Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2348 results about "Offshore wind power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Offshore wind power or offshore wind energy is the use of wind farms constructed in bodies of water, usually in the ocean on the continental shelf, to harvest wind energy to generate electricity. Higher wind speeds are available offshore compared to on land, so offshore wind power’s electricity generation is higher per amount of capacity installed, and NIMBY opposition to construction is usually much weaker. Unlike the typical use of the term "offshore" in the marine industry, offshore wind power includes inshore water areas such as lakes, fjords and sheltered coastal areas, utilizing traditional fixed-bottom wind turbine technologies, as well as deeper-water areas utilizing floating wind turbines.

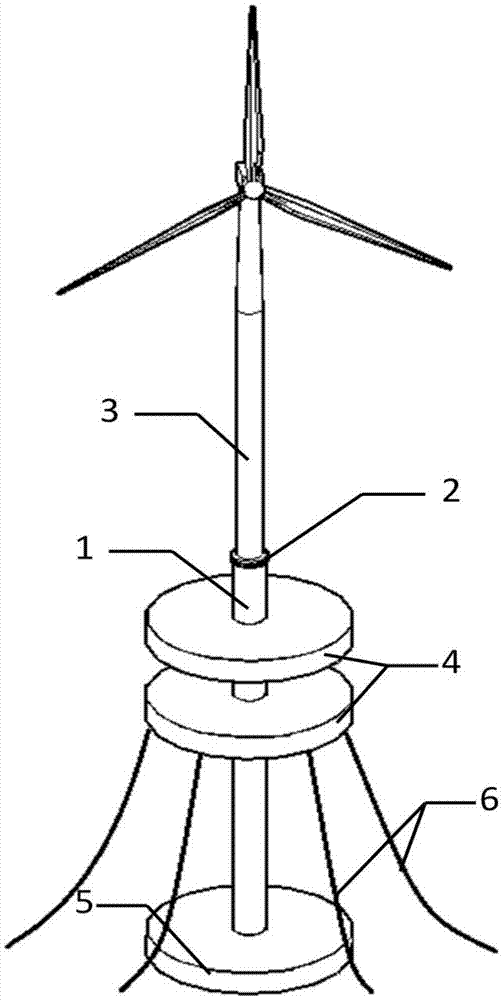

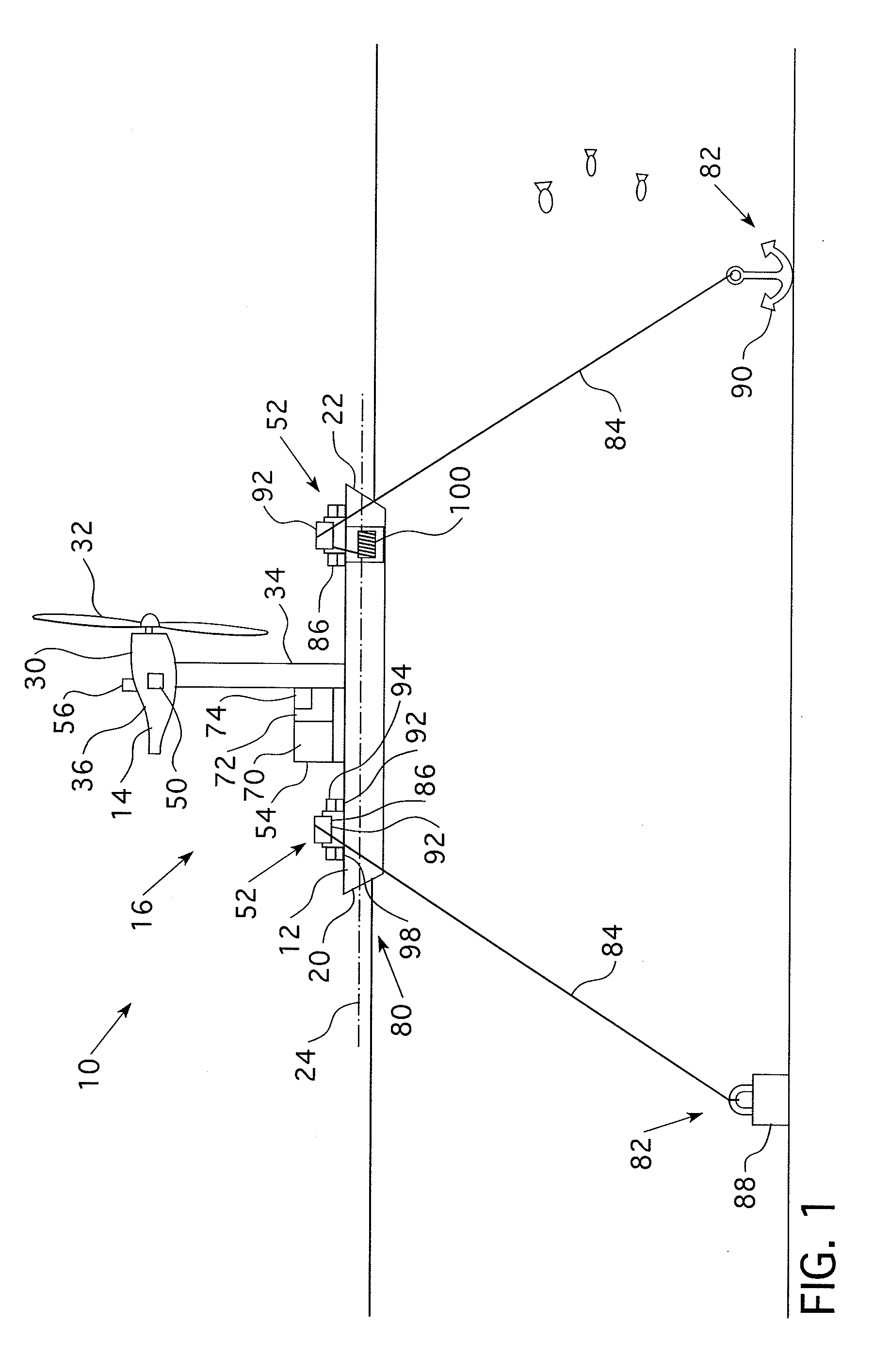

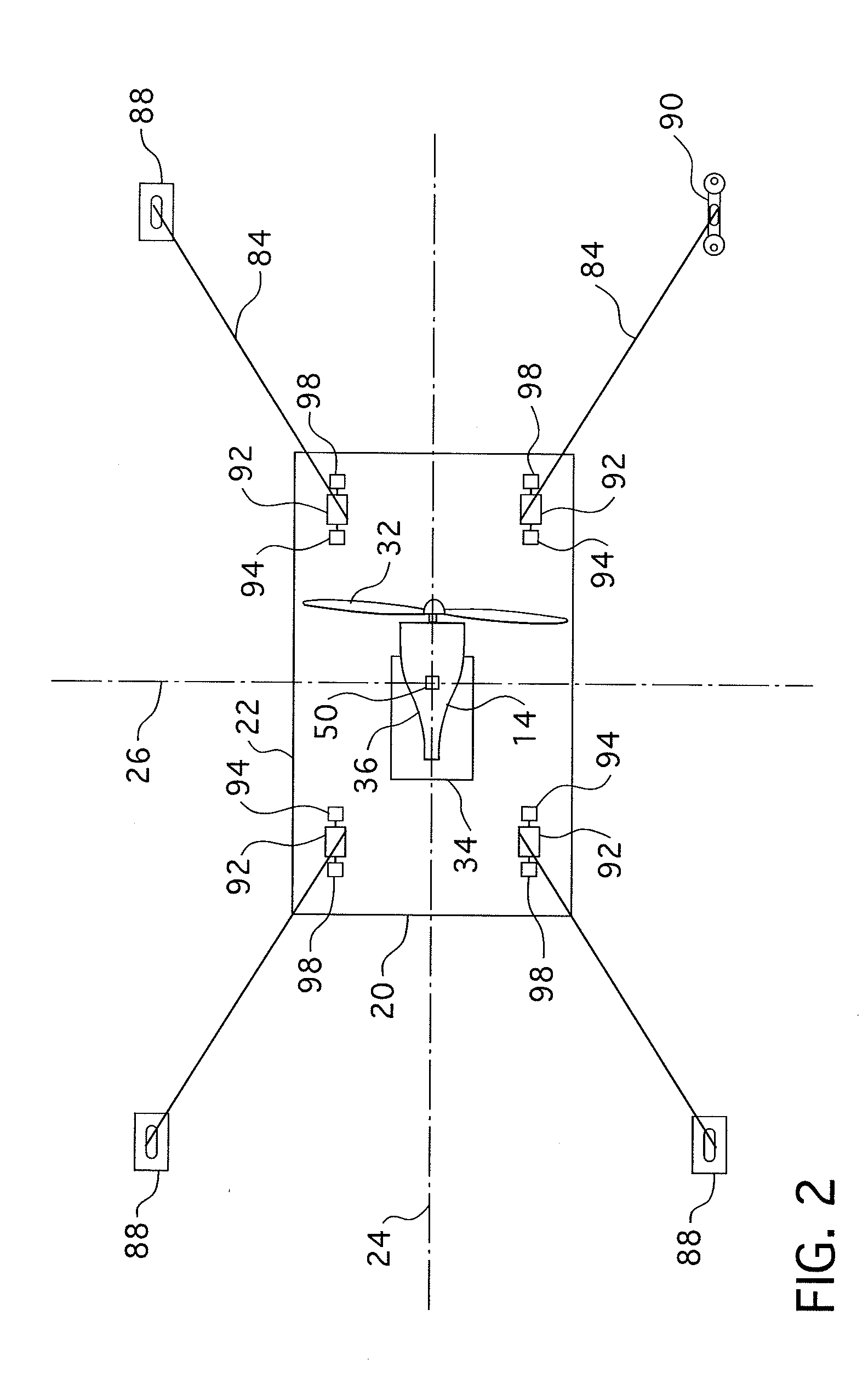

Floating offshore wind farm, a floating offshore wind turbine and a method for positioning a floating offshore wind turbine

A floating offshore wind turbine and a floating offshore wind farm with at least one floating offshore wind turbine are provided. The floating offshore wind turbine includes a floating platform anchored to an underwater ground, a wind turbine mounted on the floating platform, and a drive. The drive is adapted to horizontally move the floating platform. Further a method for positioning a floating offshore wind turbine is provided.

Owner:GENERAL ELECTRIC CO

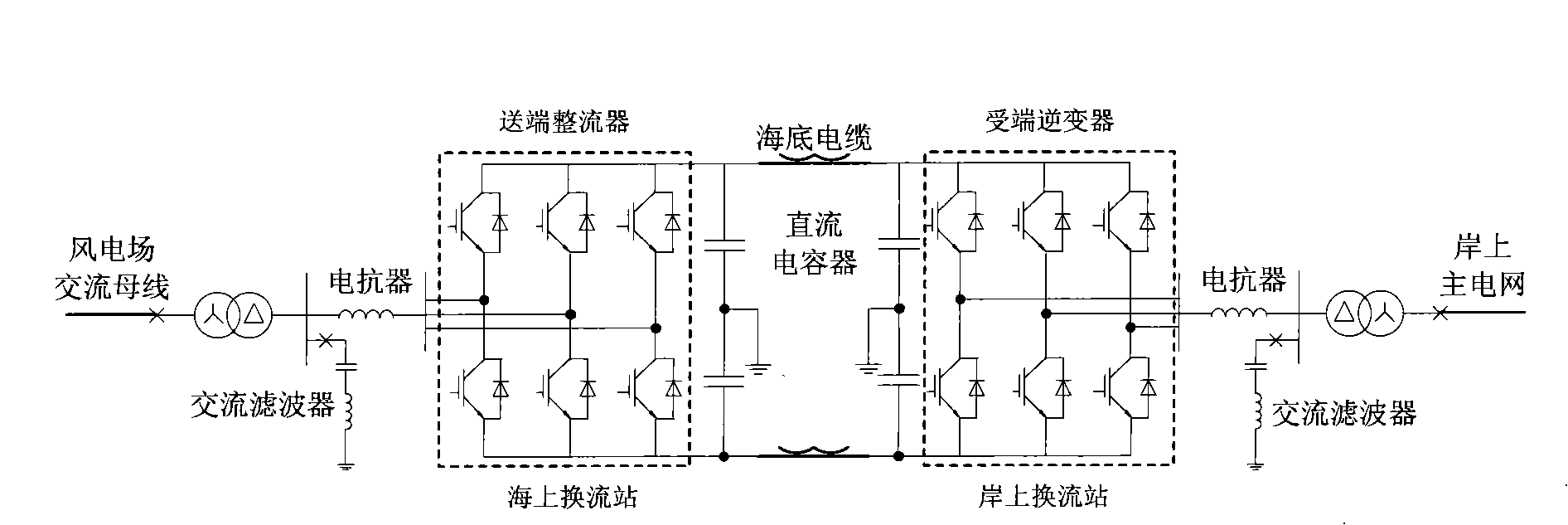

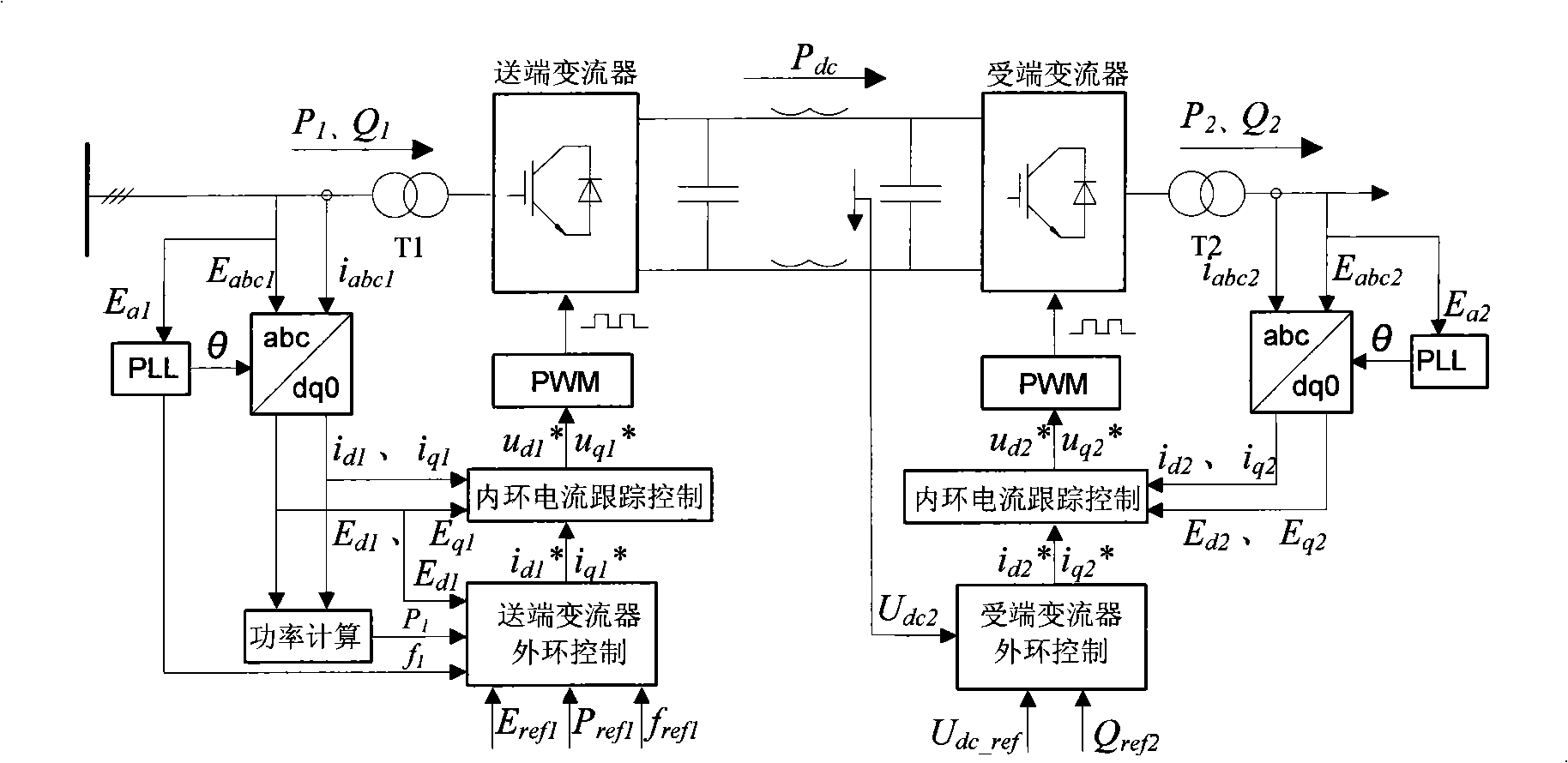

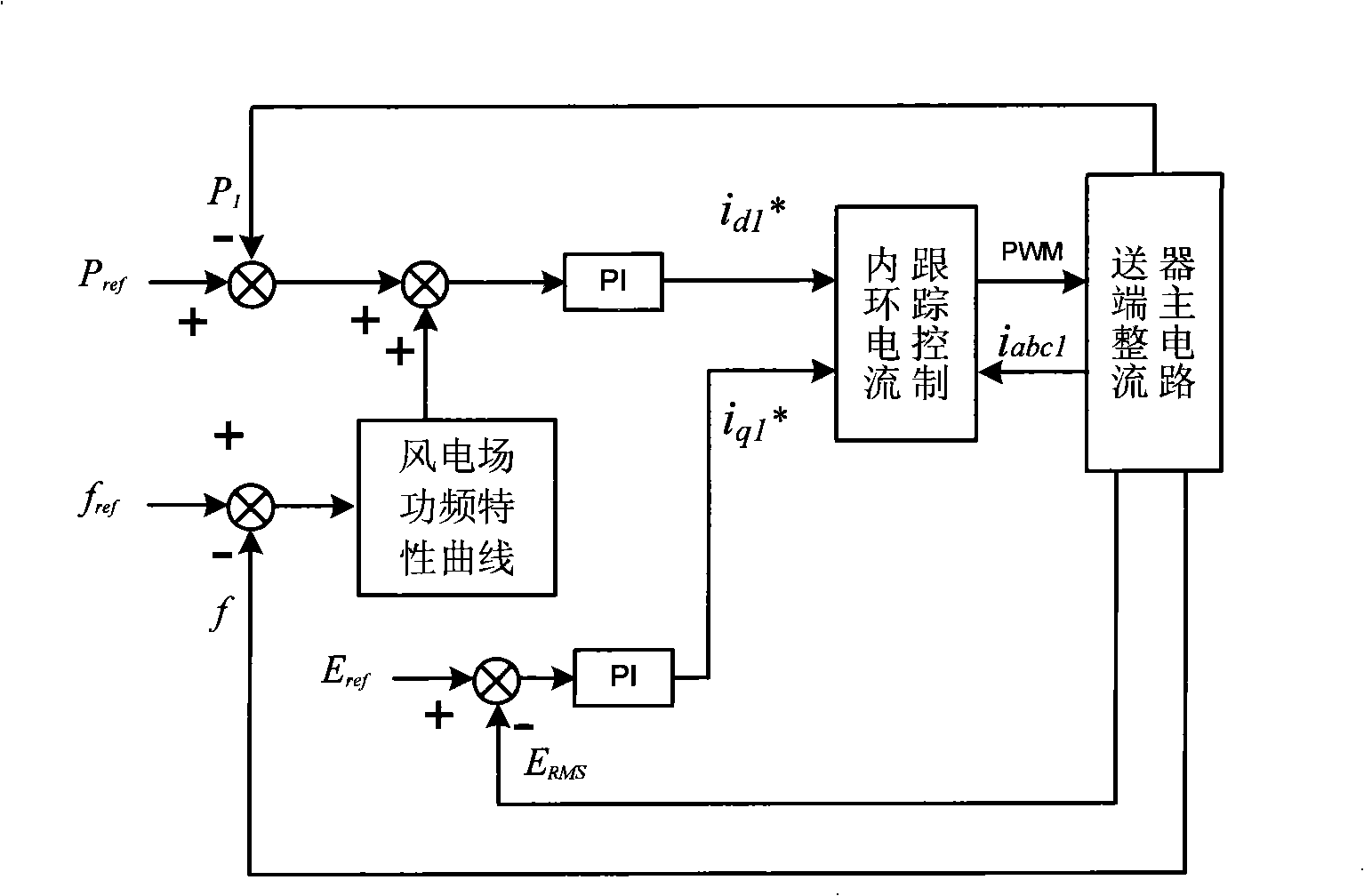

Control system of offshore wind power flexible DC power transmission current transformer

InactiveCN101295877AShort response timeReduce shockSingle network parallel feeding arrangementsWind energy generationElectric power transmissionPower quality

The invention relates to a control system of a flexible wind power DC convertor on the sea, which pertains to the technical field of power transmission in wind power generation and comprises the doubly closed loop control structure of a sending end rectifier on the sea and the doubly closed loop control structure of a receiving end inverter on the coast; the doubly closed loop control structure of the sending end rectifier on the sea is used for controlling the active power of a flexible DC transmission system and the voltage stability of a wind power AC system; the doubly closed loop control structure of the receiving end inverter on the coast is used for controlling the constant voltage of the DC side of a receiving end convertor and the dynamic regulation of the reactive power of the main network accessing end of the receiving end convertor; two control structures are mutually independent and no data communication exists between the two control structures. The control system can fast and correctly control the active power of wind power transmission on the sea as well as promote the stability of the wind power AC system on the sea and the transmission efficiency and the power quality of the whole DC transmission system.

