Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

597results about How to "Improve surface condition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

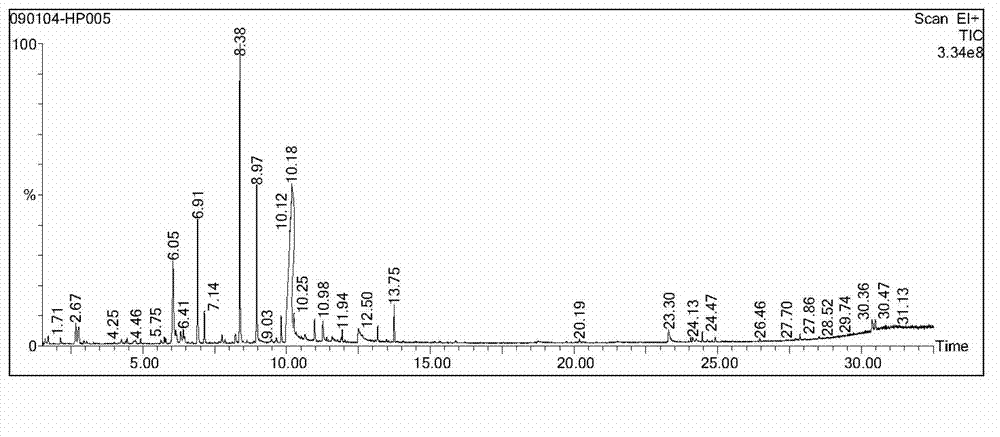

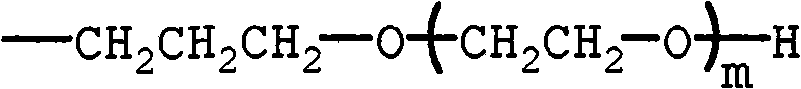

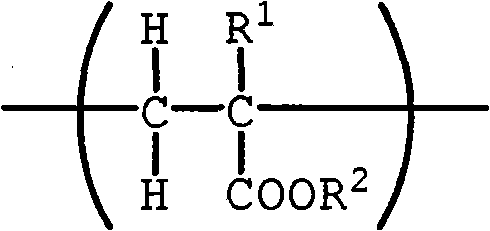

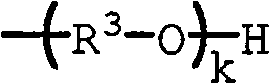

Polyoxyalkylene polyols, derivatives thereof, and process for producing the polyoxyalkylene polyols

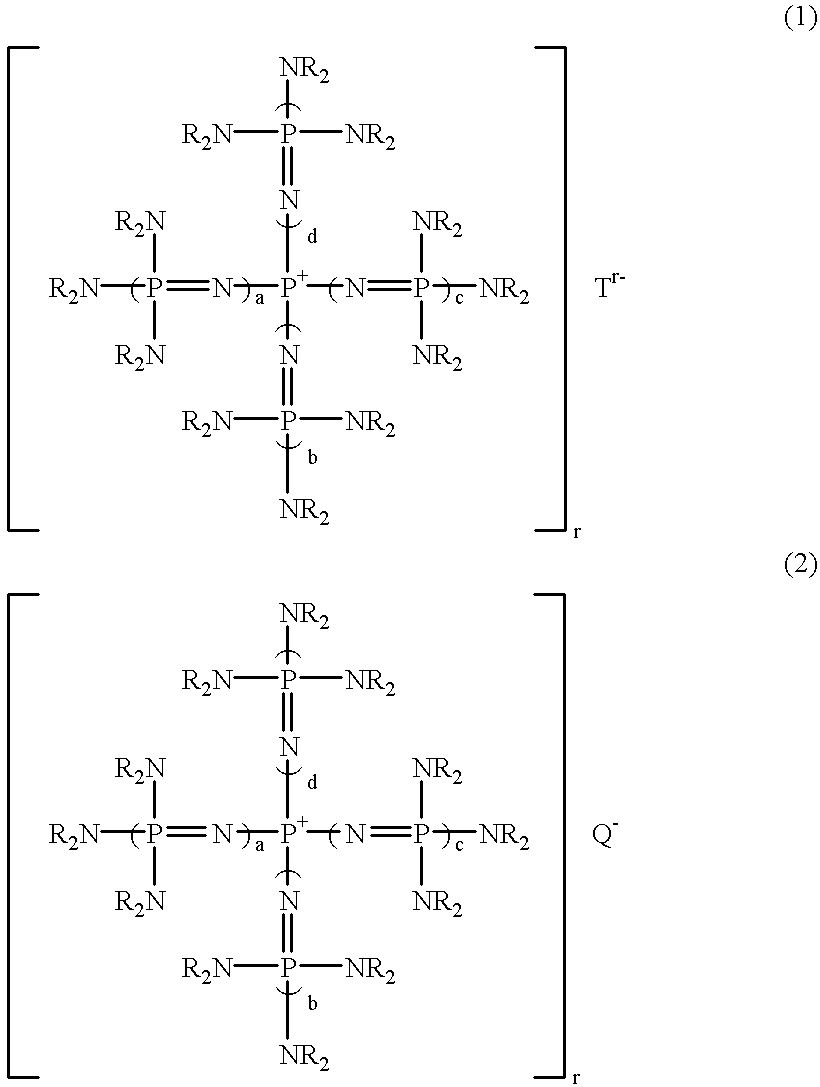

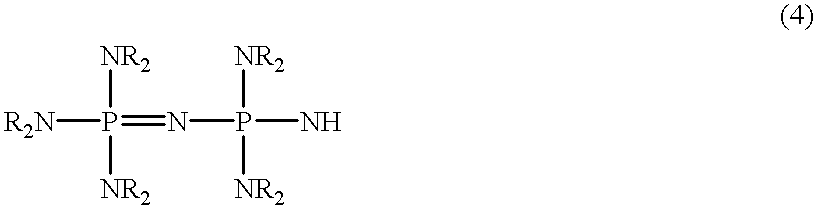

The present invention is a polyoxyalkylene polyol, its manufacture method, and derivatives, wherein: it is obtained using a phosphazenium compound as a catalyst; the hydroxyl value is 2~200 mgKOH / g; total degree of unsaturation is 0.0001~0.07 meq. / g; the head-to-tail bond selectivity of the polyoxyalkylene polyol is 95 mole %; and when the maximum height of the peak of GPC elution curve is set to be 100%, W20 is defined as the peak width at the 20% peak height, and W80 is defined as the peak width at 80% peak height, the ratio of W20 / W80 is 1.5 or greater, and less than 3.

