Nanofiber heavy-duty anti-corrosive coating, preparation method and spraying method of nanofiber heavy-duty anti-corrosive coating

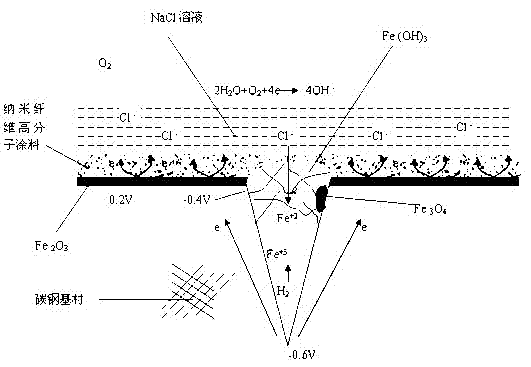

A nanofiber and heavy-duty anti-corrosion technology, which is applied in the direction of anti-corrosion coatings, asphalt coatings, polyamide coatings, etc., can solve the problems of not meeting the requirements of heavy-duty anti-corrosion in emerging industries, failing to meet heavy-duty anti-corrosion, poor corrosion resistance, etc., and achieve anti-corrosion And the effect of good functional stability, good acid and alkali resistance, and improved aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

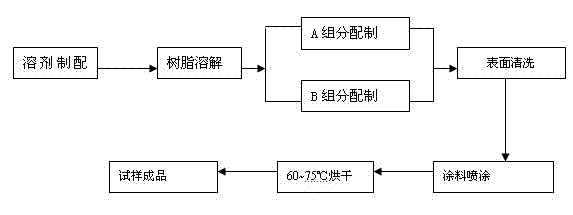

[0061] A kind of nanofiber heavy-duty anticorrosion coating is made up of component C, component A, component B by mass ratio, and described component C is mixed solvent C, and the mass and number ratio of its mixed solvent C is xylene: cyclohexanone : butanol=13 parts~17 parts: 1~4 parts: 1 part~3 parts, the mass percent of described component A is resin solution: talcum powder: large white powder: lithopone: Fe 2 0 3 -PANI nanofiber=40 parts to 70 parts: 6 parts to 8 parts: 12 parts to 22 parts: 6 parts to 10 parts: 6 parts to 20 parts, the mass percentage of the component B is polyamide: mixed mixed solvent C=40-60 parts: 40-60 parts, the resin is epoxy resin or fluorocarbon resin, acrylic resin, polyurethane resin, chlorosulfonated polyethylene resin, silicone resin, epoxy asphalt One or more than two, the resin solution is prepared by mass ratio of 40 to 70 parts of resin: 15 to 20 parts of mixed solvent C, wherein component A: component B=100 parts: 6 to 15 parts coati...

Embodiment 2

[0091] A kind of nanofiber heavy-duty anticorrosion coating is made up of component C, component A, component B by mass ratio, and described component C is mixed solvent C, and the mass and number ratio of its mixed solvent C is xylene: cyclohexanone : butanol=14 parts~16 parts: 1.5 parts~3.5 parts: 1.5 parts~2.5 parts, the mass percentage of described component A is resin solution: talcum powder: large white powder: lithopone: Fe 2 0 3 -PANI nanofibers=45 parts to 65 parts: 6.5 parts to 7 parts: 14 parts to 20 parts: 6.5 parts to 9.5 parts: 7 parts to 18 parts, the mass percentage of the component B is polyamide: mixed solvent C =45 parts to 55 parts: 45 parts to 55 parts, the resin is epoxy resin or fluorocarbon resin, acrylic resin, polyurethane resin, chlorosulfonated polyethylene resin, silicone resin, epoxy asphalt One or more than two, the resin solution is composed of 45 parts to 65 parts of resin by mass ratio: 16 parts to 19 parts of mixed solvent C, wherein compone...

Embodiment 3

[0094] A kind of nanofiber heavy-duty anticorrosion coating is made up of component C, component A, component B by mass ratio, and described component C is mixed solvent C, and the mass and number ratio of its mixed solvent C is xylene: cyclohexanone : butanol=13 parts: 4 parts: 3 parts, the mass percent of described component A is resin solution: talcum powder: white powder: lithopone: Fe 2 0 3 -PANI nanofiber=40 parts: 8 parts: 22 parts: 10 parts: 20 parts, the mass percent of described component B is polyamide: mixed mixed solvent C=40 parts: 60 parts, and described resin is resin epoxy One or more of resin or fluorocarbon resin, acrylic resin, polyurethane resin, chlorosulfonated polyethylene resin, silicone resin, epoxy asphalt, and the resin solution is composed of 55 parts of resin by mass ratio: 18 Parts of mixed solvent C, wherein component A: component B=100 parts: 6 parts of prepared coating.

[0095] Its preparation and spraying method are the same as in Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com