Seawater corrosion-resistant steel and manufacturing method thereof

A manufacturing method and seawater-resistant technology, applied in the field of corrosion-resistant steel and its manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

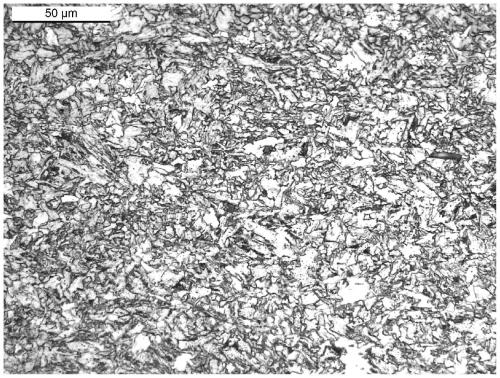

Image

Examples

Embodiment 1-6

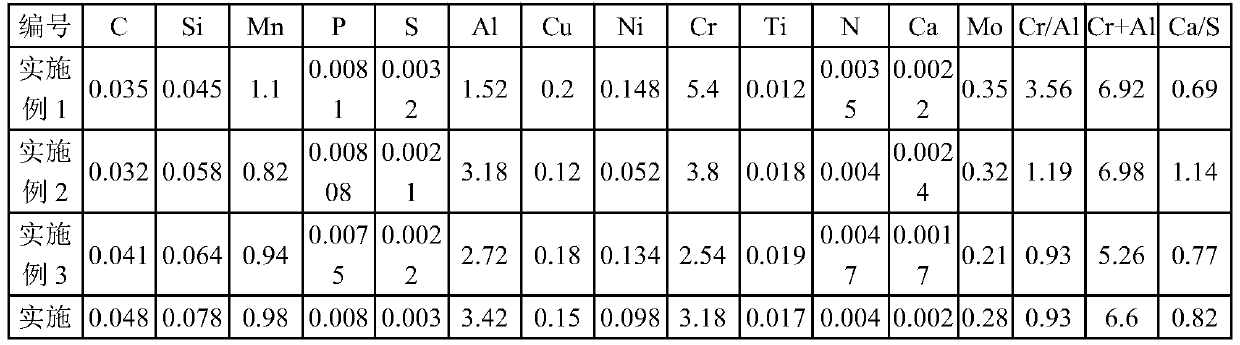

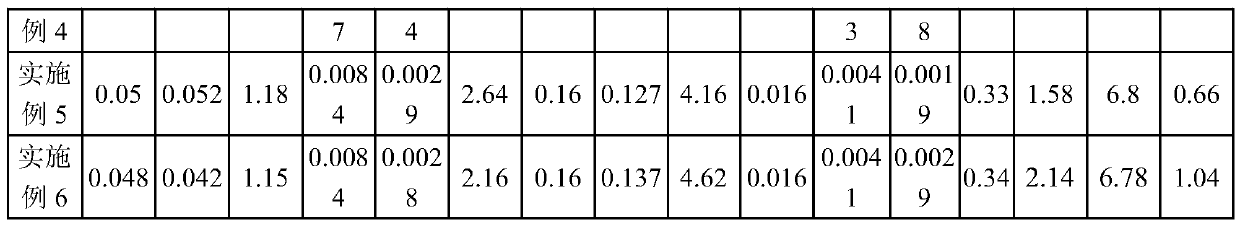

[0052] Table 1 lists the mass percentage (wt%) of each chemical element in the seawater corrosion-resistant steel of Examples 1-6. Table 1. (wt%, the balance is Fe and other inevitable impurity elements except P, S and N)

[0053]

[0054]

[0055] As can be seen from Table 1, compared with the prior art, each embodiment of this case does not adopt the Cu-Cr-Mo composition system in the prior art, and there is no higher content of P, S, C and Si. The design of Cr-Al-Mo composition system is adopted, and the corrosion resistance of seawater is improved through the addition of Cr and Al alloy elements, and the occurrence of pitting corrosion is suppressed by adding Mo, and the high content of Cr is eliminated to inhibit corrosion in seawater environment. "Reverse" effect, thereby further improving seawater corrosion resistance.

[0056] The manufacturing method of the seawater corrosion-resistant steel of embodiment 1-6 adopts the following steps to make:

[0057] (1) Smel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com