Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2221results about How to "Improve dispersion stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

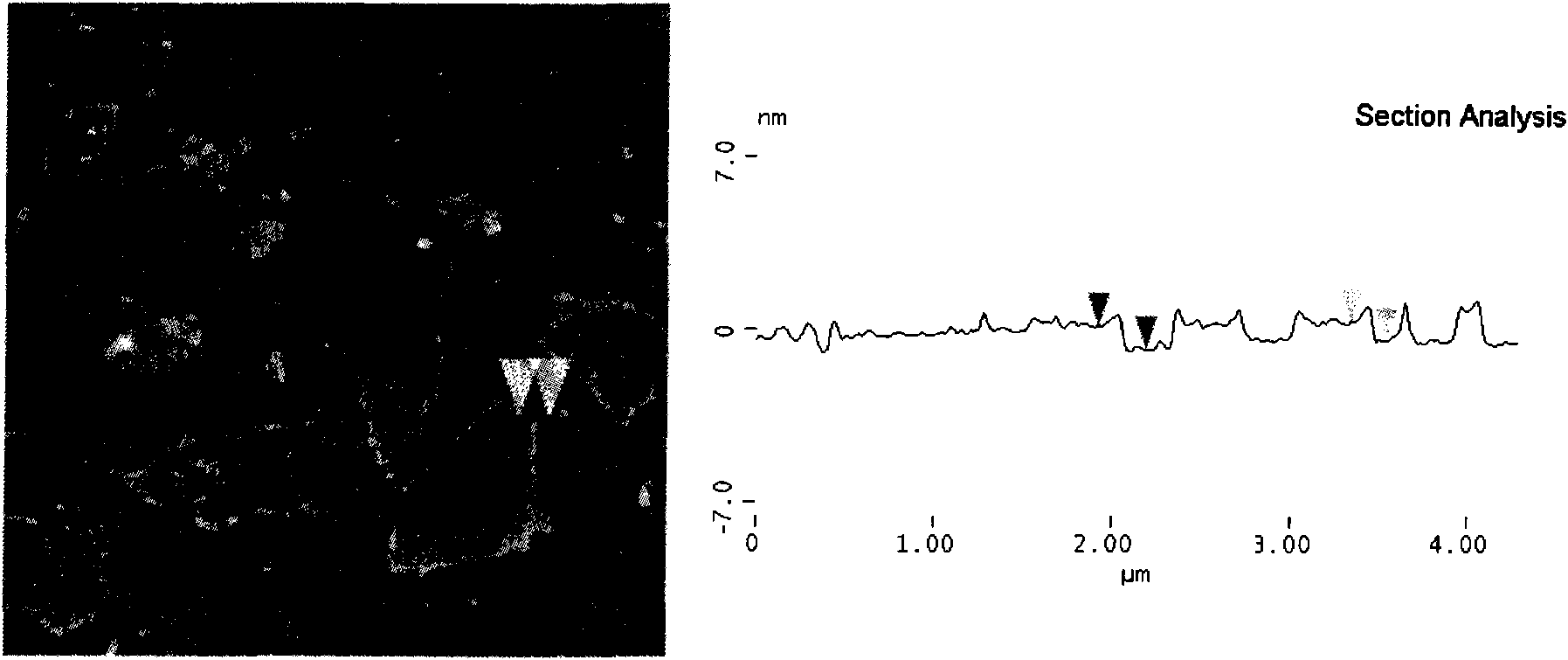

Method for preparing liquid colloidal dispersion of silver particles, liquid colloidal dispersion of silver particles, and silver conductive film

InactiveUS20060264518A1Good dispersionHighly conductive filmMaterial nanotechnologyOther chemical processesScreen printingFiltration

A process for producing a fine silver particle colloidal dispersion which can simply form conductive silver layers and antimicrobial coatings by screen printing or the like. The process is characterized by having a reaction step of allowing an aqueous silver nitrate solution to react with a mixed solution of an aqueous iron(II) sulfate solution and an aqueous sodium citrate solution to form an agglomerate of fine silver particles, a filtration step of filtering the resultant agglomerate of fine silver particles to obtain a cake of the agglomerate of fine silver particles, a dispersion step of adding pure water to the cake to obtain a first fine silver particle colloidal dispersion of a water system in which dispersion the fine silver particles have been dispersed in the pure water, and a concentration and washing step of concentrating and washing the first fine silver particle colloidal dispersion of a water system.

Owner:SUMITOMO METAL MINING CO LTD

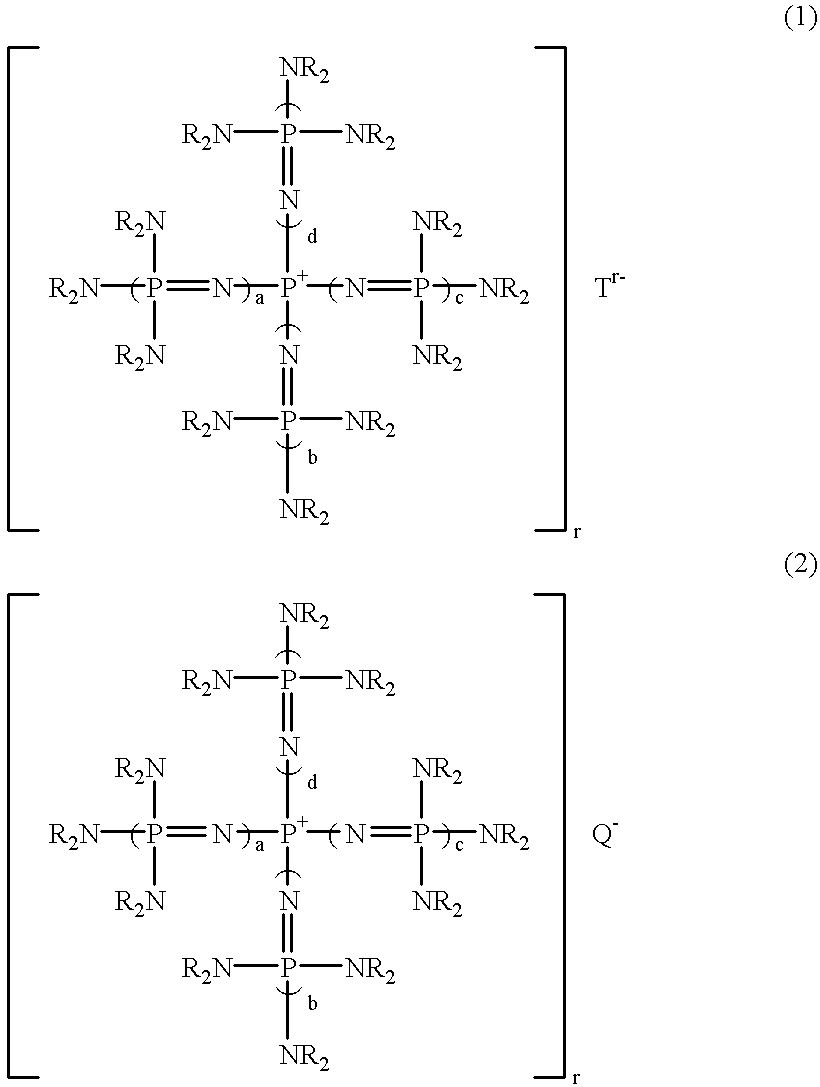

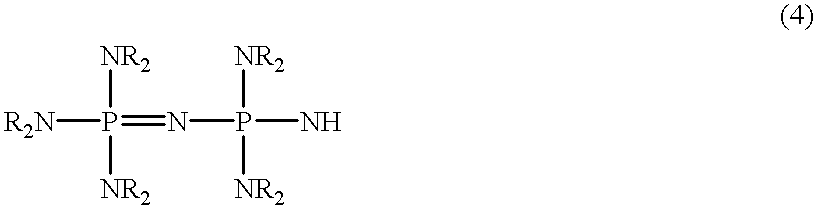

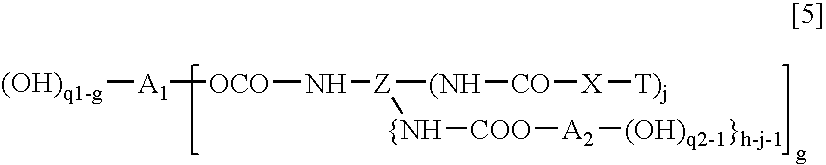

Polyoxyalkylene polyols, derivatives thereof, and process for producing the polyoxyalkylene polyols

The present invention is a polyoxyalkylene polyol, its manufacture method, and derivatives, wherein: it is obtained using a phosphazenium compound as a catalyst; the hydroxyl value is 2~200 mgKOH / g; total degree of unsaturation is 0.0001~0.07 meq. / g; the head-to-tail bond selectivity of the polyoxyalkylene polyol is 95 mole %; and when the maximum height of the peak of GPC elution curve is set to be 100%, W20 is defined as the peak width at the 20% peak height, and W80 is defined as the peak width at 80% peak height, the ratio of W20 / W80 is 1.5 or greater, and less than 3.

Owner:MITSUI CHEM & SKC POLYURETHANES INC

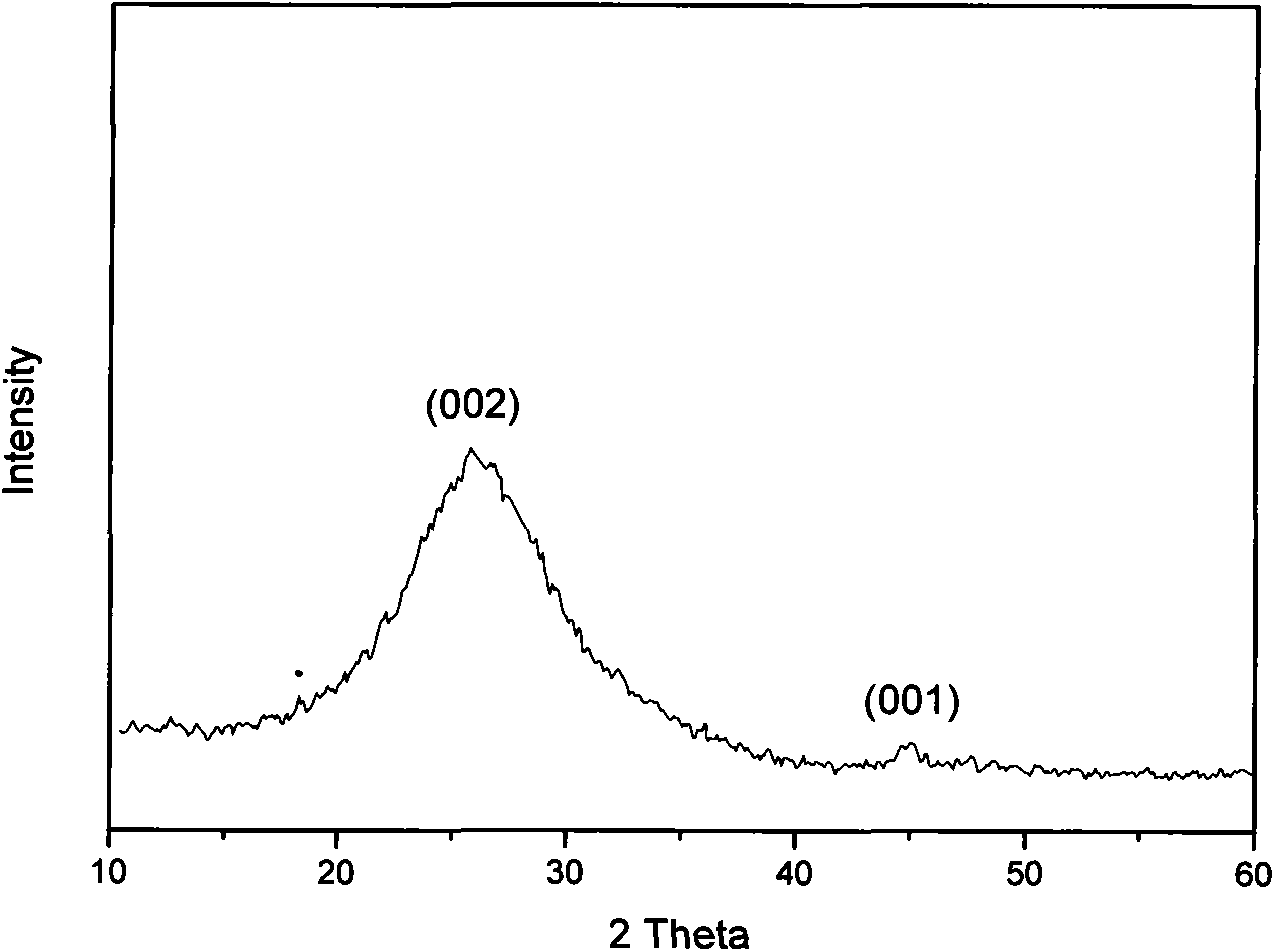

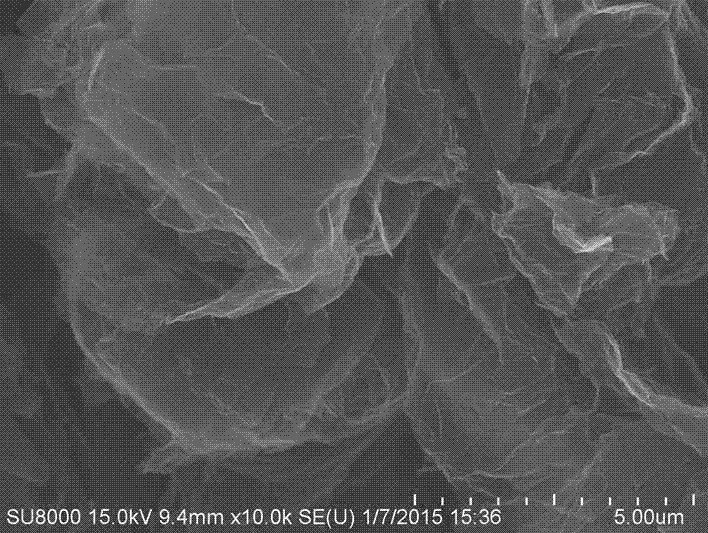

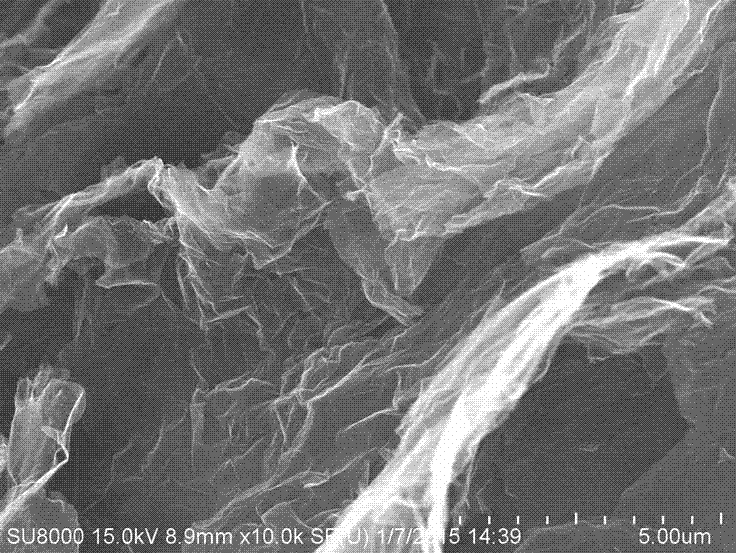

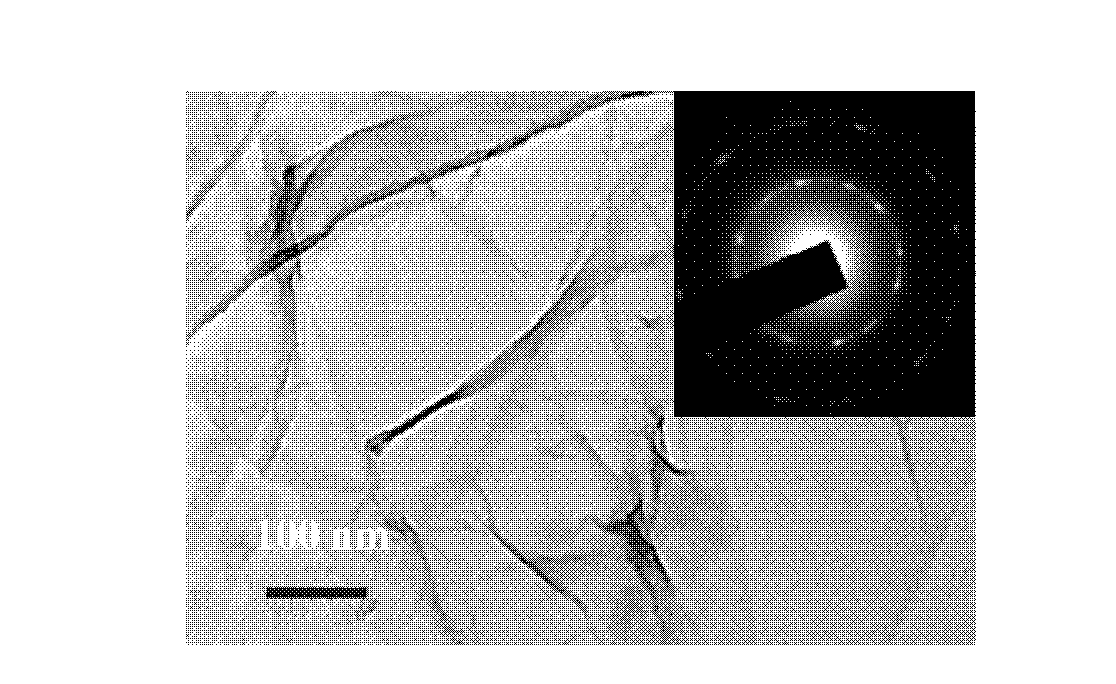

Preparation method of high-dispersivity graphene

The invention discloses a green preparation method of high-dispersivity graphene, which comprises the following steps: preparing graphite oxide, performing ultrasonic-stripping to obtain graphene oxide, adding water-soluble high polymer as a dispersant, and reducing under the irradiation of ultraviolet light to obtain high polymer surface-modified high-dispersivity graphene. The method has the advantages of simple technical process and low cost, and does not need any reducing chemical reagent; the prepared graphene has high dispersivity and stability; and the obtained high polymer surface-modified graphene is beneficial to further application.

Owner:XIANGTAN UNIV

Polishing fluid and polishing method

InactiveUS20050050803A1Inhibited DiffusionImprove dispersion stabilityPigmenting treatmentOther chemical processesWater soluble polymersWater soluble

The present invention relates to polishing slurry and polishing method used for polishing in a process for forming wirings of a semiconductor device, and the like. There are provided polishing slurry giving a polished surface having high flatness even if the polished surface is made of two or more substances, and further, capable of suppressing metal residue and scratches after polishing, and a method of chemical mechanical polishing using this. The polishing slurry of the present invention is polishing slurry containing at least one of a surfactant and an organic solvent, and a metal oxide dissolving agent and water, or polishing slurry containing water and abrasive of which surface has been modified with an alkyl group, and preferably, it further contains a metal oxidizer, water-soluble polymer, and metal inhibitor.

