Carbon nano tube/epoxide resin composite material and preparation method thereof

A technology of epoxy resin and carbon nanotubes, which is applied in the field of polymer materials, can solve the problems of low degree of functionalization and unsatisfactory compatibility of epoxy resin, etc., and achieve the effects of improved thermal performance, convenient processing, and controllable strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of a carbon nanotube / epoxy resin composite material

[0027] (1) Weigh 60g of epoxy resin into a 250ml three-neck flask, add 0.088g of plasma-activated grafted and modified carbon nanotubes, and ultrasonicate for 1h in a water bath at 70°C;

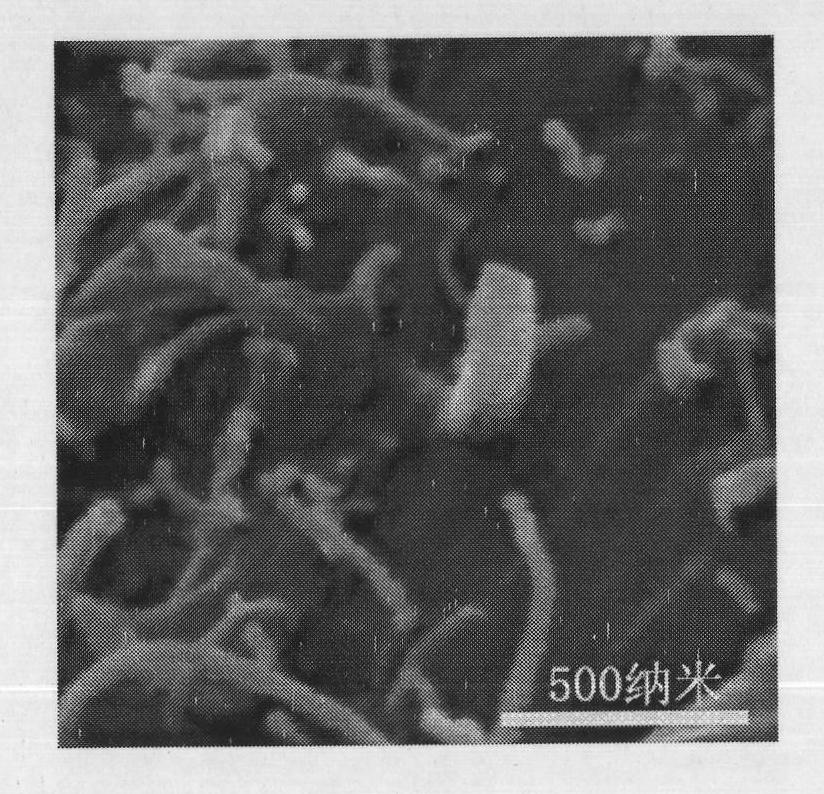

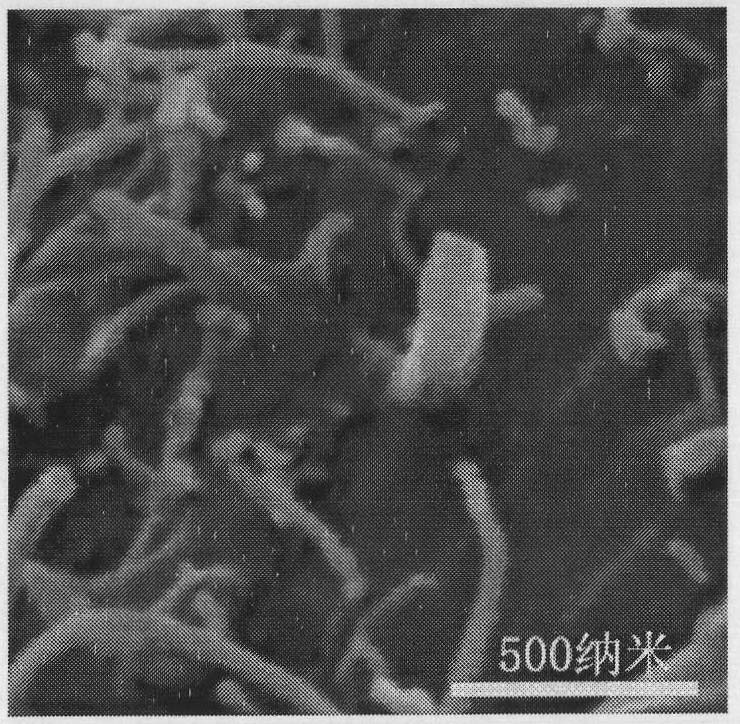

[0028] The preparation method of the carbon nanotubes modified by plasma activation described therein refers to the patent (publication number: CN101407321), wherein the diameter of the carbon nanotubes used is 30-35nm; the length is 10-20 μm; the specific surface area is >60m 2 / g; bulk density is 0.12g / m 3 ;

[0029] (2), the temperature of the carbon nanotube and epoxy resin mixture in step (1) is raised to 100°C, the stirring speed is controlled to be 600-1000rpm, the vacuum degree is 0.01MPa, and vacuum degassing is carried out for 30min;

[0030] (3) Add 28wt% curing agent 4.4-diaminodiphenylmethane to the mixture obtained in step (2), and stir at 600-1000rpm at a high speed until uniformly mixed;

[0031] (4),...

