Multielement rare earth oxide doped zirconia thermal barrier coating with craze crack structure and preparing method thereof

A technology of rare earth oxide and thermal barrier coating, which is applied in coating, metal material coating technology, air transportation, etc., can solve the problems of low coating cost, poor bonding force of plasma spray coating, etc., and achieve improved strain capacity limit, improve the effect of thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

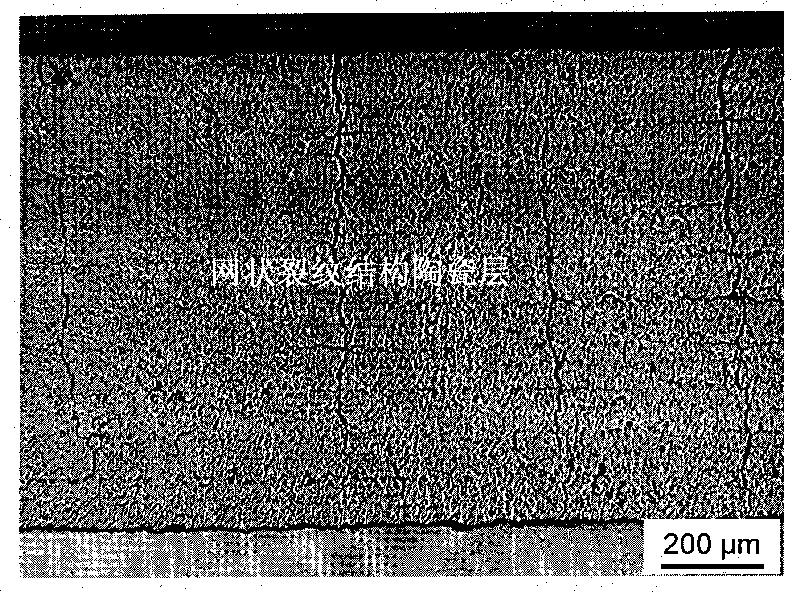

[0051] Example 1: Preparation of Coatings on Ni-based Superalloy Substrates of DZ125

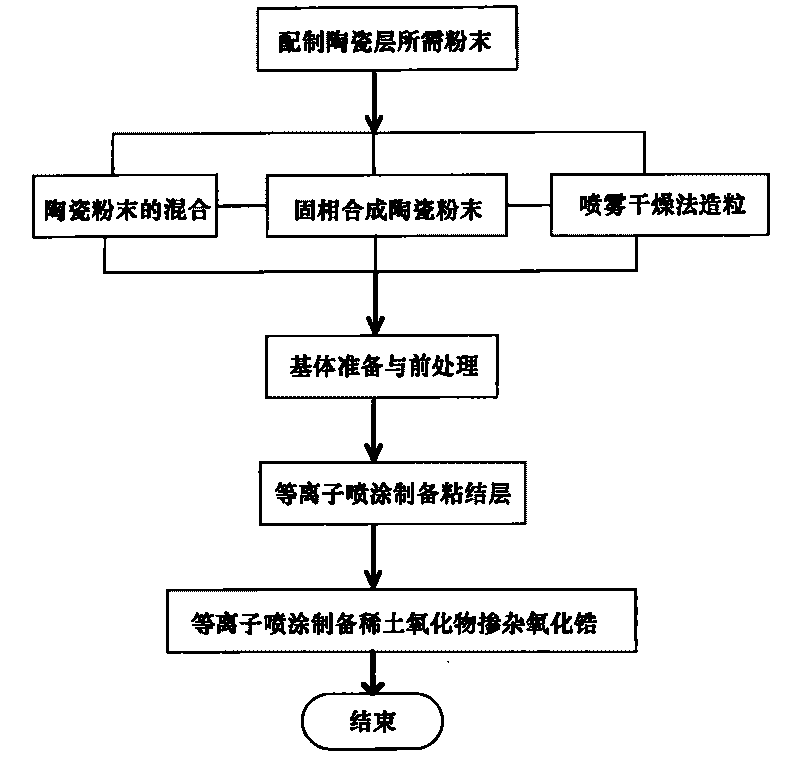

[0052] Step 1: Prepare the powder required for the ceramic layer:

[0053] (A) Weigh 170g of zirconia powder and 30g of Nd 2 O 3 , Yb 2 O 3 or Sm 2 O 3 The combination of two or more of the powders was wet-milled with a high-energy ball mill for 8 hours, and the wet-milled samples were taken out and dried in a drying oven at 120°C for 6 hours to obtain uniformly mixed rare earth oxides and zirconia fine particles. pink.