Owner:HITACHI CHEM CO LTD

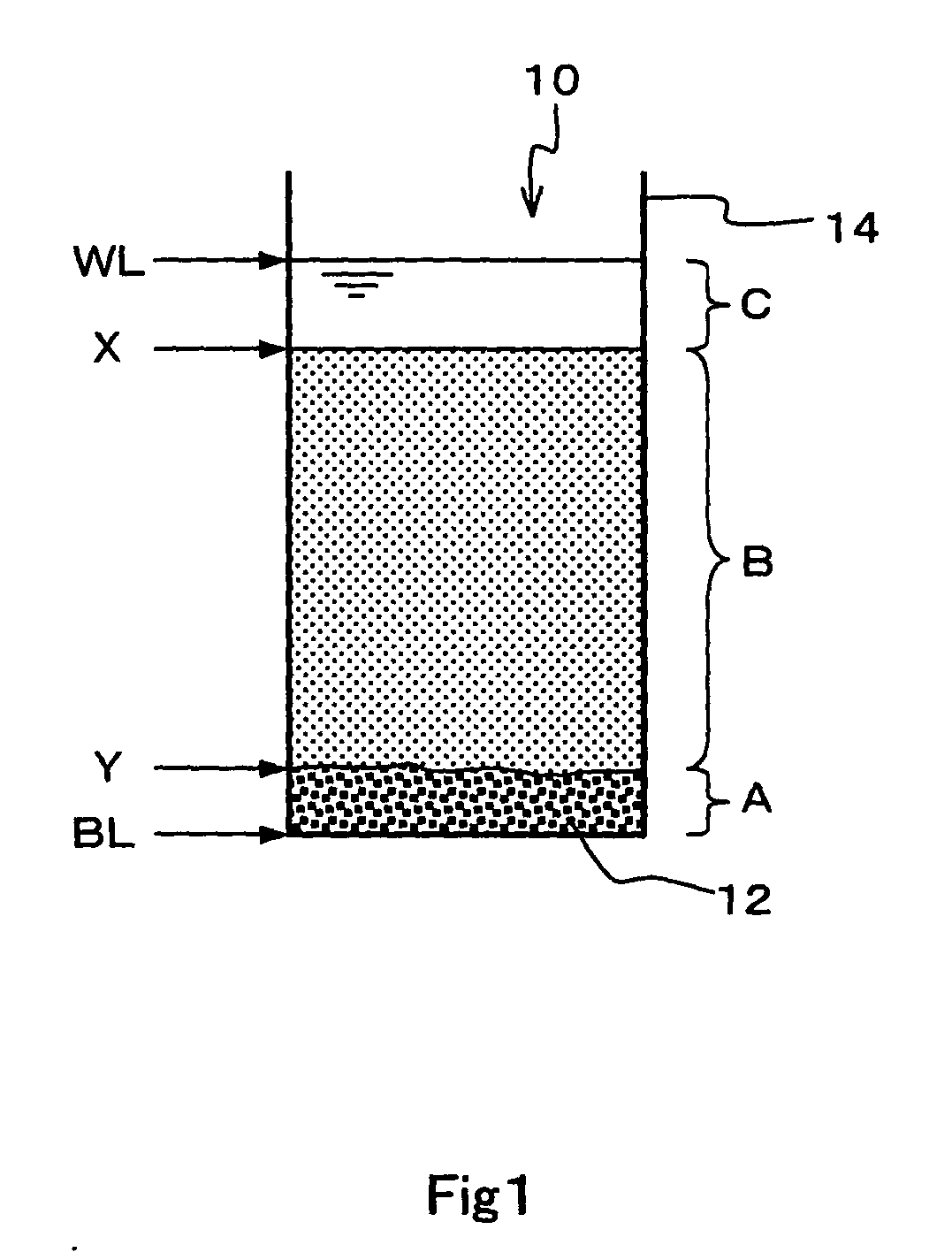

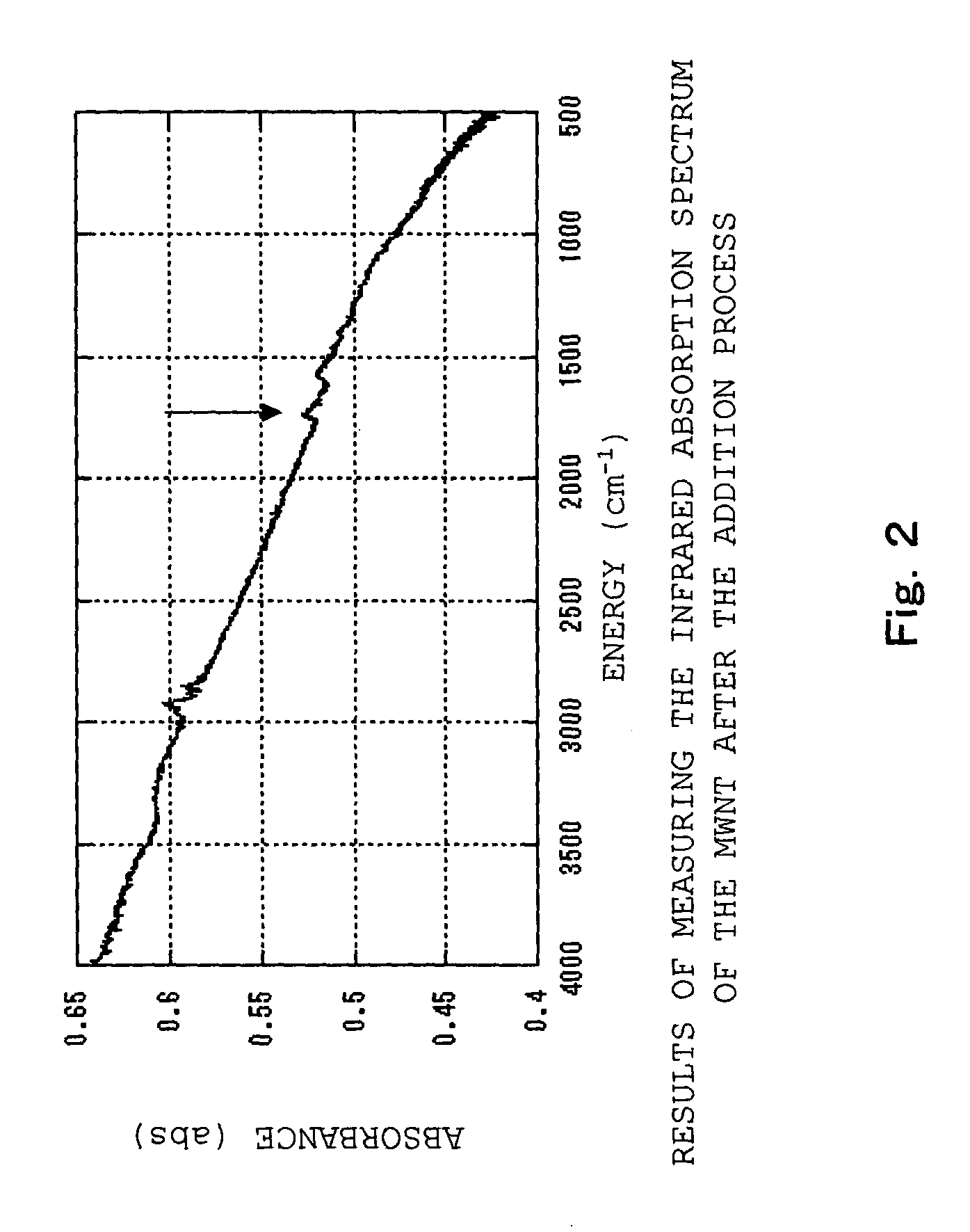

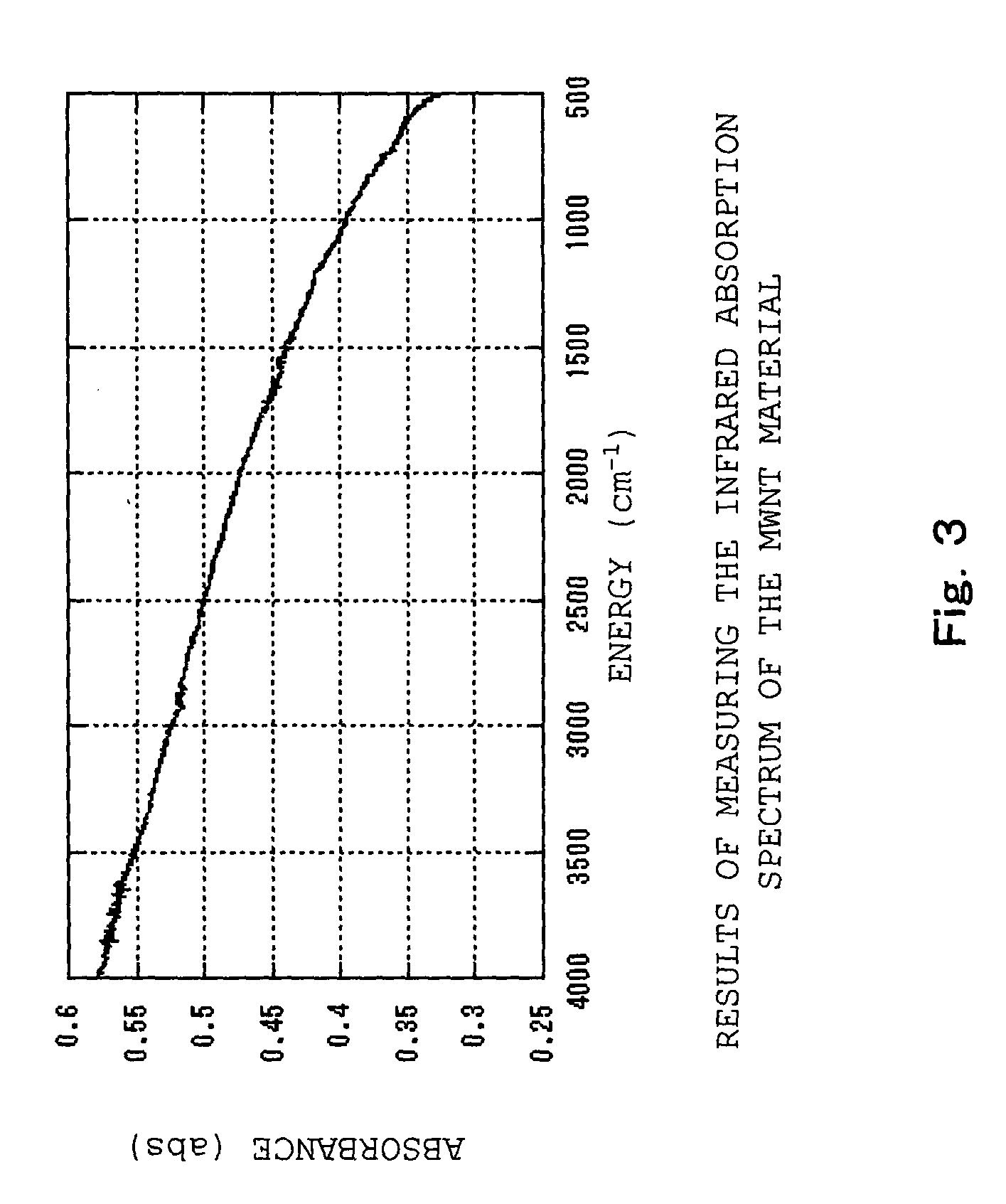

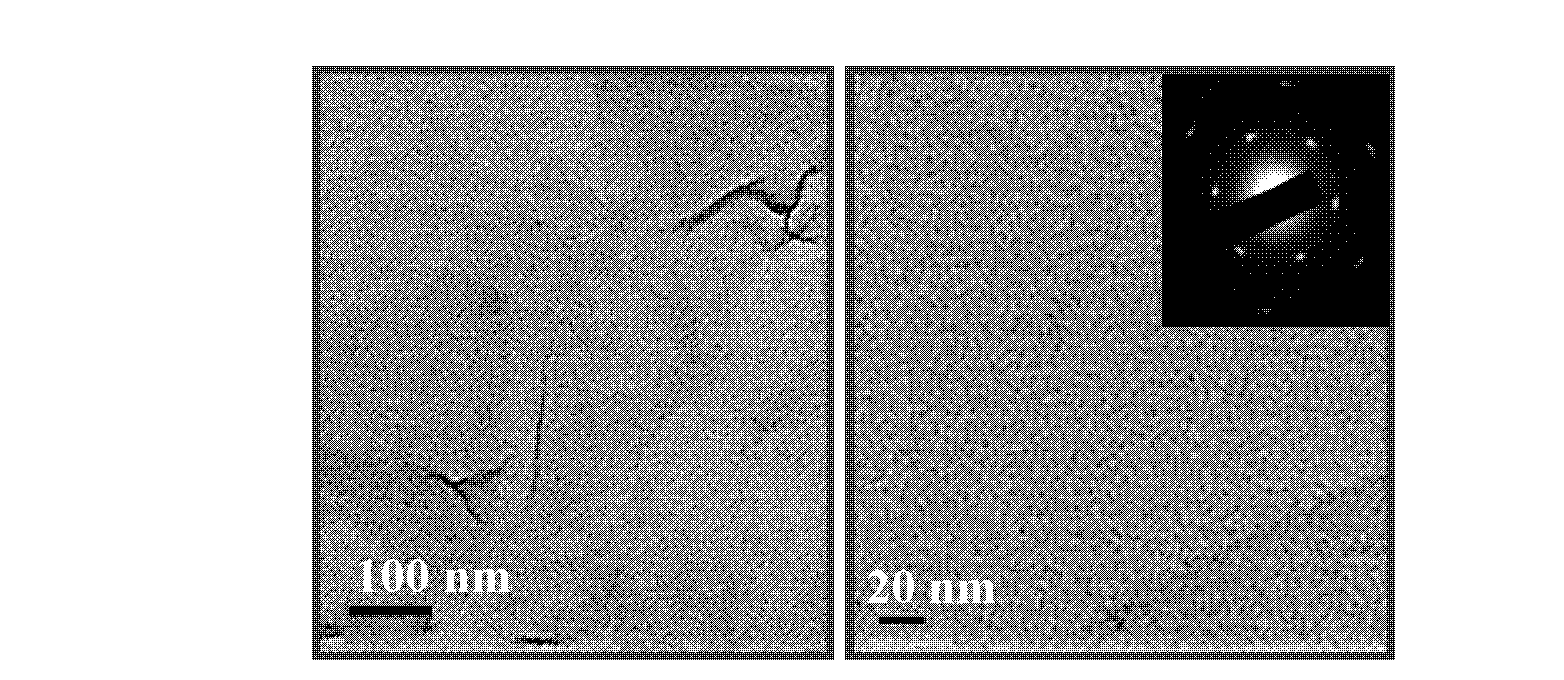

Carbon nanotube dispersion liquid and method for producing the same and polymer composite and method for producing the same

InactiveUS20040136894A1Easy to storeGood dispersionMaterial nanotechnologyIndividual molecule manipulationDispersion stabilityActive agent

By employing a method of producing a carbon nanotube dispersion liquid, in which a carbon nanotube modified with a basic or acidic functional group is dispersed in a polar solvent having a polarity opposite to a polarity of the functional group, there is provided a carbon nanotube dispersion liquid having a high dispersion stability, in which a carbon nanotube is uniformly dispersed without using any surfactant or the like. By using the carbon nanotube dispersion liquid, a polymer composite in which a carbon nanotube is uniformly dispersed without being mixed with an impurity can be provided. In addition, a method for producing the polymer composite by relatively simple procedures is also provided.

Owner:FUJIFILM BUSINESS INNOVATION CORP

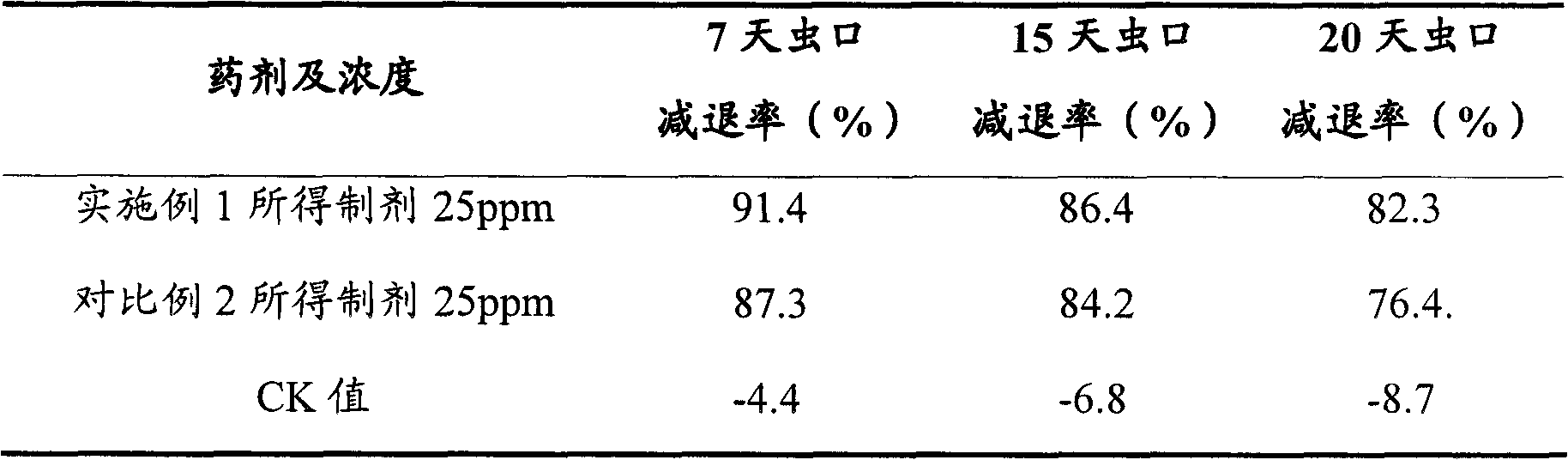

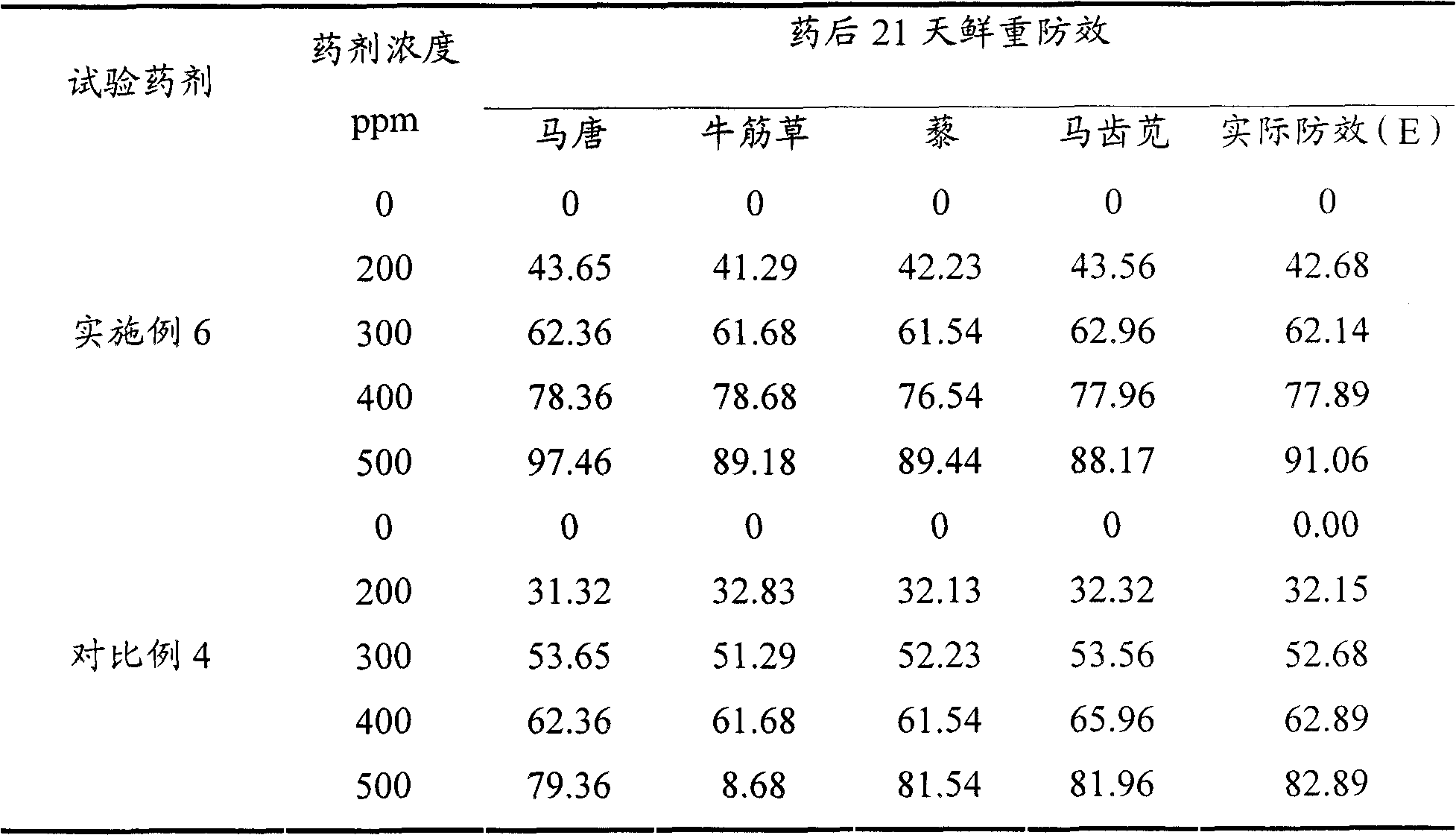

Pesticide oil suspension agent and preparation method thereof

ActiveCN101785455ASmall particle sizeGood spreadabilityBiocideFungicidesDispersion stabilityVegetable oil

The invention provides a pesticide oil suspension agent and a preparation method thereof; the pesticide oil suspension agent contains a pesticide active component, emulsifier, defoamer and a dispersion medium; and the dispersion medium is methyl oleate or the mixture of oil methyl ester and vegetable oil. The method for preparing the pesticide oil suspension agent comprises the following steps that: the dispersion medium and the emulsifier are mixed and emulsified; other components are added in to be mixed into pulp; and the pulp is ground by a grinder to prepare the oil suspension agent. Thepesticide oil suspension agent of the invention has small average grain size and high dispersion stability, has good extendibility and permeability on plant leaves, and improves the medicine effect of the product; and the preparation method of the pesticide oil suspension agent has simple process and low cost, facilitates industrial production, and has wide production application prospect.

