Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

580results about How to "Good thermal properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

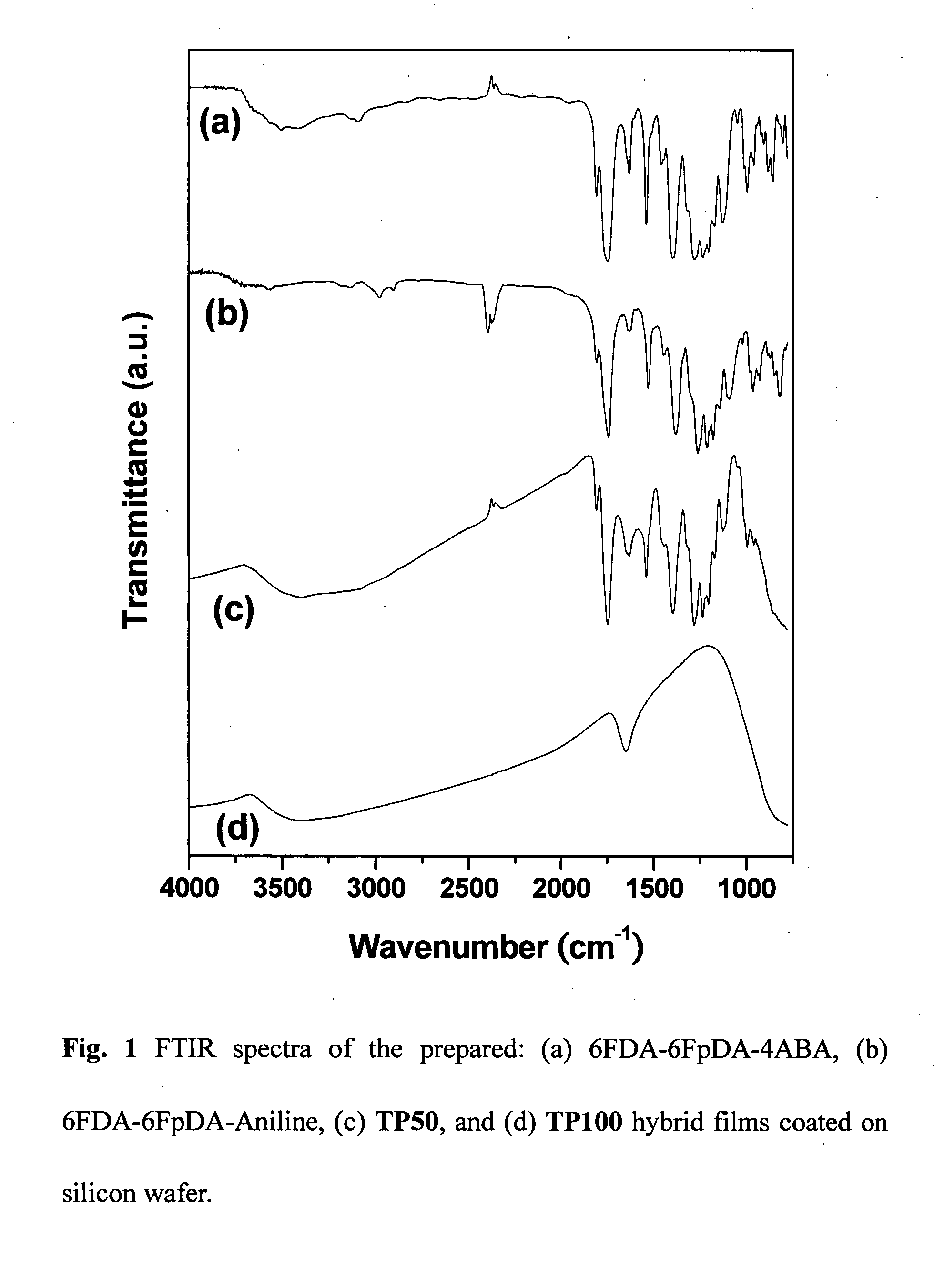

Polyimide-titania hybrid materials, their preparation, and film prepared from the materials

ActiveUS20090092759A1Good surface smoothnessImprove thermal performancePretreated surfacesCoatingsOptical transparencySide chain

The present invention relates to polyimide-titania hybrid thin film, which possesses relatively good surface planarization, excellent thermal properties (400<Td<550° C.), tunable refractive index (1.571<n<1.993), and highly optical transparency in the visible range. The present invention also relates to a method for preparing the polyimide-titania hybrid materials, which comprises producing a polyimide containing pendent and / or terminal carboxylic acid, coordinating the carboxylic acid with titanium of titanium alkoxide and sol-gel reacting of titanium alkoxide, to enhance the interaction between polyimide and titania and produce the polyimide-titania hybrid materials without macrophase separation. The present polyimide-titania hybrid materials are useful to produce the thin film having the above features.

Owner:NAT TAIWAN UNIV

Stereolithographic resins with high temperature and high impact resistance

InactiveUS6989225B2High modulusHigh elongation at breakAdditive manufacturing apparatusImpression capsMeth-Cationic polymerization

A liquid radiation-curable composition that comprises(A) at least one polymerizing organic substance comprising a mixture of(1) at least one alicyclic epoxide having at least two epoxy groups; and(2) at least one difunctional or higher functional glycidylether of a polyhydric compound;(B) at least one free-radical polymerizing organic substance comprising a mixture of(1) optionally, at least one trifunctional or higher functional (meth)acrylate compound; and(2) at least one aromatic di(meth)acrylate compound;(C) at least one cationic polymerization initiator;(D) at least one free-radical polymerization initiator;(E) optionally, at least one hydroxyl-functional aliphatic compound; and(F) at least one hydroxyl-functional aromatic compound;wherein the concentration of hydroxyl groups in the radiation-curable composition is at least about 1.1 equivalent OH groups per kilogram;wherein the concentration of epoxy groups in the radiation-curable composition is at least about 5.5 equivalent epoxy groups per kilogram; andwherein the amount of trifunctional or higher functional (meth)acrylate compound (B)(1) is from 0% to about 3% of the composition and the amount of aromatic di(meth)acrylate compound (B)(2) is at least 10% of the composition.

Owner:3D SYST INC

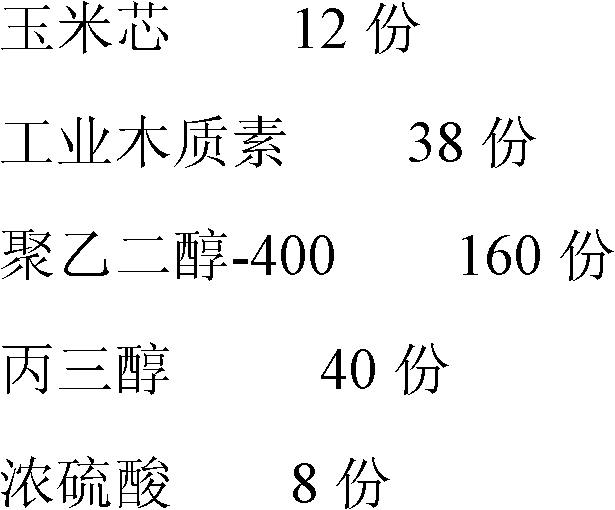

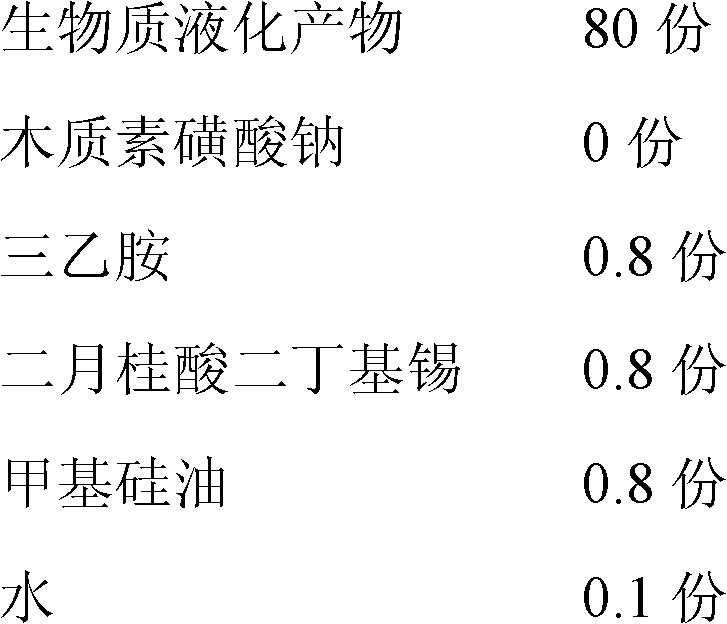

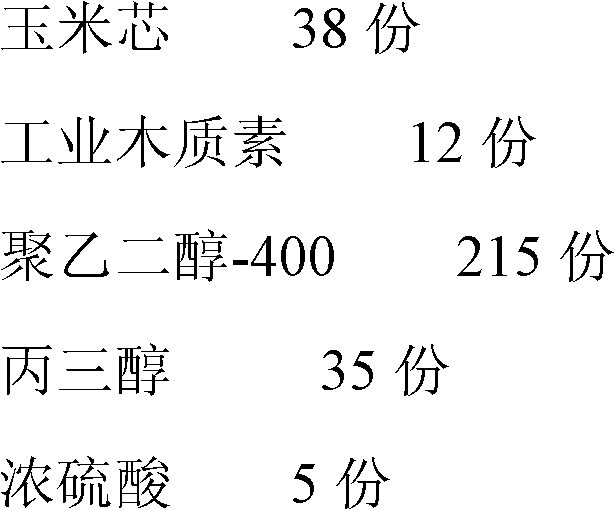

Preparation method of biomass-base polyurethane foam material

The invention discloses a preparation method of a biomass-base polyurethane foam material, belonging to the technical field of chemical industry. The method mainly comprises the following steps: mixing polybasic alcohol liquefier and liquefying catalyst, putting the mixture in a container, heating to 150-200 DEG C, adding biomass waste and industrial lignin, liquefying, and cooling to room temperature to obtain a biomass liquefied product; and mixing the prepared biomass liquefied product, foaming catalyst, foam stabilizer, foaming agent and lignosulphonate into a component A, using isocyanate as a component B, mixing the component A and component B in a mixing vessel, stirring at 20-40 DEG C at 8000-14000 rpm for 5-30 seconds, pouring the mixture into a die, naturally foaming for 5-60 seconds, standing at 80-120 DEG C for 8-24 hours, and storing at room temperature for 8-24 hours until the mixture is sufficiently aged and formed. The invention can obviously improve the properties of the biomass-base polyurethane foam.

Owner:CHINA AGRI UNIV

Conductive graphene printing ink and preparation method thereof

The invention provides a conductive graphene printing ink. The conductive graphene printing ink is composed of 0.001-80wt% of graphene, 1-60wt% of a linking material, 0.1-30wt% of an assistant, and the balance solvent. The invention also provides a preparation method of the conductive graphene printing ink. The conductive graphene printing ink has the advantages of good toughness, good die molding performance, good adhesion and good impact resistance; chemically doped graphene and chemically modified graphene in the graphene have good conductive, mechanical and thermal performances. The molecules of the chemically doped graphene comprise one or more of polyaniline, polyacetylene, polythiophene, polyparaphenylene and polypyrrole, and the functional groups of the chemically modified graphene comprise one or more of an anilino group, a pyrryl group, an imidazolyl group, a benzenesulfonic acid group, a thienyl group, a furyl group, a phenyl group, a hydroxy group, an ester group and derivative groups thereof, so the conductive performance, the mechanical performances and the dispersion stability of graphene in the printing ink are improved.

