Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77results about How to "Strong resistance to salt water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano composite aqueous epoxide resin coating material and preparation method

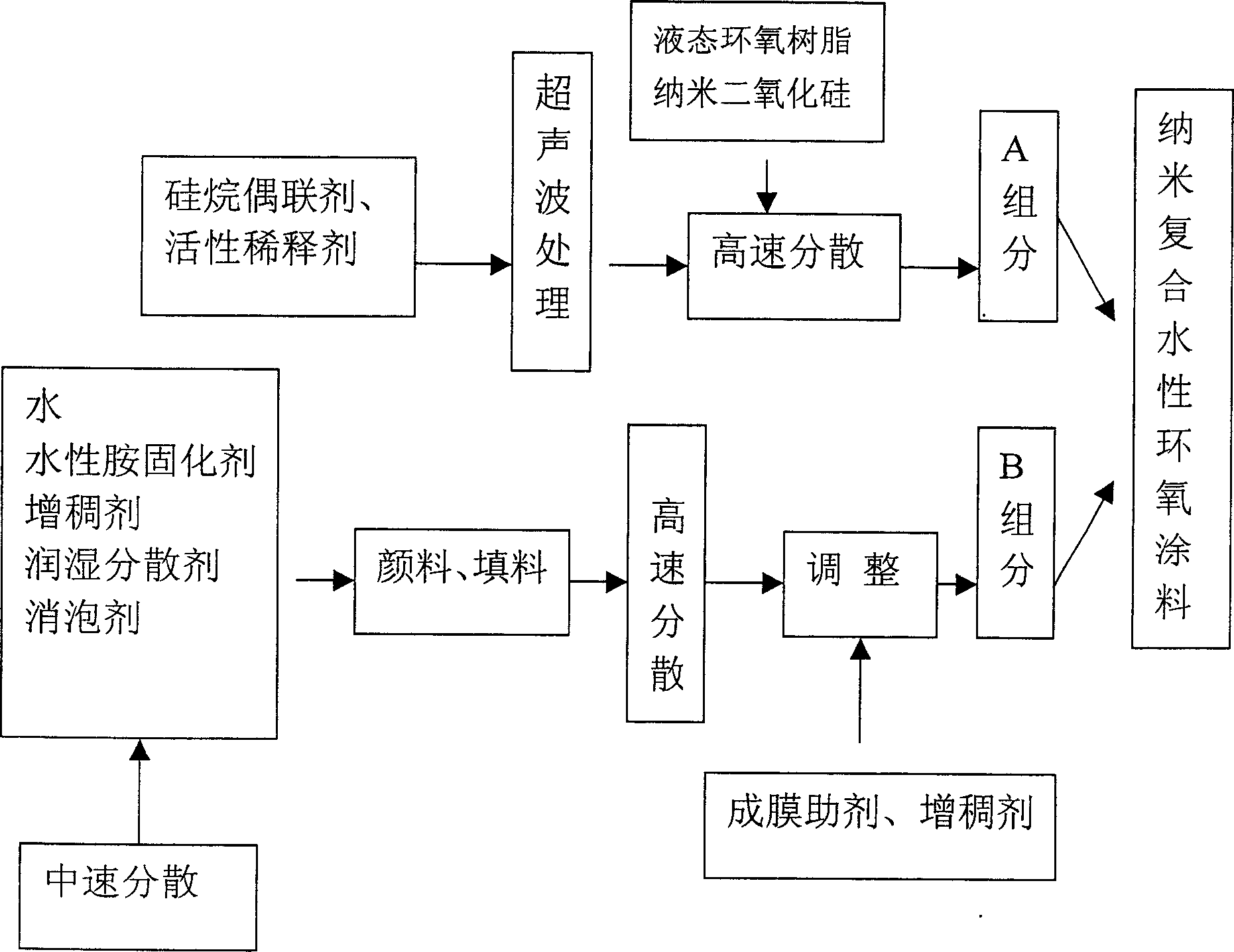

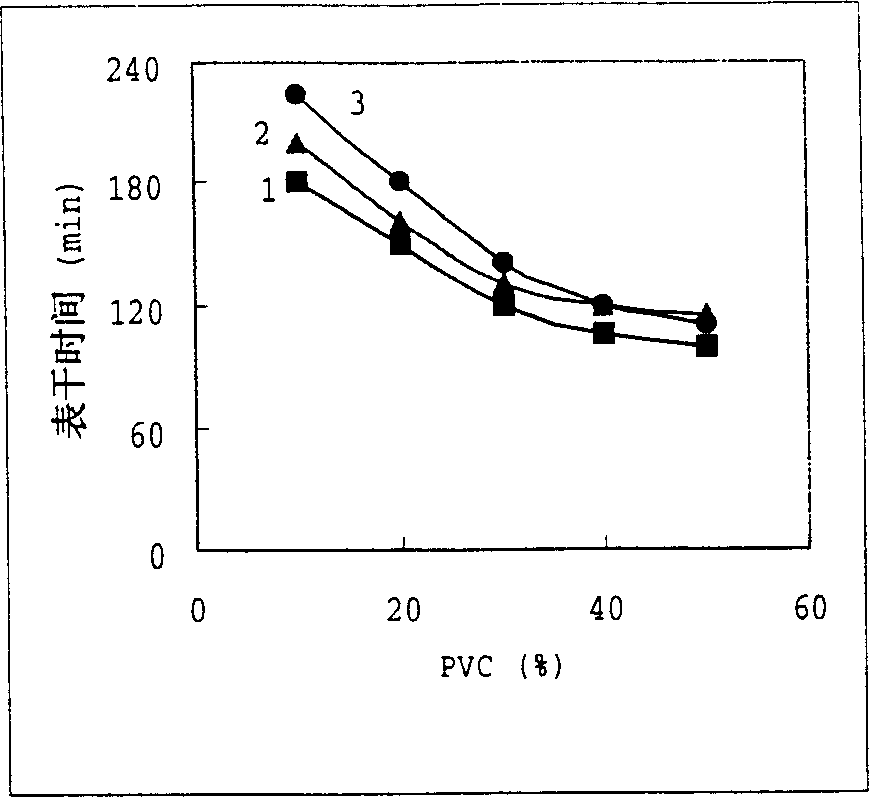

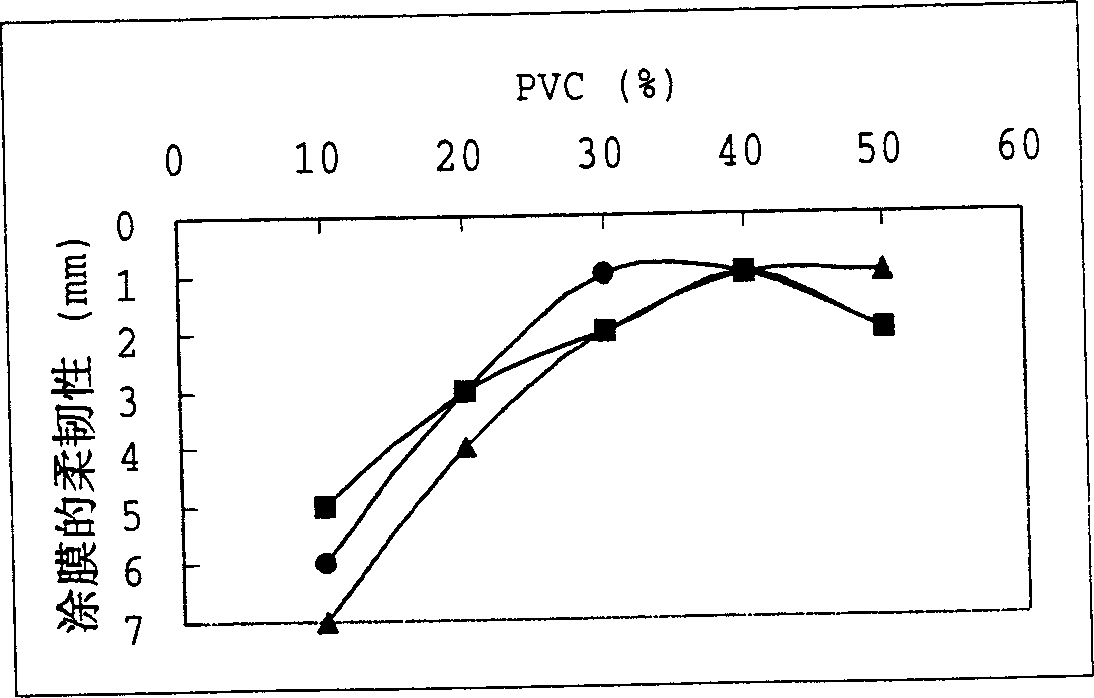

The nano composite water-base epoxy resin coating material comprises: epoxy constituent composed of epoxy resin, active diluent, nano SiO2 particle, and silane coupling agent; and water-base amic curing agent constituent composed of water-base amic curing agent, wet dispersant, defamer, paint, filler, film-forming adjuvant, thickener, and water. This invention also discloses opposite preparation method, improves greatly product properties, and has no pollution.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

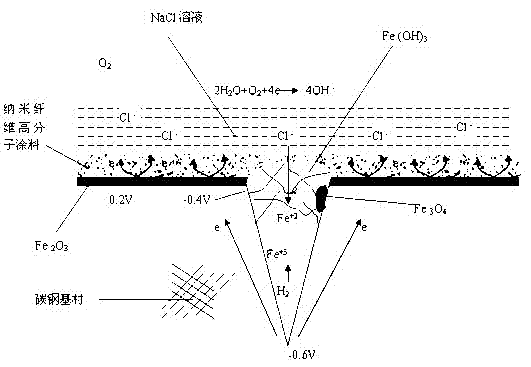

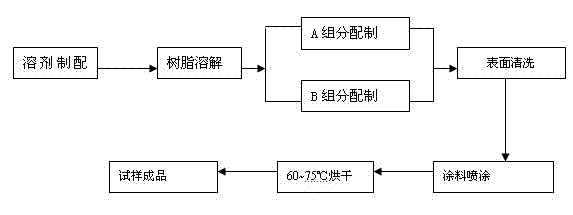

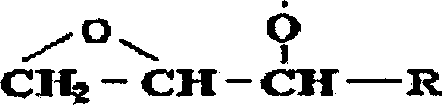

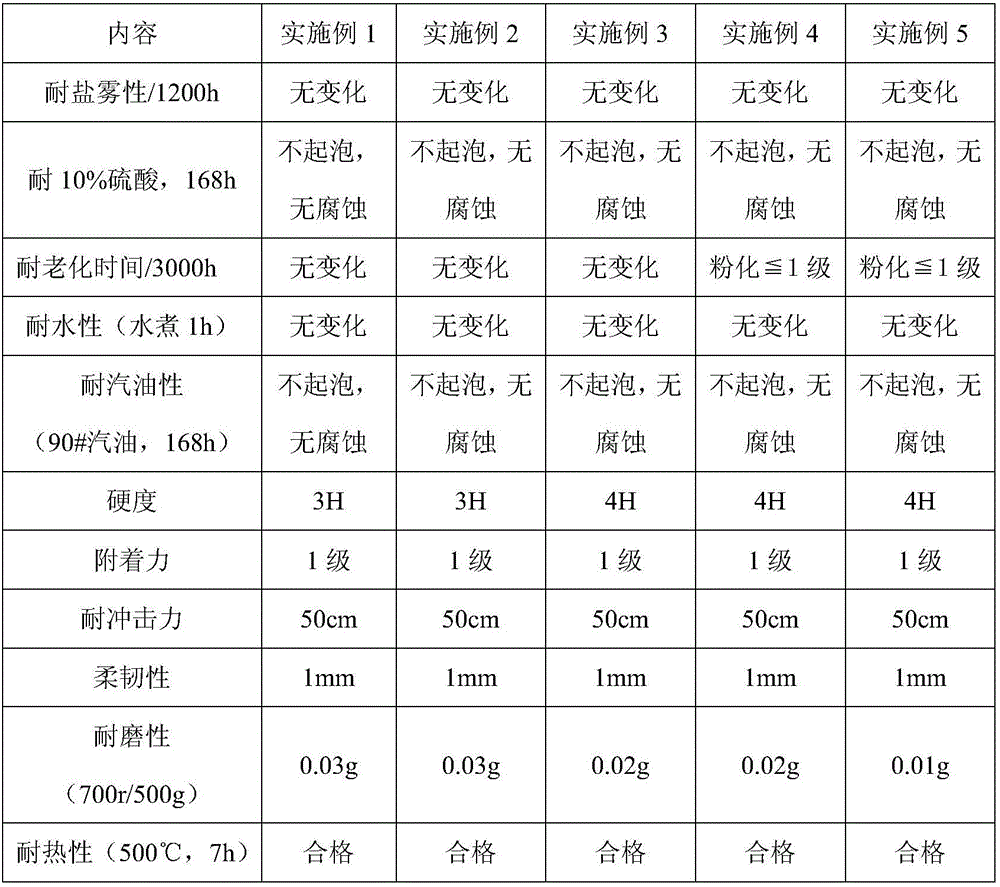

Nanofiber heavy-duty anti-corrosive coating, preparation method and spraying method of nanofiber heavy-duty anti-corrosive coating

ActiveCN102604509AStrong resistance to salt sprayStrong resistance to salt waterAnti-corrosive paintsPolyurea/polyurethane coatingsNanofiberPetrochemical