Owner:SHENZHEN NOPOSION AGROCHEM

Aqueous grinding fluid applied to super precision grinding of hard and brittle materials and application method thereof

ActiveCN102311718AGood suspensionImprove dispersion stabilityOther chemical processesLapping machinesDispersion stabilitySuspending Agents

The invention discloses an aqueous grinding fluid applied to super precision grinding of hard and brittle materials and an application method thereof. The grinding liquid contains chelant 0.1-5, a pH value regulator 5-15, a suspending agent 0.2-5, a dispersion stabilizer 0.5-10, a lubricant 5-20, an antirusting agent 0.5-5, fungicide 0-2, a defoamer 0-2 and deionized water compensating the balance of total amount of 100 parts. Under an alkali condition, the aqueous grinding fluid applied to super precision grinding of hard and brittle materials is beneficial for grinding materials with various sizes, has good suspension property and dispersion stability; when the aqueous grinding fluid is used for super precision grinding of various different hard and brittle materials, especially high-hardness materials, scratches, etching pits and other defects are not produced easily; and the grinding speed is high, the subsequent cleaning is convenient; and the aqueous grinding fluid has excellent lubricating property and antirusting property when in matched use with the grinding materials, and the mixing liquid is uniform in color and has no sediment in 48 h. When the aqueous grinding fluid is used for grinding a wafer on a grinding machine, the ground wafer is subjected to water-added ultrasonic washing, and the wafer has good surface smooth finish, no scales, etching pits and other defects, and the surface roughness can be within 2 microns.

Owner:AMER TECH CO LTD

High-purity nano diamond polishing liquid and preparing method thereof

InactiveCN101033374AEvenly dispersedImprove dispersion stabilityOther chemical processesPolishing compositions with abrasivesGranularitySlurry

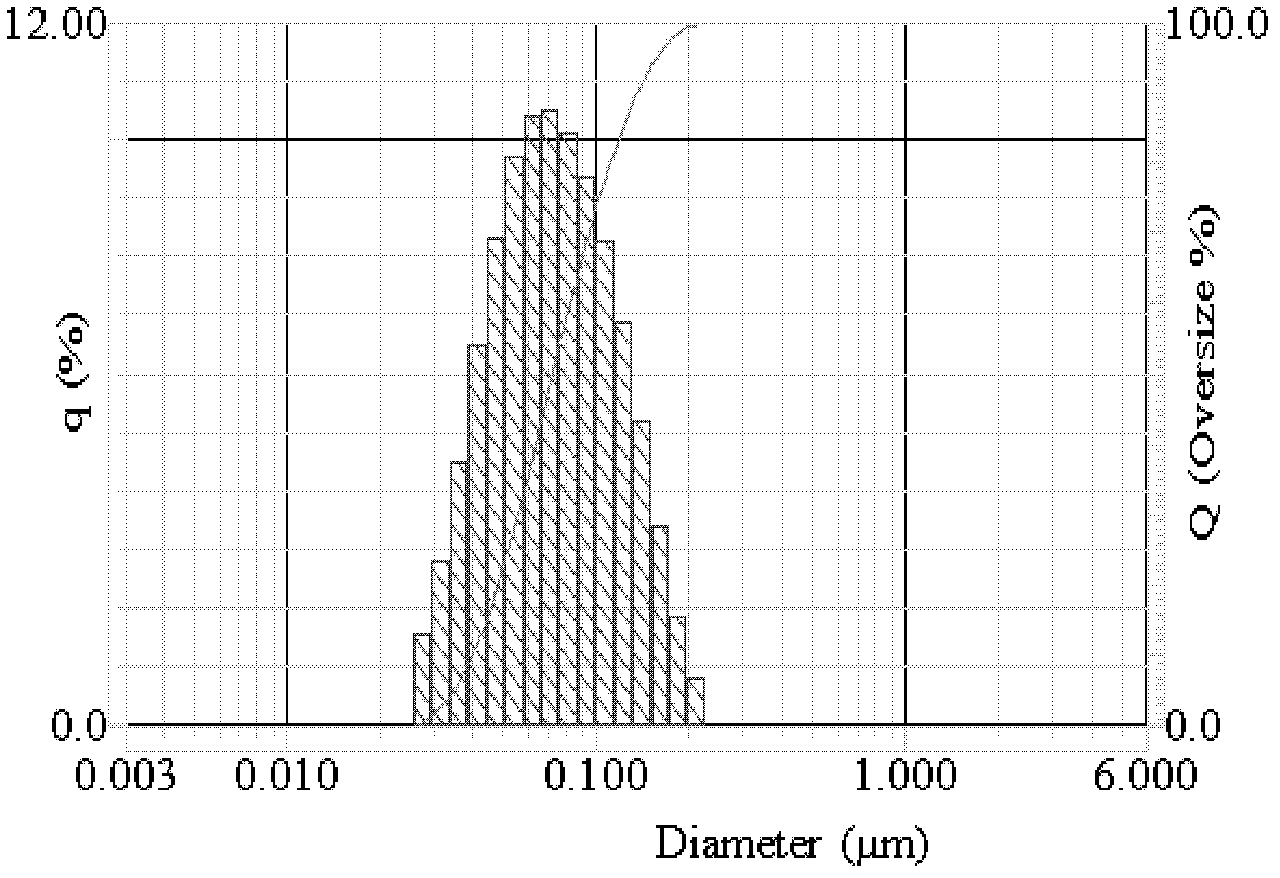

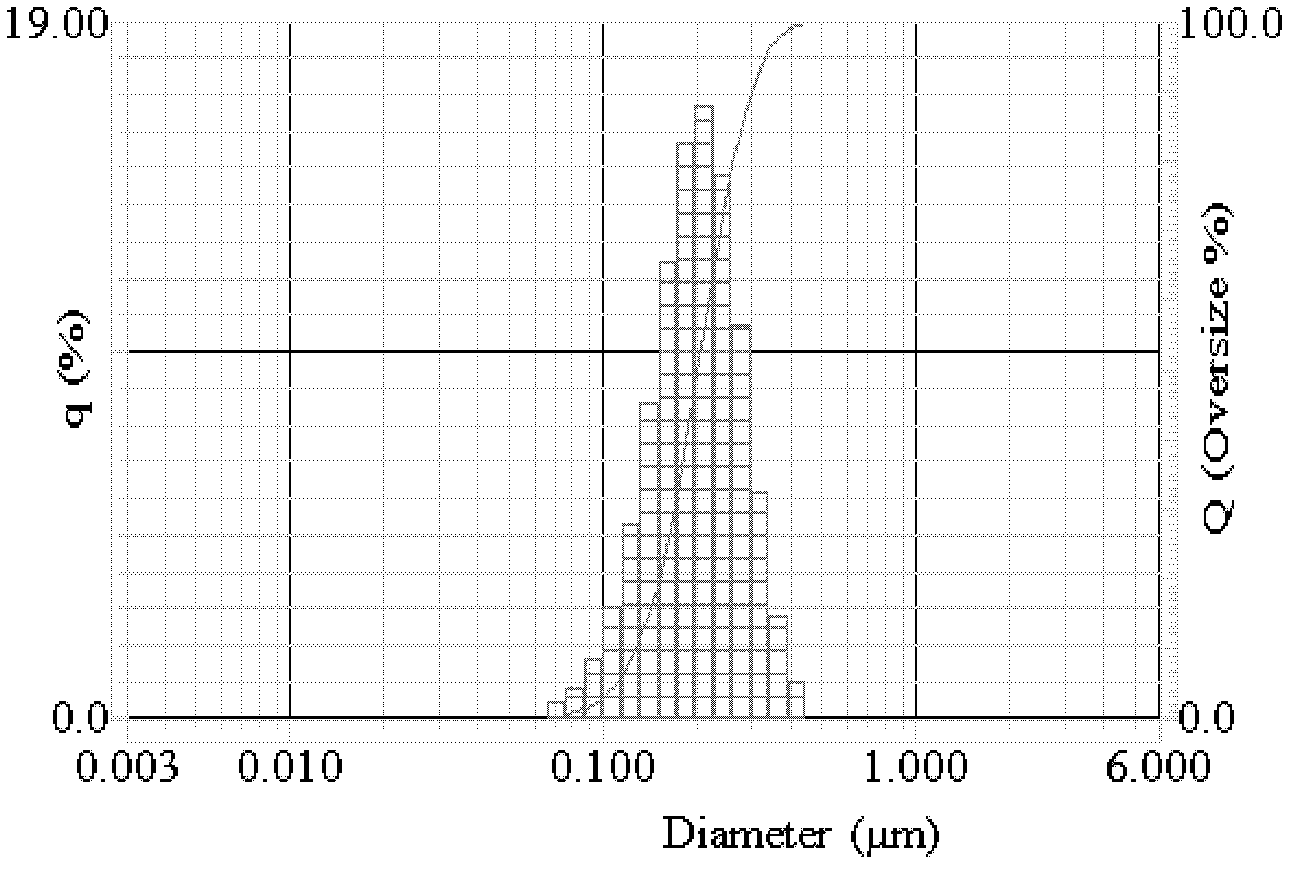

The invention relates to a kind of high purity nano-scale diamond polishing slurry for ultra-precision processing and its preparation. The high-purity polishing slurry is prepared with nano-scale diamond, wetting agent, surface modification agent, dispersing agent, chemical additives and water, and the percentage of the raw materials by weight share are as follow: 0.05~10% of the nano-scale diamond, 0.01~2% of the wetting agent, 1~5% of the surface modification agent, 0.1~10% of the dispersing agent, 0.2~1% of the chemical additives, 88.69~98.64% of water. The amounts of all the materials are weighted as 100%. The amounts of the described wetting agent, surface modification agent, dispersing agent, and chemical additives are referred to solid content. The purity of the nano-scale diamond is 99.9% and the particle size of distribution is 10~200 nm.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

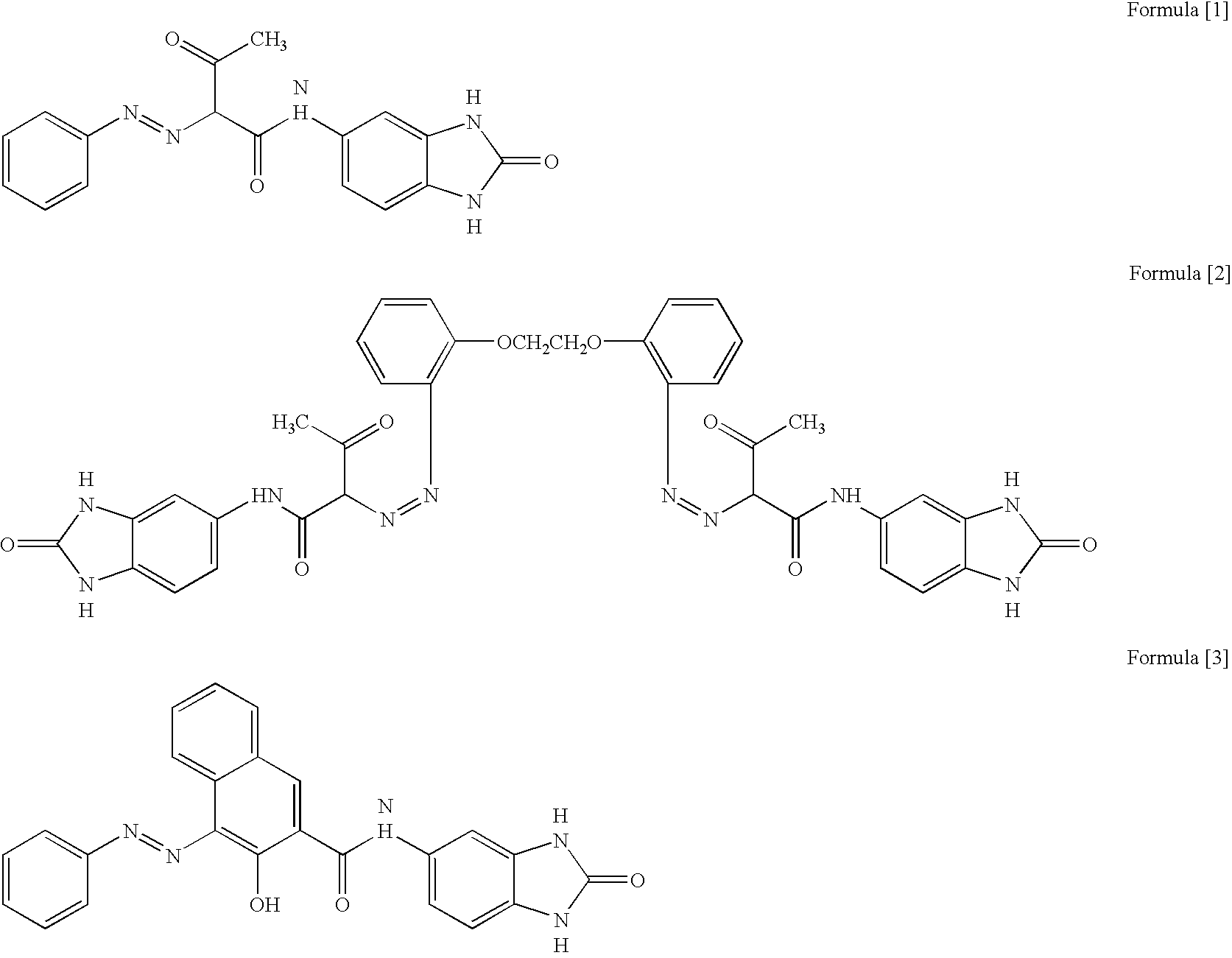

Pigment dispersions with polymeric dispersants having pending chromophore groups

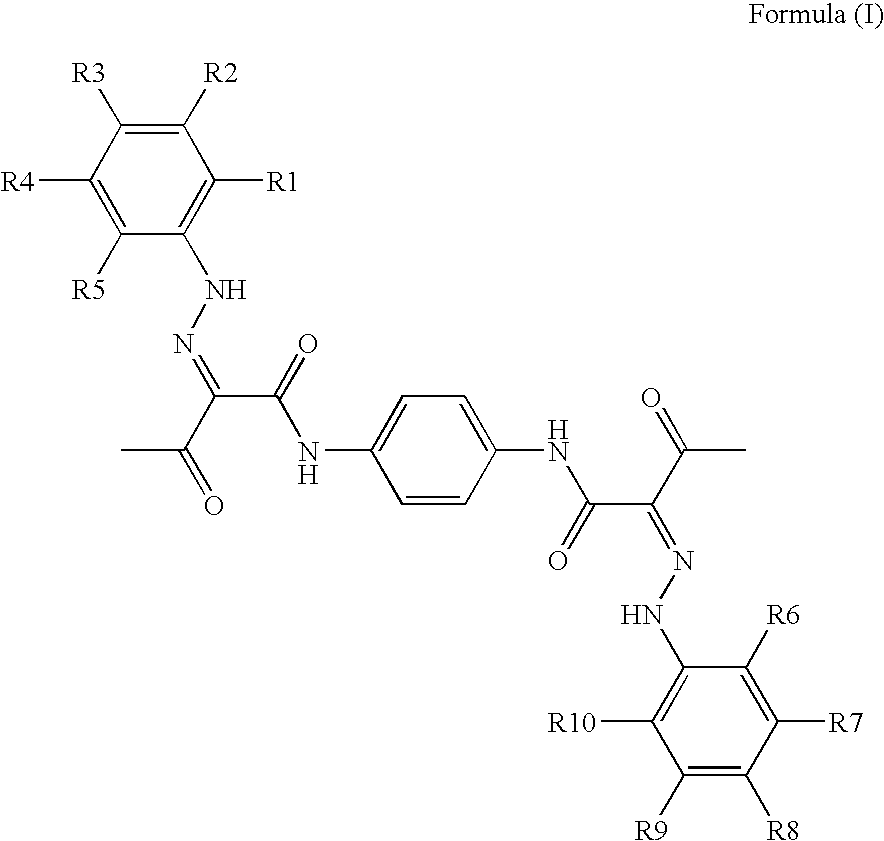

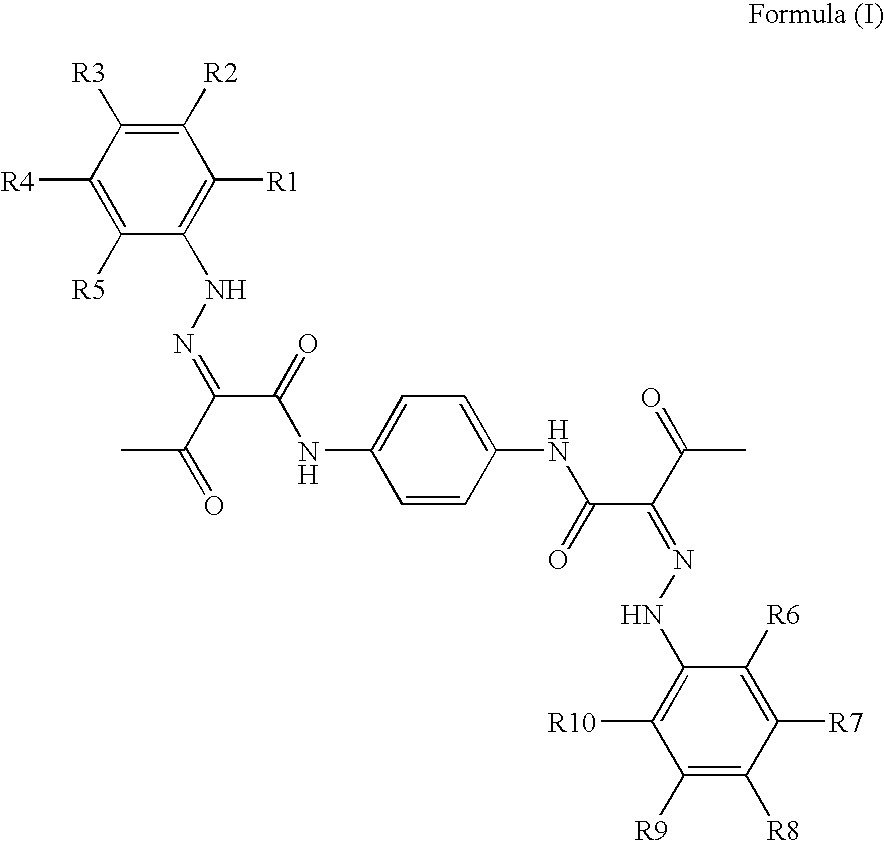

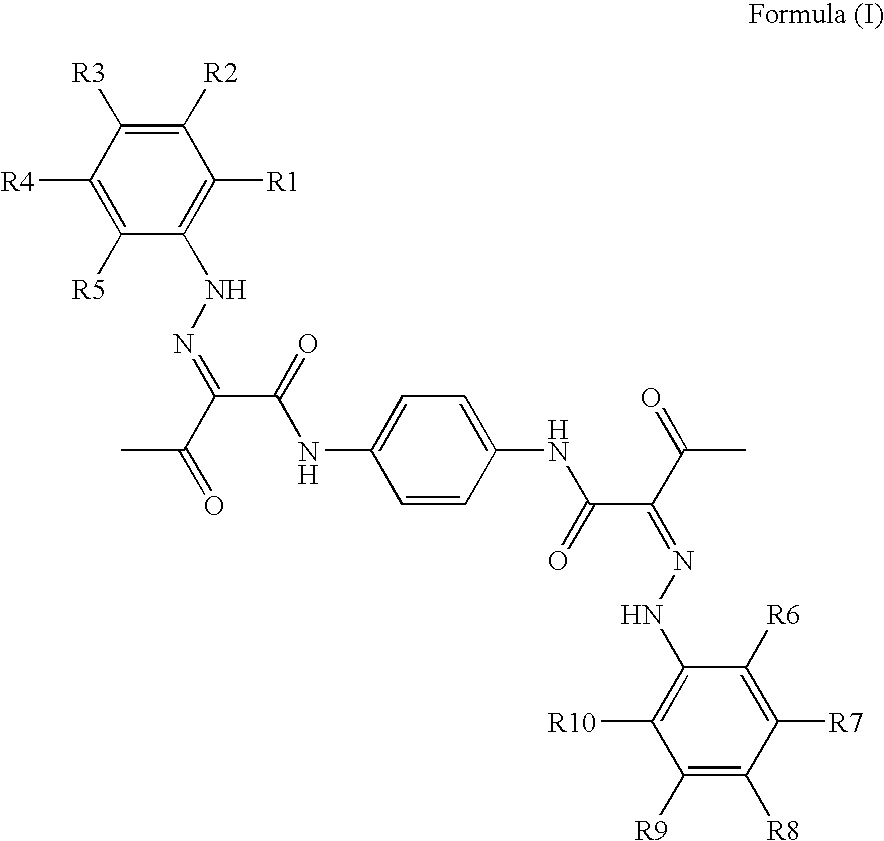

A pigment dispersion includes a color pigment represented by formula (I):whereinR1 to R10 are independently selected from the group consisting of hydrogen, a halogen atom, a methyl group, an ethyl group, a methoxy group, an ethoxy group, —CF3, —COOH, —COOCH3, —SO2NH—C6H5, —CONH—C6H5, —CONH—C6H5—CONH2, and —CONH2; and a polymeric dispersant, having via a linking group covalently linked to its polymeric backbone, at least one pending chromophore group which has a molecular weight smaller than 95% of the molecular weight of said color pigment. The pigment dispersion can be advantageously used in inkjet inks.