Owner:SHANGHAI JIAO TONG UNIV

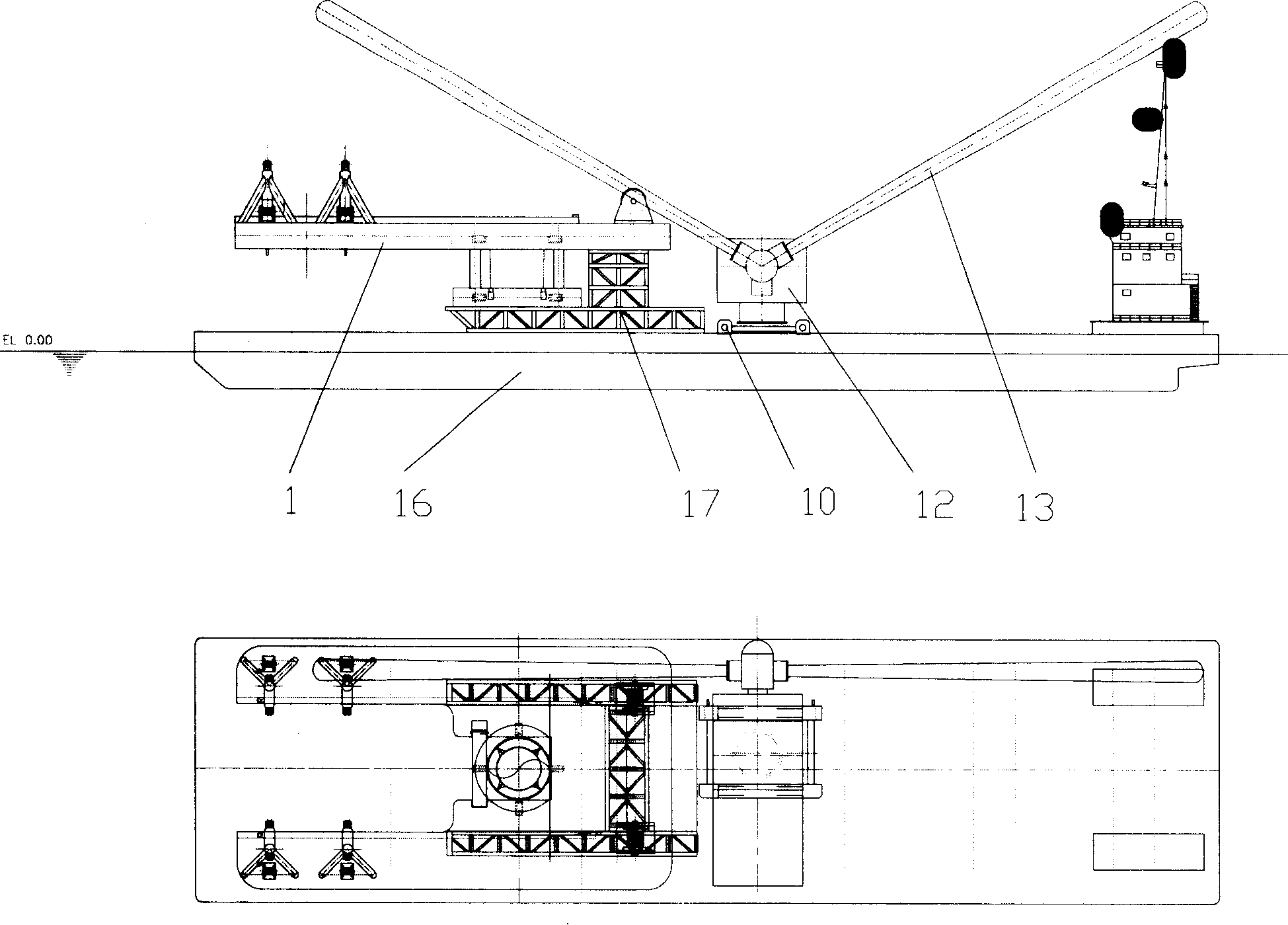

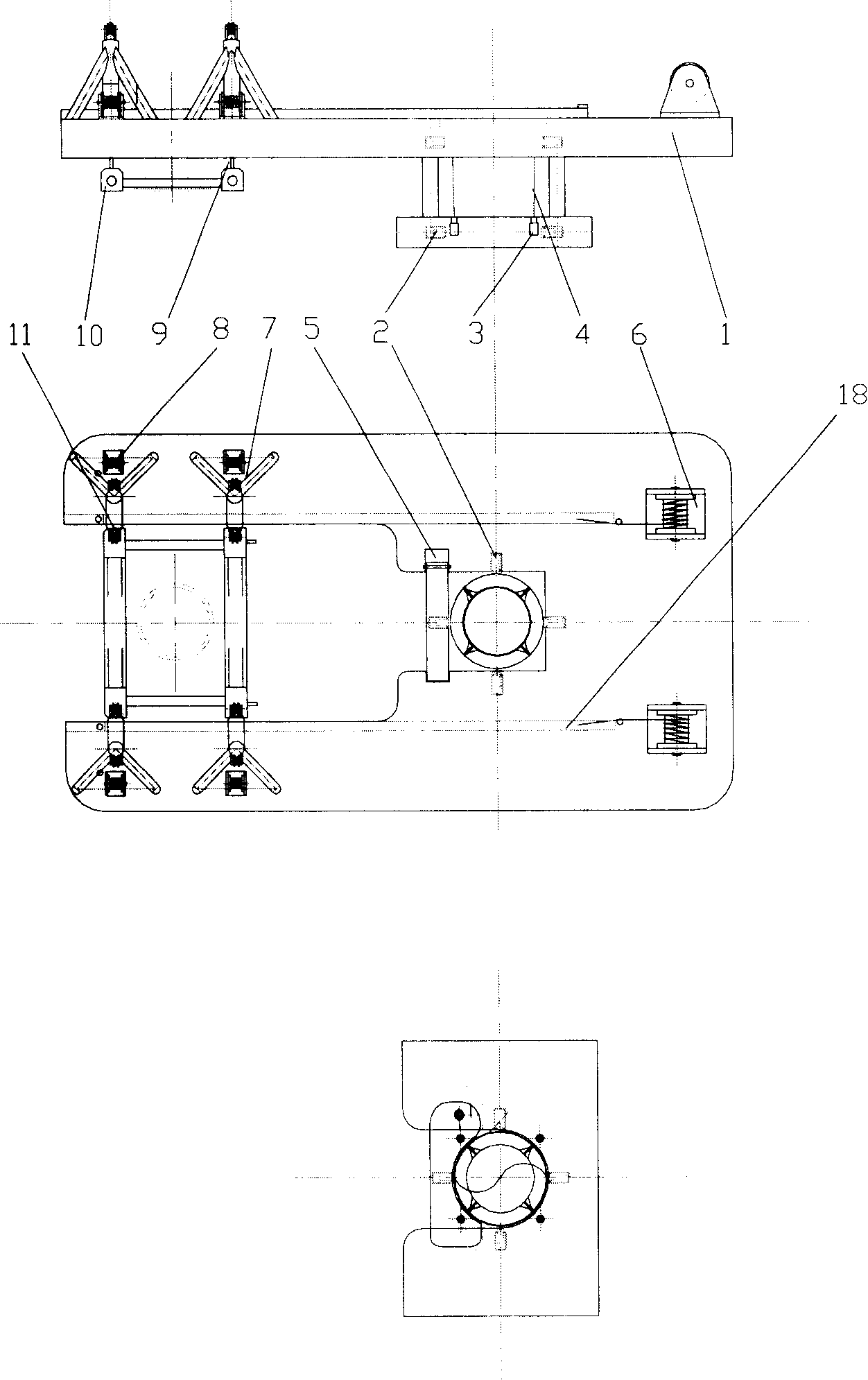

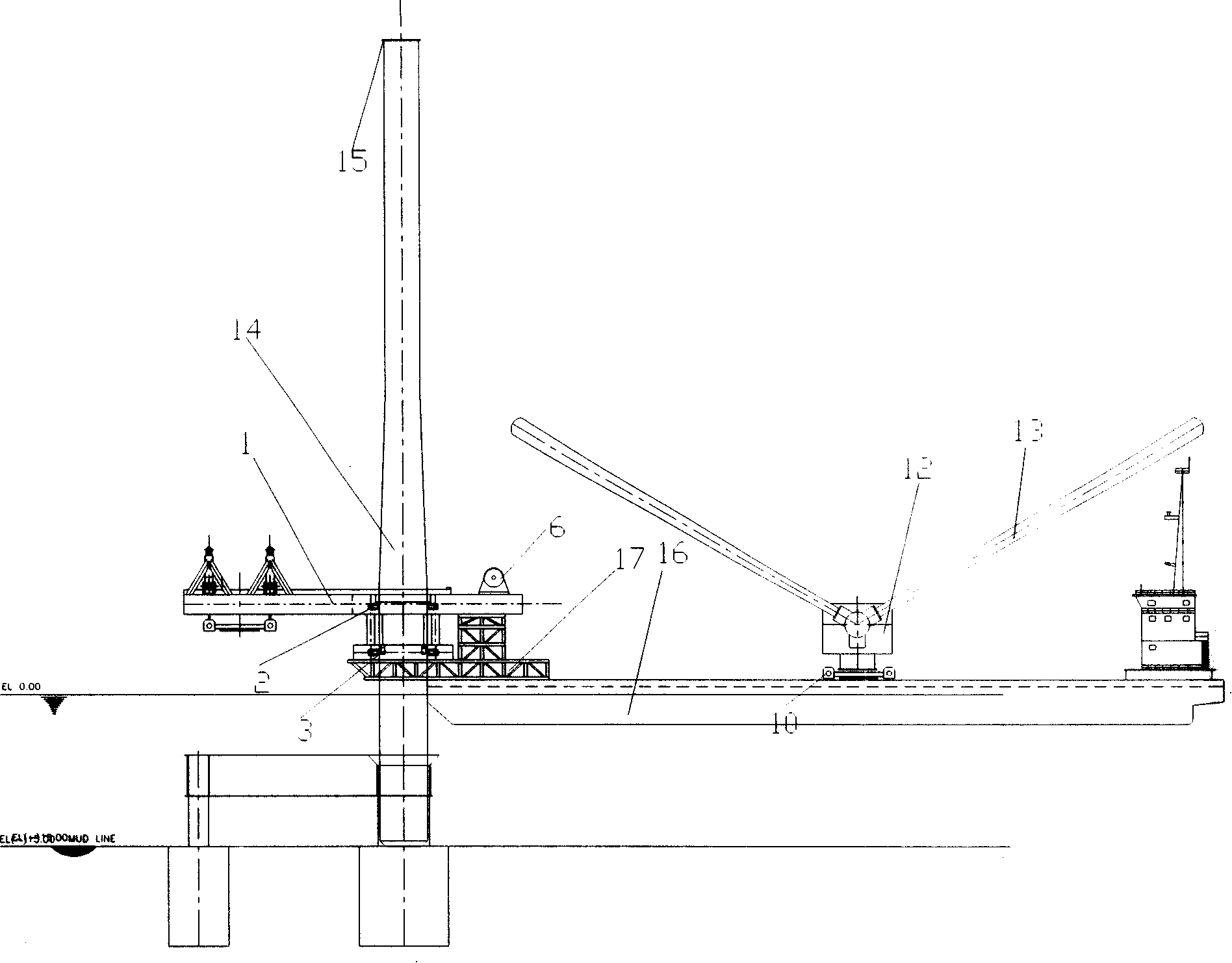

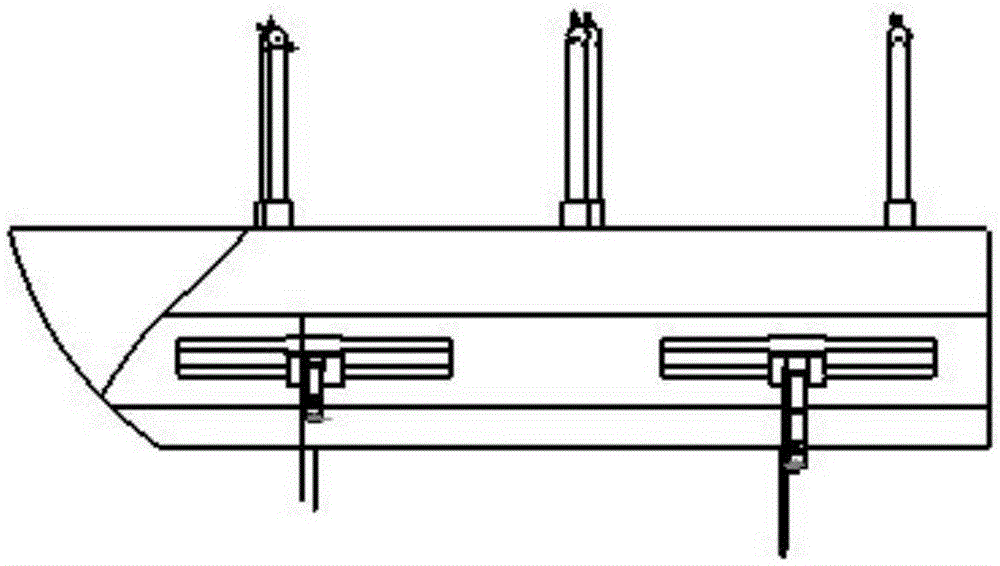

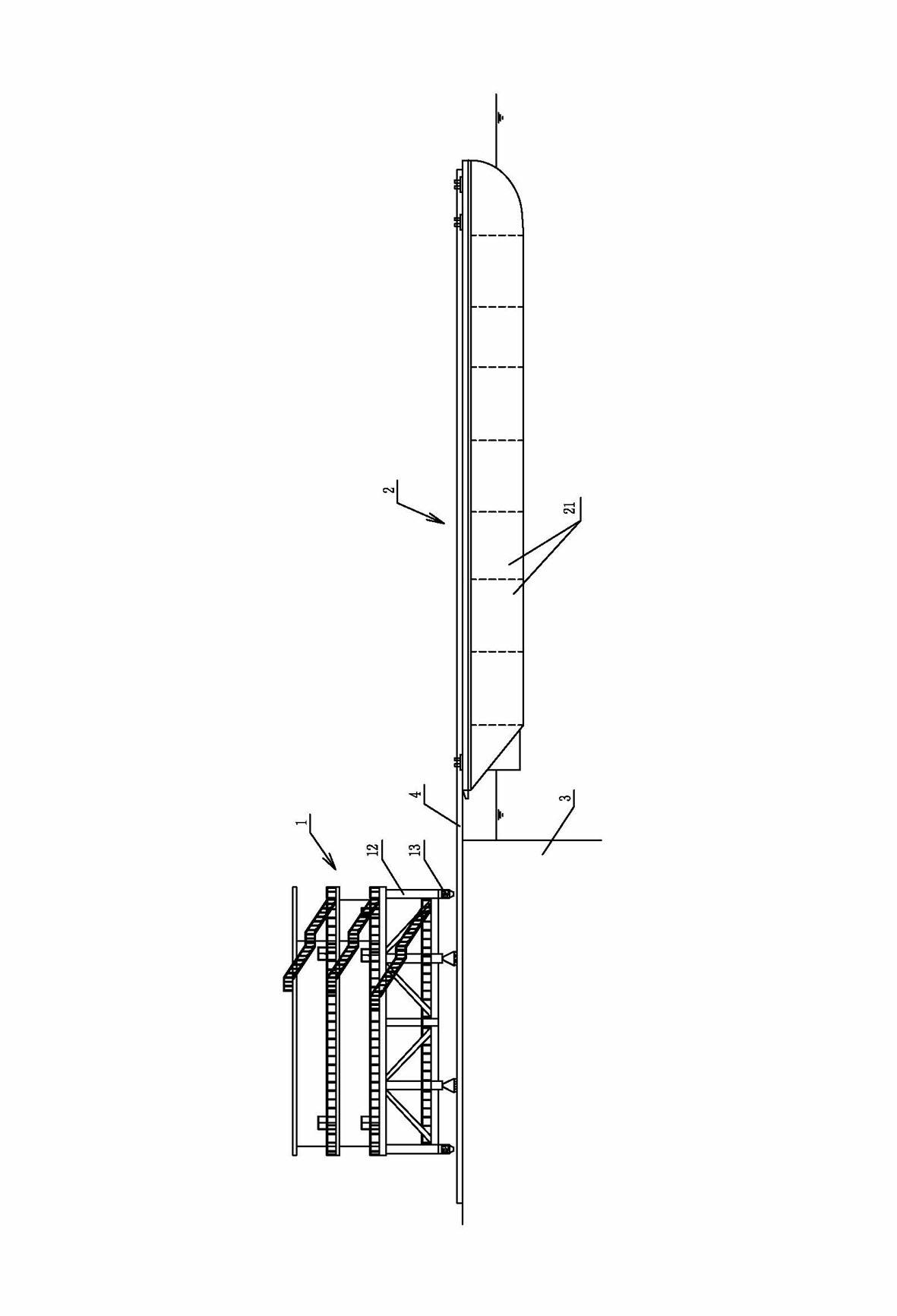

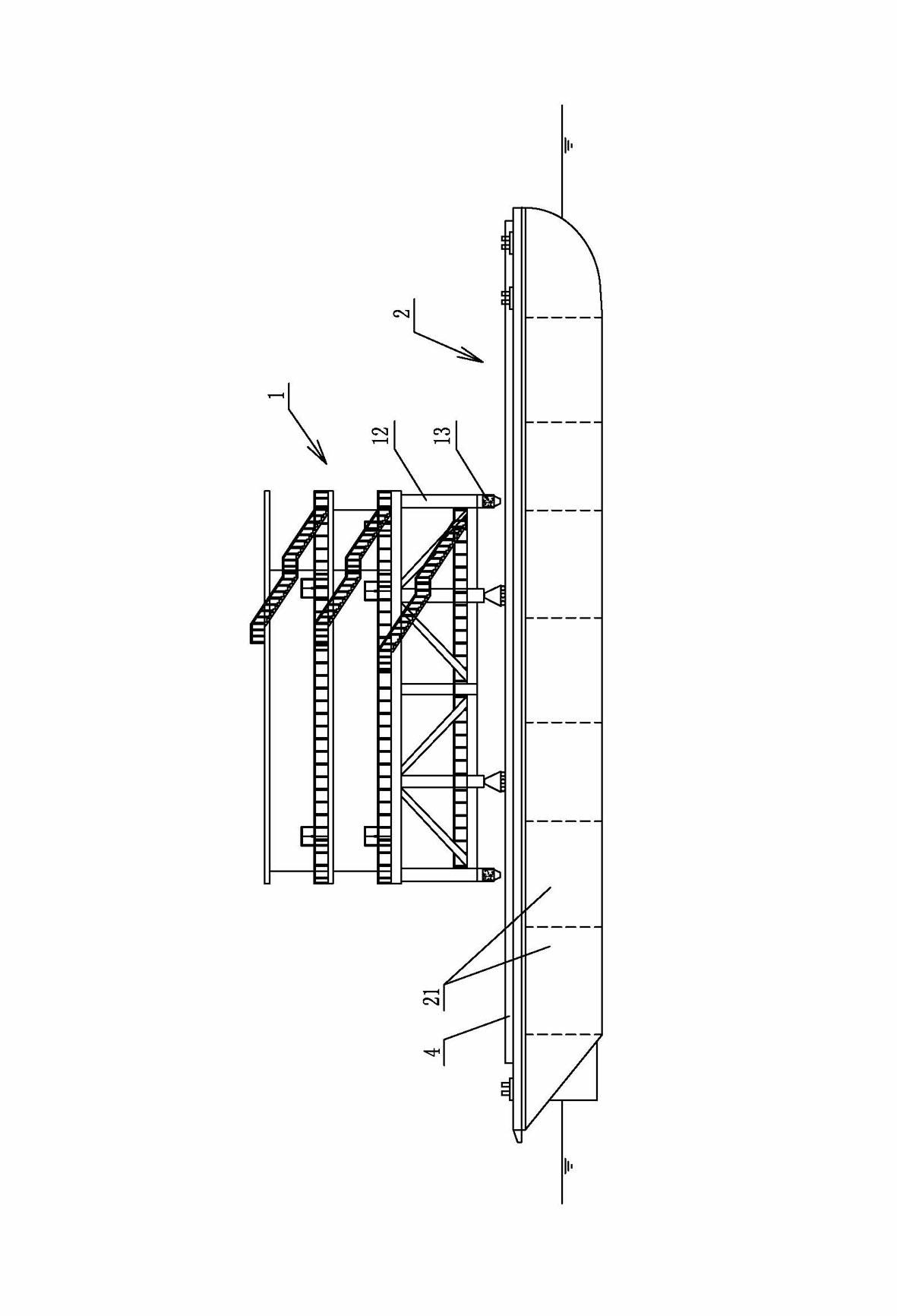

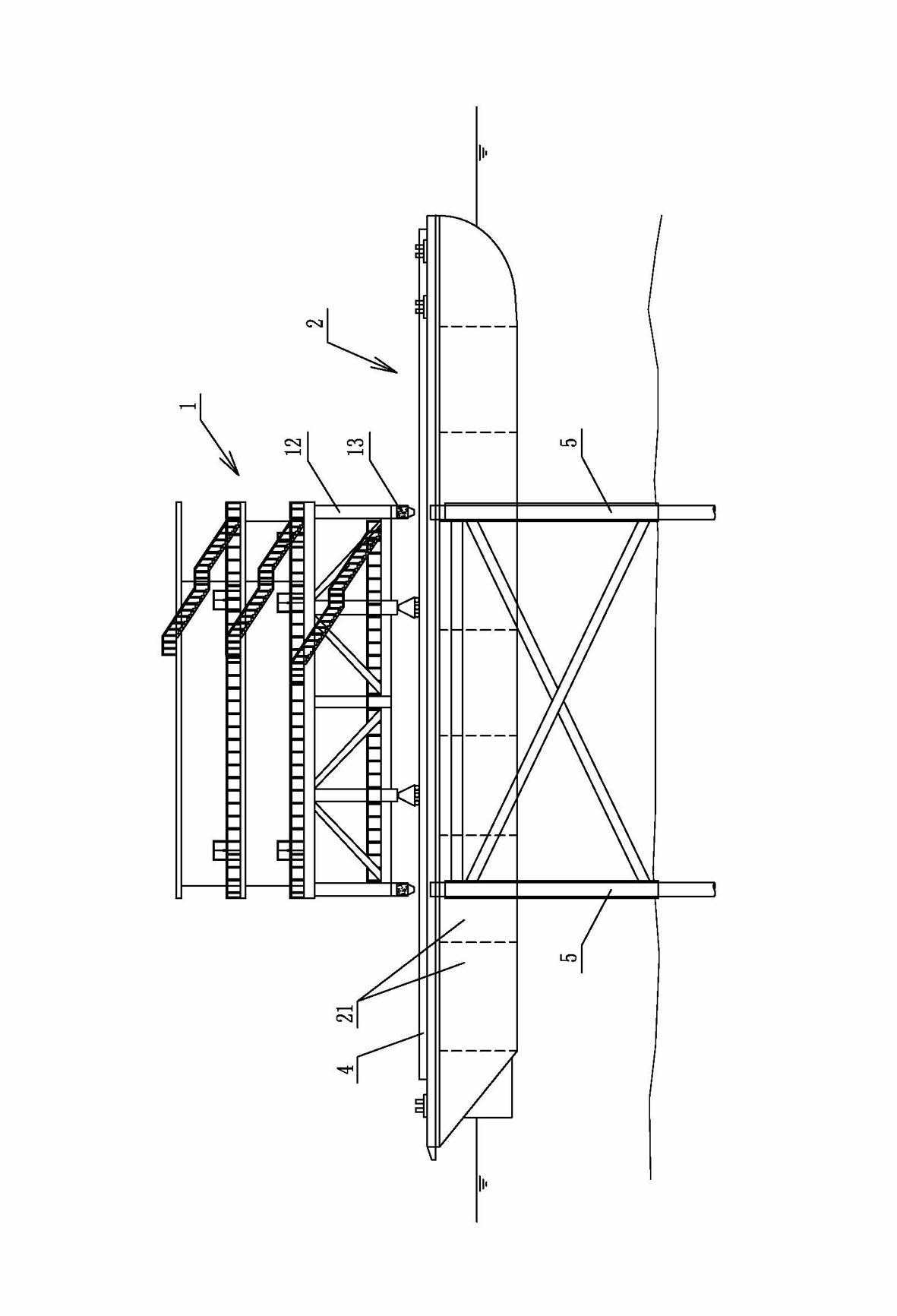

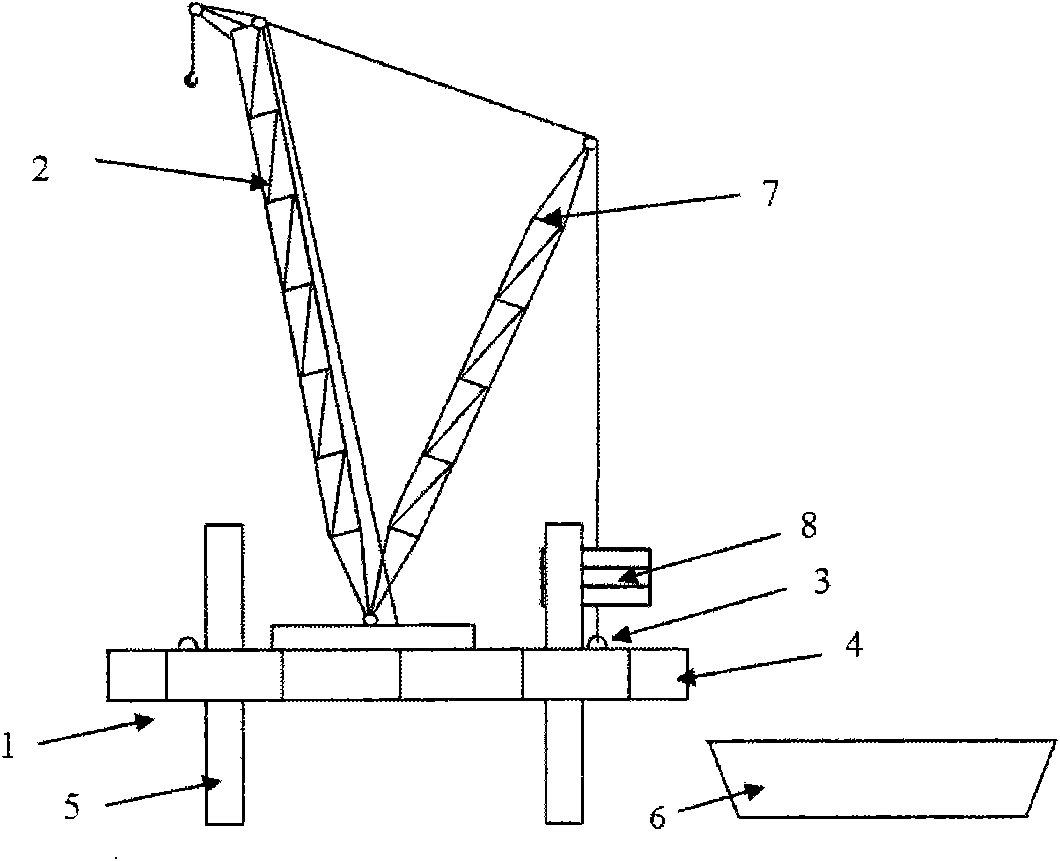

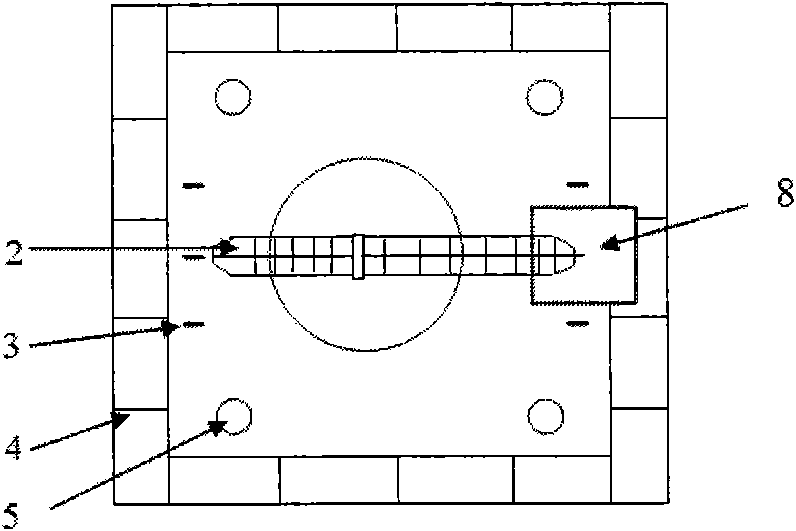

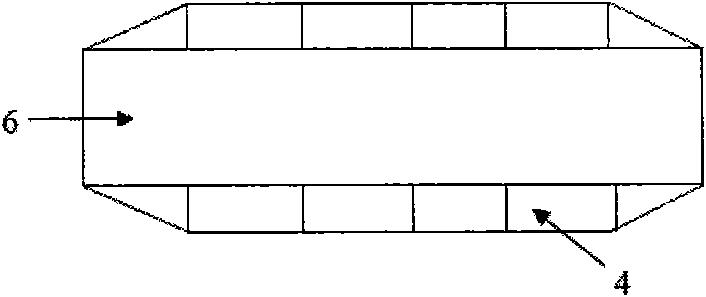

Installation construction method for wind generator set on the sea

A method for the structural design and engineering of an offshore wind power generator unit hoisting platform is provided, which is characterized in that: a special barge is adopted to convey the offshore wind power generator unit and a self-elevating wind power generator unit hoisting platform to an offshore wind tower body that has been installed beforehand; elevate a hoisting platform (1) step by step to the top of the wind tower body; lock and elevate the hoisting platform (1) with the wind tower body (14); elevate a hoisting pallet (10) and the wind power generator unit (12) to the top of the wind tower body (14) and then displace them to the position right above the top of the tower body (14), overlap with a connecting center at the top of the tower body and then carry out connection and fixing; hoist a blade (13) to the to the top of the wind tower body (14); install the blade (13) on the generator unit. Finally, lower down the hoisting platform step by step and return it to the special barge to complete the hoisting operation.

