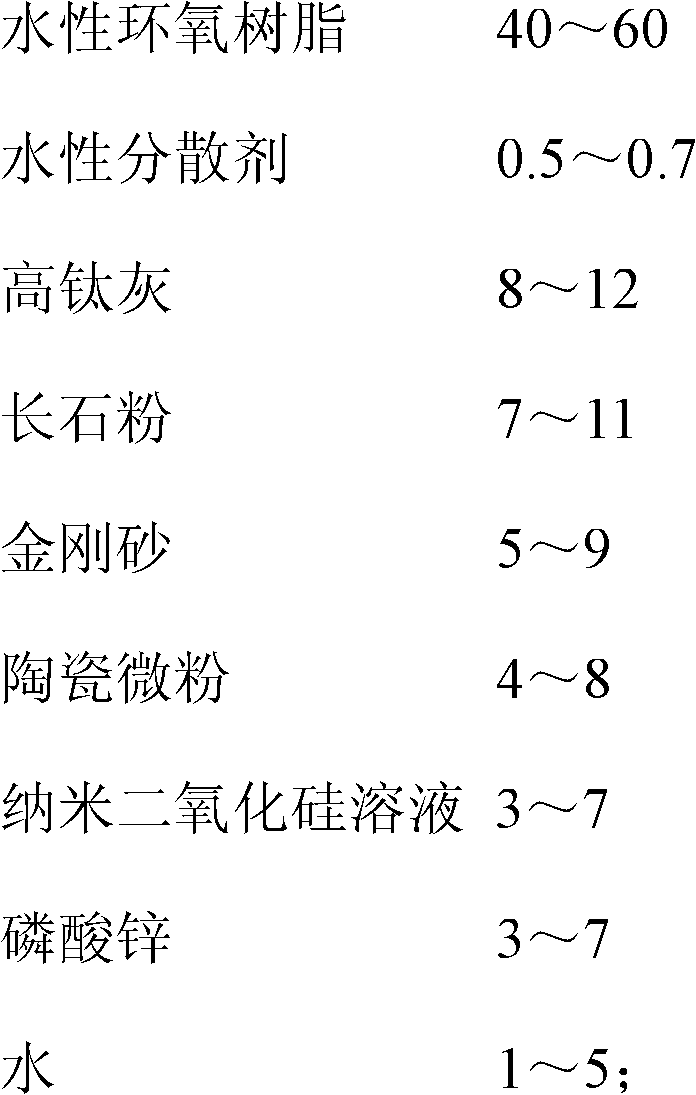

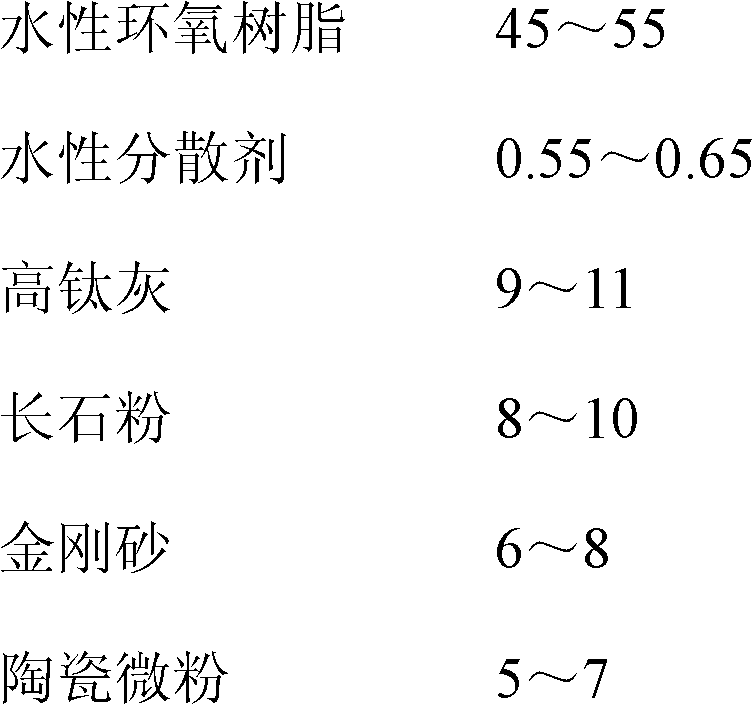

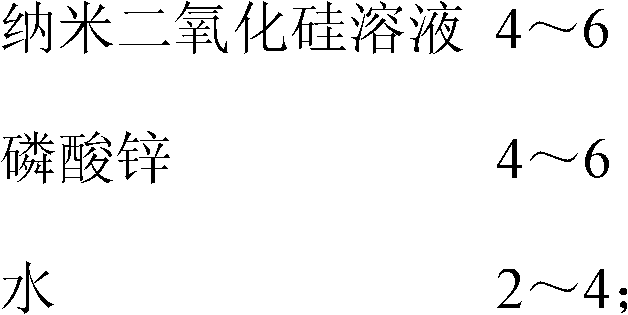

Waterborne epoxy anti-corrosive coating and preparation method thereof

InactiveCN102627905AImprove wear resistanceAccelerated corrosionAnti-corrosive paintsEpoxy resin coatingsEpoxyZinc phosphate

The invention discloses a waterborne epoxy anti-corrosive coating and a preparation method thereof. The coating comprises a component A and component B, wherein the component A comprises high titanium ash, feldspar powder, silicon carbide, ceramic fine powder, a nanometer silicon dioxide solution, zinc phosphate, water and the like; and the component B is a waterborne epoxy curing agent. The preparation method comprises the following steps of: adding a waterborne epoxy resin and a waterborne dispersing agent into a reaction kettle, starting a dispersing machine, adding the high titanium ash, feldspar powder, silicon carbide, ceramic powder, nanometer silicon dioxide solution, zinc phosphate and water in sequence, and dispersing; treating with a sand grinding machine; and adding auxiliary materials such as a waterborne antifoaming agent, a waterborne flatting agent and the like, and stirring to obtain a bottom and top-combined thick film waterborne epoxy anti-corrosive coating. The coating provided by the invention is corrosion resistant and wear resistant after one-time molding, the coating requirement of the inner wall of a steel structure bridge steel box girder is met, and the coating technical requirements of a plurality of severely-corrosive indoor steel structure platforms are met.