Owner:ZHUHAI LETONG NEW MATERIAL TECH CO LTD

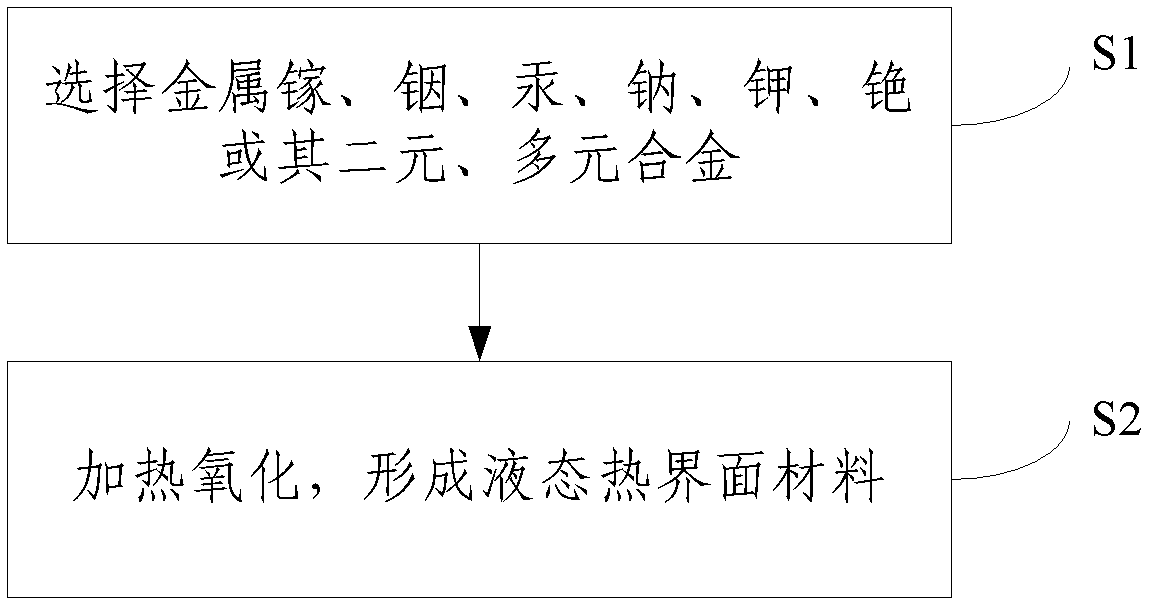

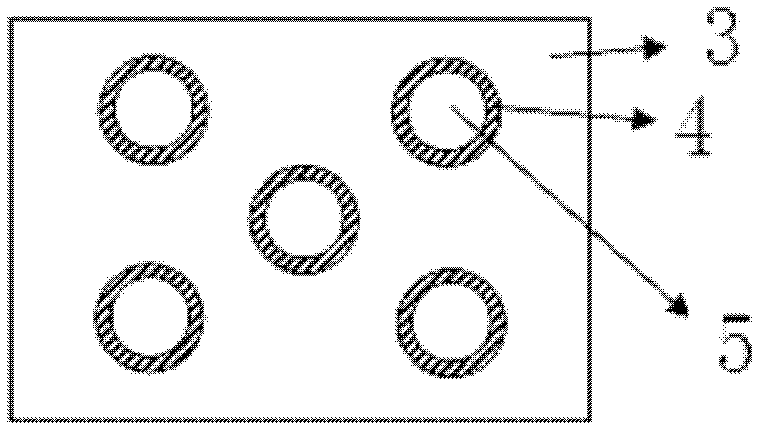

Thermal interface materials and manufacturing method thereof

The invention discloses thermal interface materials and a manufacturing method of the thermal interface materials. The interface materials are formed by means of heating and oxidization of metals such as gallium, indium, mercury, sodium, potassium, cesium or binary alloy and multicomponent alloy of the cesium. The manufacturing method comprises the following steps: selecting metals such as the gallium, the indium, the mercury, the sodium, the potassium, the cesium or the binary alloy and the multicomponent alloy of the cesium, and enabling the metals or the alloy to become liquid and enabling the liquid metals or the alloy to be placed in air or oxygen through heating. By means of placing the metals such as the gallium, the indium, the mercury, the sodium, the potassium, the cesium or the binary alloy and the multicomponent alloy of the cesium in the air and the oxygen to be oxidized to form the thermal interface materials, wettability between metal-based fluid and each interface can be greatly enhanced, thereby requirements of the thermal interface materials can be met. Due to the good thermal and wetting properties, the thermal interface materials can play significant roles in an aspect of electric chip thermal conductivity of the fields such as cryogenic engineering, boosters of computers, satellites and rockets and laser device.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

