Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89 results about "Wear corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosive wear is material degradation wherein both wear and corrosion wear mechanisms are present. The effects of both wear and corrosion can result in intense damage or material losses. The effects can be more severe than when encountering either of these two mechanisms alone.

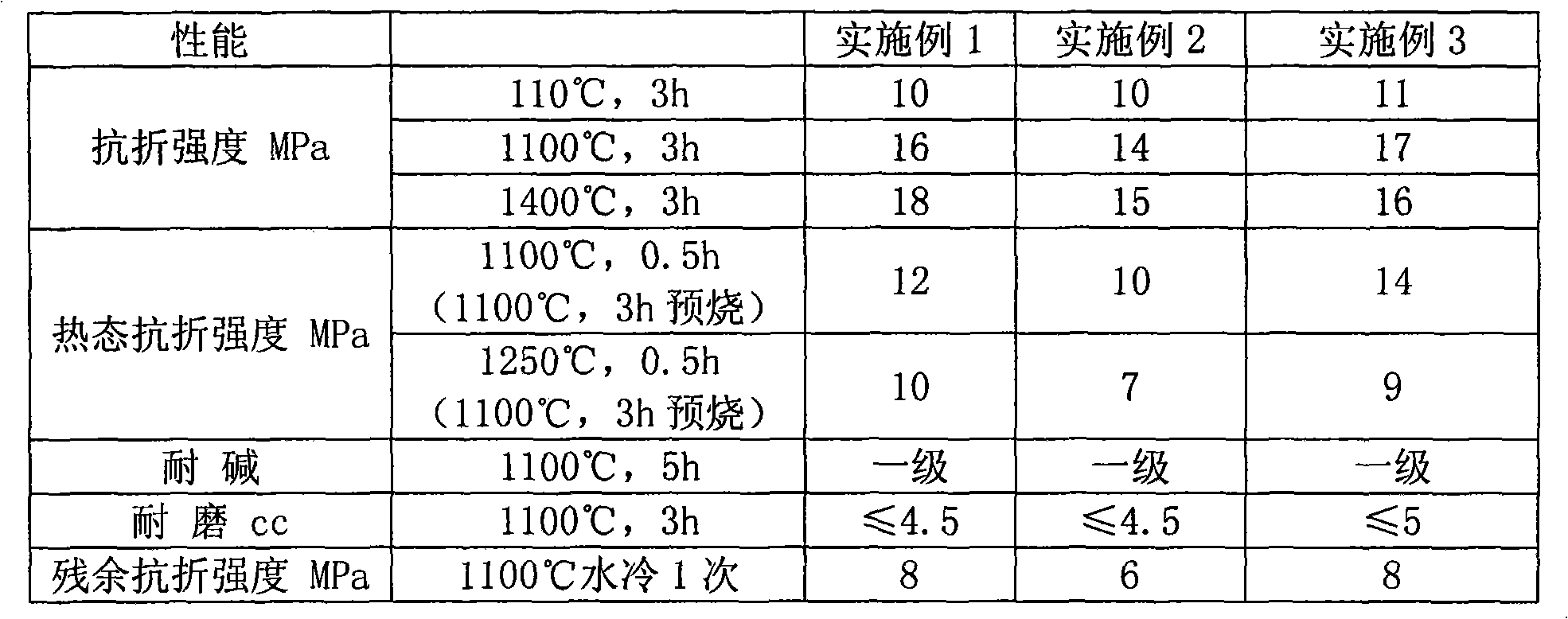

Wear and corrosion resistant castable prepared from bauxite-based homogenous material and preparation method thereof

ActiveCN101885617AUniform structureSmall fluctuations in water addition during constructionPliabilityCement kiln

The invention discloses wear corrosion resistant castable prepared from a bauxite-based homogenous material and a preparation method thereof, which belong to the technical field of castable refractory. In the invention, by using the characteristics of the bauxite-based homogenous material, such as homogeneous chemical components and structure, stable performance, mulite main crystal phase, small linear change, high high-temperature strength and certain flexibility due to mutual insertion of micro crystals and the like, the shortcomings of low middle-temperature strength and poor wear resistance and alkali corrosion resistance of the conventional high-aluminum bauxite castable are overcome, and the problems of low middle-temperature strength, poor wear resistance and poor alkali, chloride and sulphur corrosion resistance of the conventional high-aluminum and corundum castable are effectively solved. The wear and corrosion resistant castable with high middle-temperature performance is prepared. The wear corrosion resistant castable and the preparation method thereof have the advantages of small fluctuation of water adding amount in construction, stable usability, reduction rate of partial corrosion, prolonged service life and wide application to a kiln hood, a grate cooler, a tertiary air duct and a decomposing furnace of a dry process cement kiln and relative parts of other ceramic and petrified thermo-technical kilns and the like.

Owner:YANGQUAN JINYU TONGDA HIGH TEMPERATURE MATERIALS +1

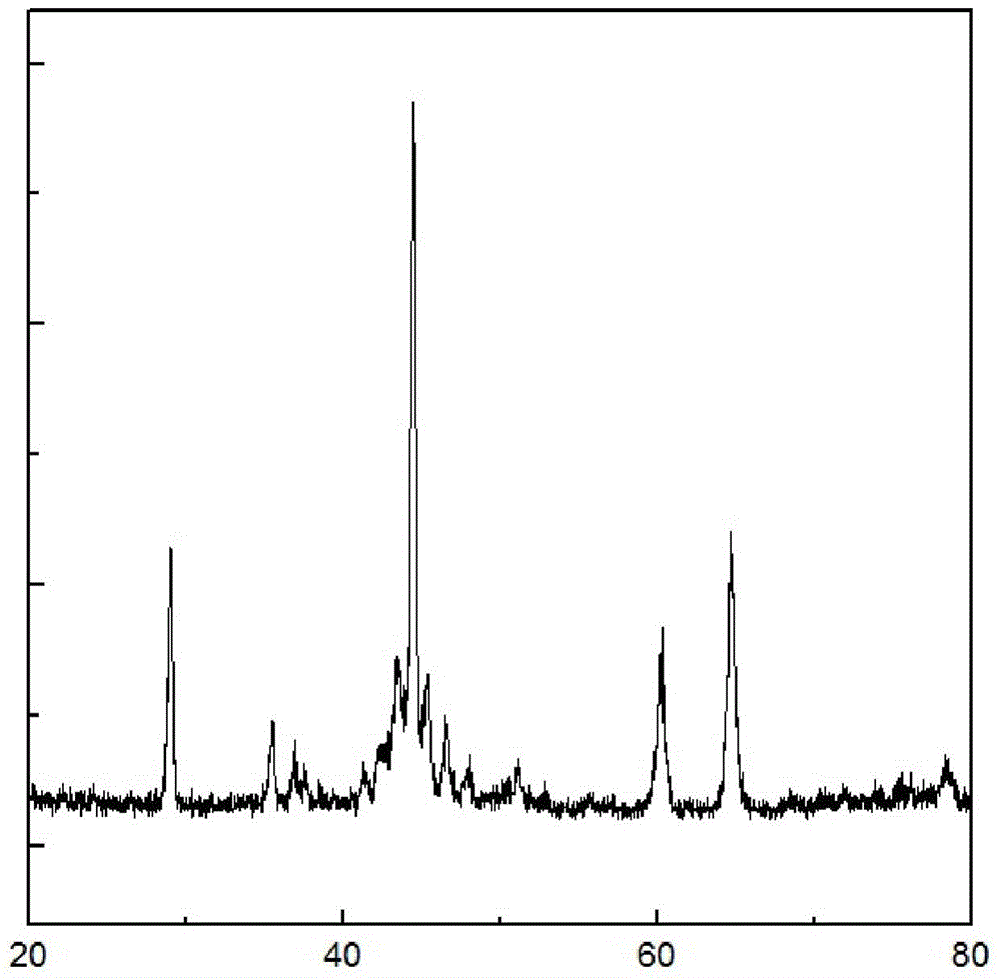

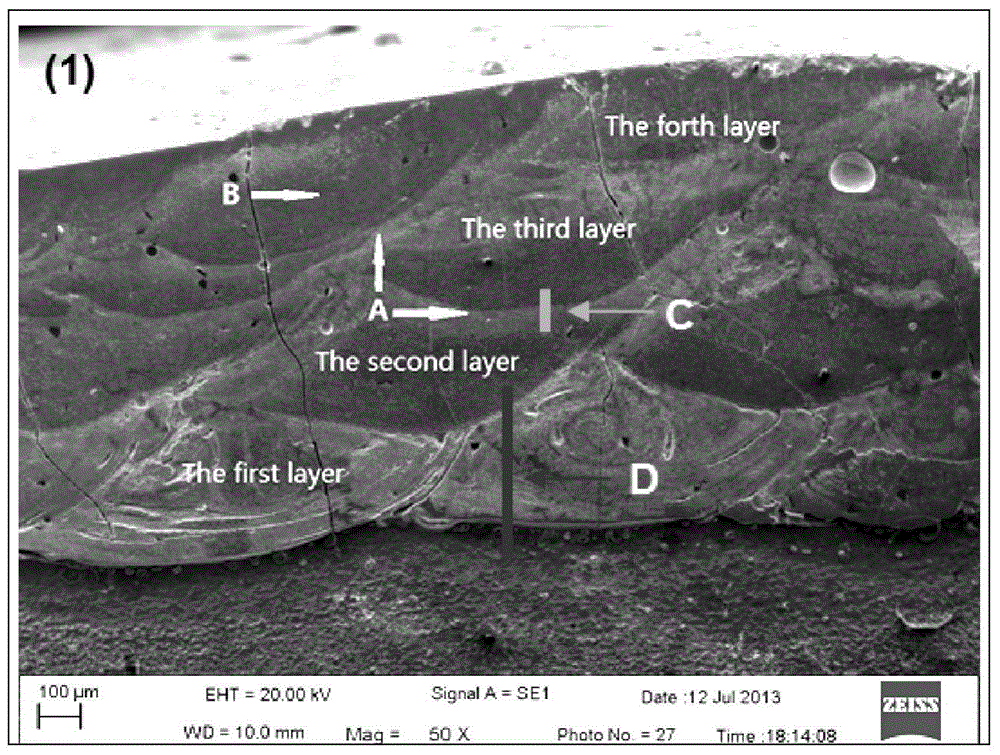

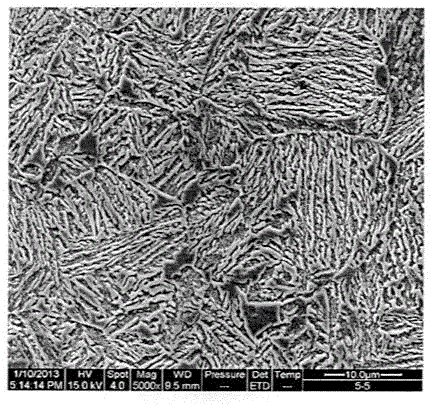

Iron-based nanocrystalline composite coating for protecting boiler tail heating surface and laser-cladding forming process of iron-based nanocrystalline composite coating

ActiveCN104357748AImprove wear and corrosion resistanceReduce corrosion wearMetallic material coating processesRare-earth elementAlloy

The invention discloses an iron-based nanocrystalline composite coating for protecting a boiler tail heating surface and a laser-cladding forming process of the iron-based nanocrystalline composite coating. The iron-based nanocrystalline composite coating comprises the following components in percentage by weight: 49.9-62.8% of Fe, 14.2-20.4% of Cr, 9.0-16.3% of Mo, 2.9-4.1% of B, 0.6-1.3% of C, 1.0-2.4% of Mn, 3.4-8.0% of W, 1.0-1.9% of Si and 0-3.9% of RE, wherein RE is a rare earth element. The forming process comprises the following steps: preparing alloy powder of the iron-based nanocrystalline composite coating; treating the surface of the boiler tail heating surface; preparing the iron-based nanocrystalline composite coating through a simultaneous powder feeding method and a laser-cladding method, wherein the laser cladding is performed for multiple times. The formed iron-based nanocrystalline composite coating is 1 mm above in thickness. The iron-based nanocrystalline composite coating can obviously enhance the wear resistance and corrosion resistance of the boiler tail heating surface, and reduce maintenance costs of worn and corroded parts and consumption of raw materials of a power plant.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

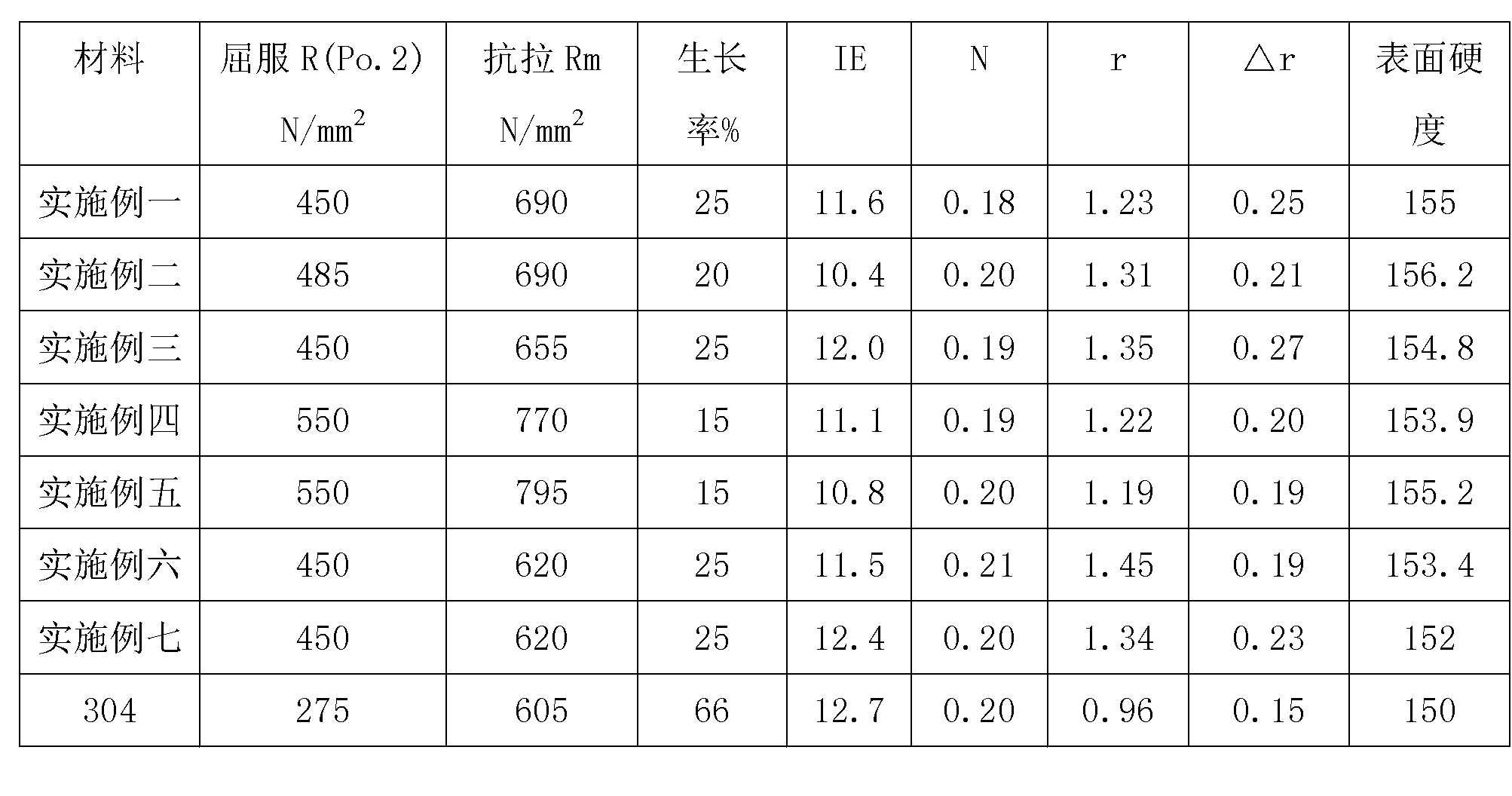

Chromium 23 nickel 6 ferrite-austenitic stainless steel pipe and fabrication process thereof

ActiveCN101353769AEasy to useHigh tensile strengthRoll mill control devicesWork treatment devicesChemical industryManufacturing technology

The invention relates to a Cr 23 Ni 6 ferrite-austenitic stainless steel which is manufactured from stainless steel materials containing components by weight percentage as follows: 22 percent to 24 percent of Cr, 5 percent to 7 percent of Ni, 3 percent to 4 percent of Mo, 0.15 percent to 0.25 percent of N, less than or equal to 0.03 percent of C and 1 percent to 2 percent of Mn, and the rest is Fe. The manufacturing technology of the Cr 23 Ni 6 ferrite-austenitic stainless steel of the invention is characterized in that: in hot piercing process, the hot piercing temperature is controlled to be 1150 DEG C to 1200 DEG C; the prior compression coefficient of a piercing plug is controlled to be 5 percent; the reduction of roller waist is controlled to be 12 percent and the ovality is controlled to be 1.08 to 1.11; in cold drawing / cold rolling process, cold deformation quantity is controlled to be below 50 percent; in heat treatment process, the solid solution temperature of products is controlled to be 1080 DEG C to 1100 DEG C and the solid solution temperature of finished products is controlled to be 1050 DEG C to 1100 DEG C. The Cr 23 Ni 6 ferrite-austenitic stainless steel has good chloride stress corrosion resistance, good pit corrosion resistance, high tensile strength and yield strength and good corrosion fatigue resistance and erosion corrosion resistance, and is widely used in the fields such as petroleum industry, chemical industry, natural gas industry and marine shipping and the like.