Owner:NEPTUNE OFFSHORE ENG DEV

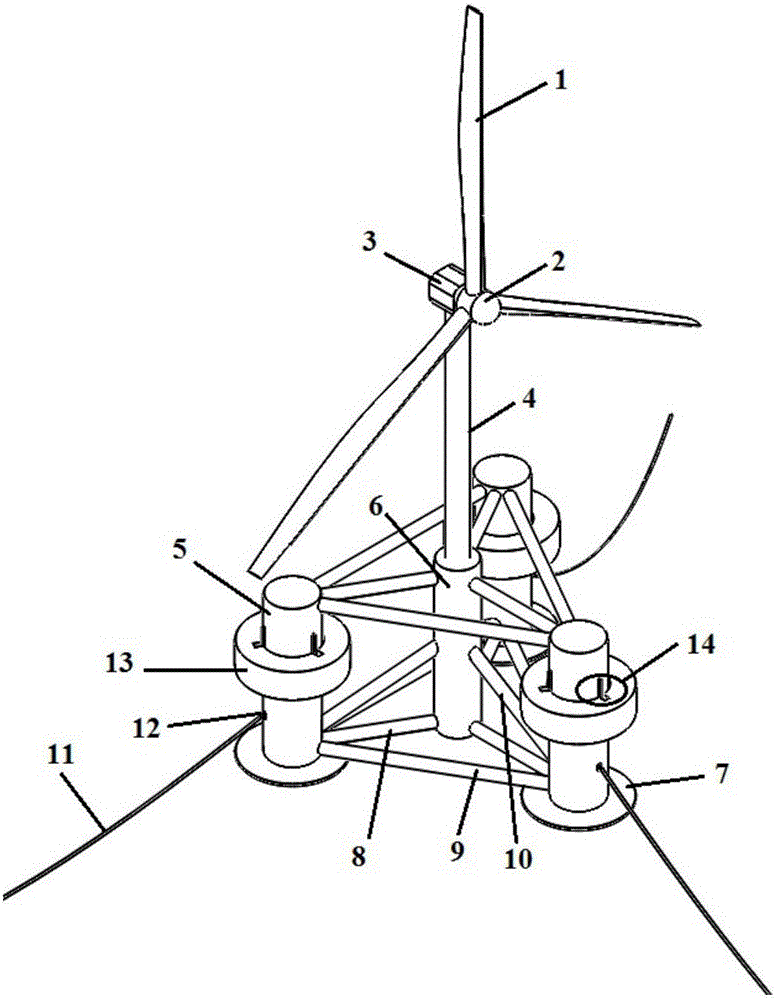

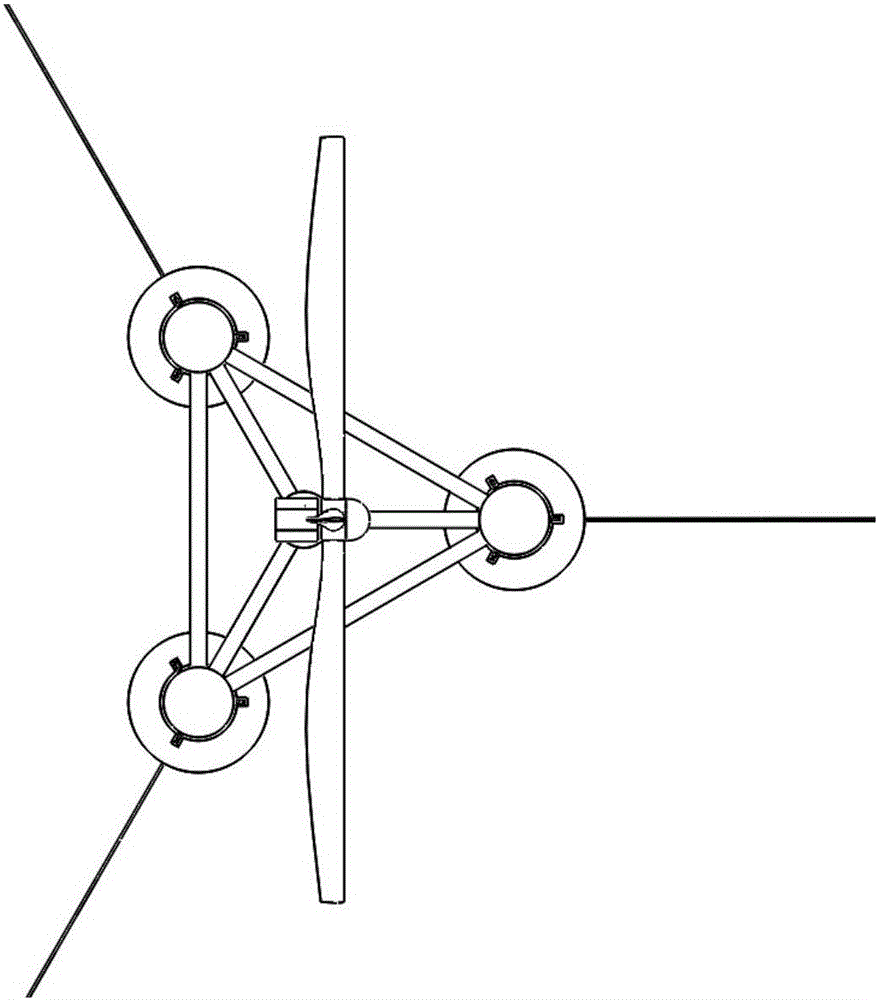

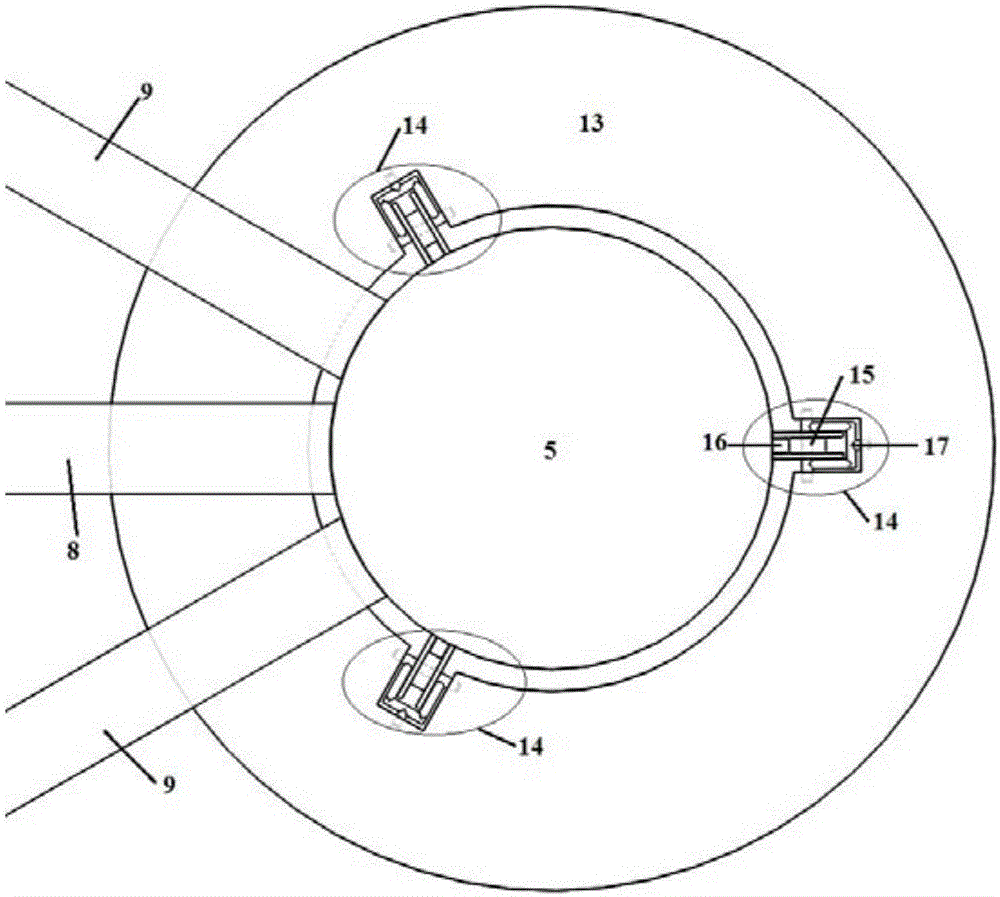

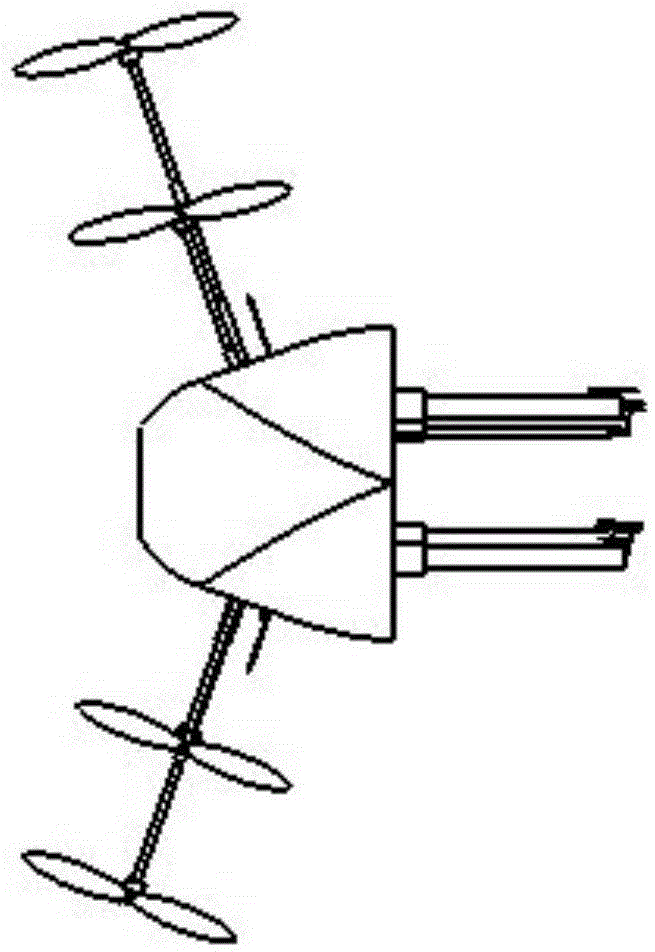

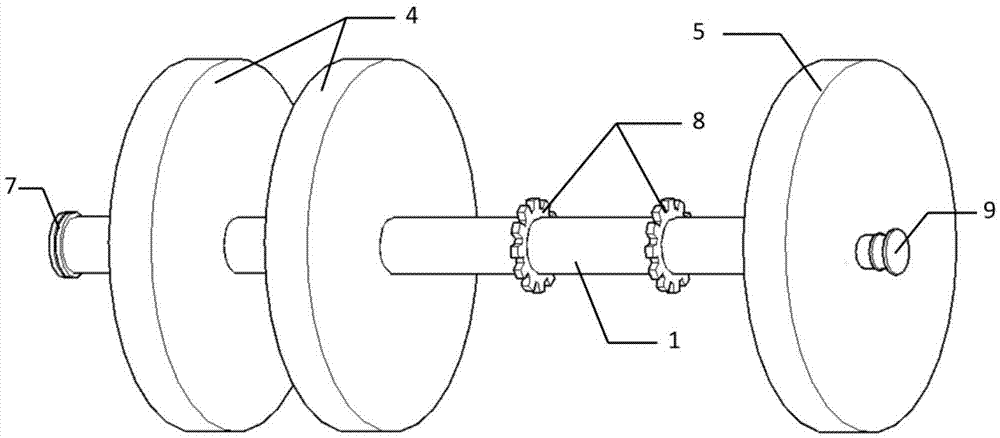

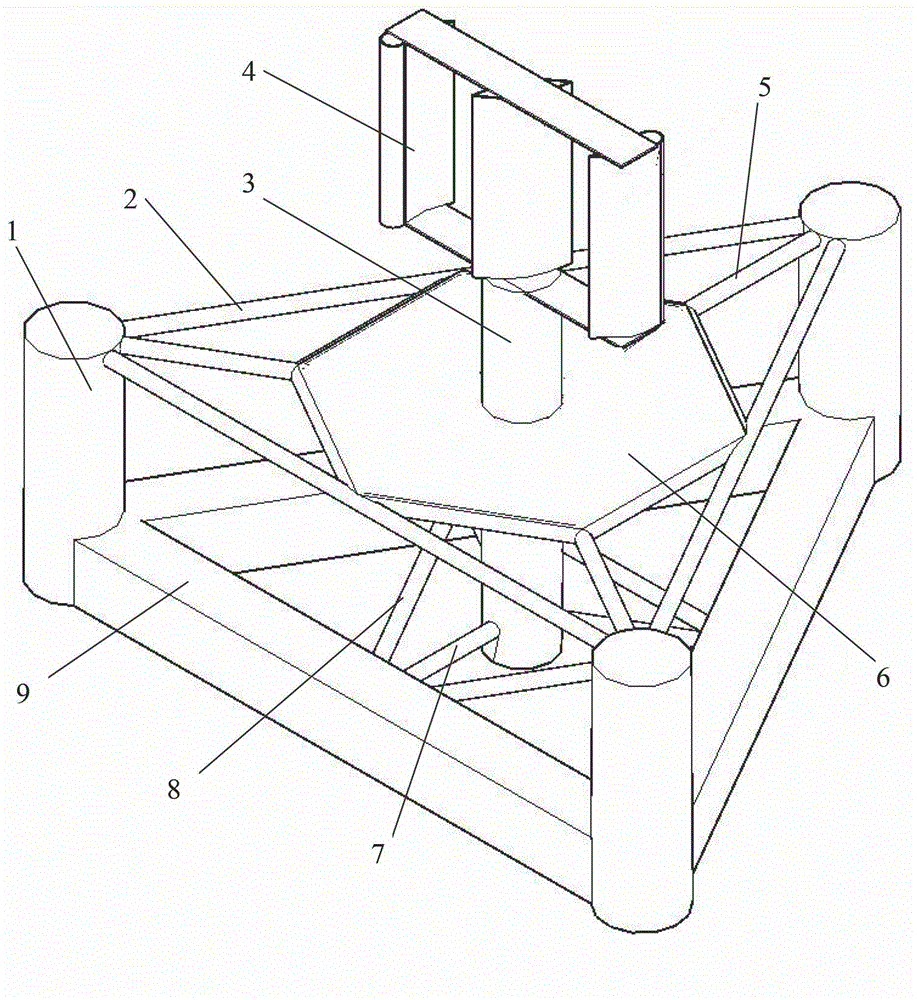

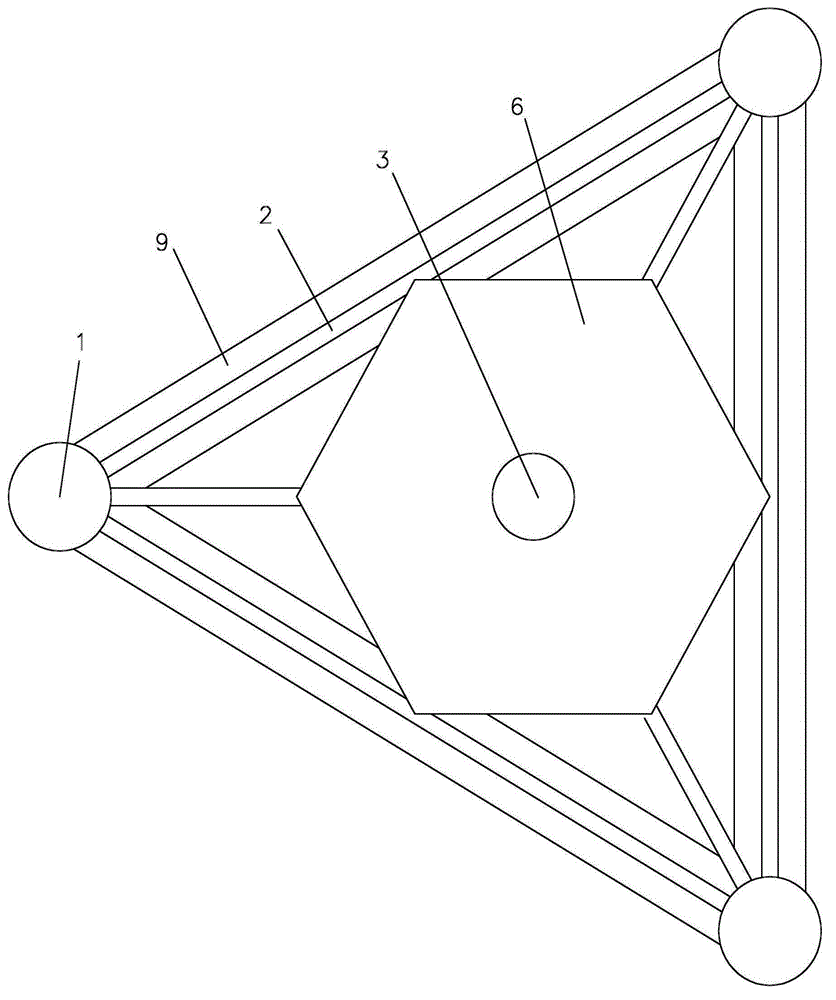

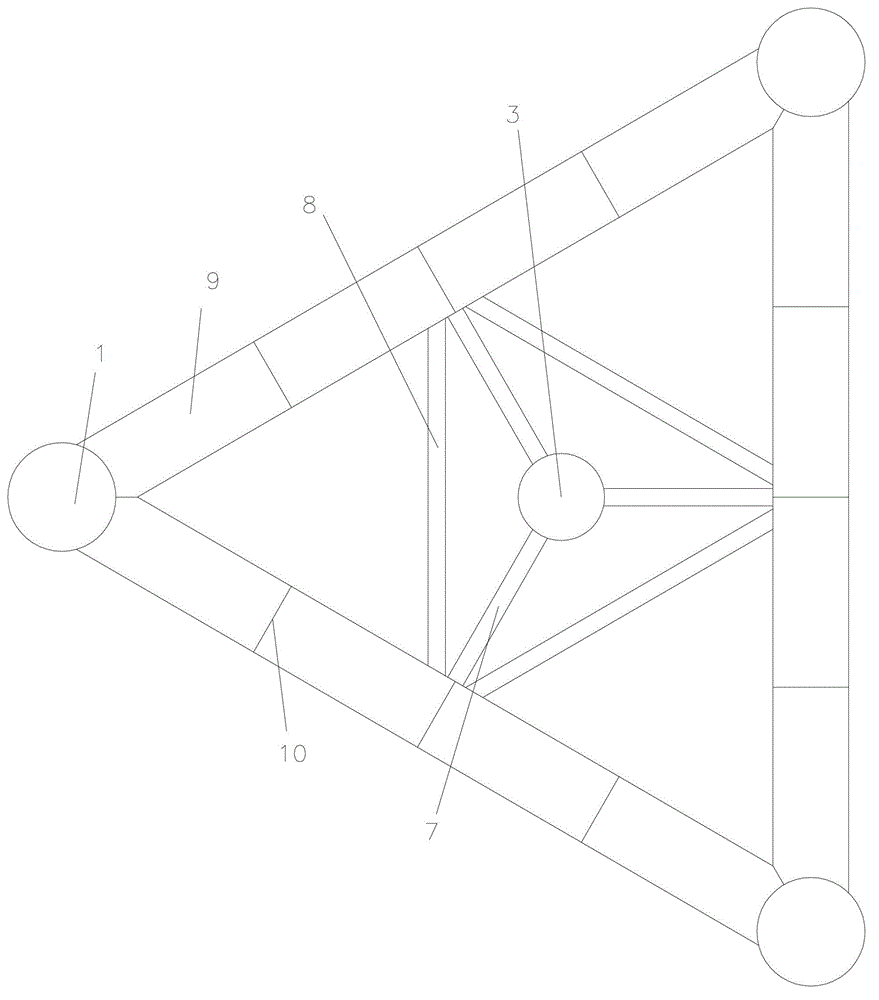

Novel floating type multi-floater wind-wave energy hybrid power generation device

InactiveCN106014862AReduce exerciseReduce the size of the wave forceWaterborne vesselsWind energy with water energyWind drivenWind wave

The invention provides a novel floating type multi-floater wind-wave energy hybrid power generation device which comprises a wind driven generator, a floating foundation platform, a wave energy capture device and connecting structures between floating bodies, wherein the wind driven generator comprises blades, a hub, a cabin and a tower; the floating type foundation platform is a semi-submersible type and is located on the sea surface by an overhung anchor chain line; the wave energy capture device comprises floaters and an energy capture (PTO) system, and the axial relative movement between the wave energy floaters and stand columns of the foundation platform under the action of wave energy is utilized to drive the PTO system to generate electric energy; and each connecting mechanism comprises a guide rail and a U-shaped wheel, and can enable the platform and the wave energy floaters to produce axial relative movement only. The novel floating type multi-floater wind-wave energy hybrid power generation device can realize the purpose of joint power generation of offshore wind energy and wave energy by utilizing mechanical energy possessed by offshore air and wave, and is good in stability, wide in applicable water depth scope, high in power generation efficiency, simple in structure form and reliable in power generation mode.

Owner:HARBIN ENG UNIV

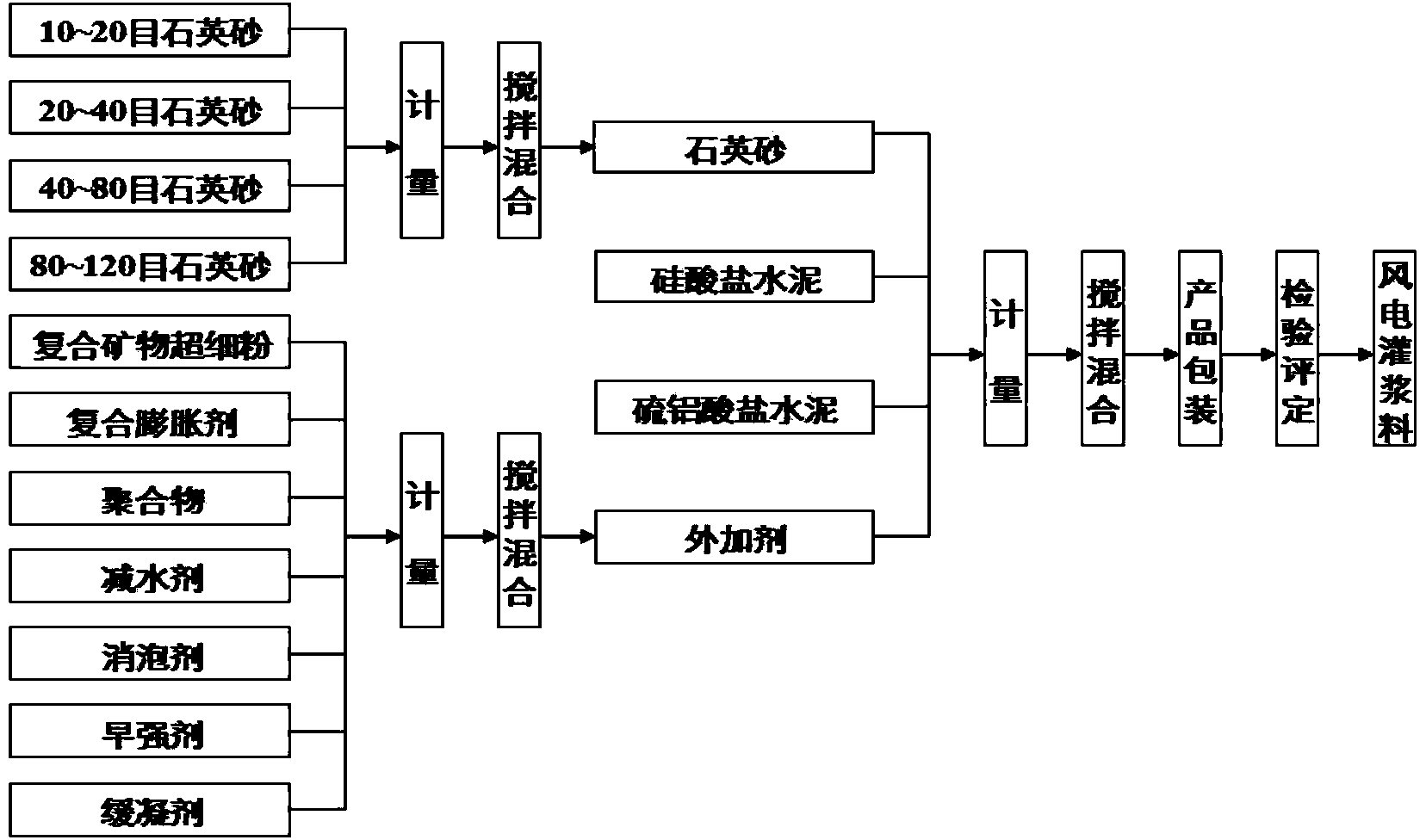

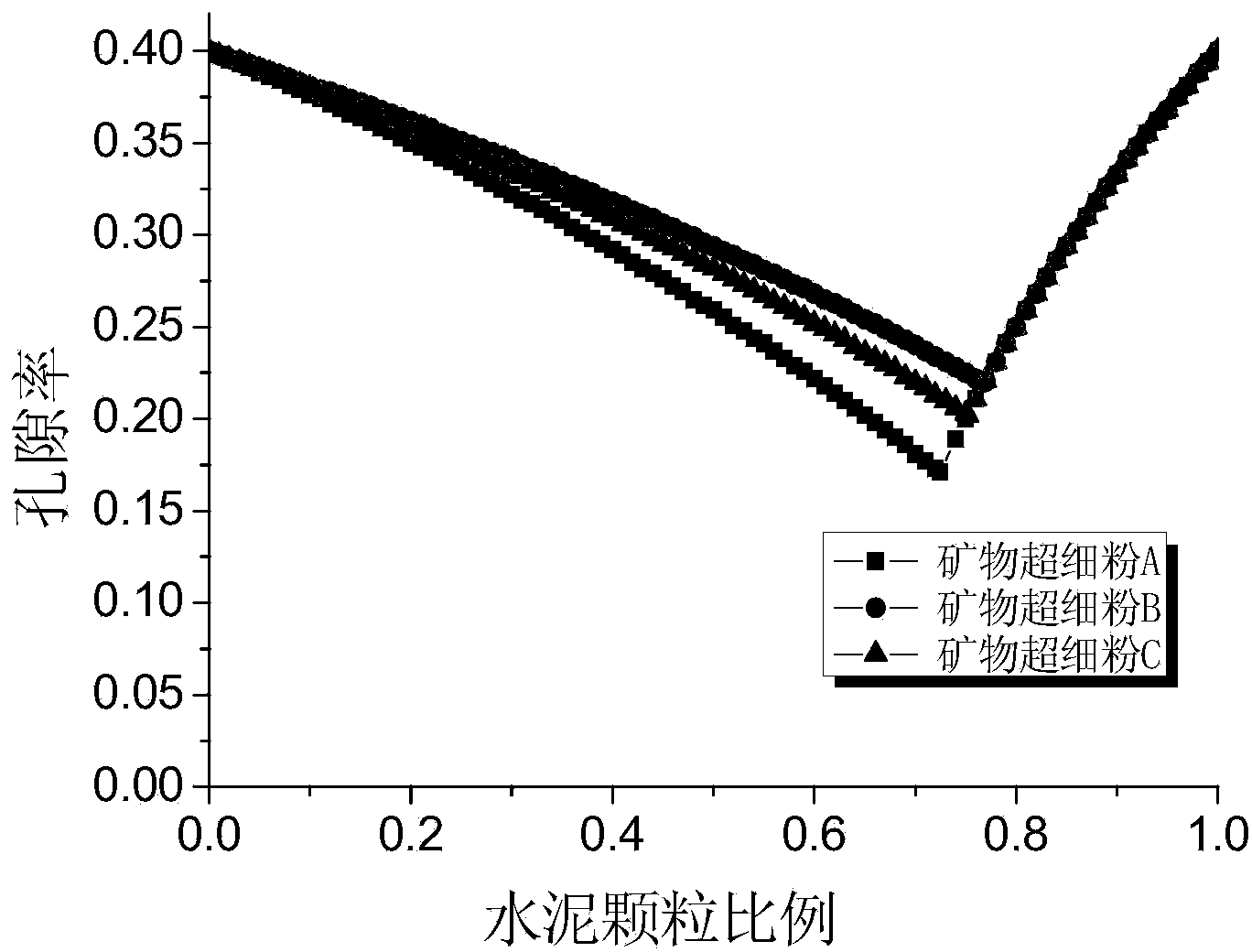

Offshore wind power duct rack grouting material and construction method thereof

ActiveCN104003681AMeet the index requirements for groutingImprove workabilityFoundation engineeringPortland cementOffshore wind power

The invention provides an offshore wind power duct rack grouting material which comprises a dry material and water, wherein the dry material comprises the following components in percentage by mass: 25.0-40.0 percent of Portland cement, 1.0-5.0 percent of sulphoaluminate cement, 45.0-55.0 percent of quartz sand and 5.0-15.0 percent of admixture; the addition amount of the water is proper. The invention further provides a construction method of the offshore wind power duct rack grouting material. According to the offshore wind power duct rack grouting material and the construction method thereof, the material has the characteristics of high liquidity, high pumpability, super-high early-strength, ultrahigh strength, high durability, good water dispersion resistance, zero shrinkage and high fatigue resistance, can be conveyed by a rubber pipeline by adopting a pumping and grouting construction mode, is suitable for underwater grouting and is also suitable for grouting connection between the offshore wind power duct rack and steel pipe pile foundation.

Owner:CCCC THIRD HARBOR ENG +2

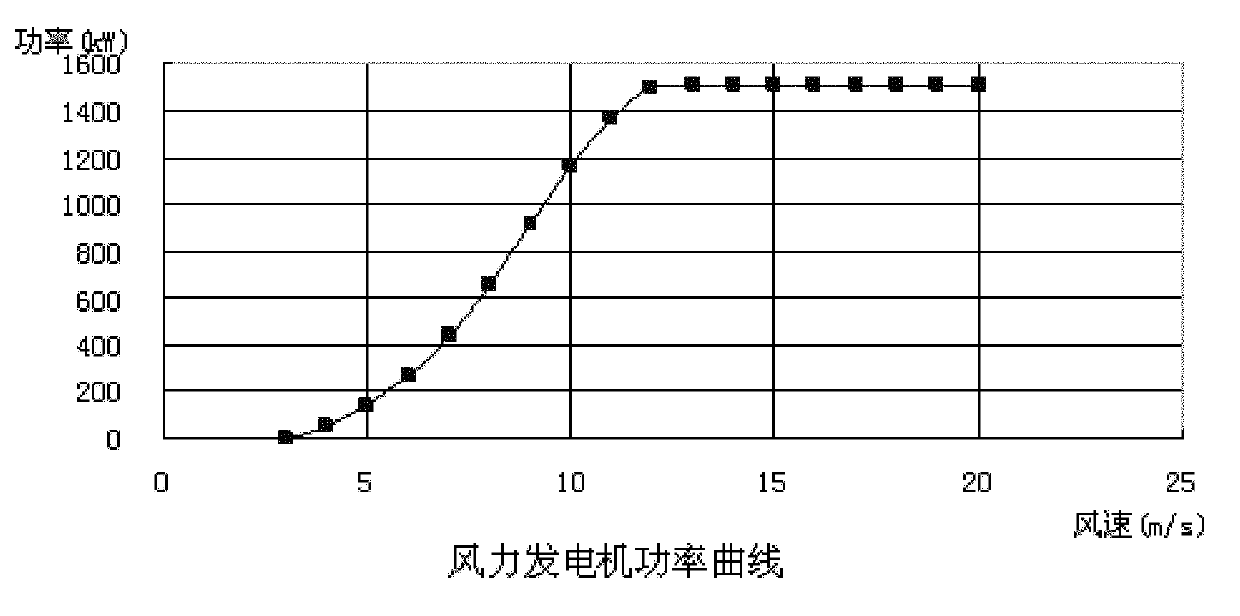

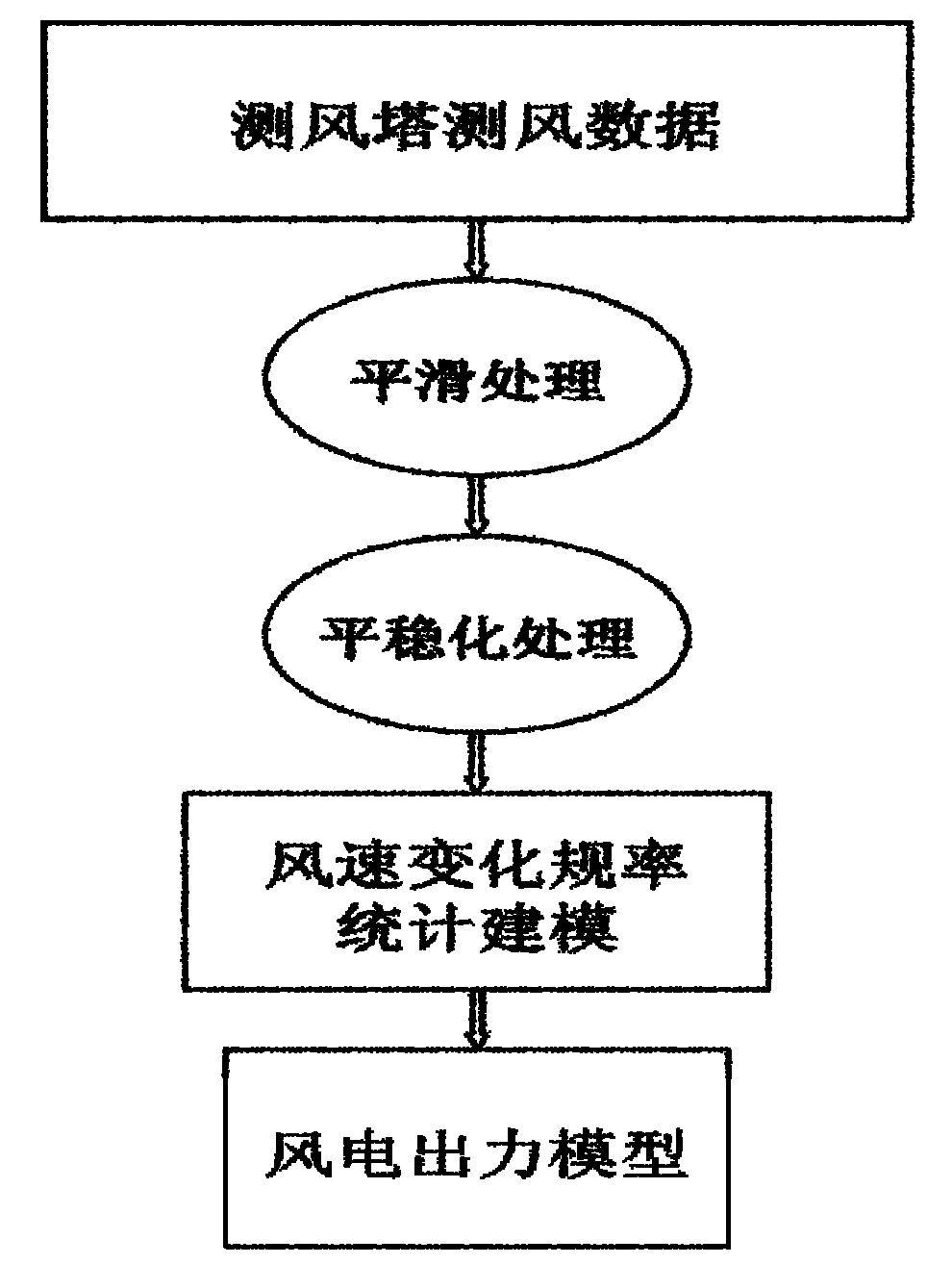

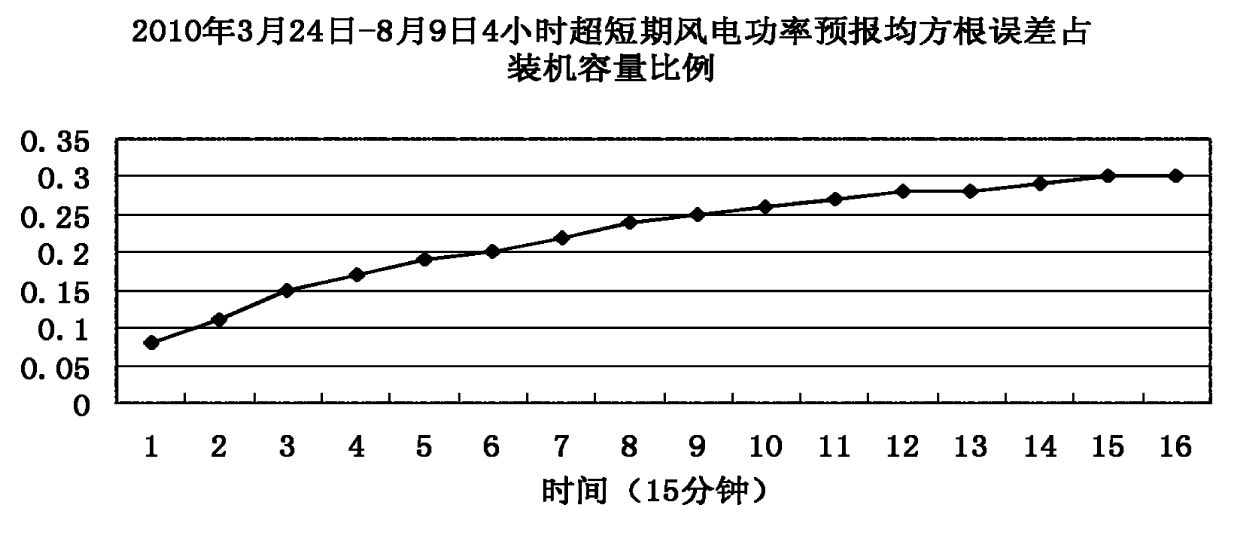

Ultra-short term wind power forecasting method based on time series method

ActiveCN102055188ALess restrictiveImprove forecast accuracyClimate change adaptationSingle network parallel feeding arrangementsEngineeringData treatment

The invention discloses an ultra-short term wind power forecasting method based on a time series method. The forecasting method comprises the following steps: 1. gathering wind measurement data of an anemometer tower adjacent to a wind power station; 2. processing data: carrying out smoothing and stabilizing treatments on the wind speed recorded by the anemometer tower; 3. carrying out wind speedprediction modeling by utilizing the time series method, respectively modeling the wind speed data subjected to the smoothing and stabilizing treatments in the step 2 according to a forecasting time resolution, and establishing 16 prediction models, and figuring out the forecast wind speed within 0-4 hours; and 4. calculating the ultra-short term wind power: calculating the prediction models which are used for forecasting the wind speed input wind power to obtain a wind power prediction result within the forecast validity. By utilizing the method provided by the invention, the wind power output within 0-4 hours of the wind power station can be forecast in a rolling mode, reasonable data support can be provided for electric network frequency modulation and the maintenance of the stable operation of the electric network, so that a dispatching department can adopt solutions in advance for various mutational situations caused by haste changes of the wind power during the electric network operation by the dispatching department.