Owner:MITSUI CHEM & SKC POLYURETHANES INC

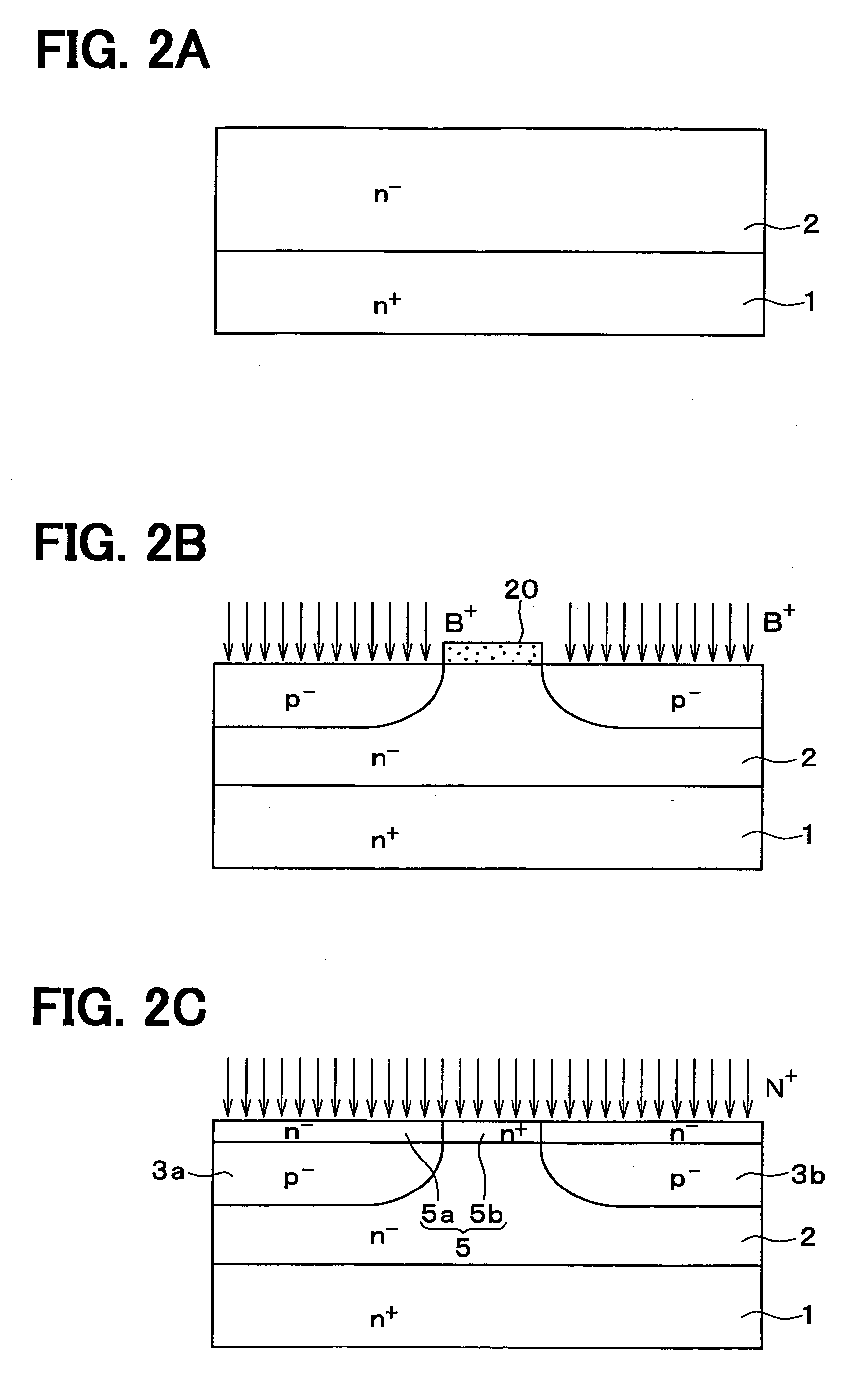

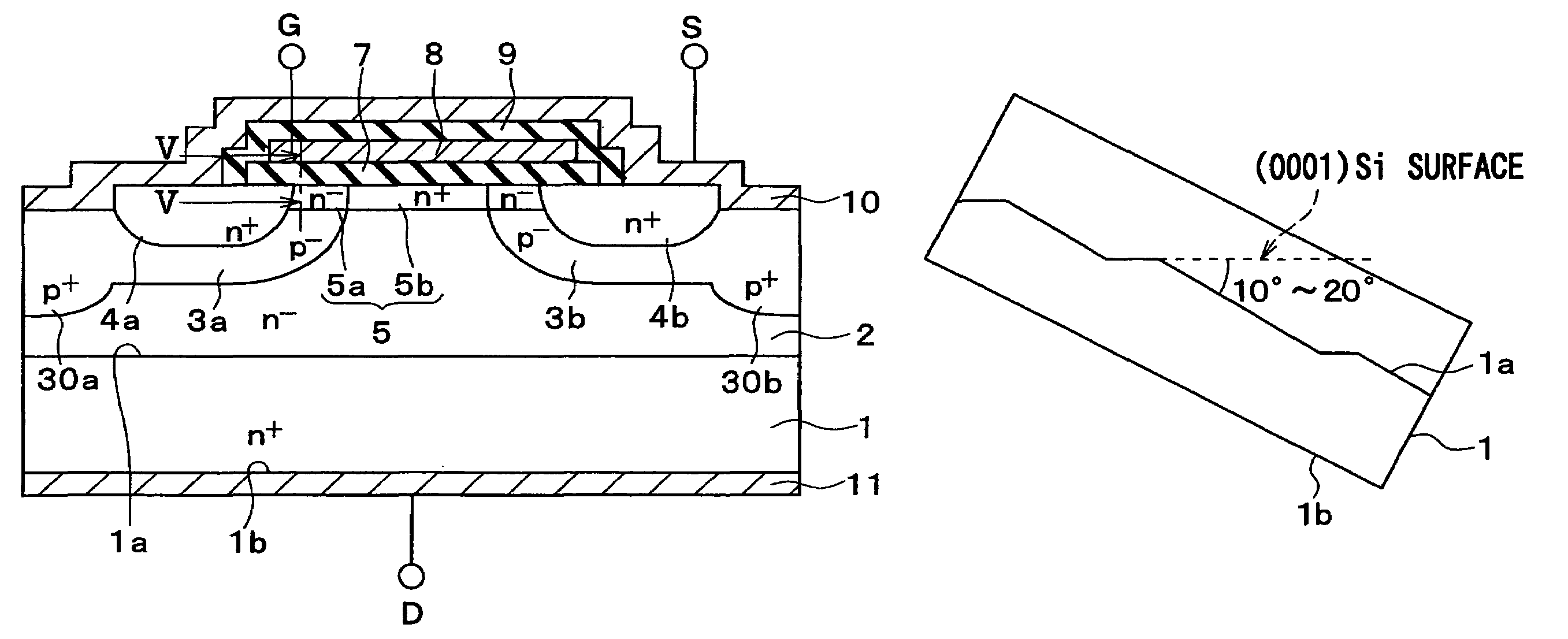

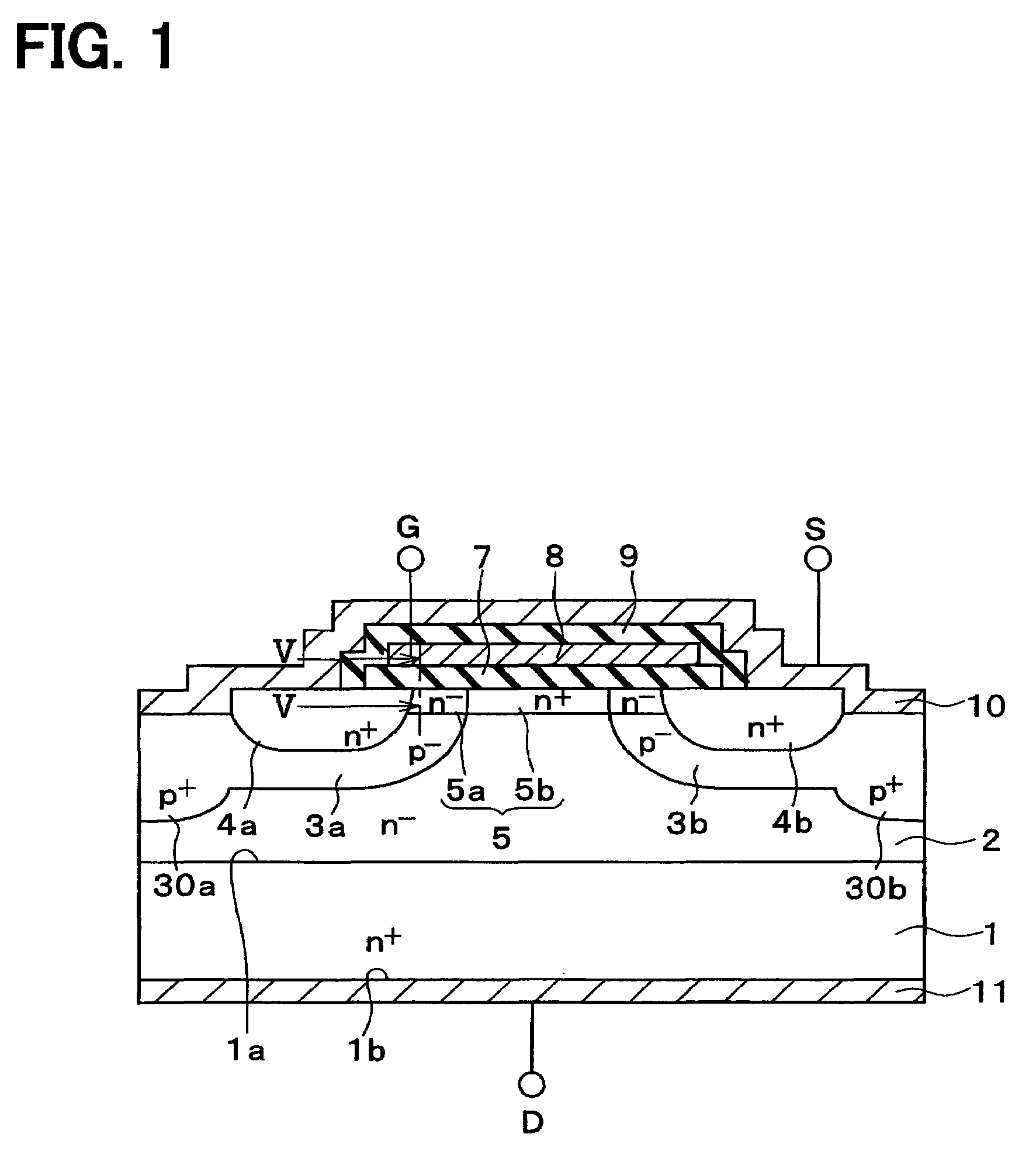

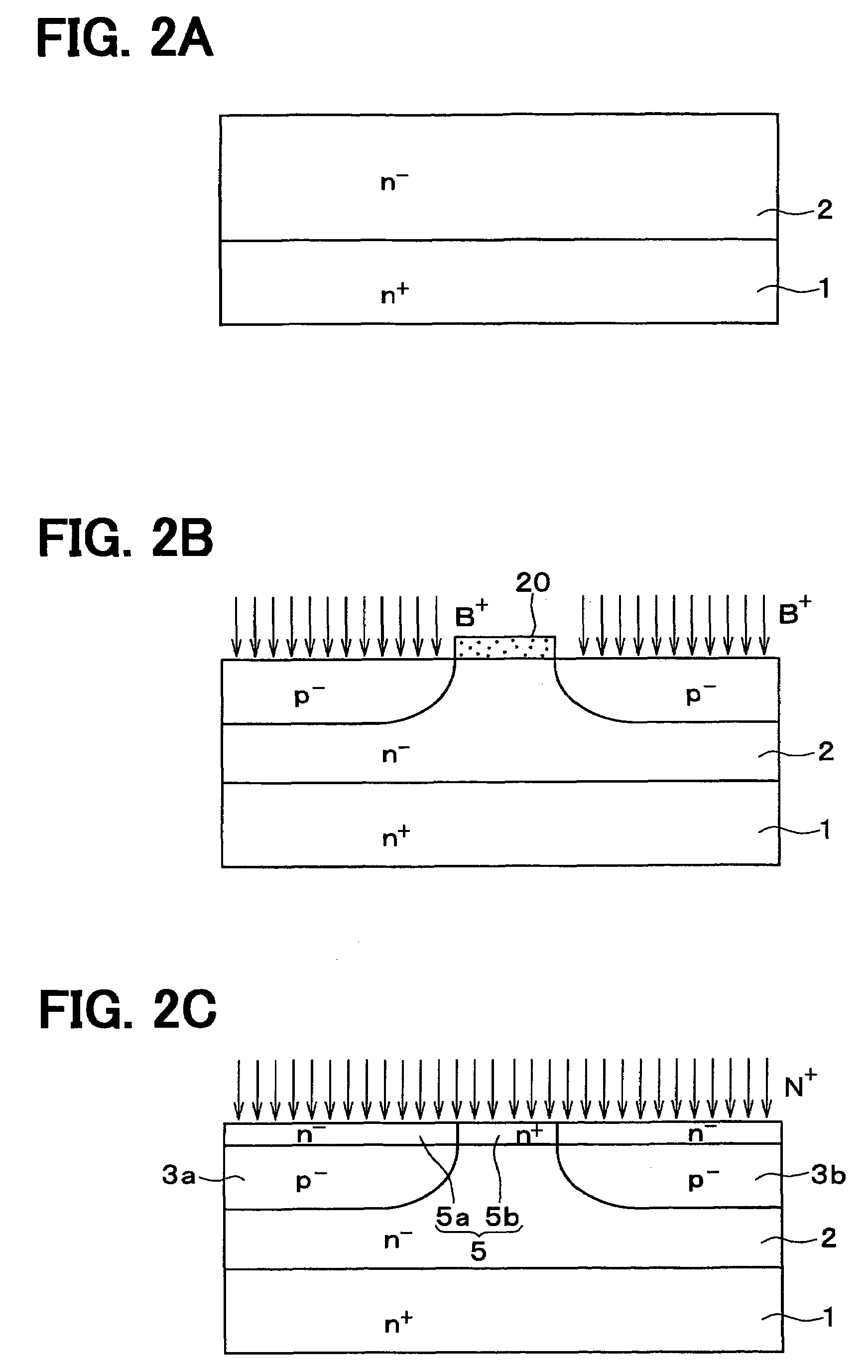

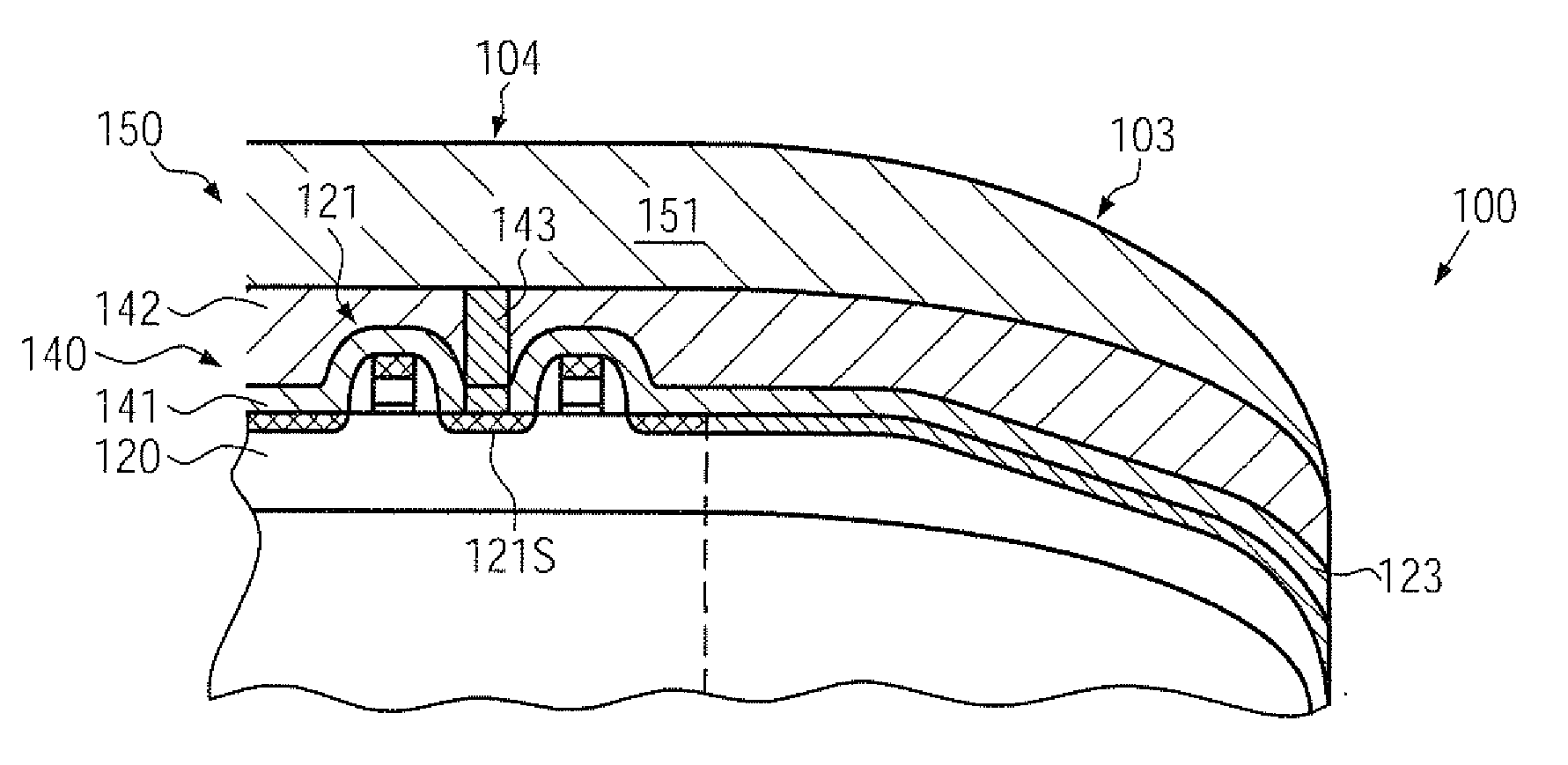

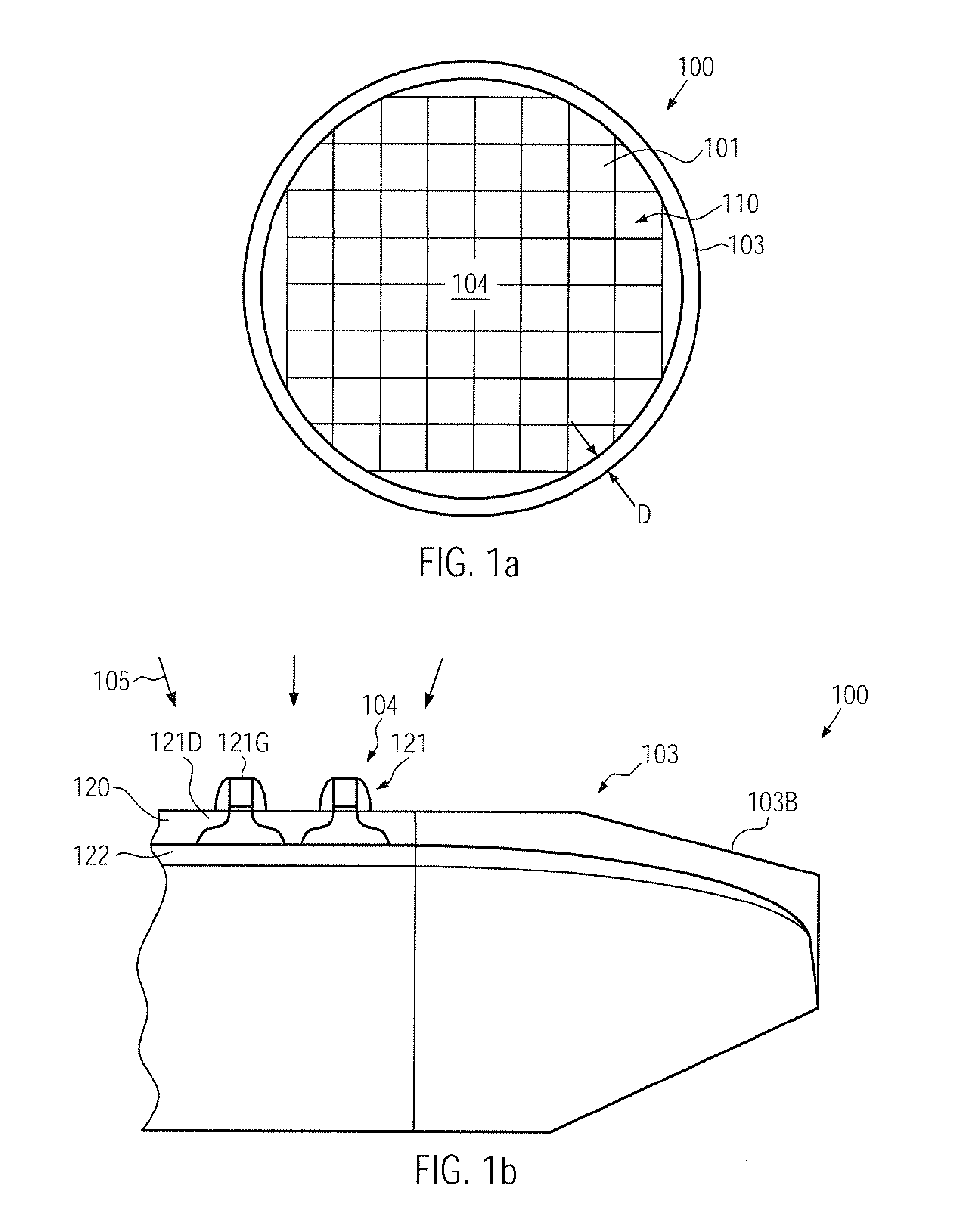

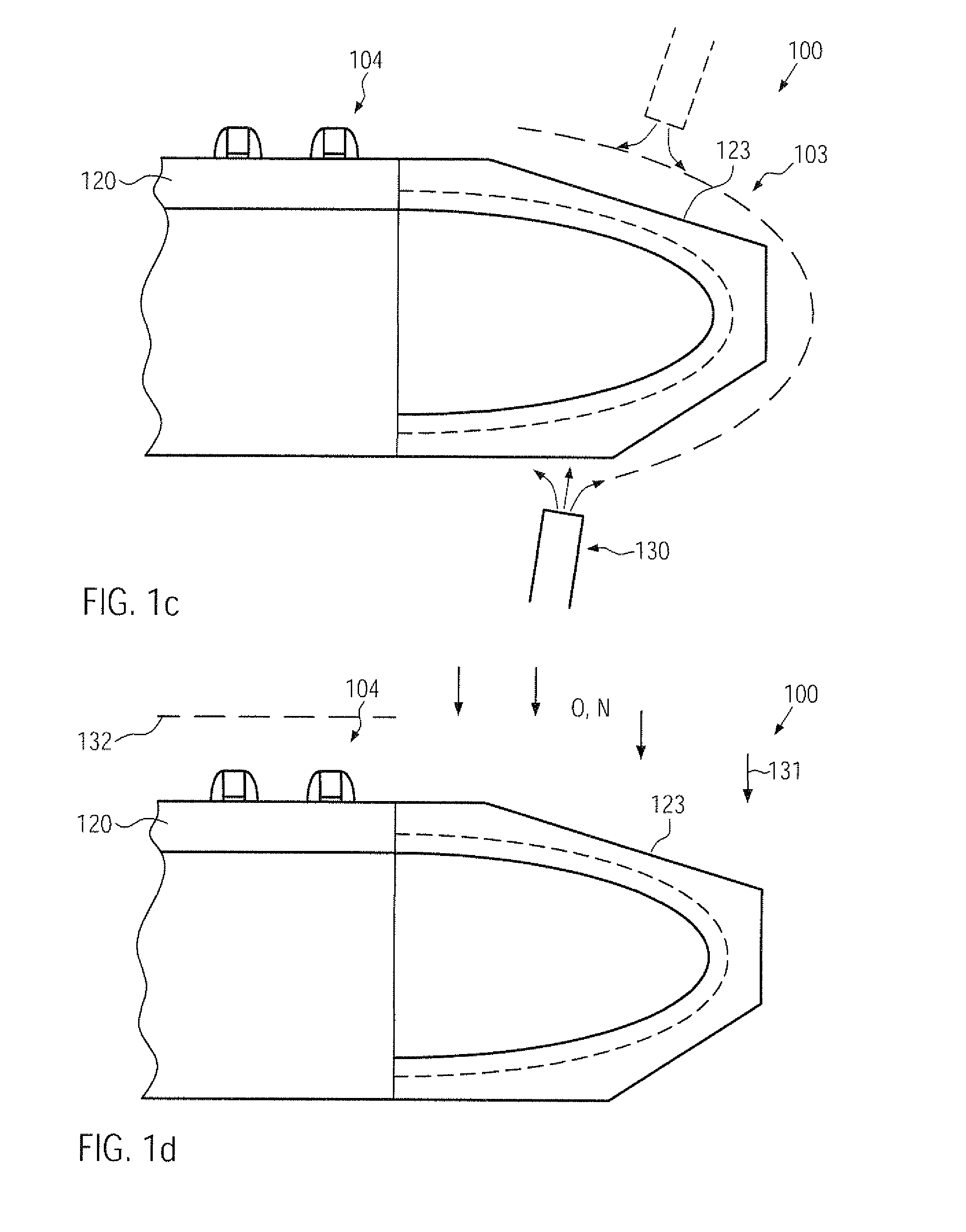

Silicon carbide semiconductor device and method for manufacturing the same

ActiveUS20050230686A1Improve surface conditionImprove regularitySemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialSemiconductor

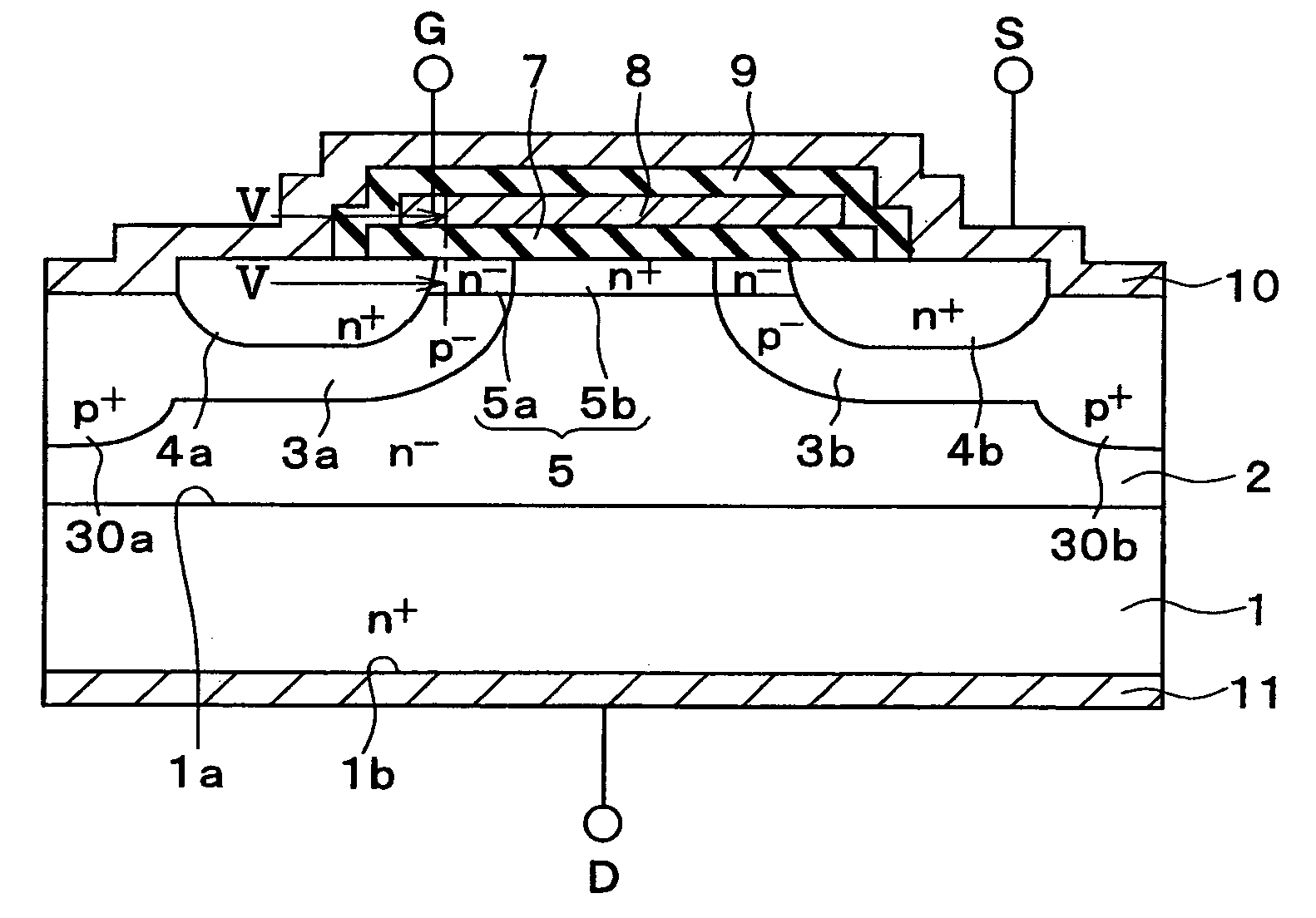

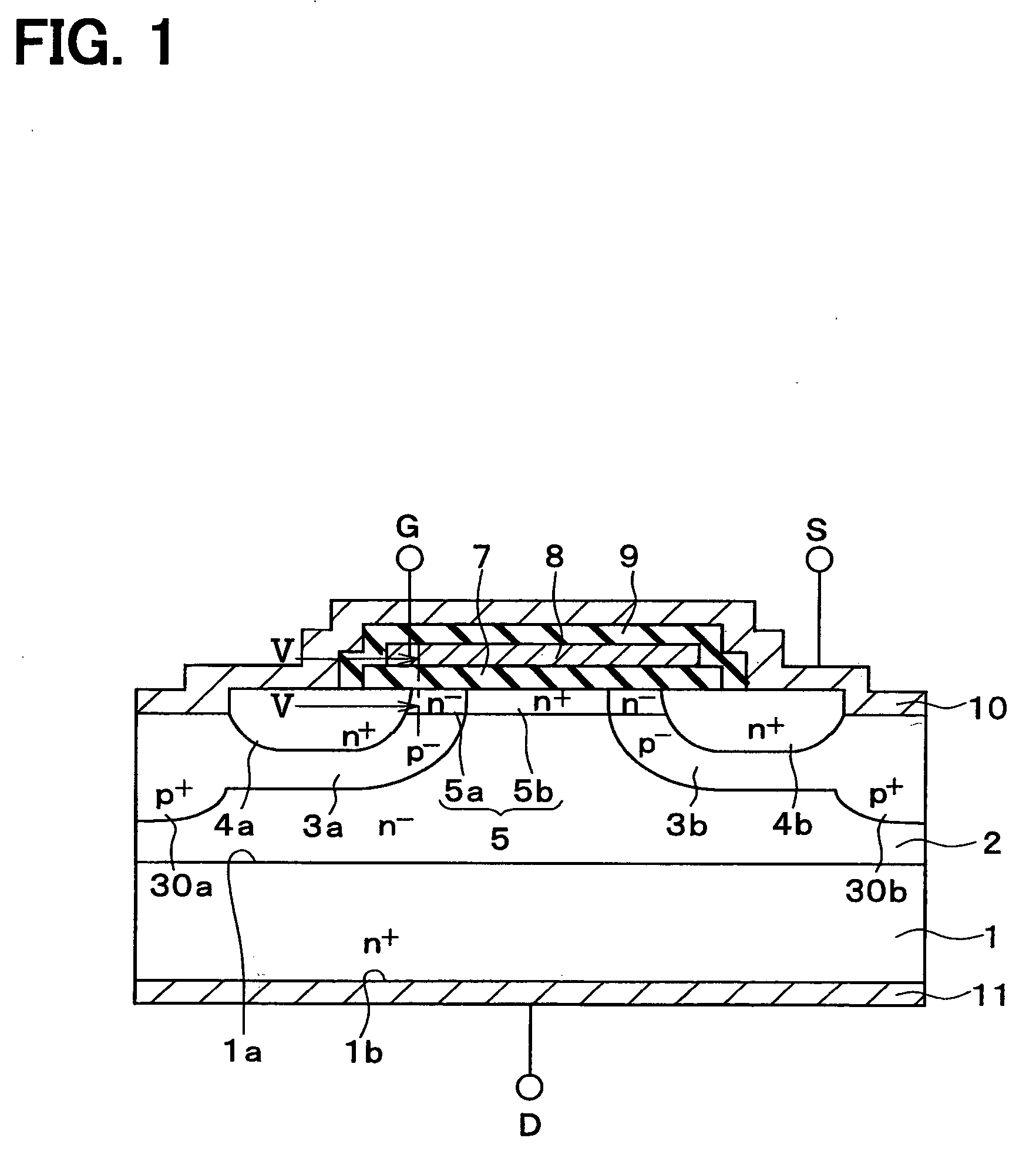

A silicon carbide semiconductor device includes: a semiconductor substrate having a principal surface and a backside surface; a drift layer disposed on the principal surface; a base region disposed on the drift layer; a source region disposed on the base region; a surface channel layer disposed on both of the drift layer and the base region for connecting between the source region and the drift layer; a gate insulation film disposed on the surface channel layer and including a high dielectric constant film; a gate electrode disposed on the gate insulation film; a source electrode disposed on the source region; and a backside electrode disposed on the backside surface.

