Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2740 results about "Plasma sprayed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma spraying is a thermal process which entails creating a coating by spraying particles softened by heat onto a substrate. The particles sprayed are normally in the form of powder which is injected into the plasma flame to be heated to high temperatures.

Plasma spraying for semiconductor grade silicon

A plasma spray gun configured to spray semiconductor grade silicon to form semiconductor structures including p-n junctions includes silicon parts such as the cathode or anode or other parts facing the plasma or carrying the silicon powder having at least surface portions formed of high purity silicon. The semiconductor dopant may be included in the sprayed silicon.

Owner:INTEGRATED PHOTOVOLTAICS

Coated semiconductor processing members having chlorine and fluorine plasma erosion resistance and complex oxide coatings therefor

ActiveUS20170301519A1High tensile bond strengthReduce pollutionMolten spray coatingElectric discharge tubesSolid solutionPlasma sprayed

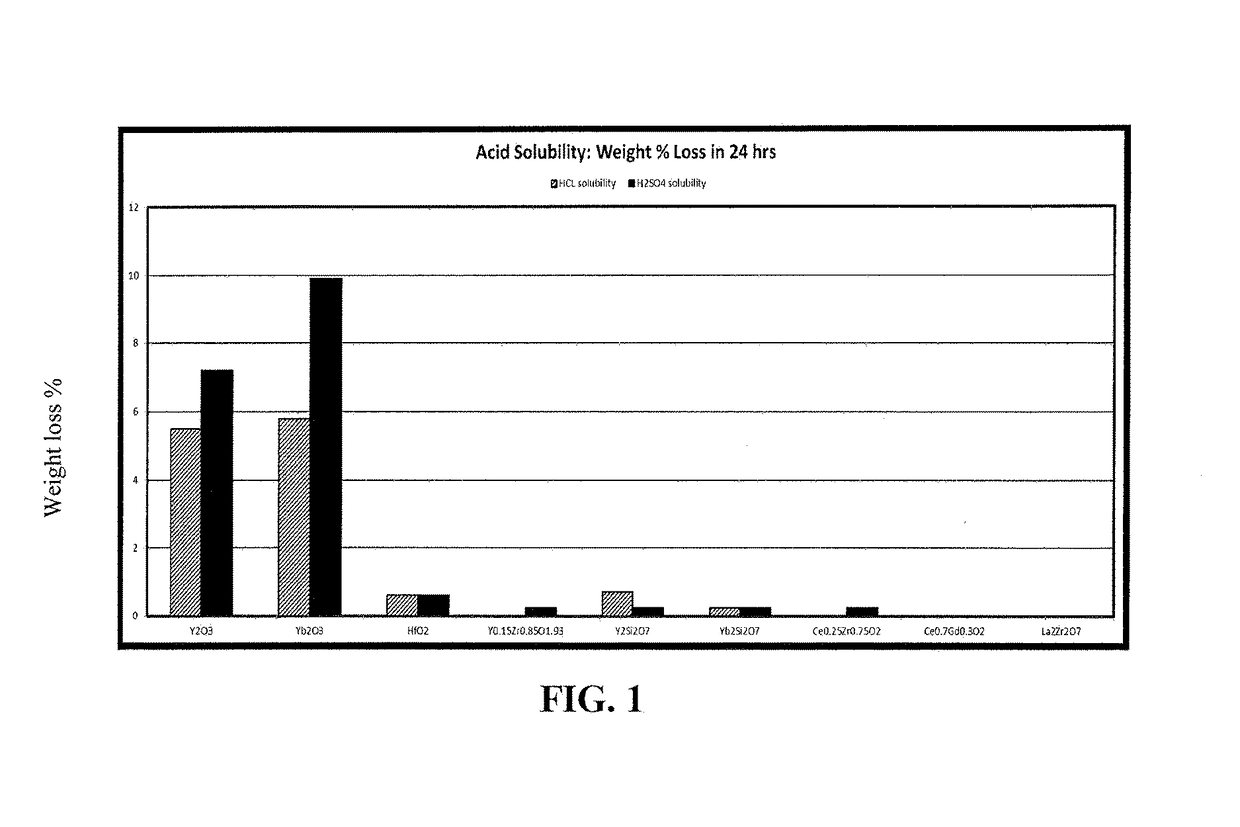

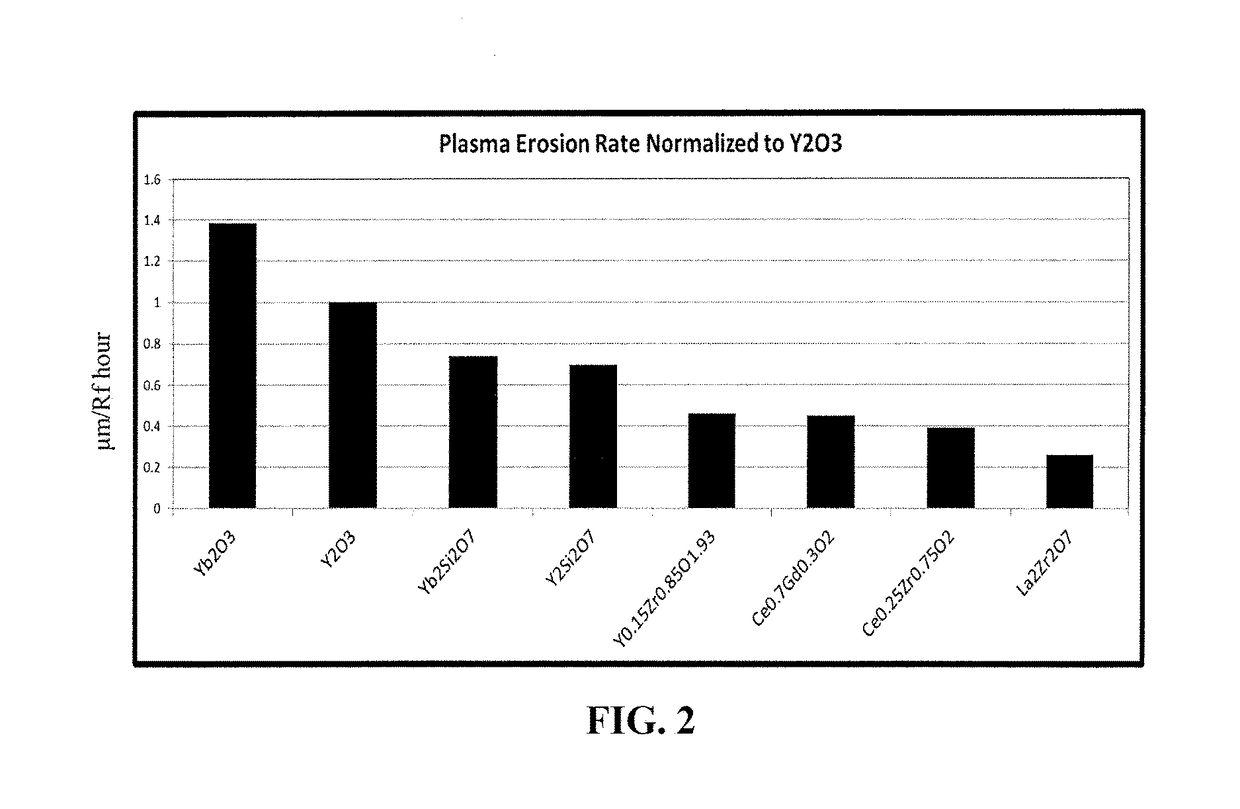

A semiconductor processing member is provided, including a body and a plasma spray coating provided on the body. The coating is an ABO or ABCO complex oxide solid solution composition, where A, B and C are selected from the group consisting of La, Zr, Ce, Gd, Y, Yb and Si, and O is an oxide. The coating imparts both chlorine and fluorine plasma erosion resistance, reduces particle generation during plasma etching, and prevents spalling of the coating during wet cleaning of the semiconductor processing member.

Owner:FM INDS

Clean, dense yttrium oxide coating protecting semiconductor processing apparatus

ActiveUS20050037193A1Extended service lifeExcellent plasma corrosion-resistanceLiquid surface applicatorsMolten spray coatingPlasma coatingChemical vapor deposition

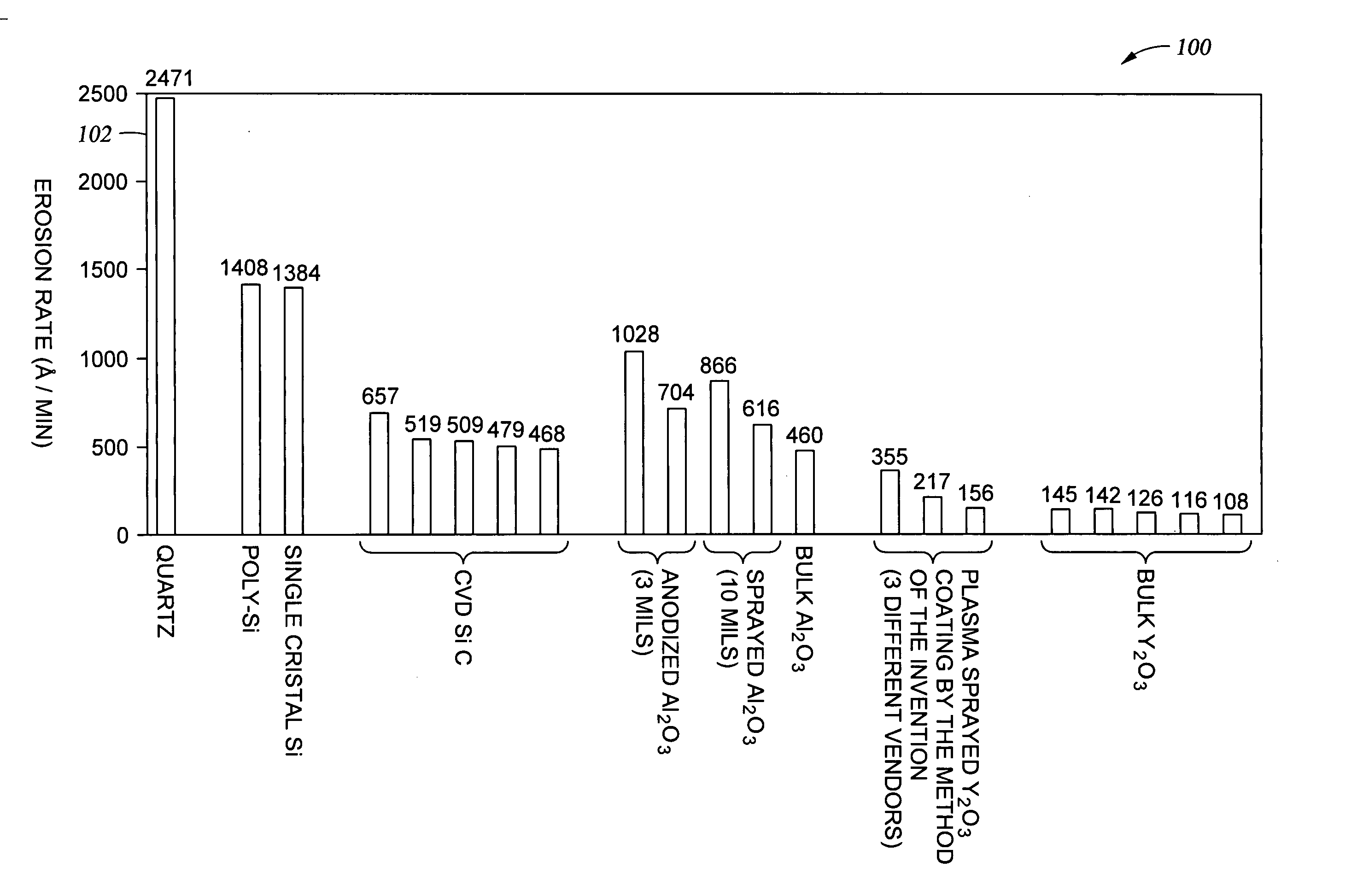

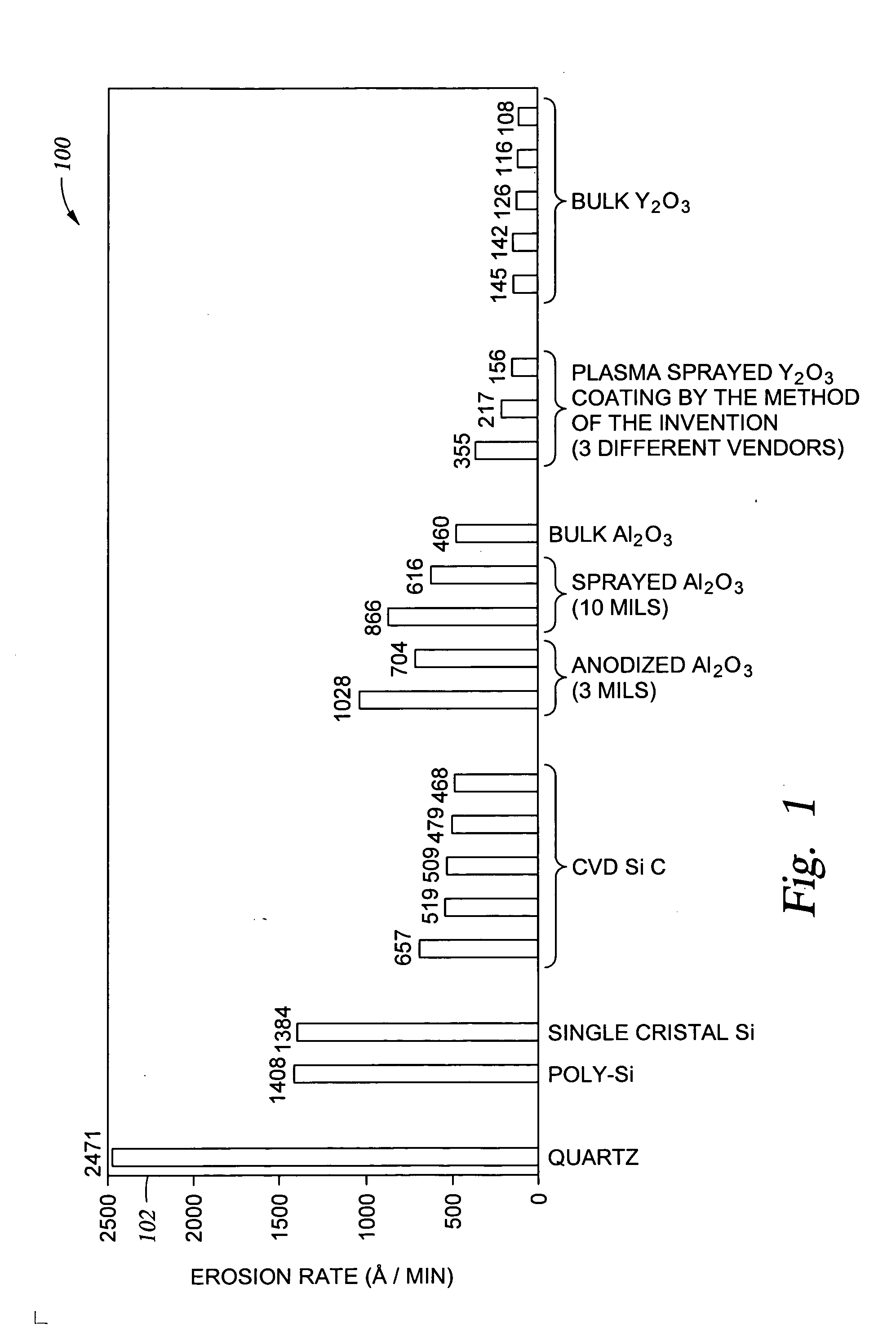

Disclosed herein is a method for applying plasma-resistant coatings for use in semiconductor processing apparatus. The coatings are applied over a substrate which typically comprises an aluminum alloy of the 2000 series or the 5000 through 7000 series. The coating typically comprises an oxide or a fluoride of Y, Sc, La, Ce, Eu, Dy, or the like, or yttrium-aluminum-garnet (YAG). The coating may further comprise about 20 volume % or less of Al2O3. The coatings are typically applied to a surface of an aluminum alloy substrate or an anodized aluminum alloy substrate using a technique selected from the group consisting of thermal / flame spraying, plasma spraying, sputtering, and chemical vapor deposition (CVD). To provide the desired corrosion resistance, it is necessary to place the coating in compression. This is accomplished by controlling deposition conditions during application of the coating.

Owner:APPLIED MATERIALS INC

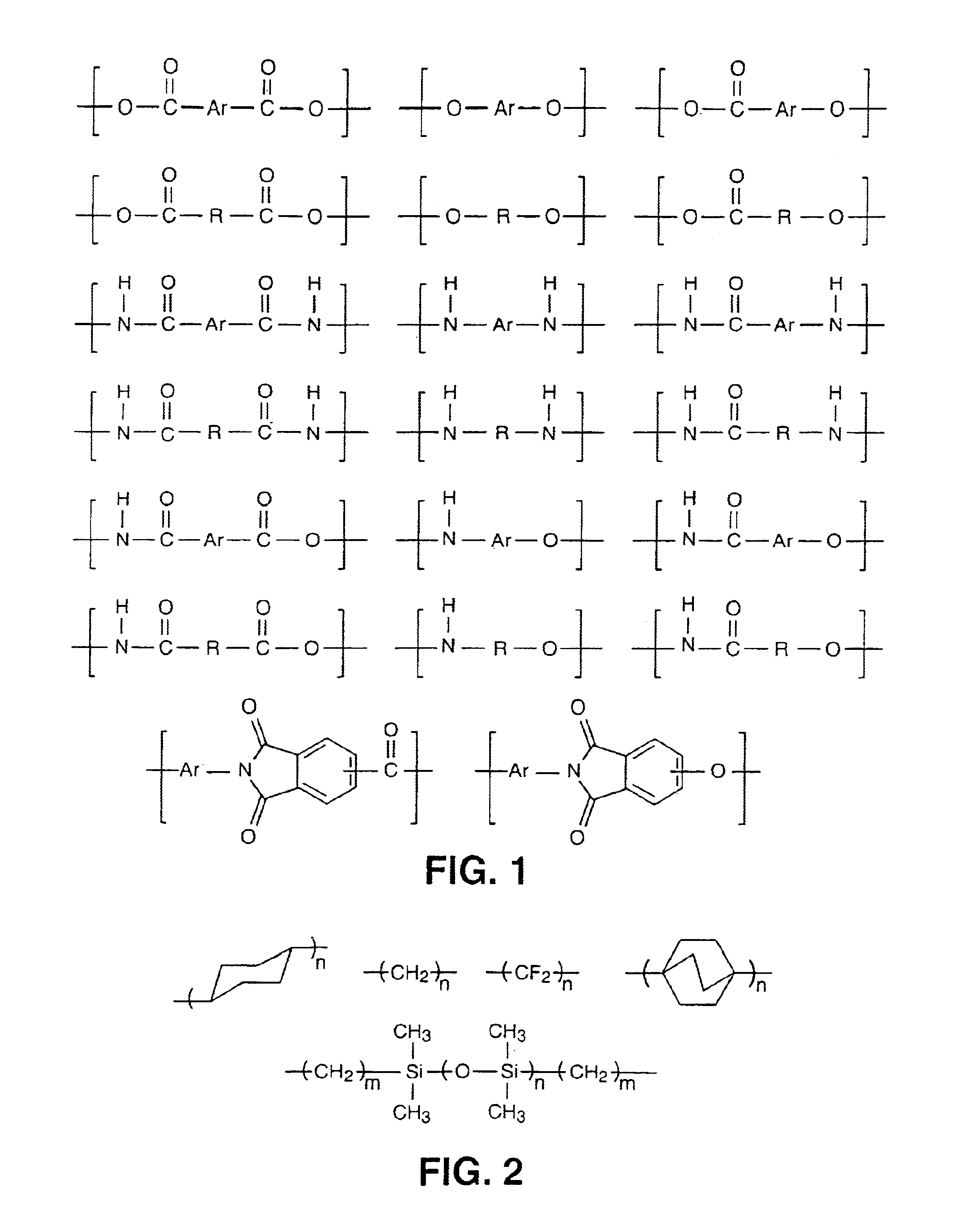

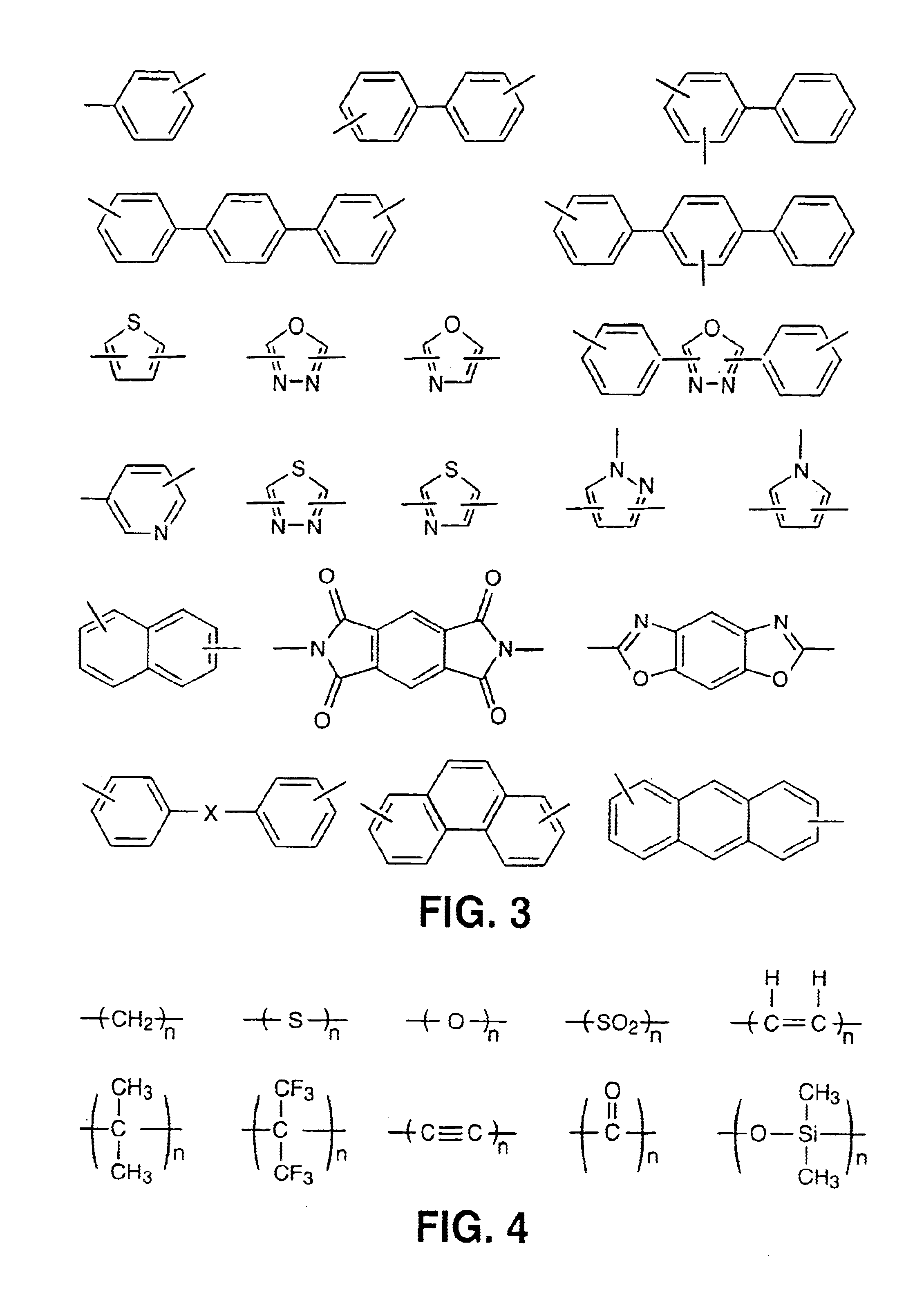

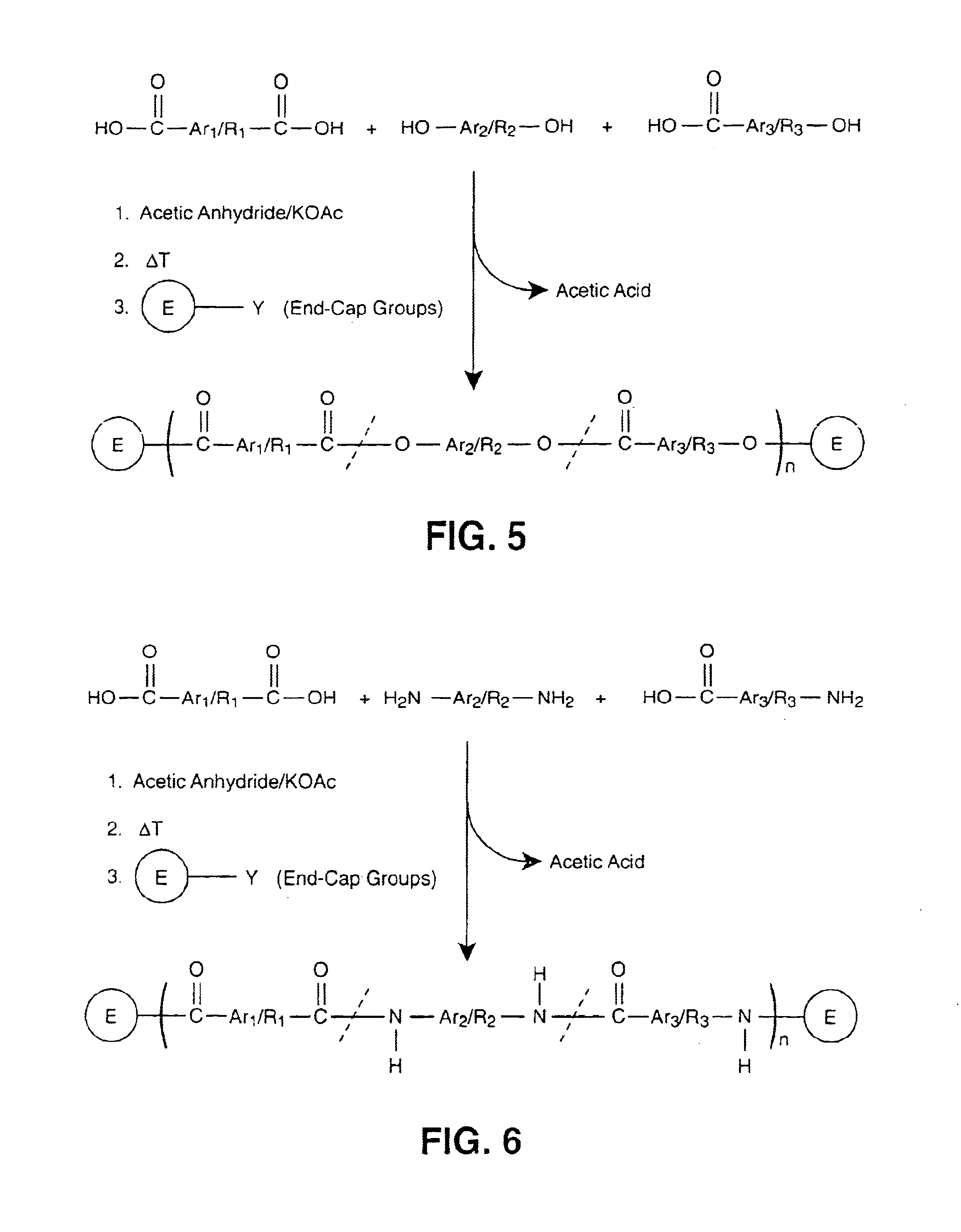

Liquid crystalline thermosets from ester, ester-imide, and ester-amide oligomers

InactiveUS6939940B2Low viscosityLow dielectric constantLiquid crystal compositionsLiquid crystallineEnd-group

Main chain thermotropic liquid crystal esters, ester-imides, and ester-amides were prepared from AA, BB, and AB type monomeric materials and were end-capped with phenylacetylene, phenylmaleimide, or nadimide reactive end-groups. The resulting reactive end-capped liquid crystal oligomers exhibit a variety of improved and preferred physical properties. The end-capped liquid crystal oligomers are thermotropic and have, preferably, molecular weights in the range of approximately 1000-15,000 grams per mole. The end-capped liquid crystal oligomers have broad liquid crystalline melting ranges and exhibit high melt stability and very low melt viscosities at accessible temperatures. The end-capped liquid crystal oligomers are stable for up to an hour in the melt phase. These properties make the end-capped liquid crystal oligomers highly processable by a variety of melt process shape forming and blending techniques including film extrusion, fiber spinning, reactive injection molding (RIM), resin transfer molding (RTM), resin film injection (RFI), powder molding, pultrusion, injection molding, blow molding, plasma spraying and thermo-forming. Once processed and shaped, the end-capped liquid crystal oligomers were heated to further polymerize and form liquid crystalline thermosets (LCT). The fully cured products are rubbers above their glass transition temperatures. The resulting thermosets display many properties that are superior to their non-end-capped high molecular weight analogs.