Owner:NORTHWEST CHINA GRID

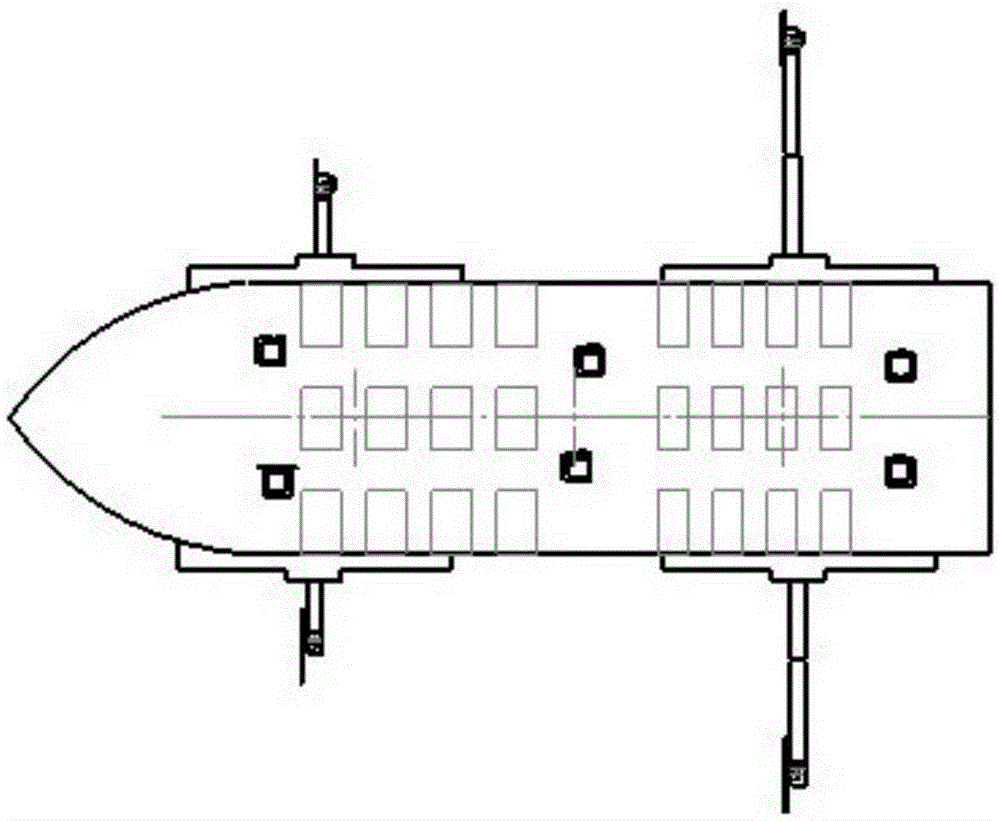

Electricity generation ship capable of comprehensively utilizing renewable energy sources

ActiveCN105240220AObvious effects in energy saving and emission reductionGuarantee the initial power consumption of developmentWater resource protectionWaterborne vesselsTidal current energyCell panel

The invention aims at providing an electricity generation ship capable of comprehensively utilizing renewable energy sources. The electricity generation ship comprises a photovoltaic electricity generation cell panel, a wind electricity generation set and a hydro electricity generation set, and independent photovoltaic electricity generation, wind electricity generation and hydro electricity generation can be carried out. The photovoltaic electricity generation cell panel, the wind electricity generation set and the hydro electricity generation set can be connected into a chip power grid at the same time for grid-connected electricity generation. When the hydro electricity generation set participates in electricity generation, a ship body is generally fixed, and a nose faces water flow. When only the photovoltaic electricity generation cell panel and the wind electricity generation set carry out electricity generation, the ship can run. Offshore wind energy, solar energy and tidal current energy are used for electricity generation to guarantee electricity in the initial stage of development of islands, and the ship can run to various islands and offshore platforms badly in need of electric energy to provide electric energy. Therefore, compared with other ships, the electricity generation ship is remarkable in effect of energy saving and emission reduction, and the emission of greenhouse gases is reduced to a large degree.

Owner:HARBIN ENG UNIV

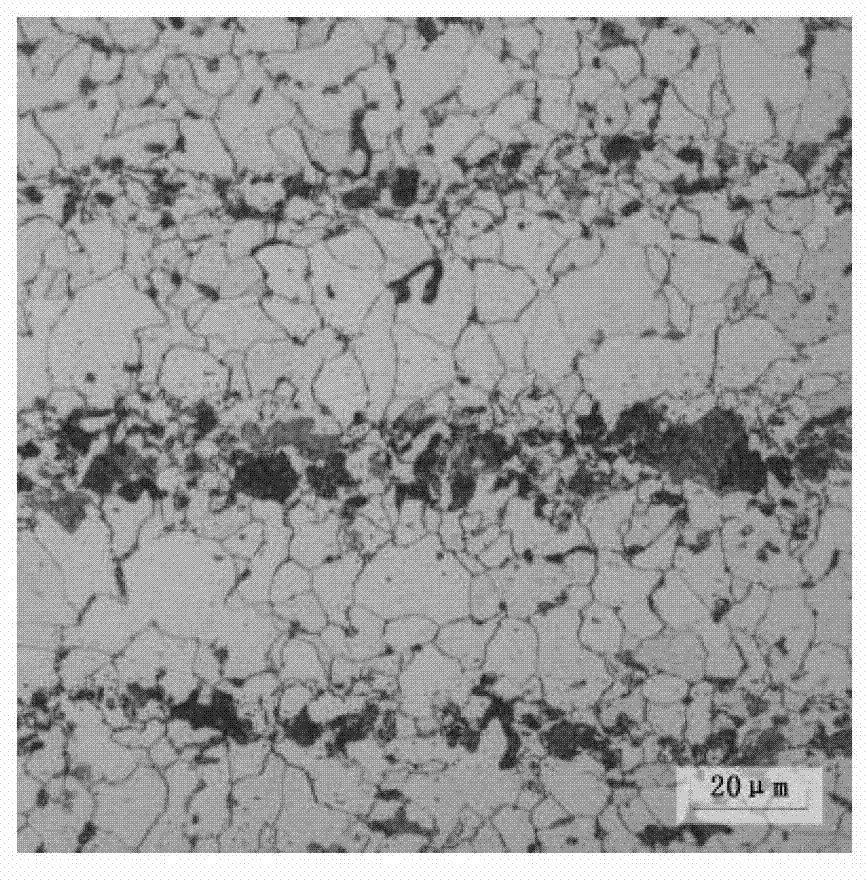

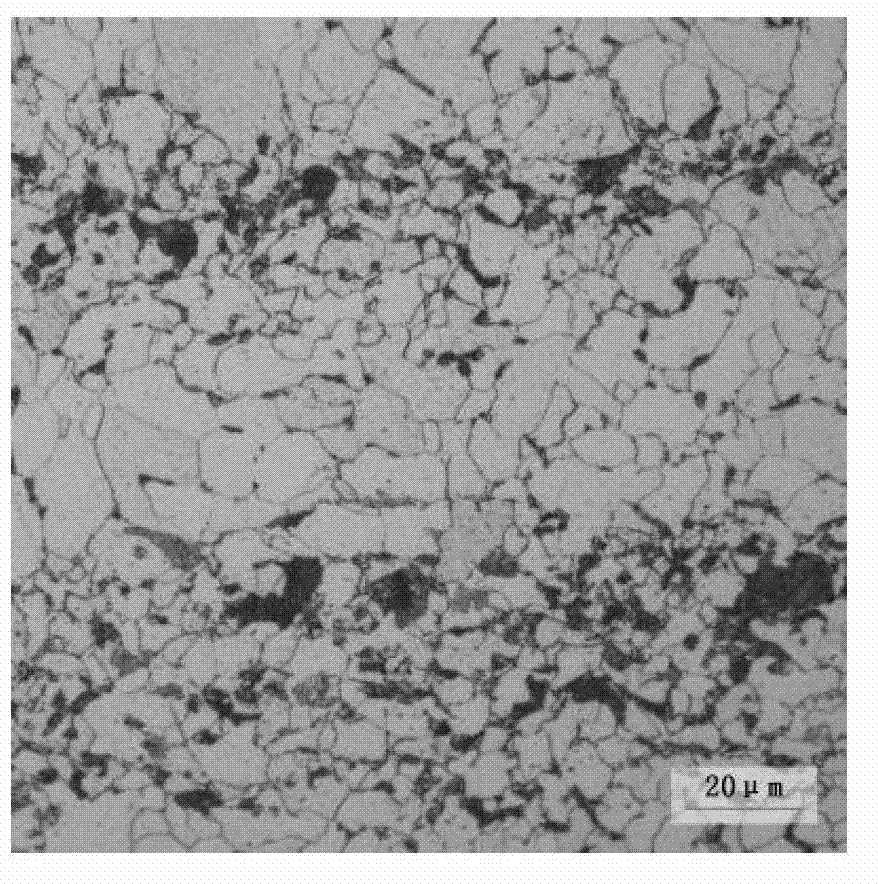

Production method of wide and heavy steel plate with excellent ultra-low-temperature toughness used for offshore wind power

The invention discloses a production method of a wide and heavy steel plate with excellent ultra-low-temperature toughness used for offshore wind power, belonging to the technical field of rolling of the wide and heavy steel plate used for offshore wind power through a continuous coasting blank. The production process comprises the steps of: molten iron, converter smelting, LF (Ladle Furnace) refining, RH (Ruhstahl Hausen) vacuum degassing, continuous casting, steel blank check, heating, phosphorous removal, rough rolling, fine rolling, ACC (Activated Calcium Carbonate) water cooling, straightening, cooling in pile, shearing, shot blasting, normalizing, checking and storage. According to the European EN110225 standard, on the basis of the continuous casting blank, through adding micro-alloying elements, such as Nb, V, Ti and the like, and reasonably controlling rolling, a cooling process and a normalizing heat treatment method, the production yield strength is 355-410 MPa, the strength of extension is 470-550 MPa, the coefficient of elongation is 26-36%, the average value of the percentage of contraction of a section in a direction Z is 35-81%, the impact absorbing energy of a core part of the steel plate at ultra-low temperature of -60 DEG C is 100-240 J, and meanwhile, the wide and heavy steel plate has steel with good using performance as well as the thickness is 40-130 mm, and the specification is S355G8+N.

Owner:QINHUANGDAO SHOUQIN METAL MATERIAL +1

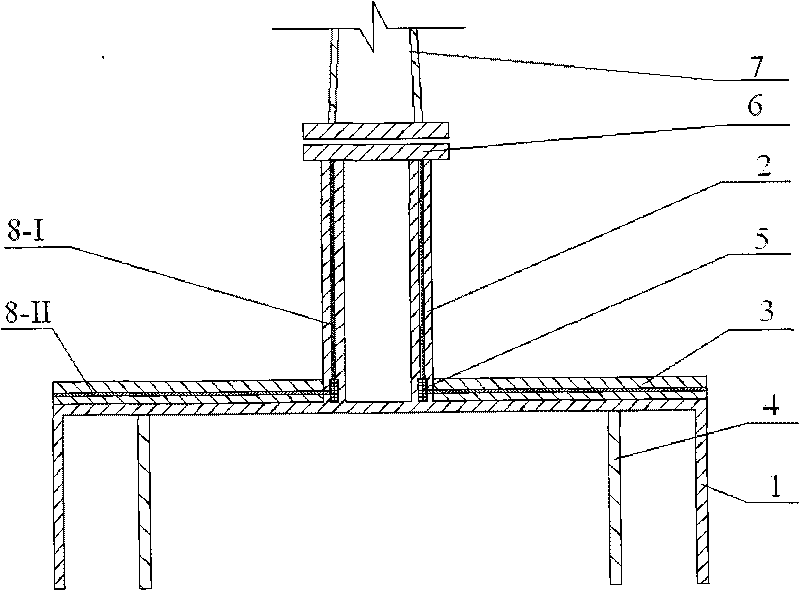

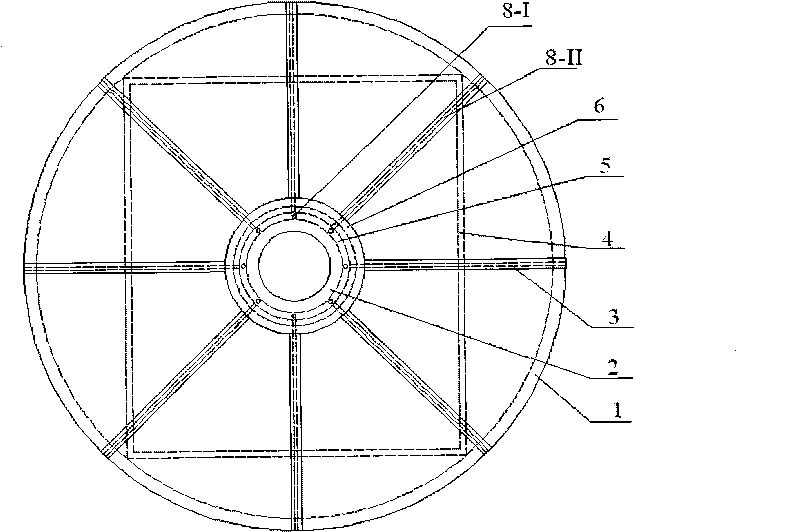

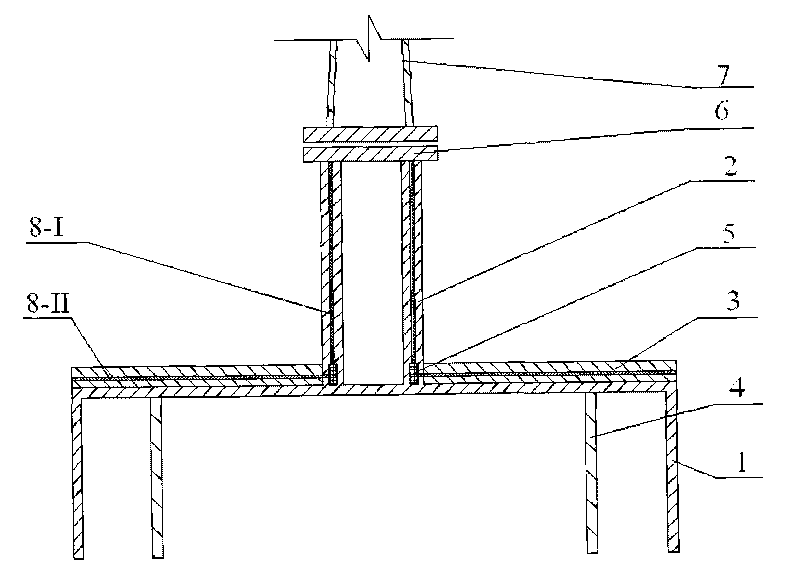

Offshore wind power unit foundation adopting prestressed concrete cylindrical structure

The invention discloses an offshore wind power unit foundation using a prestressed concrete cylindrical structure, consisting of a cylindrical foundation, prestressed cross beams and a connecting stepped drum, wherein the cylindrical foundation is in a reinforced steel bar concrete cylindrical structure and internally provided with clapboards for separating a bin; the prestressed cross beams are arranged on a sealing coping of the cylindrical foundation and radially and evenly distributed; the connecting stepped drum is in a prestressed concrete cylindrical structure; the lower end of the connecting stepped drum, the reinforced steel bar concrete cylindrical foundation and the prestressed cross beams are poured into a whole; metal rings are arranged on the joint parts; and a flange plate is arranged at the upper end of the connecting stepped drum and fixedly connected with the stepped drum of an electric generating set. The invention has the advantages that: the offshore wind power unit foundation has simple structure, convenient construction, small construction quantity, low construction cost and favorable load-carrying capability, and can be prefabricated on land and reach the construction position by traction, towing and floating so as to reduce the transportation cost; and with the prestressed concrete structure, the invention can effectively improve the structural strength, reduce the dead weight of the foundation, save materials and improve the durability and the corrosion resistance of the structure.

Owner:JLANGSU DAODA OFFSHORE WIND CONSTR TECH

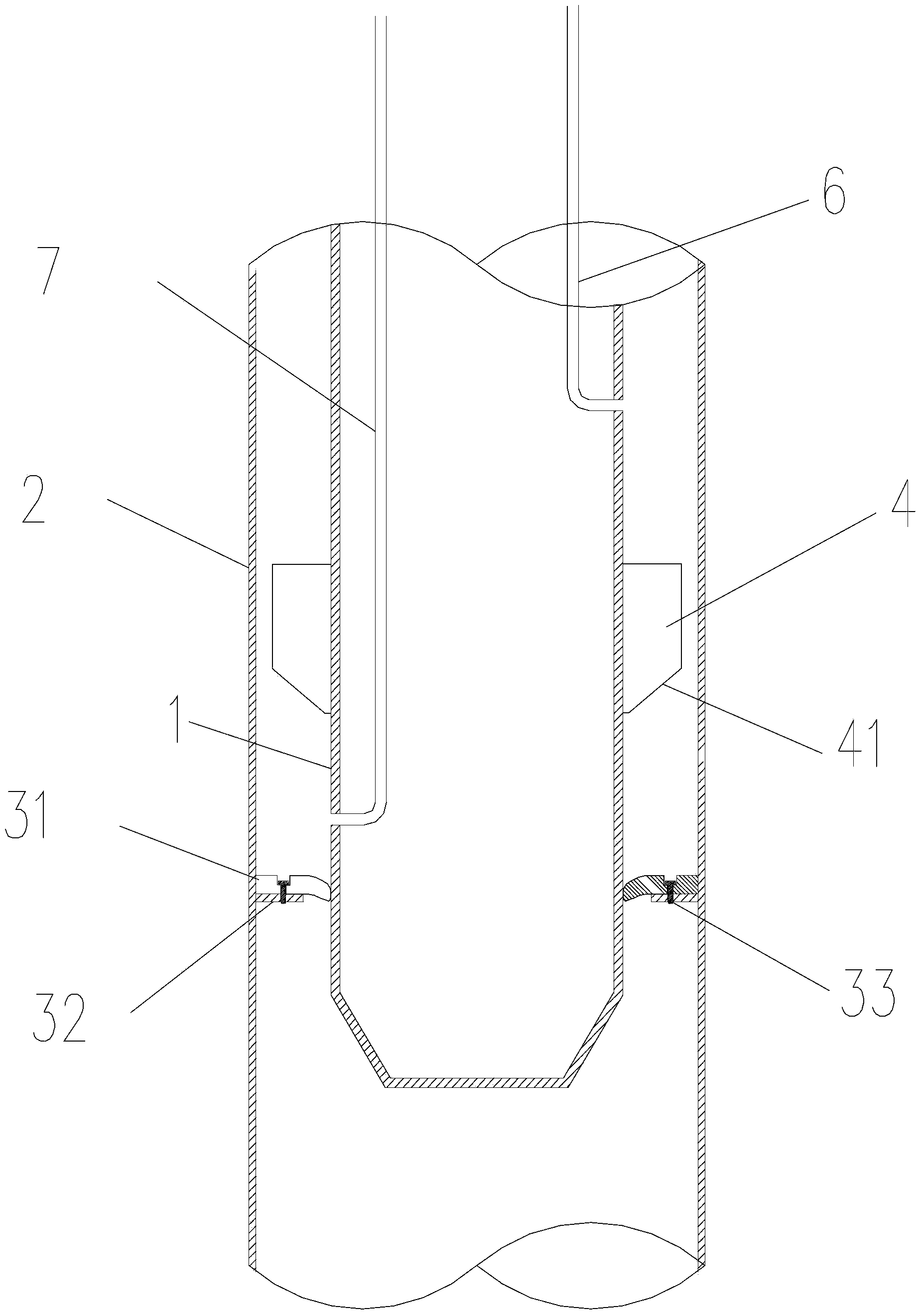

Offshore wind power spar buoyant foundation capable of towing

ActiveCN105438411AReduce resistanceSkip the dry mopping processFoundation engineeringFloating buildingsStress concentrationFatigue damage

The invention relates to an offshore wind power buoyant foundation form and in particular relates to an offshore wind power spar buoyant foundation capable of towing, which comprises a connecting column and is characterized in that the upper end of the connecting column is connected with a fan through a flange ring, a plurality of flat columnar closed air flotation boxes are arranged at the middle part of the connecting column, the closed air flotation boxes are not communicated with the connecting column, and the bottom of the connecting column is communicated with a loading cabin; a column body of the connecting column is provided with a detachable gear required for towing; and a mooring rope is arranged at the center of gravity of the buoyant foundation. Compared with the prior art, the offshore wind power spar buoyant foundation provided by the invention has the beneficial effects that the construction is convenient, rolling towage can be realized, the resistance of a wave flow is reduced, the stress concentration and fatigue damage caused by the traditional spar foundation in a wet towing process are avoided, the construction difficulty and construction cost are greatly reduced, and the offshore wind power spar buoyant foundation can be recycled. The additional mass and viscous damping of heave motion are effectively improved by virtue of the flat air flotation boxes, the water surface profile area of a buoy is effectively increased by virtue of the flat air flotation boxes on the water surface, a relatively large restoring moment is provided, the structure stability is relatively good, the center of gravity is lower than the center of flotation, and the resistance to capsizing is good.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST

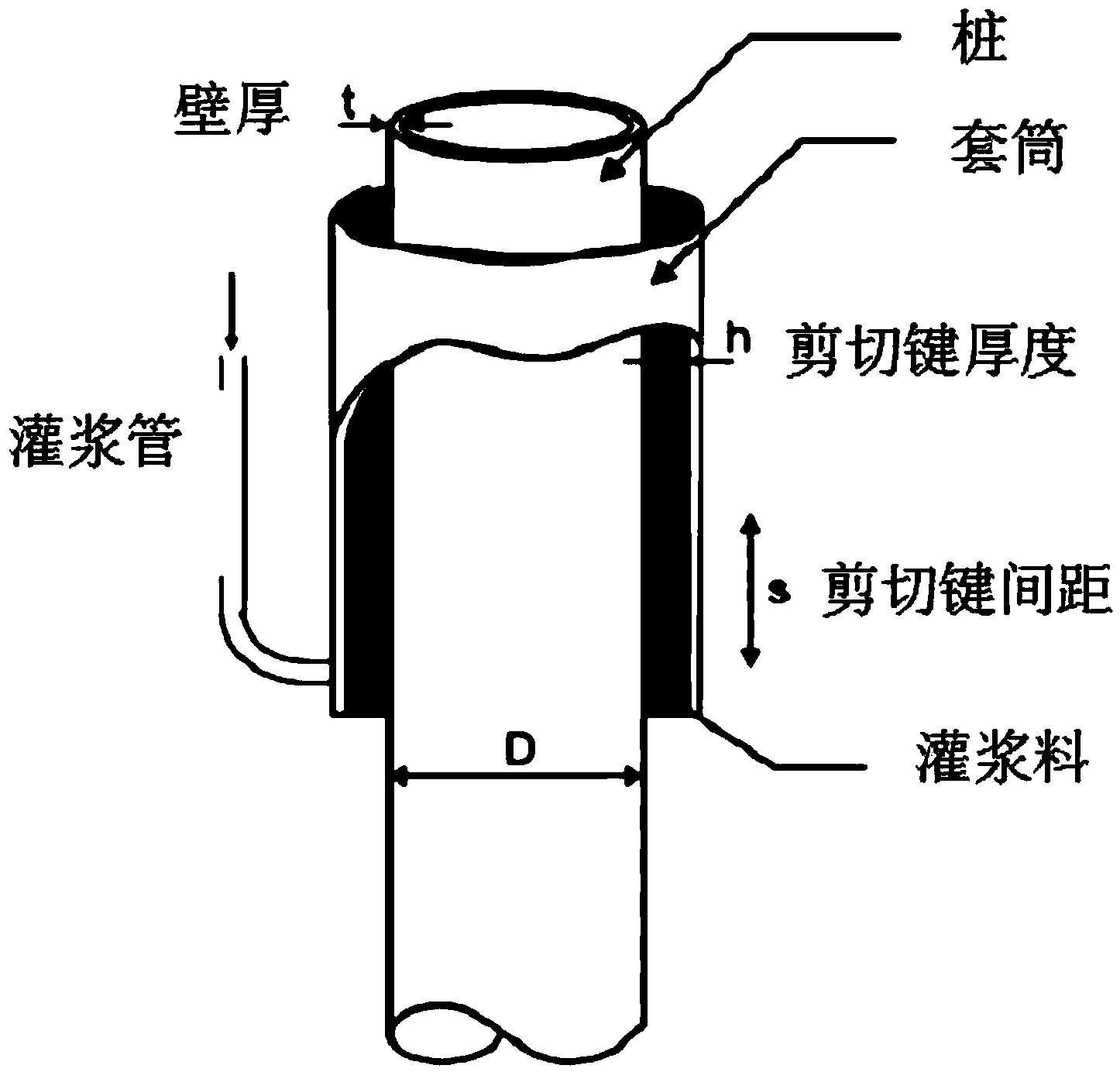

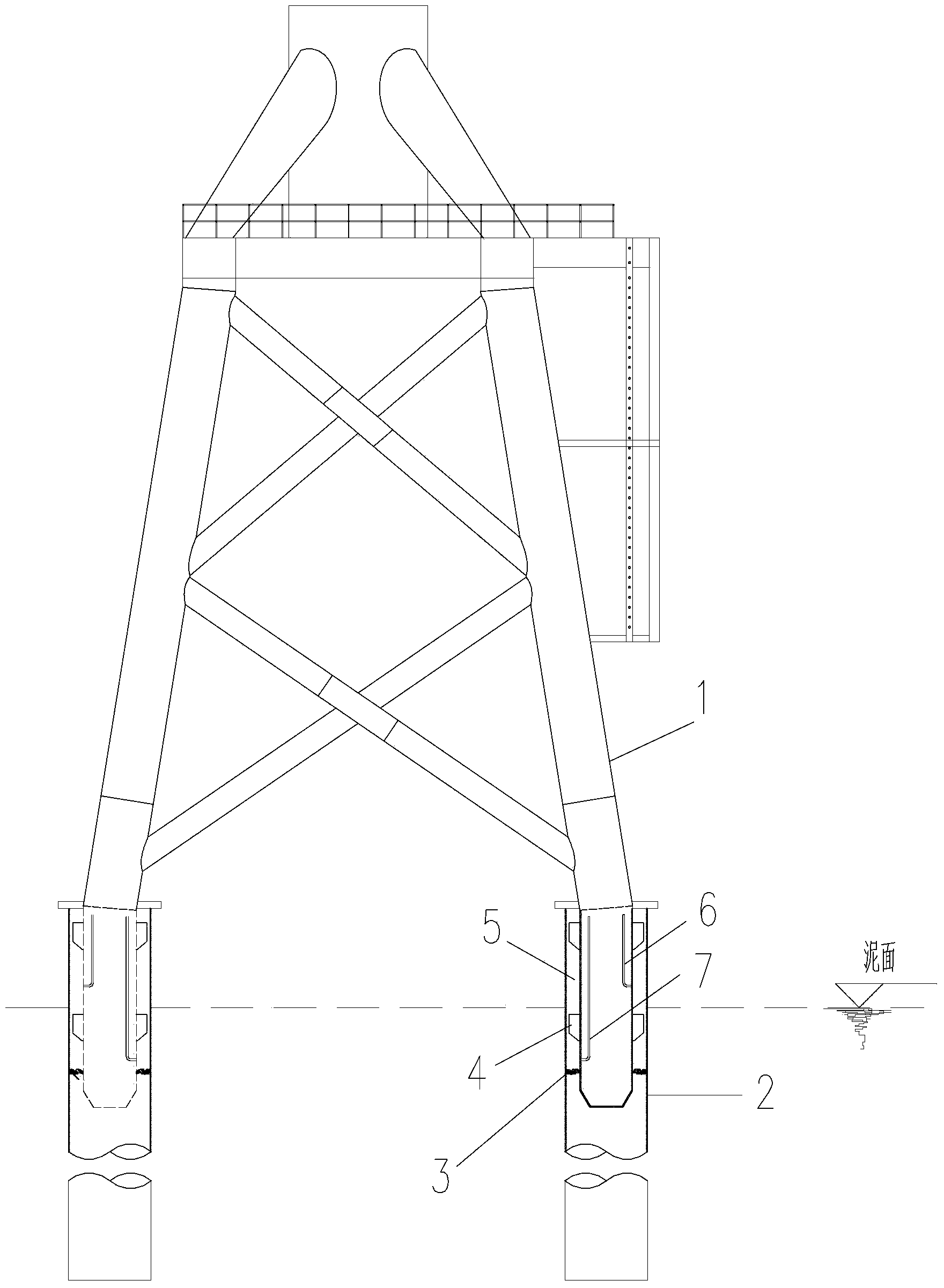

Connecting structure for jacket foundation and underwater pile foundation of offshore wind turbine and grouting method

ActiveCN103437372AInsert evenlyUniform Volume CircumferenceFoundation engineeringOcean bottomStructural engineering

The invention discloses a connecting structure for a jacket foundation and an underwater pile foundation of an offshore wind turbine, which comprises column-shaped piles on the jacket foundation of the wind turbine and tubular underwater piles, the piles correspond to the underwater piles, and are inserted into the top orifices of the underwater piles and suspended in the underwater piles, an annular stopper is arranged between the inner wall of each underwater pile and the inserted head of each pile, an annular grouting cavity is defined by the annular stopper, the pile and the underwater pile, a high-position grouting tube and a low-position grouting tube are arranged in each pile, the wall of each pile is correspondingly provided with a high-position grouting orifice and a low-position grouting orifice which communicate with the grouting cavity, the high-position grouting tubes are connected with the high-position grouting orifices, and the low-position grouting tubes are connected with the low-position grouting orifices. The purpose of the invention is to provide the connecting structure for the jacket foundation and the underwater pile foundation of the offshore wind turbine and a grouting method in order to overcome the defects of conventional offshore platform grouting processes and adapt to the structural characteristics of offshore wind power foundations.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

Buoyancy type mounting method for offshore boosting station

ActiveCN102587342ALower requirementFlexible scheduleArtificial islandsUnderwater structuresOffshore wind powerLightering

The invention relates to a buoyancy type mounting method for an offshore boosting station, which aims to be safe and high-efficiency, save expense and have low requirements on ship machines and equipment. The technical scheme includes that the buoyancy type mounting method for the offshore boosting station is characterized by comprising steps of a, building the offshore boosting station on the land; b, sliding the offshore boosting station on a barge, conveying the offshore boosting station to a specified mounting position, judging whether the bottom of a support of the offshore boosting station is higher than the top end of a foundation or not, executing a step d if the bottom of the support of the offshore boosting station is higher than the top end of the foundation, and executing a step c if the bottom of the support of the offshore boosting station is not higher than the top end of the foundation; c, controlling the barge to ascend; d, leading the barge to move into a gap of the middle of the foundation and positioning the barge; e, controlling the barge to descend, placing the support of the offshore boosting station on the foundation, simultaneously, leading the barge to continue descending until the barge is separated from the offshore boosting station, and then dragging the barge out from the bottom of the offshore boosting station; and f, welding the support with the foundation. The buoyancy type mounting method is applicable to the field of offshore wind power generation.