Owner:TIANCHANG JULONG TRAVEL PAINT

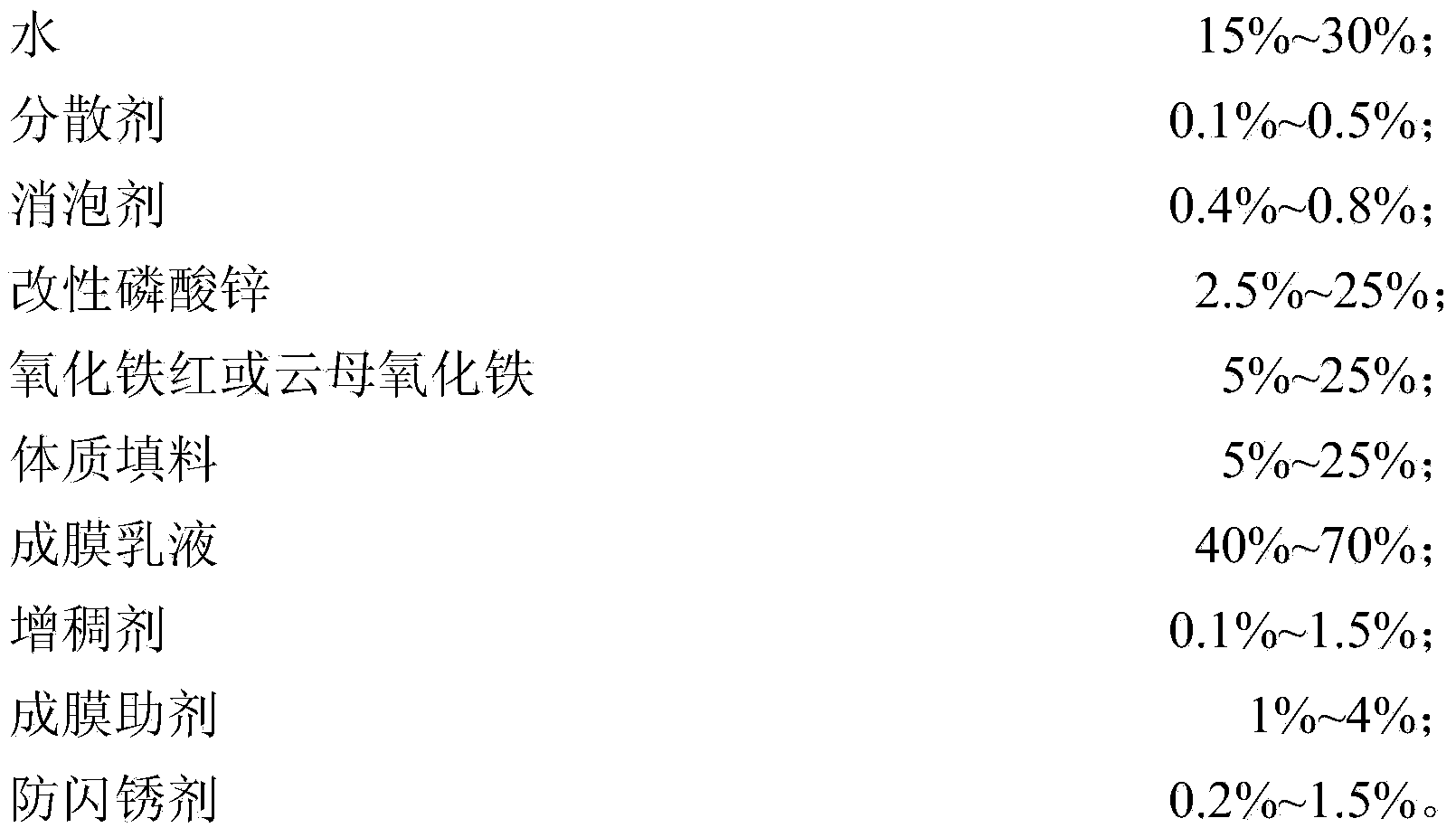

Bottom unified aqueous anticorrosive paint and preparation method

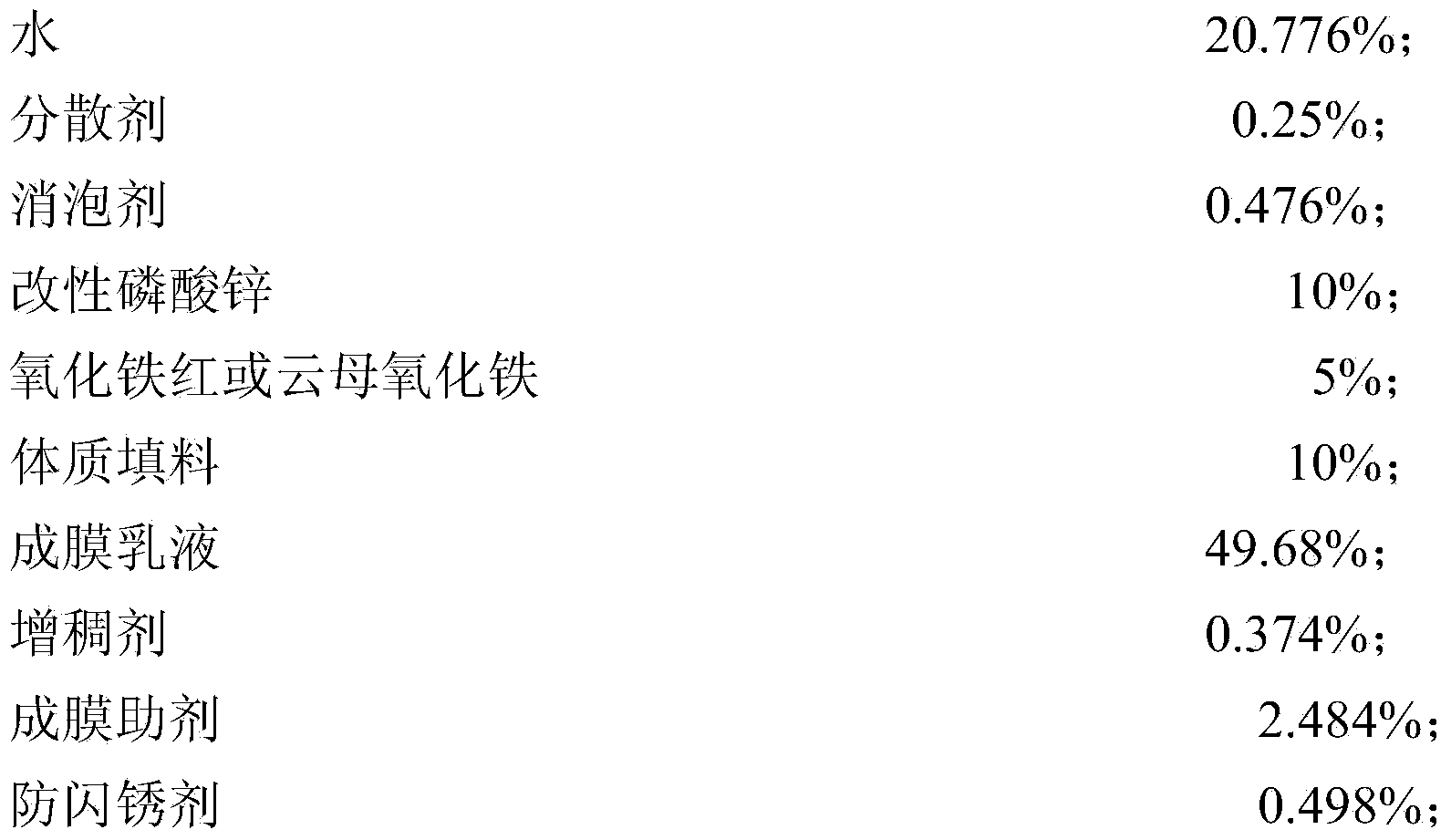

The invention discloses a bottom unified aqueous anticorrosive paint and its preparation method. the paint is composed of the following ingredients, by weight, 15-30% of water, 0.1-0.5% of a dispersant, 0.4-0.8% of an antifoaming agent, 2.5-25% of modified zinc phosphate, 5-25% of iron oxide red or mica iron oxide, 5-25% of a body filler, 40-70% of a film-forming emulsion, 0.1-1.5% of a thickening agent, 1-4% of a film-forming auxiliary agent and 0.2-1.5% of a flash-rust inhibitor. According to the bottom unified aqueous anticorrosive paint, each ingredient with specific weight percentage interacts with each other. Thus, comprehensive performance of the paint is raised, and in particular, anticorrosive performance of the paint is excellent. The paint is environmentally friendly. Problems of heavy odor, high pollution and the like existing in a traditional oil paint are solved. Meanwhile, each anticorrosion index is guaranteed. The product has simple preparation and construction technologies, is easy to carry out, is easy for large-scale industrial production, and has a wide application prospect.

