Seawater corrosion-resistant paint

A seawater and paint-resistant technology, applied in the field of paint, can solve problems such as cracks and metal fractures, and achieve the effects of reducing permeability, reducing transmittance, and excellent seawater corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

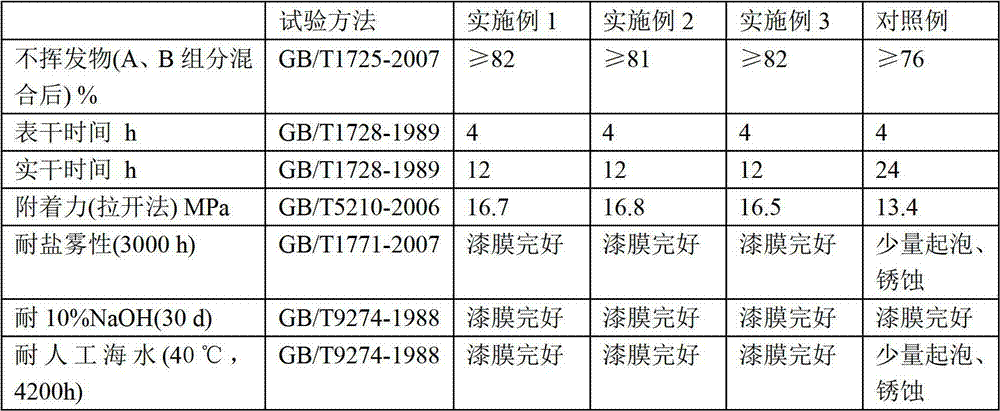

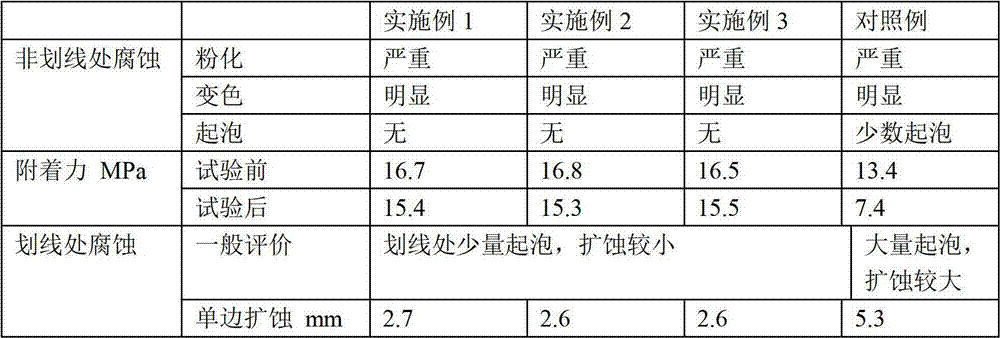

[0023] Prepare the components according to the weight ratio shown in Table 1.

[0024] Table 1 The weight ratio of Example 1 to Example 3

[0025]

[0026] The molecular weight of the above-mentioned polyvinyl acetate is 200,000 to 300,000.

[0027] The above-mentioned defoaming agent is tributyl phosphate.

[0028] The aforementioned coupling agent is silane coupling agent TM-30.

[0029] The epoxy resin is epoxy resin E-42.

[0030] The curing agent adopts phenolic hexamethylene diamine.

[0031] The solvent is ethyl acetate.

[0032] The preparation method is:

[0033] S1: Take chloroprene rubber, polytetrafluoroethylene, polyvinyl acetate, add half the weight of the solvent, and stir evenly;

[0034] S2: Add epoxy resin, petroleum resin, coupling agent, defoamer, and silica sol to the mixture obtained in S1, and stir it evenly at a speed of 600-1000 rpm;

[0035] S3: Add cerium nitrate, montmorillonite, red iron oxide, zinc phosphate, barium sulfate, aluminum tripolyphosphate, titanium ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com