Owner:DENSO CORP

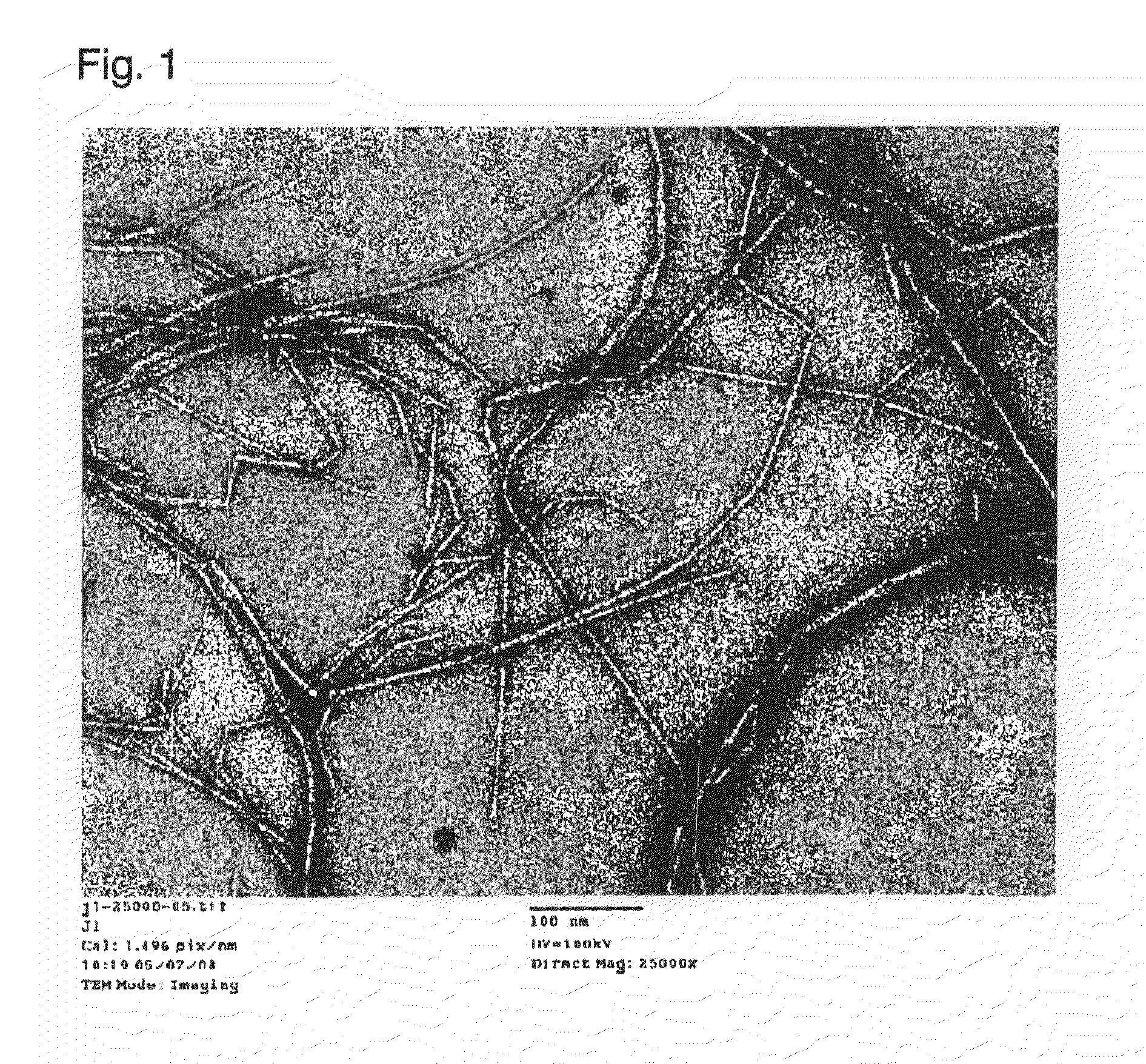

Fiber composite

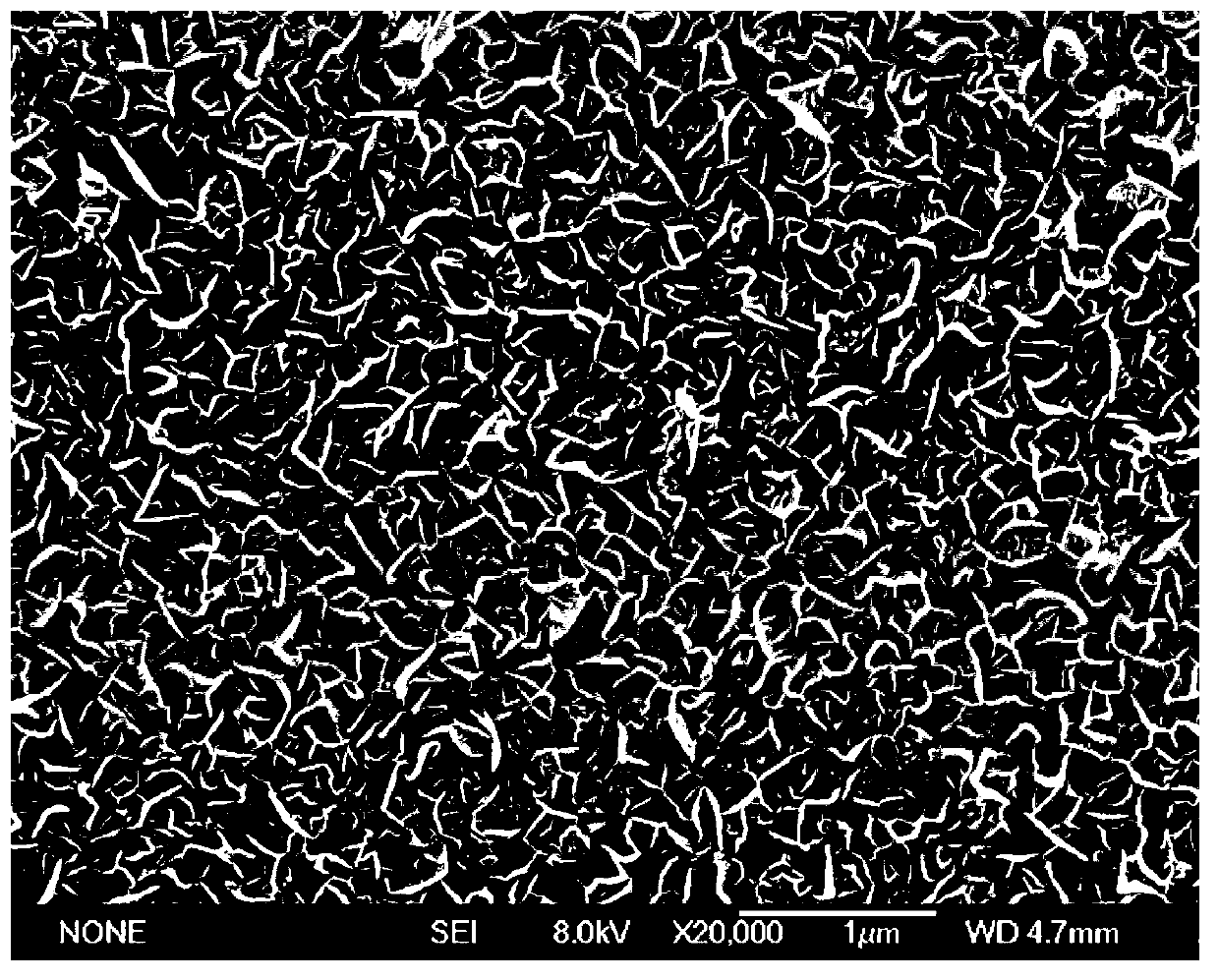

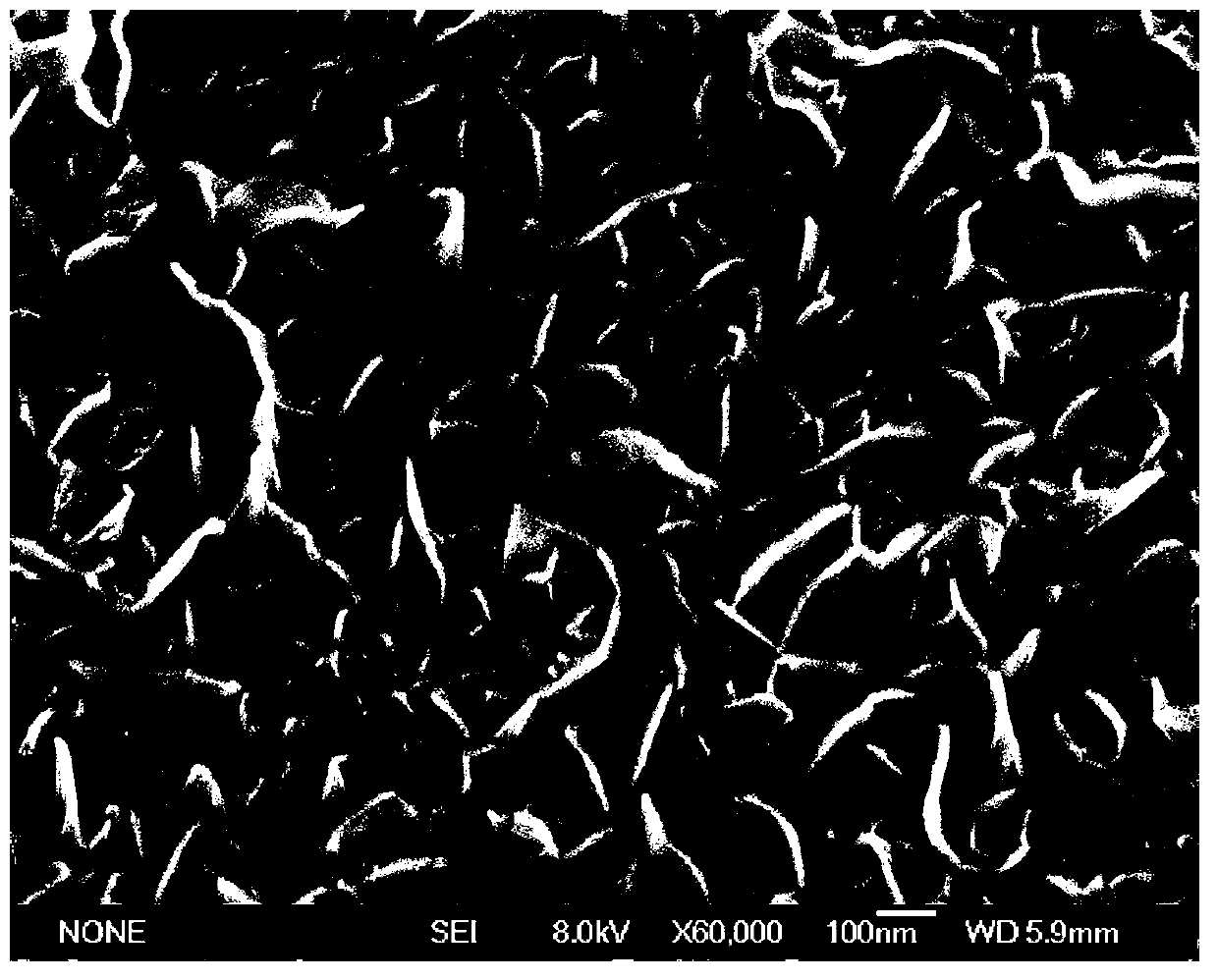

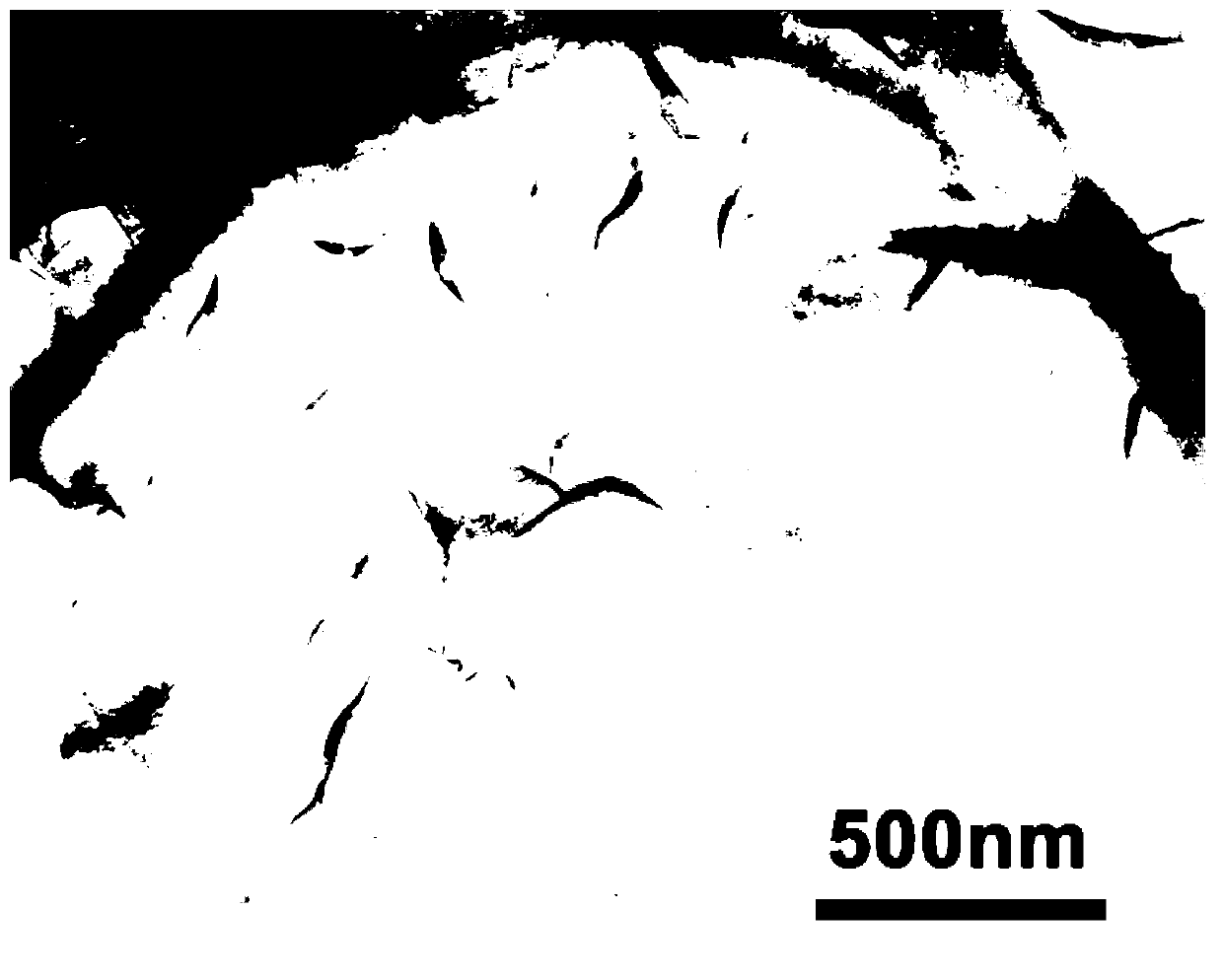

InactiveUS20100272980A1High transparencyLow water absorptionMonocomponent cellulose artificial filamentRecord information storageThermal expansionCellulose fiber

To provide a cellulose fiber composite having high transparency, low water absorption and low coefficient of linear thermal expansion.A fiber composite which comprises fibers having an average fiber diameter of at most 30 nm and a matrix material and which has a haze of at most 5 according to JIS K-7136 when the fiber composite has a thickness of 100 μm.

Owner:MITSUBISHI CHEM CORP

Cellulose acylate, cellulose acylate film, and method for production and use thereof

InactiveUS20060222786A1Good optical performanceImprove thermal stability performanceLiquid crystal compositionsThin material handlingCelluloseSulfur

A cellulose acylate solution containing a cellulose acylate which satisfies 2.5≦A+B≦3, 0≦A≦2.5, 0.3≦B≦3 (wherein A is the substitution degree of an acetyl group, and B is the sum of the substitution degrees of an acyl group having 3 to 7 carbon atoms) and whose content of sulfur atoms of residual sulfate moiety S is such that 50 ppm<S<500 ppm. When solution casting is carried out using this solution, a cellulose acylate film having good surface state and low peel-off load can be produced.

Owner:FUJIFILM CORP

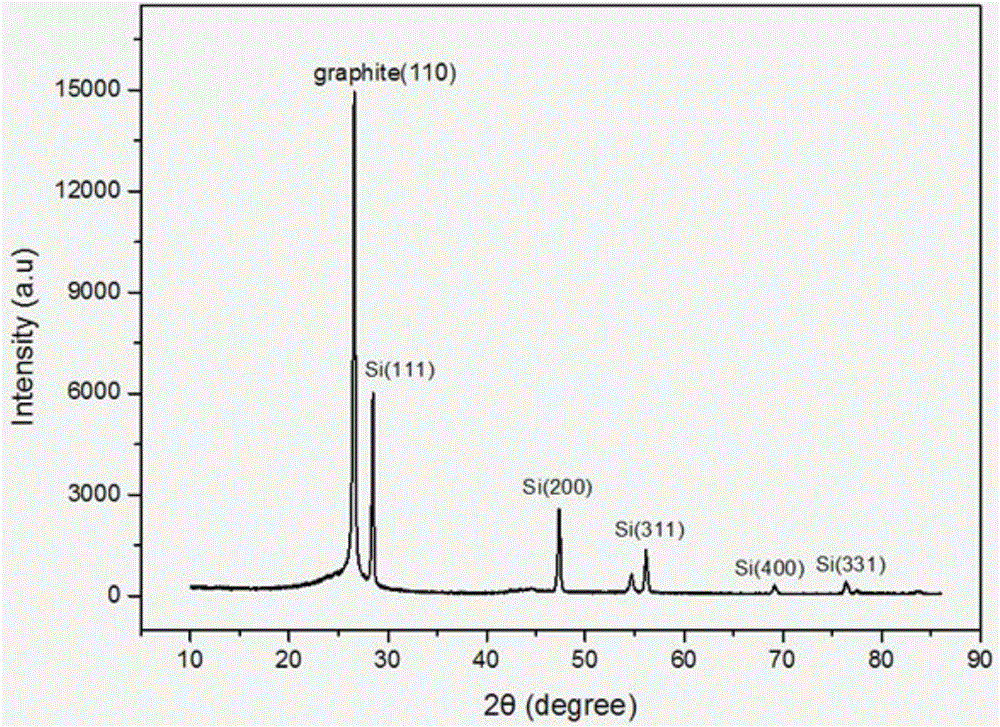

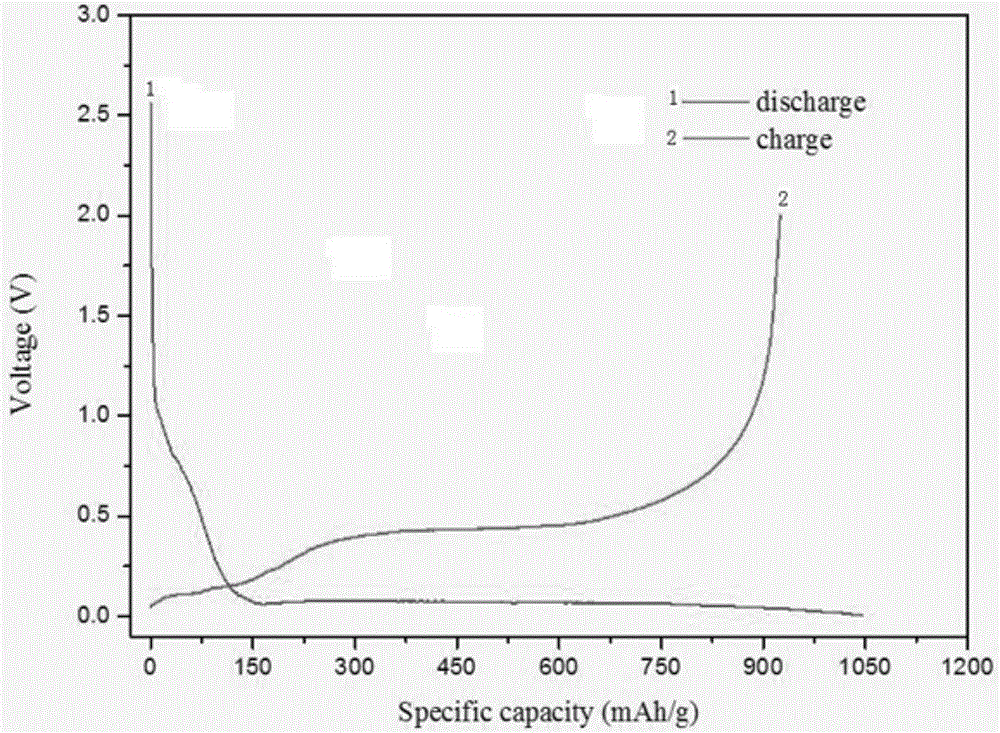

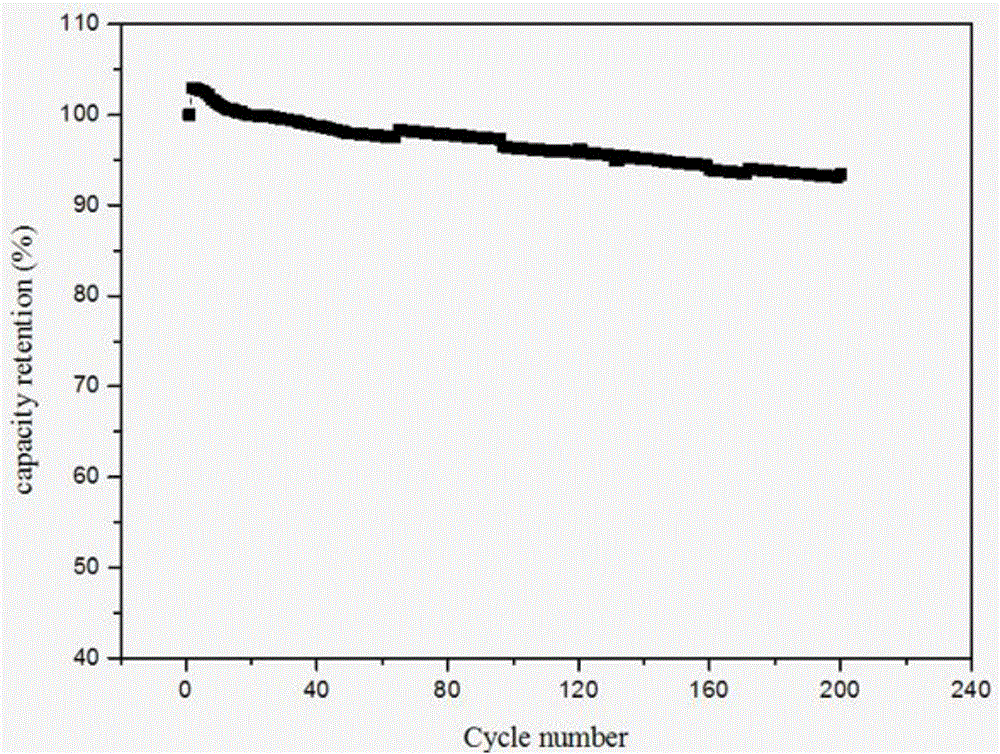

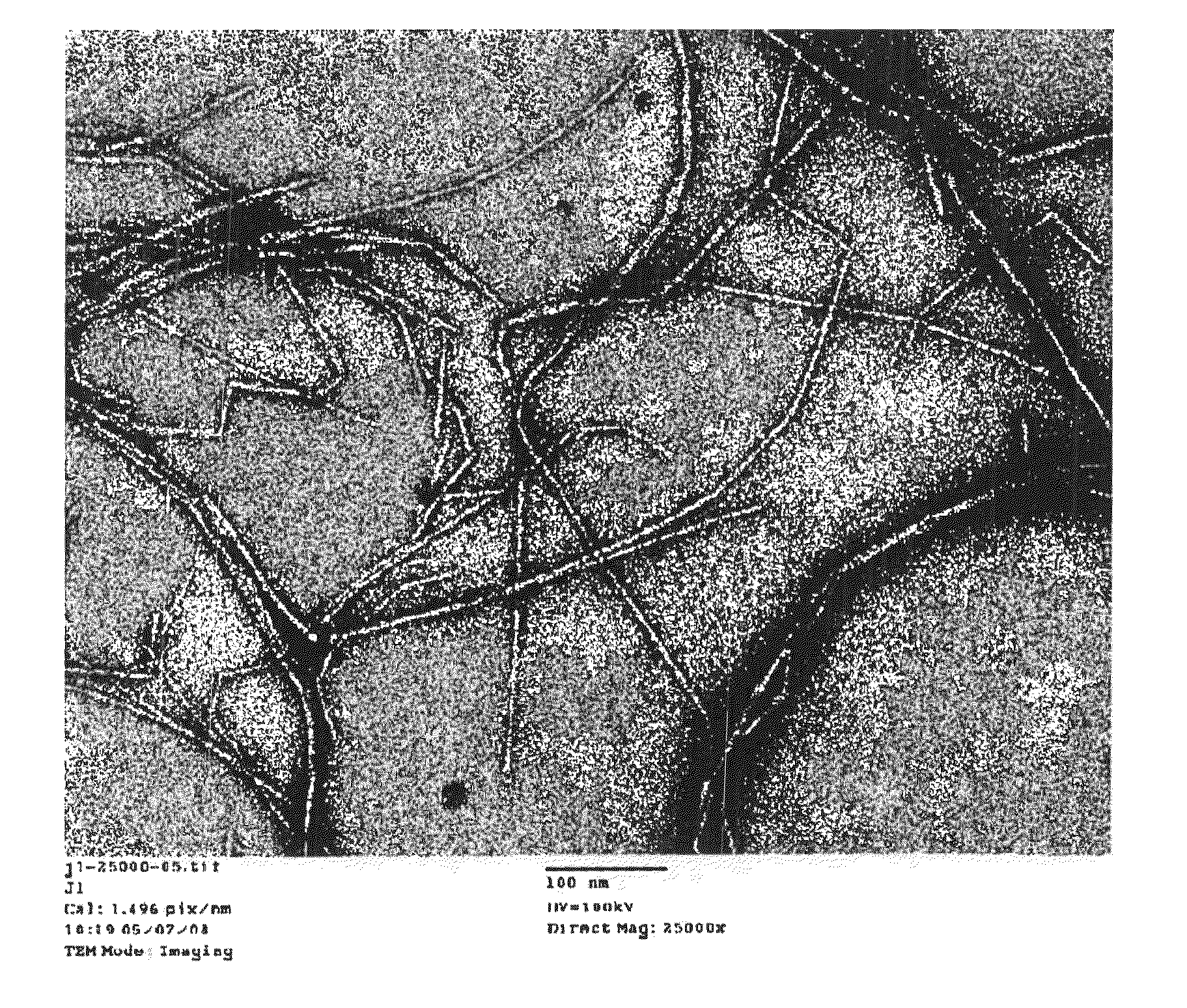

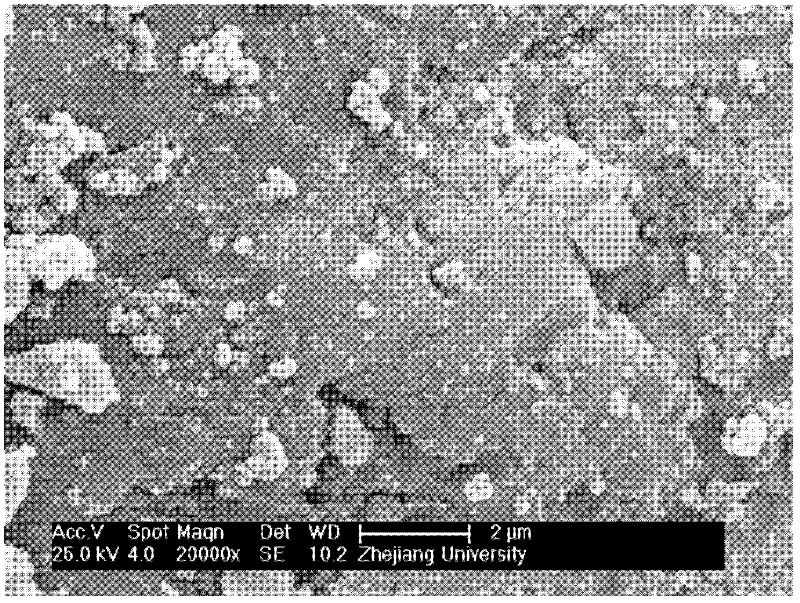

Silicon-carbon composite negative pole material preparation method and lithium ion battery

ActiveCN106257716AEvenly dispersedAvoid direct contactNegative electrodesSecondary cellsCarbon compositesElectric capacity

The invention relates to a silicon-carbon composite negative pole material preparation method and a lithium ion battery. The preparation method comprises putting nanometer silicon and graphite micro-powder into a ball mill, carrying out ball milling uniform dispersion in an organic solvent environment, carrying out vacuum drying, putting the dried mixture and asphalt into a cone-type mixer, carrying out coarse mixing, putting the mixed powder subjected to coarse mixing into a mechanical fusion machine, carrying out mechanical fusion, carrying out heat treatment in an inert gas protective atmosphere and carrying out cooling to obtain the silicon-carbon composite negative pole material. The preparation method carries out asphalt softening coating on nanometer silicon so that silicon particle and electrolyte direct contact is avoided, a capacity reduction rate is delayed, a lithium ion diffusion path is shortened, an electrode material electron conduction loss is avoided, and first charge-discharge efficiency, a charge-discharge electric capacity and cycle performances are improved. Before coating, nanometer silicon is dispersed through graphite micro-powder so that it is avoided that in asphalt coating, nanometer silicon aggregation causes local capacity excess and nanometer silicon is uniformly dispersed.

Owner:浙江超恒动力科技有限公司

Fiber composite

InactiveUS8012573B2High transparencyLow water absorptionRecord information storageMechanical vibrations separationThermal expansionFiber diameter

To provide a cellulose fiber composite having high transparency, low water absorption and low coefficient of linear thermal expansion.A fiber composite which comprises fibers having an average fiber diameter of at most 30 nm and a matrix material and which has a haze of at most 5 according to JIS K-7136 when the fiber composite has a thickness of 100 μm.