Owner:上上德盛集团股份有限公司

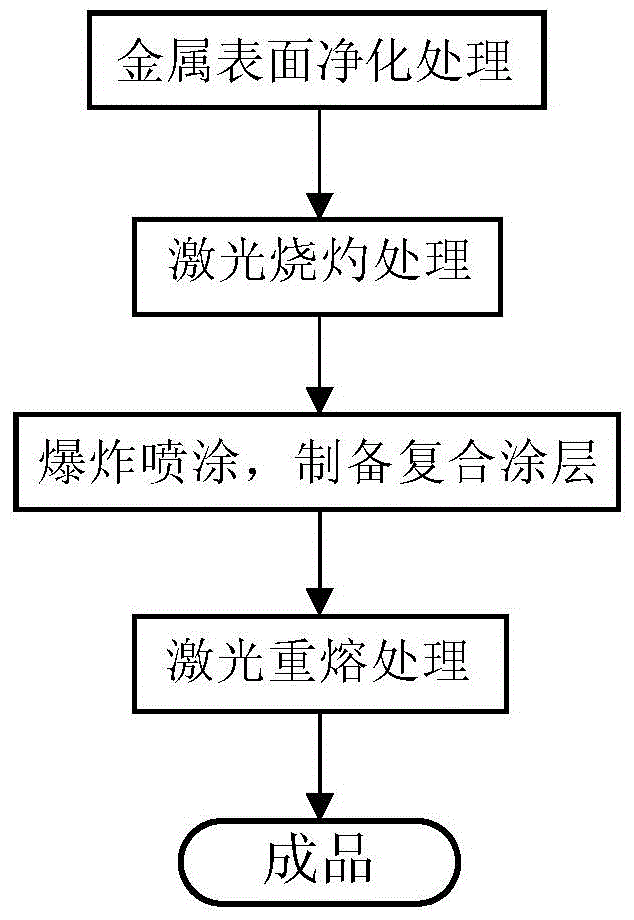

Process for spraying composite coating on metal surface

InactiveCN104789921AReduce porosityImprove microstructureMolten spray coatingWear corrosionLaser burn

The invention discloses a process for spraying a composite coating on a metal surface. The process comprises the following steps: carrying out purification treatment on the metal surface; carrying out laser burning treatment on the metal surface; carrying out explosion spray treatment on the metal surface, and preparing the composite coating; carrying out laser re-melting treatment on the composite coating prepared by an explosion spray process, on the metal surface. According to the combined process for spraying the composite coating on the metal surface, the explosion spray process is compounded with two laser heat treatment processes, so that the binding force of the coating and a matrix can be effectively improved, and the performances of corrosion resistance, wear corrosion and the like of the coating can be further improved.

Owner:上海市机械制造工艺研究所有限公司

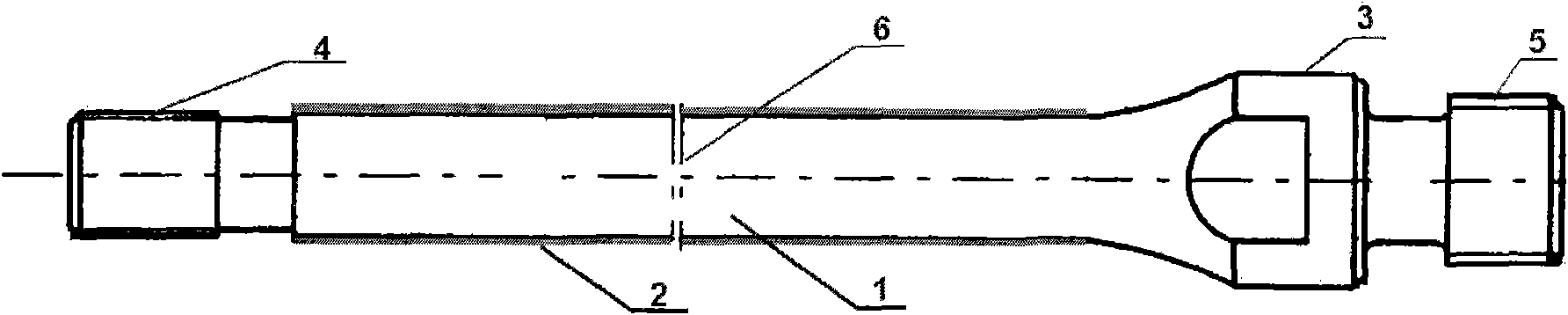

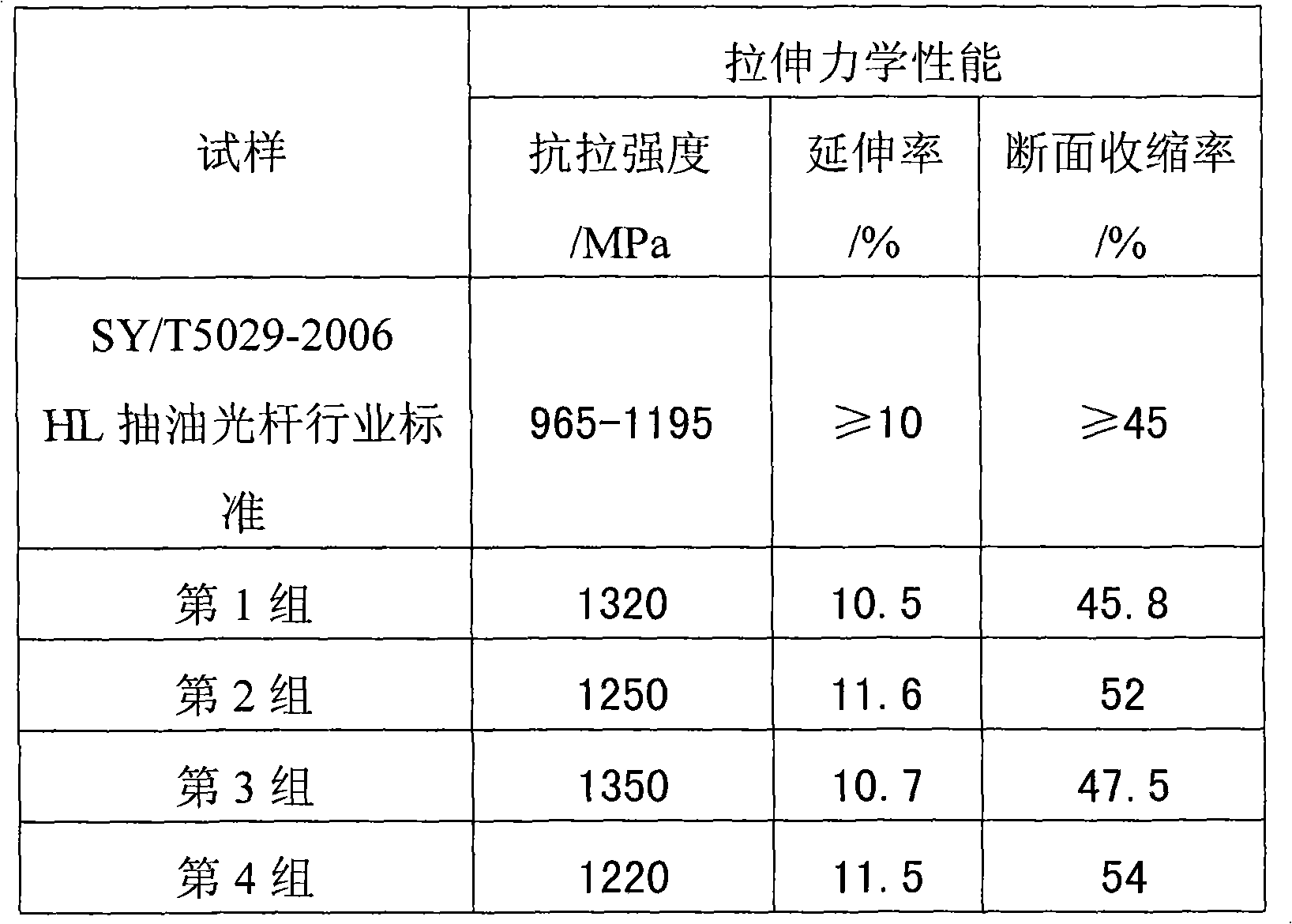

Polished sucker rod

ActiveCN101571033AImprove corrosion resistanceImprove wear resistanceDrilling rodsMetallic material coating processesWear corrosionNickel

A polished sucker rod is characterized by comprising a substrate and a nickel base alloy coating spray welded on surface of the substrate. The nickel base alloy coating is made of the following materials by mass percent: 0%-0.8% of C, 2.0-4.0% of Si, 1.5%-4.5% of B, 5.0%-14.0% of Cr, 5.0%-15.0% of Cu, no greater than 5.0% of Fe and nickel. The MC polished sucker rod has excellent comprehensive mechanical properties, which significantly enhances the tensile strength, and the nickel base alloy coating on the surface has superior wear resistance and corrosion resistance and better bending resistance, which ensures that the polished sucker rod can better satisfy the high load and wear-corrosion service environment of oil fields.

Owner:黄锦滨 +1

Corrosion-resistant stainless steel coffee pot material and preparation method thereof

ActiveCN103540864AImprove corrosion resistanceIncreased hot rollabilityWear corrosionSS - Stainless steel

The invention relates to the fields of stainless steel materials and preparation technology thereof, in particular relates to a corrosion-resistant stainless steel coffee pot material and a preparation method thereof. The corrosion-resistant stainless steel coffee pot material comprises the following chemical components in percentage by mass: 0.03-0.06% of C, 16-20% of Cr, 0.8-1.2% of Si, 0.6-1% of Mn, 2-3% of Ni, 0.0001-0.002% of B, 0.4-0.6% of V, 3-4.5% of Mo, 0.25-0.35% of W, 0.18-0.22% of N, less than or equal to 0.004% of S, less than or equal to 0.014% of P, 0.25-0.35% of Ag, 2.5-3.5% of Cu, 0.001-0.012% of Ce, 0.03-0.08% of La, and the balance of Fe and inevitable impurity elements. The corrosion-resistant stainless steel coffee pot material has strong machining property, wear corrosion resistance and antibacterial property.

Owner:WANBAOLI STAINLESS STEEL PRODS DONGGUAN

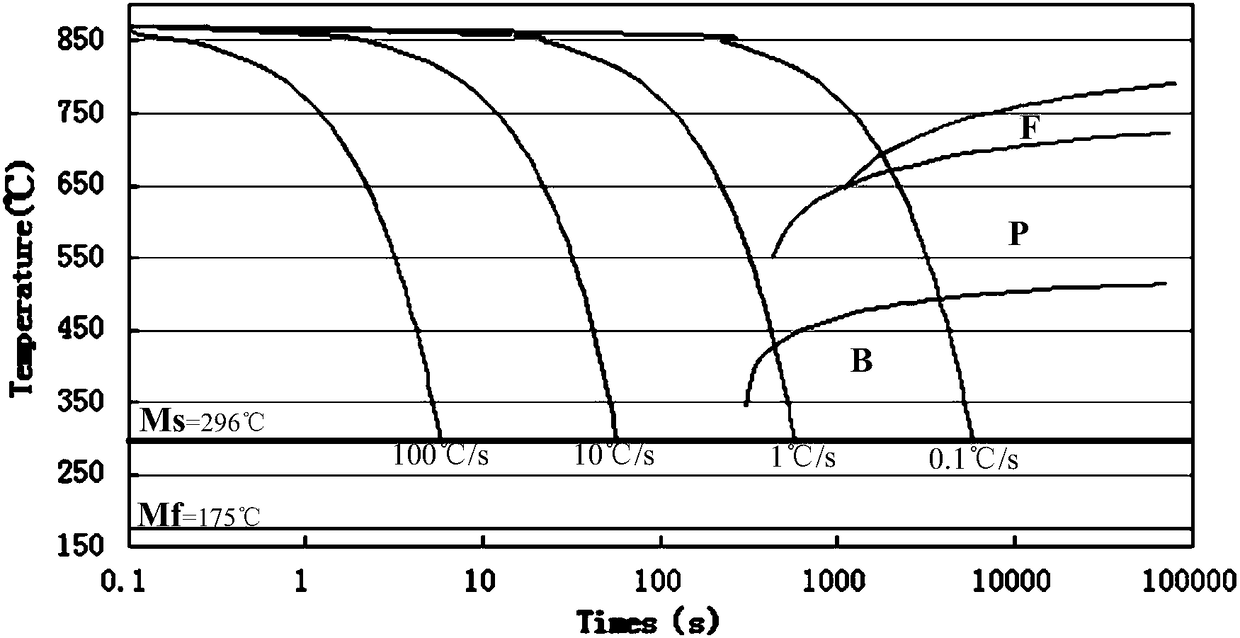

Boron-containing high-silicon bainite wear-resistant corrosion-resistant alloy and manufacturing method thereof

The invention relates to a boron-containing high-silicon bainite wear-resistant corrosion-resistant alloy and a manufacturing method thereof. The alloy comprises the following chemical components in percentage by weight: 0.3-0.6% of C, 1.6-2.6% of Si, 0.6-1.0% of Mn, 0.6-4.0% of Cr, 0.3-0.5% of Mo, 0.3-0.5% of Ni, 0.3-0.5% of Cu, 0.1-0.3% of Ti, 0.05-0.1% of B, 0.05-0.15% of Ce, 0.05-0.15% of Nb, less than 0.04% of P, less than 0.04% of S and the balance of Fe. The manufacturing method comprises the following steps: carrying out electric-furnace smelting, carrying out secondary aluminum insertion deoxidization, putting on the bottom of a casting ladle to form a casting, austenizing the casting at 850-950 DEG C, keeping the temperature for some time, putting in a salt bath at 200-260 DEG C to carry out primary isothermal quenching, keeping the temperature for 5-10 minutes, carrying out secondary isothermal quenching in a salt bath at 260-400 DEG C, keeping the temperature for 0.5-4 hours, and cooling in air to obtain the wear-resistant corrosion-resistant alloy of which the austenite-bainite base is distributed with boride. The alloy is low in preparation cost and suitable for marine silt erosion and corrosion environments, has favorable comprehensive properties of toughness, wear resistance and corrosion resistance, and can be used for dredger cutter teeth, slurry pipelines, centrifugal-pump impellers, blades and the like.