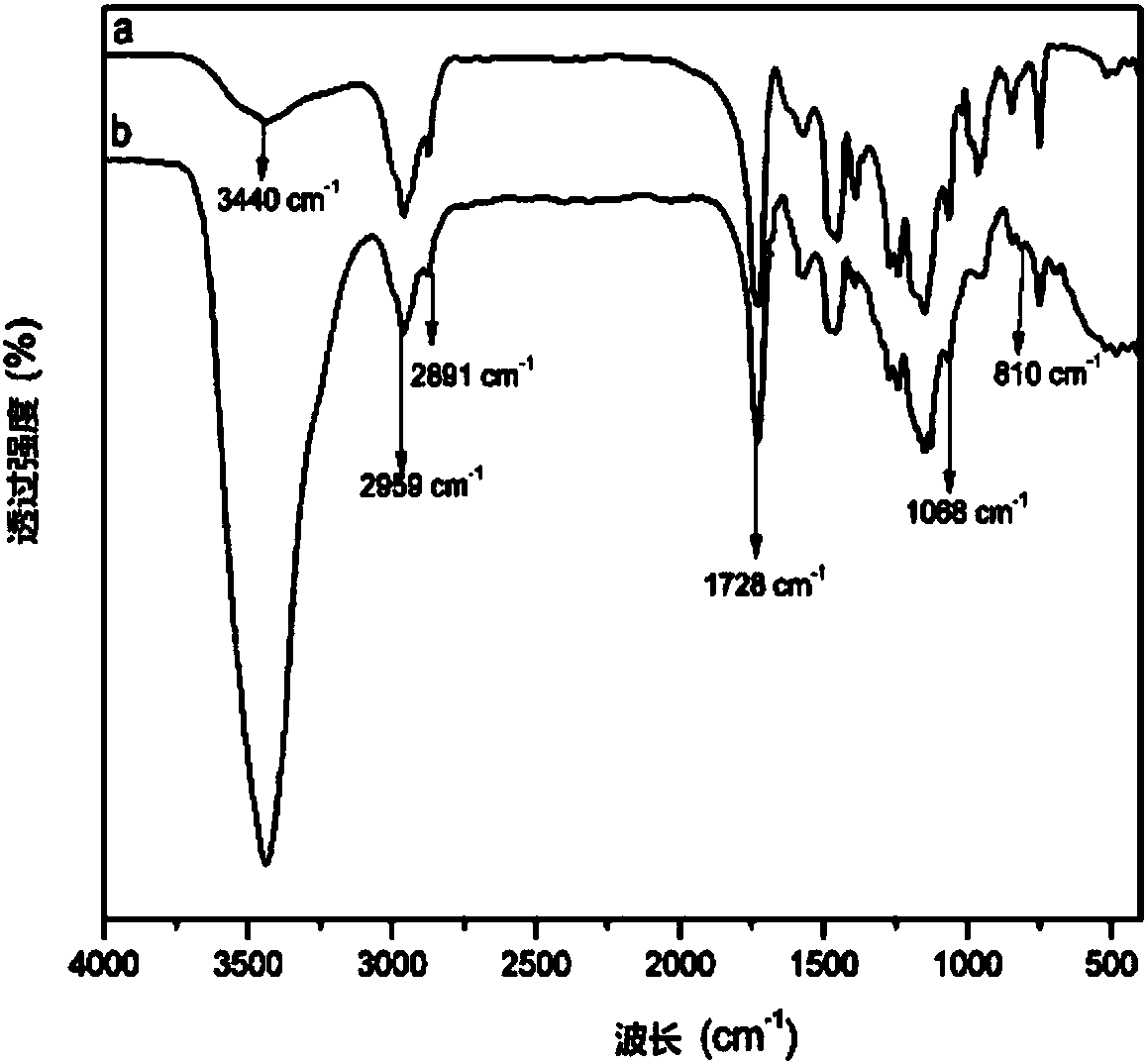

The invention discloses nanofiber heavy-duty anti-corrosive coating, a preparation method and a spraying method of the nanofiber heavy-duty anti-corrosive coating. The anti-corrosive coating comprises components C, A and B by mass ratio. The preparation method comprises the steps of preparing mixed solvent C, dissolving resin and preparing resin solution, pouring the dissolved resin solution into a ball mill for stirring and refluxing, then pouring the component A into the ball mill, uniformly stirring with a glass rod initially, performing ball milling and filtering, pouring the component B into the ball mill, uniformly stirring, adding the component B into the component A, and then uniformly stirring to obtain the nanofiber heavy-duty anti-corrosive coating. The spraying method comprises the steps of cleaning up the surface of an object to be sprayed, uniformly spraying the coating onto the surface of the object to be sprayed with a spray gun, and drying or naturally drying the sprayed surface. The nanofiber heavy-duty anti-corrosive coating has super-normal acid resistant, alkali resistant, salt resistant, water vapor corrosion resistant and harmful substances corrosion resistant capabilities, is non toxic, harmless, tasteless and environmentally friendly, and is applicable to the fields of ocean vessels, submarines, ocean engineering, drilling platforms, wharfs, water conservancy facilities, petrochemical equipment, bridge buildings, concrete facilities and the like.

Owner:西安华捷奥海新材料有限公司

Self-emulsified aqueous epoxy emulsion and method for preparing same

The present invention provides one kind of self-emulsifying water thinned epoxy emulsion and its production process. The self-emulsifying water thinned epoxy emulsion is produced through emulsion copolymerization with the polymer intermediate, which is obtained through polymerizing the mixed organosilicon monomer comprising alkenyl-containing trimethyl silane and octalkyl cyclotetrasiloxane and acrylic acid monomer, epoxy resin and acrylic acid monomer. The self-emulsifying water thinned epoxy emulsion has homogeneous particle size, high stability, and stable production process. The anticorrosive paint compounded with the self-emulsifying water thinned epoxy emulsion reaches the level of solvent type epoxy resin paint.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Epoxy polysiloxane graphene heavy-duty anticorrosion coating and preparation method

ActiveCN105860761AImprove aging resistanceImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsNitrogen gasSolvent

The invention discloses epoxy polysiloxane graphene heavy-duty anticorrosion coating, comprising component A and component B according to a weight ratio of 100:17-24; the component A includes: epoxy resin, epoxy polysiloxane and graphene; the component B includes: cashew nut shell oil-modified amine curing agent. A preparation method of this coating includes: (1), hydrogenated bisphenol A epoxy resin and epoxy polysiloxane into a reactor introduced with nitrogen, heating to 60-80 DEG C, and adding dibutyltin dilaurate; heating slowly to 125-135 DEG C, and reacting for 5-6 h; cooling to 55-60 DEG C, adding silane coupling agent, and continuing to react for 2 h; extracting with petroleum ether, and removing a solvent at 40 DEG C at low vacuum pressure of 0.08 MPa; (2), mixing the epoxy resin, the epoxy polysiloxane of step (1) and graphene, heating for dissolving, adding other materials, and mixing; the coating prepared herein has excellent properties such as aging resistance, water resistance, hardness, flexibility, and salt water resistance.

Owner:WUHAN HOSTS COATING MATERIAL CO LTD

Anticorrosive coating

InactiveCN102964967AStrong resistance to salt waterGood weather resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyDiacetone alcohol

The invention discloses an anticorrosive coating, which is prepared from the following raw materials in parts by weight: 20-35 parts of epoxy resin 618, 10-18 parts of etherified amino resin, 5-10 parts of flaky graphite, 3-6 parts of grey mica iron oxide, 5-8 parts of aluminium oxide, 3-7 parts of tertiary amine curing accelerator, 2-6 parts of silane coupling agent, 8-15 parts of ethanol ethyl ether acetate, 3-6 parts of diluent and 7-11 parts of cellulose acetate. The diluent is one or a plurality of diacetone alcohol, cyclohexanone, ethanol, methanol, ethylene glycol or ethyl ether. The anticorrosive coating provided by the invention is strong in salt water resistance, good in weather resistance and anticorrosive property, and stronger in adhesive force and wear resistance.

Owner:QINGDAO XUANWEI COATING MATERIAL

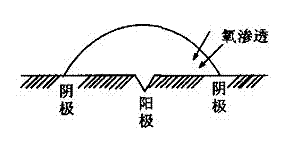

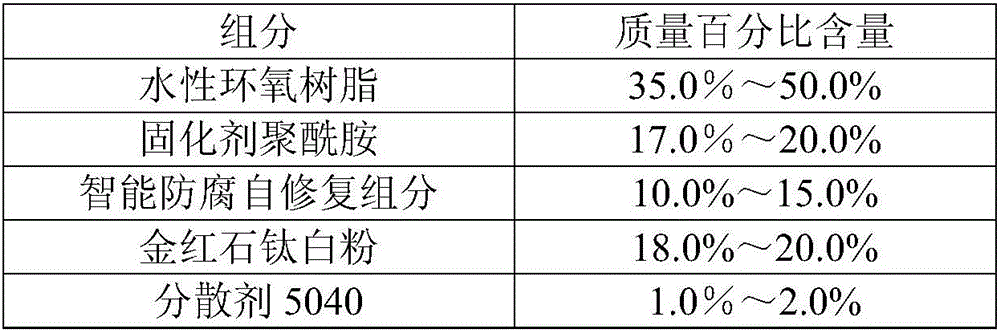

Intelligent anticorrosive and self-repairing coating and preparation method thereof

InactiveCN106433409AWith intelligent corrosion self-healing functionAccelerated corrosionAnti-corrosive paintsEpoxy resin coatingsEpoxyResin matrix

The invention discloses an intelligent anticorrosive and self-repairing coating and a preparation method thereof. The intelligent anticorrosive and self-repairing coating is prepared from the following components: waterborne epoxy resin, a curing agent polyamide, an intelligent anticorrosive and self-repairing component, rutile titanium dioxide, a dispersant 5040, a thickening agent SN-636 and a flatting agent BYK333. The preparation method comprises the following steps: firstly, carrying out in-suit polymerization on urea, a formaldehyde solution, resorcinol and ammonium chloride in a Chinese tallow kernel oil emulsification solution; after carrying out repeated filtering, washing, drying and crushing, obtaining core-shell-structured microcapsules with Chinese tallow kernel oil covered by urea formaldehyde resinand taking the core-shell-structured microcapsules as the intelligent anticorrosive and self-repairing component; and uniformly doping the intelligent anticorrosive and self-repairing component into a waterborne epoxy resin matrix, and spraying or brushing or spin-coating on a metal matrix to obtain the coating. The intelligent self-repairing coating disclosed by the invention has a good saline resisting performance, high adhesion, a good flash-rust resisting effect, a high anticorrosive capability and a long service life; and a preparation process is simple, the price is low and the raw materials are green and environment-friendly.

Owner:GUANGXI UNIV

Solvent-resistant acrylic emulsion and preparation method thereof

InactiveCN108484811AStrong adhesionGood hardness and water resistanceSalt resistanceFunctional monomer

The invention discloses a solvent-resistant acrylic emulsion, belonging to the field of acrylic emulsions. The solvent-resistant acrylic emulsion comprises 180-260 parts of water, 50-60 parts of styrene, 40-50 parts of butyl acrylate, 0.5-5 parts of acrylic acid, 1-5 parts of an anionic emulsifier, 1-5 parts of a functional monomer, 0.2-1 part of an initiator, 0.1-0.5 part of an oxidant and 0.1-0.5 part of a reducing agent. The preparation method for the solvent-resistant acrylic emulsion comprises the following steps: 1) pre-emulsification; 2) polymerization; and 3) post-elimination. The solvent-resistant acrylic emulsion provided by the invention is improved in scrub resistance and solvent resistance while having the basic performance of good adhesion, hardness, water resistance, salt water resistance, salt spray resistance, scrub resistance and the like, so the application scope of the acrylic emulsion is broadened, the application properties of the coating are enhanced, the basic performance of the emulsion is substantively improved, and the cost performance of the emulsion is greatly improved.