Owner:NASA

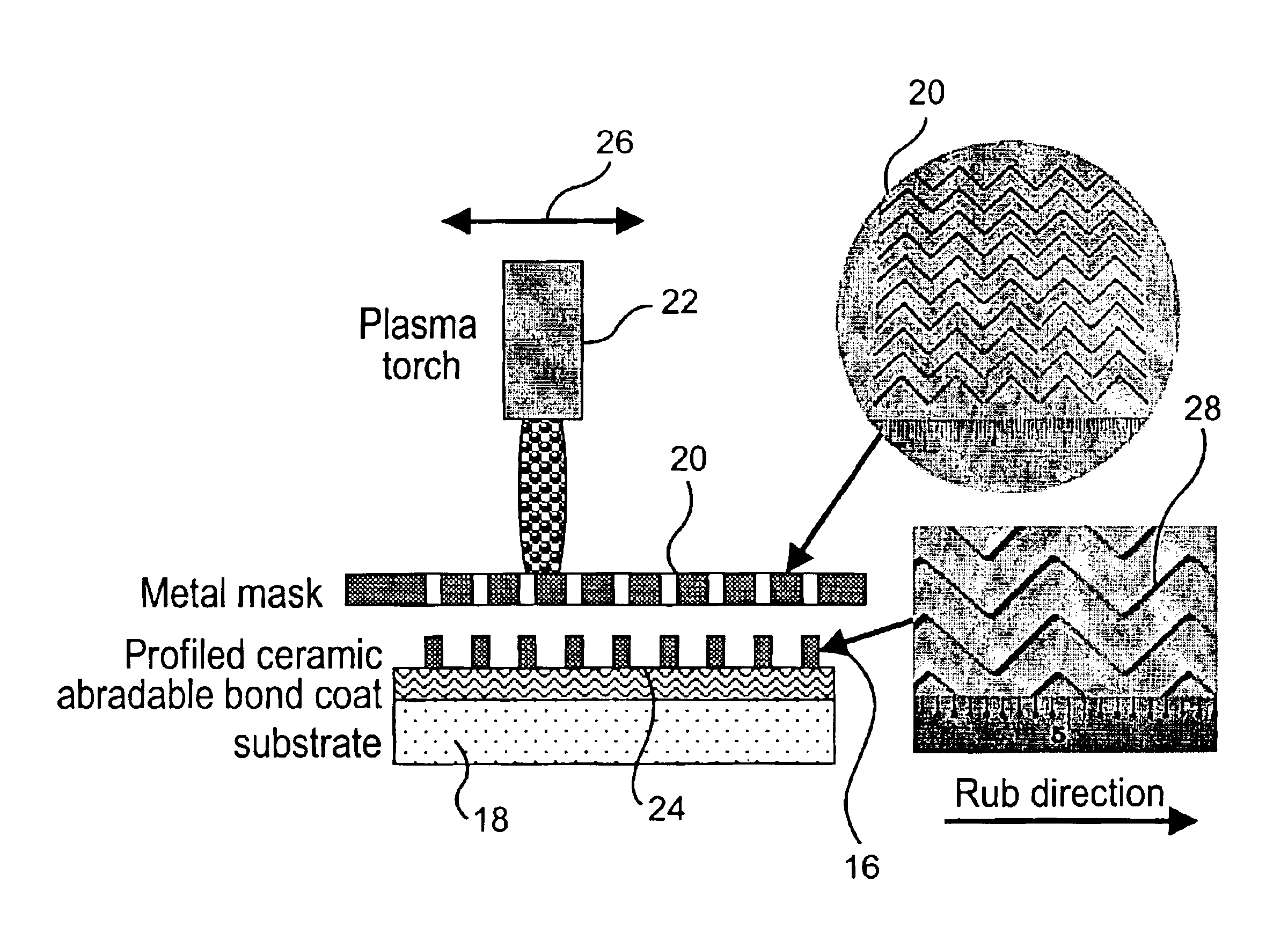

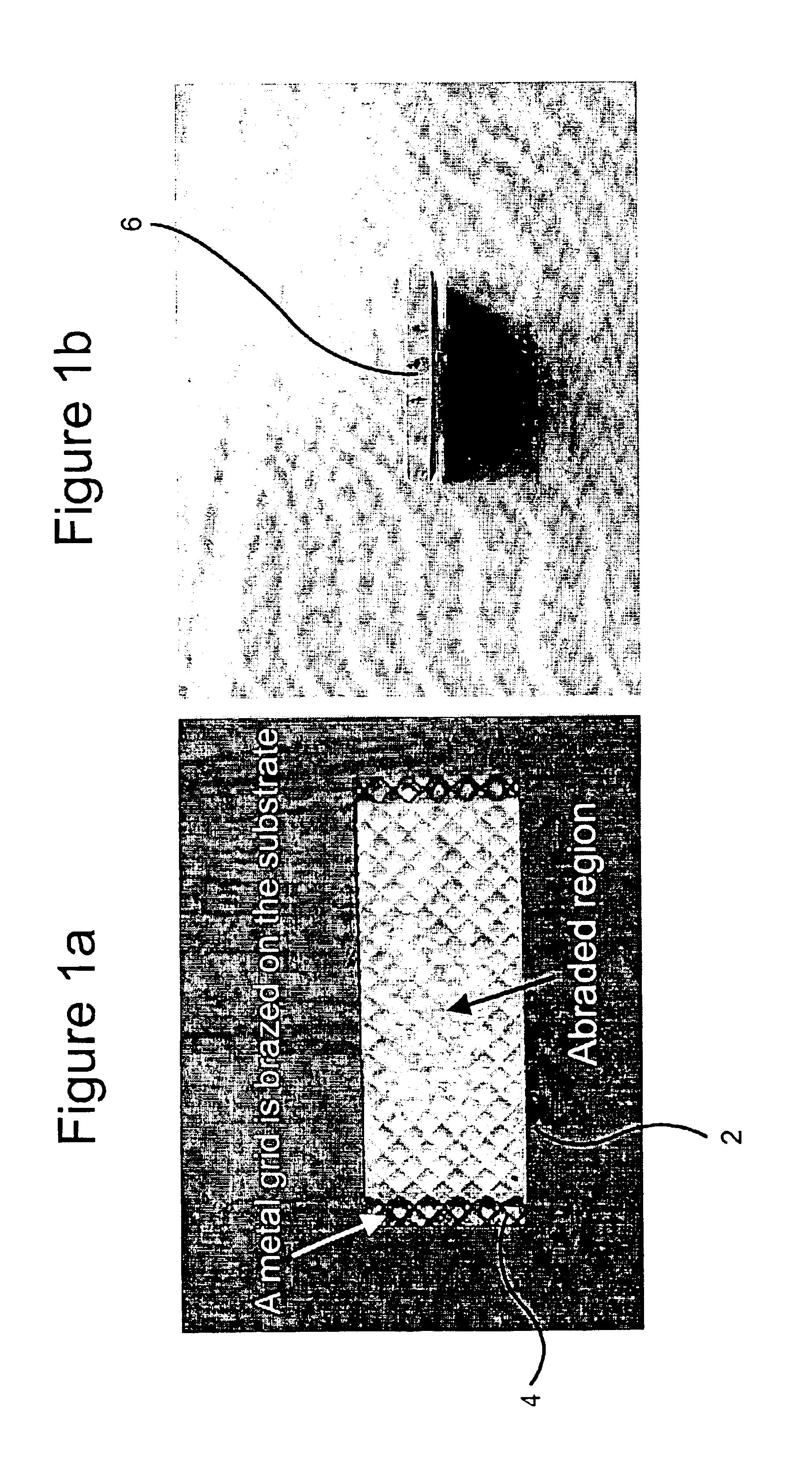

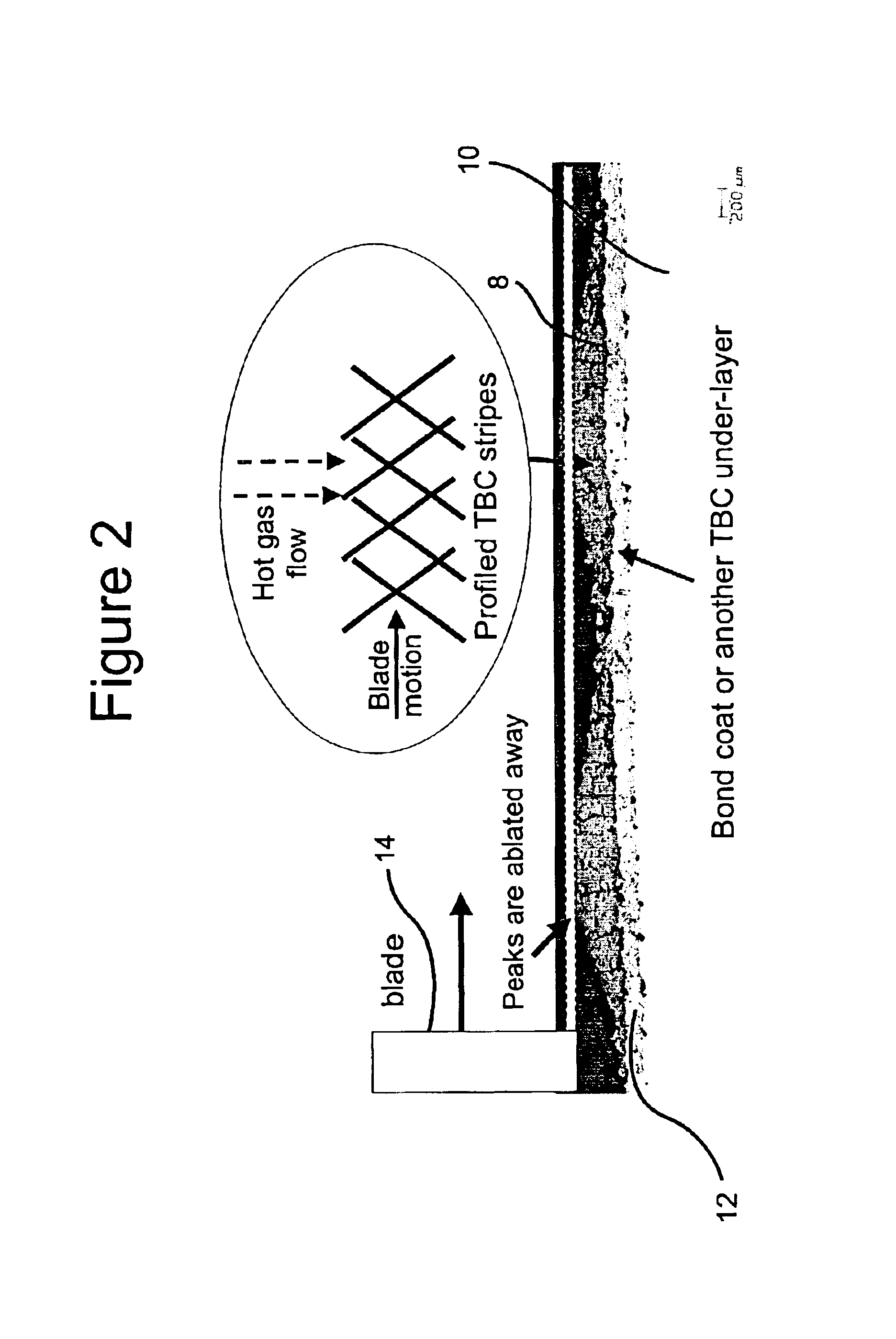

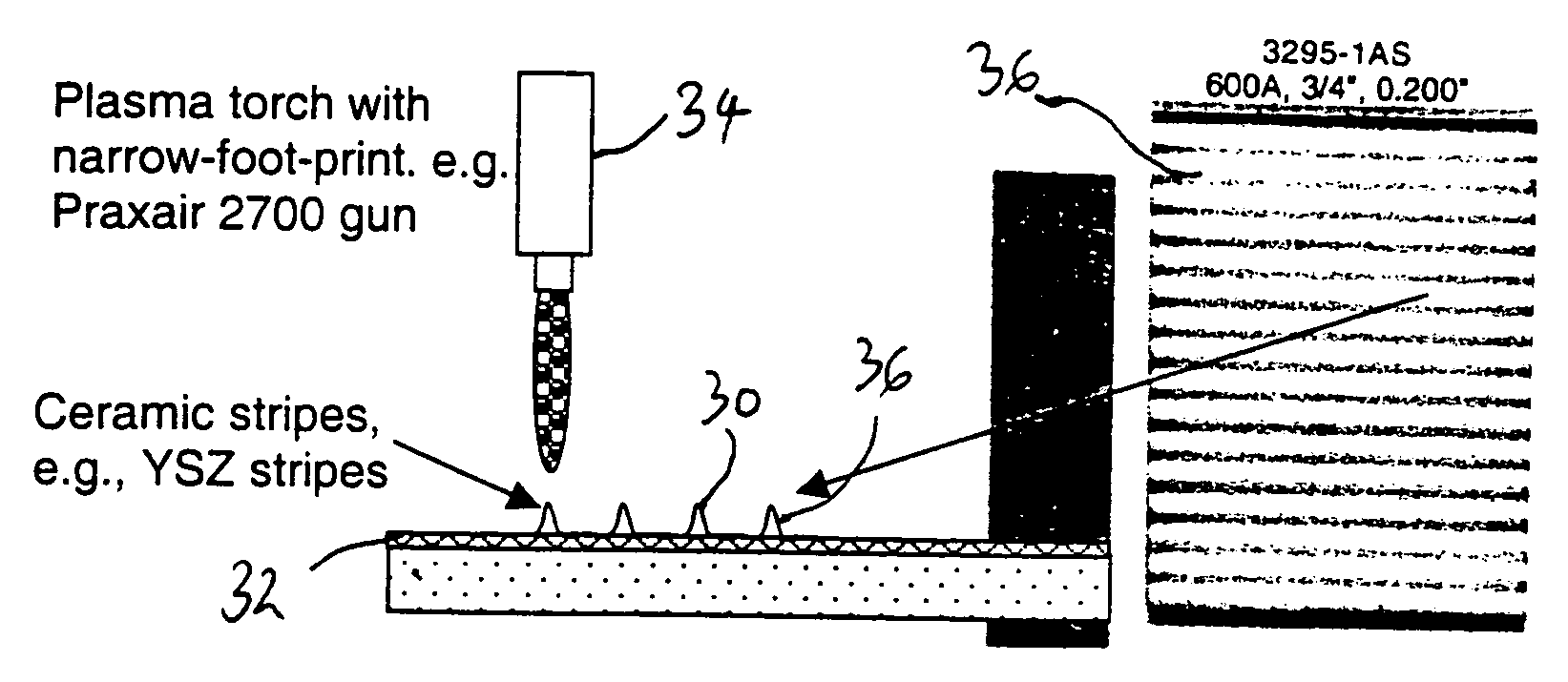

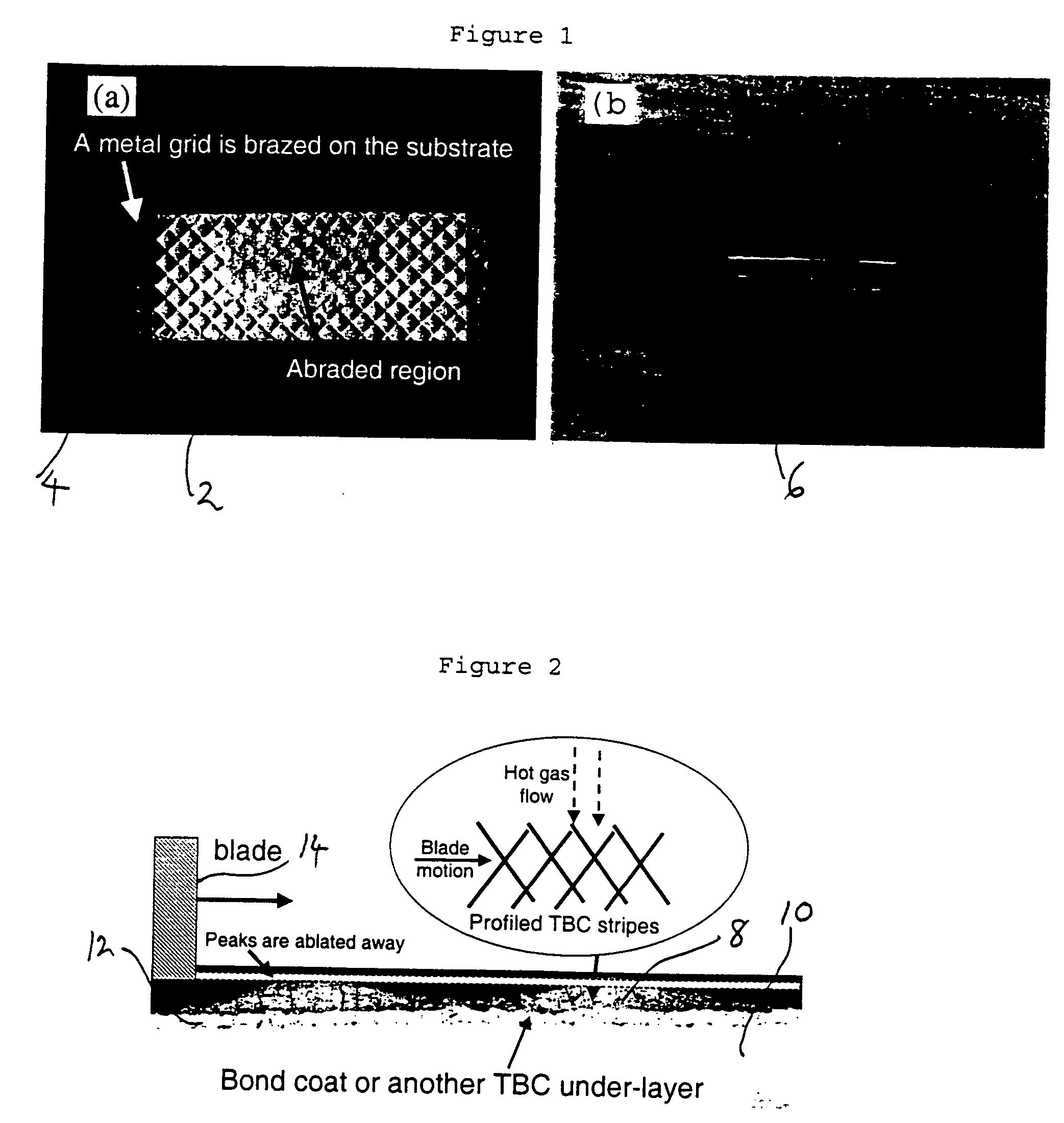

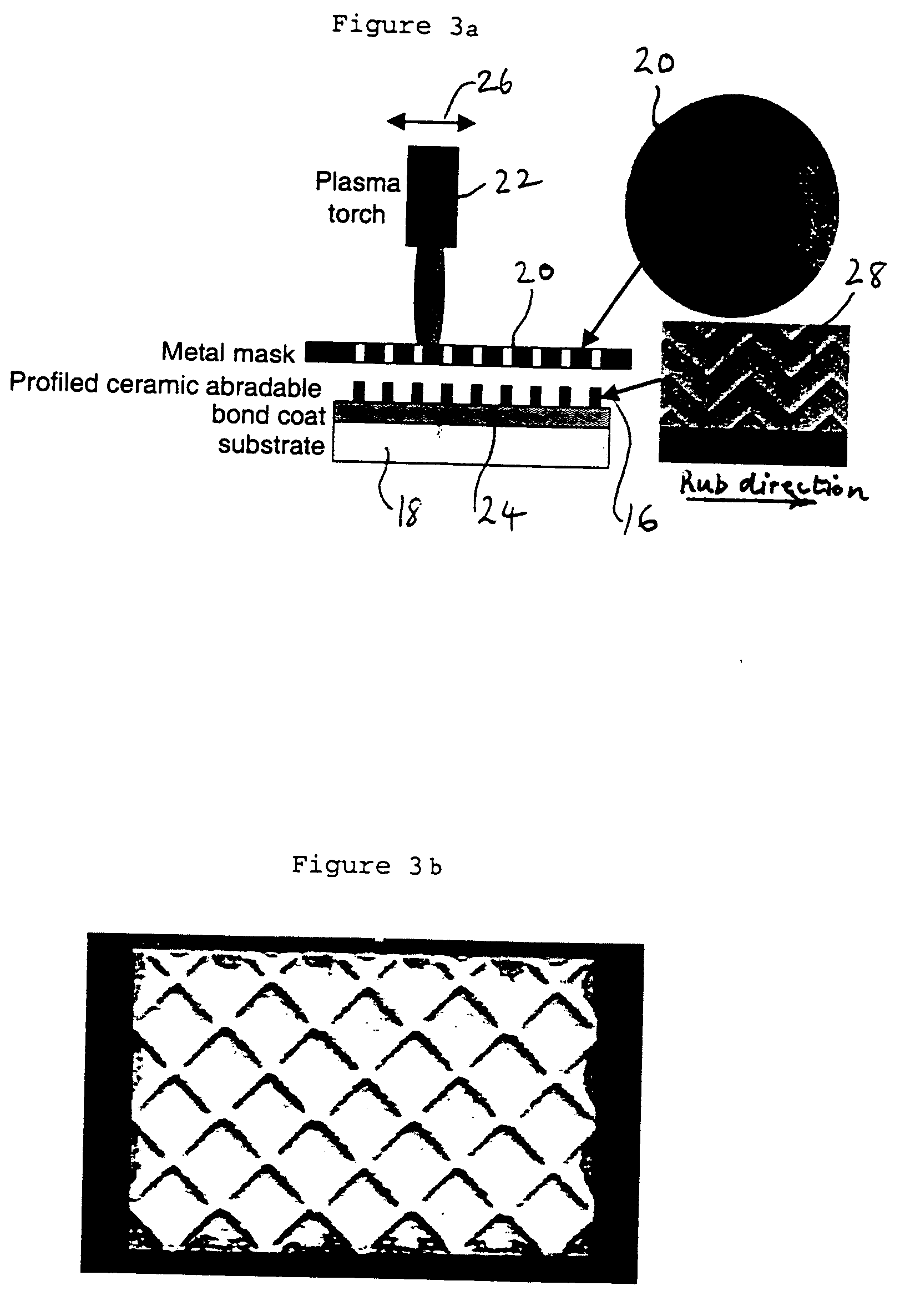

High temperature abradable coatings

InactiveUS6887528B2Solution to short lifeMolten spray coatingSpecial surfacesCeramic coatingMetallurgy

Method of producing a profiled abradable coating on a substrate in which an abradable ceramic coating composition is applied to a substrate using direct-write technology, or plasma sprayed onto the substrate through a mask or by use of a narrow foot-print plasma gun. These methods of producing abradable coatings are performed in the absence of a grid.