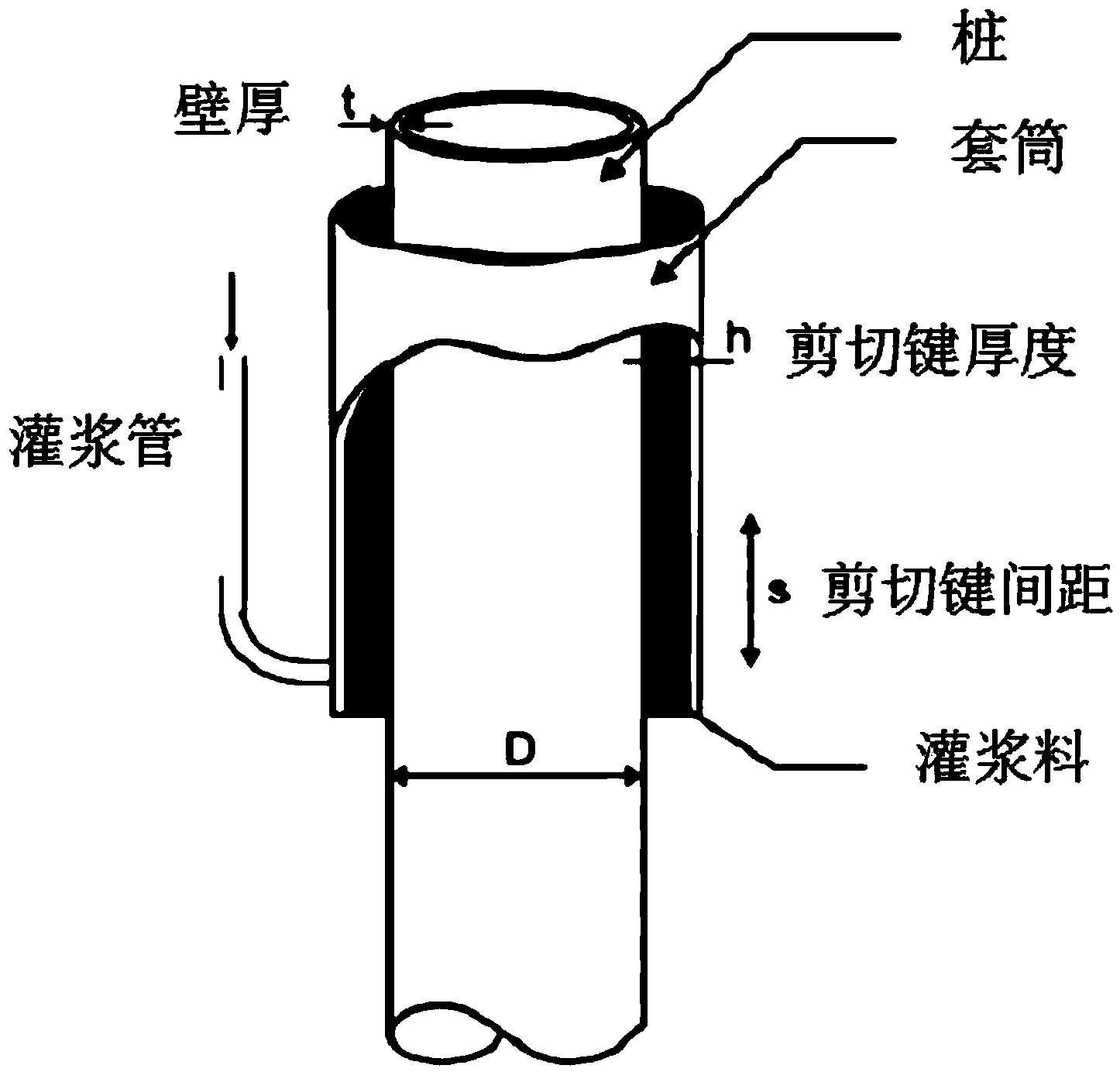

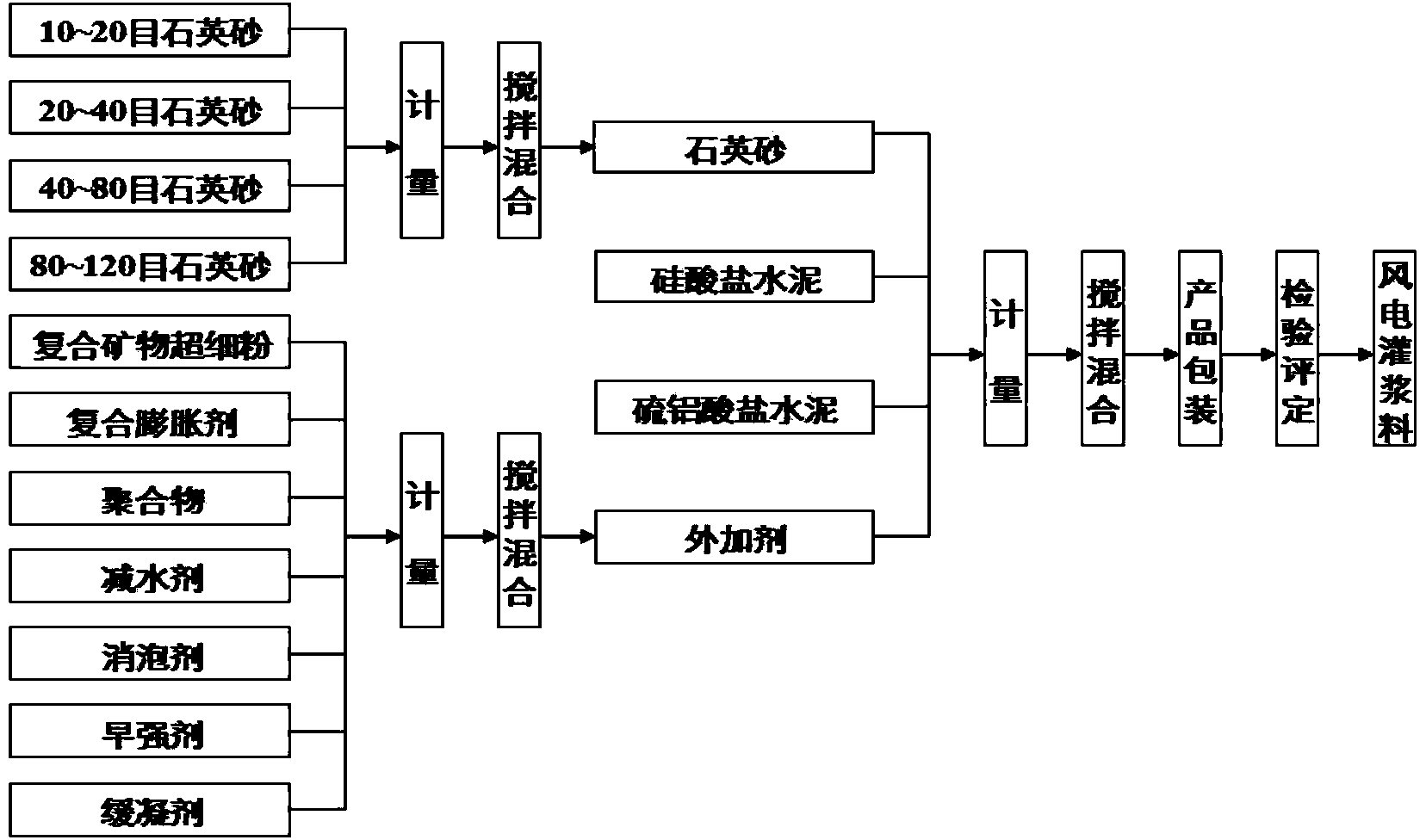

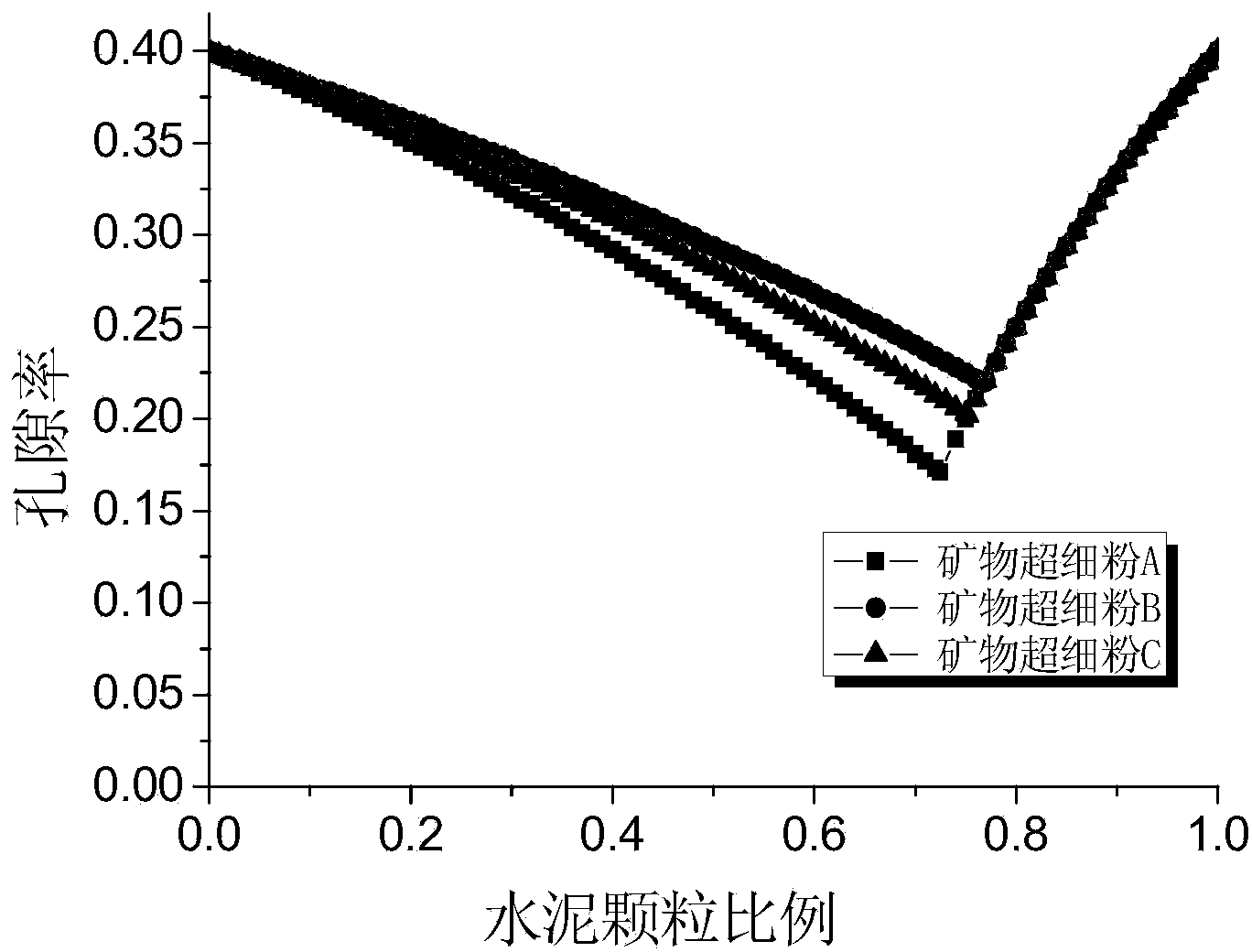

Offshore wind power duct rack grouting material and construction method thereof

ActiveCN104003681AMeet the index requirements for groutingImprove workabilityFoundation engineeringPortland cementOffshore wind power

The invention provides an offshore wind power duct rack grouting material which comprises a dry material and water, wherein the dry material comprises the following components in percentage by mass: 25.0-40.0 percent of Portland cement, 1.0-5.0 percent of sulphoaluminate cement, 45.0-55.0 percent of quartz sand and 5.0-15.0 percent of admixture; the addition amount of the water is proper. The invention further provides a construction method of the offshore wind power duct rack grouting material. According to the offshore wind power duct rack grouting material and the construction method thereof, the material has the characteristics of high liquidity, high pumpability, super-high early-strength, ultrahigh strength, high durability, good water dispersion resistance, zero shrinkage and high fatigue resistance, can be conveyed by a rubber pipeline by adopting a pumping and grouting construction mode, is suitable for underwater grouting and is also suitable for grouting connection between the offshore wind power duct rack and steel pipe pile foundation.

Owner:CCCC THIRD HARBOR ENG +2

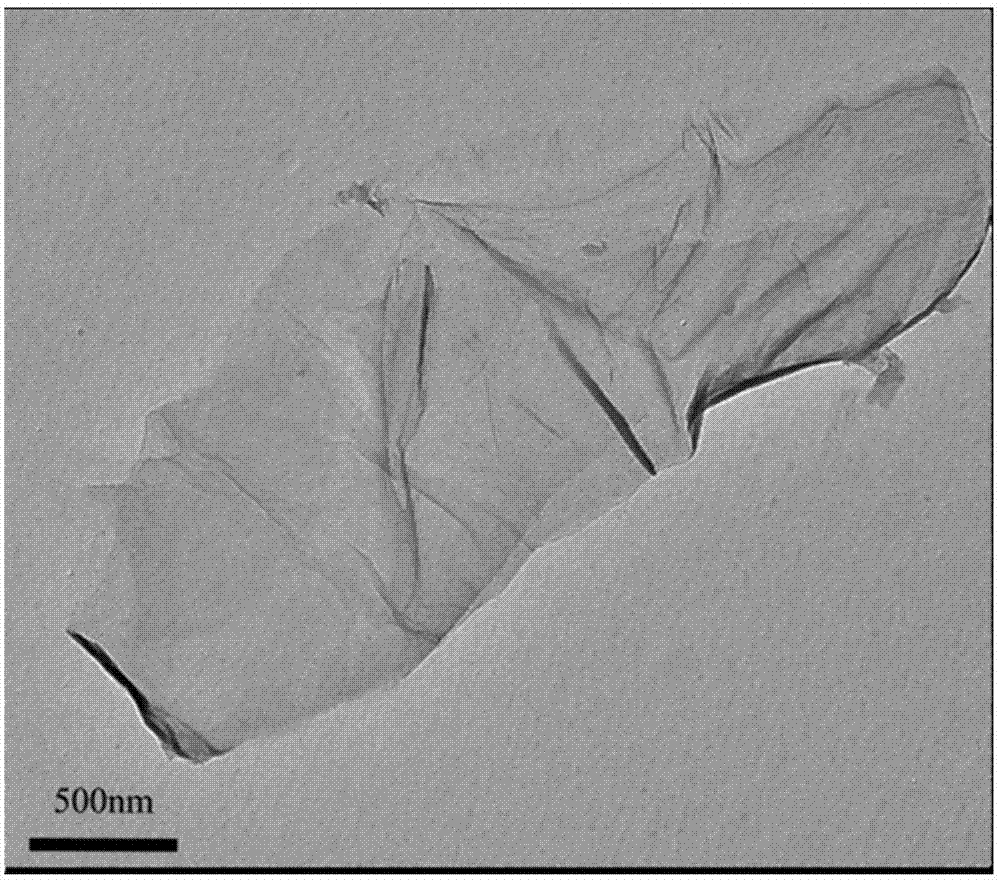

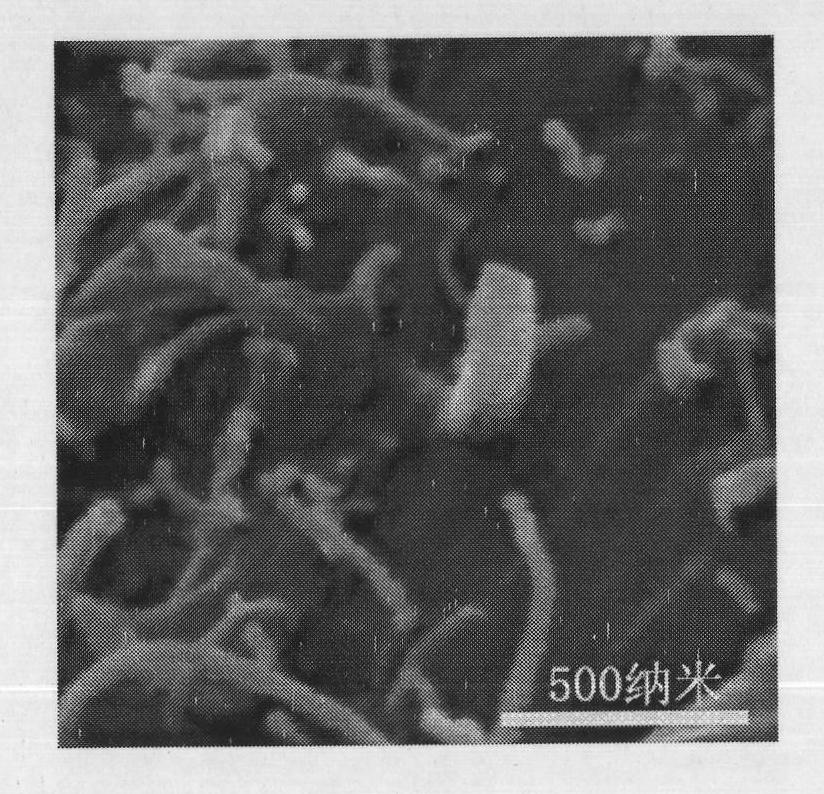

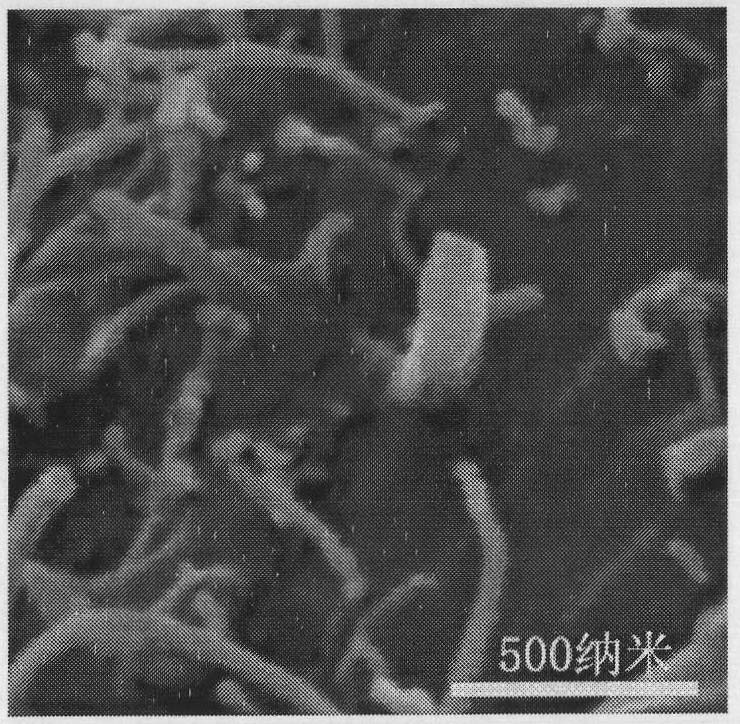

High-quality graphene dispersion method and film preparation method

ActiveCN103449420AHigh dispersible concentrationNo dispersant residueGrapheneHigh concentrationProtonation

The invention relates to the field of graphene, particularly a high-quality graphene dispersion method and a method for preparing a film from a corresponding graphene dispersion solution or slurry. Graphene powder or aggregation-state slurry is added into a micromolecule amine compound solution to carry out dispersion treatment, so that the three amine micromolecule compounds are utilized to implement dispersion of the graphene; and in the dispersion solution, the molecules of the compounds are combined with the graphene under the pai-pai interaction, the amino group protonation is utilized to electrically charge the graphene, and the electrostatic repulsion action is utilized to prevent aggregation, thereby implementing the stable dispersion of the graphene. The dispersion solution or slurry can be subjected to spray coating, roller coating, scratch coating or any other conventional coating preparation method to obtain a graphene film on the substrate surface. The method can implement high-concentration efficient dispersion on high-quality graphene with the carbon / oxygen atom ratio of greater than 20 in multiple solvents; and after the film is formed and dried, no solvent or dispersant residue exists.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

High flow misible polycarbonate polyester composition

A high flow miscible thermoplastic resin composition is disclosed which comprises structural units derived from substituted or unsubstituted polycarbonate and substituted or unsubstituted aliphatic polyester. Also disclosed is a high flow and miscible thermoplastic resin composition that comprises of structural units derived from substituted or unsubstituted polycarbonate and substituted or unsubstituted low molecular weight aliphatic polyester. In addition the composition disclosed possess good optical and thermal properties and good flow.