Owner:佛山市顺德区巴德富实业有限公司

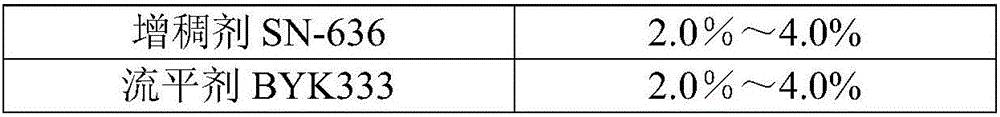

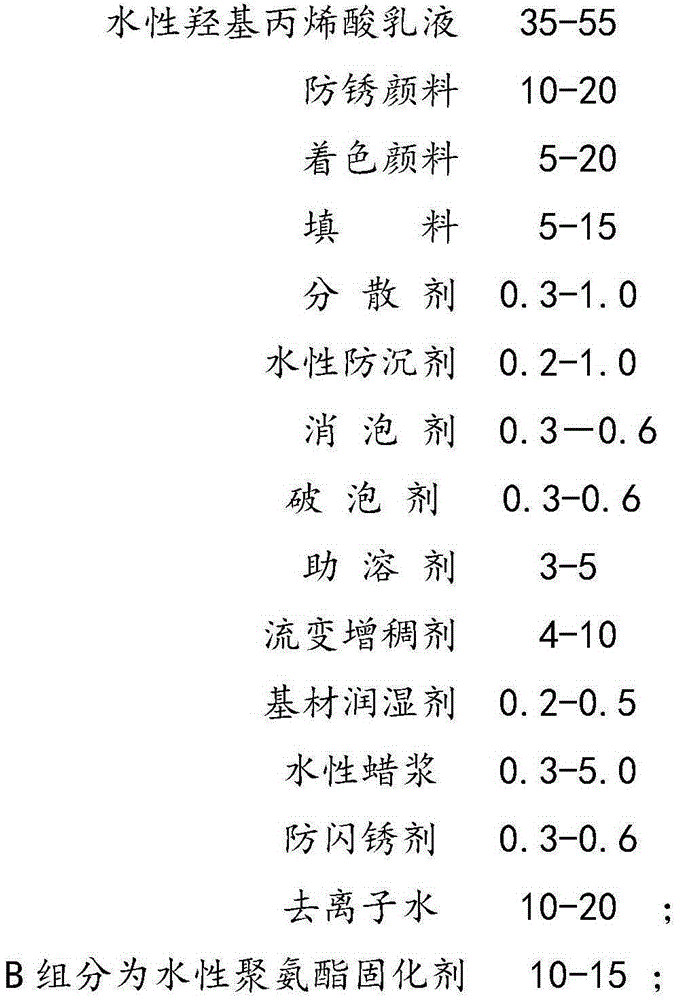

Water-borne acrylic polyurethane primer-topcoat corrosion-resistant decorative coating containing double components and preparation method of coating

InactiveCN105349019AGood outdoor weather resistanceGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsLacquerSolvent

The invention relates to a water-borne acrylic polyurethane primer-topcoat corrosion-resistant decorative coating containing double components. The water-borne acrylic polyurethane primer-topcoat corrosion-resistant decorative coating comprises a component A and a component B, wherein the component A comprises ingredients in parts by weight as follows: 35-55 parts of a water-borne hydroxyl acrylic acid emulsion, 10-20 parts of anti-rust pigments, 5-20 parts of coloring pigments, 5-15 parts of filler, 0.3-1.0 part of a dispersing agent, 0.2-1.0 part of a water-borne anti-settling agent, 0.3-0.6 parts of a defoaming agent, 0.3-0.6 parts of a foam breaker, 3-5 parts of a cosolvent, 4-10 parts of a rheological thickener, 0.2-0.5 parts of a substrate wetting agent, 0.3-5.0 parts of water-borne wax liquor, 0.3-0.6 parts of a flash rust preventing agent and 10-20 parts of deionized water; the component B comprises 10-15 parts by weight of a water-borne polyurethane curing agent. A preparation method comprises steps as follows: the raw materials are sequentially added to a container, are uniformly stirred at medium and high speeds and then are dispersed for 10 min respectively, a mixture is ground, the deionized water is added for uniform stirring, and the component A is prepared. The water-borne acrylic polyurethane primer-topcoat corrosion-resistant decorative coating containing the double components has the benefits of excellent outdoor weather fastness, adhesive force, water resistance, salt water resistance and salt fog resistance.

Owner:天津灯塔涂料工业发展有限公司

Preparation method of modified water-based polyurethane coating

InactiveCN107828328AEvenly dispersedAvoid reunionPolyurea/polyurethane coatingsCross-linkWater based

The invention discloses a preparation method of a modified water-based polyurethane coating. The method comprises the following steps of (1) utilizing dopamine for carrying out surface polymerizationfor modifying graphene; (2) adopting a polyelectrolyte for carrying out surface modification on nanosilicon dioxide; (3) uniformly mixing the modified graphene, the modified nanosilicon dioxide and water-based polyurethane, and reacting to obtain the composite modified water-based polyurethane coating. The method has the advantages of simple and easy operation, low energy consumption, environmentfriendliness, and easy industrial production; the graphene and the nanosilicon dioxide can be stably and uniformly dispersed into the water-based polyurethane, so that the agglomeration of a nanometerfiller is effectively avoided, and the storage stability of the composite modified coating is good. Meanwhile, surface active groups of the graphene and the nanosilicon dioxide are reacted with the water-based polyurethane to form a multiple cross-linked network structure, so that the composite modified coating is endowed with favorable hardness, salt water resistance, solvent resistance, heat resistant stability and favorable binding strength with a coating base material, and can be used as surface coatings of various plastics and metal plates.

Owner:管新兵

Preparation method of aqueous fluorine-modified phosphorus-containing acrylate emulsion

InactiveCN103833888AWith fine grainFlash corrosion resistantFibre treatmentCoatingsEnvironmental resistanceFunctional monomer

The invention discloses a preparation method of an aqueous fluorine-modified phosphorus-containing acrylate emulsion. The preparation method comprises the steps of firstly preparing a pre-emulsion, then preparing a seed emulsion, and carrying out emulsion polymerization, so as to obtain the milky-white and slightly-blue aqueous fluorine-modified phosphorus-containing acrylate emulsion. According to the preparation method, a phosphate emulsifier is taken as an anionic emulsifier, meanwhile, phosphate is added as a functional monomer, phosphate groups are intruded into the emulsion, so that the emulsion has the characteristics of fine granularity and flash rusting resistance, and a coating has high adhesive force and certain salt water resistance; by adding a fluorine-containing modified monomer having good effects in the reduction of surface free energy and the improvement of surface dewatering and oleophobic performance, the water resistance of the coating of the emulsion is enhanced, and the pollution resistance of the coating of the emulsion is improved; meanwhile, the utilized fluorine-containing modified monomer is a fluorine-containing acrylic monomer, so that the problems of environment friendliness and biological harm of a long-fluorocarbon-chain compound are avoided, and the prepared emulsion is environmental friendly; the utilized nonionic emulsifier does not contain APEO (alkylphenol ethoxylate) and is environmental friendly.

Owner:西安佳龙油漆新技术发展有限公司

Waterborne polyurethane severe corrosion-resisting primer and preparation method thereof

ActiveCN108250927AInhibitionEliminate Bubble ProblemsAnti-corrosive paintsPolyurea/polyurethane coatingsWaxEmulsion

The invention provides a waterborne monocomponent polyurethane severe corrosion-resisting primer and a preparation method thereof. The primer is prepared from waterborne monocomponent polyurethane emulsion, a rust resisting pigment, a coalescing agent, a defoaming agent, a thickening agent, optional wax emulsion, physical filler, a dispersing agent and deionized water. The waterborne corrosion-resisting primer provided by the invention has the advantages of high antirust ability, excellent corrosion resistance, as well as high adhesion and good water resistance of the whole paint film; in addition, the whole paint film has excellent waterproof and antifouling properties and a metal base material is strengthened.

Owner:哈尔滨雨阳佳泰环保新材料有限公司

Nanometer material modified bi-component aqueous epoxy anticorrosive paint and manufacturing method thereof

InactiveCN101921532AStrong adhesionReduce adhesionAnti-corrosive paintsEpoxy resin coatingsPolymer scienceFirming agent

Owner:HUIZHOU LIDE TECH CO LTD

High-performance priming and finishing combined paint with corrosion inhibition, pollution prevention and heavy corrosion protection functions

ActiveCN103045048AAvoid bottom, middleAvoid the problem of difficult topcoat matchingAntifouling/underwater paintsPaints with biocidesEpoxySolvent free