Owner:ZHEJIANG UNIV

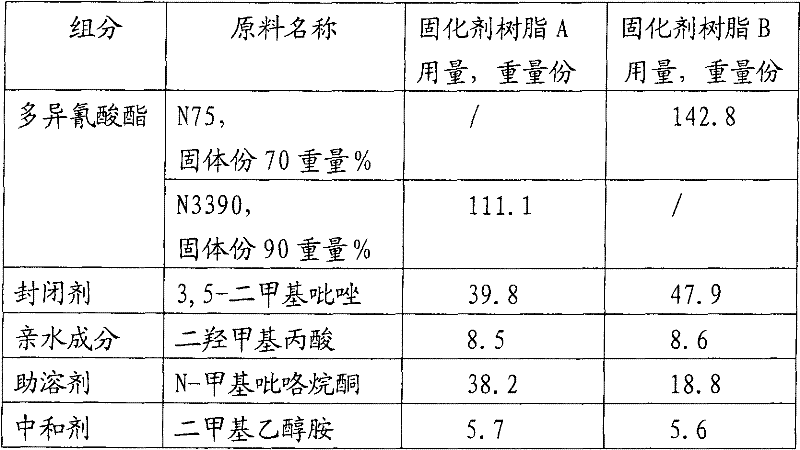

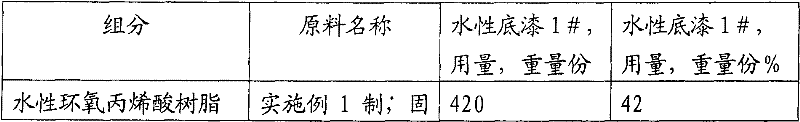

Aqueous primer used for bicycles

The invention relates to an aqueous primer used for bicycles, which comprises the following components in percentage by weight: 25-45% of aqueous epoxy acrylate resin, 2-10% of curing agent resin, 1-3% of neutralizing agent dimethylethanolamine, 2-10% of compound anticorrosive pigment, 5-20% of tinting pigment and filler, 0.1-0.5% of antifoaming agent, 0.1-0.5% of flatting agent and 20-40% of deionized water, wherein the sum of the content of all components is 100%. The aqueous epoxy acrylate resin accounts for 10-40% of the total mass of epoxy resin; the curing agent resin comprises aqueous closed-type polyurethane curing agent resin and amino curing agent resin, wherein the mass ratio of the aqueous closed-type polyurethane curing agent resin to the amino curing agent resin is 1:5-5:1; the aqueous closed-type polyurethane curing agent resin is decapsulated and solidified at the temperature of 130DEG C; the amino curing agent resin is carbinol or butylated amino melamine formaldehyderesin; and the compound anticorrosive pigment comprises modified zinc phosphate, zinc oxide and ion exchange type anticorrosive pigment. The aqueous primer disclosed by the invention is especially suitable for preventing rust and corrosion of structures, such as bicycles and the like.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

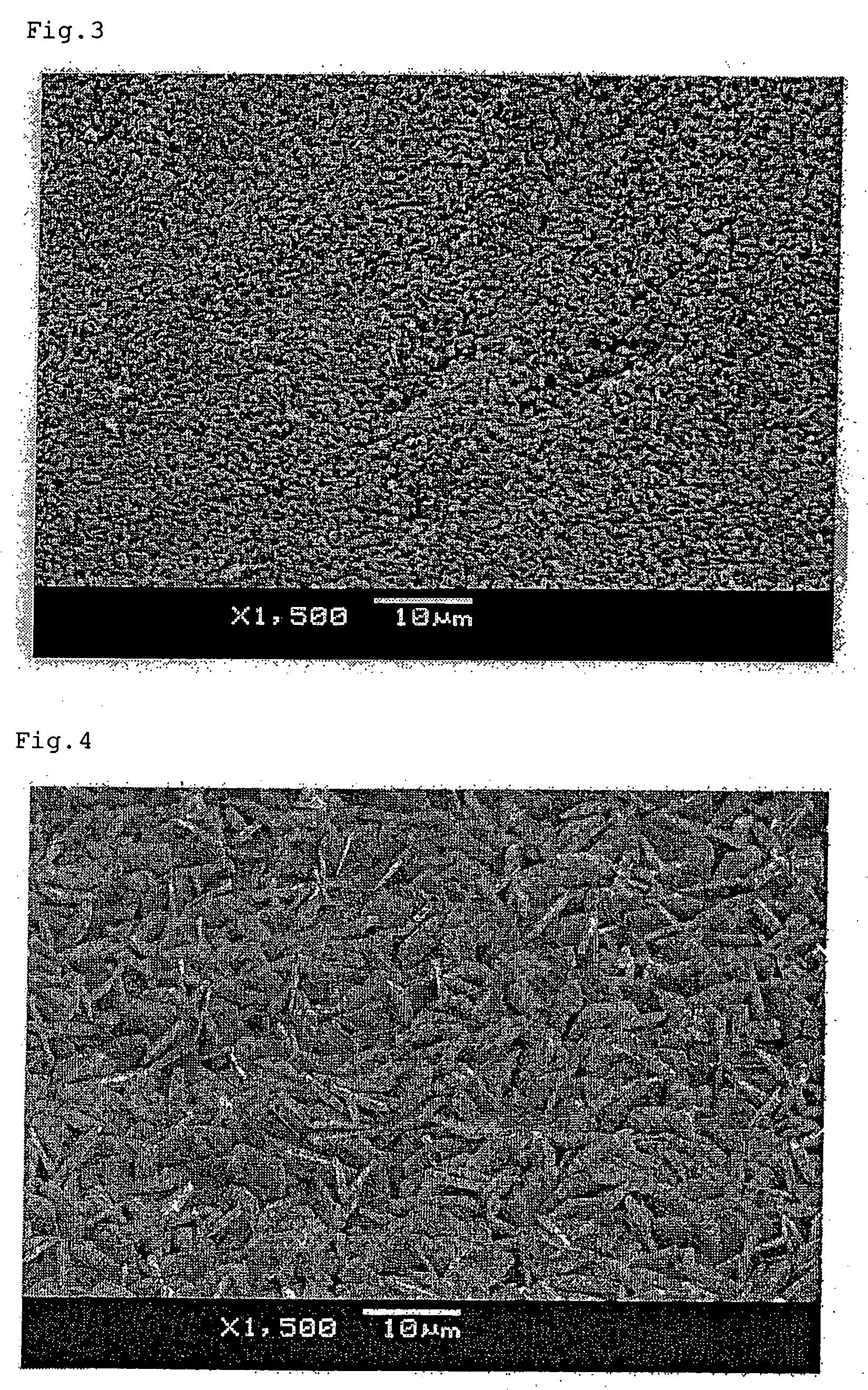

Surface conditioner containing zinc phosphate, phosphate chemical conversion treatment steelboard, coating steelboard and zinc phosphate dispersion liquid

A zinc phosphate-containing surface conditioning agent to be used for surface conditioning as pretreatment for zinc phosphate conversion coating of a metallic material, which contains from 500 to 20,000 ppm of zinc phosphate and which has a pH of from 3 to 11, wherein said zinc phosphate has an average particle size of at most 3 mu m and D90 of at most 4 mum.