Owner:SABIC INNOVATIVE PLASTICS IP BV

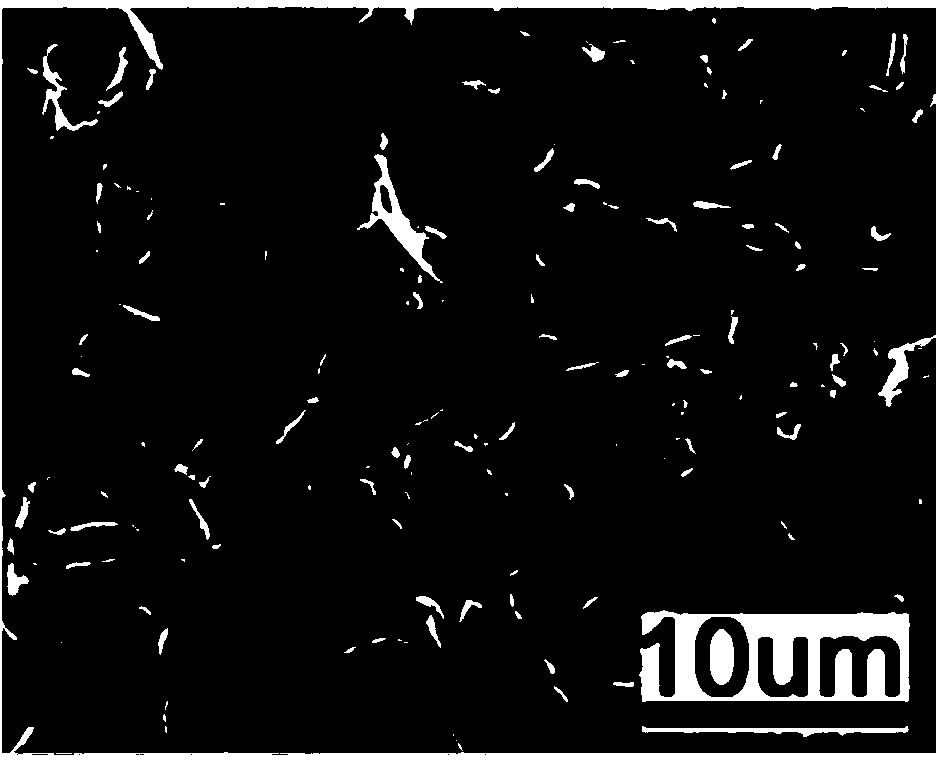

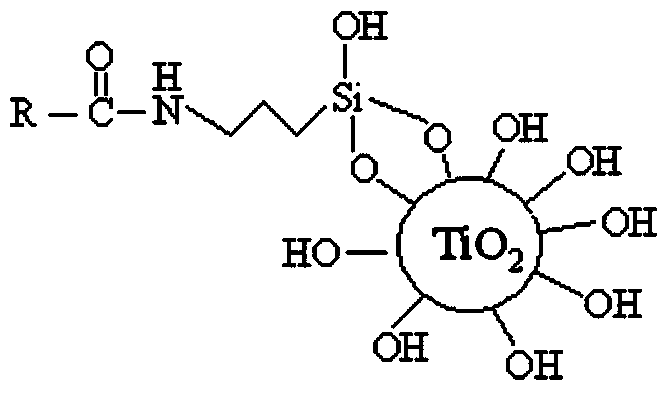

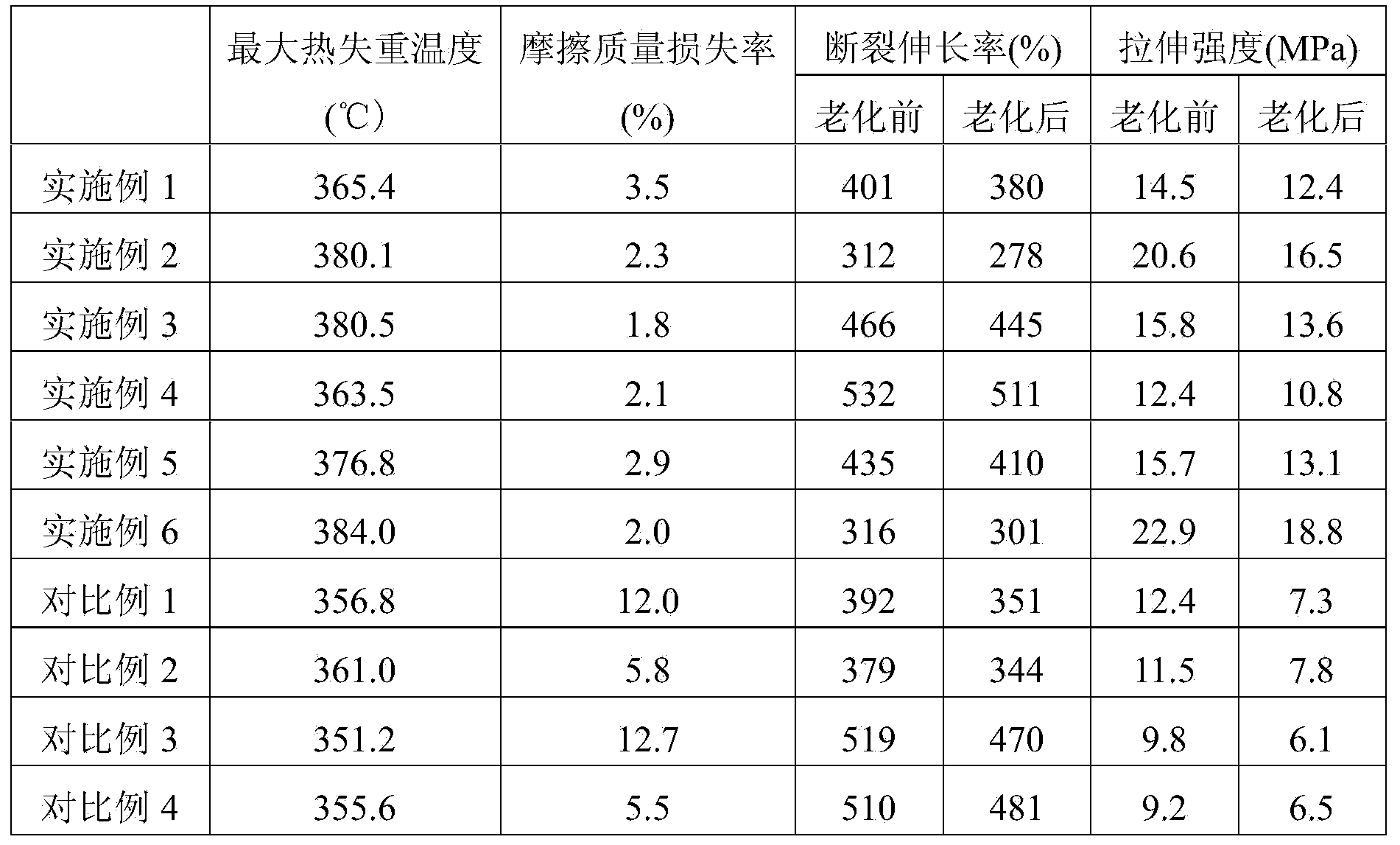

Water-based polyurethane paint containing polyether glycol/nano TiO2 hybrid material

ActiveCN104403548AGood thermal propertiesImprove mechanical propertiesPolyurea/polyurethane coatingsWater basedOrganometallic catalysis

The invention belongs to the technical field of water-based polyurethane paints, and discloses a water-based polyurethane paint containing a polyether glycol / nano TiO2 hybrid material, and a preparation method and application thereof. The paint comprises the following components in parts by mass: 25-75 parts of polyether glycol / nano titanium dioxide hybrid material, 15-65 parts of diisocyanate, 100 parts of polyether glycol, 8-16 parts of polyhydroxy-carboxylic acid, 0.05-0.5 part of organo-metallic catalyst, 0.5-10 parts of crosslinking agent, 6.2-12.4 parts of neutralizer, 1-8 parts of chain extender and 0.2-2.0 parts of defoaming agent. The paint enhances the compatibility between the nano titanium dioxide and polyurethane base, has the advantages of favorable thermal properties, favorable mechanical properties, favorable wear resistance and excellent ultraviolet resistance, and can be widely used in the fields of architectural paints, automobile paints, wood paints, electrodeposition paints, paper conditioning paints, glass fiber paints, electrophoretic paints and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Method for preparing anti-aging high-transparent polyurethane and graphene oxide composite microporous membrane material

ActiveCN102604137AImprove mechanical propertiesImprove wettabilityOxide compositeMicroporous membranes

The invention discloses a method for preparing an anti-aging high-transparent polyurethane and graphene oxide composite microporous membrane material. The method includes: preparing graphene oxide as filler, and uniformly mixing the graphene oxide into polyurethane emulsion by the aid of high dispersion wettability of flatting agent. Using the method can improve dispersibility and stability of the graphene oxide in the polyurethane emulsion, enhance the bonding force between the graphene oxide and an interface of a polyurethane matrix, and obtain the anti-aging high-transparent polyurethane and graphene oxide composite microporous membrane material. The method is simple and environment-friendly, the anti-aging performance and transparency of the composite microporous membrane material areevidently improved, and integral strength of the material is basically unaffected.

Owner:YANTAI UNIV

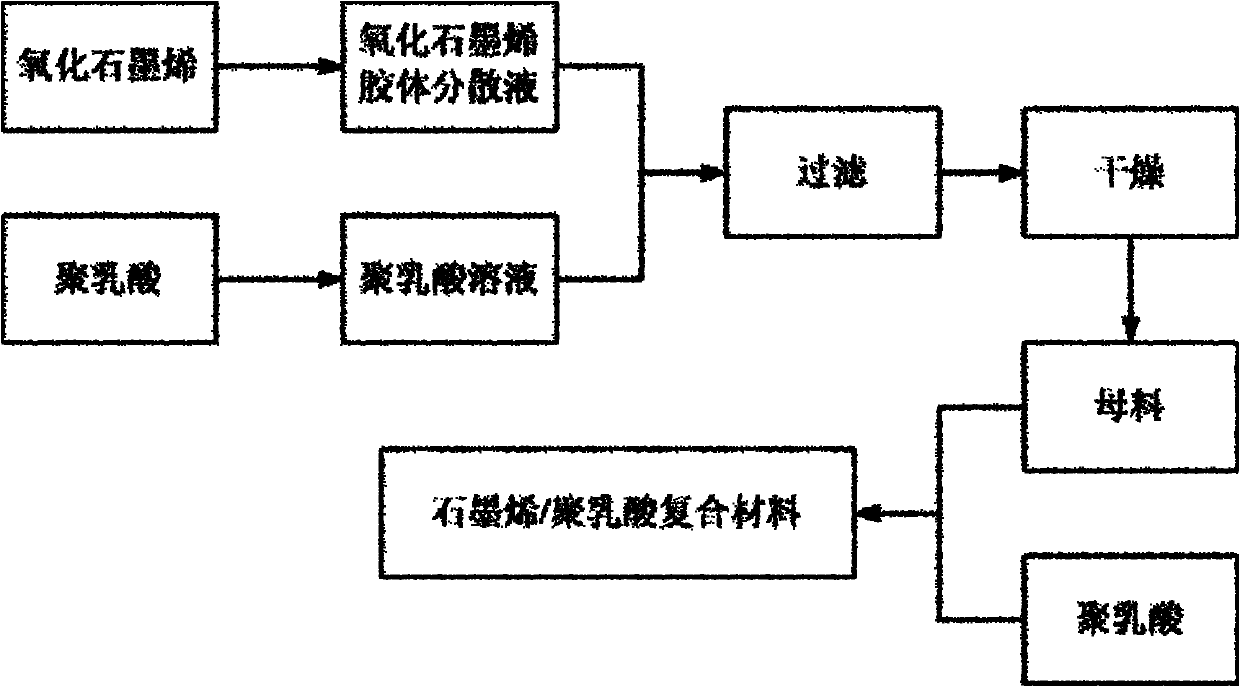

Graphene/polylactic acid composite material and preparation method thereof

ActiveCN102167894AGood mechanical propertiesGood electrical propertiesHeat deflection temperaturePolylactic acid

The invention provides a graphene / polylactic acid composite material, comprising the polylactic acid and graphene oxide, wherein the graphene oxide, by mass, accounts for 0.1% to 5% of the polylactic acid. The invention also provides a preparation method of the graphene / polylactic acid composite material,comprising the steps of: a) dispersing the graphene oxide in water for acquiring graphene oxide dispersion liquid; b) adding polylactic acid solution to the graphene oxide dispersion liquid under stirring condition, letting the uniformly stirred mixed solution stand for layering and filteringfor obtaining master batch; and c) blending the master batch with the polylactic acid for obtaining the graphene / polylactic acid composite material. Experiments show that the graphene / polylactic acidcomposite material provided in the invention has a tensile strength up to 79 MPa, a tensile elastic modulus up to 3100 MPa, a notch impact strength up to 12 KJ / m<2> and a heat deflection temperature up to 95 DEG C.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Norbornene polymer for photoresist and photoresist composition comprising the same

InactiveUS20060188806A1Improve mechanical propertiesGood thermal propertiesRadiation applicationsPhotosensitive material auxillary/base layersResistOrganic solvent

Disclosed herein is a photoresist composition which includes a norbomene copolymer having an epoxy group, an acid generator, and an organic solvent. The norbomene polymer shows superior mechanical and thermal properties, high transparency, excellent insulating properties, and particularly, improved mechanical properties due to the presence of an epoxy group. The photosensitive resin composition shows superior performance, e.g., transparence, developing properties, residual film characteristics, chemical resistance, heat resistance, and flatness. Particularly, since the photosensitive resin composition enables easy formation of a pattern as an interlayer insulating film and shows a high light transmittance even when being formed into a thin film with a relatively large thickness, it is suitable for the production of an interlayer insulating film used in the fabrication processes of LCDs.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for preparing silicon nitride ceramics through 3D printing

ActiveCN107586136AGood mechanical propertiesGood thermal propertiesAdditive manufacturing apparatusChemical industryCeramic

The invention provides a method for preparing silicon nitride ceramics through 3D printing. With the adoption of a 3D printing technology, silicon nitride ceramic parts of complicated shapes can be prepared, and a double-layer scraper molding technology in the printing process is utilized, so that beta phase silicon nitride is in oriented arrangement, and after degumming and sintering, the structured silicon nitride ceramics with complicated shapes can be obtained. The prepared silicon nitride parts have excellent reliability, mechanical properties, thermal properties, wear resistance and thelike. The invention provides a novel preparation method, and the molding problem of the silicon nitride ceramics is solved. Moreover, the material performance is improved, and the cost is reduced. According to the preparation method provided by the invention, application of the silicon nitride ceramics in the fields of medical treatment, chemical industry, electronics, aerospace and the like can be promoted.