Owner:中电建新能源集团股份有限公司

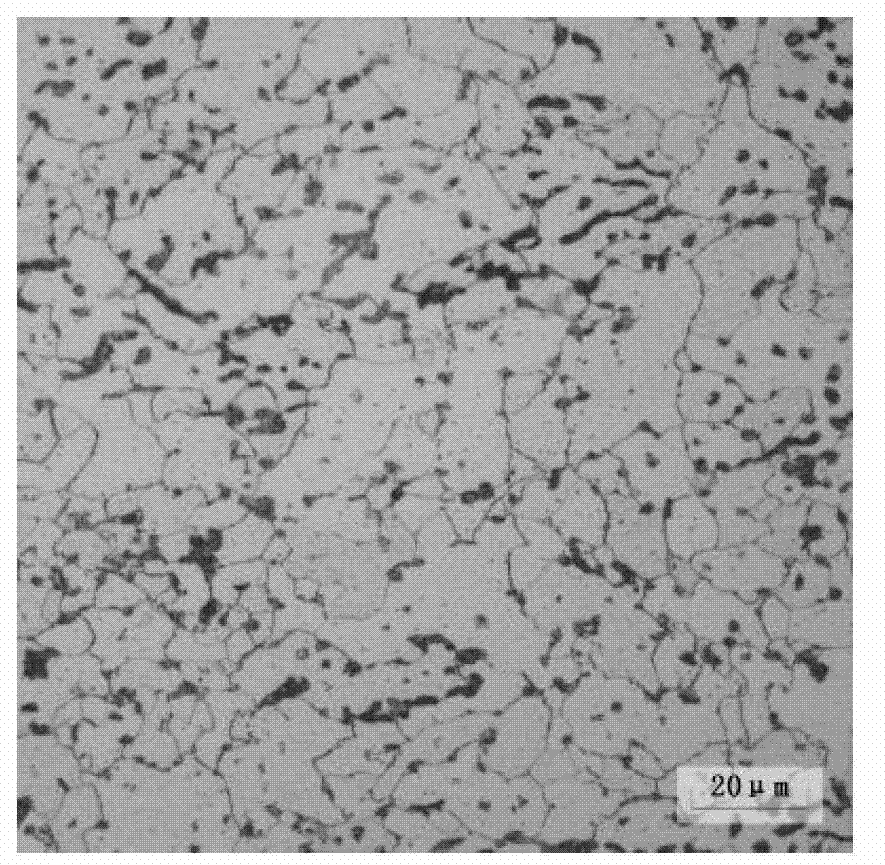

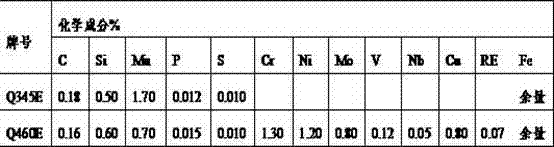

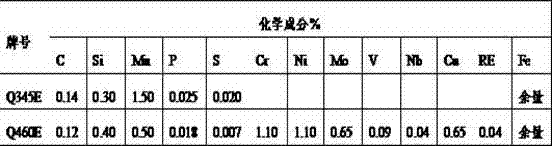

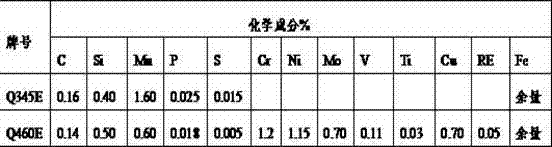

Material used in offshore wind power equipment, and workpiece manufacturing process

ActiveCN102851609AHigh yield strengthHigh tensile strengthFurnace typesHeat treatment furnacesRare earthImpurity

The invention discloses a material used in offshore wind power equipment, and a workpiece manufacturing process. The material comprises the chemical components of carbon, silicon, manganese, phosphorous, sulfur, chromium, nickel, molybdenum, vanadium, copper and rare earth, and balance of iron and inevitable impurities. According to the invention, through steps of high-quality molten iron selecting, KR molten iron pre-treating, top and bottom composite converter blowing, argon blowing treating, LF furnace refining, VD vacuum degassing treating, round billet continuous casting, heap cooling, sawing and blanking, billet heating, free forging, punching, fine coining, heat treating, mechanical processing, flaw detecting, inspecting, packaging, storing, and the like, a material used in key components of offshore wind power equipment of more than 5 megawatts can be produced. The material is advantageous than Q345E-performance steel, high yield strength, good low-temperature impact toughness, and better marine-atmosphere-corrosion resistance. The invention adopts a serried of optimizing technical measures upon smelting and manufacturing processes of the steel, such that user requirements are satisfied.

Owner:JIANGYIN HENGRUN HEAVY IND

Installation equipment of above-water wind generator and construction method thereof

InactiveCN101565091ASimple structureEasy to buildWind motor assemblyWind motor supports/mountsTowerWind force

The invention provides an installation equipment of an above-water wind generator and a construction method thereof, belonging to the technical field of above-water wind power generation, comprising a hoisting ship, a transportation barge, a hoisting machine, a hoisting ring, a telescopic floating cylinder, an inflation device, a supporting leg and a lifting device, wherein four supporting legs are fixedly arranged below the hoisting ship; the circumference of the hoisting ship is fixedly provided with a plurality of telescopic floating cylinders; the hoisting machine is fixedly arranged vertically right at the center of the upper deck of the hoisting ship; 2-10 hoisting rings are symmetrically and fixedly arranged at two sides of the hoisting machines on the upper deck of the hoisting ship respectively; the hoisting rings are connected with the back rods of the hoisting machine by wire ropes; and the circumference of the transportation barge is provided with the telescopic floating cylinders and the inflation device. The installation equipment can carry out the installation operation of the marine wind power generation towel pile foundations and fans within 0.3-5m of water depth, greatly improve the installation efficiency of the marine wind power generation towers and reduce the construction cost of the marine wind power generation fields.

Owner:LICE SCI & TECH SHANGHAI

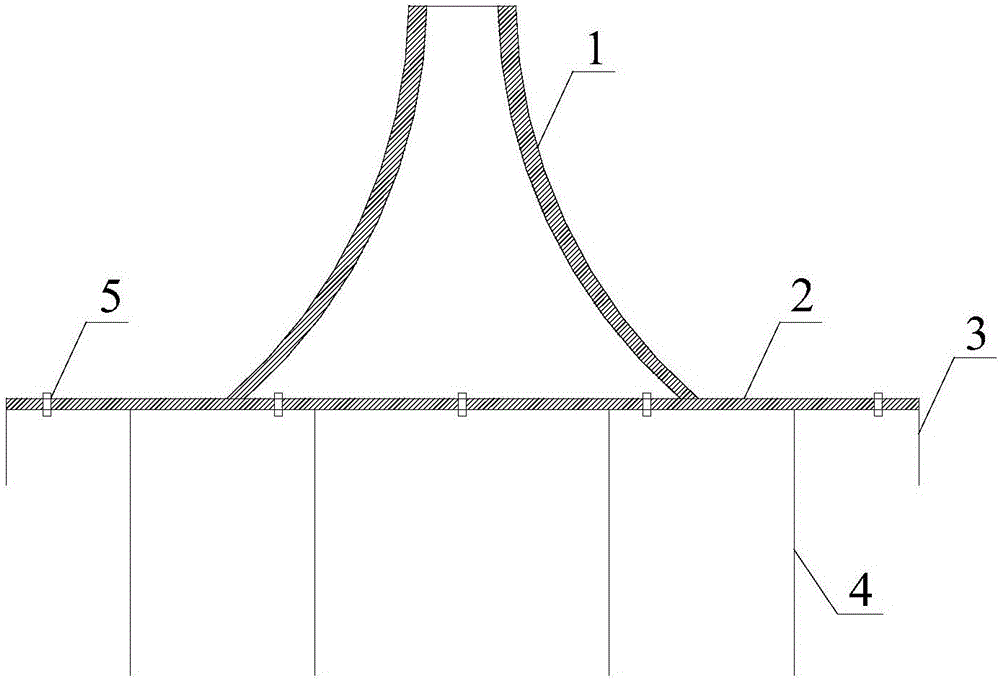

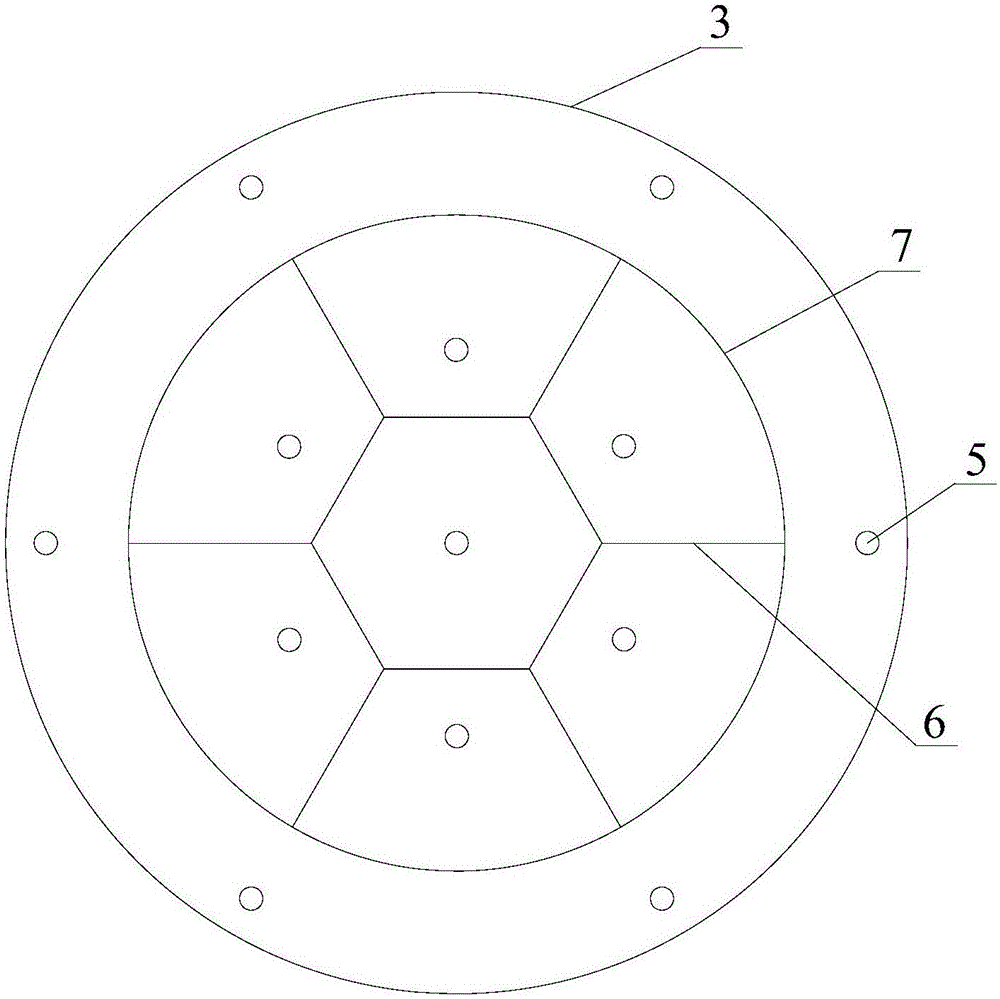

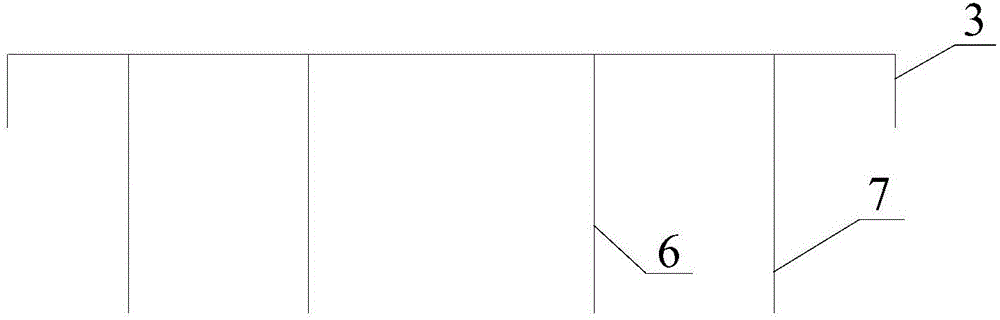

Offshore wind power combined barrel-shaped base

PendingCN107761755ALower requirementSolve difficultyFoundation engineeringMarine engineeringOffshore wind power

The invention discloses an offshore wind power combined barrel-shaped base. The offshore wind power combined barrel-shaped base comprises an upper force transmission transition section and a lower barrel-shaped structure; the upper force transmission transition section consists of a vertical steel pipe and inclined strut steel pipes; the barrel-shaped structure comprises a barrel skirt-board, a barrel top cover, bin dividing plates, I-steel beams, I-steel beam rings, a concrete top cover, support steel plates and reinforcement ribs; the semi-closed barrel-shaped structure with a downward opening is formed by the barrel skirt-board and the barrel-shaped top cover; the bin dividing plates are arranged in the semi-closed barrel-shaped structure to divide the semi-closed barrel-shaped structure into 7-15 separate semi-closed bins with downward openings; the 6-12 I-steel beams are radially and uniformly arranged on the barrel top cover, and the 3-6 ring beams are annularly arranged on the barrel top cover; the I-steel beams, the I-steel ring beams and the support steel plates are separately provided with reinforcement ribs; and the concrete top cover is arranged on the barrel top cover.By adopting the offshore wind power combined barrel-shaped base, the problems of a combined barrel-shaped base in the prior art that the structural mode is single; the application range is small; concrete prefabrication is complicated; and the like are solved.

Owner:TIANJIN UNIV

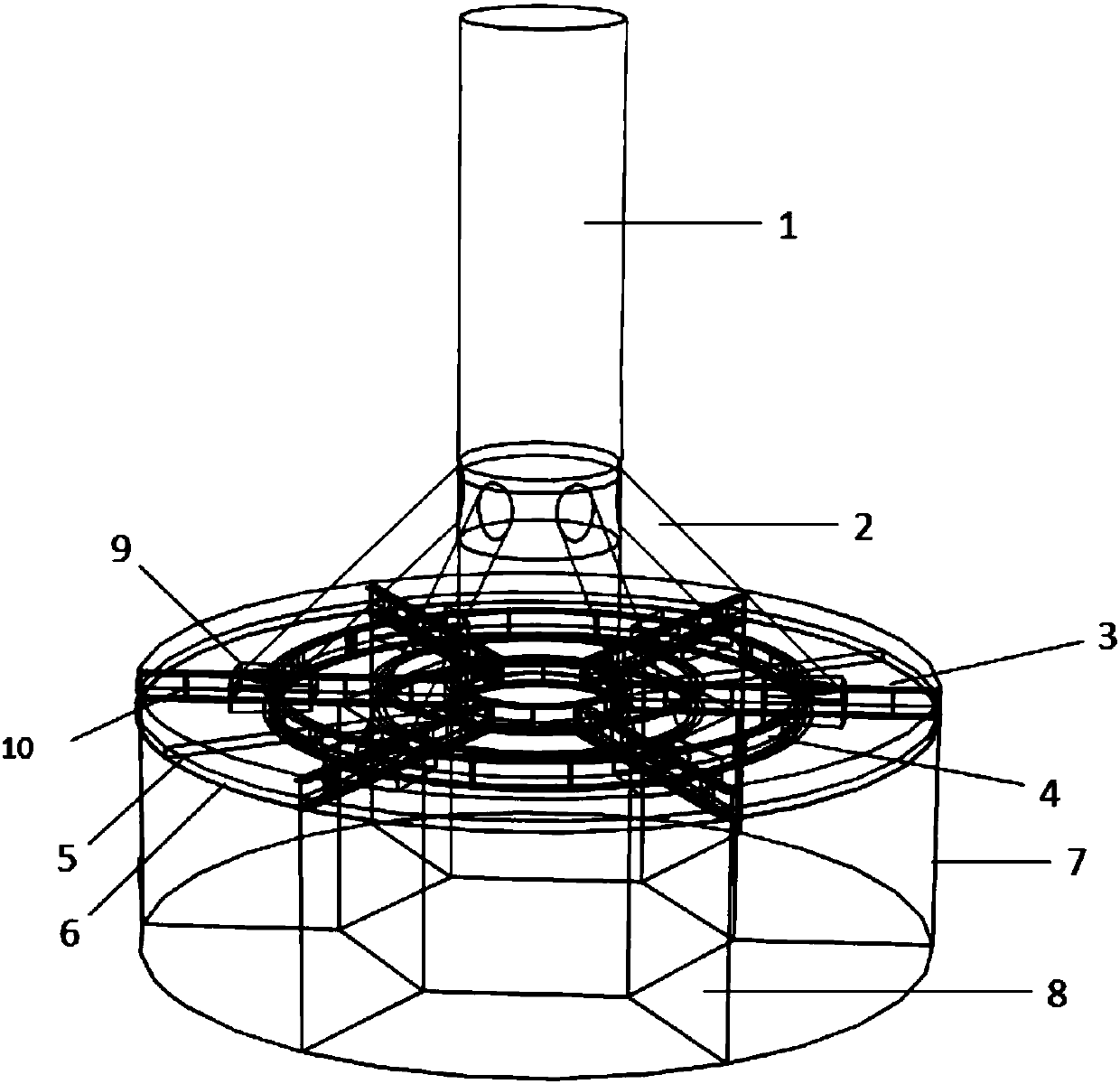

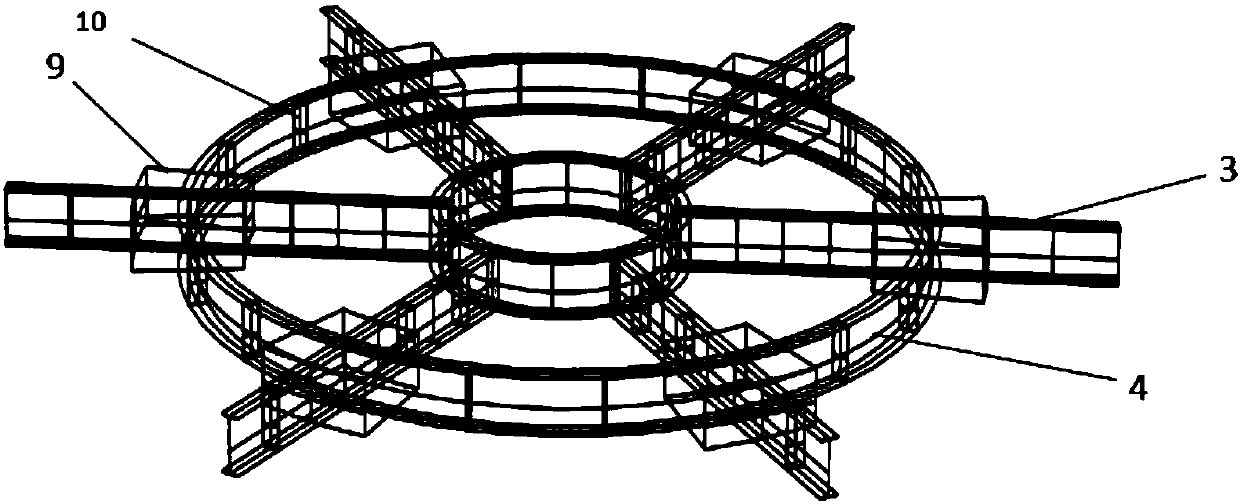

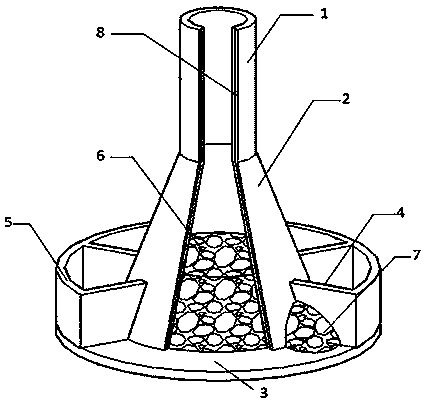

Gravity type offshore wind power foundation capable of towing in self-floating mode and construction method thereof

InactiveCN103758148AReduce dosageReduce construction costsWaterborne vesselsFoundation engineeringElectricityReinforced concrete

A gravity type offshore wind power foundation capable of towing in a self-floating mode is composed of a connecting section, a foundation body, an inner loading heap and outer loading heaps. The foundation body comprises a reinforced concrete conical barrel, a bottom plate, a side wall and ribbed plates. The bottom of the conical barrel is placed at the center of the bottom plate, the side wall is placed on the edge of the circular bottom plate, and the ribbed plates are evenly and radially distributed in an annular space between the conical barrel and the side wall. The bottom plate is fixedly connected with a rock foundation in a grouting manner. The inner loading heap is filled into the conical barrel, and the outer loading heaps are filled into cavities formed among the side wall, the ribbed plates and the bottom plate. Prestressed reinforcing steel bars are arranged both inside the conical barrel and the cylindrical wall of the connecting section, and the conical barrel and the connecting section are connected to be a whole through concrete deposit. The top of a reinforced concrete cylinder of the connecting section is connected with a fan tower barrel through a flange. The gravity type offshore wind power foundation has the advantages of being novel in structure, convenient to construct, fast in prefabricated installation, capable of conducting towing operation in the self-floating mode, short in construction period, large in control capacity, capable of obviously lowering construction cost and reducing construction project amount, and good in economy and applicability.