Owner:MITSUBISHI CHEM CORP

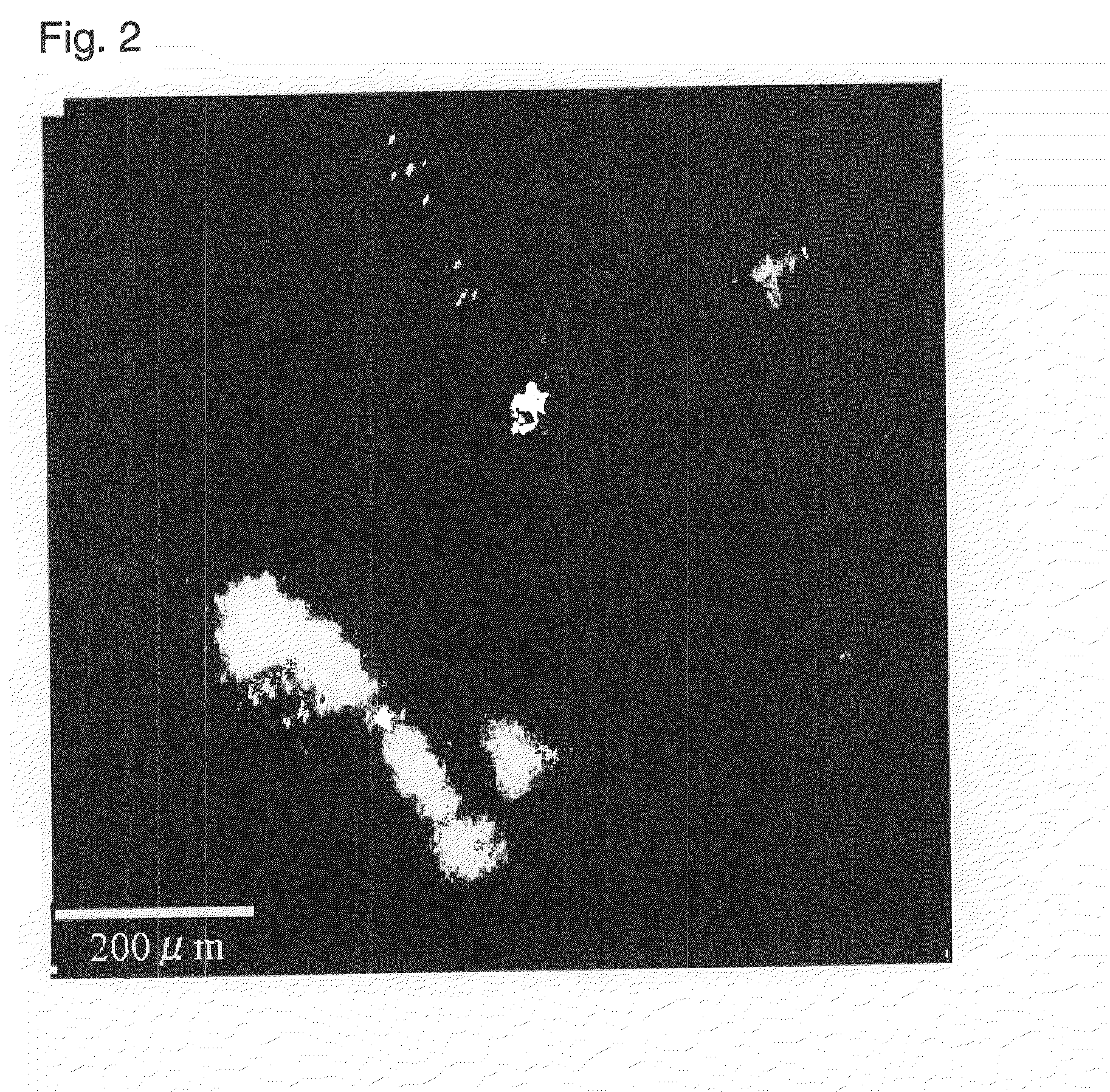

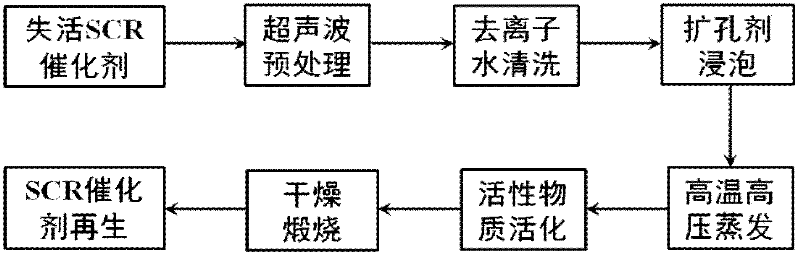

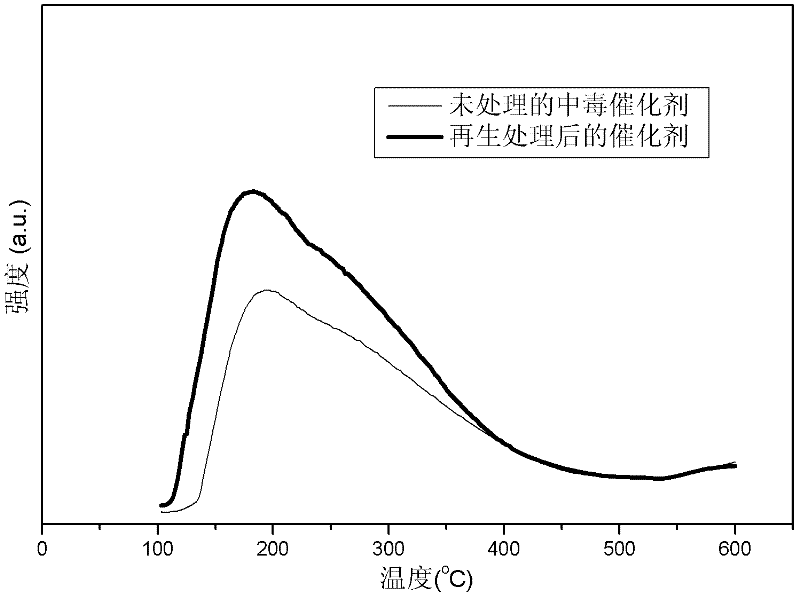

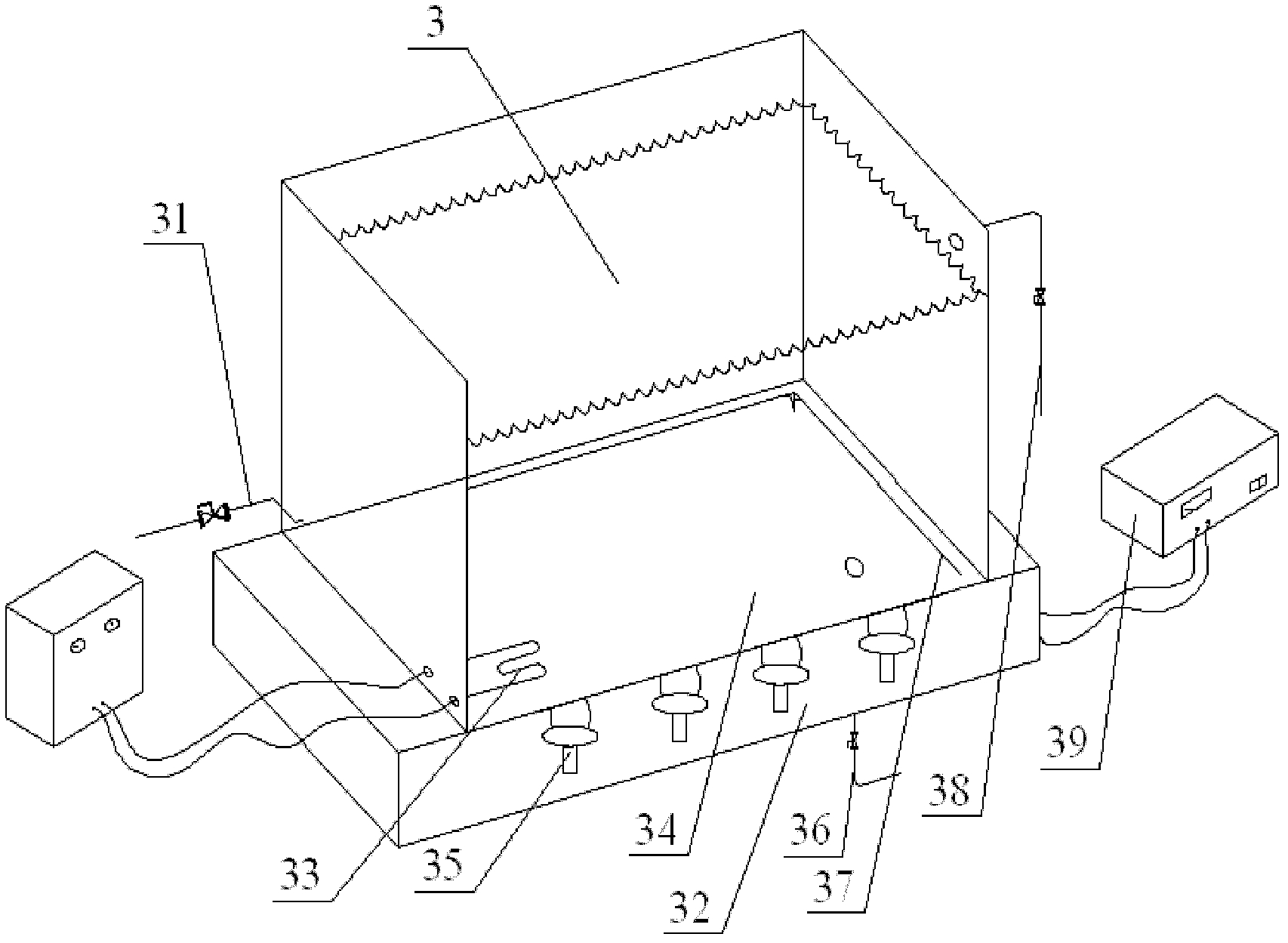

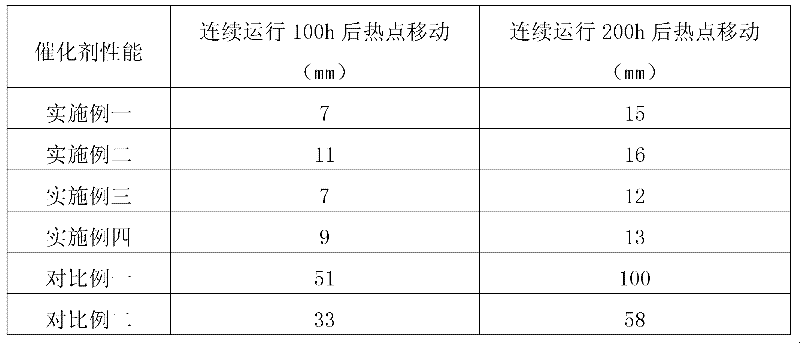

A regeneration method and device for a selective catalytic reduction denitrification catalyst

ActiveCN102266723AImprove pore structureImprove surface conditionDispersed particle separationMuffle furnacePre treatment

The invention discloses a regenerating method and a regenerating device for a selective catalytic reduction de-nitration catalyst. In the regenerating method, the industrially applied poisoned SCR (Selective Catalytic Reduction) de-nitration catalyst is subject to ultrasonic pretreatment, de-ionized water rinsing, chambering agent soaking, high-temperature high-pressure evaporation, active material activation and burning in sequence, thereby regenerating the catalyst. The regenerating device comprises a purging pool, a soaking cleaning pool, a high-pressure kettle, an oscillation water bath kettle, a drying box and a muffle furnace. The regenerating method and the regenerating device have the advantages that pore channels are loosened, the pore structure of the catalyst is obviously optimized, the surface appearance of the catalyst is obviously improved, the activity of the regenerated catalyst is greatly promoted, the practical running demand in industry is met, the raw material is easily acquired in the regeneration process, the process is simple, and the production cost of the enterprise using the SCR de-nitration catalyst is greatly lowered.

Owner:ZHEJIANG UNIV

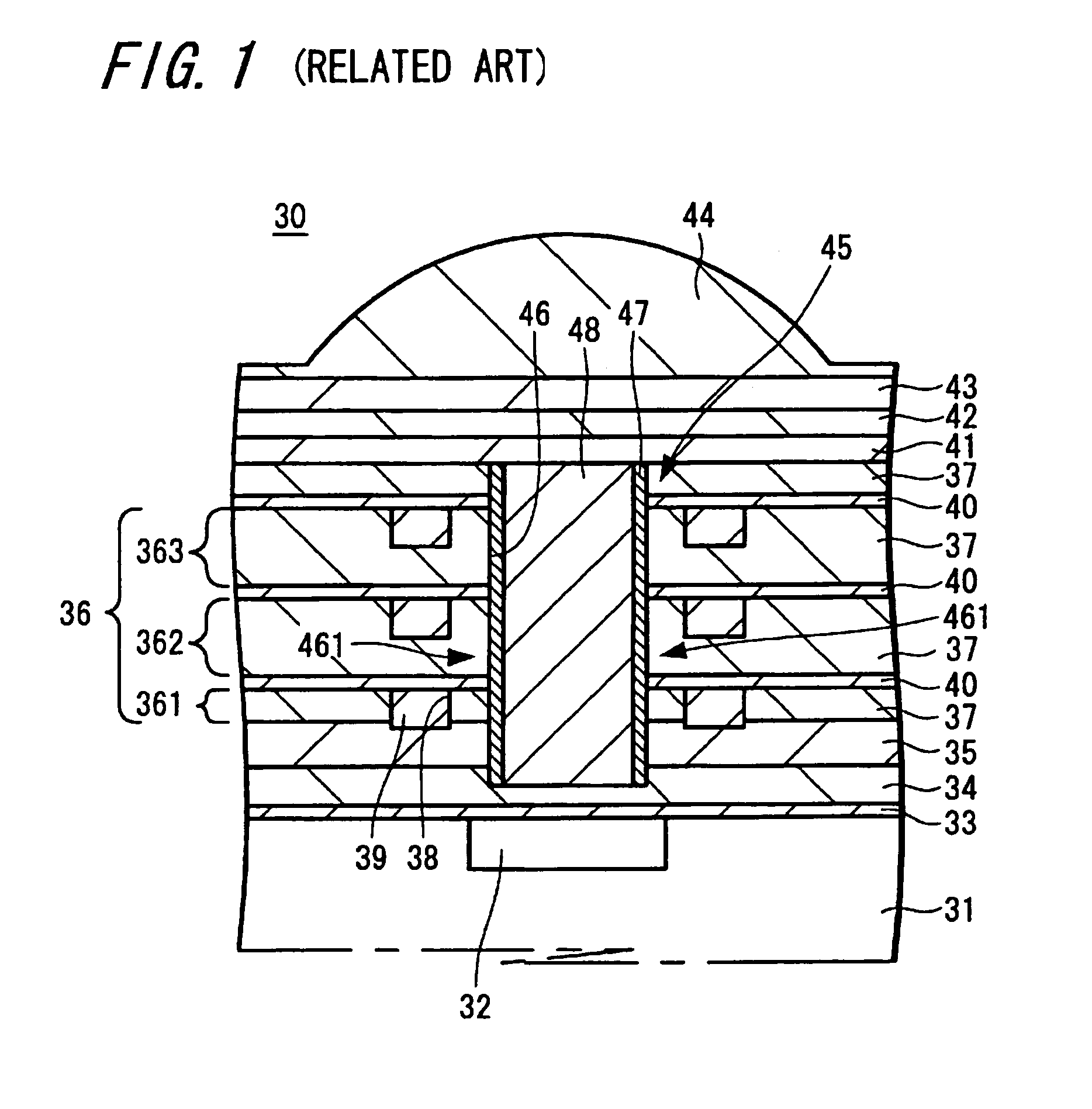

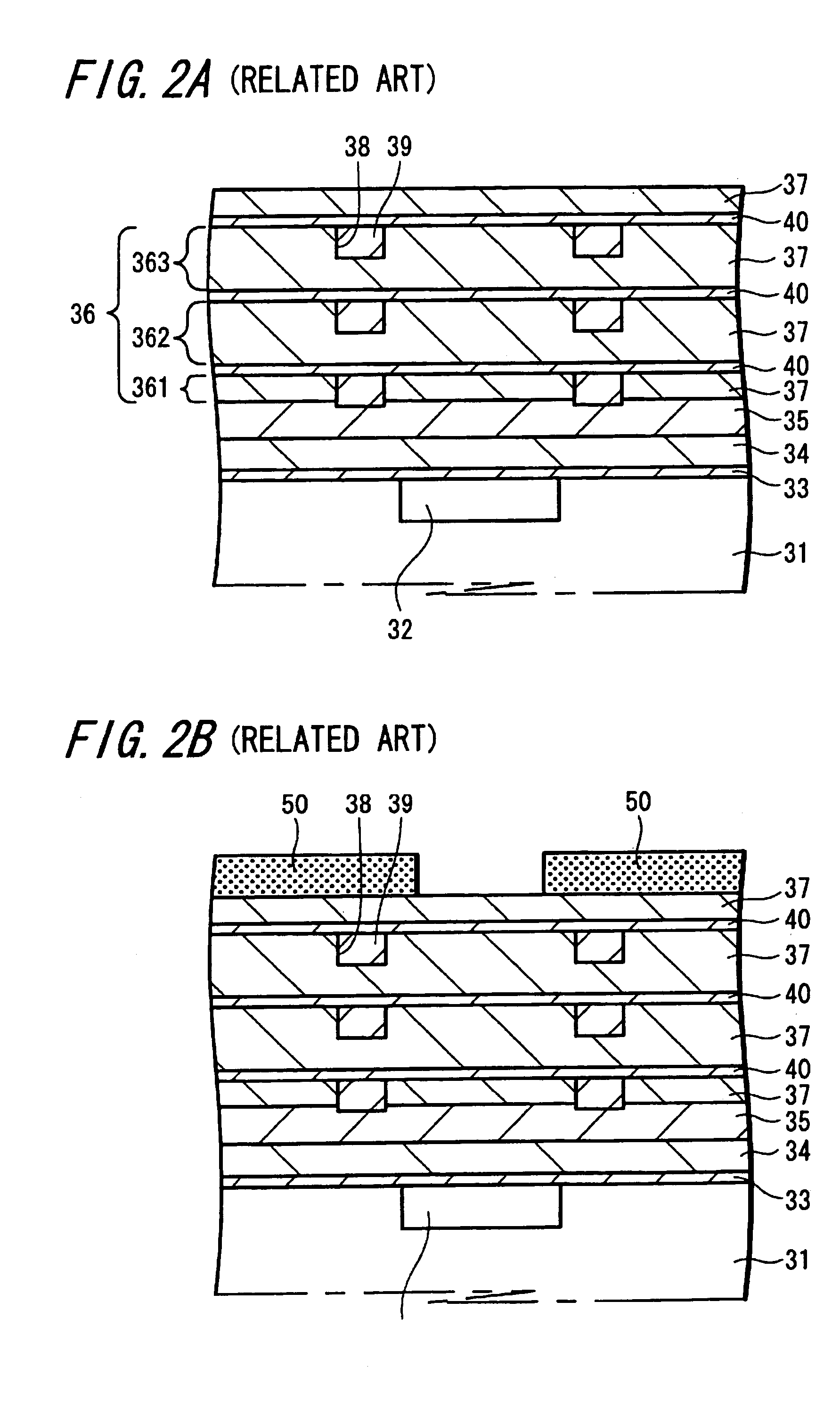

Silicon carbide semiconductor device and method for manufacturing the same

ActiveUS7365363B2Improve surface conditionImprove regularitySemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialSemiconductor

A silicon carbide semiconductor device includes: a semiconductor substrate having a principal surface and a backside surface; a drift layer disposed on the principal surface; a base region disposed on the drift layer; a source region disposed on the base region; a surface channel layer disposed on both of the drift layer and the base region for connecting between the source region and the drift layer; a gate insulation film disposed on the surface channel layer and including a high dielectric constant film; a gate electrode disposed on the gate insulation film; a source electrode disposed on the source region; and a backside electrode disposed on the backside surface.

Owner:DENSO CORP

Graphene auxiliary brazing method for ceramic matrix composite material and metal material

ActiveCN103341674AImprove surface conditionReduce residual stressSoldering apparatusGas phaseShielding gas

A graphene auxiliary brazing method for a ceramic matrix composite material and a metal material elates to a brazing method for the ceramic matrix composite material and the metal material and solves the problem that a brazed connector obtained by brazing the ceramic matrix composite material and the metal material is poor in mechanical property. The brazing method comprises the steps of placing the ceramic matrix composite material into plasma reinforcing chemical vapor deposition equipment to carry out plasma surface treatment, adding CH4 gas to regulate flow, opening a radio frequency power supply, regulating the radio frequency to deposit for 10-30min, using Ar and H2 as protection gas, cooling to the room temperature, obtaining the ceramic matrix composite material with graphene growing on the surface, placing Ti brazing filler metal between faces to be connected, placing the Ti brazing filler metal into a vacuum brazing furnace to be brazed, and finally cooling to the room temperature to finish brazing. The shear strength of a connector formed by the ceramic matrix composite material and the metal material in the brazing method can reach to 35Mpa at the room temperature.

Owner:HARBIN INST OF TECH

Glass compositions

Improved glass fibers compositions, typically useful for fire resistant blankets or containers to provide high burn-through resistance at high temperatures of 2,400° F. and higher, and typically comprising silica, sodium oxide, potassium oxide, calcium oxide, magnesium oxide, ferrous+ferric oxide, and titanium oxide; the improved glass compositions may further include alumina, lithium oxide, and boron oxide.