Owner:GUANGDONG UNIV OF TECH

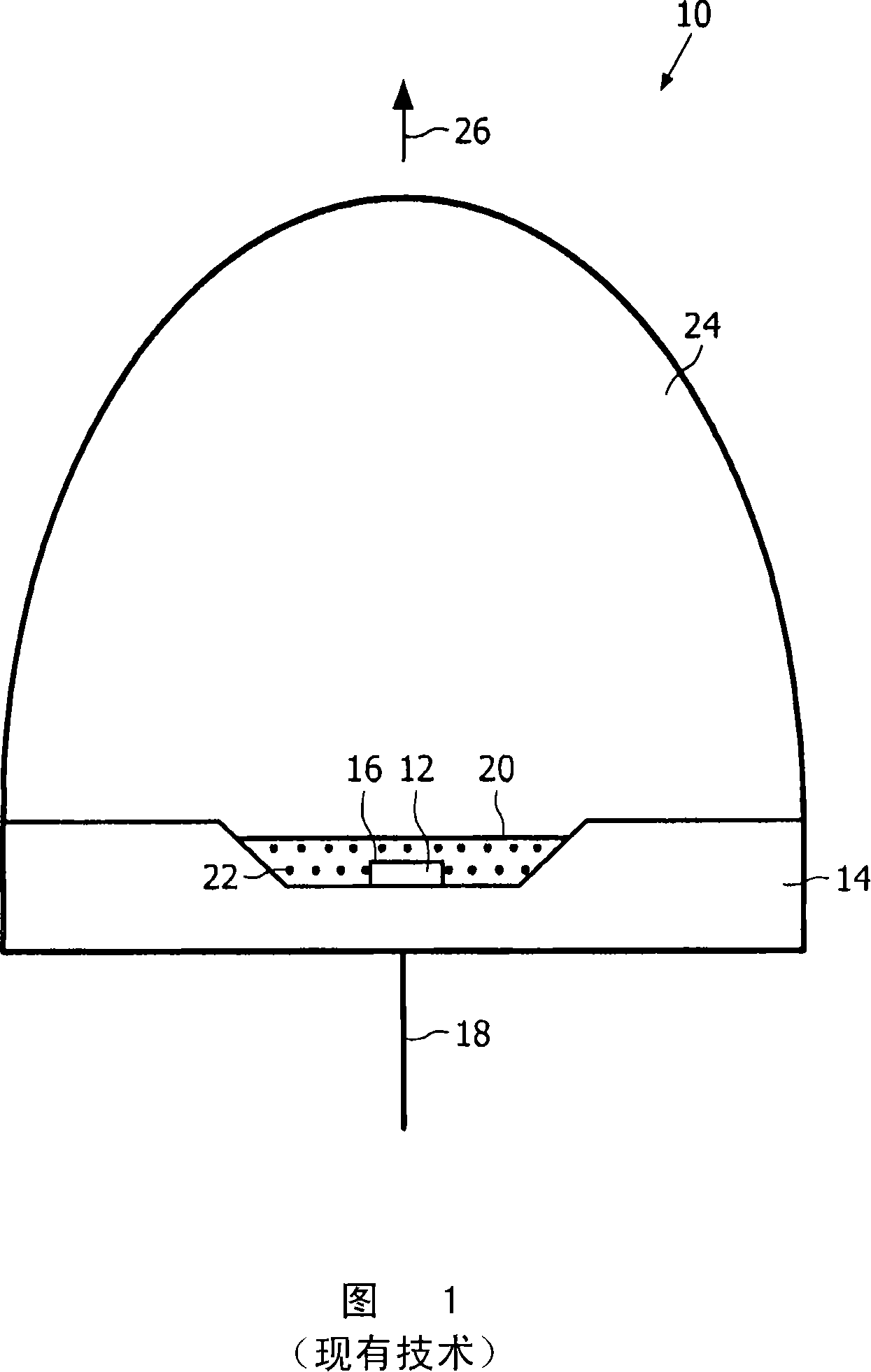

Phosphor in polycrystalline ceramic structure and a light-emitting element comprising same

ActiveCN101142857AReduce the temperatureGood thermal propertiesElectroluminescent light sourcesLuminescent compositionsPorosityCeramic composite

The invention relates to a phosphor in a polycrystalline ceramic structure and a light-emitting element provided with the same comprising a Light-Emitting Diode (LED) in which a composite structure of phosphor particles is embedded in a matrix, characterized in that the matrix is a ceramic composite structure comprising a polycrystalline ceramic alumina material, hereafter called luminescent ceramic matrix composite. This luminescent ceramic matrix composite can be made by the steps of converting a powder mixture of ceramic phosphor particles and alumina particles into a slurry, shaping the slurry into a compact, and applying a thermal treatment, optionally in combination with hot isostatic pressing into a polycrystalline phosphor-containing ceramic alumina composite structure. The luminescent ceramic matrix composite further allows a method of tuning the light-diffusing properties by changing at least one of the fractions of phosphor particles and second ceramic particles, the grain size of the particles of the ceramic composite structure, the difference in the refractive index of the particles of the ceramic composite structure, and the porosity in the polycrystalline phosphor-containing ceramic composite structure.

Owner:LUMILEDS HLDG BV

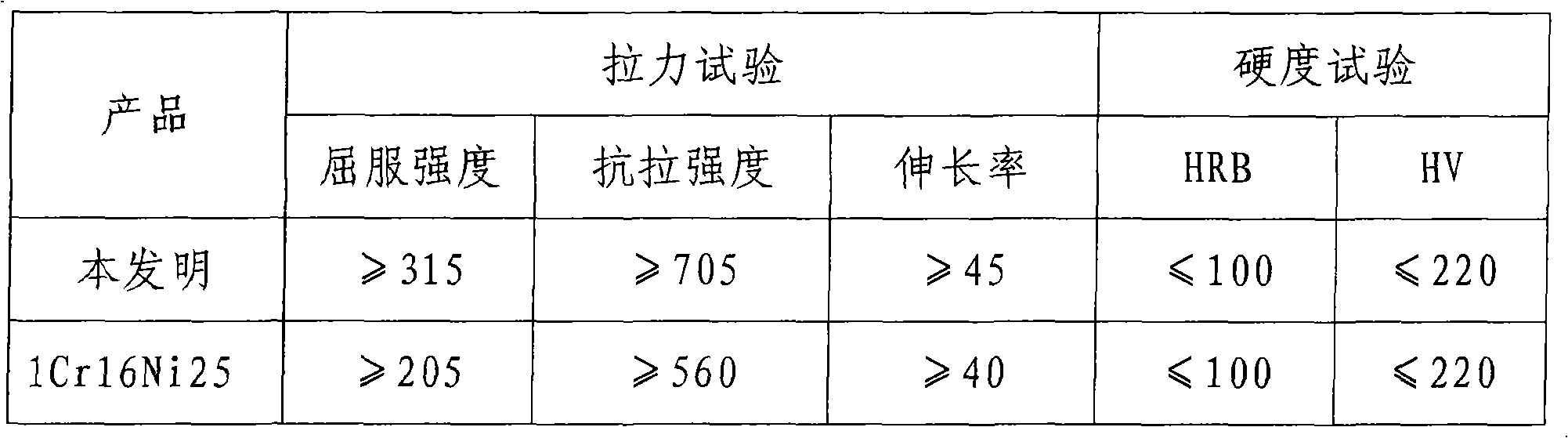

Ultra high-temperature resistant nickel-chrome alloy and manufacturing method thereof

InactiveCN101684530AImprove high temperature resistanceImprove oxidation resistanceNickelHeat processing

The invention provides an ultra high-temperature resistant nickel-chrome alloy and a manufacturing method thereof, wherein the ultra high-temperature resistant nickel-chrome alloy has a higher meltingpoint, can resist the high temperature higher than 1300 DEG C for a long time and has better tensile strength and yield strength simultaneously. The ultra high-temperature resistant nickel-chrome alloy basically comprises the following components in percentage by weight: 21-25 of Cr, 58-63 of Ni, Al which is not less than 1 and not more than 1.7, Cu which is not less than 0.5 and not more than 1.0, C which is not less than 1 and more than 0.1, Si which is not less than 0.5 and more than 0, Mn which is larger than 0 and not more than 1.0, S which is larger than 0 and less 0.015, and the balance of Fe. The manufacturing method comprises the following steps: mixing the materials according to the alloy components and then smelting; carrying out secondary refining; first heating the mixture to900-1200 DEG C, keeping the temperature for 10-40 minutes, and then forging; cold processing; and water cooling. The invention improves the high-temperature resistant performance, the tensile strength and the yield strength of the alloy, and has better comprehensive benefit. The manufacturing method solves the problems of alloy smelting and heat processing, and improves the product purity.

Owner:杭正奎

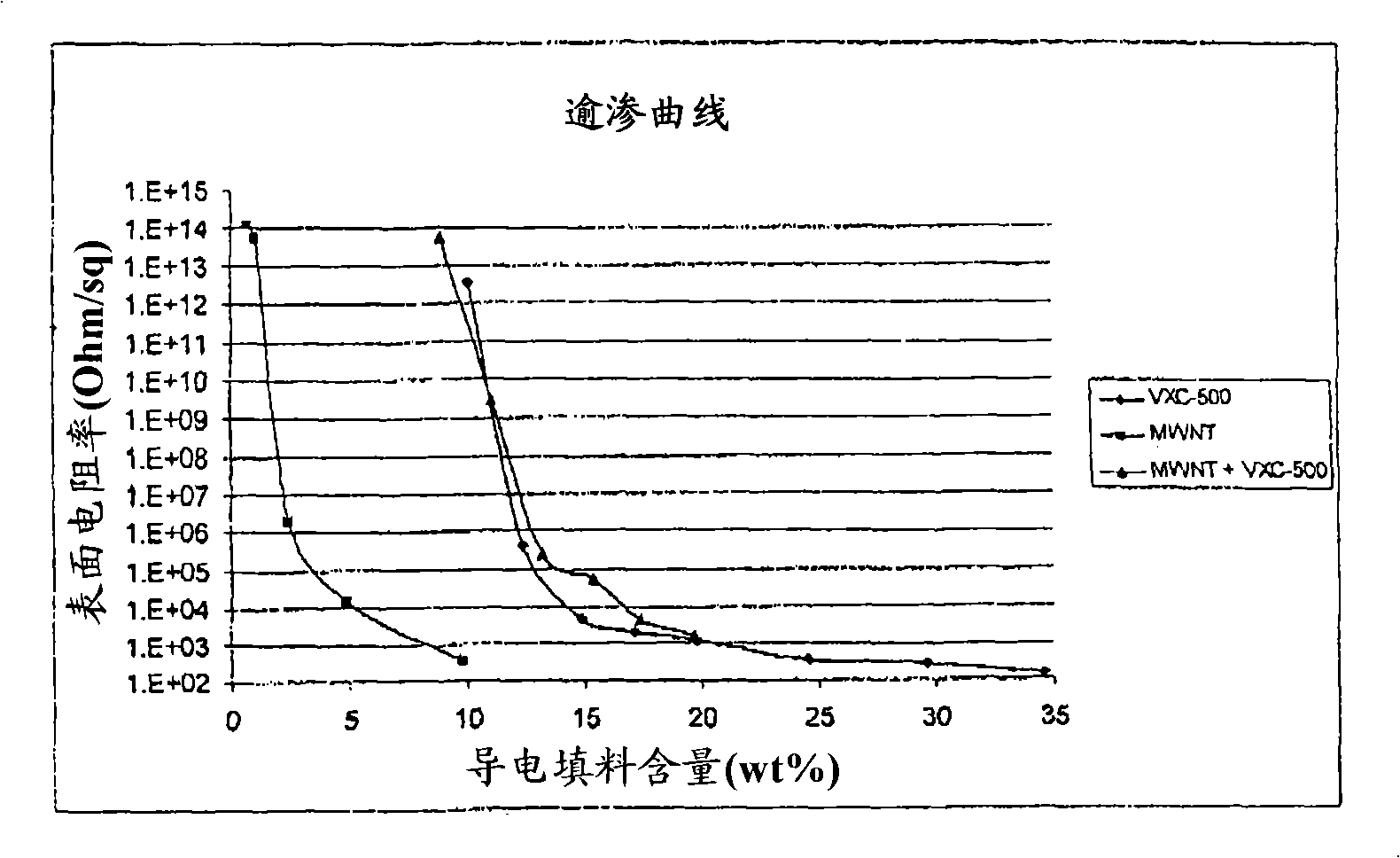

Polymeric compositions containing nanotubes

InactiveCN101283027AHigh conductivity rangeImprove smoothnessMaterial nanotechnologyNon-conductive material with dispersed conductive materialPolymer sciencePolymer chemistry

A polymeric composition containing at least one polymer and carbon nanotubes is described. The polymeric composition can have carbon nanotubes that are multi-wall carbon nanotubes and / or single-wall carbon nanotubes. The compositions can also contain carbon black. Also described are various articles made from the polymeric compositions including cables and other articles.