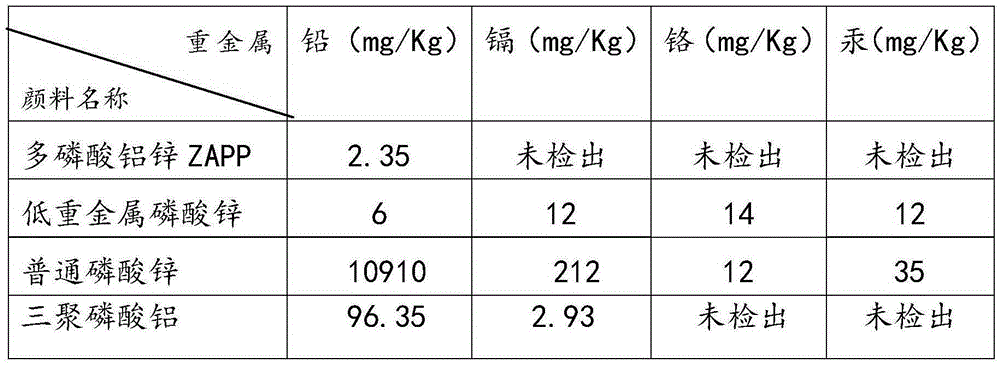

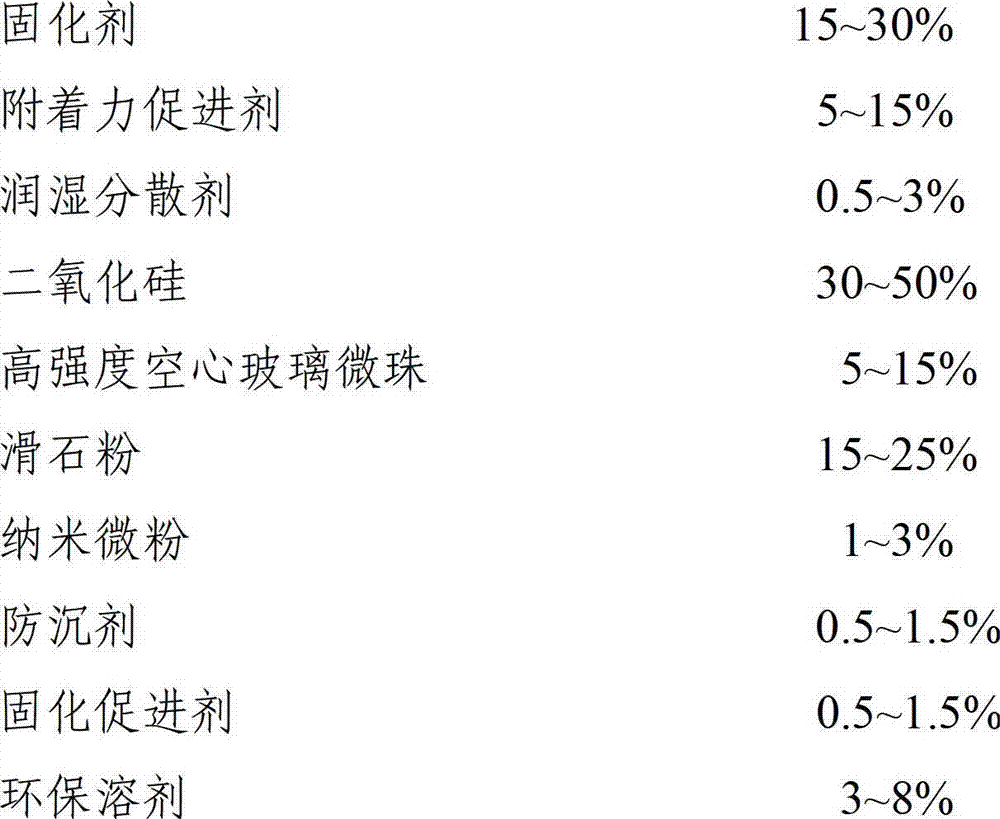

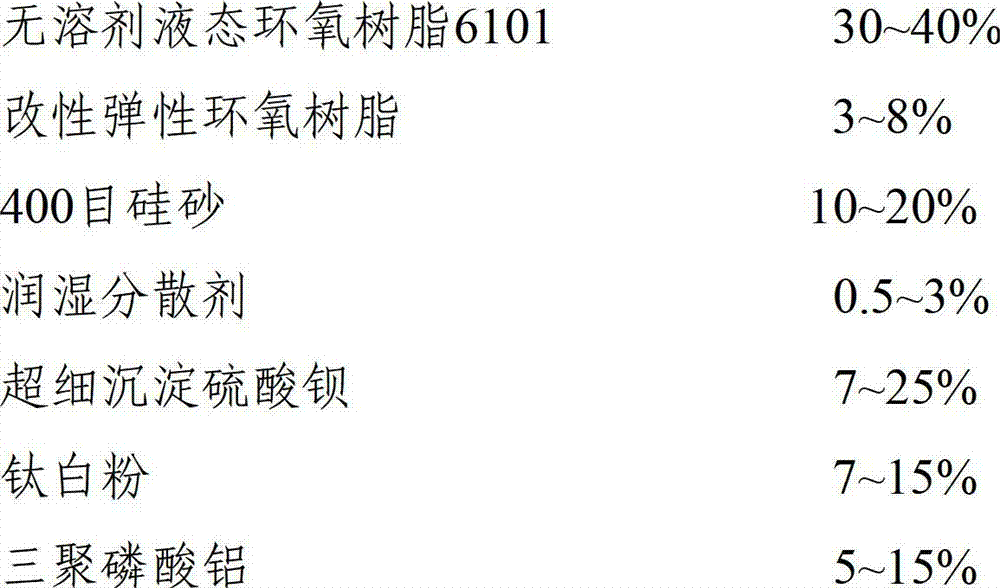

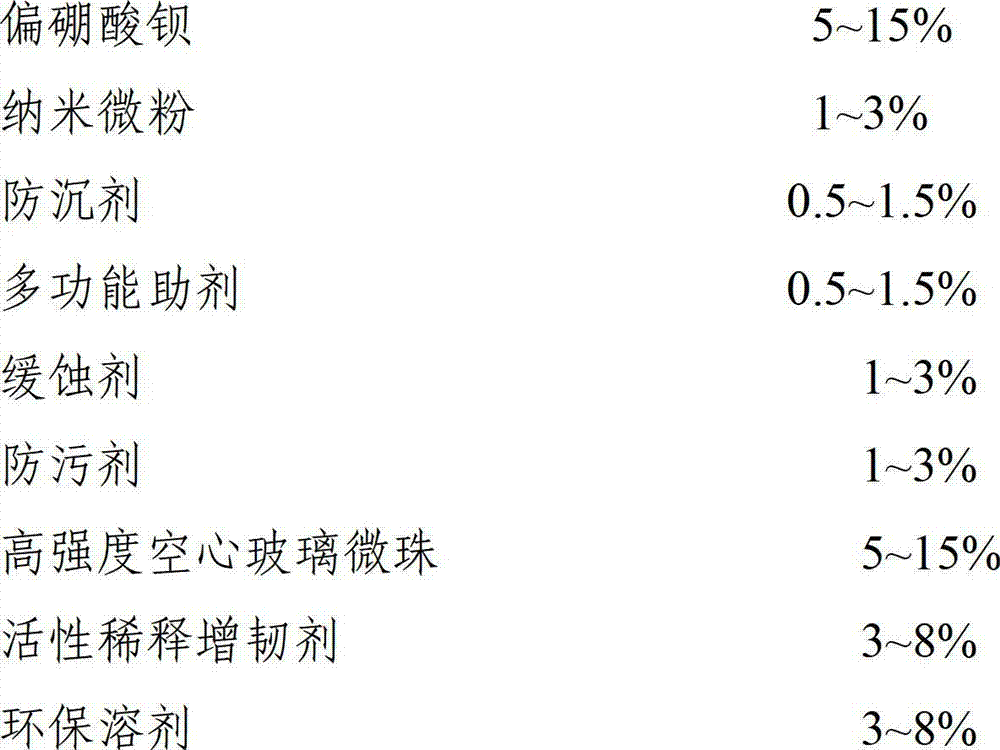

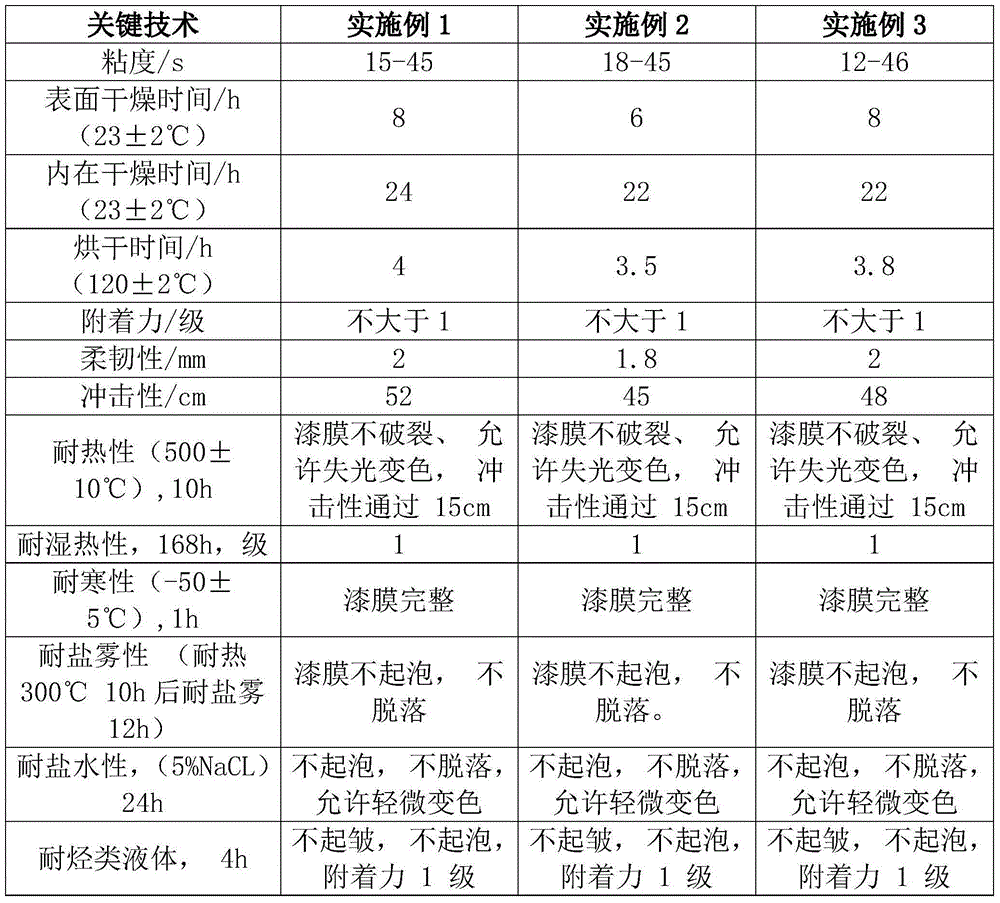

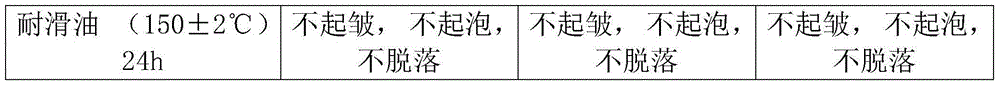

The invention discloses a high-performance priming and finishing combined paint with corrosion inhibition, pollution prevention and heavy corrosion protection functions. The paint comprises two components: a component A includes a curing agent, an adhesion promoter, a wetting dispersant, silicon dioxide, hollow glass beads, talcum powder, nano micro powder, an anti-settling agent, a curing accelerator and an environment-friendly solvent; and a component B includes solvent-free liquid epoxy resin, modified elastic epoxy resin, silica sand, a wetting dispersant, superfine precipitated barium sulfate, titanium dioxide, aluminum triphosphate, barium metaborate, nano micro powder, an anti-settling agent, multi-functional auxiliaries, a corrosion inhibitor, an anti-fouling agent, high-strength hollow glass beads and an environment-friendly solvent. By aid of reasonable allocation of the component concentration, the paint has excellent adhesive force, durability, abrasion resistance and impact resistance, and excellent salt water resistance, oil resistance, alkali resistance and a certain degree of acid resistance; and the solid content is high, and the construction is convenient.

Owner:江阴市天邦涂料股份有限公司

Heat-resistant paint and preparation method thereof

InactiveCN104861866AImprove heat resistanceImprove the decorative effectPolyurea/polyurethane coatingsPhosphoric acidALUMINUM PHOSPHATE

The invention relates to the technical field of paints, in particular to heat-resistant paint and a preparation method thereof. The heat-resistant paint is prepared from the following components in parts by mass: 8-12 parts of tung oil, 3-5 parts of quartz powder, 1-3 parts of aluminum phosphate, 4-9 parts of polyarylsulfone resin, 4-9 parts of polyimide resin, 5-7 parts of butanol, 3-7 parts of nonisocyanate polyurethane, 2-4 parts of china clay, 2-4 parts of talcum powder, 5-8 parts of cobalt iso-octoate, 0.2-1.2 parts of an anti-settling agent, 8-18 parts of a curing agent and 2-6 parts of an anti-cracking agent. The heat-resistant paint has the benefits that 1 the heat-resistant paint prepared by mixing the tung oil, the polyarylsulfone resin, the polyimide resin, the butanol, the nonisocyanate polyurethane, the talcum powder and the cobalt iso-octoate is good in heat-resistant effect, and has excellent physical and chemical properties such as the decorative property, the heat resistance, the salt fog resistance, the salt water resistance, the water resistance, the cold tolerance, the oil resistivity, the hydrocarbon solvent resistance, the adhesive force, the impact strength and the flexibility.

Owner:ZHANGJIAGANG SHANMU NEW MATERIAL TECH DEV

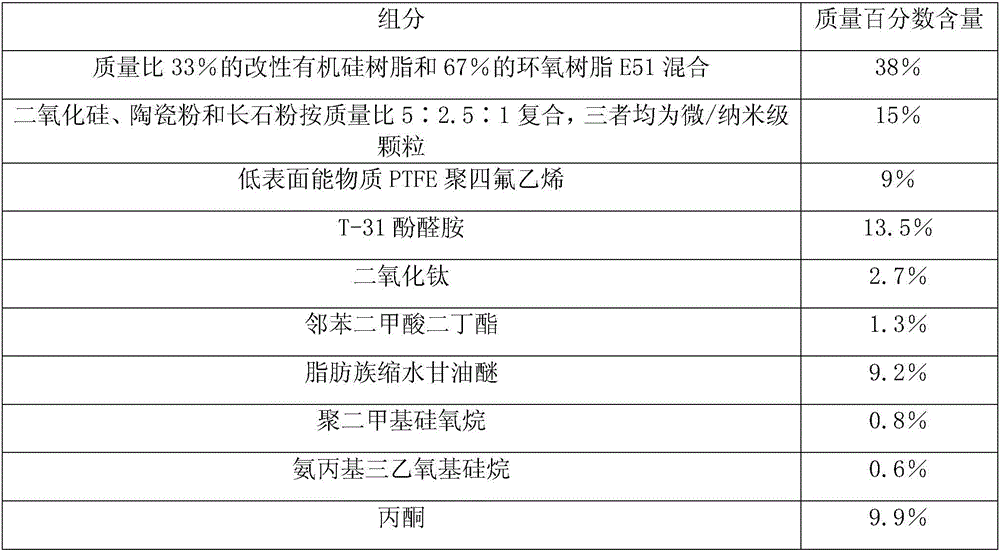

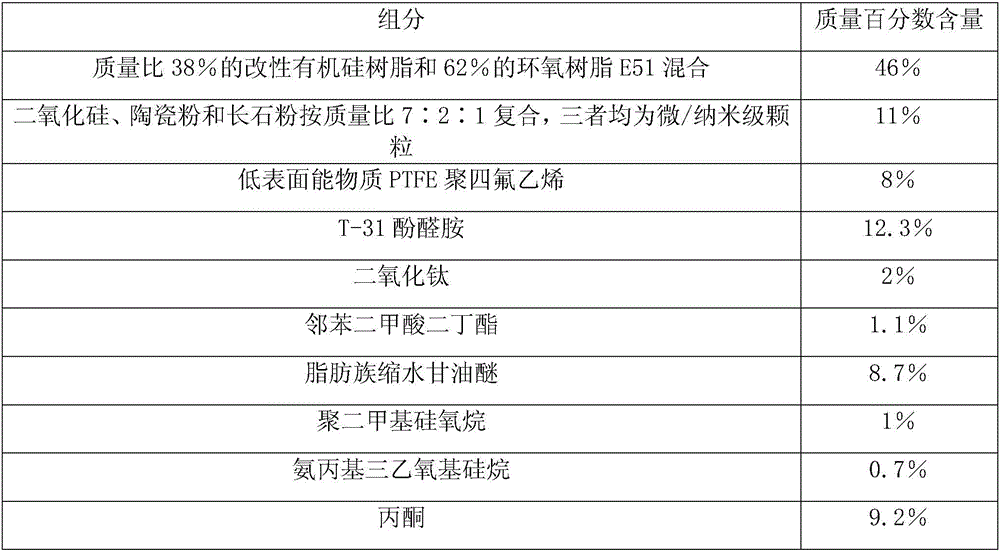

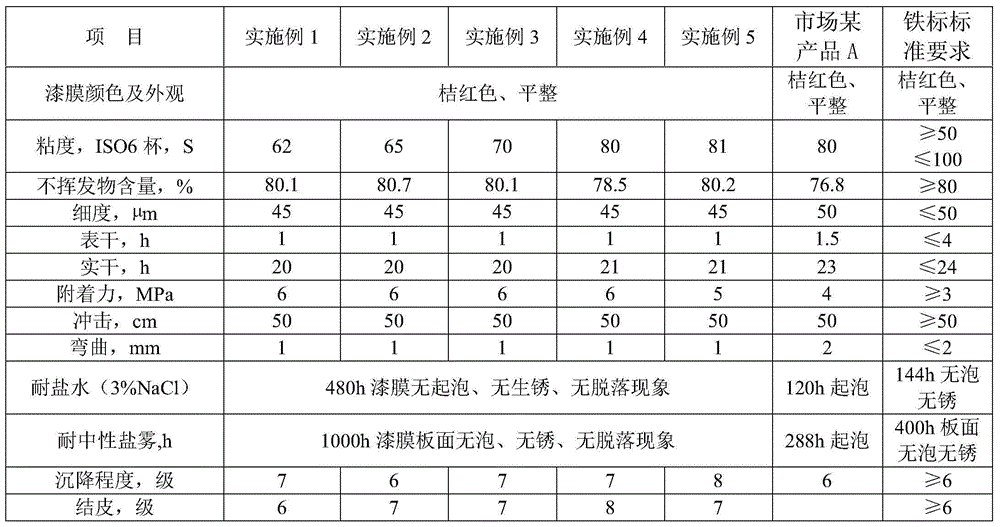

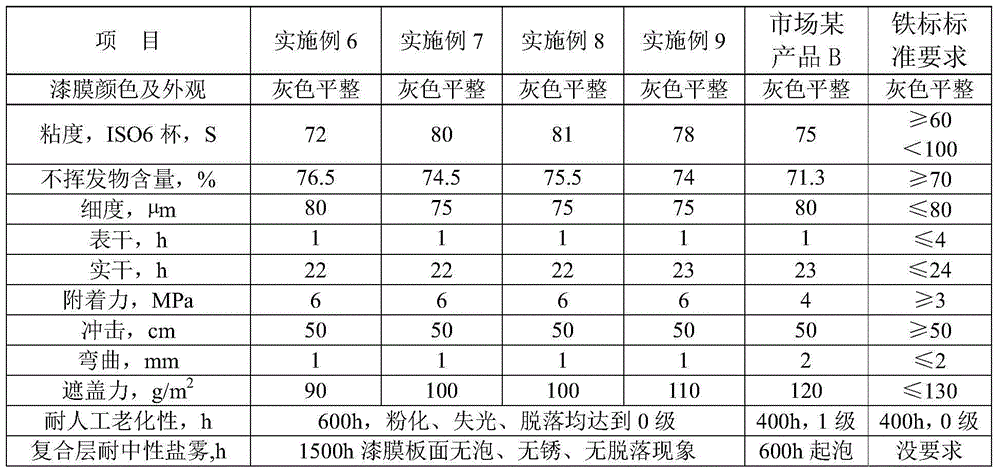

Hydrophobic corrosion-resistant ceramic paint and preparing method thereof

InactiveCN106010122AImprove performanceStrong adhesionAntifouling/underwater paintsPaints with biocidesEnvironmental resistanceEpoxy

The invention discloses a hydrophobic anti-corrosion ceramic coating, which uses epoxy resin and modified silicone resin as a film-forming material, and adds various fillers, auxiliary agents and solvents, including body fillers, pigments and fillers, curing agents, coloring Agent, toughener, diluent, leveling agent, epoxy coupling agent and solvent. The hydrophobic anti-corrosion ceramic coating of the present invention has stable performance, strong adhesion, excellent salt water resistance, strong acid and alkali corrosion resistance, good weather resistance, high hardness, and excellent wear resistance; and it is environmentally friendly and non-toxic (low VOC), and has Good protection, decoration and functional effects, low price of raw materials, simple preparation method, suitable for the surface of metal substrates that need to be protected under harsh corrosion environments.