Owner:AGFA NV

Heat radiation material, heat radiation structure, and preparation method and application thereof

InactiveCN103205075AImprove interface performanceImprove compatibilityLayered productsHeat-exchange elementsSolventRadiation

The invention provides inorganic heat radiation nano-grade material aqueous slurry, a heat radiation material comprising the inorganic heat radiation nano-grade material aqueous slurry, and preparation methods and applications thereof. The inorganic heat radiation nano-grade material aqueous slurry comprises the components comprising, by weight, 10-25 parts of an inorganic heat radiation nano-grade material, 0.5-20 parts of a modifier solution, and 50-100 parts of a solvent. The heat radiation material comprises, by weight, 10-30 parts of the inorganic heat radiation nano-grade material aqueous slurry, 40-80 parts of aqueous high-molecular resin, 20-30 parts of latex, 10-40 parts of a film-forming auxiliary agent, 0.5-5 parts of an auxiliary agent, and 5-20 parts of a diluting agent. With the application of the inorganic heat radiation nano-grade material aqueous slurry, compatibility and system dispersion stability of the inorganic heat radiation nano-grade material and the high-molecular material are improved, such that the unique heat radiation material with excellent heat radiation performance and with the inorganic heat radiation nano-grade material aqueous slurry is obtained.

Owner:REGAL PAPER TECH

Process for producing aqueous fluoropolymer dispersion and aqueous fluoropolymer dispersion

ActiveUS20070135558A1Efficient productionLow total surfactant contentSemi-permeable membranesFibre treatmentPolymer scienceOctanol

The present invention provides a method of producing a fluoropolymer aqueous dispersion by which the fluorine-containing emulsifier contained in the fluoropolymer aqueous dispersion as obtained after polymerization can be efficiently removed as well as a fluoropolymer aqueous dispersion low in fluorine-containing emulsifier concentration. The present invention is a method of producing a fluoropolymer aqueous dispersion which comprises carrying out a concentration treatment comprising a concentration operation of a pretreatment fluoropolymer aqueous dispersion, wherein the pretreatment fluoropolymer aqueous dispersion is obtained by carrying out a polymerization in an aqueous medium in the presence of a fluorine-containing surfactant (A), the fluorine-containing surfactant (A) is a fluorine-containing surfactant having an octanol / water partition coefficient of 1.5 to 3.5.

Owner:DAIKIN IND LTD

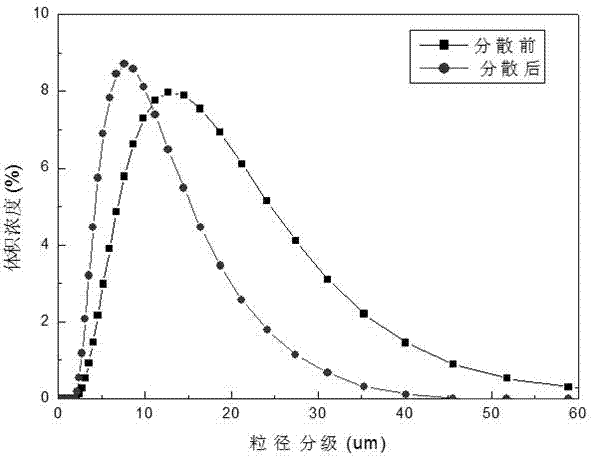

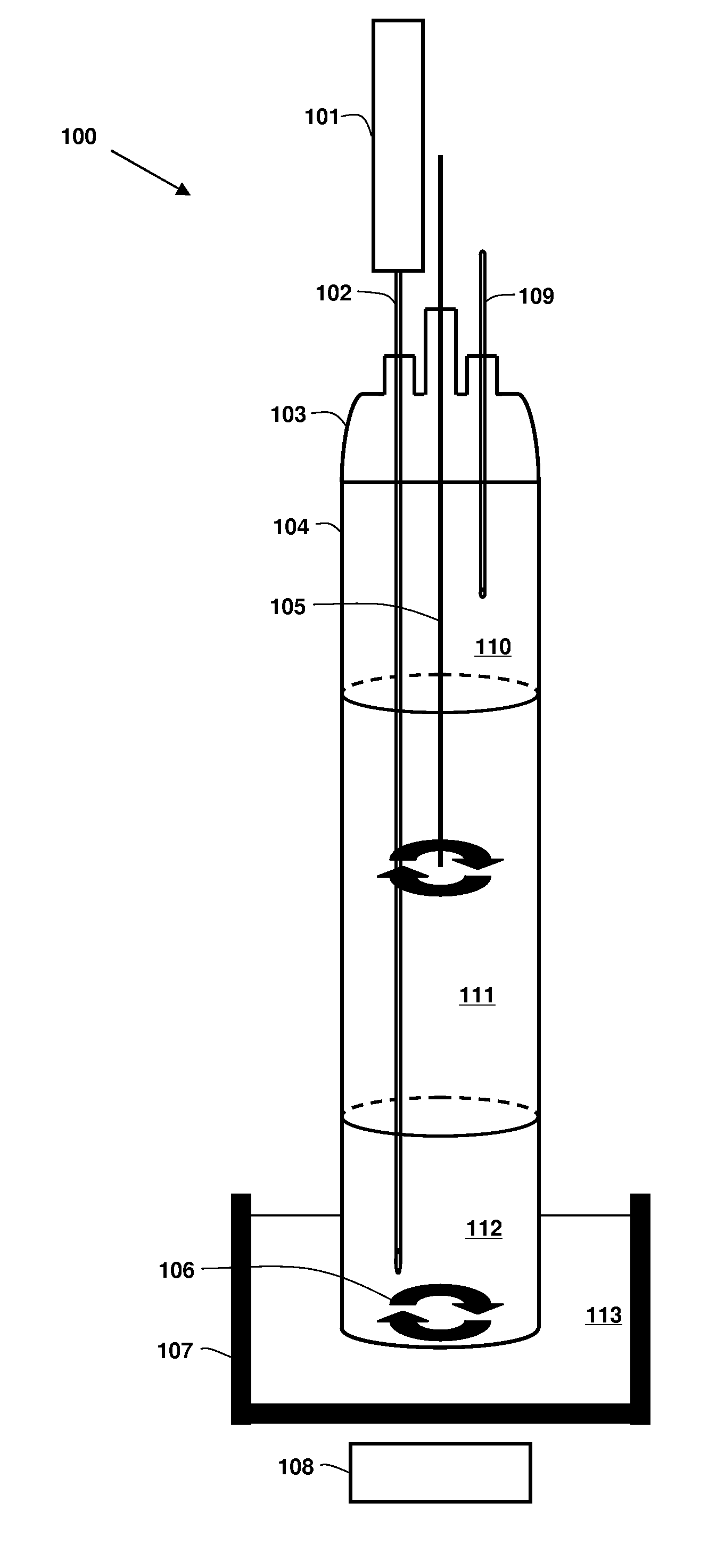

Method for preparing grapheme dispersion liquid

ActiveCN104772064AShorten dispersion timeIncrease productivityMixer accessoriesDispersion stabilityColloid

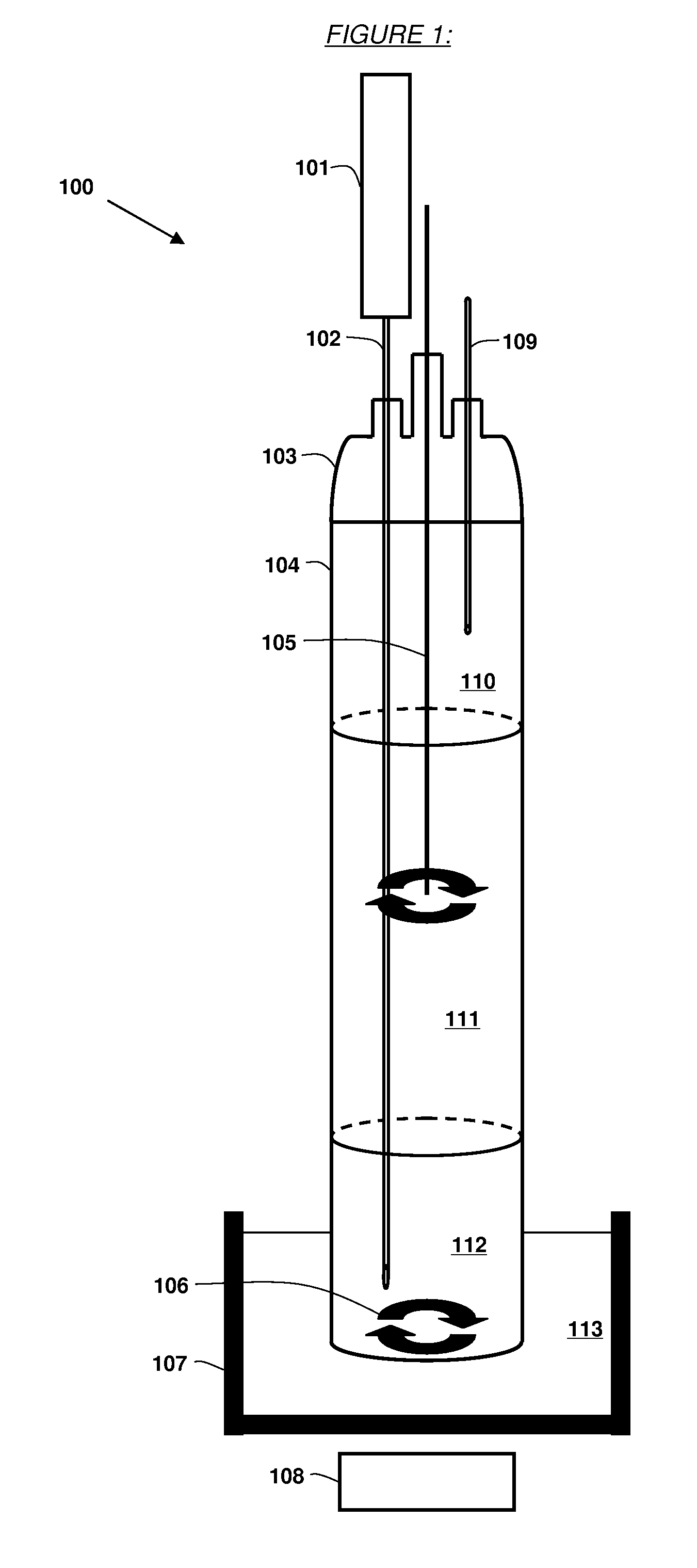

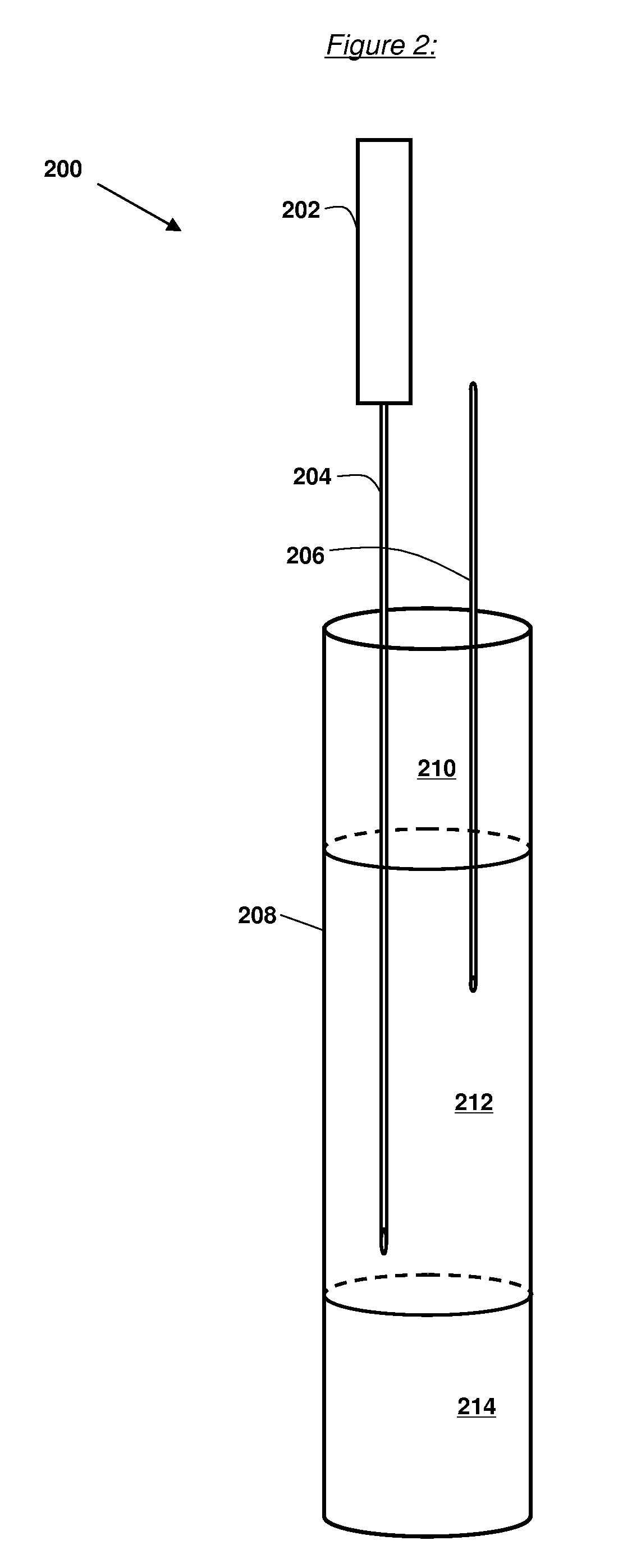

The invention discloses a method for preparing grapheme dispersion liquid. The method comprises the following steps: (1) uniformly mixing grapheme and a dispersant in a solvent to obtain a uniformly mixed solution; and (2) dispersing the uniformly mixed solution by a dispersing device for 0.5-24 hours to obtain the grapheme dispersion liquid, wherein the rotation speeds of a high shearing dispersion head and a colloid grinding disc are regulated to be within 100-14000rpm, the rotation speed of an electric mixer is at 10-2000rpm, an energy-concentration ultrasonic probe is additionally arranged, the ultrasonic frequency is within 20-80kHz and the dispersion temperature is 0-20 DEG C after being regulated by a cooling system. According to the method for preparing the grapheme dispersion liquid, the dispersion time is saved and the production efficiency is improved due to the adoption of multiple dispersion methods and synergic action, the cost is low, the operation is easy, and the method is nontoxic, free of pollution and beneficial for batch production, has high dispersion stability and a bright prospect of large-scale industrial application.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