Owner:GENERAL ELECTRIC CO

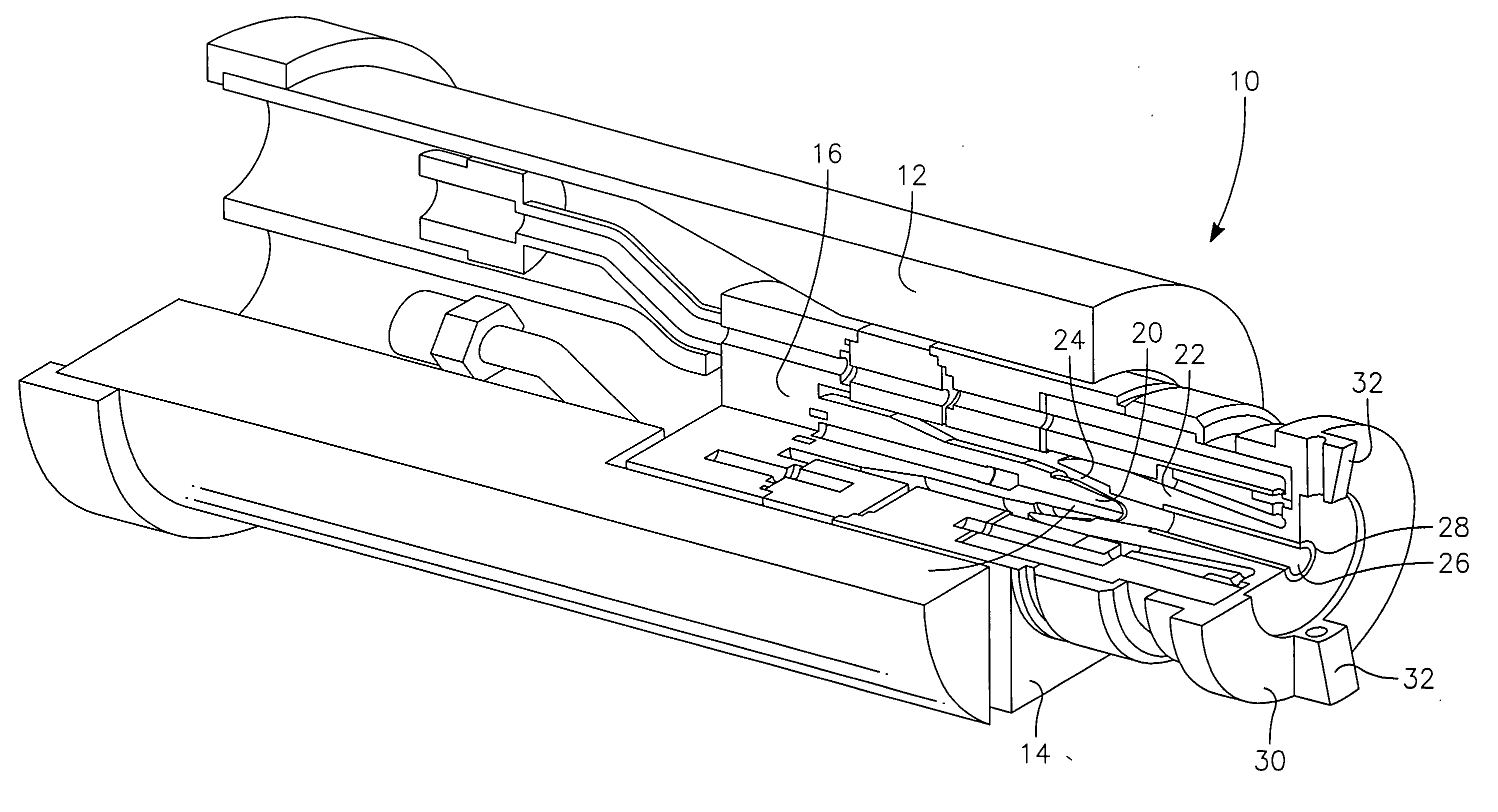

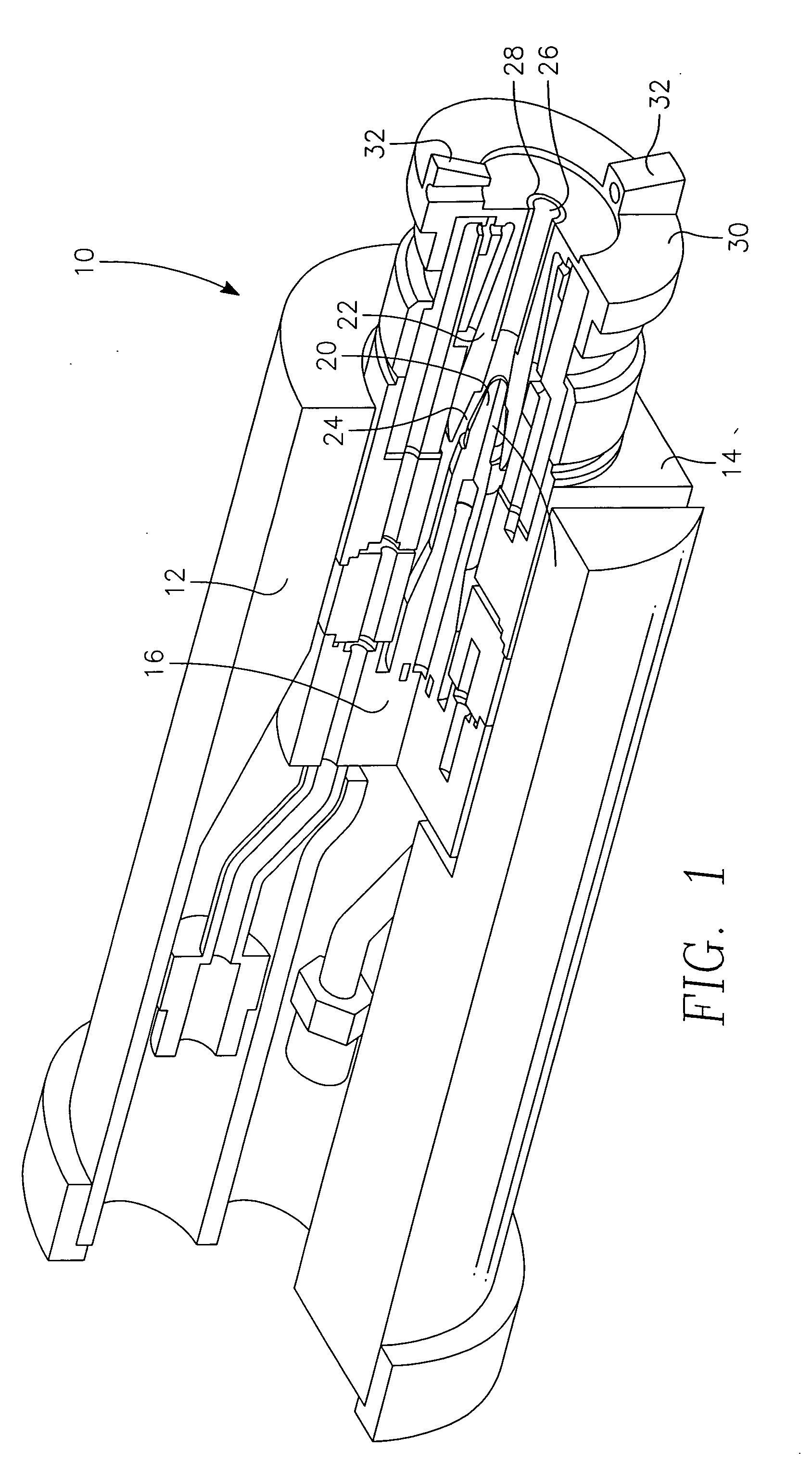

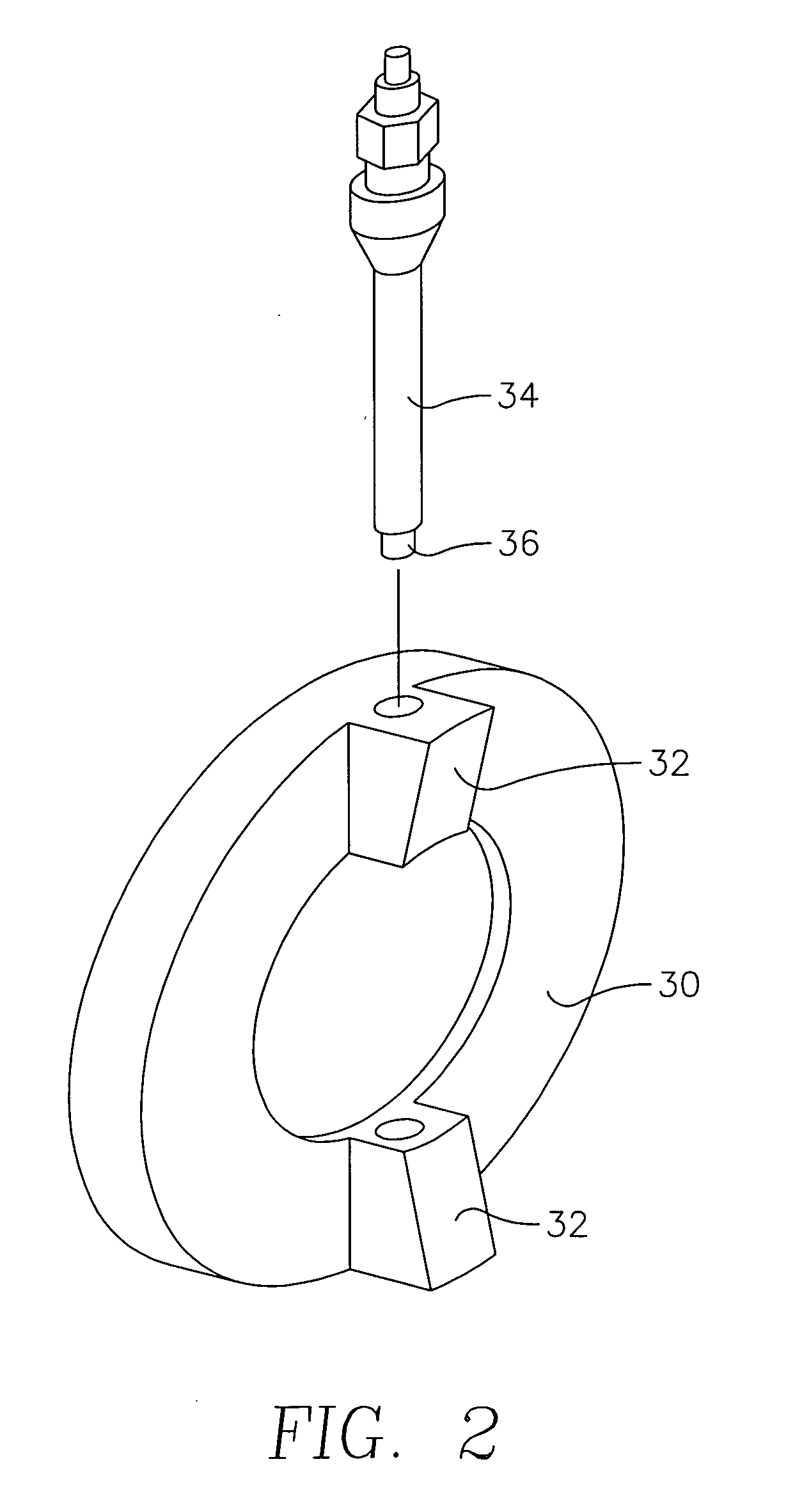

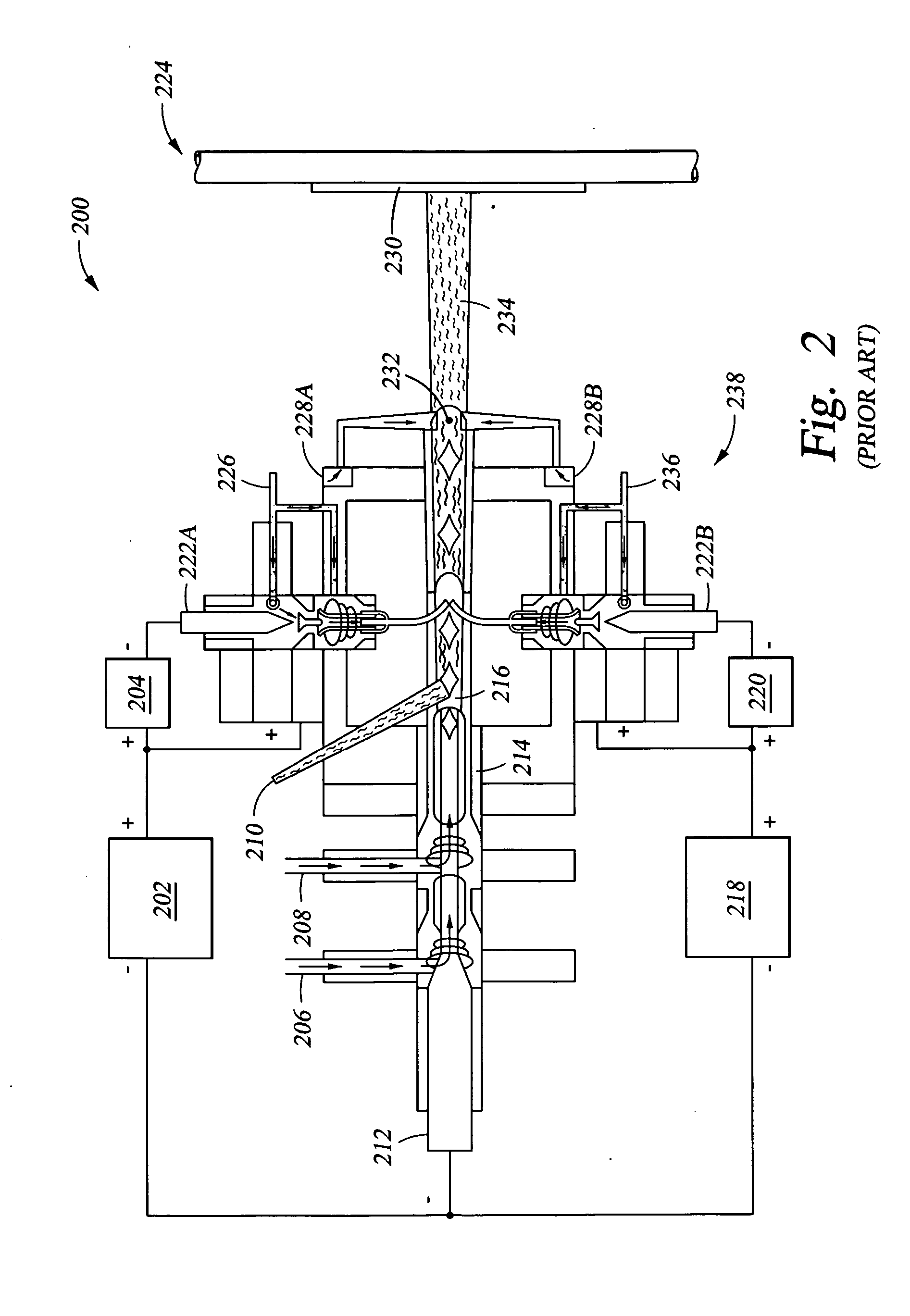

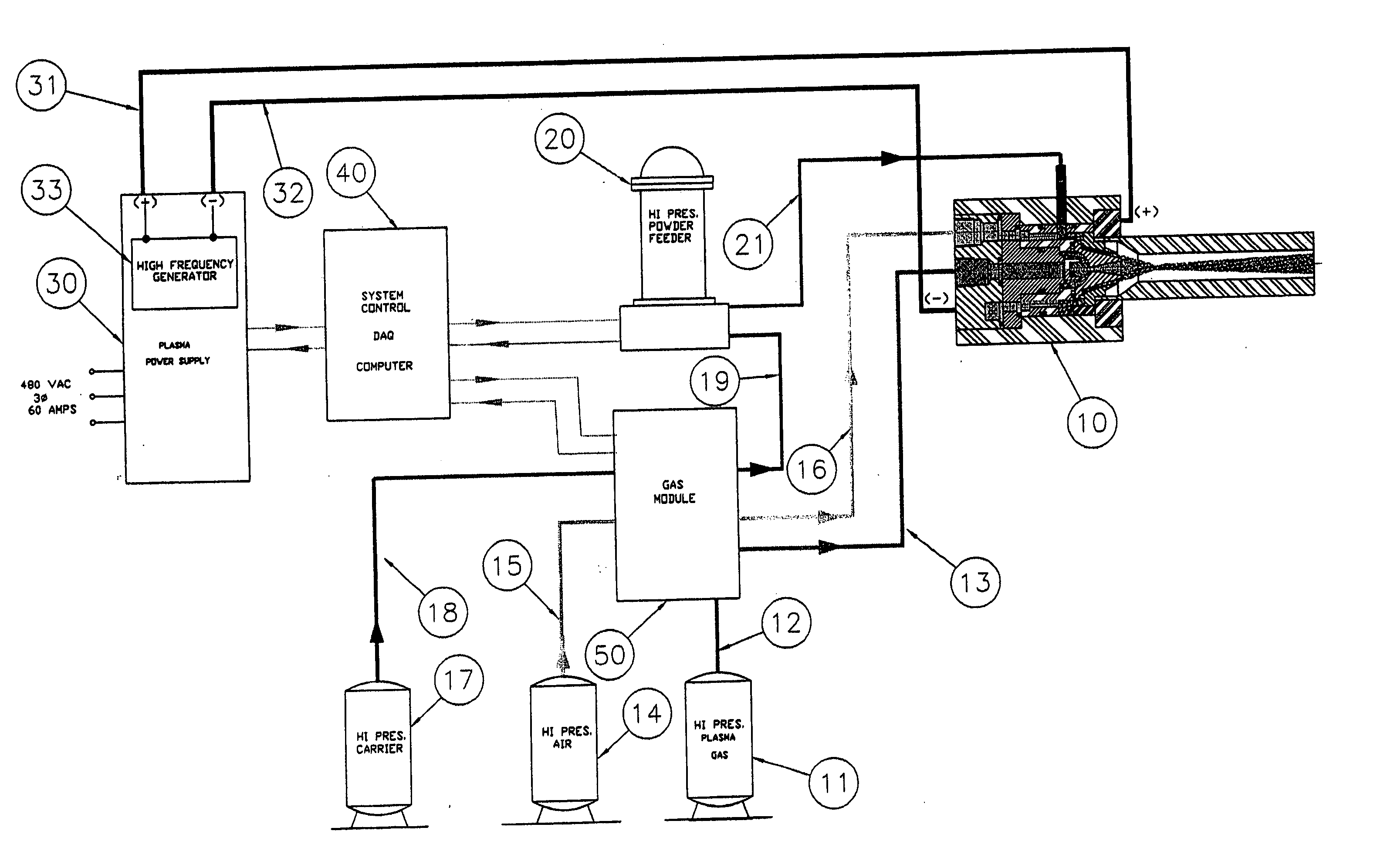

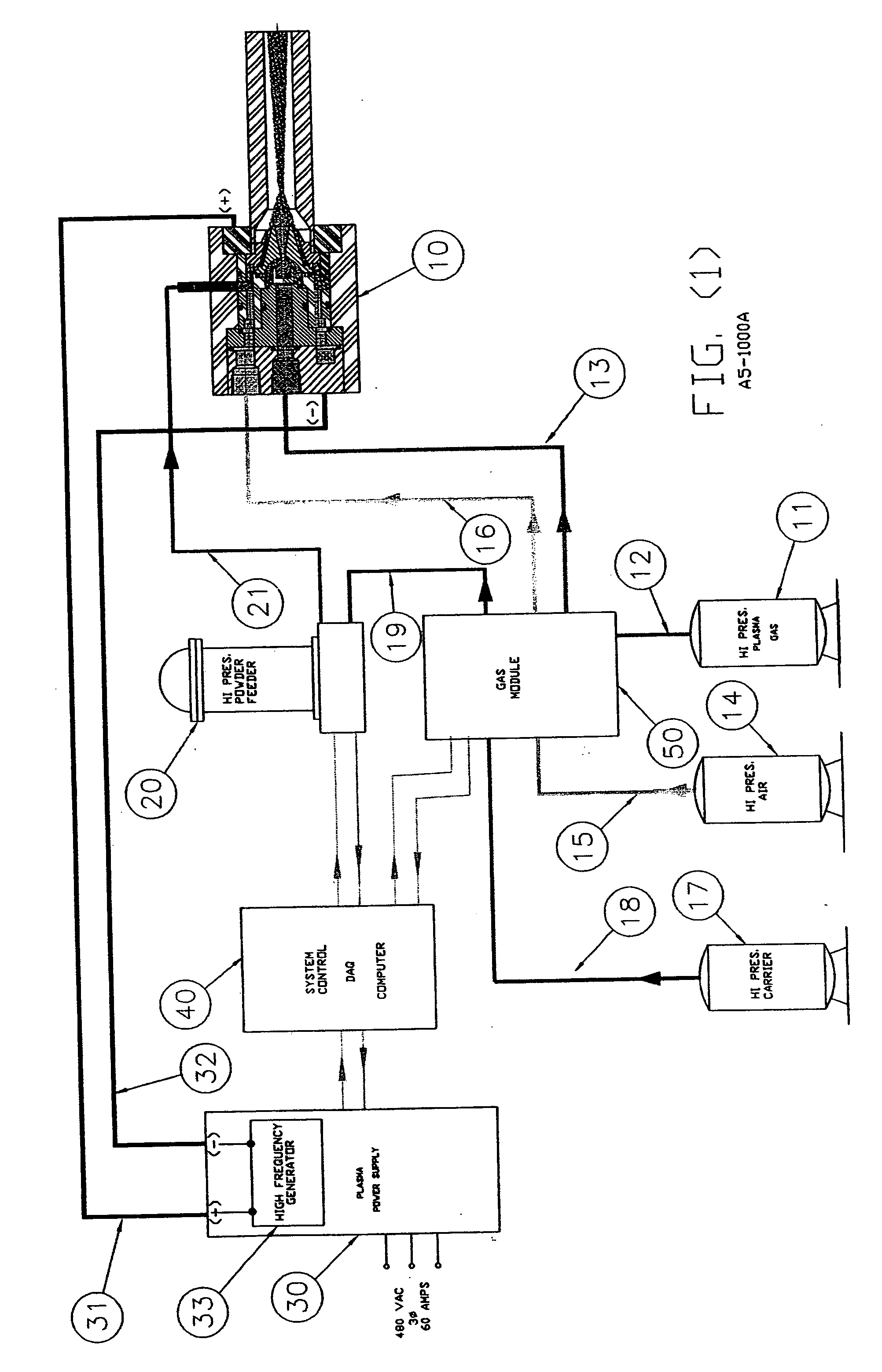

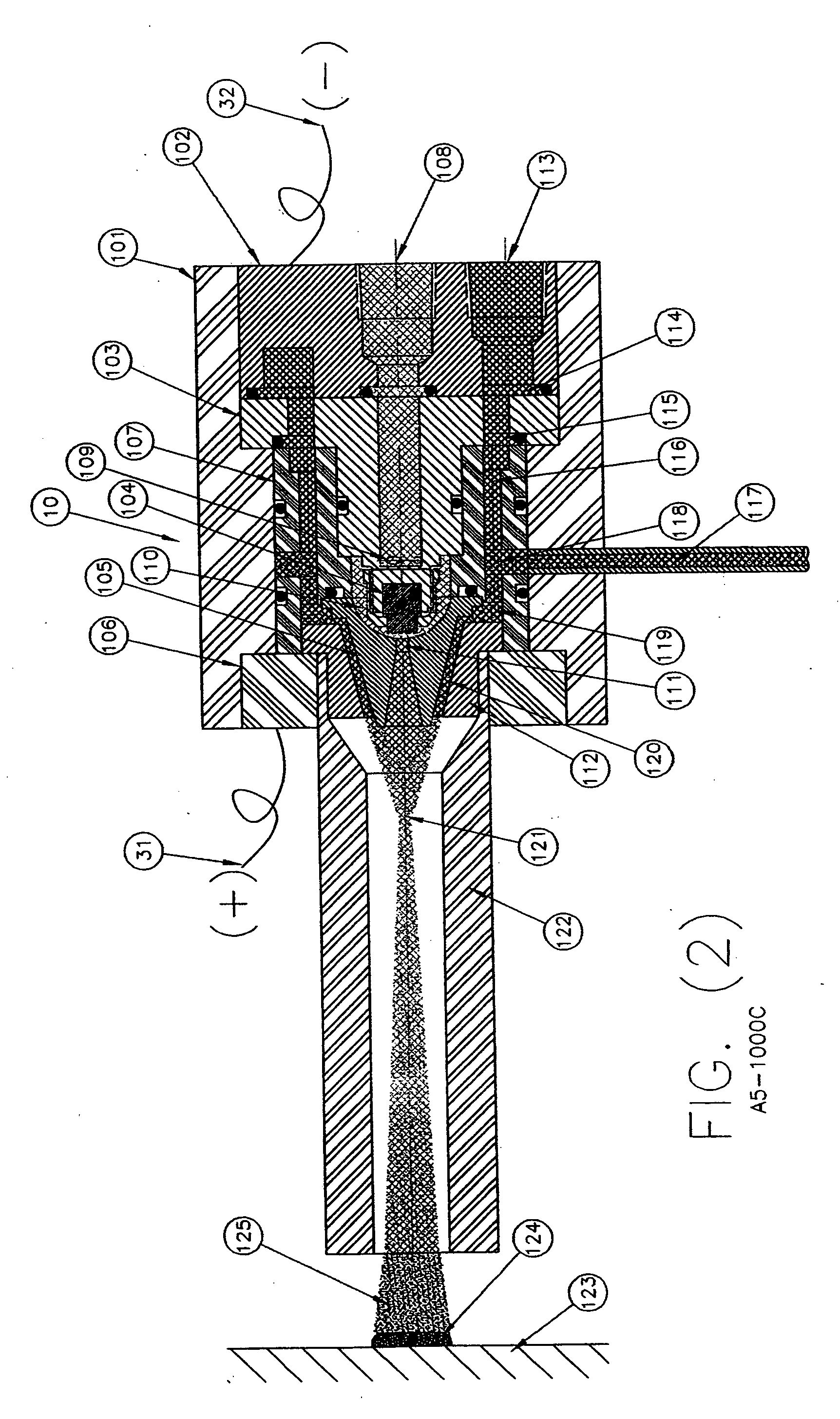

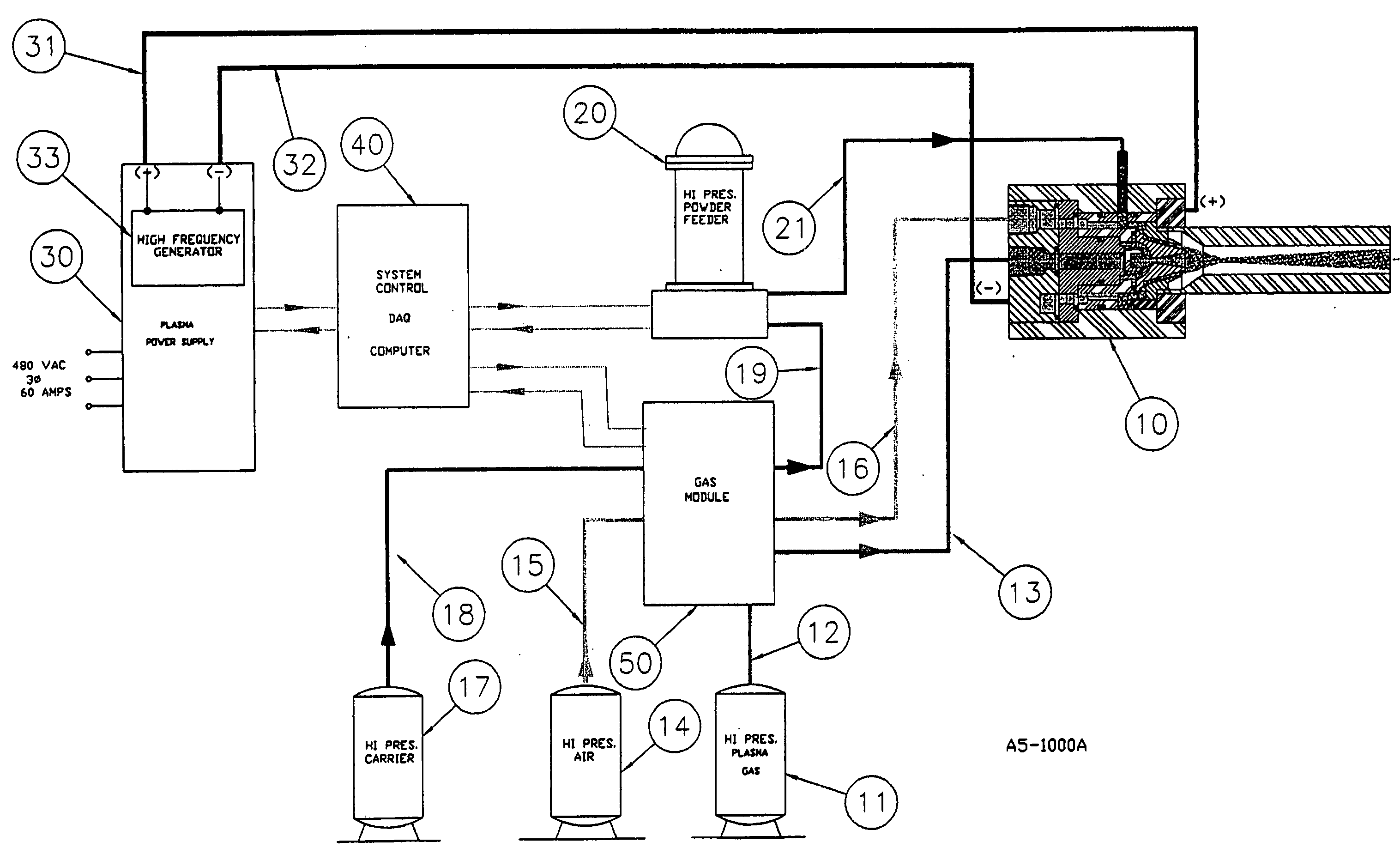

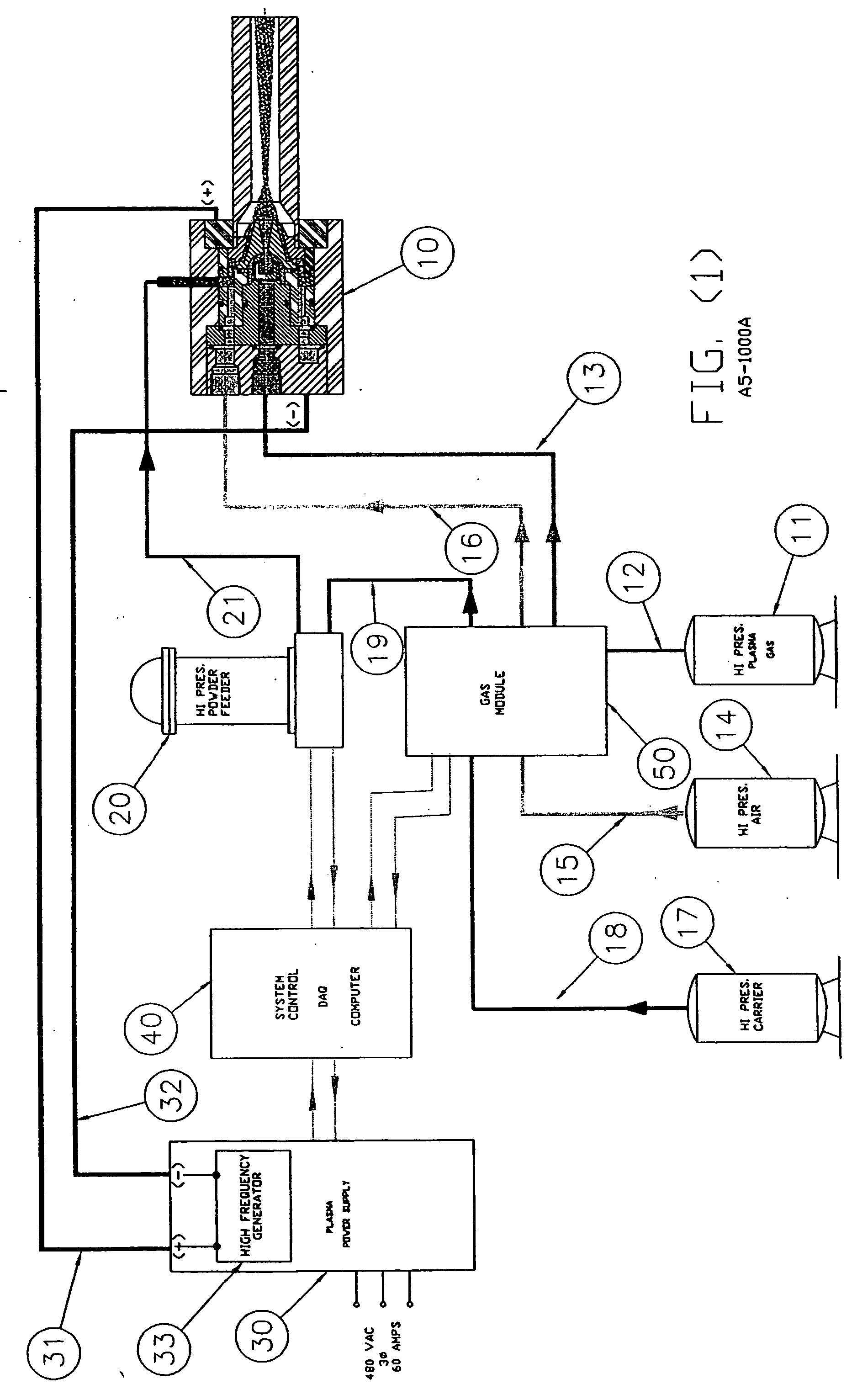

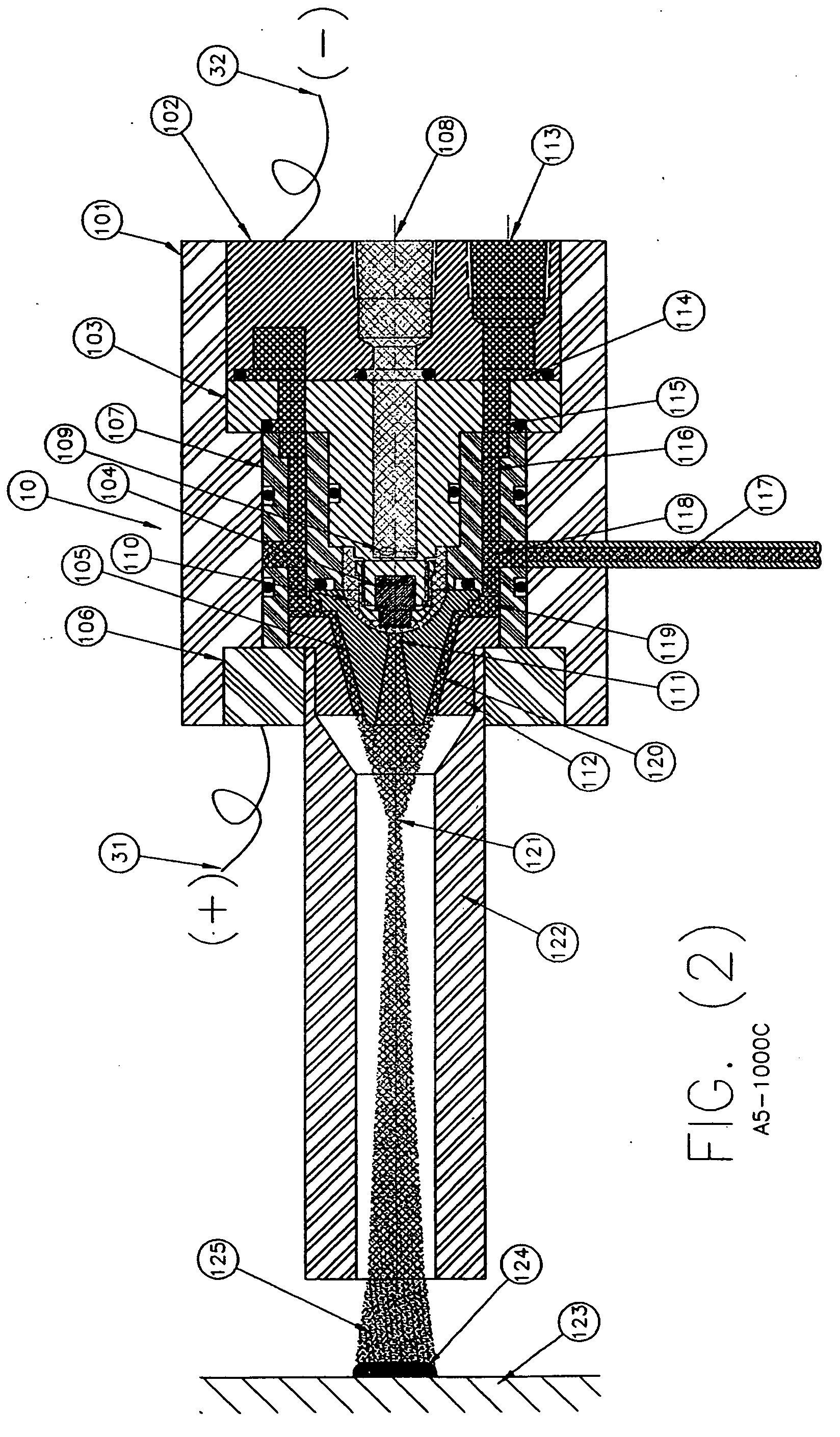

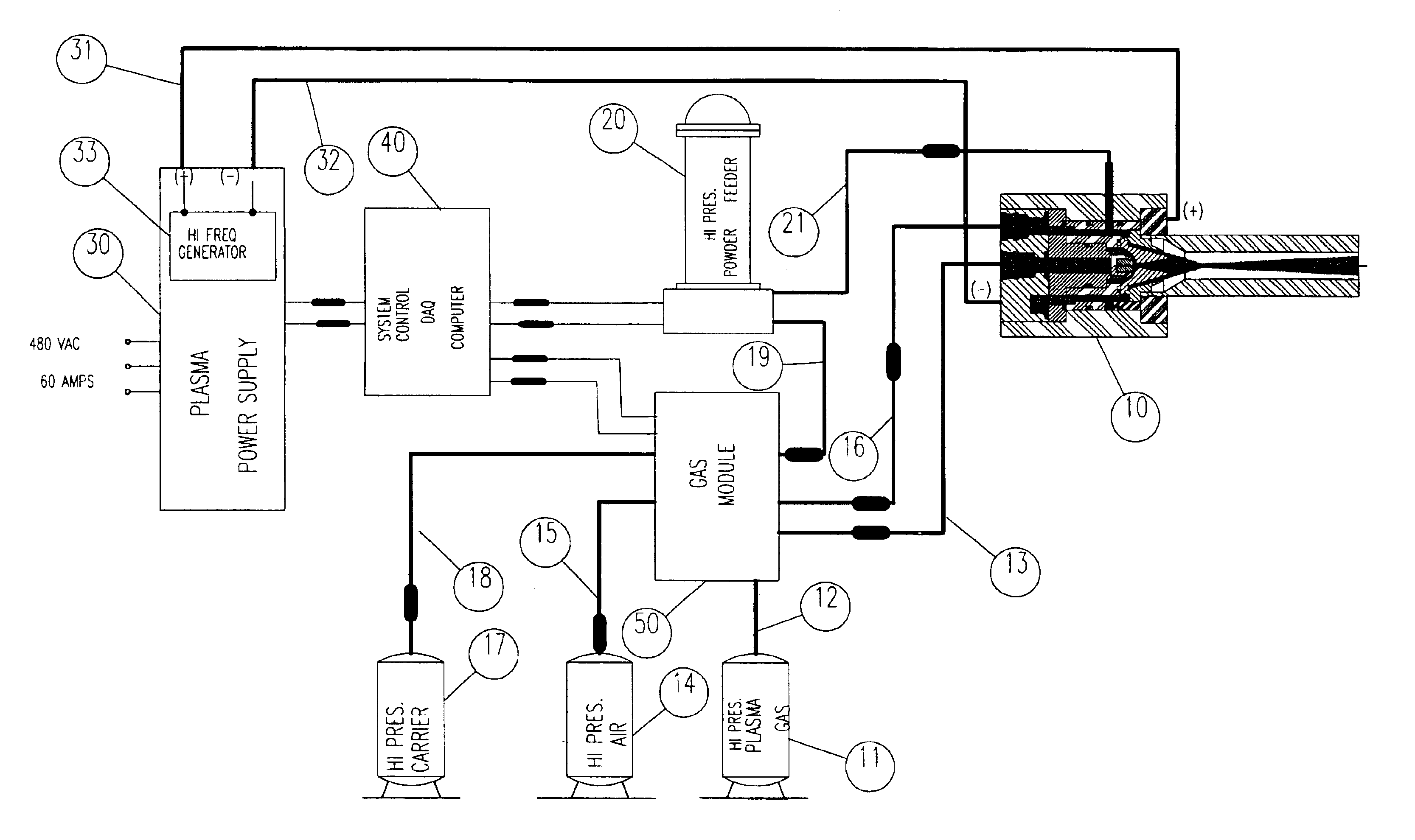

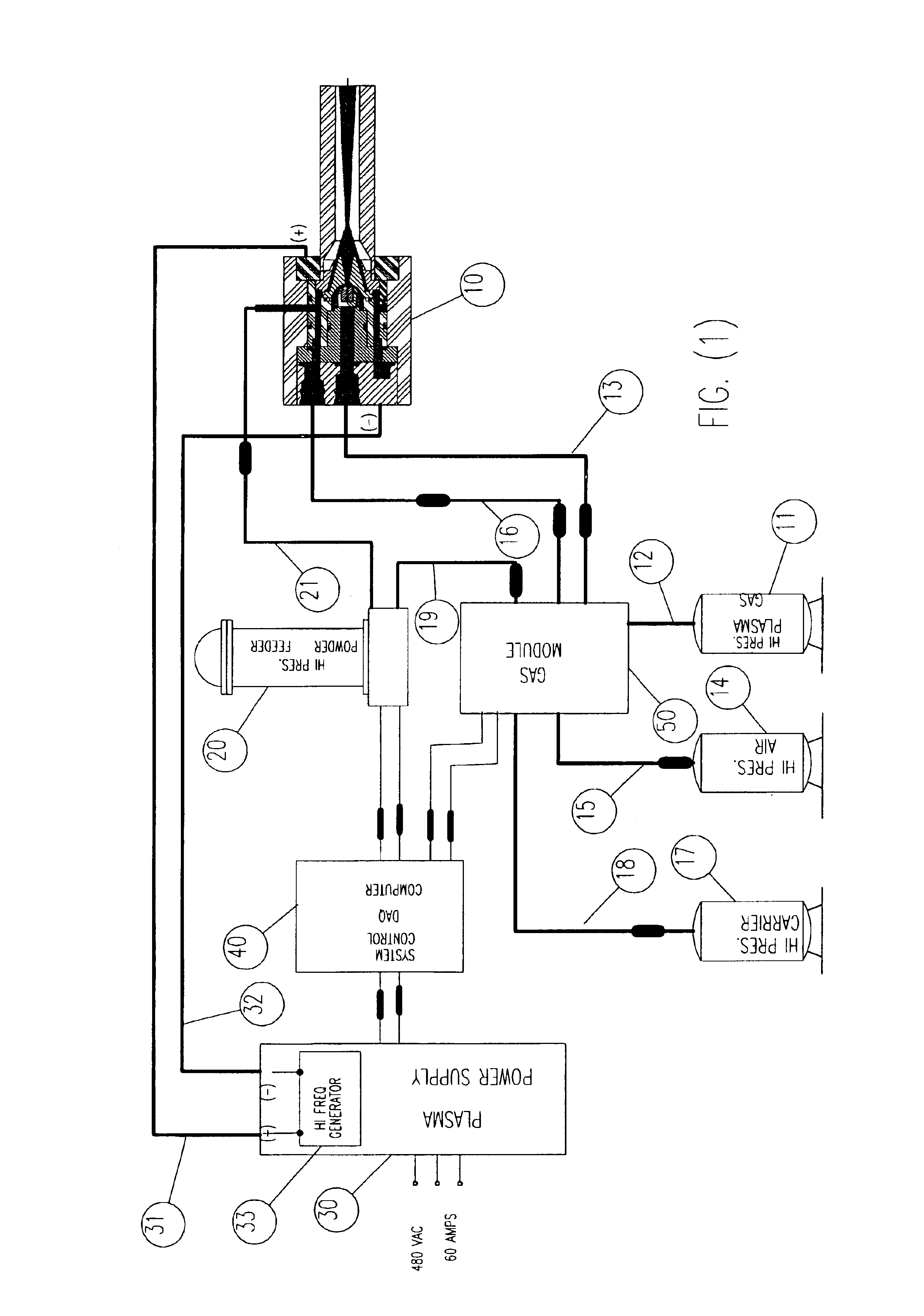