Owner:NIPPON PAINT SURF CHEM +1

Slag-free low-temperature rapid electrolytic phosphorizing liquid and phosphorizing process thereof

ActiveCN102719872AIncrease productivityPhosphating temperature is lowPhosphatisationWire rodZinc phosphate

The invention provides slag-free low-temperature rapid electrolytic phosphorizing liquid and a phosphorizing process thereof. The phosphorizing liquid comprises, by mass, zinc ions 10-80g / L, phosphate radicals 10-120g / L, accelerators 41-160g / L, organic acid 0-5g / L and dissolved metal elements 0.1-10g / L, wherein the phosphate radicals refer to P2O5. According to the process, inert titanium plates or titanium nets serve as anodes while treated steel wire rods serve as cathodes, a zinc phosphate film is uniformly formed on the surfaces of the steel wire rods by applying a certain current, and the film weight is higher than 4g / m<2> so as to meet drawing requirements. The phosphorizing temperature ranges from 10 DEG C to 60 DEG C, the phosphorizing time is 5-120 seconds, phosphorized slags are avoided, and accordingly the phosphorizing process has the obvious advantages of high efficiency, energy conservation and environmental protection.

Owner:派诺(湖北)绿色化学智造有限公司

Fire-proof corrosive-resistant paint for superthin steel structure

A fireproof and corrosive-resistant pigment for super-thin steel construction is prepared by mixing acrylic modified resin with amino modified resin and epoxy resin proportionally to obtain mixed resin base materials and proportioning carbonizing catalyst polyphosphacid ammonium, carbonizing agent pentaerythrite, foaming agent cyanurotriamide with solvent 200# solvent oil, antiseptic zinc phosphate, butyrin acetate, titanium pigment, chlorinated paraffin, zinc oxide and auxiliaries. It has thin coating, excellent decorative function and adhesion. It can be used for hotels, shopping and enterprises

Owner:刘清龚

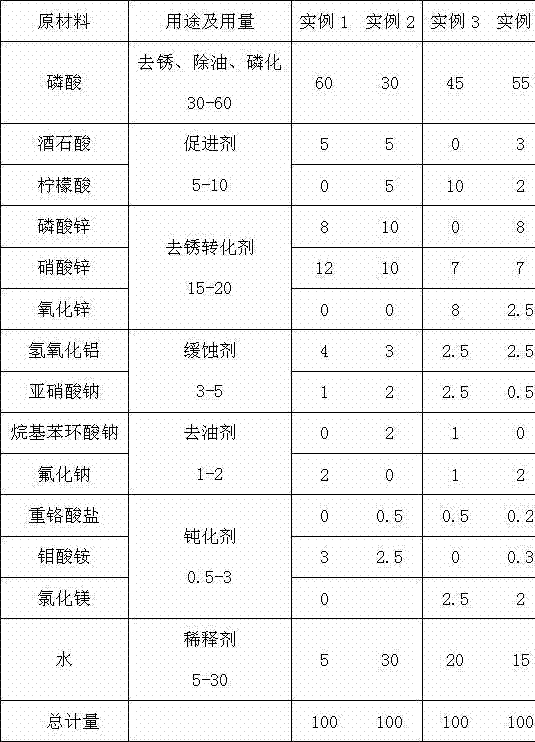

Multifunctional metal surface treatment solution

InactiveCN102925883AThe formula is scientific and reasonableAchieve rust removalMetallic material coating processesAluminium hydroxidePhosphoric acid

The invention discloses a multifunctional metal surface treatment solution which comprises the following components in percentage by mass: 30-60 percent of phosphoric acid, 5-10 percent of accelerator, 15-20 percent of derusting transforming agent, 3-5 percent of corrosion inhibitor, 1-2 percent of degreaser, 0.5-3 percent of passivator and 5-30 percent of water, wherein the accelerator is tartaric acid or / or citric acid, the derusting transforming agent is zinc phosphate or / and zinc nitrate or / and zinc oxide; the corrosion inhibitor is aluminium hydroxide or / and sodium nitrite, the degreaser is sodium alkylbenzenesulfonate or / and sodium fluoride; and the passivator is bichromate or / and ammonium molybdate or / and magnesium chloride. The multifunctional metal surface treatment solution has the advantages of scientific and reasonable formula, capability of removing rust, preventing rust and removing grease by being directly sprayed on the surface of metal, and also capability of replacing an anti-corrosive primer.