Owner:CHANGXING DETIAN ENG MACHINERY

Anti-pitting abrasion-resistant oil pipe and manufacture thereof

InactiveCN1439838ATemperature resistantAnti-stressCorrosion preventionSolid state diffusion coatingHigh resistanceChemical plating

An antiwear oil pipe resisting tubercular corrosion is prepared through pretreating oil pipe, gas-phase nitrifying to form the ferric nitride or carbon-contained ferric nitride on the surface of oil pipe, activating, washing, chemical plating a sacrificial anode type protecting layer, and post-treating. Its advnatages are high surface hardness and high resistance to tubercular corrosion, high temp. compression and deformation.

Owner:ZHEJIANG UNIV

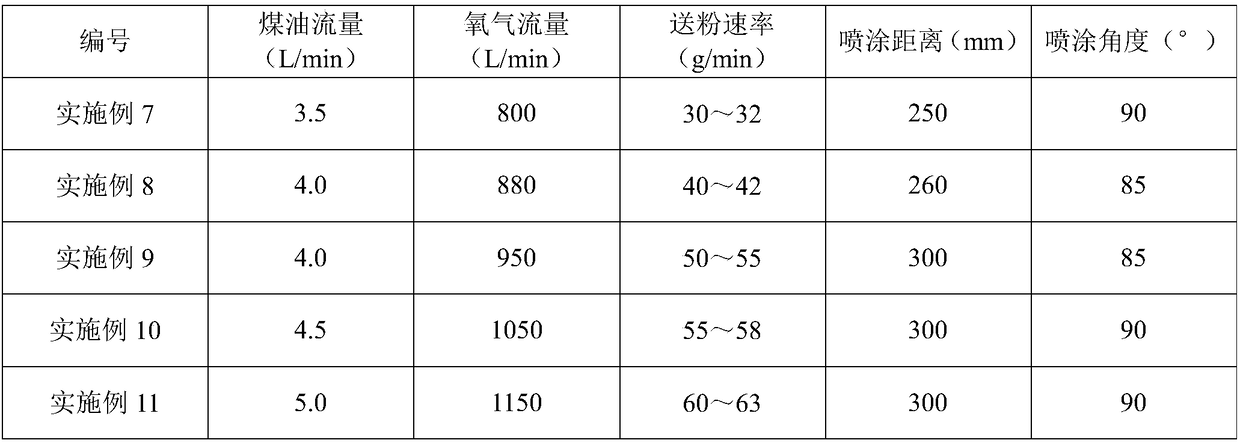

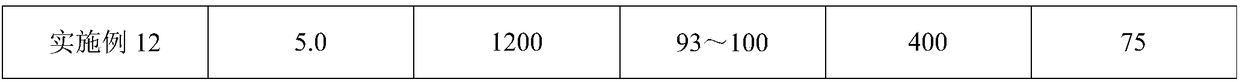

Method for preparing high-carbon high-niobium high-chromium wear-corrosion resistance alloy coating by utilizing supersonic spraying and pre-alloyed powder used in method

ActiveCN109055885AImprove liquidityReduce difficultyMolten spray coatingMolten stateThermal spraying

The invention relates to the technical field of thermal spraying and material surface protection, and particularly relates to a method for preparing a high-carbon high-niobium high-chromium wear-corrosion resistance alloy coating by utilizing supersonic spraying and pre-alloyed powder used in the method. Aimed at solving the problems that a common alloy coating prepared in the prior art can be easily dissolved partially in a matrix when being heated and re-melted, crystal grains rapidly grow in a high-temperature molten state, abrasion resistance of the coating is reduced, content of carbide and carbon in a common coating alloy material is low, the wear resistance is generally as good as that of the ceramic coating, so that the application working condition of the common coating alloy material is limited, the following preparation process is adopted for preparing the high-carbon high-alloy amorphous pre-alloyed powder and comprises the following steps of weighing raw materials and mixing the raw materials, adding a cemented carbide ball, a forming agent and a wet grinding medium, and carrying out ball milling under a protective atmosphere; filtering and drying to obtain the pre-alloyed powder; and the pre-alloyed powder is used for preparing the high-carbon high-niobium high-chromium wear-corrosion resistance alloy coating through adopting the supersonic spraying method. According to the method, the coating has the advantages of being high in density and smooth in surface.

Owner:ZHEJIANG UNIV OF TECH

Low-alloy abrasion-proof and corrosion resistant steel and method for producing the same

InactiveCN101423916AStrong resistance to seawater corrosionImprove corrosion resistanceElectric furnaceProcess efficiency improvementWear corrosionWear resistant

The invention relates to low alloy wearing resistance corrosion resistance steel which is suitably used in the ocean mud-sand wearing and corrosive environment, which is produced by the following steps: Mn-Si-Cr-Mo system non-carbide bainite alloy steel is taken as research basis, the carbon content and other alloy element contents are properly adjusted, elements of Al, Nb and rare earth contributing to improving the corrosion resistance of the alloy steel are added for modification, and the Mn-Si-Cr-Mo-Al system non-carbide bainite steel is formed by the progression quenching heat treatment process, so that the low alloy wearing resistance corrosion resistance steel is obtained. The steel has good obdurability, wearing resistant and corrosion resistant comprehensive performance and welding repair performances, and can be used to solve the problem of repairing worn blades of a centrifugal pump of a ship, and can also be applied to other ocean wearing resistance welding parts.

Owner:HOHAI UNIV +1

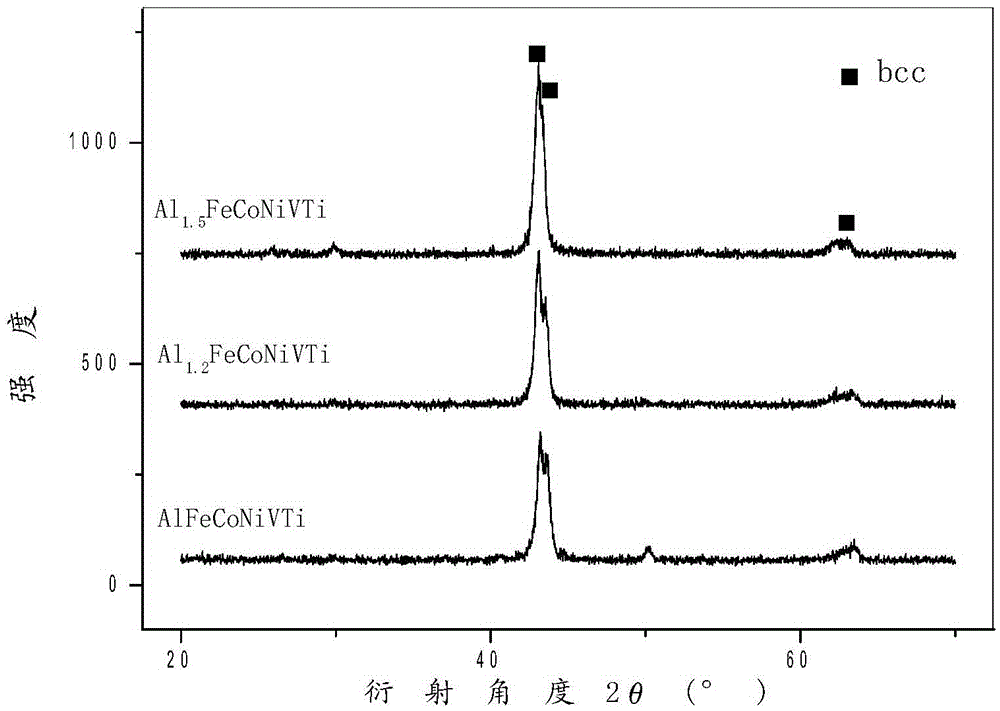

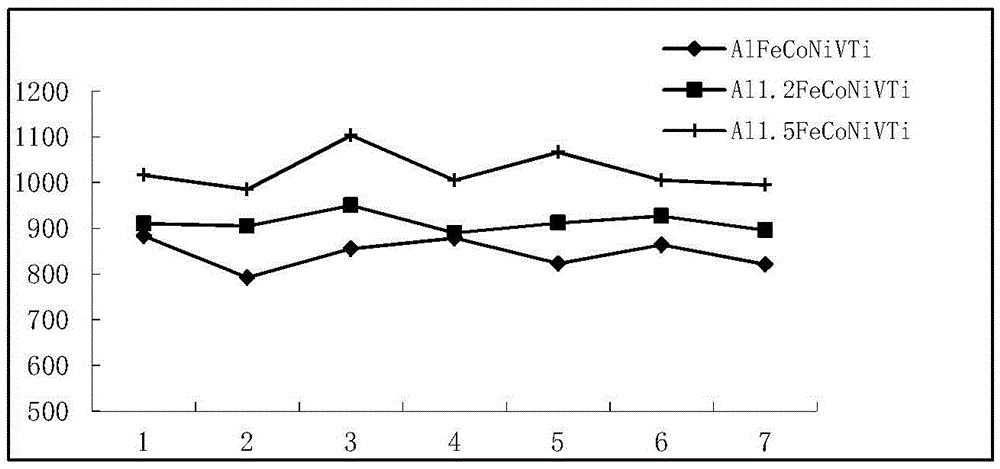

High-hardness, single-phase and high-entropy alloy coating and preparation method and application thereof

ActiveCN105671545AHigh hardnessExcellent resistance to electrochemical corrosionEngine manufactureHydro energy generationWear corrosionHigh entropy alloys

The invention discloses a high-hardness, single-phase and high-entropy alloy coating and a preparation method and application thereof. The preparation method comprises the following steps of mixing Al powder, Fe powder, Co powder, Ni powder, V powder and Ti powder according to the molar ratio of Al:Fe:Co:Ni:V:Ti=(x=1.0-1.5):1:1:1:1:1, and then preparing a AlxFeCoNiVTi high-entropy alloy coating on the surface of a part, wherein x=1.0-1.5, the hardness range of the coating is 800-1100 HV, and the coating is of a body-centered cubic (bcc) single-phase solid solution structure. The body-centered-cubic-structure single-phase solid solution high-entropy alloy coating obtained by a laser cladding method is high in hardness and excellent in electrochemical corrosion resistance, has good wear-corrosion resistance, and is particularly suitable for protecting surfaces of parts such as blades of hydraulic turbines and blades of fans.

Owner:SHANDONG UNIV OF SCI & TECH

Anti-corrosion conductive ceramic electrode material for sewage and sludge treatment and preparation method thereof

ActiveCN105523761AGood for anodizingUnique electrochemical performanceWater/sewage treatment by electrochemical methodsElectrochemical sludge treatmentFiberEpoxy

The invention discloses an anti-corrosion conductive ceramic electrode material for sewage and sludge treatment and a preparation method of the anti-corrosion conductive ceramic electrode material. The anti-corrosion conductive ceramic electrode material is characterized in that carbon is used as aggregate; the anti-corrosion conductive ceramic electrode material is prepared from artificial graphite, graphitized mesocarbon microbeads, a reinforcement binder, graphitized carbon fiber and E-44 epoxy resin. The preparation method comprises the following steps of adding a Ti4O7 functional additive having strong electrode performance, simultaneously adding one or several of ceramic anti-wear-corrosion components of TiB2, TiO2, TiC, B2O3, SiO2 and SiC, carrying out solidification, compression molding and high-temperature sintering after adding a mixing solvent and completely mixing the mixture, and finally preparing the anti-corrosion conductive ceramic electrode material. According to the anti-corrosion conductive ceramic electrode material and the preparation method, disclosed by the invention, aiming at an actual working situation of a sewage and sludge treatment environment, unique anti-corrosion components are added while low specific resistance of the anti-corrosion conductive ceramic electrode material is ensured, not only are wearing resistance and corrosion resistance of traditional ceramics obtained, but also excellent conductivity and excellent electrochemical performance are obtained, and the service life is up to more than 3500 hours.

Owner:JIANGSU UNITED CERALLOY MATERIALS TECH

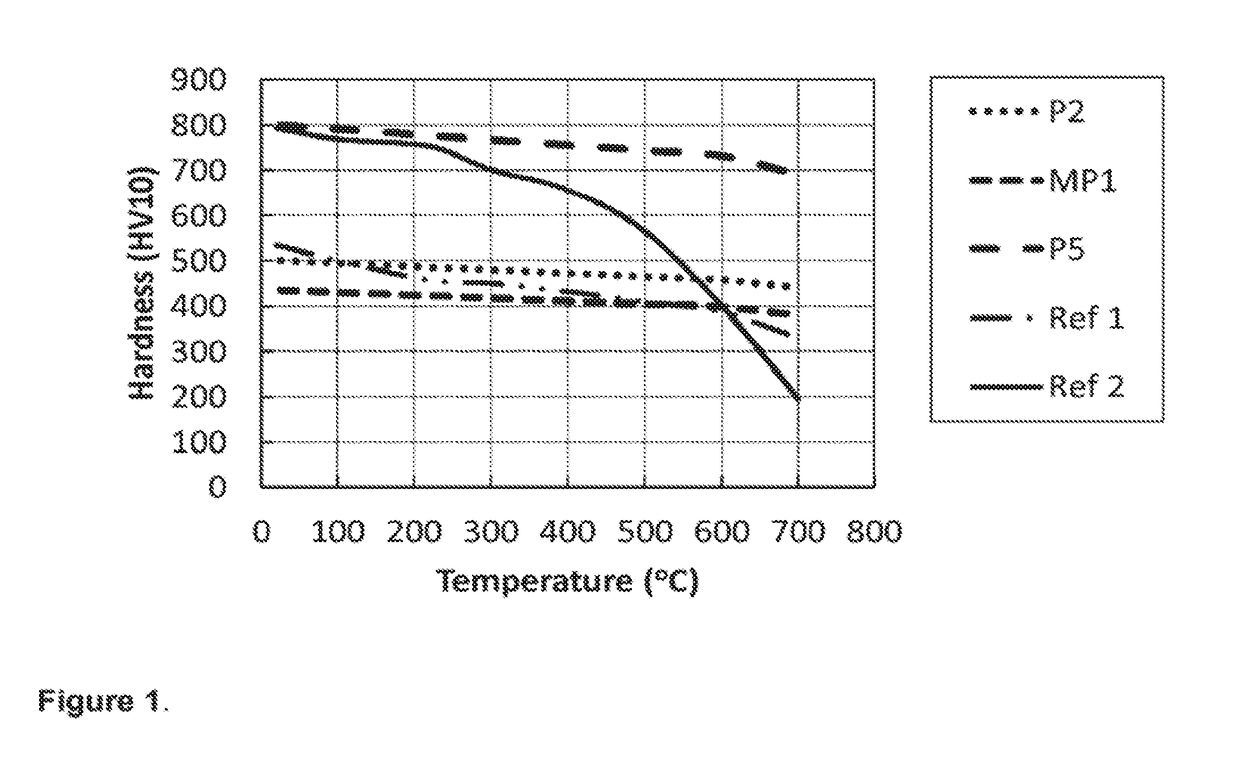

New powder composition and use thereof

ActiveUS20180066343A1Improve thermohardnessHigh heat intensityArc welding apparatusMetallic material coating processesThermal sprayingAlloy

A laser cladding or plasma transferred arc overlay welding process may be used advantageously to apply and to control the material properties of a coating designed for protecting the substrate against wear, corrosion and oxidation at elevated temperature. Furthermore, a laser cladding or plasma transferred arc overlay welding process may be used to apply the coating alloy materials in applications where traditional thermal spray or weld-applied coatings are not practical. By using these welding methods very good bonding is achieved by fusion during welding. At the same time the properties of the clad layer is preserved by the limited dilution typical of these two welding methods compared traditional overlay welding, by e.g. Gas Tungsten Arc Welding and the like.