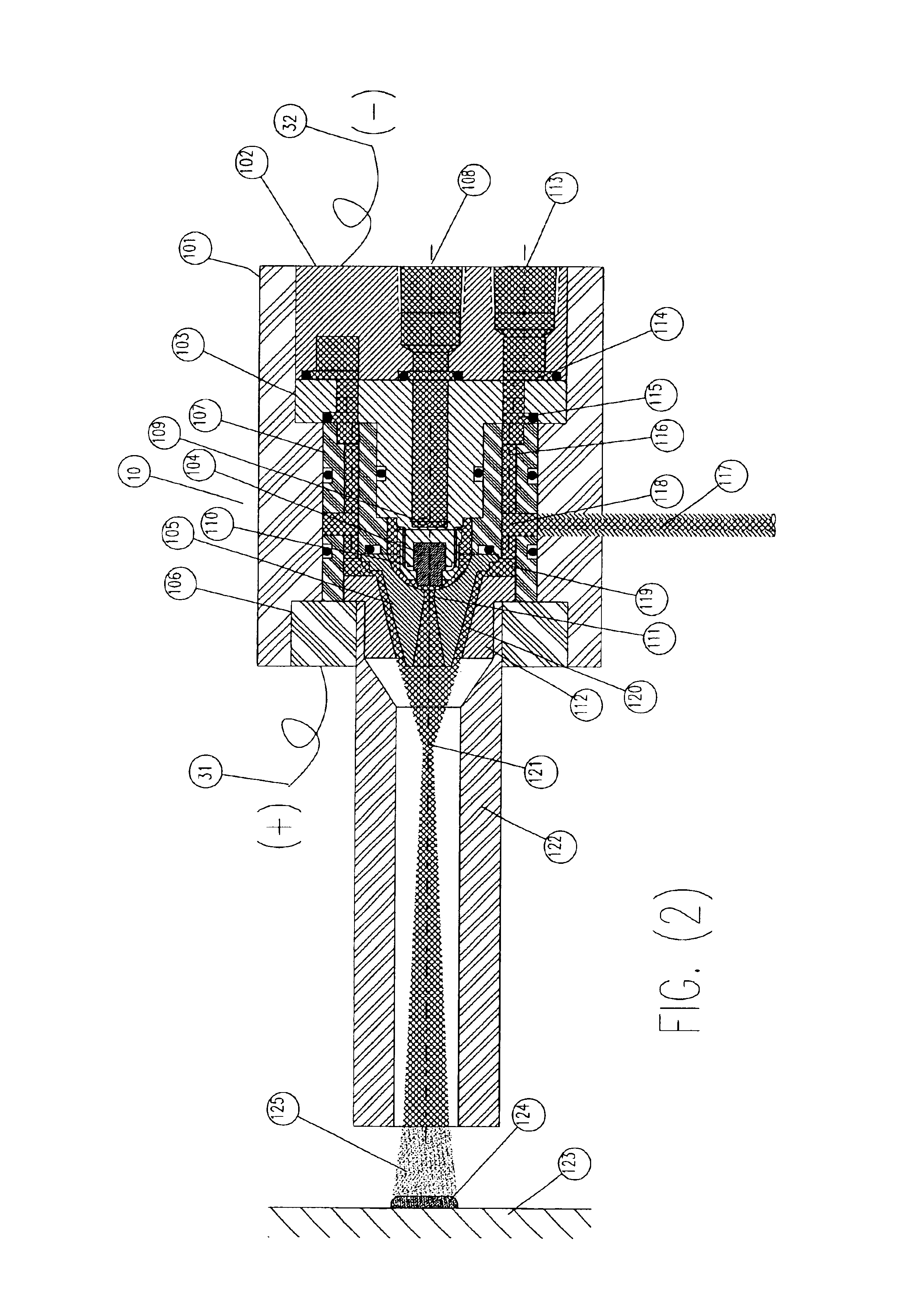

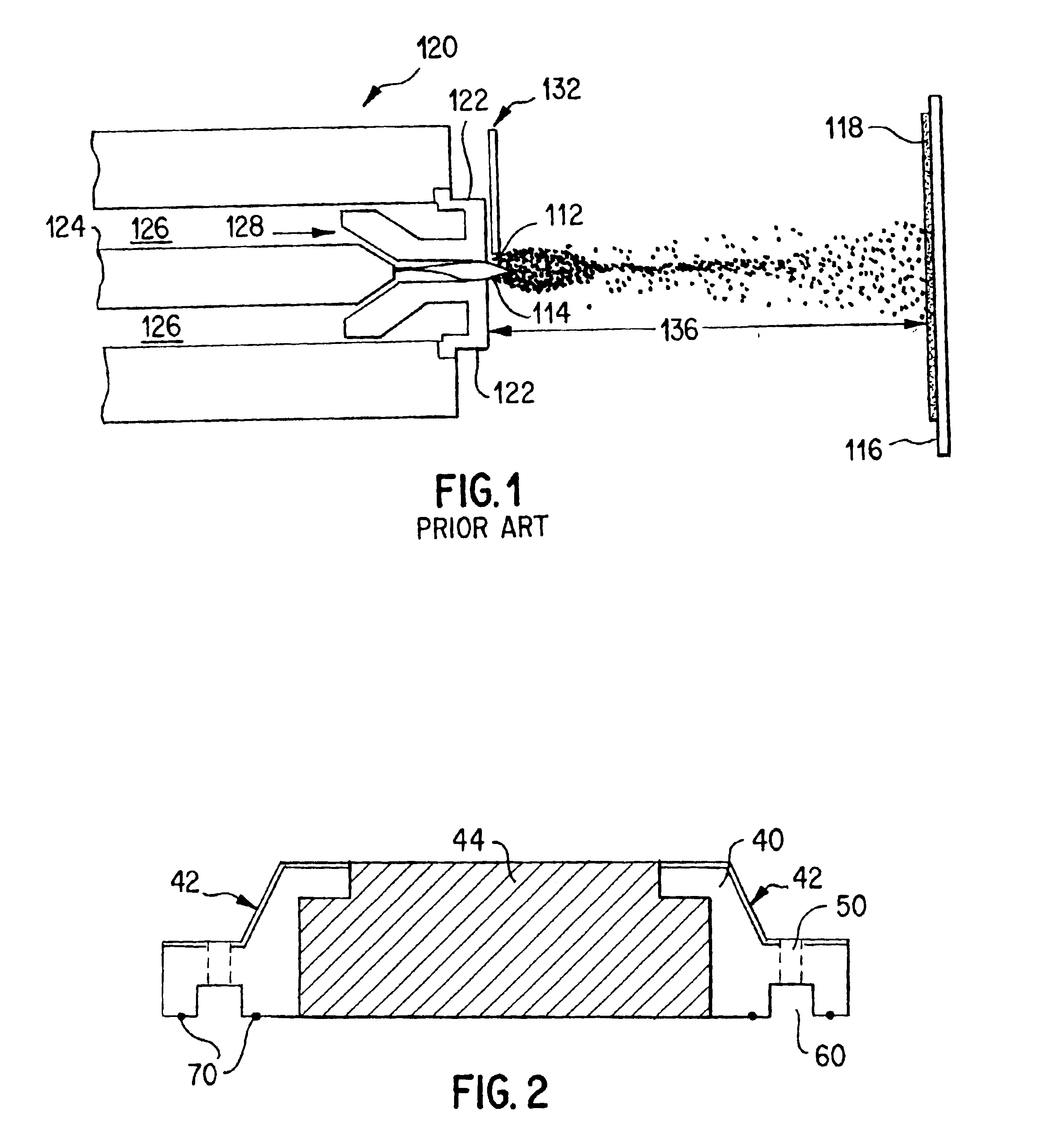

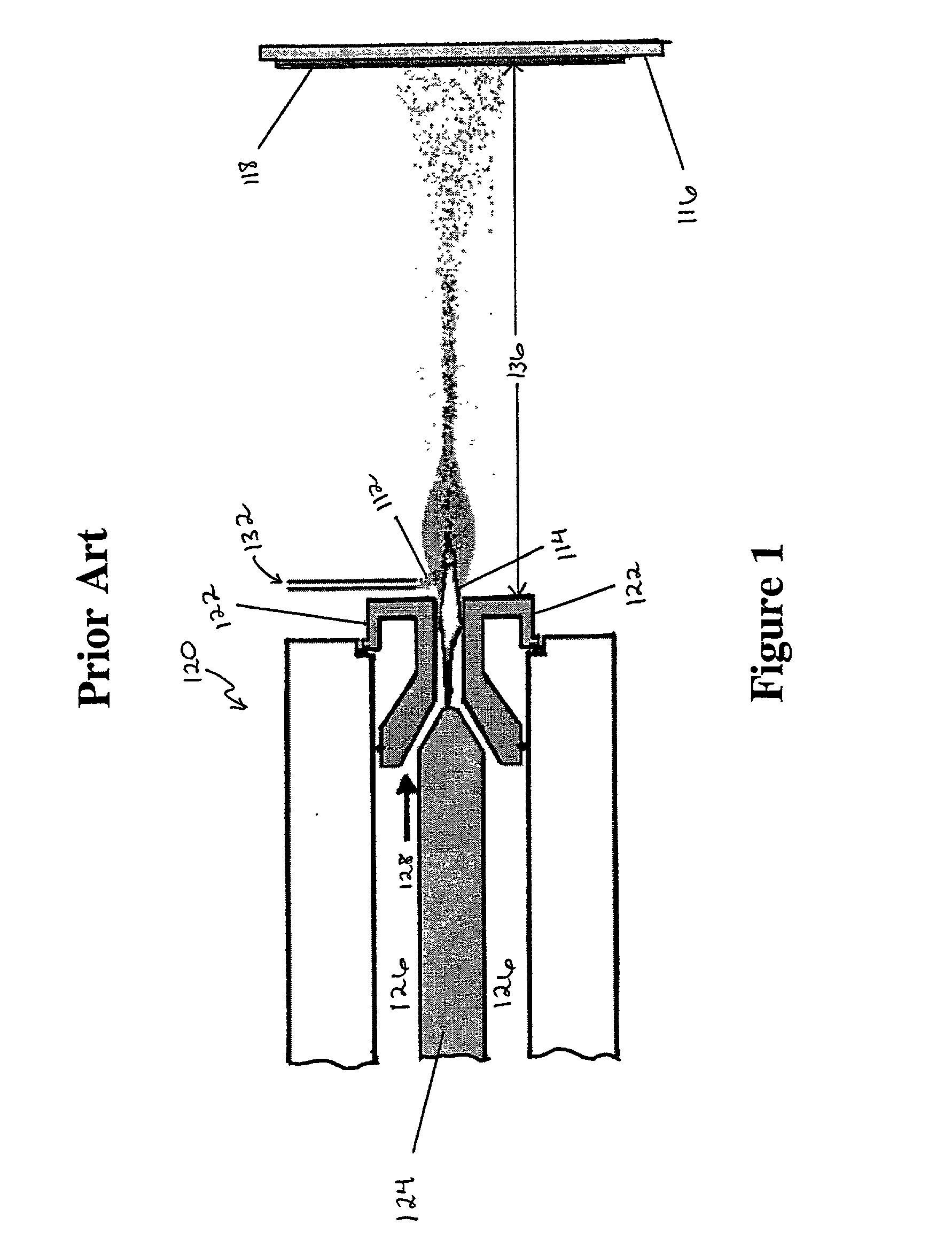

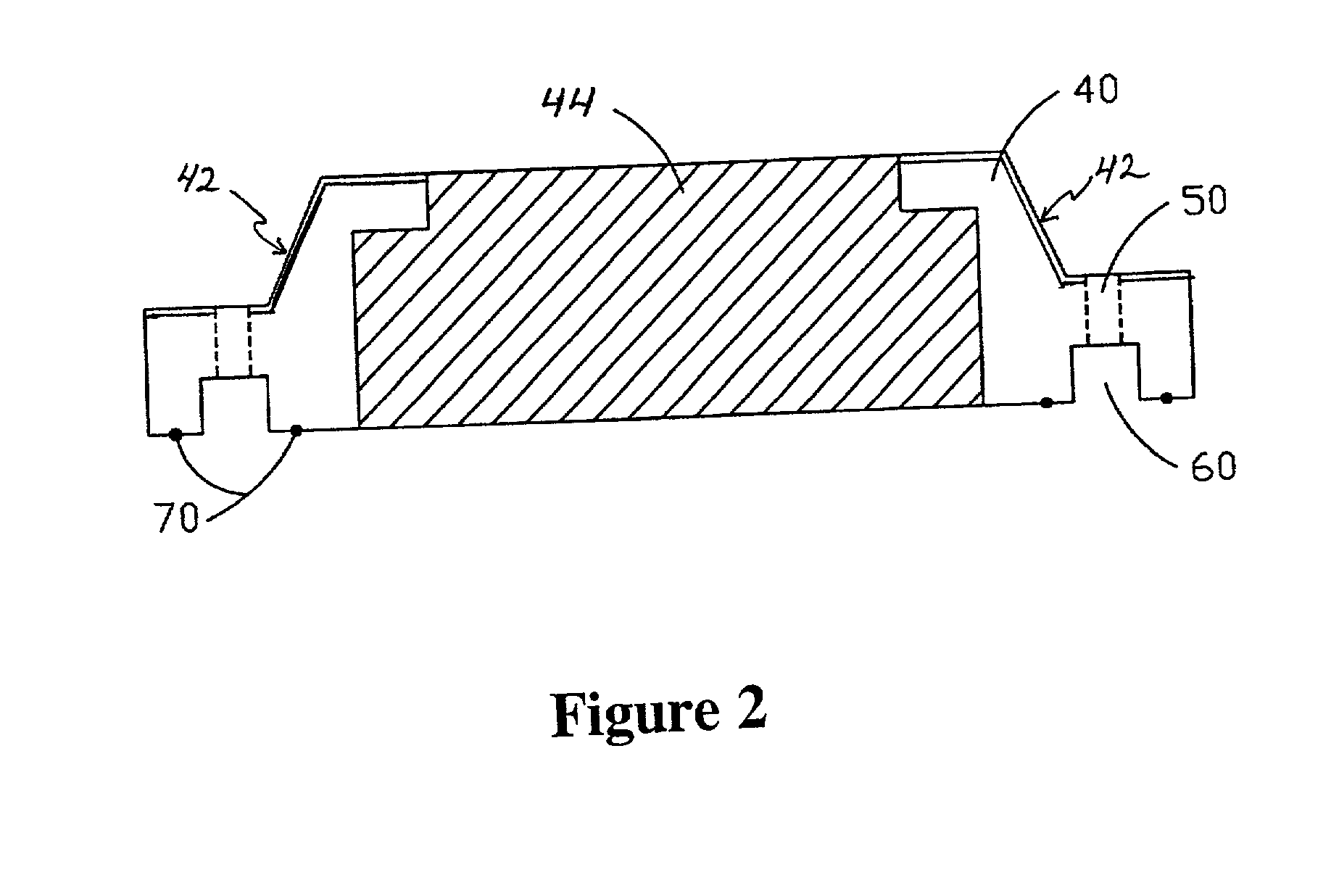

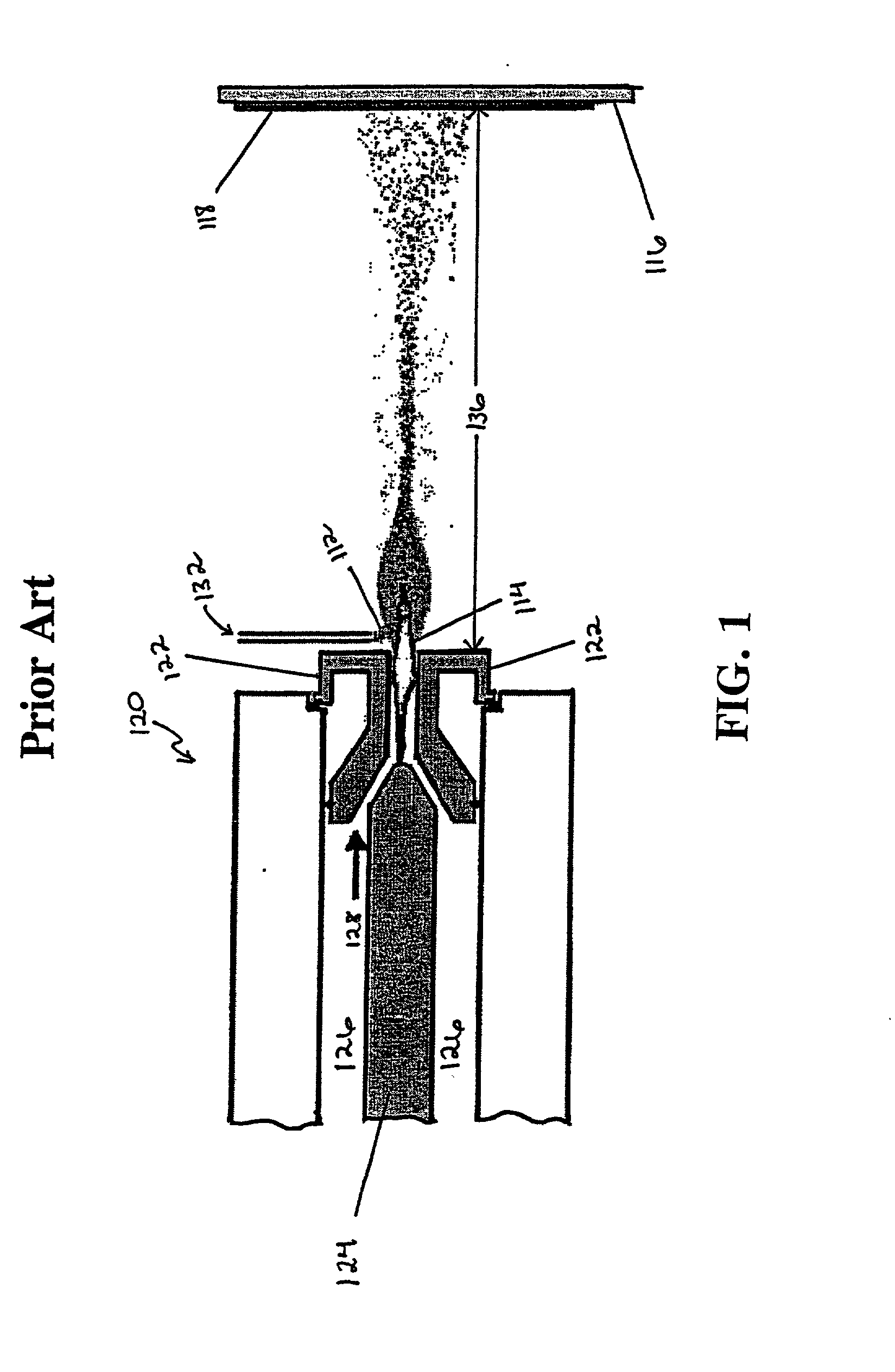

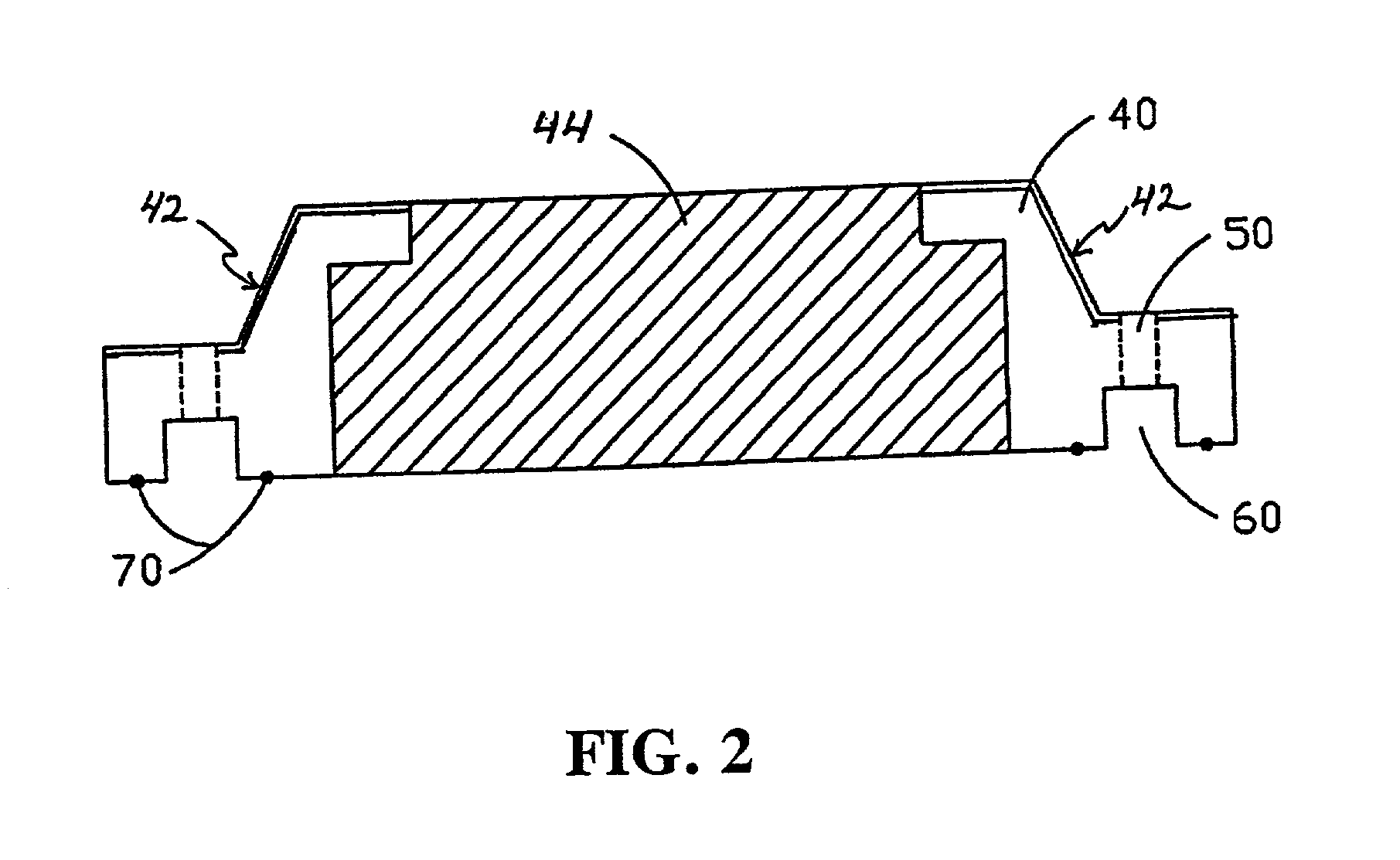

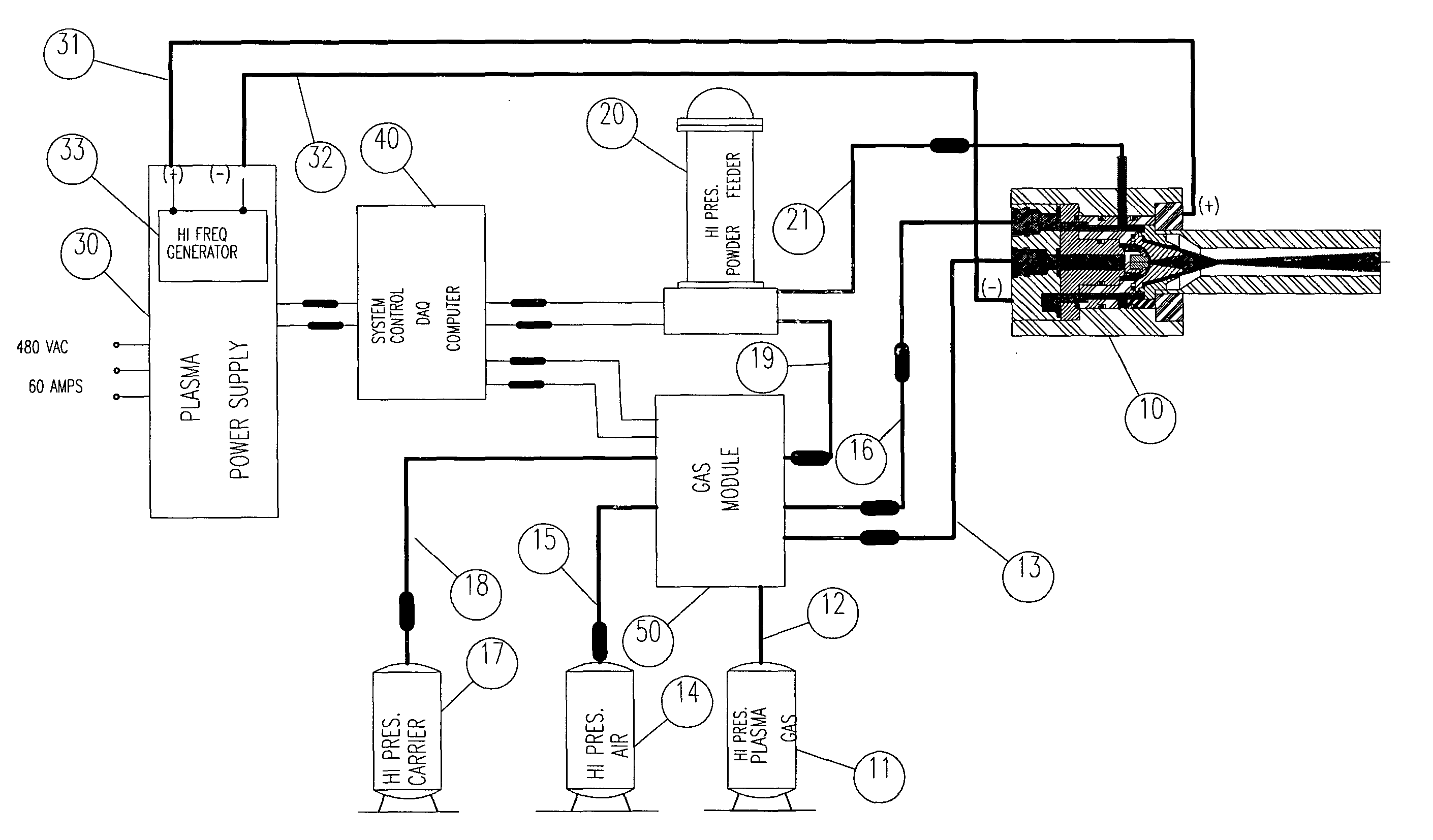

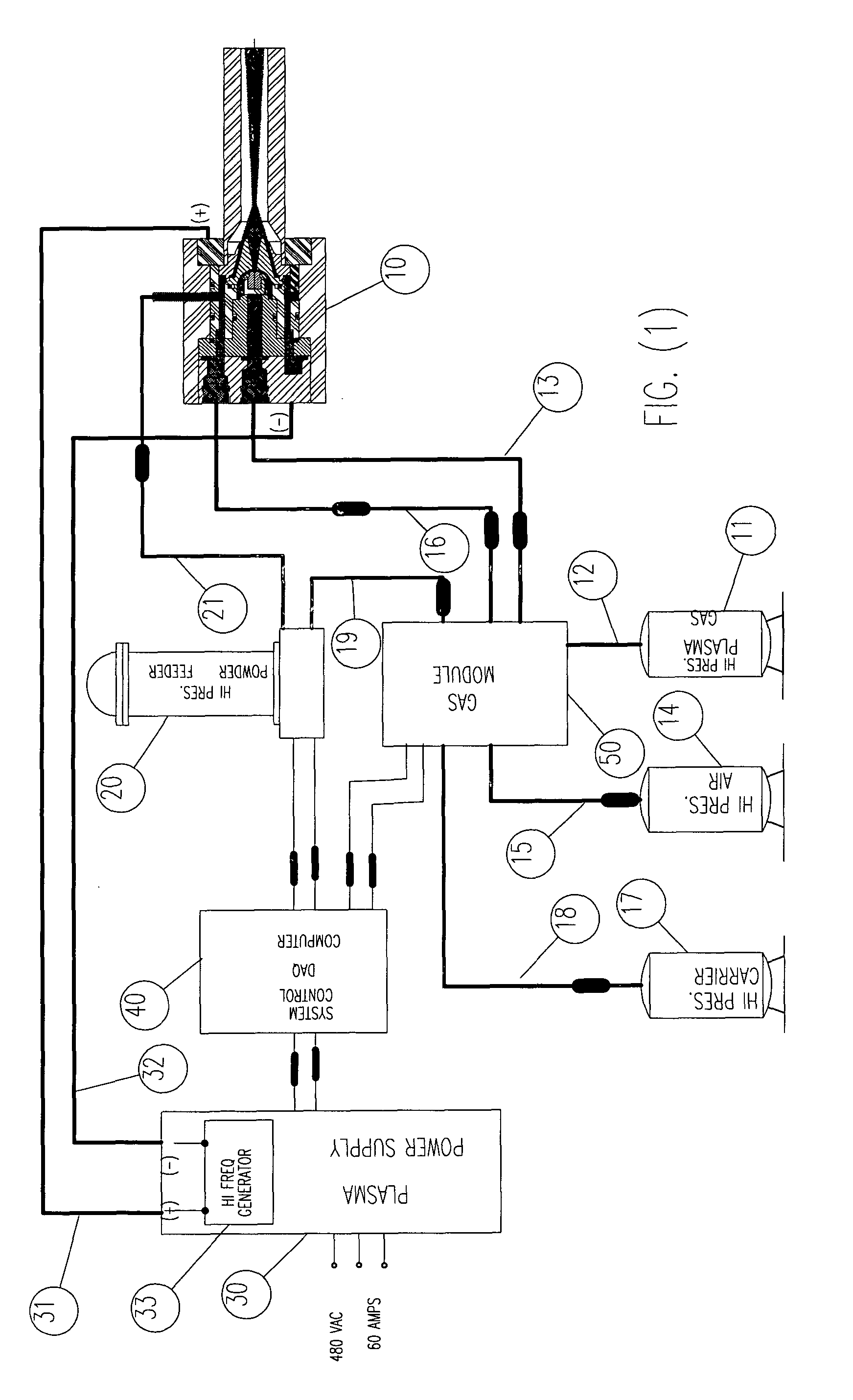

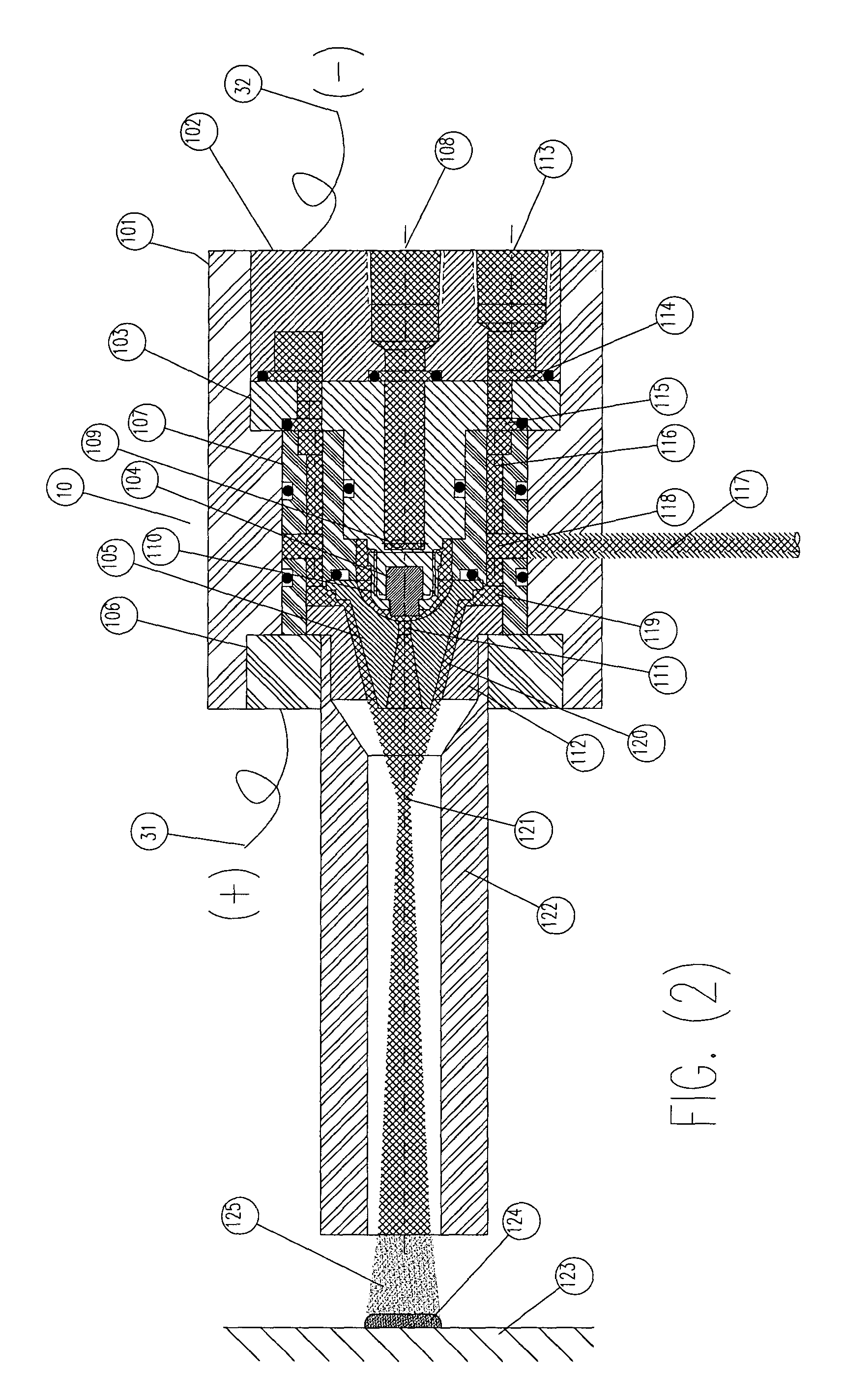

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050120957A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns.

