Epoxy polysiloxane graphene heavy-duty anticorrosion coating and preparation method

A technology of epoxy polysiloxane and graphene, which is applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of affecting the anti-corrosion effect of epoxy resin, easy coating of coatings, and poor weather resistance, etc., to achieve Excellent leveling performance, stable price, and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

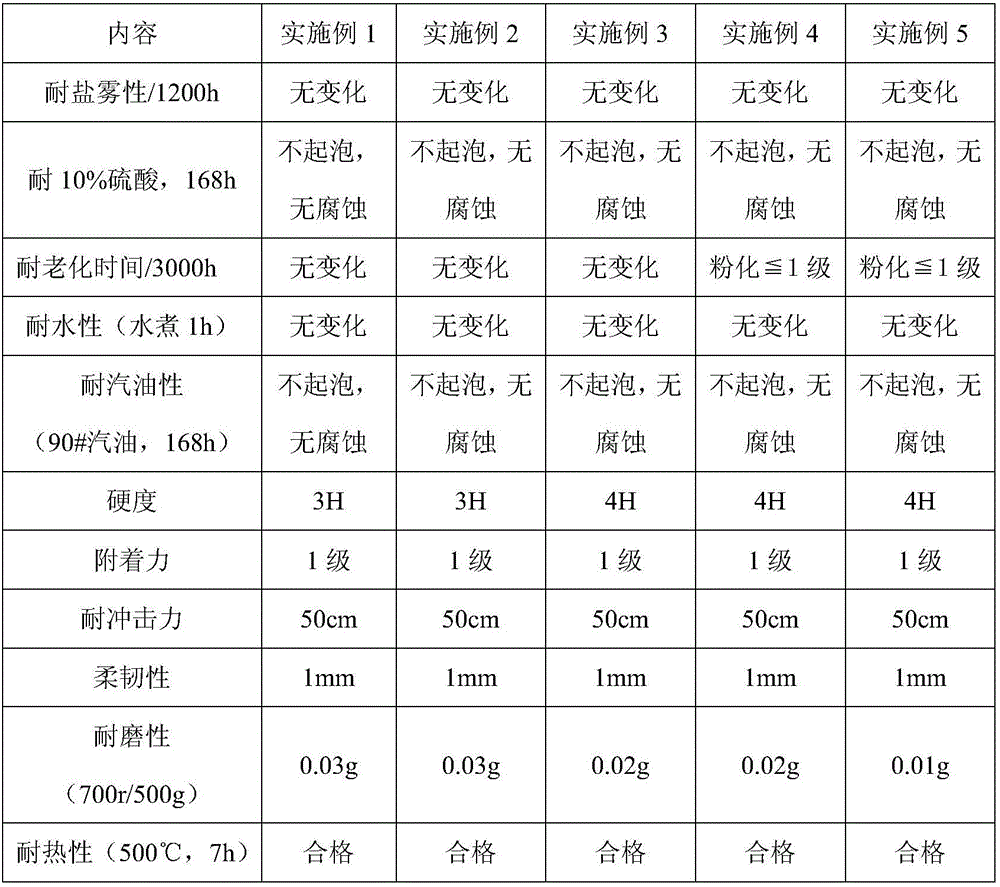

Examples

Embodiment 1

[0033] A kind of epoxy polysiloxane graphene heavy anticorrosion coating, its preparation steps are as follows:

[0034] (1) Synthesis of epoxy polysiloxane: 48g of hydrogenated bisphenol A epoxy resin and 52g of methoxypolysiloxane were added to a nitrogen-filled reactor, the temperature was raised to 70°C, and 0.1g of dilauric acid dilaurate was added dropwise. Butyl tin; then slowly increase the temperature to 135°C, the reaction time is 6h; cool down to 60°C, add 2g of 3-aminopropyltrimethoxysilane dropwise at the same time, continue the reaction for 2h; finally add petroleum ether for extraction, the petroleum ether layer is the sample mixture Liquid, low pressure vacuum (-0.08MPa, 40°C) to remove solvent, cooling to obtain epoxy polysiloxane.

[0035] (2) Weigh 29.0 g of hydrogenated bisphenol A epoxy resin, 10.0 g of epoxy polysiloxane of step (1) and 4.0 g of graphene according to the proportion, mix and heat to 50° C. in a water bath for dissolution to obtain a mixed ...

Embodiment 2

[0040] A kind of epoxy polysiloxane graphene heavy anticorrosion coating, its preparation steps are as follows:

[0041] (1) Synthesis of epoxy polysiloxane: Add 45g of hydrogenated bisphenol A epoxy resin and 52g of methoxy polysiloxane into a nitrogen-filled reactor, heat up to 80°C, and add 0.1g of dilauric acid dilaurate dropwise Butyl tin; then slowly raise the temperature to 125°C, the reaction time is 6h; cool down to 55°C, add 2.5g of 3-aminopropyltriethoxysilane dropwise at the same time, continue the reaction for 2h; finally add petroleum ether for extraction, the petroleum ether layer is the sample Mixed solution, low pressure vacuum (-0.08MPa, 40°C) to remove solvent, cooling to obtain epoxy polysiloxane;

[0042] (2) Weigh 30 g of hydrogenated bisphenol A epoxy resin, 10.0 g of epoxy polysiloxane of step (1) and 4.0 g of graphene according to the proportion, mix and heat to 50° C. in a water bath for dissolution to obtain a mixed resin.

[0043] (3) Add 2.0g of p...

Embodiment 3

[0047] A kind of epoxy polysiloxane graphene heavy anticorrosion coating, its preparation steps are as follows:

[0048] (1) Synthesis of epoxy polysiloxane: 60g of hydrogenated bisphenol A epoxy resin and 40g of methoxypolysiloxane were added to a nitrogen-filled reactor, the temperature was raised to 80°C, and 0.1g of dilauric acid dilaurate was added dropwise. Butyl tin; then slowly raise the temperature to 145°C, the reaction time is 5h; cool down to 60°C, add 1.5g of 3-aminopropyltrimethoxysilane dropwise at the same time, continue the reaction for 2h; add petroleum ether for extraction, and the petroleum ether layer is the sample mixture , low-pressure vacuum (-0.08MPa, 40°C) to remove the solvent, and cool to obtain epoxy polysiloxane.

[0049] (2) E-51 epoxy resin 20.0g, hydrogenated bisphenol A epoxy resin 9.0g, step (1) epoxy polysiloxane 7.0g and graphene 8.0g are called according to the proportioning, and the water bath is heated to 50 after mixing ℃ for dissoluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com