Owner:THE FRONTIER TECH RES INST OF TIANJIN UNIV

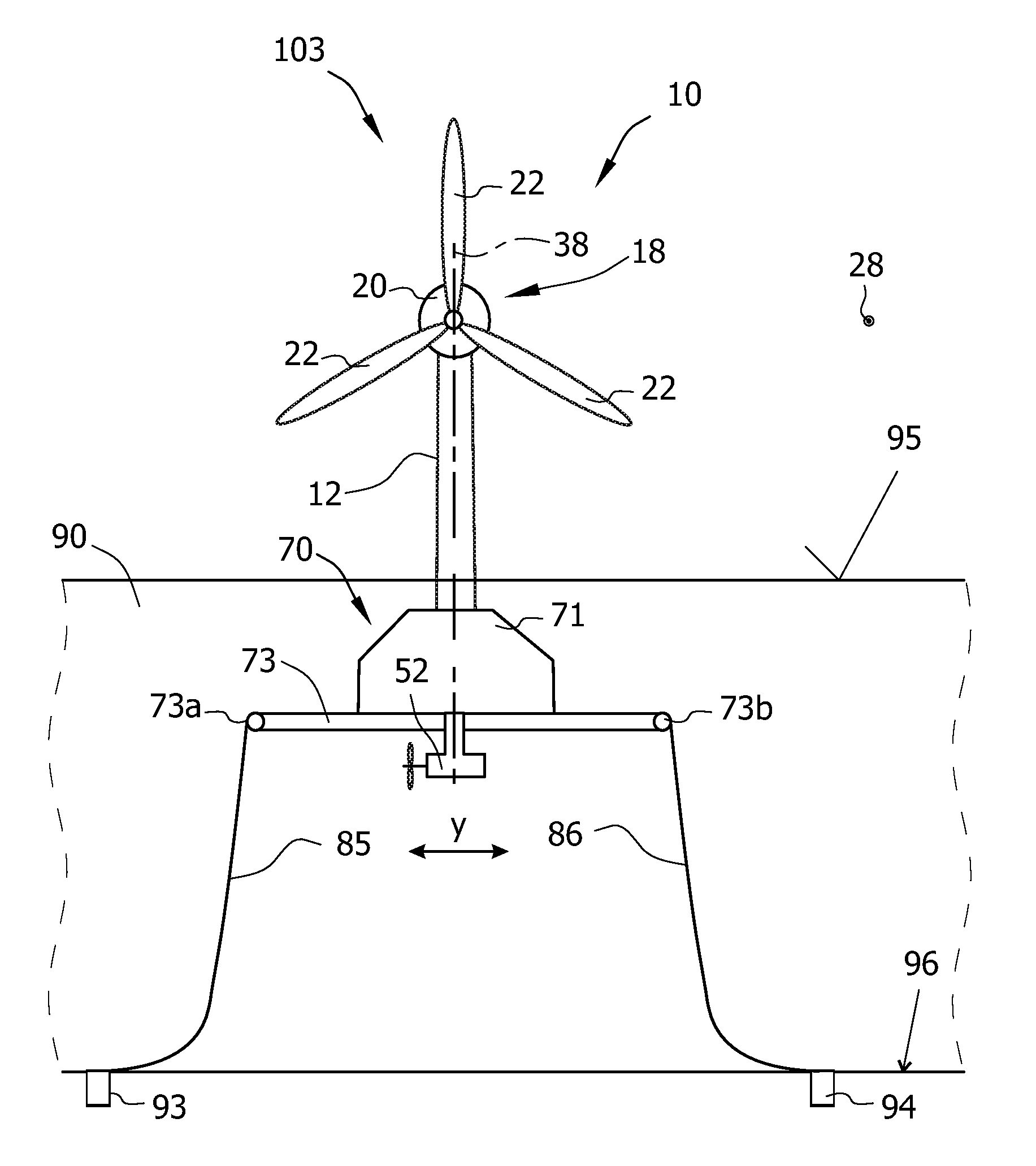

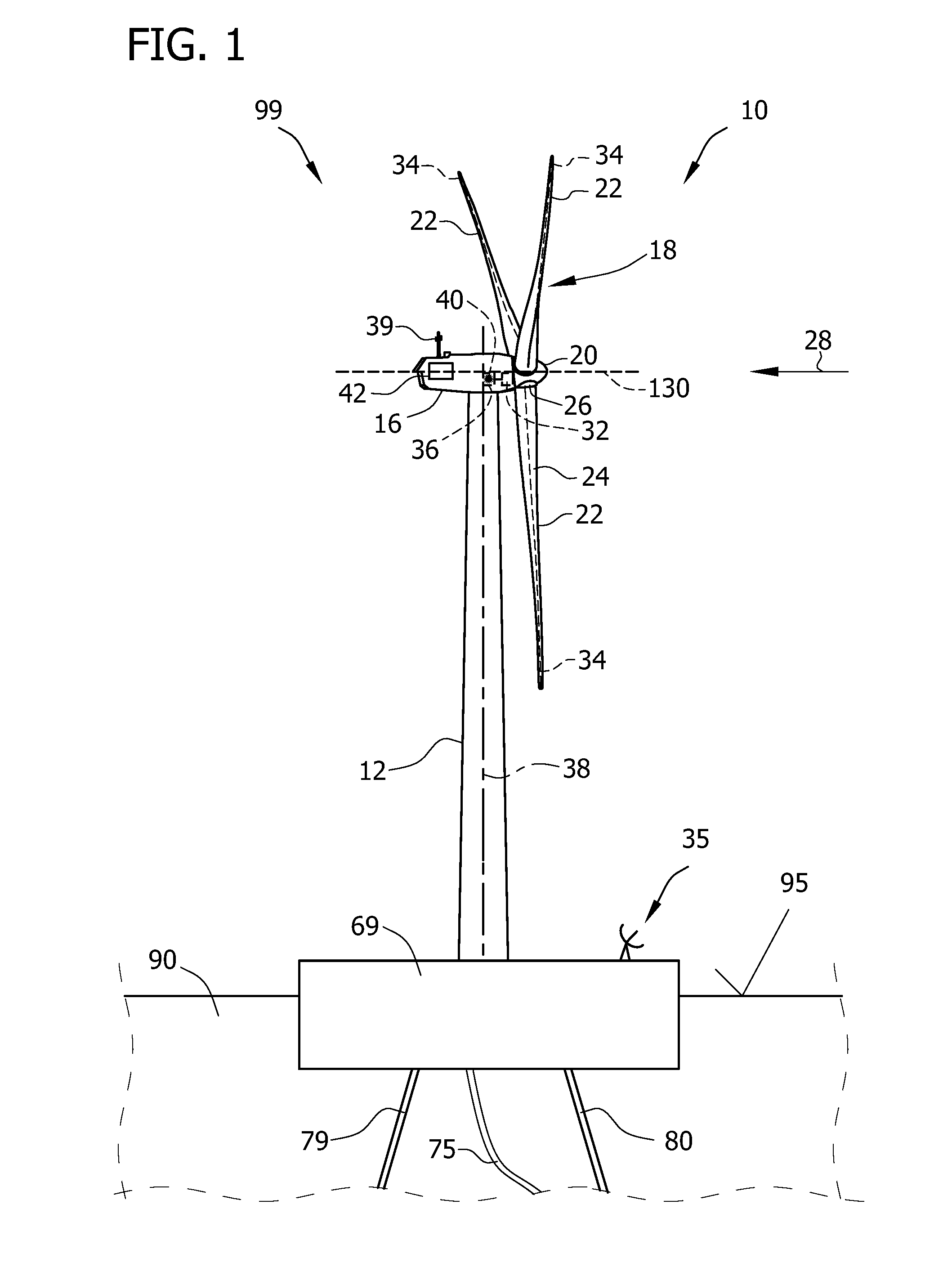

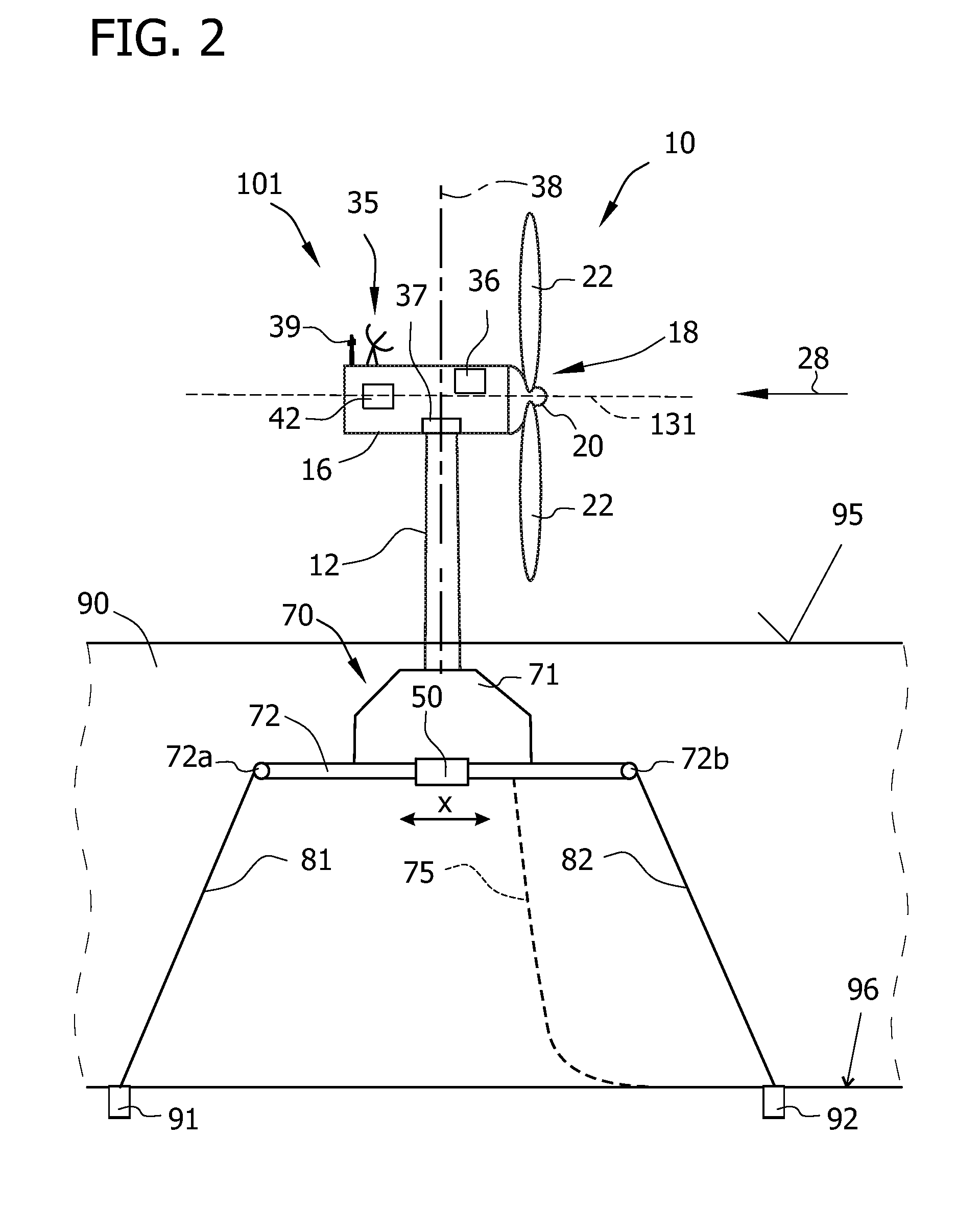

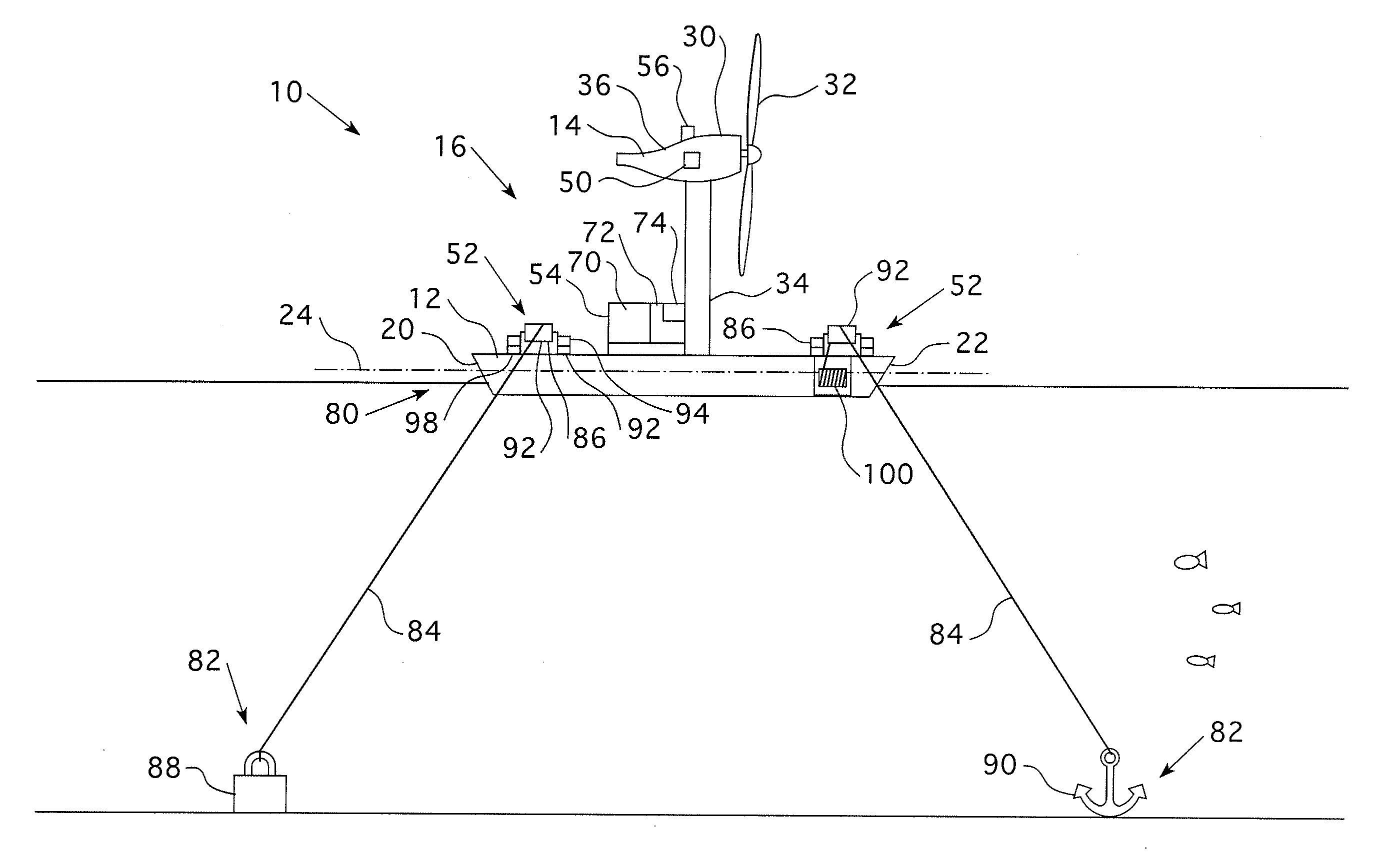

Active control system for floating offshore wind turbine platforms

InactiveUS20120304911A1Reduce relative motionWind motor controlDigital data processing detailsElectricityControl system

A dynamic anchoring system for use in stabilizing a floating platform is provided. The dynamic anchoring system includes a mooring assembly having a plurality of rodes each with an adjustable length. As waves cause the platform to rock, the length of each rode is adjusted in a manner to counteract the motion created by the waves. Thus, the platform remains substantially level. The platform supports a wind turbine on a mast. At least one motion sensor on the mast provides motion data indication the direction and speed of the hull's motion.

Owner:GE ENERGY POWER CONVERSION TECH

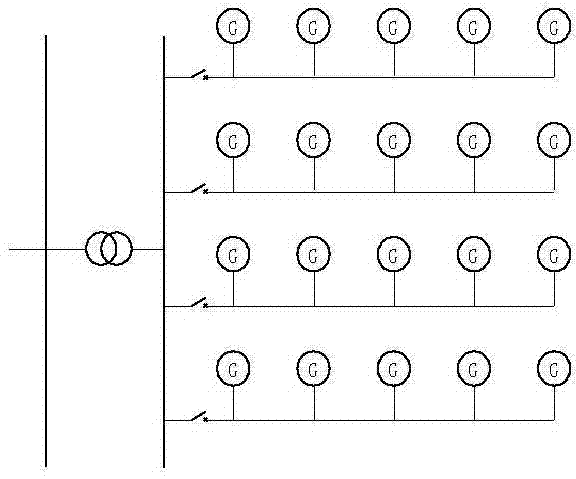

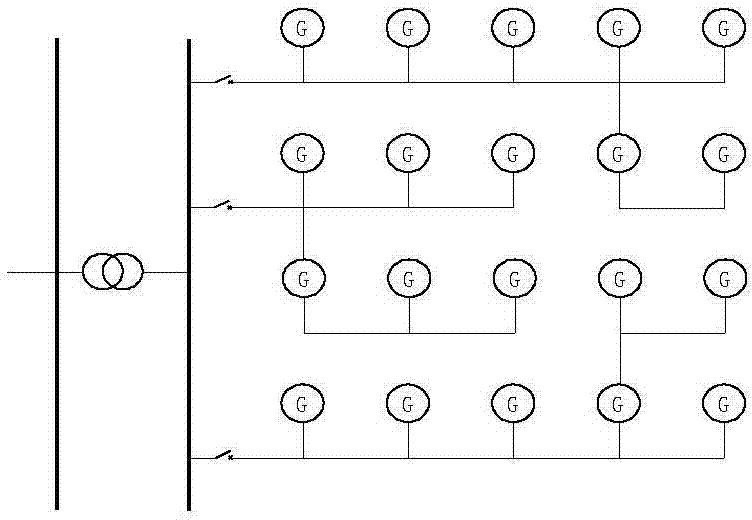

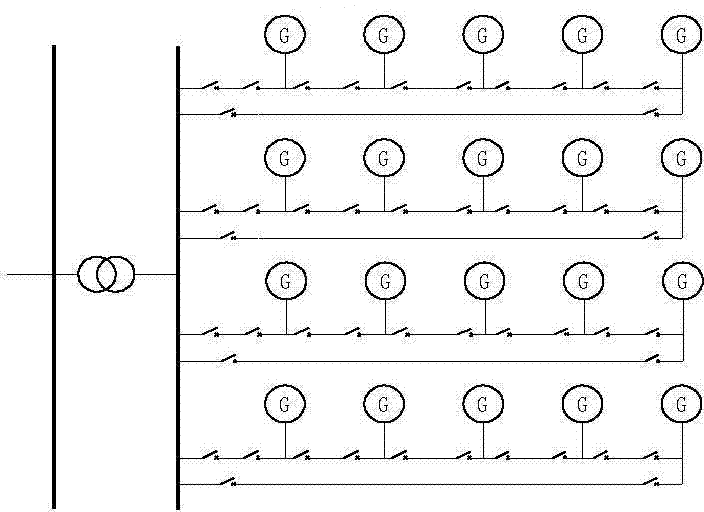

Method for selecting type of topological structure of offshore wind power plant current collecting system

ActiveCN104281737ALow costReduce construction costsSpecial data processing applicationsEngineeringOffshore wind power

The invention discloses a method for selecting the type of a topological structure of an offshore wind power plant current collecting system. The method comprises the following steps of estimating the construction cost of the offshore wind power plant current collecting system; estimating the reliability loss of an offshore wind power plant; estimating the economic cost of the offshore wind power plant current collecting system; primarily selecting the type of offshore wind power plant current collecting system topology to obtain an optimal topology set; performing electric modular modeling simulation on the optimal topology set of the offshore wind power plant current collecting system, and on the basis, estimating electrical voltage supply amount loss of the topological structure; estimating the comprehensive cost of the optimal topology set of the offshore wind power plant current collecting system; selecting the type of the optimal topology set of the offshore wind power plant current collecting system, and selecting the optimal topology of the offshore wind power plant current collecting system. The method is simple and practical, multiple factors required to be considered during type selection of the offshore wind power plant topological structure are uniformly concluded into cost, and the problem that the dimension is not consistent is solved, so that the result is more simple, and quick type selection of the topological structure of the offshore wind power plant current collecting system is facilitated.

Owner:SOUTH CHINA UNIV OF TECH +1

Compound bucket foundation with skirtboard and construction method thereof

InactiveCN106759445AEasy constructionCompact structureFoundation engineeringElectricityReinforced concrete

The invention belongs to the field of offshore wind power foundations and discloses a compound bucket foundation with a skirtboard and a construction method thereof. The foundation comprises a steel bucket structure, a reinforced concrete top cover and a reinforced concrete transitional section; the outer edge of the top cover of the steel bucket structure is expanded out of the steel bucket structure and a steel skirtboard is welded; the lower portion of the reinforced concrete top cover is connected to the steel bucket structure through a shearing force nail and the upper portion is in pouring connection to the reinforced concrete transitional section. The construction method comprises the following steps: performing self-weight submerging and negative pressure submerging successively till the bottom of the steel skirtboard enters a seabed; and then extracting water through a water extraction pipe on the inner wall of the steel skirtboard to increase the sinking force of the compound bucket foundation. The foundation provided by the invention is simple in structure, convenient to construct and low in cost, and self-floating towing and negative pressure sinking can be performed, and the skirtboard is additionally arranged, so that the antidumping and anti-erosion properties of the foundation in normal use can be enhanced. Moreover, the sinking force of the foundation is effectively improved, and meanwhile, soil plug development in the steel bucket foundation is reduced.

Owner:TIANJIN UNIV

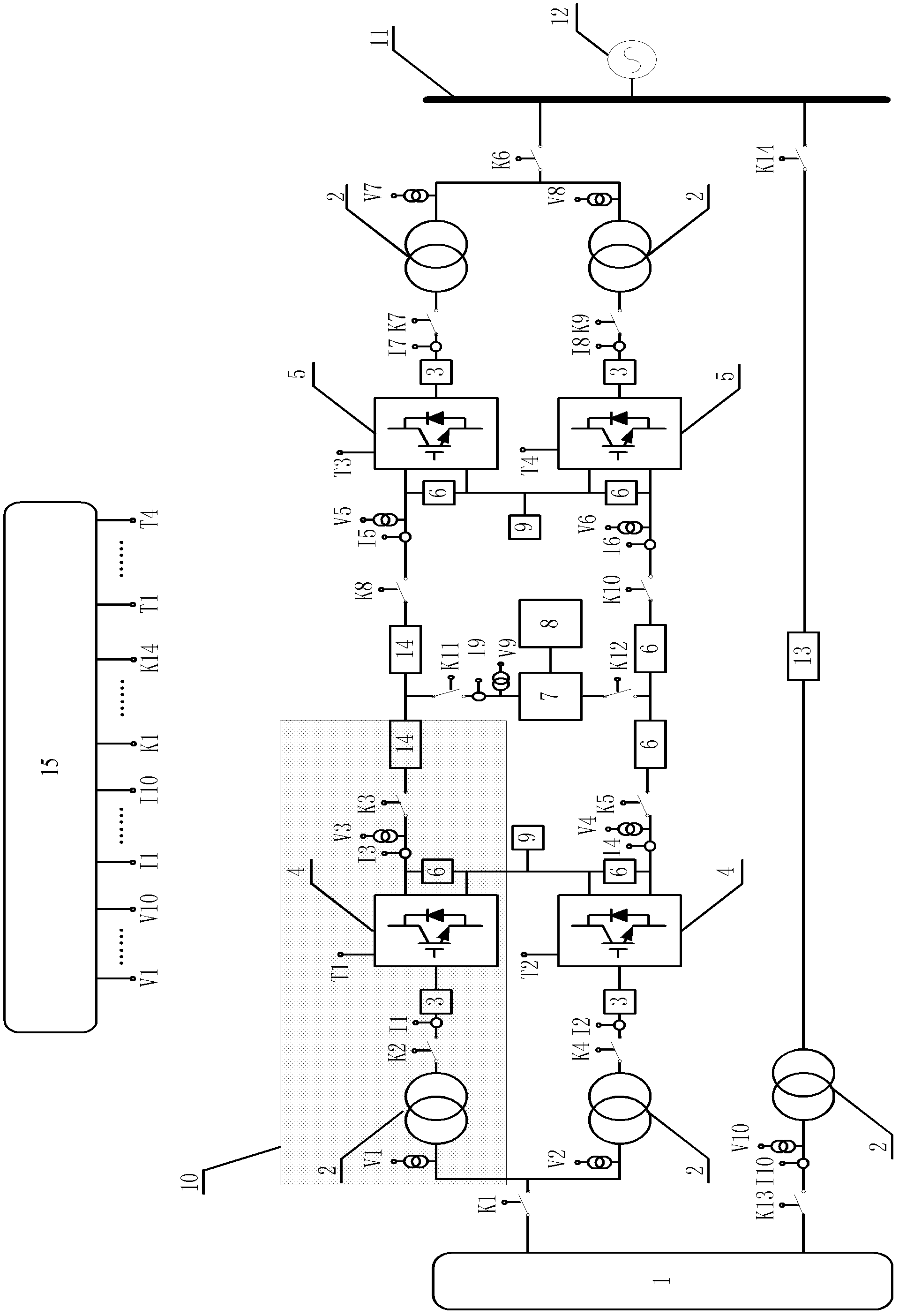

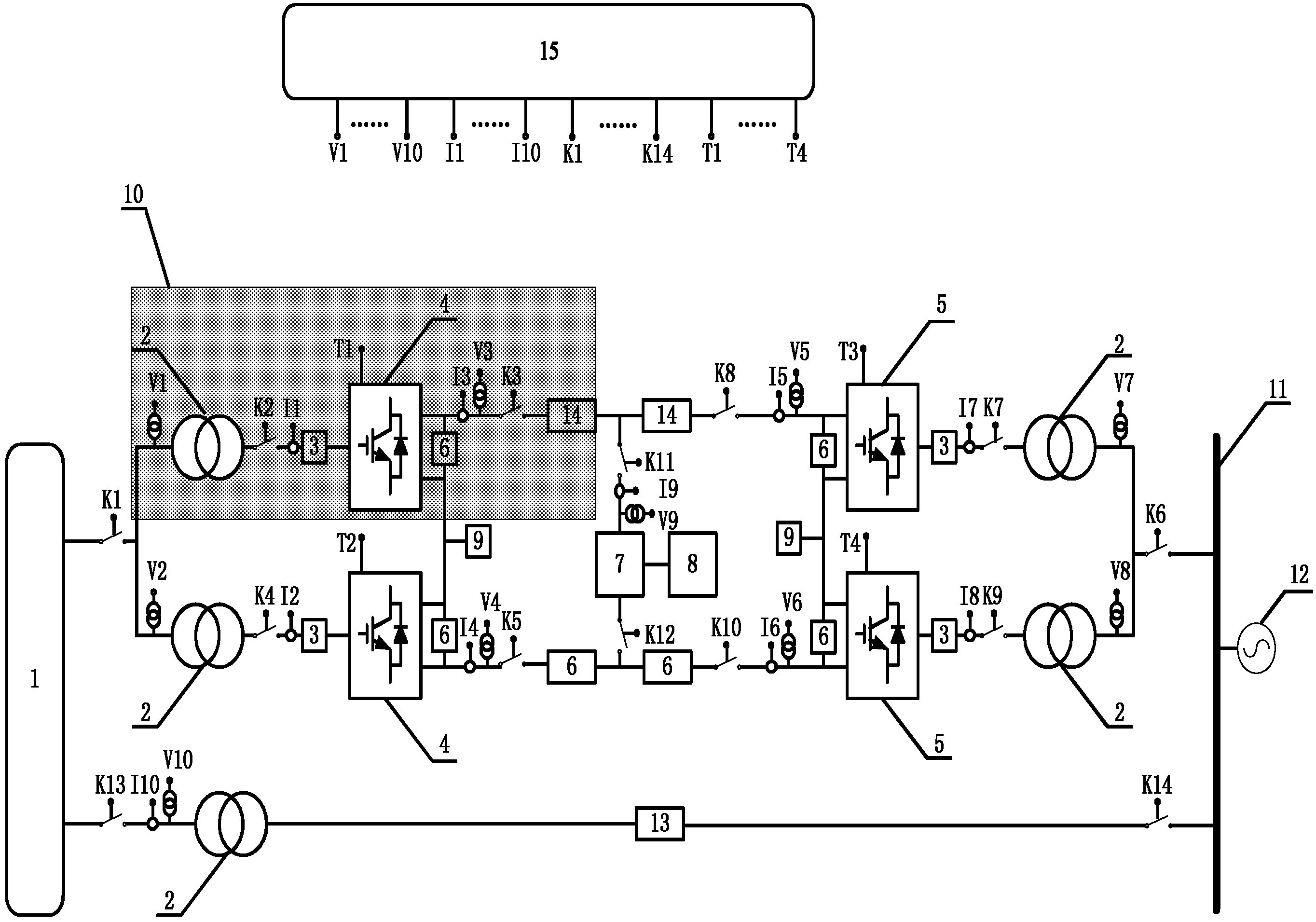

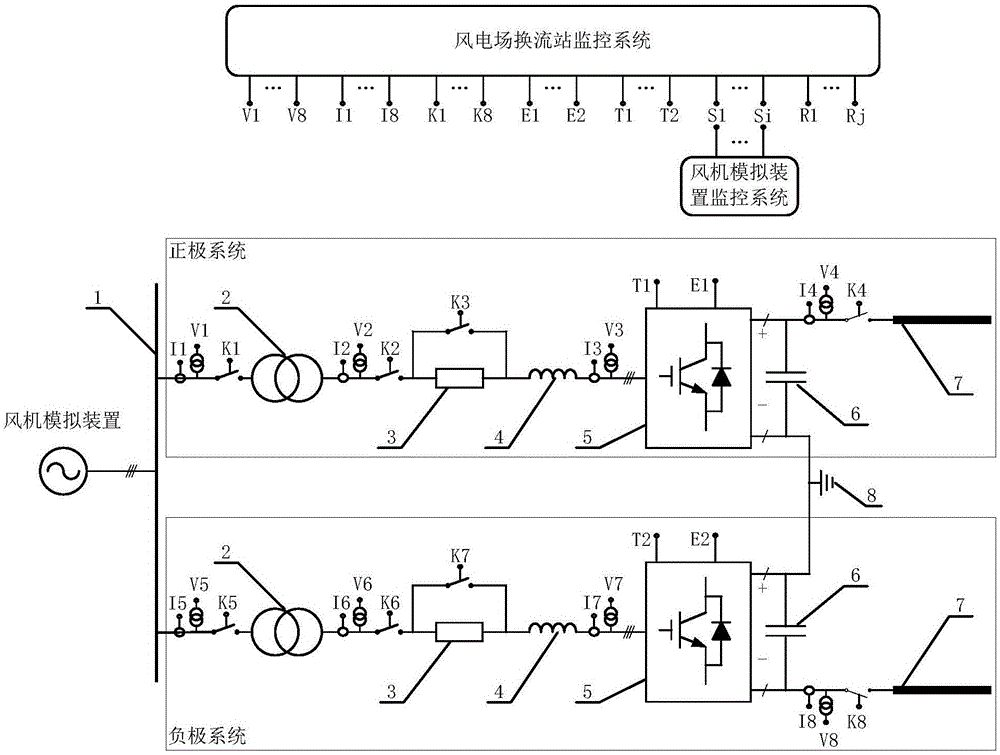

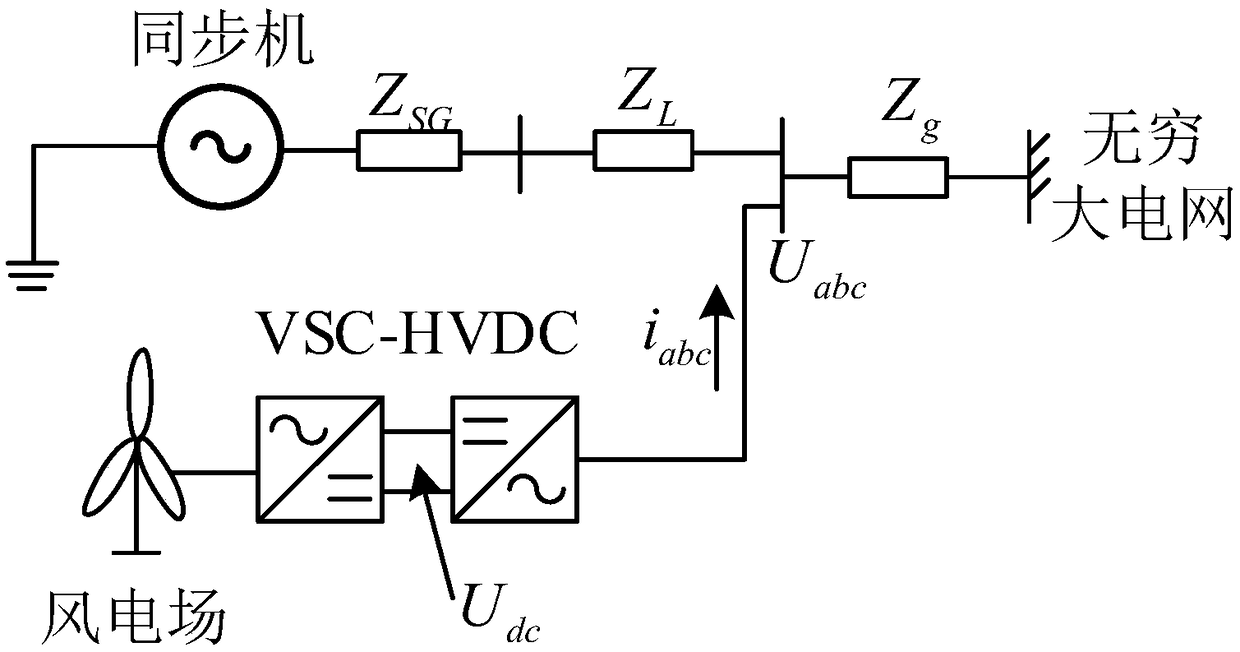

Movable model device of system of offshore wind power synchronized through flexible DC (Direct Current) power transmission

InactiveCN102427245AEasy to understandSingle network parallel feeding arrangementsWind energy generationElectric power transmissionMicrocontroller

The invention discloses a movable model device of a system of offshore wind powder synchronized through flexible DC (Direct Current) power transmission. The movable model device comprises a main circuit system and a control protection system, wherein the main circuit system comprises an offshore wind power generator unit simulation device, a flexible DC power transmission system, an AC (Alternating Current) bus and a movable model grid, the flexible DC power transmission system is respectively connected with the offshore wind power generator unit simulation device and the AC bus through solid switches and consists of an even number of structural units, wherein each structural unit comprises a converter transformer, a reactor, a voltage source type converter, a DC capacitor, a grounded circuit, a DC line, a solid switch and voltage and current mutual inductor elements, and the control protection system comprises a background computer, a microcontroller system and a data acquisition card system. The movable model device disclosed by the invention provides a reliable and convenient research platform and test environment for a main circuit design, dynamic response characteristic analysis, control policy design and control system of the system of offshore wind powder synchronized through flexible DC power transmission.