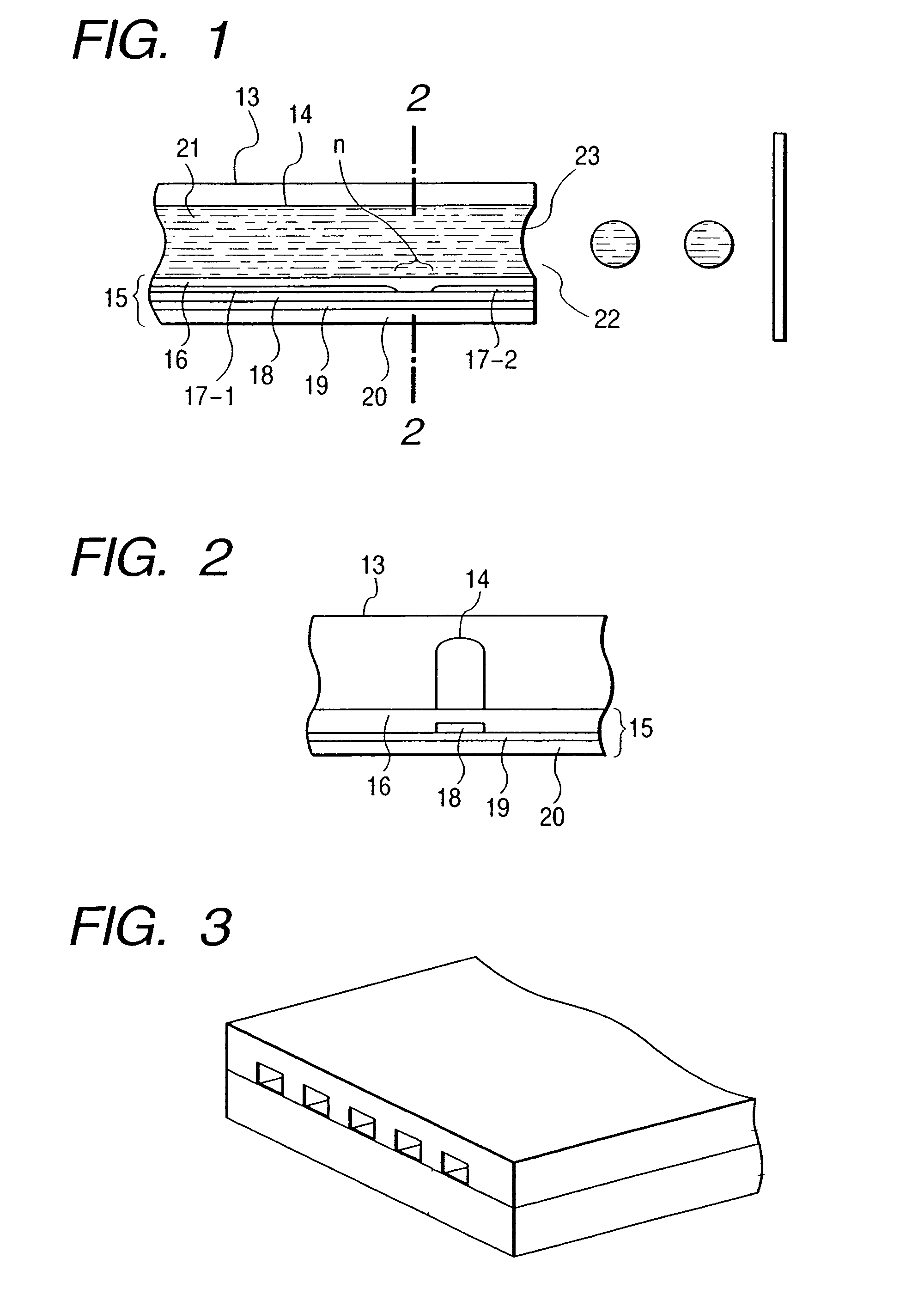

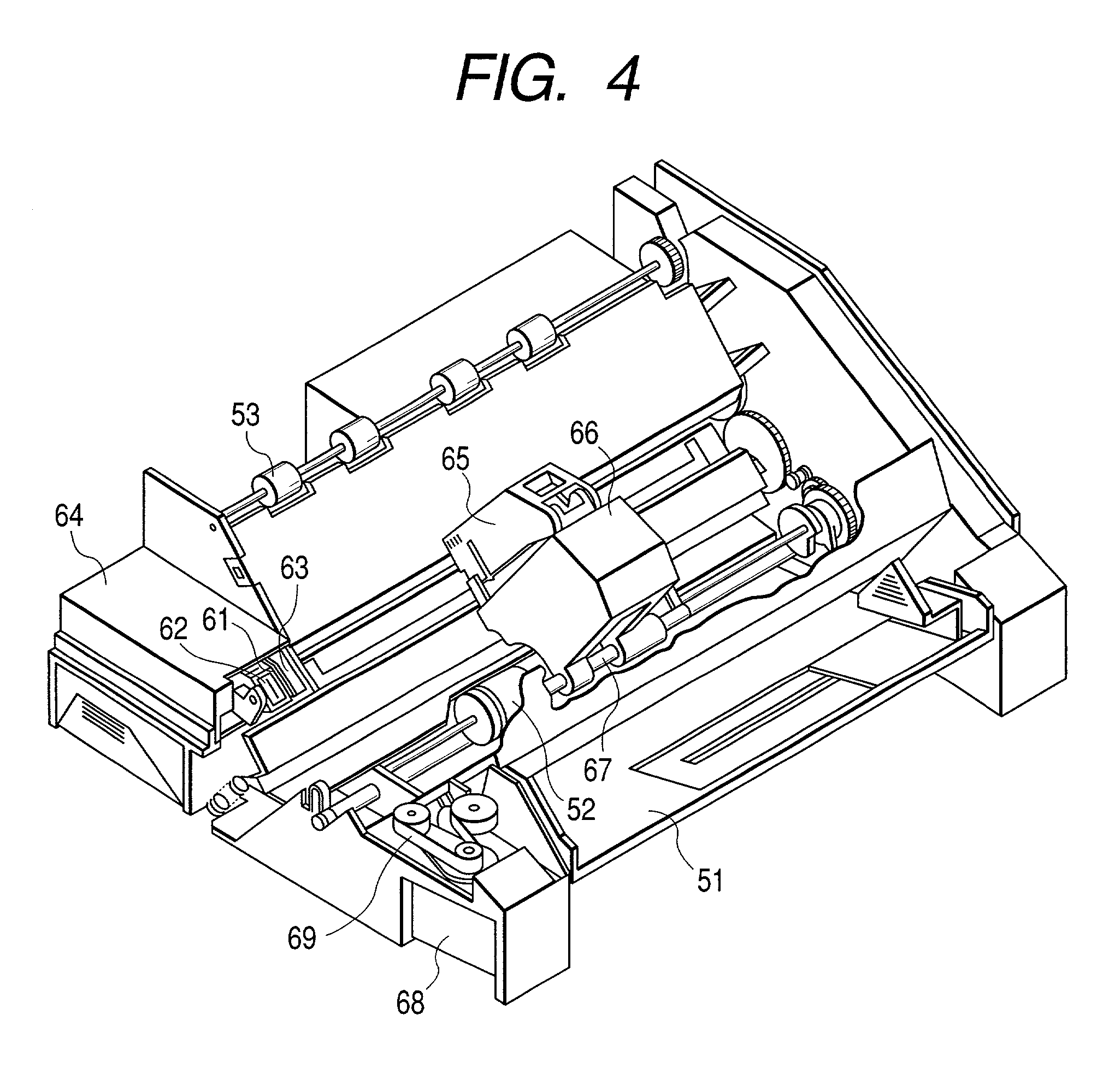

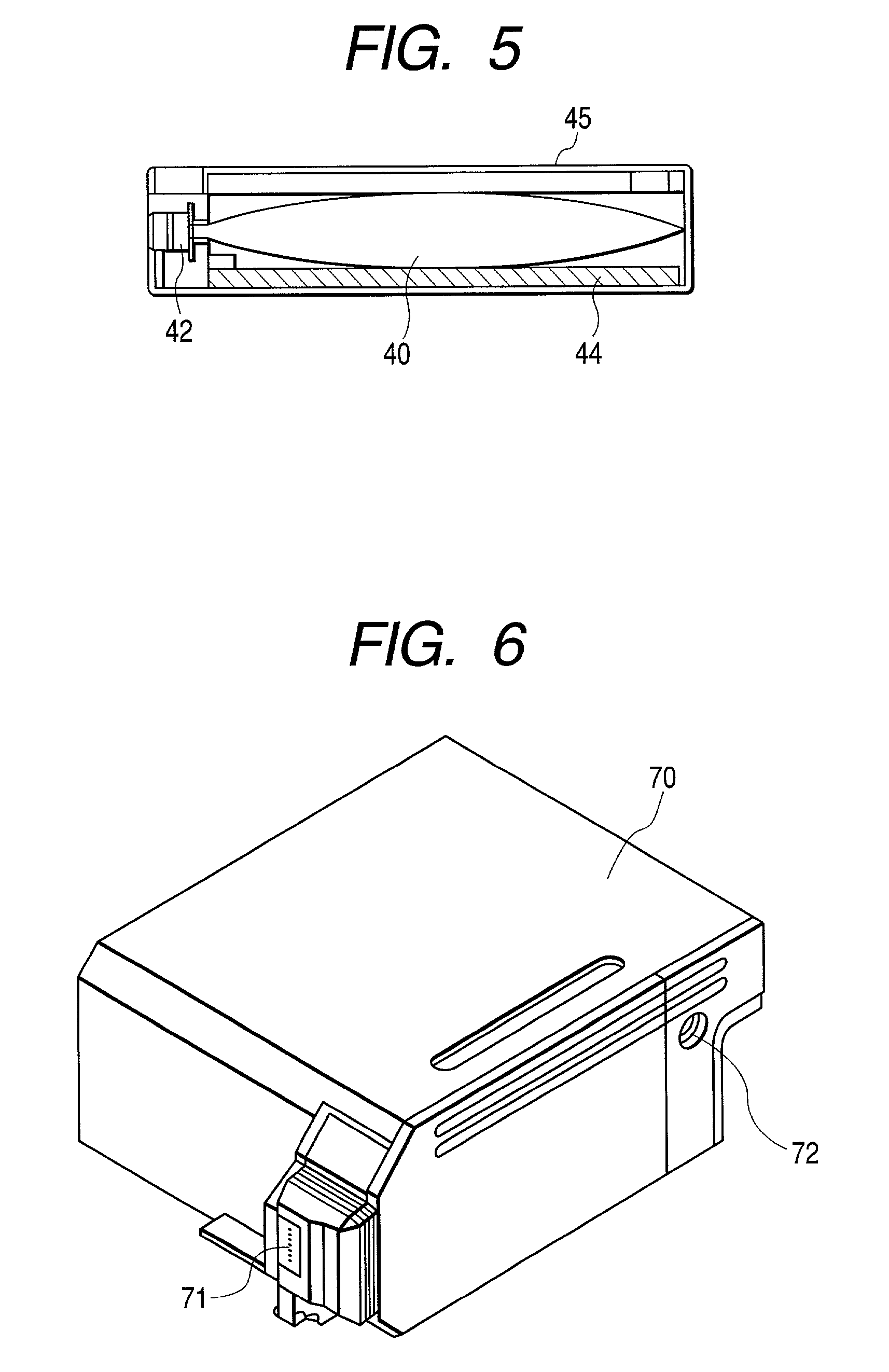

Colored fine resin particles and production process thereof, aqueous dispersion of colored fine resin particles and production process of aqueous dispersion of colored fine resin particles, ink , ink cartridge, recording unit, ink-jet recording apparatus, and ink-jet recording process

InactiveUS7008977B2Good rub-off resistanceExcellent water fastnessInksOrganic dyesDispersion stabilityWater insoluble

The invention provides colored fine resin particles useful as coloring materials for inks which can provide images having good water fastness, weather fastness and rub-off resistance and are excellent in dispersion stability, and a production process thereof. The colored fine resin particles have a structure in which a pigment coated with a water-insoluble resin is encapsulated with a copolymer composed of at least a polymerizable unsaturated monomer and a reactive emulsifier.

Owner:CANON KK

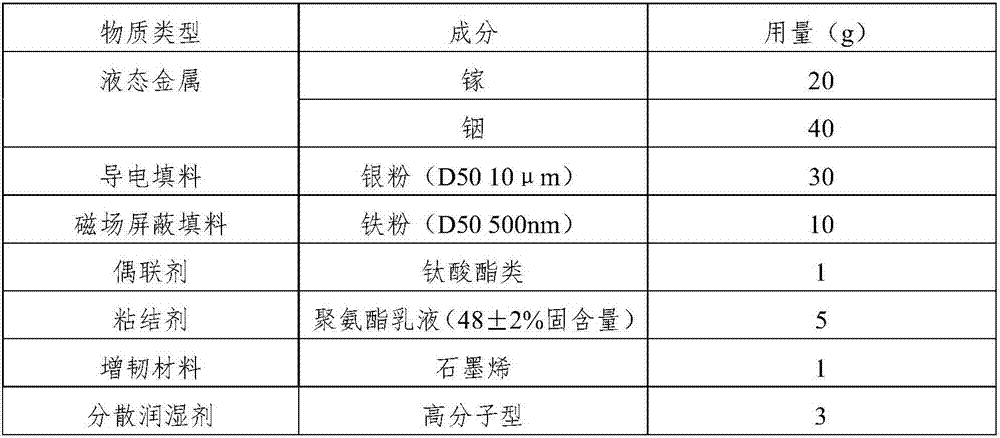

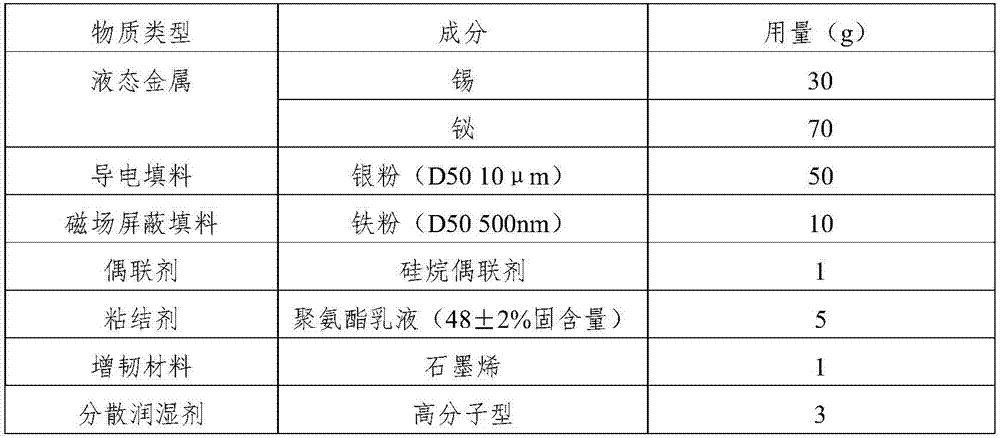

Electromagnetic shielding coating material and preparation method thereof

ActiveCN107573745AGood compatibilityImprove dispersion stabilityMagnetic/electric field screeningElectrically-conductive paintsHazardous substanceLiquid metal

The invention provides an electromagnetic shielding coating material. The electromagnetic shielding coating material comprises 40-70% of liquid metal, 10-40% of a conductive filler, 5-15% of a magnetic shielding filler, 0.5-2% of a coupling agent, 1-10% of a binder, 0.5-2% of a toughening material and 0.5-2% of a wetting dispersing agent, wherein the liquid metal is low-melting-point metal with the melting point of 300 DEG C or below or a conductive nanofluid formed by mixing low-melting-point metal nanoparticles with a fluid dispersant. For the first time, the concept of taking the liquid metal as a conductive auxiliary binder and a conductive auxiliary flow aid is put forward and implemented, and the liquid metal replaces a non-conductive solvent and a non-conductive binder to form the electromagnetic shielding coating material system. Besides, the electromagnetic shielding coating material neither contains any toxic or harmful substances nor produce any volatile organics, is high infilm forming speed, has the characteristics of being safe and environmentally friendly, convenient to construct and low in cost, and can be widely applied to a plurality of fields including militaryscience, electronics, aerospace, buildings and the like.

Owner:BEIJING DREAM INK TECH CO LTD

Polychromic ink composition depending on viewing angle

InactiveUS20020033117A1Coating obtainedImprove dispersion stabilityPigmenting treatmentInksPolymer chemistryPigment

A polychromic ink composition depending on viewing angle comprises 0.5 to 40% by weight of cholesteric liquid crystal polymer particles whose maximum particle diameter is 1 to 200 mum, 1.0 to 30.0% by weight of binder resins, 0.05 to 20% by weight of pigments with a deep-colored coloring matter whose average particle diameter is 0.01 to 0.5 mum, 0.01 to 5.0% by weight of a shear-thinning property imparting agent, and water with respect to the total amount of the ink composition.