Owner:郭衡怀

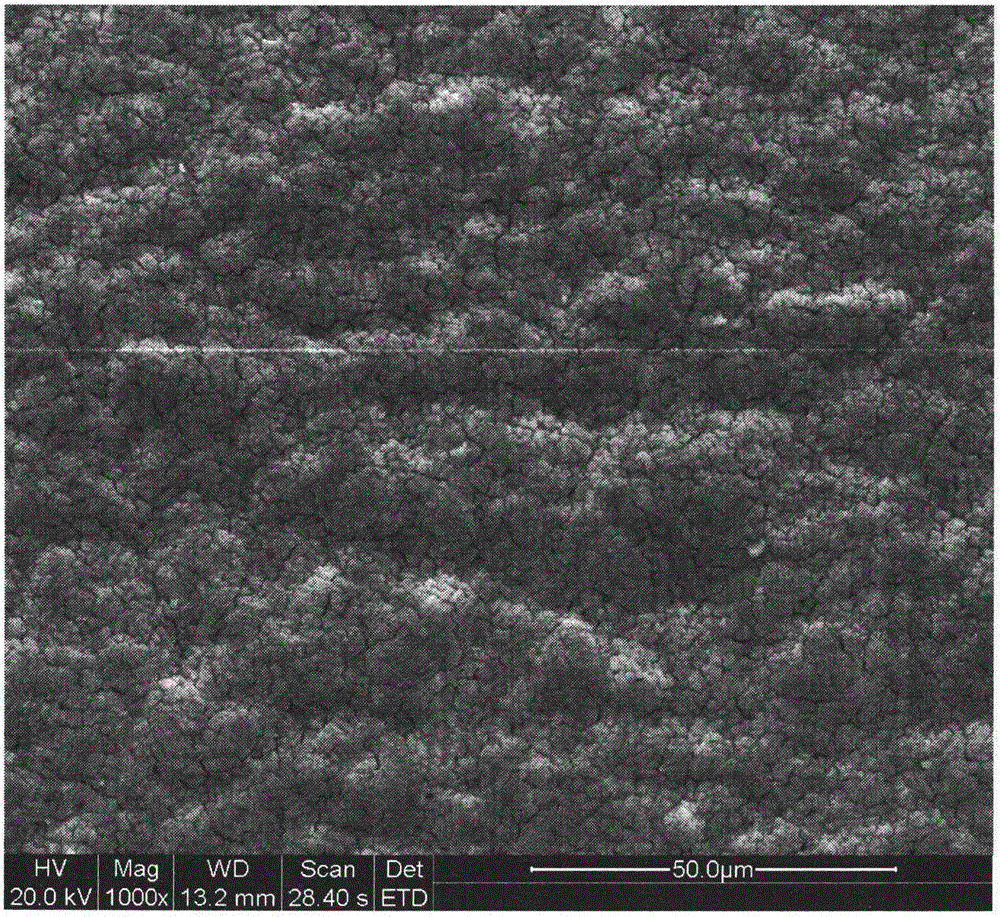

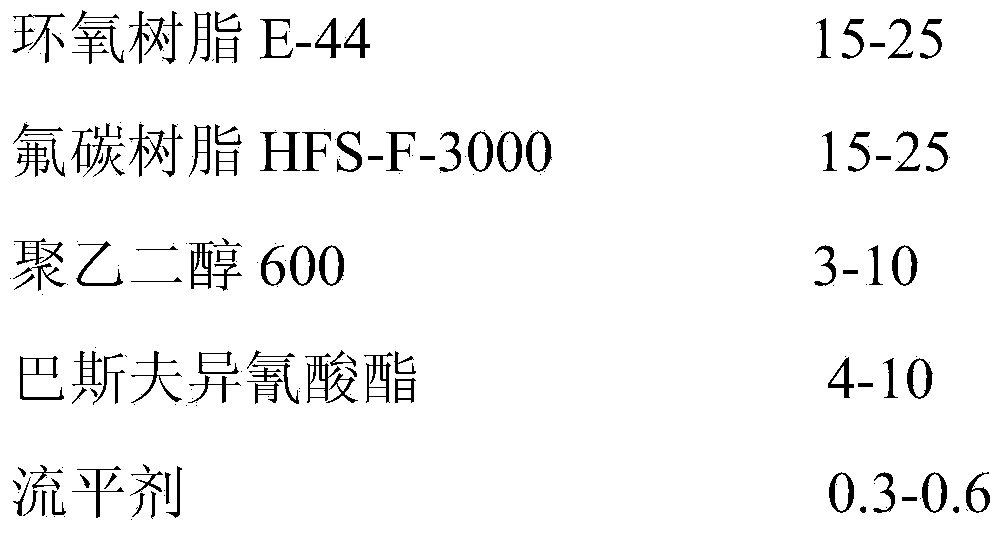

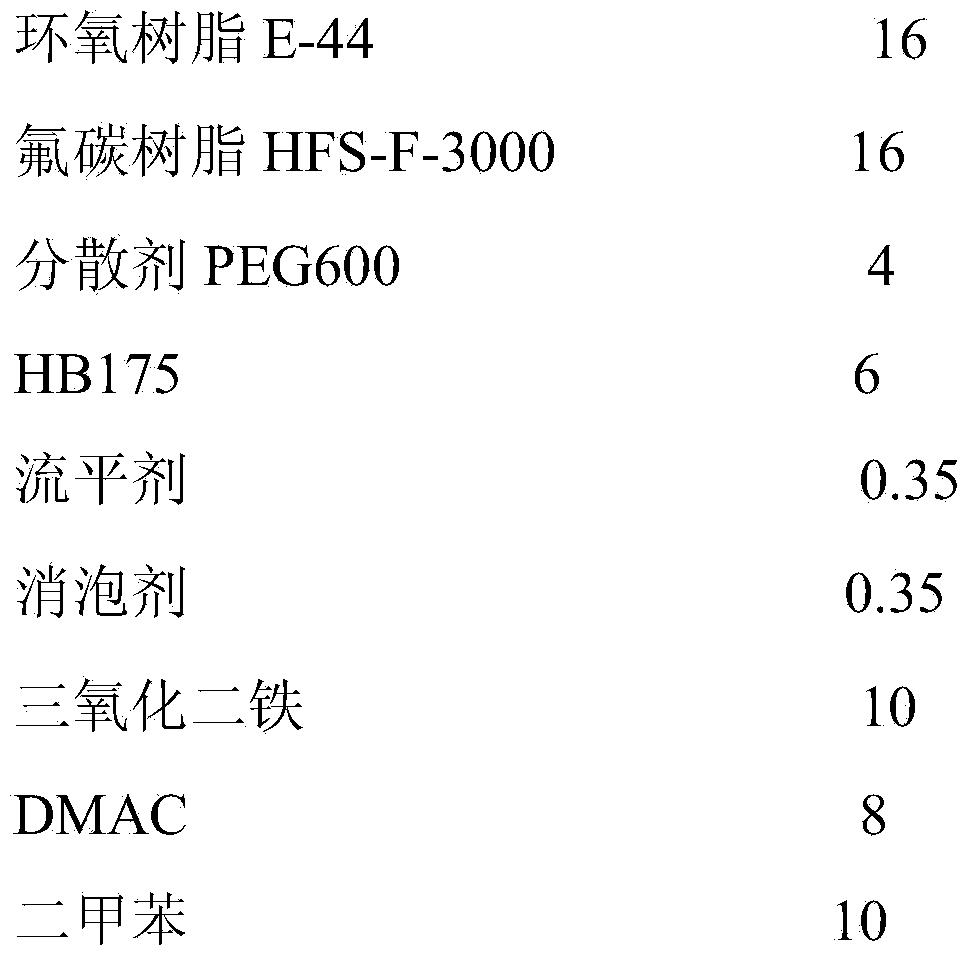

Oceanic heavy corrosion resistant self-stratifying coating

ActiveCN103525284AImprove anti-corrosion performanceStrong adhesion between layersAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyZinc phosphate

The invention discloses an oceanic heavy corrosion resistant self-stratifying coating which is prepared by using a conventional preparation process under the coordination of all functional auxiliaries including epoxy resin-44 and fluorocarbon resin HFS-F-3000 as base stocks, Basf isocyanate as a curing agent, N-dimethylacetamide and dimethylbenzene as solvents, polyethylene glycol 600 as a dispersing agent and ferric oxide and zinc phosphate as pigments. The oceanic heavy corrosion resistant self-stratifying coating has favorable corrosion resistance and strong interlayer adhesion, and can be used for realizing one-step industrial coating, reducing processes, lowering cost and greatly increasing the actual production efficiency.

Owner:SHANDONG UNIV OF SCI & TECH

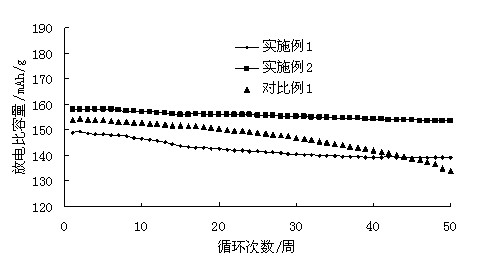

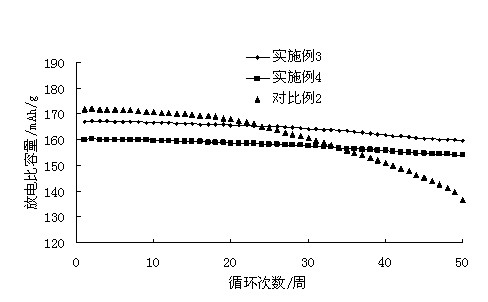

Lithium ion battery anode material and manufacturing method thereof

InactiveCN102637877AUniform particle sizeHas a layered crystal structureCell electrodesPhosphateManganese

The invention discloses a lithium ion battery anode material and a manufacturing method of the lithium ion battery anode material. The anode material is cobalt nickel oxide manganese with a layer structure and has the chemical composition of LiNil-x-yCoxMnyO2, wherein x is equal to and larger than 0.15 and is equal to and less than 0.3, and y is equal to and larger than 0.2 and is equal to and less than 0.4. The manufacturing method provided by the invention has the following steps: the cobalt nickel oxide manganese powder is manufactured through a coprecipitation method, metal phosphate is adopted as a cladding material with the cladding quantity as 0.5-1.5% of the anode material; and the cobalt nickel oxide manganese is externally cladded by zinc phosphate through fluidization. The cladded battery material after modification with the manufacturing method has high special capacity and has good cycling stability at high temperature.