[0054] (B) put the fine powder obtained in (A) step into a high-temperature furnace, set the heating rate of the furnace to be 3°C / min, adjust the reaction temperature to be 1400°C, react after 24 hours with the furnace and be cooled to room temperature, take out the ball mill to 5 μm or less.

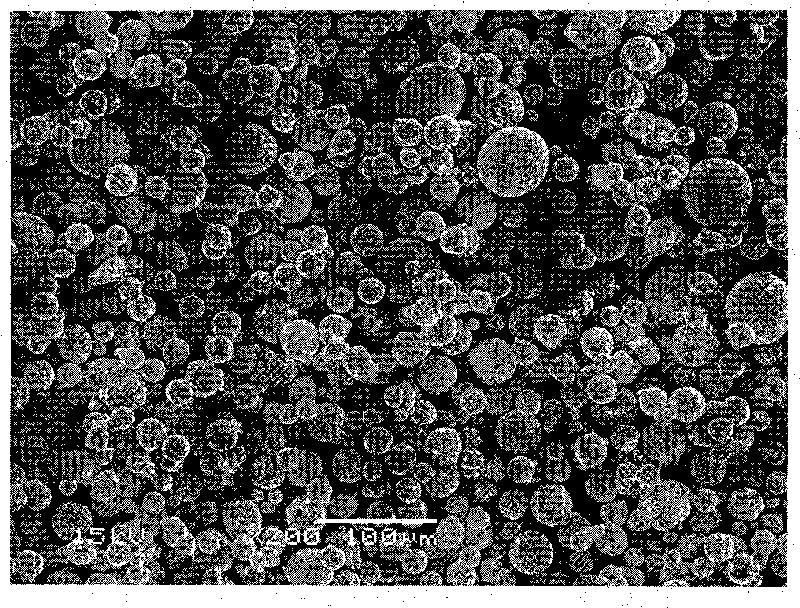

[0055] (C) prepare slurry according to powder: deionized water: binder = 1: 1: 0.2 (mass ratio), the binder component is peach gum, after stirring with a stirring ball mil...

Embodiment 2

[0066] Example 2: Preparation of Coatings on DD3Ni-Based Superalloy Substrates

[0067] Step 1: Prepare the powder required for the ceramic layer:

[0068] (A) Weigh 270g of zirconia powder and 30g of Gd 2 O 3 , Sc 2 O 3 or Yb 2 O 3 The combination of two or more of the powders was wet-milled with a high-energy ball mill for 20 hours, and the wet-milled samples were taken out and dried in a drying oven at 120°C for 6 hours to obtain uniformly mixed rare earth oxides and zirconia fine particles. pink.

[0069] (B) put the fine powder obtained in (A) step into a high-temperature furnace, set the heating rate of the furnace to be 3°C / min, adjust the reaction temperature to be 1300°C, react after 24 hours with the furnace and be cooled to room temperature, take out the ball mill to 5 μm or less.

[0070] (C) prepare slurry according to powder: deionized water: binder = 1: 1: 0.2 (mass ratio), the binder component is peach gum, after stirring with a stirring ball mill for...

Embodiment 3

[0081] Example 3: Fabrication of Coated Screens on DD6Ni-Based Superalloy Substrates

[0082] Step 1: Prepare the powder required for the ceramic layer:

[0083] (A) Weigh out 380 g of zirconia powder and 20 g of La 2 O 3 , CeO 2 and Y 2 O 3 The combination of two or more of the powders was wet-milled with a high-energy ball mill for 1 hour, and the wet-milled samples were taken out and dried in a drying oven at 120°C for 6 hours to obtain uniformly mixed rare earth oxides and zirconia fine particles. pink.

[0084] (B) put the fine powder obtained in (A) step into a high-temperature furnace, set the heating rate of the furnace to be 3°C / min, adjust the reaction temperature to be 1500°C, react after 12 hours with the furnace and be cooled to room temperature, take out the ball mill to 5 μm or less.

[0085] (C) prepare slurry according to powder: deionized water: binder = 1: 1: 0.2 (mass ratio), the binder component is peach gum, after stirring with a stirring ball mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com