Owner:SAKURA COLOR PRODUCTS CORPORATION

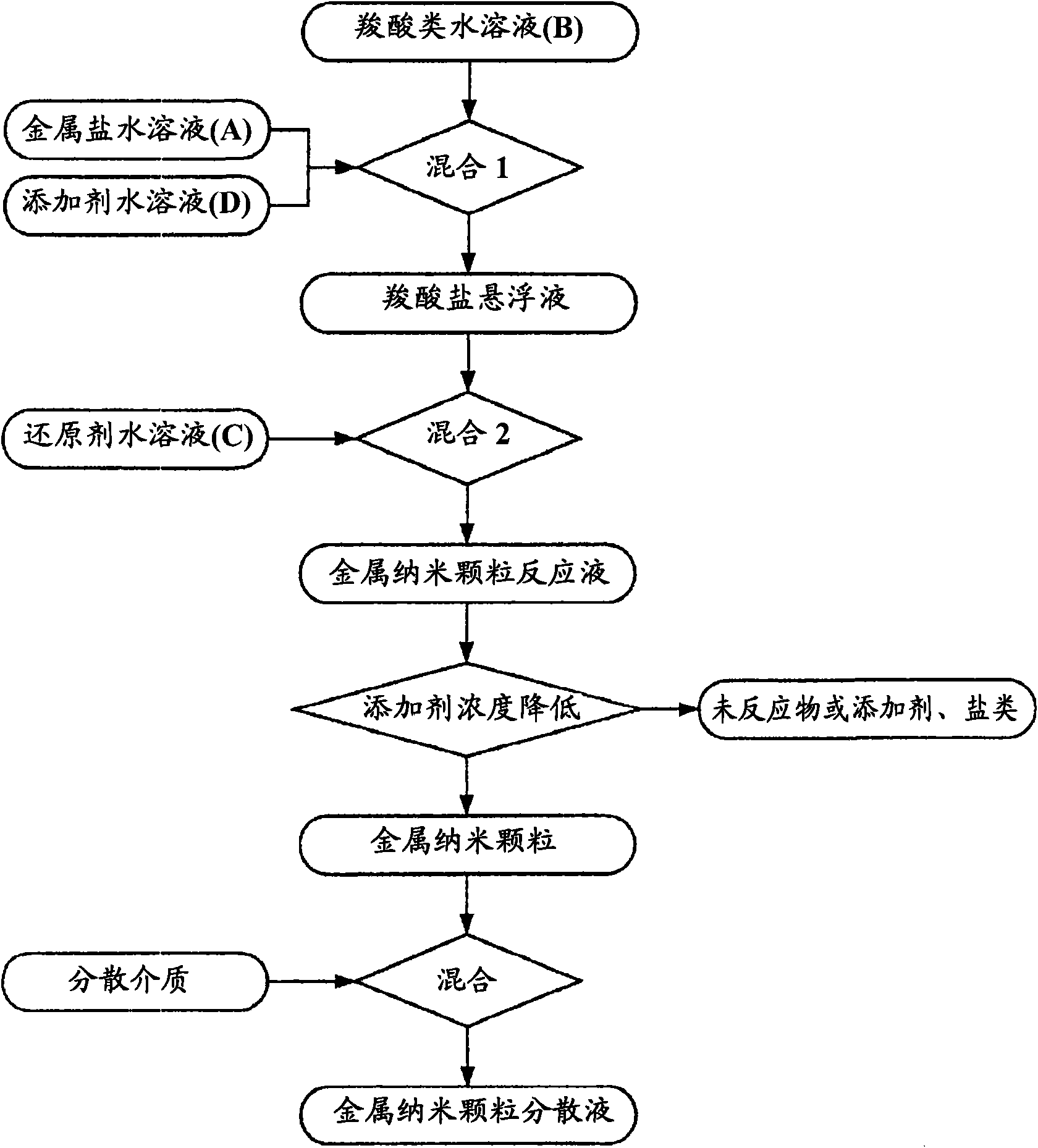

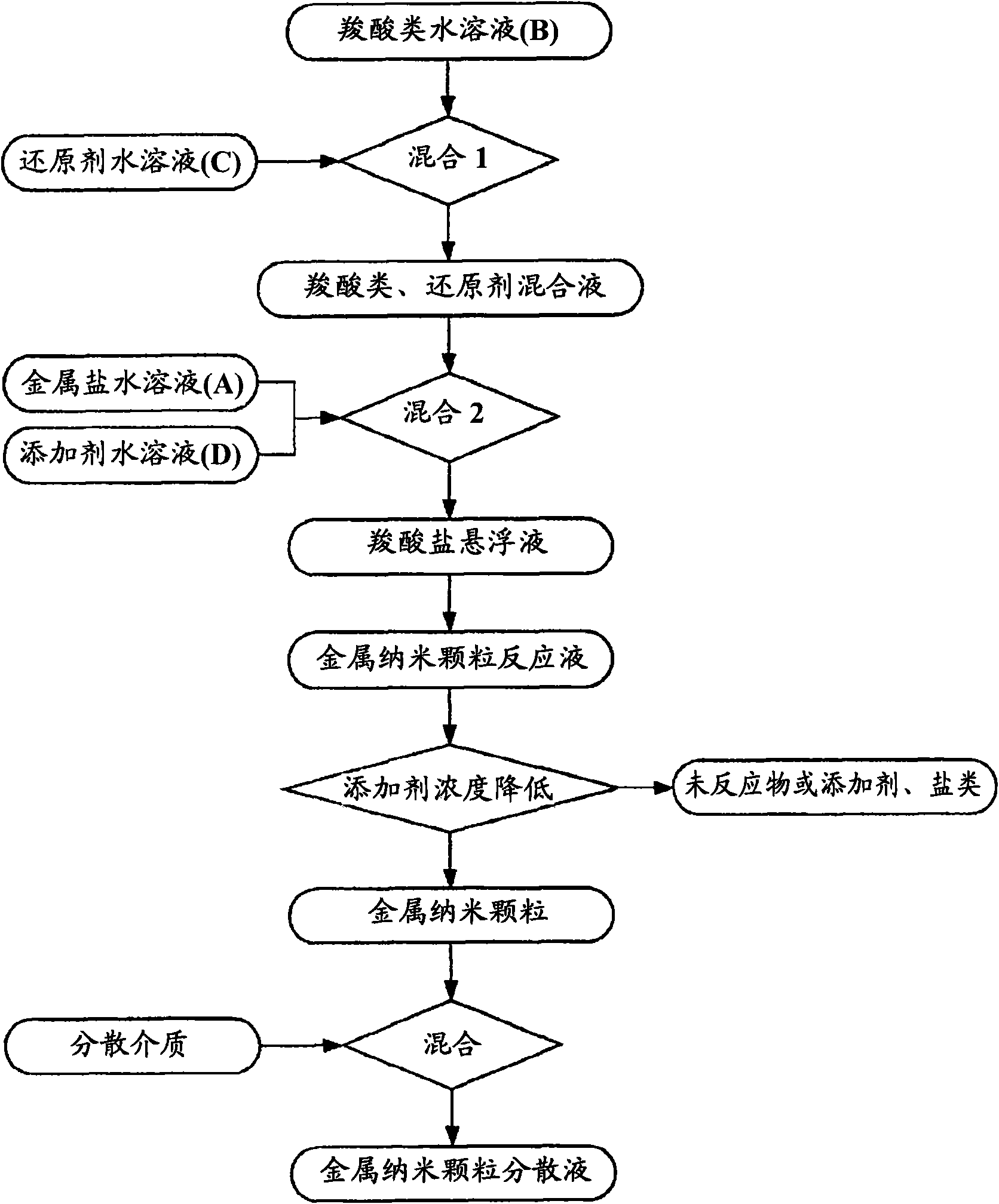

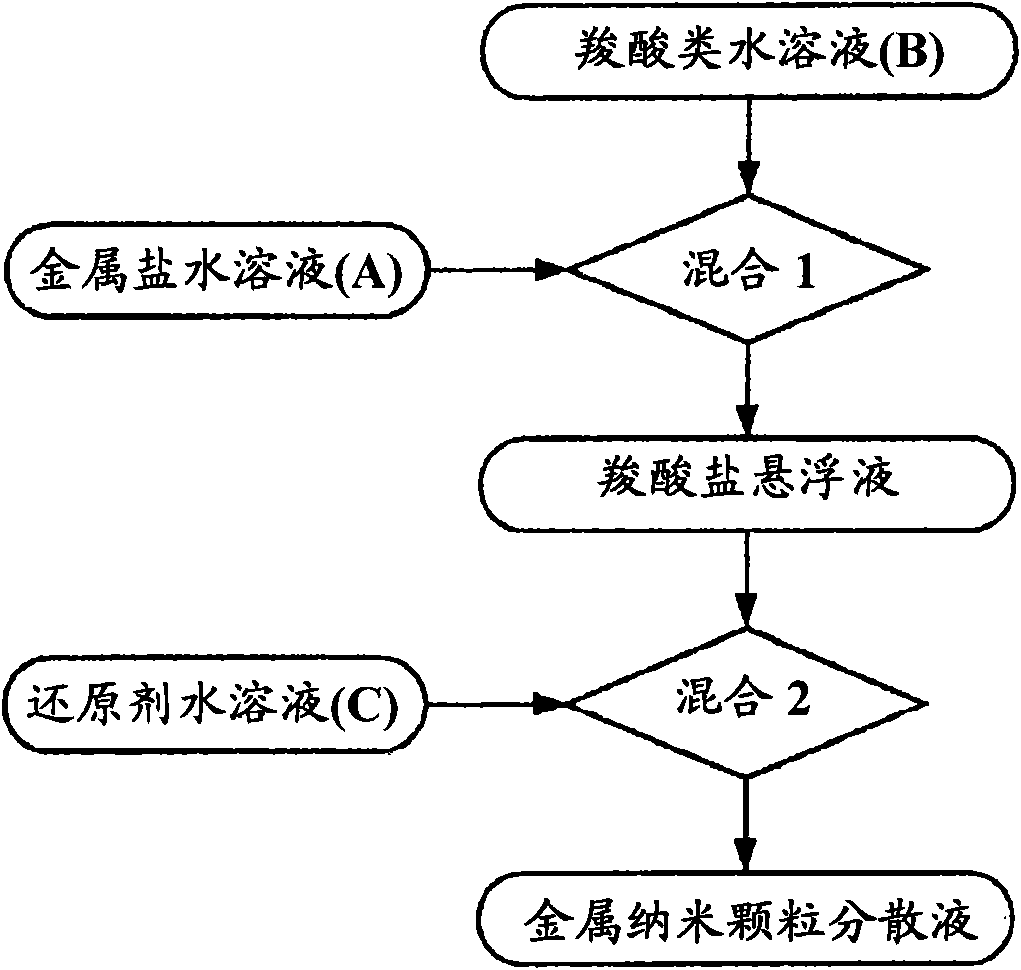

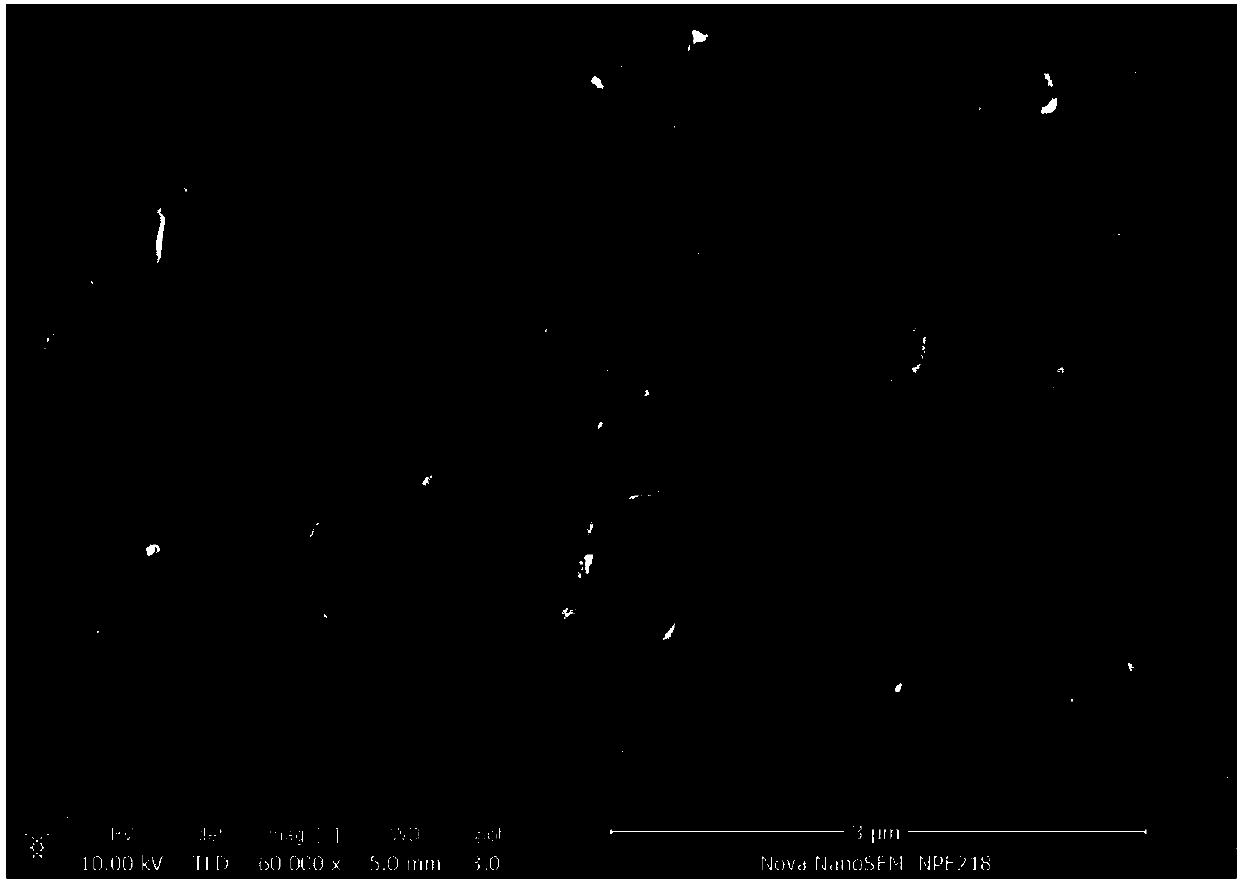

Dispersion solution of metal nanoparticle, method for production thereof, and method for synthesis of metal nanoparticle

ActiveCN101622090AEasy to prepareReduce concentrationCable/conductor manufacturePhysical chemistryConductive materials

An object is to provide: a method for producing a dispersion solution of a metal nanoparticle, which enables to control the shape or particle size of the metal nanoparticle within a wide range; a dispersion solution of a metal nanoparticle, which has excellent dispersion stability; and a method for producing the dispersion solution. Another object is to provide: a dispersion solution of a metal nanoparticle, which has a volume resistivity of 2 to 6 x 10<-6> Omega cm which is a value useful for use as an electrically conductive material; and a method for producing the dispersion solution. Still another object is to provide a method for the synthesis of a metal nanoparticle, which can synthesize a metal nanoparticle from an insoluble metal salt without using no corrosive material and can produce a metal nanoparticle suitable as an electrically conductive material.

Owner:MITSUBISHI MATERIALS CORP

Conductive graphene printing ink and preparation method thereof

The invention provides a conductive graphene printing ink. The conductive graphene printing ink is composed of 0.001-80wt% of graphene, 1-60wt% of a linking material, 0.1-30wt% of an assistant, and the balance solvent. The invention also provides a preparation method of the conductive graphene printing ink. The conductive graphene printing ink has the advantages of good toughness, good die molding performance, good adhesion and good impact resistance; chemically doped graphene and chemically modified graphene in the graphene have good conductive, mechanical and thermal performances. The molecules of the chemically doped graphene comprise one or more of polyaniline, polyacetylene, polythiophene, polyparaphenylene and polypyrrole, and the functional groups of the chemically modified graphene comprise one or more of an anilino group, a pyrryl group, an imidazolyl group, a benzenesulfonic acid group, a thienyl group, a furyl group, a phenyl group, a hydroxy group, an ester group and derivative groups thereof, so the conductive performance, the mechanical performances and the dispersion stability of graphene in the printing ink are improved.

Owner:ZHUHAI LETONG NEW MATERIAL TECH CO LTD

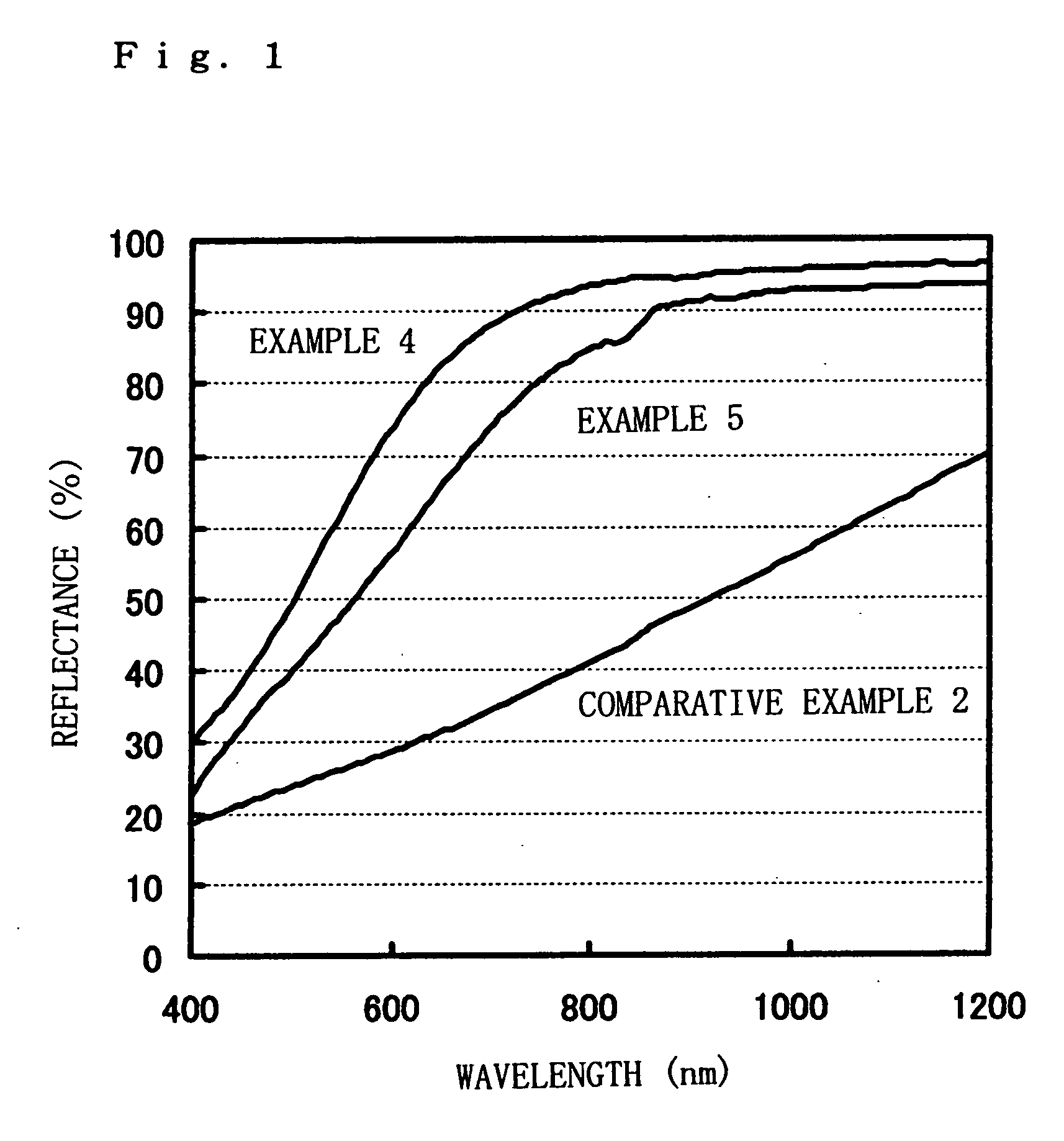

Photocatalyst containing metallic ultrafine particles and process for producing said photocatalyst

InactiveUS7759281B2Improve dispersion stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsHigh concentrationDispersion stability

There is disclosed a photocatalyst which comprises a substrate having a photocatalytic function and metallic nanocolloid particles that are supported on the substrate by the use of a metallic nanocolloid liquid substantially free from a protective colloid formation agent. A highly active photocatalyst containing metallic ultrafine particles is provided by bringing a substrate such as fine particles having a photocatalytic function into contact with a metallic nanocolloid liquid which is substantially free from a protective colloid formation agent, and which has favorable dispersion stability even if containing metallic nanocolloid particles in a relatively high concentration. Accordingly the photocatalyst containing metallic ultrafine particles can be produced at a low cost without being restricted on the place of production.

Owner:NIPPON SHEET GLASS CO LTD

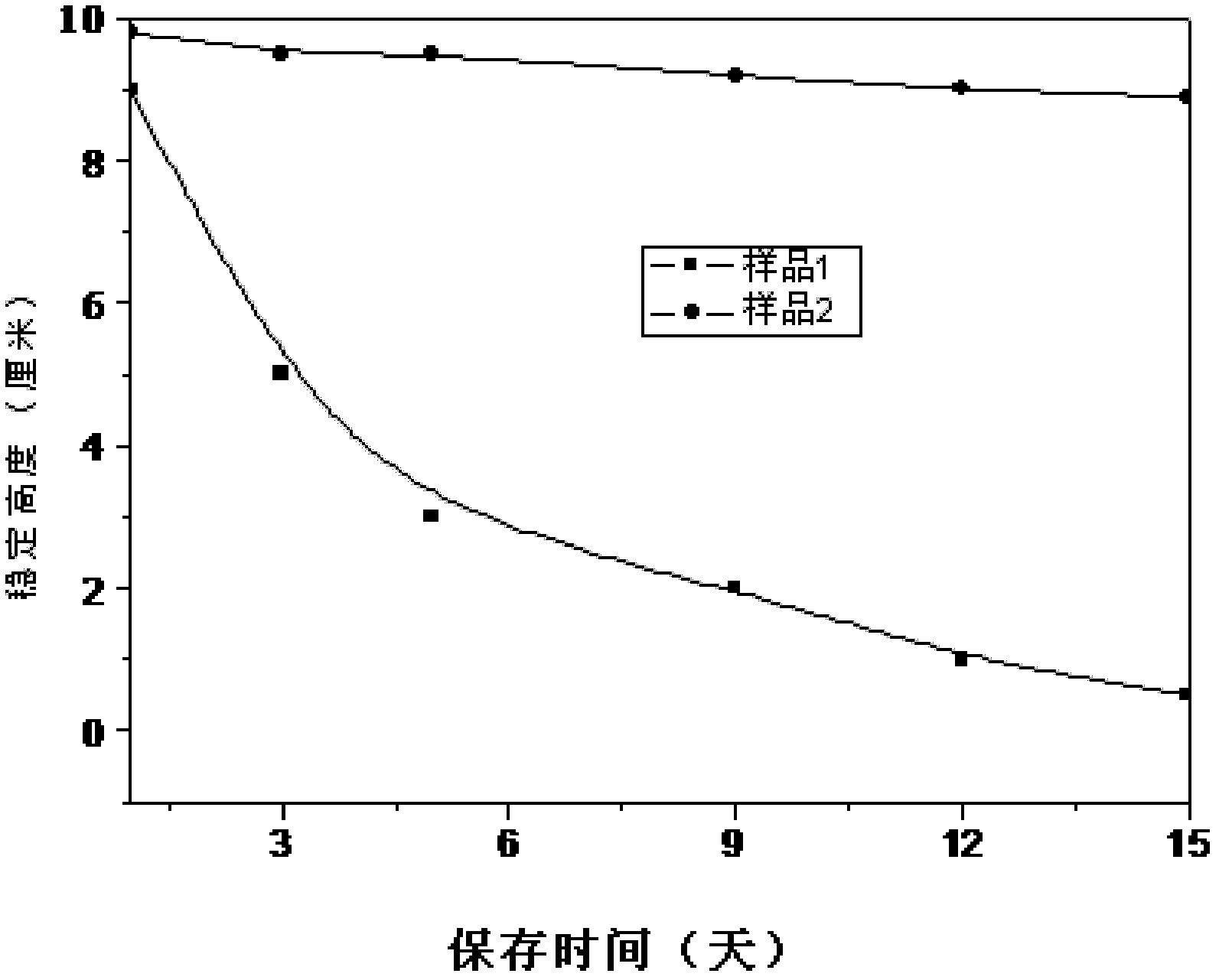

Waste rubber powder modified asphalt composition for increasing storage stability and preparation method thereof

ActiveCN101143968AImproved dispersion and storage stabilitySimple ingredientsBuilding insulationsAsphaltWaste rubber

The invention provides a rubber modified asphalt composition for improving storage stability and a method for preparing the same. Firstly, one or more liquid additives are used to spray the rubber powders, and then the treated waste rubber powders are added into basic asphalt. At appropriate temperature, the rubber powder modified asphalt of the invention can be obtained after treated by high shearing or colloid grinding equipments for a while. The method provided by the invention not only has a simple technology and obviously improves the stability of the rubber powder modified asphalt, and the prepared modified asphalt has good high-and-low temperature performance.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

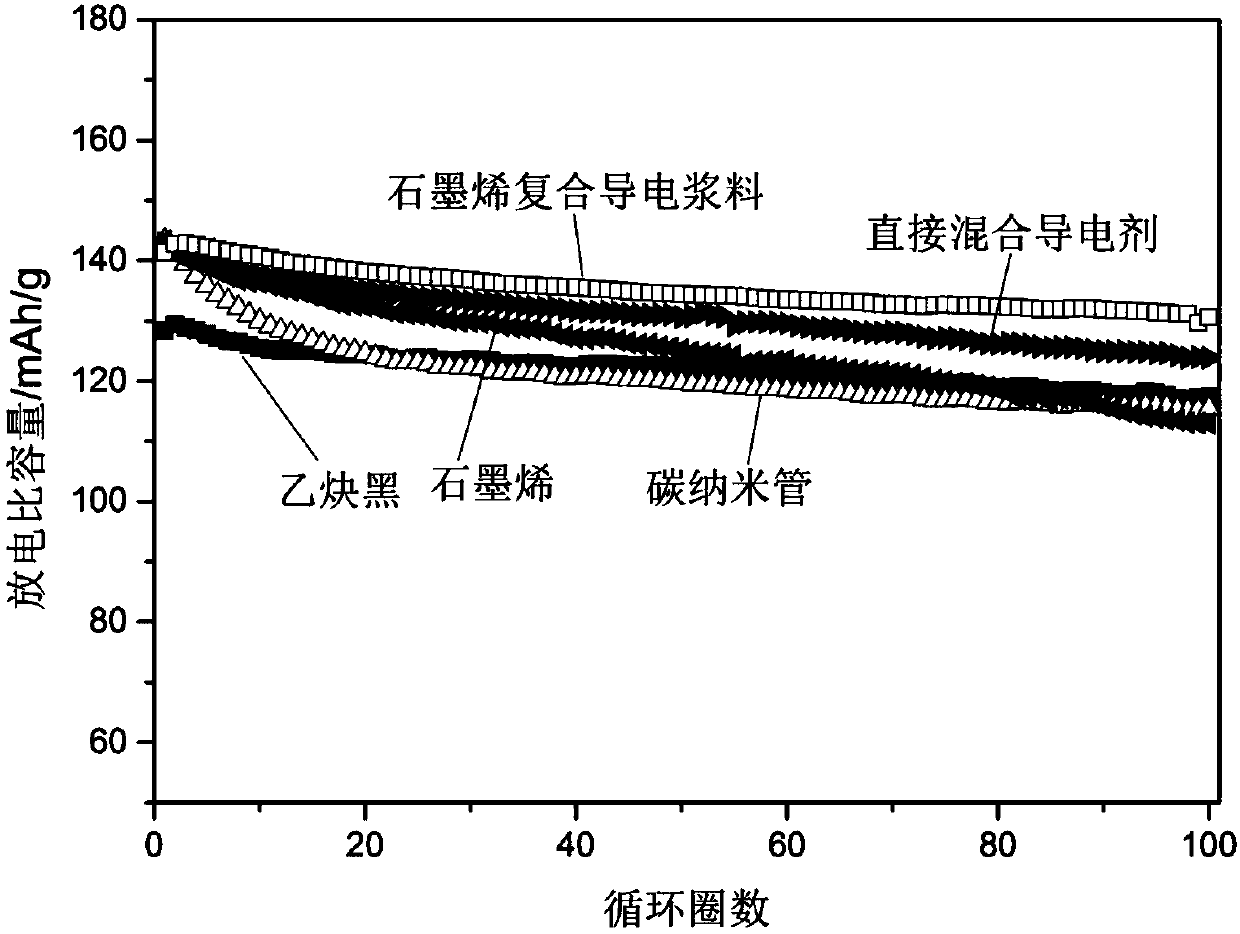

Graphene composite conductive slurry as well as preparation method and application thereof

InactiveCN107689452AImprove electrochemical performanceLower internal resistanceCell electrodesSecondary cellsInternal resistanceGraphene flake

The invention discloses graphene composite conductive slurry as well as a preparation method and application thereof. The graphene composite conductive slurry comprises graphene, a non-flaky conducting agent, a dispersing agent, a solvent and a viscosity regulator; the non-flaky conducting agent is at least partially embedded between graphene flakes. The preparation method comprises the followingsteps: mixing expanded graphite, the dispersing agent and the solvent uniformly and performing shear stripping to prepare first slurry; adding the non-flaky conducting agent into the first slurry, andperforming partial intercalation treatment at least through a grinding mode to disperse the non-flaky conducting agent and the graphene flakes uniformly to prepare second slurry. The graphene composite conductive slurry has excellent dispersing stability, enables an active material to show up excellent electrochemical property when being in a lithium ion battery, and can improve the electrode capacity, reduce the internal resistance of the battery and improve cycling performance; meanwhile, the preparation method has the advantages of simple process, high operability, wide raw material source, low cost and the like.