Owner:HOGANAS AB

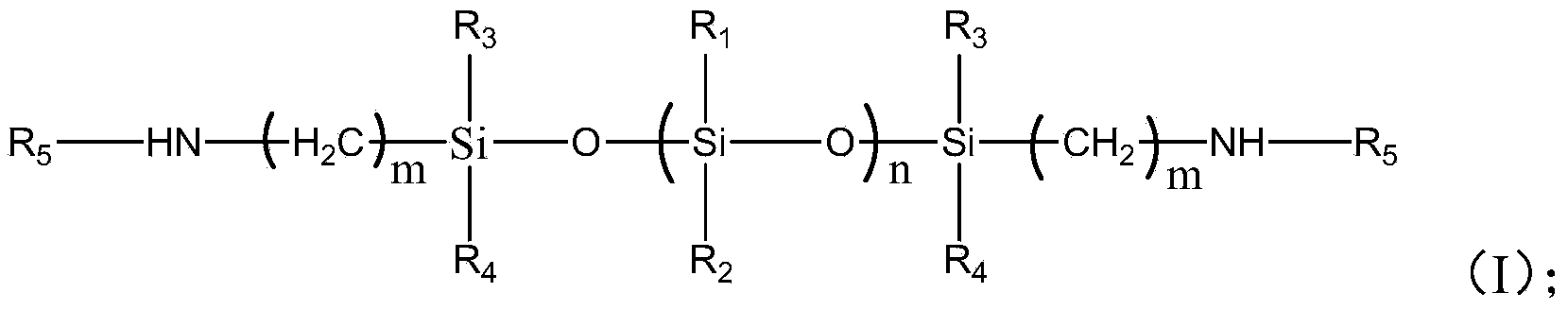

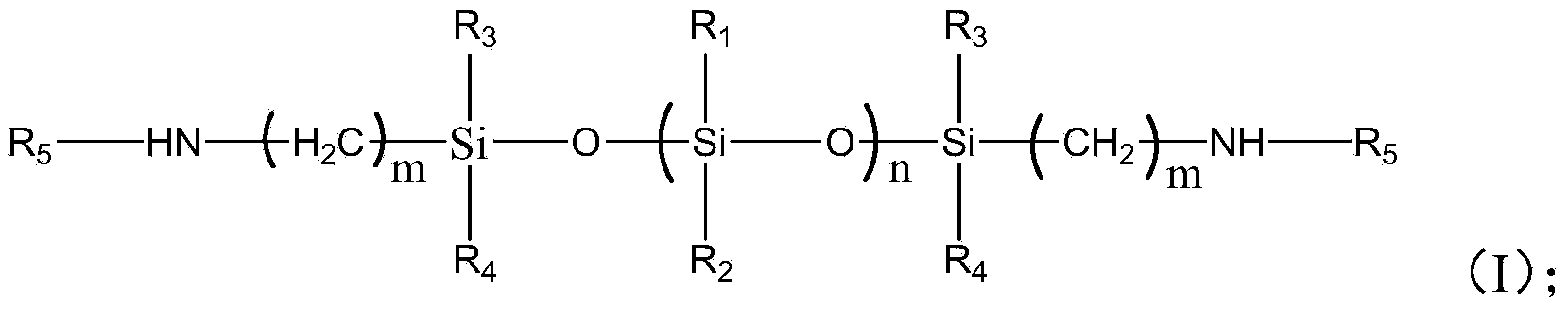

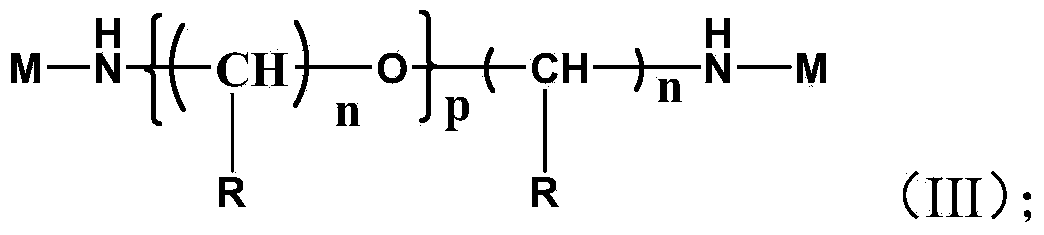

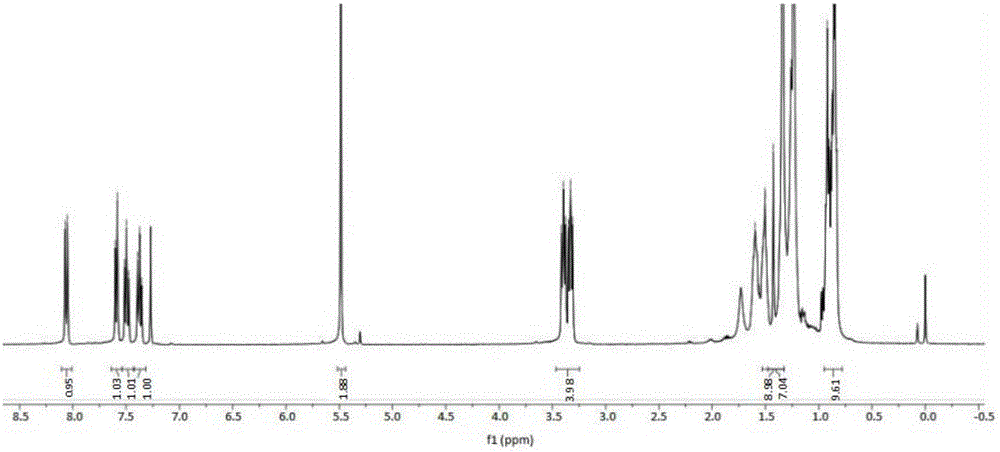

Polyureas copolymer with main chain containing siloxane composition unit and preparation method thereof

ActiveCN103834034AAvoid stickingExtended service lifePolyurea/polyurethane coatingsPolyesterEnd-group

The invention discloses a polyureas copolymer with a main chain containing siloxane composition units; the polyureas copolymer comprises the following constitution units: polysiloxanes constitutional units of aminoalkyl termination; polyether constitutional units of high-molecular amino termination; polyether alcohol or polyester alcohol constitutional units; single molecule chain extension double amine or low molecular amino termination polyether constitutional units; isocyanate constitutional units. Through the design of polysiloxanes molecular composition of aminoalkyl termination and adjustment of molecule mass; on one hand, a reaction amino group and an alkyloxy crosslinking group are introduced on a terminal group; on the other hand, a chain alkyl group or a perfluoro alkyl group are designed on a side chain; simultaneously three function hydroxy or amino groups are embedded in the composition, thereby obtaining excellent anti adhesiveness, abrasion resistance, corrosion resisting, impact resistance and anti contamination functions, effectively preventing contamination objects from pasting on special equipment, improving anti pollution function, solving adherence of adherence fluid, anti pollution and wearing corrosion problems, satisfying demands of different application fields, and prolonging service life of the special equipment.

Owner:HUBEI UNIV +1

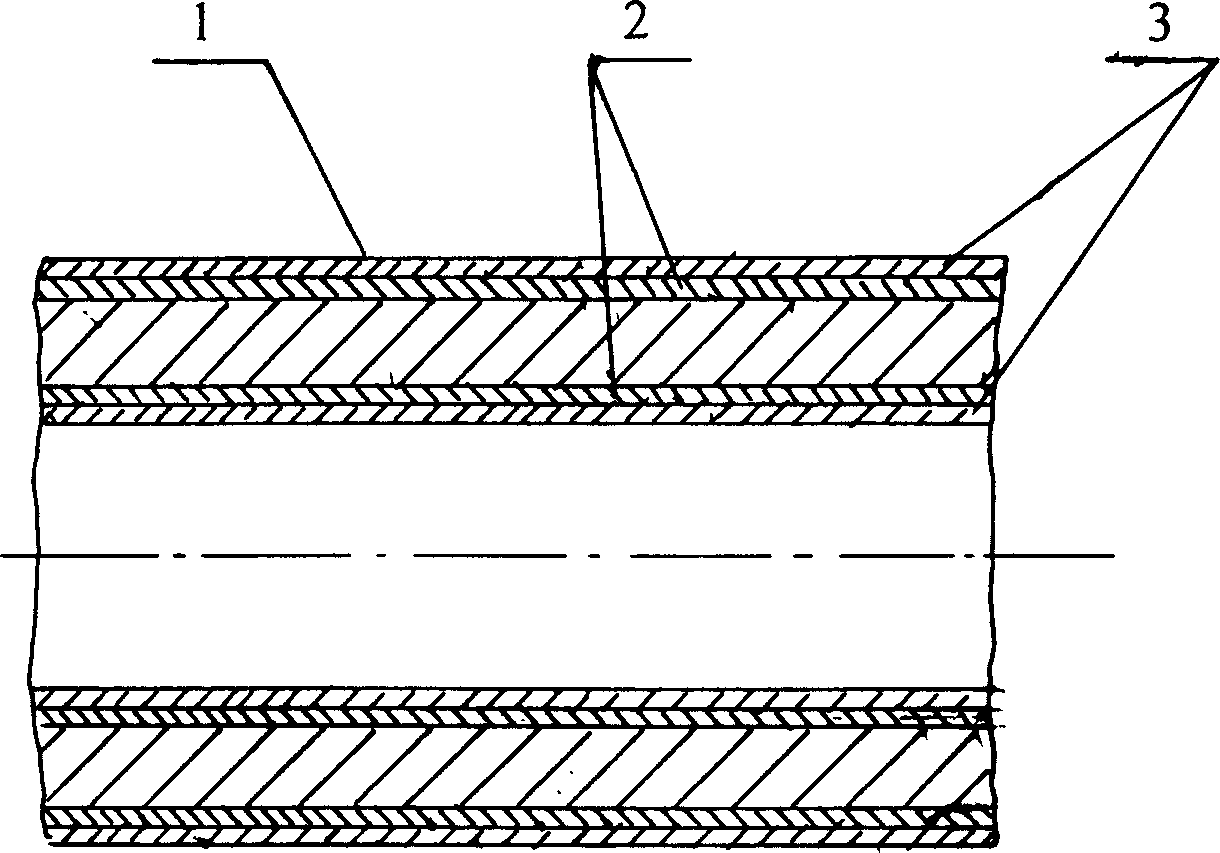

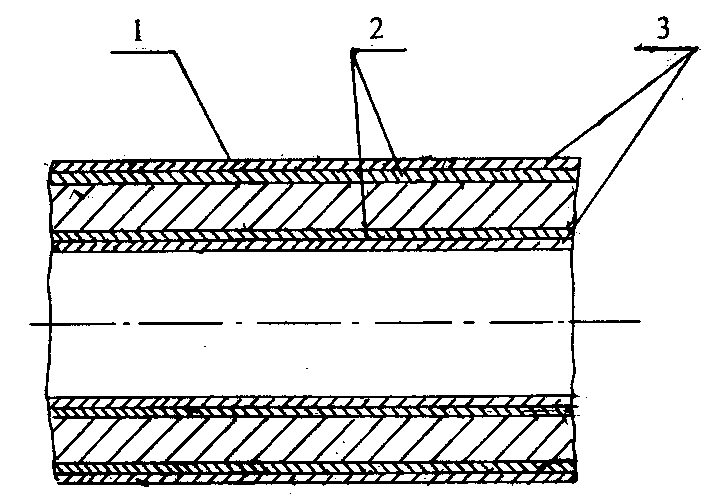

Ceramic polymer-material wear-resistant anticorrosion composite pipe and manufacturing method thereof

InactiveCN101638520AHigh hardnessImprove anti-corrosion performanceRigid pipesTubular articlesWear corrosionWear resistant

The invention provides a ceramic polymer-material wear-resistant anticorrosion composite pipe and a manufacturing method thereof. The composition proportioned in portion by weight of the composite pipe is 10 to 50 portions of polymer material and 30 to 90 portions of ceramic particles. The polymer material and the ceramic particles are mixed well, heated to between 50 and 250 DEG C and prepared into the ceramic polymer-material wear-resistant anticorrosion composite pipe. The polymer material is a mixture of one or two types of anticorrosion plastics or rubber. The invention solves the deficiency that single-material and steel-plastic delivery pipelines in the prior art cannot meet the requirements of bearing certain pressure and wear and resisting strong corrosion. The invention has the advantages of utilizing the high hardness, good corrosion resistance and wear resistance of ceramics and the good corrosion resistance, good toughness and impact resistance of plastics or rubber to manufacture the pipelines with ceramic-plastic, ceramic-rubber and ceramic-rubber-plastic composite materials so as to ensure that the pipelines have good wear-corrosion resistance and good toughness andimpact resistance, thereby greatly reducing use cost and ensuring more extensive use.