Owner:GUANGXI UNIV

Water-based primer for railroad bridge and preparation method thereof

InactiveCN104479527AFast dryingStrong anti-corrosion abilityAnti-corrosive paintsPolyester coatingsSkin agentIon

Owner:成都拜迪新材料有限公司

Modified high chlorinated polyethylene antirust coating and preparation method thereof

InactiveCN103756441AGood acid and alkali resistanceStrong resistance to salt waterFireproof paintsAnti-corrosive paintsSalt waterFerric Oxide Red

The invention provides modified high chlorinated polyethylene antirust coating and a preparation method thereof. The modified high chlorinated polyethylene antirust coating comprises the following raw materials in parts by mass: 72-78 parts of high chlorinated polyethylene resin, 10-12 parts of polyvinyl chloride resin, 5-7 parts of zinc borate, 8-10 parts of tributyl citrate, 0.6-1.2 parts of polyvinyl acetate, 0.1-0.5 part of a stabilizer, 8-10 parts of iron oxide red, 8-14 parts of mica powder, 30-40 parts of toluene and 15-18 parts of ethyl acetate. The modified high chlorinated polyethylene antirust coating has good resistance to acid and base and salt water resistance, is relatively short in drying time, convenient to coat and free of limitation of seasons and can be cured at a low temperature; the preparation method provided by the invention is simple and practicable and is suitable for large-scale popularization and application.

Owner:SUZHOU CITY BANGCHENG ELECTRICITY TECH

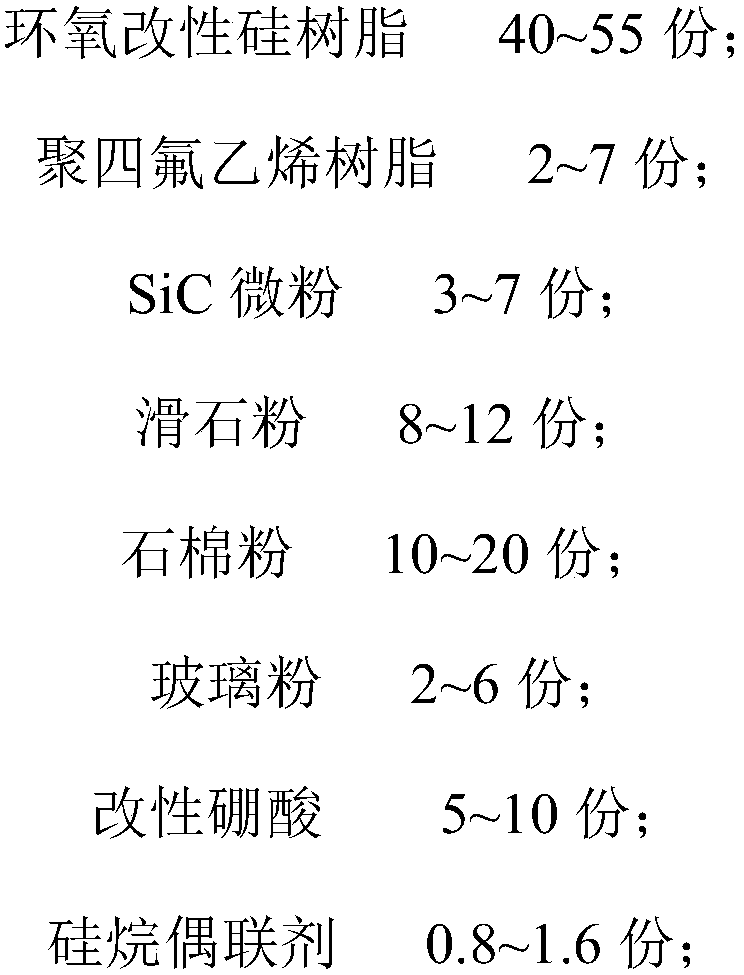

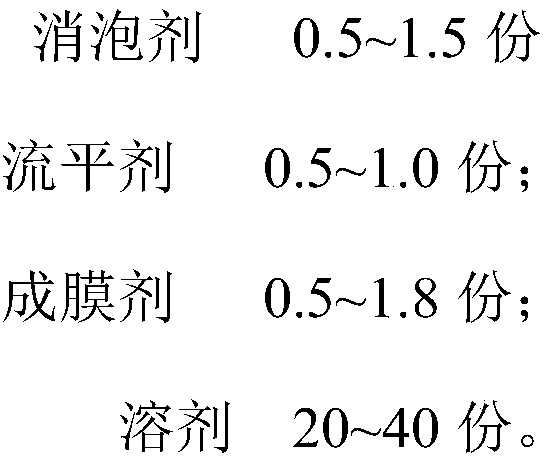

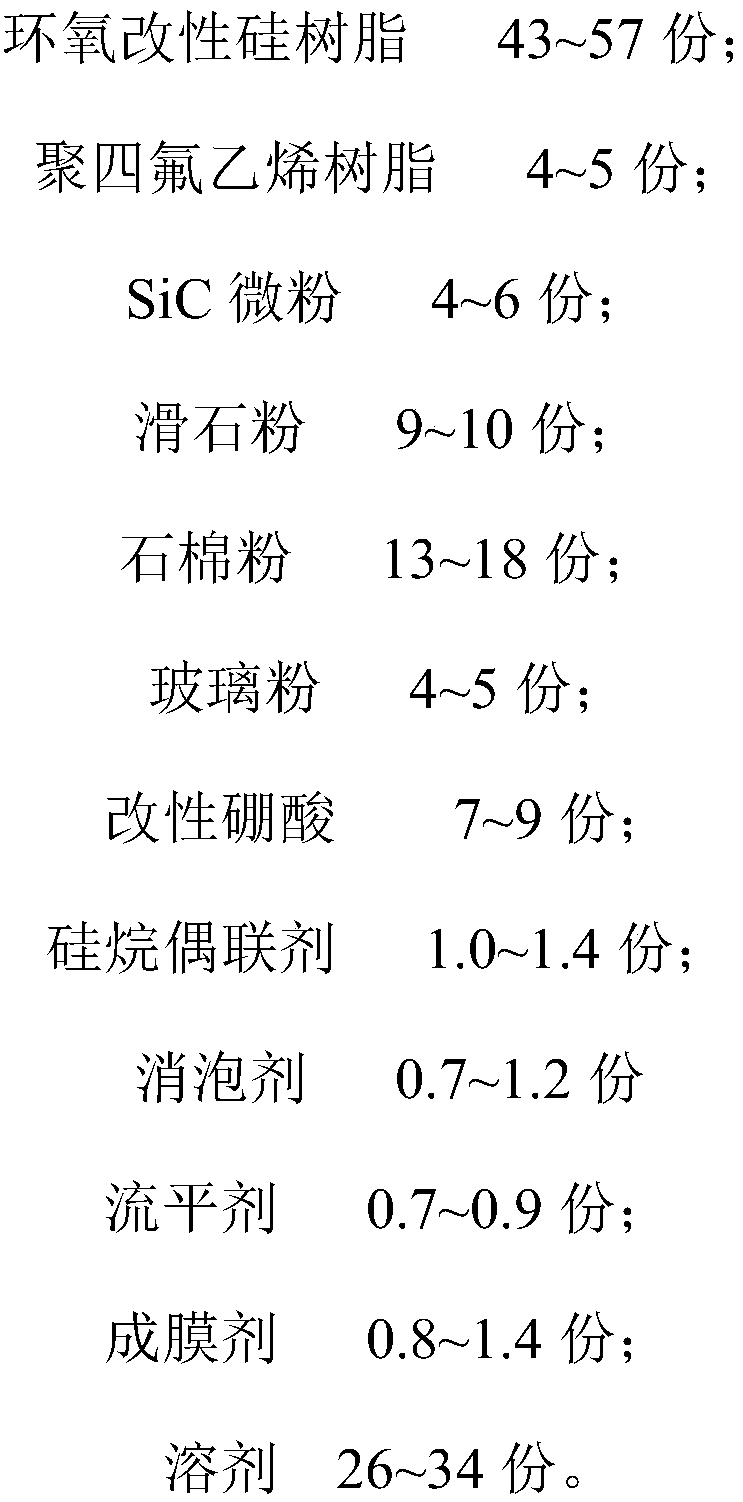

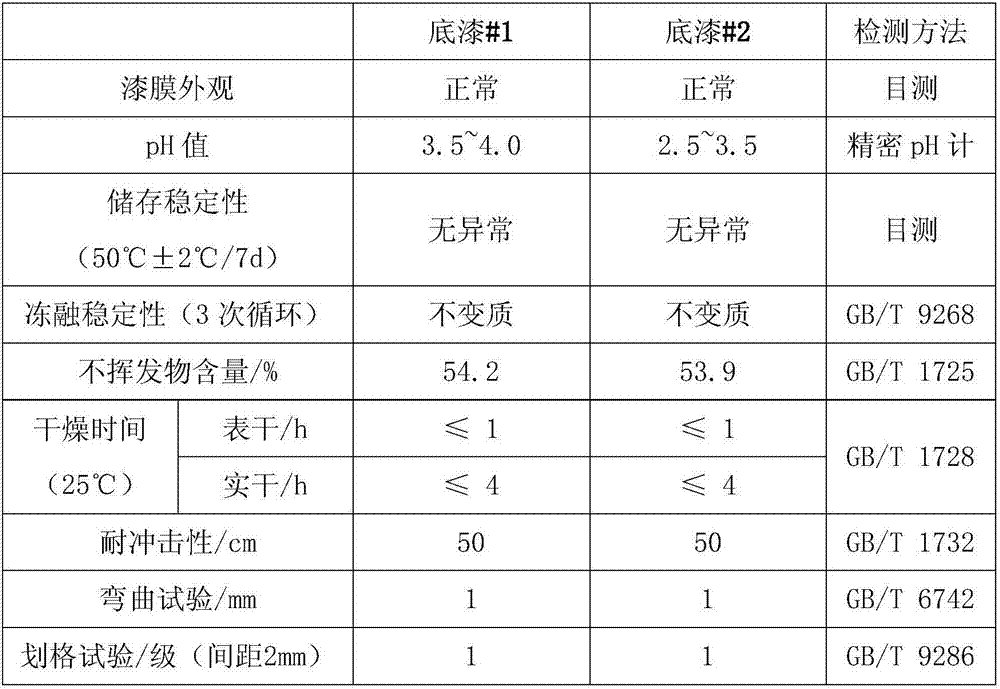

High temperature-resistant anticorrosive paint and preparation method thereof

InactiveCN109054633AImprove adhesionReduce surface tensionFireproof paintsAnti-corrosive paintsEpoxyPolymer science

The invention discloses high temperature-resistant anticorrosive paint and a preparation method thereof. The high temperature-resistant anticorrosive paint is prepared from the following raw materials: epoxy-modified silicon resin, polytetrafluoroethylene resin, SiC micro powder, talcum powder, asbestos powder, glass powder, modified boric acid, a silane coupling agent, a defoaming agent, a flatting agent and a film-forming agent. The paint not only has excellent high temperature resistance performance and flame retardation performance, but also has good anticorrosive performance of salt fog resistance, water resistance, salt water resistance, ageing resistance and the like, can adapt to different construction modes, and is ideal heat-resistant anticorrosive paint.