Owner:SHANDONG UNIV

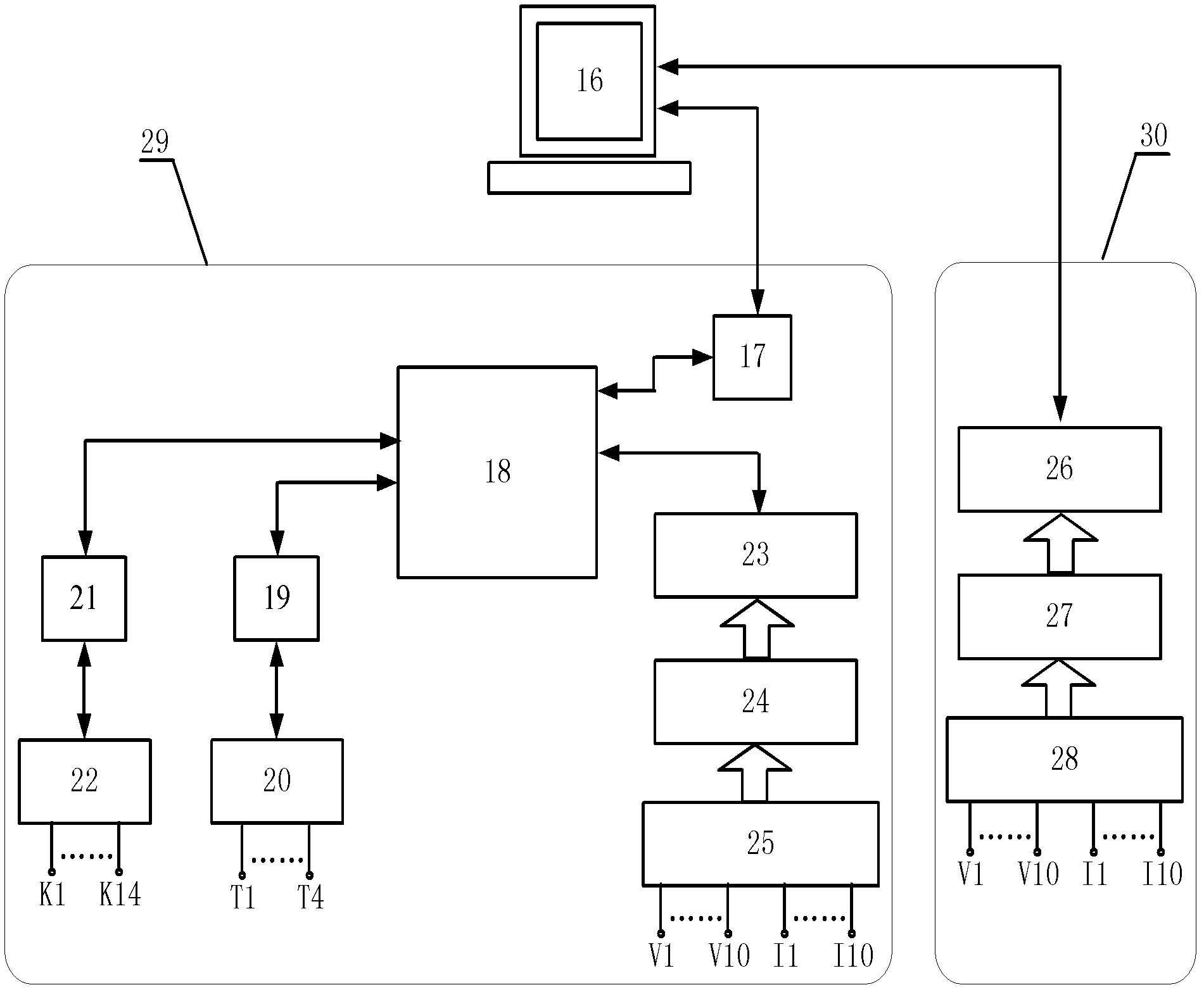

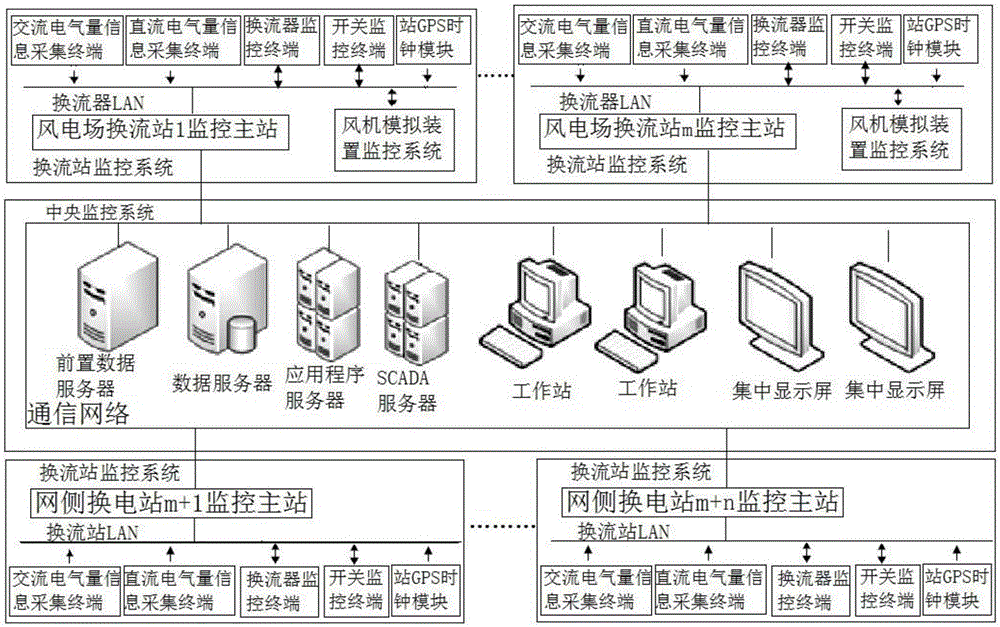

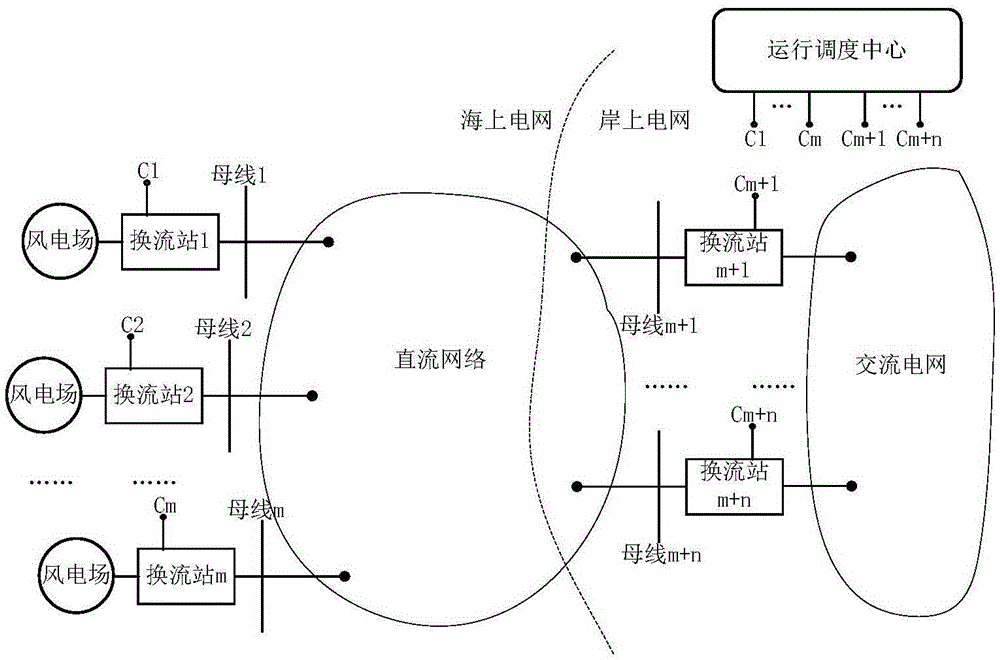

Dynamic simulation system of offshore wind power power-transmission and grid-connected system through VSC-MTDC

ActiveCN105024397ASingle network parallel feeding arrangementsWind energy generationElectricityControl system design

The invention discloses a dynamic simulation system of an offshore wind power power-transmission and grid-connected system through a VSC-MTDC. A main circuit frame of a grid-connected system is given, a design scheme of a monitoring system is improved, a monitoring system framework based on a central monitoring system and convertor station monitoring system double-layer structure is provided, an interface scheme of a fan simulation device monitoring system and a convertor station monitoring system is given, and a coordination control method between VSC-MTDC power transmission system network side converter stations is designed. The dynamic simulation system is advantageous in that a reliable and convenient research platform is provided for a system scheme of the offshore wind power power-transmission and grid-connected system through the VSC-MTDC, control system design, control strategy research and dynamic response characteristic analyses, and a good test environment is provided for system engineering development and debugging.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

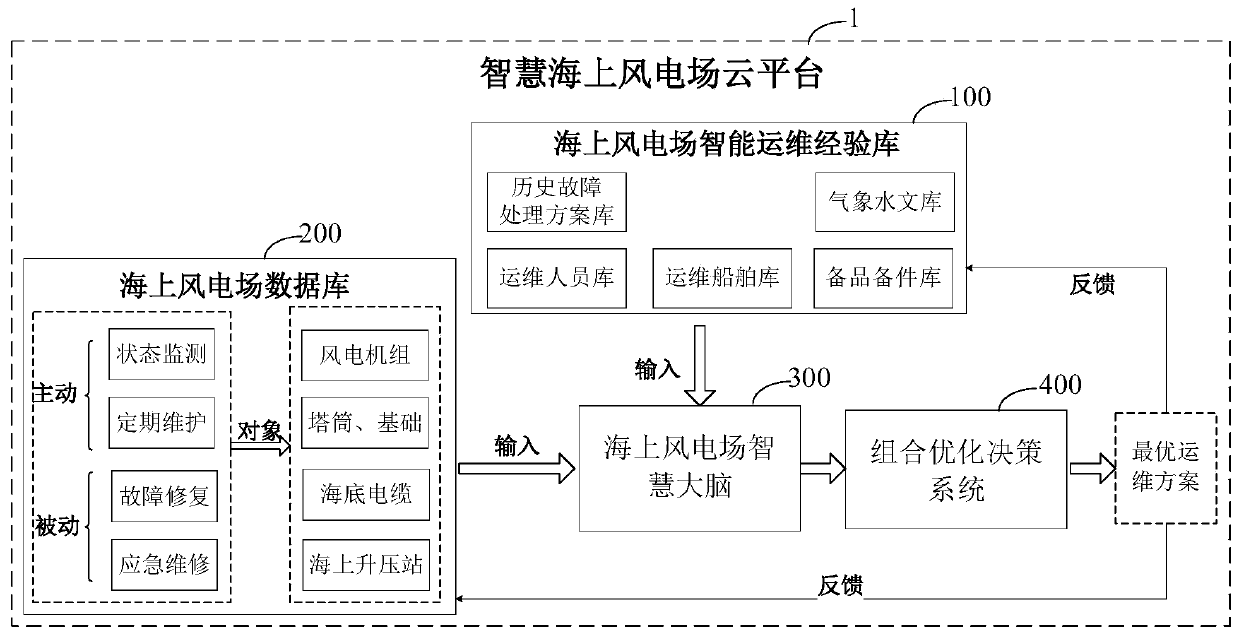

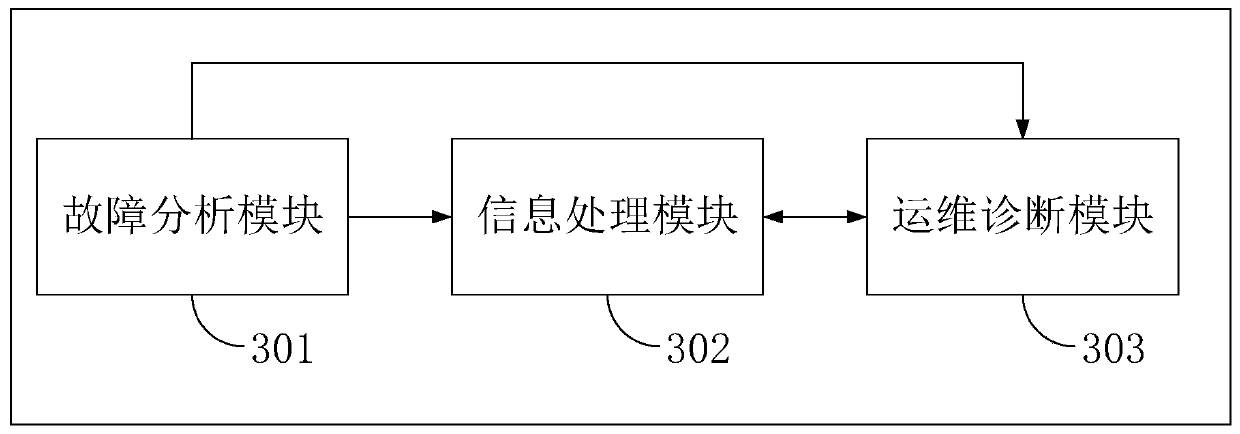

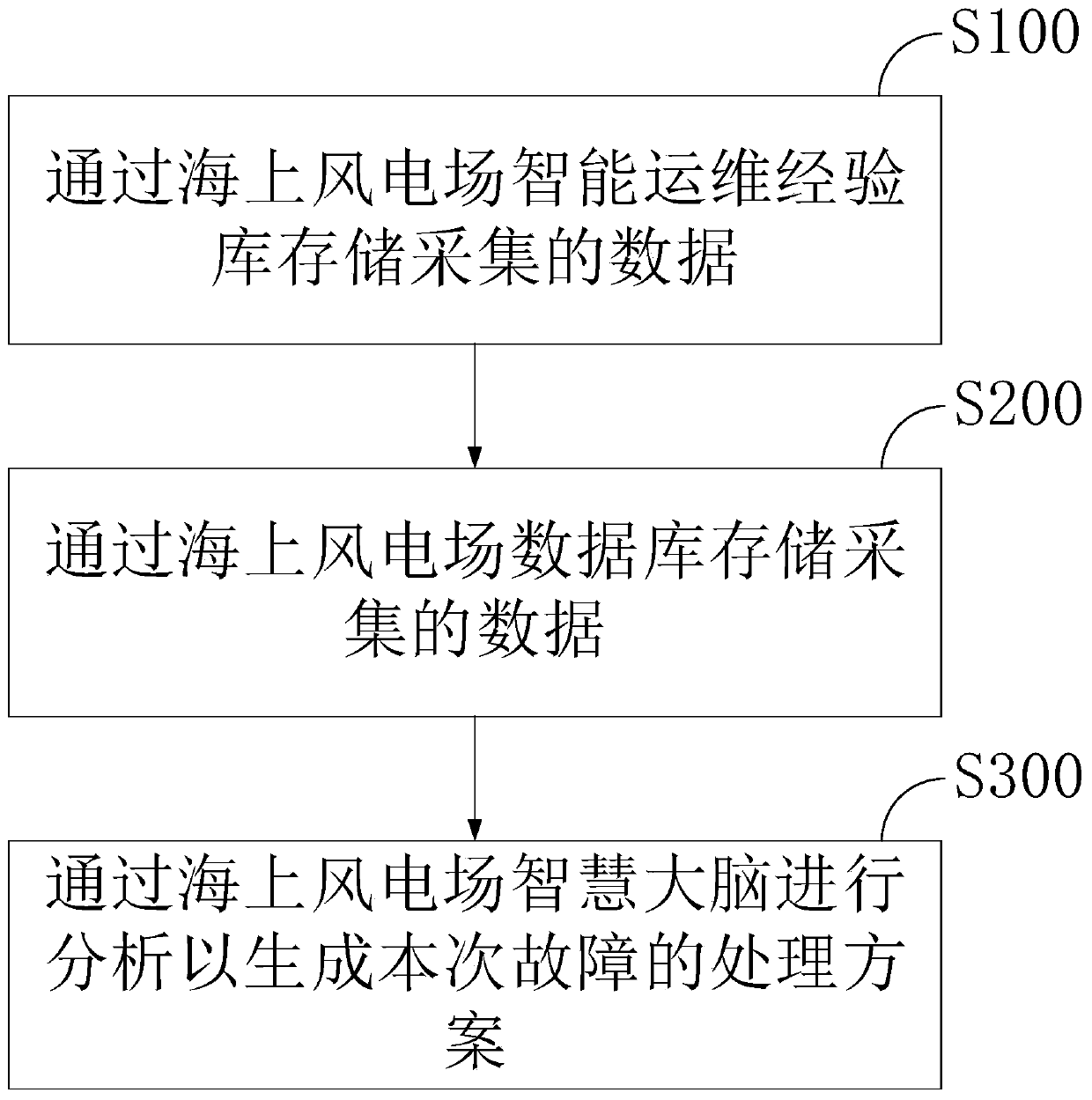

Offshore wind power plant intelligent operation and maintenance management system and management method

InactiveCN110222851AScientific wisdom managementComprehensive intelligent managementData processing applicationsElectricityPeaking power plant

The invention provides an offshore wind power plant intelligent operation and maintenance management system and management method, the management system comprises an intelligent offshore wind power plant cloud platform, and the intelligent offshore wind power plant cloud platform comprises an offshore wind power plant intelligent brain and an offshore wind power plant intelligent operation and maintenance experience library and an offshore wind power plant database which are connected with the offshore wind power plant intelligent brain; the offshore wind power plant intelligent brain is usedfor storing the real-time operation state information and the fault information of each device stored in the offshore wind power plant database; and combining the historical fault statistics and processing scheme, the meteorological and hydrological information, the operation and maintenance personnel management and control information, the operation and maintenance ship management and control information and the spare part information, and analyzing to generate a processing scheme of the current fault. Through scientific and comprehensive intelligent operation and maintenance management, theoffshore wind power fault processing task is accurately planned, the offshore operation and maintenance efficiency can be improved, the shutdown loss of the wind power plant caused by fan faults is reduced, and meanwhile safe and efficient execution of the offshore operation and maintenance work is guaranteed.

Owner:北京千尧新能源科技开发有限公司

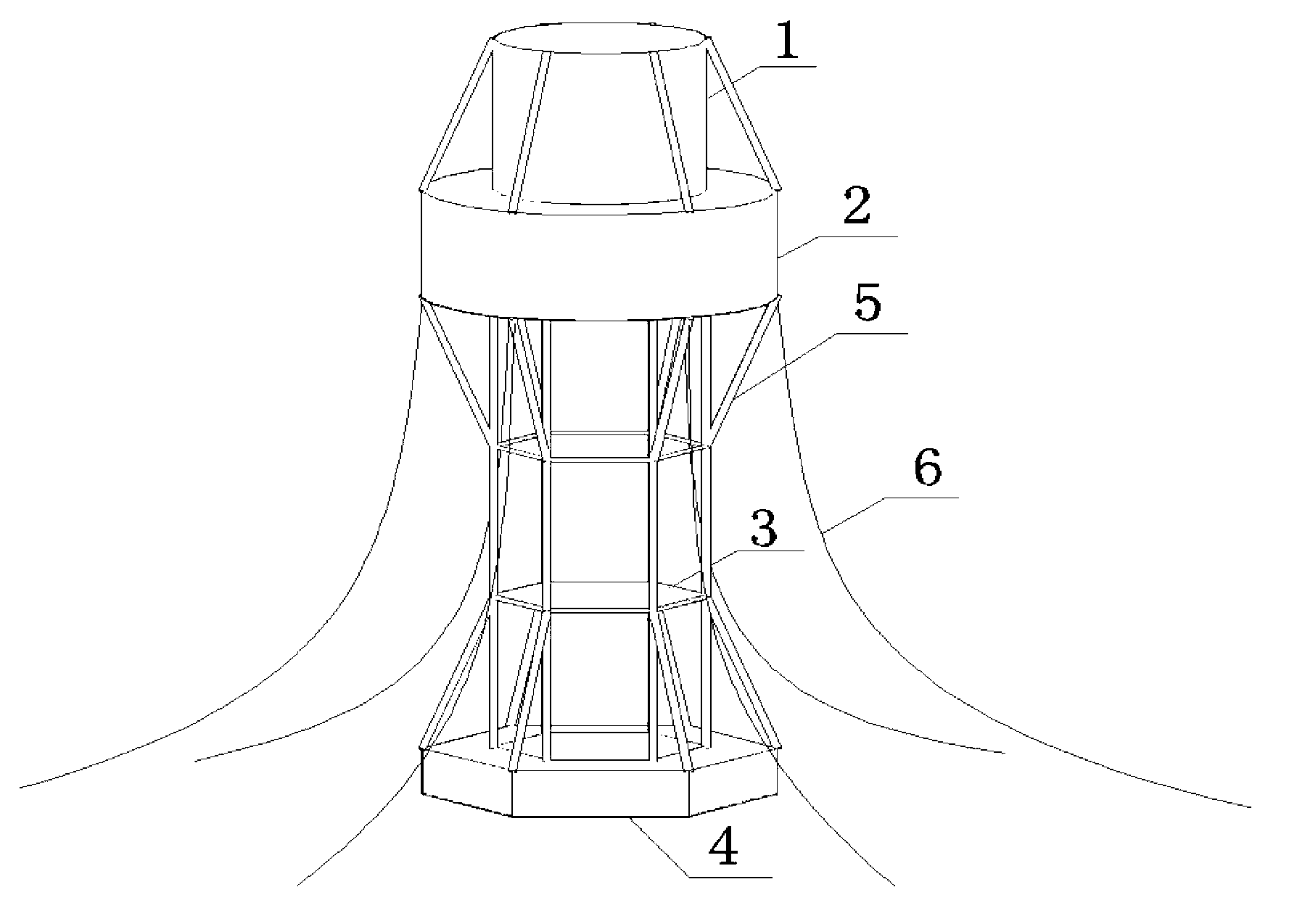

Offshore wind power floating foundation suitable for small water plane with water depth below 100m

InactiveCN103010417AReduce draftSmall sectionFloating buildingsMarine engineeringOffshore wind power

The invention discloses an offshore wind power floating foundation suitable for a small water plane with water depth below 100m. The offshore wind power floating foundation comprises an upper flotation tank, an active ballast tank connected to the lower side of the flotation tank, and an lower cement ballast tank and an anchoring system which are positioned at the lower part, wherein the cross section of the active ballast tank is larger than that of the flotation tank, and the active ballast tank and the cement ballast tank are connected through a truss structure. The offshore wind power floating foundation is smaller in water plane, strong in stability and capable of resisting stormy waves, lower in engineering cost and installing cost, better in economy and simple and convenient to construct, solves the technical problems that the stability and the seakeeping performance are reduced, and the like caused by smaller water depth, can be installed in a water area under 100m and is used as a floating foundation of a draught fan with high power about 5MW.

Owner:TIANJIN UNIV

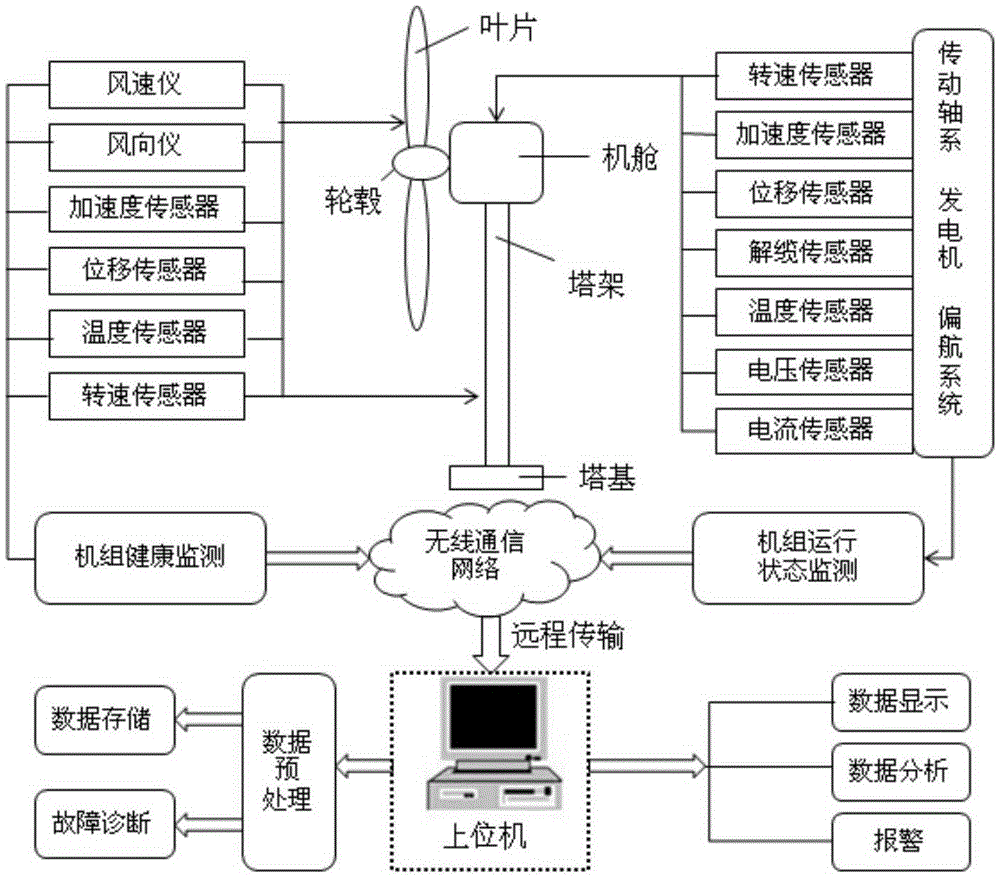

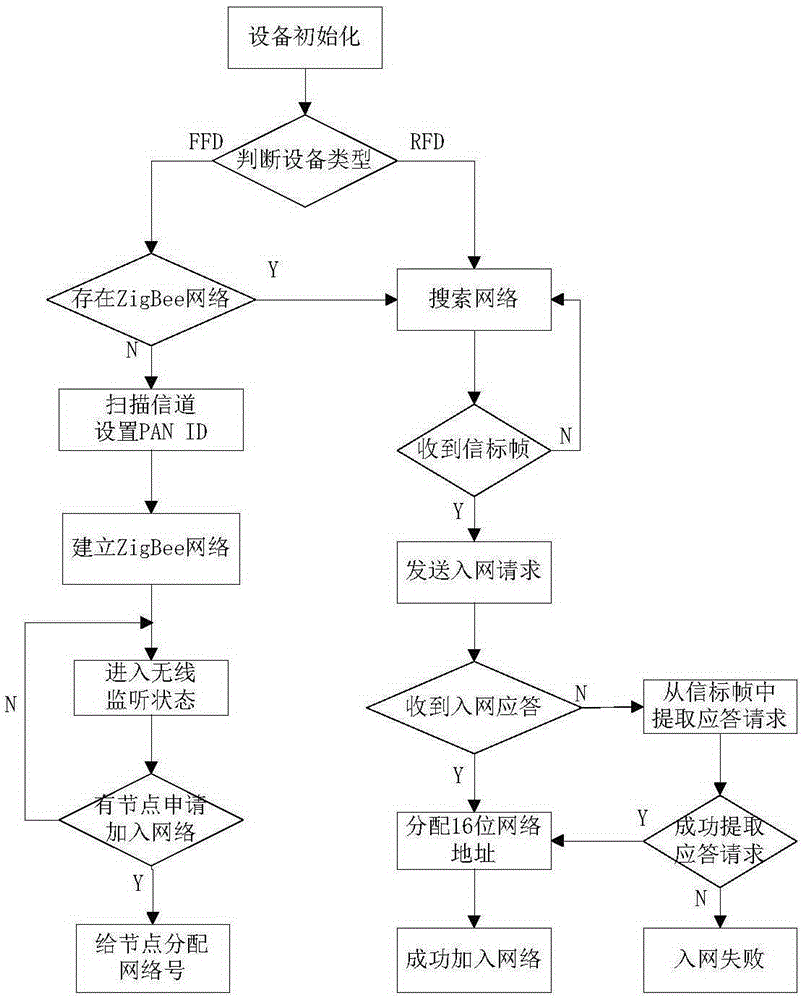

Remote offshore wind power monitoring device based on ZigBee and GPRS techniques

InactiveCN105351152AReduce monitoring costsReduce development difficultyTransmission systemsFinal product manufactureElectricityState parameter

The invention relates to the field of offshore wind power, relates to a remote offshore wind power monitoring device based on ZigBee and GPRS techniques and in particular relates to a remote offshore wind power monitoring communicating system. Sensors are arranged on blades, a transmitting system, a cabin and a tower frame of an offshore wind turbine to collect operation parameters and state parameters of the offshore wind turbine; data of the sensors are gathered through a ZigBee wireless sensor network, and the data are transmitted to a remote monitoring platform through a GPRS network; the monitoring platform can analyze and further process the data to obtain parameters which can show the rotating speed, the vibration, the temperature, the voltage and the current of the offshore wind turbine in real time; and the monitored parameters are stored in a database, the vibration signals of the offshore wind turbine are analyzed to early find fault of the offshore wind turbine. Thus, convenience is brought to maintainers to process the fault in time, serious accidents are avoided, and the operating and maintaining cost of the offshore wind turbine is reduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

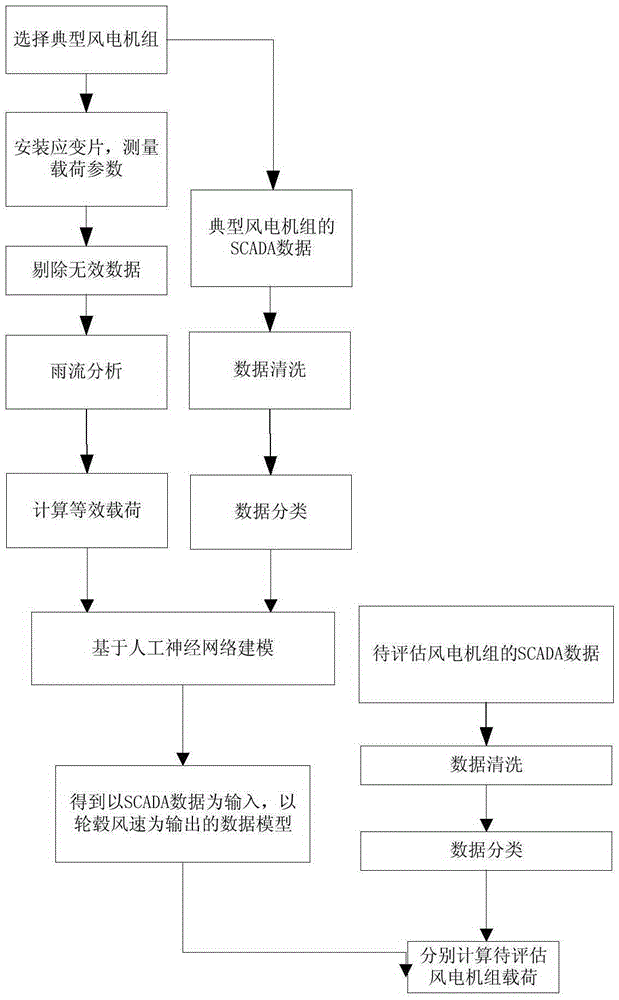

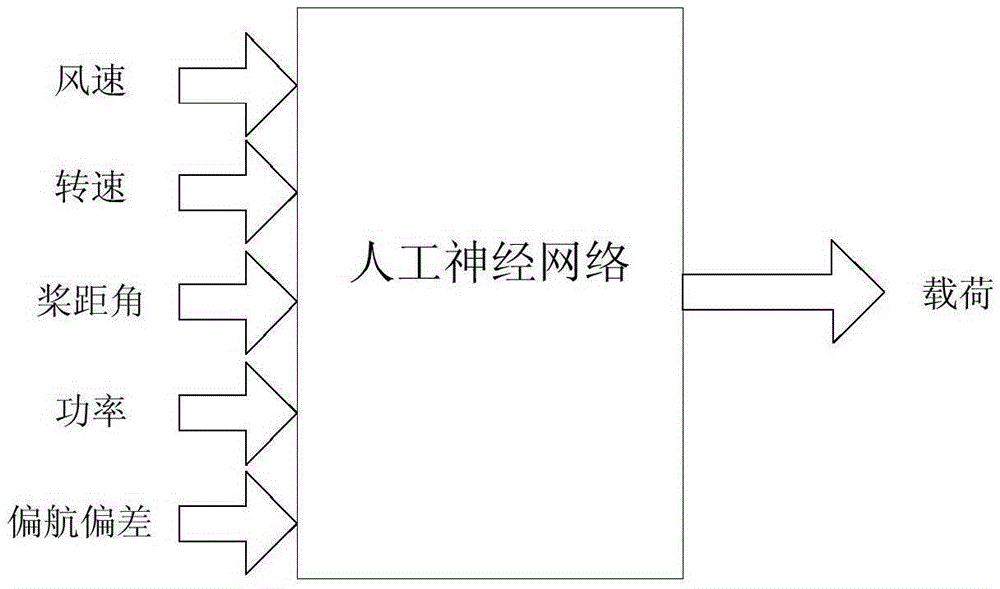

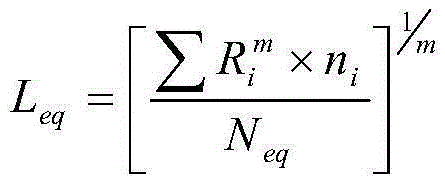

Wind farm load long-term evaluation method

PendingCN106815771AImprove accuracyAvoid running tests one by oneData processing applicationsRenewable energy source integrationElectricityLoad model

The invention relates to a wind farm load long-term evaluation method comprising the following steps: selecting a typical wind turbine unit; testing the load of the typical wind turbine unit, and calculating the equivalent load; acquiring SCADA data synchronized with measured data of the typical wind turbine unit, and classifying the data according to the operation status of the typical wind turbine unit; based on the theory and method of an artificial neural network, building a model based on the SCADA data and the load test result; and applying the load model of the typical wind turbine unit to other wind turbine units in a wind farm, and calculating the load of a wind turbine unit to be evaluated based on the SCADA data. The method is very suitable for monitoring the load of a running wind farm (especially an offshore wind farm) for a long time. The fatigue accumulation of all the wind turbine units in a wind farm can be evaluated. The cost and time needed for unit-by-unit test are reduced greatly while the accuracy of load evaluation is ensured.