Embodiment 2

[0041] In step (1), the mass of the carbon nanotubes modified by plasma activation grafting was changed to 0.172 g, and other conditions and steps were exactly the same as in Example 1.

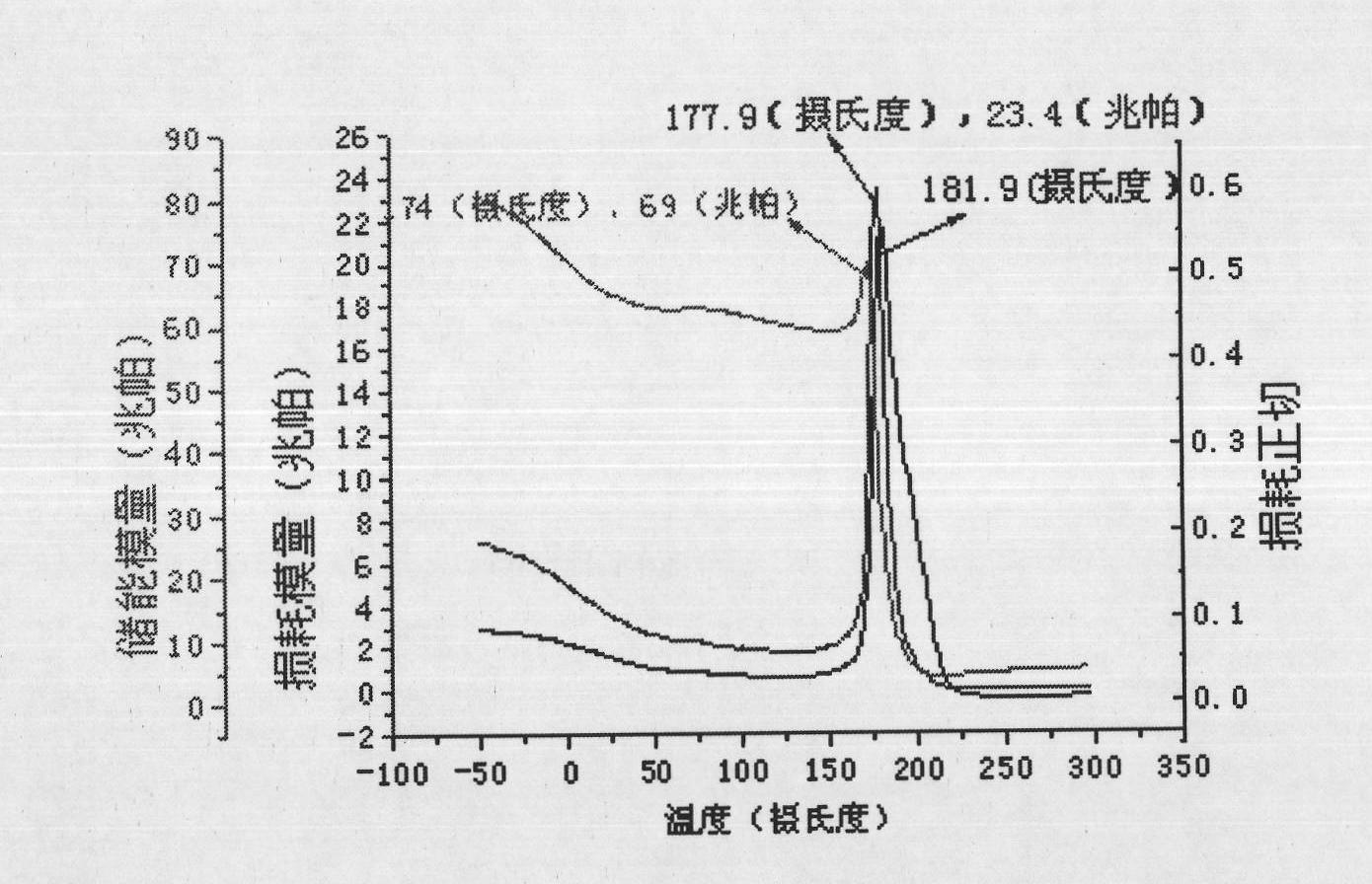

[0042] The tensile strength of the obtained composite material is 50.3MPa, the tensile modulus is 2003.0MPa, and the elongation at break is 2.30% respectively; the glass transition temperature of the composite material is 182.2°C. Compared with the same mass fraction of unfunctionalized carbon nanotubes / epoxy resin composite system (tensile strength 32.96MPa, tensile modulus 1854.26MPa, elongation at break 2.13%, glass transition temperature 181.6 ℃), there is a significant increase.

Embodiment 3

[0044] In step (1), the mass of the carbon nanotubes modified by plasma activation grafting was changed to 0.264 g, and other conditions and steps were exactly the same as in Example 2.

[0045] The tensile strength of the obtained composite material is 57.84MPa, the tensile modulus is 2323MPa, and the elongation at break is 4.95% respectively; the glass transition temperature of the composite material is 183.1°C.

[0046] Compared with the same mass fraction of unfunctionalized carbon nanotubes / epoxy resin composite system (tensile strength 39.96MPa, tensile modulus 1954.26MPa, elongation at break 2.23%, glass transition temperature 184.3 ℃), there is a significant increase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com