Owner:WUHU ZHANGHONG ENG TECH CO LTD

Preparation method of acrylate copolymerization emulsion for high-adhesion heavy anti-corrosion coating

InactiveCN105218725AImprove water resistanceGood resistance to salt sprayAnti-corrosive paintsWater basedEmulsion

The invention discloses acrylate copolymerization emulsion for a high-adhesion heavy anti-corrosion coating and a preparation method thereof. The copolymerization emulsion is prepared from, by weight, 55-60 parts of butyl acrylate, 80-90 parts of styrene, 25-30 parts of methyl methacrylate, 15-20 parts of methyl acrylate, 1-2 parts of acrylic acid, 0.5-1 part of initiating agents, 4-6 parts of emulsifying agents, 200-250 parts of deionized water, 0.0001-0.0002 part of pH regulating agents and 5-10 parts of film forming auxiliaries. The preparation method comprises the steps that firstly, the deionized water and part of the emulsifying agents are mixed in a reaction kettle; secondly, an initiating agent solution and a pre-emulsifying solution are prepared separately; lastly, the initiating agent solution and the pre-emulsifying solution are dropwise added in the reaction kettle, and then the temperature is increased. According to the acrylate copolymerization emulsion for the high-adhesion heavy anti-corrosion coating and the preparation method thereof, the acrylate copolymerization emulsion is prepared through a semi-continuous dropwise adding mode, and therefore the obtained acrylate copolymerization emulsion has the good water resistance, salt spray resistance and salt water resistance; the copolymerization emulsion is suitable for preparing the water-based heavy anti-corrosion coating and can achieve the good anti-corrosion effects.

Owner:NANTONG REPAIR AIR CHEM BIOENG

Water-based rust transfer primer applicable to rusted steel surface and its preparation method

ActiveCN107151491AGood storage stabilityGood rust conversion efficiencyAnti-corrosive paintsWater basedPhosphate

The invention discloses a water-based rust transfer primer applicable to a rusted steel surface and its preparation method. The water-based rust transfer primer is applied to the rusted steel surface. The water-based rust transfer primer is prepared from vinylidene chloride-acrylonitrile- acrylate multi-copolymerization emulsion, phosphate modified polyacrylate water dispersing body, non-ionic wet dispersing agent, anti-settling agent, pigment, filler, polyether siloxane defoaming agent, coalescing agent, base material wetting agent, isothiazolinone, polyurethane associated thickening agent and water. The water-based rust transfer primer is one-component and self-drying type product; the water-based rust transfer primer has the advantages of being high in storage stability and good in rust transferring efficiency; the formed coating has excellent water vapor isolating property and long-acting corrosive resistance.

Owner:NANJING CHANGJIANG PAINT

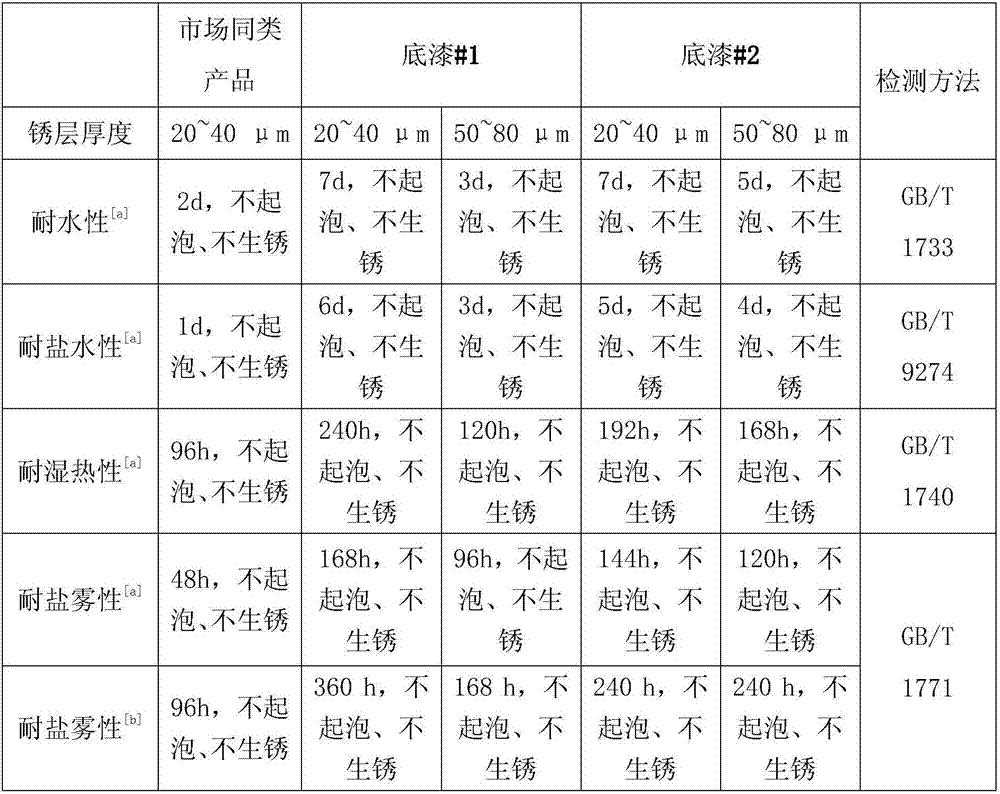

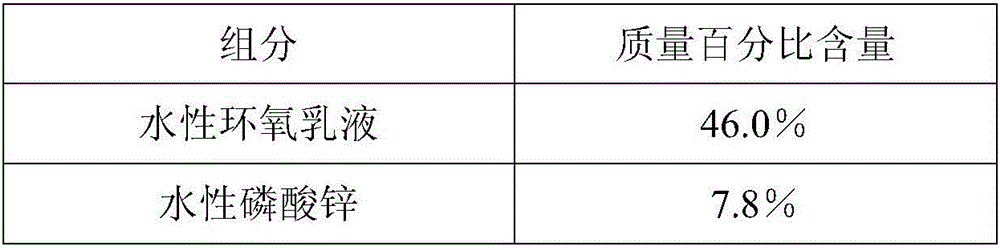

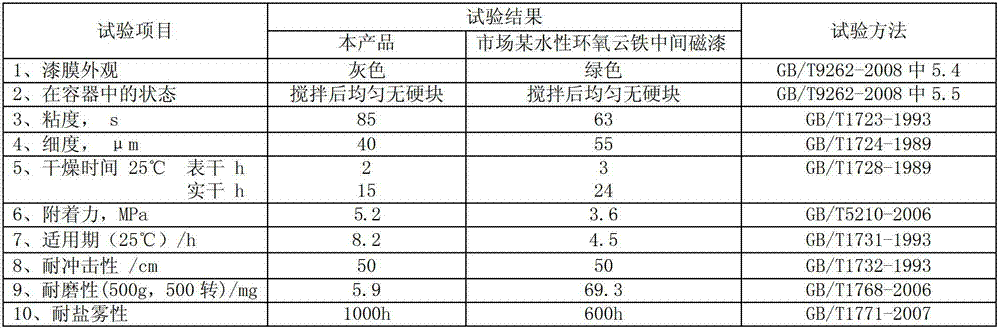

Waterborne epoxy anticorrosive antirust paint and preparation method thereof

The invention discloses a waterborne epoxy anticorrosive antirust paint. With a waterborne epoxy elusion as a matrix, a plurality of pigment fillers and assistants, the waterborne epoxy anticorrosive antirust paint comprises a waterborne epoxy emulsion, water-based zinc phosphate, modified aluminum triphosphate, rutile titanium dioxide, a coalescing agent, a water-based defoamer, a thickener SN636, a wetting agent PE-100, a fungicidal preservative, a flash rusting agent, a dispersing agent 5040, a flatting agent and deionized water. The waterborne epoxy anticorrosive antirust paint is environmentally friendly; the raw materials are low in price; the preparation process is simple; meanwhile, the salt-water resistance is excellent; the adhesive force is high; and the flash rusting effect is good.

Owner:卢朝霞

High weather-resistant and anti-interference anticorrosive paint for power distribution cabinet

InactiveCN104497796AImprove film formationImprove the decorative effectAnti-corrosive paintsEpoxy resin coatingsXylyleneCelestine

The invention discloses a high weather-resistant and anti-interference anticorrosive paint for power distribution cabinets. The anticorrosive paint is characterized by comprising the following raw materials by weight: 22-25 parts of ethylene propylene terpolymer, 30-36 parts of bisphenol A type epoxy resin, 2-3 parts of chlorinated paraffin, 4-6 parts of glycol, 1-2 parts of dibutyl phthalate, 2-4 parts of vermiculite powder, 2-3 parts of celestite powder, 1-2 parts of triphenylmethyl ethylphenol polyoxyethylene ether, 2-3 parts of sodium benzoate, 5-7 parts of talcum powder, 2-3 parts of molybdenum pentachloride, 1-2 parts of vinyl tri(beta-methoxy ethoxy) silane, 1-2 parts of sulfonated lanolin calcium soap, 1-2 parts of carboxymethyl cellulose, 15-17 parts of butyl acetate, 6-9 parts of xylene and 4-7 parts of an aid. The paint provided by the invention has good decorative effect on the power distribution cabinet under natural conditions, and the paint film is smooth and flat, has good gloss and high weather resistance, and is not easy to turn yellowing or chalking; the added additive promotes the film forming ability of the paint, and also has anti-electromagnetic interference effect to prevent the interference on the electronic equipment in the power distribution cabinet, so as to avoid error signal.