Owner:CABOT CORP

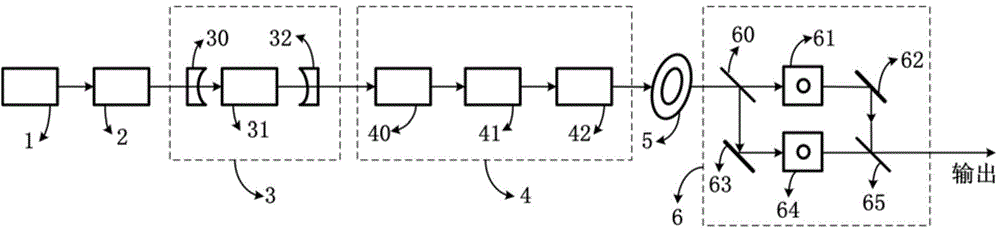

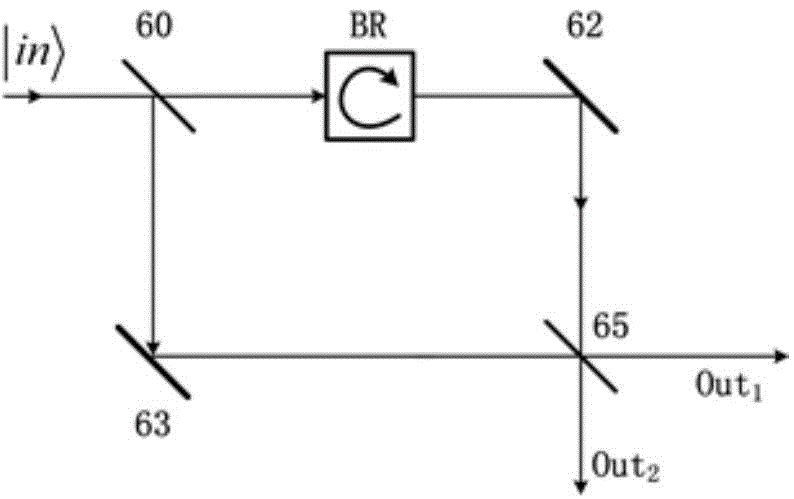

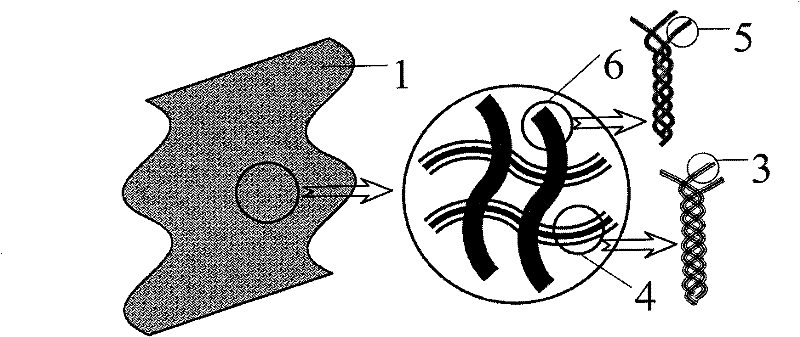

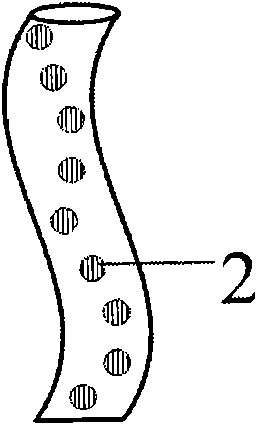

Production system and method for polarization-orbital angular momentum mixed entangled state single photon

ActiveCN104466655ASimple structureEasy to useLaser detailsCoupling light guidesResonant cavityMomentum

The invention discloses a production system and method for a polarization-orbital angular momentum mixed entangled state single photon. The system comprises an LD pumping source, an optical coupling system, a laser resonant cavity, a light beam regulating unit, a Q-plate converter and a purification unit, all of which are connected in sequence. The LD pumping source is used for producing pumping light and providing an input signal for the system. The optical coupling system is used for carrying out collimation and focusing on the pumping light. The laser resonant cavity is used for providing feedback energy, and the direction and frequency of the pumping light are selected. The light beam regulating unit is used for regulating the pumping light and outputting a horizontal polarization single photon. The Q-plate converter is used for converting the horizontal polarization single photon into the polarization-orbital angular momentum mixed entangled state single photon. The purification unit is used for carrying out purification on the polarization-orbital angular momentum mixed entangled state single photon. The high-purity polarization-orbital angular momentum mixed entangled state single photon can be stably produced, and the system structure and the production process are simple.

Owner:GUANGDONG INCUBATOR TECH DEV CO LTD

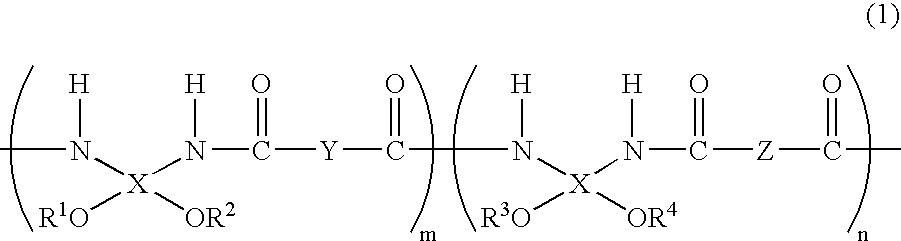

Polyimide and coating composition formed thereby

The present invention relates to a polyimide and a coating composition formed thereby, wherein the polyimide is represented by a formula (1), two ends of the polyimide respectively have two -COOH capping groups. The coating composition of the present invention comprises the polyimide and a hardener having two to six functional groups which can be reacted with the -COOH. A polyimide coating and a polyimide film formed by the coating composition of the present invention have excellent solution resistance and coefficient of thermal expansion (CTE), and can be applied to active (passive) assembly, optical materials, touch panels, copper clad laminates, flexible electronic materials, or protection materials of integrated circuit modules, or thin film base materials of glass thin film touch panels.

Owner:ETERNAL MATERIALS CO LTD

Polyamide-imide copolymer film and method of preparing polyamide-imide copolymer

ActiveUS20140243482A1Improve mechanical propertiesExcellent optical propertiesNon-linear opticsPolymer sciencePolyamide-imide

Disclosed herein is a polyamide-imide copolymer film, comprising a copolymer resin in which a unit structure derived from TFDB (2,2′-bistrifluoromethyl-4,4′-biphenyl diamine), a unit structure derived from 6FDA (4,4′-(hexa-fluoroisopropylidene)diphthalic anhydride), a unit structure derived from BPDA (3,3′,4,4′-biphenyltetracarboxylic dianhydride) and a unit structure derived from TPC (terephthaloyl chloride or 1,4-benzenedicarbonyl chloride) are copolymerized, wherein the copolymer resin has a weight average molecular weight of 10,000˜400,000.

Owner:KOLON IND INC

A composite fabric containing liquid metal

ActiveCN102296405AQuick exportImprove thermal conductivityFibre treatmentWoven fabricsTextile fiberYarn

The invention relates to a compound-type fabric containing liquid metal. The fabric can be completely woven by blended fiber yarn of a liquid-metal-containing fiber, and can also be woven by mixing a natural fiber yarn and blended fiber yarn of the liquid-metal-containing fiber, wherein the liquid-metal-containing fiber is a textile fiber the surface of which is adhered with liquid metal nanoparticles, a tubular textile fiber the pipe of which is filled with liquid metal, or a reticular casing-pipe-type textile fiber which is woven by nanowires and the reticular casing pipe of which is filledwith liquid metal; and the liquid metal is gallium metal, gallium-based alloy, Na-K alloy or wood metal containing indium. The compound-type fabric can be made into a single layer, two layers or three layers according to requirements, can be used as a basic fabric for manufacturing articles such as clothes, trousers, shoes and hats, gloves, stockings, bedclothes and pillowcases and the like, can endow clothing and household articles with temperature adjusting, radiation proofing, electrostatic resisting and sterilizing and antimicrobial functions, has stable performance and high reliability, needs not to be added with other organic components, and can be used for making up the defect of the property singleness of the traditional fabric.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