Owner:GLASS

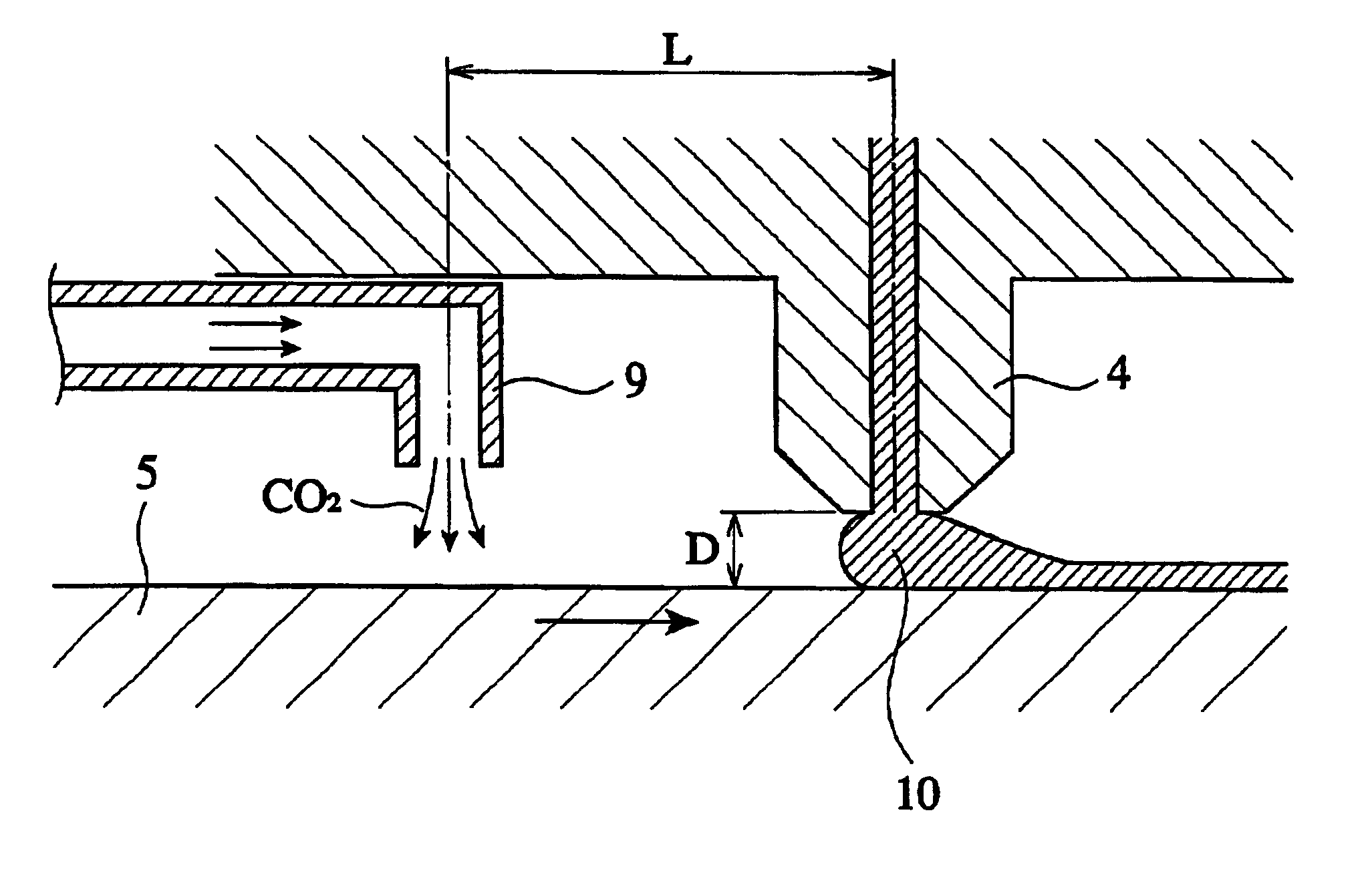

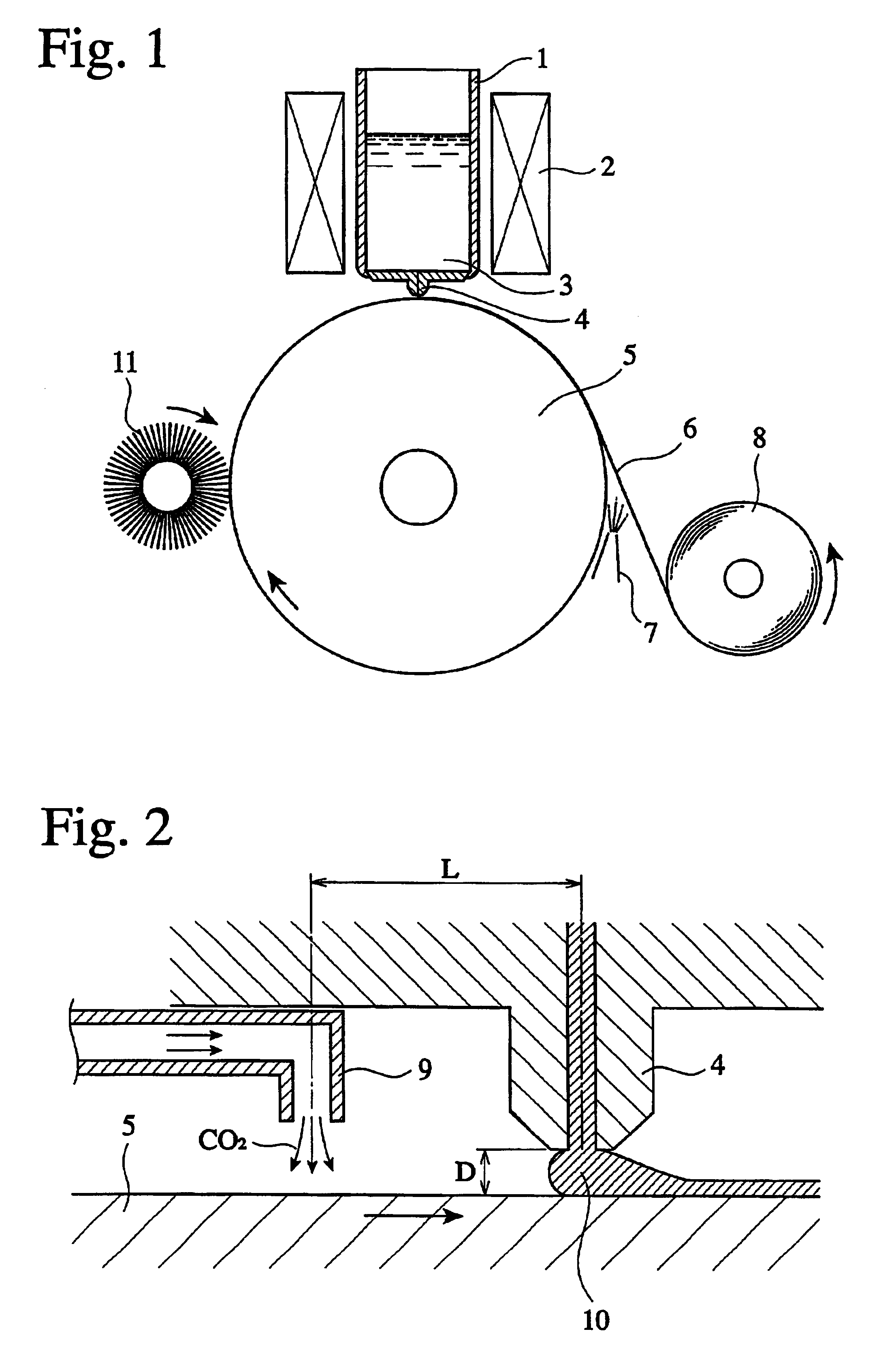

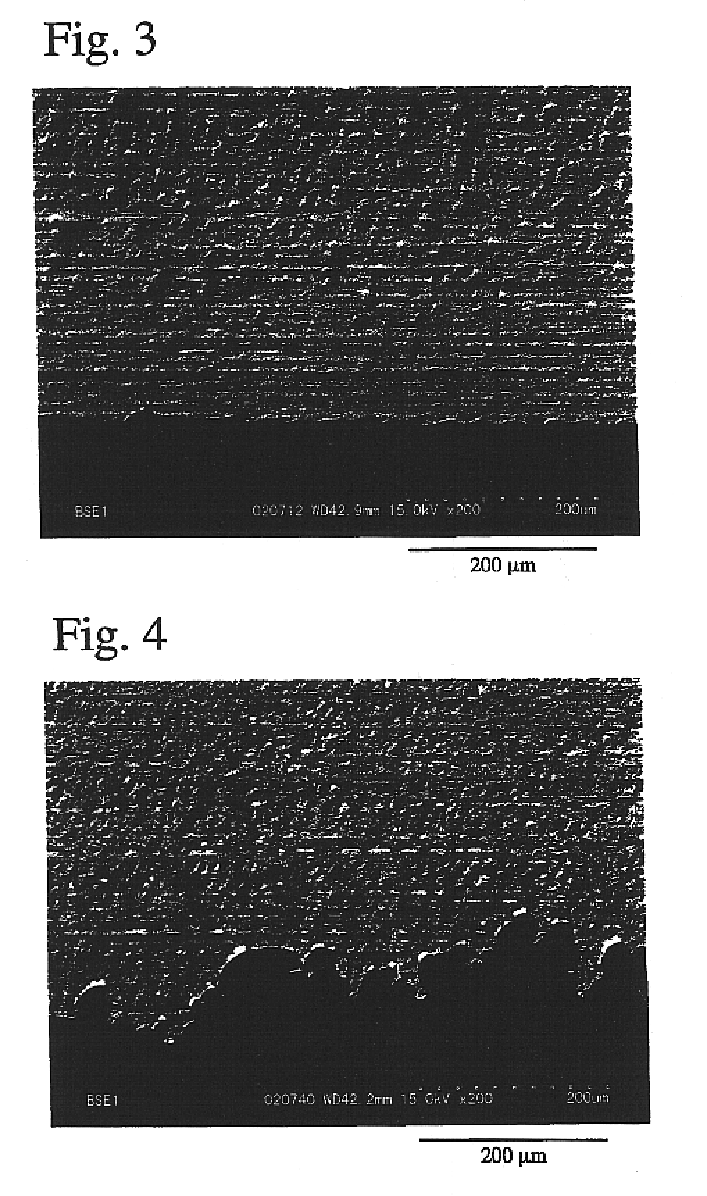

Method for producing amorphous alloy ribbon, and method for producing nano-crystalline alloy ribbon with same

An amorphous alloy ribbon free from embrittlement and crystallization and having excellent surface conditions and shape in edge portions is produced by (a) preparing an alloy melt having a composition comprising 13 atomic % or less of B and 15 atomic % or less of at least one selected from the group consisting of transition elements of Groups 4A, 5A and 6A, the balance being substantially Fe; (b) ejecting the alloy melt at a temperature from the melting point of the alloy +50° C. to the melting point of the alloy +250° C. through a nozzle onto the cooling roll rotating at a peripheral speed of 35 m / second or less, a distance between a tip end of the nozzle and the cooling roll being 200 mum or less; (c) starting to supply a gas based on CO2 to the alloy melt after the surface temperature of the cooling roll has become substantially constant; and (d) grinding the cooling roll while supplying the gas based on CO2.

Owner:HITACHI METALS LTD

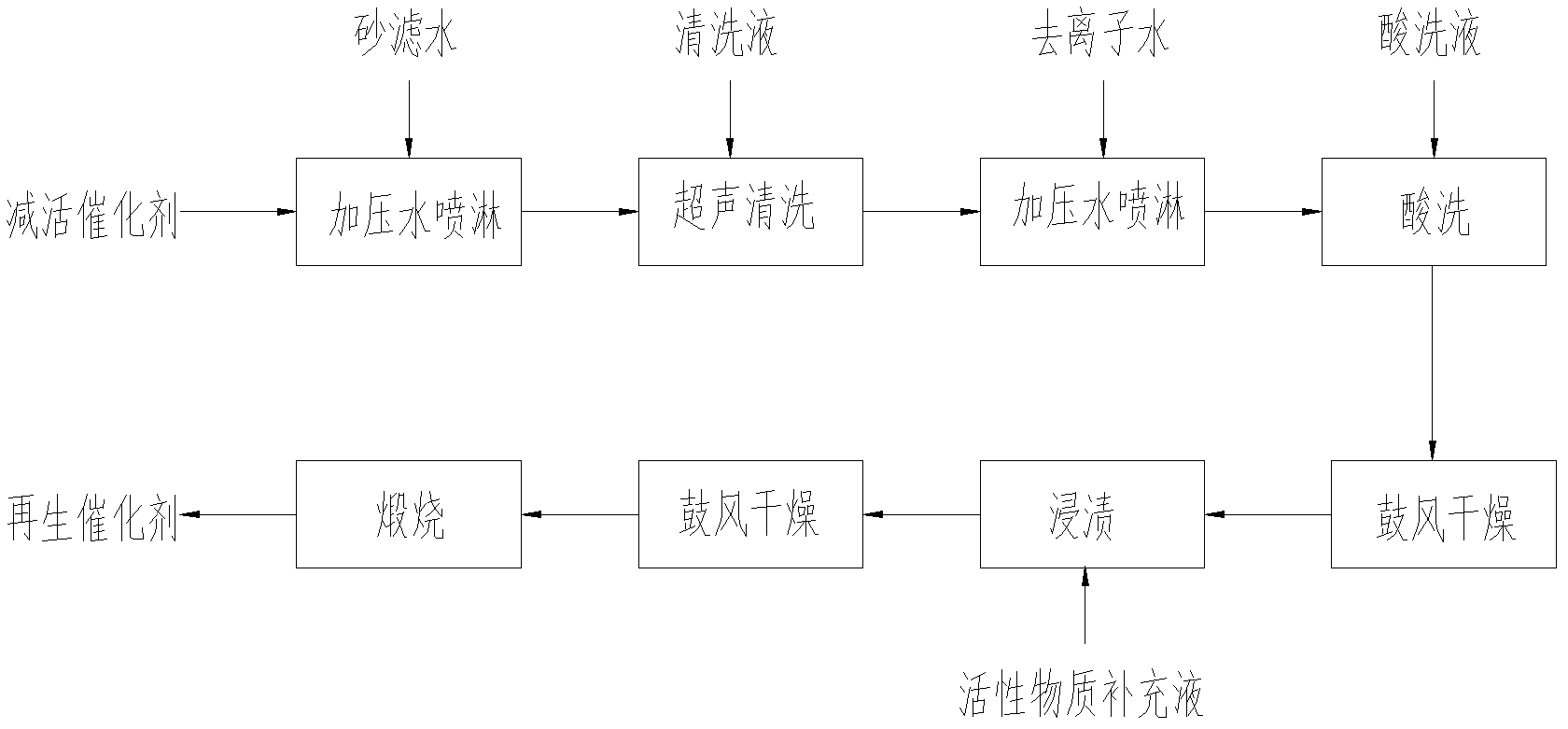

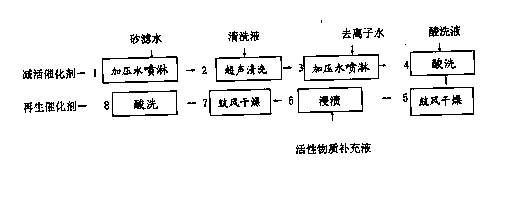

Regeneration technology of V-Ti-based honeycomb SCR denitration catalyst, and apparatus thereof

InactiveCN102658170AGuaranteed structural strengthImprove surface conditionDispersed particle separationCatalyst regeneration/reactivationActive componentHoneycomb

The invention discloses a regeneration technology of a V-Ti-based honeycomb SCR denitration catalyst, and an apparatus thereof. A deactivated catalyst in the technology is regenerated through steps of pressurized water spraying, ultrasonic cleaning, secondary pressurized water spraying, air blow drying, active component supplement, secondary air blow drying, step calcining, and the like. Parameters of the regeneration technology, which comprise components of a cleaning solution, a pickling solution and an active supplement solution, are provided. By adopting the technology, the denitration activity of the deactivated catalyst is recovered, the structural strength of the catalyst is maintained, and the SO2 oxidation frequency is reduced. The apparatus used for realizing the technology comprises a pressurized water spraying pool, an ultrasonic cleaning pool, a secondary pressurized water spraying pool, a pickling pool, an air blow drying pool, an active component supplement pool, a secondary air blow drying pool, a calciner and the like which are sequentially arranged, and the device can realize the hoisting transport regeneration of a regeneration module, and has the characteristics of simplicity, convenient operation, and high efficiency.

Owner:XI AN JIAOTONG UNIV

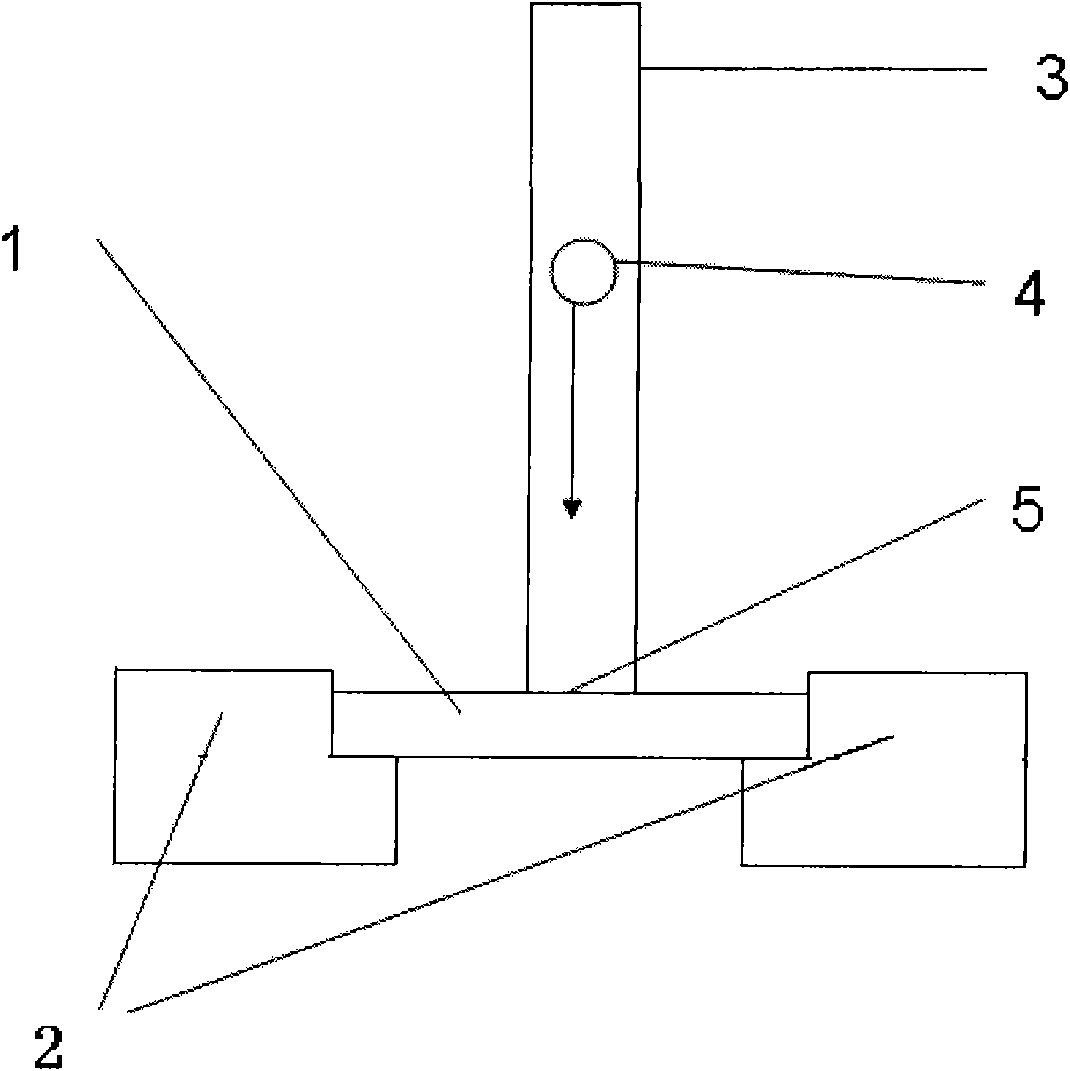

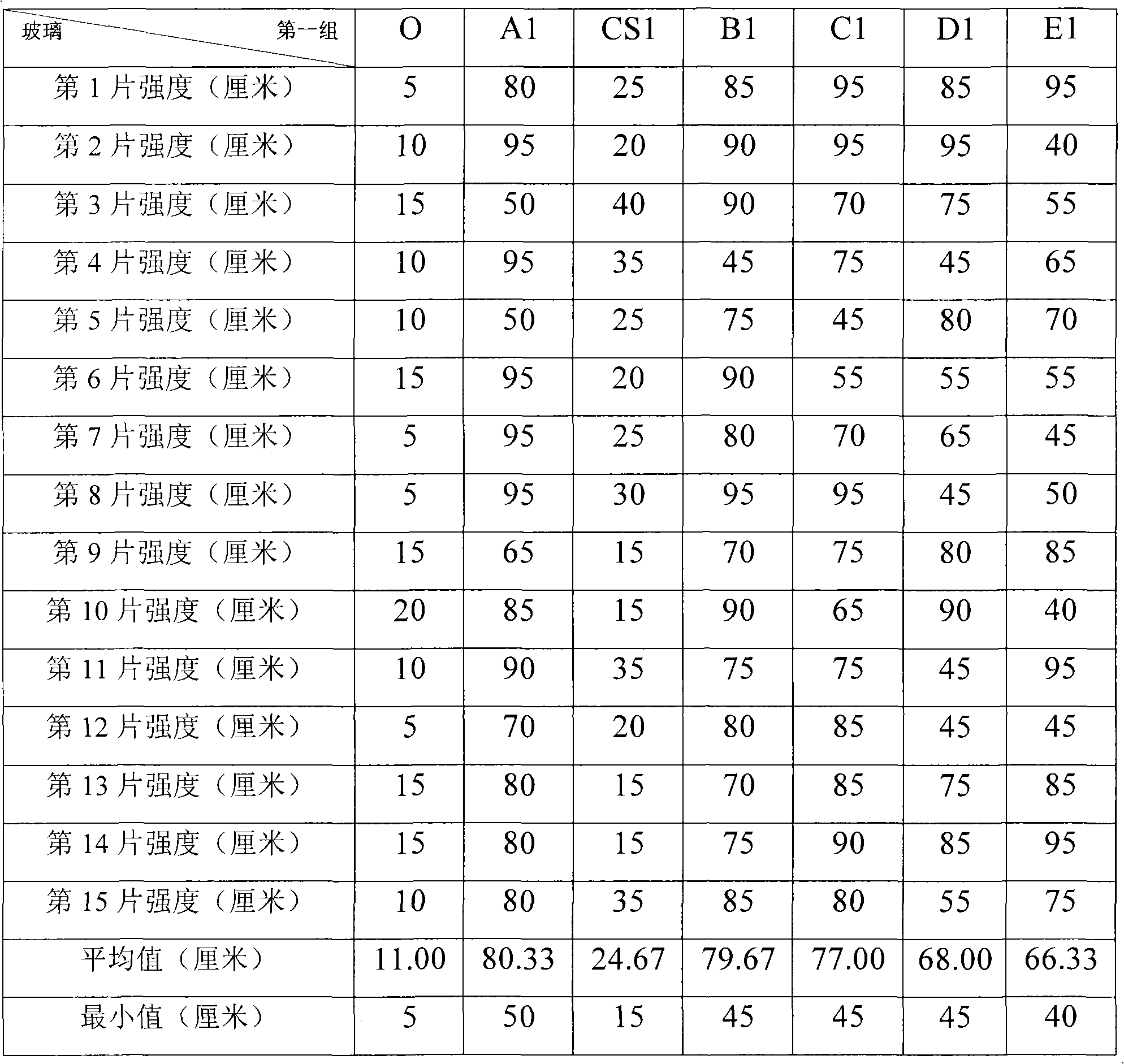

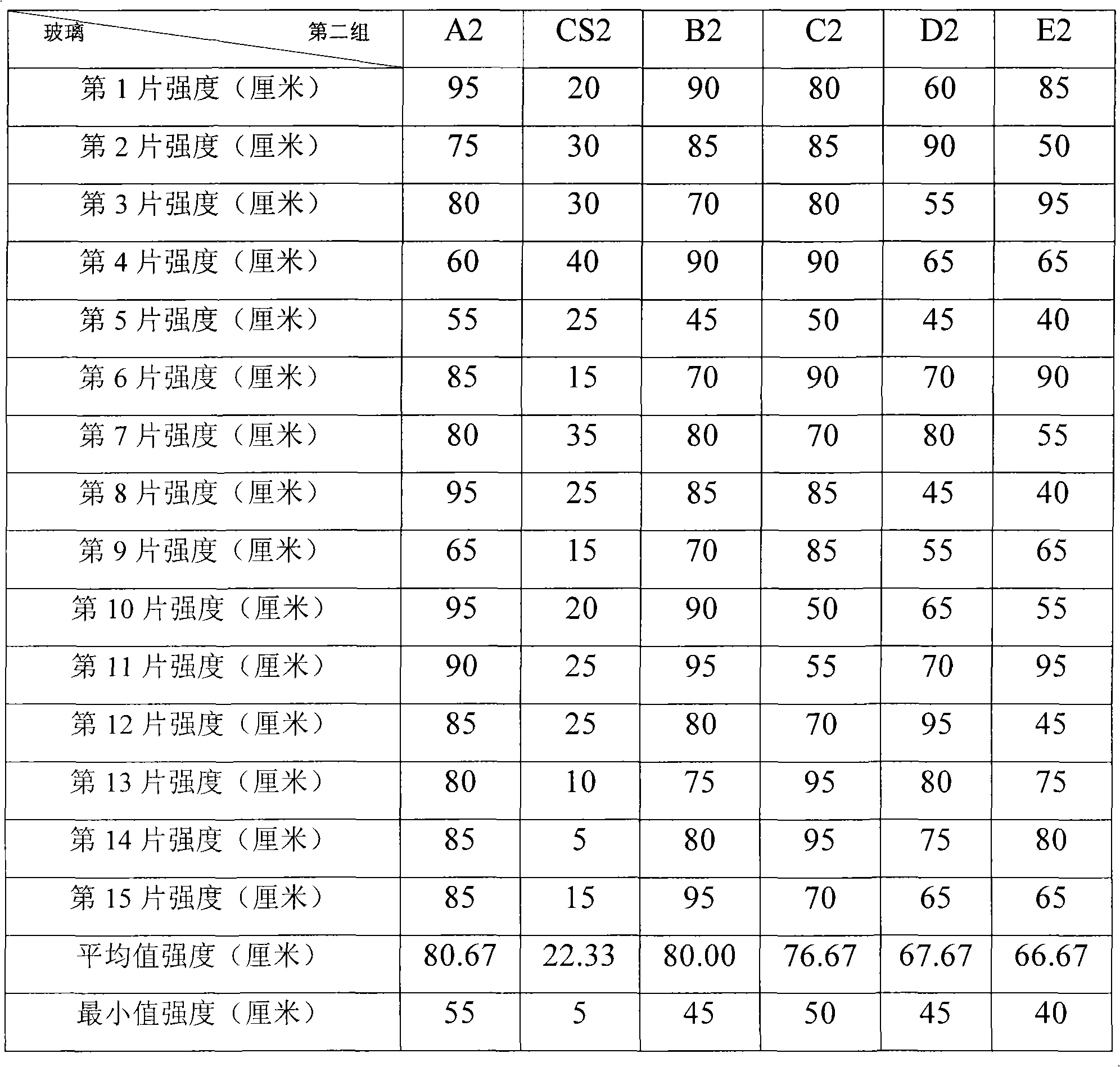

Method for improving strength of glass

The invention provides a method for improving the strength of glass. The method comprises the following steps: performing chemical strengthening on the glass; and performing mechanical polishing on atleast one surface of the glass after the chemical strengthening. According to the method for improving the strength of the glass, the strength of the glass can be greatly improved and reliably maintained only by removing a defective layer in a certain thickness on the surface of the strengthened glass; and the method has simple operation and convenient control, and is convenient for industrialized production. In addition, the method effectively reduces a defective part on the surface of the glass by performing the mechanical polishing, can better improve the strength of the glass without performing chemical strengthening repeatedly on the glass, and reduce the corrosion to the glass and the damage to the optical performance of the glass by chemical drugs so that the glass has better luster and transmittance. The glass strengthened by the method provided by the invention is particularly suitable for a mobile phone display window.