Owner:襄阳瑞福特电力设备有限公司

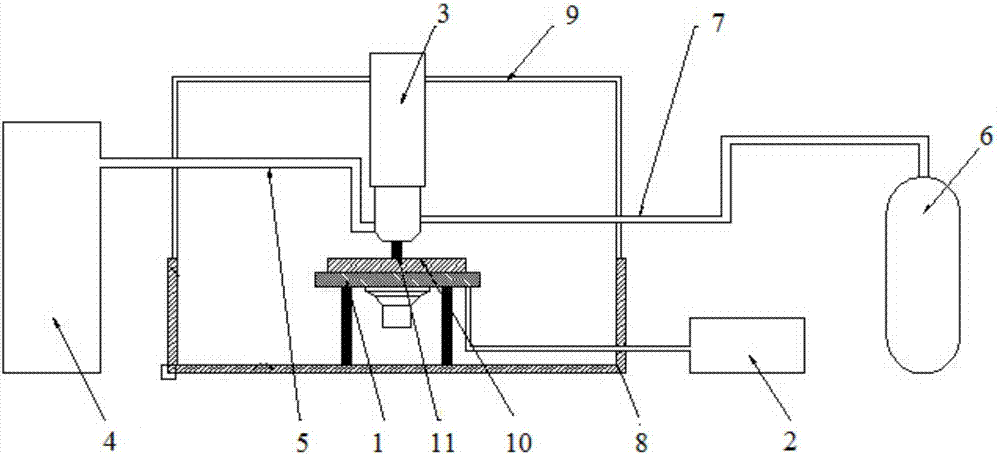

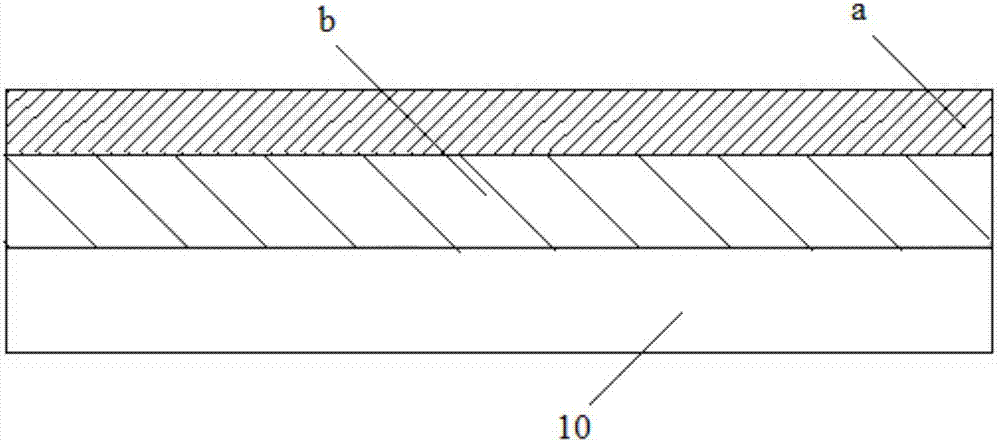

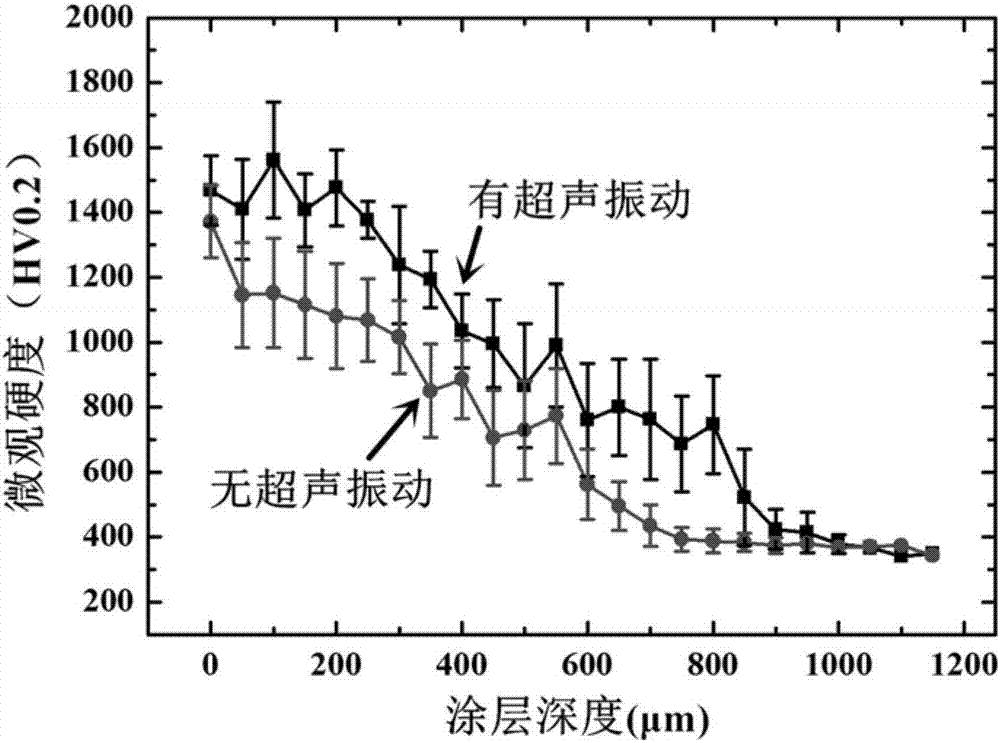

Method and device for preparing fine-grain Ti3Al/TiN gradient coatings on titanium and titanium alloy surfaces

InactiveCN106947970ATightly boundImprove coating qualitySolid state diffusion coatingSuperimposed coating processLaser scanningTitanium alloy

The invention provides a method for preparing fine-grain Ti3Al / TiN gradient coatings on titanium and titanium alloy surfaces. The method includes the steps that under the nitrogen atmosphere, laser scanning processing, synchronous in-situ aluminum powder feeding and ultrasonic vibration treatment are simultaneously conducted on the titanium and titanium alloy surfaces of workpiece substrates, so that the fine-grain Ti3Al / TiN gradient coatings are prepared on the titanium and titanium alloy surfaces. The invention further provides a device for preparing the fine-grain Ti3Al / TiN gradient coatings on the titanium and titanium alloy surfaces. The method has the advantages that operation is easy and convenient, locating heating can be achieved, contact processing is avoided, a needed preparation time is short, and the depths of the Ti3Al / TiN gradient coatings are controllable. Compared with the prior art, the prepared fine-grain Ti3Al / TiN gradient coatings have the advantages of being free of air holes and cracks, having low surface roughness, achieving grain refinement, having high hardness and good wear-corrosion resistance, being reduced in surface residual stress and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

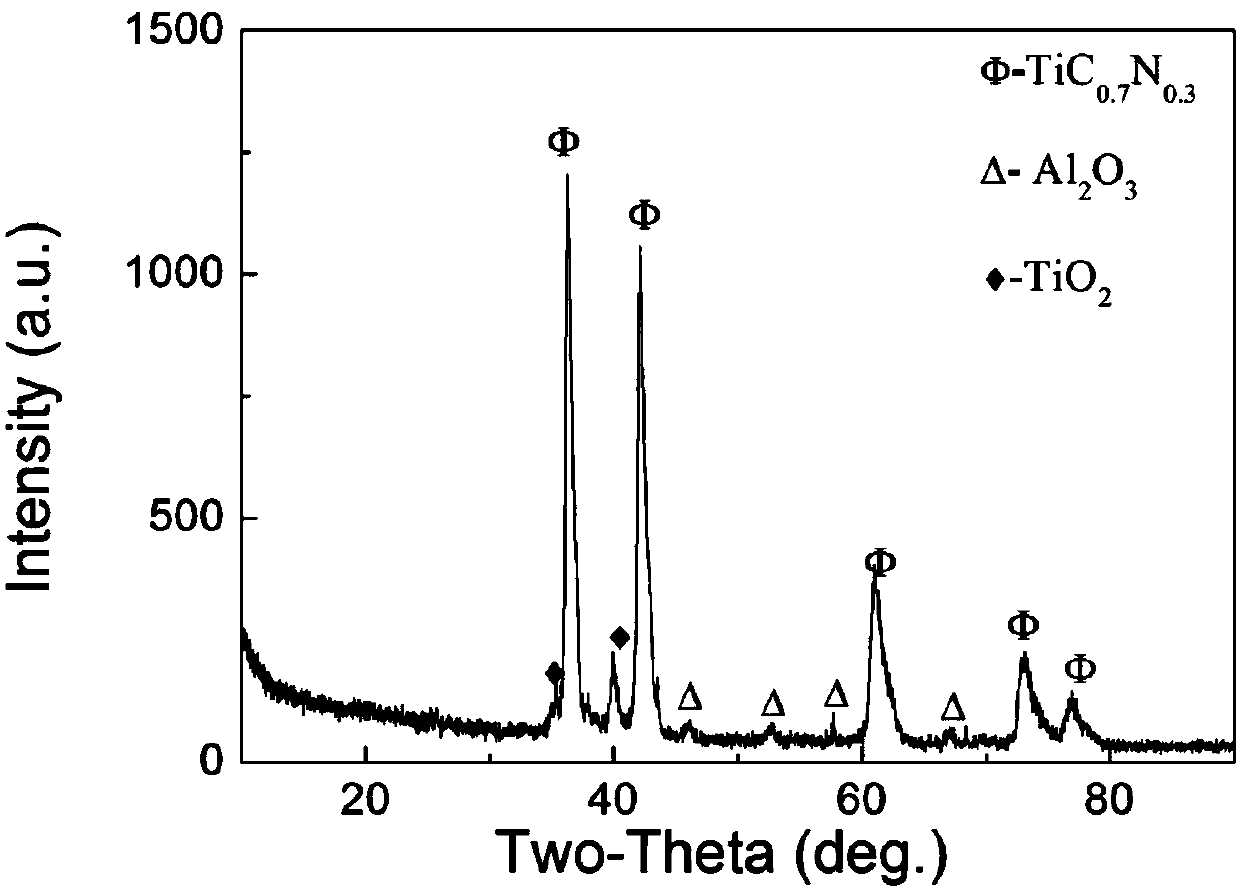

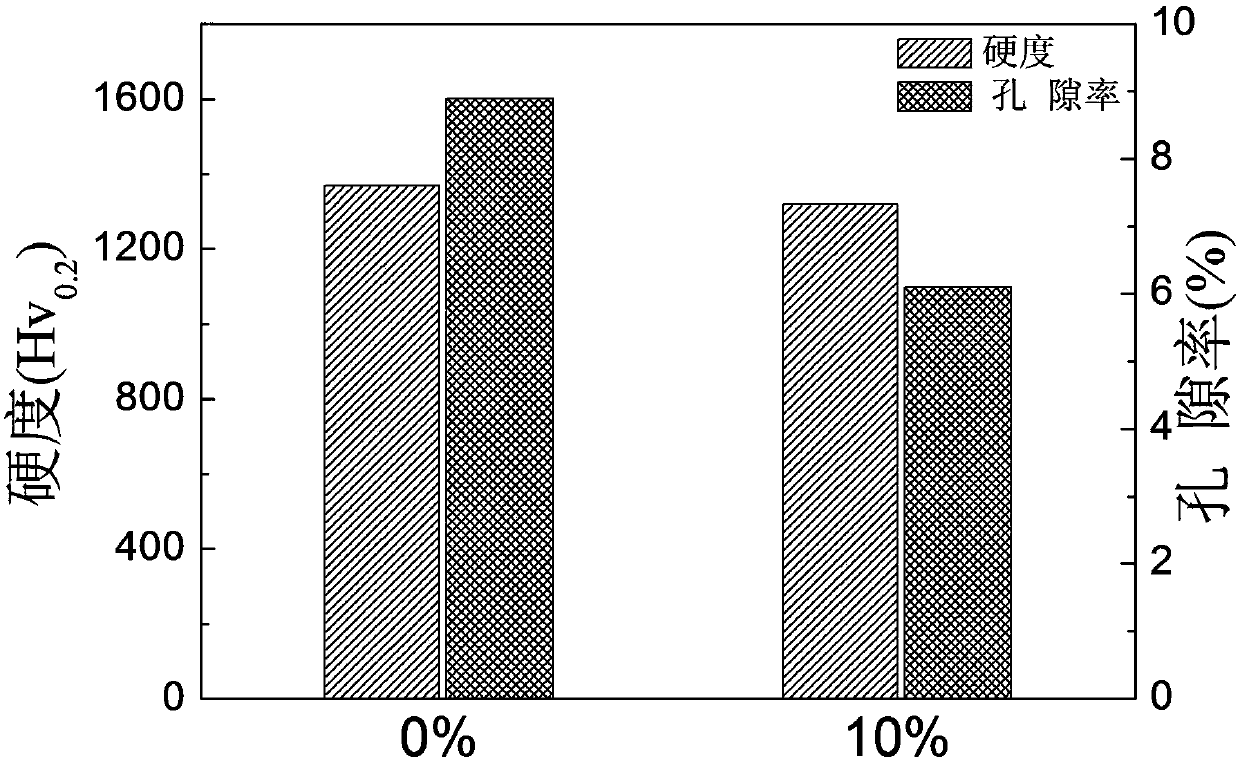

Preparation method for TiCN-Al2O3 ceramic composite coating

ActiveCN107653431AHigh hardnessImprove wear resistanceMolten spray coatingCeramic compositeWorking environment

The invention provides a preparation method for a TiCN-Al2O3 ceramic composite coating. The method comprises the following steps that 1, a base body sample is subjected to surface roughening treatment; 2, Ti-C composite powder and Al2O3 powder are mechanically stirred and mixed to obtain spray feeding composite powder; 3, the surface of a base body is pre-sprayed with self-melting alloy powder ofNi-10%wtAl to obtain a bonding bottom layer with the thickness 90-120 [mu]m; and 4, the surface of the bonding bottom layer is sprayed with the spray feeding composite powder to obtain the TiCN-Al2O3composite coating with the thickness 300-500 [mu]m. The plasma-sprayed TiCN-Al2O3 ceramic composite coating has excellent performance of high hardness and abrasion and corrosion resistance, is suitable for workpieces under the abrasion and corrosion working environment such as the fields of manufacturing of cars and machinery such as cutters, drill bits and molds, aerospace industry and the like,and has extremely wide application prospects.

Owner:HEBEI UNIV OF TECH

Stainless steel production method

InactiveCN103805870AImprove pitting resistanceGood resistance to crevice corrosionWear corrosionCavitation

The invention relates to a stainless steel production method. The stainless steel comprises the following chemical components (wt.%): 0.01-0.03 of C, 0.05-0.1 of Si, 1-2 of Mi, 0.01-0.001 of S, 0.0015-0.015 of P, 30-35 of Cr, 3-4 of Mo, 0.2-0.8 of Cu, 0.1-0.01 of Le, and the balance Fe. The production method includes: vacuum smelting, electroslag refining, forging cogging, hot rolling molding, cold drawing, and heat treatment. The stainless steel welding material produced by the method has good pitting resistance, crevice corrosion resistance, cavitation and wear corrosion resistance in seawater medium and high fatigue strength.

Owner:丹阳市锦雄机械制造有限公司

Biphase alloy steel tank container seal head and preparation technology thereof

ActiveCN103173697AGood resistance to chloride stress corrosionImprove pitting resistanceTank containerMechanical property

The invention discloses a biphase alloy steel tank container seal head and a preparation technology thereof. The seal head is characterized in that the biphase alloy steel comprises the following components in percentage by mass: less than 0.030% of C, less than 1.00% of Si, less than 2.00% of Mn, 21.00-23.00% of Cr, 4.50-6.50% of Ni, 0.14-0.20% of N, 3.00-3.50% of Mo, less than 0.030% of P, less than 0.020% of S and the balance of Fe and inevitable impurities. The biphase alloy steel tank container seal head has the characteristics of good chloride stress corrosion resistance under low stress, good hole corrosion resistance, good corrosion fatigue resistance and erosion corrosion resistance, good comprehensive mechanical property, good weldability, small heat crack tendency and no preheating before the welding and thermal treatment after the welding, can be welded with heterogeneities such as austenitic stainless steel or carbon steel.