Owner:鹏威多凌(浙江)新材料科技股份有限公司

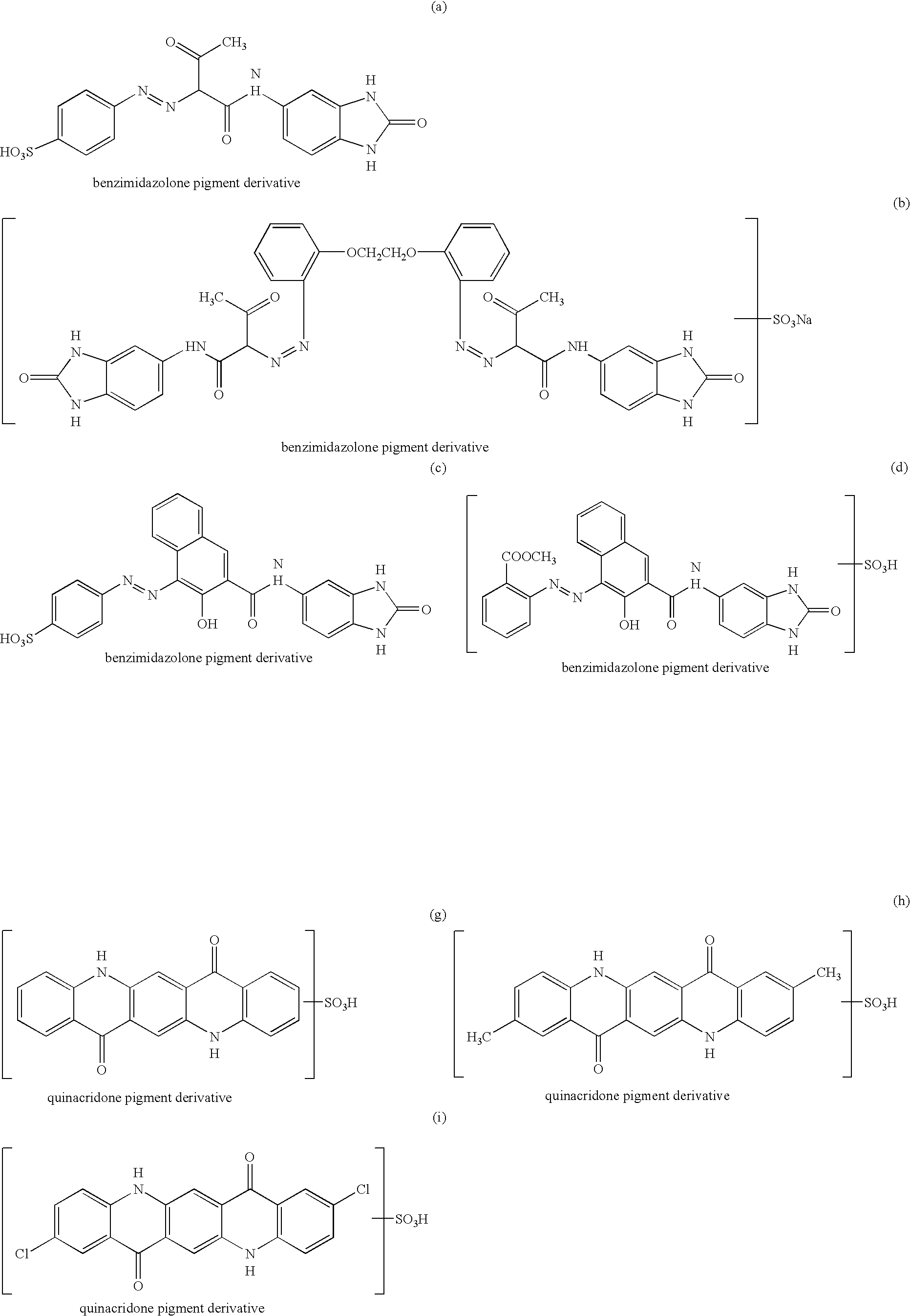

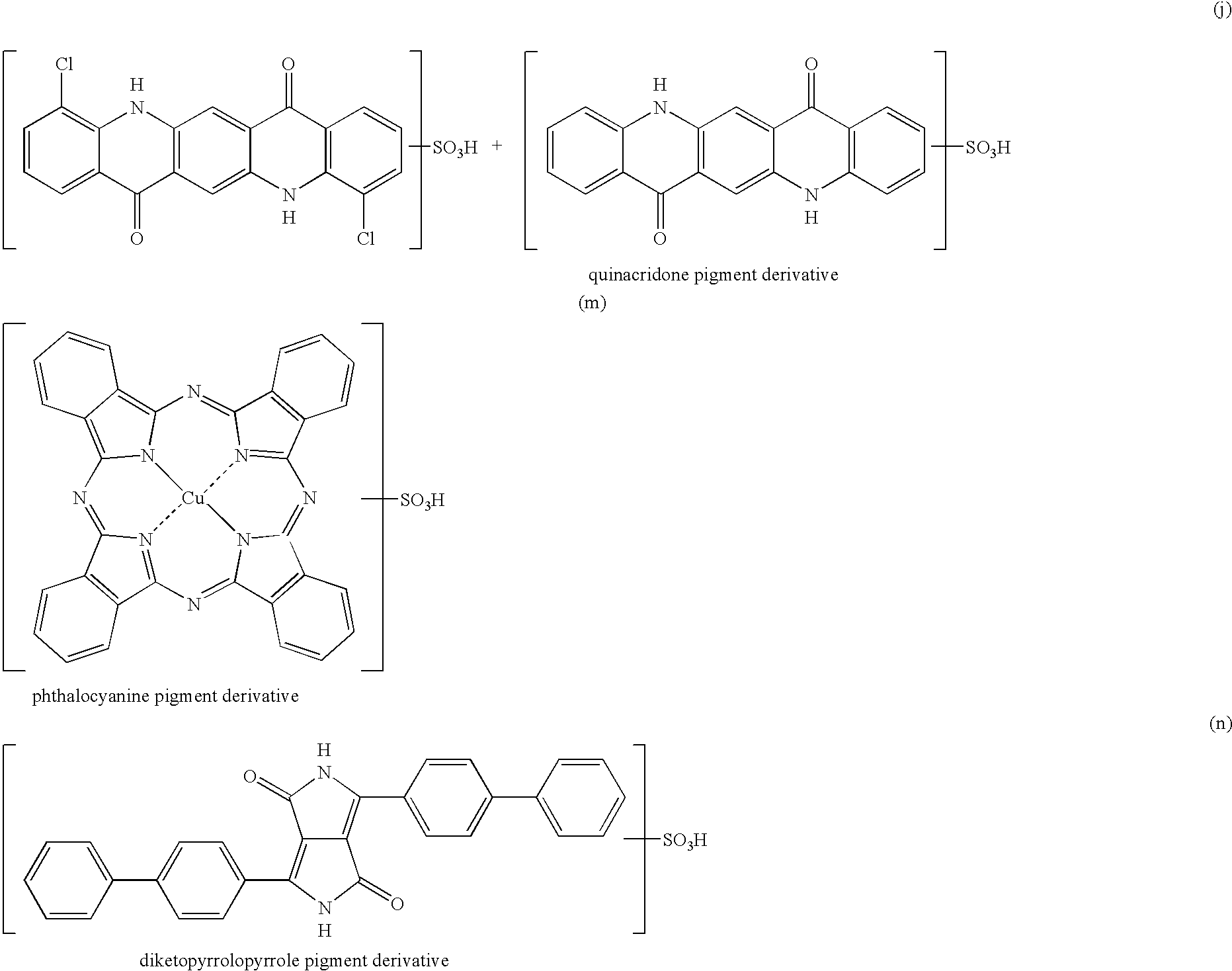

Water-based pigment dispersion, use thereof and process for the production thereof

A water-based pigment dispersion comprising 100 parts by weight of a pigment, 3 to 30 parts by weight of a sulfonic acid group-containing pigment derivative and water, wherein the sulfonic acid group-containing pigment derivative has only one sulfonic acid group in a molecule of a pigment of which the type is the same as the type of the pigment to be dispersed, the sulfonic acid group forms at least one salt selected from the group consisting of ammonia salt, an organic amine salt and a salt in which at least 15% of the sulfonic acid group is liberated and the rest is a salt with monovalent metal, the content of metal ion having a valence of at least 2 in a solid matter of the above water-based pigment dispersion is 500 ppm or less, and the above pigment is dispersed in water according to electrostatic repulsion due to the sulfonic acid group-containing pigment derivative adsorbed on the particle surface of the pigment, an inkjet recording liquid containing the same and process for the production thereof.

Owner:TOYO INK SC HOLD CO LTD

Processes for dispersing substances and preparing composite materials

InactiveUS20100152326A1Improve dispersion stabilityGood dispersionOther chemical processesOrganic dyesNanoparticleCarbon nanotube

Disclosed herein are processes for dispersing a plurality of unaggregated particles, such as nanoparticles and microparticles, in a viscous medium. The dispersions can be used for making a variety of useful materials, such as carbon nanotube composites.

Owner:MINUSNINE TECH

Fluosilicic modification water-soluble acrylic resin dispersion and application thereof

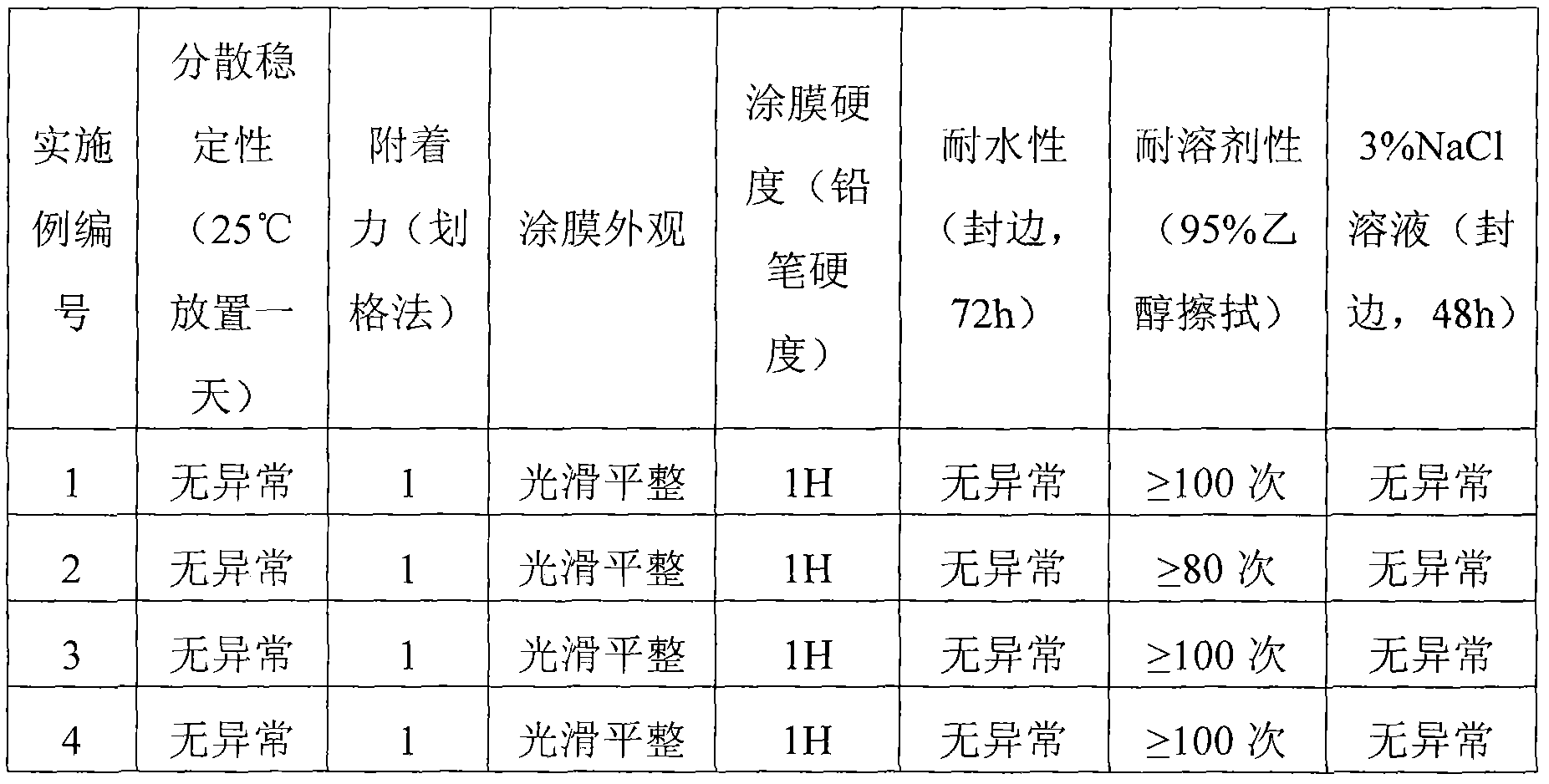

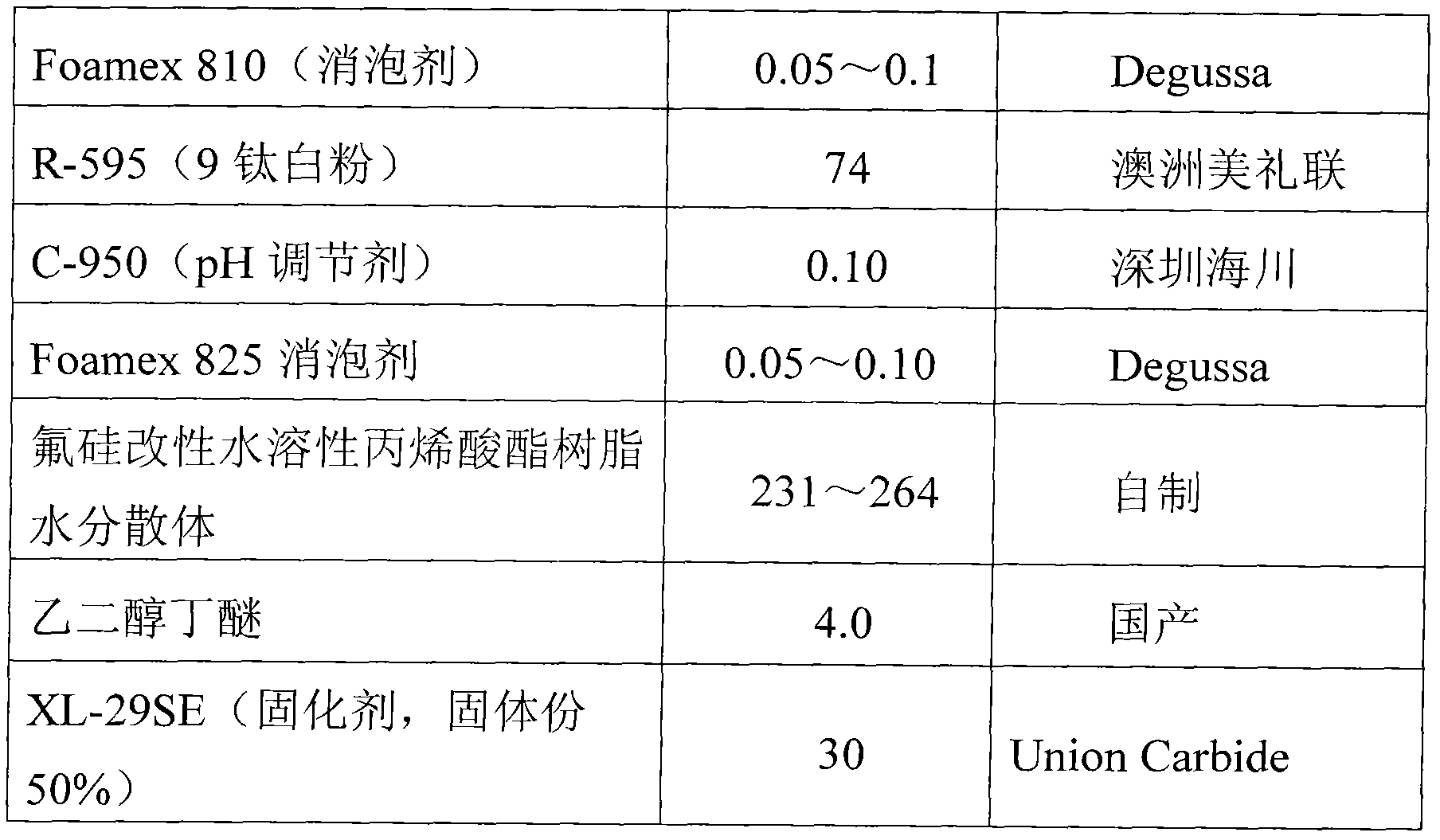

The invention provides a fluosilicic modification water-soluble acrylic resin dispersion and an application thereof. The dispersion is prepared from 20-50% of non-functional (methyl) acrylic ester, 5-35% of fluorinated acrylic ester monomer, 5-15% of carboxyl group-containing alkene monomer, less than or equal to 15% of vinyl monomer, 2-20% of (methyl) hydroxyl acrylate, 1-5% of organic silicon modified monomer, 15-30% of low carbon alcohol, 0.5-4% of inhibitor and 0.1-1.8% of molecular regulator according to a radical solution polymerization method. Based on solid parts, the acidic value of the dispersion is 20-100 mg KOH / g; the glass-transition temperature is 5-40 DEG C; the dispersion has a good appearance and dispersion stability as well as good water diluent property; a film obtained by cross-linking and curing a polycarbodiimide cross-linking agent and the dispersion has excellent water tolerance, solvent tolerance, high temperature tolerance, smooth property, stain tolerance and humidity resistance; the adhesion and hardness are improved; and the dispersion has strong practicable value and can be used for substrates such as wooden wares, metals, plastics and the like.