Owner:BYD CO LTD

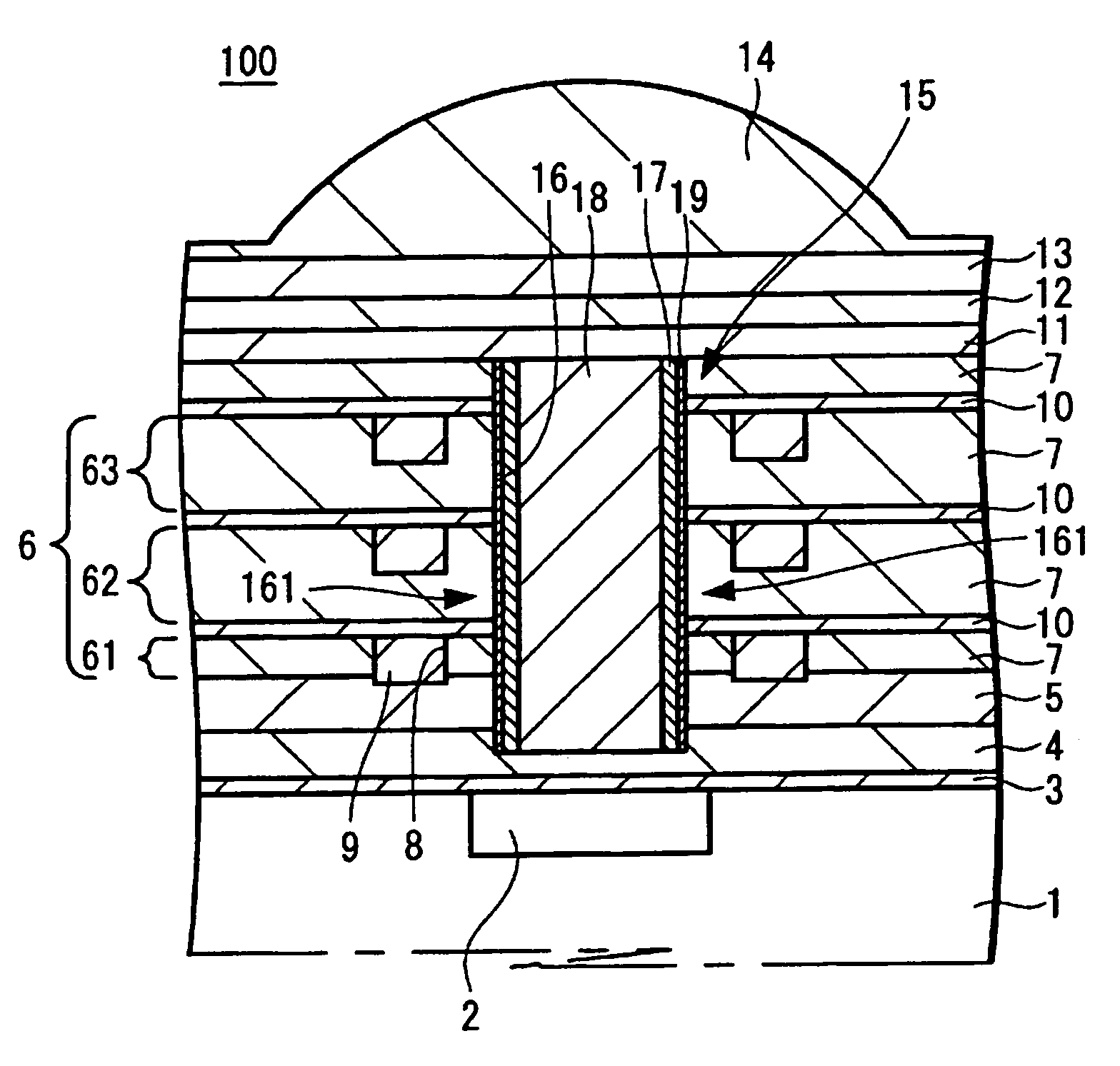

Solid-state image pickup device with non-hydrogen-absorbing waveguide

InactiveUS7041956B2Avoid absorptionSatisfactory surface conditionTelevision system detailsBeam/ray focussing/reflecting arrangementsGroup elementSurface conditions

A solid-state image pickup device 100 is constructed in which a waveguide 15 is formed in an insulating layer on a light-receiving sensor portion 2, a side wall 161 of the waveguide 15 is covered with a reflective film 17 made of an Al film deposited by a CVD method, an underlayer film 19 is formed between the reflective film 17 and the side wall 161 of the waveguide 15 and the underlayer film 19 is made of a VIb-group element. It is possible to obtain a solid-state image pickup device including a waveguide in which hydrogen supplied to the light-receiving sensor portion 2 can be restrained from being absorbed by the underlayer film 19 and which has the reflective film 17 of high reflectivity with satisfactory surface condition, satisfactory coverage and excellent adhesion.

Owner:SONY CORP

Catalyst for coal-to-natural gas methanation reactor and preparation method thereof

ActiveCN102259004AIncrease profitLow costGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsChemistryOxide

The invention discloses a catalyst used in a coal natural gas methanation reactor. The catalyst comprises the following components in percentage by weight: 10-40% of an active component, 40-75% of a carrier, 5-20% of a first auxiliary agent, 2-15% of a second auxiliary agent and 2% of graphite, wherein the active component is NiO; the carrier is Al2O3; the first auxiliary agent is one or two of rare earth metal oxide La2O3, CeO2 or Sm2O3; and the second auxiliary agent is CuO. The preparation method of the catalyst comprises the following steps: preparing a mixed solution, heating and precipitating, filtering the precipitate, washing a filter cake, drying, baking and shaping. The obtained catalyst has the advantages of simple components, low cost, good catalytic activity and high stability, and is easy to prepare.

Owner:HUANENG CLEAN ENERGY RES INST

Enhancing adhesion of interlayer dielectric materials of semiconductor devices by suppressing silicide formation at the substrate edge

InactiveUS20100248463A1Reduce yield lossImprove defectsSemiconductor/solid-state device manufacturingSemiconductor devicesMetal silicideProtection layer

Adhesion of dielectric layer stacks to be formed after completing the basic configuration of transistor elements may be increased by avoiding the formation of a metal silicide in the edge region of the substrate. For this purpose, a dielectric protection layer may be selectively formed in the edge region prior to a corresponding pre-clean process or immediately prior to deposition of the refractory metal. Hence, non-reacted metal may be efficiently removed from the edge region without creating a non-desired metal silicide. Hence, the further processing may be continued on the basis of enhanced process conditions for forming interlayer dielectric materials.

Owner:TAIWAN SEMICON MFG CO LTD

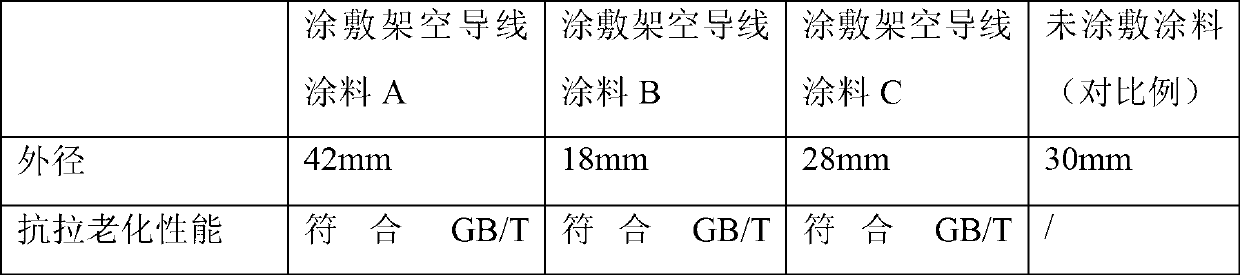

Coating for improving performance of overhead conductor comprehensively

ActiveCN102977700AImprove anti-aging propertiesImprove self-cleaning performanceInsulated cablesPolyurea/polyurethane coatingsVinyl etherEngineering

The invention relates to the technical field of overhead conductors of electric transmission lines, in particular to a coating for improving the performance of an overhead conductor comprehensively. The overhead conductor coating comprises the components in percentage by weight as follows: 38-59% of FEVE (fluoro ethylene-vinyl ether) fluorocarbon resin, 30-50% of an organic solvent, 10-20% of a curing agent and 1-12% of an auxiliary agent. The coating has good ageing resistance and self-cleaning performance as well as a high heat radiation coefficient. The surface condition of a common steel-core aluminium twisted wire is improved comprehensively through the application of the coating, so that the carrying capacity, the ant-icing performance and the corona characteristic of a common steel-cored aluminium strand are improved.

Owner:SHANGHAI ELECTRIC CABLE RES INST +1

Preparation method of flashing compound for tile

The invention provides a preparation method of a waterproof and weather-resistant flashing compound special for filling slits between tiles. The flashing compound comprises components by weight of 25-35% of portland cement, 50-68% of quartz sand (70-110 mesh), 5-10% of bauxite cement, 1.5-2% of redispersible emulsion powder, 1-2% of cellulose ether, 0.3-0.6% of powder antifoaming agent, 0.3-0.6% of powder water repellent and 0.3-0.6% of high efficiency water reducing agent. Compared with a flashing compound of a prior art, the flashing compound of the invention has characteristics of wide construction range, strong adhesive force, water resistance, and weather resistance, and can be widely used in slit filling of tiles and other construction materials; therefore, the flashing compound has promising popularization and application values.

Owner:胡舜钦 +1

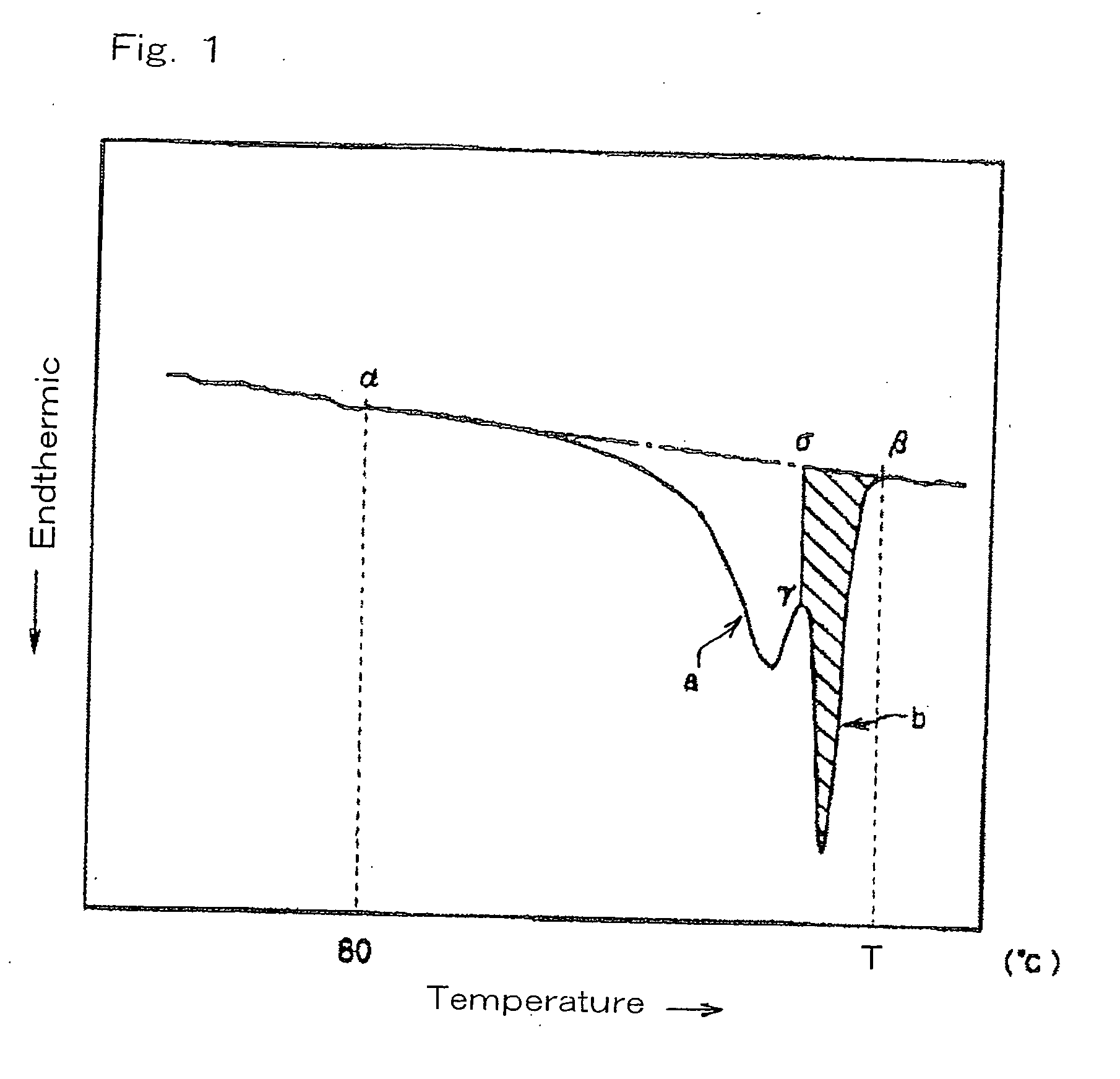

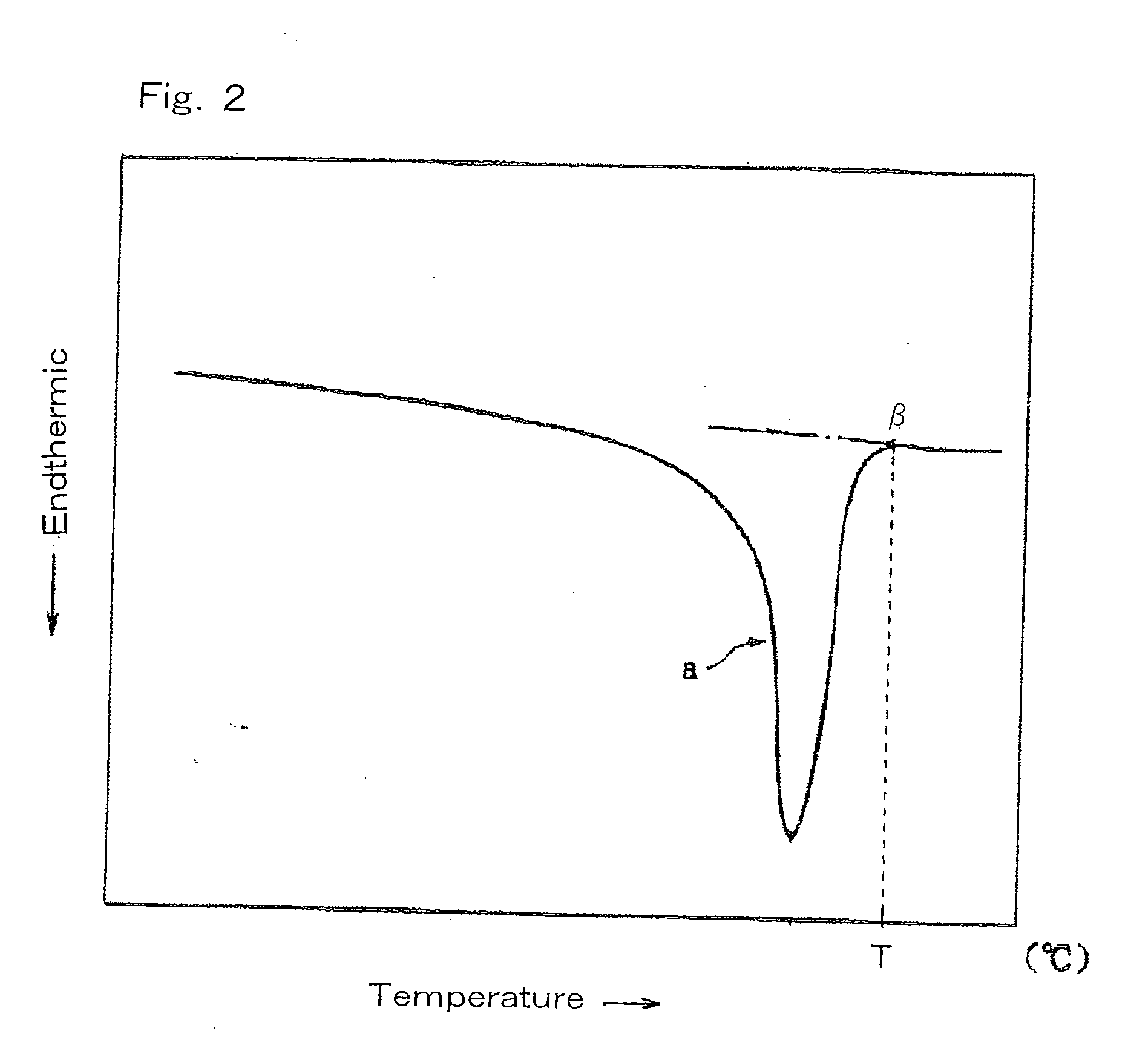

Foamed polyolefin resin beads

InactiveUS20090169895A1Good surface conditionExcellent mechanical strengthSynthetic resin layered productsCellulosic plastic layered productsChemistryAntistatic agent

The present invention relates to foamed polyolefin resin beads. Further, the present invention provides foamed resin beads obtained by foaming and expanding composite resin beads which include a core layer constituted by a polyolefin resin and a covering layer which covers the core layer constituted by a polyolefin resin, wherein (a) the polyolefin resin constituting the core layer is a crystalline polyolefin resin, (b) the polyolefin resin constituting the covering layer is a crystalline polyolefin resin which has a lower melting point (B) than a melting point (A) of the polyolefin resin constituting the core layer, wherein a temperature difference [(A)−(B)] between the melting point (B) and the melting point (A) is more than 0° C. and 80° C. or less, or a noncrystalline polyolefin resin which has a softening point (C) lower than the melting point (A) of the polyolefin resin constituting the core layer, wherein a temperature difference [(A)−(C)] between the softening point (C) and the melting point (A) is more than 0° C. and 100° C. or less, and 10% by weight or more and less than 50% by weight of polymer type antistatic agent is contained in the covering layer. The foamed polyolefin resin beads of the present invention provide foamed polyolefin resin beads are excellent in fusion properties between beads at the time of molding in a mold, capable of providing a molded foamed article which is excellent antistatic performance, has no deterioration of the antistatic performance with age, whose antistatic performance is not humidity dependent, does not contaminate packaging products, has a good molded foamed article surface, and has excellent mechanical properties.