Owner:YIXING HOKKAI HEAD PLATE

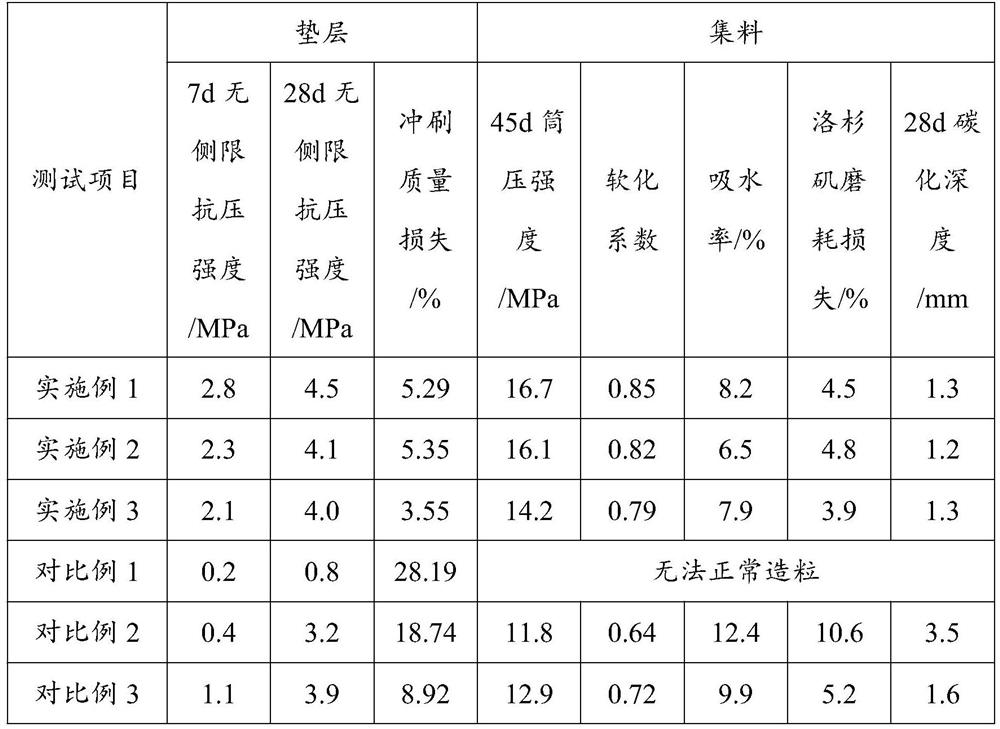

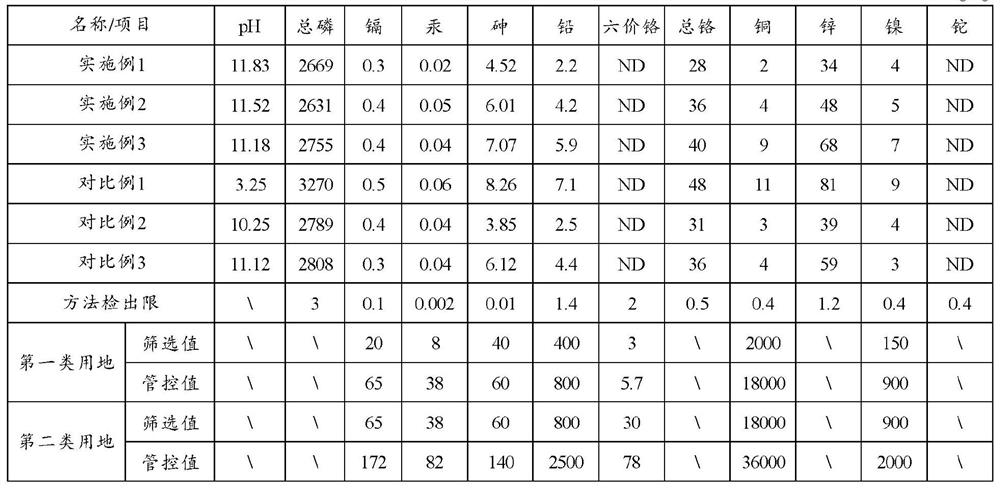

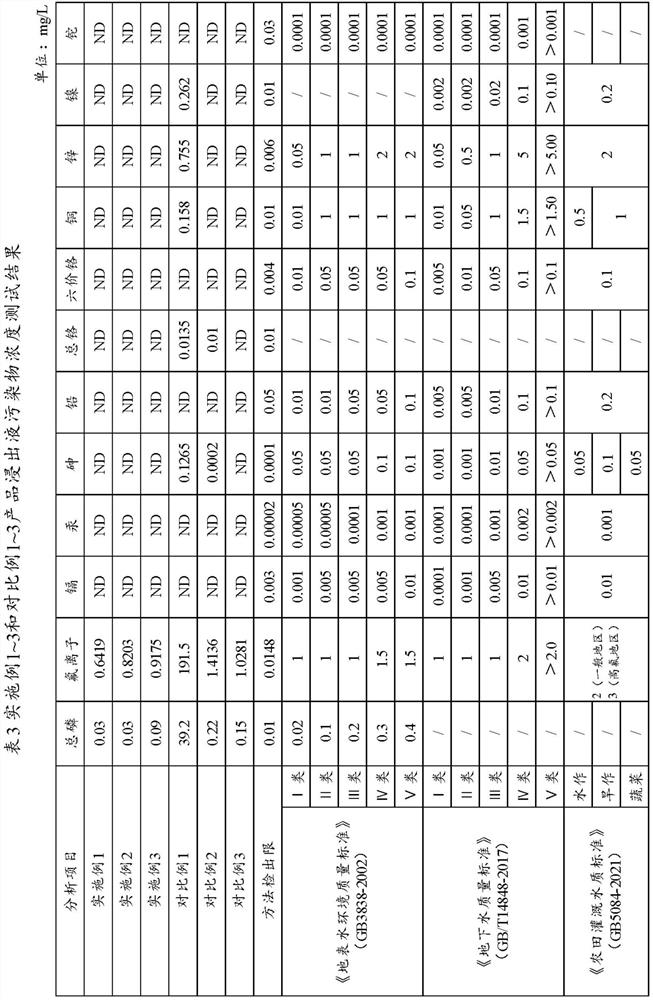

Phosphogypsum hardening agent and preparation method and application thereof

The invention relates to the technical field of harmless treatment of solid wastes, in particular to a phosphogypsum hardening agent as well as a preparation method and application thereof. The ardealite hardening agent provided by the invention is prepared from the following preparation raw materials in parts by weight: 1580 to 1780 parts of ardealite, 10 to 30 parts of a modifier, 100 to 130 parts of an active mineral admixture, 100 to 140 parts of cement, 15 to 40 parts of metakaolin, 10 to 35 parts of coal gangue slag, 5 to 10 parts of an early strength agent and 50 to 80 parts of water. The ardealite hardener can effectively enhance the early strength of ardealite, reduce the initial setting time and the final setting time of the hardened ardealite, improve the durability, the wear corrosion resistance and the erosion resistance of a material after ardealite hardening, and meanwhile, the material after ardealite hardening can meet the environmental quality standards of soil, surface water and underground water, and has a good application prospect. The problem that a large amount of ardealite is difficult to treat and utilize due to poor ardealite performance at present is solved.