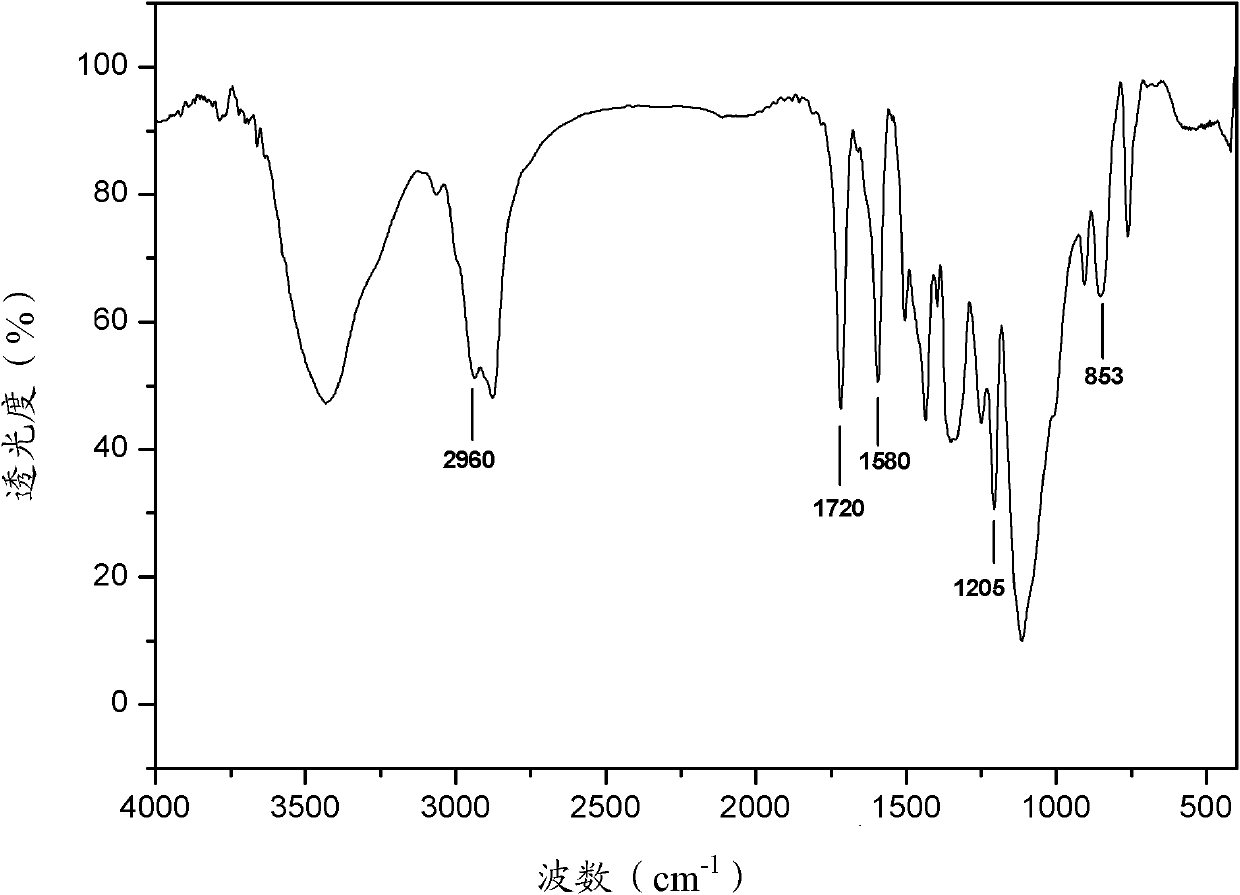

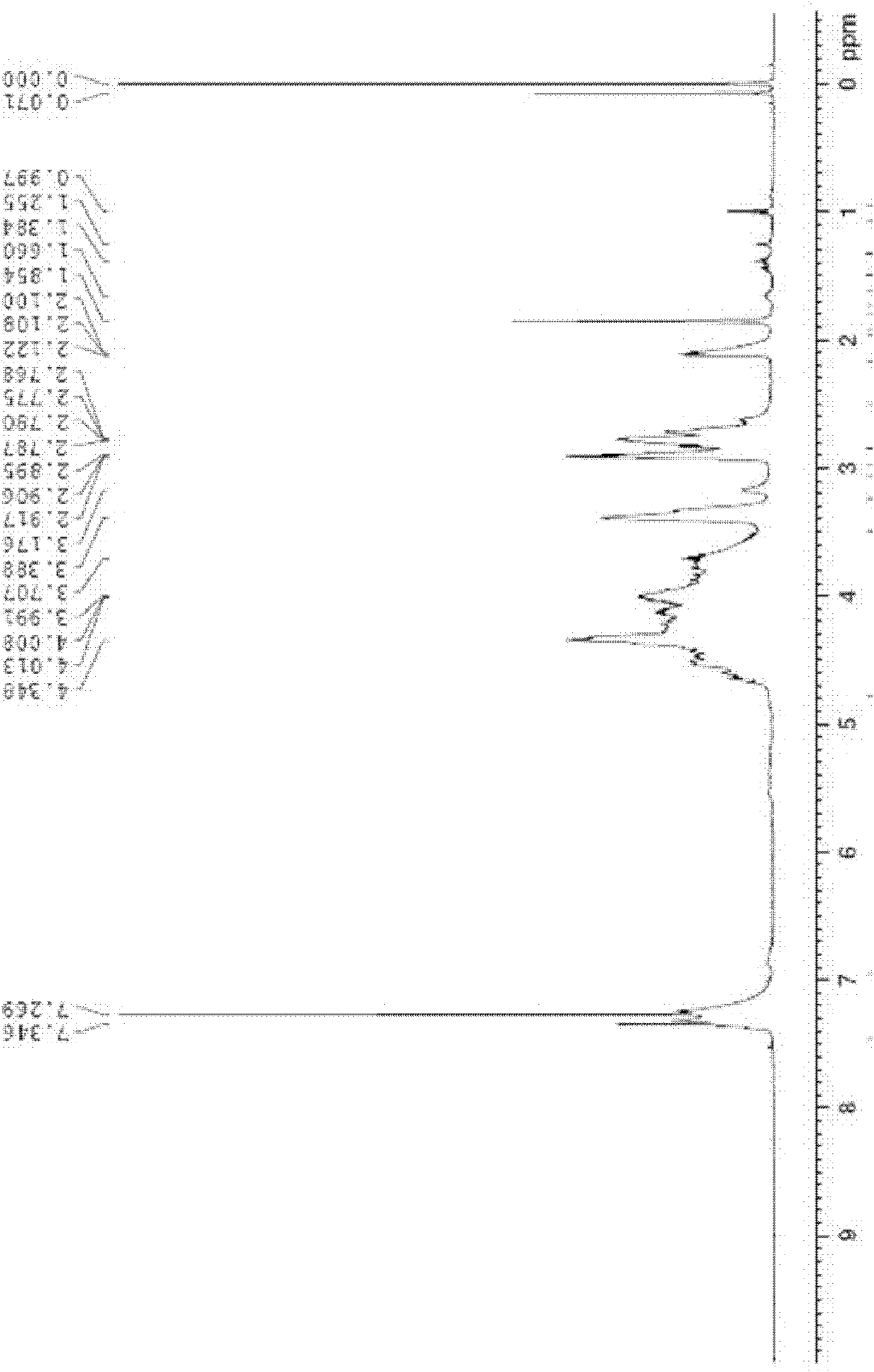

Method for carrying out graft modification on graphene by virtue of styrene-maleic anhydride copolymer

The invention discloses a method for carrying out graft modification on graphene by virtue of a styrene-maleic anhydride copolymer. The method comprises the following steps: taking graphite powder as a raw material, preparing graphene oxide (GO) by utilizing an improved Hummers' process, then grafting maleic anhydride to the GO by adopting a monomer grafting way, then taking a free radical initiator, styrene and maleic anhydride as functional modification reagents, carrying out in situ polymerization, solvent washing and centrifugal separation, and drying, so that styrene-maleic anhydride copolymer grafted graphene oxide is obtained. Grafting ratio of the obtained SMAFG is 20-50%. The styrene-maleic anhydride copolymer grafted graphene oxide can be well dispersed and form stable chemical bonding in a process of preparing a styrene-maleic anhydride copolymer grafted graphene oxide / polymer matrix composite material with the polymer matrix and has the effect of better improving mechanical and thermal properties of a polymer.

Owner:TIANJIN POLYTECHNIC UNIV

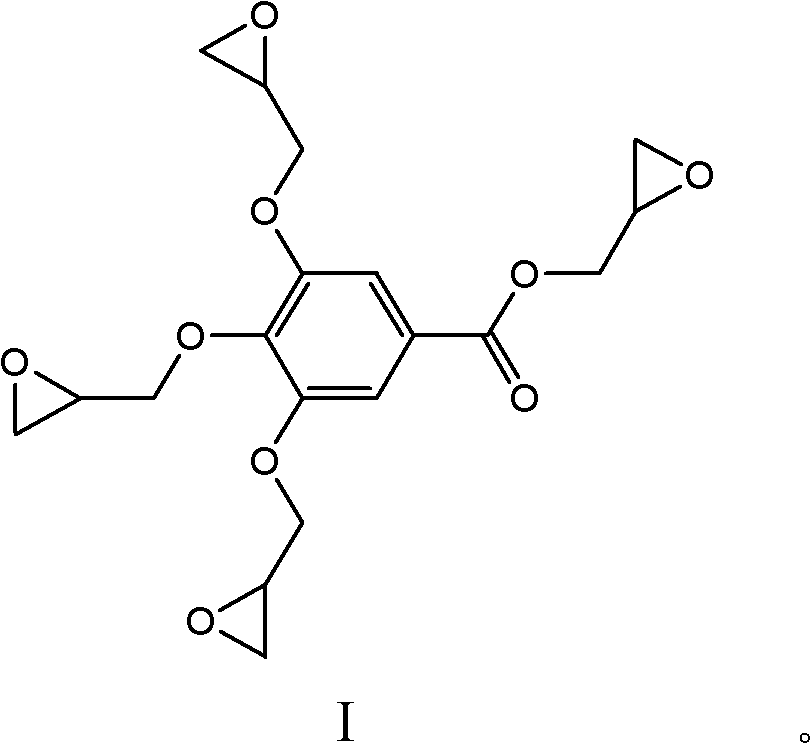

A kind of epoxy resin based on gallic acid and its preparation method and application

ActiveCN102276788AHigh epoxy valueIncrease crosslink densityEpoxy resin adhesivesEpoxy resin coatingsPolymer scienceGallic acid ester

The invention discloses an epoxy resin based on gallic acids with a structure shown as the formula I, which has high epoxy values and also has higher crosslinking density after being cured, thus having good mechanical property and thermal property. The invention also discloses a preparation method of the epoxy resin based on the gallic acids, comprising the following steps: mixing the gallic acids, epoxy halogenopropane and a catalyst and reacting for 2-5 hours at the temperature of 100-120 DEG C; cooling to 20-40 DEG C; adding alkaline compounds and water and continuing to react for 2-5 hours; and washing, removing a solvent and drying to obtain the epoxy resin based on the gallic acids. The preparation method is simple in process, good in controllability and easy to implement industrially. The invention also provides an application of the epoxy resin based on the gallic acids. The epoxy resin based on the gallic acids is particularly applied to preparing composite materials, epoxy adhesives and coatings.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

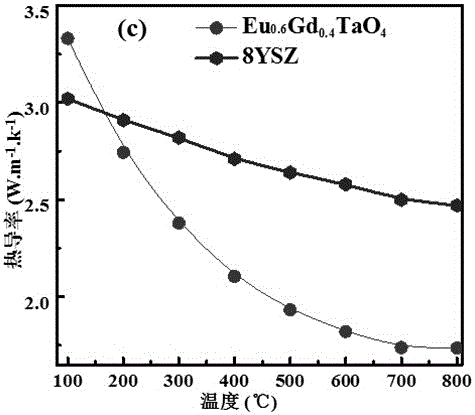

Preparation method of double-rare-earth-ion tantalite high-temperature ceramic

The invention relates to a preparation method of double-rare-earth-ion tantalite high-temperature ceramic and belongs to the technical field of high-temperature ceramic preparation. The molecular formula of the double-rare-earth-ion tantalite high-temperature ceramic is shown in the description (REa / REb = Y, La, Nd, Sm, Eu, Gd, Dy, Er and Yb, and REa and REb are not the same type of rare earth elements). The used raw materials are rare earth oxide and tantalum oxide andare weighed in proportion, the weighed raw materials and absolute ethyl alcohol are put in a ball milling tank for mixing and sealing, then the mixture is put on a planetary ball mill for ball milling, the mixture can be evenly mixed, and primary sintering is performed after the mixed powder is dried and screened; the cooled and taken-out sample is grinded, ball-milled, dried and screened and then is put in a mold for compaction, and then secondary sintering is performed. The preparation method is high in purity, low in impurity content, low in product device cost and suitable for batch production, and the product is expected to be a novel ceramic material resistant tohigh temperature, oxidation and abrasion.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method for nanometer TiO2 modified composite phase change microcapsule

ActiveCN105056854AHigh phase change enthalpyConstant phase transition temperatureMicroballoon preparationMicrocapsule preparationAlkaneCross-link

The invention discloses a preparation method for a nanometer TiO2 modified composite phase change microcapsule. The preparation method comprises the following steps: preparing a core material from n-alkane and alkyl stearate, preparing a wall material from methyl methacrylate, butyl acrylate, ethyl acrylate, a cross-linking agent and nanometer TiO2 and mixing the core material with the wall material so as to obtain an oil phase A; dissolving a reactive emulsifier in deionized water so as to prepare a water phase B; adding the oil phase A into the water phase B and carrying out ultrasonic dispersion so as to form an O / W pre-emulsion; heating the O / W pre-emulsion and adding an initiator into the O / W pre-emulsion so as to prepare a nanometer TiO2 modified composite phase change microcapsule emulsion; and subjecting the nanometer TiO2 modified composite phase change microcapsule emulsion to standing and carrying out filtering, washing and drying so as to obtain the nanometer TiO2 modified composite phase change microcapsule. According to the preparation method, under the condition of usage of reactive emulsifier, nanometer TiO2 is used to modify the wall material, so the phase change microcapsule with a small and uniform size is prepared.

Owner:SHAANXI UNIV OF SCI & TECH

Material for an insulating film, coating varnish for an insulating film, and insulating film and semiconductor device using the same

InactiveUS7049371B2Good electrical propertiesGood thermal propertiesPlastic/resin/waxes insulatorsSemiconductor/solid-state device manufacturingPolymer scienceOligomer

A material for an insulating film which comprises a copolymer obtained by reacting a polyamide having a specific structure and a reactive oligomer as a component forming the film; a coating varnish for an insulating film which comprises this material and an organic solvent; an insulating film which comprises a layer of a resin comprising as a main structure a polybenzoxazole which is obtained by treating the above material or the above coating varnish by heating so that condensation reaction and crosslinking reaction take place and has fine pores; and a semiconductor device which comprises an insulating interlayer film for multi-layer wiring comprising the insulating film and / or a surface protective film comprising the insulating film. Excellent electrical, thermal and mechanical properties are exhibited and a low permittivity can be achieved.

Owner:SUMITOMO BAKELITE CO LTD

Carbon nano tube/epoxide resin composite material and preparation method thereof

The invention discloses a carbon nano tube / epoxide resin composite material and a preparation method thereof. The preparation method is as follows: weighing certain amount of eposide resin, putting the eposide resin into a flask; adding plasma-grafted and activated carbon nano tube; after water bath and ultrasonic treatments, stirring the mixture under high speed of 600-1000rpm, and removing the babbles under vacuum condition; at the same time heating to 100 DEG C and then adding 4,4-diaminodiphenyl methane which serves as curing agent; stirring under high speed of 600-1000rpm until the mixture is even; pouring the mixture into a silicone rubber mold to be cured; and finally cooling to room temperature along with the furnace. In this way, the carbon nano tube / epoxide resin composite material can be prepared. The invention realizes even dispersion of the carbon nano tube in the matrix of epoxide resin, the amino-group at the chain terminal of the functional carbon nano tube participates in the curing reaction of the epoxide resin and greatly enhances the interface interaction between the carbon nano tube and the matrix, and the composite material prepared through the method has high strength and high heat resistance.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Photosensitive Resin Composition and Organic Insulating Film Produced Using the Same

InactiveUS20080145783A1Improve mechanical propertiesGood thermal propertiesPhotosensitive materialsPhotosensitive materials for photomechanical apparatusSolventStructural unit

A photosensitive resin composition is provided. The composition includes an acrylic copolymer, a photoacid generator and a solvent. The acrylic copolymer includes structural units of Formulae 1, 2, 3 and 4, which are described in the specification. The composition exhibits excellent performance characteristics in terms of mechanical and thermal properties, transmittance, insulating properties, transparency, developability, residual film ratio, heat resistance, flatness and the like. Particularly, the use of the composition facilitates the formation of a pattern as an interlayer insulating film. The composition can also be used to produce a thick film with high transmittance. Therefore, the composition is effectively used as a material for an interlayer insulating layer in LCD fabrication processes. An organic insulating film produced using the composition is also provided.