Owner:JSP CORP

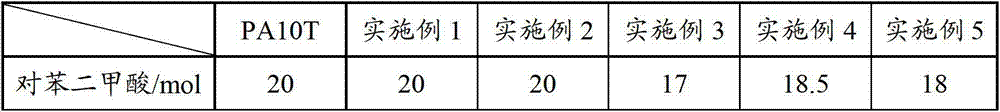

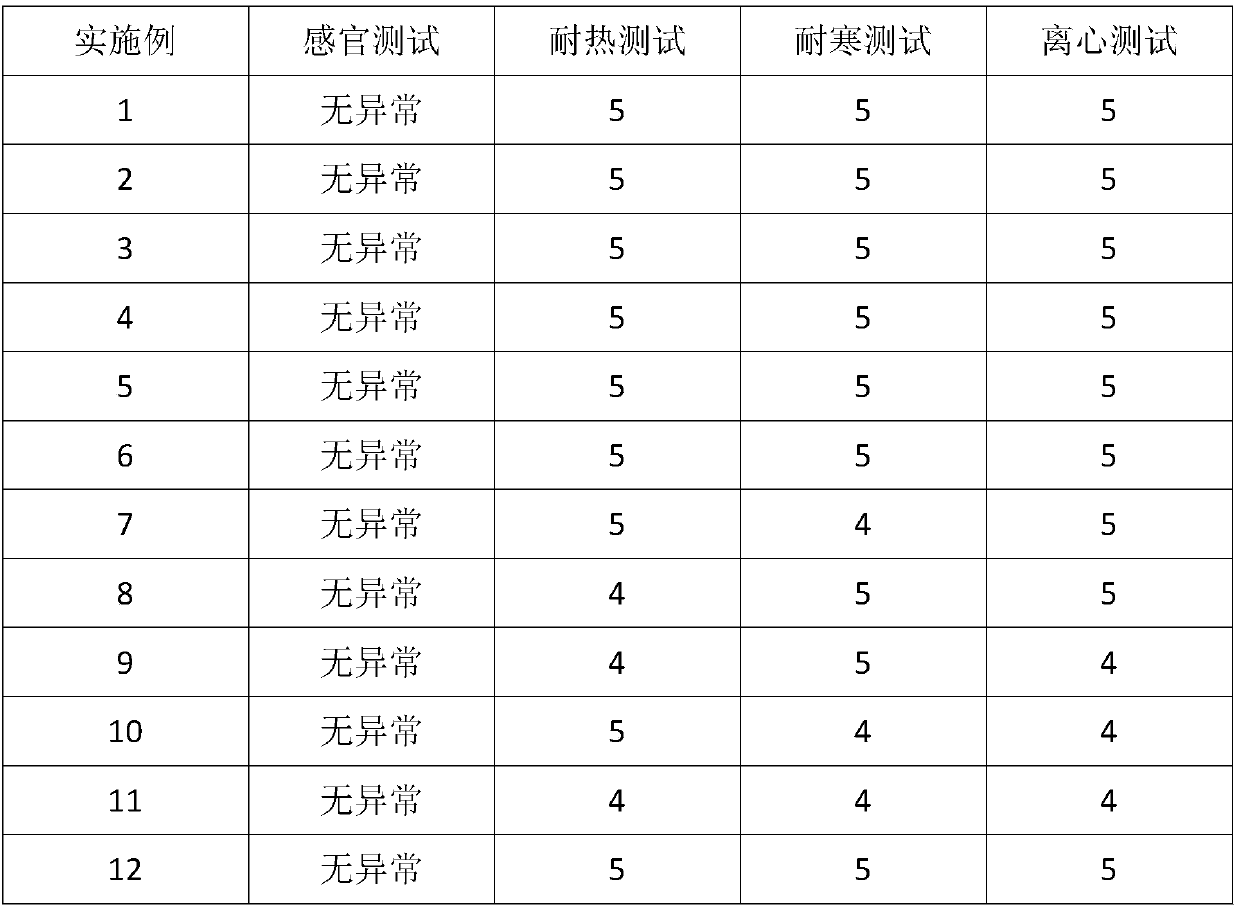

Polyamide resin and application thereof as well as polyamide composition consisting of same

The invention discloses polyamide resin and application thereof as well as a polyamide composition consisting of the same. A repetitive unit of the polyamide resin is composed of the following components: dicarboxylic acid unit accounting for 80-100% of polyamide resin by mol, aliphatic diamine unit accounting for 80-100% of polyamide resin by mol and having 2-14 carbon atoms and lactam or aminocarboxylic acid unit accounting for 0-20% of polyamide resin by mol and having 6-14 carbon atoms; in the polyamide resin, the content of bio-based carbon is over 45%; and the mol content of the bio-based carbon is calculated by the following formula: content of bio-based carbon=(molar weight of bio-based carbon / total molar weight of organic carbon)*100%. The polyamide resin disclosed by the invention has low gas volatile substance, and thus the polyamide composition prepared from the same also has low gas volatile substance and can be applied to the field of food contact. The prepared polyamide composition has good surface state after reflow soldering.

Owner:KINGFA SCI & TECH CO LTD +1

Anti-aging anti-wrinkle composition and applications thereof

PendingCN109602668AImprove stabilityImprove surface conditionCosmetic preparationsToilet preparationsAsiatic pennywortBaical Skullcap Root

The invention relates to the field of daily chemical products, in particular to an anti-aging anti-wrinkle composition and applications thereof. In view of the above technical problem, on the one hand, the present invention firstly provides the anti-aging anti-wrinkle composition, and the preparation raw materials include a moisturizing agent, a skin conditioning agent, and a thickening agent; theskin conditioning agent comprises a plant extract; and the plant extract is selected from one or more of glycine soja seed extract, swertia bimaculata extract, apple seed extract, ginkgo leaf extract, asiatic pennywort herb extract, giant knotweed rhizome extract, baical skullcap root extract, tea leaf extract, glycyrrhiza glabra root extract, mayweed flower extract, rosemary leaf extract and ceratonia siliqua seed extract.

Owner:ZHEJIANG KANGMANJIA DAILY NECESSITIES CO LTD

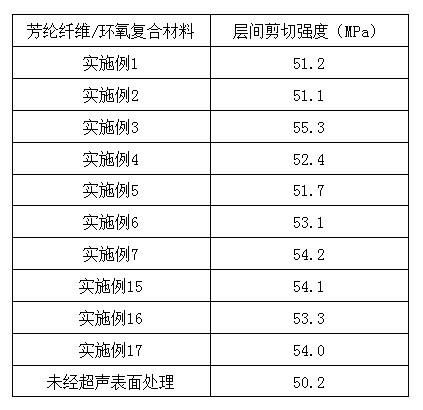

Ultrasonic surface modification treatment method for aramid fibers

InactiveCN102605606AImprove surface conditionQuality improvementFibre typesUltrasonic/sonic fibre treatmentPolymer scienceOrganic solvent

The invention provides an ultrasonic surface modification treatment method for aramid fibers. One or more amidic organic solvents in any proportion are selected as an ultrasonic treatment medium; under an ultrasonic action, fiber surfaces can be etched effectively by the amidic solvents; simultaneously, the sticking points among aramid fiber filaments can be reduced, and the state of the surfaces can be improved, so that the bonding strength between a resin and a fiber is increased; and meanwhile, the online treatment of the fibers is easy to realize by the ultrasonic treatment, and the time for modifying the fiber surfaces is shortened.

Owner:中蓝晨光化工有限公司

Diamond sintered body and method for producing same

InactiveUS20100112332A1High strengthGood wear resistanceDrawing diesLayered productsTungstenChromium

Provided are a diamond sintered body having higher strength and more excellent wear resistance than a conventional diamond sintered body, and a method for producing such a diamond sintered body. The diamond sintered body includes diamond particles, a binder, and a void. The diamond particles have a content of not less than 80% by volume but less than 98% by volume. The binder includes a solid solution containing at least one element selected from a group consisting of titanium, zirconium, vanadium, niobium, and chromium, carbon, and tungsten, as well as an iron group element. Neighboring ones of the diamond particles are bonded to one another. The method provides such a diamond sintered body.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

Manufacturing method and process device of reactivated cleaning agent for regeneration of honeycomb SCR (selective catalytic reduction) denitration catalyst

InactiveCN103736527AEasy to cleanFast cleaningCatalyst regeneration/reactivationAcid washingEngineering

The invention discloses a manufacturing method and process device of a reactivated cleaning agent for regeneration of a honeycomb SCR (selective catalytic reduction) denitration catalyst. The deactivated SCR denitration catalyst in the process device is regenerated through the steps of pressurized water spraying, ultrasonic cleaning, secondary pressurized water spraying, acid washing, forced air drying, active component supplementation, secondary forced air drying, step-by-step calcination and the like in sequence. By using (NH4)2SO4 as a main component of an acid washing solution, potential hazards caused by sulfuric acid are avoided, and the economic performance and the safety are realized. The components such as EDTA (ethylene diamine tetraacetic acid) are added into the cleaning agent, and under the chelation of the EDTA and heavy metal elements, the toxic action on the denitration catalyst caused by the heavy metal elements can be well eliminated. According to the process, the denitration activity of the deactivated catalyst can be recovered, and meanwhile, the structural strength of the catalyst can be kept. The process device is simple, suitable for regeneration in hoisting transportation, and high in efficiency. By the promotion of the process, the performance of the regenerated honeycomb SCR catalyst can be improved, the replacement cost of the catalyst is saved, and the process has an important significance on NOX control.

Owner:高同柱

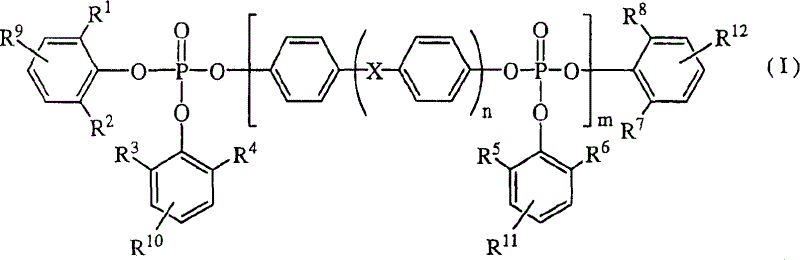

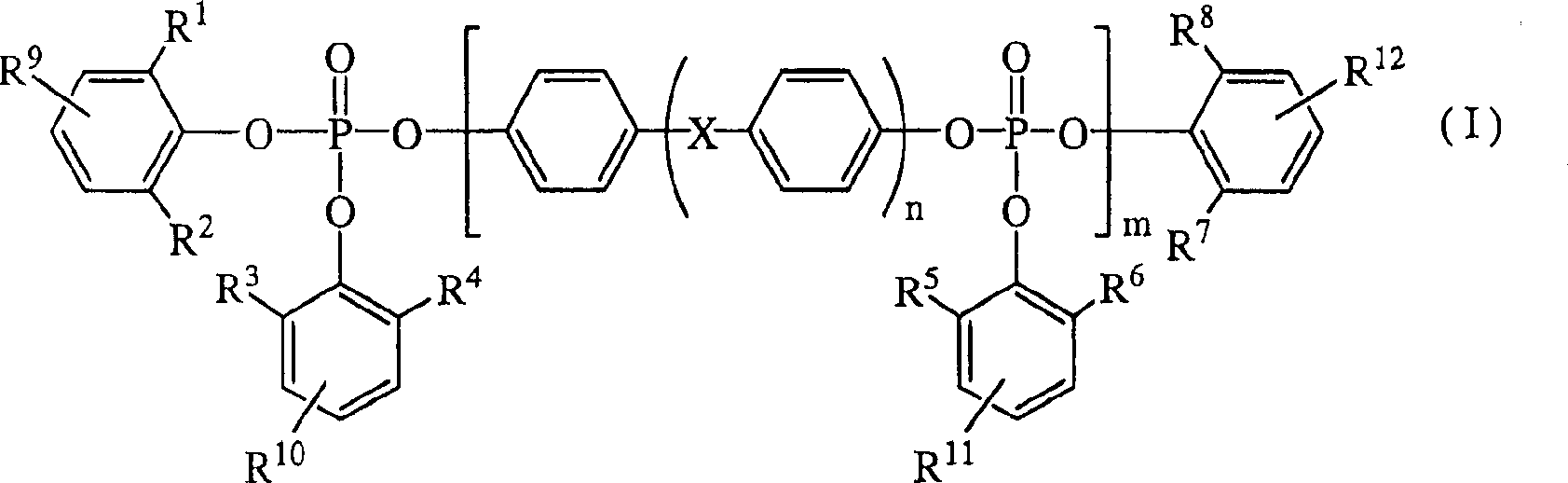

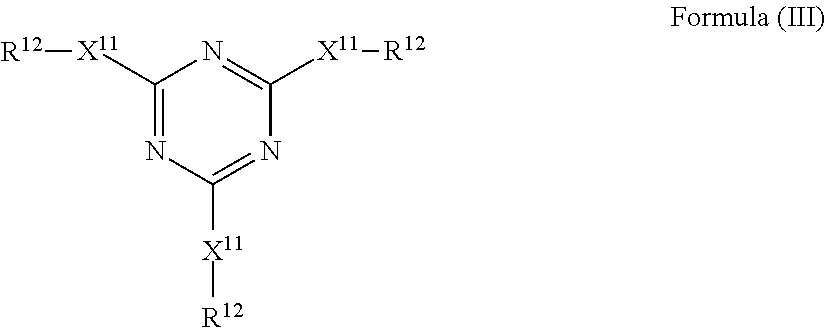

Polyarylene thioether resin composition

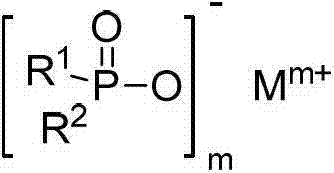

Provided is a polyarylene sulfide resin molded article having a good surface state which can be molded at a significantly high crystallization speed without impairing heat resistance, mechanical properties, chemical resistance, dimensional stability and flame retardancy of polyarylene sulfide resins. The resin composition comprises (A) 100 pts. wt. polyarylene sulfide resin, (B) 0.1-10 pts. wt. aromatic phosphate of a specific structure, and (C) 3-35 pts. wt. polyphenylene oxide resin.

Owner:POLYPLASTICS CO LTD

Cellulose ester film, polarizer and liquid crystal display device

InactiveUS20110001904A1Improve production efficiencyImprove surface conditionSynthetic resin layered productsPolarising elementsCellulose ester membraneCarbon number

A cellulose ester film comprising at least one polycondensate ester that comprises a dicarboxylic acid residue mixture having an average carbon number of from 5.5 to 10.0 and comprising an aromatic dicarboxylic acid residue and an aliphatic dicarboxylic acid residue, and an aliphatic diol residue having an average carbon number of from 2.5 to 7.0.

Owner:FUJIFILM CORP

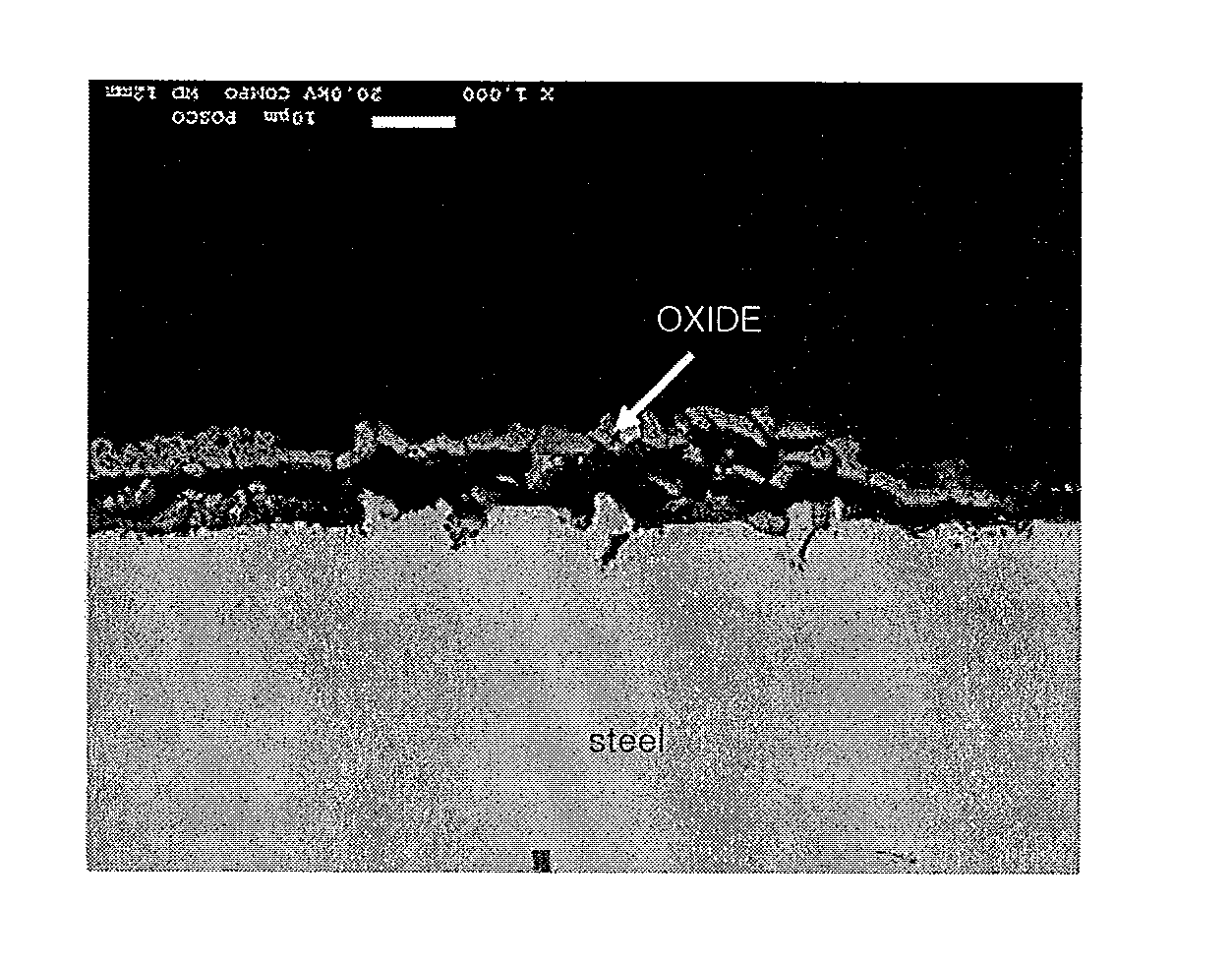

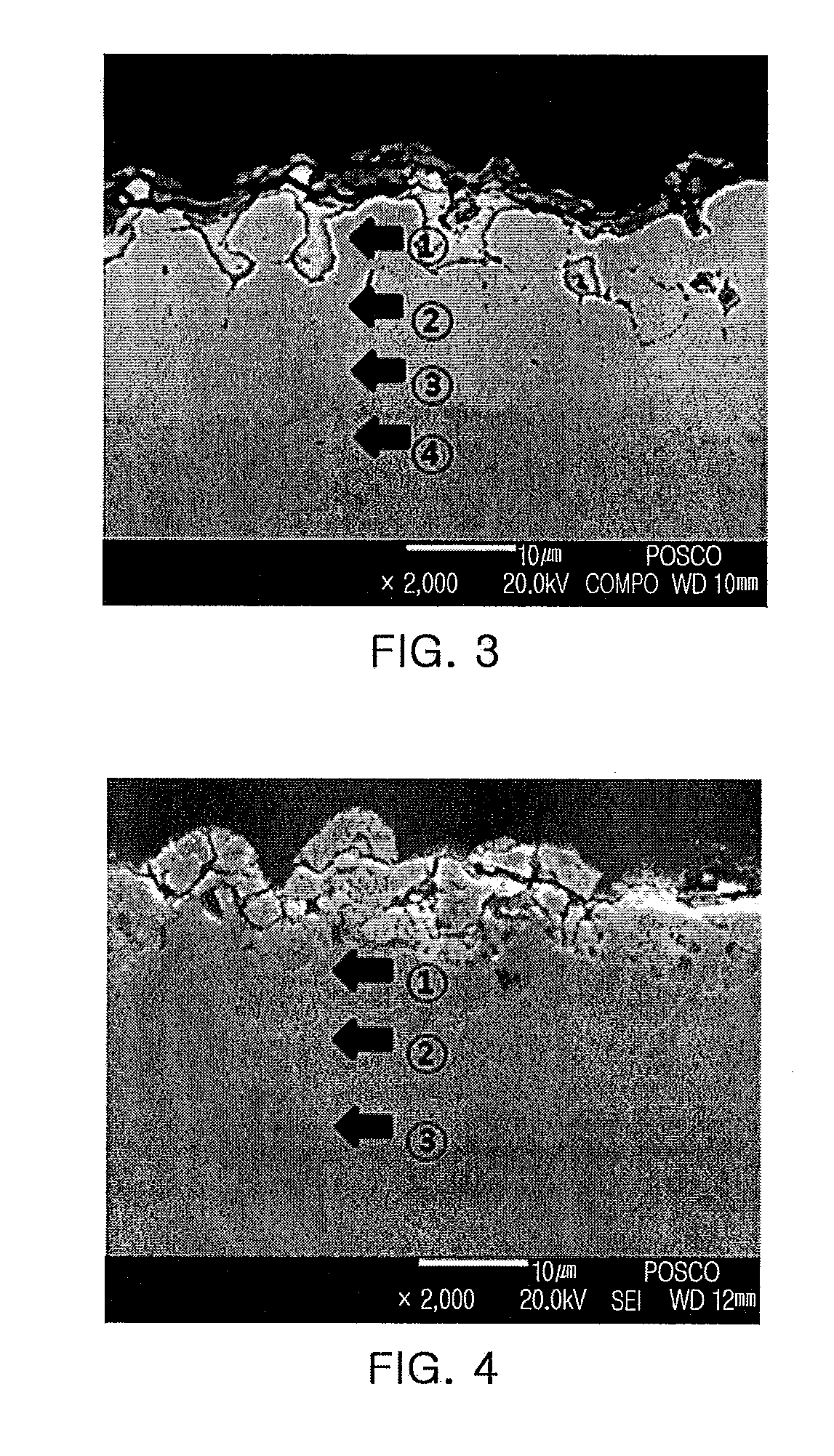

Zinc-plated steel sheet for hot pressing having outstanding surface characteristics, hot-pressed moulded parts obtained using the same, and a production method for the same

ActiveUS20120267012A1High melting temperatureDeterioration of layer be preventedHot-dipping/immersion processesSolid state diffusion coatingGibbs free energyOxygen

Provided is a zinc-plated steel sheet for hot pressing having outstanding surface characteristics, comprising: a steel foundation plate comprising a metal surface diffusion layer of which the Gibbs free energy reduction per mole of oxygen during oxidation is less than that of Cr; an aluminum-rich layer containing at least 30 wt. % of aluminium formed on the surface diffusion layer, and a zinc plating layer formed on the aluminum-rich layer. In this way, a metal having a low affinity for oxygen is coated to an effective thickness prior to annealing and thus the creation of annealing oxides at the surface of the steel sheet is suppressed and a uniform zinc plating layer is formed, and alloying of the zinc plating layer is promoted during press-processing heat treatment. Cracking in the steel foundation plate during hot press molding is prevented.