Owner:FLAME SPRAY IND

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050252450A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns. The system also includes a rotating member for coating concave surfaces and internal bores or other such devices which can be better coated using rotation.

Owner:FLAME SPRAY IND

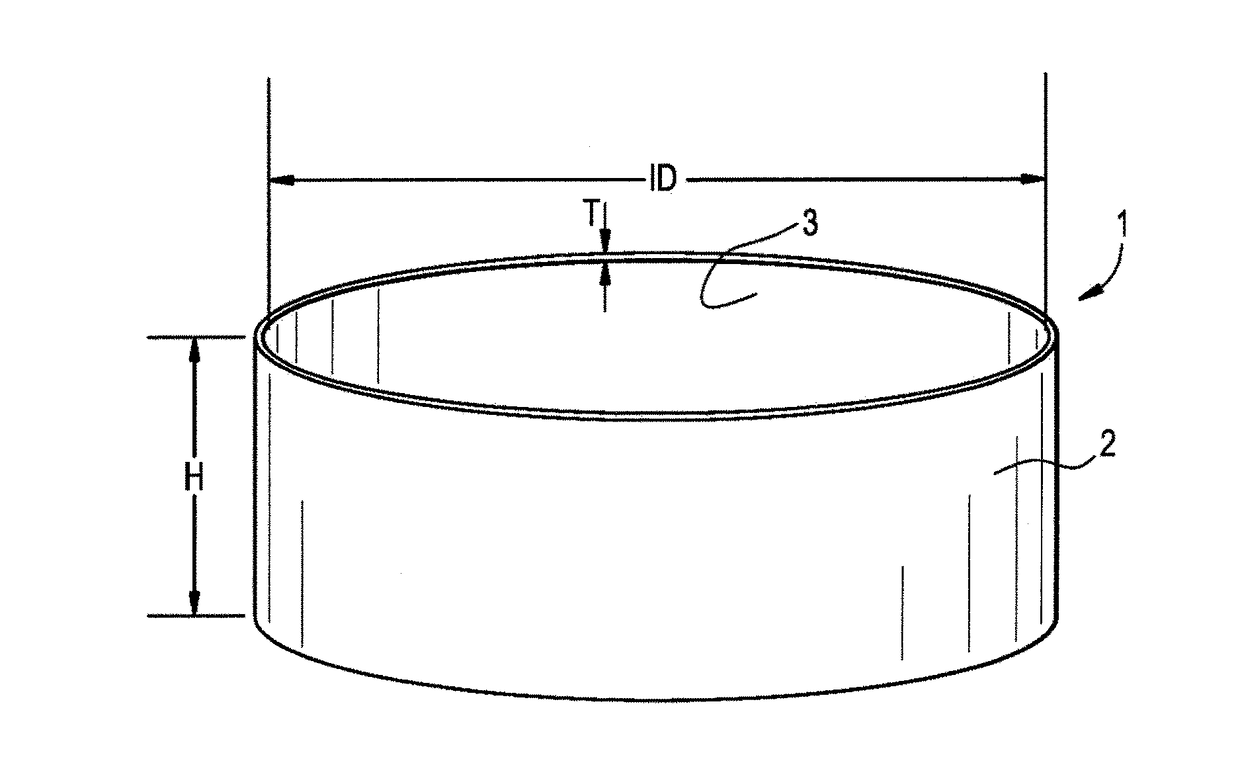

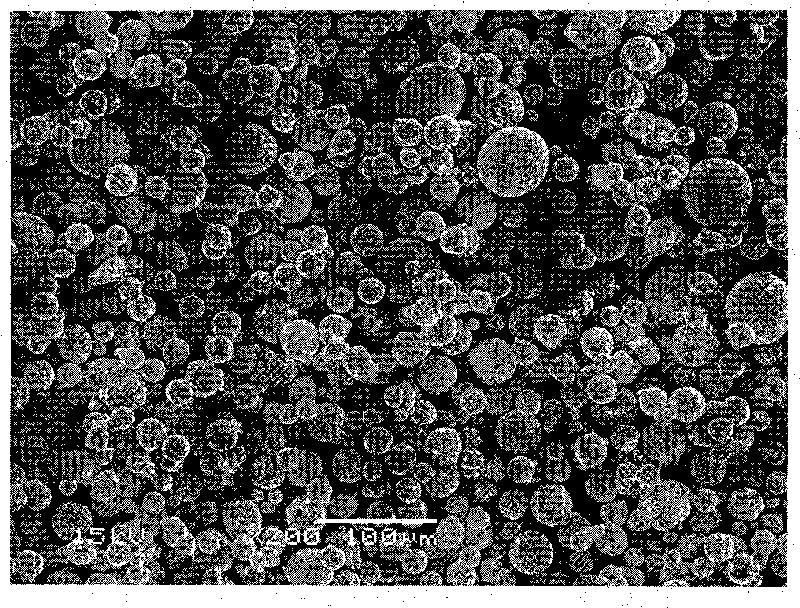

Thermal spray spherical particles, and sprayed components

InactiveUS6916534B2High densityImprove adhesionMolten spray coatingSynthetic resin layered productsBreaking strengthThermal spraying

Spherical particles of a rare earth (inclusive of yttrium)-containing compound and having a breaking strength of 10-300 MPa and an average particle diameter of 10-80 μm are suitable for plasma spraying.

Owner:SHIN ETSU CHEM IND CO LTD

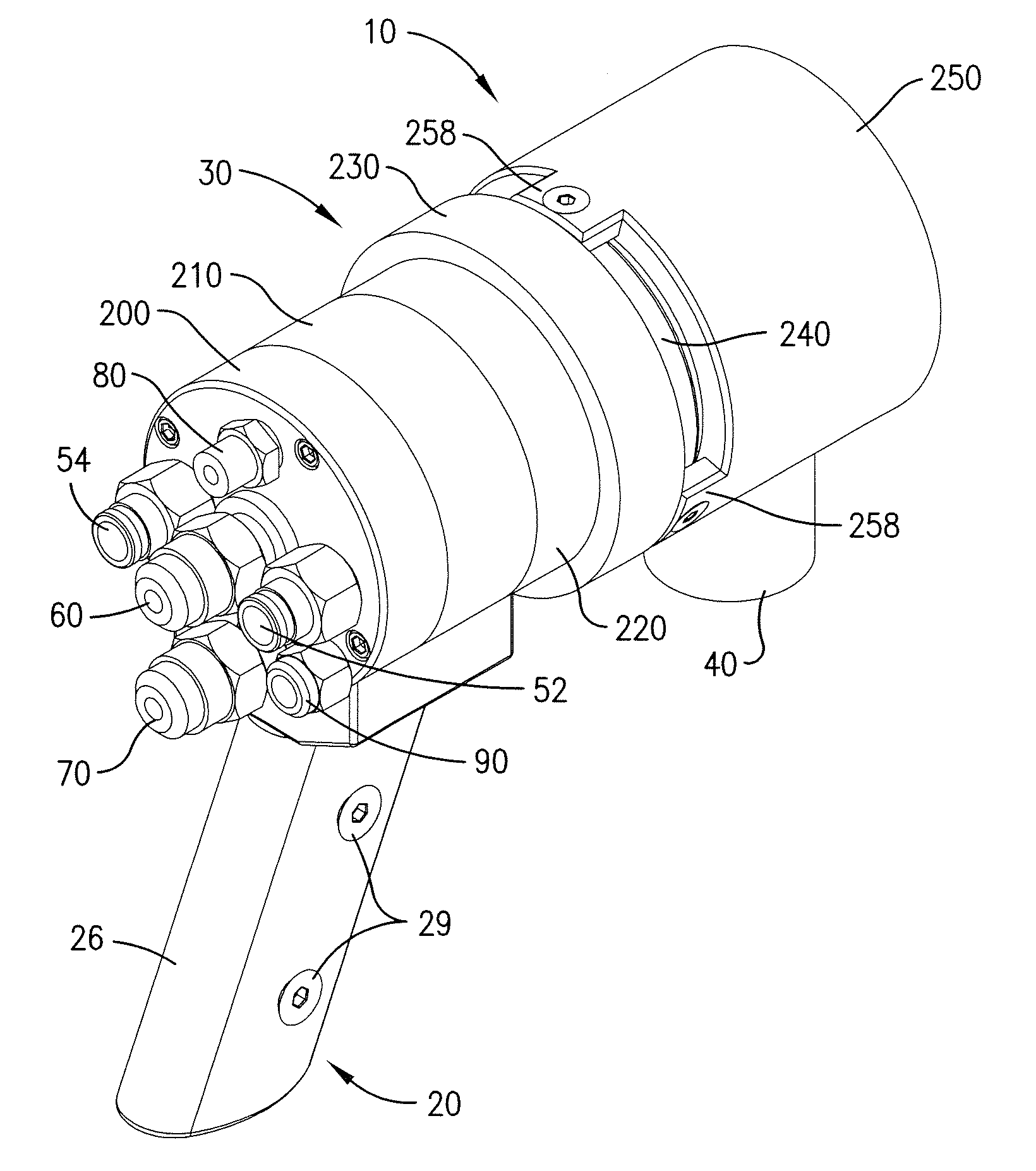

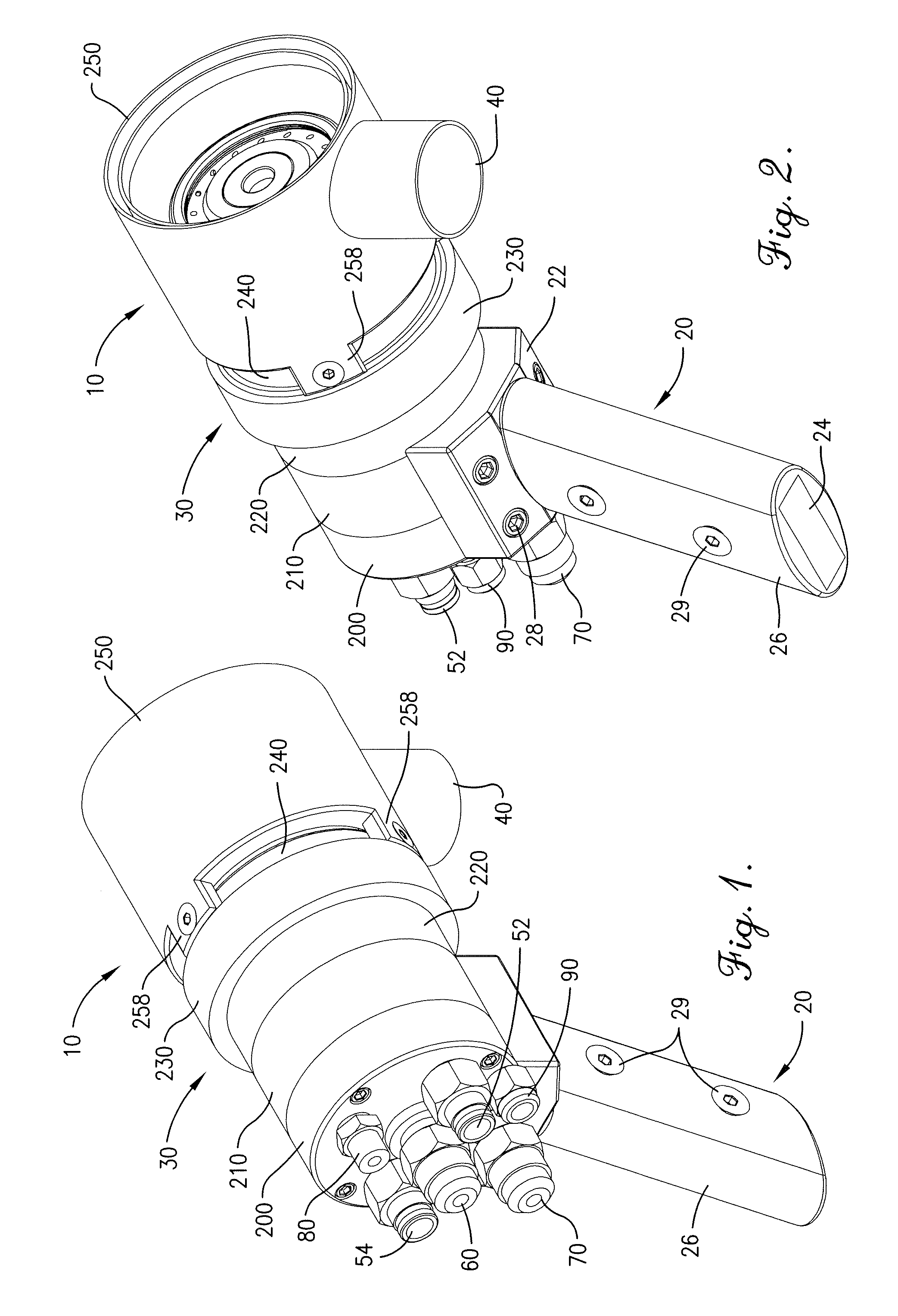

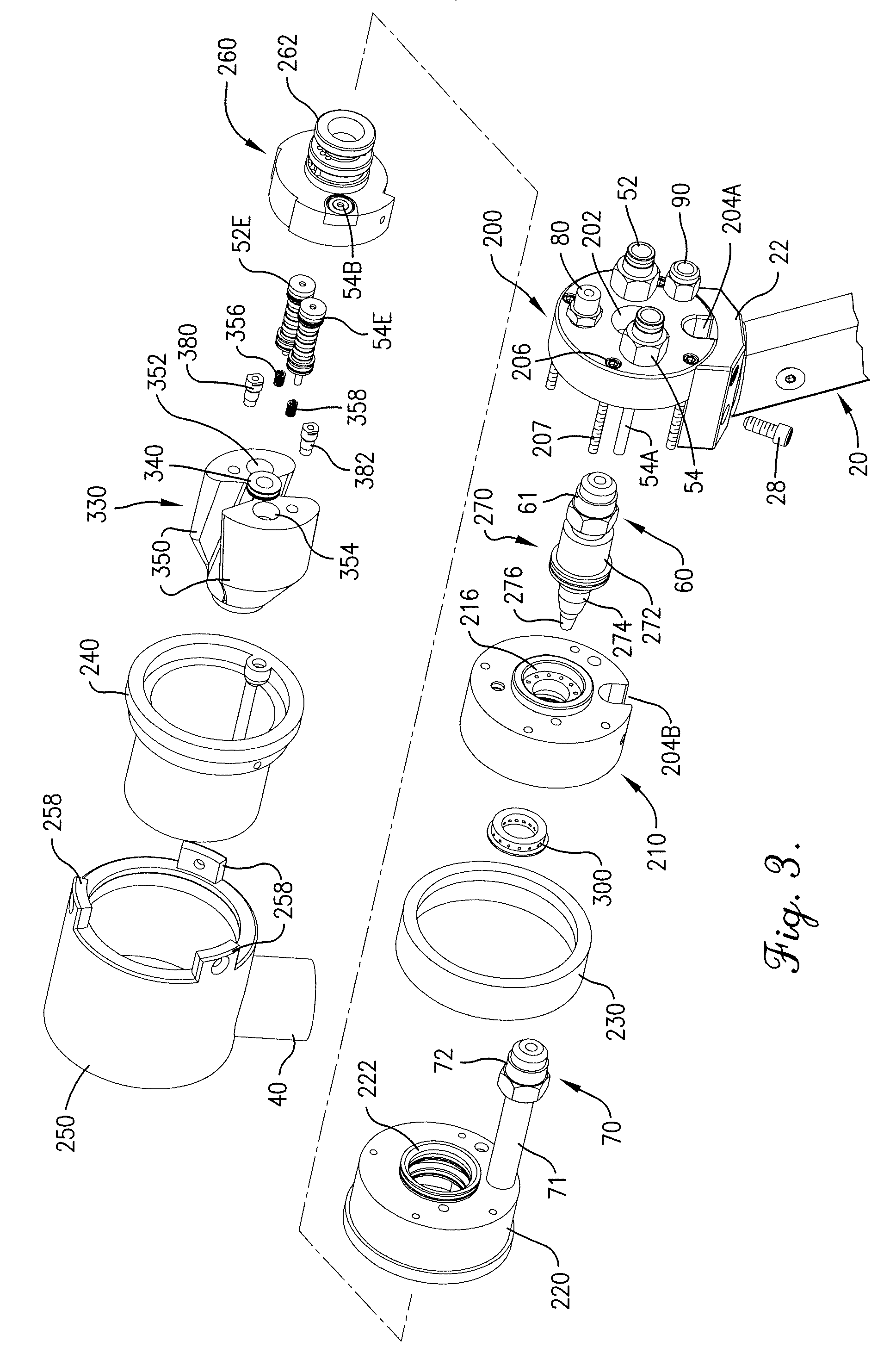

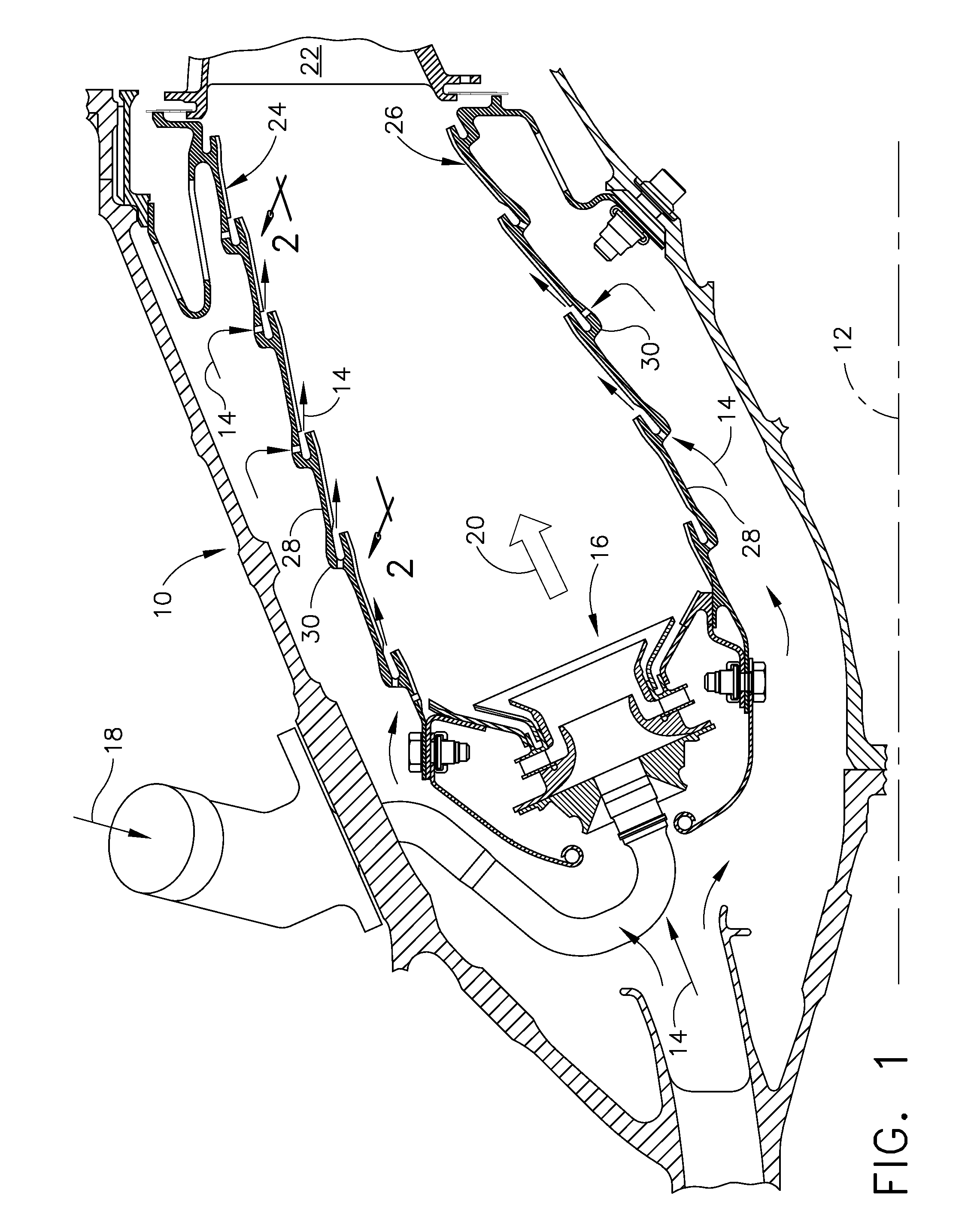

Apparatus and method for applying antifoulants to marine vessels

ActiveUS20080116178A1Avoid pollutionPrevent flame conditionLiquid surface applicatorsElectric heatingBond coatingPlasma generator

A plasma spray apparatus in the form of a gun is utilized to apply an antifoulant coating to marine vessels. The apparatus includes a plasma generator, an electrophoresis element, a heating element, a shield gas element, a liquid cooling system, a forced air system, and a vacuum system. The plasma generator ionizes gas to create a plasma stream, which is utilized in part to supply energy to the heating element that heats a powder material. The heated powder material is exposed to the electrophoresis element to create a covalently bonded coating material. The coating material is injected into the plasma stream and is applied to a target surface. The shield gas element injects a gas flow to surround and protect the plasma and coating material stream as the stream is in flight to the target surface. The liquid cooling system cools portions of the plasma generator and heating element. The forced air system cools a portion of the target surface as the coating material is being applied. The vacuum system removes fumes and stray particles during the application process.

Owner:REINTJES MARINE SURFACE TECH

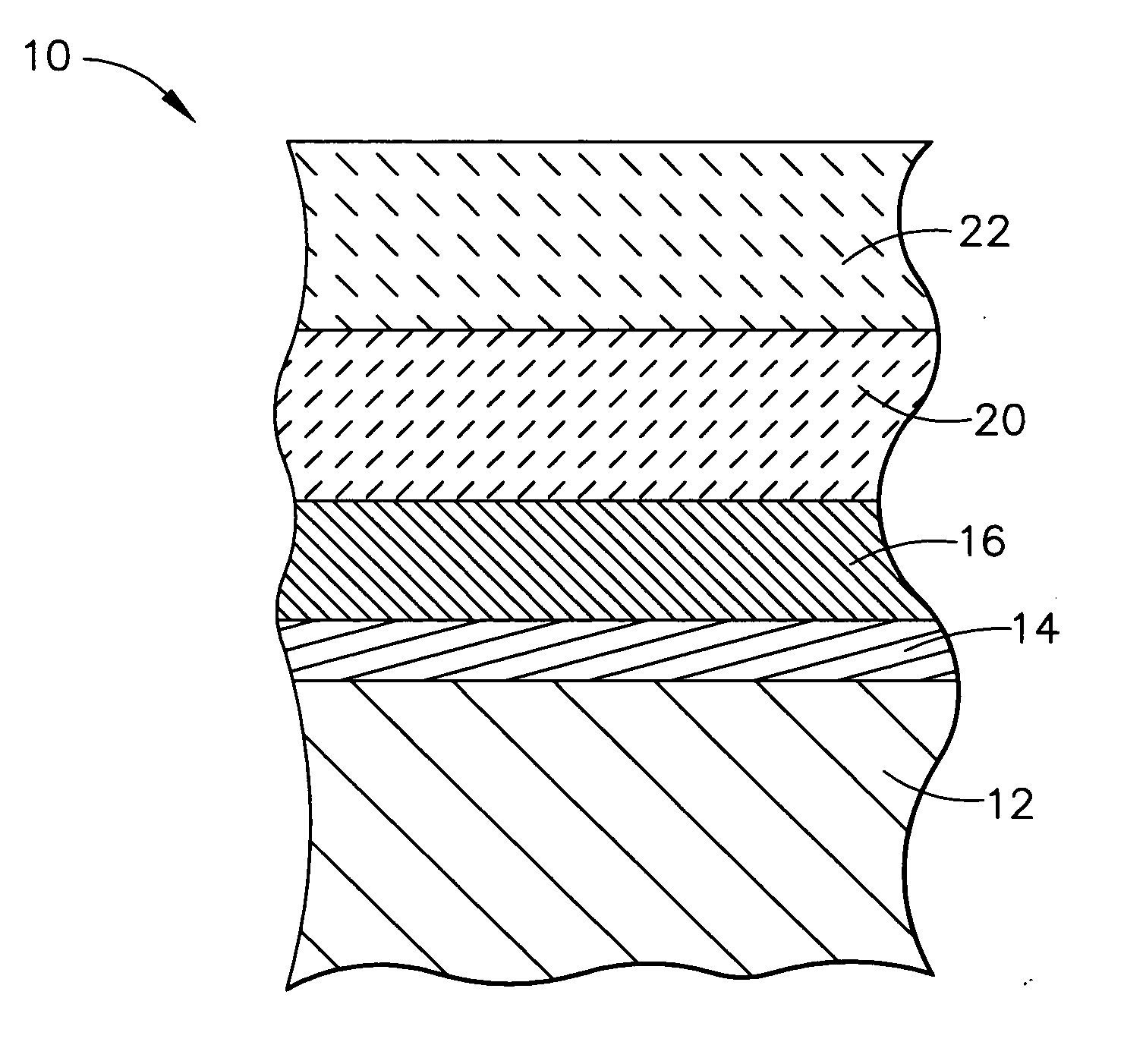

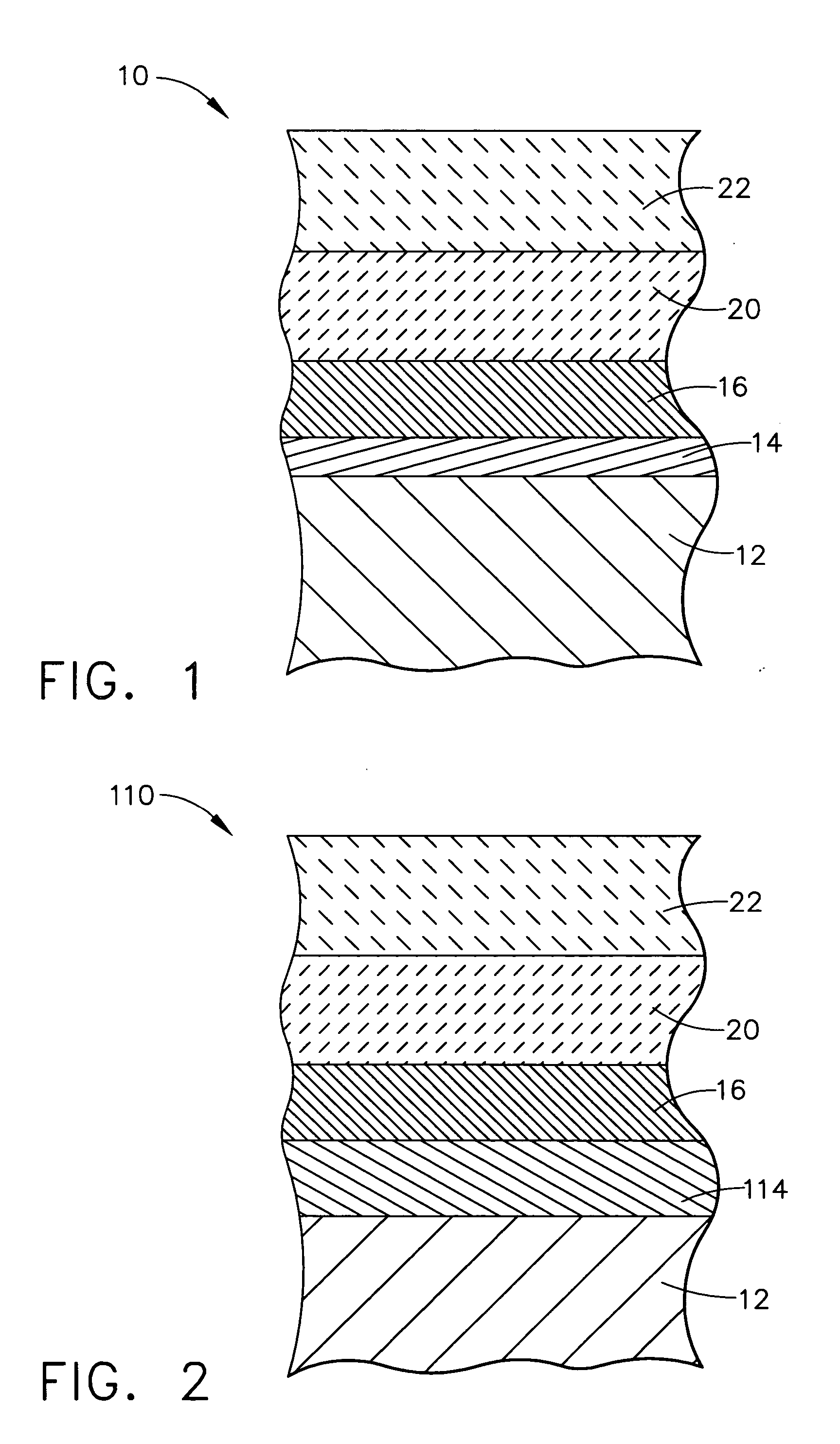

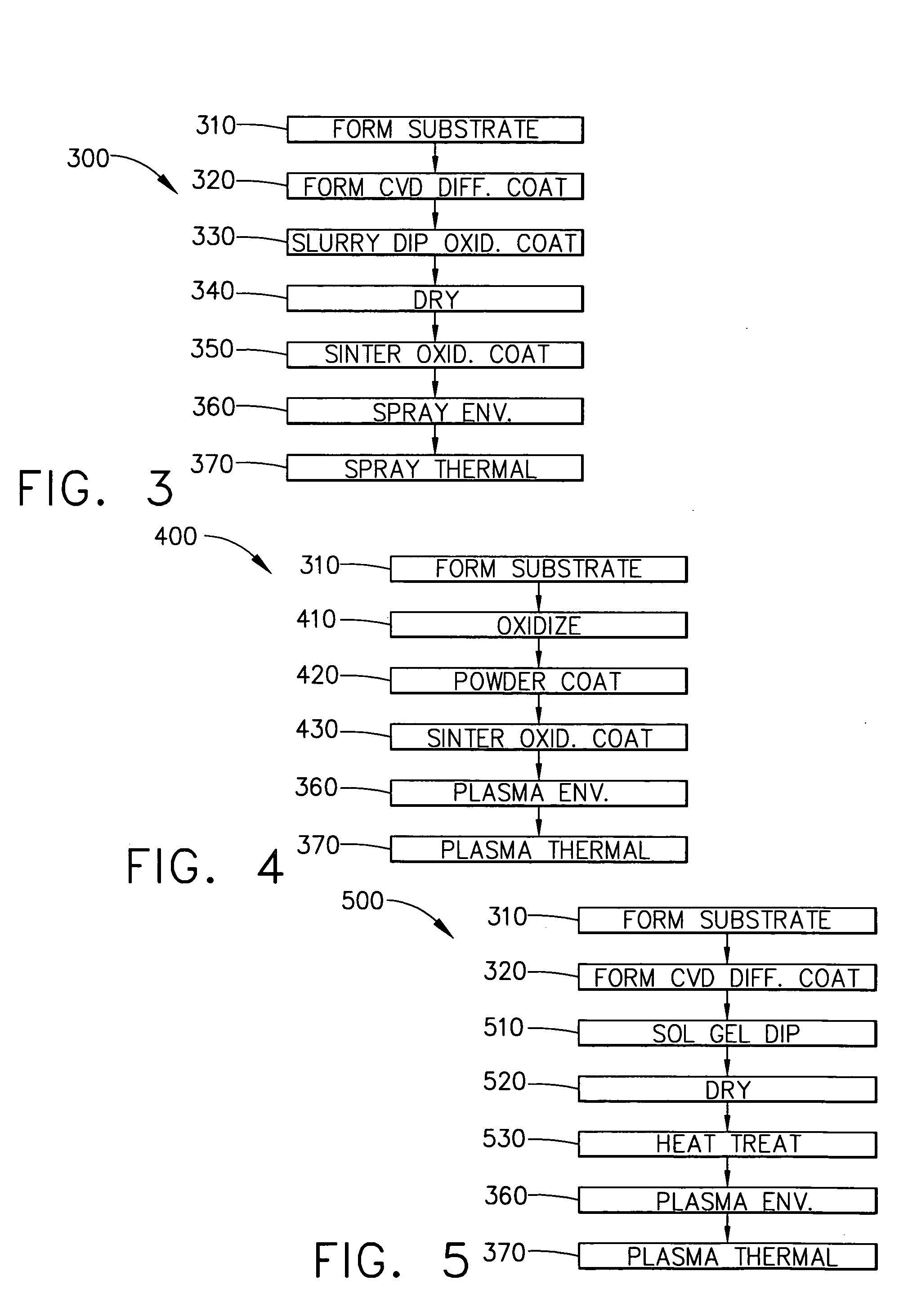

Oxidation barrier coatings for silicon based ceramics

ActiveUS20050112381A1Avoid Explosion HazardsContinuous combustion chamberBlade accessoriesElectron beam physical vapor depositionGas phase

A protective barrier coating system including a diffusion barrier coating and an oxidation barrier coating and method for use in protecting silicon-based ceramic turbine engine components. A complete barrier coating system includes a thermal barrier coating of stabilized zirconia and an environmental barrier coating of an alloyed tantalum oxide. The oxidation barrier coating includes a layer of metallic silicates formed on a substrate of silicon nitride or silicon carbide to be protected. The oxidation barrier coating can include silicates of scandium, ytterbia or yttrium. The oxidation barrier coating may also include an inner layer of Si2ON2 between the diffusion barrier and the metallic silicate layer. The oxidation barrier coating can be applied to the substrate by spraying, slurry dipping and sintering, by a sol-gel process followed by sintering, by plasma spray, or by electron beam-physical vapor deposition. The diffusion layer of essentially pure Si3N4 can be applied to the substrate to prevent the migration of damaging cations from the protective layers to the substrate and is preferably formed by chemical vapor deposition. A method for protecting silicon based substrates can comprise a step of forming an oxidation barrier coating on a substrate, where a step of forming the oxidation barrier includes a step of sintering the oxidation barrier and substrate in a wet gas containing hydrogen.

