Offshore wind power combined barrel-shaped base

A cylindrical foundation and offshore wind power technology, which is applied in basic structure engineering, construction, etc., can solve the problems of small scope of application, single composite cylindrical foundation structure, complex concrete prefabrication, etc., and achieves the effect of reducing construction difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

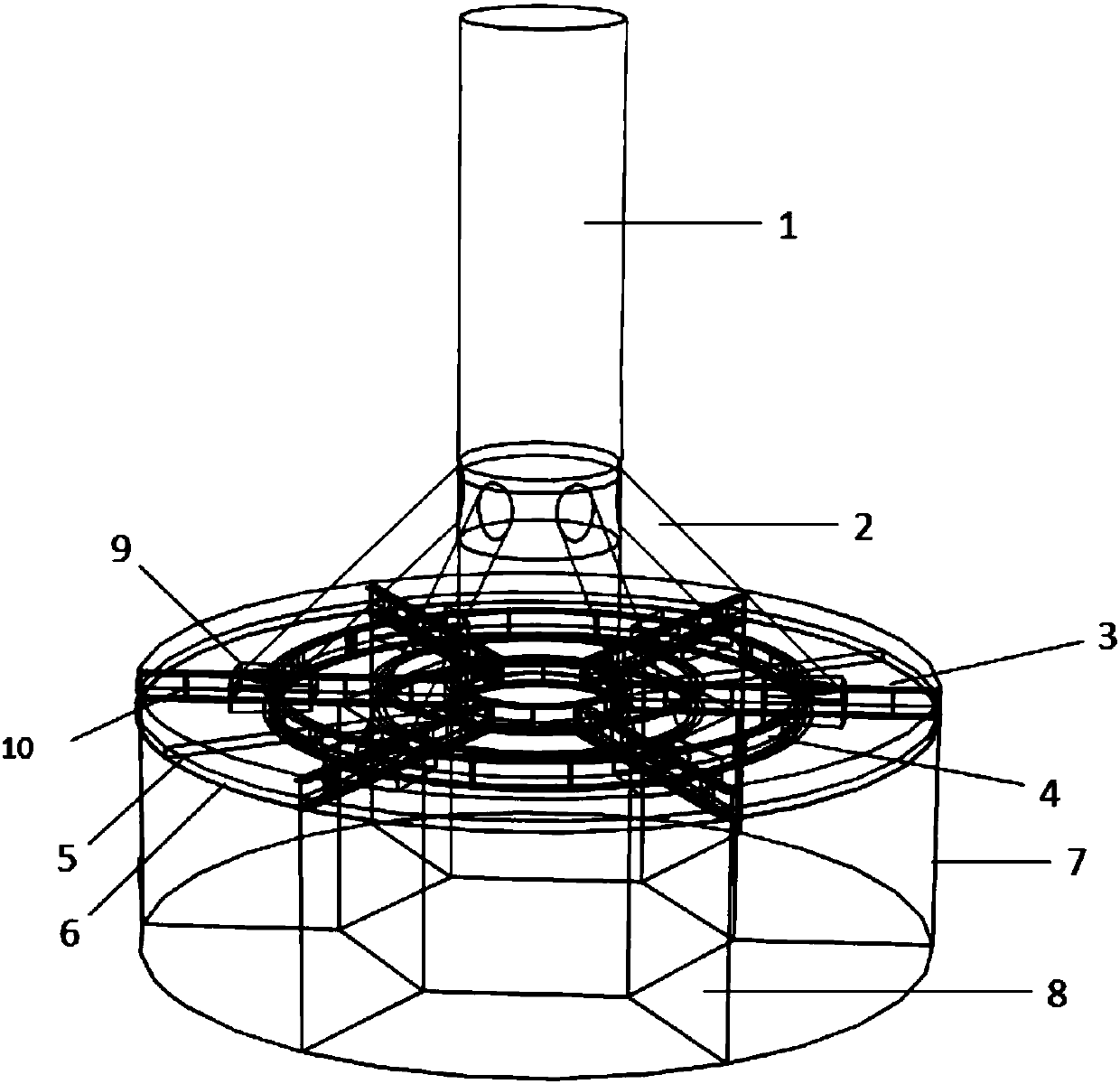

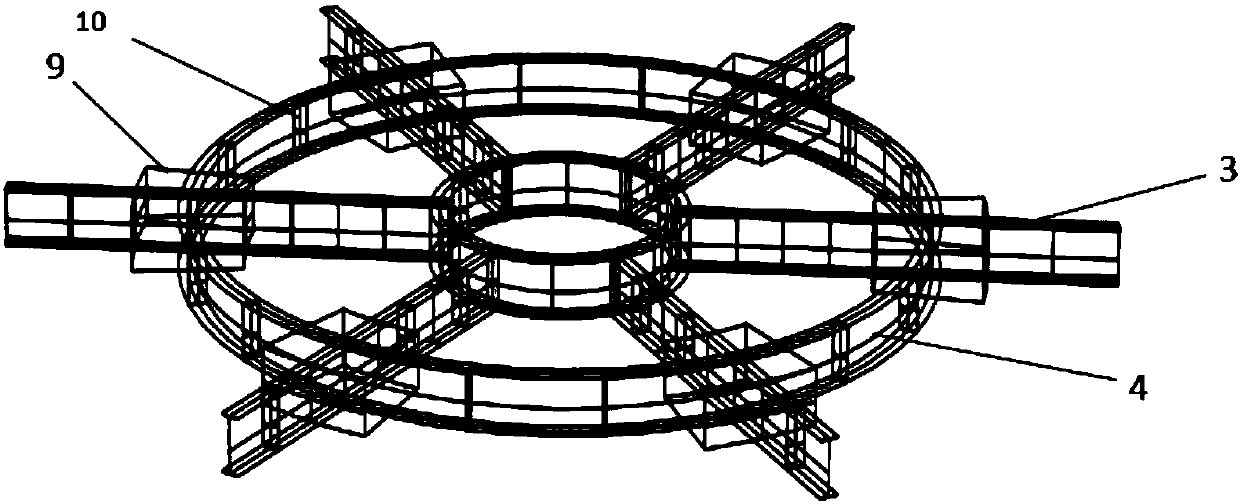

[0015] Such as figure 1 and figure 2 As shown, a new offshore wind power composite cylindrical foundation is composed of an upper force transmission transition section and a lower cylindrical structure. The upper force transmission transition section is composed of an upright steel pipe 1 and a diagonally braced steel pipe 2; the diagonally braced steel pipe 2 is evenly arranged around the upright steel pipe 1. 2 Use a steel pipe with a thickness of 2cm and a diameter of 1.5m. 6 diagonally braced steel pipes 2 are evenly distributed around the upright steel pipe 1. The upper support point of the diagonally braced steel pipe is 8m away from the bottom, and the lower support point is arranged on the I-beam. The supporting steel plate 9 adopts a 2cm thick steel plate. The tube structure is composed of tube skirt 7, tube roof 6, subdivision plate 8, I-beam main girder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com