Owner:POHANG IRON & STEEL CO LTD

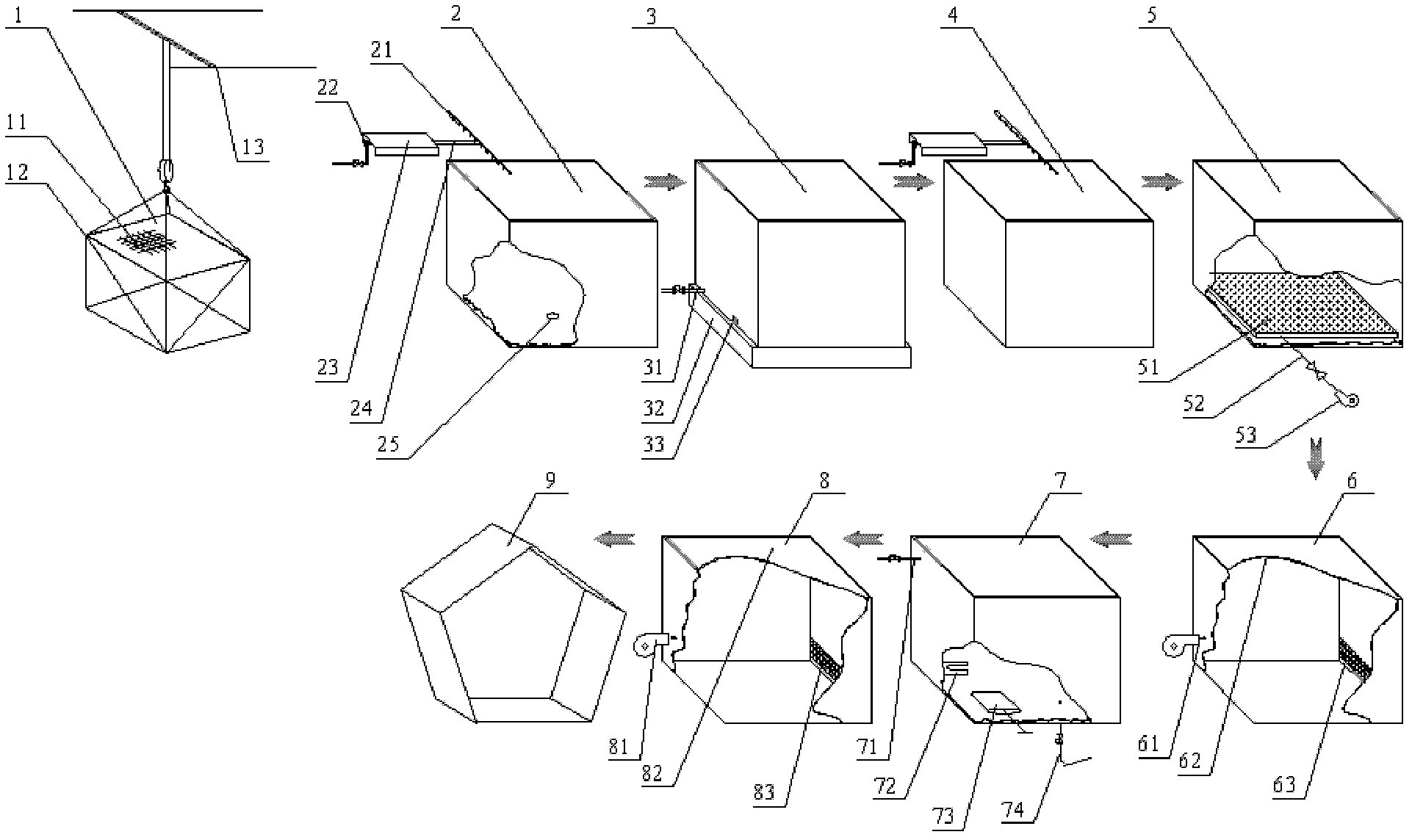

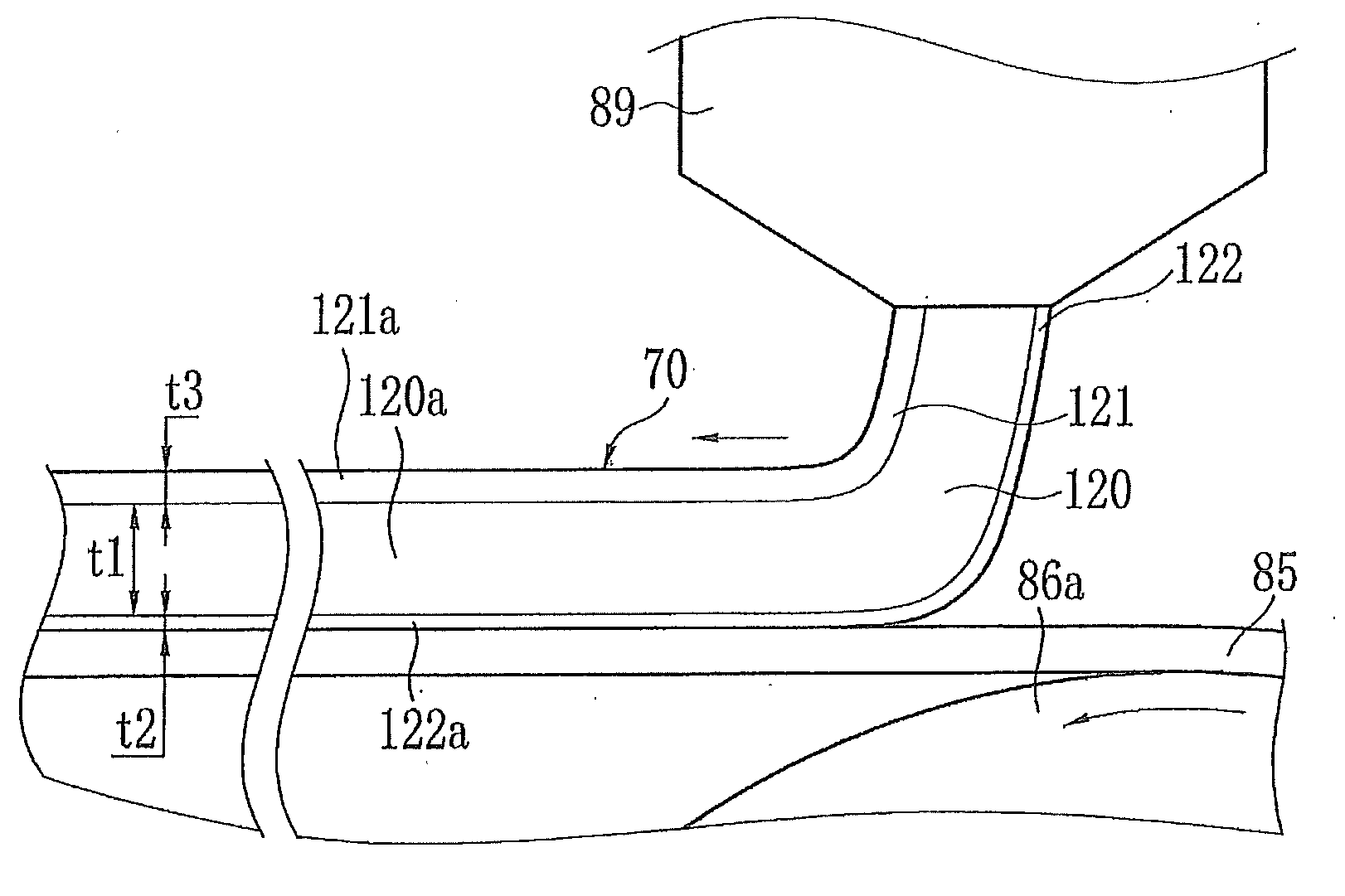

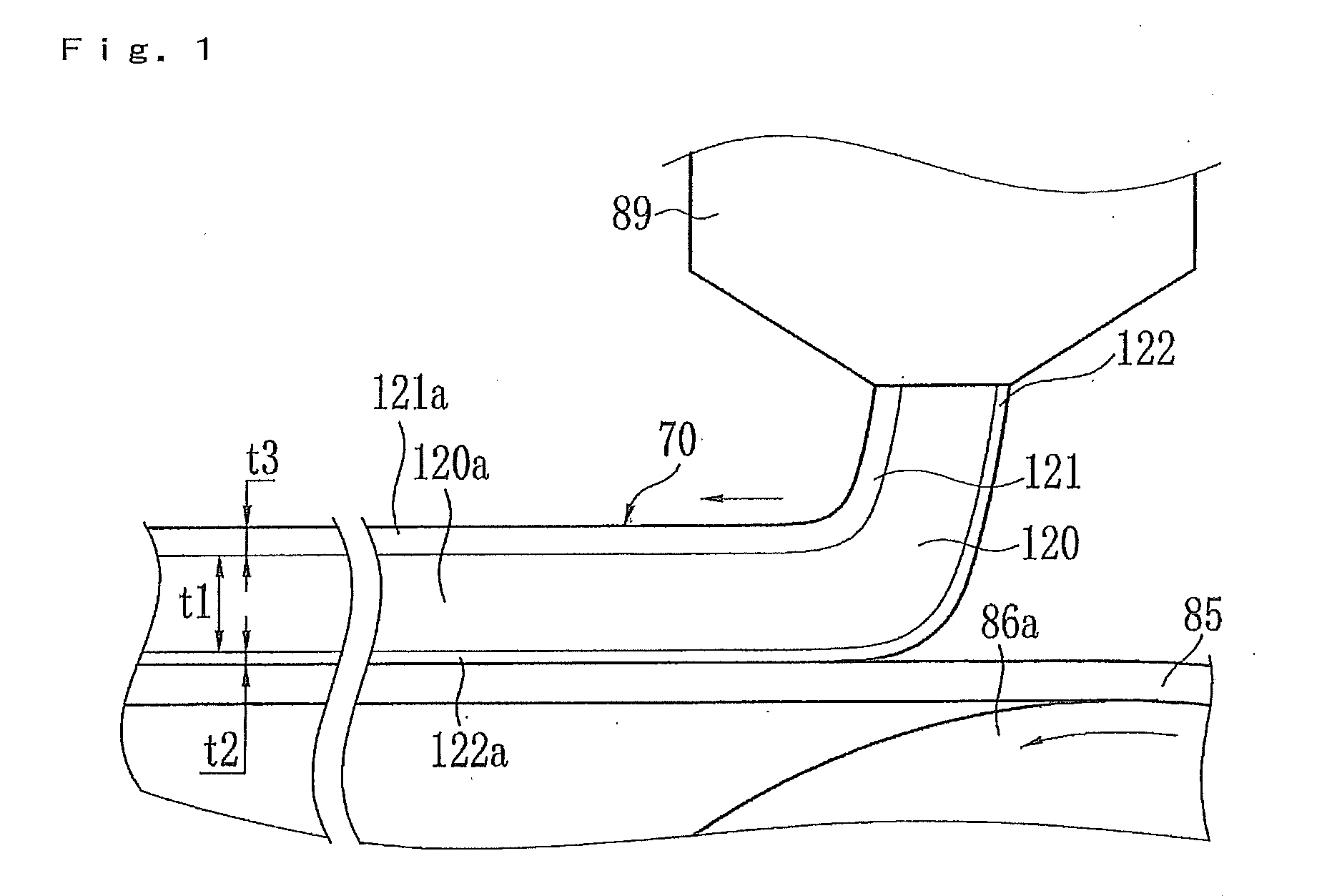

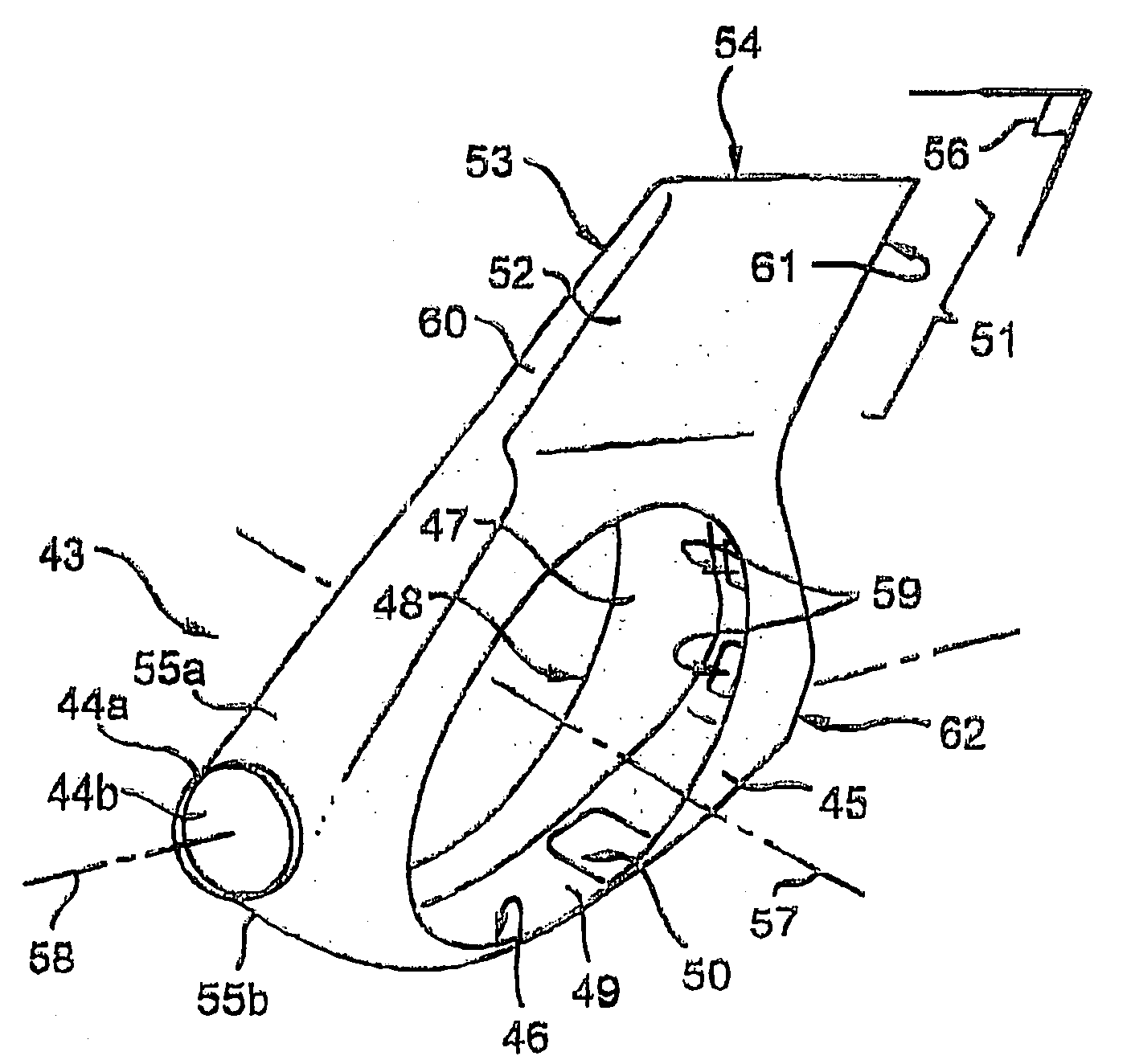

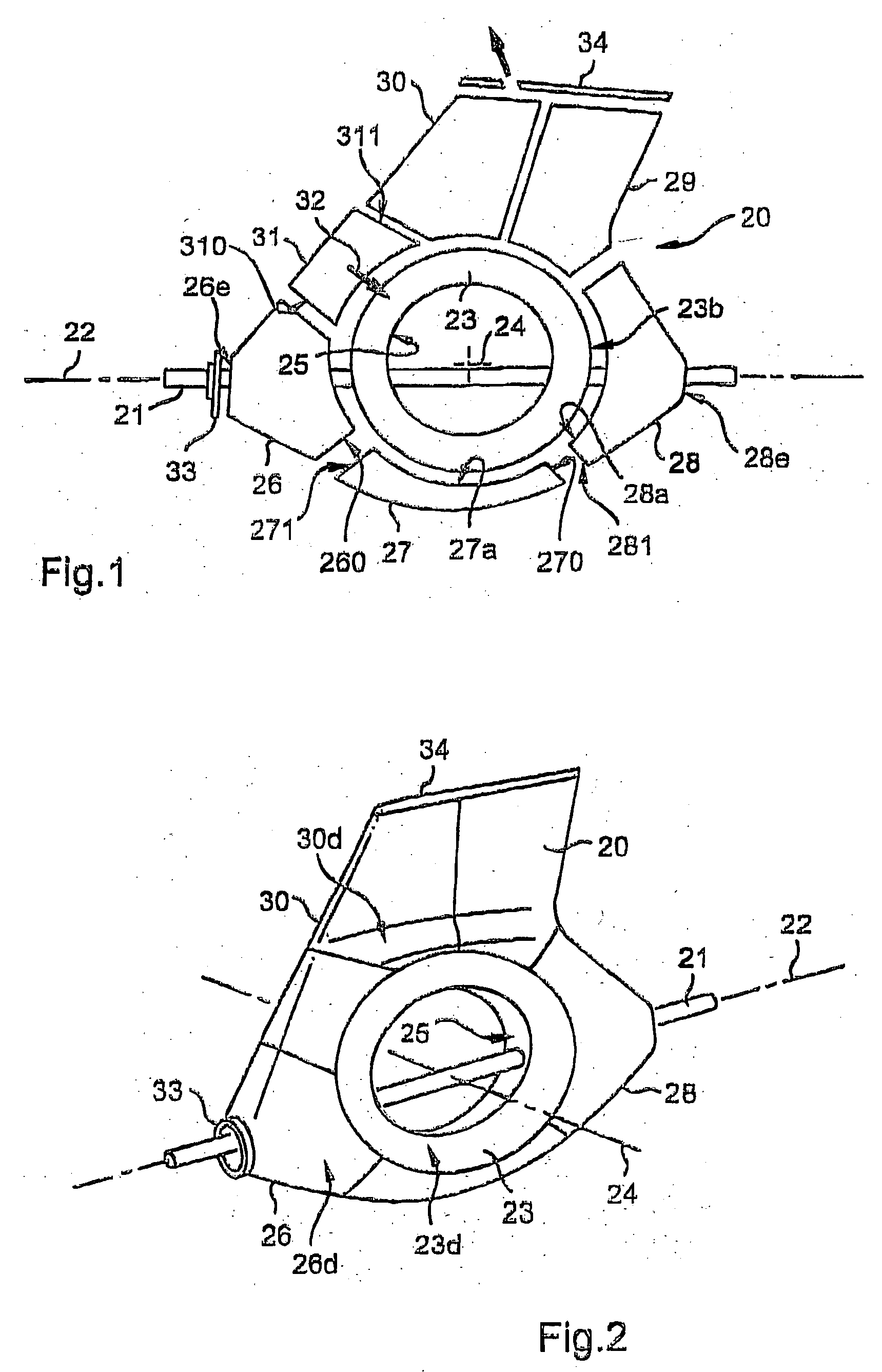

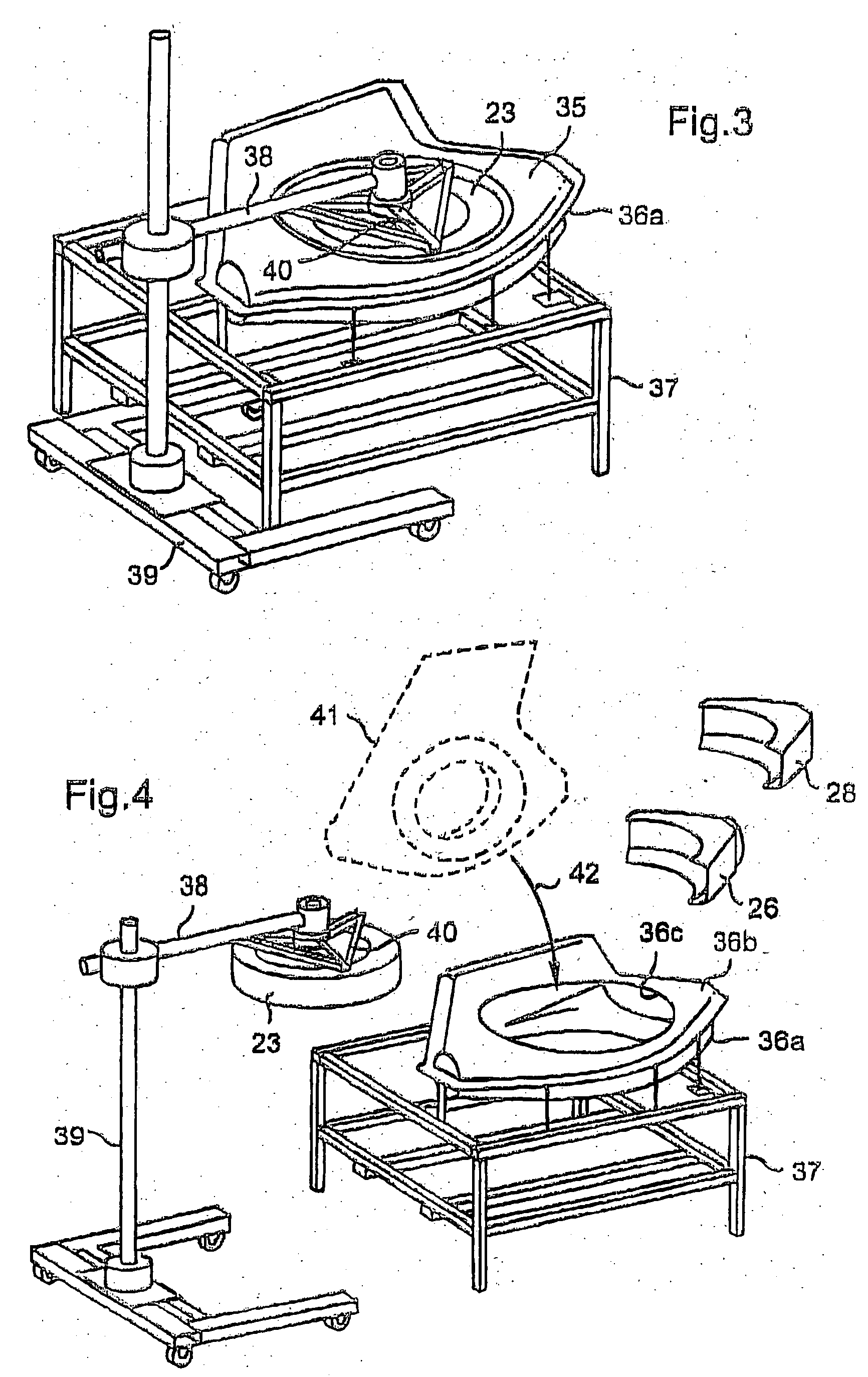

Method and apparatus for manufacturing a helicopter rotor fairing, and a fairing obtained thereby

ActiveUS20060169835A1Improve surface conditionAvoid foldingAircraft assemblyDomestic articlesEngineeringShaft collar

The invention relates to a method of manufacturing a tail structure for a rotary wing aircraft, the structure comprising: a tubular portion or duct (63) presenting two ends and including two collars or flanges (66, 70) extending respectively from each of said two ends; and two curved fairing side walls (45, 47) extending respectively around the two collars or flanges; said two side walls being made of a composite material comprising an organic matrix and reinforcement; in a method of the invention, the side walls are united by solidifying the matrix.

Owner:EUROCOPTER

Releasing agent composition and releasing material

ActiveCN101952380AHigh glossExcellent peelabilityOther chemical processesFilm/foil adhesivesAcrylic resinGlass transition

Disclosed is a releasing agent composition having excellent gloss, releasing power and surface state, which can maintain excellent releasability even after repeated use. The releasing agent composition contains a hydroxy group-containing acrylic resin having a specific structure, an amino resin, and a silicone resin having a functional group which can be chemically bonded to at least one of the hydroxy group-containing acrylic resin and the amino resin. The hydroxy group-containing acrylic resin has a hydroxyl number of 10-150 mgKOH / g, a glass transition temperature of 20-100 DEG C and a weight average molecular weight of 20,000-100,000.

Owner:株式会社力森诺科 +1

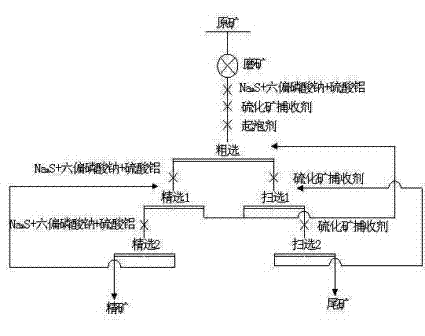

Method for beneficiating high-peat copper sulphide ore

The invention discloses a method for beneficiating high-peat copper sulphide ore and relates to a method for beneficiating nonferrous metals, which specifically relates to a method for beneficiating high-peat copper sulphide ore; regulating agent and composite inhibitor are added before floating ore pulp and after graining raw ore; flotation environment and mineral surface state in ore pulp are improved in the method disclosed by the invention; the inhibition capacity of inhibitor on easily-floated gangue mineral and selective collection of collecting agent on mineral are enhanced; compared with the traditional method for beneficiating pre-deslimed peat, a technical procedure is simplified by the invention; the loss of available mineral caused by pre-deslimed peat is avoided; and the recycle rate of copper is increased by about more than 18%.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com