Owner:JIANGSU BLUESTAR GREEN TECH

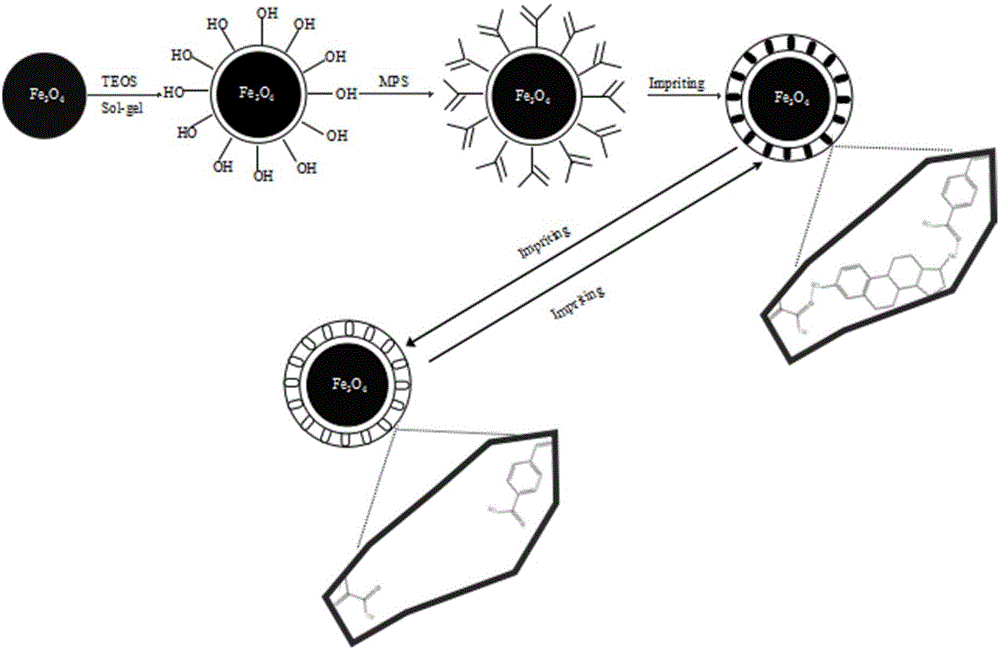

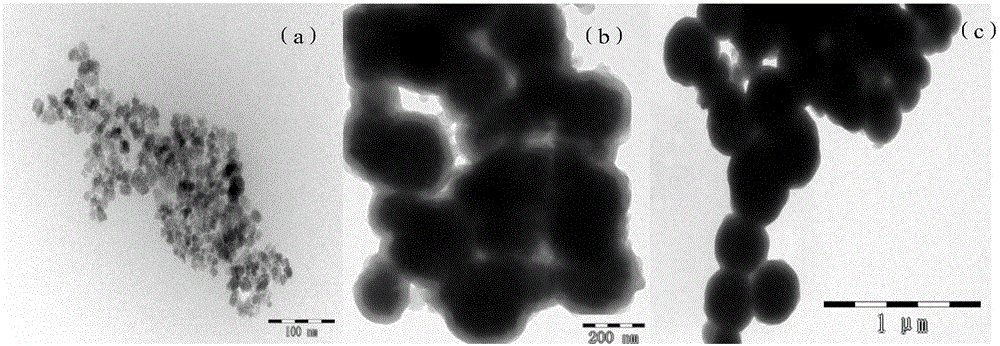

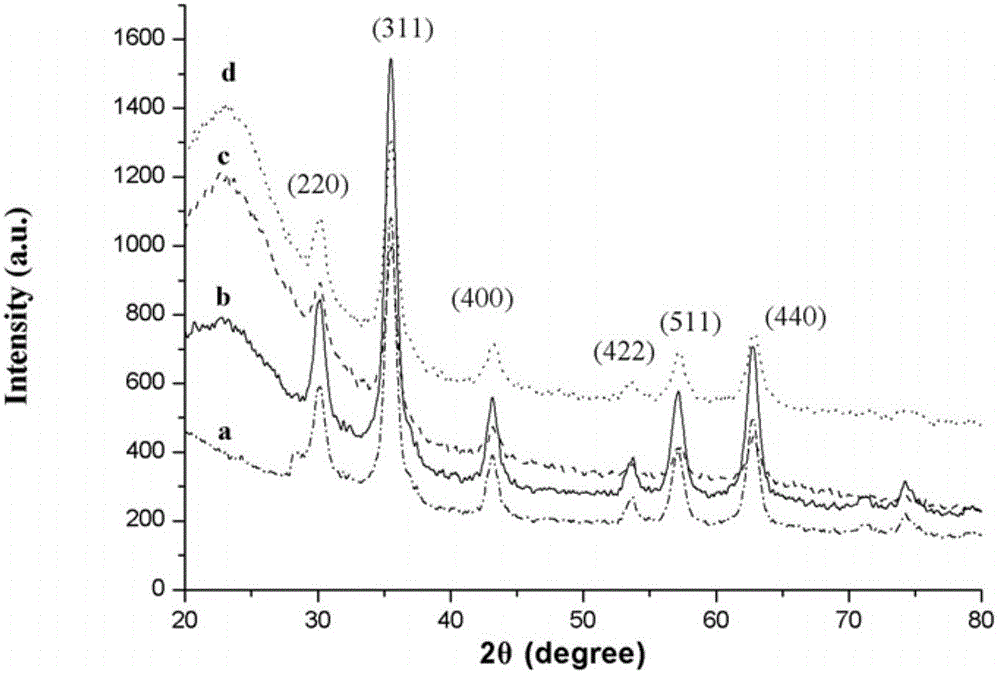

Preparation method for molecular imprinting material and molecular imprinting material prepared through preparation method

InactiveCN105107482AGood biocompatibilityImprove antioxidant capacityOther chemical processesAlkali metal oxides/hydroxidesSolubilityFunctional monomer

The invention provides a preparation method for a molecular imprinting material and the molecular imprinting material prepared through the preparation method. The preparation method comprises the steps that silicon oxide is coated on the surfaces of magnetic ferroferric oxide nanometer particles, the magnetic ferroferric oxide nanometer particles are modified with gamma-(methacryloyl chloride) amino propyl trimethoxy silane to obtain magnetic ferroferric oxide nanometer particles with propenyl on the surfaces, the magnetic ferroferric oxide nanometer particles with the propenyl on the surfaces serve as carriers, estrogen receptors are simulated, functional monomers are optimized, a surface imprinting technology is adopted, and then the molecular imprinting material which can simultaneously identify seven kinds of environmental endocrine disrupting chemicals is prepared. According to the preparation method, the easy separation of a magnetic nanometer material, the good water solubility of a silicon oxide nanometer material, the specific recognition ability of molecular imprinting polymers and the surface imprinting technology are mutually combined, the preparation technology is simple, the conditions are mild, the prepared molecular imprinting material is large in adsorption capacity, fast to respond, high in magnetism, good in chemical stability and high in repeating utilization rate, and the problems that at present, multiple trace, steroid and phenol environmental endocrine disrupting chemicals are difficult to simultaneously identify, separate and enrich are solved.

Owner:INST OF QUALITY STANDARD & TESTING TECH FOR AGRO PROD OF CAAS

Process for production of polymer polyol, and polymer polyol

A polymer polyol comprising 25 to 60 mass % polyol (A) and 40 to 75 mass % of polymer particles (B1) formed by polymerizing ethylenically unsaturated monomer in the polyol (A), the ethylenically unsaturated monomer having the content of acrylonitrile and / or styrene is not less than 50 mass %, wherein (B1) has a particle size of not more than 100 μm and contains not less than 95 mass % of particles with the particle size of 0.01 to 10 μm; and the total content of acrylonitrile and styrene is not more than 20 ppm; and process for producing the polymer polyol. The polymer polyol exhibits a reduced residual monomer content and excellent filtration property and is useful as a raw material in the production of polyurethane or the like.

Owner:SANYO CHEM IND LTD

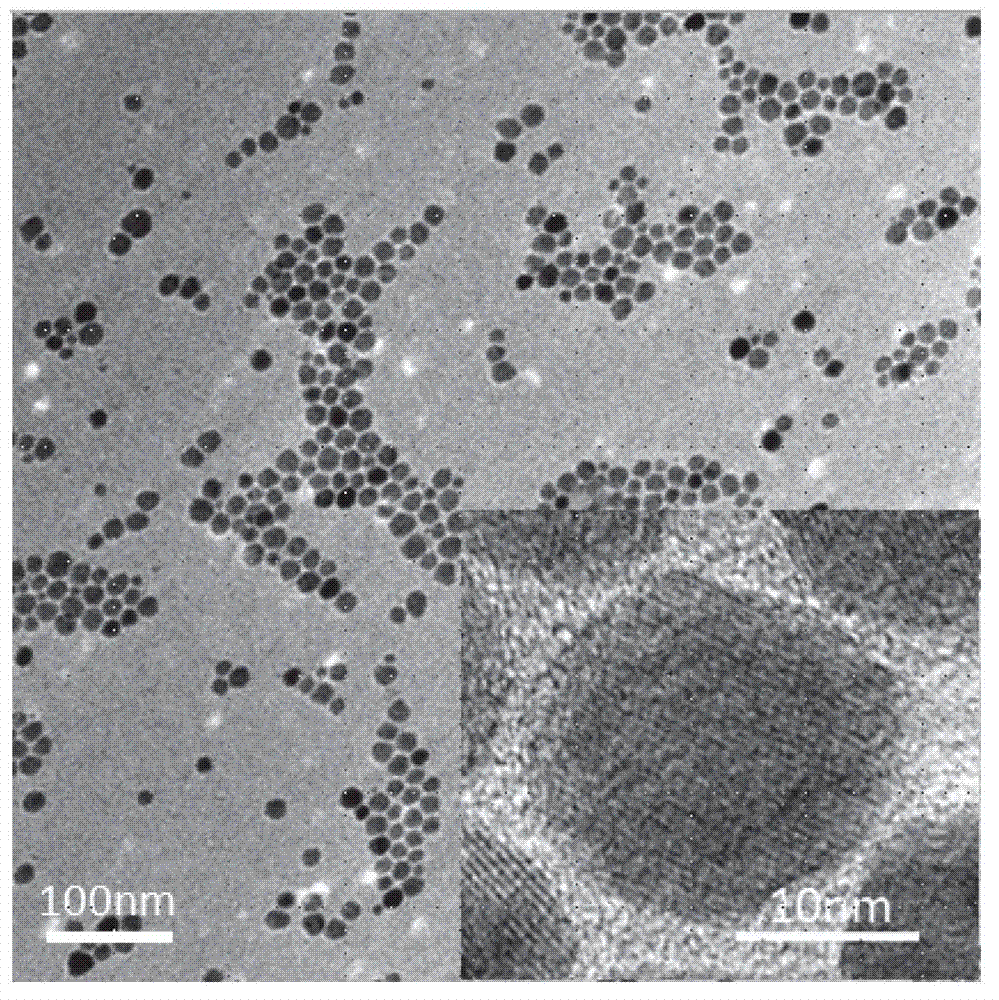

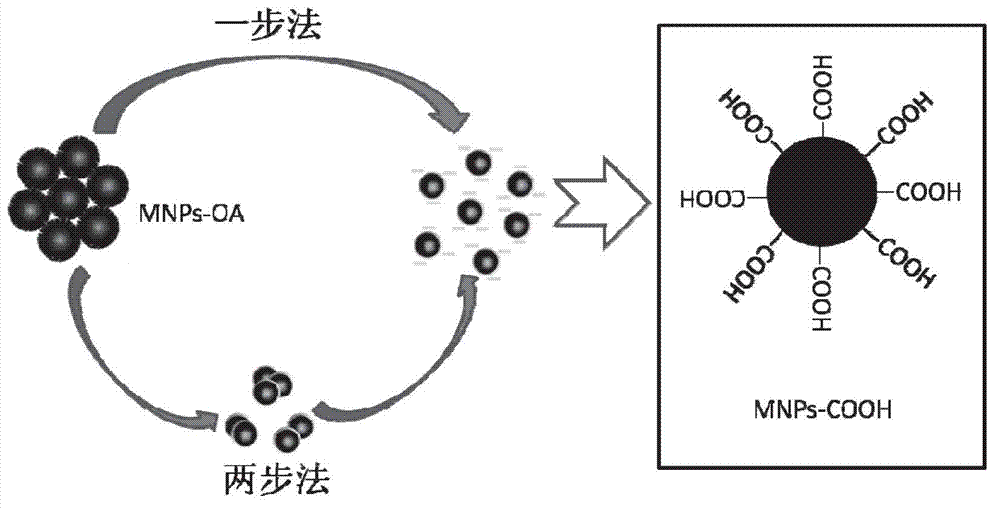

Fe3O4 nano-particles with high dispersion stability in water phase, and preparation method thereof

InactiveCN102815753AImprove dispersion stabilityImprove hydrophilicityFerroso-ferric oxidesNanotechnologyDispersion stabilitySolvent

The invention discloses Fe3O4 nano-particles with high dispersion stability in water phase, and a preparation method of the Fe3O4 nano-particles. The surface ligand of each Fe3O4 nano-particle is poly-carboxyl organic molecule with three or more carboxyl groups; the preparation method of the Fe3O4 nano-particles comprises the steps of: firstly, taking high boiling point organic solvent as solvent and oleic acid as the ligand; carrying out high-temperature thermal decomposition on iron oleate to obtain mono-dispersed oil-soluble Fe3O4 nano-particles; and then, adopting a method of ligand exchange, and using the poly-carboxyl organic molecules to replace the oleic acid ligands on the surfaces of the oil-soluble Fe3O4 nano-particles to obtain the water-soluble Fe3O4 nano-particles. The preparation method is convenient in operation process, low in requirement for equipment and low in price of the needed raw materials, and by-products are pollution-free. The water-soluble Fe3O4 nano-particles have better water system dispersion stability within the pH value range of 2-13, and a new economical and practical method is provided for preparing hydrophilic Fe3O4 nano-particles applied to the biological medicine field.

Owner:SHANGHAI JIAO TONG UNIV

Waste rubber powder modified asphalt composition and its preparation method

ActiveCN1765998AUniform dispersion stabilityUniform storage stabilityBuilding insulationsWaste rubberDiluent

The invention provides a method to improve the storage stability for waste rubber powder modified asphalt. Wherein, the opposite compound comprises: 70~98.5% basic asphalt, 1~29.5% waste rubber, 0~10.0% diluent, and 0.1~5.0% coupling agent. The method comprises: adding the agents with given ratio into the waste rubber powder past 60-item screen to mix evenly; adding the treated rubber powder into asphalt to grinde for 30~190min by special device. As the alkoxy in coupling agent can form chemical bonding with inorganic filler to form organic active monomolecular layer between interfaces, this product can improve obviously the storage stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing graphene

ActiveCN102126720AImprove dispersion stabilityMild reaction conditionsNanotechnologyHydrogenSingle layer graphene

The invention discloses a method for synthesizing graphene, belonging to the technical field of materials and relating to synthesis for the graphene by photochemistry and hot chemistry solution methods based on an organic negative hydrogen donor as a reducing agent. The method comprises the following steps: pre-treating graphite; oxidizing the graphite; stripping the oxidized graphite to form graphene oxide; and reducing the grapheme oxide by the organic negative hydrogen donor under the conditions of heating or illuminating. In the method, the organic reducing agent such as organic negative hydrogen donor is used, and the illuminating or heating method is adopted under the condition of no any stabilizer, thus a large amount of single-layer graphene is obtained in a short reaction time, and simultaneously, the clean graphene can be obtained by using a simple extraction treatment method.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

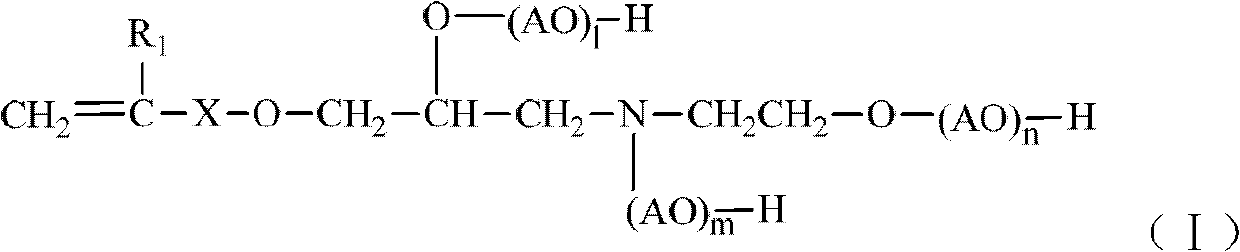

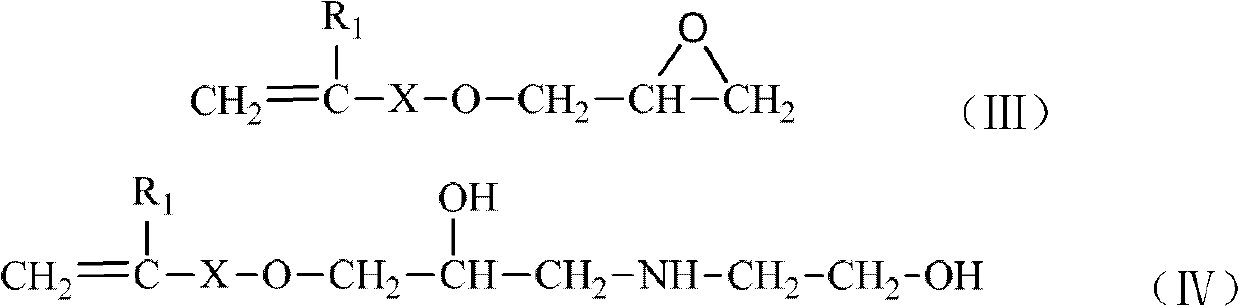

Unsaturated polyether monomer, comb-like branched copolymer cement dispersant prepared by the same, and preparation method thereof

The invention relates to an unsaturated polyether monomer, a comb-like branched copolymer cement dispersant prepared by the monomer, and preparation methods of the monomer and the dispersant. The unsaturated polyether monomer has the general formula (I), wherein R1 is H or -CH3; X is a linking group selected from -CH2-, -CH2CH2-, -OCH2CH2-, -OCH2CH2CH2CH2-; AO is ethylene oxide group and / or propene oxide group; l, m and n are all repeating units of AO; and the sum of l, m and n is an natural number of 10 to 50. The dispersant has the following chemical structure (VI), wherein x, y and z represent mole percentages of three structural units in the copolymer, and the sum of x, y and z is 100%. Preferably, x is 10% to 50%, y is 40% to 80% and z is 0% to 30%. The preparation method of the dispersant is simple and does not need organic solvents or complex esterification. The dispersant is advantageous in low dosage, good dispersibility and small slump loss.

Owner:连云港苏博特新材料有限公司 +2

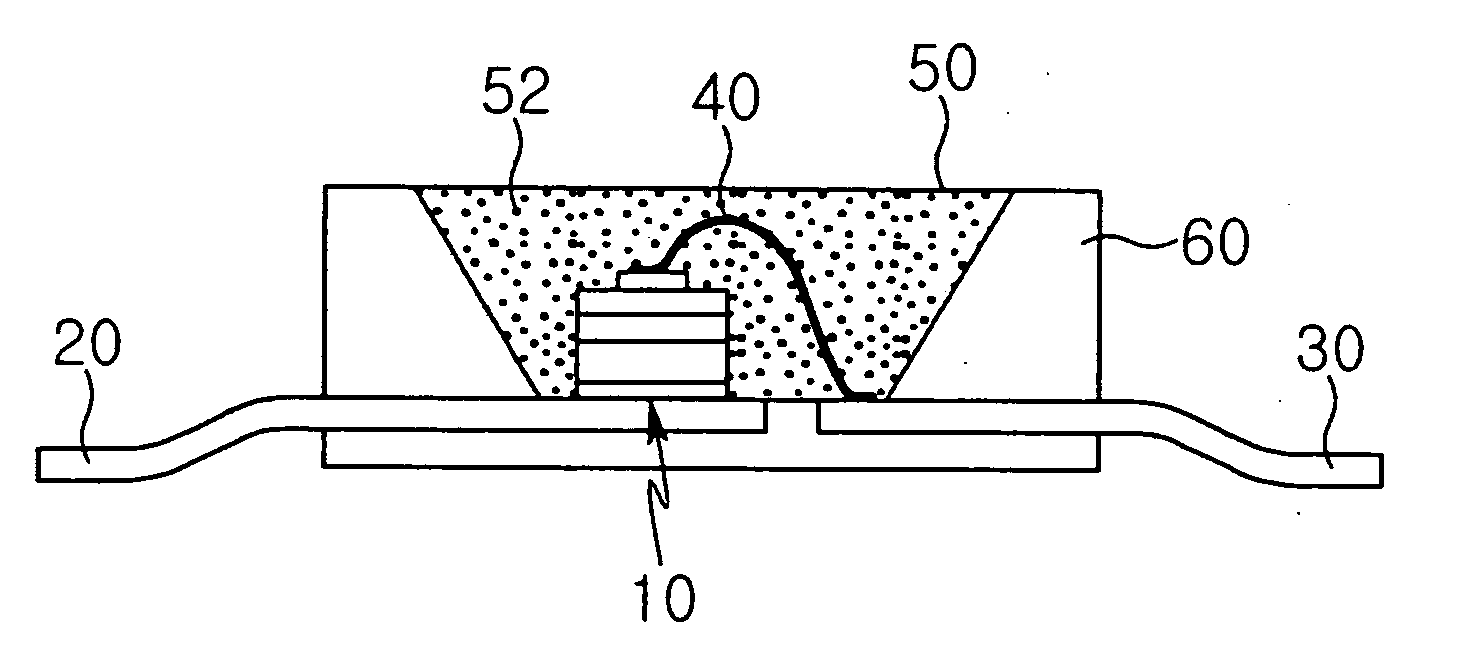

Color-converting light emitting device including fluorescent powder having large grain diameter, method of producing the same, and resin composition used therein

InactiveUS20050285494A1Dispersion stability is excellentHigh brightnessSolid-state devicesCoatingsGallium nitrideParticle-size distribution

Disclosed is a color-converting light emitting device, which includes a light emitting element for emitting light with a predetermined wavelength and a color-converting member for absorbing a portion of light emitted from the light emitting element to convert the wavelength of the light into another wavelength. The present invention provides the color-converting light emitting device, which includes a gallium nitride-based light emitting diode having an emission spectrum at a visible ray region, and a color-converting member absorbing light from the diode to convert the wavelength of the light into another wavelength. The color-converting member includes a transparent resin and a garnet-based fluorescent powder dispersed in the transparent resin, and the fluorescent powder has a grain size distribution in which a minimum grain diameter is 10 μm or more and a mean grain diameter (d50) is 20 μm or more.

Owner:LUMIMICRO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com