Preparation method for TiCN-Al2O3 ceramic composite coating

A ceramic composite, ticn-al2o3 technology, applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of poor structure and performance stability, and achieve low cost, low wear, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

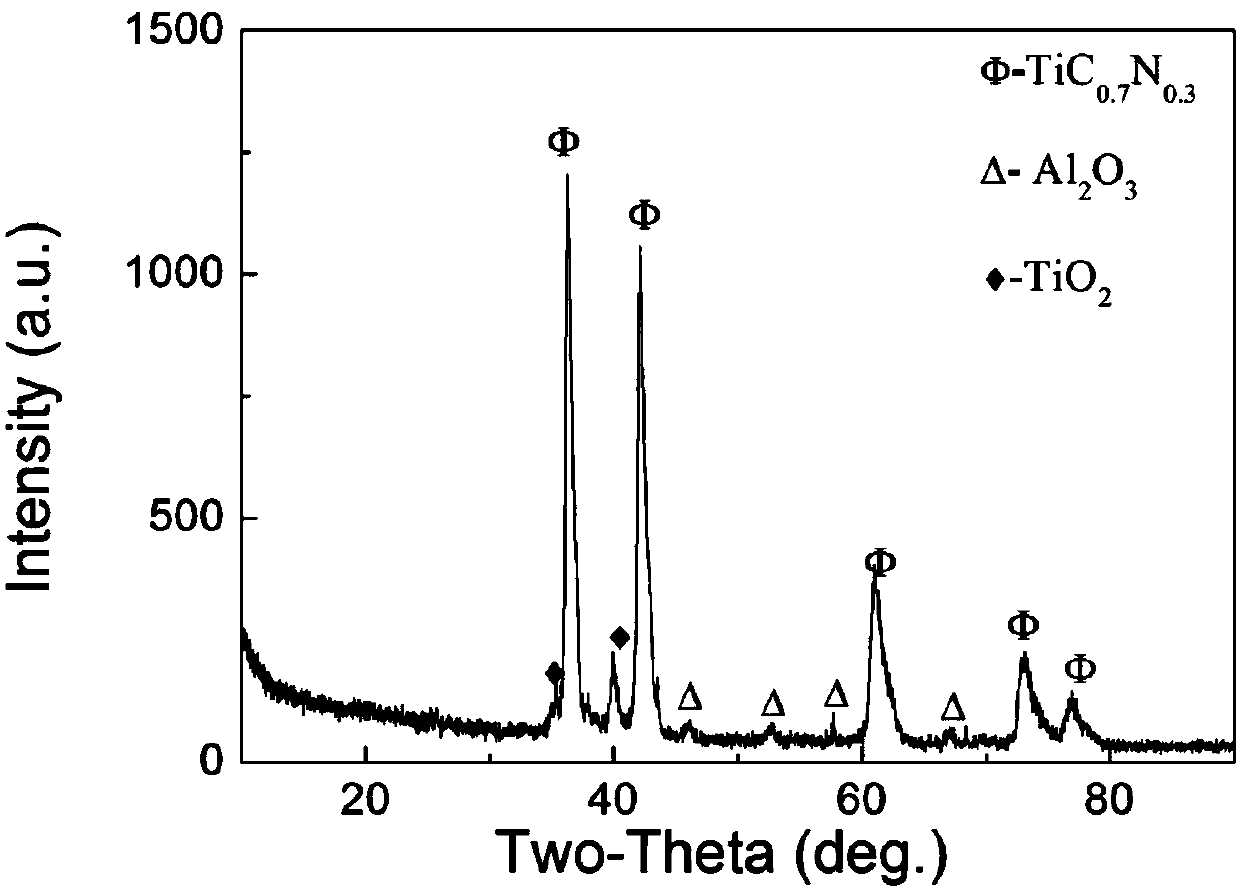

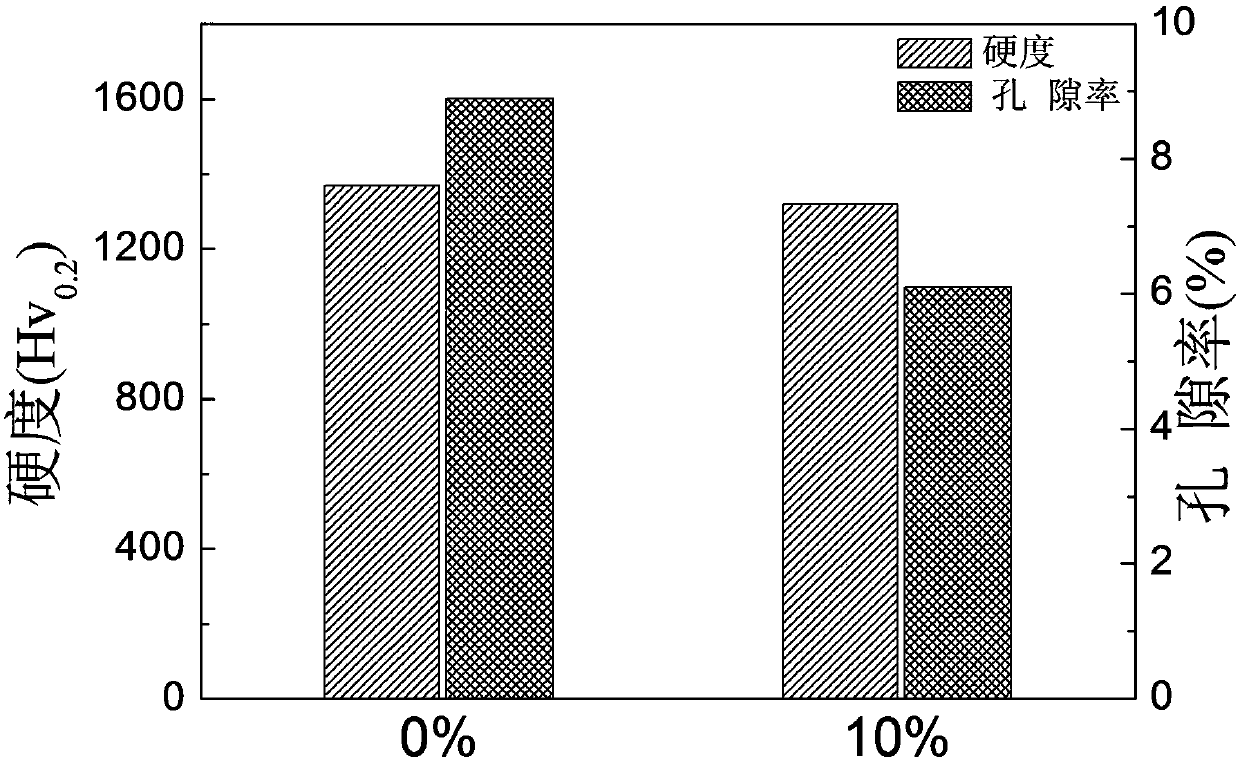

[0036] In this example, TiCN-Al was prepared by reactive plasma spraying process on the surface of 45# steel matrix sample 2 o 3 Ceramic composite coating, the main phase of the coating is TiC 0.7 N 0.3 , Al 2 o 3 Uniformly distributed in the layer gap or hole, crack area in the form of strips, which reduces the porosity of the coating and obtains a dense composite coating.

[0037] The preparation method of this coating is as follows:

[0038] (1) Put the 45# steel substrate sample into the TPS-1 pneumatic sandblasting machine, and perform surface roughening treatment by sandblasting to obtain a surface roughness Ra of 2.5-13.0 / μm. During the sandblasting process, the abrasive particles are sucked into the nozzle, accelerated in the high-pressure airflow, and sprayed onto the surface of the substrate to obtain a clean and rough surface and increase the bonding force between the substrate and the coating;

[0039] (2) Using the spray granulation method, the original Ti p...

Embodiment 2

[0047] In this example, TiCN-Al was prepared by reactive plasma spraying process on the surface of 45# steel matrix sample 2 o 3 Ceramic composite coating, the main phase of the prepared coating is TiC 0.7 N 0.3 , a small amount of Al 2 o 3 Distribute evenly in the coating in strips.

[0048] The preparation method of the coating is as follows:

[0049] Using a powder feeder, the spray feed composite powder containing two spherical agglomerated powders is sent into the plasma flame, and sprayed onto the surface of the bonding layer to obtain TiCN-Al 2 o 3 Ceramic composite coating, in which the spherical Al in the feed composite powder is sprayed 2 o 3 Agglomerated powder quality 20%, other steps are identical with example 1.

[0050] TiCN-Al prepared above 2 o 3 The SEM images of ceramic composite coatings are similar to figure 1 As shown, the structure of the coating is relatively dense, forming Al 2 o 3 gathering area.

[0051] TiCN-Al prepared above 2 o 3 ...

Embodiment 3

[0055] In this example, the reactive plasma spraying process was used to prepare TiCN-Al on the surface of the substrate sample. 2 o 3 Ceramic composite coating, the main phase of the prepared coating is TiC 0.7 N 0.3 and Al 2 o 3 , a large amount of Al 2 o 3 aggregate to form a brittle zone.

[0056] The preparation method of the coating is as follows:

[0057] Using a powder feeder, the spray feed composite powder containing two spherical agglomerated powders is sent into the plasma flame, and sprayed onto the surface of the bonding layer to obtain TiCN-Al 2 o 3 Ceramic composite coating, in which the spherical Al in the feed composite powder is sprayed 2 o 3 Agglomerated powder quality 30%, other steps are identical with example 1.

[0058] TiCN-Al prepared above 2 o 3 The SEM images of ceramic composite coatings are similar to figure 1 As shown, the structure of the coating becomes loose, and there is a large amount of Al 2 o 3 gathering area.

[0059] TiC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com