Owner:HONEYWELL INT INC

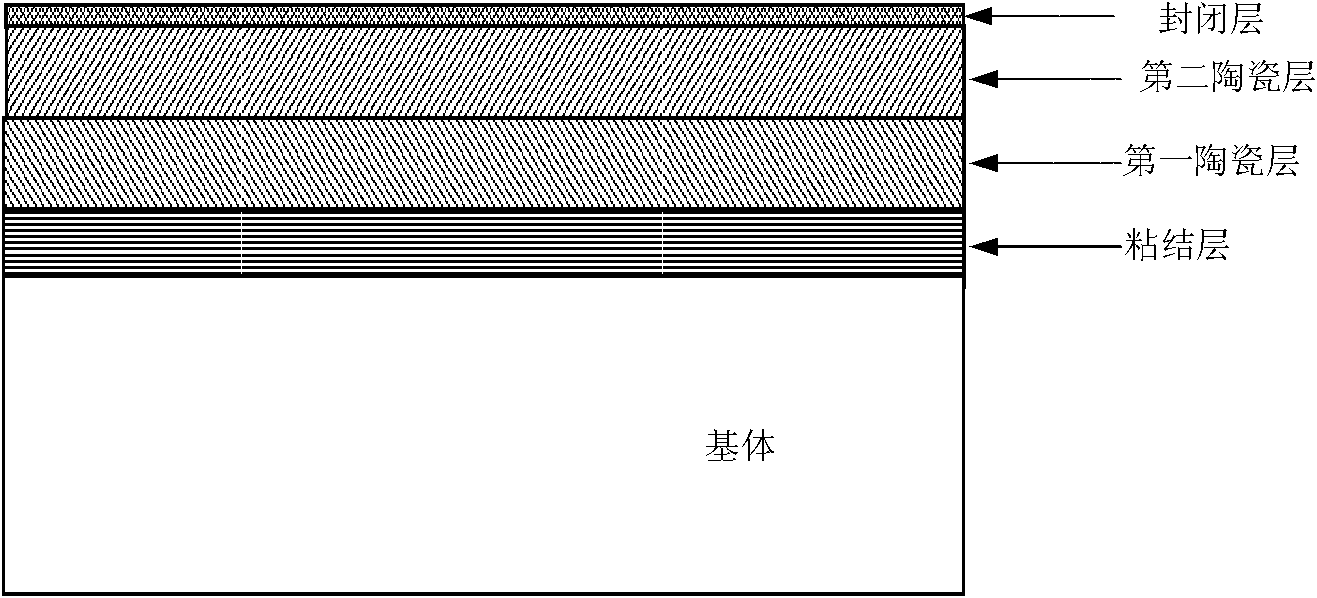

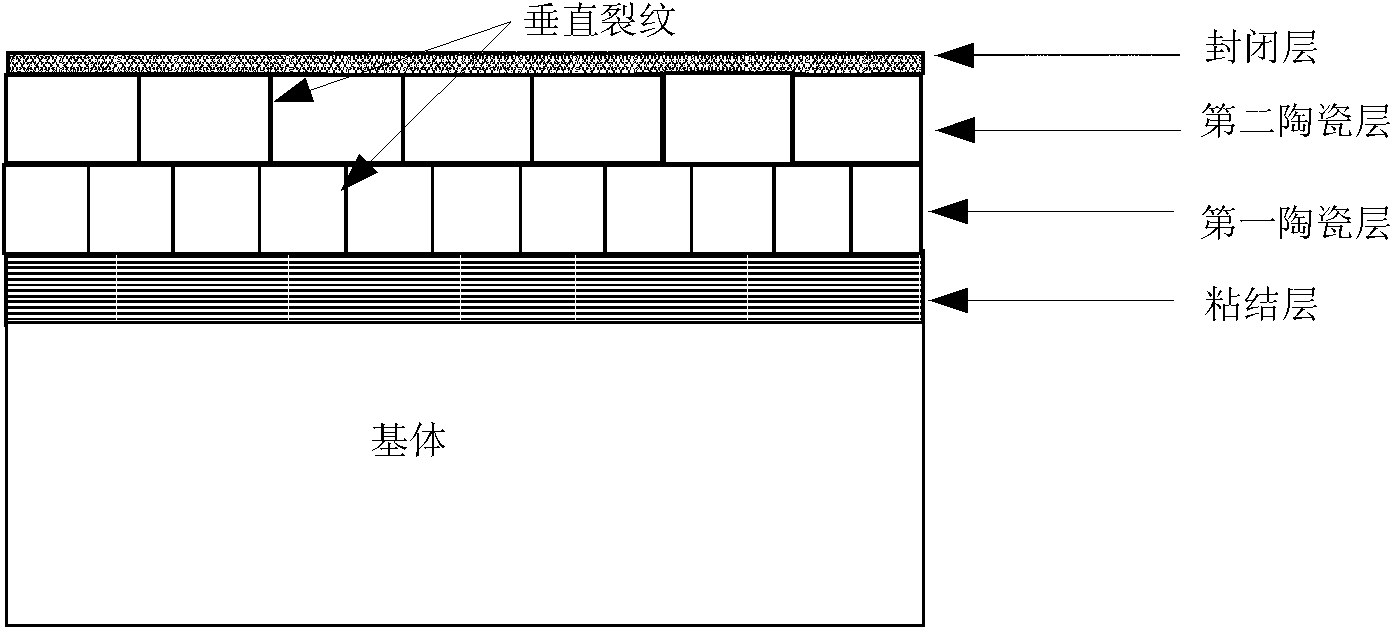

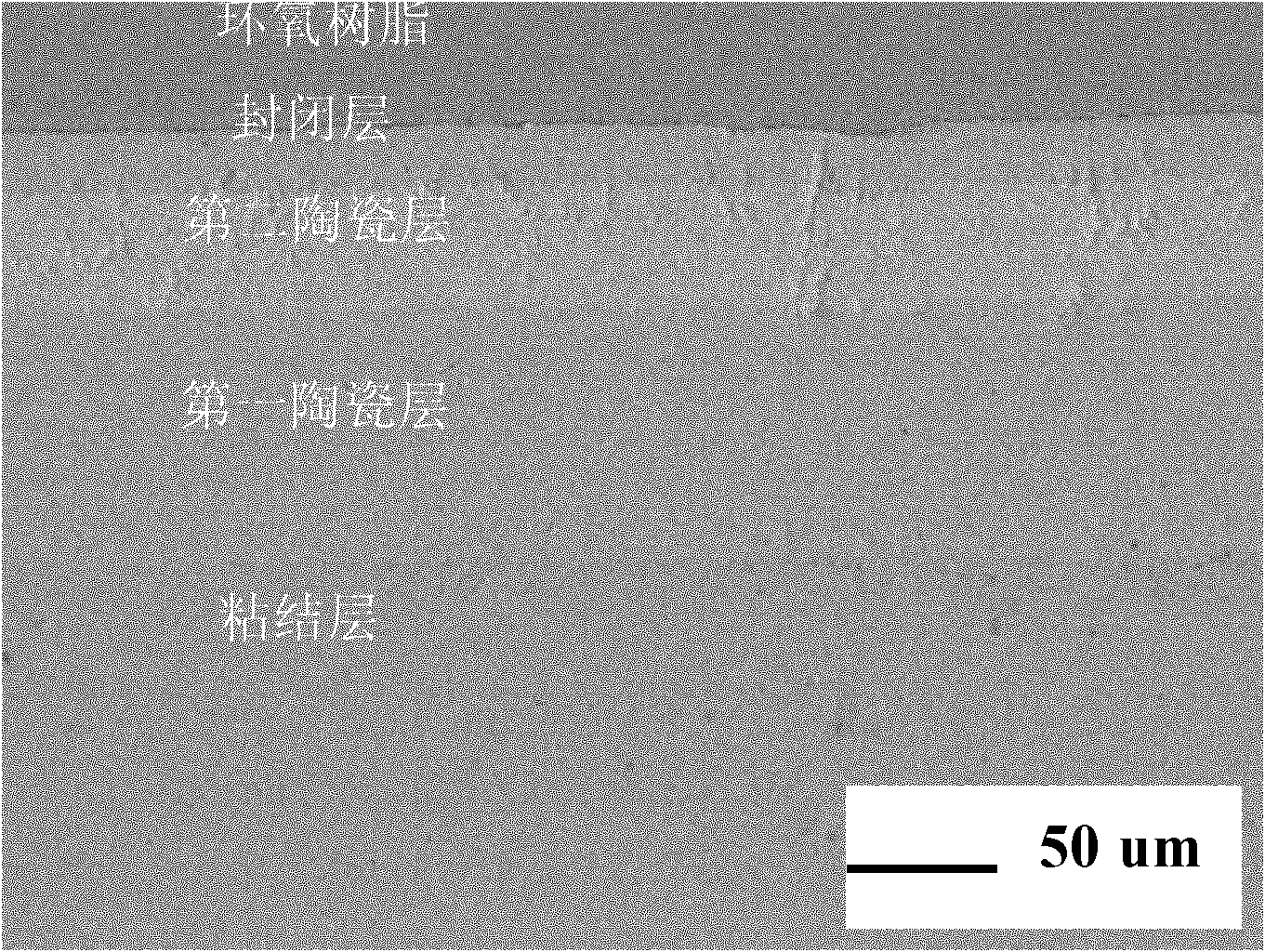

Multilayer thermal barrier coating and preparation method thereof

InactiveCN102127738ANo layer peeling phenomenon occursImprove hot corrosion resistanceMolten spray coatingVacuum evaporation coatingPorosityElectron beam physical vapor deposition

The invention provides a multilayer thermal barrier coating and a preparation method thereof. The multilayer thermal barrier coating sequentially comprises an adhesion layer, a first ceramic layer, a second ceramic layer and a closing layer from bottom to top, wherein the closing layer has the thickness of 10-30 micros and the porosity of 2-8 percent and is made from the Al2O3. The thermal barrier coating can be prepared by adopting an electron beam physical gas-phase deposition technology or a plasma spraying method. The multilayer thermal barrier coating provided by the invention can avoid the stripping of the ceramic layers in a thermal circulating process, the thermal erosion resistance of the thermal barrier coating is greatly improved than the dual ceramic layers; and vertical crackles are introduced in the ceramic layer through improving a conventional plasma spraying process so that the thermal shock life of the thermal barrier coating is greatly prolonged.

Owner:BEIHANG UNIV

Plasma spray method for applying a coating utilizing particle kinetics

InactiveUS6861101B1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorHigh pressure

A method of operation of a plasma torch. A cold high pressure carrier gas containing a powder material is injected into a cold main high pressure gas flow and then this combined flow is directed coaxially around a plasma exiting from an operating plasma generator and converging into the hot plasma effluent, mixing with the effluent to form a gas stream with a net temperature, based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, such that the powdered material will not melt. The combined flow with entrained is directed through a supersonic nozzle accelerating the flow to supersonic velocites sufficient that the particles striking the workpiece achieve kinetic energy transformation into elastic deformation of the particles as they impact the workpiece forming a cohesive coating.

Owner:FLAME SPRAY IND

Cerium oxide containing ceramic components and coatings in semiconductor processing equipment and methods of manufacture thereof

InactiveUS6830622B2Reduce corrosionReduce erosion rateLiquid surface applicatorsMolten spray coatingCeramic coatingCerium

Owner:LAM RES CORP

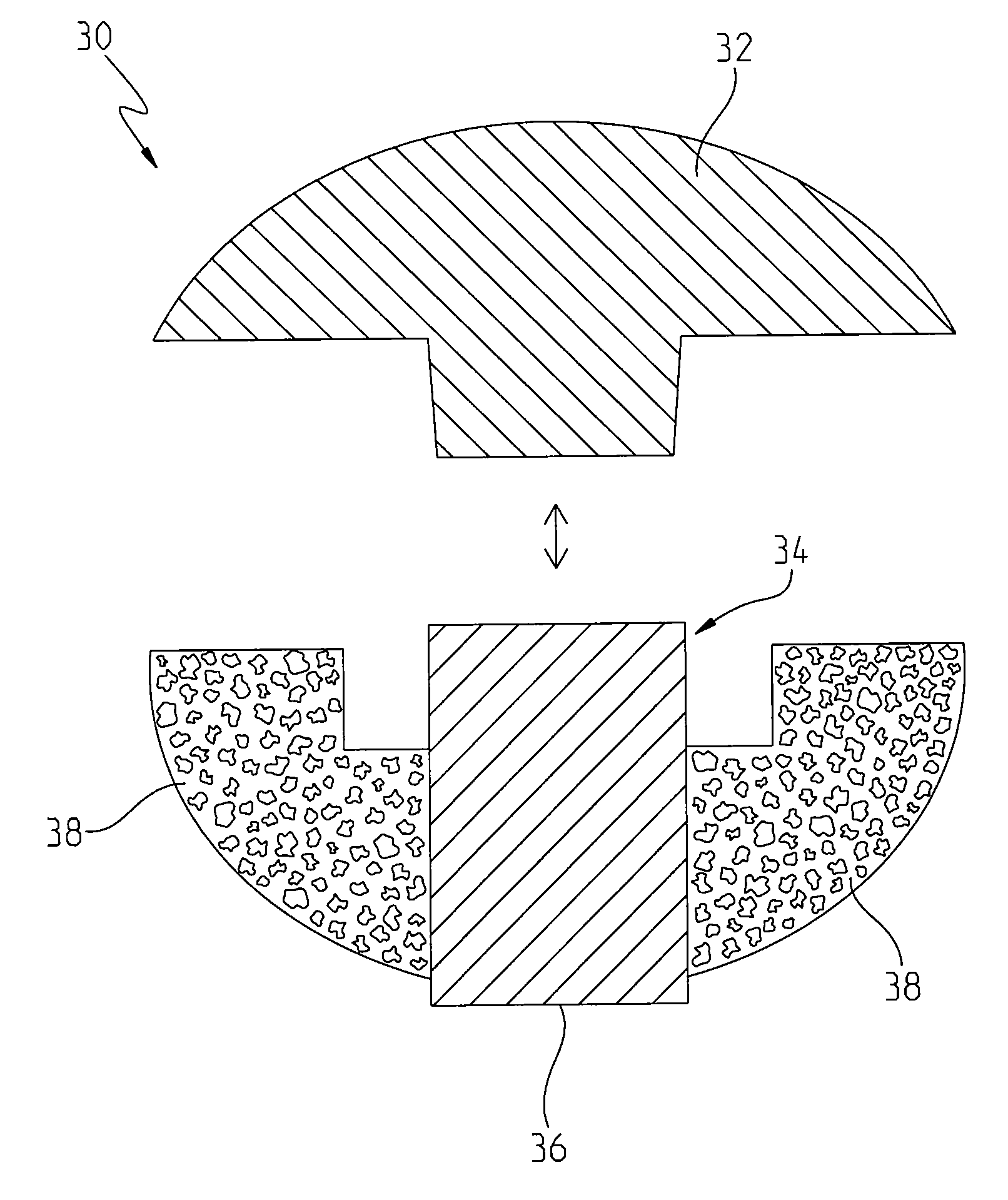

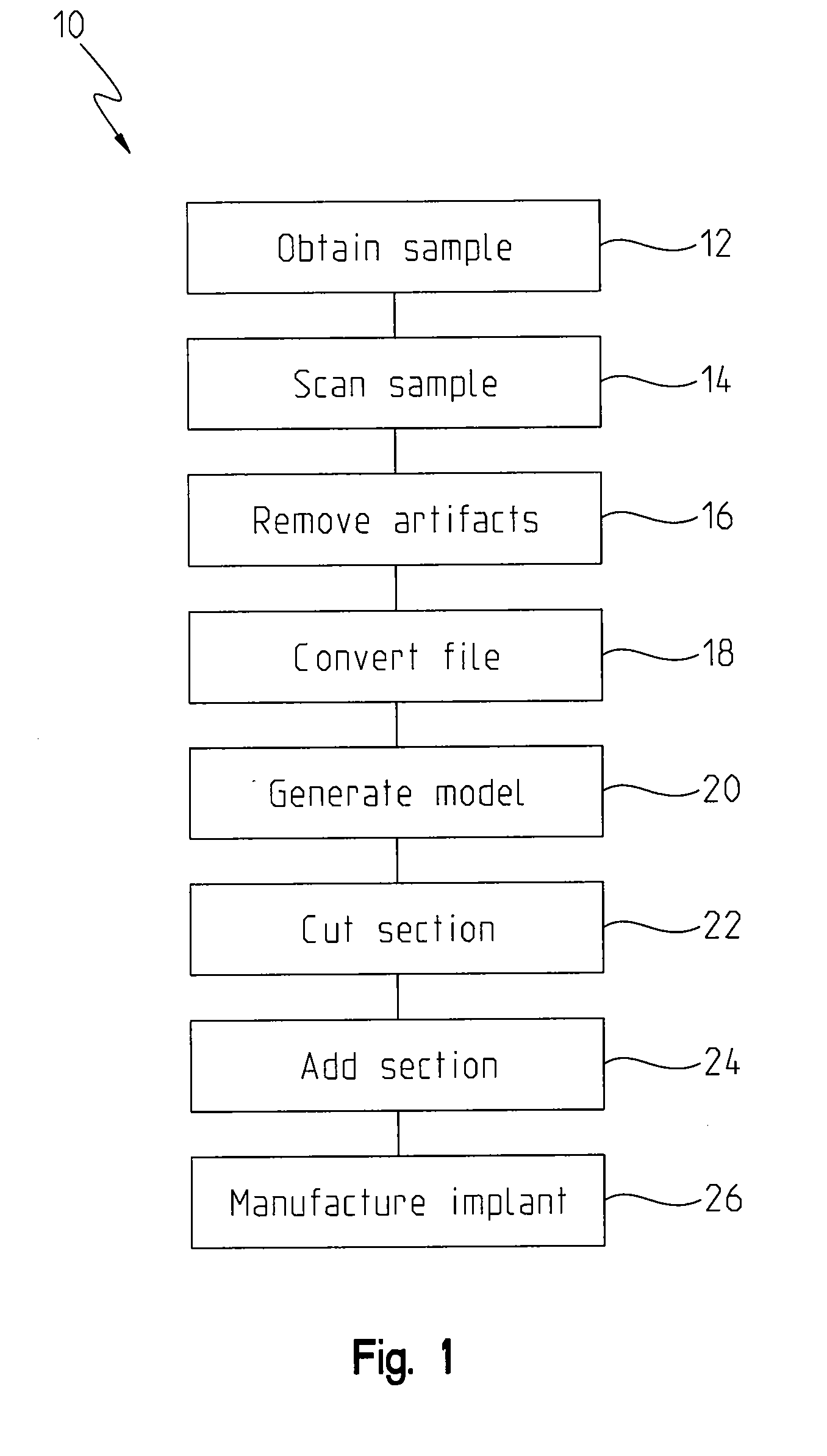

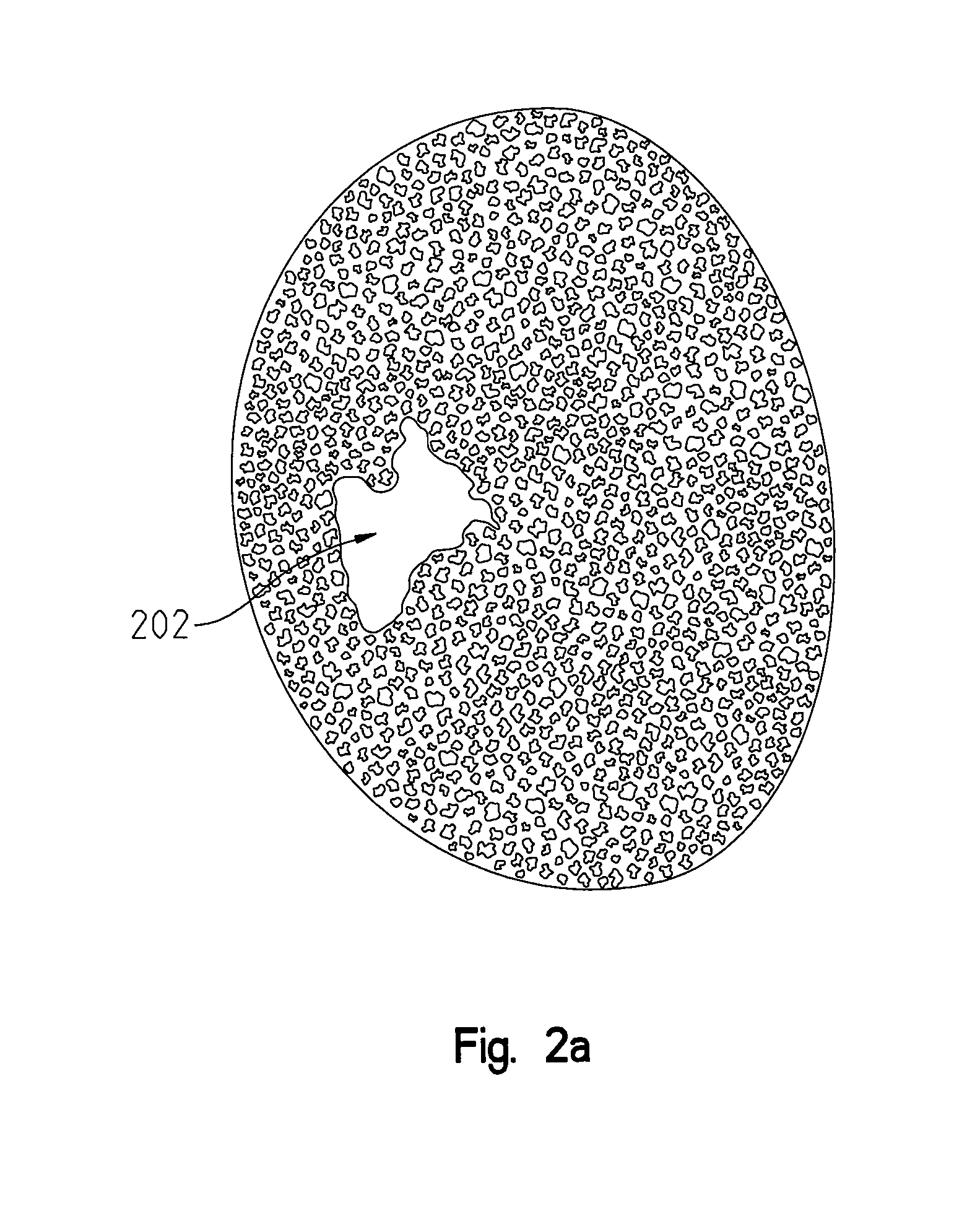

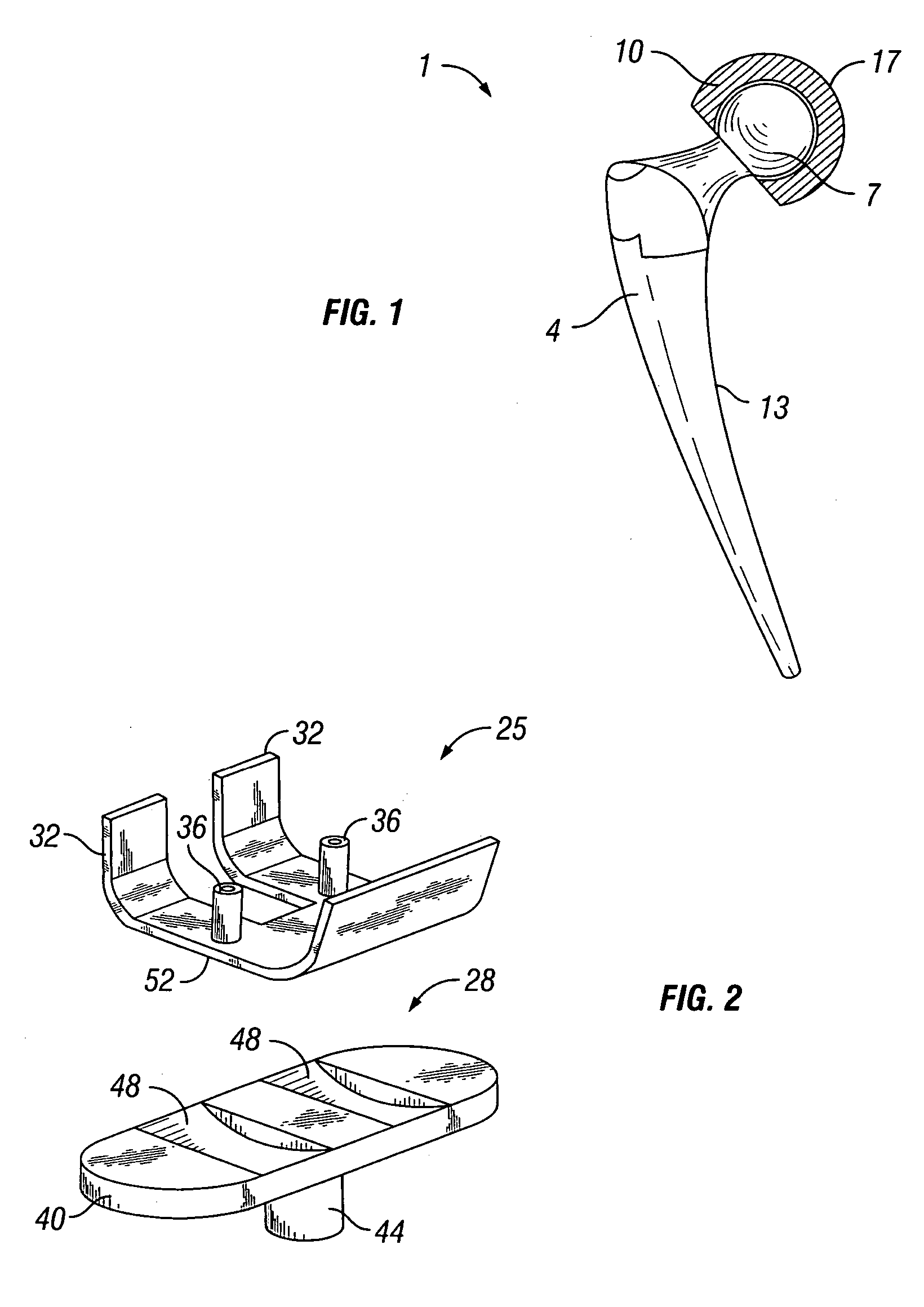

Metallic structures having porous regions from imaged bone at pre-defined anatomic locations

ActiveUS20140371863A1Additive manufacturing apparatusBone implantParticulate debrisStructure of the Earth

Owner:BIOMET MFG CORP

Rare earth element oxyflouride powder spray material and sprayed article

InactiveUS20140057078A1Increase resistanceImprove corrosion resistanceFireproof paintsMolten spray coatingRare-earth elementHigh resistance

A spray material comprising rare earth element oxyfluoride particles having an aspect ratio of up to 2, an average particle size of 10-100 μm, and a bulk density of 0.8-2 g / cm3, and containing not more than 0.5 wt % of carbon and 3-15 wt % of oxygen is suitable for air plasma spraying. An article having a sprayed coating of rare earth element oxyfluoride has high resistance against plasma etching and a long lifetime.

Owner:SHIN ETSU CHEM IND CO LTD

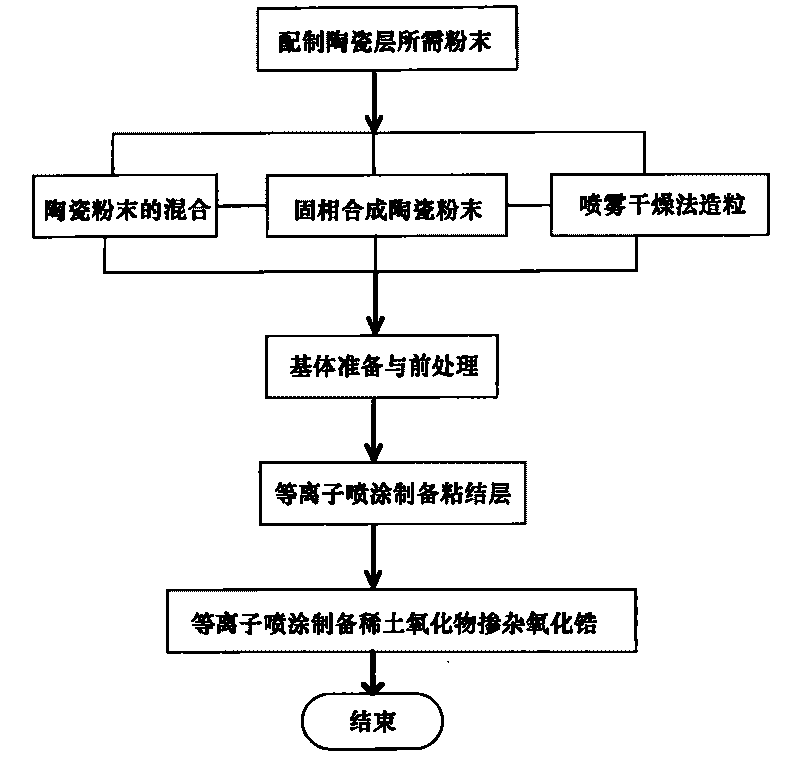

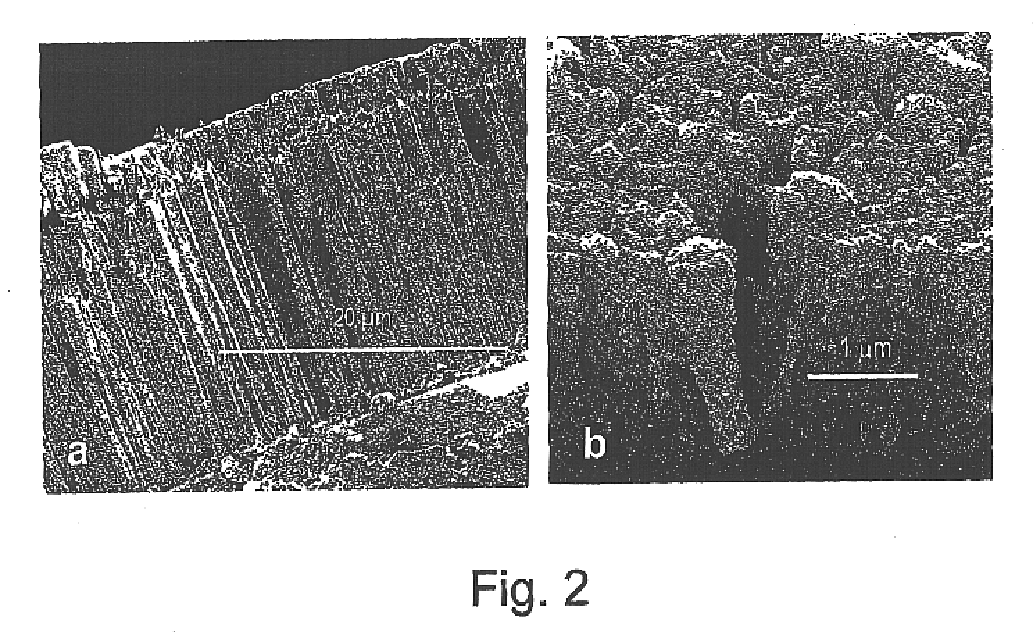

Multielement rare earth oxide doped zirconia thermal barrier coating with craze crack structure and preparing method thereof

InactiveCN101723667AGood phase stability at high temperatureLow temperature for long-term useMolten spray coatingEfficient propulsion technologiesThermal insulationRare earth

The invention discloses a method for preparing a rare earth oxide doped zirconia thermal barrier coating with a craze crack structure, which solves the problems of low thermal shock resistance property, difficult further thermal conductivity reduction and the like of the thermal coating prepared by conventional plasma spraying. Under the condition of the plasma spraying technology, the preheating temperature of a base body, the moving speed of a plasma spraying gun and a powder delivery rate are adjusted, then a rare earth oxide doped zirconia thermal barrier coating (BH-TBCO1) with a craze crack structure and stable thermodynamics is prepared. The rare earth oxide doped zirconia thermal barrier coating with a craze crack structure has good high-temperature phase stability at the temperature below 1300 DEG C; the thermal insulation property of the thermal barrier coating is further enhanced, and the thermal insulation temperature achieves more than 150 DEG C and is enhanced by more than 50% when compared with the coating prepared by the conventional plasma spraying; the thermal shock life of the coating exceeds 4000 cycles and is enhanced by more than 1 time when compared with the coating prepared by the conventional plasma spraying.