Owner:WUHU HONGKUN AUTO PARTS

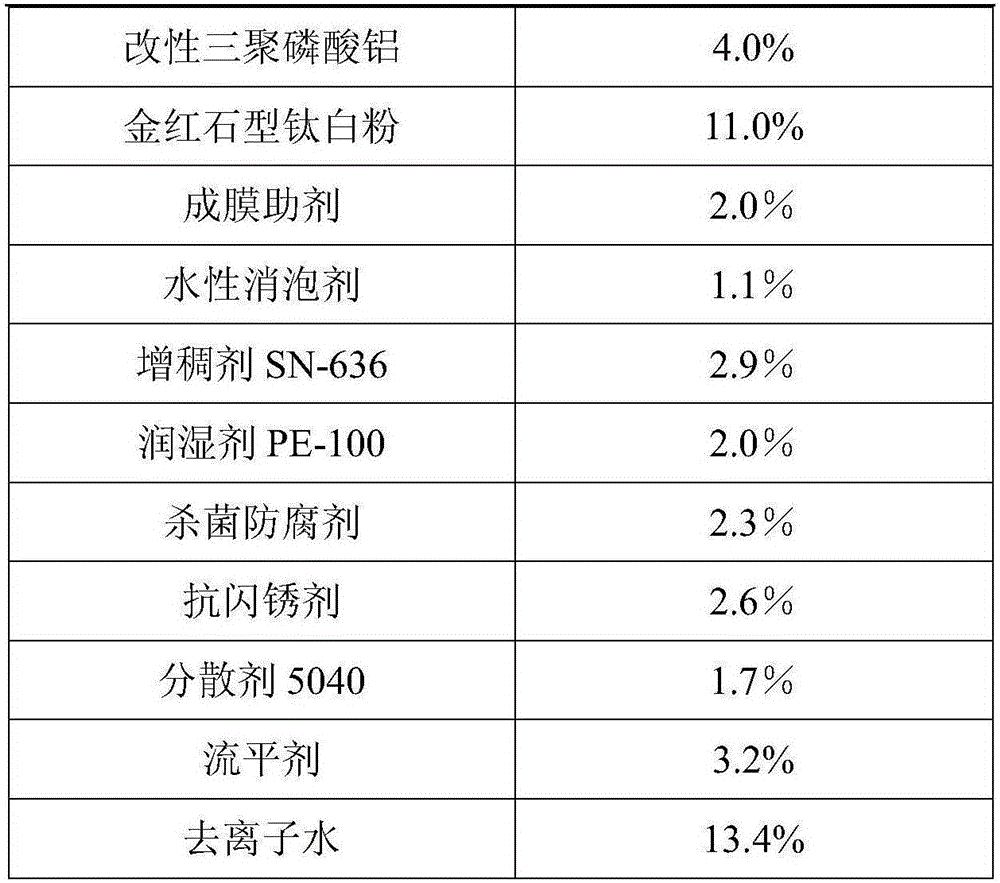

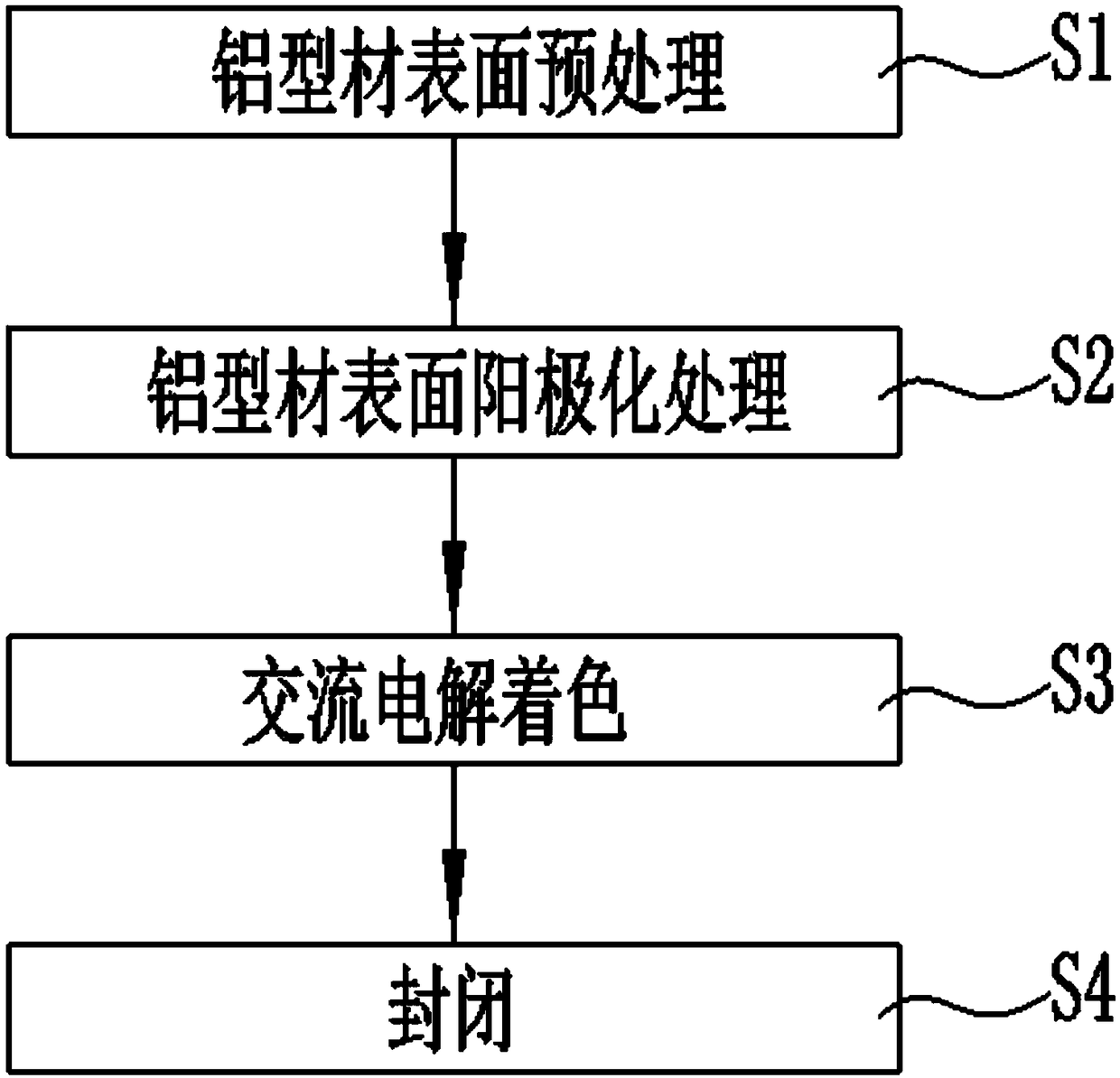

Method for producing black aluminum profile by using anodized single nickel salt for coloring and aluminum profile

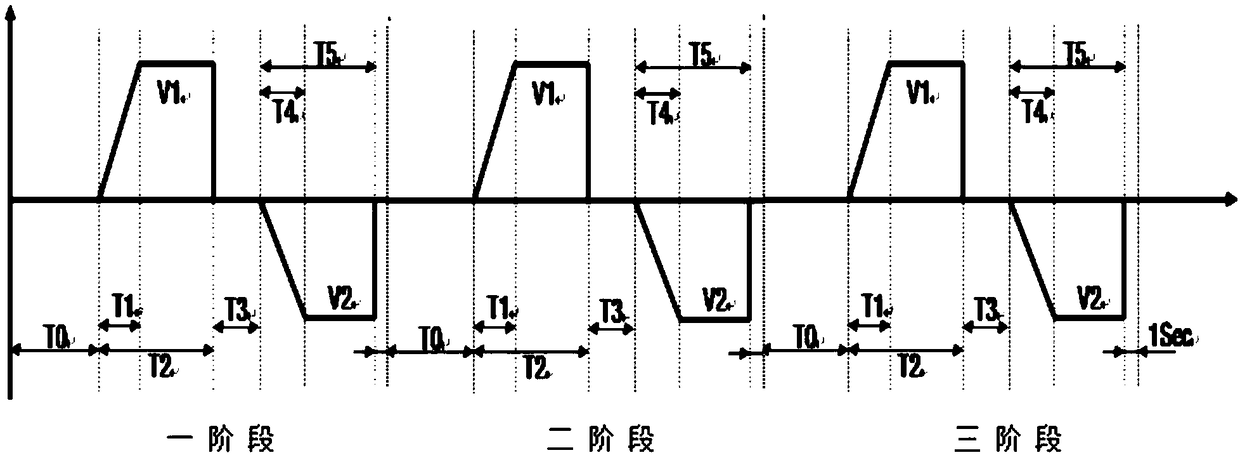

The invention provides a method for producing a black aluminum profile by using anodized single nickel salt for coloring. The method specifically comprises the steps of aluminum profile surface pre-treatment, aluminum profile surface anodizing, alternate-current electrolytic coloring, boiling water sealing and the like, and in the process of alternate-current electrolytic coloring, the aluminum profile is subjected to voltage control coloring at three stages. Meanwhile, the invention provides the black aluminum profile obtained according to the method. The method for producing the black aluminum profile by using the anodized single nickel salt for coloring is implemented under a normal-temperature environment, and energy consumption is low; a dense anode oxide film with high surface smoothness is obtained after anodizing is completed; and the continuous and stable pure black anodized aluminum profile is produced after three-stage coloring treatment is carried out, and is uniform and bright in surface, small in color difference, good in decoration effect, and well resistant to rust, salt water, salt spray, humidity, heat, cold and scratch.

Owner:肇庆亚洲铝厂有限公司

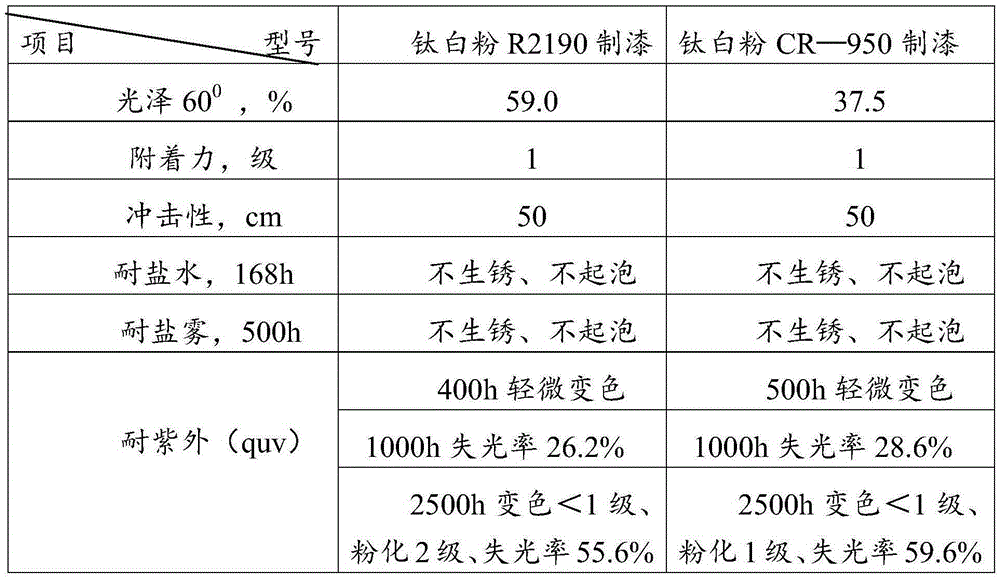

Heat resistant aluminum color epoxy organosilicon paint and preparation method thereof

ActiveCN102516870AImprove the decorative effectImprove heat resistancePolyamide coatingsPaints with free metalsEpoxyCyclohexanone

The invention relates to a heat resistant aluminum color epoxy organosilicon paint. The paint is characterized in that the paint comprises, by weight, 100 parts of a component I which is an H61-1 epoxy modified organosilicon resin; 30 parts of a component II which comprises 80-100 parts of a polyamide resin, 40-50 parts of toluene, 40-50 parts of butanol and 10-20 parts of cyclohexanone; and 20 parts of a component III which is floating aluminum powder. The invention also relates to a preparation method of the paint. The preparation method comprises the following steps: 1, preparing the H61-1 epoxy modified organosilicon resin; 2, adding the polyamide resin, toluene, butanol and cyclohexanone to a burdening basin, stirring them for 15min at a low-medium speed of 200-400r / min, and packaging after the solid test qualification; 3, packaging the floating aluminum powder after examining; and 4, mixing the component I, the component II and the component III according to a ratio of 100:20:20, allowing them to stand for 20min, and packaging them after examining. The paint has the following beneficial effect: the paint possess excellent physical and chemical performances of decorativeness, heat resistance, salt spray resistance, salt water resistance, water resistance, cold resistance, oil resistance, hydrocarbon solvent resistance, adhesion force, impact, flexibility and the like.

Owner:天津灯塔涂料工业发展有限公司

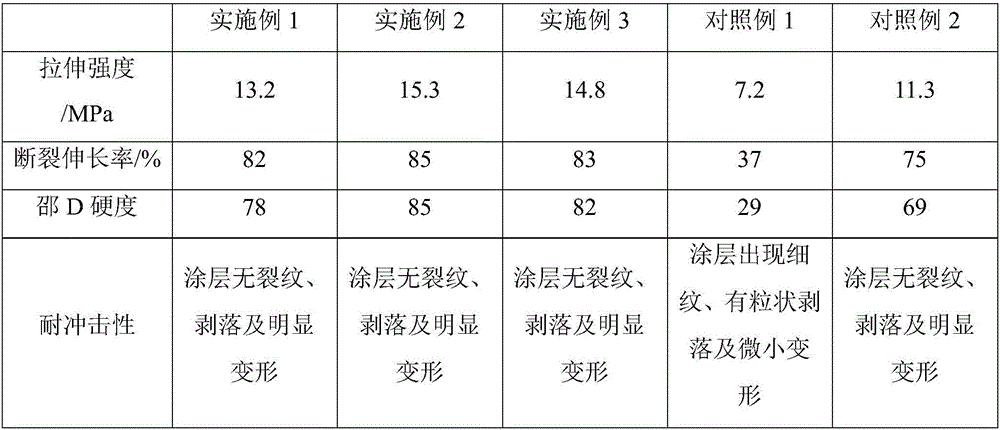

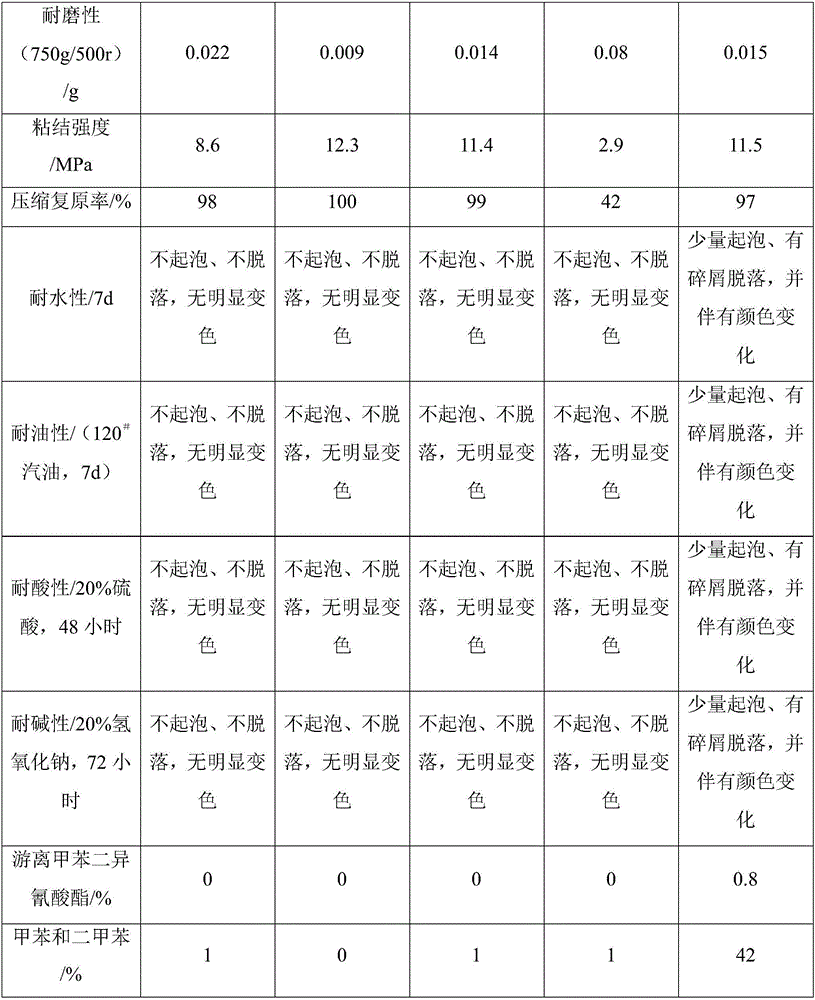

Graphene-based/montmorillonite-modified polyurethane floor material and preparation method thereof

InactiveCN106566401AGood mechanical propertiesImprove impact resistancePolyurea/polyurethane coatingsMontmorilloniteChloride

The invention discloses a graphene-based / montmorillonite-modified polyurethane floor material and a preparation method thereof. The graphene-based / montmorillonite-modified polyurethane floor material is prepared from the following components in parts by weight: 27-47 parts of polyurethane, 7-14 parts of isocyanate, 3-6 parts of a defoaming agent, 1-4 parts of a wetting dispersant, 1-6 parts of a water absorbent, 1-4 parts of a catalyst, 6-18 parts of graphene, 8-17 parts of montmorillonite, 3-11 parts of ferric chloride, 3-12 parts of sodium carbonate, 3-17 parts of hydrochloric acid and 8-19 parts of borax. Compared with the prior art, the graphene-based / montmorillonite-modified polyurethane floor material disclosed by the invention has the advantages that no free isocyanate is produced in the product, no organic volatile substances are introduced, and the mechanical and chemical properties are good.