Owner:CHEIL IND INC

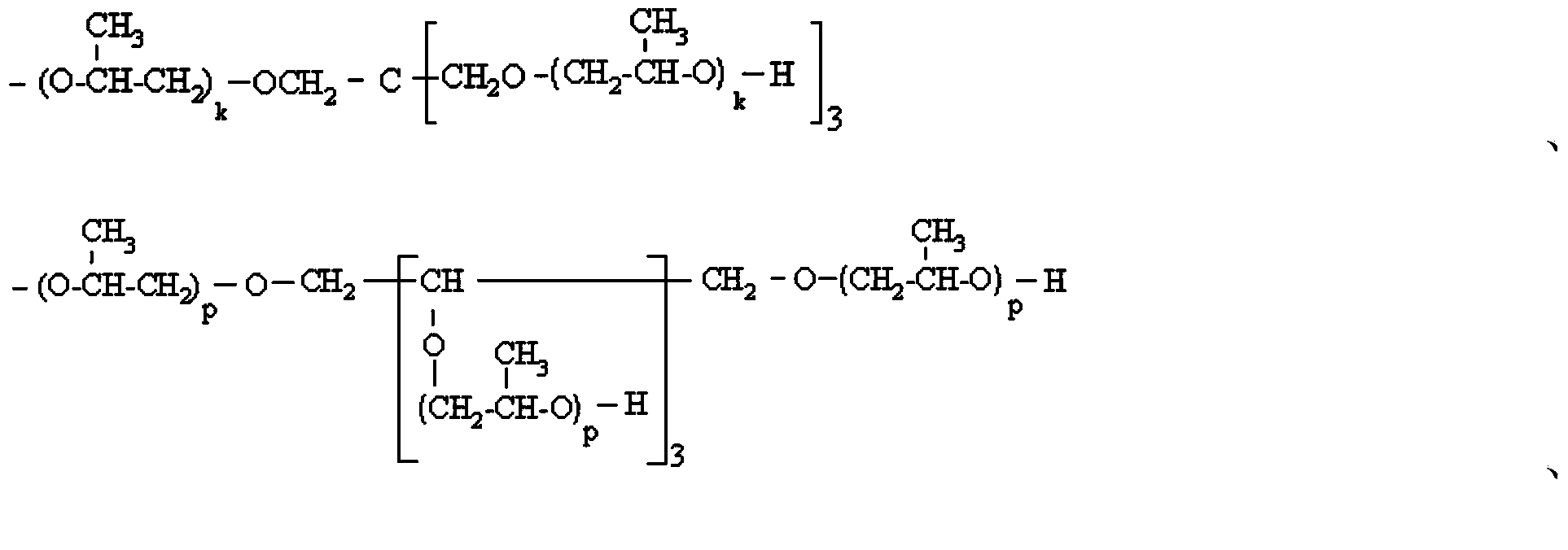

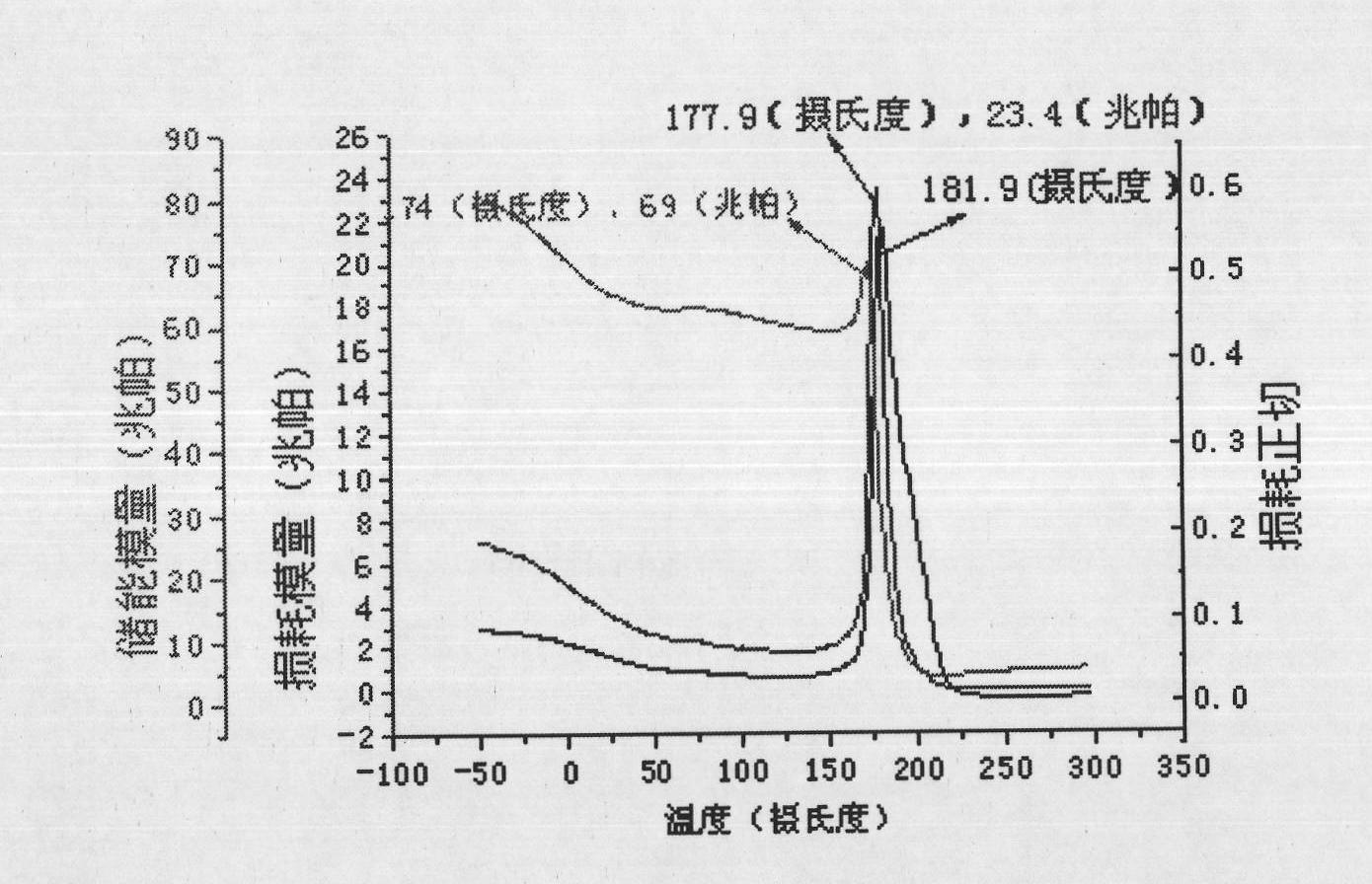

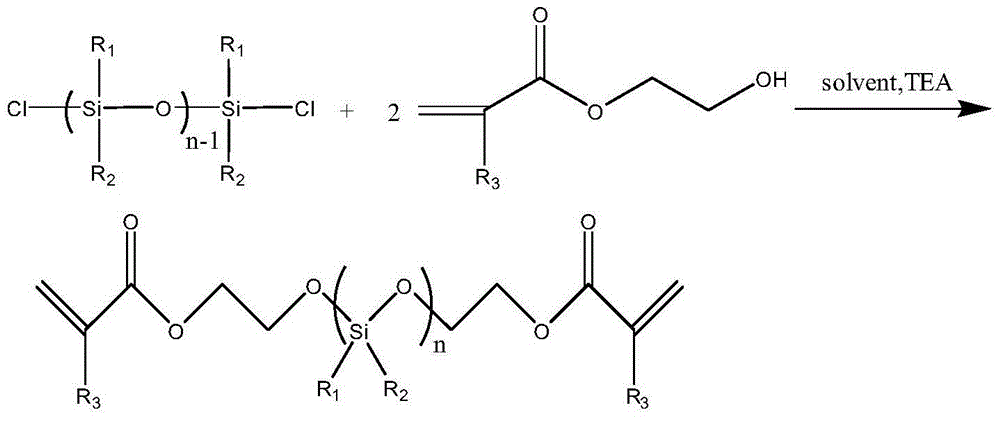

Photosensitivity siloxane and hyperbranched polyether polyol-containing photosensitive resin composition used for used for three-dimensional rapid moulding

ActiveCN104914675AClear structureSmall molecular weightPhotosensitive materials for photomechanical apparatusRapid prototypingFunction group

The invention relates to the three dimensional rapid moulding photosensitive resin field, and discloses a photosensitivity siloxane and hyperbranched polyether polyol-containing photosensitive resin composition. The composition is suitable for a light-cured three dimensional rapid moulding technology, and comprises A)a low-viscosity photosensitivity group (methyl) acrylate group-containig siloxane with usage amount being 0.1-30wt%; B) hyperbranched polyether polyol with number-average molecular weight being 400-20000g / mol and usage amount being 0.1-50wt%; C)an epoxide group-containing cation light-cured compound with usage amount being 5-70 wt%; D)an unsaturated bond function group-containing free radical light-cured compound usage amount being 2-30 wt%; E)a cation photoinitiator usage amount being 1-10 wt%; F)a free radical photoinitiator usage amount being 1-10 wt%; G)a filling material usage amount being 1-20wt%; H)other auxiliary materials usage amount being 0.1-5wt%. The photosensitive resin composition has good mechanics, calorifics performance and solidification performance of a solidification object after laser three dimensional rapid moulding.

Owner:HANGZHOU LEYI NEW MATERIAL TECH CO LTD

Epoxy resin based on 2,5-furandicarboxylic acid, preparation method and application thereof

InactiveCN102952253AReduce pollutionSave oil resourcesEpoxy resin adhesivesEpoxy resin coatingsDual effectEnvironmentally friendly

The present invention discloses an epoxy resin based on 2,5-furandicarboxylic acid, which is a compound has a structure represented by a formula I, is prepared by directly adopting biological origin2,5-furandicarboxylic acid as a raw material, is a biological-base, green and environmentally friendly product, and has dual effects of petroleum resource saving and environment protection. The present invention further discloses a preparation method for the epoxy resin based on 2,5-furandicarboxylic acid, wherein the preparation method has characteristics of simple preparation, good controllability and easy performing. The present invention further discloses an application of the epoxy resin based on 2,5-furandicarboxylic acid, wherein the epoxy resin based on 2,5-furandicarboxylic acid can be applicable for composite materials, epoxy adhesives, coatings and other fields, wherein the epoxy resin based on 2,5-furandicarboxylic acid can be adopted to prepare cured products containing the epoxy resin based on 2,5-furandicarboxylic acid, and can be adopted as a composite material to provide excellent mechanical property and excellent thermal property. Formula I.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Fusion-method-prepared functional graphene cellulose fiber and preparation method thereof

ActiveCN106149083AGood physical and mechanical propertiesFar infrared is goodSpinning head liquid feederMonocomponent cellulose artificial filamentCellulose fiberUltraviolet protection

The invention discloses fusion-method-prepared functional graphene cellulose fiber. The fiber mainly comprises 0.5-10.0% of graphene and 90.0-99.5% of cellulose. A preparation method of the graphene cellulose fiber comprises procedures of graphene dispersion liquid preparation, cellulose / ionic liquid mixture preparation, mixing, pre-fusing, spinning solution preparation and spinning. The far infrared normal emissivity of the prepared functional graphene cellulose fiber reaches 0.83-0.98, the ultraviolet protection coefficient reaches 62.78-560.21, the ultraviolet a transmittance is smaller than 4.92%, and compared with common viscose, the graphene cellulose fiber has the advantage that the thermal decomposition temperature is raised by 10-42 DEG C. By means of the method, the production process is short, less pollution is caused to the environment, the requirement of sustainable development is met, and the method has great significance for achieving a high-temperature melt spinning route of the functional cellulose.

Owner:潍坊欣龙生物材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com