Owner:CHINA ELECTRIC POWER RES INST +3

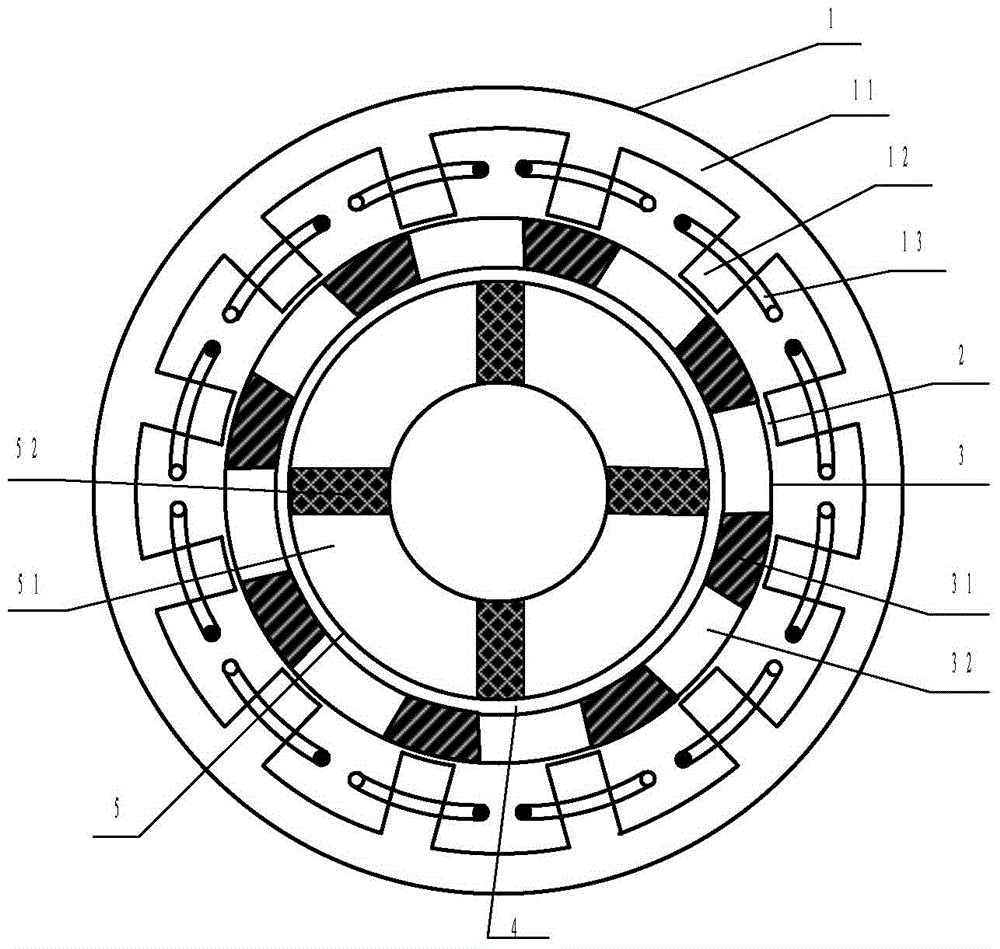

Dual-stator superconductive exciting field modulating motor

ActiveCN104883015AImprove space utilizationCompact structureDynamo-electric machinesSuperconductor elements usagePower flowConductive materials

The invention discloses a dual-stator superconductive exciting field modulating motor comprising a first stator, a rotor, a second stator which are successively arranged from outside to inside or from left to right. A first air gap is formed between the first stator and the rotor. A second air gap is formed between the second stator and the rotor. The first stator comprises a stator yoke and an armature winding. The stator yoke is provided with a first side surface close to the rotor. The armature winding is arranged on the first side surface. The rotor comprises magnetic conductive iron core blocks and non magnetic conductive material blocks which are arranged at intervals. The second stator comprises a non magnetic conductive stator support and a high-temperature superconductive exciting winding fixed to the non magnetic conductive stator support. The dual-stator superconductive exciting field modulating motor is small in size, light in weight, high in efficiency, utilizes a characteristic that a high-temperature superconductive winding is suitable for DC, prevents liquid coolant rotary seal required by a conventional rotor excitation high-temperature superconductive motor, and is simple in structure. The stators of the motor are modular structures so as to be easy to transport and install. The motor has good application prospect in the field of offshore wind power.

Owner:SOUTHEAST UNIV

Floating foundation of offshore wind-driven generator

ActiveCN102865198AShake suppressionCurb tiltFoundation engineeringWind energy generationWind drivenOcean bottom

The invention discloses a floating foundation of an offshore wind-driven generator, comprising at least one floating foundation unit; the floating foundation unit comprises a tower column, a wind-driven generator, a plurality of float bowls, a connecting rod, a square support, a first supporting rod and a second supporting rod; the wind-driven generator is arranged at the upper end of the tower column; the plurality of float bowls are uniformly distributed at the periphery of the tower column, the lower ends of the adjacent float bowls are fixedly connected through the square support, and the upper ends of the adjacent float bowls are fixedly connected through the connecting rod; the upper ends of the float bowls are fixedly connected with the middle part of the tower column through the first supporting rod, and the square support fixed at the lower ends of the float bowls is fixedly connected with the lower end of the tower column through the second supporting rod; and the square support is located below the surface of seawater, and the lower ends of the float blows are fixedly connected with the seabed. The floating foundation disclosed by the invention is favorable in stability and capable of adjusting the position of the center of the gravity and the resonant frequency of the wind-driven generator and reducing the unbalance degree of bulk movement of the floating foundation in waves. Changed power combination is realized through a plurality of floating foundations so that different power utilization requirements are met.

Owner:SOUTH CHINA UNIV OF TECH

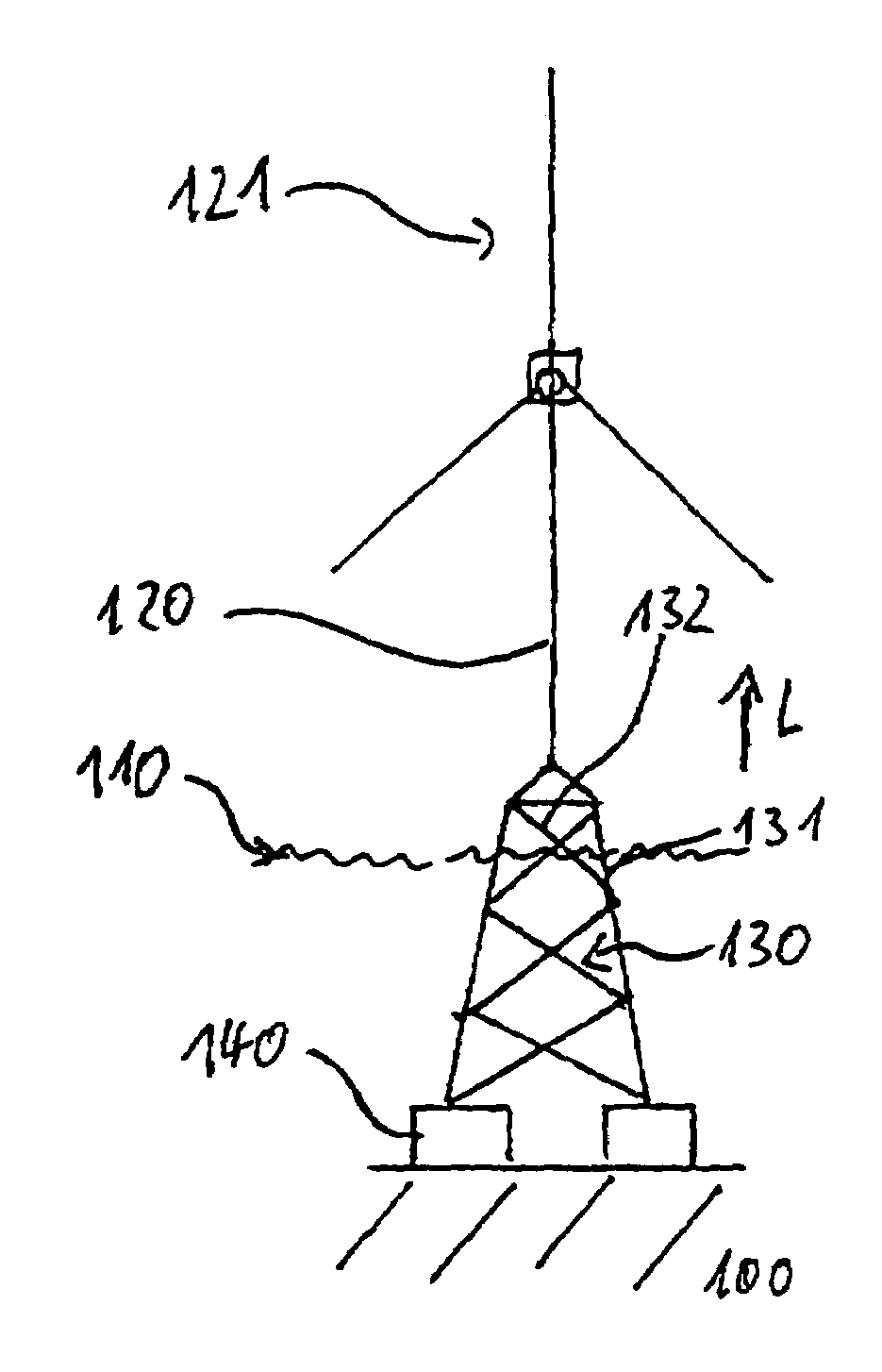

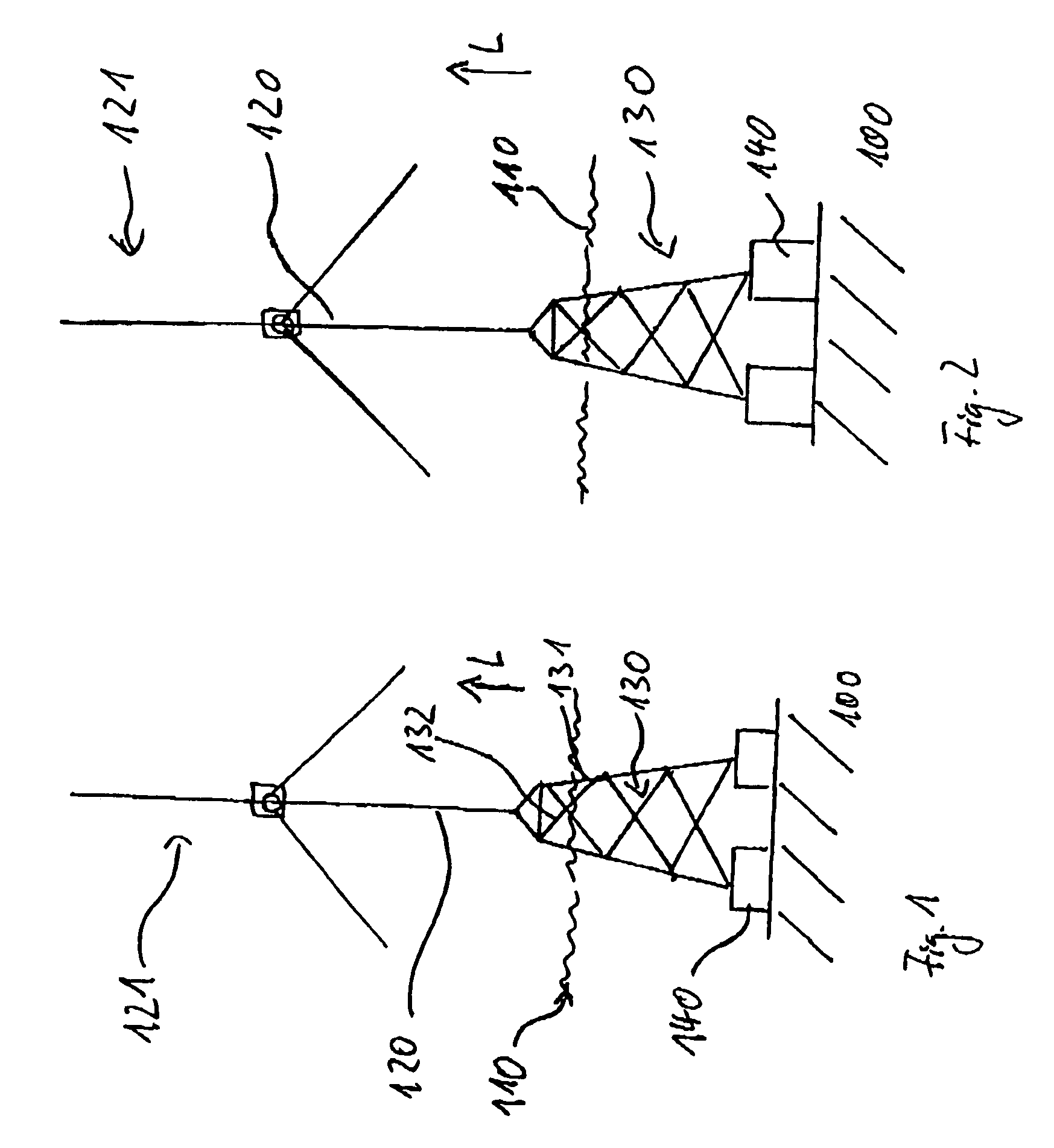

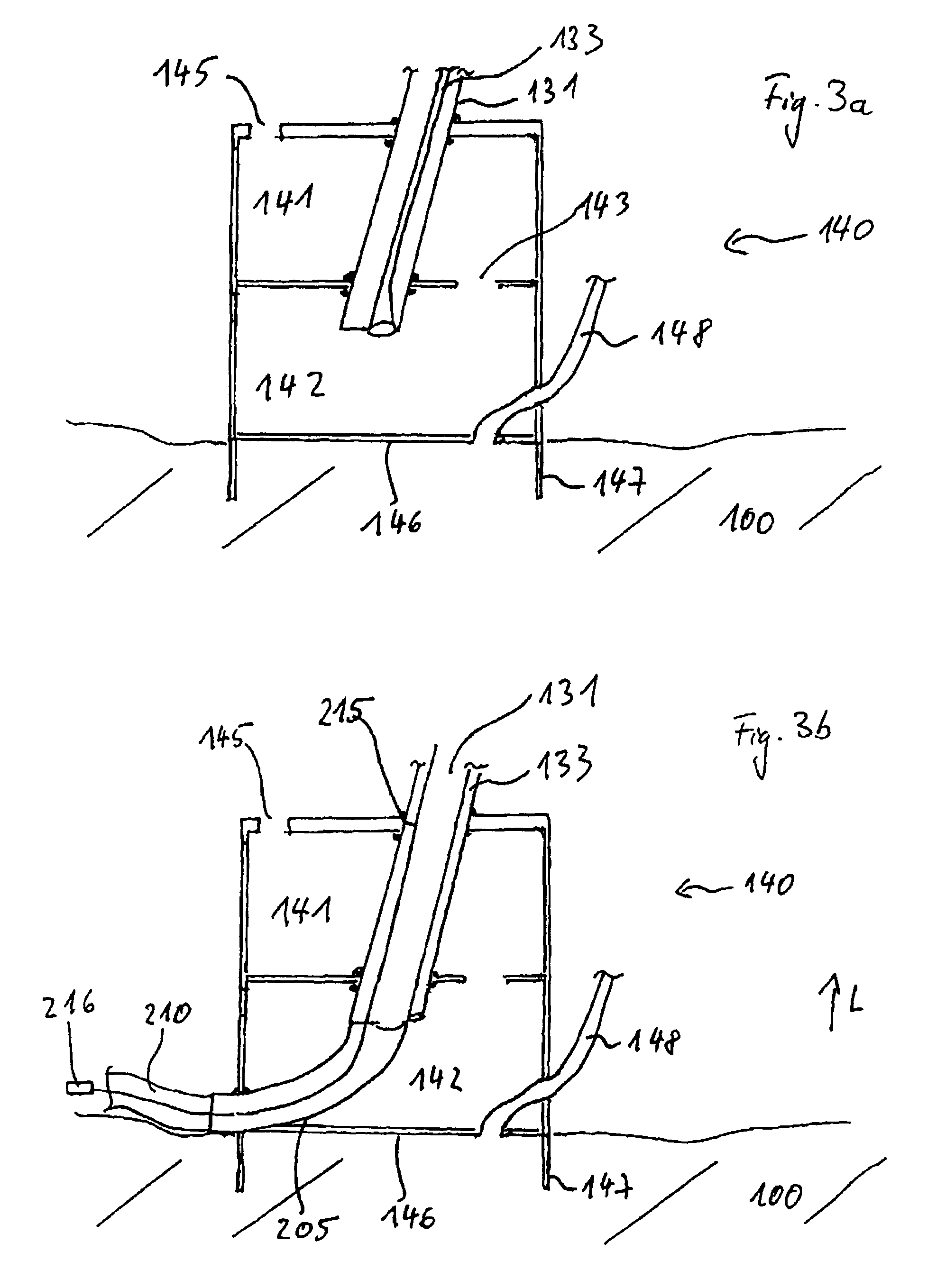

Offshore wind energy system with non-skid feet

This invention entails a wind energy system for offshore use with a longitudinal direction (L) running substantially vertically to an ocean surface in the erected state and with a plurality of feet determined for making contact with the ocean bottom whose extensions in the longitudinal direction (L), especially the depth and / or relief of the ocean bottom, are adapted to a predetermined erection site.

Owner:SIEMENS GAMESA RENEWABLE ENERGY SERVICE GMBH

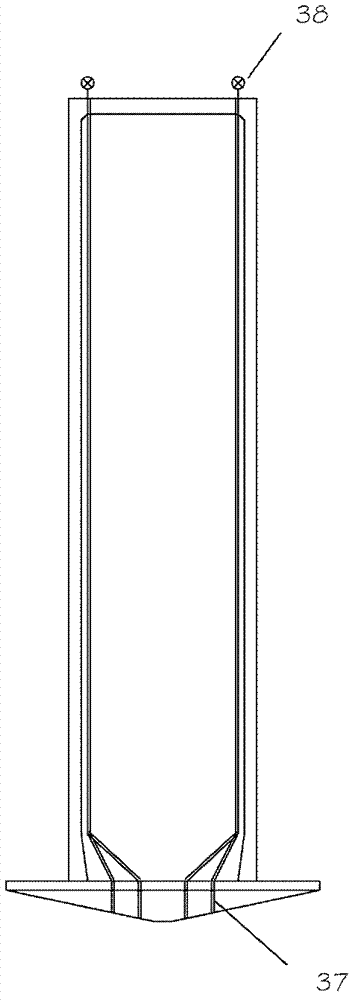

Local buoyancy ocean platform of offshore wind power, bridge and ocean structure, and construction method

ActiveCN103362113AIncrease horizontal resistanceImprove stabilityArtificial islandsUnderwater structuresMarine architectureMulti platform

The invention discloses a local buoyancy ocean platform of offshore wind power, a bridge and an ocean building, and a construction method. The platform comprises at least one buoyancy cylinder, wherein the buoyancy cylinders are arranged vertically; the bottoms of the buoyancy cylinders are conical; and the buoyancy cylinders are hollow cylinders. Buoyancy of the buoyancy cylinders can be used for offsetting the weight of partial hydraulic buildings; small-bore bored piles or small-bore driven piles are arranged at the bottoms of the buoyancy cylinders, and fixed with seabed bed rock or a supporting layer, and support an external force together with a soil layer at the conical bottoms of the buoyancy cylinders; a tilting load borne by a whole foundation is converted into a vertical pressing and up-pull load of a single buoyancy cylinder foundation by a multi-buoyancy-cylinder space structure; the bearing capacity and the tilting resistance of the foundation are very high; multiple platforms can be connected into a multi-platform system; the platform can be cast in land, prefabricated, or assembled on a coast, and then hauled, towed and floated to a mounting position; and the platform is applied to ocean green energy sources such as the offshore wind power, the bridge and the ocean building with a soil layer of above 5m and water depth of about 5m to 50m, and has great potential economic benefits.

Owner:黄灿光 +1

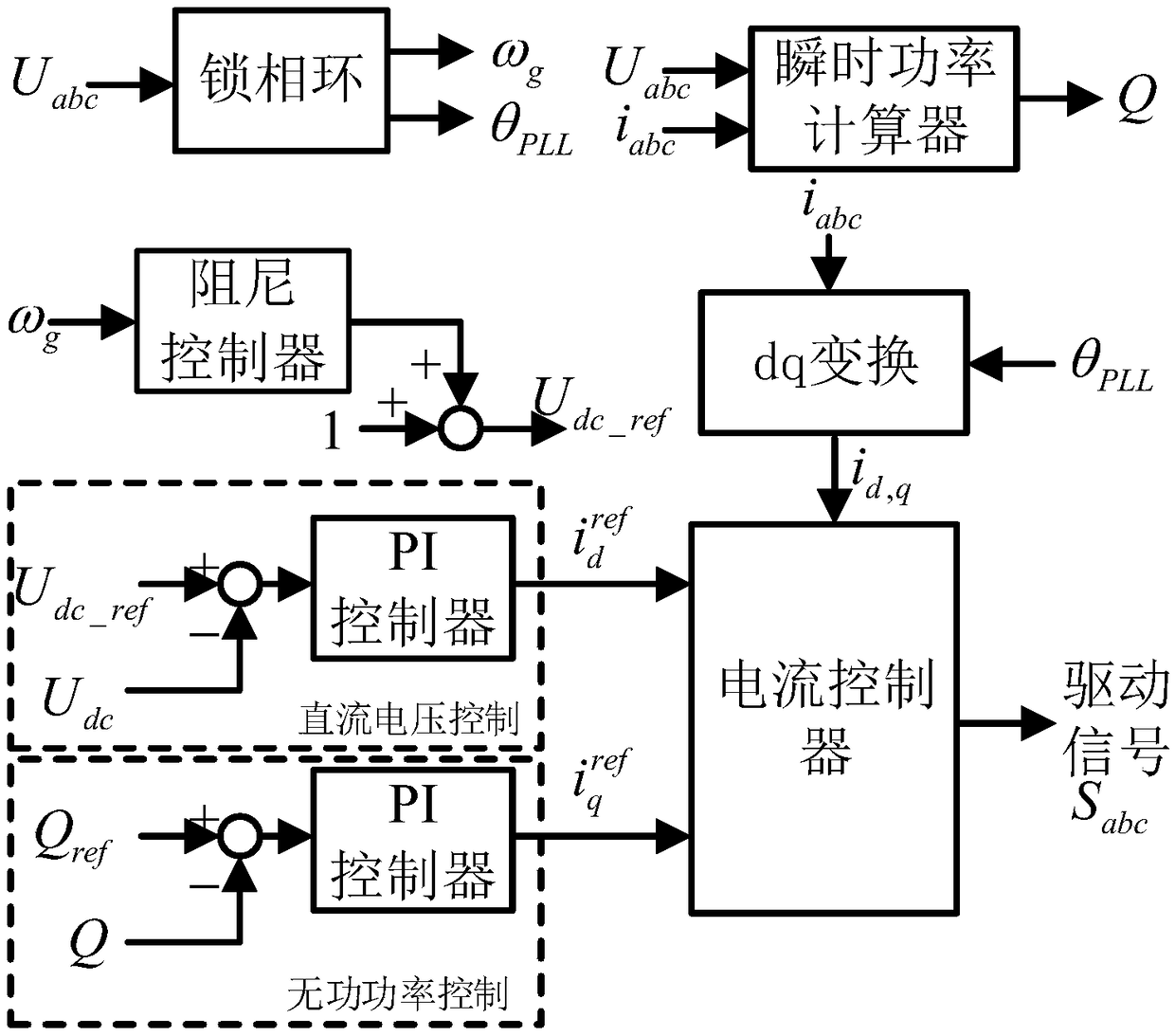

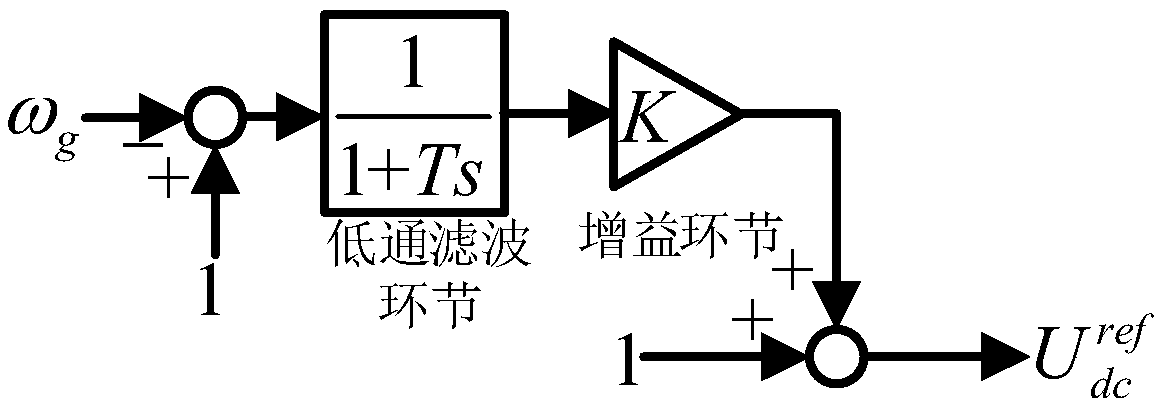

A low frequency oscillation damping control method for offshore wind power VSC-HVDC output system

InactiveCN109217335AGuaranteed uptimeGuarantee friendlinessElectric power transfer ac networkSingle network parallel feeding arrangementsElectricityHybrid system

The invention discloses a low frequency oscillation damping control method for an offshore wind power VSC-HVDC output system; Specifically for the offshore wind power via VSC-HVDC output system, in AC / DC hybrid system, DC system operates at rated power, and AC system oscillates at low frequency due to large disturbance, so it is necessary to add damping controller to restrain low frequency oscillation. The invention only needs to be implemented in The DC voltage control of VSC- HVDC converter station and the frequency-based predecessor control only need a proportional link and a filter link.The frequency-based predecessor control of HVDC converter station only needs a proportional link and a filter link. When the low frequency oscillation occurs after the disturbance of AC power network,the change of frequency signal is transmitted to DC voltage, The change of DC voltage will cause the change of active power and damp the low frequency oscillation of AC system, which can not only keep the stable operation of the converter station, but also provide better damping effect for the low frequency oscillation of AC system connected with the converter station, and guarantee the VSC- HVDCdc system operation safety and stability and the friendliness of power grid.

Owner:HUAZHONG UNIV OF SCI & TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com