Owner:BEIHANG UNIV

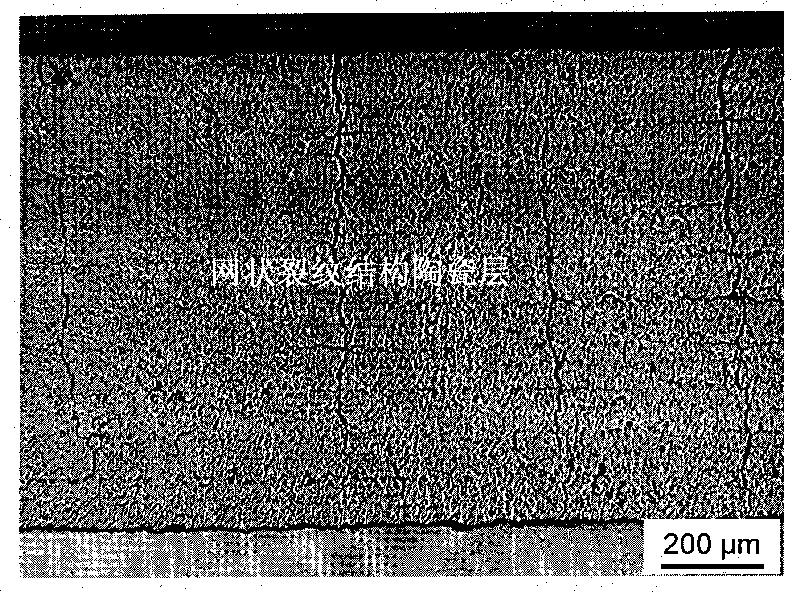

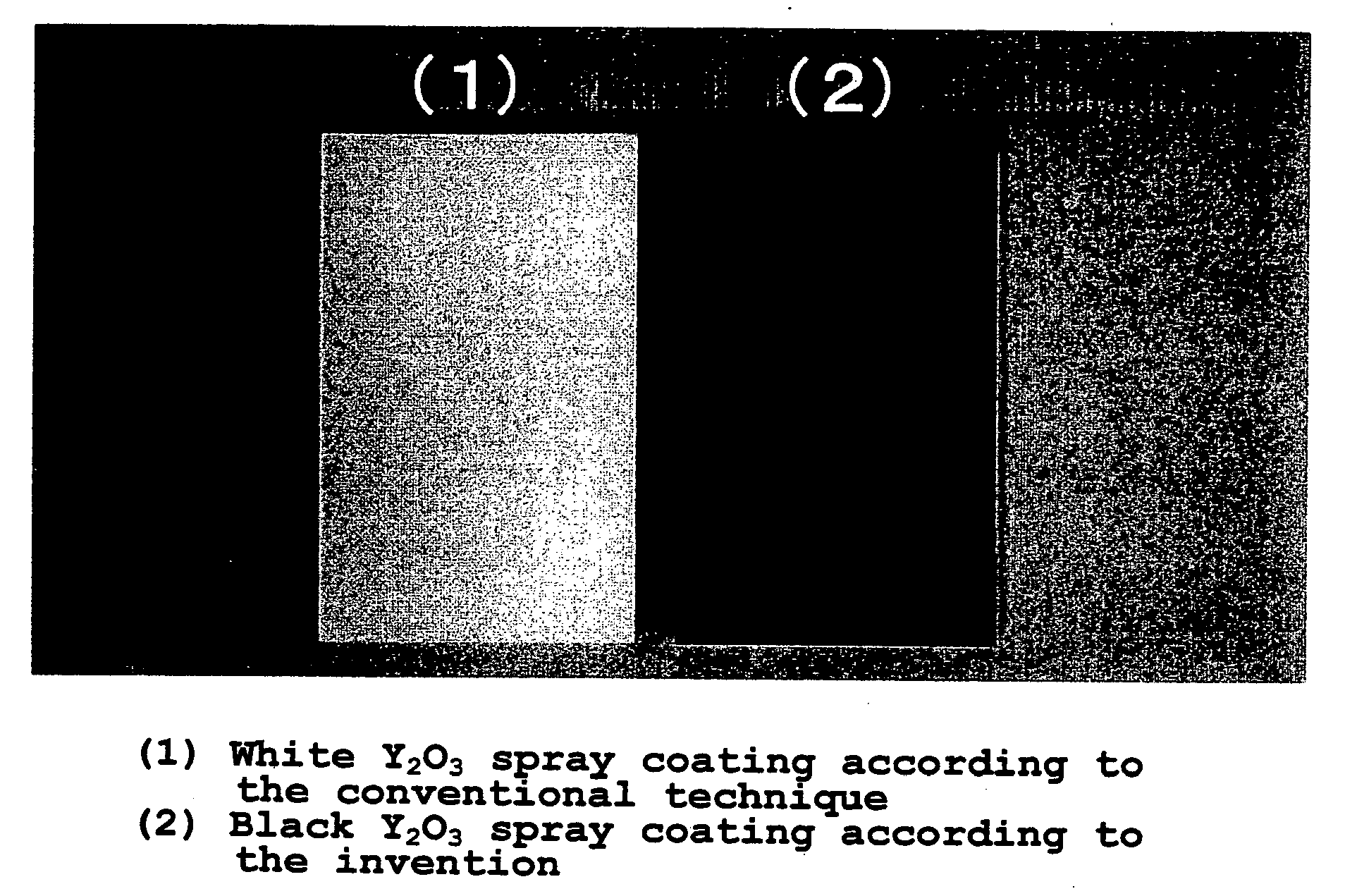

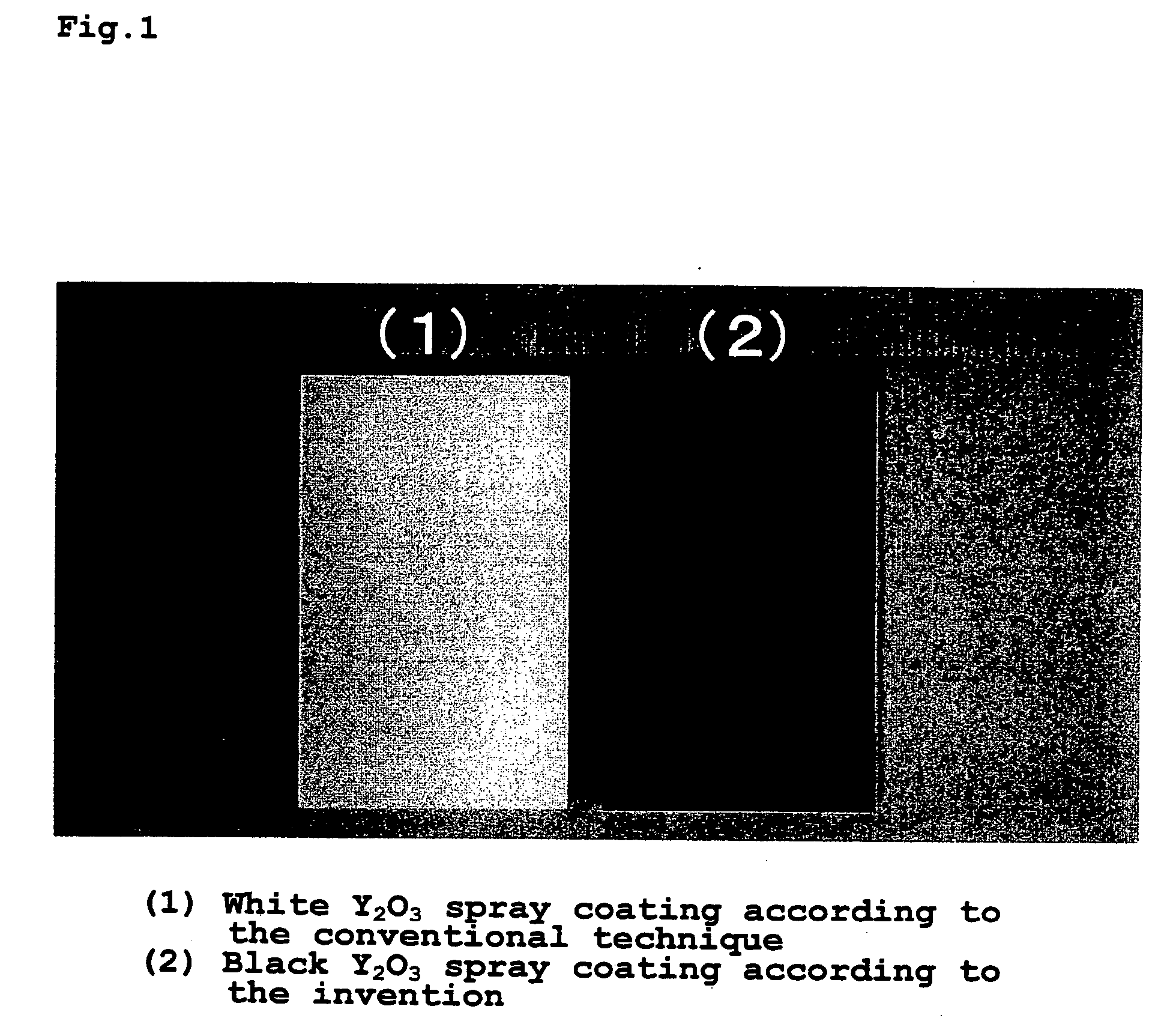

Y2O3 spray-coated member and production method thereof

A member is obtained by forming a Y2O3 black spray coating on a surface of a substrate or covering the surface of the substrate with a Y2O3 black spray coating through an undercoat or a middle layer. This coating has good heat characteristics and is good in the resistance to damaging through a high hardness. The Y2O3 black spray coating is produced by subjecting white Y2O3 powdery material to a plasma spraying in an inert gas atmosphere containing substantially no oxygen or by forming a Y2O3 white spray coating and then irradiating an electron beam or a laser beam to this coating to melt at least a part of the white coating under heating to thereby smoothen denseness and blacken the surface of the coating.

Owner:TOCALO CO LTD

High temperature abradable coatings

InactiveUS20050164027A1Solution to short lifeLiquid surface applicatorsMolten spray coatingMetallurgyCeramic coating

Method of producing a profiled abradable coating on a substrate in which an abradable ceramic coating composition is applied to a substrate using direct-write technology, or plasma sprayed onto the substrate through a mask or by use of a narrow foot-print plasma gun. These methods of producing abradable coatings are performed in the absence of a grid.

Owner:GENERAL ELECTRIC CO

Corrosion resistant component of semiconductor processing equipment and method of manufacture thereof

InactiveUS20020086545A1Electric discharge tubesSemiconductor/solid-state device manufacturingLiquid crystallinePolymer science

A corrosion resistant component of a plasma chamber includes a liquid crystalline polymer. In a preferred embodiment, the liquid crystalline polymer (LCP) is provided on an aluminum component having an anodized or non-anodized surface. The liquid crystalline polymer can also be provided on an alumina component. The liquid crystalline polymer can be deposited by a method such as plasma spraying. The liquid crystalline polymer may also be provided as a preformed sheet or other shape adapted to cover the exposed surfaces of the reaction chamber. Additionally, the reactor components may be made entirely from liquid crystalline polymer by machining the component from a solid block of liquid crystalline polymer or molding the component from the polymer. The liquid crystalline polymer may contain reinforcing fillers such as glass or mineral fillers.

Owner:LAM RES CORP

Calcium phosphate bone graft material, process for making same and osteoimplant fabricated from same

A calcium phosphate bone graft material comprising an amorphous calcium phosphate glassy phase of from about 30 to about 100 volume % is obtained by plasma spraying calcium phosphate-containing powder onto a target to produce a deposited layer and removing the deposited layer from the target to provide the calcium phosphate bone graft material.

Owner:OSTEOTECH INC

Cerium oxide containing ceramic components and coatings in semiconductor processing equipment and methods of manufacture thereof

InactiveUS20020142611A1Reduce corrosionReduce erosion rateLiquid surface applicatorsMolten spray coatingCeramic coatingCerium

A corrosion resistant component of semiconductor processing equipment such as a plasma chamber comprises a cerium oxide containing ceramic material as an outermost surface of the component. The cerium oxide containing ceramic material comprises one or more cerium oxides as the single largest constituent thereof. The component can be made entirely of the cerium oxide containing ceramic material or, alternatively, the cerium oxide containing ceramic can be provided as a layer on a substrate such as aluminum or an aluminum alloy, a ceramic material, stainless steel, or a refractory metal. The cerium oxide containing ceramic layer can be provided as a coating by a technique such as plasma spraying. One or more intermediate layers may be provided between the component and the cerium oxide containing ceramic coating. To promote adhesion of the cerium oxide containing ceramic coating, the component surface or the intermediate layer surface may be subjected to a surface roughening treatment prior to depositing the cerium oxide containing ceramic coating.

Owner:LAM RES CORP

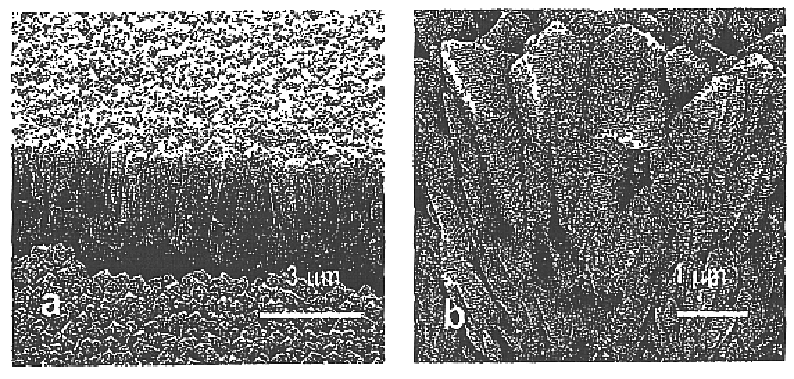

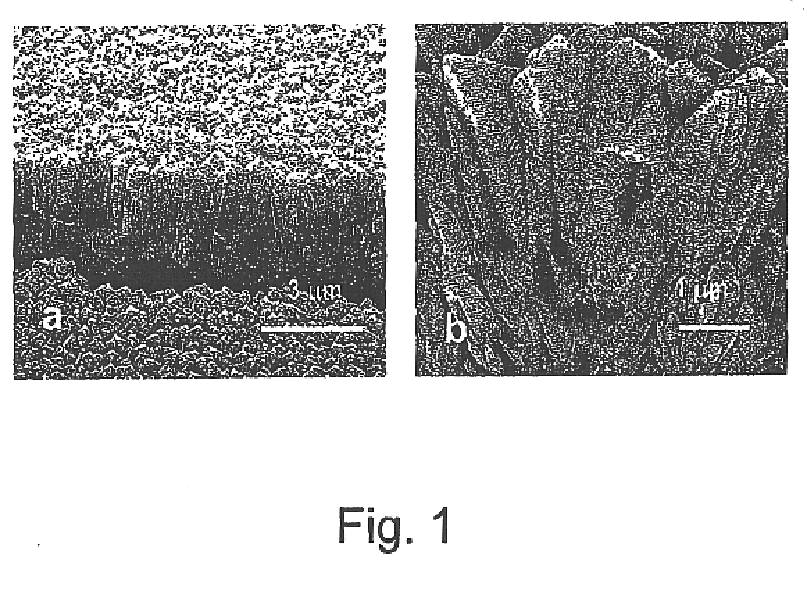

Monazite-based thermal barrier coatings

Monazites and xenotimes are rare-earth phosphates showing a combination of properties expected to be suitable for thermal barrier coatings. For example, lanthanum phosphate (La-monazite) can be used to form thermal barrier coatings to protect superalloy and ceramic parts exposed to high temperature and damage by sulfur, vanadium, phosphorus and other contaminants. The monazite or xenotime coatings can be applied using any of the common application methods including EB-PVD, laser ablation and plasma spraying. The stoichiometry of the coatings can be modulated according to the stoichiometry of specially prepared starting target (source) material. The most effective coatings appear to be largely crystalline and show a columnar structure with feather-like microstructure. For La-monazite, effective coatings between 10 and 500 micrometers in thickness can be deposited on substrates having temperatures between about 750° C. and about 950° C.

Owner:TELEDYNE SCI & IMAGING

Plasma sprayed porous coating for medical implants

A prosthesis having an oxidized zirconium surface and a porous textured surface is described. A major advantage of the prosthesis is increased service life. Additionally, a process of manufacturing the prosthesis is described.

Owner:SMITH & NEPHEW INC

Nanometer zirconium oxide thermal barrier coating and preparation method thereof

ActiveCN102094164AWon't spreadHigh strengthMolten spray coatingEfficient propulsion technologiesThermal insulationThermal barrier coating

The invention relates to a nanometer zirconium oxide thermal barrier coating and a preparation method thereof. The nanometer zirconium oxide thermal barrier coating is characterized by comprising an adhesive layer and a ceramic layer, wherein NiCrAlY is prepared on the adhesive layer by adopting supersonic flame spraying and comprises the following components in percentage by weight: 20-30% of Cr, 4.0-10% of Al, 0.3-0.7% of Y, and the balance of Ni; a ZrO2 / Y2O3 layer is prepared as the ceramic layer by adopting plasma spraying, the ceramic layer is a nanometer zirconium oxide layer comprising5%-8% of partially stable yttrium oxide, and zirconium oxide powder is at a nanometer grade. The oxidation-resisting thermal barrier coating is prepared on a metal surface by combining the supersonic flame spraying with the plasma spraying, has better combining capacity with a base body and both thermal shock resistance and thermal insulation superior to those of a common ZrO2 / Y2O3 thermal barrier coating.

Owner:沈阳天贺新材料开发有限公司

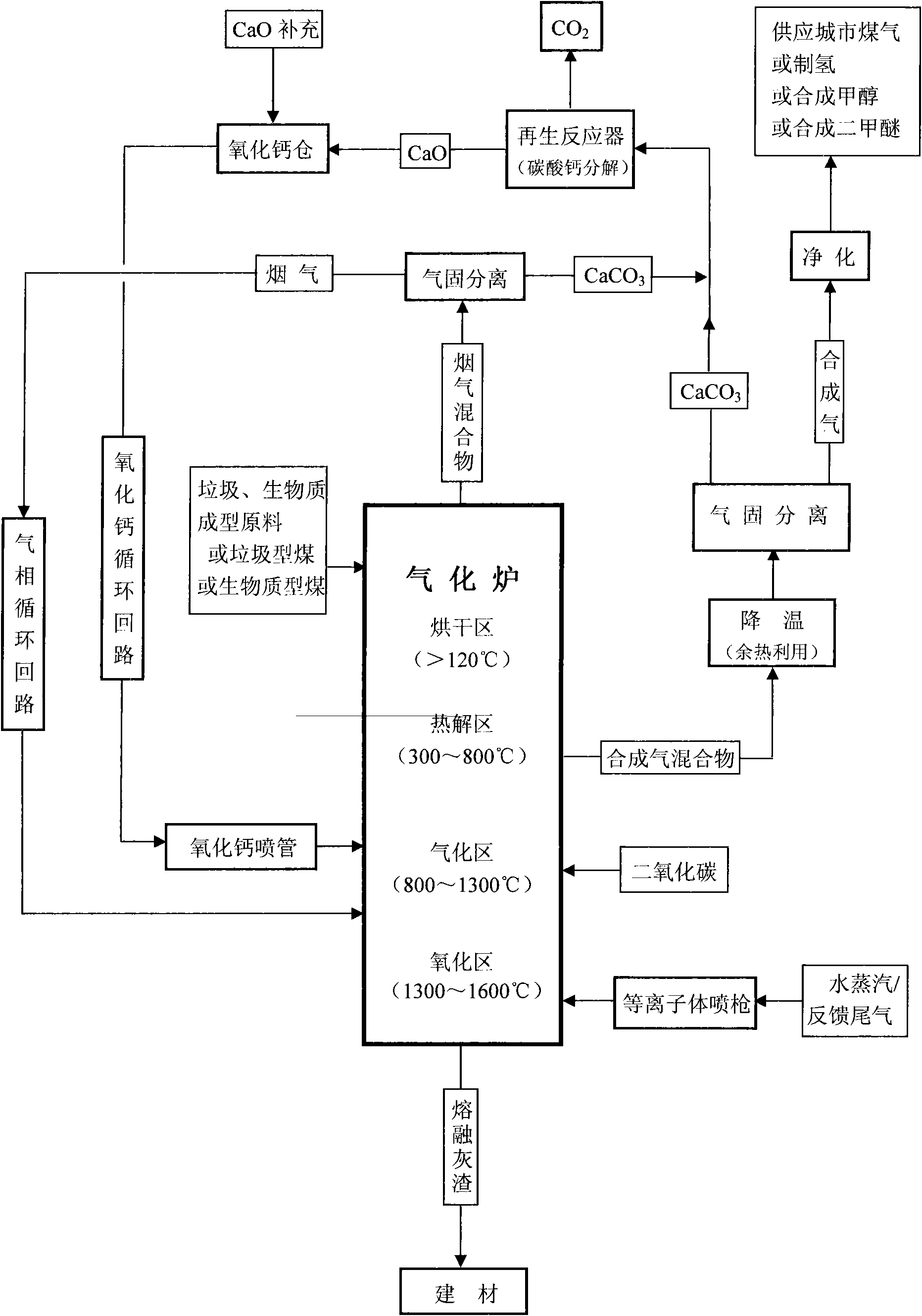

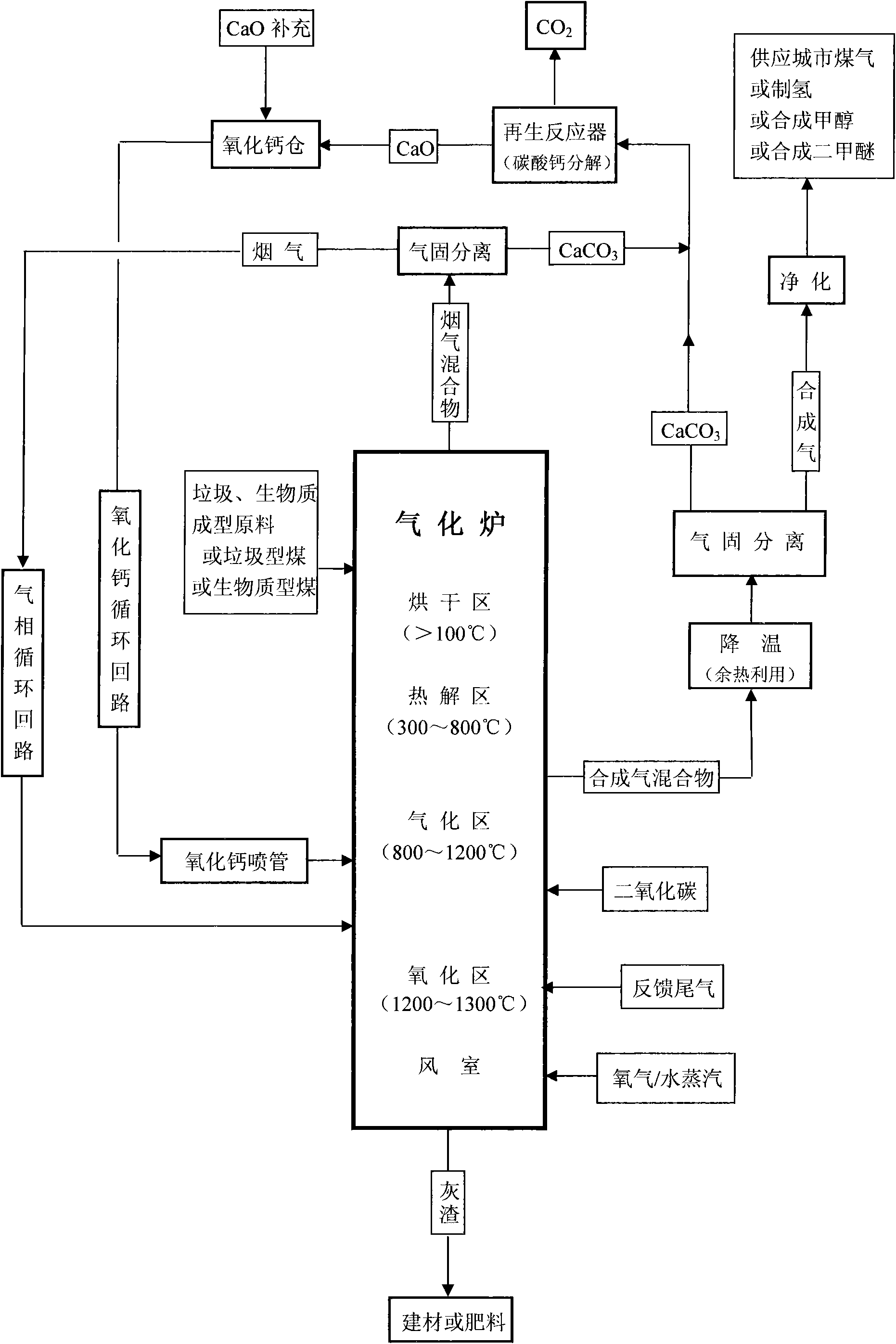

Gasification process for producing synthesis gas from garbage and biomass raw materials

InactiveCN101525118AEliminate pollutionHarmlessHydrogen productionSpecial form destructive distillationGas phaseWater vapor

The invention provides a gasification process for producing synthesis gas from garbage and biomass raw materials, which relates to a gasification processing technique of garbage and biomasses. The gasification process is characterized in that the technological process mainly comprises a raw material solid matter process, a gas phase circulation loop, a calcium oxide circulation loop and a synthesis gas drawing process; one or a mixture of more garbage, the biomasses and coal is sent into a gasification furnace to perform gasification so as to generate the synthesis gas; and simultaneously, calcium oxide is sent into the gasification furnace, an exothermic reaction of absorbing carbon dioxide by the calcium oxide provides the heat required by the gasification reaction in the furnace, and water vapor is sent into a plasma spraying gun and is heated to more than 3,100 DEG C to generate H2, O, O2 and H2O<*> which are sprayed into the gasification furnace to perform reactions with the garbage and the biomasses and supply heat into the furnace. The gasification process adopts a measure to spray the calcium oxide into the furnace to not only greatly reduce the electric energy consumption of the plasma spraying gun, but also improve the quality and the yield of the synthesis gas, thus the aim of transforming the garbage and the biomasses into clean energy can be achieved easily.

Owner:周开根

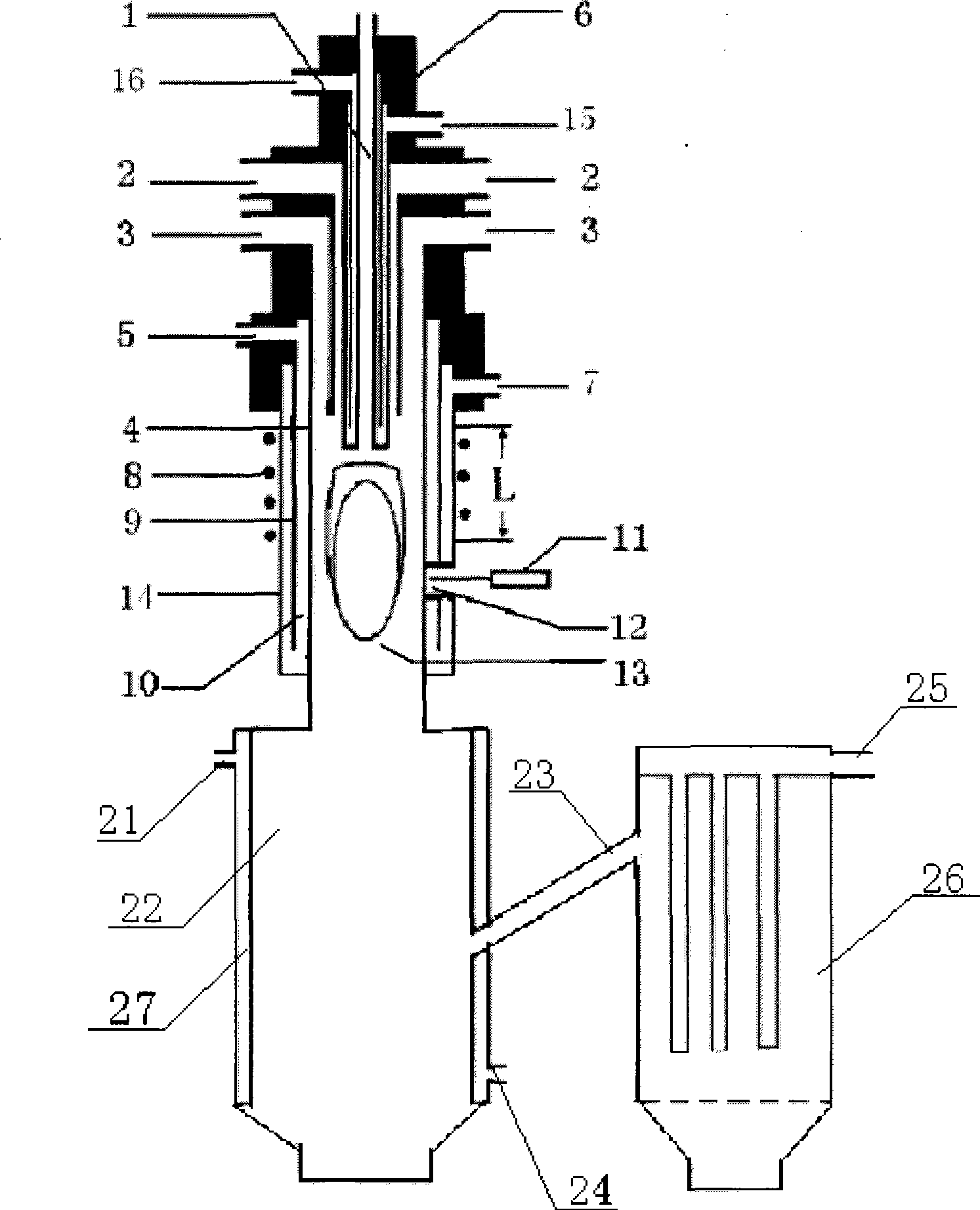

Globular titanium micro-powder or ultra-micro powder preparation device and method

The invention belongs to a process for preparing and processing powder material by taking plasma as a heat source, in particular to a process and an apparatus of metal titanium powder material for powder metallurgy, plasma spray, injection forming, gel injection molding and the like. The invention has the advantages that: the adoption of the high temperature spheroidization and rapid condensation special spheroidization technique can improve the sphericity and purity of titanium powder, and both a reactor and the titanium powder spheroidization process are cooled with circulating water, thereby ensuring the sealing performance of equipment, also reducing the use of inert gases, effectively reducing costs, improving the production efficiency and guaranteeing the purity of spherical titanium powder.