Owner:KUNMING UNIV OF SCI & TECH

Aqueous phosphating composition and process for metal surfaces

InactiveUS6179934B1High-quality coatingLess spaceSolid state diffusion coatingZinc phosphateHydroxylamine

An aqueous zinc phosphate conversion coating that contains 5 to 50 g / L of phosphate ions, 0.2 to 10 g / L of zinc ions, and 0.5 to 4.0 g / L as hydroxylamine of a hydroxylamine source, and also: (1) contains 0.01 to 5.0 g / L polycarboxylic acid or salt thereof and / or starch phosphate; or (2) has a zinc ions / phosphate ions weight ratio below 0.27 and a zinc ions concentration of at least 2.0 g / L forms high quality zinc phosphating coatings on metal surfaces even if the surfaces have not been previously conditioned by contact with a dispersion of colloidal titanium.

Owner:HENKEL CORP

Preparation method of long-afterglow luminescent material zine phosphate

InactiveCN1443827ASimple preparation processVariety of afterglow colorsLuminescent compositionsPhosphateNitrogen gas

The present invention relates to a long afterglow luminous material zinc phosphate. Its preparation method includes the following steps: mixing the carbonates, oxides, phosphates, nitrates, acetaets and sulfates of the above-mentioned elements in the representation formula as raw material to obtain their mixture, grinding said mixture and flux and uniformly mixing them; selecting air, nitrogen gas, carbon, carbon monoxide gas, hydrogen gas or nitrogen-hydrogen mixed gas, presintering at 200-600 deg.C for 2-6 hr., cooling to room temp., secondary grinding and uniformly mixing them, sintering at 500-1100 deg.C for 4-10 hr. so as to obtain said invented product.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Waterborne antirust paint and preparation method thereof

ActiveCN105238232AImprove densification performanceImprove shielding effectAntifouling/underwater paintsPaints with biocidesEpoxyPolymer science