Owner:湖北昌耀新材料工程技术研究有限责任公司

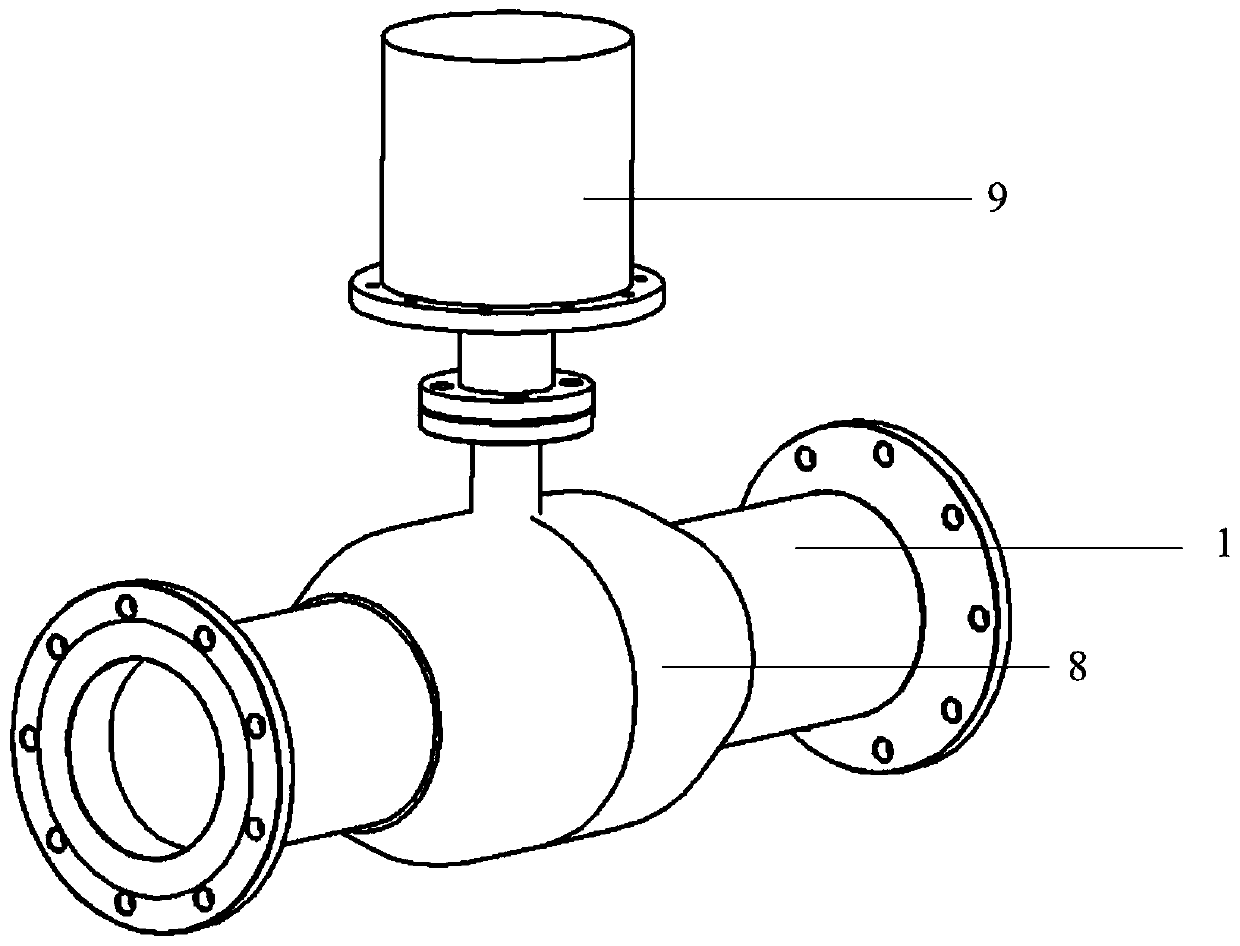

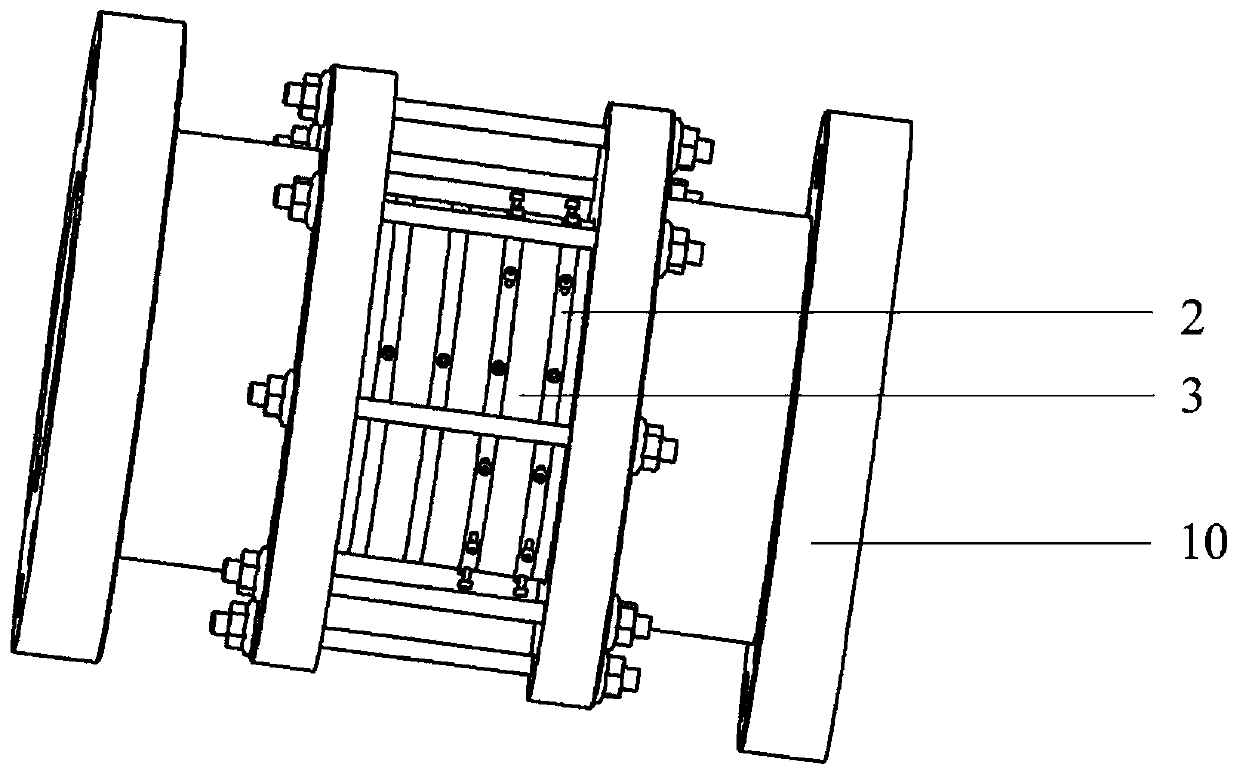

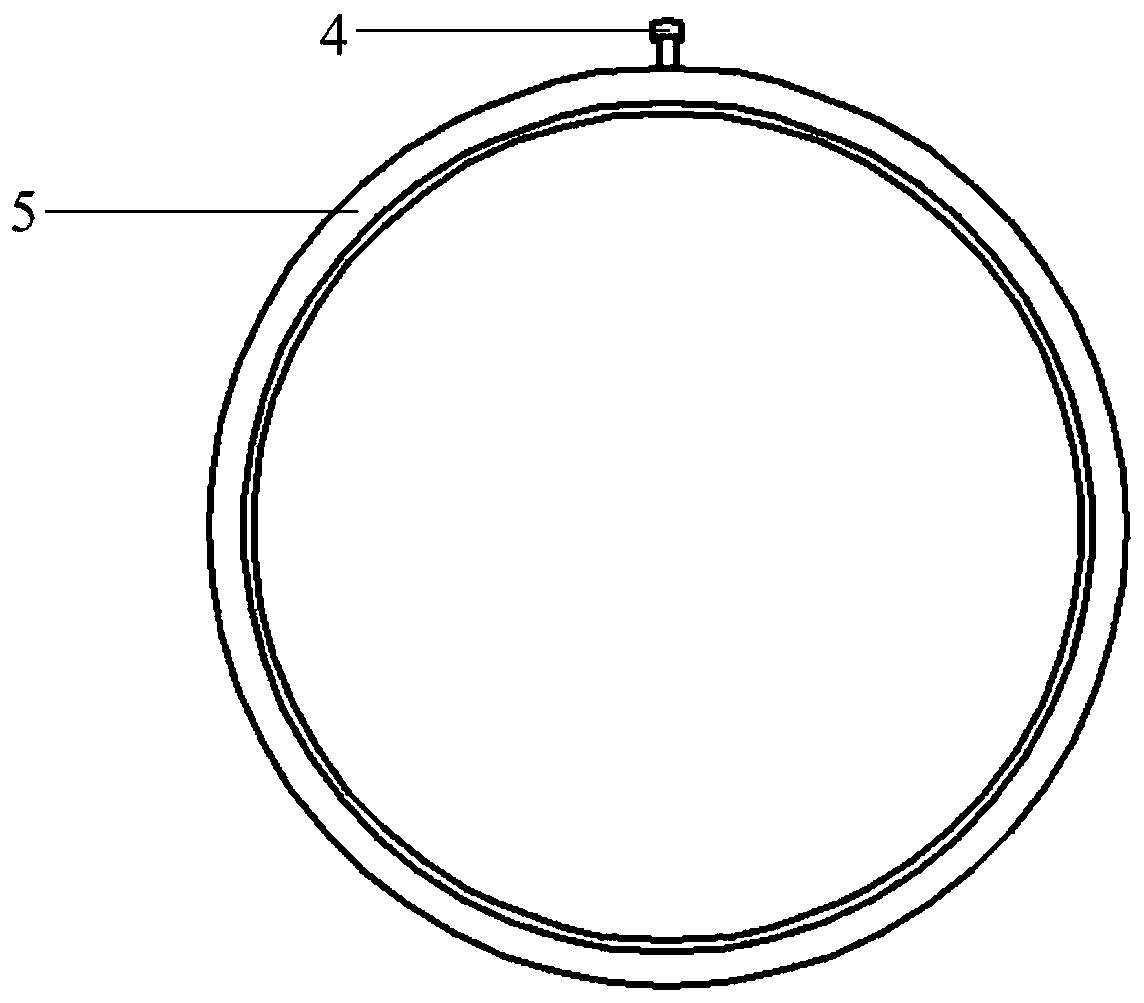

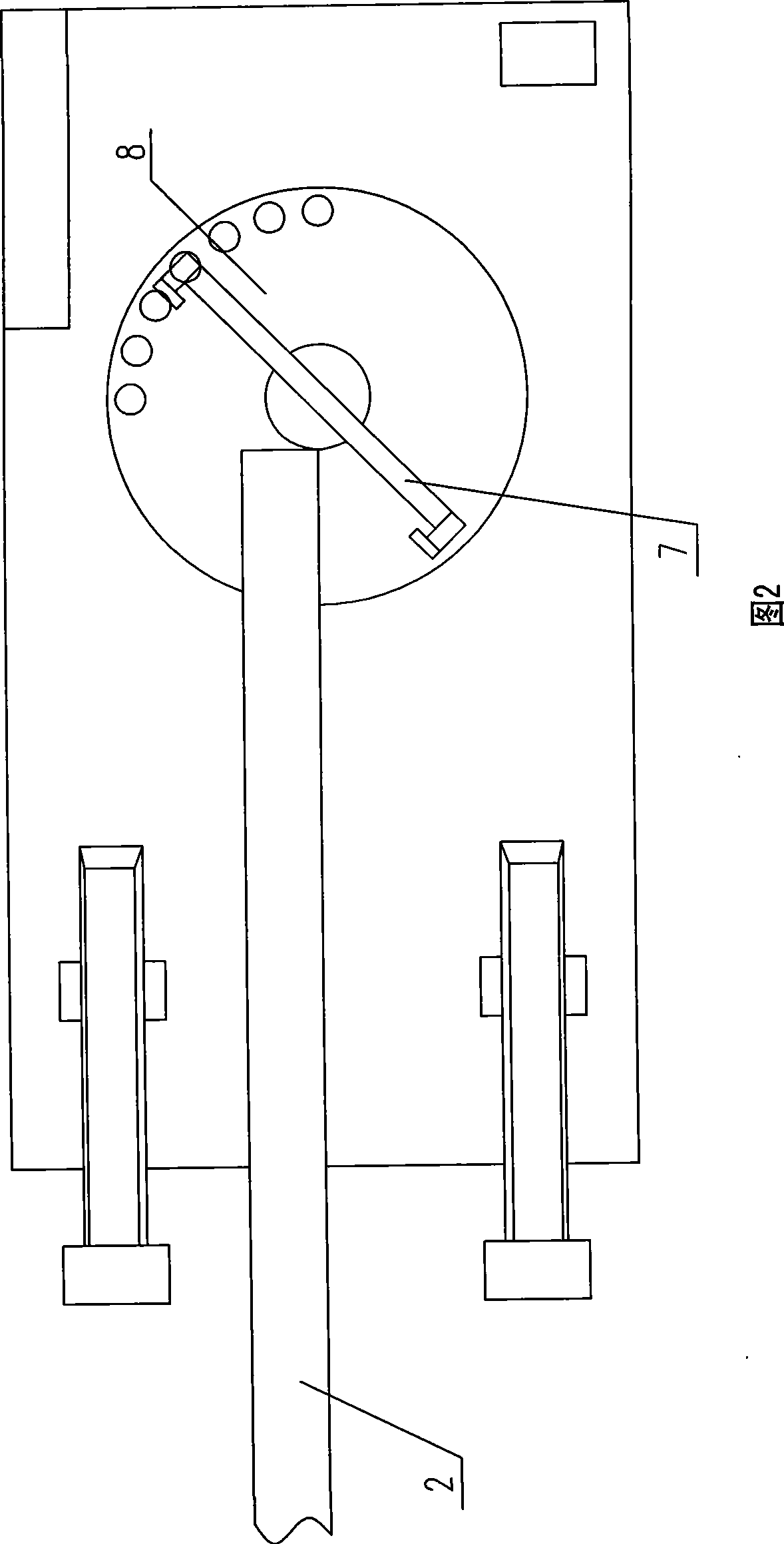

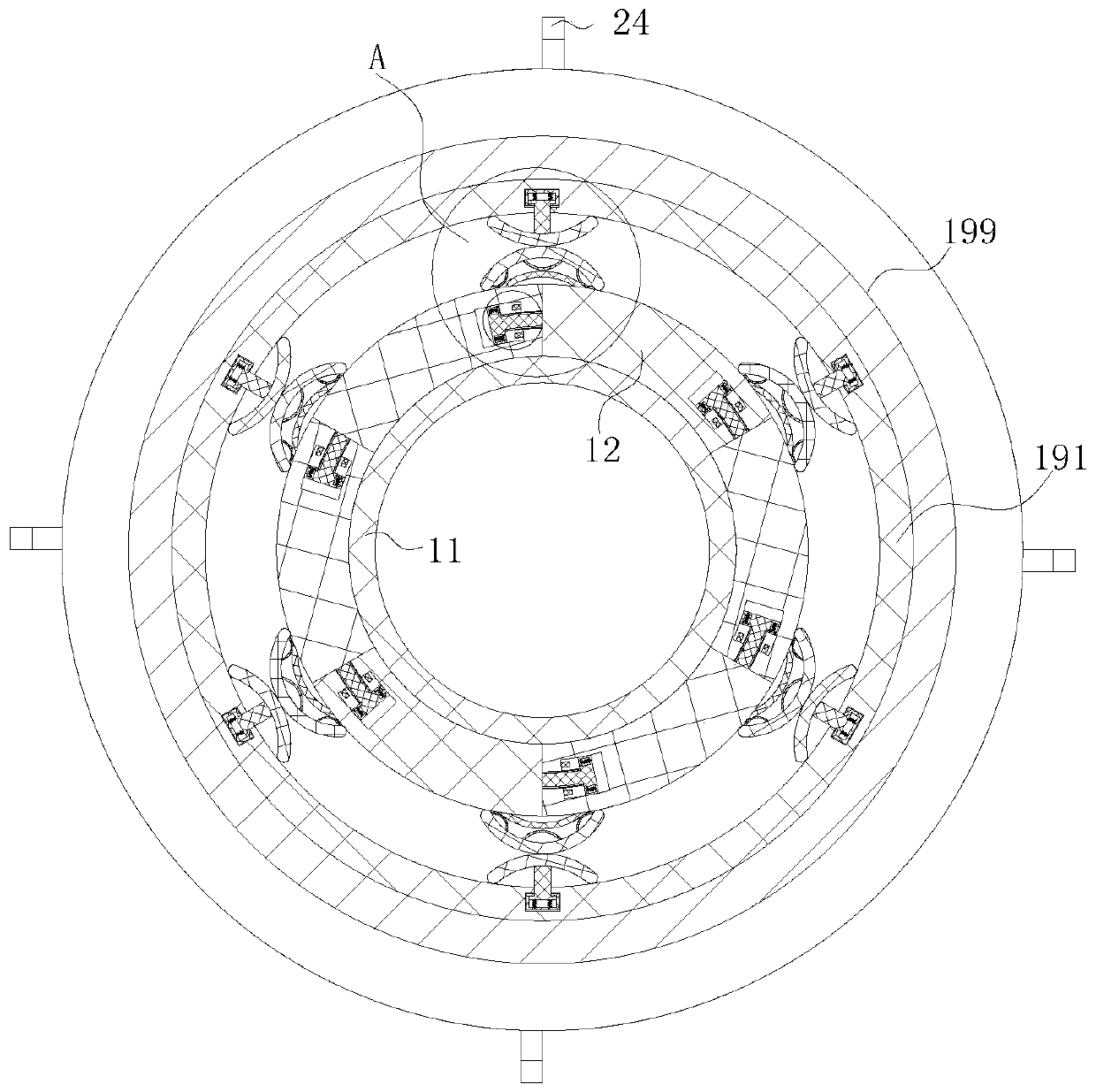

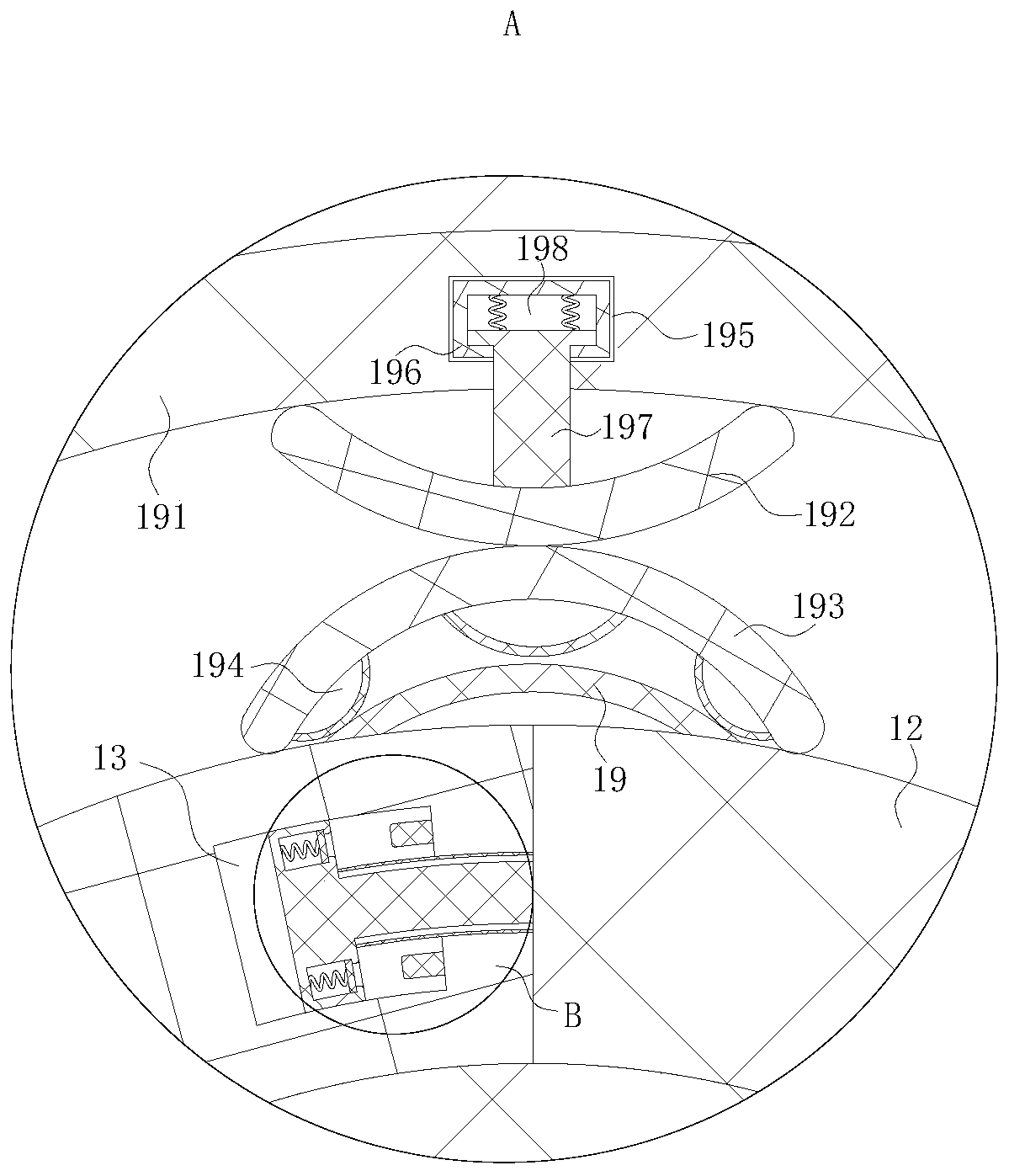

Pipeline inner wall wear corrosion monitoring device and monitoring method thereof

ActiveCN109765134AEffective protective measuresReal-time monitoring of wear rateWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceLoss rateVoltmeter

The invention discloses a pipeline inner wall wear corrosion monitoring device and a monitoring method thereof. The pipeline inner wall wear corrosion monitoring device includes an annular wear corrosion sensor, an external pressure chamber and an electronic chamber, the annular wear corrosion sensor is placed in the external pressure chamber, and a potentiostat, a zero-resistance galvanometer, ahigh-precision digital voltmeter, a relay switch, a micro-resistance meter and a signal acquisition controller are placed in the electronic chamber; the sensor is connected to a pipeline through an end flange, an corrosion element and a temperature reference element are both connected to the micro-resistance meter, and the micro-resistance meter measures resistance of each partition, and the resistance is used for calculating the total metal loss rate of the inner wall of the pipeline; an electrode element, a potential reference element and the corrosion element form a three-electrode system,and the corrosion rate is obtained by measuring linear polarization of the corrosion element through the potentiometer and the zero-resistance galvanometer; and a difference between the total loss rate and the corrosion rate is the wear rate. The annular wear corrosion sensor can predict occurrence of wear corrosion in the pipeline, and evaluate the wear rate and corrosion rate of the pipeline inreal time.

Owner:DALIAN UNIV OF TECH

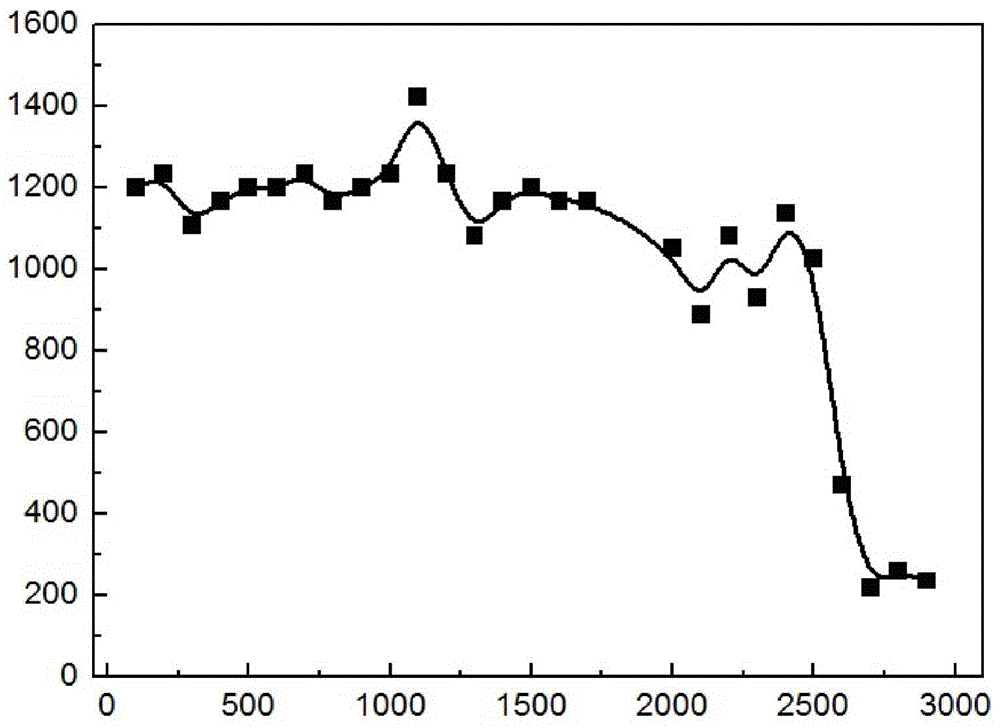

Voltage increasing subsection heating high-temperature erosion abrasion machine

The invention relates to a pressurized multistage heating high temperature erosion abrasion tester for simulating abrasion research of a coal burning boiler of a heat power plant, comprising a high temperature air-heating furnace, an abrasive grain feeder, a sample heating erosion machine, an erosion air feeding piping, after the erosion air feeding piping impenetrates the high temperature air-heating furnace, and directly passes over the sample heating erosion machine, an exit of the erosion air feeding piping points to the middle of a sample block vertically arranged in the sample heating erosion machine and forms a certain angle, an exit of the abrasive grain feeder is connected on the erosion air feeding piping between the high temperature air-heating furnace and the sample heating erosion machine. Provided is a pressurized multistage heating high temperature erosion abrasion tester for simulating erosion-corrosion operating conditions of the coal burning boiler of the heat power plant and validating spray coating performance of the boiler. Compared with the prior art, the invention has the advantages of good erosion abrasion simulating effect, short testing period, high testing efficiency and low testing cost.