Owner:江苏悠谷未来科技有限公司

Salt-water-resistant waterborne acrylic coating

The invention discloses a salt-water-resistant waterborne acrylic coating. The salt-water-resistant waterborne acrylic coating comprises the following raw materials in parts by weight: 140-180 parts of waterborne epoxy-modified acrylic emulsion, 20-30 parts of fumed silica, 14-20 parts of heavy calcium carbonate, 6-10 parts of precipitated barium sulfate, 10-16 parts of coal gangue powder, 2-4 parts of tetrabutyl titanate, 4-8 parts of water-based defoamer, 3-6 parts of coalescing agent, 2.5-4.5 parts of antifreeze, 2.5-4.5 parts of water-based wetting and leveling agent, 2.5-4.5 parts of water-based preservative, 2.5-4.5 parts of water-based thickener, and 100-140 parts of water. According to the salt-water-resistant waterborne acrylic coating, the obtained coating has excellent curing performance, has a large coating film density, has excellent adhesion, and has extremely high salt water resistant performance, and meanwhile, the phenomenon of coating film sagging is overcome, and thecoating has a long service life.

Owner:合肥林邦门业有限公司

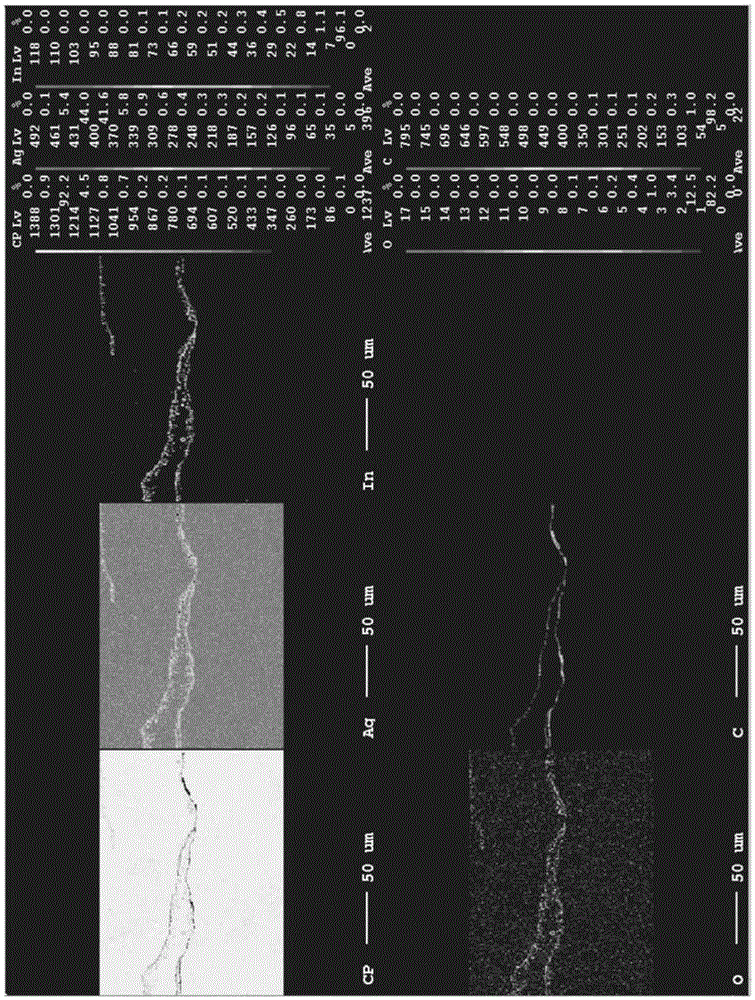

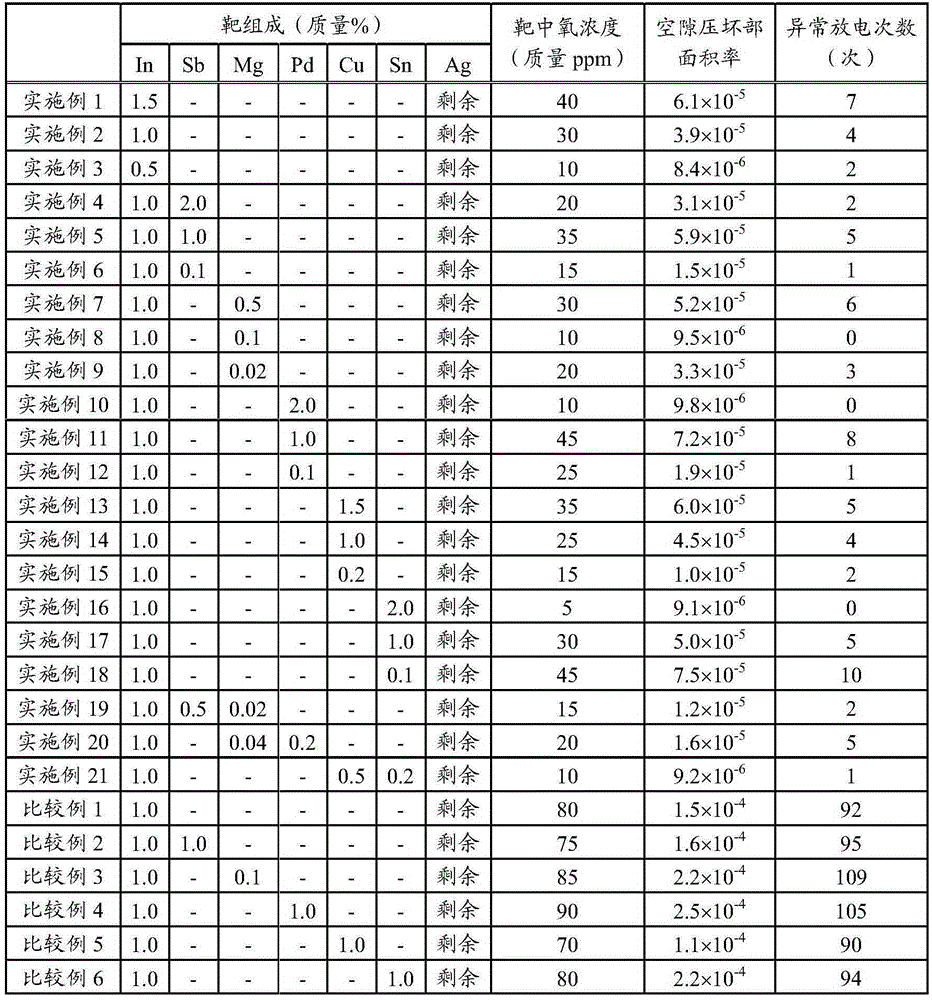

Ag alloy sputtering target

ActiveCN105378140AImprove reflectivityImprove heat resistanceElectroluminescent light sourcesSolid-state devicesSputteringMetallurgy

The present invention provides an Ag alloy sputtering target by which it is possible to perform stable DC sputtering. This Ag alloy sputtering target contains 0.1-1.5 mass% In, the balance being a composition comprising Ag and unavoidable impurities, the concentration of oxygen being 50 mass ppm or less. In the entire area in the direction of thickness of the target, the proportion of area of a crushed void portion measured by an ultrasonic damage detection device is 1.0x10-4 or less in relation to the area of the sputtering surface.

Owner:MITSUBISHI MATERIALS CORP

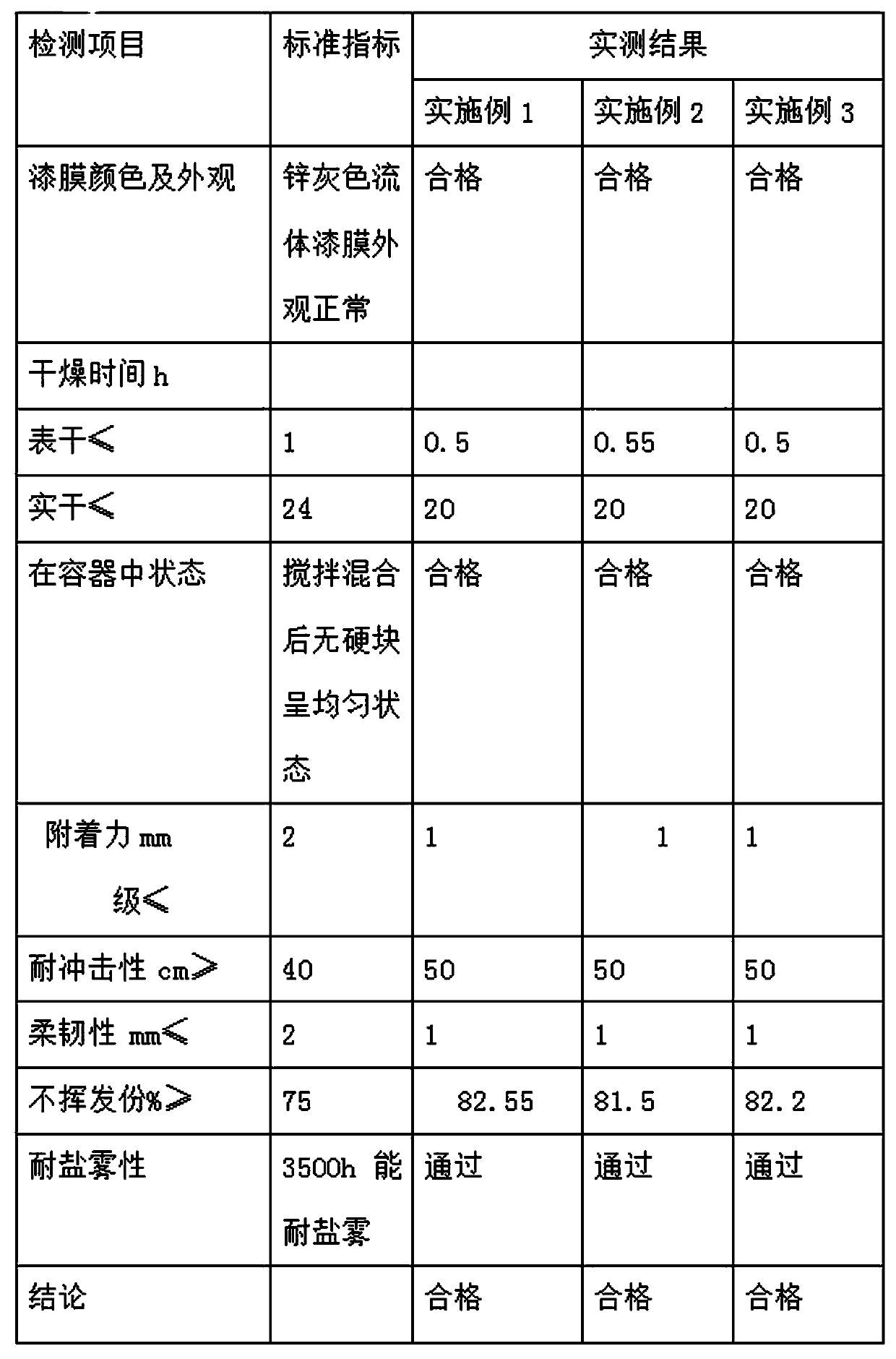

Compound cold galvanized coating

InactiveCN110305502AImproves barrier protectionGood resistance to salt sprayAnti-corrosive paintsSolventSalt water

The invention discloses a compound cold galvanized coating. The compound cold galvanized coating comprises, by weight, 7-9 parts of modified acrylic resin, 77-79 parts of zinc powder, 1-3 parts of aluminum powder and 11-13 parts of a coating solvent, wherein the acid value of the modified acrylic resin is 0-5mgKOH / g, and the glass-transition temperature of the modified acrylic resin is 20-60DEG C.The compound cold galvanized coating has the advantages that the solid content in the compound cold galvanized coating is more than 80%, the zinc content in a dry film is more than 90%; compared withthe addition of the singular zinc powder, the addition of flake electrostatic conductive aluminum powder to the coating further improves the barrier protection effect of the coating film on the ironand steel surface, and salt water resistance and salt fog resistance are better, and meanwhile, cathodic protection is well provided, and the iron and steel surface can be protected for a long time even in the harsh marine environment; the anticorrosion performance can be comparable to hot galvanizing, flexibility and practicability are even better than hot galvanizing, and the compound cold galvanized coating is widely used in large bridges, airports, stations, offshore facilities and other steel structures.

Owner:南通万邦采涂料有限公司

Water-based epoxy enamel paint

ActiveCN102827527AImprove anti-corrosion performanceCause harmAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention discloses a water-based epoxy enamel paint being a two-component coating which is prepared by epoxy resin emulsion, curing agents, tinting pigments, auxiliaries and so on. The water-based epoxy enamel paint has tough paint films and the advantages of excellent adhesion, flexibility, abrasive resistance and shock resistance and good chemical resistance, solvent resistance, water resistance, salt water resistance, durability and corrosion resistance. The water-based epoxy enamel paint is widely applied to the surface rust protection of ships, steel structures, wharf steel facilities and so on.

Owner:重庆南方漆业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com