The invention discloses waterborne antirust paint and a preparation method thereof. The waterborne antirust paint is prepared from, by mass, 10-25 parts of waterborne acrylic acid modified epoxy ester, 0.6-1.2 parts of neutralizer, 20-30 parts of deionized water, 0.5-1.5 parts of dispersing agents, 0.2-0.5 part of defoaming agent, 14-18 parts of iron oxide red, 2-4 parts of mica powder, 6-10 parts of modified zinc phosphate, 10-14 parts of precipitated barium sulphate, 1-2 parts of propylene glycol, 10-15 parts of styrene-acrylic emulsion, 0.5-1.0 part of coalescing agent, 0.5-1.0 part of waterborne flush rust prevention agent, 0.5-1.5 parts of thickening agents and 0.2-0.5 part of mildew prevention agent. The waterborne antirust paint is high in film hardness, good in adhesive force and excellent in corrosion-resistant performance and mechanical performance, dryness and initial water resistance of paint films are remarkably improved due to the addition of styrene-acrylic emulsion, and the flush rust restraining performance of paint films is improved due to the addition of the waterborne flush rust prevention agent. Water serves as the diluent for the waterborne antirust paint, VOC emission in production and construction projects is greatly reduced, and the waterborne antirust paint is safe, environmentally friendly and capable of being widely used for paint coating on the aspects of steel structures, pipelines, automobile parts and the like.

Owner:西北永新涂料有限公司

Production method of cold-drawn precision seamless steel pipes

InactiveCN104338777AImprove performanceImprove low temperature impact toughnessAcid washingLubrication

The invention relates to a production method of cold-drawn precision seamless steel pipes. The production method comprises the steps of: heating: pipe blanks are heated in an annular furnace; perforation: the heat pipe blanks are perforated by a perforation machine; annealing: the pipe blanks are annealed; cold rolling: the annealed pipe blanks are leaded into a pipe rolling machine for cold rolling to obtain rolled pipes; stress relieving: the rolled pipes are leaded into a heating furnace for heating to obtain annealed pipe blanks; acid washing treatment: the acid washing is performed for the annealed pipe blanks to remove scales on the surfaces; phosphating treatment: zinc phosphate chemical generation films are formed on the surfaces of the pipe blanks; saponification treatment: such lubrication films as metallic soaps are formed on the films; cold drawing: the cold drawing is performed for the pipe blanks to be cold drawn to obtain cold-drawn pipes; normalization air-cooling treatment; first straightening treatment; induction furnace quenching treatment; box furnace tempering treatment; honing; thermal straightening treatment; and obtaining of the cold-drawn precision seamless steel pipes. The production method obtains the cold-drawn precision seamless steel pipes with high yield strength, high tensile strength, precise sizes and smooth surfaces.

Owner:WUXI DAJIN HIGH PRECISION COLD DRAWN STEEL TUBE

Surface conditioner and method of surface conditioning

ActiveUS20050187326A1Improve dispersion stabilityInhibit galvanic corrosionOther chemical processesMetallic material coating processesMonomer compositionPhosphate

A surface conditioner contains zinc phosphate particles of D50 of 3 μm or less and has a pH of 3 to 12, and also contains at least one of (1) carboxylate group-containing copolymers obtained by copolymerizing a monomer composition containing at least one species selected from acrylic acid, maleic acid, maleic anhydride, itaconic acid and itaconic anhydride in an amount less than 50% by weight and at least one species selected from the group consisting of a sulfonic acid monomer, styrene, olefin monomers, amino group-containing monomers and certain polyoxyalkylene derivatives, (2) certain polyamino acids, and (3) certain phosphate esters.

Owner:NIPPON PAINT SURF CHEM

Anti-drag wear-resistant solvent-free coating with low-viscosity for pipeline

ActiveCN102417780AStrong adhesionGood flexibilityAnti-corrosive paintsEpoxy resin coatingsEpoxyWear resistant

The invention relates to the technical field of coatings, in particular to an anti-drag wear-resistant solvent-free coating with low-viscosity for a pipeline. The anti-drag wear-resistant solvent-free coating with the low-viscosity comprises a component A and a component B, wherein the component A comprises epoxy resin, an active diluent, a flatting agent, an antifoaming agent, a dispersant, a thixotropic agent 1, a thixotropic agent 2, zinc phosphate, silica, iron oxide red powder, aluminum triphosphate and white pottery powder; the component B comprises modified amine and a thixotropic synergistic agent; and the component A and the component B are used together in the mass ratio of (3-5):1. The solvent-free coating with the low-viscosity has the positive effects of freeness from volatilizable solvent, capability of eliminating coating pin holes, high adhesion, high permeation resistance, high wear resistance, high corrosion resistance, smooth coating surface after being sprayed, good anti-drag and wear-resisting effects, and popularization and application prospects.

Owner:SHANGHAI HILONG SHINE NEW MATERIAL

Aqueous rusty anti-corrosion paint and preparation method thereof

ActiveCN101701126AGood weather resistanceImprove salt spray resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyZinc phosphate

The invention provides an aqueous rusty brushing anti-corrosion paint for an electric transmission and transformation iron tower and a preparation method thereof; the formulation of the paint comprises liquid epoxide resin, aqueous epoxy hardener, rustproofing pigment, extender pigment and other paint additives, and deionized water is used as solvent; liquid epoxide resin includes bisphenol A-type liquid epoxide resin and I-type aqueous epoxy hardener, the rustproofing pigment includes aluminium trippolyhosphate, zinc phosphate and the like, and the extender pigment includes barium sulfate, talcum powder and titanium and the like; the anti-corrosion paint prepared by the invention can be used for anticorrosion of a rusted iron tower surface, slight treatment to the surface of the rusted iron tower is only needed, so as to remove surface bulk materials, grease and other bulk material, and then coating can be carried out; the coating can remarkably improve the corrosion resistance of steel products and has good salt fog resistance and weather resistance.

Owner:CHINA ELECTRIC POWER RES INST +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com