Owner:SOUTHWESTERN INST OF PHYSICS

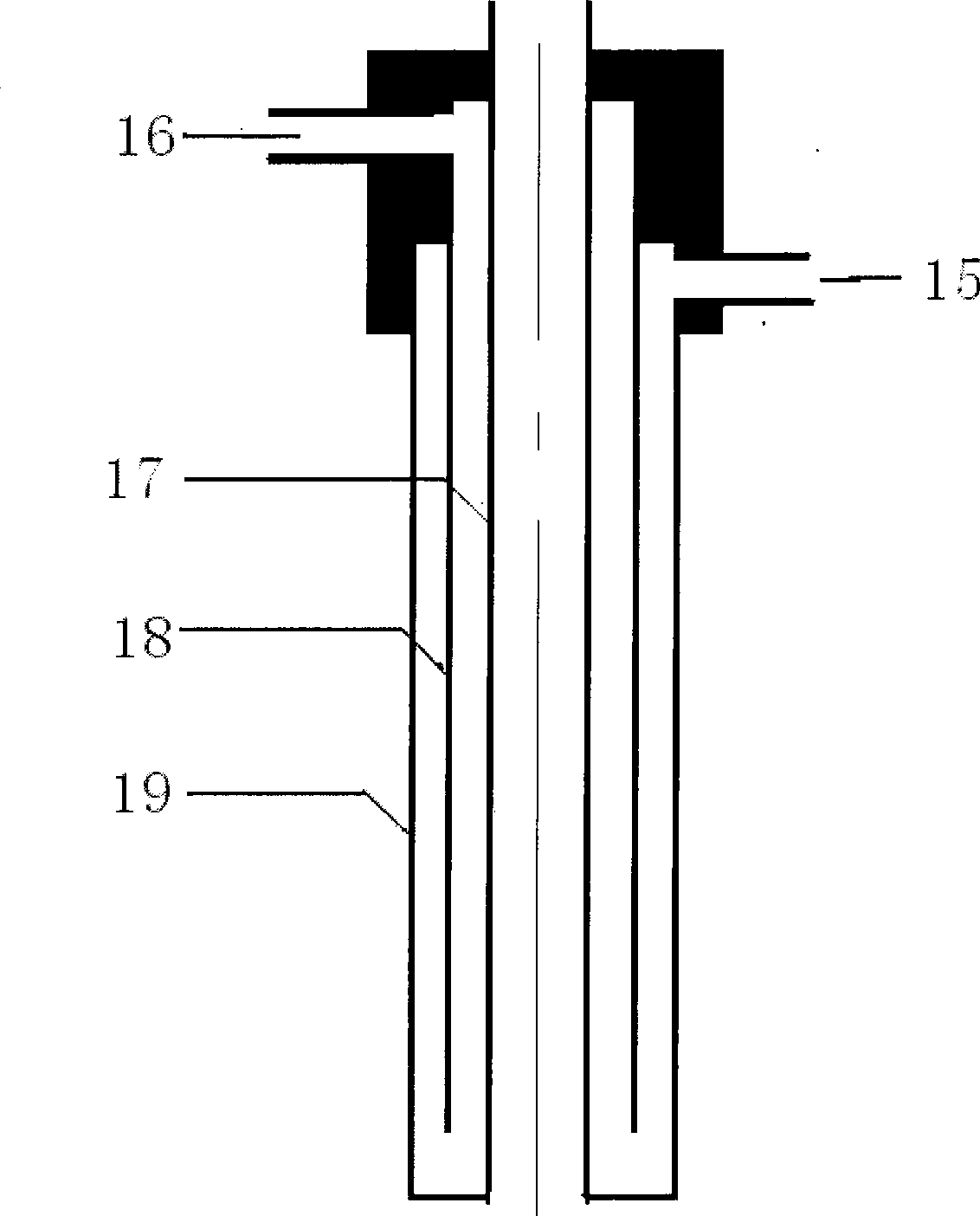

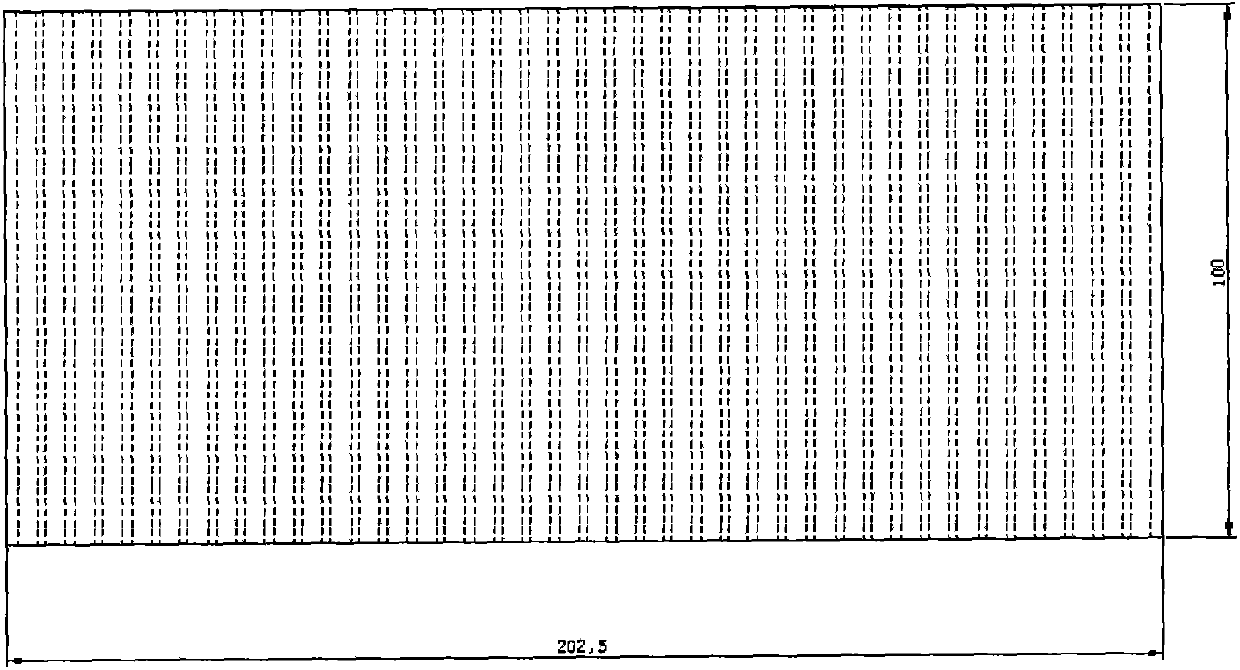

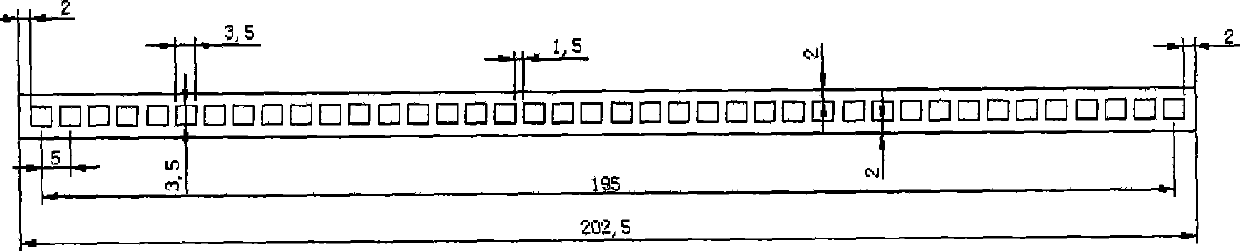

Preparation method of hollow flat plate structure type ceramic filter membrane element

ActiveCN103623711ALower sintering temperatureSmall filter resistanceSemi-permeable membranesAluminium hydroxideChemical separation

The invention provides a preparation method of a hollow flat plate structure type ceramic filter membrane element. The method comprises the following steps: (1) preparing a hollow structure type ceramic membrane supporting body by using an extrusion molding method, namely sintering aluminum hydroxide obtained by calcination at 600 DEG C as a main raw material to prepare the ceramic membrane supporting body; (2) preparing the ceramic filter membrane by using a plasma spray method. When the ceramic membrane supporting body is prepared, the selected and used raw material is calcined aluminum hydroxide, so that the sintering temperature of the ceramic membrane supporting body can be greatly reduced, and the sufficient strength of the supporting body can be guaranteed; when the ceramic filter membrane layer is prepared, the thickness of the filter membrane can be excellently controlled by using the plasma spray process, and the filter resistance is reduced; the membrane layer has the uniform pore size distribution and the high separation accuracy; the membrane layer is closely combined with the supporting body. The ceramic filter membrane is prepared by using plasma spraying without sintering, so that the process is simple, the production cost of the ceramic filter membrane can be effectively reduced, the production efficiency is improved, and the process can be widely applied to the fields of sewage treatment and filtration, solid-liquid chemical separation, and the like.

Owner:雅安沃克林环保科技有限公司

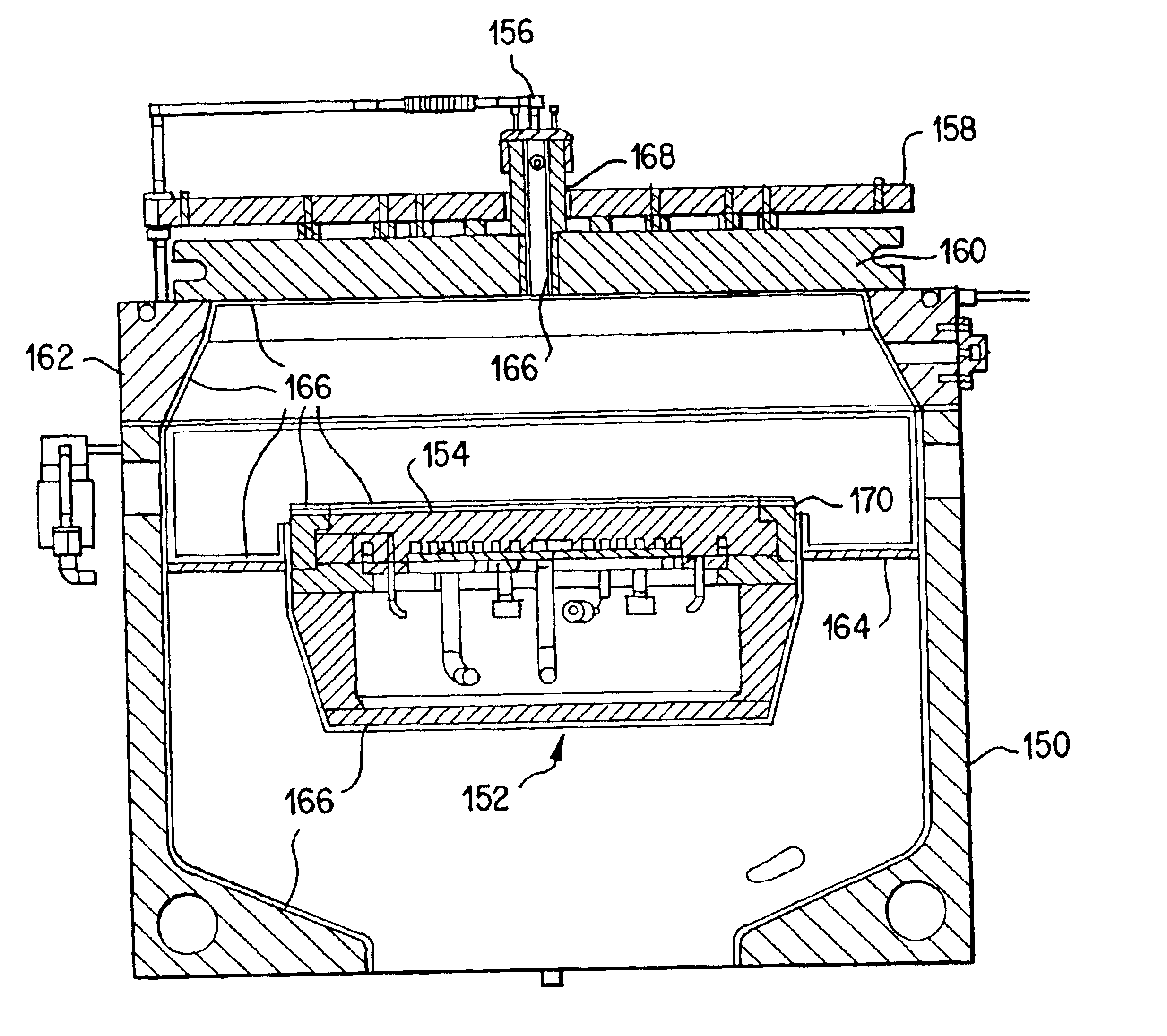

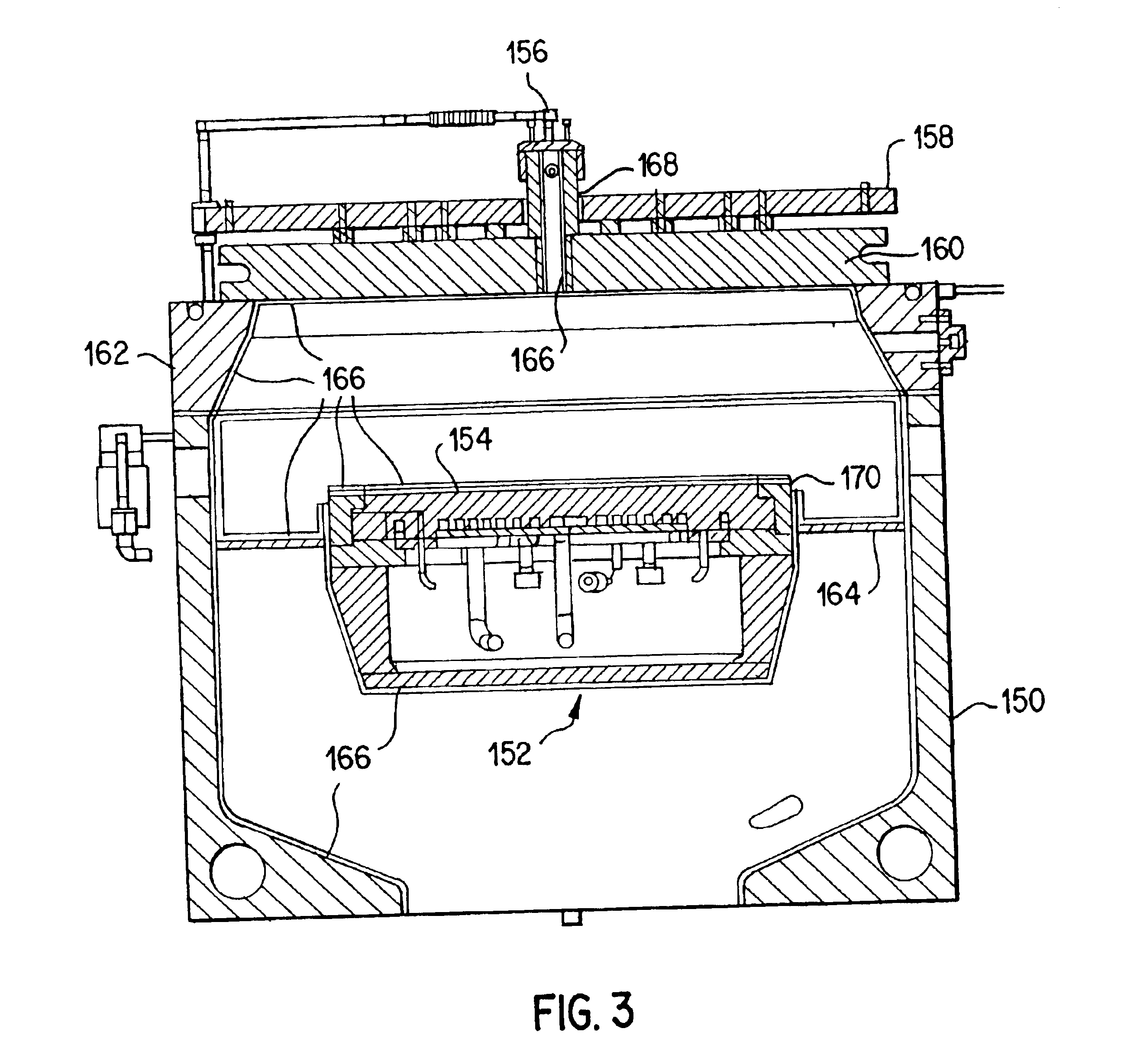

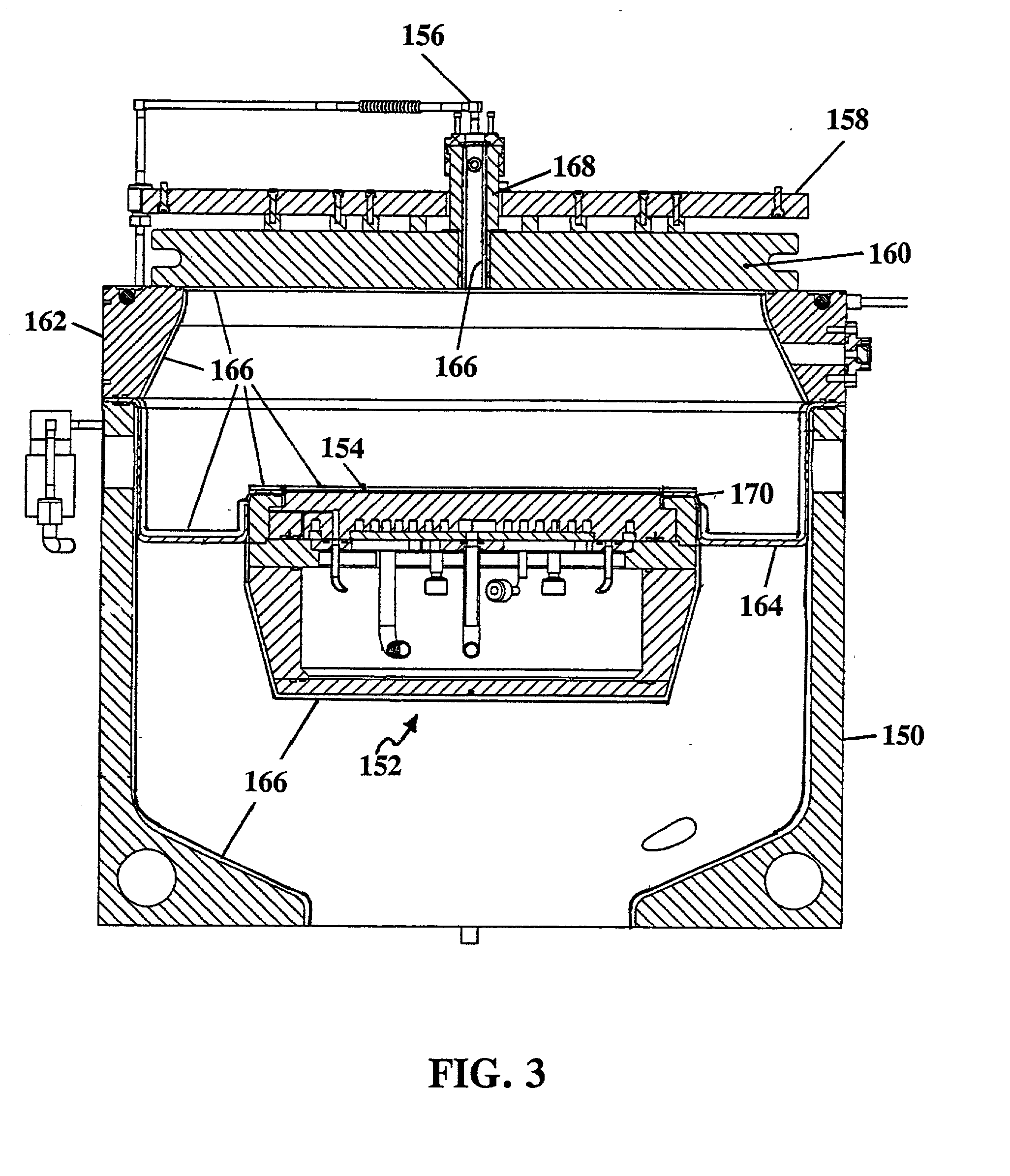

Rotary plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS6986471B1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorMaterials science

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns. The system also includes a rotating member for coating concave surfaces and internal bores or other such devices which can be better coated using rotation.

Owner:FLAME SPRAY IND

Non-stick pan coating layer and preparation method thereof

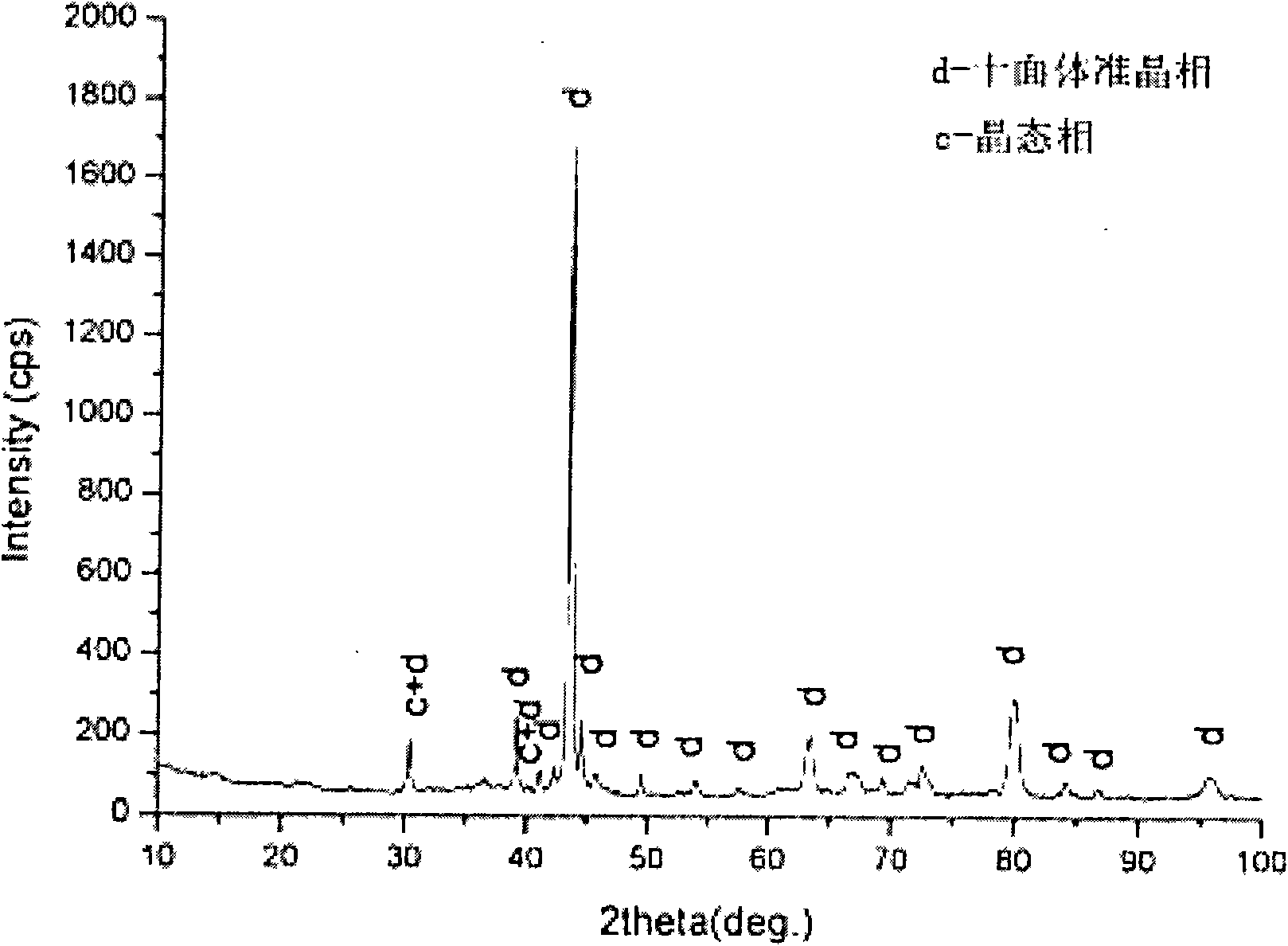

The invention provides a non-stick pan coating layer and a preparation method thereof. The coating layer comprises Al-Cu-Fe-Cr-B quasicrystalline alloy which has components as follows by the atomic percentage: 70-90 of Al, 1-15 of Cu, 5-15 of Fe, 5-15 of Cr, and the balance of B and unavoidable impurity. The method comprises the specific steps as follows: (1) smelting alloy materials with a spraying device at a temperature of 900-1100 DEG C to prepare alloy powder; (2) spraying the alloy coating layer on a boiler basal body with a plasma spraying device, with a main gas feed rate of 65 L / min, a secondary gas feed rate of 20-30 L / min, an arc current of 550-590A, an arc voltage of 45-60V, a powder delivering amount of 10-15 g / min, and a coating layer thickness of about 100-200 micro. At a cooking temperature, the invention has the advantages of stable chemical property, large rigidness, lower cost than Teflon or organic silicon, low surface friction coefficient, and the like.

Owner:鞠汉清

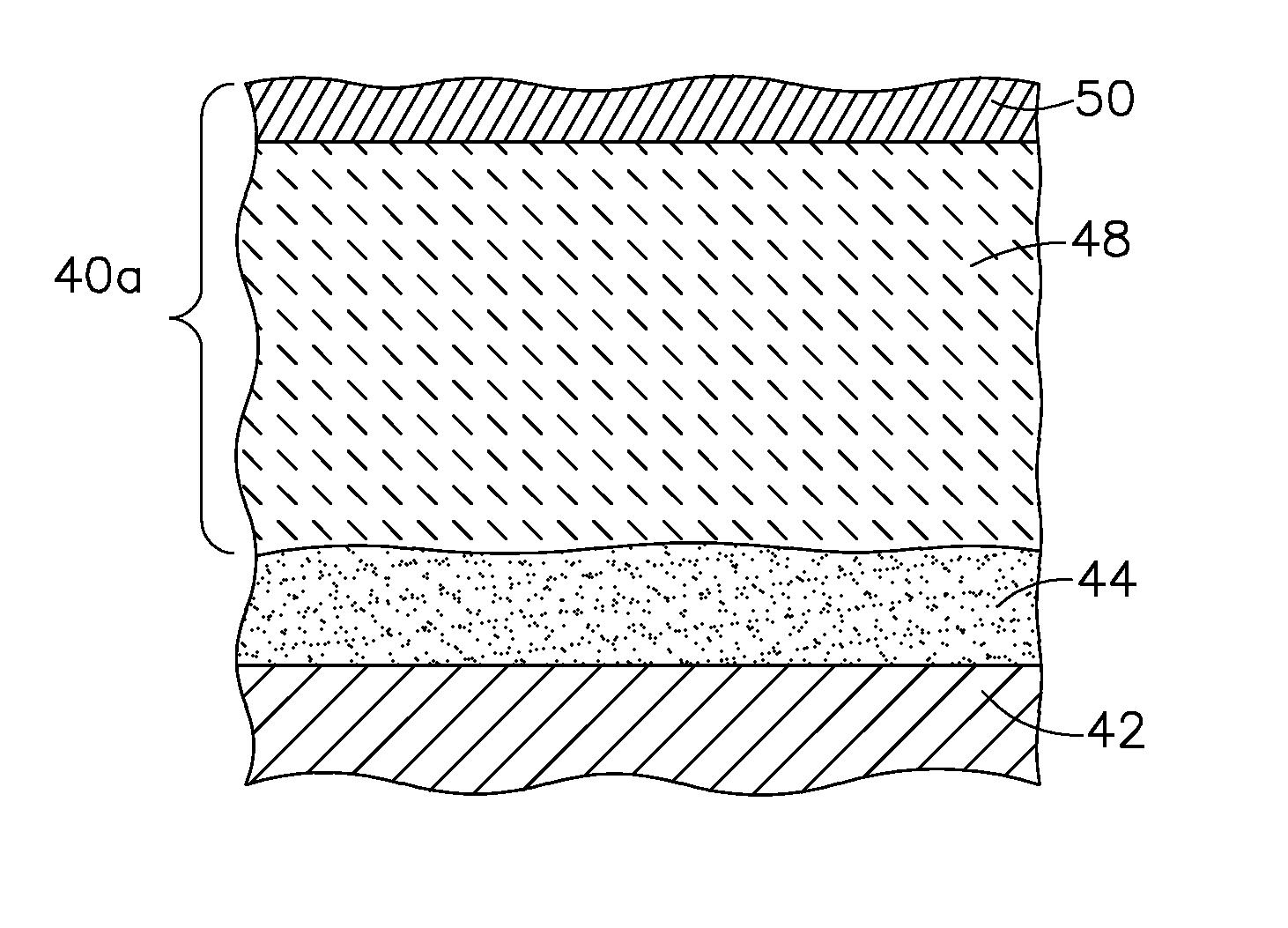

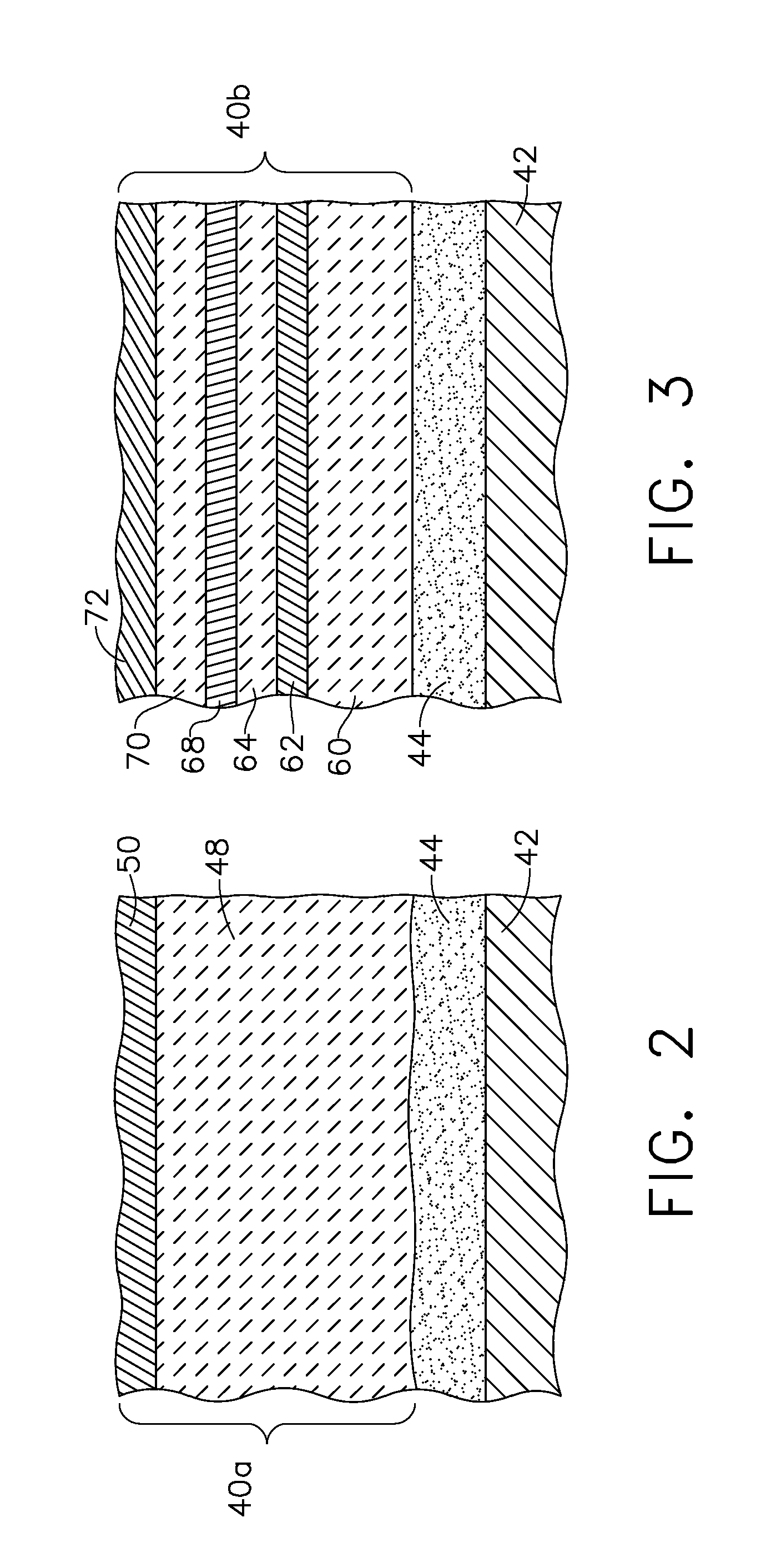

Coating Systems for Protection of Substrates Exposed to Hot and Harsh Environments and Coated Articles

InactiveUS20110151219A1Reduce the effectUsed in environmentContinuous combustion chamberMolten spray coatingCoating systemOxygen

Coating system for reducing CMAS infiltration of substrates includes at least an inner ceramic layer and an outer alumina-containing layer. The outer layer includes up to 50 percent by weight titania. Additional ceramic layers and alumina-containing layers may be provided. The coating may be used for gas turbine engine components. Deposition techniques for the coating layers may depend on the end use of the component. Coated articles include a substrate, an optional bond coat on the substrate and a coating over the bond coat or on at least a portion of the substrate in the absence of a bond coat. The inner ceramic layer(s) exhibit a microstructure indicative of a deposition technique selected from thermal spray, physical vapor deposition, and suspension plasma spray, whereas the outer alumina-containing layer exhibits a microstructure indicative of suspension plasma spray, solution plasma spray, and a high velocity oxygen fuel spray.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com