Owner:刘少光

Method for preparing multiphase ceramic coating by self-reaction electric arc spraying

InactiveCN102877018AHigh reactive adiabatic combustion temperatureHigh melting point ceramic liquid phaseMolten spray coatingMicro nanoIn situ reaction

The invention discloses a method for preparing a multiphase ceramic coating by in-situ reaction synthesis, characterized by: selecting a proper metal skin material to prepare cored wires, wherein a reactive drug core of self-propagating high-temperature synthesis (SHS) system is coated by the metal skin material; using electric arc spraying equipment to conduct self-reaction electric arc spraying, in the spraying process, igniting the highly exothermic SHS reaction by electric arc, rapidly generating a target ceramic phase while using arc energy and heat release of the SHS reaction to obtain a high temperature ceramic melt, and spreading the high temperature ceramic melt on the surface of a metal matrix by using high pressure atomizing gas, and using the characteristic of rapid solidification of the high temperature ceramic melt to obtain the high performance multiphase ceramic coating with a micro-nano crystal structure. The invention has the advantages of simple equipment, low cost and wide applicability, and can be applied for surface strengthening and protection of components which suffer wearing, corrosion and high temperature environment in military and civil industrial equipment.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Low-alloy abrasion-proof and corrosion resistant steel and method for producing the same

InactiveCN101423916BImprove corrosion resistanceFix fixesElectric furnaceProcess efficiency improvementWear corrosionWear resistant

The invention relates to low alloy wearing resistance corrosion resistance steel which is suitably used in the ocean mud-sand wearing and corrosive environment, which is produced by the following steps: Mn-Si-Cr-Mo system non-carbide bainite alloy steel is taken as research basis, the carbon content and other alloy element contents are properly adjusted, elements of Al, Nb and rare earth contributing to improving the corrosion resistance of the alloy steel are added for modification, and the Mn-Si-Cr-Mo-Al system non-carbide bainite steel is formed by the progression quenching heat treatment process, so that the low alloy wearing resistance corrosion resistance steel is obtained. The steel has good obdurability, wearing resistant and corrosion resistant comprehensive performance and welding repair performances, and can be used to solve the problem of repairing worn blades of a centrifugal pump of a ship, and can also be applied to other ocean wearing resistance welding parts.

Owner:HOHAI UNIV +1

Coal water wear and corrosion resistant steel plate for railway coal transport vehicle and manufacturing method thereof

The invention discloses a coal-water abrasion and corrosion resistant steel plate for a railway coal transport vehicle and a manufacturing method thereof. The coal-water abrasion and corrosion resistant steel plate comprises the chemical components of, by weight, 0.01-0.15% of C, 0.10-0.50% of Si, 0.20-1.0% of Mn, 0.020% or less of P, 0.010% or less of S, 0.20-0.60% of Cu, 0.50-1.5% of Ni, 0.20-2.0% of Cr, 0.030-0.10% of Sb, 0-0.25% of Mo, 0-0.05% of Nb, 0-0.05% of V, 0-0.10% of Ti, 0-0.005% of B and the balance Fe and impurities, wherein C, Cr and Ni need to meet the relation of 1.6%<=12C+Cr / Ni<=2.8%. The steel plate is manufactured through the ten steps of blast-furnace iron melting, molten iron pre-desulfuration, converter smelting, LF+RH refining, plate blank continuous casting, cast blank slow cooling, plate blank heating, hot continuous rolling, laminar flow cooling and reeling, the yield strength of the steel plate is 450 MPa grade, the steel plate is excellent in mechanical performance, the service life of the steel plate under the coal-water abrasion and corrosion environment can be greatly prolonged, and the obvious competition advantage in the railway coal transport vehicle carriage manufacturing industry is achieved.

Owner:武汉钢铁有限公司

Wear-corrosion-resistant polyurethane material

The invention discloses a wear-corrosion-resistant polyurethane material comprising the raw materials: polytetrahydrofuran glycol, dimethyl-biphenyl diisocyanate, bis(hydroxymethyl)butyric acid, triisopropanolamine, hydroquinone bis(2-hydroxyethyl)ether, nano titanium dioxide, 3-isocyanate propyl triethoxy silane and stannous caprylate. A preparation process of the wear-corrosion-resistant polyurethane comprises the steps: taking dried polytetrahydrofuran glycol, heating up, adding a dimethyl-diphenyl diisocyanate solution drop by drop, carrying out heat preservation stirring, heating up, adding a bis(hydroxymethyl)butyric acid solution drop by drop, carrying out heat preservation stirring, cooling, adding a triisopropanolamine solution and a hydroquinone bis(2-hydroxyethyl)ether solution drop by drop, carrying out heat preservation stirring, and purifying to obtain an intermediate material; introducing nitrogen gas, taking an intermediate material solution, adding stannous octoate, heating up, adding a modified nano titanium dioxide solution drop by drop, carrying out heat preservation stirring, and purifying to obtain the wear-corrosion-resistant polyurethane material. The wear-corrosion-resistant polyurethane material has the advantages of good wear resistance, good corrosion resistance and high mechanical properties.

Owner:CHUZHOU GLOBAL POLYURETHANE TECH CO LTD

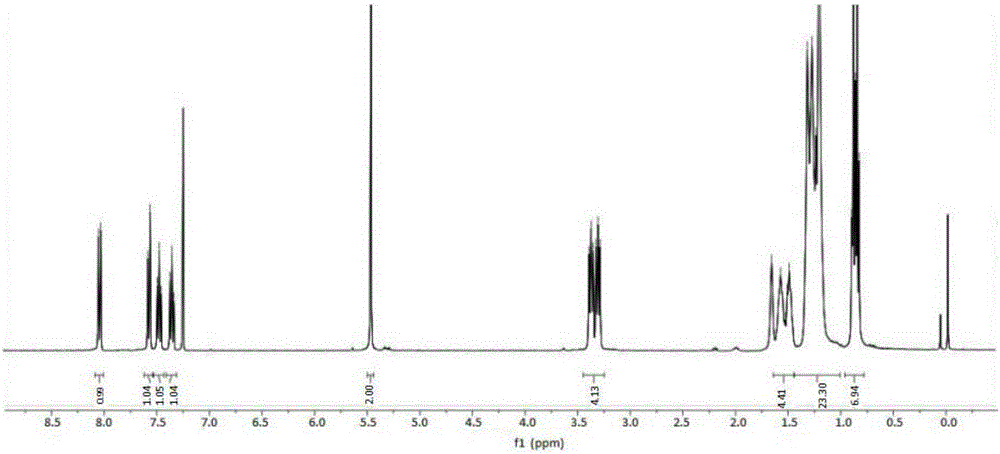

Alkyl acetamidobenzotriazole derivative lubricating oil additive and preparation method thereof

InactiveCN107522670AImprove heat resistanceGood extreme pressure and anti-wear propertiesOrganic chemistryAdditivesOil additiveAlkyl amine

The invention discloses a biodegradable alkyl acetamidobenzotriazole derivative lubricating oil additive which does not contain sulfur, phosphorus, halogens and metal elements as well as a preparation method and application thereof. The preparation method comprises the following steps: under the action of alkali, performing amidation on alkyl amine and chloroacetyl chloride to obtain alkyl chloroacetamide; and then performing a nucleophilic substitution reaction with benzotriazole to obtain a target compound of a formula I. The preparation method disclosed by the invention is simple in preparation method, mild in process condition, easily available in raw material, low in preparation cost and high in synthetic yield. The novel alkyl acetamidobenzotriazole derivative can be independently used as an extreme pressure anti-wear corrosion-resistant additive of lubricating oil, also can be used with other lubricating oil additives in a compound manner, also can be used in common working conditions and high-temperature working conditions, can improve the bearing capacity of basic oil obviously and improve the anti-wear performance, and is the lubricating oil additive which is environmentally friendly and multi-functional. The formula I is as shown in the specification.

Owner:DONGGUAN UNIV OF TECH

600HB hardness wear-corrosion-resistant steel plate used for slurry dredging pipes, and production method thereof

The invention discloses a 600HB hardness wear-corrosion-resistant steel plate used for slurry dredging pipes, and a production method thereof. The 600HB hardness wear-corrosion-resistant steel platecomprises, by weight, 0.36 to 0.42% of C, Si<=0.01%, 1.6 to 2.0% of Mn, P<=0.015%, S<=0.005%, 0.2 to 1.0% of Al, 0.3 to 1.2% of Cr, 0.001 to 0.002% of B, N<=0.005%, one element or two elements selected from 0.01 to 0.03% of Nb or 0.01 to 0.025% of Ti, and the balance Fe and unavoidable impurities, wherein 6.65N<Nb+Ti<=0.045. Both the wear resistance and the corrosion resistance are taken into consideration in preparation; the 600HB hardness wear-corrosion-resistant steel plate possesses excellent wear resistance, and is mainly used for preparation of dredging pipes used in reclamation projectand navigation channel dredging; the corrosion resistance degree is 5 times of that of common pipes, so that dredging efficiency is increased greatly, and operation cost is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

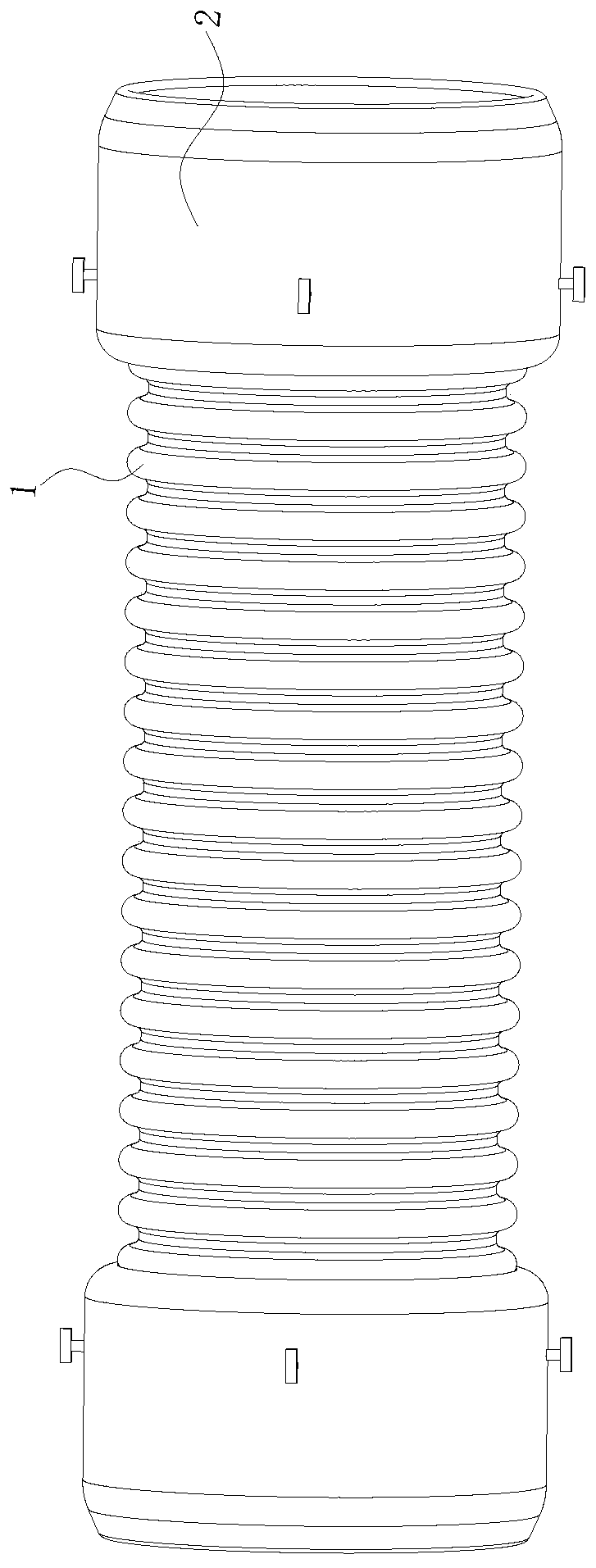

Anti-corrosion corrugated pipe for natural gas conveying

ActiveCN111350889APrevent outflowRelieve pressureEngine sealsCorrosion preventionWear corrosionCorrosive substance

The invention belongs to the technical field of corrugated pipes, and particularly relates to an anti-corrosion corrugated pipe for natural gas conveying. Joints are connected to the positions, located at the two ends of a long pipe, of the outer surface of the long pipe in a sleeving manner. The long pipe comprises an elastic hose. The elastic hose is made of an anti-corrosion material. Evenly-arranged arc blocks are fixedly connected to the outer surface of the elastic hose and are attached to one another to form a round pipe. A first sliding groove is formed in the end face of one side of each arc block. A first sliding block is fixedly connected to the end face of the other side of each arc block, and the first sliding blocks are arranged in the first sliding grooves and are in slidingconnection with the first sliding grooves. The anti-corrosion corrugated pipe is mainly used for solving the problems that in existing corrugated pipes, structures are single, most corrugated pipes adopt single-layer corrugated pipe structures, the defects of poor anti-corrosion performance, poor anti-pressure ability, easy wear and the like exist in the corrugated pipes of this kind, during use,cracks or wear or corrosion is prone to being generated, damage is prone to being caused, and consequently the service life is shortened.

Owner:宁波市浴耀管业有限公司

Hybridized aramid silicone aerogel modified flame-retardant polypropylene foaming plate and preparation method thereof

The invention discloses a hybridized aramid silicone aerogel modified flame-retardant polypropylene foaming plate and a preparation method thereof. A hybridized aramid silicone aerogel filler in foaming materials is obtained by mixing an aramid pulp solution with a silica sol system, an aerogel compound with a porous network structure and high in toughness, heat resistance and flame retardant is finally obtained. Melt strength can be effectively increased by adding the aerogel compound into a resin system, effects of reinforcement, flame retardance, nucleation and the like are achieved, usage amount of a traditional flame retardant is reduced, porosity of the system can be effectively increased, resin foaming is facilitated, traditional flame retardant materials of molybdenum disulfide, diethyl phosphonate aluminum and the like are combined, and the lightweight polypropylene foaming composite material with good flame-retardant effect is finally prepared; the composite material is even in porosity, crush and heat resistant, resistant to wear corrosion, economic and durable and quite promising in application.

Owner:阜阳市三郁包装材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com