Coating for improving performance of overhead conductor comprehensively

A technology for overhead wires and coatings, applied in the direction of polyurea/polyurethane coatings, coatings, conductors, etc., can solve the problems of damaged wire surface coating, poor self-cleaning ability of coatings, poor anti-aging performance of coatings, etc. The effect of cleaning ability, anti-aging performance improvement, high surface heat scattering coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

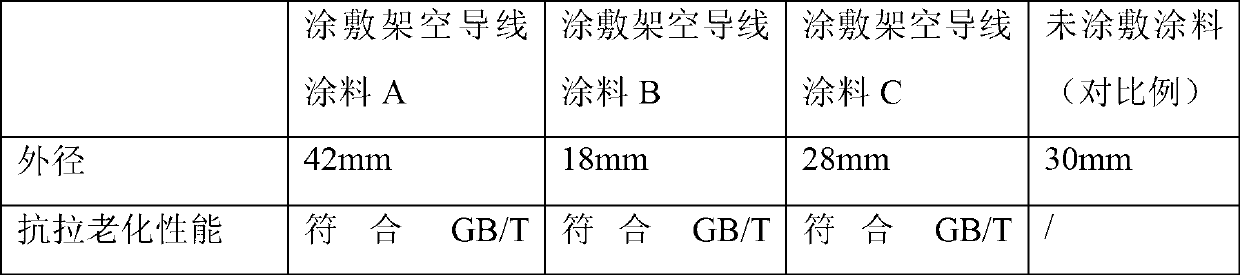

Embodiment 1

[0041] 1) Mix FEVE fluorocarbon resin and butyl acetate at a mass percentage ratio of 1:1 and disperse with a high-speed disperser for about 10 minutes, then grind the mixture with a sand mill until the fineness reaches 25 μm to obtain a fluorocarbon resin dispersion.

[0042] 2) Mix the fluorocarbon resin dispersion and hexamethylene diisocyanate biuret at a ratio of 16:3 by mass, disperse at a high speed for about 15 minutes, and then obtain a mixed solution.

[0043] 3) Add zinc oxide to the mixed solution prepared above at a mass percentage of 9:1, and when heated to 30-50°C, fully stir and mix it evenly with a high-speed disperser, and grind it to a fineness of 30 μm, that is The trolley wire coating A with the required properties can be obtained.

Embodiment 2

[0045] 1) Mix FEVE fluorocarbon resin and methyl isobutyl ketone at a ratio of 1.5:1 by mass and disperse with a high-speed disperser for about 15 minutes, then grind the mixture with a sand mill until the fineness reaches 25 μm to obtain a fluorocarbon resin dispersion .

[0046] 2) Mix the fluorocarbon resin dispersion and hexamethylene diisocyanate biuret at a ratio of 5:1 by mass, disperse at a high speed for about 15 minutes, and then obtain a mixed solution.

[0047] 3) Add titanium oxide to the mixed solution prepared above at a mass percentage of 9:1, and when heated to 30-50°C, fully stir and mix it evenly with a high-speed disperser, and grind it to a fineness of 30 μm, that is A trolley wire coating B with the required properties can be obtained.

Embodiment 3

[0049] 1) Mix FEVE fluorocarbon resin and butyl acetate at a ratio of 1.3:1 by mass and disperse it with a high-speed disperser for about 10 minutes, then grind the mixture with a sand mill to a fineness of 25 μm to obtain a fluorocarbon resin dispersion.

[0050] 2) Mix the fluorocarbon resin dispersion and hexamethylene diisocyanate trimer at a ratio of 6:1 by mass, disperse at a high speed for about 20 minutes, and then obtain a mixed solution.

[0051] 3) Add zinc oxide to the mixed solution prepared above at a mass percentage of 10:1, and when heated to 30-50°C, fully stir and mix it evenly with a high-speed disperser, and grind it to a fineness of 30 μm, that is A trolley wire coating C with the required properties can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com